Bowknot rope automatic forming machine for shoemaking

An automatic forming machine and bowknot technology, which is applied in knotting, textiles and papermaking, and textile material cutting, can solve the problems of uneven bowknot shapes, difficult to unify specifications, and low production efficiency, and achieve good product consistency, The effect of high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

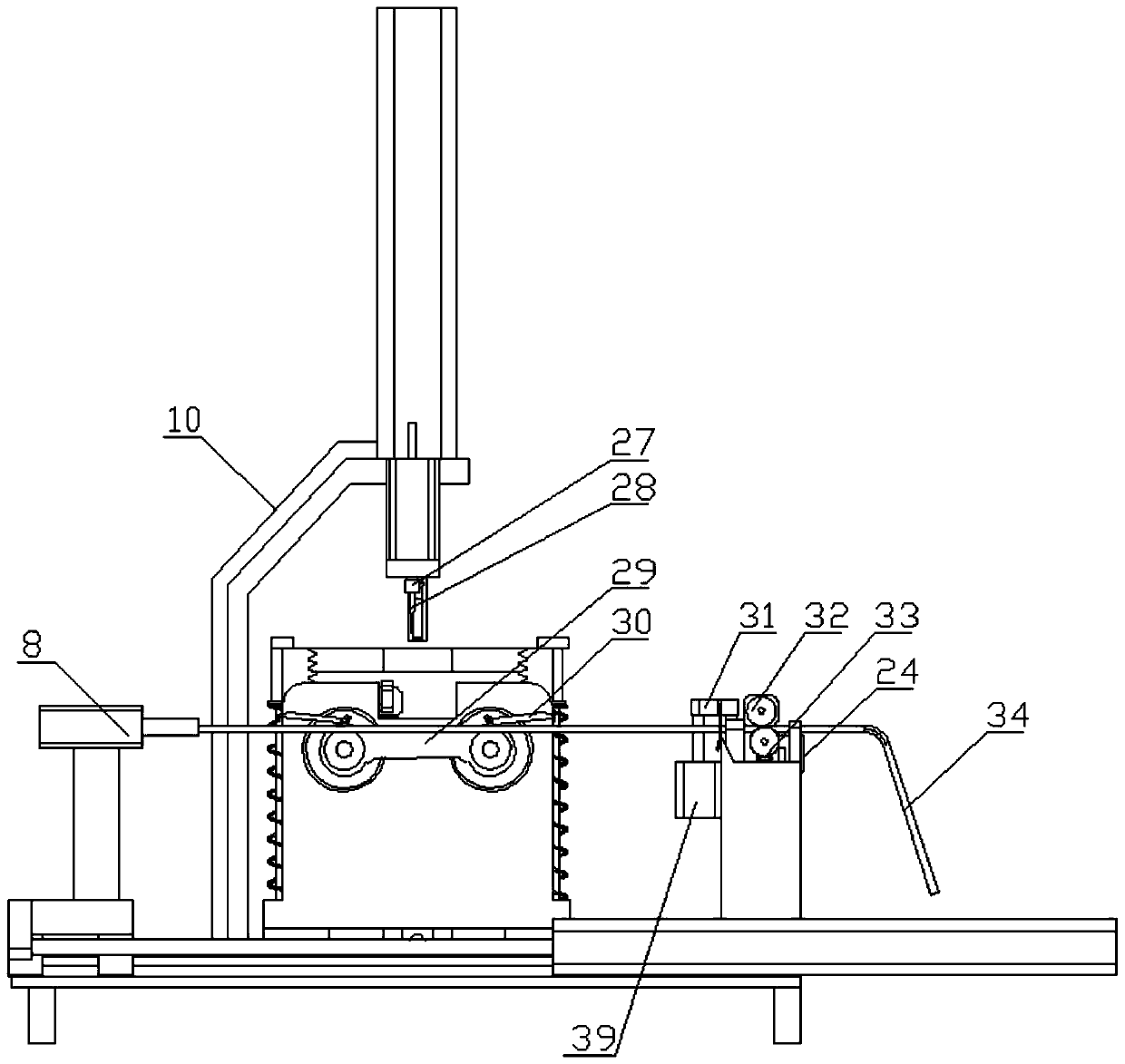

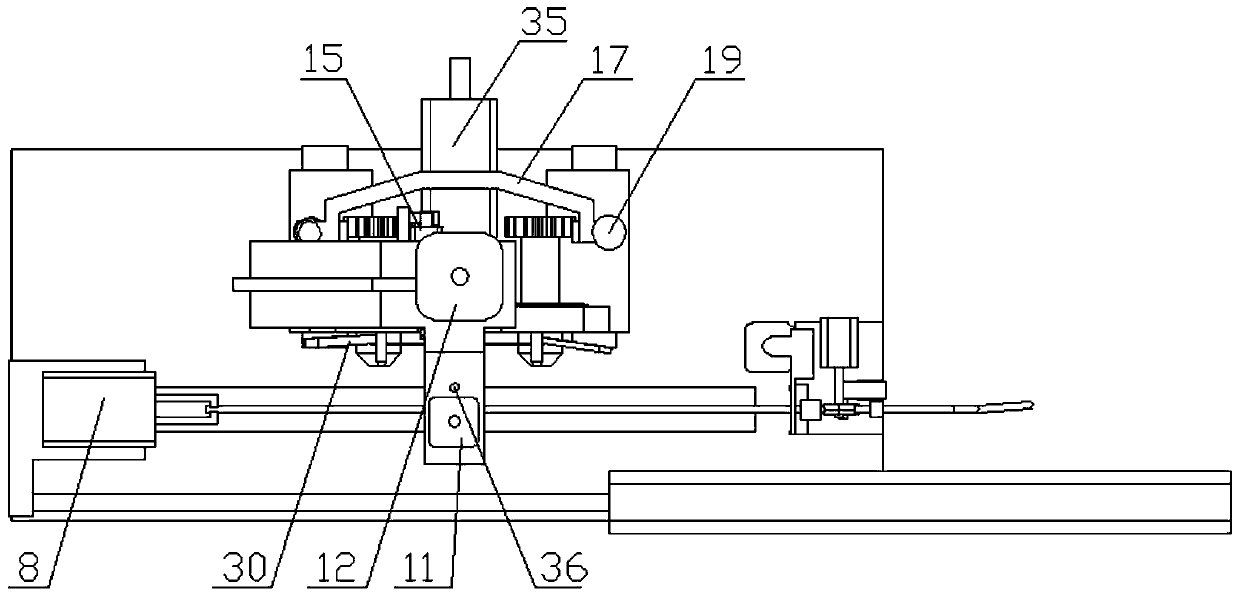

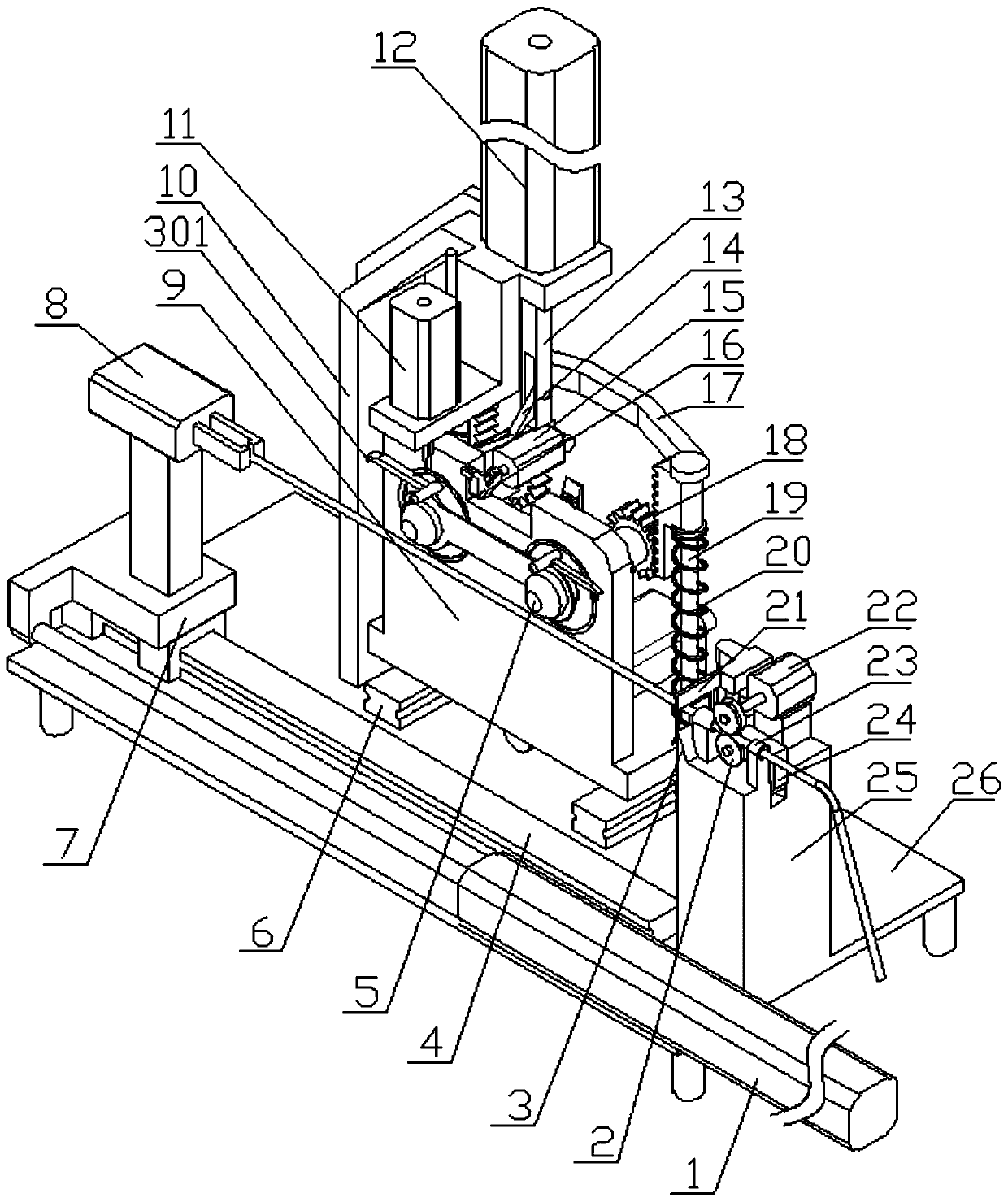

[0033] Such as Figure 1-Figure 5 As shown, the present invention relates to a bowknot rope automatic forming machine for shoemaking, comprising a base 26, a support 25 is fixed at one end of the base 26, the shape of the support 25 is a cuboid, and the support 25 is installed There is a feeding device, which is used to realize the clamping and feeding of the bow rope 34; a cutting device is arranged on the outlet side of the feeding device on the support 25, and is used to realize cutting to length after feeding.

[0034] The feeding device includes a driving wheel 32 arranged up and down and a driven wheel 2, the driving wheel 32 is installed on the output end of the feeding motor 22, and the driven wheel 2 is rotatably mounted on a support arm 24 through a pin shaft, the The support arm 24 is L-shaped and the lower end is hinged on the support 25, and a pressure spring 33 is arranged between the free end of the support arm 24 and the support 25, which is used to make the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com