Water-jet loom in cross weaving mode

A water-jet loom and frame technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve problems such as increasing production costs, reducing equipment service life, impact and vibration wear of cam mechanisms, and achieves elimination of wrinkles and smooth running Smooth, high-grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

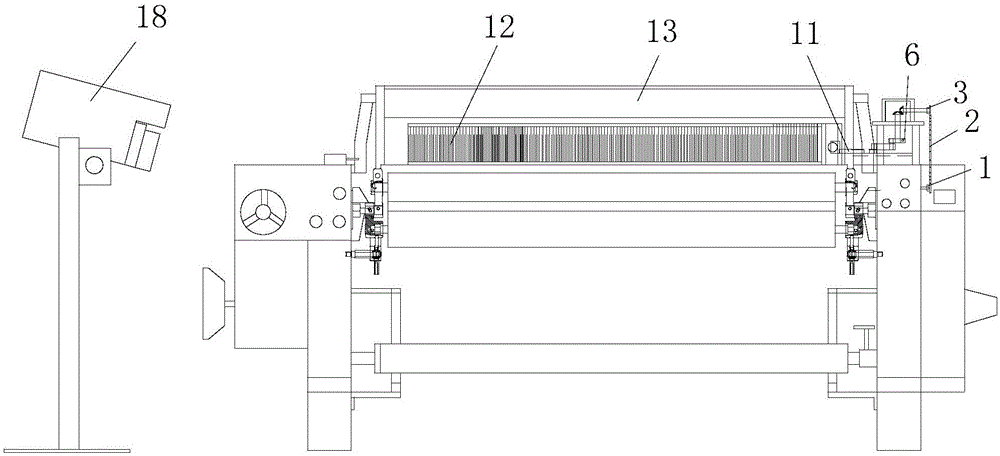

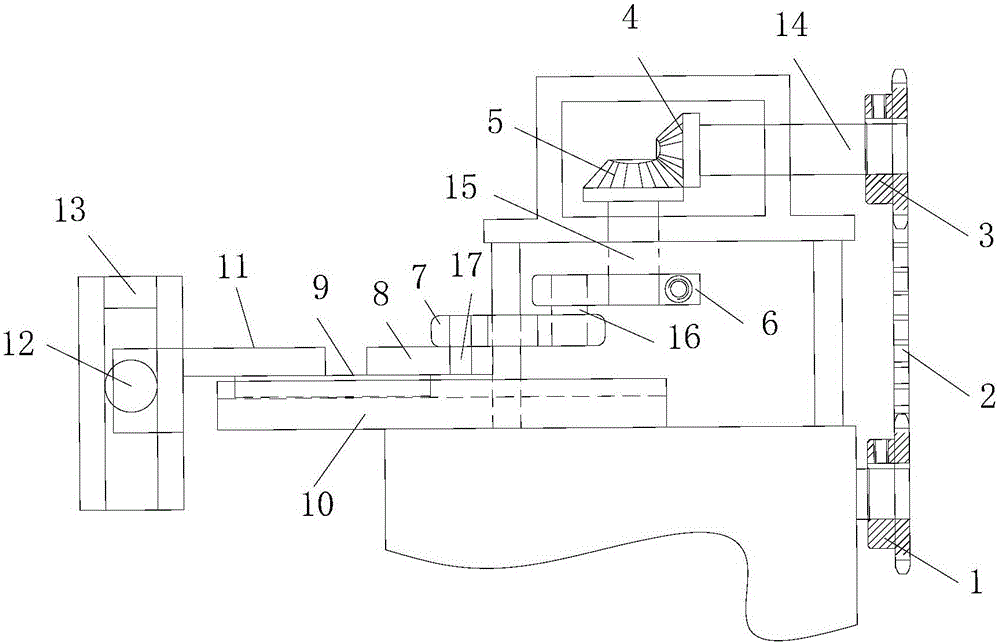

[0033] Such as Figure 1 to Figure 6 As shown, a twisted water jet loom includes a frame, and the frame is provided with an opening mechanism, a weft insertion mechanism, a let-off mechanism and a coiling mechanism.

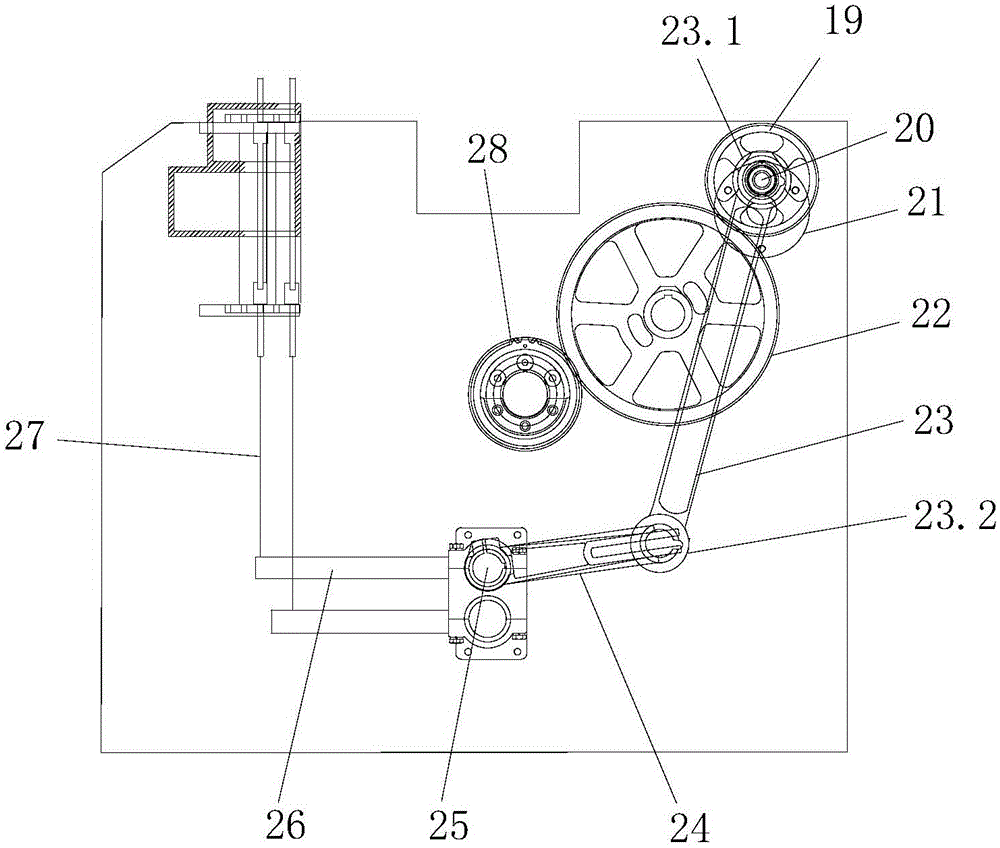

[0034] The opening mechanism includes a heald frame 13, a heald frame driving part that drives the heald frame 13 to move up and down, a twisted heald reed 12 arranged on the heald frame 13, and a twisted heald reed that drives the twisted heald reed 12 to move laterally back and forth Drive unit:

[0035]The heald frame driving part comprises a split disc 21, a split connecting rod 23, a rocking bar 24, a heald lifting shaft 25 and a driving assembly for driving the split disc 21, and the upper rod head 23.1 of the split connecting rod 23 is connected with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com