Silicone tunable optical filter and making method thereof

A filter and bulk silicon technology, applied in the field of bulk silicon tunable optical filters and fabrication, can solve problems such as high stress control requirements, deformed transmitted light signals, residual stress, etc., achieve good optical performance, simple processing technology, The effect of high structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

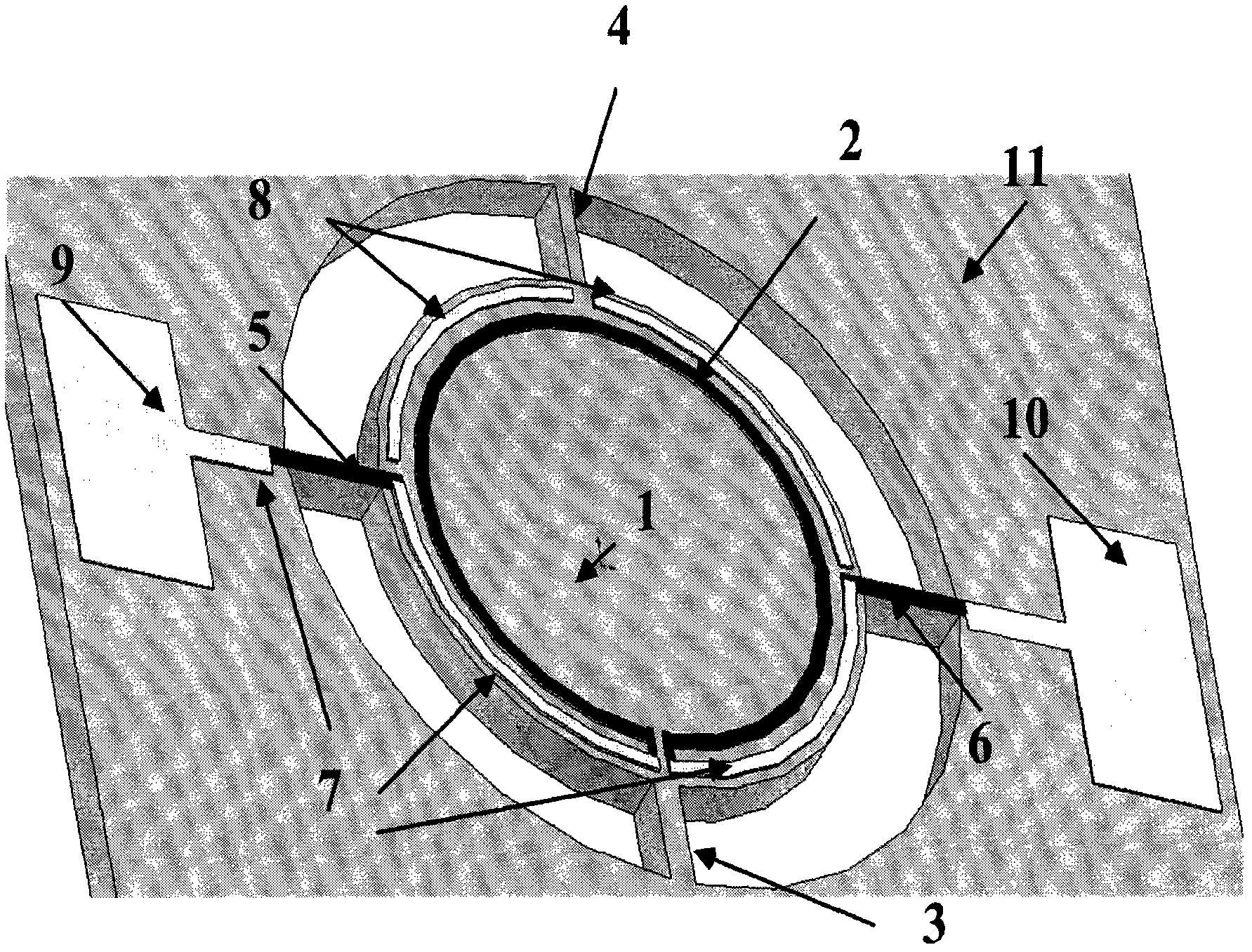

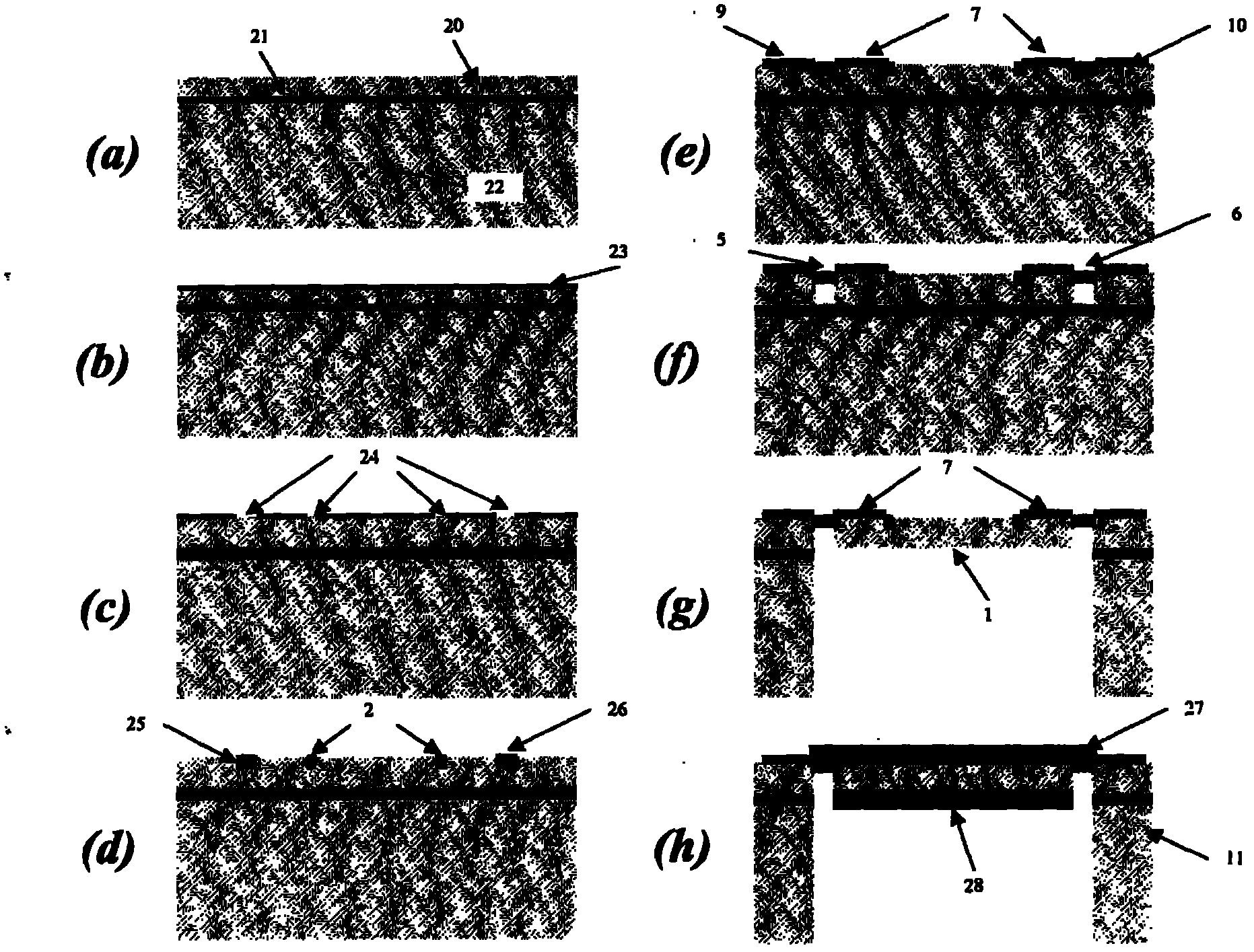

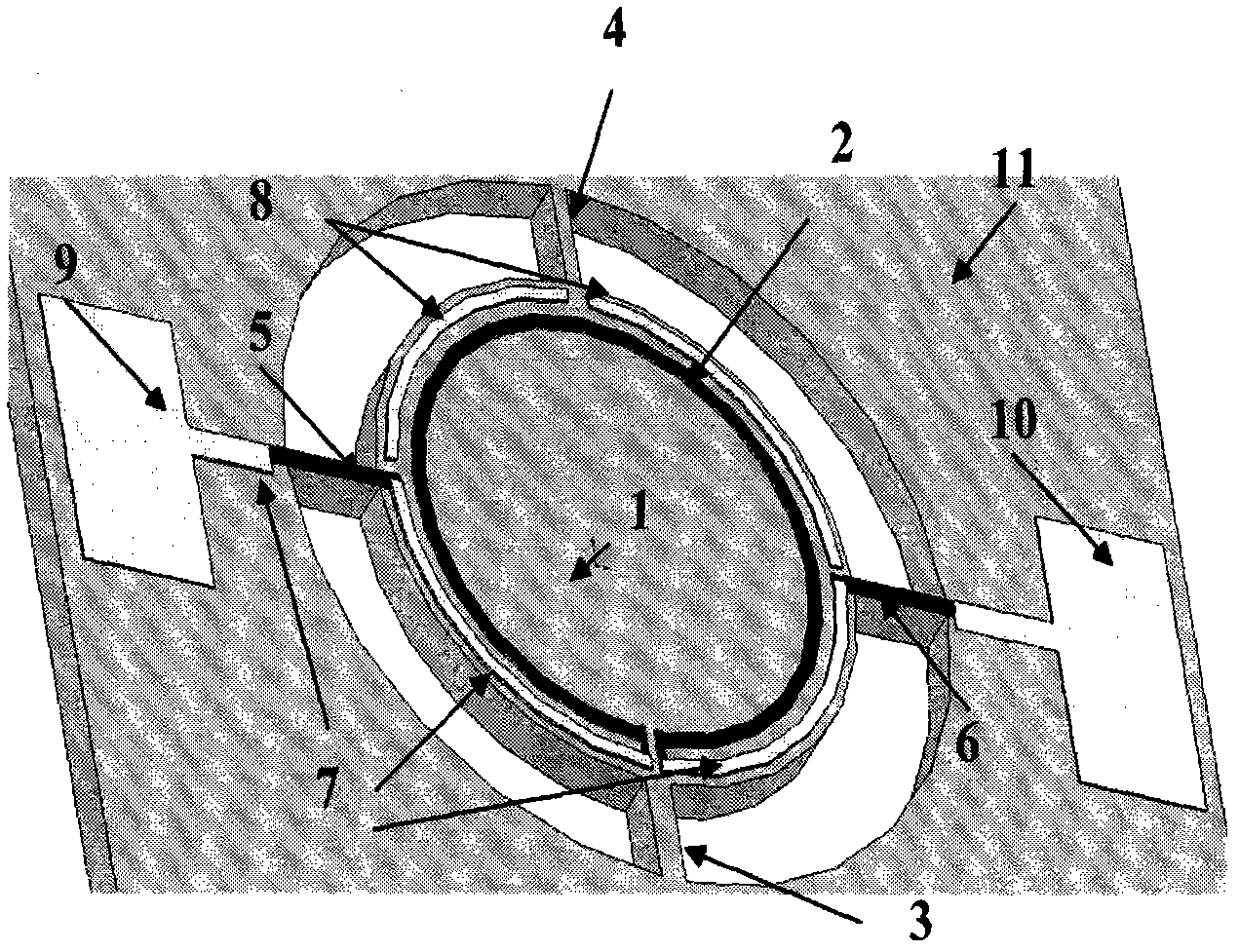

[0022] A bulk silicon tunable optical filter proposed by the present invention consists of a bulk silicon tuning cavity 1, a highly doped bulk silicon resistance heater 2, a lower cantilever beam 3, an upper cantilever beam 4, and a left cantilever beam 5 with a highly doped surface 1. A right cantilever beam 6 with a highly doped surface, a metal wire 7, a stress balance metal wire 8, a left lead area 9, a right lead area 10, and a supporting silicon substrate 11. Its structure is as figure 1 shown. The bulk silicon tuning cavity 1 is entirely composed of a single crystal silicon device layer of a high-resistivity SOI silicon wafer, and has good parallelism and surface optical quality. At the same time, the bulk silicon tuning cavity 1 can produce a large optical aperture. The highly doped bulk silicon resistance heater 2 is made of high-concentration semiconductor doping material, which can produce the heating resistance value required by the design, and use it to uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com