Cam mechanism, loom and method for decoupling the cams from the cam mechanism roller

A cam mechanism and cam technology, which are applied in the cam opening mechanism, textile, textile and papermaking, etc., can solve the problems of unprovable leveling device and complex shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

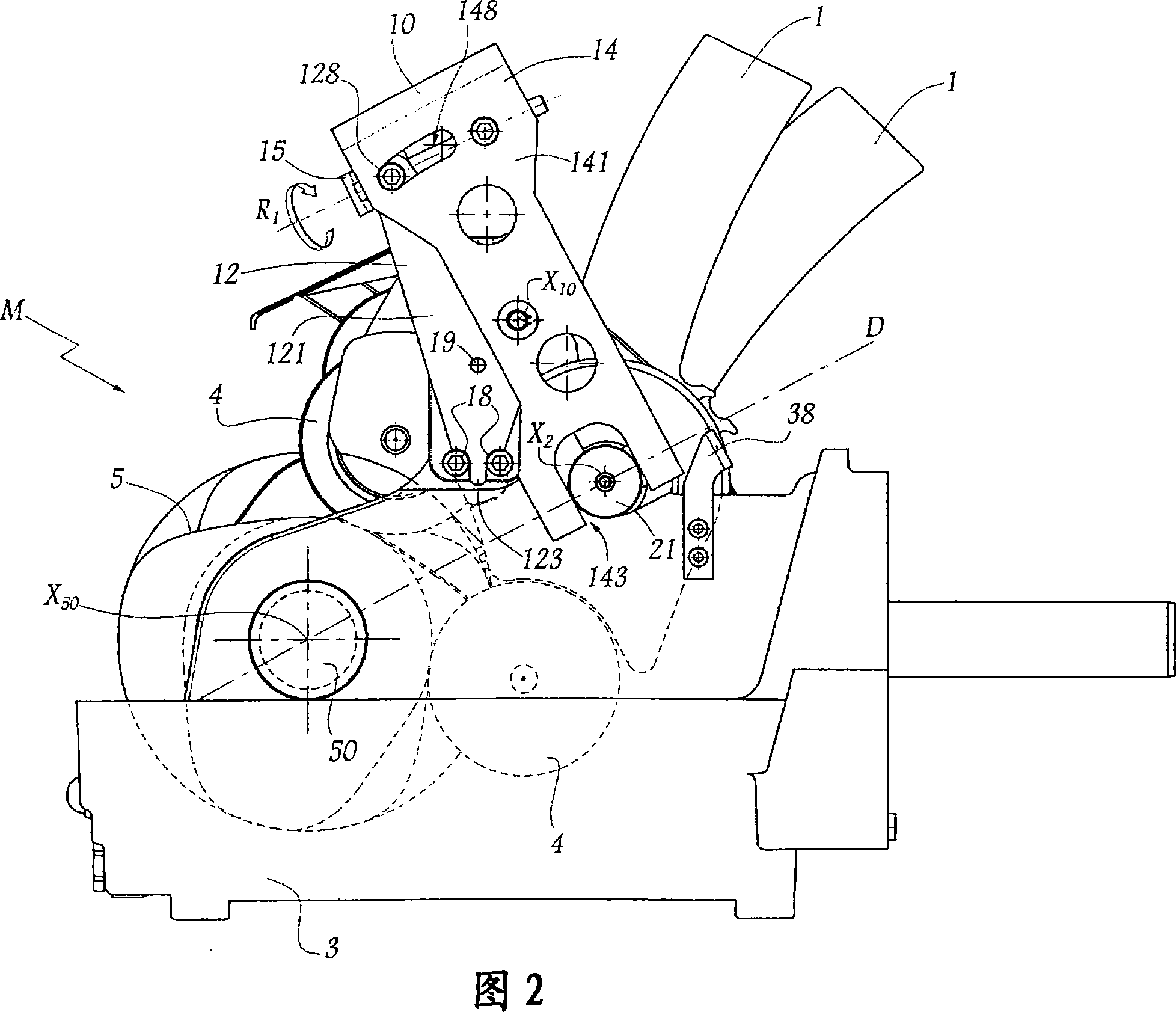

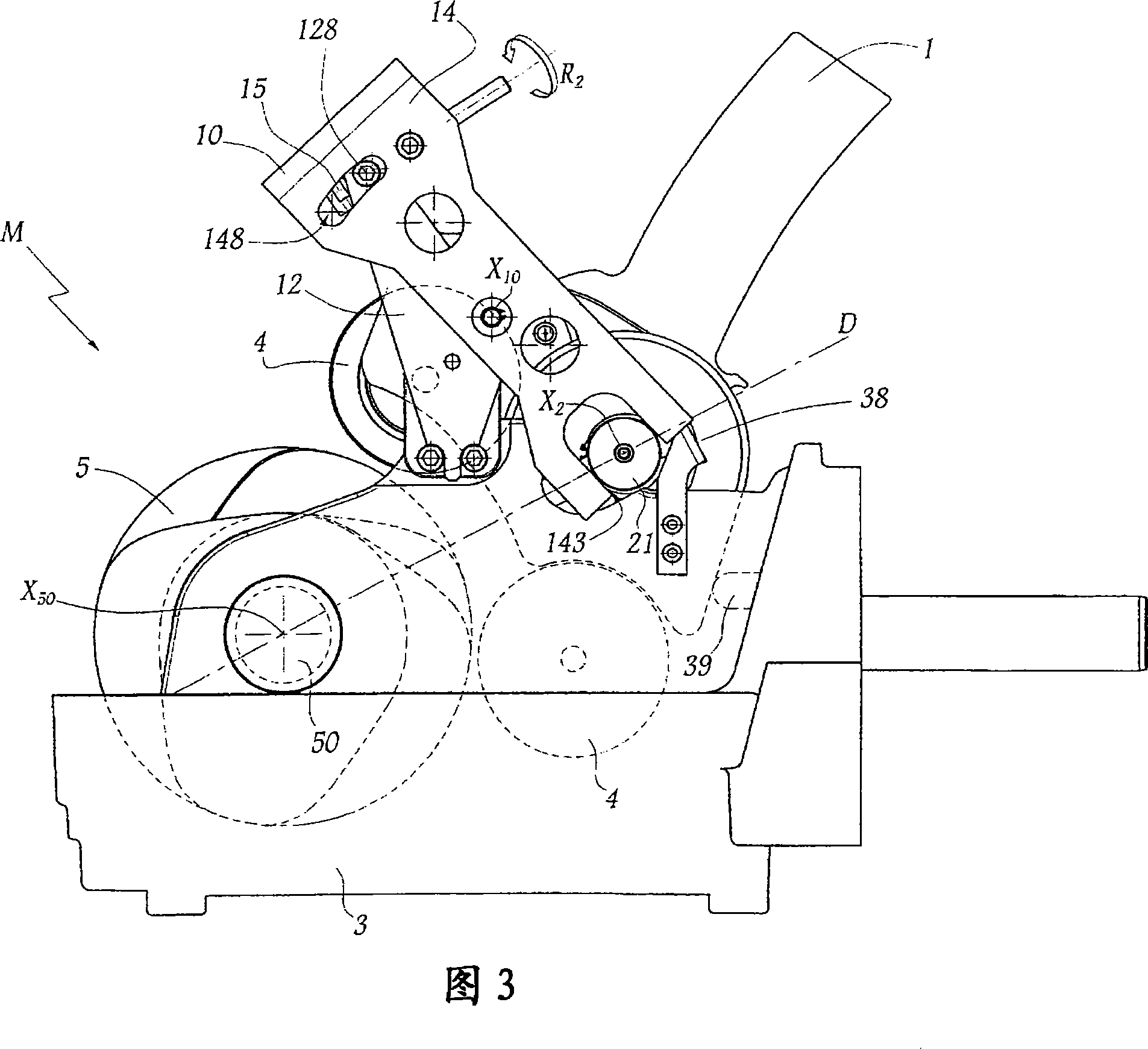

[0025] In the present invention, "non-leveling configuration" or "operating configuration" of a cam mechanism refers to the configuration of the mechanism when the loom on which the mechanism is installed is in the operating configuration. Likewise, a "leveled configuration" of a cam mechanism refers to a mechanism configuration in which the cam is separated from the rollers of the oscillating lever—in other words, the contact between the cam and the rollers is loosened.

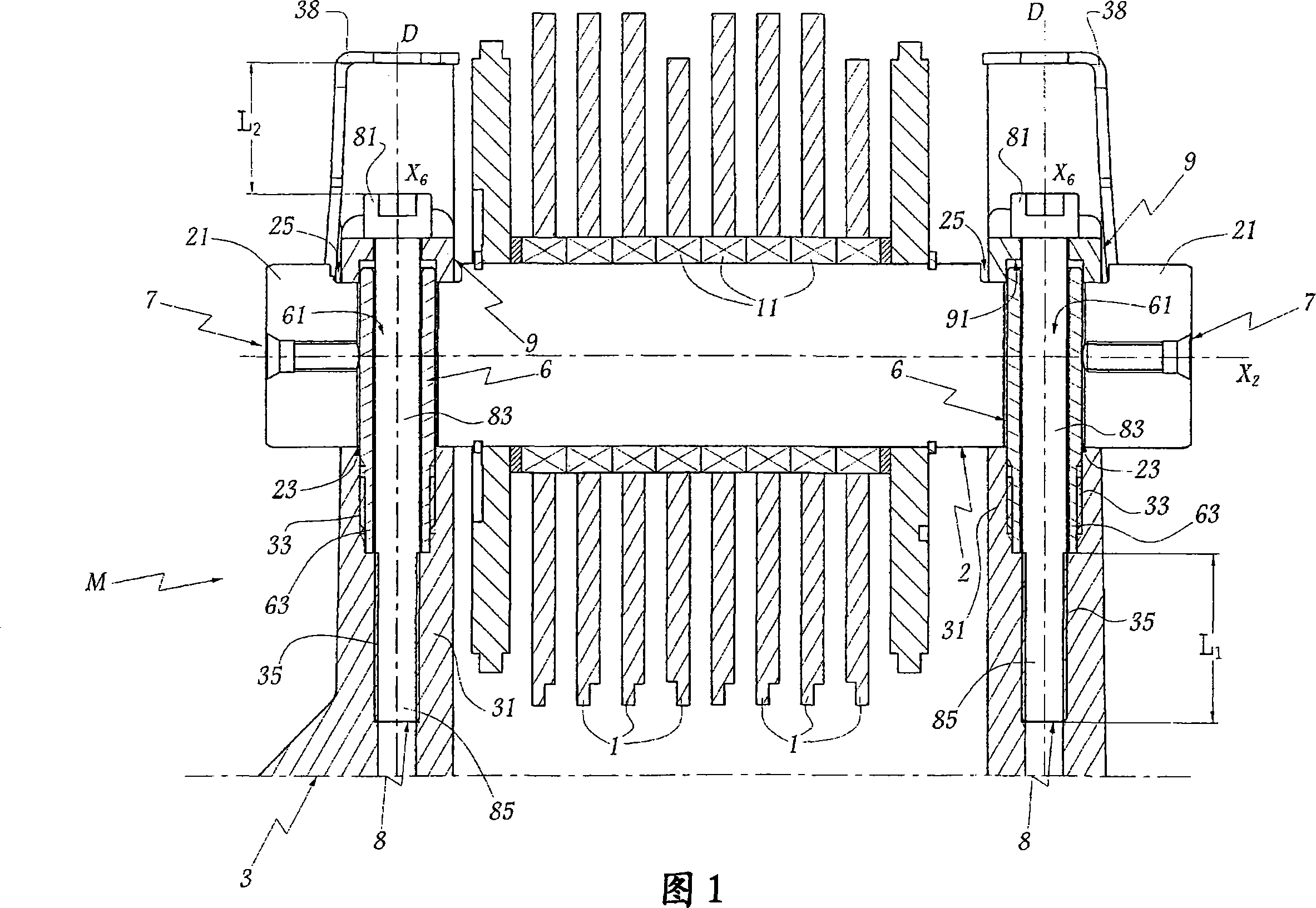

[0026] The cam mechanism M shown in Figures 1-3 is used in a loom (not shown) comprising a plurality of heald frames whose alternating vertical movement is controlled by the mechanism M.

[0027] The mechanism M comprises a plurality of oscillating rods 1, one for each heald frame of the loom, all mounted about the longitudinal axis X 2 The common non-rotating shaft 2 pivots, which is supported by the supporting structure 3 of the mechanism. The rotational guidance of the pivot lever 1 about the shaft 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com