Automatic rope knotting device

An automatic knotting and rope technology, applied in knotting, textile and papermaking, etc., can solve the problems of slow speed, high labor cost and low efficiency, and achieve the effect of ingenious process, strong practicability and reasonable mechanism layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

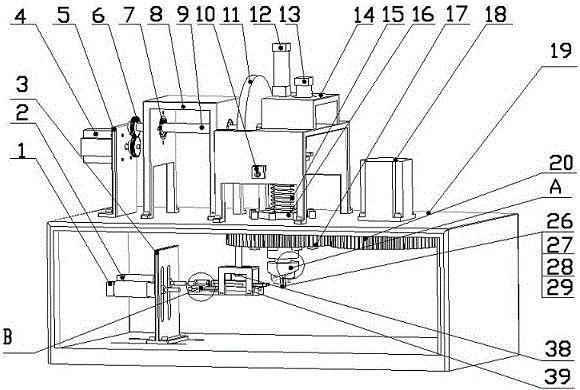

[0029] Provide further explanation to this device in conjunction with accompanying drawing:

[0030] refer to Figure 1-8 The labels given in , the cylinder base 3, the cam stepper motor base 5, the stepped shaft base 8, the cylinder and the tweezers shaft base 14 are respectively fixed on the total base 19, and the cylinders 1 and 2 are fixed on the cylinder base 3.

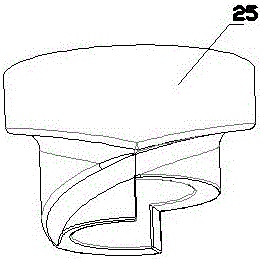

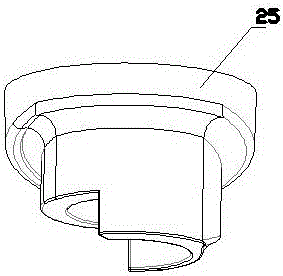

[0031] The cam stepper motor 4 is fixed on the cam stepper motor base 5, the boss gear 6 (1) is installed on the output shaft of the boss stepper motor 4, and the active boss gear 6 (2) meshes with another boss gear , the boss gear 6 (2) is installed on the stepped shaft 9, the stepped shaft 9 is installed on the stepped shaft base 8 through the bearing 7 (1) and the bearing 7 (2), the disc cam 11 is connected with the stepped shaft 9 through a key, The disc cam 11 is matched with the roller 22. The roller 22 is installed on the central axis horizontal plate 23 through the roller shaft 21. The central axis 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com