Hot rolling double-layer thermometal composite coiled material/plate finishing production line

A composite coil and bimetallic technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of disc shearing edge failure, speed difference, high manpower and equipment investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0179] The specific structure, working principle and technical effect of each component of the production line of the present invention will be described in detail below in conjunction with the accompanying drawings. Except for the components mentioned below, the other components involved in the production line adopt known technologies, which will not be repeated here.

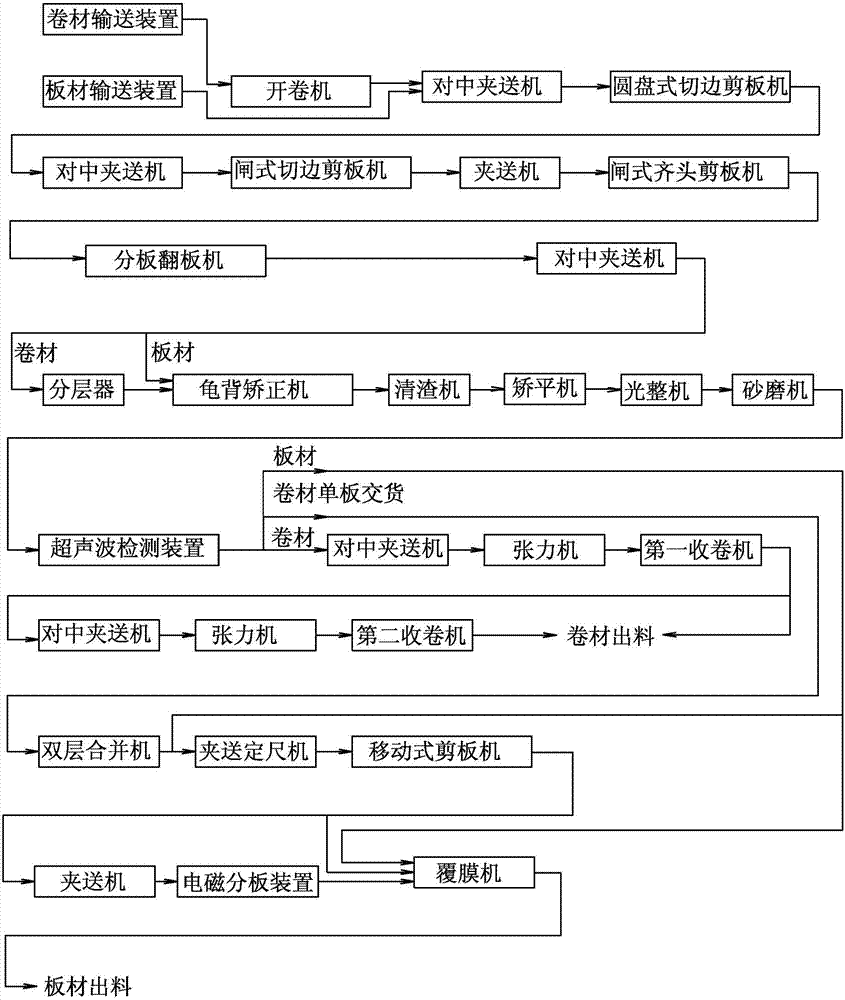

[0180] figure 1 The process flow of the production line of the present invention is shown, and the process flow of the double-layer bimetal composite coil and the double-layer bimetal composite plate will be described in detail in the last part of the description.

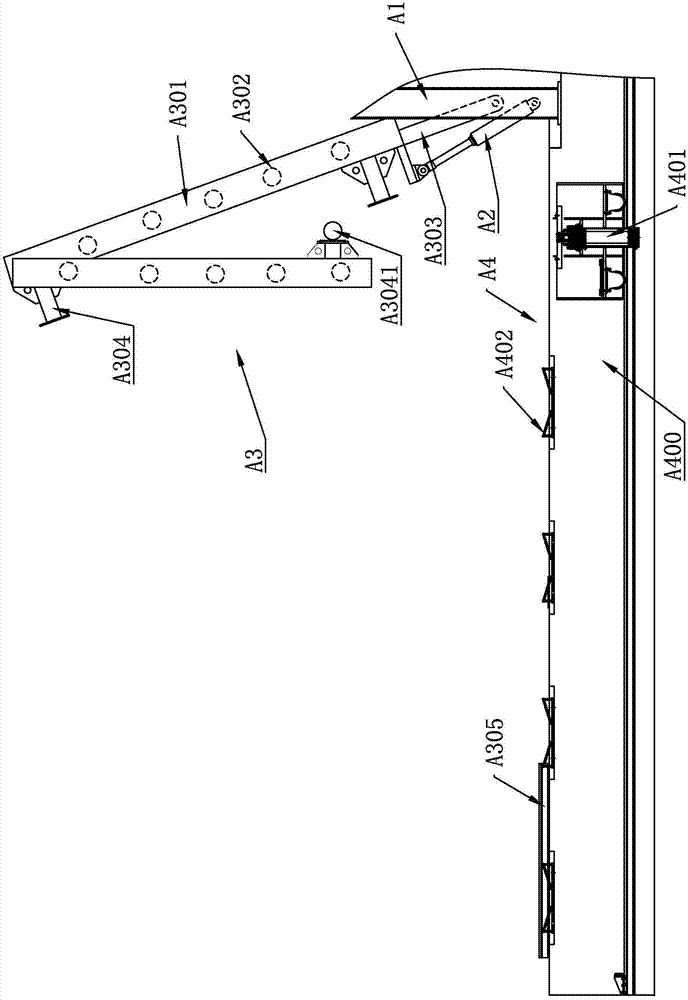

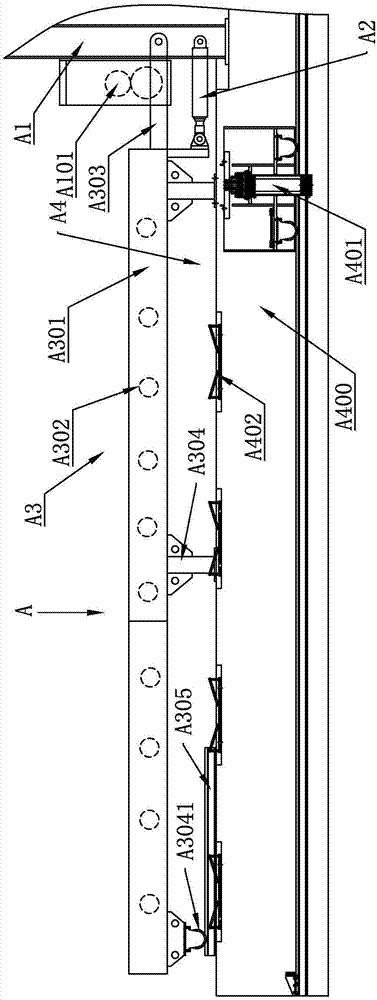

[0181] Figure 2 to Figure 5 Shown is the feeding device of the present invention.

[0182] Such as Figure 2 to Figure 5 Commonly shown, the plate conveying device A3 driven by the first power device A2 is hinged on the first frame A1, and the coil conveying device A4 is also arranged upstream of the first frame A1; the plate conveying device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com