Automobile seat backrest grid forming mechanism

A technology for car seats and molding mechanisms, applied in the direction of online network, other household appliances, household appliances, etc., can solve the problems of inability to meet large-scale production, low work efficiency, high labor intensity, etc., and achieve a wide range of applications and reduce workload. , the effect of improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

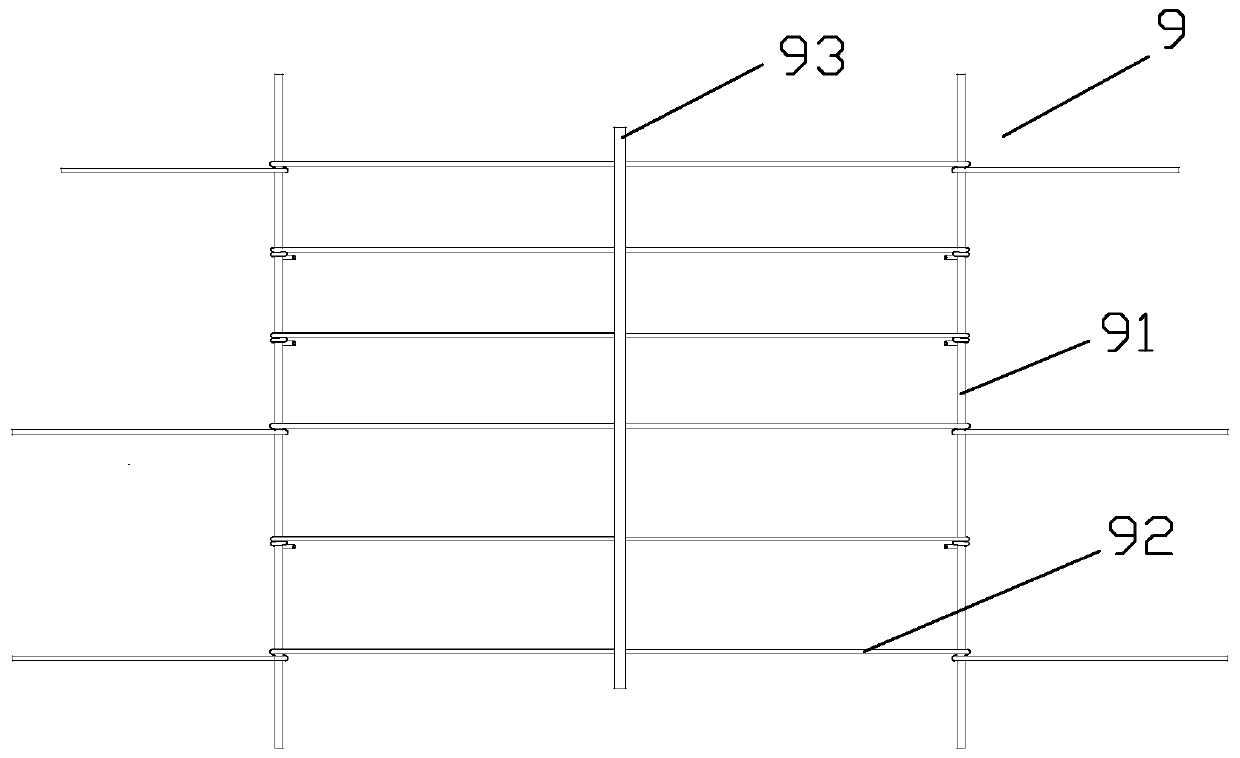

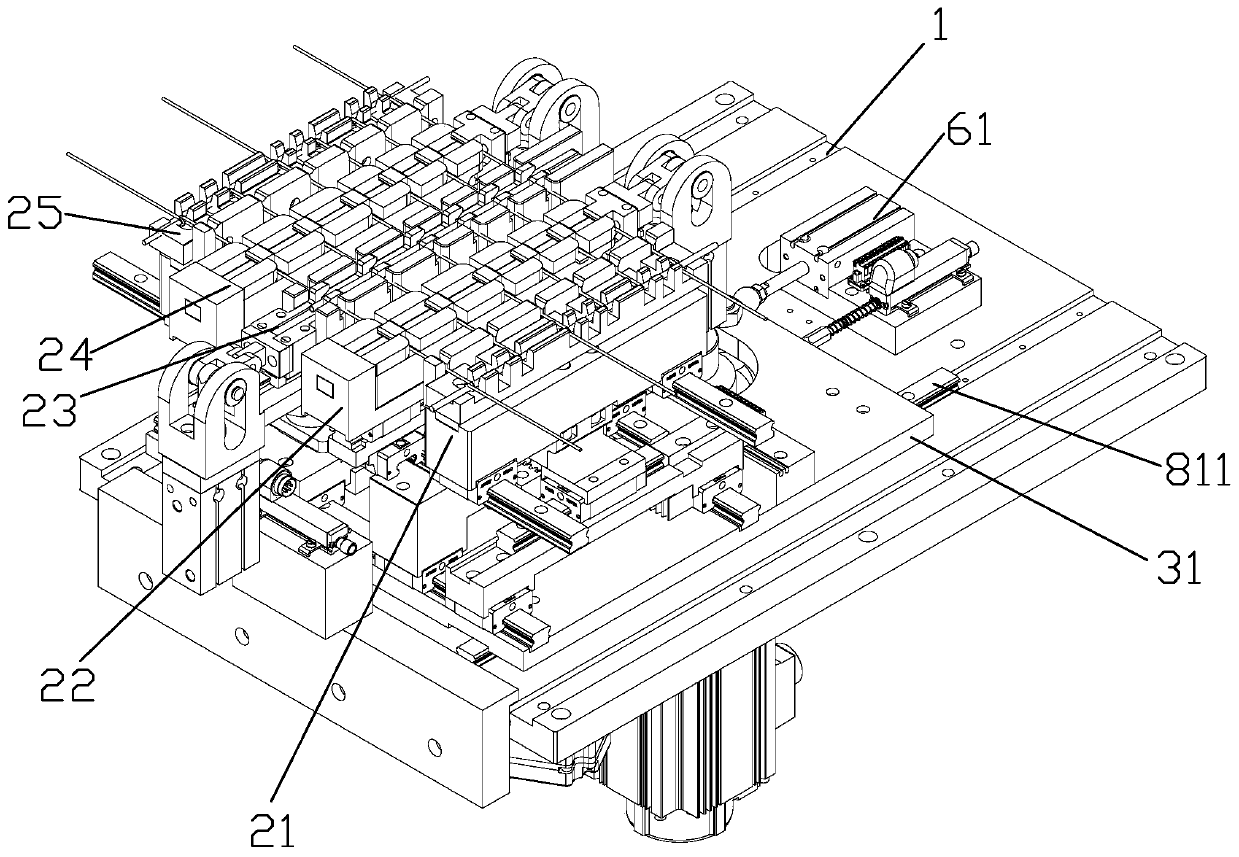

[0021] see Figure 3 to Figure 11 . The car seat back grid forming mechanism according to an embodiment of the present invention includes a frame 1, a forming jig 2, a longitudinal movement assembly, two sets of first transverse movement assemblies, two sets of second transverse movement assemblies and a driving mechanism.

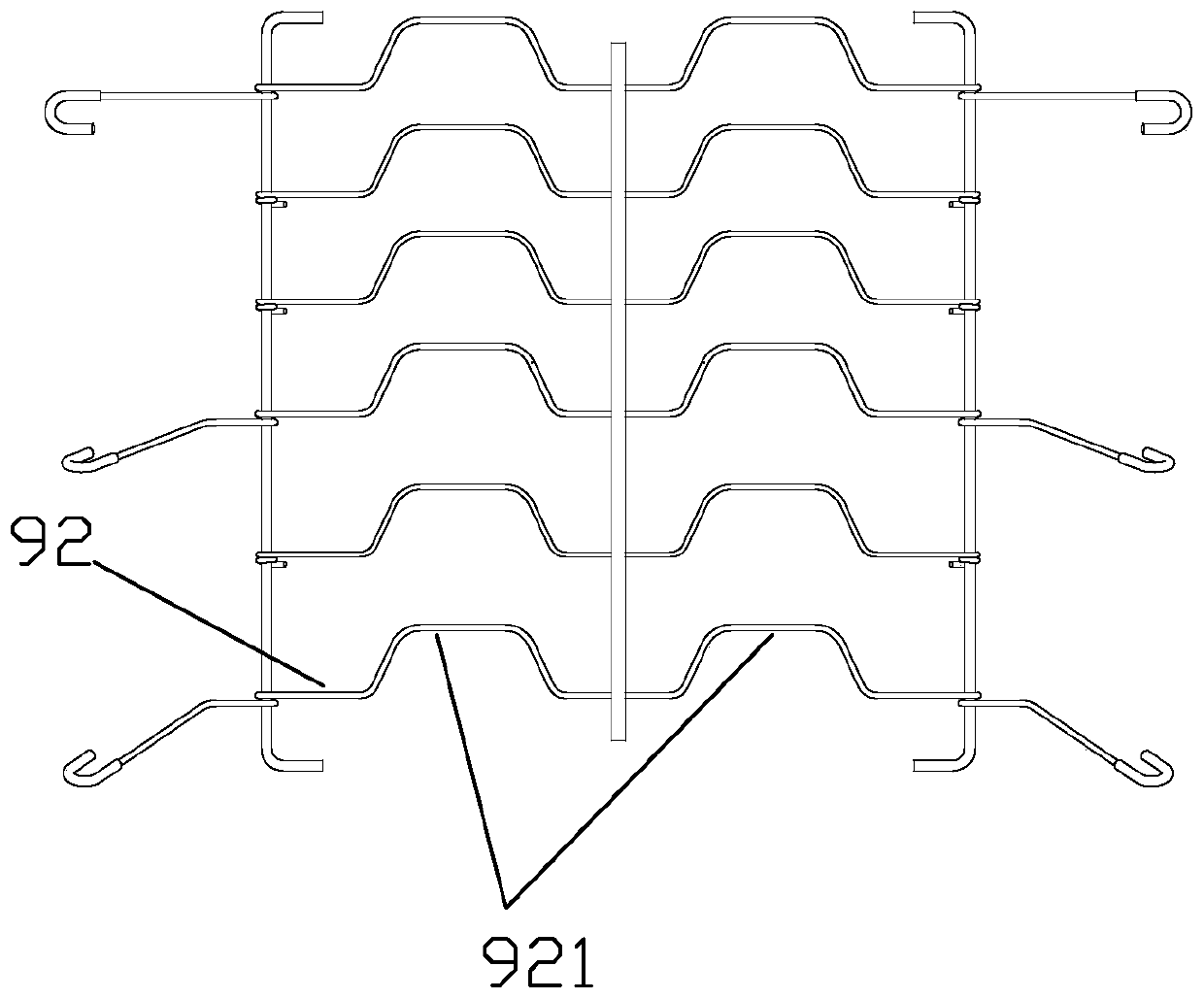

[0022] The forming jig 2 includes five rows of forming modules, which sequentially include a first forming module 21, a second forming module 22, a third forming module 23, and a fourth forming module 24 from one side to the other along the transverse direction And the fifth molding module 25. The third molding module 23 is fixedly arranged on the frame 1 and will not move. Each row of forming modules is longitudinally spaced with N+1 forming blocks 20, and forming grooves 26 for accommodating the transverse steel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com