Modular stacked switch cabinet

A switchgear and modularized technology, applied in pull-out switchgear, switchgear, switchgear with horizontal pull isolation, etc. The effect of assembly line operation, improving production efficiency and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

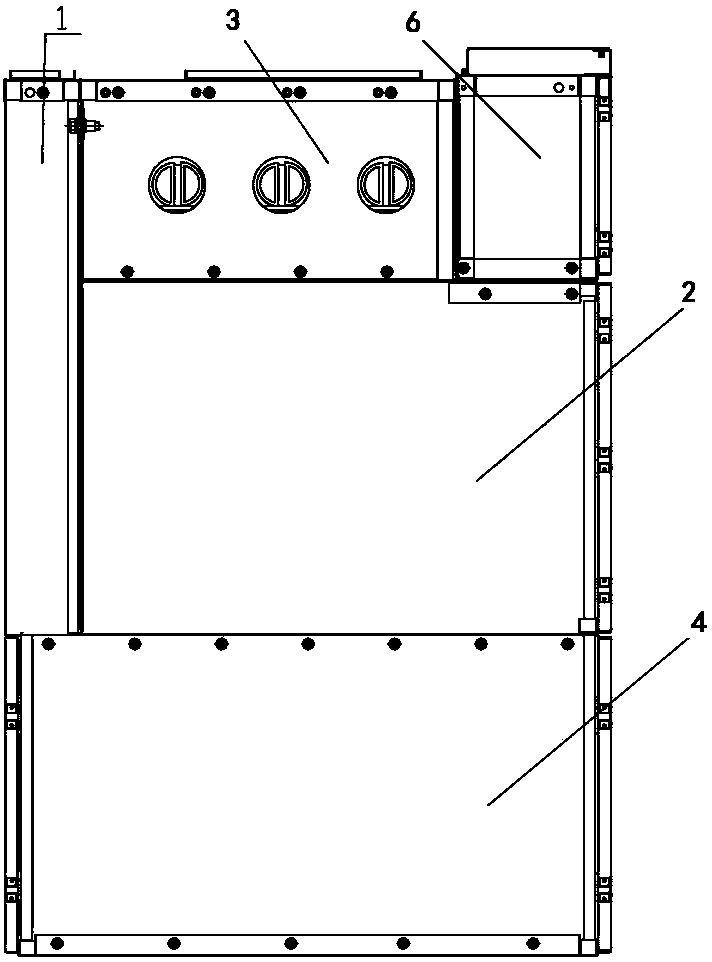

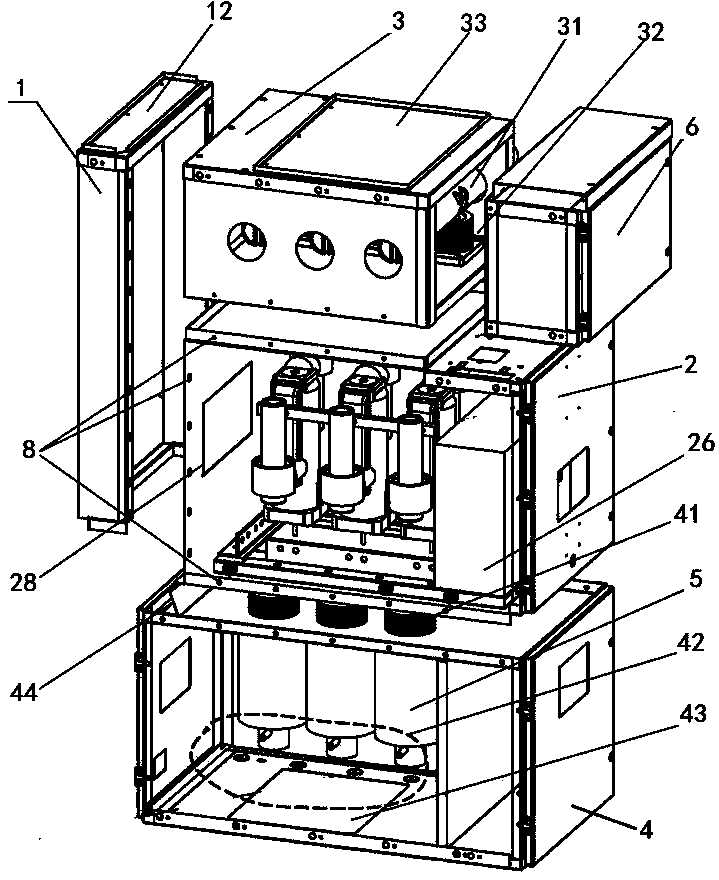

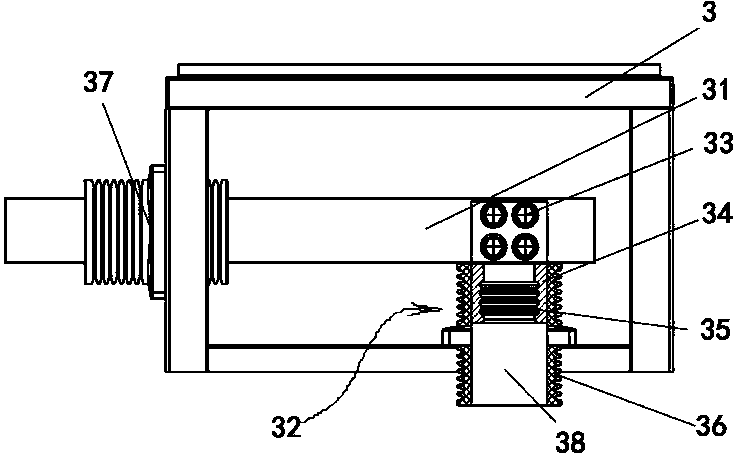

[0026] Figure 1-Figure 9 As shown, the modular stacked switchgear of the present invention includes a pressure relief chamber module 1 , a busbar chamber module 3 , an instrument box module 6 , a circuit breaker chamber module 2 , and a cable chamber module 4 . Each module includes a box structure shell and the corresponding functional devices inside the shell. The shell of each module adopts a closed sheet metal box structure, which is made of thin steel plates and assembled with bolts after bending. The sides of the shell can be Separate disassembly allows for easy installation of internal components.

[0027] The direction with larger size in the horizontal direction of the switch cabinet is the front-to-back direction, and the direction with smaller size in the horizontal direction of the switch cabinet is the left-right direction. The cable chamber module 4 is at the bottom, the pressure relief chamber module 1 and the circuit breaker chamber module 2 are placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com