Patents

Literature

114results about "Knotting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

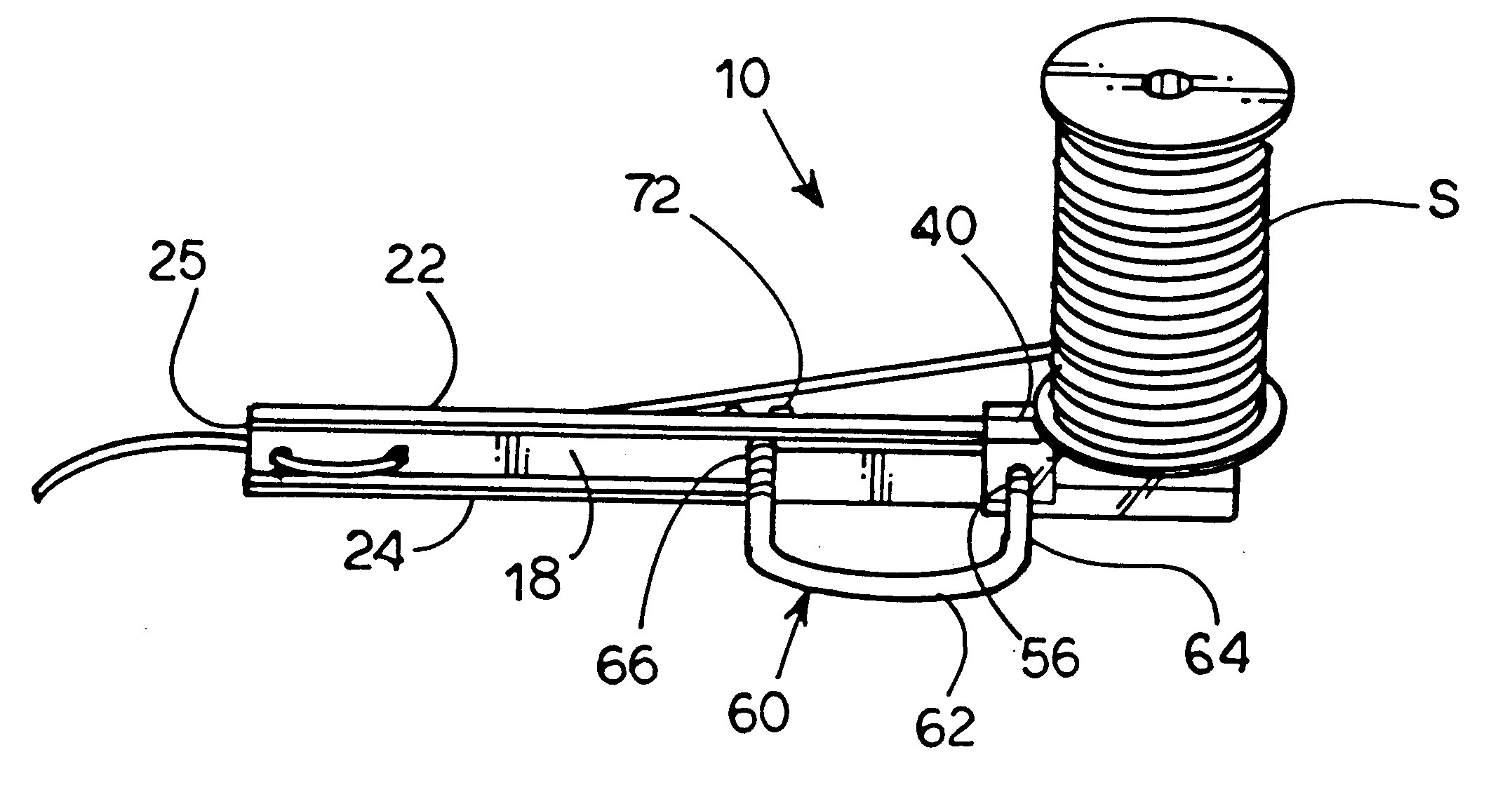

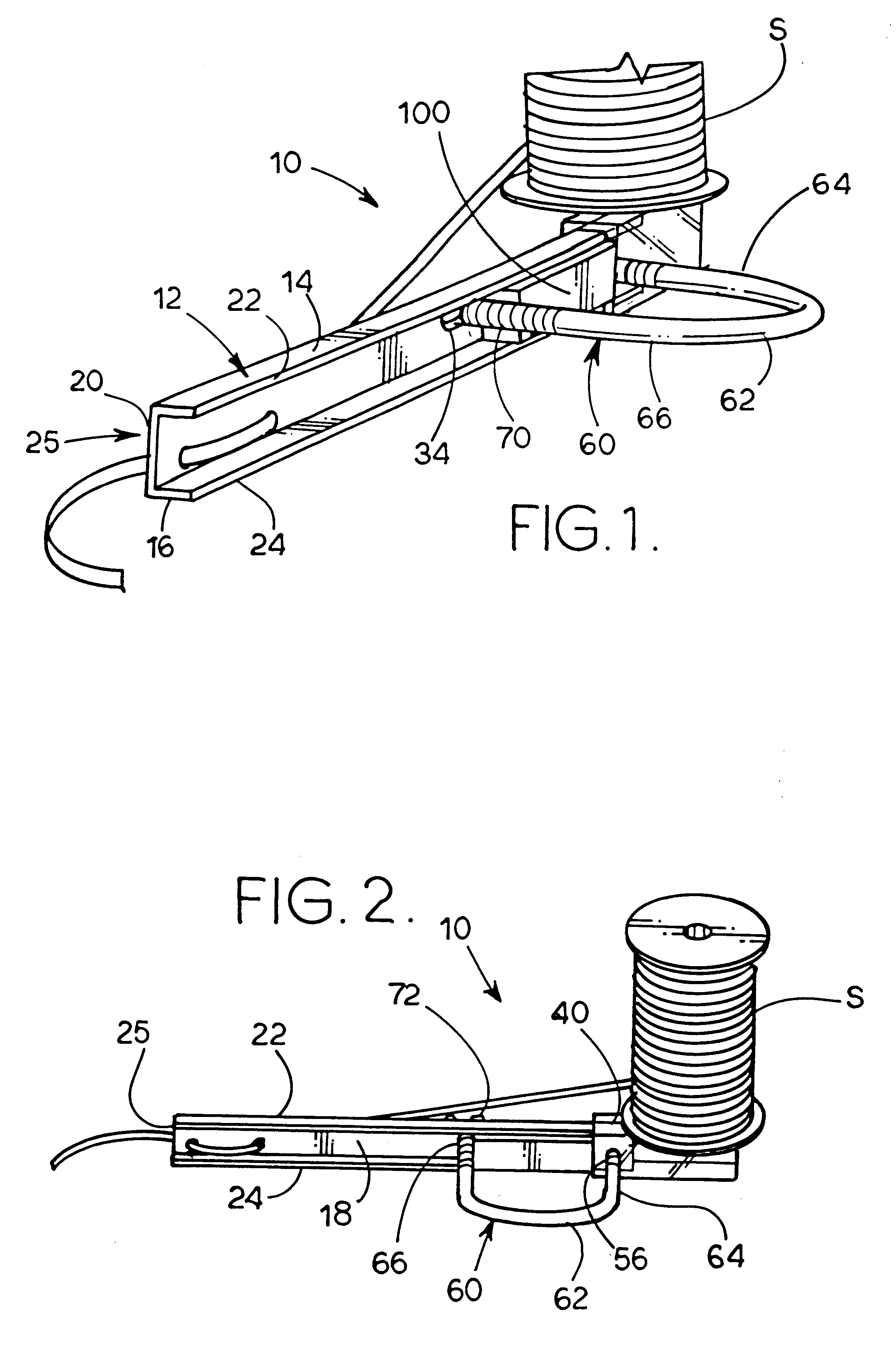

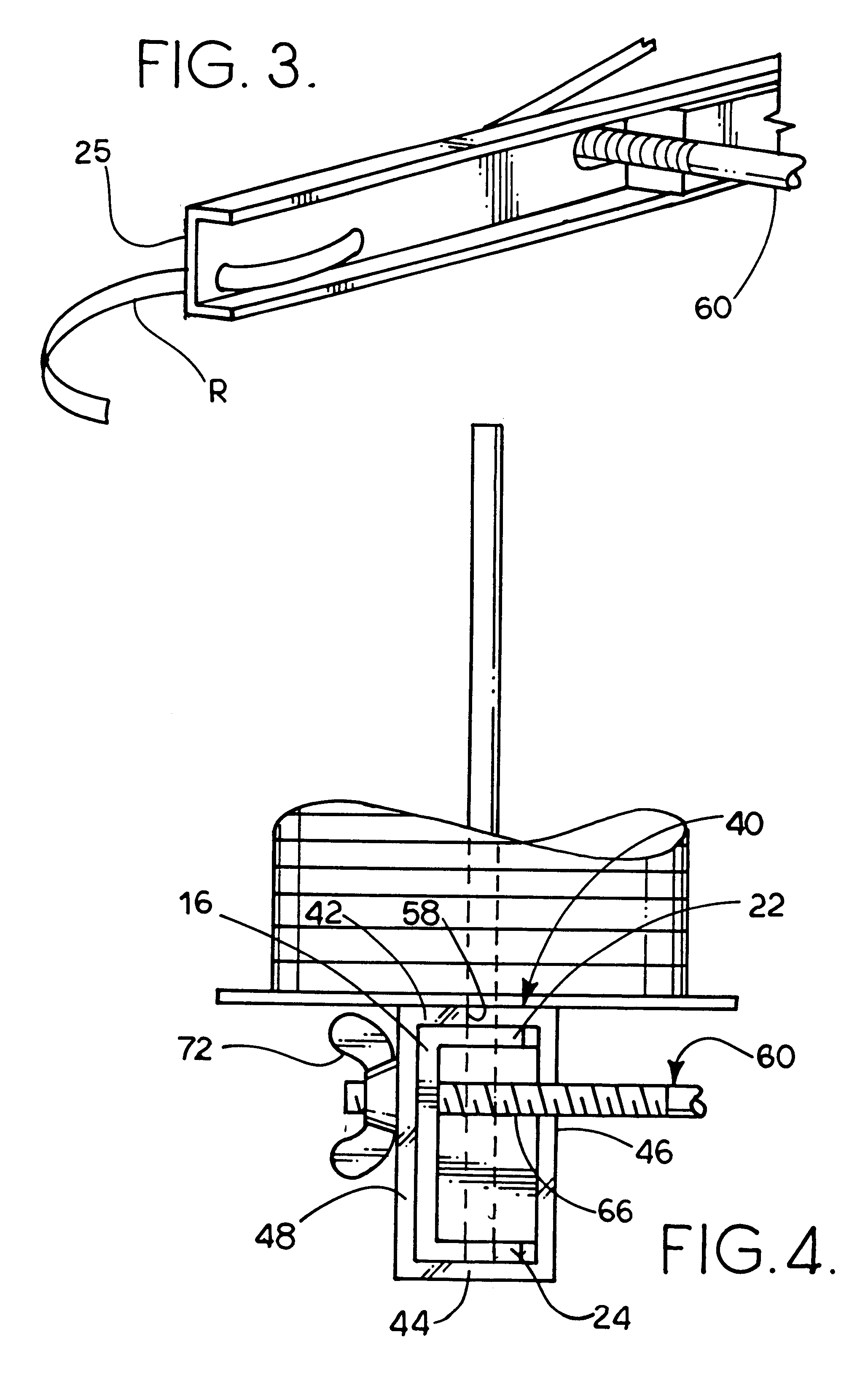

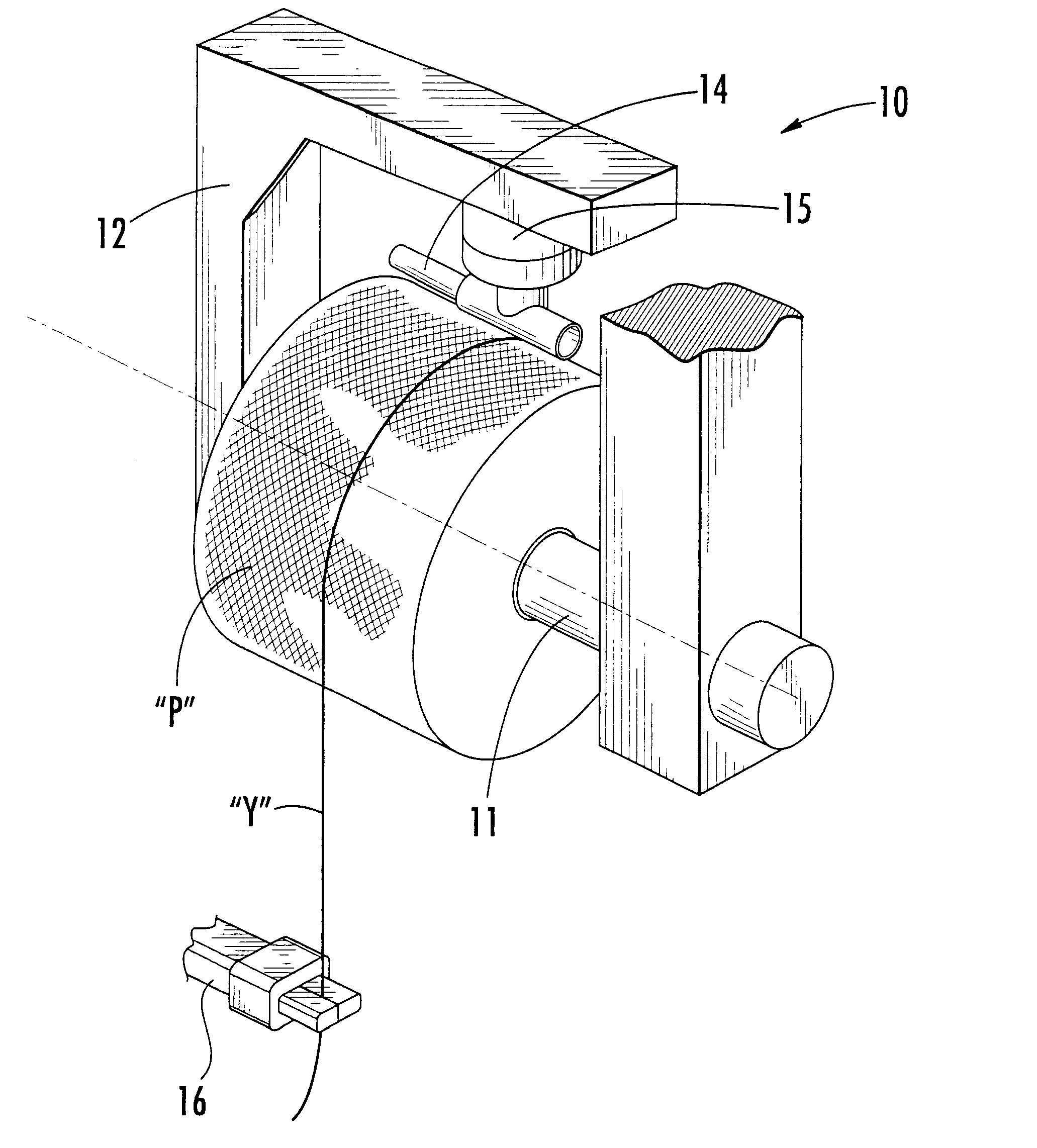

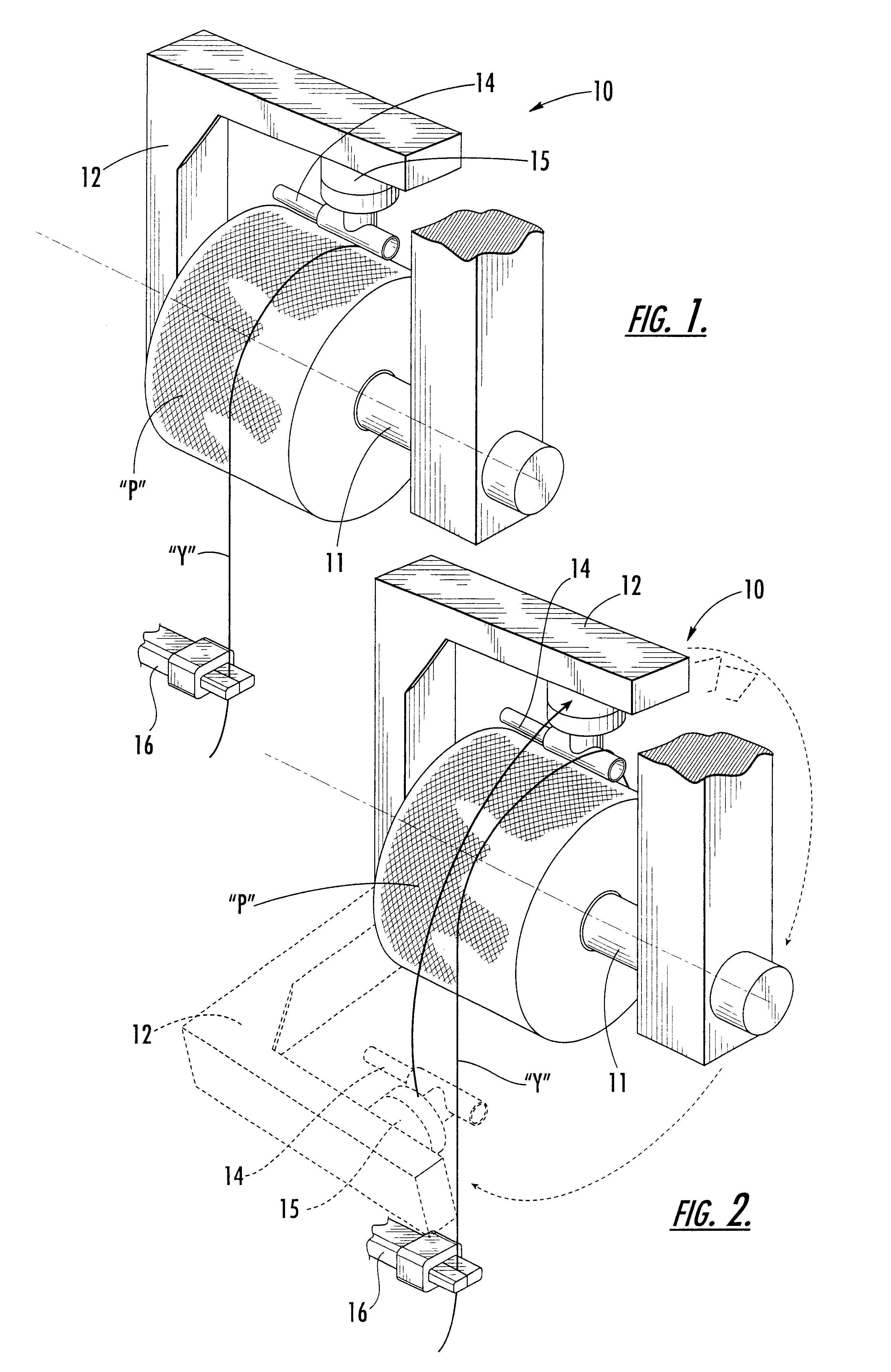

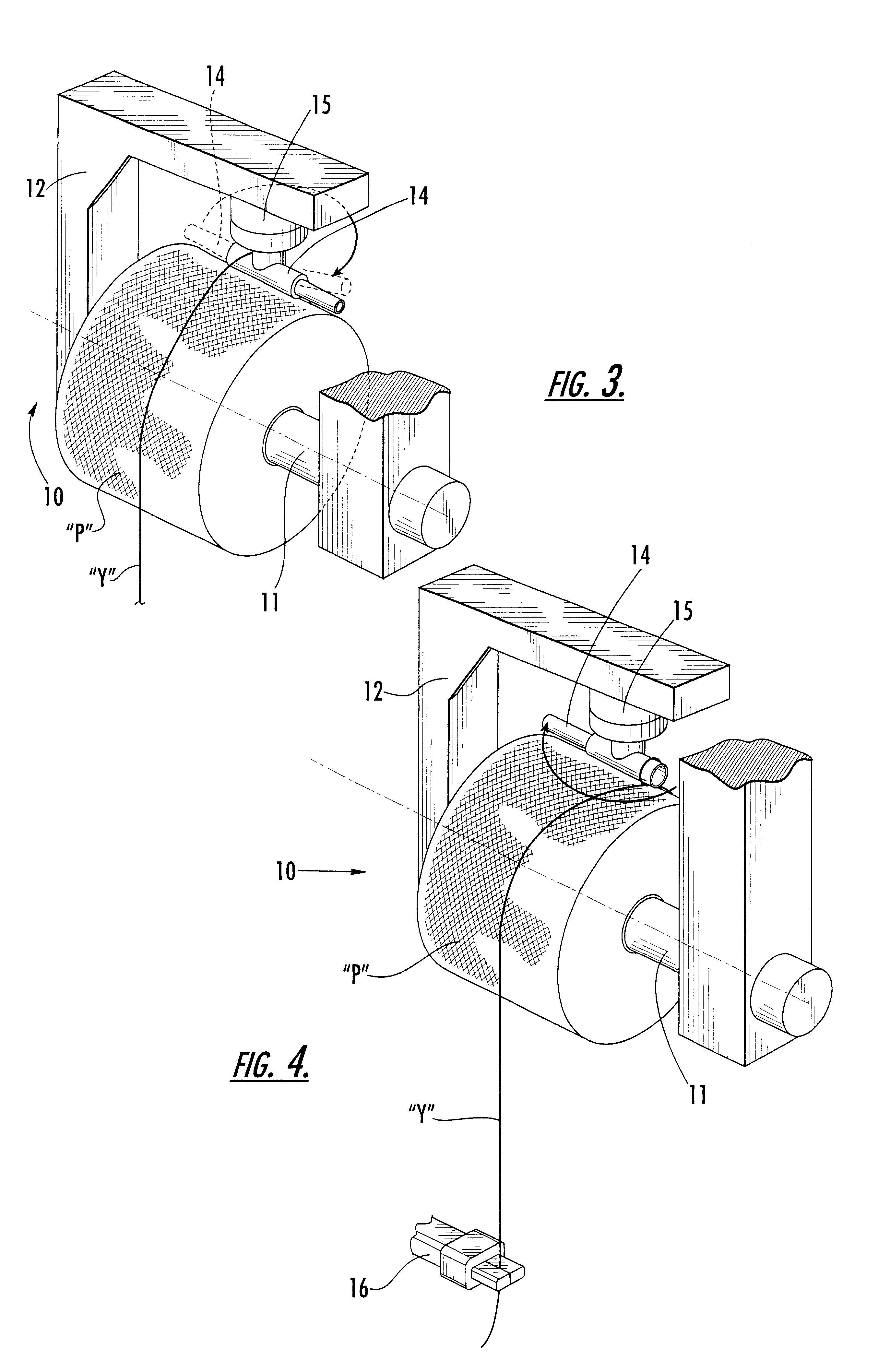

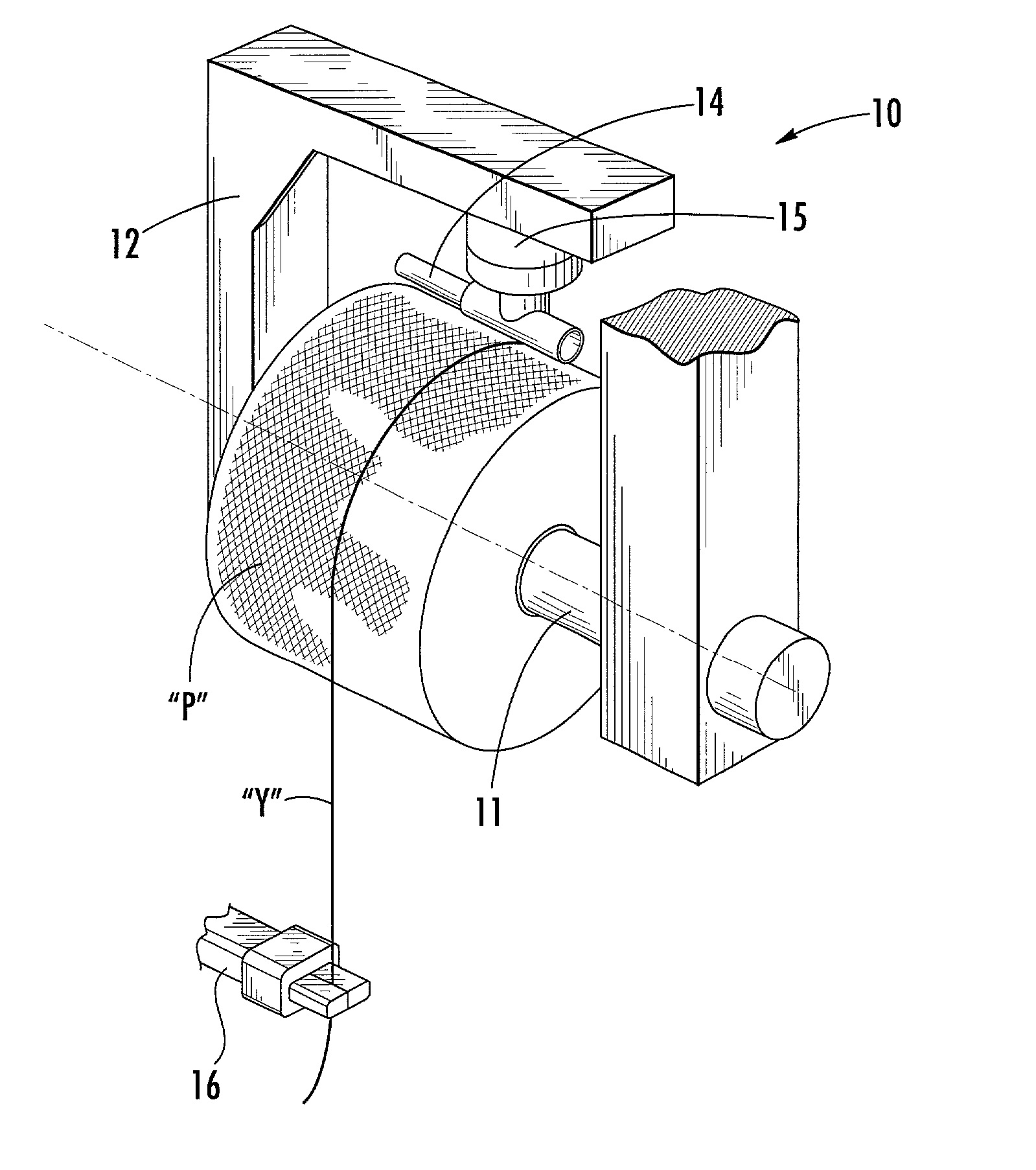

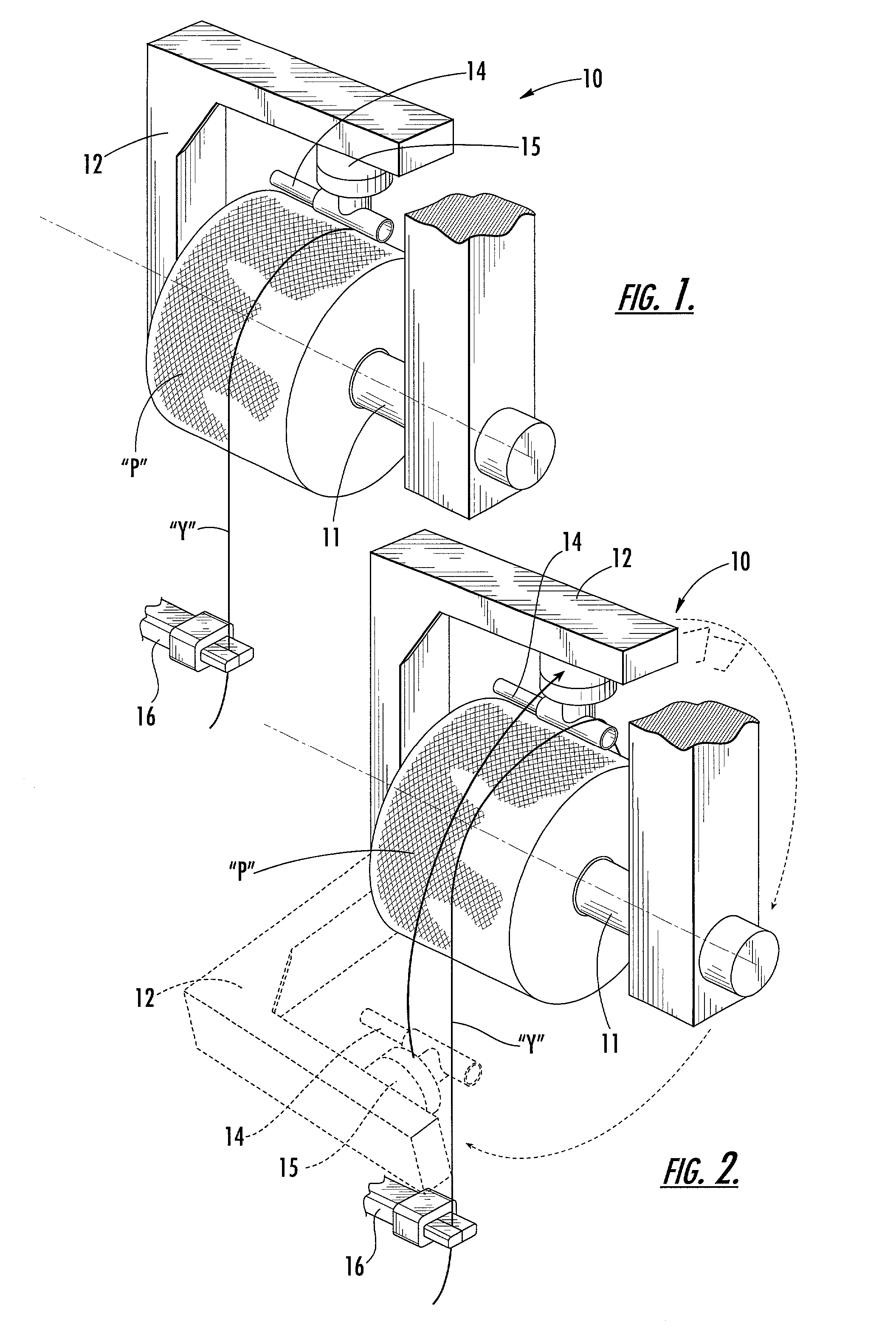

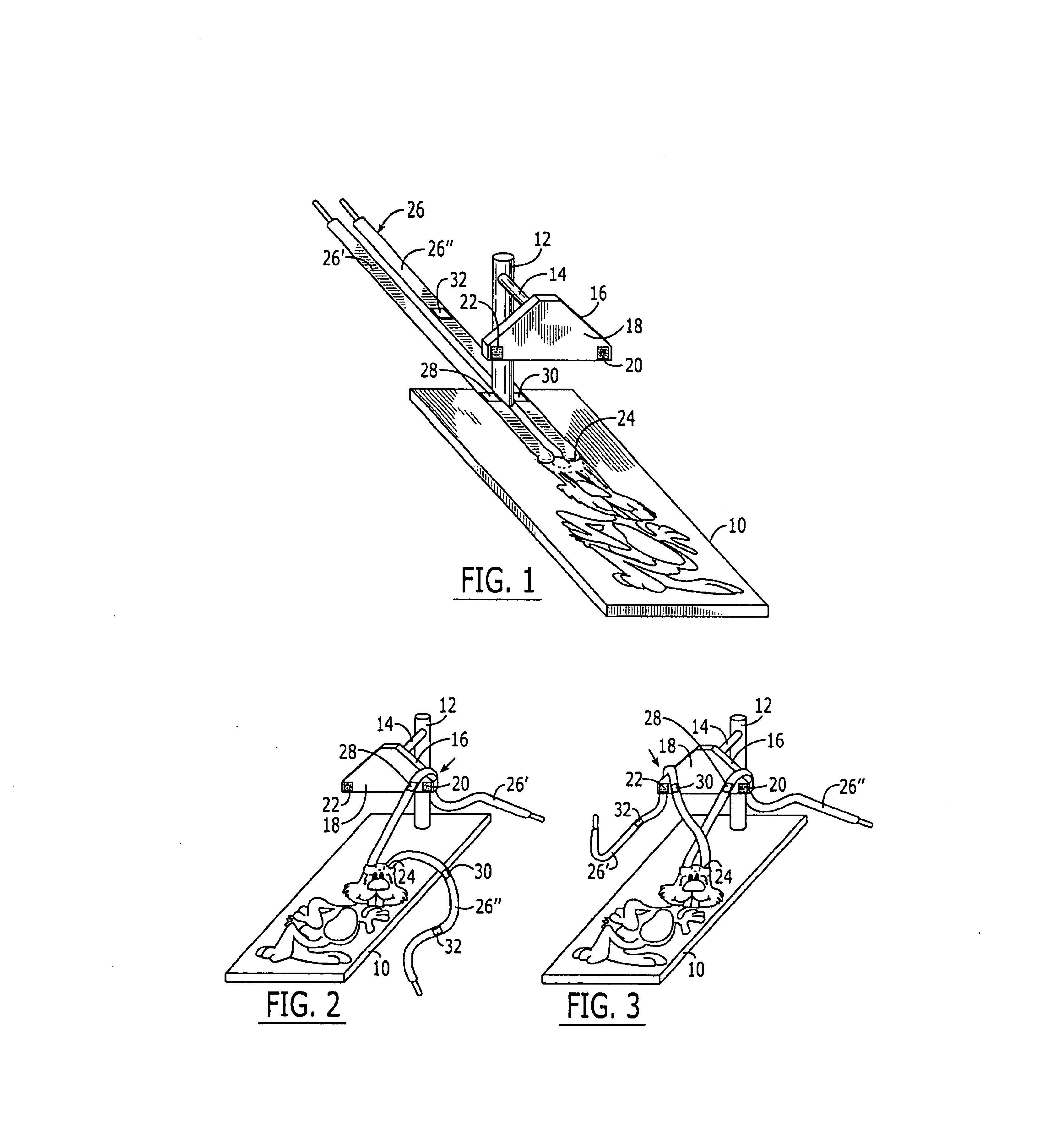

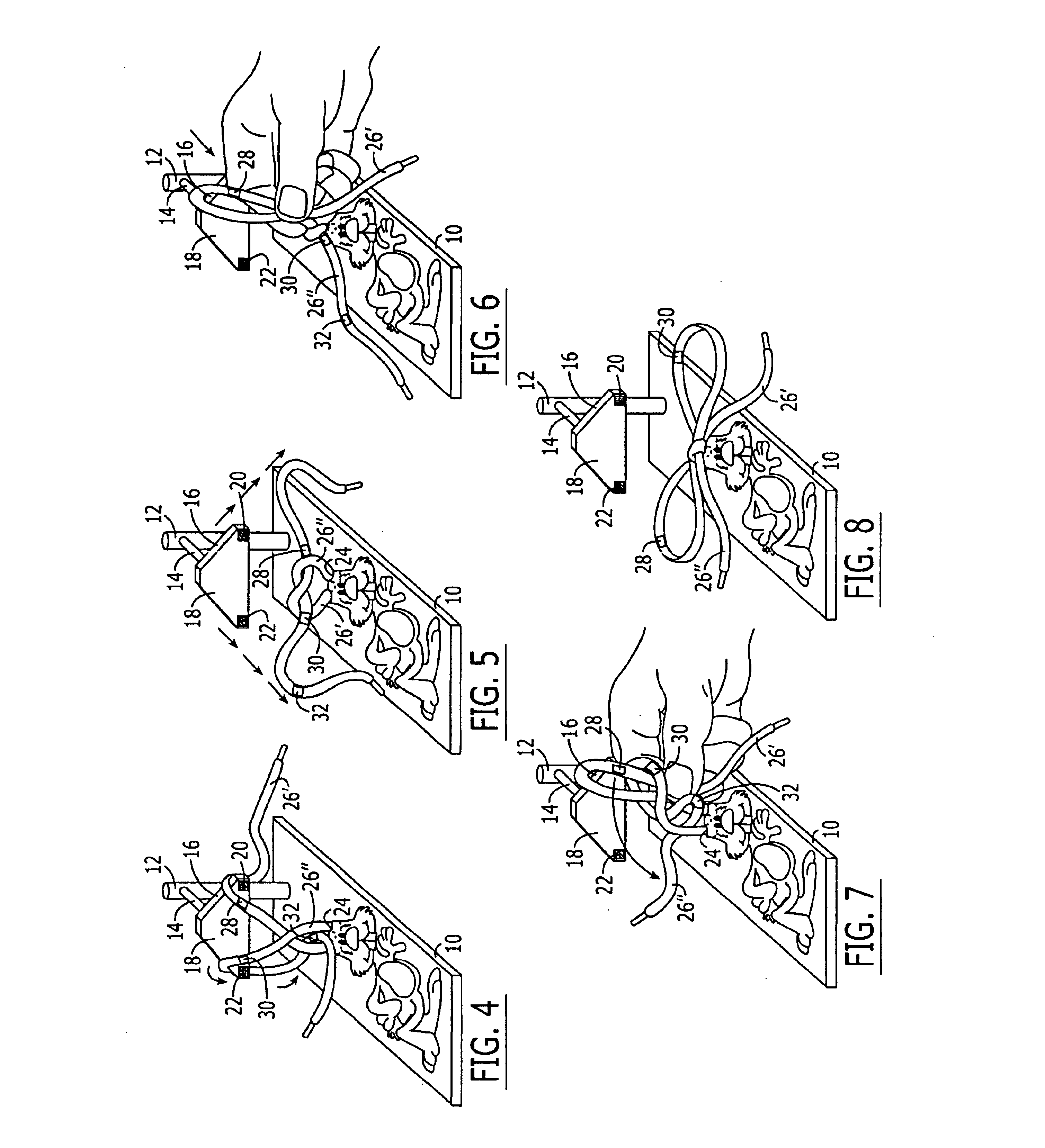

Unit for tying a balloon and securing a ribbon to the balloon

A unit is mounted directly on a tank of pressurized gas used to inflate a balloon and includes a supporting bracket having ribbon-accommodating holes defined through one end thereof and a support section on the other end. A ribbon supporting spool is rotatably mounted on the support section and ribbon drawn off the spool is threaded through the ribbon-accommodating holes to be captured in a knot formed in the neck of the balloon after that neck has been drawn around the supporting bracket and formed into a knot. A method of forming a knot in the balloon and capturing the ribbon therein is also disclosed.

Owner:CARLSON LELAND R

Device and kit for making knotted string accessories

Owner:CROREY DAVID J

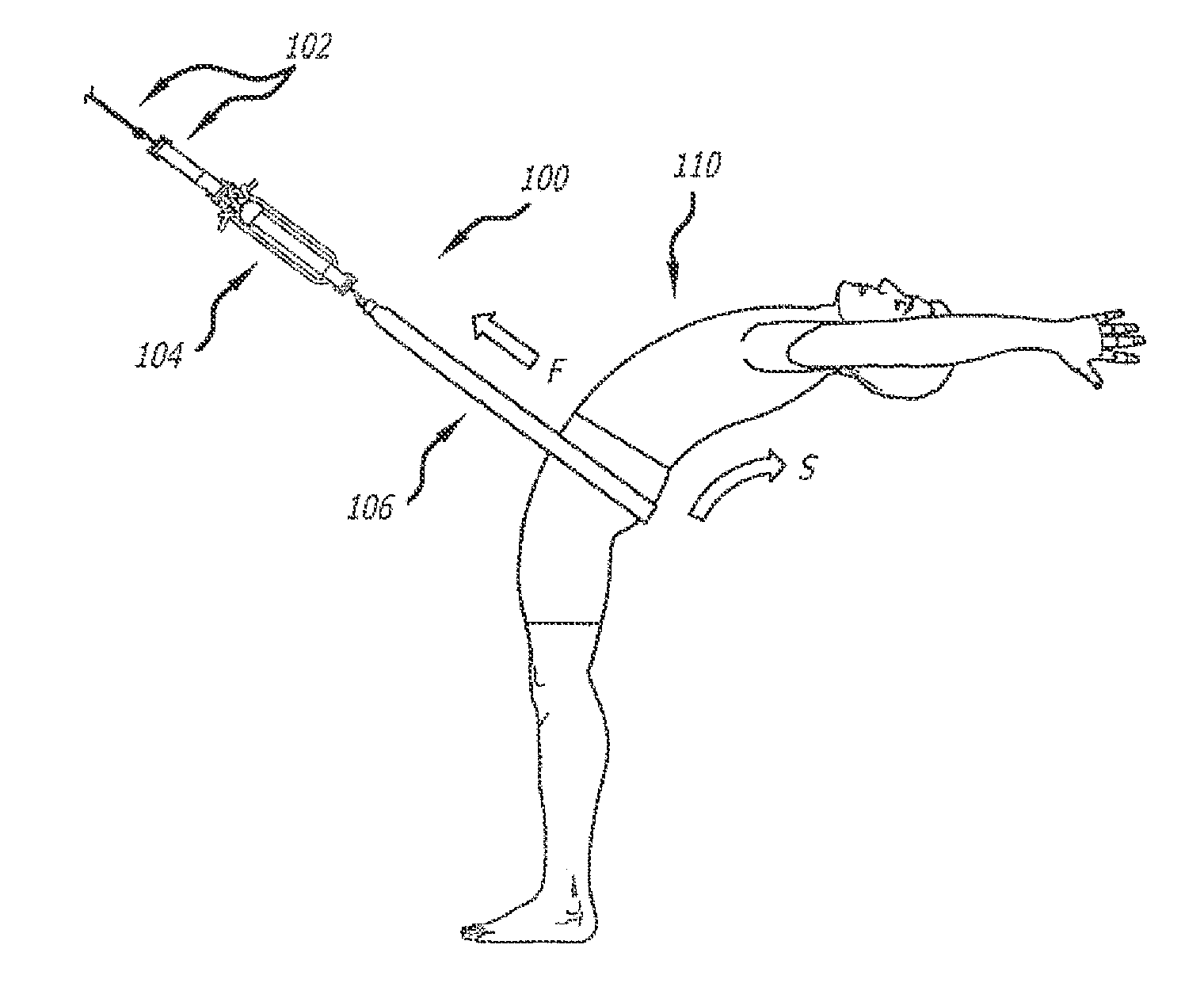

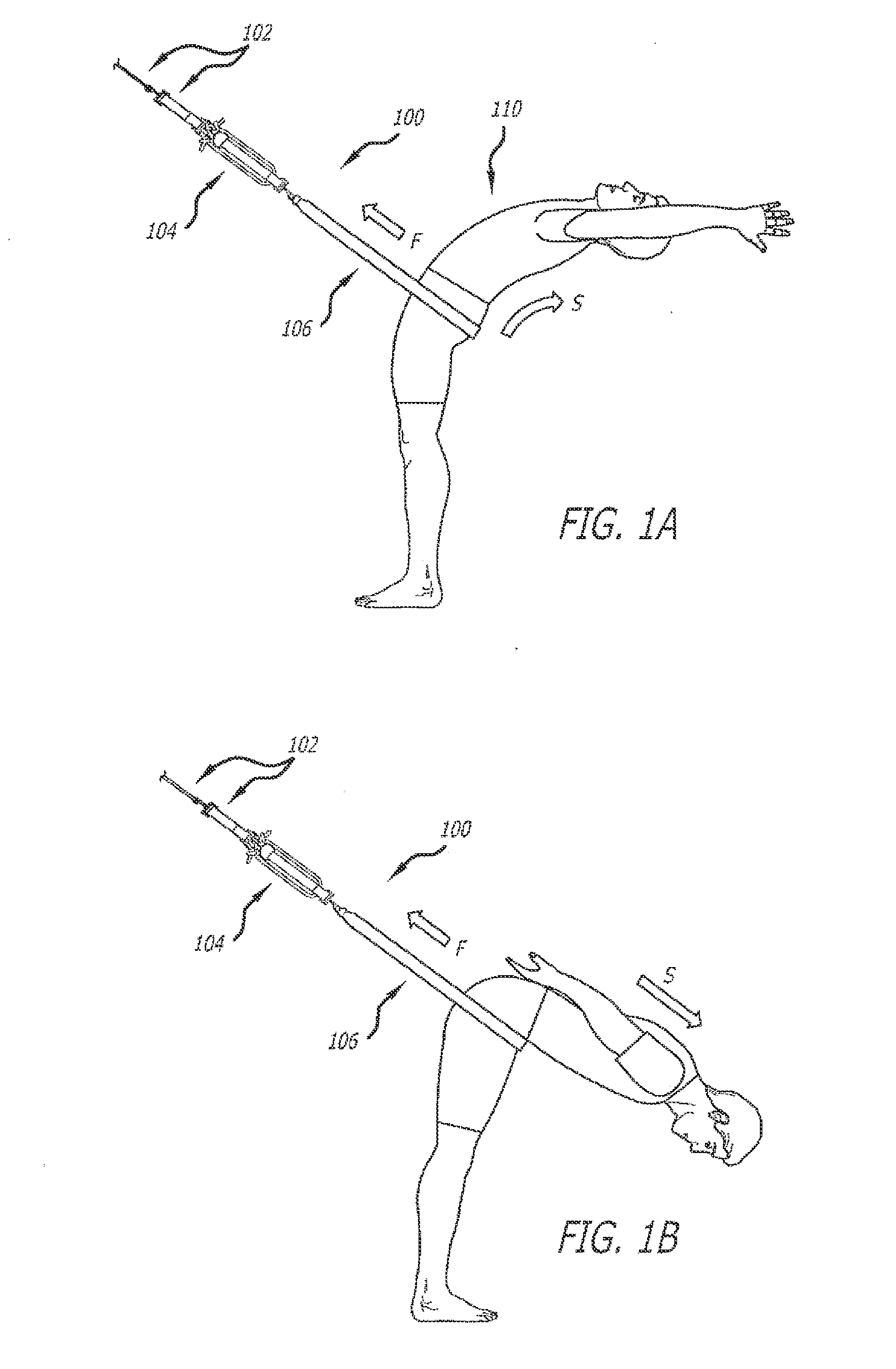

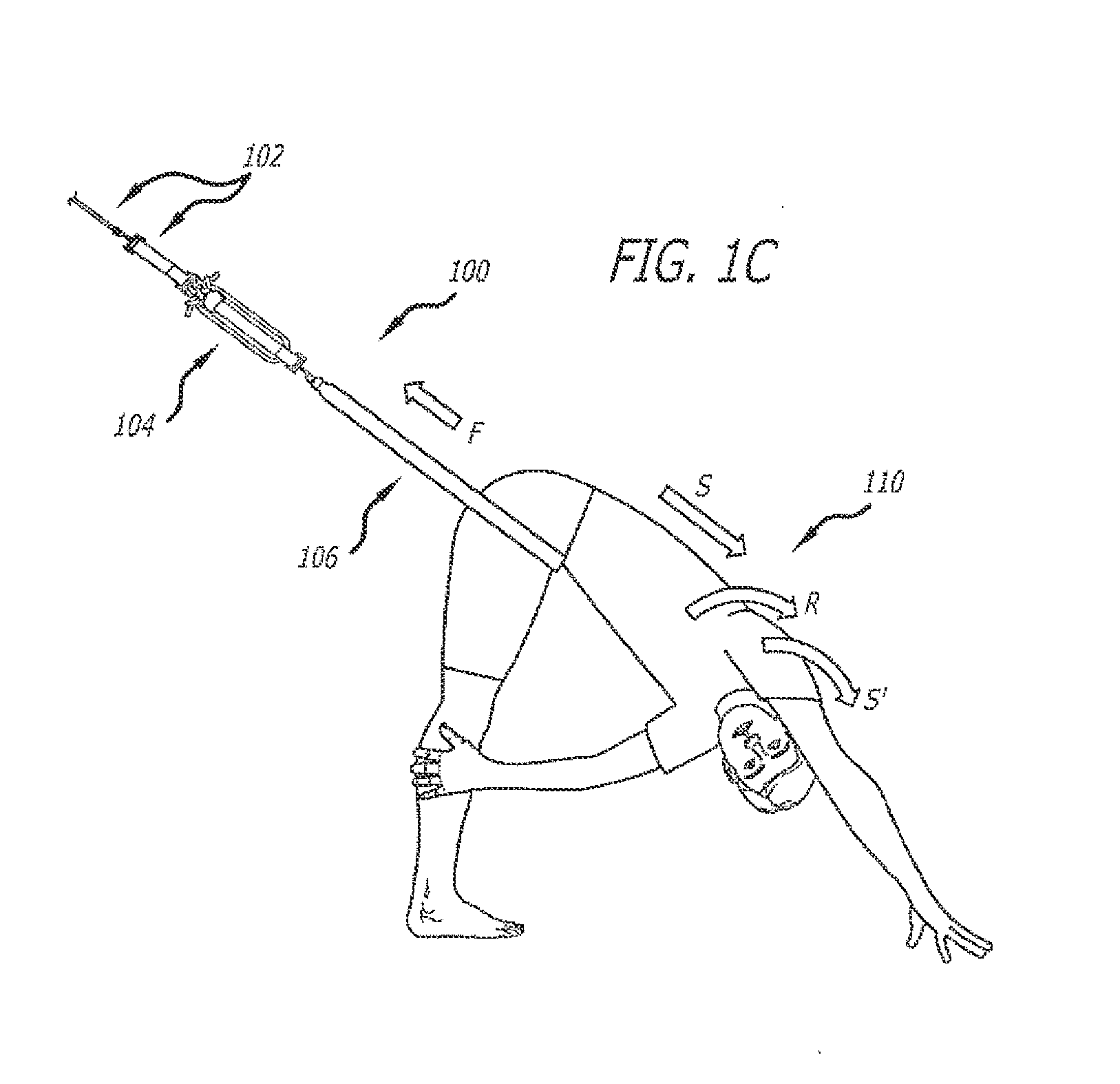

Full body exercise band system

Owner:YOGA BENT

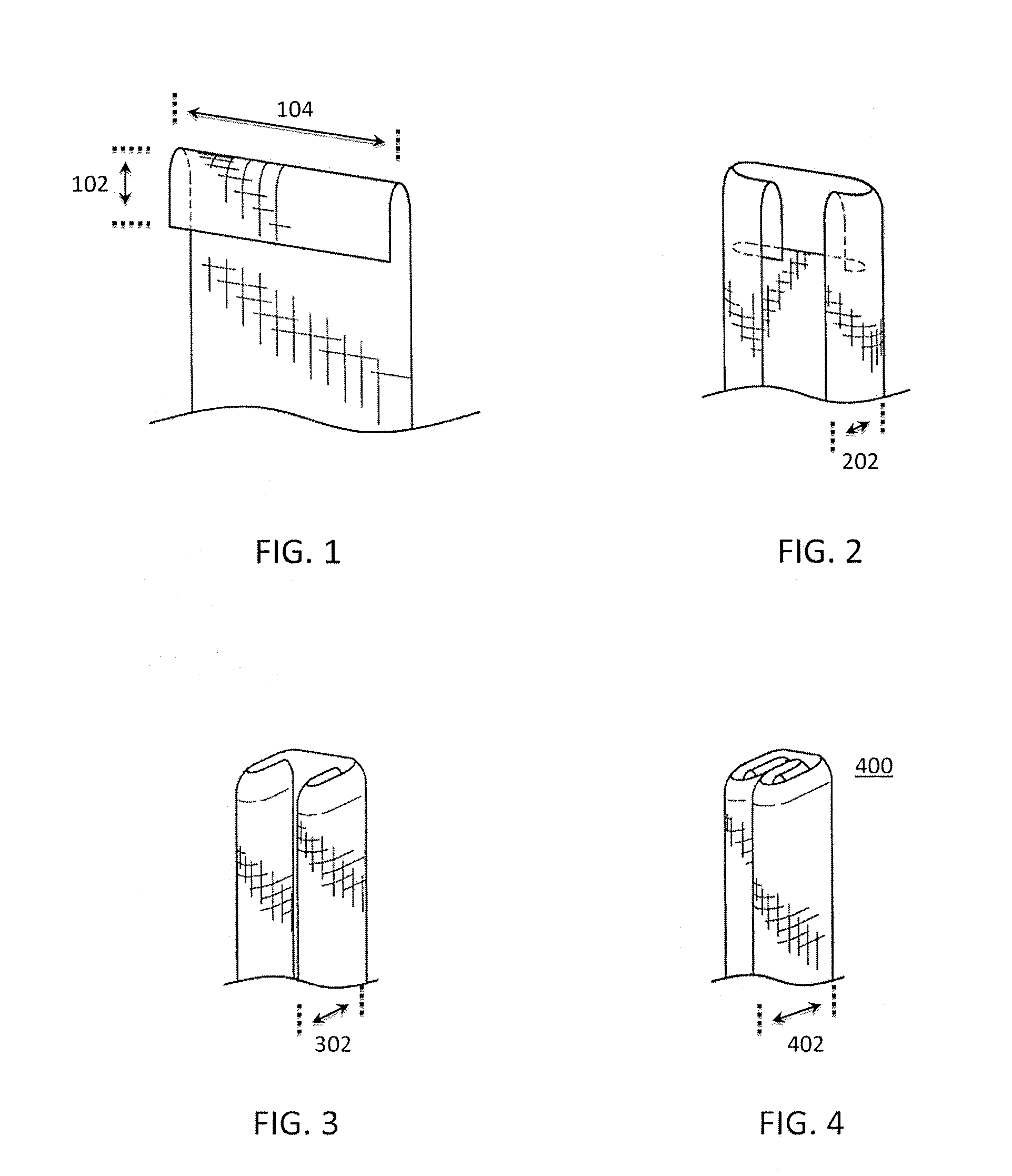

Device and kit for making knotted string accessories

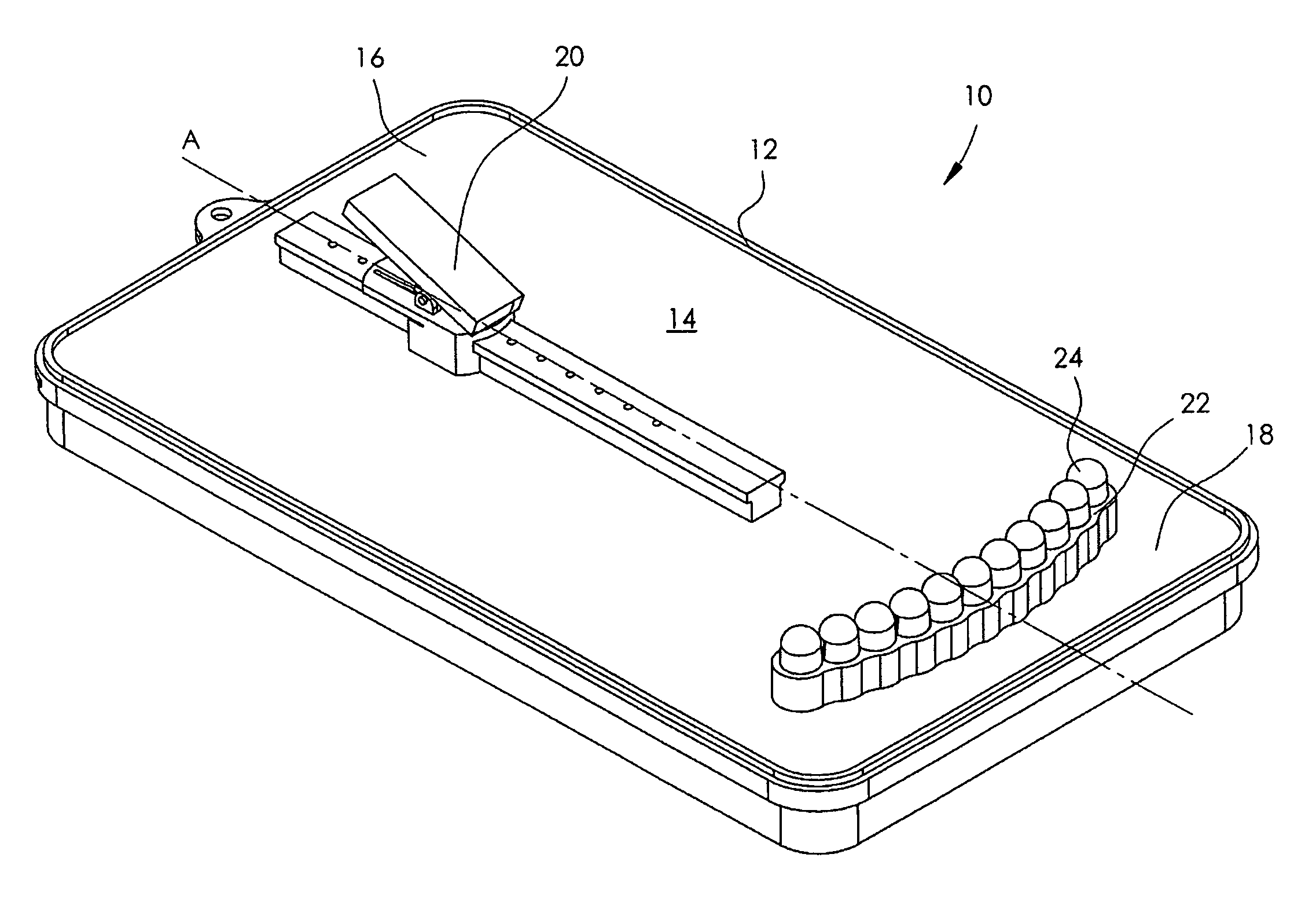

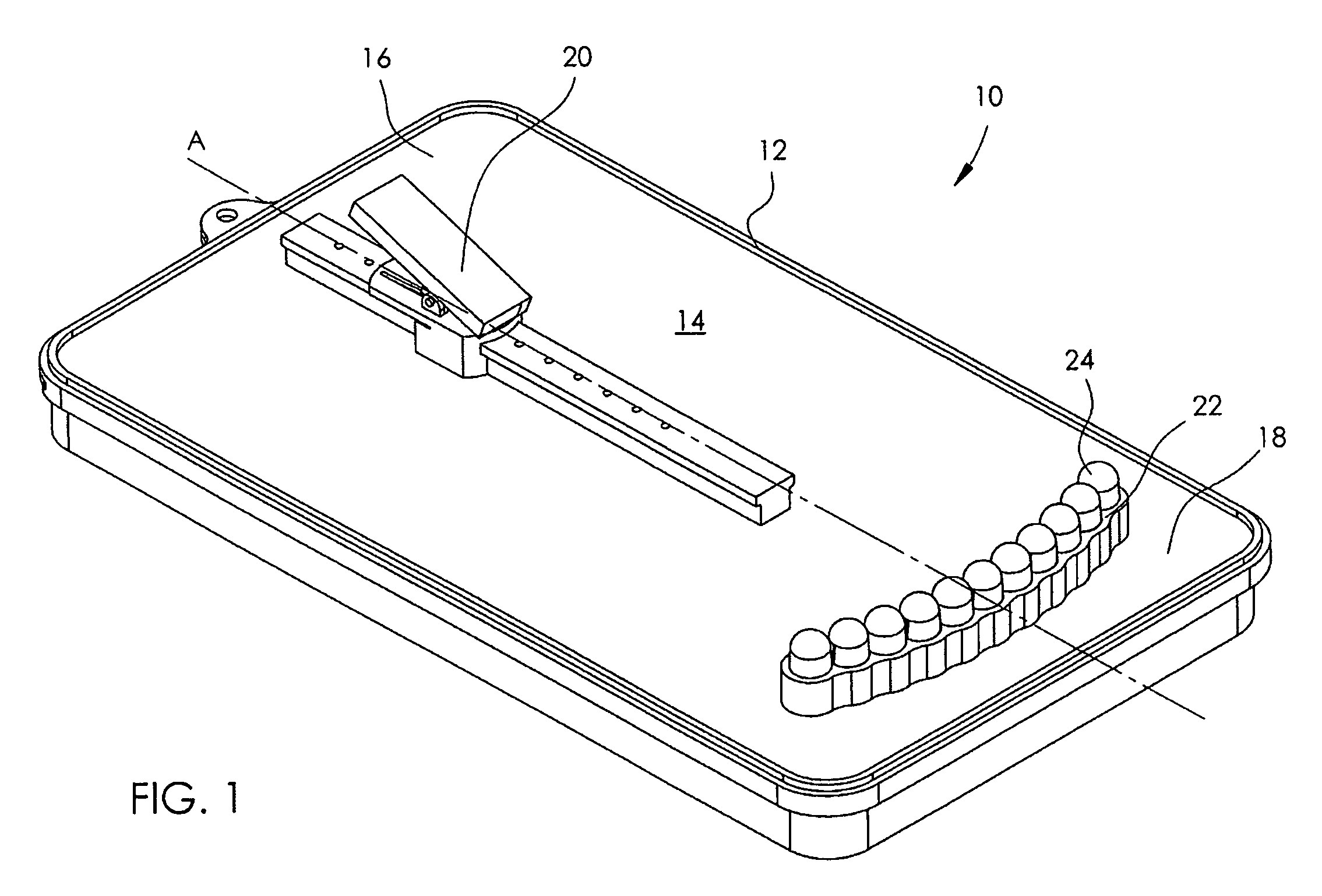

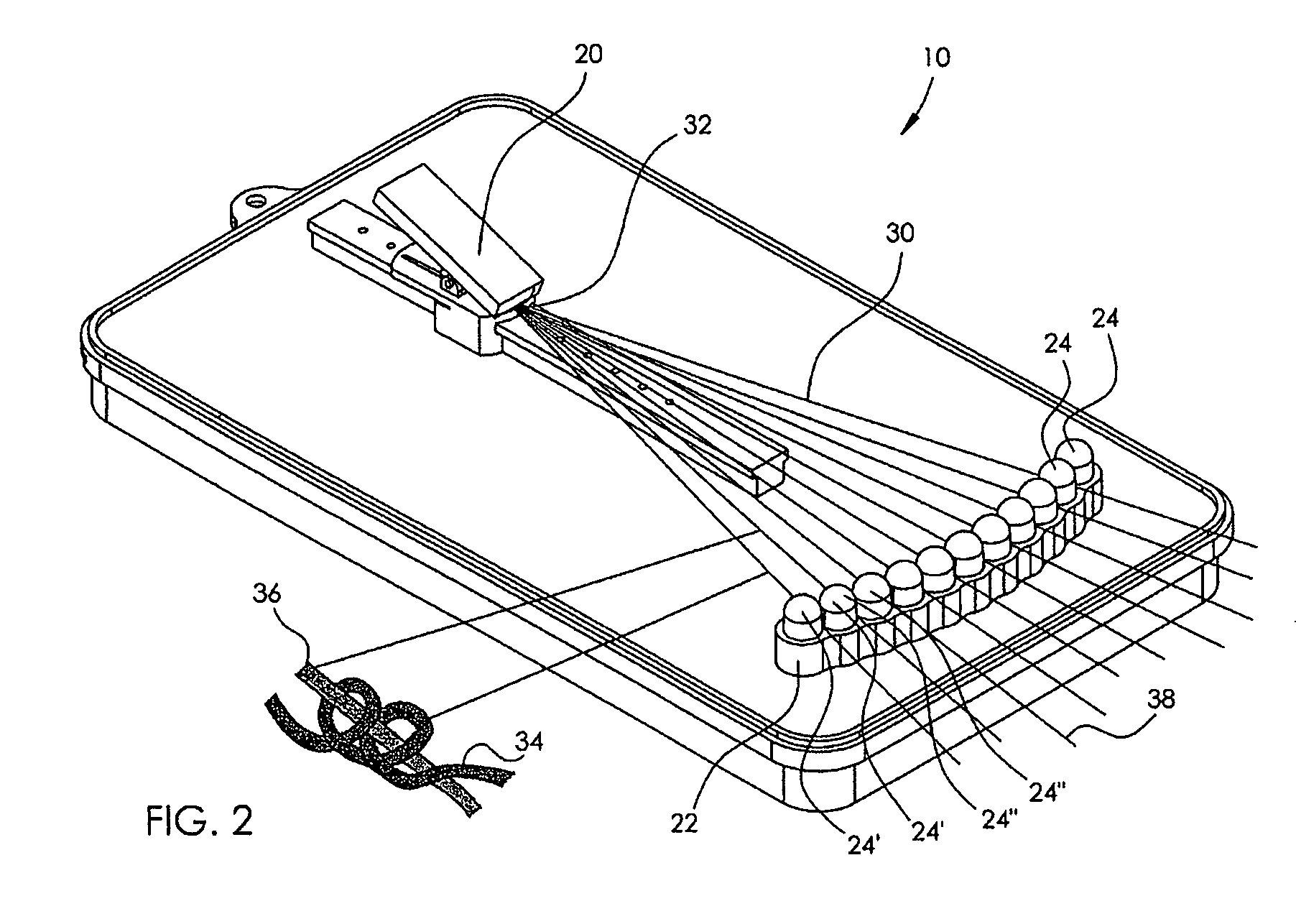

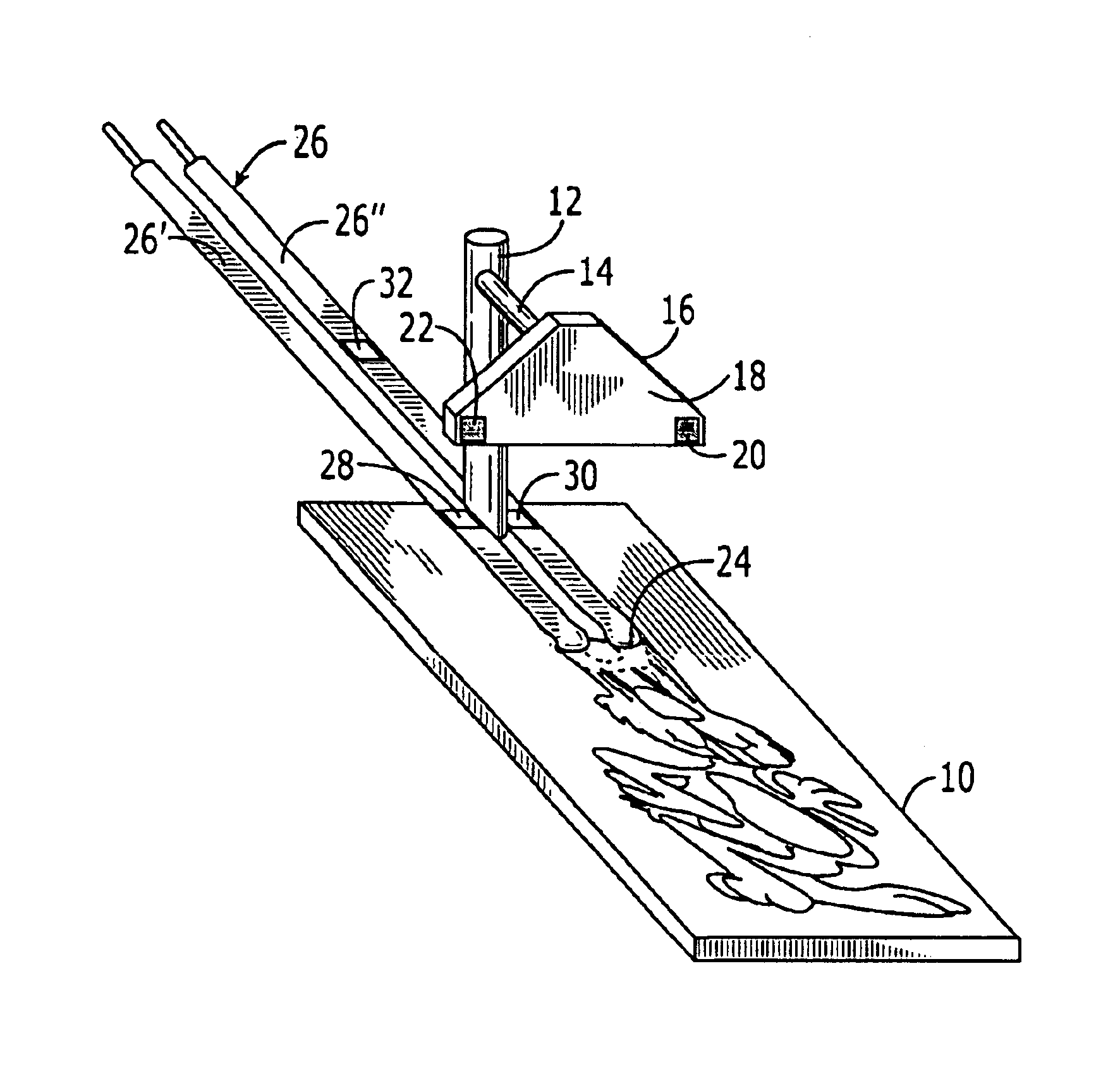

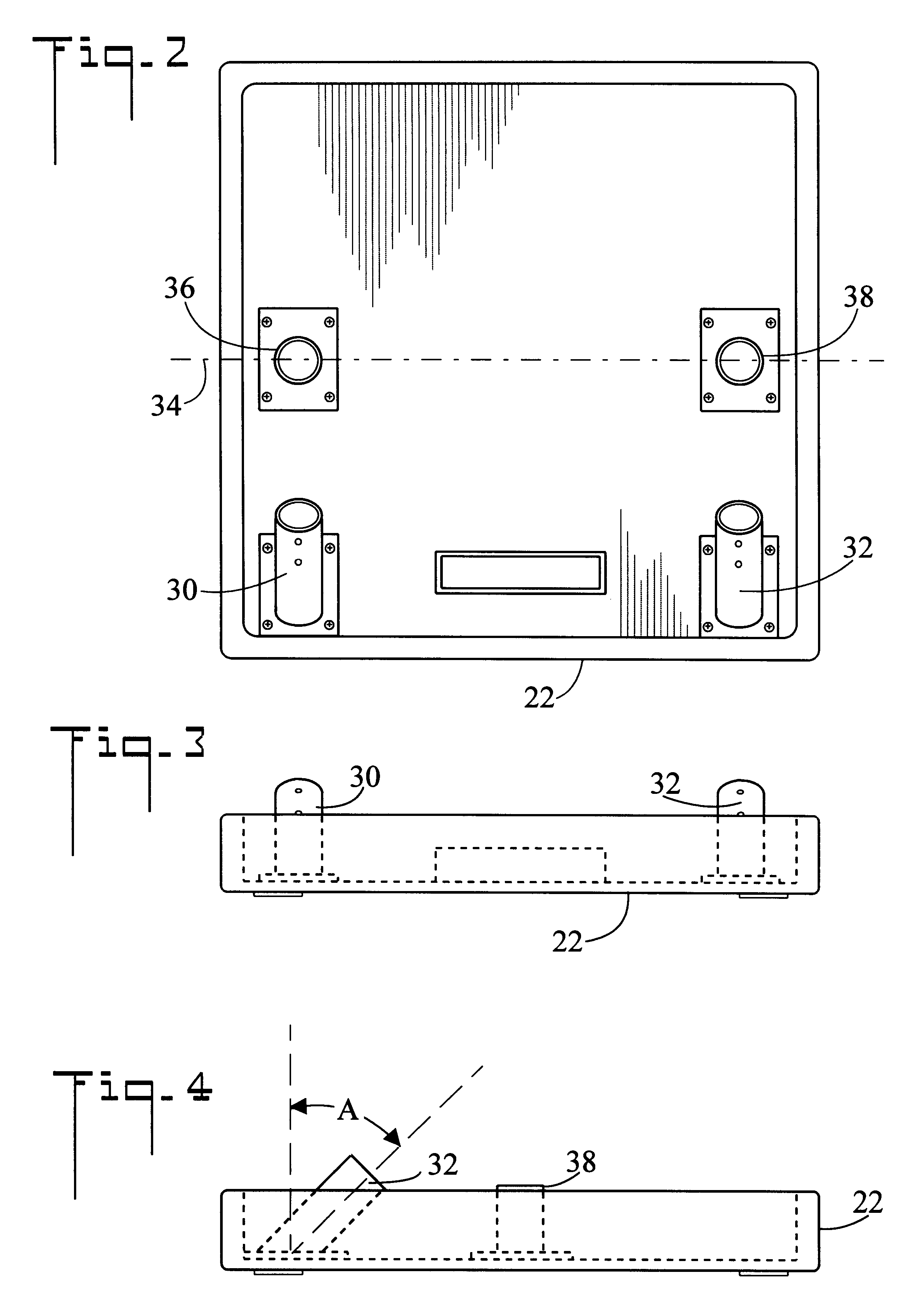

Disclosed herein are embodiments of devices and kits for making knotted string accessories. One embodiment of a device comprises a base having a substantially planar surface with a first end, a second end opposite the first end, and a longitudinal axis. A securing member is connected to the substantially planar surface proximate to the first end and is configured to secure a first end of the plurality of individual strings. An elongated holder is connected to the substantially planar surface proximate the second end and perpendicular to the longitudinal axis and comprises a plurality of raised portions positioned along the elongated holder and extending outward from the substantially planar surface in close proximity to one another, wherein adjacent raised portions are configured to retain individual strings. An embodiment of a kit comprises the device and a plurality of string for use with the device.

Owner:CROREY CREATIONS

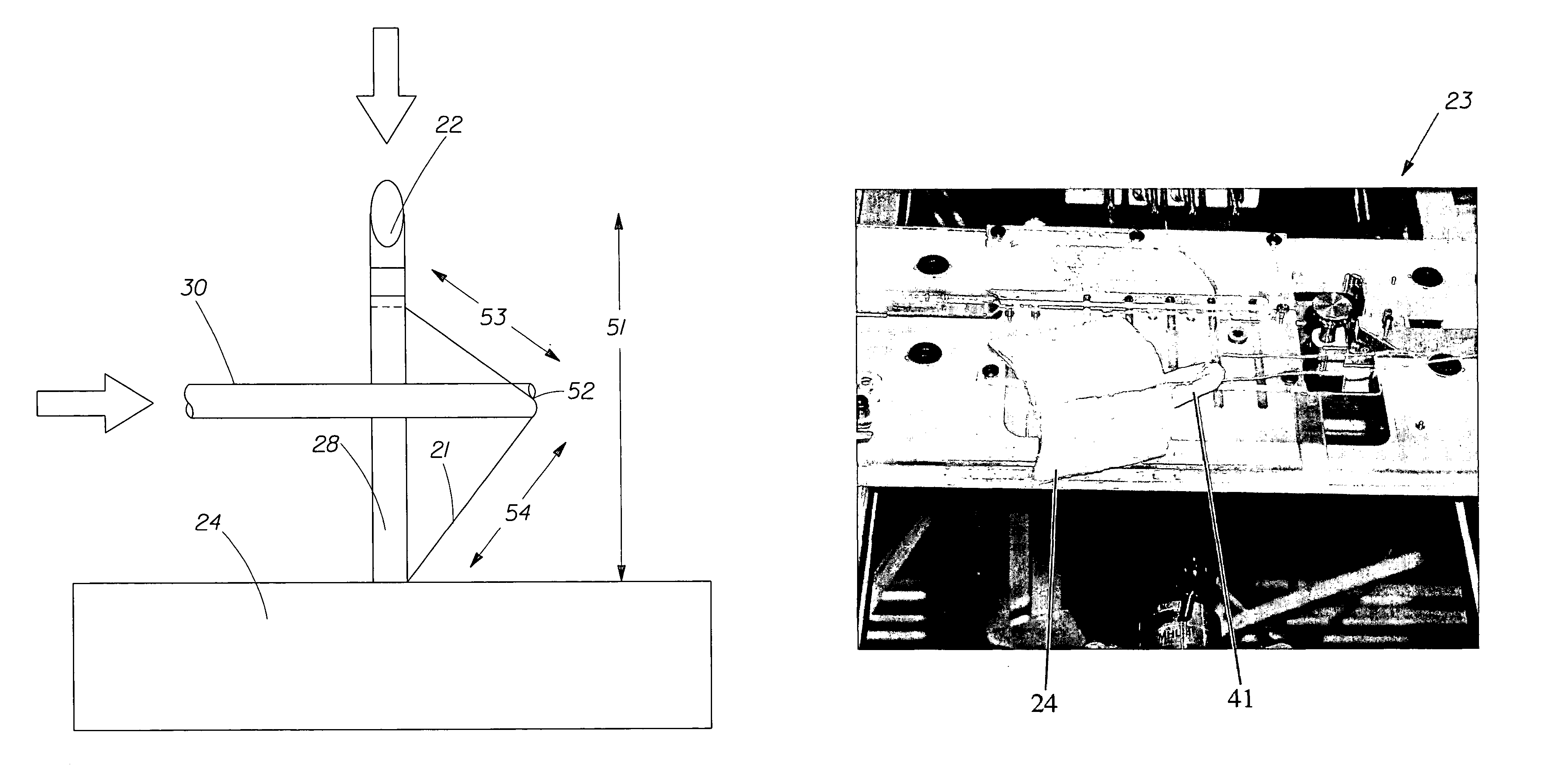

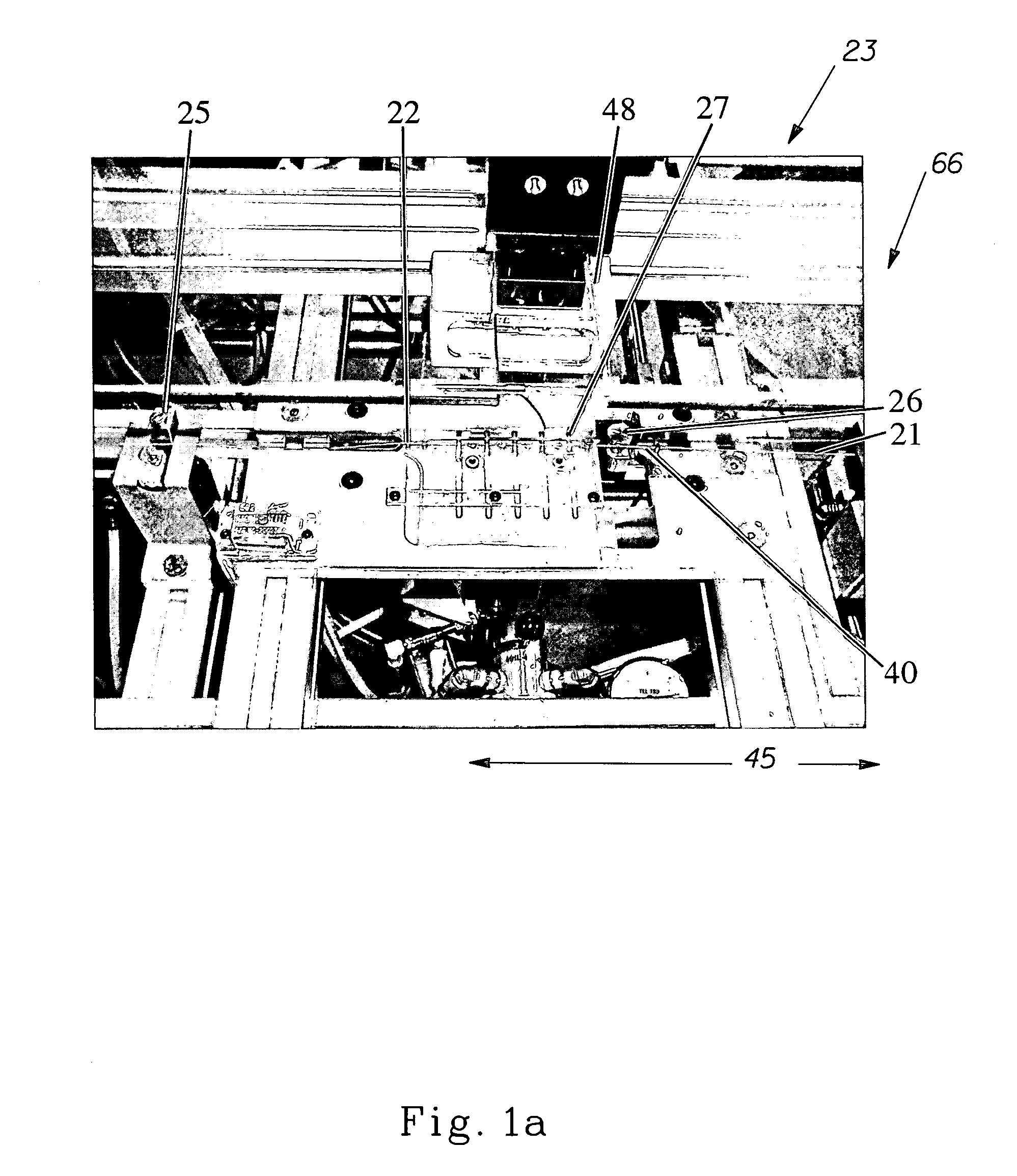

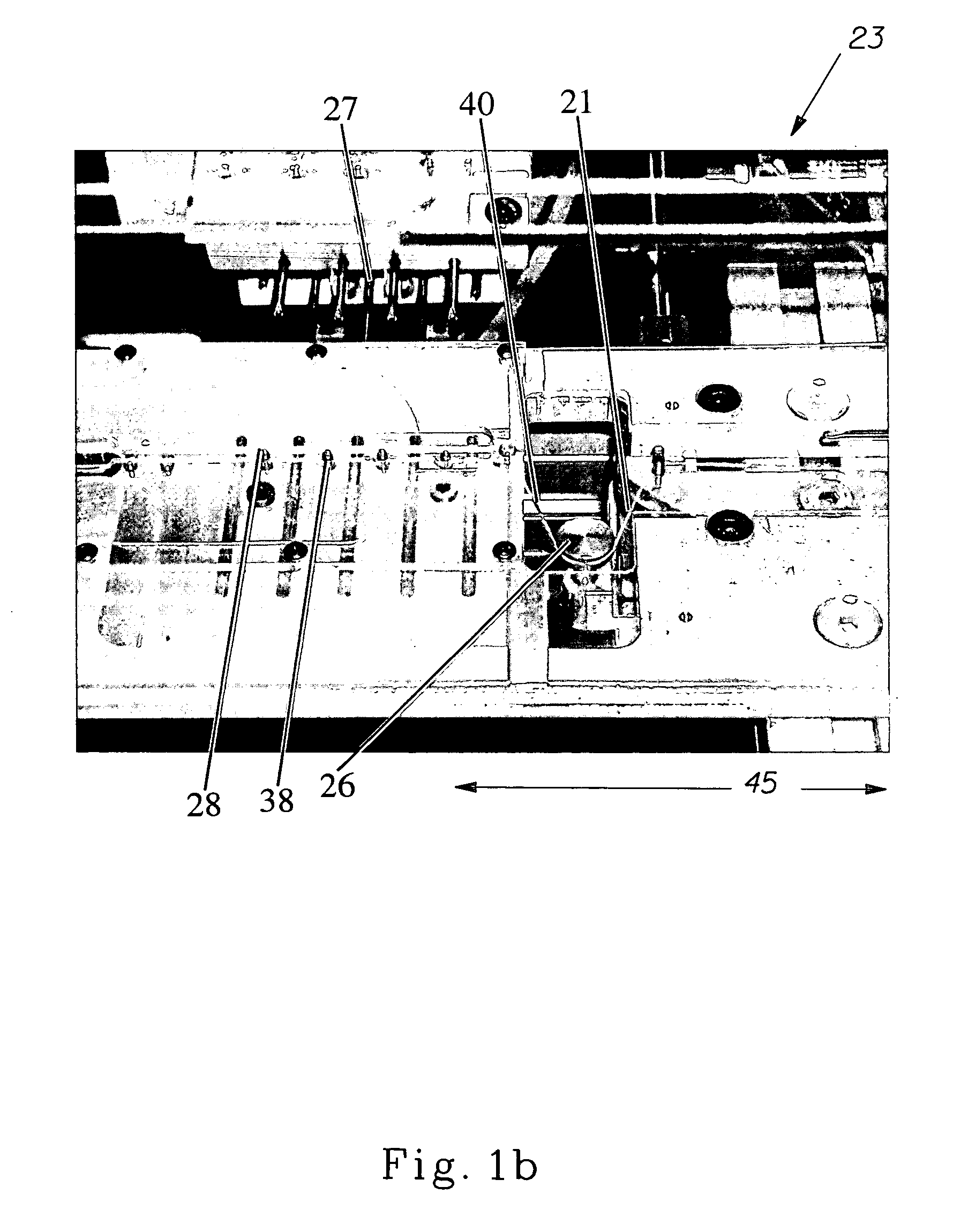

Method and apparatus for cord attachment

Owner:THE PROCTER & GAMBLE COMPANY

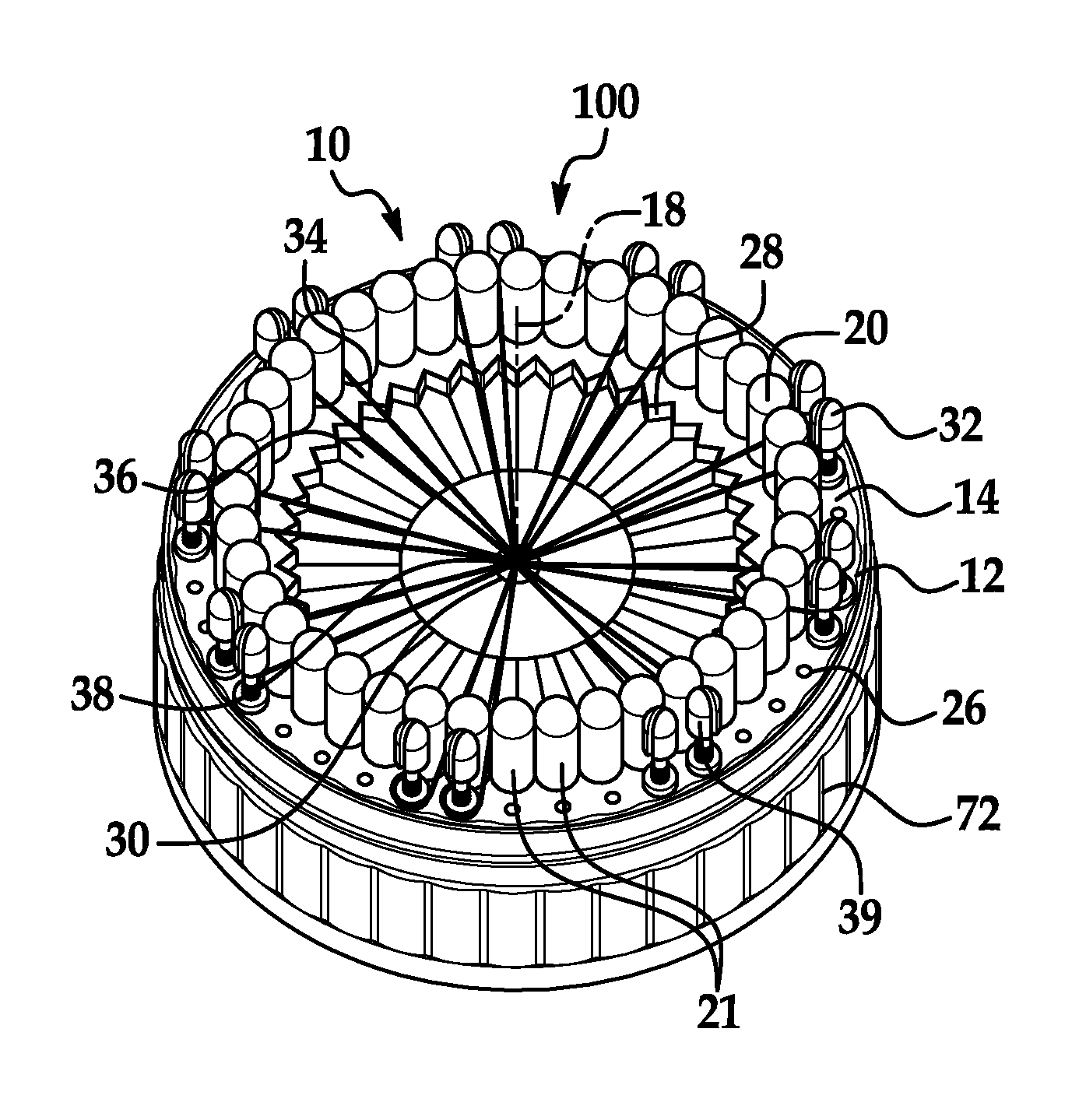

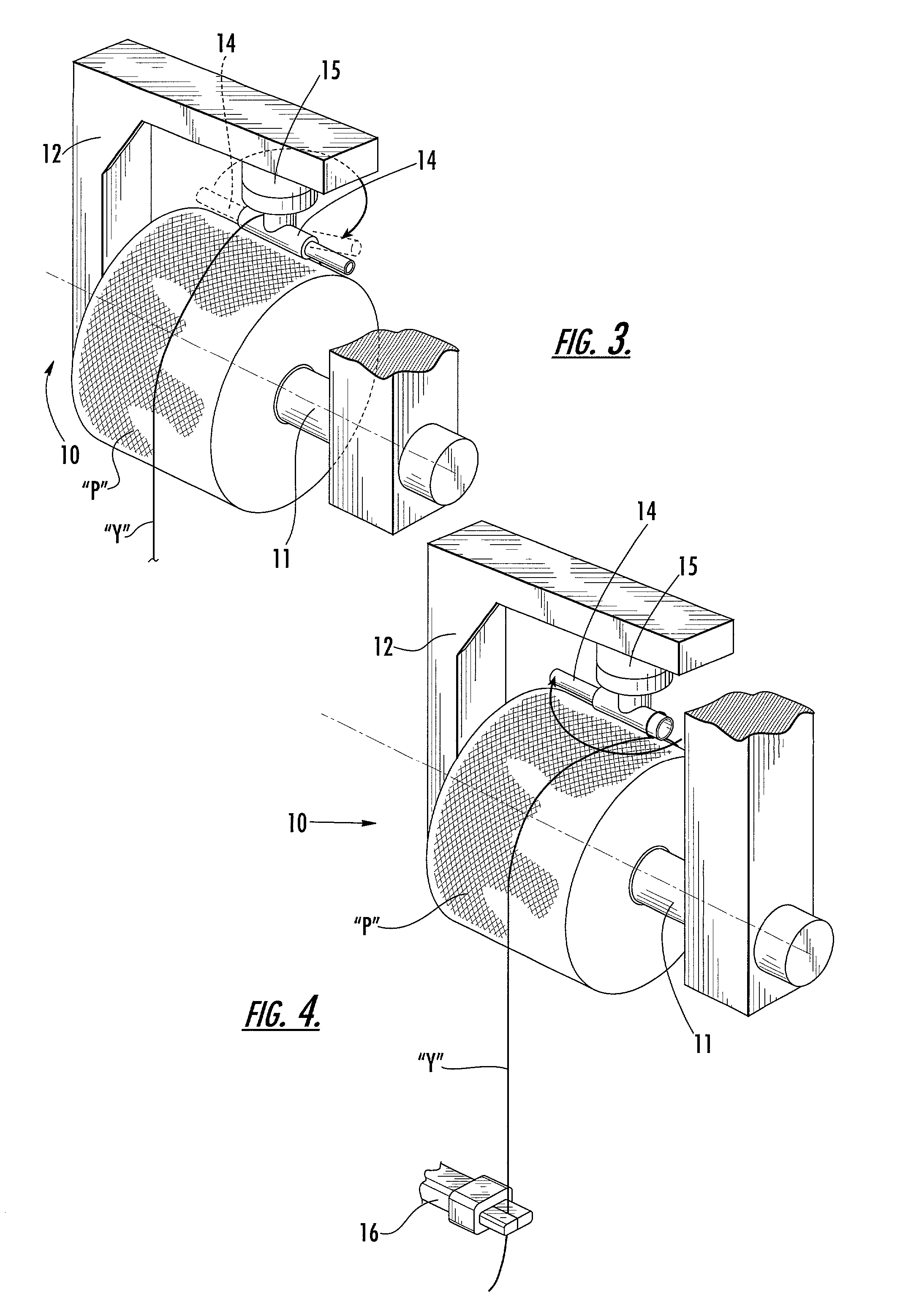

Automatic knot-tying machine

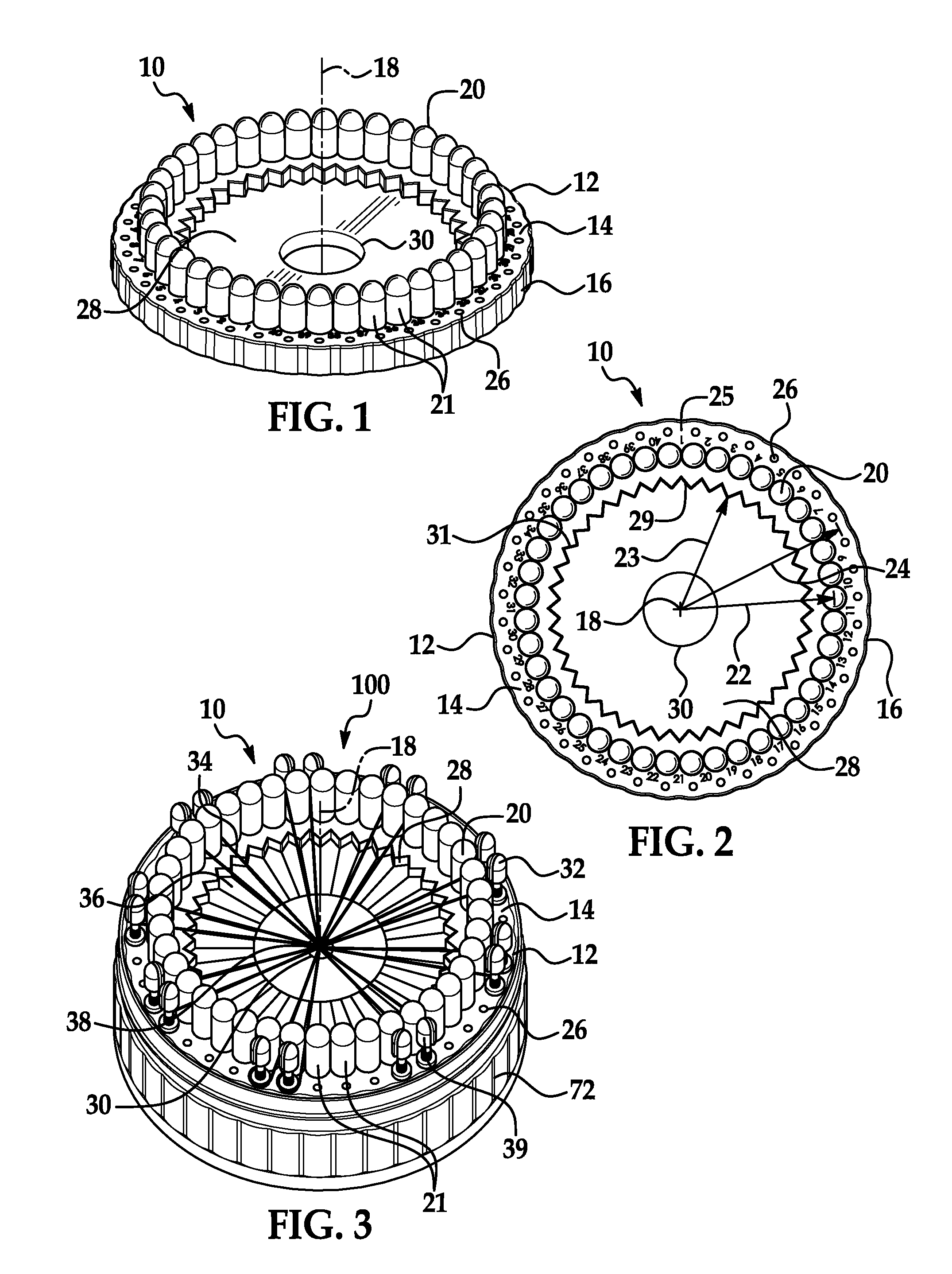

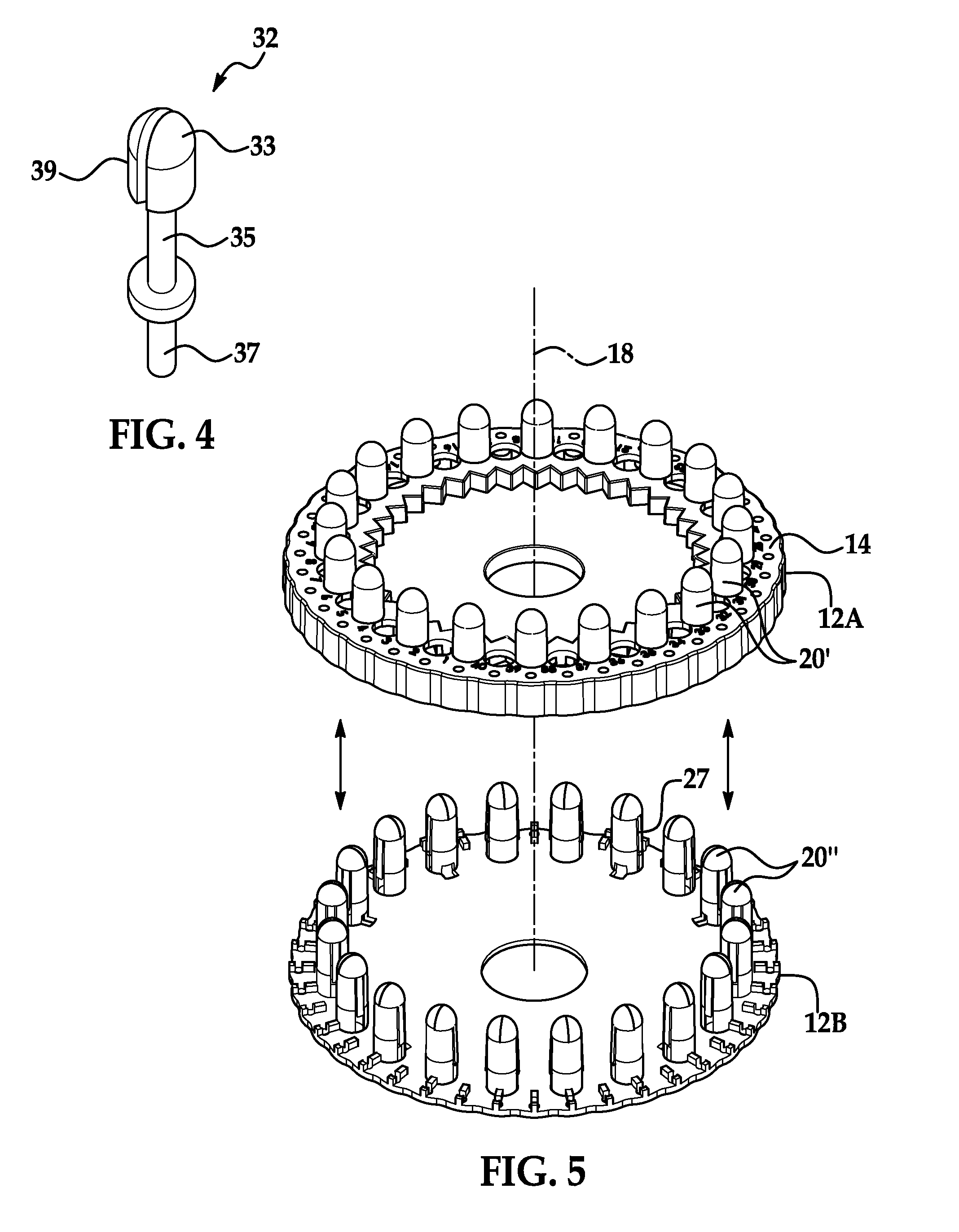

A knot-tying machine, including a package support for holding a package having a supply of a strand material with an exposed free end wound onto an outer surface of the package, a strand gripper for releasably gripping and holding a length of the strand adjacent the exposed free end of the strand, a loop-forming assembly for forming a loop in the length of the strand adjacent the exposed free end of the strand and intermediate the gripper and the package, the package support and the loop-forming assembly mounted for rotational movement relative to each other for forming the loop in the strand, and a knot-forming assembly for forming a slip-knot in the loop of the strand formed by the loop-forming assembly adjacent the free end thereof, the slip-knot being adapted to be subsequently removed when desired by pulling on the free end of the strand. The package support may be stationarily mounted and the loop-forming assembly mounted for rotation around the periphery of the package support for capturing the length of the strand adjacent the exposed free end of the strand for forming a loop therein.

Owner:BELMONT TEXTILE MACHINERY

Automatic knot-tying machine

A knot-tying machine, including a package support for holding a package having a supply of a strand material with an exposed free end wound onto an outer surface of the package, a strand gripper for releasably gripping and holding a length of the strand adjacent the exposed free end of the strand, a loop-forming assembly for forming a loop in the length of the strand adjacent the exposed free end of the strand and intermediate the gripper and the package, the package support and the loop-forming assembly mounted for rotational movement relative to each other for forming the loop in the strand, and a knot-forming assembly for forming a slip-knot in the loop of the strand formed by the loop-forming assembly adjacent the free end thereof, the slip-knot being adapted to be subsequently removed when desired by pulling on the free end of the strand. The package support may be stationarily mounted and the loop-forming assembly mounted for rotation around the periphery of the package support for capturing the length of the strand adjacent the exposed free end of the strand for forming a loop therein.

Owner:BELMONT TEXTILE MACHINERY

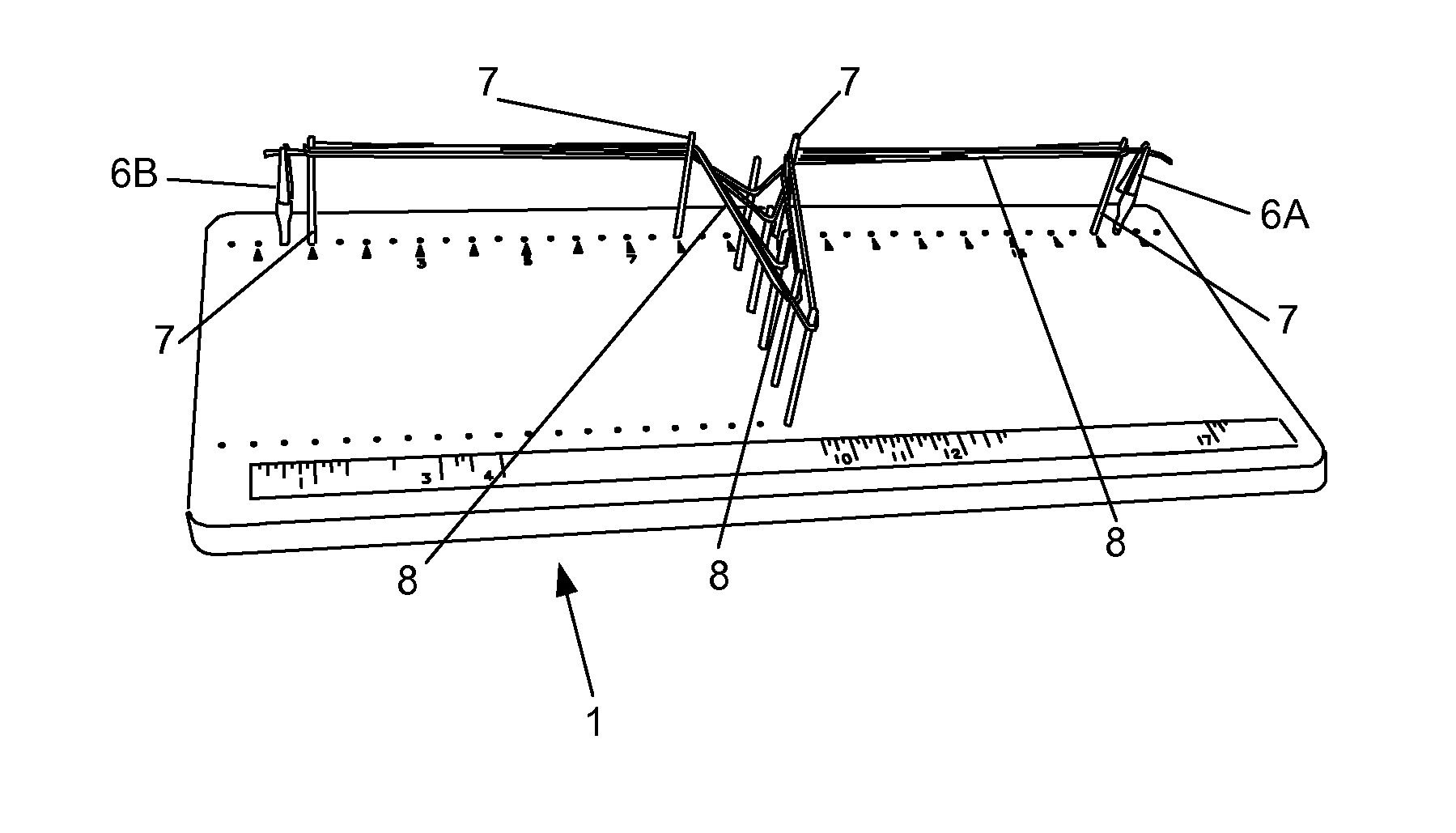

Hand-strung jewelry construction board

Owner:YOUNGER SANDRA

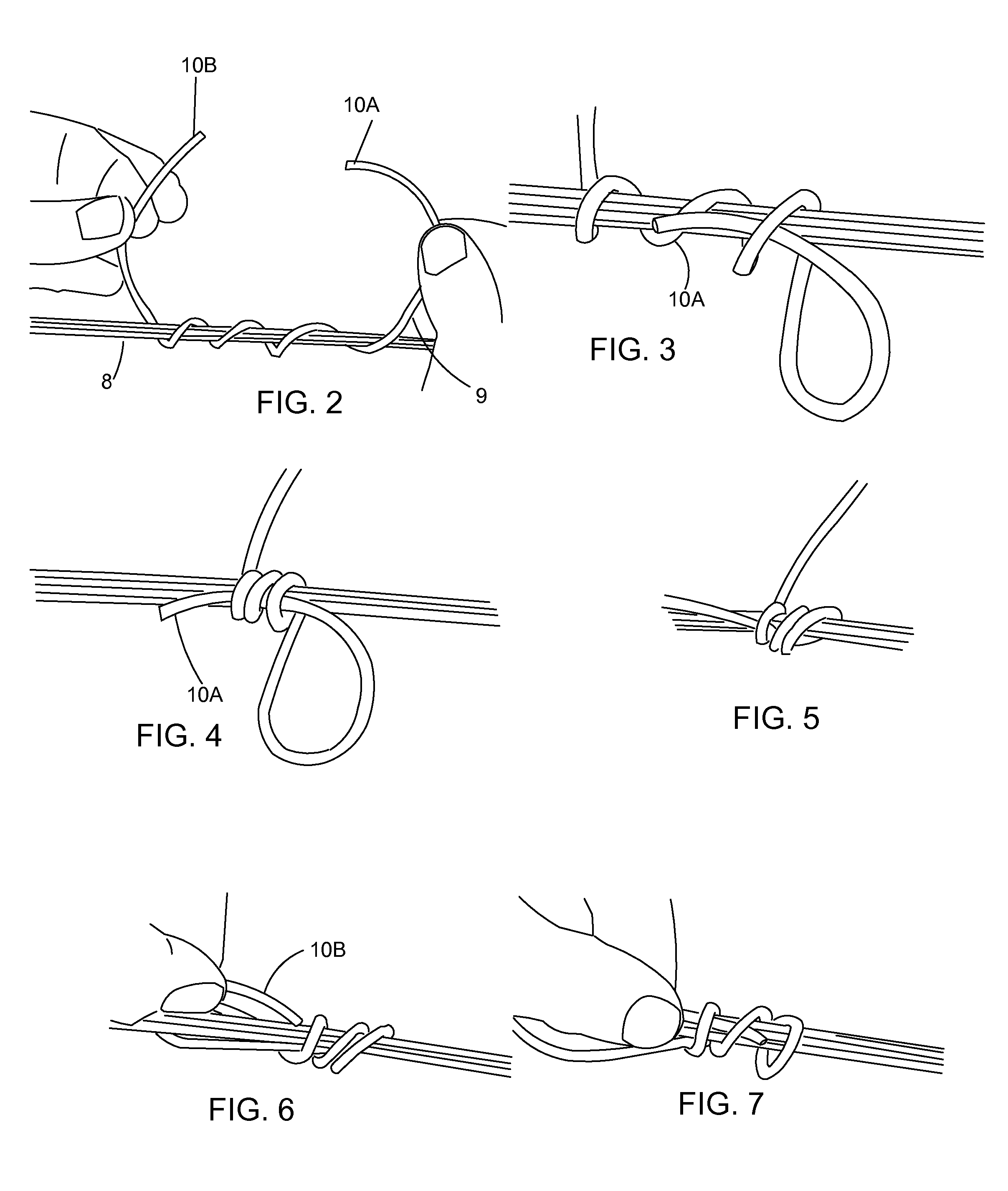

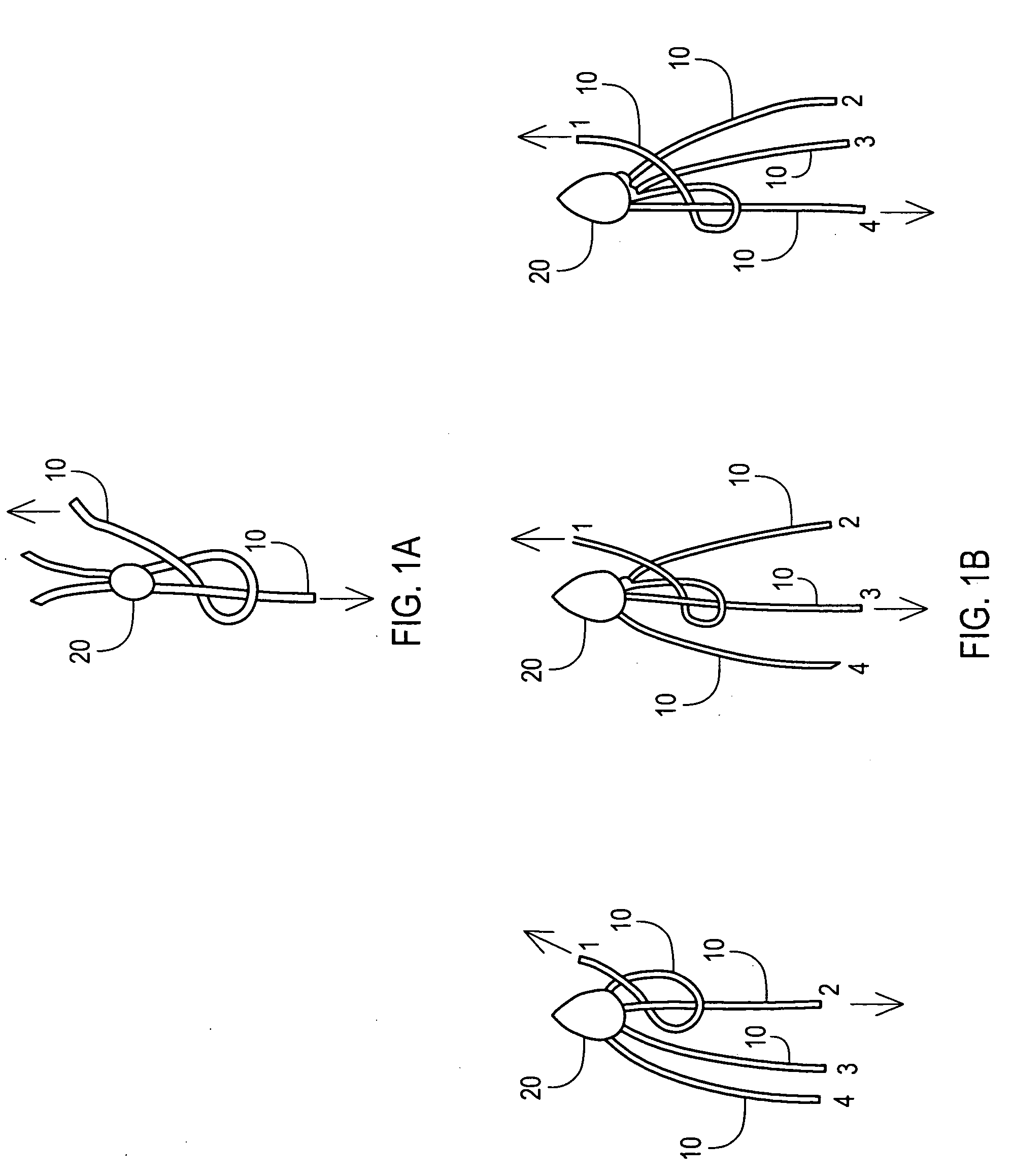

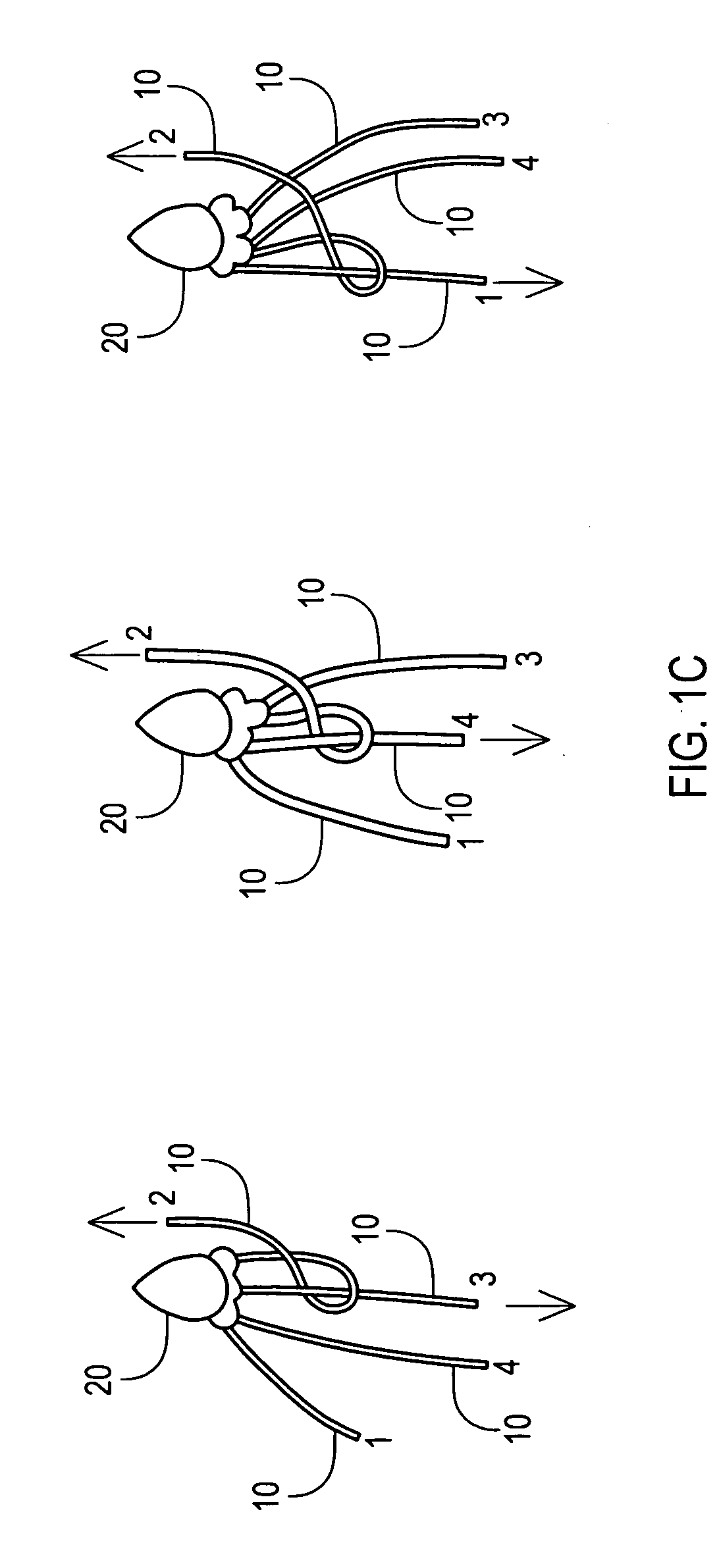

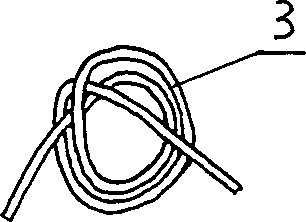

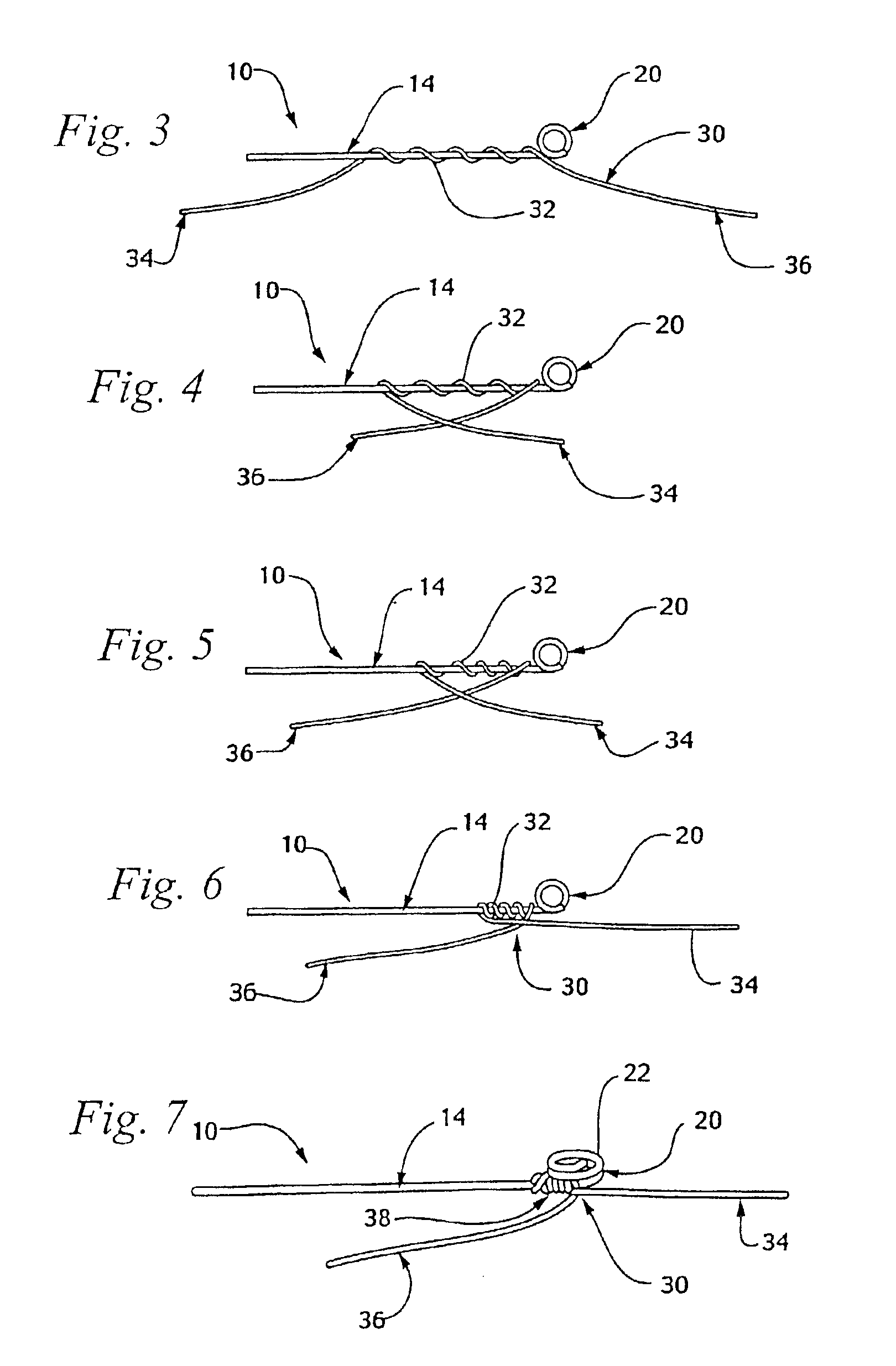

Mechanical knot formation method of heterogenous 8-shaped knot

InactiveCN101597837AReduce slippageImprove reliabilityKnottingBundling machine detailsAlpha shapeEngineering

The invention discloses a mechanical knot formation method of a heterogenous 8-shaped knot, which belongs to the technical field of strapping. The heterogenous 8-shaped knot is formed by changing one of two X-shaped cross structures at the middle part of the standardized 8-shaped knot into Chinese doughnut-shaped twisted structure. The heterogenous 8-shaped knot is formed by the following steps: hawk-mouth-shaped knotter jaw hooks the rope to finish two circles of twisting so that one end head of the rope crosses an alpha-shaped rope ring encircling the knotter jaw, thus forming the heterogenous 8-shaped knot. The heterogenous 8-shaped knot has more complex twisting relation and increased twisting area than half-knot, thus effectively reducing slipping of buckles at the tensioning state of the rope and improving reliability and stability of buckles.

Owner:CHINA AGRI UNIV

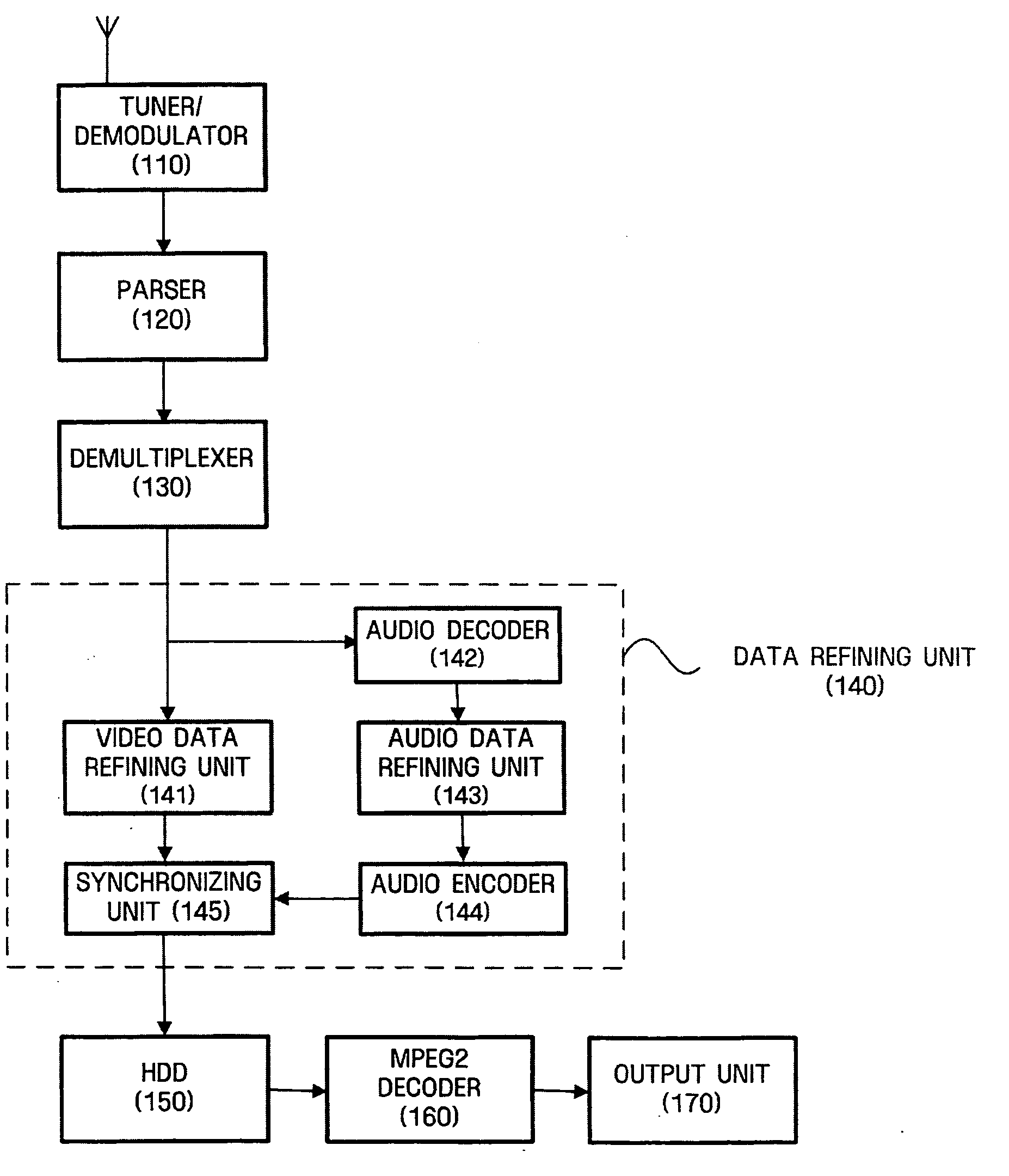

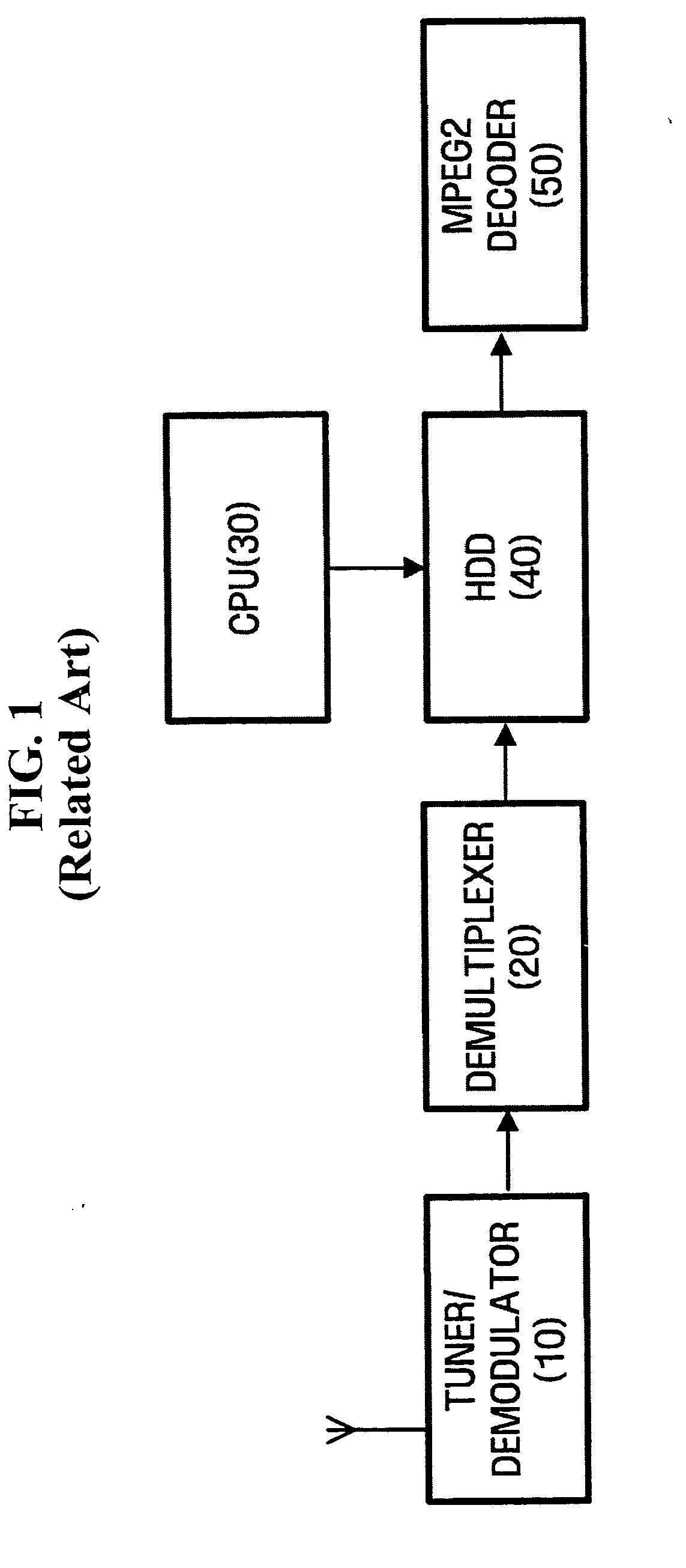

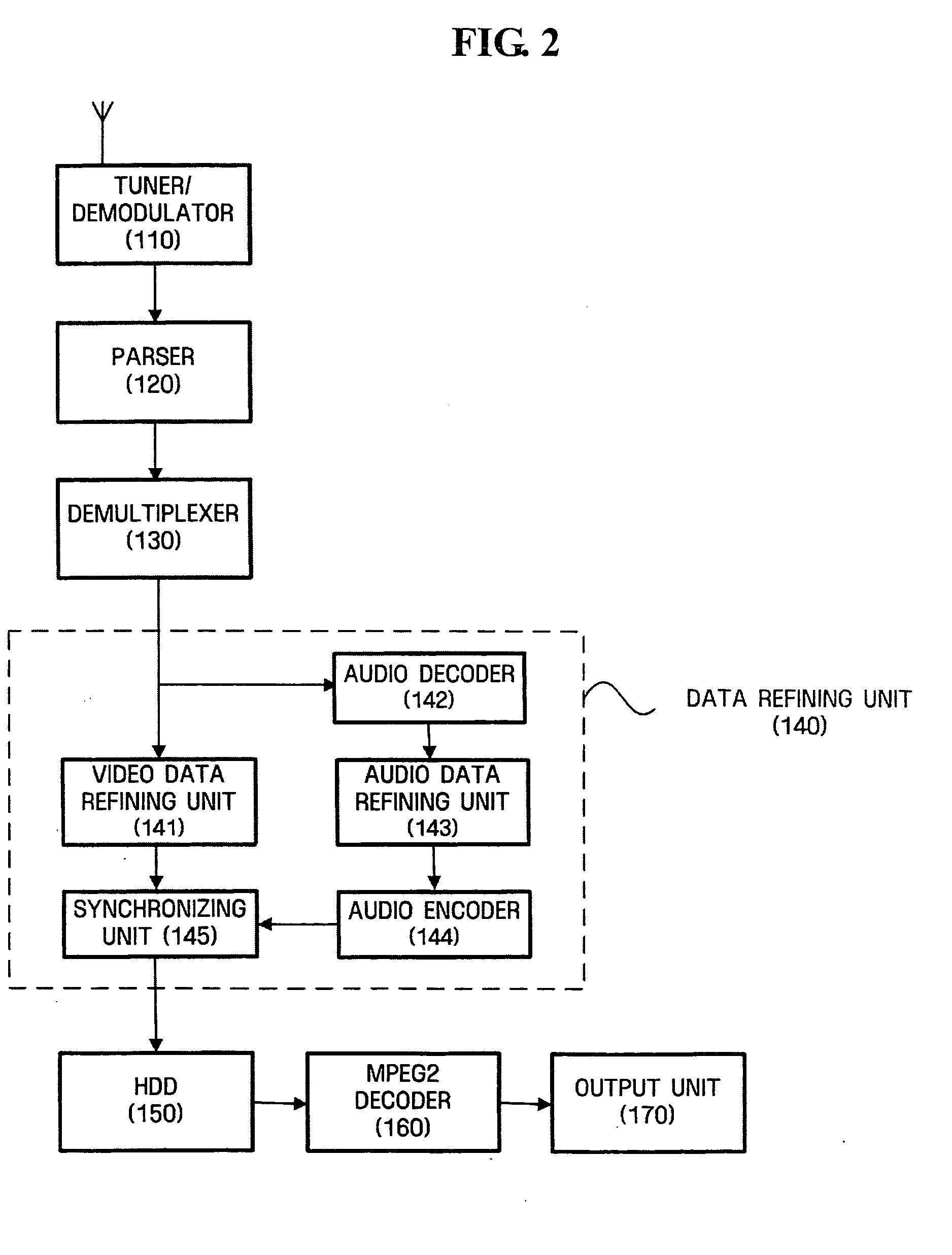

Apparatus and method for synchronizing reproduction time of time-shifted content with reproduction time of real-time content

An apparatus and method are provided for synchronizing a reproduction time of a time-shifted content with a reproduction time of a real-time content. The apparatus includes a tuner / demodulator which tunes broadcasting signals and demodulates the tuned digital broadcasting signals so as to output the broadcasting signals in forms of transport streams, a demultiplexer which demultiplexes the output transport streams so as to divide the transport streams into video data, audio data, and supplementary information and output the video data, audio data, and supplementary information, a data refining unit which removes unnecessary frames from the video data and the audio data, and an HDD which stores the video data and the audio data, from which the unnecessary frames are removed.

Owner:SAMSUNG ELECTRONICS CO LTD

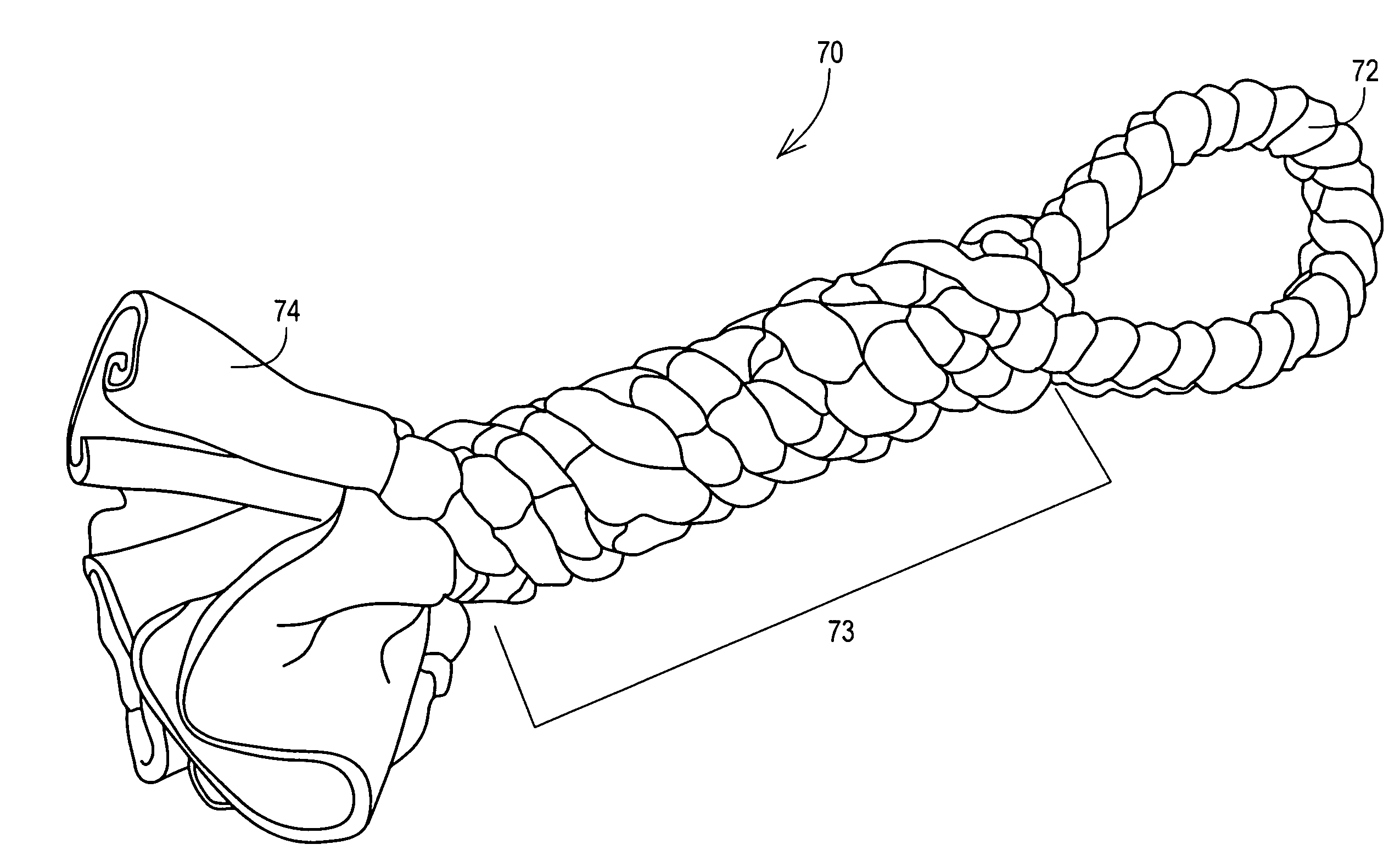

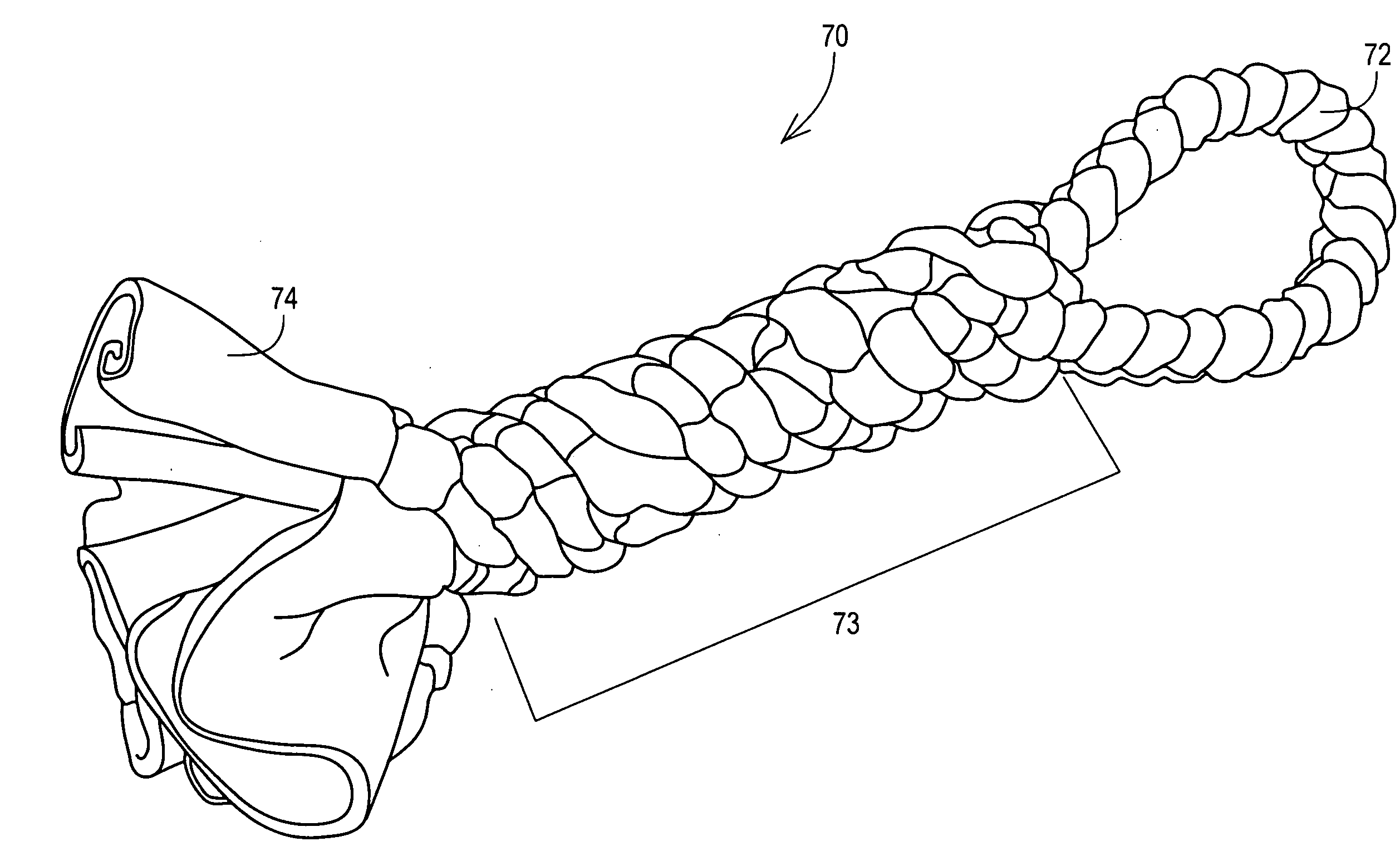

Pet toy

Owner:FREEMAN LISA

Pet toy

Owner:FREEMAN LISA

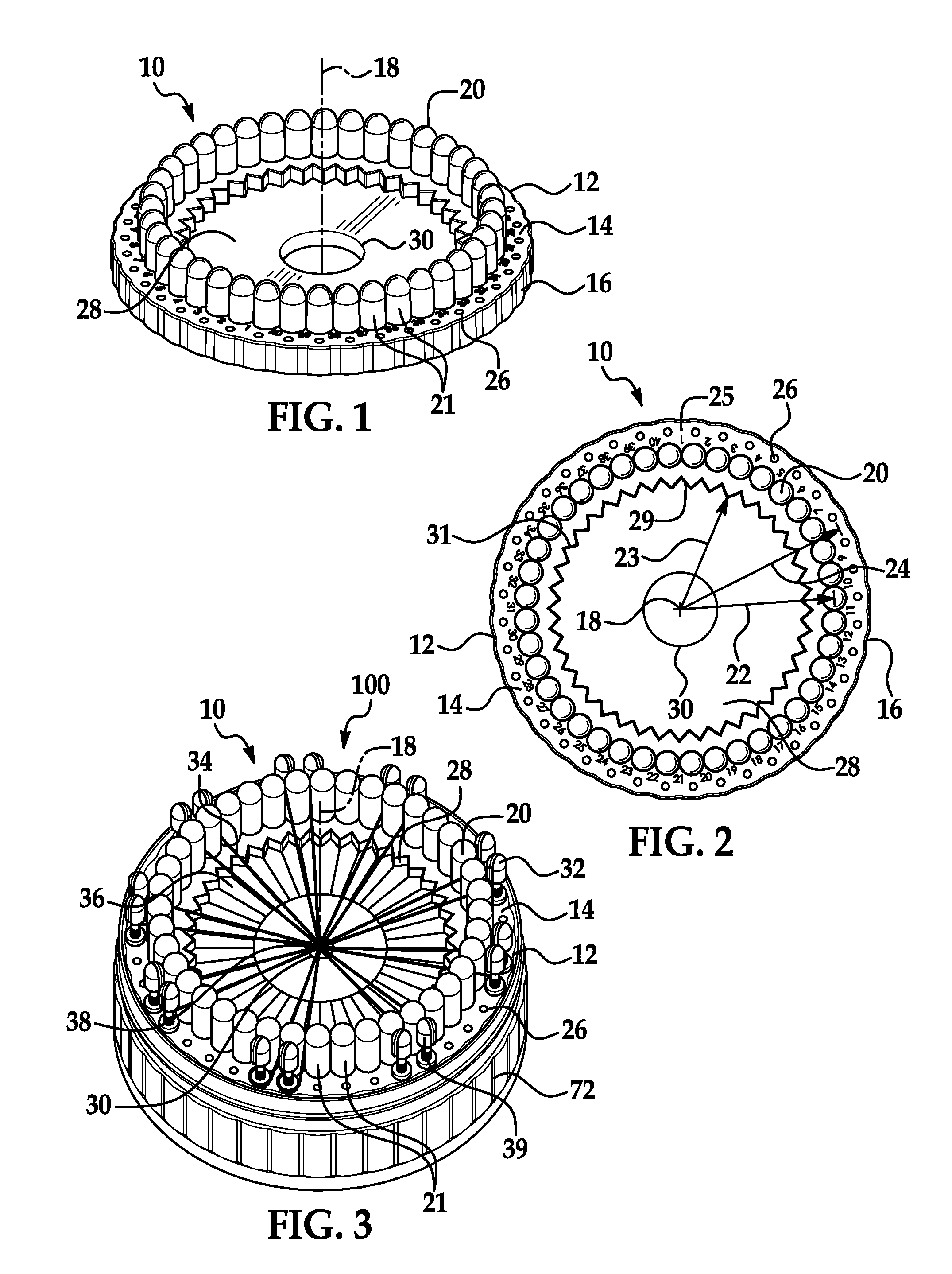

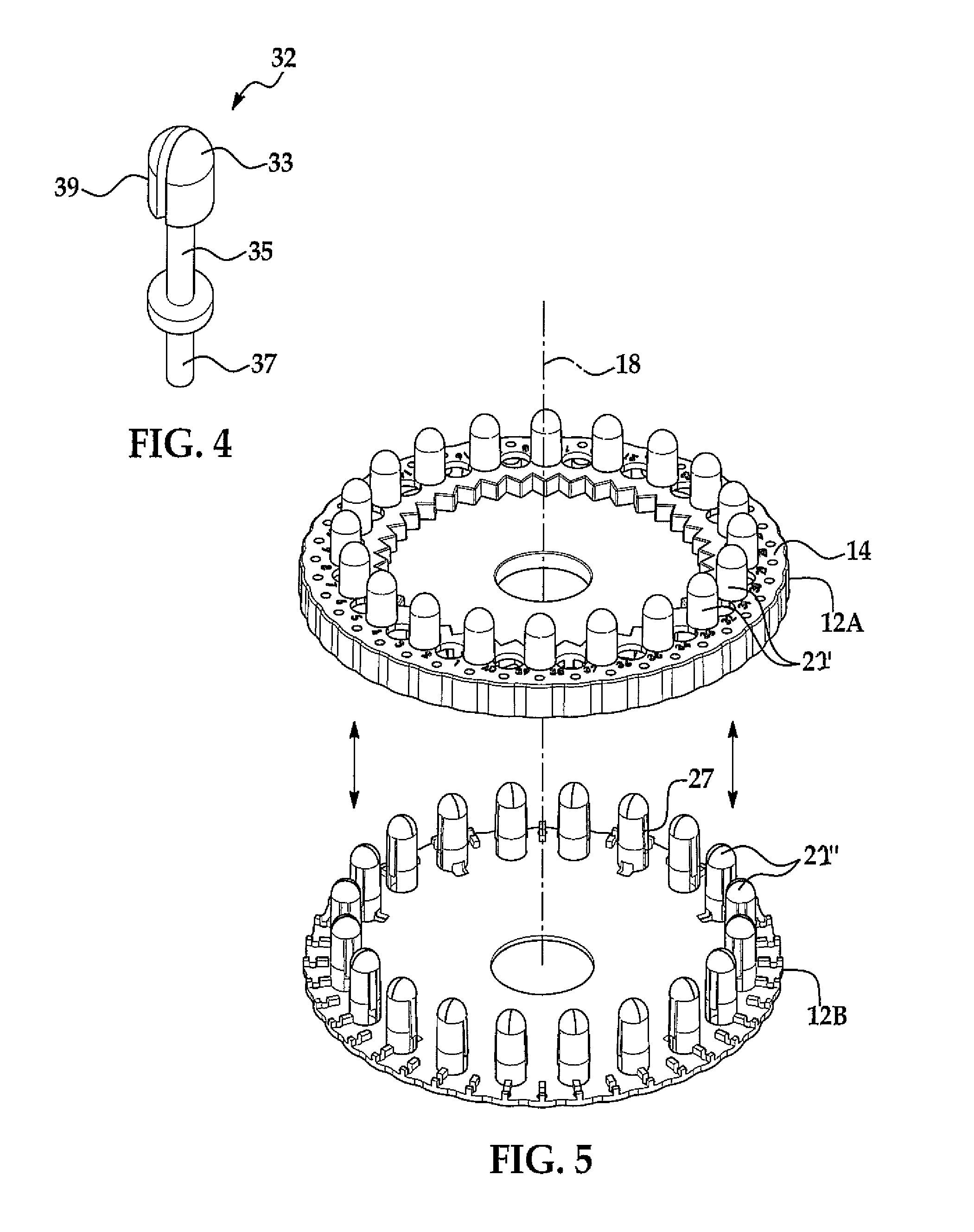

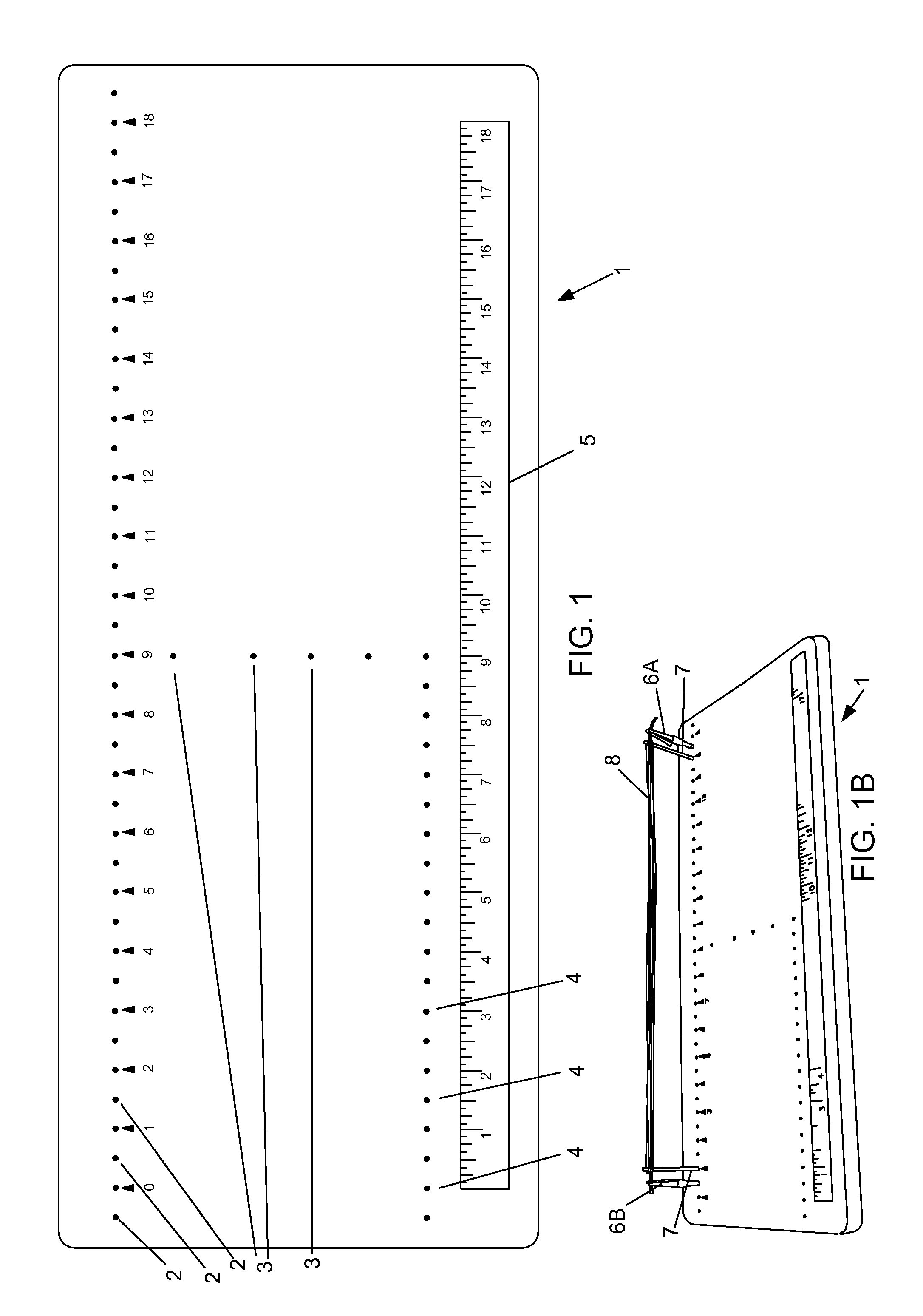

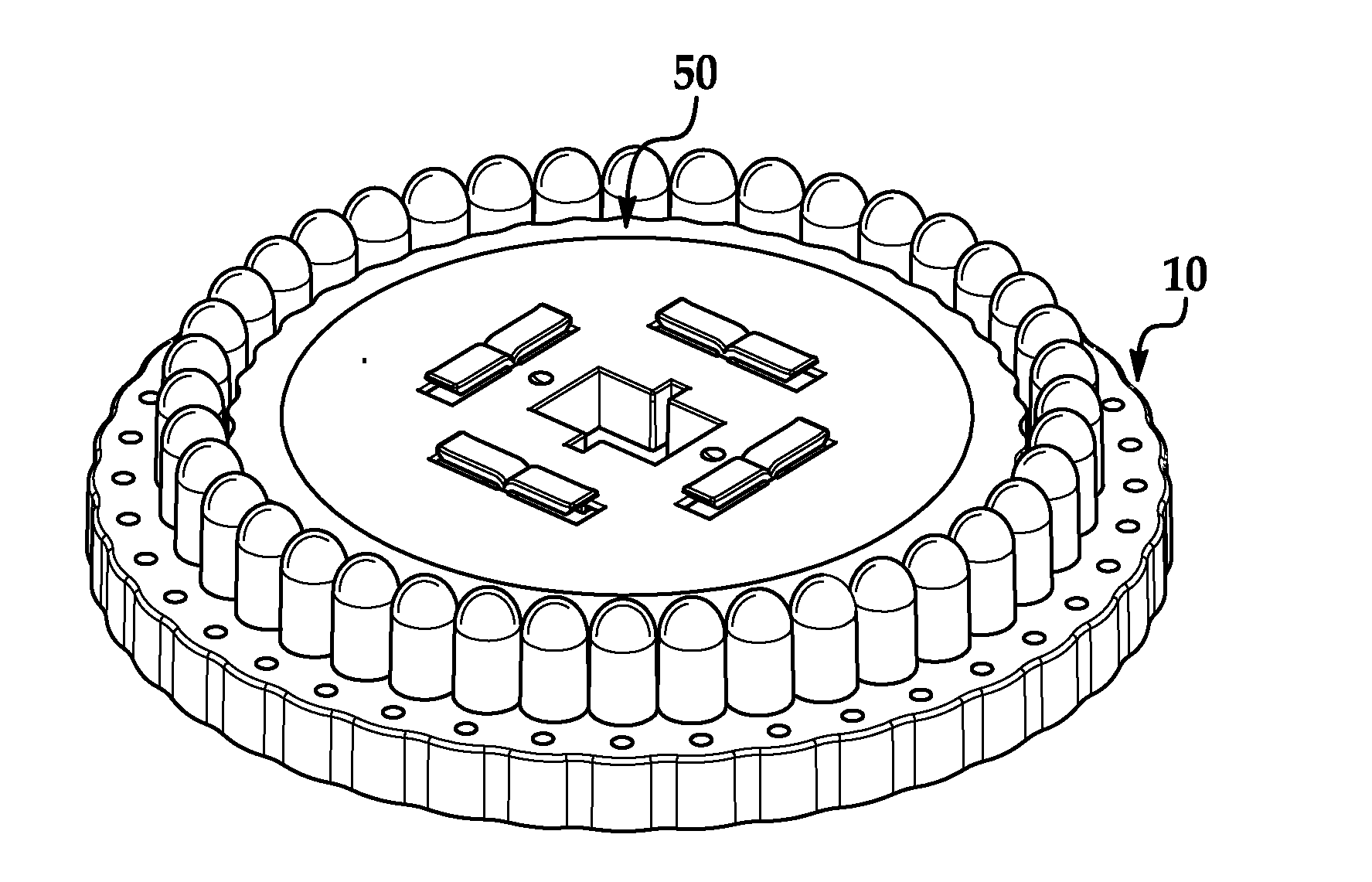

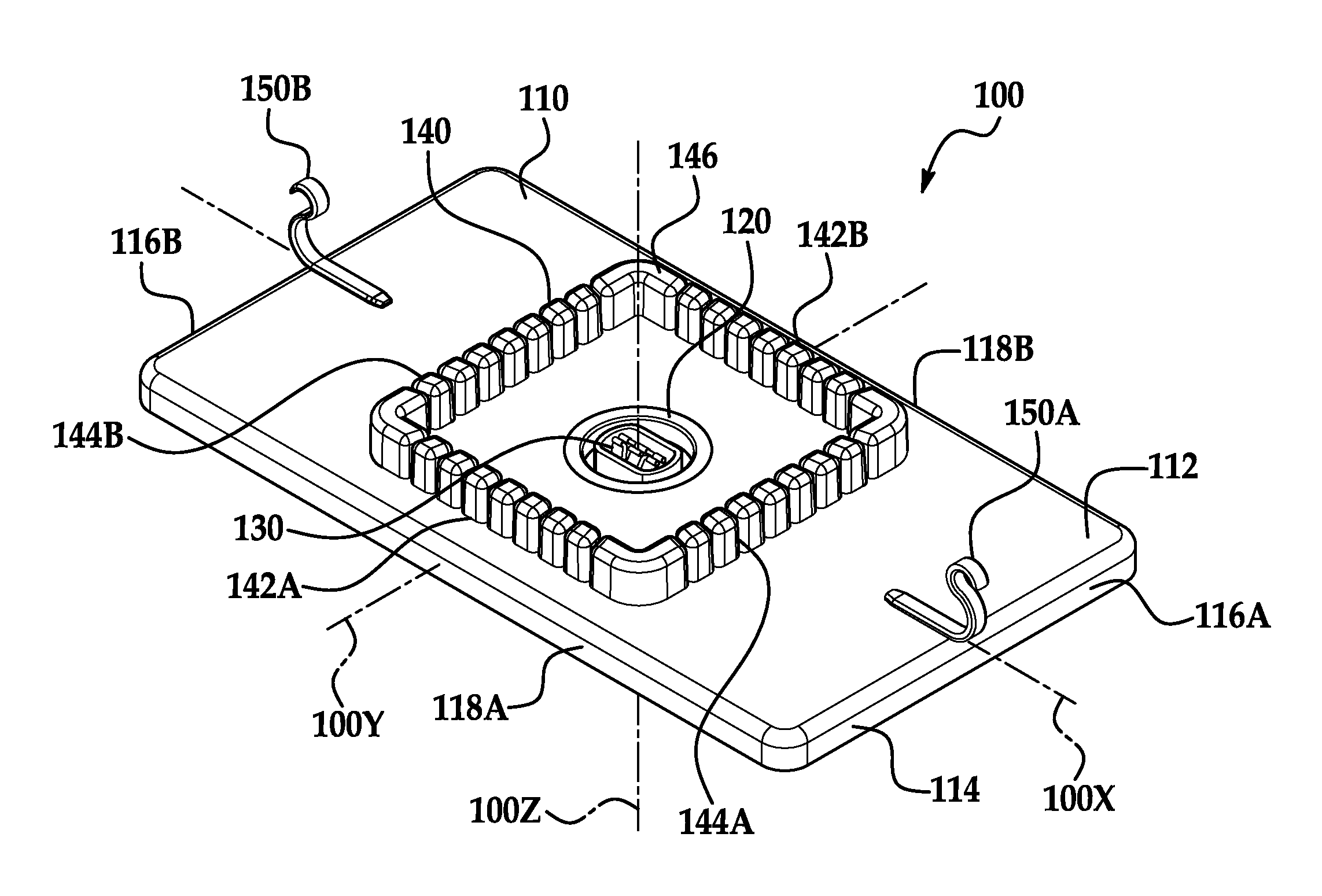

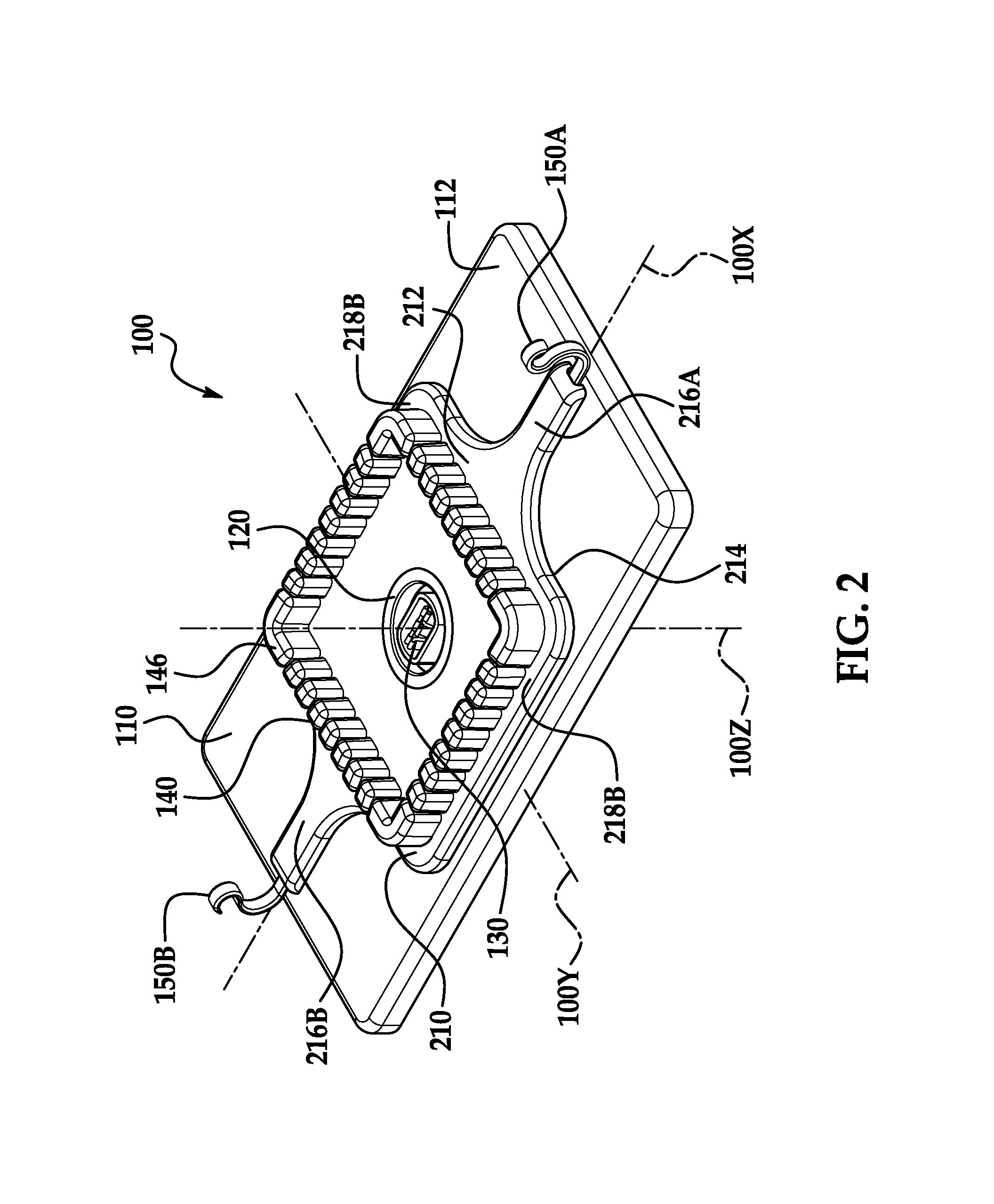

Device and kit for making knotted string accessories

Disclosed herein are embodiments of devices and kits for making knotted string accessories. Embodiments of a device comprise a base that has a substantially planar surface, a perimeter, and a center axis. Furthermore the embodiments include a plurality of holders connected to the substantially planar surface proximate to the perimeter of the base, located at a distance from the center axis, wherein the plurality of holders are configured to retain individual strings. Embodiments of a kit comprise the device, a plurality of strings for use with the device, and storage compartments.

Owner:CROREY DAVID J

Bow tying learning device

Owner:HERNDON JOHN

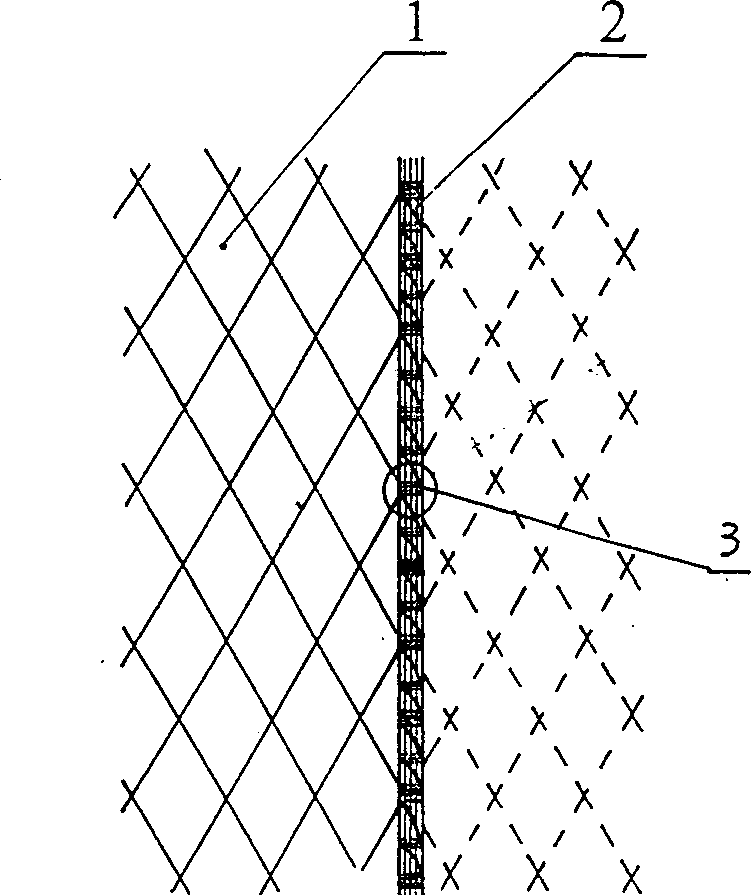

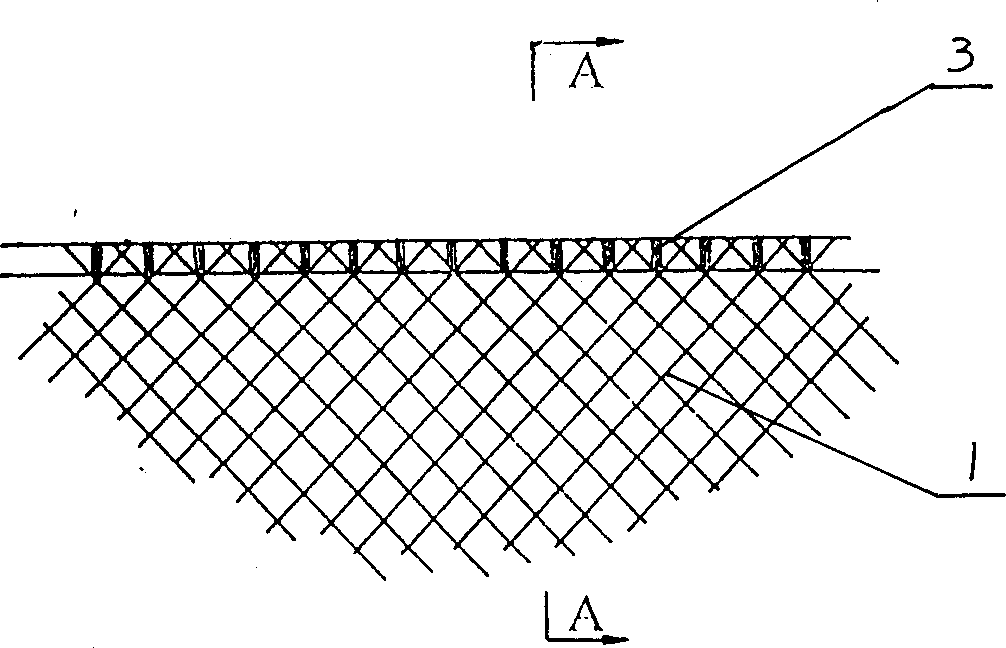

Technology for binding fish-culturing net or netted appliance

InactiveCN1354976AImprove the forceAvoid breakingClimate change adaptationKnottingEngineeringUltimate tensile strength

A technology for binding the netted appliance for culturing fish in deep sea includes such steps as cutting the netted fabric to needed shapes and sizes, sewing and binding with ropes, and features its additional edge-binding step. Its advantages include high strength, uniform stress, and not deforming or not being damaged by waves easily.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

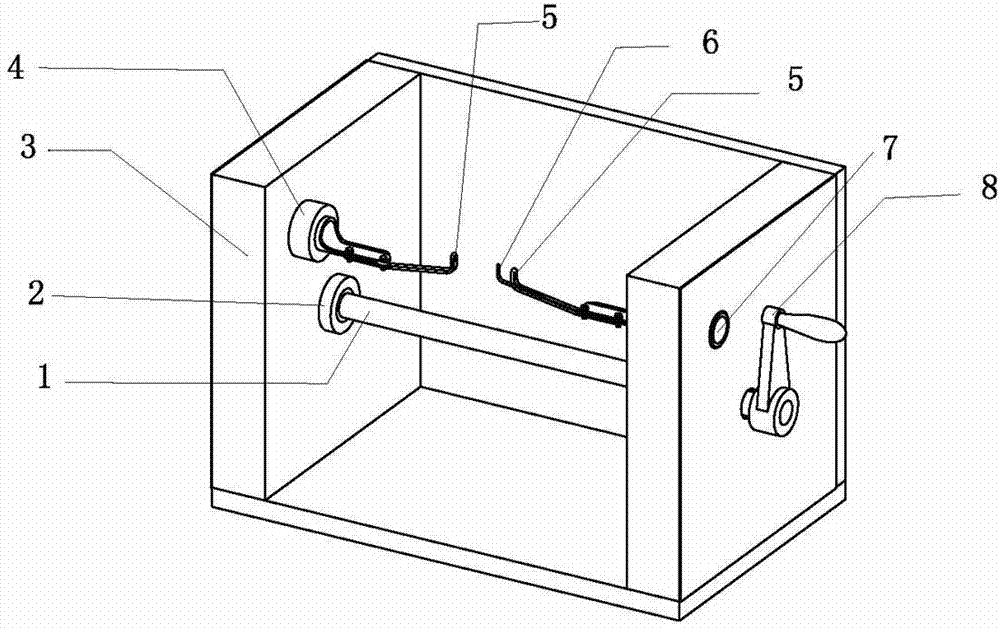

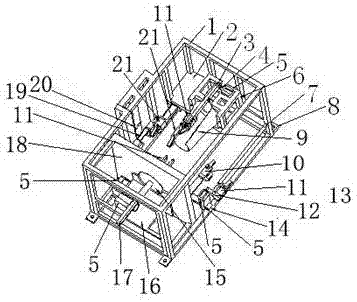

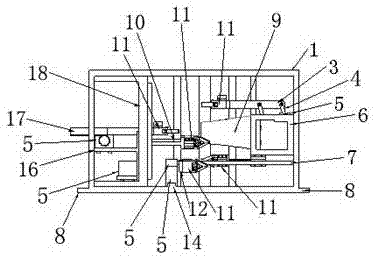

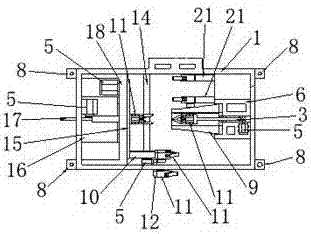

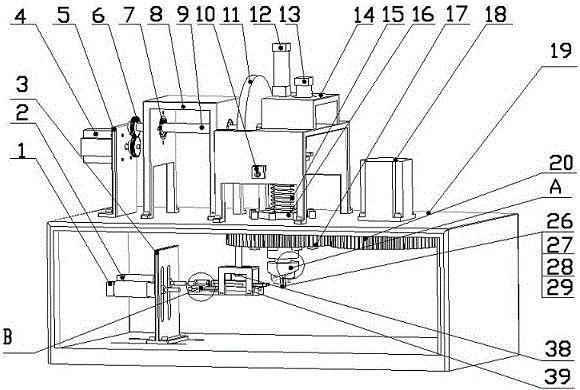

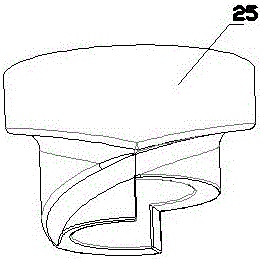

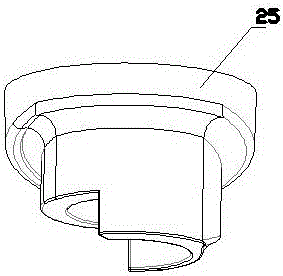

Knot tying machine and knot product preparation method thereof

The invention belongs to the field of machinery and provides a knot tying machine and a knot product preparation method. In the knot tying machine, a spindle penetrates through the inside of a case to be fixed on end plates on two sides of the case by bearings; two ends of the spindle are respectively positioned outside the end plates on the two sides and are respectively provided with driving gears; driven shafts are fixedly arranged on the end plates on the two sides of the case by bearings respectively; one ends of the driven shafts are fixedly provided with driven gears and the other ends of the driven shafts are positioned inside the case; the driving gears are meshed with the driven gears; the driven shafts on the two sides of the case are respectively provided with fixing hooks for fixing rope yarns; the driven shaft on one side of the case is also provided with a yarn winding hook; and the yarn winding hook is arranged between the fixing hooks at two ends of the case. The knot tying machine is provided with a yarn feeding hole and a discharging hole and can avoid intertwining between knot products; and through the adoption of the knot tying machine, mechanical production of the knot products is realized and the manufacturing efficiency and the product quality are improved.

Owner:杨艳香

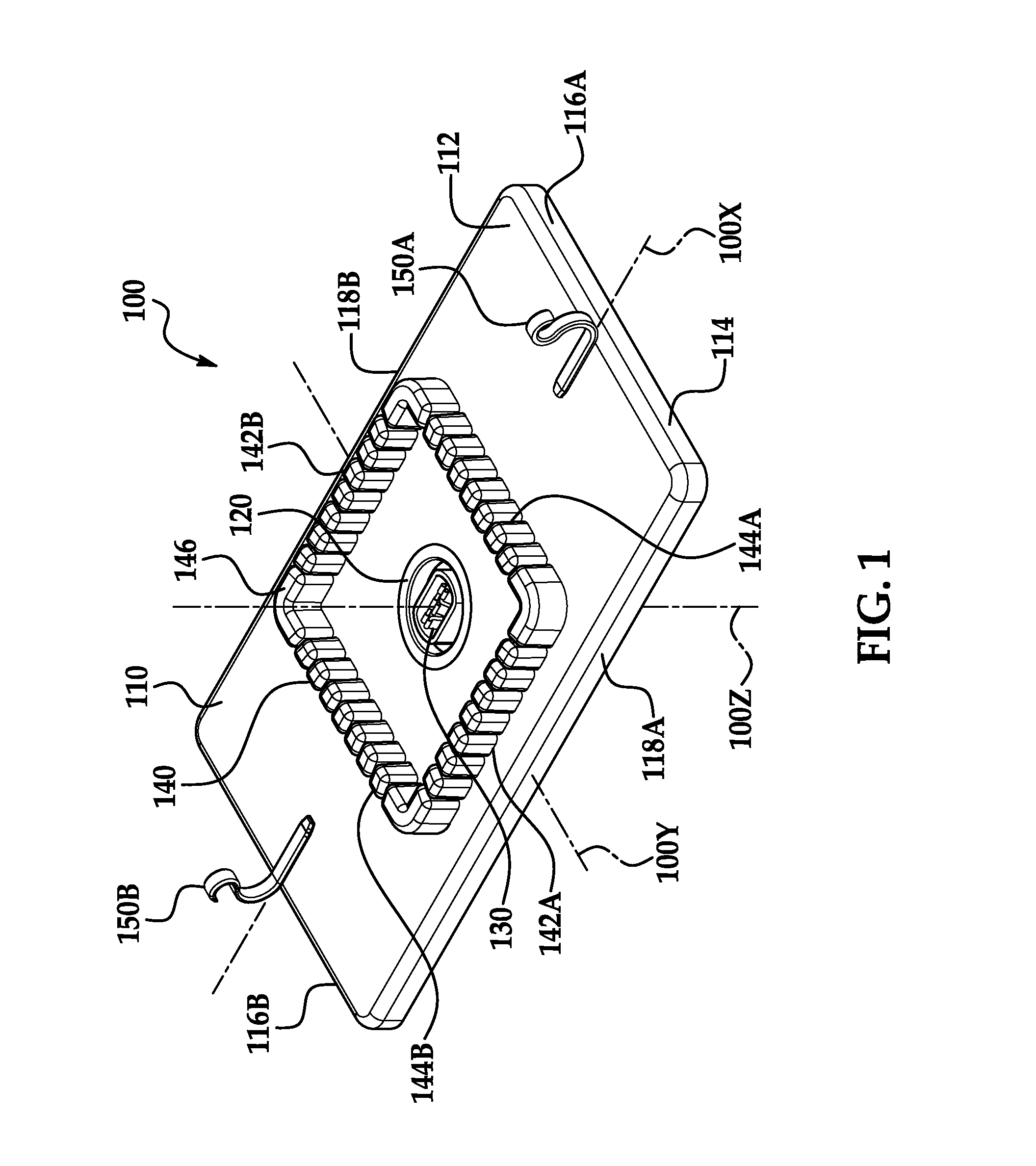

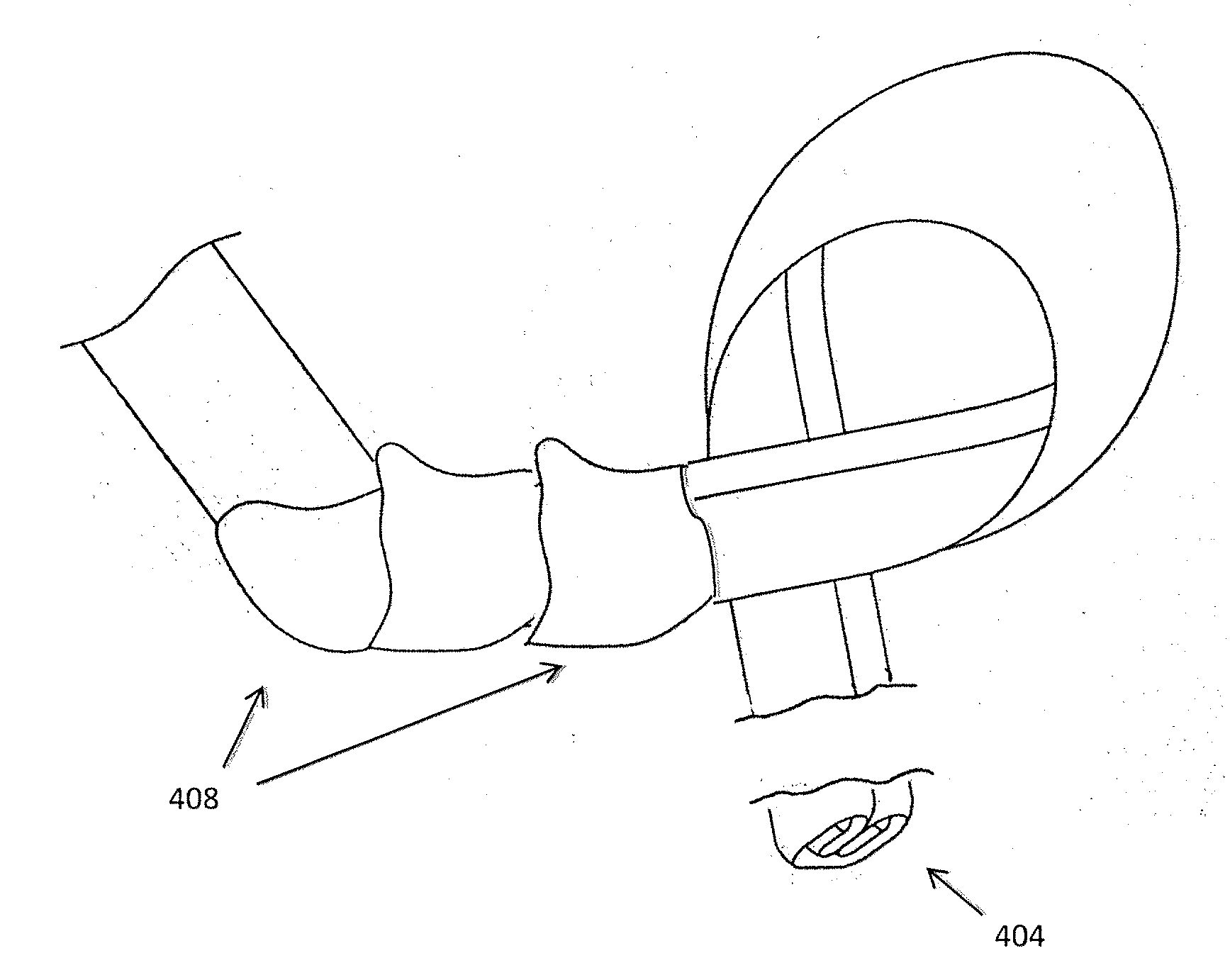

Device and kit for making knotted lanyard accessories

Disclosed herein are embodiments of devices for making knotted string accessories. Embodiments of the device may include a center axis, a base having a substantially planar surface such that the center axis extends perpendicular to the substantially planar surface of the base, a securing member proximate to the center axis and configured to secure a central portion of each of a plurality of individual strings, and a plurality of holders connected to and extending away from the substantially planar surface of the base, the plurality of holders configured to retain a first end portion and a second end portion of each string in the plurality of individual strings, the plurality of holder spaced apart from and positioned symmetrically about the securing member.

Owner:CROREY DAVID J

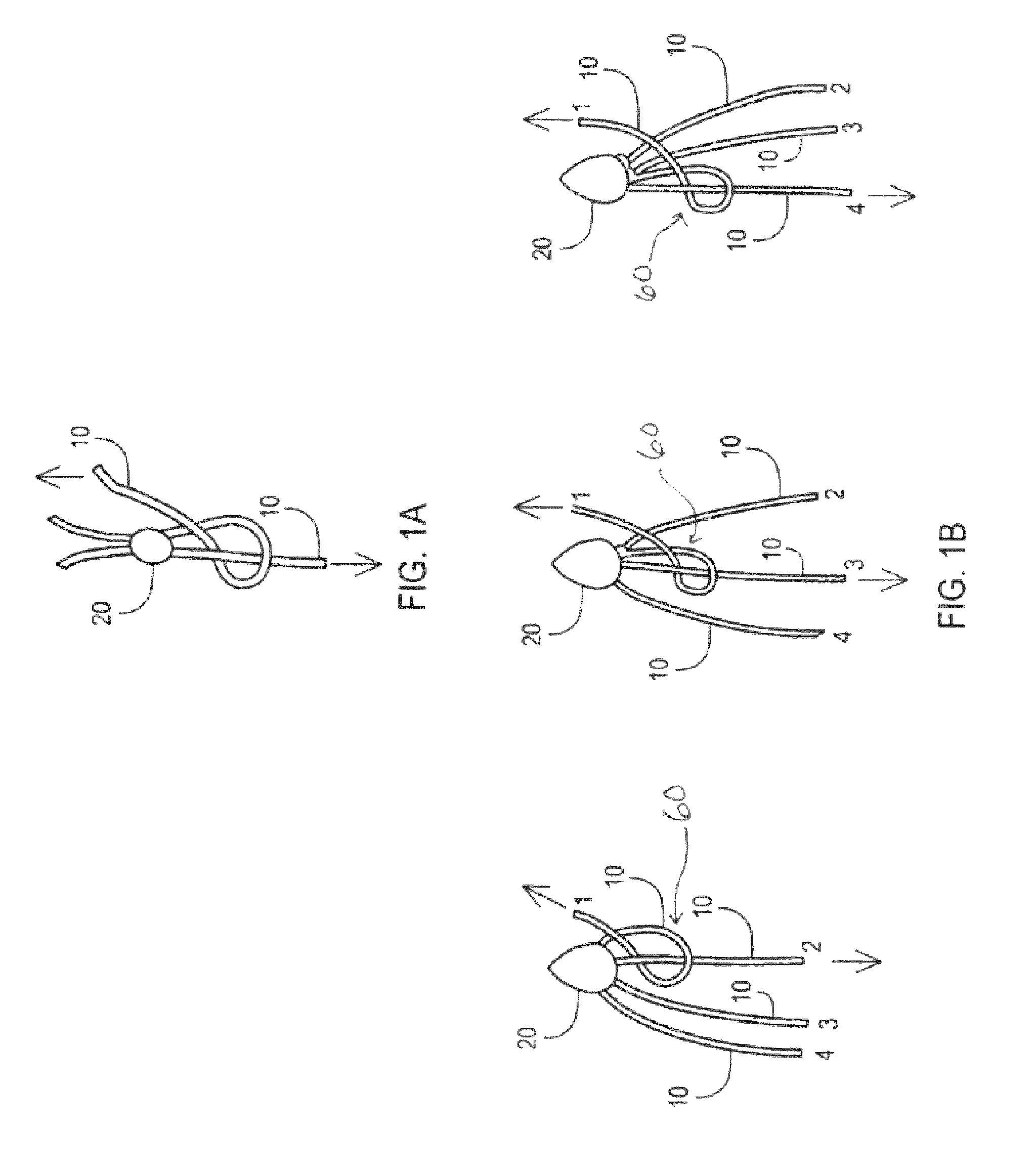

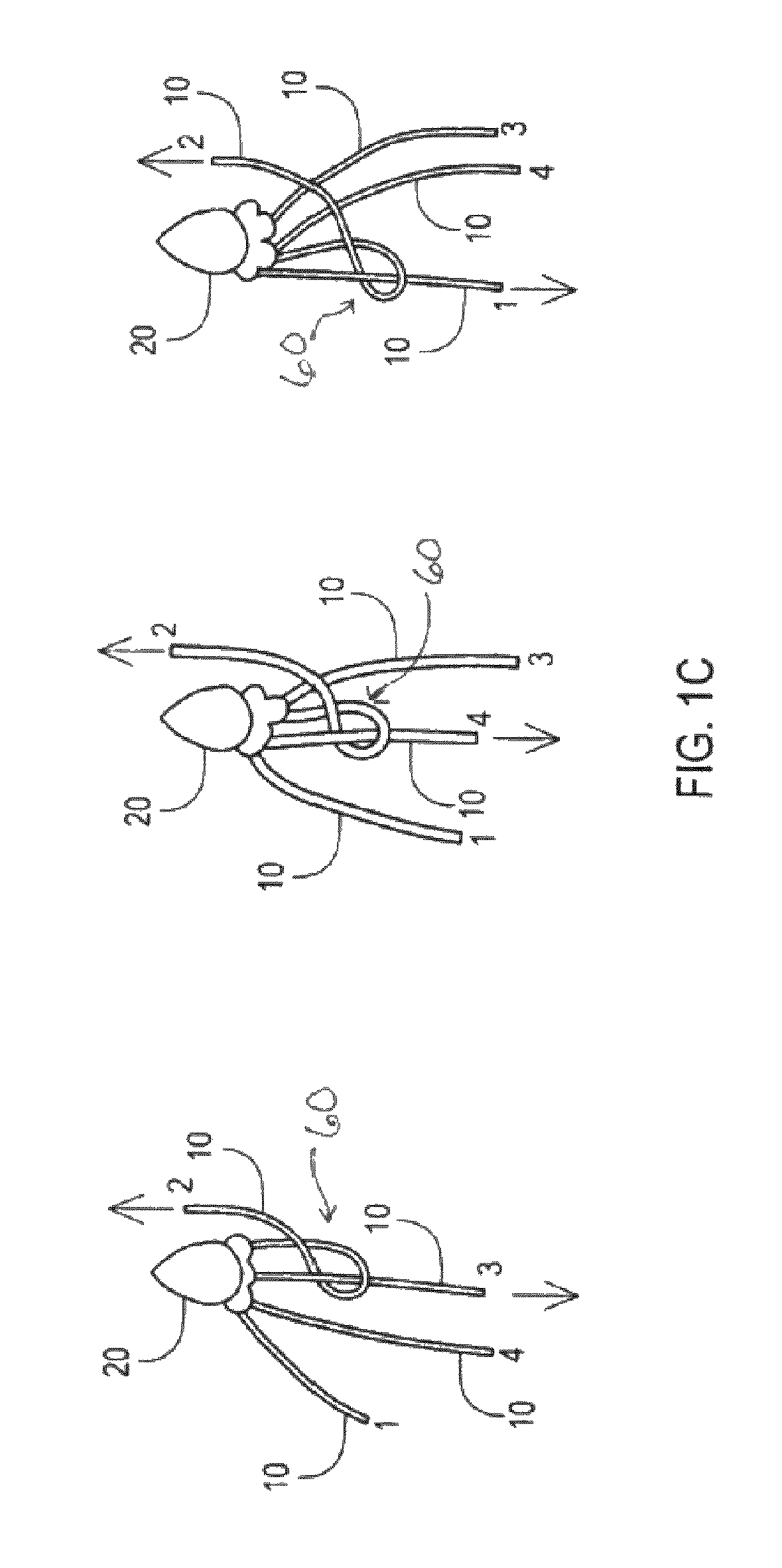

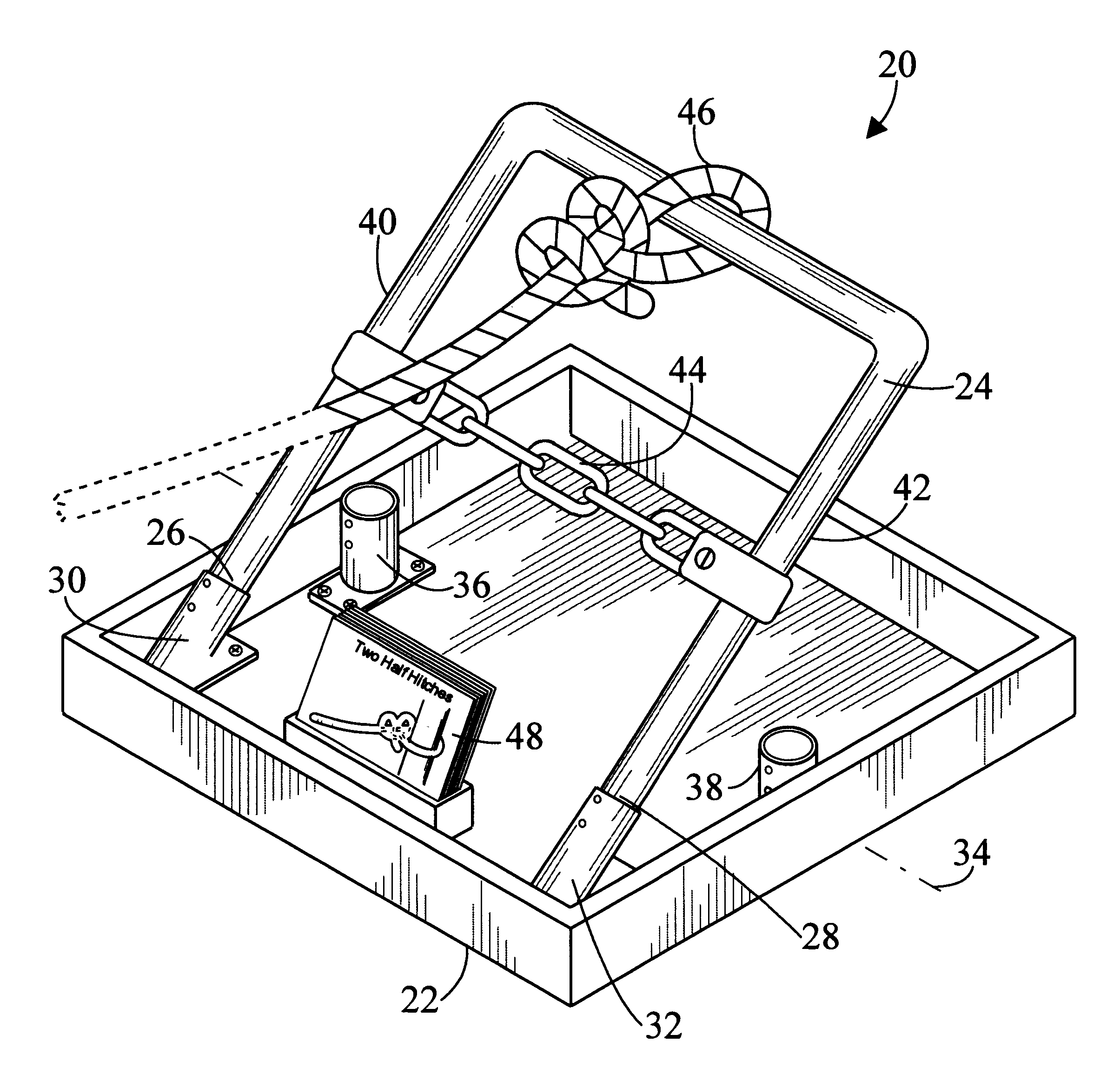

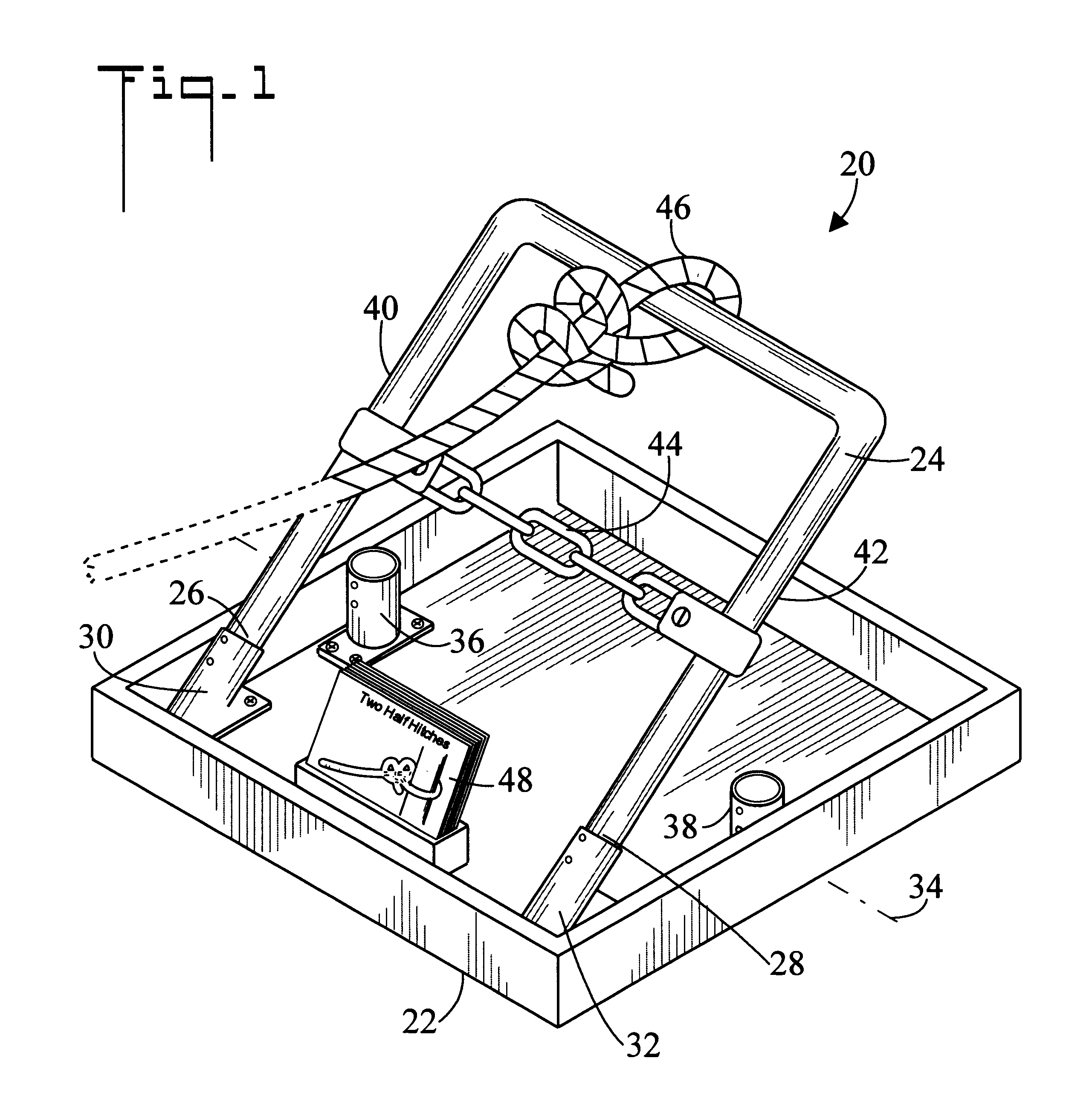

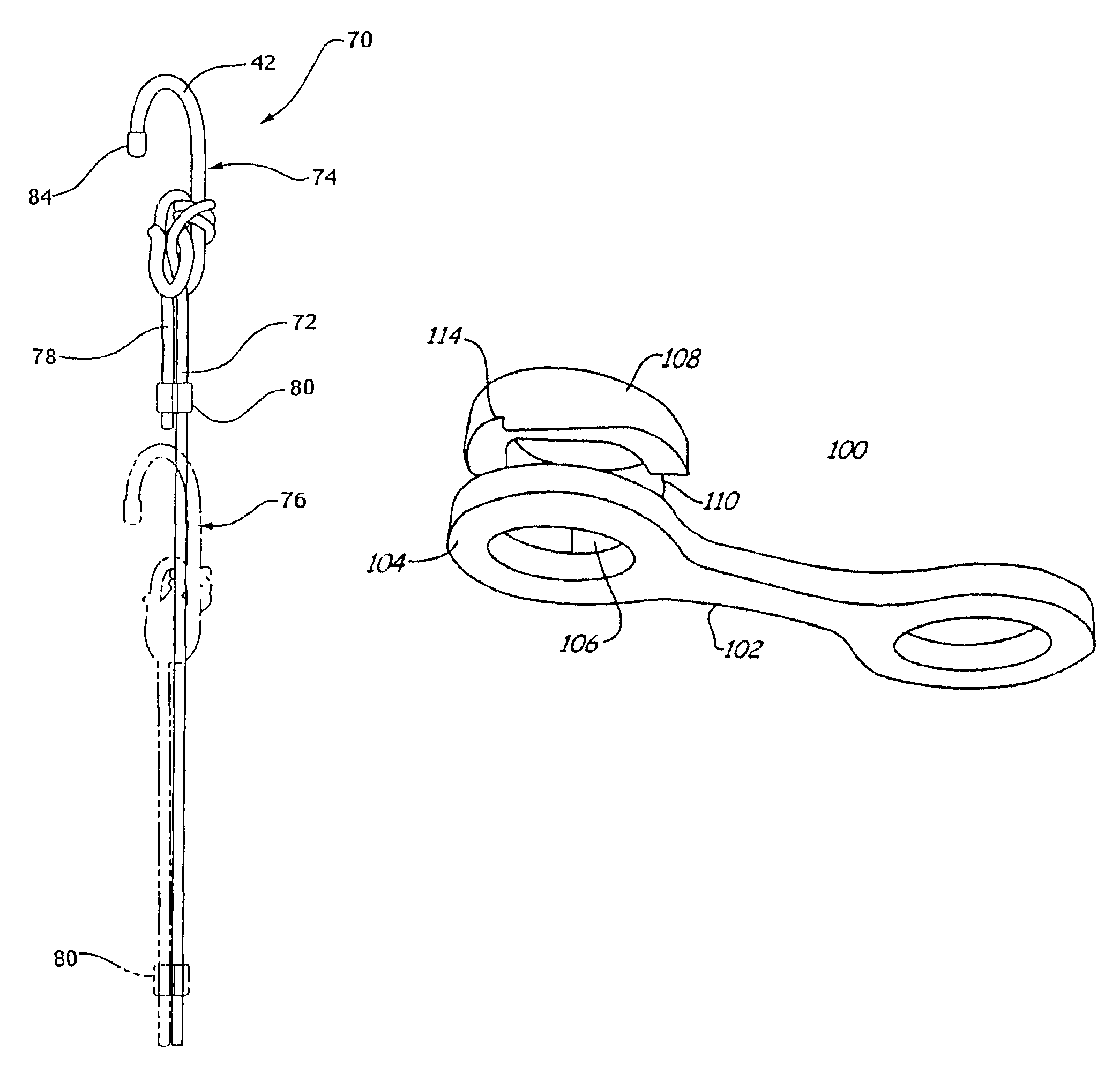

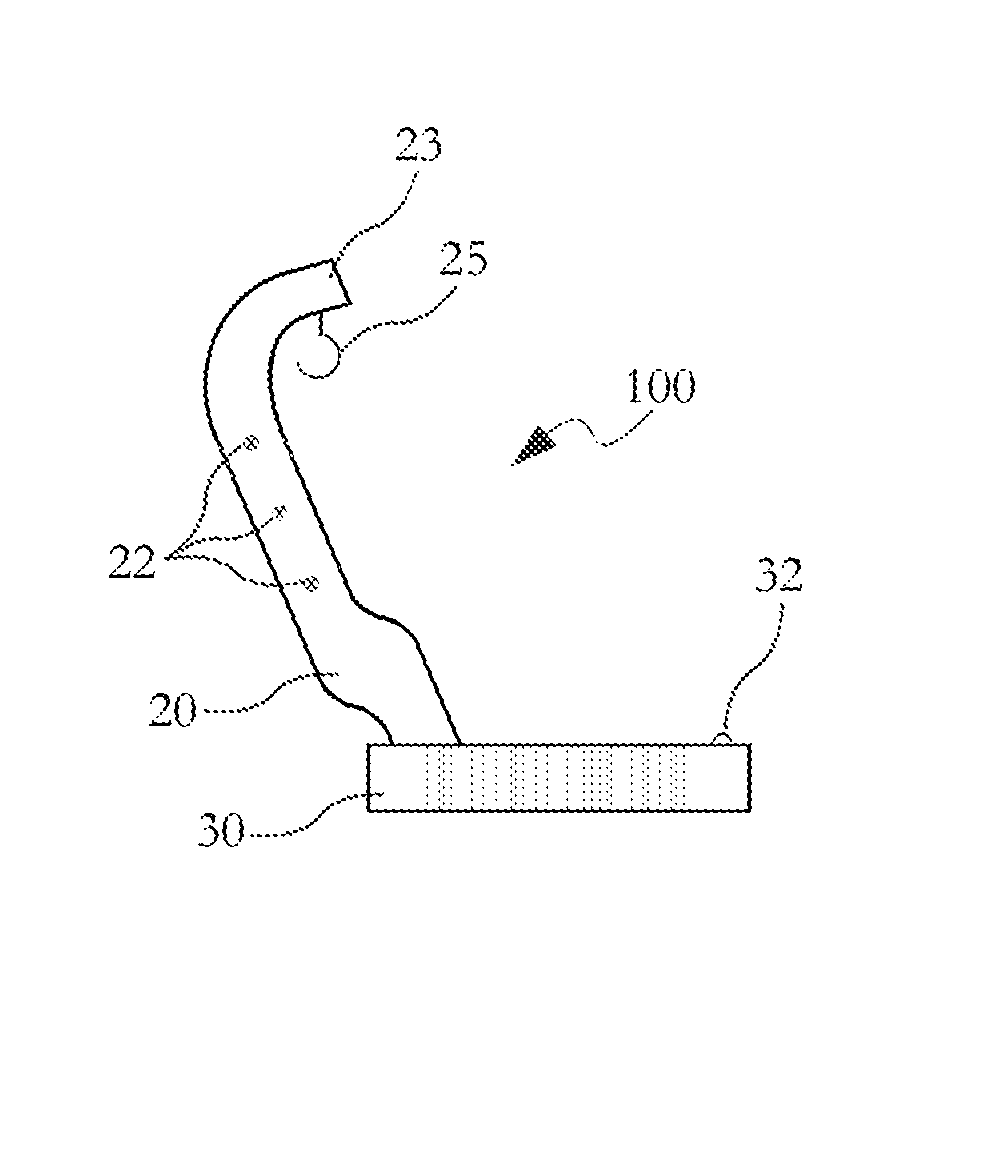

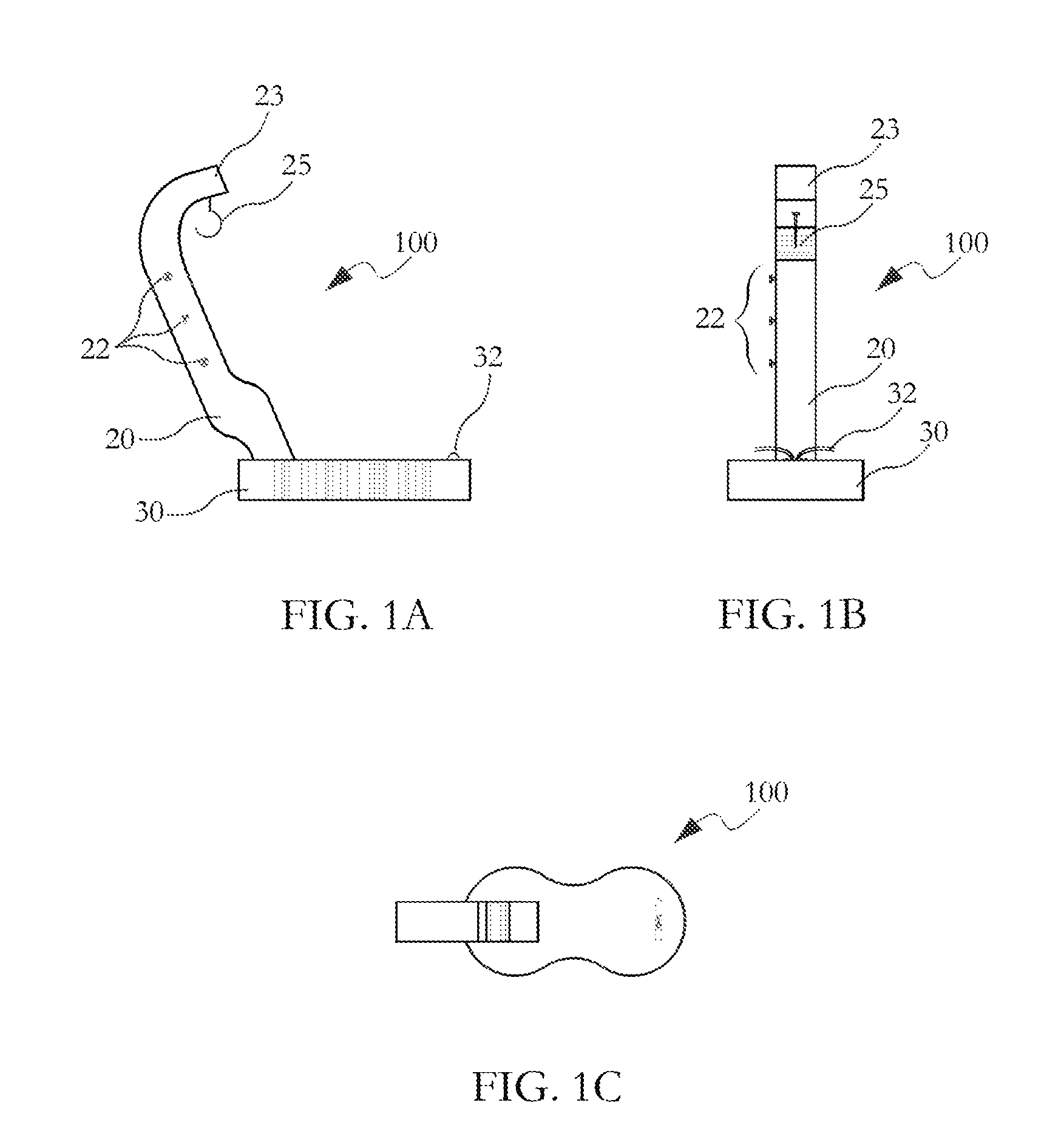

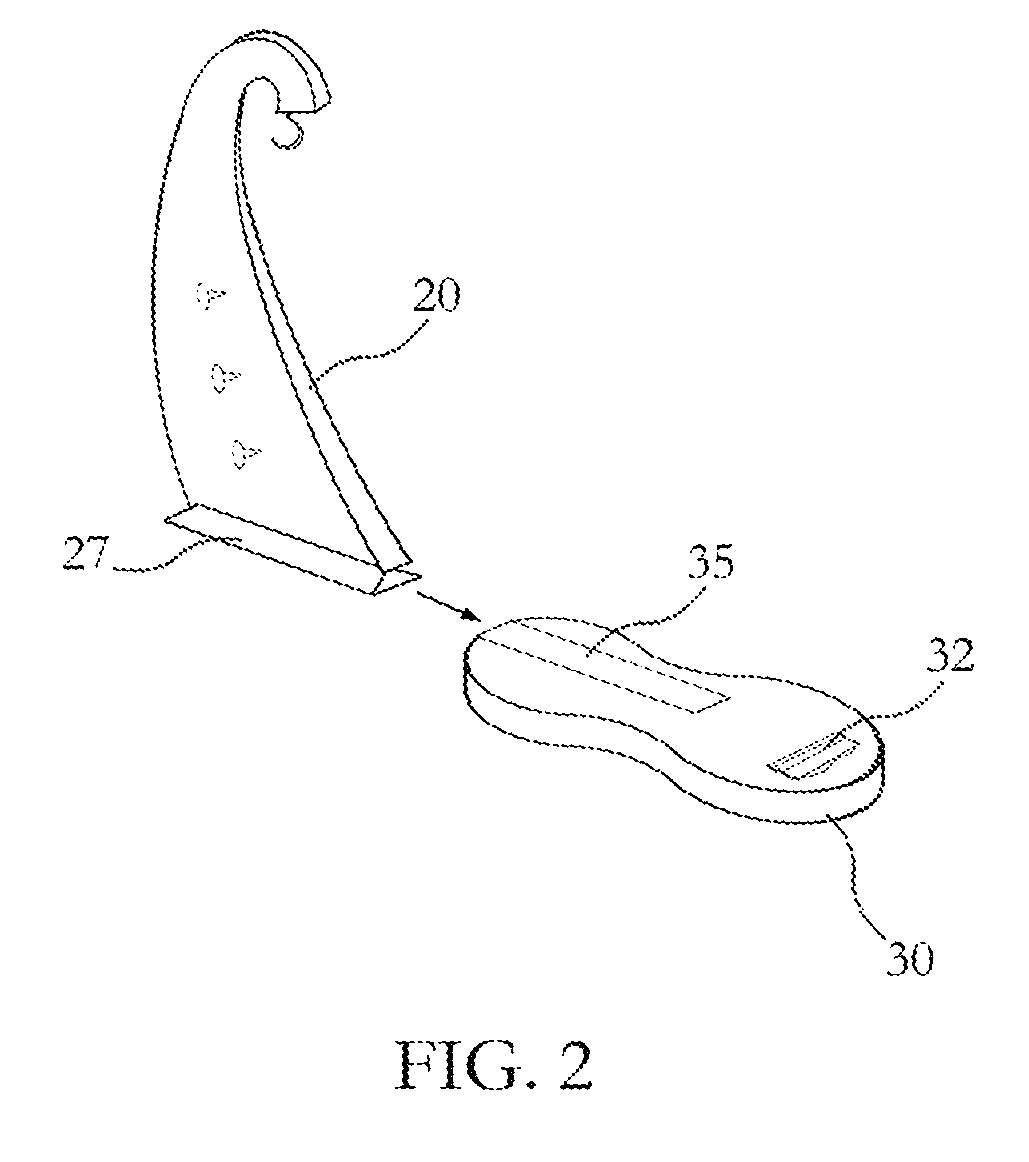

Apparatus for practicing knot tying and method of use

InactiveUS6217086B1Easy to transportEasy to disassembleKnottingFilament handlingEngineeringKnot tying

An apparatus for practicing knot tying (20) includes a base (22) to which is attached an inverted U-shaped member (24). A chain (44) is connected between the arms (40, 42) of the U-shaped member. A user then uses a rope (46) to practice tying knots about the U-shaped member and the chain. The chain can also be used to affix a rope for practicing the tying of bends. Knot-tying instruction cards (48) assist in the practice process.

Owner:LETOURNEAU DANA

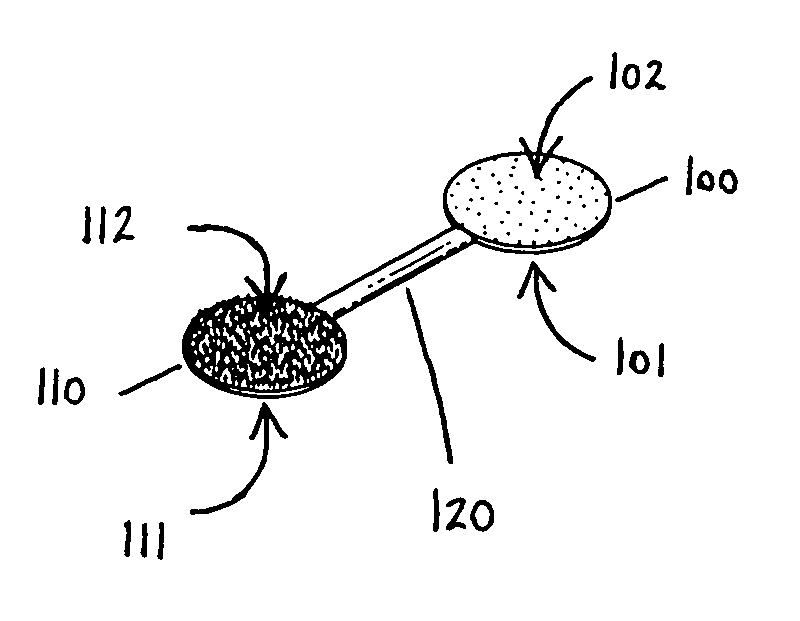

Pigtail fastener

An apparatus for releasably securing a line having a cross sectional thickness and at least one free end. The fastener has a shaft dimensioned for wrapping the line around the shaft. The shaft has a pair of ends at least one of which includes: an insertion structure extending from the end that defines an insertion opening and a retaining structure extending from the end a distance greater than the cross sectional thickness of the line. The retaining structure defines a retention aperture operably dimensioned smaller than the cross sectional thickness of the line. When the free end of the line is inserted through the opening, positioned adjacent the shaft, wrapped around the shaft and positioned in the retention aperture, the line is thereby releasably secured.

Owner:PIGTAIL FASTENER

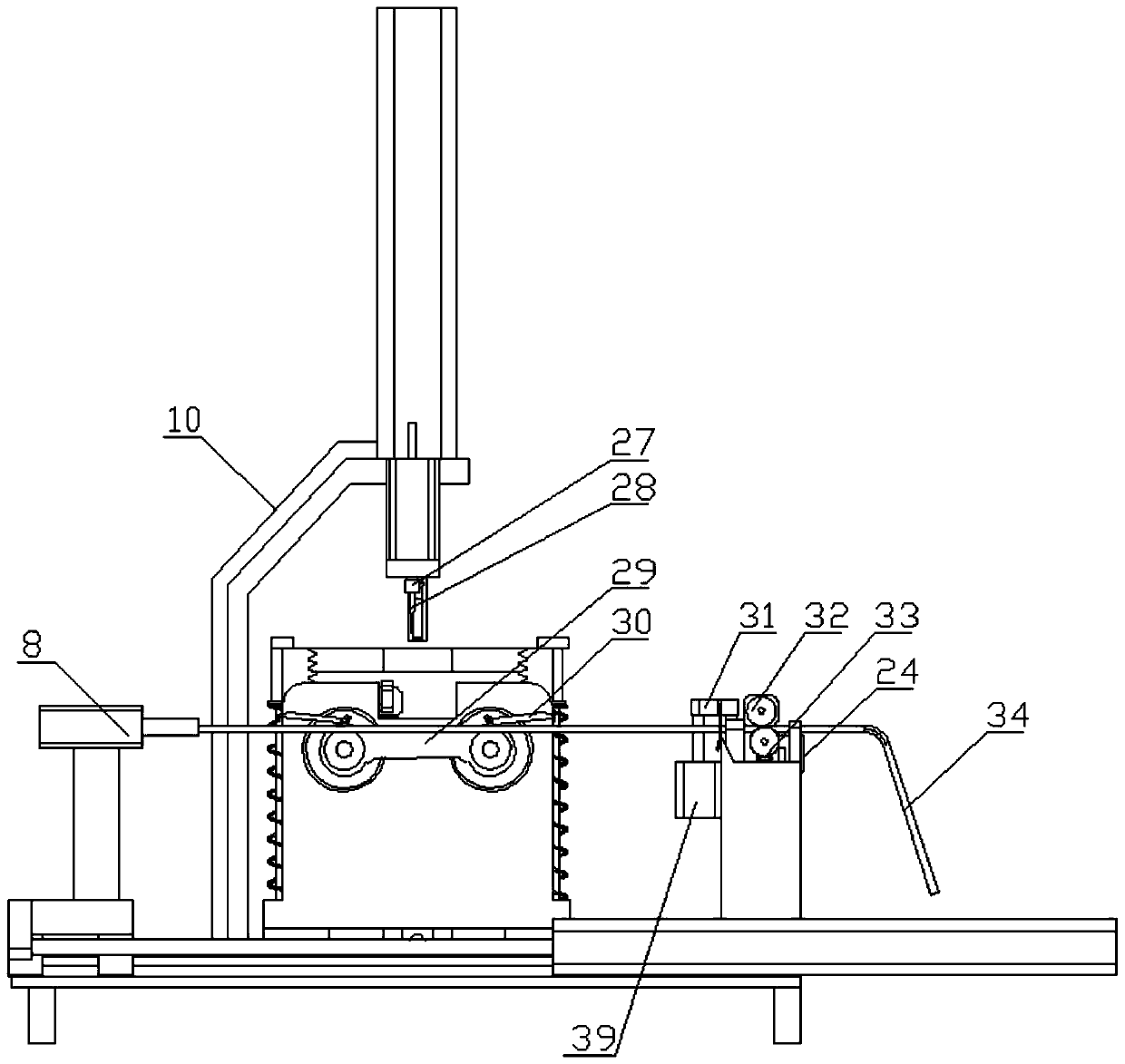

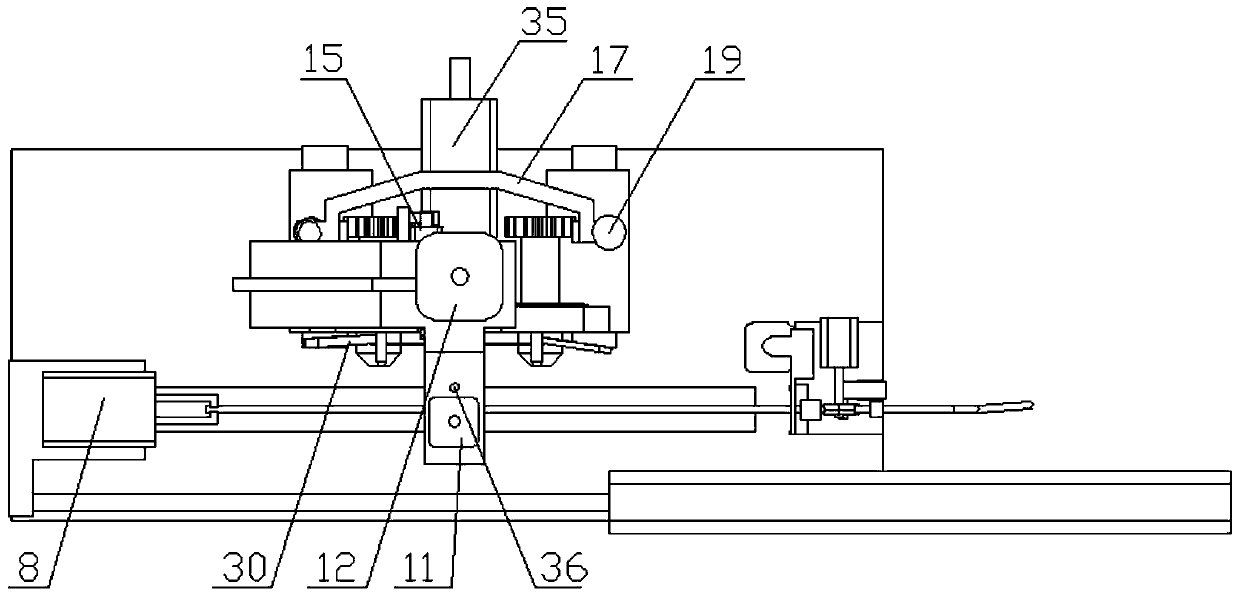

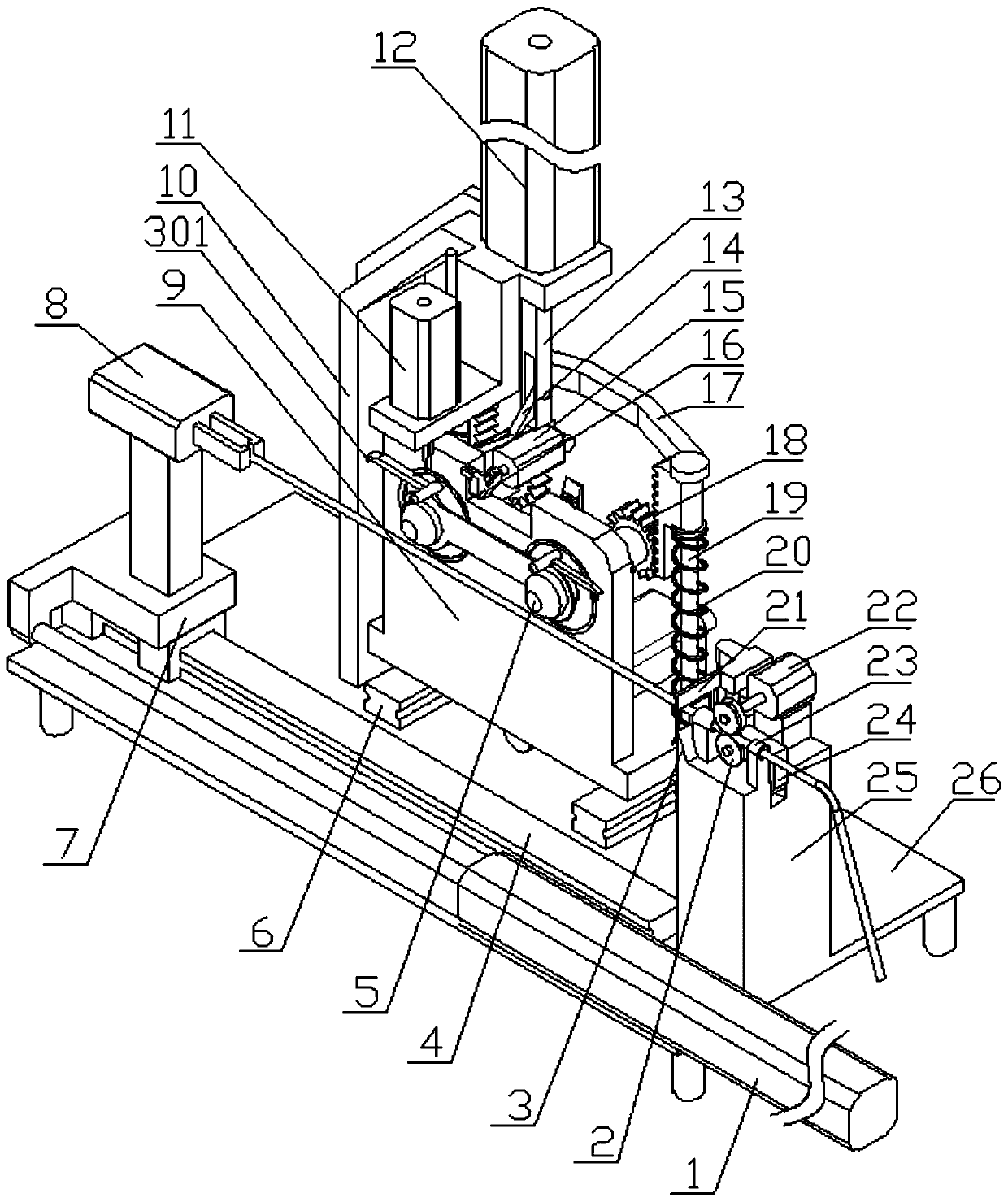

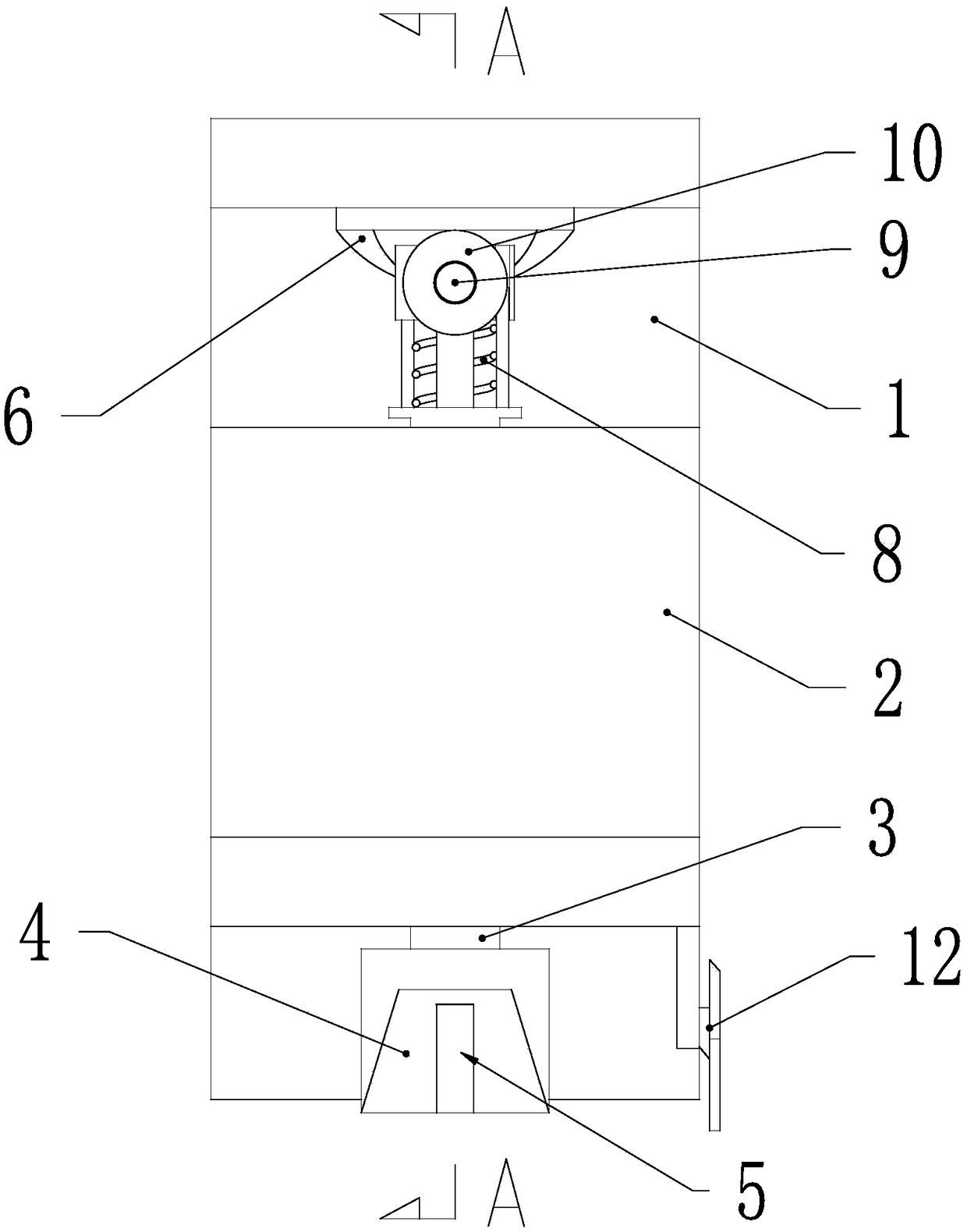

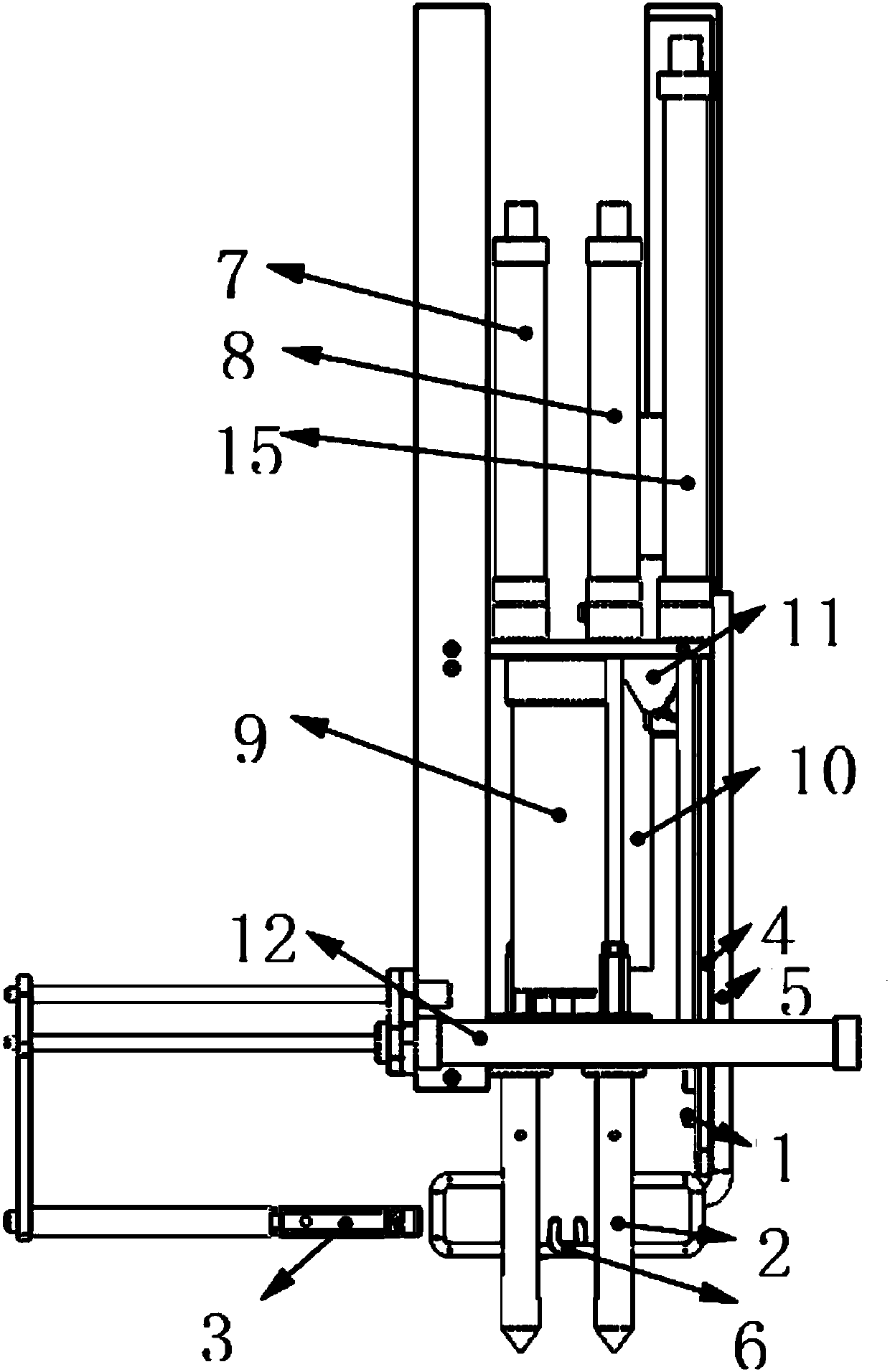

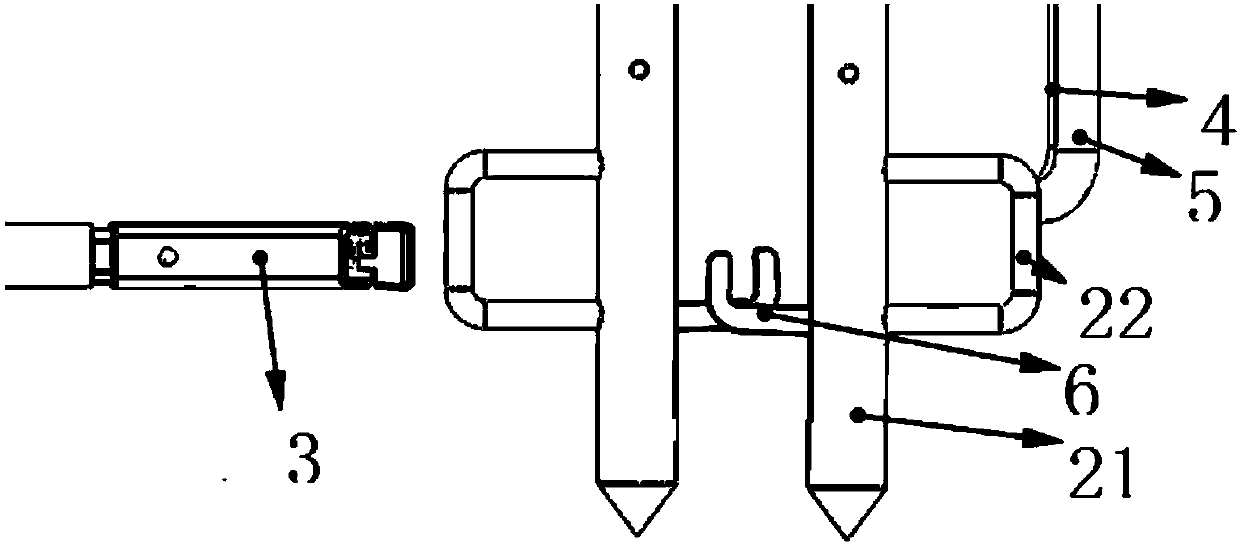

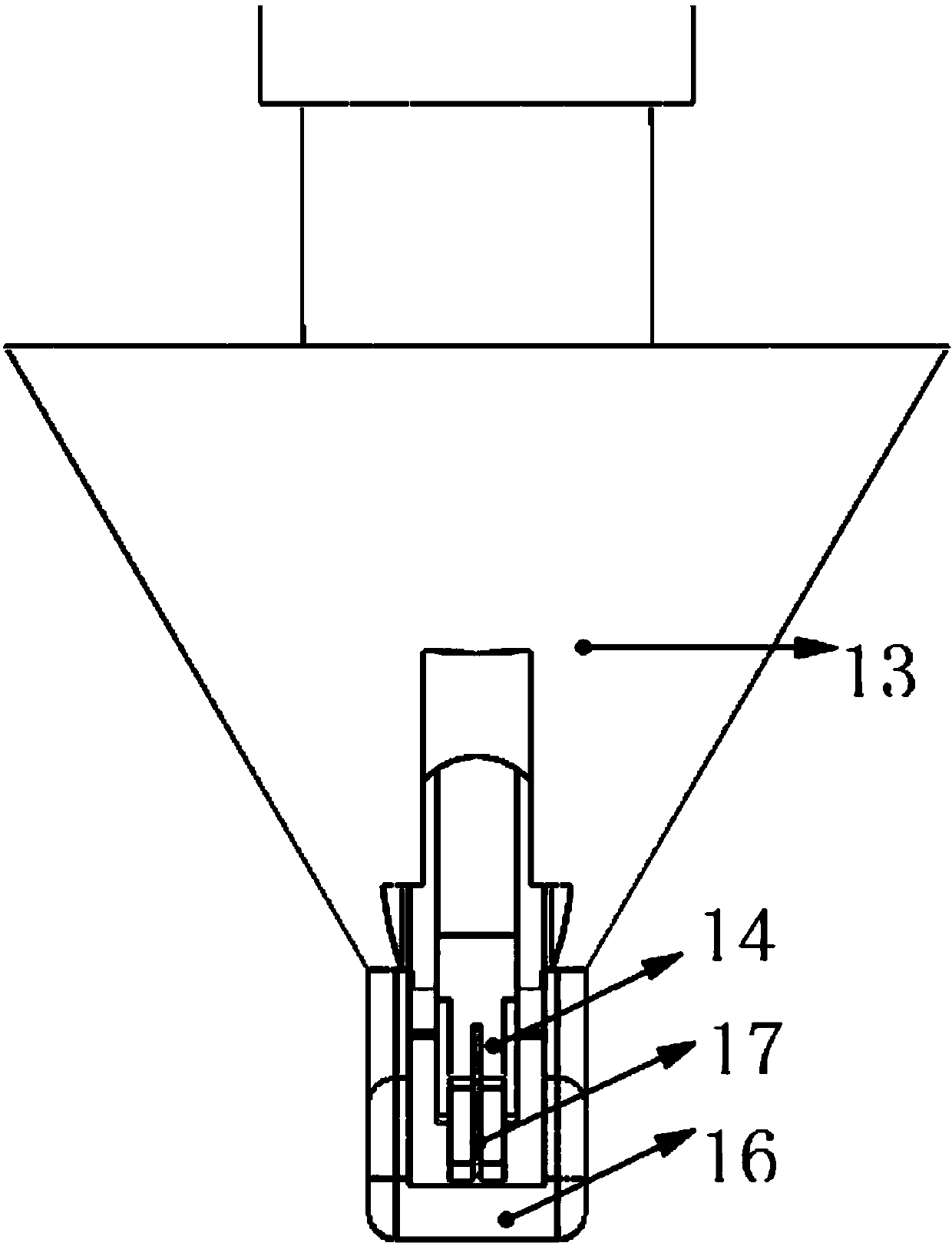

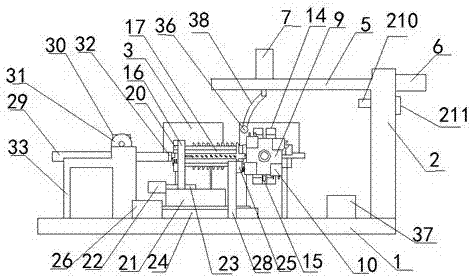

Bowknot rope automatic forming machine for shoemaking

InactiveCN111254579ARealize automatic formingRealize clamping and feedingKnottingSevering textilesRotational axisMolding machine

The invention discloses a bowknot rope automatic forming machine for shoemaking. The bowknot rope automatic forming machine for shoemaking comprises a machine base, a cutting-off device, a rope pulling device, a sliding plate frame, two rotating shafts, and a driving device, wherein a feeding device is mounted at one end of the machine base through a support seat and is used for clamping and feeding of a bowknot rope; the cutting-off device is mounted at the part, located on one side of an outlet of the feeding device, of one end of the machine base through the support seat and used for realizing sizing cutting; the rope pulling device is longitudinally mounted on the machine base along the machine base through a reciprocating sliding mechanism and is used for clamping and pulling out theto-be-knotted bowknot rope sent out through the feeding device; the sliding plate frame is mounted on the machine base through two sliding guide rails, is connected with a feeding air cylinder mountedon the machine base, and is used for pushing the sliding plate frame to reciprocate along the sliding guide rails; the two rotating shafts are rotatably mounted on the sliding plate frame in parallel; rope winding rods are mounted on shaft shoulders, close to the front end, on the two rotating shafts, and are used for driving the bowknot rope to be wound and formed during rotation; and the driving device is mounted on the sliding plate frame and is in transmission connection with the rotating shafts. The machine has the advantages of being high in automation degree, high in manufacturing efficiency, low in labor intensity and good in product consistency.

Owner:JINHOU GRP WEIHAI SHOES

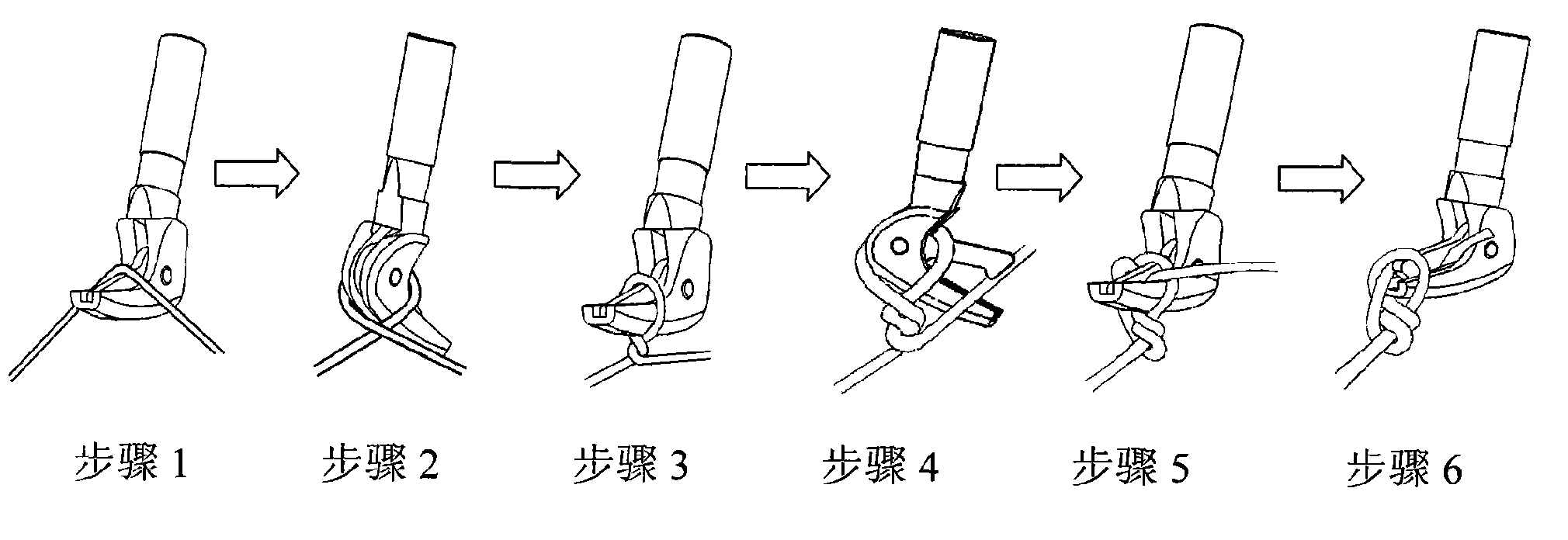

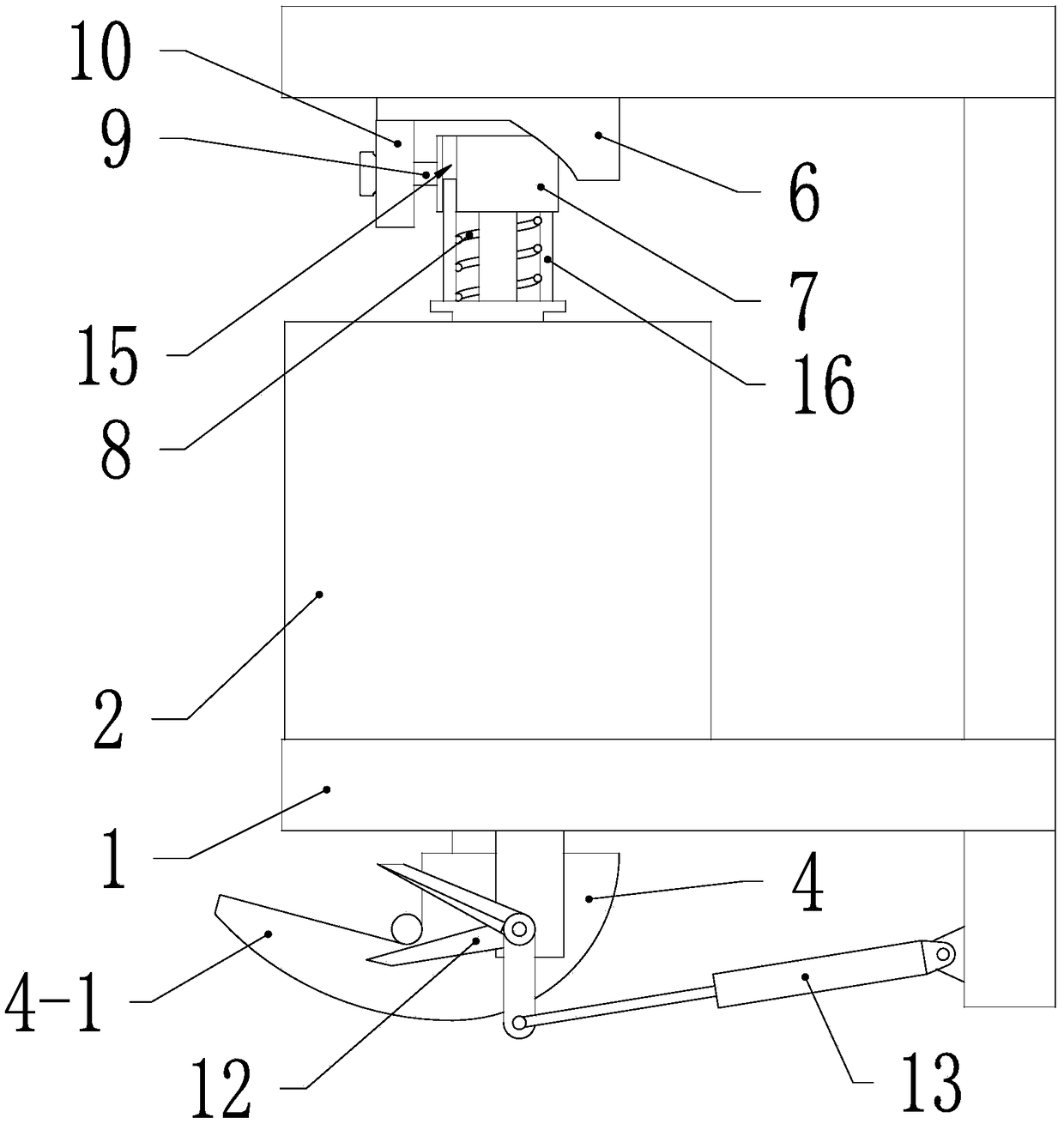

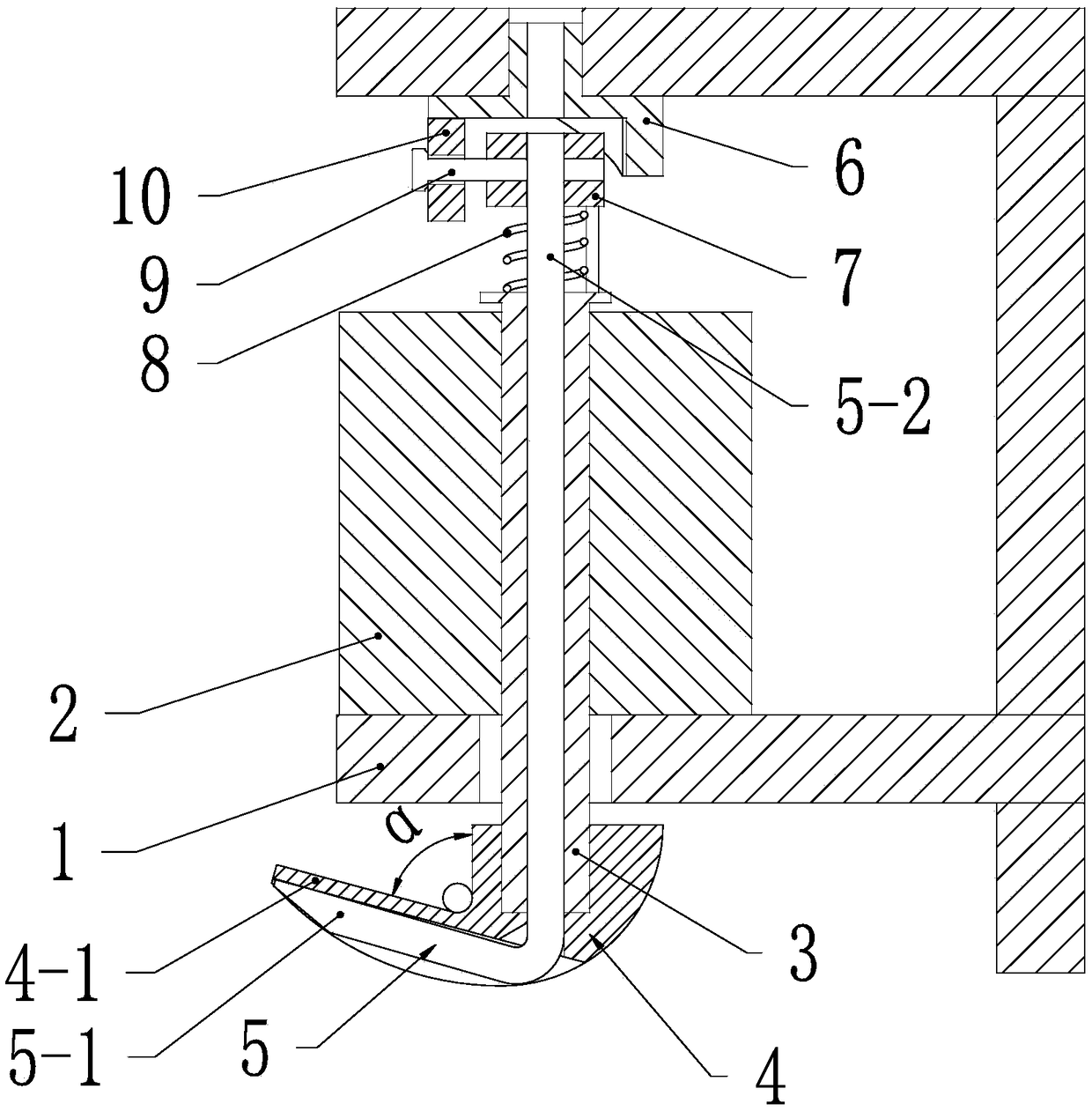

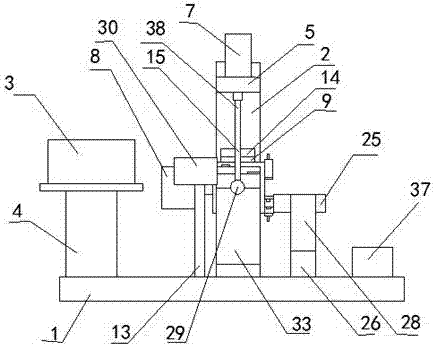

Hank tie knotting device used for hank reeling machine

PendingCN109338589ARealize automatic knottingImprove efficiencyKnottingOther manufacturing equipments/toolsAutomationEngineering

The invention relates to a hank tie knotting device used for a hank reeling machine. The hank tie knotting device comprises a rack, a hollow-shaft motor is fixedly connected with the rack, one end ofa rotary shaft of the motor is connected with a knotting hook, a thread clamping hook is coaxially arranged in the rotary shaft, the thread clamping hook comprises a movable hook head and a hook handle which are mutually connected, the hook handle can slide axially and is inserted into a central hole of the rotary shaft, the two ends of the hook handle stretch out of the rotary shaft, the movablehook head and the knotting hook are arranged at the same end of the rotary shaft, and the movable hook head of the thread clamping hook is located on the outer side of a fixed hook head of the knotting hook. The rack is further provided with a driving mechanism used for driving the thread clamping hook to move forth and back in the axial direction of the rotary shaft, and the thread clamping hookand the rotary shaft synchronously rotate. By means of the knotting device, a hank tie can be automatically knotted, after automation is achieved, the positions of knots of all the hank ties are same,the lengths of the hank ties are equal, and the hank tie quality is improved.

Owner:张家港市塘桥镇鹿苑鑫森纺纱厂

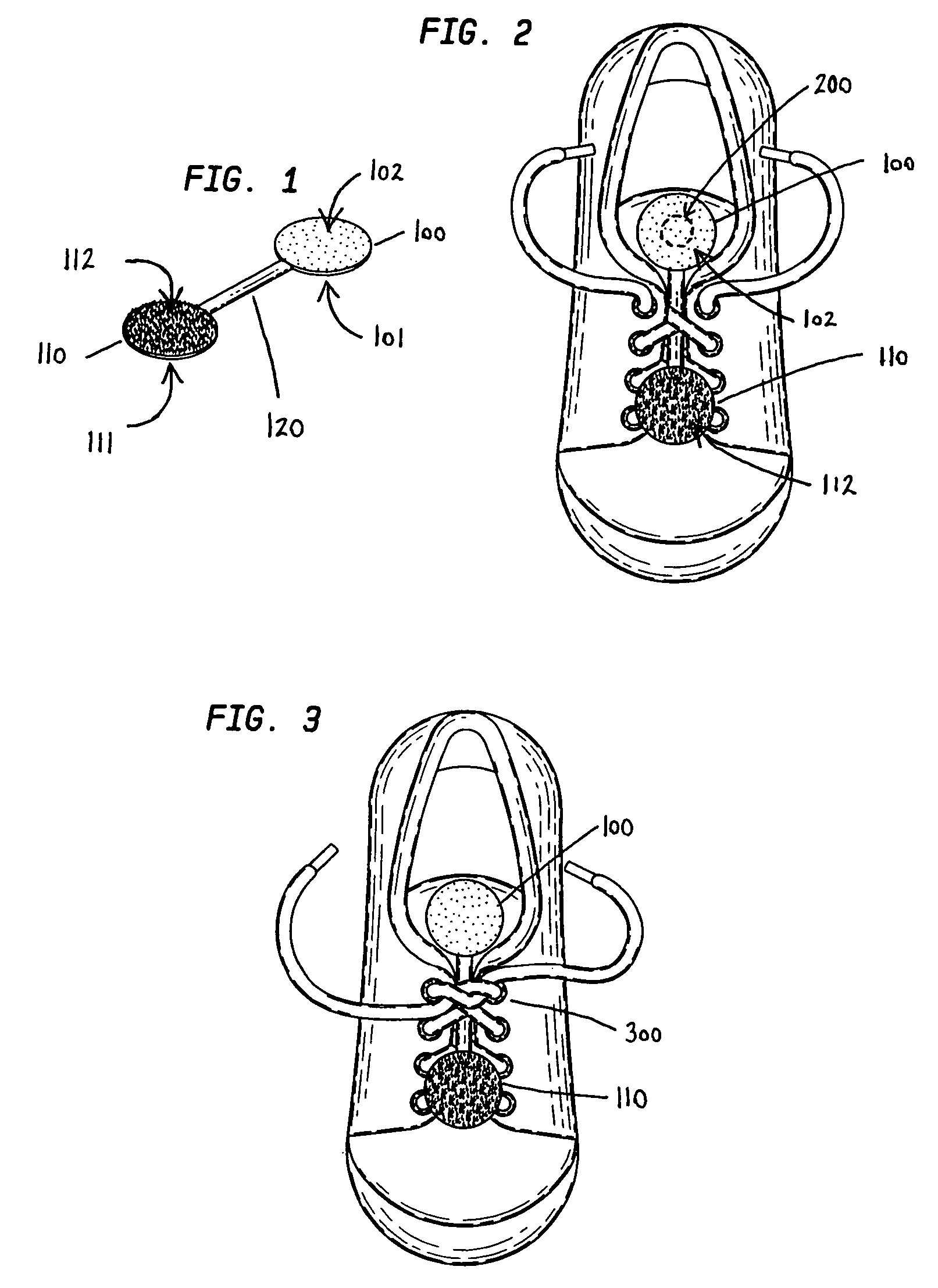

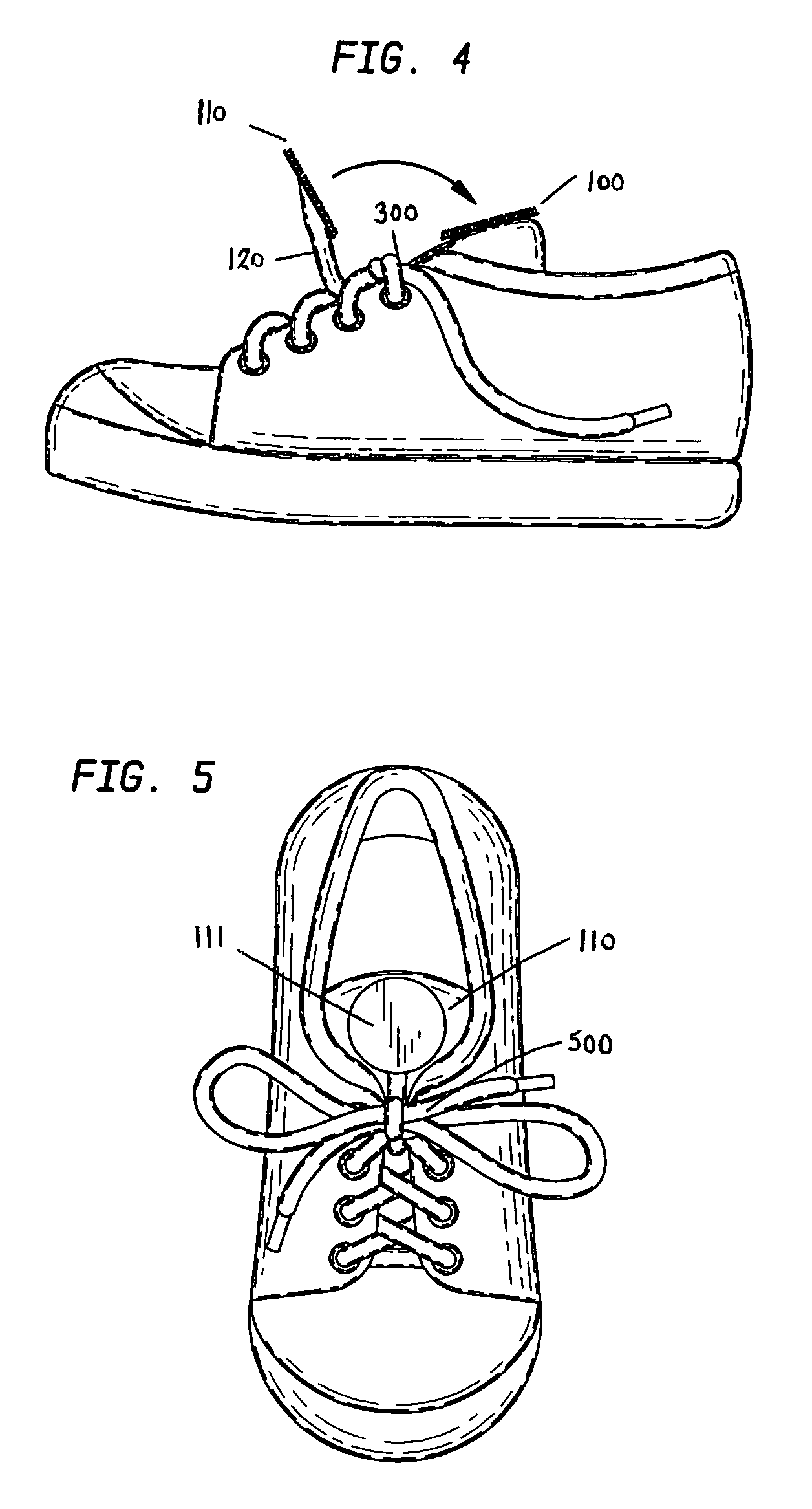

Shoelace knot assisting device

The present invention is a device for assisting users in tying their shoelaces properly. The device will help users tie bow-type knots by securing the initial crossover knot in place while the complete bow-type knot is being tied. The device can be used by children learning how to tie shoelace knots or by any person who is having difficulty tying shoelaces.

Owner:BURNS JAMES +1

Textile reeling automatic splitting tie knotting device and splitting tie knotting method

PendingCN108049021ATight knotReduce labor intensityKnottingOther manufacturing equipments/toolsYarnElectric machinery

The invention discloses a textile reeling automatic splitting tie knotting device and a splitting tie knotting method. The textile reeling automatic splitting tie knotting device comprises a thread lifting device. Thread compressing devices are arranged on the outer side of the thread lifting device, a thread clamping device is arranged on the outer end surface of a yarn machine, a vacuum copper pipe A and a vacuum copper pipe B are parallelly arranged on a side of the thread lifting device, thread lifting hooks are symmetrically arranged at the bottoms of the thread compressing devices, a cylinder A and a cylinder B are arranged on the tops of the thread compressing devices and are connected with the two thread lifting hooks, a motor A is arranged on the thread compressing devices, a motor B is arranged on a side of the motor A and is connected with a knotting machine, and the thread clamping device is connected with the outsides of the thread compressing devices by a cylinder D. Thetextile reeling automatic splitting tie knotting device and the splitting tie knotting method have the advantages that double-'8'-shaped ties can be formed by the textile reeling automatic splitting tie knotting device, the work efficiency can be effectively improved, the labor intensity of textile reeling workers can be relieved, start and end threads of reeled yarns can be effectively knotted, thread ends can be conveniently found by means of follow-up rewinding, and yarns can be effectively split and knotted by the aid of the splitting tie knotting method.

Owner:杨正云

Jewelry loom

Owner:STEVENSON LESLEY

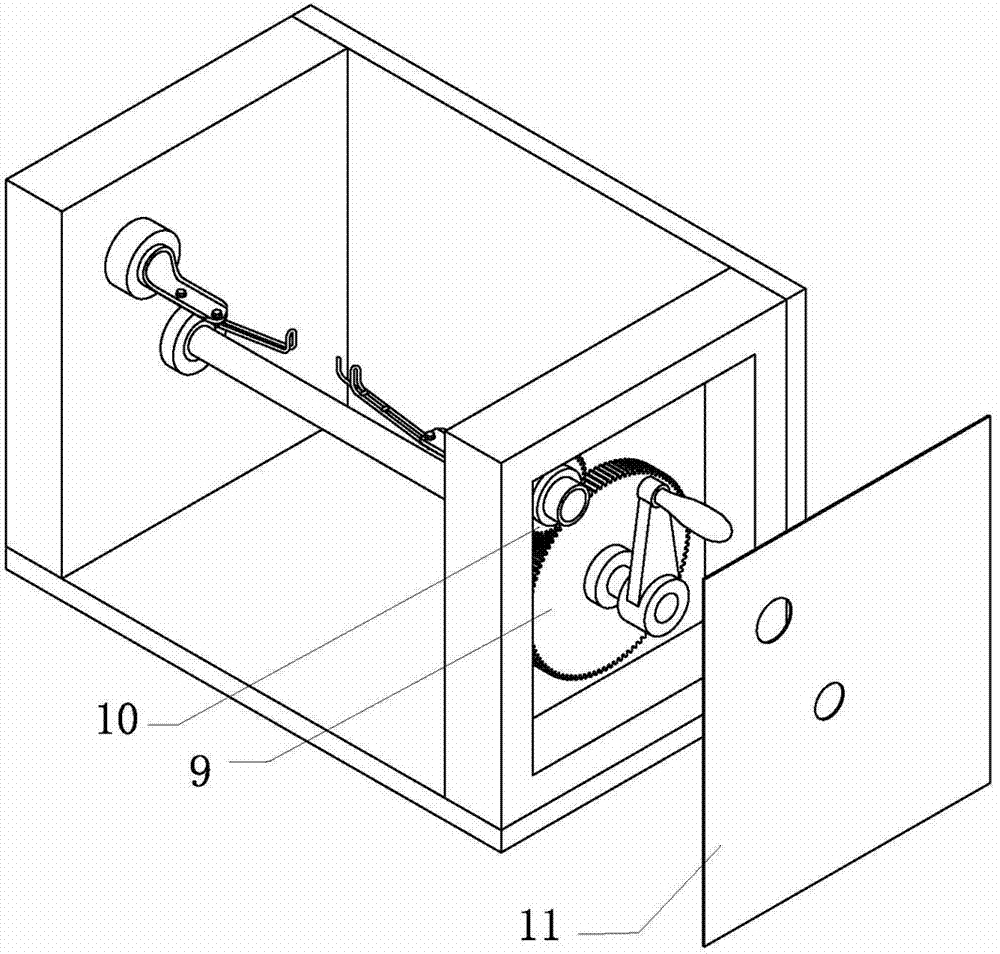

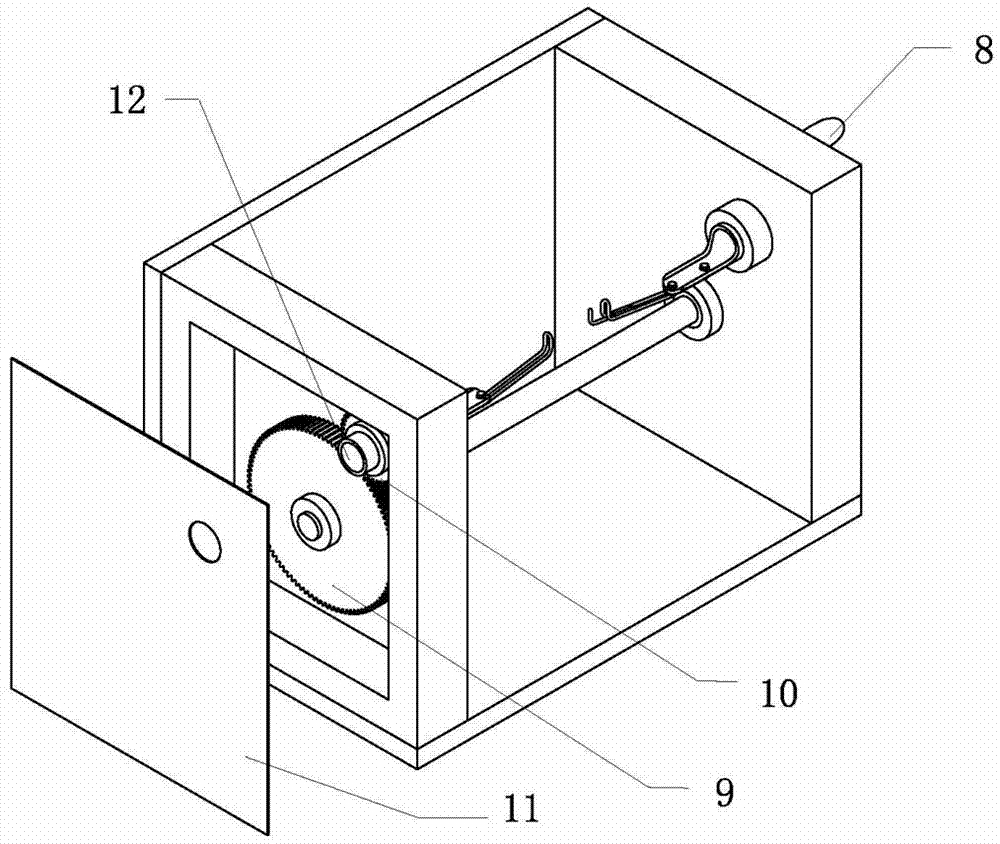

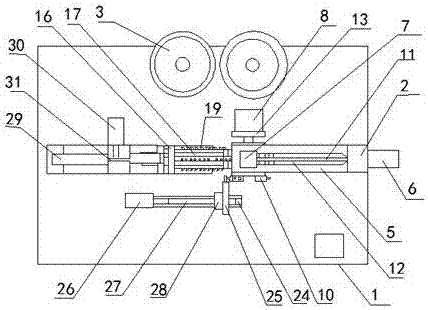

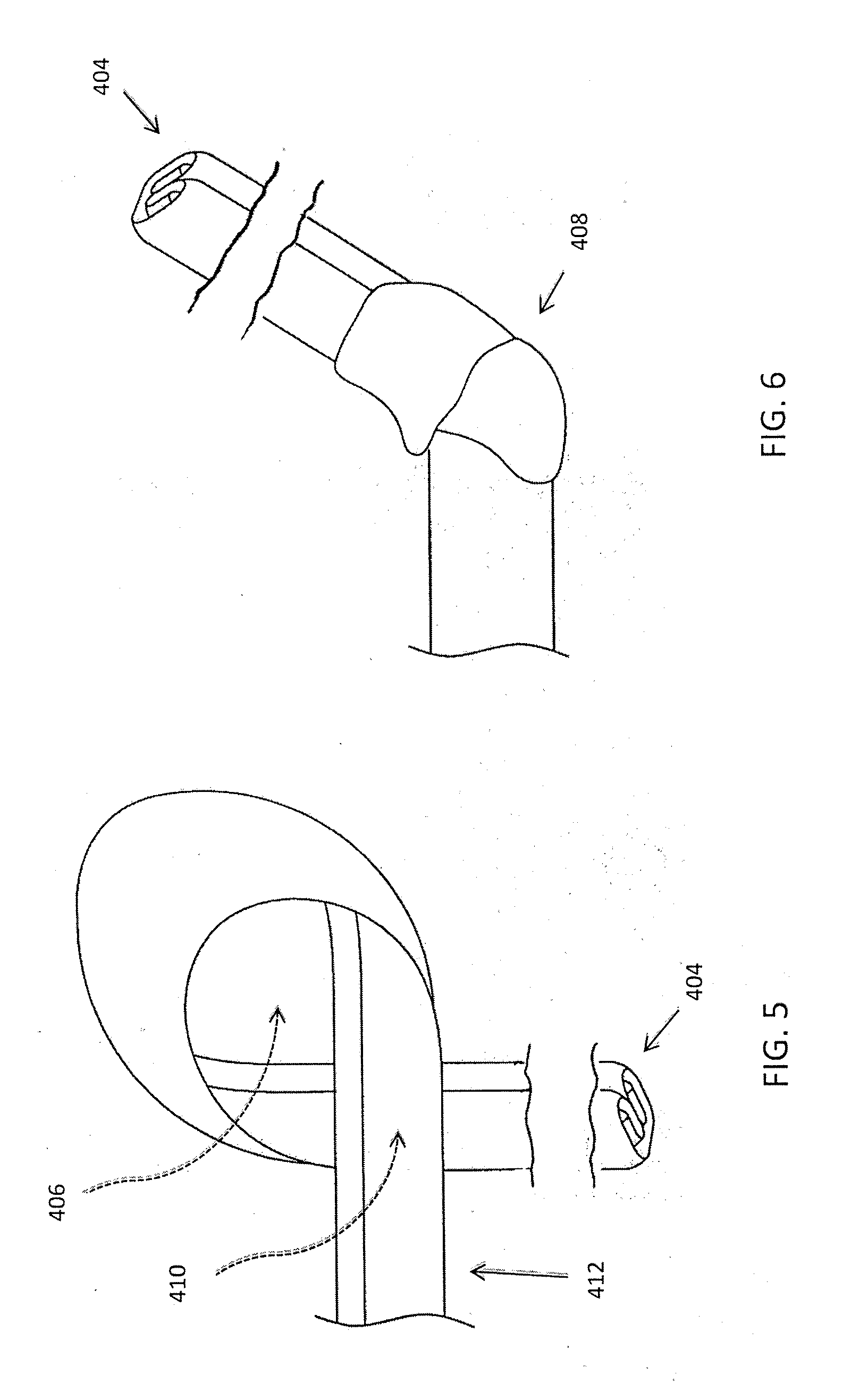

Automatic tying machine of overhand knot and application method thereof

The invention relates to an automatic tying machine of overhand knot and an application method thereof. The automatic tying machine of overhand knot comprises a frame, one side of the inside of the frame is fixedly provided with a tying sleeve that is perpendicular to the side, a tying mechanical arm extensible into the axis of the tying sleeve is hinged to the top of the tying sleeve, one side of the frame corresponding to the tying sleeve is fixedly provided with a rotary mechanical arm that may rotate around the edge of the tying sleeve with the tying sleeve serving as the center of circle and a tightening mechanical arm that may move along the axis of the tying sleeve, a traction mechanical arm is slidably connected to the frame in a horizontal direction perpendicular to the tightening mechanical arm through a guide rail, a limiting rod perpendicular to the guide rail is fixed to the lateral side of the frame at one end of the guide rail, a cutter having a cutting edge facing the limiting rod is fixed to the lateral side of the frame at the other end of the guide rail, and two auxiliary mechanical arms facing the guide rails and used for limiting a rope are fixed between the cutter side and the tying sleeve within the frame. The automatic tying machine of overhand knot is intended to save manpower and improve overhand knot tying efficiency.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

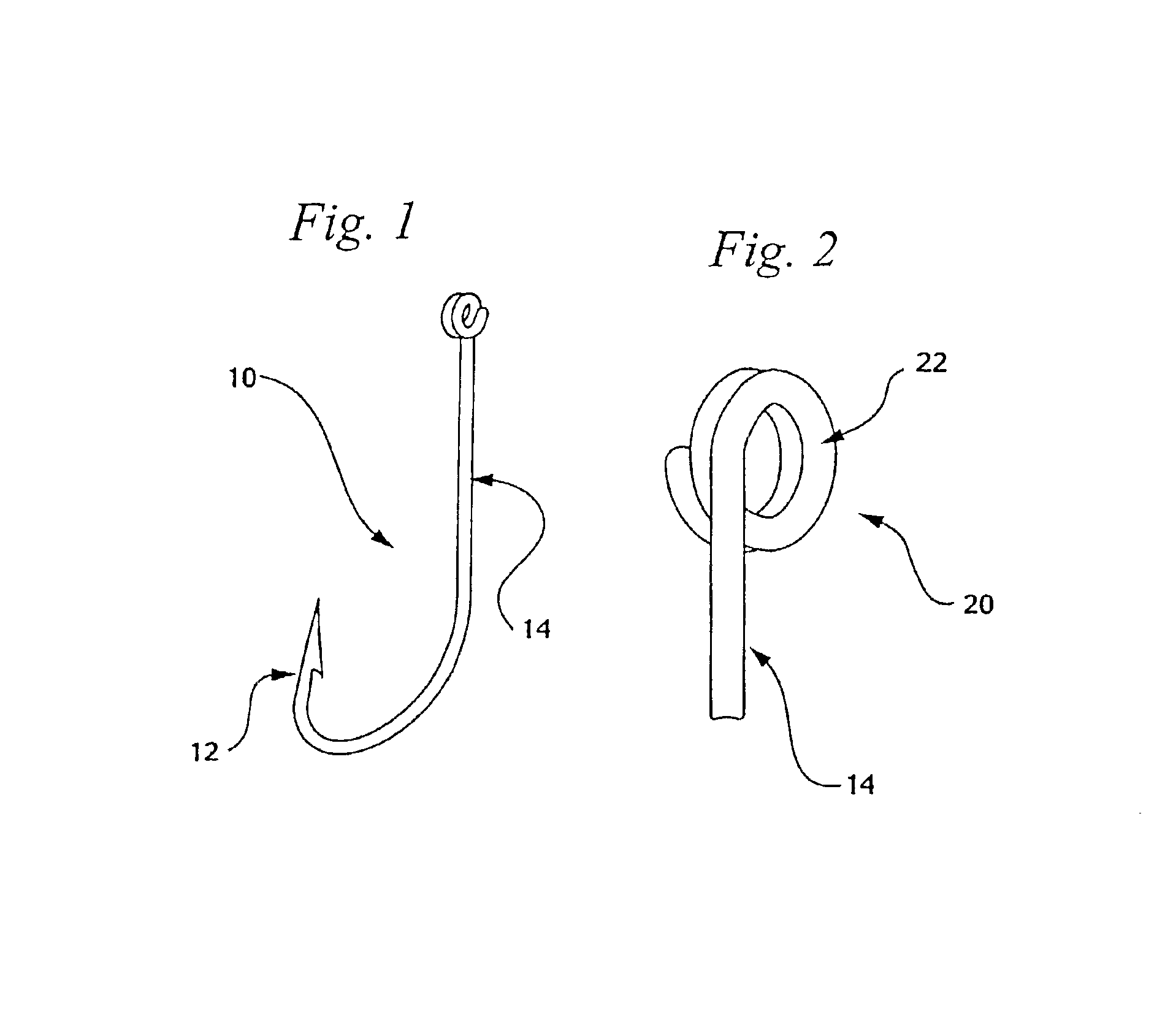

Knot tying method

The invention provides a knot tying method. According to the method, a double-strand string knot tying device is used, the device comprises a machine frame, a string storage device, a string winding device, a knot forming device, a shearing device and a controller, wherein the string storage device is fixedly arranged on the rear side of the upper surface of the machine frame, the string winding device arranged under a beam comprises an air cylinder, a first electric driving device, a second electric driving device, a string winding plate, a first mechanical arm, a pull rod, a string winding rod and a first bearing board, the knot forming device comprises a ring forming device, a thread end clamping device and a knot forming driving device, the ring forming device is located directly on the left side of the string winding plate, the thread end clamping device is located directly in front of the ring forming device, the knot forming device installed on the left side of the ring forming device comprises a driving rod, a sixth electric driving device, a gear wheel, a third mechanical arm and a guiding rail base, and the shearing device installed in the middle of a string winding ring comprises two fourth mechanical arms and a set of scissors.

Owner:余坚

Decorative knot sequence and method for its formation

Owner:KAPLAN CHARLOTTE

Weaving method of Shuichang line thousands bead and weaving device therefor

The invention discloses a weaving method for crystal wires thousands pearls and the product. The process is: selects wires with needed length and color, fixes the longitude wires on proper position according to demands, fixes the latitude wires on the longitude wires, the longitude wires are used as axle, the latitude wires are twisted and knotted on the longitude wires until the needed length. The invention can increase or decrease the longitude wires according to demands. A hand holds one of the longitude wires, another end is racked by mouth, and the other hand twists the latitude wire, the surface of the product are pearl structure.

Owner:吴家秀

Automatic rope knotting device

The invention relates to an automatic rope knotting device. The automatic rope knotting device comprises a rope clamping module, a rope winding module, a rope pulling module, a support device, a control system and the like, wherein the rope clamping module is provided with a bottom clamp, a rotary disc stepping motor, a gear, a slewing bearing, an air cylinder and a support frame of the air cylinder; the rope winding module is provided with a cam stepping motor, a bulge gear, a step shaft, a disc-shaped cam, a roller, a spring, a linear bearing, a center shaft, a rope winding shaft, a center shaft transverse plate and a support assembly; the rope pulling module is provided with an air cylinder, a pair of forceps, a shaft of the forceps, a sleeve cylinder and a support assembly. The automatic rope knotting device has the advantage that by utilizing the connection and mutual movement between the modules, units and assemblies, the rope knotting efficiency is improved.

Owner:厦门创业人环保科技股份有限公司

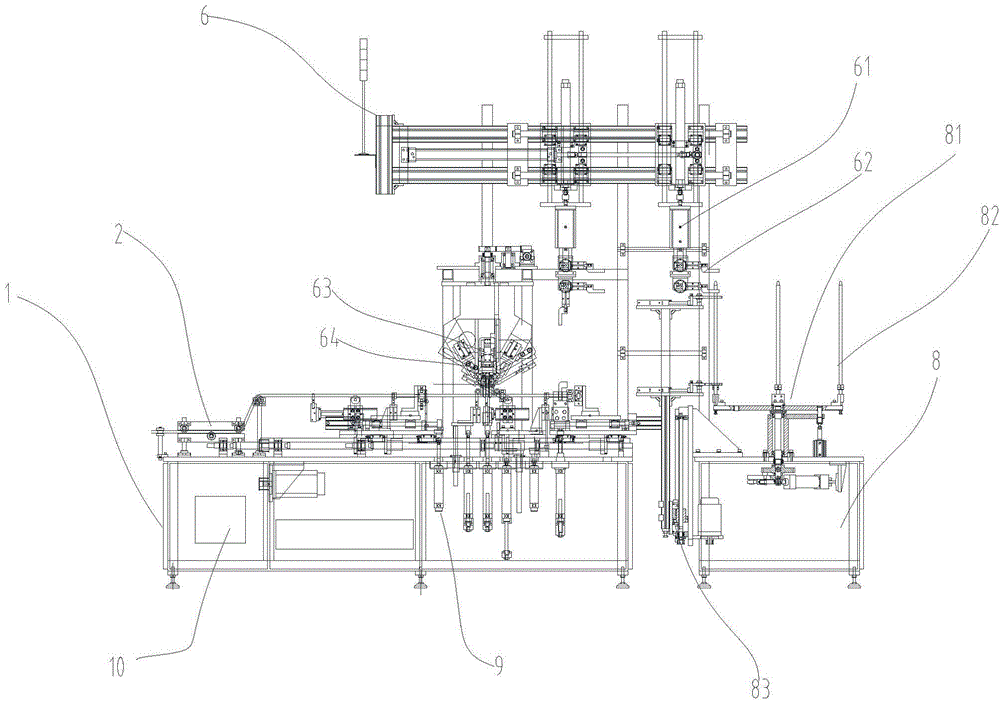

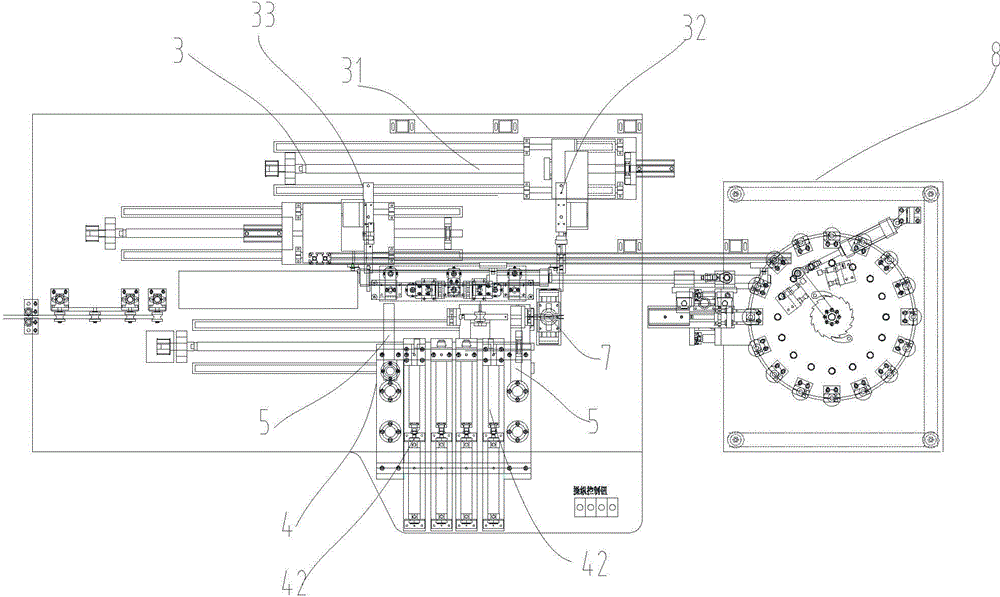

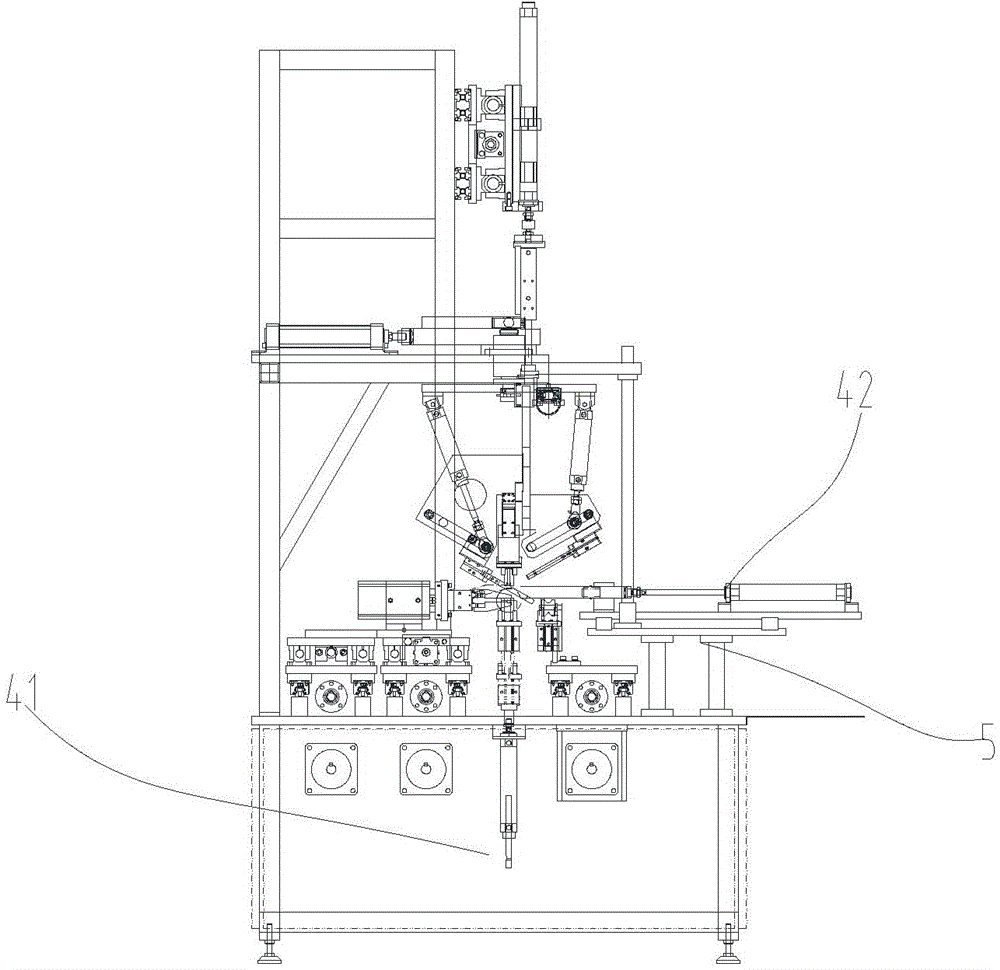

A ball-threading and knot-tying machine

The invention provides a ball-threading and knot-tying machine comprising a main frame. The main frame is provided with a fixed length cutting machine, a rope clamping stepping mechanism, a rope lifting mechanism, a ball fixing rod, a carrier, a knot locking mechanism and a ball embracing groove. The fixed length cutting machine is arranged at one end of the main frame. The rope clamping stepping mechanism is arranged on the inner side of the fixed length cutting machine. The rope lifting mechanism is arranged on the outer side of the fixed length cutting machine. The carrier is arranged on the outer side of the rope clamping stepping mechanism. A ball grabbing mechanism and a knot tying mechanism are arranged on the carrier. The ball embracing groove is arranged below the ball grabbing mechanism. Through automatic operation of an air cylinder and mechanical parts, the rope is knotted, the quality, the appearance and the yield of products are improved, the production cost is reduced and large-scale production is achieved.

Owner:SHANGHAI DINGSAI AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com