Patents

Literature

96results about "Hand looms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

String bead loom

InactiveUS7147008B2Maintain proper tensionImprove performanceHand loomsEngineeringMechanical engineering

Owner:SAYLER WAYNE E

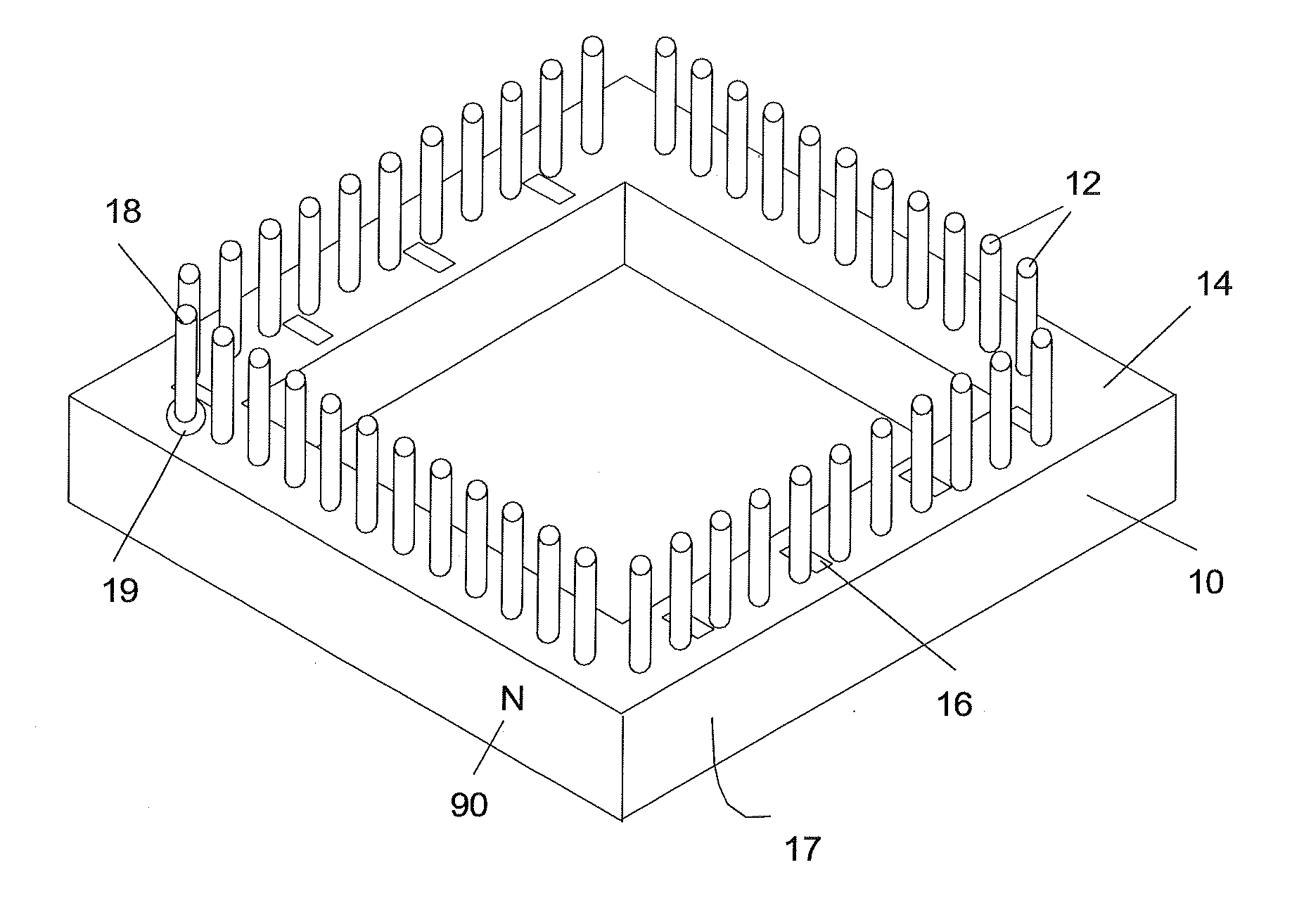

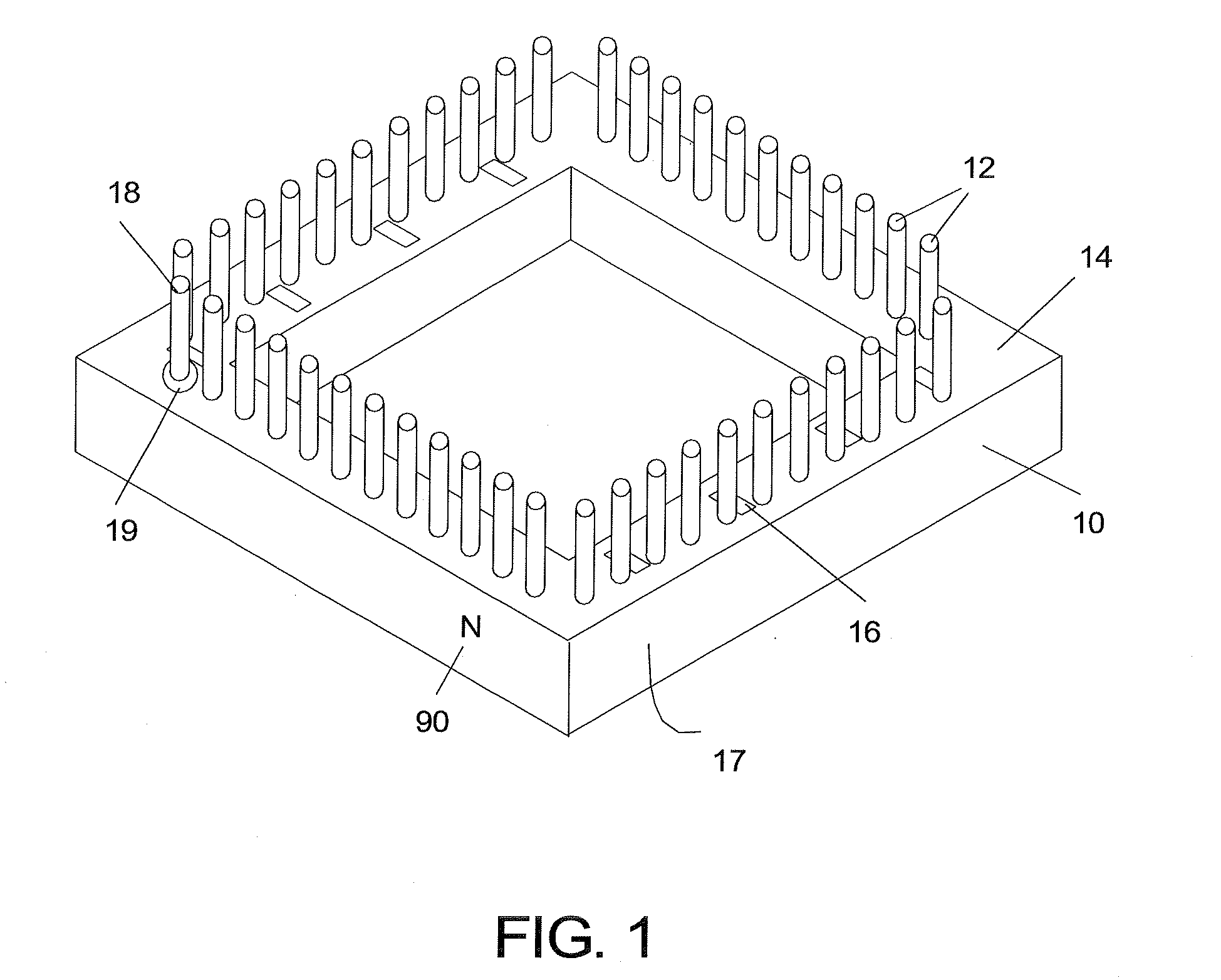

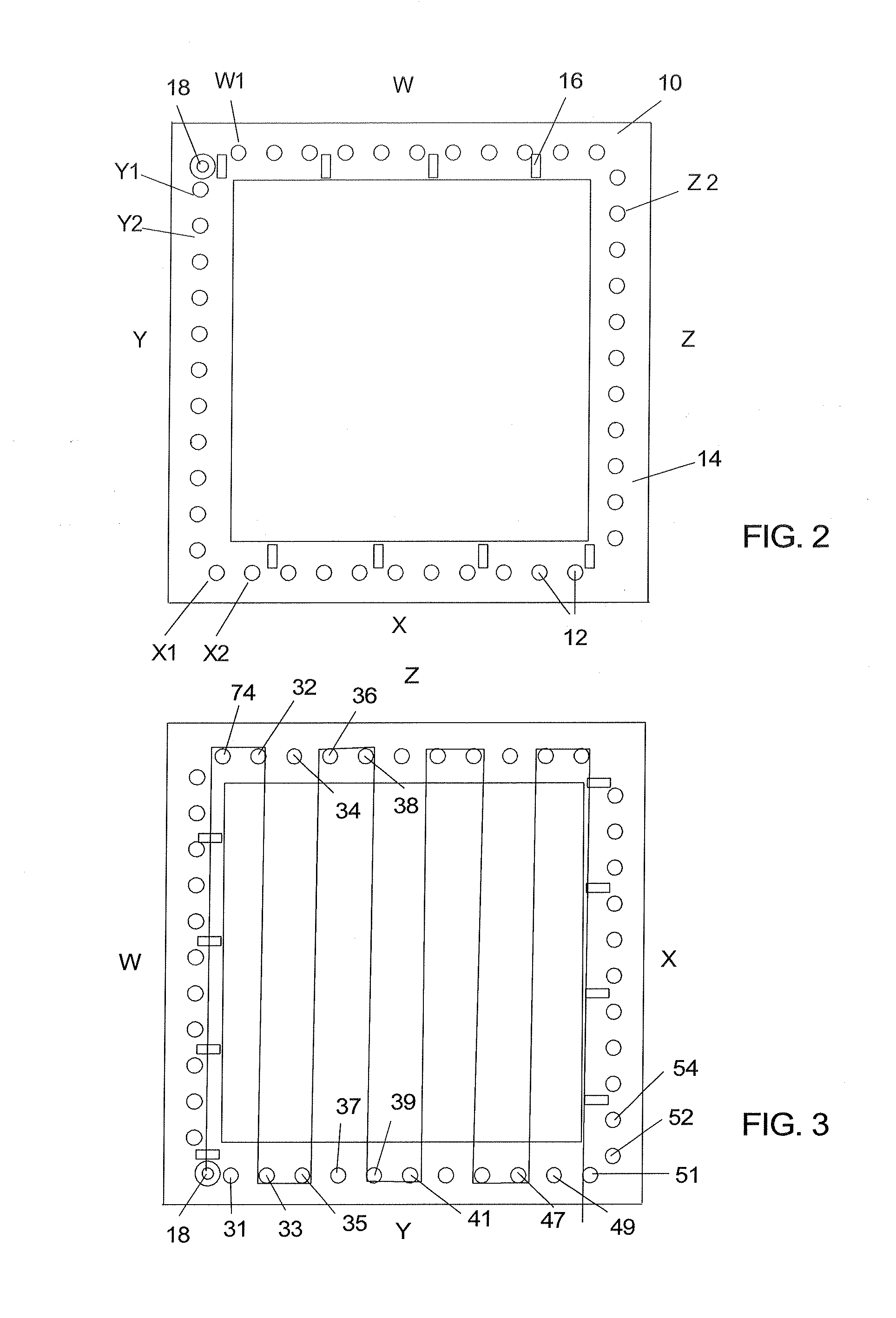

Modular adjustable frame hand loom

ActiveUS8316894B2Easy constructionReduce manufacturing costAuxillary apparatusContainer/bottle contructionYarnAbutment

An adjustable knitting and weaving hand loom includes differently shaped elongate sections. Tabs and channels connect the sections to form a closed frame by connecting adjoining sections in end-to-end abutment. The tabs and mating channels form sliding joints between adjoining sections. Each of the sections is provided with a series of substantially uniformly spaced holes or bores. End-most holes through the tabs and the channels are aligned when the axial tabs are fully slidably mated within associated axial channels. Pegs are dimensioned to be received both within aligned end-most holes at each slip joint and intermediate holes. The pegs are inserted into aligned end-most bores or holes function both to secure yarn during knitting and to lock the axial tabs from inadvertently separating from mating axial channels by movements along the direction of insertion.

Owner:SCHAUB RENE

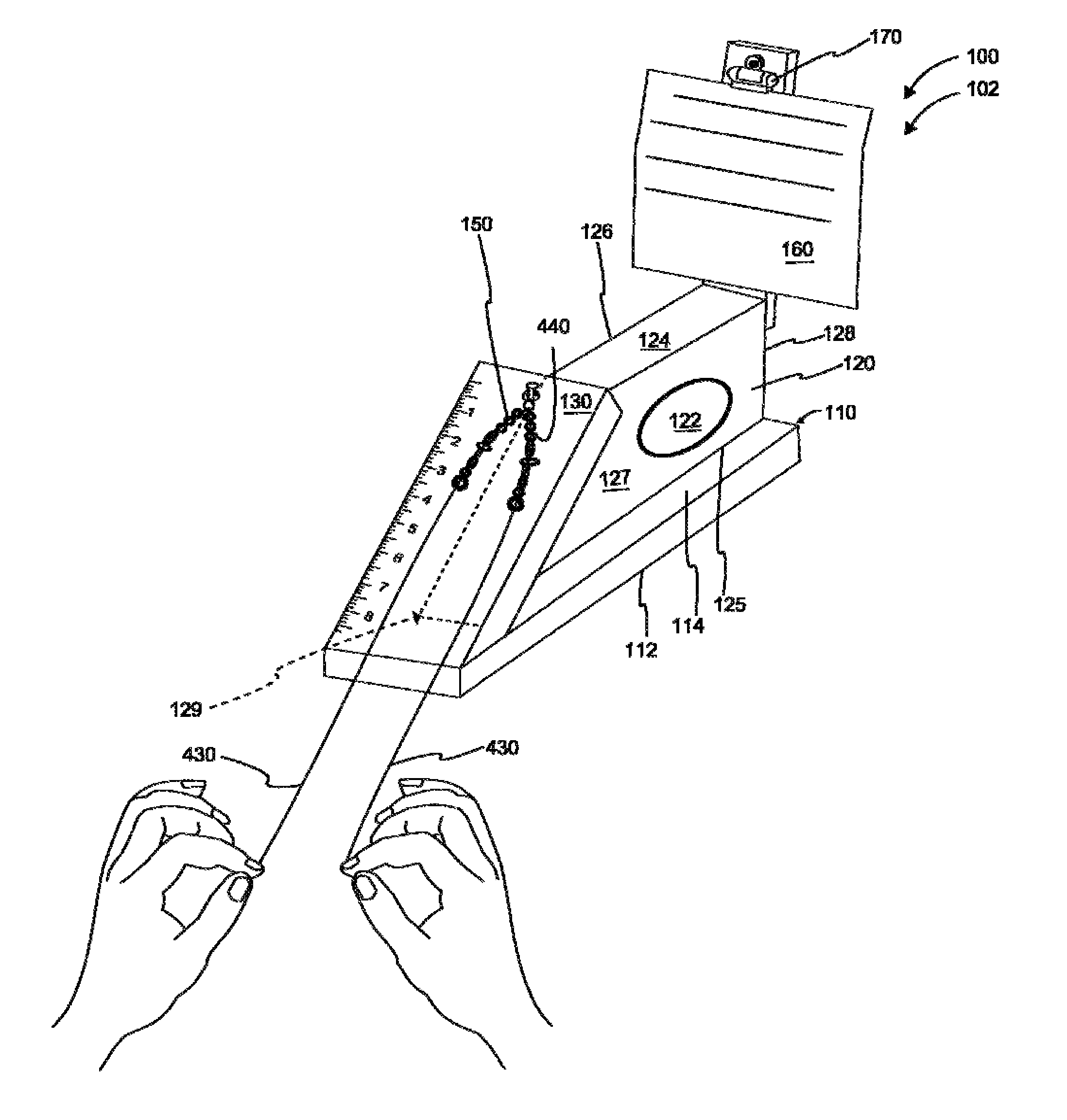

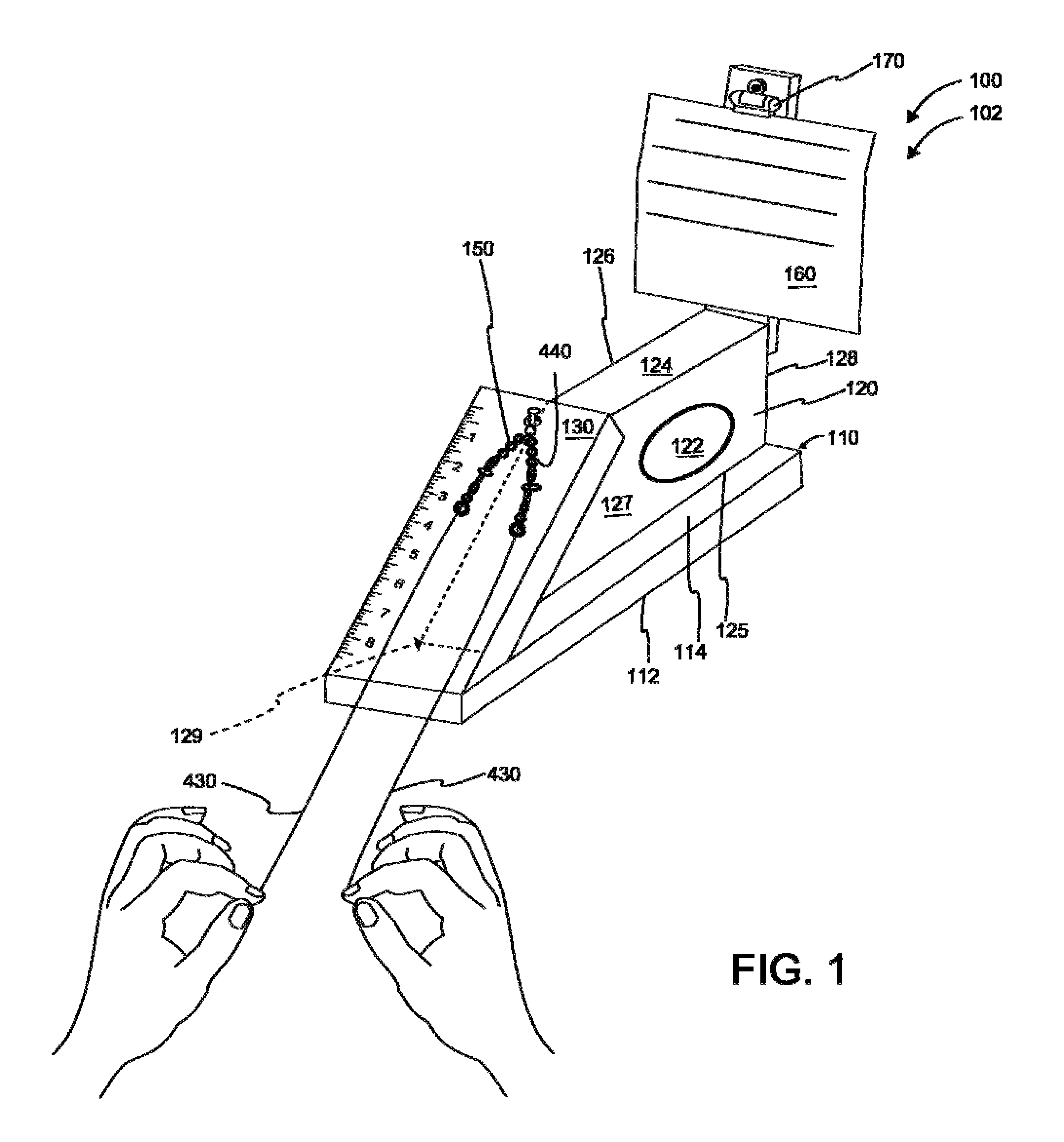

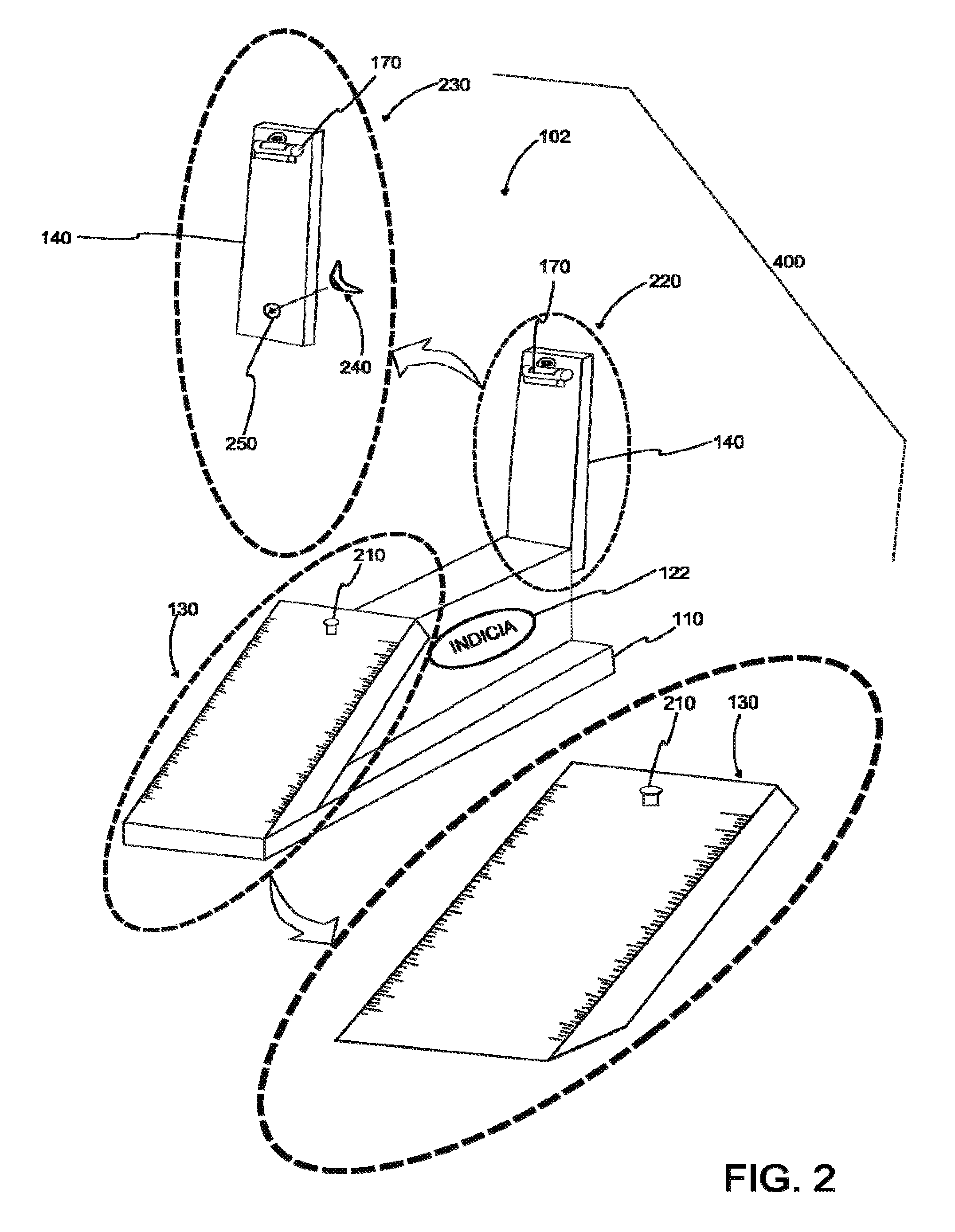

Beadin' butler systems

InactiveUS20100212770A1Small sizeEasy positioningJewelleryTextile cablesSizingBiomedical engineering

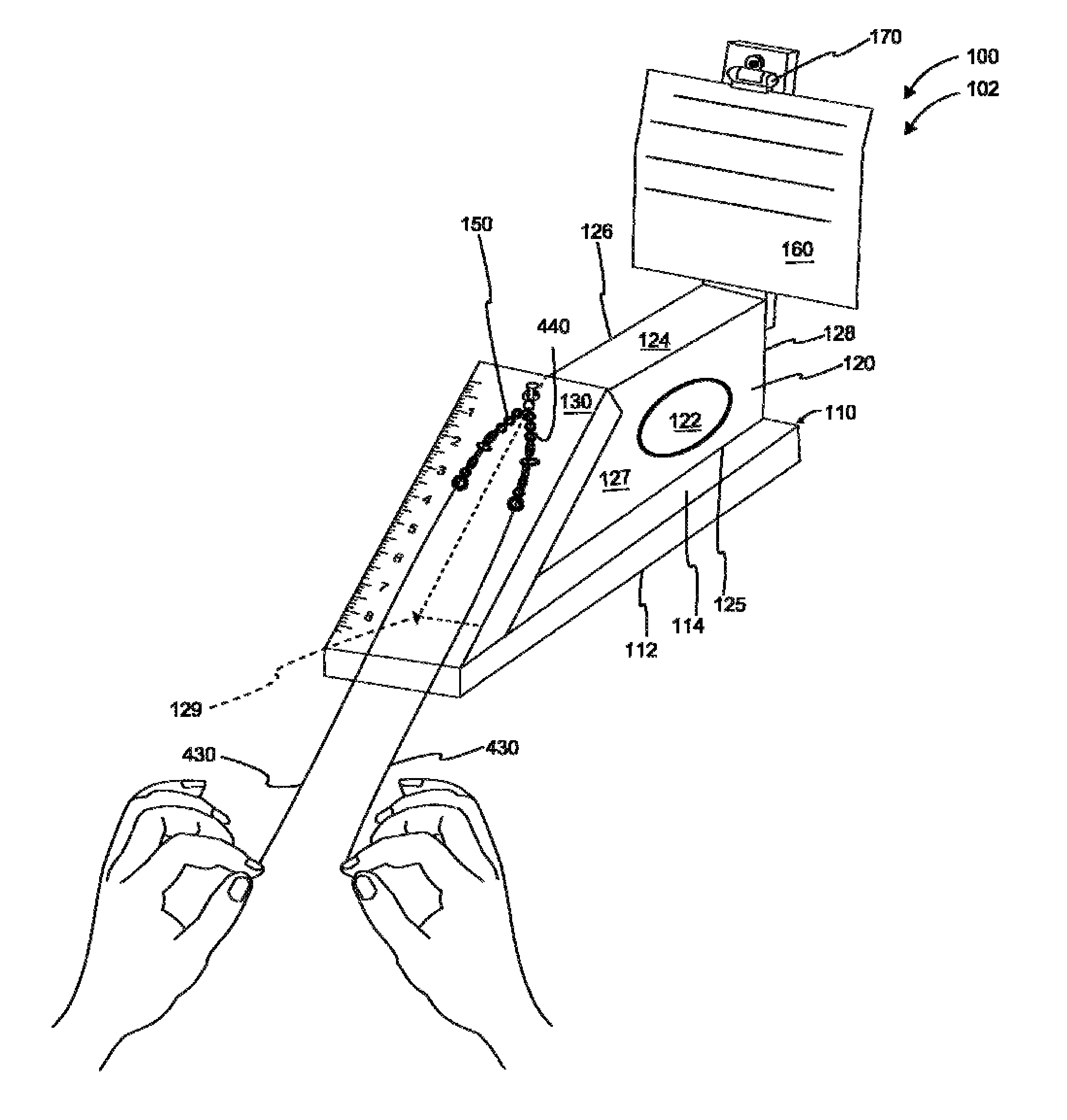

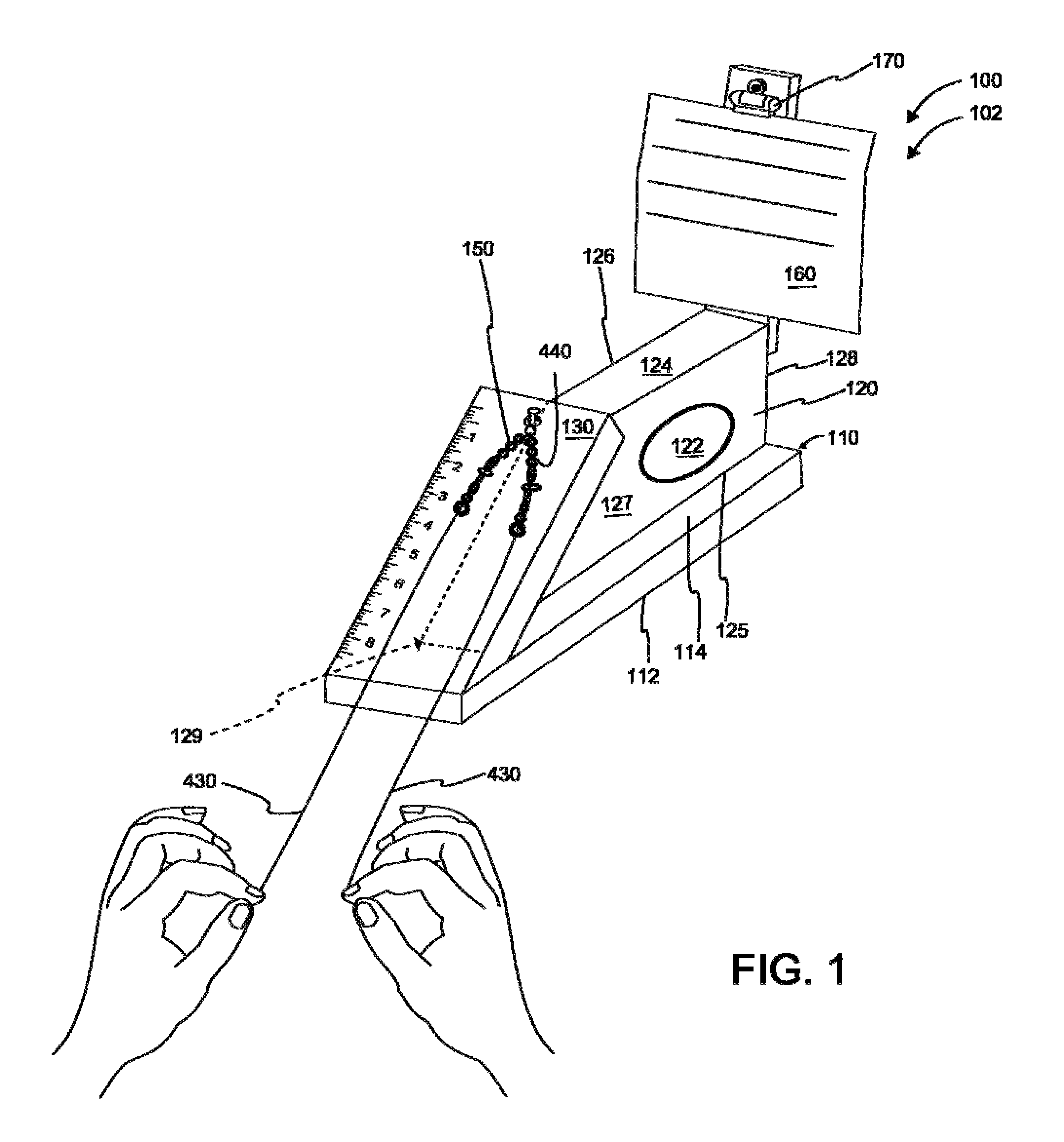

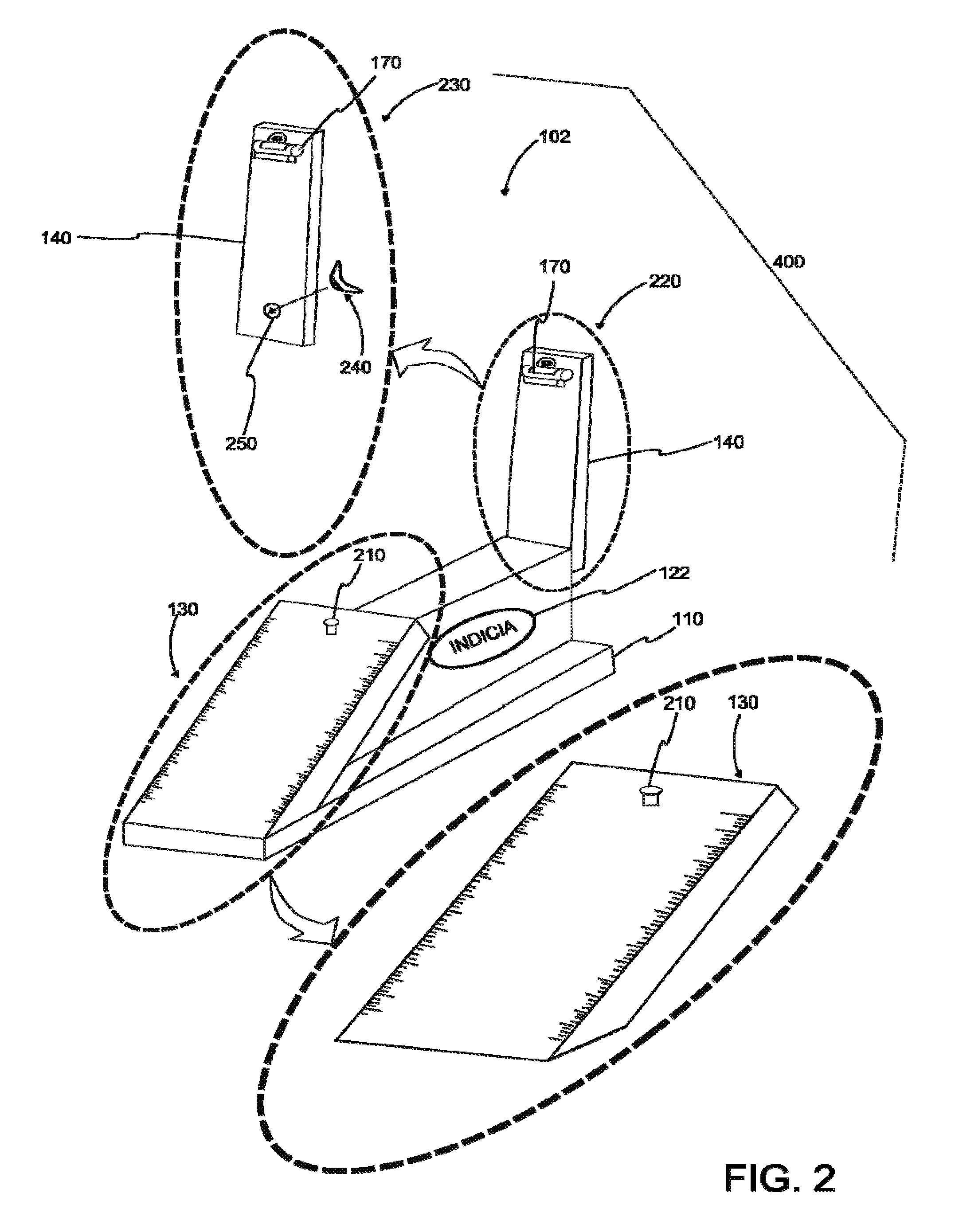

An apparatus for assisting manufacturing by jewelry makers and facilitating the positioning, stringing, cross-weaving, peyote chain maille, and accurate sizing for but not limited to necklaces, bracelets, and other hand woven beaded products. The present bead weaving device disclosed herein comprises the following components: an inclined sizing plate optionally including an imperial-measure graduated scale and / or a metric-measure graduated scale, a brass toggle half securer, a stabilizer, a support base and removably couplable peyote block attachment and a support arm. The support base of the Beadin' Butler may be adapted for use on the lap of a user or on the surface of a substrate such as a table. A method of using the bead weaving device is also disclosed herein.

Owner:WELDER ROBERT F +1

Face finishing of cotton-containing fabrics containing immobilized fibers

InactiveUS6233795B1Strength can be balancedHighly cost-effectiveFilament handlingBall sportsFiberEngineering

Owner:MILLIKEN & CO

Portable hand loom and weaving method

InactiveUS20070270010A1Easy to learnTotally portableEngagement/disengagement of coupling partsCoupling contact membersHand heldEngineering

Owner:WALTER DOUGLAS B

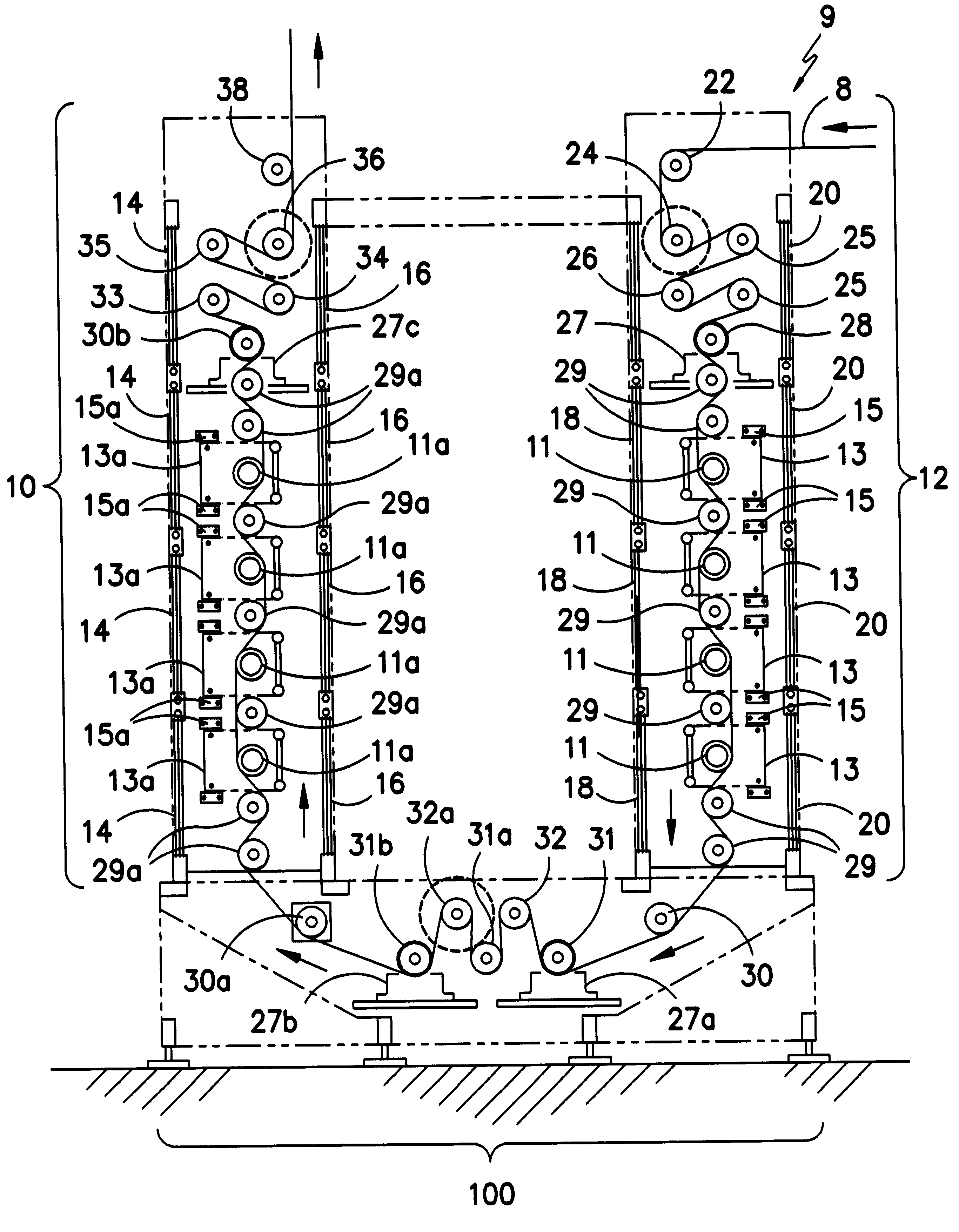

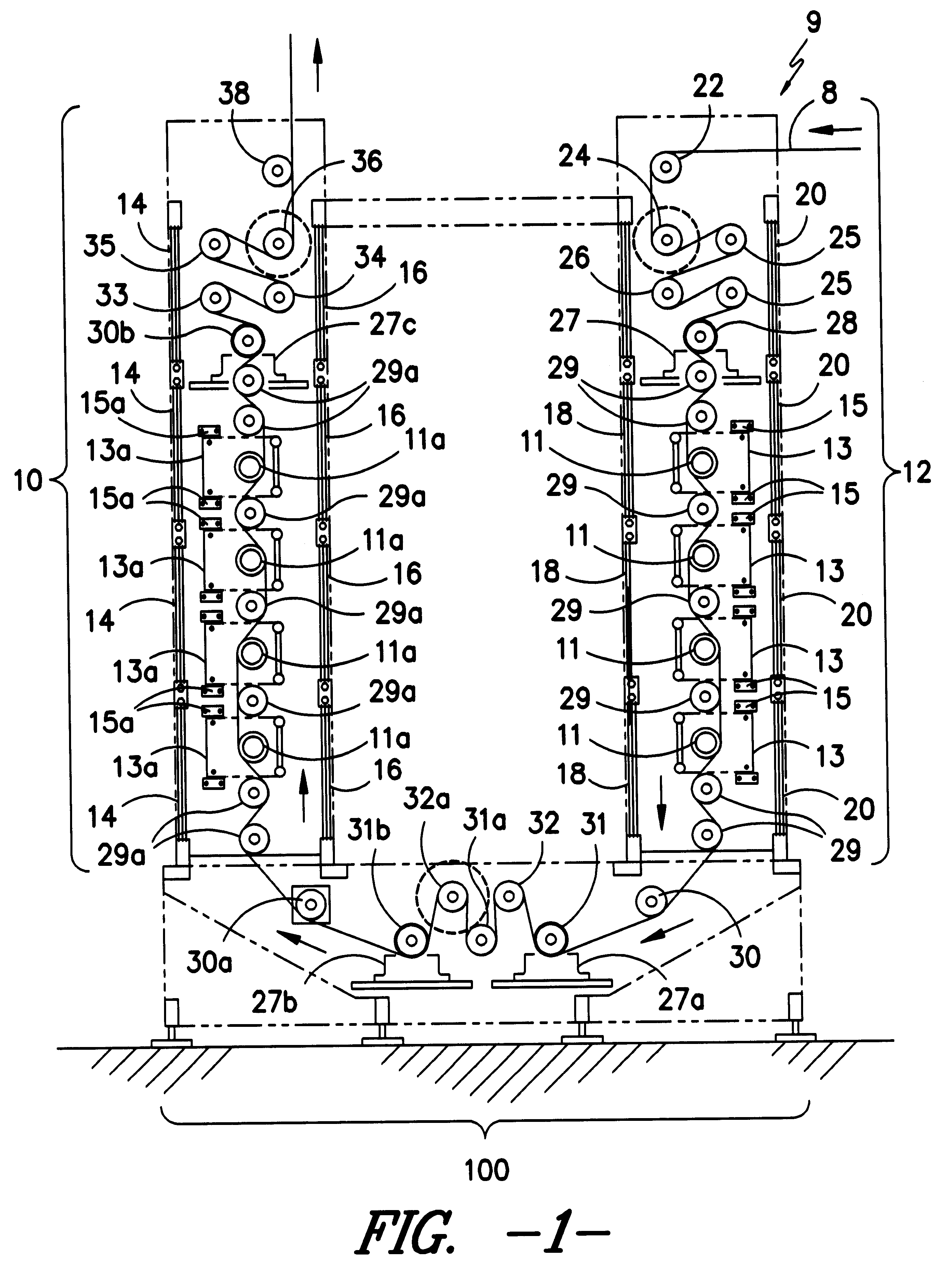

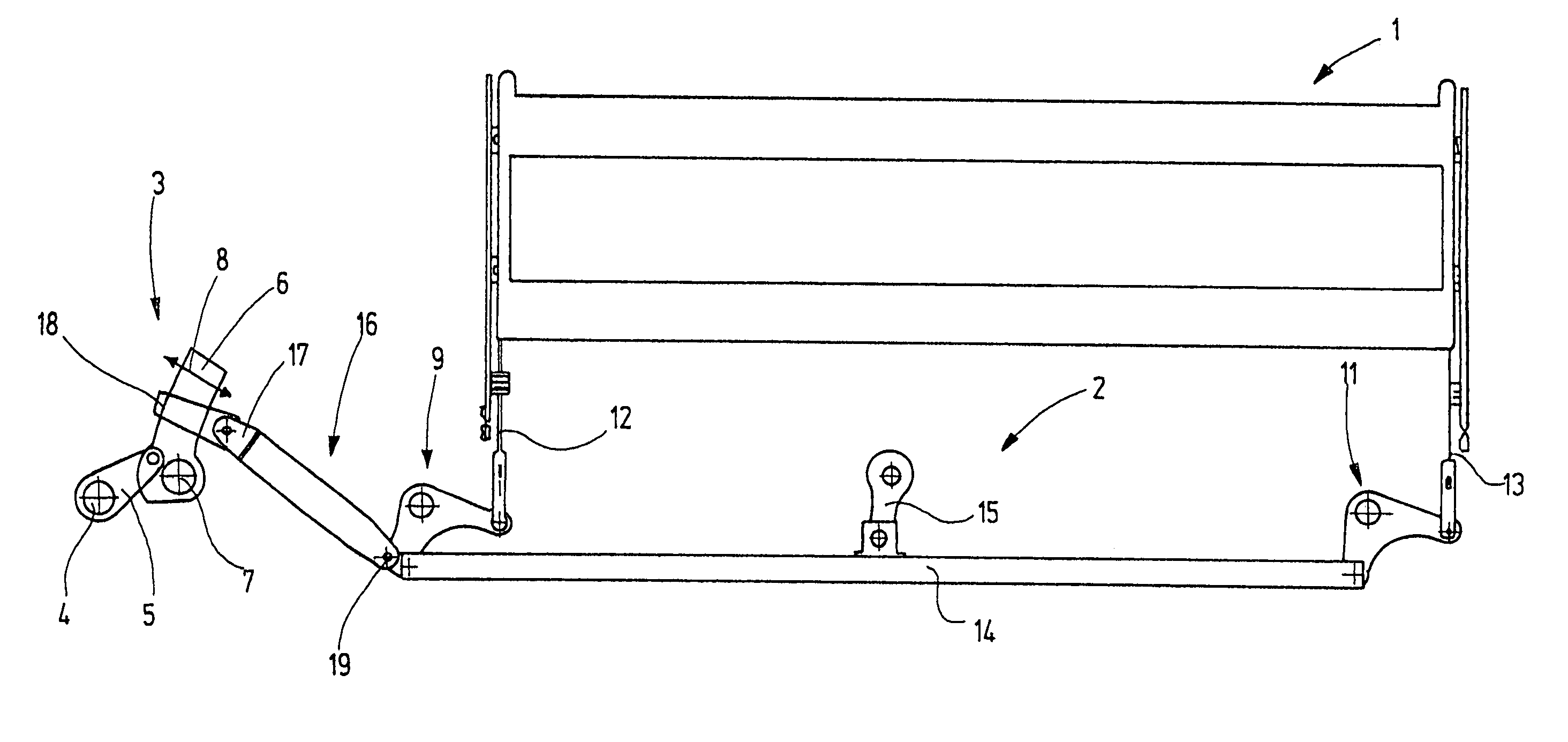

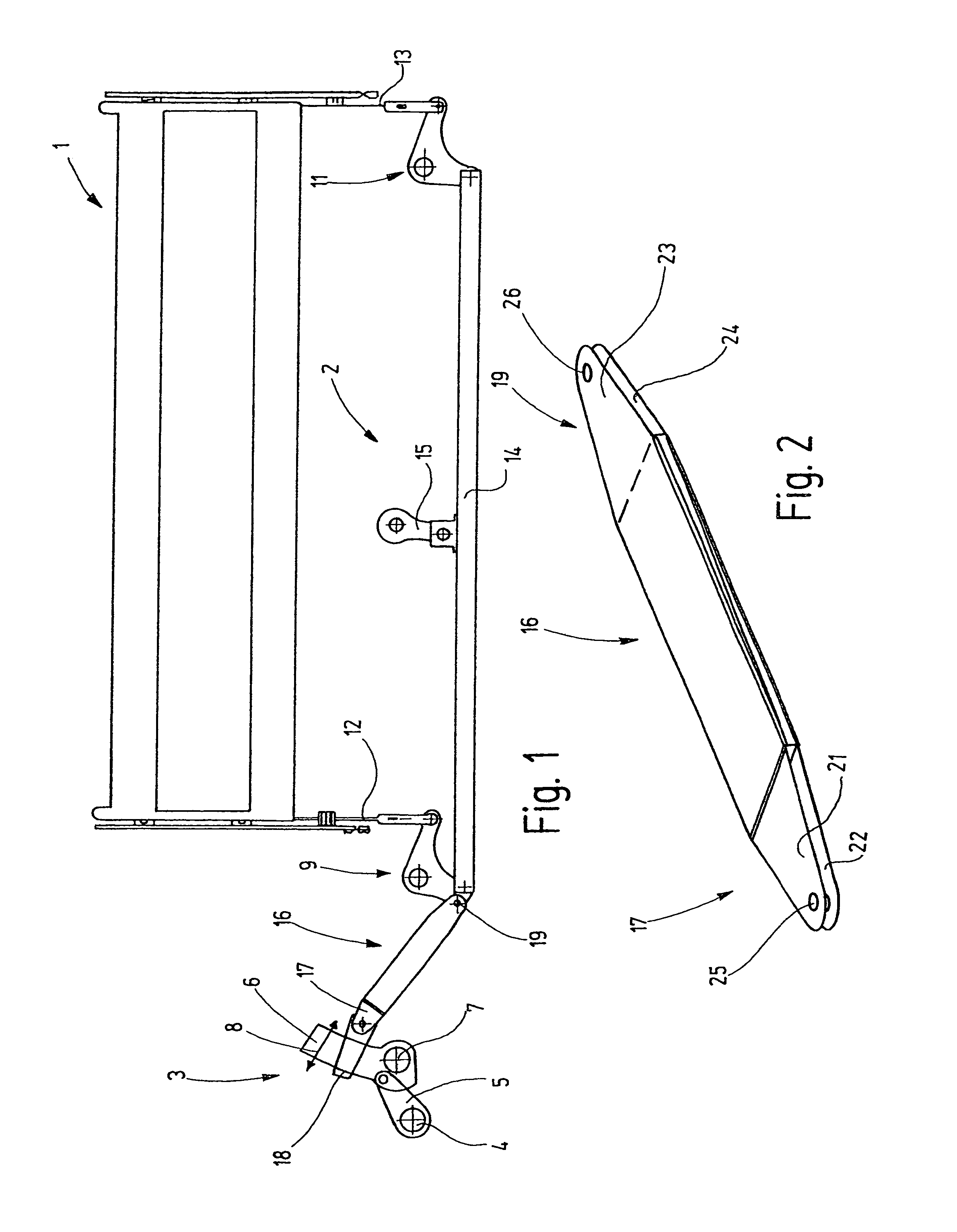

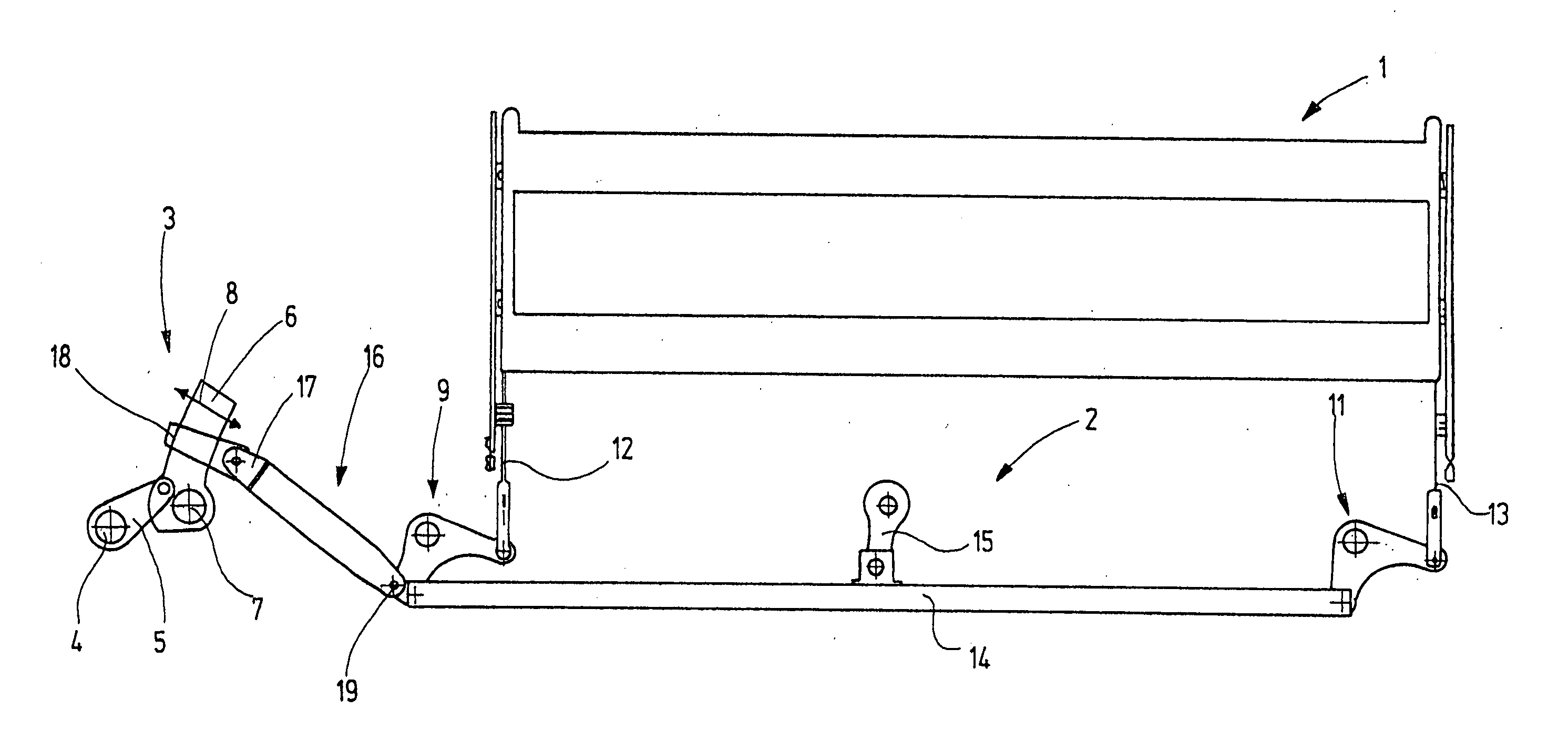

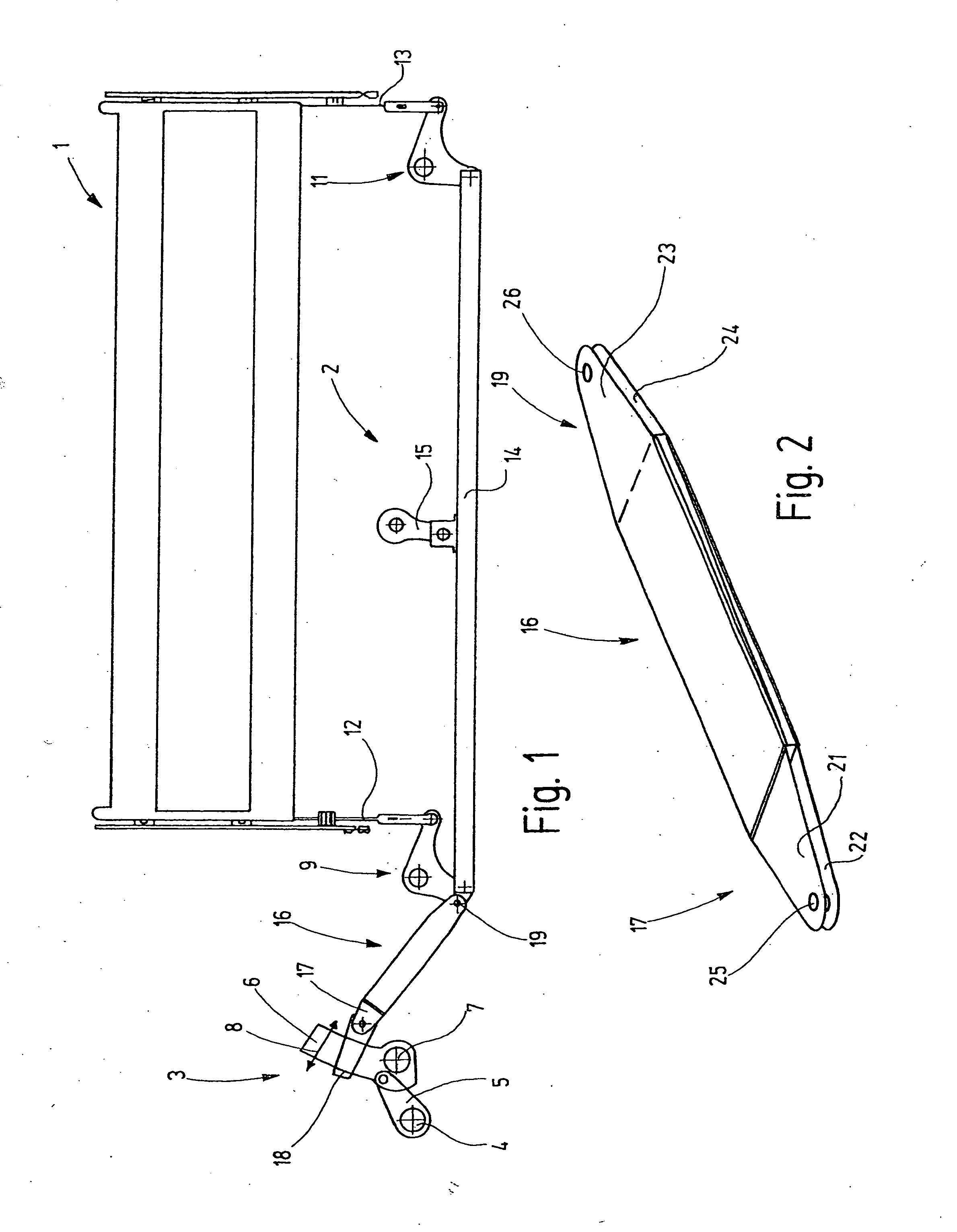

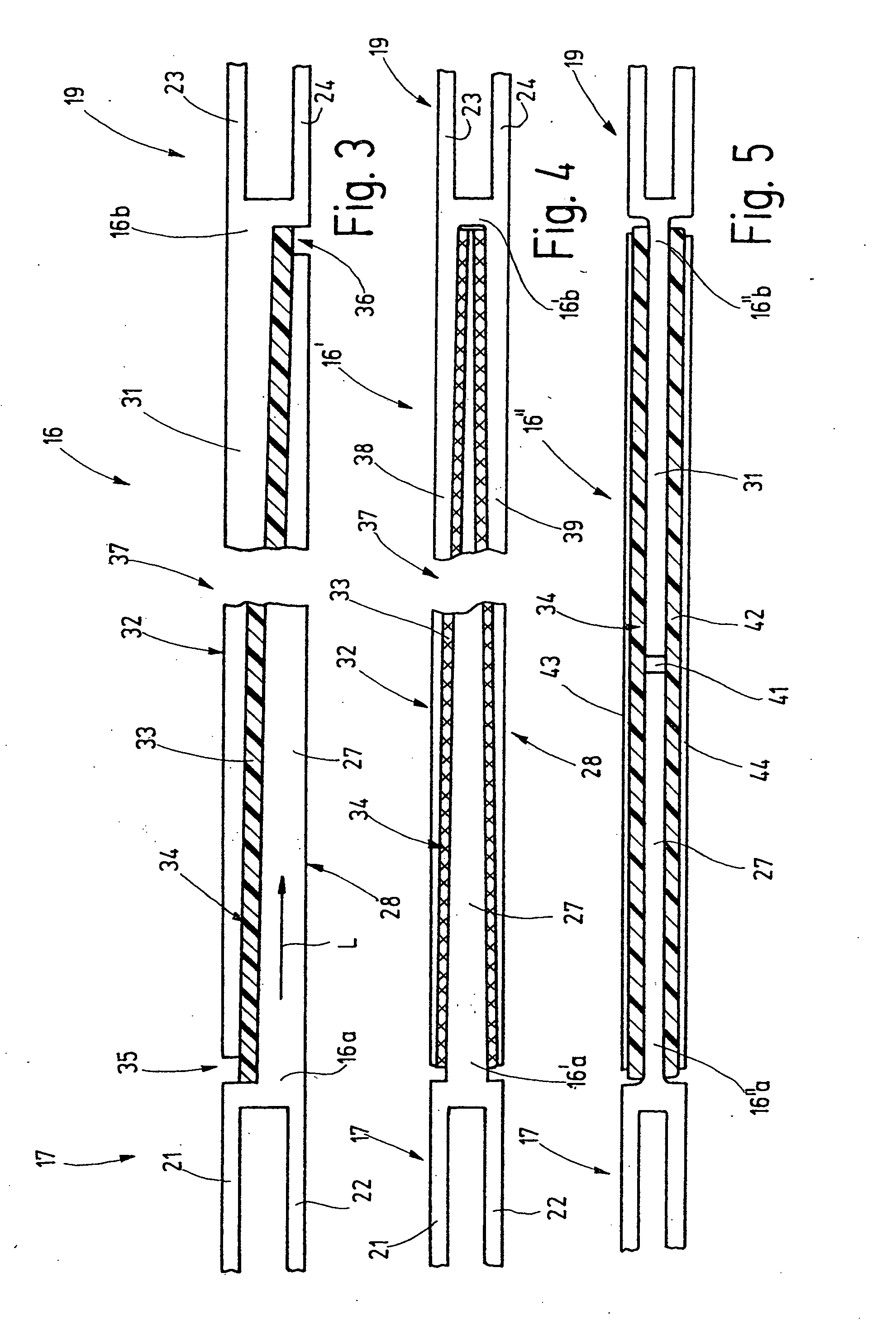

Low-vibration shedding system

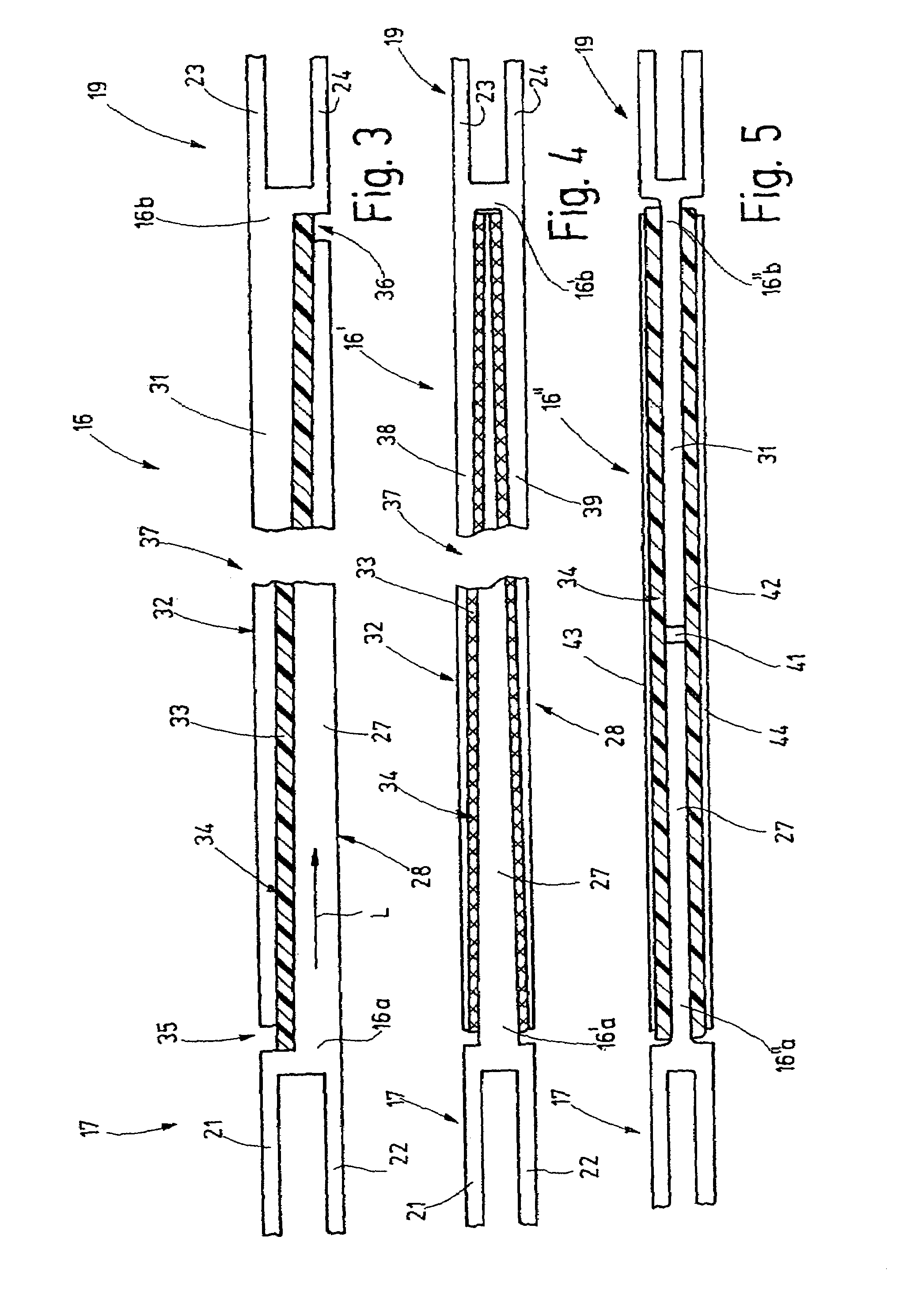

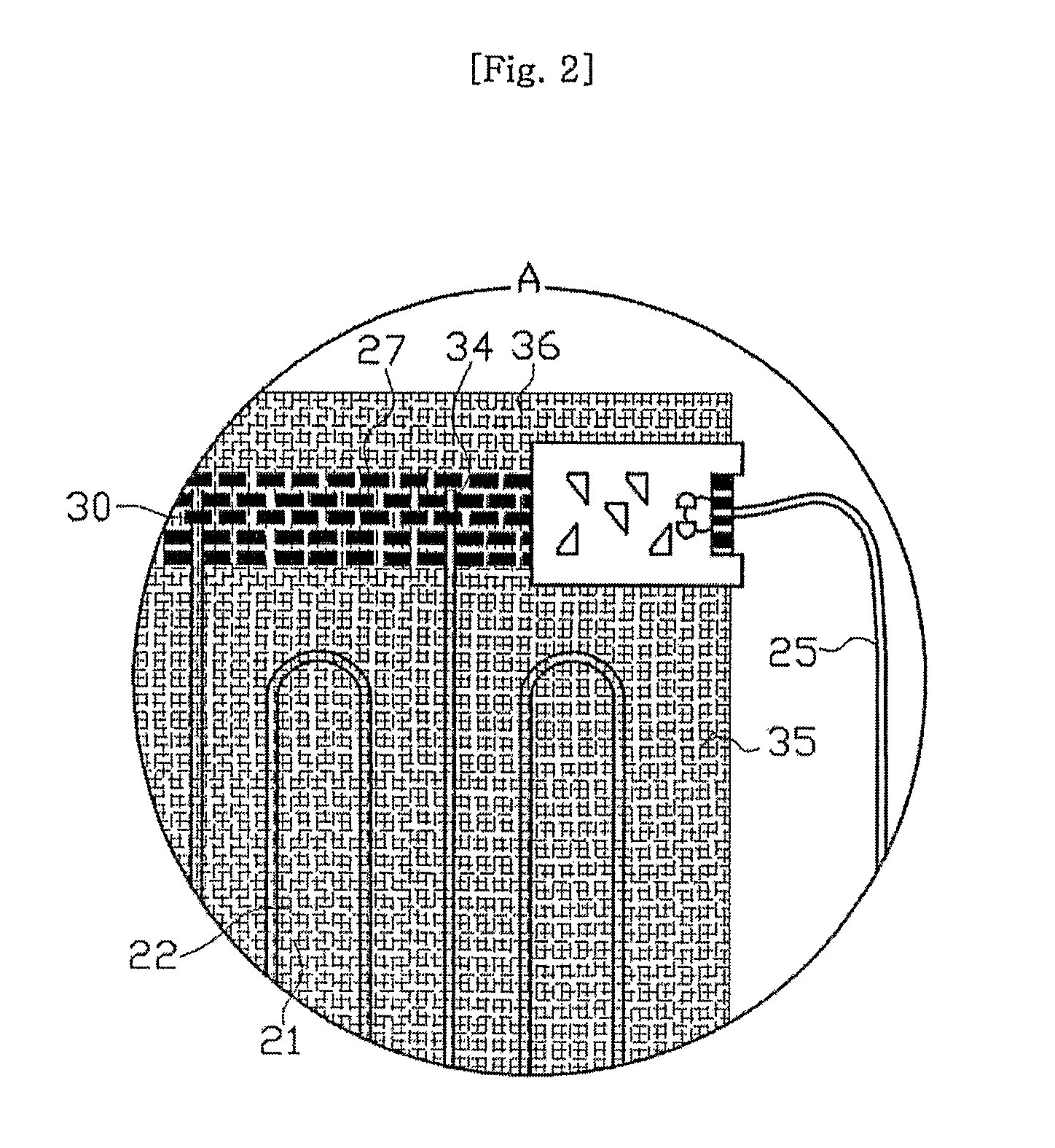

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

Orthogonal weaving for complex shape preforms

ActiveUS7247212B2Low costImprove performanceWeft knittingOrnamental textile articlesEngineeringNear net shape

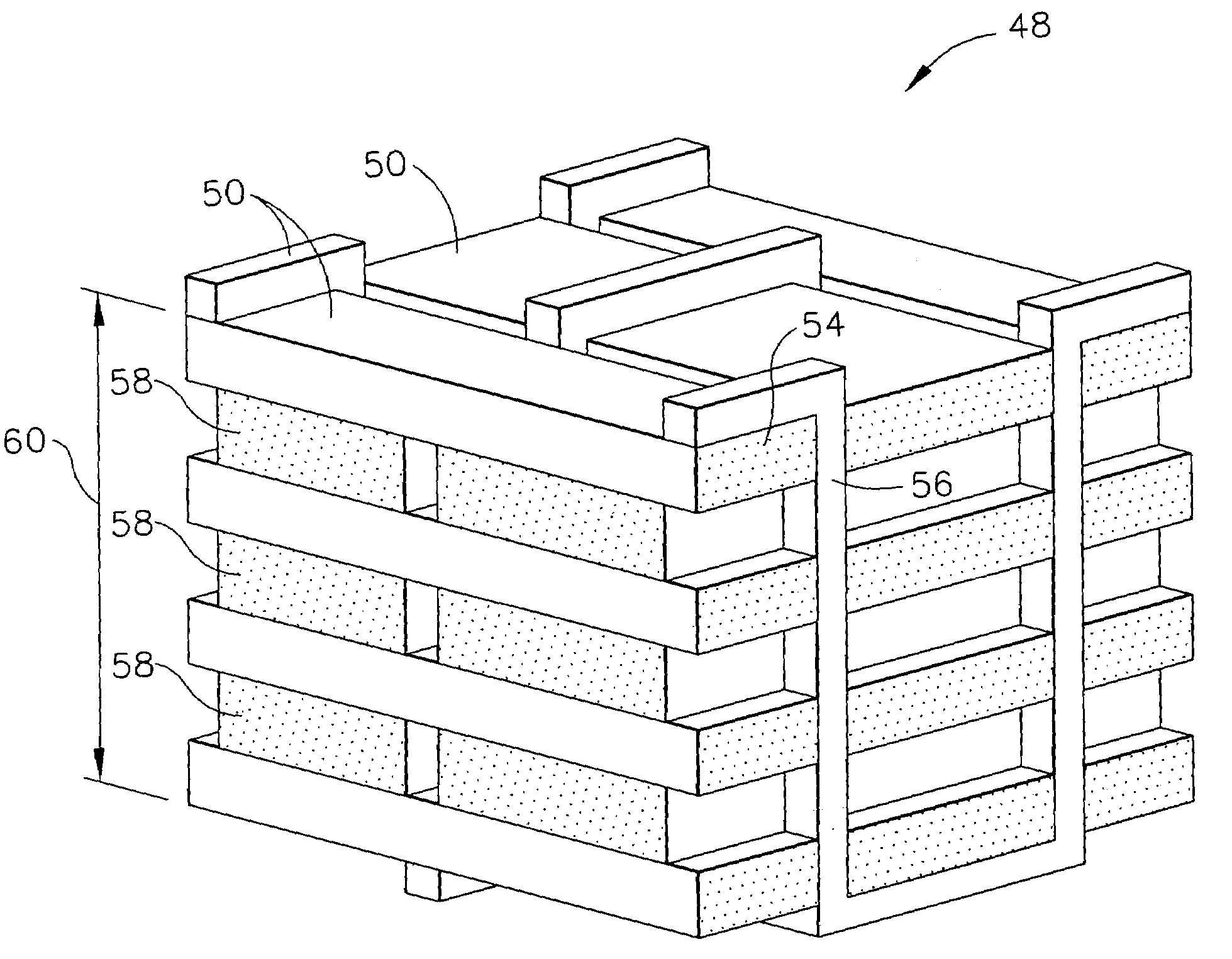

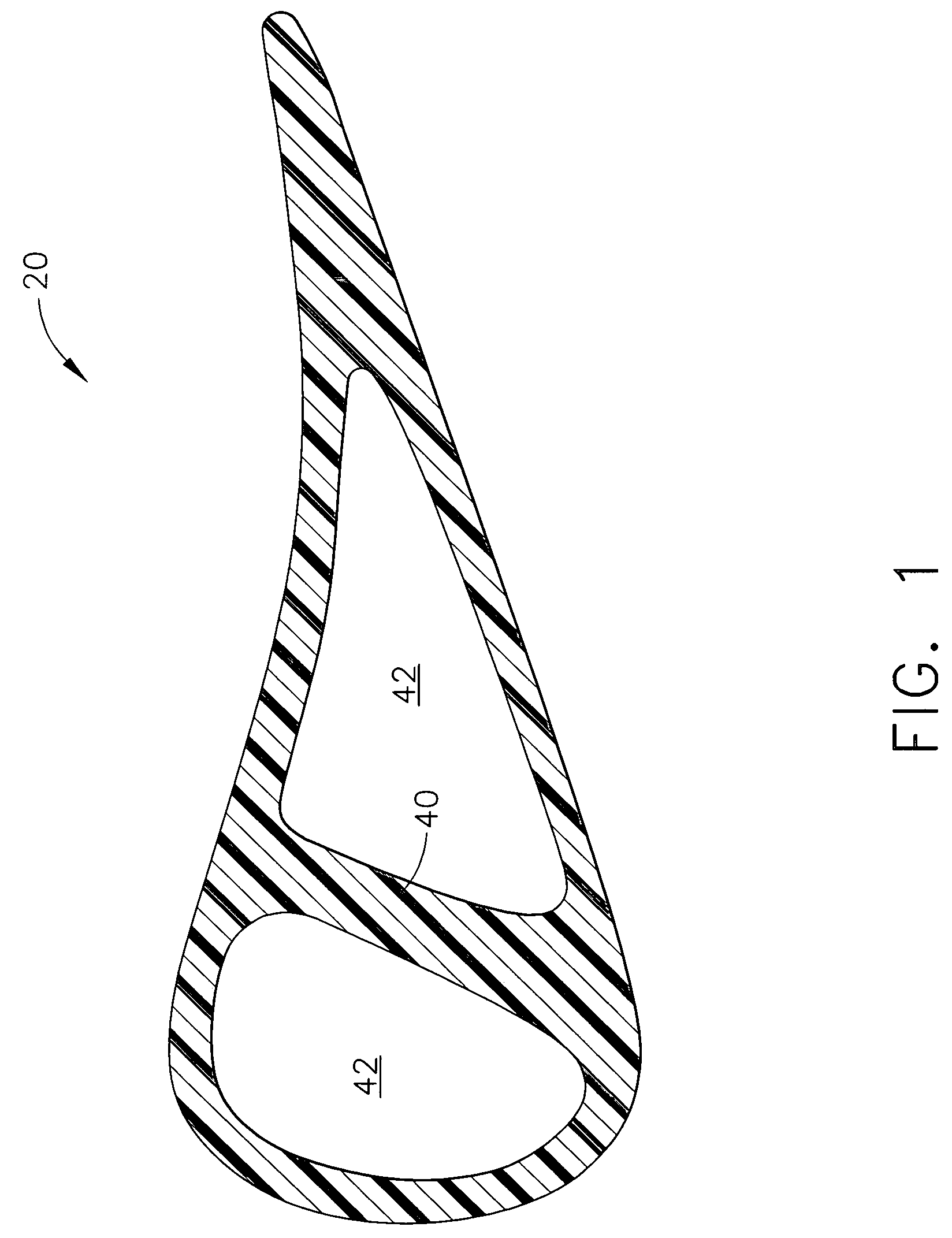

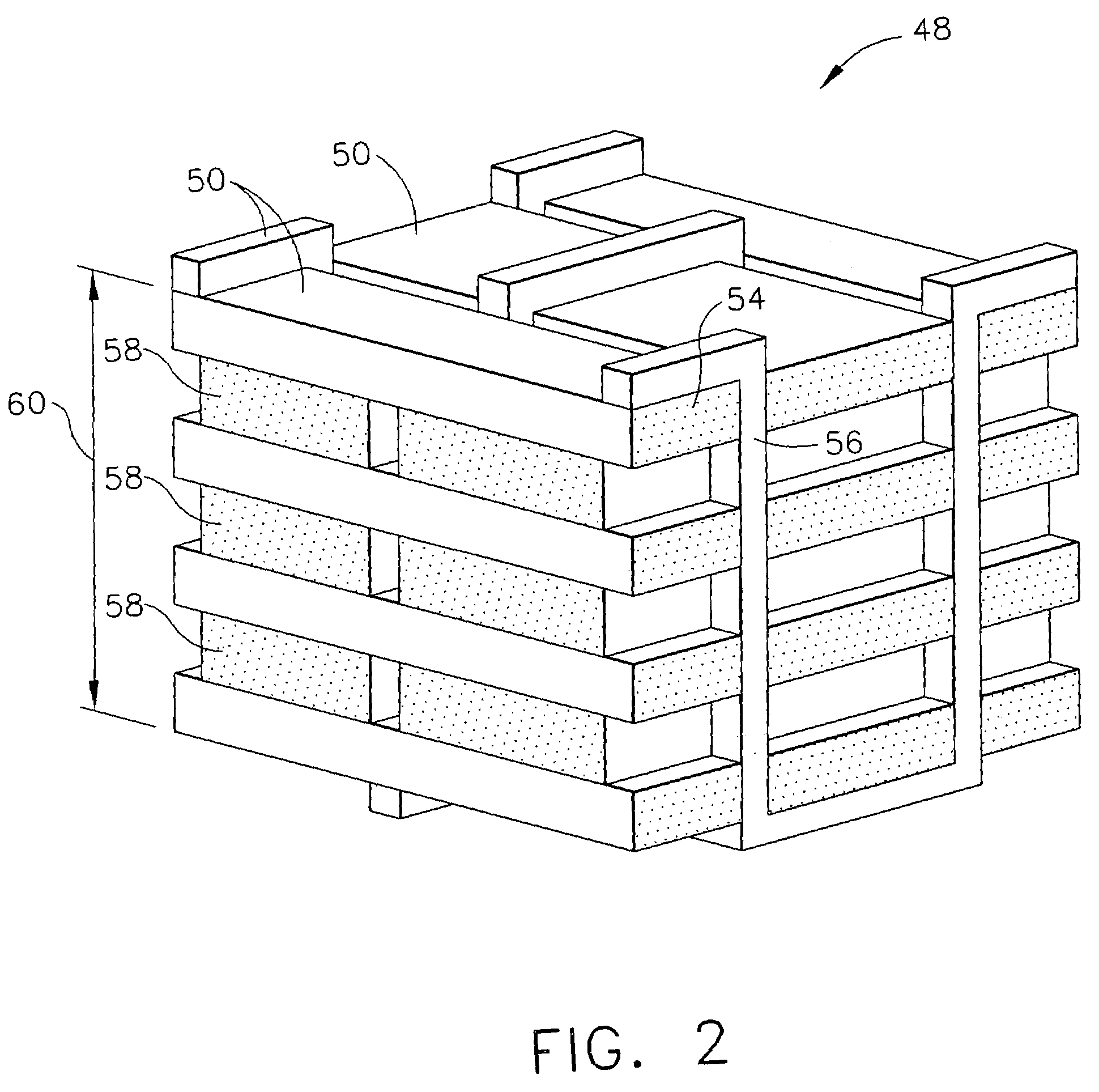

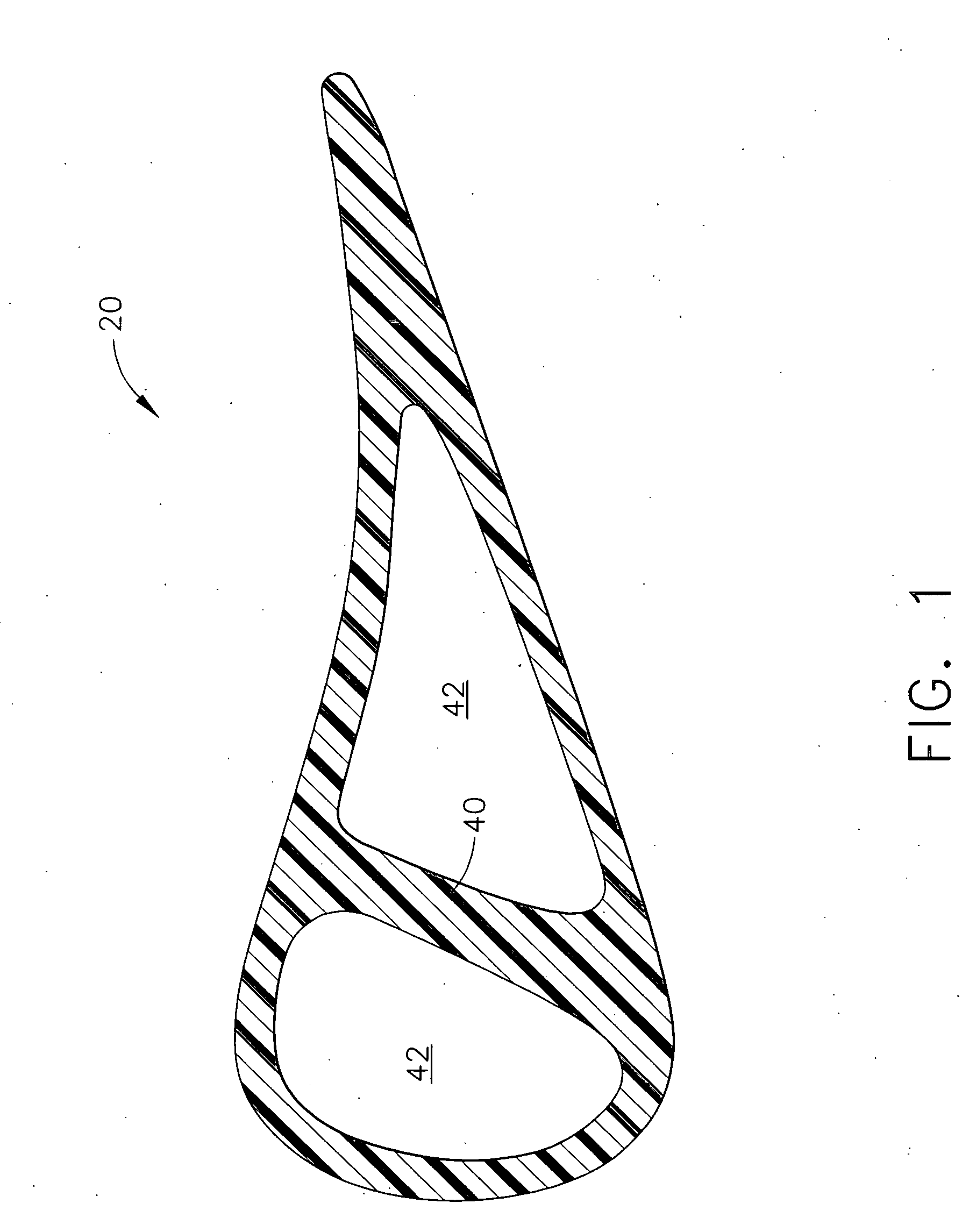

An orthogonal stitch-weave method and fiber architecture. The architecture allows near-net-shape composite preforms to be fabricated, thereby reducing costs associated with complex preform shapes and increasing desired strengths of the composite.

Owner:GENERAL ELECTRIC CO

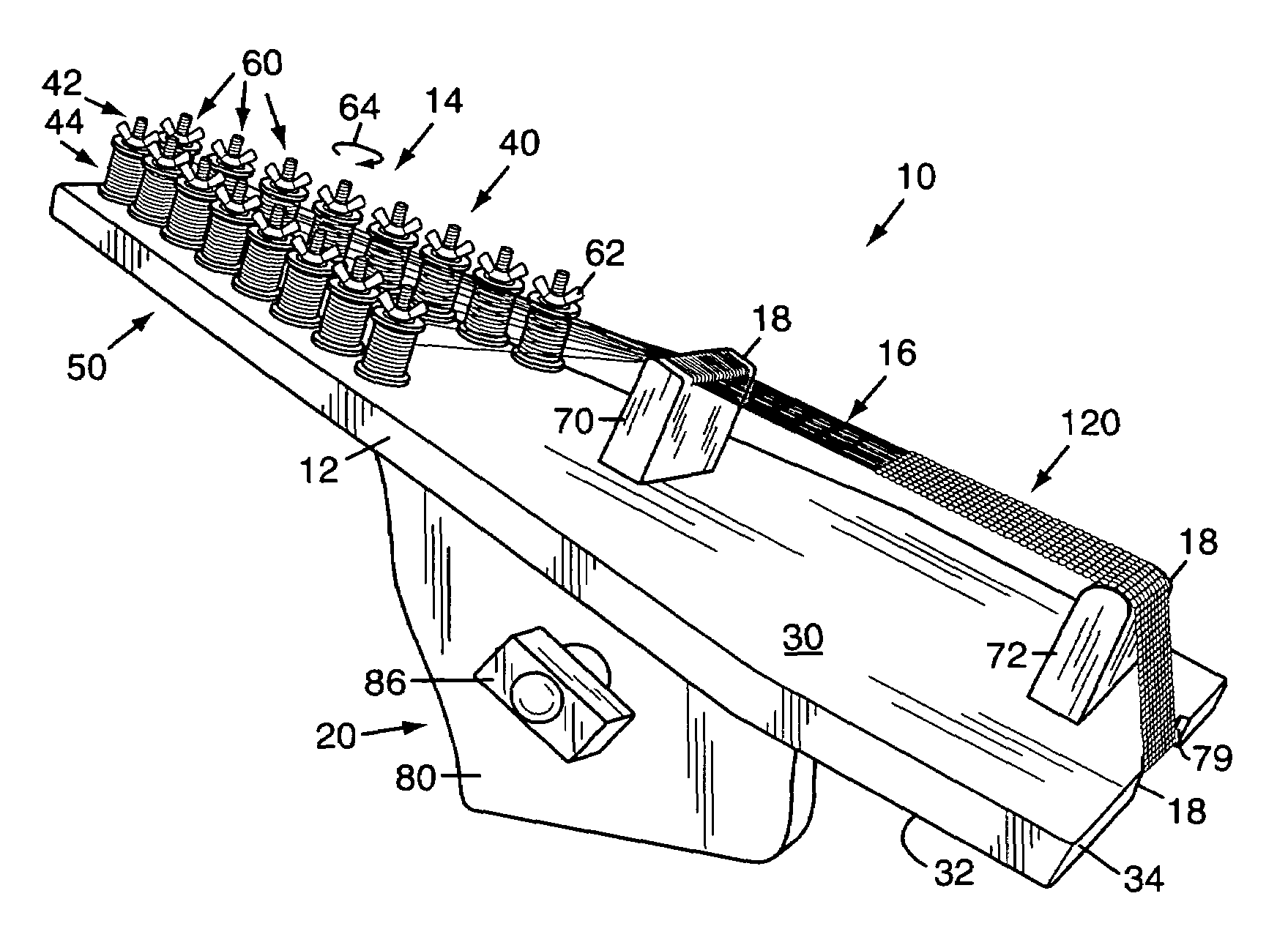

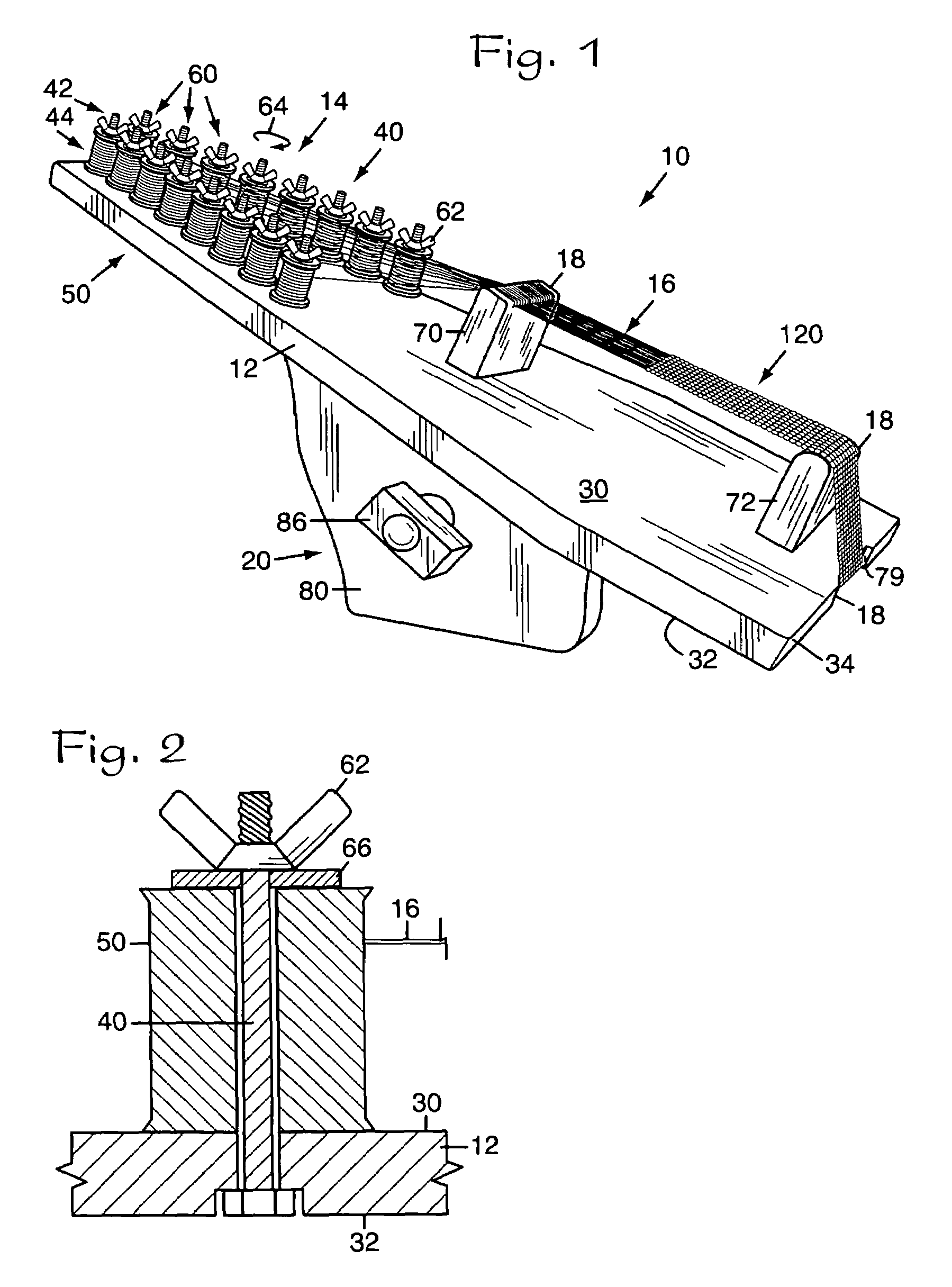

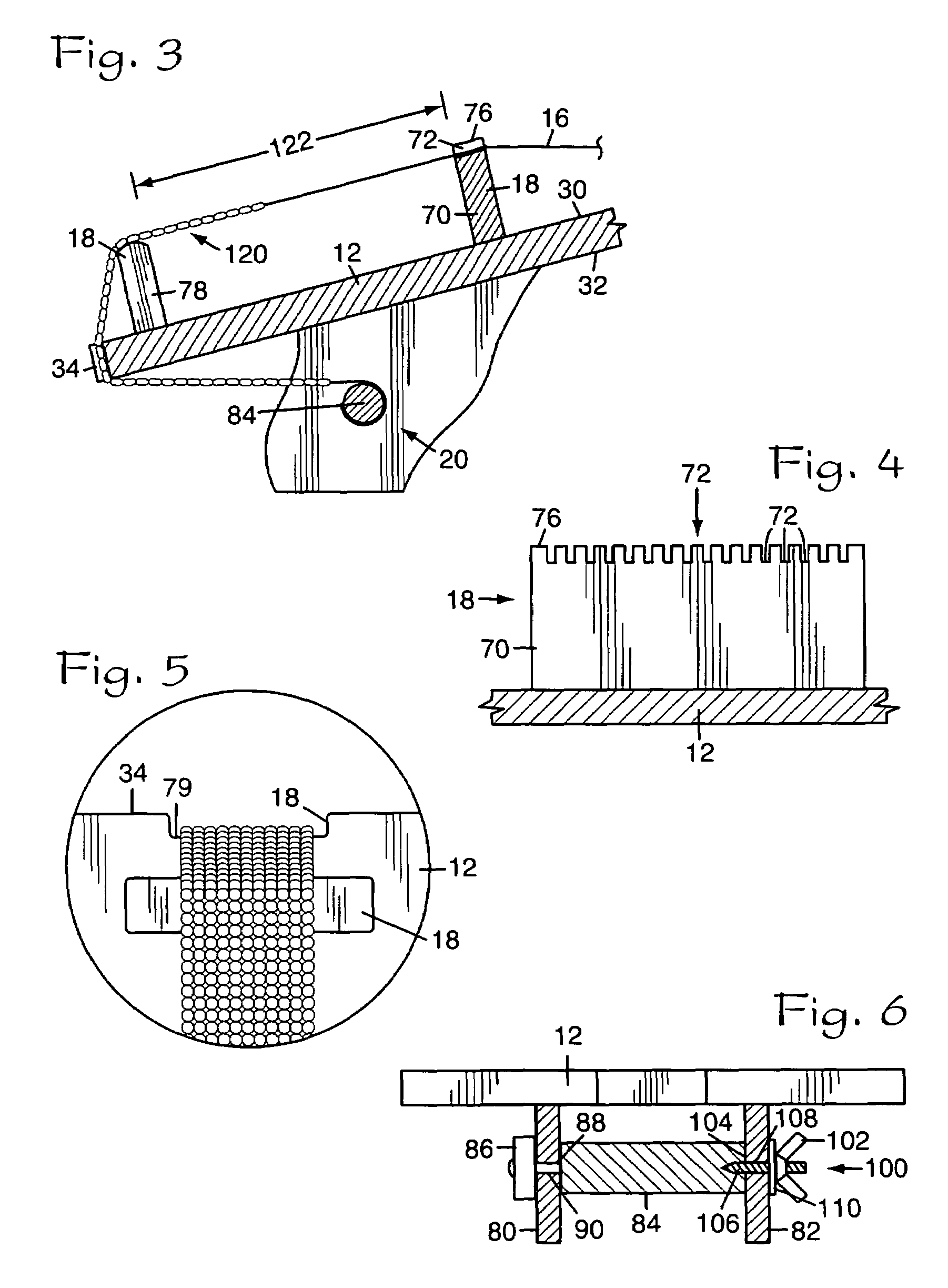

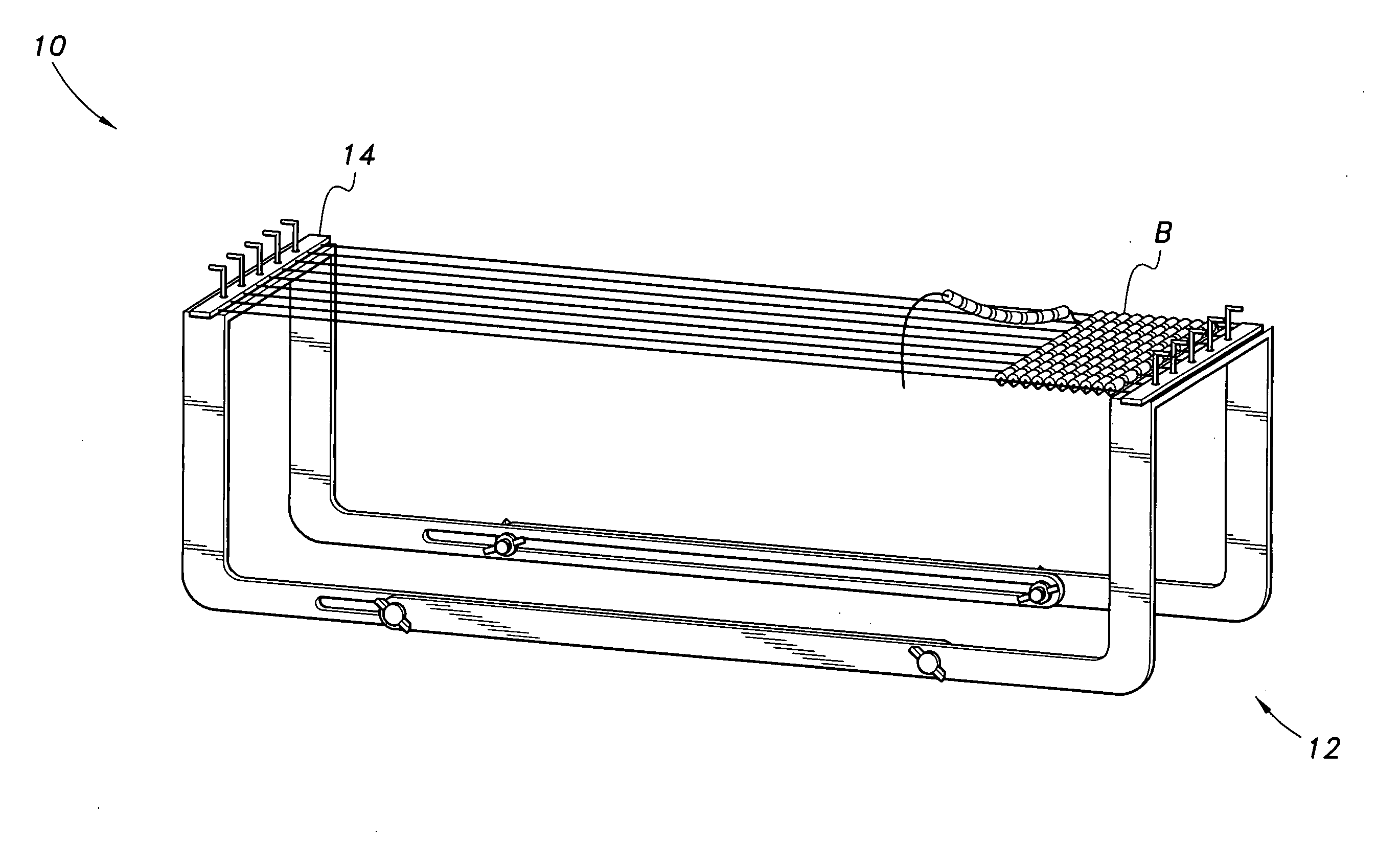

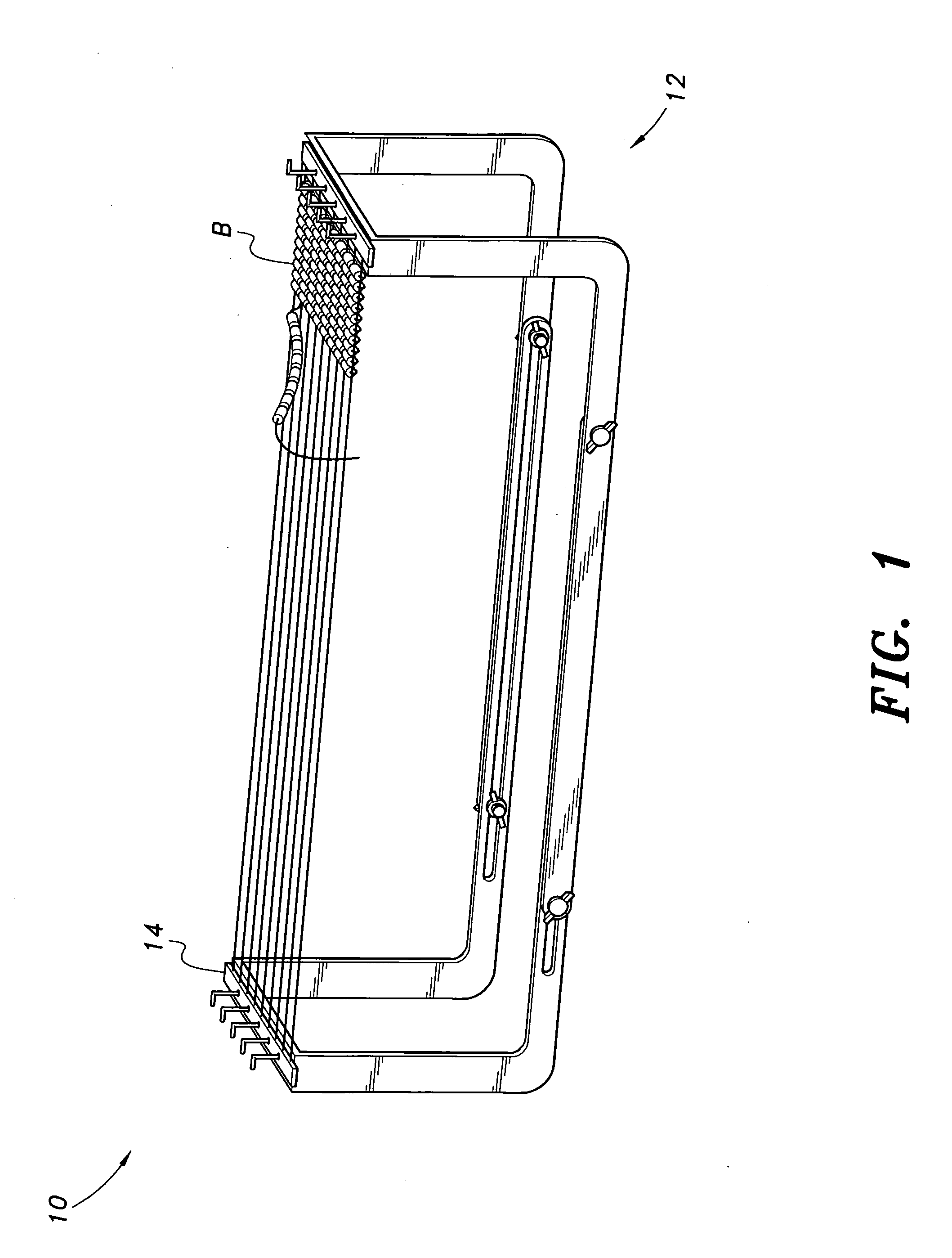

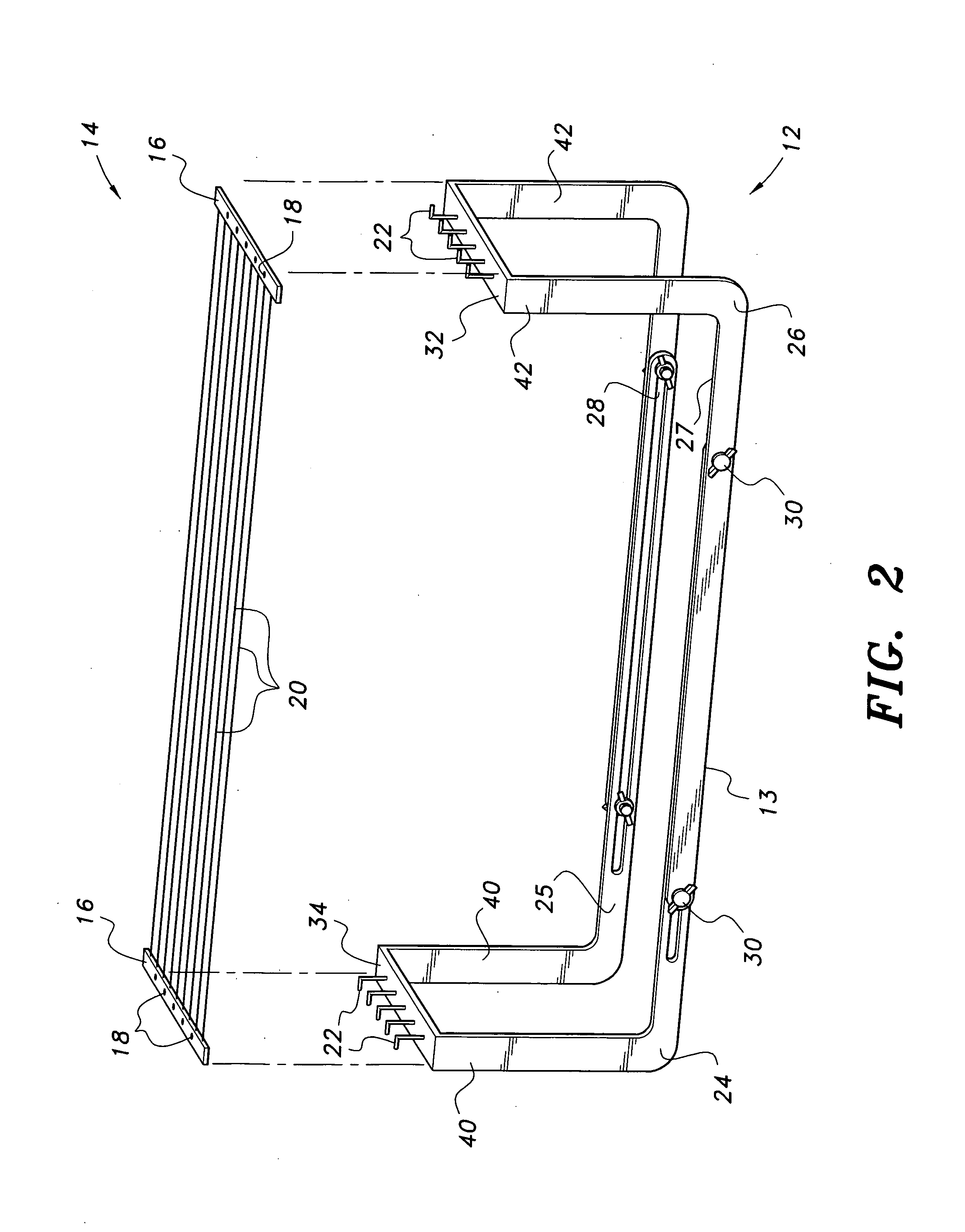

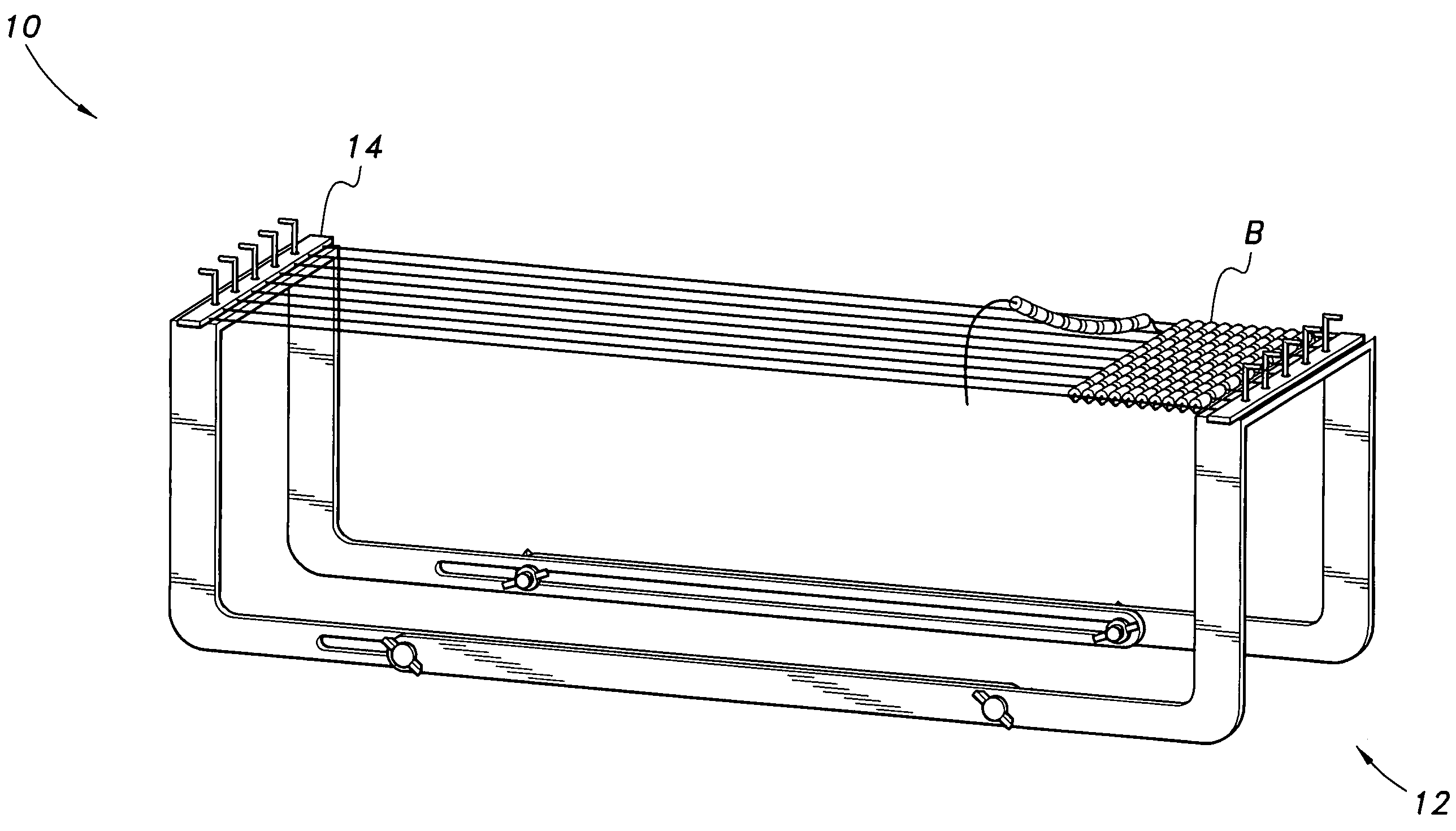

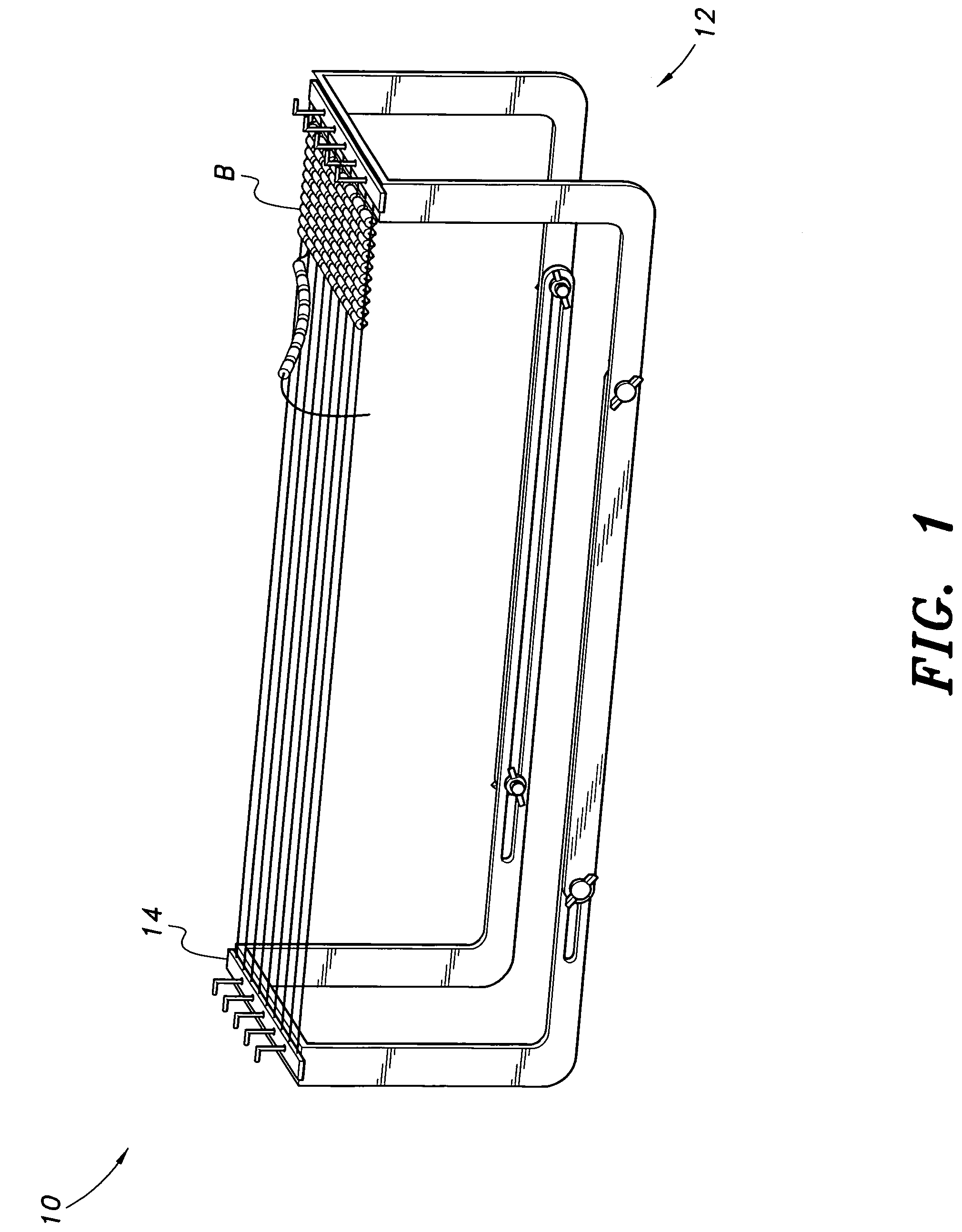

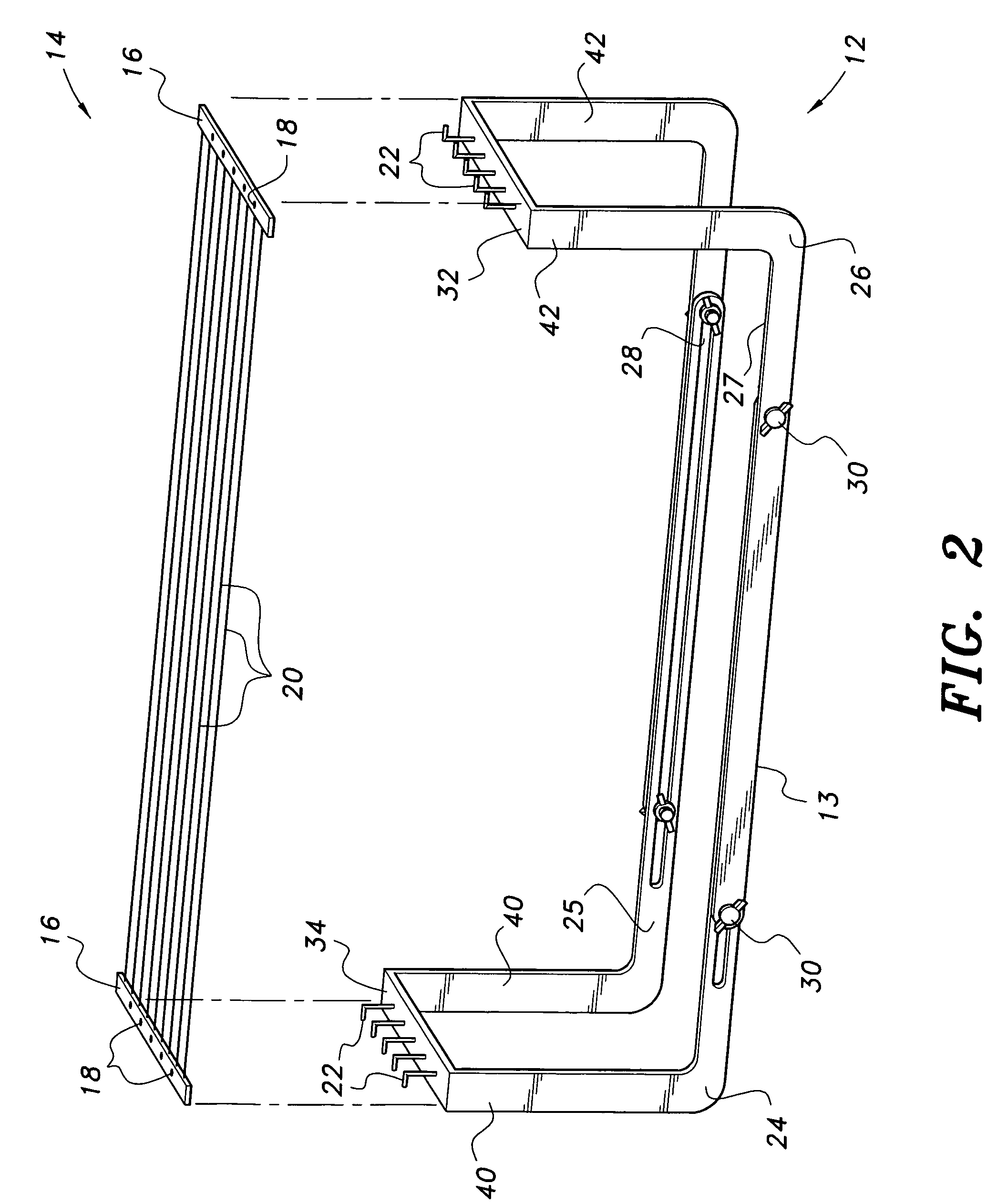

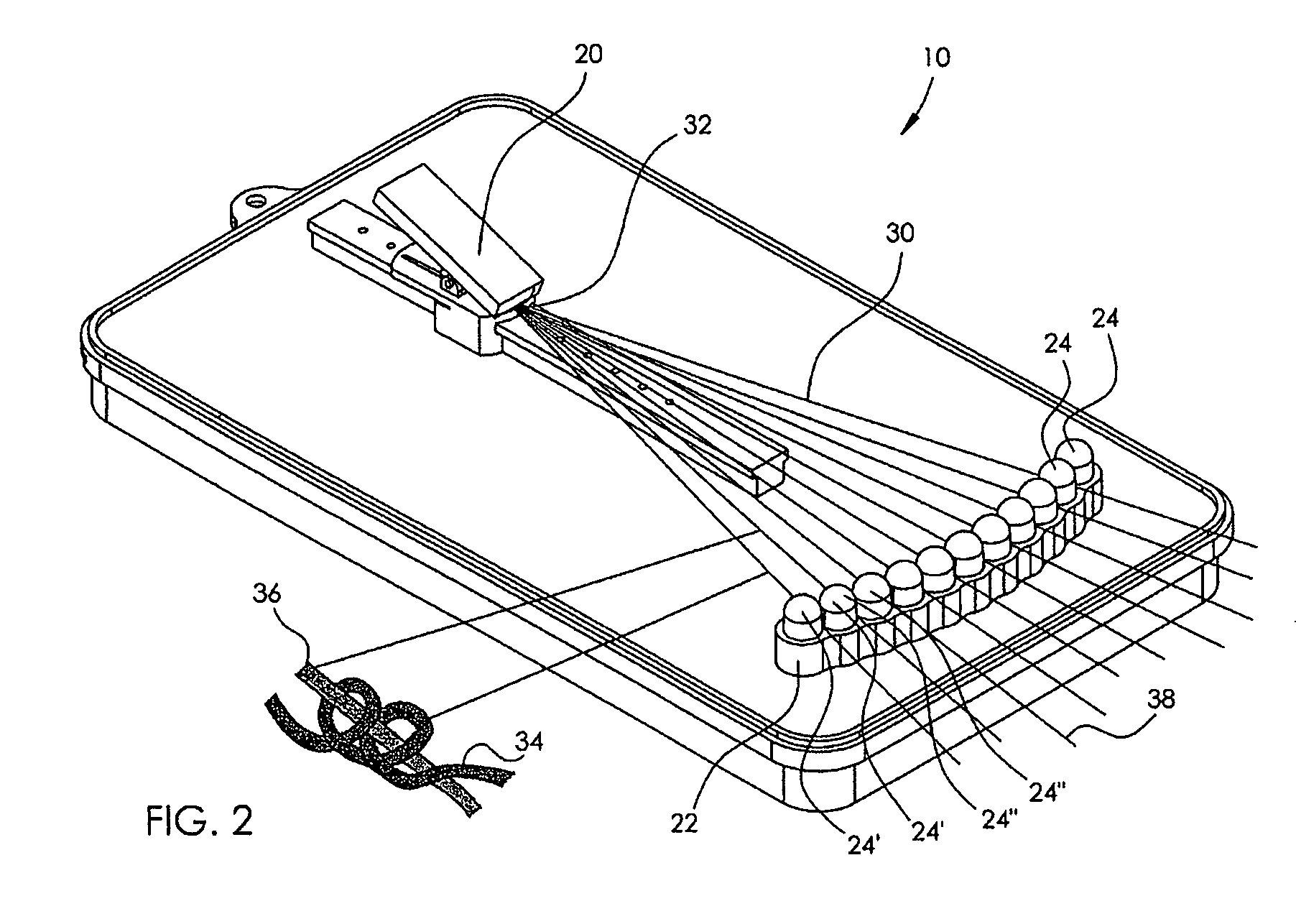

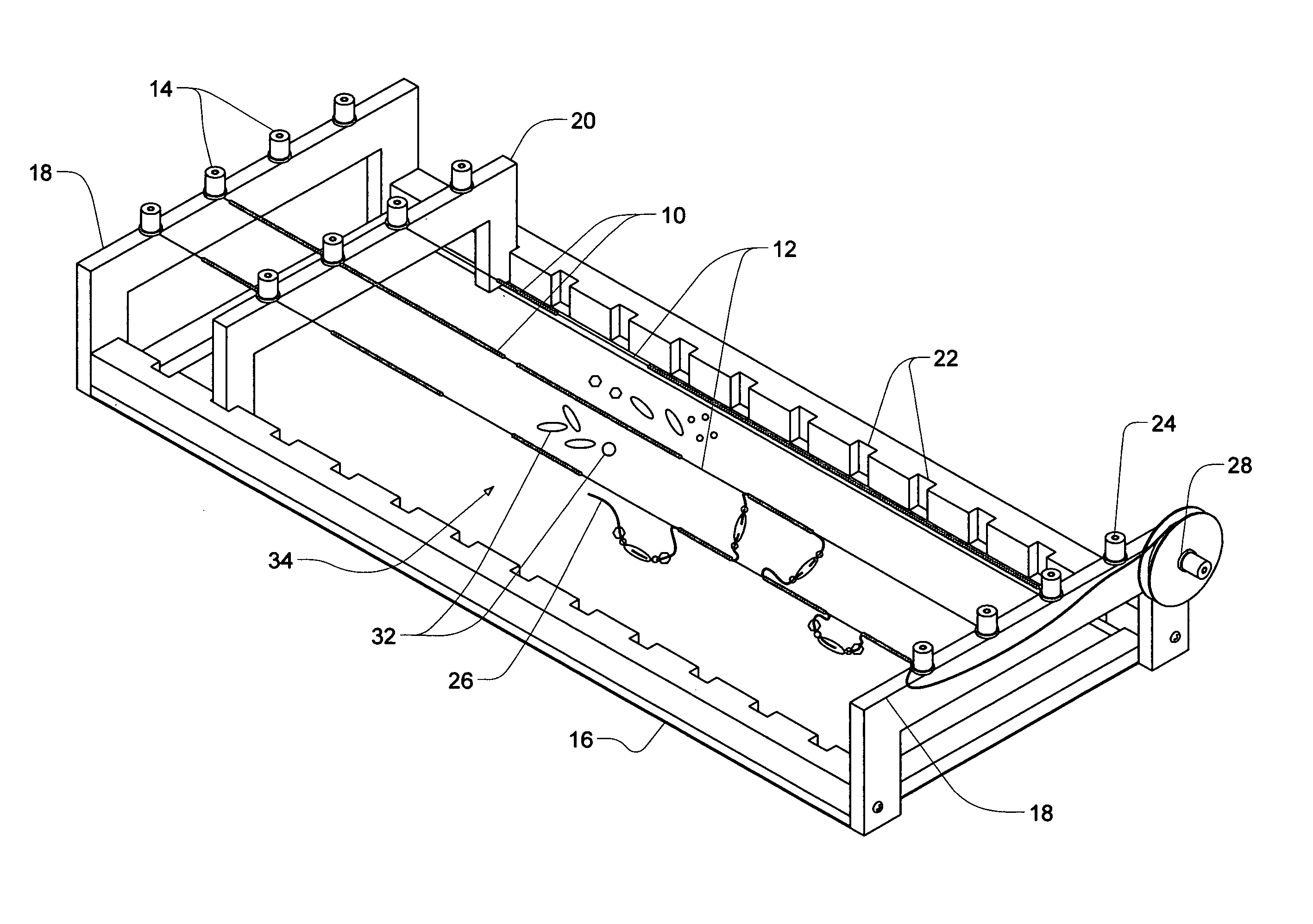

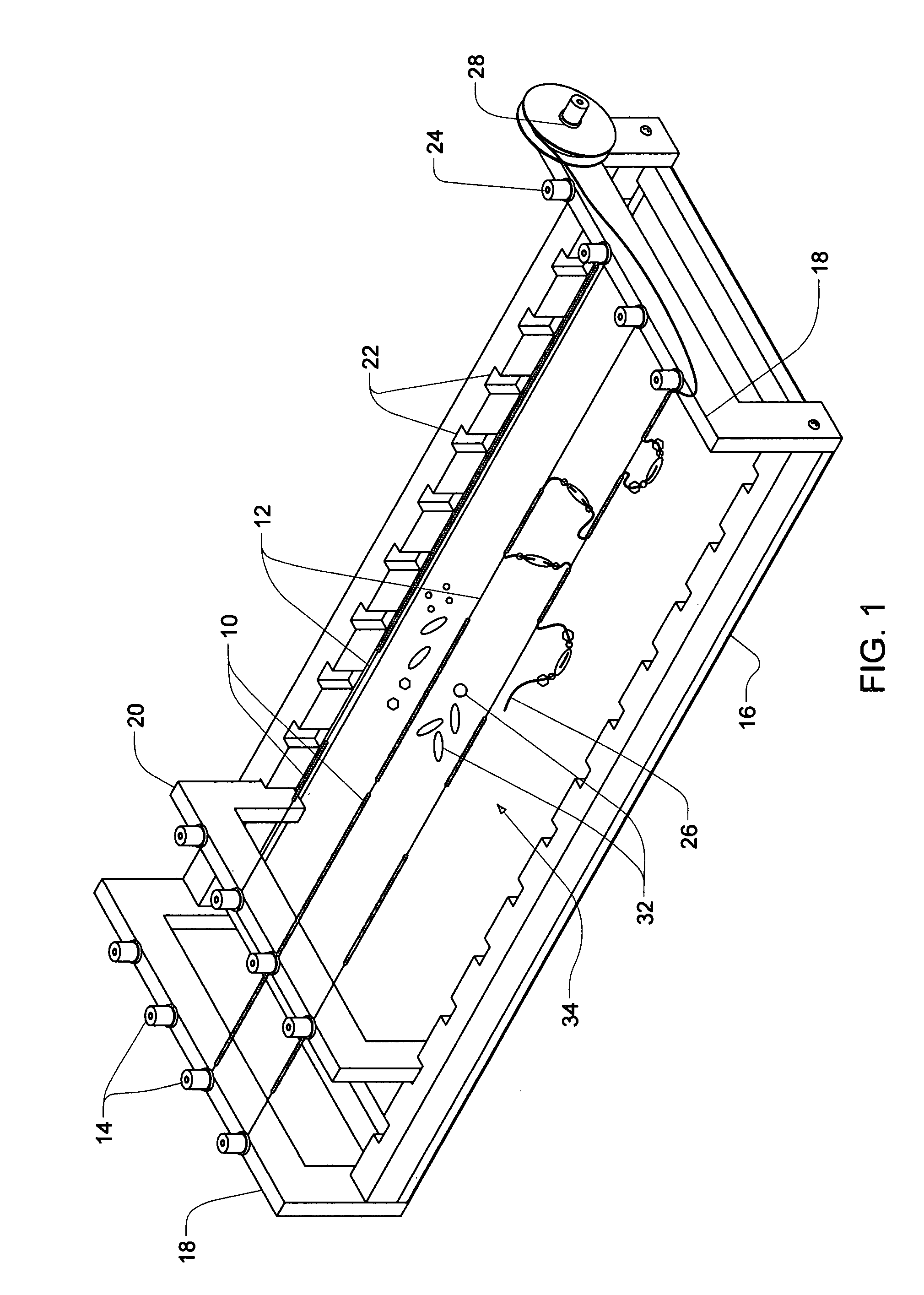

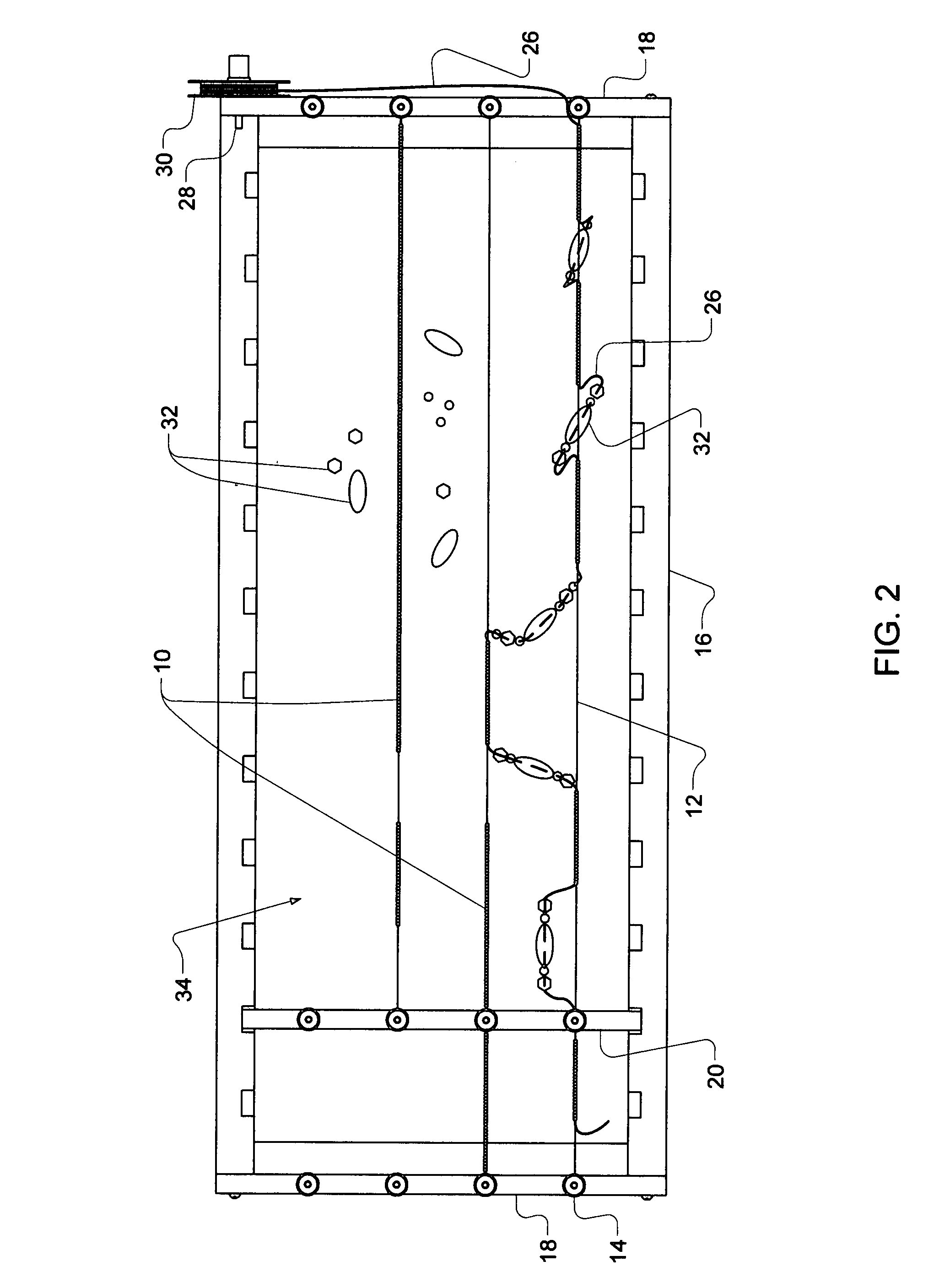

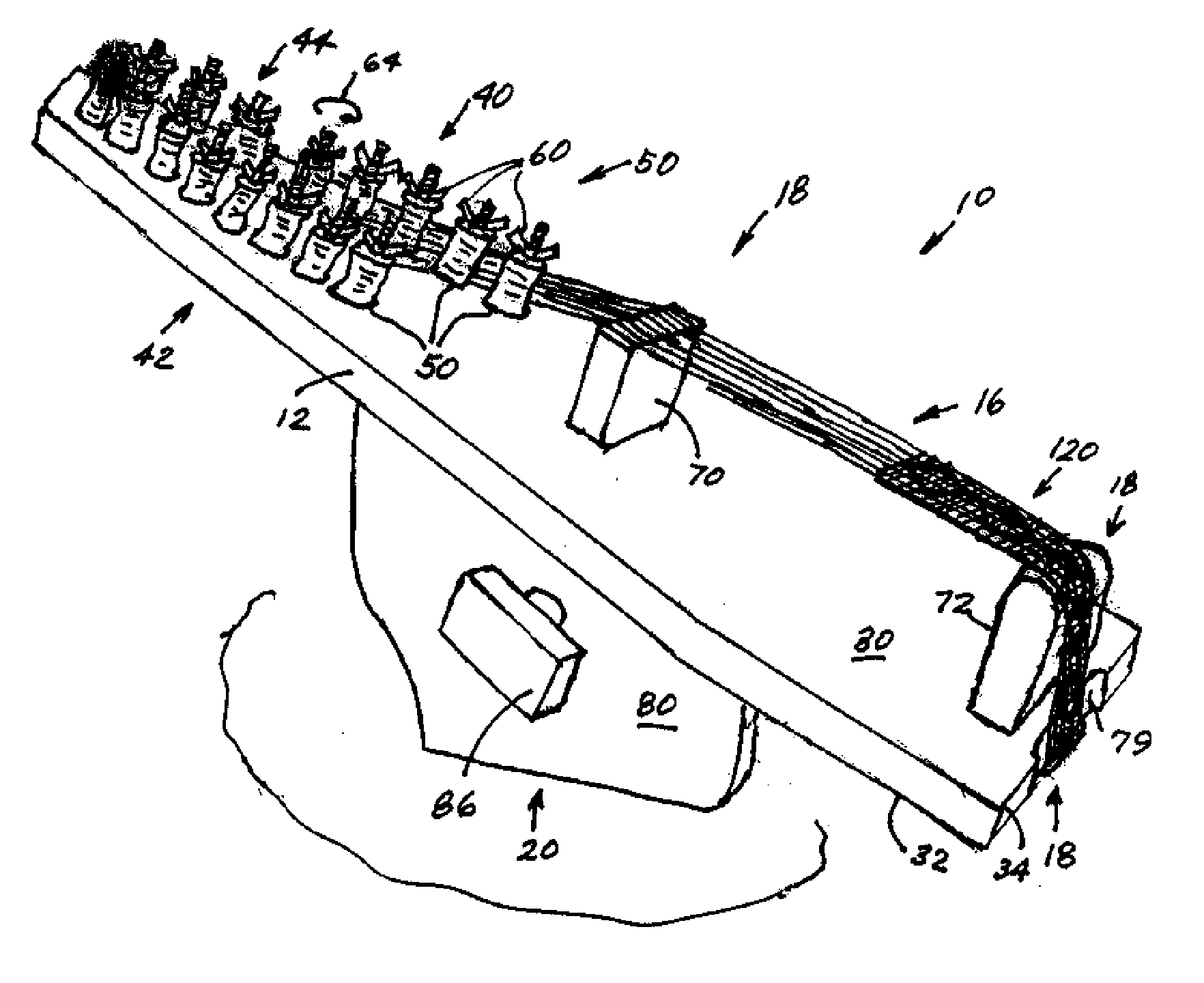

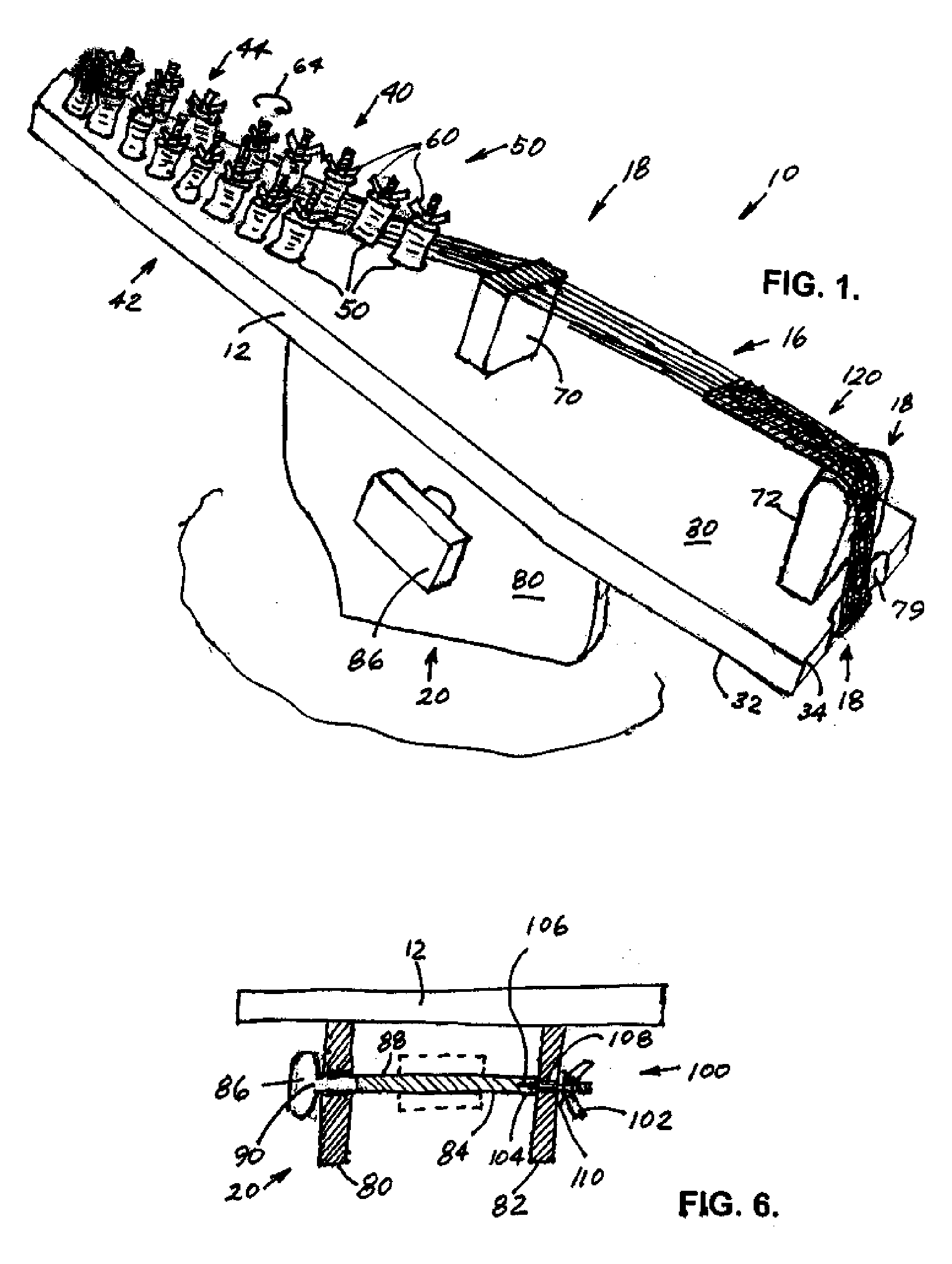

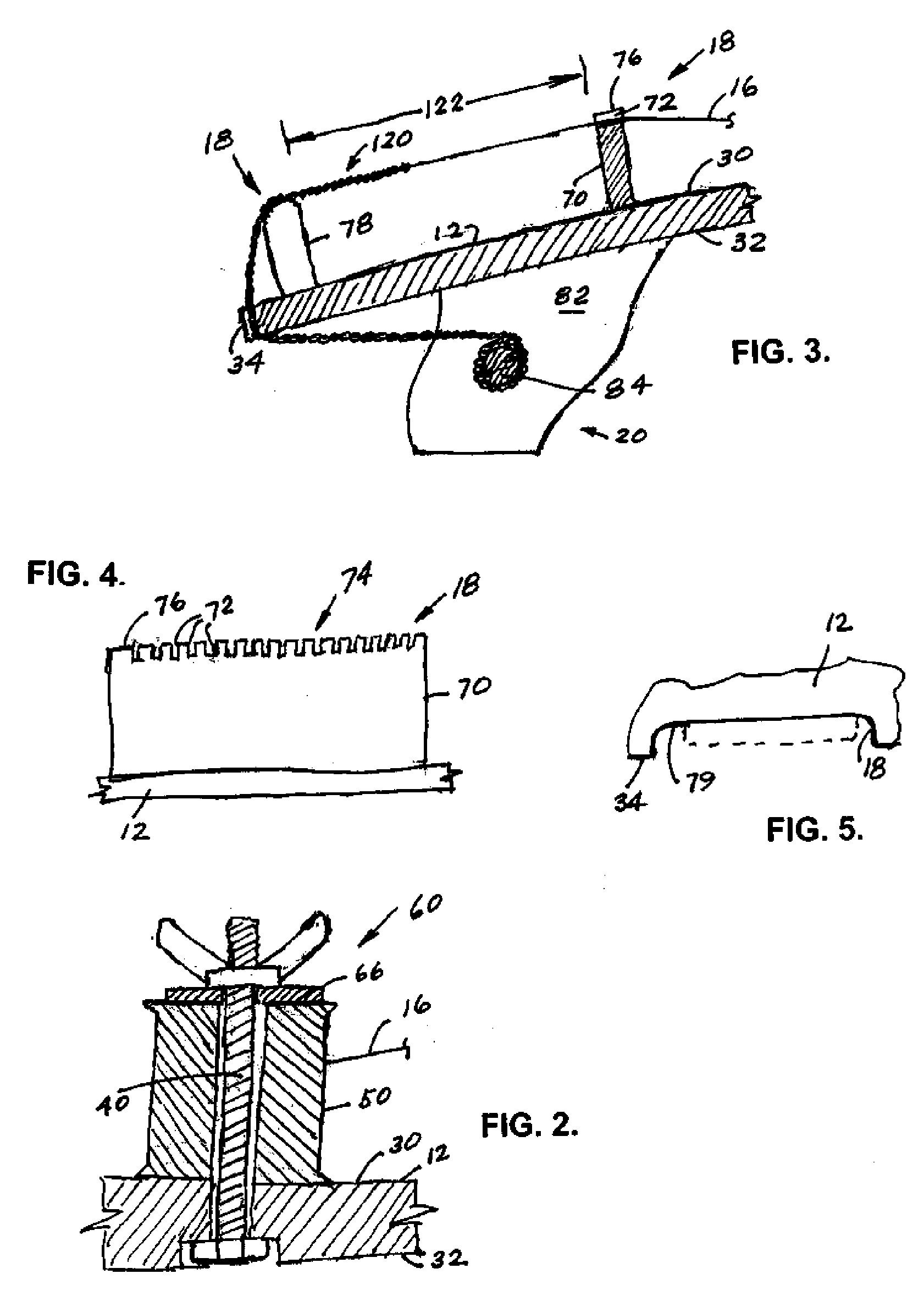

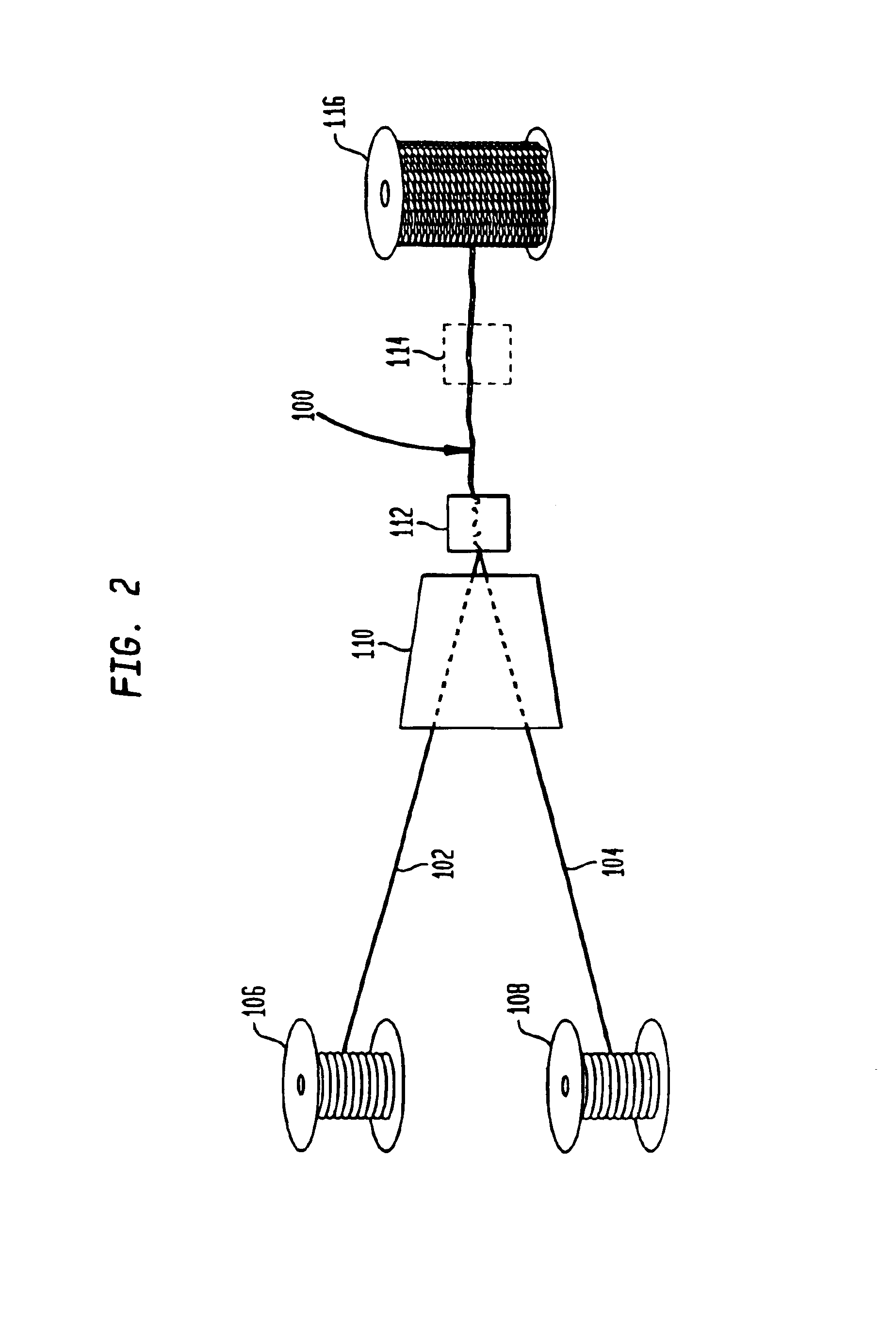

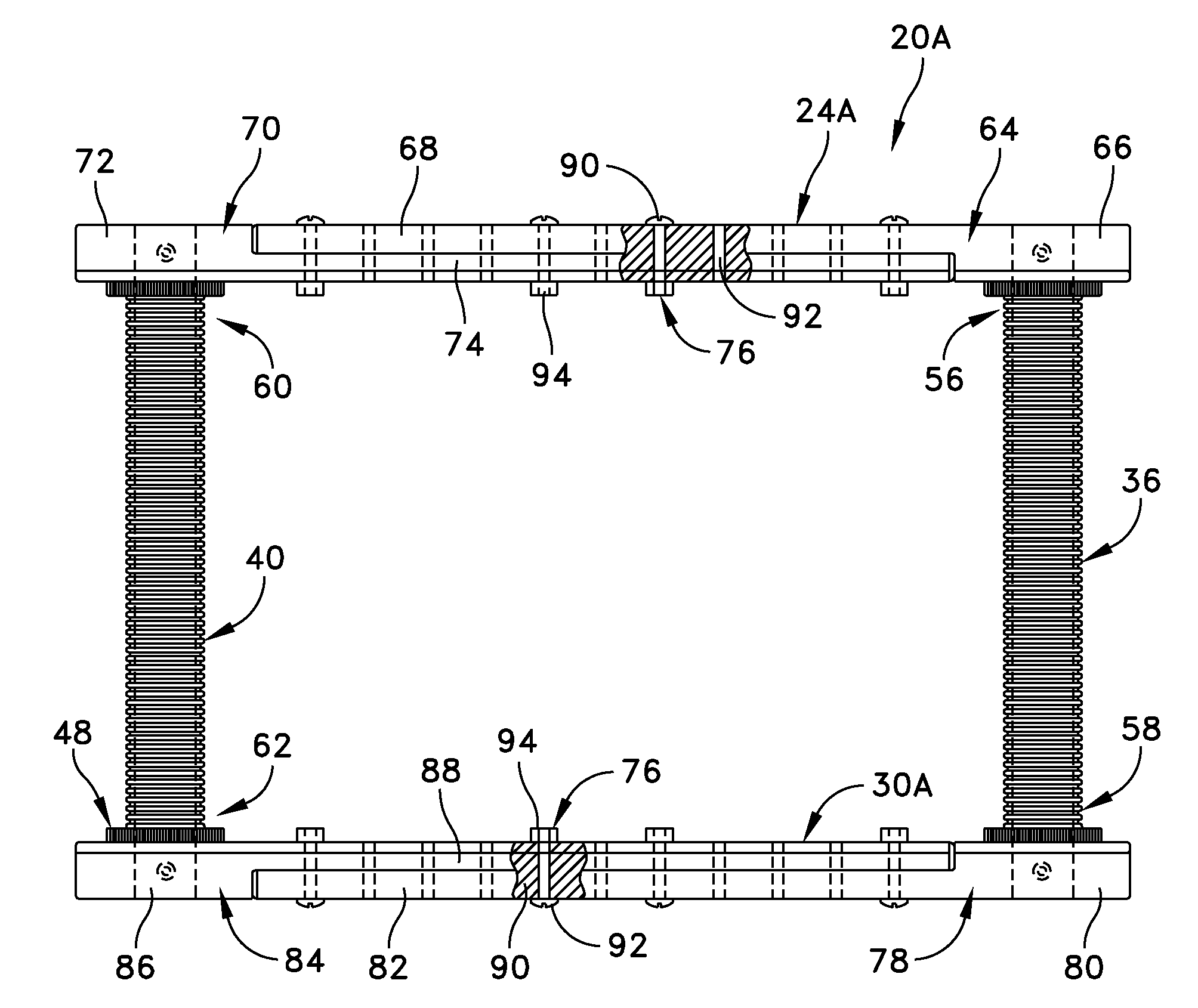

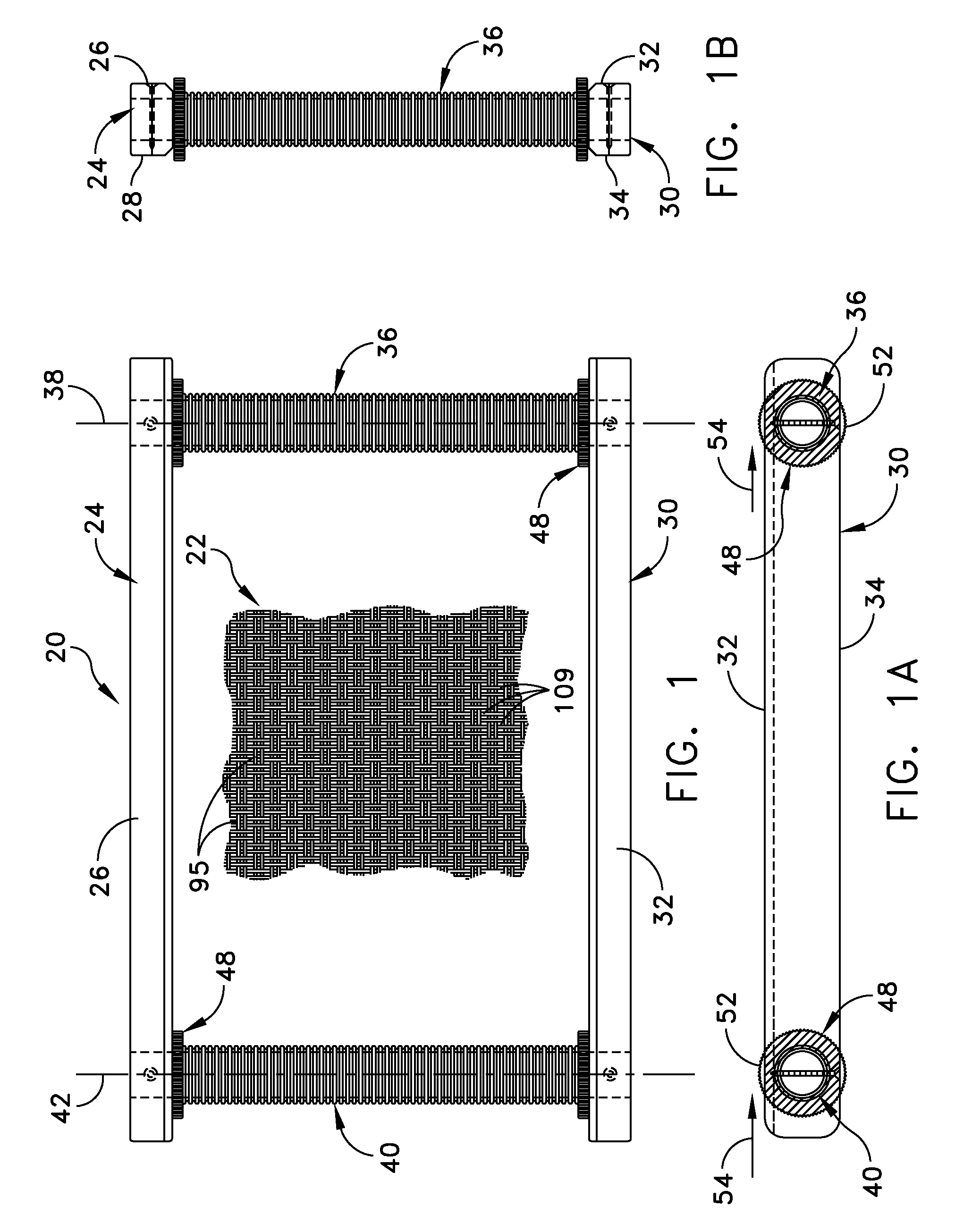

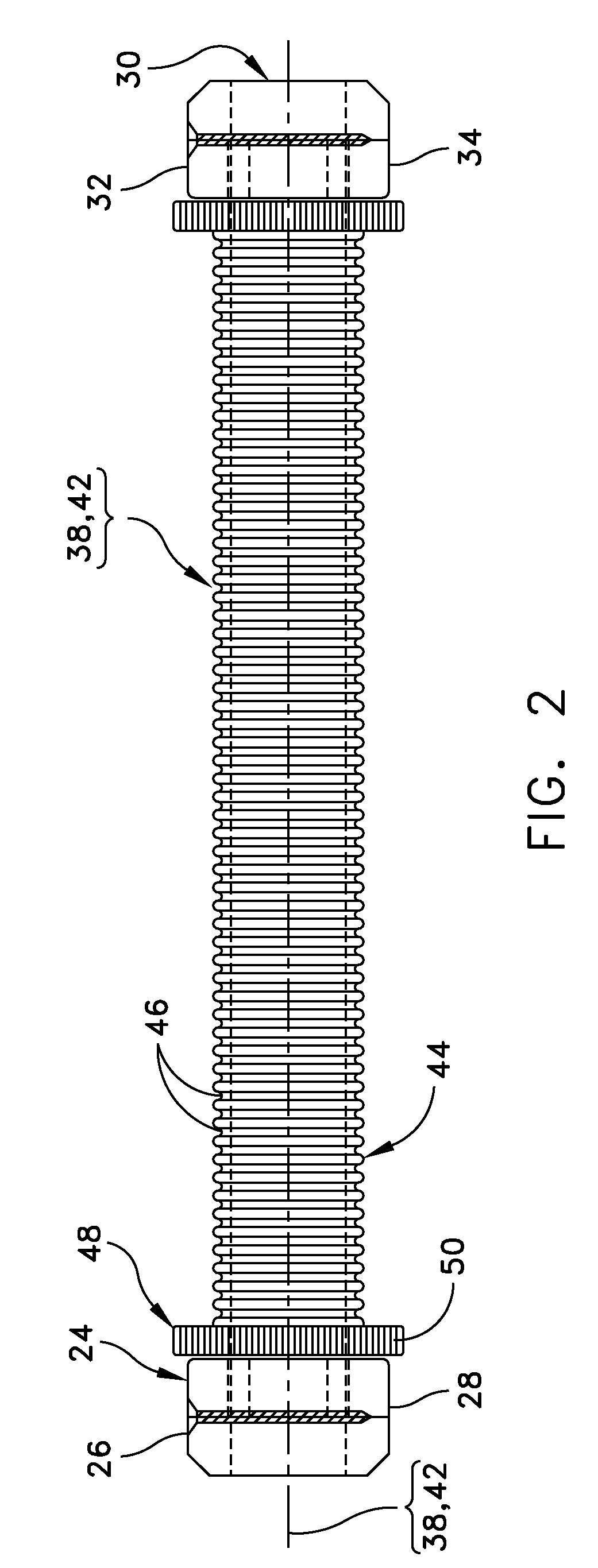

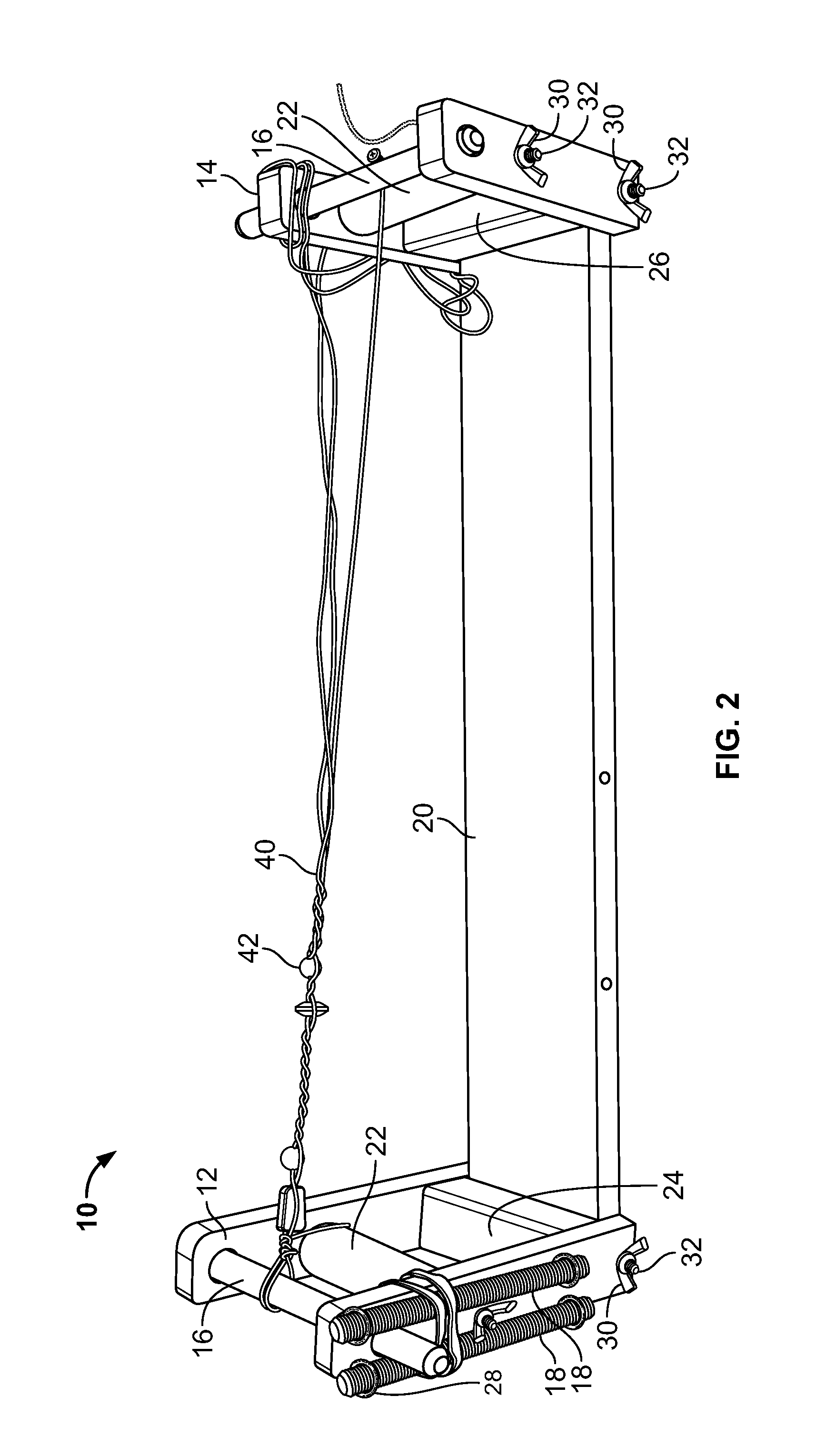

Beading loom with removable warp thread cartridge

The beading loom with a removable warp thread cartridge has warp threads mounted in a cartridge that is removably received in a frame of the loom, allowing the user to bead the threads in a conventional manner, but without having to wrap the threads on the loom manually. Once finished with one beading product, the user may then remove the cartridge from the loom and replace the beaded project with a fresh cartridge of warp threads. The frame has an elongated base having an adjustable length along the longitudinal direction.

Owner:SKAFLESTAD KRISTINE K

High performance laminated tapes and related products for ballistic applications

Highly uniform woven fibrous structures formed from fibrous tapes, wherein the tapes constitute the warp and weft tapes of a woven fabric. The individual fibrous tapes may be woven or non-woven, and may be formed as narrow tapes or may be cut from a wider fabric web.

Owner:HONEYWELL INT INC

Beading loom with removable warp thread cartridge

The beading loom with a removable warp thread cartridge has warp threads mounted in a cartridge that is removably received in a frame of the loom, allowing the user to bead the threads in a conventional manner, but without having to wrap the threads on the loom manually. Once finished with one beading product, the user may then remove the cartridge from the loom and replace the beaded project with a fresh cartridge of warp threads. The frame has an elongated base having an adjustable length along the longitudinal direction.

Owner:SKAFLESTAD KRISTINE K

Device and kit for making knotted string accessories

Disclosed herein are embodiments of devices and kits for making knotted string accessories. One embodiment of a device comprises a base having a substantially planar surface with a first end, a second end opposite the first end, and a longitudinal axis. A securing member is connected to the substantially planar surface proximate to the first end and is configured to secure a first end of the plurality of individual strings. An elongated holder is connected to the substantially planar surface proximate the second end and perpendicular to the longitudinal axis and comprises a plurality of raised portions positioned along the elongated holder and extending outward from the substantially planar surface in close proximity to one another, wherein adjacent raised portions are configured to retain individual strings. An embodiment of a kit comprises the device and a plurality of string for use with the device.

Owner:CROREY CREATIONS

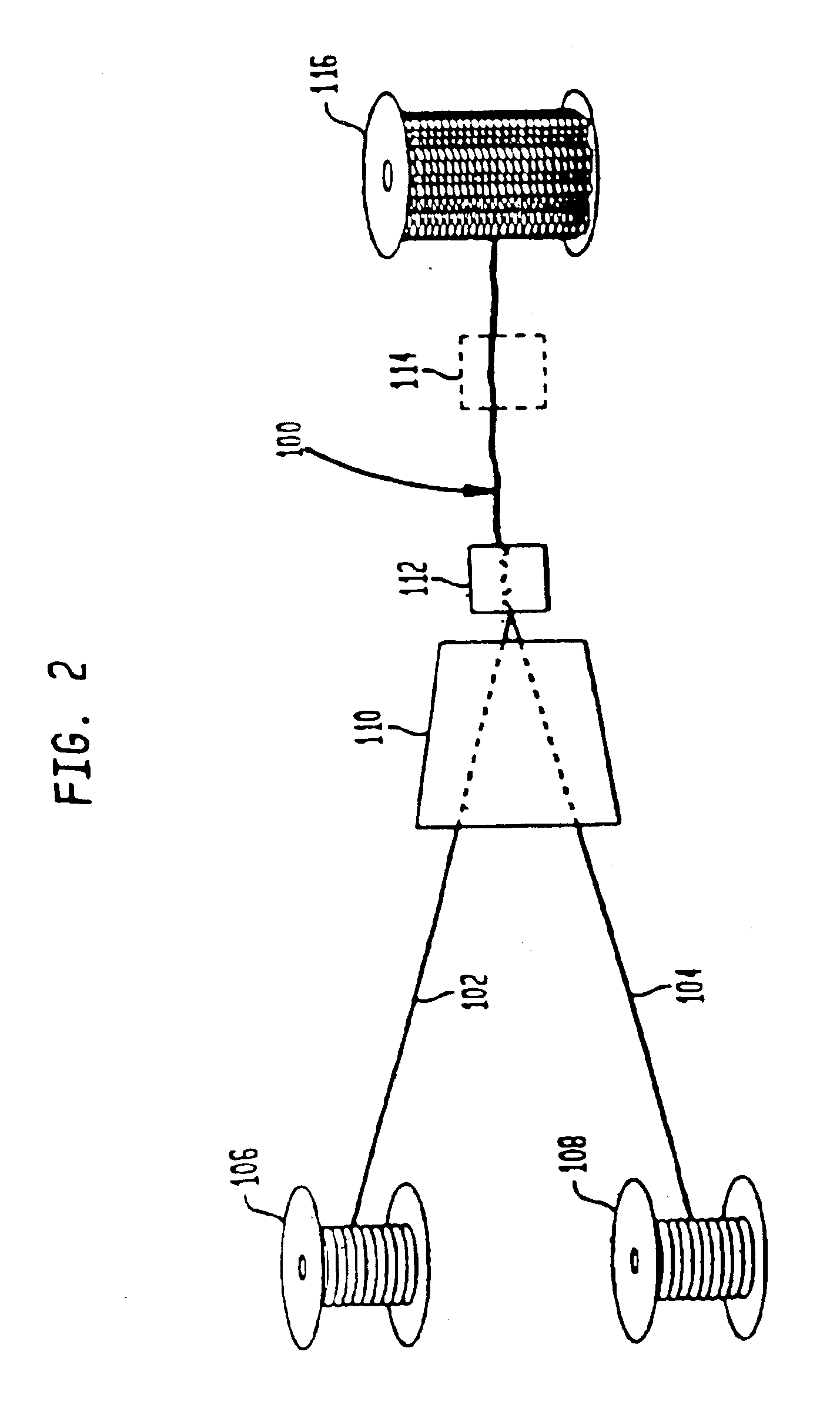

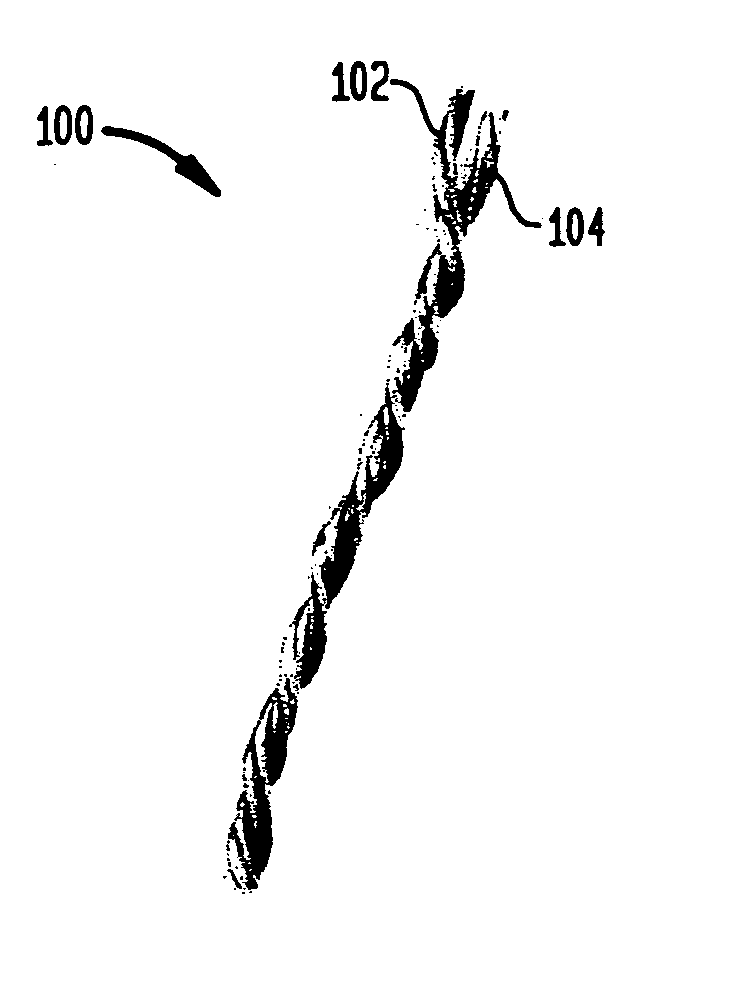

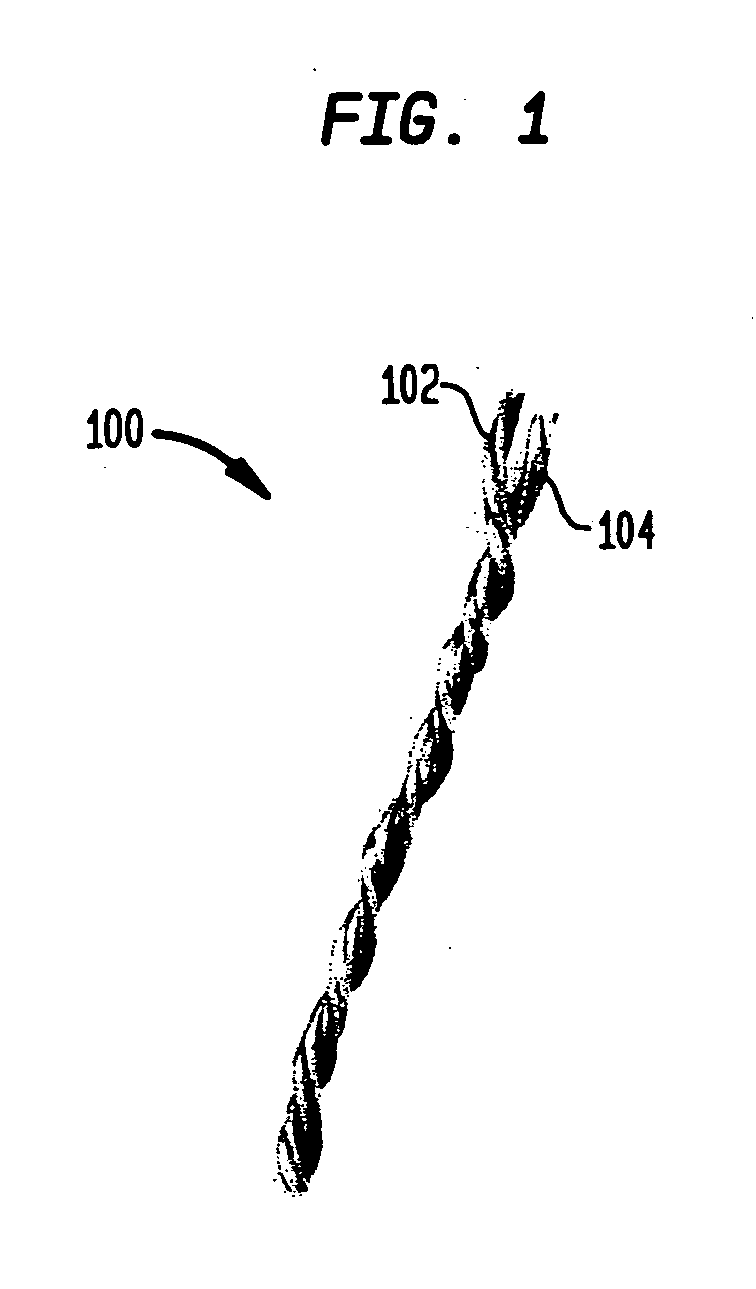

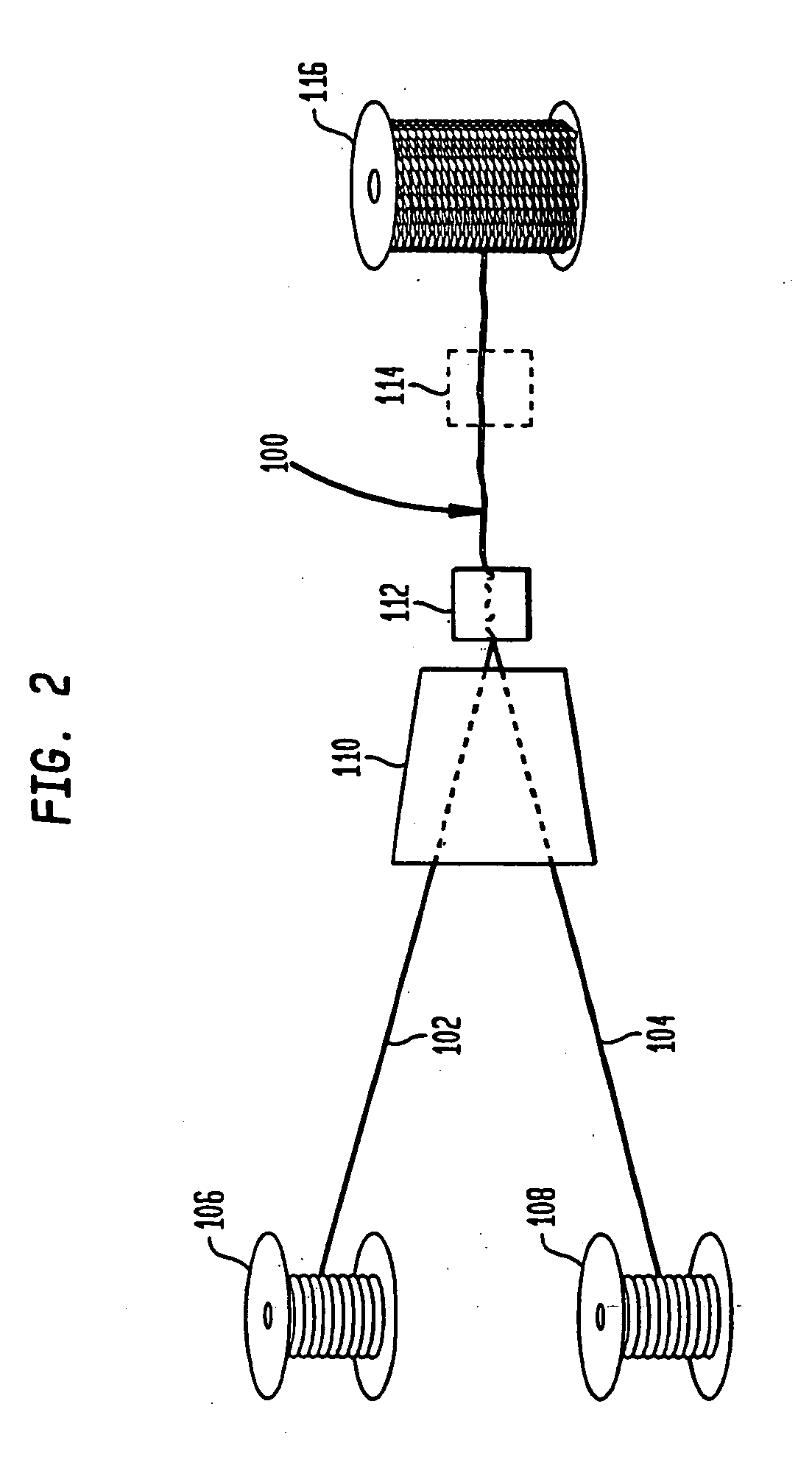

Method of making furniture with synthetic woven material

An article of furniture is made from elongated polymer filaments. The polymer filaments may be monofilaments or plural filaments which are twisted together and heat set to prevent their untwisting during the subsequent weaving process. The heat setting of the polymer filaments is achieved by heating the polymer material either before or after the twisting process.

Owner:CASUAL LIVING WORLDWIDE

Bead stringing apparatus for faster beading of original designs

InactiveUS8066035B1Saving of lost beadworkEliminates unnecessary rigid partHand loomsClothes making applicancesWork spaceEngineering

A bead stringing apparatus that enables the user to quickly restring pre-strung beads, of the type that are on temporary strings, commonly available in bead stores. The connectors on the apparatus pull both ends of the temporary string in a taut position over an open work space. This aligns the pre-strung beads automatically along the temporary string allowing them to be restrung easily by a permanent string or wire. The user can quickly resting rows of the pre-strung beads by putting their wire through the aligned holes and when the wire exits a row of the pre-strung beads the user can add in other loose beads on their wire to go in and between the pre-strung beads. This allows the user to create infinite designs and patterns of beadwork. The open work space around the pre-strung beads provides flexibility and ample room for the newly incorporated loose beads to hang down onto the permanent wire out of the way of the beading process. The pre-strung beads can also be measured along the temporary string for bead patterning.

Owner:STEVENS DENISE M

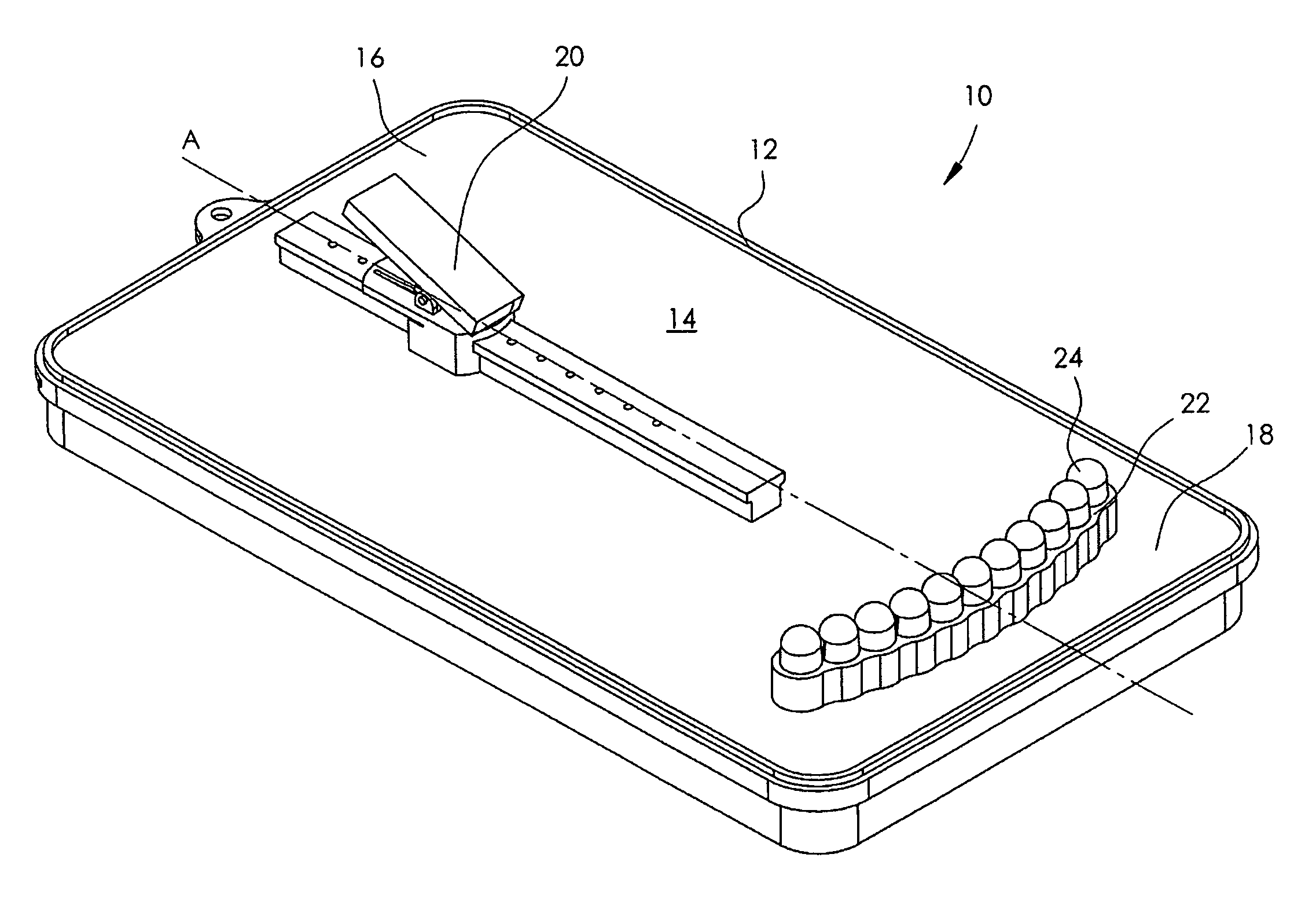

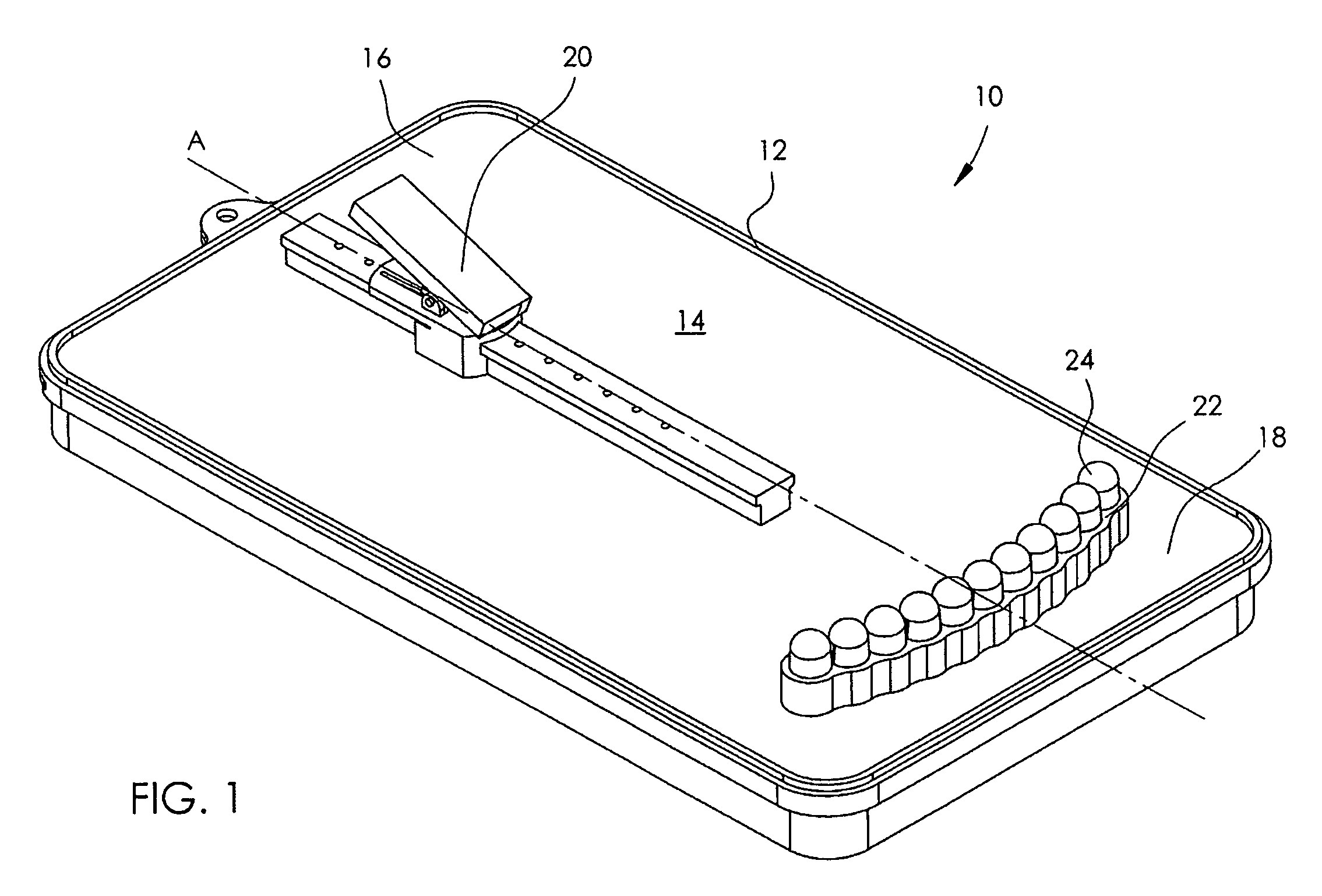

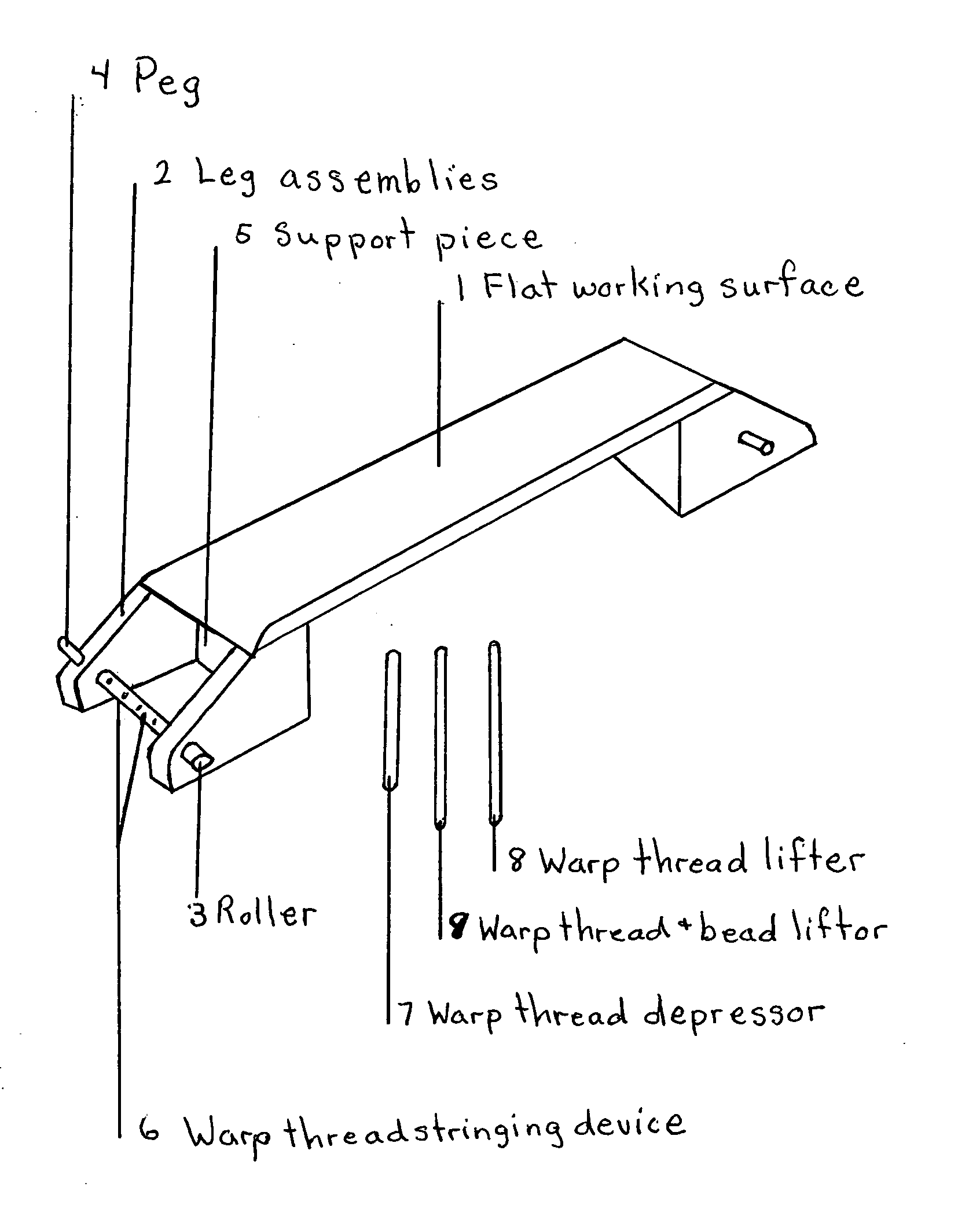

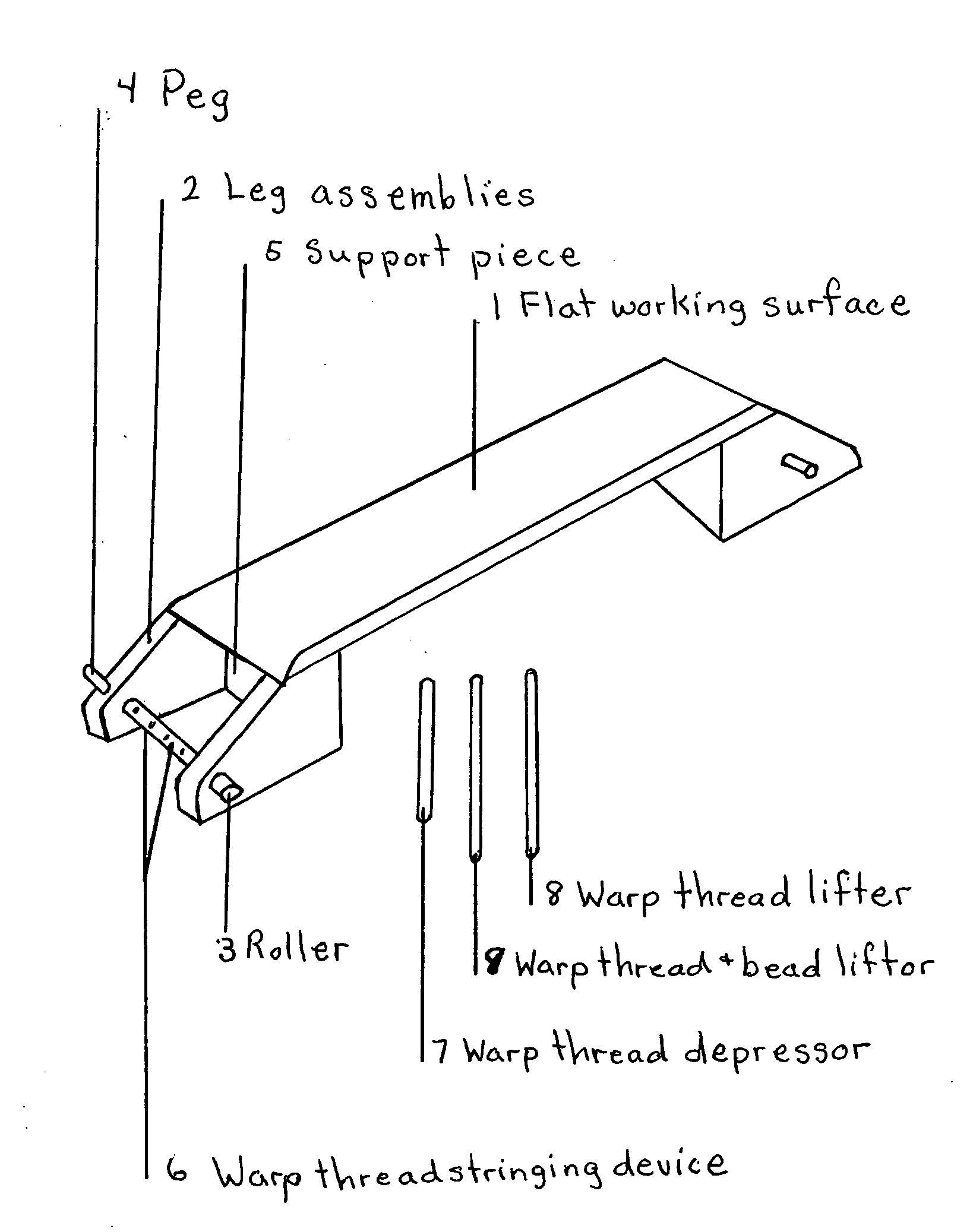

Hand beading loom and method of use

A new design of beading loom which has a solid flat beading surface. This flat surface beading loom provides a stable support for the warp threads and beads. Unlike conventional beading looms the warp threads are not attached to an open frame and suspended in air. The beads are supported between the warp threads and the warp threads and therefore the lower weft thread are held down by a warp thread depressor while the beading needle and upper weft thread are passed back through the beads. The number of beads that can be passed through with one pass is only limited by the length of the beading needle. Preferably a 7 inch lacing needle which will pass threaded several times through a size 11 Delica bead. This loom is easily used by children and is helpful in alleviating stress on the muscles, tendons and joints of the upper body.

Owner:SPOR DEBORAH EVELYN +1

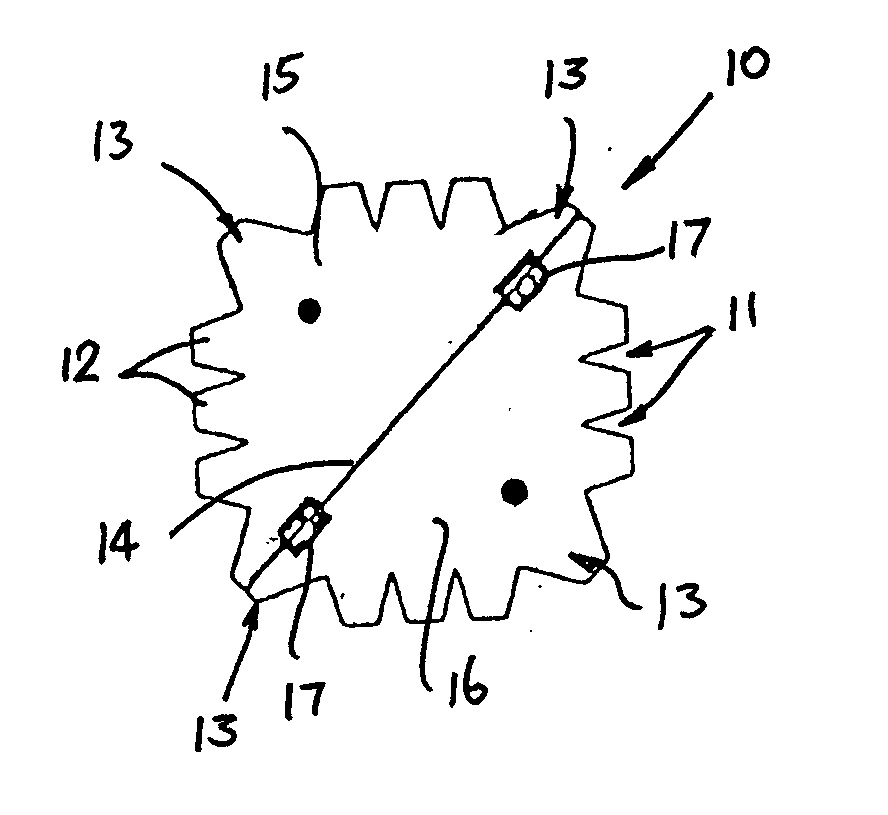

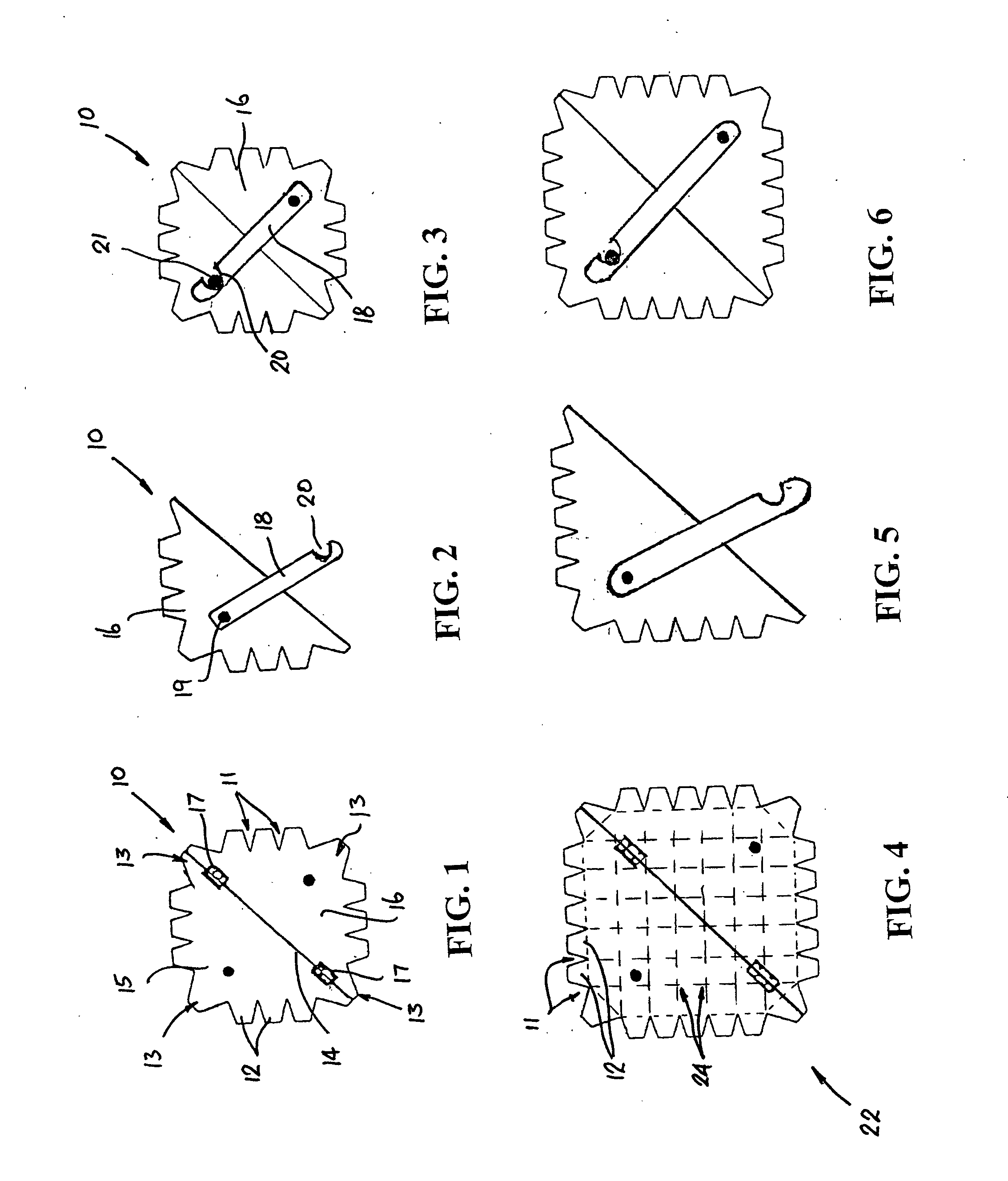

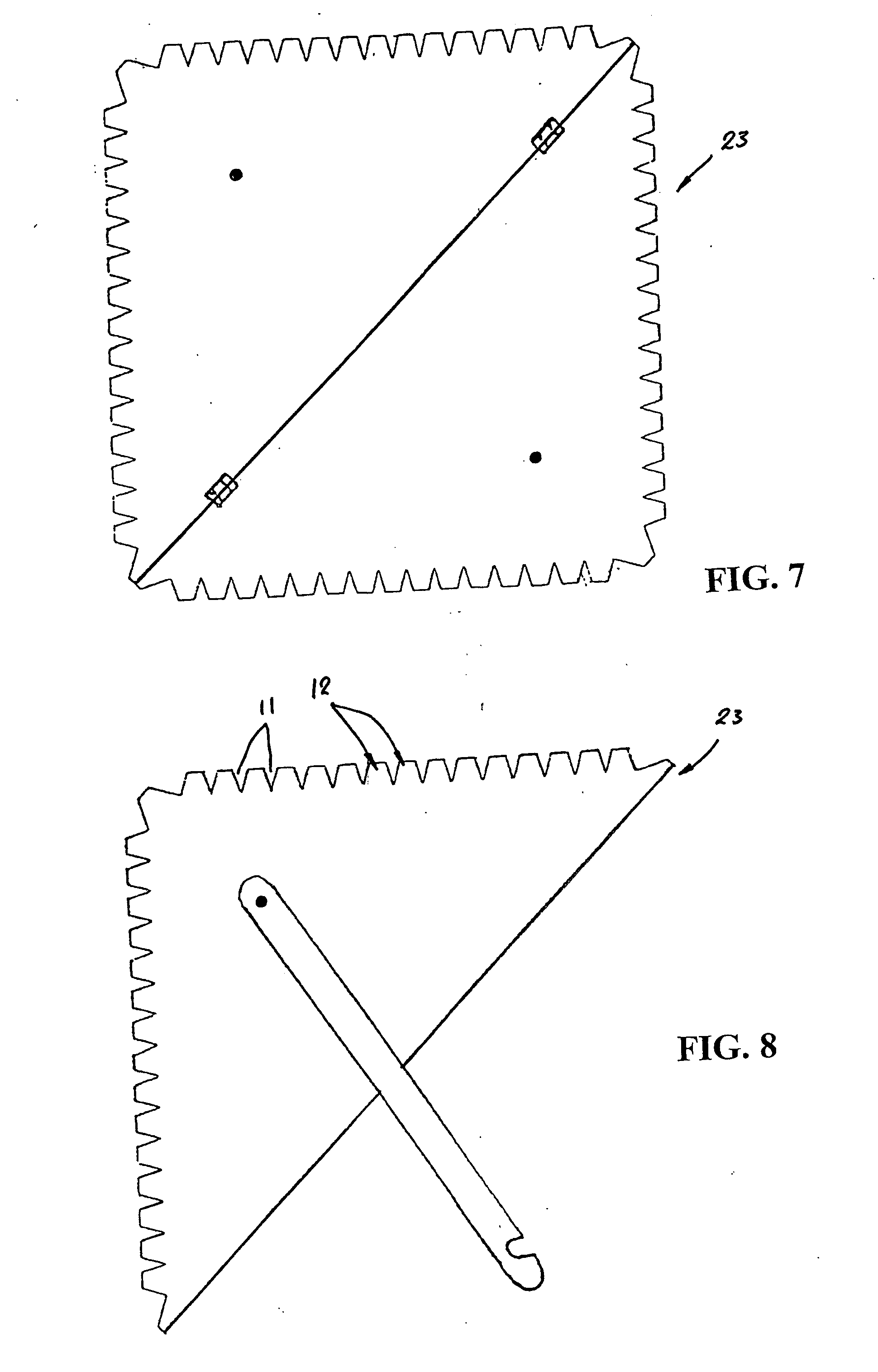

String bead loom

InactiveUS20060157137A1Maintain proper tensionImprove performanceHand loomsEngineeringMechanical engineering

Owner:SAYLER WAYNE E

Bead weaving device

An apparatus and method of using a bead weaving device for assisting manufacturing by jewelry makers and facilitating the positioning, stringing, cross-weaving, peyote chain maille, and accurate sizing for but not limited to necklaces, bracelets, and other hand woven beaded products. The bead weaving device includes the following components: an inclined sizing plate optionally including an imperial-measure graduated scale and / or a metric-measure graduated scale, a brass toggle half securer, a stabilizer, a support base and removably couplable peyote block attachment and a support arm. The support base of the device is adapted for use on the lap of a user or on the surface of a substrate such as a table.

Owner:WELDER ROBERT F +1

Combination weave using twisted and nontwisted yarn

An article of furniture is made from elongated polymer filaments. The polymer filaments may be monofilaments or plural filaments, which are twisted together and woven with polymer strands of non-twisted yarn to form a woven portion of material. The woven portion can be used to form the seat or back rest of a seating article of furniture for indoor or outdoor use.

Owner:CASUAL LIVING WORLDWIDE

Low-vibration shedding system

InactiveUS20050051228A1Good oscillation absorptionImprove axial rigidityWeft knittingDobbiesCouplingEngineering

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

Hand loom

A loom that includes a first elongated beam having upper and lower surfaces; a second elongated beam having upper and lower surfaces parallel to and spaced from the first beam; a first transverse roller having a first longitudinal axis rotatably mounted on and extending between the first and second beams; a second transverse roller having a second longitudinal axis parallel to and spaced from the first transverse roller rotatably mounted on and extending between the first and second beams; each transverse roller having a peripheral surface formed with a plurality of equally sized and spaced annular grooves, each groove lying in a plane perpendicular to the longitudinal axis of its associated roller; and a disk-shaped thumb wheel having a textured peripheral edge surface fixed to each roller with a center aligned with the longitudinal axis of the roller.

Owner:GREENE PLASTICS CORP

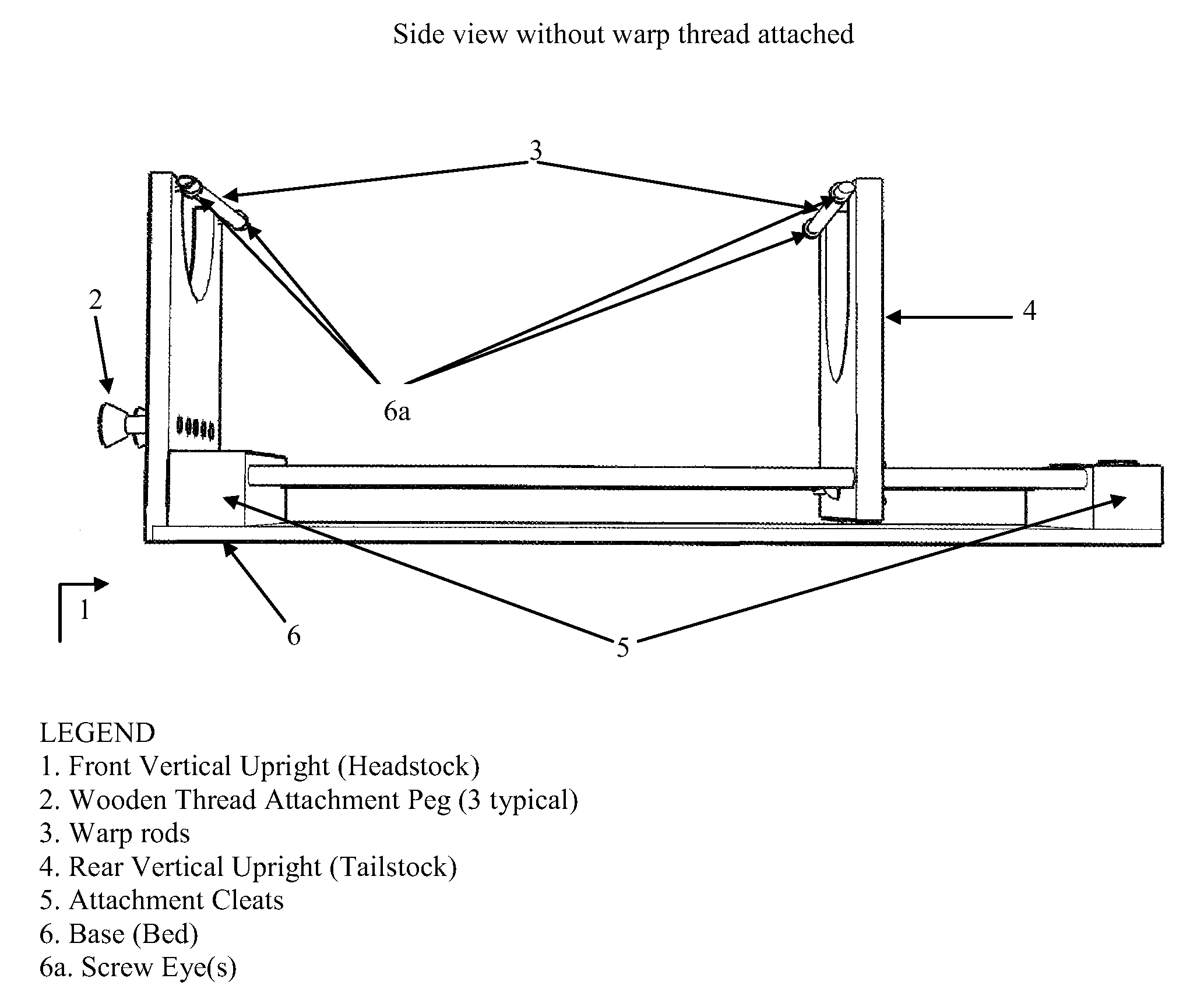

Ricks beading loom

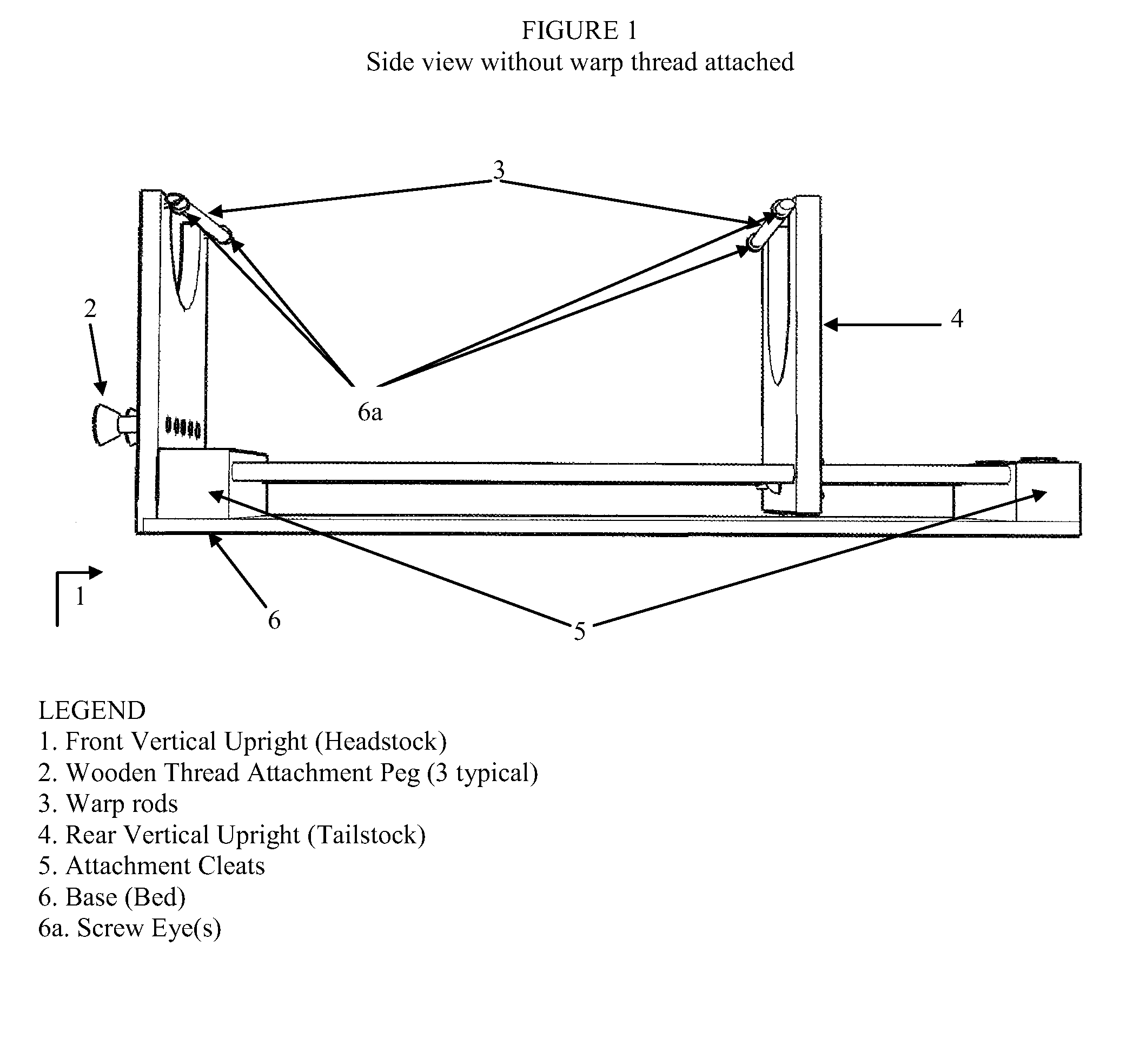

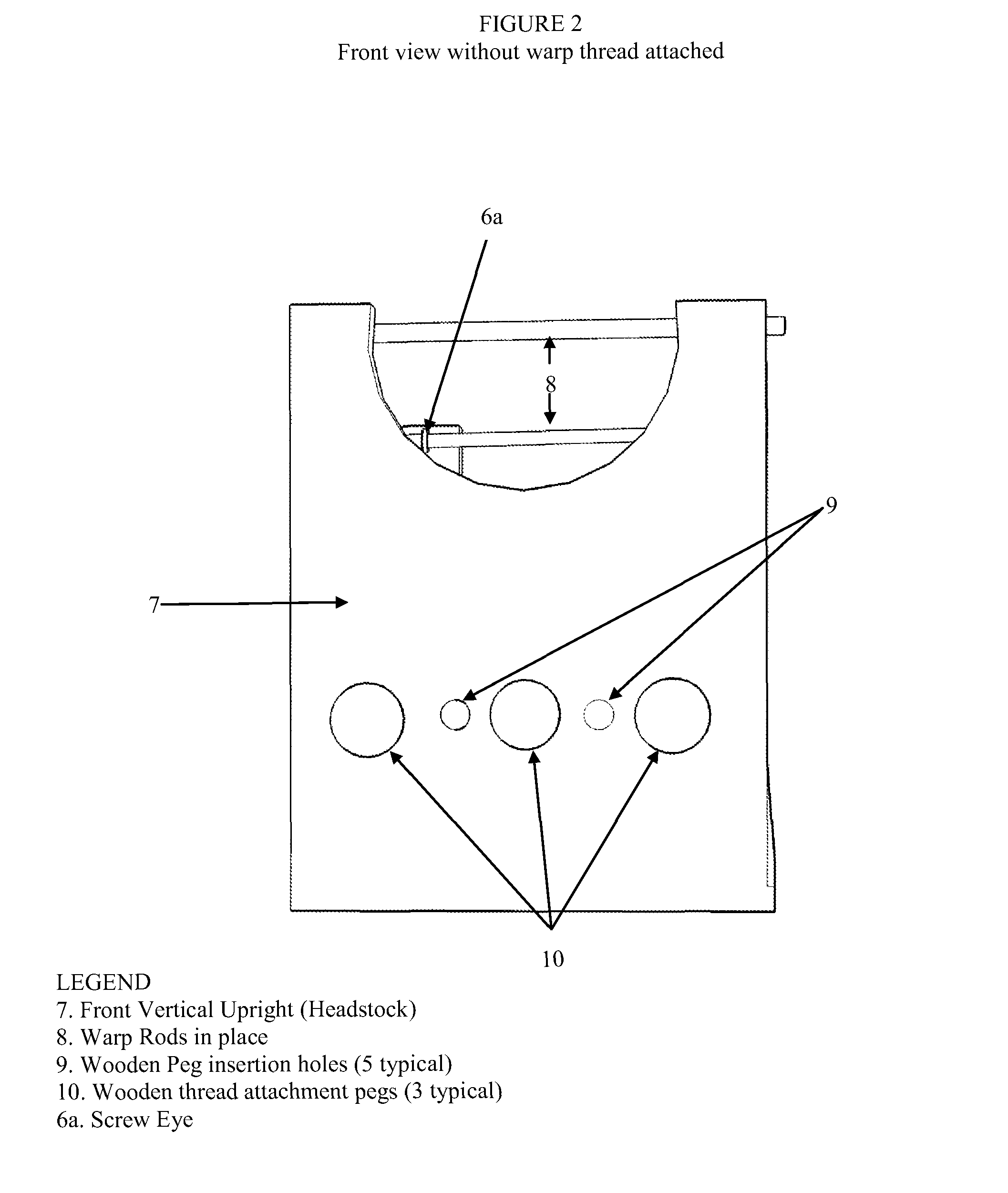

A new and unique innovation in the art of bead weaving on a loom by eliminating the numerous remaining ends of the warp threads which, in other methods, must be woven back into the finished project. The innovation results in having only two remaining warp threads instead of many. The innovation also provides a new method for adjustment of the project length through the use of a “floating” rear vertical upright tailstock.

Owner:RICKS PAUL CUTHBERT

Loom for weaving, macramé, and braiding with jewelry

A loom includes a first fork, having a first interchangeable anchor point for a cord; a second fork, having a second interchangeable anchor point for the cord; and a base to retain the first fork and the second fork at generally perpendicular angles to the base. The first and second anchor points are positioned so as to provide an area for a user's hands to be inserted underneath the cord and between the forks to allow the hands to manipulate jewelry items into the cord. A tall fork and a short fork support the attachment points perpendicular to the base. The interchangeable anchor points are selectable between dowels and threaded warp bolts.

Owner:SPEAR SHERRY

Method of making furniture with synthetic woven material

An article of furniture is made from elongated polymer filaments. The polymer filaments may be monofilaments or plural filaments which are twisted together and heat set to prevent their untwisting during the subsequent weaving process. The heat setting of the polymer filaments is achieved by heating the polymer material either before or after the twisting process.

Owner:CASUAL LIVING WORLDWIDE

Portable looming template

InactiveUS20050205150A1Easy to disassembleFormed simply and effectivelyHand loomsYarnBiomedical engineering

A portable looming template for creating fabric from yarn comprising a rectangular planar body having a series of indentations in its perimeter defined between adjacent projecting fingers around which the yarn may be looped. The template may comprise a pair of planar members which may be connected together with hinges to be movable between a position in which they define the rectangular body for use and a folded position to permit release of the fabric article from the template.

Owner:JENNER CAROLYN KAYE +1

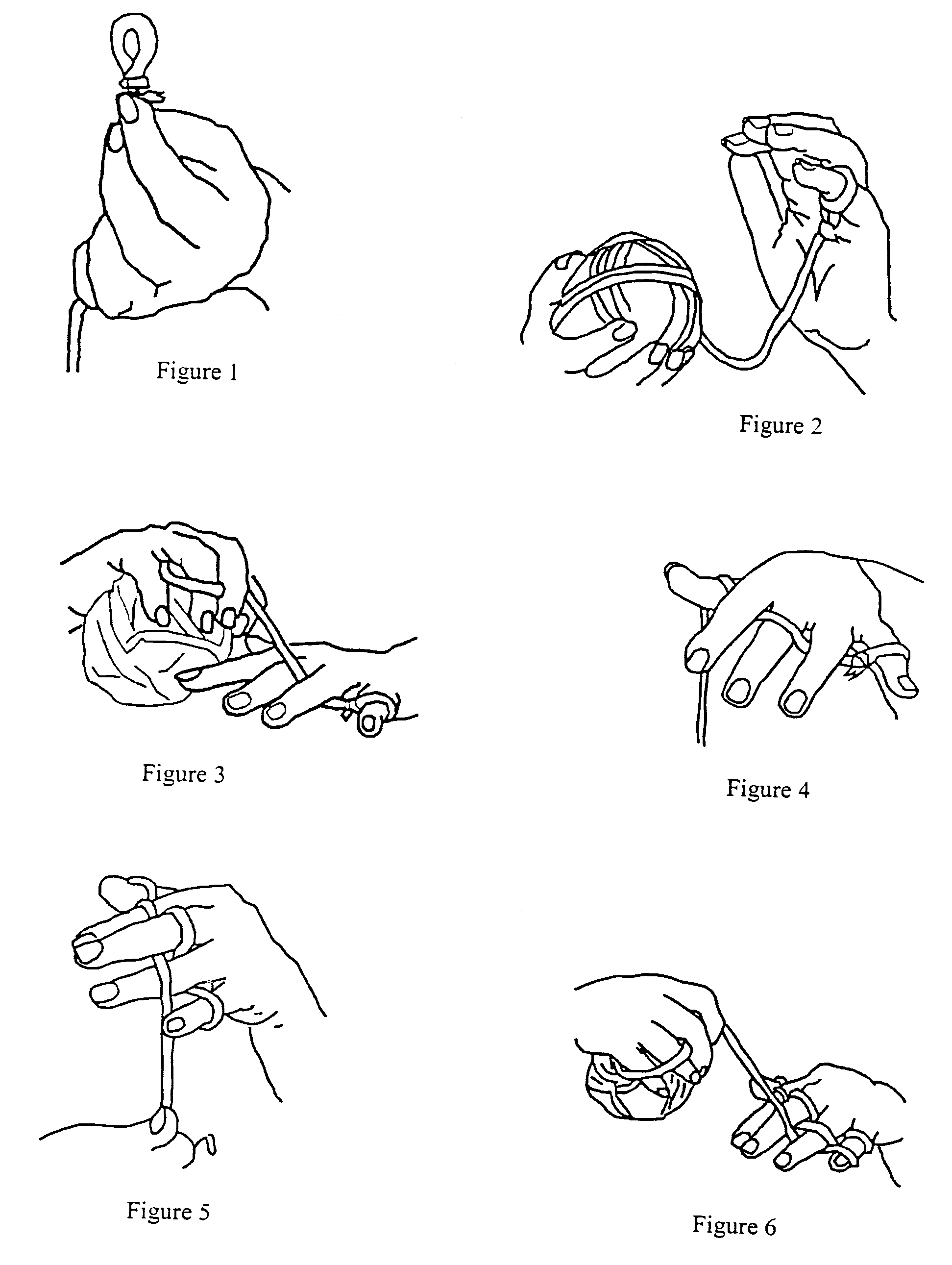

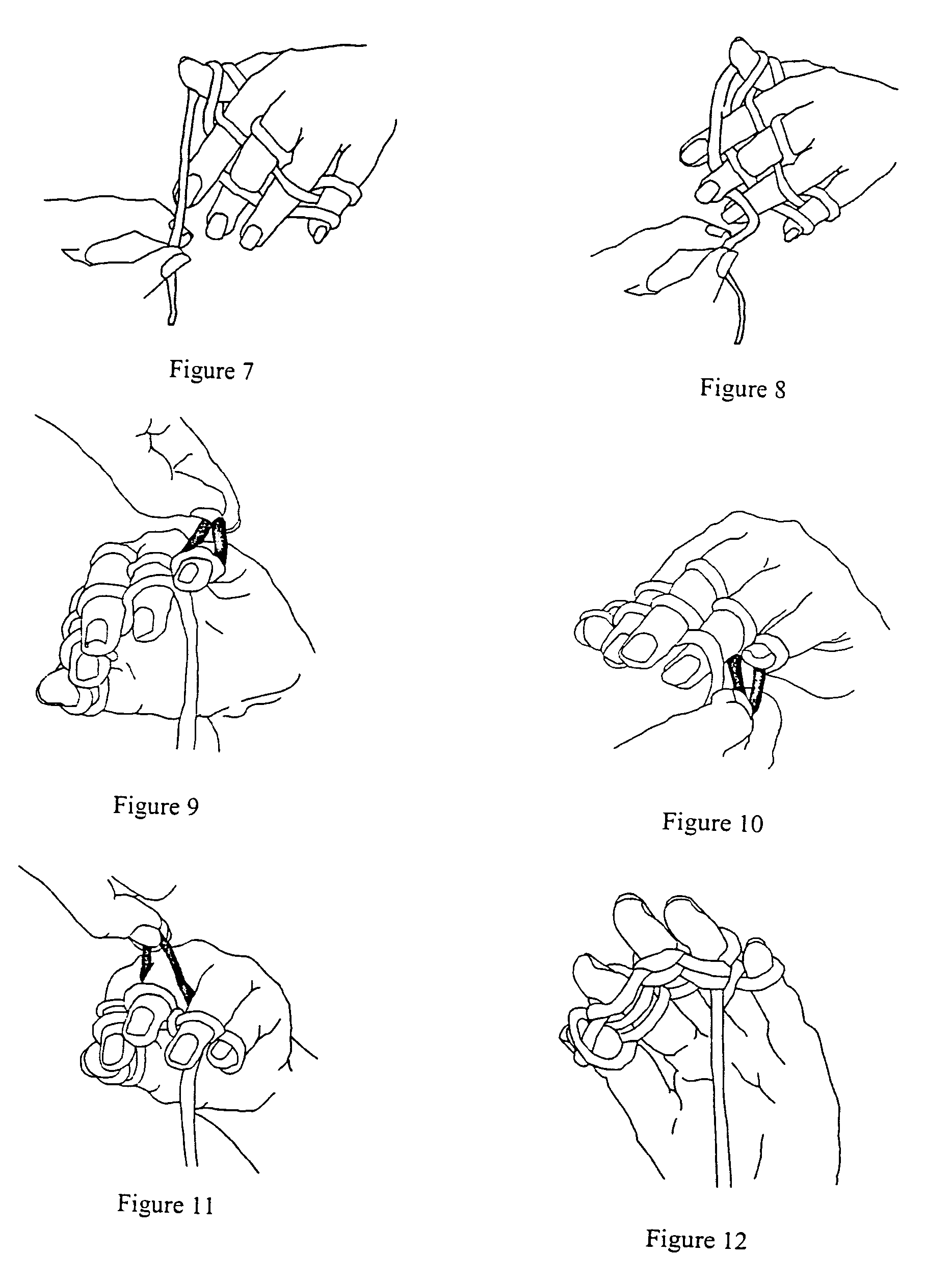

Method for hands only weaving

A process for weaving that can be implemented using just the hands as the loom and shuttle, a weaving material such as yarn, an instrument for cutting like nail clippers or a small pair of scissors, and an object for intermissions in the process such as a paper clip. The weaving process is simplified to the most basic concepts of weaving that can be enjoyed by any age group, such as, but not limited to, from five-year-old children to adults. The absence of barriers like cumbersome weaving looms permits the process to be practiced in a multitude of settings.

Owner:MURCAR DIANA LYNN

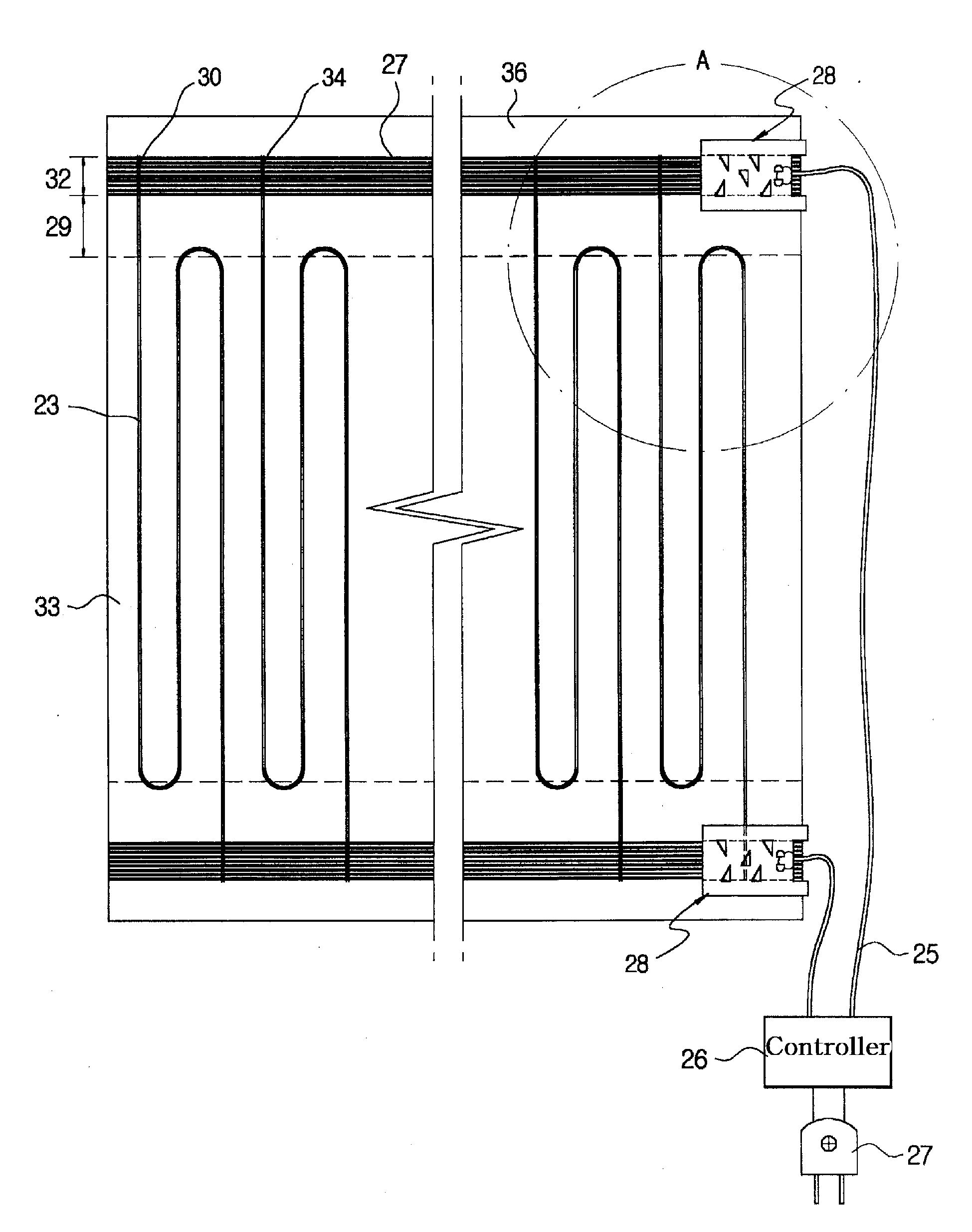

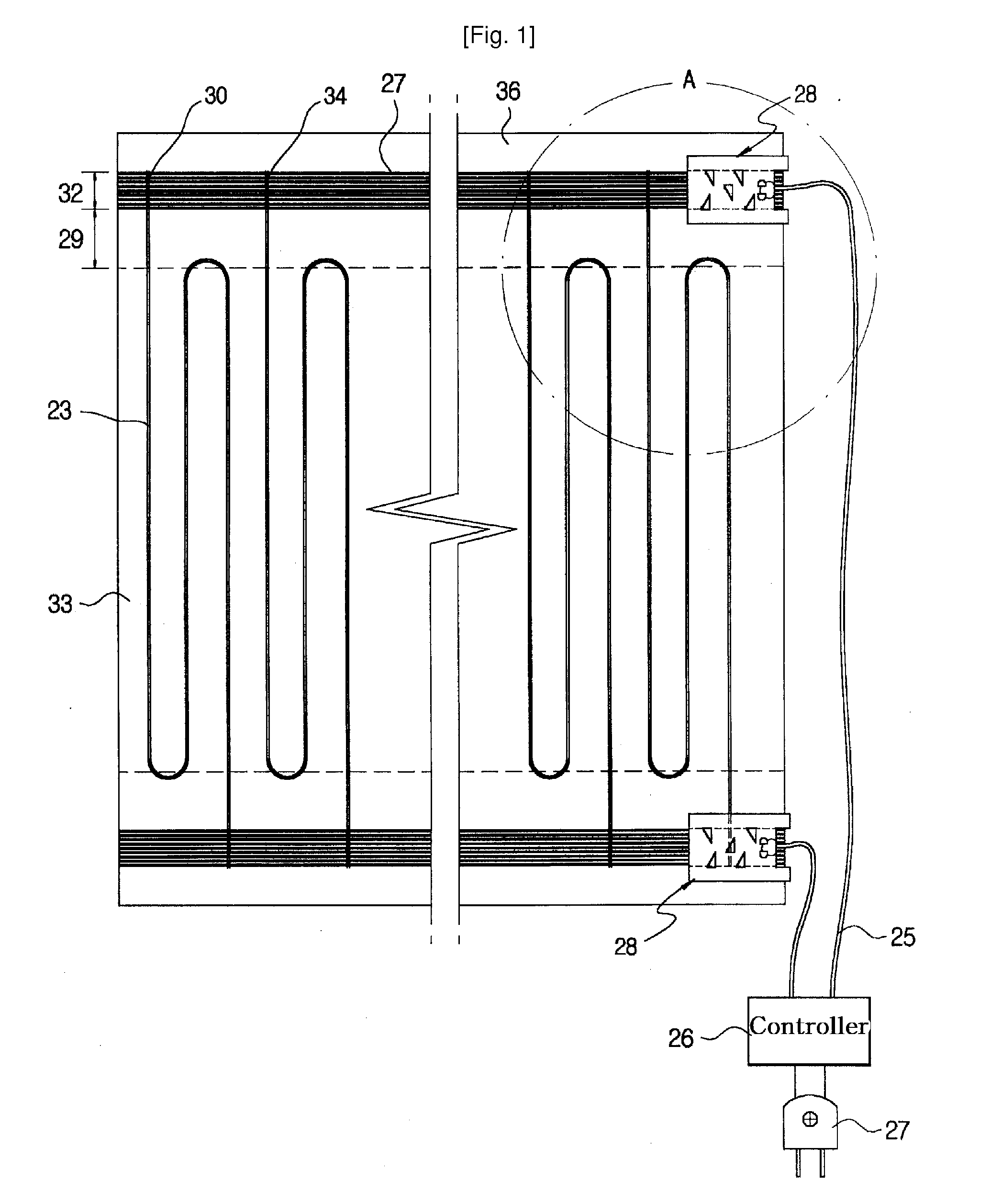

Heating Fabric and Manufacturing Method Thereof

InactiveUS20080135120A1Firmly connectedReduce product failureCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

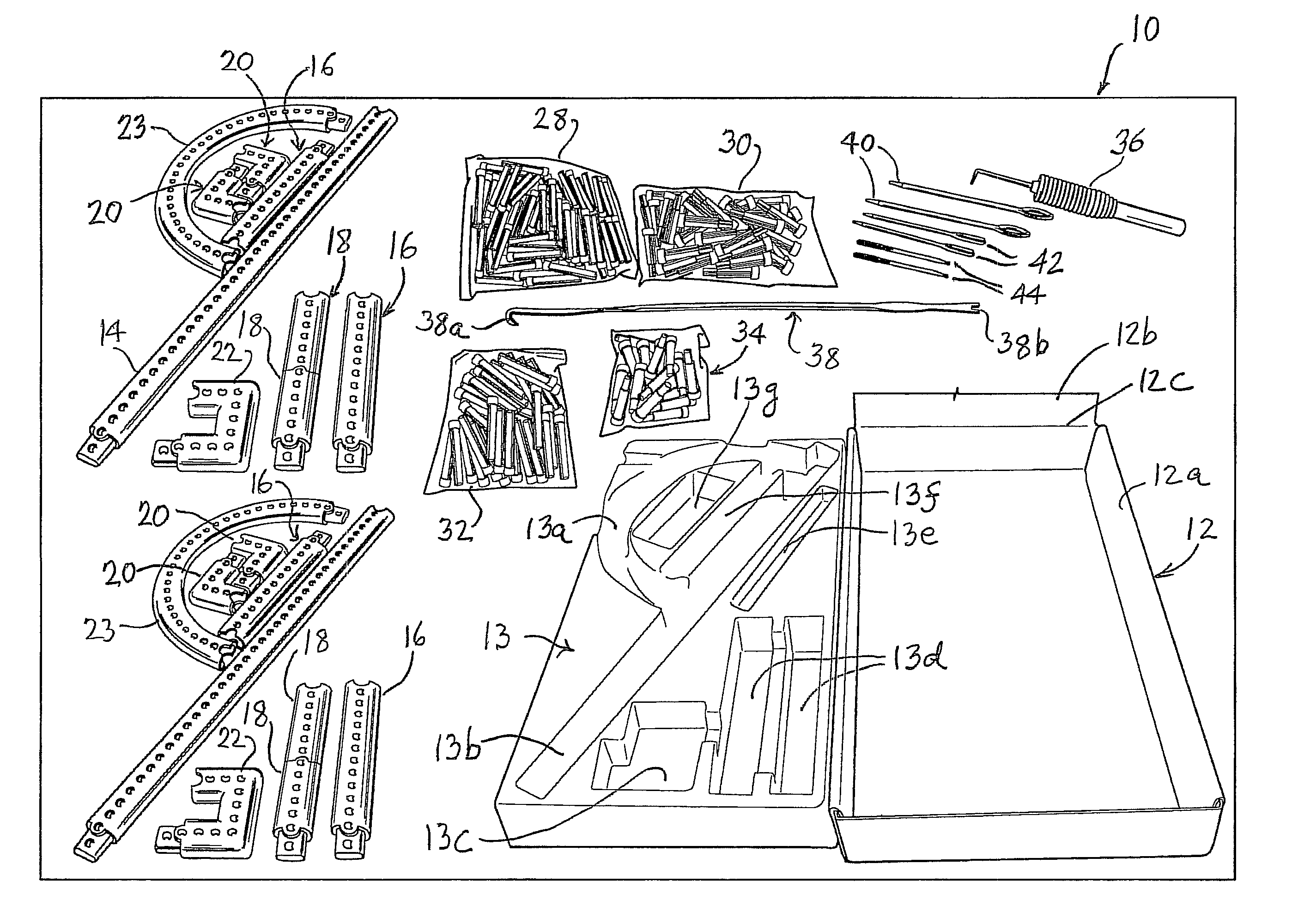

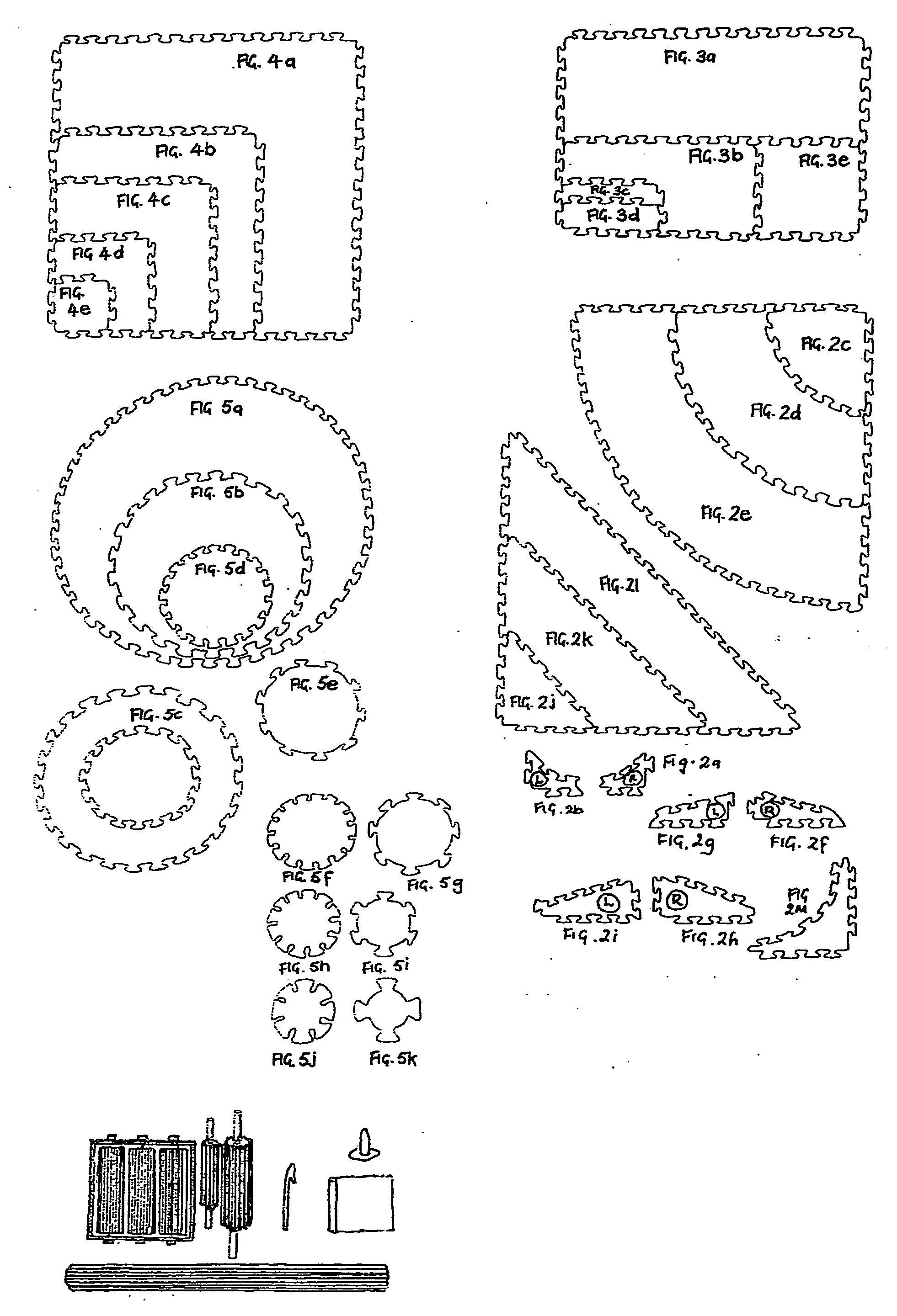

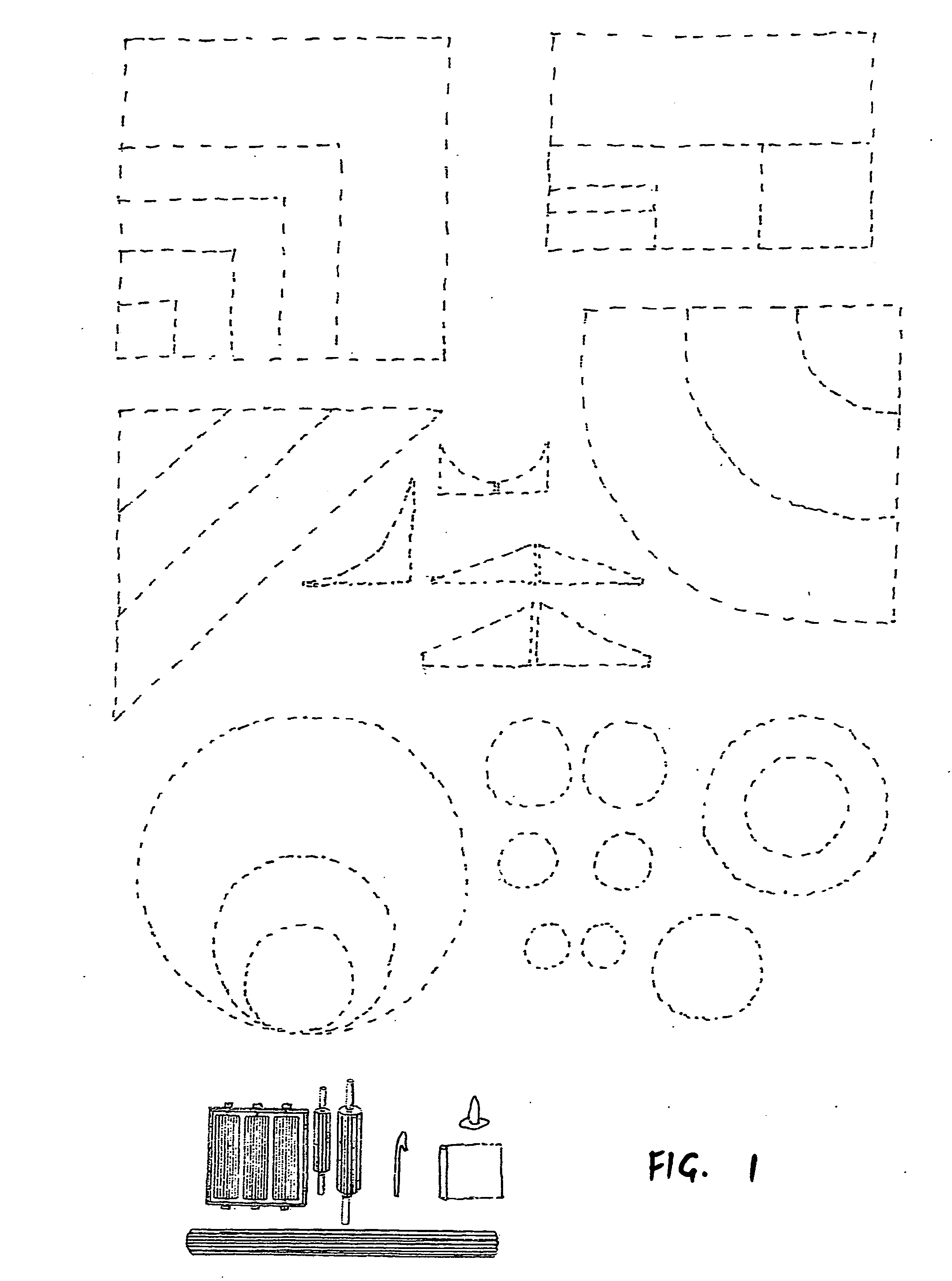

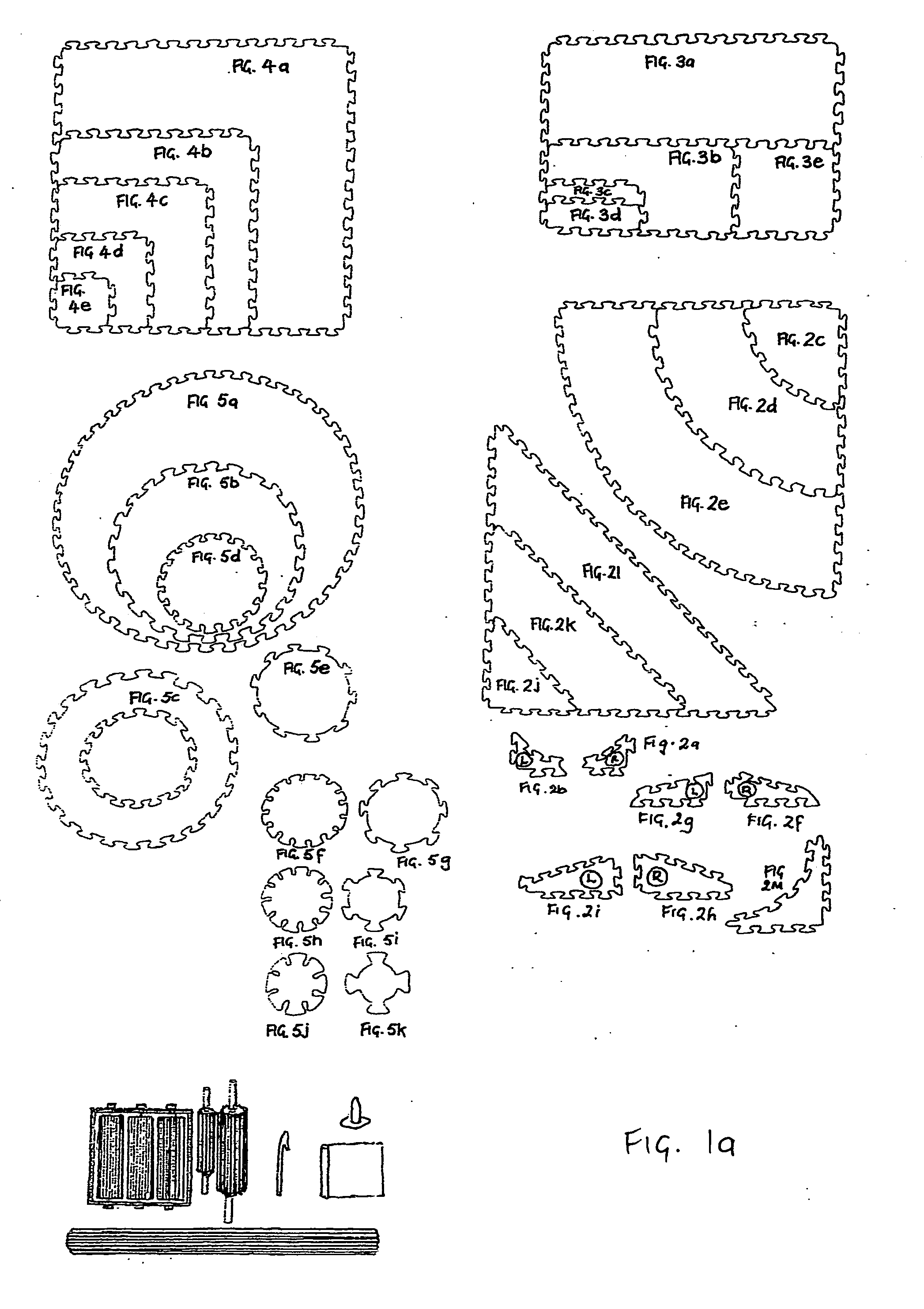

Felting loom system and method for producing felted woven fibre art textile shapes

InactiveUS20150096643A1Stimulate strong consumer desireAppealing tactileHand loomsCombined useEngineering

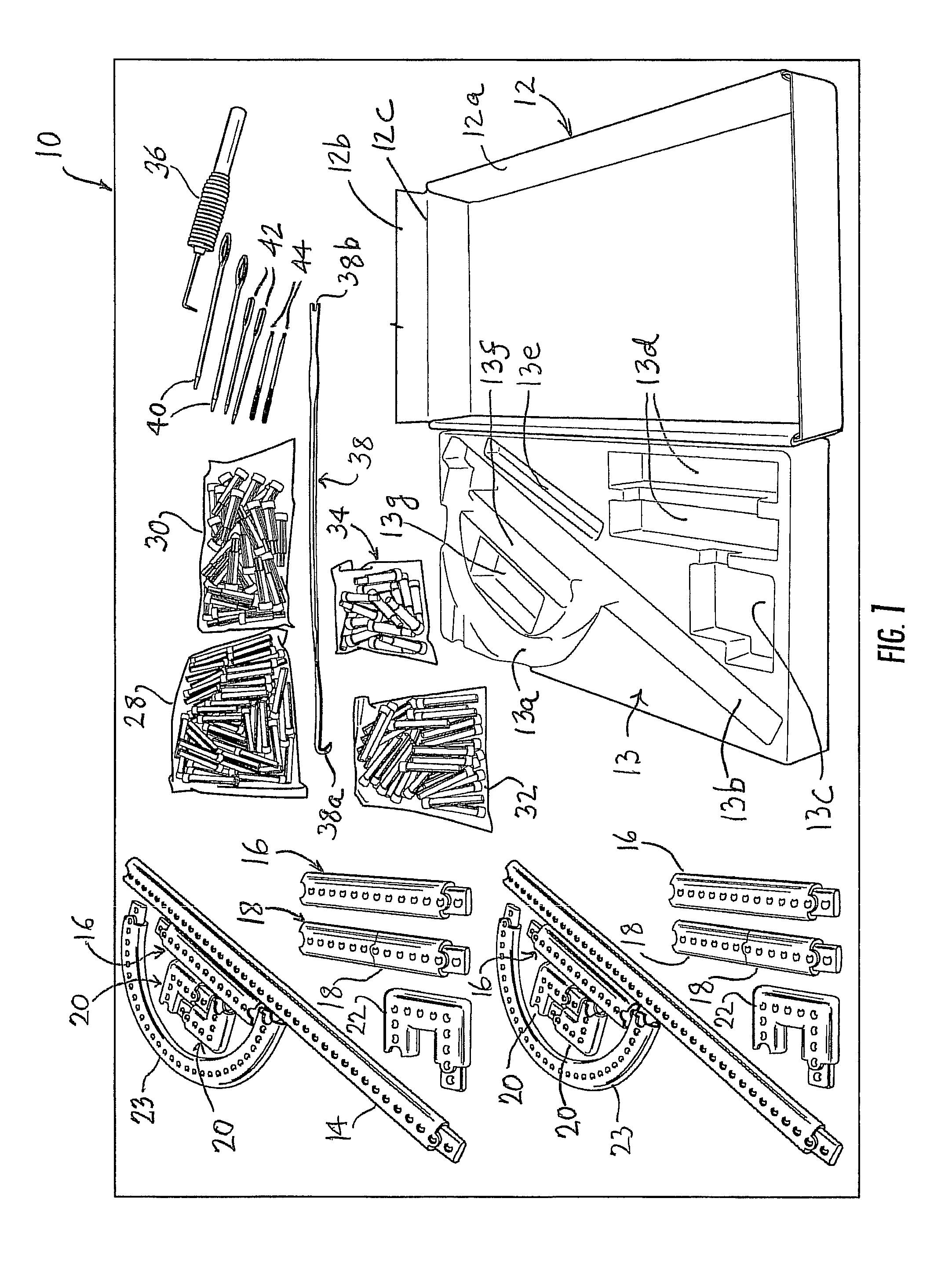

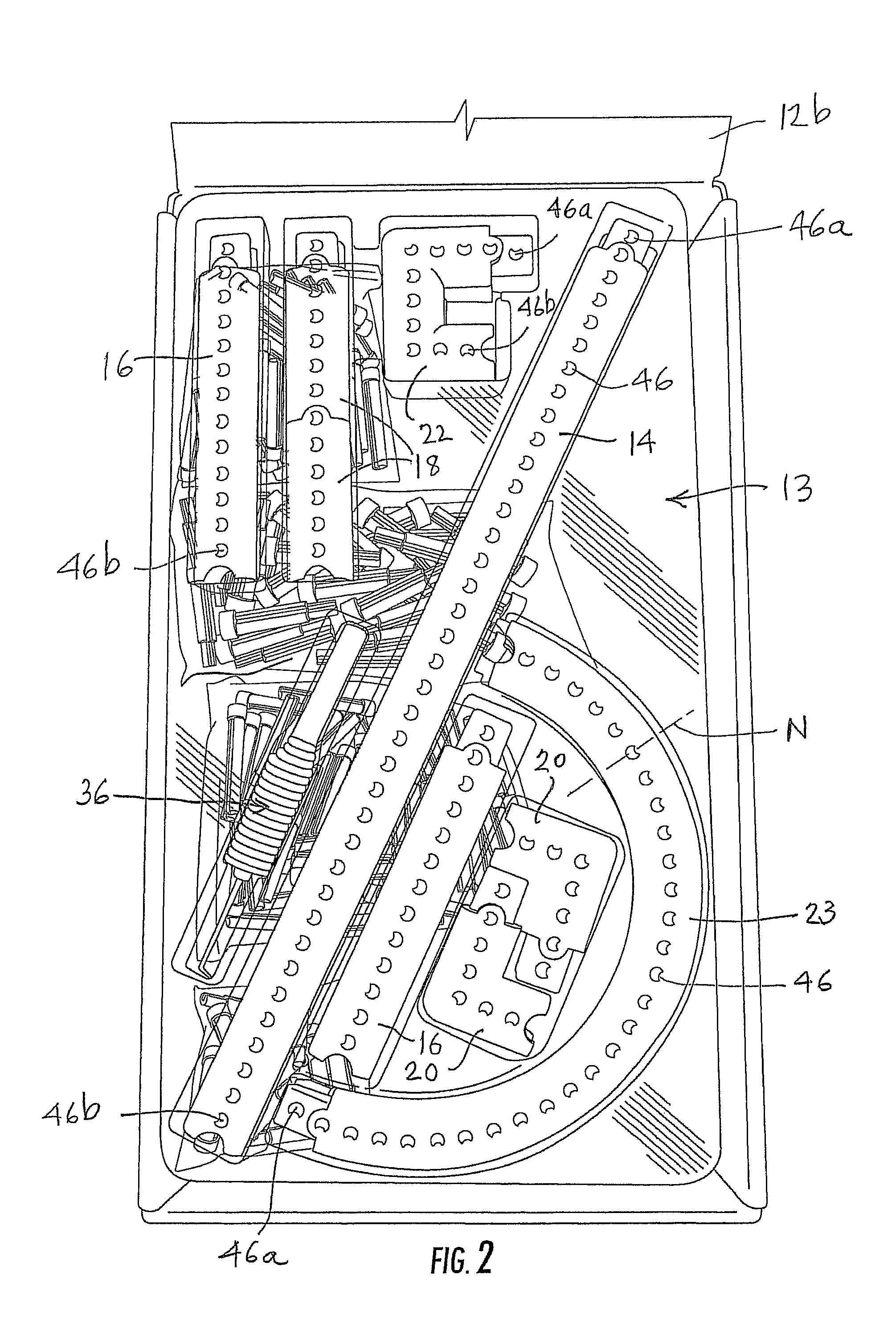

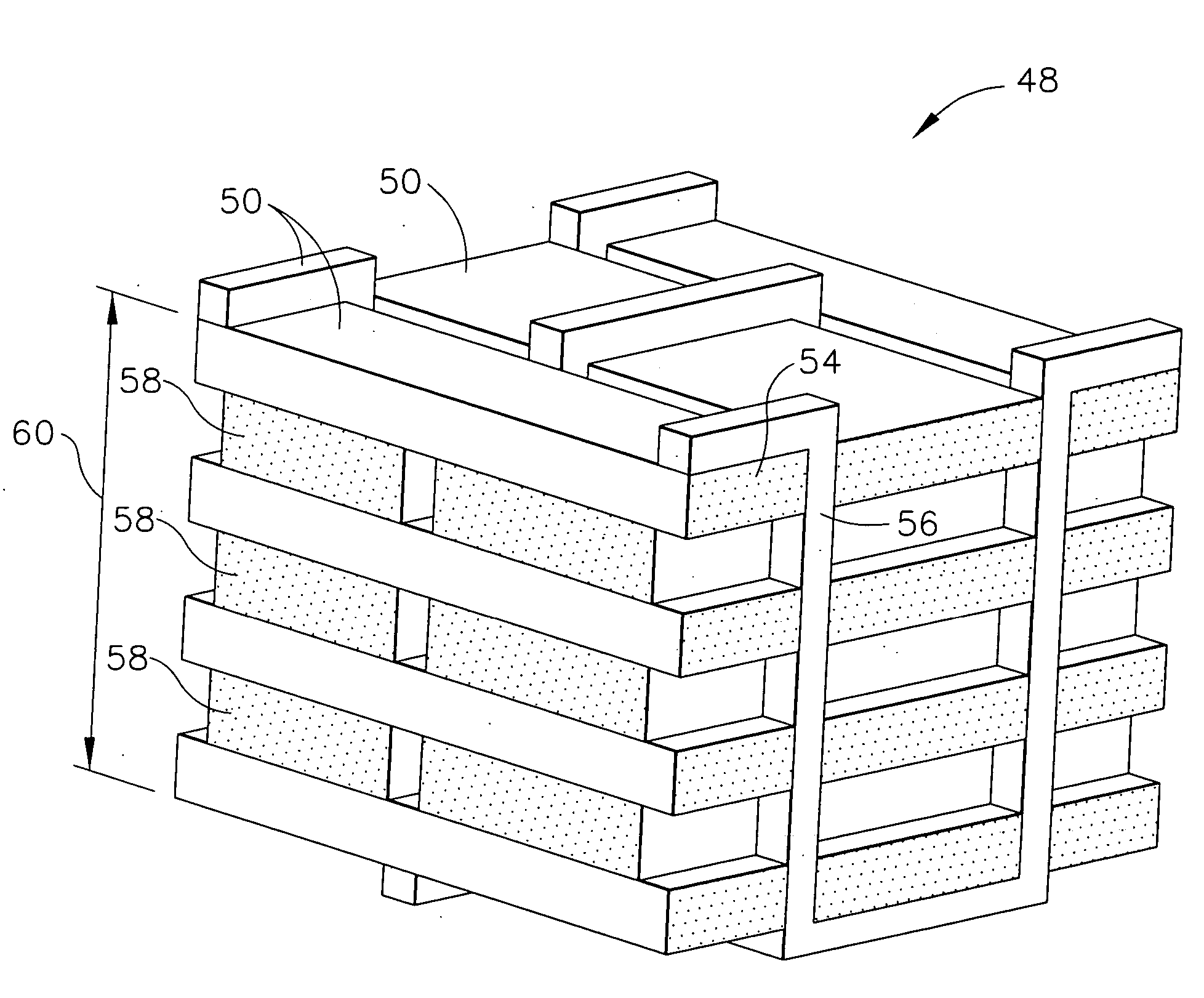

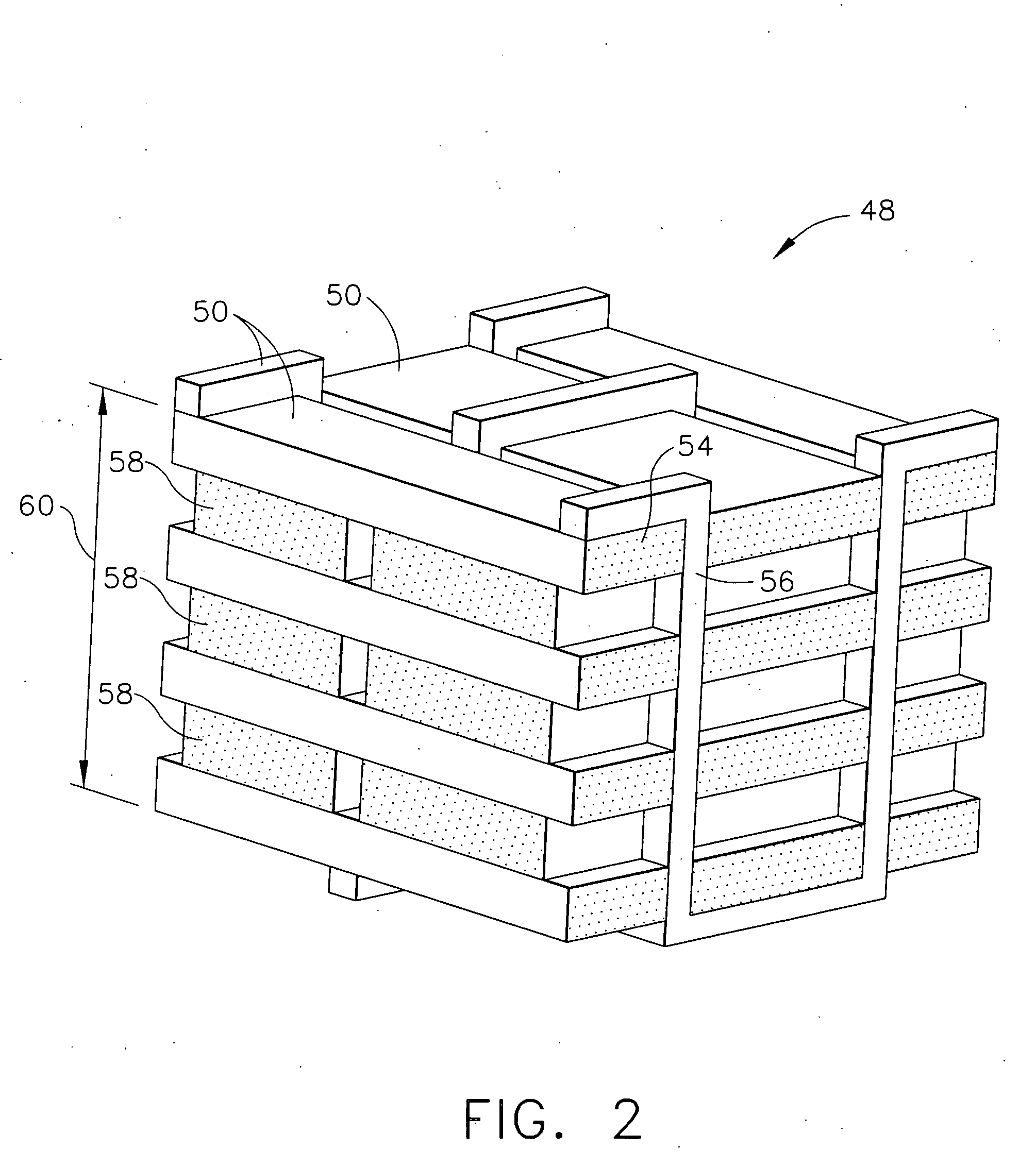

The invention disclosed, is a felting loom system and method, for producing felted woven, fibre art textile shapes. The handcrafting apparatus kit comprises, multi-shaped and sized, interlocking loom blocks and method auxiliary tools. Employed individually, or as assembled loom frameworks, the loom blocks, provide supportive structural foundations, to carry out the inventive method's, multi-functional procedures. Utilized conjointly, the texturized surfaces of the loom block structures and the roller tool components, further generate friction, for the method's practical processing requirements. The variety of loom block construction, configurations and utility functional purposes, enables creative flexibility for fibre artisans to produce wide ranges of felted textile shapes, sizes and constructed fibre art compositions. Felted woollen fibrous layers, with the addition of imported and encapsulated, hand woven constituent properties and manufactured, in accordance with the system's method process, result in the production of artistic, novel textile structural shapes, with multi-functional applications.

Owner:LAWRENCE BONNY +1

Faced finished fabrics containing immobilized fibers

InactiveUS6230376B1Highly cost-effectiveEliminates pillingFibre treatmentFilament handlingUltimate tensile strengthBiomedical engineering

Owner:MILLIKEN & CO

Orthogonal weaving for complex shape preforms

ActiveUS20060130957A1Improve performanceLow costWeft knittingOrnamental textile articlesEngineeringNear net shape

An orthogonal stitch-weave method and fiber architecture. The architecture allows near-net-shape composite preforms to be fabricated, thereby reducing costs associated with complex preform shapes and increasing desired strengths of the composite.

Owner:GENERAL ELECTRIC CO

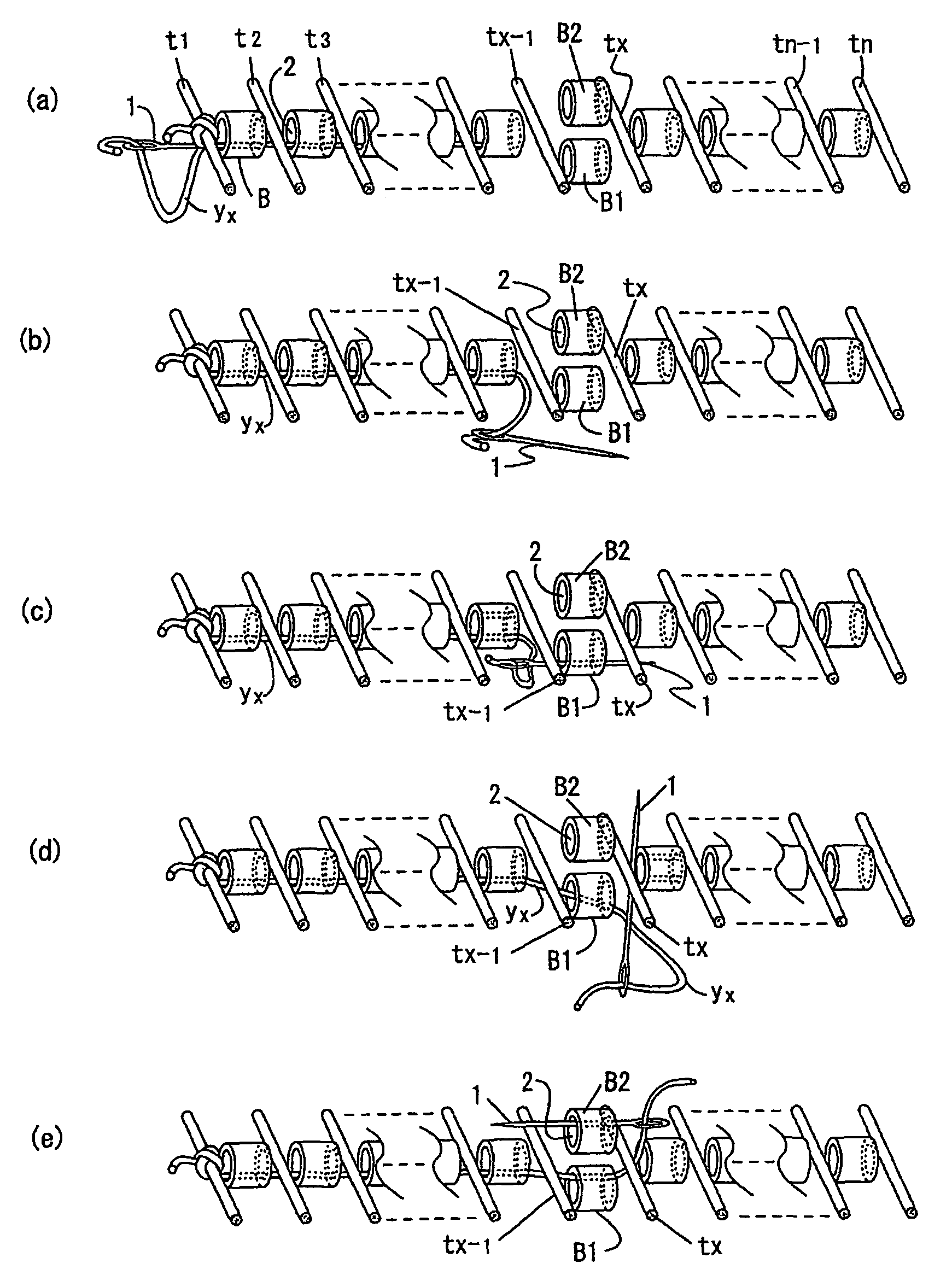

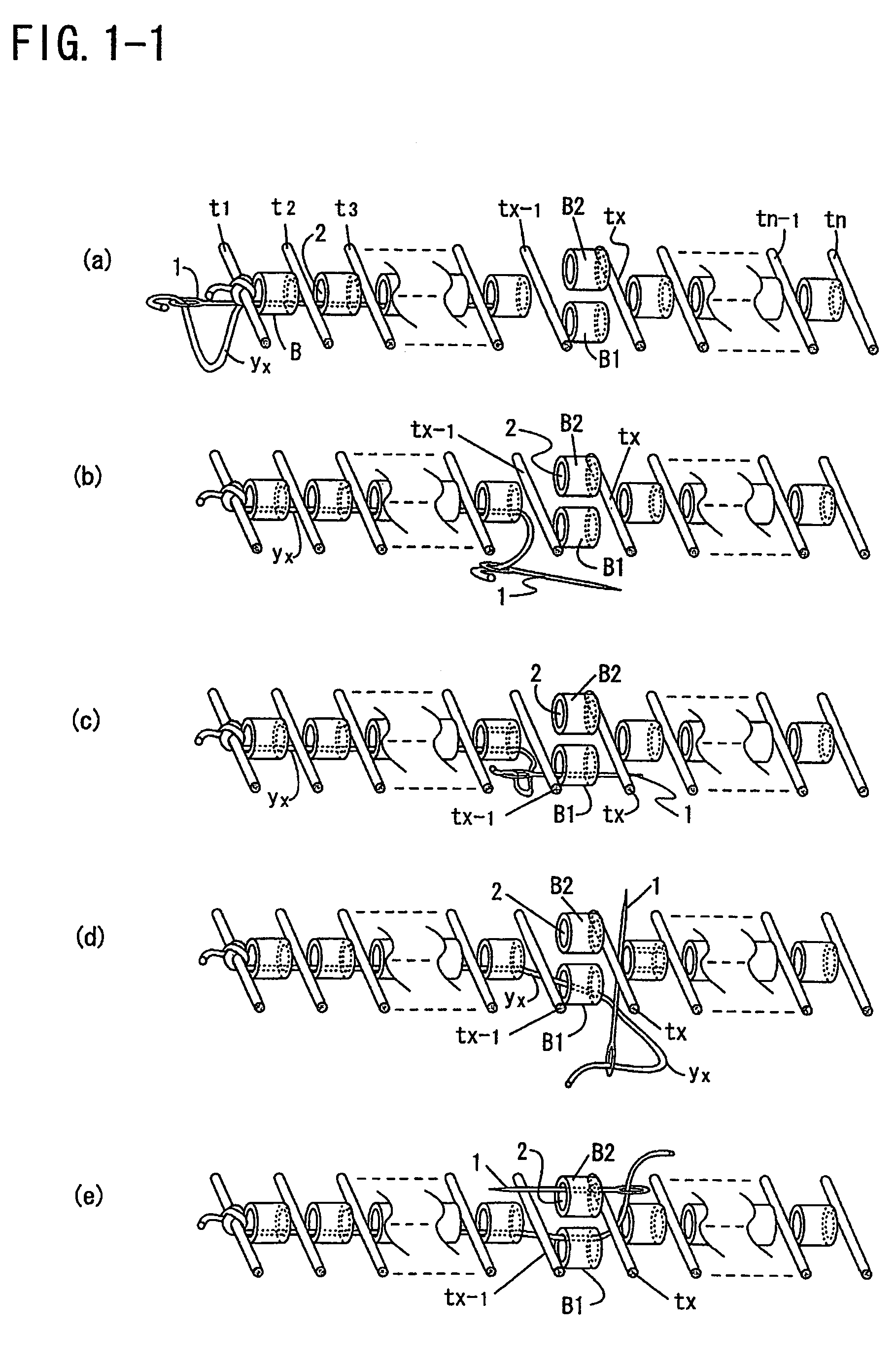

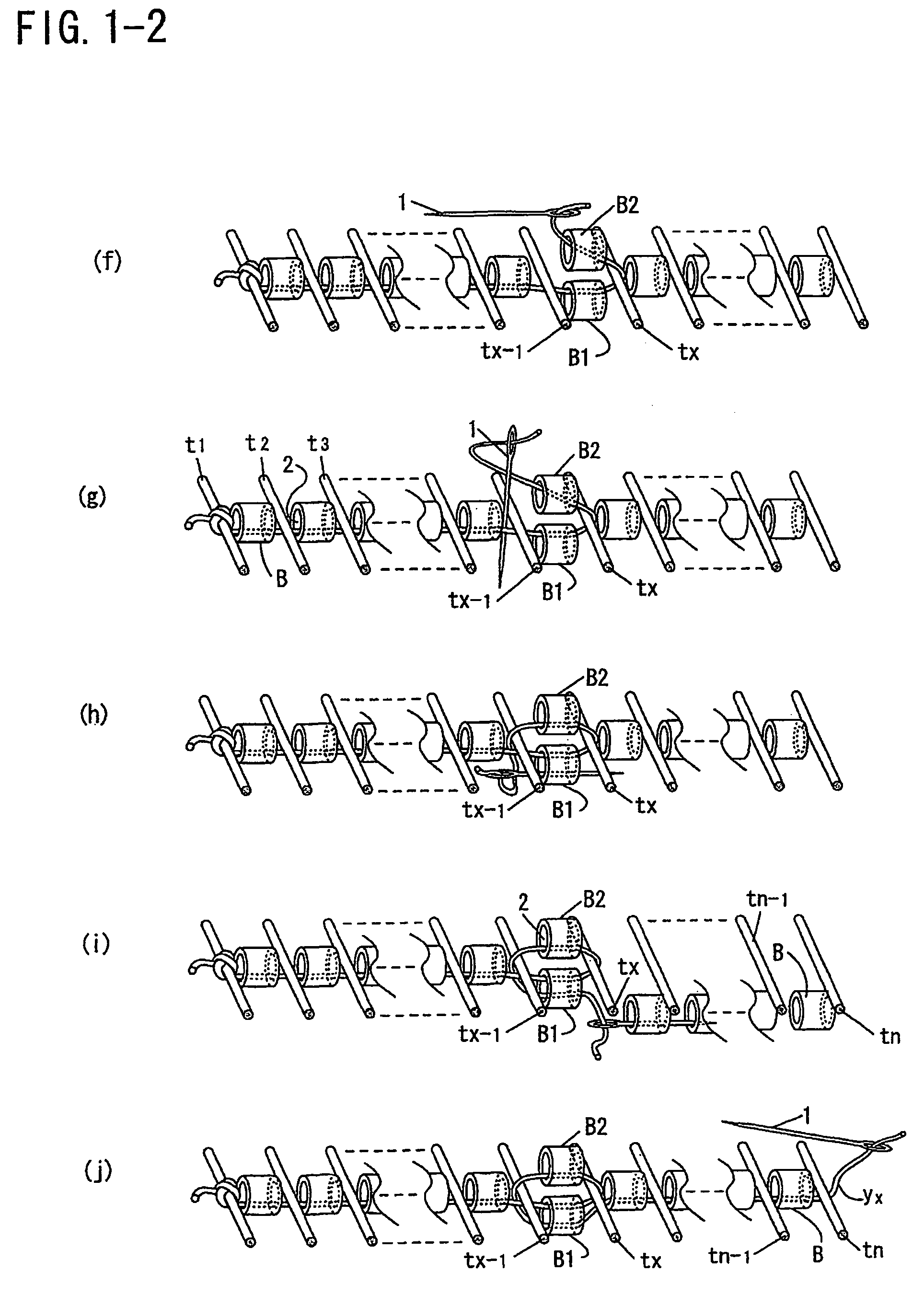

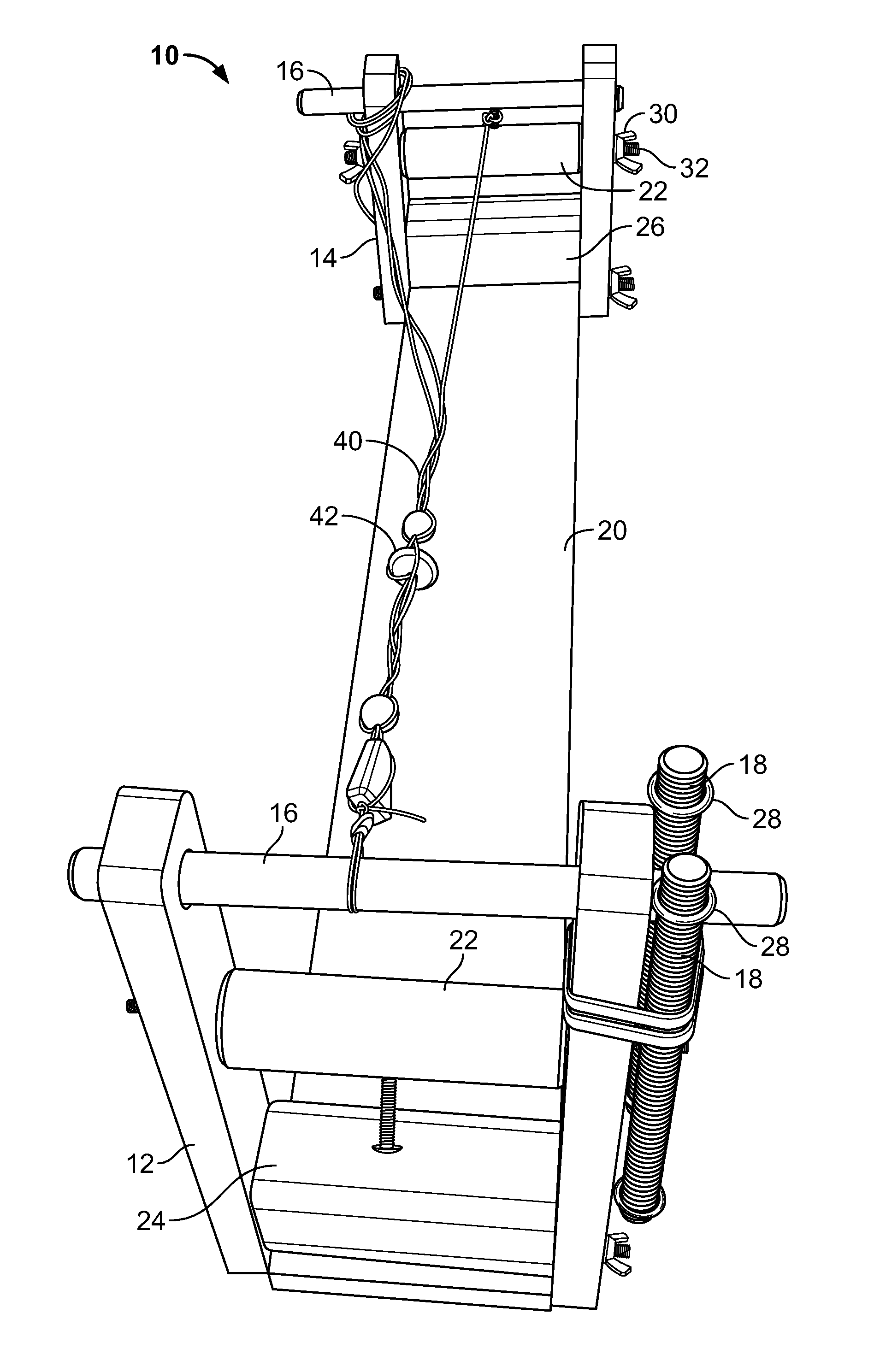

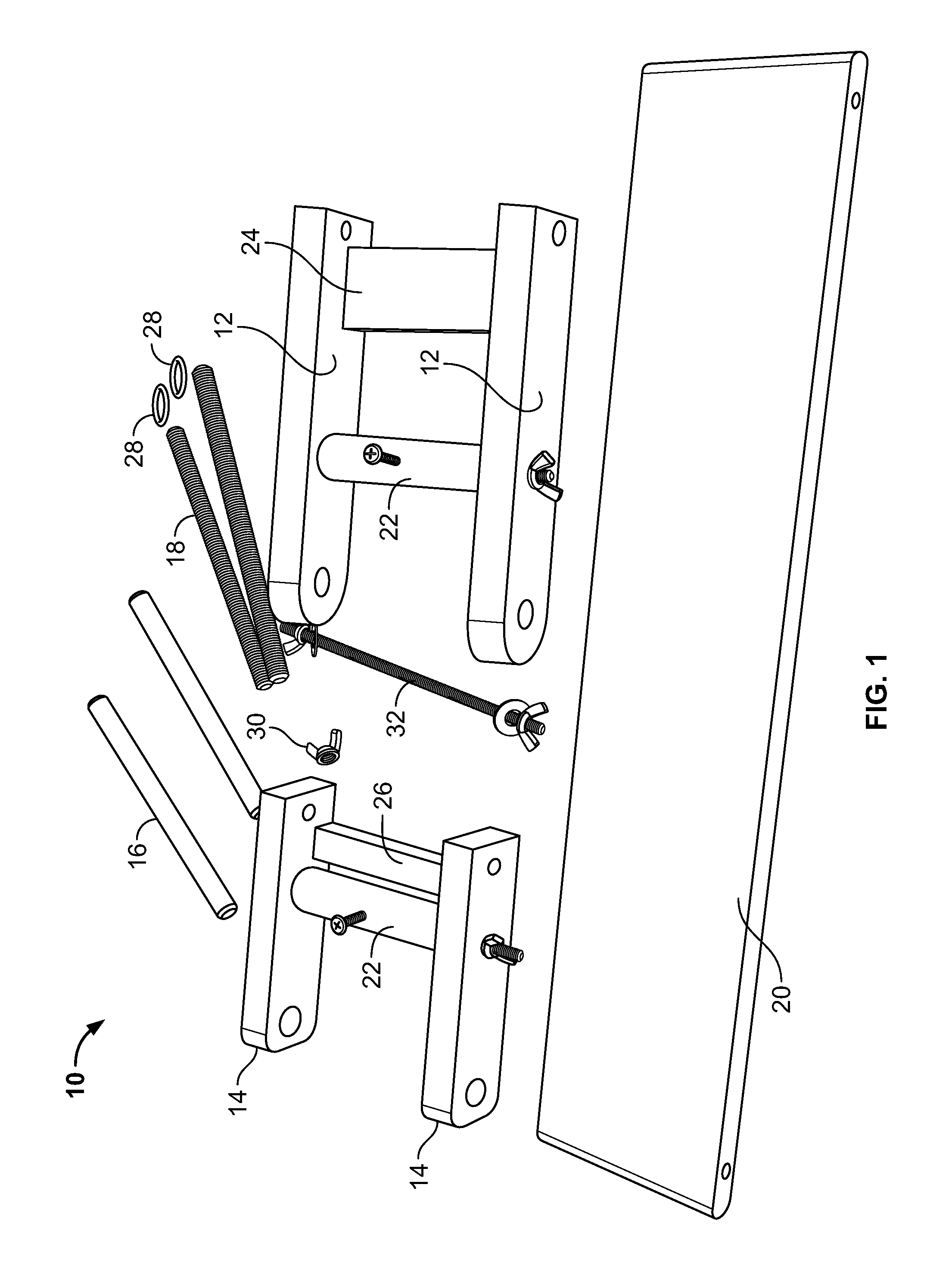

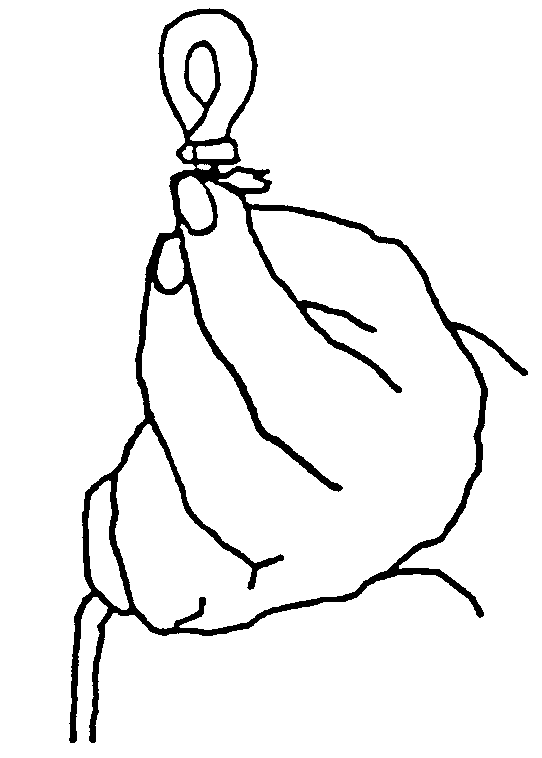

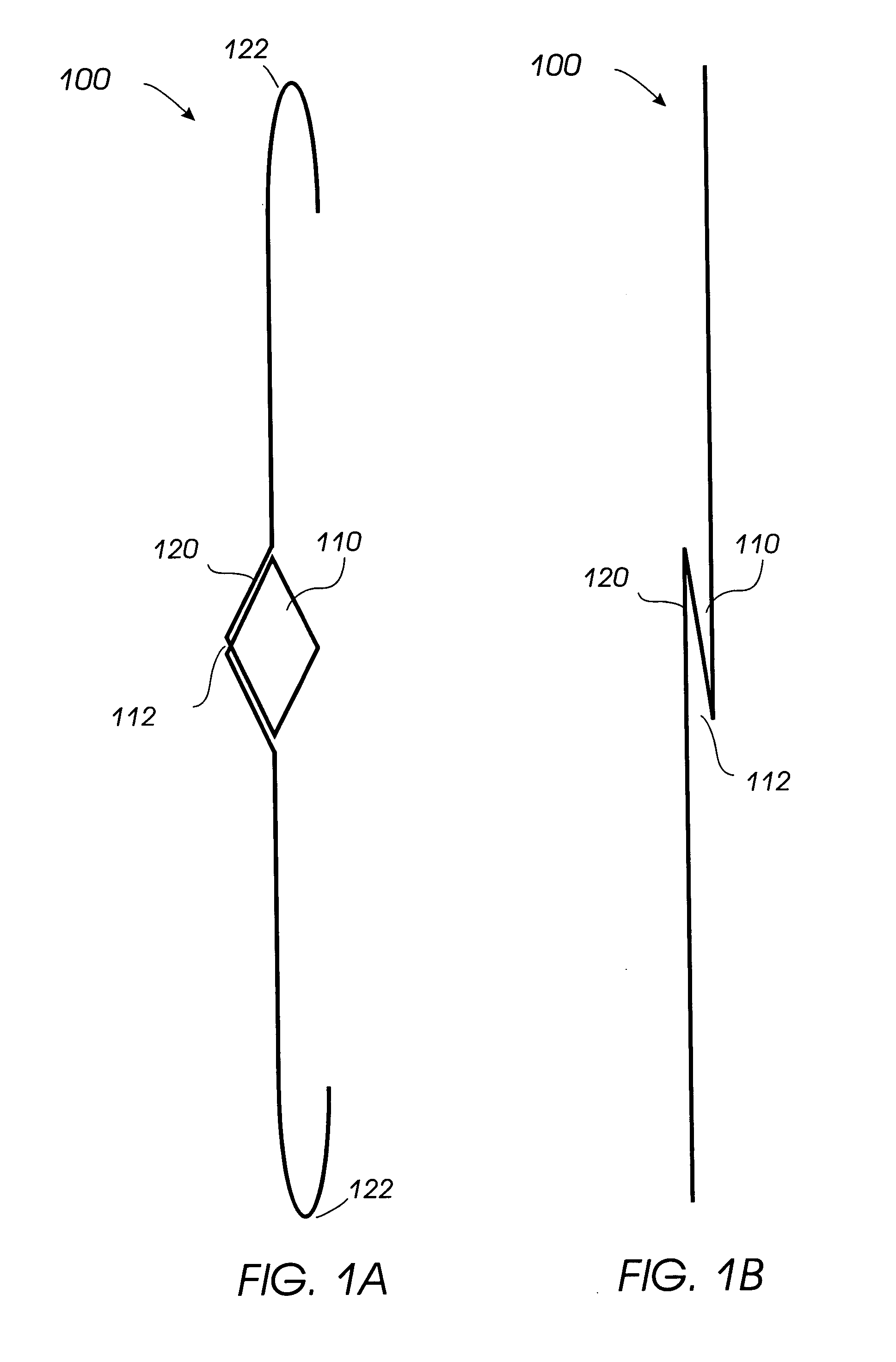

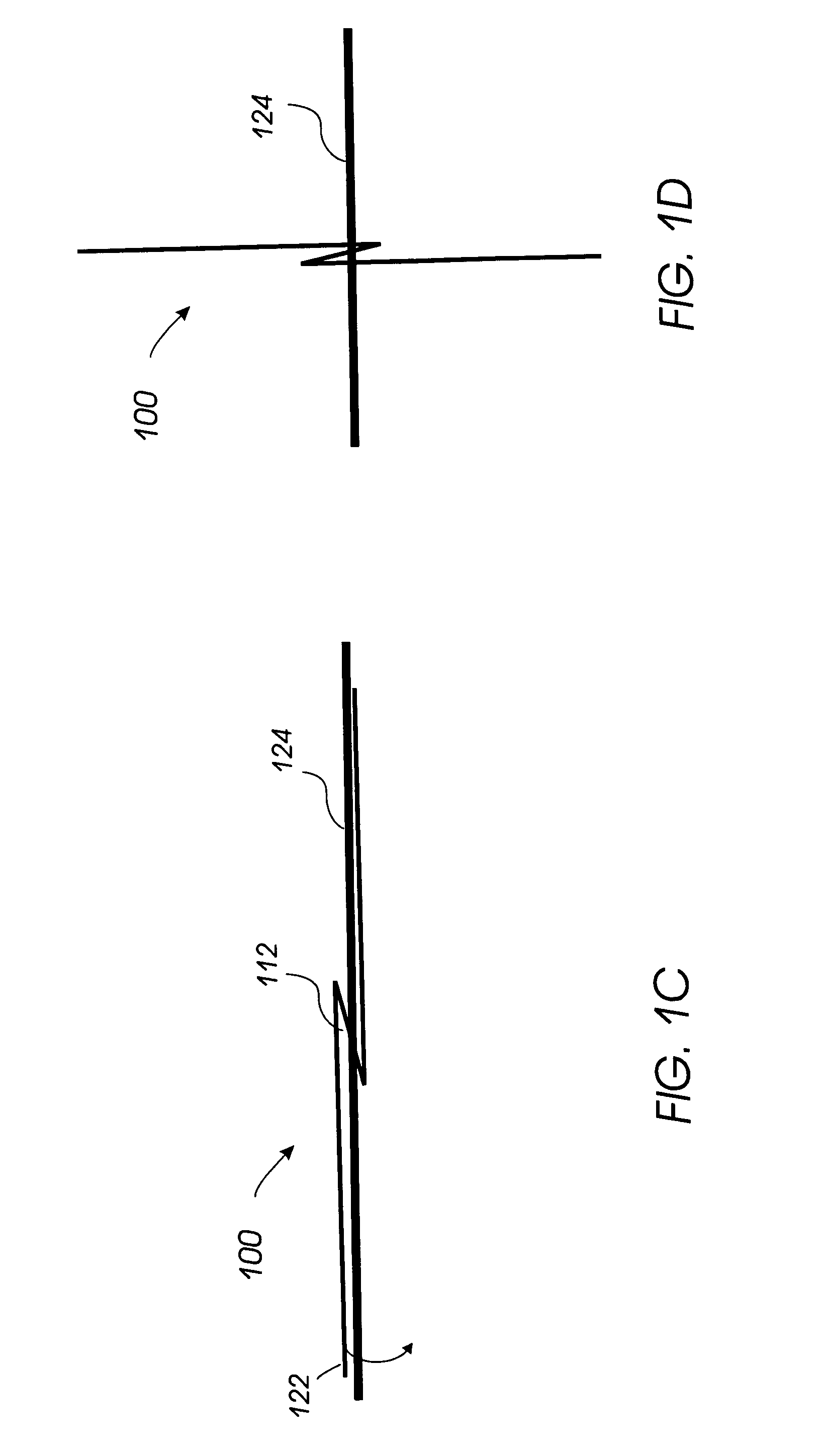

Apparatus and method for warping a loom

InactiveUS20050061384A1Quick SetupFast threadingLeno shedding mechanismAuxillary apparatusEngineering

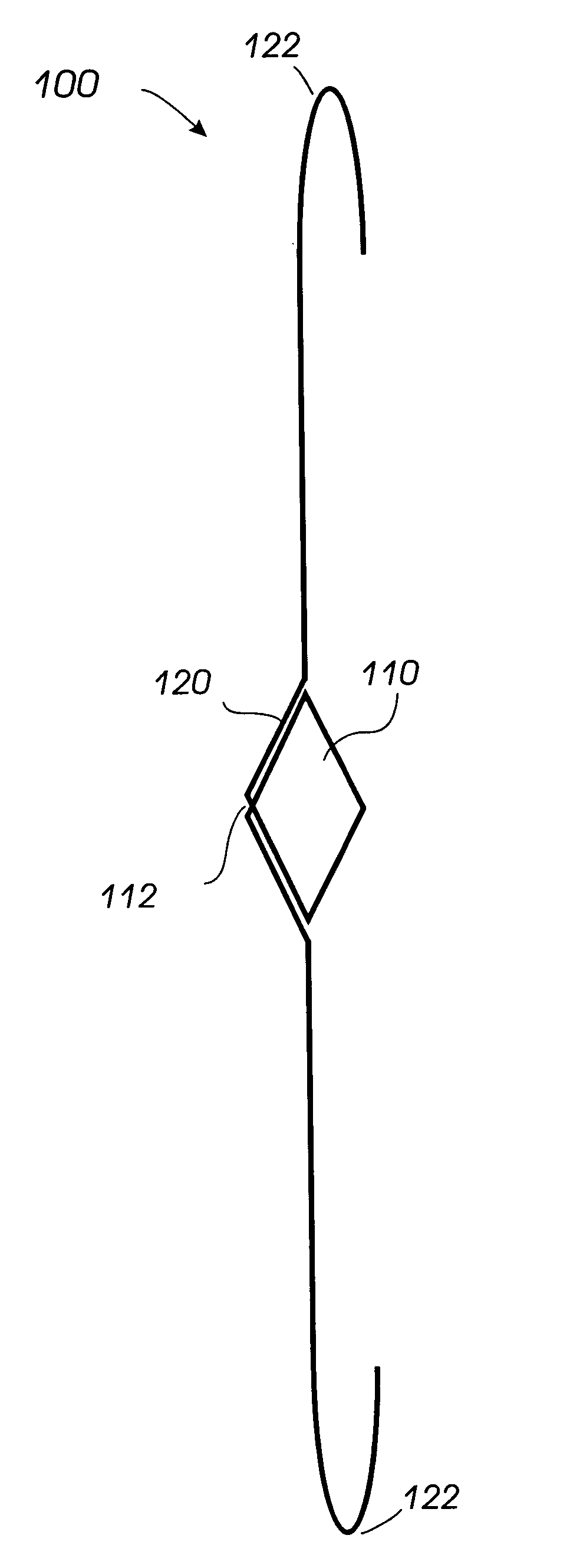

An apparatus and method for warping a loom includes a heddle with an open or openable break in the circumference of its eyelet that allows insertion and removal of warp thread with simple motions through the break while both ends of the warp threads are fastened to the loom. A warp beam includes a plurality of retaining members that retain parallel strands of warp thread in a spaced relationship to one another. A length of warp thread is wound in consecutive parallel lines between two spaced apart warp beams. The combination of openable heddles and warp beams with warp thread retaining members allow a loom or knitting device to be rapidly set-up, allow for easy correction of mistakes, and for the removal and reloading of the heddles or a weaving project in mid-production.

Owner:HOLLY DAVID A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com