Patents

Literature

70results about How to "Stress smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

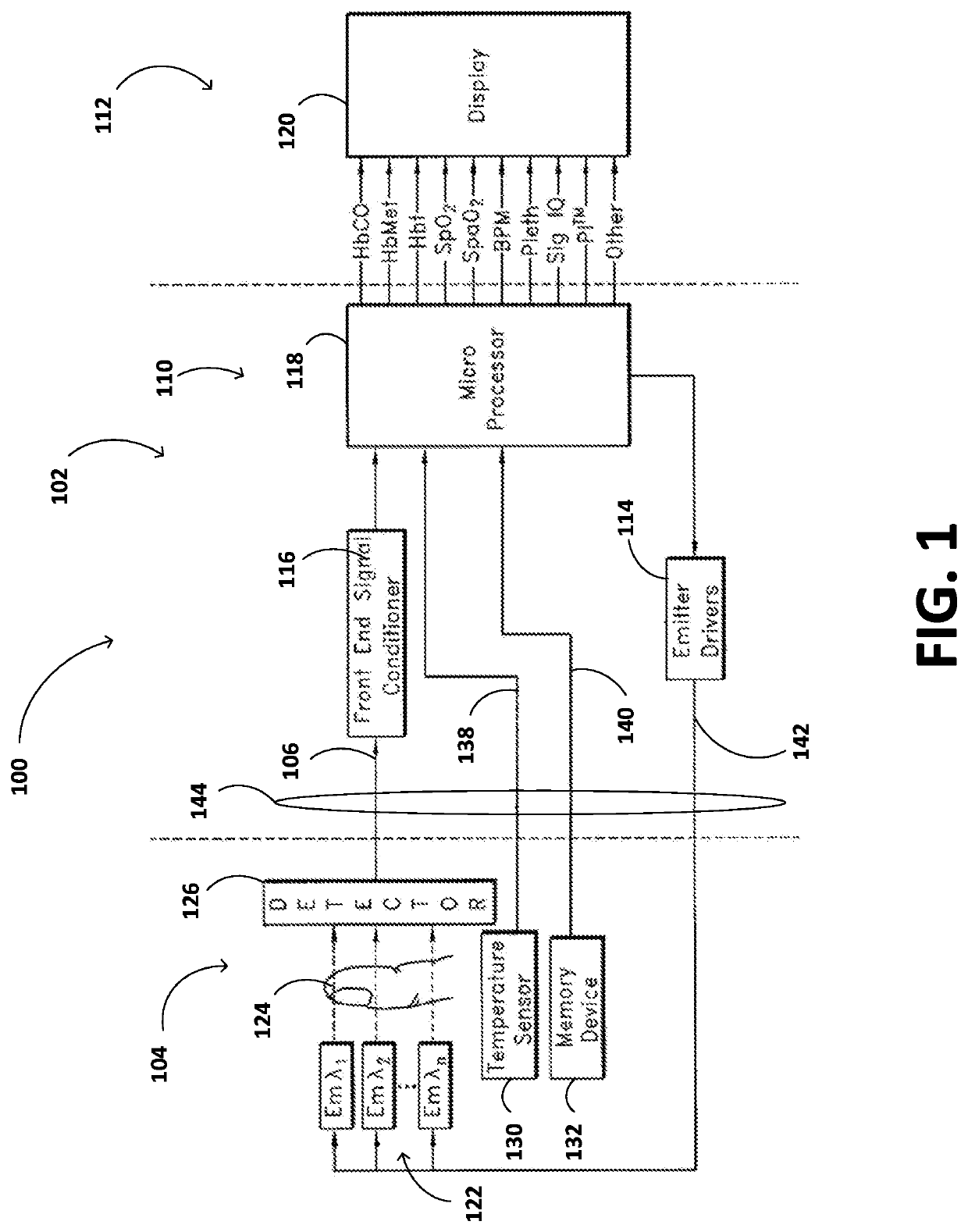

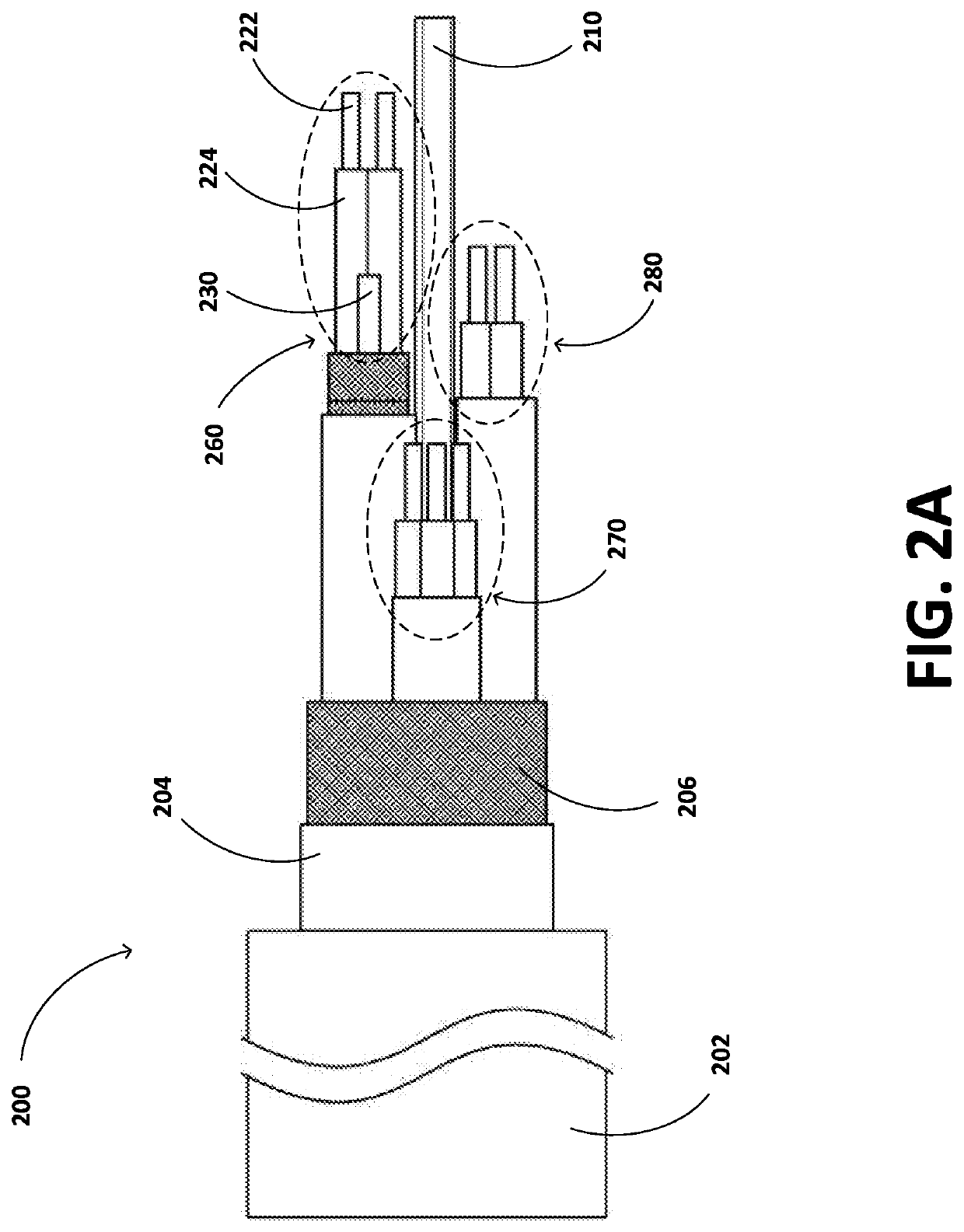

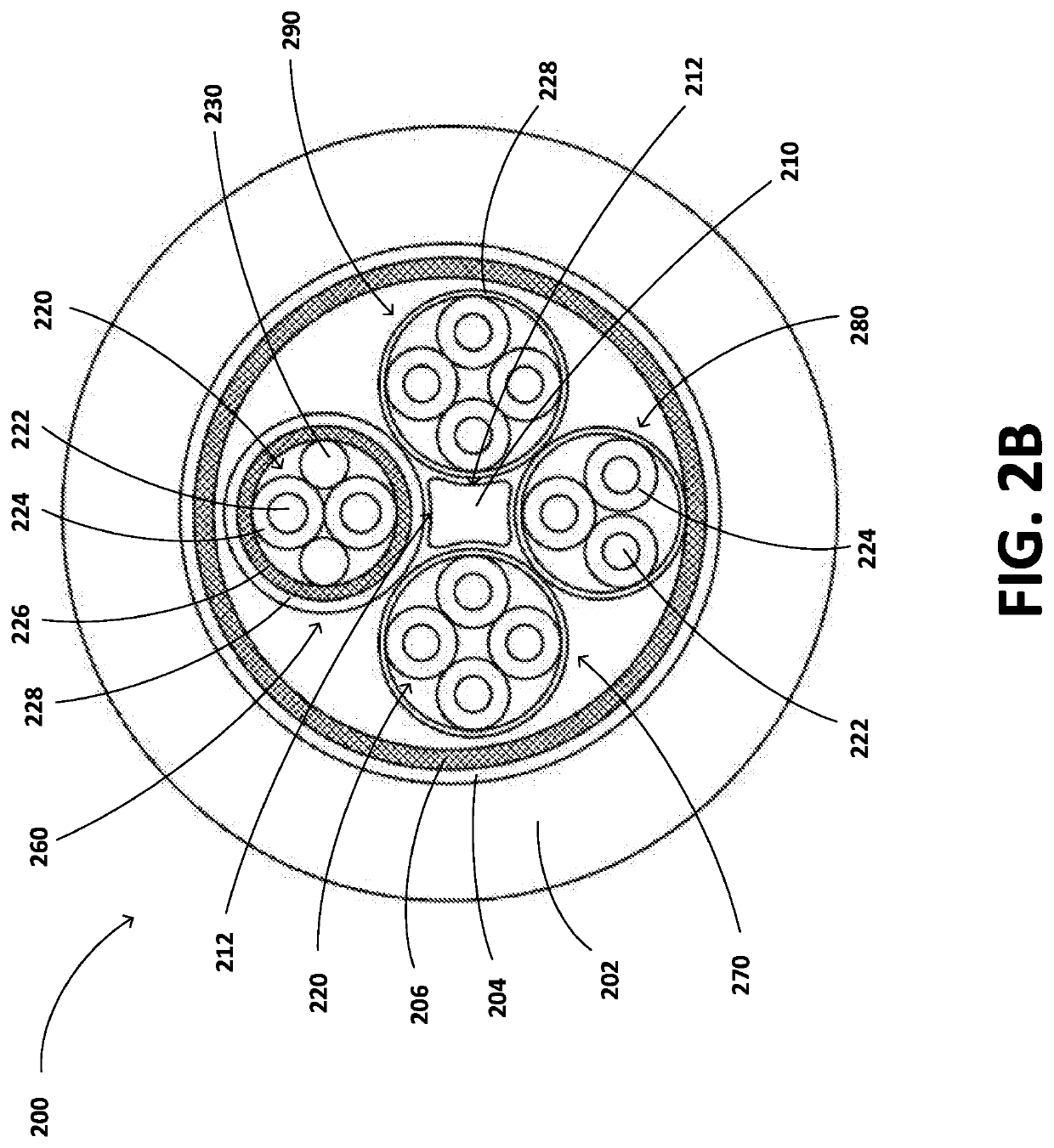

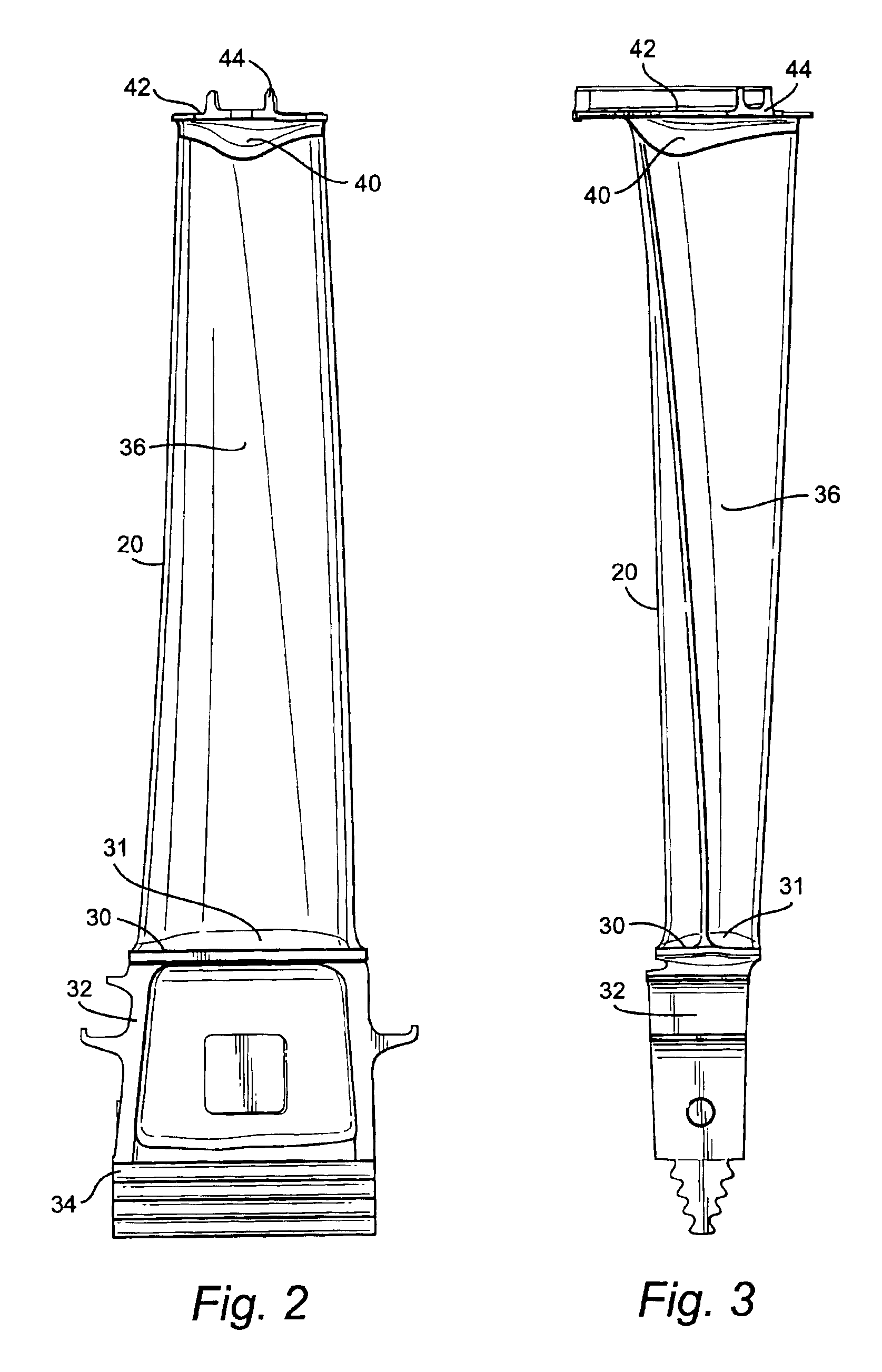

Low noise oximetry cable

ActiveUS20200113497A1Improved and flexible and durable overall constructionReduce harmDiagnostic recording/measuringSensorsEngineeringPhysical therapy

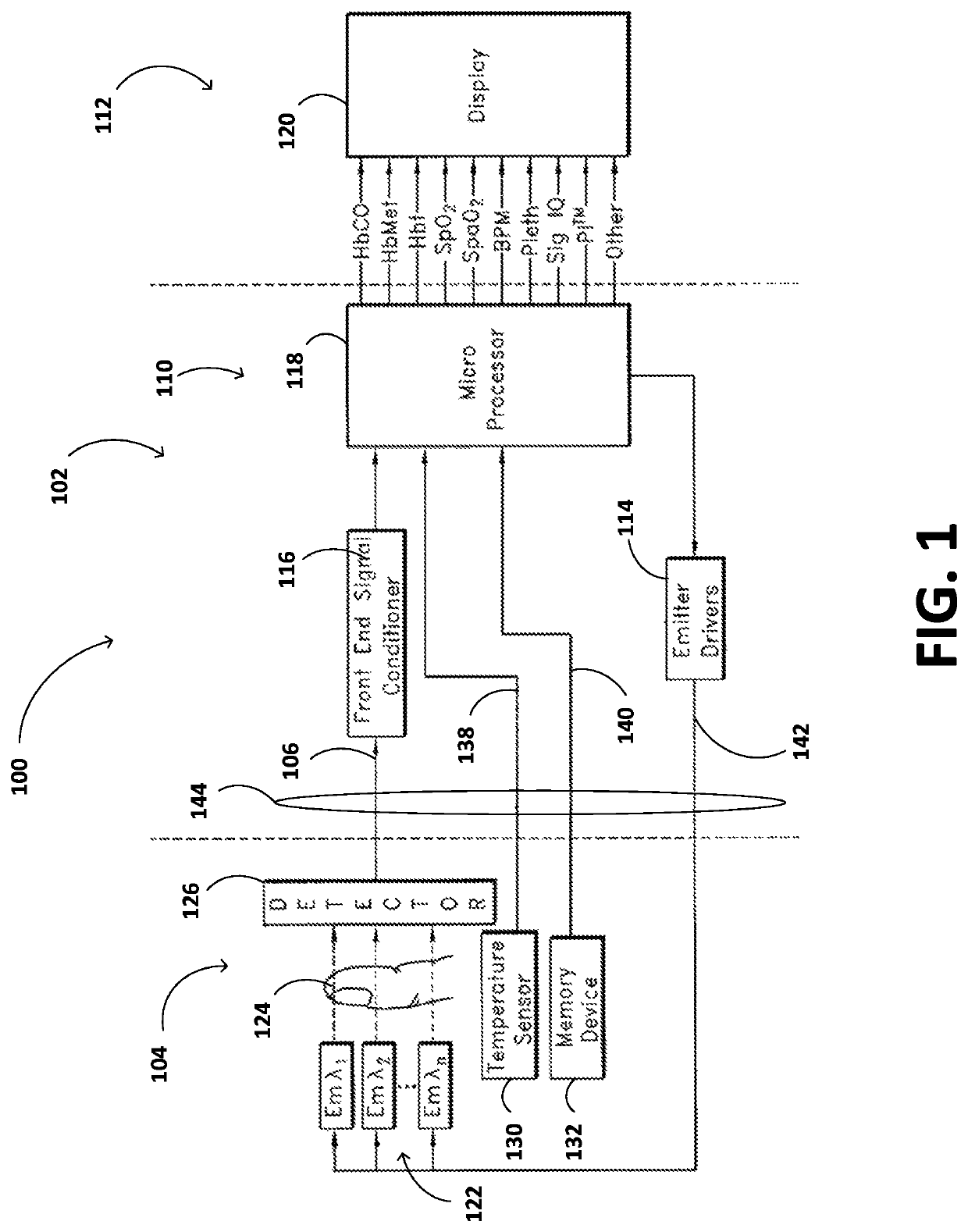

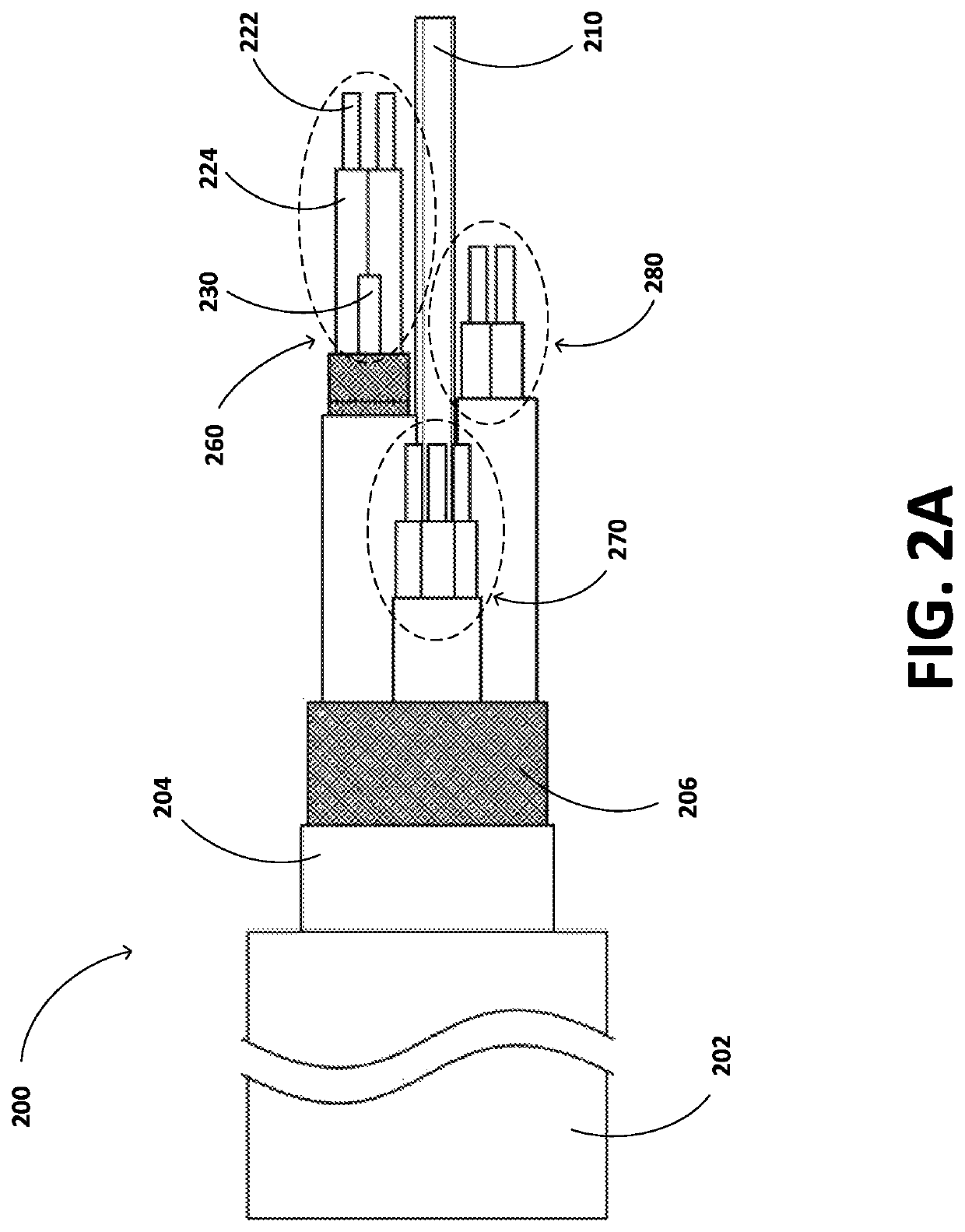

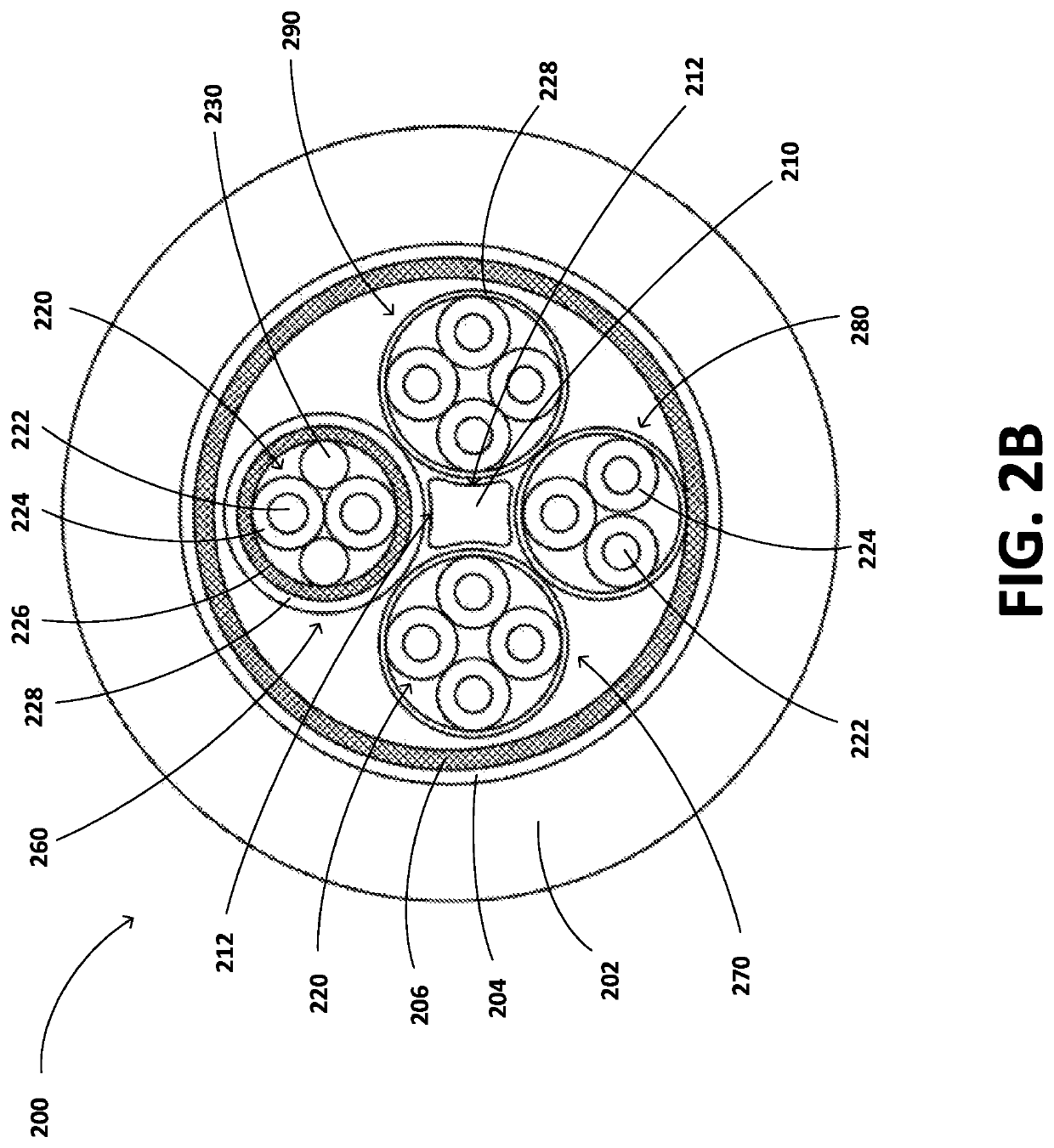

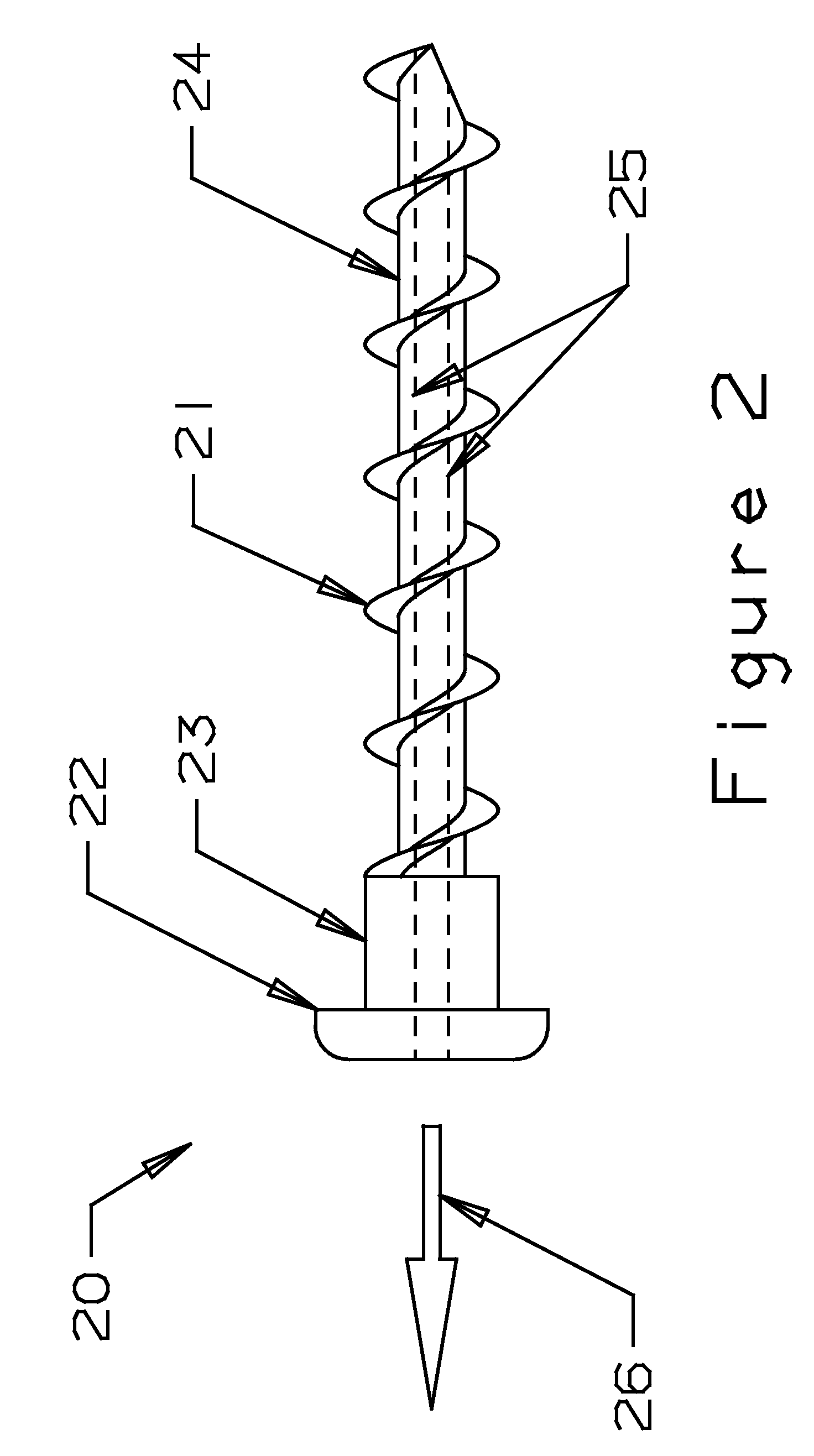

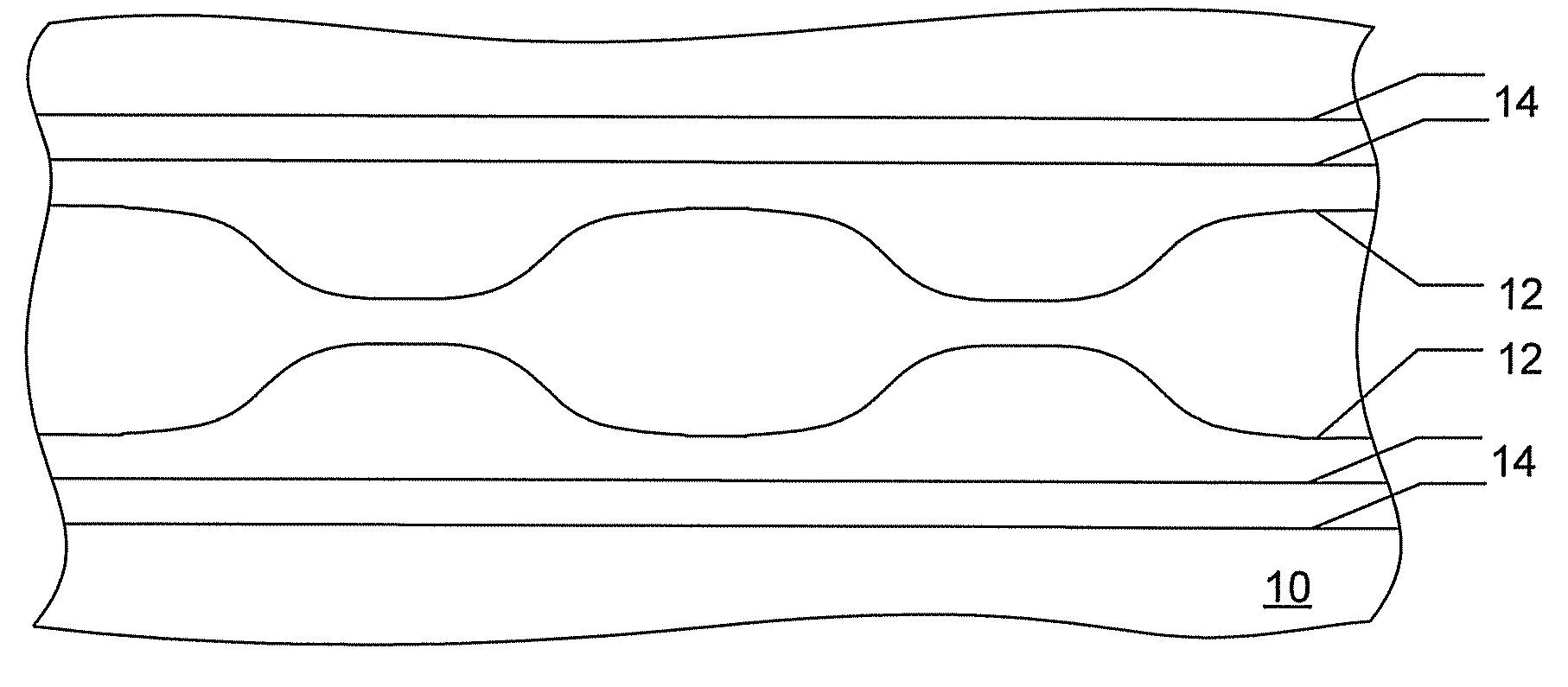

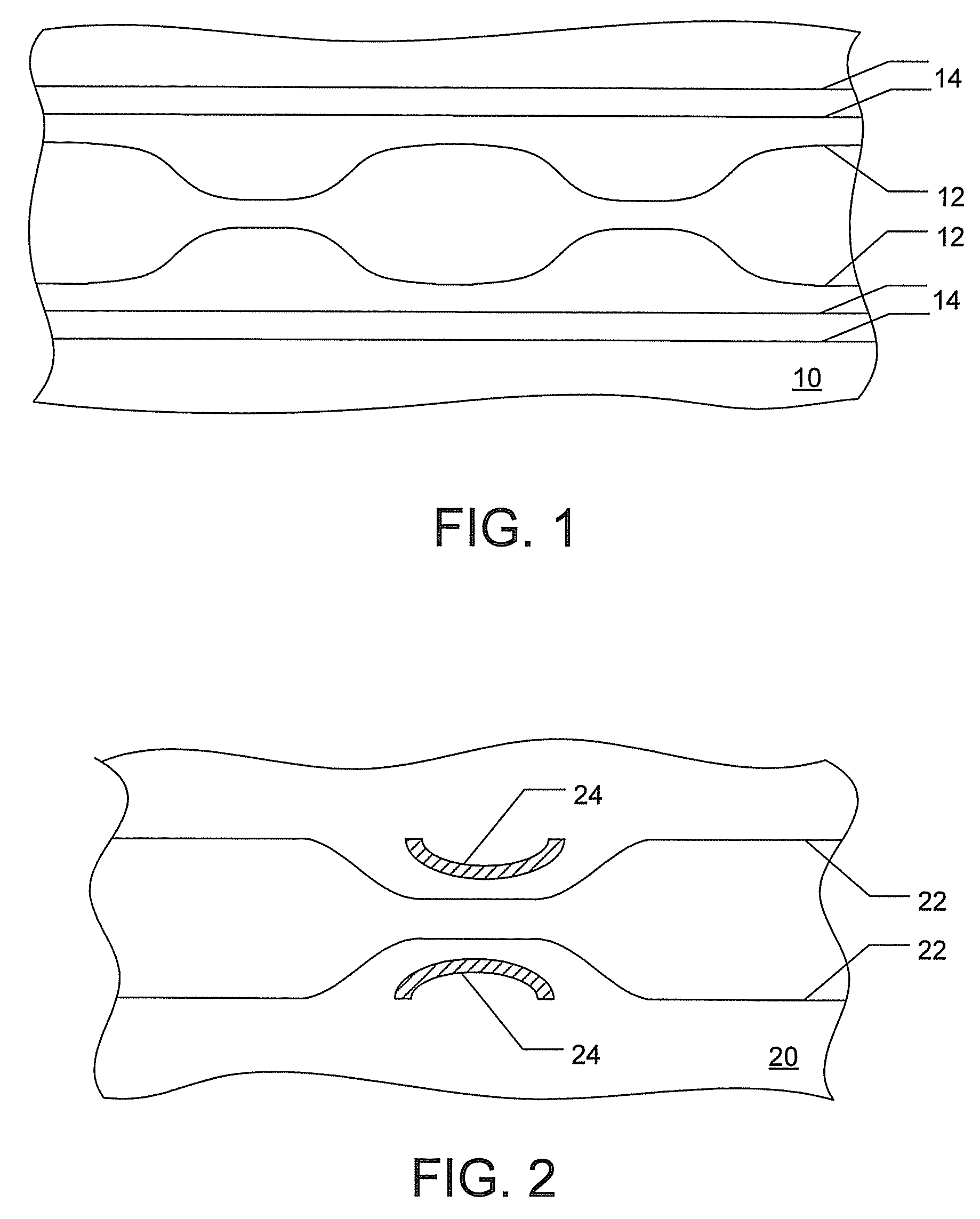

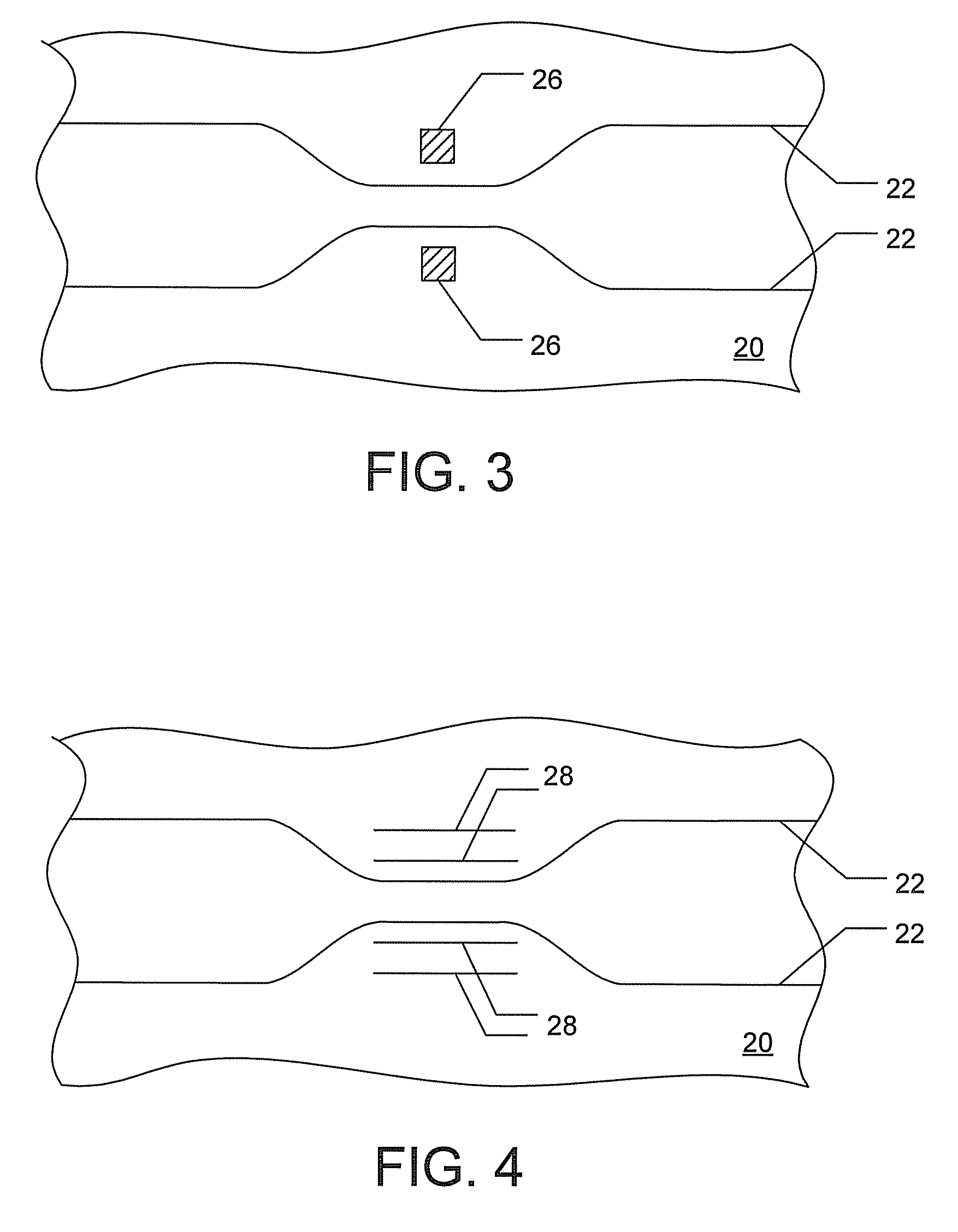

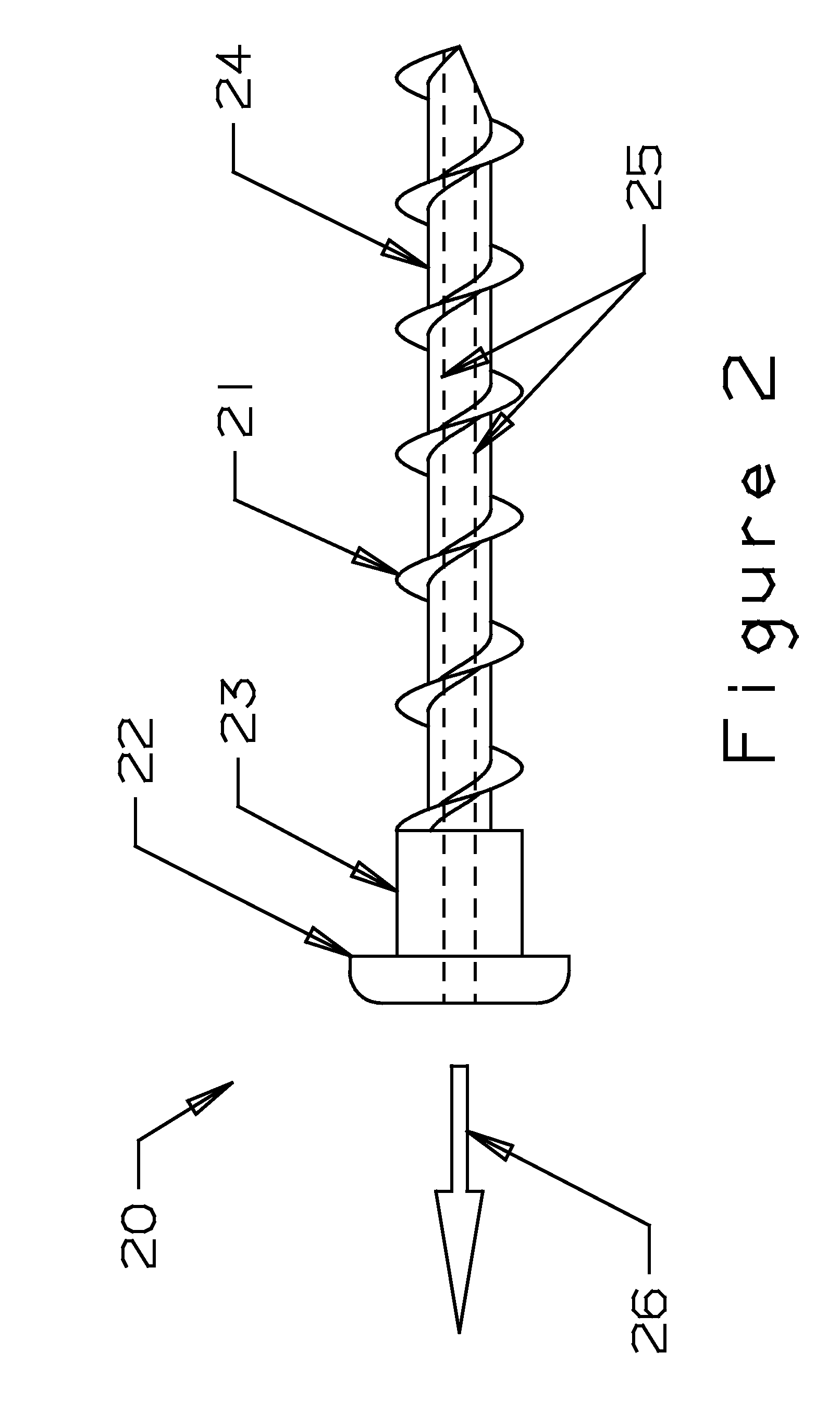

The present disclosure includes a cable for a patient monitoring system. The cable can have a flexible and durable overall construction that enables the cable to withstand repeated winding and unwinding and prevent kinks from developing. The cable may include multiple bundles encased in inner jackets that reduce the amount of friction against other cable elements and allows the bundle to move more freely inside an outer jacket of the cable. The multiple bundles may include multiple wires or cords. The cable can include a flexible core that runs through the middle of the cable. The multiple bundles can be twisted, weaved, or untwisted around the core.

Owner:MASIMO CORP

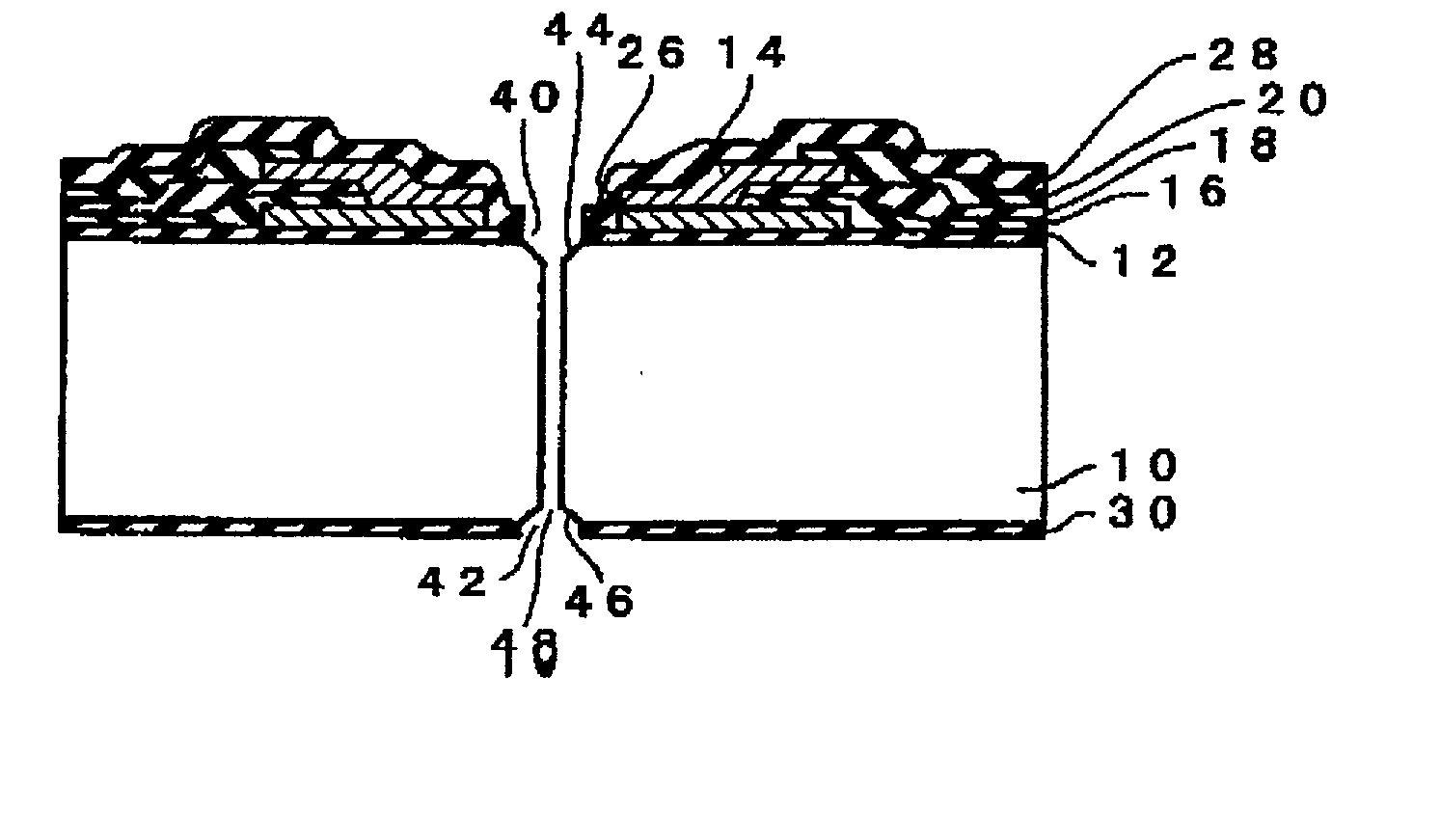

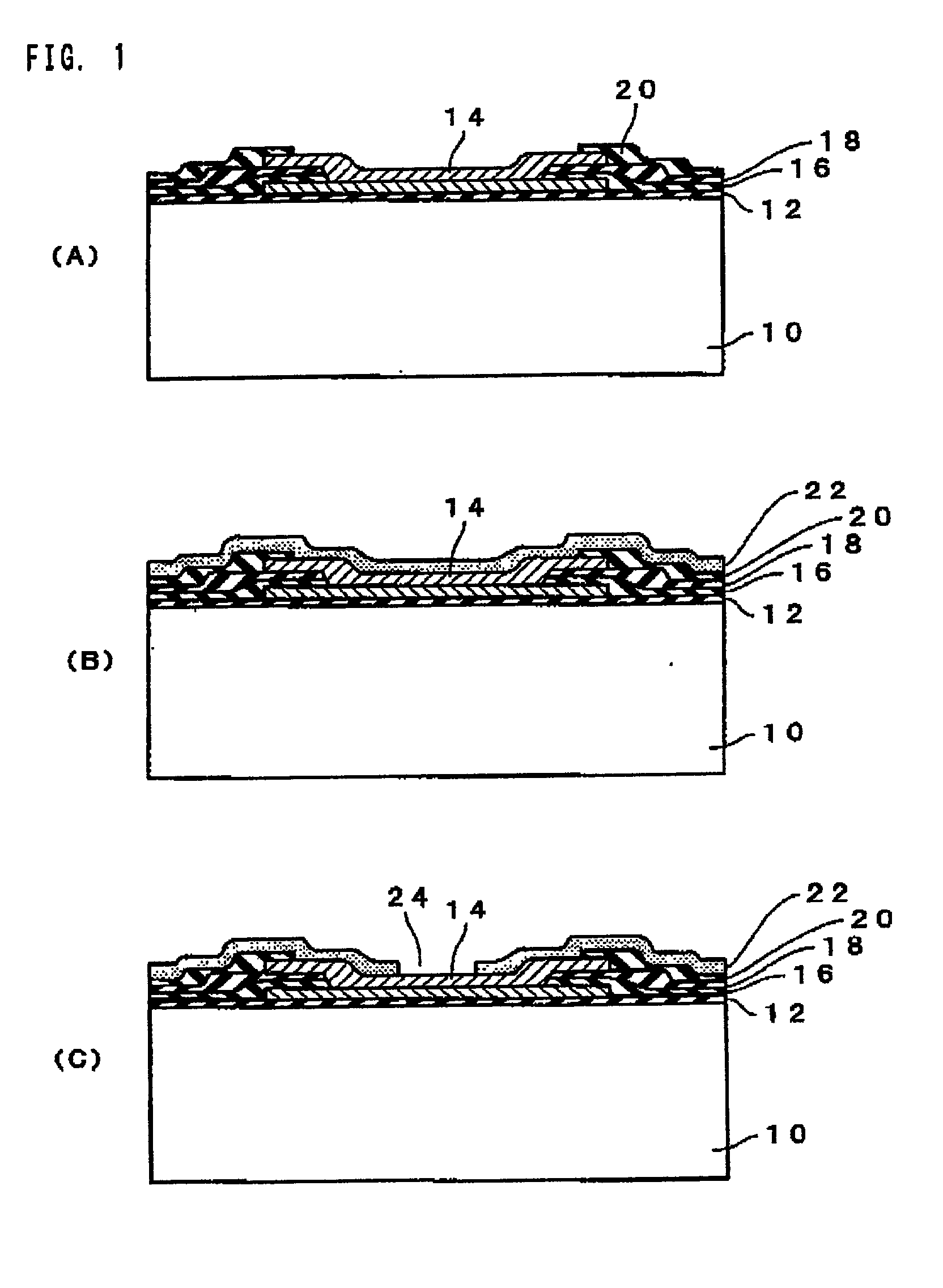

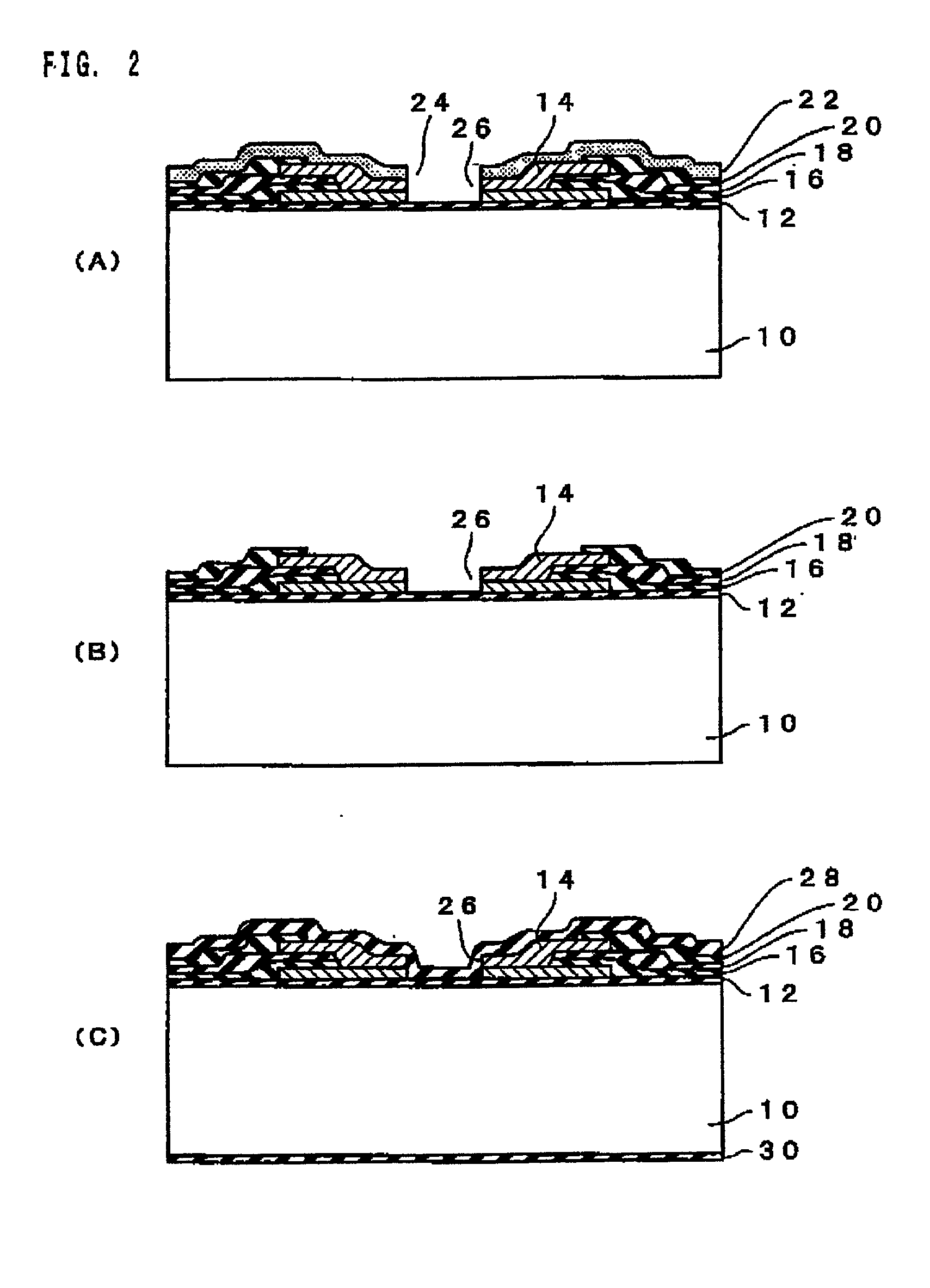

Semiconductor device and manufacturing method therefor, circuit substrate, and electronic apparatus

InactiveUS20020151171A1Stress smoothWeaken energySemiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

A semiconductor device and a manufacturing method therefor, a circuit substrate, and electronic apparatus are provided, in which electrical connection can be performed with high reliability and with ease. The manufacturing method for a semiconductor device includes the steps of forming a penetration hole 50 in a semiconductor chip 10 having an electrode 14, and forming a conductive layer 70 in the region including the inside of the penetration hole 50. Regarding the penetration hole 50, an intermediate portion is formed to be larger than an open end portion, and the conductive layer 70 is formed by applying a coating of a liquid containing metal fine particles by an ink-jet method.

Owner:SAMSUNG ELECTRONICS CO LTD

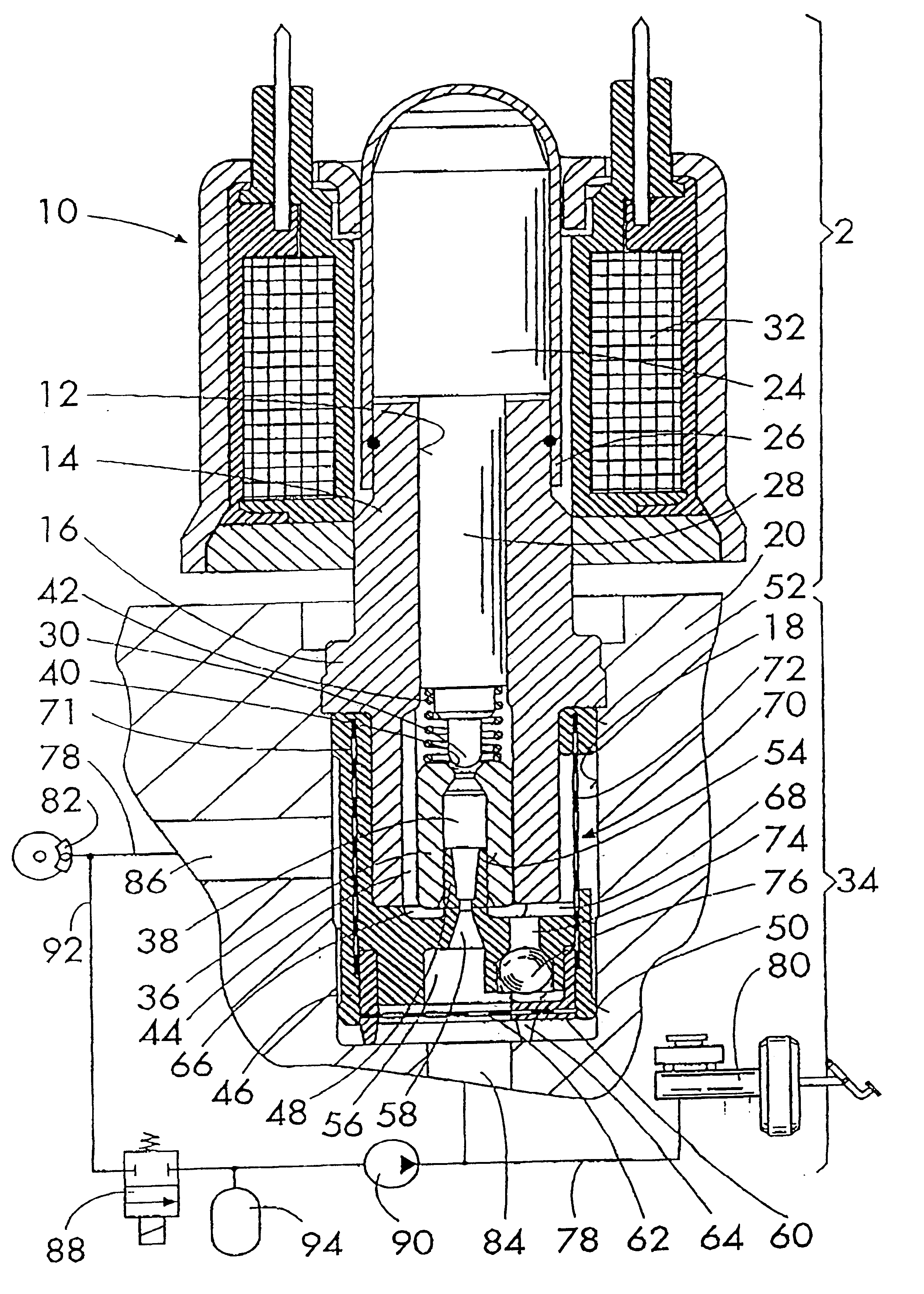

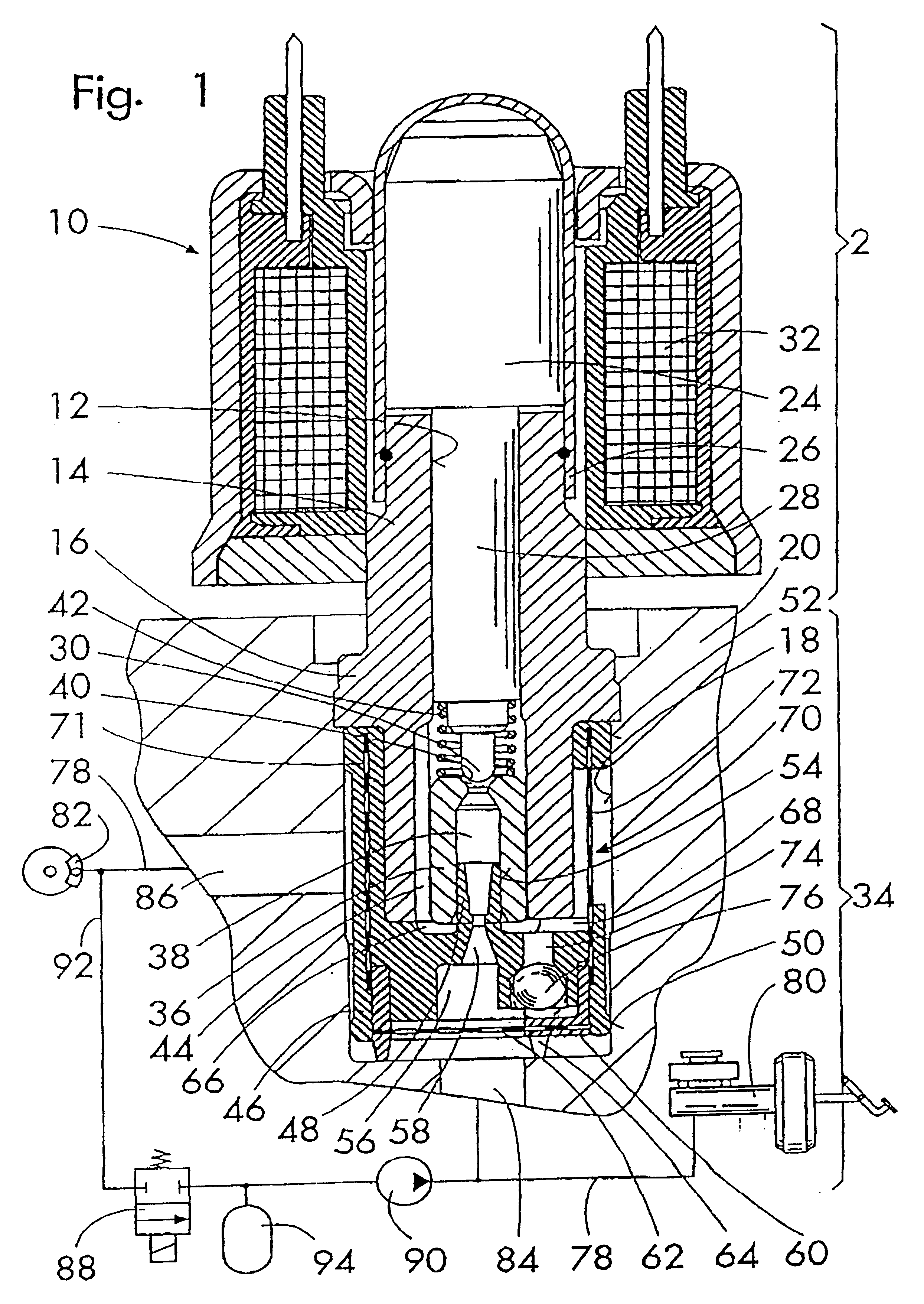

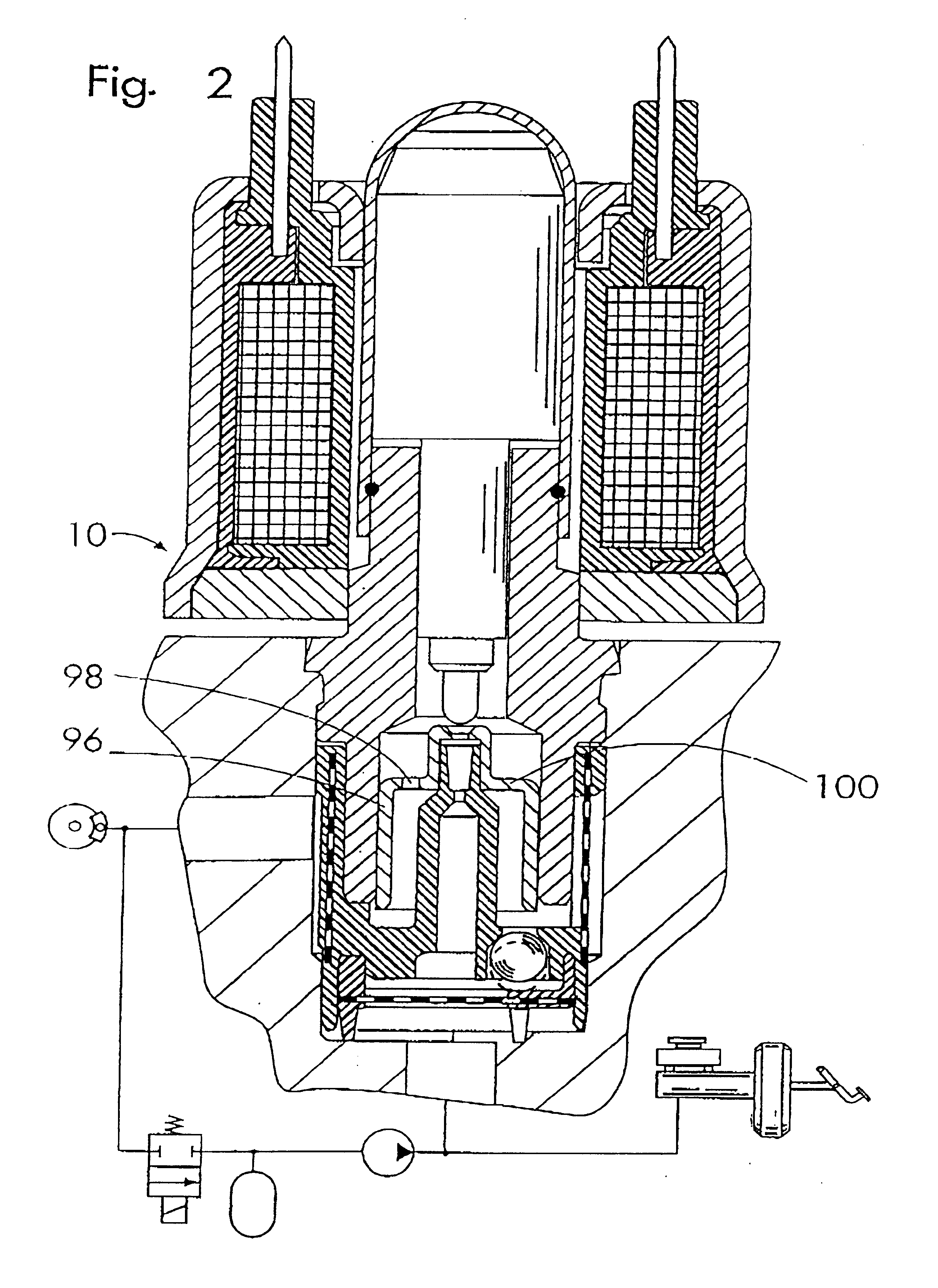

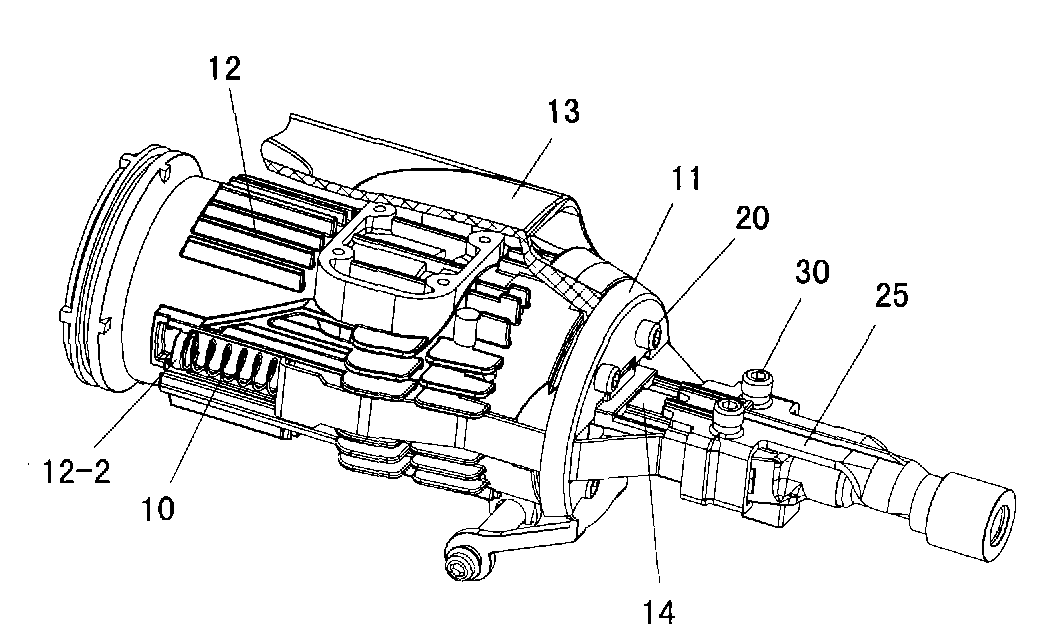

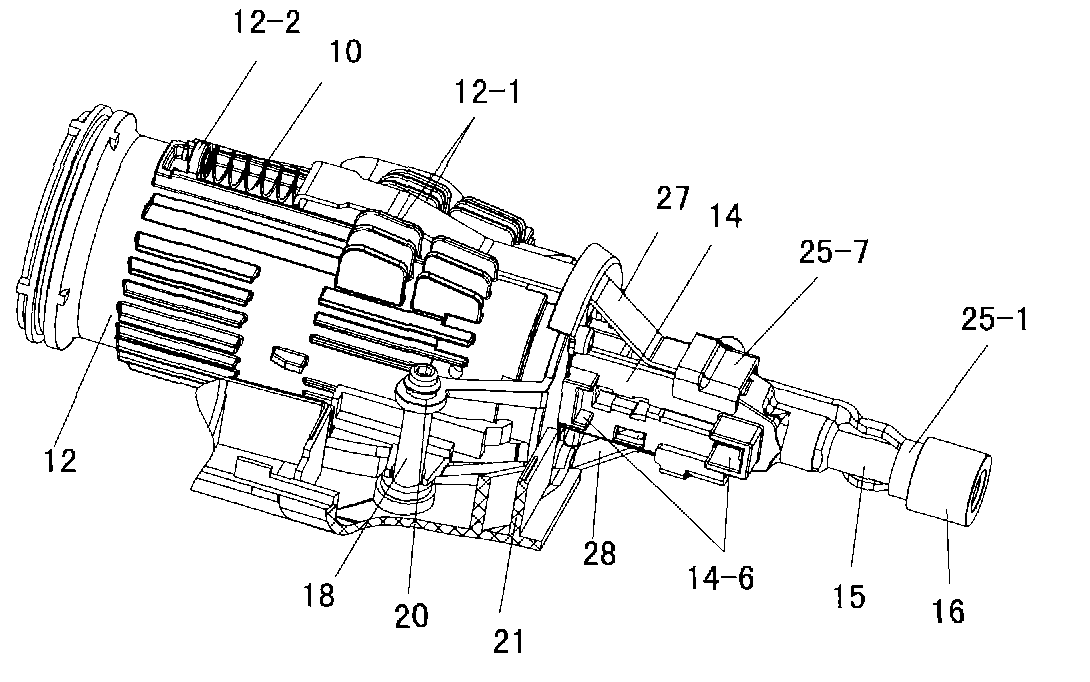

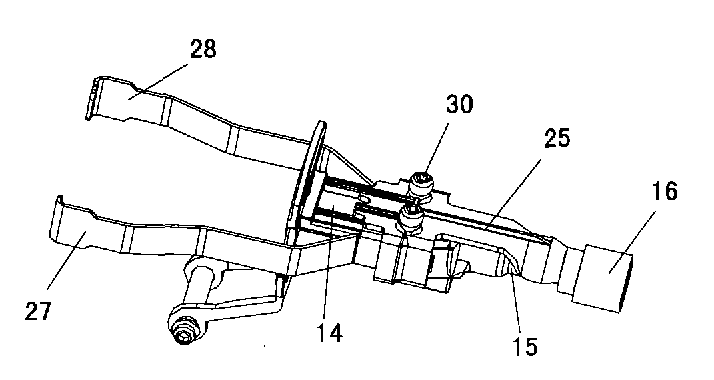

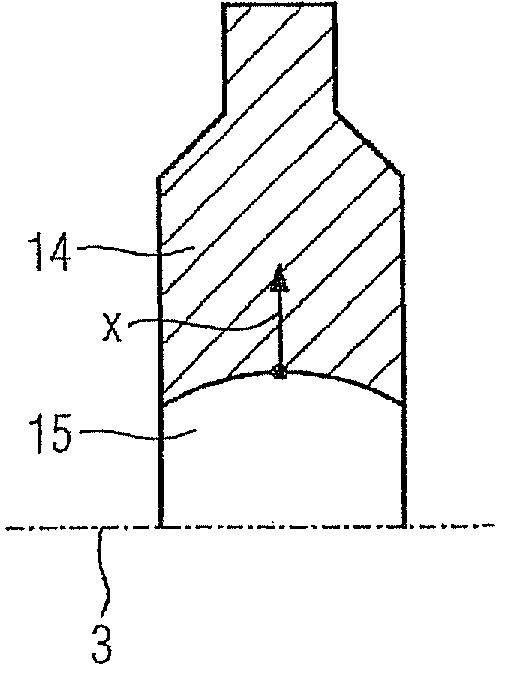

Solenoid valve for a slip-regulated hydraulic brake system of a vehicle

InactiveUS6254199B1Strongly pressedEasy to manufactureOperating means/releasing devices for valvesPipeline systemsSolenoid valveHydraulic brake

A rod-shaped solenoid valve that is provided for insertion into a receiving bore of a hydraulic block of an antilock hydraulic brake system of a vehicle, wherein a fluid influx takes place through an axial bore of a valve seat part that is inserted into a valve support. For simple sealing, a plastic end piece is placed onto the end of the valve support that prodrudes into the receiving bore and seals the valve support in relation to the receiving bore and also seals the valve seat part.

Owner:ROBERT BOSCH GMBH

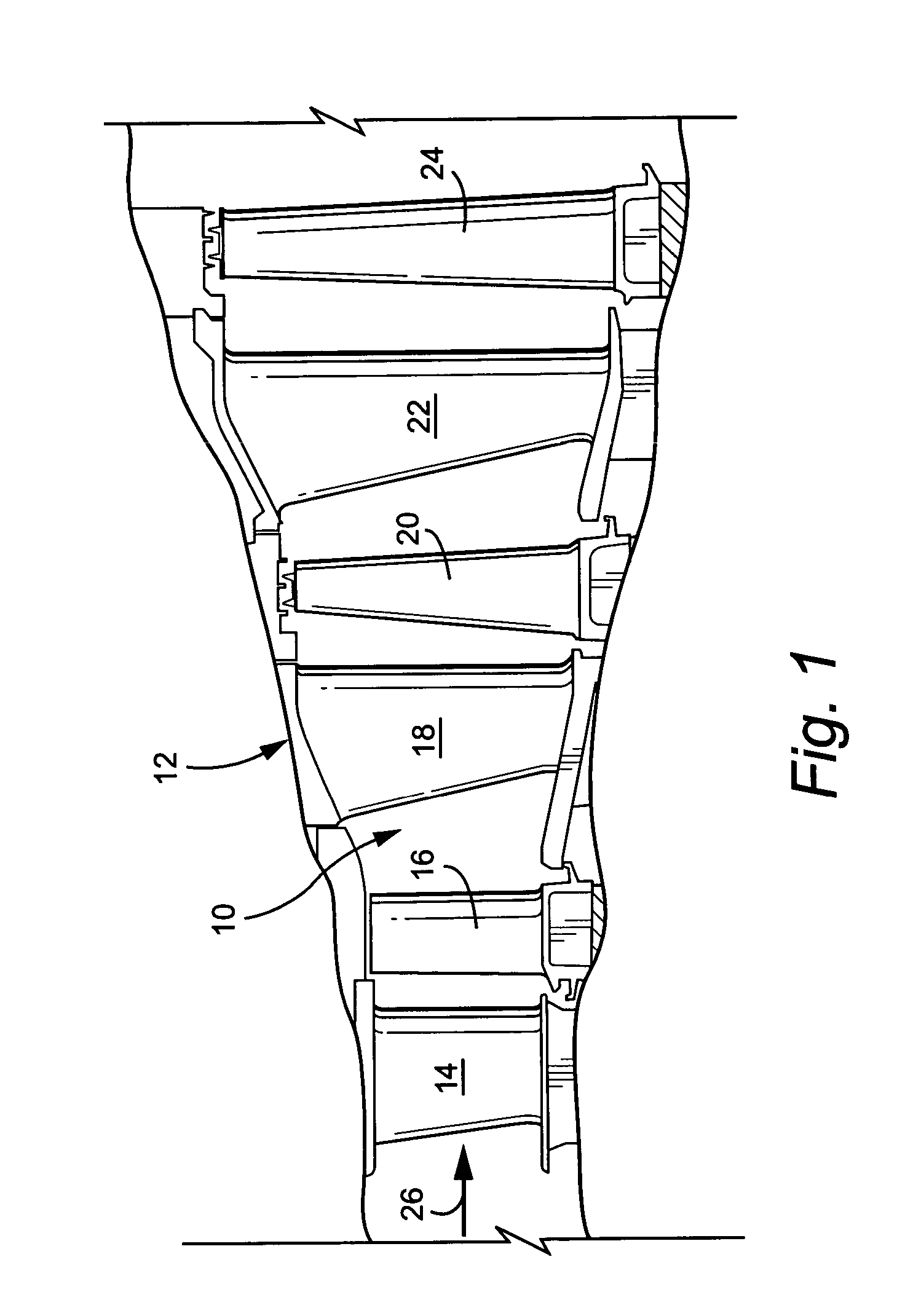

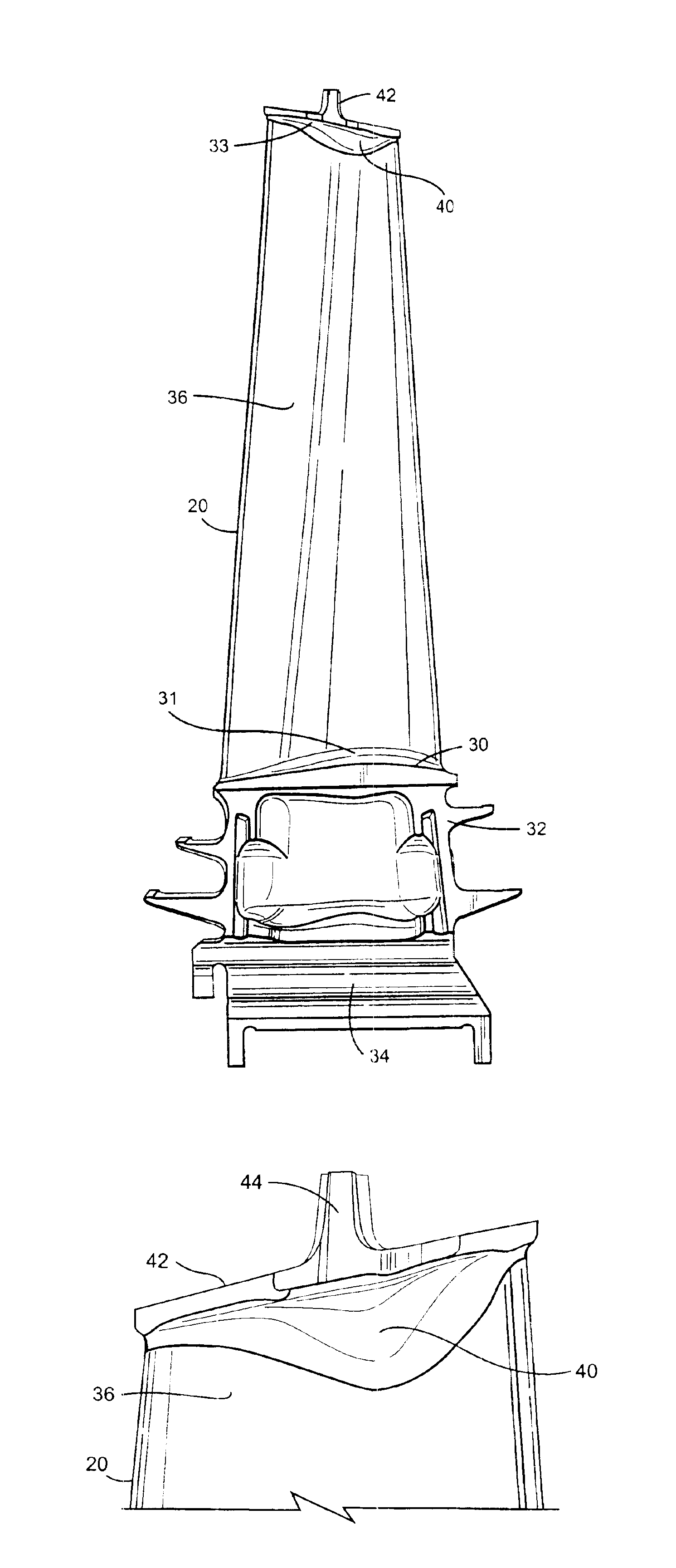

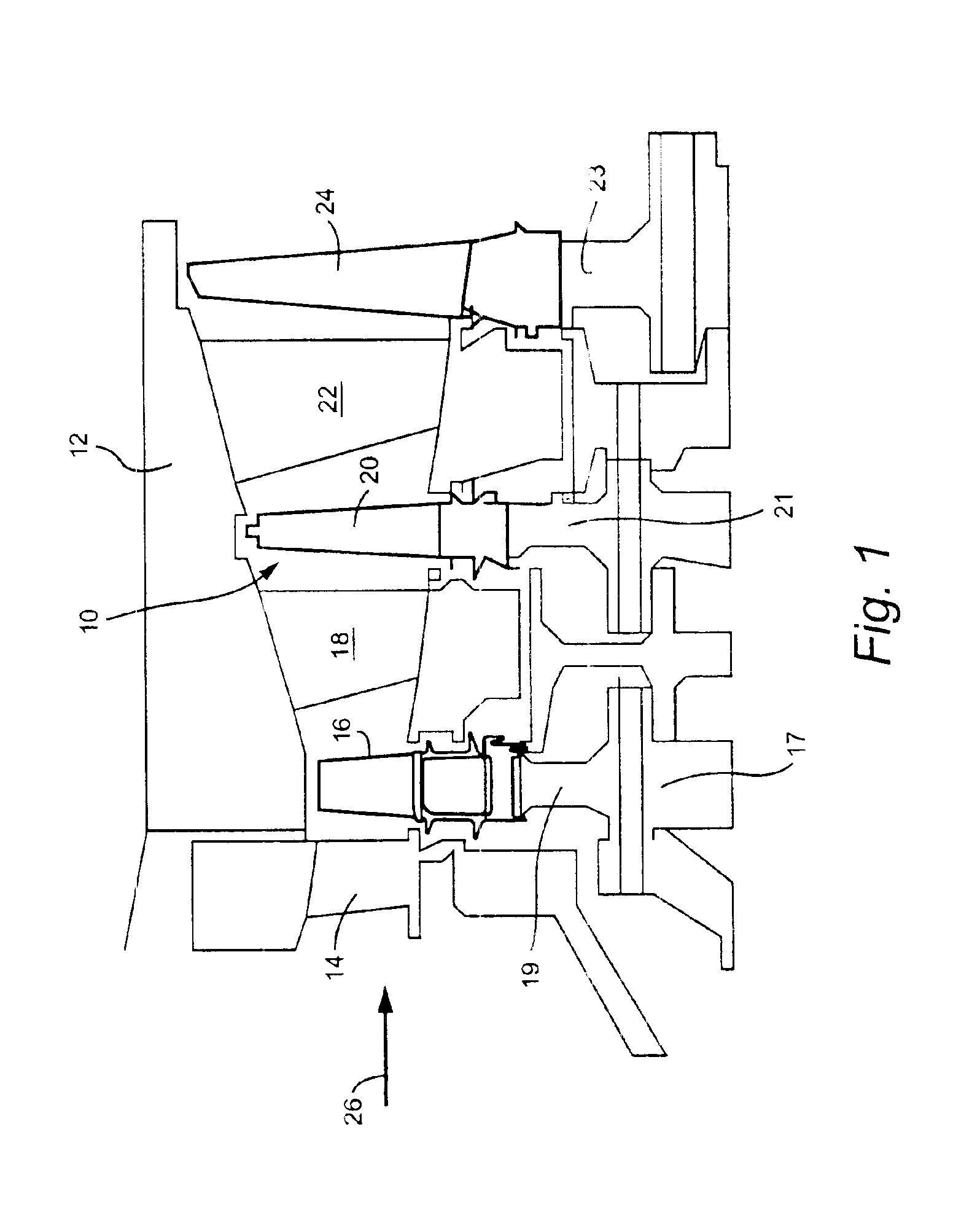

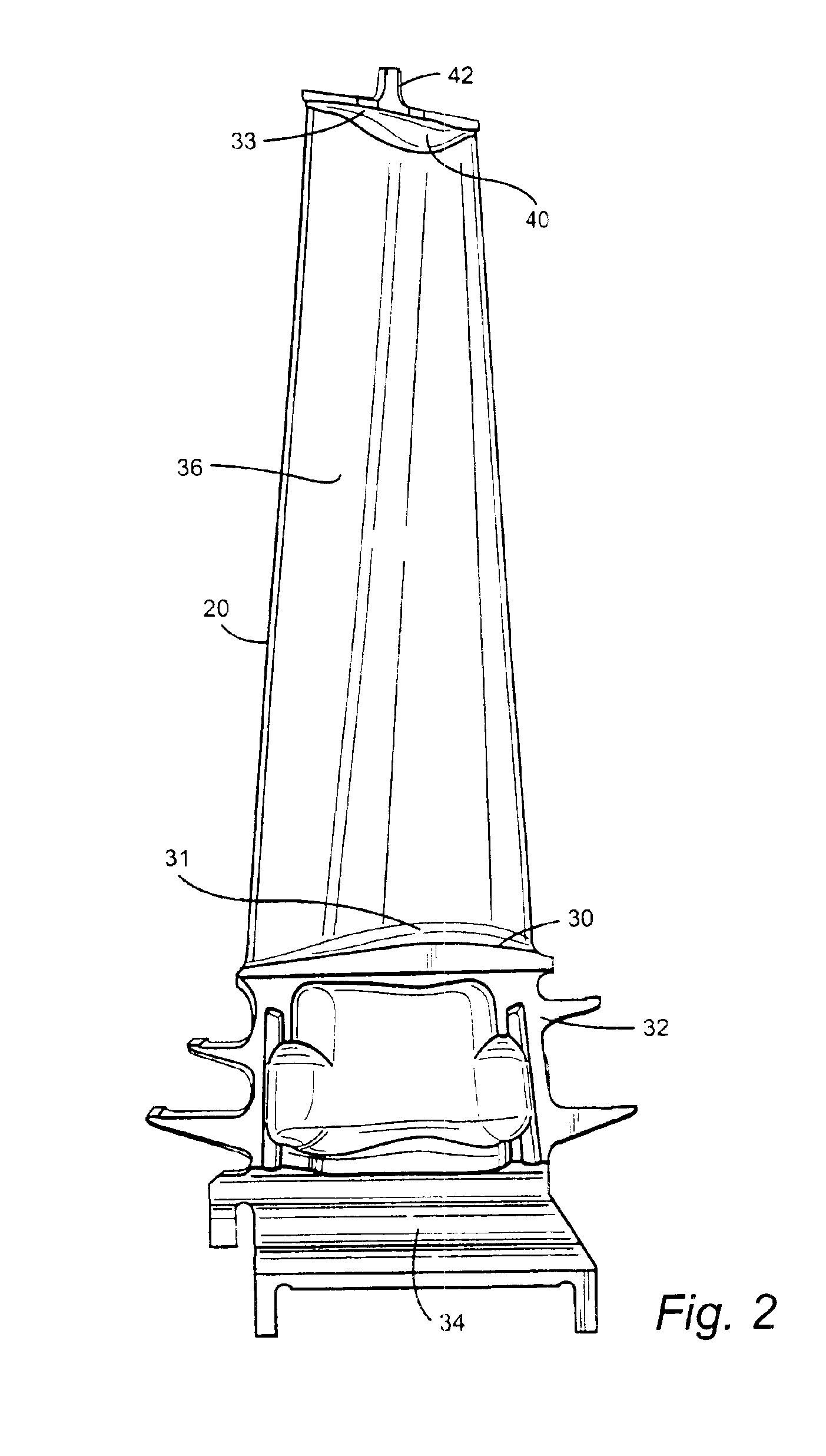

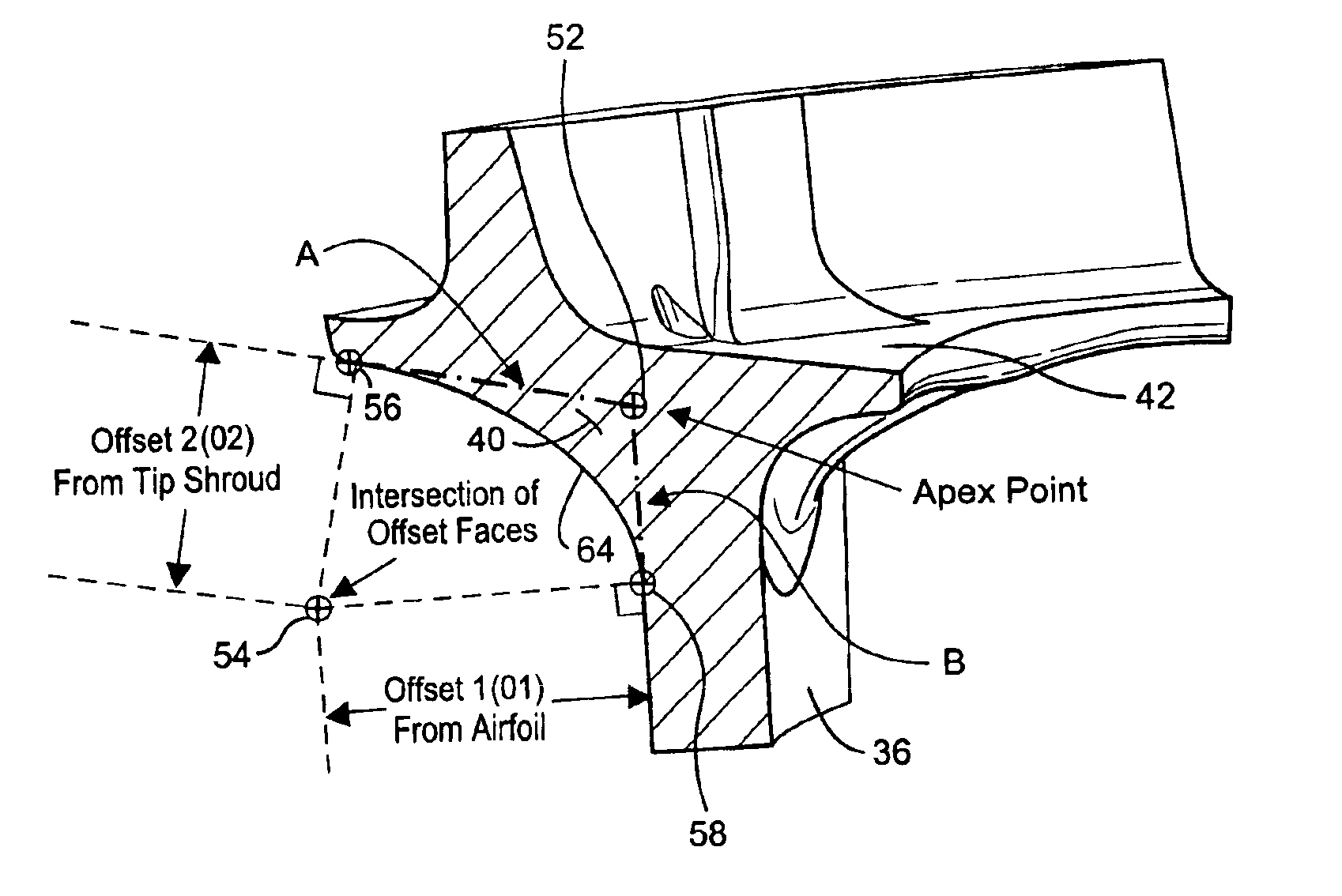

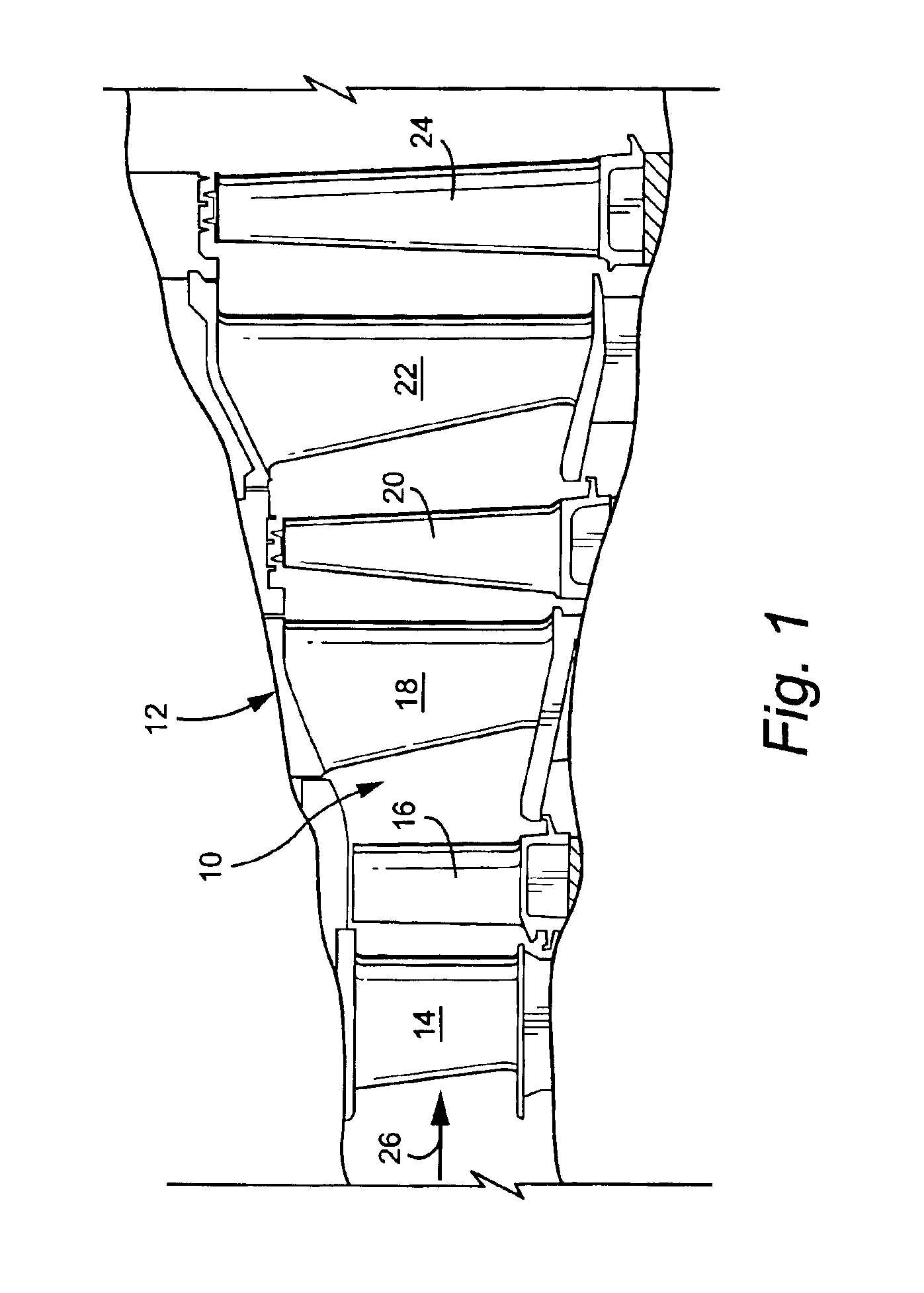

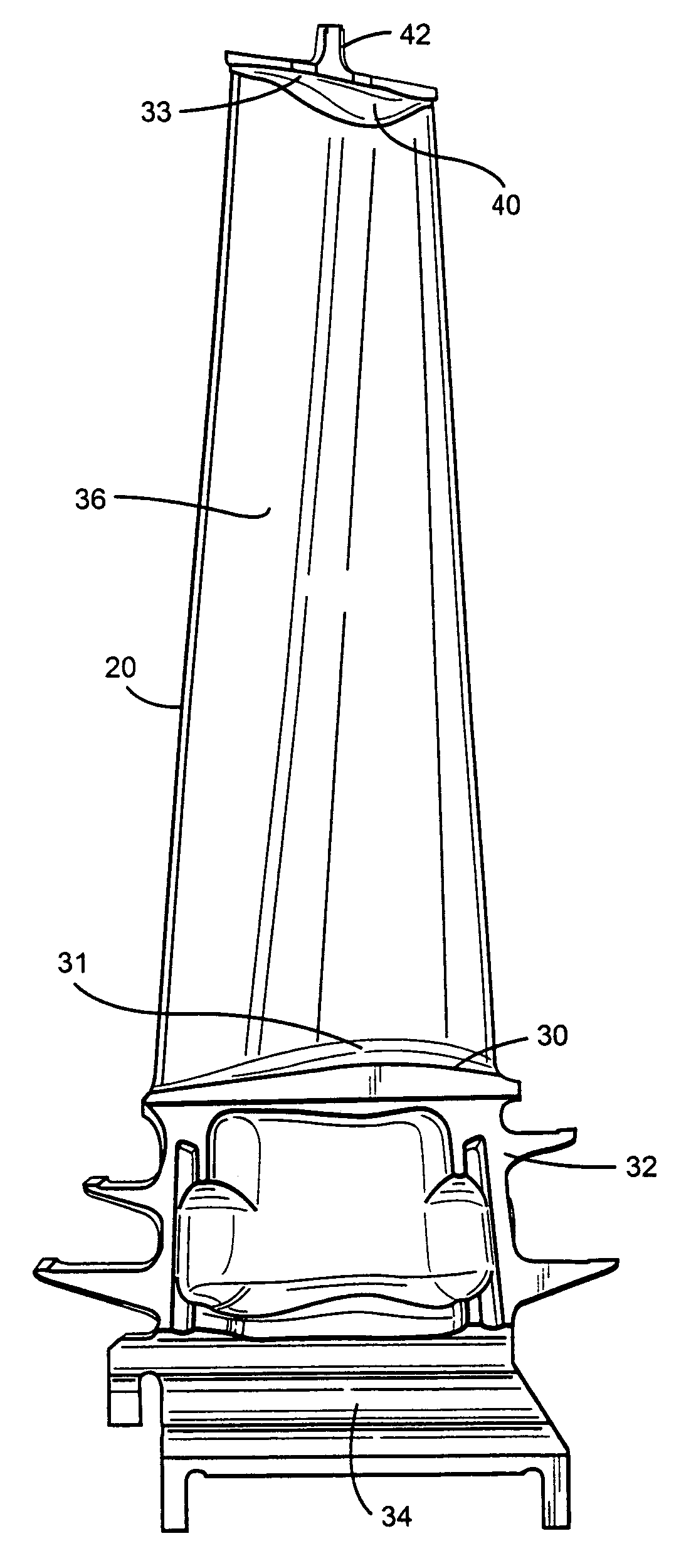

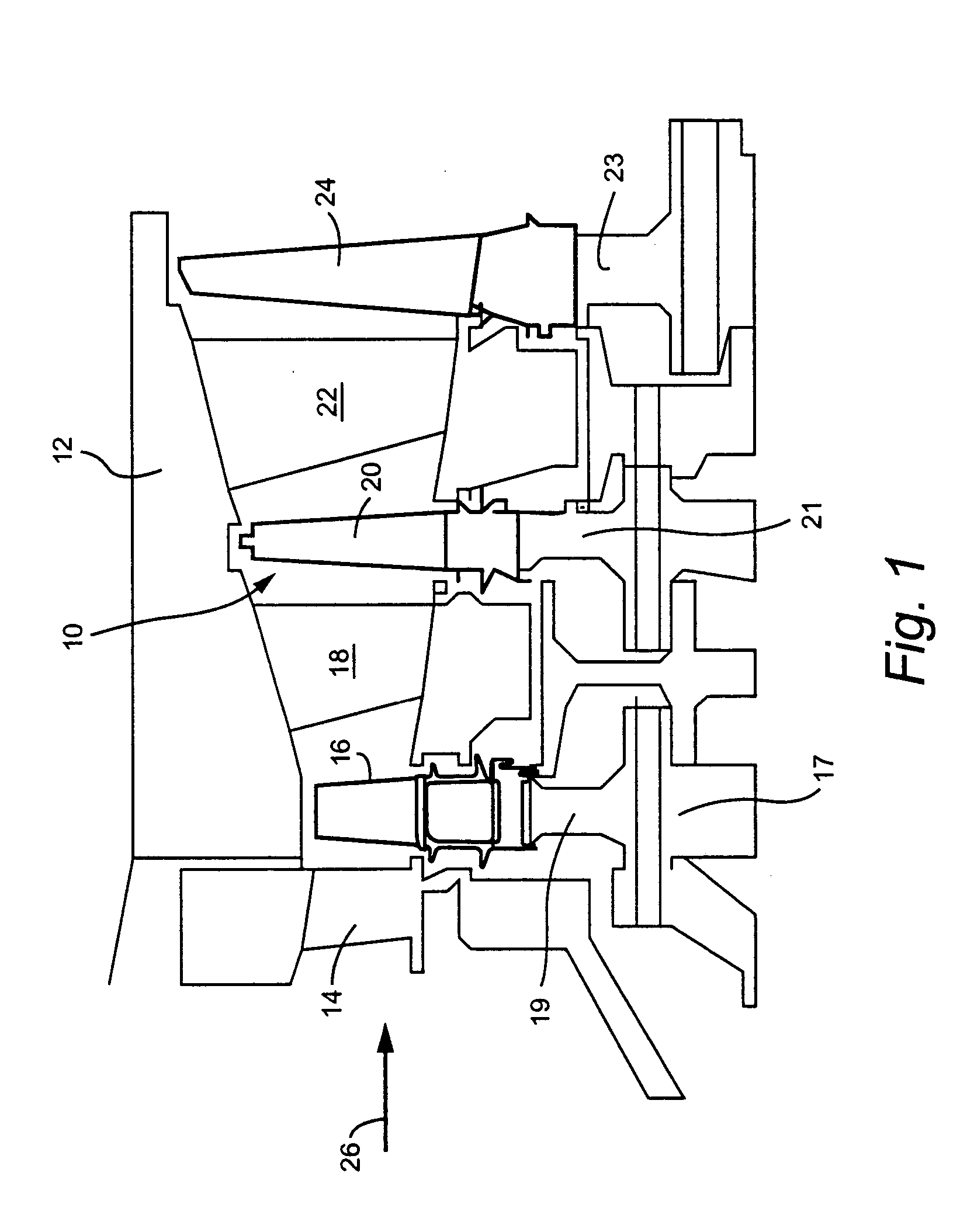

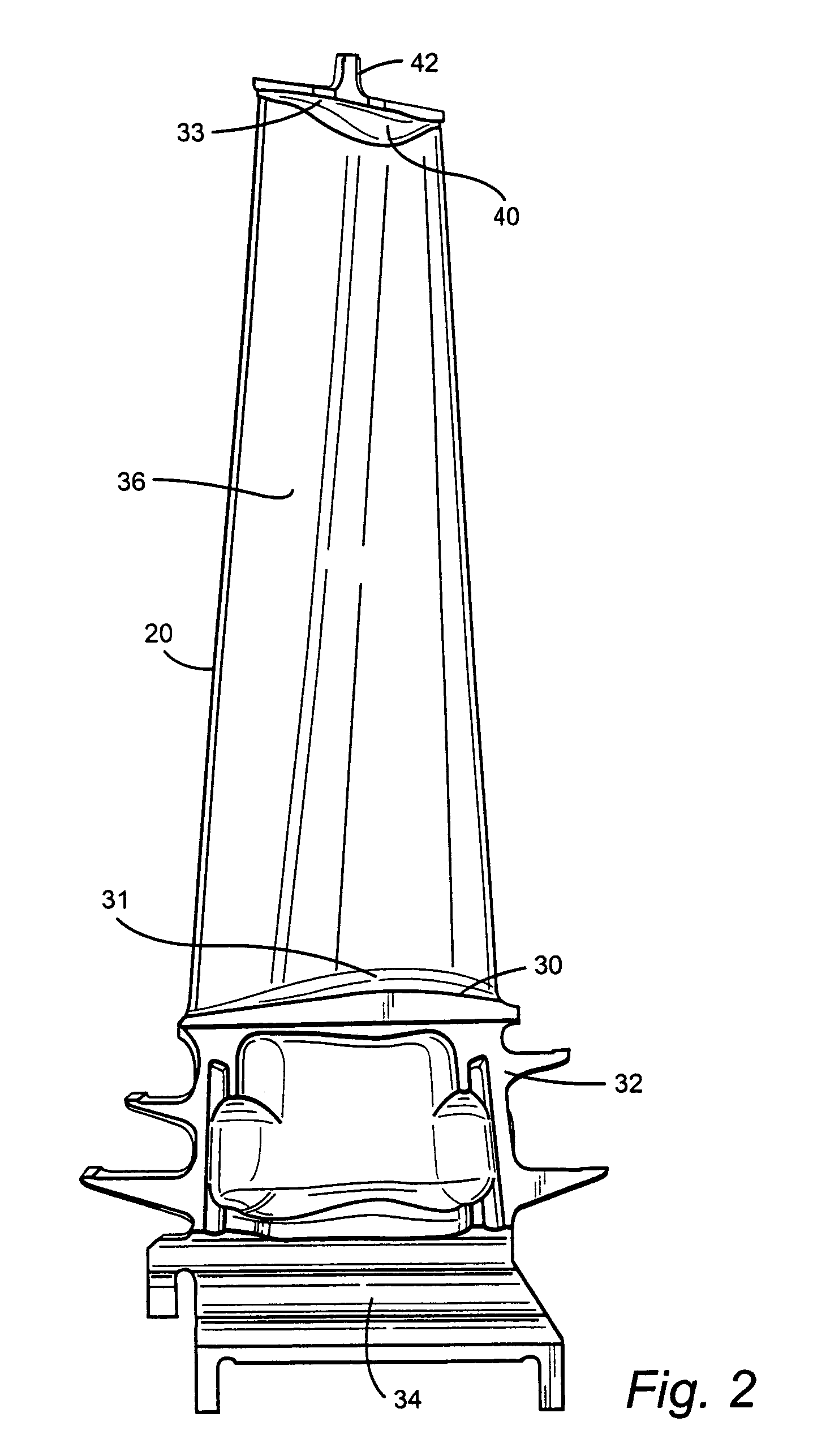

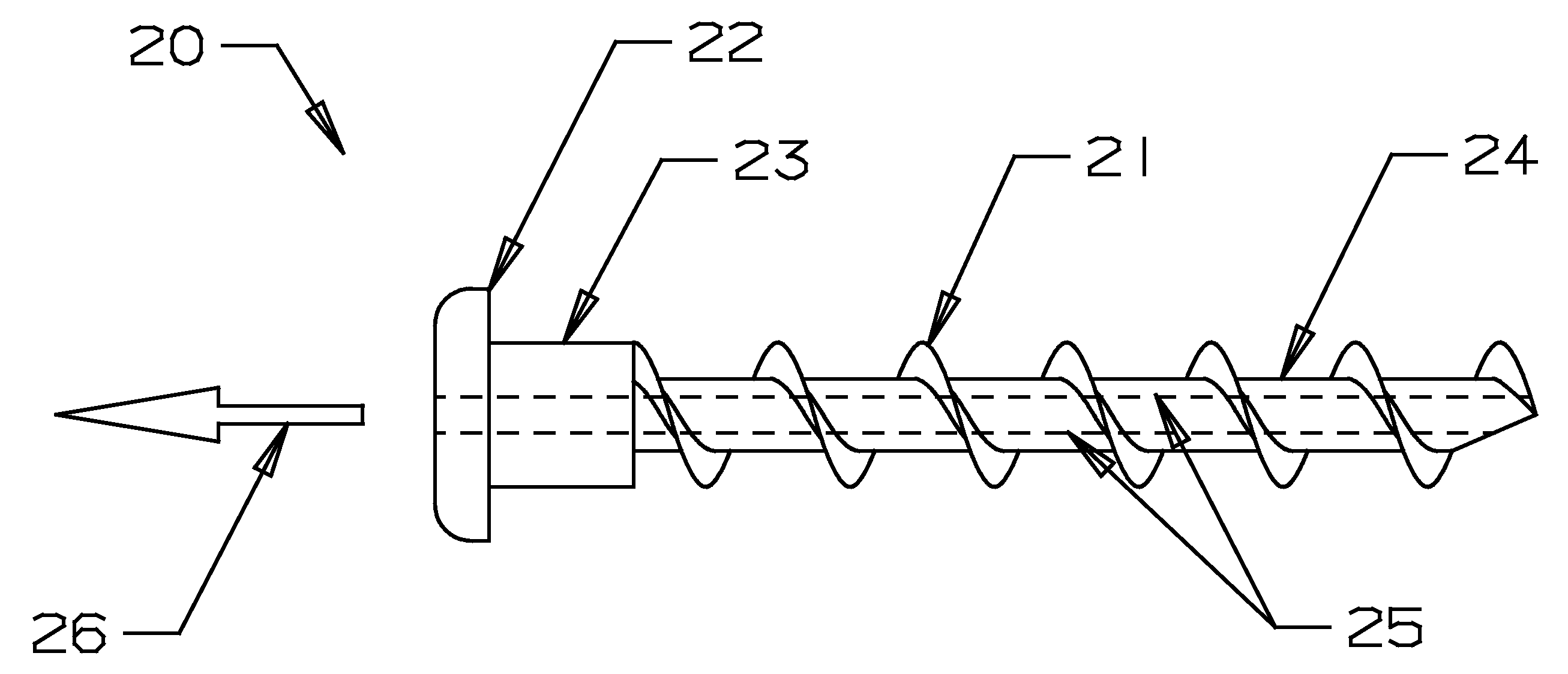

Conical tip shroud fillet for a turbine bucket

ActiveUS20050106025A1Minimizes creepMinimizes massPropellersEngine manufactureTurbine bladeEngineering

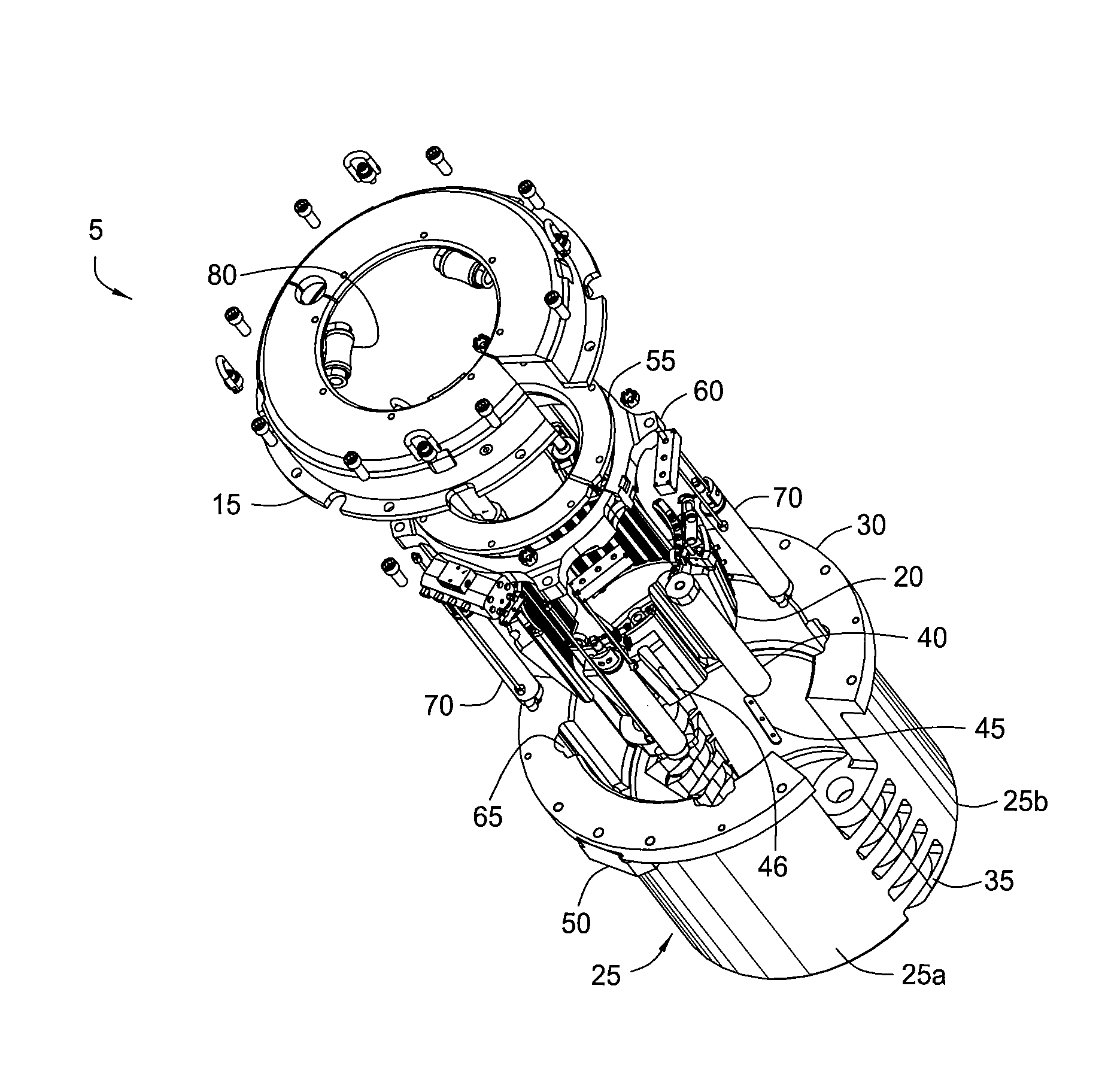

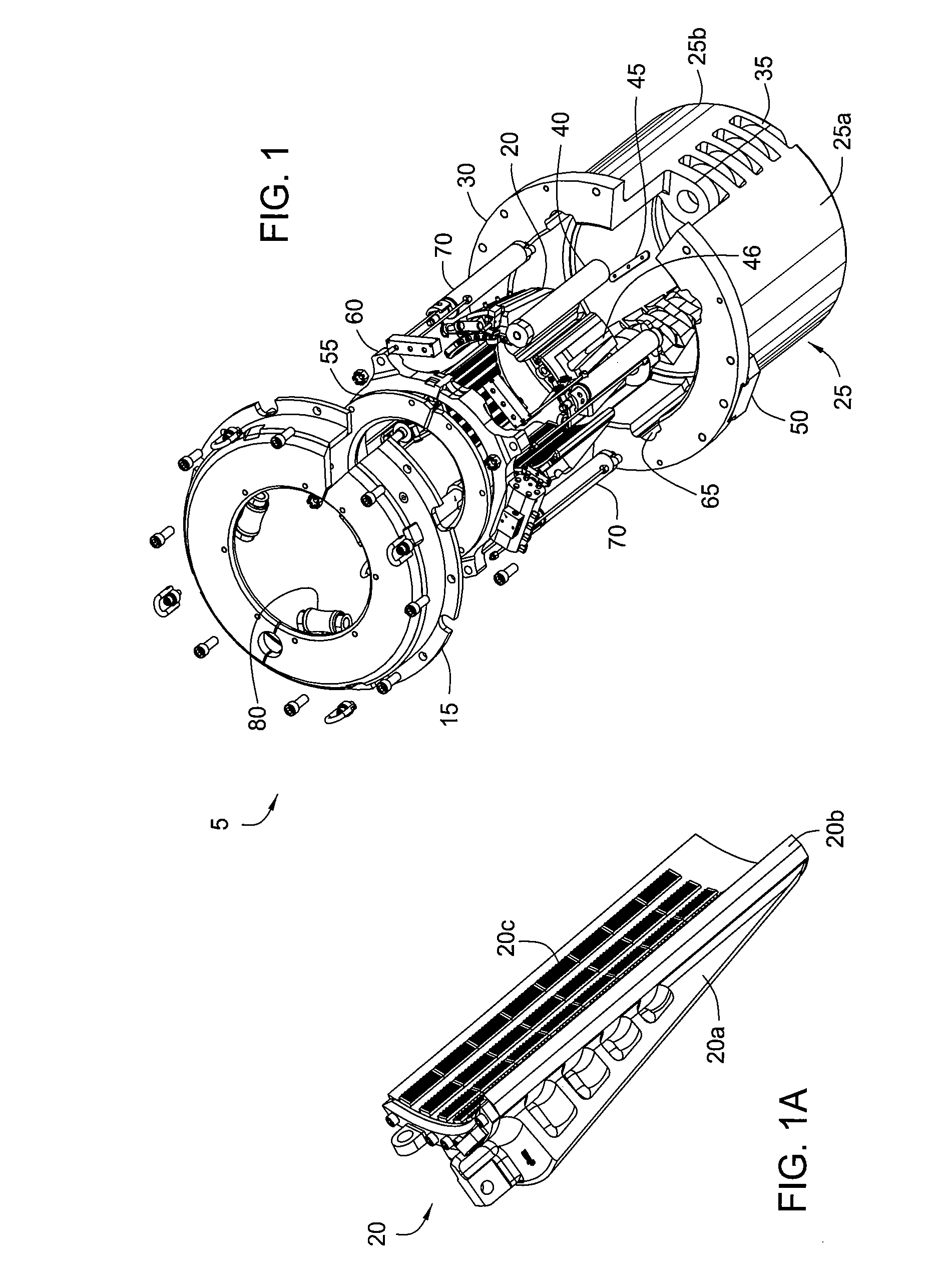

A turbine bucket airfoil has a conical fillet about the intersection of the airfoil tip and tip shroud having a nominal profile in accordance with coordinate values of X and Y, offset 1, offset 2 and Rho set forth in Table I. The shape parameters of offset 1, offset 2 and Rho define the configuration of the fillet at the specified X and Y locations about the fillet to provide a fillet configuration accommodating high localized stresses. The fillet shape may be parabolic, elliptical or hyperbolic as a function of the value of the shape parameter ratio of D1D1+D2at each X, Y location where D1 is a distance between an intermediate point along a chord between edge points determined by offsets O1 and O2 and a shoulder point on the fillet surface and D2 is a distance between the shoulder point and an apex location at the intersection of the airfoil tip and tip shroud.

Owner:GENERAL ELECTRIC CO

Low noise oximetry cable

ActiveUS11389093B2Improved and flexible and durable overall constructionReduce noiseDiagnostic recording/measuringSensorsLow noisePhysical medicine and rehabilitation

The present disclosure includes a cable for a patient monitoring system. The cable can have a flexible and durable overall construction that enables the cable to withstand repeated winding and unwinding and prevent kinks from developing. The cable may include multiple bundles encased in inner jackets that reduce the amount of friction against other cable elements and allows the bundle to move more freely inside an outer jacket of the cable. The multiple bundles may include multiple wires or cords. The cable can include a flexible core that runs through the middle of the cable. The multiple bundles can be twisted, weaved, or untwisted around the core.

Owner:MASIMO CORP

Conical tip shroud fillet for a turbine bucket

InactiveUS6857853B1Minimizes creep and massStress smoothPropellersEngine manufactureEngineeringTurbine

Owner:GENERAL ELECTRIC CO

Conical tip shroud fillet for a turbine bucket

ActiveUS7063509B2Minimizes creep and massStress smoothPropellersEngine manufactureEllipseTurbine blade

A turbine bucket airfoil has a conical fillet about the intersection of the airfoil tip and tip shroud having a nominal profile in accordance with coordinate values of X and Y, offset 1, offset 2 and Rho set forth in Table I. The shape parameters of offset 1, offset 2 and Rho define the configuration of the fillet at the specified X and Y locations about the fillet to provide a fillet configuration accommodating high localized stresses. The fillet shape may be parabolic, elliptical or hyperbolic as a function of the value of the shape parameter ratio of D1D1+D2at each X, Y location where D1 is a distance between an intermediate point along a chord between edge points determined by offsets O1 and O2 and a shoulder point on the fillet surface and D2 is a distance between the shoulder point and an apex location at the intersection of the airfoil tip and tip shroud.

Owner:GENERAL ELECTRIC CO

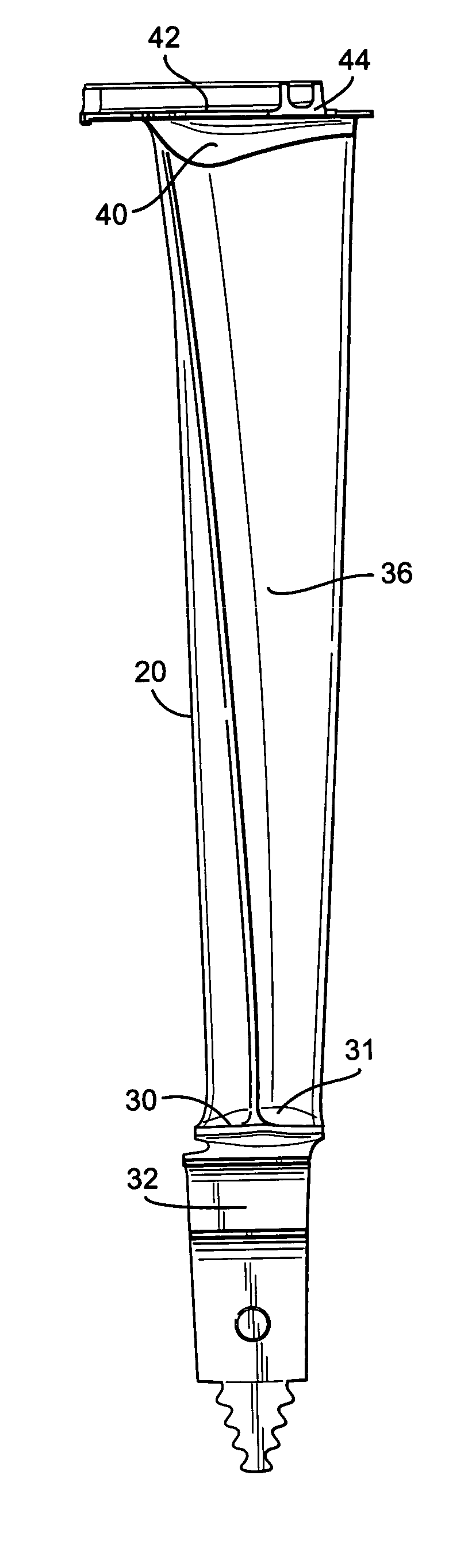

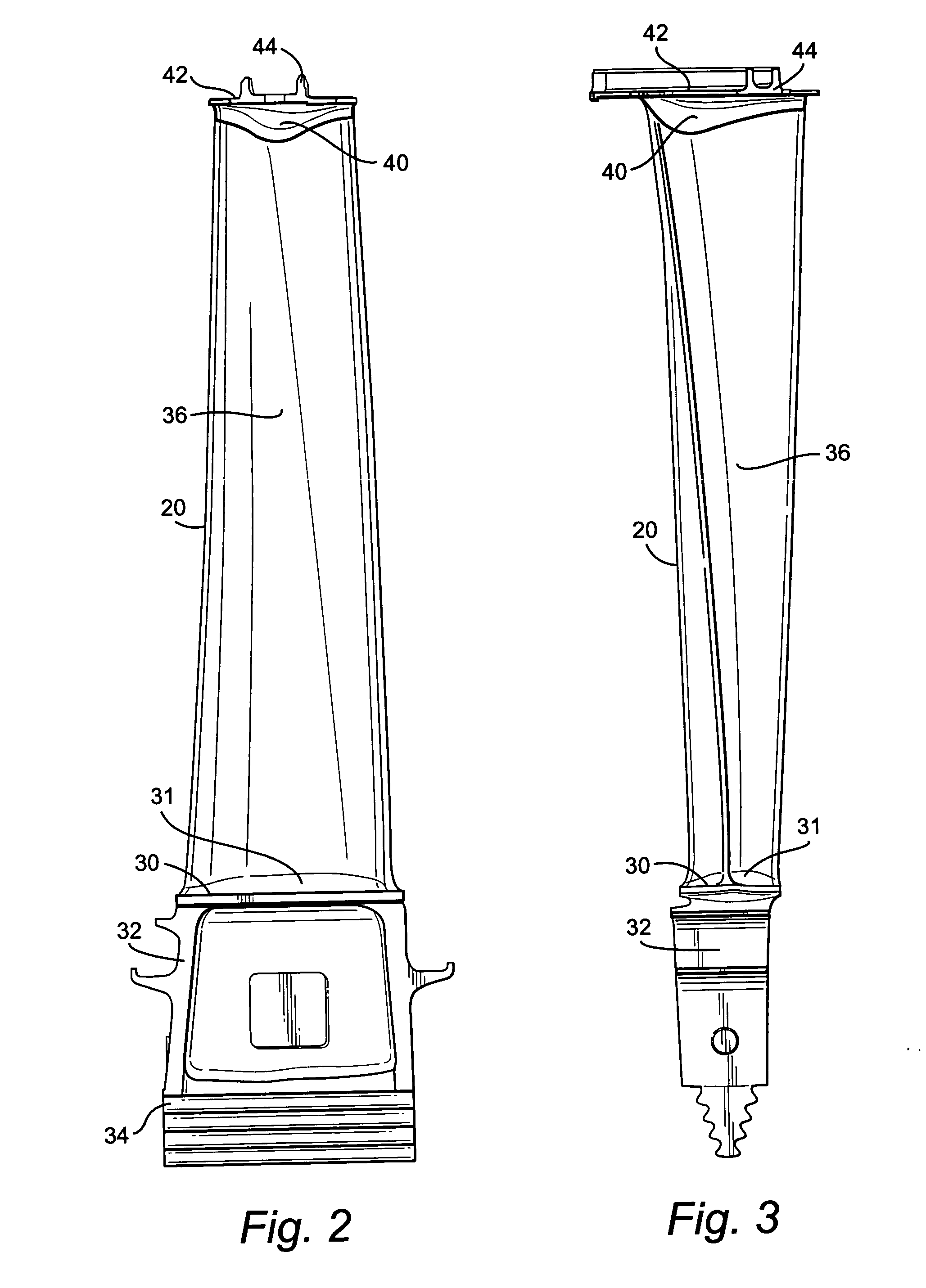

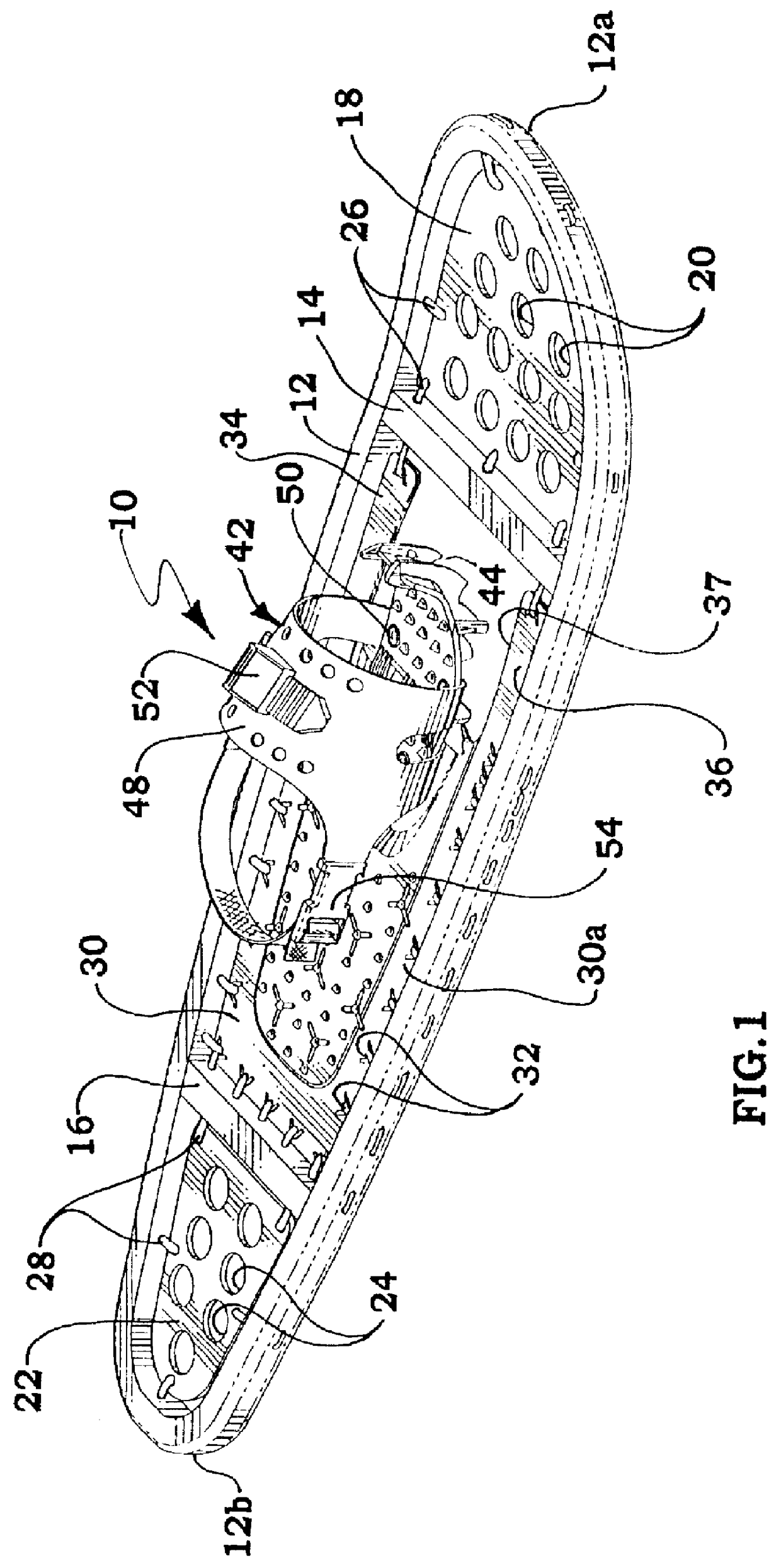

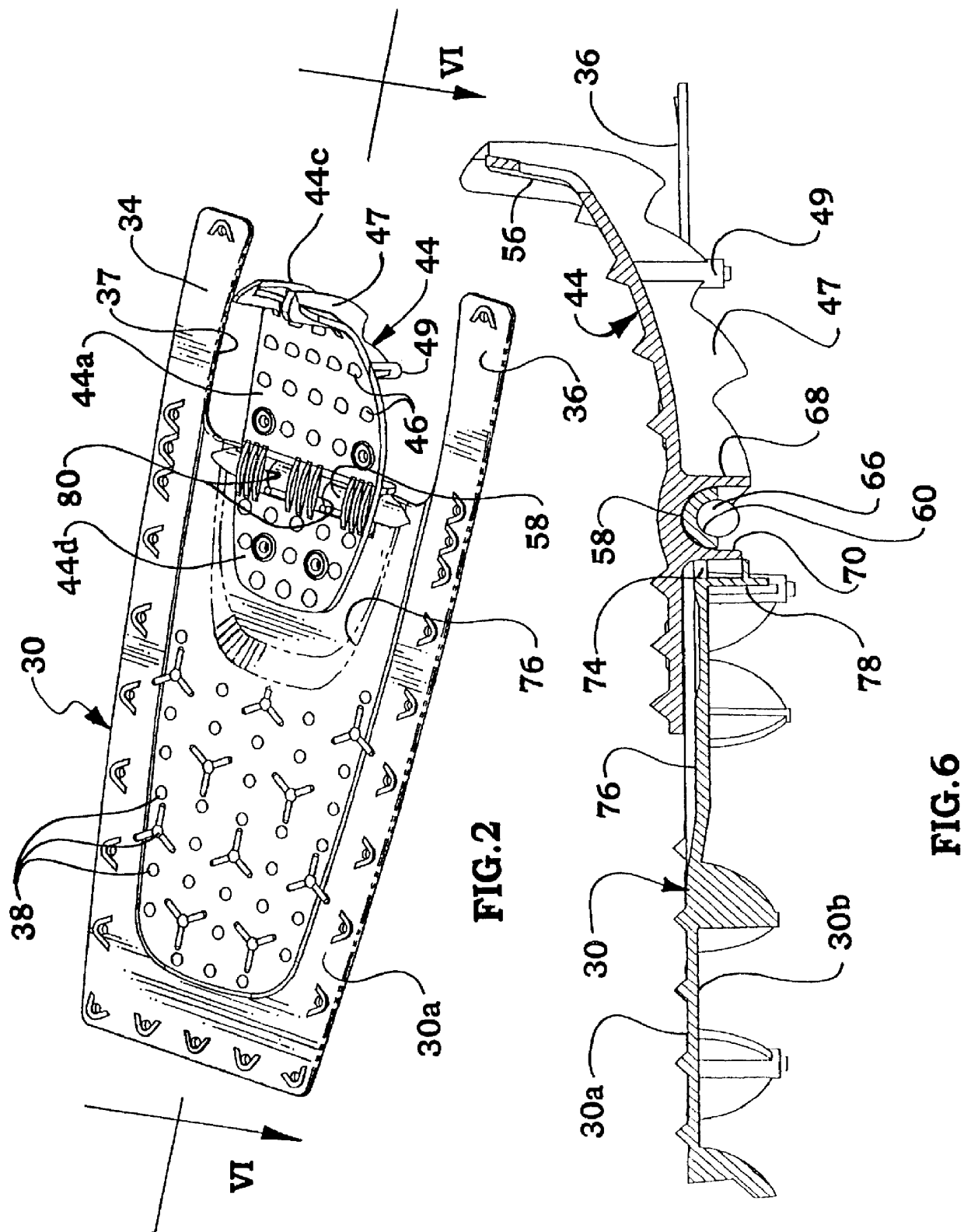

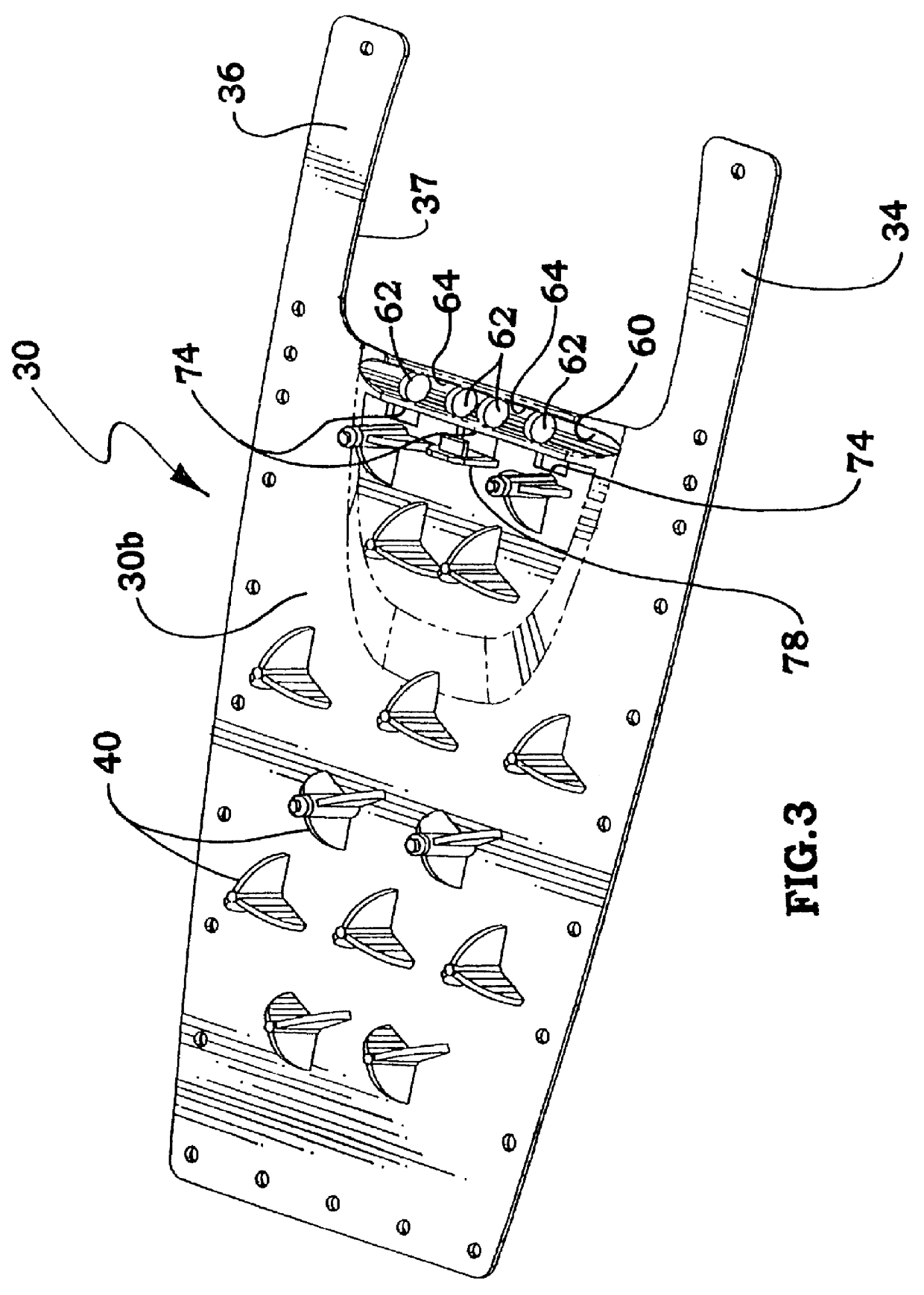

Snowshoe with pivotable harness hinged on a semi-rigid decking

InactiveUS6163984AEnhance gripping actionEasy constructionFootwearSnow shoesPlastic materialsClosed loop

The snowshoe includes a closed loop frame carrying an intermediate decking attached to the frame. The decking is made from a full sheet of semi-flexible plastic material, and is peripherally attached to the frame. A toe hole is provided at the front end portion of the decking. On its edge rearwardly adjacent to the toe hole, the decking forms an integral first hinge, in the form of an arcuate boss having an upwardly convex upper surface, and a downwardly concave lower surface. A harness is pivotally attached to the decking. The harness has a cradle plate made of semi-flexible plastic material, and a flexible strap attached thereto. The cradle has an upper surface for receiving the foot of the person wearing the snowshoe, and a lower surface which forms an integral second hinge, in the form of an arcuate seat and a pair of cylindrical lugs spacedly adjacent to the arcuate seat. The cradle second hinge is releasably engaged in the decking first hinge, the decking arcuate boss being slidingly engaged between the cradle lugs and the cradle seat, so that the decking supports the cradle.

Owner:FABER GUY +1

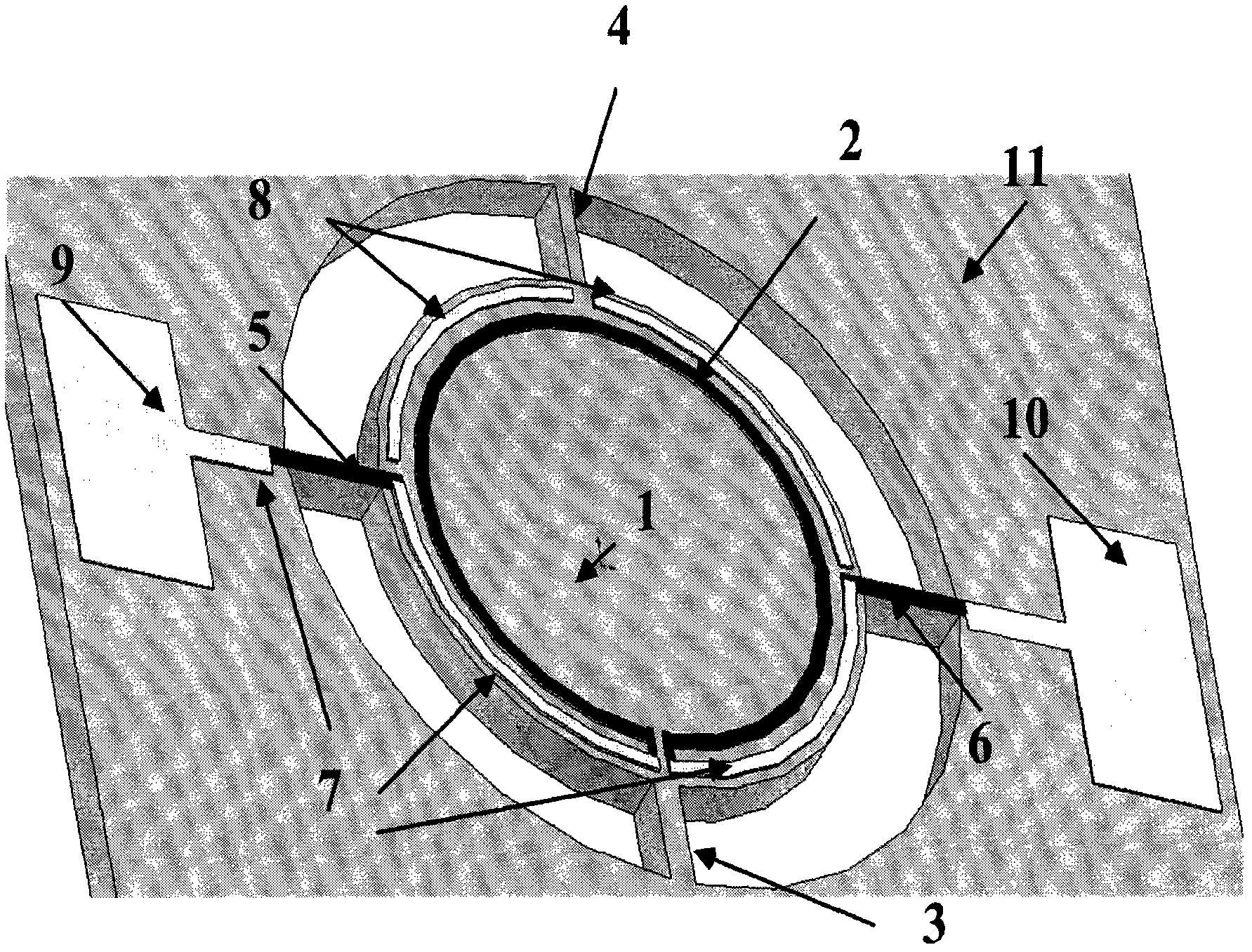

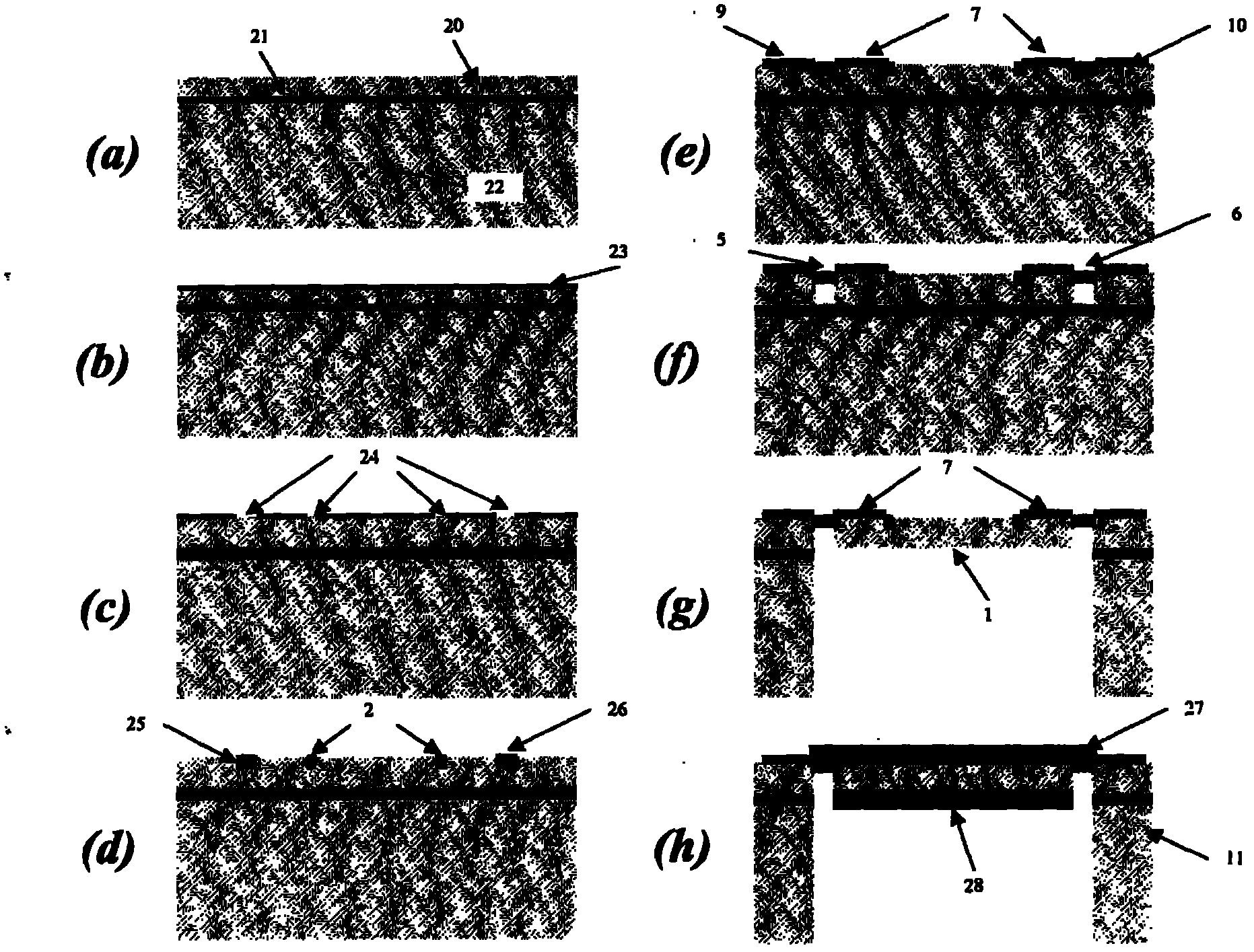

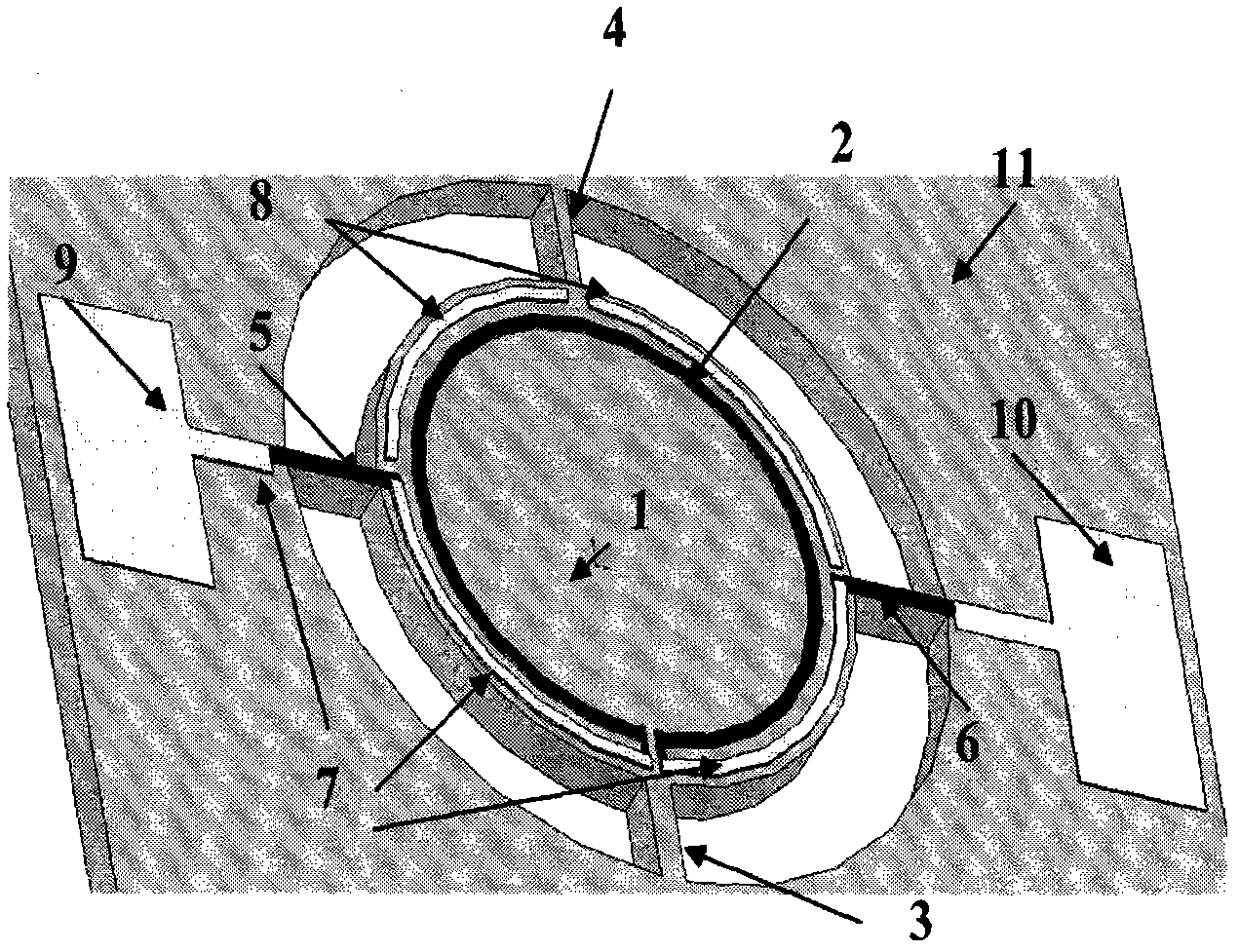

Silicone tunable optical filter and making method thereof

The invention provides a silicone tunable optical filter, comprising a silicone tuning cavity, a highly-doped silicone resistance heater, a lower cantilever beam, an upper cantilever beam, a left surface highly-doped cantilever beam, a right highly surface doped cantilever beam, a metal lead, a stress balancing metal lead, a left lead region, a right lead region and an SOI (Silicon-on-Insulator) supporting silicon substrate 11. The silicone tunable optical filter is obtained by using an SOI wafer with high resistance and a silicone machining process. A making method provided by the invention comprises the following steps of: (a) making a highly doped region on the surface of an SOI wafer device layer; (b) sputtering metal on the surface of the wafer device layer and making a metal structure; (c) making the silicone tuning cavity and each cantilever beam structure on the surface of the wafer device layer; (d) releasing the silicone tuning cavity and the cantilever beam structure from asubstrate layer of the lower surface of the silicon wafer; and (e) making high reflective films on the upper and lower surfaces of the silicone tuning cavity to form an optical F-P interference cavity body. The made filter has the advantages of very good optical performance, simple making process and high structural reliability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Conical tip shroud fillet for a turbine bucket

A turbine bucket airfoil has a conical fillet about the intersection of the airfoil tip and tip shroud having a nominal profile in accordance with coordinate values of X and Y, offset 1, offset 2 and Rho set forth in Table I. The shape parameters of offset 1, offset 2 and Rho define the configuration of the fillet at the specified X and Y locations about the fillet to provide a fillet configuration accommodating high localized stresses. The fillet shape may be parabolic, elliptical or hyperbolic as a function of the value of the shape parameter ratio of D1D1+D2at each X, Y location where D1 is a distance between an intermediate point along a chord between edge points determined by offsets O2 and O2 and a shoulder point on the fillet surface and D2 is a distance between the shoulder point and an apex location at the intersection of the airfoil tip and tip shroud.

Owner:GENERAL ELECTRIC CO

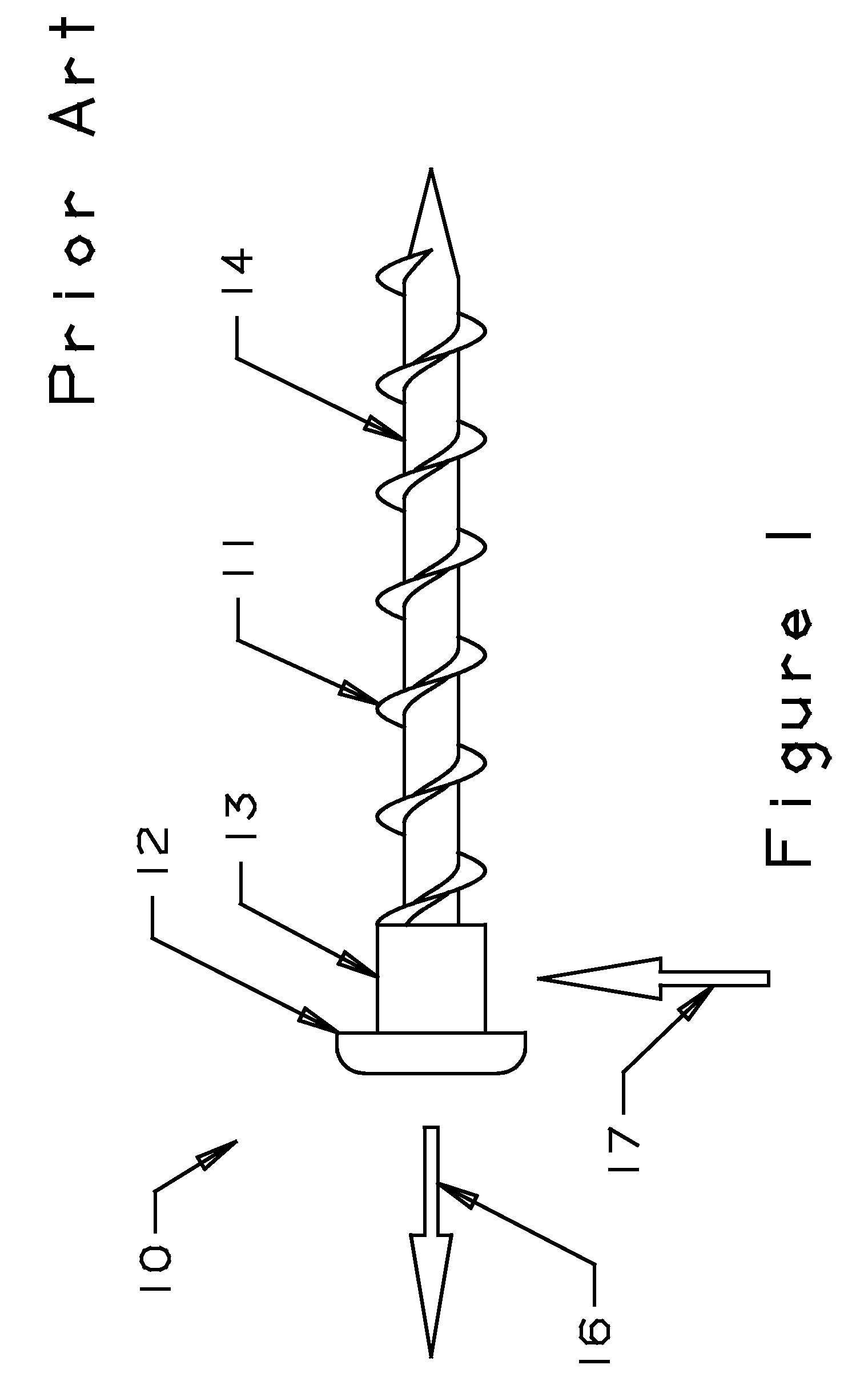

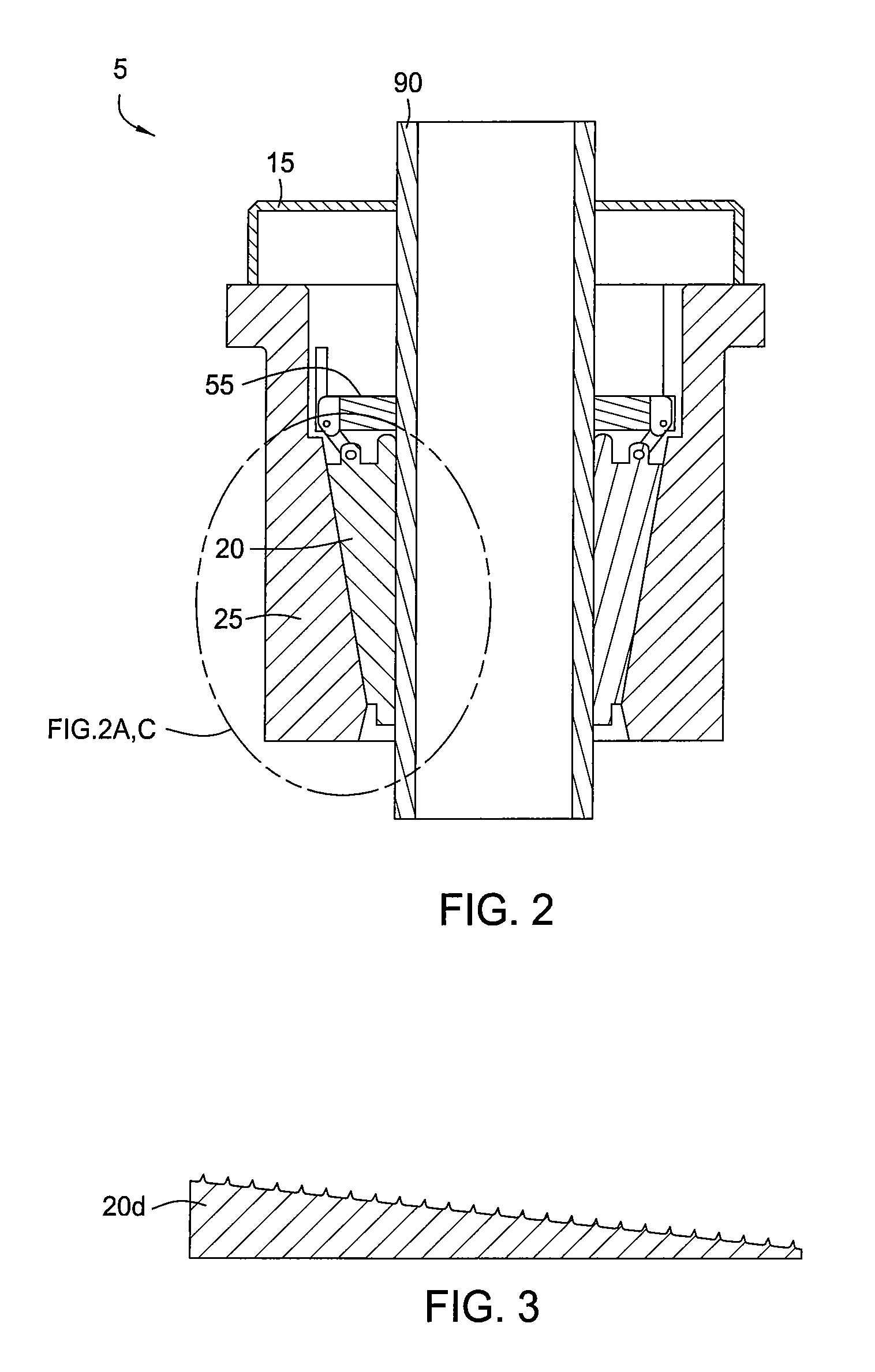

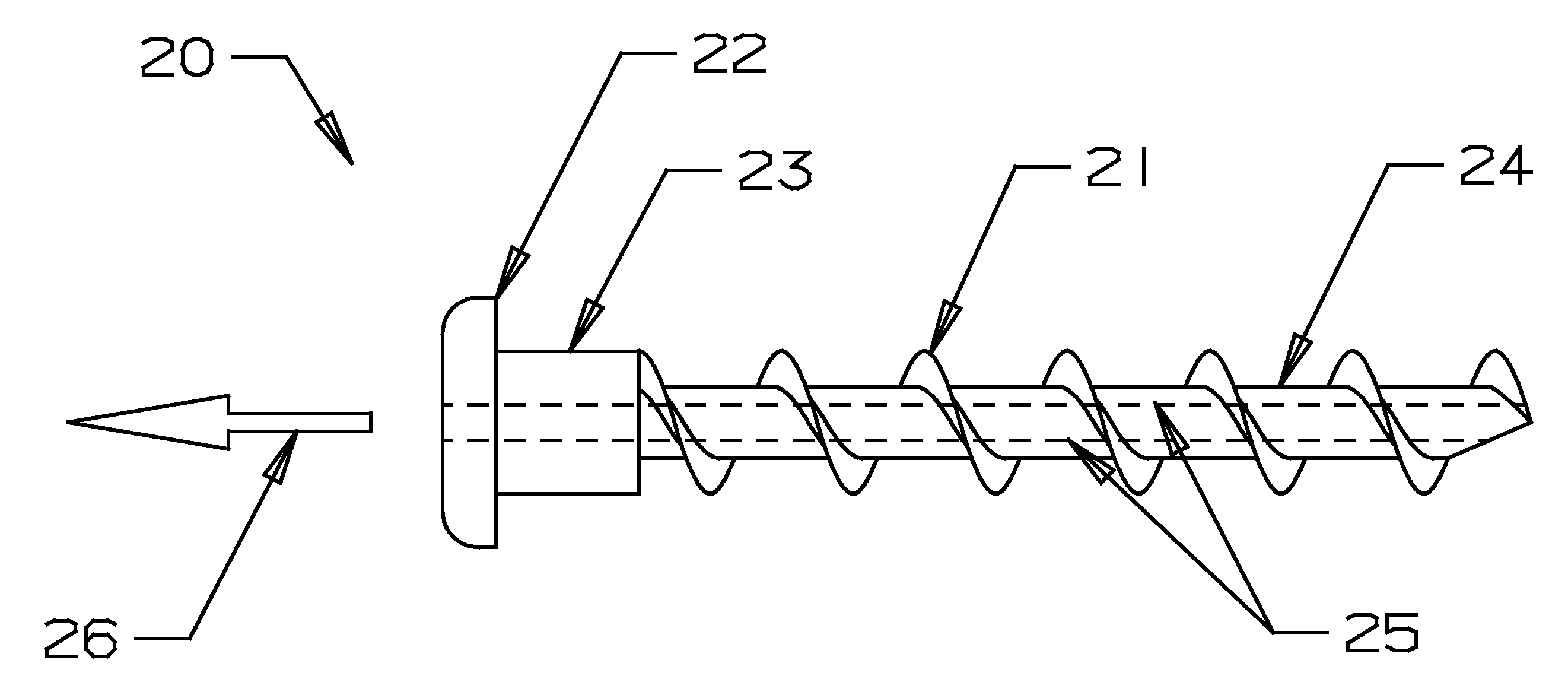

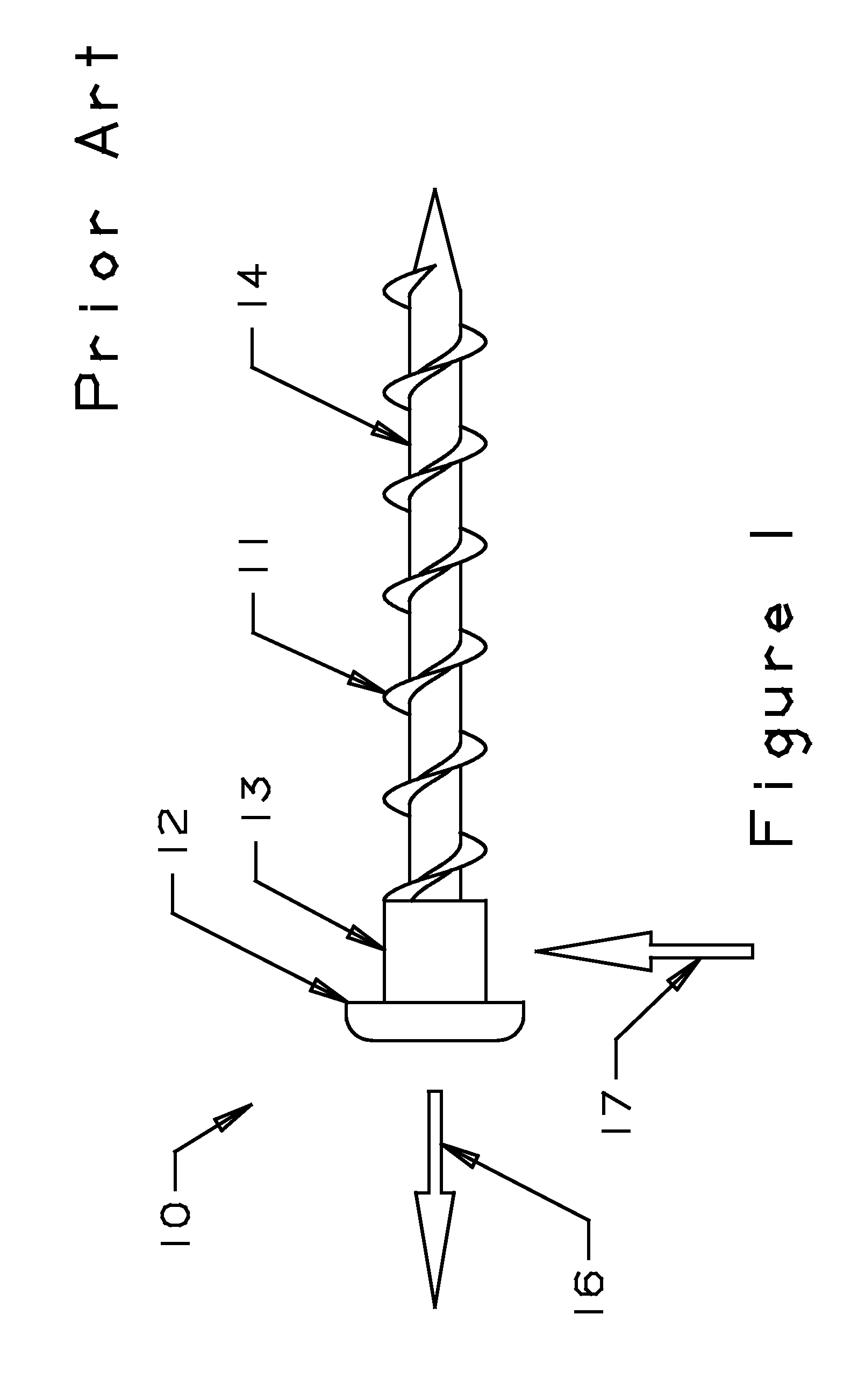

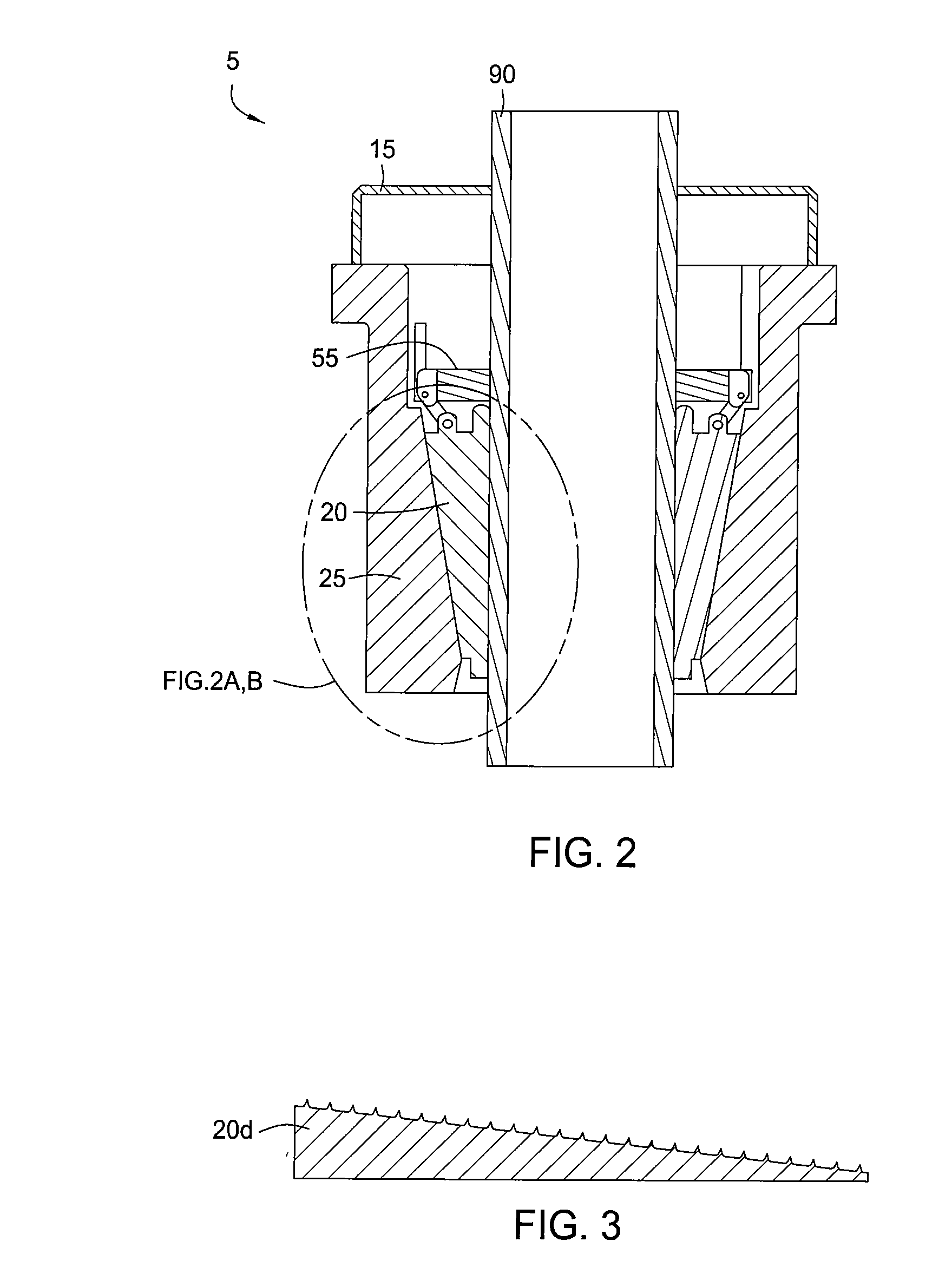

Bone screw for orthopedic apparatus

InactiveUS20090018592A1Uniform loadEvenly distribute stressSuture equipmentsBone implantOrthopedic apparatusIliac screw

A bone screw deforms on the same order as the bone, thus providing substantially uniform loading along an entire length of the thread of the bone screw. The bone screw of the present invention evenly distributes stress by matching the effective cross-sectional area of the bone screw times its modulus of elasticity with the effective cross-sectional area of the parent material (i.e. bone) times its modulus of elasticity so that they are preferably substantially equal to each other.

Owner:PITBLADDO RICHARD B

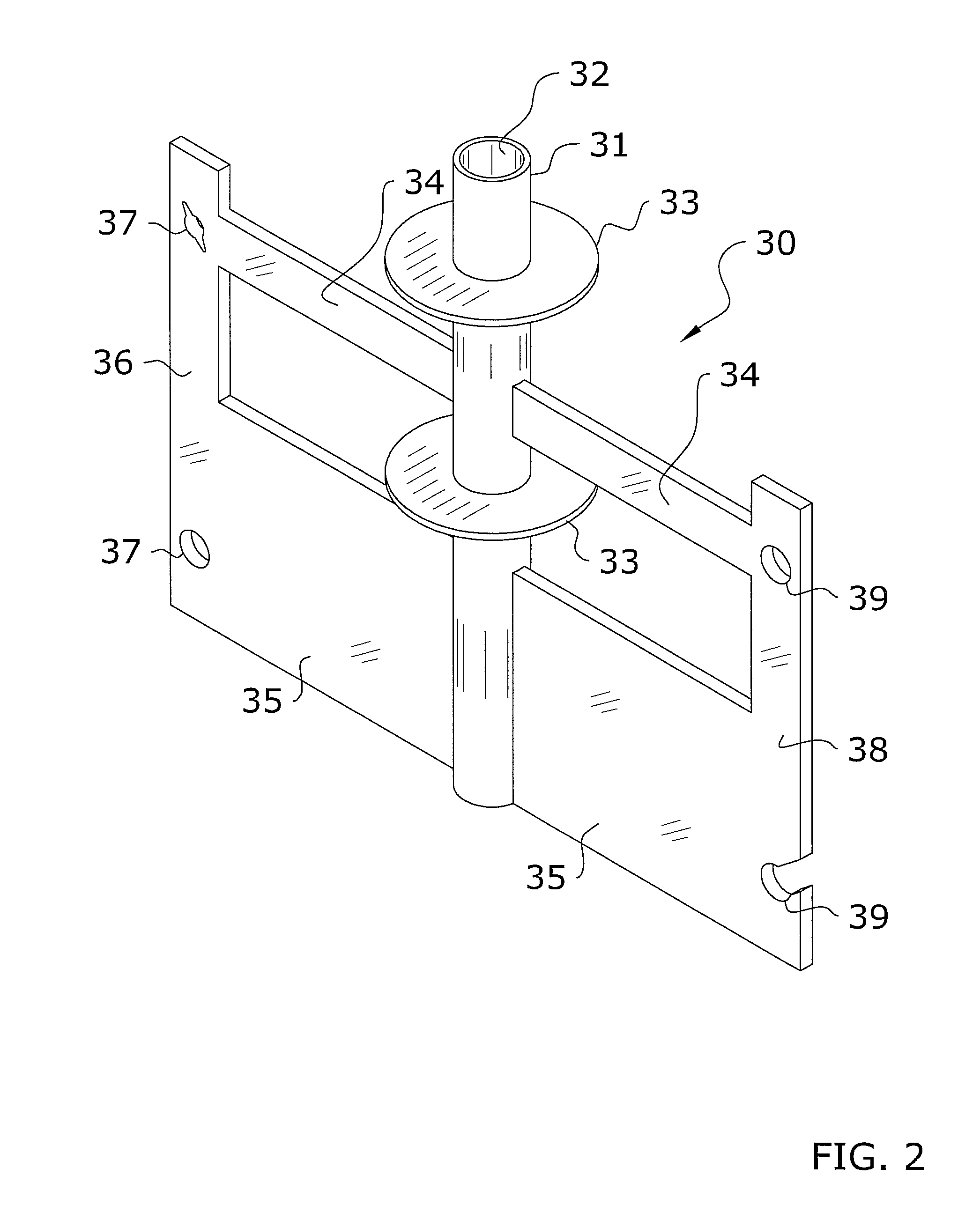

Equalized load distribution slips for spider and elevator

Owner:WEATHERFORD TECH HLDG LLC

Methods to reduce polarization dependent loss in planar lightwave circuits

InactiveUS20080279497A1Reducing polarization dependent lossReduce polarizationCoupling light guidesOptical waveguide light guideOptical axisWaveguide

Polarization dependent loss may be reduced by providing at least one dummy waveguide or at least one dummy metal structure. Polarization dependent loss may also be reduced by imposing a mechanical force on the OIC to exert mechanical stress thereby changing at least one of the birefringence and the optical axes of at least one waveguide. And polarization dependent loss may be reduced by forming a metal heater using a first set of metal deposition parameters; forming a conductive metal structure contacting the metal heater using a second set of metal deposition parameters; and selecting the first set of metal deposition parameters and the second set of metal deposition parameters to reduce stress.

Owner:NEOPHOTONICS CORP

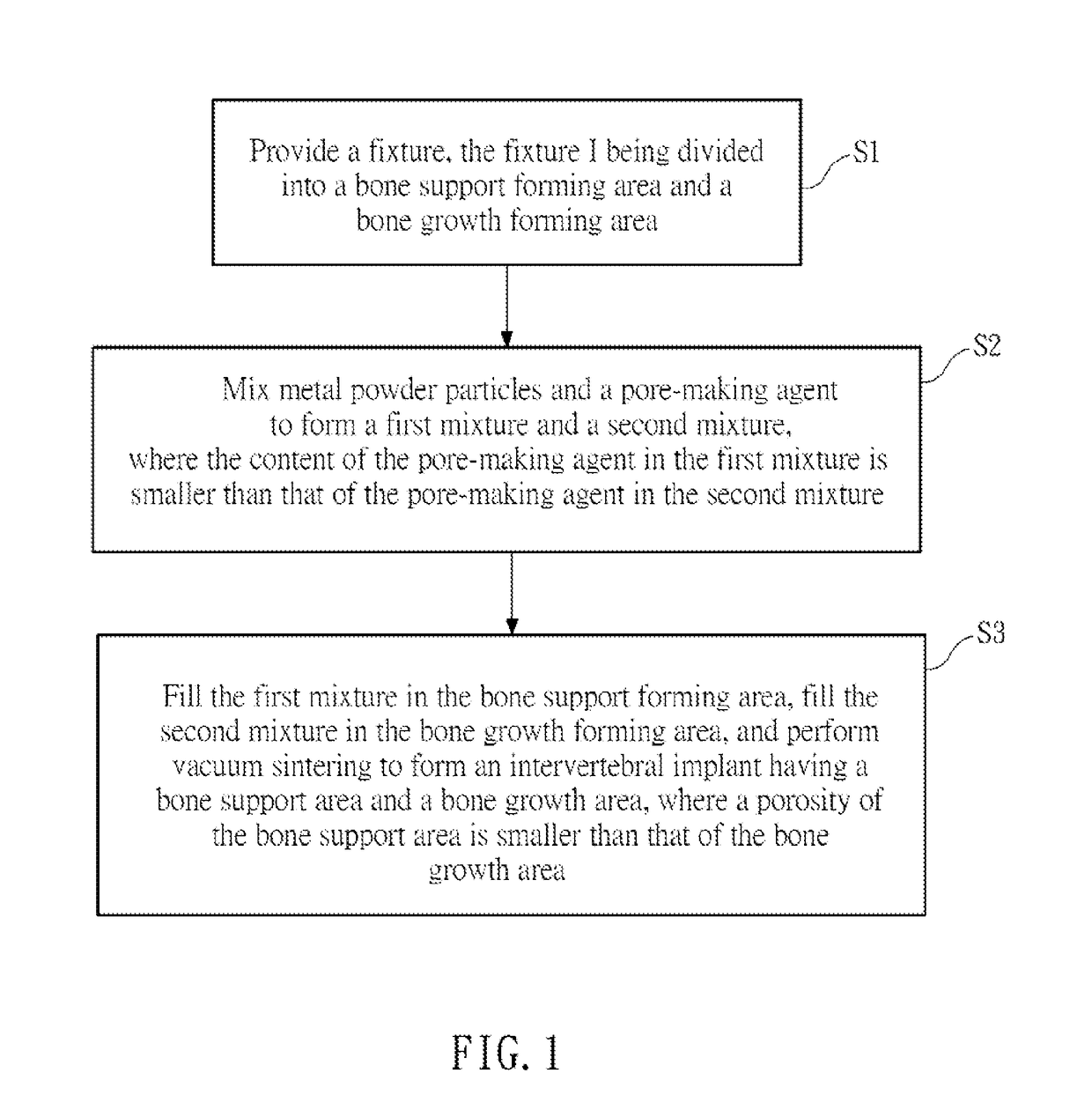

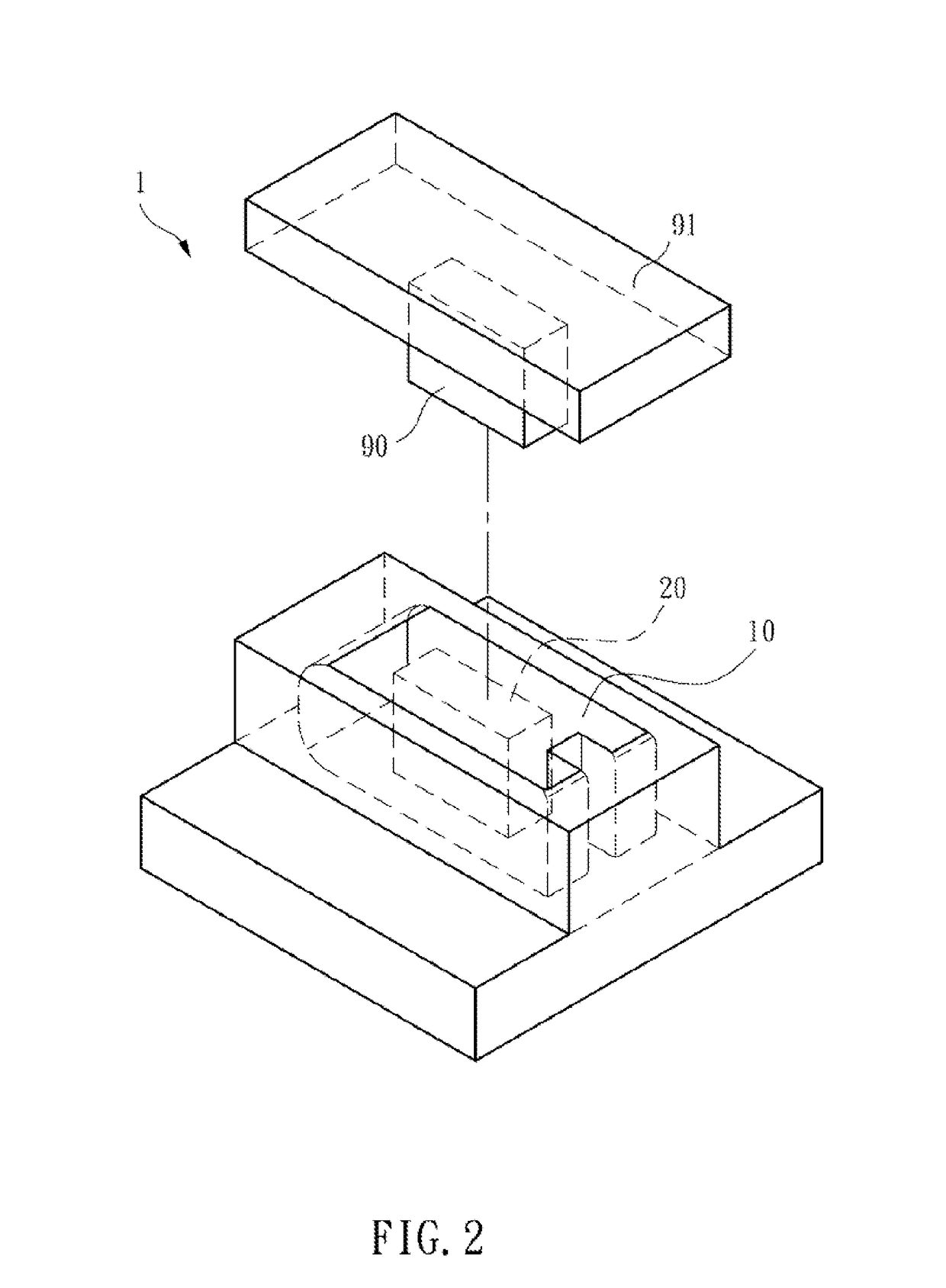

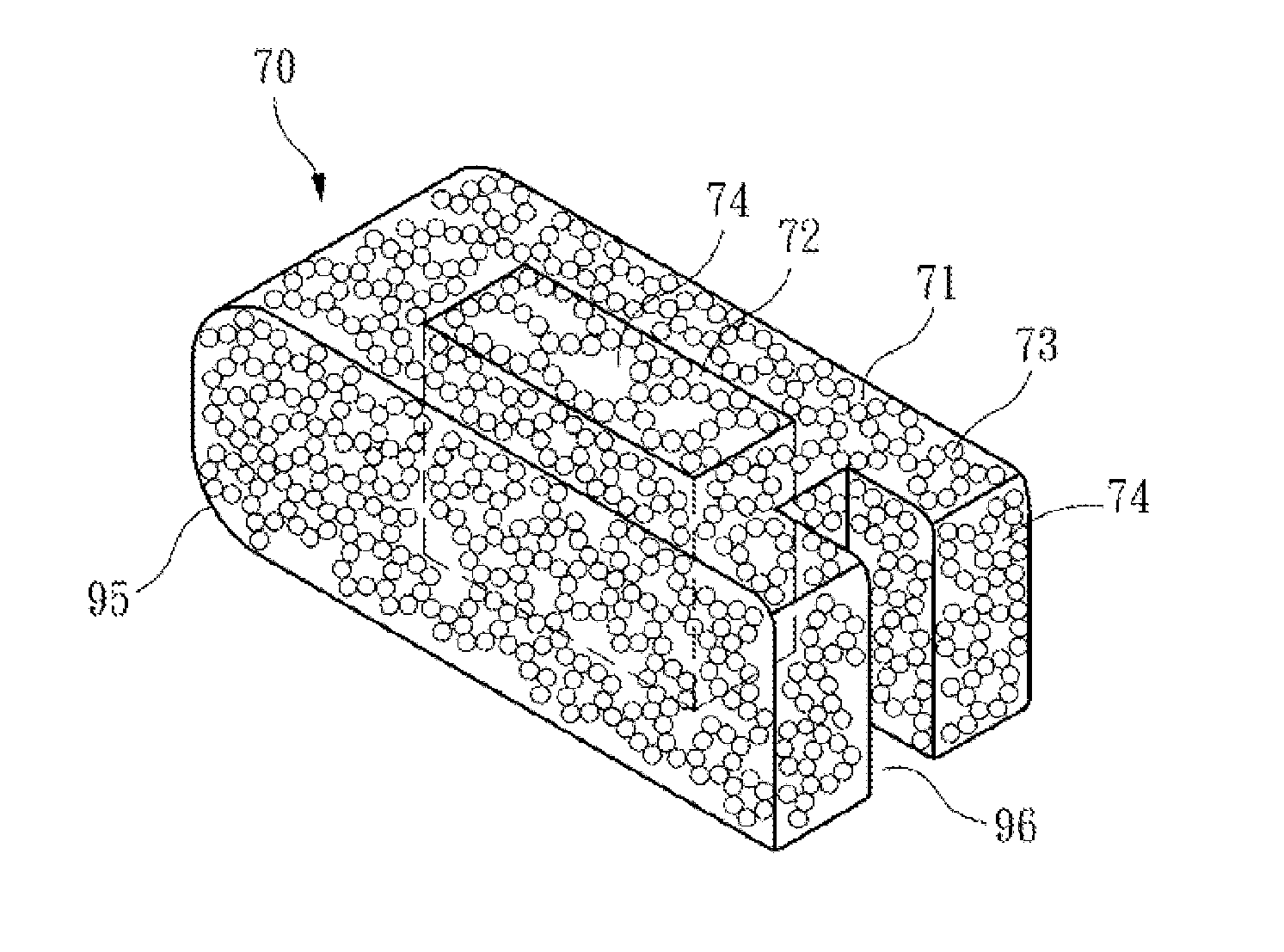

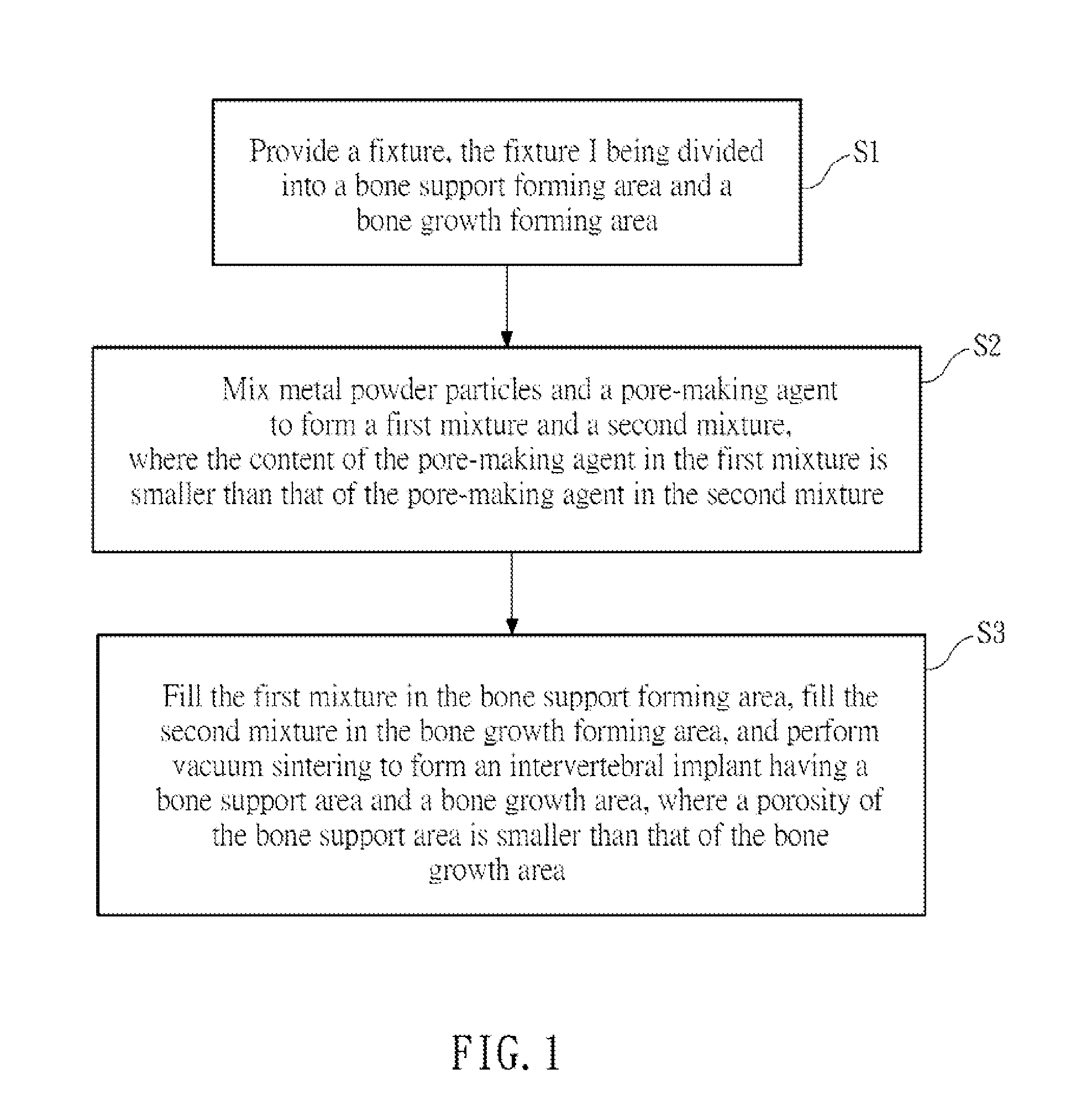

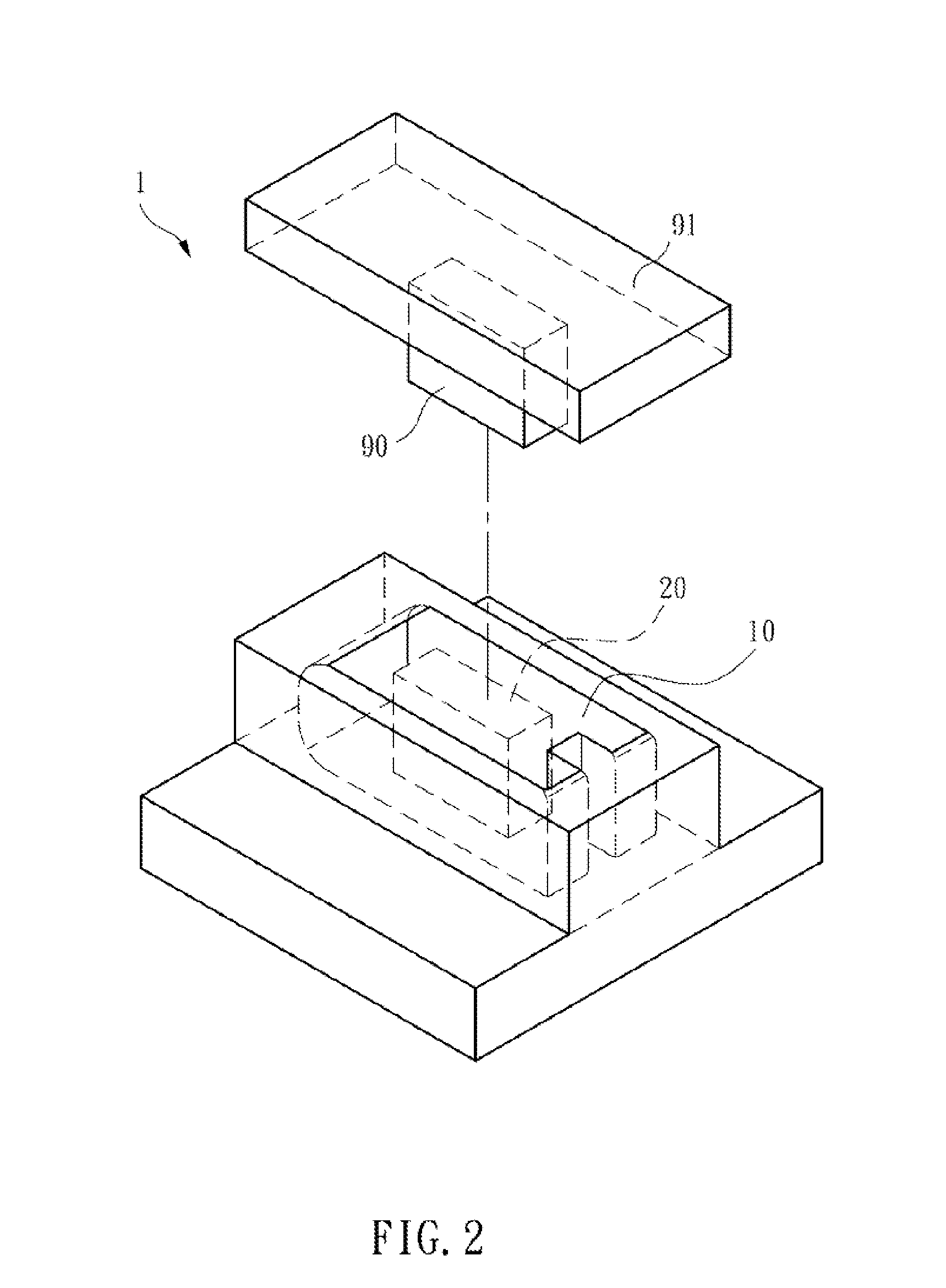

Intervertebral implant

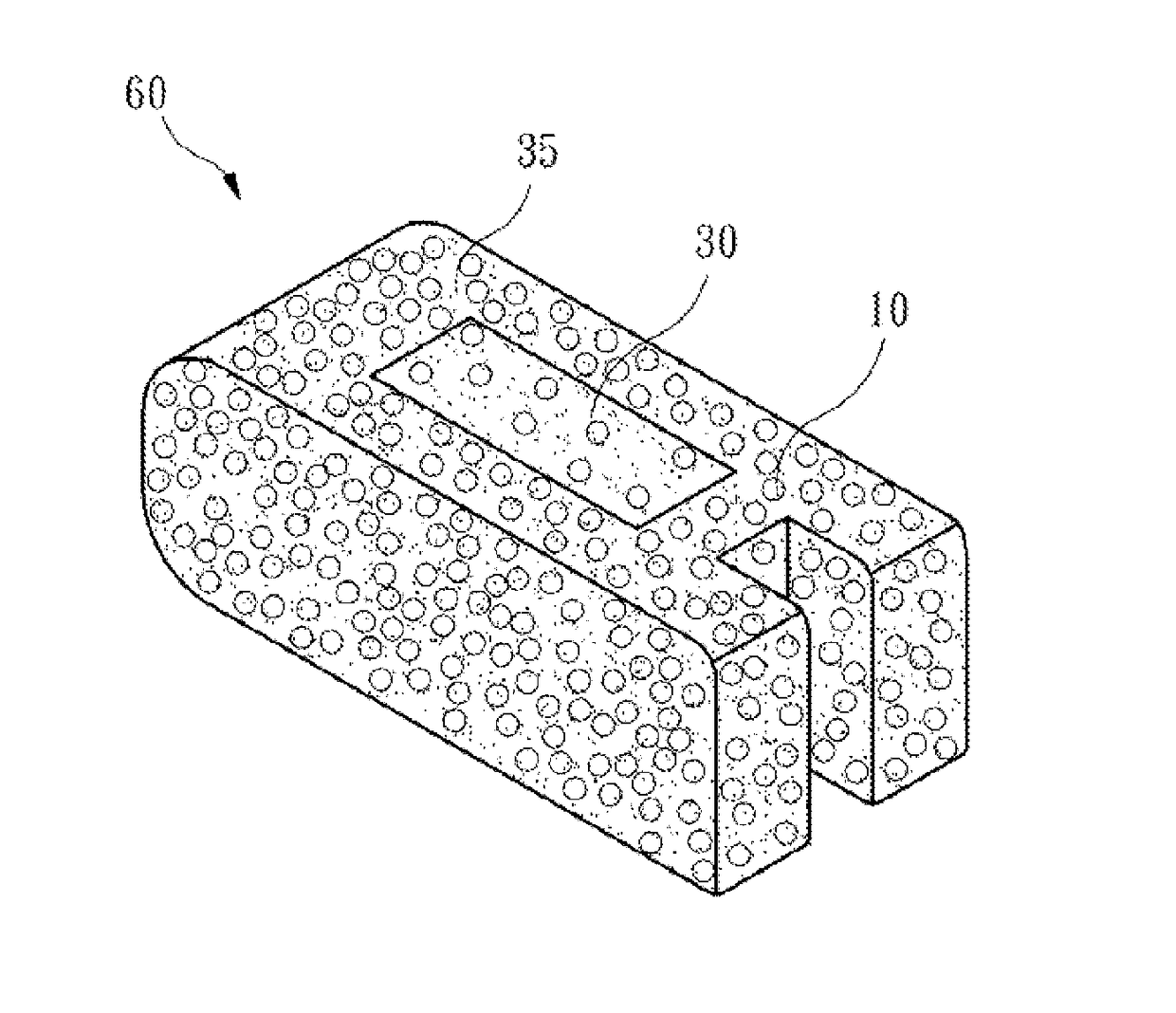

ActiveUS9610174B2Uniform particle sizeStress smoothJoint implantsSpinal implantsPorosityBiomedical engineering

An intervertebral implant is a porous structure formed of a plurality of metal balls, and the intervertebral implant includes a bone support area and a bone growth area. The bone support area and the bone growth area each have a plurality of connecting holes, and a porosity of the bone support area is smaller than that of the bone growth area.

Owner:METAL INDS RES & DEV CENT

Bone Screw For Orthopedic Apparatus

InactiveUS20120101534A1Uniform loadStress smoothSuture equipmentsDental implantsOrthopedic apparatusIliac screw

A bone screw deforms on the same order as the bone, thus providing substantially uniform loading along an entire length of the thread of the bone screw. The bone screw evenly distributes stress by matching the effective cross-sectional area of the bone screw times its modulus of elasticity with the effective cross-sectional area of the parent material (i.e. bone) times its modulus of elasticity so that so that the linear deformation of each is preferably substantially equal to the other.

Owner:PITBLADDO RICHARD B

Equalized load distribution slips for spider and elevator

InactiveUS20060254866A1Evenly distribute stressStress smoothBraking element arrangementsDrilling rodsLoad distributionMechanical engineering

Owner:WEATHERFORD TECH HLDG LLC

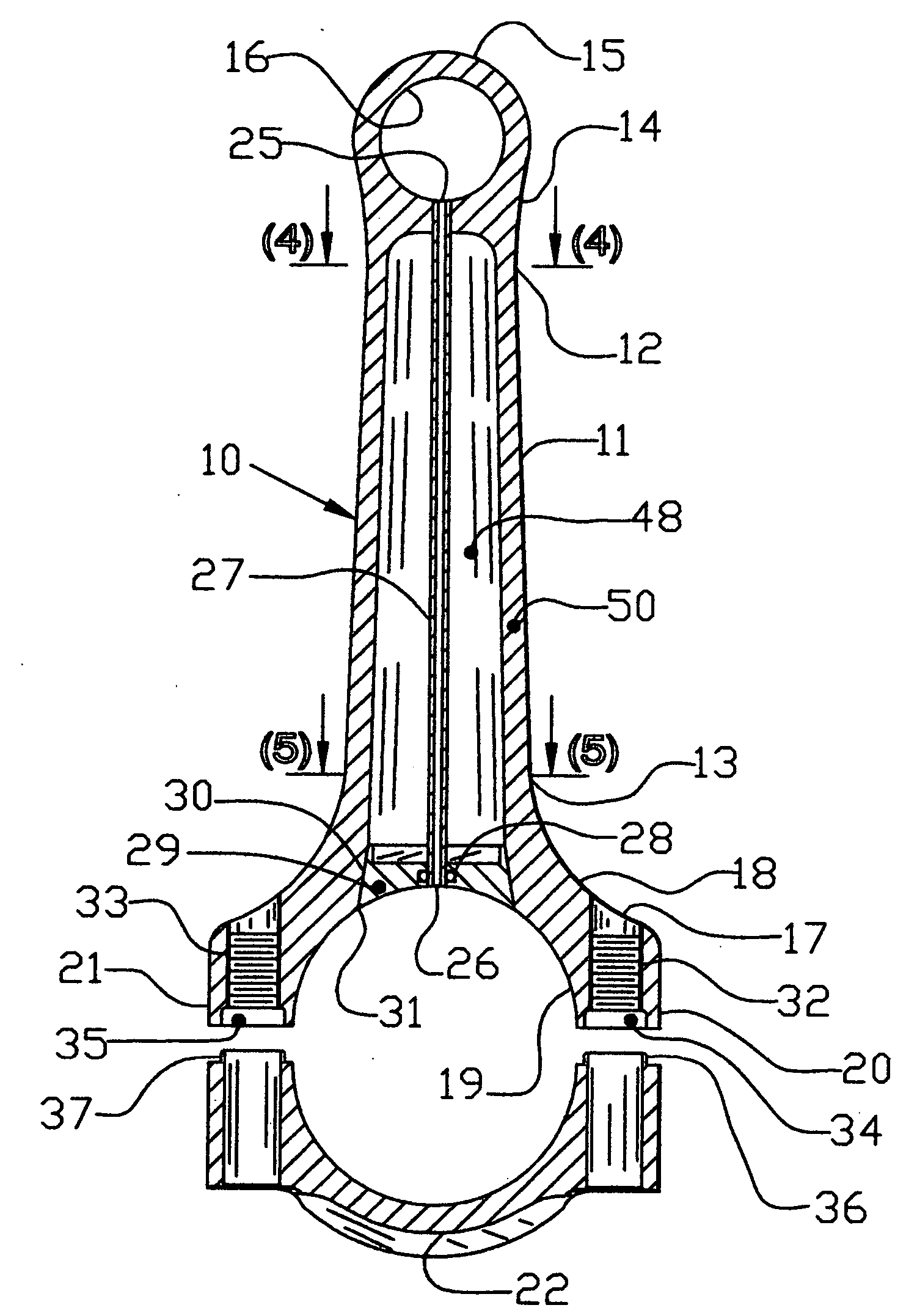

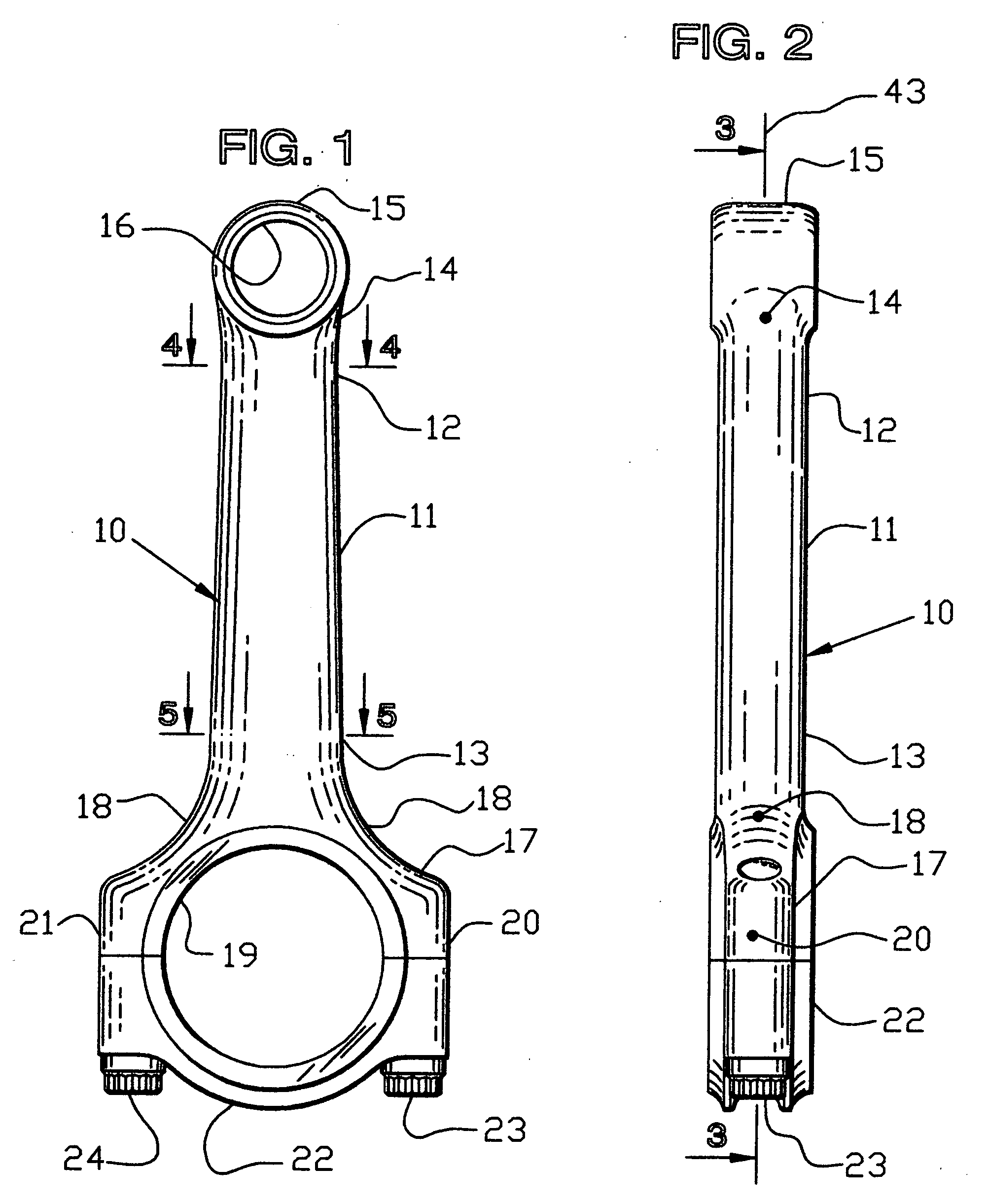

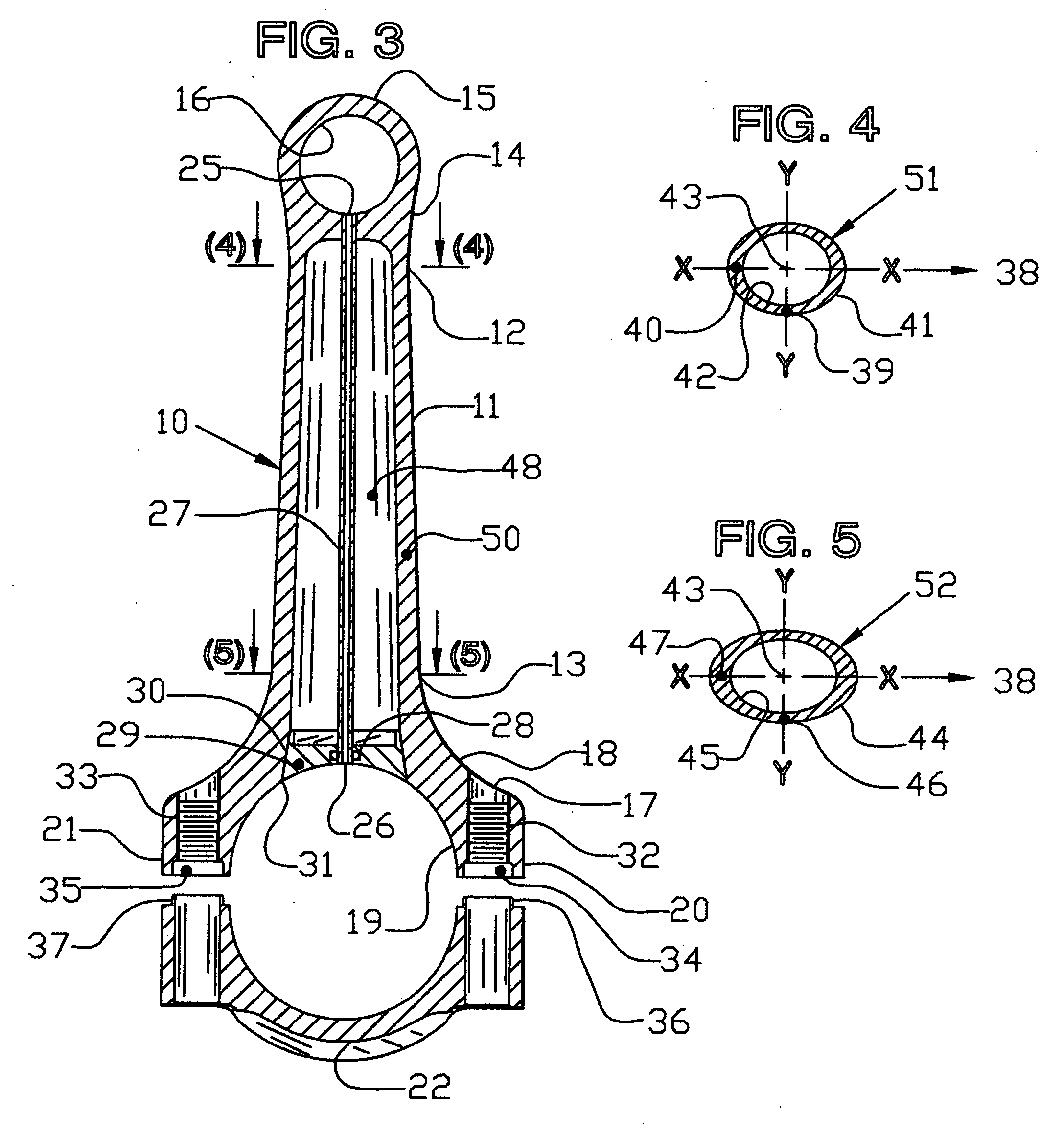

Engine connecting rod for high performance applications and method of manufacture

InactiveUS20050145060A1Reduce in quantitySimplifies and facilitates accurateControlling membersControlled membersStress levelReciprocating motion

An internal combustion engine connecting rod, having an embodiment defining a hollow beam member and a process of manufacture are disclosed. The improvement substantially reduces beam tensile and compressive stress levels through application of elliptical and oval beam sections, conserving reciprocating and rotating connecting rod weight required in high performance engine applications.

Owner:WEAVER ROBERT R

Intervertebral implant

ActiveUS20150150689A1Easy to integrateGood mechanical compatibilitySpinal implantsTissue regenerationPorosityBone growth

An intervertebral implant is a porous structure formed of a plurality of metal balls, and the intervertebral implant includes a bone support area and a bone growth area. The bone support area and the bone growth area each have a plurality of connecting holes, and a porosity of the bone support area is smaller than that of the bone growth area.

Owner:METAL INDS RES & DEV CENT

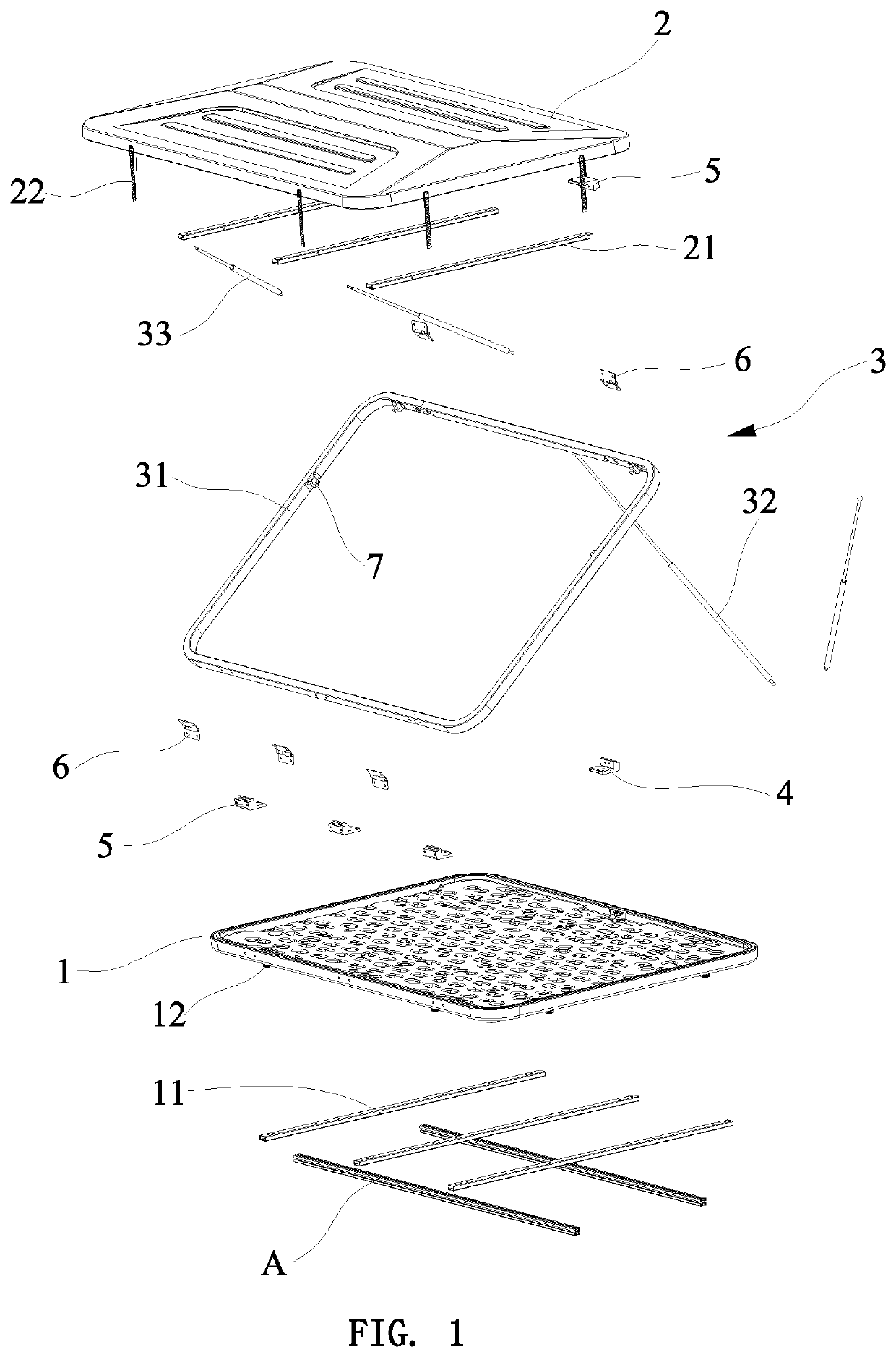

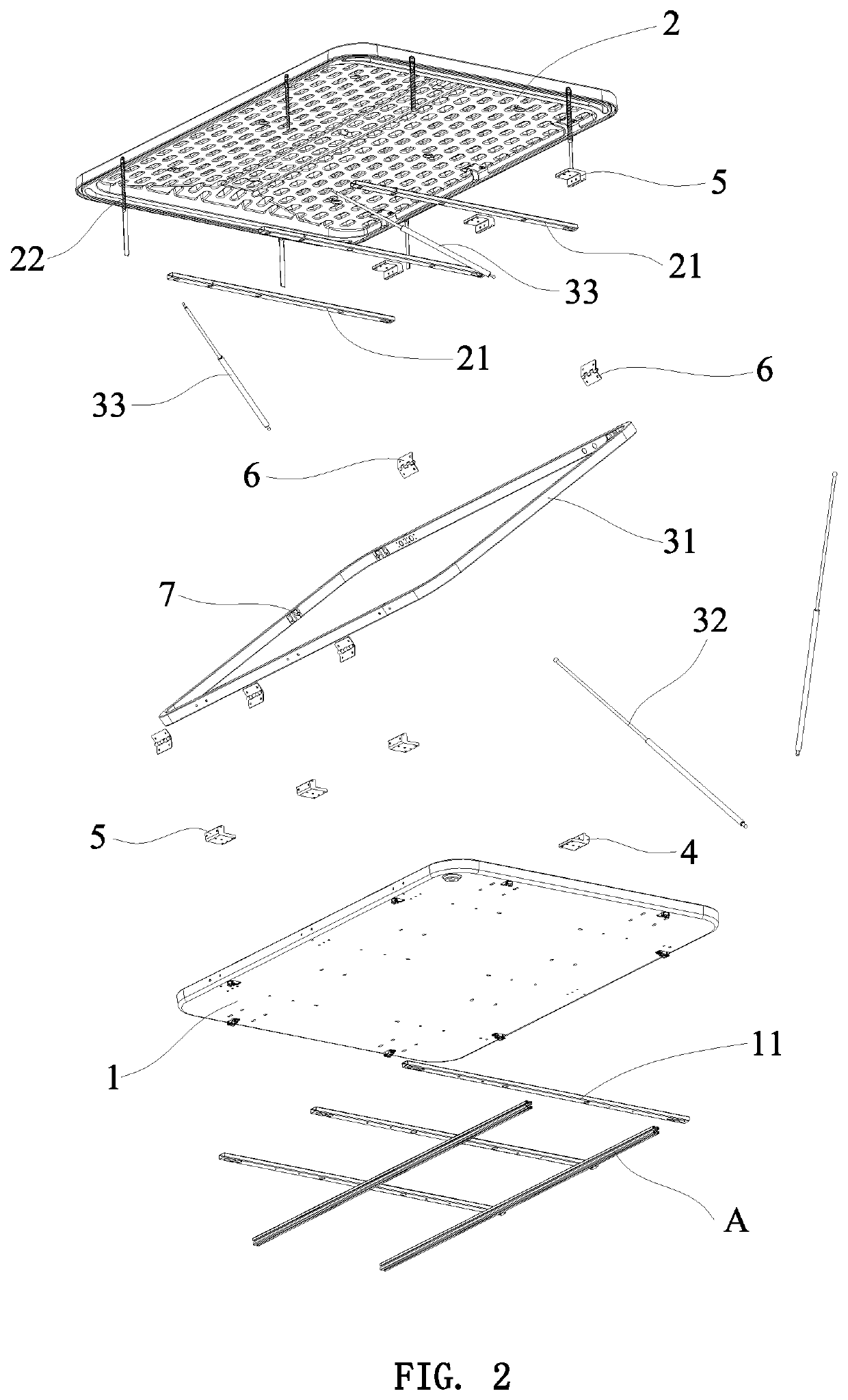

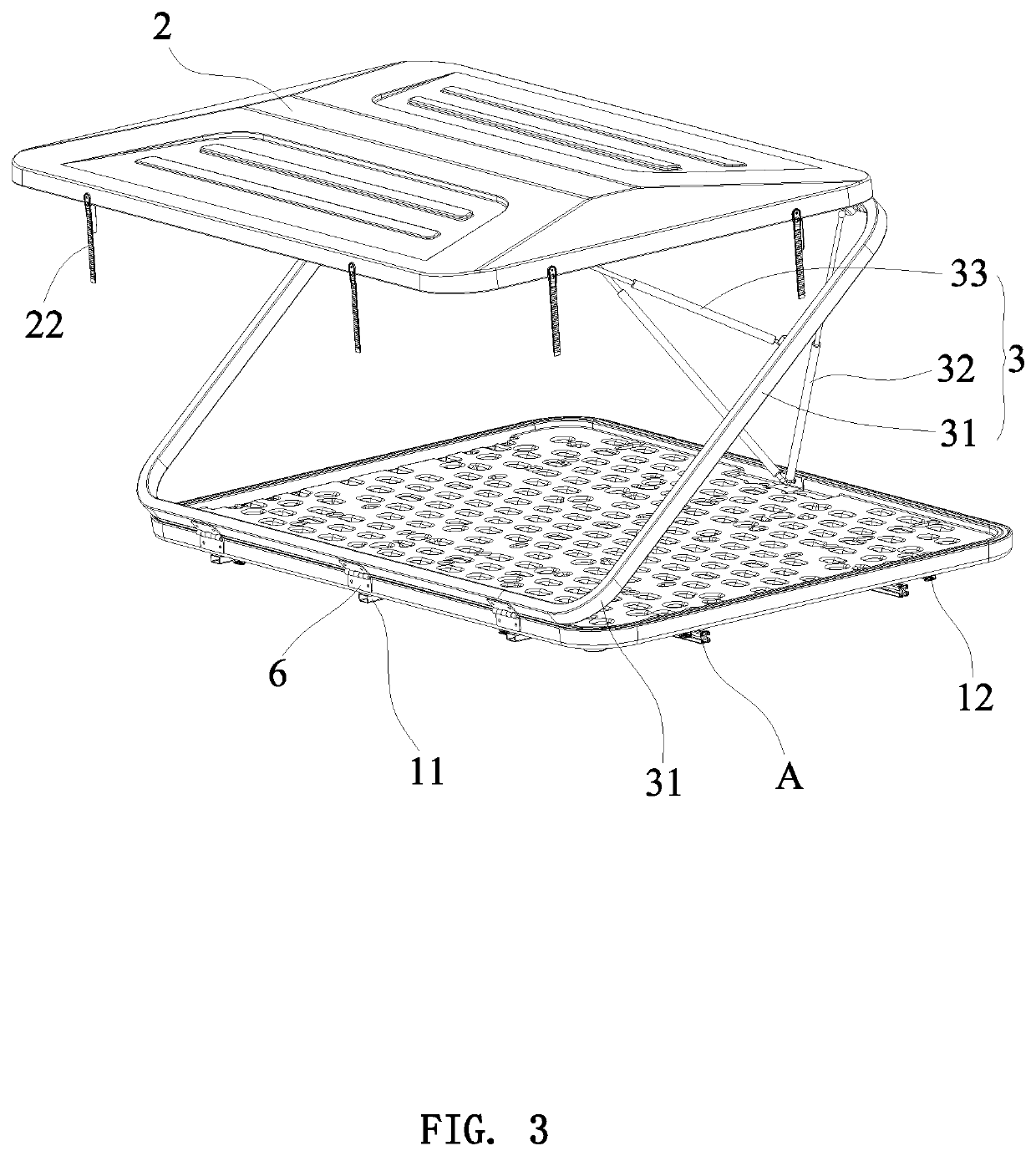

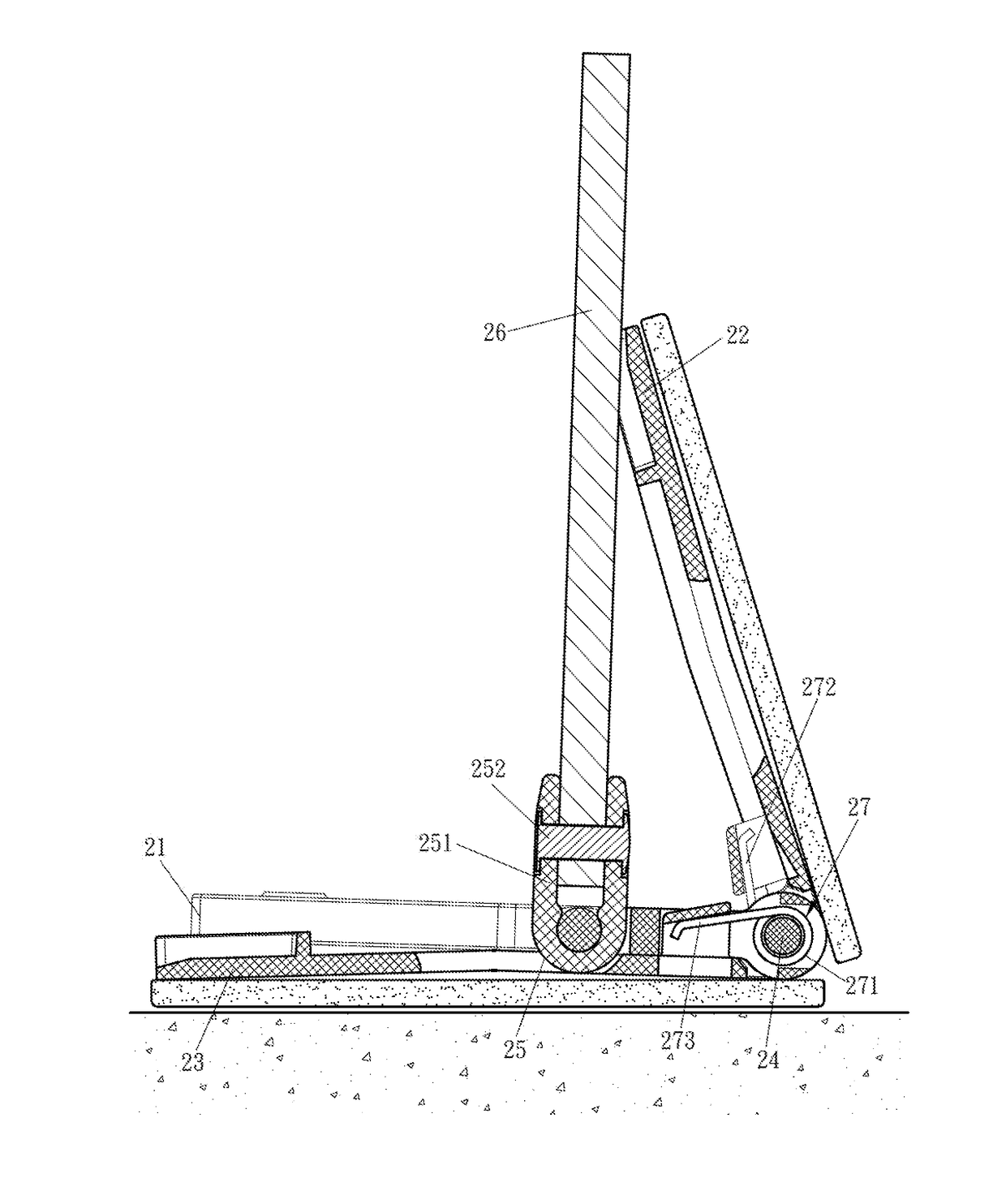

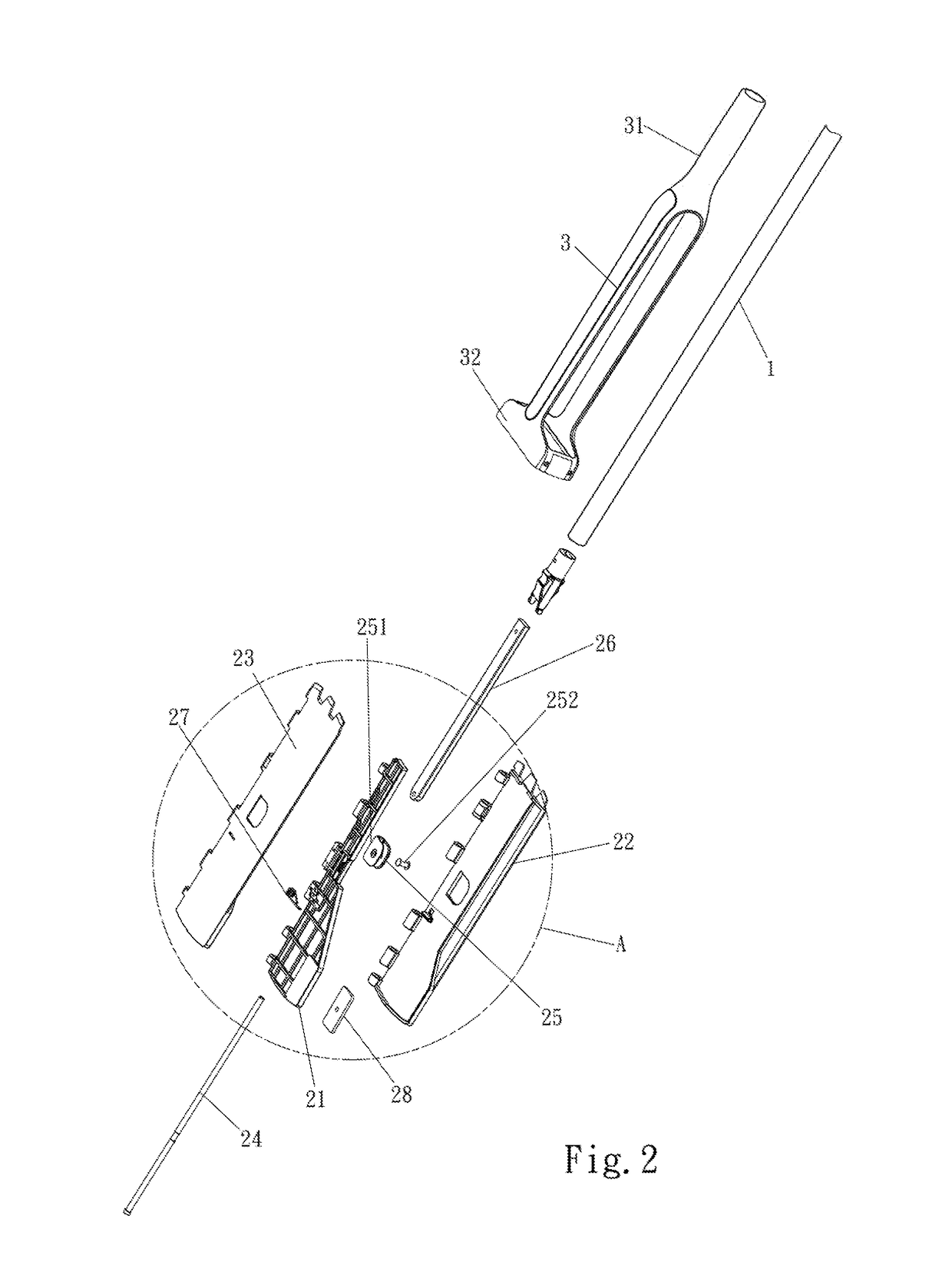

Foldable vehicle roof tent

ActiveUS10590675B2Stable supportEven by forceTents/canopiesVehicle with living accommodationSupport plane

Owner:Q YIELD OUTDOOR GEAR

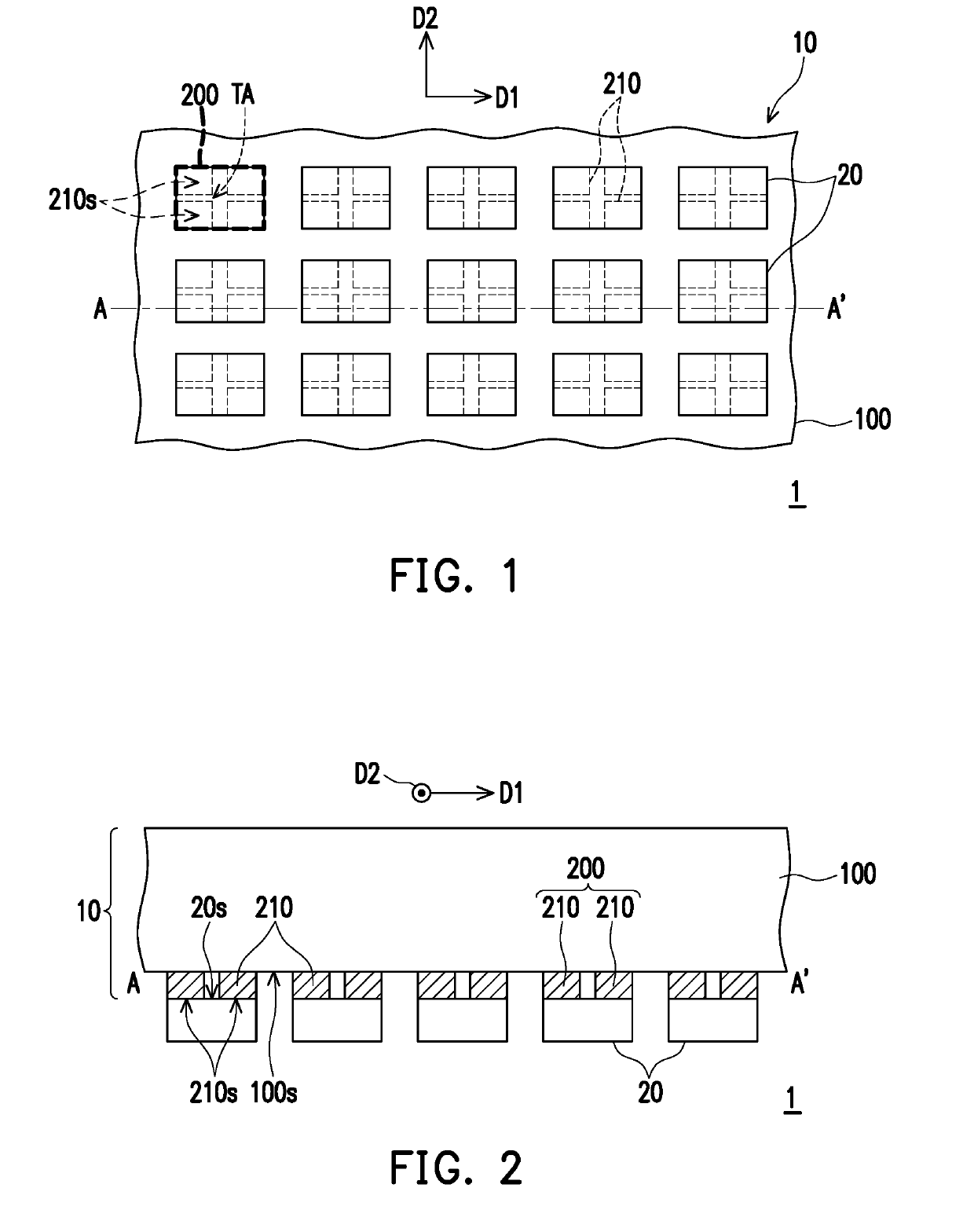

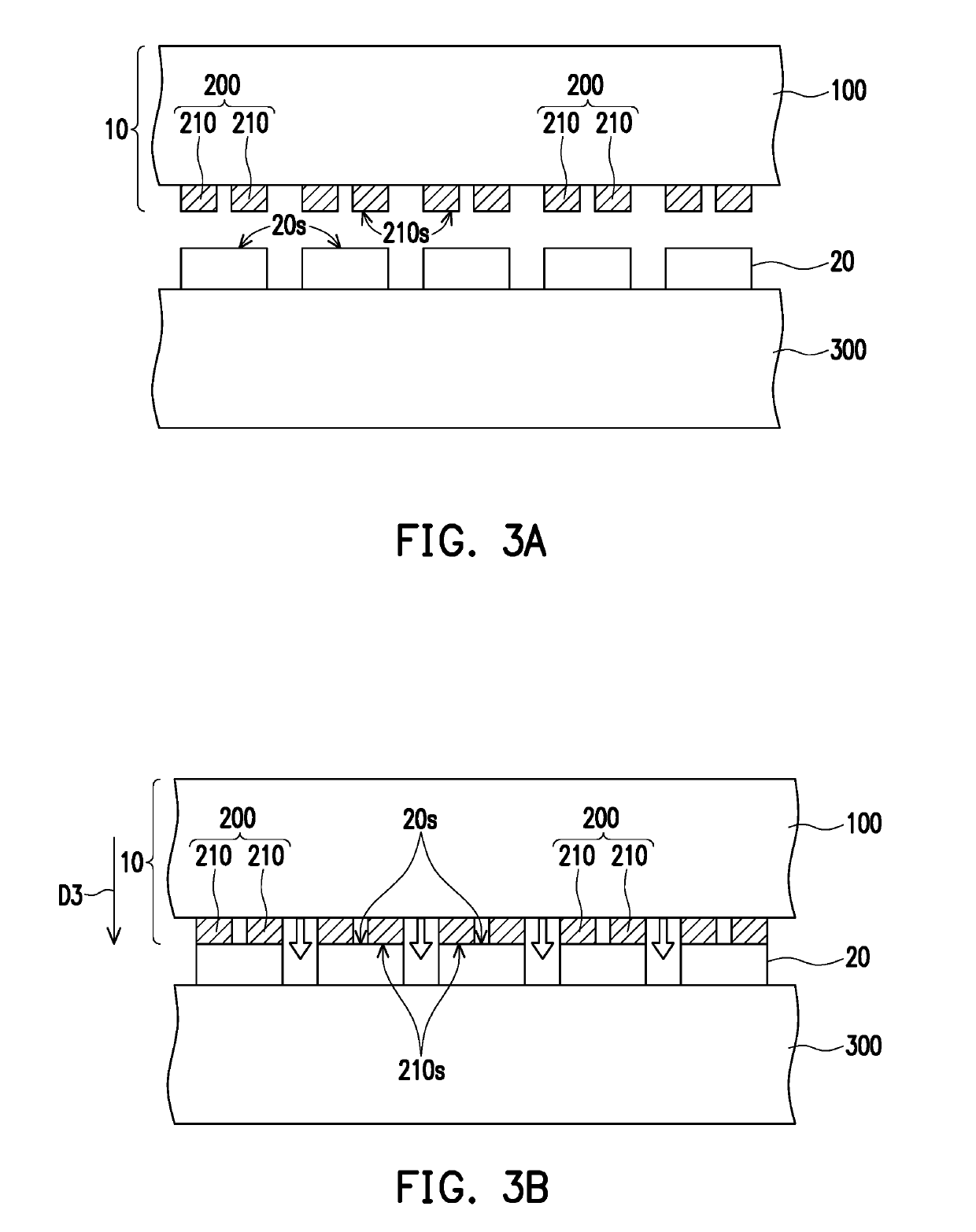

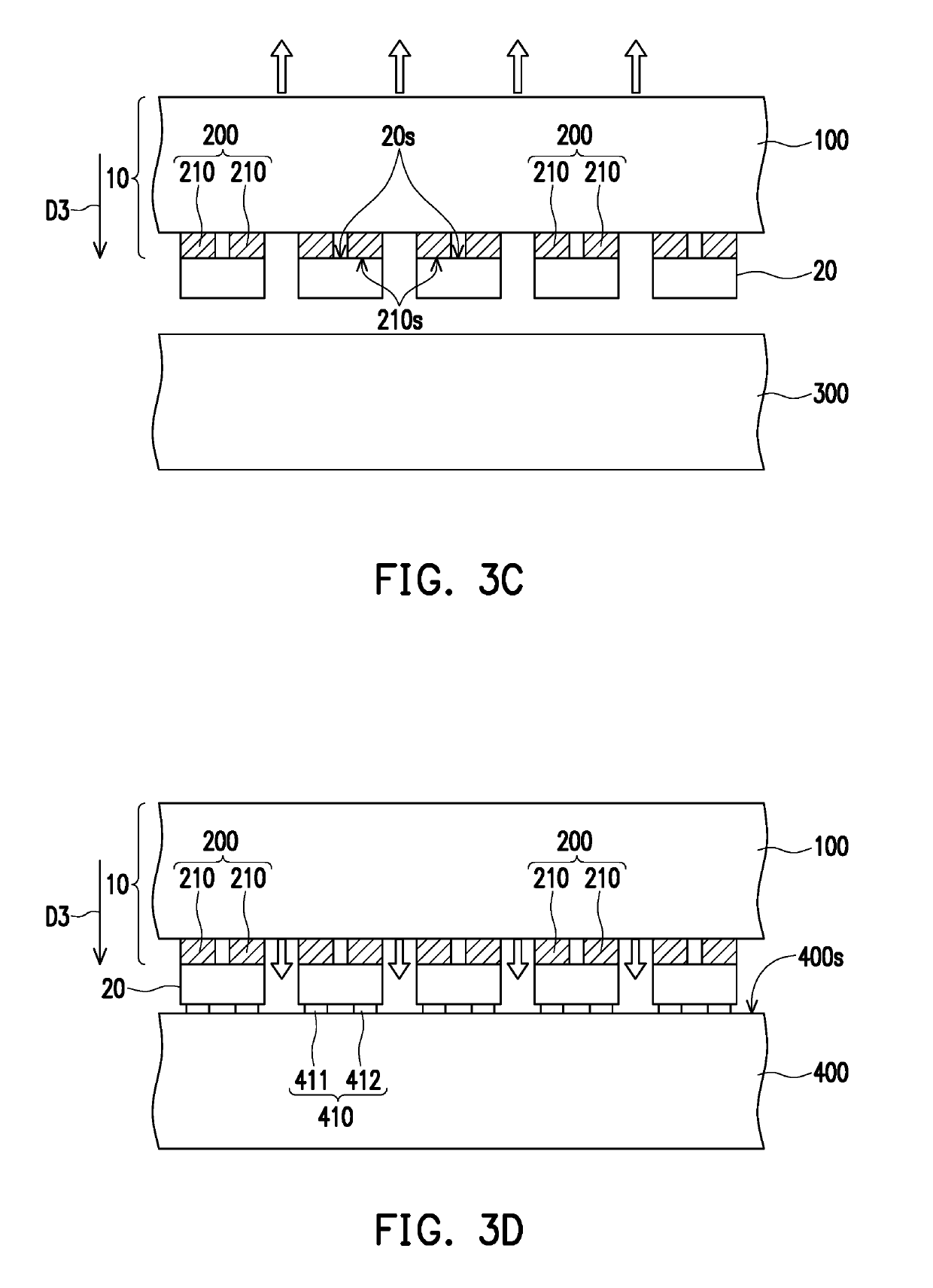

Carrier structure and micro device structure

ActiveUS20190189496A1Great processing latitudeEasy to processSolid-state devicesSemiconductor/solid-state device manufacturingMicro devicesEngineering

A carrier structure suitable for transferring or supporting a plurality of micro devices including a carrier and a plurality of transfer units is provided. The transfer units are disposed on the carrier. Each of the transfer units includes a plurality of transfer parts. Each of the transfer parts has a transfer surface. Each of the micro devices has a device surface. The transfer surfaces of the transfer parts of each of the transfer units are connected to the device surface of corresponding micro device. The area of each of the transfer surfaces is smaller than the area of the device surface of the corresponding micro device. A micro device structure using the carrier structure is also provided.

Owner:PLAYNITRIDE DISPLAY CO LTD

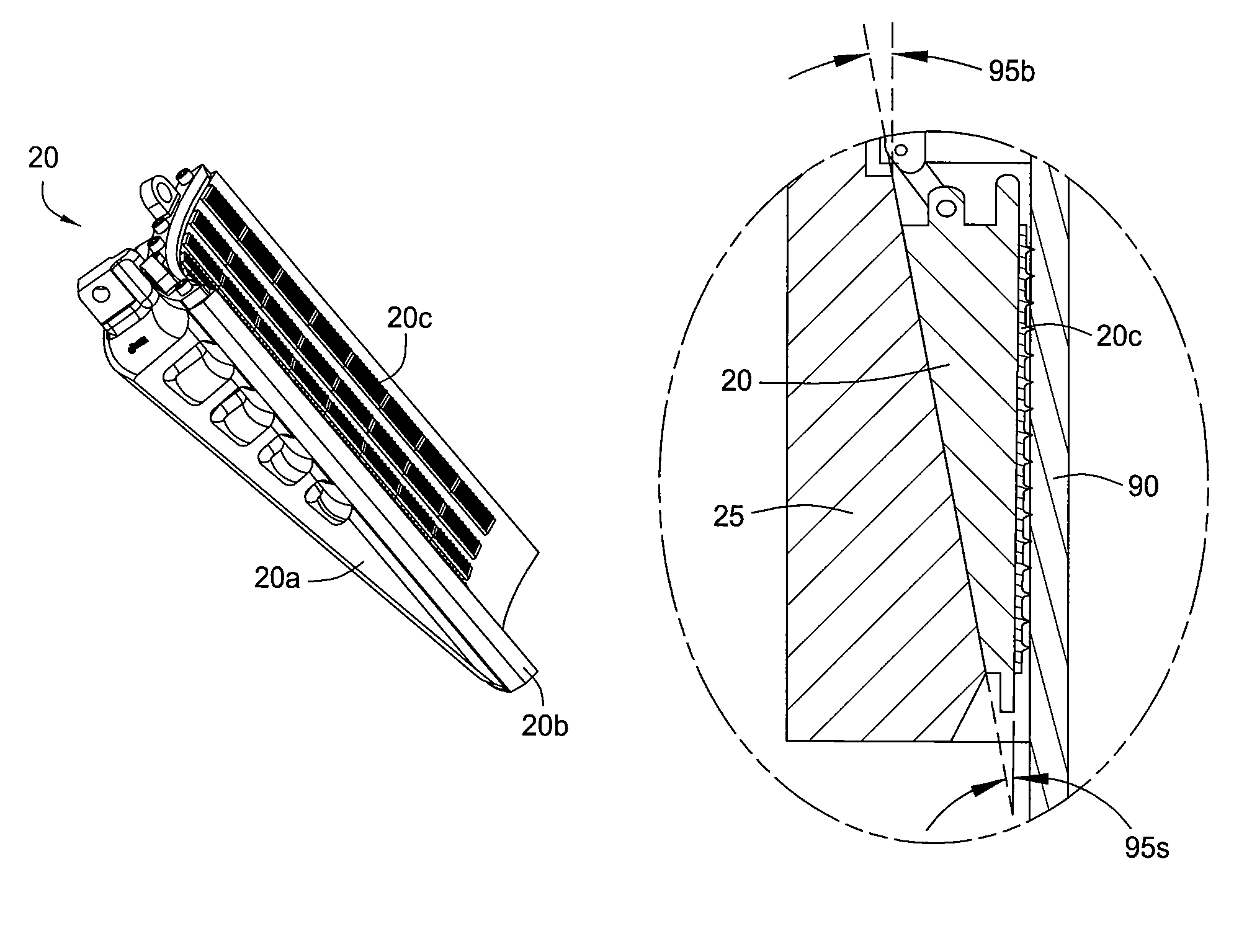

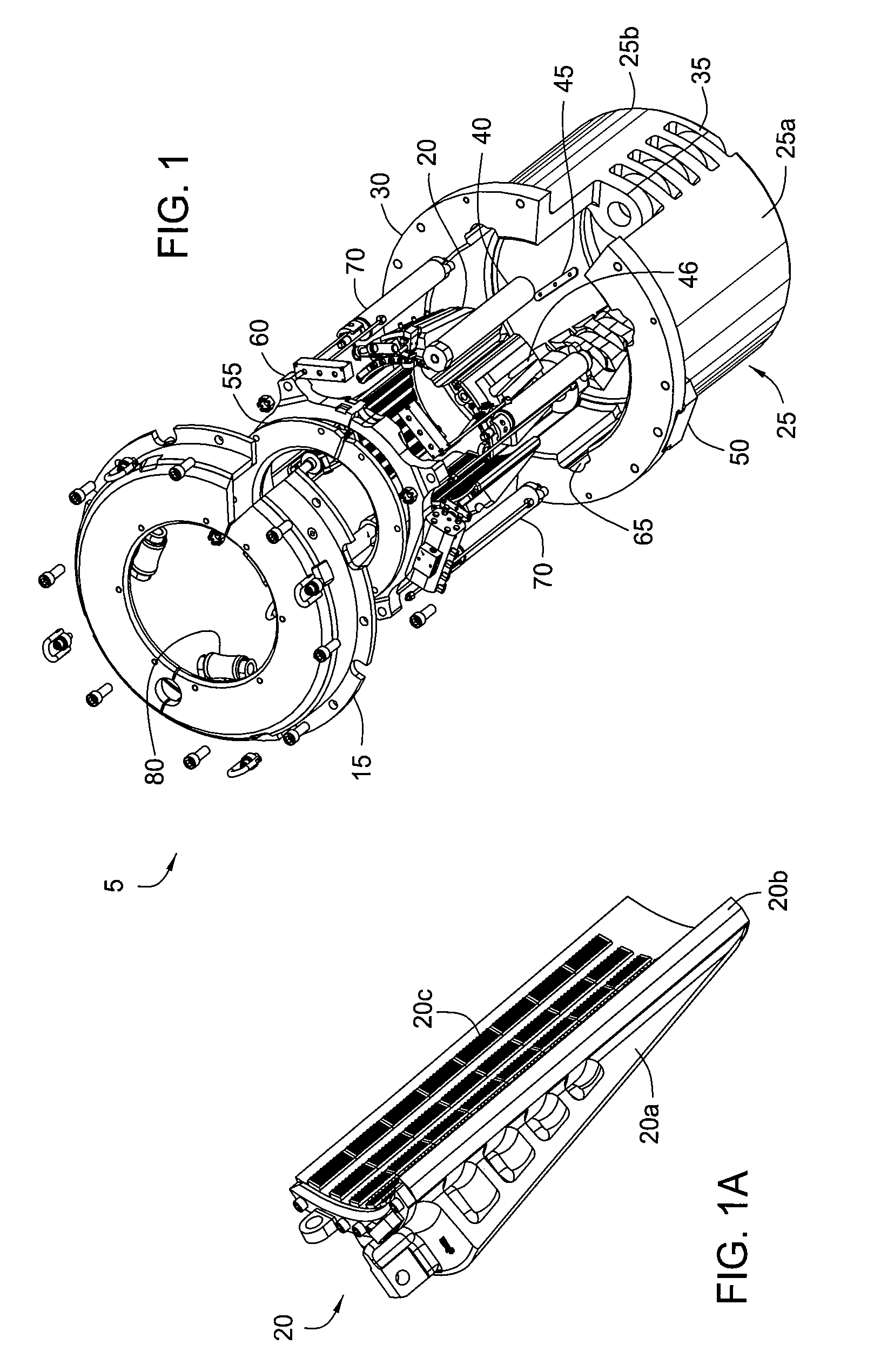

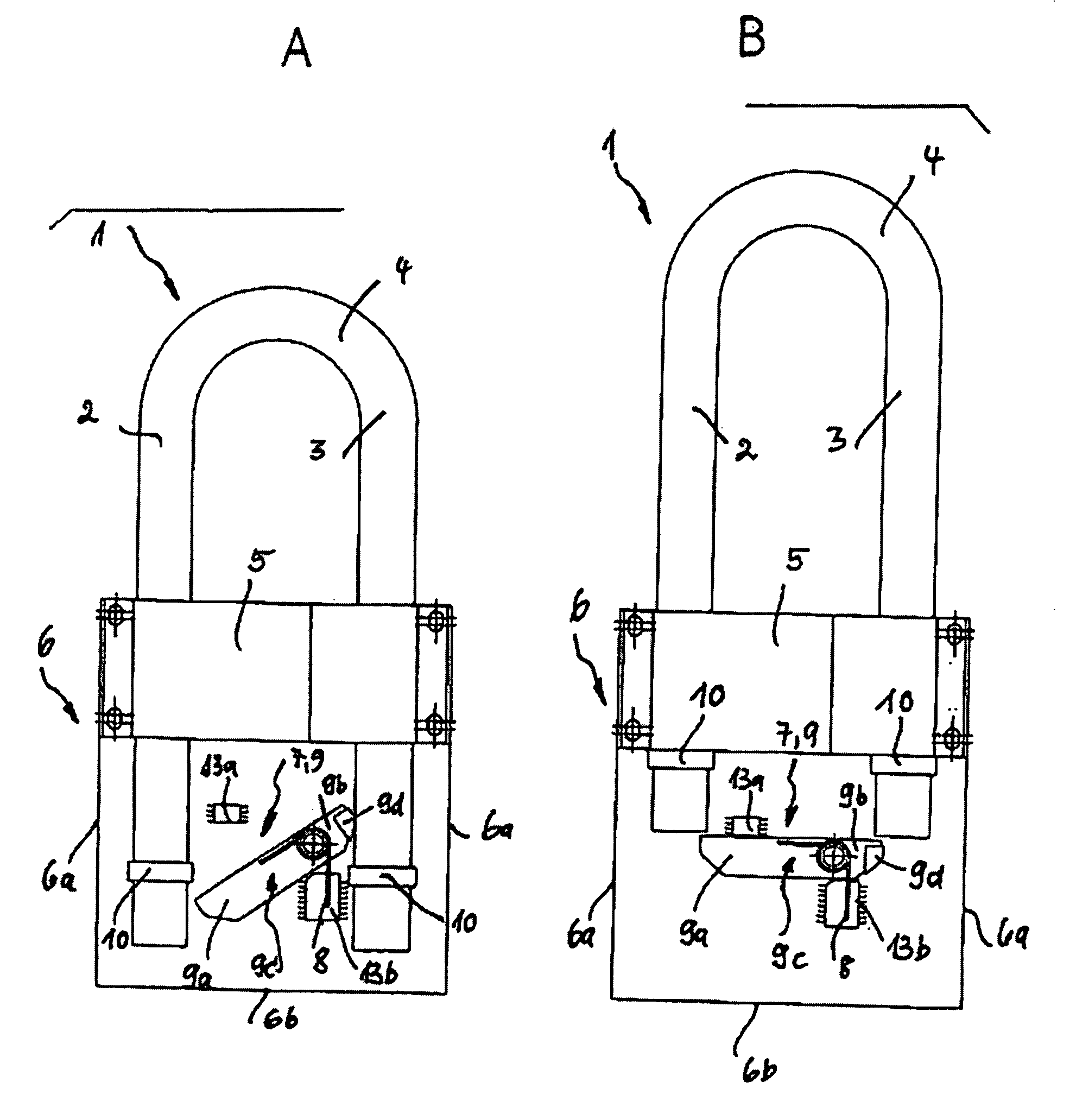

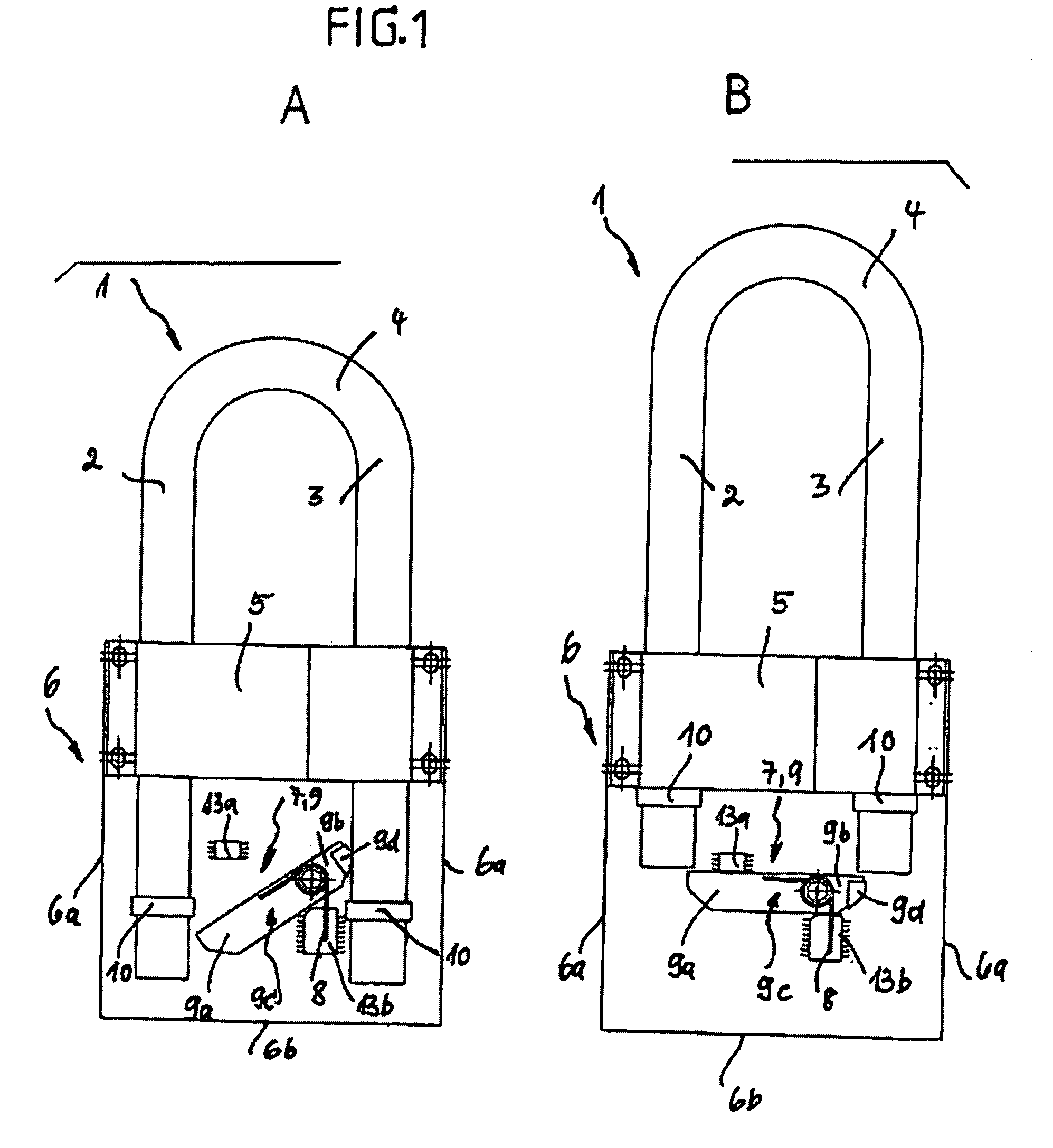

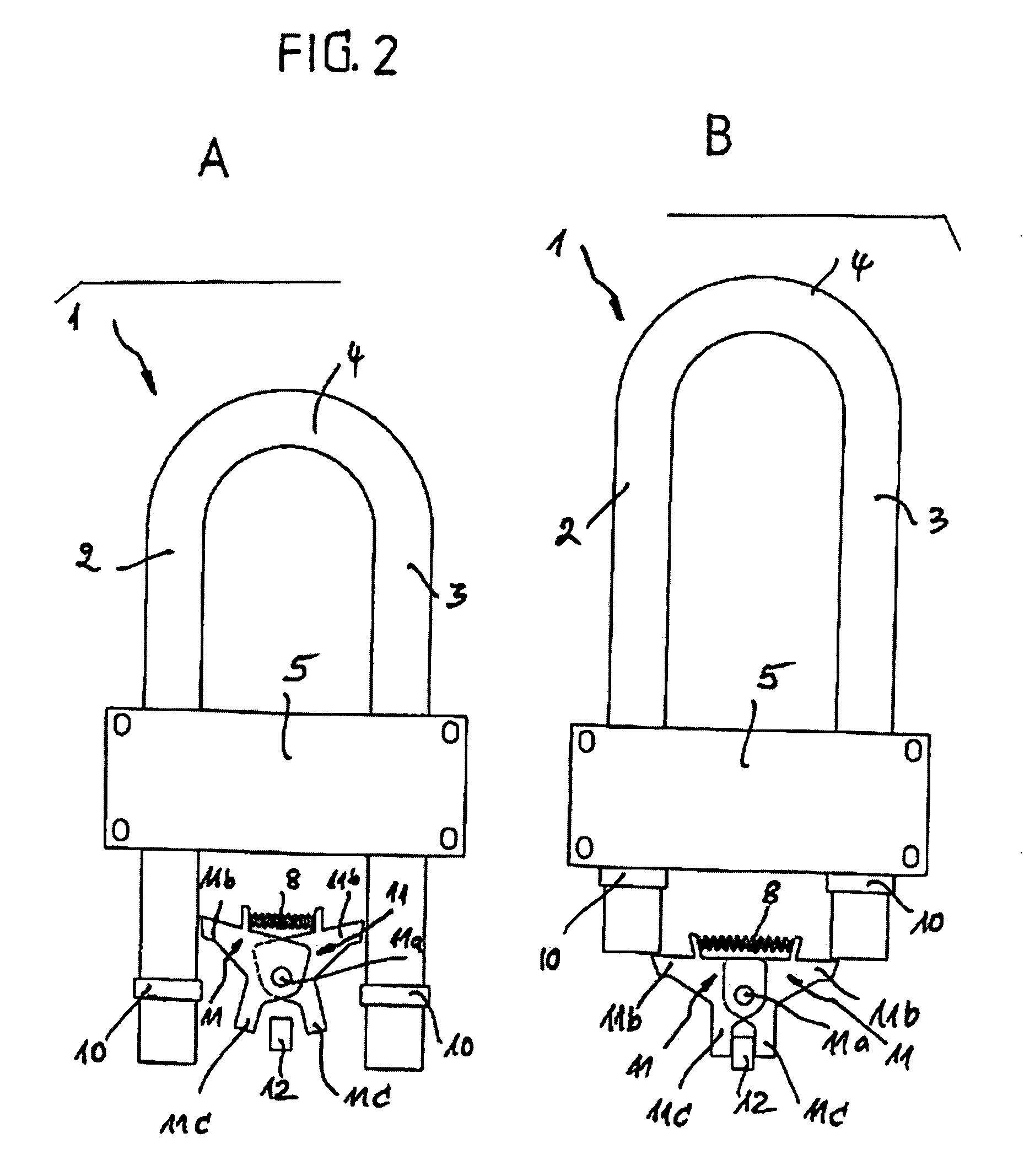

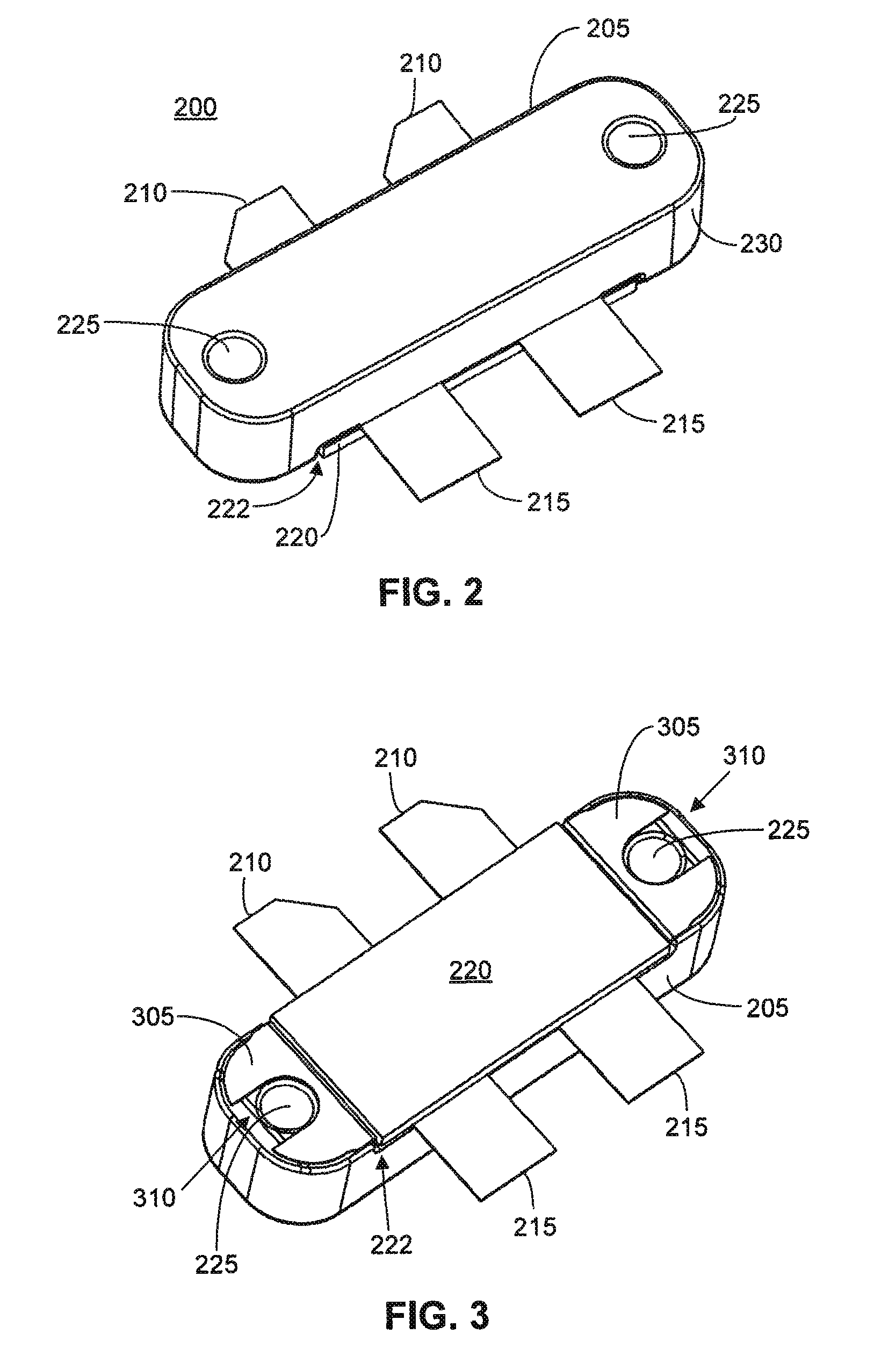

Rollover protection system for motor vehicles with a sensor-controlled actively deployable rollover body

InactiveUS20080197613A1Reduce assemblyReduce componentsPedestrian/occupant safety arrangementRolloverMobile vehicle

The invention is based on a known rollover protection system for motor vehicles with a rollover body that is held guided in a holder affixed to the vehicle, a drive under spring tension for sensor-controlled deployment of the rollover body from a resting position to a protective position, and a locking device for the rollover body when deployed in the protective position. In order to create a very simple, low-cost and yet highly effective locking device, i.e. a block against retraction of the roll bar after a deployment due to an accident, the invention provides a detent pawl arrangement articulated in a pivoting manner and affixed to the vehicle and under spring tension in the locking direction by a retaining spring, with two extensions extending at least across the width of the rollover body, that in the protective position of the rollover body can be pivoted into direct active contact with corresponding supports on the rollover body.

Owner:AUTOMOTIVE GROUP ISE INNOMOTIVE SYST EURO

High Pressure, High Temperature Back-Up with a Circumferential Relief

InactiveUS20110104318A1Improve carrying capacityIncrease pressurePressurized chemical processConfectioneryHigh pressureBiomedical engineering

In one aspect of the present invention, a cartridge assembly for connection to the frame of a high-pressure, high-temperature press comprises a front end comprising a back-up intermediate and coaxial with an anvil and a piston, the anvil comprising a proximal end in contact with the back-up and a distal end that forms part of a pressurized chamber within the frame, the back-up comprising a proximal end comprising a first diameter proximate an interface with a distal end of the piston, and a distal end comprising a second diameter proximate an interface with the proximal end of the anvil, the back-up comprising one or more circumferential reliefs disposed on the first diameter.

Owner:NOVATEK IP

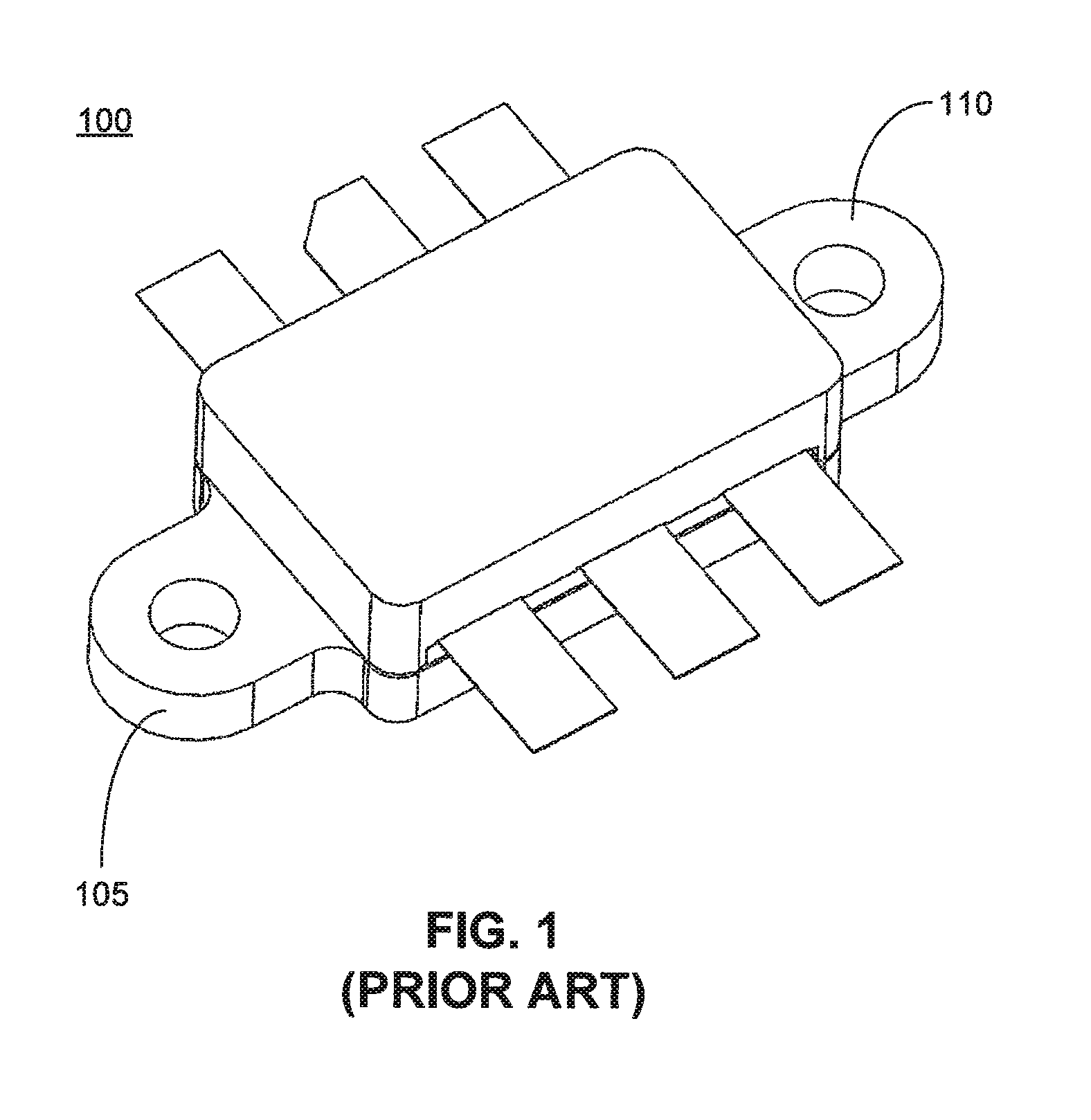

RF package

ActiveUS8410601B2Improve deformationProvide rigiditySemiconductor/solid-state device detailsSolid-state devicesStress distributionEngineering

An RF package includes a substrate mountable on a base plate, a non-conductive cover overlying the substrate, and quasi-serpentine stepped source leads attached to an upper surface of the substrate and extending from at least one of a pair of opposite sides of the upper surface of the substrate to tapered lower surfaces of the cover. The cover includes a recess to receive the substrate. The recess includes stress distribution surface areas to engage and press outer edge portions of opposite sides of the substrate against a base plate or heat sink. The tapered lower surfaces of the cover engage with and press against the stepped source leads when securing the RF package to the base plate or heat sink using one or more fasteners or bolts. The cover includes structural features to improve preferential deformation when a mounting force is applied.

Owner:MICROSEMI CORP

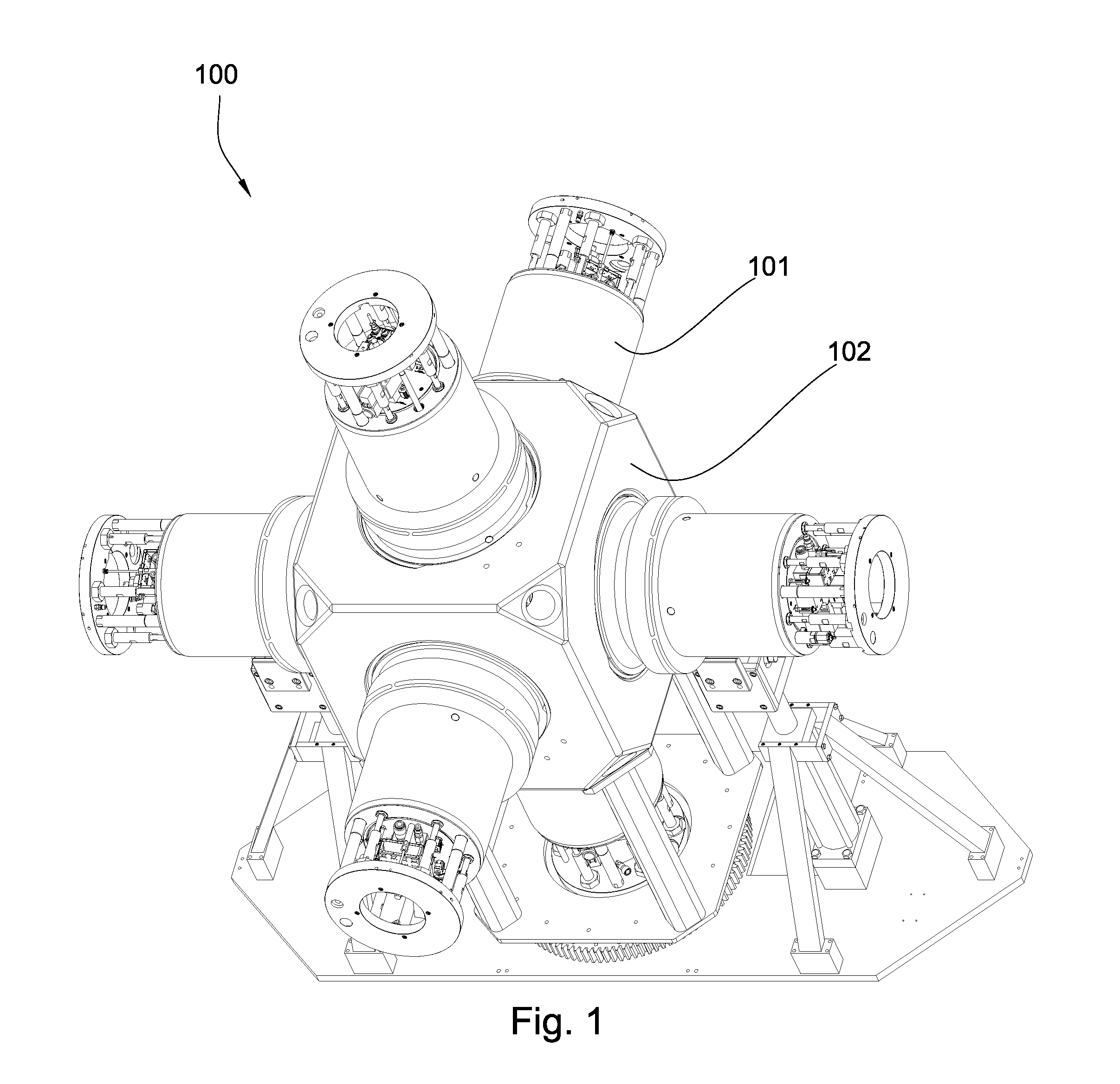

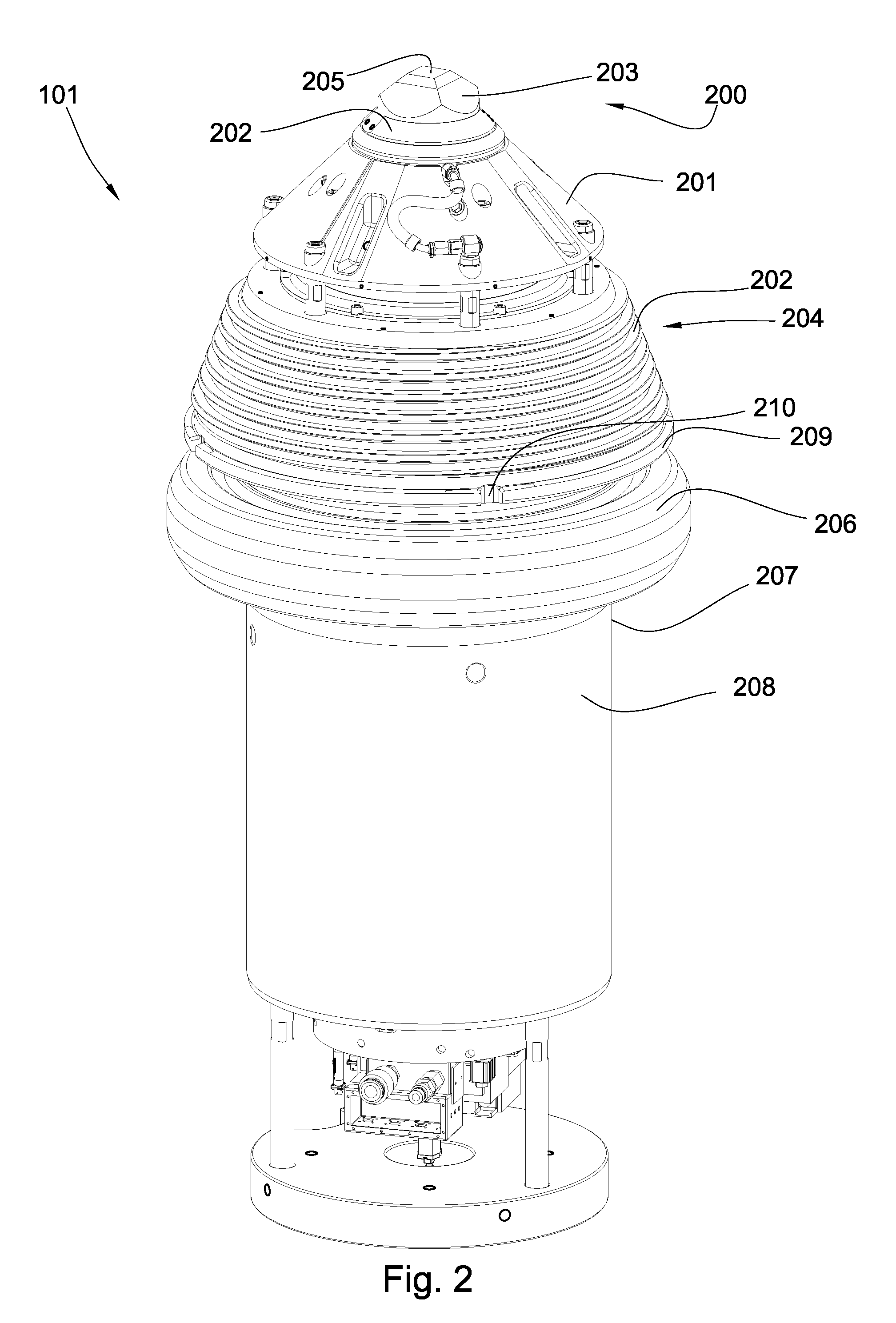

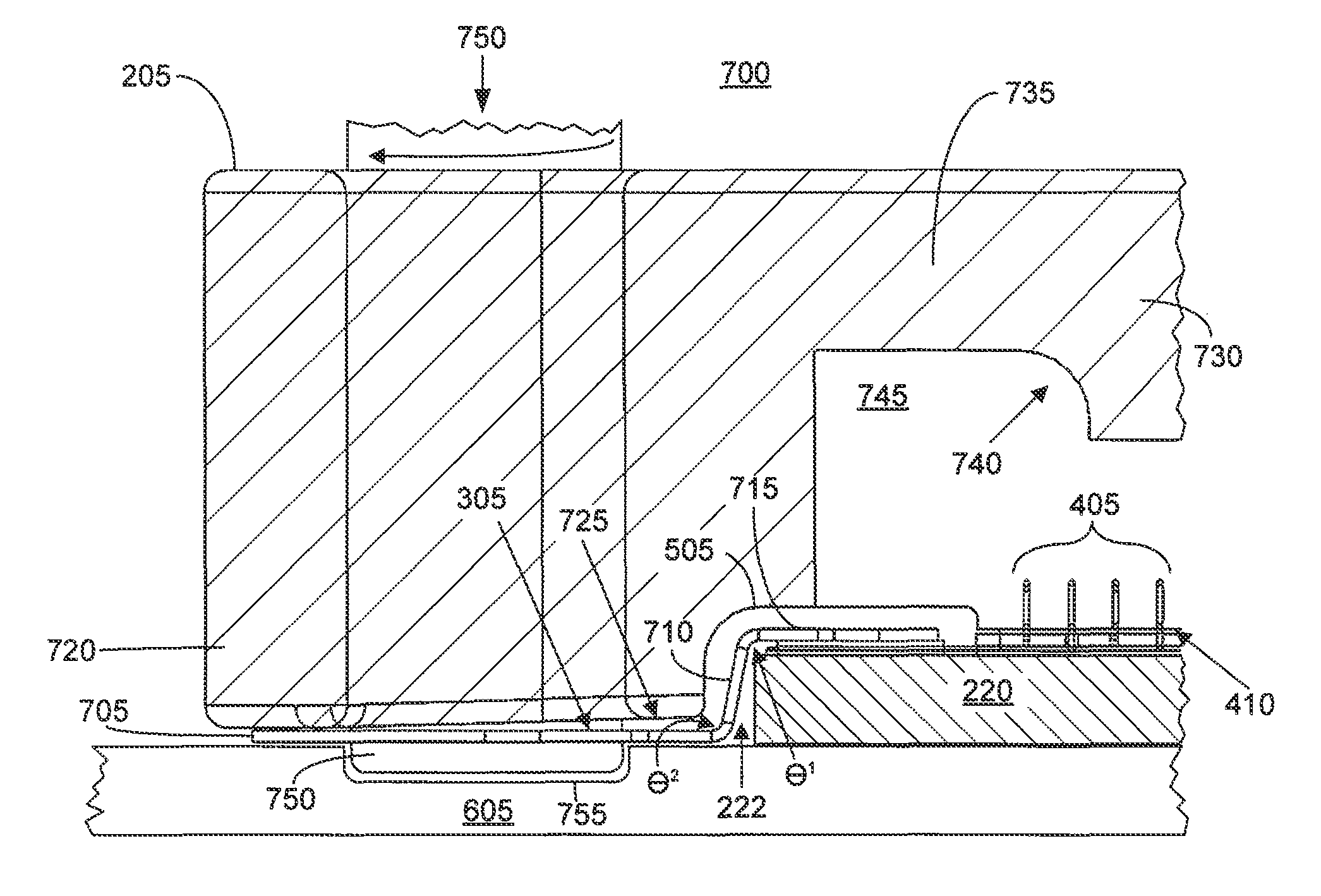

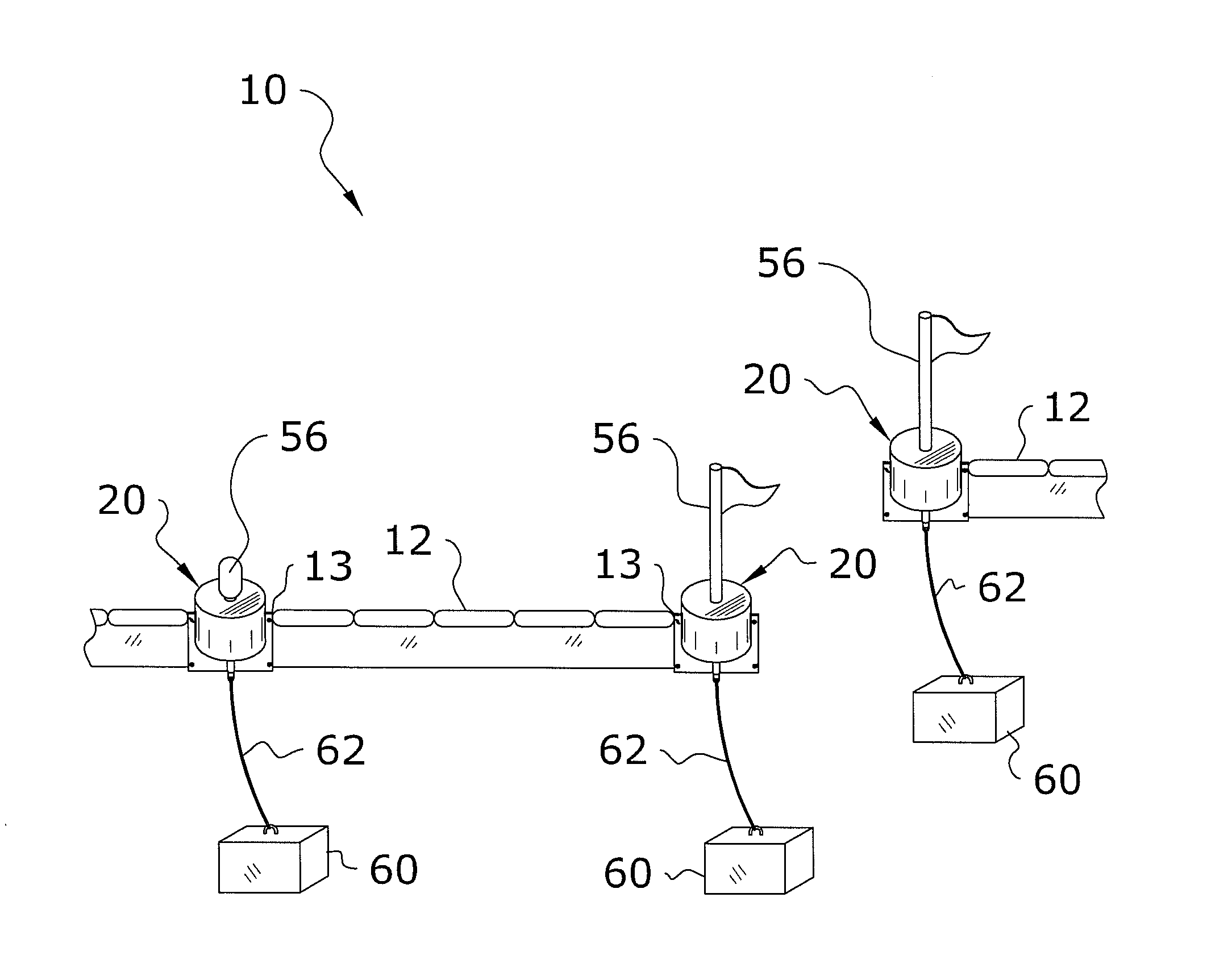

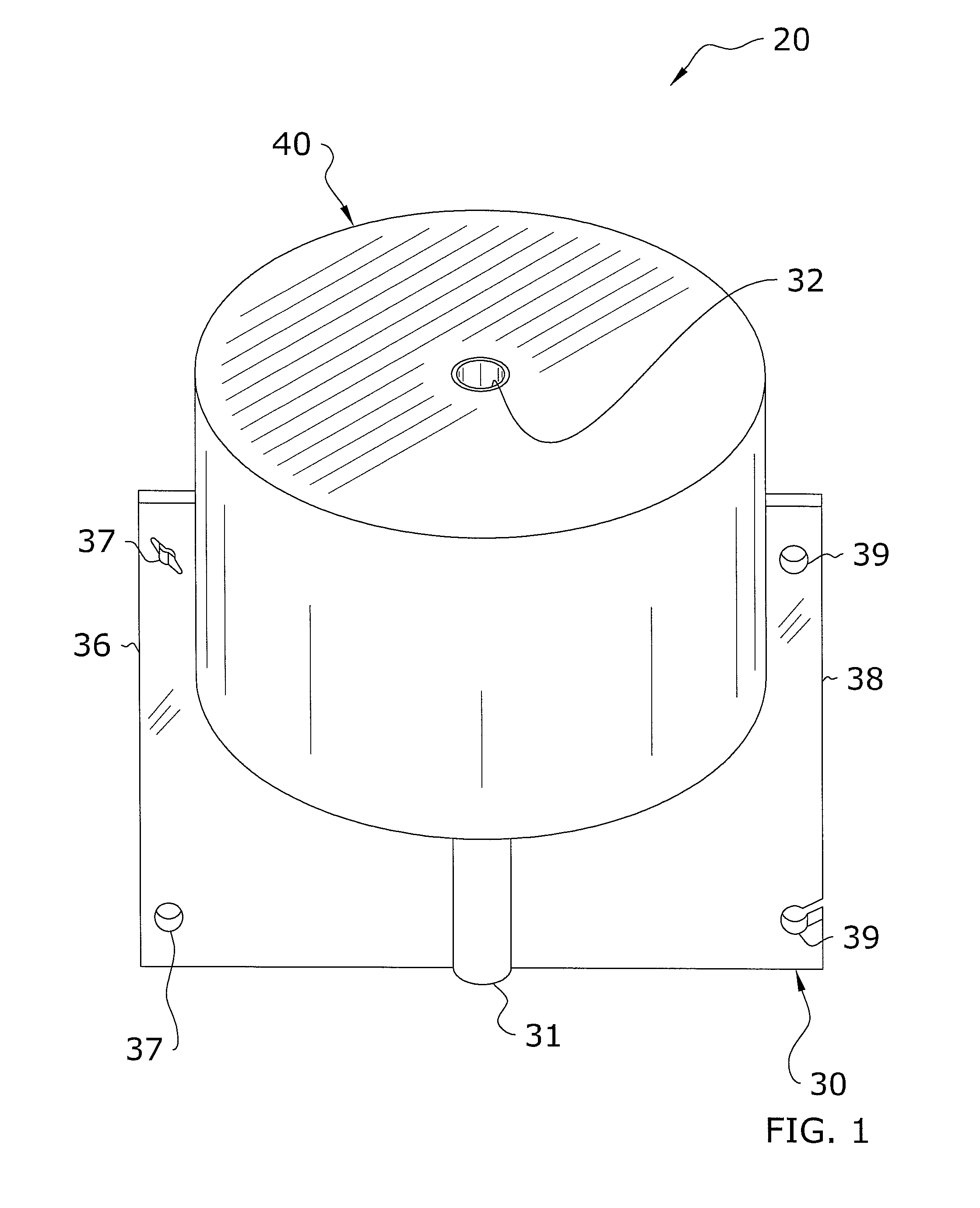

Boom mooring system

InactiveUS8303212B2Stress smoothEffective anchoringWater cleaningWaterborne vesselsMooring systemBuoy

A boom mooring system for anchoring containment booms over extended periods and in varying sea conditions. The system generally includes a buoy having a frame, a buoyancy member mounted thereto, connecting plates located on first and second ends of the frame for connecting containment booms, and an anchor secured to the frame for mooring the buoy. The frame evenly distributes stresses caused from securely anchoring the containment boom in a dynamic sea environment. The anchor may be secured to the frame in various manners, such as via a pipe movably extending through the frame or an elongated member, such as a rope, cable, etc. secured to the frame or pin of the frame. Various signaling devices may extend from the buoy, such as lights, flags, etc. to designate presence of the buoys and containment boom and / or to designate openings in the containment boom to allow passage of spill response vessels.

Owner:LARA KIM A

Gas power nail gun

The invention relates to a gas power nail gun, belonging to the technical field of gas power tools. The lower part of a cylinder body in a casing of the nail gun is fixedly connected with a nailing seat; a bunting head is installed at the lower part of the nailing seat; an extending flange and guide grooves are respectively arranged at two sides of the cylinder body; a left bunting arm and a right bunting arm are respectively embedded in the guide grooves at two sides; the upper end surfaces of the bunting arms are connected with the extending flange through a bunting arm spring; vertical slide rails are arranged at two sides of the nailing seat; a gun nozzle and a guide tube are installed at the lower end; a guard board inner wall and a guard board which are vertical to positioning planes are respectively extended on the positioning planes of two sides of the upper end of the bunting head; the guard board inner wall and the guard board are connected by inner wall steps; the guard board inner wall and the nailing seat form a moving pair; the lower ends of the left bunting arm and the right bunting arm are respectively provided with inner walls; and the lower end surfaces of the inner walls are abutted on the corresponding inner wall steps. The invention has simple structure, material saving and economic cost, and the parts are mutually tenoned and embedded into a whole after assembling, thus ensuring that the left bunting arm and the right bunting arm are under balanced stress.

Owner:NANJING TENGYA PRECISE TECH DEV CO LTD

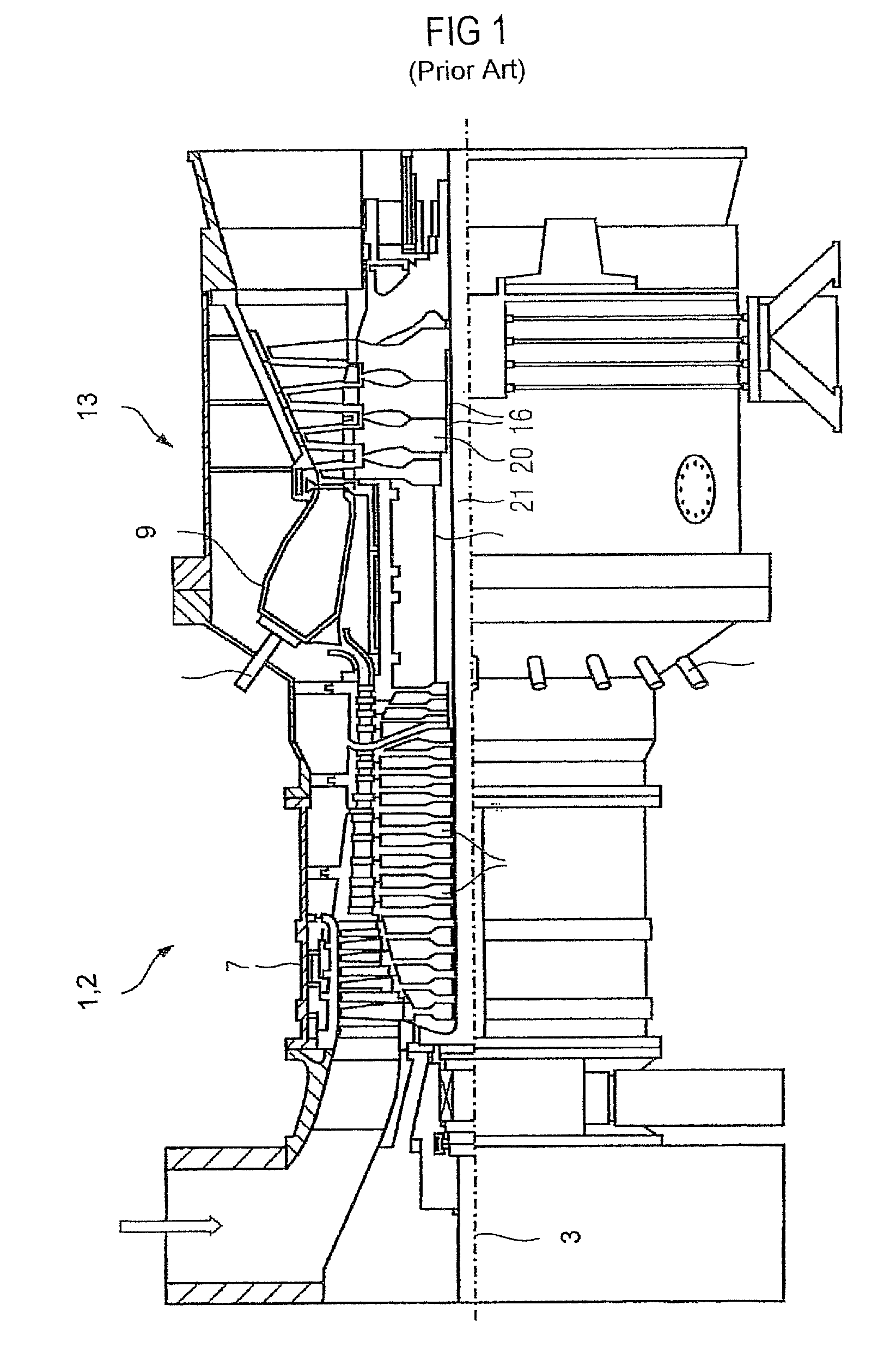

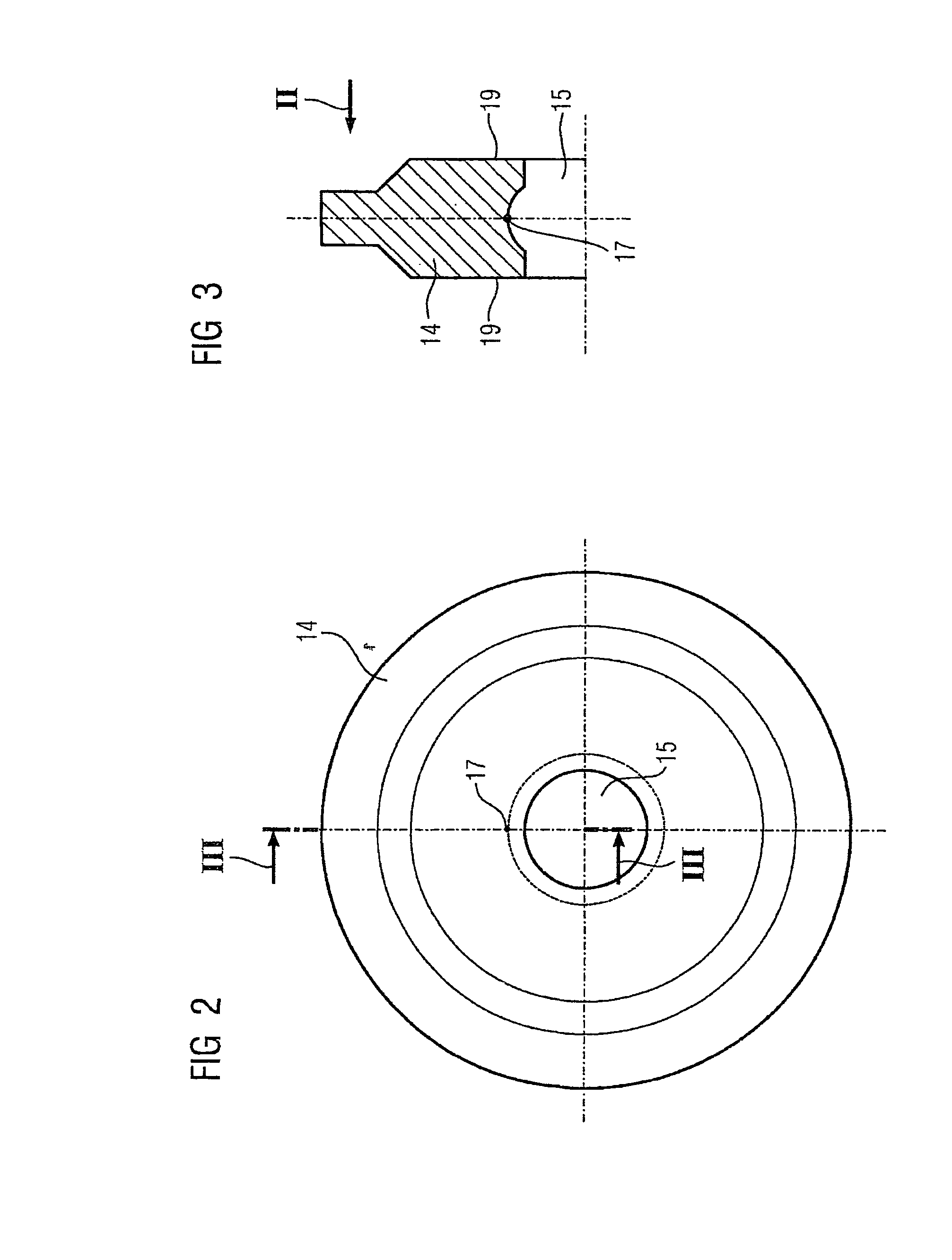

Turbo machine with a rotor which has at least one rotor disk with a bore

InactiveUS7819632B2Increased compressive residual stressIncreases Mises reference stressEngine manufacturePump componentsTangential stressEngineering

The invention relates to a rotor disk for the rotor of a non-positive displacement machine with at least one borehole extending in an axial direction. The aim of the invention is to provide a rotor disk for a non-positive displacement machine that has an increased serviceable life. To this end, the boring extends in an at least partially convex manner whereby having an enlarged diameter in the middle area in order to increase internal compressive stress an to reduce tangential stresses.

Owner:SIEMENS AG

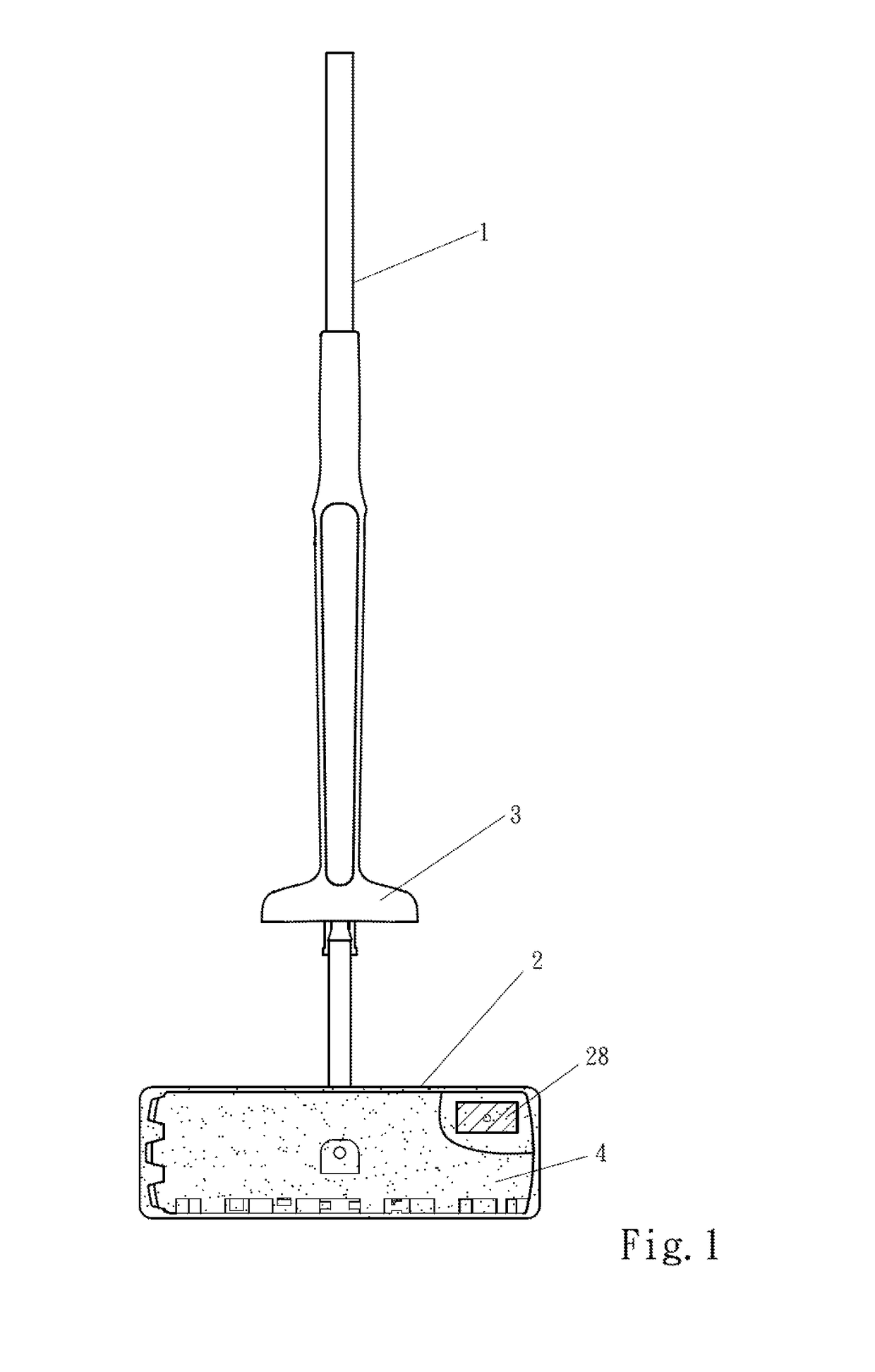

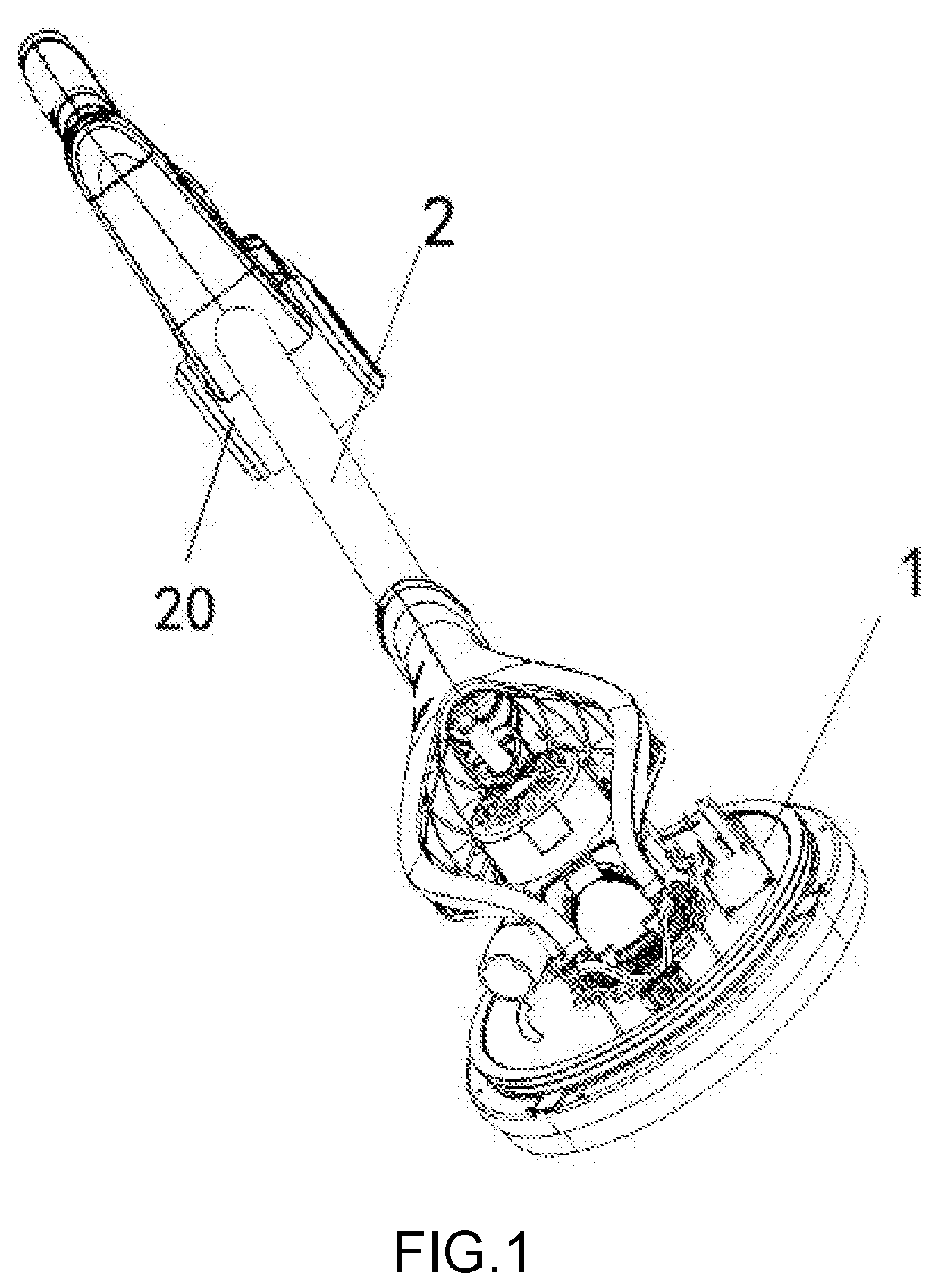

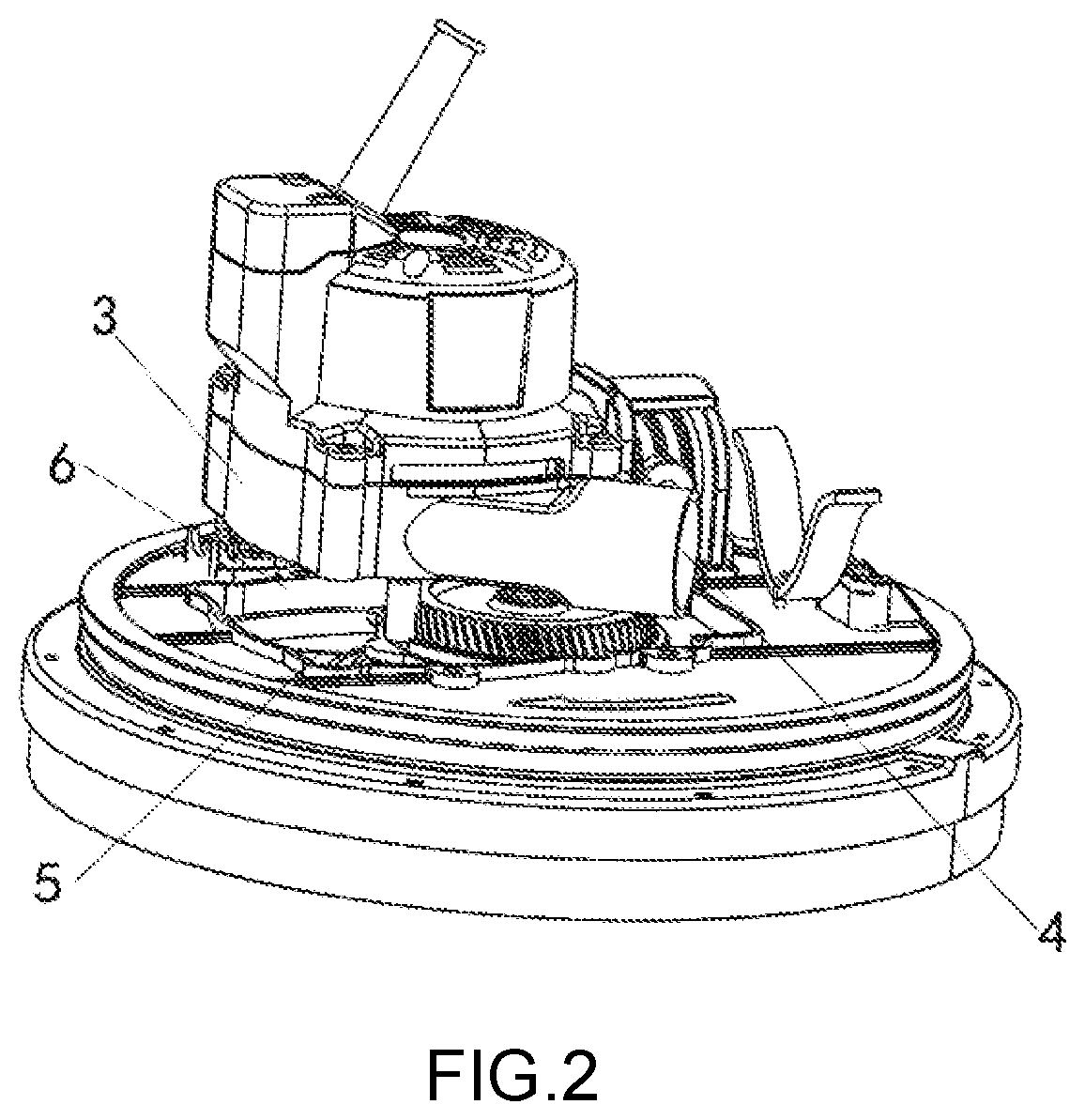

Double-sided mop

ActiveUS20170086637A1Quality improvementFlexible operationCarpet cleanersFloor cleanersUniversal jointEngineering

A double-sided mop according to this invention, being provided to solve the problems of a conventional mop on poor floor mopping quality, includes a mop pole, a mop head connecting to the mop pole, and a cleaning cloth provided on the surface of mop head. The mop head includes a mounting plate, a first panel, a second panel, a hinged shaft, a universal joint, and an elastic part, in which the mounting plate is provided between the first panel and the second panel, the mounting plate is hinged and connects to the hinged shaft together with the first panel and the second panel, the elastic part applies a force to clamp the first panel and the second panel, the universal joint is installed on the mounting plate by rotation, and the mop pole connects to the universal joint.

Owner:JIAXING JACKSON TRAVEL PROD CO LTD

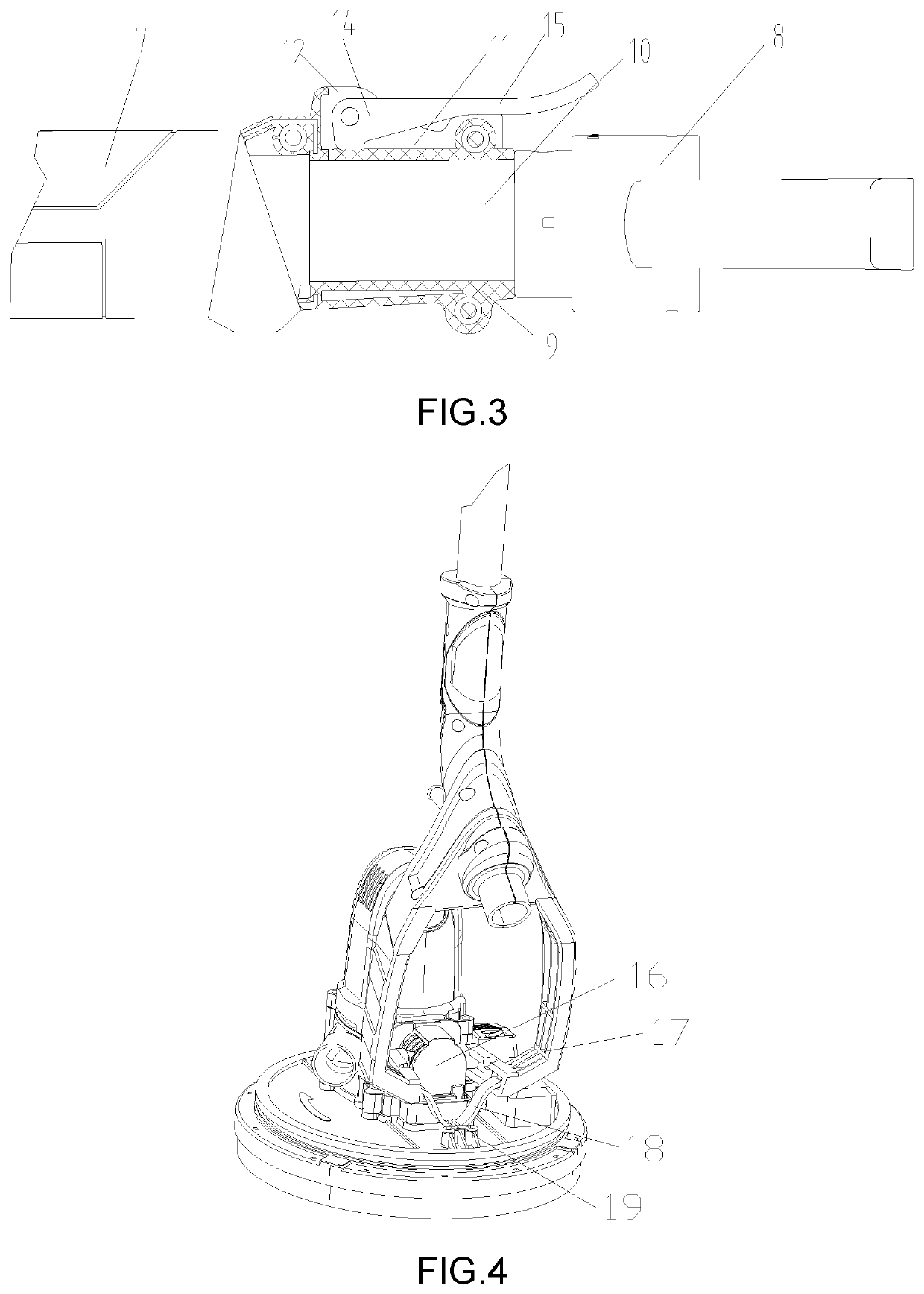

Battery Powered Long-Lever Sander

InactiveUS20200147741A1Evenly stressLess effortGrinding drivesPlane surface grinding machinesEmbedded systemElectrical battery

The utility model discloses a battery powered long-lever sander. The battery powered long-lever sander includes a sander head assembly and a handle. The sander head assembly is connected to the handle and includes a housing and a sanding disc that is disposed in the housing. The battery powered long-lever sander further includes a driving system connected to the sanding disc and configured to drive the sanding disc to run. The driving system is electrically connected to a driving power source, and the driving power source is a battery pack so that the sander can be used without limitations of plugging of a power wire and thus can be used more conveniently.

Owner:LI TINGJIN

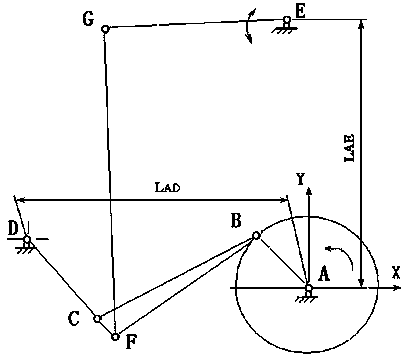

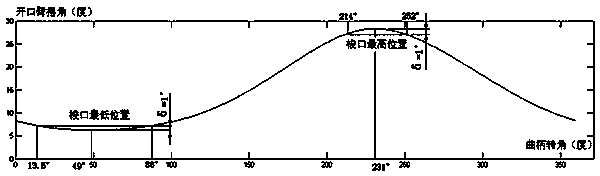

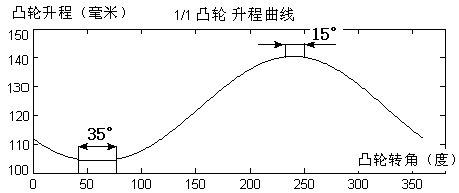

Design method of six-rod shedding mechanism with long pause angle at lowest position of shed

ActiveCN104032438AReduce stressStress smoothCam shedding mechanismGearingDesign methodsCurvilinear motion

The invention discloses a design method of a six-rod shedding mechanism with a long pause angle at the lowest position of a shed. In the design, a connecting rod curve of a crank-rocker mechanism is used, and 8-shaped curve movement is carried out by virtue of a connecting rod point on the extending surface of a first connecting rod of the crank-rocker mechanism; a double-rod component is connected to the connecting rod point in series; the plane motion of the connecting rod point is used for driving a shedding arm to swing by an input connecting rod of the double-rod component; when the connecting rod point moves along the arc section at the right end of the 8-shaped curve, the swing point of the shedding arm is approximately motionless, so that one shedding arm of the shedding mechanism has asymmetric pause angles at two limiting positions and especially has the long pause angle at the lowest position of the shed; furthermore, a hinge joint link mechanism is simple, the stress of a revolute pair is less than that of a lower pair, and the revolute pair is smooth in stress and less in impact, so that the design method is suitable for the improvement and the design of the shedding mechanism of a loom and are especially suitable for a high-speed wide loom.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

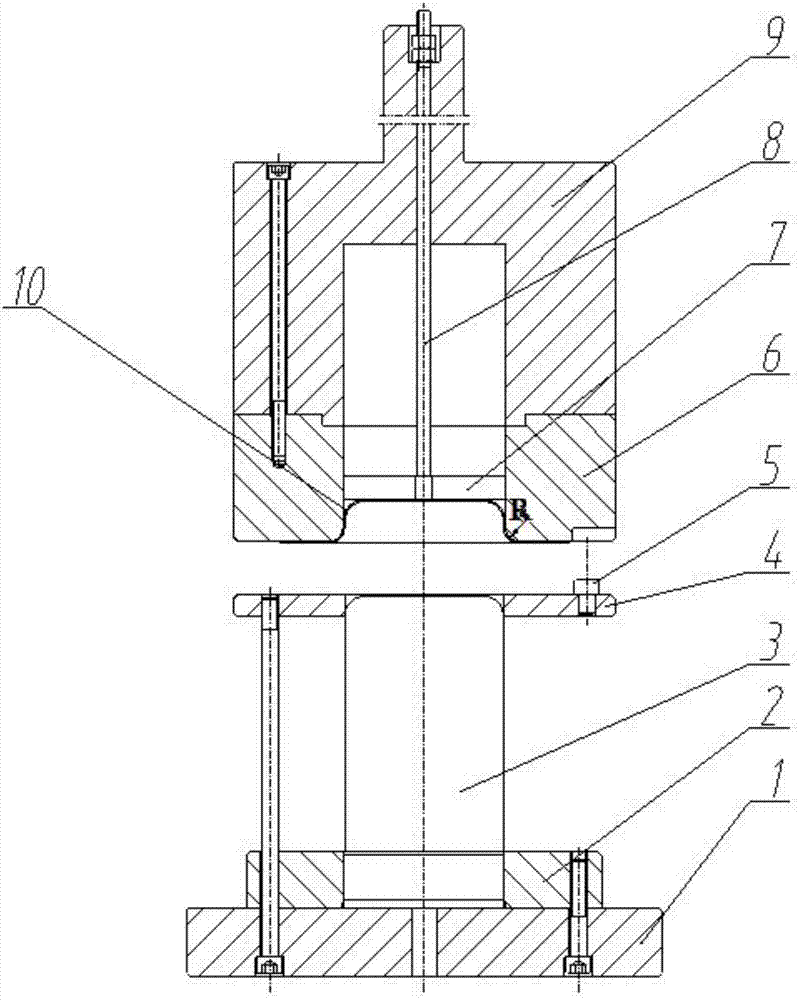

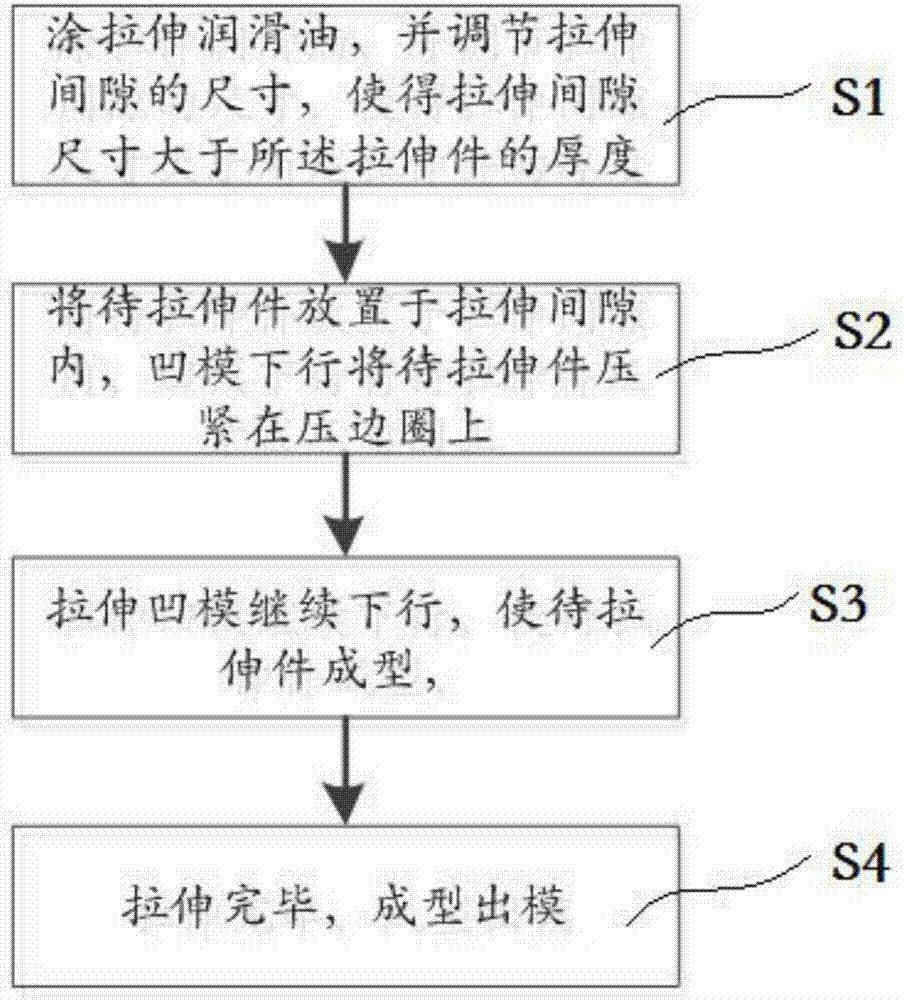

Titanium-aluminum-steel composite pan stretching tool and stretching forming method

PendingCN107457324AStress smoothTake advantage of thermal conductivityShaping toolsStripping-off devicesTitaniumCooker

The invention relates to the technical field of cooker forming manufacture, and provides a titanium-aluminum-steel composite pan stretching tool and a stretching forming method. The stretching tool comprises a stretching female die and a stretching male die matched with the stretching female die; a stretching gap for placing a piece to be stretched is formed between the stretching female die and the stretching male die; the piece to be stretched in placed into the stretching gap, and is a titanium-aluminum-steel three-layer composite piece; the stretching female die comprises an upper die base and a push rod arranged on the upper die base; the stretching male die comprises a lower die base and a binder ring arranged on the lower die base; and a limiting dowel is further arranged on the binder ring, and adjusts the size of the stretching gap, so that the size of the stretching gap is larger than the thickness of the piece to be stretched. The method comprises the steps of coating lubricating oil, adjusting the gap thickness, moving and stretching, and forming a mold. The titanium-aluminum-steel composite pan stretching tool and the stretching forming method solve the problems of material fracturing and wrinkling during a production process of a titanium-aluminum-steel three-layer composite pan, and meanwhile, with the three-layer arrangement, the problems of safety, heat transfer and application environment are solved.

Owner:西安庄信新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com