Patents

Literature

482 results about "Grinding teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

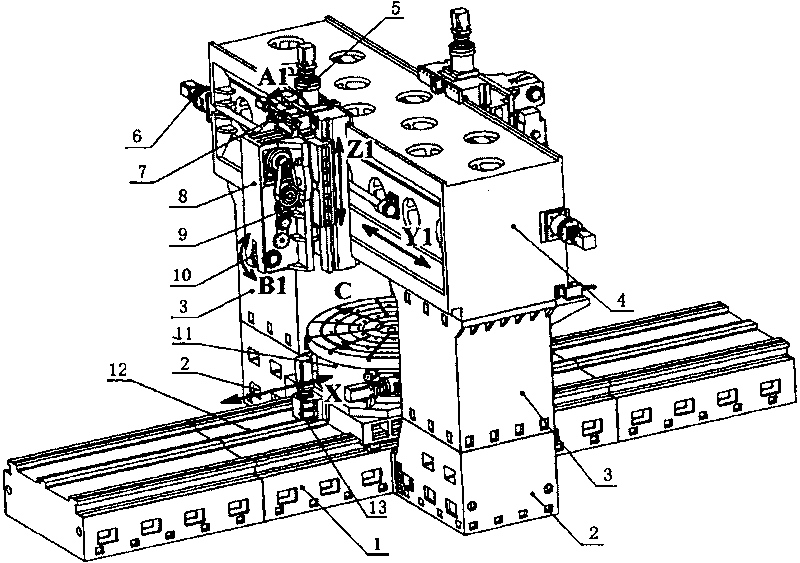

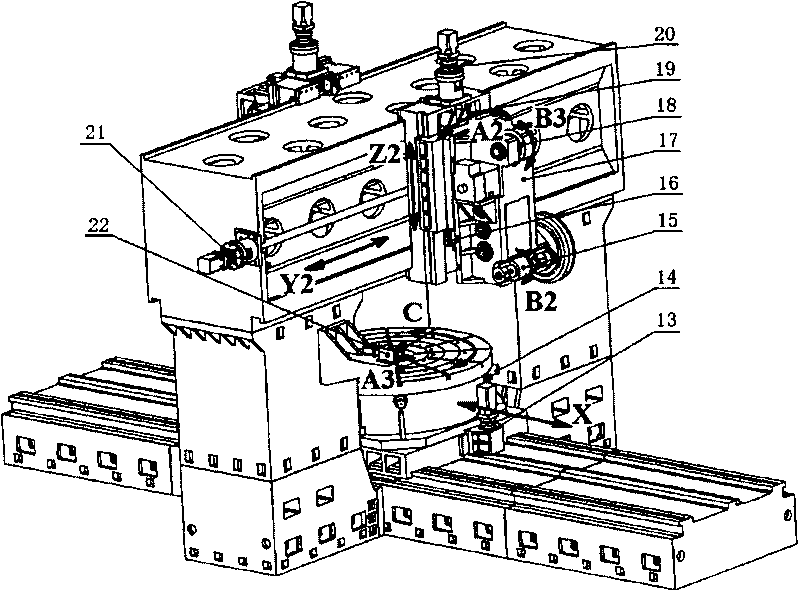

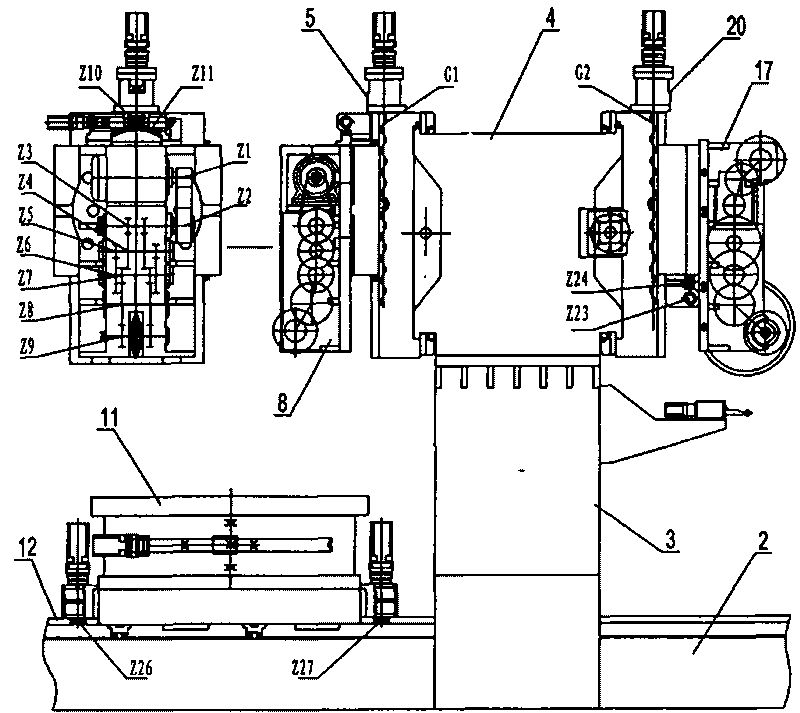

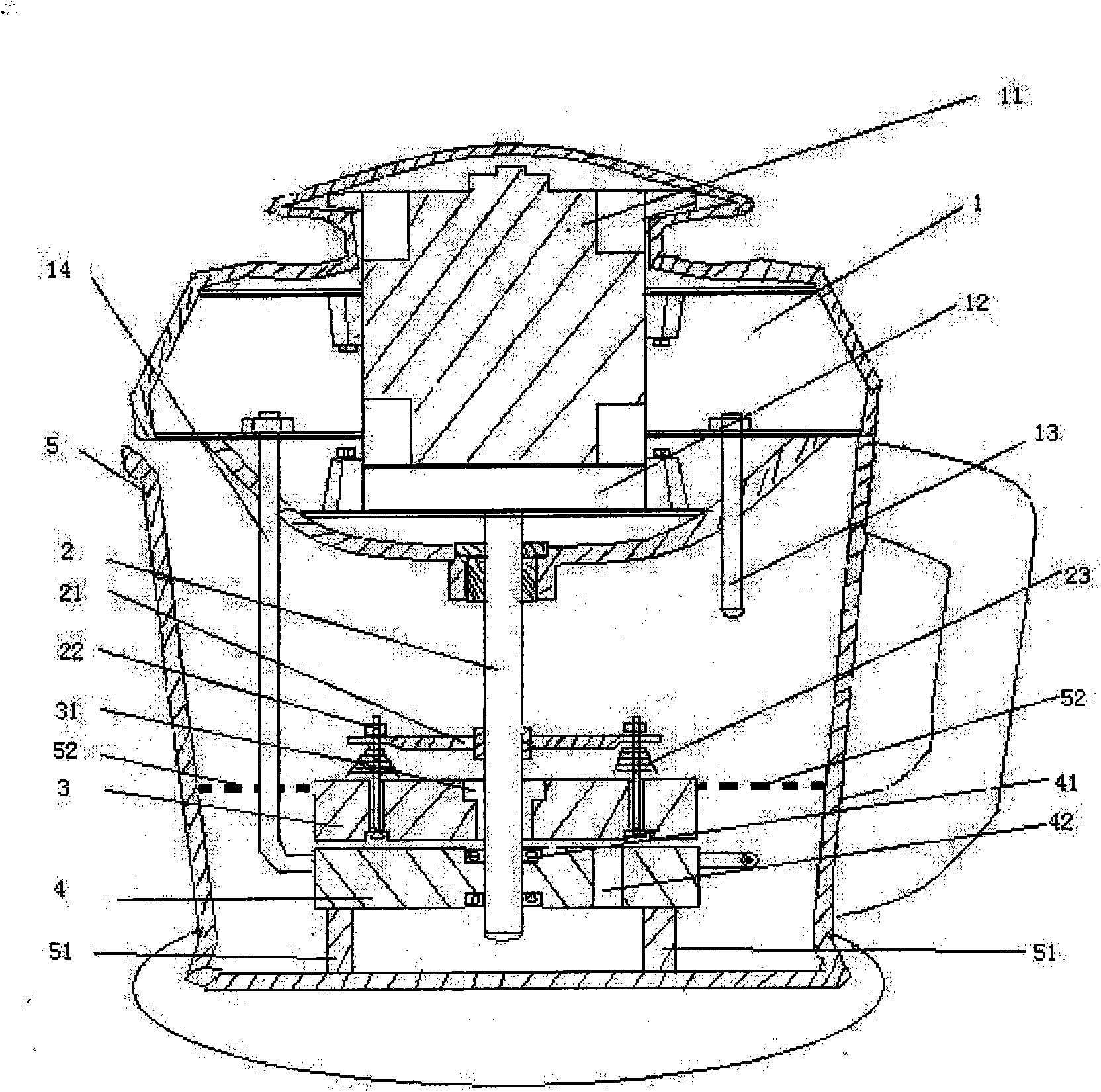

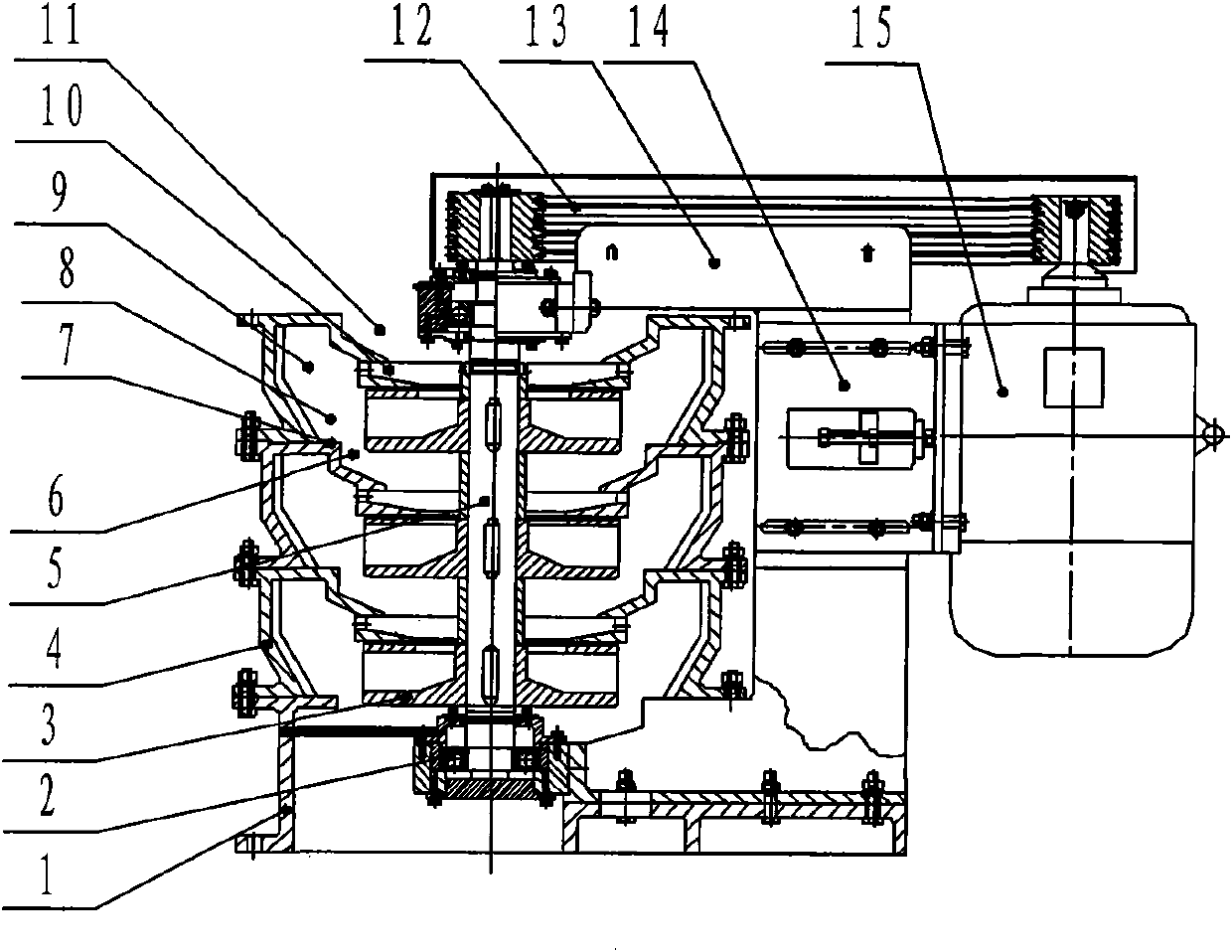

Large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine

ActiveCN101700620AImprove machining accuracyImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersHobbingGear wheel

The invention relates to a large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine adopting a beam both-side bearing structure by respectively hanging a milling gear headstock and a hobbing and grinding gear headstock at the left side and the right side of a beam. Compared with the prior art, the invention adopts the design concepts of polar coordinates and modularization and enables the connection sizes of lathes, bases, and the like as well as Y-direction and Z-direction feeding systems of a milling gear and a hobbing and grinding gear to have interchangeability, thereby decreasing the manufacture cost, lowering the assembly difficulty and improving the machining precision and the machining efficiency of large-module large-diameter gears. The invention integrates the machining characteristics for roughly and finely machining a milling gear, precisely spreading into a hobbing gear and molding a grinding gear with respective optimal process velocities and reasonably arranges a milling, hobbing and grinding gear headstock transmission chain capable of satisfying the requirements for molding the milling gear, spreading into the hobbing gear and molding the grinding gear.

Owner:NANJING UNIV OF TECH

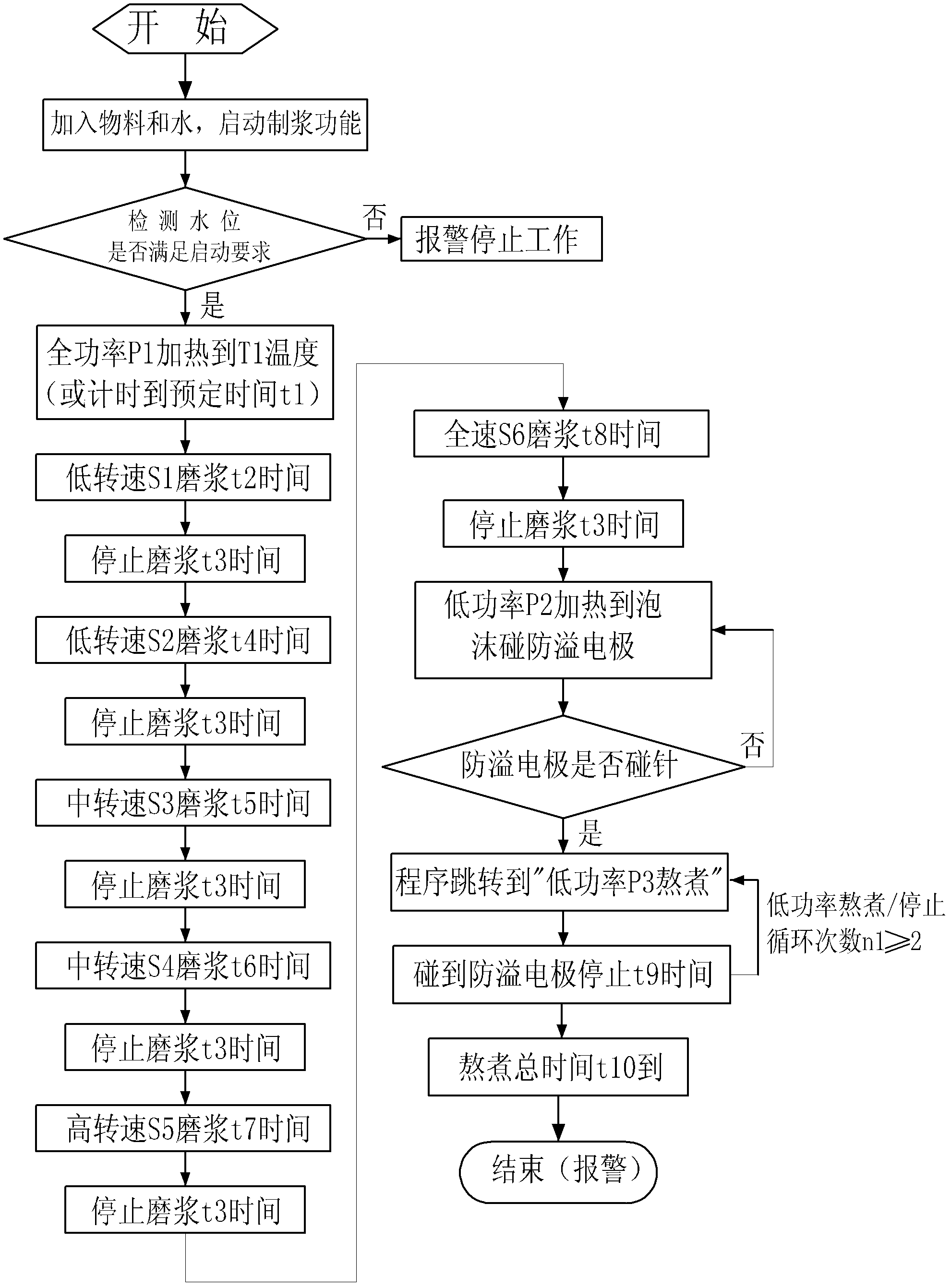

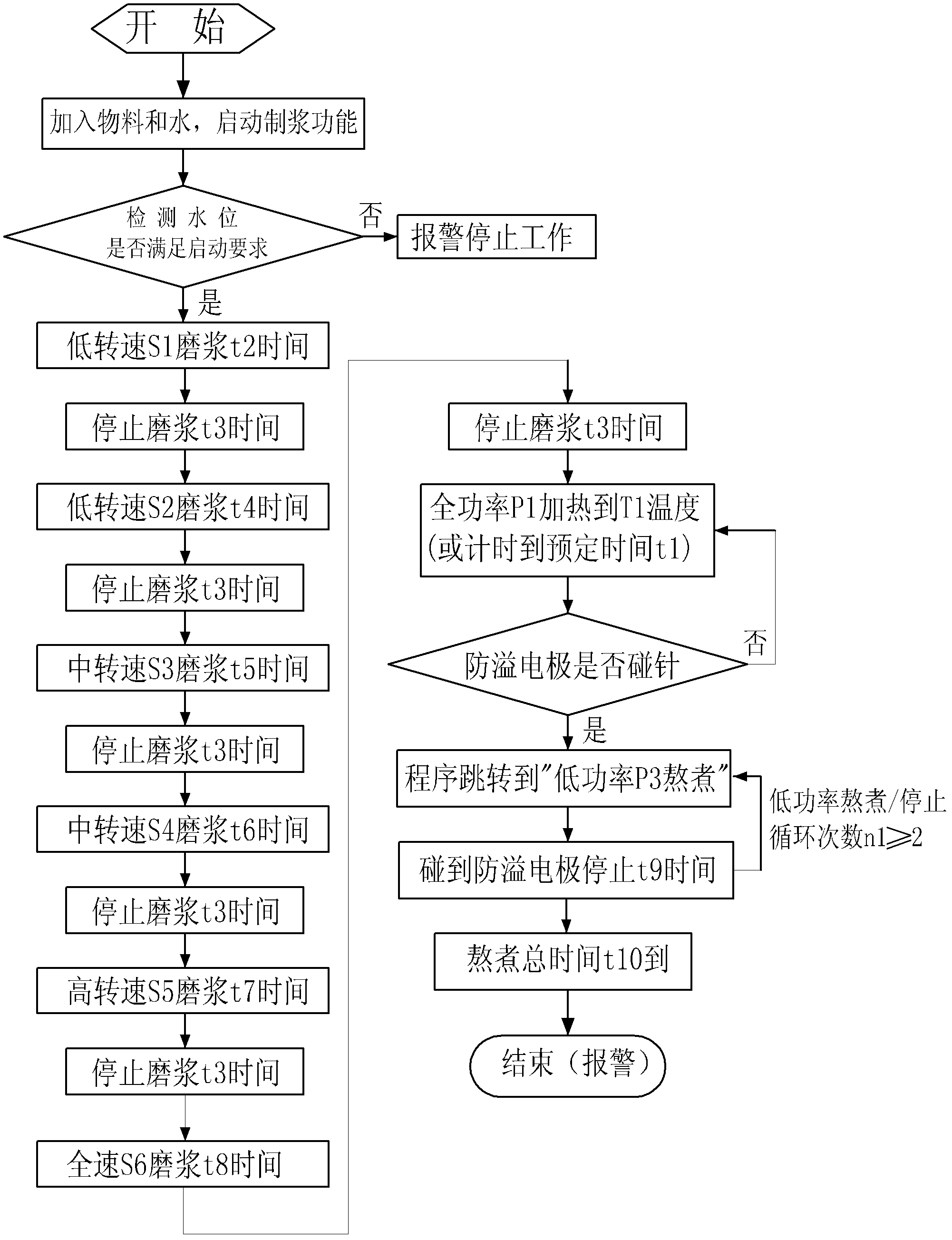

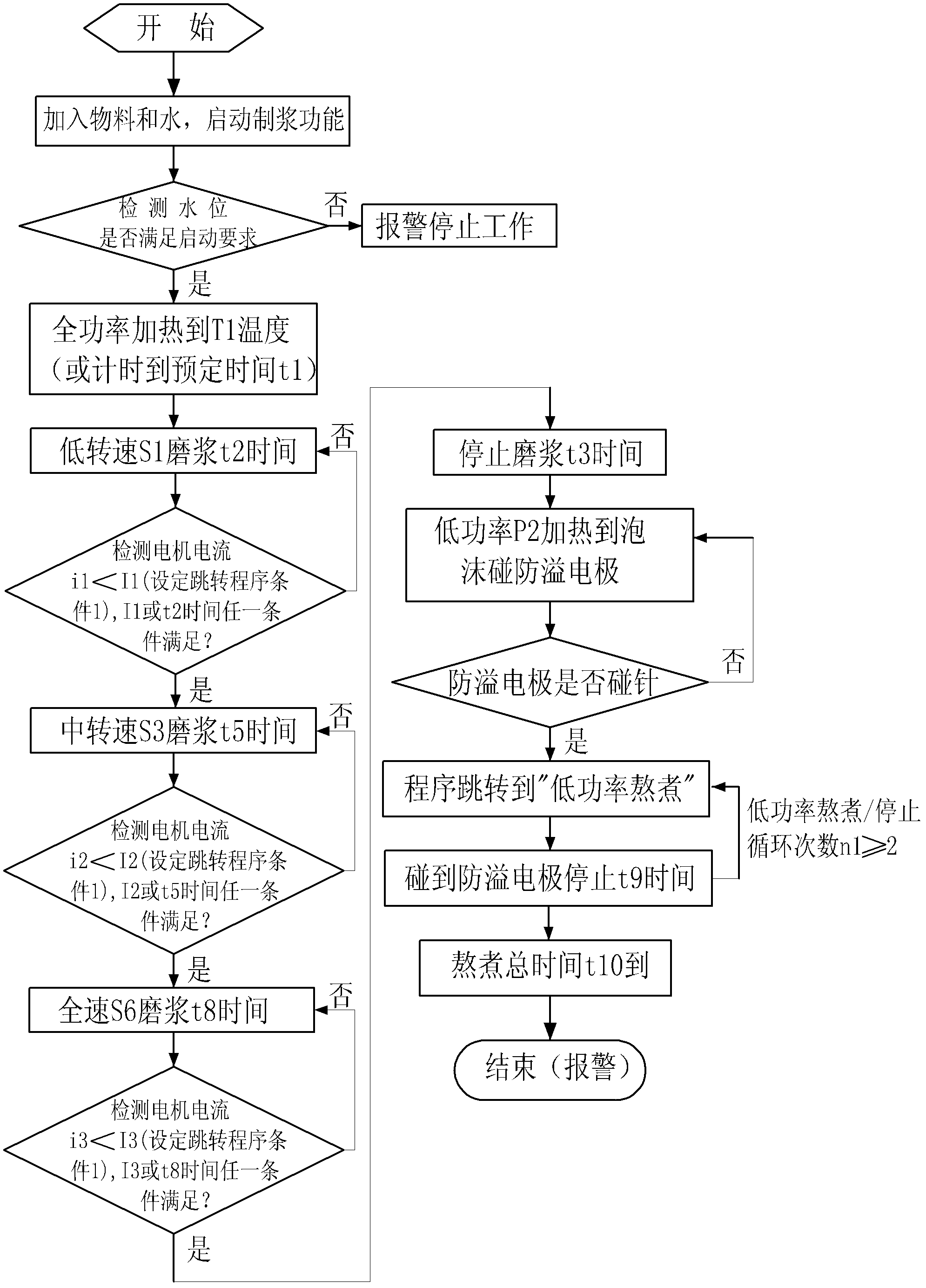

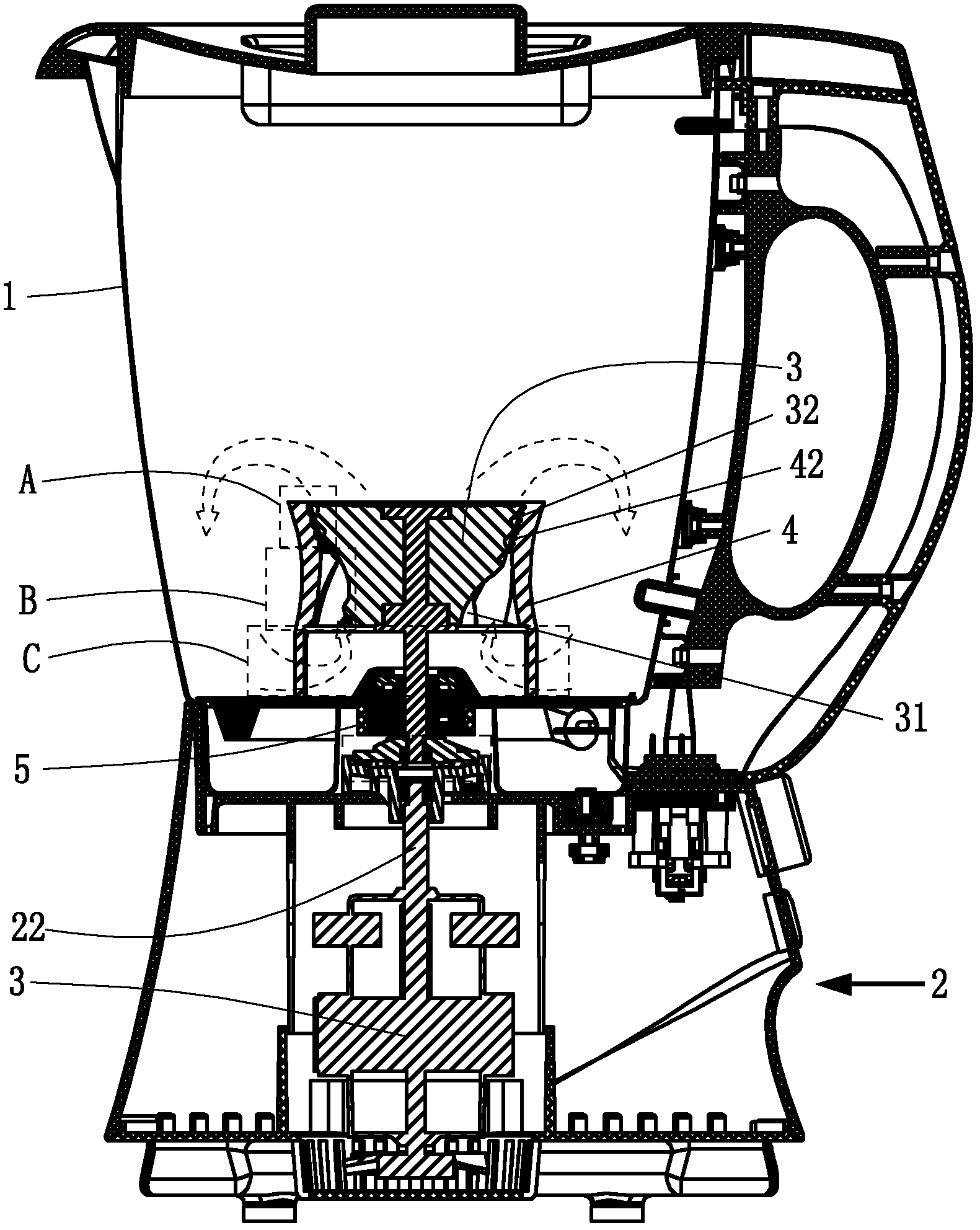

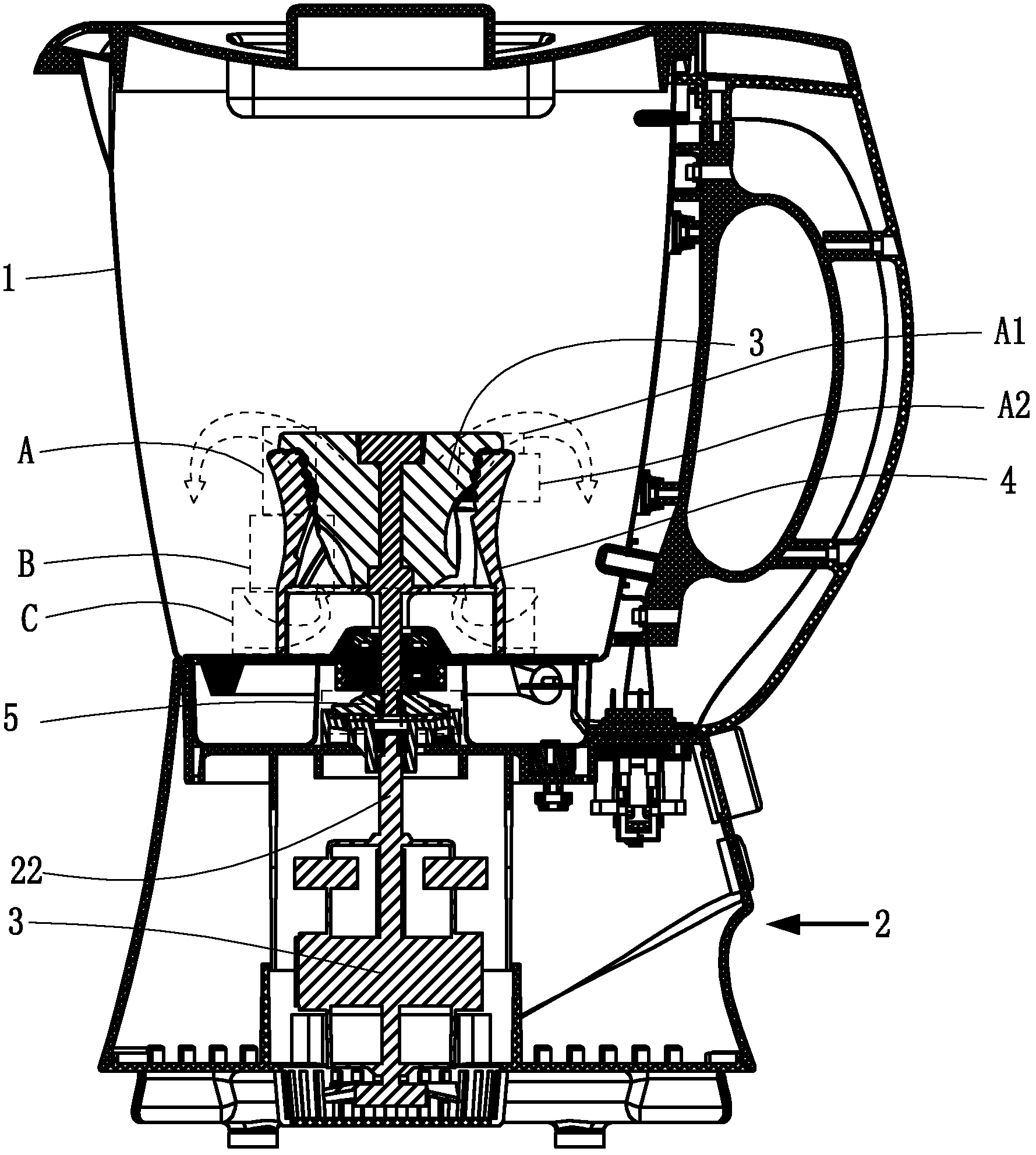

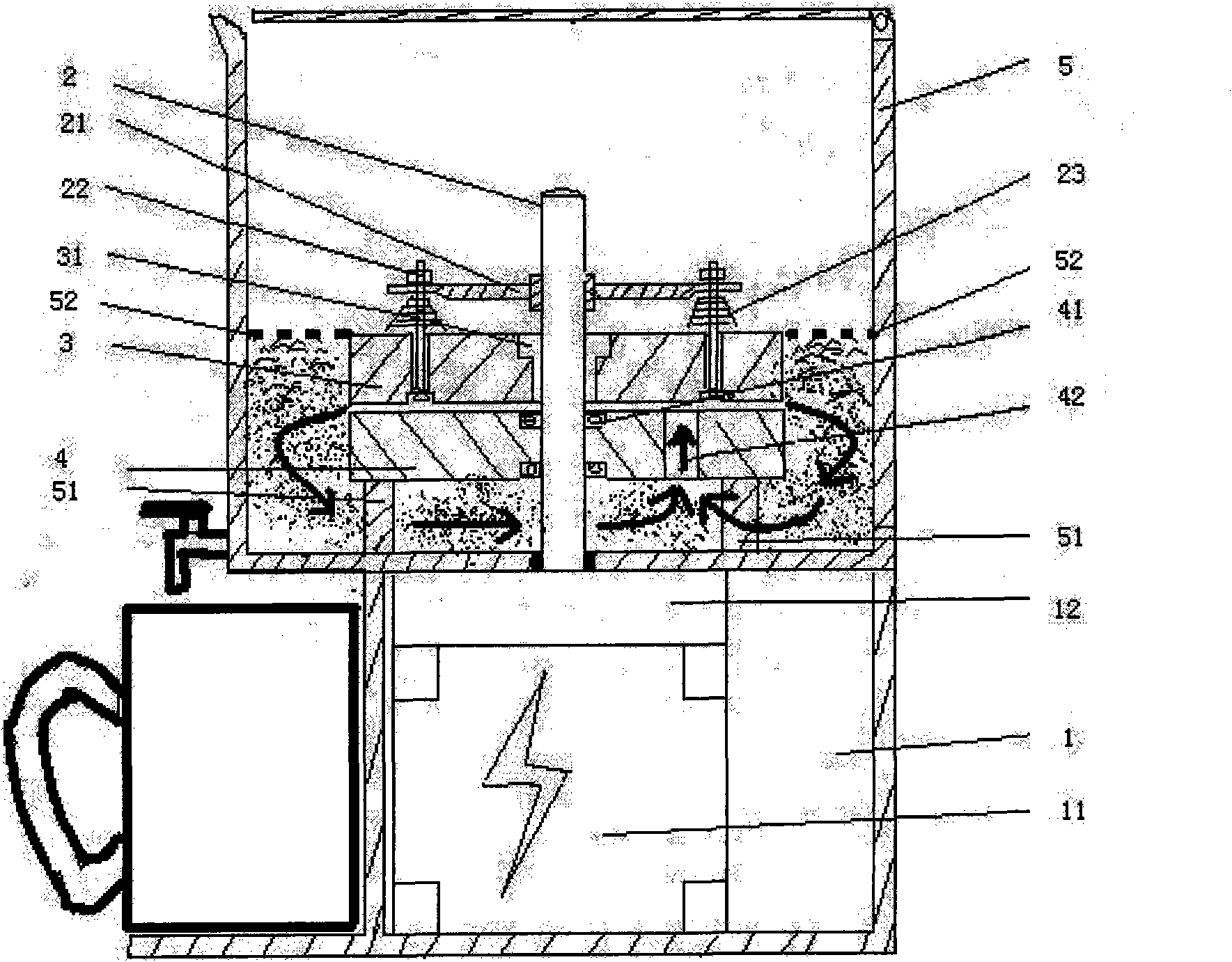

Grinding soymilk machine with multifunctional operation mode and its speed-regulating grinding method

The invention belongs to the field of small household electrical appliances in kitchens, in particular relates to a soymilk maker and particularly relates to a grinding soymilk maker with multifunctional operation modes and a speed-adjusting milk grinding method thereof. The grinding soymilk maker comprises a central processing control unit, an input control unit, a motor control unit, a detection unit, a milk grinding speed-adjusting unit and a heating unit. The speed-adjusting milk grinding method comprises the following stages: a) feeding stage; b) liquid level detection stage; c) pre-heating stage H1; d) speed-adjusting milk grinding stage; e) heating stage H2; and f) boiling stage. By adopting the grinding soymilk maker and the speed-adjusting milk grinding method thereof, grinding teeth of a grinding unit can be effectively protected according to different rotational speeds; simultaneously, milk material which is ground out is finer by low-speed grinding of active ingredients in material and extrusion of the material.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

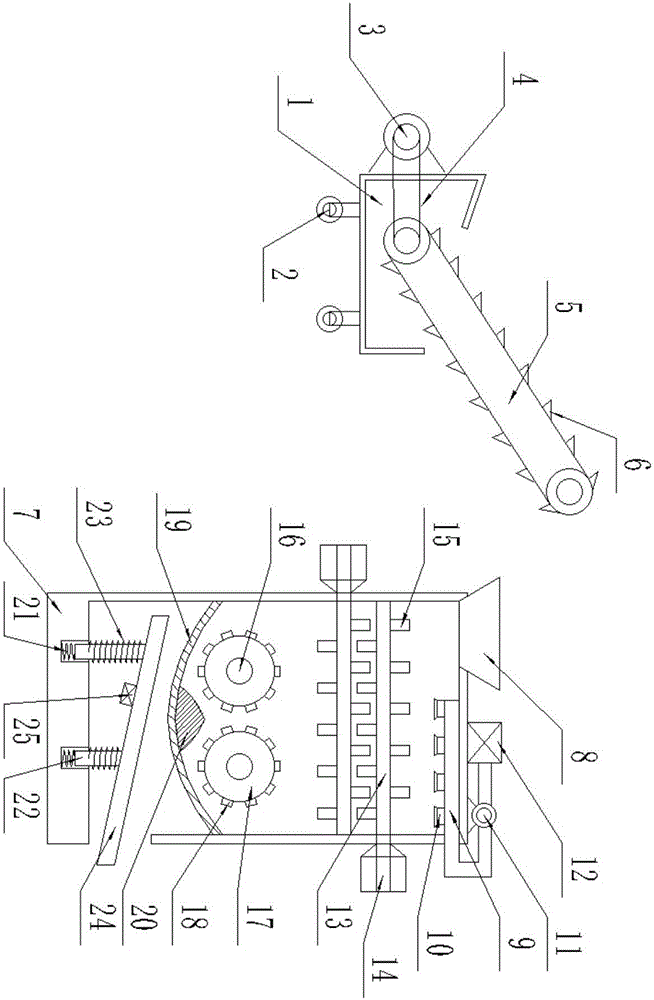

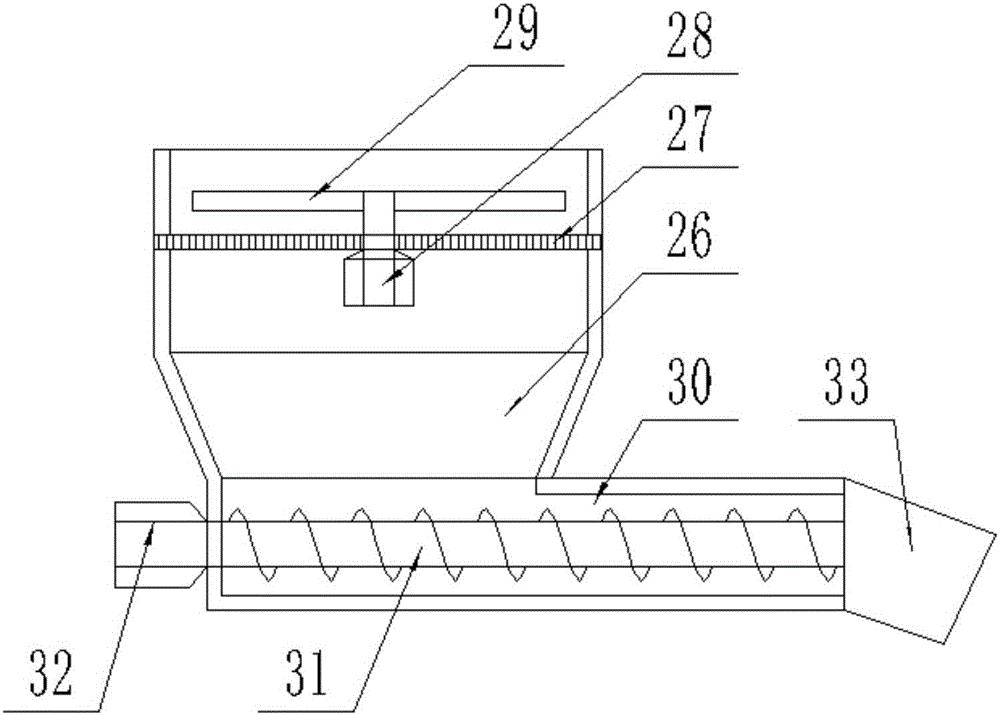

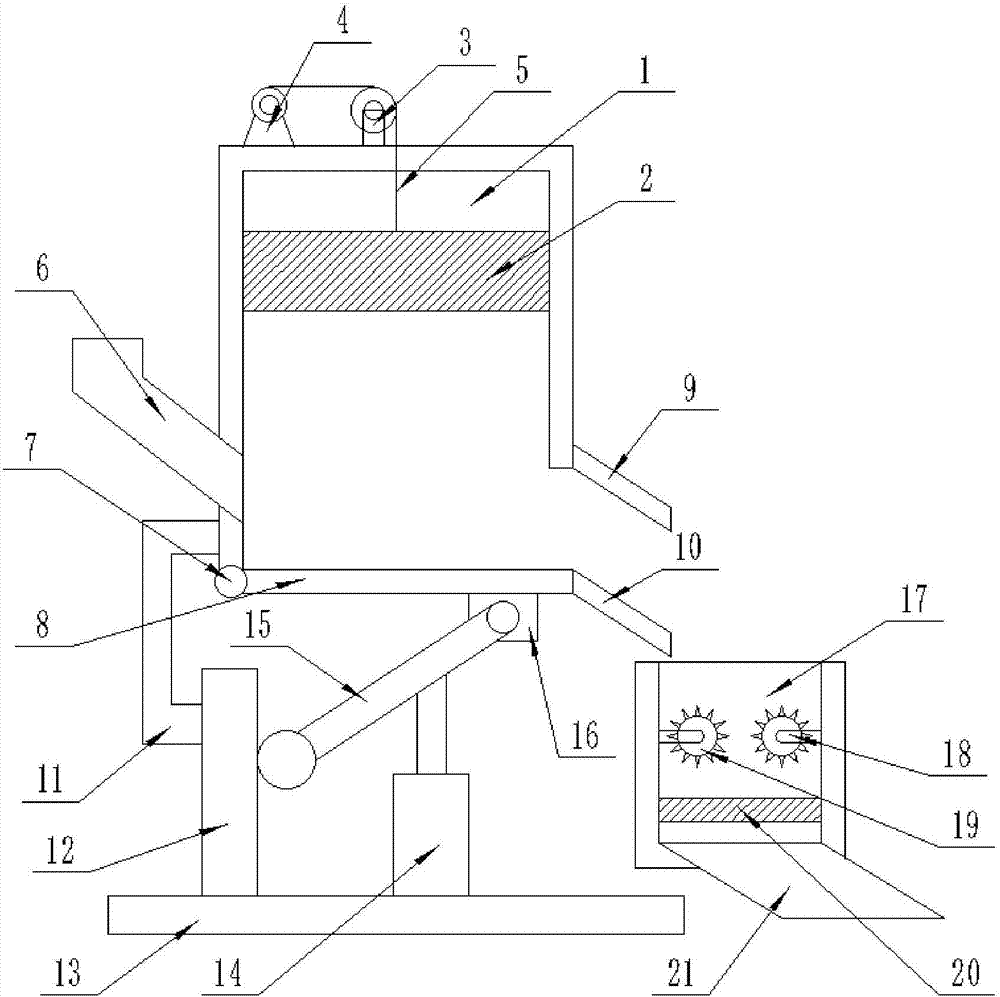

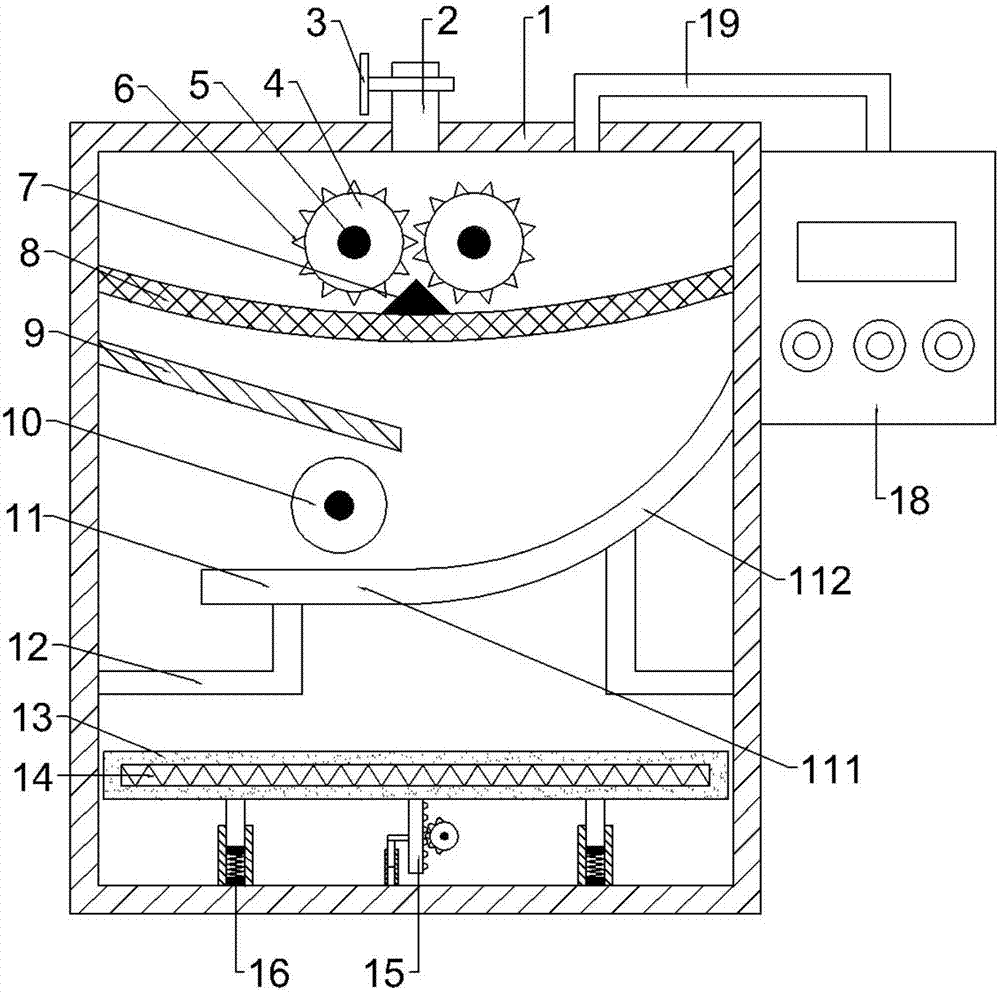

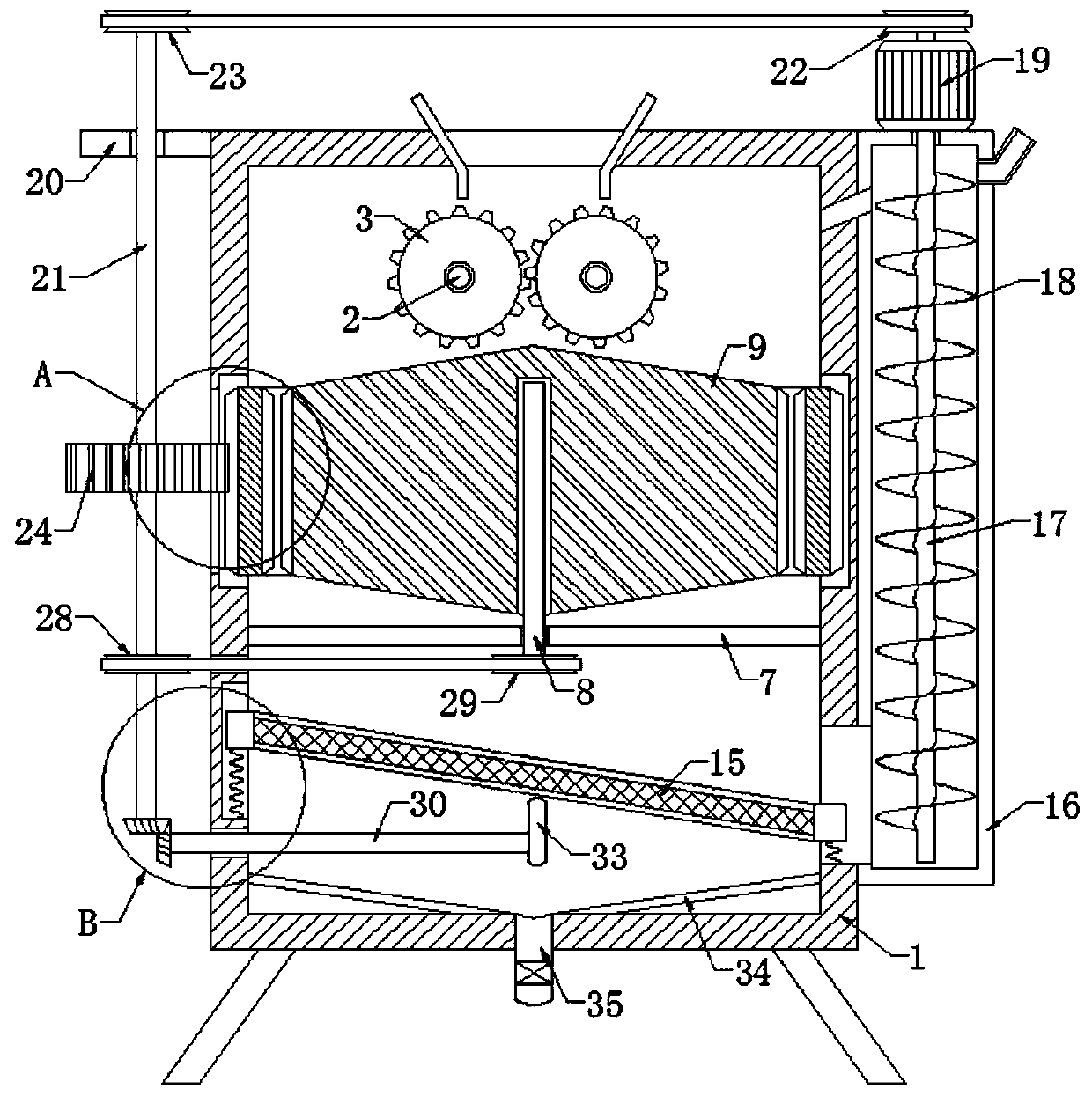

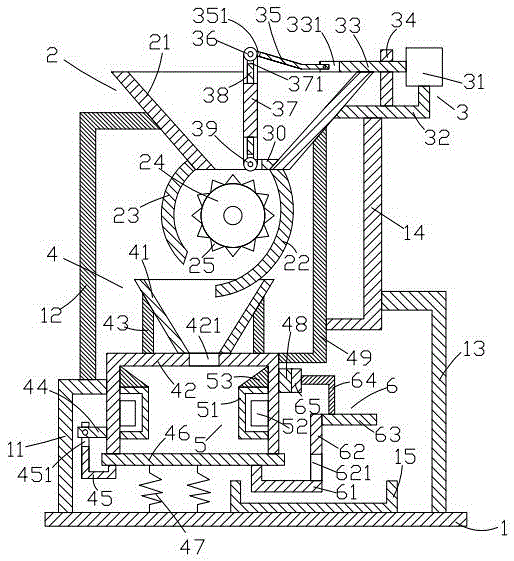

Construction waste treatment device with dual functions of crushing and screening

InactiveCN106824485ASimple structureReduce manufacturing costSievingScreeningMotor driveDual function

The invention discloses a construction waste treatment device with dual functions of crushing and screening. The construction waste treatment device has the advantages of being reasonable and simple in structure, low in production cost, convenient to install, good in crushing effect, convenient to use and the like. Multiple crushing is conducted on construction waste by a multi-level crushing device, the crushing effect is good, and the size of the construction waste after the crushing can meet the requirements of recycling and reusing; when the construction waste treatment device is in use, the construction waste is put into a lifting box and carried to a crushing chamber through a material net on a synchronous belt, firstly the construction waste is crushed through crushing blades and ground through grinding teeth, when the construction waste becomes thin and small particles, the particles are filtered by a first filtering net, when the particles are relatively large, grinding continues to be carried out, filtered particles enter a screening chamber through an oblique plate, a screening motor drives a screening plate, and the particles are screened on a screening net, fall into a transport chamber, and finally go to a transport vehicle to be collected.

Owner:徐勇

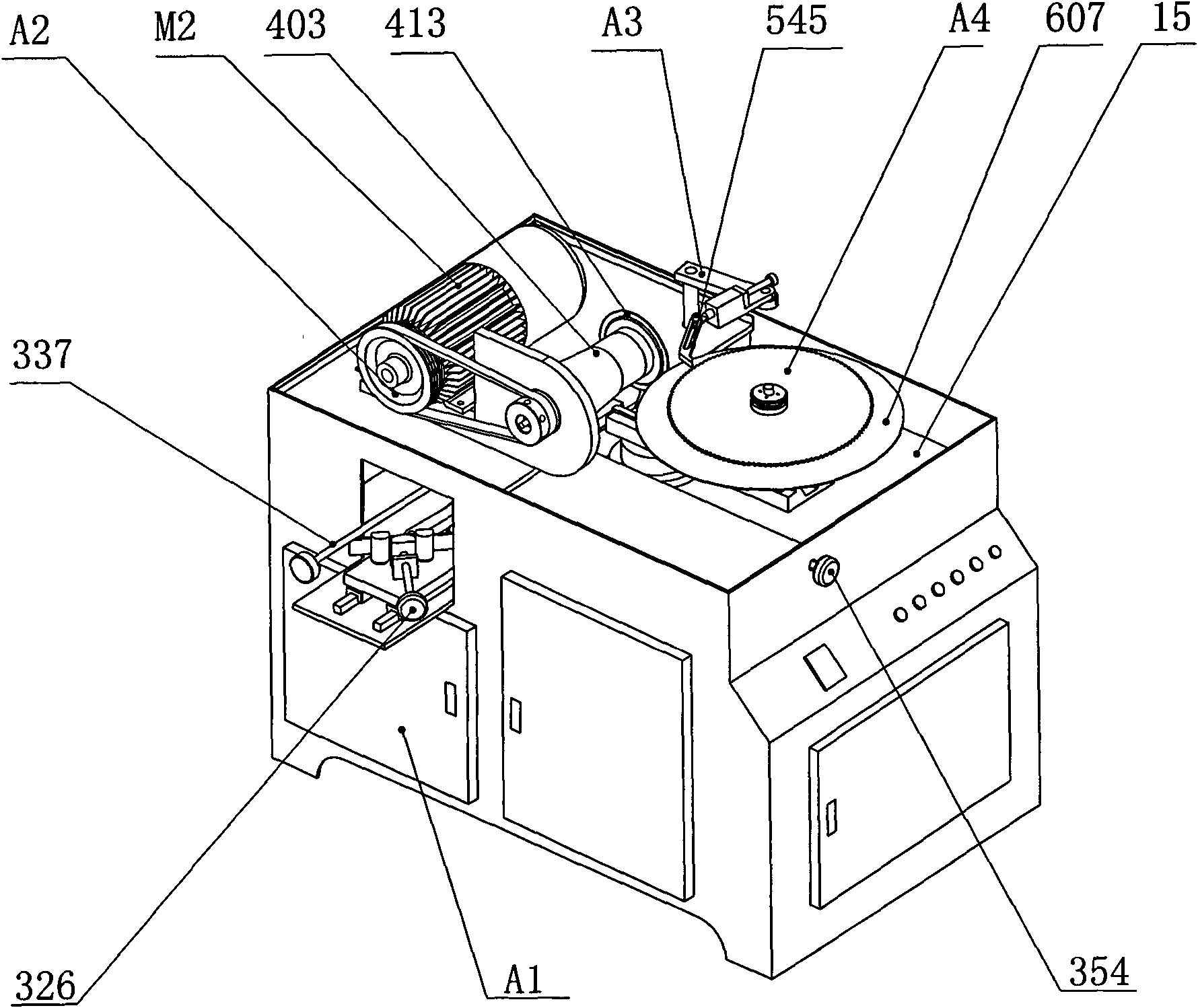

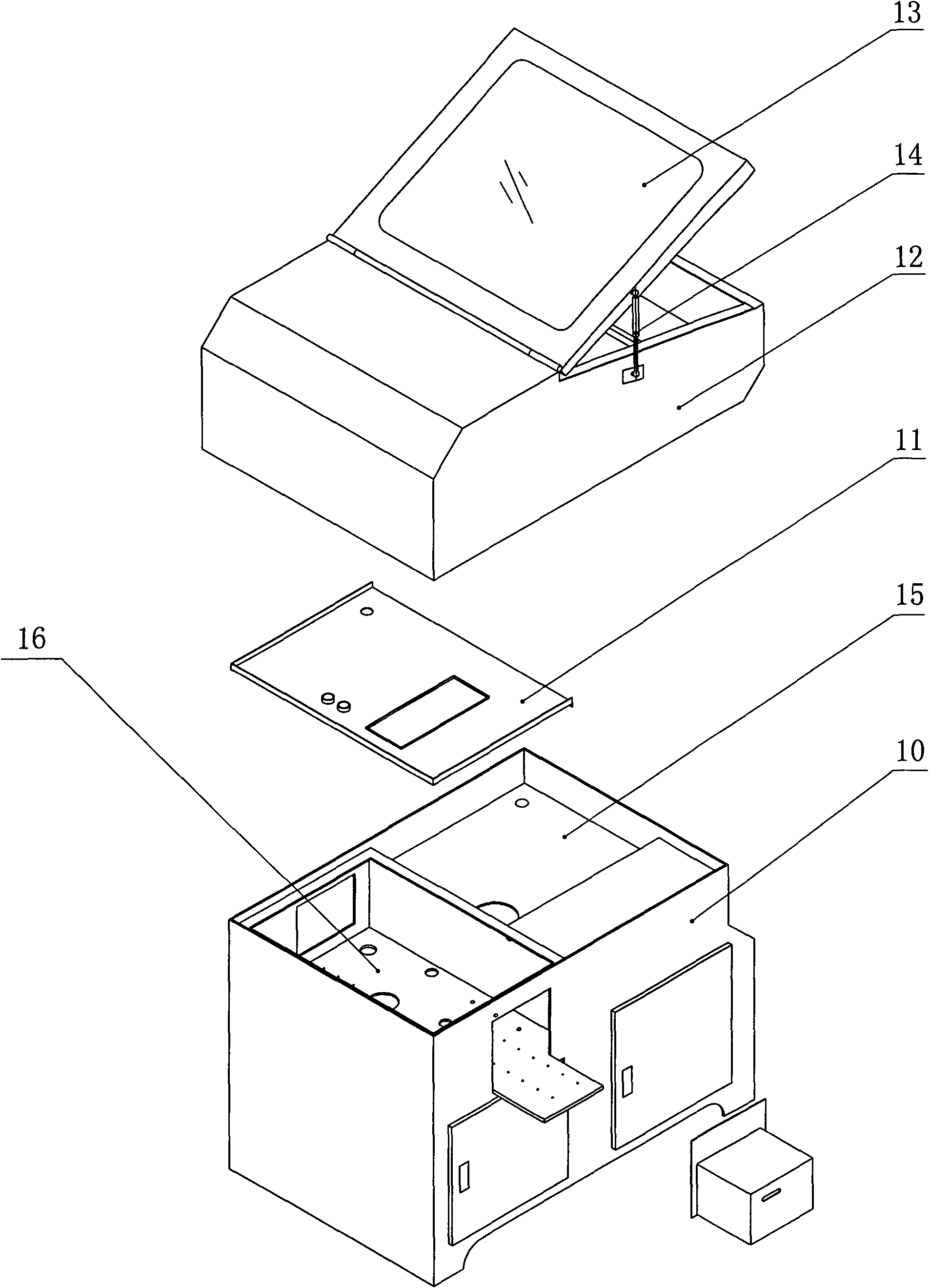

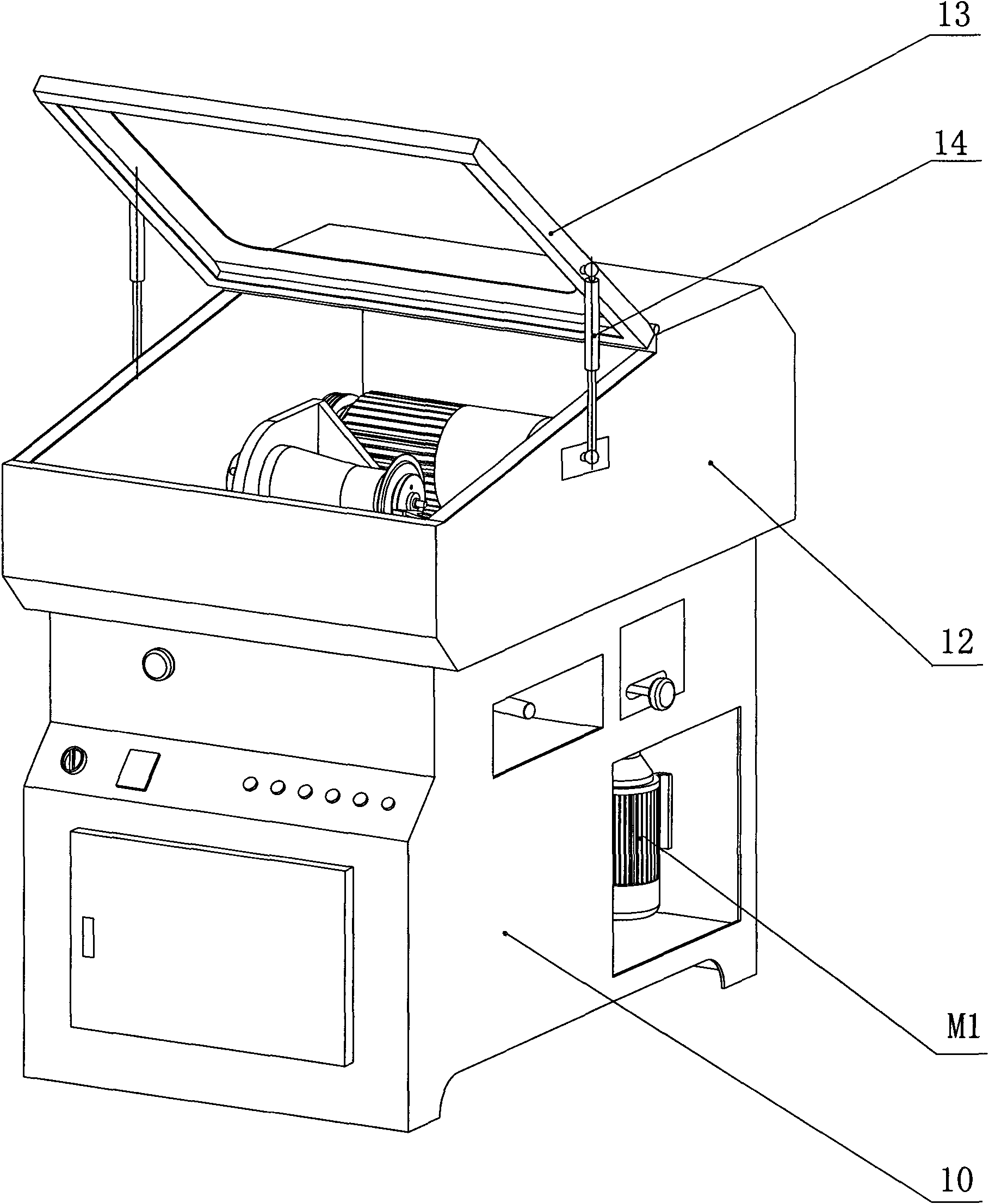

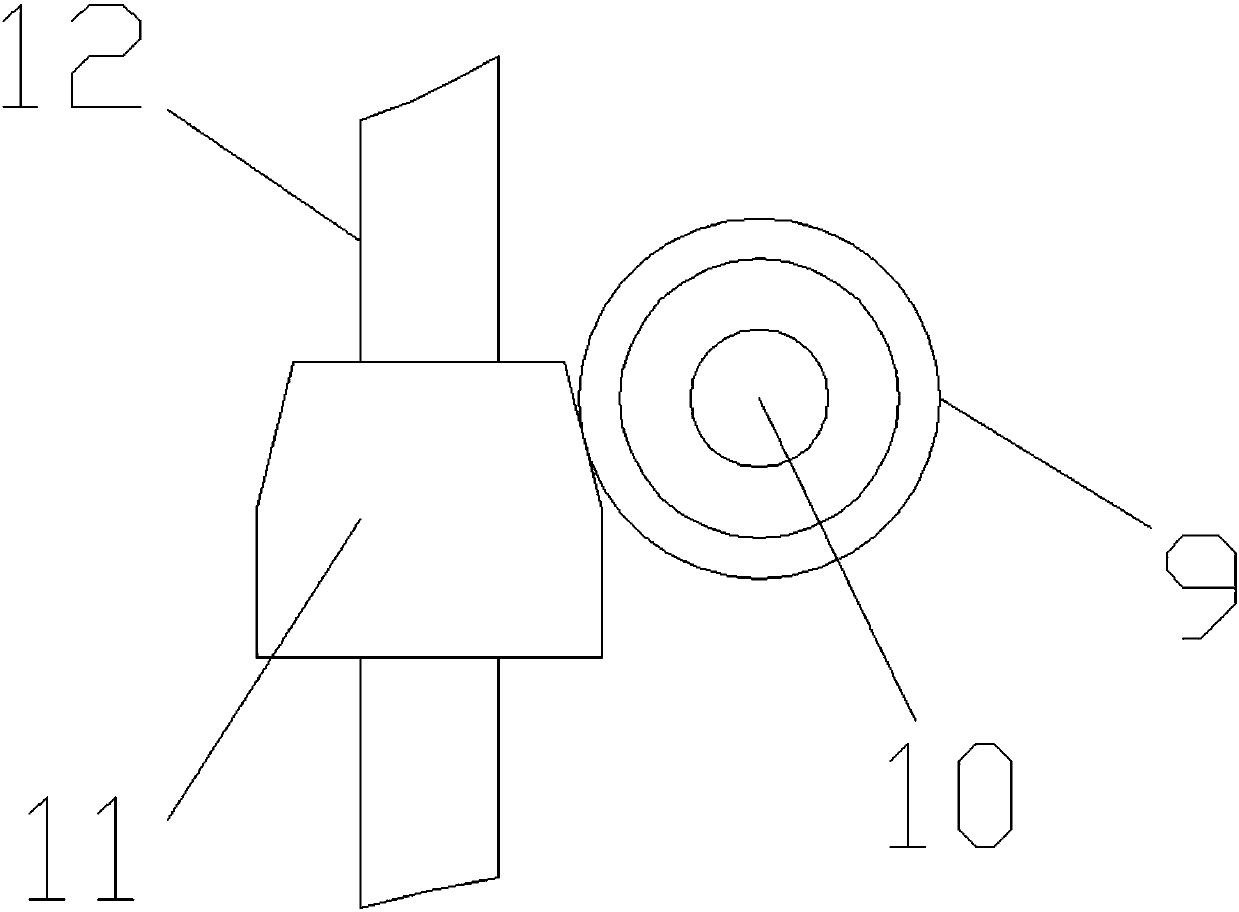

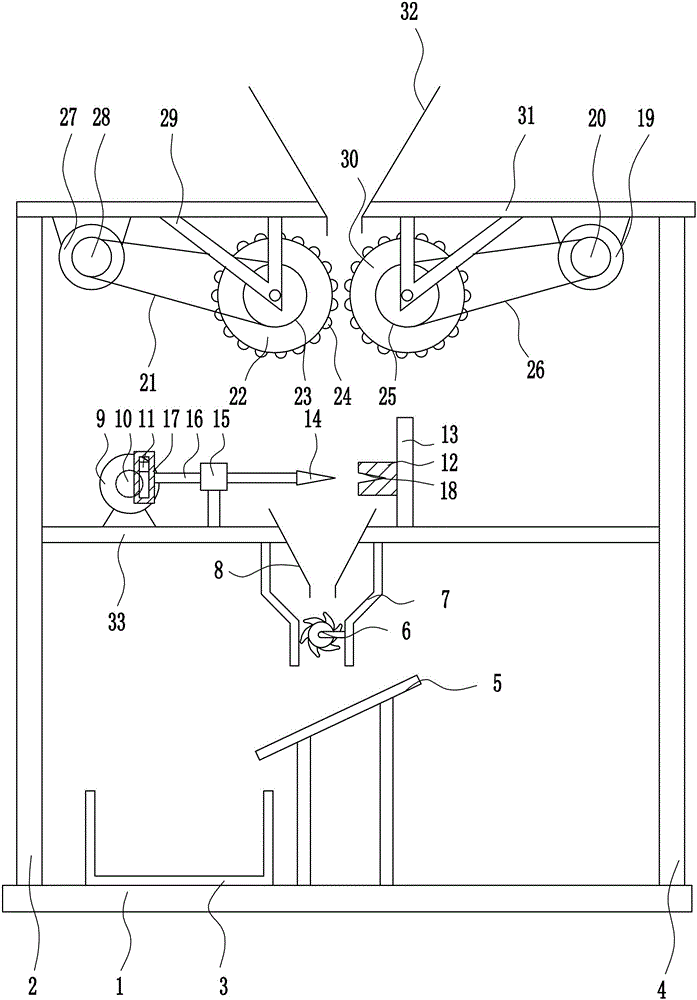

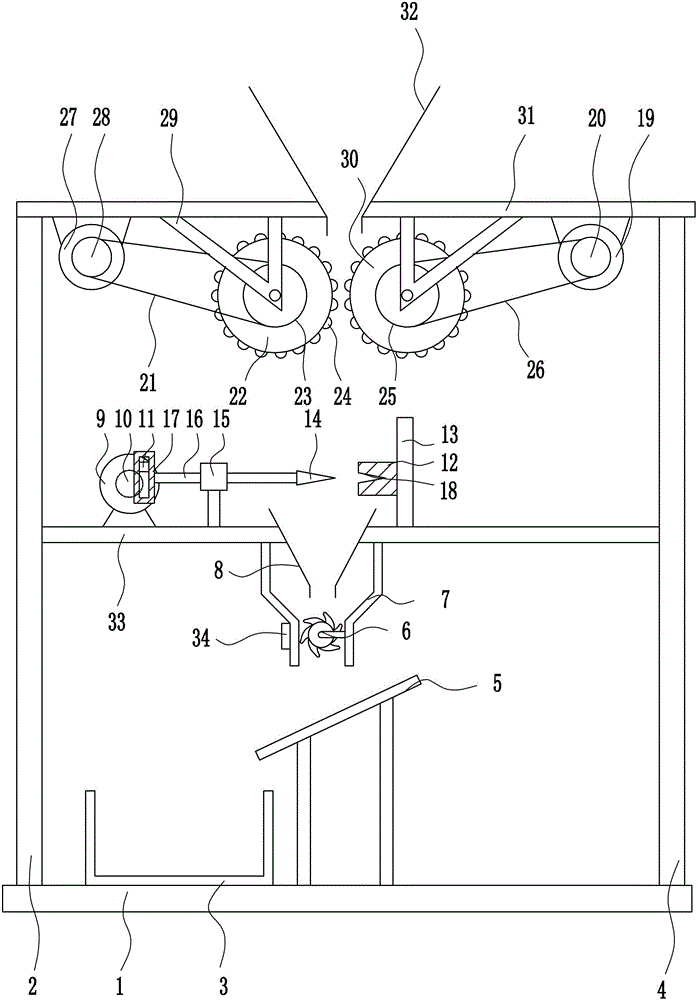

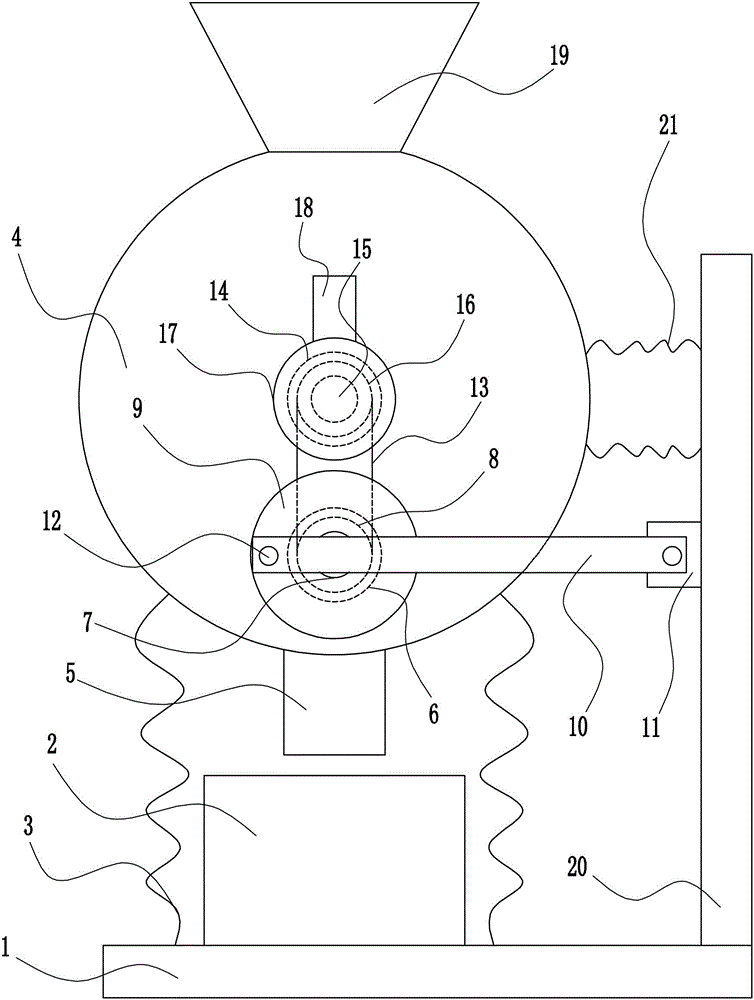

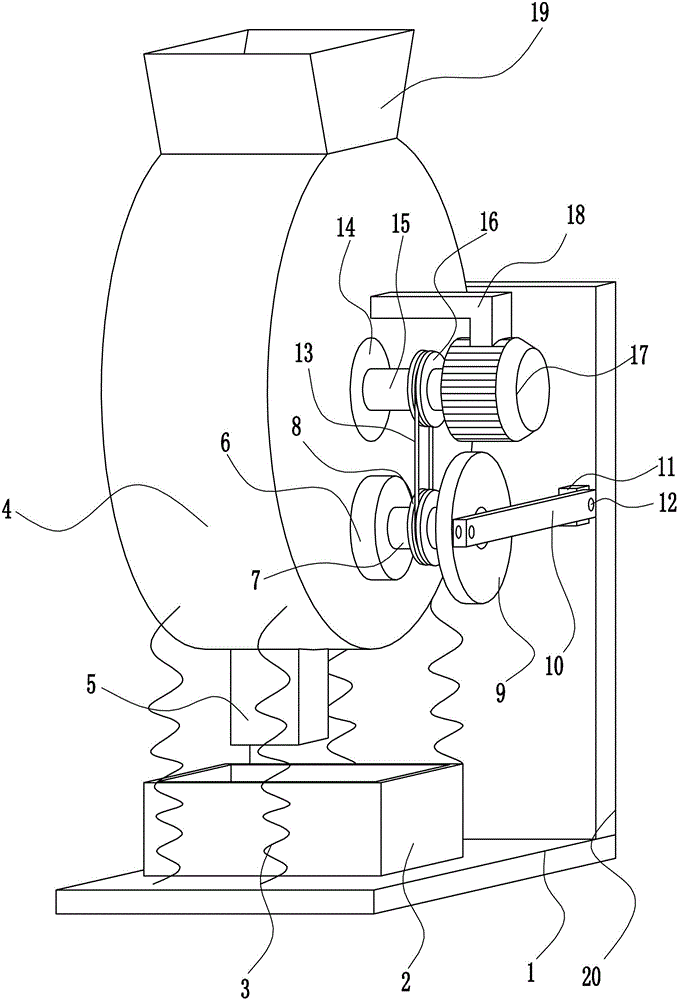

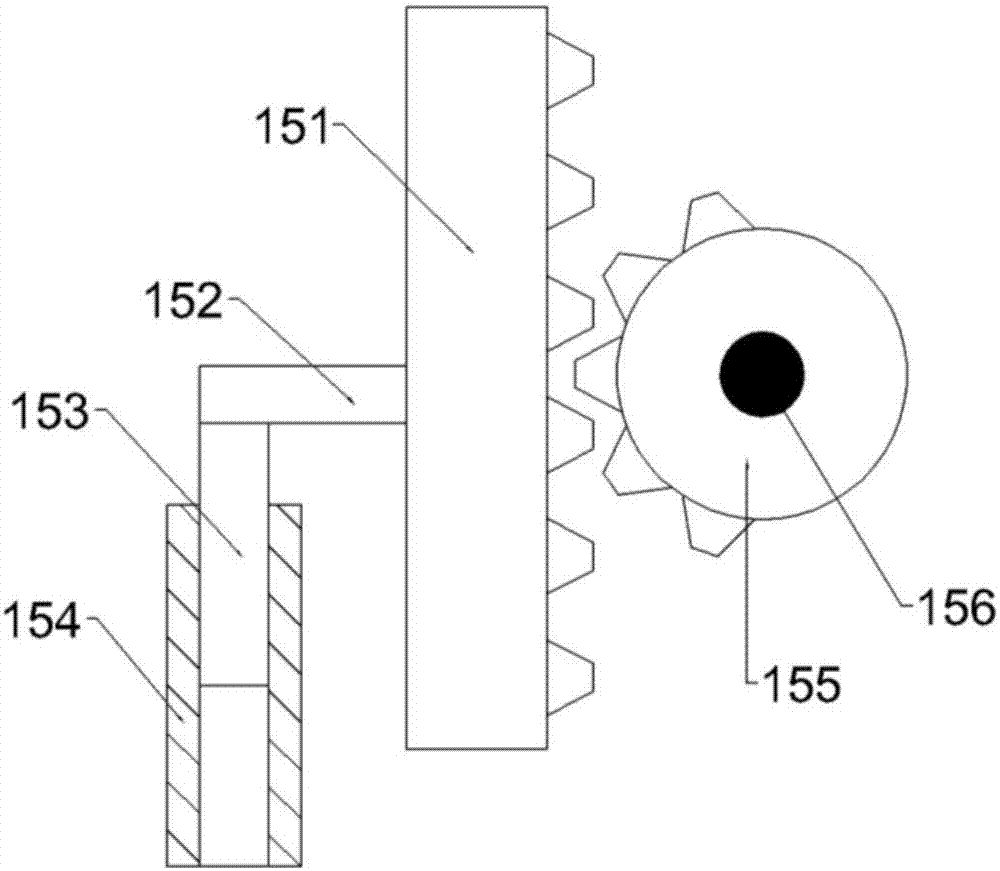

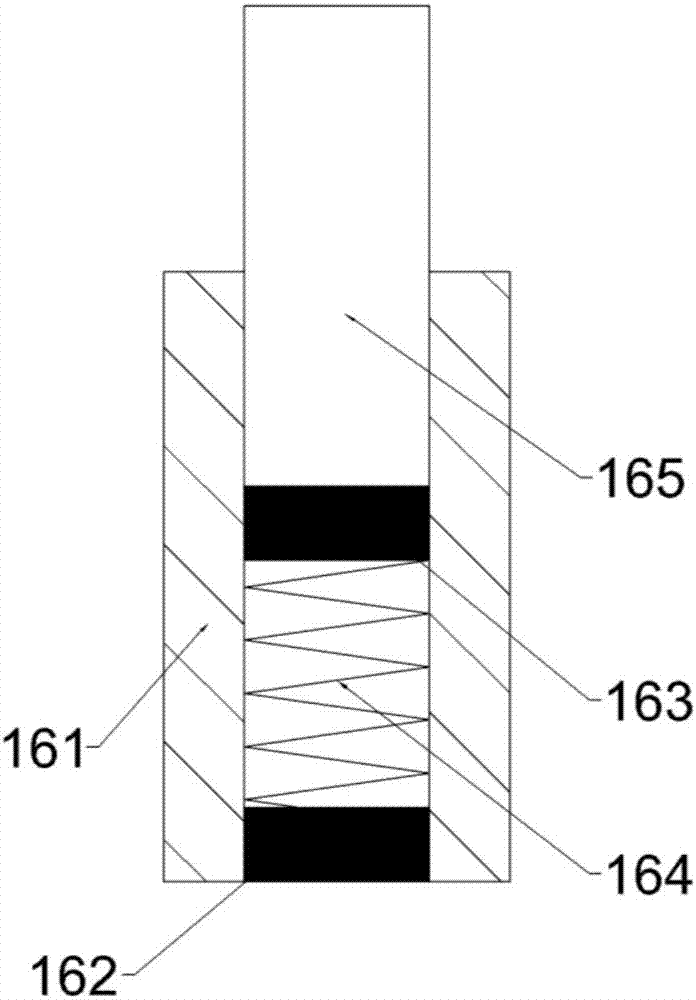

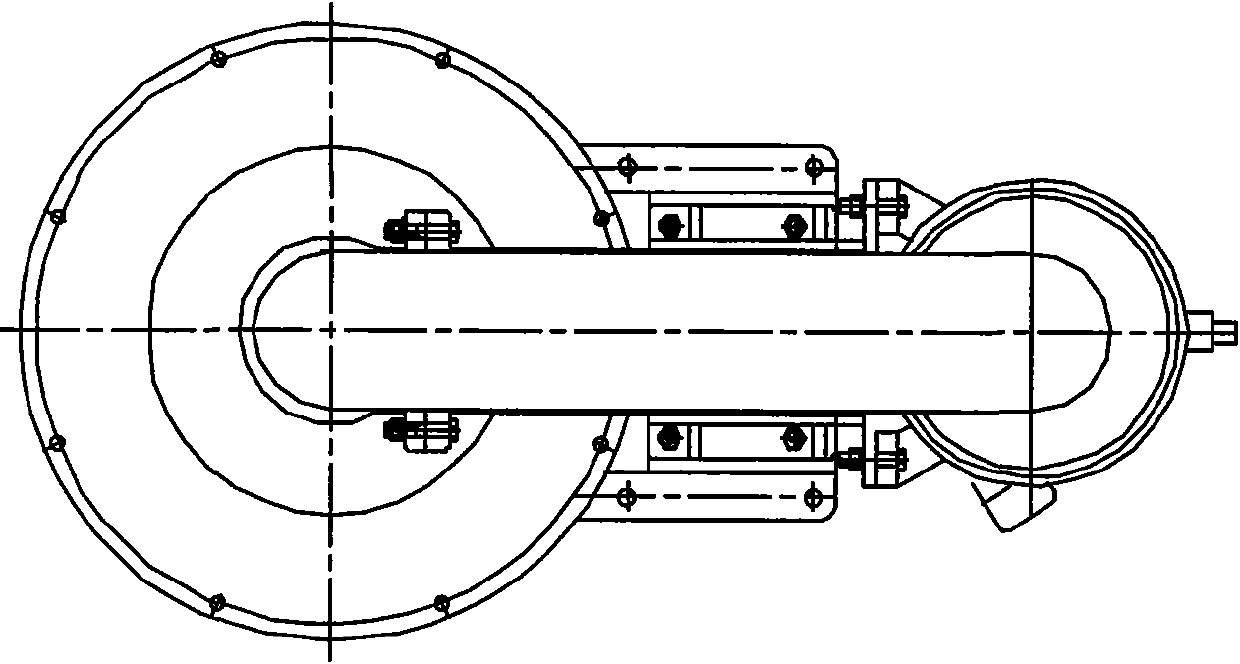

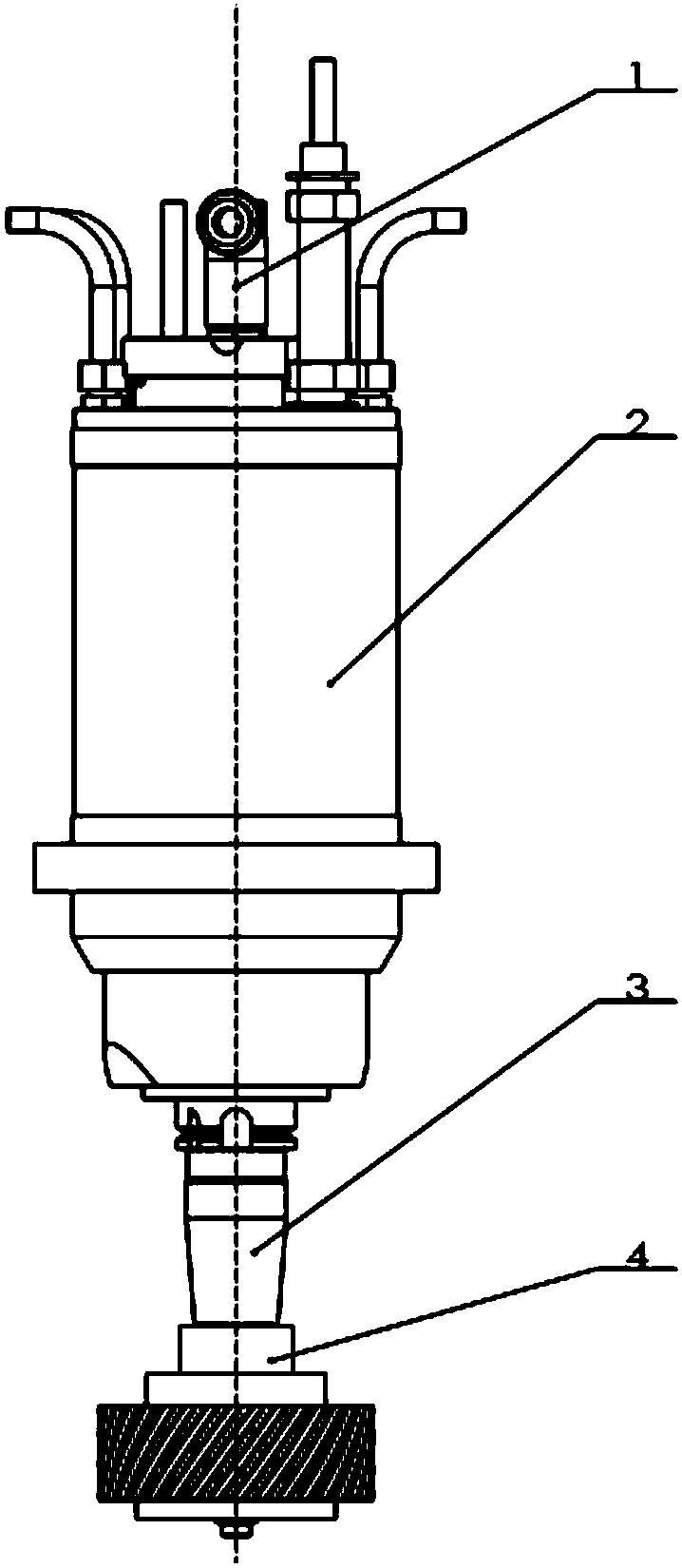

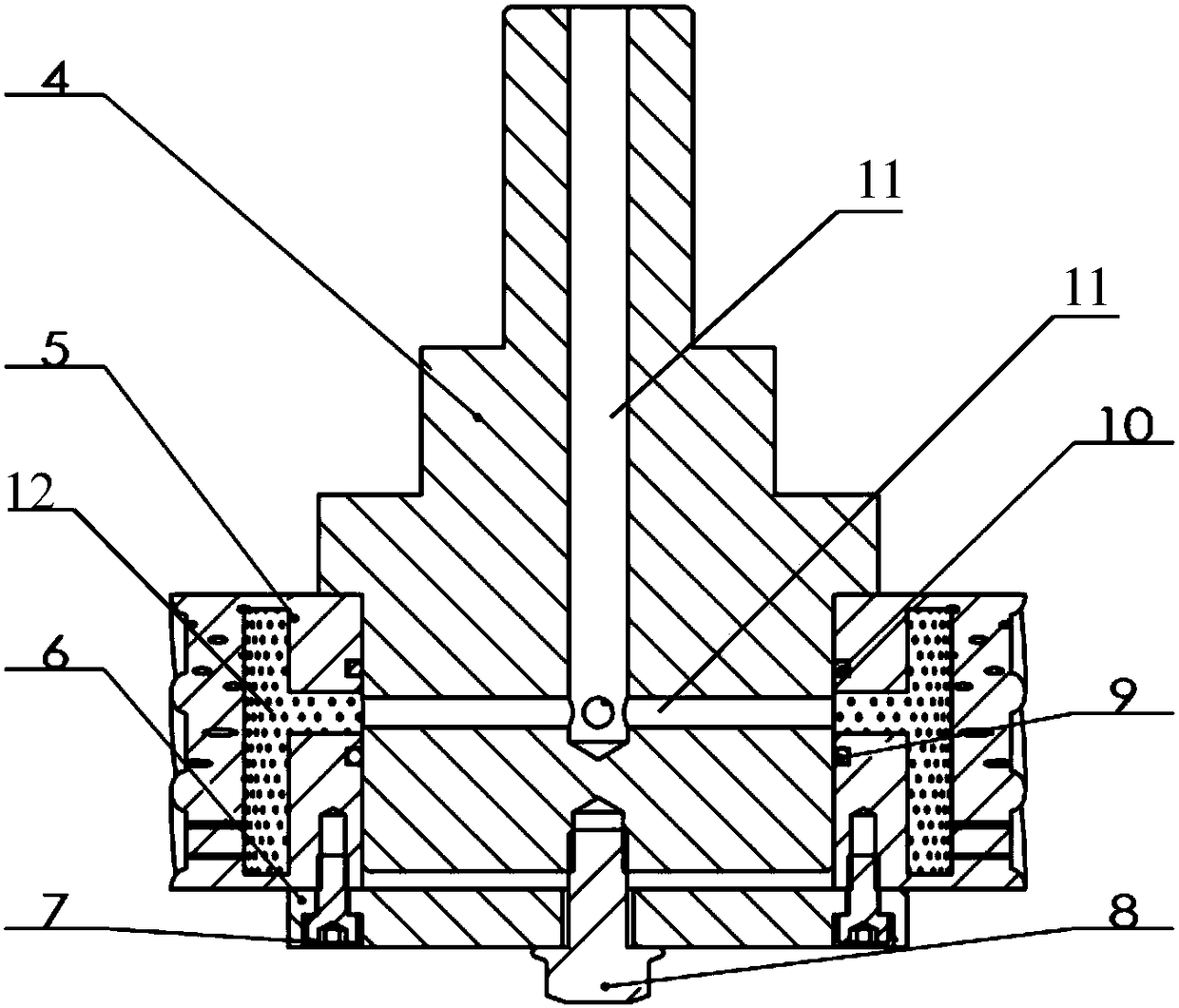

Saw blade grinding machine of metal circular saw blade

ActiveCN101658962AHeight adjustableSawing tools dressing arrangementsReciprocating motionCircular saw

The invention relates to a saw blade grinding machine of a metal circular saw blade, which comprises a machine frame, a grinding tooth and cutting knife driving device and a saw blade positioning device, wherein the grinding tooth and cutting knife driving device and the saw blade positioning device are arranged on the machine frame; the grinding tooth and cutting knife driving device comprises acutting knife drive motor which can drive a cutting knife to rotate, and the saw blade positioning device comprises a central shaft which can be fixedly connected with the metal circular saw blade; amain power driving system and a first eccentric wheel are also arranged on the machine frame; the saw blade grinding machine of the metal circular saw blade is characterized in that the main power driving system comprises a main drive motor which can drive the first eccentric wheel to rotate; and the first eccentric wheel can drag the grinding tooth and cutting knife driving device to carry out areciprocating motion by a first stroke conversion system. By the design and the connection of a flexible structure, the entire machine realizes the mechanical automation of the processing process, andthe processing accuracy of the saw blade is high. Because the invention has the characteristics, the invention can be used for a sawtooth grinding machine of the metal circular saw blade.

Owner:广东捷泰克智能装备有限公司

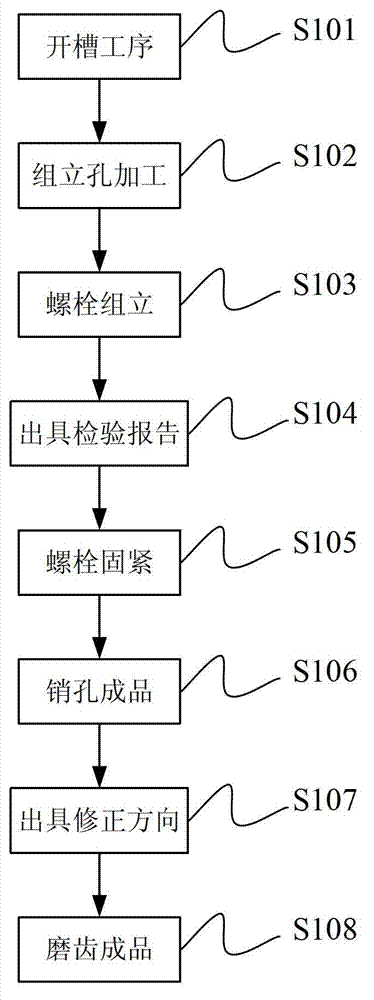

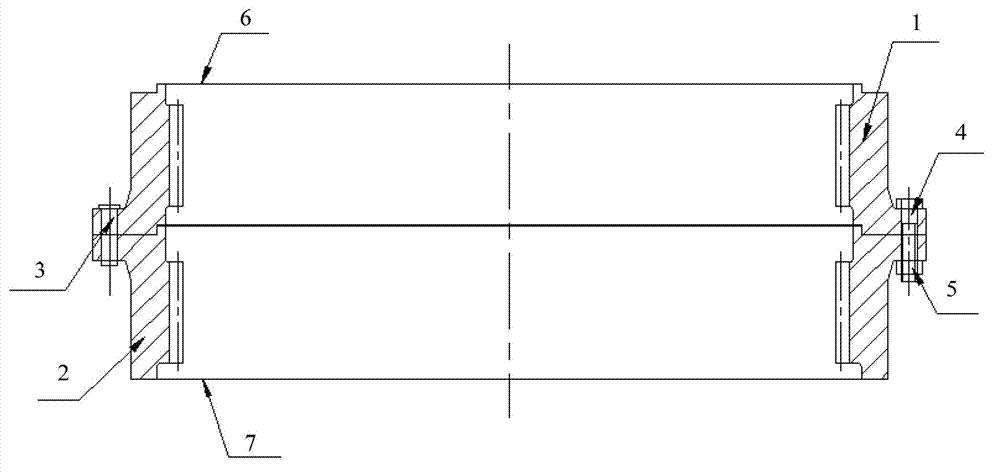

Method for machining combined herringbone tooth part

The invention discloses a method for machining a combined herringbone tooth part. The method includes the steps of machining slots of two helical tooth part and machining an assembly hole on a first helical tooth part; aligning centering errors of the herringbone tooth and machining several assembly holes evenly distributed on a second helical tooth part; aligning centering errors of the herringbone tooth and performing assembly; re-inspecting the centering errors of the herringbone tooth and issuing a centering inspection report; aligning the pitch circle run-out according to the centering inspection report and fastening the pitch circle run-out through a bolt after centering of the herringbone tooth; finishing pinholes on the two helical tooth parts and drilling assembly holes left on the second helical tooth part; re-inspecting the centering errors of the herringbone tooth and providing a correction direction of one of the two helical tooth parts; and decomposing the two helical tooth parts and grinding teeth according to the correction direction to obtain the finished product. According to the method, through three times of alignment of the herringbone tooth centering, two times of error re-inspection of the herringbone tooth centering, tooth grinding, slotting, matching, assembly hole drilling and tooth grinding, drawing design requirements are met.

Owner:CHONGQING GEARBOX

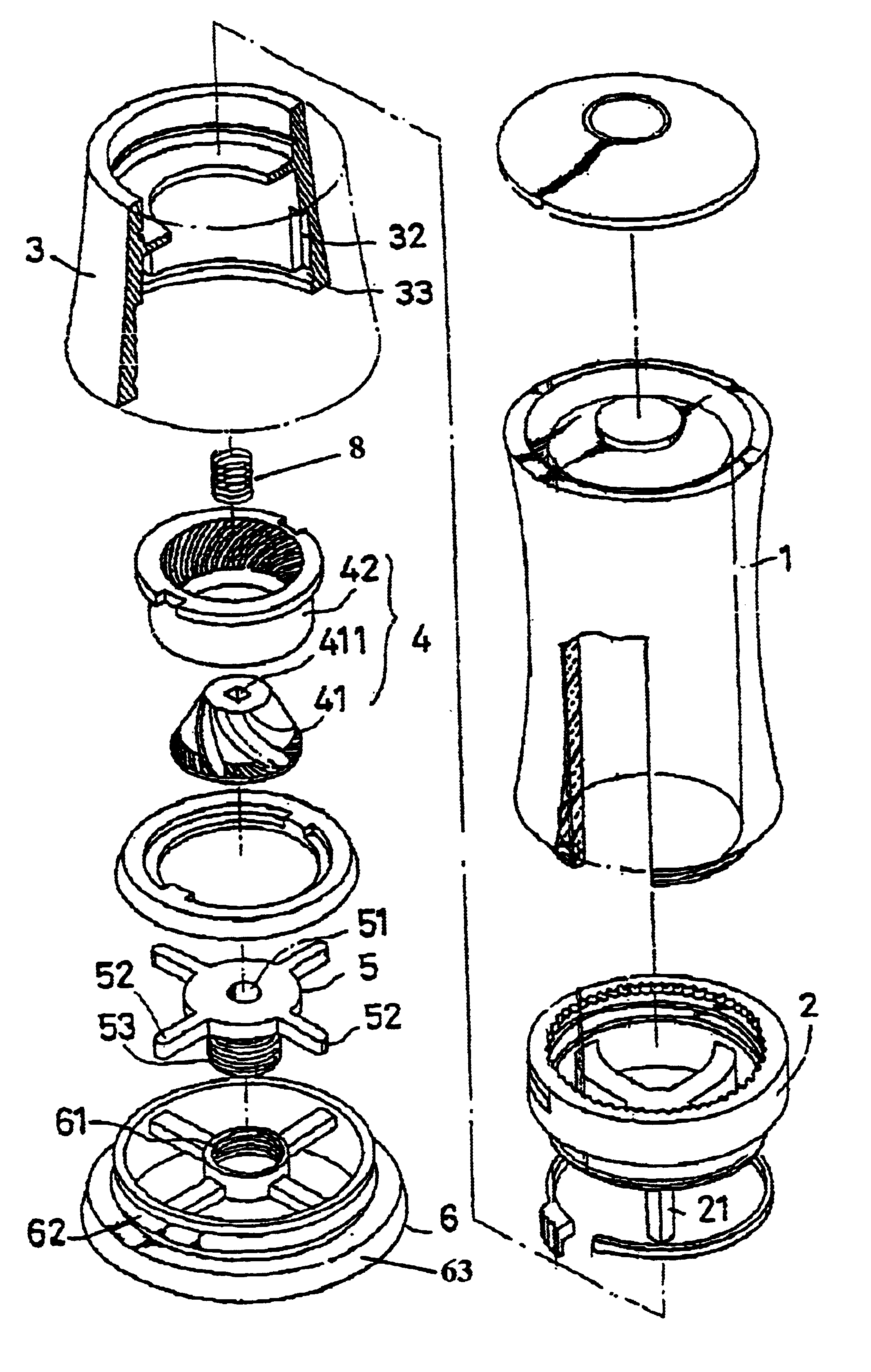

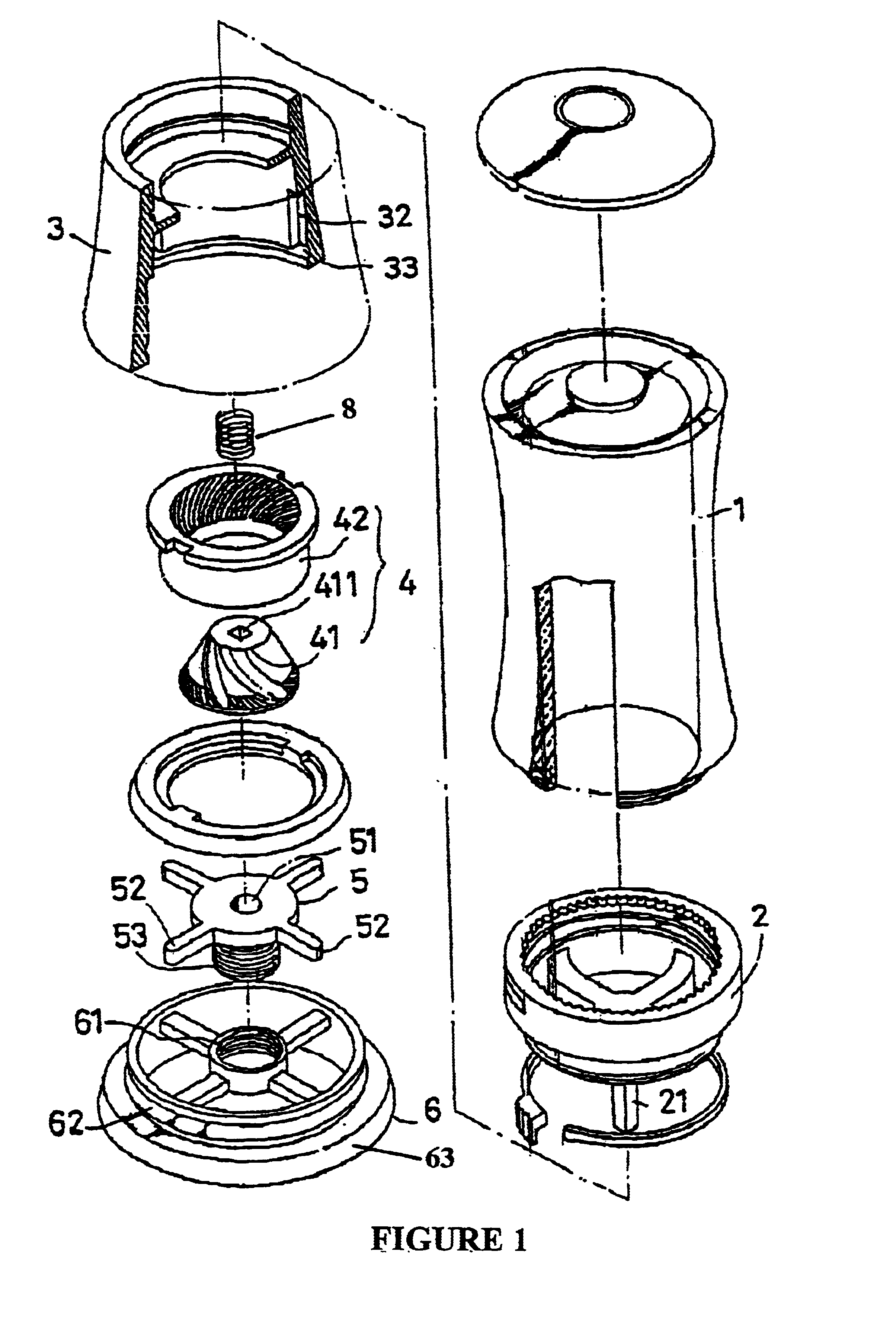

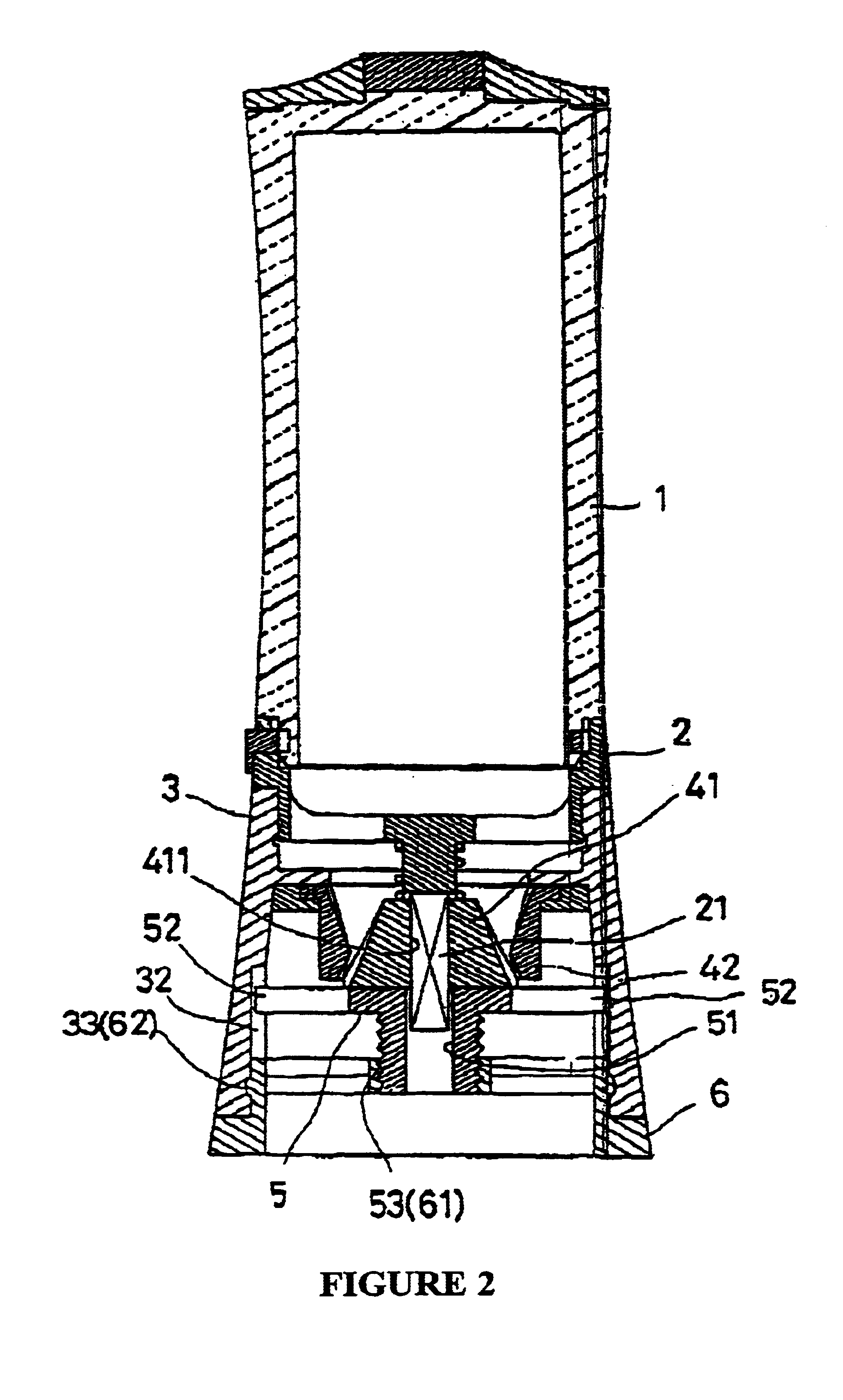

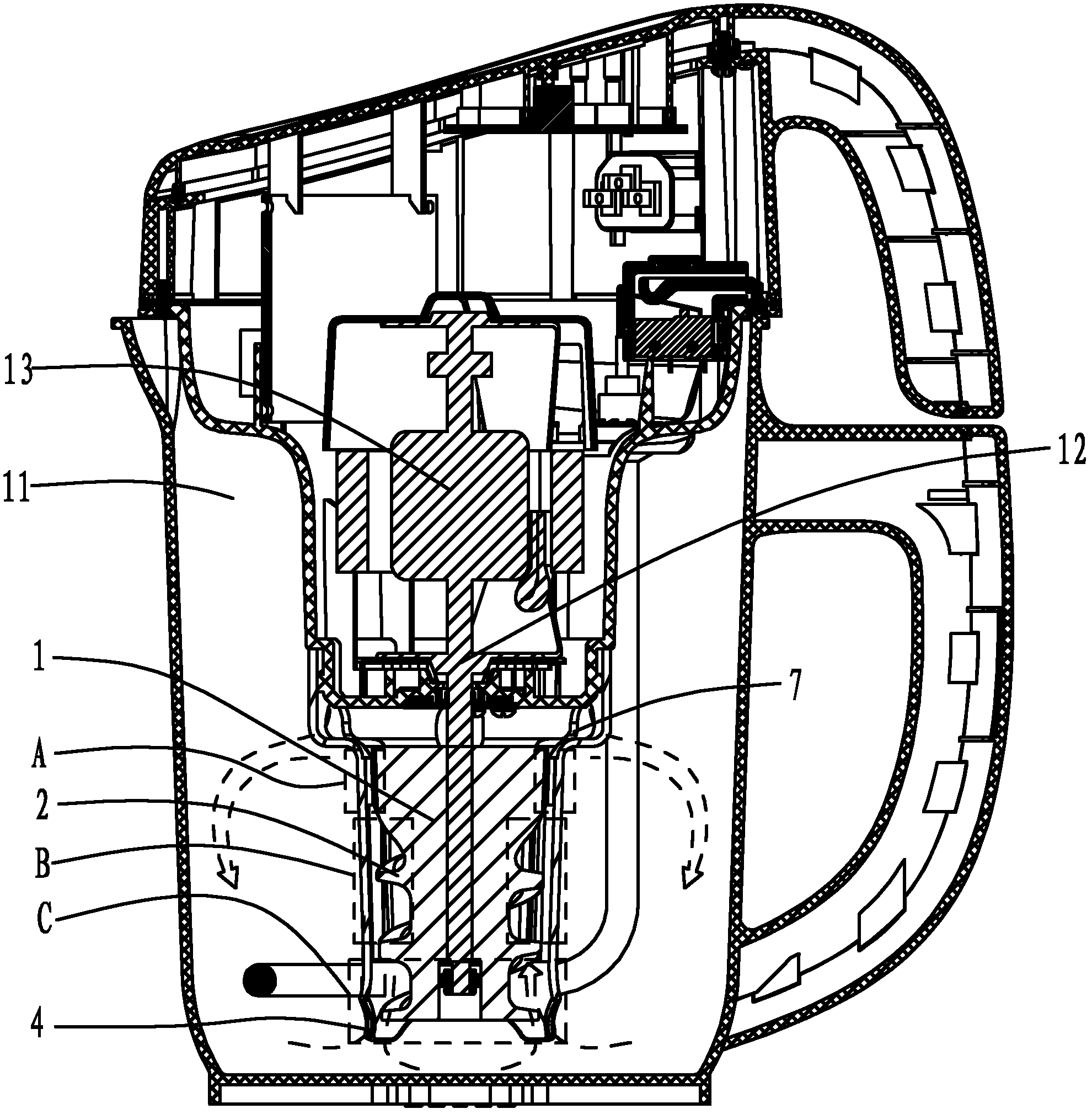

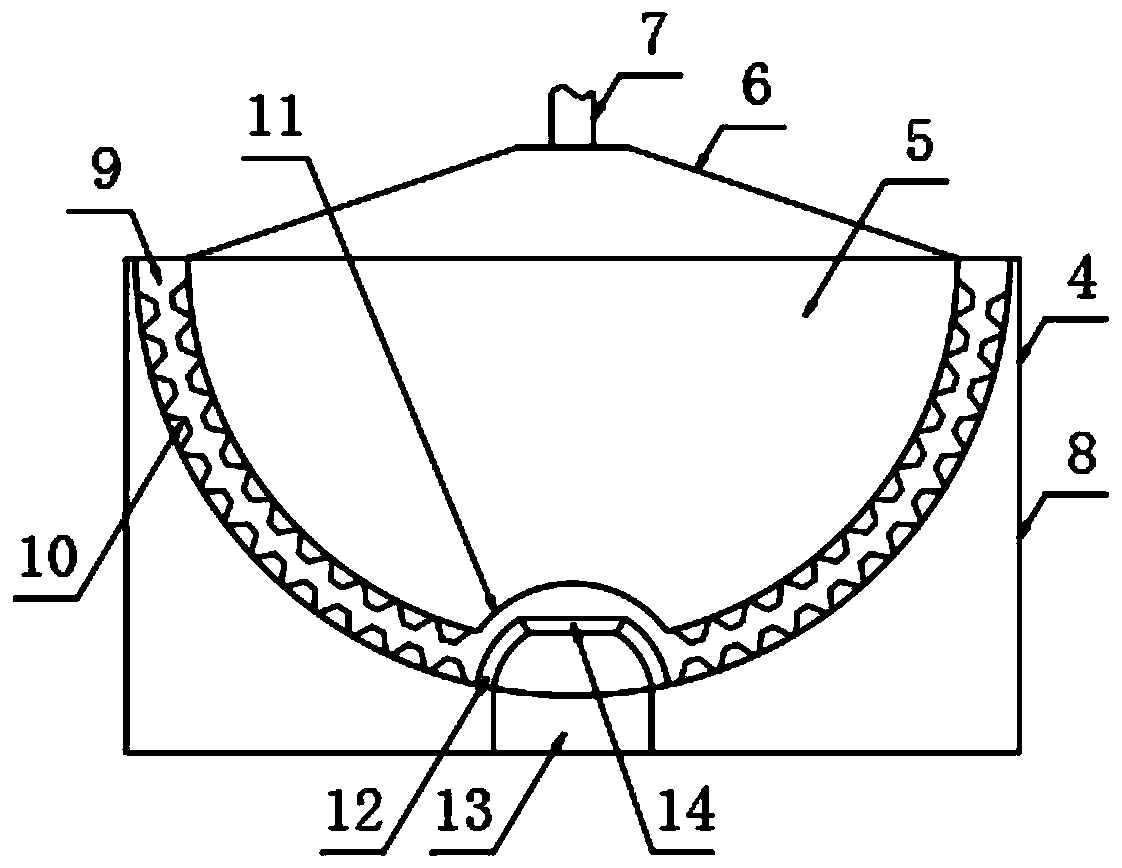

Soy milk making machine

InactiveCN102188159AStable jobReduce vibrationBeverage vesselsMilk substitutesLow noiseHigh concentration

The invention belongs to the field of small kitchen electric appliances and particularly relates to a soy milk making machine. The soy milk making machine comprises a milk making container and a base arranged under the milk making container, a motor arranged in the base is provided with a motor shaft extending in the milk making container, a movable grinding head is fixedly arranged on the bottomend of the motor shaft, and a static grinding head which is matched with the movable grinding head is fixed in the milk making container. When in fitting, the movable grinding head is arranged in an annular closed space of the static grinding head. The movable grinding head is in detachable connection with the motor shaft. The soy milk making machine has the advantages that the motor is arranged in the base, so that the motor is stable, vibrates slightly and produces low noise during work; the movable grinding head can be provided with different movable grinding guide teeth according to different grinding materials, so that the soy milk making machine is convenient to use and can adapt to the grinding of different materials; primary grinding, coarse grinding and fine grinding can be respectively realized with different screw teeth or grinding teeth, so that milk is finer and smoother and has higher concentration; besides, the movable grinding head and the motor shaft are in detachablestructures, a shaft coupling is arranged between the movable grinding head and the motor, and the movable grinding head can be freely detached and changed and is easy to clean.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Mechanical material grinding device

PendingCN107971112ASimple structureReduce manufacturing costGrain treatmentsHydraulic cylinderEngineering

The invention discloses a mechanical material grinding device which is reasonable and simple in structure, low in production cost, convenient to install and capable of effectively grinding and refining raw materials. The raw materials enter a grinding chamber from a feeding opening. A rolling motor can collect or release a grinding block through a cable, the grinding block grinds the raw materials, after grinding is finished, a hydraulic cylinder is contracted, the raw materials are separated from a bottom plate and enter a smashing chamber, smashing wheels carry out smashing, after being smashed, the raw materials are filtered through a filter screen, the large-particle raw materials continue to be smashed by the smashing wheels, the raw materials are separated from a discharging pipe andenter the grinding chamber, the first grinding wheel and the second grinding wheel grind the raw materials, grinding teeth on grinding rollers carry out further grinding on the raw materials, finally, the raw materials are subjected to thorough refining treatment through refining wheels, and under the effect of an air pressure rod, the refining wheels can move left and right and achieve refiningin place.

Owner:NANTONG INST OF TECH

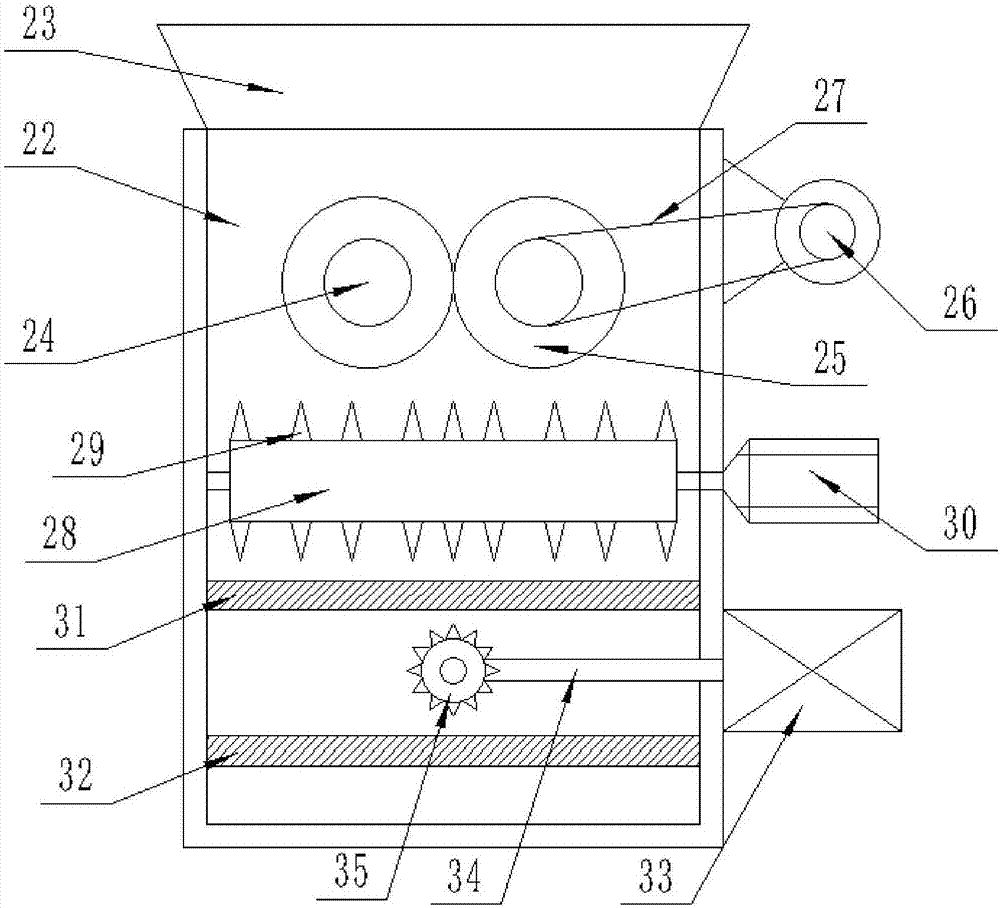

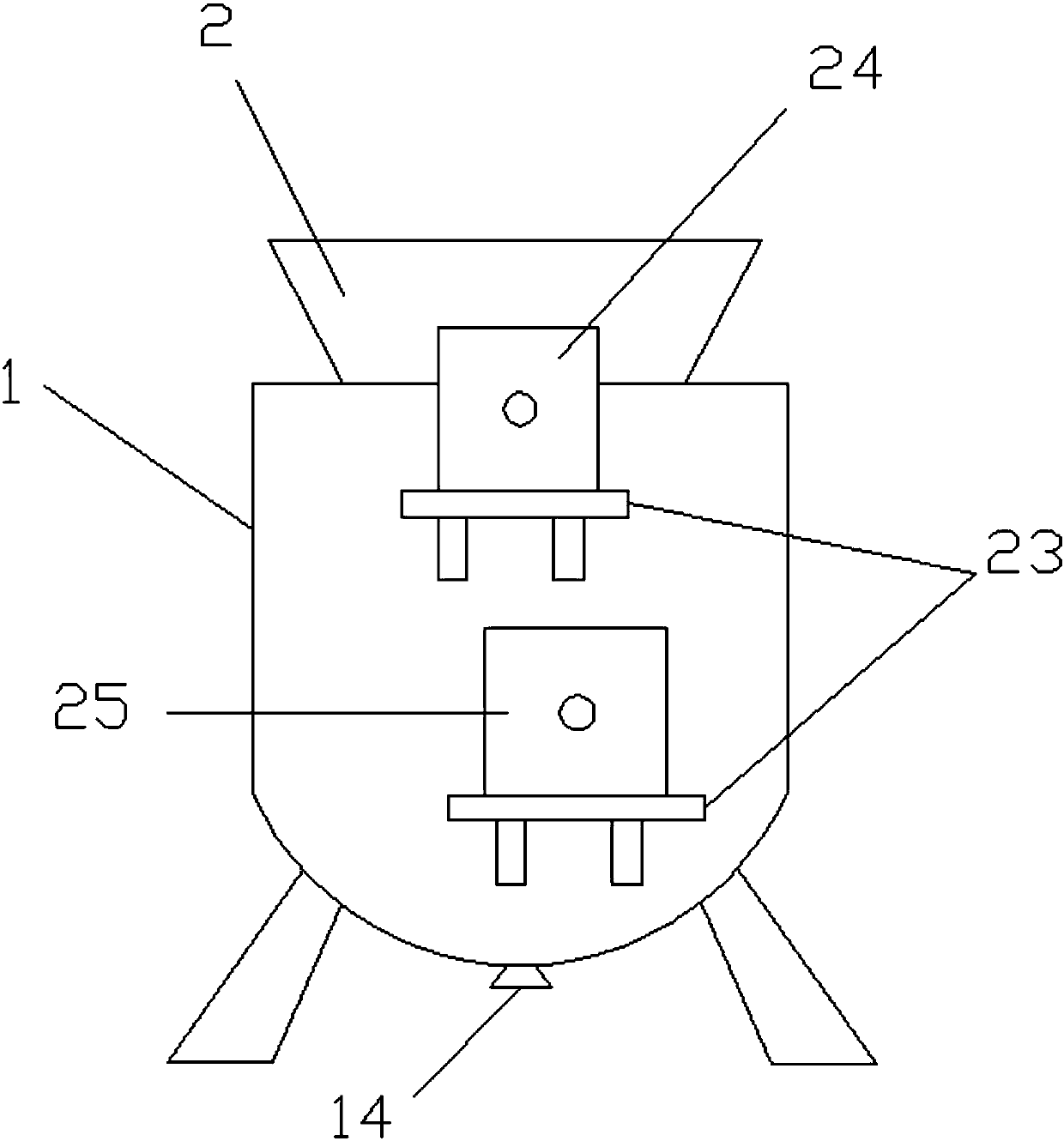

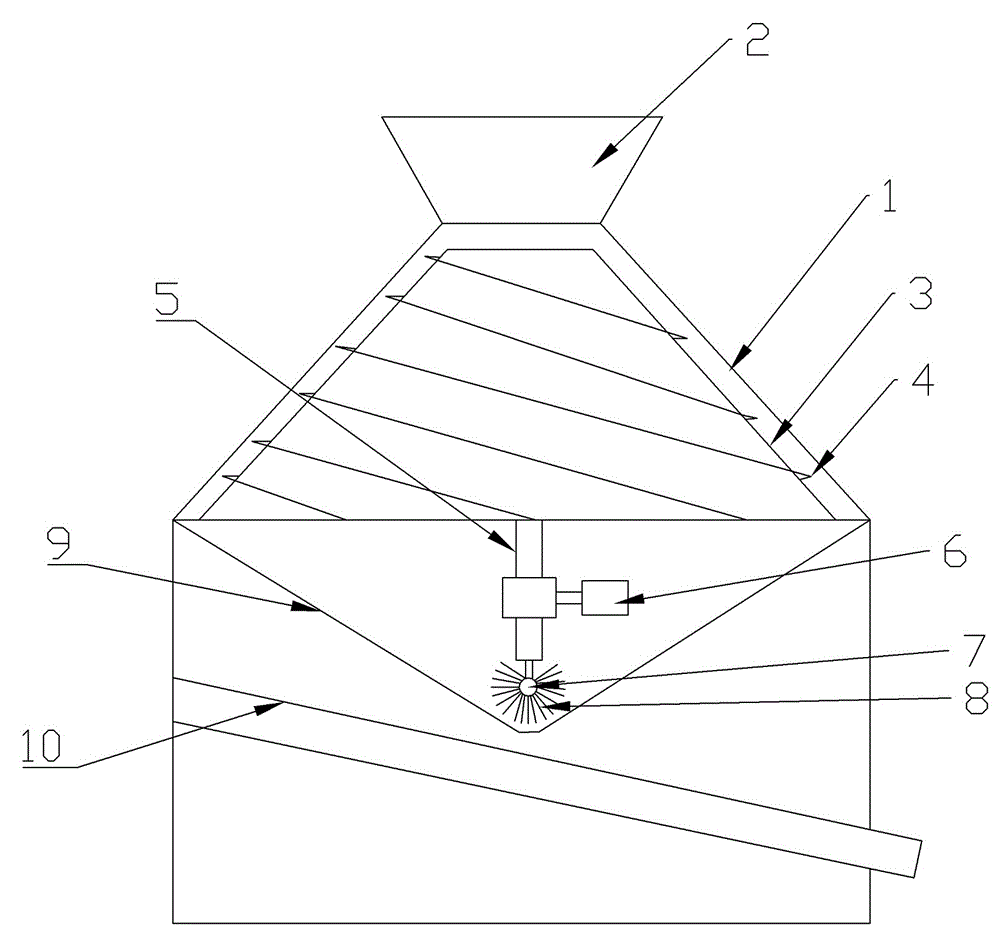

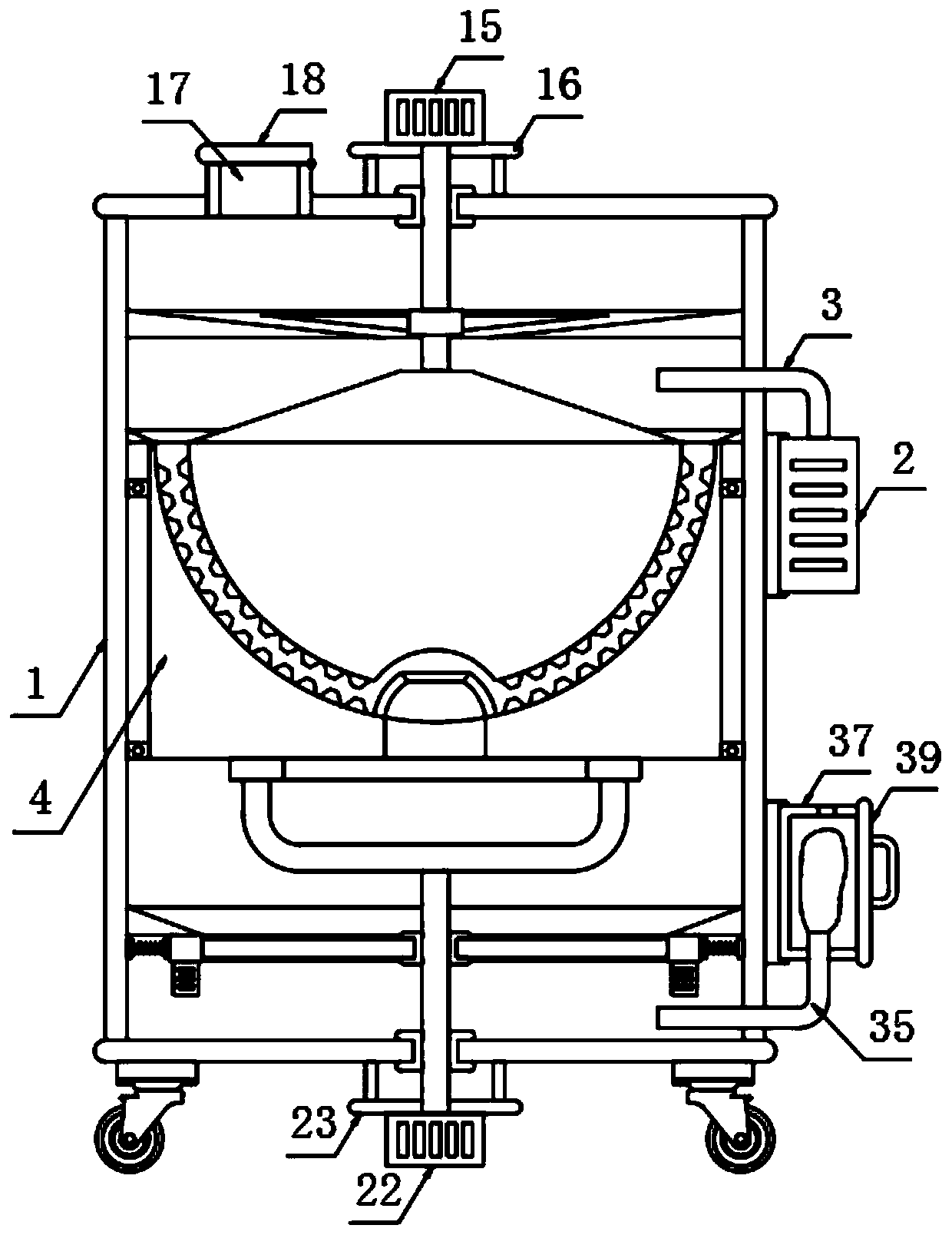

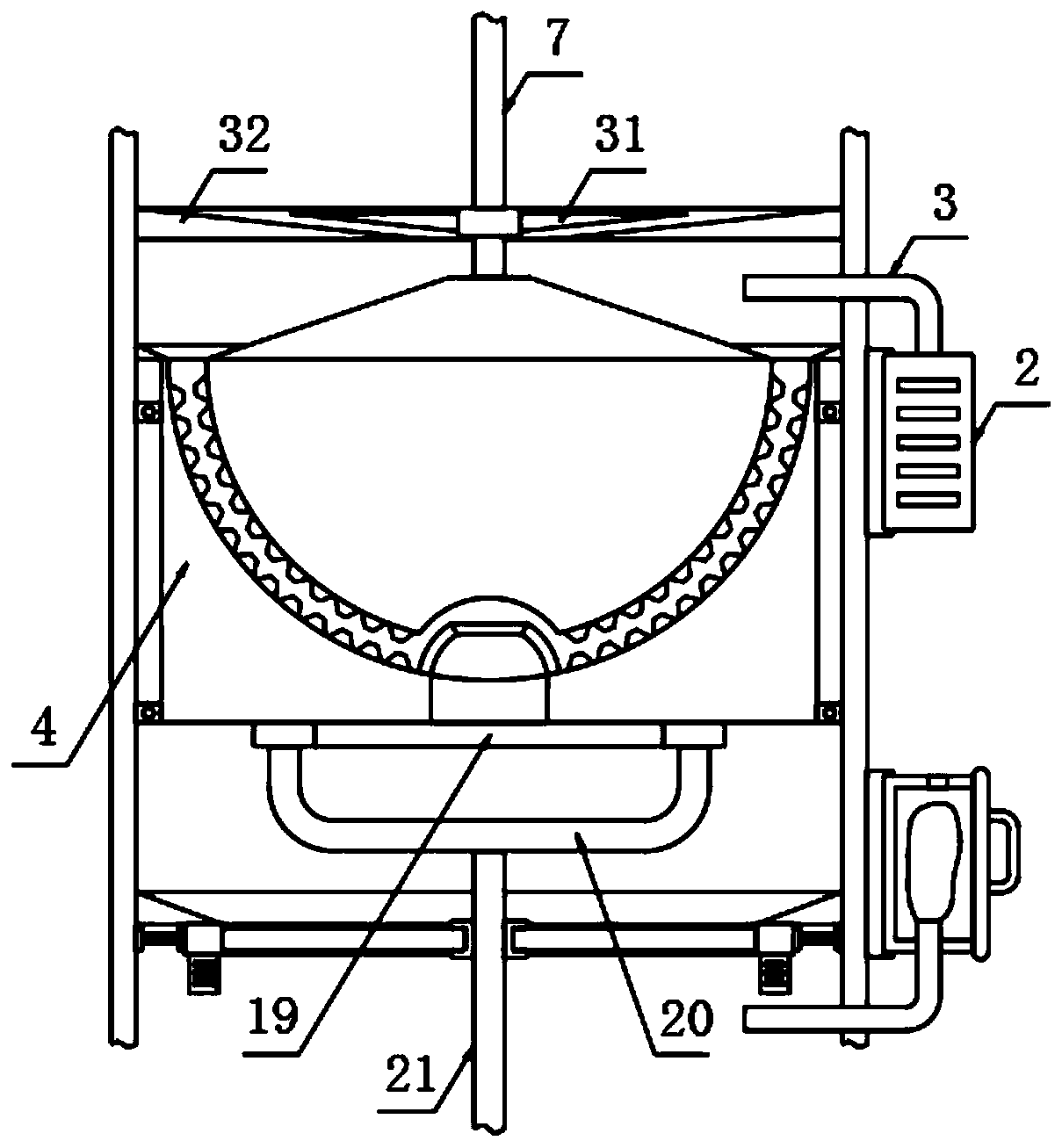

High-efficiency crushing and grinding device for traditional Chinese medicines

InactiveCN107626385AImprove crushing efficiencyFor subsequent grindingGrain treatmentsEngineeringGrinding teeth

The invention discloses a high-efficiency crushing and grinding device for traditional Chinese medicines. The high-efficiency crushing and grinding device comprises a shell; the shell is of a cylinderstructure; supporting legs are symmetrically arranged on the left side and the right side of the bottom of the shell; a feeding hopper is arranged at the top of the shell; a preliminary crushing mechanism is arranged at the position, corresponding to the bottom end of the feeding hopper, of the top of the shell; a rotating disc is arranged in the middle of the shell; a grinding base is arranged on the lower side of the rotating disc; the left side and the right side of the grinding base are fixed to the inner wall of the shell through inclined rods; a vertical rotating shaft is arranged in the middle of the grinding base in a sleeved mode; the rotating disc is arranged at the top end of the vertical rotating shaft on the upper side of the grinding base in a sleeving mode; a plurality of grinding teeth are uniformly arranged on the peripheral edge of the outer side of the rotating disc; and grinding teeth are also arranged on the position, corresponding to the rotating disc, of the inner wall of the shell; the bottom end of the vertical rotating shaft extends into the bottom of the shell; and a grinding disc is arranged at the bottom end of the vertical rotating shaft. According tothe high-efficiency crushing and grinding device, the preliminary crushing mechanism is ingeniously arranged, and therefore the crushing efficiency is high, subsequent grinding can be facilitated, and materials can be prevented from being stuck; and in addition, a secondary grinding mechanism is ingeniously arranged, and therefore the structure is compact, and the grinding efficiency is high.

Owner:WUHAN MATENG TECH DEV

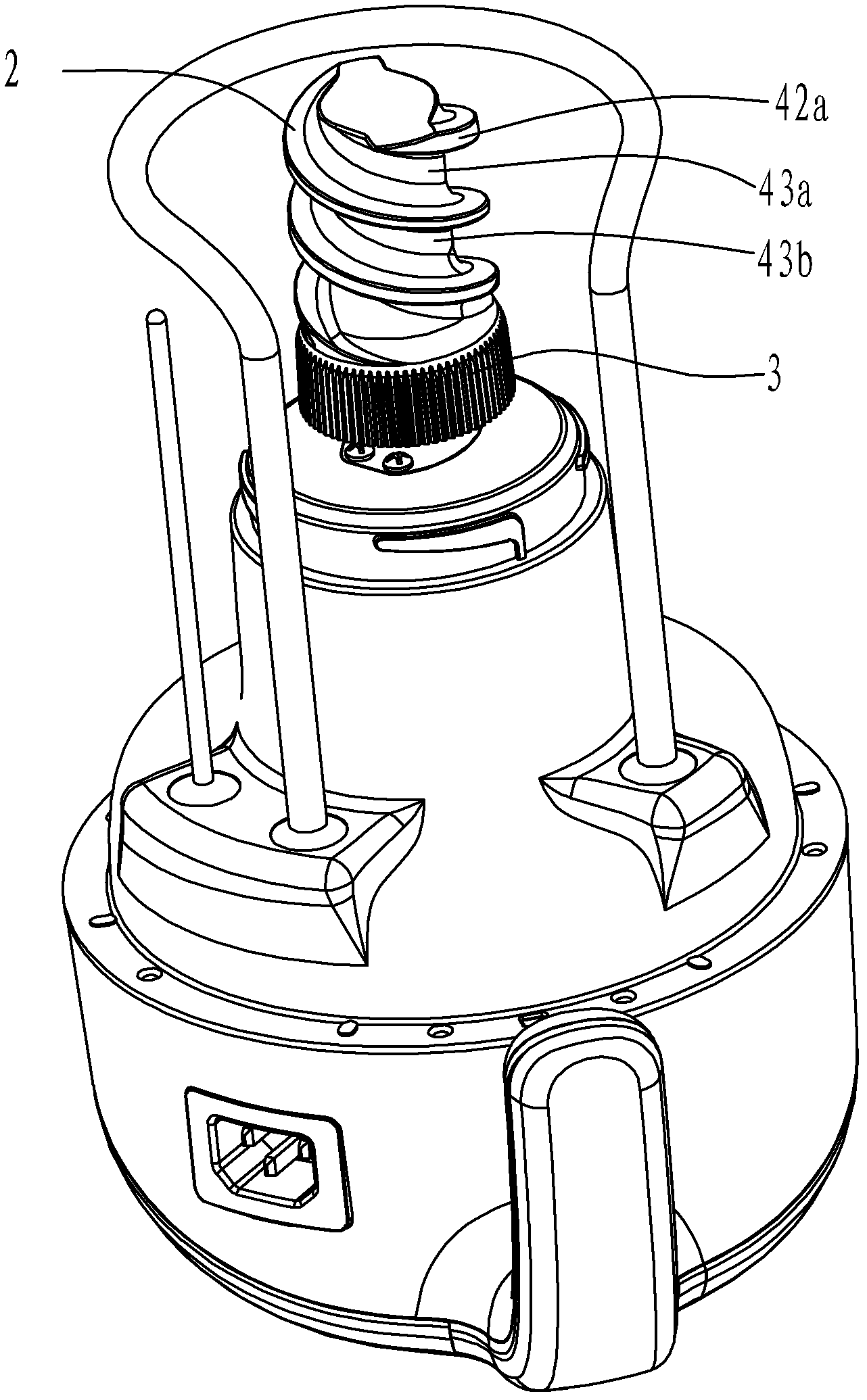

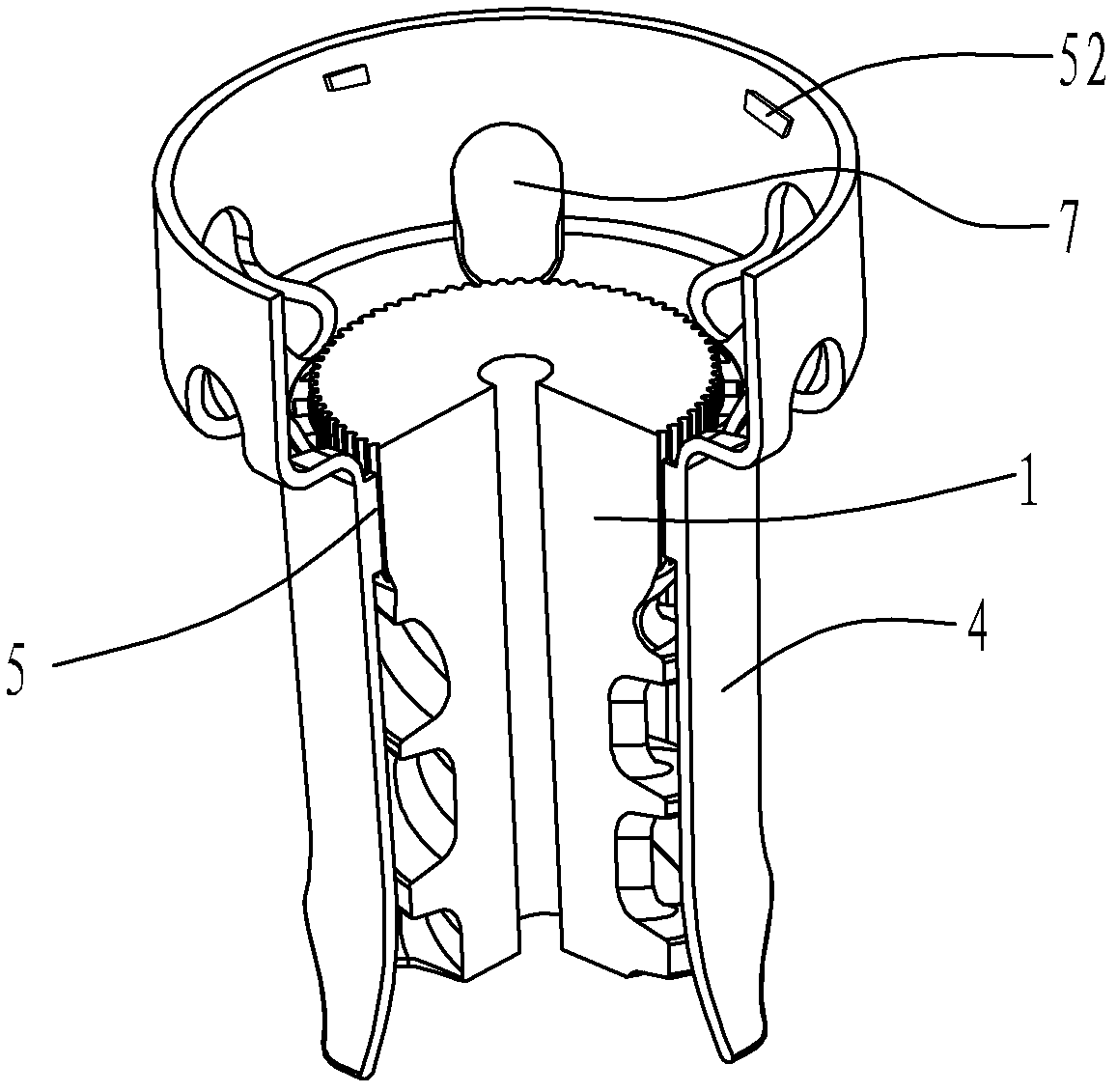

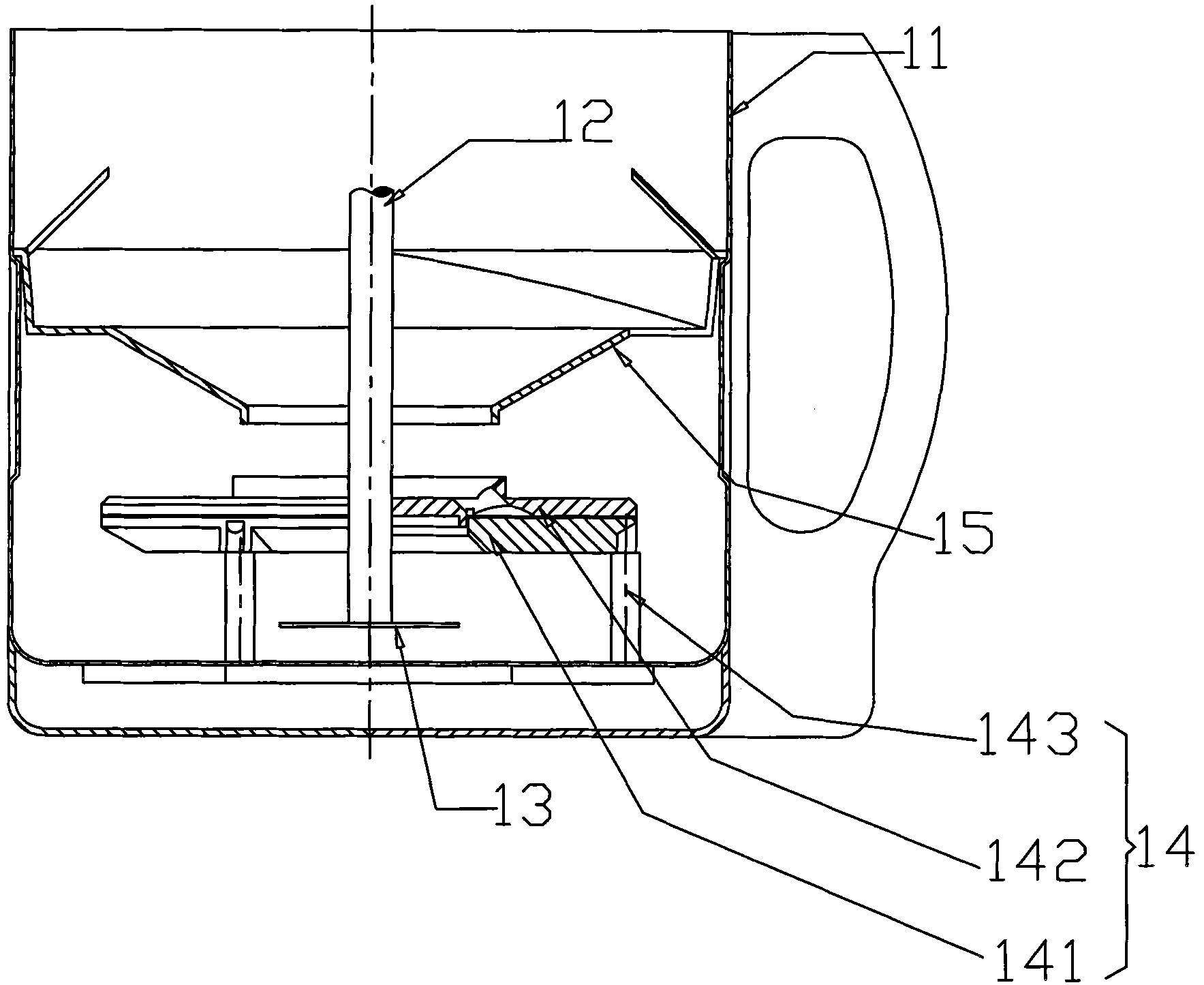

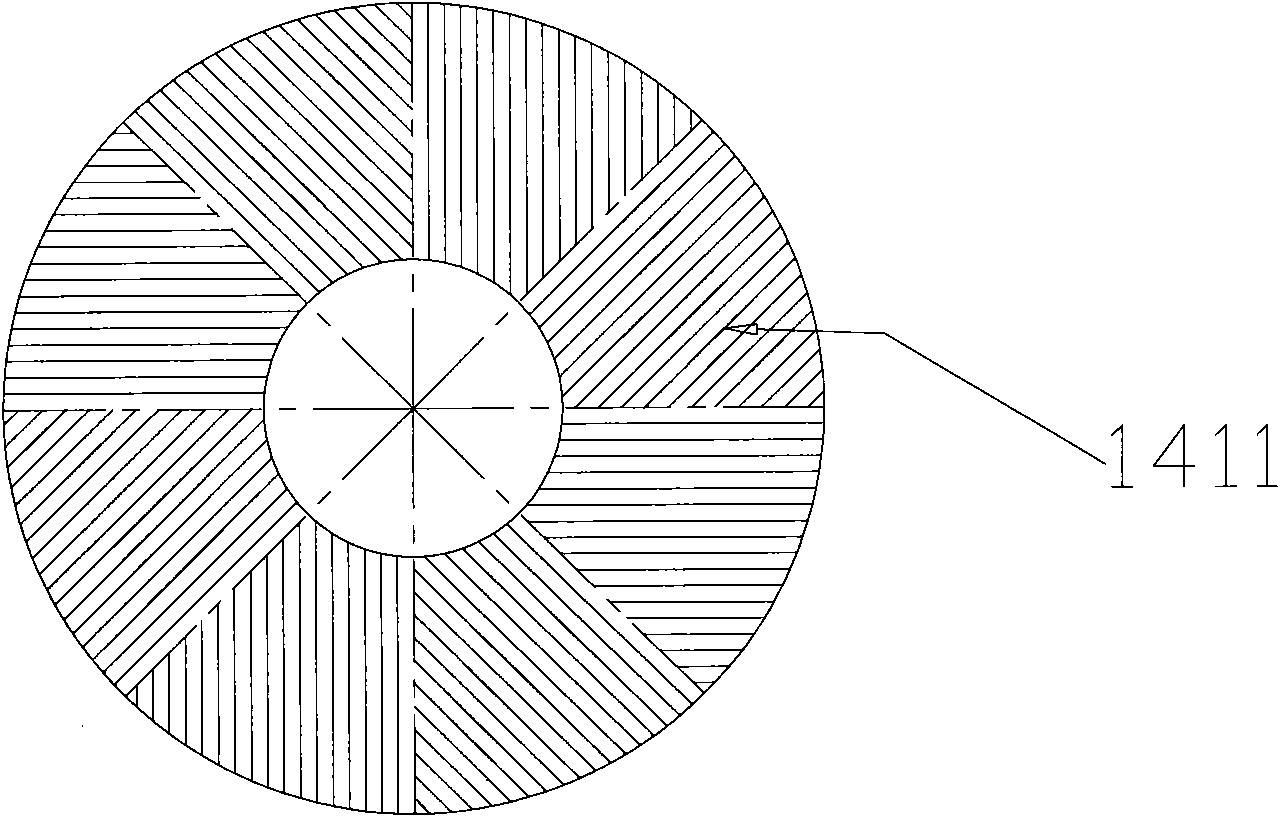

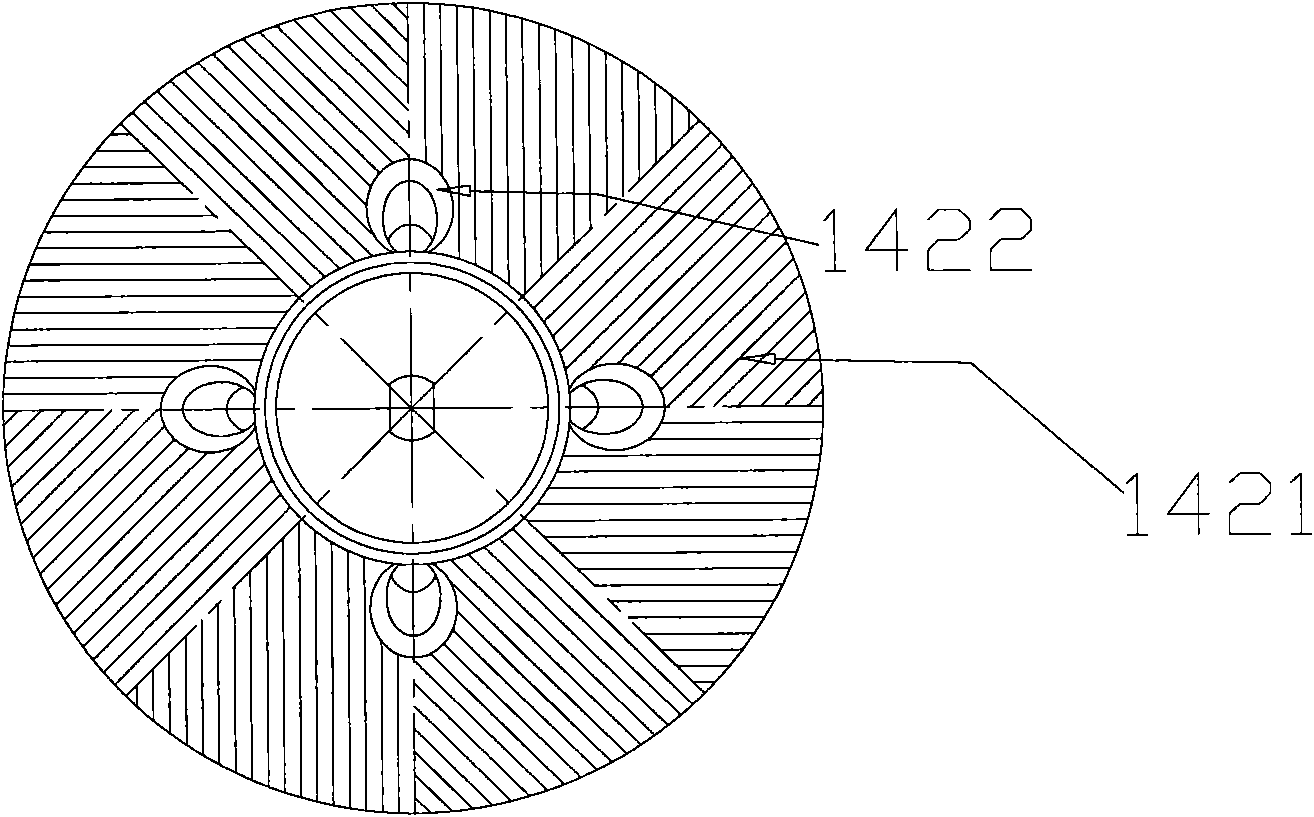

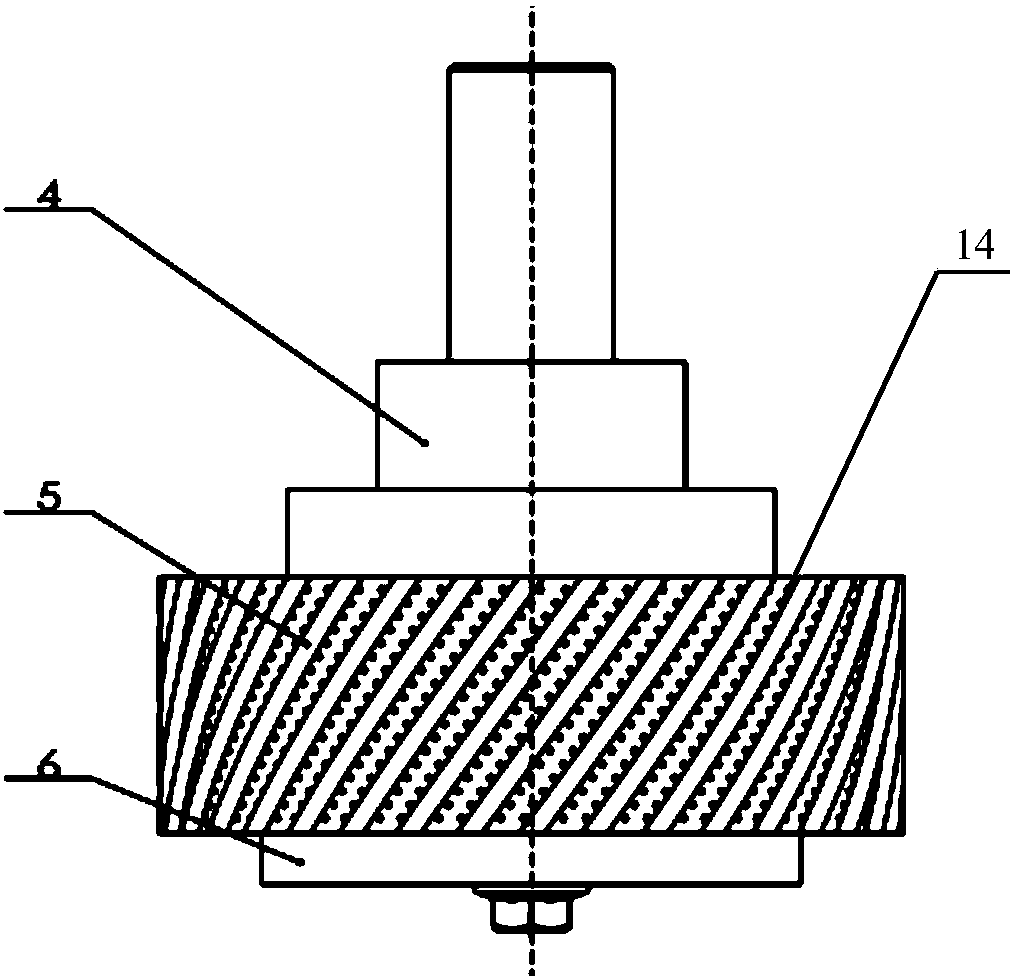

Novel pulping mechanism and pulping machine

InactiveCN101803874AFew partsRealize circular grindingBeverage vesselsMilk substitutesFruit juiceGrinding teeth

The invention relates to a novel pulping mechanism and a pulping machine. The pulping mechanism comprises a movable grinding disk and a static grinding disk, wherein the movable grinding disk is positioned at the upper side, and the grinding surface of the movable grinding disk is provided with convex grinding teeth; and the static grinding disk is positioned at the lower side, the grinding surface of the static grinding disk is provided with convex grinding teeth and feeding holes penetrating through the upper surface and the lower surface of the static grinding disk, and material and liquid enter the space between the two grinding disks through the feeding holes from the lower part of the static grinding disk for grinding; The pulping mechanism is soaked in the liquid, the height between the pulping mechanism and the bottom of a container is greater than the particle diameter of the material, the grinding teeth are used for discharging the liquid through rotation of the movable grinding disk to generate negative pressure in the grinding space, and the material at the lower part is pressed into the grinding surface from the lower part of the pulping mechanism for grinding. The pulping machine realizes the cyclical fine grinding effect by utilizing the pulping mechanism. The invention is suitable for families, has good pulping effect and little discharged residues, fully releases nutrient components in the material, and can effectively prevent the nutrient components from being damaged. The produced soybean milk, fruit juice and the like are nutrient, healthy and good in taste.

Owner:陈家明 +1

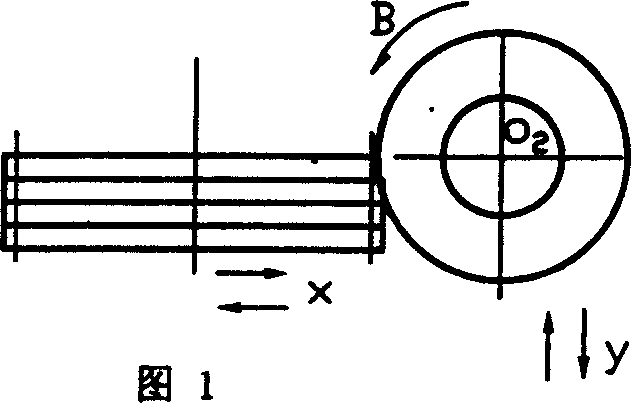

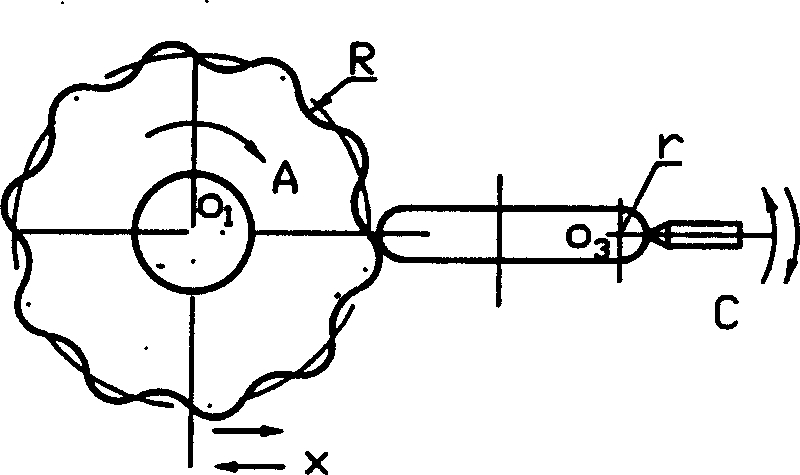

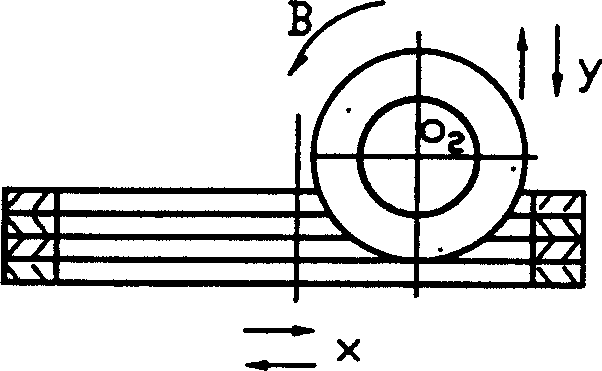

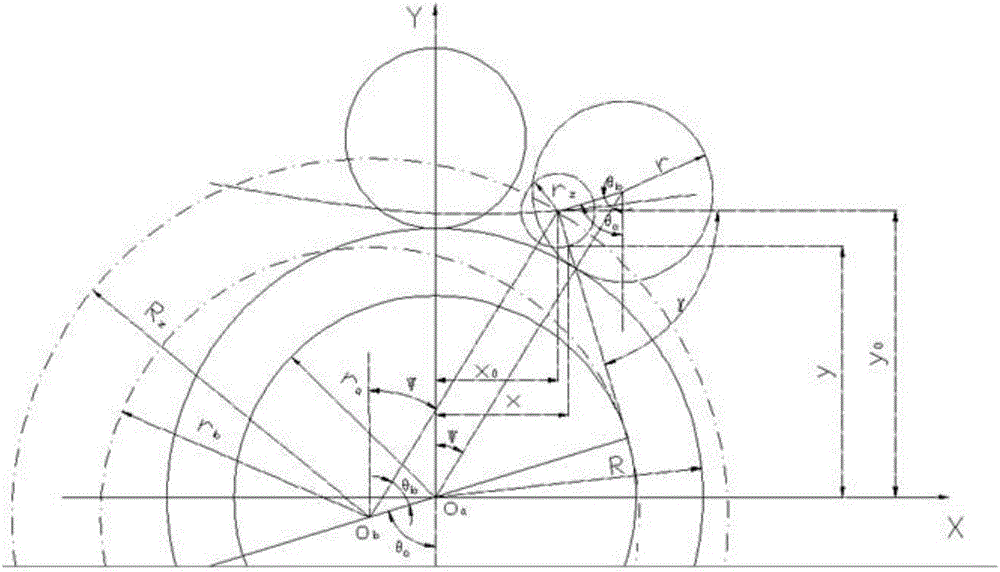

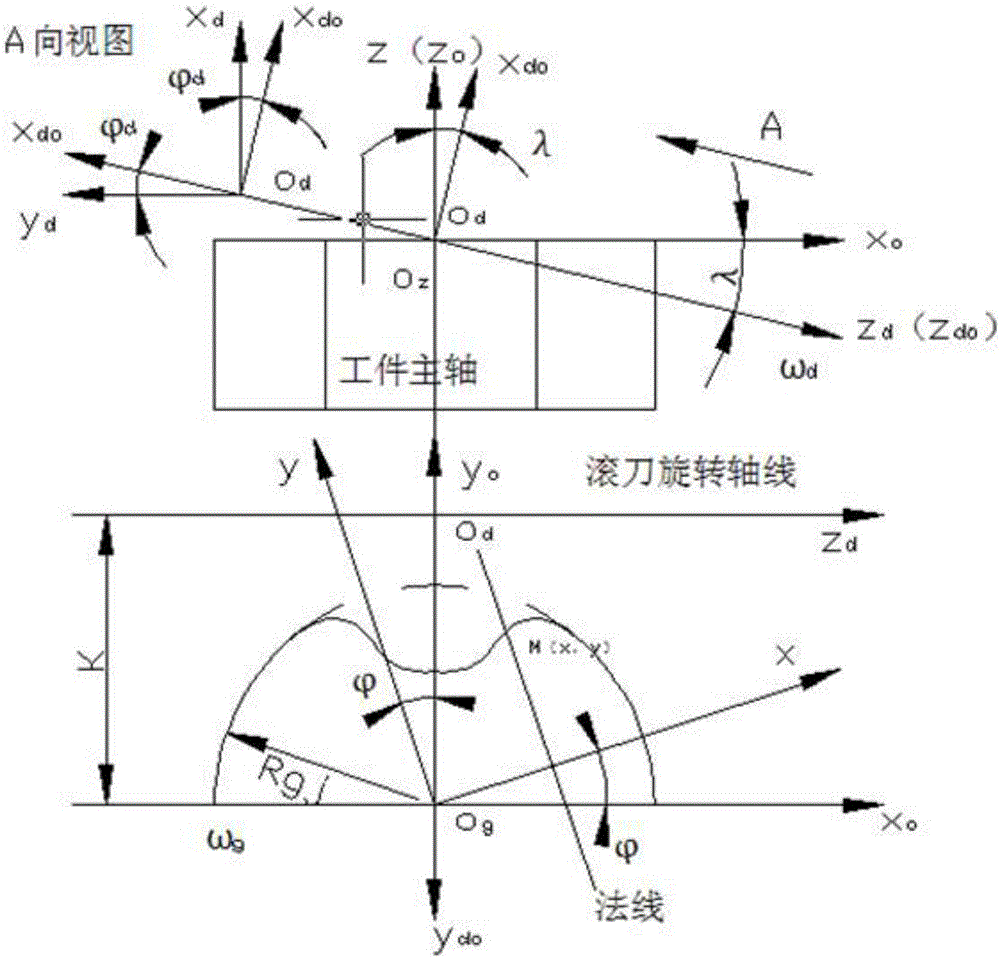

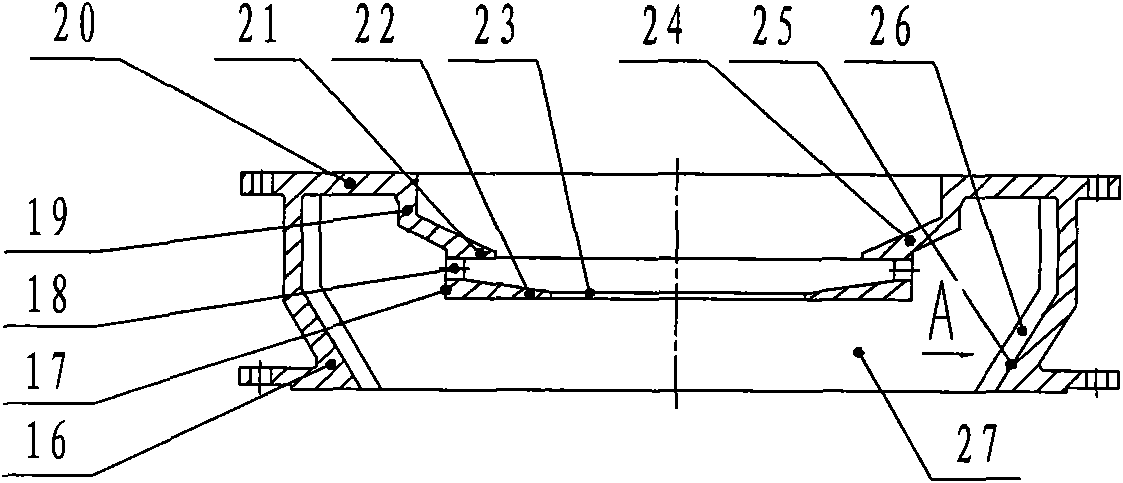

Digital controlled method for grinding teeth of cycloidal gear, and its appts.

A numerally controlled tooth grinding method for cycloid gear features that an abrasive disk is driven by a cranker-connecting rod mechanism to linearly reciprocate for forming an equivalent cylindrical grinding surface and the cycloid gear to be machined is driven by a dual-coordinate numerally controlling system controlled by microcomputer to shift and rotate, so enveloping whole tooth profile of cycloid gear.

Owner:CHONGQING UNIV

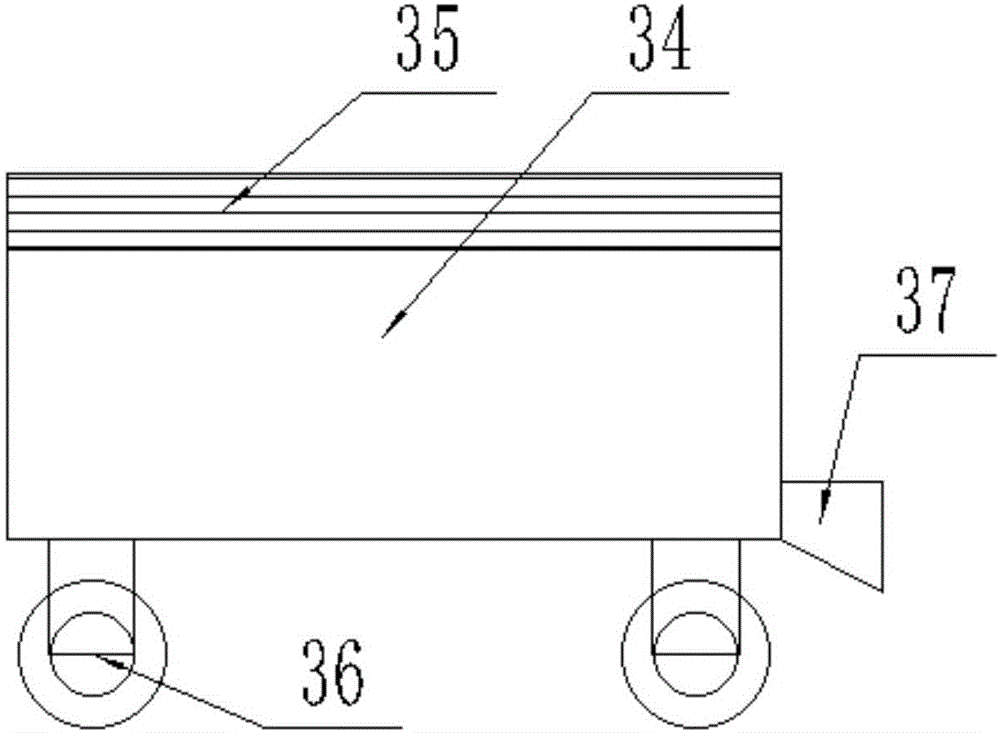

Efficient maize straw crushing device

InactiveCN106269167AReduce volumeEasy to operateFeeding-stuffGrain treatmentsEngineeringGrinding wheel

The invention relates to a crushing device, in particular to an efficient maize straw crushing device and aims at providing an efficient maize straw crushing device small in size, simple in operation and high in crushing speed. For solving the technical problem, the efficient maize straw crushing device comprises a base plate, a left frame, a collecting box, a right frame, a sliding way, an electric crushing wheel, a crushing box, a blanking hopper I, a turntable, a motor I, a sliding block, a cushion block, a baffle, a blade, a guiding sleeve, a guiding rod, a reset sliding rail, a motor II, a small belt wheel I, a belt I, a grinding wheel I, a large belt wheel I, grinding teeth, a large belt wheel II, a belt II, a motor III, a small belt wheel II, a V-shaped fixing frame, a grinding wheel II, a top plate, a blanking hopper II and a fixing plate, wherein the top of the base plate is sequentially provided with the left frame, the collecting box, the sliding way and the right frame from left to right. The efficient maize straw crushing device achieves the effects of small size, simple operation and high crushing speed.

Owner:陈英豪

Grape juice extractor

InactiveCN105077520AIncrease contact areaPress the juice thoroughlyJuice extractionGrape wineEngineering

The invention relates to mechanical grape crushing and processing equipment, in particular to a grape juice extractor for grade seed and peel removal. The grape juice extractor for grade seed and peel removal comprises a circular truncated cone shaped grinding box, wherein a circular truncated cone shaped grinding disc matched with the grinding box is arranged in the grinding box, grinding teeth are arranged on the side face of the grinding disc, an axial rotary shaft and a motor are arranged in the grinding disc, and an output shaft of the motor is connected with the rotary shaft. An inlet is formed in the top end of the grinding box, a filtering mechanism is arranged at the bottom end of the grinding box and comprises a filter screen and a stirring ball for stirring grape pomace on the filter screen, the stirring ball is connected with the bottom of the rotary shaft, the filter screen is inverted-cone-shaped, and the top of the filter screen is connected with the bottom end of the grinding box. A conveying trough for receiving juice is arranged under the filter screen. The grape juice extractor makes grape juice in a mechanical way, is high in production efficiency and thorough in juice extraction, is not in contact with the outside in the whole process, is clean and hygienic and is suitable for popularization and application in grape juice production and wine production.

Owner:重庆龙佰绪生态农业开发集团有限公司

Medicinal material grinding machine for traditional Chinese medicine health maintenance product production

ActiveCN106732977AFlexible swingExtended service lifeGrain treatmentsPulp and paper industryGrinding teeth

The invention relates to a medicinal material grinding machine, in particular to a medicinal material grinding machine for traditional Chinese medicine health maintenance product production and aims at achieving the technical purpose of providing the medicinal material grinding machine for traditional Chinese medicine health maintenance product production, wherein the medicinal material grinding machine is thorough and uniform in grinding. To achieve the above technical purpose, the medicinal material grinding machine for traditional Chinese medicine health maintenance product production is provided and comprises a bottom plate, a collecting frame, first springs, a grinding box, a discharging hopper, a first bearing block, a first rotating shaft, a first belt wheel, a rotary disc, a swinging rod, a fixing block and the like. The first springs are symmetrically connected to the left side of the top of the bottom plate in a hook connecting manner. The tops of the first springs are connected with the grinding box in a hook connecting manner. A feeding hopper is welded to the top of the grinding box. An eccentric grinding barrel is driven to rotate through control over rotation of a rotation motor, medicinal materials are ground through cooperation of the eccentric grinding barrel and grinding teeth, and meanwhile the grinding box is driven to swing left and right.

Owner:江西兴淦医药科技有限公司

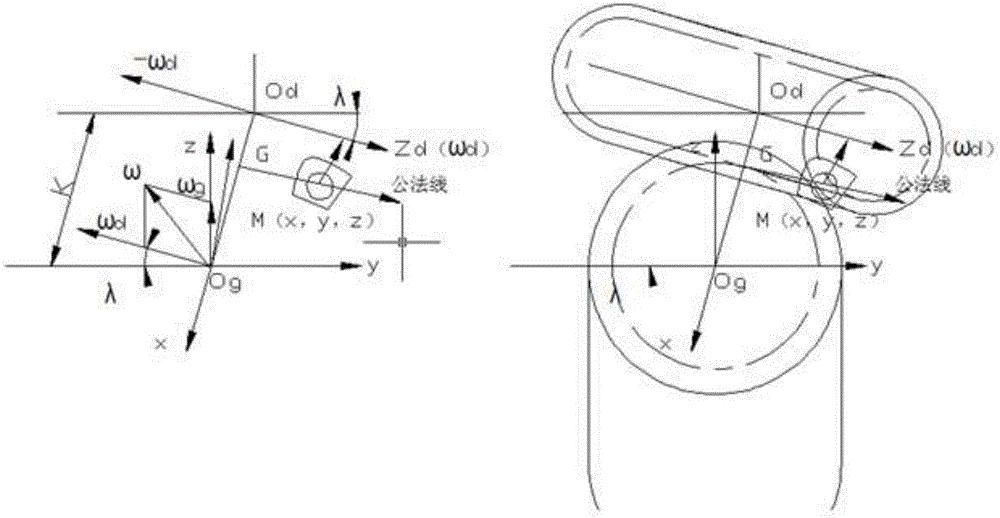

Grinding method for numerical-control worm grinding wheel of cycloid gear

The invention relates to a grinding method for a numerical-control worm grinding wheel of a cycloid gear. The space engagement theory is utilized, the three-dimensional profile equation of the worm grinding wheel of the machined cycloid gear is deduced according to the three-dimensional profile equation of the cycloid gear, and the cycloid gear is subjected to fine polishing through the worm grinding wheel. The grinding method has remarkable advantage compared with a cycloid gear forming and grinding technique, and intermittent machining is replaced by continuous machining. Meanwhile, the generating motion precision stability is higher than the intermittent Intermittent precision, so that the gear polishing precision is remarkably improved, the gear polishing production cost is remarkably reduced, and the gear polishing efficiency is remarkably improved. The grinding method is applied to a machine tool used for grinding the cycloid gear through the worm grinding wheel, a special clamp table for corresponding workpieces is designed, two cycloid gear blanks are positioned and installed at a time, and the spatial positions of the two cycloid gear blanks are determined. An online measuring head is additionally arranged on one side of the worm grinding wheel so as to position the spatial position of the worm grinding wheel. By means of the combination of the two techniques, rapid and accurate tool setting of the cycloid gear blanks and the worm grinding wheel is achieved.

Owner:CHONGQING UNIV

Soil sample treatment device with vibration drying function for environmental detection

InactiveCN107389394AAccelerate evaporationMeet the testing requirementsPreparing sample for investigationGranularityEnvironmental remediation

The invention discloses a soil sample treatment device with a vibration drying function for environmental detection. The soil sample treatment device comprises a casing, wherein a feeding hole is formed in the top of the casing; a pair of grinding rollers is arranged in the casing below the feeding hole; centers of the grinding rollers are supported by grinding roller shafts; a plurality of grinding teeth are uniformly arranged on the circumferences of the grinding rollers; an intercepting screen is arranged below the grinding rollers and is arc-shaped, and a bulge is formed in the center of the intercepting screen; a grinding plate is arranged below the intercepting screen; the grinding plate comprises a horizontal plate and an arc plate; the horizontal plate and the arc plate are spliced; a grinding roller is arranged above the horizontal plate; a vibration plate is arranged below the grinding plate; a resistive heater is arranged in the vibration plate; a vibration device is arranged in the middle on the lower side of the vibration plate and comprises a rack; the lower side of the rack is fixedly connected with the middle on the lower side of the vibration plate. The soil sample treatment device disclosed by the invention has the beneficial effects that soil is subjected to stepwise grinding treatment, so that the soil granularity meets a detection requirement.

Owner:郑州永泰澳新商贸有限公司

Chinese medicinal material repeated grinding device

InactiveCN108097405AEasy to GrindGuaranteed grinding qualityNon-rotating vibration suppressionGrain treatmentsCouplingGrinding teeth

The invention discloses a Chinese medicinal material repeated grinding device. The Chinese medicinal material repeated grinding device comprises a base. Supporting plates are arranged at the left andright ends of the base. The left end of the supporting plate at the right end and the right end of the supporting plate at the left end are provided with two connecting shafts correspondingly. The connecting shaft at the left end is provided with a notch. A second motor is arranged in the notch. A crushing cavity is arranged between the connecting shafts. A crushing shaft is arranged in the crushing cavity. The left side of the crushing shaft is connected with the second motor through a coupling. The upper and lower ends of the crushing shafts are provided with crushing blades. The front sideof the crushing cavity is provided with a feed port. The upper and lower sides of the crushing cavity are provided with grinding cavities. The left and right ends of each grinding cavity are providedwith third motors. The front side of each third motor is provided with a rotary shaft. A grinding roll is arranged on the outer side of each rotary shaft. The outer side of each grinding roll is provided with grinding teeth. A screening cavity is arranged on the outer side of each grinding cavity. A filter screen is arranged in each screening cavity. The outer side of each screening cavity is provided with a discharge port. The Chinese medicinal material repeated grinding device can effectively guarantee that Chinese medicinal materials are crushed and ground repeatedly and cyclically and accordingly, the grinding quality of the device can be effectively guaranteed.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

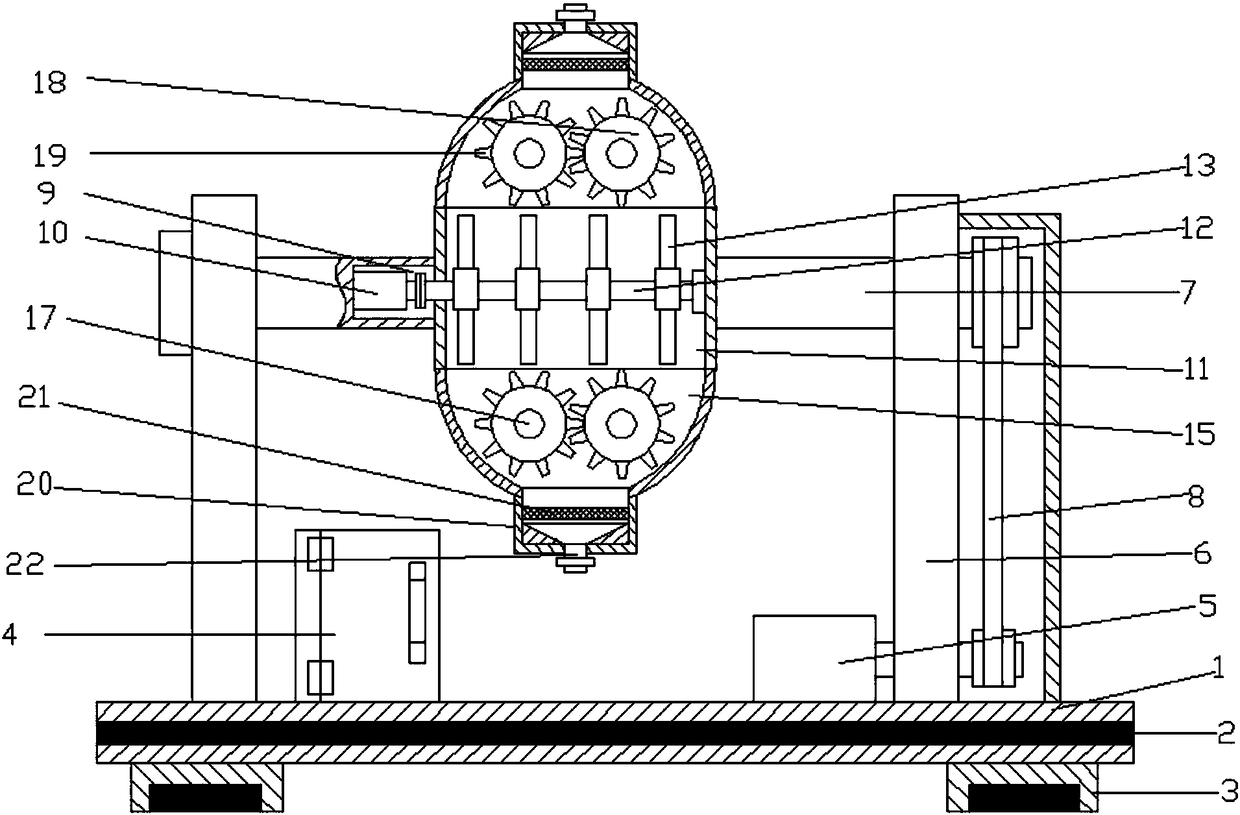

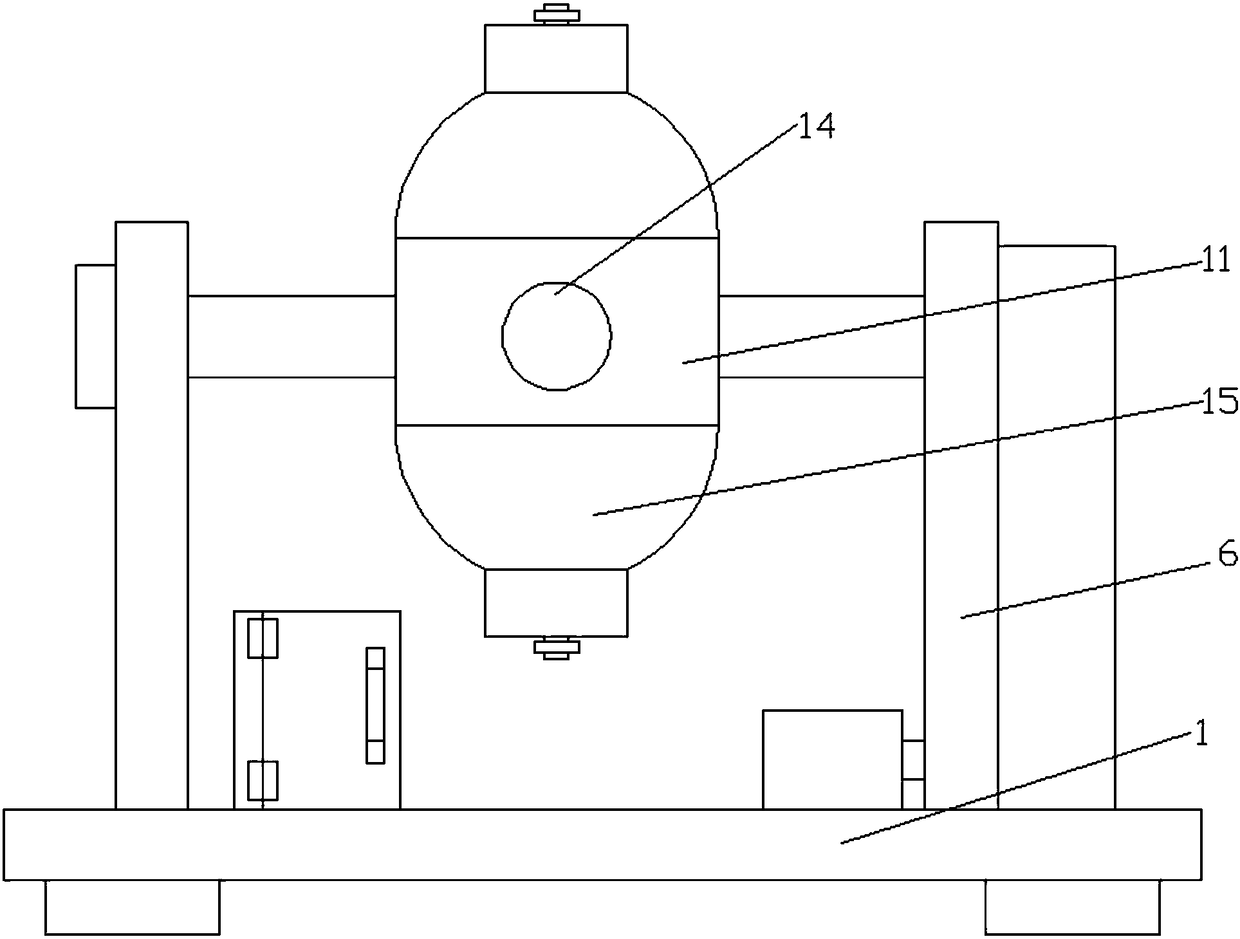

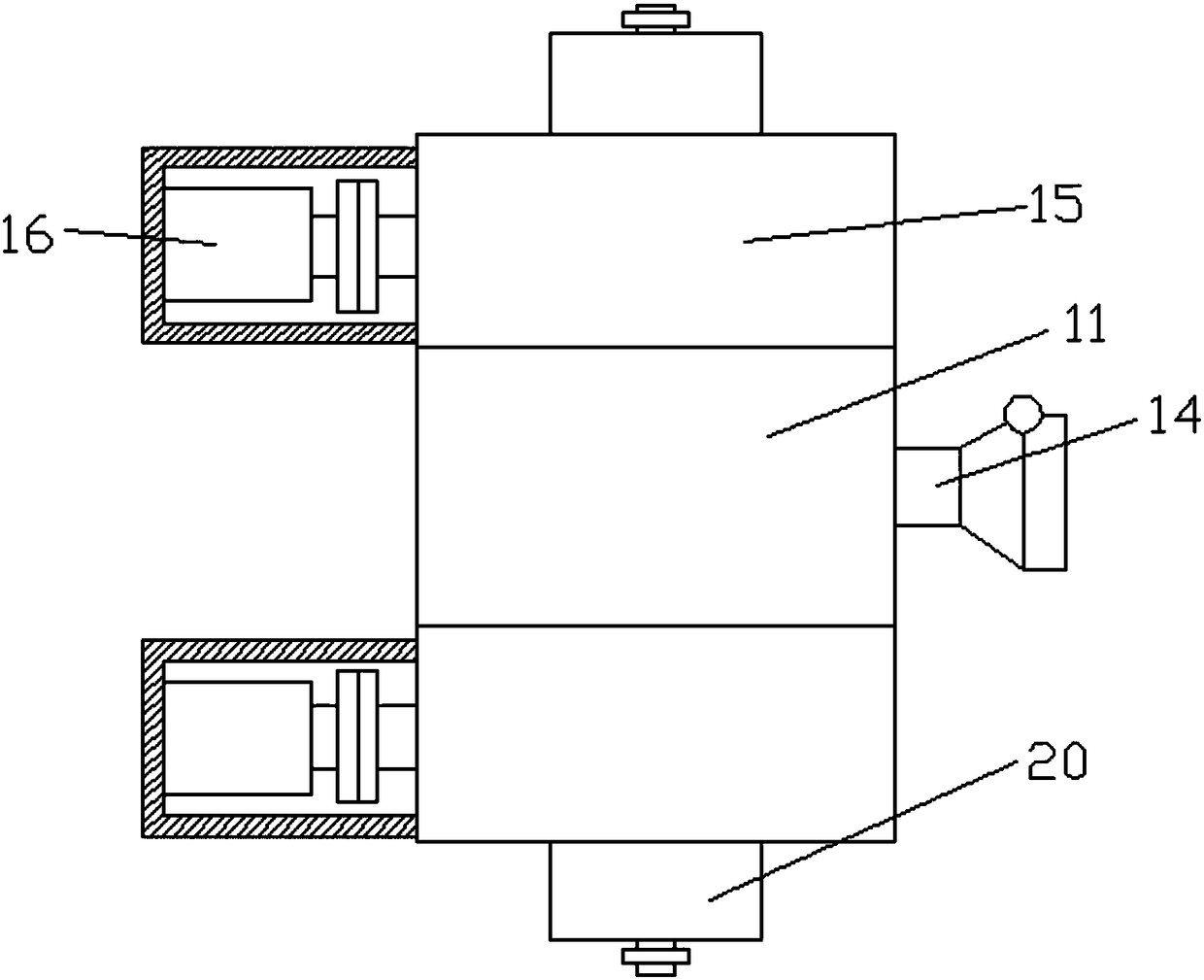

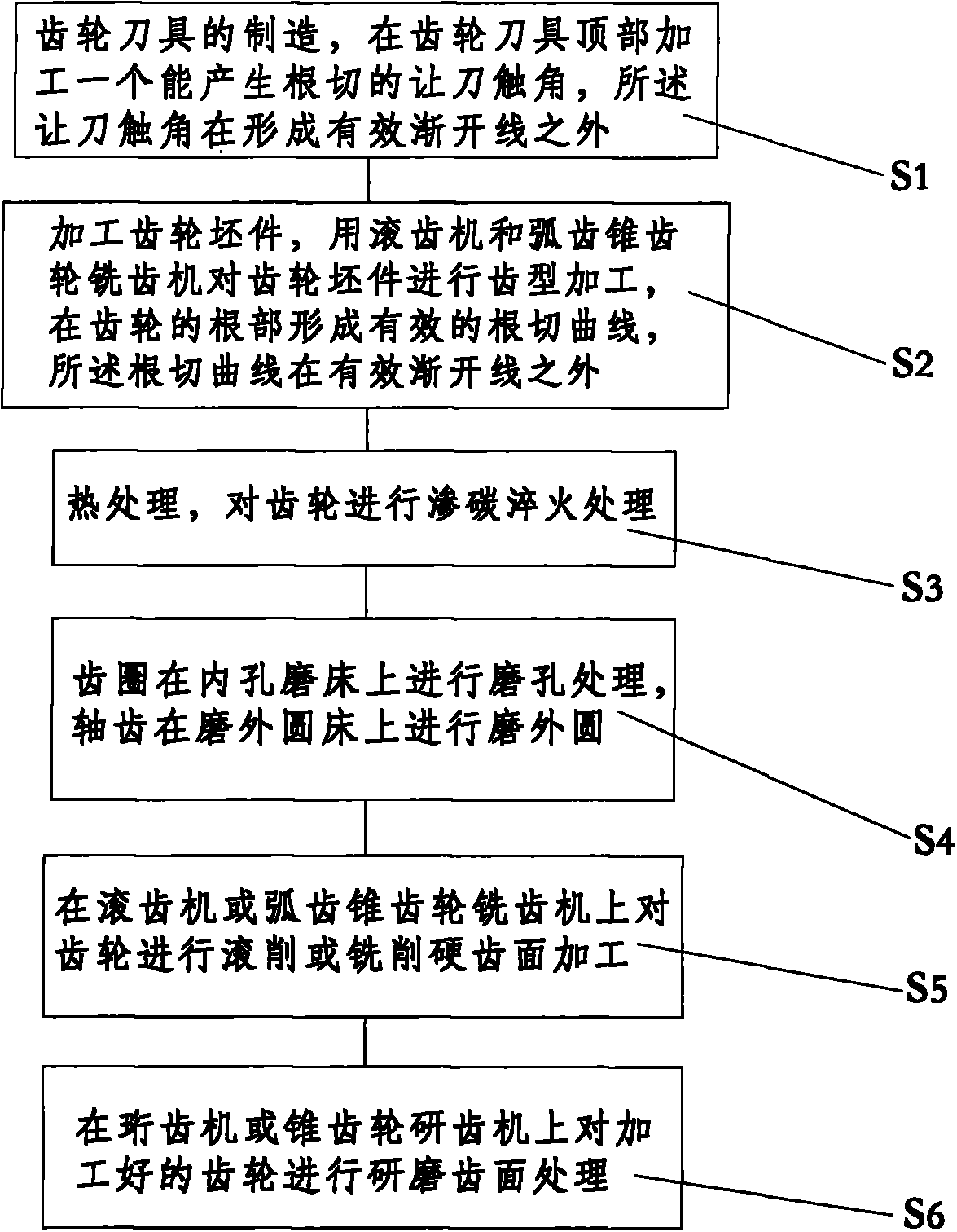

Machining method for hardened face gear

InactiveCN103831599ALow resolutionCost changeGear teeth manufacturing toolsGear teethHobbingGear wheel

The invention relates to a machining method for a hardened face gear. The machining method comprises the following steps of (1) manufacturing a gear cutter, and machining a cutter relieving feeler capable of generating undercutting on the top of the gear cutter, wherein the cutter relieving feeler is formed outside an effective involute; (2) machining a gear blank, using a gear hobbing machine and a spiral bevel gear milling machine for conducting toothed machining on the gear blank, and forming an effective undercutting curve at the root of the gear; (3) conducting heat treatment, and conducting carburizing and quenching treatment on the gear; (4) conducting hole grinding treatment on an inner hole grinding machine with a gear ring, and conducting outer circle grinding on an outer circle grinding machine with a shaft gear; (5) conducting rolling or milling hardened face machining on the gear on the gear hobbing machine or the spiral bevel gear milling machine; (6) conducting toothed face grinding treatment on the machined gear on a gear honing machine or a bevel gear lapping machine. The machining method for the hardened face gear has the advantages that the tooth portion of the gear is high in machining precision, the cost of grinding teeth is low, and the machining efficiency is high.

Owner:重庆市坤津机械厂

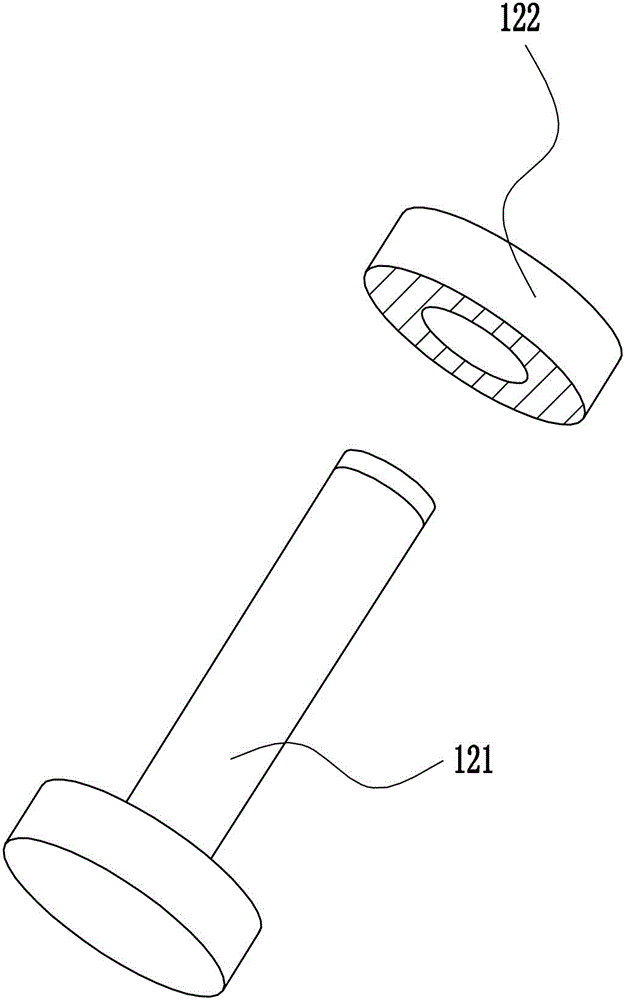

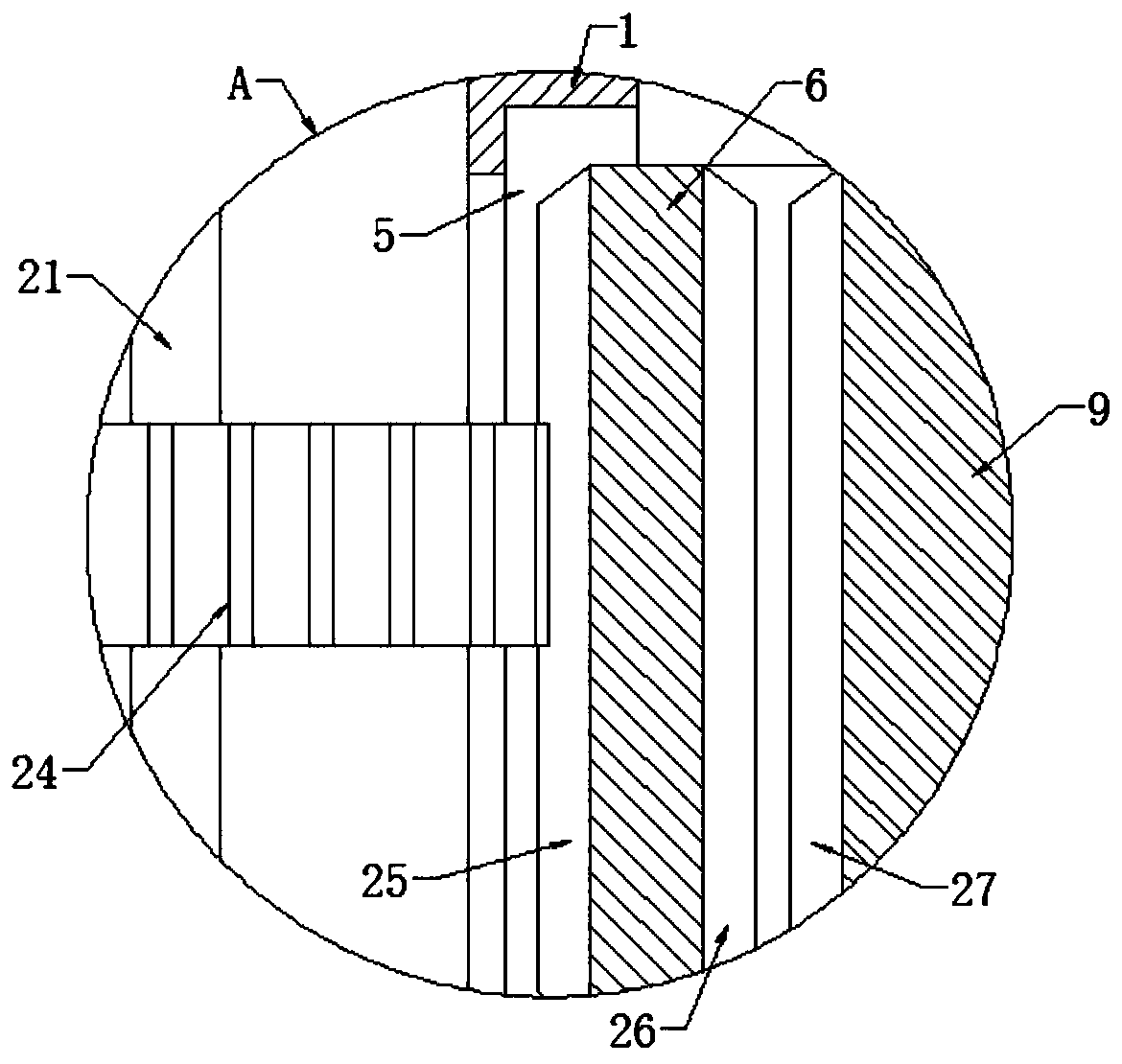

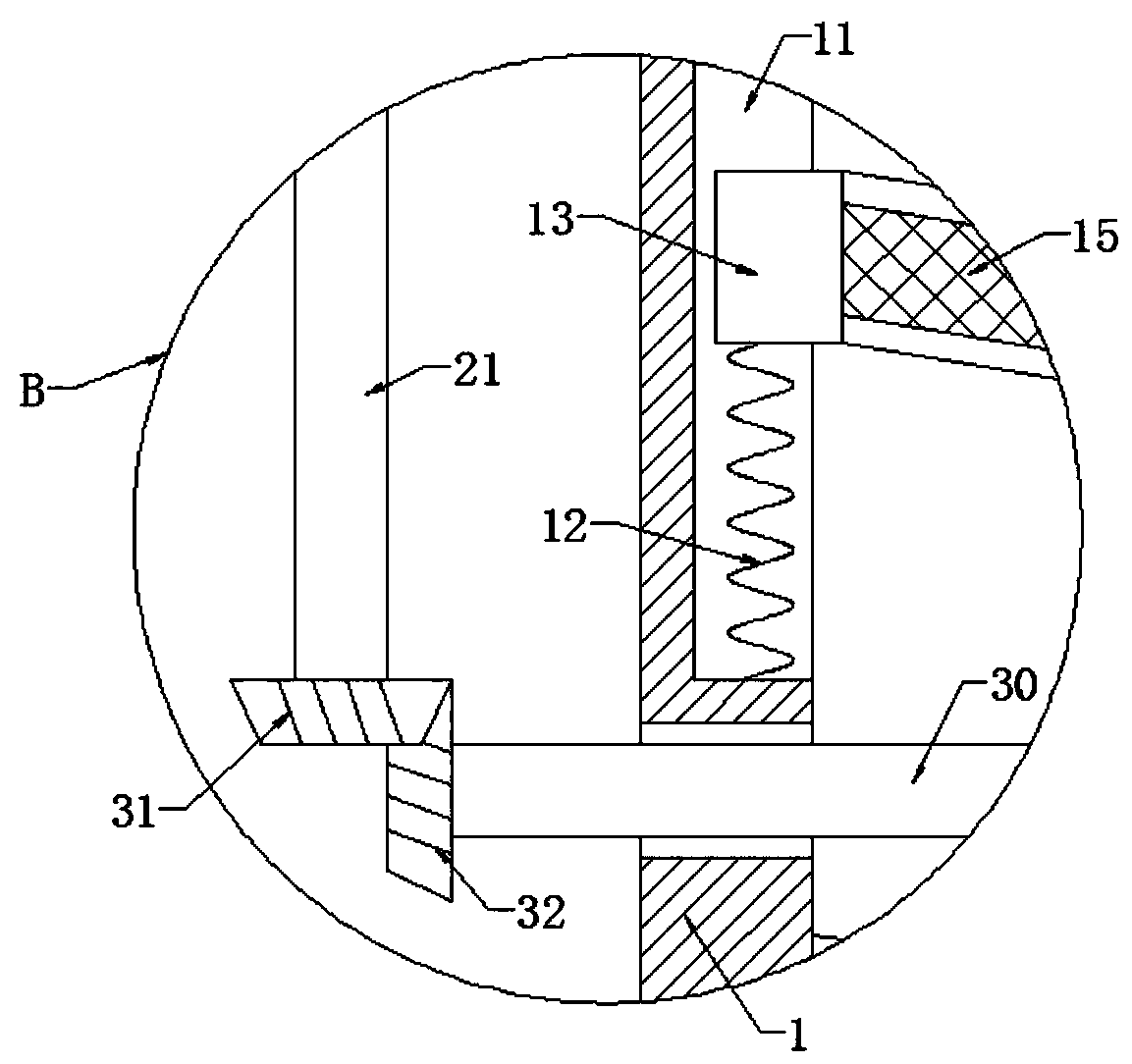

Spice mill with means for infinitely setting the grinding fineness

The present invention provides a spice mill, in particular a pepper mill, having an improved design for setting the fineness of ground particles produced by the mill. Outer grinding teeth are located within a fixed seat. The fixed seat is connected to a rotating seat by means of a convex annular bead and a concave annular groove, thereby preventing movement of the rotating seat away from the fixed seat when the rotating seat is rotated in order to set the fineness of the ground particles. Inner grinding teeth are positioned within the outer grinding teeth and supported by a lift seat. Spokes on the lift seat are positioned within guide grooves located on the inner wall of the fixed seat whereby, on rotation of the rotating seat, the lift seat is moved upward or downward and the inner grinding teeth are shifted upwards or downwards, thereby setting the size and the fineness of the ground particles produced by the mill.

Owner:MOHA MODERNE HAUSHALTWAREN AG

Tooth grinding food

The invention provides a tooth grinding food which is made of a composition comprising wheat meal, grease, sugar and a leavening agent at least. The tooth grinding food is characterized in that the wet gluten content of the wheat meal or the wheat meal and starch is below 20 percent, preferably below 18 percent; and on the basis of 100 parts by weight of the sum of the wheat meal and the starch, the tooth grinding food comprises 14-22 parts of grease, 18-26 parts of sugar and 0.05-0.1 part of leavening agent, and the expansion ratio is between 1.0 and 1.2. The tooth grinding food is produced by a crisp biscuit production process, has proper hardness, is difficult to break and drop, is suitable for an infant to grind teeth and is beneficial to the growth of the teeth of the infant.

Owner:贝因美股份有限公司 +1

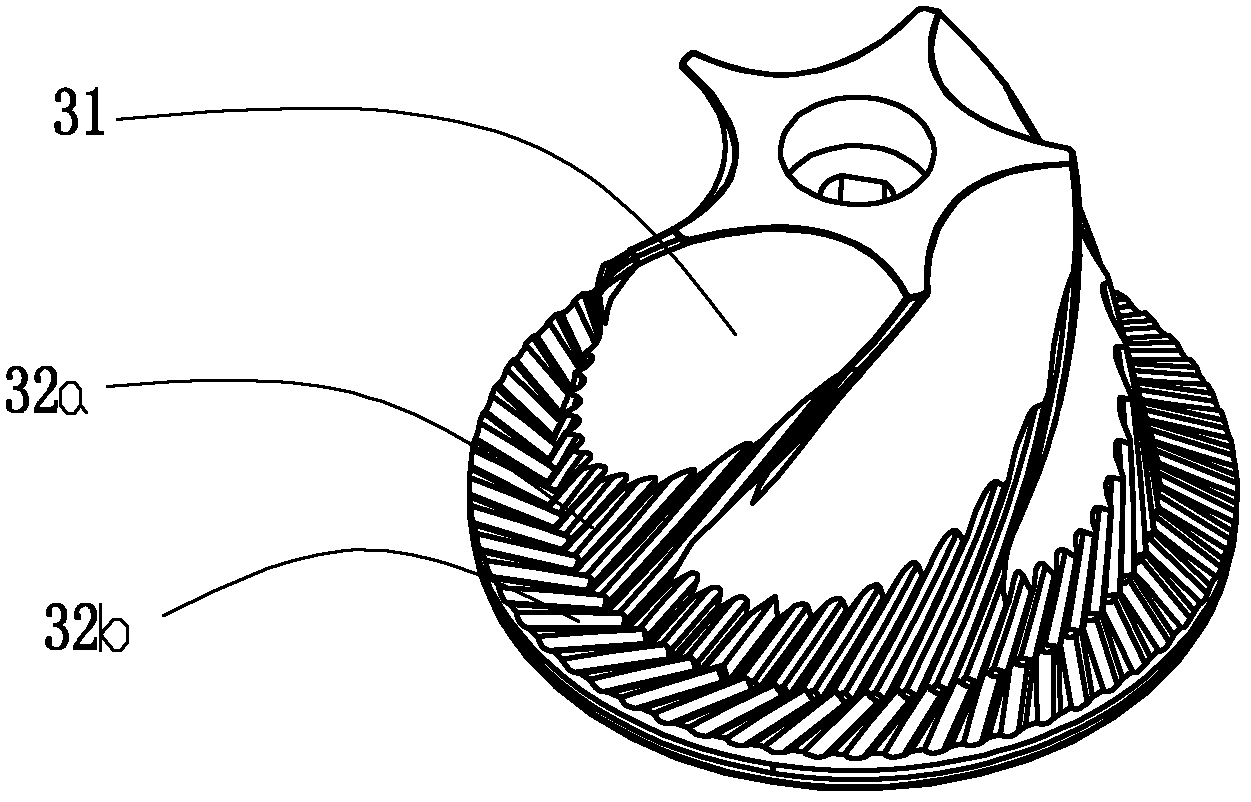

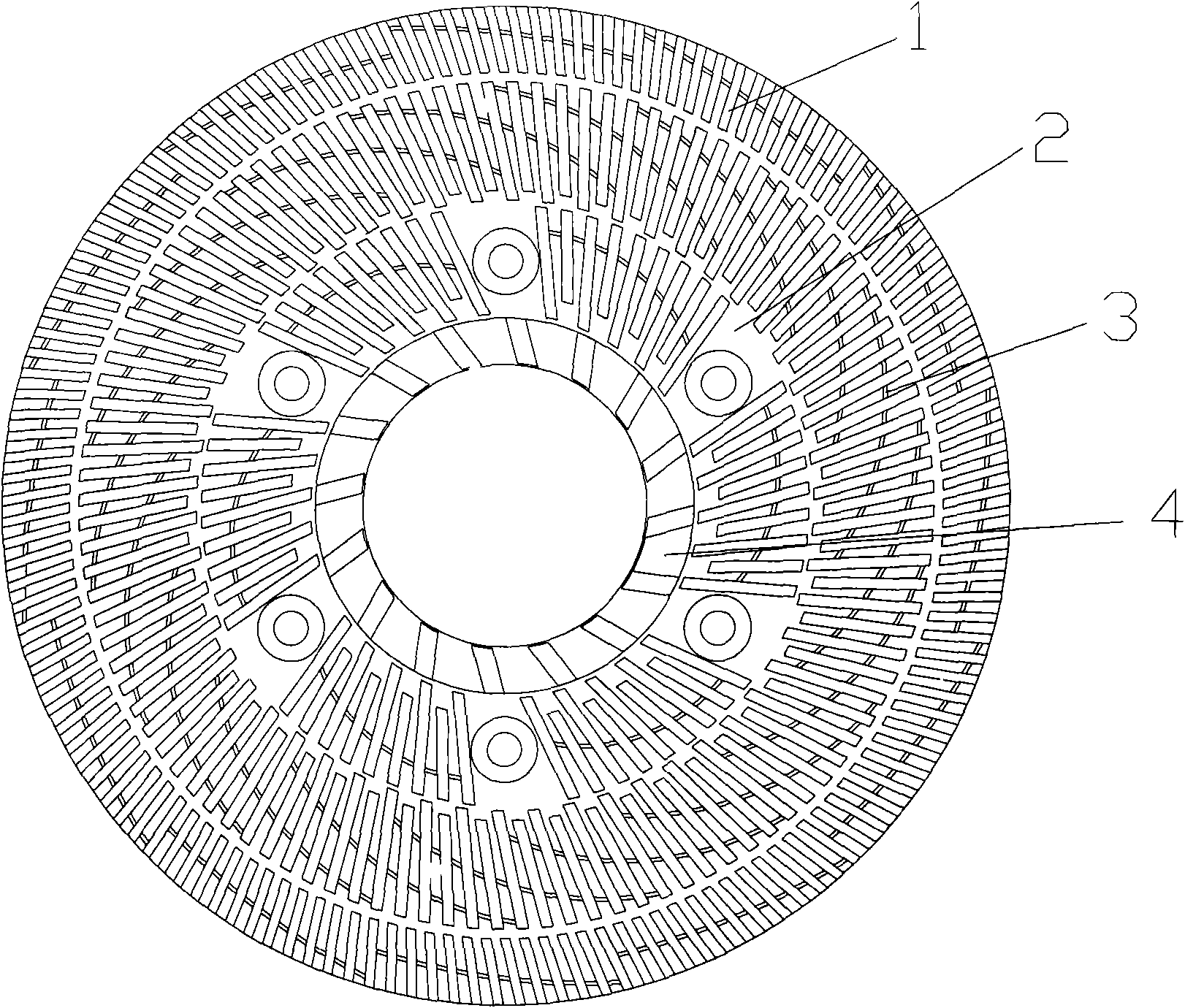

Grinding sheet for disc grinder and manufacturing method thereof

InactiveCN101654888AReduce wasteImprove yieldSolid state diffusion coatingFurnace typesEngineeringSurface processing

The invention provides a grinding sheet for a disc grinder and a manufacturing method thereof. The grinding sheet comprises grinding teeth and grinding sheet base body which are respectively processed twice for forming, wherein the grinding teeth which are arranged into a plurality of concentric circles are uniformly distributed on the grinding sheet base body around a center shaft of the grinding sheet base body, pulp baffle plates are arranged among the grinding teeth, and the pulp baffle plates positioned on a same circle form spiral pulp baffling lines on the surface of the grinding sheetbase body. The manufacturing method of the grinding sheet comprises the following steps: firstly, manufacturing the grinding teeth needed by the grinding sheet, and carrying out the surface processing of the grinding teeth; then processing a mould according to the designed form of the grinding sheet, installing the grinding teeth and the pulp baffle plates on the mould, and then casting or vulcanizing the mould provided with the grinding teeth; forming the grinding sheet base body, and simultaneously fixing the grinding teeth on the grinding sheet base body; and finally cooling a taper to finish the manufacturing process. The grinding sheet has good pulp grinding effect and long service life; in addition, the grinding sheet adopts a post forming method, thereby greatly reducing the material cost of the grinding sheet and the waste of materials.

Owner:SOUTH CHINA UNIV OF TECH

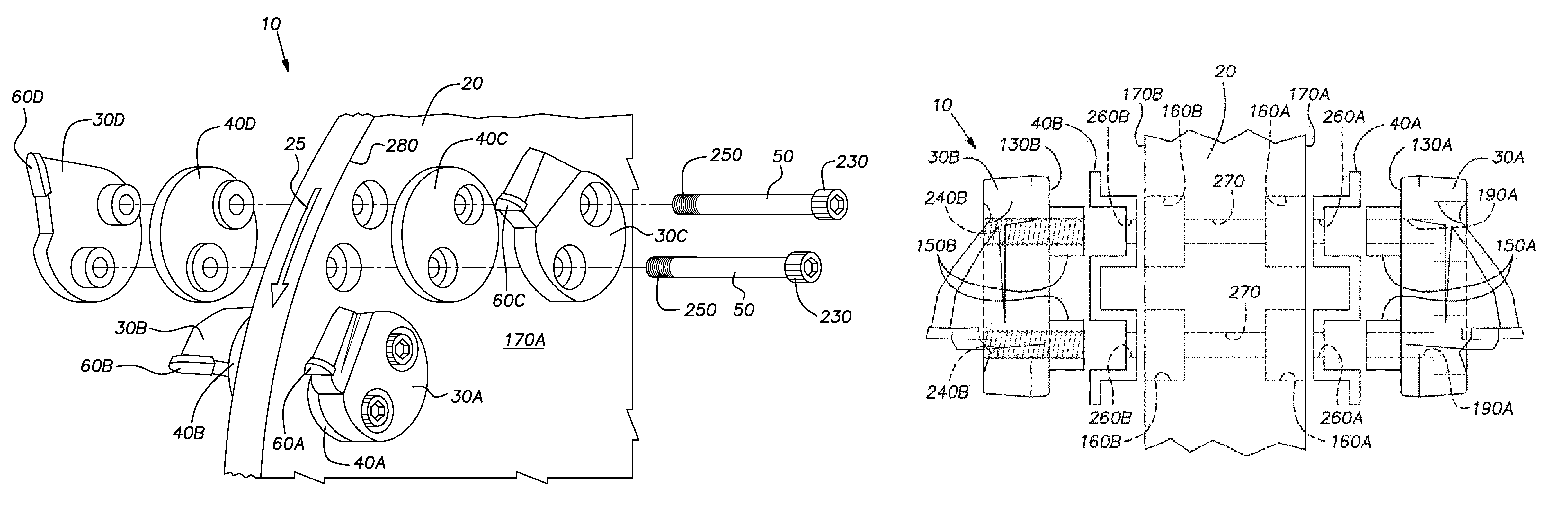

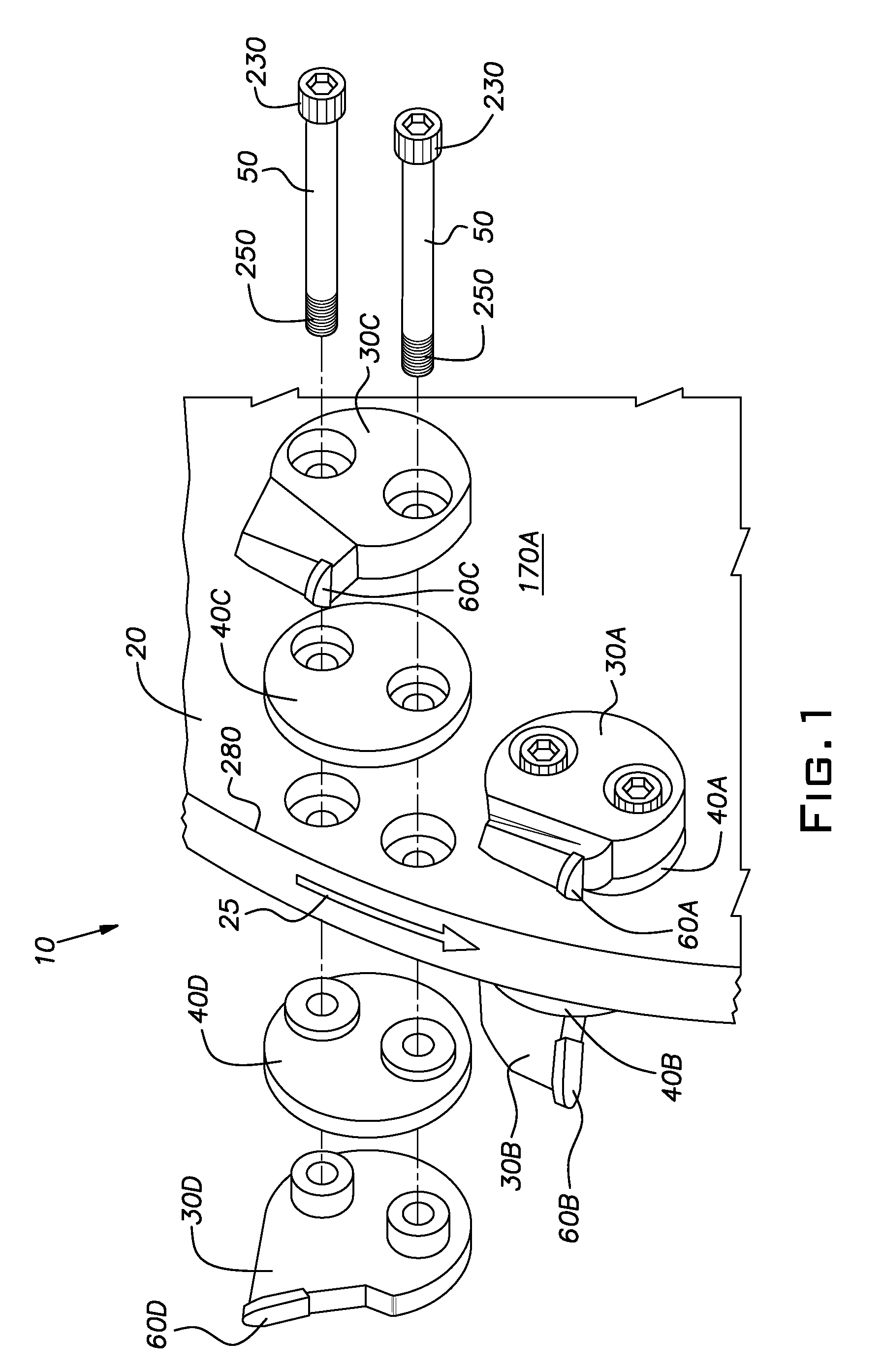

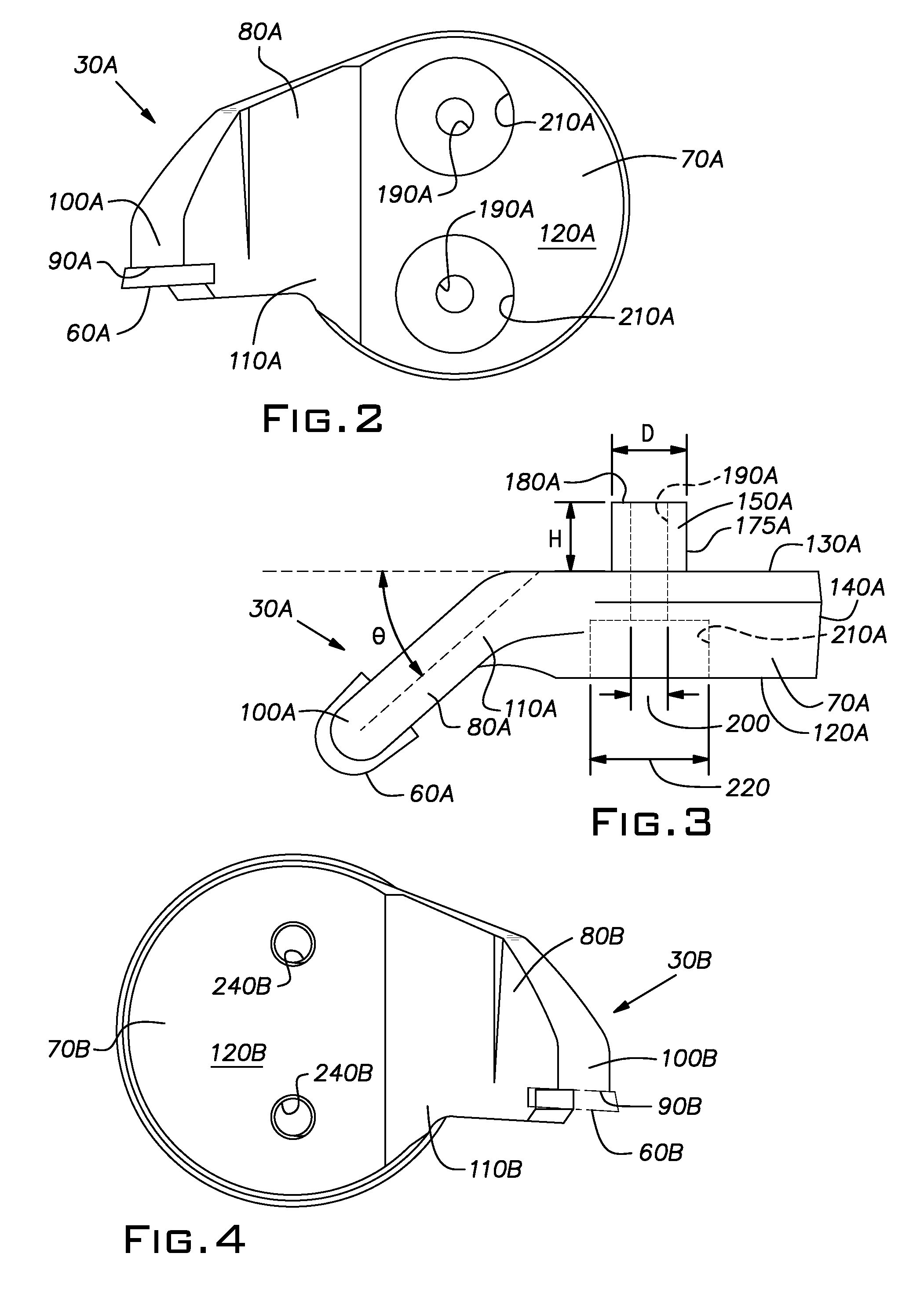

Tree stump grinding teeth

ActiveUS7694704B2Protect the surfaceMulti-purpose machinesProfiling/shaping machinesEngineeringGrinding wheel

Owner:GOSSETT JOHNNY

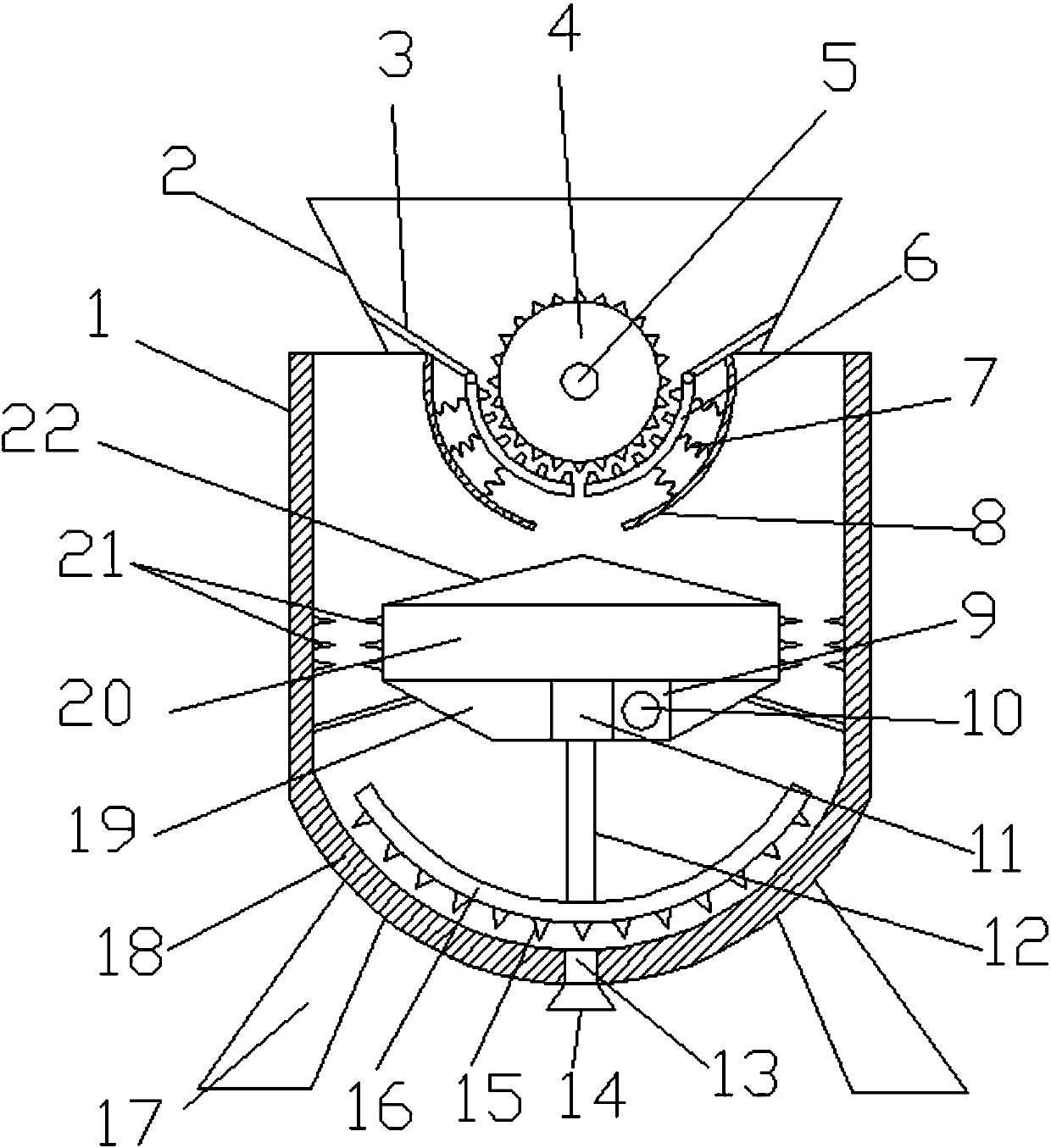

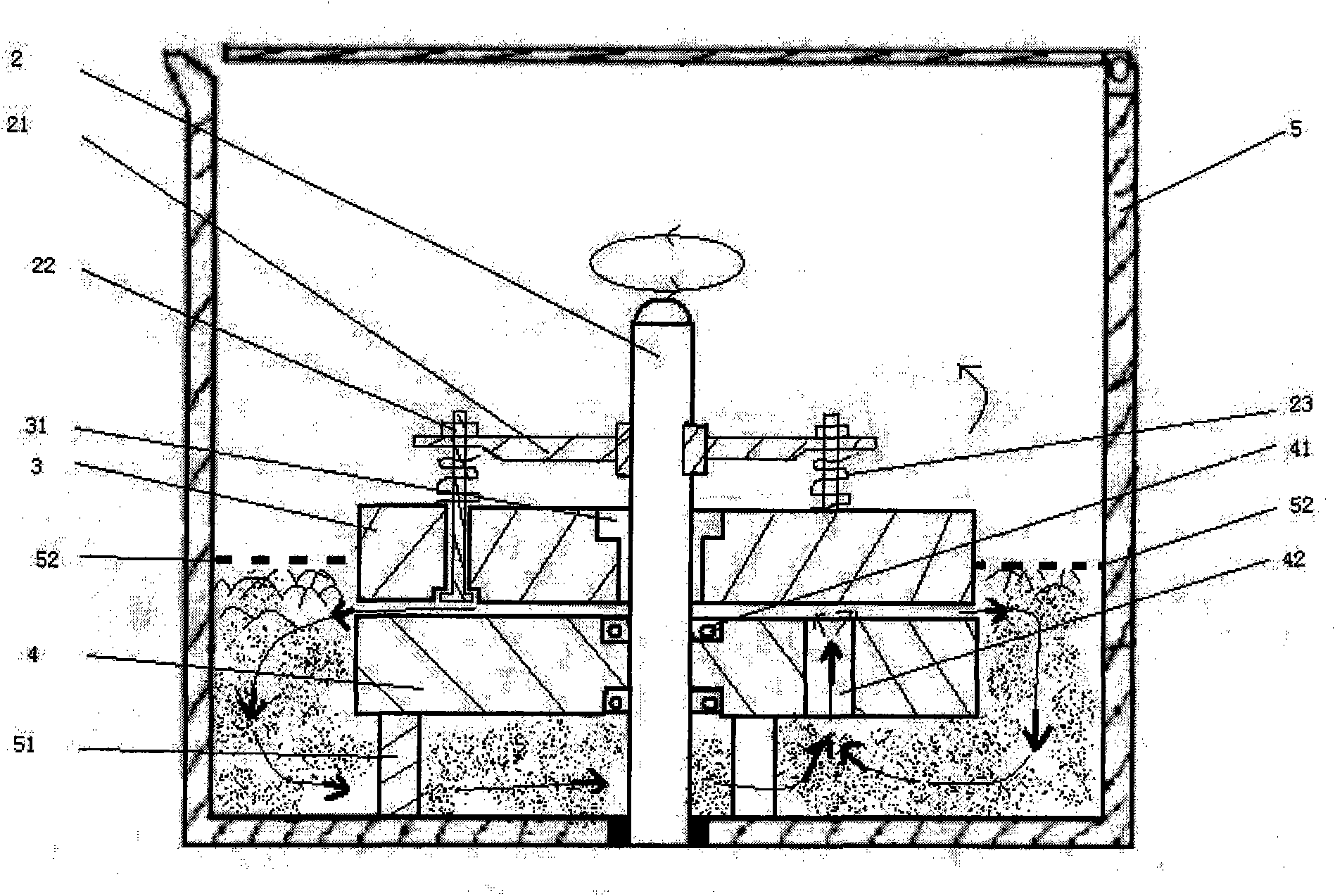

Vertical multi-stage coaxial impact crushing sorting unit

InactiveCN101767049ASimple structureFew spare partsGas current separationGrain treatmentsSingle stageEngineering

The invention relates to a vertical multi-stage coaxial impact crushing sorting unit, which is structurally characterized in that an impact crushing sorting mechanism or a plurality of impact crushing sorting mechanisms are arranged along a vertical main shaft from top to bottom; the heads and the tails of two adjacent impact crushing sorting mechanisms of the impact crushing sorting mechanisms are in head-tail make connection; the whirling motion crushing cavity of each impact crushing sorting mechanism is a semi-closed annular space the top of which is sealed and the bottom of which is opened; the space is provided with a plurality of pulse exhaust vents communicated with the whirling motion crushing cavity and space in a hopper; in the whirling motion crushing cavity, a reaction conical surface which corresponds to a rotor jet orifice is arranged, wherein the diameter distribution of the reaction conical surface is an inverted big-end-up cone, and the surface thereof is distributed with grinding teeth; and a discharging flange bulges at the inner side of an annular roof in the whirling motion crushing cavity. The single-stage crushing sorting and multi-stage flow crushing are carried out on crushed substances from top to bottom by connecting multi-stage impact crushing sorting mechanisms with similar structures on the vertical main shaft in series in manner of closed circuit, thereby realizing the crushing sorting work of discharge multi-stage flow crushing, discharge impact crushing, discharge whirling motion crushing, discharge centrifugal sorting, discharge centrifugal screening and the like.

Owner:黄如健

Ball-milling mixer for producing drilling-milling-integration hard alloy

The invention discloses a ball-milling mixer for producing a drilling-milling-integration hard alloy. The ball-milling mixer comprises a barrel, wherein two grinding rollers are rotationally connectedto the upper portion of the inner wall of the barrel through two rotating shafts correspondingly, a first annular groove is formed in the inner wall of the barrel, a first circular ring is slidably connected to the inner wall of the first annular groove, a transverse plate is fixedly connected to the inner wall of the barrel, the upper end of the transverse plate is rotationally connected with acylinder through a connecting rod, and the upper end and the lower end of the cylinder are conical. According to the mixer, by arranging the grinding rollers, first grinding teeth and second grindingteeth, materials can be fully and finely ground, a cam collides with a transverse rod in a clearance mode through rotation of a transverse column, the materials ground again can be filtered, large particles in the ground materials are removed, through rotation of a spiral blade of an auger, the large particles filtered by a filter screen can be conveyed, manual conveying of the large particles isnot needed, and the working intensity is reduced.

Owner:北京享云智汇科技有限公司

Manufacturing method of independent welded grinding-tooth-shaped bimetal band saw blade

The invention relates to a manufacturing method of an independent welded grinding-tooth-shaped bimetal band saw blade, which sequentially comprises the following five steps of carrying out forming processing and heat treatment on a tooth part material; carrying out forming processing and heat treatment on a steel band back material; welding the tooth part material and the steel band back material which are subjected to heat treatment into one whole body; carrying out heat treatment on a welding region; carrying out forming processing on the welded tooth part material, the welding region and the welded steel band back material, removing welding slag generated in the welding process and processing a cutting edge on the tooth part material. The tooth part material and the steel band back material are respectively and separately subjected to heat treatment before welding without adopting a process of carrying out online quenching and annealing on a current composite material, so that performance of the tooth and back materials can be sufficiently utilized; the tooth part material and the steel band back material are respectively subjected to forming processing, so that the condition that the tooth part material and the steel band back material are cut after being welded to cause cutting on most of the tooth part material is avoided and loss of raw materials is reduced.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

Soybean milk machine

ActiveCN102188157AAchieve mechanical mass productionEasy to cleanBeverage vesselsMilk substitutesWear resistantEddy current

The invention belongs to the field of small kitchen appliances, and particularly relates to a soybean milk machine. The soybean milk machine comprises a movable grinding head arranged on a motor shaft, wherein the movable grinding head comprises a liquid flow driving device which is provided with at least one screw tooth, and a movable grinding tooth arranged at the upper end of the liquid flow driving device; and the liquid flow driving device has a rough shape of a cylinder or rod or inverted cone. When a material is prepared, the movable grinding head rotates at a high speed in a static grinding material guiding cavity to form driven liquid flow so as to produce rotary suction eddy current, and the material is rotatablely sucked into the liquid flow driving device, is coarsely ground and further is subjected to fine grinding by using the movable grinding tooth. The gap gradually becomes smaller from the bottom to top, and the grinding process in which the coarse material is ground into the fine material is realized at the same time. A grinding mechanism of the soybean milk machine has a good grinding effect, and the grinding head is easy to process and is wear-resistant.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Multifunctional molecular biology experiment specimen grinding device

The invention discloses a multifunctional molecular biology experiment specimen grinding device, and relates to the field of grinding devices. The multifunctional molecular biology experiment specimengrinding device comprises an enclosure, wherein the side surface of the enclosure is equipped with a fan and is equipped with an air inlet tube in a penetrating mode; the air inlet tube is connectedto the fan; a grinding mechanism is arranged inside the enclosure; the grinding mechanism comprises a hemi-spherical grinding block; a circular table shaped connecting block is fixedly arranged on thetop of the hemi-spherical grinding block; the top of the circular table shaped connecting block is fixedly equipped with an upper rotary rod; the bottom of the hemi-spherical grinding block is equipped with a grinding base; a hemi-spherical grinding slot is formed in the top of the grinding base; grinding teeth are arranged at each of the outer side of the hemi-spherical grinding block and the inner side of the hemi-spherical grinding slot; a groove is formed in the bottom of the hemi-spherical grinding block; a blocking cover plate is fixedly arranged on the bottom of the groove; and the blocking cover plate is fixedly connected to the inner wall of the hemi-spherical grinding slot. In practical use, material recycling is not required, so that operation steps are effectively reduced, grinding efficiency is improved, and the practical use effect is better.

Owner:HUNAN UNIV OF CHINESE MEDICINE

Multifunctional soymilk grinder with grinding function

ActiveCN101861894AImprove grinding qualityPlain designBeverage vesselsMilk substitutesPulp and paper industryKnife blades

The invention is applicable to the field of daily necessities, and discloses a multifunctional soymilk grinder with a grinding function, which comprises a blade used for crushing soybeans. A grinding device is also arranged in the soymilk grinder and comprises a fixed grinding plate and a movable grinding plate, and the surfaces of the fixed grinding plate and the movable grinding plate are both provided with grinding teeth used for further grinding soymilk flowing into the grinding device; the fixed grinding plate is fixed on the bottom of the soymilk grinder through a plurality of positioning columns, the movable grinding plate can rotate relative to the fixed grinding plate and is used for grinding, and the movable grinding plate and the blade rotate under control of a common motor shaft; and the soymilk grinder also comprises a diversion cup which is arranged on the upper part of the grinding device and is used for diverting the soymilk crushed by the blade into space between the fixed grinding plate and the movable grinding plate. The invention greatly improves the soymilk grinding quality, and facilitates the popularization of the soymilk grinder.

Owner:深圳嘉兰图工业设计有限公司

Surface-brazed abrasive particle internal spraying lubricating liquid grinding wheel and grinding device with grinding wheel

ActiveCN108393815AReduce dosageReduce usageGrinding wheel securing apparatusBonded abrasive wheelsWear particleEngineering

The invention discloses a surface-brazed abrasive particle internal spraying lubricating liquid grinding wheel and a grinding device with the grinding wheel. The grinding device comprises a grinding wheel basal body, a sealing ring, a mounting connecting shaft, an end surface pressing plate and the like. A liquid runner is arranged on the mounting connecting shaft; the grinding wheel basal body isprovided with an inner cavity communicating with the liquid runner; a brazing process is used for brazing spiral line type grinding teeth with dense tooth structures on a spiral boss on the outer circular surface of the grinding wheel basal body; and lubricating cooling liquid separation holes are formed between the grinding teeth through related machining processes. The grinding wheel basal bodyrealizes connection with the mounting connecting shaft through the end surface pressing plate and bolts. When parts are grinded, the lubricating cooling liquid enters an inner cavity of the grindingwheel by a runner in the mounting connecting shaft, and is precisely and uniformly acted on a grinding area through the lubricating cooling liquid separation holes on the grinding wheel basal body forlubricating and cooling the grinding area to guarantee the grinding quality of machined parts.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Environment-friendly medical waste treatment device

InactiveCN105665413AFast and efficient crushingAvoid cloggingSolid waste disposalMedical waste disposalFixed frameMedical waste

An environment-friendly medical waste treatment device comprises a bottom plate, a feeding device, a pushing device, a frame device, heating devices and a holding device. The bottom plate is provided with a first support, a second support, a third support, a fourth support and a material collecting tank. The feeding device comprises a feeding hopper, a first bent plate, a second bent plate, a first wheel and grinding teeth. The pushing device comprises an air cylinder, a first fixing frame, a first push rod, a first positioning rod, a second push rod, a first runner, a first fixing rod, a second fixing rod, a second runner, a second cross rod and a conveying belt. The frame device comprises a feeding frame, a frame body, a first supporting rod, a first cross rod, a rotating frame, a baffle, springs, a first magnet and a fifth support. Each heating device comprises a heat dissipation frame, a heating bar and a triangular block. The holding device comprises a first holding frame, a first vertical rod, a first holding rod, a second holding frame and a second magnet. By means of the environment-friendly medical waste treatment device, rapid and effective smashing treatment can be conducted on medical waste.

Owner:黄玉强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com