Patents

Literature

197 results about "Ring number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The customer support phone number of Ring Go is 0905 009 1122 (Click phone number to call). The postal and official address, email address and phone number (helpline) of Ring Go Service Center and Ring Go customer service phone number is given below.

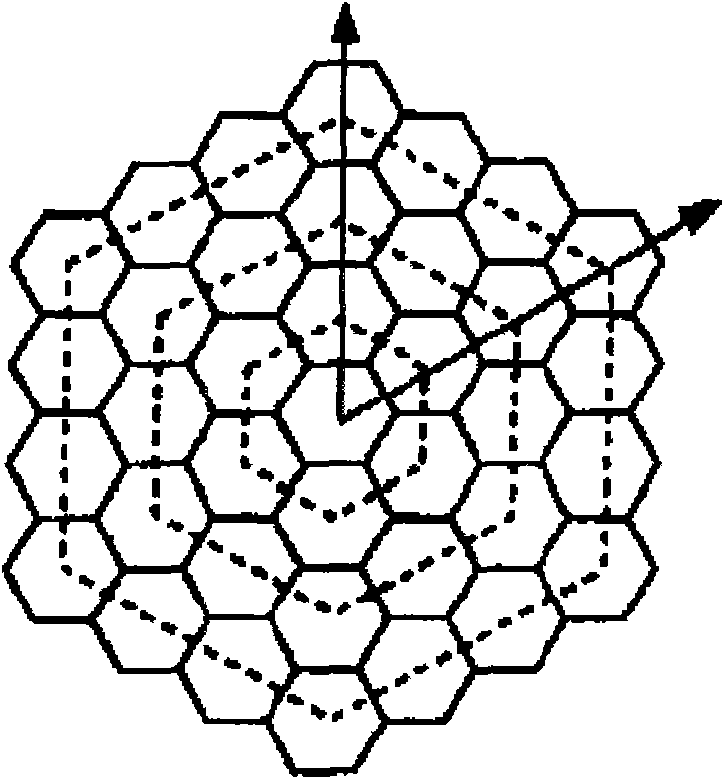

System and method for ad hoc network access employing the distributed election of a shared transmission schedule

InactiveUS20020067736A1Eliminate negotiationMore controlledNetwork topologiesTime-division multiplexTime division multiple accessTransmission schedule

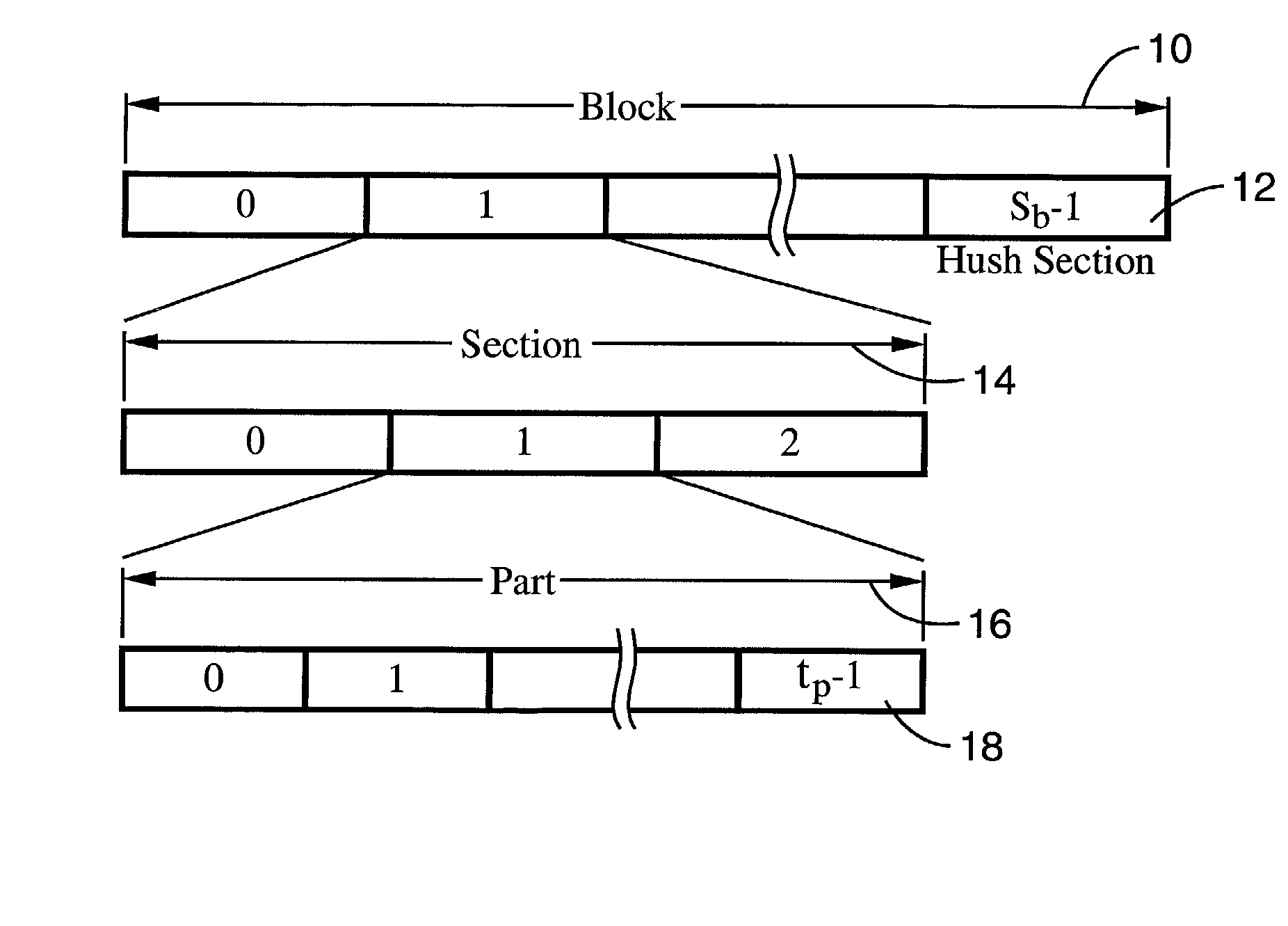

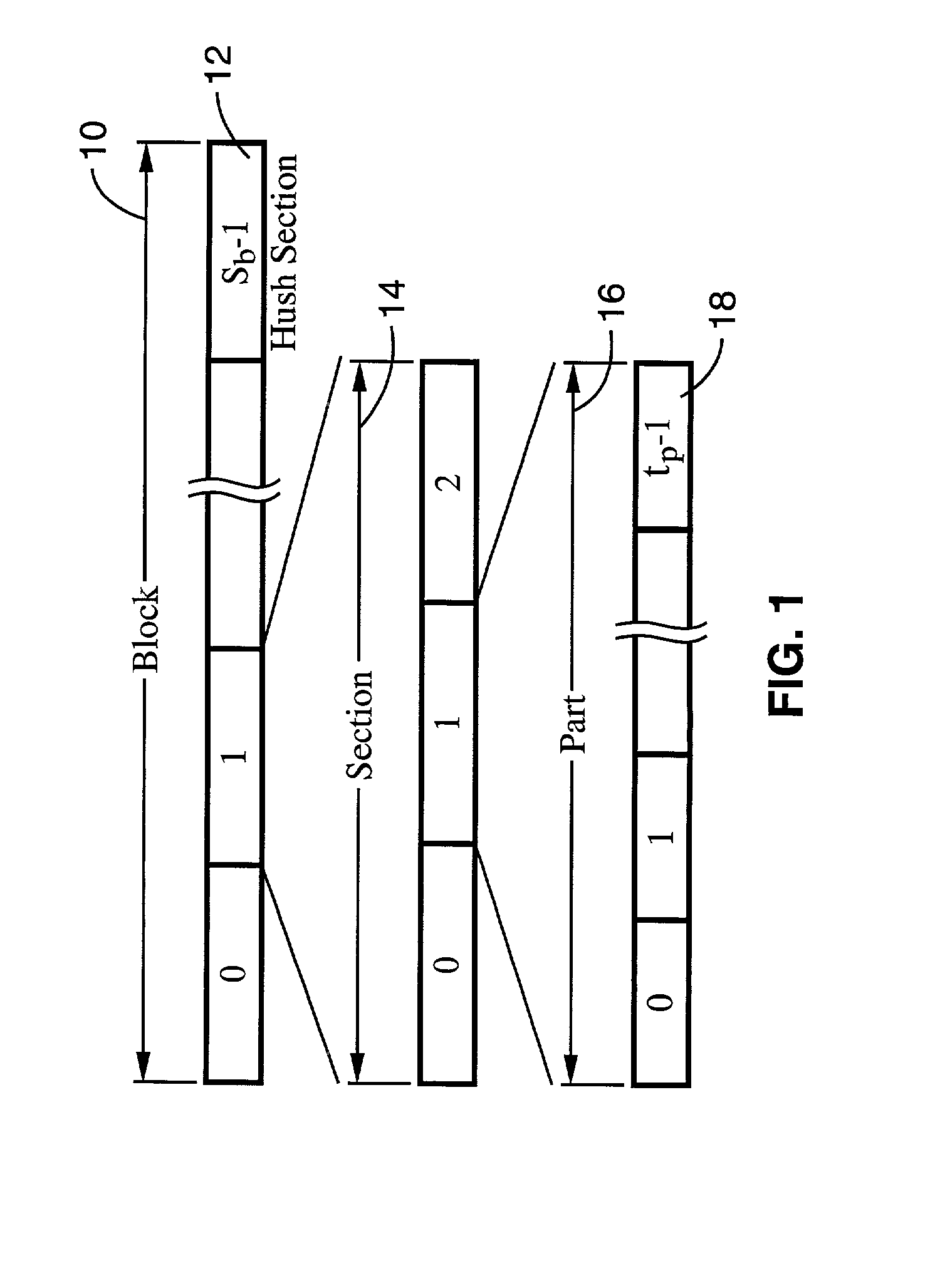

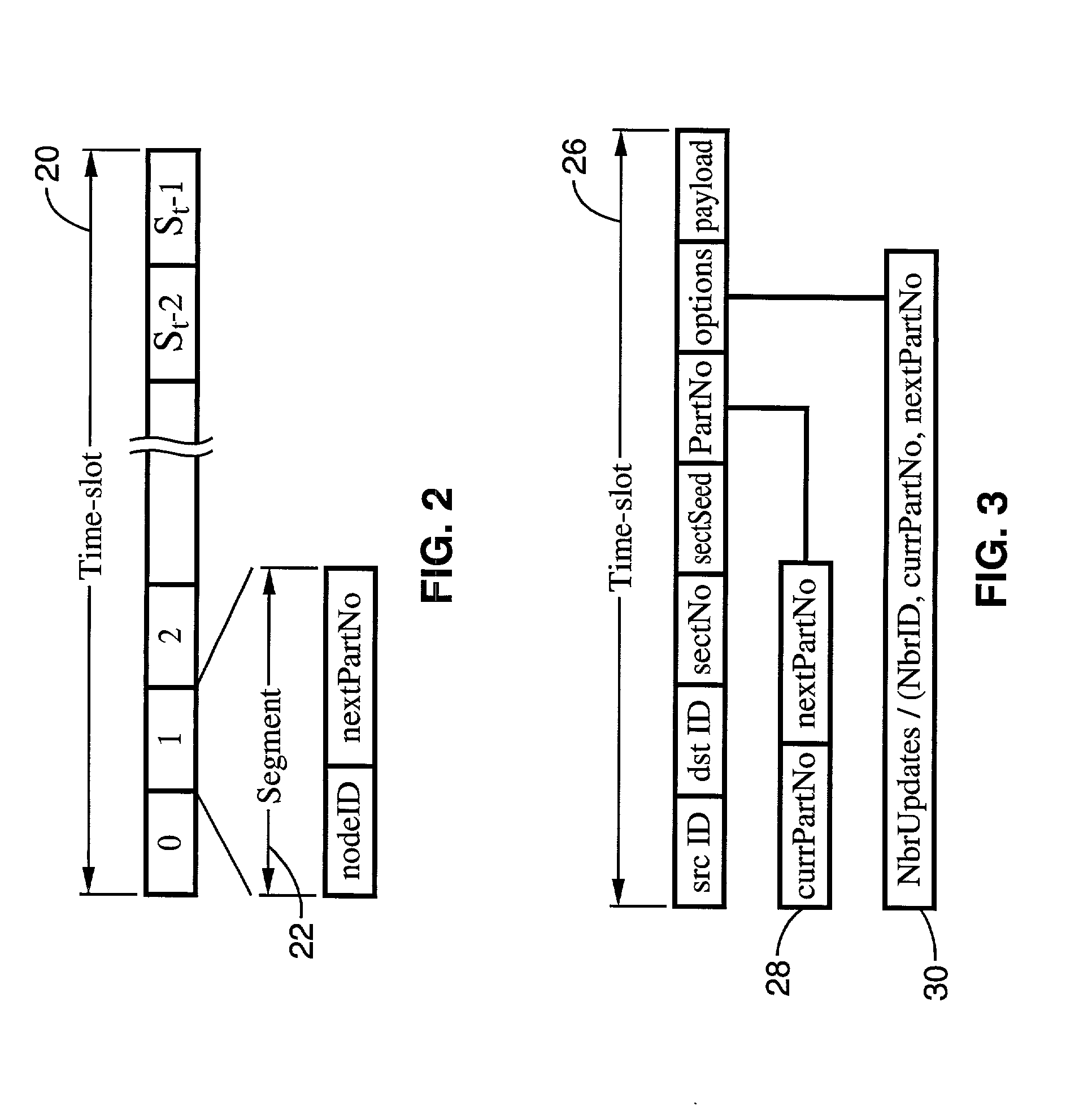

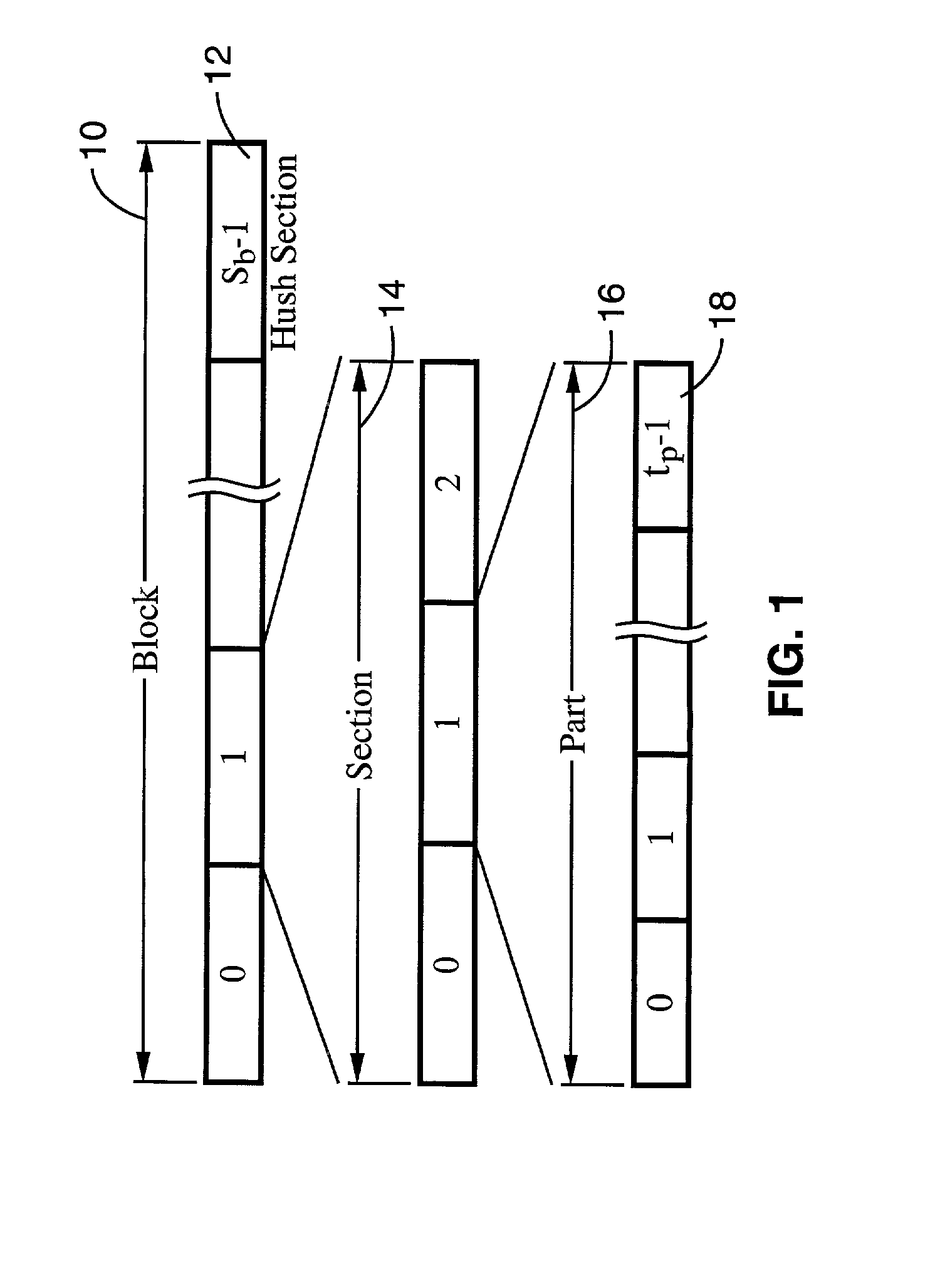

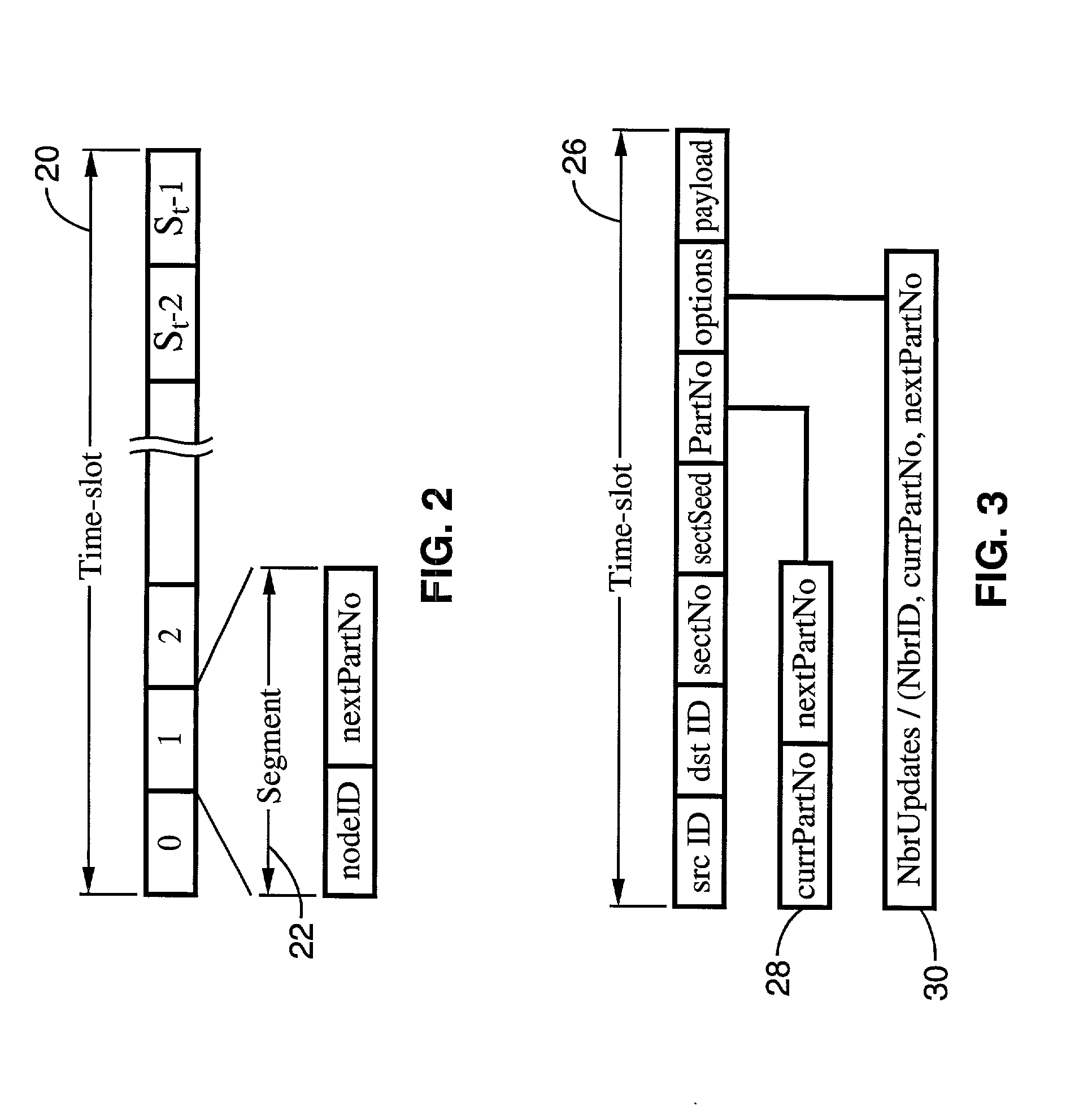

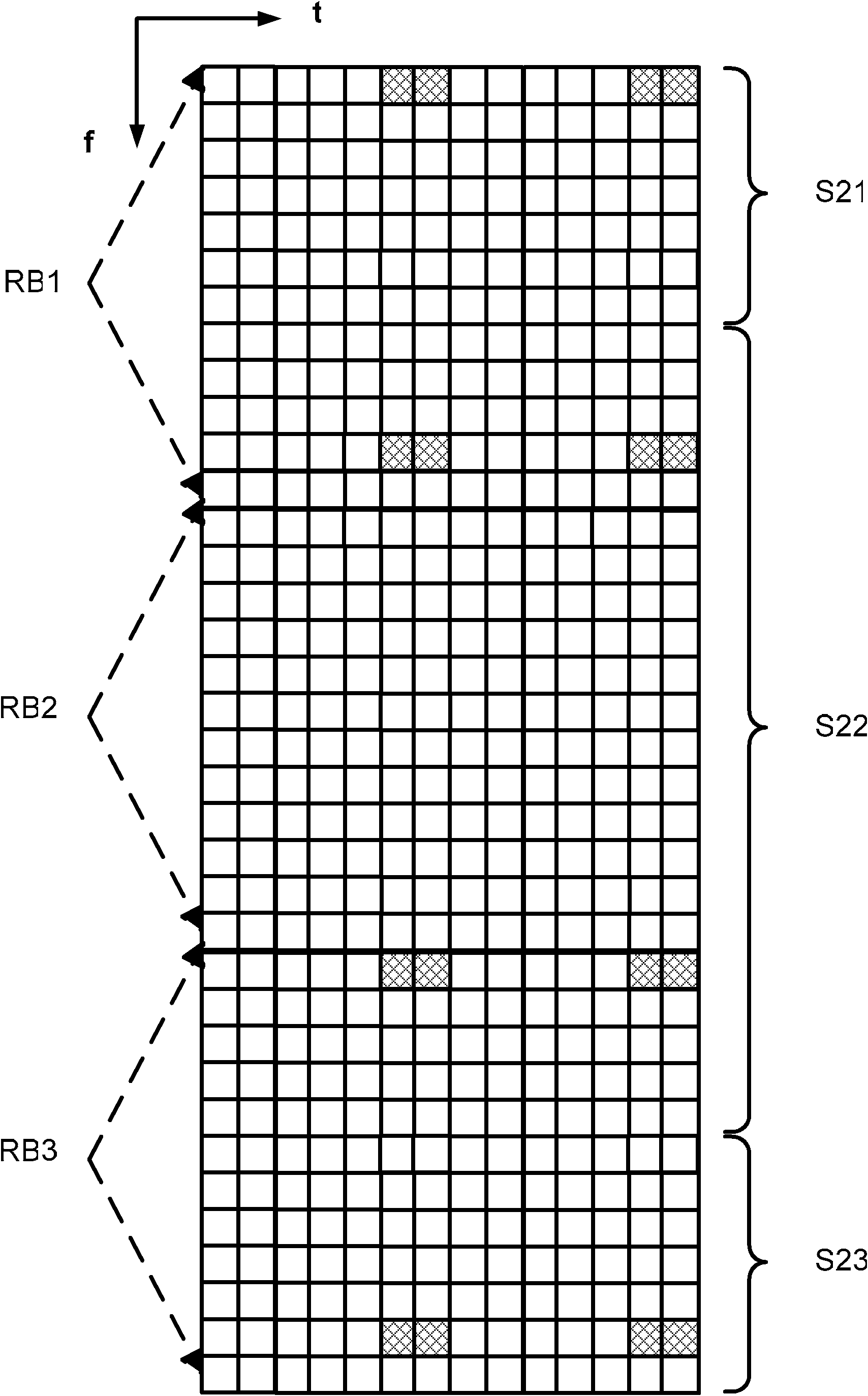

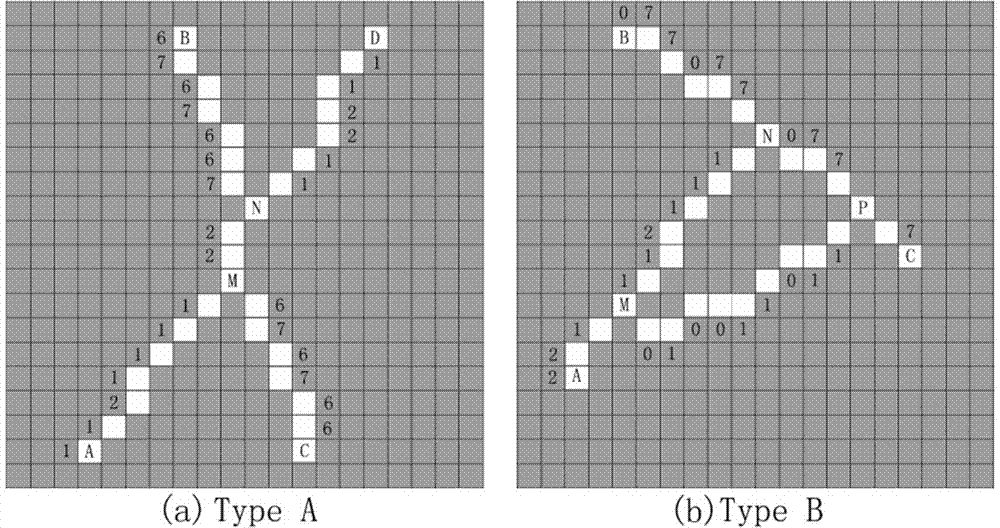

A system and method of providing distributed election of a shared transmission schedule within an ad hoc network. The invention includes a collision-free access protocol which resolves channel access contentions for time division multiple access (TDMA) of a single channel. Time-slots are organized into part numbers, which are included within sections, a sequence of which define a block. Each node is given a ring number according to its location within the network topology and maintains local neighbor information along with its own part number and message digest. Collision-free channel access is automatically scheduled and repetitious contention phases are resolved by a random permutation algorithm operating in message digests. An empty time-slot utilization method is also described and data packets may also be transmitted subject to a non-zero collision probability within a blind section of the block.

Owner:RGT UNIV OF CALIFORNIA

System and method for ad hoc network access employing the distributed election of a shared transmission schedule

InactiveUS7046639B2Eliminate CollisionsControl moreNetwork topologiesTime-division multiplexTime division multiple accessTransmission schedule

A system and method of providing distributed election of a shared transmission schedule within an ad hoc network. The invention includes a collision-free access protocol which resolves channel access contentions for time division multiple access (TDMA) of a single channel. Time-slots are organized into part numbers, which are included within sections, a sequence of which define a block. Each node is given a ring number according to its location within the network topology and maintains local neighbor information along with its own part number and message digest. Collision-free channel access is automatically scheduled and repetitious contention phases are resolved by a random permutation algorithm operating in message digests. An empty time-slot utilization method is also described and data packets may also be transmitted subject to a non-zero collision probability within a blind section of the block.

Owner:RGT UNIV OF CALIFORNIA

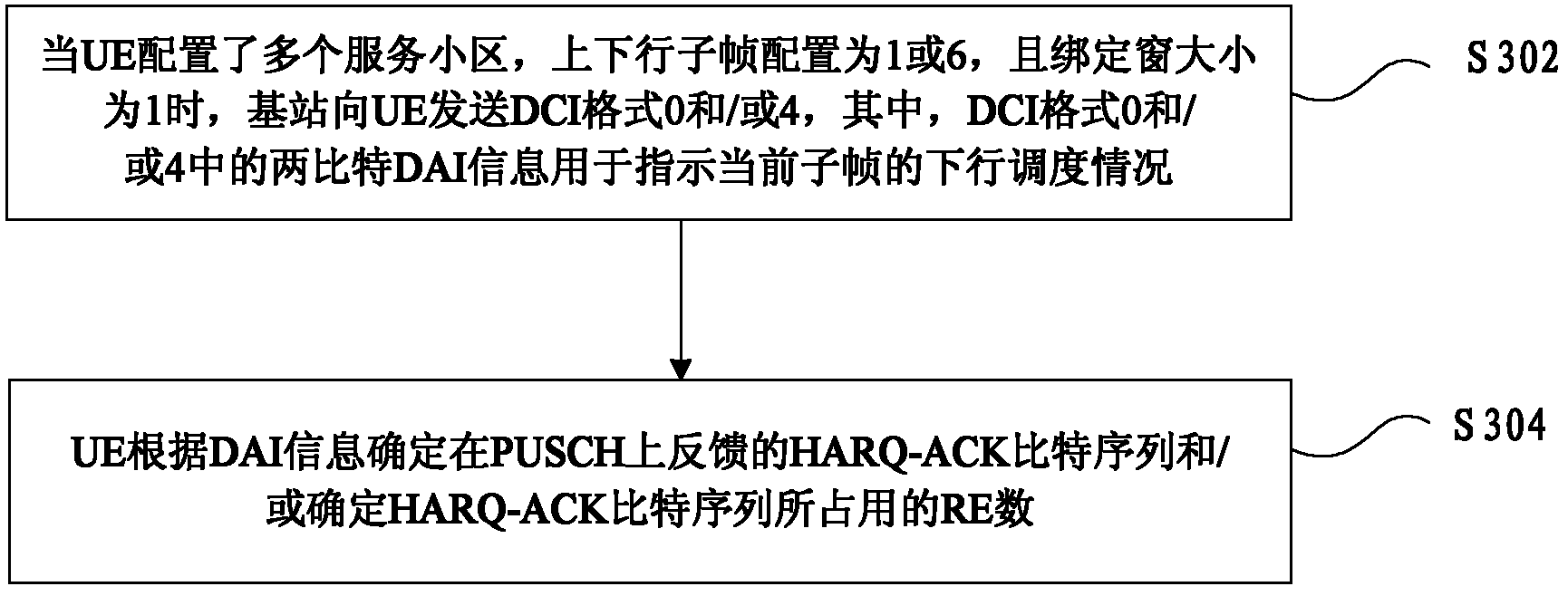

Feedback processing method and system for HARQ (Hybrid Automatic Repeat Request) -ACK (Acknowledge Character)

ActiveCN102223219ASolve the case of size 1To achieve the effect that meets the actual needsError prevention/detection by using return channelWireless communicationUser equipmentComputer science

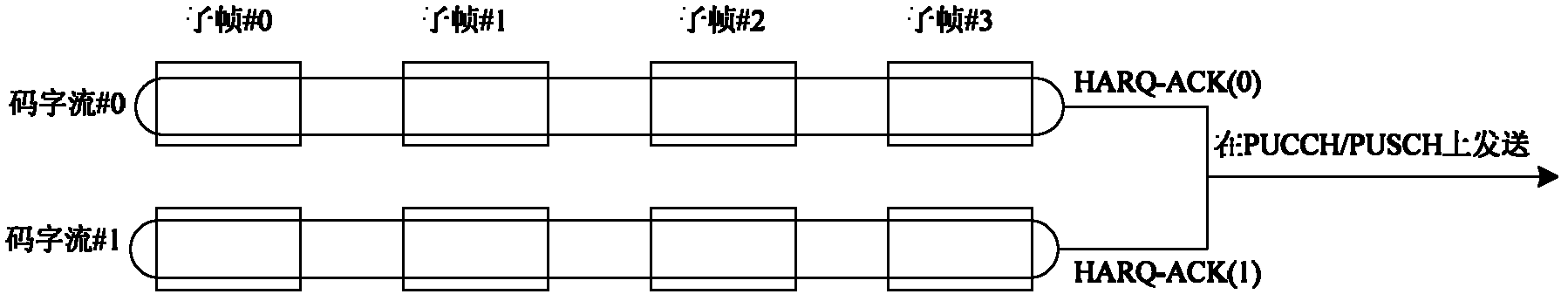

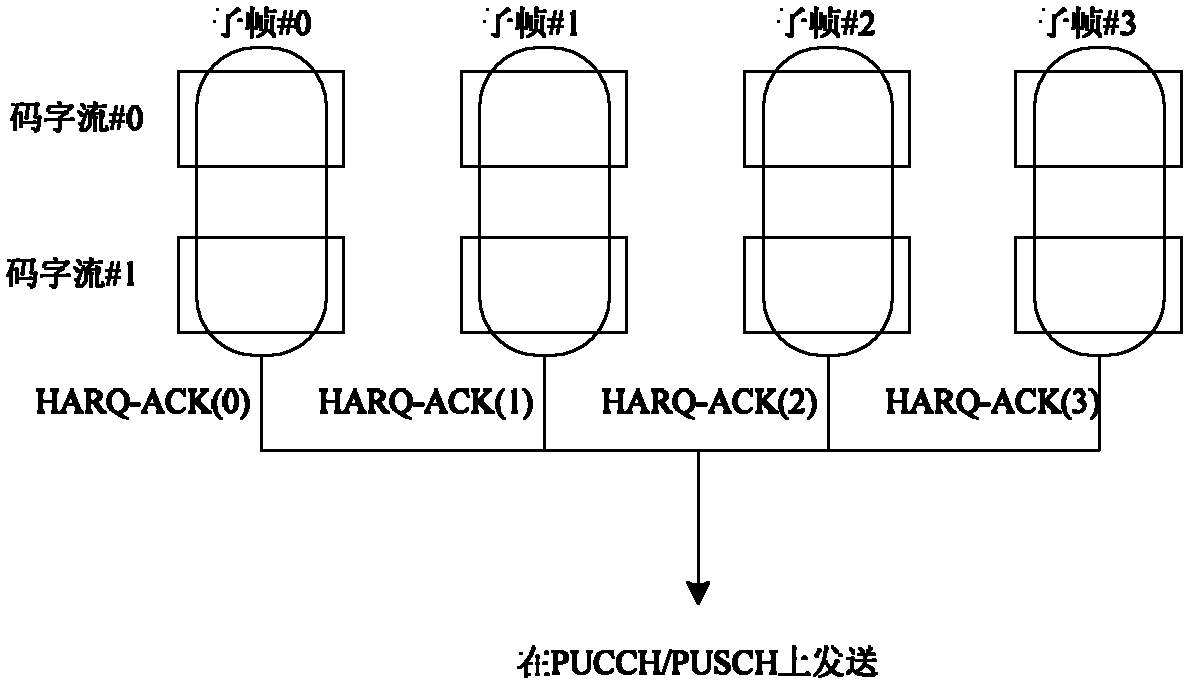

The invention discloses a feedback processing method and system for HARQ(Hybrid Automatic Repeat Request)-ACK (Acknowledge Character). The method comprises the following steps that when the UE (user equipment) is provided with a plurality of service districts, the uplink subframe and the downlink subframe is configured as 1 or 6 and the size of the tying window is 1, the substation sends 0 and / or 4 in the form of DCI to the UE, wherein the two bit downlink allocation index (DAI) information of 0 and / or 4 in the form of DCI is used for indicating the downlink scheduling situation of the current subframe; and the UE determines the HARQ-ACK bit sequence and / or determines the RE number occupied by the HARQ-ACK bit sequence according to the DAI information. The method and the system achieve the effect that the size and the occupied resource unit of the HARQ-ACK bit sequence meets the practical requirement.

Owner:ZTE CORP

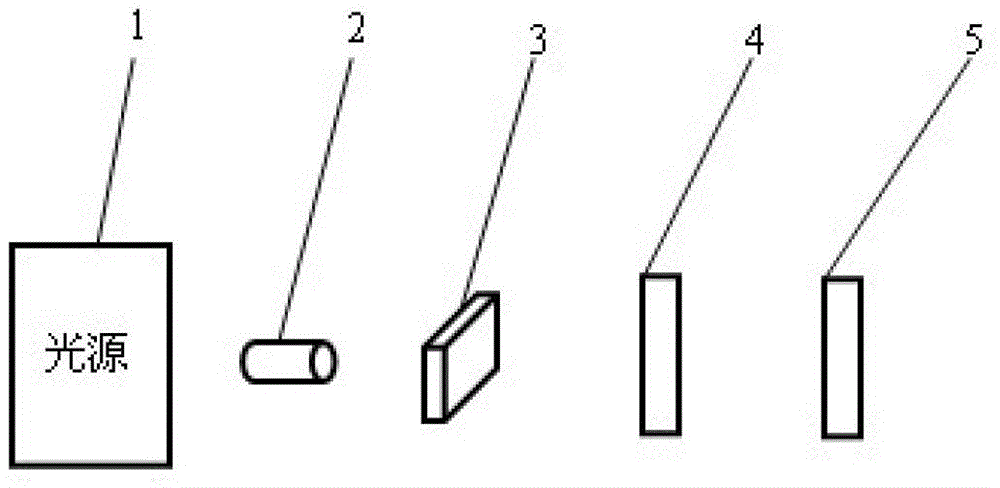

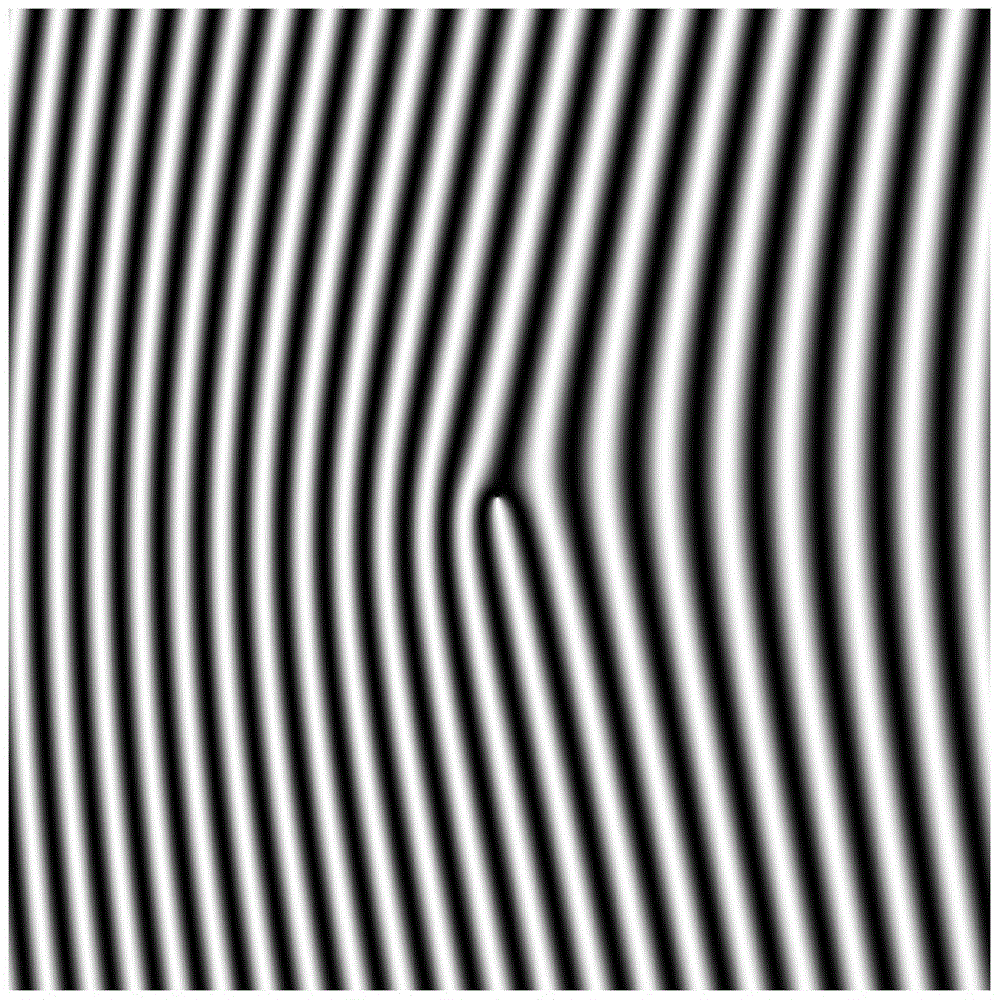

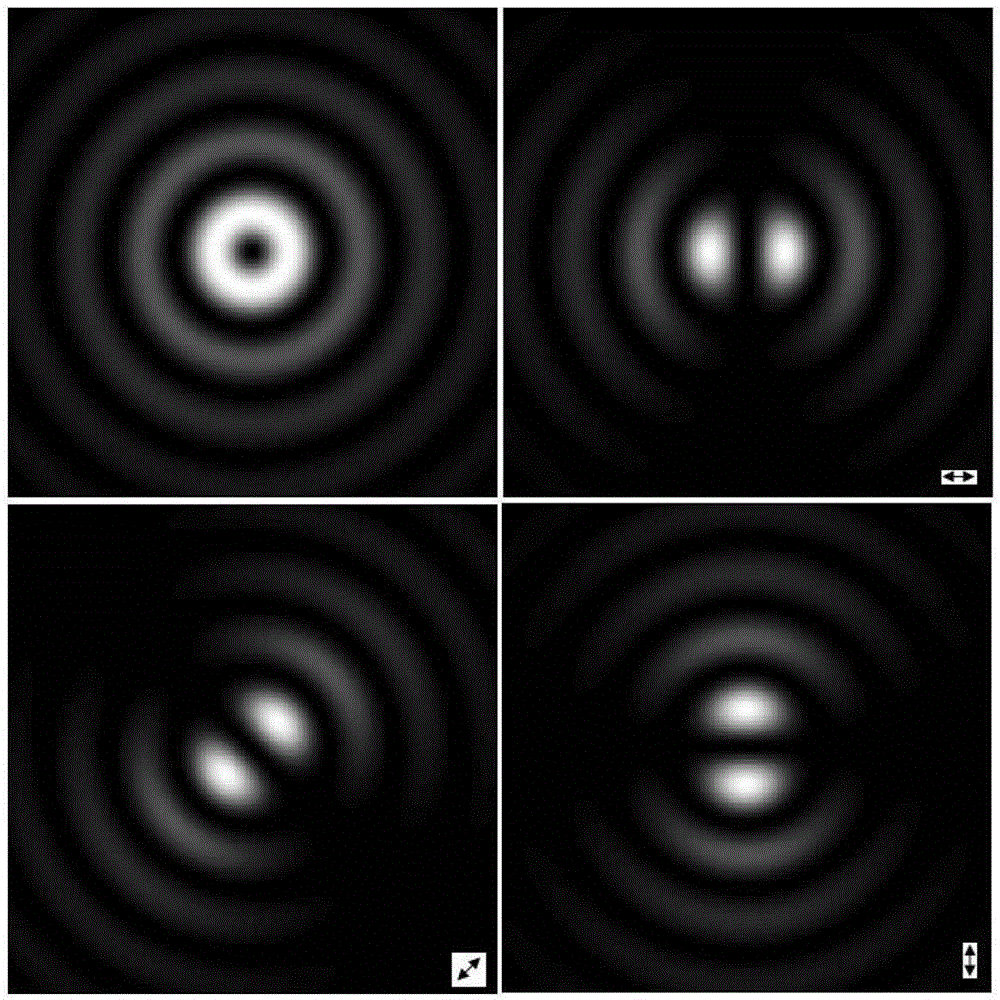

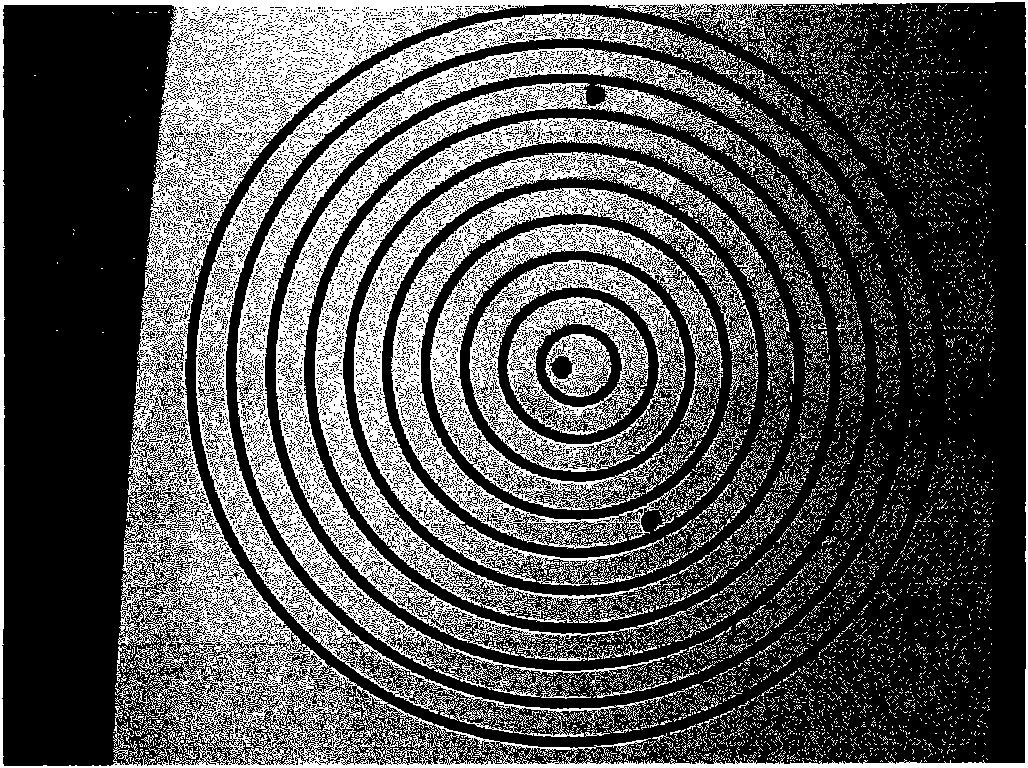

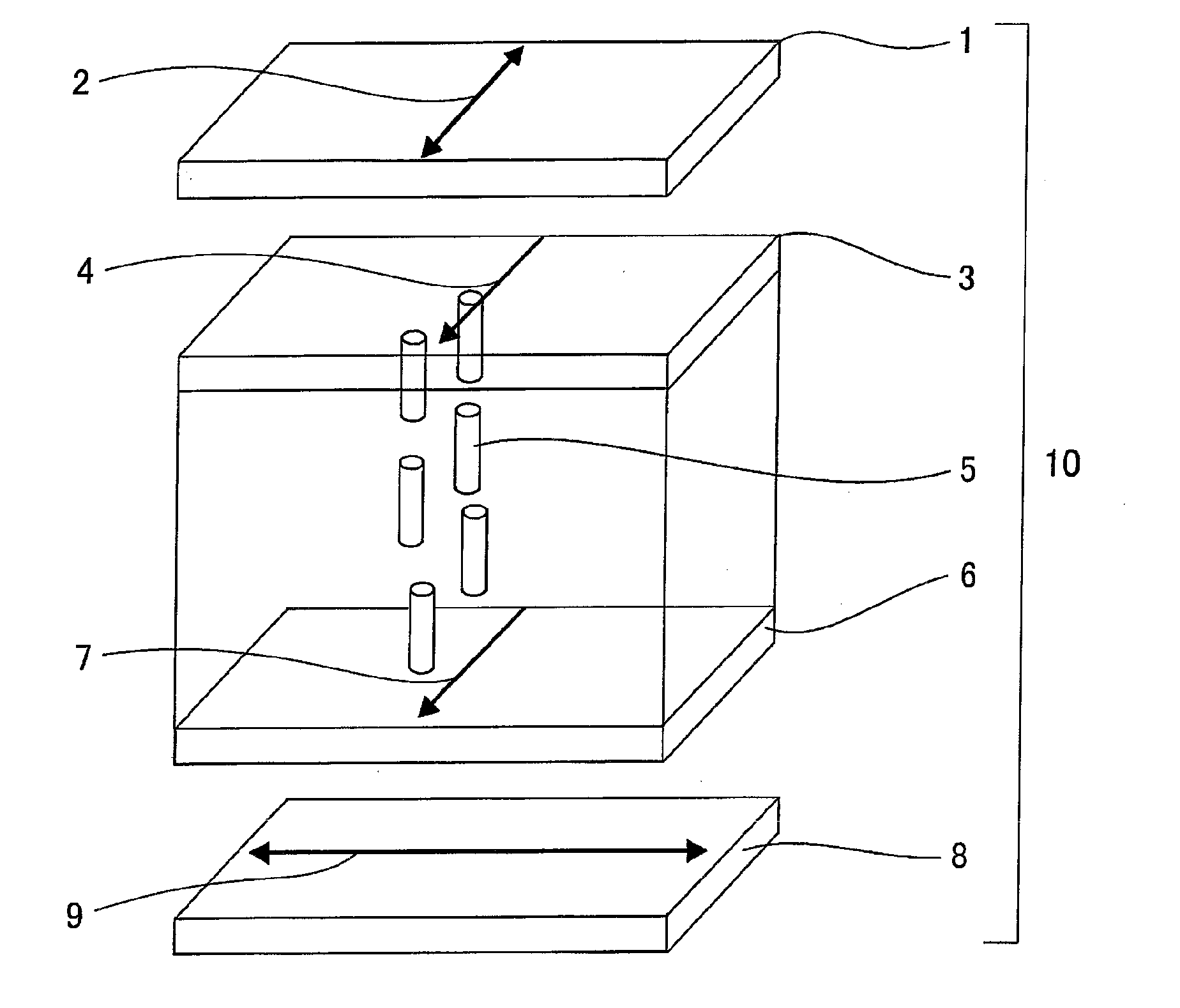

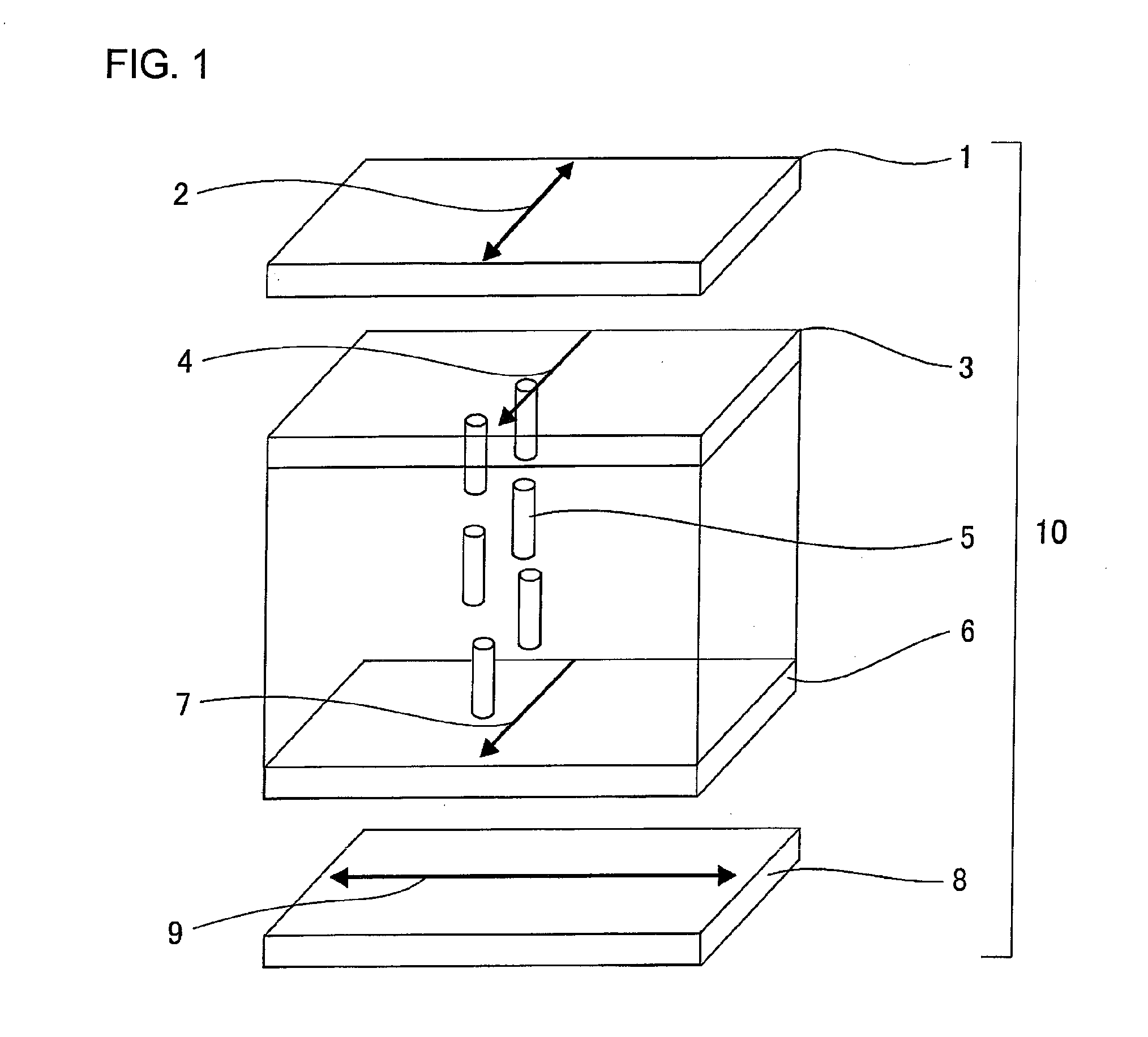

System and method for generating radial Bessel-Gaussian beam

The invention discloses a system for generating a radial Bessel-Gaussian beam. The system comprises a beam expander, a computer-controlled spatial light modulator, a vortex phase plate and a radial polarization convertor that are sequentially arranged in a light direction of a light source generating linearly polarized light, wherein a topological charge of the vortex phase plate is 1; and a calculation hologram generated by a computer is loaded to the spatial light modulator to form a calculation holographic grating, so that a first order Bessel-Gaussian beam is generated. The vortex phase plate is rotated to ensure that phase structure distribution of the vortex phase plate is right opposite to the phase structure distribution of the Bessel-Gaussian beam coming out of the spatial light modulator, and a vortex phase of the Bessel-Gaussian beam is eliminated. Then, the Bessel-Gaussian beam with the vortex phase being eliminated passes through the radial polarization convertor. Radial polarization Bessel-Gaussian beams with different ring numbers can be generated by generating different holograms due to the flexibility of the holograms of the computer, and have self-restorability.

Owner:SUZHOU UNIV

Method for constructing quasi-cyclic low-density parity-check code (QC-LDPC code)

InactiveCN101753149AGood error correction performanceFlexible designError correction/detection using multiple parity bitsParity-check matrixTheoretical computer science

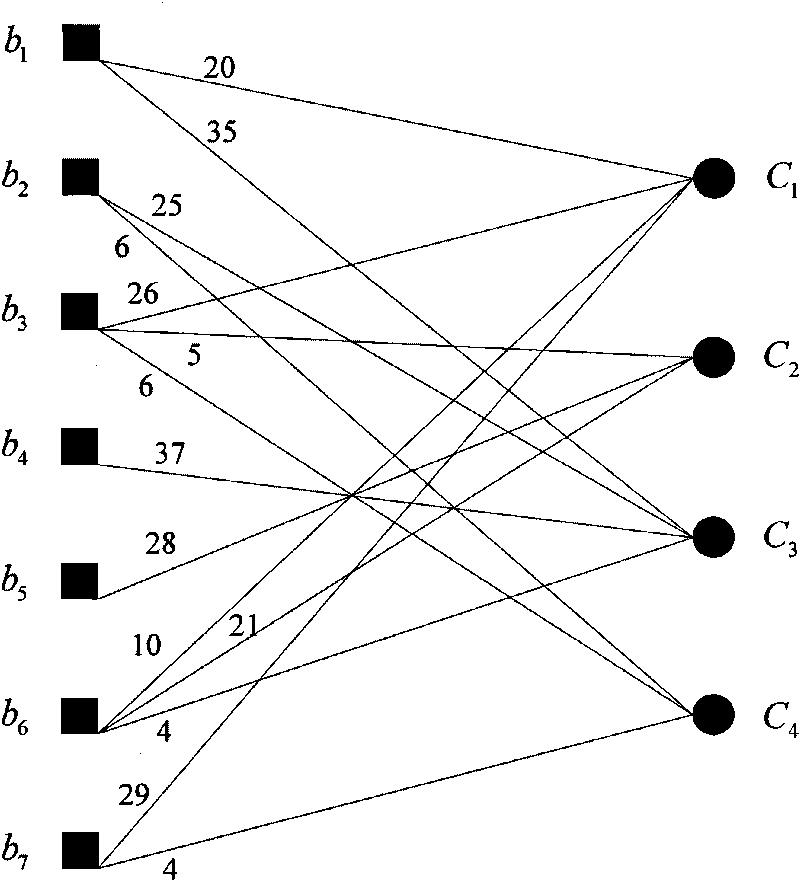

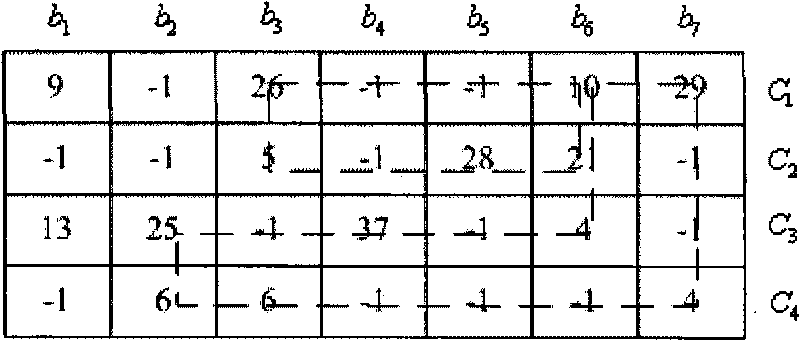

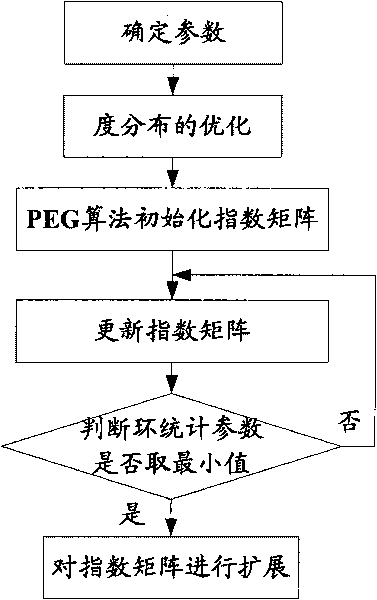

The invention provides a method for constructing a quasi-cyclic low-density parity-check code (QC-LDPC code), which comprises the following steps: determining a parameter of an encoding matrix; constructing an exponential matrix M (H) of a QC-LDPC code parity check matrix; using a progressive edge growth (PEG) algorithm of the QC-LDPC code parity check matrix to initialize the exponential matrix M (H); endowing the exponential matrix each nonnegative element to form a cyclic shift value with the longest minimum ring and the least ring number; carrying out iteration replacement on the elements in the exponential matrix; and completing the iteration replacement process of the exponential matrix by an exponential matrix iteration assignment algorithm of the QC-LDPC code parity check matrix. The method for constructing the QC-LDPC code of the invention can guarantee the girth and the average minimum girth of the code maximized so as to obtain excellent error code correcting performance.

Owner:ACAD OF BROADCASTING SCI SARFT

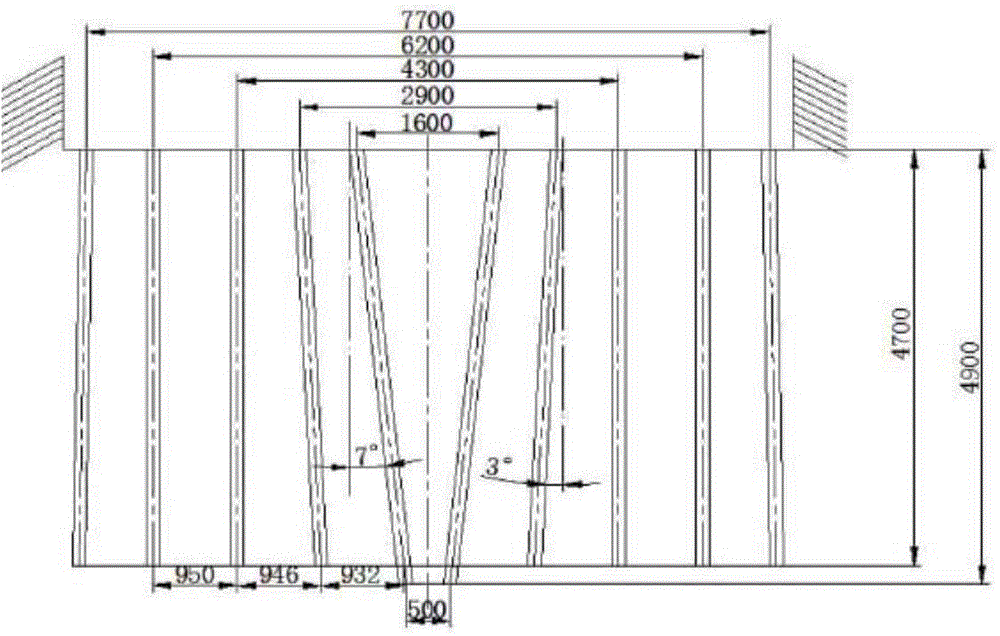

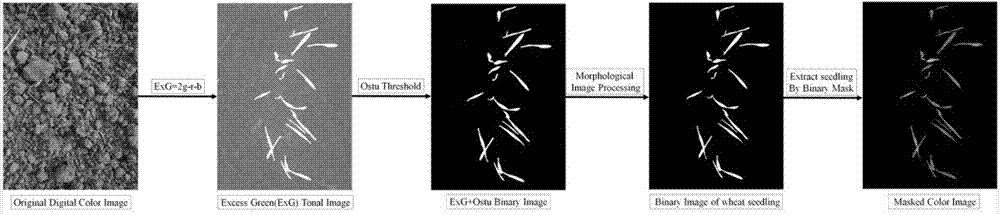

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

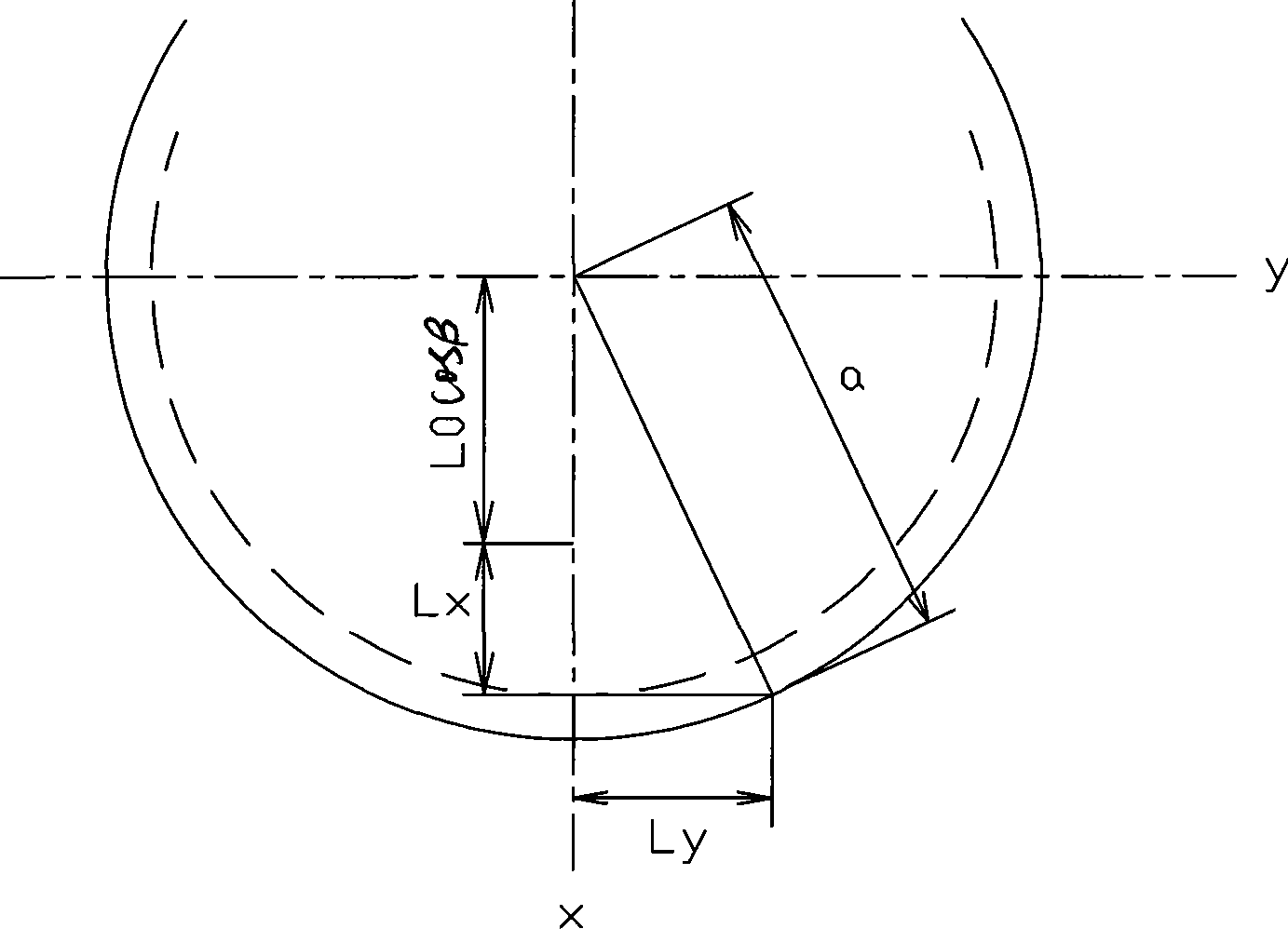

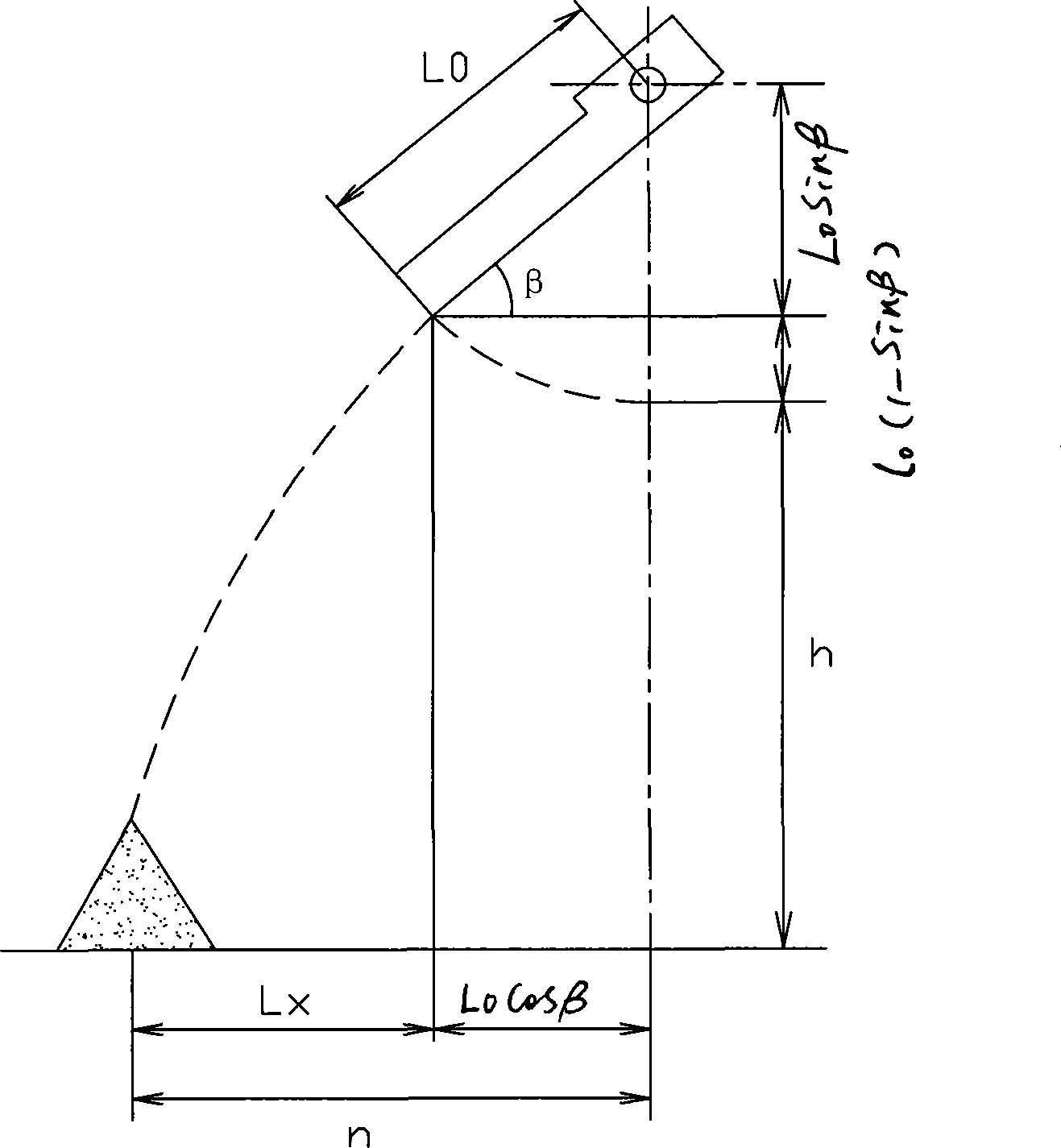

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

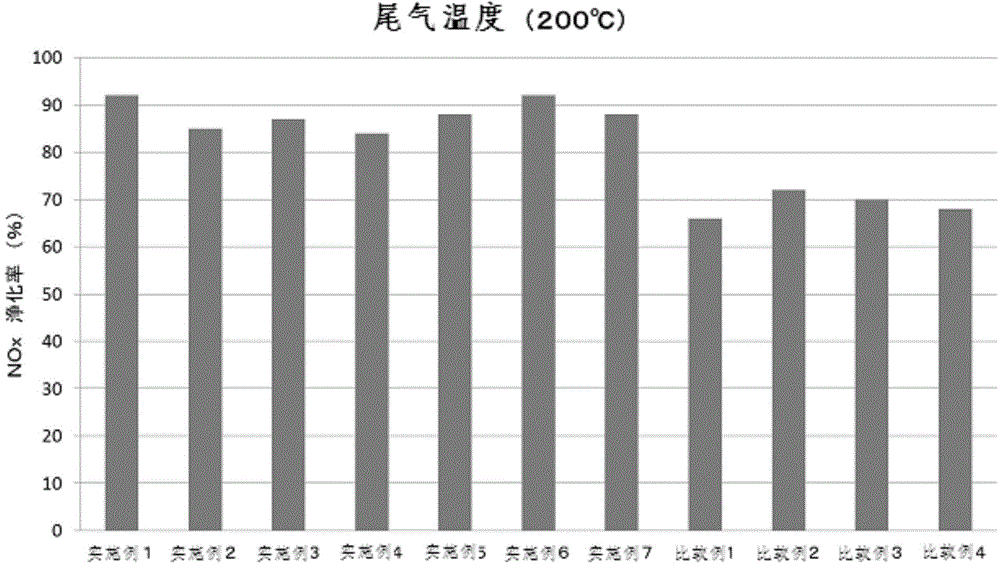

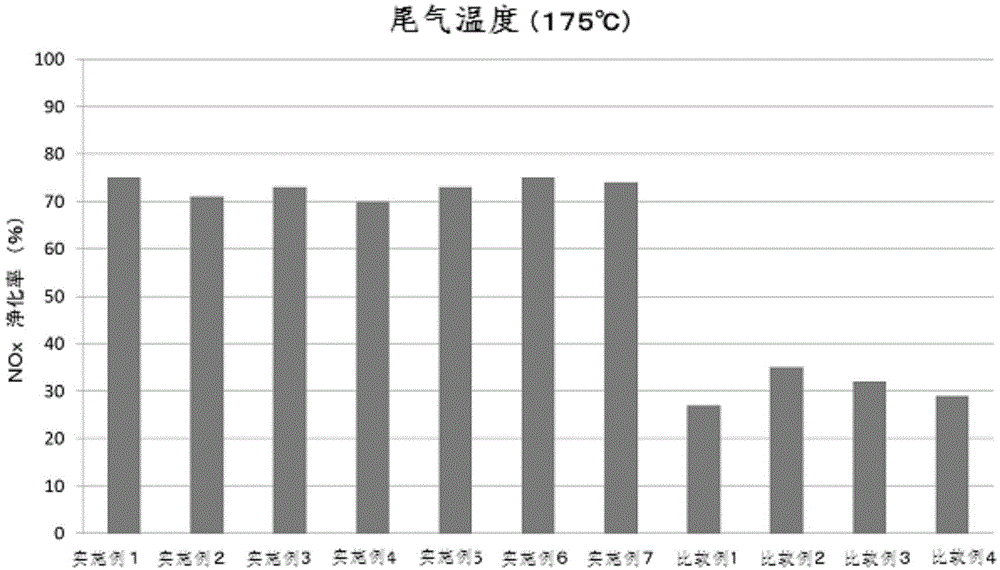

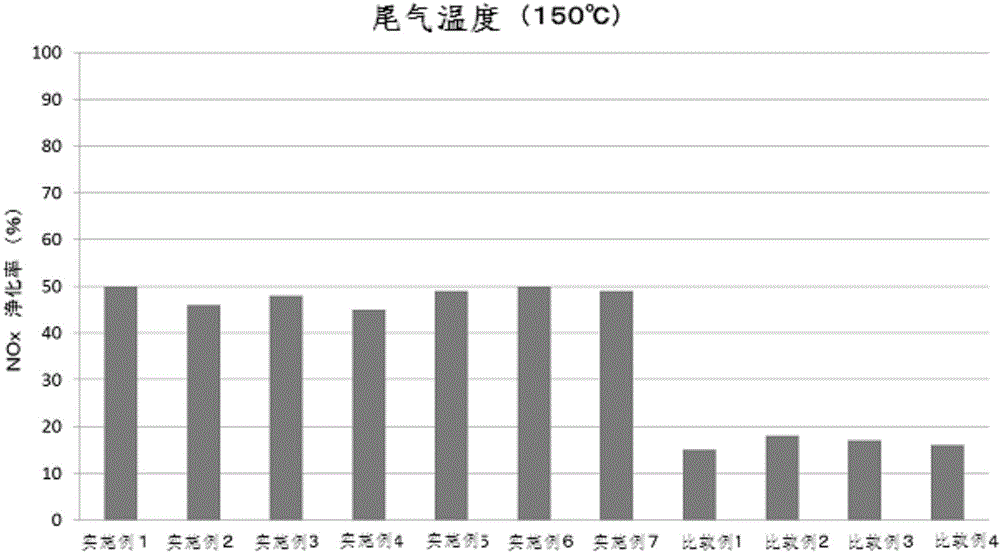

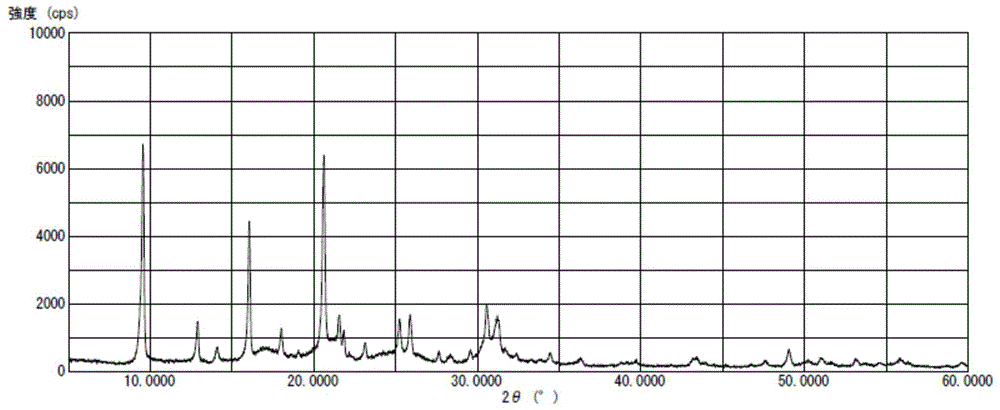

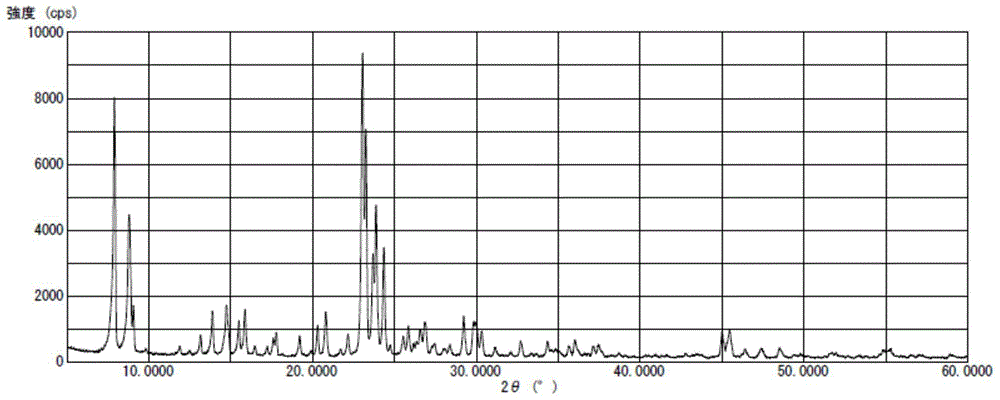

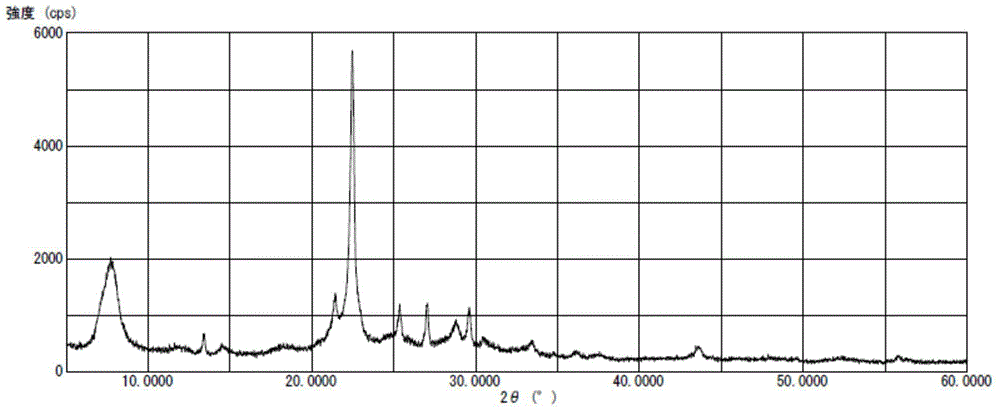

Copper-based SCR catalyst and preparation method thereof

ActiveCN104128200AThe production process is simpleLow temperature activeCatalyst carriersMolecular sieve catalystsCopper(II) chlorideOxygen

The invention provides a simple method for preparing a copper (II) ion-supported SCR catalyst having a NOx purifying performance at a low temperature. The SCR catalyst is prepared by mixing hydrogenation synthesized zeolite crystals with the largest oxygen ring number of 8-12 and a three dimensional structure with an aqueous solution of copper (II) nitrate ions or copper (II) chloride ions with the pH value of 0.1-3.0 without filtering or washing. The BET specific surface area of the copper-based SCR catalyst is 50-80m<2> / g, the copper-based SCR catalyst has low temperature activity, hydrothermal durability and NOx purifying performance, and the exhaust gas NOx purifying rate of the copper-based SCR catalyst at below 200DEG C reaches above 80%.

Owner:清华大学苏州汽车研究院(吴江) +1

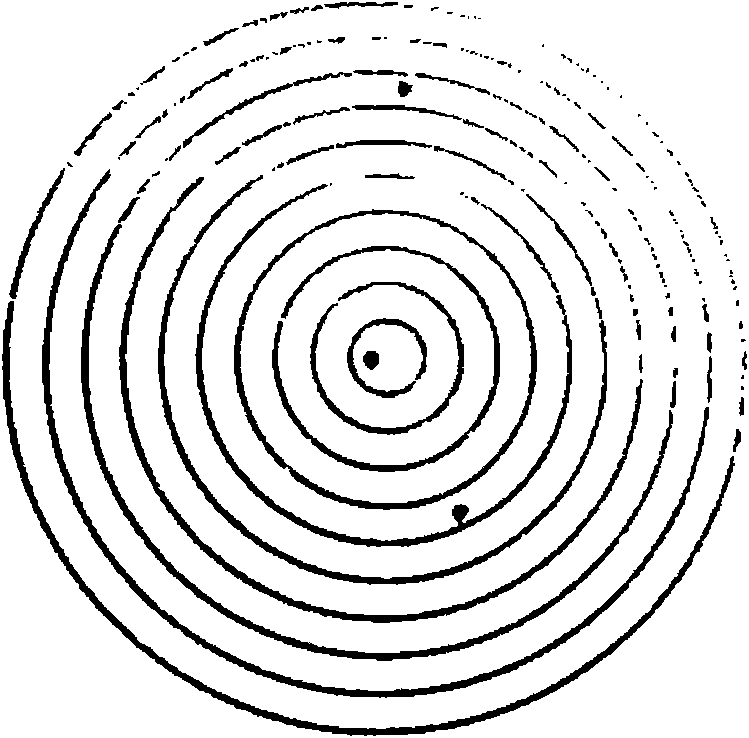

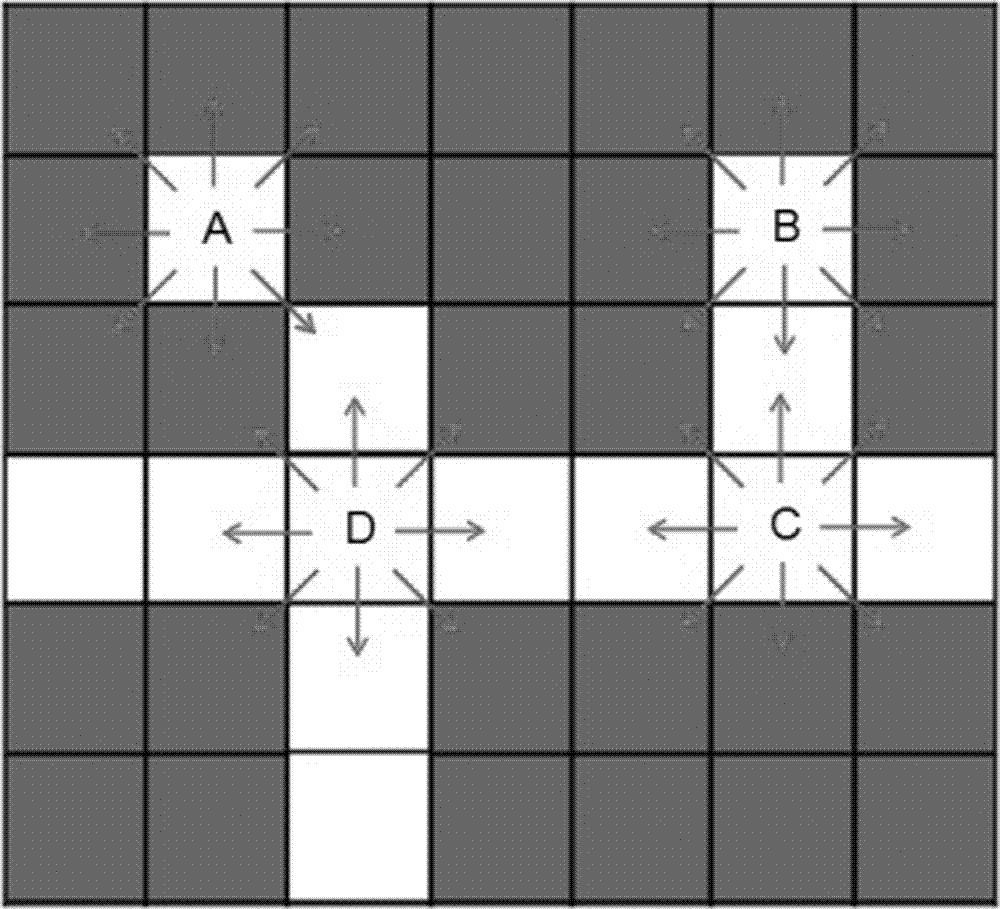

Automatic target identifying method based on image processing technology

InactiveCN101937509ARealize identificationReduce the impactCharacter and pattern recognitionTarget surfaceImaging processing

The invention discloses an automatic target identifying method based on an image processing technology, which comprises the following steps of: 1, carrying out binaryzation processing to a preprocessed target surface image by selecting a proper threshold to ensure that the processed image only has target ring lines and bullet holes; and obtaining radius of each of other ring lines in sequence; 2, distinguishing by utilizing the different sizes of radii of the ring lines and the bullet holes, analyzing the image with a mathematical morphological image processing method, then carrying out repeated dilation and erosion operation on the image to obtain the image containing the bullet holes, and then finding out a gravity center pixel coordinate of each bullet hole; 3, calculating the center coordinate of each bullet point by calculating mean values of all pixel coordinate in the bullet point, and testing an area expression which the center coordinate meets by substituting the center coordinate to the expression of each area so as to further determine the ring number of the bullet point so that the target is identified. The invention has the advantages of high-efficiency operation and accurate target identification.

Owner:SHAOXING COUNTY RUIQUN TEXTILE MACHINERY TECH

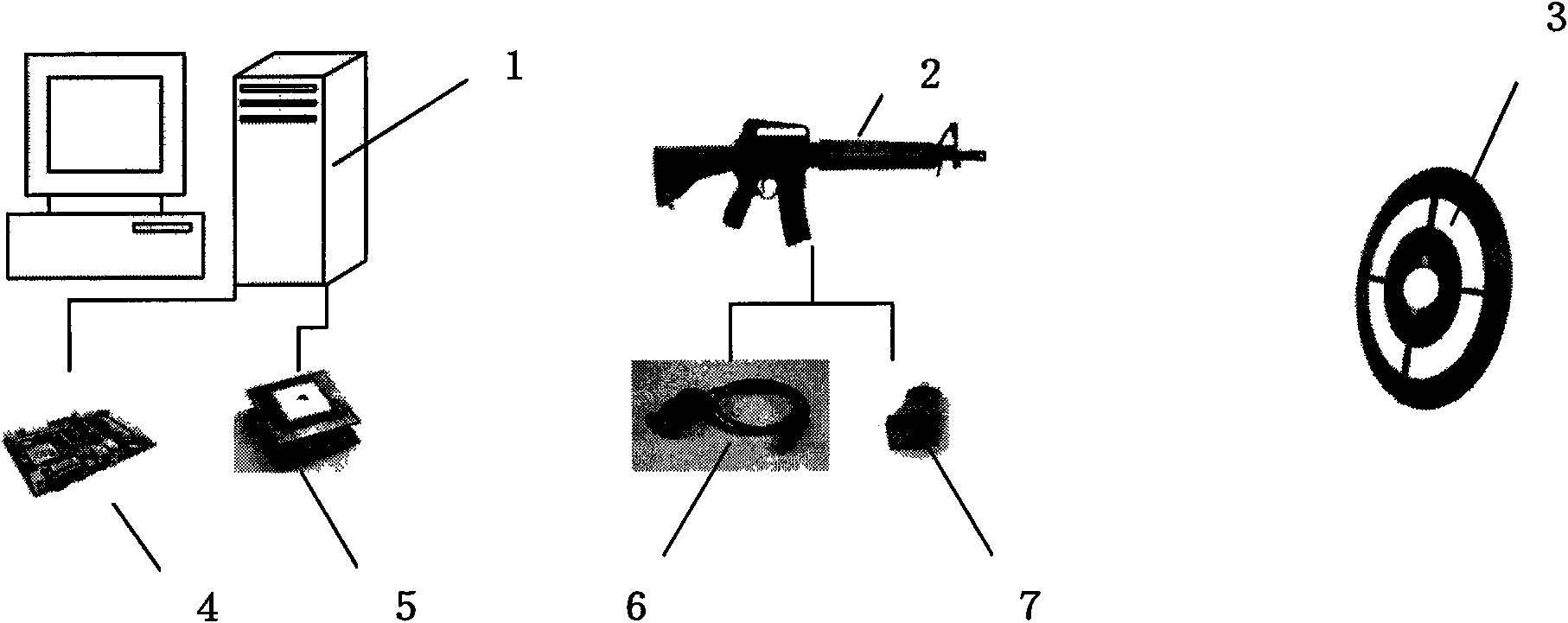

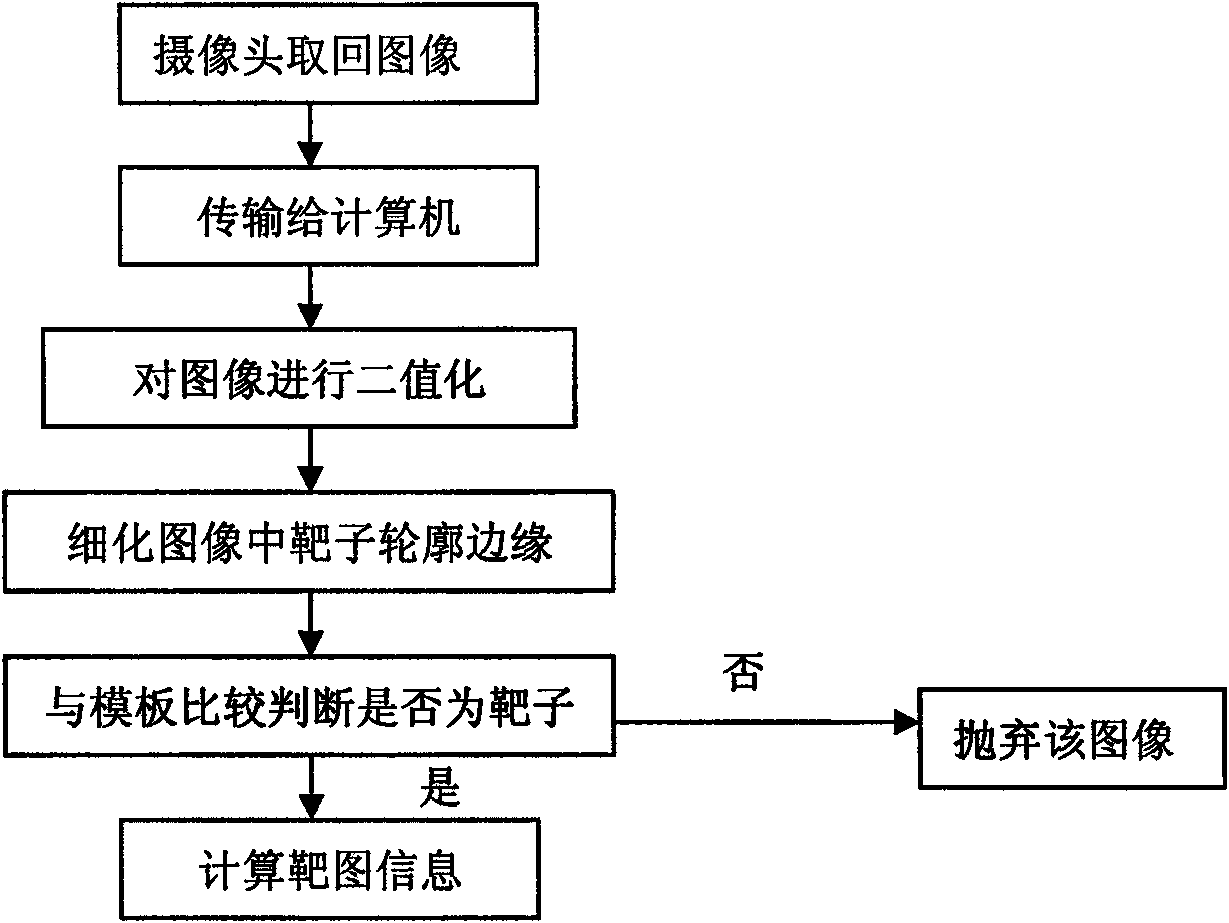

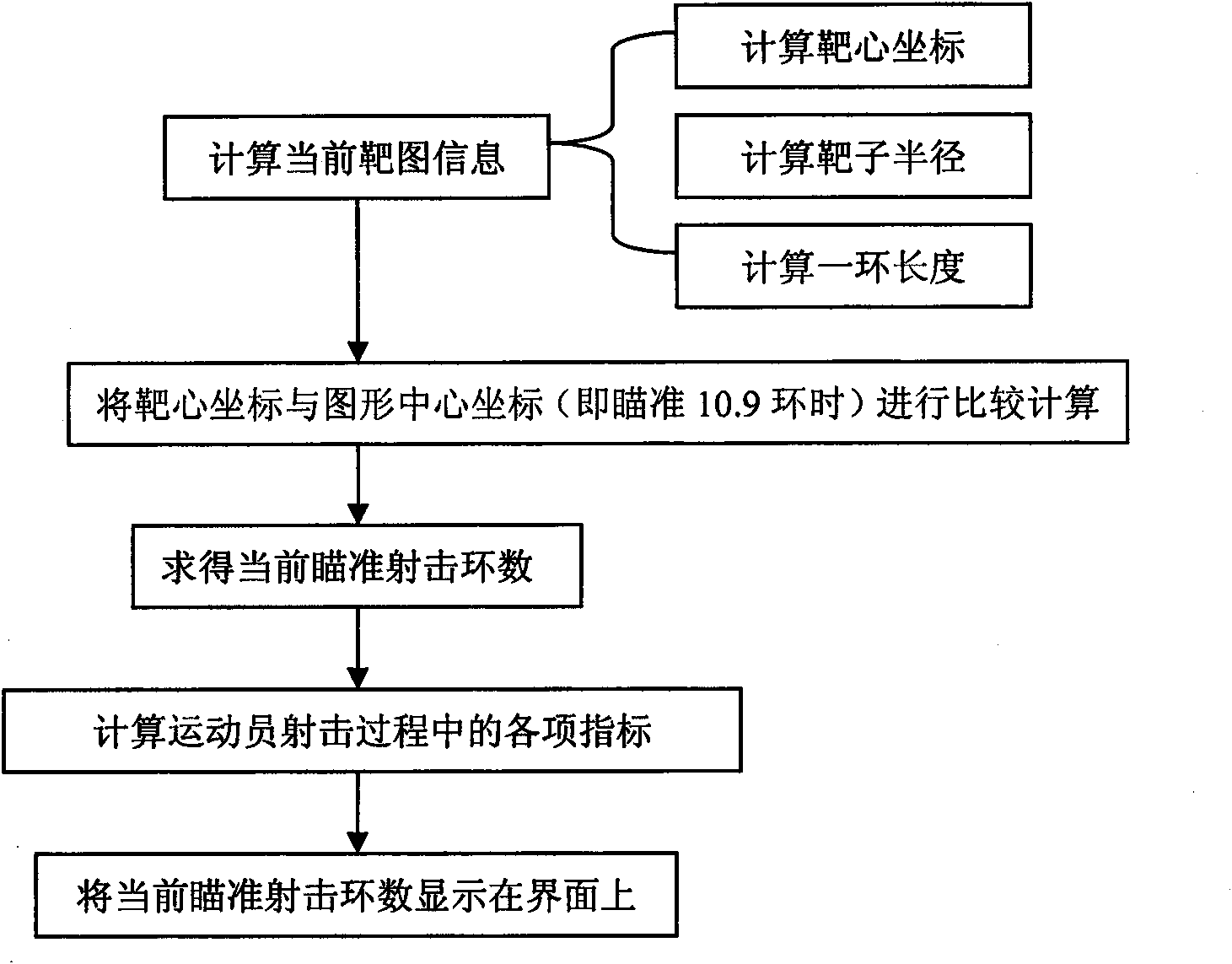

Shooting auxiliary training system and image-based bulls eye positioning method

InactiveCN101598520AHighlight substantiveReduce in quantityTraining adaptationWireless videoImage processing software

The invention relates to a shooting auxiliary training system and image-based bulls eye positioning method. The system mainly comprises a computer, a gun, a target, a wireless video capture card, a wireless trigger receiving device, a wireless micro camera and a wireless trigger. The method is characterized in that: (1) the up and down and the left and right of an image shot when the center of the camera aims at the center of a shooting object are symmetrical about the aiming point of the center of the camera; (2) when a shooter holds the gun and aims at the center of the target, the center of the image shot by the camera is coincided with the center of the target image; (3) the image is shot by the camera, and the contact ratio of the center of the target image and the central position of the image is processed by and image processing software in the computer, so as to determine the ring number aimed by the shooter at the moment. The system has no special requirement on the target, requires no ball firing and has simple device and low cost; the whole shooting process can be monitored, replayed and analyzed, and the technical parameters of the shooter can be analyzed by a path formed by the aiming point in the shooting process.

Owner:SHANXI UNIV

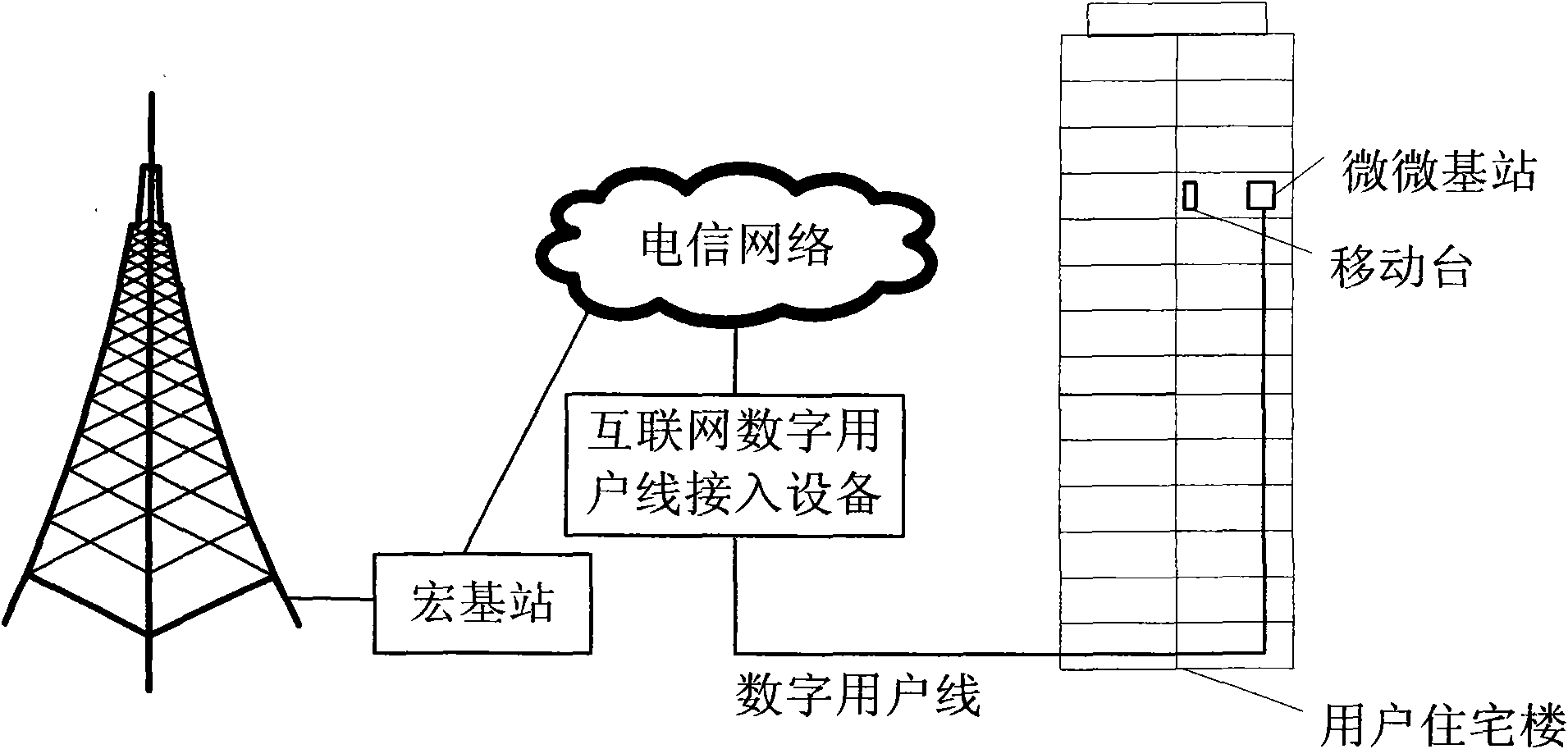

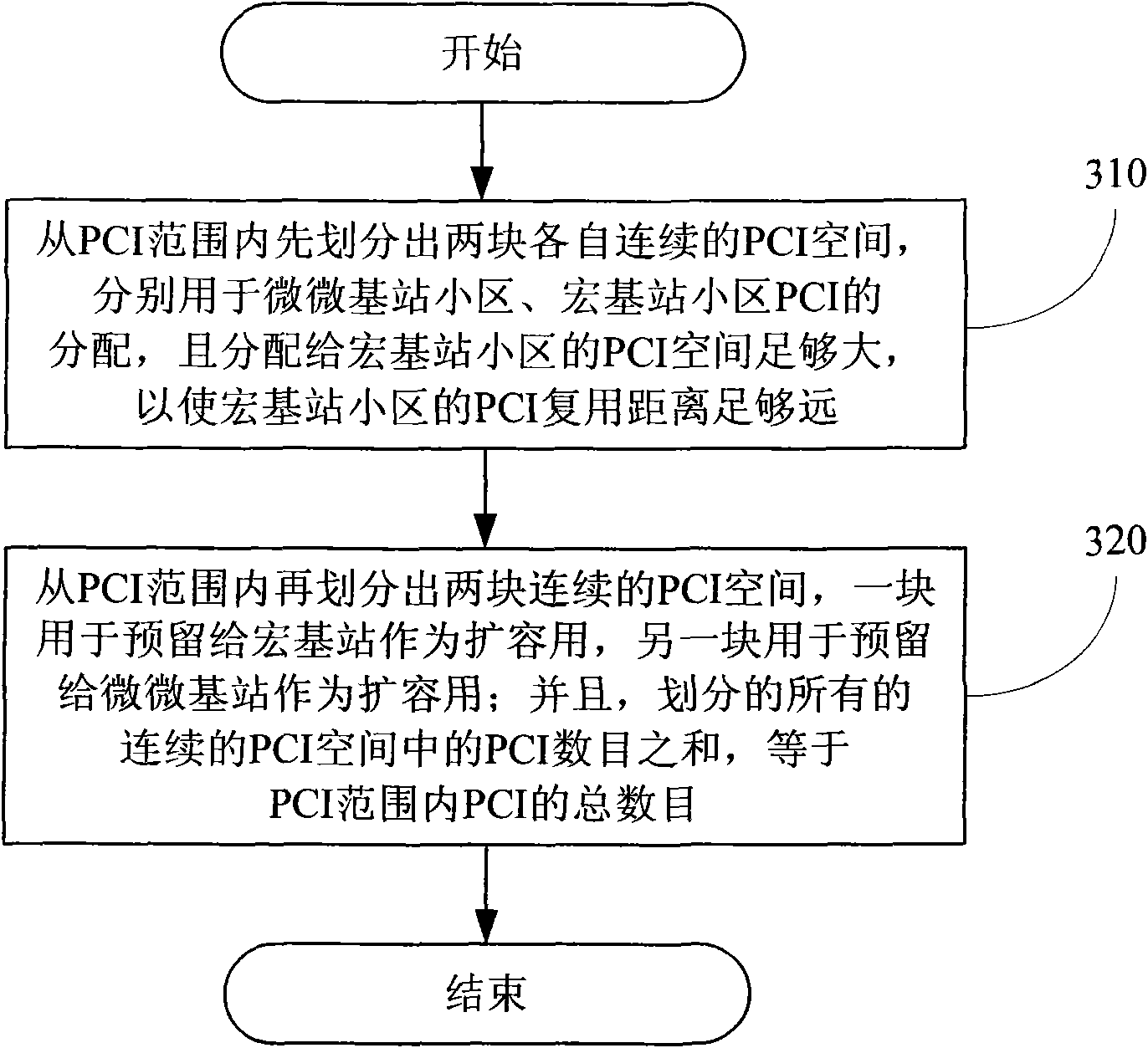

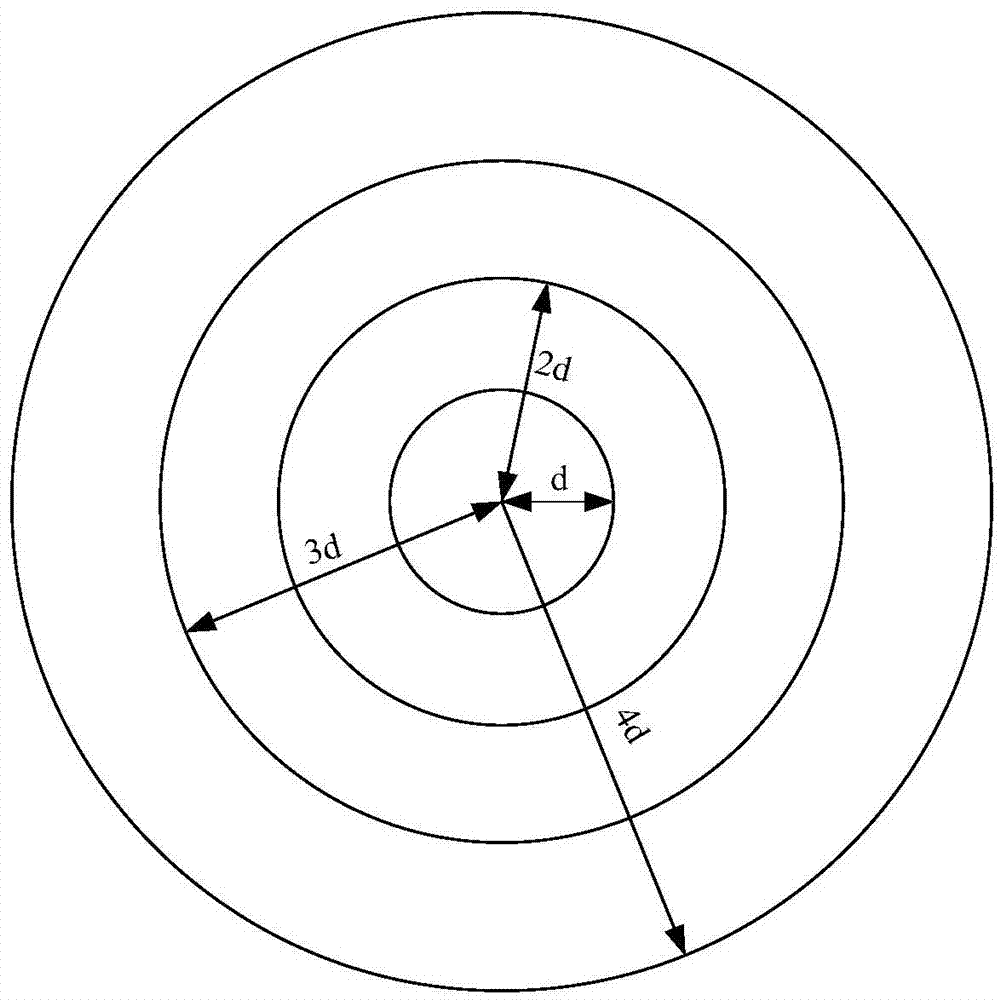

Distribution method of PCIs (Physical Cell Identities) in long-term evolution network

The invention discloses a distribution method of PCIs (Physical Cell Identities) in a long-term evolution network. The method comprises the following steps of: firstly, partitioning two respectively continuous PCI spaces in a PCI range, wherein one is used for distributing PICs in a picocell, and the other is used for distributing PCIs in a micro base cell; distributing a PCI space large enough to the micro base cell so that the PCI multiplexing distance in the micro base cell is far enough, which means the multiplication of ring number of enough macrocell clusters forming the micro base by the cell diameter, and the enough large PCI space means that the number of the distributed PCIs is at least equal to the total cell number of the enough macrocell clusters. On the premise that the macrocell clusters and the picocell are ensured to use different PCI spaces, the PCI multiplexing distance of the macrocell is far enough, PCI conflict probability among picocells is lower, and resources are preserved for network expansion.

Owner:ZTE CORP

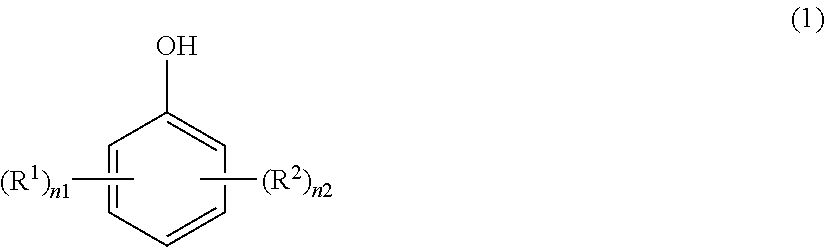

Polarizing plate and liquid crystal display device

InactiveUS20140057060A1Excellent in polarizer durabilitySmall amount of curlLiquid crystal compositionsNon-linear opticsTectorial membraneHydrogen

A polarizing plate includes, in the following order: a transparent protective film; an adhesive layer; and a polarizer, and the transparent protective film has a thickness of from 5 to 60 μm and contains at least one resin and a compound (A) having at least one hydrogen bond-forming hydrogen-donating group and a ratio of a molecular weight to an aromatic ring number of 190 or less.

Owner:FUJIFILM CORP

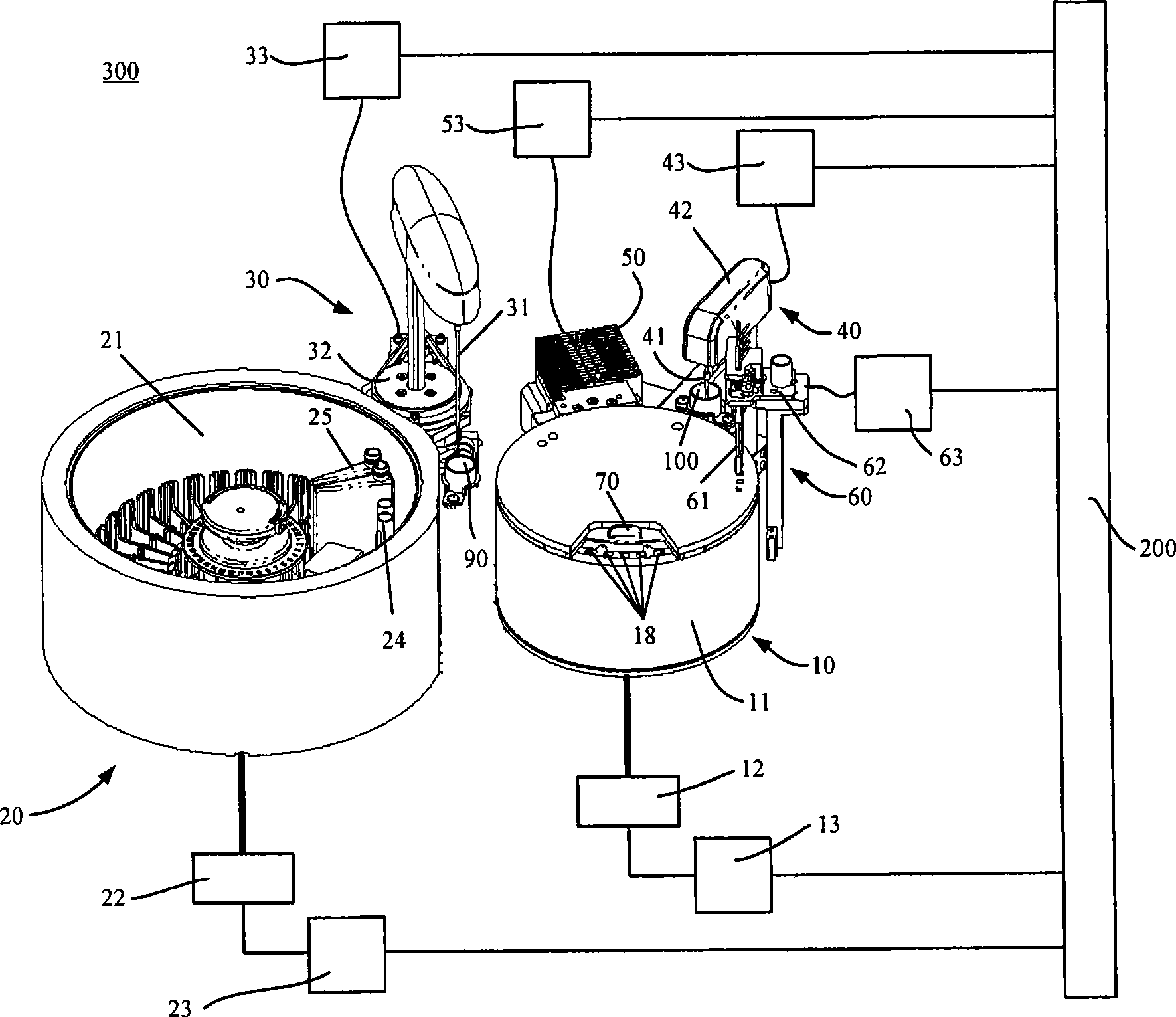

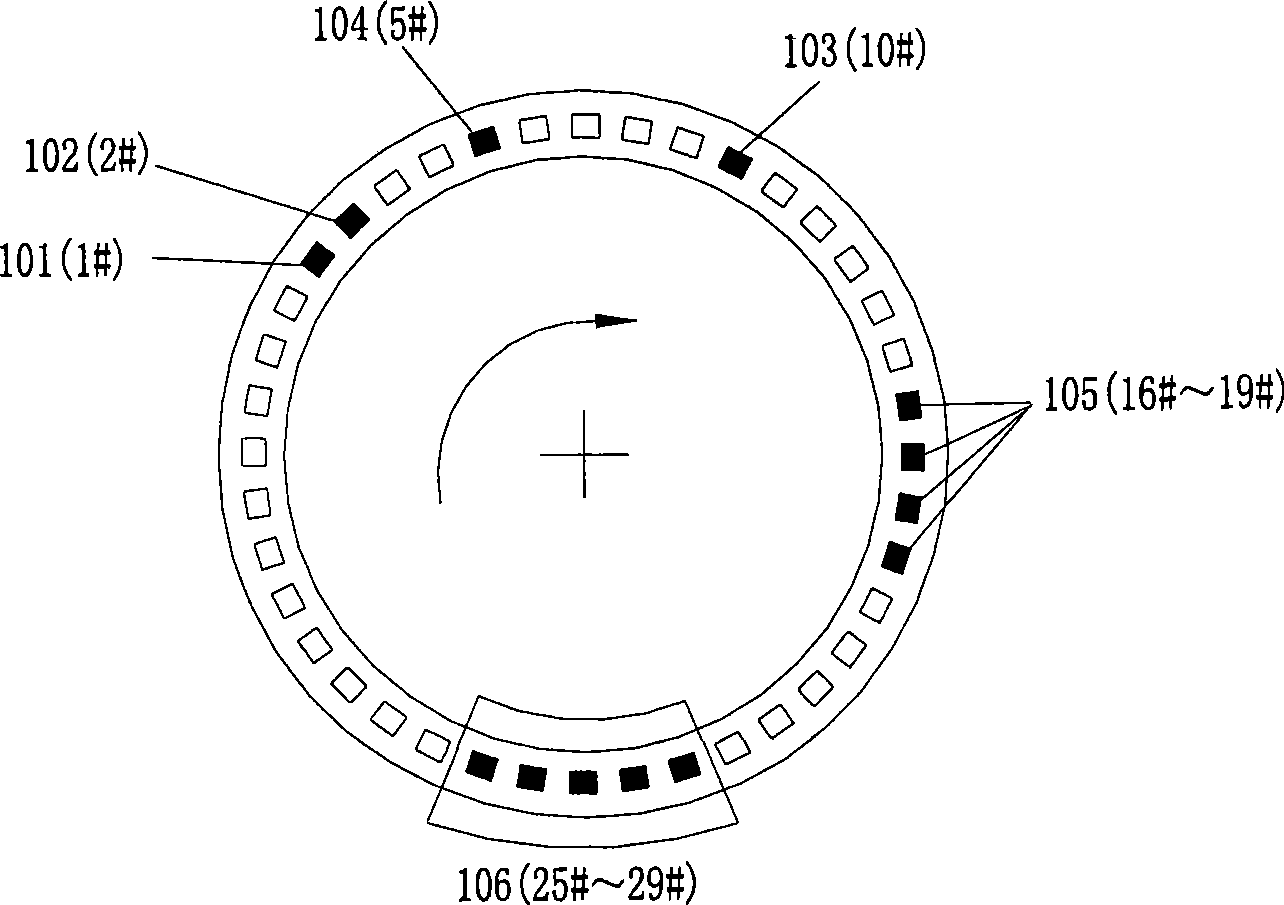

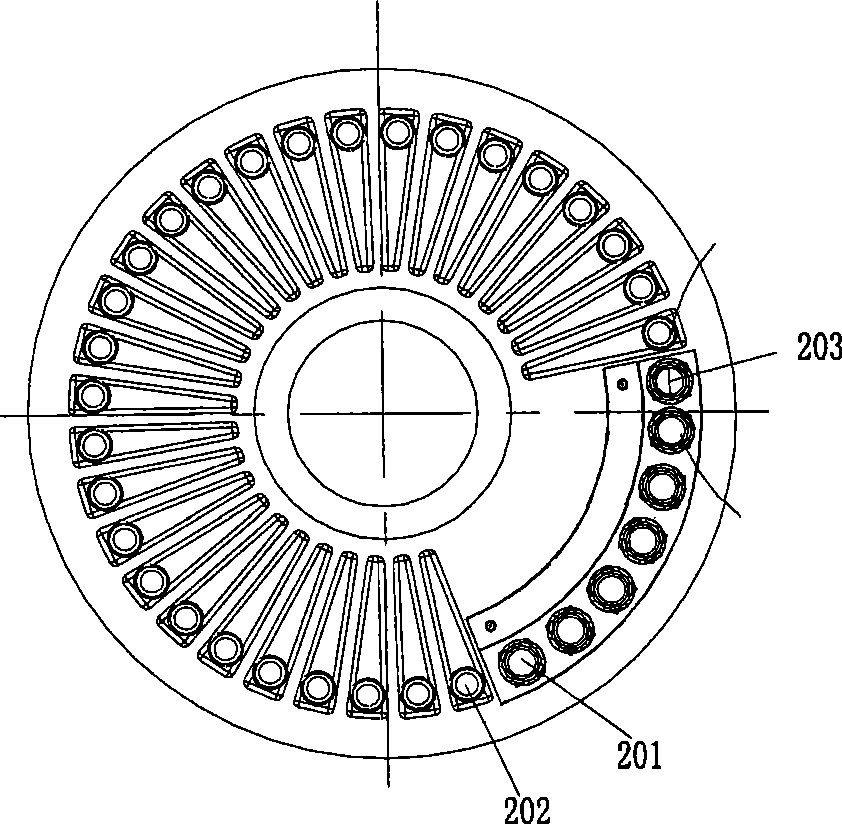

Sample analytical device and sample analytical method

The invention provides a sample analyzing device which aims at solving the problem that the prior art can not consider both cost and constant speed test of a single-double reagent project. The device comprises a reaction disc, a sample / reagent disc and a sampling pin. The reaction disc has at least three stoppages and three rotations in each working period; the number of respective rotated cup sizes of three rotations is fixed after the integral number of rotated rings is removed; and the accumulated rotated ring number R is plus or minus one cup size (R is more than or equal to 1). Accordingto requirements, a sample vessel or a reagent vessel rotates to a sample / reagent absorption position through the sample / reagent disc in each working period. According to requirements, the sampling pin carries out the addition of a sample action sequence, a first reagent action sequence and a second reagent action sequence in different periods respectively, wherein sample exhaust action, first reagent exhaust action and second reagent exhaust action are completed in different stopping periods of the reaction disc respectively. The invention also provides a method for analyzing a sample.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

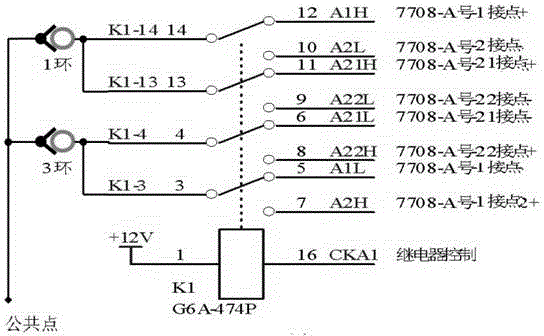

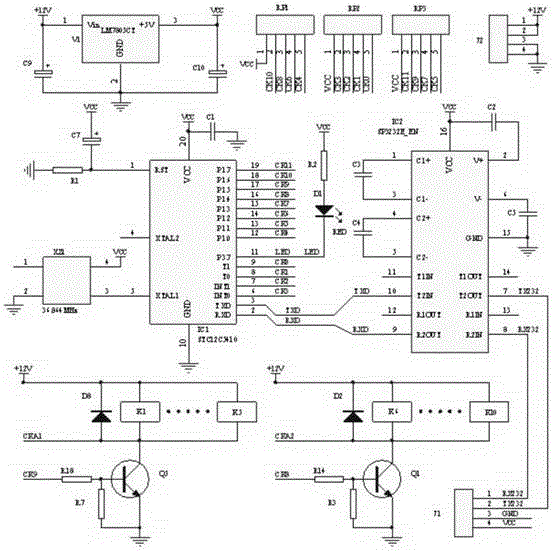

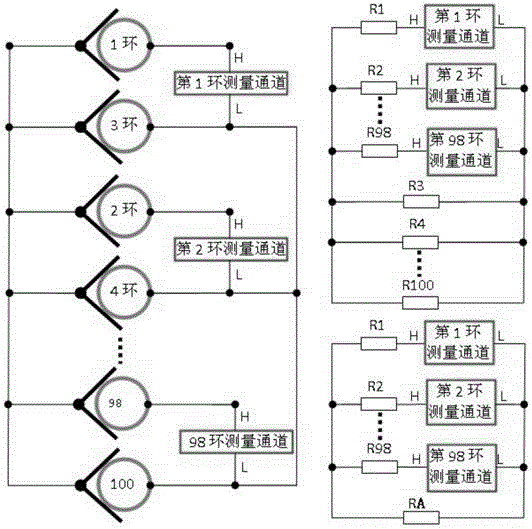

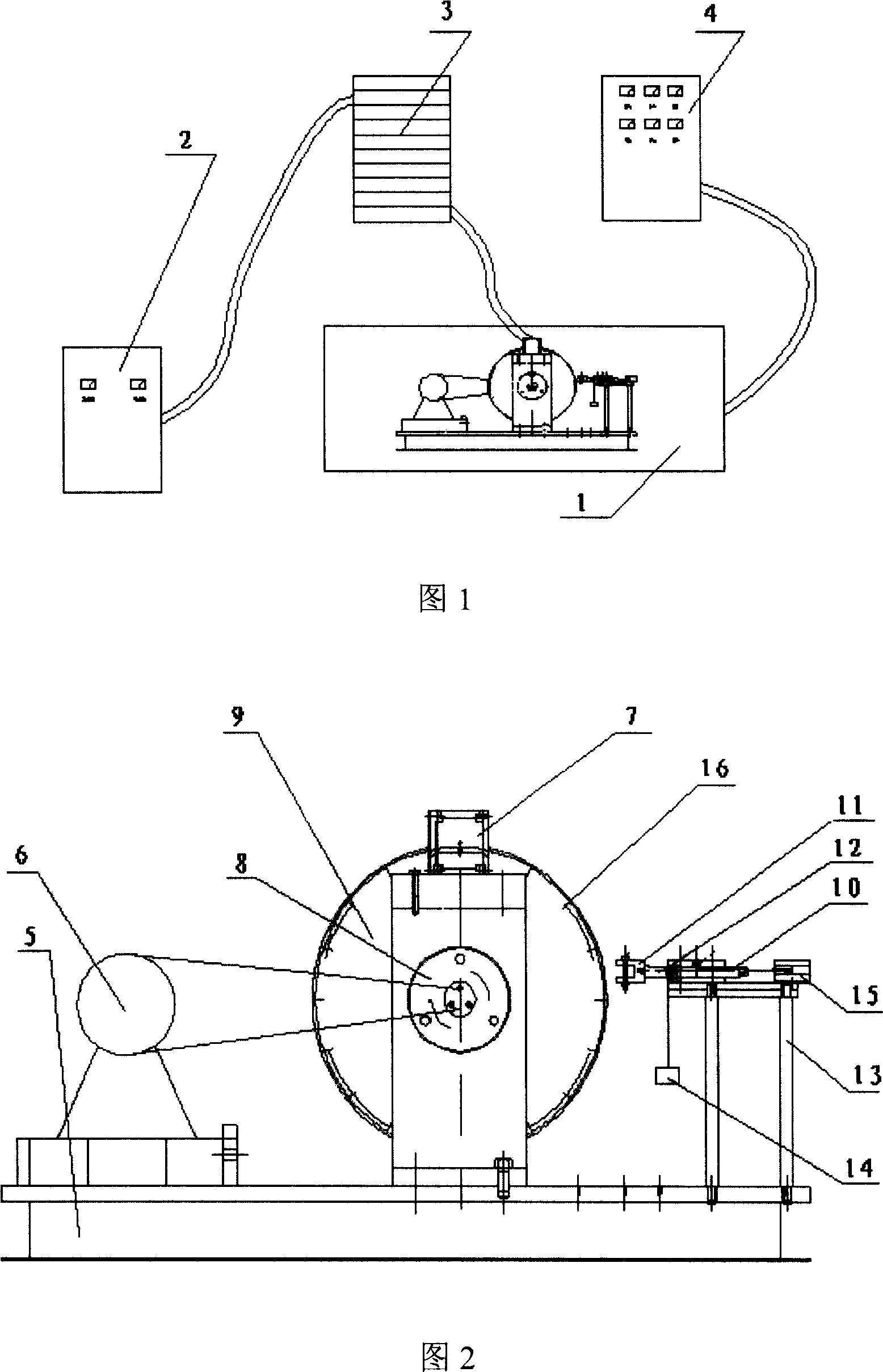

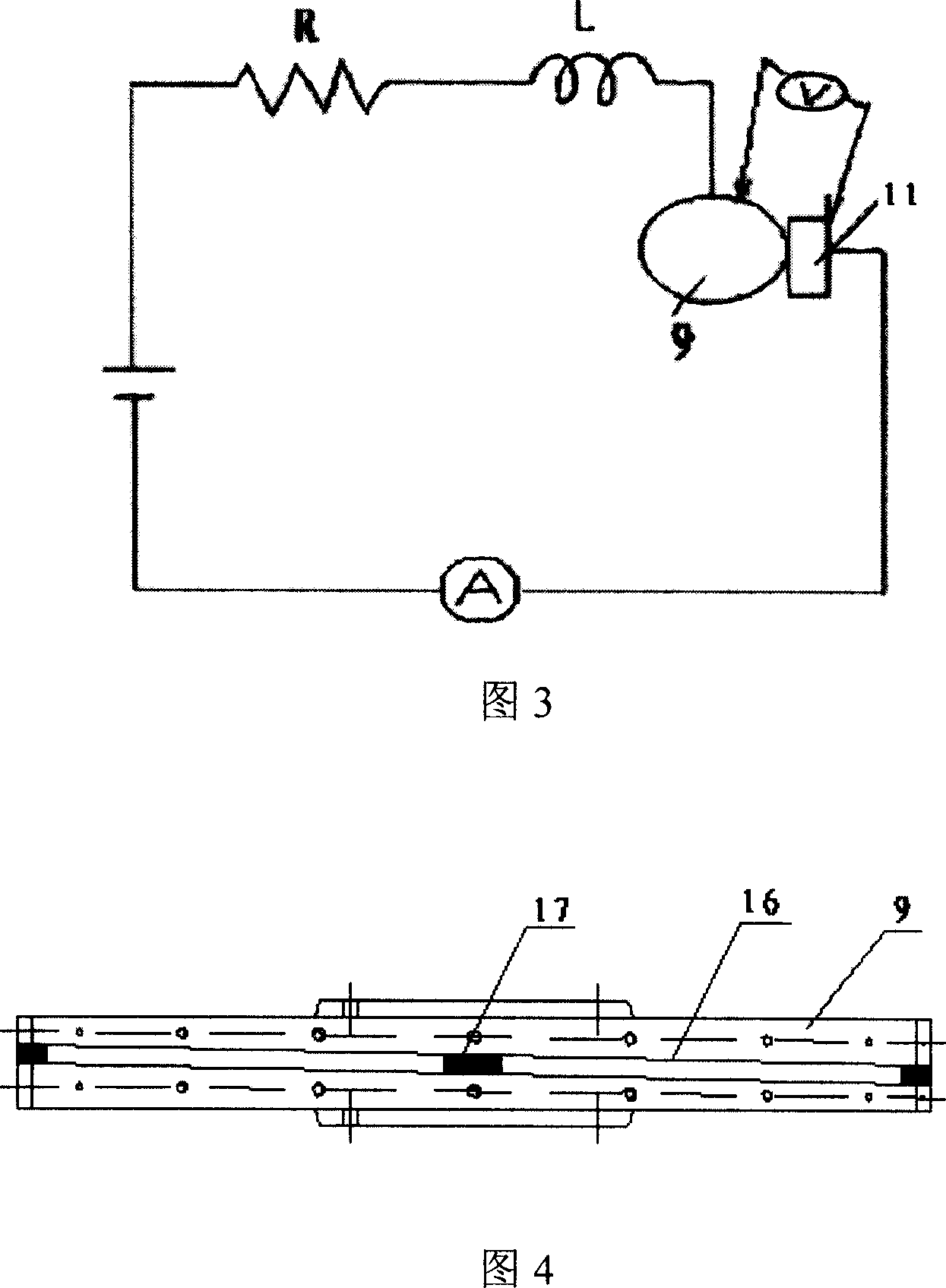

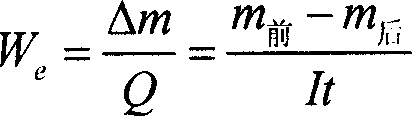

Measuring device and measuring method for dynamic contact resistors of conductive devices

ActiveCN103604993ATest accurateHigh measurement accuracyResistance/reactance/impedenceAviationElectrical resistance and conductance

A measuring device and a measuring method for dynamic contact resistors of conductive devices are disclosed. The invention provides a special-purpose measuring device for accurately measuring dynamic and static contact resistors which are applied to conductive devices in a variety of models in the aviation and aerospace field. The measuring device comprises a liquid crystal display, an industrial control computer system, a multipath micro resistor measurement unit, a switch control module, a keyboard, a mouse, a system power supply, a test connection cable, conductive devices to be measured and the like. According to the invention, dynamic and static contact resistors between conducting rods and electric brushes of conductive devices in a variety of models such as 96 rings, 76 rings, 60 rings, 54 rings and the like can be accurately measured, parameters such as the measuring ring number, the measuring mode, the measuring number of times and the like of the conductive devices can be set, and functions such as automatic sampling, storage, processing of measured data, and report generation, historical data query and the like are achieved.

Owner:SHAANXI AEROSPACE TIMES NAVIGATION EQUIP CO LTD

Device for measuring high-speed electrical sliding wear

InactiveCN101008596AEffective electrical wear test resultsUsing mechanical meansInvestigating abrasion/wear resistanceMeasurement deviceDevice form

This invention discloses one high speed slide electrical friction loss measurement device, which comprises electrical loss mechanic device, power control part, resistance box and test meter, wherein, the mechanic device forms loop circuit between copper disc and test materials through high speed rotation copper disc and slide electrical contact materials to make the test materials generate electrical arc erosion by relative motion to test for one load charge, one line or weight friction loss and rotation ring number; the power control part is to provide direct power to the mechanic device and the resistance box is to adjust interface friction mechanic device current size.

Owner:XIAN UNIV OF TECH

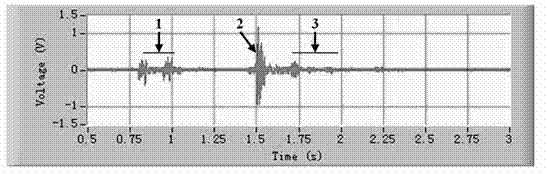

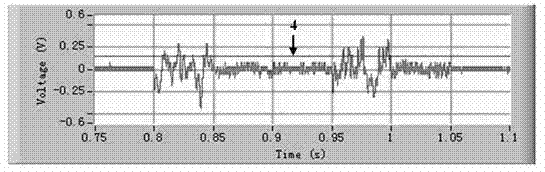

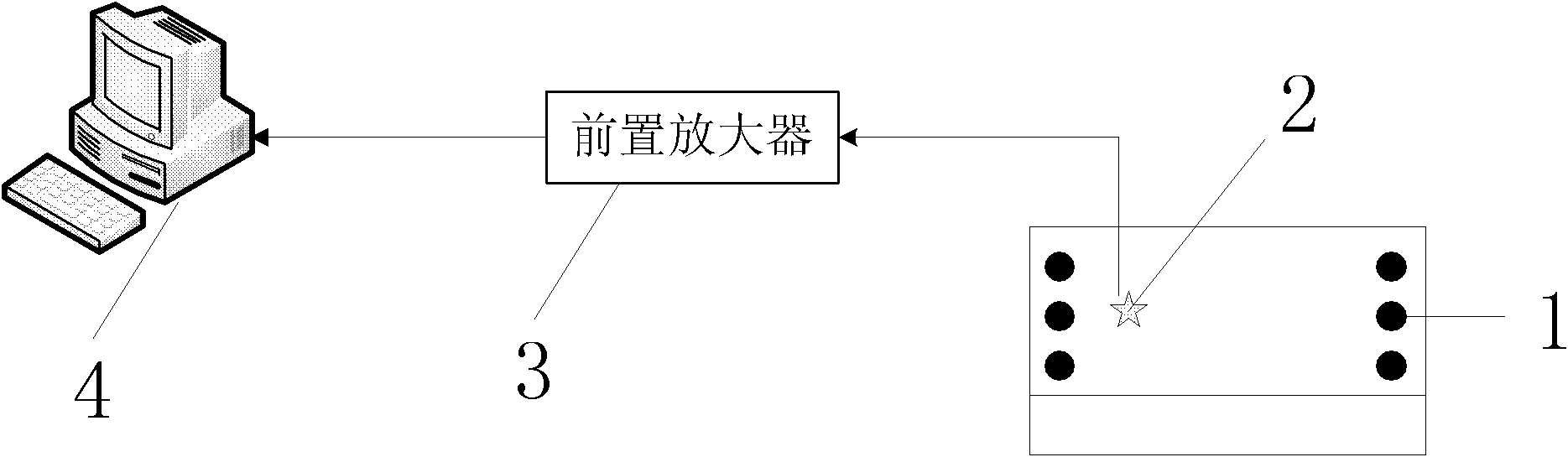

Resistance spot welding nugget nucleation dynamic quality nondestructive testing method

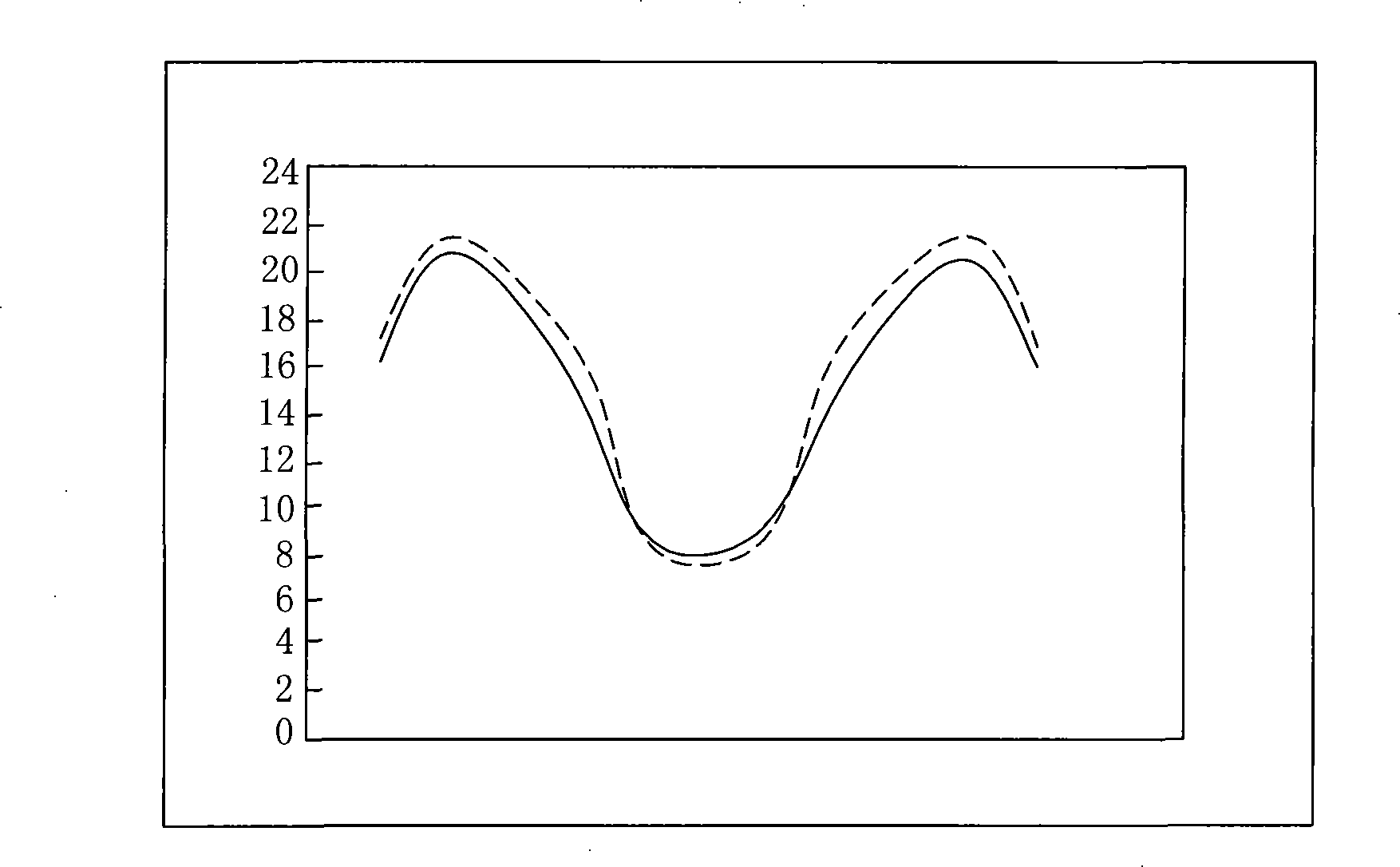

ActiveCN102654482AEasy to implementReduce design and manufacturing costsMaterial analysis using acoustic emission techniquesUsing subsonic/sonic/ultrasonic vibration meansEngineeringRing number

The invention discloses a resistance spot welding nugget nucleation dynamic quality nondestructive testing method which comprises the following steps of: acquiring the structure load acoustic emission signal in the resistance spot welding process, and drawing a dynamic curve chart; extracting the acoustic emission signals of the electrode loading stage, nugget nucleation stage and crack generation stage from the dynamic curve; counting the ringing number and total energy of the acoustic emission signals respectively; splitting the resistance spot welding sample nugget, and measuring the diameter, height and crack length of the actual nugget; establishing a sample pair to form a training set; establishing a nugget size artificial neural network and a crack length artificial neural network respectively, and training the obtained sample by use of the Back Propagation neural network algorithm; and applying the trained model to the real-time detection of the nugget size and the crack generation. According to the invention, online testing of the quality of multiple common resistance spot welding nuggets of metal structure material can be realized relatively accurately.

Owner:JIANGSU MENSCH AUTO PARTS

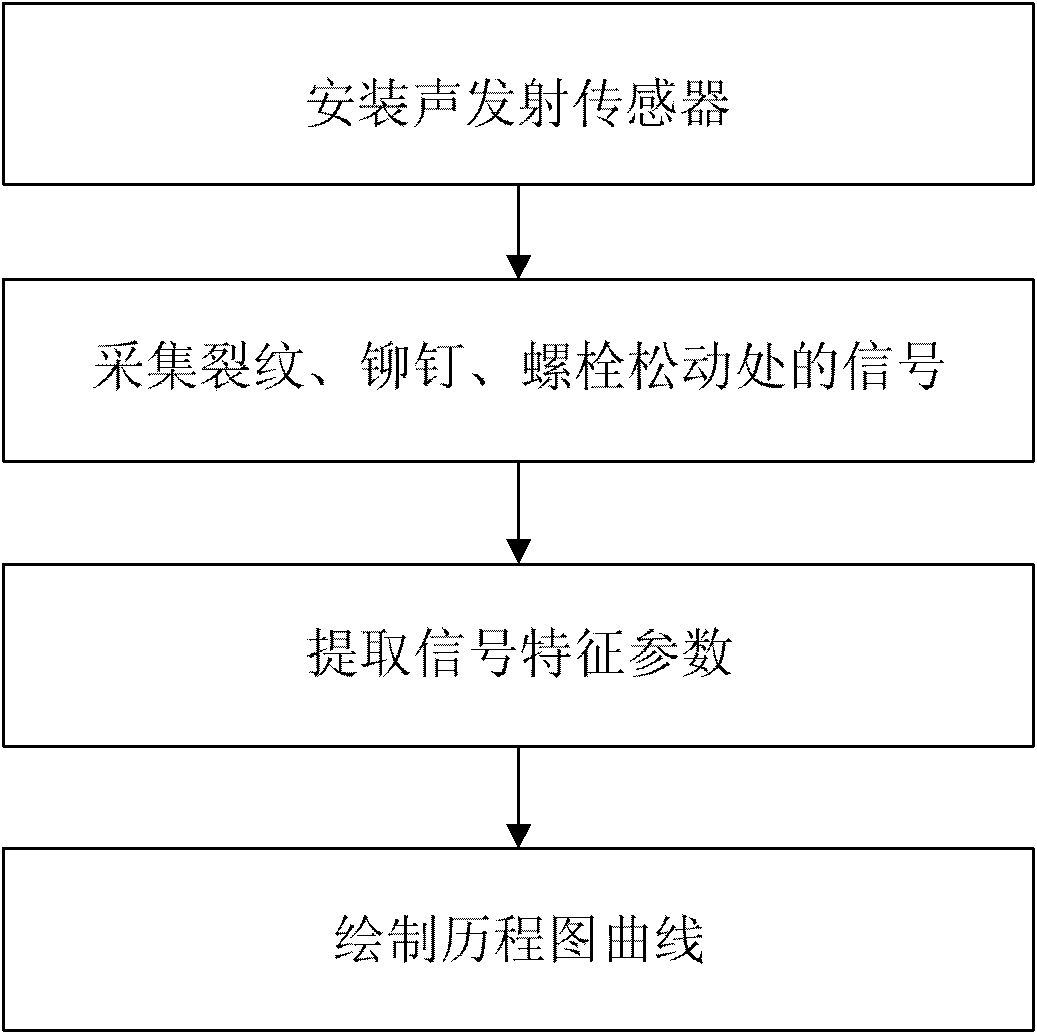

Method for identifying damage of aircraft structural parts based on acoustic emission detection

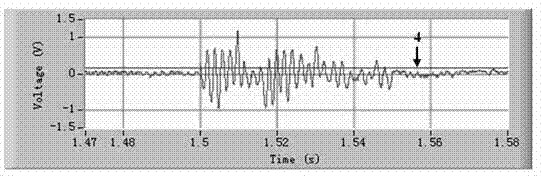

InactiveCN102426197AMaterial analysis using acoustic emission techniquesStress concentrationSignal on

The invention provides a method for identifying damage of aircraft structural parts based on acoustic emission detection. The method comprises the following steps: applying load to rivets, loose bolts and cracks on the aircraft structural parts so that an acoustic emission sensor can respectively receive a rivet deformation acoustic emission signal, an acoustic emission signal generated by the loose bolts and a crack propagation acoustic emission signal on the aircraft structural parts; obtaining five characteristic parameters of the three signals, such as duration time, signal amplitude, ring number, energy and peak frequency, and distinguishing the characteristics of the parameter values of the three signals; and comparing the characteristic parameters of the three signals, drawing 'energy-peak frequency' and 'energy-amplitude' progress graphs of the three signals, and distinguishing the graphic characteristics of the three signals. The method provided by the invention has the advantages that detection signals for micro-deformation of the rivets caused by stress concentration, bolt looseness, fatigue crack propagation and the like on the aircraft structural parts can be distinguished so as to early find structural change; therefore, the method is significant to safety operation of equipment.

Owner:BEIHANG UNIV +1

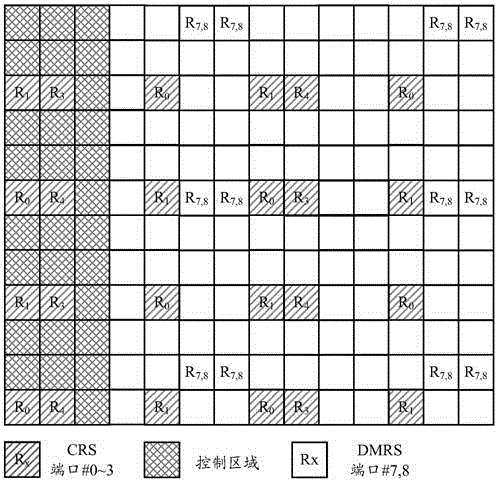

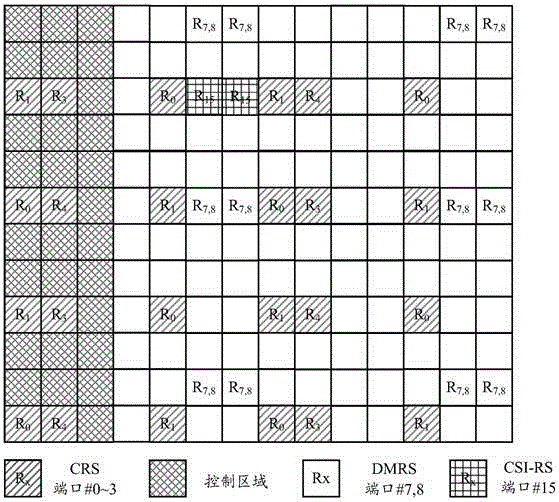

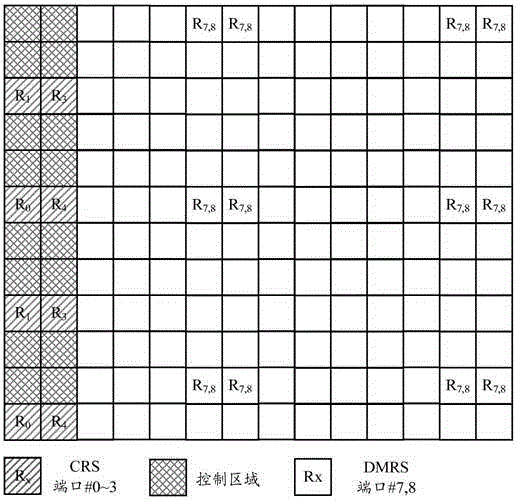

Downlink data repeated transmission method and equipment

ActiveCN106209330ASame number of available REsTransmission path divisionSignal allocationData transmissionDemodulation

The invention discloses a downlink data repeated transmission method and equipment. The problem that the inter-sub-frame merging of the data cannot be performed in multi-sub-frame repeated transmission since the available RE numbers for the resource mapping of the data transmission in different sub-frames are different is solved. The method comprises the following steps: determining a sub-frame set of a physical downlink channel for repeated transmission; beginning mapping from a specific start symbol position in the first time slot of the current sub-frame while performing the resource mapping on the physical downlink channel in each sub-frame of the determined sub-frame set, mapping to all resources except the resource corresponding to a reference signal for demodulation; and sending the physical downlink channel according to the resource mapping mode.

Owner:DATANG MOBILE COMM EQUIP CO LTD

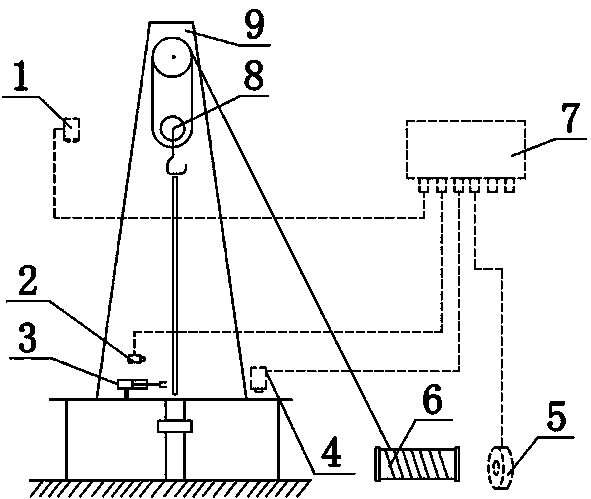

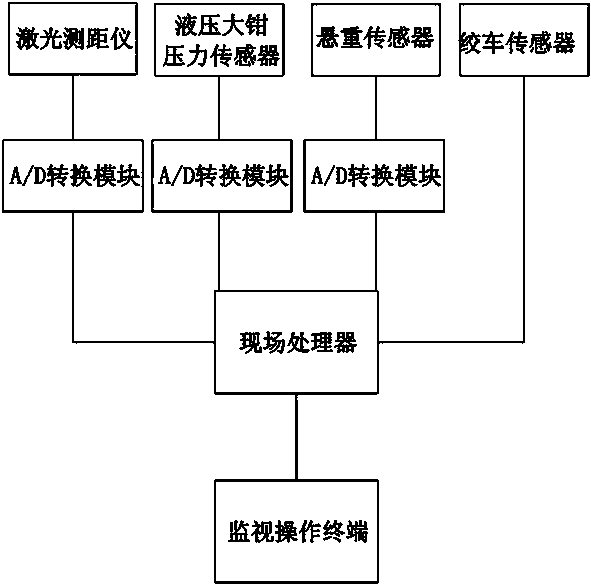

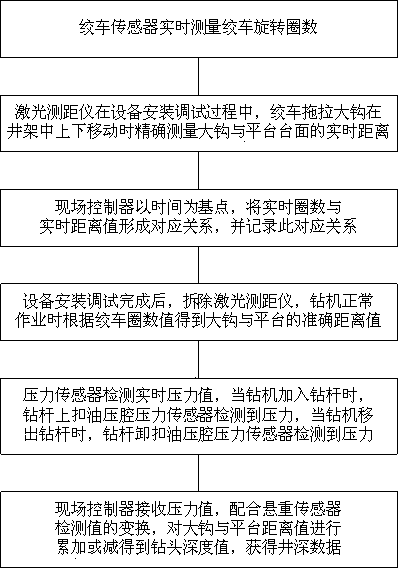

Petroleum drilling well depth measuring system and method

The invention discloses a petroleum drilling well depth measuring system and method. The system comprises a winch sensor, a pressure sensor, a hanging load sensor, a laser range finder, a field controller and a monitoring operation terminal. According to the method, the laser range finder is fixed on a large hook during system initial assembly debugging, the large hook is controlled by a winch to move vertically, the onsite controller records the displacement value of the laser range finder and the ring number of the winch in real time to form the corresponding relation between the value of each ring and the displacement value, and the height value of the large hook is read automatically according to the ring number value program of the winch during normal during normal well drilling. In the drilling process, a hydraulic power tong pressure sensor transmits signals to indicate unfastening or fastening and the corresponding hanging load value change, a controller judges whether a drill pipe enters or leaves through the program, and the height change values of the large hook is accumulated to obtain the well depth and the drill bit position value. The system and method overcomes the shortcoming that the traditional measuring mode is in accurate in measurement or complex in measurement work and inconvenient to operate, and is capable of accurately measuring the well depth and the drill bit position and capable of displaying the well depth data in real time without manual operation.

Owner:CHENGDU HANGTIAN PHOTOELECTRIC TECH

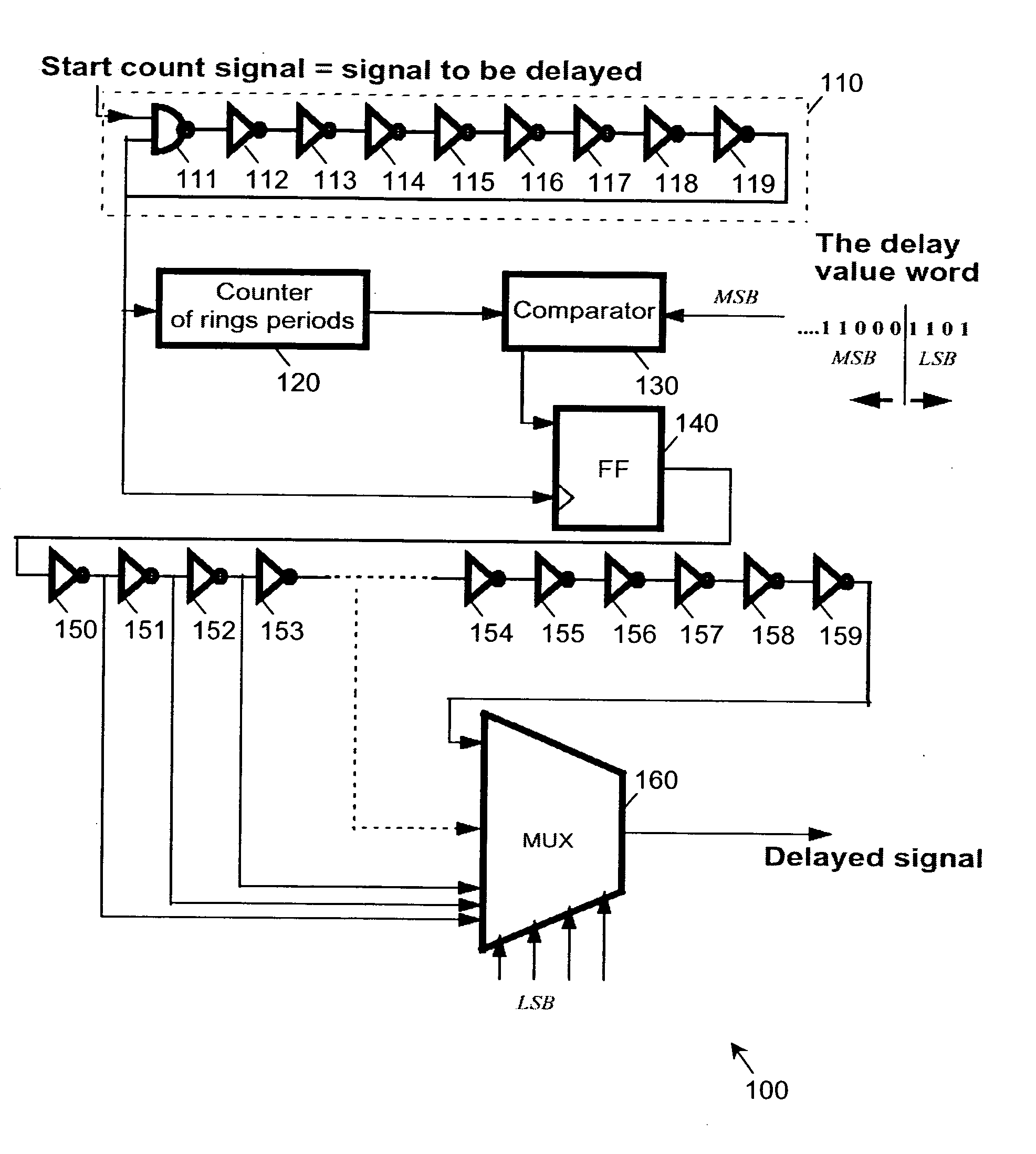

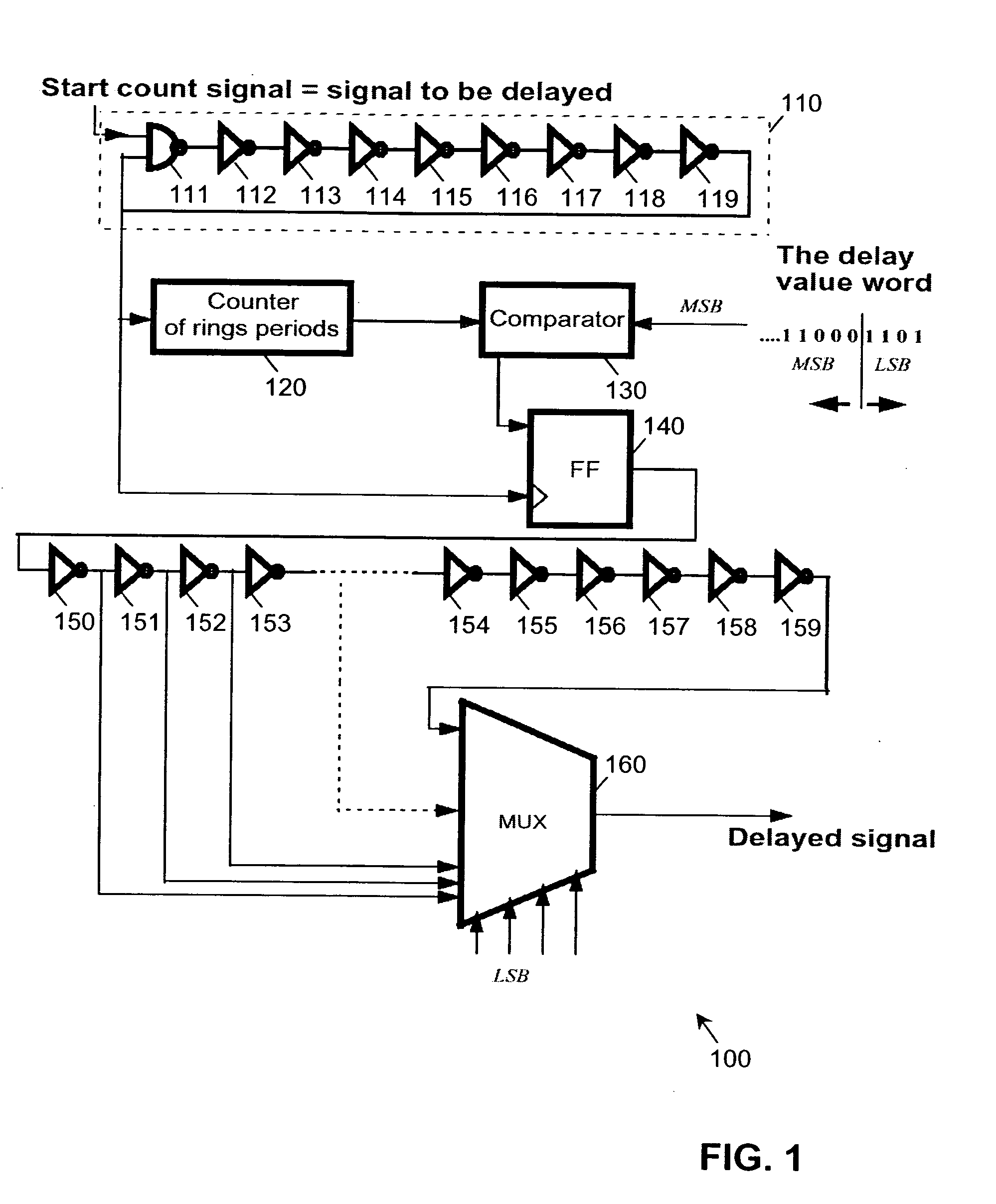

Arrangement and method for digital delay line

ActiveUS20040263266A1Pulse automatic controlPulse generation by logic circuitsLow distortionDigital delay line

An arrangement (100) and method for a high precision and low distortion digital delay line with infinite delay. The digital delay line has an oscillating ring (110) with an odd number of inverting elements that triggers a counter (120). A comparator (130) compares the counter and the MSB of a given delay word. A line of inverters (150-159), double the odd number in the ring oscillator, is connected to a MUX (160) controlled by the LSB of the delay word. This provides the advantages of: high resolution due to use of a small, basic component, self-delay ring oscillator; small silicon area due to use of a special decoding scheme use the rings number to produce large delays; and easy implementation as a digital block in an integrated circuit using a standard cells library to build the ring and the decoder.

Owner:NXP USA INC

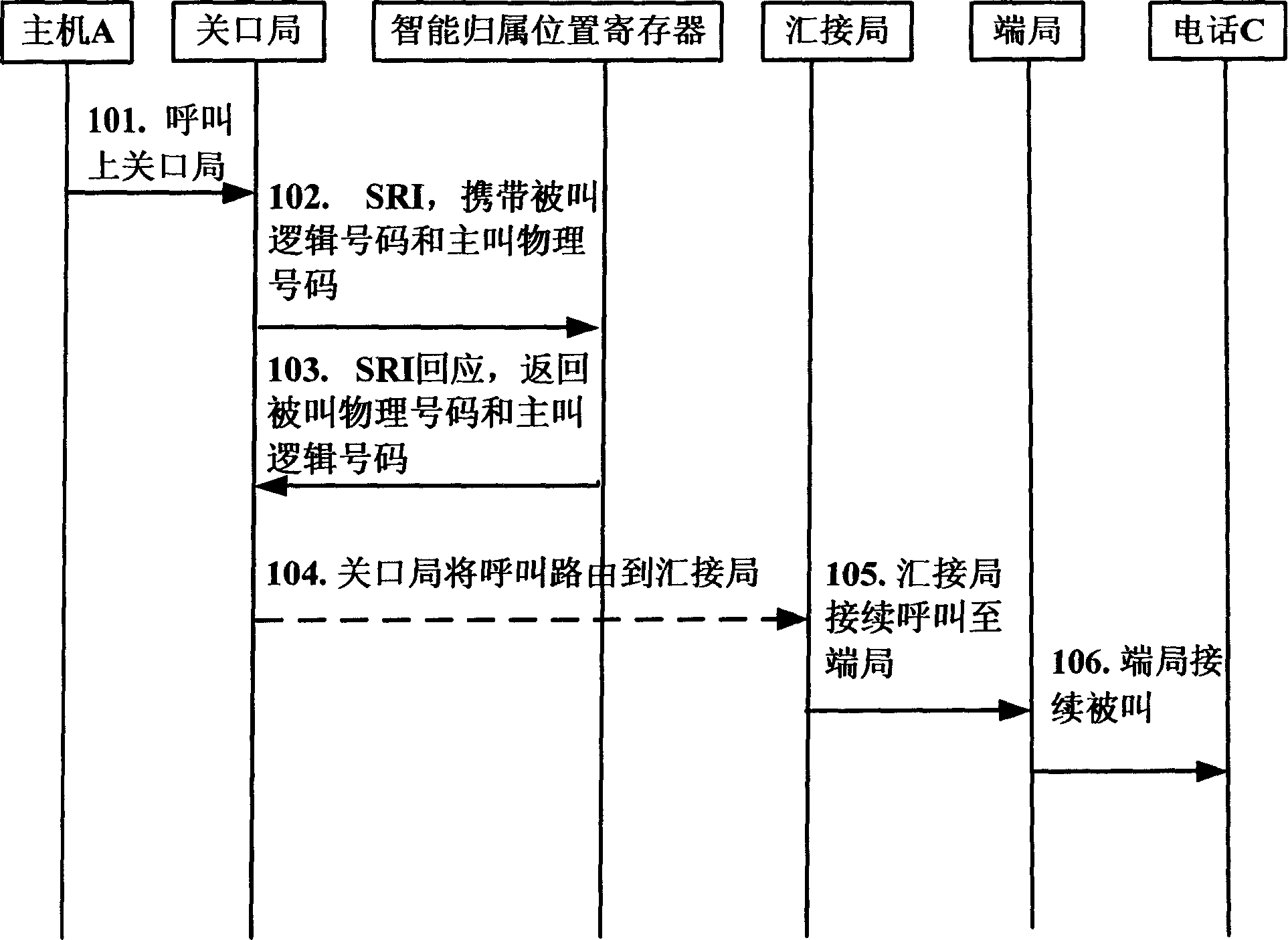

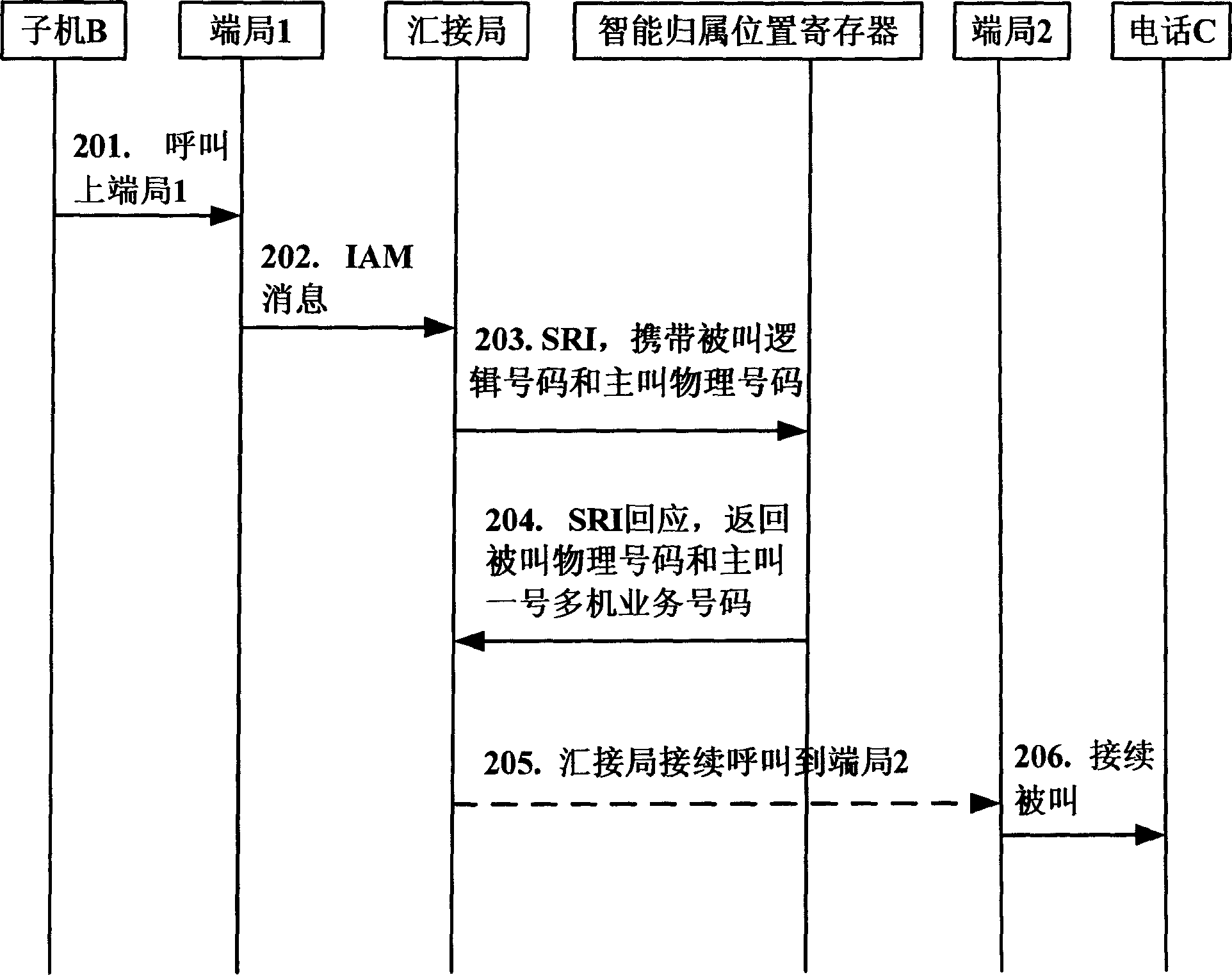

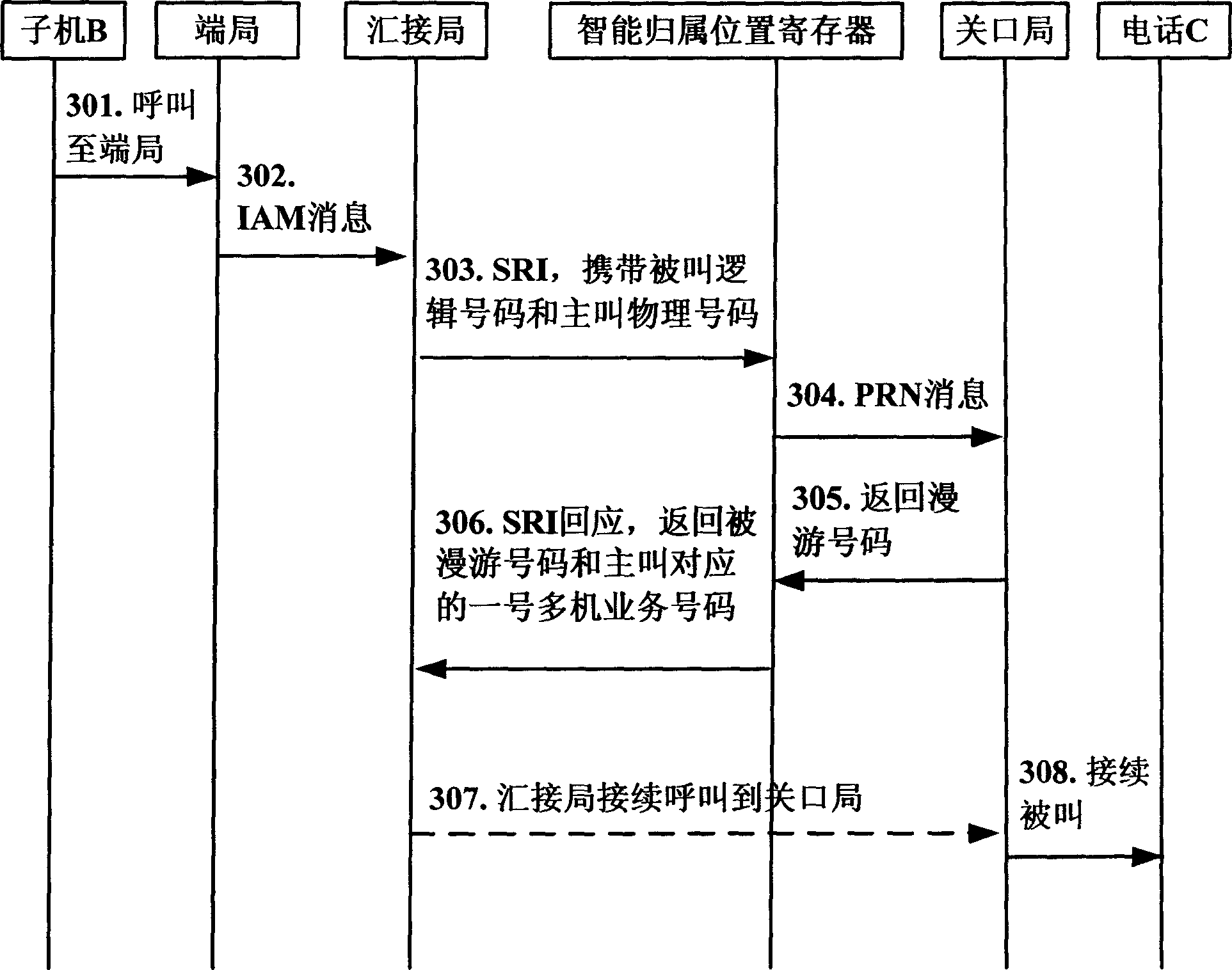

Method and system for realizing services of many phone numbers by one phone number

The method comprises: saving the corresponding relation between the number of multi phones at one number service and the physical number of slave set of multi phone at one number service; saving the simultaneous ring information which takes the number of multi phone at one number service as the simultaneous ring triggering number and takes the physical number of slave set of multi phone at one number service as the simultaneous ring number in the control node; completing the decision for deciding if the calling number and called number registers a multi phone at one number service by using intelligent home location register; returning the simultaneous ring access code of service switch node corresponding to the called number or / and the number of multi phone at one number service corresponding to the calling number; after receiving the returned simultaneous ring access code, the service switch node triggers the simultaneous ring service of intelligent network service control node.

Owner:HUAWEI TECH CO LTD

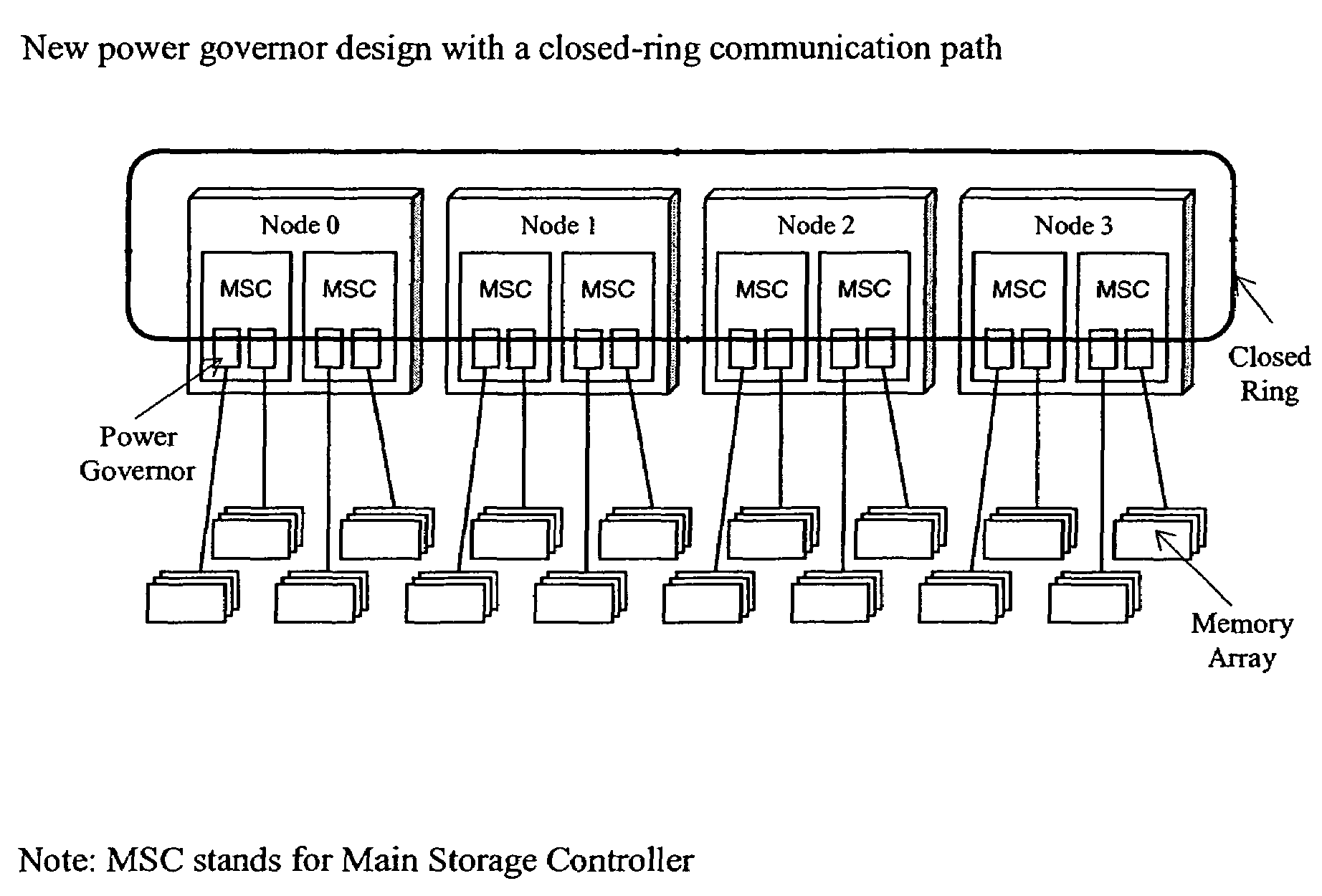

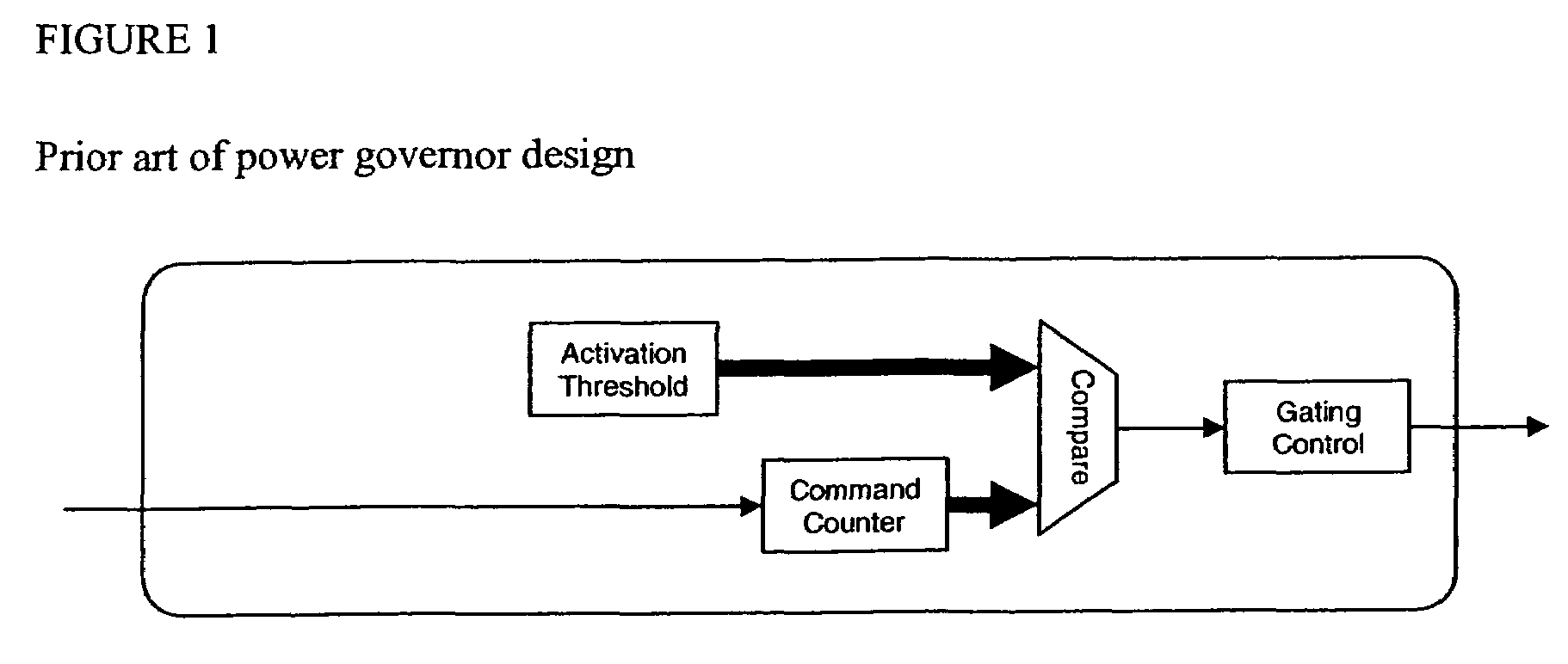

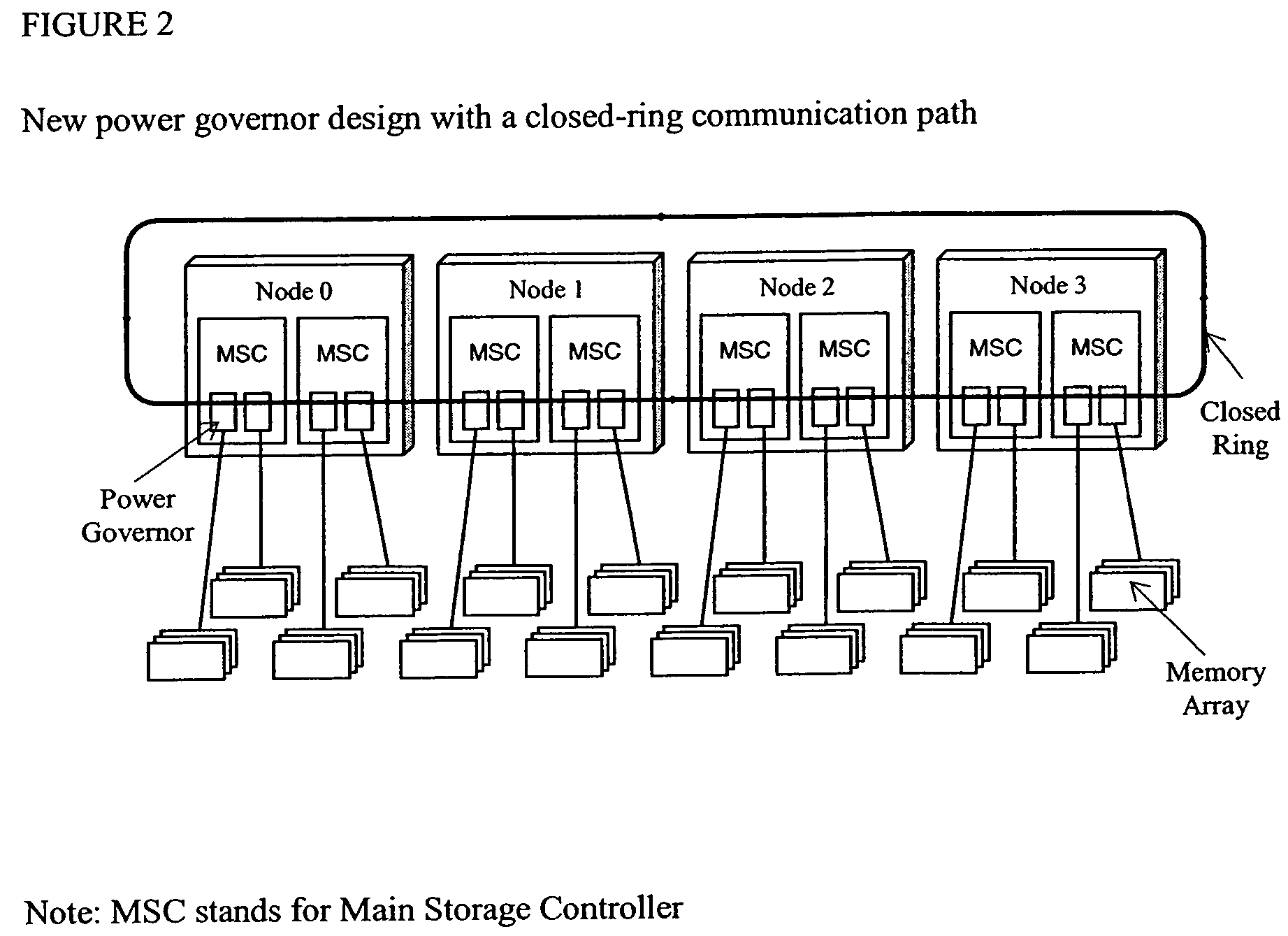

System and method for regulating system power by controlling memory usage based on an overall system power measurement

InactiveUS7340618B2Maximum accuracy and efficiency and performanceHardware monitoringDigital storageTraffic capacityComputerized system

A power governor for DRAM in a multi-node computer system regulating memory power consumption of an entire computer system employs a closed ring that connects all the power governors within the system to enable them to work in concert so that each of the power governors has the knowledge of memory activities within the entire system. They then control and limit the memory usage based on a true overall measurement instead of just local measurement. Each nodal power governor has memory command counter, ring number receiver, ring number transmitter, governor activation controller, and memory traffic controller. Each nodal power governor counts the weight of memory command. The degree of limiting actual memory activities can be programmed when the governor is active. Besides, the command priorities can be adjusted in activation too. A hybrid ring structure can be employed with a nodal power structure to achieve the fastest number circulation speed economically.

Owner:IBM CORP

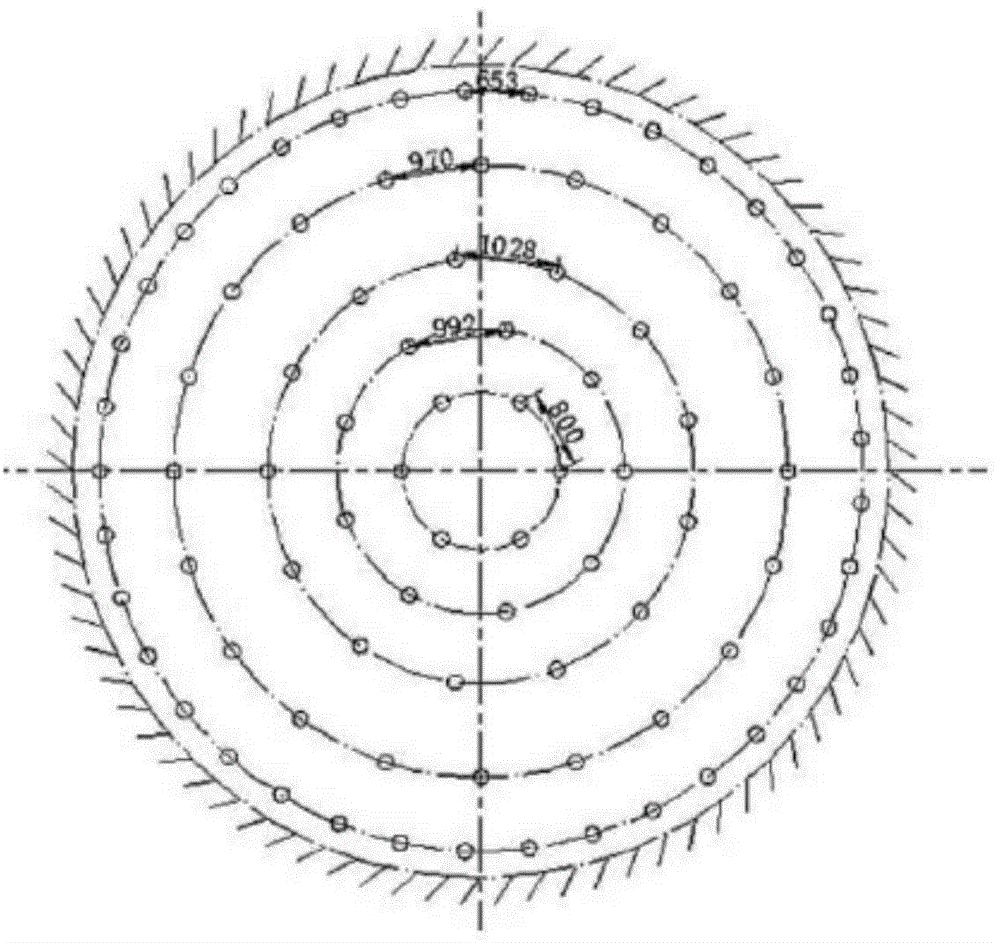

Gradient pre-splitting blasting method and device of lancing cartridges around vertical shaft

An embodiment of the invention discloses a gradient pre-splitting blasting method and device of lancing cartridges around a vertical shaft. The method includes distributing directional-breaking blasthole rings around the vertical shaft, distributing wedge-cut blasthole rings in the center and distributing main blasthole rings with preset ring number from the center to outside; setting a blasting sequence that the directional-breaking blasthole rings blast first, and the blasthole rings from the center to outside blast sequentially; sequentially dividing the directional-breaking blasthole rings into a plurality of directional-breaking areas and setting the corresponding area blasting sequence; subjecting the directional-breaking areas to segmentation and setting the corresponding segmental axial blasting sequence; putting explosive into lancing tubes and inserting nonel detonators corresponding to the segmental axial blasting sequence into the lancing tubes to make lancing cartridges; placing the lancing cartridges in directional-breaking blastholes around the vertical shaft, filling and sealing the wedge-cut blastholes and the main blastholes, and connecting the blastholes to form a detonating network. By the use of the gradient pre-splitting blasting method and device, blasting damage is reduced during the blasting, and blasting effect is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Projectile location method based on image recognition

ActiveCN109034156AAvoid interferenceLow costImage analysisCharacter and pattern recognitionImaging processingRing number

In order to solve the defects of high cost of consumable materials and easy damage of equipment of intelligent target reporting system in the prior art, the invention provides a bomb point positioningmethod based on image recognition, which is characterized by comprising the following steps: S1, selecting bullet type before firing, corresponding to bullet hole template in a database; 2, collecting target paper image through an image acquisition device, and comparing that target paper image template store in a database to identify the target paper; at that same time, the digital template of the re number in the target pap image being determined according to the target paper template; S3, capturing continuous images stored in the image processing device, comparing each frame image with theprevious frame image separately, judging whether the target paper is shaken or not, and if the target paper is shaken, starting a new bullet hole identification process to generate position information of the new bullet hole; S4. the position information of the new bullet hole being sent to the server, and the server sends the position information to the display mechanism to complete the display.The invention has the advantages of high reliability and low cost.

Owner:洛阳国花新能源科技有限公司

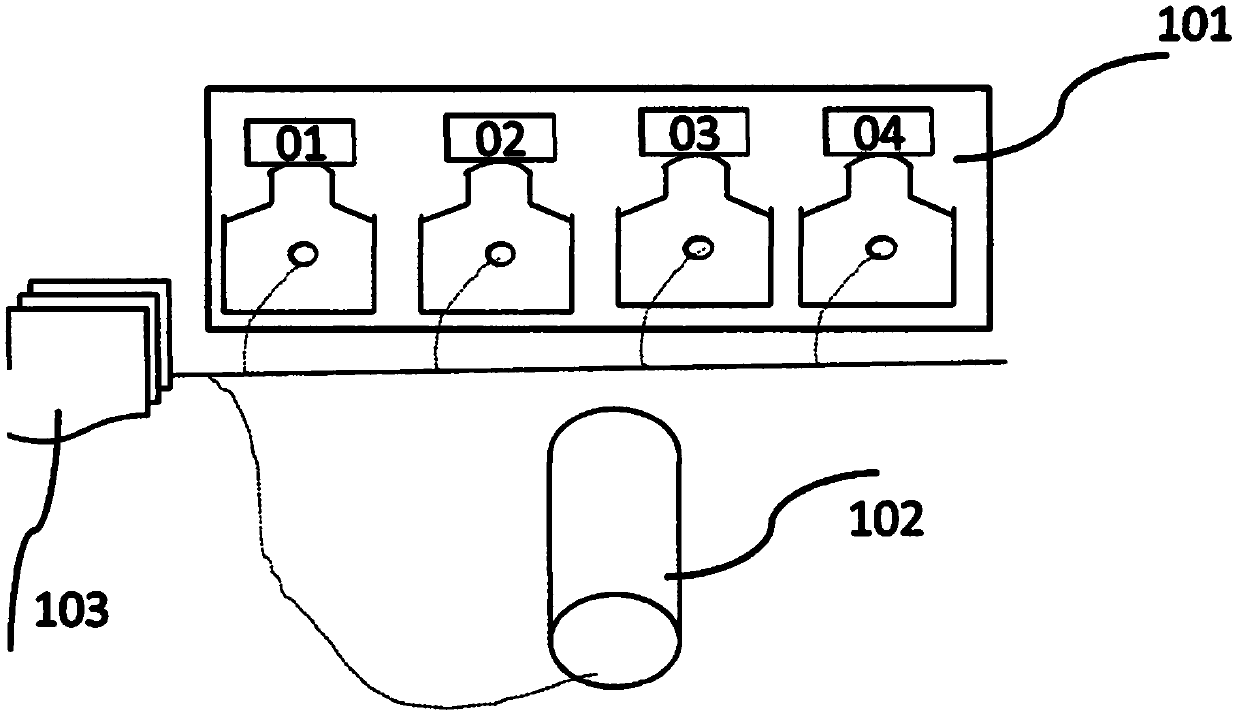

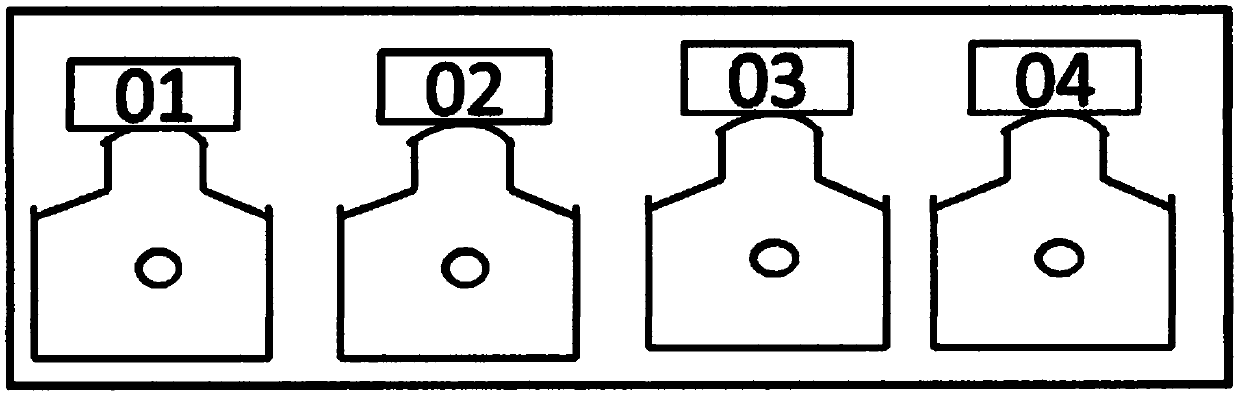

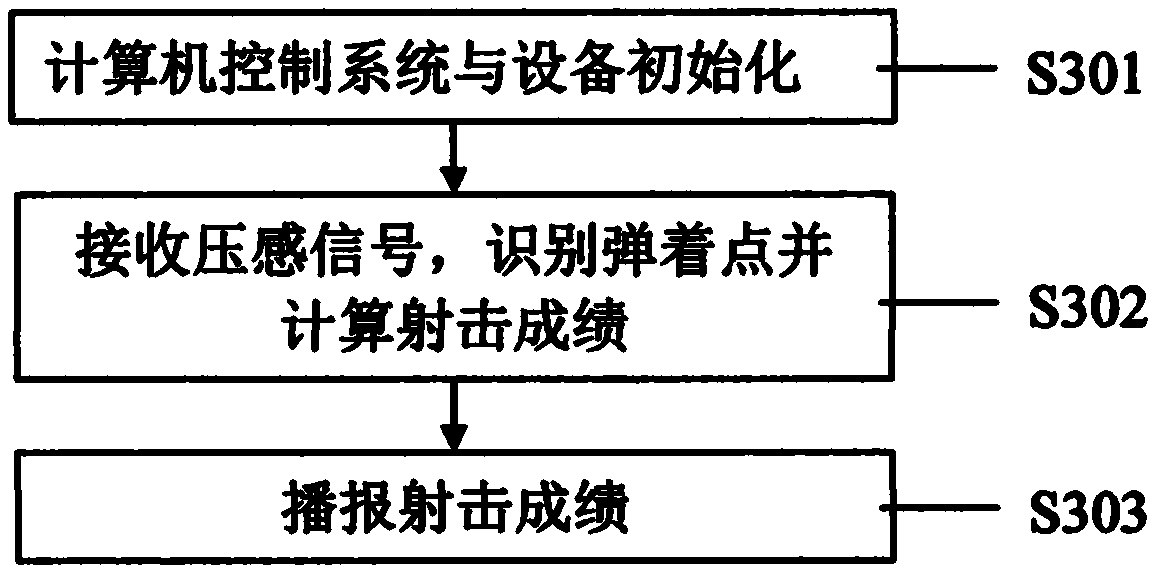

Training ground multi-target-position automatic target-scoring method and system based on high-definition camera

The invention discloses a training ground multi-target-position automatic target-scoring method and system based on a high-definition camera. The method comprises the steps that digital mark numbers are arranged on target surfaces of a plurality of target positions placed in parallel target surface directions; the high-definition camera is adopted to shoot panoramic images of all target positionsin the direction perpendicular to the target surfaces; target surface images and the digital mark numbers of all target positions are identified on the shot panoramic images; a pressure sensor is mounted on each target position, current target surface images of the corresponding target positions are stored according to pressure sensing information generated by shooting, the radius ranges of the target ring numbers are inquired according to the distances between the identified shot point coordinates and the target center coordinates, and shooting results are obtained; whole field shooting results and shot point calculation images are output through liquid crystal displays; and individual firing scores are singly played to all shooters through sound playback devices. The positions where bullets in the target surfaces enter the target surfaces are obtained, the high-precision, high-resolution, high-speed automatic target-scoring system is achieved, and the system is as shown in an abstract drawing.

Owner:ENG UNIV OF THE CHINESE PEOPLES ARMED POLICE FORCE

SCR catalyst containing copper and iron composite bases and preparation method of SCR catalyst

InactiveCN104607239AAchieve purification effectMaintain hydrothermal durabilityCatalyst carriersMolecular sieve catalystsFiltrationOxygen

The invention discloses an SCR catalyst containing synthetized zeolite and copper-iron composite bases, in particular an SCR catalyst which still has a NOx purification property in a low-temperature region after an aquathermal durability test and a sulfur oxide durability test. The preparation method of the SCR catalyst disclosed by the invention comprises the step of concocting a hydrogenated synthetized zeolite crystal with an aqueous solution through a mixing working procedure, wherein the largest oxygen ring number of the hydrogenated synthetized zeolite crystal is 8, and the hydrogenated synthetized zeolite crystal has a three-dimensional structure; the pH value of the aqueous solution is 0.1-0.7, and the aqueous solution contains copper (II) ions and iron (III) ions; a filtration working procedure and a cleaning working procedure are not needed.

Owner:清华大学苏州汽车研究院(吴江) +1

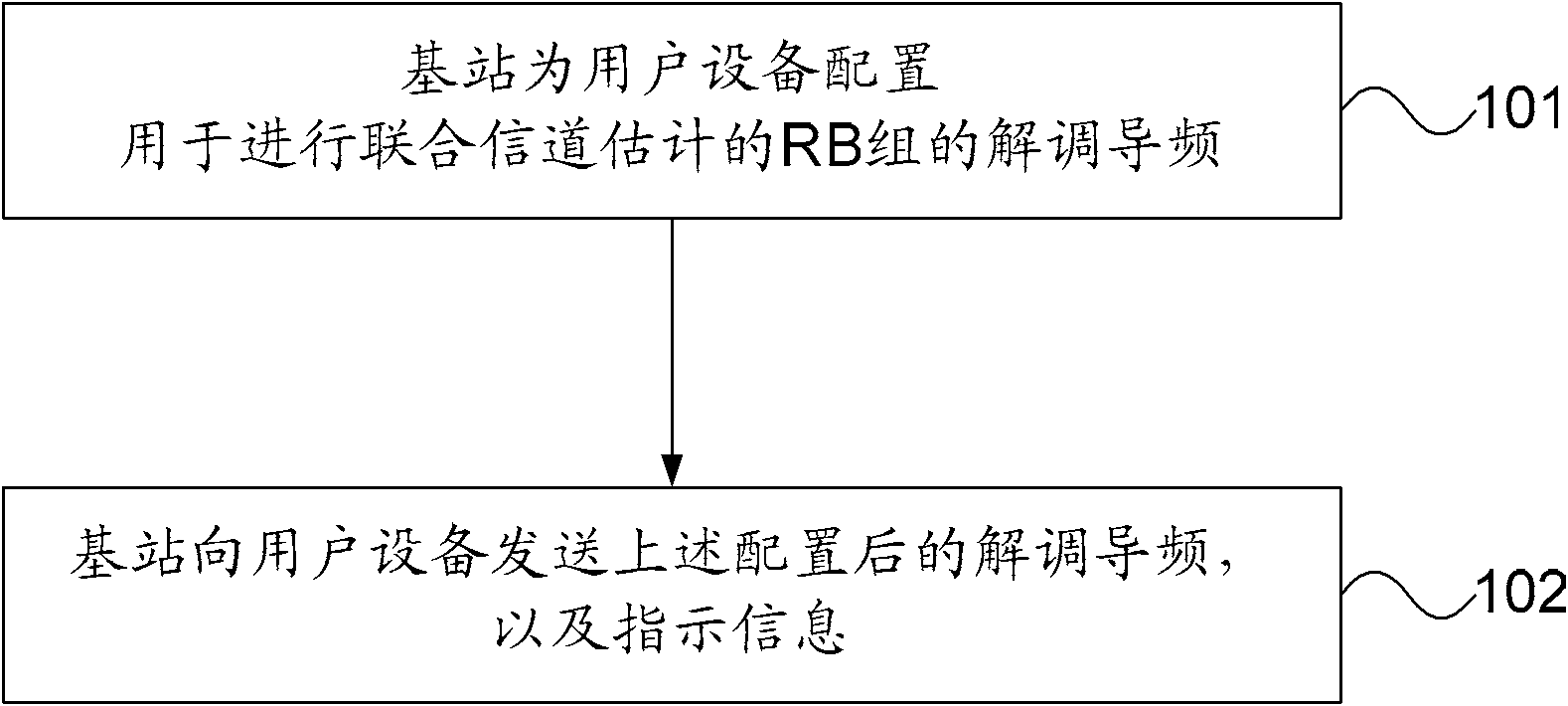

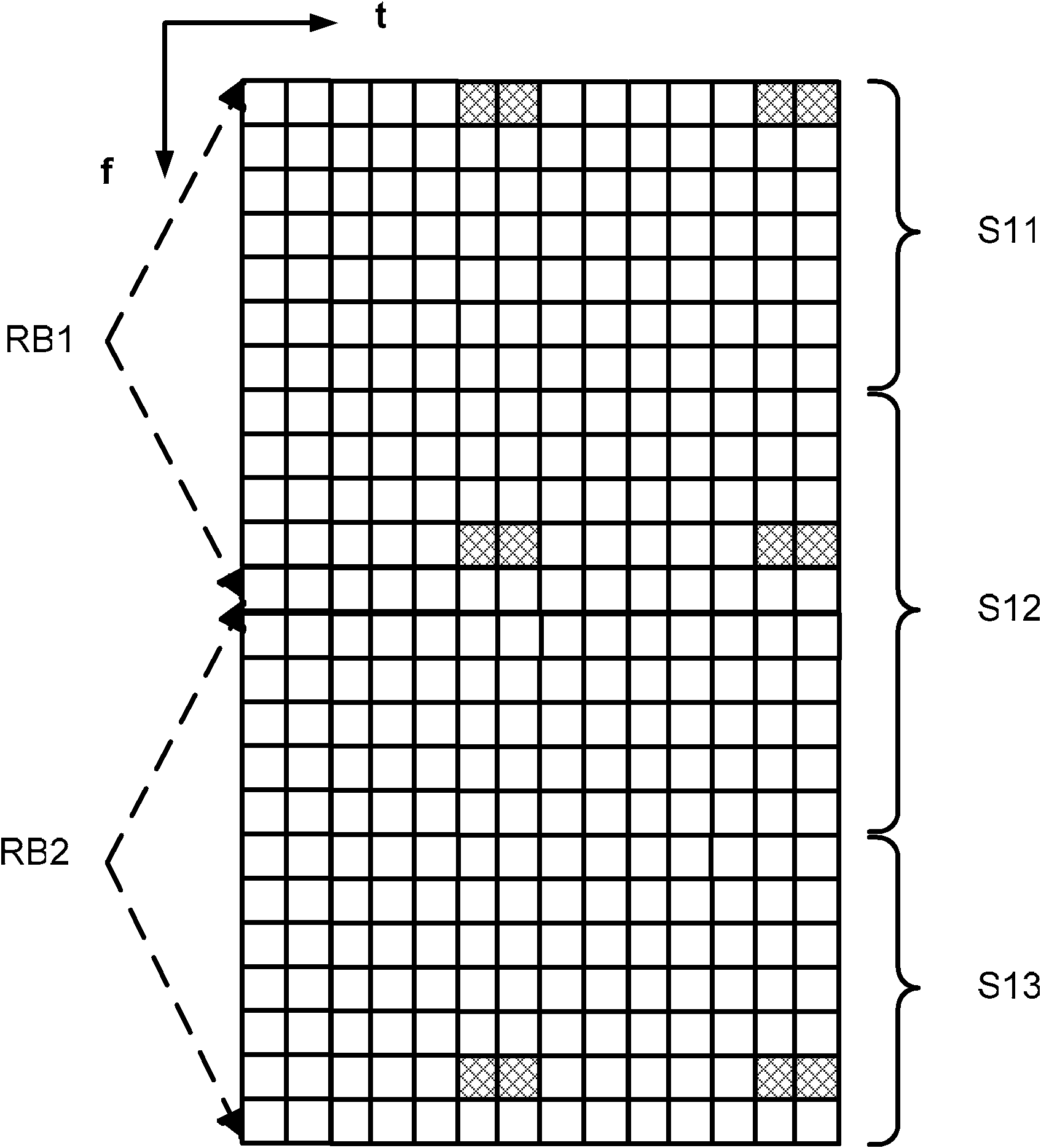

Method and base station for sending resource blocks and performing combined channel estimation, and user equipment

ActiveCN102739593ASave transmission resourcesIncrease data transfer rateBaseband system detailsMulti-frequency code systemsResource blockData transmission

An embodiment of the invention provides a method and a base station for sending resource blocks (RBs) and performing combined channel estimation, and a piece of user equipment. The method of sending the resource blocks comprising that: demodulation pilot of an RB group used for performing combined channel estimation is configured for the user equipment by the base station, so that resource unit RE number occupied by the demodulation pilot of each RB in a demodulation pilot pattern after the configuration is less than or equal to N (N=XY), and the total number of RE occupied by the demodulation pilot in the RB group is less than N*M, wherein, the RB group is a combination of a plurality of RBs, M is the number of RBs included in the RB group, X is the number of OFDM symbols occupied by the demodulation pilot configured in a single RB on performing the single RB channel estimation, and Y is the number of subcarriers occupied by the demodulation pilot in each OFDM symbol, in which the demodulation pilot configured in the single RB is located, when the single RB channel estimation is performed. The method can correspondingly configure the pilot according to the number of the resource blocks from the combined channel estimation, thereby saving the transmission resources and increasing the data transfer rate.

Owner:HUAWEI TECH CO LTD

Method for distributing raw materials with high zinc content in blast furnace with bell-less top

InactiveCN102010922APrevent escapeAvoid cloggingBlast furnace componentsBlast furnace detailsThroatMaterial distribution

The invention discloses a method for distributing raw materials with high zinc content in a blast furnace with a bell-less top, which comprises the following steps of: (1) controlling ore batch weight to be greater than a critical value, and ensuring that the average thickness of ore at the furnace throat is 8 to 10 percent of the diameter of the furnace throat; (2) adopting a material distribution mode from a small angle to a large angle increasingly at distributor chutes on the furnace top, and ensuring that small particle burden and powder caused by mass flow particle segregation are distributed from the center of the blast furnace to a part 1 / 3 away from the edge of the furnace wall when a material tank discharges materials; (3) selecting double-ring single pile top large-angle distribution for ore and coke gears, distributing outer-ring ore according to the maximum angle, ensuring that the ore and coke angular difference is -2 degrees and the angular difference of the inner and outer rings of the ore and the coke is 6 degrees, controlling the materials distributed in the inner ring to account for 50 to 60 percent of the total burden, making the ring number of the outer ring distribution at least two, and ensuring that the outer-ring distribution pipe top covers the inner-ring distribution pipe top; (4) adopting a positive packaging and ore-coke unequal line packaging method; and (5) regularly performing tank turning operation on tank-combined blast furnace with the bell-less top, and controlling 4 to 5 tank turning cycle periods in a material column.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

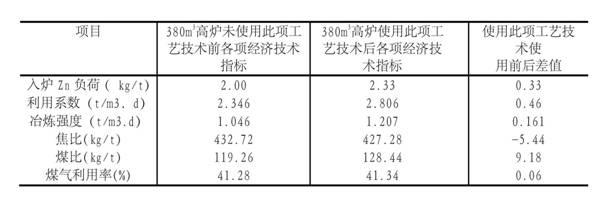

Wheat seeding counting method

ActiveCN105447860ALow input costSolve the problem of difficult to recognize countingImage enhancementImage analysisChain codeRing number

The invention discloses a wheat seeding counting method. The method comprises the following steps of wheat seeding image acquisition: vertically acquiring a wheat seeding image in a wheat seeding leaf stage; wheat seeding skeleton extraction: using a color characteristic to extract the wheat seedings in the wheat seeding image and extracting a skeleton of a wheat seeding area binary image; wheat seeding skeleton analysis: using an Harris angle point detection algorithm to detect an angle point of the skeleton, using a Freeman chain code to simplify the wheat seeding image skeleton into one line segment, and using the angle point detection algorithm and a closed area detection algorithm to detect an angle point number NCP of the skeleton and a closed ring number NCR of a closed polygon respectively; wheat seeding calculating: using a formula to calculate a wheat seeding number NS, wherein the formula is NS=NCP-NCR+1. By using the method, labor saving and time saving are achieved; and problems that shape difference of the wheat seedings is large, wheat seedings have different postures, and the wheat seedings are overlapped, bonded and difficult to count are solved.

Owner:YANGZHOU UNIV

Turbocharging executing device spring processing process

The invention discloses a turbocharging executing device spring processing process, which is characterized by comprising the following steps of 1, material selection; 2, spring coiling: a steel wire blank is coiled into a cylindrical spiral spring according to the prefabricated height, outer diameter and ring number; 3, tempering: the spring is placed into a temper furnace for distressing temper; 4, spring grinding: the two end surfaces of the spring are flatly ground; 5, flaw detection; 6, shot blasting: coarse and fine twice shot blasting are adopted, the diameter of the first shot blasting is greater than the diameter and the intensity of the second shot blasting; 7, secondary tempering; 8, standing processing; 9, heat forming processing; 10, fine grinding; 11, sorting; 12, packaging. Through special heat treatment, the produced high-quality spring has the hardness being 45-50HRC, the full-stroke reciprocating movement in high-temperature environment being 280 DEG C can reach three hundred thousand times, and the elasticity loss rate does not exceed 40 percent.

Owner:常宁市福宏弹簧有限公司

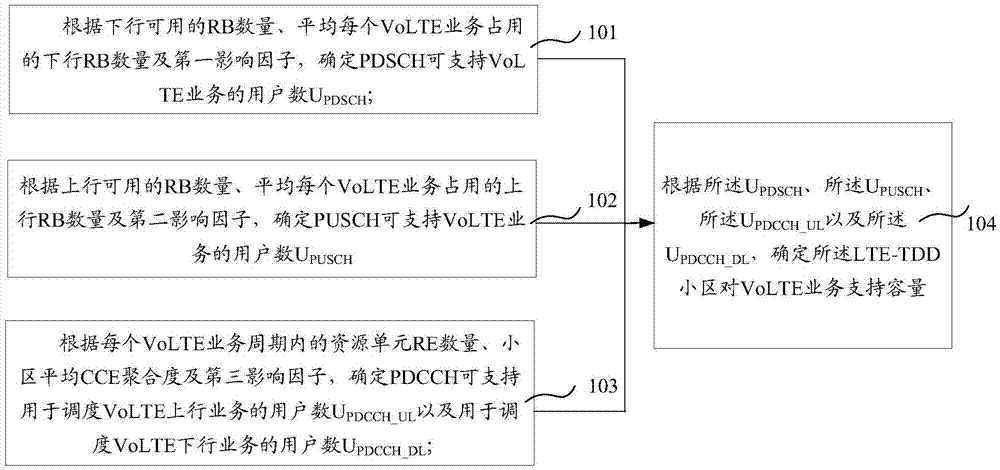

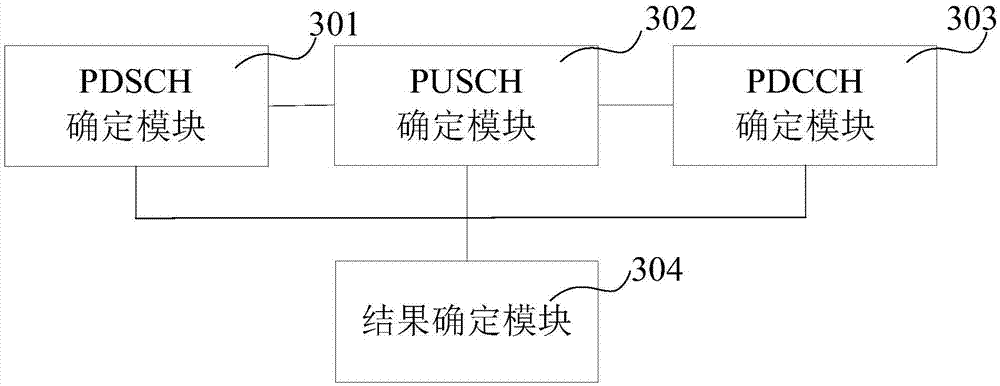

Method and device for determining LTE-TDD cell service support capacity

The invention discloses a method and device for determining LTE-TDD cell service support capacity. The method comprises the following steps: determining user number capable of supporting a VoLTE service of a PDSCH according to the downlink available RB number, the downlink RB number averagely occupied by each VoLTE service, and a first influence factor; determining the user number capable of supporting the VoLTE service of the PUSCH according to the uplink available RB number, the uplink RB number averagely occupied by each VoLTE service, and a second influence factor; and determining the user number capable of supporting and used for scheduling the VoLTE uplink service of the PDCCH and a user number used for scheduling the VoLTE downlink service according to the RE number in each VoLET service period, the cell average CCE aggregation degree and the third influence factor. The method for determining LTE-TDD cell service support capacity disclosed by the embodiment of the invention have important significance for the whole planning and service development strategy of the network.

Owner:CHINA MOBILE GROUP SHAIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com