Hand beading loom and method of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

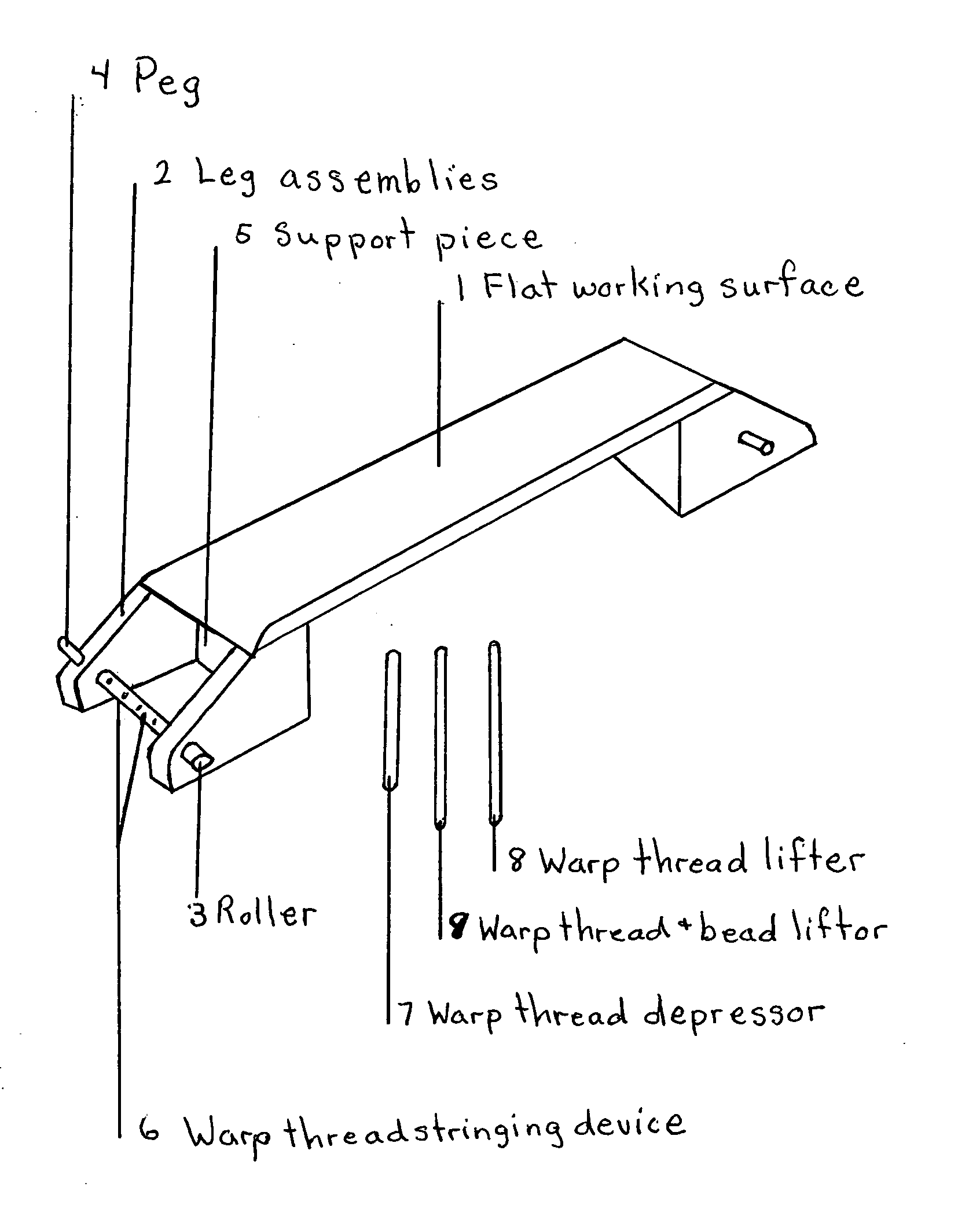

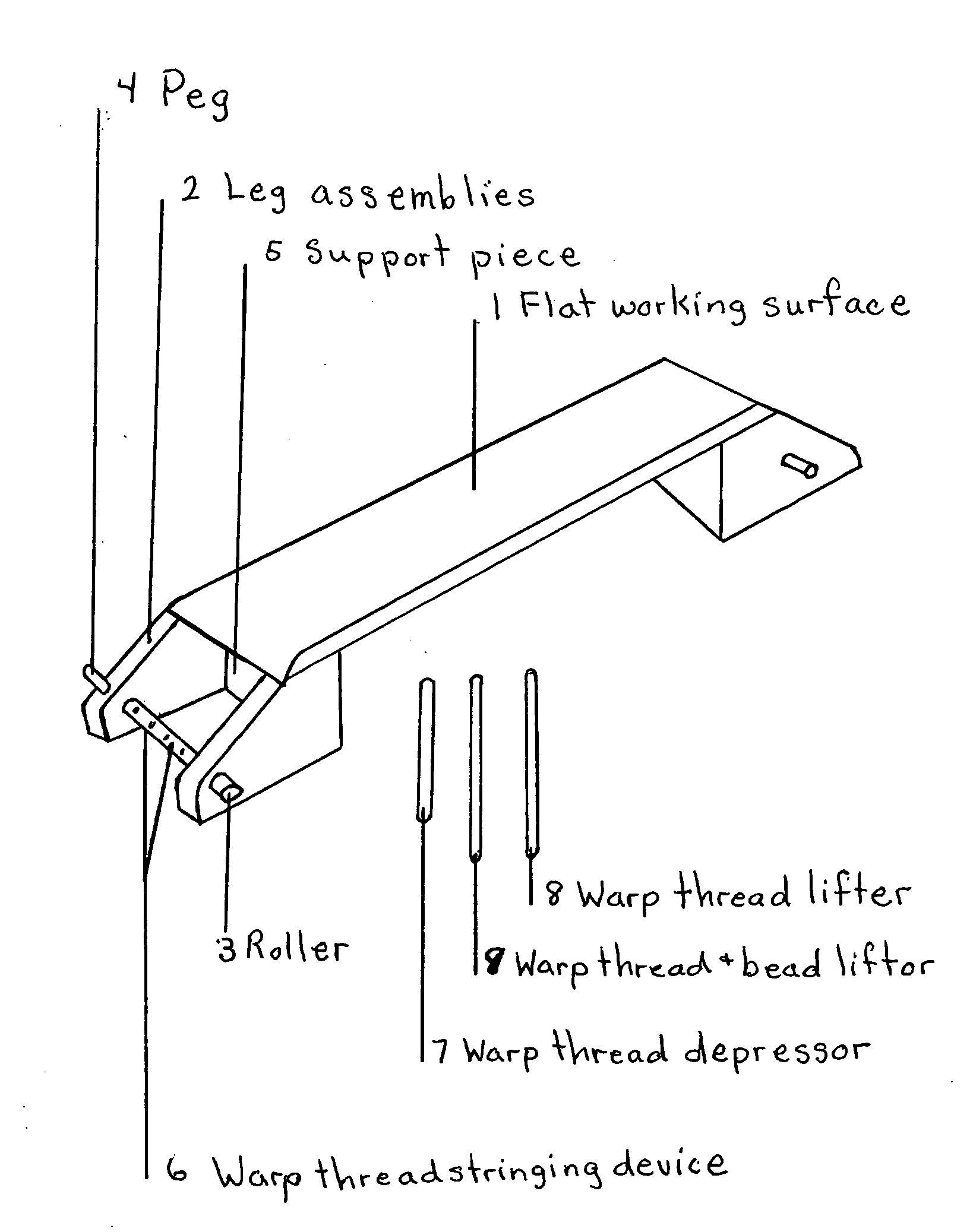

[0015] This loom can be constructed from wood, metal, plastic or any other suitable material. This loom can be constructed any size or dimensions desired. The loom is comprised of a body with a flat working surface with smooth curved ends attached to legs. Attached in the leg supports are roller devices and peg holes. Support pieces are attached to the legs and the body and behind the rollers. Attached to the rollers are warp thread stringing devices. At one end of the rollers where the rollers sit inside the support legs are peg holes, spaced at intervals around the circumference of the rollers. A second component of the loom and essential to the method of use is and elongated unattached part which will be referred to as the warp thread lifter. The preferred dimensions of the warp thread lifter are approximately ½ inch in width and ⅛ inch thick. The length is determined by the width of the flat working surface of the loom. The edges of the warp thread lifter where it makes contact ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com