Digitized surface blasting operation method

An open-air, blasting design technology, applied in blasting and other directions, to achieve the effect of improving blasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

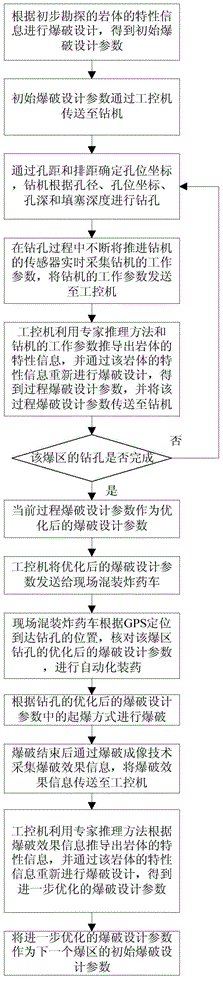

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The K deposit of the Monywa Copper Mine in Myanmar is a concealed porphyry-type copper deposit produced in the altered andesite porphyrite. The altered andesite porphyrite is a dike-like epigenetic intrusion with a steep edge. The surrounding rocks are gently inclined sandstone and pyroclastic rocks, which are mainly distributed on the east and west sides of the deposit. The mineralized zone descends from the surface, with a burial depth of about 600m, and the rock masses are all subject to strong sericitization alteration. The main ore body is produced in the structural fracture zone of altered andesite porphyrite, showing branched and network vein quartz sulfide veins. The ore minerals are mainly pyrite and chalcocite, followed by a small amount of chalcocite and copper blue. The gangue minerals are mainly quartz, fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com