Patents

Literature

63results about How to "Automatic sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Searching engine with automating sorting function

ActiveCN1873642AImprove accuracyNarrow searchSpecial data processing applicationsUser inputDocument preparation

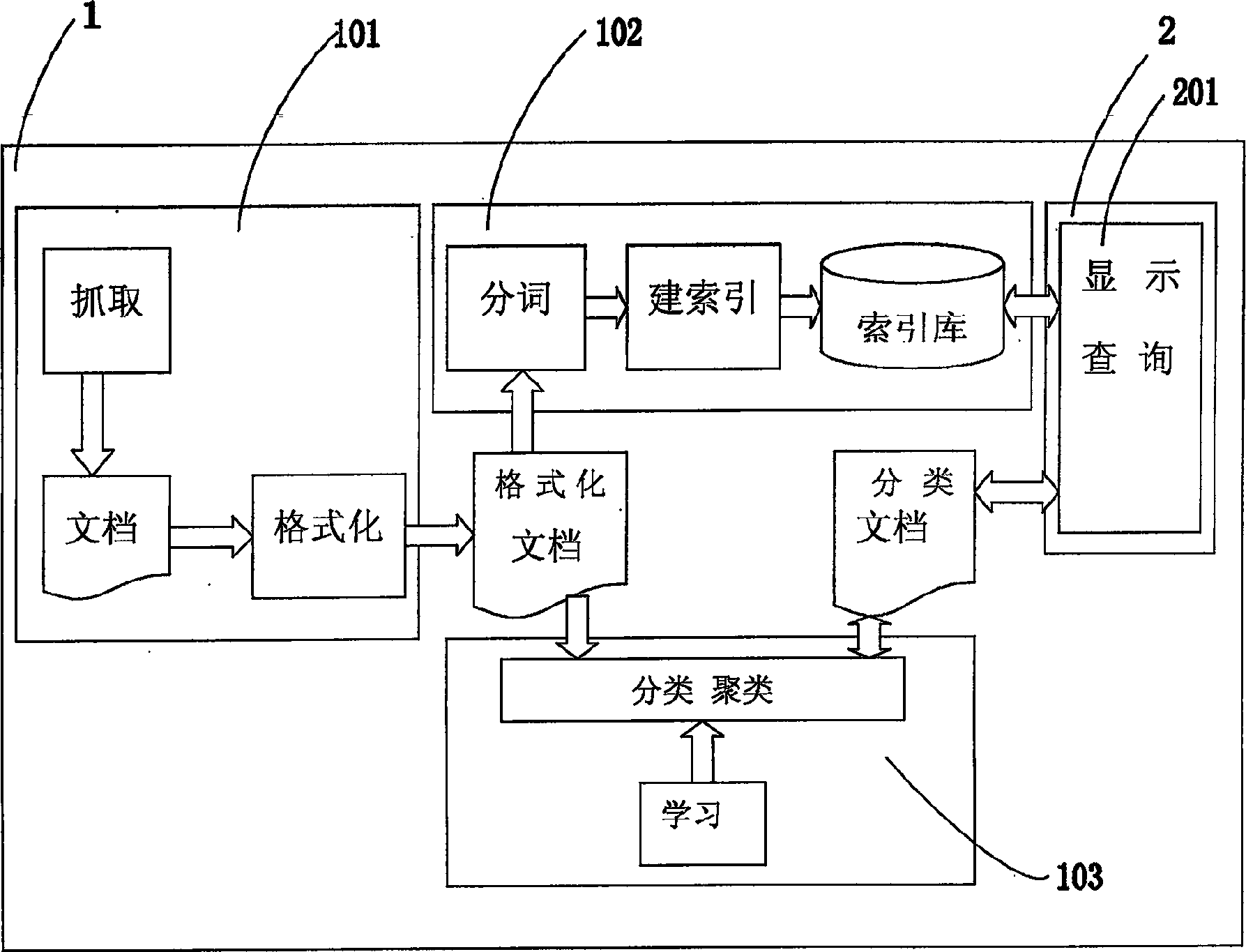

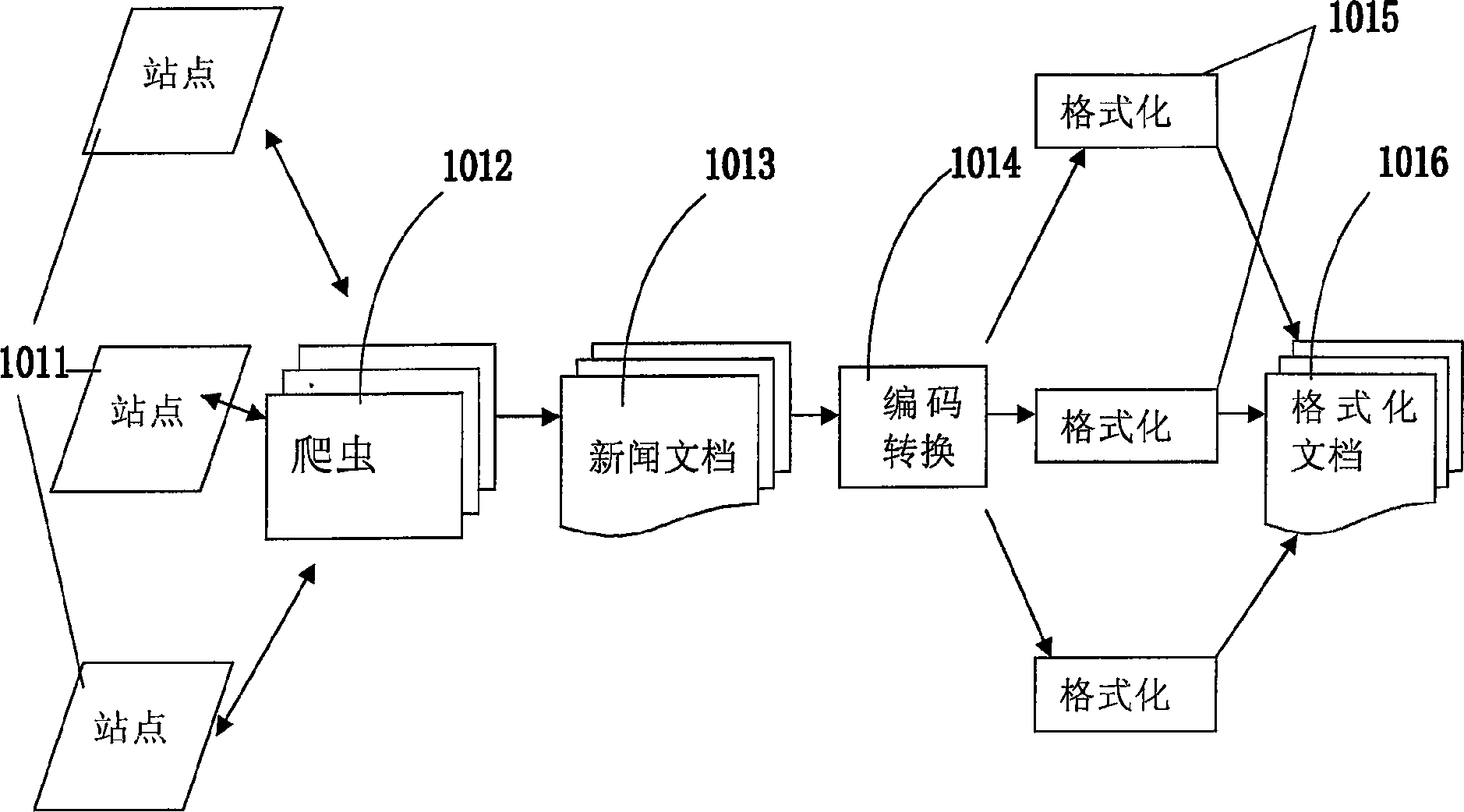

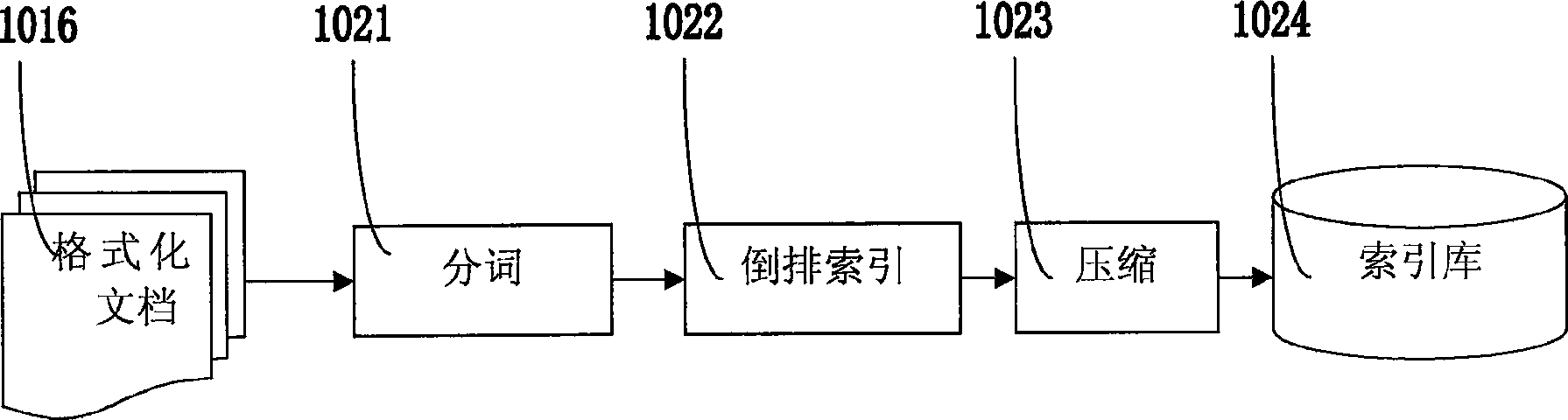

The invention discloses a search engine with automatic classification function, it includes: the automatic collection and the pretreatment module, which are used to automatically collect the documents from the network, and carry out the pretreatment, and transfer the documents for the computer to read and real-time renews documents; the index module, which is used on the participle after the automatic collection and the pretreatment module processing formatted documents, after and separately gives the participle the word and the documents entrusts with word marking and documents marking, according to word marking and the documents marking, establish index access; the automatic classified module, which can be used in to train and classify automatically the formatted documents that had to deal with; the searches display module, which searches suitable document based keyword appearance in the server, and setups in the client. The invention can classify and search effectually and intellectualized document by Chinese and English.

Owner:上海世纪互联信息系统有限公司

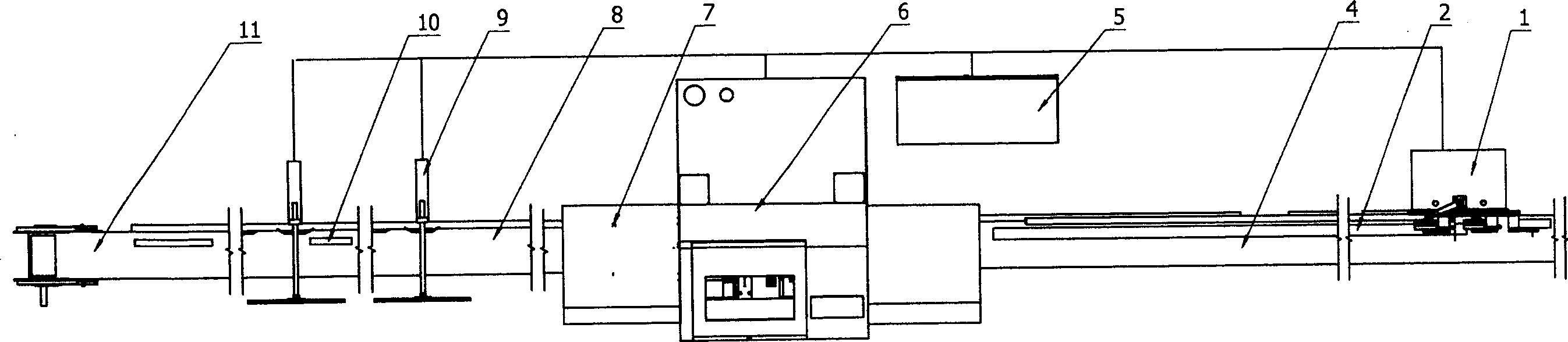

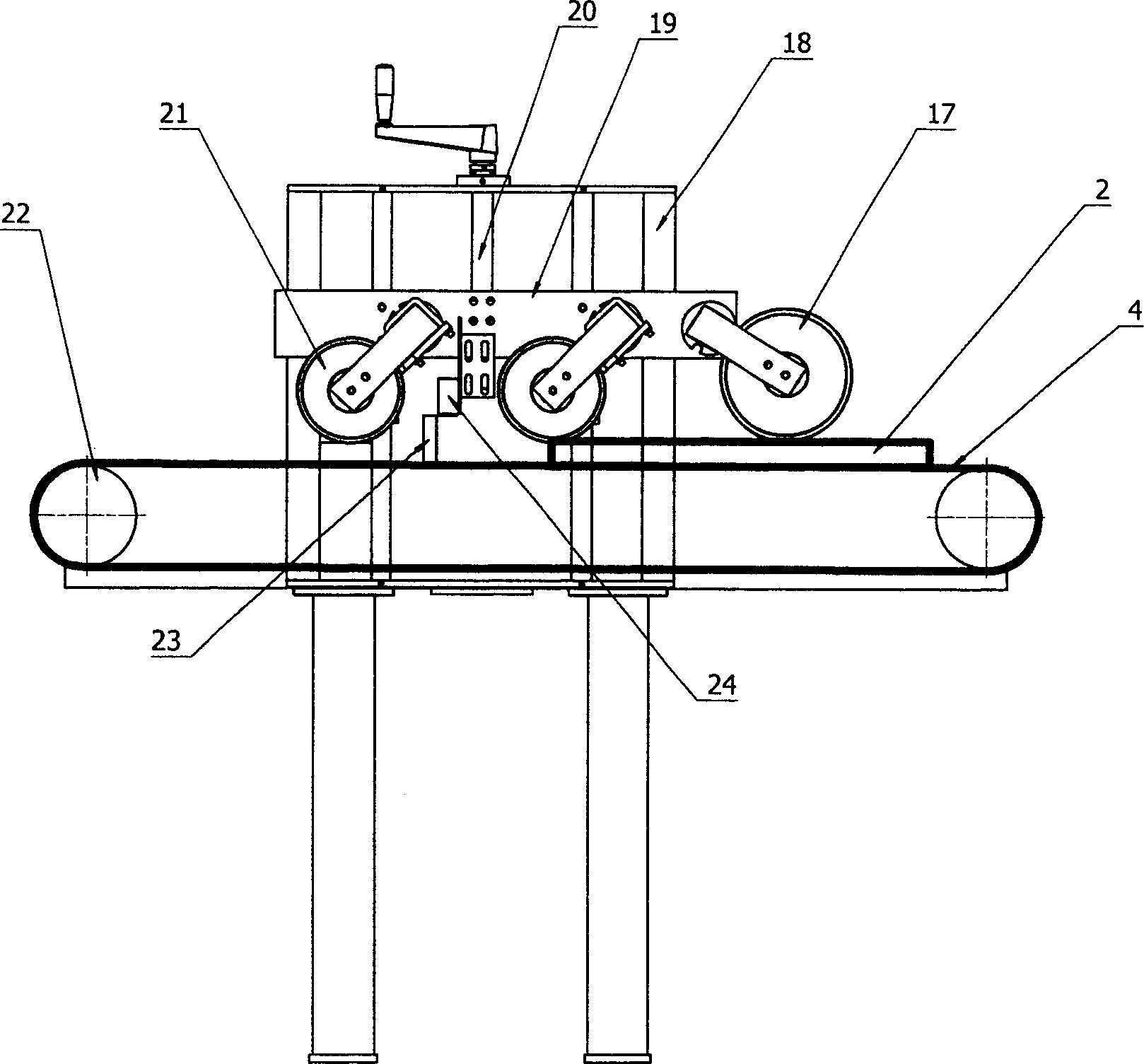

Timber selecting and chopping method and selection chopping saw therefor

InactiveCN1827319AIncrease productivityImprove operating rateLoading equipmentAdjusting equipmentComputer science

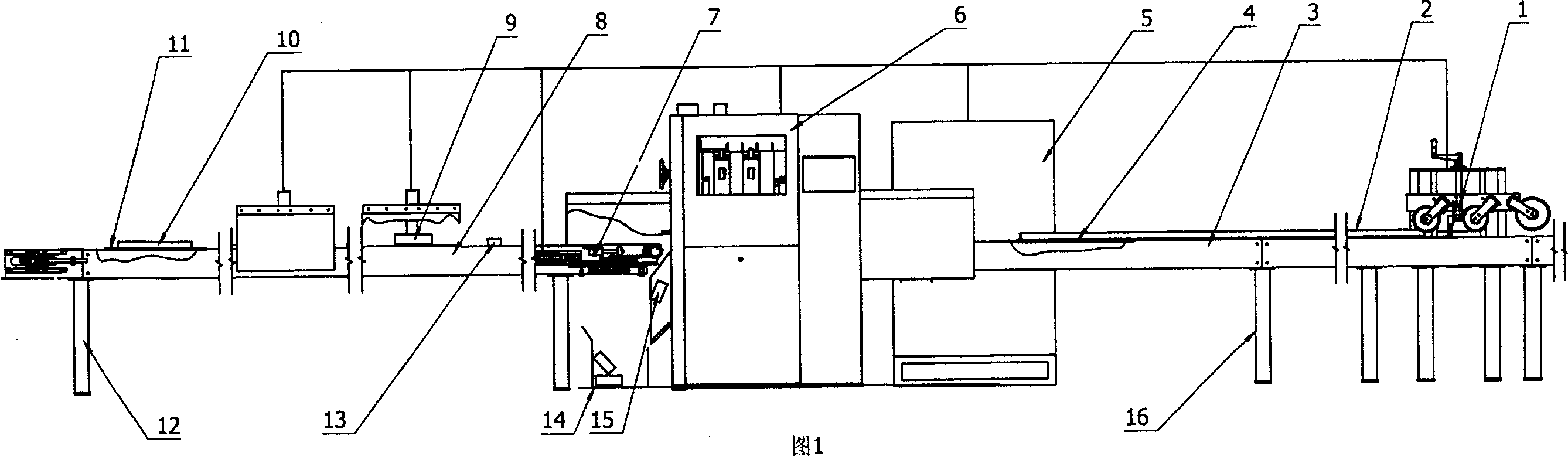

The invention discloses a timber optimized truncate method and relative optimized truncate saw. First, inputting the saw data list which comprises target saw length and quality parameters into the computer; when the sawed timber that longitudinally supplied passes the position relative to the detecting device, the detecting device reads the information of sawed timber into the computer, and the computer according to the input saw data list and said information to select the optimized sawing method; the saw machine according to said method processes truncating on the timber. Two sides of said truncate machine individually have a feeding platform and a finished product classifying platform; wherein, said feeding platform has a detecting device; said finished product classifying platform has a finished product classifying device; and a waste removing device is arranged between them.

Owner:JIANGSU JIANGJIA MACHINERY

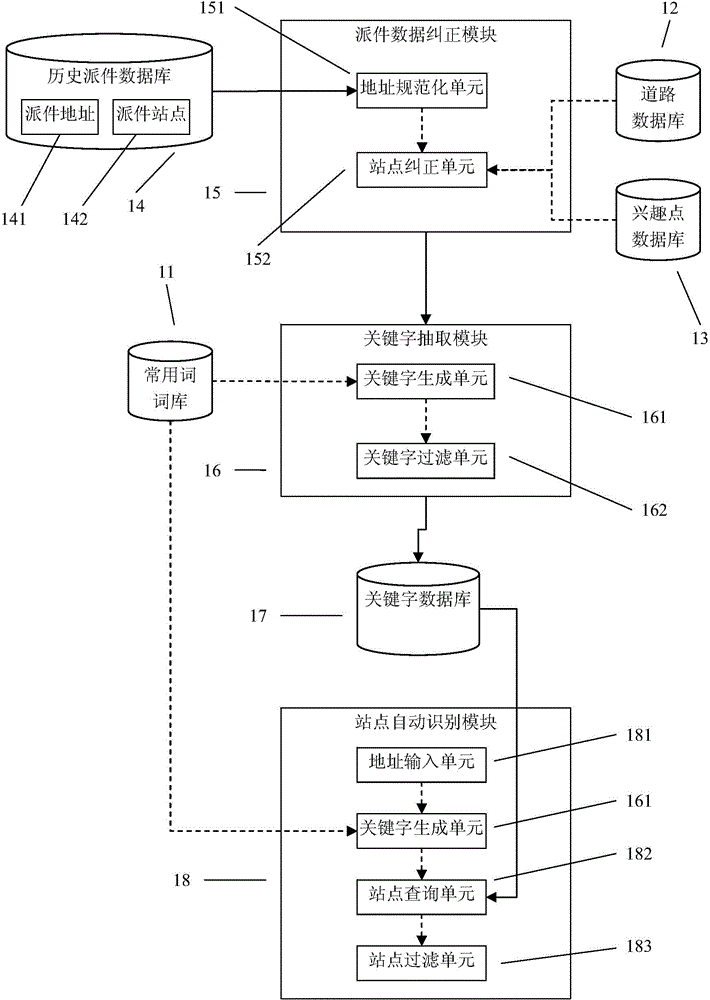

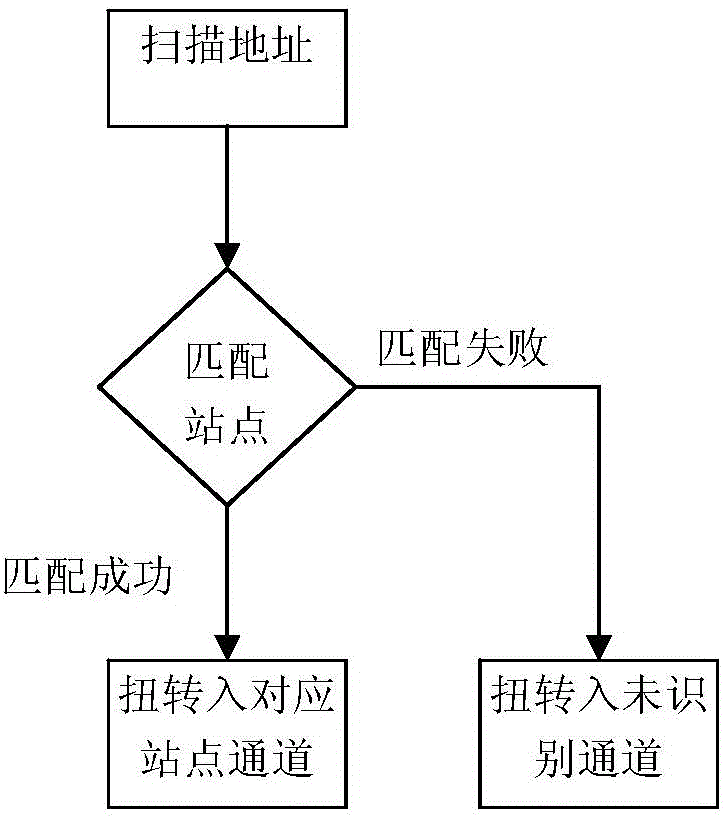

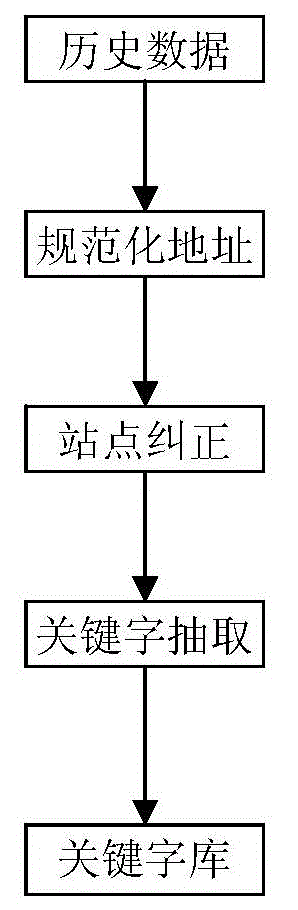

Automatic sorting system and automatic sorting method for express delivery

ActiveCN104624509AAutomatic sorting automatically realizedAutomatic sortingSortingSpecial data processing applicationsSemi automaticComputer module

The invention relates to an automatic sorting system, and discloses an automatic sorting system and an automatic sorting method for express delivery. The automatic sorting system for the express delivery comprises a common word library, a road database, an interest point database, a history delivery database, a delivery data correcting module, a keyword extracting module, a keyword database and an automatic station identifying module. The automatic sorting method comprises the following main steps: keyword database modelling, address scanning and station matching. The invention provides the automatic sorting system and the automatic sorting method for the express delivery, wherein by adopting the automatic sorting system, the identification of delivery stations of the express delivery can be automatically completed without manual interference, sorting of transfer stations and terminal stations of the express delivery can be realized, very high accuracy can be ensured, the problems of easy error occurrence, misoperation, time and labor wasting and the like in a traditional manual sorting method or a semi-automatic sorting method in the express delivery industry are solved, automatic sorting by computers and machines is realized, and the sorting efficiency of the express delivery industry is greatly improved.

Owner:ZHEJIANG BAISHI TECH

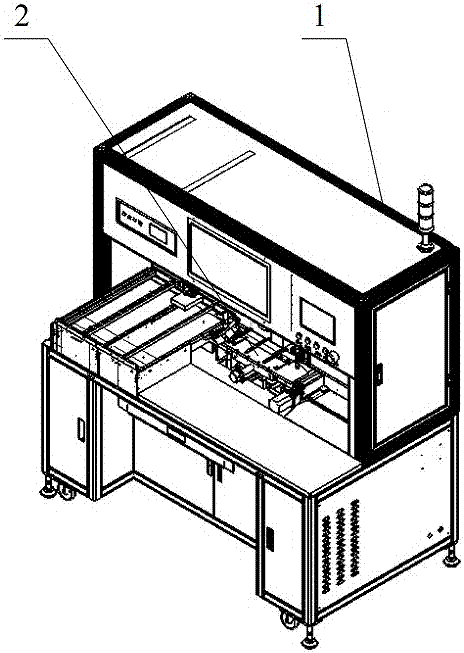

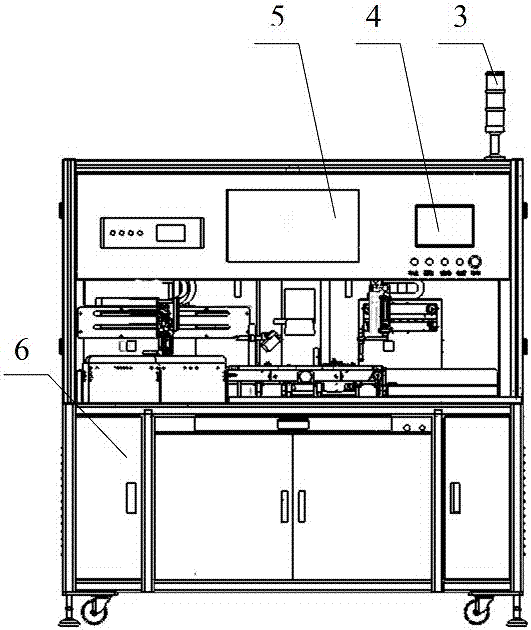

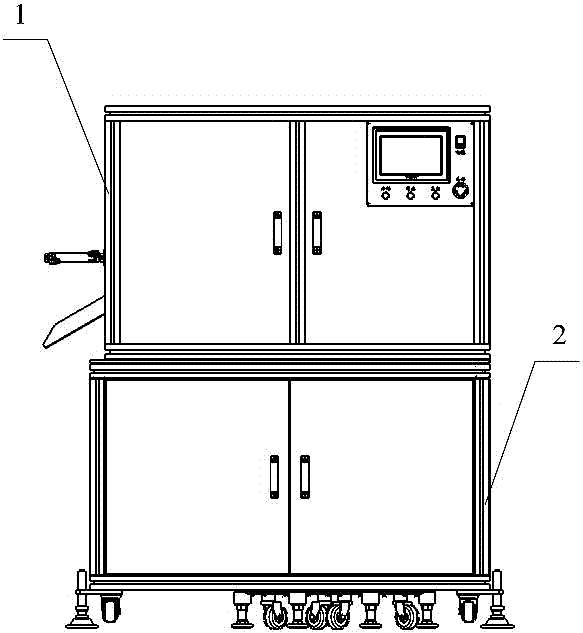

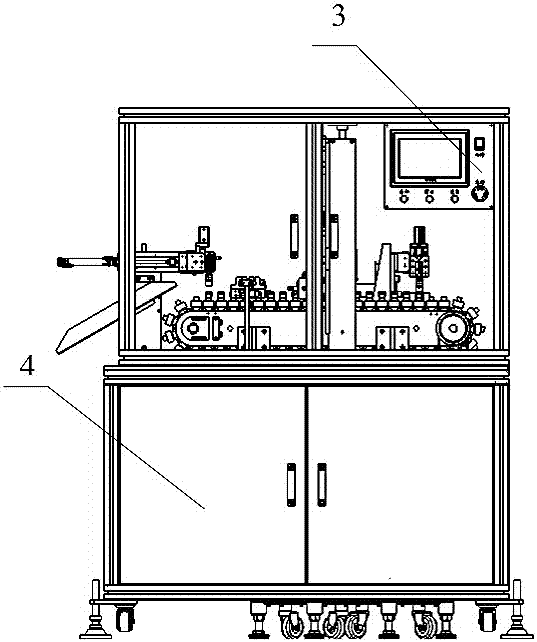

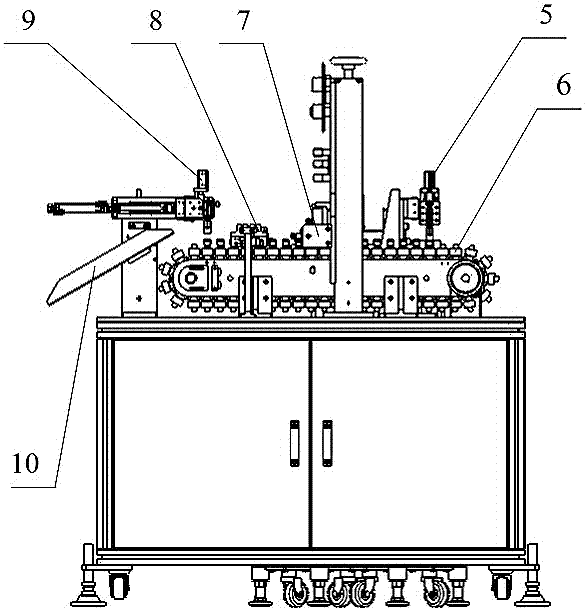

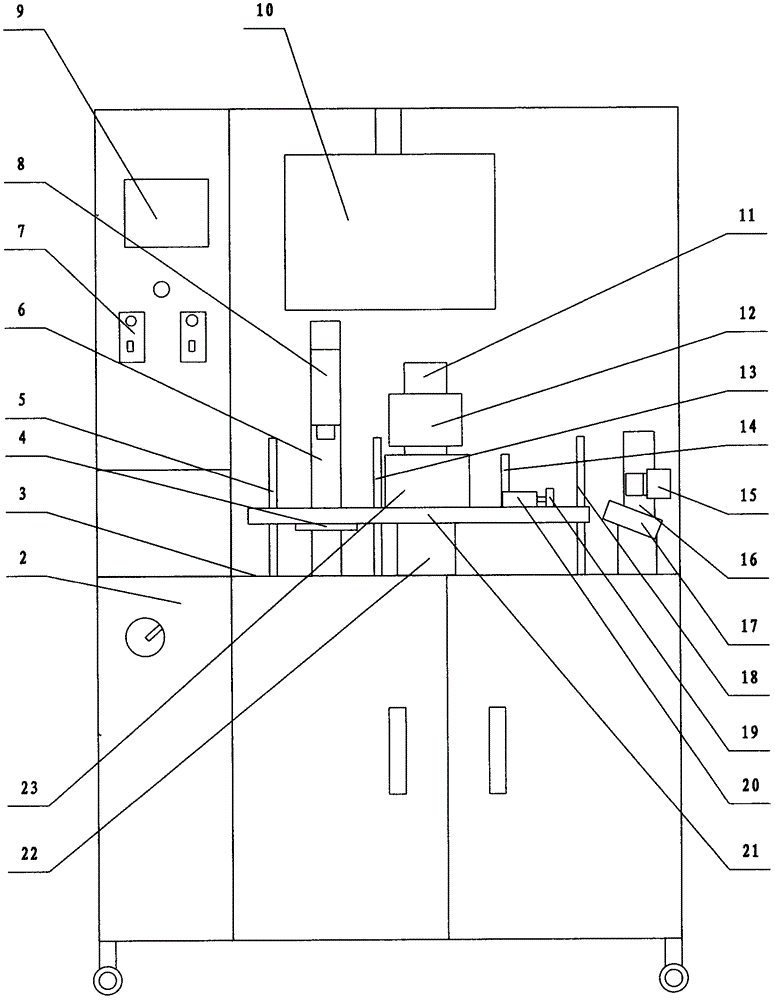

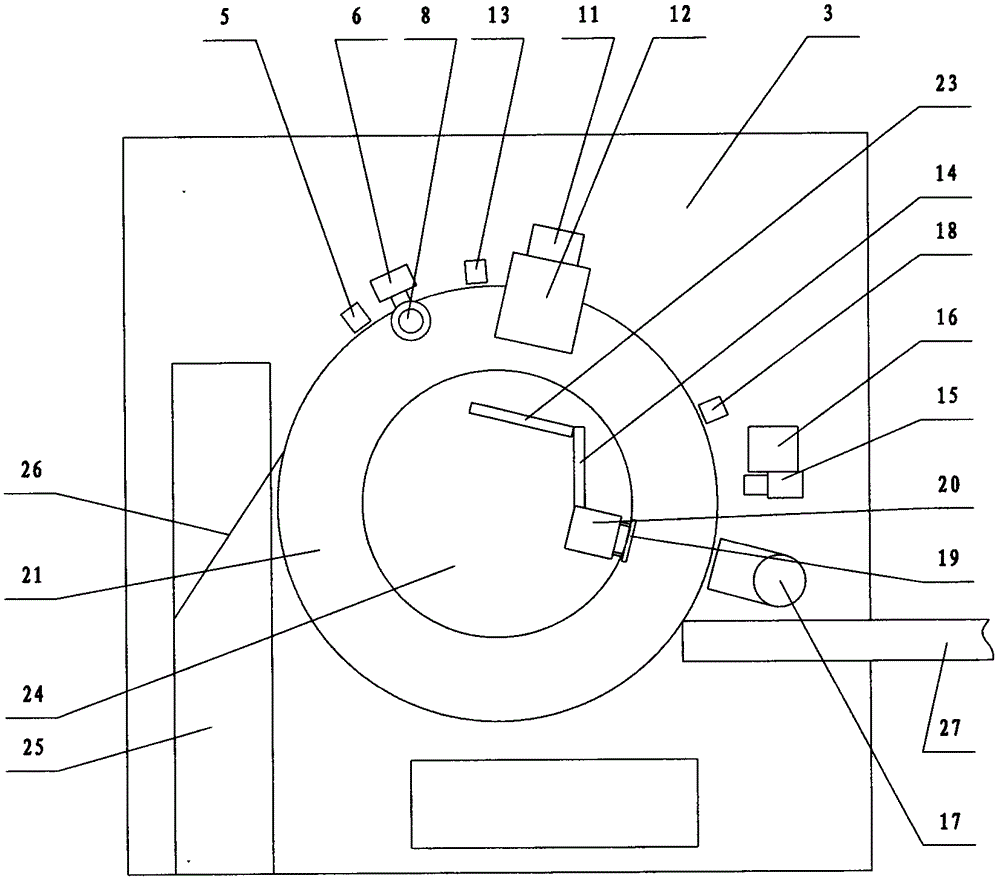

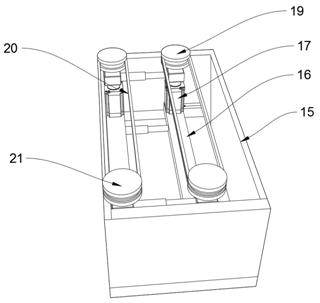

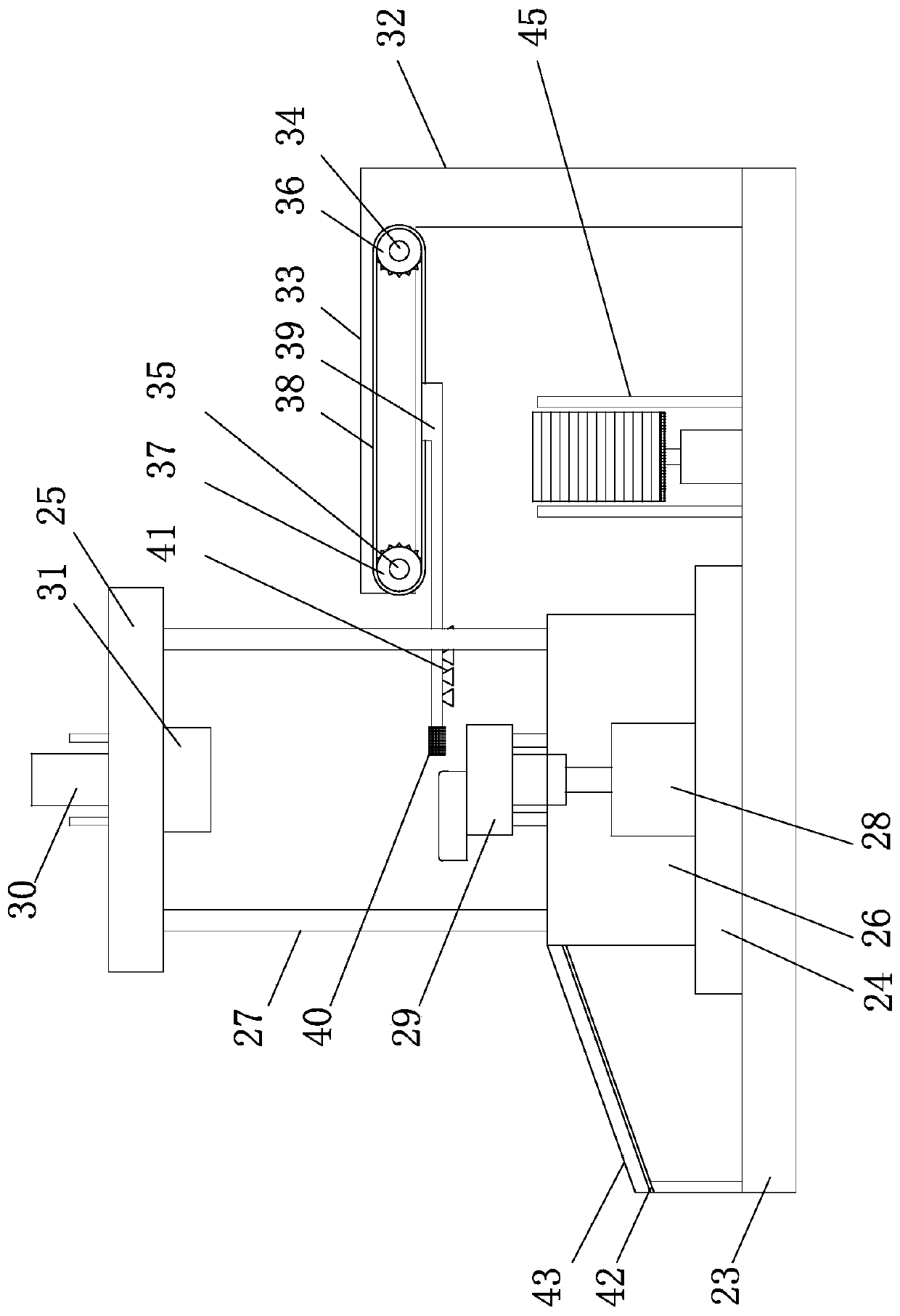

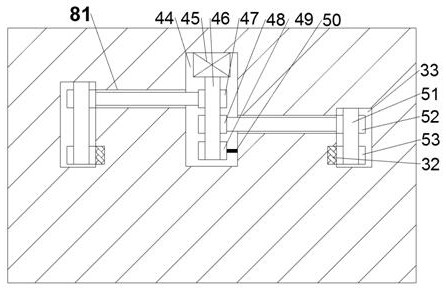

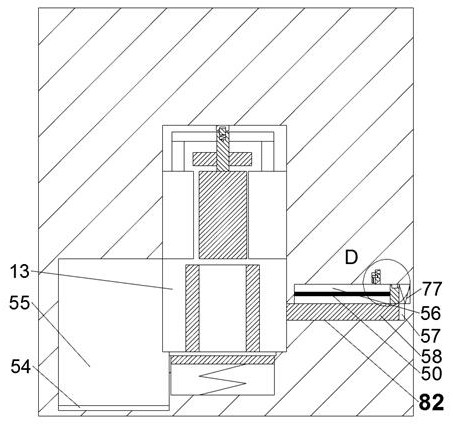

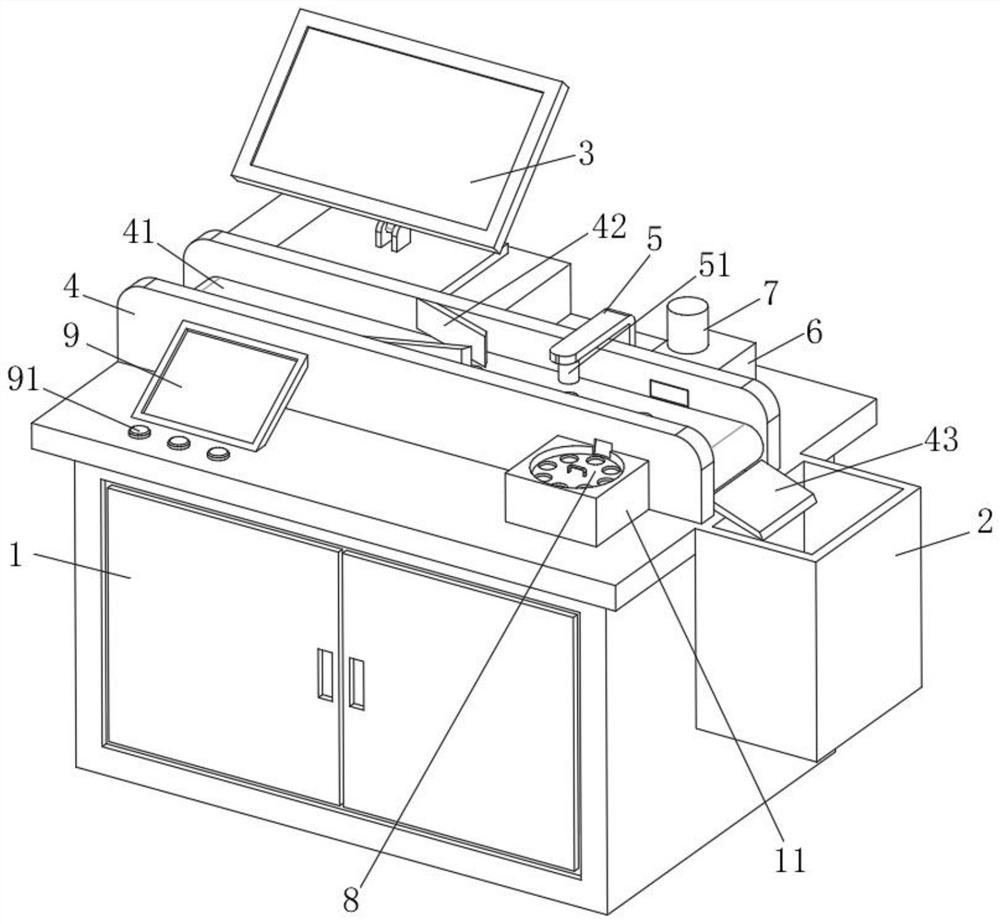

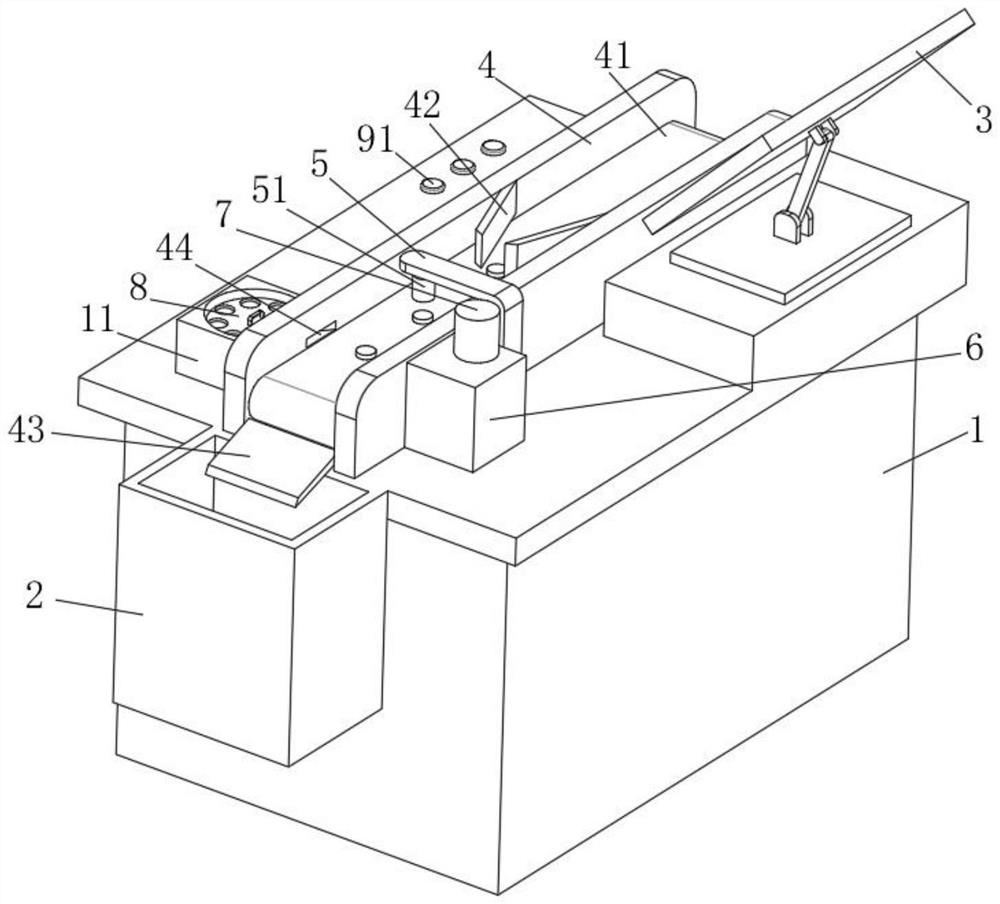

Automatic lithium battery laser marking machine

InactiveCN107350630AImprove marking efficiencyImprove marking qualityMetal working apparatusLaser beam welding apparatusEngineeringLaser

The invention is aimed at providing an automatic lithium battery laser marking machine high in efficiency and quality. The automatic lithium battery laser marking machine can automatically conduct laser making on lithium batteries through a laser marking device and meanwhile can automatically sort out unqualified products from qualified products after laser marking.

Owner:张浩洋

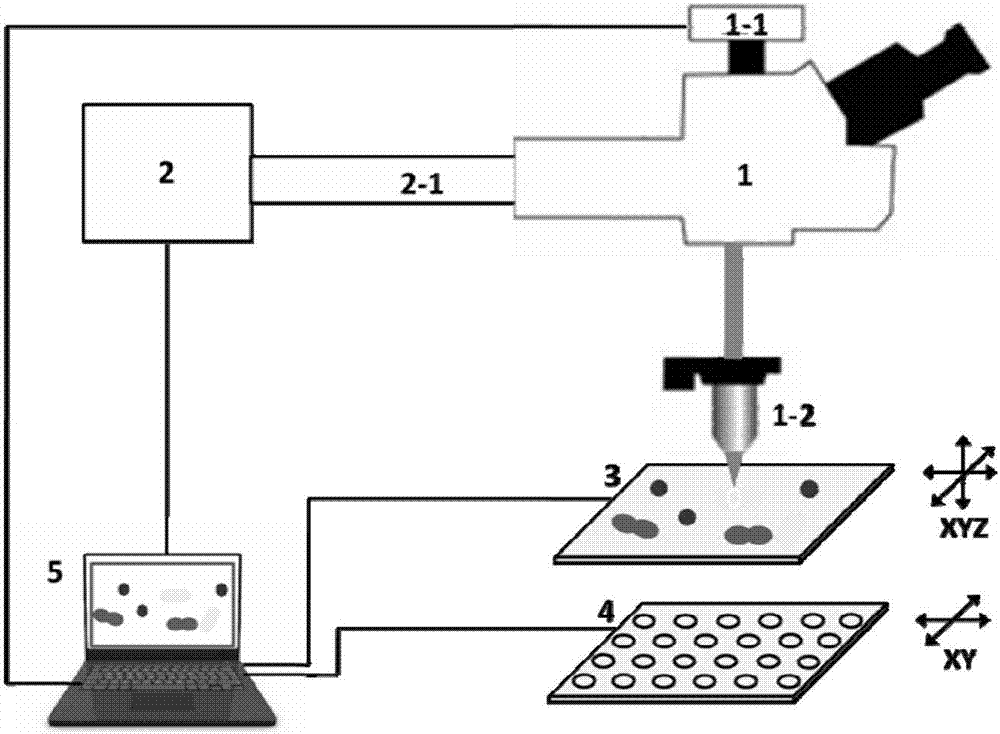

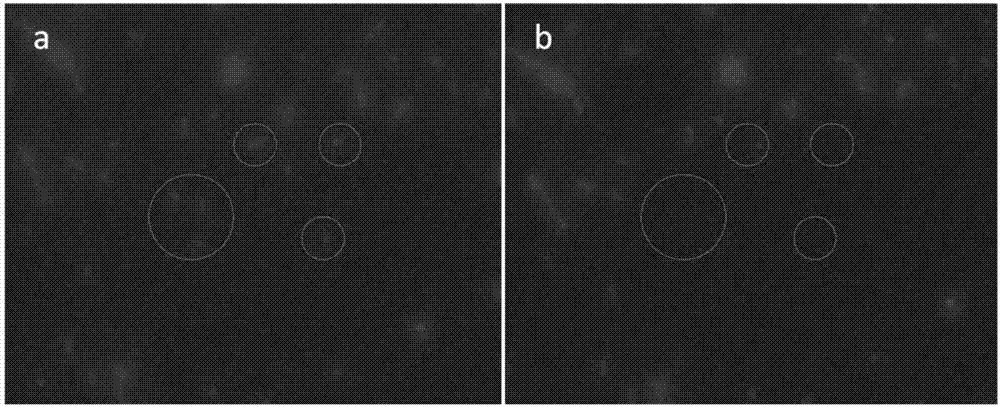

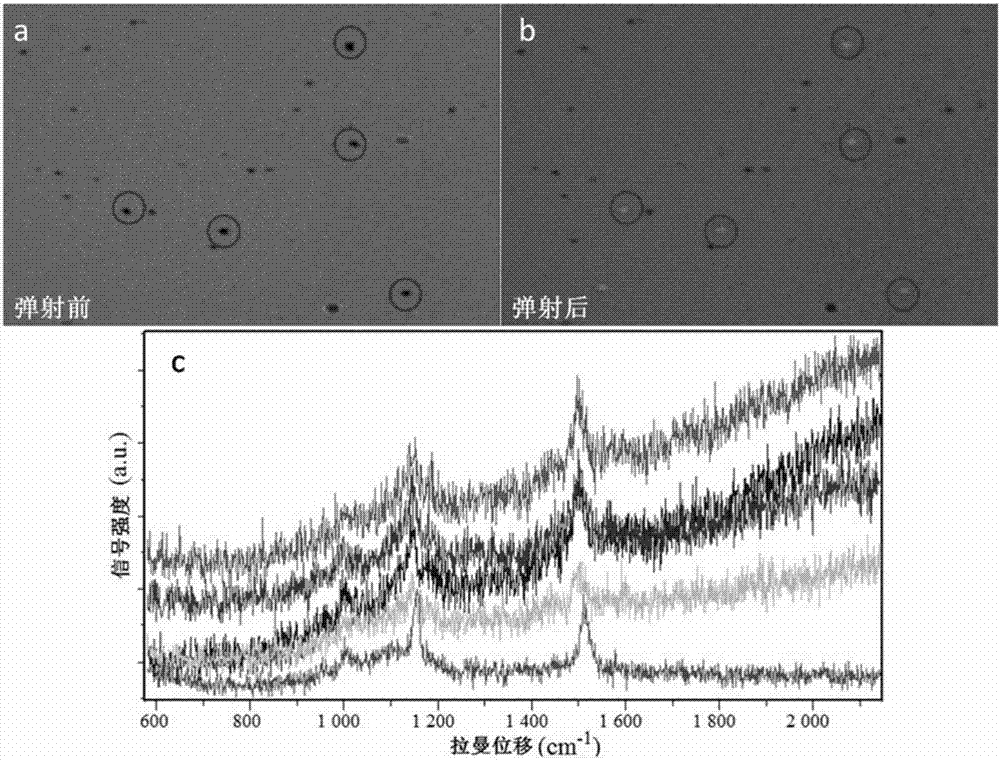

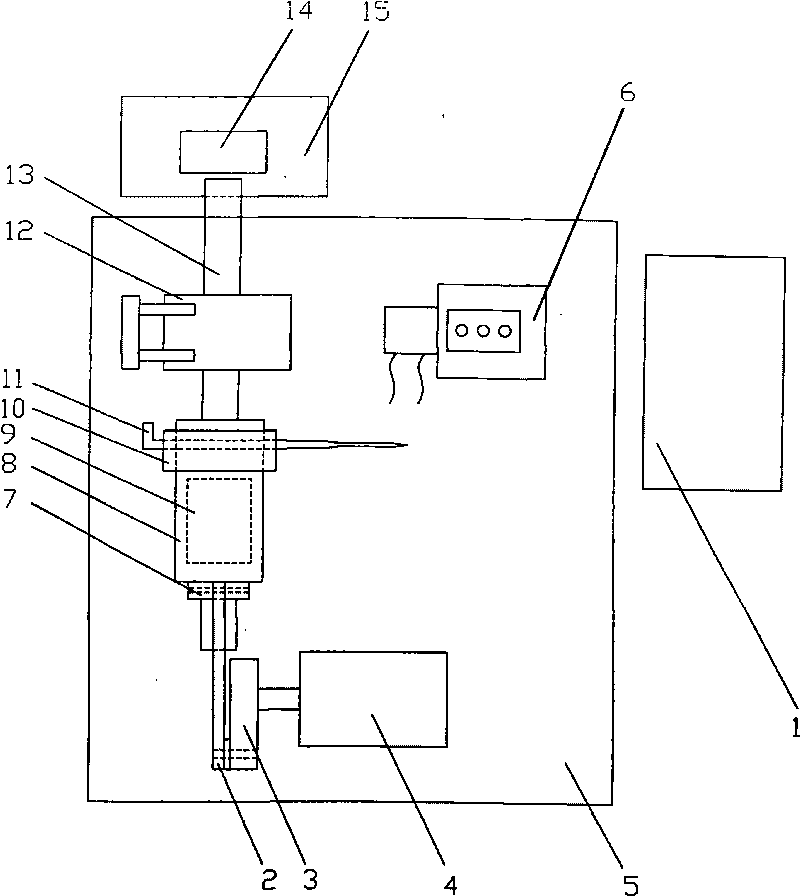

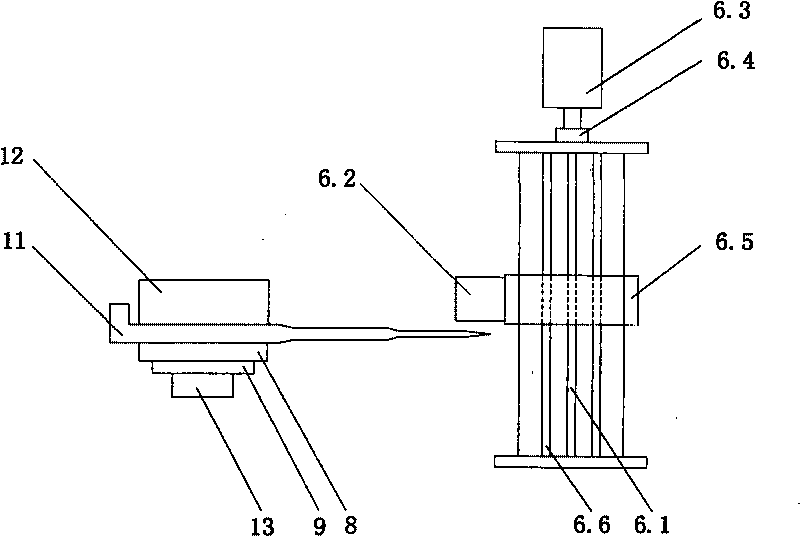

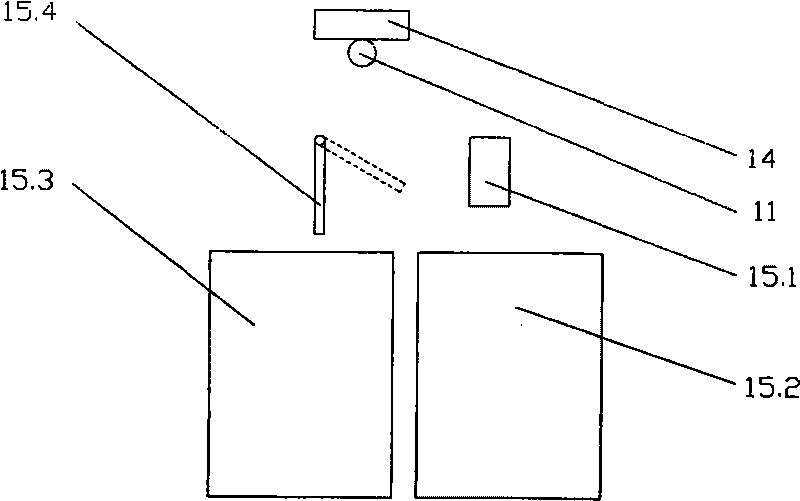

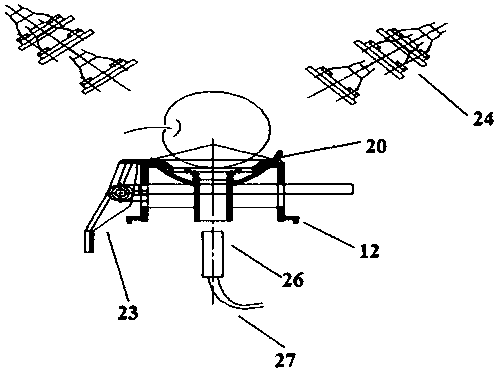

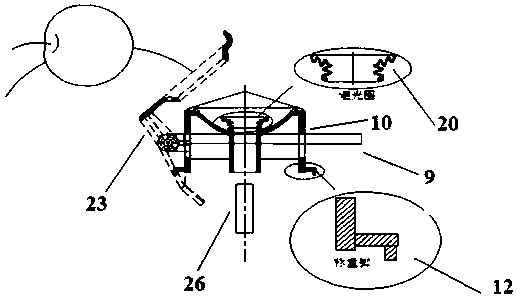

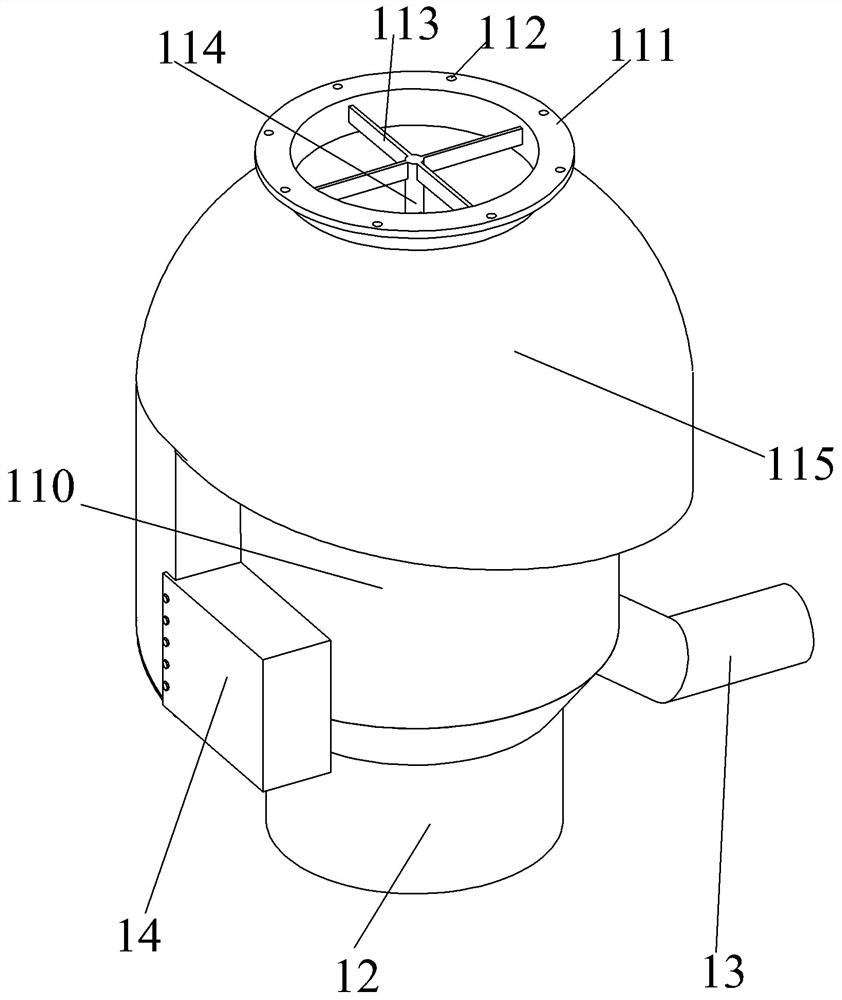

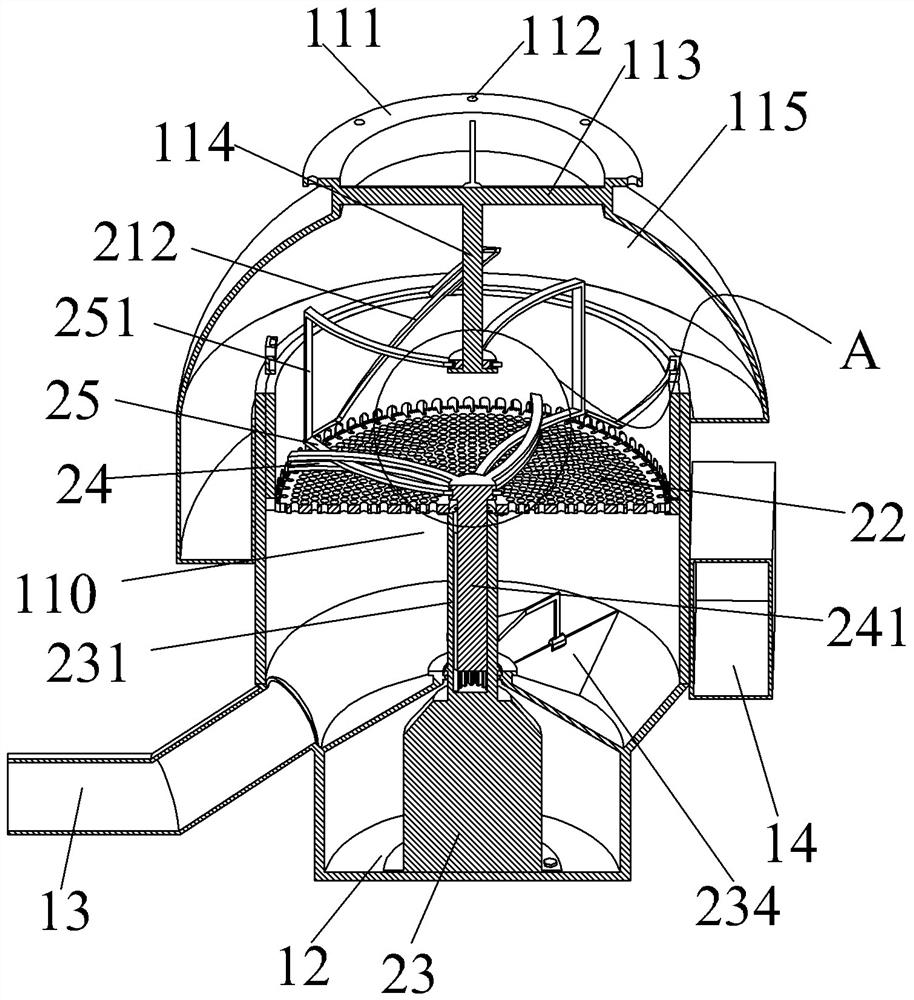

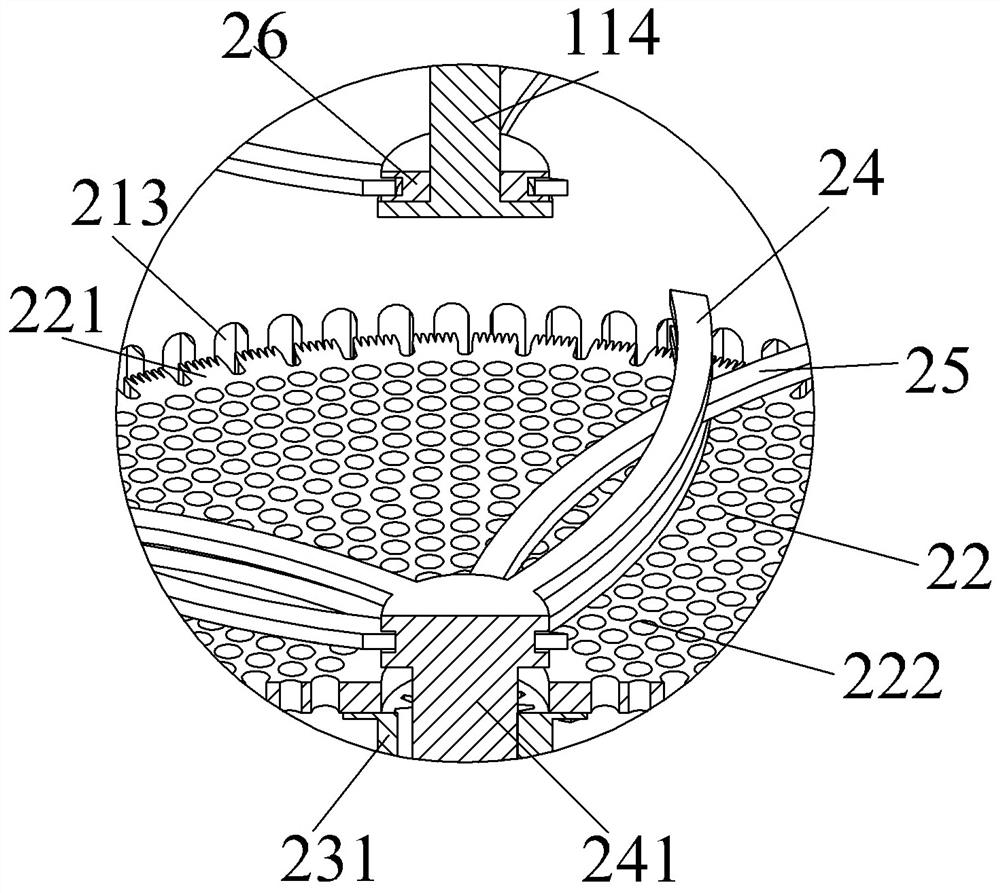

High-throughput automatic sorting and receiving system for microorganism single cells

InactiveCN107490545AQuick sortingReceive quicklyInvestigating moving fluids/granular solidsMicro imagingMicroorganism

The invention relates to a high-throughput automatic sorting and receiving system for microorganism single cells. The system comprises a microscope imaging module, a cell separation module, a pulse laser module, a cell receiving module and a control terminal. An sorter for the microorganism single cells can automatically identify the microorganism single cells, and can couple optical images, fluorescence images, Raman spectrum and various other observation modes to realize the rapid and automatic sorting and receiving of the microorganism single cells at a low hardware cost and a high processing throughput.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Automatic sorting device for dismantled electric meters

The invention relates to automatic assembly line mechanical equipment, in particular to an automatic sorting device for dismantled electric meters. The automatic sorting device comprises a data detection and collection section, a labeling section and a sorting section. The data detection and collection section, the labeling section and the sorting section are sequentially connected in series. A first support, a detection table, a jacking transfer device and an image collection device are arranged in the data detection and collection section. A second support, a second conveyor and a labeling machine are arranged on the labeling section. A lifting conveyor, multiple sliding ways, multiple material boxes and a frame are arranged on the sorting section. The sliding ways are fixed in parallel through the frame. The inlet of each sliding way is adjacent to the lifting conveyor. The inlets of the sliding ways are located in the same vertical line. One material box is arranged below the outlet of each sliding way. The automatic sorting device is easy to operate, high in accuracy, high in efficiency and capable of automatically sorting the dismantled electric meters, and the problems that data images cannot be stored and data sources of the dismantled electric meters are difficult to trace in the prior art are solved.

Owner:山东瑞吉德自动化股份有限公司

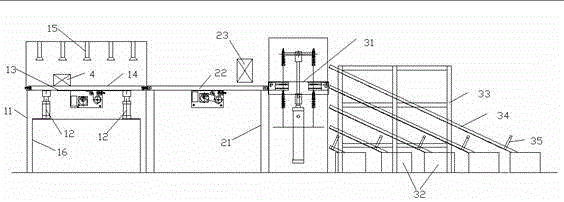

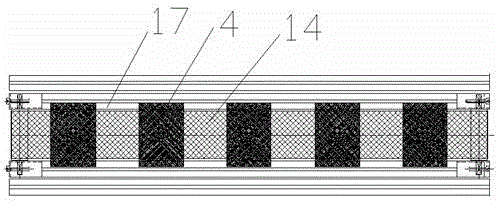

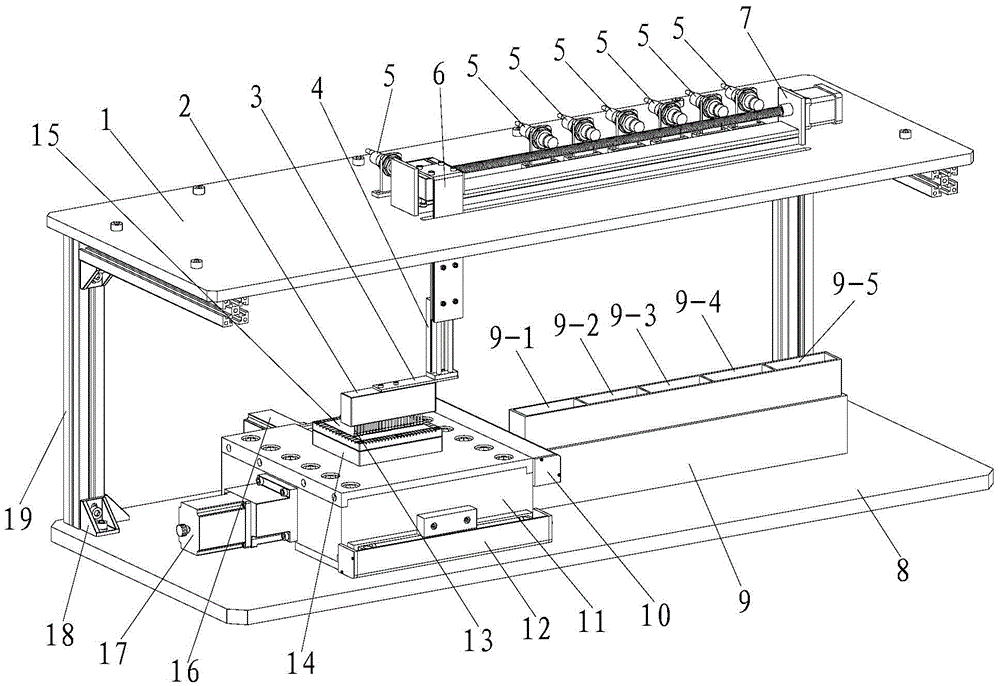

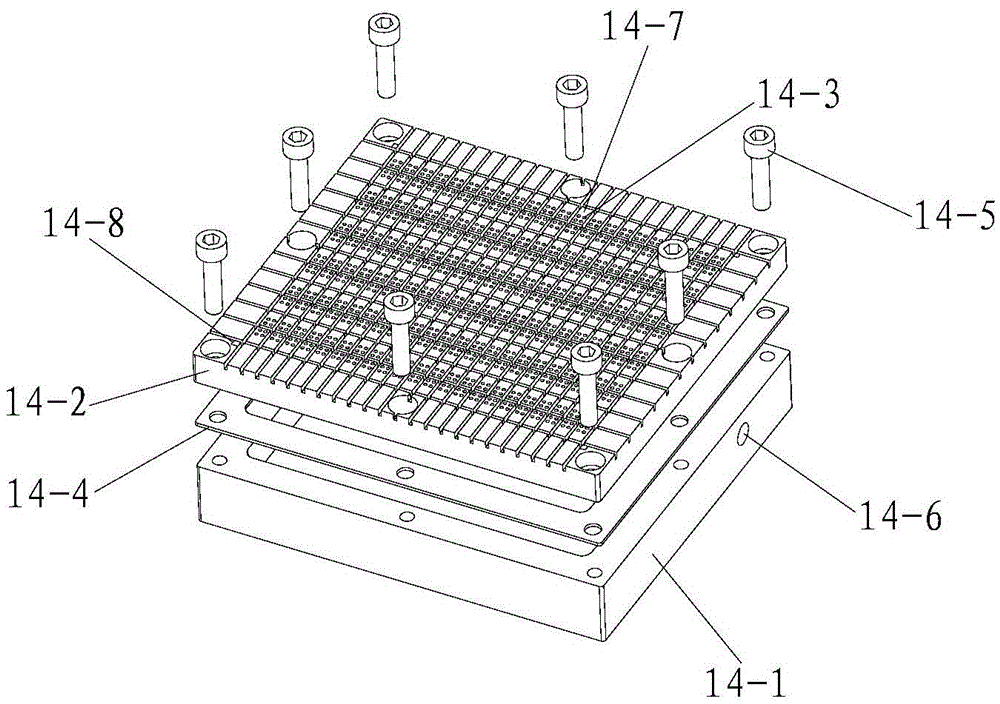

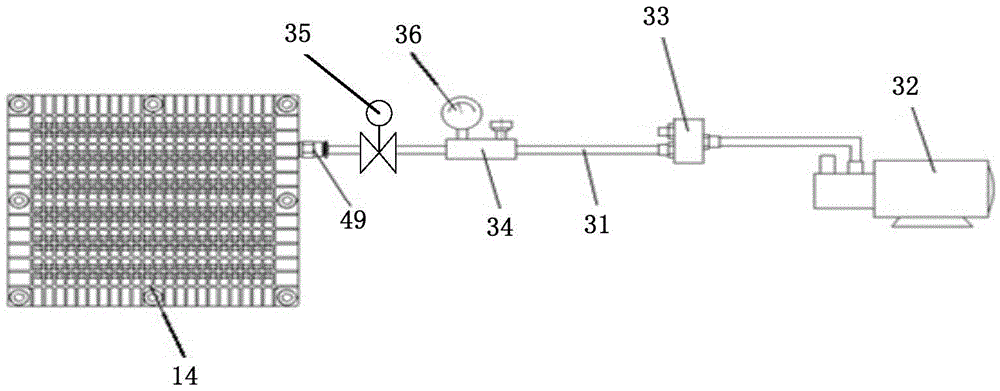

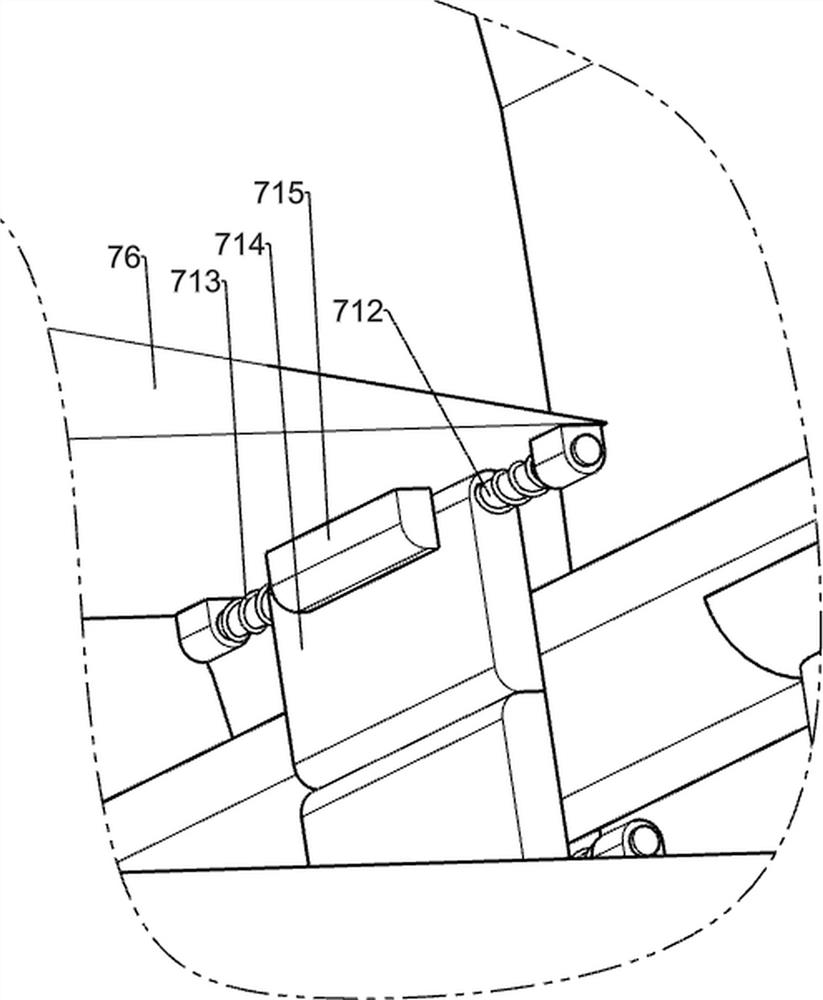

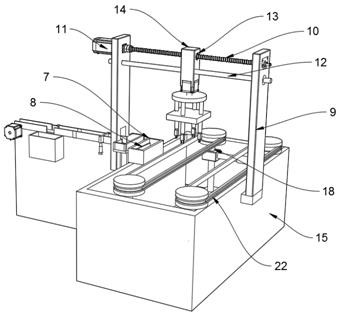

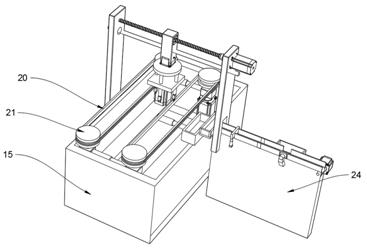

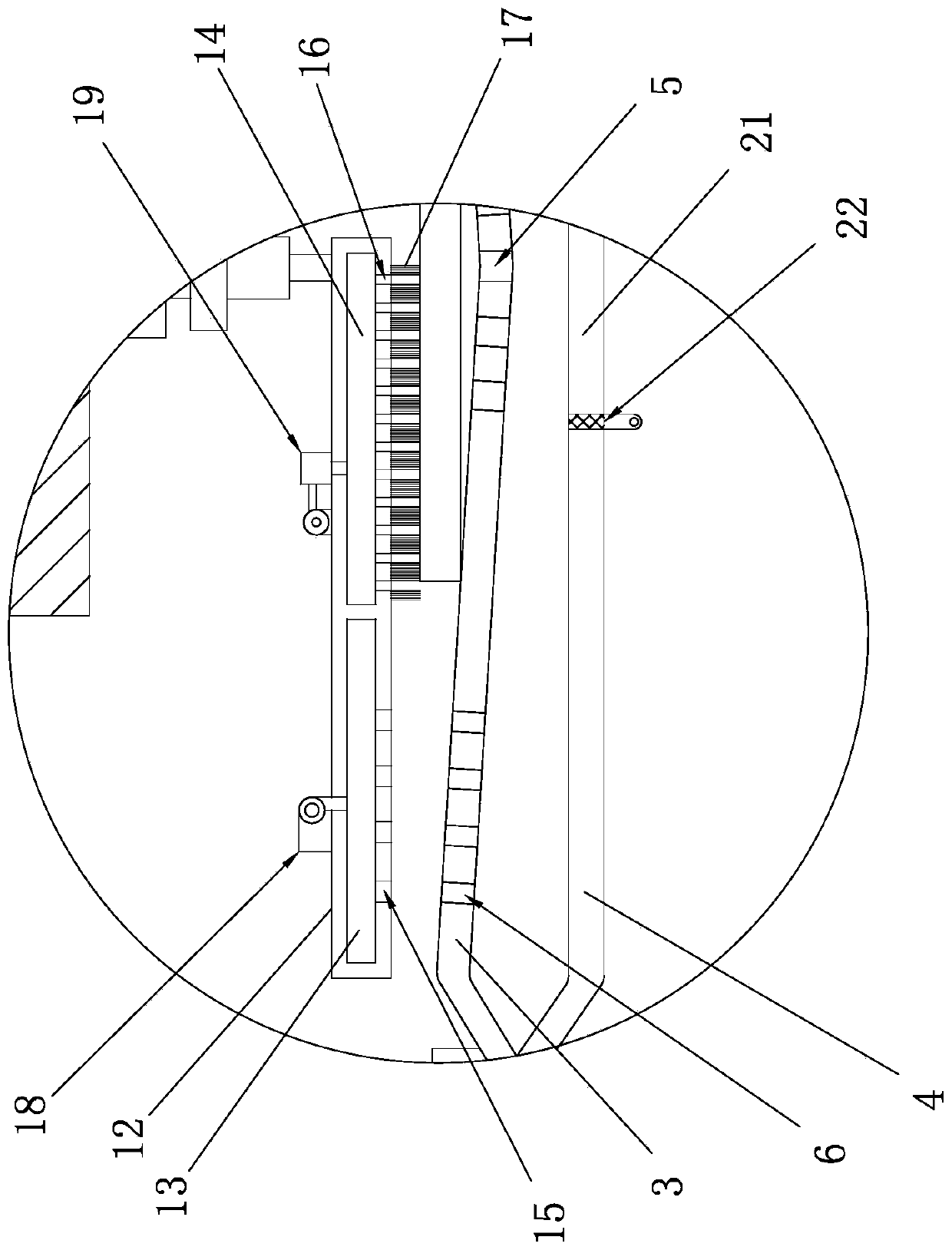

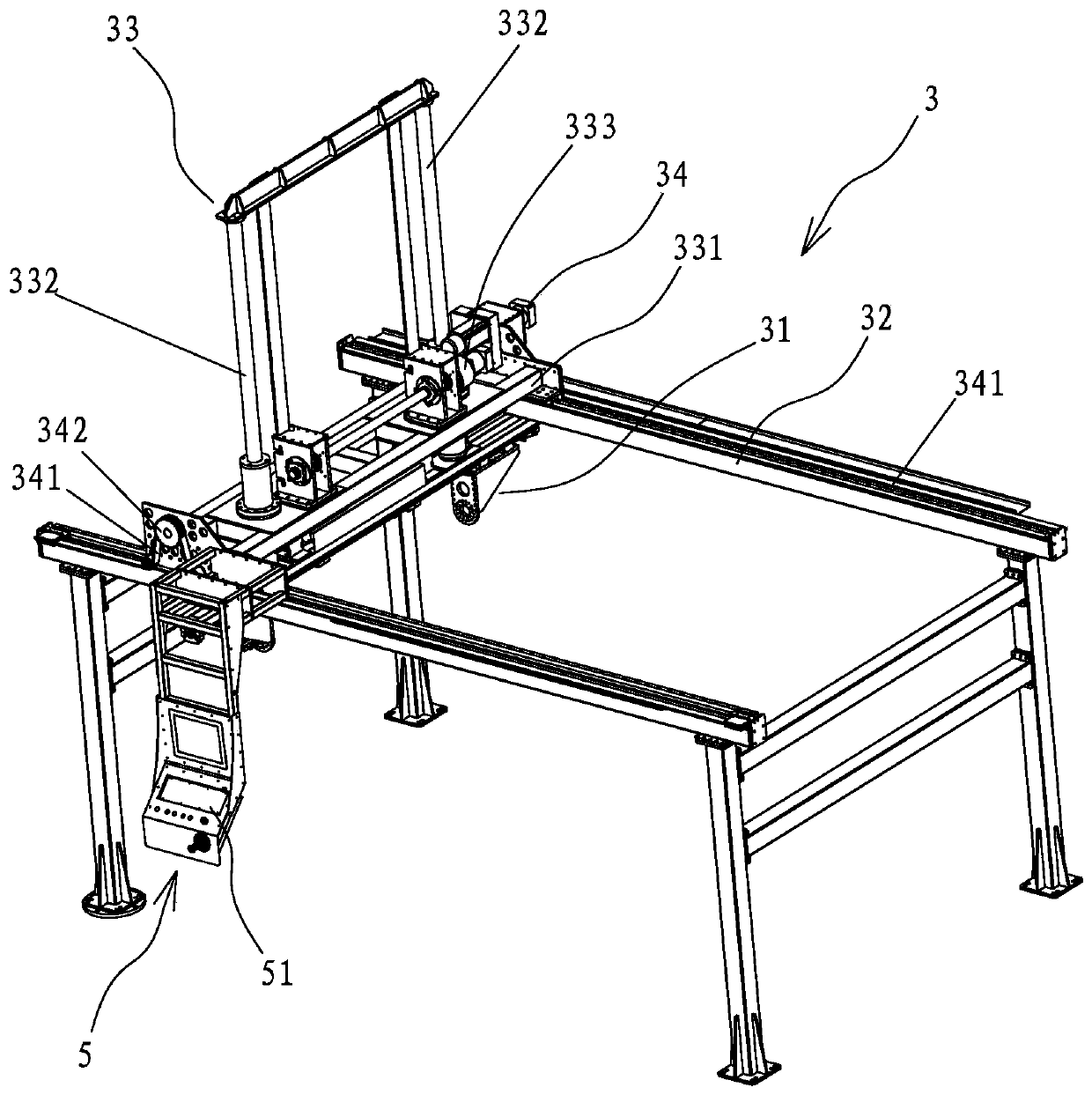

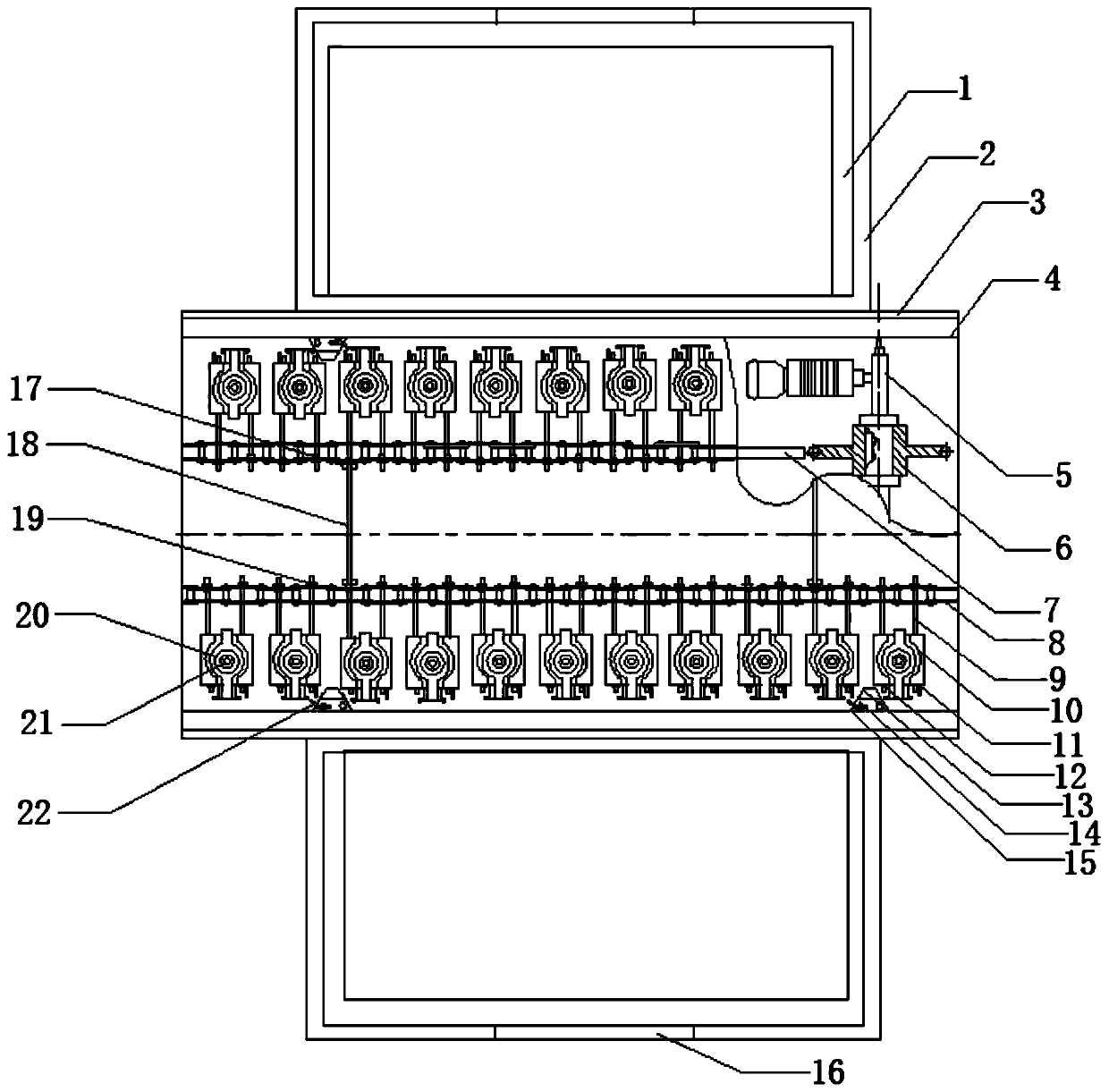

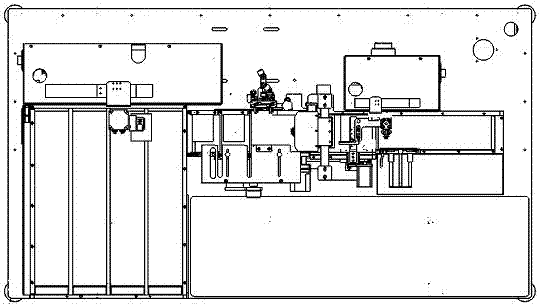

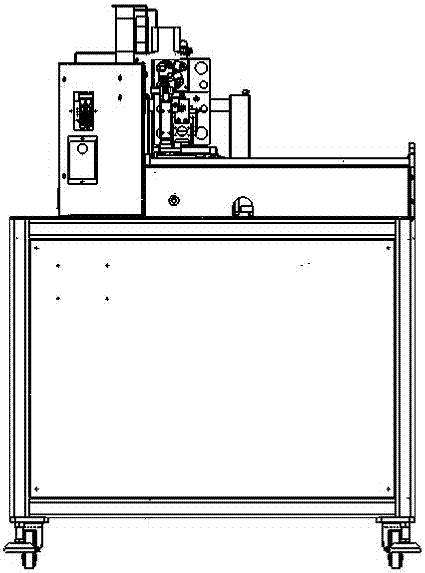

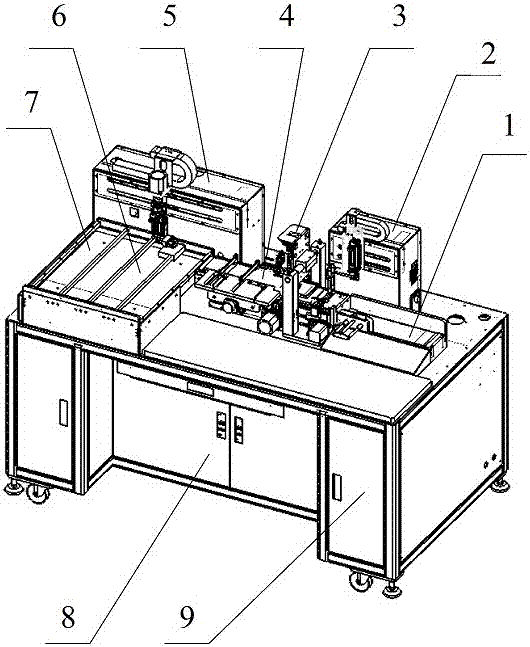

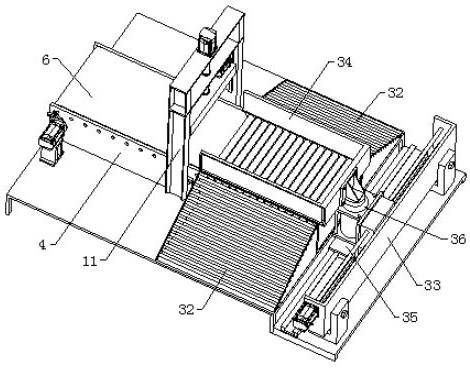

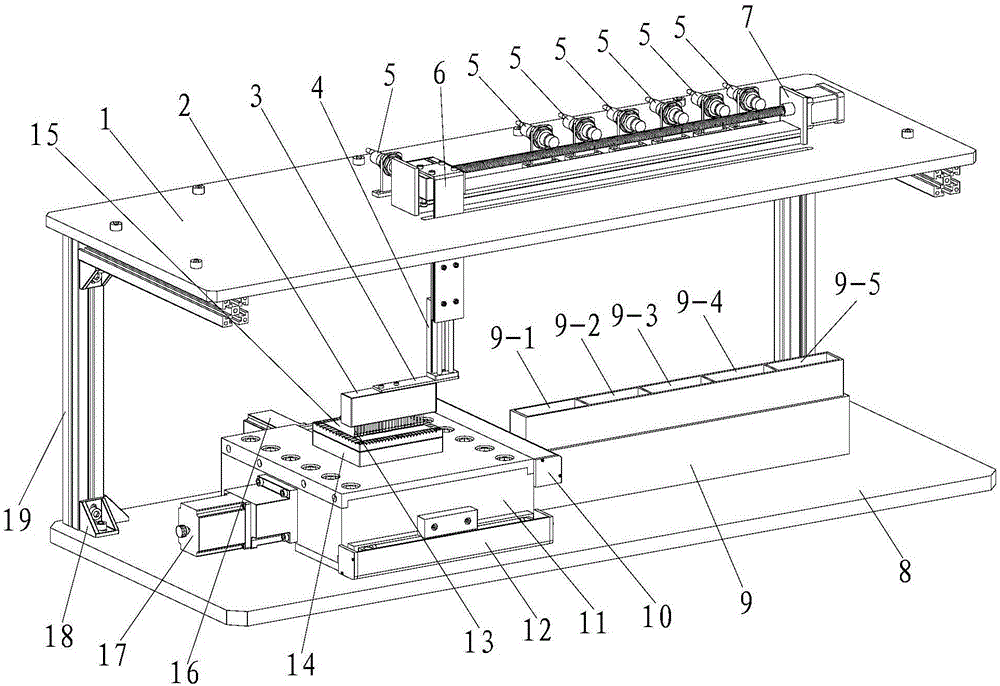

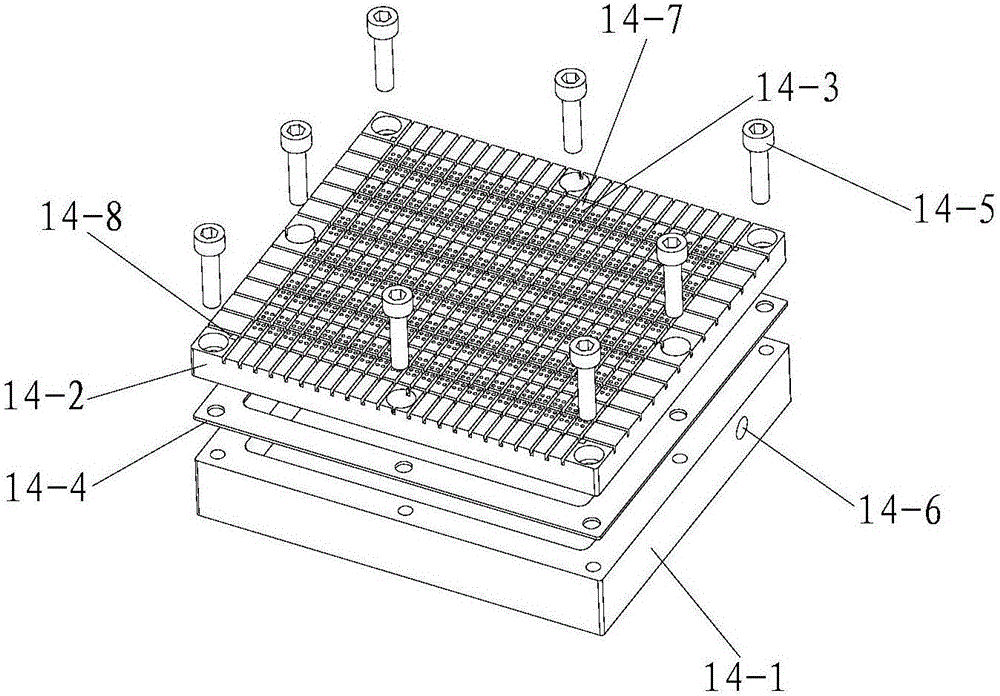

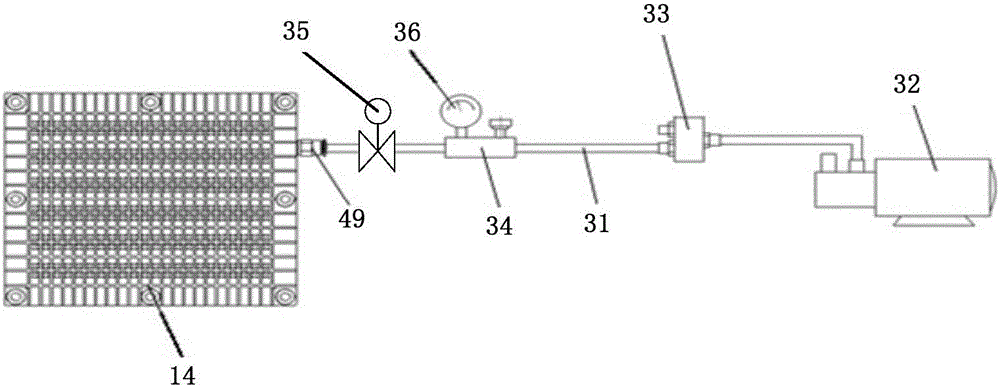

Automatic sorting device and method for large-array resistance strain plates

InactiveCN105618394ACompact structureNovel and reasonable designSortingPneumatic circuitData acquisition

The invention discloses an automatic sorting device for large-array resistance strain plates. The device comprises a frame, a positioning and fixing mechanism, an adsorption and sorting mechanism, a positioning and sorting mechanism, a computer, a data acquisition board card and an output amplifier board. The frame comprises an upper top plate, a lower bottom plate and supporting columns. The positioning and fixing mechanism comprises a two-dimensional moving platform, a vacuum adsorption table and a first vacuum adsorption loop. The adsorption and sorting mechanism comprises an adsorption head mounting box, multiple vacuum adsorption heads, a second vacuum adsorption loop and a pneumatic loop, wherein the vacuum adsorption heads are arranged in the adsorption head mounting box, and the lower ends of the vacuum adsorption heads stretch out of the adsorption head mounting box. The positioning and sorting mechanism comprises a ball screw sliding table, a cylinder sliding table and a second pneumatic loop. The invention further discloses an automatic sorting method for the large-array resistance strain plates. The device and method are novel and reasonable in design, low in realizing cost, high in work reliability and practicability, capable of improving the production efficiency, lowering the labor intensity of workers and product production cost, and high in application and popularization value.

Owner:SHAANXI UNIV OF TECH

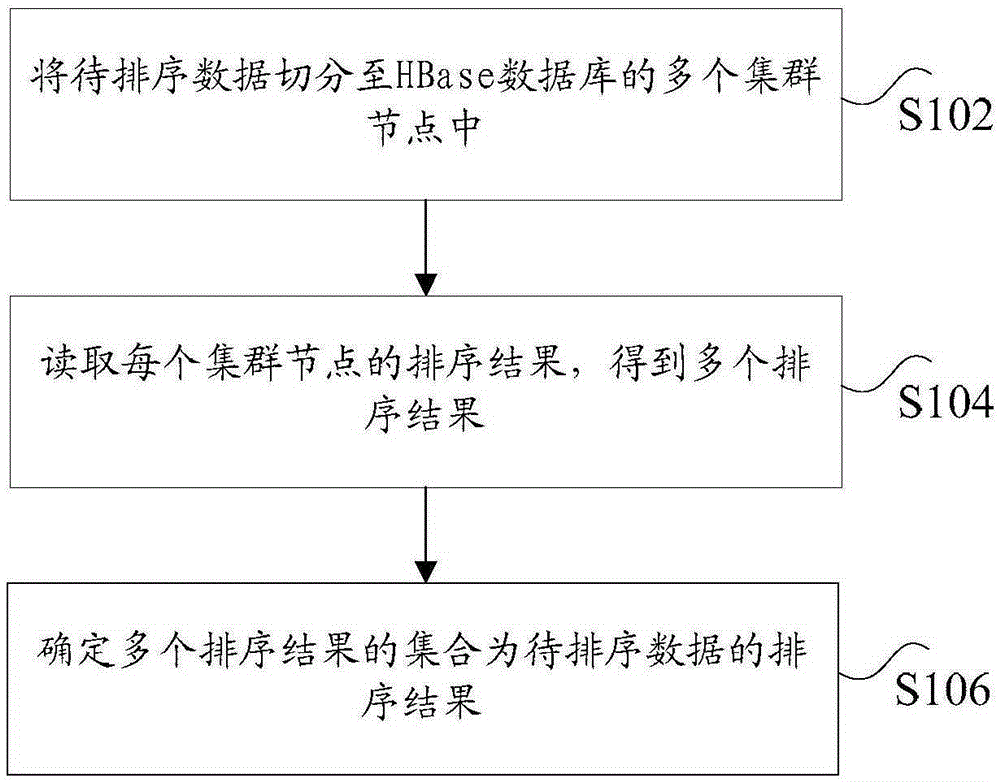

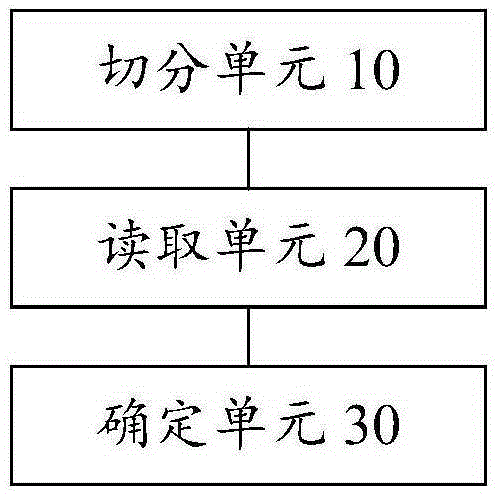

Data ranking method and device based on HBase database

ActiveCN106649385AReduce sorting timeAutomatic sortingSpecial data processing applicationsRankingData mining

The invention discloses a data ranking method and a device based on a HBase database. The method comprises the steps that the to-be-ranked data are segmented into multiple cluster nodes in HBase database, wherein each cluster node after being given the segmented data executes a row-key value ranking method in HBase database; the ranked results for each cluster node are read, and multiple ranking results are obtained, wherein each cluster node after executing the row-key value ranking method and performing rankings on the segmented data obtains a ranked result; the collections of multiple ranking results are determined as the ranking results of the to-be-ranked data. The technical problem that in the prior art the efficiency of data ranking is low is solved.

Owner:BEIJING GRIDSUM TECH CO LTD

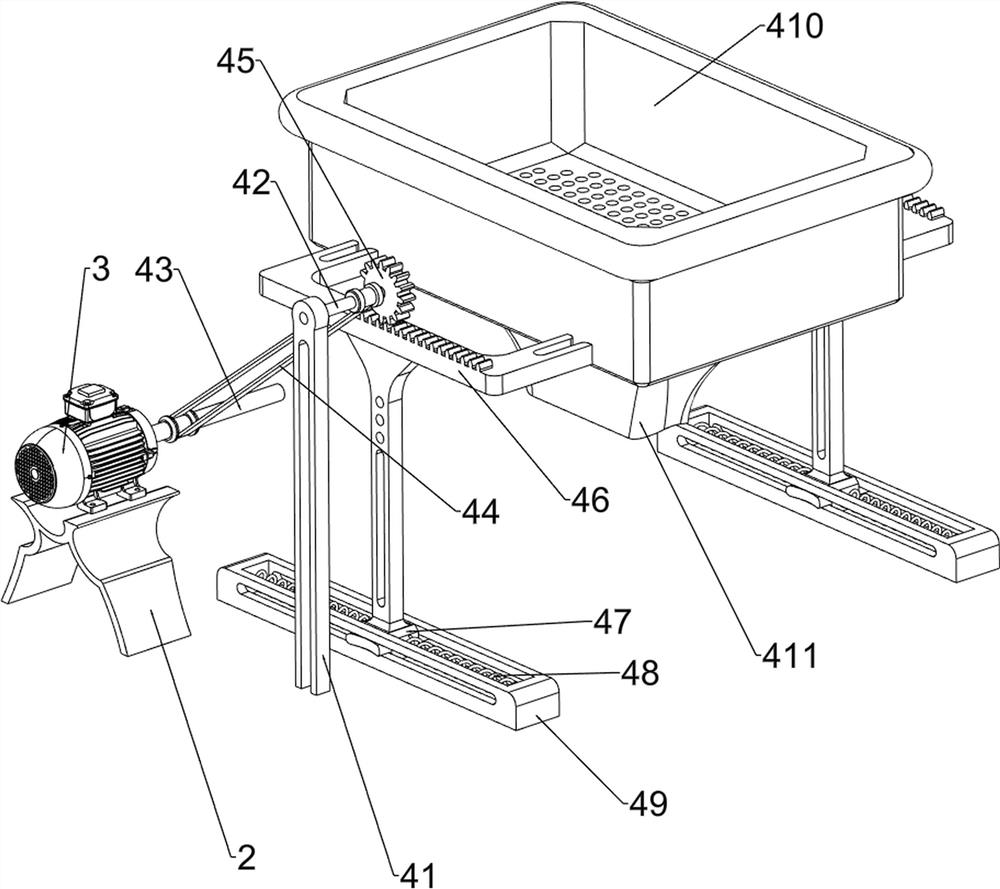

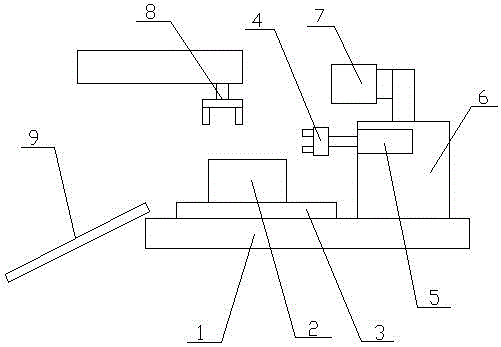

Red bean sorting equipment for agricultural planting

PendingCN112916192ATo achieve the collection effectAutomatic sortingWet separationAgricultural engineeringElectric machinery

The invention relates to sorting equipment, in particular to red bean sorting equipment for agricultural planting. The red bean sorting equipment for agricultural planting aims at achieving the technical effects that red beans can be automatically sorted, and bad red beans can be collected. The red bean sorting equipment for agricultural planting comprises a bottom plate, wherein the bottom plate is used for installing the whole equipment; a support frame, wherein the support frame is arranged in the middle of one side of the upper portion of the bottom plate; a motor, wherein the motor is arranged at the upper portion of the support frame; a screening mechanism, wherein the screening mechanism is arranged at the upper portion of the bottom plate; and a manual discharging mechanism, wherein the manual discharging mechanism is arranged on one side of the upper portion of the bottom plate. The red bean sorting equipment achieves the effects that the red beans can be automatically sorted, and the bad red beans can be collected; and water is added into a water tank, so that the bad red beans can float on the water surface, the bad red beans can be removed in the process that a scraping plate moves left and right, and the effect of collecting the bad red beans is achieved.

Owner:熊克强

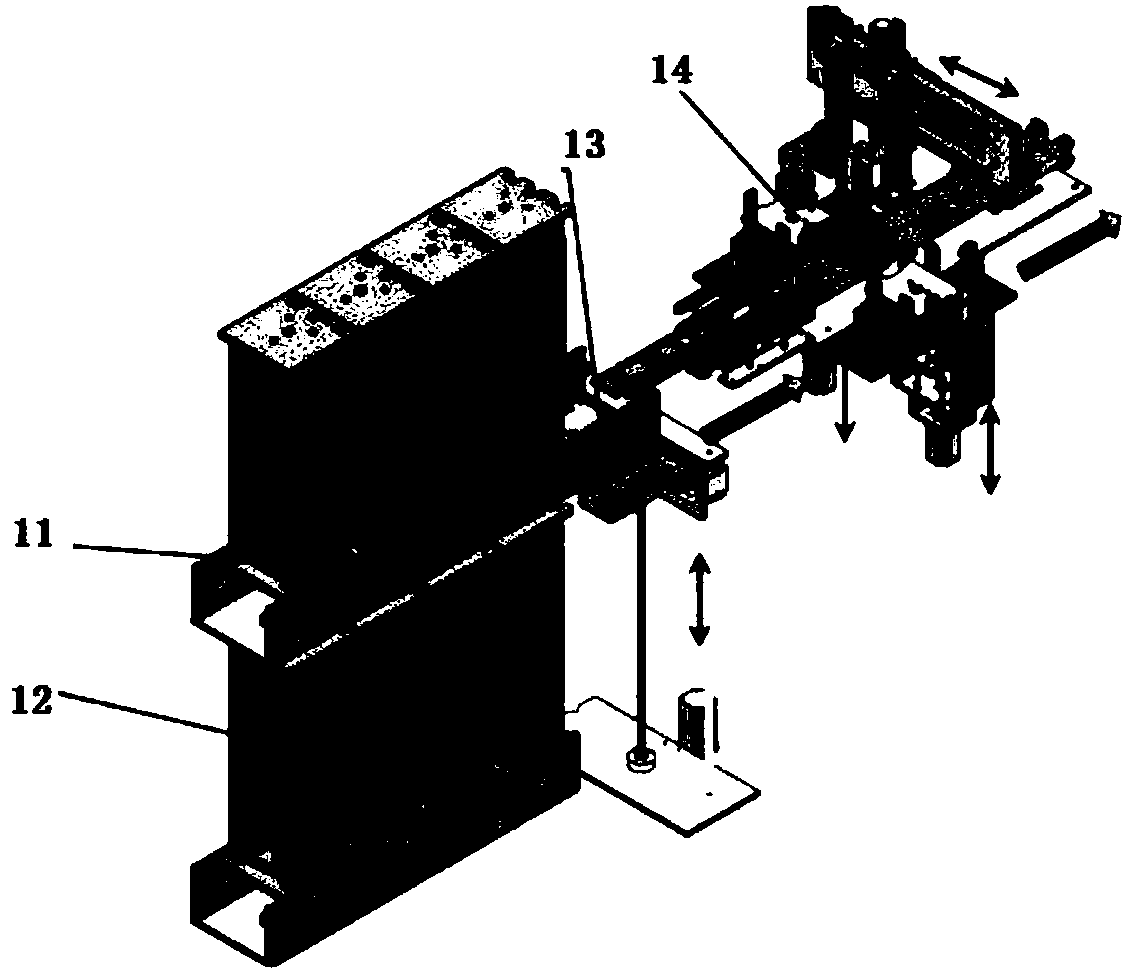

Automatic silicon wafer sorting equipment

PendingCN109550704AAutomatic sortingEfficient sortingSortingElectrical resistance and conductanceSilicon

The invention provides automatic silicon wafer sorting equipment. The equipment comprises a feeding part, a detecting part and a discharging part which are sequentially arranged; the detecting part comprises a transmission mechanism, a positioning mechanism, surface detecting modules, a geometric parameter detecting module and a resistivity detecting module, wherein the transmission mechanism is arranged in the detecting part and used for transmitting silicon wafers; the positioning mechanism is arranged at the starting end of the transmission mechanism, and is used for positioning dischargedsilicon wafers from wafer discharging baskets; the surface detecting modules are arranged on the side surface and the upper surface of the transmission mechanism and used for detecting the appearancedefects of the surface of the silicon wafer; the geometric parameter detecting module is arranged in the detecting part and used for measuring the thickness of the silicon wafer; and the resistivity detecting module is arranged in the detecting part and used for measuring the electric loss of the silicon wafer. The equipment has the beneficial effects that a belt transmission line, the appearancedetecting, the geometrical parameter detecting, the resistivity detecting, the laser marking and other functions are integrated, so that automatic, efficient and accurate sorting of the silicon waferis realized, the capacity of silicon wafer detecting sorting is effectively improved, the silicon wafer is guaranteed to be sorted freely according to resistivity, thickness, appearance and other parameters, and the false detecting rate can be reduced.

Owner:TIANJIN HUANXIN TECH DEV

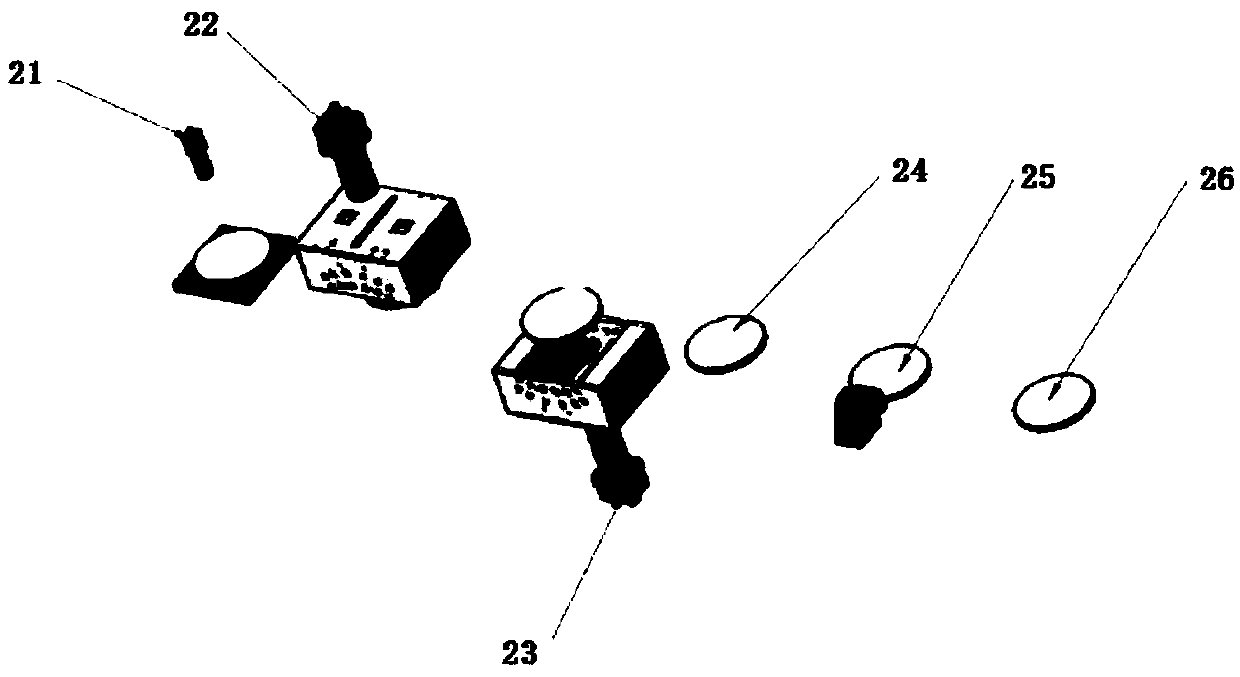

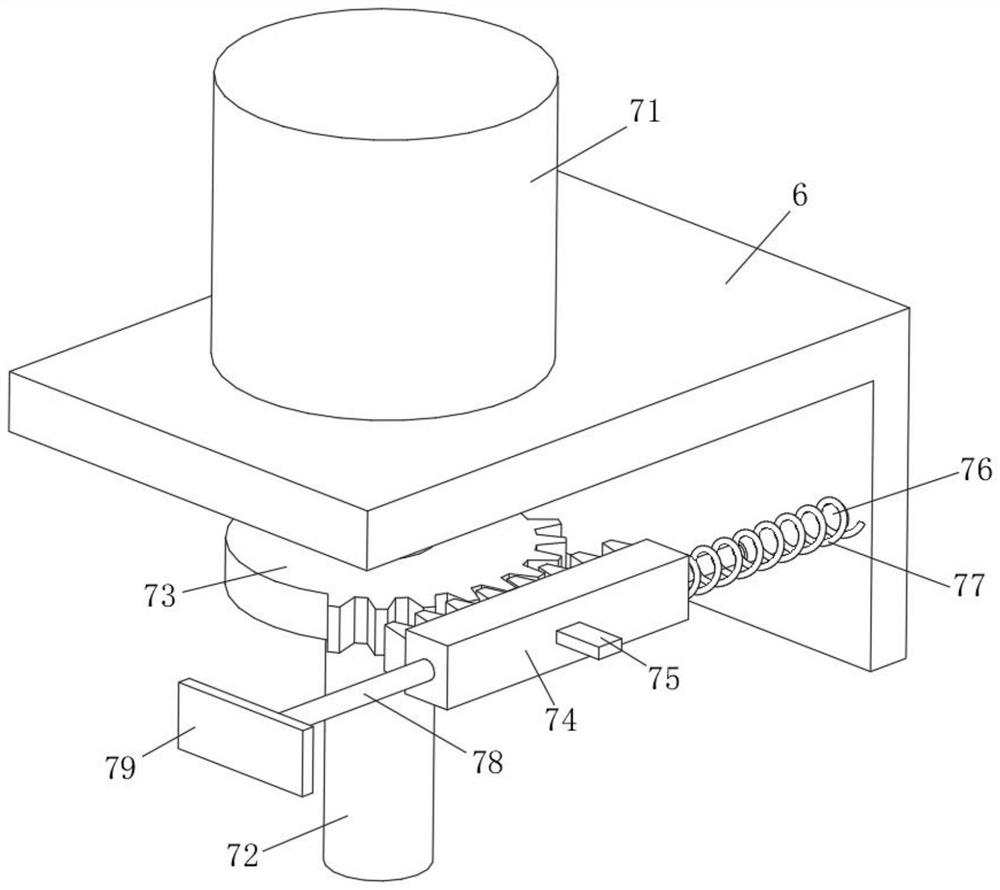

Pricking pin coaxiality sorting device

InactiveCN101758029AAutomatic sortingSimple and fast operationUsing electrical meansSortingEngineeringSingle chip

The invention discloses a pricking pin coaxiality sorting device which is characterized in that a guide rail with a slide block is arranged on a table top, one end of the guide rail is suspended outside the table top, a sorting device is arranged right below the suspended end of the guide rail, and a first electric magnet is arranged right above the suspended end of the guide rail; a flat board with a tank is arranged on the slide block, one end of the flat board with the tank, opposite to the direction of the suspended end of the guide rail, is provided with a connecting block connected withan eccentric wheel on a rotating shaft of a first stepping motor arranged on the table top through a connecting rod, the connecting rod can freely move in the direction of the axis of the guide rail relative to the connecting block and the eccentric wheel, a friction board is arranged right above the guide rail near to the suspended end of the guide rail, and a detecting device is arranged on thetable top at one side of the guide rail and opposite to the friction board; and the first stepping motor, a second stepping motor in the detecting device, a contact block, the first electric magnet and a second electric magnet in the sorting device are electrically connected with a single-chip machine. The pricking pin coaxiality sorting device conveniently and high-efficiently realizes the automatic sorting of excellent and bad pricking pin coaxialities.

Owner:ZHEJIANG UNIV

Full-automatic labeling machine for cable socket

PendingCN107298219AAutomatic fast labelingContinuous labelingLabelling machinesEngineeringMechanical engineering

The invention aims to provide a full-automatic labeling machine for a cable socket. The full-automatic labeling machine for the cable socket provided by the invention is capable of automatically loading, automatically conveying the cable socket, automatically labeling the two sides of the cable socket, automatically detecting the condition of the labeling and automatically sorting qualified products and unqualified products. The production efficiency and quality of the cable socket labeling are greatly promoted.

Owner:张亚平

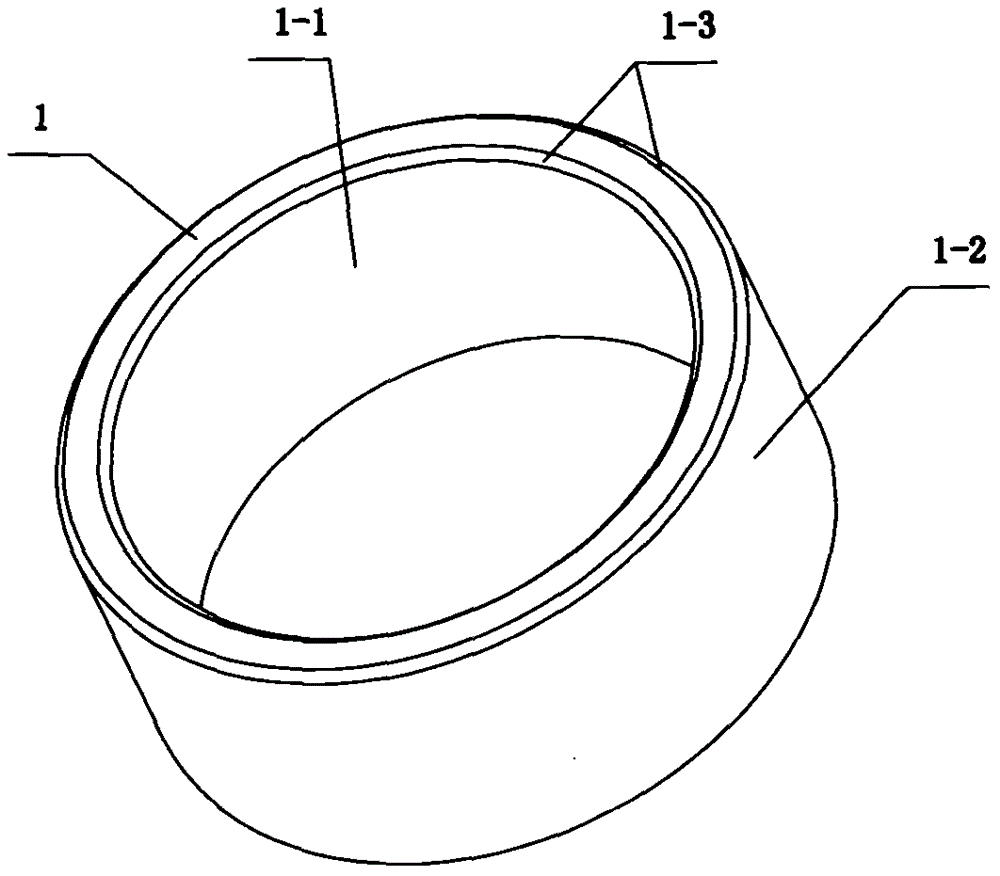

Sleeve cylinder surface inspection device

PendingCN106442552AGuaranteed stabilityImprove detection accuracyOptically investigating flaws/contaminationUsing optical meansEngineeringAutomation

The invention discloses a sleeve cylinder surface inspection device. The device comprises a rack (2) provided with a working table (3), a control assembly, a diaphanous glass turnplate (21) made of glass, a surface defect detecting mechanism, a chamfering defect detecting mechanism, a high-degree defect detecting mechanism and a conveying mechanism of a sleeve (1). The control assembly is connected to the rack (2), the glass tuinplate (21) is rotationally connected to the working table (3), and the surface defect detecting mechanism, the chamfering defect detecting mechanism and the high-degree defect detecting mechanism are sequentially arranged on the positions between an inlet end and an outlet end of the conveying mechanism, connected to the positions, close to the outer side edge of the glass turnplate (21), of the rack (2) respectively and electrically connected with the control assembly respectively. By means of the structure, the production efficiency is greatly improved, the degree of automation is high and the detection precision is high.

Owner:NINGBO YONGXIN PRECISION PIPE

Automatic plug-in machine for plug-in mounting production of specially-shaped electronic elements

ActiveCN113710006ATo achieve the purpose of weldingIncrease productivityPrinted circuit assemblingSortingEngineeringElectronic component

The invention discloses an automatic plug-in machine for plug-in mounting production of specially-shaped electronic elements, which comprises a plug-in moving assembly, one end of the plug-in moving assembly is connected with a plug-in mounting assembly, a transmission assembly is arranged below the plug-in mounting assembly, one side of the transmission assembly is provided with an electronic component conveying assembly, the plug-in mounting assembly comprises a servo motor, and one end of the servo motor is connected with a rotating plate. One end of the rotating plate is connected with four first electric telescopic rods and clamp connecting plates arranged at the ends, away from the rotating plate, of the first electric telescopic rods. According to the invention, an insertion end of an electronic component is dipped into tin liquid in a tin liquid box by a micro electric clamp; and then the micro electric clamp inserts the insertion end of the electronic component into the circuit board, so that the purpose of welding when the electronic component is inserted into the circuit board is achieved; and compared with the traditional technology, the production efficiency of the specially-shaped electronic component is greatly improved, and the current production requirement is met.

Owner:南通祥峰电子有限公司

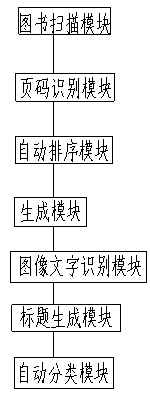

Book input system of computer

InactiveCN108171110AAutomatic sortingCharacter and pattern recognitionComputer moduleComputerized system

The invention discloses a book input system of a computer. The system comprises a book scanning module, a page number recognition module, an automatic sorting module and a generation module, wherein the book scanning module is used for scanning pages of a book and storing the pages into the computer; the page number recognition module is used for recognizing page numbers of the book and marking corresponding page numbers for corresponding scanned pictures; the automatic sorting module is used for sorting the scanned pictures according to the page numbers; and the generation module is sued forintegrating the sorted scanned pictures so as to generate a book document. The book input system of the computer is capable of automatically recording scanned books into a computer system and automatically sorting the books, so that the operation is very convenient.

Owner:苏州市东皓计算机系统工程有限公司

Forming process and equipment for stainless steel food steamer

InactiveCN109773026AAchieve Wipe CleanupChange contact surfaceMetal-working feeding devicesCleaning using toolsPunchingWork in process

Owner:浙江东蓝机电有限公司

Device for checking opening/closing of storage box of automobile instrument desk

InactiveCN106226052AAutomatic sortingImprove detection accuracyMachine part testingSortingEngineeringDesk

The invention provides a device for checking the opening / closing of a storage box of an automobile instrument desk. The device comprises a base plate, a mounting support on the base plate, a guide rail on the lower end of the mounting support, a clamping device on the right side of the mounting support, an opening / closing cylinder on the right end of the clamping device, and a checking device on the right end of the opening / closing cylinder. The checking device checks the operating physical force during working of the opening / closing cylinder. The mounting support simulates installation of the storage box, and the opening / closing cylinder drives the clamping device to pull the storage box. The checking device checks the operating physical force to detect whether the storage box is qualified. The detection precision is increased, manpower can be saved, and unqualified products can be sorted out automatically. The work efficiency is improved.

Owner:芜湖新泉汽车饰件系统有限公司

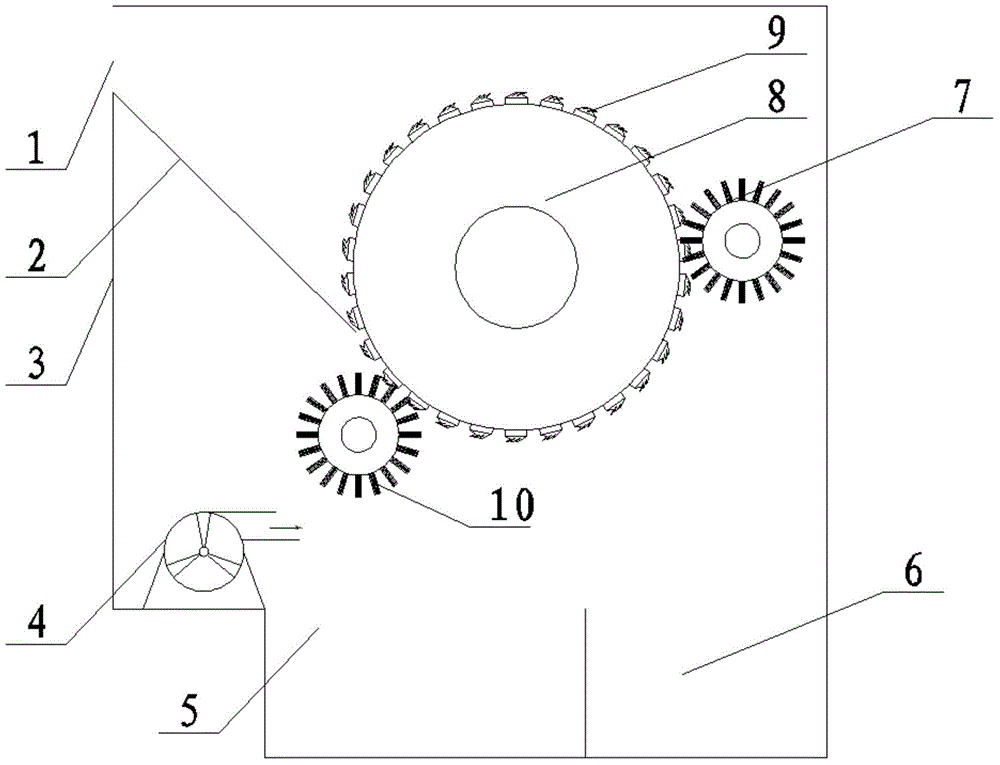

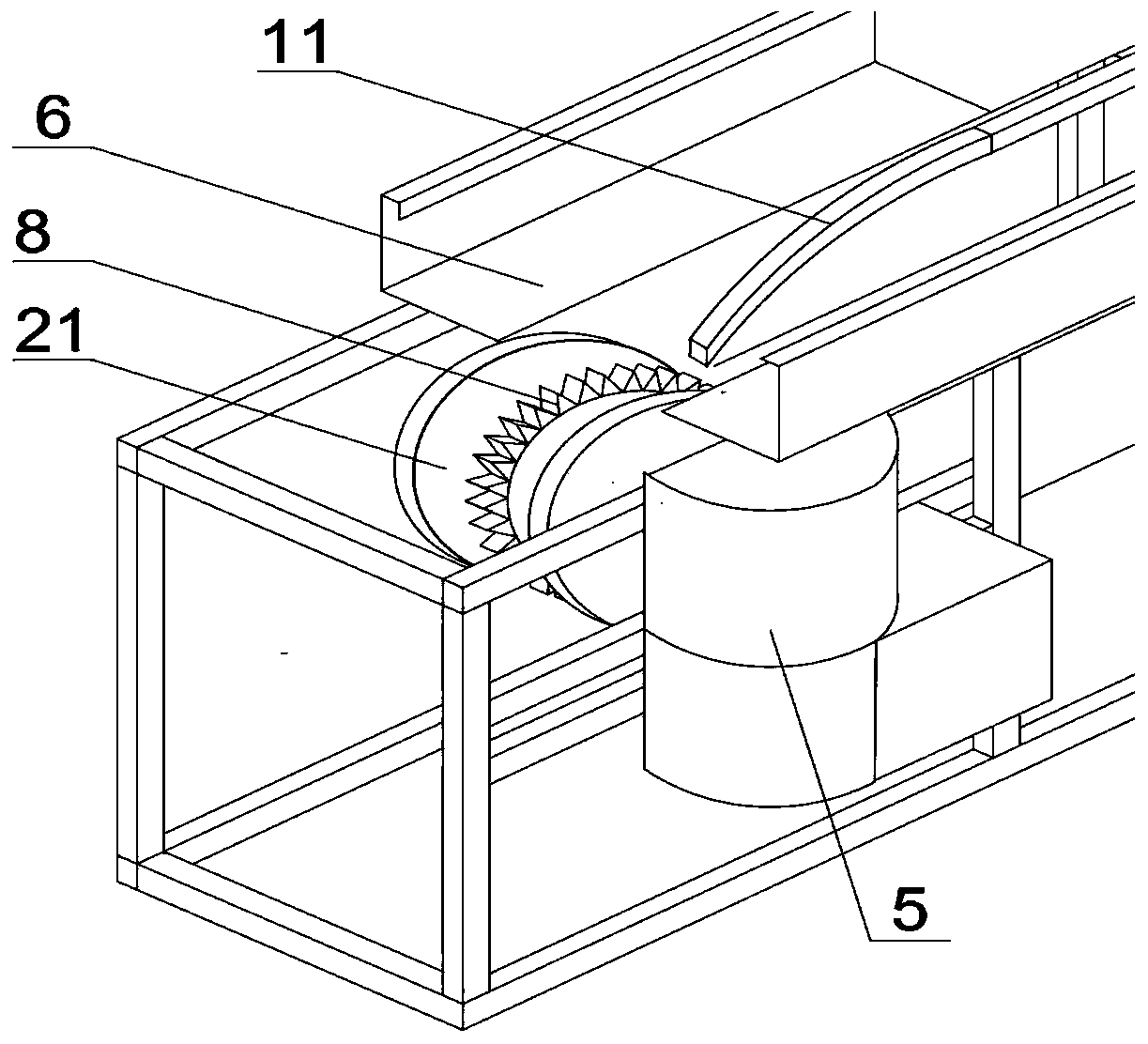

Novel plastic bag and rubbish sorting device

The invention discloses a novel plastic bag and rubbish sorting device capable of automatically sorting plastic bags out of rubbish. The novel plastic bag and rubbish sorting device comprises a hollow shell. The top end of one side of the shell is provided with a rubbish inlet. The lower edge of the rubbish inlet is provided with a guide plate inclining downwards. The tail end of the guide plate is close to the wheel edge of a sorting wheel. The sorting wheel is evenly provided with a plurality of claws with the sorting wheel as the circle center. The novel plastic bag and rubbish sorting device further comprises a first hair brush. A hair brush body of the first hair brush makes contact with the wheel edge of the side, away from the guide plate, of the sorting wheel. The novel plastic bag and rubbish sorting device further comprises a second hair brush, the second hair brush is arranged below the guide plate, and a hair brush body of the second hair brush makes contact with the wheel edge of the sorting wheel. A draught fan is fixedly arranged below the second hair brush, and an air outlet of the draught fan faces the first hair brush. The bottom of the shell is divided into two grooves by a partition plate, namely a rubbish groove and a plastic groove which are formed side by side, and the groove away from the air outlet of the draught fan is the plastic groove.

Owner:XIAN SHANGSHANG ELECTROMECHANICAL

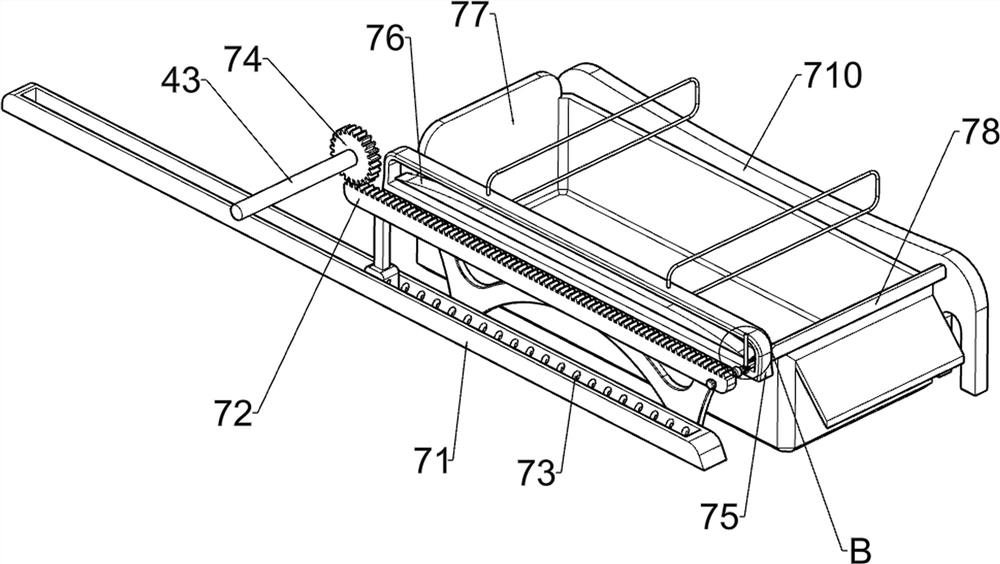

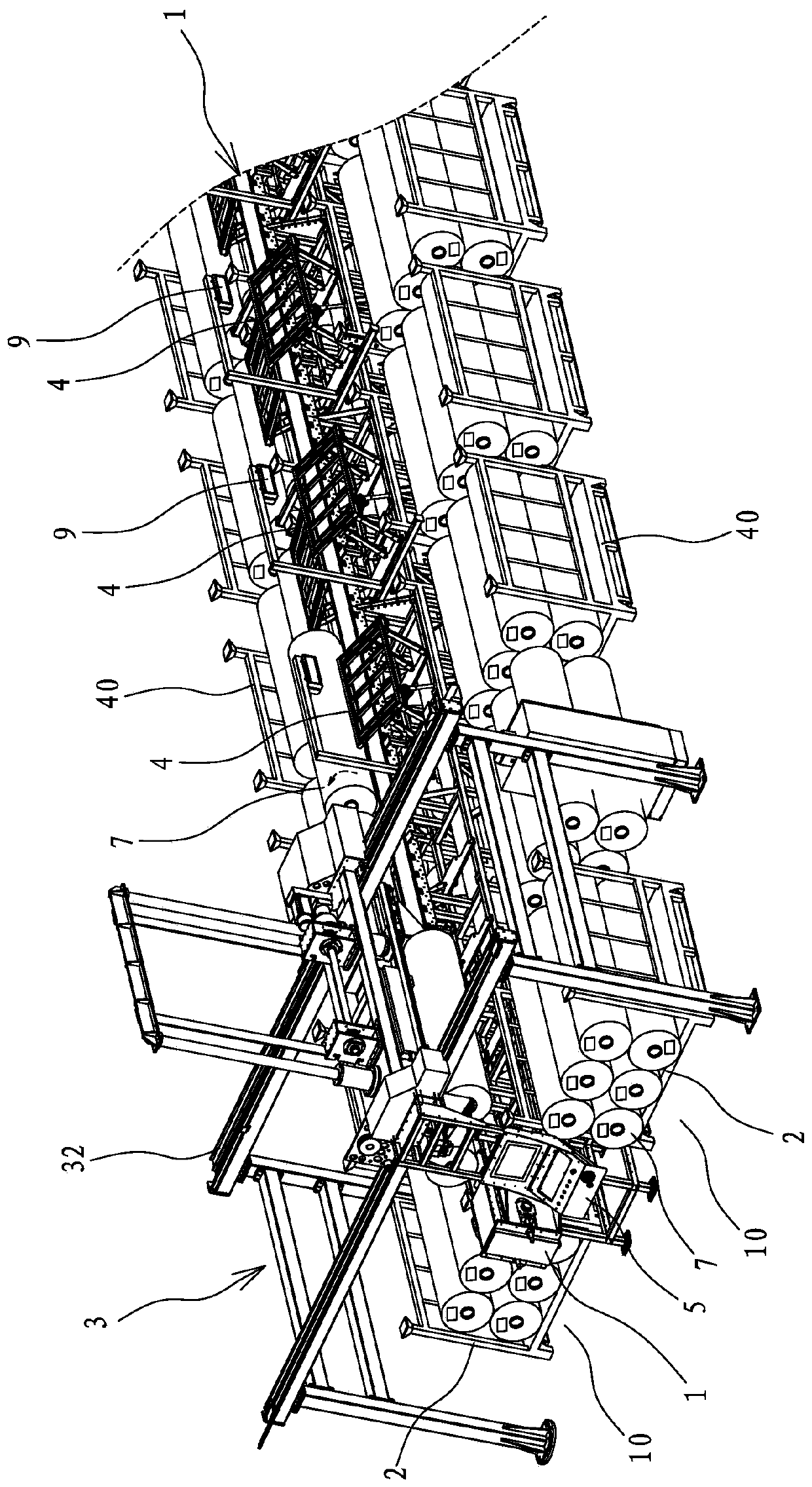

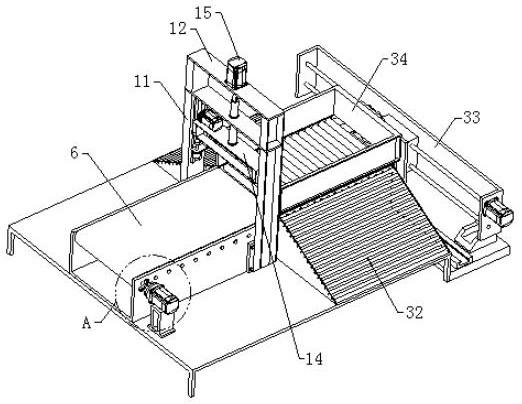

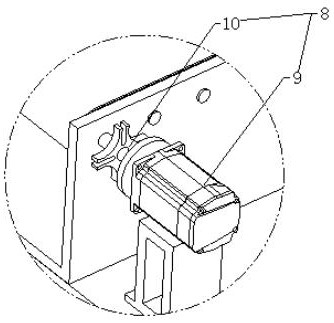

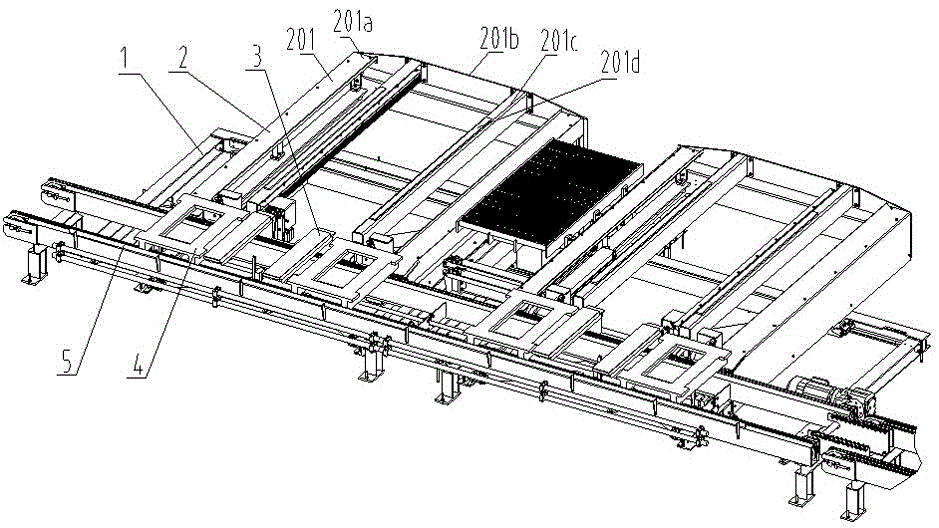

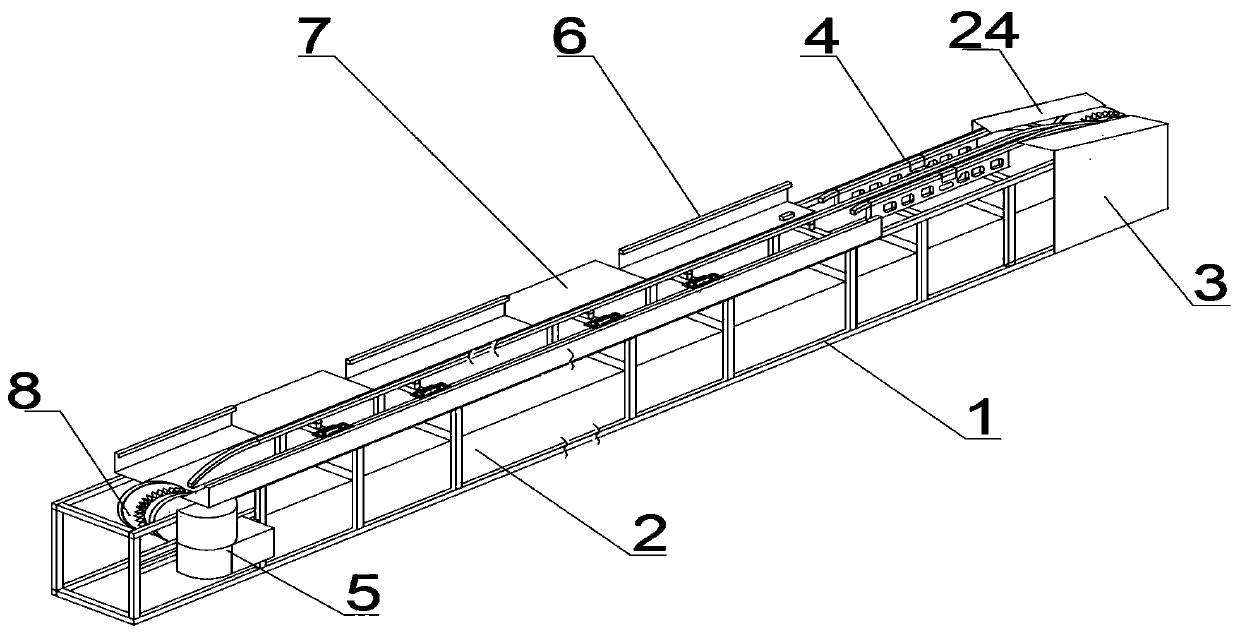

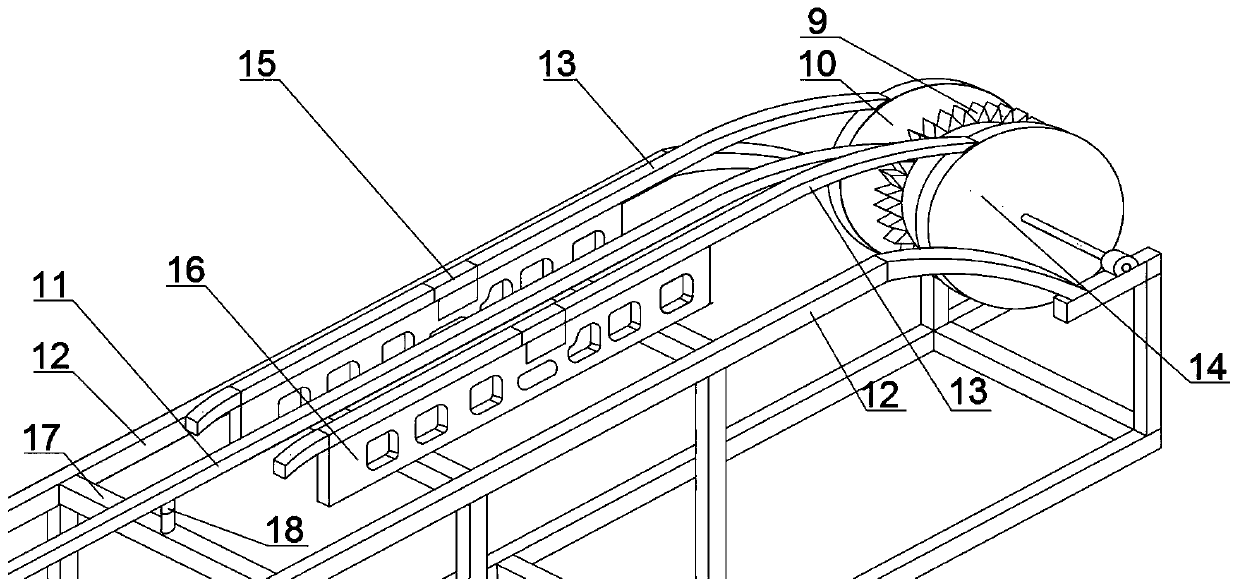

Automatic sorting method for fed cloth rolls

ActiveCN110182595ARealize automatic inputEasy to operateConveyorsControl devices for conveyorsProduction lineControl system

The invention discloses an automatic sorting method for fed cloth rolls. Through cooperation of a production line, a material taking device, discharging mechanisms and a control system, the cloth rolls are clamped by the material taking device and placed on the production line, and specifications of the cloth rolls are input into the control system to determine the corresponding discharging mechanisms to be started; the cloth rolls are moved forwards and conveyed on the production line according to a certain beat and a certain stroke each time; the cloth rolls are moved forwards for n strokesand then moved to the discharging mechanisms corresponding to the cloth roll specifications; the control system sends control instructions to the discharging mechanisms corresponding to the cloth rollspecifications at the interval of the movement of the production line, and the discharging mechanisms start to discharge the cloth rolls from the production line; the cloth rolls are clamped and placed on the production line one by one at the interval of the movement of the production line, and the specifications of the cloth rolls are input into the control system one by one; and the cloth rollswith different specifications can be discharged at the corresponding discharging mechanisms, so that the cloth rolls are automatically sorted, the sorting efficiency is high, the labor demand is low,and the labor intensity is low.

Owner:中山益达服装有限公司 +1

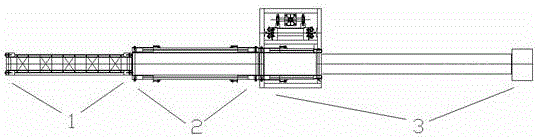

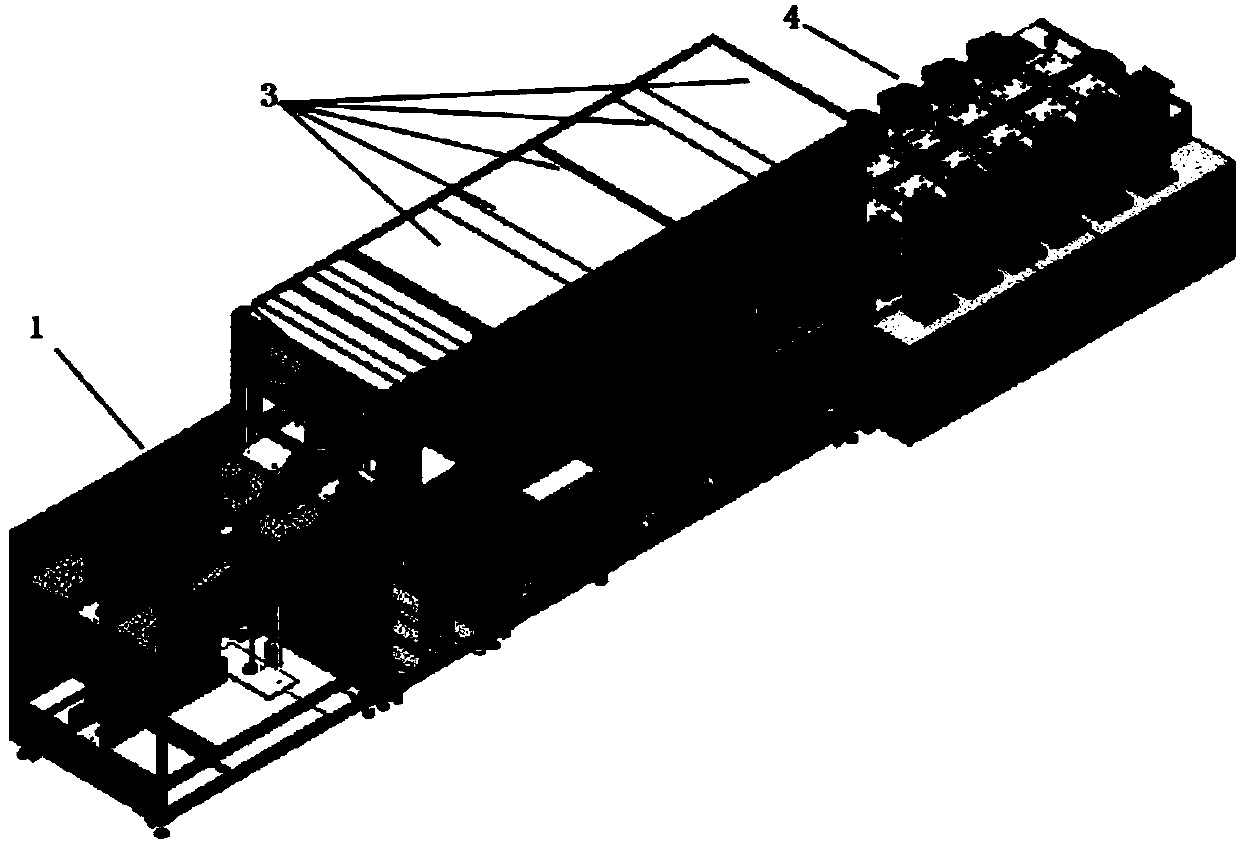

Visible-near infrared spectrum transmission type fruit quality on-line detection and sorting production line

InactiveCN110449369AImprove qualityMeet the needs of large-scale commercial processingSortingProduction lineVisible near infrared

The invention provides a visible-near infrared spectrum transmission type fruit quality on-line detection and sorting production line. The production line comprises a mechanical conveying device, a visible-near infrared spectrum detection device and a sorting control device, wherein the mechanical conveying device conveys fruits into a detection area of the visible-near infrared spectrum detectiondevice; the visible-near infrared spectrum detection device deals with detection results and transmits the detection results to the sorting control device through pulse signals; and the fruits are sorted by turning fruit trays of the mechanical conveying device sideways.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Lithium battery thickness automatic detection machine

InactiveCN107282459AImprove detection efficiencyImprove detection qualitySortingEngineeringLithium battery

The object of the present invention is to provide a high-efficiency, high-quality lithium battery thickness automatic detection machine. The lithium battery thickness automatic detection machine can automatically detect the thickness of the lithium battery with a displacement sensor, and at the same time, it can also automatically sort unqualified products and qualified products.

Owner:张亚平

Roughing treatment system before dry automatic sorting and drying of waste glass

ActiveCN112657662ASolve the sorting problemAutomatic sortingSolid waste disposalGrain treatmentsProcess engineeringBelt conveyor

The invention discloses a roughing treatment system before dry automatic sorting and drying of waste glass. The roughing treatment system comprises a vibrating feeder, a belt conveyor is arranged at an outlet of the vibrating feeder, and an L-shaped vibrating distributing device and a bar vibrating screen are sequentially arranged at an outlet of the belt conveyor; a first manual hand-sorting belt conveyor and a second manual hand-sorting belt conveyor which are parallel to each other are respectively arranged at an outlet of the bar vibrating screen; a pneumatic three-way distributor is arranged at an outlet of the first manual hand-sorting belt conveyor, and a single-section hammer crusher and a double-roller crusher are arranged at two distribution ports of the pneumatic three-way distributor respectively; a finger-shaped sieve and a winnowing machine are sequentially arranged at an outlet of the double-roller crusher; and outlets of the second manual selection belt conveyor, the single-section hammer crusher and the finger-shaped sieve are connected to a waste glass drying system through conveyors. According to the system, large impurities in waste glass can be removed, the treatment requirement of roughing before drying is met, and the treatment effect is improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

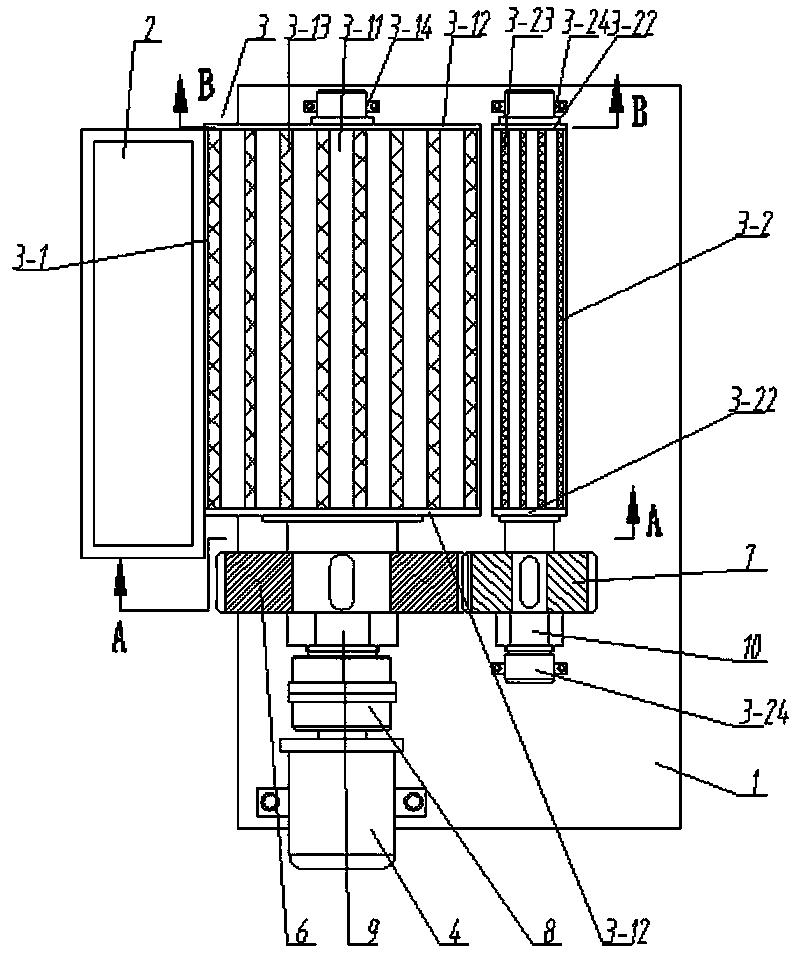

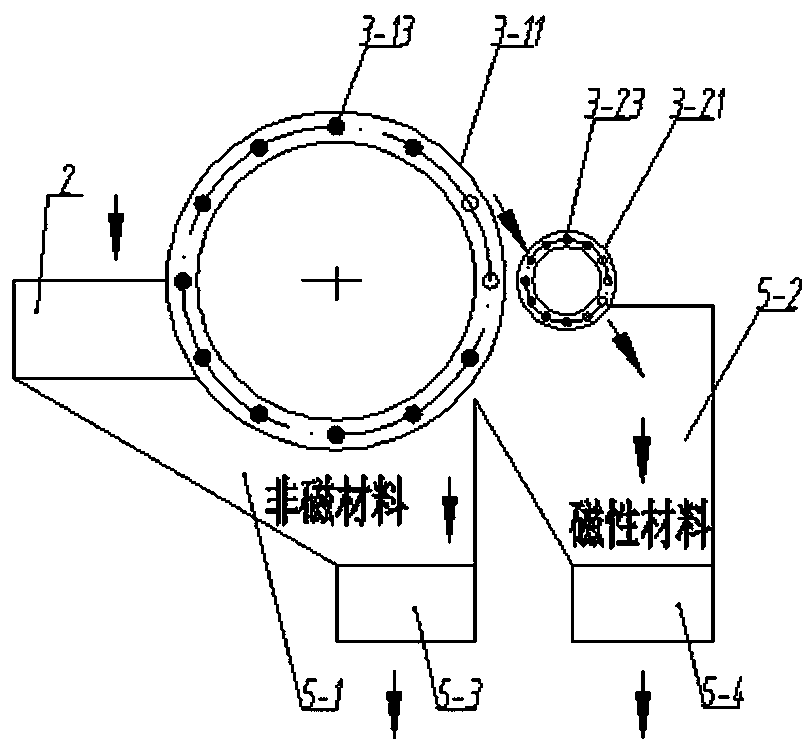

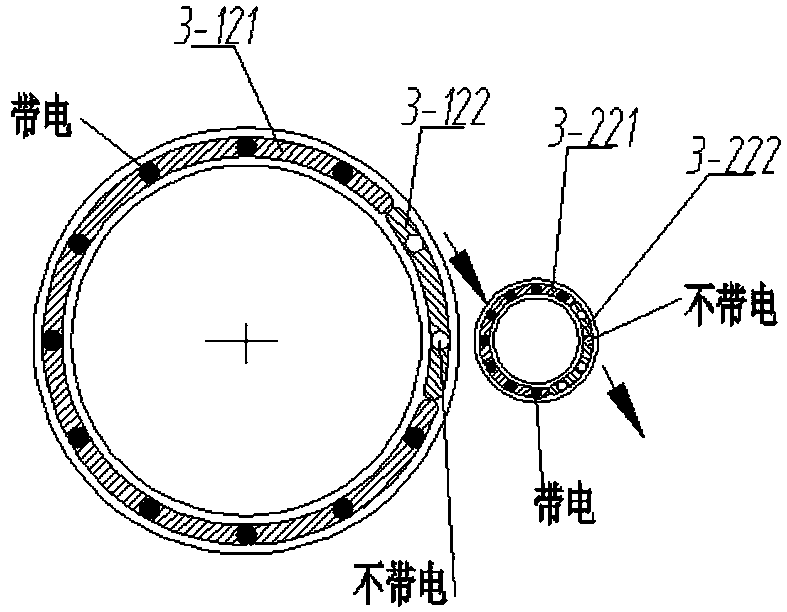

Brushless magnetic separation device and method

PendingCN109701738AGood demagnetization effectGood energy saving effectMagnetic separationDrive motorMaterial Separation

The invention relates to a brushless magnetic separation device and method. The device comprises a rack, a feeding hopper, a magnetic separation device, a driving motor and a material separation bin.The magnetic separation device is arranged above the material separation bin and comprises an iron separation device and an iron discharging device, the feeding hopper is located at a feeding side ofthe iron separation device, and the iron discharging device is located at an discharging side of the iron separation device. The iron separation device and the iron discharging device are driven by adriving motor to operate and rotate oppositely. A material enters the material separation bin from the feeding hopper, wherein non-ferrous materials are directly discharged from a discharging openingof the material separation bin, and ferrous materials are adsorbed by the iron separation device, conveyed to the iron discharging device and conveyed to an iron discharging opening of the material separation bin through the iron discharging device for discharging. The magnetic discharge effect is good, and incomplete magnetic discharge caused by insufficient sweeping force is avoided. The magnetic separation part is of a double-roller structure, and has clear magnetic selection and magnetic discharge functions and materials are discharged from different channels. A single motor is used for driving in the magnetic separation process, and the energy-saving effect is good. A magnetic control device is adopted, and magnetic materials can be automatically sorted.

Owner:LIUPANSHUI NORMAL UNIV

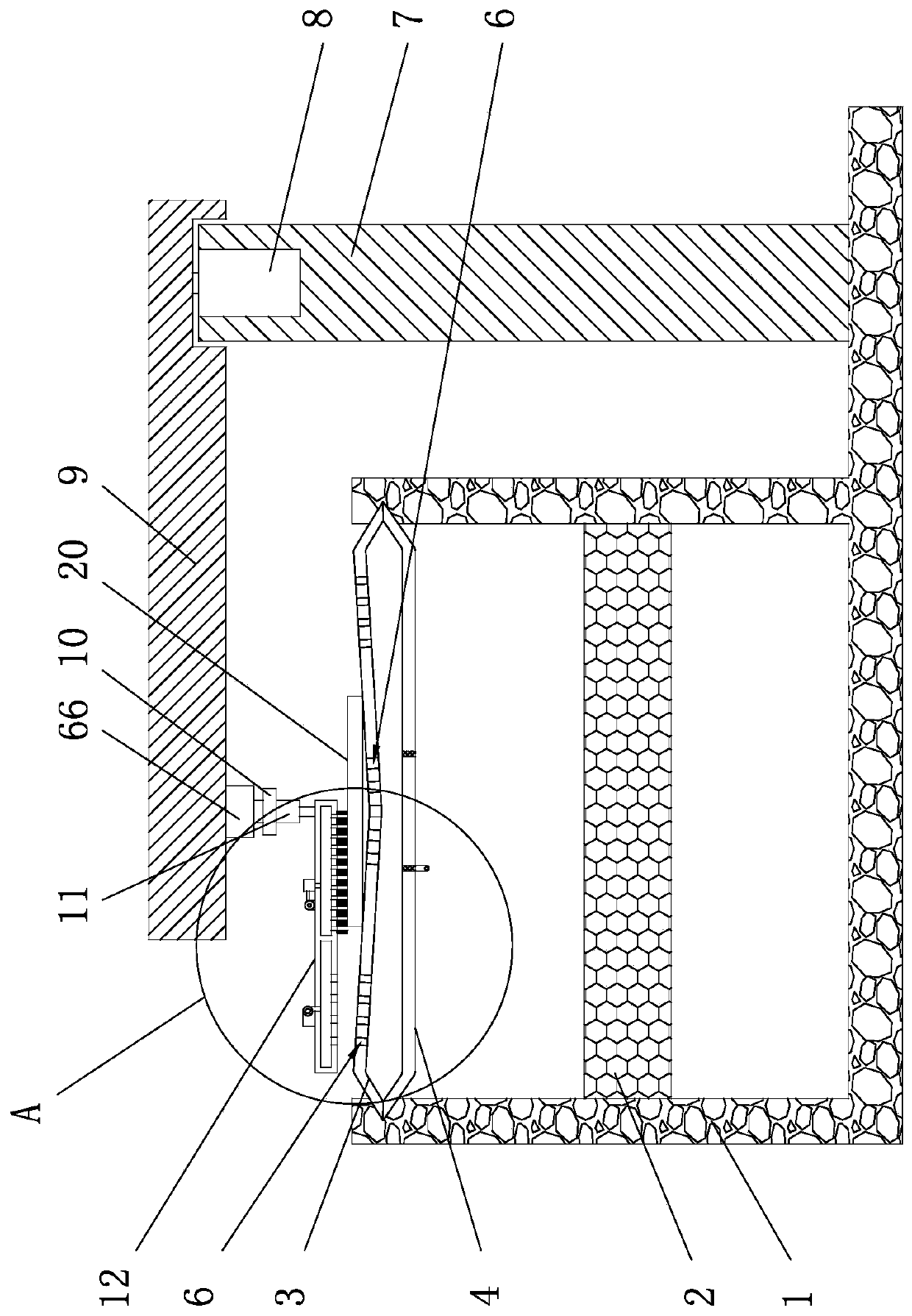

Subsequent sand removal inspection device for cast pipe fitting

InactiveCN111906037ASimple structureEasy to useCleaning using toolsSortingPore diameterStructural engineering

The invention discloses a subsequent sand removal inspection device for a cast pipe fitting. The subsequent sand removal inspection device comprises a box body, wherein a working cavity is formed in the box body; the lower inner wall of the working cavity is fixedly connected with a working conveyor belt for conveying a part to be detected; a reworking cavity communicating with the working cavityis formed in the rear inner wall of the working cavity; the lower inner wall of the reworking cavity is fixedly connected with a reworking conveyor belt for conveying an unqualified part; and a detection mechanism for detecting whether the pore diameter of the part is qualified or not is arranged in the upper inner wall of the working cavity. The subsequent sand removal inspection device disclosedby the invention is simple in structure and convenient to use; the subsequent sand removal inspection device can be used for automatically carrying out necessary operation on the part needing to be subjected to sand removal and inner diameter detection, so that time and labor are saved; unqualified products can be automatically sorted out and a condition that outgoing products are unqualified isprevented; and furthermore, a detection block can also be automatically replaced, so that the inner diameters of the parts with different types and different inner diameters are detected.

Owner:福清市鸿远科技有限公司

Intelligent numerical-control machining and sorting equipment based on sonic crack detection

InactiveCN112517441AAutomatic sortingImprove efficiencySortingMetal working apparatusEngineeringMachining

The invention relates to the technical field of numerical-control machining, in particular to intelligent numerical-control machining and sorting equipment based on sonic crack detection. The intelligent numerical-control machining and sorting equipment comprises a conveying mechanism, a detecting mechanism and a sorting mechanism, wherein the conveying mechanism is arranged on a base; the detecting mechanism is arranged inside the conveying mechanism; and the sorting mechanism is arranged on the base. The intelligent numerical-control machining and sorting equipment is characterized in that the conveying mechanism comprises a rectangular conveying frame, a plurality of first rollers, a conveying belt, a plurality of second rollers and a clearance driving assembly; the rectangular conveying frame is horizontally arranged on the base; the first rollers are distributed and arranged at one end of the interior of the rectangular conveying frame in the length direction of the rectangular conveying frame; the conveying belt is wound among all the first rollers; the second rollers are distributed and arranged at the other end of the interior of the rectangular conveying frame in the length direction of the rectangular conveying frame; and the clearance driving assembly is arranged on the base, positioned on one side of the rectangular conveying frame, and used for driving the first rollers to rotate in a clearance manner. According to the technical scheme, the all-around detection of machined parts can be achieved based on ultrasonic waves, the machined parts can be automaticallysorted, and the efficiency can be improved.

Owner:董广振

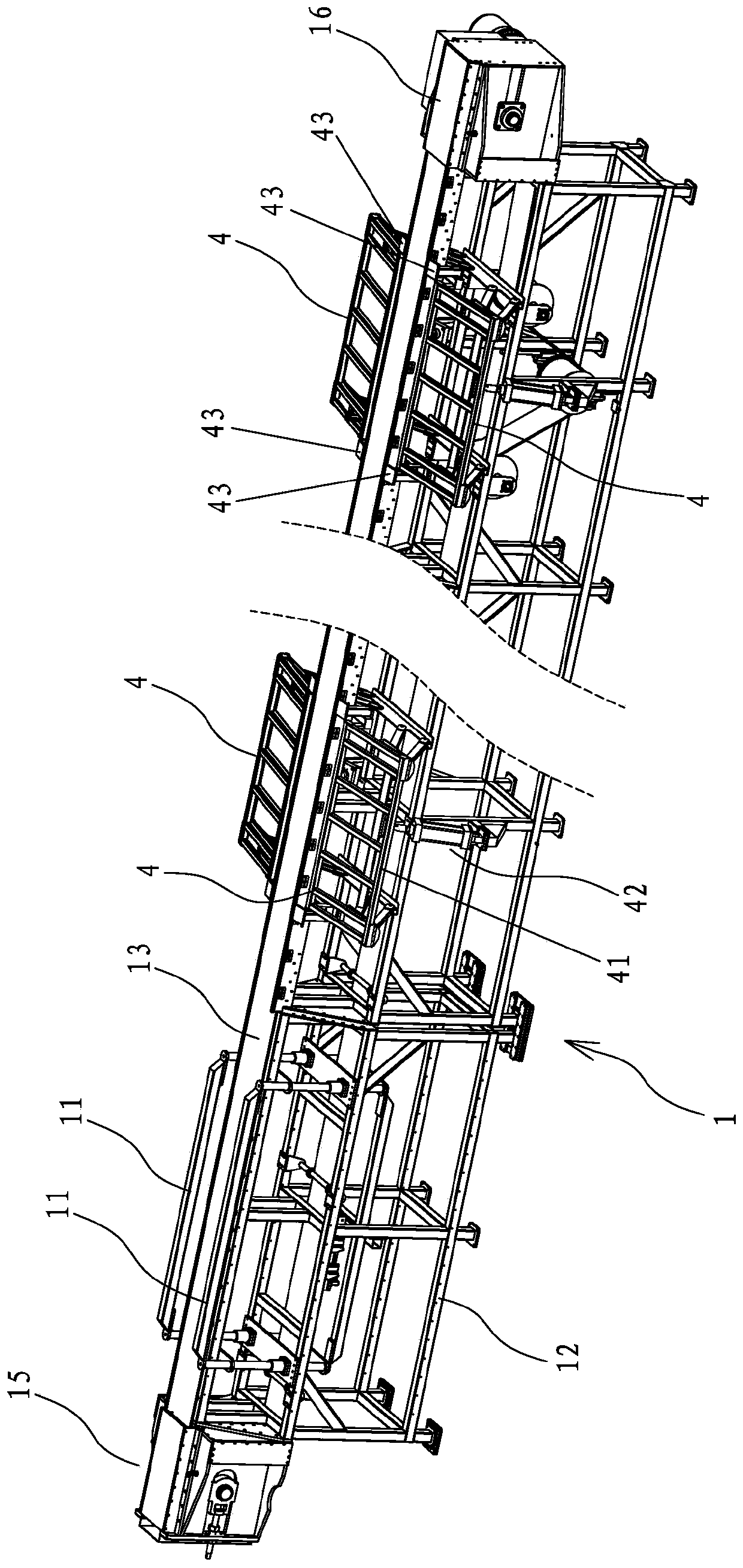

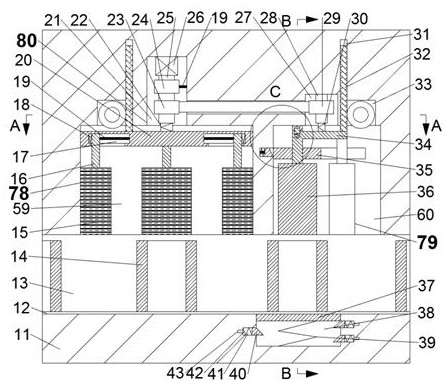

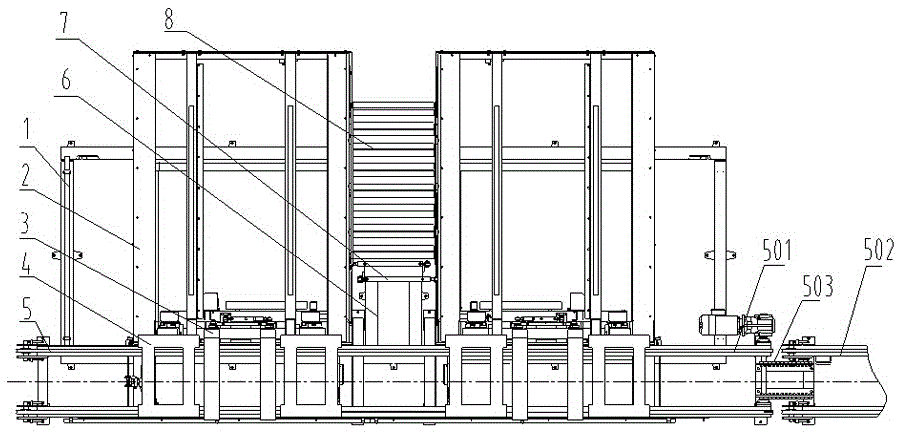

Automatic sorting and unloading apparatus and method of aerated concrete products

Disclosed is an automatic sorting and unloading apparatus and method of aerated concrete products. The apparatus comprises a basic frame, two large trolleys capable of moving on the basic frame, and two small trolleys capable of moving on the large trolleys, both the small trolleys are provided with lifting devices, both opposing sides of the two large trolleys are horizontally provided with a plurality of supports, the supports on the large trolleys are arranged in a staggered manner and are at the same height with upper end supporting surfaces of the large trolleys, and after the lifting devices lift and separate two same types of products, the small trolleys transport the products to a next station. The problem of sorting building blocks and plates produced by die arranging after exiting from an autoclave can be solved, the building blocks and plates produced by die arranging are automatically sorted and unloaded when existing from the autoclave, conditions are created for late automatic packaging, labor intensity of laborers is reduced, labor consumption is reduced, breakage rate in a manual transferring process is reduced, production efficiency is greatly improved, and production cost is lowered.

Owner:洛阳中冶建材设备有限公司

Household domestic sewage treatment method and device

PendingCN113026876AAutomatic sortingAvoid jammingDomestic plumbingStructural engineeringSewage treatment

The invention relates to a household domestic sewage treatment device. The household domestic sewage treatment device comprises a grinding device, a collecting device and a cutting device, wherein the grinding device is provided with a grinding disc and a grinding cylinder; a plurality of guide grooves are formed in the inner wall of the grinding cylinder; the grinding disc is arranged at the lower part of the inner side of the grinding cylinder; a collecting groove is formed in a shell and is positioned on the outer side of the grinding cylinder; the cutting device comprises a cutting shaft and a plurality of cutting knife groups, and comprises a cutting fixed knife and two cutting rotary knives; the cutting fixed knife is connected with a torsional spring for preventing the cutting fixed knife from rotating; and the outer end of each cutting fixed knife is inserted into one guide groove. According to the household domestic sewage treatment method and device, the cutting fixed knife is matched with the cutting rotary knives, so that the crushing efficiency is improved; garbage with the hardness greater than a preset value is pushed to grinding teeth after being cut once, and the garbage with the hardness greater than the preset value and the volume greater than the preset value is automatically sorted through the clamping action of the cutting knife groups.

Owner:JIANGSU XIDING ENVIRONMENTAL PROTECTION EQUIPCO

Automatic sorting method of large-array resistance strain gages

InactiveCN106216269ACompact structureNovel and reasonable designSortingElectrical resistance and conductanceData acquisition

Owner:SHAANXI UNIV OF TECH

Weighing type multi-stage fruit sorting table

PendingCN109772737AThe main structure is reasonableReliable control principleSortingDrive motorEngineering

The invention belongs to the technical field of fruit sorting equipment, and relates to a weighing type multi-stage fruit sorting table. The weighing type multi-stage fruit sorting table includes a transmission part, a weighing table, a fruit protecting shell, a sorting opening, a main rotating wheel, a main driving wheel, a sorting frame, a fruit scale, a popup device, an infrared sensor, a fruittransferring vehicle and a console, a main body frame is composed of the sorting frame, the transmission part is arranged at the back end of the sorting frame, and the weighing table is arranged at the upper part of the back end of the sorting frame; and the fruit scale is mounted on the weighing table, the infrared sensor is arranged at the front end of the weighing table and mounted on the backside of the fruit protecting shell, the fruit projecting shell is fixed on the upper side of the sorting frame, the sorting opening is formed in the fruit protecting shell, the popup device is arranged on the opposite side of the sorting opening, a driving motor is arranged at the front end of the sorting frame, and the fruit transferring vehicle is mounted on the sorting frame and can move. Thewhole equipment body structure is reasonable and controlled by the console, sorting of the unlimited stage can be conducted according to the weight of the fruit, the full automation of the fruit sorting is achieved, the fruit sorting is accurate, and the production efficiency is high.

Owner:平度市林焱精密机械厂

Surface detection device for optical filter product

The invention discloses a surface detection device for an optical filter product, which comprises an operation table, the upper surface of the operation table is communicated with a protective cylinder, one side surface of the operation table is fixedly provided with an inferior-quality product collection box, the upper surface of the operation table is fixedly provided with a display, the upper surface of the operation table is provided with a bracket, and the bracket is fixedly provided with a support. The opposite faces of the supports are rotationally connected with a conveying belt, flow guide plates are fixedly installed on the opposite faces of the supports, a sliding plate is fixedly installed at one end of each support and arranged above a defective product collecting box, and a trapezoidal outlet is formed in one side face of each support in a penetrating mode. According to the optical filter surface inspection device, through cooperation of all the assemblies, rapid inspection can be achieved when the surfaces of optical filters are inspected, qualified products and unqualified products can be automatically sorted, loss caused by friction between the optical filters can be avoided when the optical filters are collected, and therefore manpower and time are saved, and the production efficiency is improved. And the working efficiency is improved and the cost is saved.

Owner:六安原景智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com