Patents

Literature

272results about "Cam shedding mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

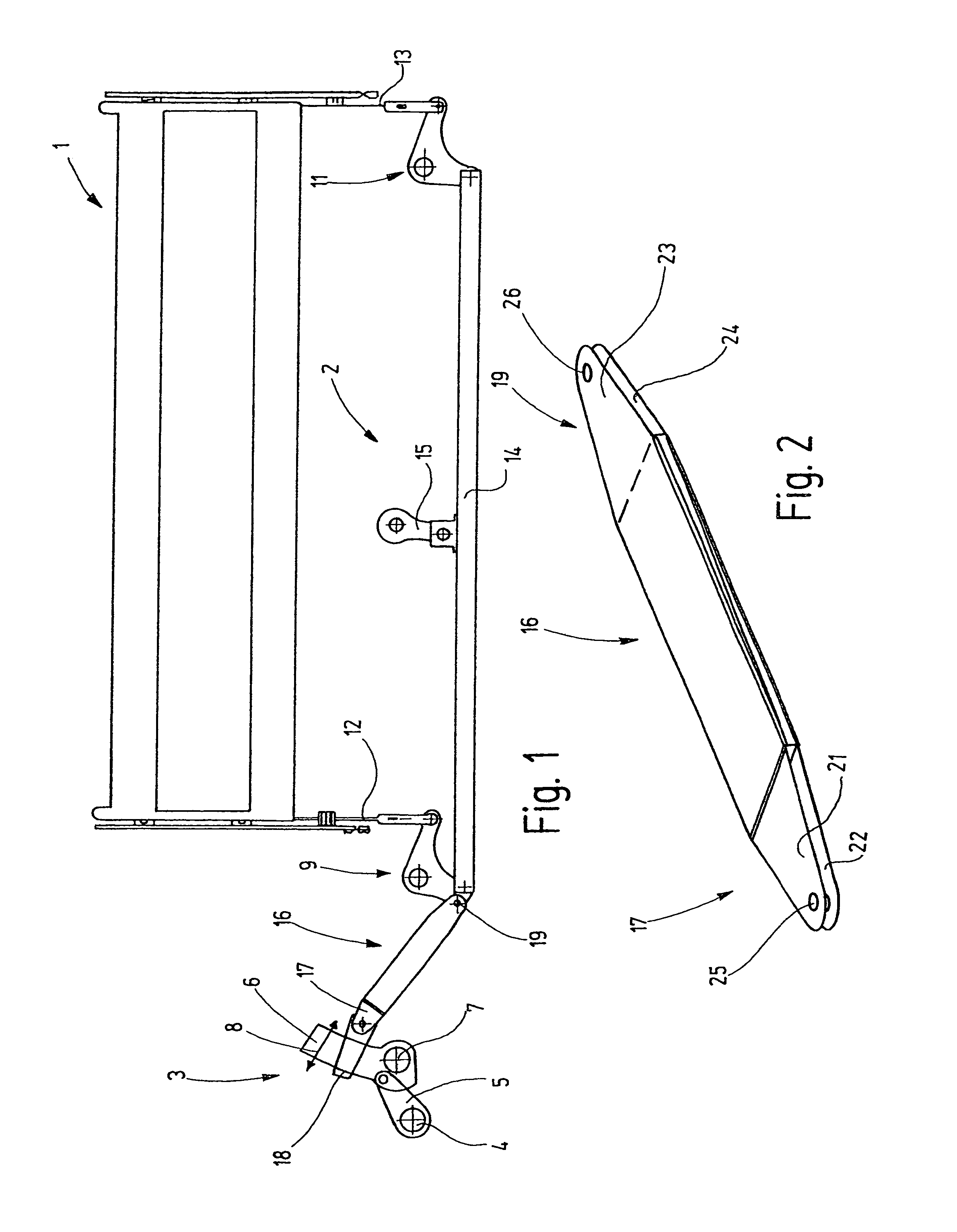

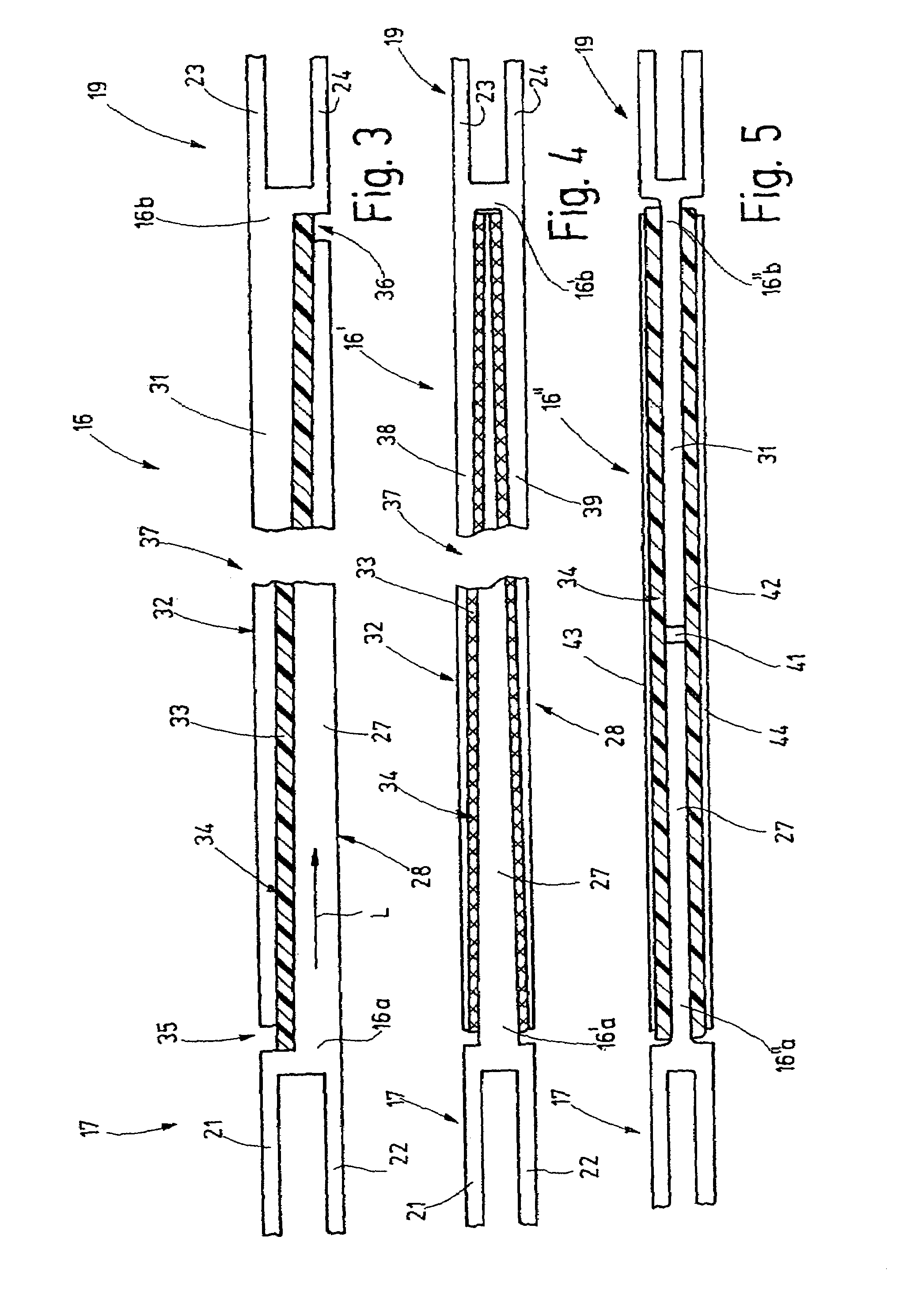

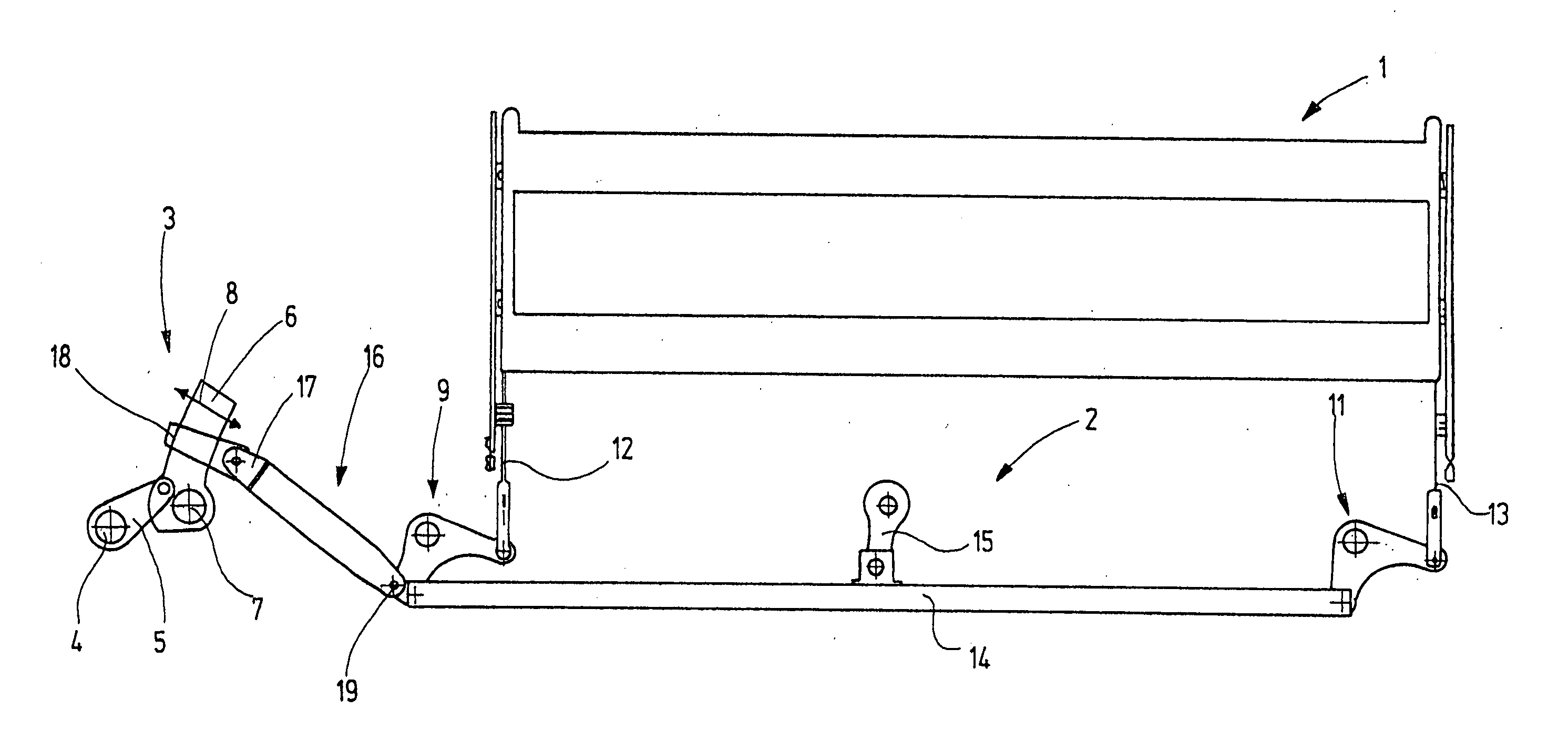

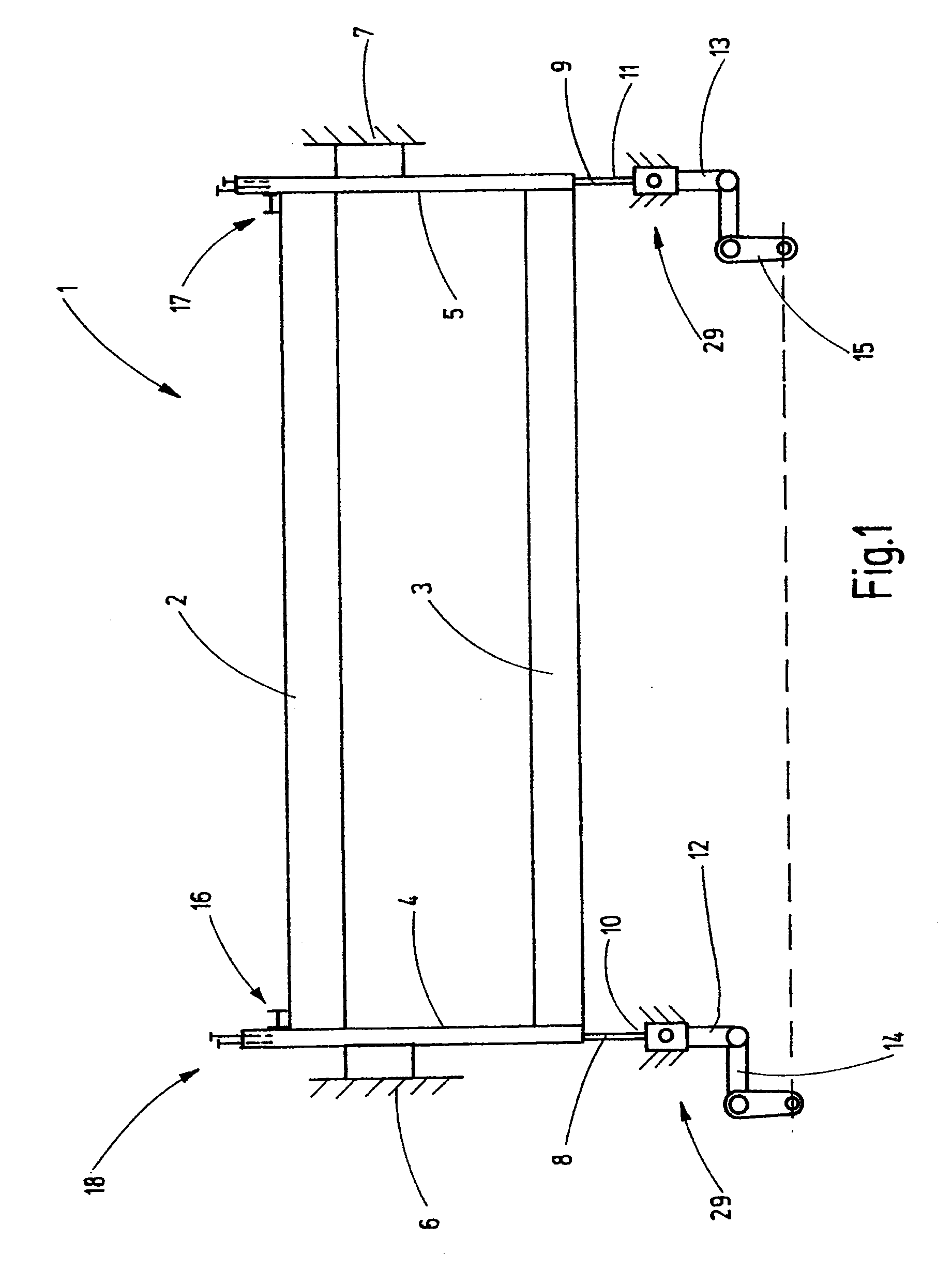

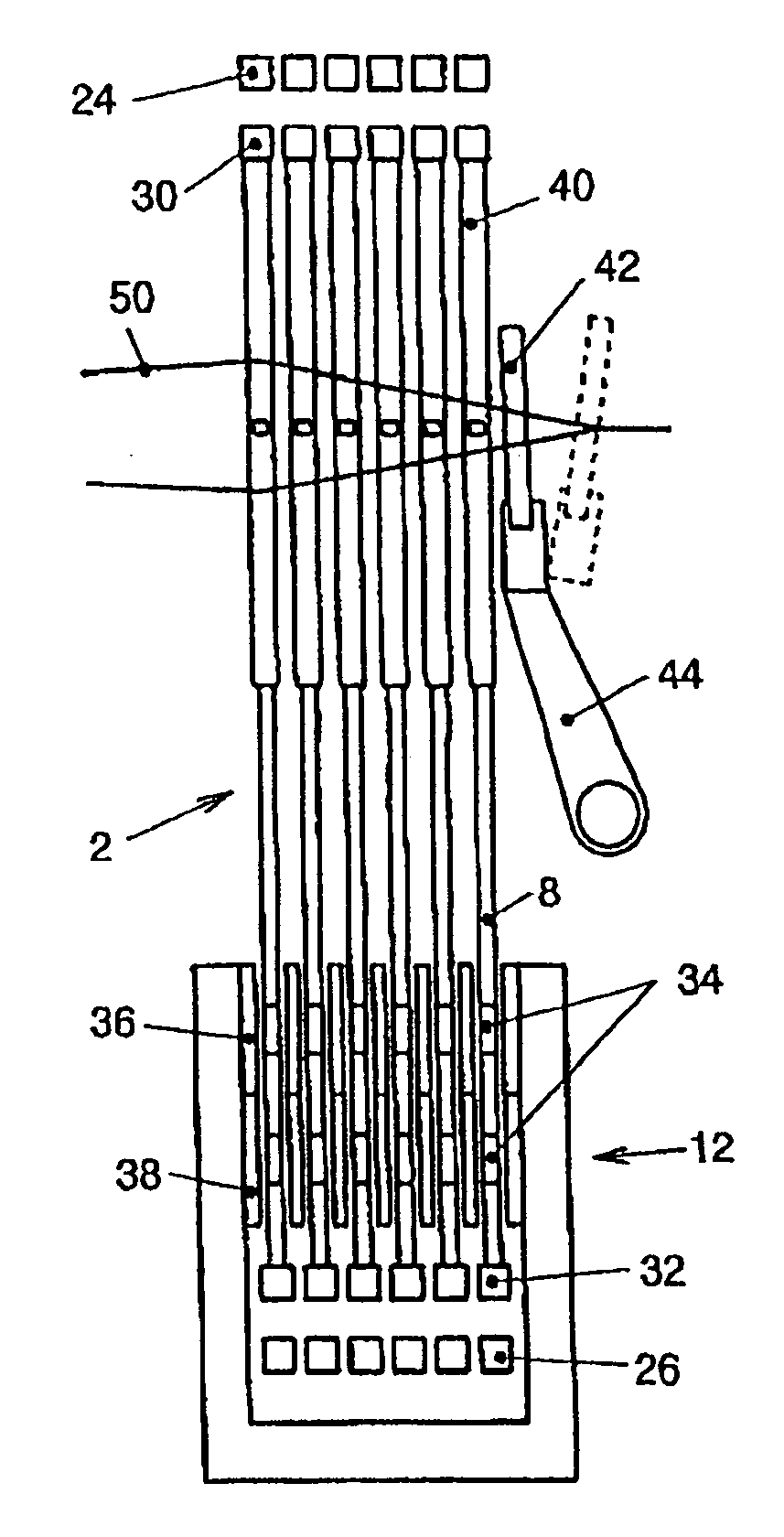

Low-vibration shedding system

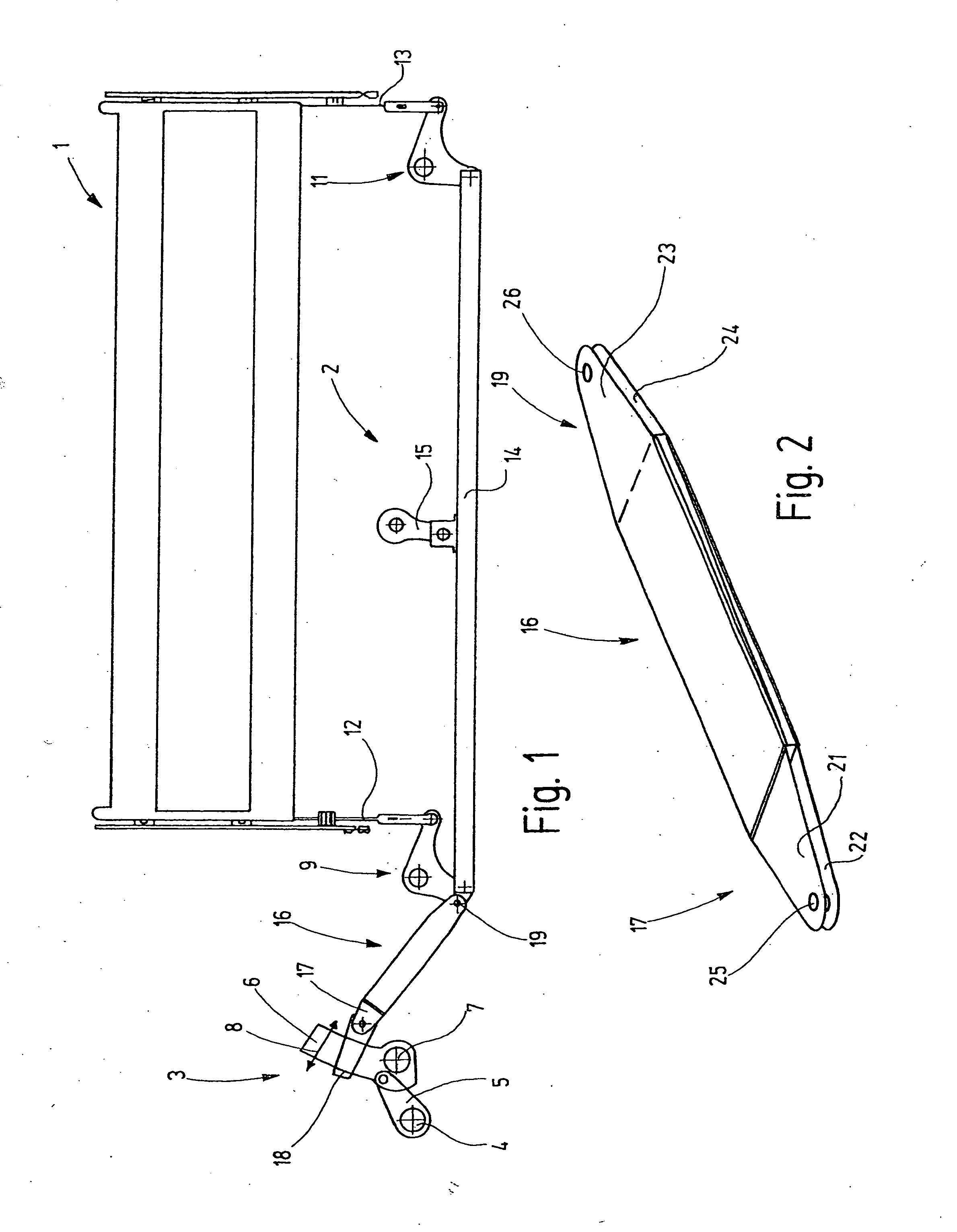

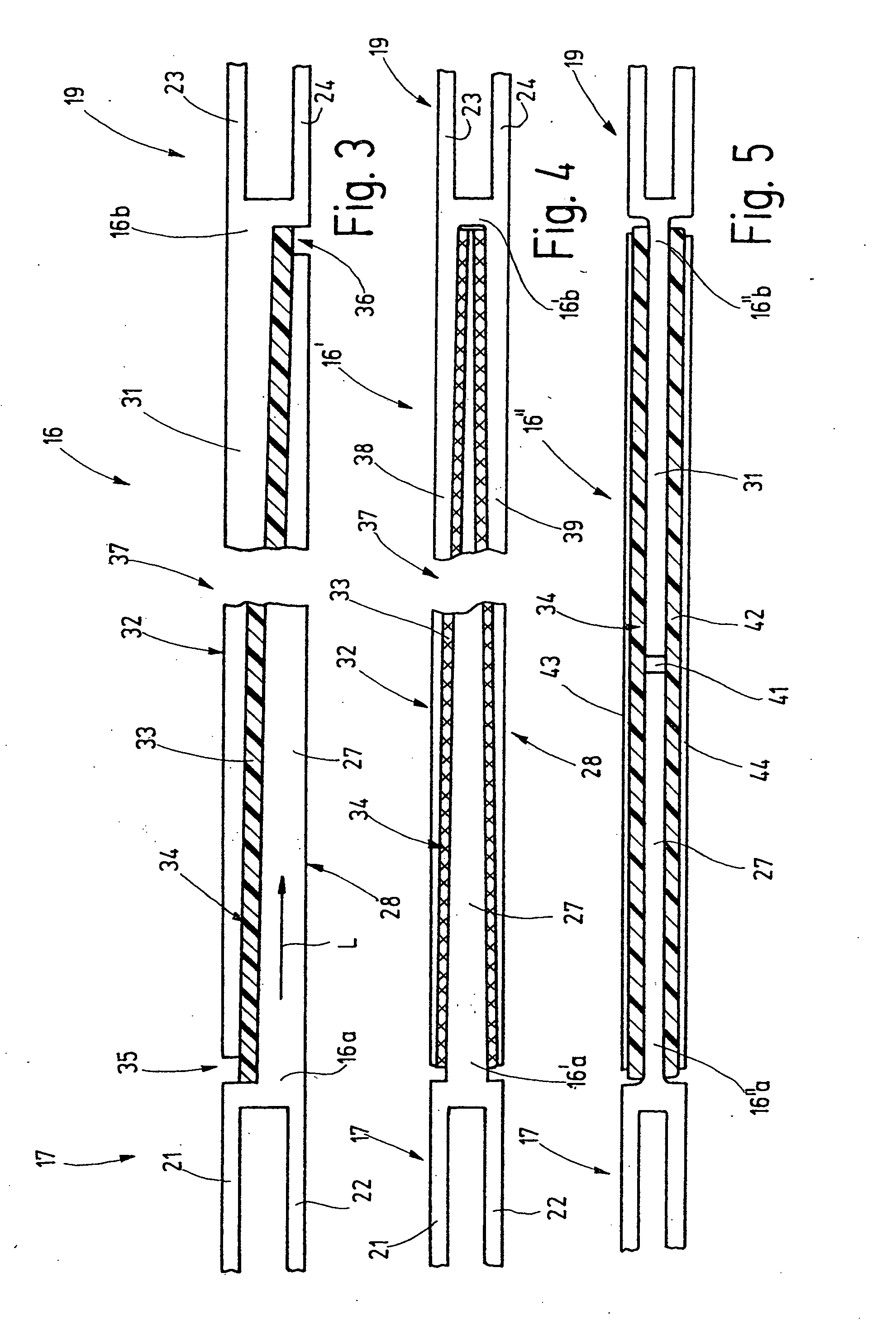

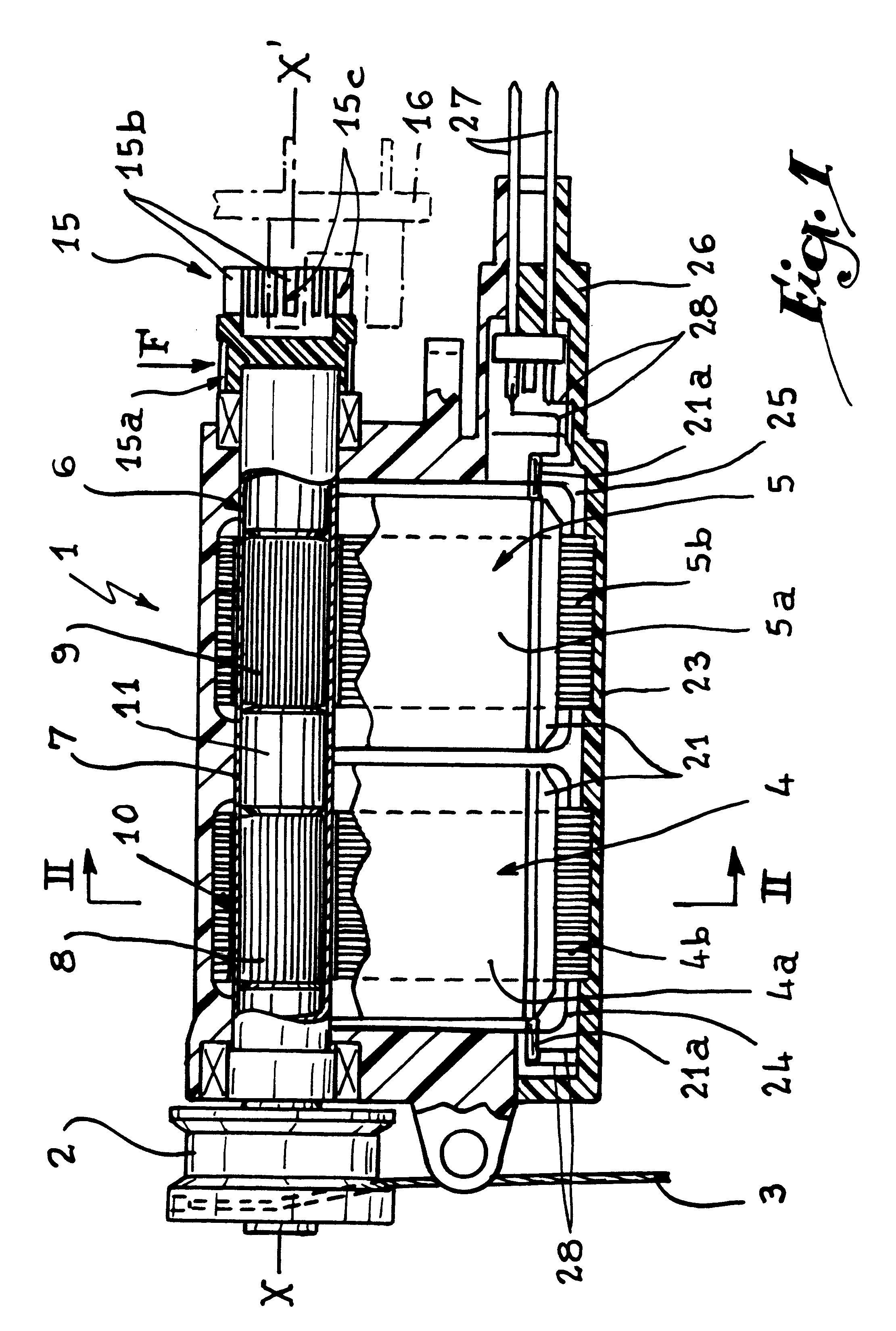

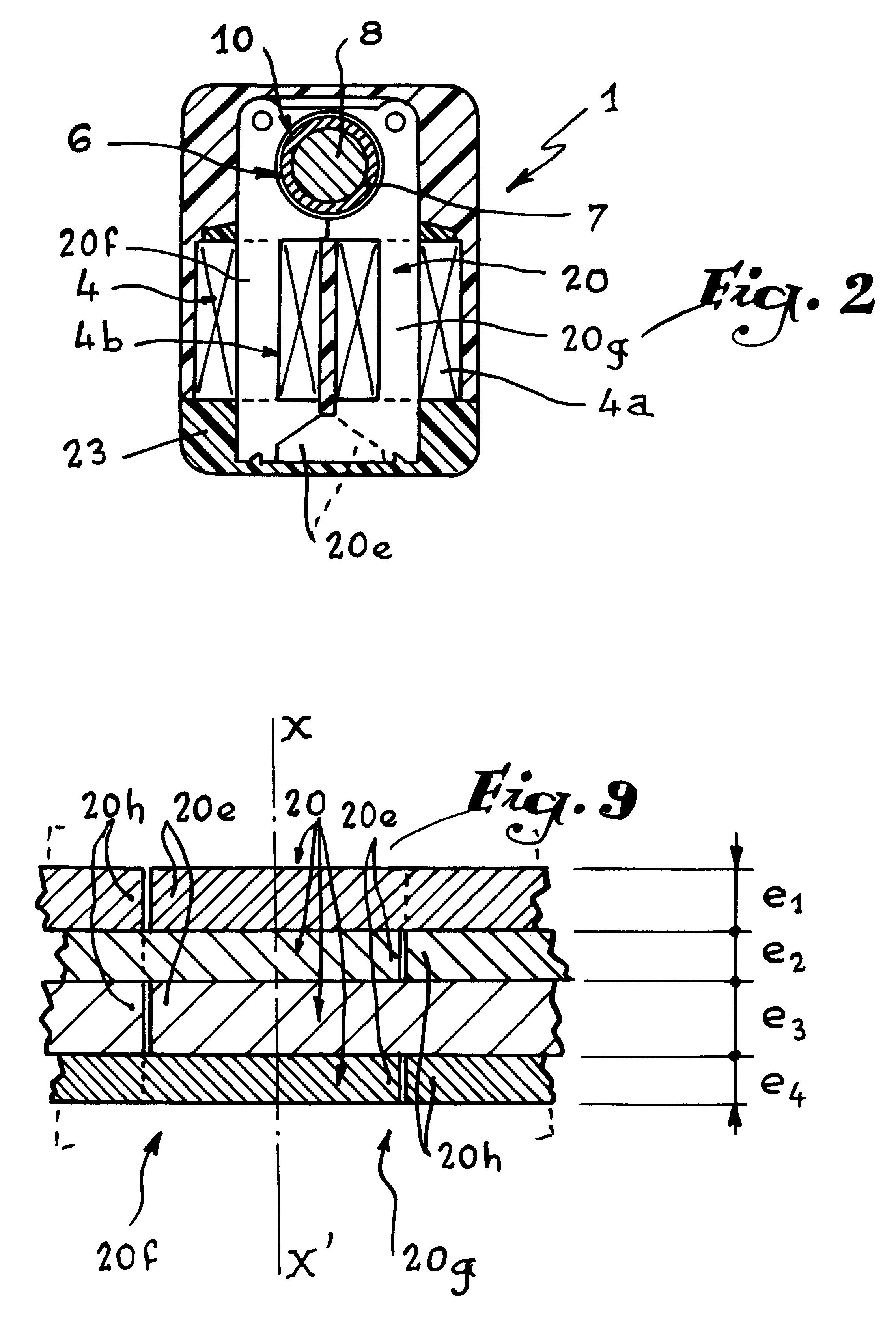

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

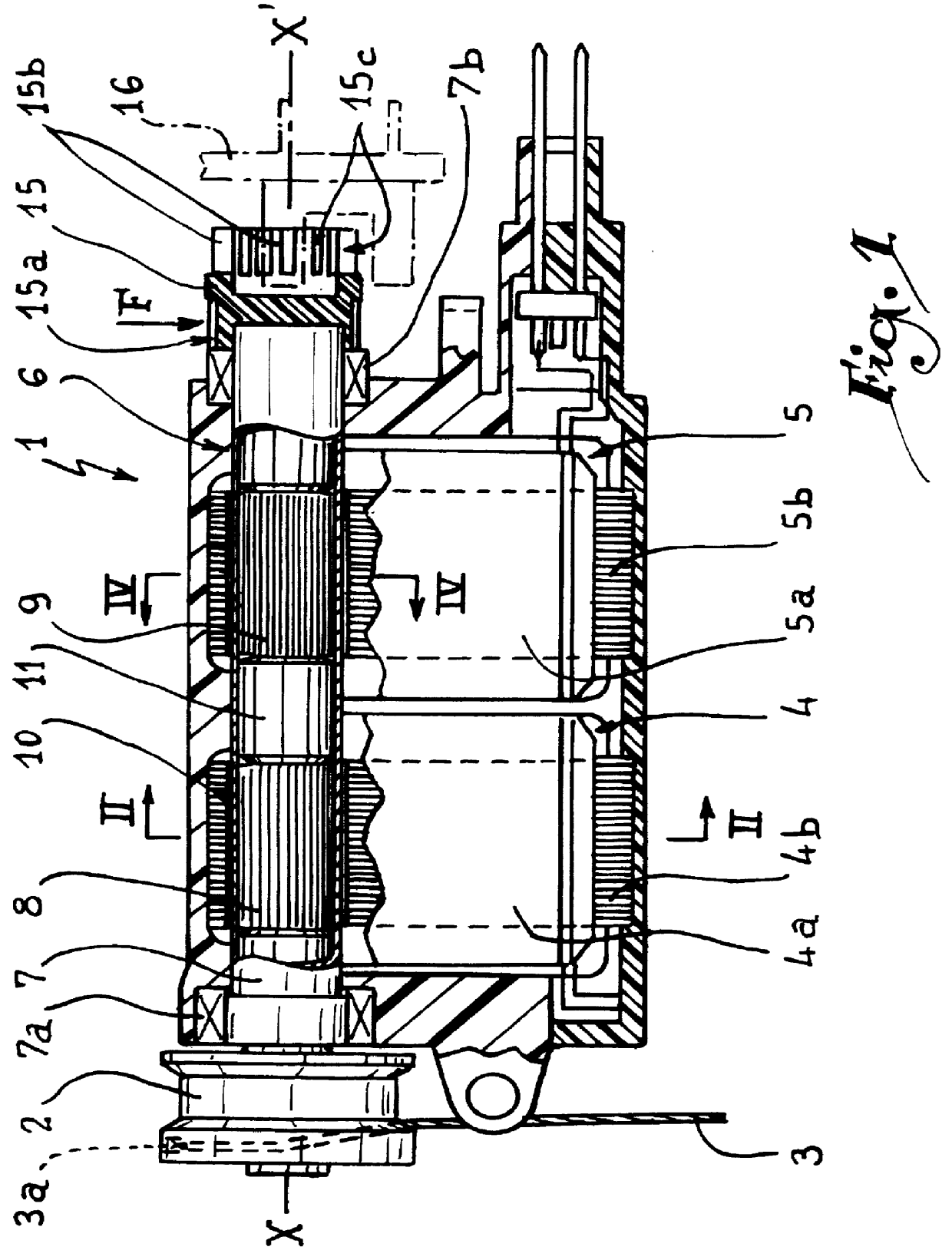

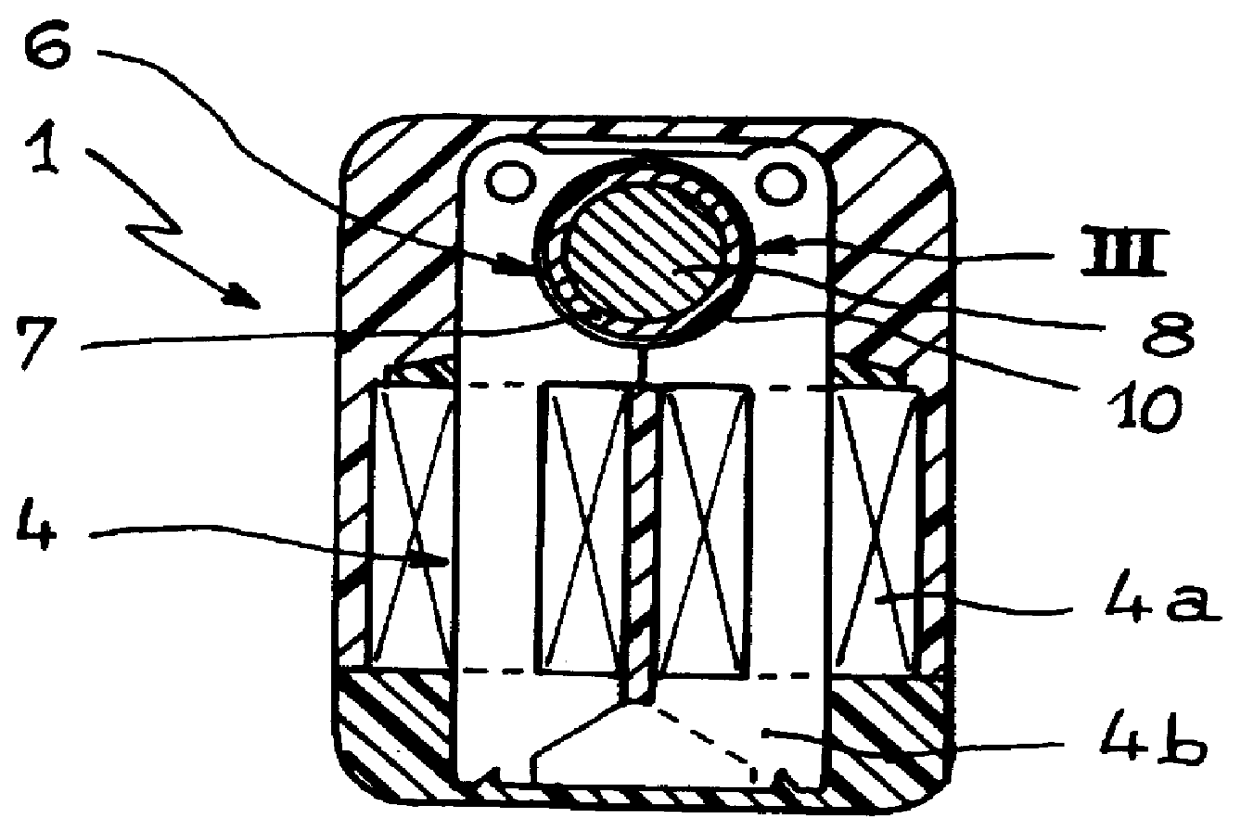

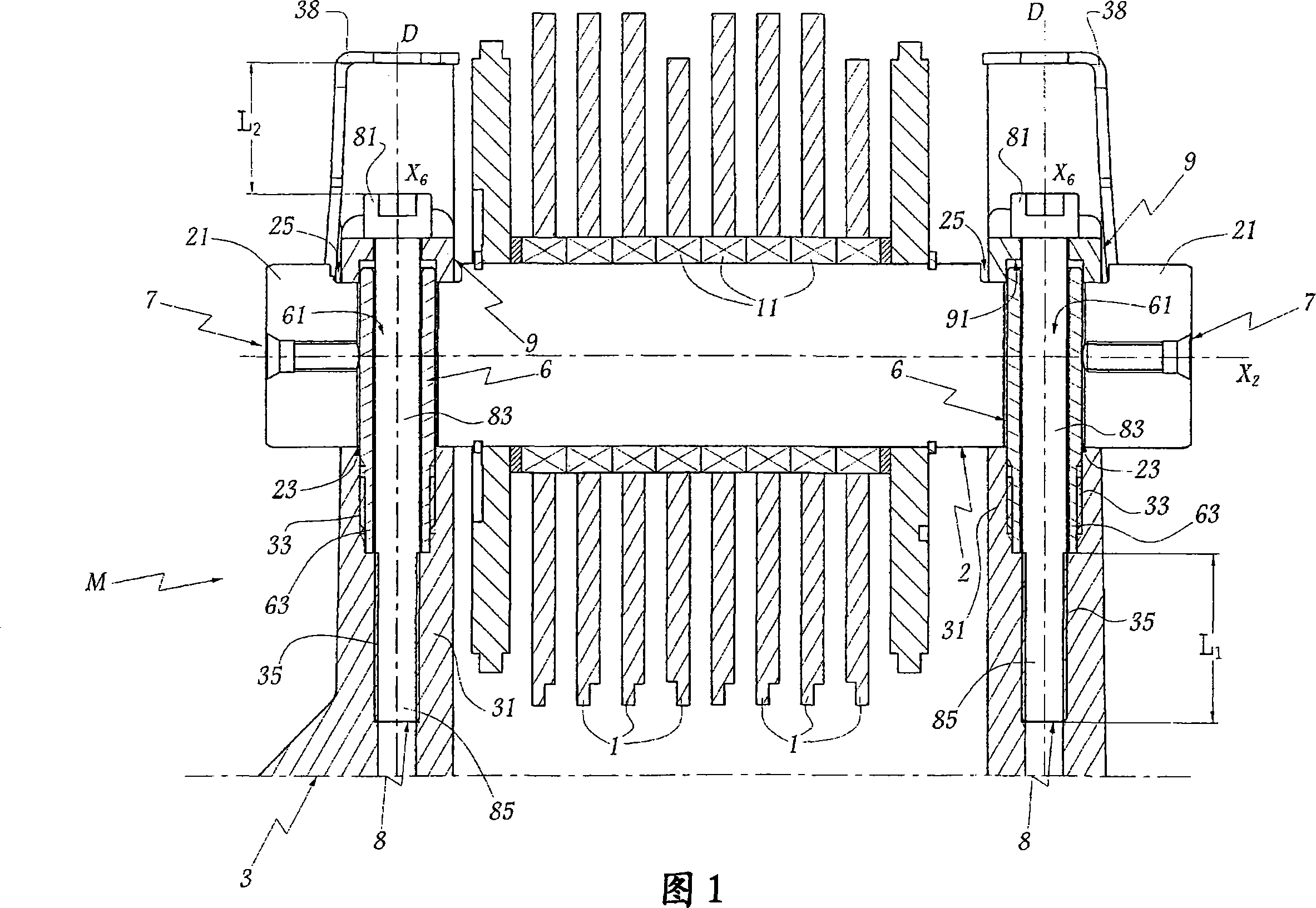

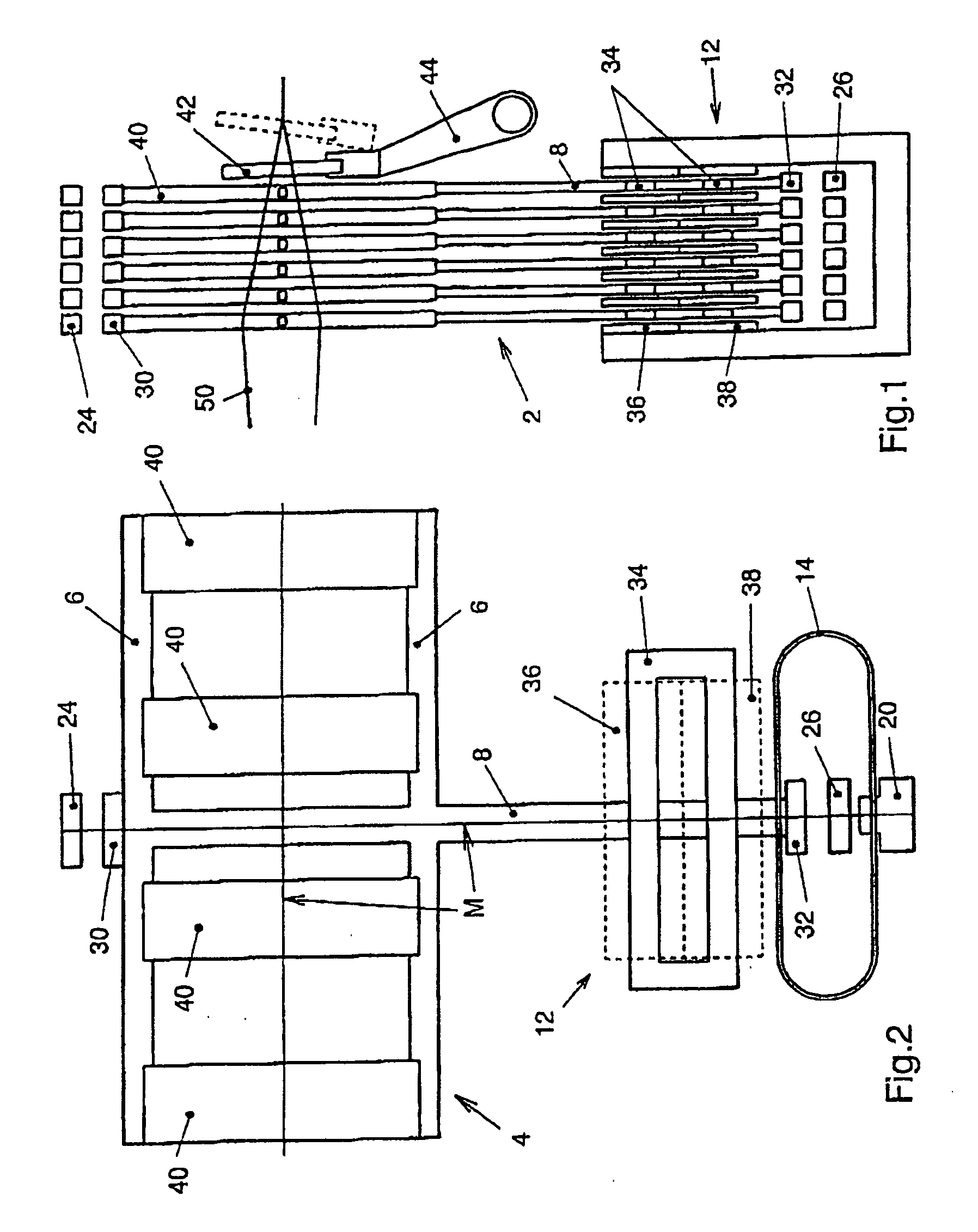

Drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have a external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

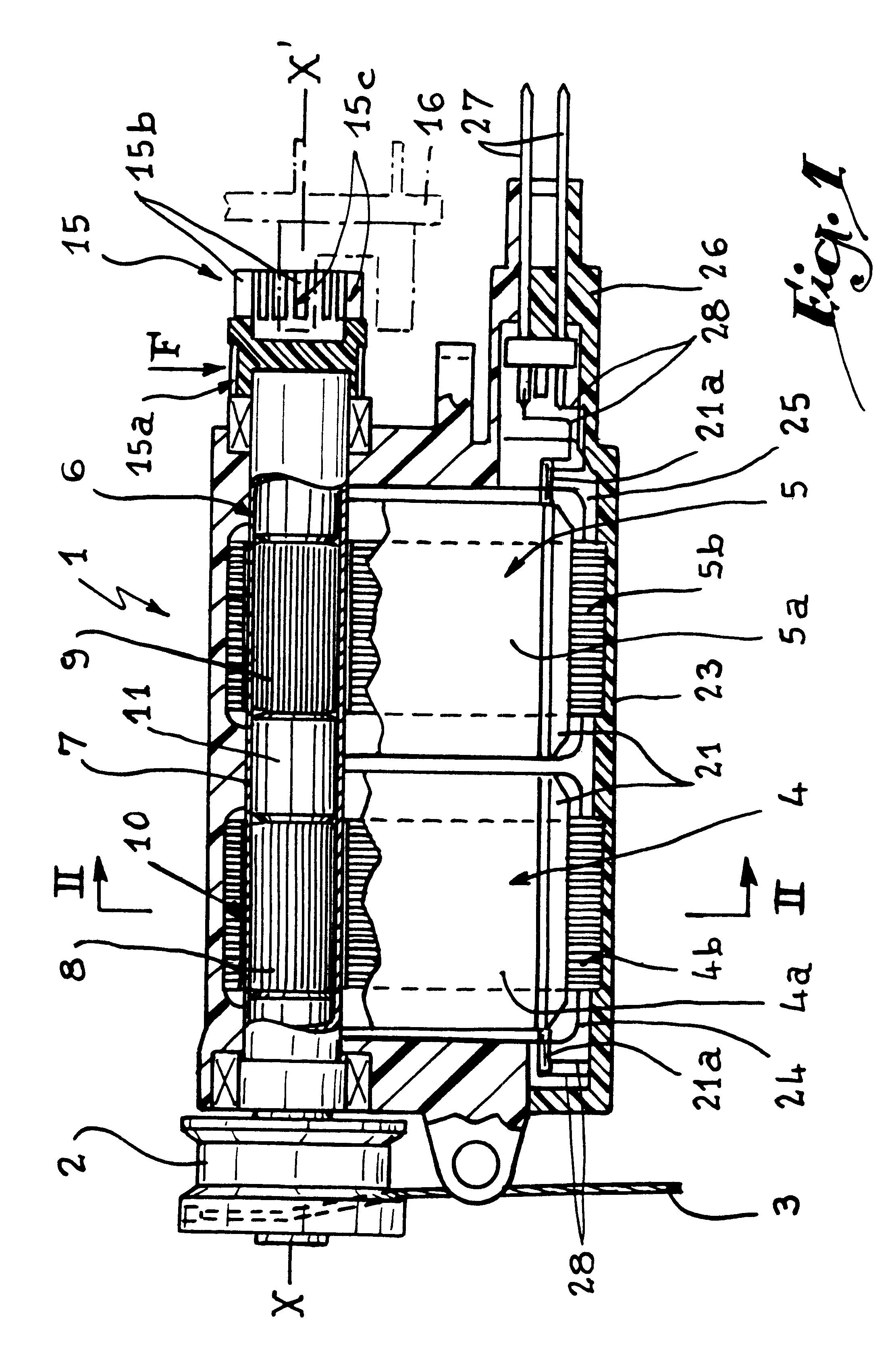

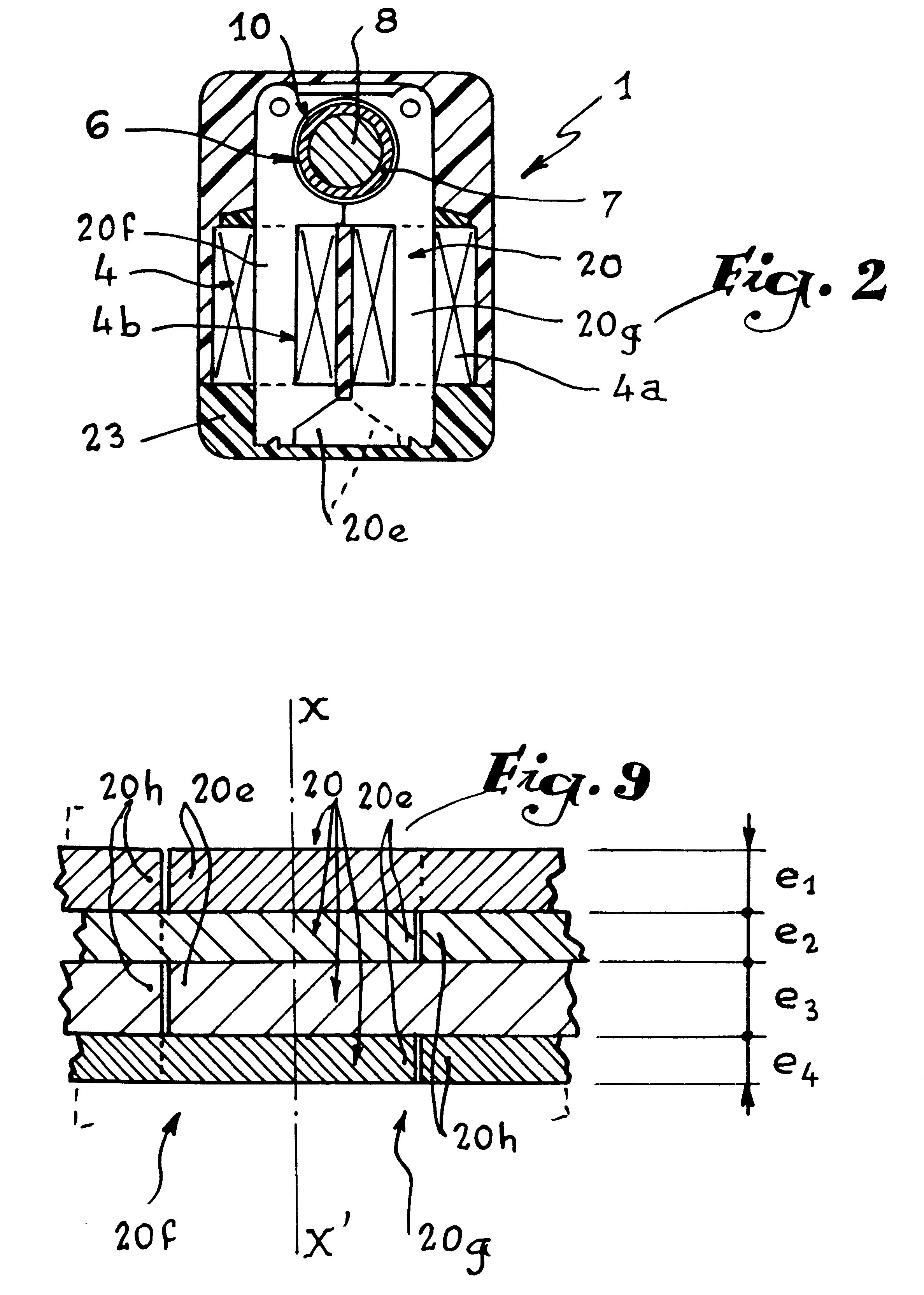

Electrical rotating actuator for forming a weaving loom shed

InactiveUS6105630AEasy to manufactureReduce the overall diameterJacquardsDobbiesElectrical polarityEngineering

An electrical rotating apparatus for controlling a harness cord associated with the shed of a weaving loom which includes an actuator including a rotor and a stator. The rotor is formed of at least two permanent magnets which are mounted within a tube so as to be spaced axially with respect to one another and wherein a plurality of stator elements are also provided offset axially relative to an axis of rotation of the rotor such that each of the plurality of rotors corresponds with a separate one of the plurality of stators. The polarities of one or the other of the permanent magnets or the stator elements are offset angularly relative to the axis of rotation.

Owner:STAUBLI FAVERGES SA

Shed forming device and weaving loom of the jacquard type equipped with such a device

ActiveCN1550592ARealize one-way controlEfficient driveJacquardsCam shedding mechanismJacquard loomStructural engineering

Owner:施托布利里昂公司

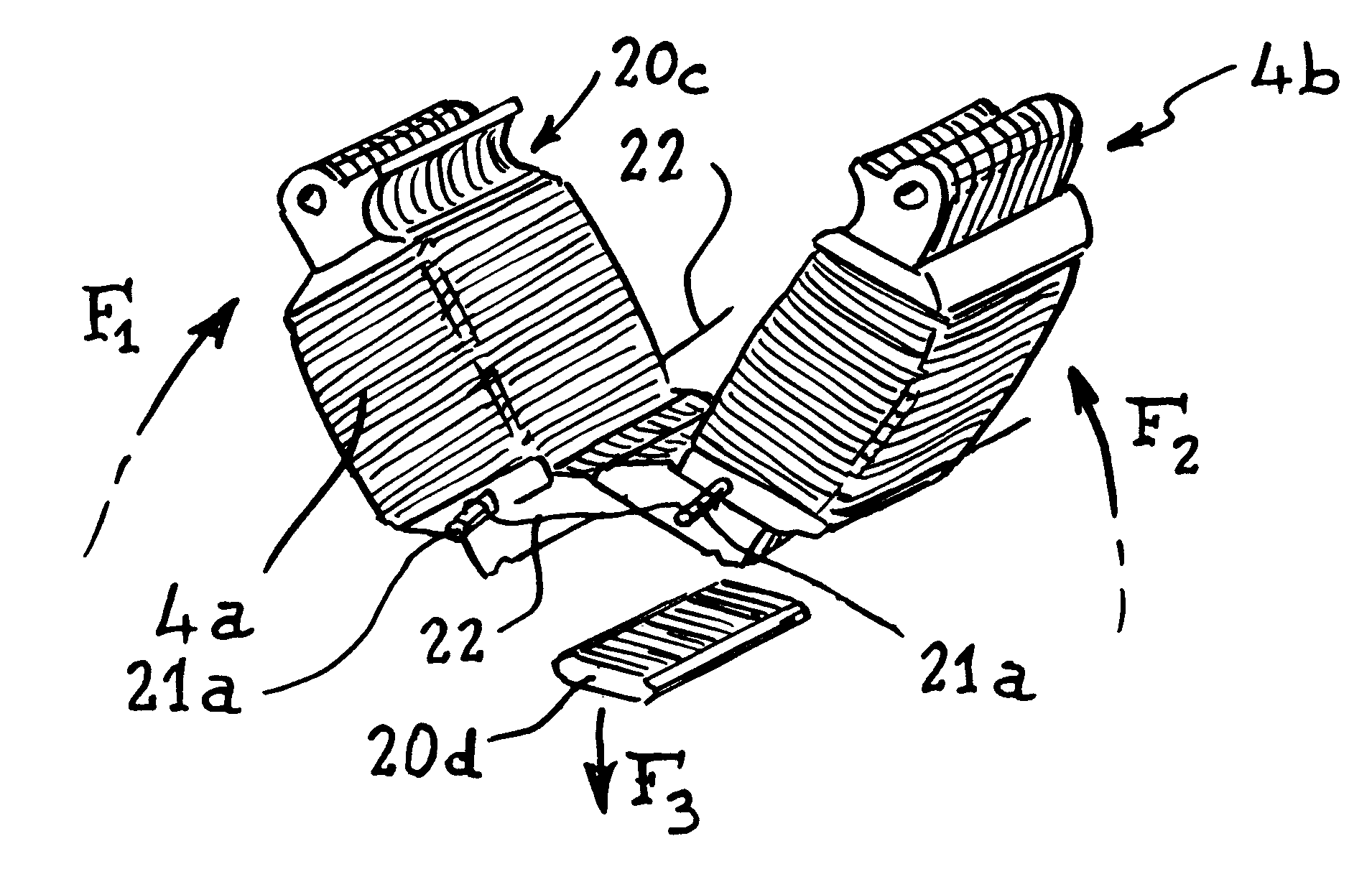

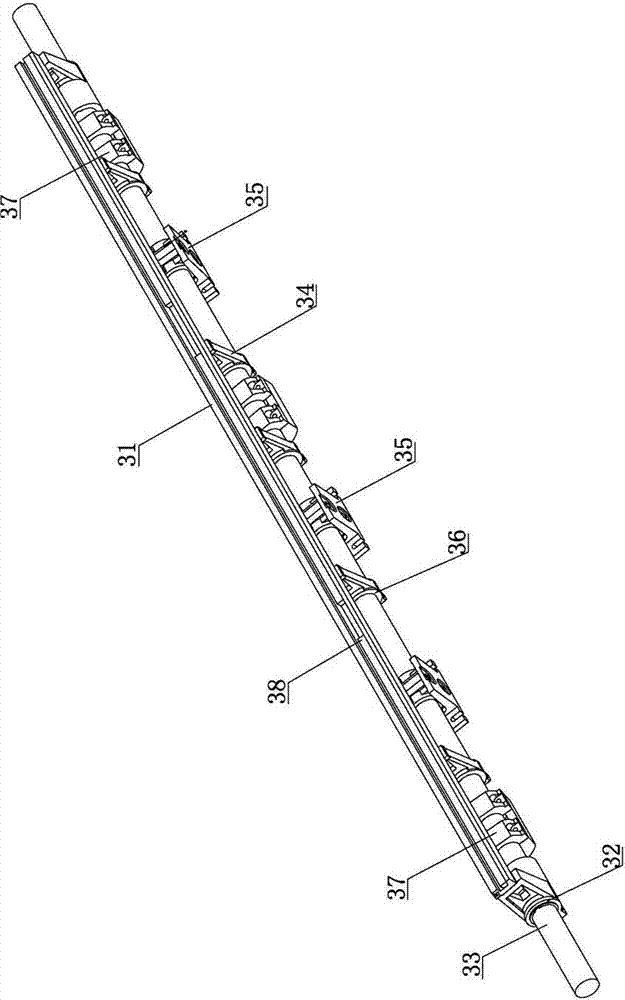

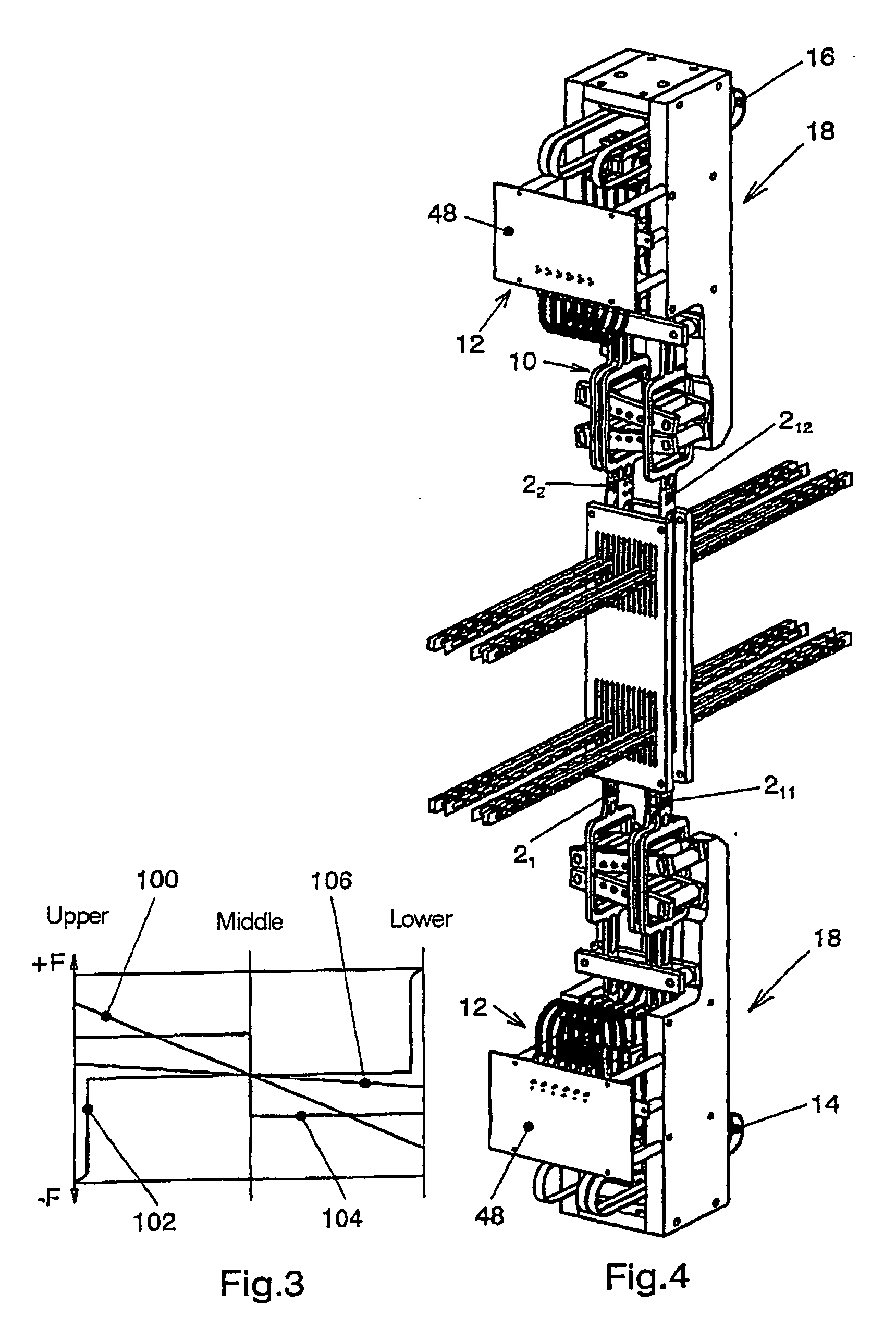

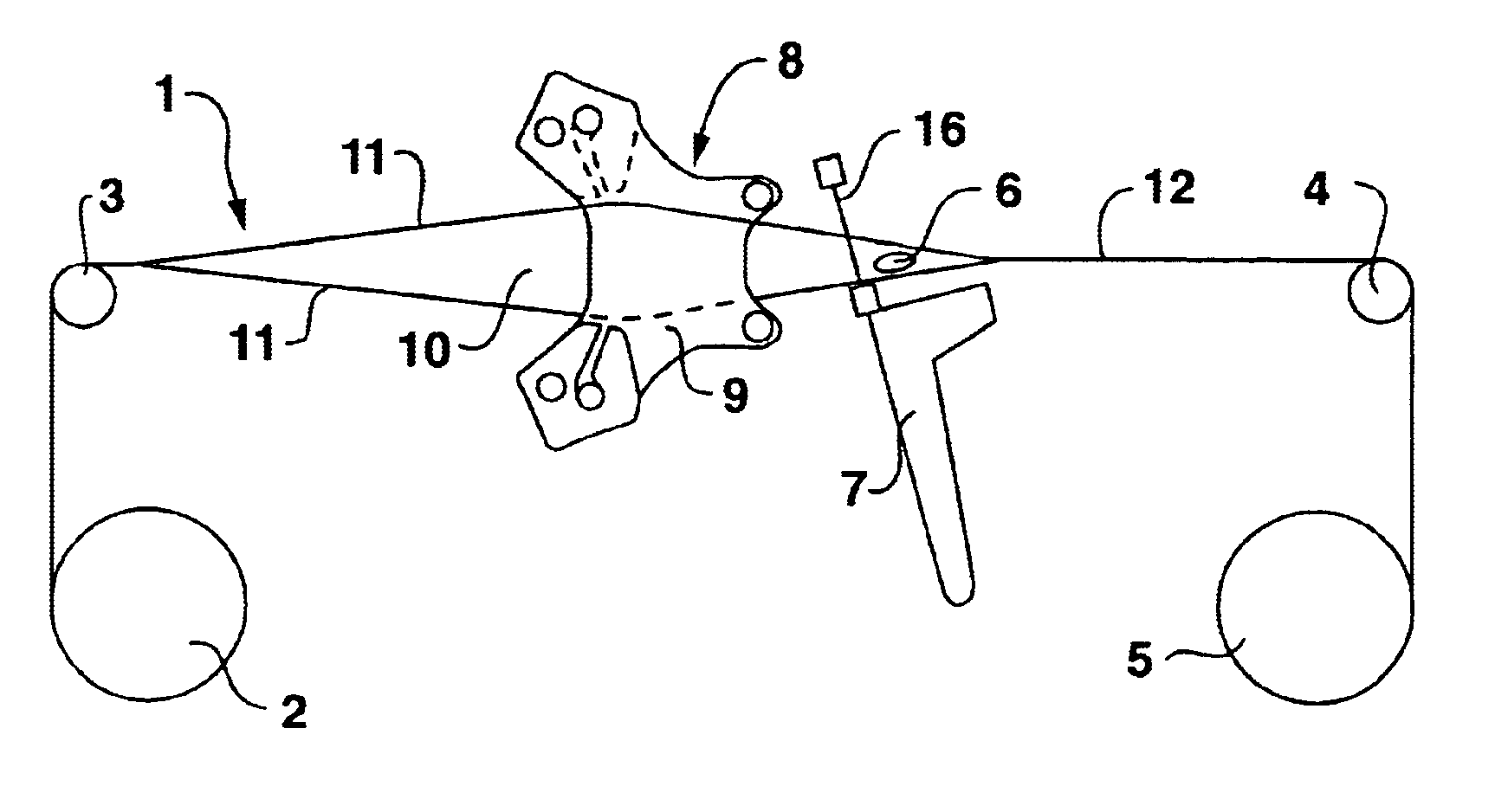

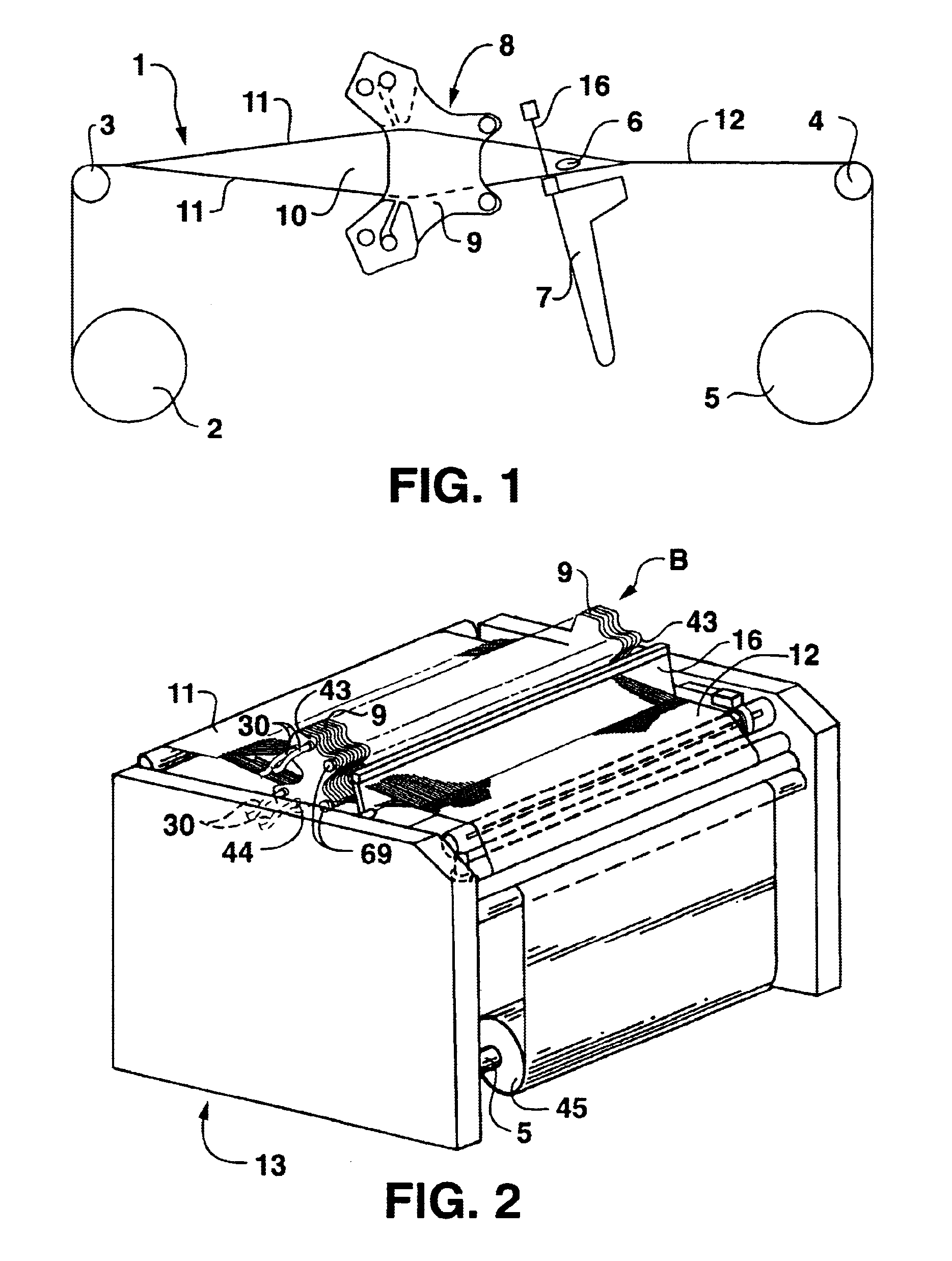

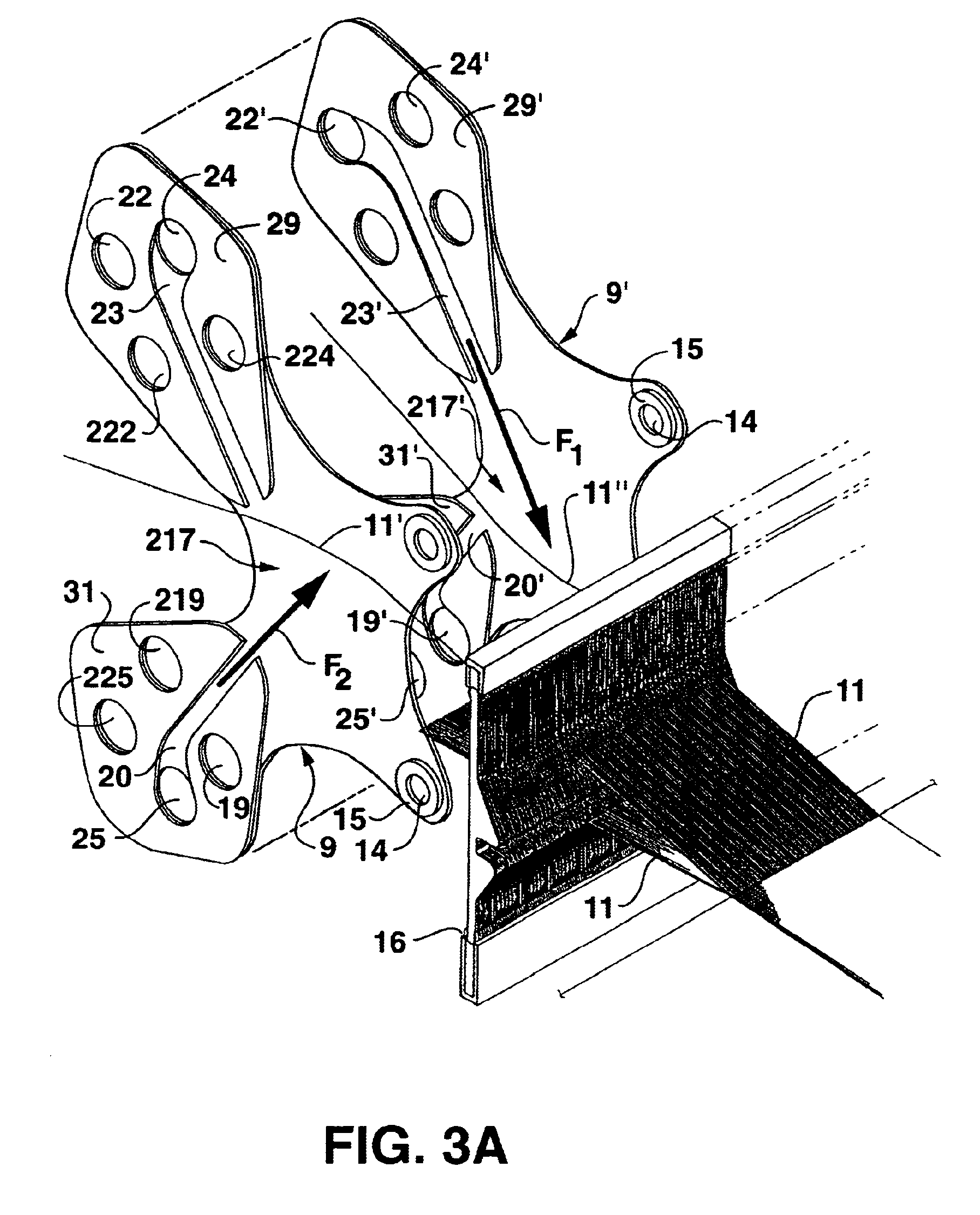

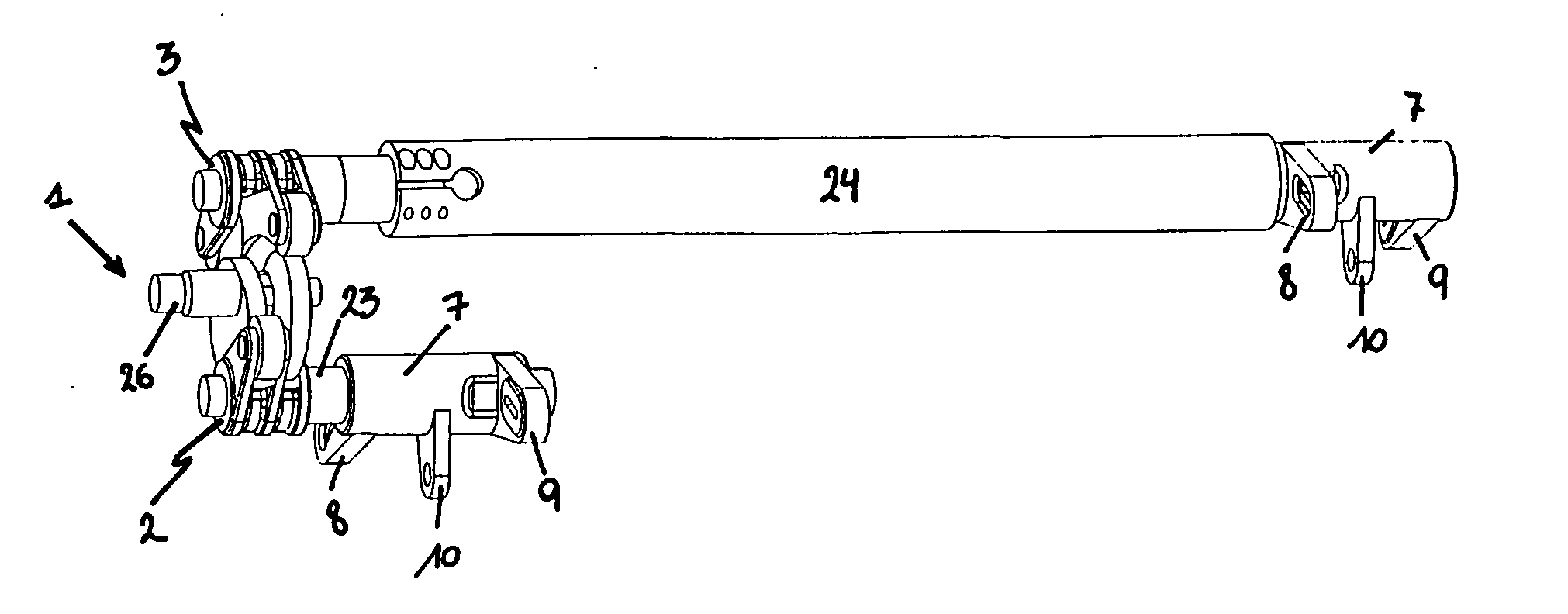

Low-vibration shedding system

InactiveUS20050051228A1Good oscillation absorptionImprove axial rigidityWeft knittingDobbiesCouplingEngineering

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

Shedding device in weaving machine

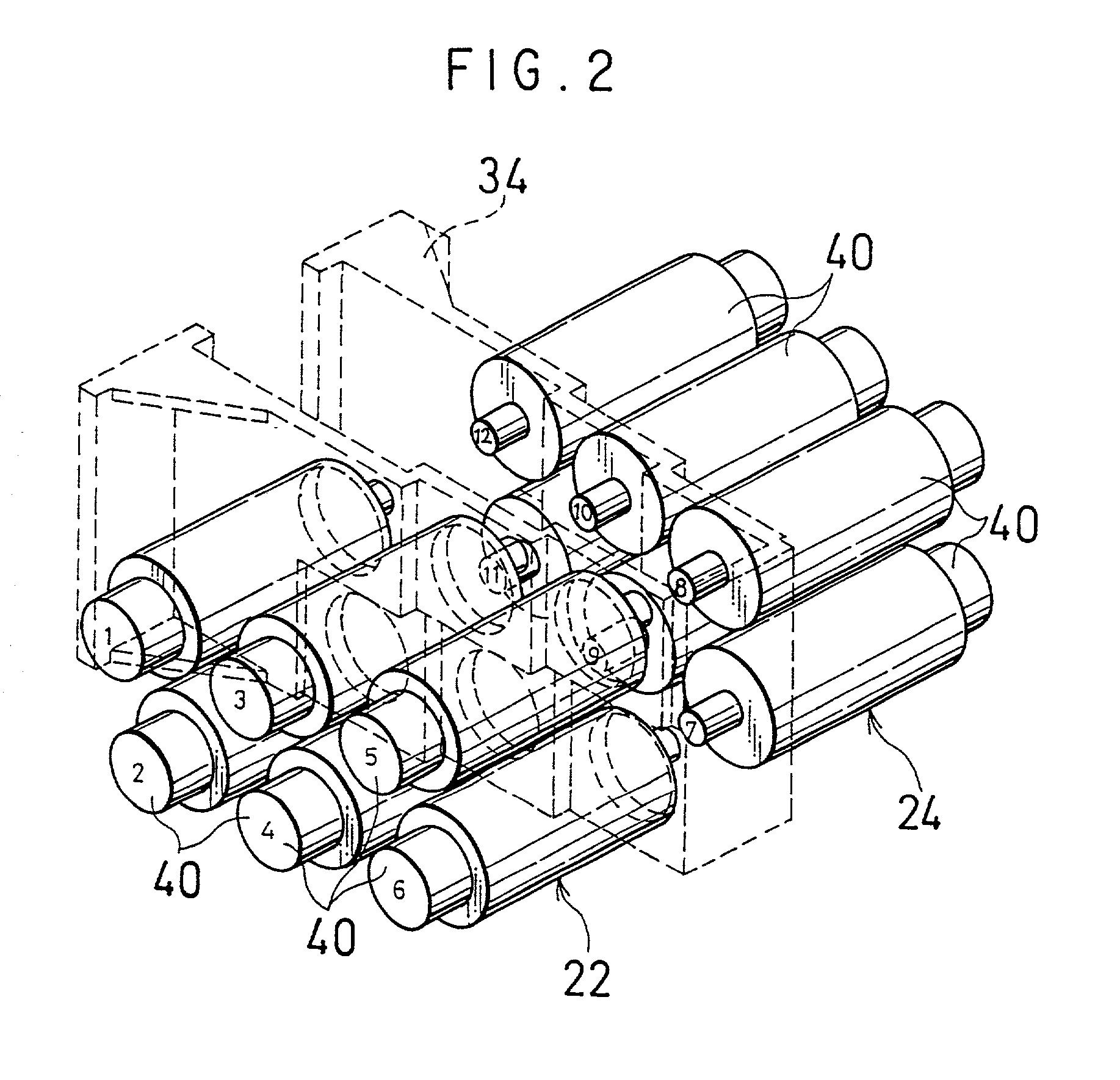

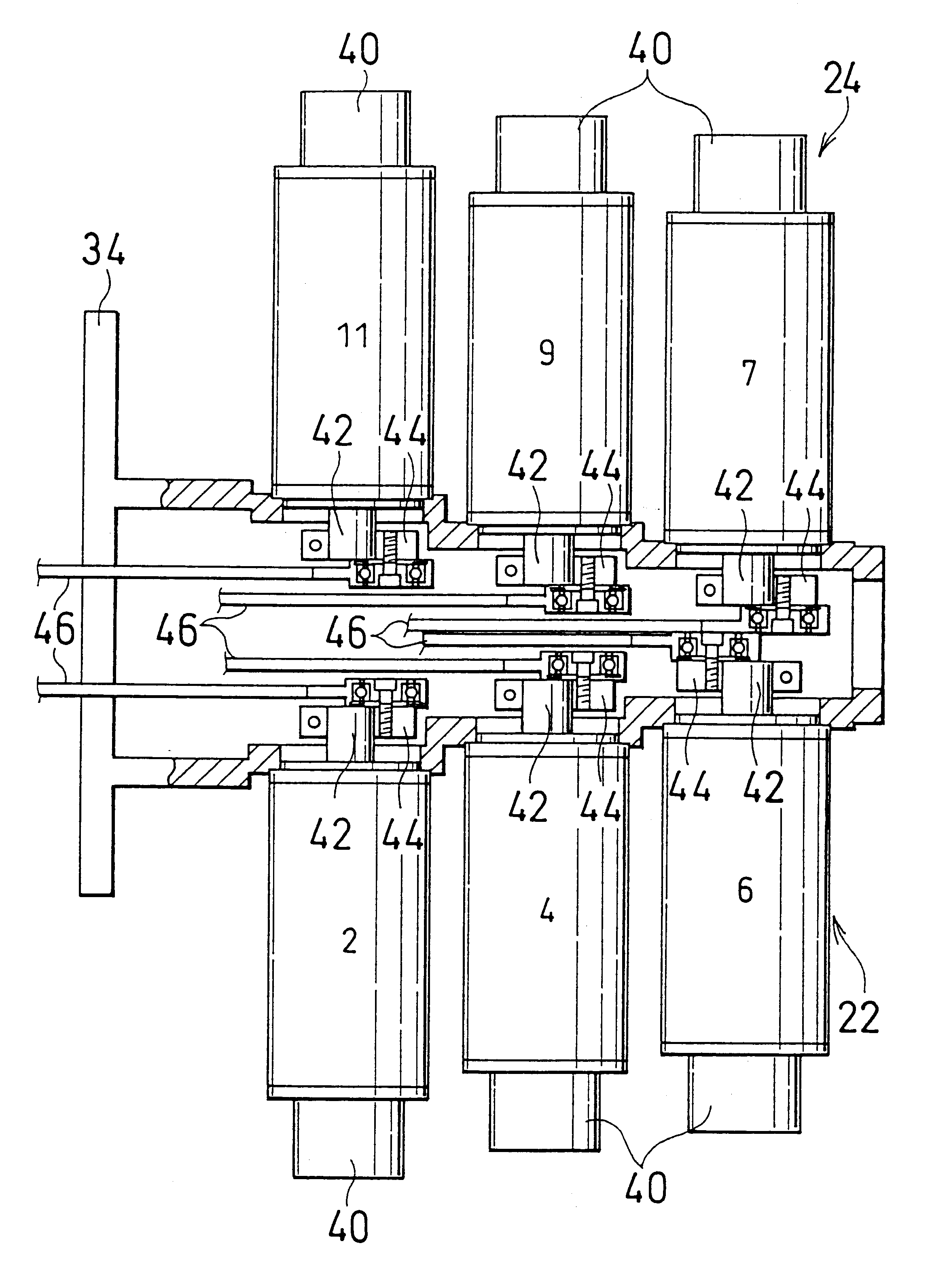

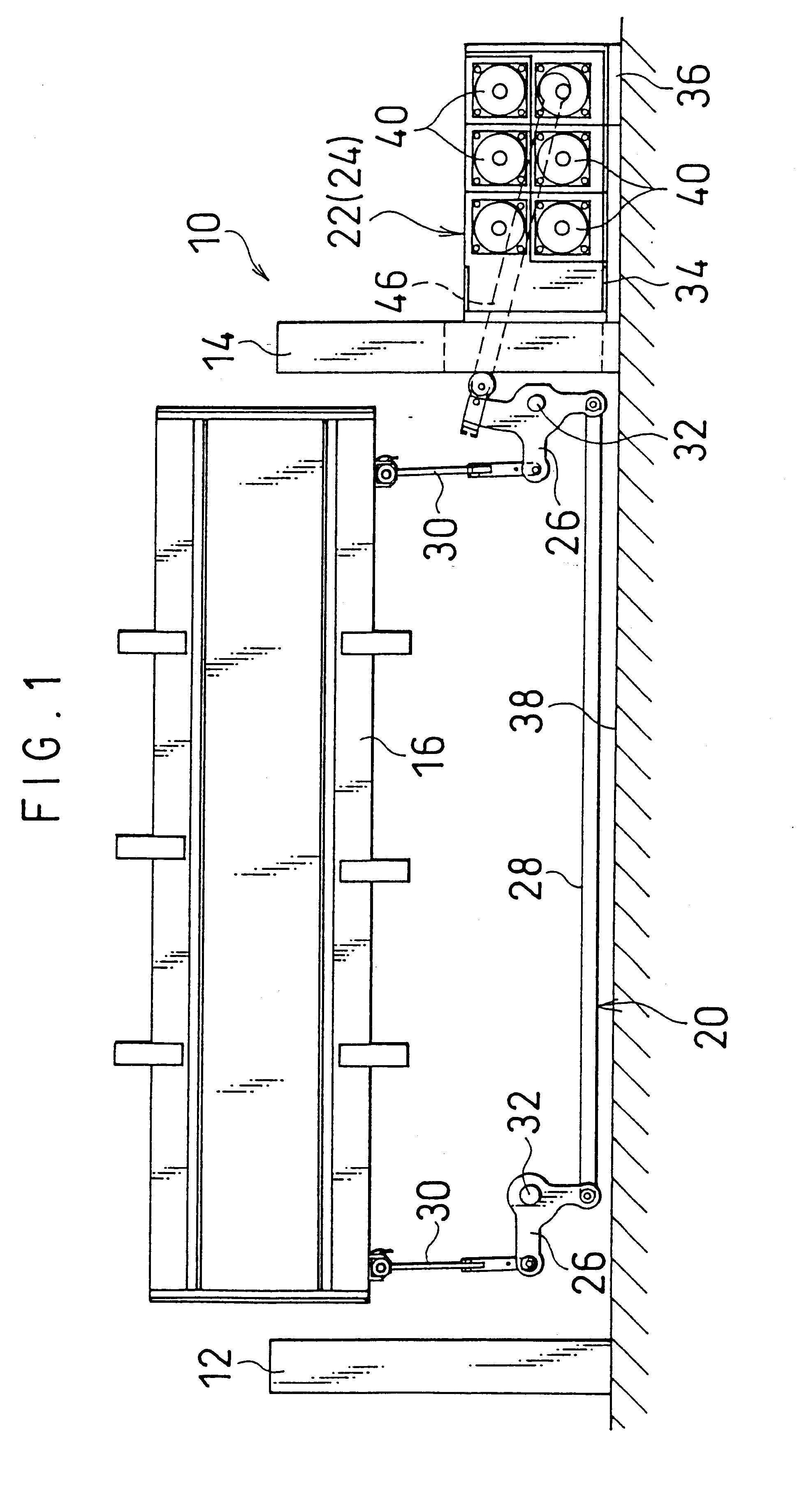

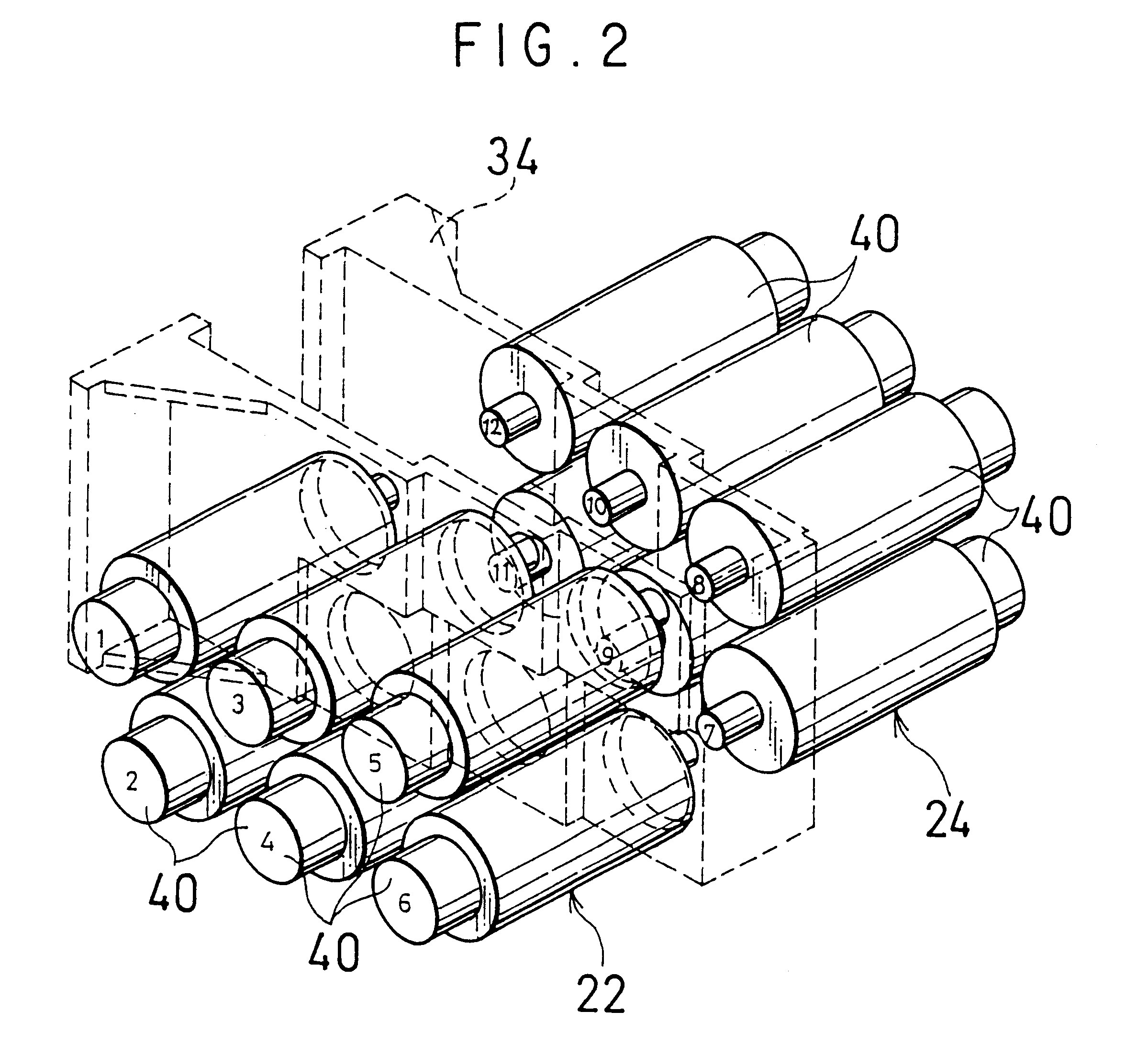

InactiveUS20020046777A1Improve directionIncrease distanceCam shedding mechanismOther shedding mechanismMarine engineeringElectric motor

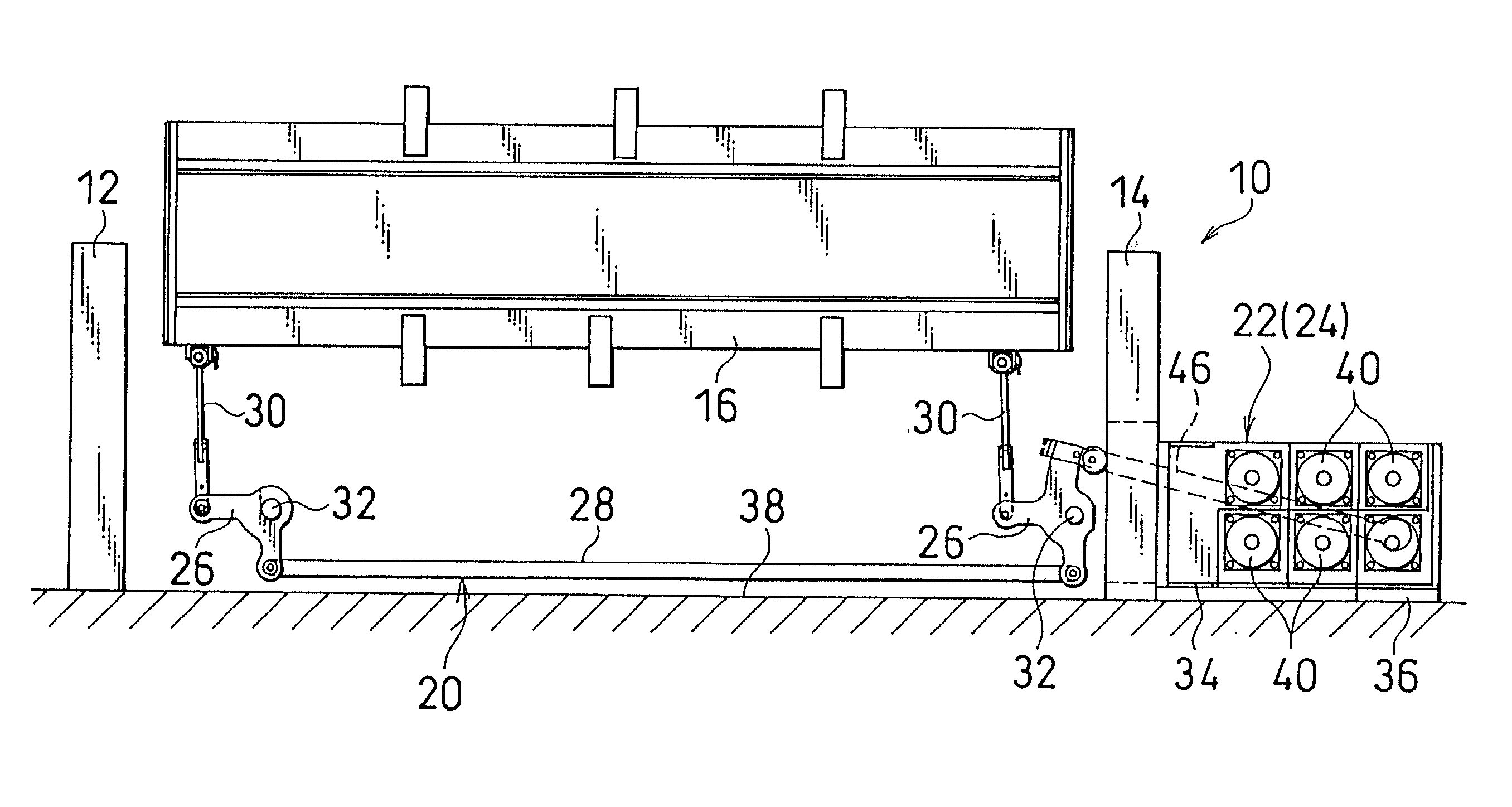

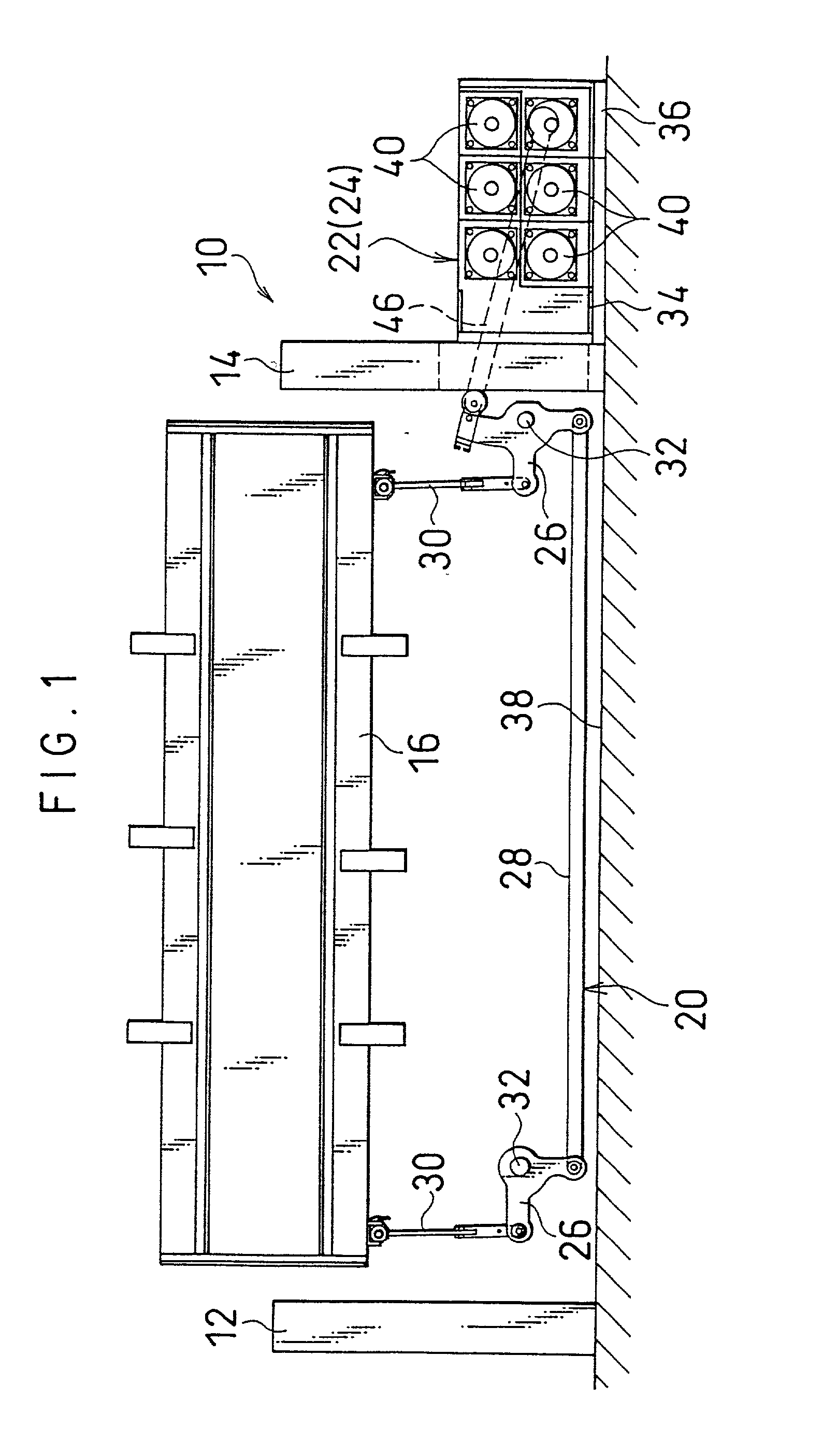

A shedding device in a weaving machine comprises one or more motor groups including a plurality of motors provided in every heald frame and directing their output shafts in the forward and backward direction of the weaving machine. The motors of each motor groups are arranged in the upward and downward, rightward and leftward directions, and two or more motors operating as at least part of the motor group are arranged in the longitudinal direction of a connecting member connecting the motors with support mechanisms of the heald frames to form one or more motor rows opposing to one or more connecting members, and adjoining motors in the motor row or rows are related to non-adjoining heald frames among the heald frames corresponding to the support mechanisms.

Owner:TSUDAKOMA KOGYO KK

Electric motor drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have an external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

Heald-frame height adjusting apparatus

InactiveCN101624738AEasy height adjustment workReduce manufacturing costsDobbiesCam shedding mechanismEngineeringMechanical engineering

Owner:TSUDAKOMA KOGYO KK

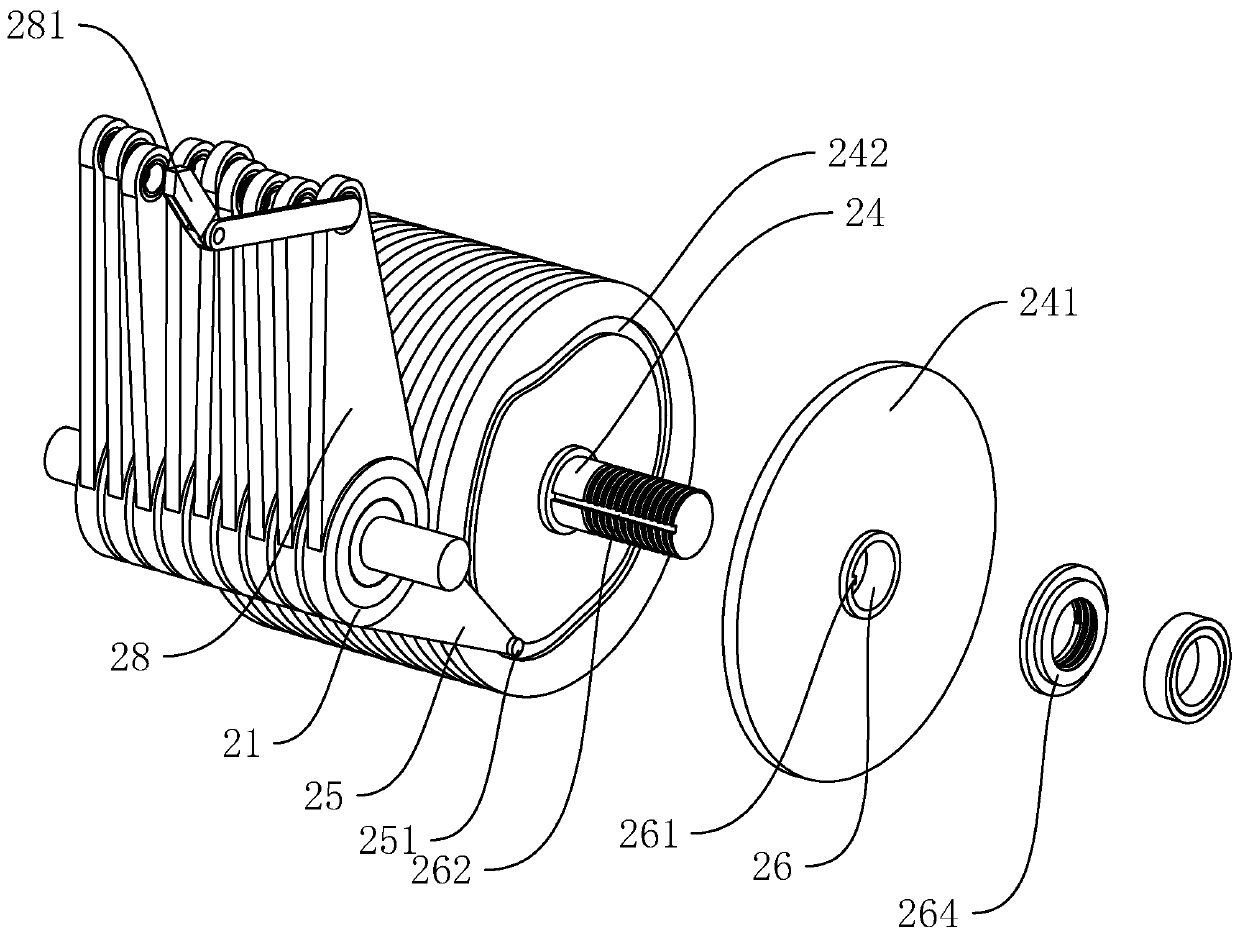

Process of manufacturing an electrical rotating actuator such as for use in weaving looms and weaving systems

InactiveUS6237213B1Efficient transferEasy to employJacquardsCam shedding mechanismEngineeringRotary actuator

A method of forming a stator for an electrical actuator of a type which may be used in weaving looms and weaving systems wherein a stack of armature plates having two-spaced sections are initially wrapped with an electrically conductive wire to create two coils afterwhich the stack is folded to sever severable bridge elements of the stack and to form an armature to include a tubular housing for a rotor.

Owner:STAUBLI FAVERGES SA

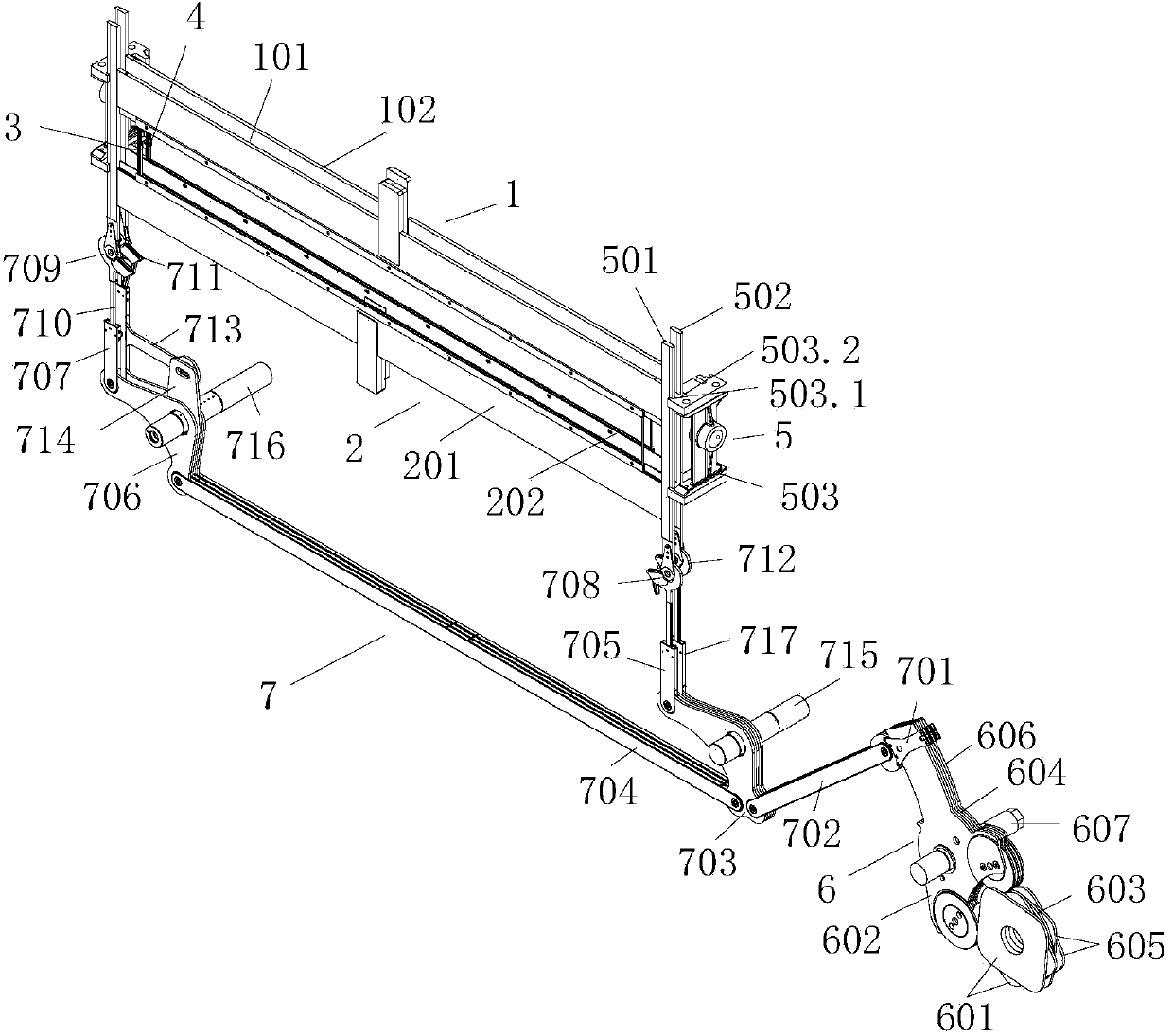

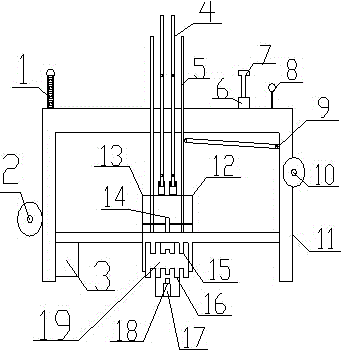

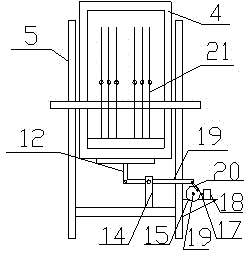

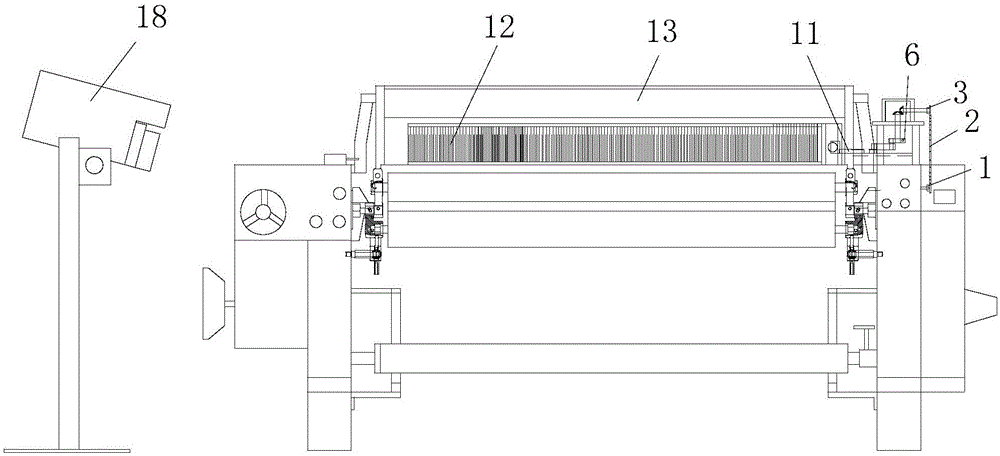

Cross woven opening device of weaving machine

The invention discloses a cross woven opening device of a weaving machine. The cross woven opening device comprises a heald frame mechanism, a driving device, a guide mechanism and a transmission mechanism as well as a heald frame upper beam and a heald frame lower beam, wherein the heald frame upper beam comprises a first upper heald frame and a second upper heald frame; the heald frame lower beam comprises a first lower heald frame and a second lower heald frame; the first upper heald frame and the first lower heald frame are positioned in a same vertical plane; the second upper heald frame and the second lower heald frame are positioned in a same vertical plane; multiple first cross woven reeds are transversely and uniformly arranged between the first upper heald frame and the first lower heald frame; multiple second cross woven reeds opposite to the first cross woven reeds are transversely and uniformly arranged between the second upper heald frame and the second lower heald frame; the first cross woven reeds and the second cross woven reeds comprise upper reed beams and lower reed beams; multiple sheet full reed teeth are formed between the upper reed beams and the lower reed beams; a semi-reed tooth is arranged between each two adjacent full reed teeth. According to the invention, high-speed operation is promoted, the staggered motion time of warp yarns is short, the weft insertion time can be increased, weft insertion is promoted, and the application range is wide.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

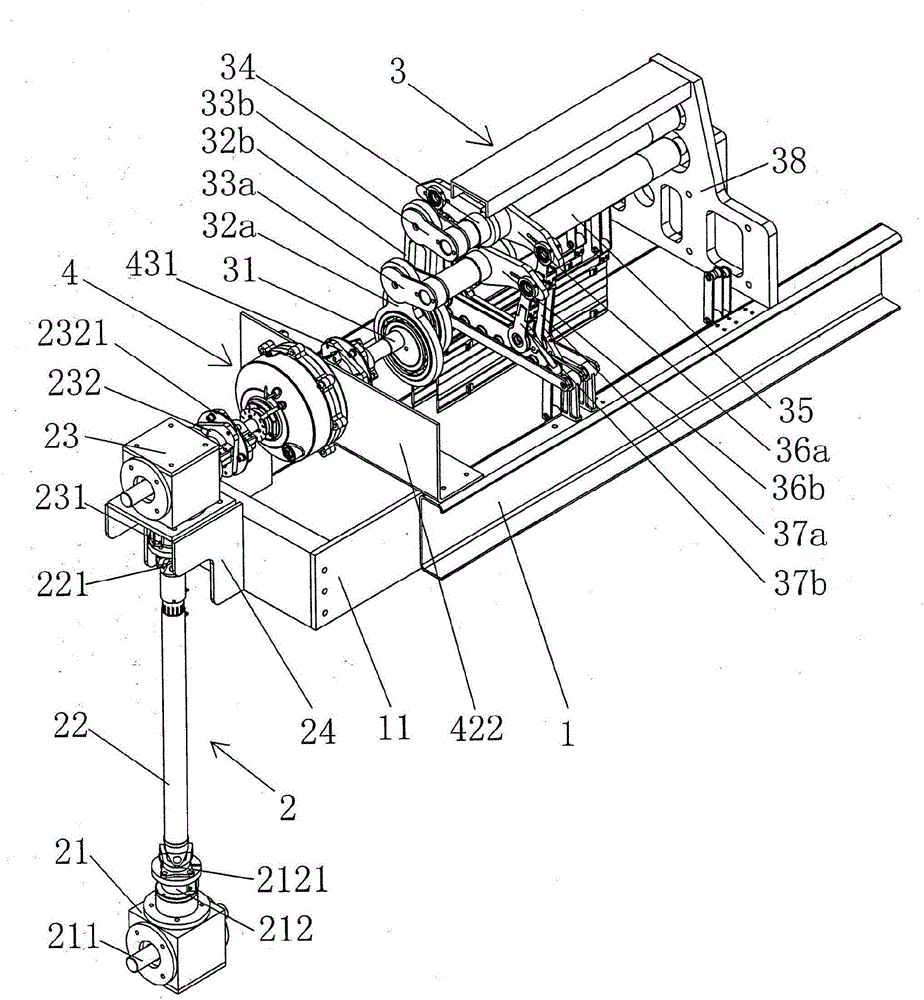

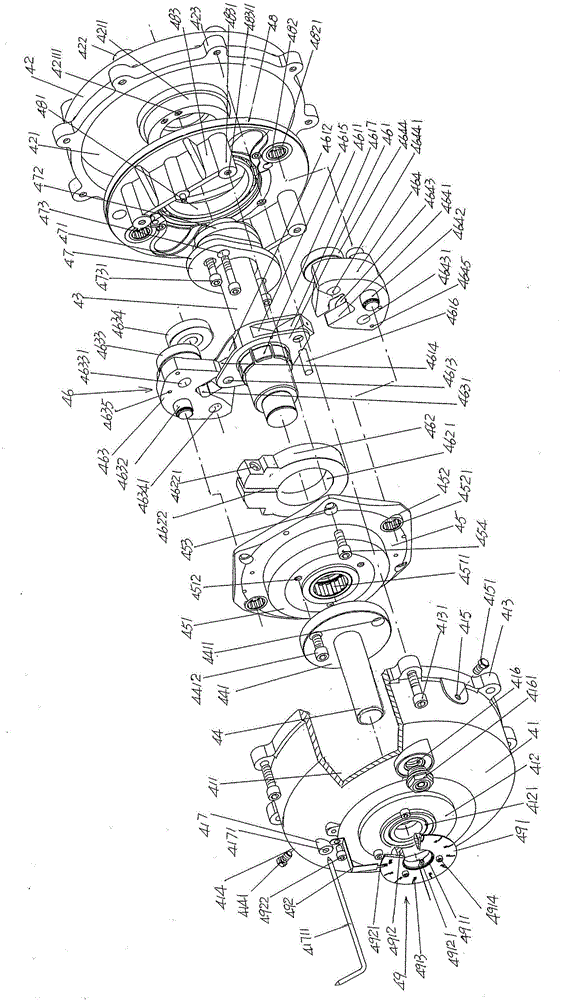

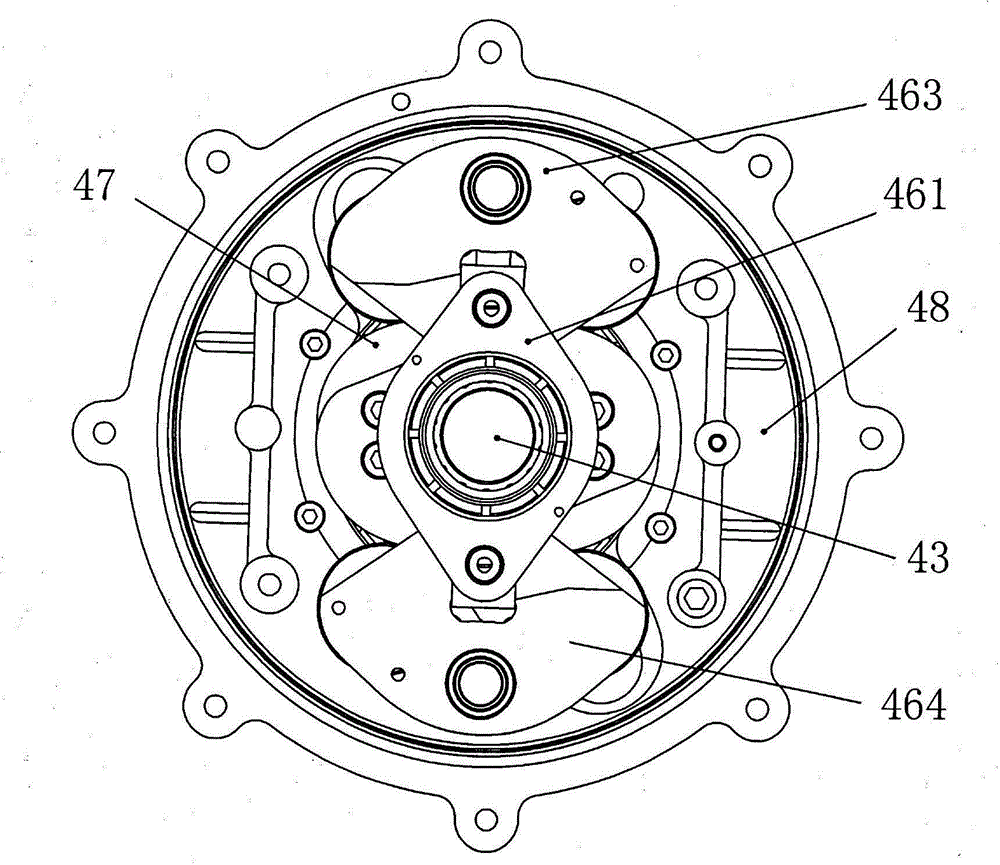

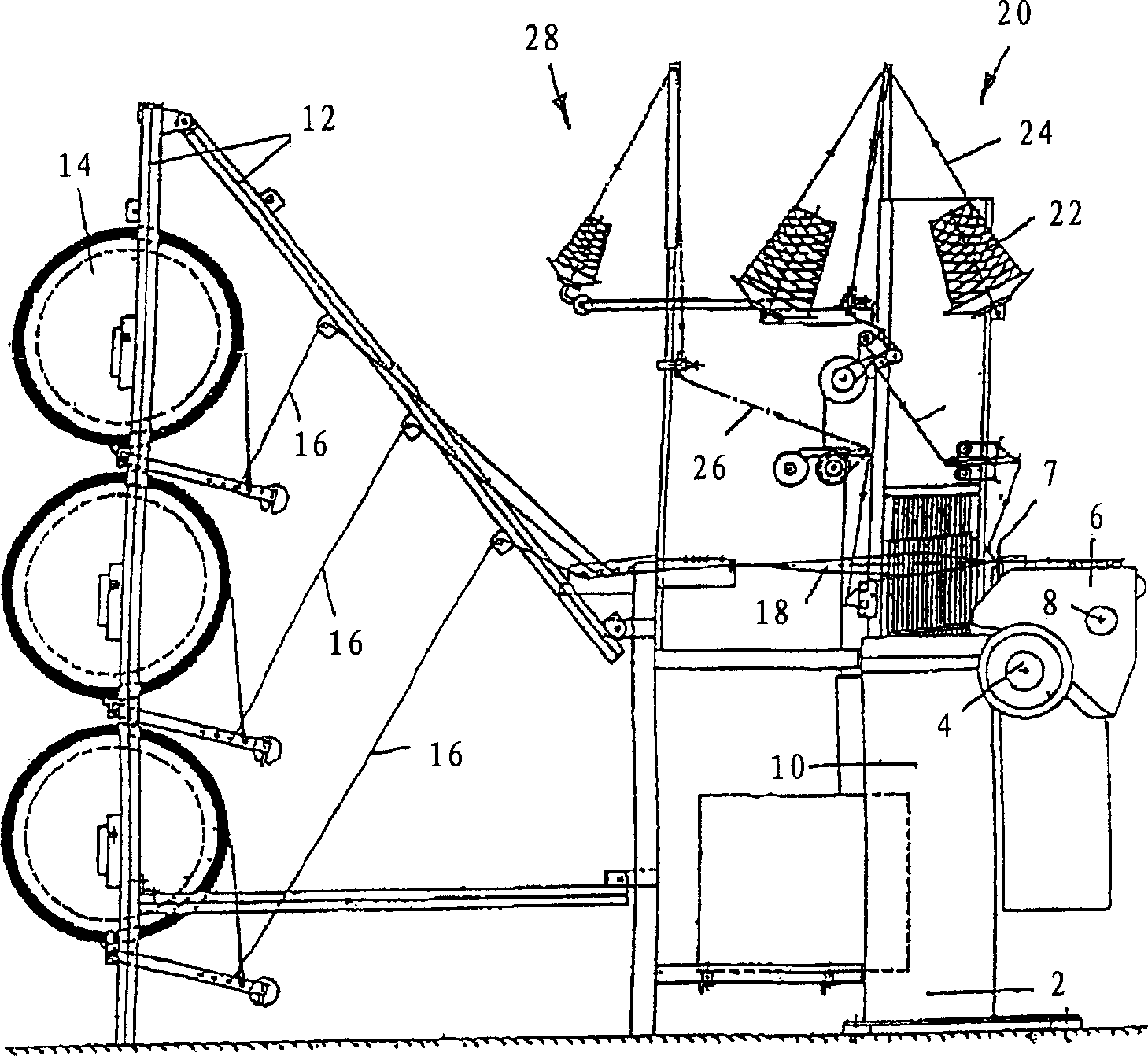

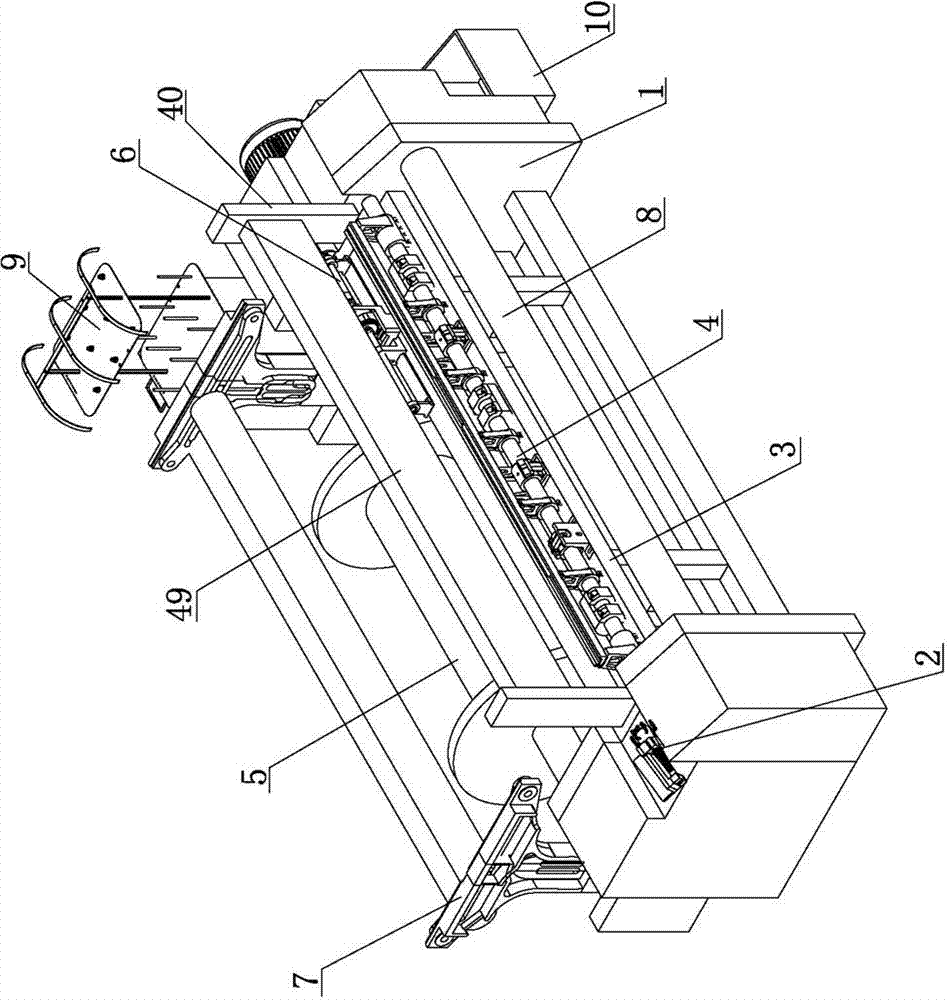

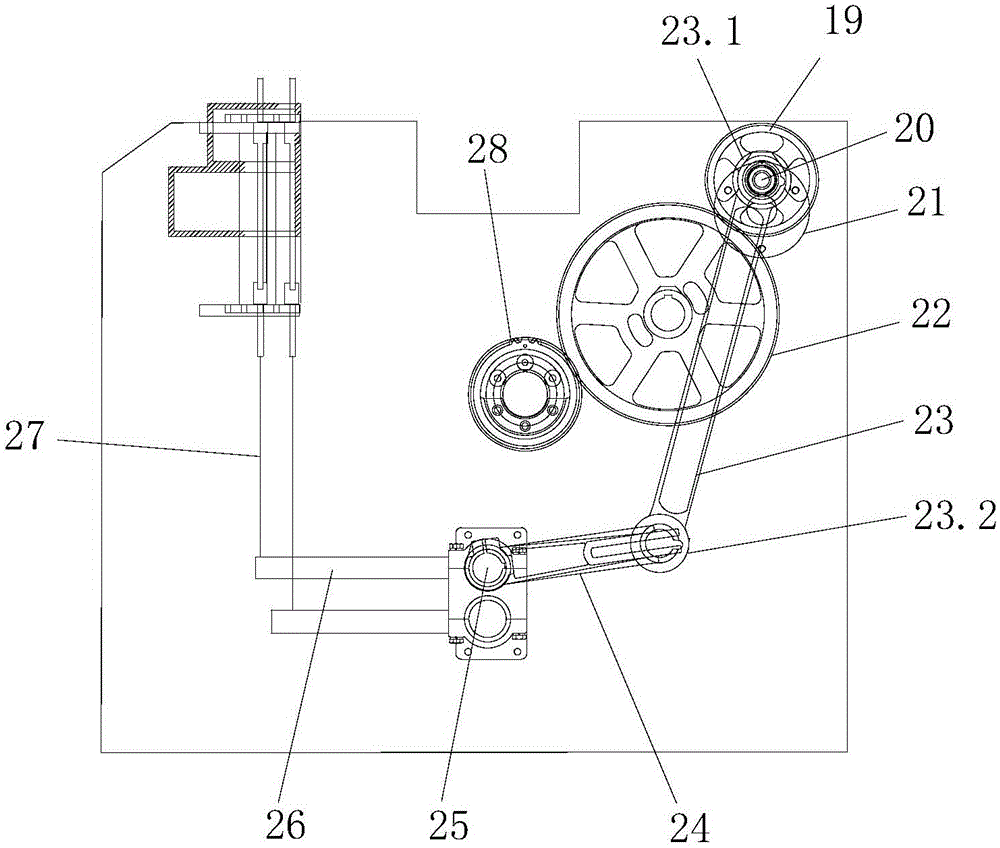

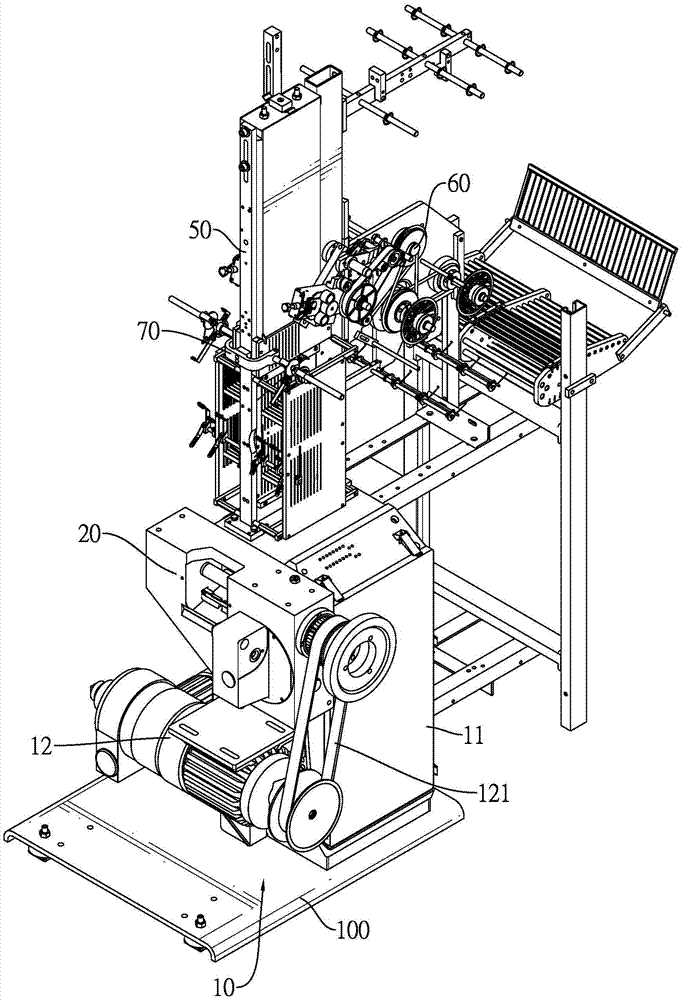

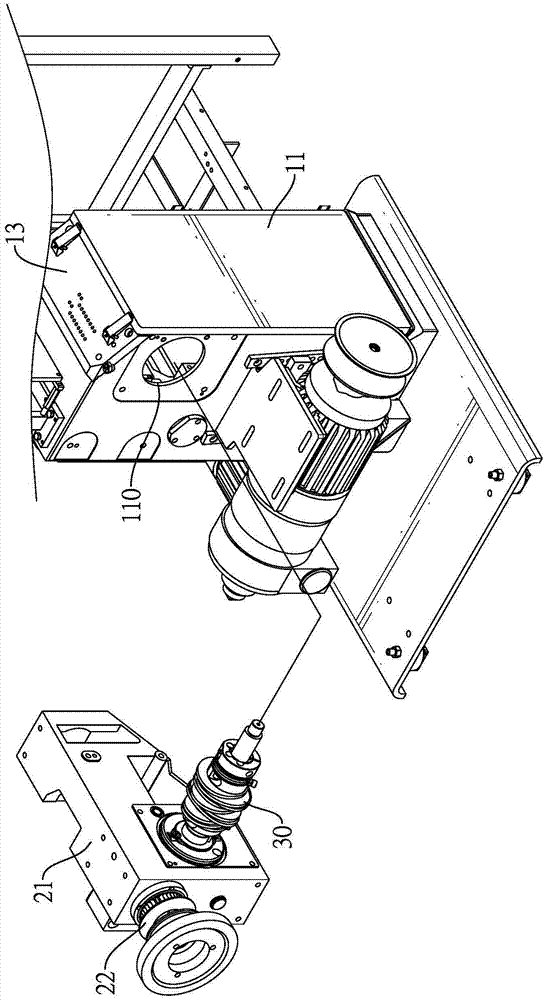

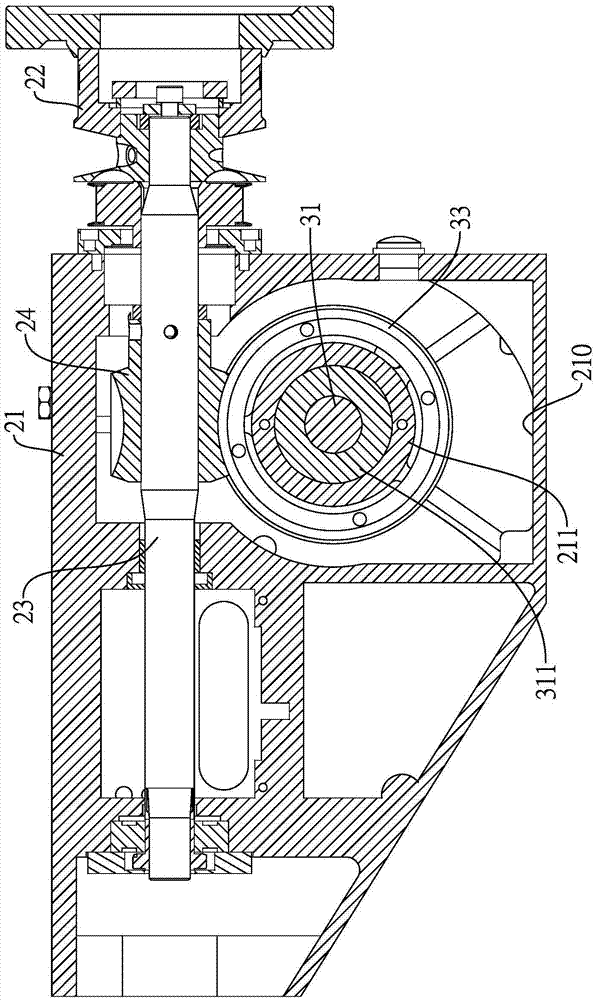

Crank rocker type electronic jacquard machine

The invention relates to a crank rocker type electronic jacquard machine and belongs to the technical field of textile machinery. The crank rocker type electronic jacquard machine comprises a machine frame, a power input mechanism and a heald lifting mechanism, wherein the power input mechanism is arranged on the machine frame and is in transmission connection with a main shaft of a loom in a use state; the heald lifting mechanism is also arranged on the machine frame. The crank rocker type electronic jacquard machine is characterized by further comprising a cam speed changing mechanism, wherein the cam speed changing mechanism corresponds to a position between the power input mechanism and the heald lifting mechanism and is in transmission connection with the power input mechanism and the heald lifting mechanism simultaneously. According to the crank rocker type electronic jacquard machine, the equipment investment is reduced; the grade of fabrics is improved, and the fabrics are embodied with an ideal economic added value; the whole-set cost of the crank rocker type electronic jacquard machine is controlled in a reasonable range, and routine check and maintenance are facilitated; the running effect of the jacquard machine is ensured.

Owner:常熟纺织机械厂有限公司

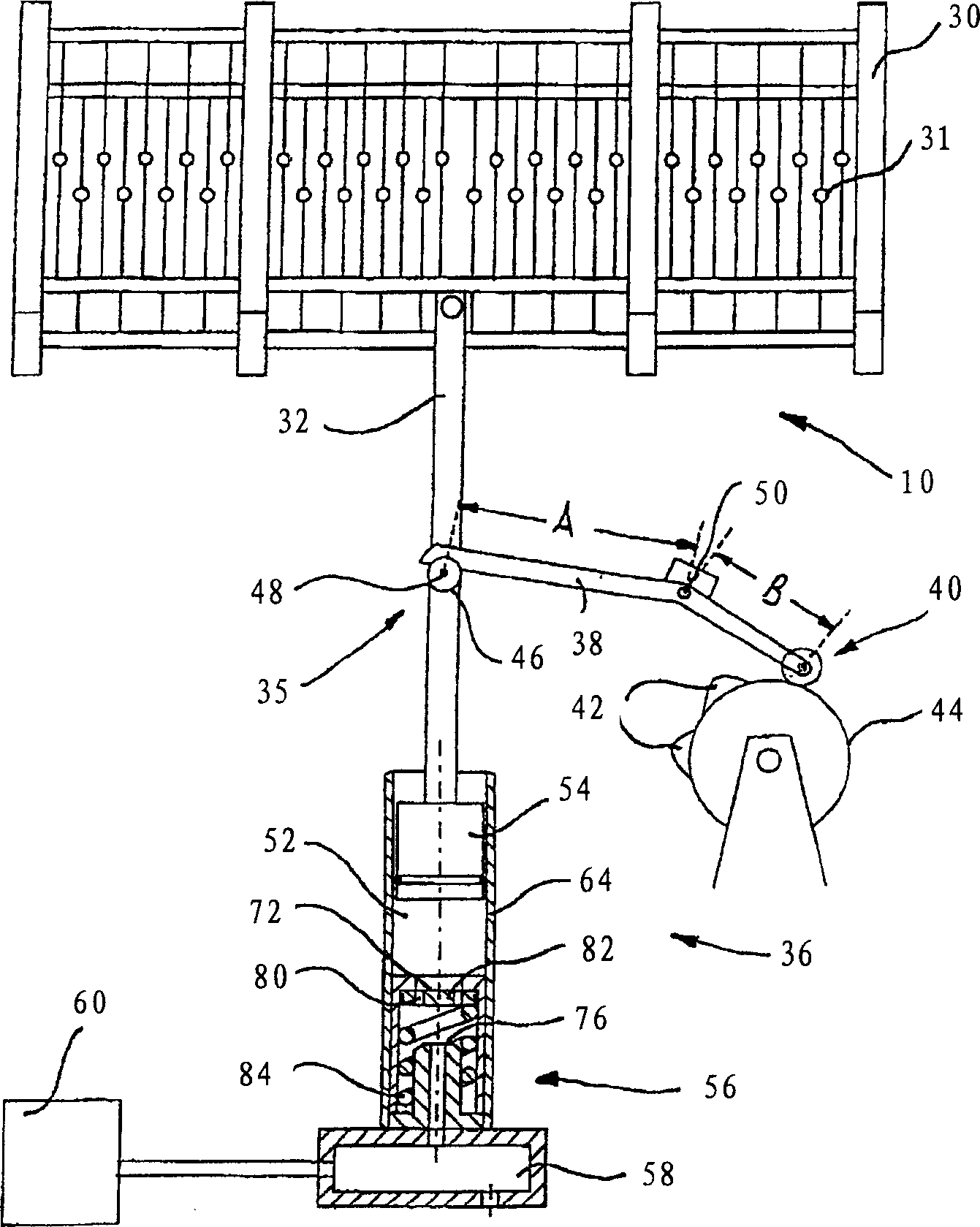

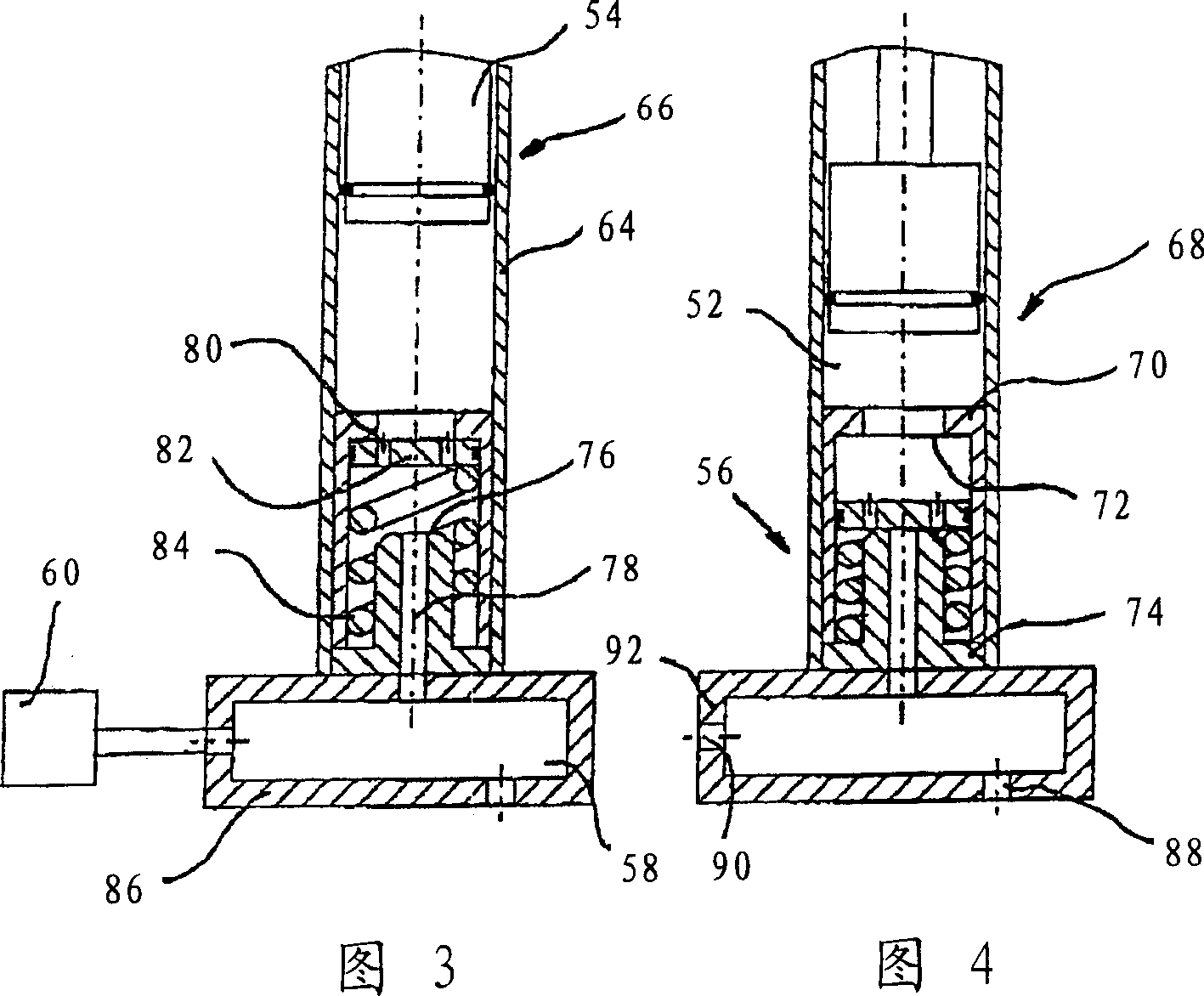

Thread control device for a textile machine in particular for a shedding device

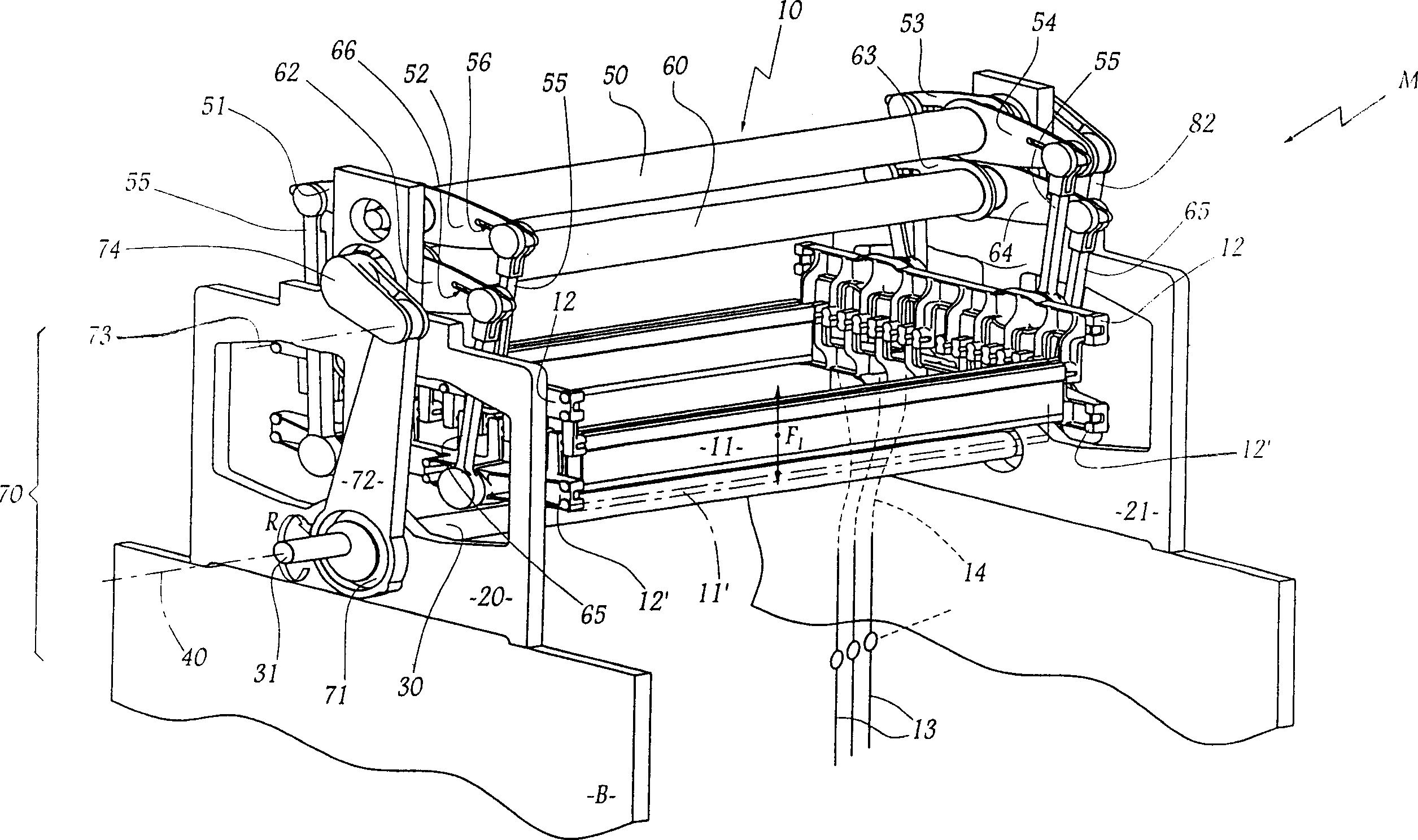

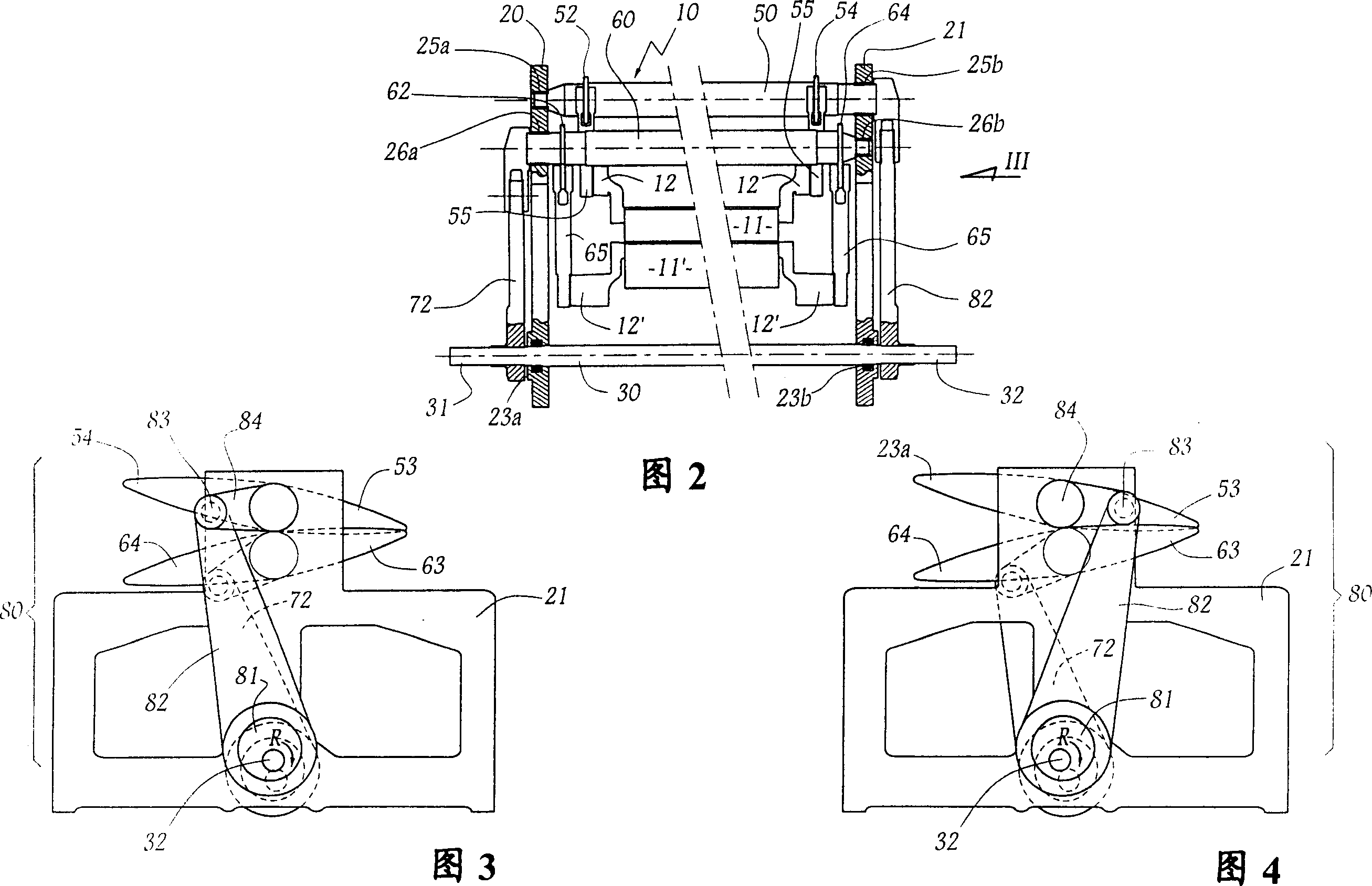

The invention relates to a thread control device for a textile machine, in particular, for a shedding device, with at least one thread guide body (31) which may be displaced in one displacement direction by means of a positive drive (35) and in the opposite direction by means of a non-positive, pneumatic return device (36). The return device (36) thus comprises a cylinder / piston unit (64,54), the cylinder chamber of which (52) is connected to a compressed gas source (60) by means of a valve (56). An improvement in control is achieved when the valve (56) comprises a first valve seat (72) connected to the cylinder chamber (52) and a second valve seat (76), between which a valve body (82), provided with at least one throttle point (80), may be displaced, pre-tensioned in the rest position by means of a spring (84) against the first valve seat (72), in which the throttle point (80) is ineffective and the valve body (82) blocks the communication with the compressed gas source (60) when the valve body (82) is in contact with the second valve seat (76).

Owner:TEXTILMA AG

Electrical rotating actuator for forming a shed in a weaving loom

InactiveUS6534892B2Efficient transferEasy to employJacquardsCam shedding mechanismEngineeringActuator

Stators for an electrical actuator of a type which may be used in weaving looms and weaving systems wherein a stack of armature plates having two-spaced sections are wrapped with an electrically conductive wire to create two coils afterwhich the stack is folded to sever severable bridge elements of the stack and to form an armataure to define a tubular housing for a rotor.

Owner:BRAUN DOMINIQUE +2

Portable semi-automatic Kesi-weaving machine device

The invention discloses a portable semi-automatic Kesi-weaving machine device. The portable semi-automatic Kesi-weaving machine device comprises a frame, a warp-conveying device, a wefting device and a coiling device. A motor opening device is arranged between the warp-conveying device and the coiling device. A pattern-reflecting plate is further installed between the motor opening device and the coiling device. The position, where the right side of the pattern-reflecting plate protrudes out of the frame, is provided with a pattern-reflecting plate hand wheel. A weft-beating device is arranged between the wefting device and the coiling device. The portable semi-automatic Kesi-weaving machine device has following advantages: the portable semi-automatic Kesi-weaving machine device is conveniently carried and favorably used for modern teaching; transfer from factorization to small-sized home-based design is achieved; a conventional mode of drawing on warp yarns is discarded so that a weaving mode is further realized; by adoption of the method of the pattern-reflecting plate, the effect of not deforming a finished product is achieved; and the opening device is flat during opening operation so that bright light rays are realized for facilitating selecting wefts.

Owner:IANGSU COLLEGE OF ENG & TECH

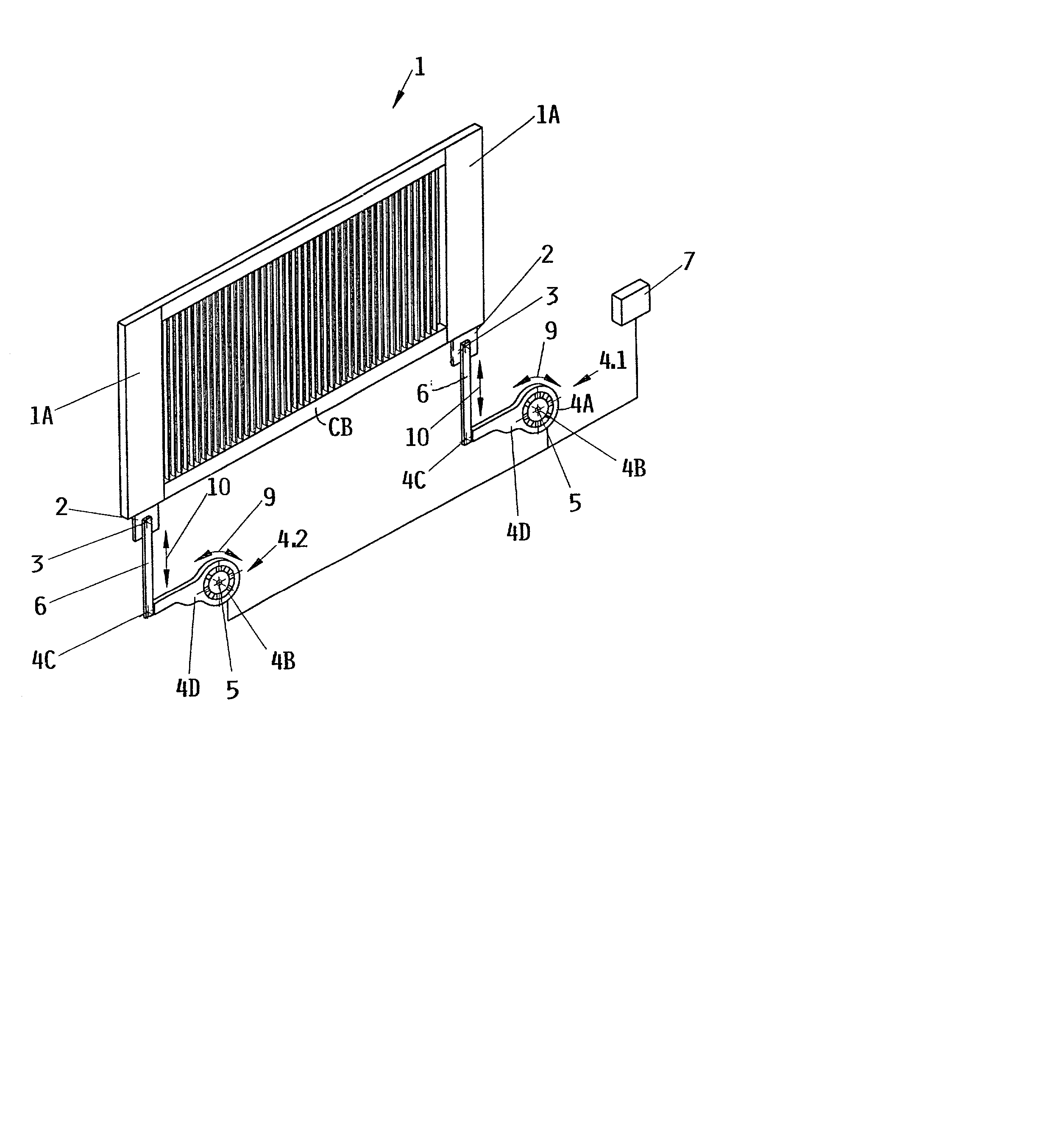

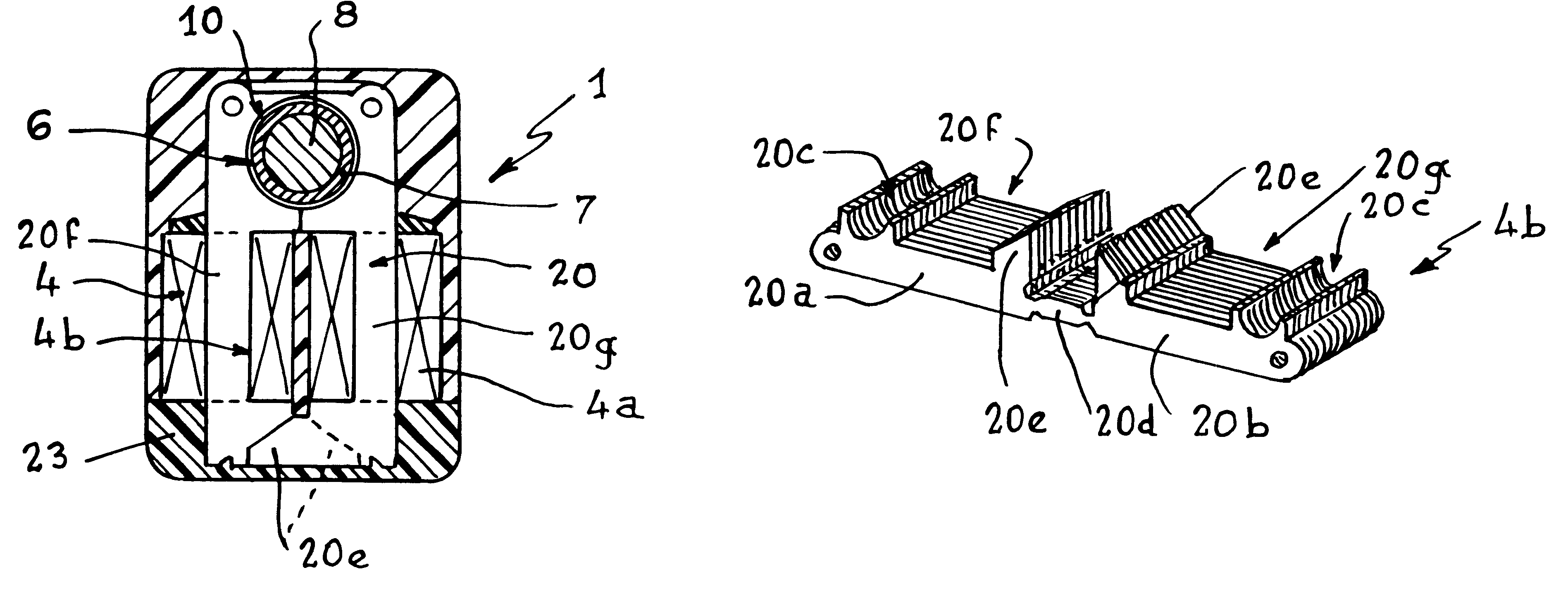

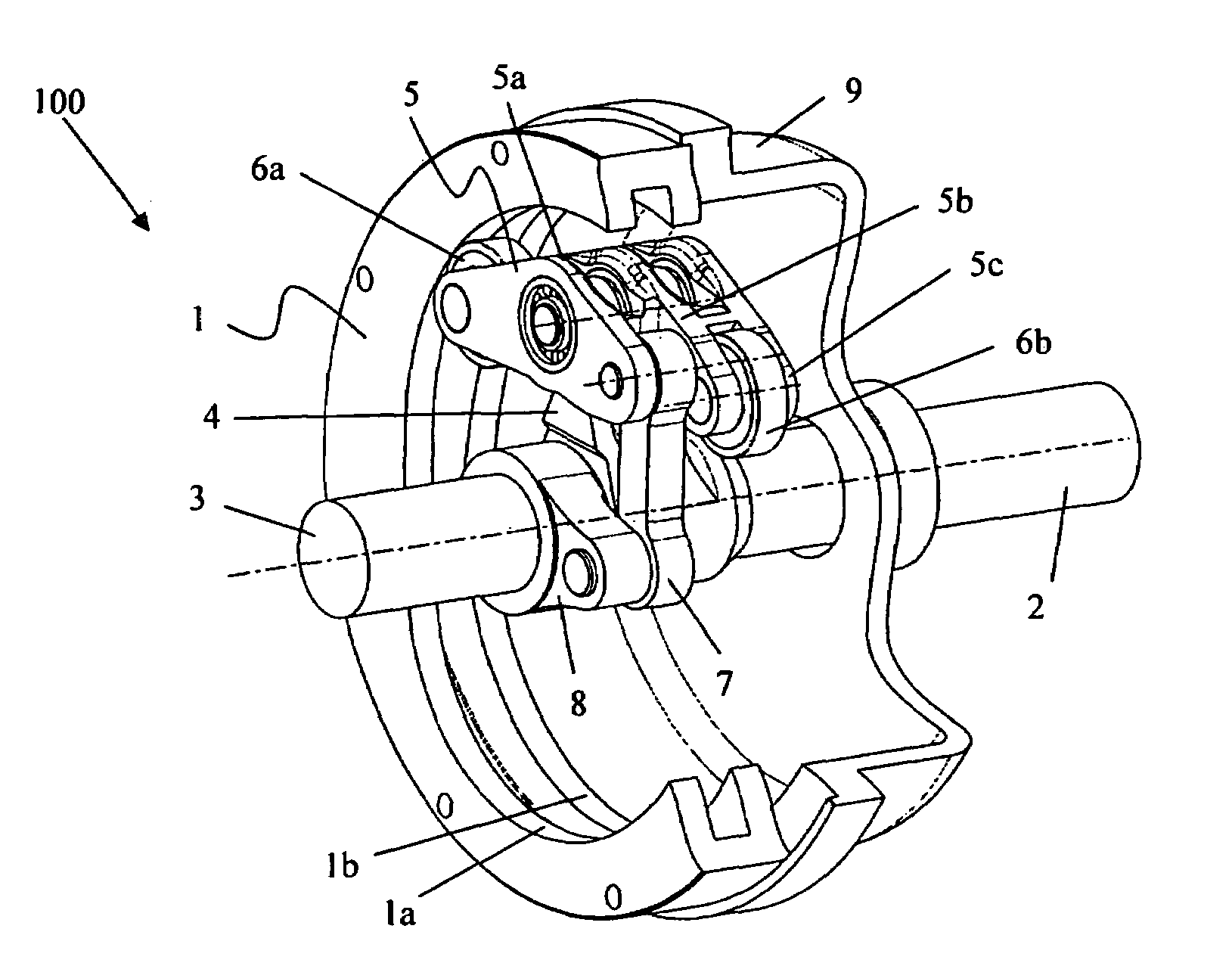

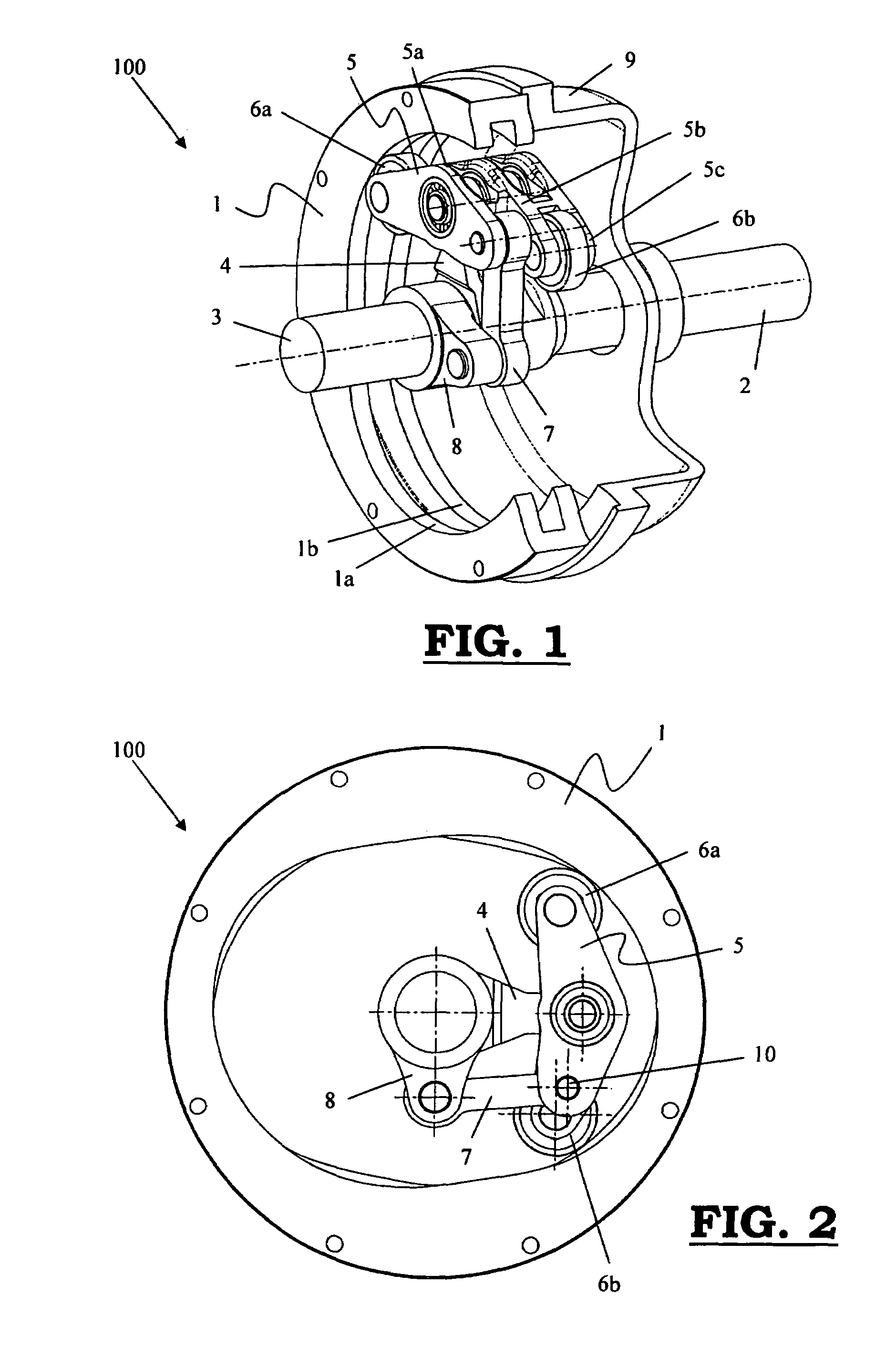

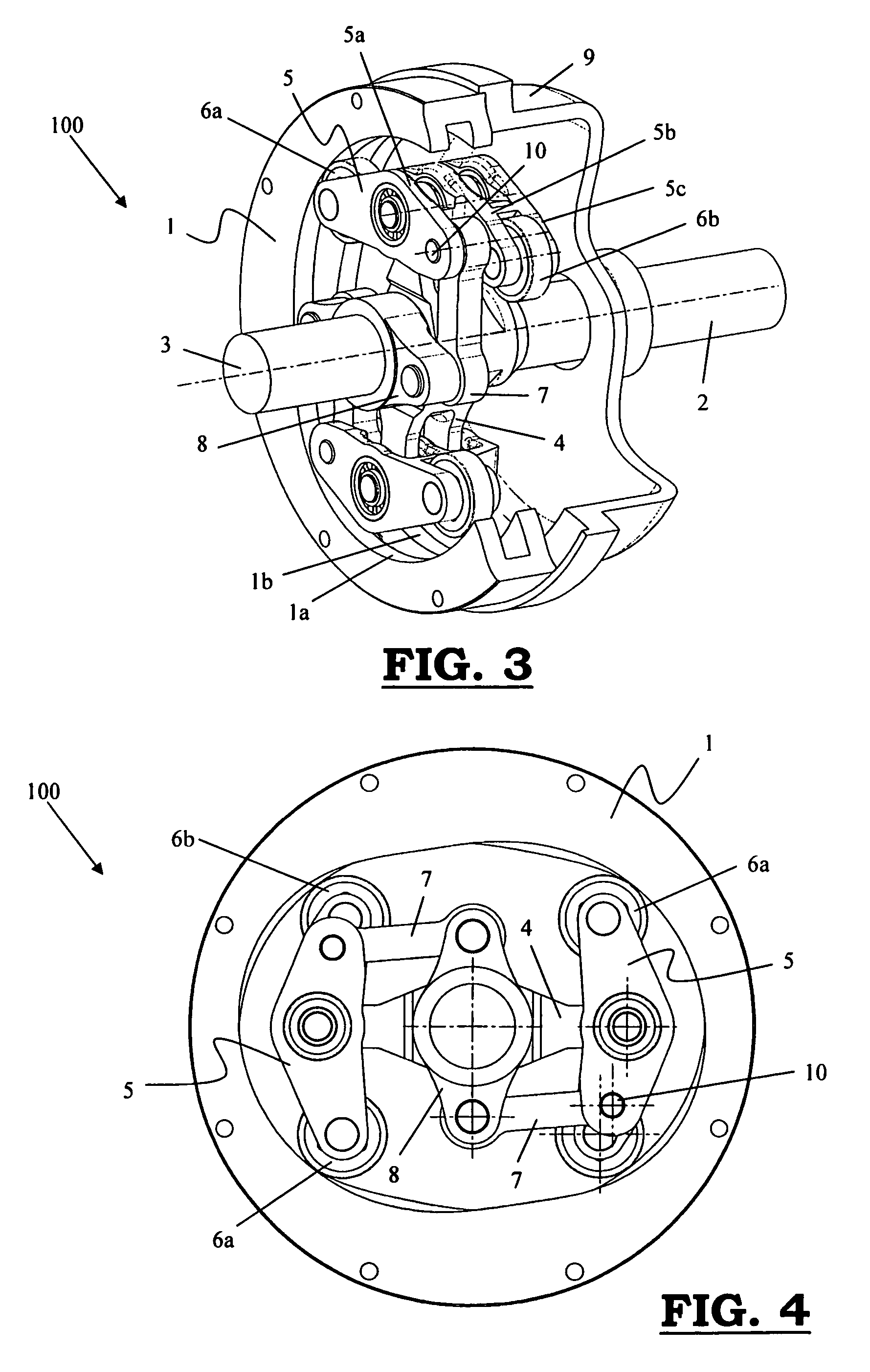

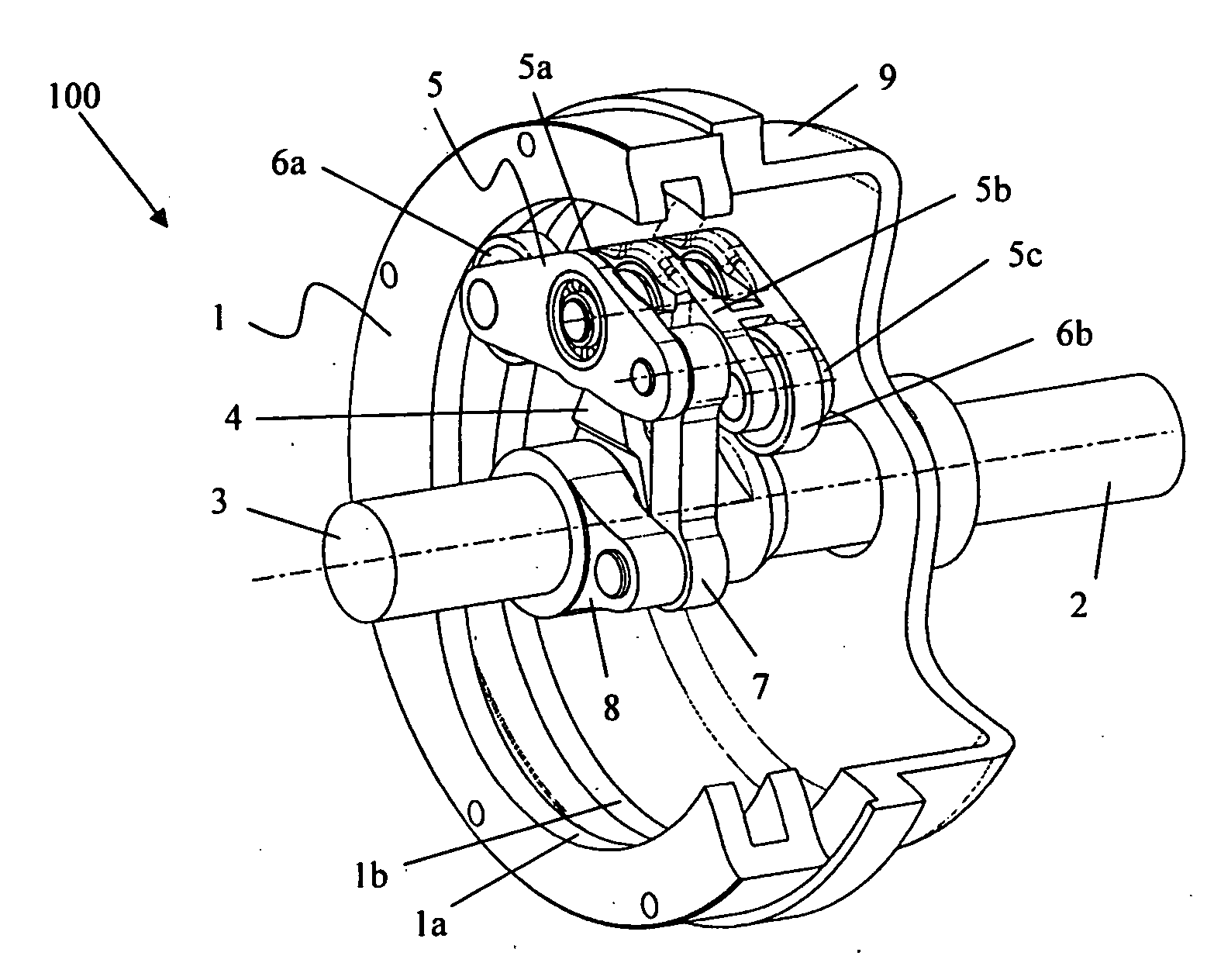

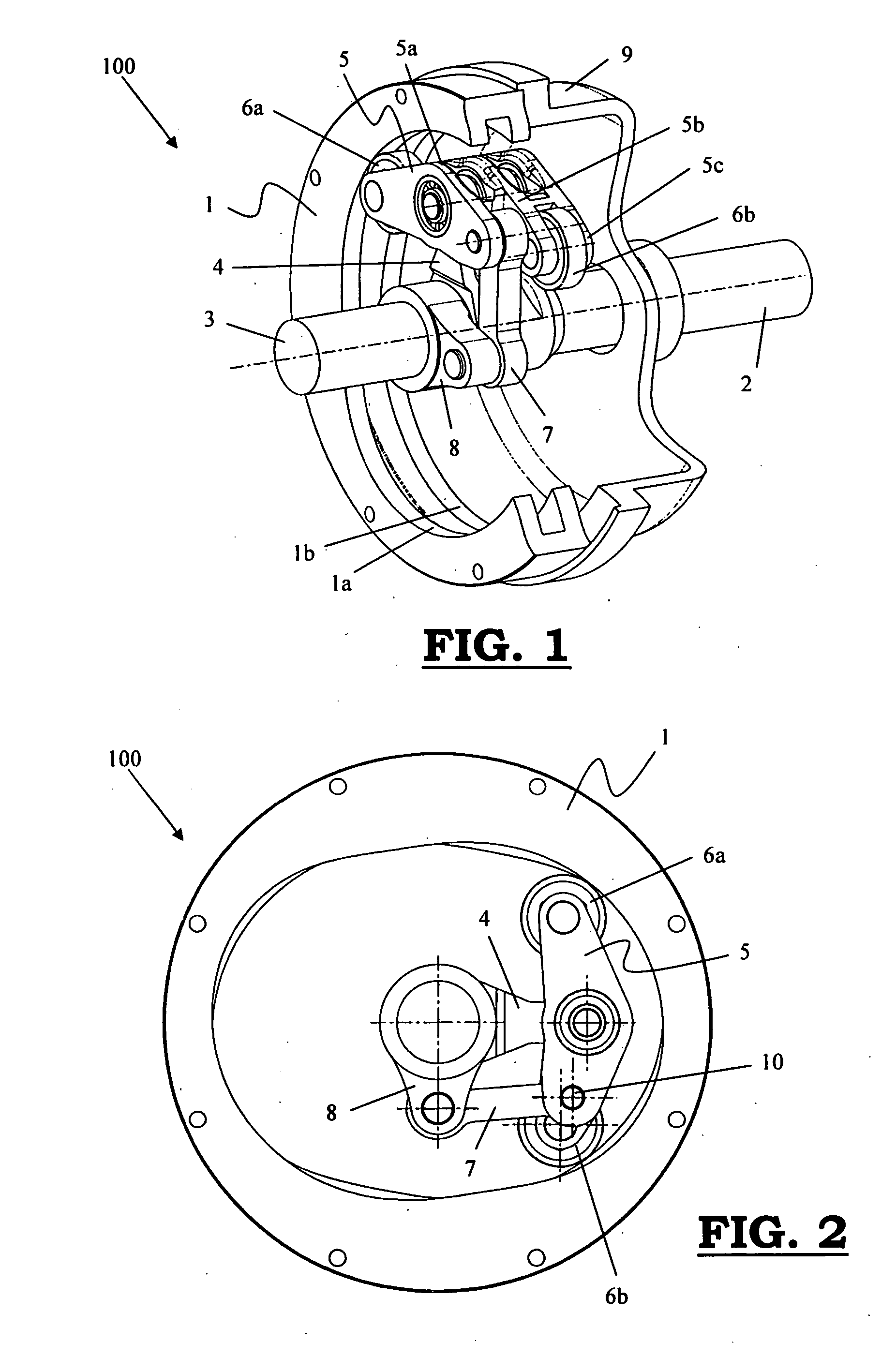

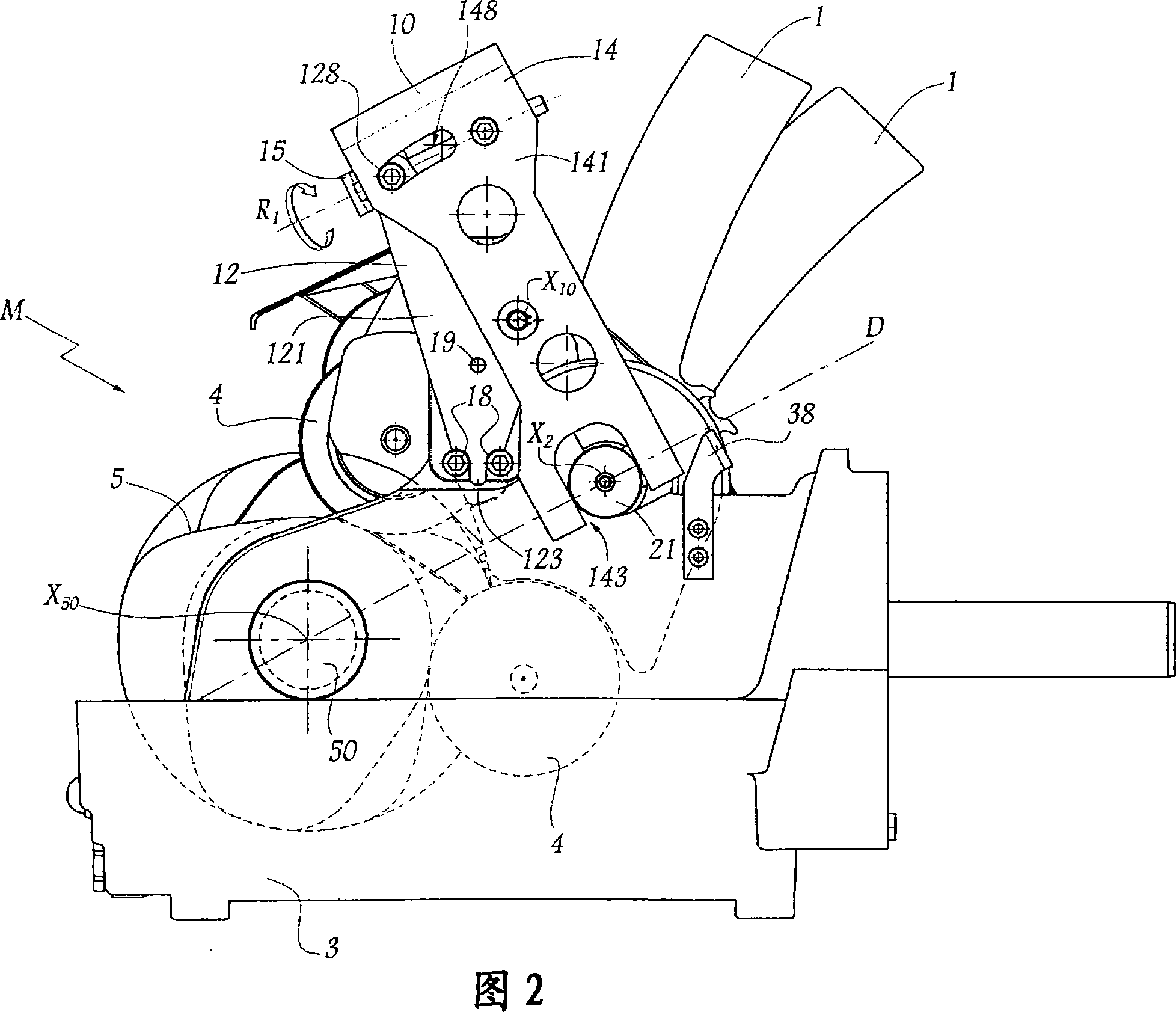

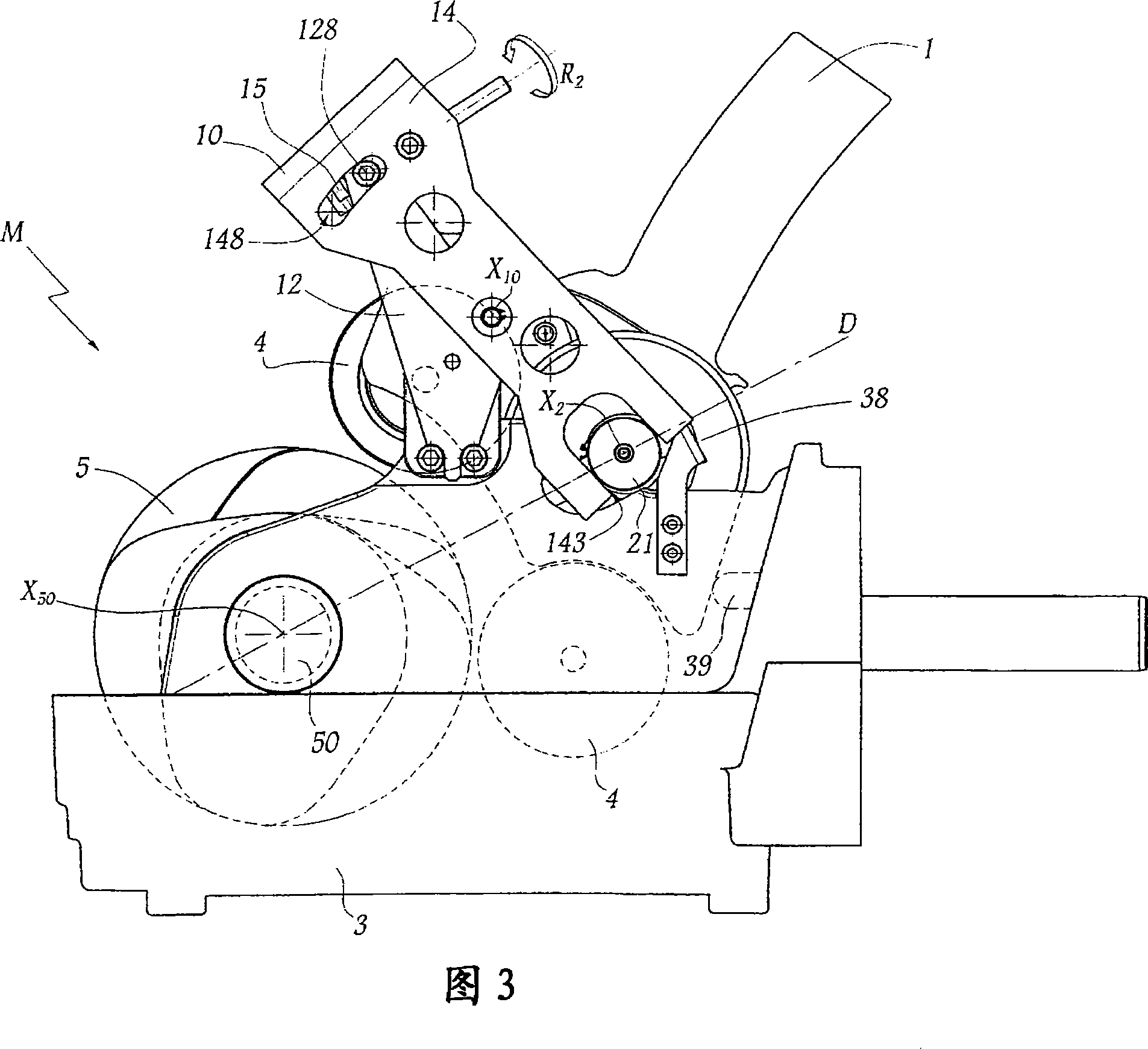

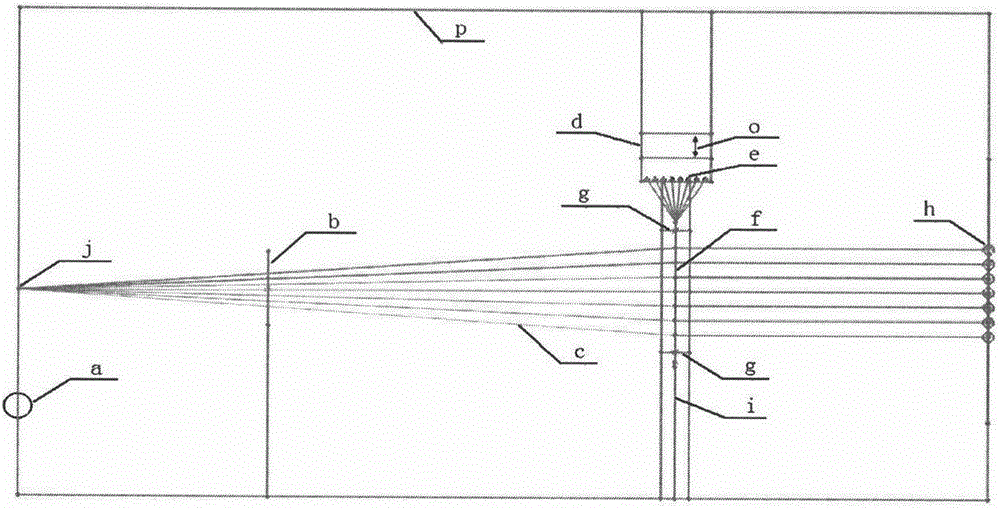

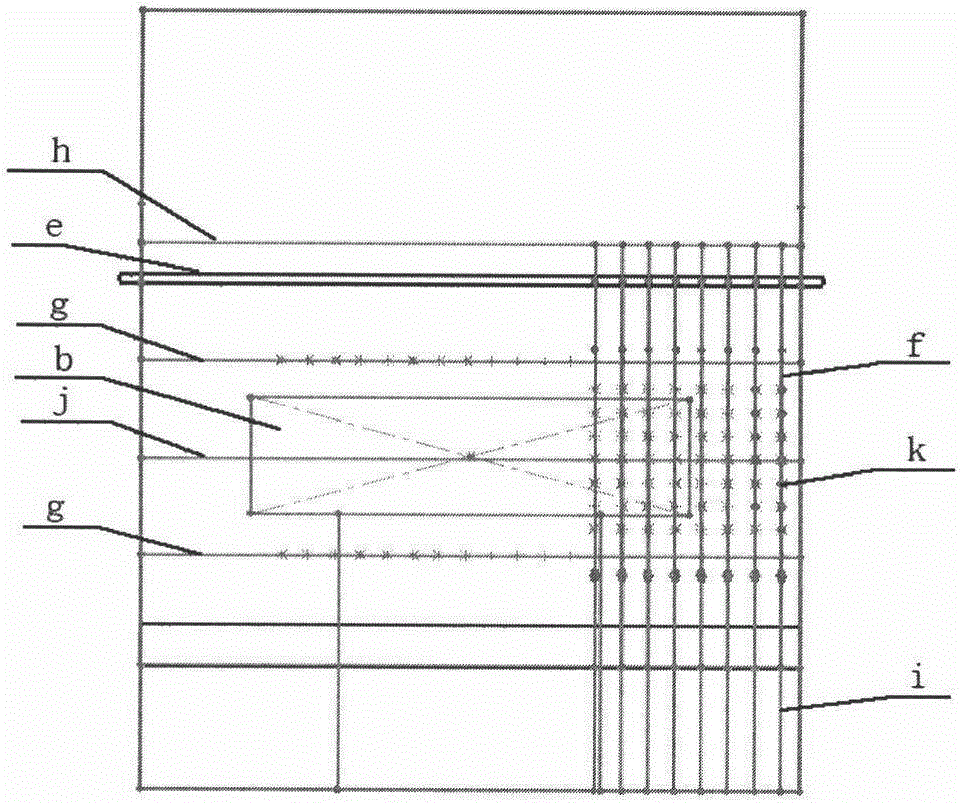

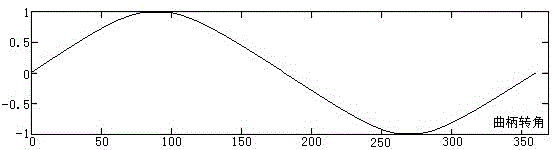

Device for modulating a first rotational motion of an input shaft to a second, different from the first, rotational motion of an output shaft in textile machines

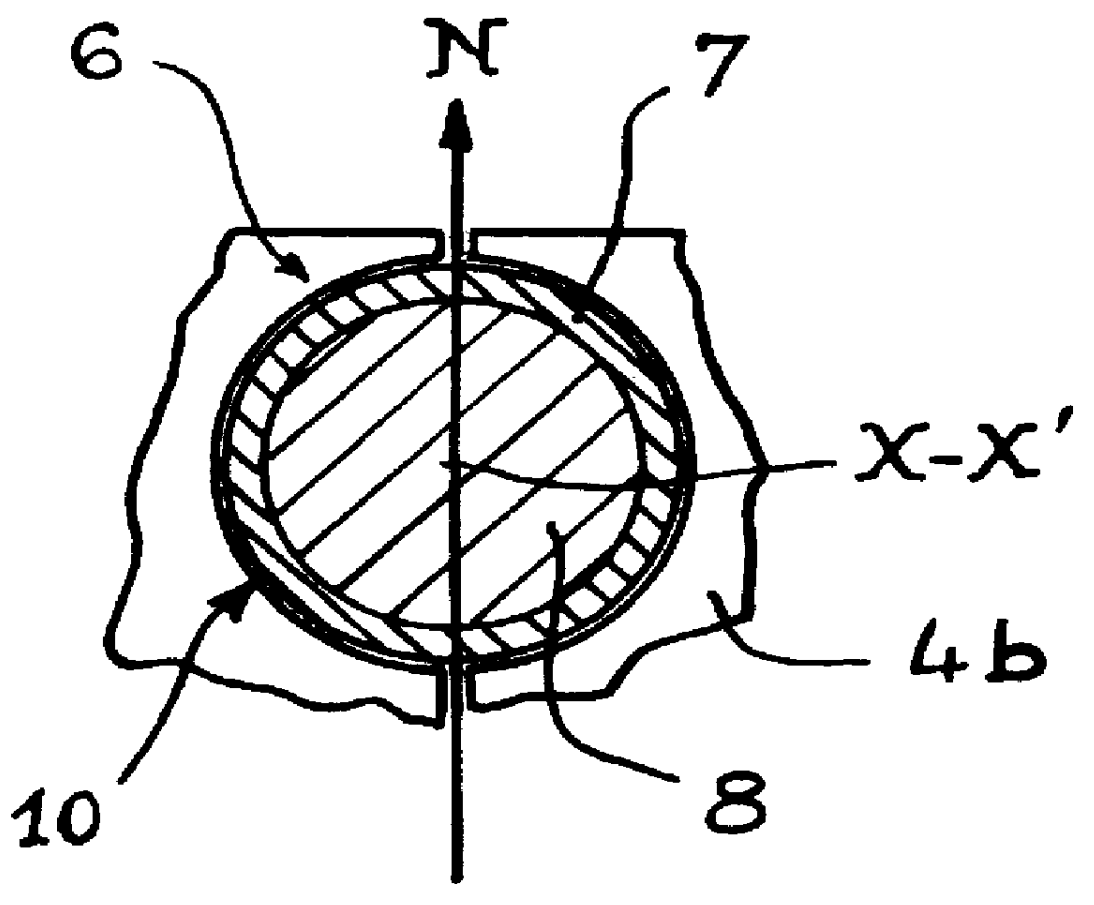

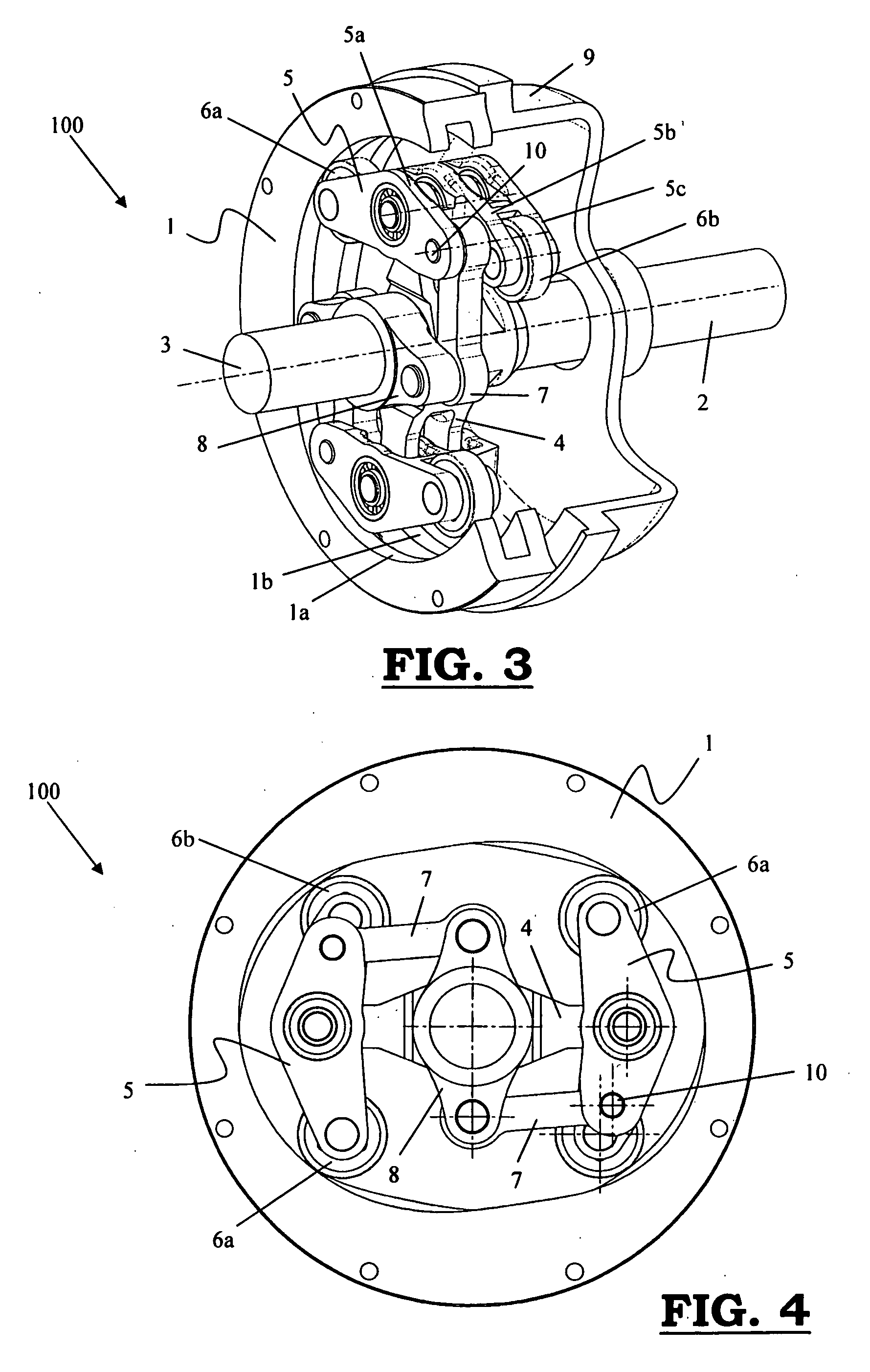

A device for modulating a first rotational motion of an input shaft (2) to a second, different from the first, rotational motion of an output shaft (3)in textile machines has a fixed complementary cam (1) provided with at least two cam profiles (1a, 1b). At least one cam follower (5) is linked to the input and the output shafts (2, 3) and is provided with at least two contact rollers (6a, 6b), each following a different cam profile (1a, 1b), because of which the cam followers (5)are performing a rocking motion. The cam profiles (1a, 1b)arc internal cam profiles.

Owner:N V MICHEL VAN DE WIELE

Velveteen air jet loom

PendingCN106987981AStable tension controlWeaving speed is fastCam shedding mechanismPile-fabric loomsNumerical controlAir-jet loom

The invention relates to a velveteen air jet loom. The velveteen air jet loom comprises a machine frame, a numerical control velveteen let-off mechanism, a velveteen shaft let-off mechanism, a bottom shaft let-off mechanism, a warp stop mechanism, an opening mechanism, a beating-up mechanism, an air jet weft insertion mechanism, a reeling mechanism, a batching mechanism and an electric control box. The velveteen shaft let-off mechanism lets pile warp off through the numerical control velveteen let-off mechanism, lets ground warp off through the bottom shaft let-off mechanism, the warp are conveyed into the air jet weft insertion mechanism from the opening mechanism through the warp stop mechanism, the air jet weft insertion mechanism is driven by the beating-up mechanism to complete weaving of double-layer velveteen, and then the double-layer velveteen is conveyed to a double-layer cutting mechanism, cut apart, and reeled through the reeling mechanism so as to be conveyed to the batching mechanism for collection.

Owner:JIANGSU YOUCHENG CNC TECH CO LTD

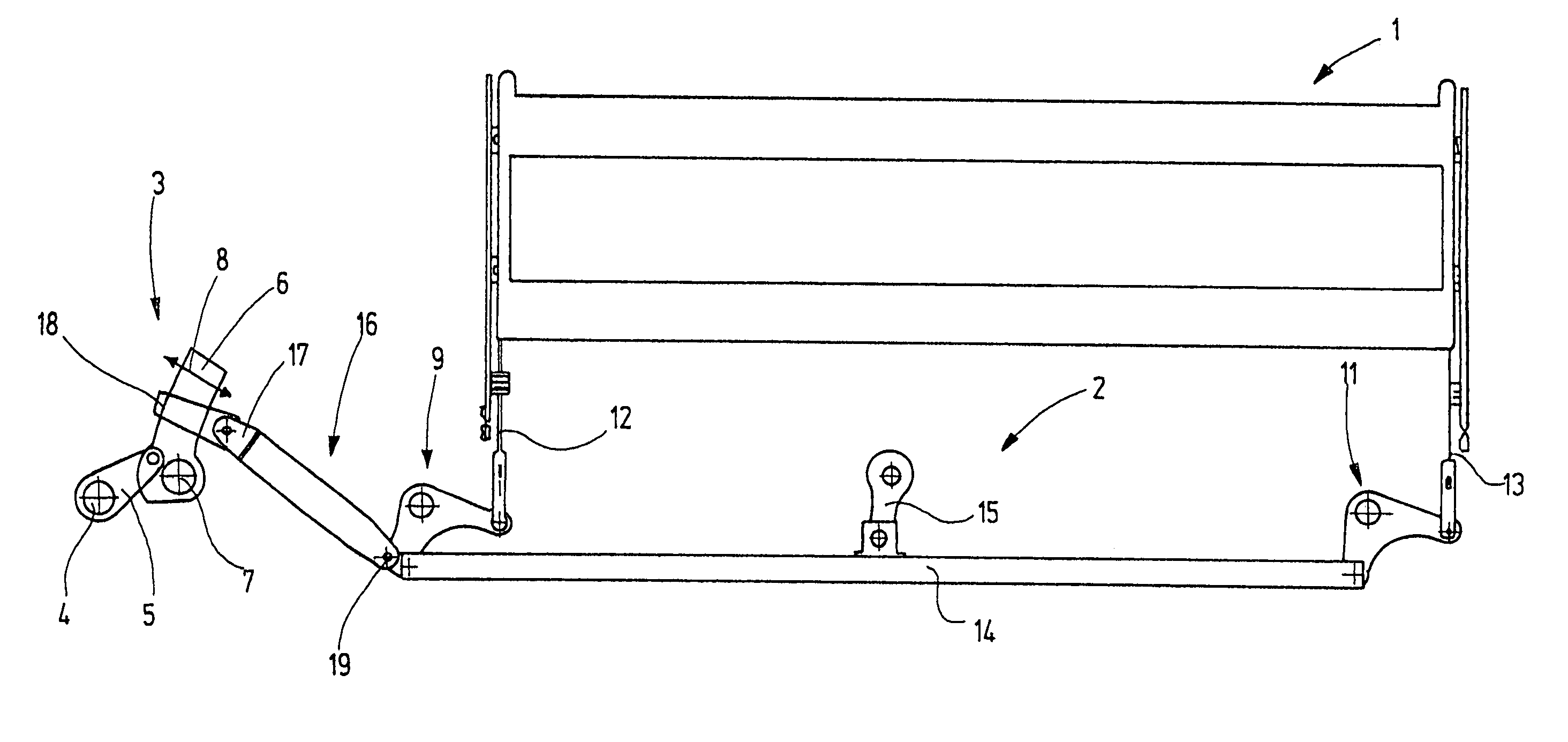

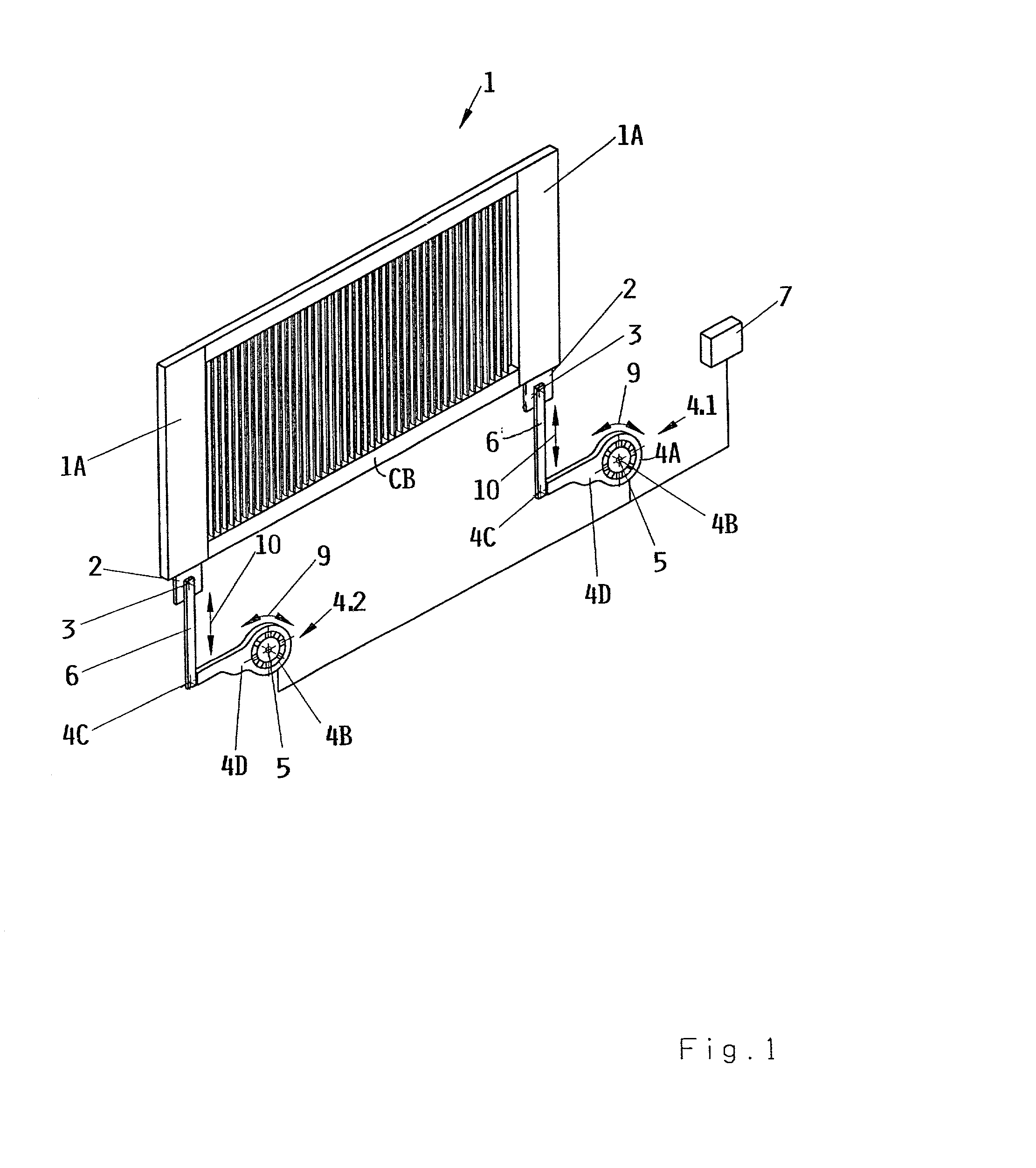

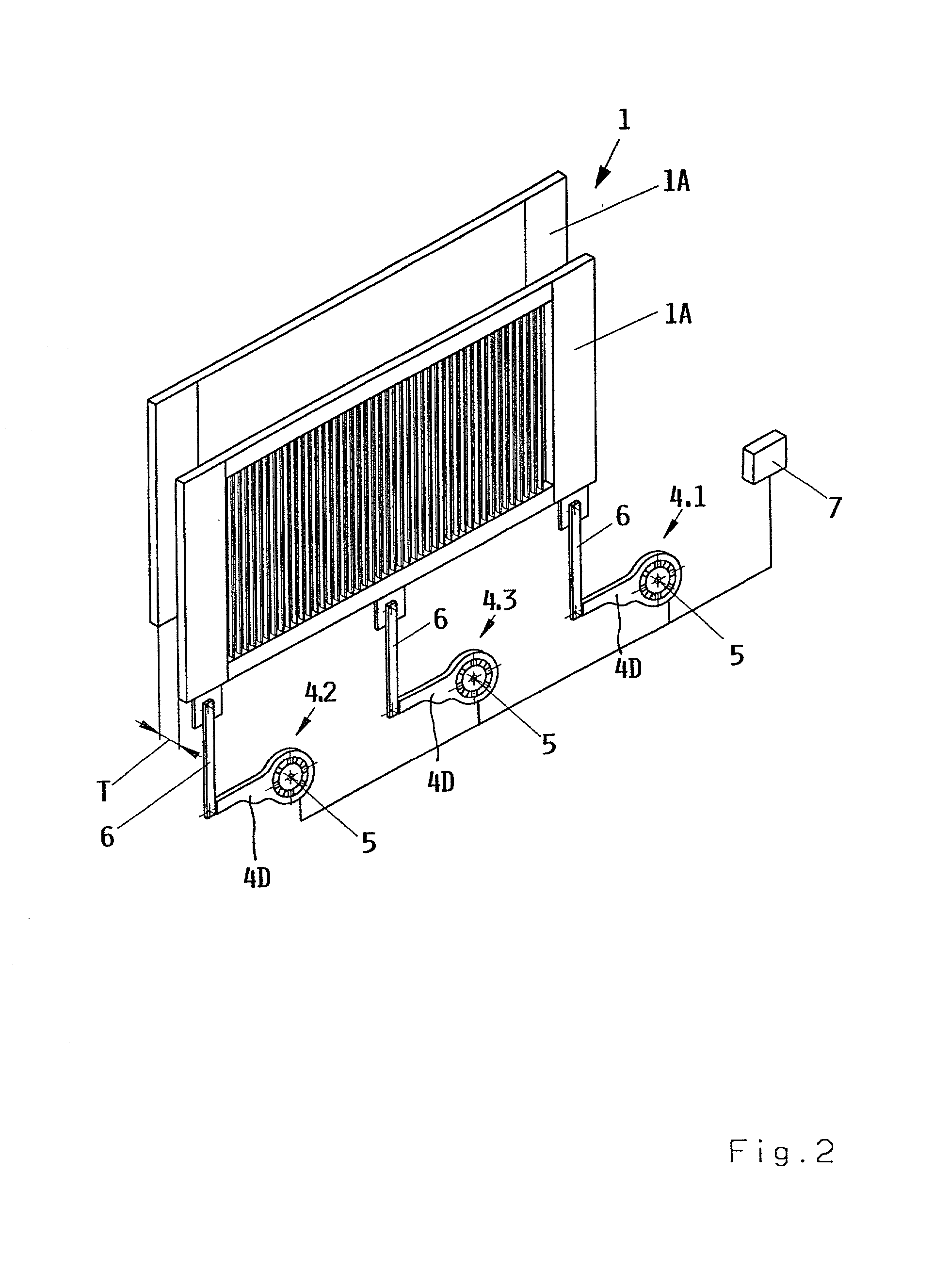

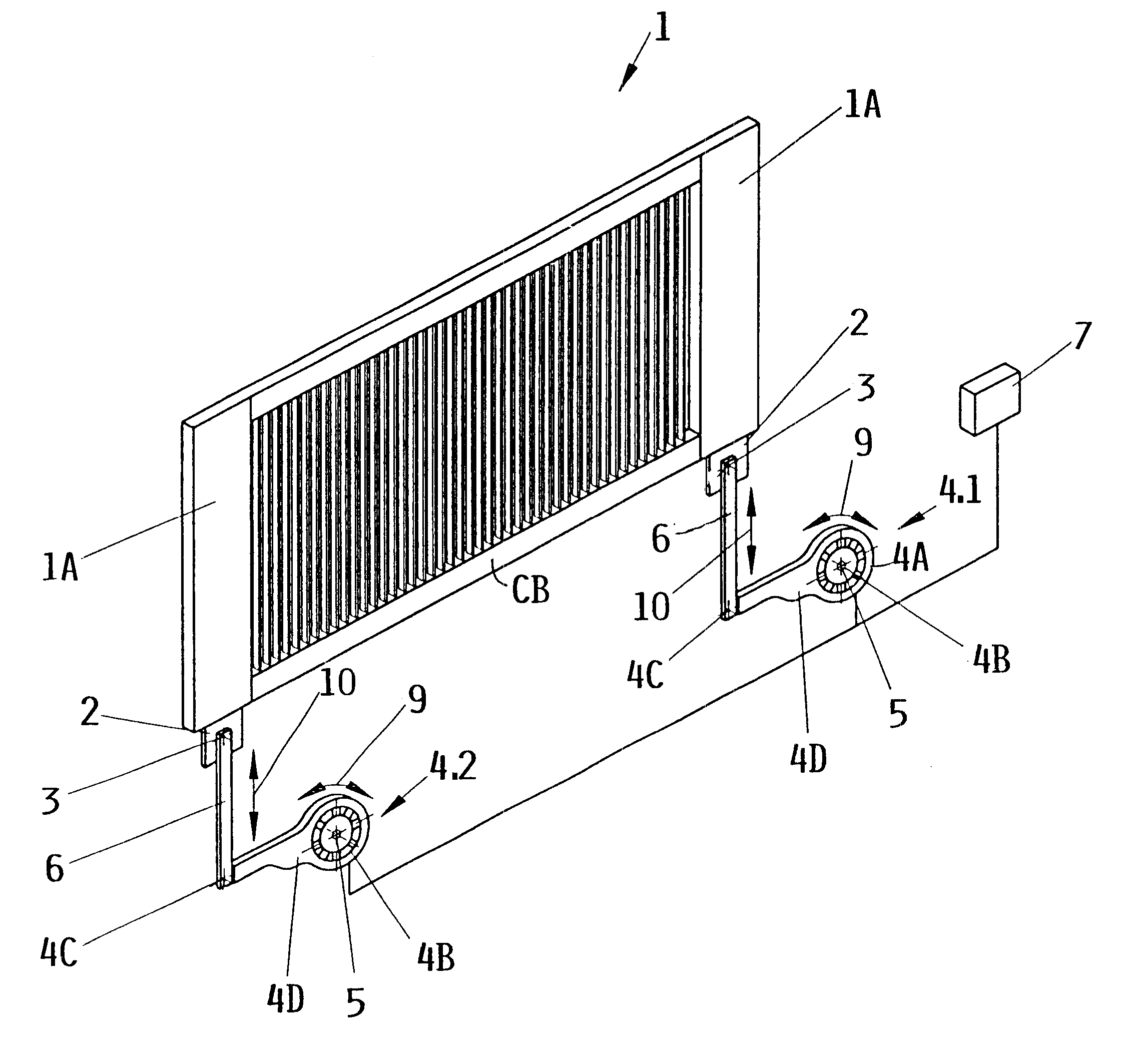

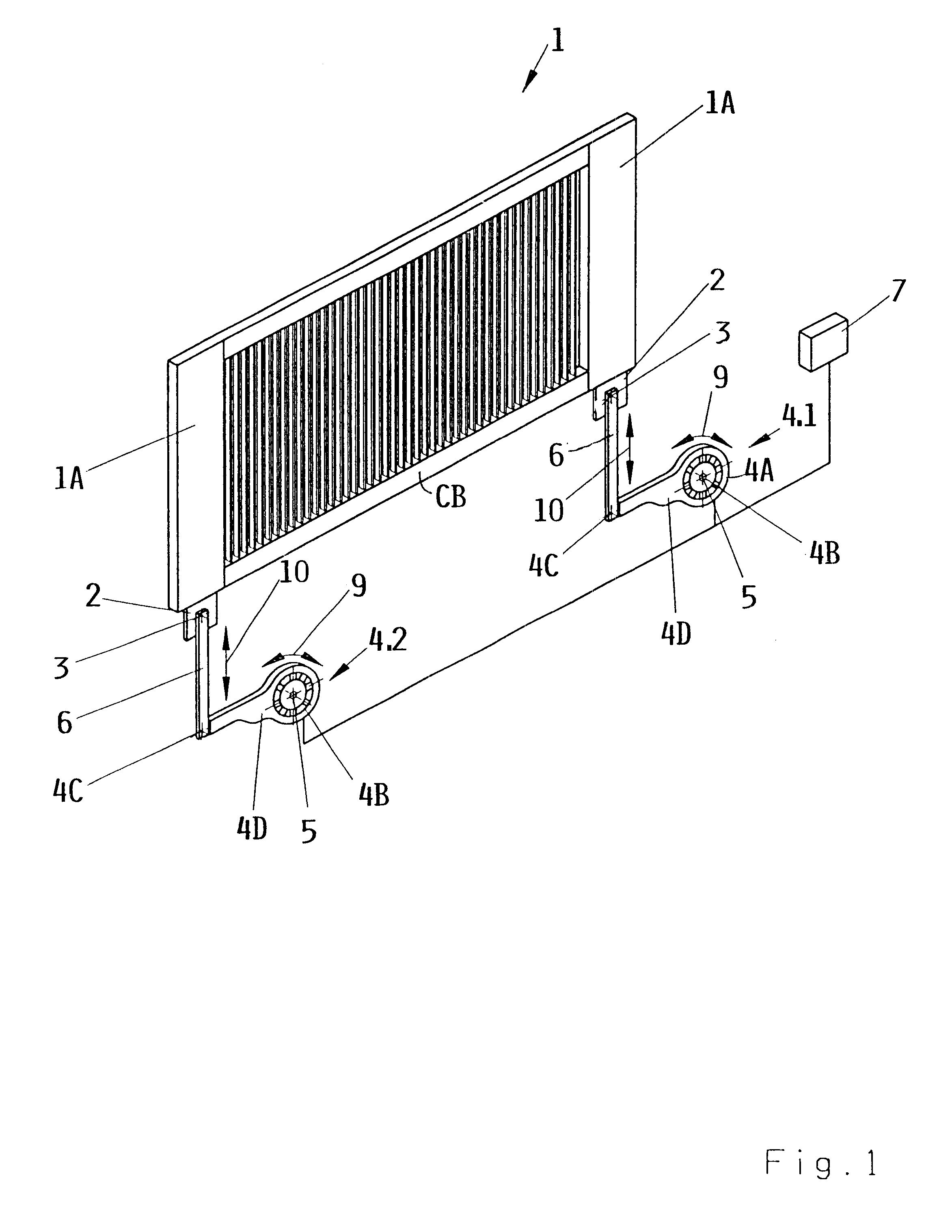

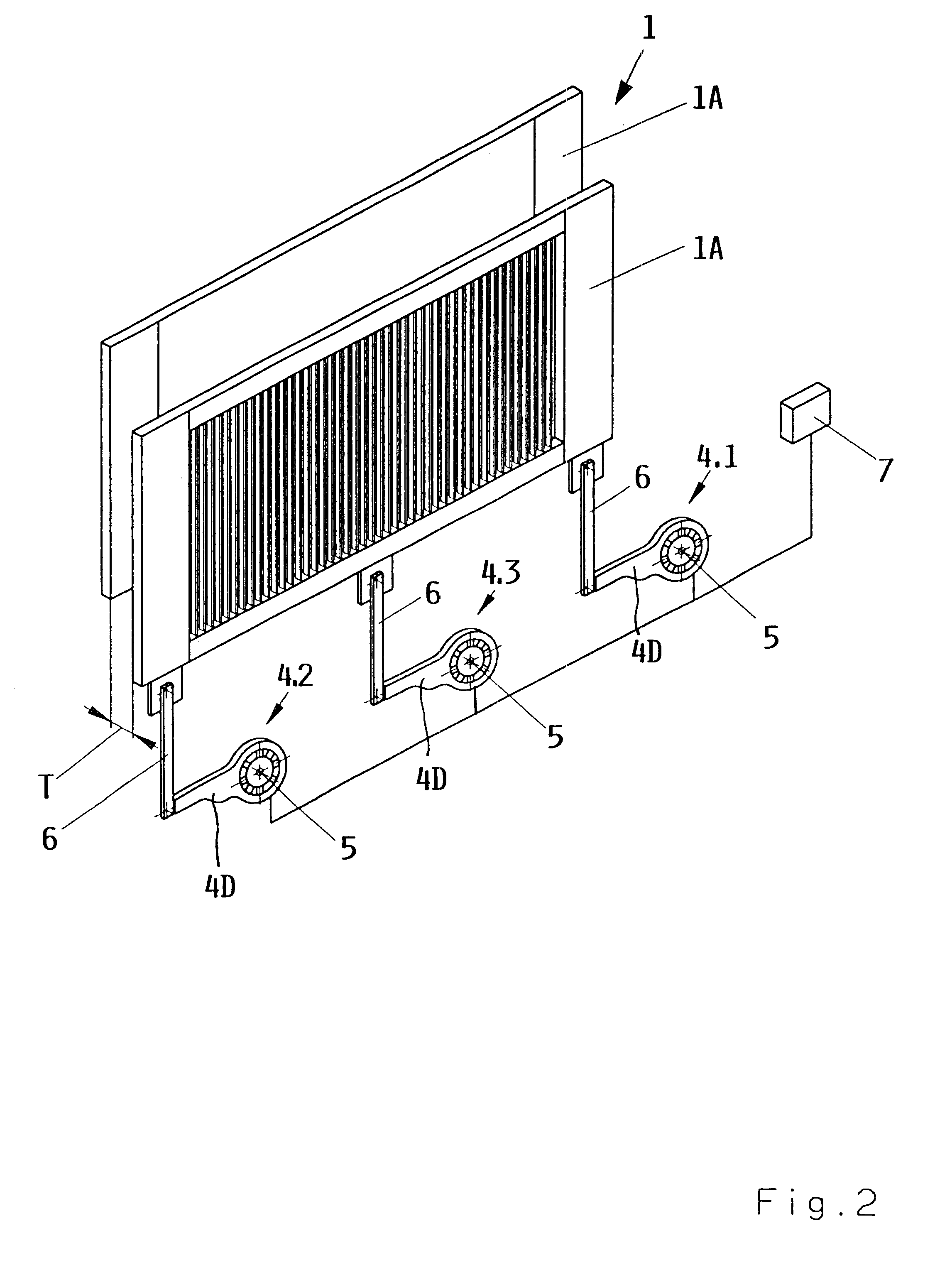

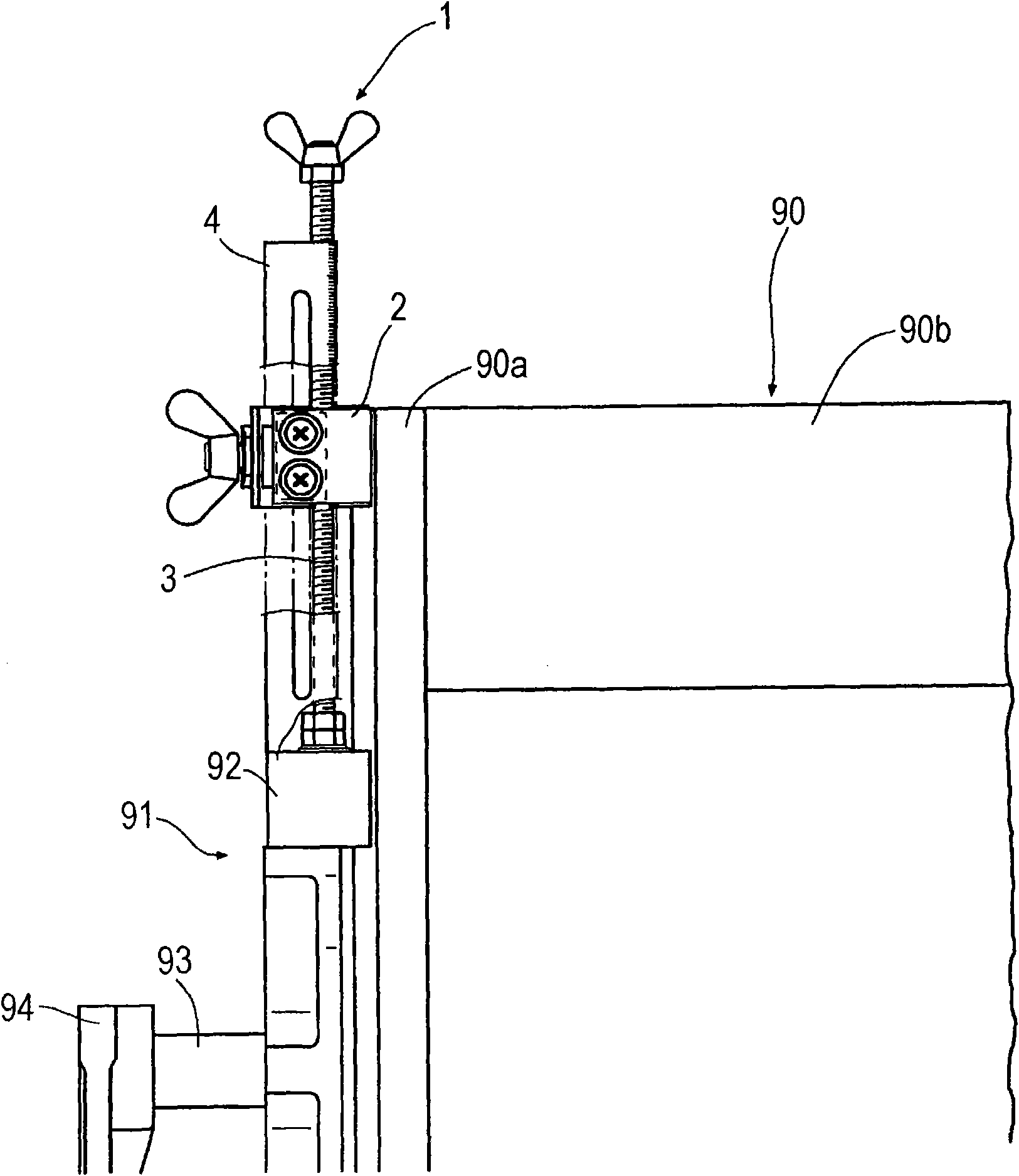

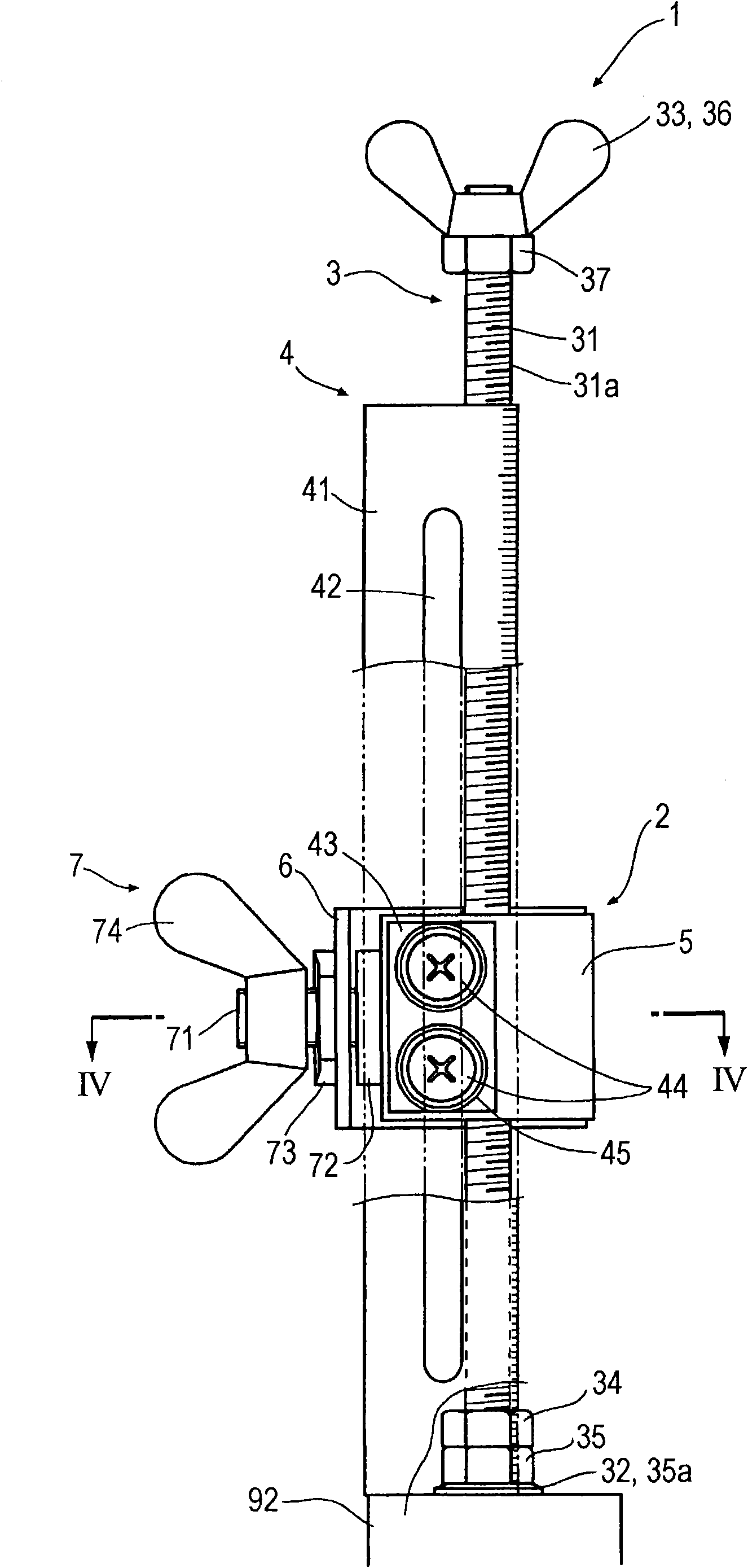

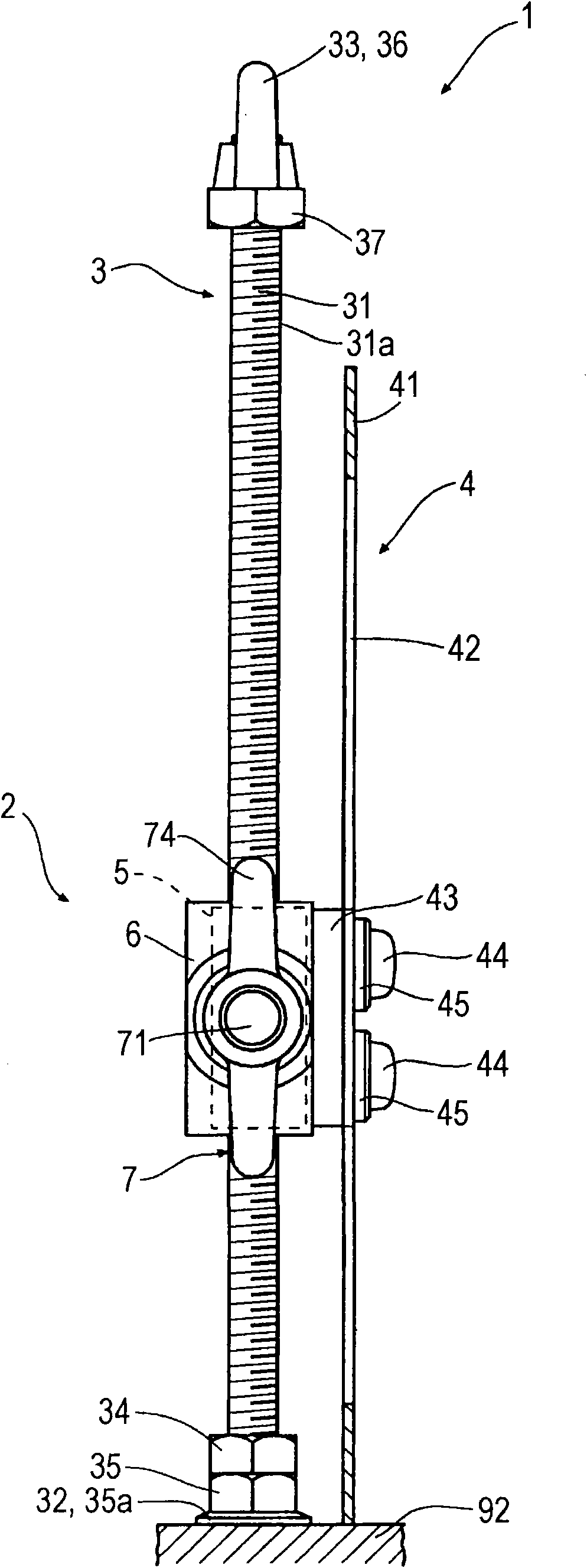

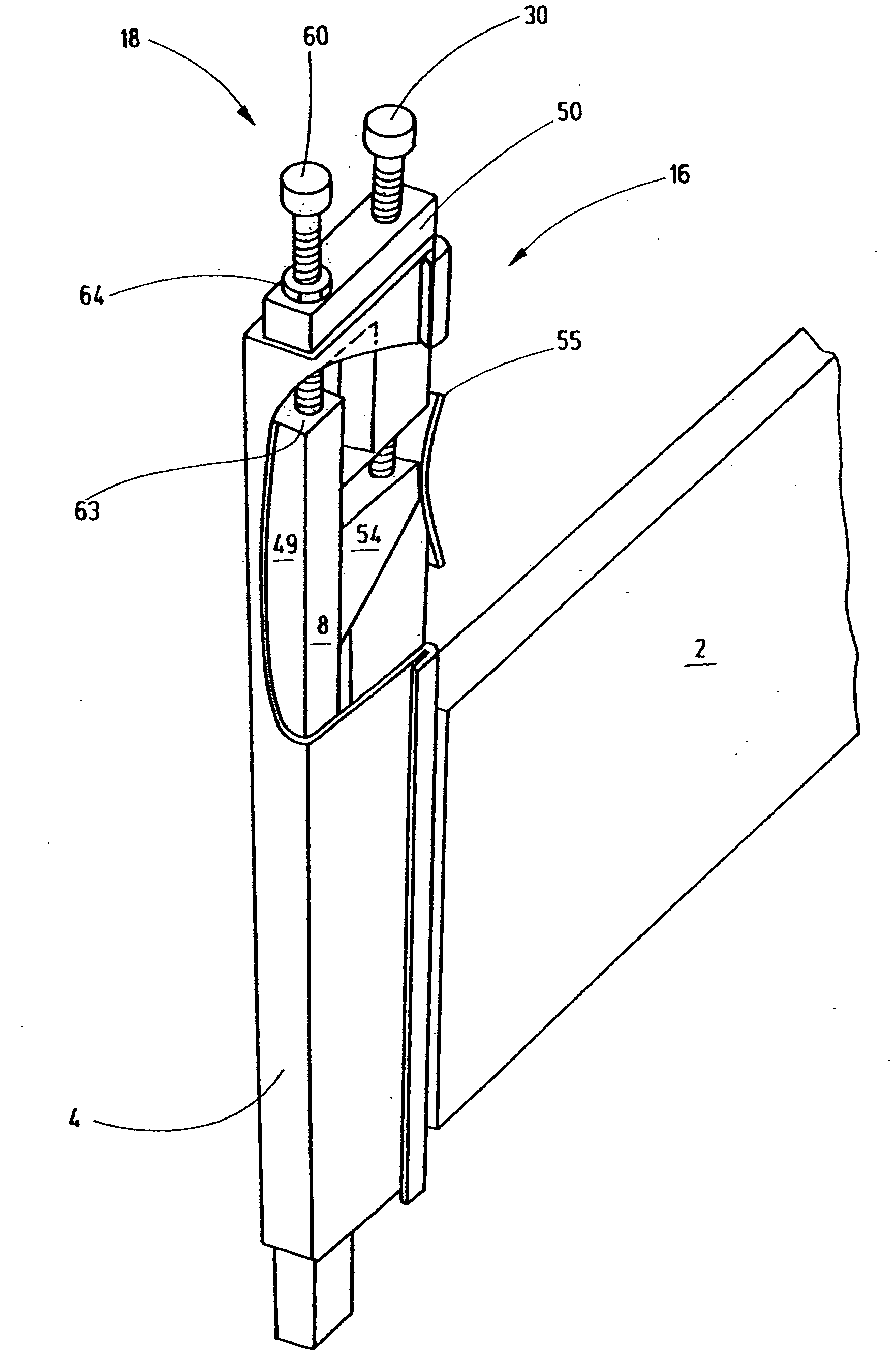

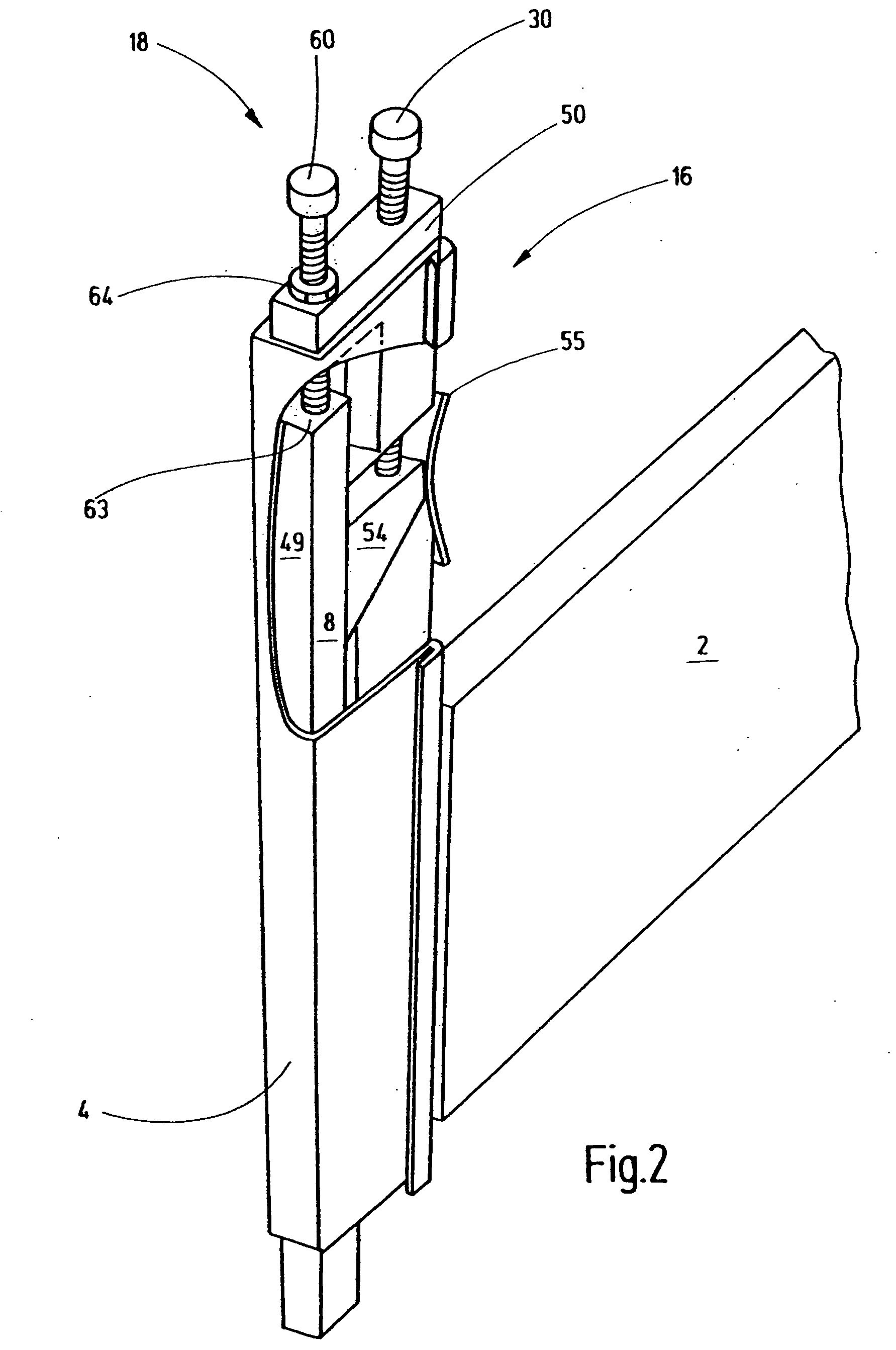

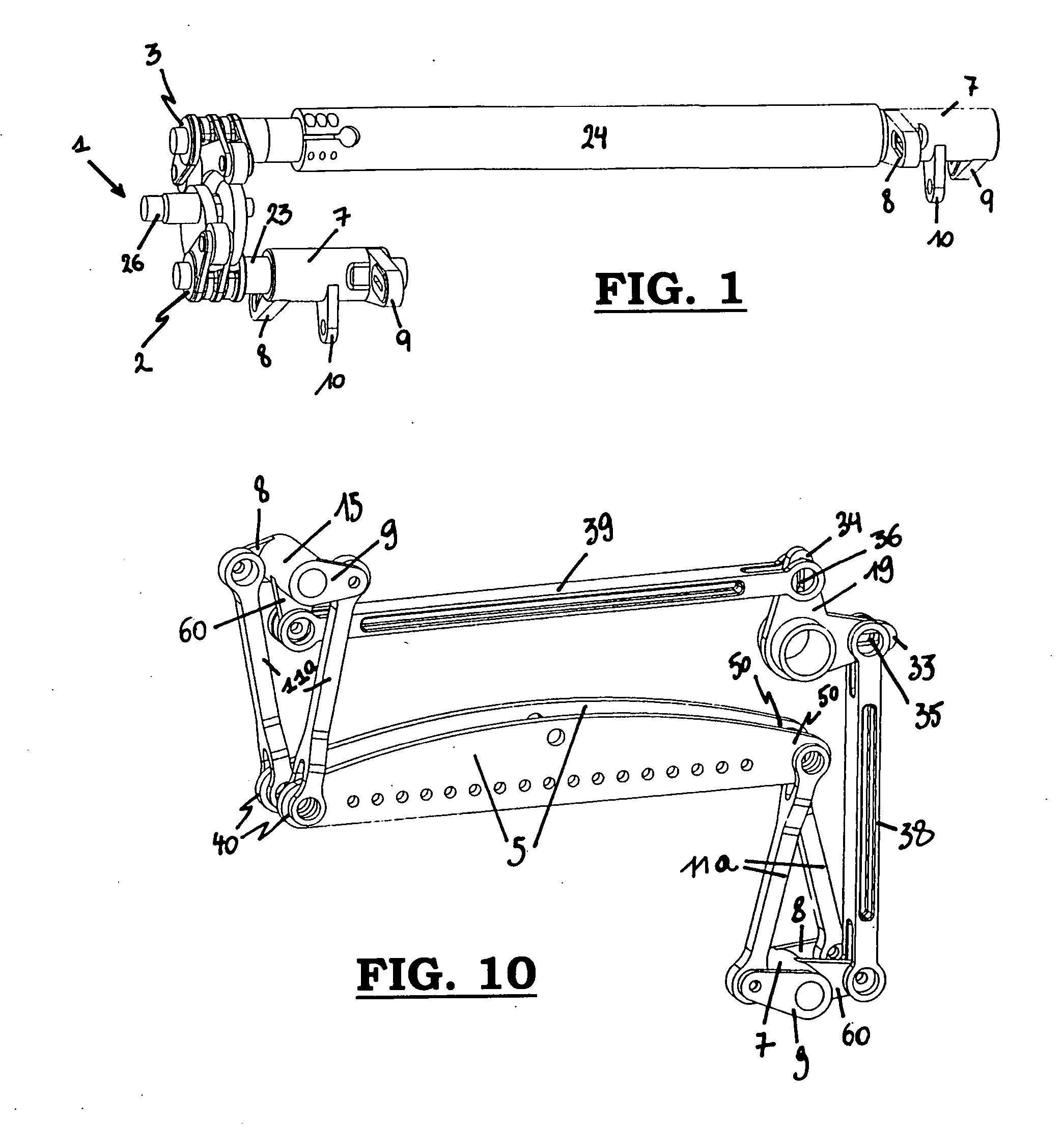

Shaft connecting device for a heald shaft

InactiveUS20090000687A1Reliable force transmissionReliable transmissionCam shedding mechanismLoomsLoad bearingAerospace engineering

A shaft connecting device (18) that comprises a thrust rod (8) and a lateral support (4) that fit into each other with minimal transverse play. In addition, the shaft connecting device (18) comprises a clamping device (16) with a stop means (60, 60′, 66) and a fixation means (30, 30′), the latter connecting the lateral support (4) and the thrust rod (8) exclusively on their respective upper ends to each other. Any opening, closing and adjusting of the connections between the thrust rod (8) and the lateral support (4) is possible in a particularly simple and convenient manner. The lateral support (4) and the thrust rod (8) support each other, thus resulting in a high dynamic load-bearing capacity. The overall design is simple, clear and cost-effective.

Owner:GROZ BECKERT KG

Device for modulating a first rotational motion of an input shaft to a second, different from the first, rotational motion of an output shaft in textile machines

The invention relates to a device for modulating a first rotational motion of an input shaft (2) to a second, different from the first, rotational motion of an output shaft (3) in textile machines, comprising: a fixed complementary cam (1) provided with at least two cam profiles (1a, 1b); at least one cam follower (5), which is linked to the input and the output shafts (2, 3) and which is provided with at least two contact rollers (6a, 6b), each following a different cam profile (1a, 1b), because of which the said cam followers (5) are performing a rocking motion, wherein the said cam profiles (1a, 1b) are internal cam profiles.

Owner:N V MICHEL VAN DE WIELE

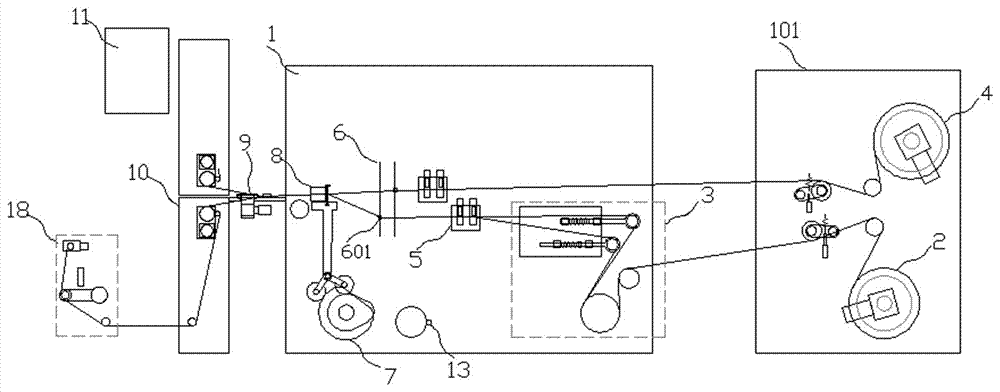

Main machine system of air jet loom

ActiveCN103572473ASimple structureImprove stabilityCam shedding mechanismLoomsAir-jet loomButt joint

The invention relates to a main machine system of an air jet loom. The main machine system comprises a rack, a weft insertion mechanism, a beating-up mechanism, shedding mechanisms, a let-off mechanism, a temple mechanism, a back beam frame, a take-up mechanism, a yarn end treatment mechanism and a dustbin, wherein the weft insertion mechanism is arranged on one side of the front end of the rack and in butt joint with the beating-up mechanism; the beating -up mechanism is installed on the rack; the shedding mechanisms are arranged above and below the beating-up mechanism; the back beam frame is installed at the back end of the rack, and the take-up mechanism is installed at the front end of the rack; the let-off mechanism is located below the back beam frame; the temple mechanism is arranged above the beating-up mechanism; the yarn end treatment mechanism is installed on one side of the back beam frame; and the dustbin is installed at the bottom of the front end of the rack. The main machine system of the air jet loom has the advantages of simple structure, good stability, small size, high production efficiency and the like, and can greatly improve the quality of cloth covers and the like.

Owner:SHAOXING TEXTILE MACHINERY GRP

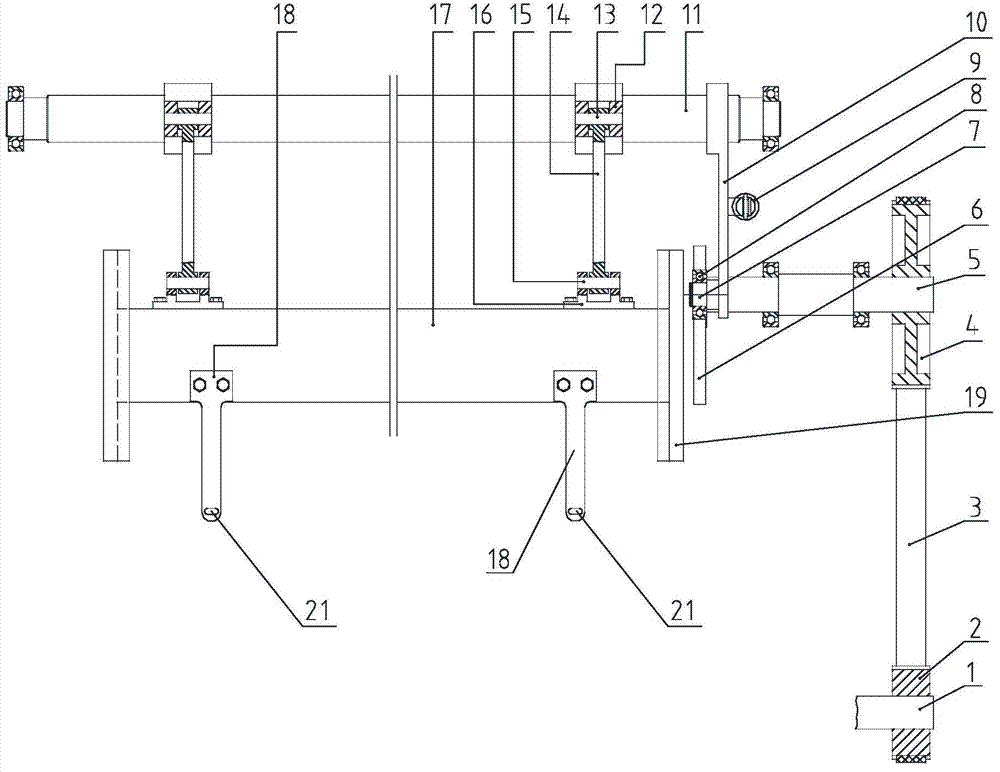

Cam mechanism, loom and method for decoupling the cams from the cam mechanism roller

The invention provides a cam mechanism, a loom and a method for decoupling the cams in relation to the cam followers of a cam mechanism. The cam mechanism for forming a shed on the loom comprising swing levers for driving a heald frame, wherein the swing levers are pivoting fixed on a same shaft and disposed with followers moving according to the cam of the mechanism. The shaft acts a translational motion along the back direction of the followers from the radial of the cam relatively to the the support structure of the mechanism, to decouple the cam and the followers. Therefor, The mechanism comprises at least a post for guide the shaft to translate along the back direction, wherein the post is fixed relatively to the support structure of the mechanism and is contained in a bearer of the shaft, and the bearer extends in a transverse direction relatively to a direct axis of the shaft.

Owner:STAUBLI FAVERGES SA

Shedding apparatus for a weaving machine, in particular for a ribbon weaving machine

InactiveUS20090277529A1Low noise operationOptimize allocationDobbiesCam shedding mechanismSpring forceEngineering

In order to make a small space requirement, a low energy requirement and therefore an increased weaving frequency possible in a shedding apparatus, a spring drive is proposed which is connected to magnetically acting holding means. The holding means are capable of holding the heddle frame in an upper shed position and in a lower shed position counter to the spring force. Furthermore, the heddle frame is connected to a linear motor. A heddle movement can be initiated by said linear motor. According to the invention, the spring drive is configured as a tension / compression spring which is designed in such a way that, during operation of the heddle frame at the resonant frequency of the spring drive the greater part of the kinetic energy can be obtained from the spring drive.

Owner:TEXTILMA AG

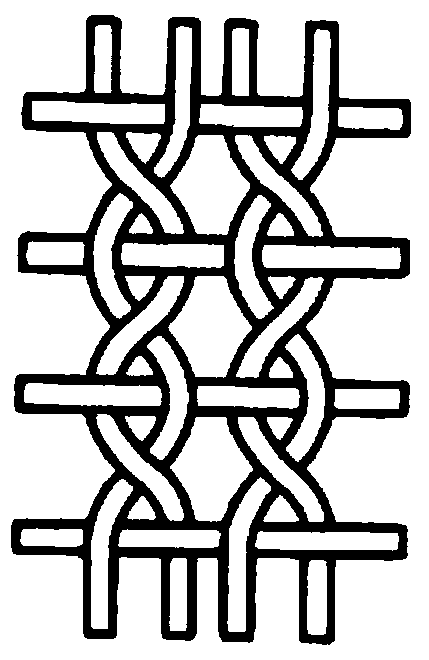

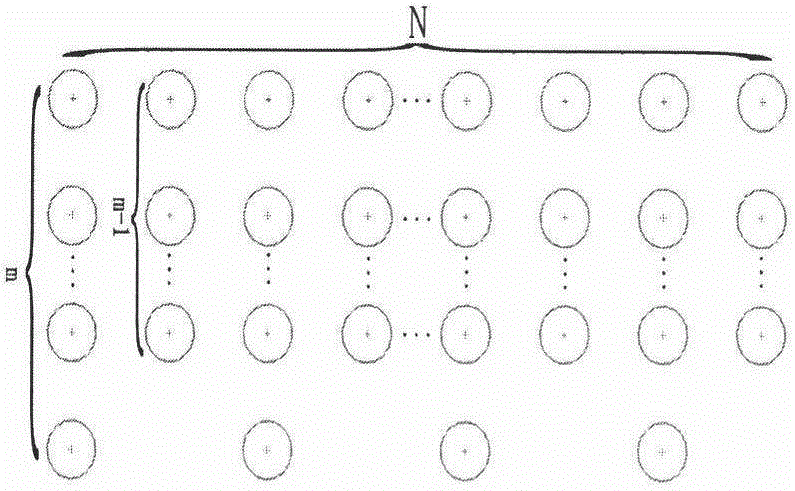

Weaving method for 2.5D satin weave structural fabric

InactiveCN106149168AEasy to bendAchieve interweaving effectCam shedding mechanismWoven fabricsEngineeringThick wall

The invention relates to a weaving method for a 2.5 D satin weave structural fabric. The method comprises the steps that warp is arranged on a multi-layer warp carrier of a three-dimensional loom on the basis of the rank rules, a three-dimensional loom opening device is modified, a special opening unit is designed and installed, particularly, a shedding sequence and an opening motion are designed on the basis of the warp and weft interweaving structural characteristics of a satin fabric, two-time lifting is performed on warp columns, all warp columns generate height differences, weft is introduced between two layers of warp in sequence, the weft is pushed into a weaving opening, and the fabric weaving is achieved. By adopting the technical scheme, weaving of the 2.5 satin weave structural fabric can be achieved. On the surface of the 2.5 D fabric, weaving points of warp and weft have the organizational structural characteristics of the plane satin fabric, the number of the weaving points of the weft and warp of the 2.5 D satin fabric is small, the better wettability, drapability and deformability are achieved, and the fabric used as an enhancing body can meet the requirement of a hook face thick wall composite material for the overall shape and performance of the fabric.

Owner:TIANJIN POLYTECHNIC UNIV

Water-jet loom in cross weaving mode

The invention discloses a water-jet loom in a cross weaving mode. The water-jet loom comprises a stander, wherein an opening mechanism, a weft guide mechanism, a warp conveying mechanism and a rolling mechanism are arranged on the stander; the opening mechanism comprises a heald frame, a heald frame driving part for driving the heald frame to move up and down, a leno heald steel reed arranged on the heald frame, and a leno heald steel reed driving part for driving the leno heald steel reed to move in a reciprocating manner; the heald frame driving part comprises an open plate, an open connection rod, a rocker rod, a heald lifting shaft and a driving assembly for driving the open plate; the upper rod head of the open connection rod is connected with the open plate, and the lower rod head is connected with one end of the rocker rod; the other end of the rocker rod sleeves the shaft end of the heald lifting shaft; the open plate is eccentrically connected with the open connection rod; an included angle between the open connection rod and the rocker rod is 120 degrees; the heald frame driving part comprises a chain wheel assembly, a gear assembly, a connection rod assembly and an adjustment block assembly for adjusting the travel of the leno heald steel reed. The water-jet loom runs steadily, is high in precision and can meet the demand for high-speed opening of the water-jet loom.

Owner:QINGDAO KAISHUO MACHINERY TECH CO LTD

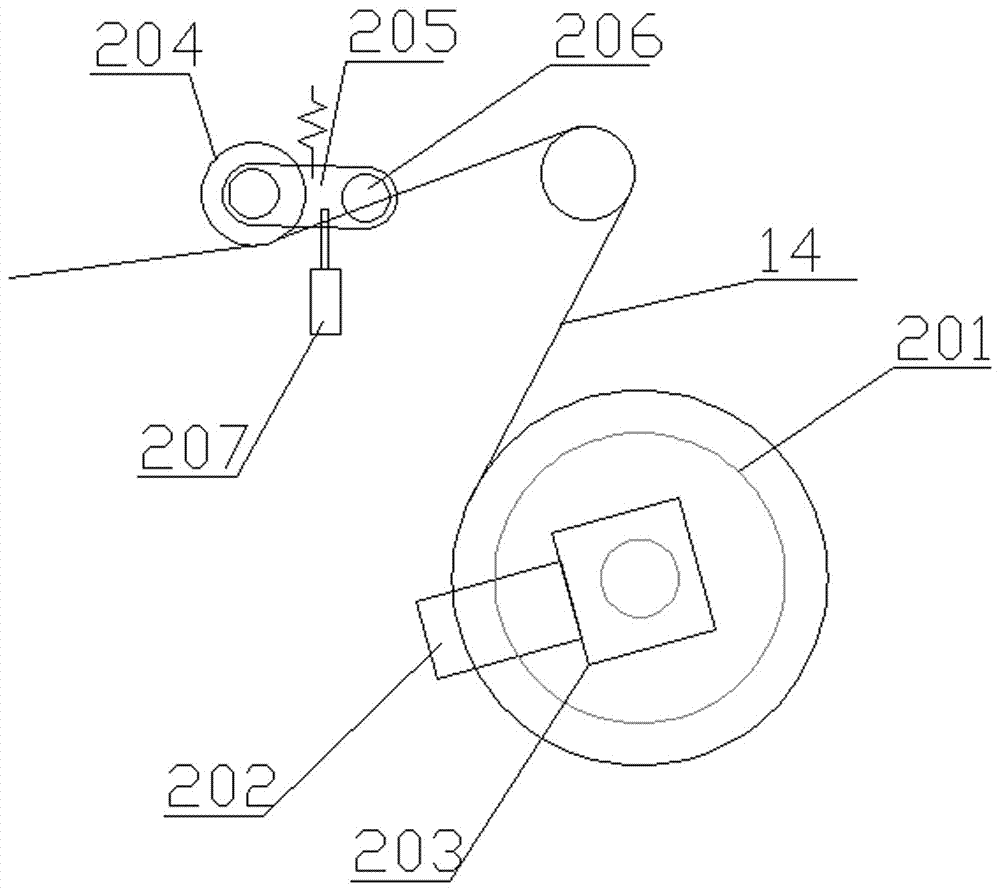

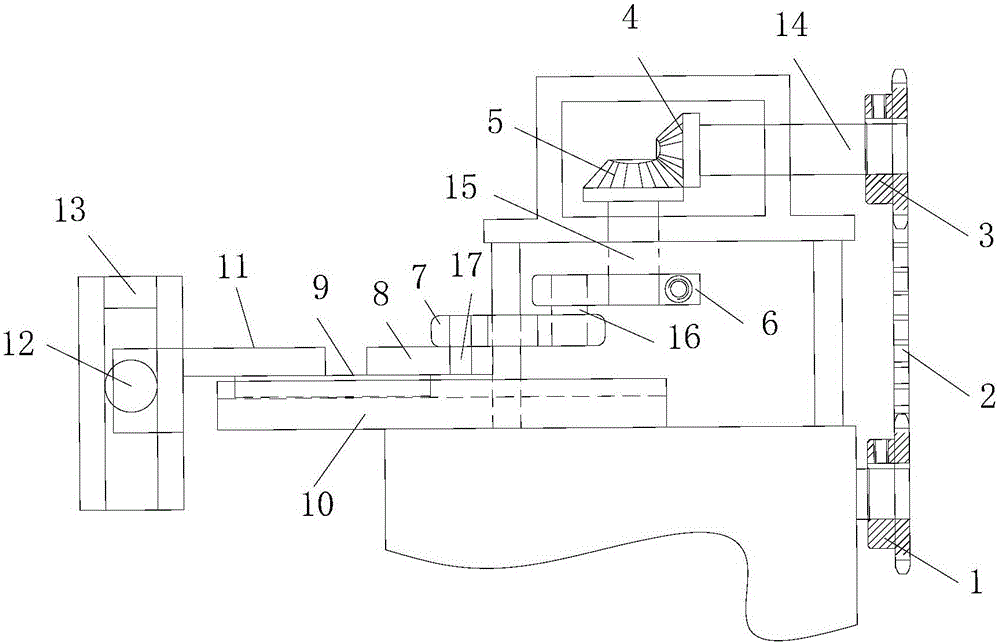

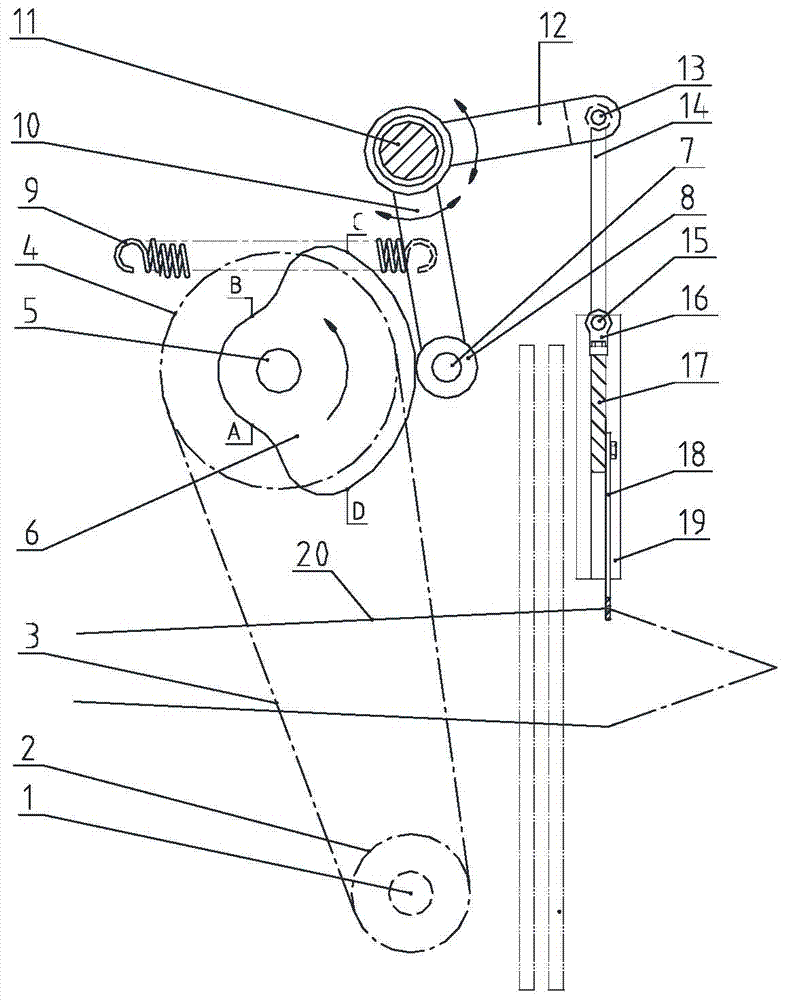

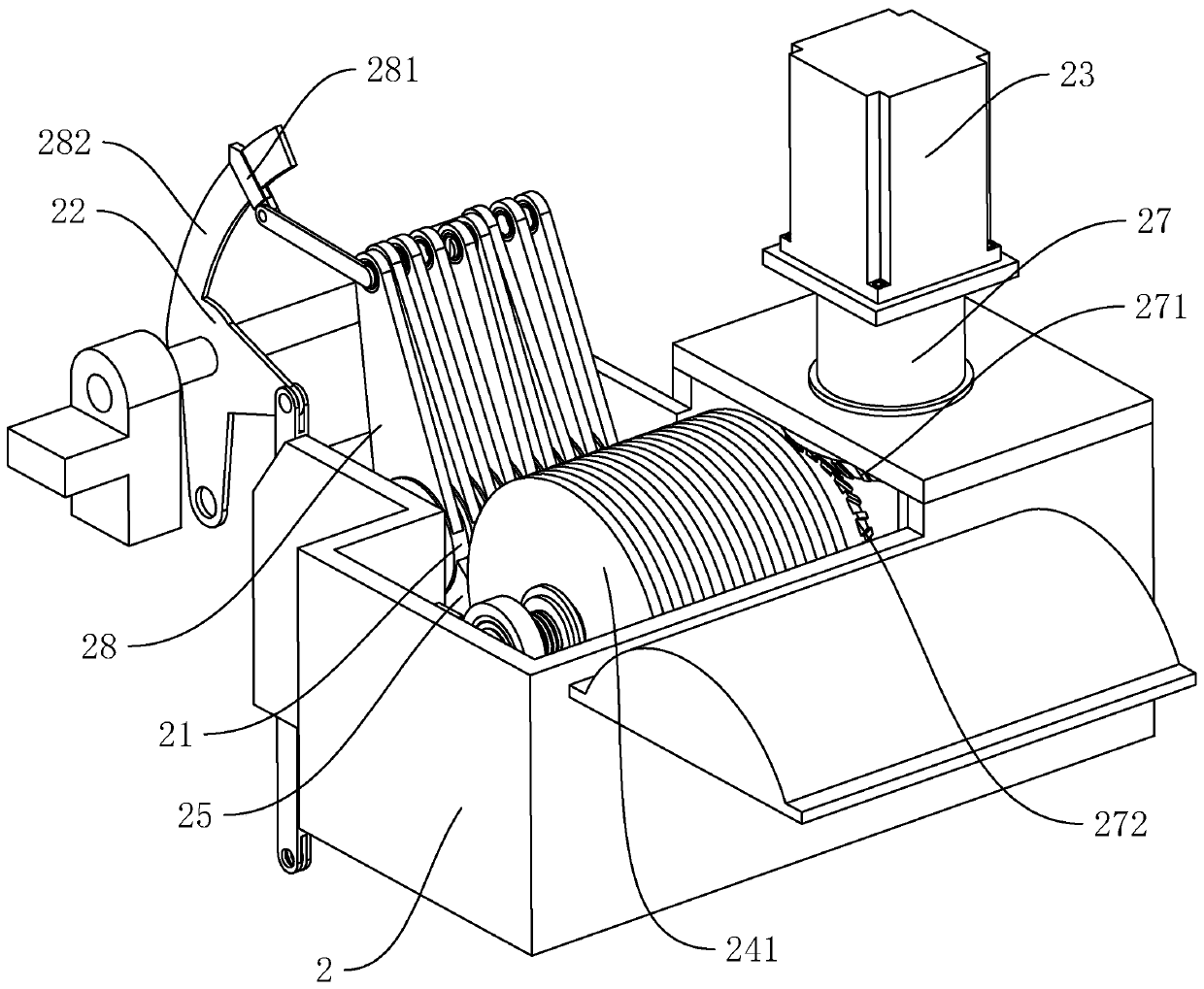

Suspender opening mechanism and plastic woven fabric water-jet loom

ActiveCN104499145AOptimal Control StructureReduce processCam shedding mechanismLoomsDrive shaftReciprocating motion

The invention discloses a suspender opening mechanism and a plastic woven fabric water-jet loom with the suspender opening mechanism. The suspender opening mechanism comprises a transmission shaft, a cam, a rotor, a rotor shaft, a rotor arm lever, a swinging shaft, a connection rod mechanism, a shedding beam and a guiding plate, wherein one end of the transmission shaft is connected with a power device or a power transmission assembly, and the other end of the transmission shaft is connected with the cam; the rotor is mounted on the rotor shaft and is tightly pressed on the outer edge of the cam; the rotor shaft is connected with one end of the rotor arm lever and the other end of the rotor arm lever is fixedly arranged on the swinging shaft; the connection rod mechanism is used for driving the shedding beam to do reciprocating motion up and down; a shedding plate group is arranged at the lower part of one end of the shedding beam or one shedding plate group is arranged at the lower part of each of the two ends of the shedding beam; each shedding plate group at least comprises two shedding plates; and a suspender threading hole is formed in the lower end of each shedding plate. The water-jet loom disclosed by the invention can be used for weaving a woven fabric, and also can be used for weaving a suspender into the woven fabric, so that the procedures are saved and the production efficiency is improved.

Owner:QINGDAO JINSANYANG TEXTILE MACHINERY

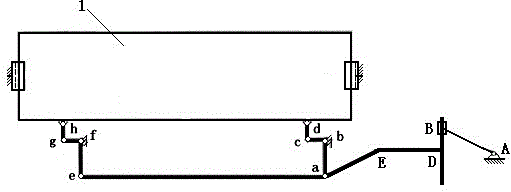

Flat opening mechanism with moving pair

InactiveCN102912504AEliminate sources of vibrationAvoid damageCam shedding mechanismLoomsAir-jet loomEngineering

Owner:JIANGSU WANGONG TECH GRP CO LTD

Method and device for forming a shed in a weaving machine

A shed-forming device and a method for using it are provided for creating a shed of warp yarns in a weaving machine. The shed-forming device includes a plurality of yarn separating elements operably disposed to one another within the weaving machine. The yarn separating elements individually separate the warp yarns into operational zones between the yarn separating element. A fluid supply apparatus supplies fluid to the yarn separating elements in the shed-forming device. The yarn separating elements direct the fluid to contact the warp yarns, forcing the warp yarns to form changeable sheds to allow proper weaving.

Owner:GENDELMAN MIKHAIL +1

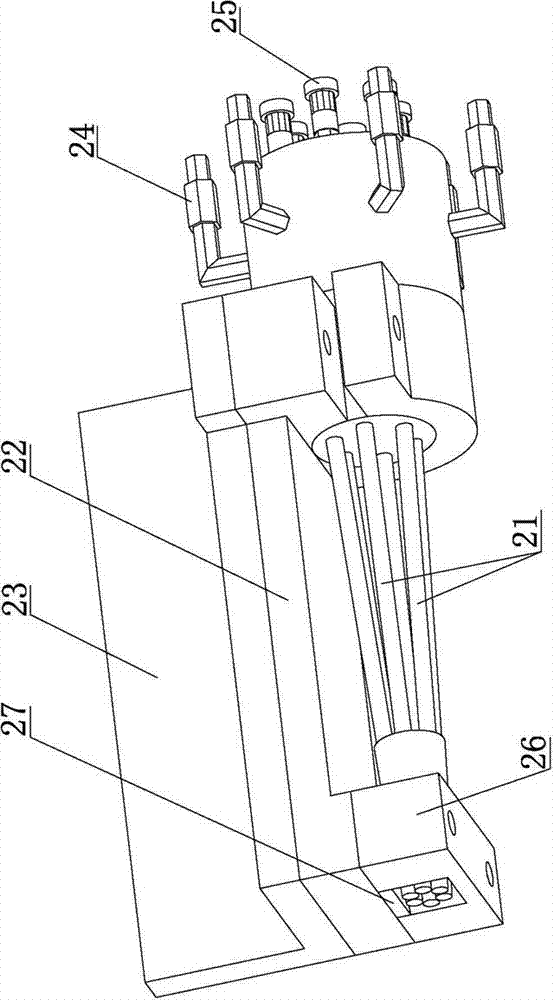

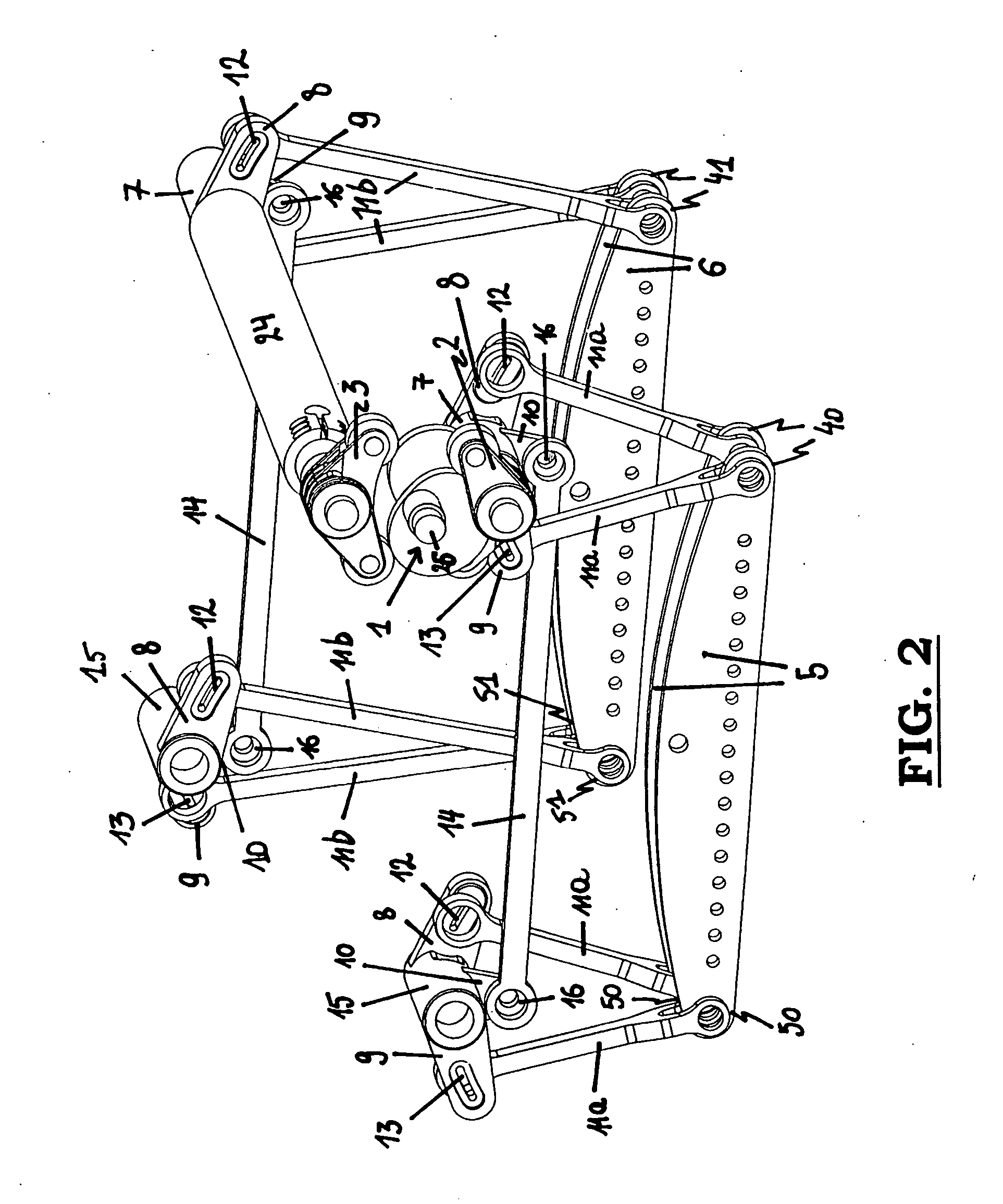

Jacquard machine

The invention relates to a Jacquard machine, comprising at least two knife grids (5, 6) moving up and down in opposition on either side of the Jacquard machine, the Jacquard machine comprising a single-sided drive (1) for driving at least one driving lever (2,3) which is provided for driving the motion of the knife grids (5, 6) on either side of the Jacquard machine, and one traversing rocking shaft (24) being provided to transmit the motion of the said driving lever (2 and 3 respectively) to the knife grids (5, 6) of one of the sides of the Jacquard machine.

Owner:VAN DE WIELE MICHEL

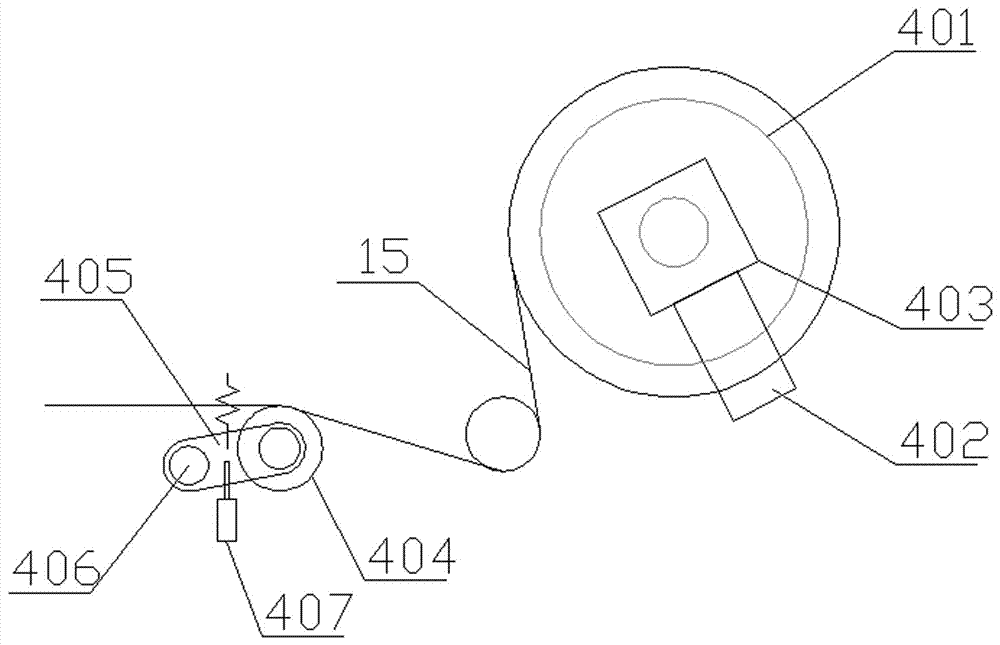

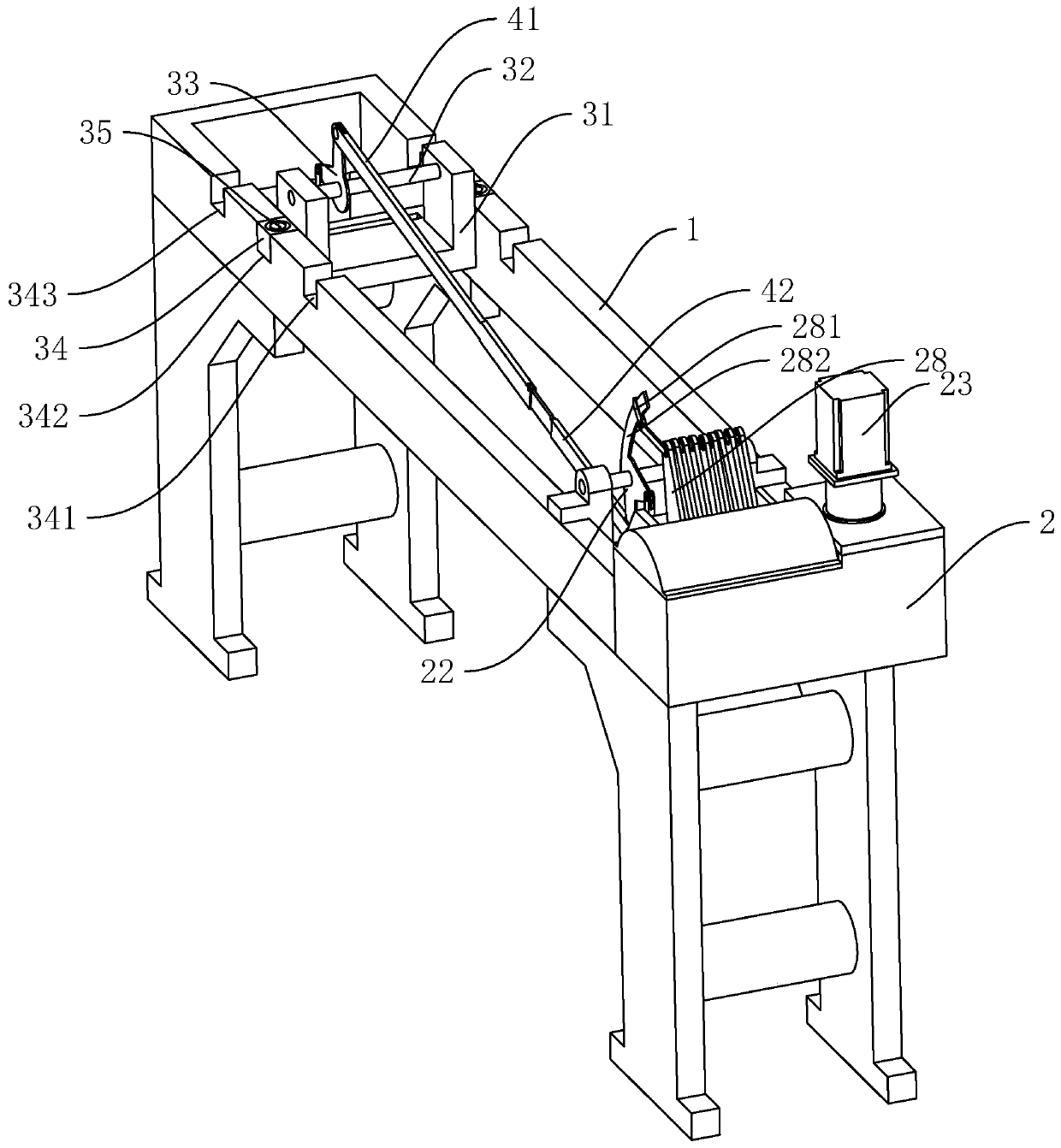

Ribbon loom transmission apparatus

ActiveCN106854788AIncrease the number of timesImprove the inconvenienceCam shedding mechanismLoomsCamRocker arm

The present invention discloses a ribbon loom transmission apparatus, which is provided with a base table group, wherein the outer edge position of the base table group is provided with a worm wheel box transmission group, a cam group and a cutter closing rocker arm group are arranged inside the base table group, and the worm rod of the worm wheel box transmission group is engaged with the worm wheel of the cam group so as to drive a cam sheet to bear against the cutter closing rocker arm group to drive a heald frame. According to the present invention, by engaging the eight-tooth molding worm rod with the worm wheel, the rotation speed of the cam shaft can match the improving of the rotation speed of the main shaft, such that the number of the interweaving action of the ribbon loom heald frame is increased so as to improve the ribbon productivity; and the cam sheet has the four-phase profile curve, such that the cam sheet operation jerky degree can be reduced so as to reduce the wear on the cam sheet, and the cam sheet jitter situation can be improved so as to further prolong the service lives of the heald frame group and the accessories.

Owner:郑 正 雄

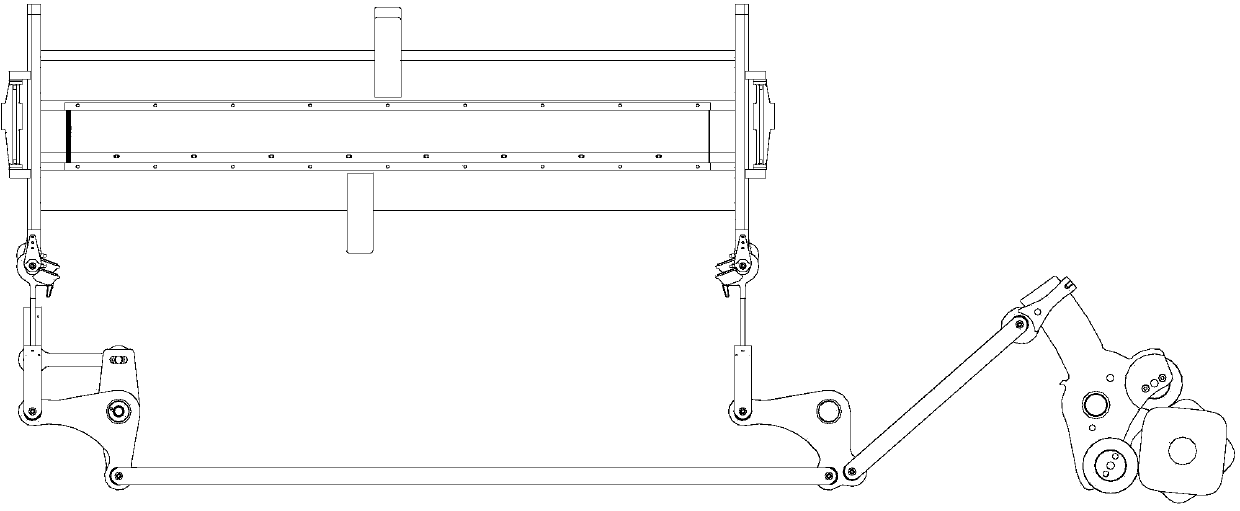

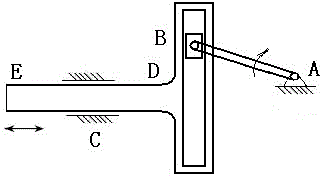

Cam opening device suitable for various door widths

The invention discloses a cam opening device suitable for various door widths, relates to textile equipment, and aims to solve the problem that cloth with different doors cannot be weaved. The cam opening device suitable for various door widths comprises a horizontal beam, a driving system, a driven system and a connecting rod, wherein the driving system comprises a box body, a cam group, a pendulum disc, a driving blade and an alternating current motor; the driven system comprises a movable base, a driven main shaft and a driven blade, wherein the movable base is provided with a lug, and thehorizontal beam is sequentially provided with a first notch, a second notch and a third notch which are clamped and matched with the lug in the length direction; the connecting rod comprises a left section and a right section, and a length adjusting piece is arranged between the left section and the right section. According to the cam opening device suitable for various door widths, the distance between the driving system and the driven system is adjusted, and the length of the connecting rod is correspondingly adjusted, so that the technical effect of adapting to different doors is achieved.

Owner:嘉兴市金河纺织有限公司

Electric shedding device in weaving machine

InactiveUS6450209B1Improve directionIncrease distanceCam shedding mechanismLoomsEngineeringElectric motor

A shedding device in a weaving machine including one or more motor groups with a plurality of motors corresponding to a plurality of heald frames which are supported by a plurality of supporting mechanisms arranged in the forward and backward direction of the weaving machine. The motors of each motor group are arranged in the upward and downward, rightward and leftward directions. Two or more motors operating as at least part of the motor group form one or more motor rows. Each motor is connected to the supporting mechanism of a heald frame through a connecting member. Adjacent motors in the motor row or rows are related to non-adjacent heald frames among the heald frames corresponding to the support mechanisms.

Owner:TSUDAKOMA KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com