Patents

Literature

92 results about "Depth in a well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, "depth" also refers to the location itself.

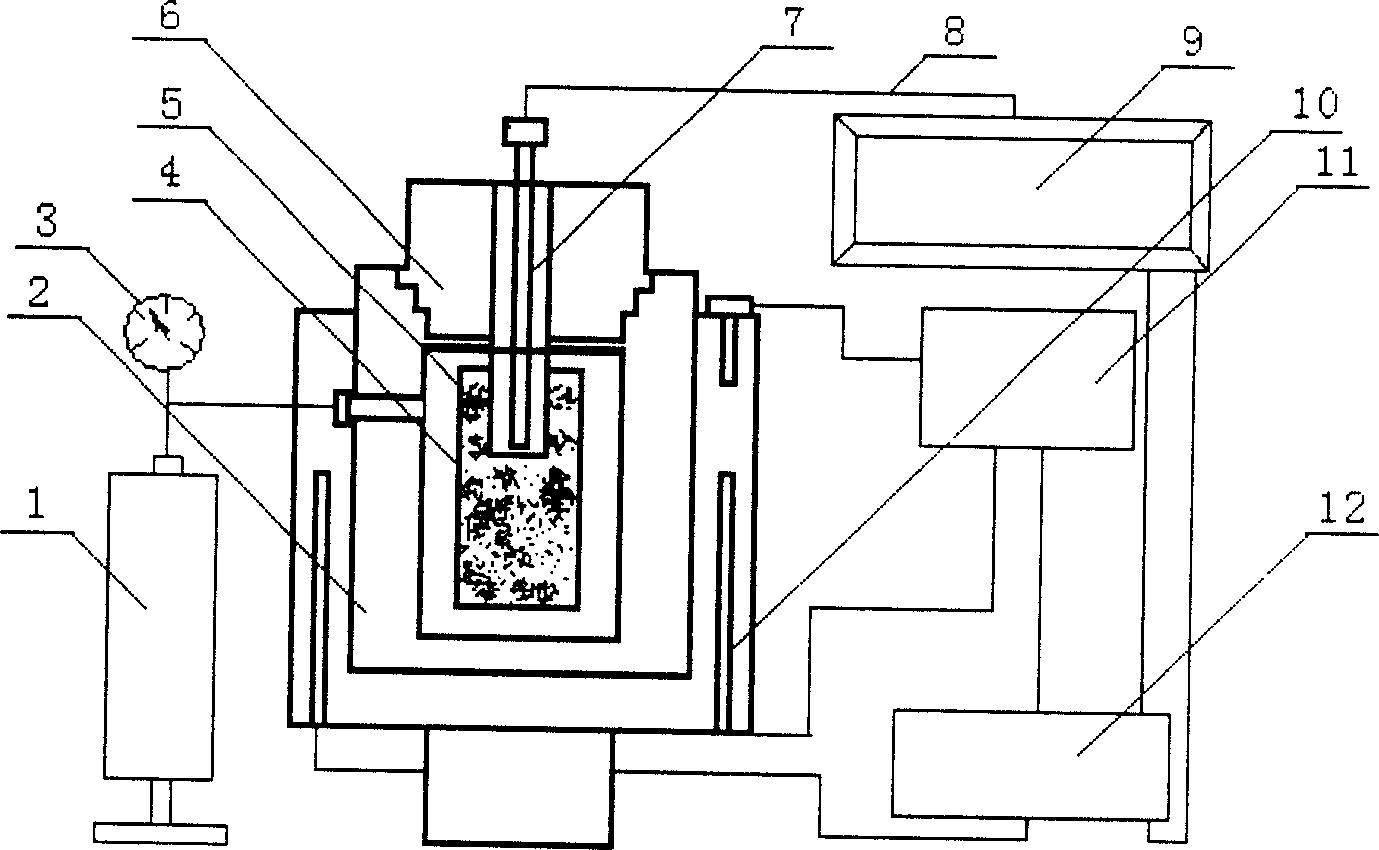

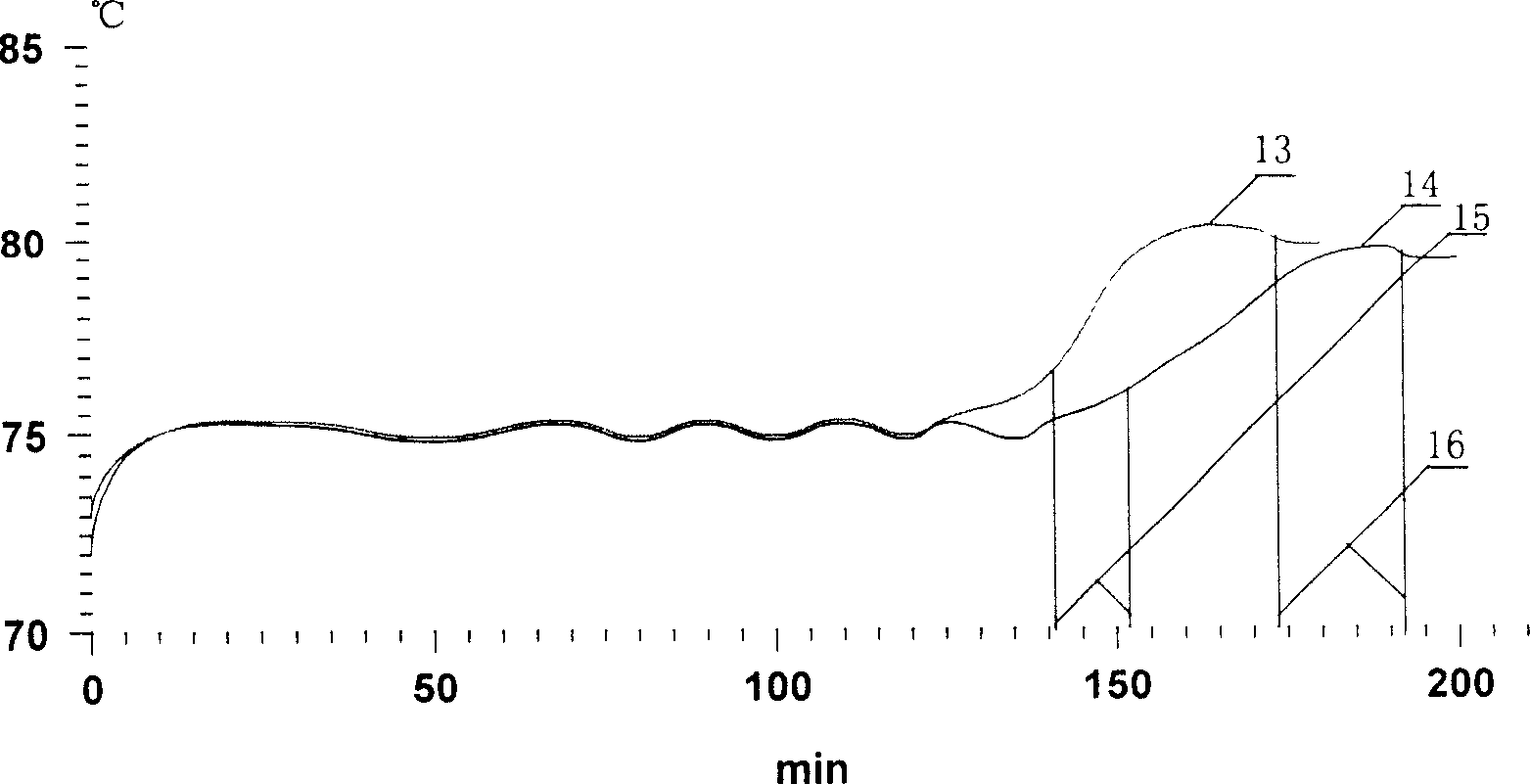

High temperature high pressure oil well cement paste coagulation instrument and its coagulation time measuring method

InactiveCN1676873AMeet the required conditionsEasy to operateSurveySealing/packingDepth in a wellData treatment

The invention is a method which surveys the coagulation status and its relevant time of annular cement under high pressure and high temperature, while simulating different depths and static conditions. It is adaptive to activities such as petroleum well and gas well reinforcement, squeezing cement, pouring cement seal and leakage repairing. The invention provides with the ability of surveying starting and ending time of different coagulation periods, in cement liquor under high temperature and high pressure, by surveying the variation of heat released by cement hydrating. First pre-heat the kettle to a experiment temperature, then put in it with a cup filled with prepared cement liquor in a reactor, seal reactor and increase the pressure to experiment value after the temperature is stable both outside and inside; initiate data processing system so to record the temperature variation automatically with a computer; finally figure out the coagulation starting and ending time by time-temperature curve line. The problem that surveying is difficult under high temperature and high pressure, is resolved with the invention which is adopted with the indirect contacting continuous survey of temperature variation.

Owner:SOUTHWEST PETROLEUM UNIV

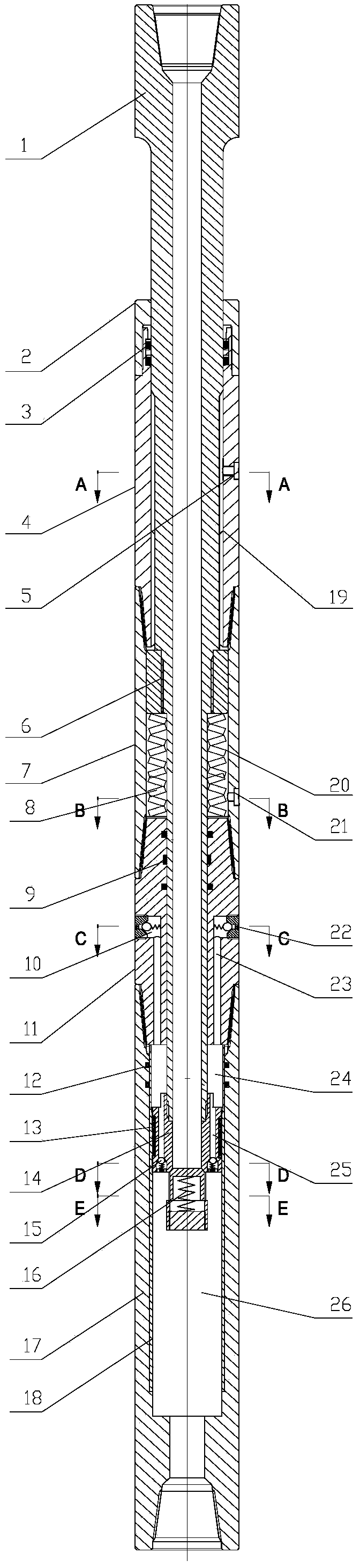

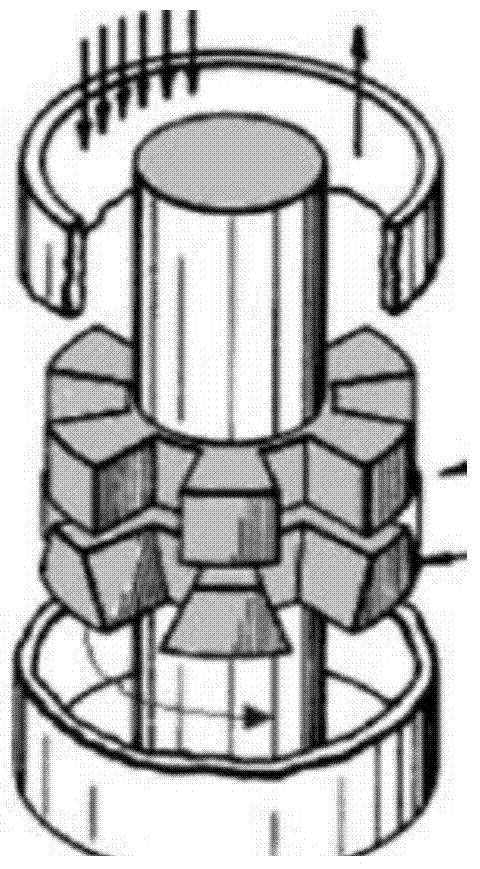

Device for improving oil and gas well drilling speed

ActiveCN103899250ALoop does not affectCircular impactLiquid/gas jet drillingVibration drillingDepth in a wellWell drilling

The invention belongs to the field of petroleum engineering and particularly relates to a device for improving the oil and gas well drilling speed. The device for improving the oil and gas well drilling speed comprises a mandrel body, a spline outer barrel, a spring protection barrel, a spring assembly, a spring lower plugging connector, a piston assembly and a pressurization assembly outer barrel, and is characterized in that the mandrel body is connected with the piston assembly in a threaded mode, the spline outer barrel, the spring protection barrel, the spring lower plugging connector and the pressurization assembly outer barrel are connected together through threads, and the spring assembly is arranged in the spring protection barrel. Energy for working of the device is provided by vibration of a drill stem and is increased along with the increase of the depth of a well, and the adverse effect of vibration is reduced by the working process of the device; by adopting the device, both the rock breaking efficiency and the well bottom cutting carrying effect are improved; the device is simple in structure and stable in performance, and other risks will not be caused by drilling operation when the device is used; the structure of the drill stem does not need changing, normal use of the device will not be affected by the types of drills, and therefore the device is wide in application range and convenient to popularize and use.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

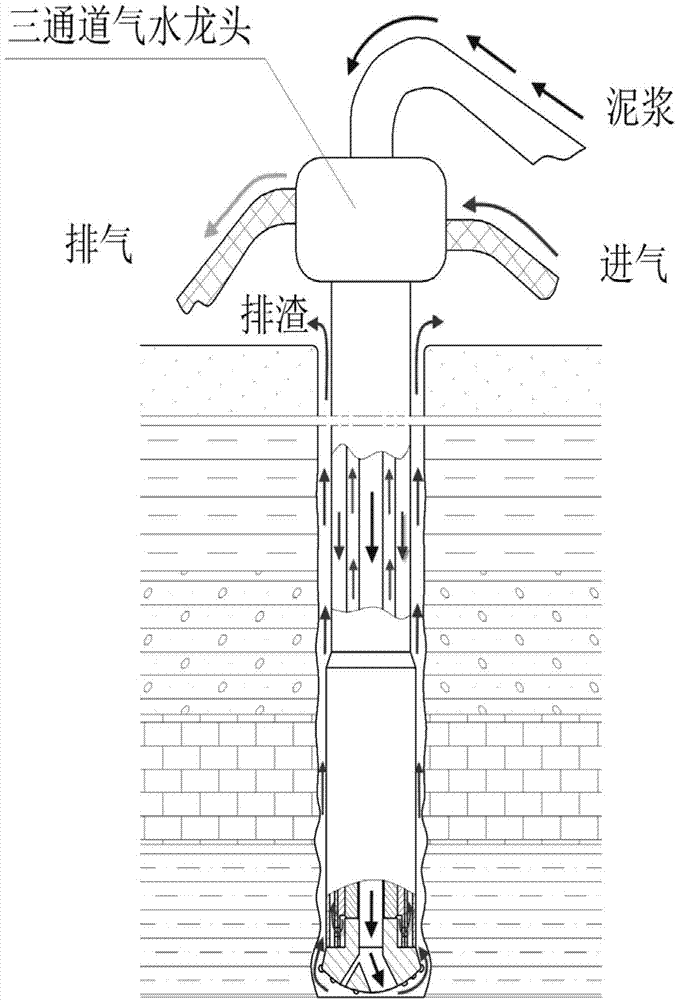

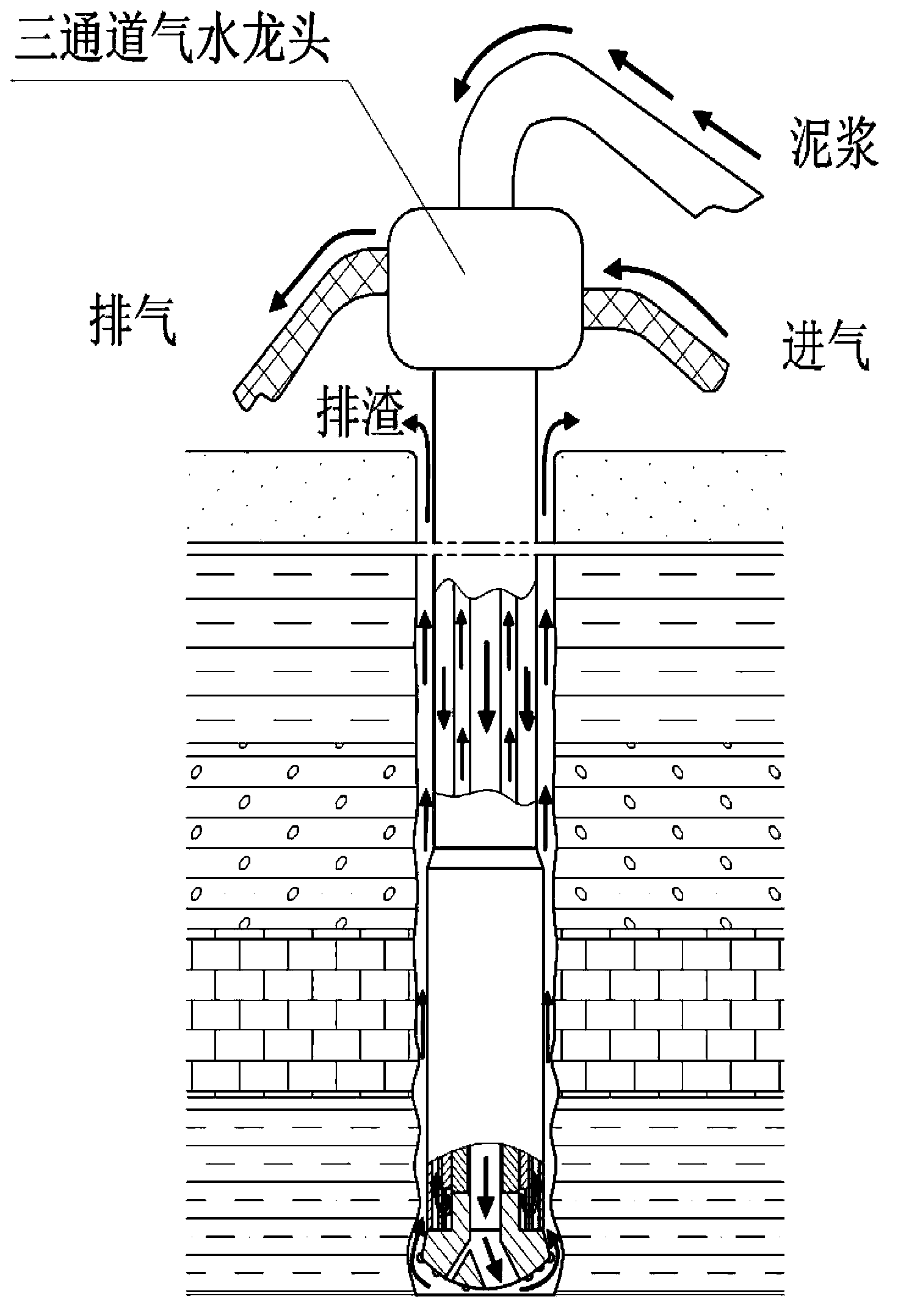

Mud retaining wall and air down-the-hole hammer drilling tool and drilling technology

InactiveCN102966304AImprove connection strengthEasy to unscrewDrilling rodsBorehole drivesDepth in a wellWell drilling

The invention relates to a mud retaining wall and air down-the-hole hammer drilling tool and a drilling technology. The drilling tool is in a coaxial three-channel structure; an inner layer drilling rod is provided with a center channel; the inner layer drilling rod and a middle layer drilling rod form a second channel; the middle layer drilling rod and an outer layer drilling rod form a third channel; the three-channel drilling tool in the drilling process and a hole wall form a fourth channel for independent circulation of mud and compressed air; an outer pipe of the drilling tool adopts threaded connection; two layers of inner pipes are spliced; the connection strength is high; the sealing property is good; screwing and dismounting are facilitated. The compressed air drives a down-the-hole hammer to impact detritus, so that the hard rock drilling efficiency can be improved by more than ten times; the compressed air is closed and cycled in down-the-hole equipment and free from the influence of variations of well depth and confining pressure; the wind pressure and air supply are reduced greatly; the well mouth contamination is prevented; the energy-saving, environment-friendly and low-cost drilling is achieved; the mud drilling is used while the air drilling is used; the effective protection on the well wall is achieved; the adaptability to various complex formations is improved; and the drilling safety is ensured.

Owner:JILIN UNIV

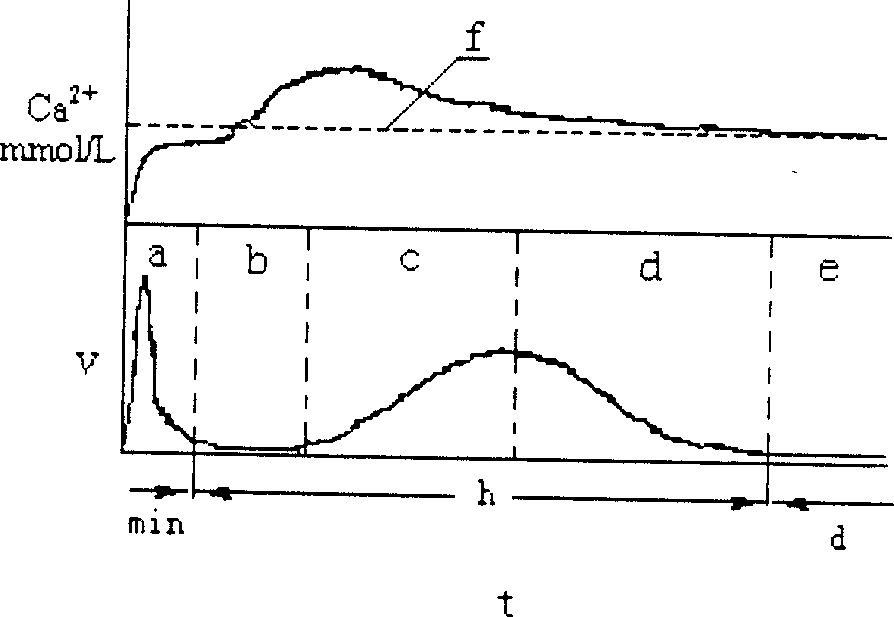

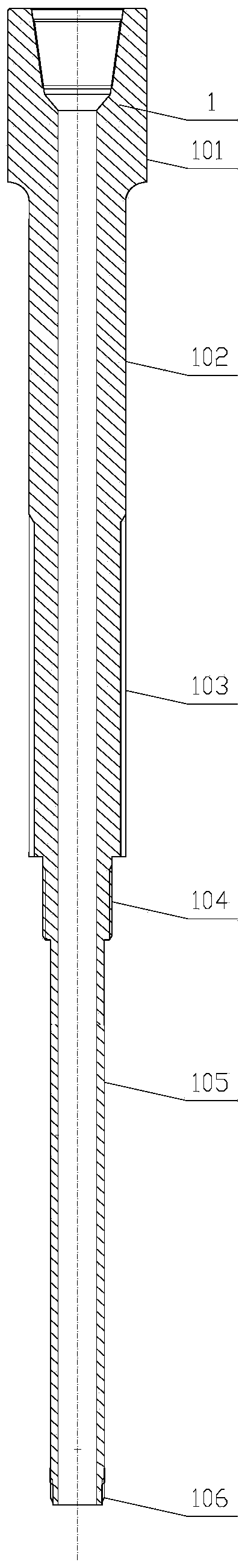

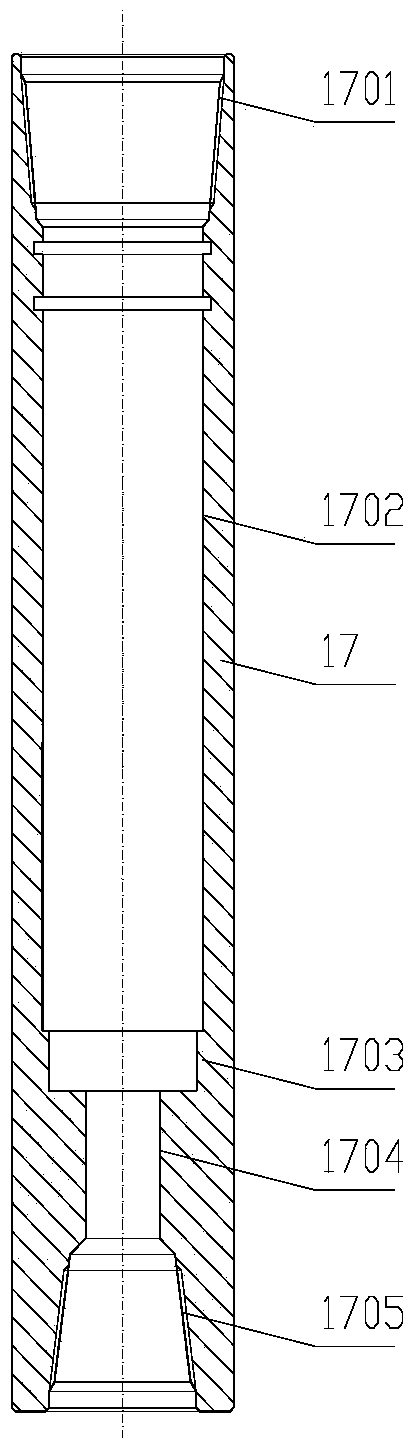

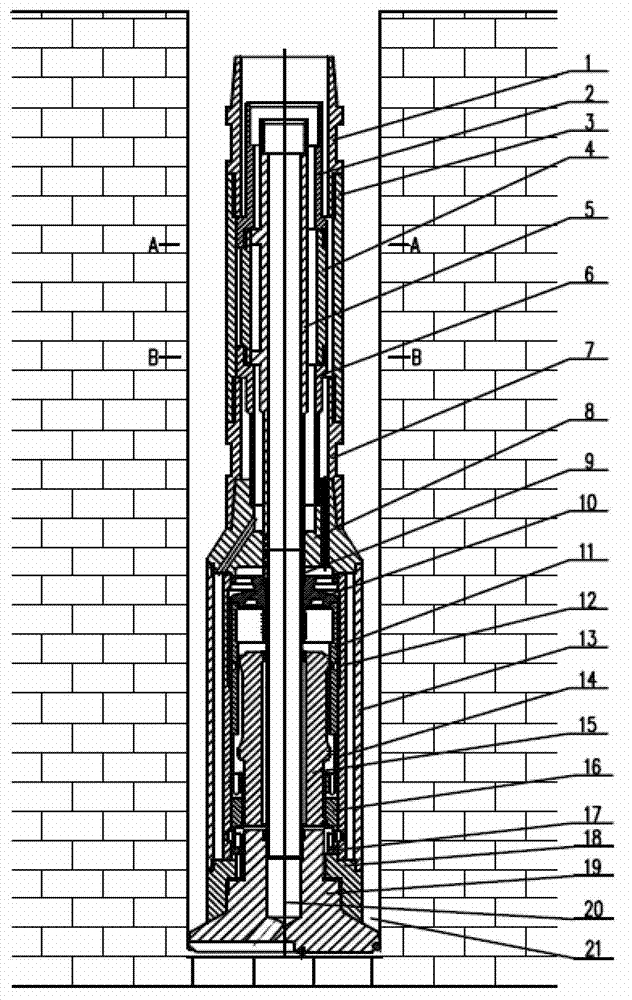

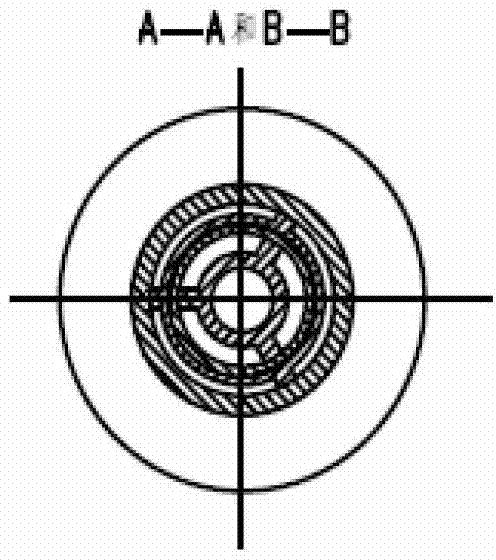

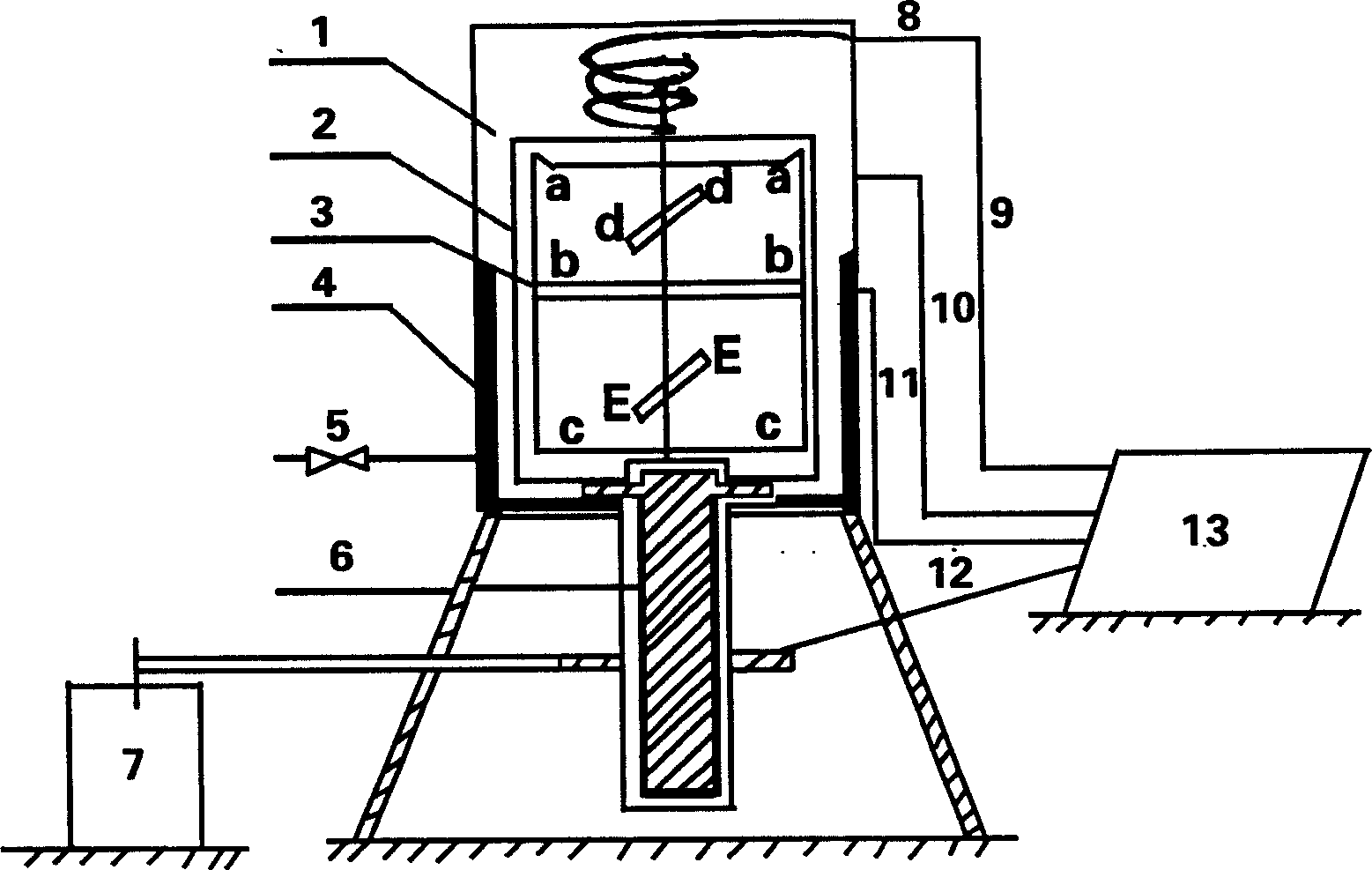

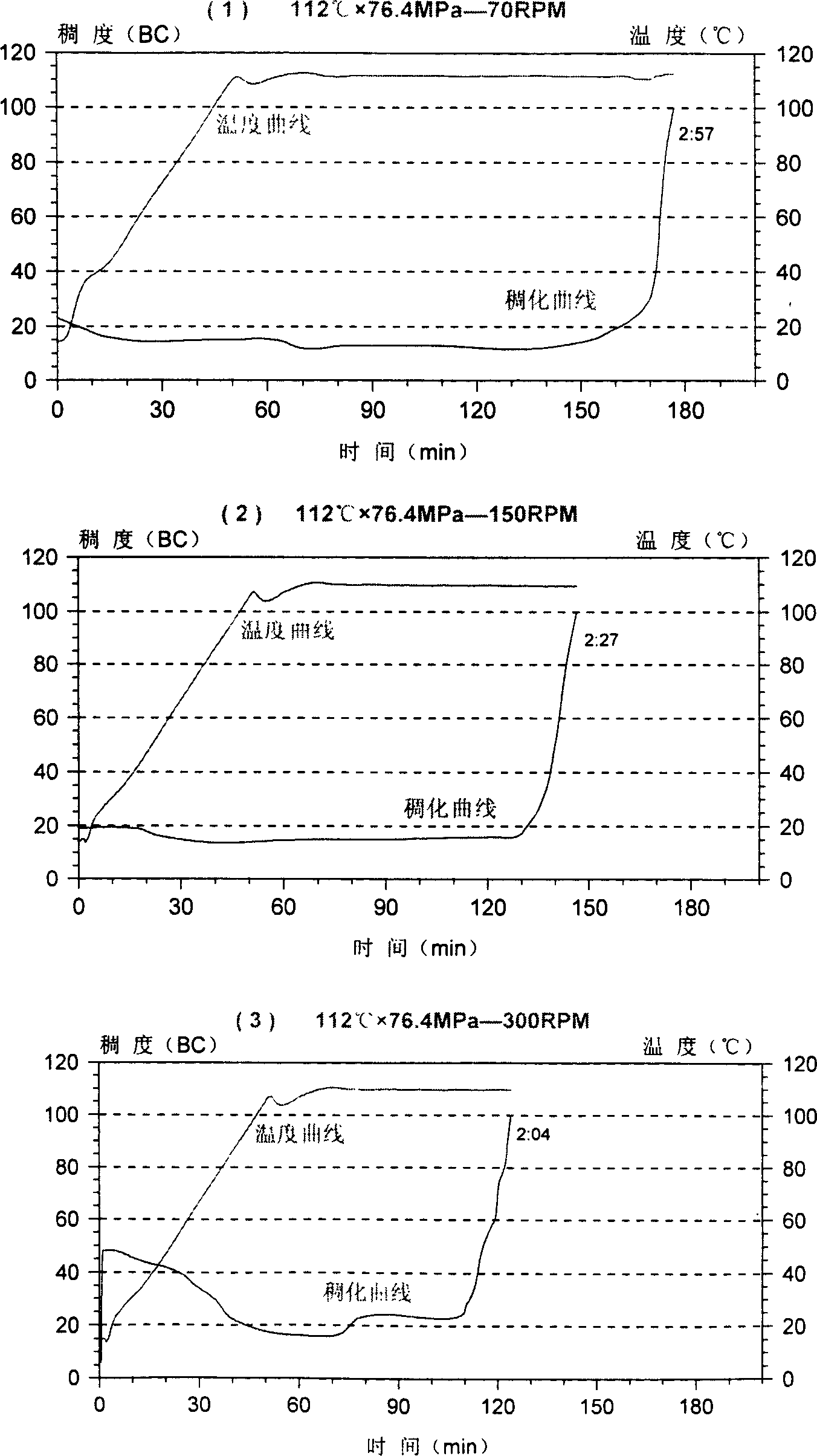

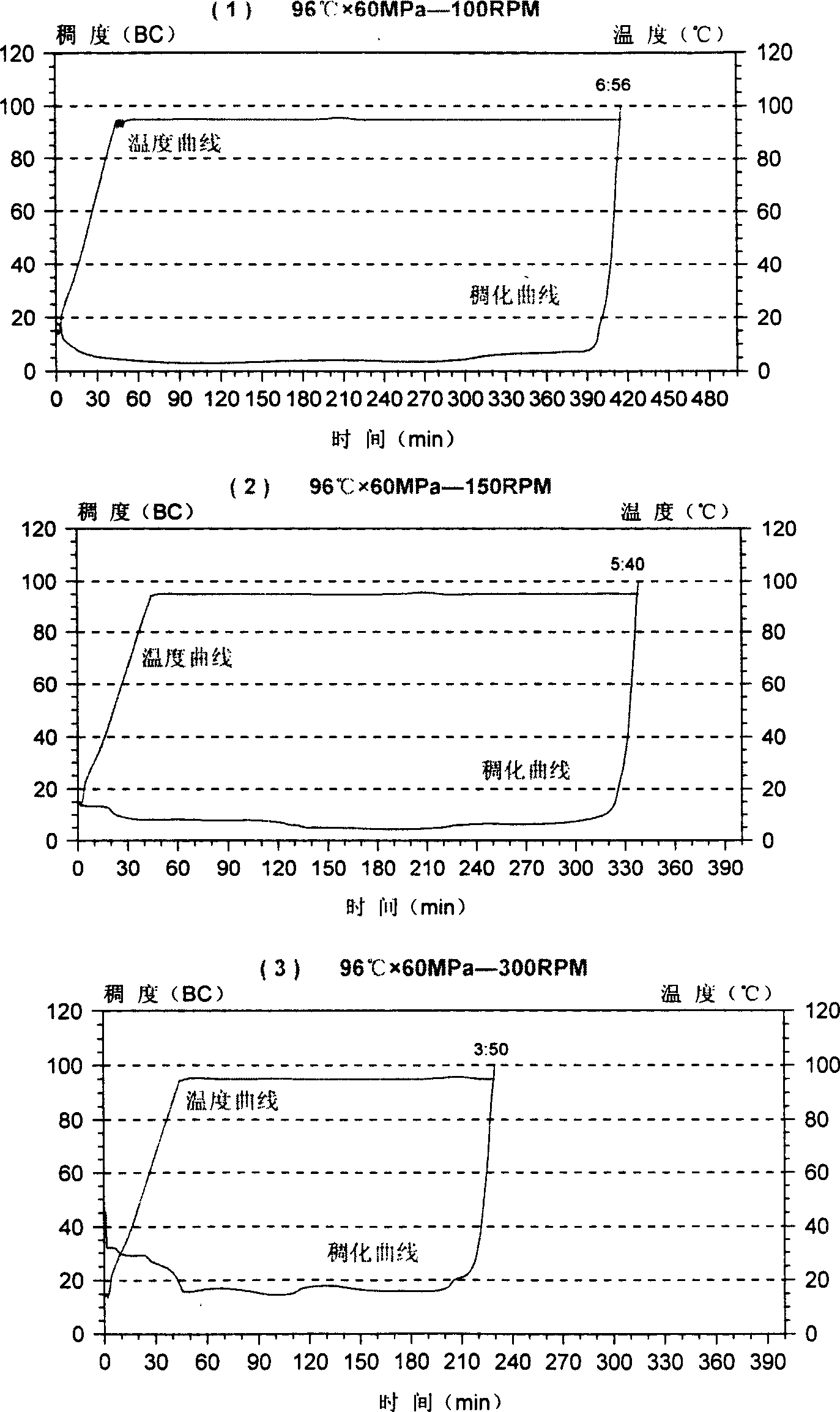

Variable speed supercharge oil well cement consistometer and thickening time measuring method thereof

InactiveCN1570599AEnsure construction safetyQuality assuranceFlow propertiesDepth in a wellMeasuring instrument

This invention relates to a method for better simulating and measuring mud thickness and thickening time. And it solves the problem of discrepancy between the measured mud thickness and thickening time and the real situation. And it employs a supercharged consistometer with variable speed, and plasm cup rotary speed is infinite and its rotary speed ranges from ten to six hundred round per minute. The method is the following: first to determine the shearing circum-space speed according to injecting speed of mud plasm and theological characteristic of the oil well, then to determine the average shearing force and speed when consistometer special paddle rotates; finally to confirm the mud plasm thickening time and paddle stimulating speed. This invention can ensure the safety construction of oil well casing and cementing and the quality of well wall concretion and agglutination.

Owner:SOUTHWEST PETROLEUM UNIV

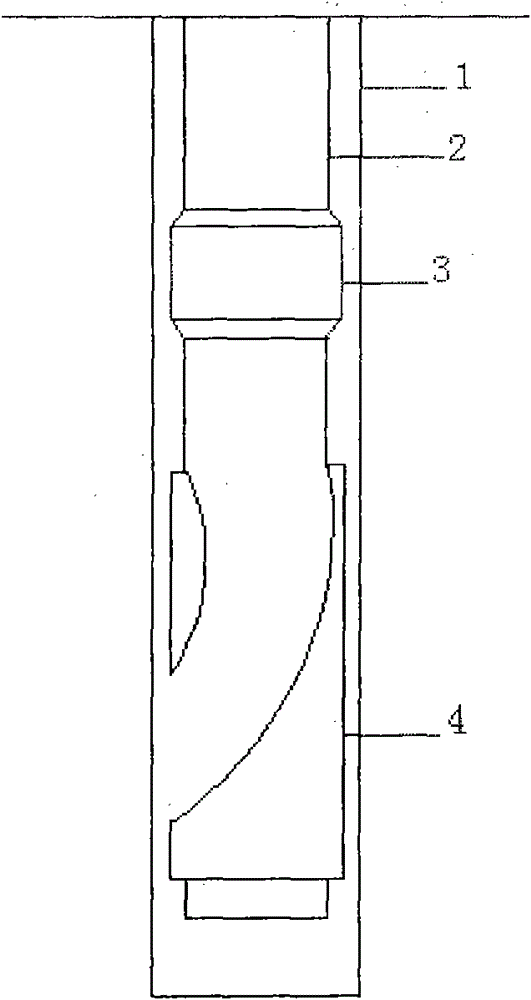

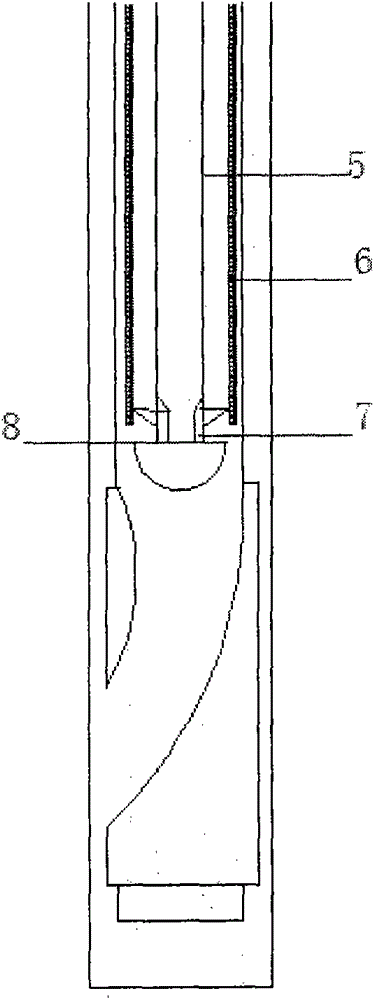

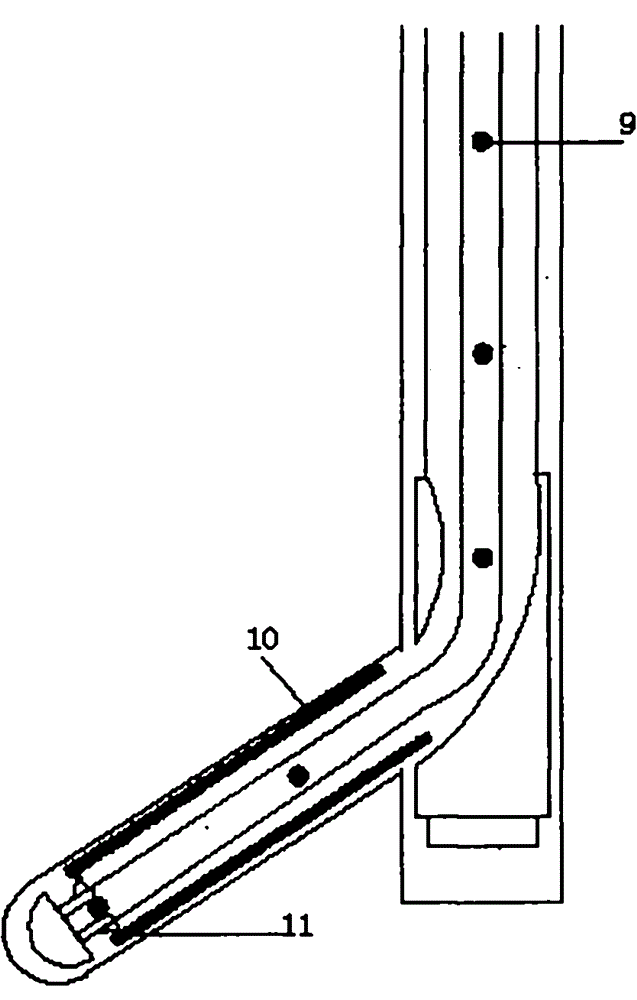

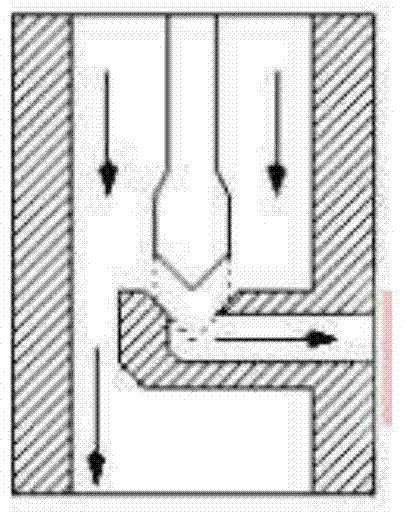

Drilling and completion integration device and method using coiled tubing carrying sieve tubes for sidetracking

The invention provides a pinnate branch well sidetracking and completion integration device and method using a coiled tubing carrying sieve tubes. The technical scheme relates to such devices as a tubing anchor, a diverter, the coiled tubing, a sieve tube separating device and a jet bit. The method comprises the steps of tripping in a tubing provided with the anchor and the diverter after the casing cementing of a main horizontal well section; tripping in the coiled tubing carrying the sieve tubes from the inside of the tubing after setting the direction and anchoring the tubular column; using abrasive jet flow to perform window sidetracking; when the sidetracking reaches the designed well depth of branch well holes, separating the sieve tubes from the separating device and leaving the sieve tubes in the branch well holes through ball throwing and pressure building in the coiled tubing; taking the coiled tubing from the well hole at the same time; performing the window sidetracking and ball throwing separation after adjusting the well depth and the direction of the tubing again. Thus, the drilling and completion integration process using the coiled tubing carrying the sieve tube for sidetracking is completed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

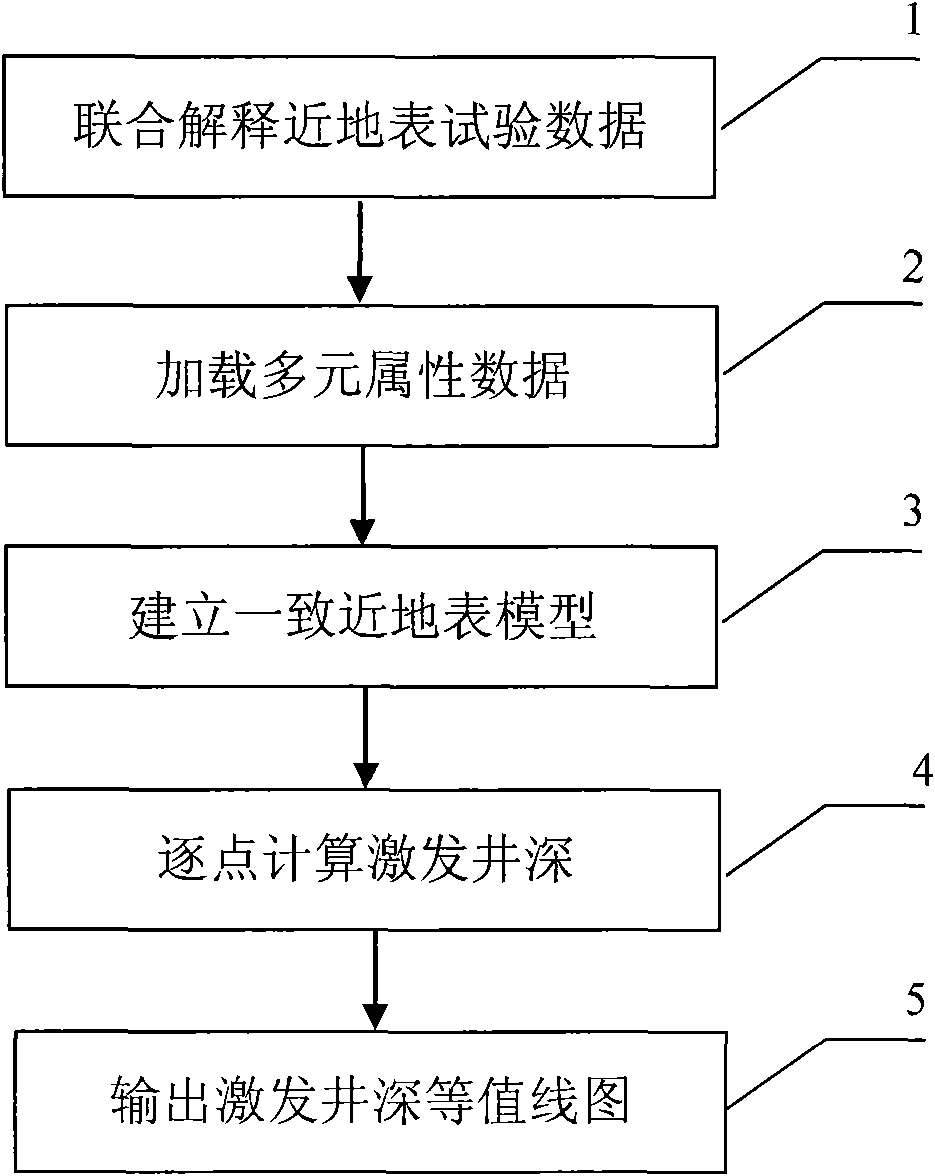

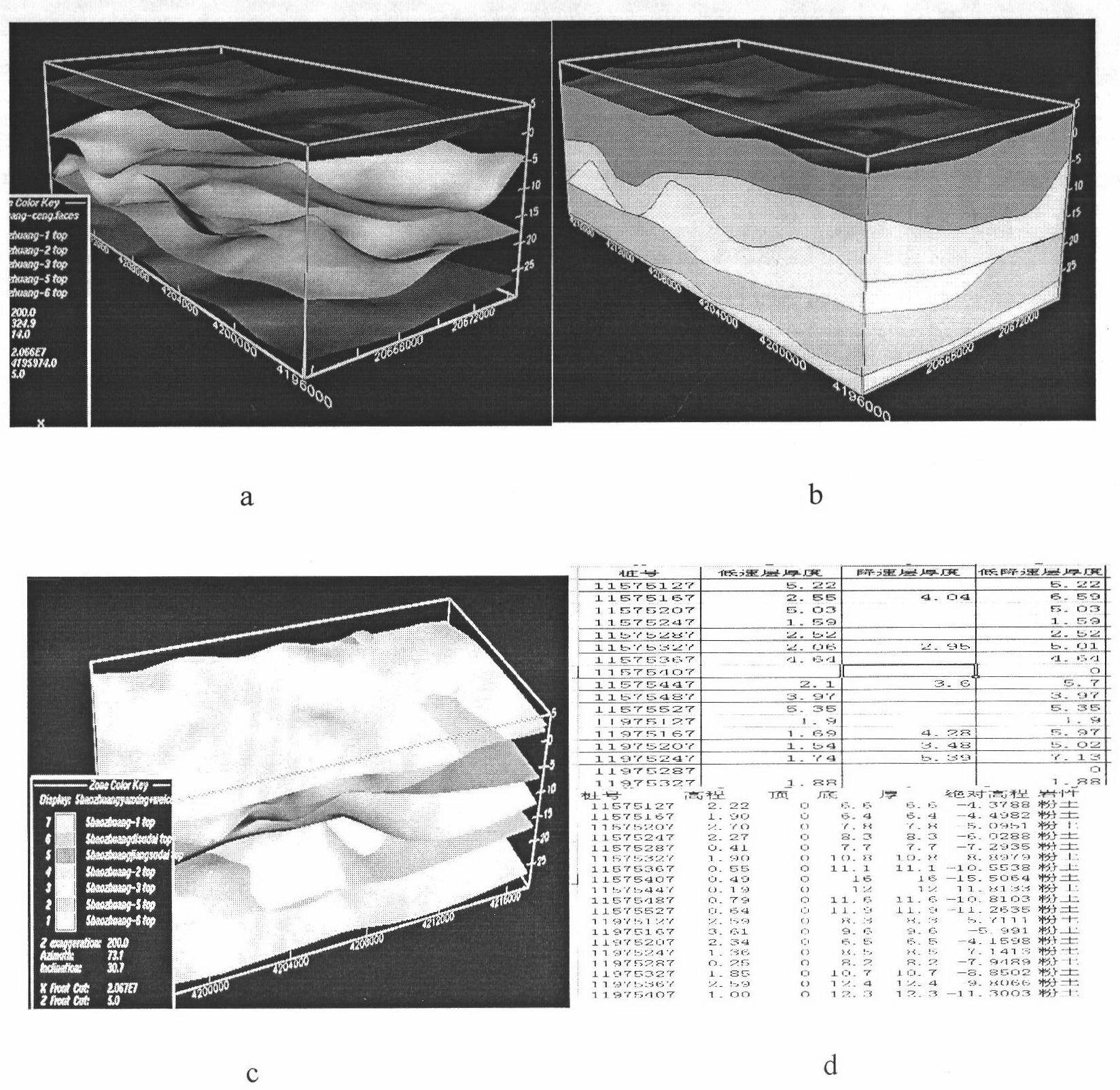

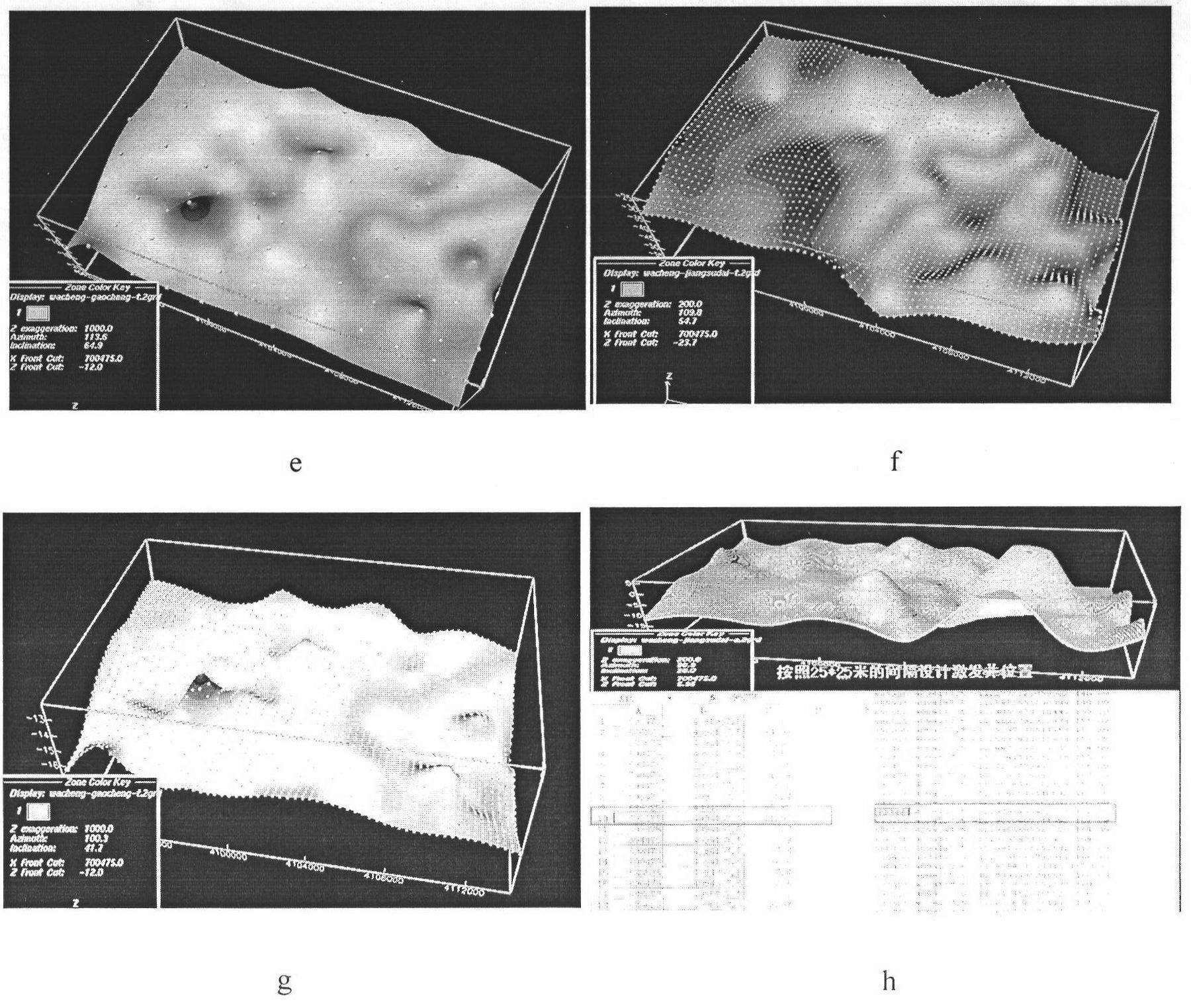

Point-by-point excitation well depth designing method based on uniform near-surface model

InactiveCN101788686ASimple designImprove recording signal-to-noise ratioSeismic signal processingSeismology for water-loggingLithologyDepth in a well

The invention discloses a point-by-point excitation well depth designing method based on a uniform near-surface model. The method comprises the following steps of: A. obtaining optimum lithological hierarchical data and optimum speed hierarchical data by combining interpretation; B. programming a data conversion interface program and loading multiple attribute data; C. establishing a comprehensive and uniform near-surface model according to the lithological hierarchical data and the optimum speed hierarchical data obtained after combining interpretation, data of the submersible surface and submersible well, speed data and absorption attenuation A values; D. carrying out point-by-point excitation well depth designing and static correction value calculation on the uniform near-surface model; and E. loading the generated excitation well depth dispersive point data into the system again to generate a contour map in a CGM (Computer Graphic Metafile)format, marking a position by using a small rectangular patters, displaying the depth value of the point, and plotting the processed result map by using a plotter. The invention can optimize the excitation well depth design, enhance the signal-to-noise ratio of the earthquake collecting single-shot record, and greatly improve the information quality.

Owner:CHINA PETROCHEMICAL CORP +1

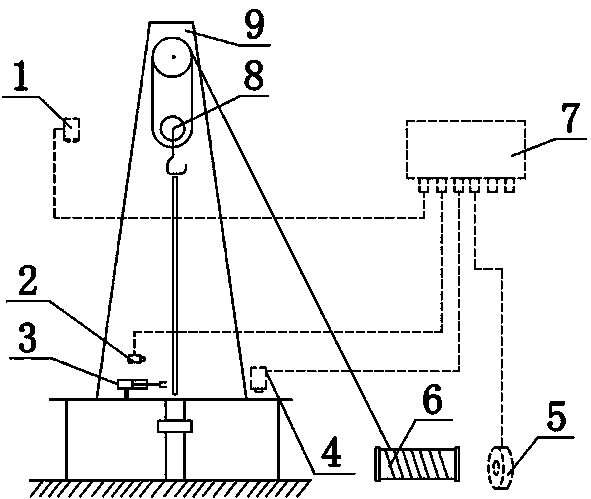

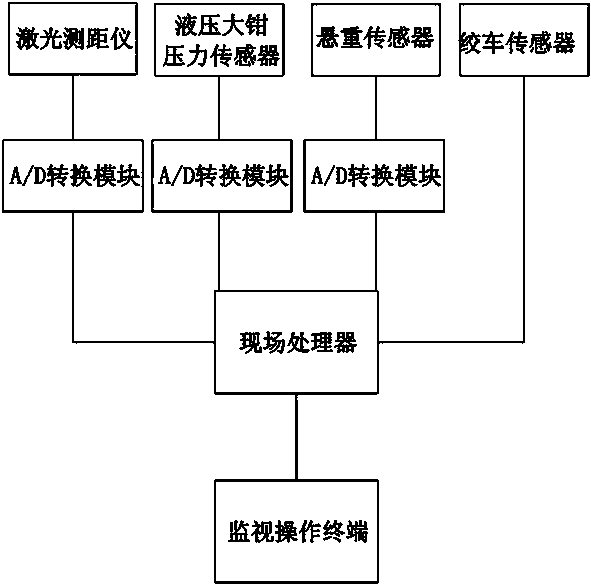

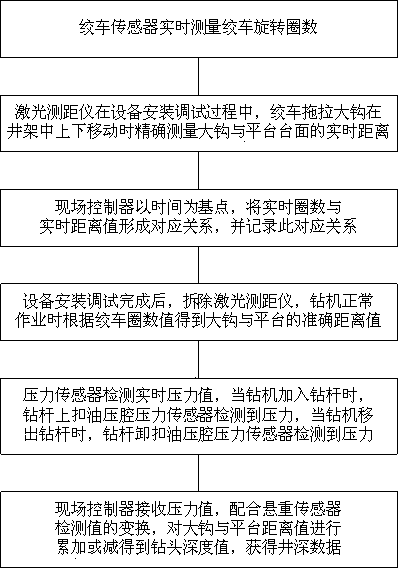

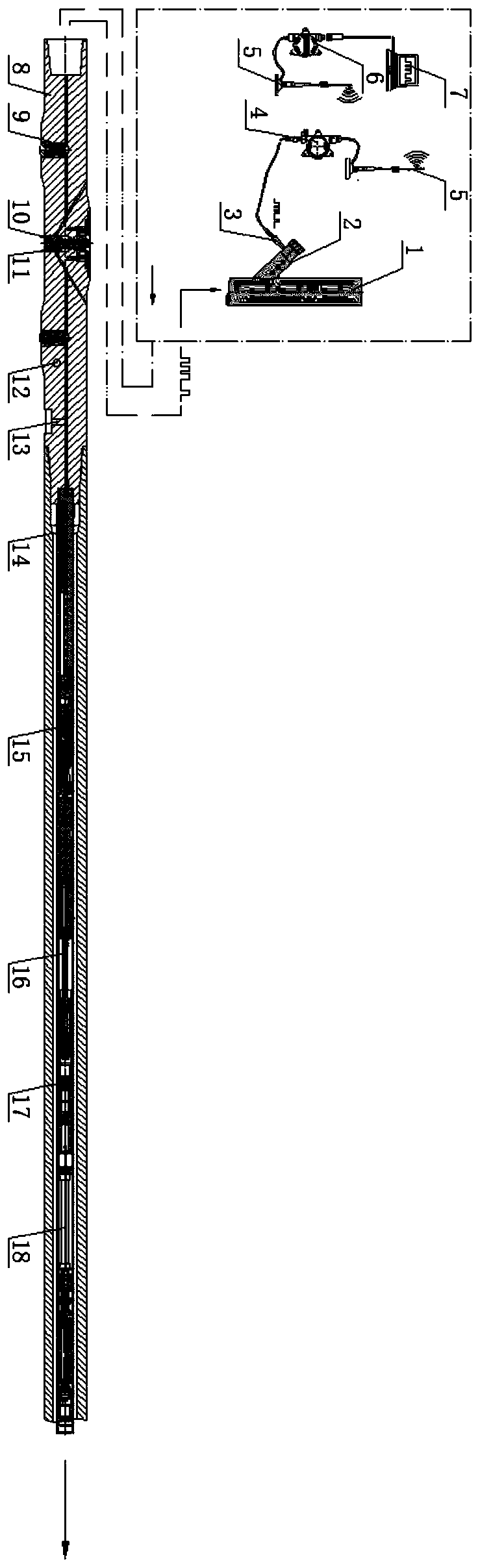

Petroleum drilling well depth measuring system and method

The invention discloses a petroleum drilling well depth measuring system and method. The system comprises a winch sensor, a pressure sensor, a hanging load sensor, a laser range finder, a field controller and a monitoring operation terminal. According to the method, the laser range finder is fixed on a large hook during system initial assembly debugging, the large hook is controlled by a winch to move vertically, the onsite controller records the displacement value of the laser range finder and the ring number of the winch in real time to form the corresponding relation between the value of each ring and the displacement value, and the height value of the large hook is read automatically according to the ring number value program of the winch during normal during normal well drilling. In the drilling process, a hydraulic power tong pressure sensor transmits signals to indicate unfastening or fastening and the corresponding hanging load value change, a controller judges whether a drill pipe enters or leaves through the program, and the height change values of the large hook is accumulated to obtain the well depth and the drill bit position value. The system and method overcomes the shortcoming that the traditional measuring mode is in accurate in measurement or complex in measurement work and inconvenient to operate, and is capable of accurately measuring the well depth and the drill bit position and capable of displaying the well depth data in real time without manual operation.

Owner:CHENGDU HANGTIAN PHOTOELECTRIC TECH

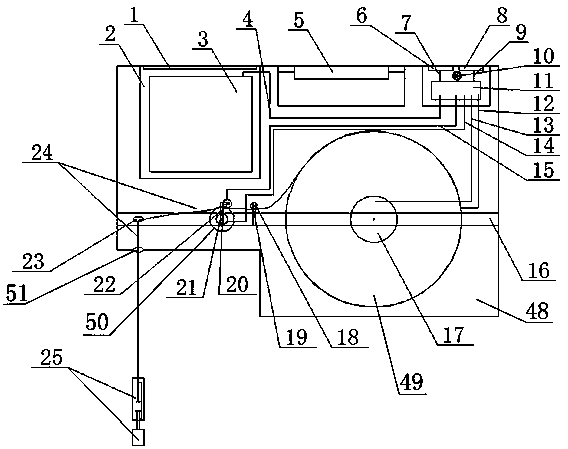

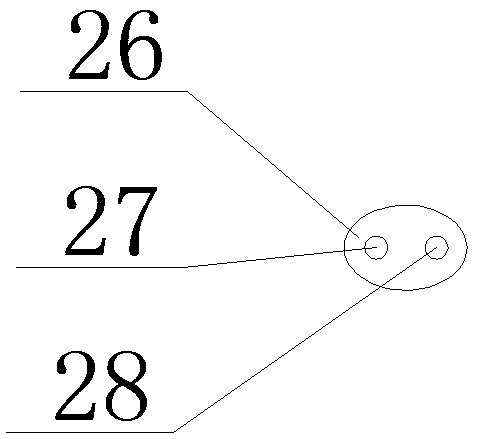

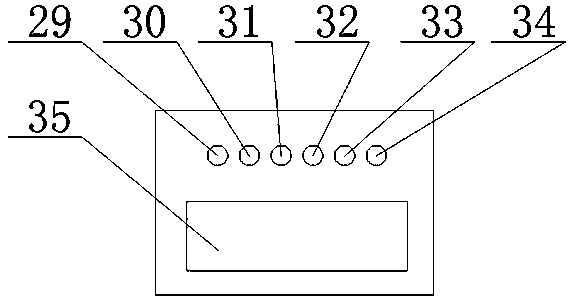

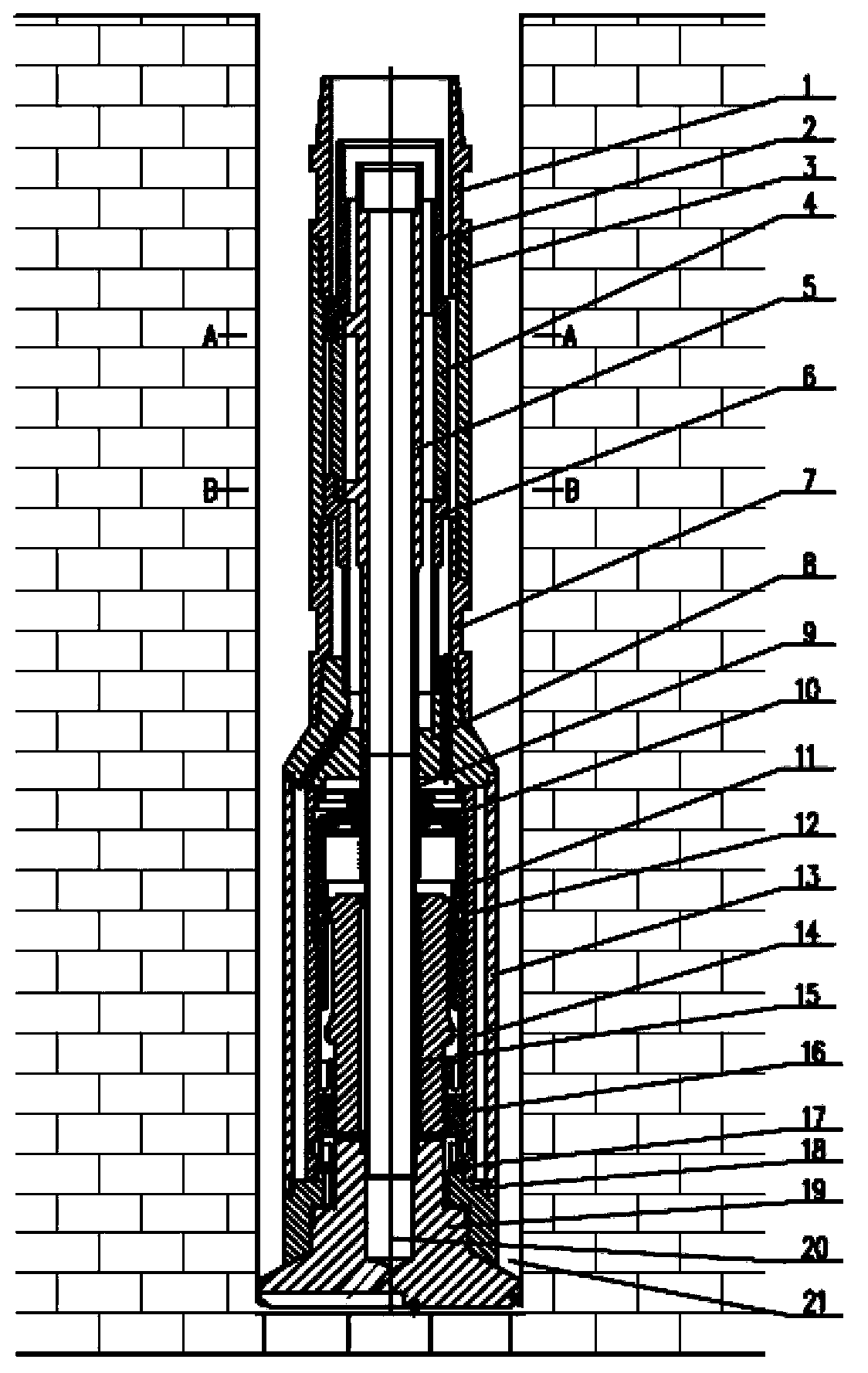

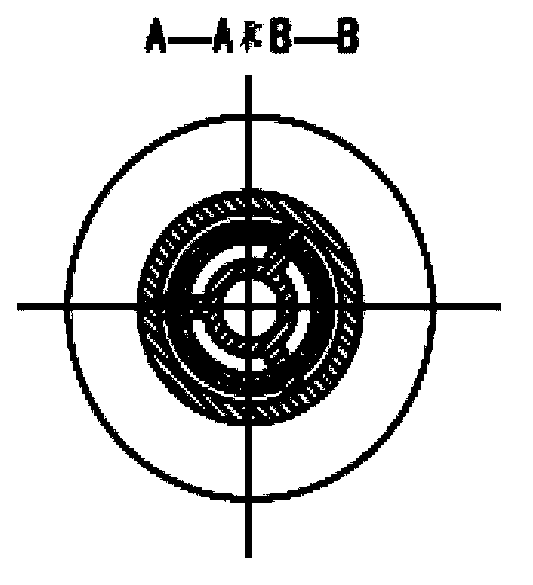

Portable automatic measuring instrument and measuring method for ground water level and well depth

PendingCN109307544AFully automatedRealize integrationMachines/enginesElectric/magnetic depth measurementDepth in a wellMeasuring instrument

The invention relates to a portable automatic measuring instrument and a measuring method for ground water level and well depth, and belongs to the technical field of special equipment for monitoringground water level and well depth. One end of a measuring line (24) is wound on a main line wheel (49); and the other end of the measuring line (24) passes between a length counter sensor (22) and a line conveying wheel (50), and is connected with a measuring probe (25) through a first measuring line guide hole (23) and then a second measuring line guide hole (51) at the bottom of the shell. The measuring line (24) is composed of a measuring line insulating layer (26), a first lead wire (27), and a second lead wire (28); and the measuring line insulating layer (26) is arranged outside the first lead wire (27) and the second lead wire (28). According to the portable automatic measuring instrument and the measuring method for ground water level and well depth, the measurement for the water level and the well depth are integrated, so that the measurement is greatly simplified, the labor intensity is relieved, the errors that may be caused by artificial sensations in the well depth measurement are eliminated, and the accuracy of the measurement data is greatly improved.

Owner:河北省地质环境监测院

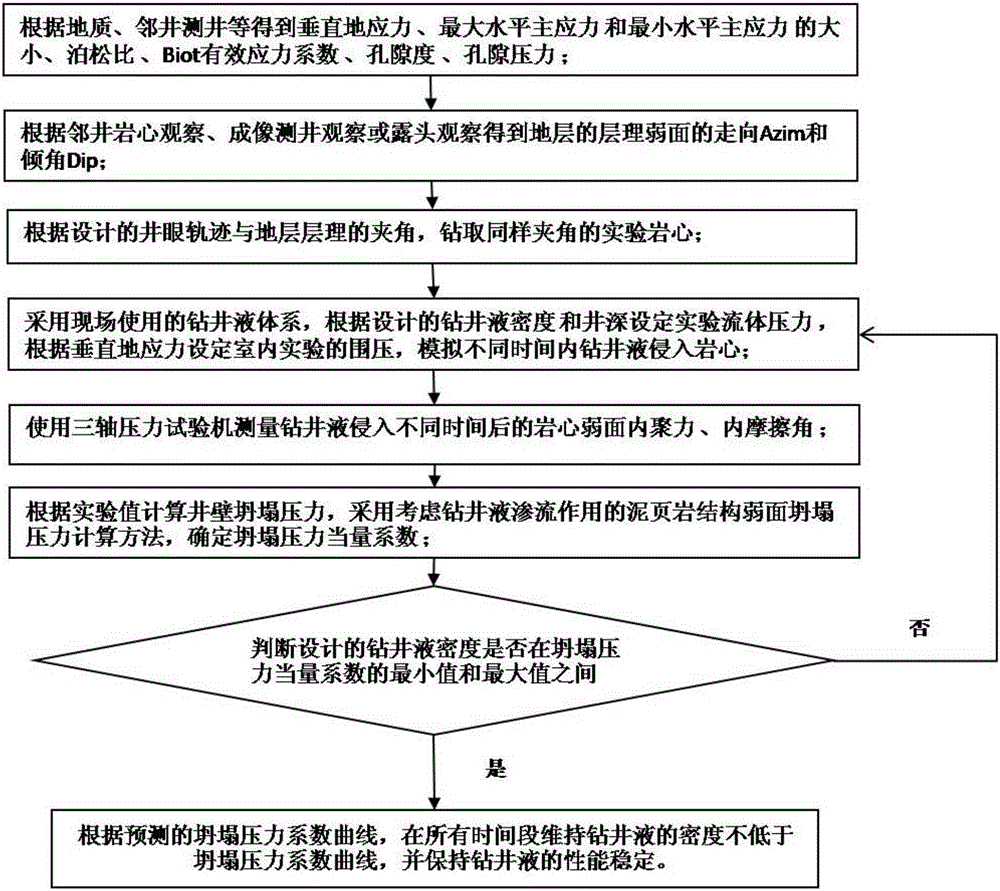

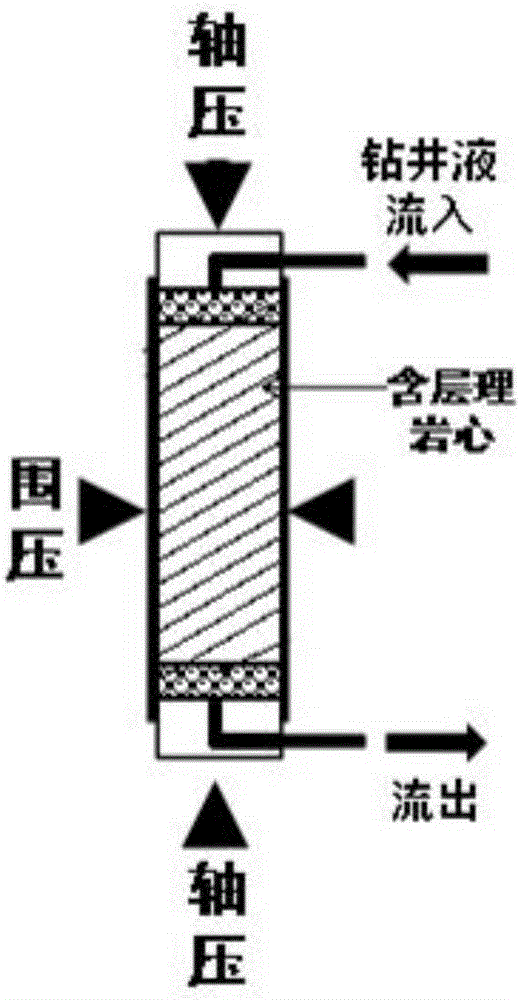

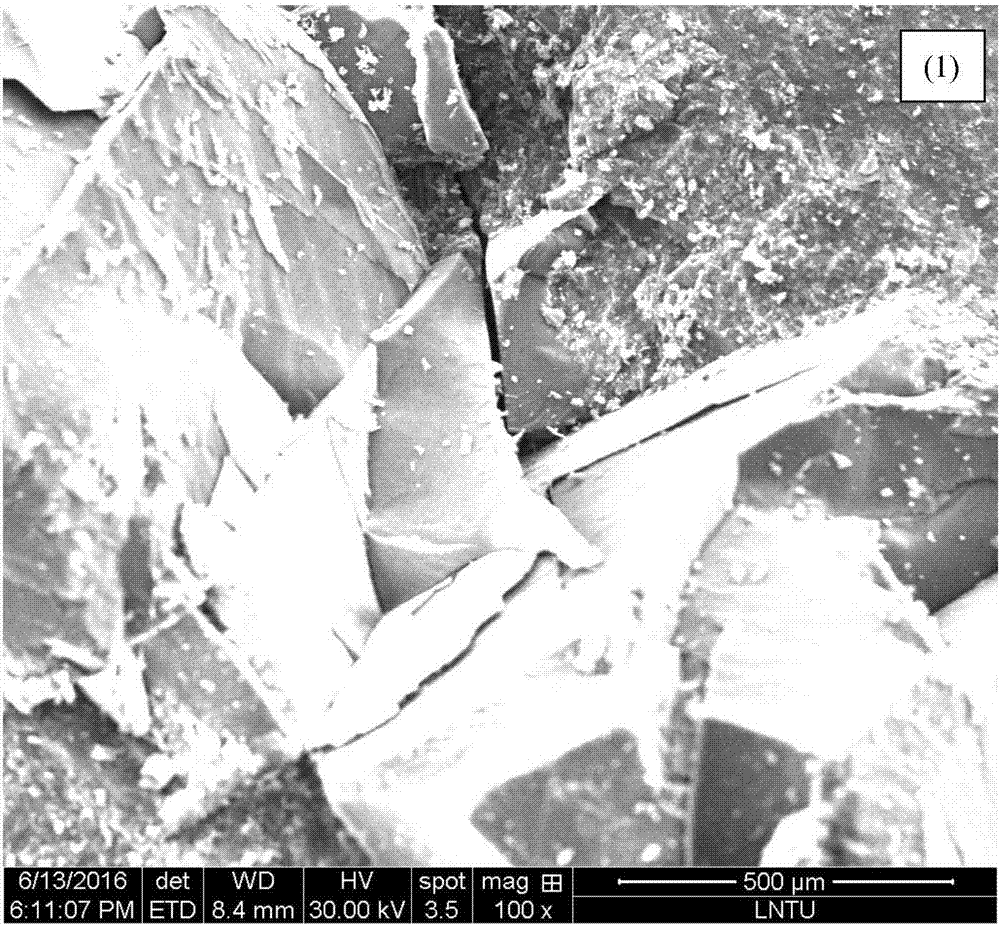

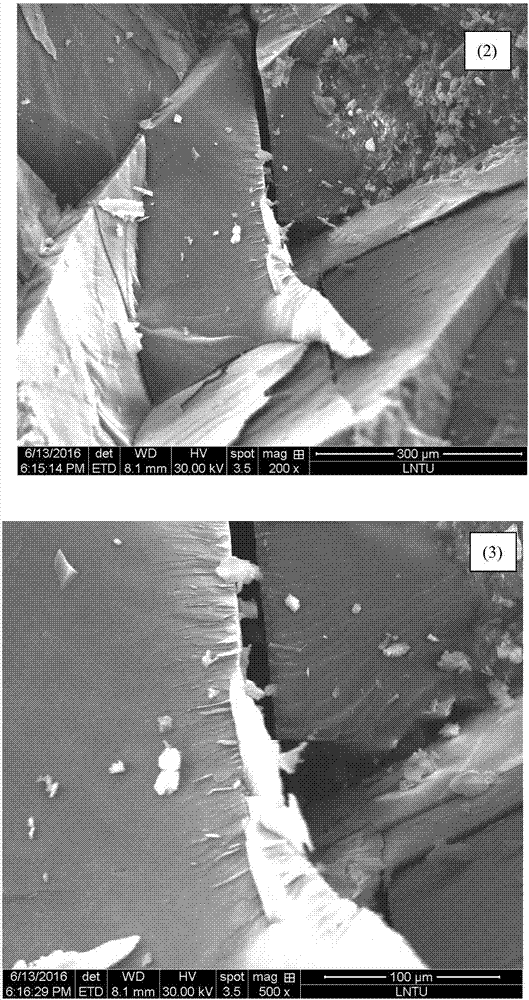

Calculation method of borehole sloughing pressure applicable to the bedding fractured stratum

The invention provides a calculation method of borehole sloughing pressure applicable to the bedding fractured stratum which belongs to the technical field of oil and natural gas exploitation and well drilling. The method comprises the steps of: in the simulated environment in different time after the drilling fluid soaking into the rock core, calculating the strength parameter of the weak side of the core, calculating the borehole collapsing force, setting the experimental liquid pressure based on the design density of the drilling fluid and the well depth, simulating the infiltration status of the rock core caused by the drilling fluid in different time, and measuring the cohesive force and internal friction angle of the core weak side after different moments of drilling fluid infiltration, by calculation obtaining the curve of collapsing force relative to the time under the condition of drilling fluid infiltration, determining the stability of the borehole, thereby optimizing the drilling fluid density of different moments. The method solves the problem of the reliance on experiences to regulate the drilling fluid density, can guarantee the drilling safety and reduces the drilling costs.

Owner:CHINA PETROLEUM & CHEM CORP +1

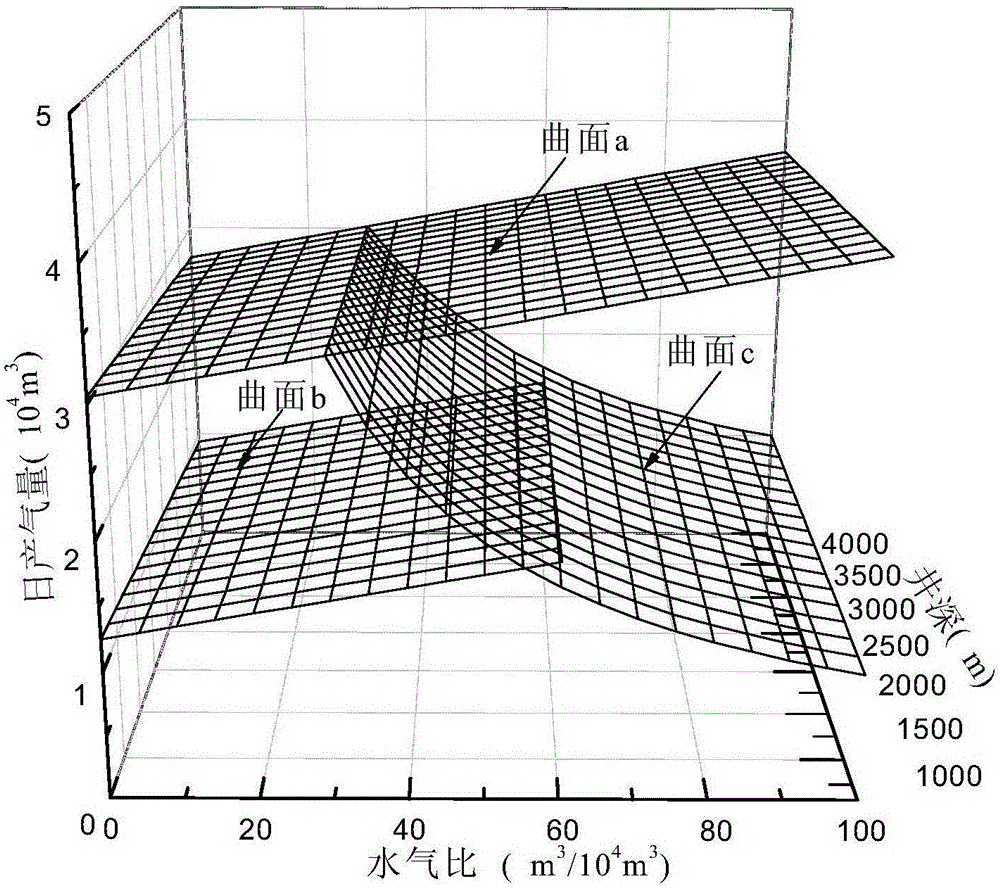

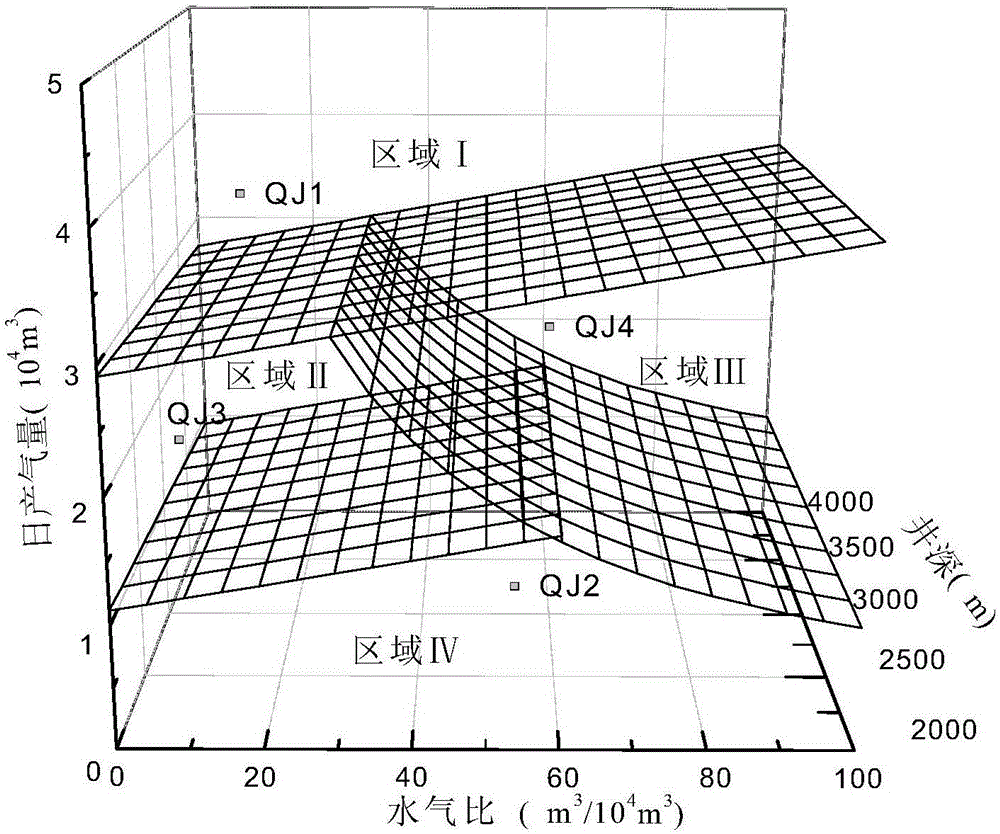

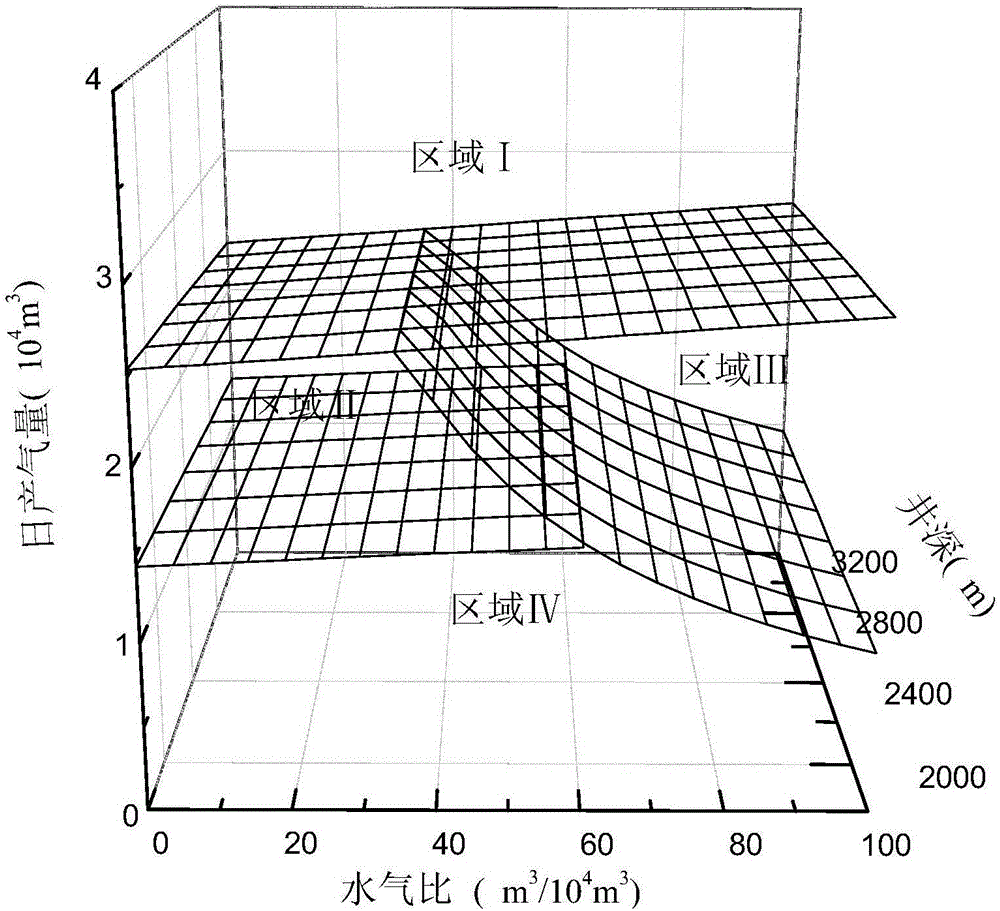

Building method and application of three parameter-gas well drainage gas recovery technology optimizing model

ActiveCN106570273ADrainage gas recovery process is simpleDrainage gas recovery process is fastSpecial data processing applicationsDepth in a wellFlow curve

The invention relates to the technical field of natural gas exploitation and in particular relates to a building method and an application of a three parameter-gas well drainage gas recovery technology optimizing model. A difficulty of rapid selection of drainage gas recovery technology for water-producing gas well is solved. The building method comprises steps of first, collecting production parameters of a water-producing gas well of a gas field, then calculating different daily gas production of a given oil pipe aperture and natural gas critical liquid carrying flow under a water-gas ratio at different well depths, drawing out natural gas critical liquid carrying flow curves (a,b) of maximum and minimum oil pipe apertures on daily gas production, water-gas ratio and well depth three-dimensional model, and drawing out a curve (c) with liquid production amount being 95m<3> on the three-dimensional model. The natural gas critical liquid carrying flow calculated by the method meets on-site production condition in a better way; and the building method is advantaged by quick determination of gas well drainage gas recovery technology based on simple parameters such as daily gas production, water-gas ratio and the well depth.

Owner:PETROCHINA CO LTD +1

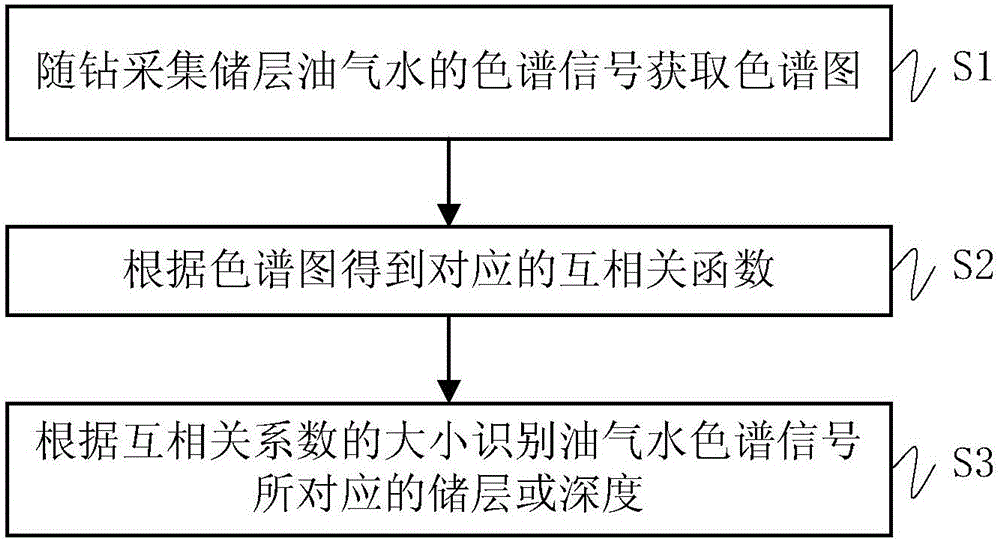

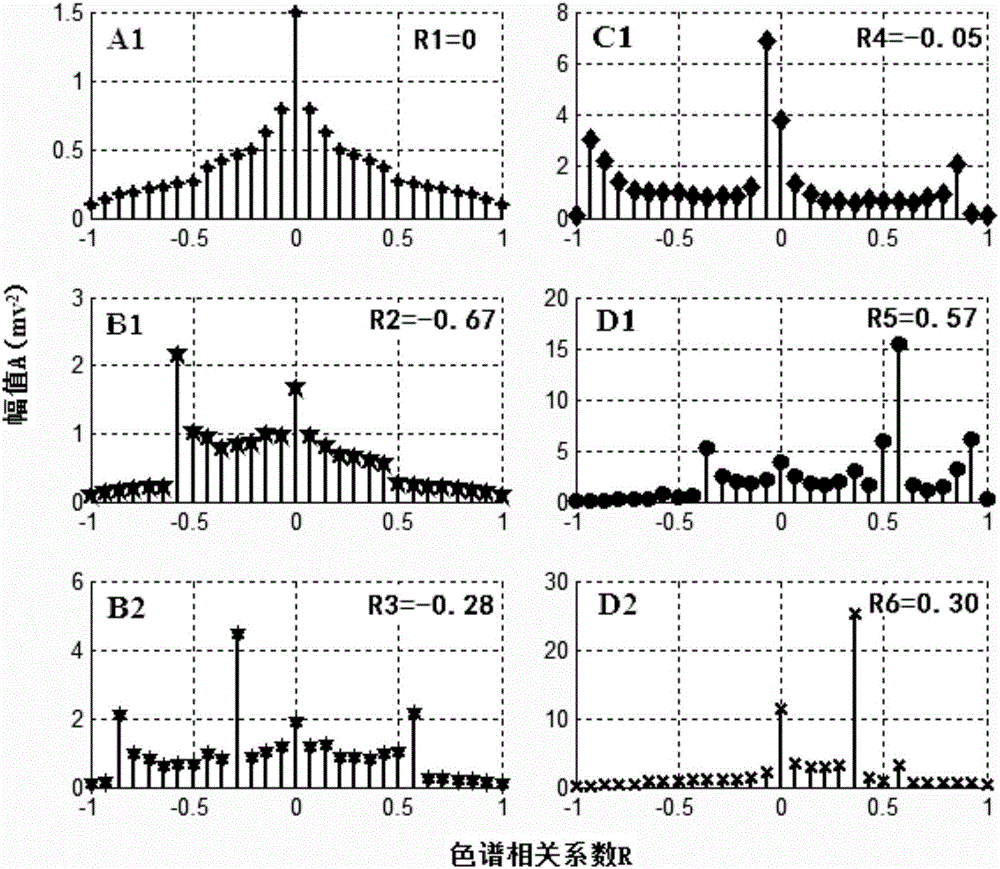

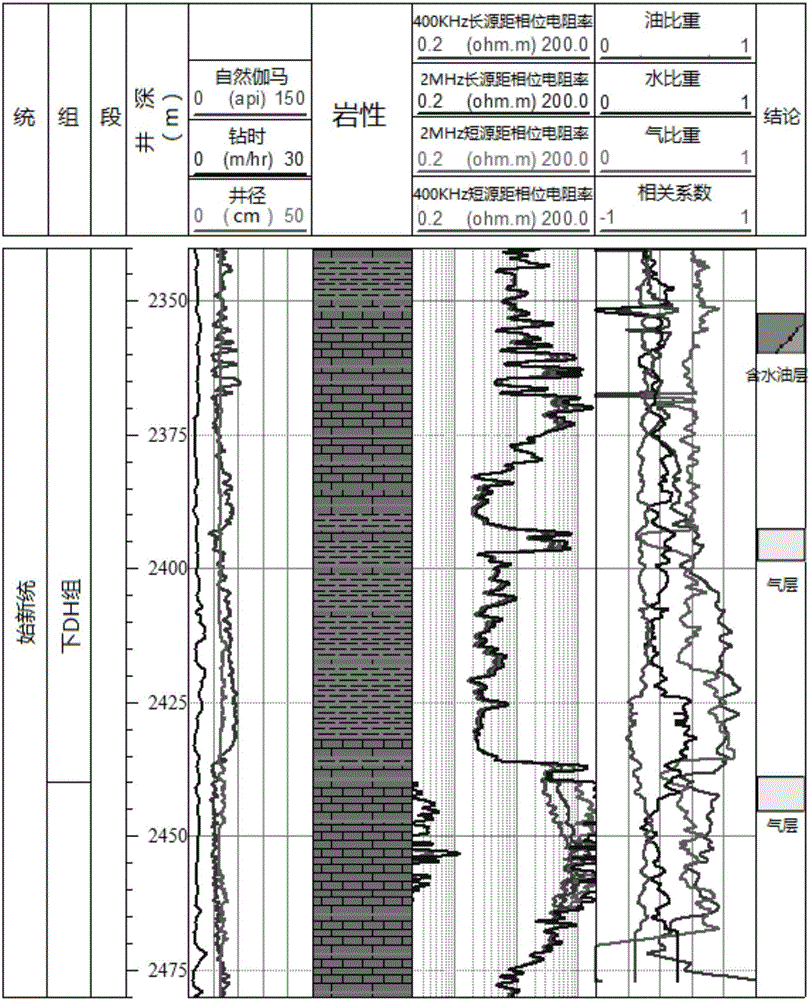

While-drilling multi-parameter analysis-based oil-gas-water identification method and system

The invention discloses a while-drilling multi-parameter analysis-based oil-gas-water identification method. The method comprises the steps that chromatography signals of oil-gas-water in a reservoir stratum are acquired while drilling so that chromatograms are obtained; the cross-correlation function of the oil-gas-water chromatography on a continuous shaft depth and a standard chromatography and water-oil-gas characteristic parameters are obtained according to the chromatograms; and the cross-correlation function is subjected to Fourier inversion to obtain cross-correlation coefficients of any two chromatograms, and reservoir stratums or depths corresponding to the oil-gas-water chromatography signals are identified according to the changing direction of upper-and-lower-layer oil-gas-water features which are reflected by the amplitudes of the cross-correlation coefficients. According to the while-drilling multi-parameter analysis-based oil-gas-water identification method, gasometry chromatography is characterized in that the position of each component is known qualitatively after separation, and the chromatograms are regarded as spectrograms for analogy-analysis and calculation of correlations among the chromatograms and the three characteristic parameters representing the oil-gas-water features; reservoir stratum fluid features can be effectively identified; and the method especially has a very good effect for aquosity.

Owner:SHANGHAI SHENKAI GASOLINEEUM TECH +1

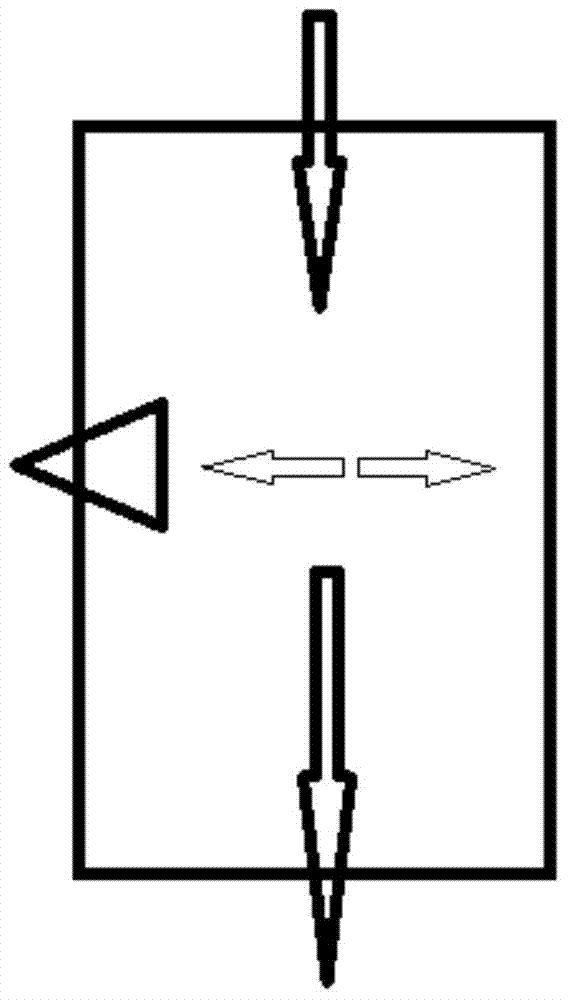

Down-hole slurry pulse signal generation device

ActiveCN103670380AIncrease transfer rateGuaranteed transmission speedSurveyDepth in a wellCommunications system

The invention provides a down-hole slurry pulse signal generation device. The down-hole slurry pulse signal generation device comprises a plurality of driving valves and a plurality of communication systems corresponding to the driving valves in a one-to-one mode. Due to the arrangement of the multiple driving valves, the types of generated data signals while drilling is more; due to the arrangement of the independent communication systems, the overall transmission speed can be effectively guaranteed, and the precision of detection is guaranteed to a certain extent. In addition, in combination with multiple modulation modes, the data transmission rate is further increased. The signals can be controlled to be strong or weak through selection of the outer diameter of each driving valve and the inner diameter of a limiting base so that the transmitting speed of the data signals while drilling can be guaranteed, the downhole slurry pulse signal generation device can be suitable for working environments with different wells, different displacements and different well depths, and therefore the adaptability to the various environments is greatly improved; the number of working driving valves can be controlled, and therefore high flexibility is obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

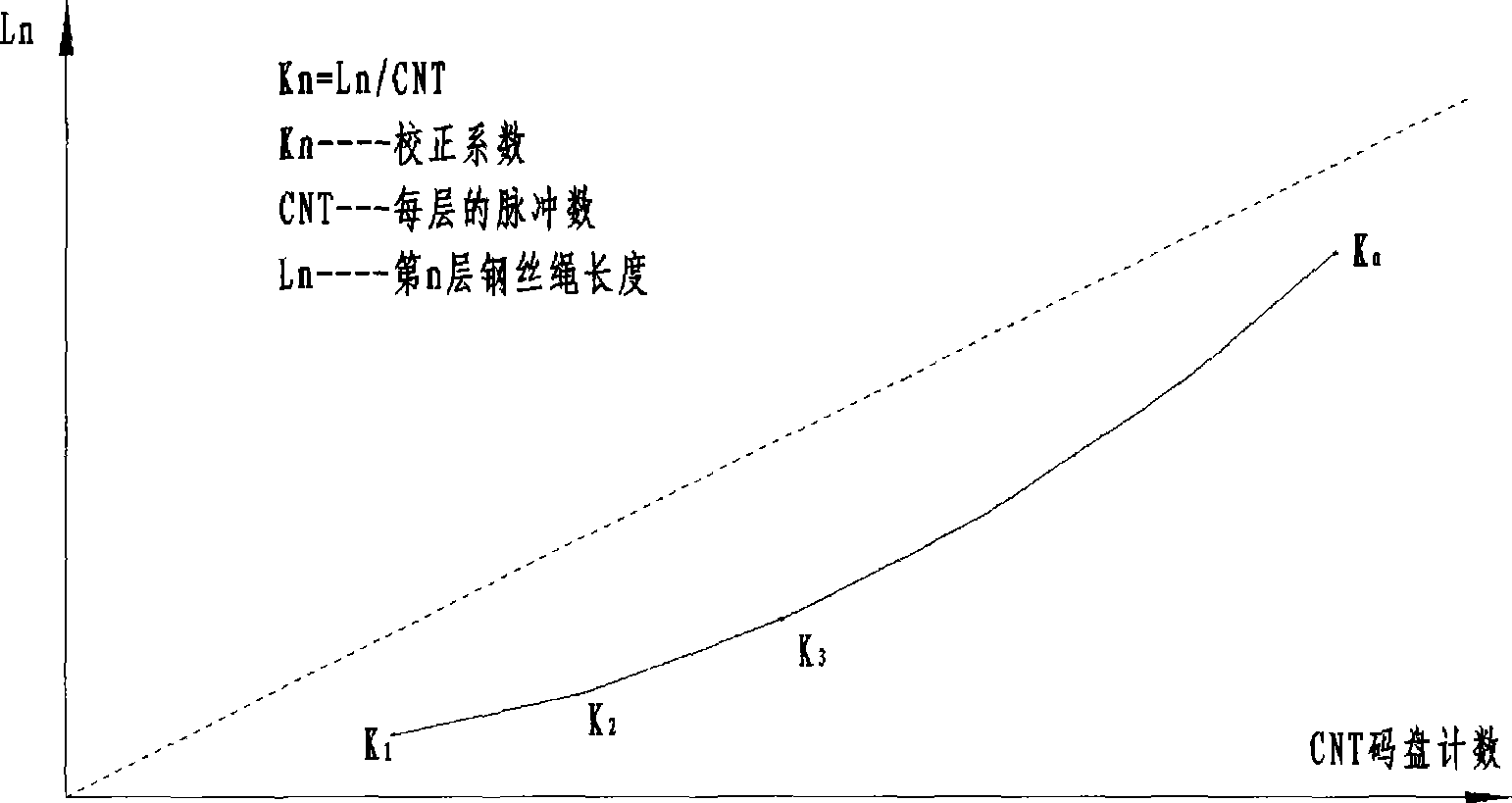

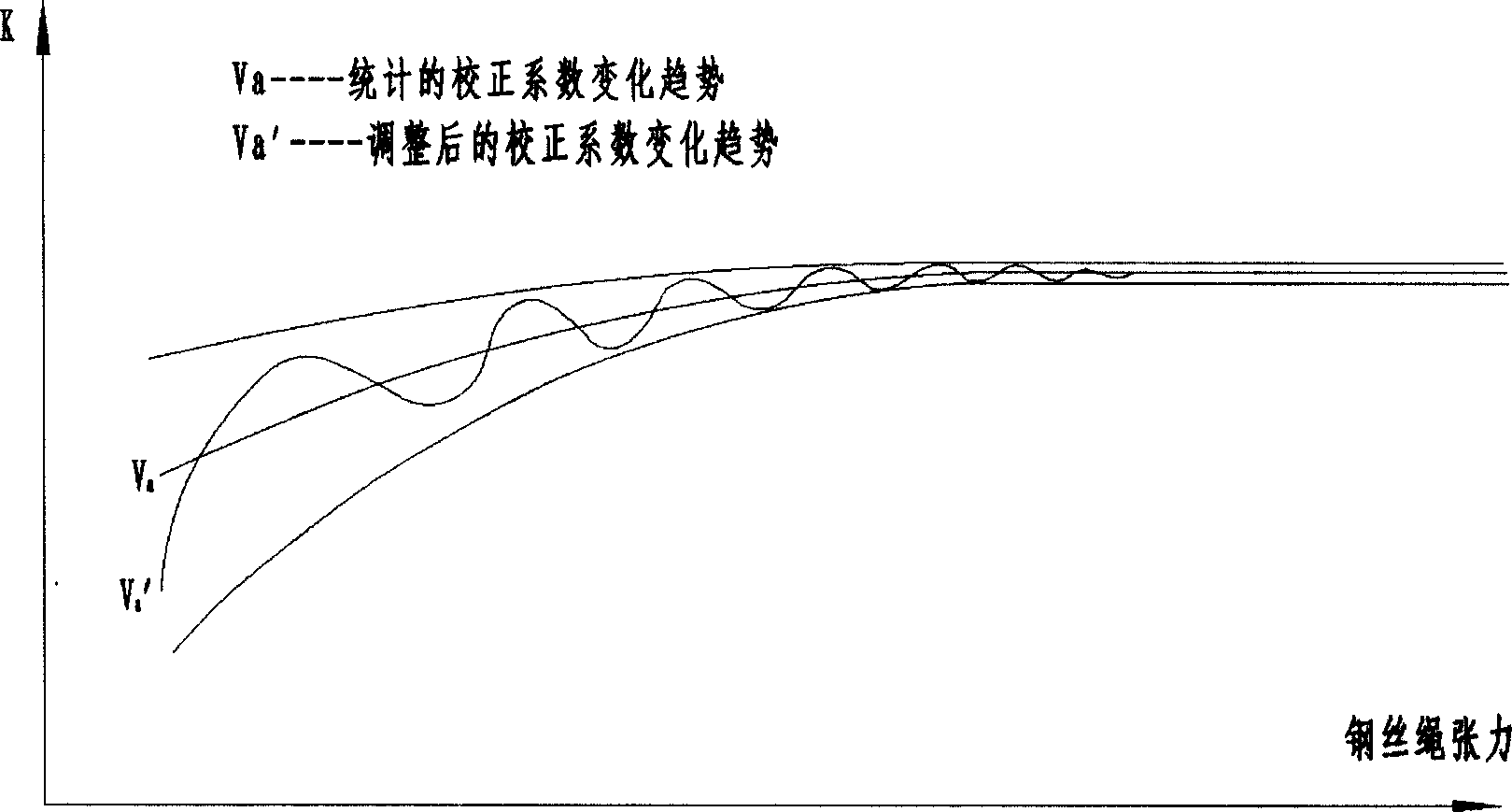

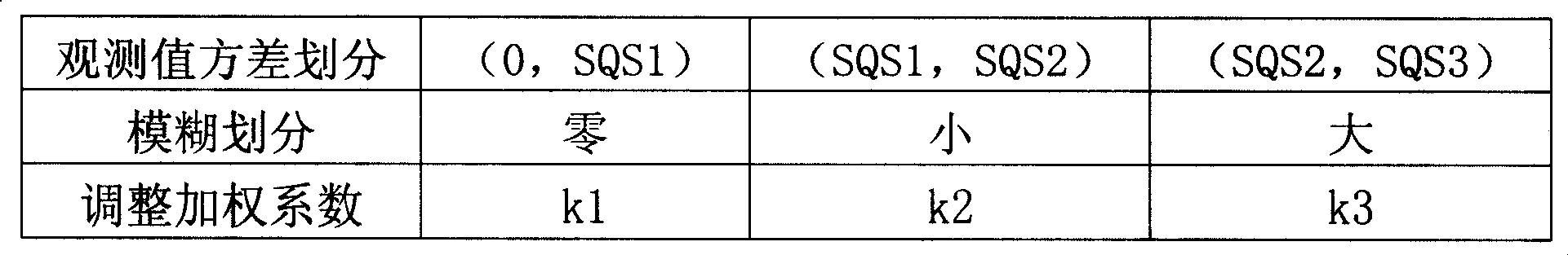

Method for correcting depth trace of self-adapting well drilling

The invention relates to a method for correcting the depth trace of self-adapting well drilling, in particular to a new method for correcting the well depth trace of the well drilling, which belongs to the technical field of measurement well drilling. The method comprises the following steps: firstly, obtaining correction coefficients (K1, K2, K3, ... Kn) according to the variations of coded disc counts and the variations of a drilling tool corresponding to each layer of wire ropes of a winch; secondly, training the correction coefficients with observed well depth, and dividing the variance of observed values and measured values into three regions, wherein each region corresponds to zero, big and small fuzzy numbers, and each fuzzy number corresponds to weighting coefficients k1, k2 and k3; and thirdly, counting the variations of the correction coefficients simultaneously to obtain the variation trend Va of the correction coefficients. The trained correction coefficients can make the variations of the correction coefficients automatically trend to influences on the correction coefficients by various factors; and the depth of the well drilling measured by the method trends to the precision gradually, the measuring errors are attenuated quickly, and the errors generated by initial depth correction and error corrections of the correction coefficients caused by introducing error observed values are eliminated effectively.

Owner:中石化石油工程技术服务有限公司 +3

Method for extracting coal bed gas under wells through alternate cooling and heating function

InactiveCN107575185AImprove connectivityImprove recovery efficiencyFluid removalCoal waterDepth in a well

The invention discloses a method for extracting coal bed gas under wells through the alternate cooling and heating function, and belongs to the technical field of unconventional oil and gas production. The method comprises the steps that (1) vertical well drilling is carried out from the ground, a well pattern is arranged, the wells are drilled till a coal layer, the number of the wells is largerthan or equal to 2, at least on well in the arranged well pattern is a work well, and the other wells are adopted as gas extraction and production wells; (2), a heat source is input into the coal layers from the work well, the temperature of the heat source is adjusted to range from 380 DEG C to 450 DEG C, the coal layer is heated, and when the temperature of the coal layer is larger than or equalto 350 DEG C, heating is stopped; (3), liquid nitrogen is injected into the coal layer through the work well, the injection amount of the liquid nitrogen is determined according to different geological conditions and coal body features, and after the liquid nitrogen is vaporized, refrigeration is finished; and (4), the step 2 and the step 3 are repeated many times, the coal layer is located in analternate work state all the time, and coal layer gas is extracted in the gas extraction and production wells. According to the method, coal layer gas extraction can be effectively carried out, and the coal layer gas extraction speed and the extraction rate are increased.

Owner:LIAONING TECHNICAL UNIVERSITY

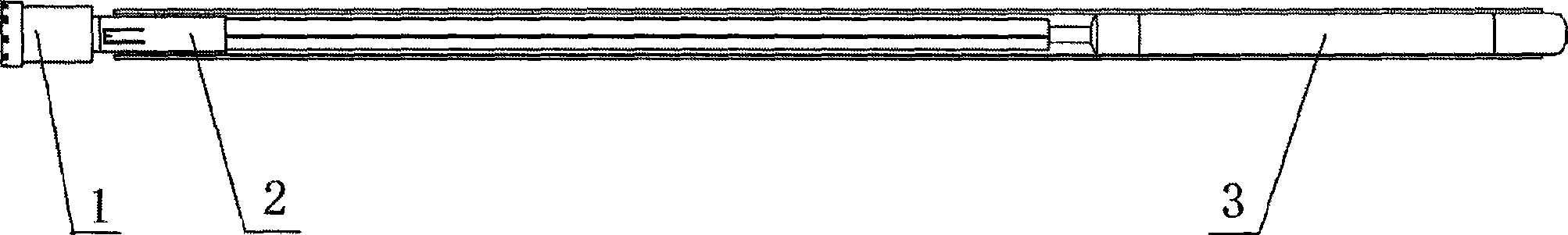

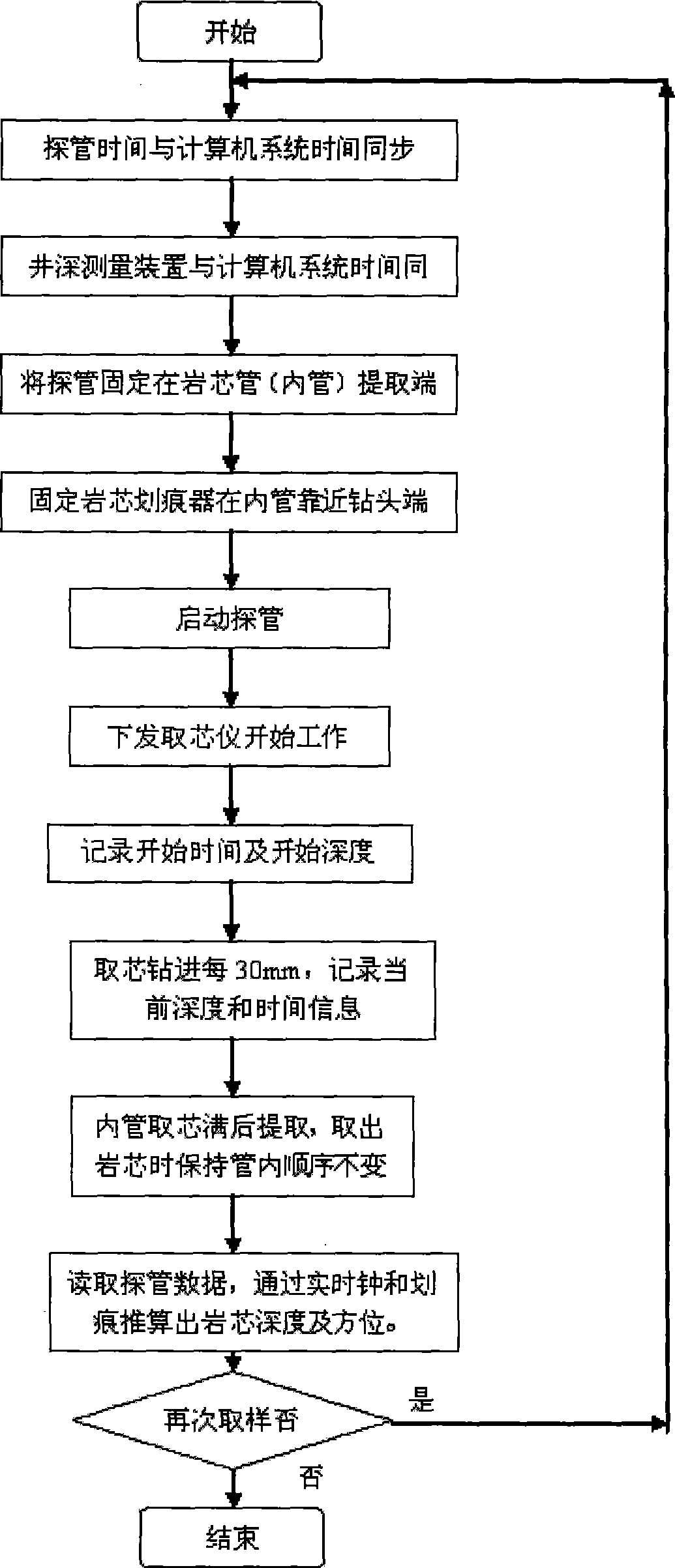

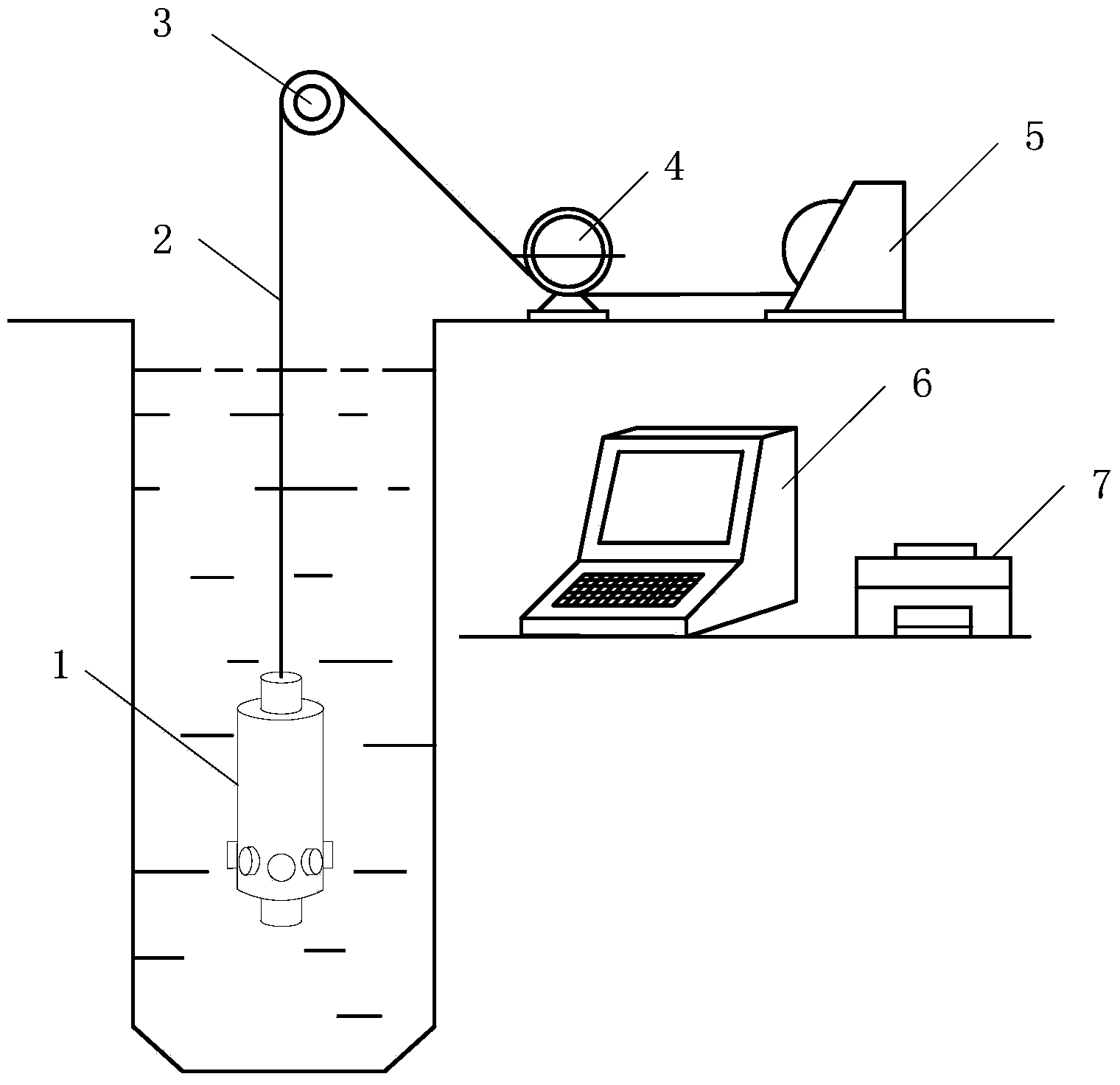

Multi-point oriented coring system and method for drill core

InactiveCN101532373AAzimuth is calculated correctlyTiming acquisitionSurveyCore removalDepth in a wellReal-time clock

The invention discloses a multi-point oriented coring system and a method for drill core. The system includes: a rope coring part, an underground orientation device, a searching tube orientation unit, a PC machine and a software kit, a printer, a ground winch and a deep measurement system. The invention also discloses a multi-point oriented coring method for drill core which includes steps as follows: confirming the drill core position and a corresponding relationship relative to magnetic north orientation in a same time according with a real-time clock of a drill core orientation instrument and a real-time clock of the underground deep device, accordingly, calculating the inner drill core orientation of the whole coring pipe correctly.

Owner:BEIJING LIUHE GREATNESS TECH

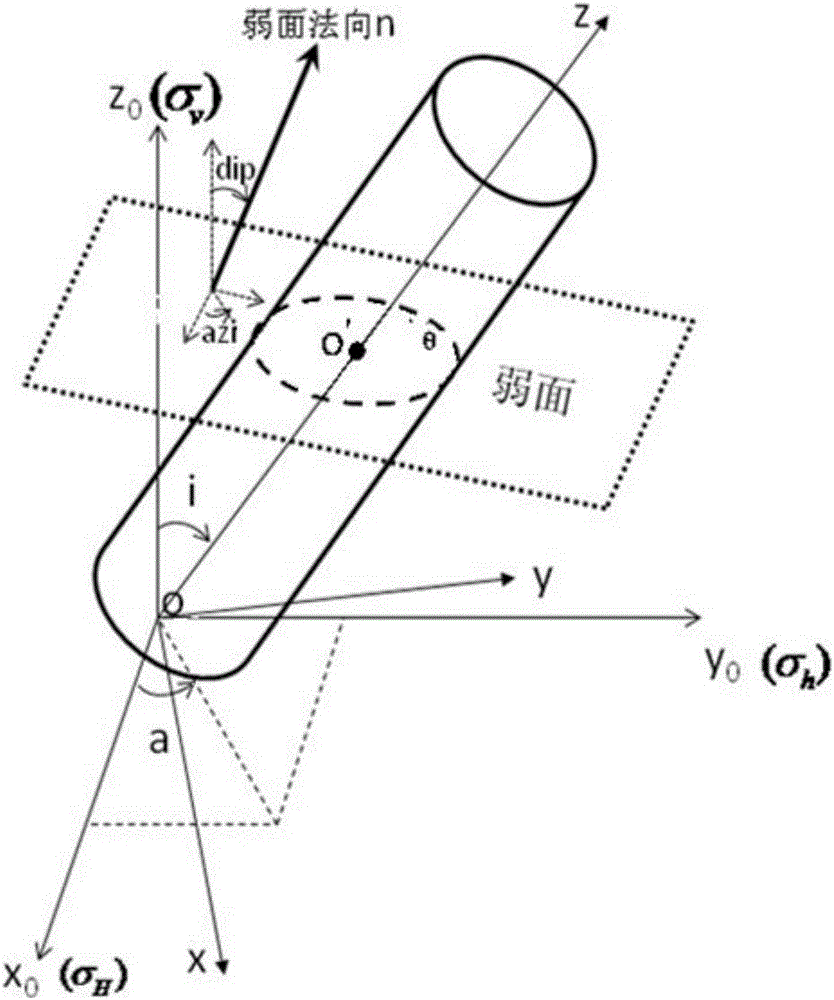

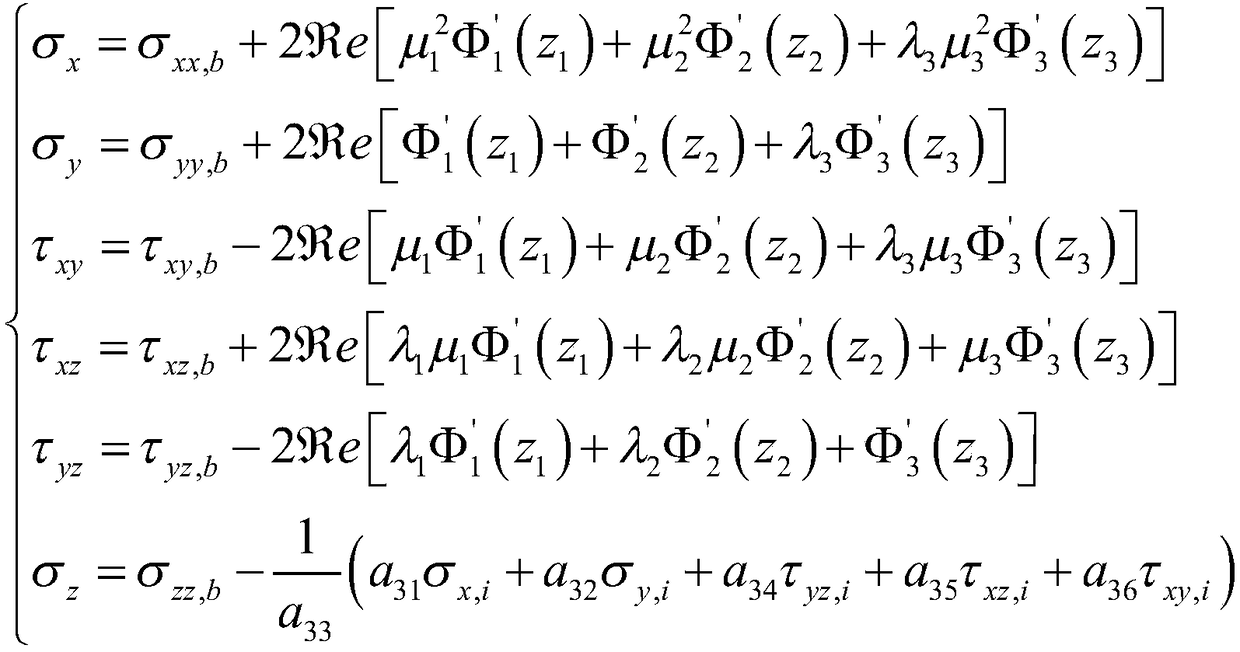

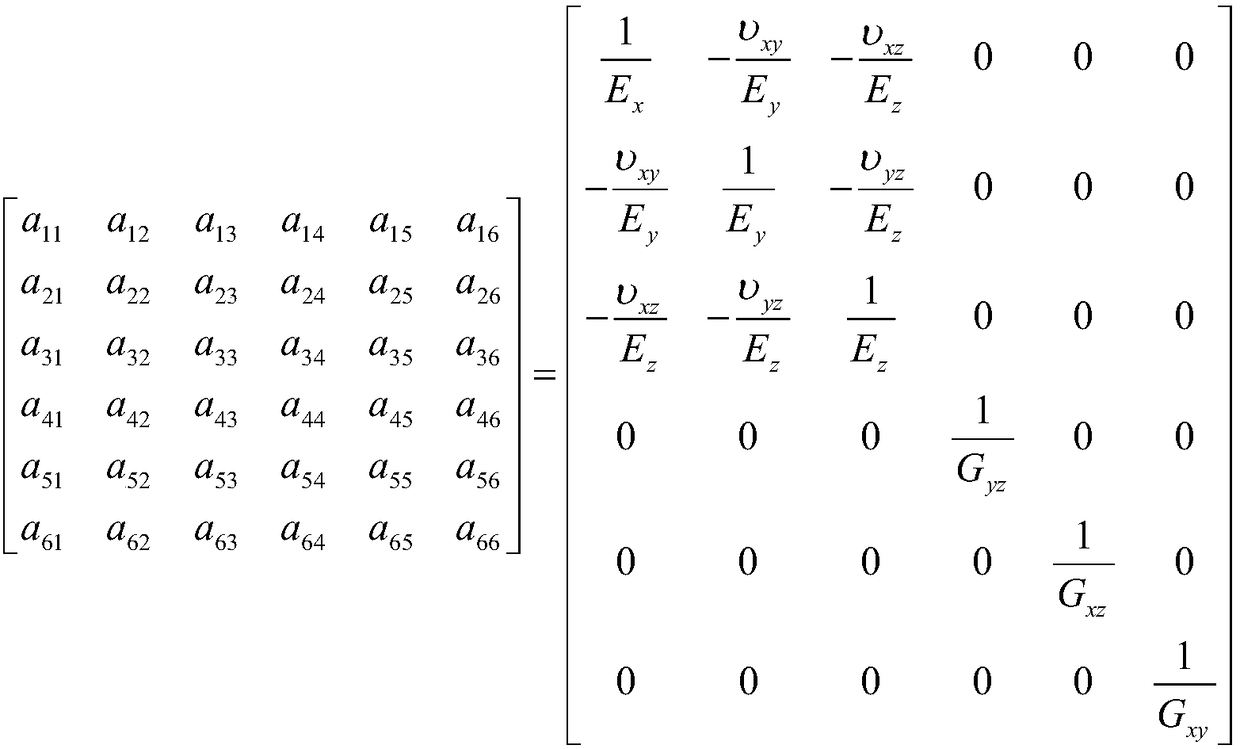

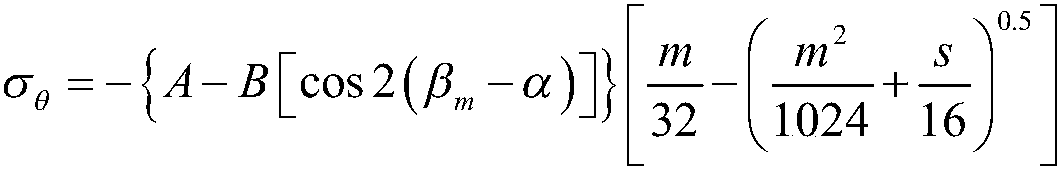

Method for designing safety drilling fluid density window during shale formation drilling

ActiveCN108843313AReliable Design ResultsReduce crackingBorehole/well accessoriesDepth in a wellRectangular coordinates

The invention relates to a method for designing a safety drilling fluid density window during shale formation drilling. The method specifically comprises the following steps: testing crustal stress, formation pore pressure and the like; transforming a borehole rectangular coordinate system, a geostress coordinate system and a geodetic coordinate system; calculating each stress component of the well walls caused by geostress and drilling fluid pressure in the borehole; transforming effective stress of each stress component on the well walls in the borehole rectangular coordinate system into aneffective stress form in a borehole polar coordinate system; deducing mechanical laws of tensile and compressive shear failure occurring in wall rock during shale drilling, namely calculating the pressure of drilling fluid in the borehole when tensile and compressive shear failure occurs at different positions of the wall along the circumferential direction of the borehole, and respectively determining the converted drilling fluid density corresponding to the fracture pressure and collapse pressure; summarizing the converted drilling fluid density corresponding to the fracture pressure and collapse pressure at all well depths on the interval of interest of a target well, and drawing the safety drilling fluid density window. According to the method disclosed by the invention, the design result of the safety drilling fluid density window is true and reliable.

Owner:NORTHEAST GASOLINEEUM UNIV

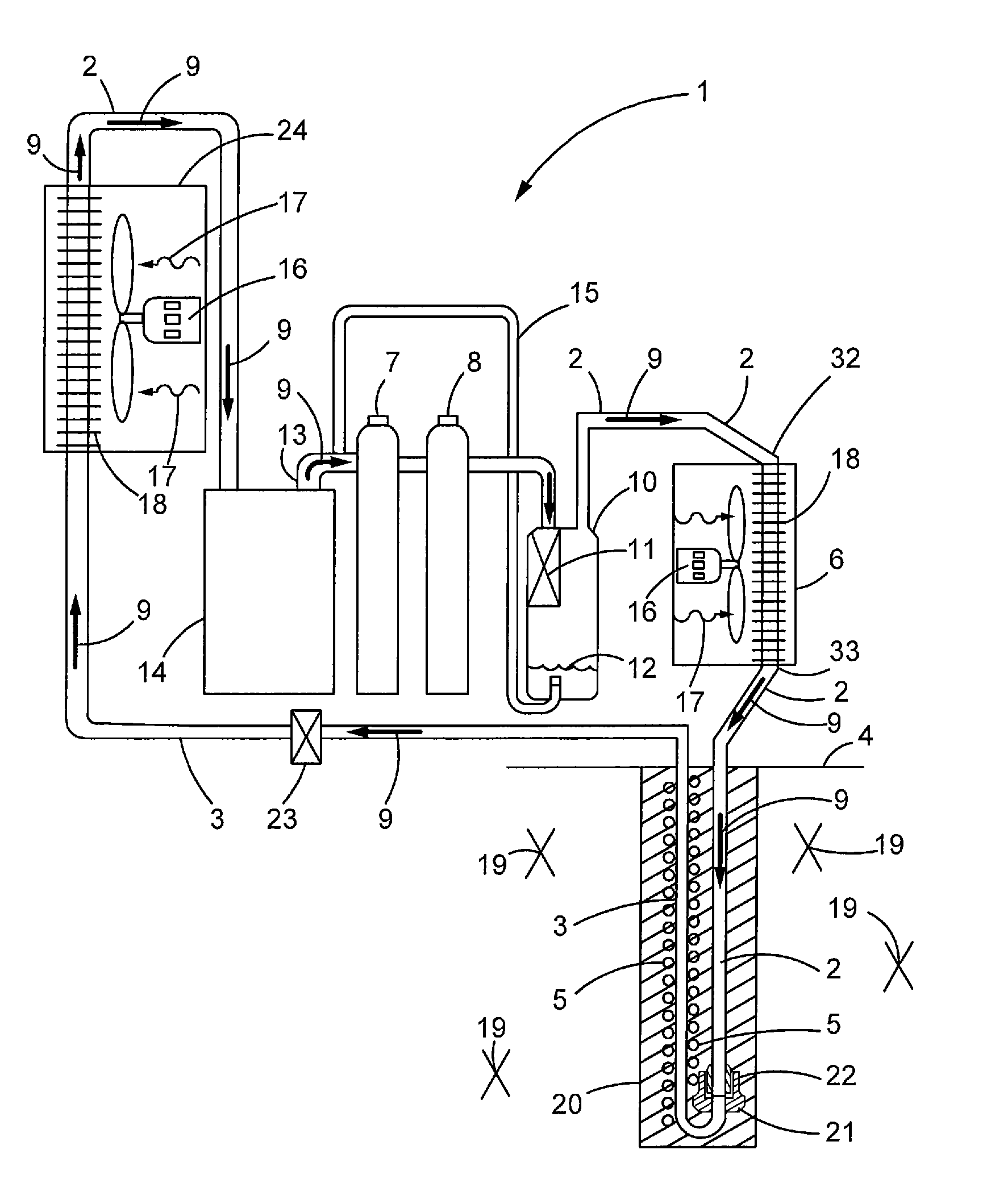

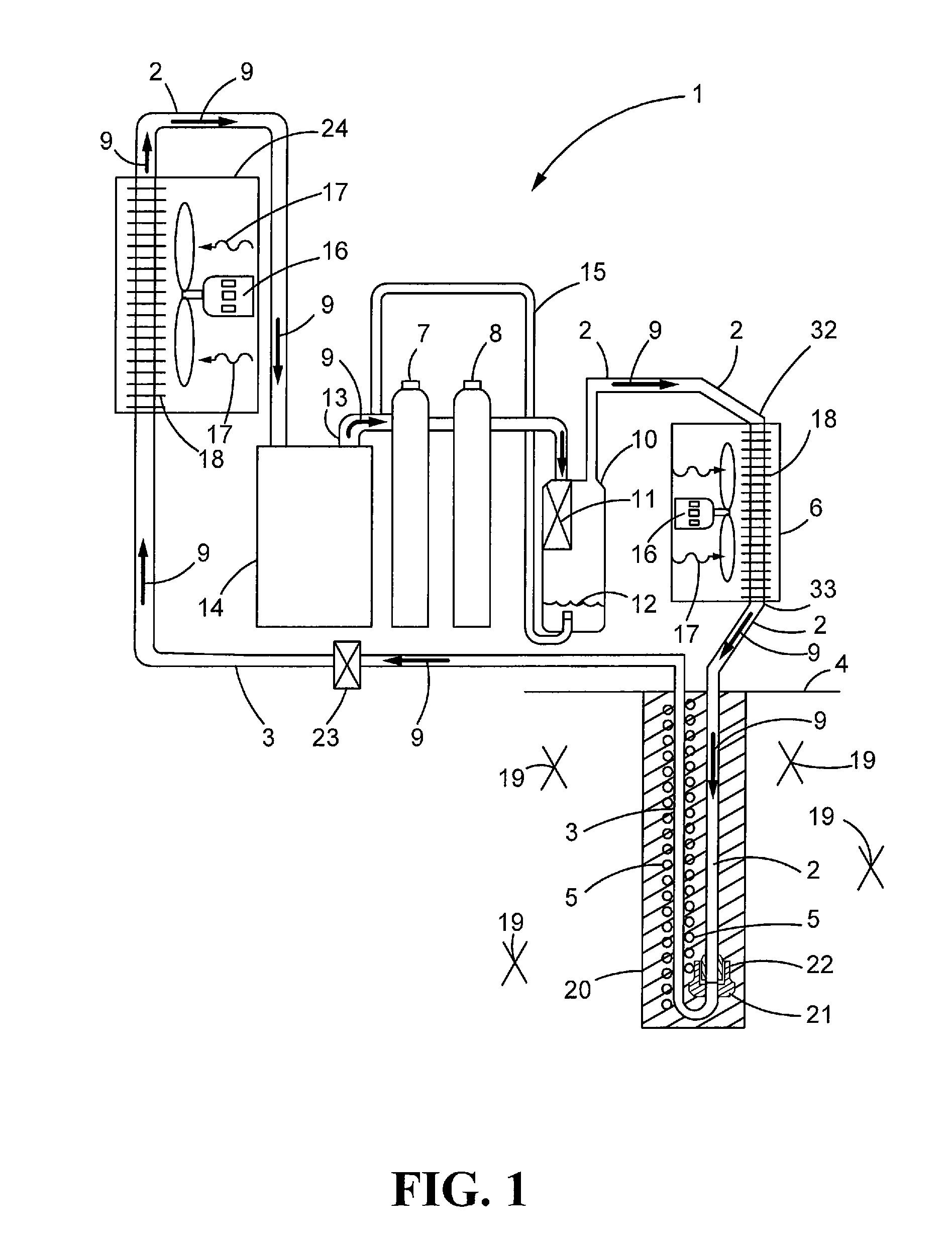

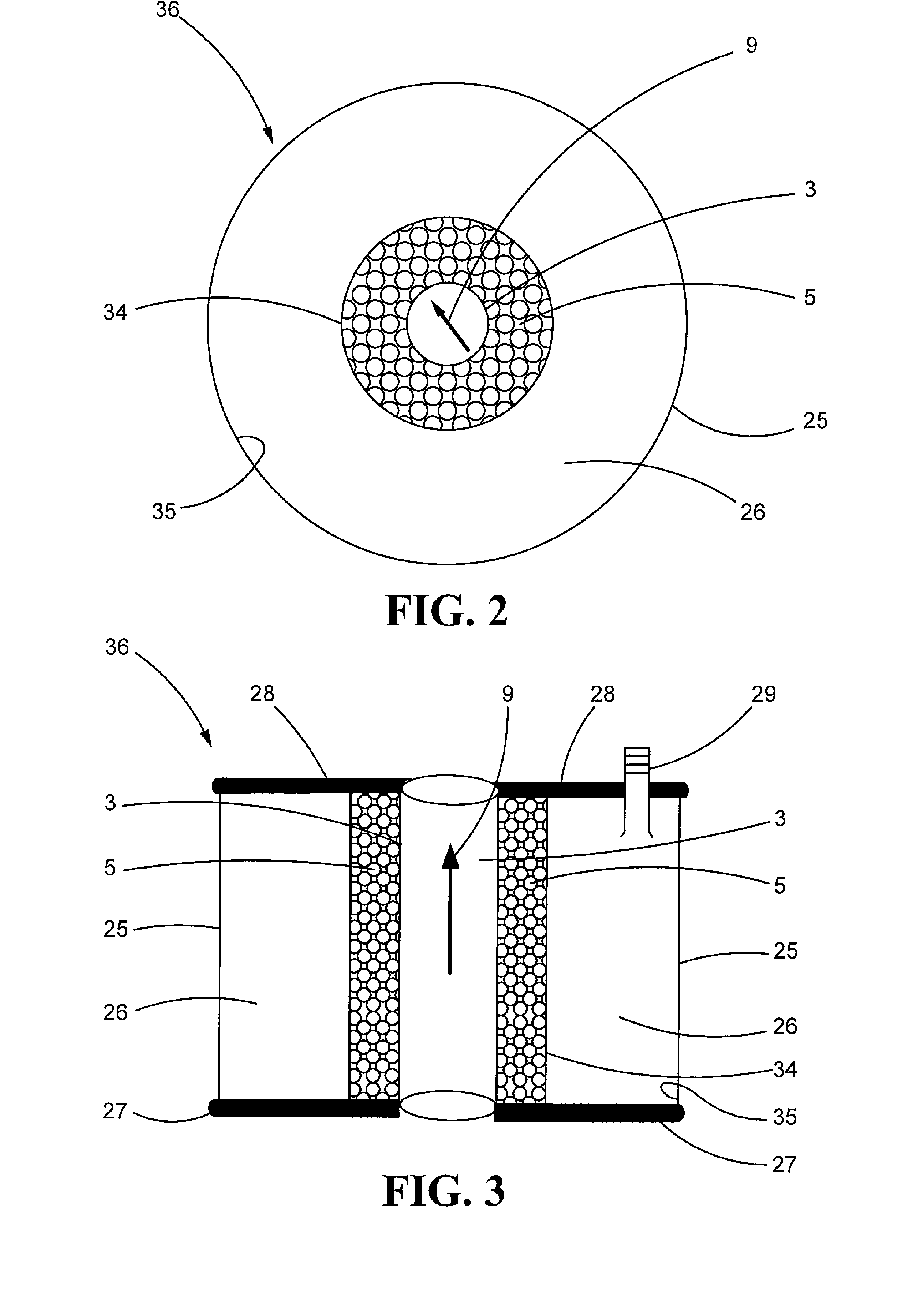

Sub-Surface Insulation and well Depth Reduction for DX Geothermal Heat Pump and Refrigeration System

At least one of a DX geothermal refrigeration system design, a reverse-cycle DX geothermal heat pump system design, a DX geothermal cooling mode only system design, and a DX geothermal heating mode only system design, which utilize the sub-surface geology with a grouted well as a heat sink in the cooling / refrigeration mode, and as a heat source in the heating mode; with an optional air-source high level heat sink for use in the refrigeration mode; with optional multiple sub-surface larger sized vapor refrigerant lines, as well as with a super-efficient vacuum insulation design for relevant sub-surface refrigerant transport tubing, and with an optional specially designed electronic expansion valve.

Owner:EARTH TO AIR SYST

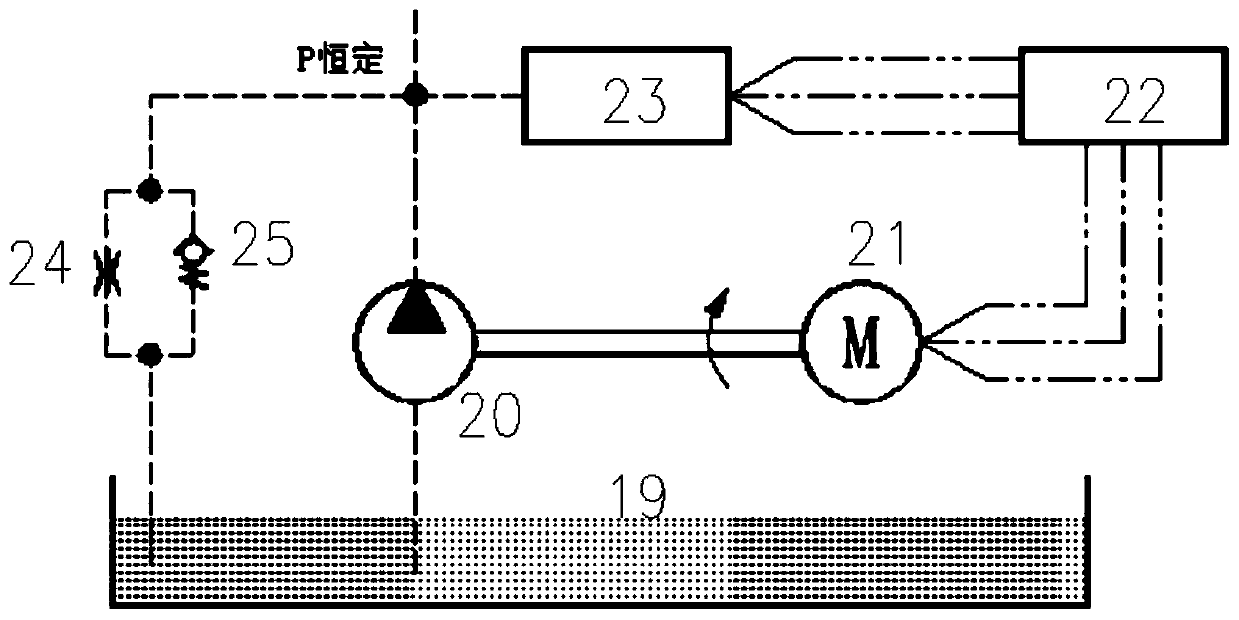

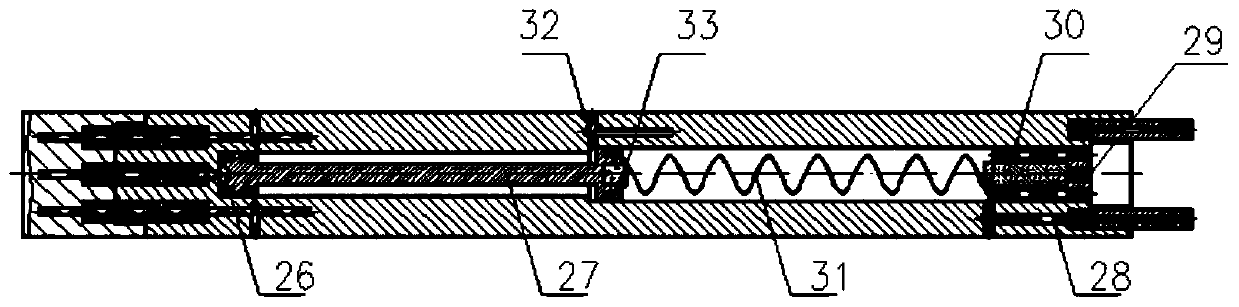

Method and device for measuring downhole formation fluid pressure

ActiveCN110230490AStable pressureIncrease or decrease the pressure valueSurveyDepth in a wellWireless transceiver

The invention discloses a method and device for measuring downhole formation fluid pressure. The device comprises ground equipment and downhole apparatus, wherein the downhole apparatus is connected with the ground equipment; the ground equipment comprises a vertical pipe, a three-way pipe is installed on the vertical pipe, a pressure sensor is installed at the position of the three-way pipe, thepressure sensor is connected with a wireless pressure sensor main machine through a data line, the wireless pressure sensor main machine is connected with a sucker antenna, the sucker antenna is in signal connection with a wireless transceiver, and the wireless transceiver is connected with a data processing meter; and the downhole apparatus comprises a thrust assembly, and a thrust module and a probe module are installed on the thrust assembly. According to the method and device for measuring the downhole formation fluid pressure, the magnitude of different thrust force is set according to different well depths, when shallow well measurement is carried out, the energy consumption of the downhole apparatus can be reduced, and meanwhile, the risk of pressure damage to the well wall due to too large thrust force is reduced; and when deep well measurement is carried out, the thrust force is reasonably increased to enable the seal between a sealing probe and a well wall mud cake to be reliable, the influence of annulus pressure on formation fluid is reduced, and thus the accuracy of the measurement is improved.

Owner:BEIJING LIUHE GREATNESS TECH

Design method for strength of casing string

InactiveCN103726795ASimple design methodSimplify the design processDrilling rodsDrilling casingsInternal pressureDepth in a well

The invention discloses a design method for the strength of a casing string. The method includes the steps of determining the steel grade and wall thickness of the first section of a casing, determining the length of the first section of the casing tripping in a well, carrying out internal pressure strength check on the first section of the casing, computing the length of the first section of the casing tripping in the well, and designing the second section of the casing, the third section of the casing and the like according to the steps until the designed casing reaches the well depth. The design method can be successfully applied to the strength design for the casing strings, the design method and process are simple, and the design cost is greatly reduced.

Owner:代文姣

Confining liquid system beneficial for stability of barefoot well wall of high temperature and high pressure well

The invention discloses a confining liquid system beneficial for the stability of a barefoot well wall of a high temperature and high pressure well. The confining liquid system is prepared from the following components in parts by weight: 100 parts of fresh water, 10-20 parts of sodium bentonite, 2-4 parts of potassium chloride, 5-7 parts of caustic soda, 2-4 parts of low-viscosity polyanionic cellulose, 2-6 parts of a high temperature-resistant filtrate reducer, 10-20 parts of organic resin, 6-8 parts of a diluent, 7-9 parts of sulfonated lignite, 30-40 parts of sulfonated gilsonite, 2-4 parts of calcium oxide and 1-300 parts of barite. The confining liquid system is relatively good in rheological property, low in filter loss property and well in wall stability, and the problem that an electrical logging tool encounters resistance due to the situation that visual and thick mud cakes easily form on the well wall as the open hole section is exposed to well mud for a long time in the electrical logging operation period during the process of high temperature and high pressure well drilling can be solved; the confining liquid is applicable to the high temperature and high pressure well with the temperature of 150-220 DEG C, the long-term stability can reach 3 days, and the confining liquid has no special demand for well depth and is good in adaptability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Mud retaining wall and air down-the-hole hammer drilling tool and drilling technology

InactiveCN102966304BImprove connection strengthEasy to unscrewDrilling rodsBorehole drivesDepth in a wellWell drilling

Owner:JILIN UNIV

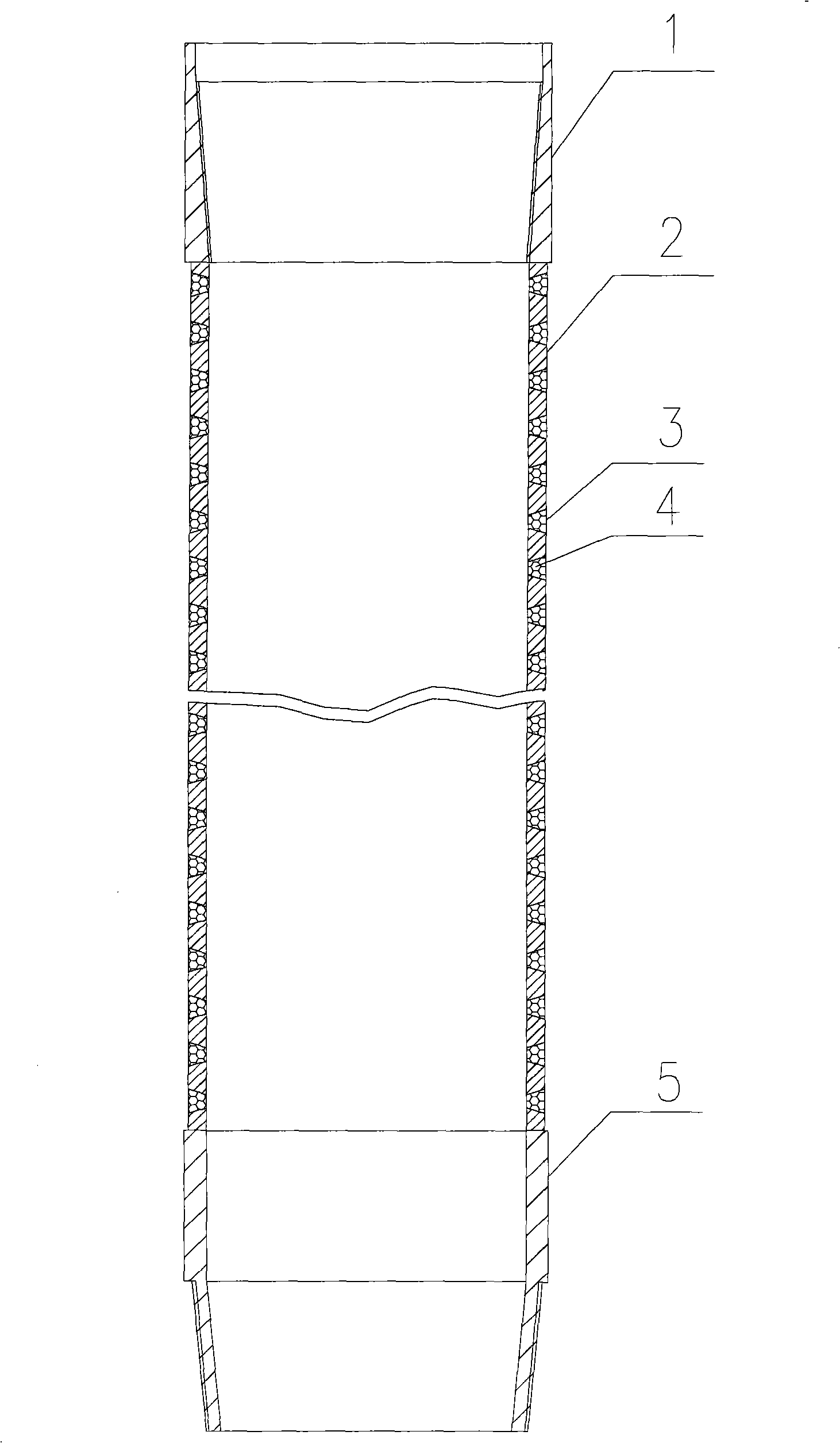

Oil gas well completion temporary blocking liner tube

InactiveCN101275464AWill not deformDoes not affect strengthFluid removalManufacturing technologyDepth in a well

The invention relates to an oil and gas well completion temporary plugging lining pipe, which is used for the under-balanced well completion after under-balanced drilling, belonging to the field of whole process under-balanced drilling well completion snubbing manufacturing technology. Based on the characteristic that temporary plugging agent can melt under high temperature, the invention designs an oil and gas well completion temporary plugging lining pipe which has an upper joint and a lower joint, and is equipped with through sieve pores with temporary plugging agent inside on the pipe body, solves the problem that a tail pipe is perforated in the prior art, resulting in tail pipe deformation, and is in an unfixed state in a well, bringing in trouble to subsequent works, the sieve pores of the temporary plugging lining pipe are processed on the ground, thus the temporary plugging lining pipe has the characteristics of convenient process and deformation improbability, a different binder can be selected in accordance with a different well depth to implement temporary plugging, after the lining pipe is put in the well, the temporary plugging agent can melt slowly when the temperature in the well reaches to a preset value, thus a temporary lining pipe having sieve pores can be obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

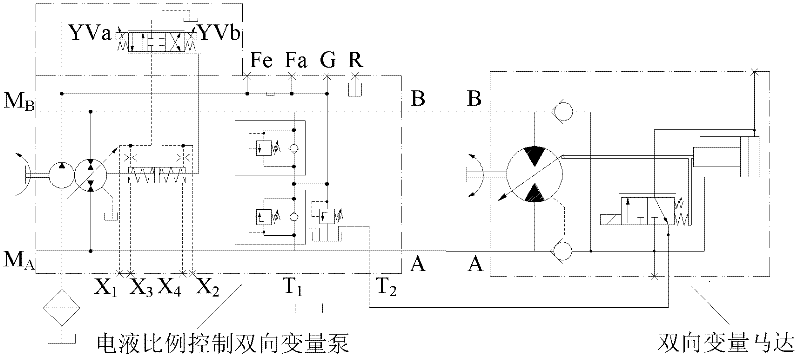

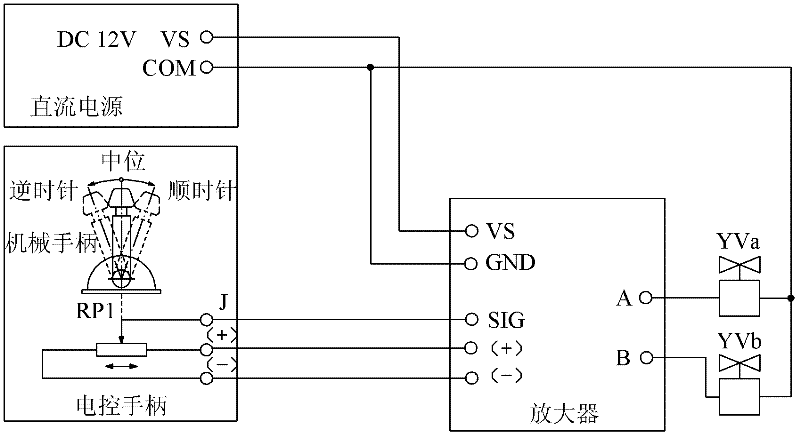

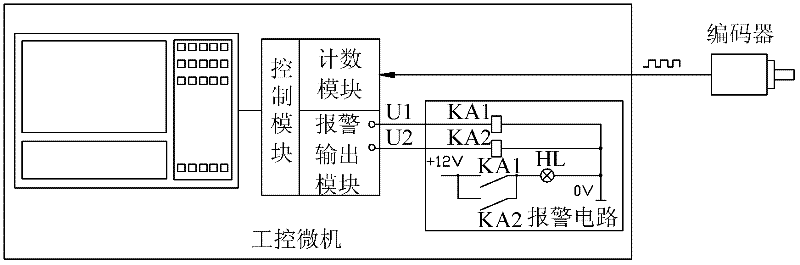

System, device and method for realizing operation protection of logging winch

ActiveCN102390790ARealize automatic decelerationRealize running automatic protectionSurveyWinding mechanismsProportional controlDepth in a well

The invention discloses a system, a device and a method for realizing the operation protection of a logging winch. The system comprises a depth monitoring system and a winch operation control device, wherein the depth monitoring system is used for comparing a detected instant well depth with a preset well depth and outputting an alarm signal to the winch operation control device if a comparison result is less than a threshold value; and the winch operation control device is used for controlling the logging winch to operate at a low speed by a preset low-speed control signal according to the input alarm signal. In the invention, correlation is established between a power system of the existing logging winch and the depth monitoring system, so that the automatic speed reduction protection of the operation of the winch and the safety protection of an instrument carried on the logging winch are realized. Moreover, part properties of a two-way variable displacement pump can be controlled according to the design requirement and an electro-hydraulic proportion, and a lifting or descending operation speed after the speed of the winch is automatically reduced is set in a certain range.

Owner:CHINA NAT OFFSHORE OIL CORP +1

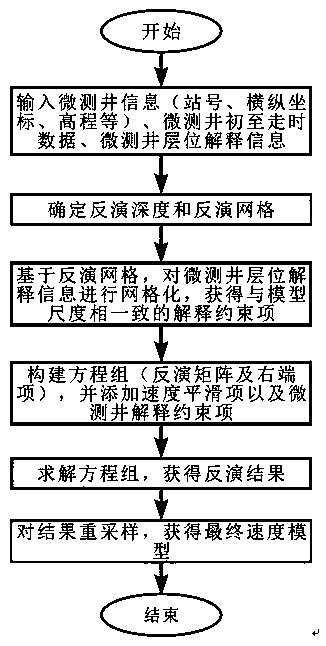

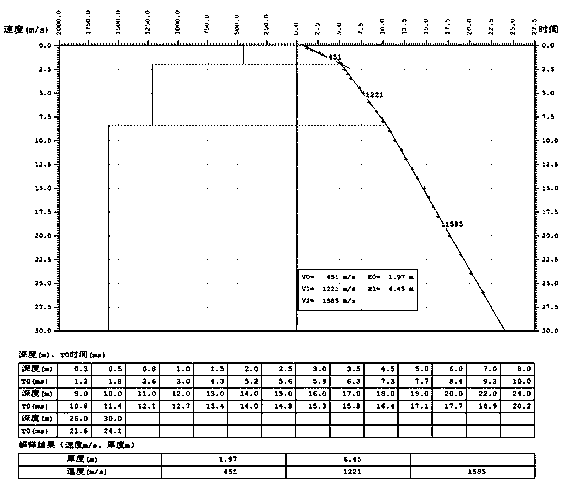

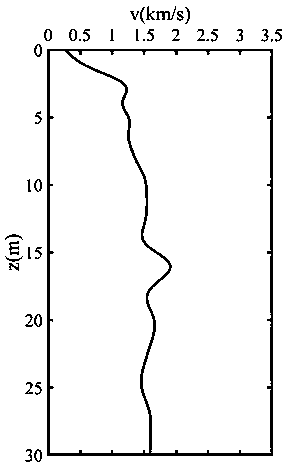

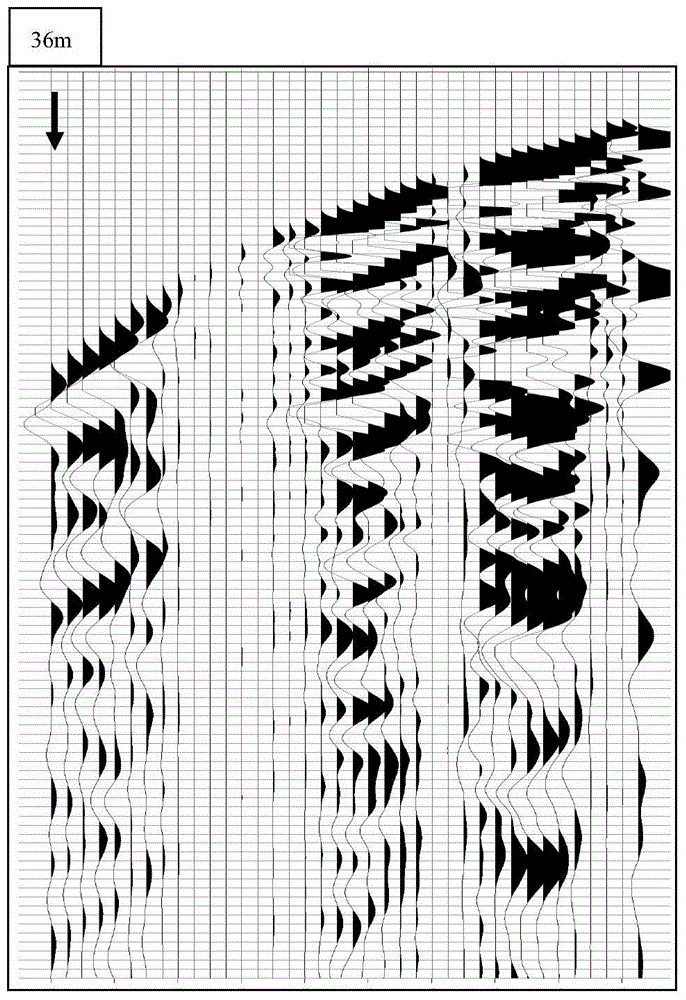

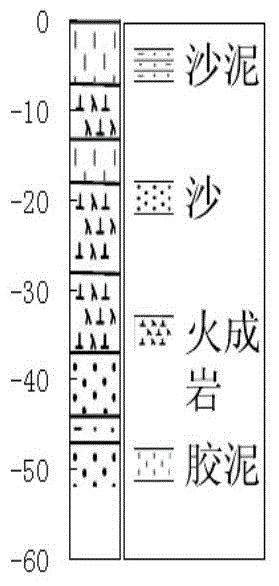

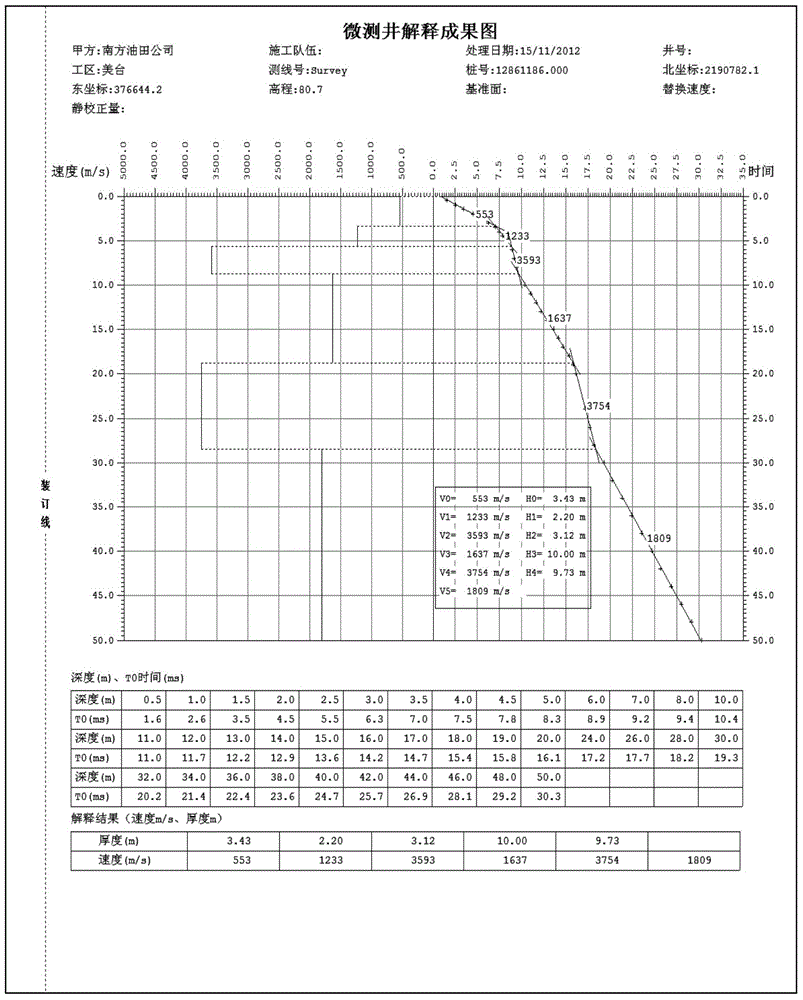

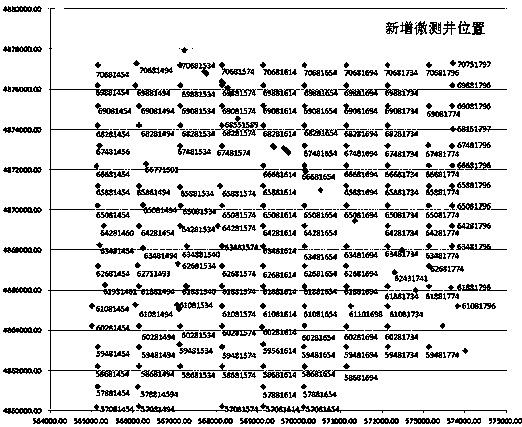

Micro-logging tomography method designed by aiming at excitation well depth

ActiveCN109884710AIncrease credibilityGuarantee collection qualitySeismic signal processingSeismology for water-loggingDepth in a wellHorizon

The invention provides a micro-logging tomography method designed by aiming at excitation well depth. The method comprises the following steps that: inputting micro-logging information, micro-loggingfirst-arrival travel time data and micro-logging horizon explanation information; determining inversion depth and an inversion grid; on the basis of the determined inversion grid, carrying out gridding on the micro-logging horizon explanation information to obtain an explanation constraint item consistent with a model size; constructing an equation set, and adding a speed smooth item and a micro-logging explanation constraint item; solving the equation set to obtain an inversion result; and resampling the result to obtain a speed model which conforms to requirements. By use of the micro-logging tomography method designed by aiming at the excitation well depth, human influences are lowered, obtained speed distribution contains more near-surface construction details so as to be convenient inobtaining accurate optimal excitation depth and guaranteeing the collection quality of seismic data, and therefore, a foundation is laid for subsequent seismic data processing.

Owner:CHINA PETROLEUM & CHEM CORP +1

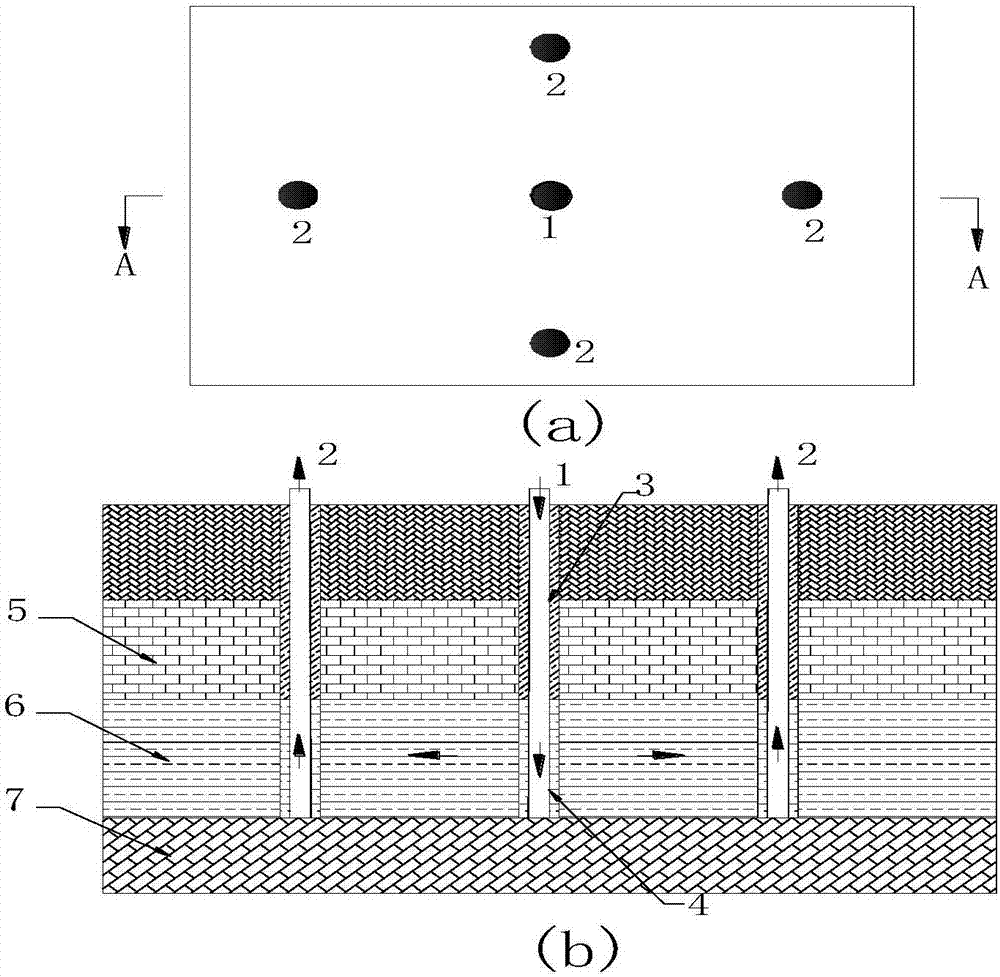

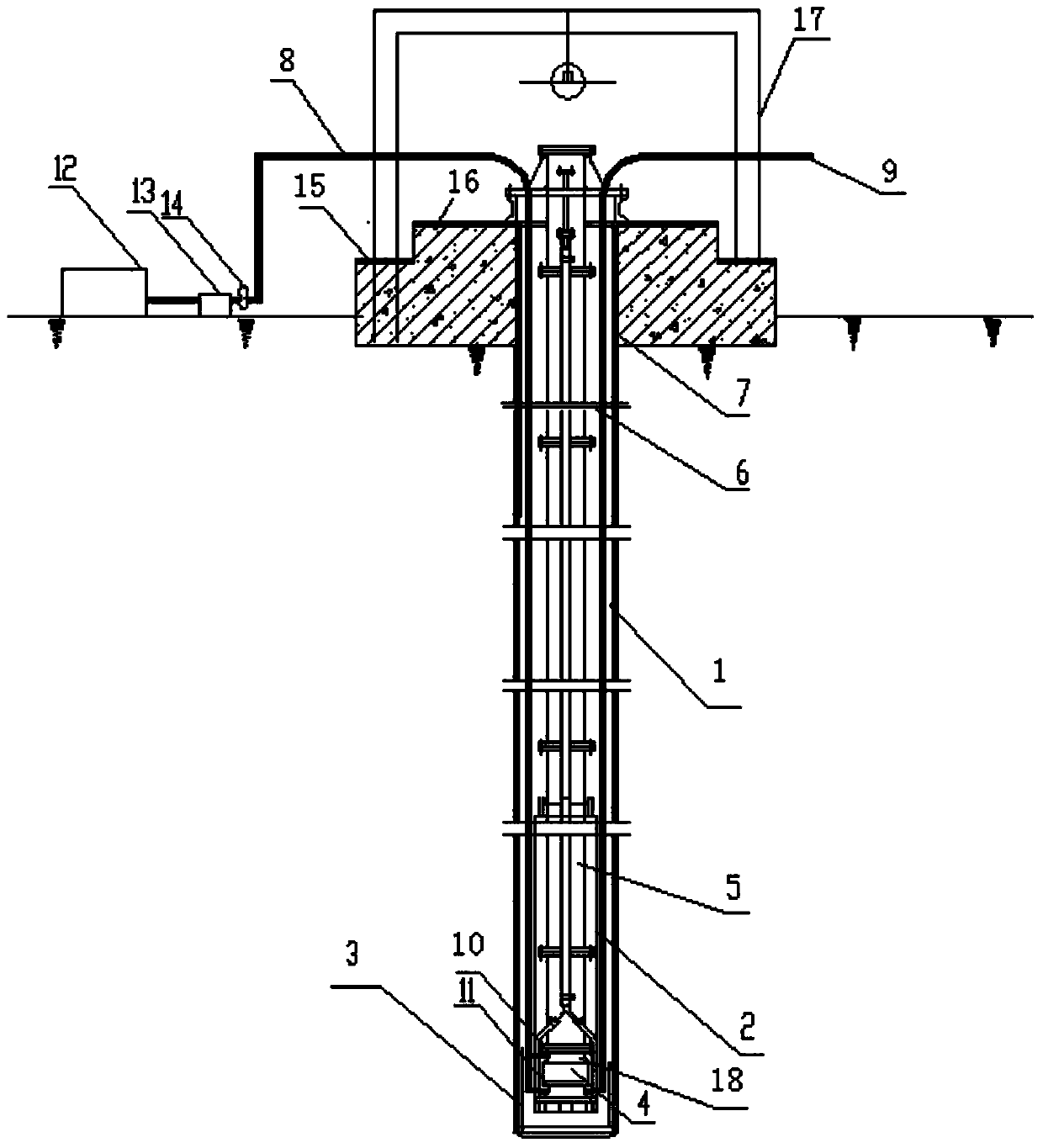

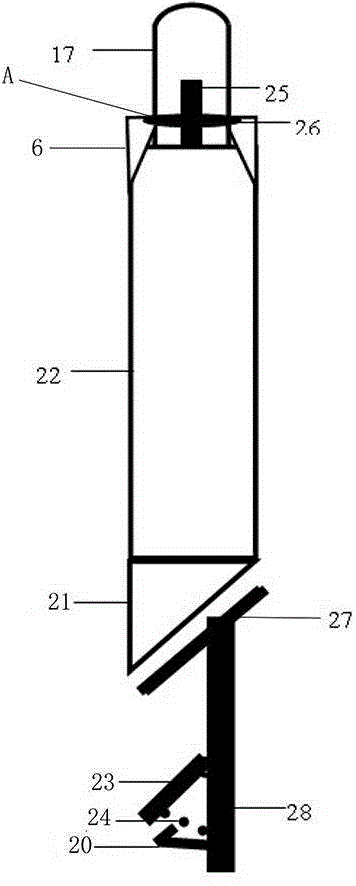

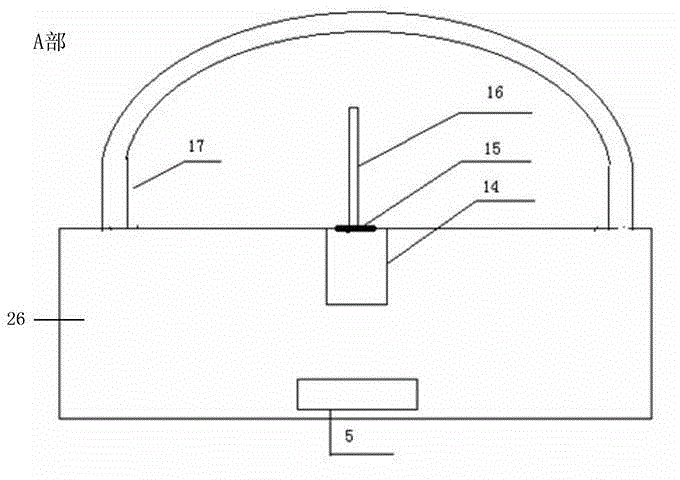

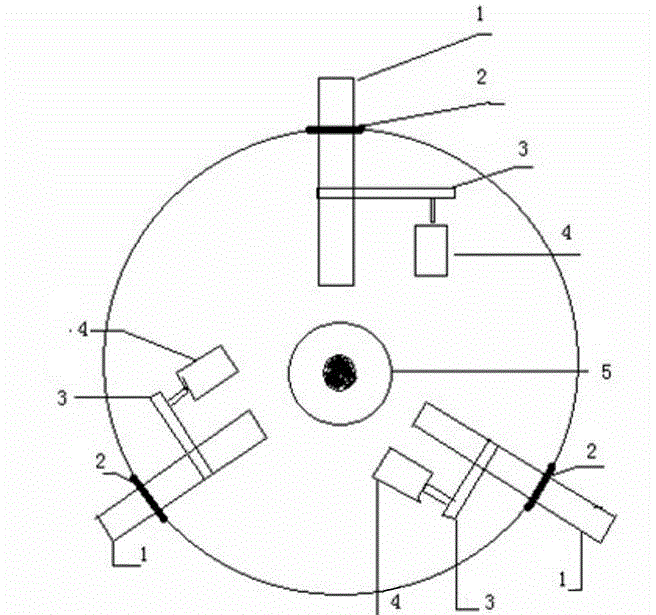

Brine drilling and exploiting system and method for dynamic cleaning and salt deposition resisting in closed cycle mode

ActiveCN104196498AReduce adhesionGuaranteed continuous stabilityPump componentsFluid removalHigh concentrationImpeller

The invention discloses a brine drilling and exploiting system and a method for dynamic cleaning and salt deposition resisting in a closed cycle mode. The drilling system comprises a brine exploiting well (1), a brine diving electromotor (2), a screening pipe (3), a brine diving pump (4), a well inner pipe (5), a well opening pipe fixing steel channel (6) and a well opening pipe (7). A salt resisting brine mud fixing well table (15) and a well lid steel plate (16) are arranged at a well opening, and a support lifting device (17) for overhauling a brine sucking device is arranged on the upper portion of the well lid steel plate (16). The screening pipe (3) is located on the inner side of the bottom well wall of the brine exploiting well (1). The well opening pipe (7) is located at the position, close to the inner side of the well wall, of the salt resisting brine mud fixing well table (15), and the #-shaped well opening pipe fixing steel channel (6) is welded to the position below the well opening pipe. The brine diving pump (4) is fixedly arranged at the position with a certain depth in a well, and a fresh water pipe (8) extends into the well from the ground. A closed cycle dynamic cleaning method is adopted, deposited salt at an impeller and a runner can be dissolved through passing fresh water or lose adhesive force and is finally discharged from a water outlet pipe (9) to be discharged together with collected brine, and therefore stable exploitation of high-concentration and supersaturation brine in the deep portion can be achieved.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Method for designing cannon well depths based on microlog and non-seismic data

ActiveCN104375187AEfficient disseminationSolve deep structure problemsSeismology for water-loggingDepth in a wellGeomorphology

The invention relates to a method for designing cannon well depths based on microlog and non-seismic data. The method comprises the steps that the well depths are initially designed, the surface structure is surveyed in a non-seismic mode, an interpretation profile map of the surface structure is obtained, the depths of all exciting points are spread and drawn in the map, the adjusted exciting depths and the lengths of explosive columns are added, and the comprehensively-designed cannon well depths are obtained. The method for designing the cannon well depths based on the microlog and the non-seismic data can compensate for the defect that the density of the microlog is relatively low, after the non-seismic comprehensive surface survey is implemented, it can be ensured that the exciting points of seismic cannons are located in favorable exciting layers, so that it is ensured that the explosive exciting energy can effectively spread towards the underground deep layer, and an effective mean is provided for obtaining effective deep layer seismic reflection signals, improving the seismic effect and solving the problem of a deep layer structure. Due to the fact that the number of drilling wells in seismic exploration is huge, and the operation of reducing the exciting depth in a sand and mud layer to the reasonable small depth also has obvious economic significance on lowering the seismic exploration cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

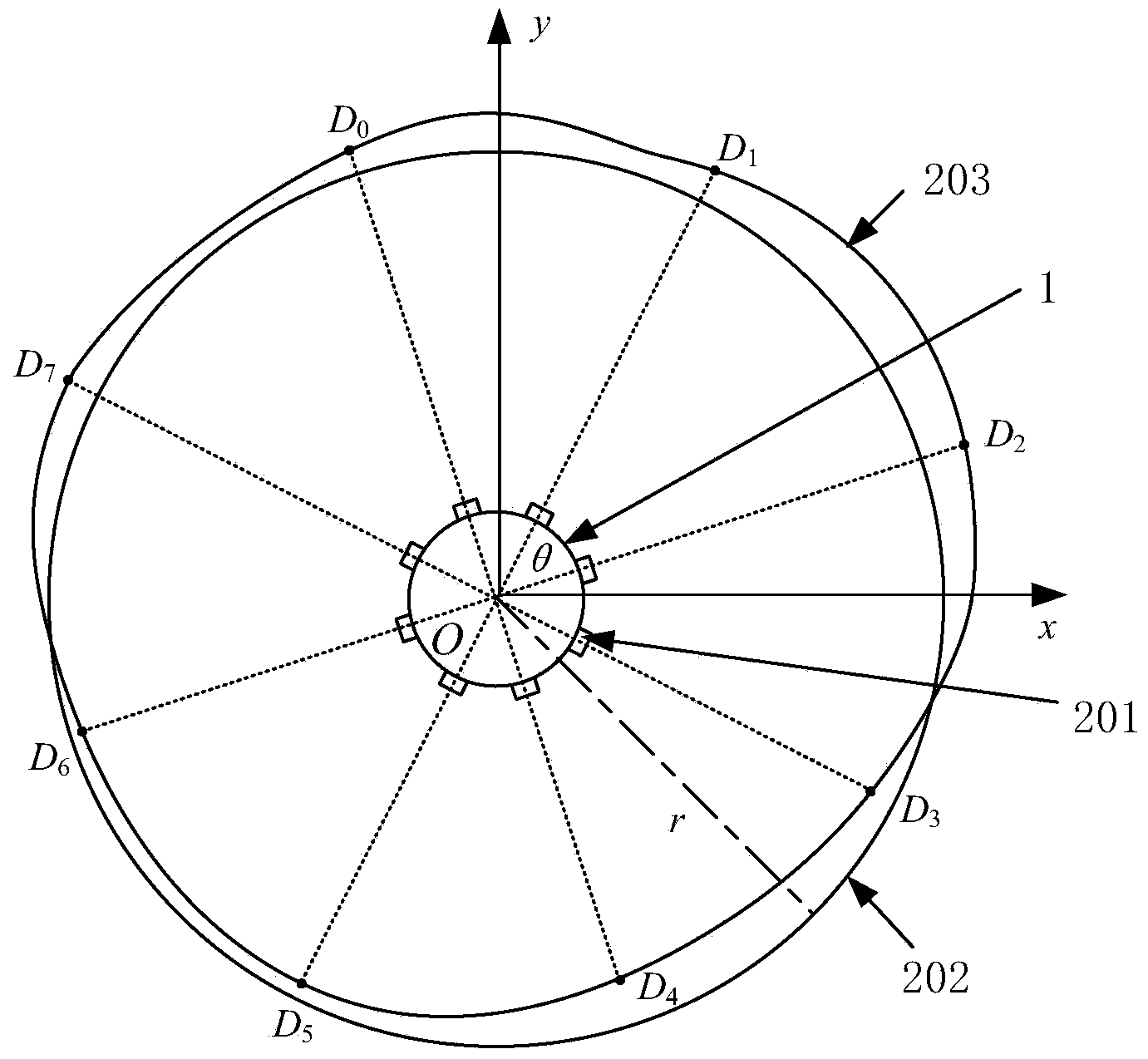

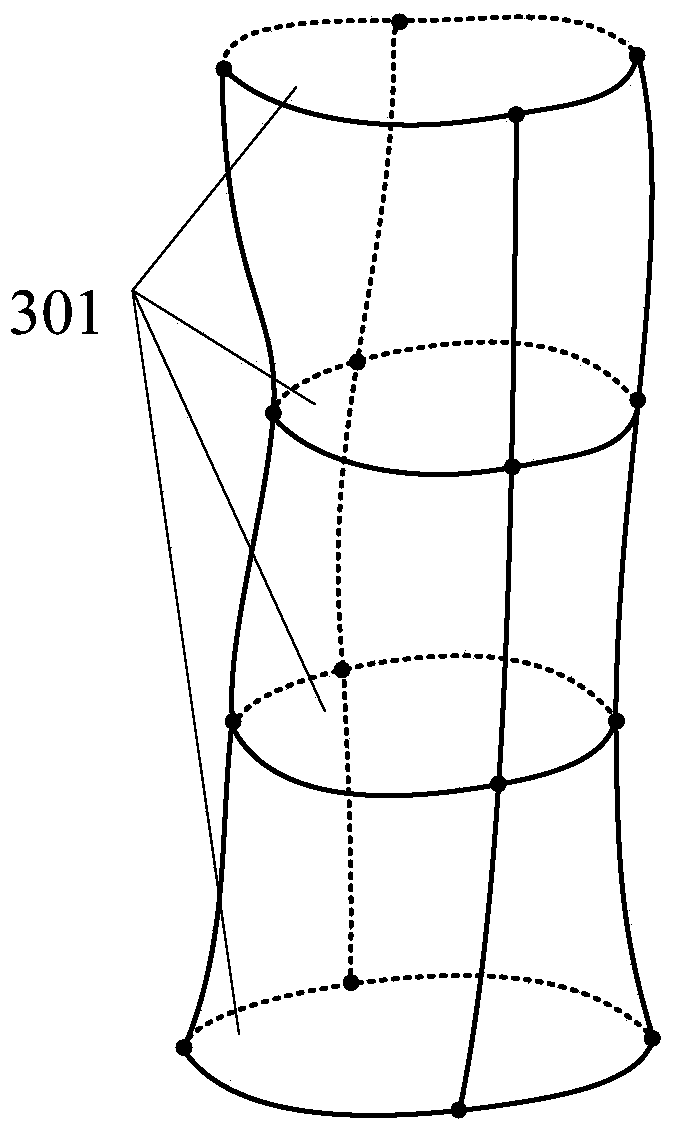

Logging method of ultrasonic logger system

ActiveCN104074503AReduce the number of fitting stitchesComputing speed advantageSurveySpecial data processing applicationsDepth in a wellUltrasonic sensor

The invention discloses a logging method of an ultrasonic logger system. An underground gauge of the ultrasonic logger system is of a cylinder shape, m ultrasonic transducers with included angles of theta are evenly distributed at the bottom of the underground gauge, the underground gauge is perpendicularly hung in a well by a cable, the cable is connected with a logging winch by a depth gauge, the logging winch is connected with a well workstation, and the well workstation is connected with a printer. The underground gauge is dropped perpendicularly by the depth gauge, the underground gauge measures the well diameter, the depth gauge measures the dropping length of the cable to obtain the well depth data, and the well diameter data and the well depth data are transmitted to the well workstation. The logging method includes that the well workstation processes the received well diameter data by means of quadratic Bezier curve, or rational quadratic Bezier curve fitting horizontal section algorithm to obtain a well diameter which can correctly reflect the actual shape of a horizontal section.

Owner:SHANDONG UNIV OF SCI & TECH

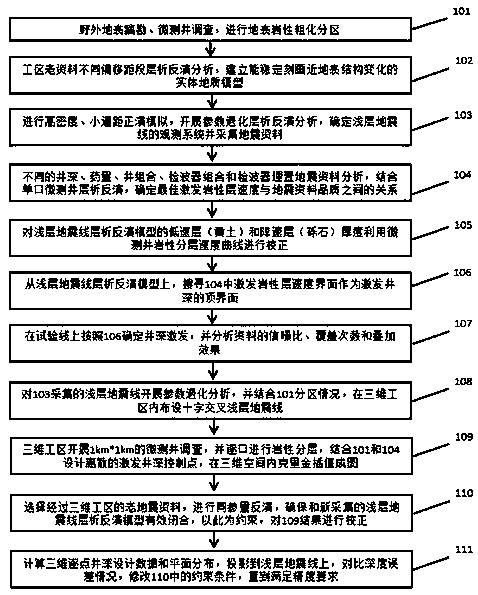

Point-line-plane three-dimensional point-by-point well depth design method

ActiveCN110501757AImprove qualityGuaranteed rationalityGeological measurementsLithologyDepth in a well

The invention provides a point-line-plane three-dimensional point-by-point well depth design method. The method includes: step one, carrying out tomography inversion on different offset sections by using old data of a work area to obtain a near-surface forward model; step two, designing forward modeling shallow seismic line acquisition parameters; step three, searching for a velocity correspondence relationship of an inversion model of a shallow seismic line for correction and carrying out correction; step four, searching for a velocity interface of exciting the lithostrome on based on the corrected shallow seismic line tomographic inversion model; step five, carrying out 1km*1km micrologging surveying on the work area, carrying out lithological layering layer by layer, and carrying out 3Dinterpolation to form a well depth design map; step six, carrying out same-parameter tomographic inversion on old data through a 3D work area and constraining and correcting a result in the step five; and step seven, 3D point-by-point excitation well depth designing and mapping of the work area old data and shallow seismic line tomographic inversion constraining. With the provided method, the rationality and accuracy of the mountain data excitation well depth design can be guaranteed effectively, so that the quality of seismic data collection is improved and the good foundation is laid for improving the imaging accuracy of prestack depth migration.

Owner:CHINA PETROLEUM & CHEM CORP +1

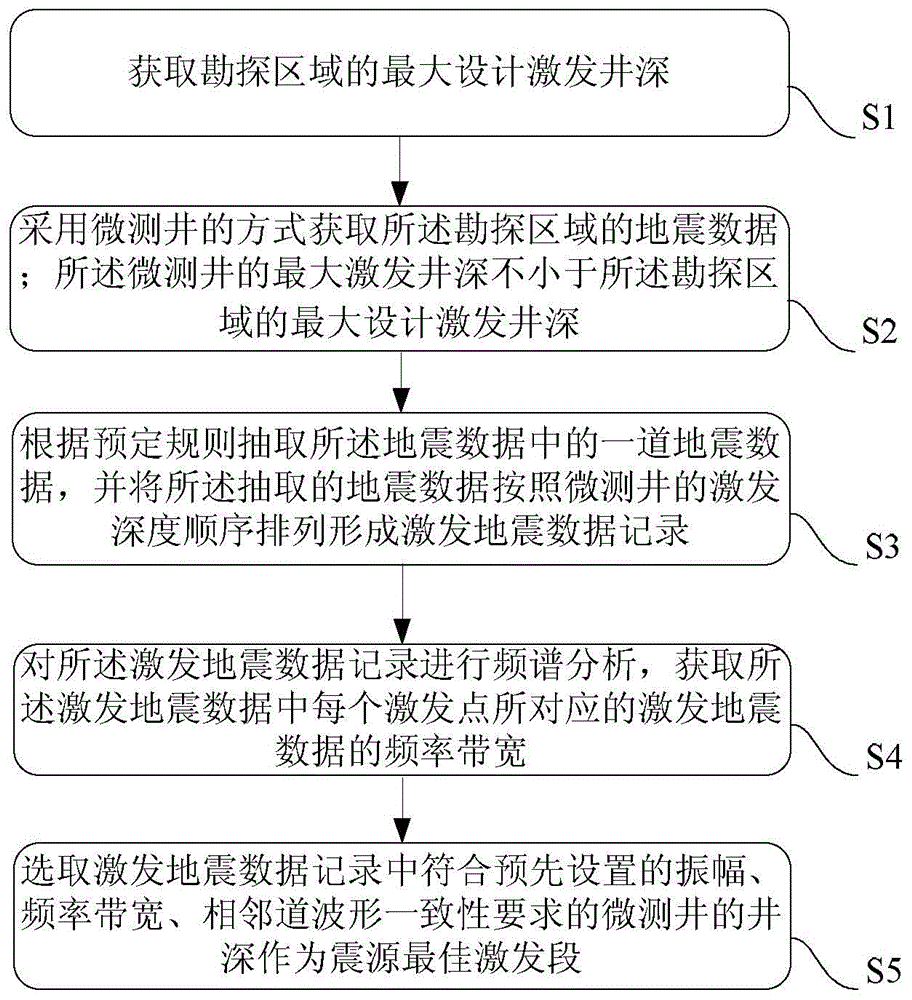

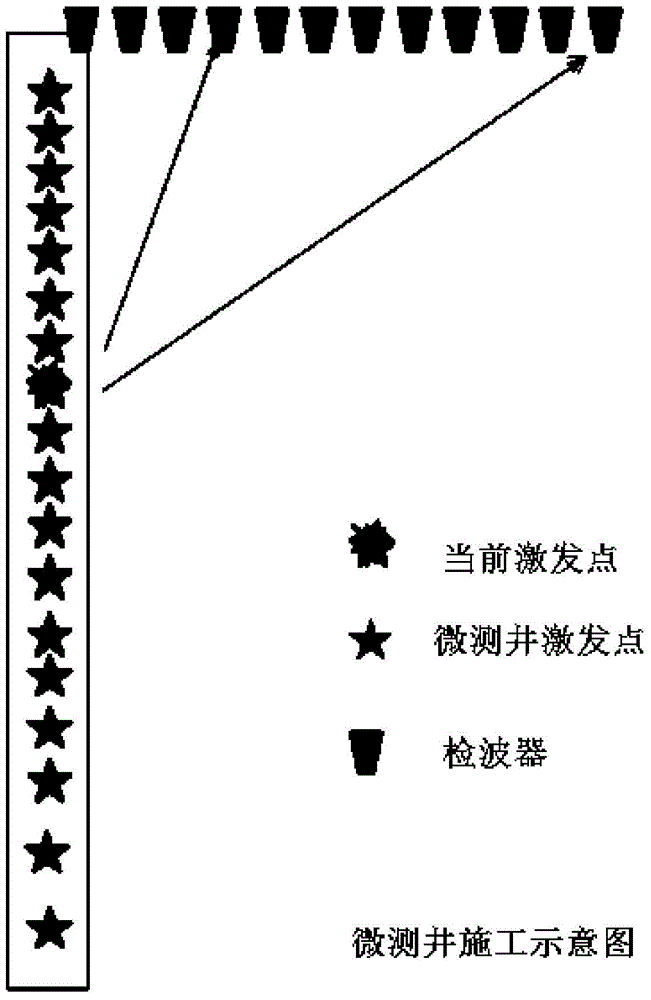

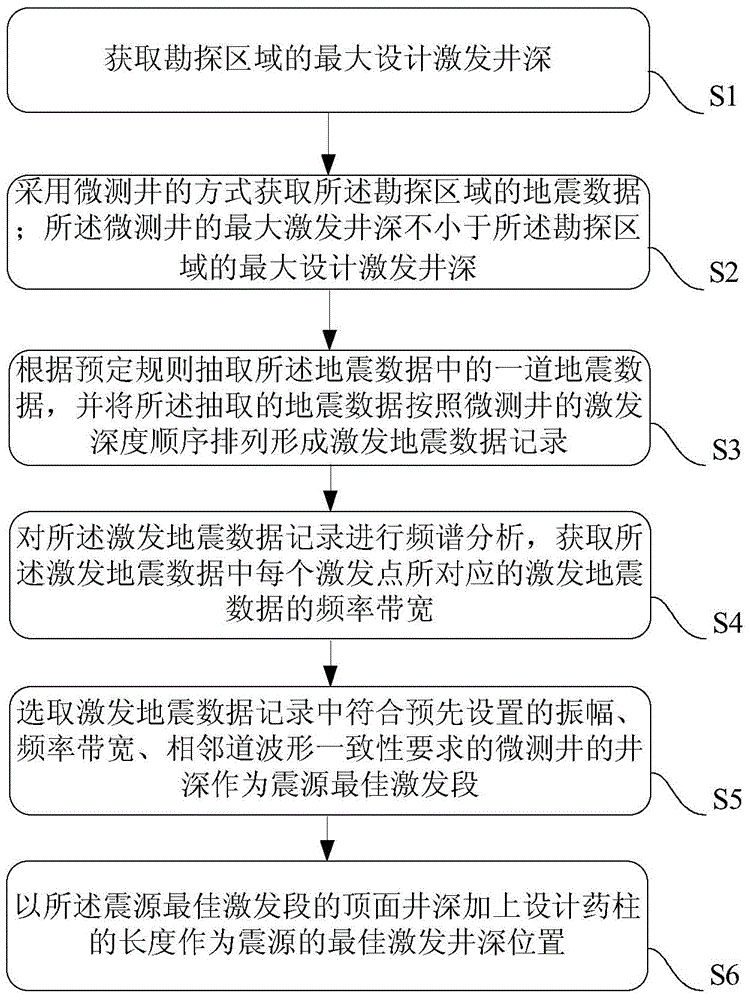

Method and system for designing depth of seismic source excitation well

InactiveCN104459799AImprove stimulation effectLarge amplitudeSeismic signal processingSeismology for water-loggingDepth in a wellSignal-to-noise ratio (imaging)

The invention provides a method and system for designing the depth of a seismic source excitation well. The method includes the steps of S1, obtaining the maximum designed depth of the excitation well in an exploration region; S2, obtaining seismic data of the exploration region in a micro-logging mode; S3, extracting a set of seismic data in the seismic data according to a preset rule, and arranging the extracted seismic data according to the micro-logging excitation depth order to form an excitation seismic data record; S4, carrying out frequency spectrum analysis on the excitation seismic data record to obtain the frequency bandwidth of the excitation seismic data; S5, selecting the micro-logging well depth, meeting a preset amplitude, frequency bandwidth and adjacent channel waveform coincidence requirement, in the excitation seismic data record to serve as an optimal seismic source excitation segment. By means of the method and system, the reasonable seismic source excitation well depth can be obtained through design in a complex earth surface region, the seismic source excitation effect can be improved, and the signal to noise ratio of collected seismic data can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Installation structure and installation method of earthquake electromagnetic disturbance sensor

ActiveCN104020499AThe size of the observation site is not highAvoid interferenceElectric/magnetic detectionAcoustic wave reradiationDepth in a wellStructure of the Earth

The invention provides an installation structure and installation method of an earthquake electromagnetic disturbance sensor. According to the method, a deep well is adopted for installation, an observation well is dug in an observation station, the inclination of the well is smaller than 5 degrees, a totally closed metal or nonmetal magnetic-free casing pipe is adopted, the electromagnetic disturbance sensor is vertically installed at the proper position within 1000 meters of the well depth, a locating base used for supporting the gravity of the electromagnetic disturbance sensor and a horizontal adjusting device used for adjusting the electromagnetic disturbance sensor to keep horizontal are arranged, a swinging ring is fixed to the top of the sensor and used for placing the sensor into the well and fixing the sensor, signals monitored by the sensor are sent to ground equipment through a signal cable, a cement well table is built at a well mouth, and a cement cover is additionally arranged for protection. According to the installation structure and installation method of the earthquake electromagnetic disturbance sensor, the structure is simple, implementation is easy, cost is low, and the floor space is small; interference of a high-voltage power transmission system, a rail transit system, large electric equipment, a metalloid pipeline system and a metalloid pipeline changing a surface electrical property structure, man-made interference and the like can be avoided effectively.

Owner:郑州晶微电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com