Knot tying machine and knot product preparation method thereof

A knotting machine and knotting technology, which is applied in the field of machinery, can solve the problems of low production efficiency and product quality, large labor cost, and slow weaving speed, so as to improve production efficiency and product quality, improve production efficiency, and avoid winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

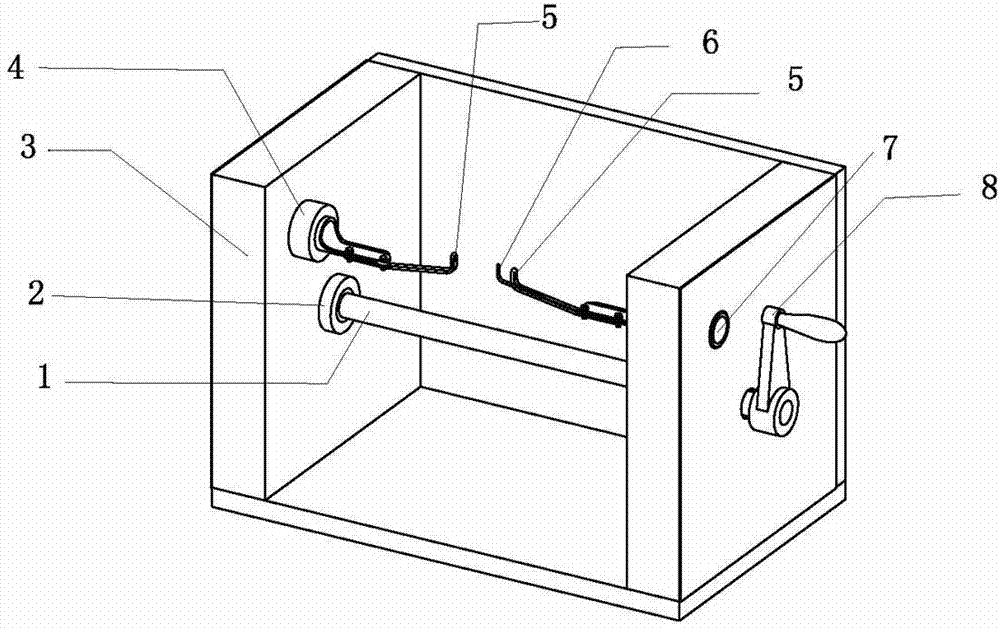

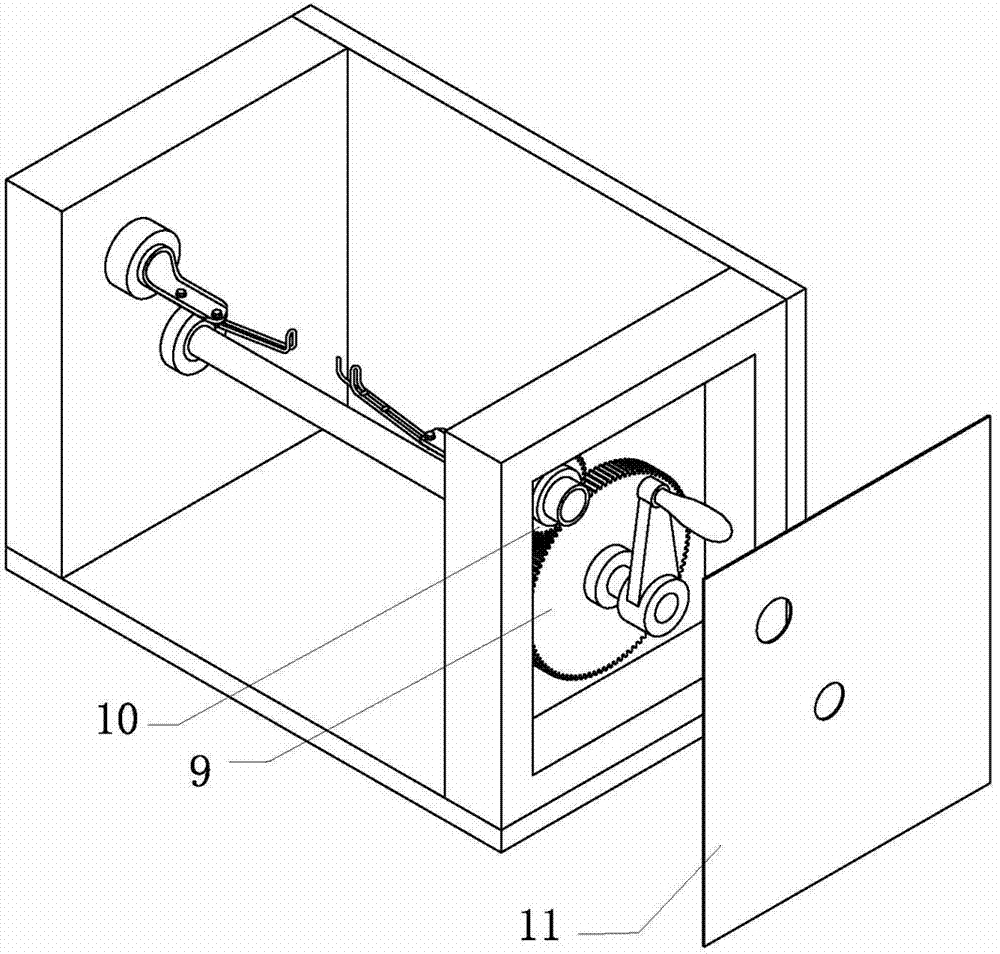

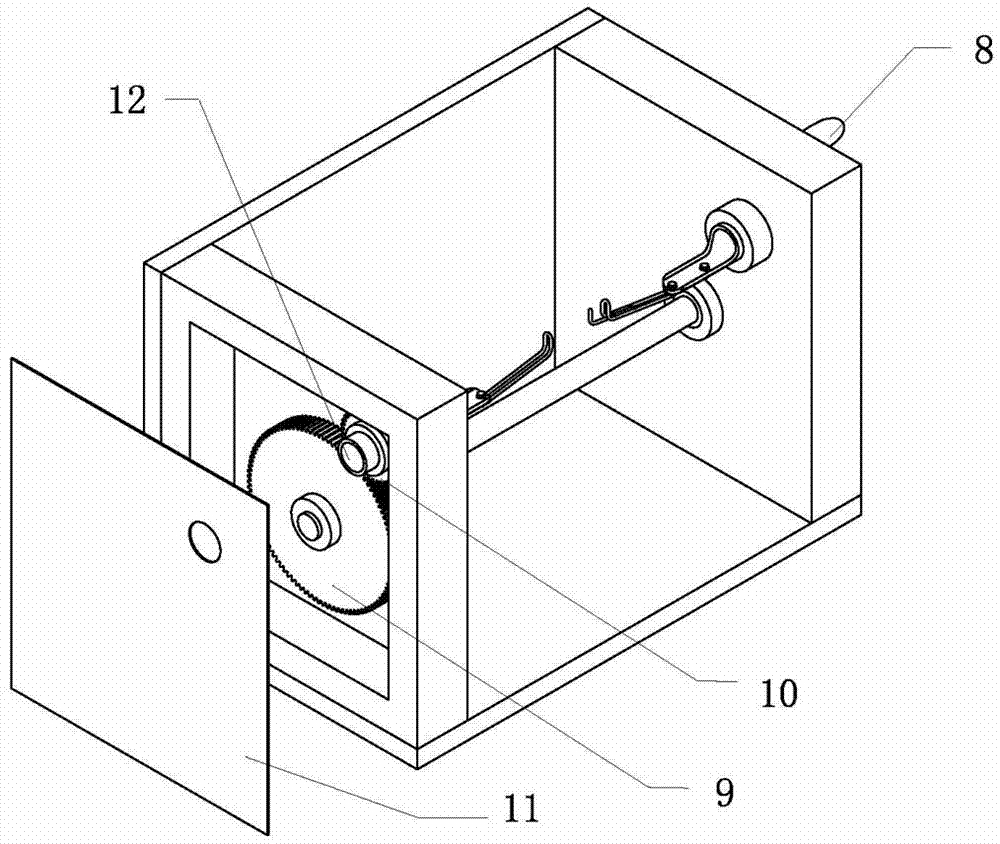

[0027] like figure 1 , 2 Shown in , 3, a kind of knotting machine comprises casing, main shaft 1, driving gear 9 and driven gear 10, and described main shaft 1 passes through the inner side of casing and is fixed on the end plate of casing both sides by bearing, two of main shaft 1 The ends are respectively placed on the outside of the end plates on both sides, and the two ends of the main shaft outside the end plates on both sides of the case are respectively provided with the driving gear 9; the end plates on both sides of the case are respectively fixed with driven shafts 4 through bearings. One end of the shaft 4 is fixed with the driven gear 10, and the other end of the driven shaft 4 is placed inside the cabinet; the driving gear 9 and the driven gear 10 mesh with each other; Fixed hooks 5 for fixing the ropes are respectively provided, wherein the driven shaft 4 on one side is also provided with a winding hook 6, and the position of the winding hooks 6 is arranged bet...

Embodiment 2

[0046] This embodiment is an improvement on the basis of Embodiment 1. The structure of the knotting machine in this embodiment is the same as in Embodiment 1; the knot product prepared by the knotting machine in this embodiment is a double-strand knot product, and the preparation method Include the following steps:

[0047] First pass one end of the rope, the raw material of the knot product, through the wire feeding hole 7 from the outside of the end plate of the knotting machine, and then pass this end around the fixed hook 5 on the left and the fixed hook on the right in turn. 5 two times each to form a double-layer coil between the two fixed hooks 5; then the other end of the rope is stuck on the said winding hook 6; at this time, turn the operating lever 8 to make the The part of the other end of the rope is wound on the double-layer coil between the above-mentioned two fixed hooks 5, and when winding 6-10 circles, stop turning the joystick 8; then pass the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com