Oil gas well completion temporary blocking liner tube

A technology for oil and gas wells and liners, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve problems such as well wall collapse, large liner deformation, and unusable wellbore, so as to reduce perforation, The effect of speeding up the pace and saving the cost of perforating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

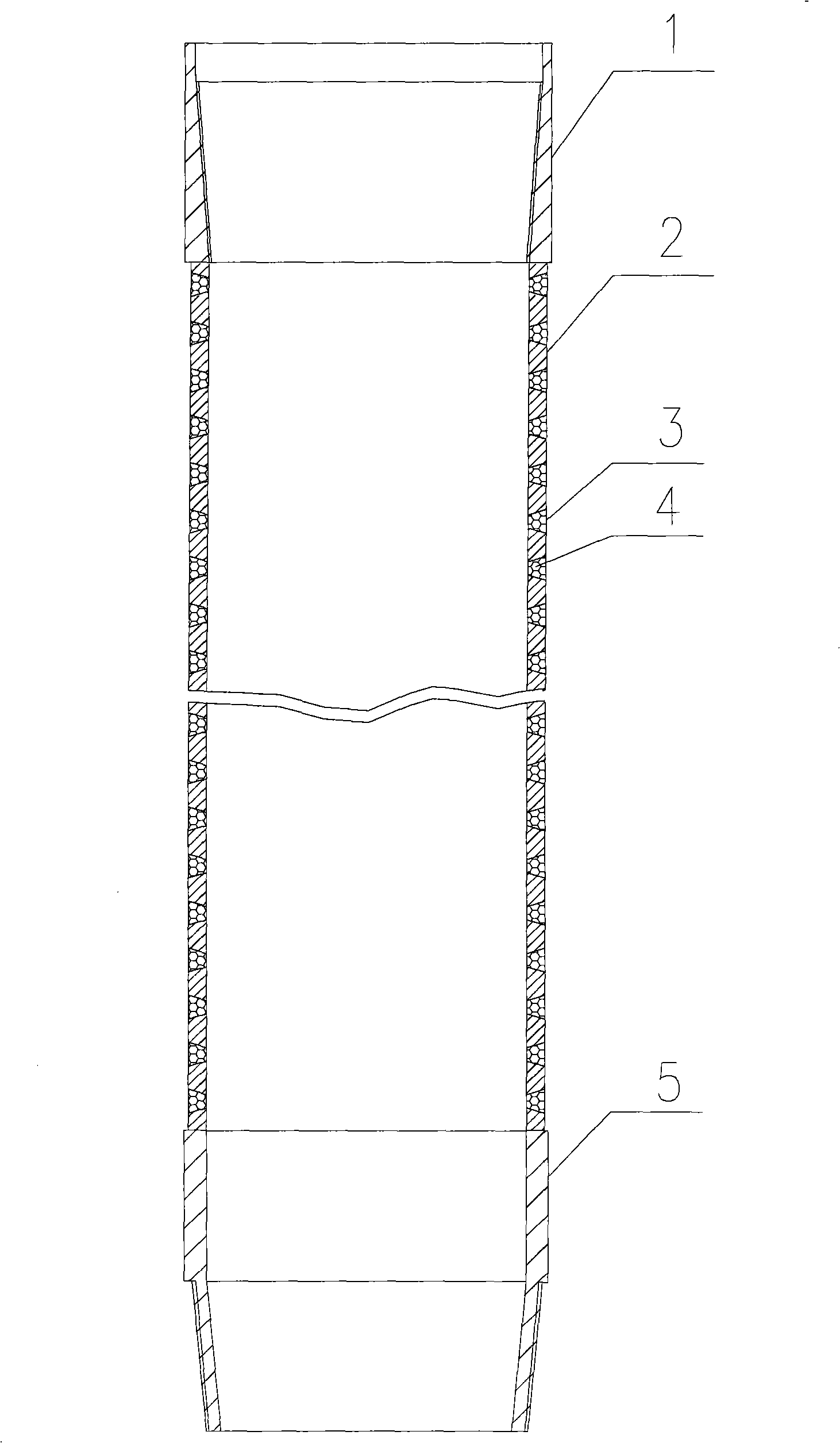

[0007] Provide the embodiment of the present invention below in conjunction with accompanying drawing: the present invention comprises pipe body 2 and joint, the two ends of pipe body are provided with upper joint 1 and lower joint 5, have the conical cone of 8-10mm on the circumference of pipe body 2 Shaped sieve hole 3, the conical sieve hole 3 that runs through the pipe body 2 is conical, the diameter of a hole on the inner wall of the pipe 80°C; the specific implementation method is: on site according to the needs Determine the required length of the pipe string, and then drill the tapered screen hole 3 through the inside and outside of the pipe body 2 of the ordinary casing according to the size of the gas volume, so that the screen pipe with the screen hole 3 is made. Due to the implementation of underbalanced Running the pipe string under pressure needs to prevent the crude oil or natural gas in the well from entering the pipe through the screen holes during the running ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com