Patents

Literature

2067 results about "Spiral line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

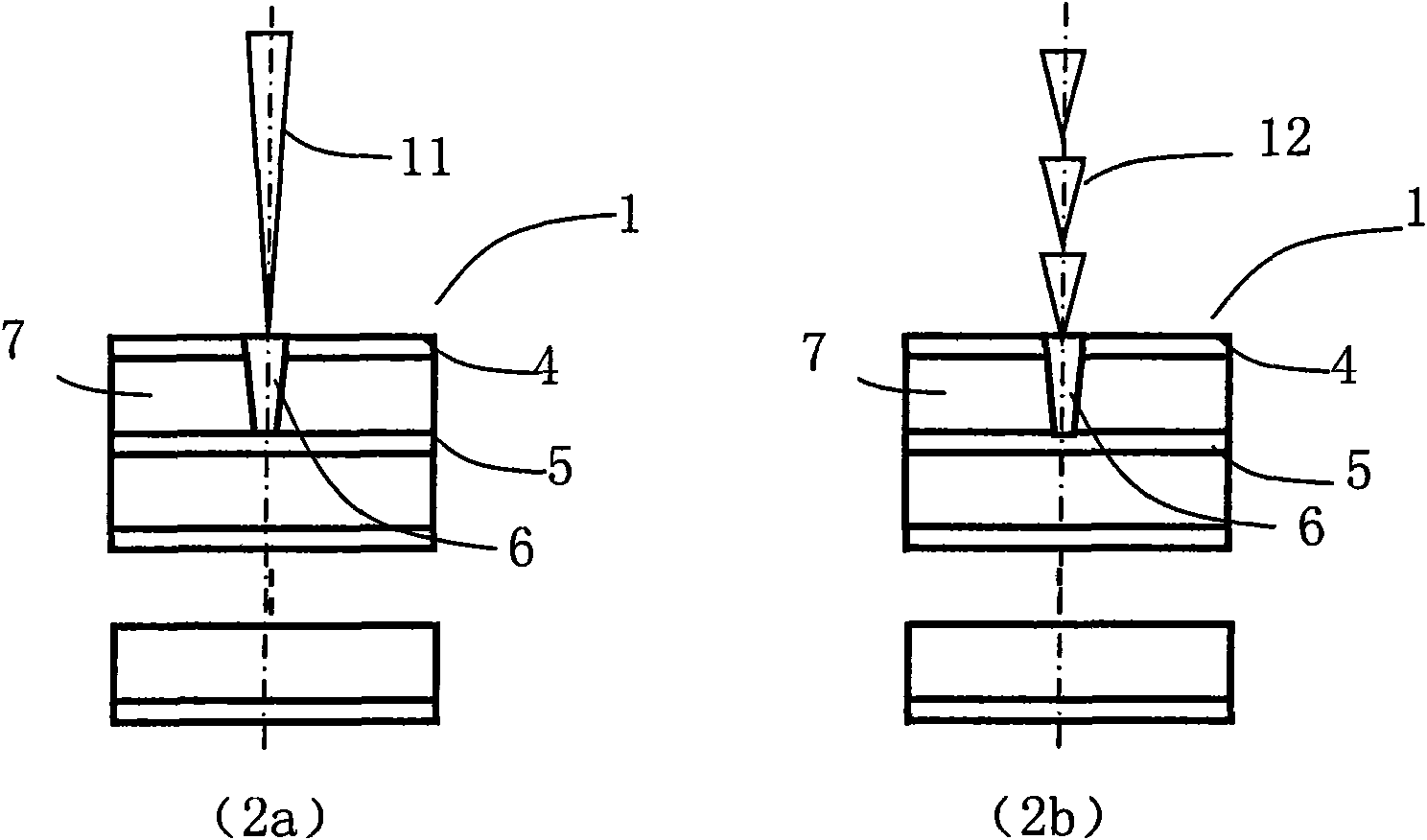

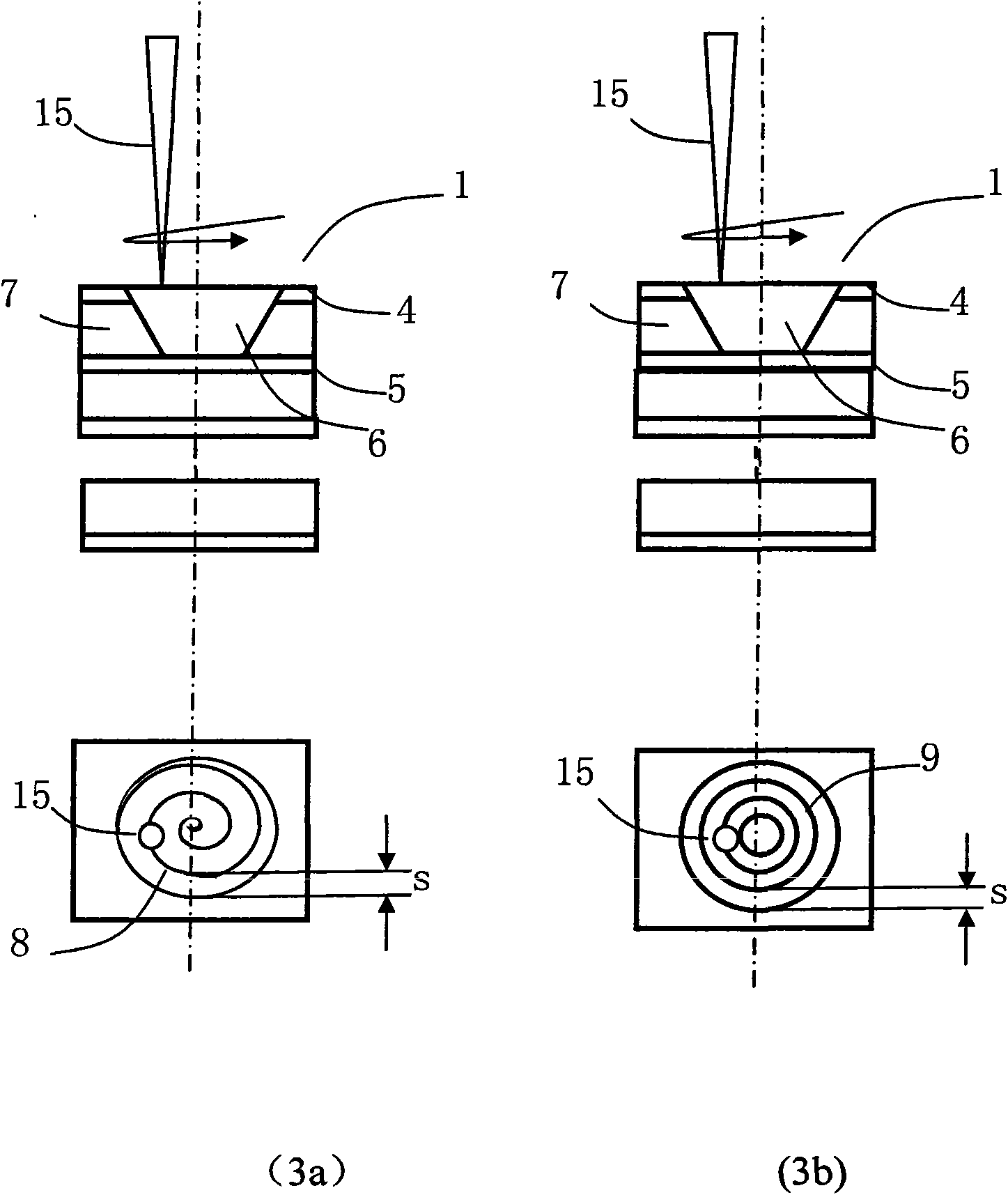

Method for processing blind hole by laser

InactiveCN101610643AAvoid Scanning RequirementsRemove distortionConductive material mechanical removalLaser beam welding apparatusUv laserLaser processing

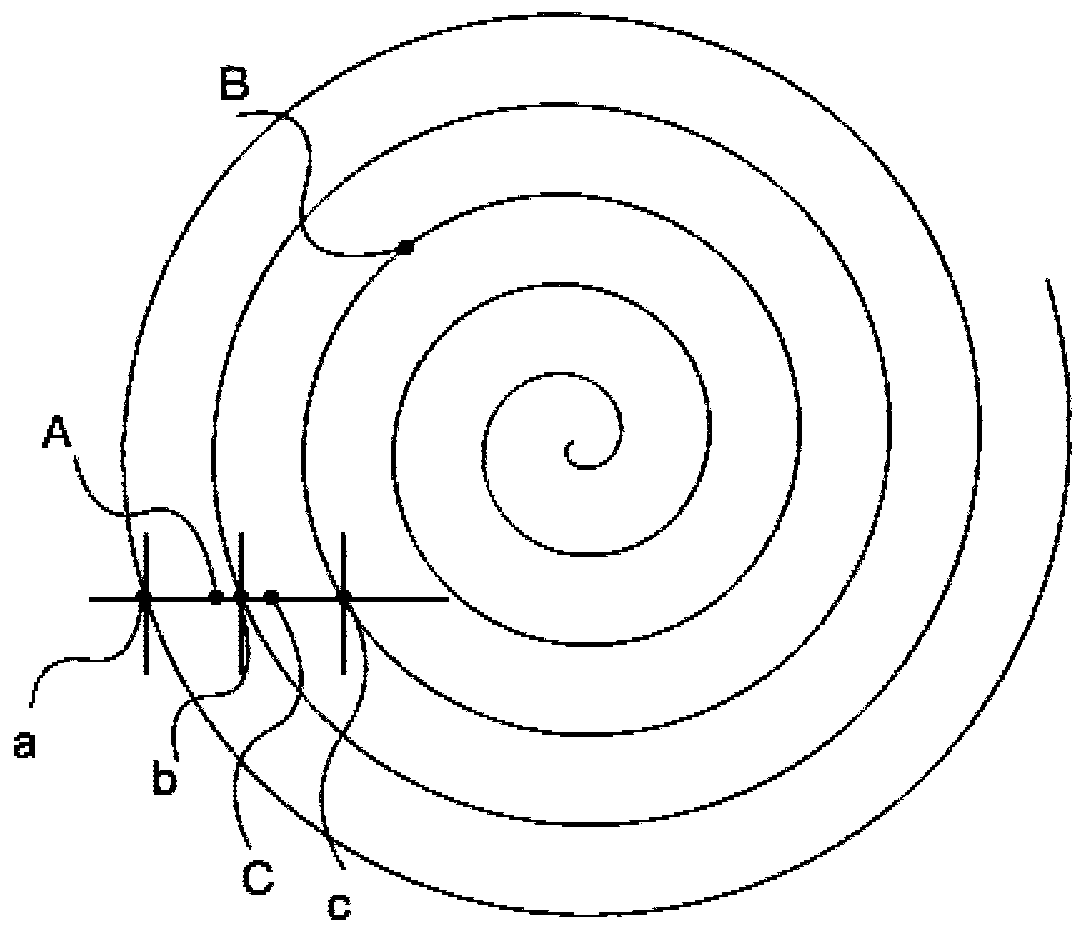

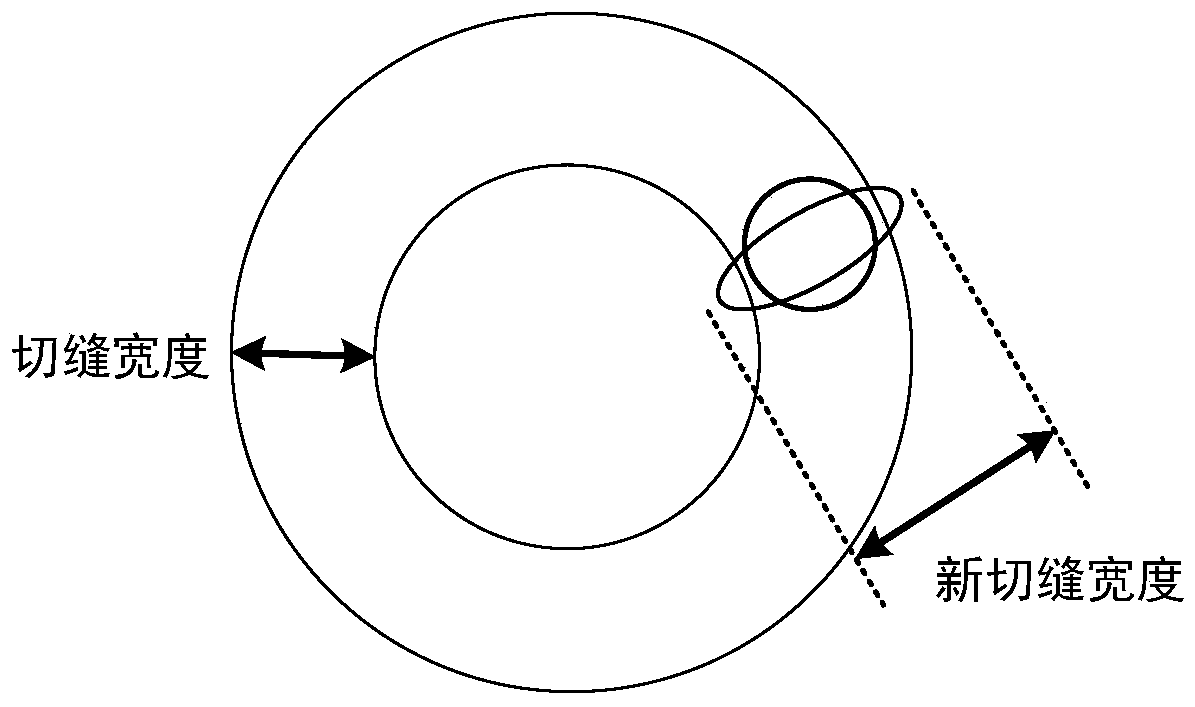

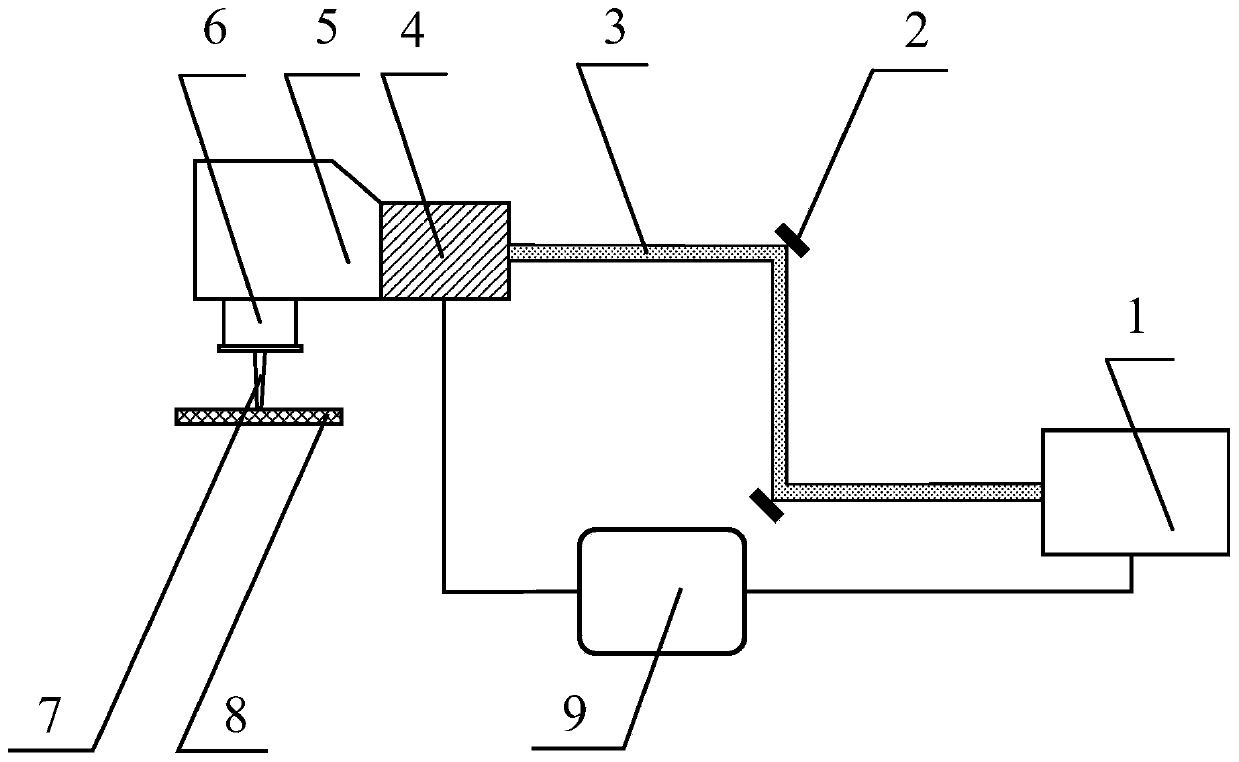

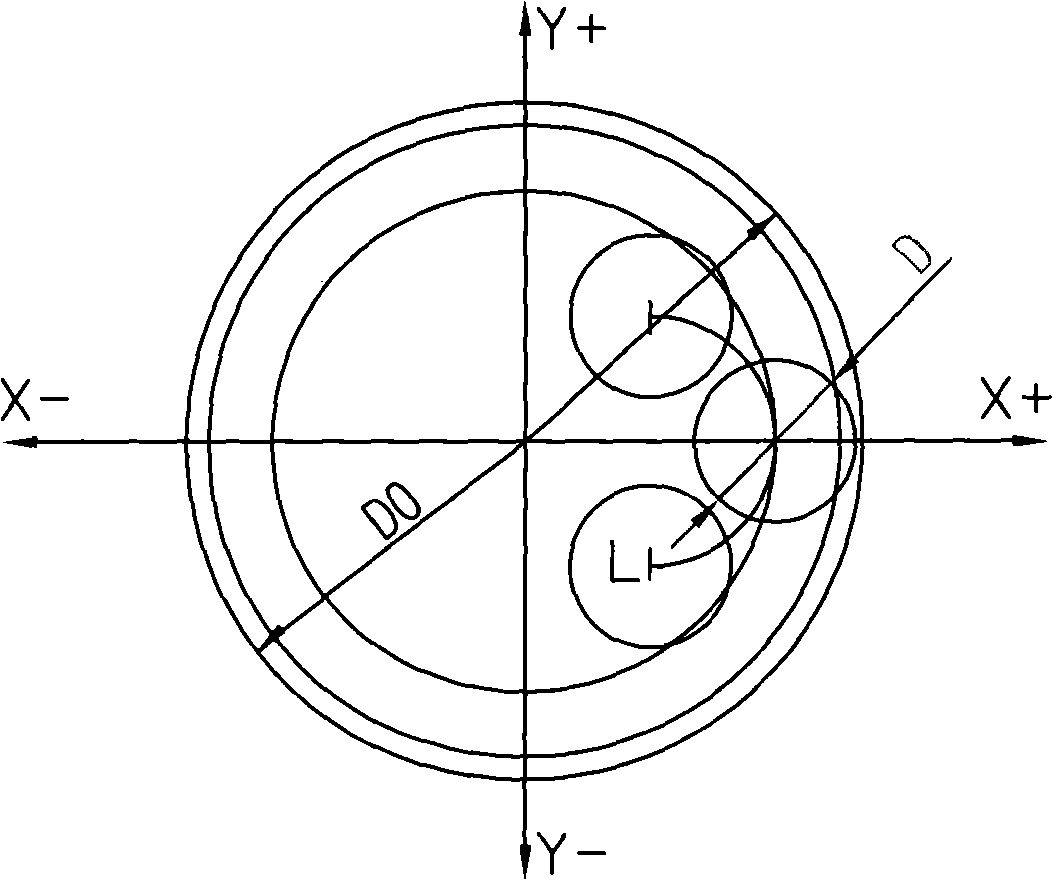

The invention discloses a method for processing a blind hole by laser. The method combines fixed point UV laser impulse and UV laser spiral line or concentric circle scanning and is used for one-step blind hole processing or multi-step blind hole processing on multilayer circuit board. The method divides the UV laser blind hole drilling process into two parts, namely a part with an area near the circle center of the blind hole not more than UV laser spot diameter and a part with an area more than the UV laser spot diameter. Fixed point UV laser impulse is adopted to drill the blind hole, so as to remove material in the region with an area near the circle center not more than UV laser spot diameter; then UV laser spiral line or centric circle scanning method is adopted to move outside, so as to remove the material in the region with an area near the circle center more than UV laser spot diameter until meeting set blind hole size; and one-step blind hole or multi-step blind hole processing is drilled by UV laser through two steps or more steps. The method can ensure processing quality consistency of each blind hole, can greatly reduce bottom unevenness of the blind hole, and also can improve margin quality of blind hole processing.

Owner:HUAZHONG UNIV OF SCI & TECH

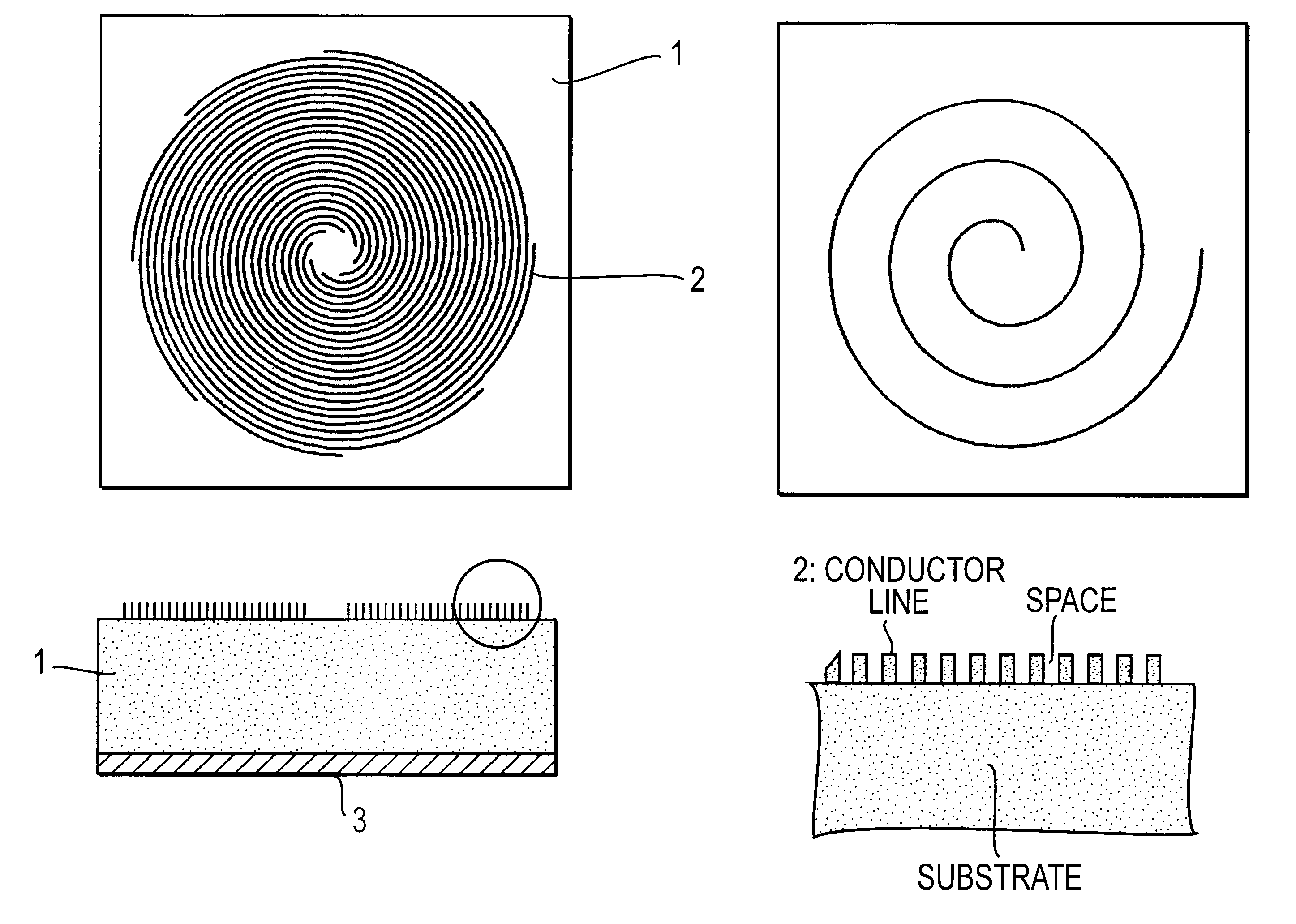

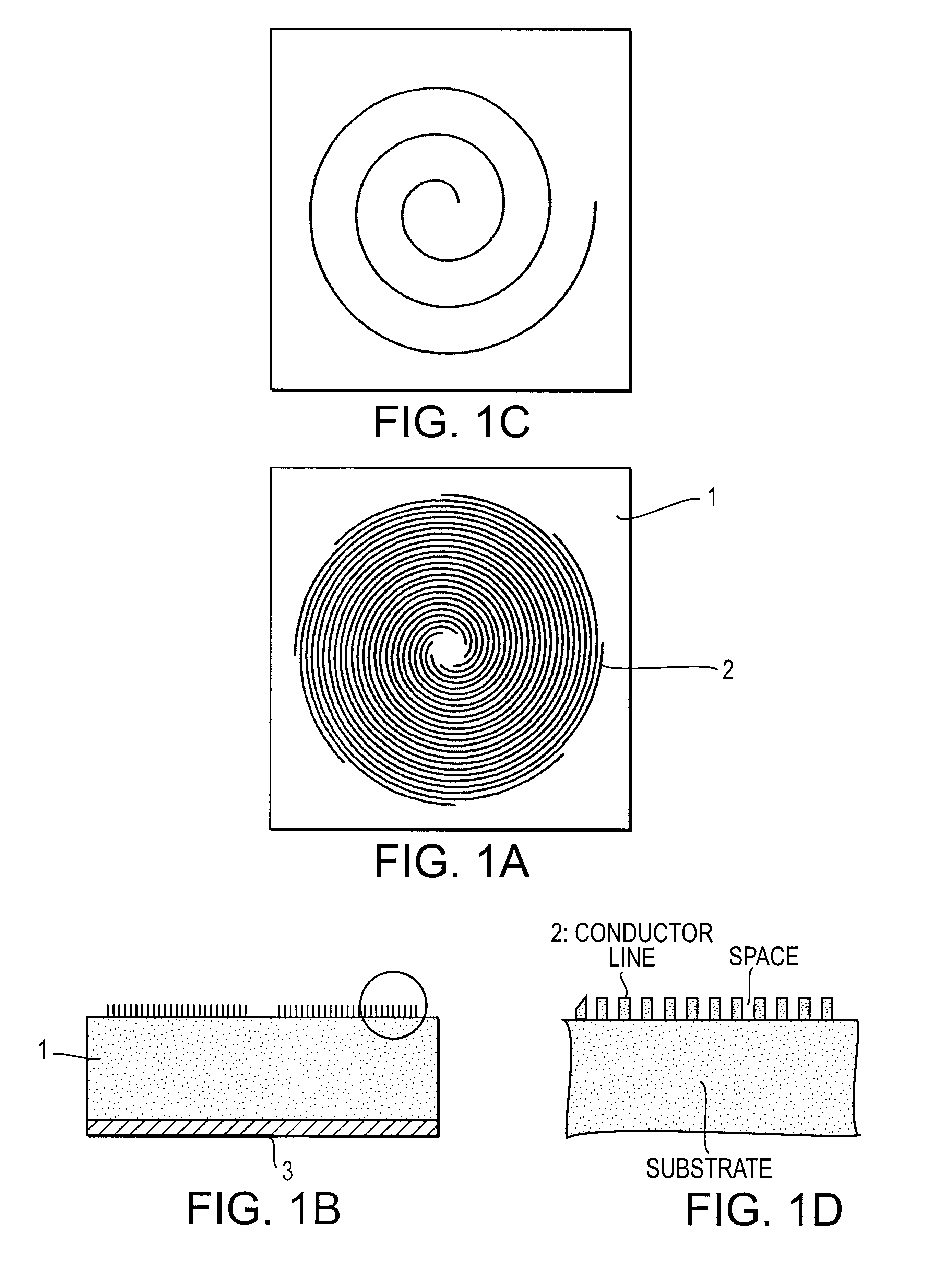

Resonator, filter, duplexer, and communication device

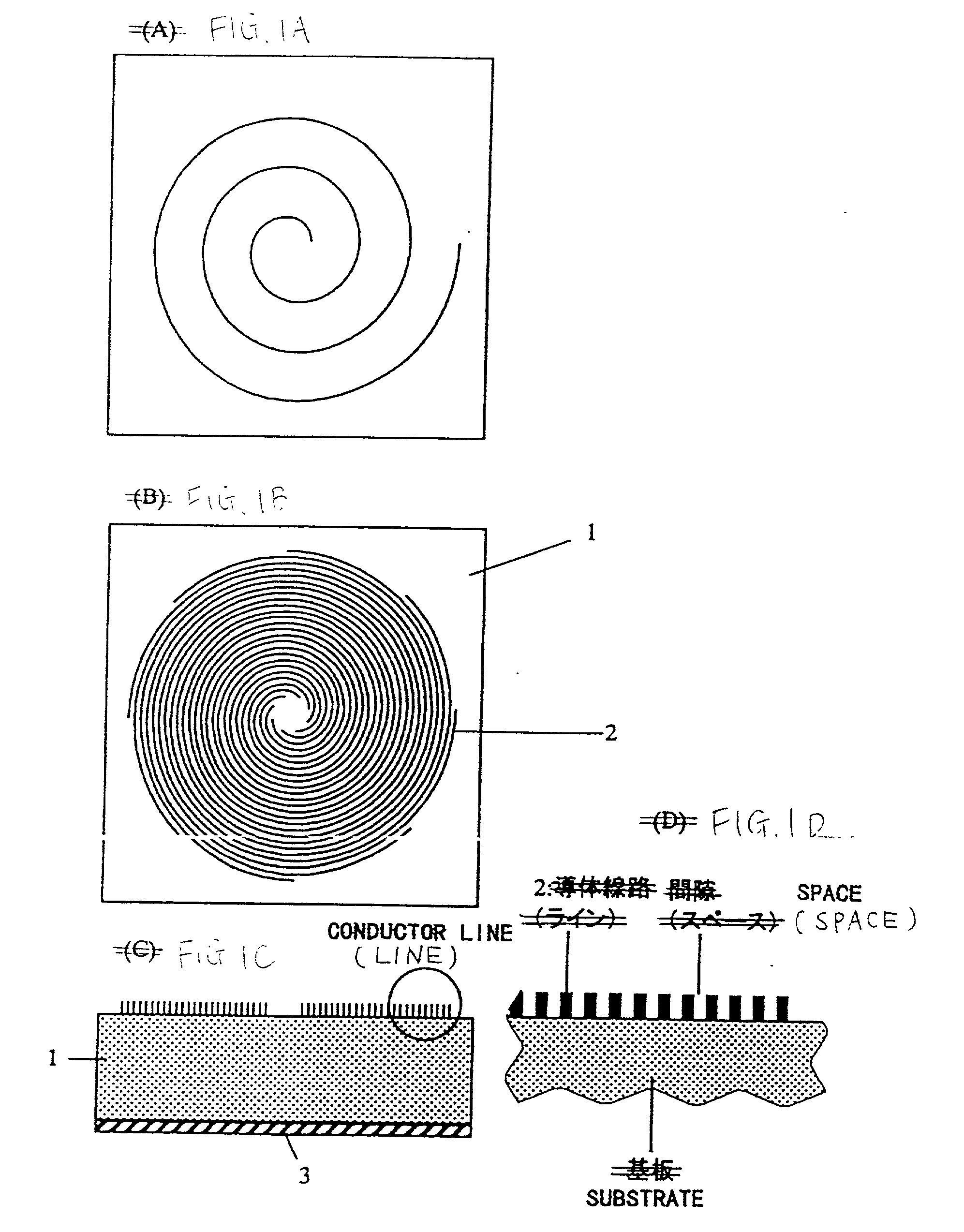

InactiveUS20020000893A1Guaranteed current efficiencySuppress power lossSuperconductors/hyperconductorsSuperconductor devicesCapacitanceSpiral resonator

A resonator, a filter, and a duplexer are provided which are capable of very effectively suppressing the power loss caused by the edge effect, and which allow a great reduction in the overall size to be achieved. Also, a communication device including the above-mentioned filter or duplexer is provided. A ground electrode is formed over the bottom surface of a dielectric substrate, and a multiple spiral line pattern is formed on the top surface thereof. A radial line pattern is further formed on this surface with an insulation layer interposed therebetween. By thus disposing the radial pattern adjacently to the multiple spiral resonator constituted of the above-mentioned multiple spiral line, an electrostatic capacitance is added to the multiple spiral resonator. This reduces the occupation area of the resonator on the substrate, and improves the loss reduction effect.

Owner:MURATA MFG CO LTD

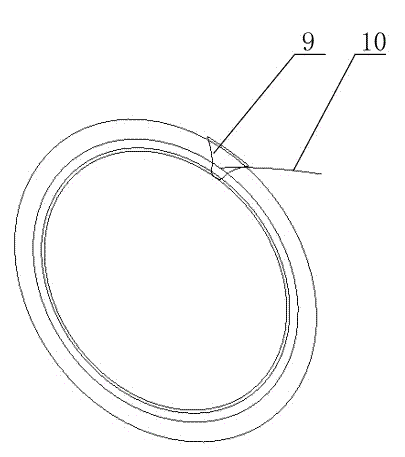

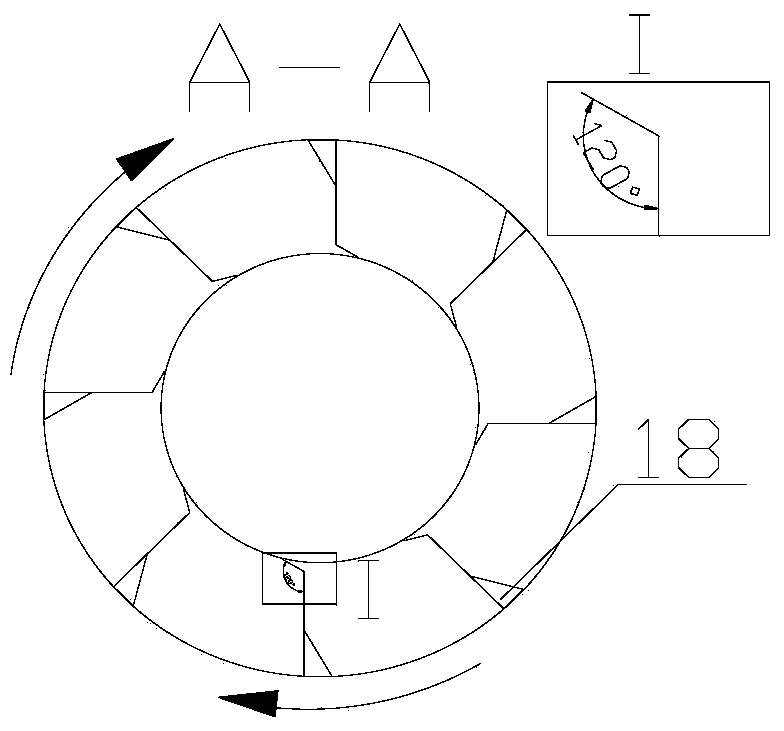

Unit for sealing end surface of 3D helical flute with double helix angles

InactiveCN1415877AImprove compression performanceIncreasing the thicknessEngine sealsFluteEngineering

Owner:JOHN CRANE TECH TIANJIN

High precision modeling method of involute helical gear

ActiveCN102289534ACombine accuratelyAvoid errorsSpecial data processing applicationsInvoluteEngineering

A method for modeling an involute helical gear accurately comprises the following steps: first step: setting related parameters; second step: establishing an involute and a transition curve by a curve equation, setting a toothspace center line and drawing a dimensional tooth profile; third step: inputting a spiral line equation and establishing a spiral line; fourth step: generating a toothspace by mixed scanning and an array, and cutting a gear blank by Boolean operation to form a gear model; and fifth step: applying a gear model to practical gear machining or simulation analysis. According to the method, a formula suitable for three-dimensional software is deduced based on the basic principle of the involute helical gear and the engagement of a rack and a gear, the original fussy programming computation is saved; besides, the formation of the entity can be highly fitted to provide technical support for the subsequent manufacture and analysis of the helical gear; and the method is not only suitable for a standard profile gear but also a non-standard gear profile, and has remarkable scientific research value and economic efficiency.

Owner:WUXI YONGKAIDA GEAR

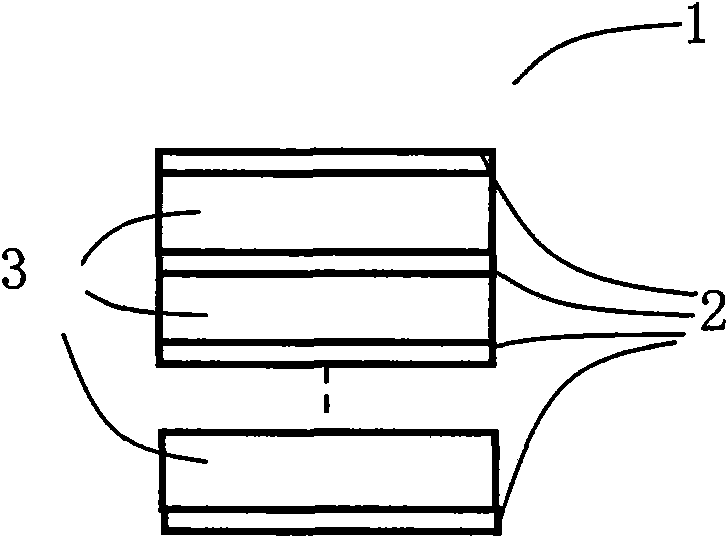

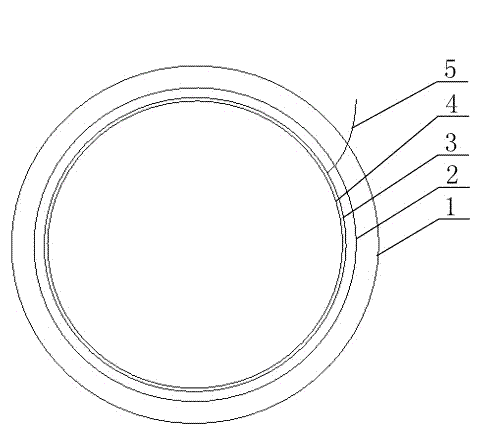

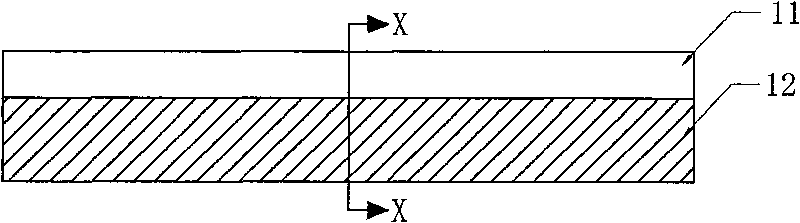

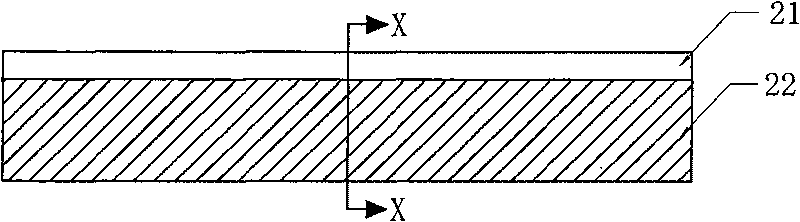

Spiral-line multi-pole lug lithium ion battery and method for manufacturing same

InactiveCN101714624AImprove consistencyReduce cornersFinal product manufactureSecondary cellsInternal resistanceEngineering

The invention provides a spiral-line multi-pole lug lithium ion battery and a method for manufacturing the same, and belongs to the field of batteries. The spiral-line multi-pole lug lithium ion battery comprises an anode sheet, a cathode sheet and a membrane arranged between the anode sheet and the cathode sheet, wherein mixed paste made of an active substance is coated on a current collector; a blank position is reserved on a front side of one edge in a length direction of the anode sheet, and a blank position is reserved on a back side of one edge in the length direction of the anode sheet; the rest parts are coated with the paste; the mixed paste made of the active substance is coated on the current collector; a blank position is reserved on the front side of one edge in the length direction of the cathode sheet, and a blank position is reserved on the back side of one edge in the length direction of the cathode sheet; and the rest parts are coated with the paste. The spiral-line multi-pole lug lithium ion battery is characterized in that: pole lugs are arranged at intervals on the reserved blank position of the anode sheet; and the pole lugs are arranged at intervals on the reserved blank position of the cathode sheet. The distance between a pole sheet and an electrode terminal, the internal resistance, and heat generation while discharging are reduced; the safety and the rate of finished products are improved; and the problem that a small battery is not suitable for lamination is solved.

Owner:GUANGZHOU FULLRIVER BATTERY NEW TECH

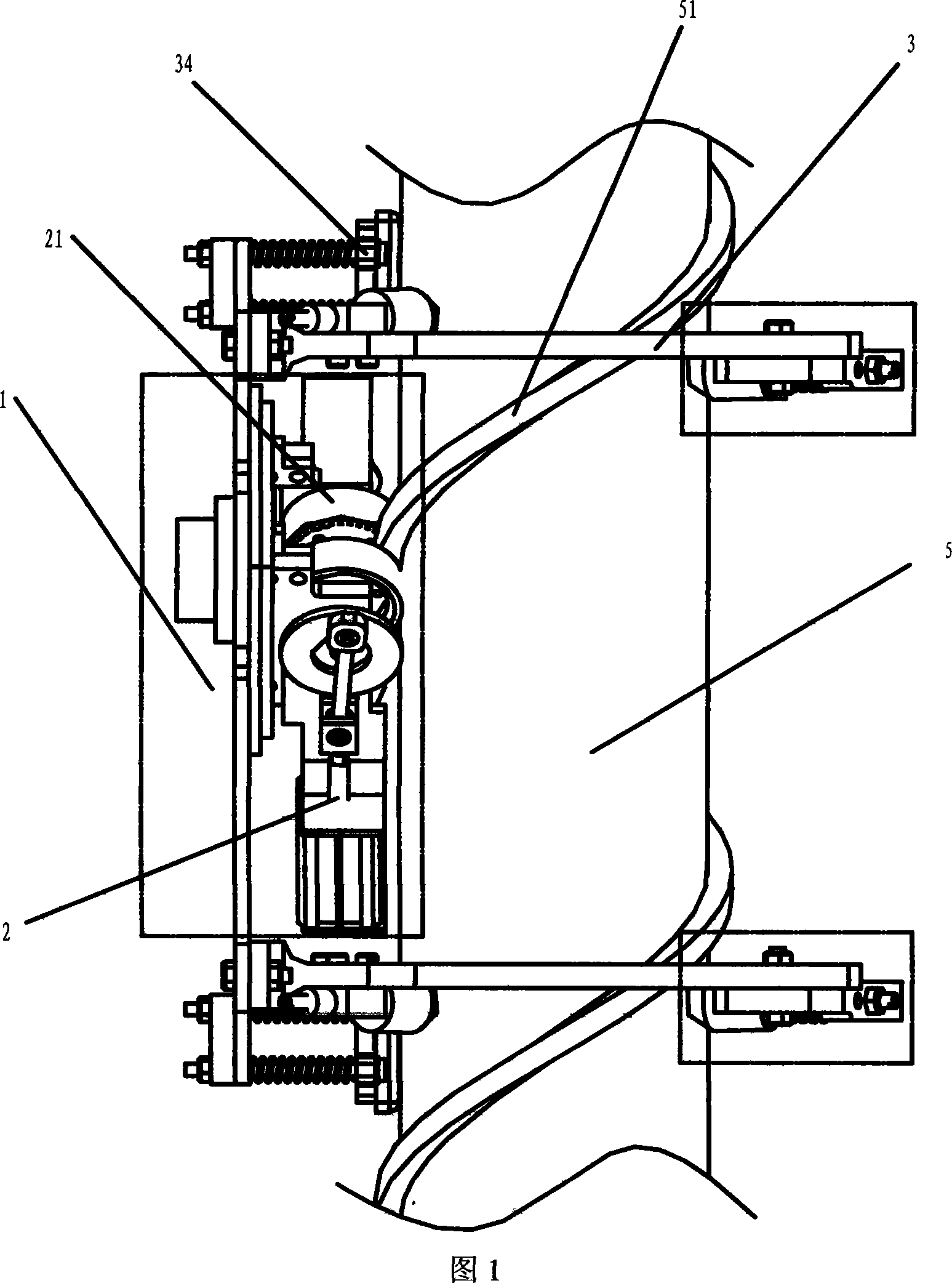

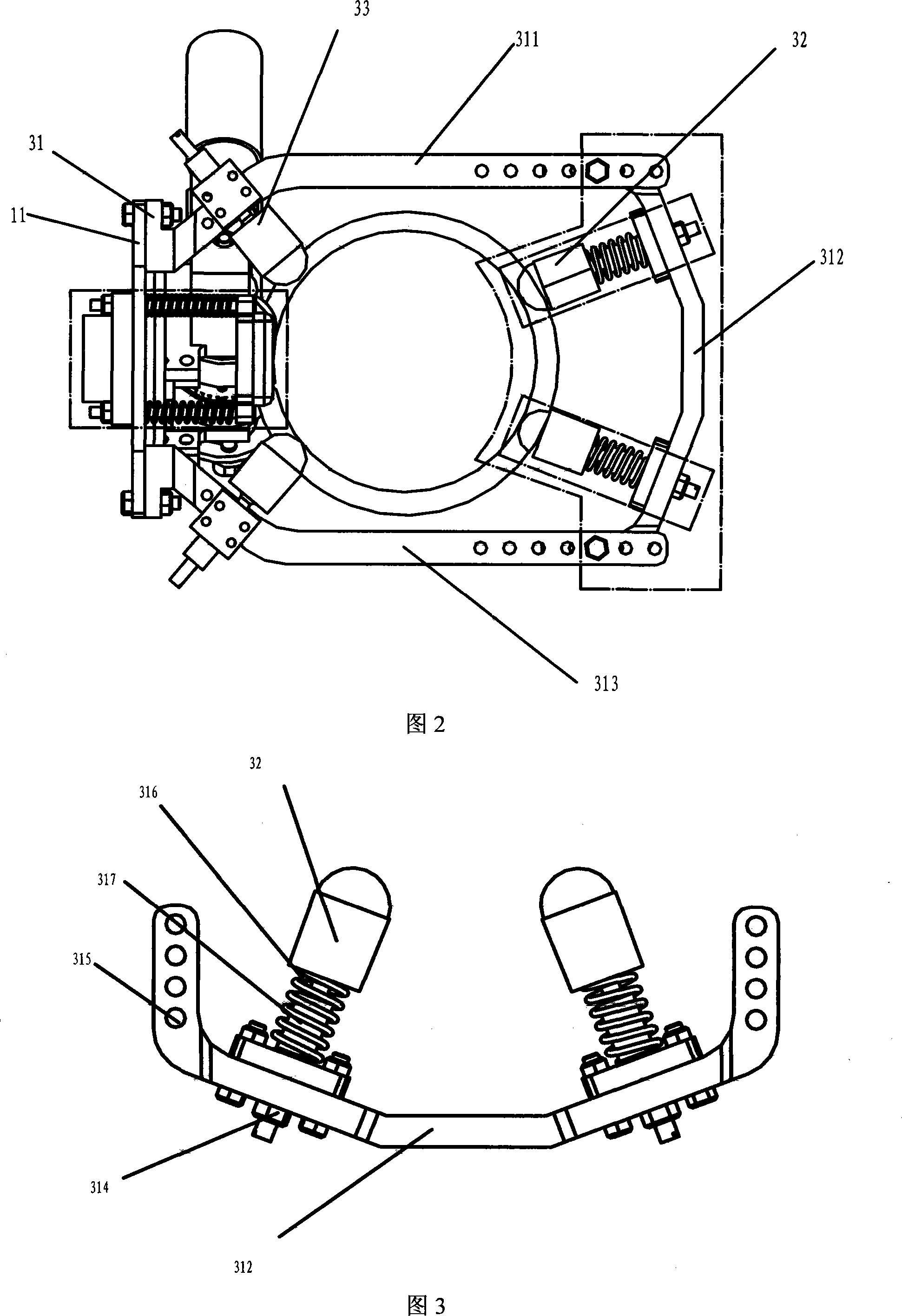

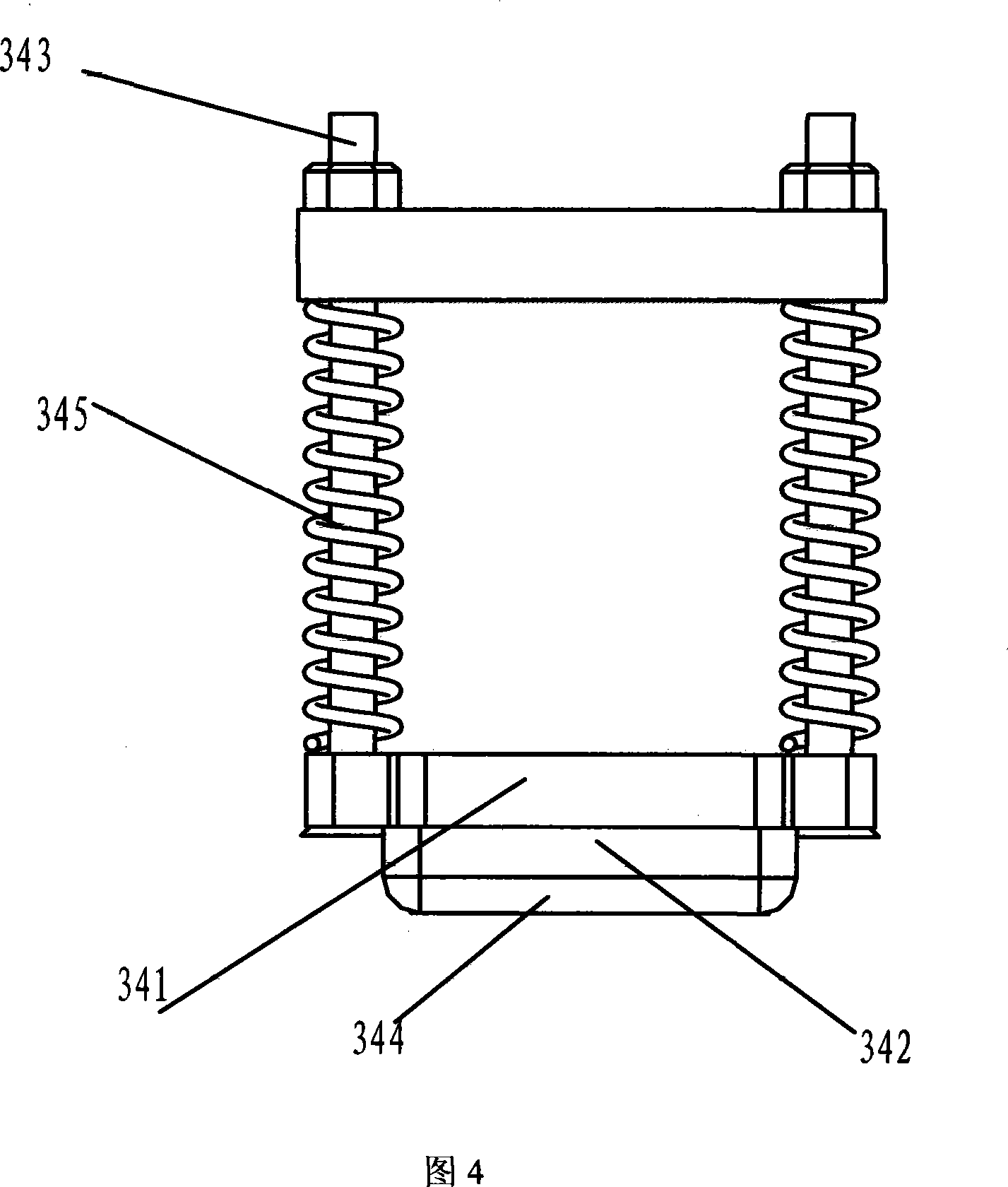

Scroll cable detecting robot

The invention discloses a spiral line cable detecting robot which consists of a cart, an upper and a lower supporting hugging devices symmetrically distributed along the cable which are connected together. The robot is characterized in that the active cart is provided with a climbing device and a magnetic absorbing device; two supporting horizontal levers are provided with hugging devices; the climbing device includes a lithium battery fixed in the cart and a DC motor fixed on one side of the driving wheel in the cart; power of the DC motor is supplied by the lithium battery, and the DC motor drives the driving wheel of the cart to rotate by a drive axle, so as to drive the whole robot to spirally climb along a water transmission line of the cable; the hugging devices and the magnetic absorbing device work together to tightly press the driving wheel onto the surface of the cable. The climbing device can rotate for any degree relative to the cart, so as to adapt to the water transmission line with different thread pitch; power supply by the lithium battery is more suitable for the environment of high-altitude operation; the robot is also provided with a descending device, which is safer and more reliable in use. The invention has simple and reasonable structure, is convenient in maintenance, can have high climbing speed, is applicable in detection of the spiral line cable of large cable-stayed bridges as well as lamps and other rod types.

Owner:SOUTHEAST UNIV

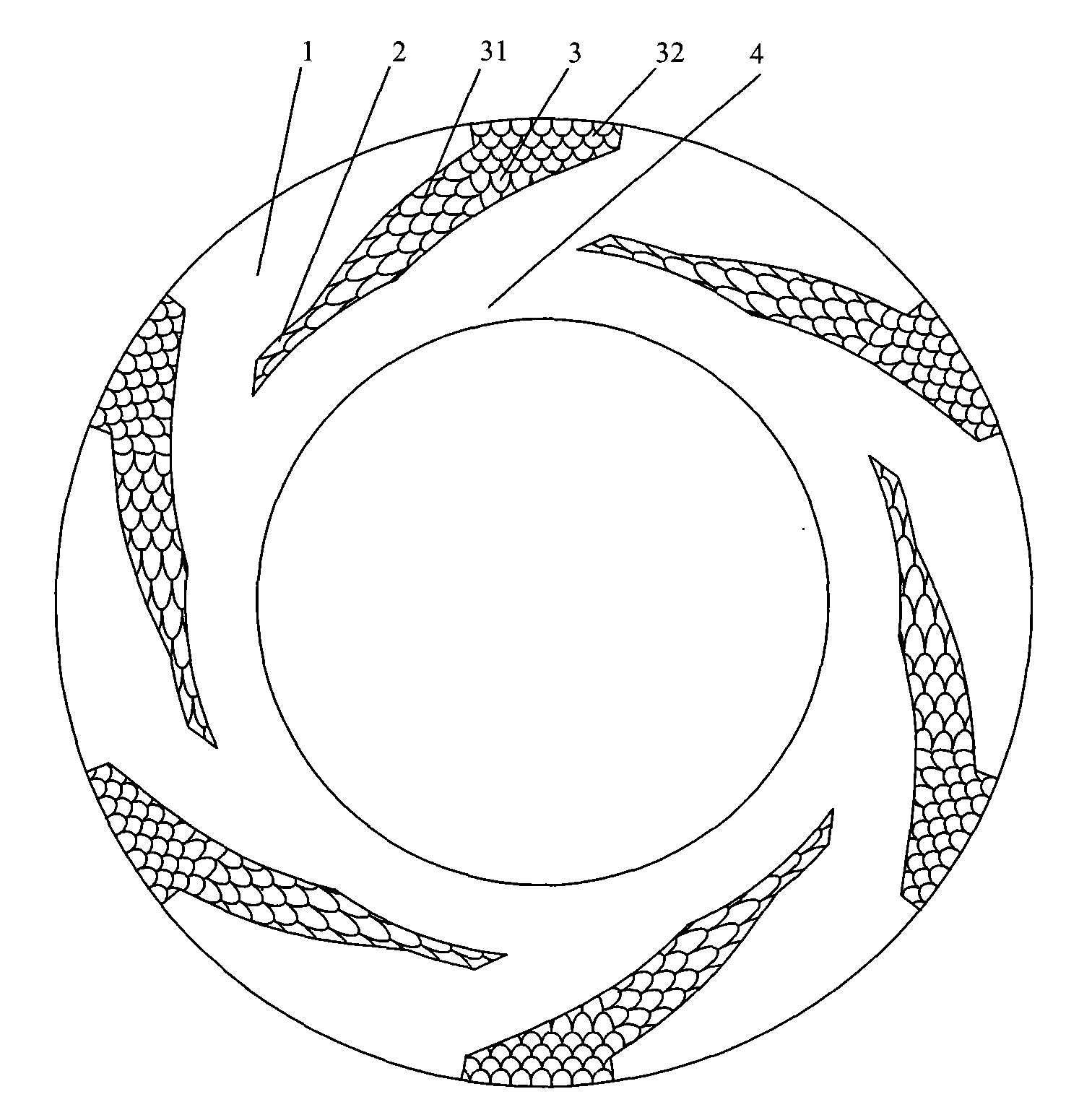

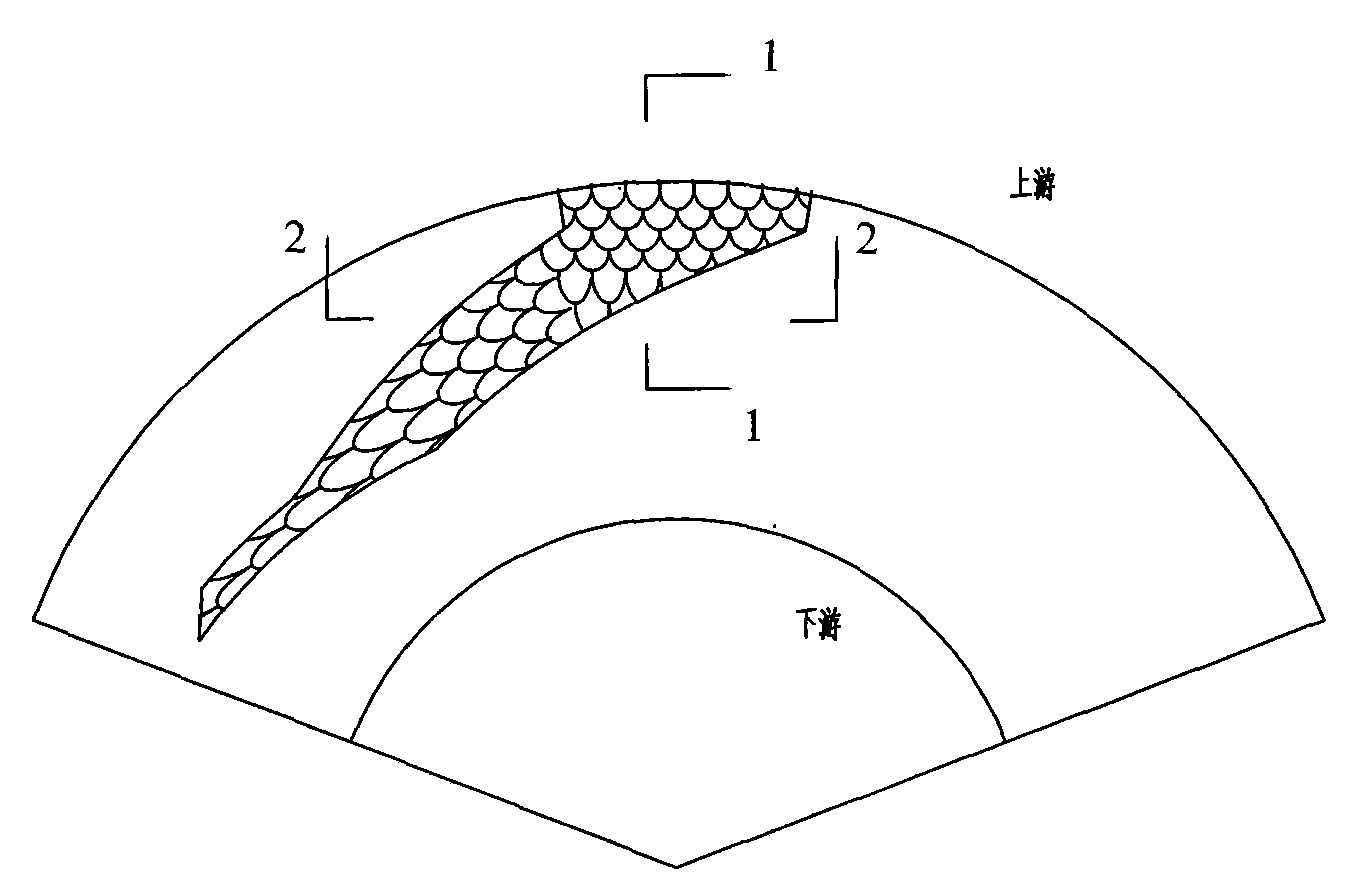

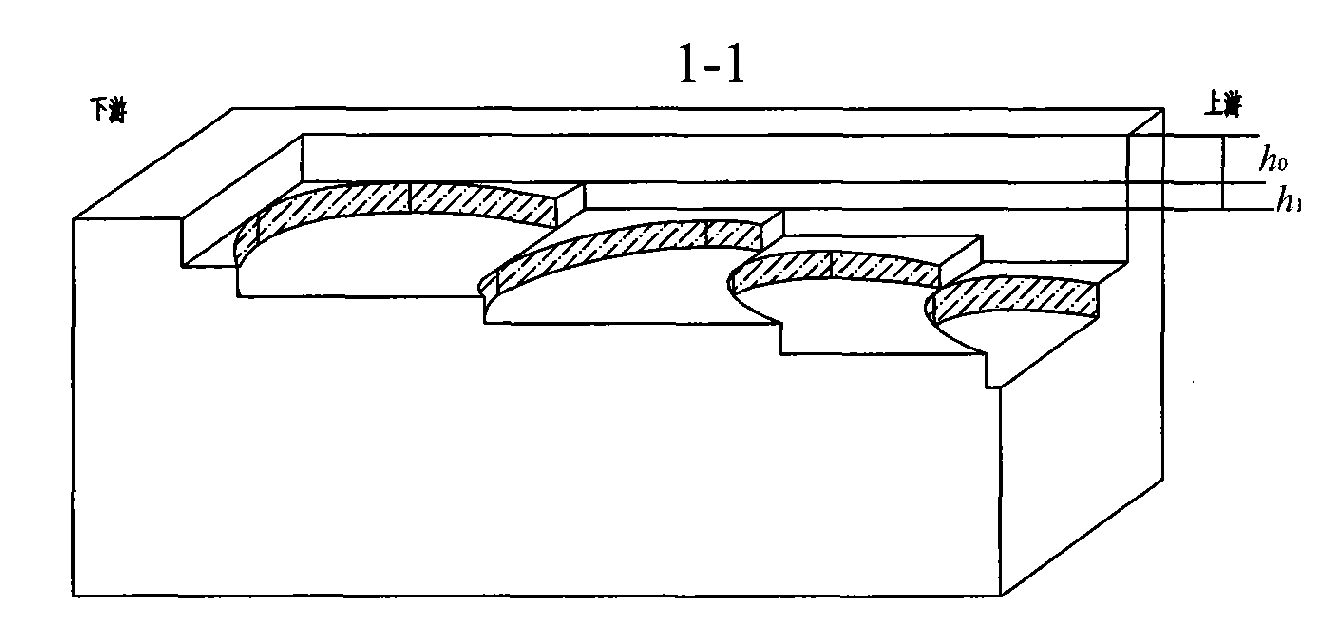

Gas end surface sealing structure with three-dimensional feather-like textured bottom shaped grooves

A gas end surface sealing structure with three-dimensional feather-like textured bottom shaped grooves comprises a dynamic ring and a static ring which are used for sealing a mechanical end surface. As for the dynamic ring and the static ring, at least one sealed end surface is provided with a plurality of three-dimensional shaped grooves. Non-grooved areas among the three-dimensional shaped grooves serve as sealing weirs. Each three-dimensional shaped groove consists of a pumping groove and a spiral groove which are provided with bottoms similar to feather texture features. The pumping grooves are radially distributed and positioned at the upstream part of the sealed end surface. The depths of the pumping grooves are gradually reduced from upstream parts to downstream parts. The pumping groove is connected with the spiral groove. Spiral angles of spiral lines at windward lateral walls of the spiral grooves are greater than the spiral angles of spiral lines at leeward lateral walls. The depths of the spiral grooves are gradually reduced from upstream parts to downstream parts. A continuous planar ring-band sealing dam is arranged at downstream parts of the spiral grooves. The gas end surface sealing structure has the advantages of strong static pressure and dynamic pressure effect of fluid on the end surface, good low-speed start-up performance, excellent pressure resistibility, strong anti-articulation capability, little leakage and good wearability.

Owner:ZHEJIANG UNIV OF TECH

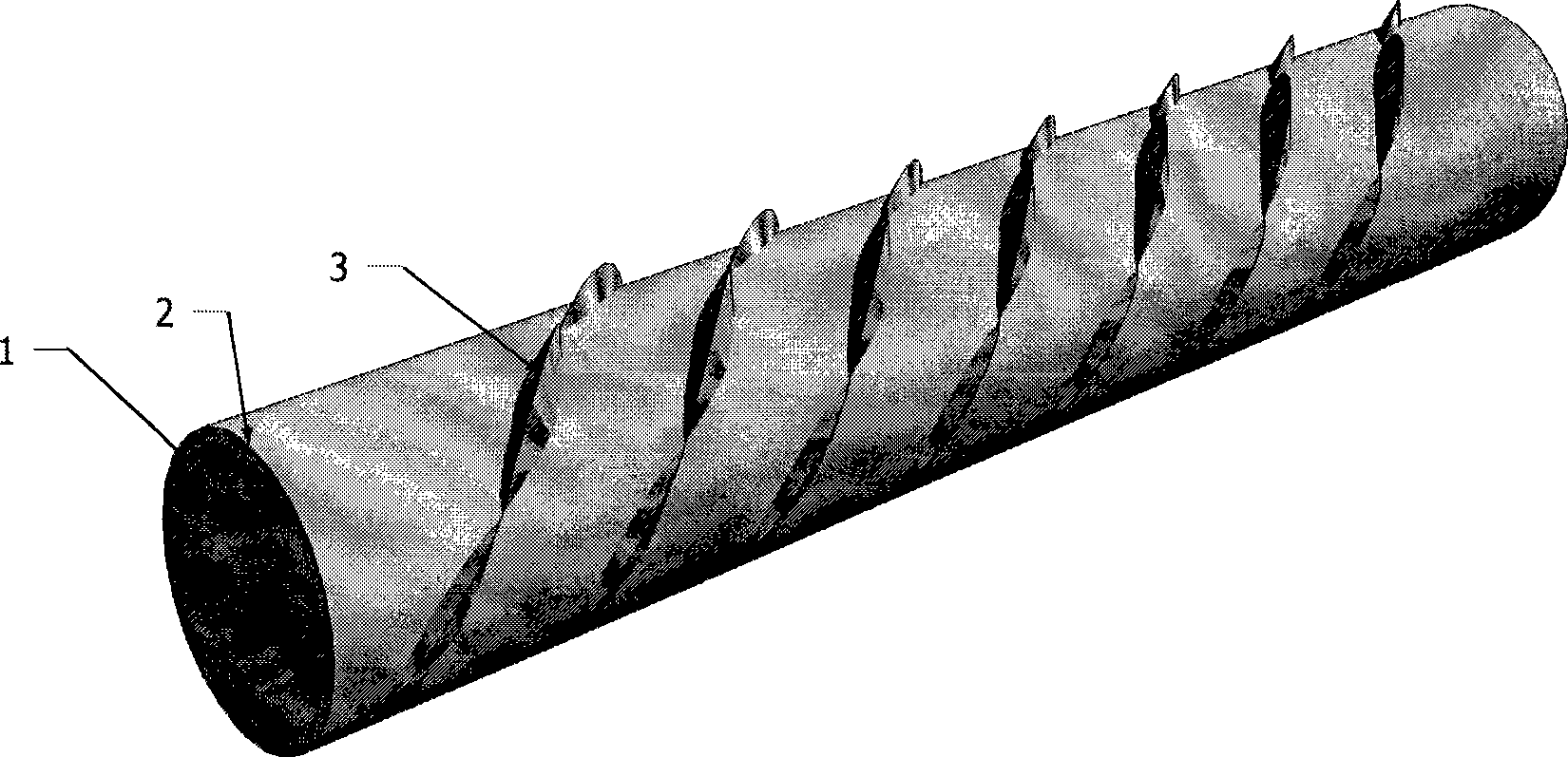

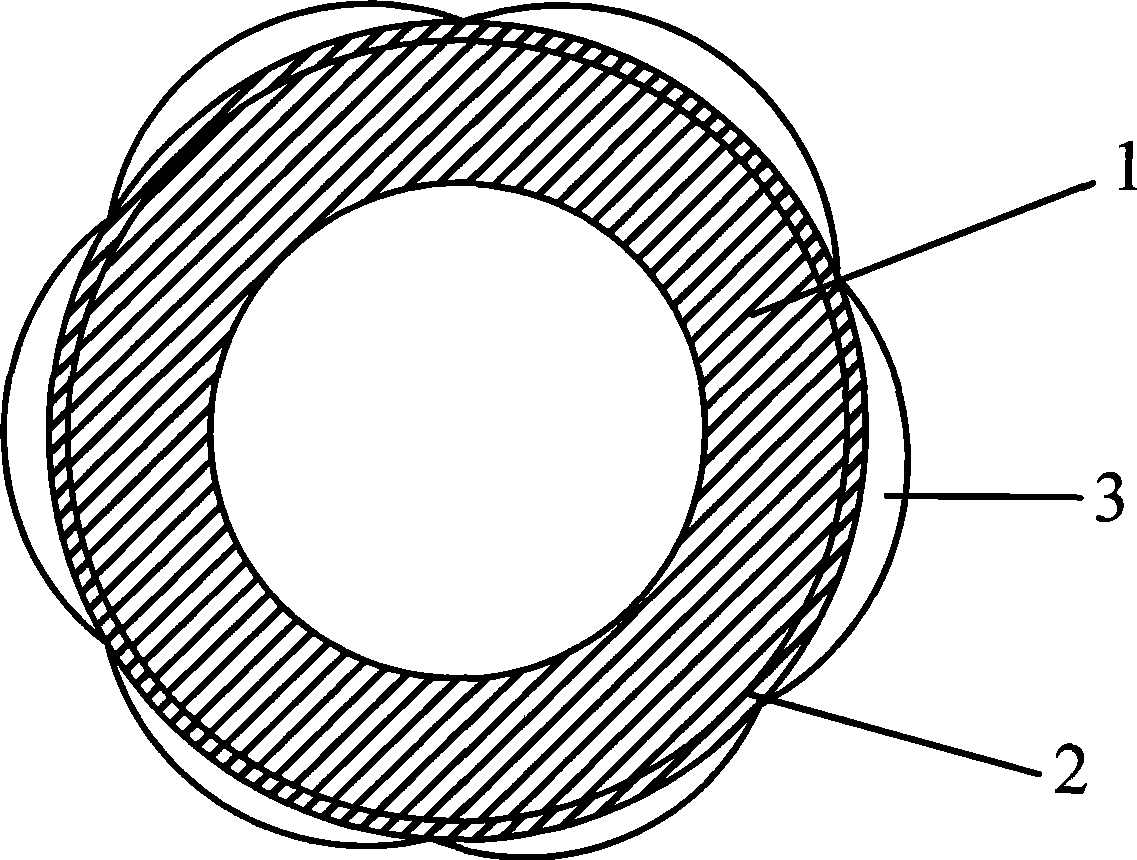

Suppressing vibration method for marine riser vortex-induced vibration and suppressing vibration apparatus thereof

InactiveCN101387188AReduce the amplitudeReduce weightDrilling rodsDerricks/mastsVertical tubeEngineering

The invention relates to a vibration inhibiting method and a vibration inhibiting device capable of effectively inhibiting vortex-induced vibration of a marine riser. The vibration inhibiting device is provided with the riser, an air guide sleeve on the riser, and a flow disturbing device which is fixed on the air guide sleeve, and is characterized in that the flow disturbing device is a flow disturbing rib which is formed by a plurality of end-to-end crescent-shaped flow disturbing ribs; and the flow disturbing rib is arranged on the outer surface of the air guide sleeve in the form of being winded by a spiral line, and the screw pitch of the flow distributing rib is 5 to 15 times of the outside diameter of the riser. The vibration inhibiting method comprises the following steps: firstly, the air guide sleeve which is enwrapped and fixed on the outer surface of the riser is prepared according to the outside diameter of the riser required to be protected; secondly, one flow disturbing rib or a plurality of flow disturbing ribs which are manufactured are fixed on the outer surface of the air guide sleeve in advance according to the screw pitch or the position of the spiral line which is predefined and marked on the outer surface of the air guide sleeve; and thirdly, the air guide sleeve provided with the flow disturbing rib is arranged on the outer surface of the riser. Therefore, the vibration inhibiting method and the vibration inhibiting device can effectively inhibit the vortex-induced vibration of the riser; the weight of the device can be reduced from 30 percent to 60 percent; and the construction cost can be greatly reduced.

Owner:OCEAN UNIV OF CHINA

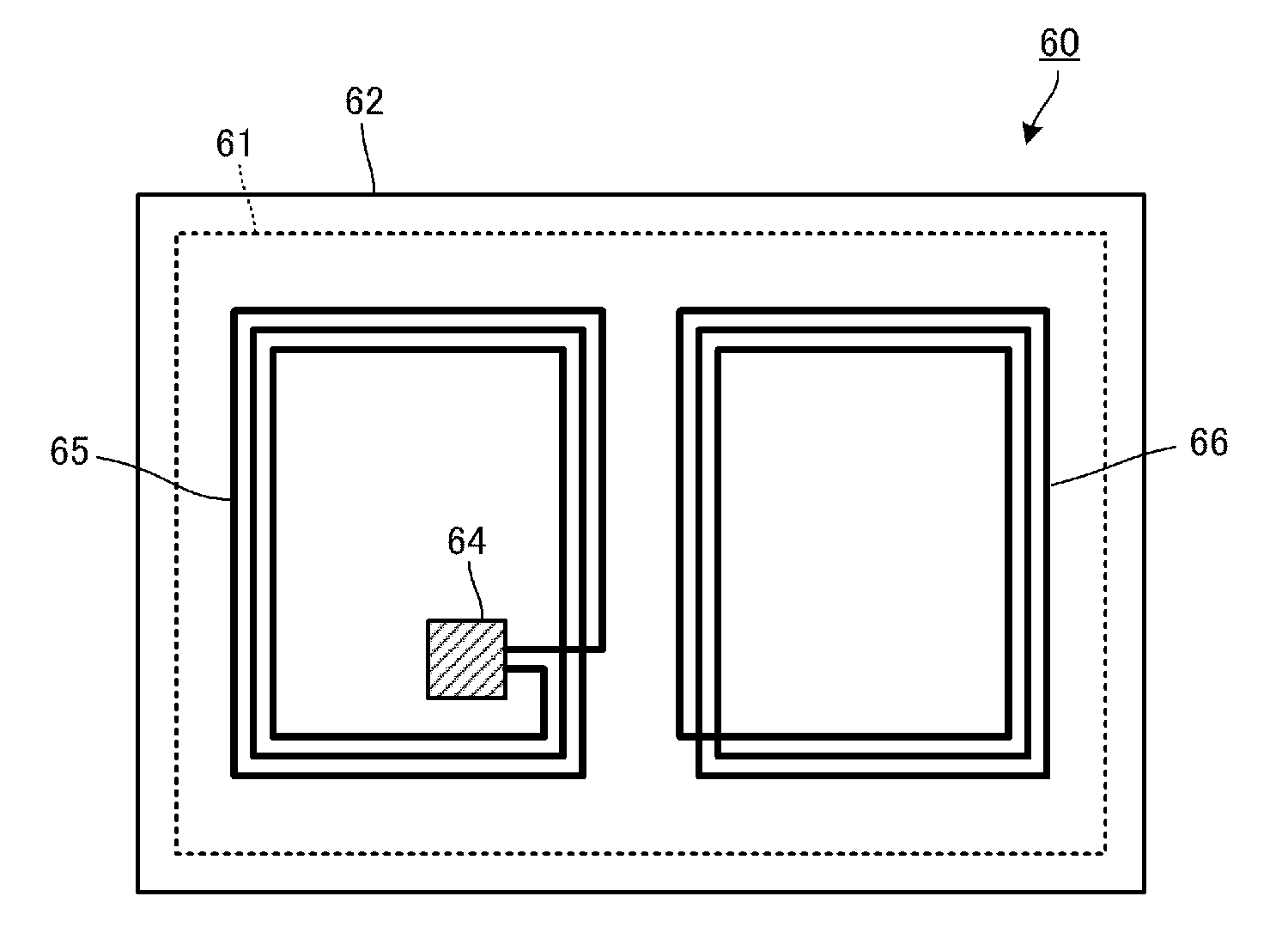

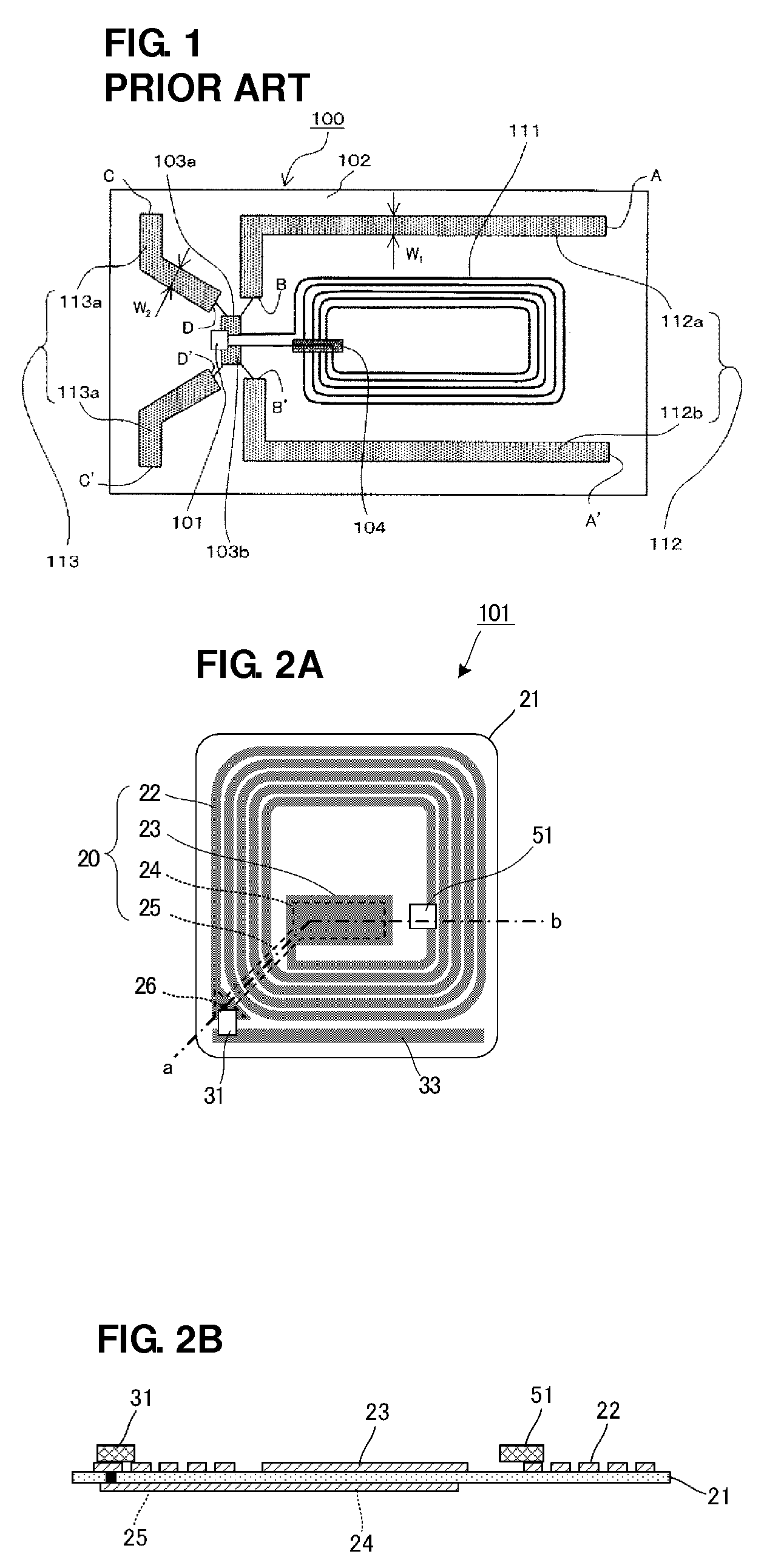

Wireless IC device

ActiveUS20080246664A1Good radiation characteristicsReduce device sizeSimultaneous aerial operationsRadiating elements structural formsCapacitanceEngineering

A wireless IC device includes a spiral line electrode portion and a first capacitance electrode connected to the inner end of the line electrode portion, which are disposed on the top surface of a substrate. A second capacitance electrode opposing the first capacitance electrode and a cross line electrode, which connects the second capacitance electrode and a connecting portion that connects the top and bottom surfaces, are disposed on the bottom surface of the substrate. The connecting portion electrically connects the outer end of the line electrode portion and an end of the cross line electrode. A wireless IC is mounted such that terminal electrodes thereof are connected to the connecting portion and an end of a radiating electrode. A radiating / resonating electrode including the line electrode portion, the capacitance electrodes, and the cross line electrode can act both as a resonant circuit for a resonant tag and as a radiating electrode serving as an RFID tag.

Owner:MURATA MFG CO LTD

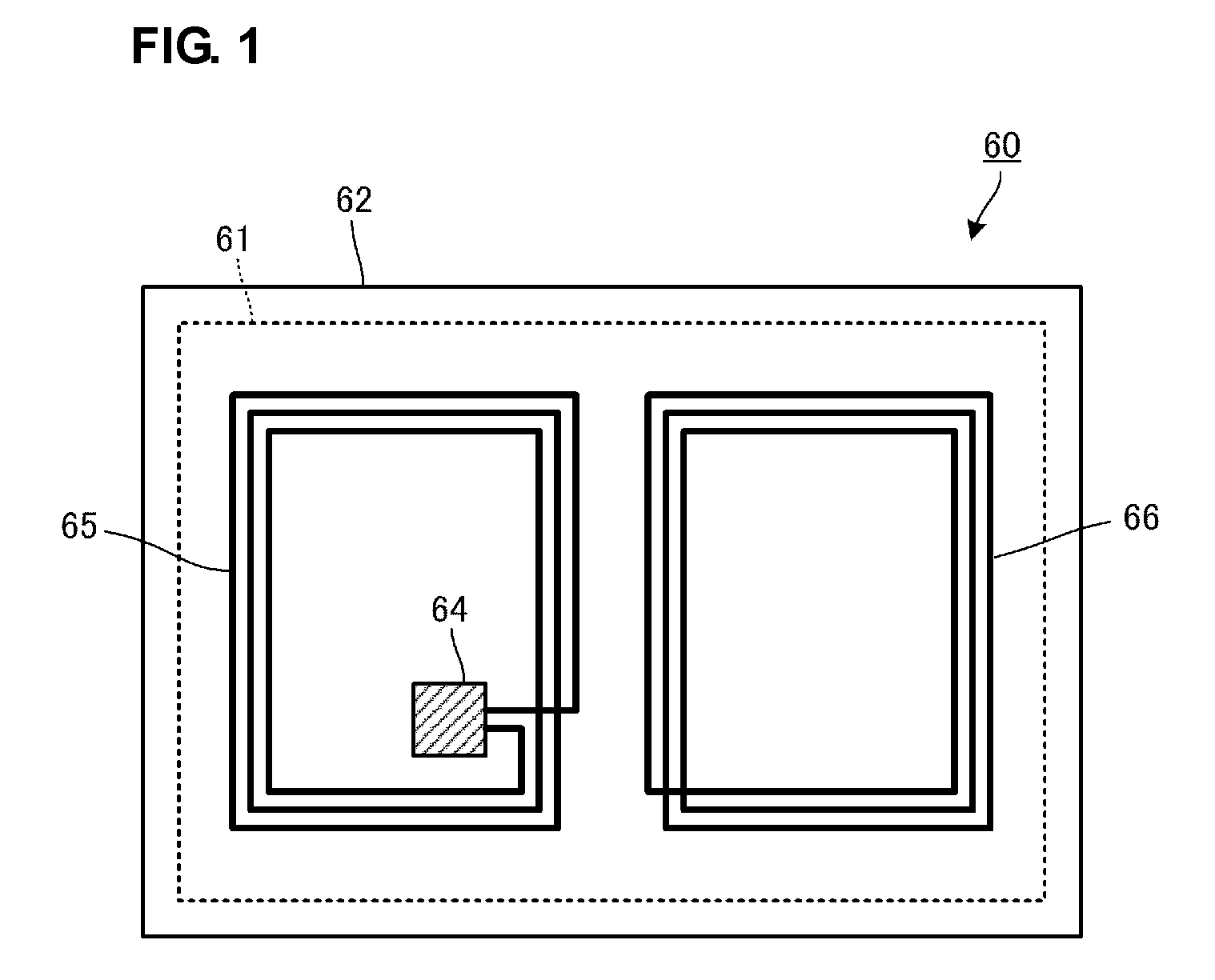

Radio IC device

InactiveUS20110090058A1Good radiation characteristicsSimultaneous aerial operationsCircuit arrangementsEngineeringIc devices

A radio IC device that can be used in a plurality of frequency bands for RFID tags and that is compact and has superior radiation characteristics is provided. A spiral line electrode portion and a first side electrode, extending from an inner end thereof, of a capacitor electrode portion are provided on a top surface of a sheet-shaped substrate, and a second side electrode arranged to face the first side electrode and a crossing line electrode are provided on a bottom surface of the substrate. A first radio IC chip is arranged at a location in the line electrode portion, and a second RFID tag radio IC is arranged so as to be connected to a front-to-back connection portion and an end of an electric-field radiation electrode portion. The radio IC chip rectifies an RF signal in a first frequency band and outputs and supplies power to the second RFID tag radio IC.

Owner:MURATA MFG CO LTD

Peeling machine for orange

InactiveCN1631272AHigh success rate of one-time peelingImprove productivityVegetable peelingFood treatmentProduction rateSEMI-CIRCLE

Disclosed is an orange barking machine, which comprises a peel cutting device, a barking device, a transfer arrangement connected therewith, a mated sprinkling arrangement, and an electric controller, the peel cutting device comprises a high speed rotating peel cutting knife roller, an upper guide plate and a lower guide plate, the peel cutting knives on the knife roller are arranged along the single-head spiral lines at equal appearing interval on the roller surface, the barking device comprises bicycle chain conveyor belt and shift rod rows, each husking roll is equipped with even teeth in the shape of semi-circles with coated silicone rubber material.

Owner:象山双鱼轻工机械有限公司

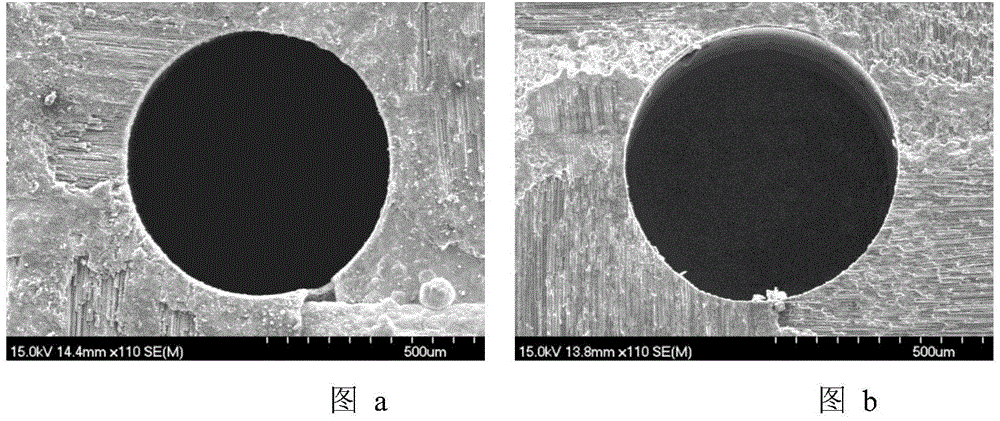

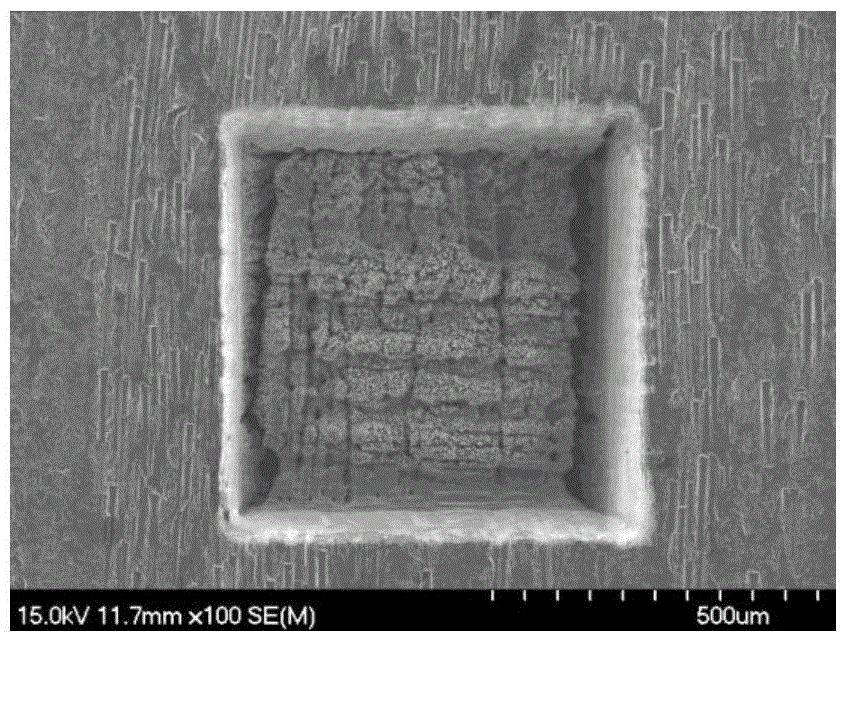

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

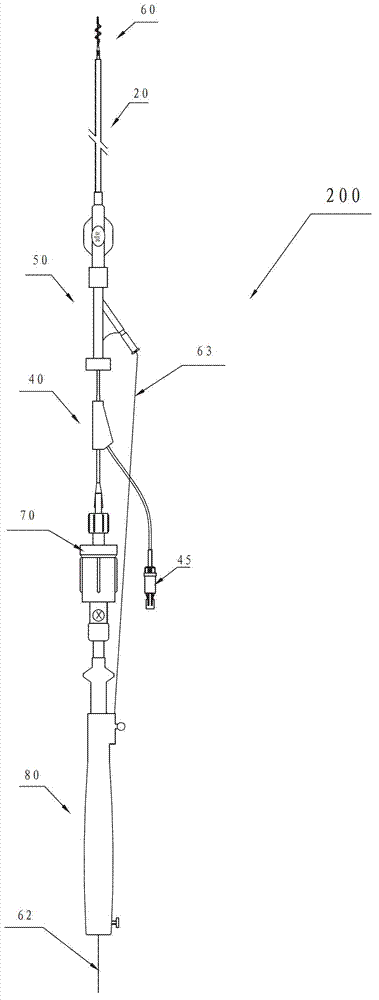

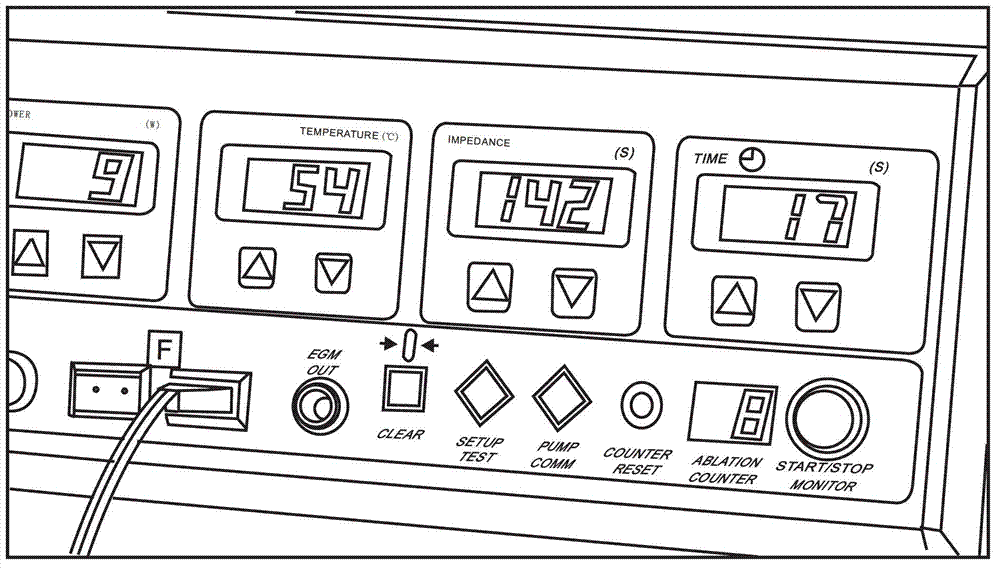

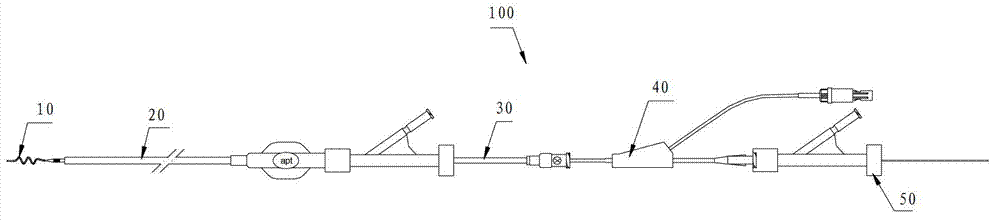

Radiofrequency ablation electrode catheter of renal artery rail

ActiveCN102772249AAvoid damageTo achieve the purpose of treating resistant hypertensionSurgical instruments for heatingResistant hypertensionSpiral line

The invention discloses a radiofrequency ablation electrode catheter of a renal artery rail. The radiofrequency ablation electrode catheter aims at improving resistant hypertension treatment effect and is safe and convenient. The radiofrequency ablation electrode catheter is provided with a spiral rail guide wire and a radiofrequency ablation catheter, wherein the far end of the spiral rail guide wire is spiral, and the radiofrequency ablation catheter slides along a spiral line of the spiral rail guide wire. Compared with the prior art, a spiral spring at the far end of the spiral rail guide wire is released to be in the shape of a spiral circle and is located in an artery rail vessel and attached to the inner wall of the artery rail vessel. The radiofrequency ablation catheter slides along the spiral line of the spiral rail guide wire to perform radiofrequency ablation and breaks sympathetic nerves attached to the inner wall of the artery rail vessel so as to achieve the purpose of treating resistant hypertension. According to the radiofrequency ablation electrode catheter, a surgeon can easily control different positions of the radiofrequency ablation catheter on the spiral circle for ablation, operation is convenient, harm to the renal artery is small, surgeries are safe, and treatment effect is remarkably improved.

Owner:APT MEDICAL INC

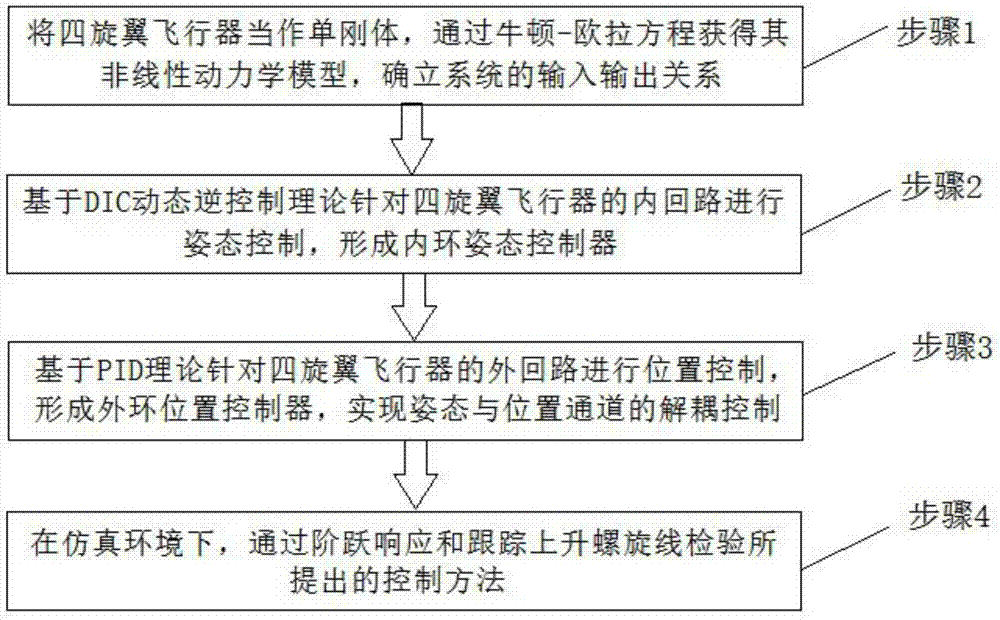

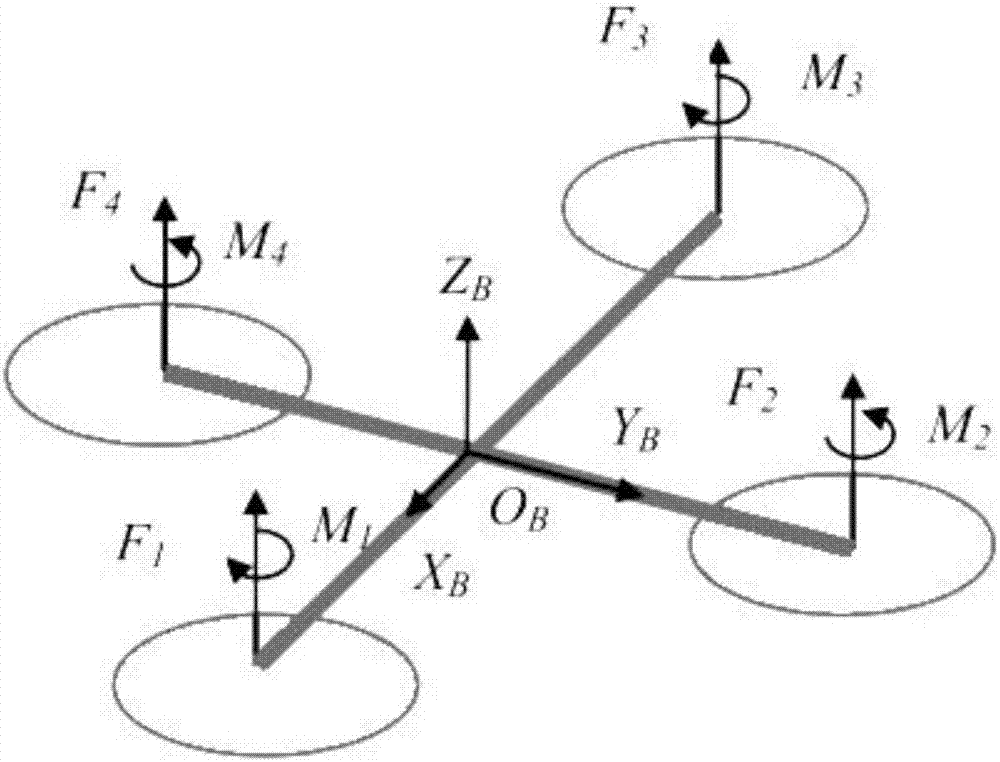

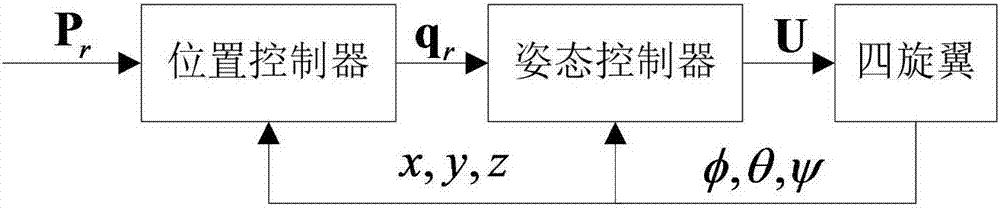

Four-rotor aircraft attitude and position hybrid control method based on DIC-PID

InactiveCN106933104AAchieving Robust ControlImprove control effectAttitude controlAdaptive controlAttitude controlStep response

The invention discloses a four-rotor aircraft attitude and position hybrid control method based on DIC-PID. The method comprises the steps that 1 a four-rotor aircraft is used as a single rigid body, and the nonlinear dynamics model is acquired through a Newton-Euler equation to determine in-out relation of a system; 2 attitude control is carried out on the internal loop of the four-rotor aircraft based on a DIC dynamic inverse control theory to form an inner ring attitude controller; 3 position control is carried out on the external loop of the four-rotor aircraft based on a PID theory to form an outer ring position controller, and decoupling control of attitude and position channels is realized; and 4 in a simulation environment, the proposed control method is tested through step response and a tracking rising spiral line. The hybrid control method provided by the invention has better ability to suppress external disturbance and unmodeled dynamics, and can meet the requirements of attitude control and position control of the four-rotor aircraft.

Owner:苏州炎晶电子科技有限公司

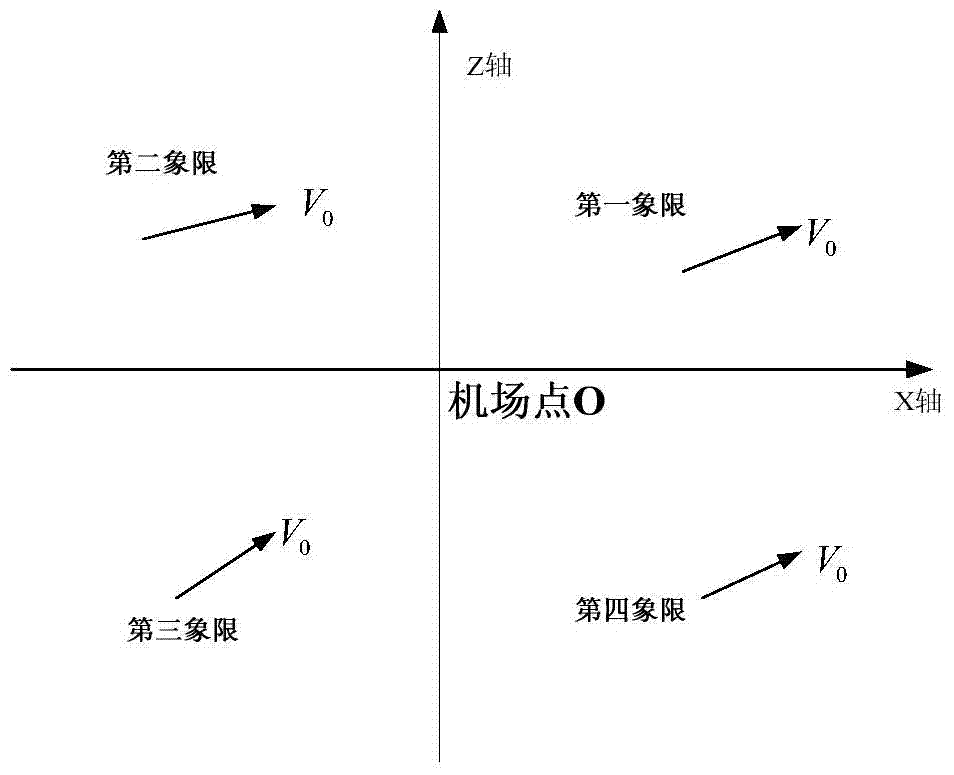

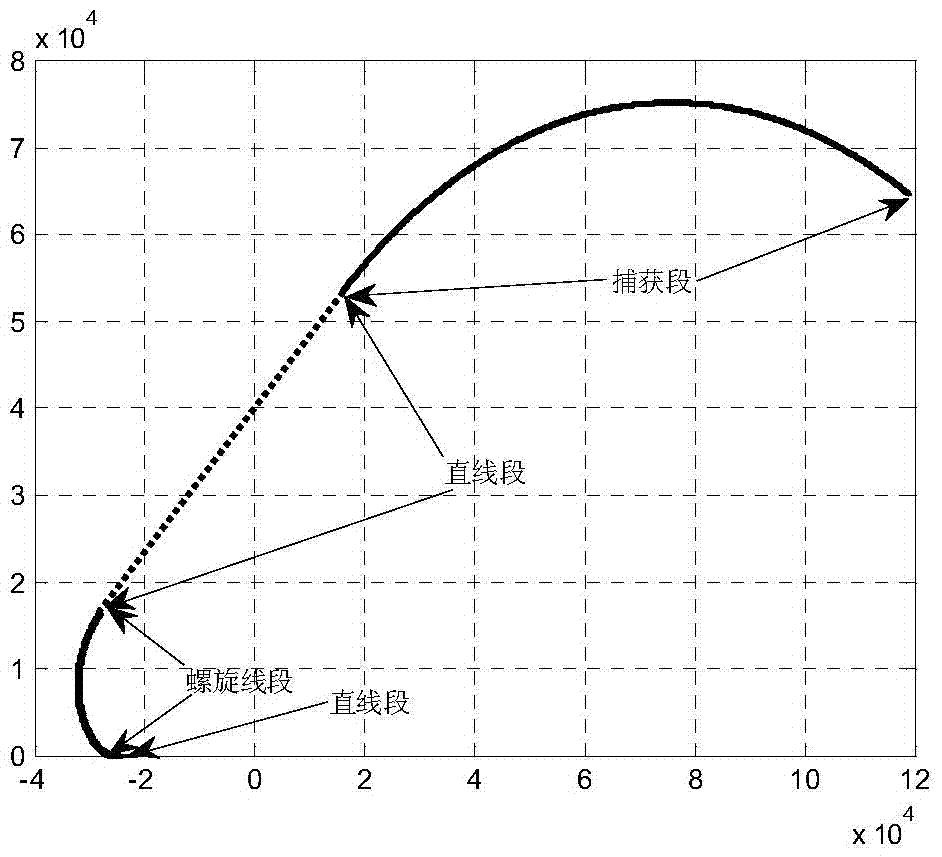

Geometric-programming-based gliding aircraft terminal area energy management trajectory planning method

ActiveCN104714553AReduced mobility requirementsQuick planningPosition/course control in three dimensionsGeometric programmingTrajectory planning

The invention discloses a geometric-programming-based gliding aircraft terminal area energy management trajectory planning method which is used for solving the technical problem that an existing gliding aircraft terminal area energy management trajectory planning method is poor in practicability. According to the technical scheme, on the basis of the state of an aircraft entering a TAEM section, a geometric programming method is utilized for rapidly planning a reasonable and feasible TAEM plane trajectory; on the basis of the TAEM plane trajectory planning, height deduction is performed, and therefore a complete trajectory planning strategy is given. Due to the fact that the aircraft enters an entry of an automatic landing section in a spiral-line mode in the geographic planning process, the sudden overload change phenomenon is effectively avoided, and therefore the requirement for the aircraft maneuverability is lowered; meanwhile, during trajectory planning, the state of the aircraft at the TAEM section at the initial moment is considered, corresponding flight paths are planned in a classified mode for the entering state of the aircraft, the reasonable trajectory can be rapidly planned, the requirements for different entering directions are met, and the planning speed is high through simulation verification.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

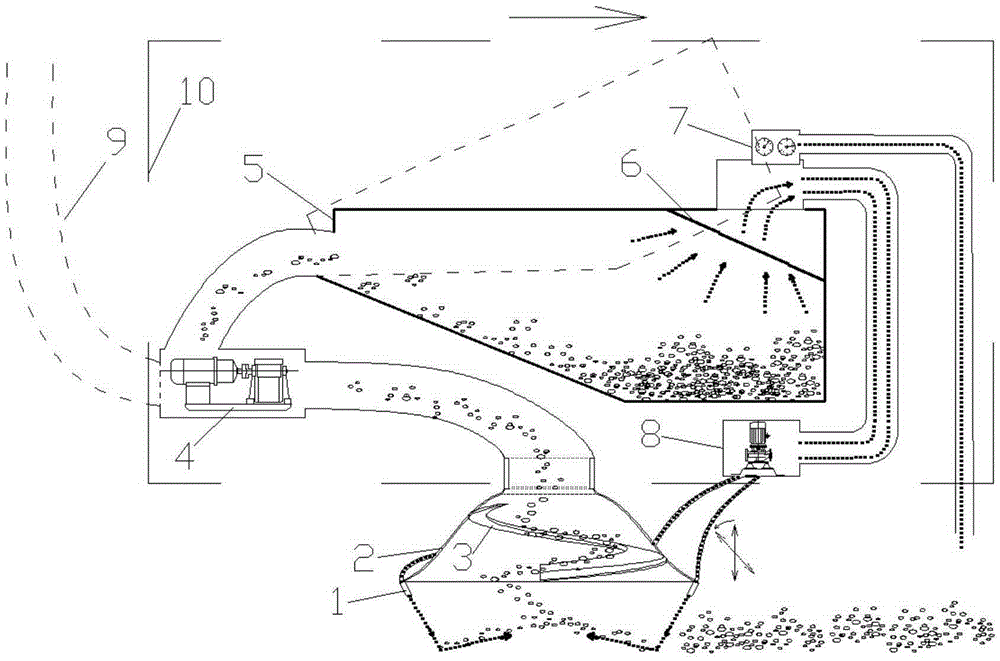

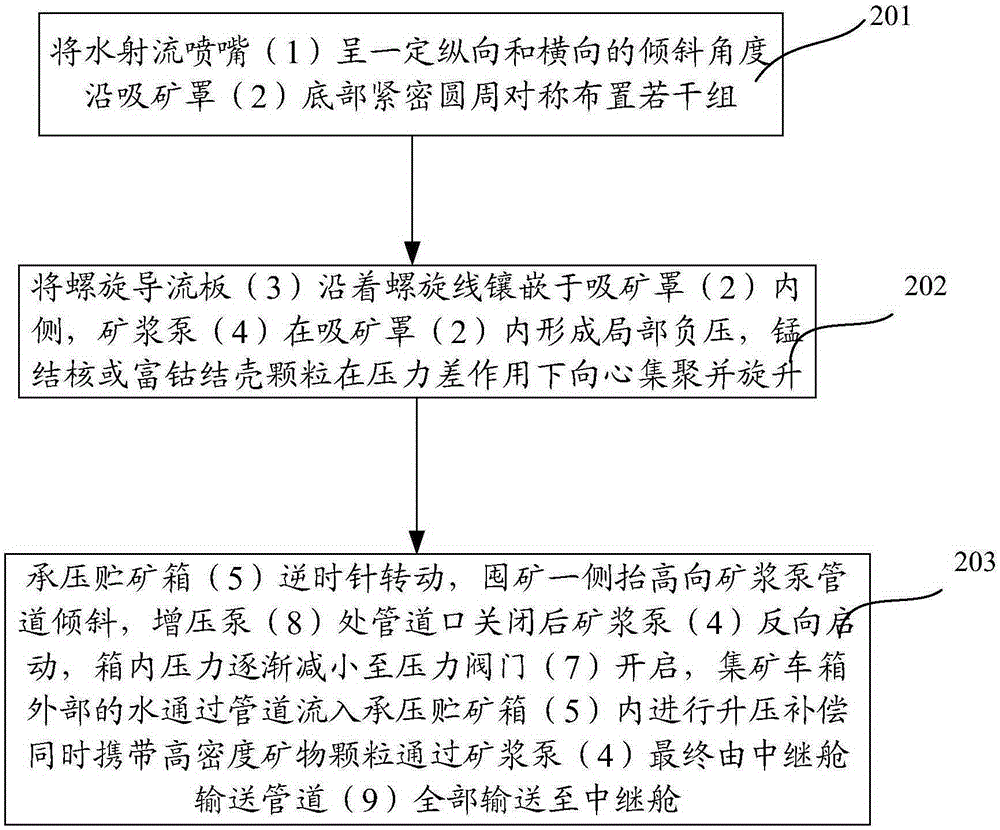

Submarine ore collecting vehicle and ore collecting method thereof

The invention discloses a submarine ore collecting vehicle and an ore collecting method thereof. The submarine ore collecting vehicle comprises water jet nozzles (1), an ore sucking hood (2), a spiral flow guiding plate (3), an ore slurry pump (4), a pressure-bearing ore storage tank (5), a relay cabin conveying pipeline (9) and an ore collecting vehicle cabin body (10), wherein the water jet nozzles (1) are closely arranged into a plurality of groups along the bottom of ore sucking hood (2) at certain vertically and transversely inclined angles; the spiral flow guiding plate (3) is embedded into the inner side of the ore sucking hood (2) along a spiral line; the ore slurry pump (4) is connected to the ore sucking hood (2) through an ore slurry pump pipeline, so that local negative pressure is formed in the ore sucking hood (2), and a vertical-axis whirlpool which flows upwards is formed under the flow guiding action of the spiral flow guiding plate (3); the ore slurry pump (4) conveys collected ores to a relay cabin through the relay cabin conveying pipeline (9), and is further connected with the pressure-bearing ore storage tank (5). The submarine ore collecting vehicle and the ore collecting method have the advantages of being environmentally friendly, efficient, lower in energy consumption, and reliable.

Owner:SHANGHAI JIAO TONG UNIV

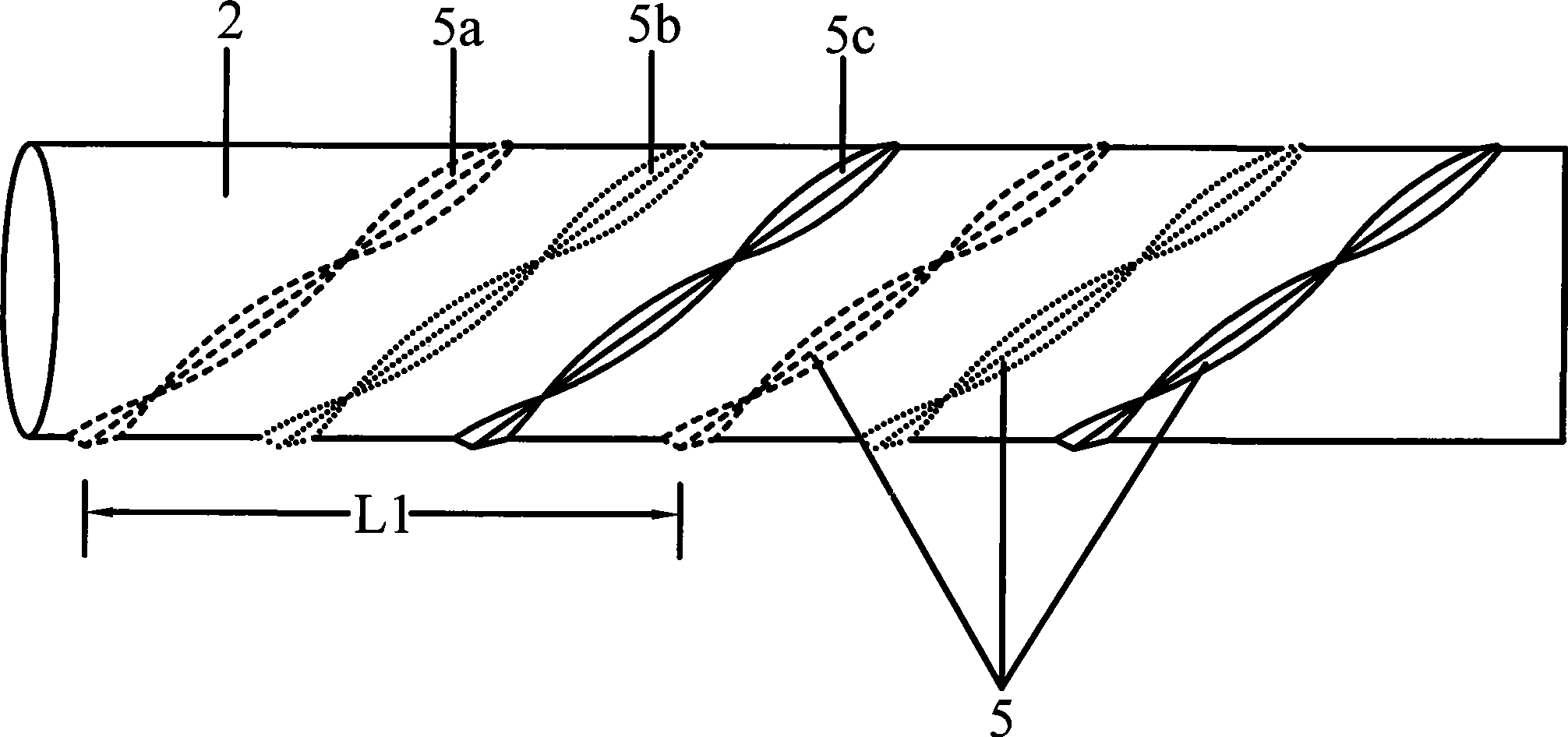

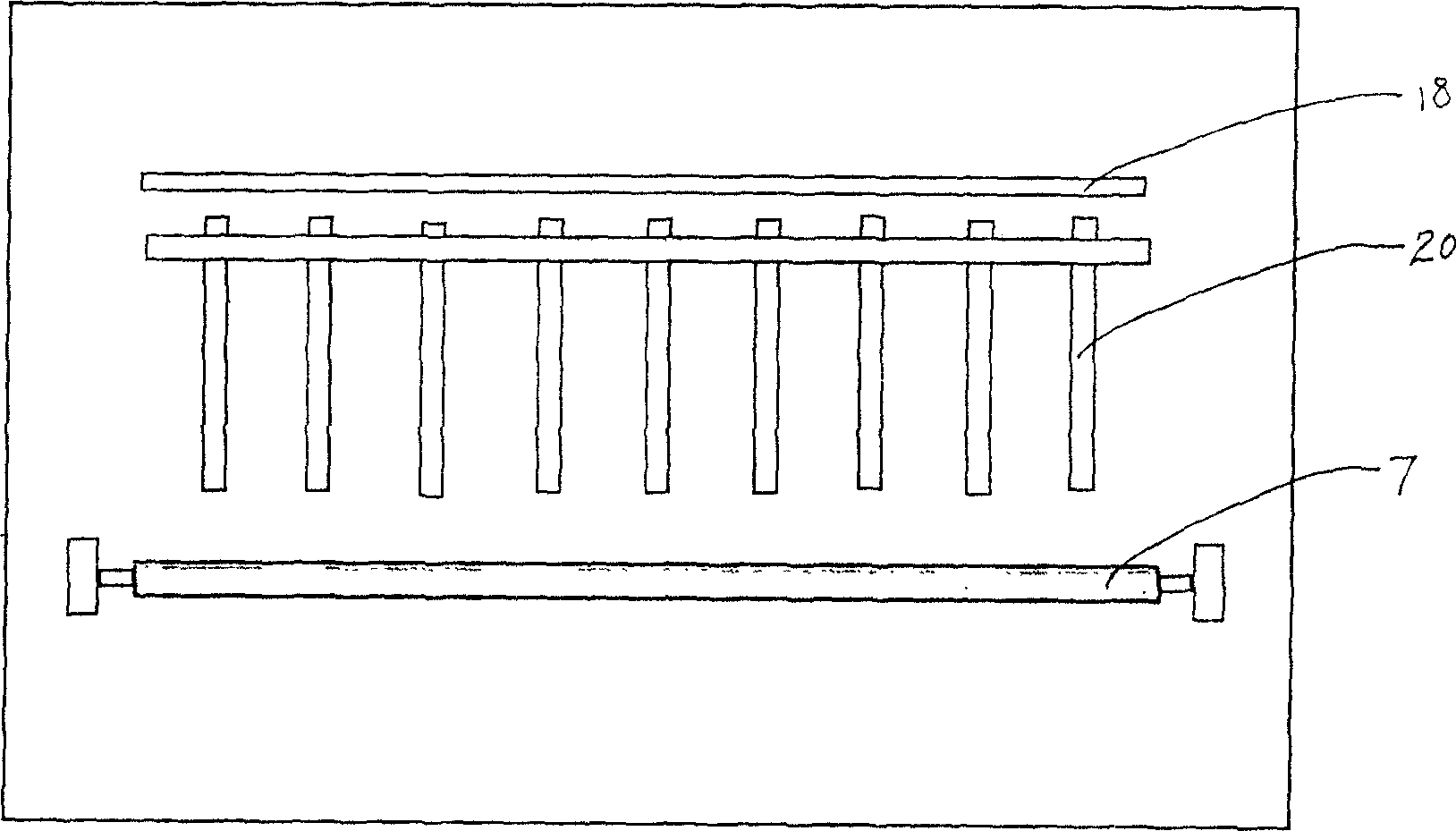

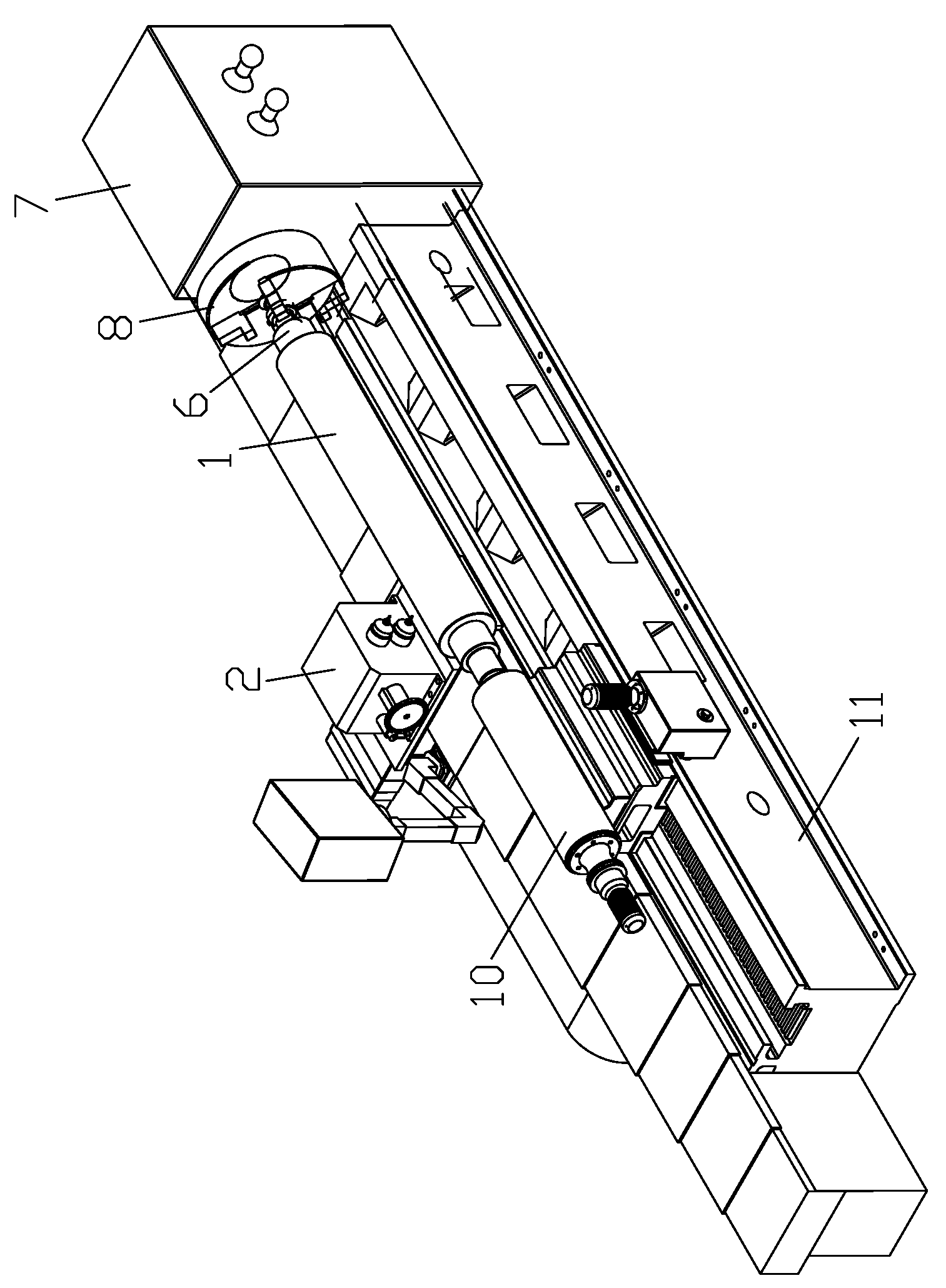

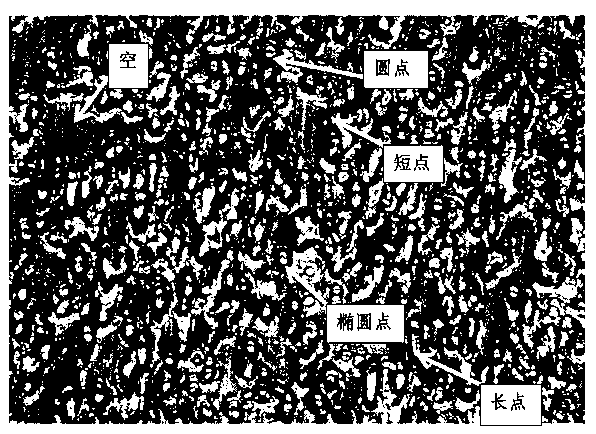

Method and device for processing multi-head laser disordered and textured roller surface

ActiveCN102699524AHigh hardnessIncrease the amount of steelLaser beam welding apparatusNumerical controlPulse beam

The invention relates to a method and a device for processing a multi-head laser disordered and textured roller surface. The method comprises the steps: controlling each pulse laser device to generate a plurality of disordered pulse laser beams by a plurality of random signal generators, and processing a plurality of spiral lines without an overlapped track on the roller surface after focusing, wherein the distance between two adjacent spiral lines is smaller than 150% of a diameter value of a laser speckle; a helical pitch of the spiral line is equal to a numerical value obtained from the distance between the adjacent spiral lines multiplied by quantity of the spiral lines, and the pulse laser device follows a random variable emitted by each random signal generator and changes the duty ratio and frequency of each laser pulse beam at random. The processing device comprises a numerical control roller machine tool, a plurality of lasers and a plurality of laser processing heads; and axial uniform movement are carried out by the the laser processing heads along a lateral bus of the roller. By the scheme, the roller which really accords with disordered requirements can be manufactured; the method for processing the roller surface by laser has the advantages of high disordered rough surface hardness and low production cost without pollution, and the steel quantity of the roller is greatly improved.

Owner:WUHAN HGLASER ENG CO LTD

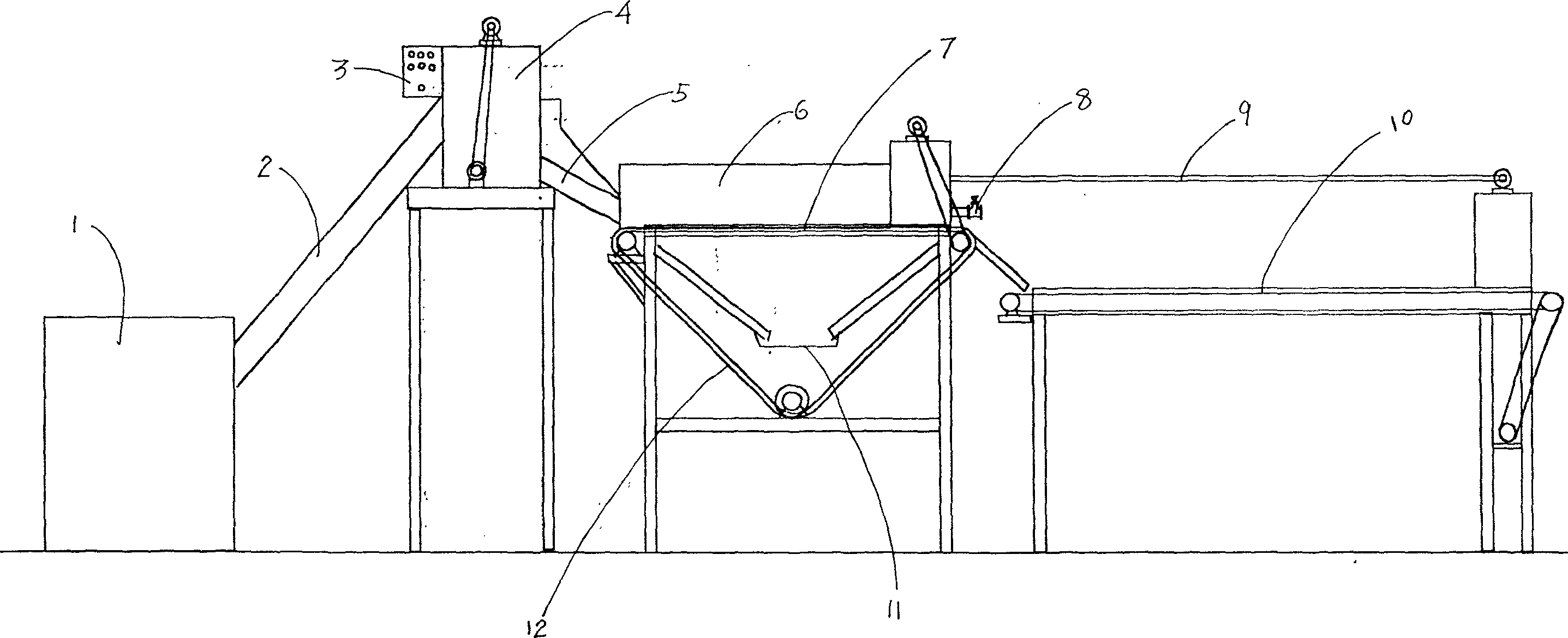

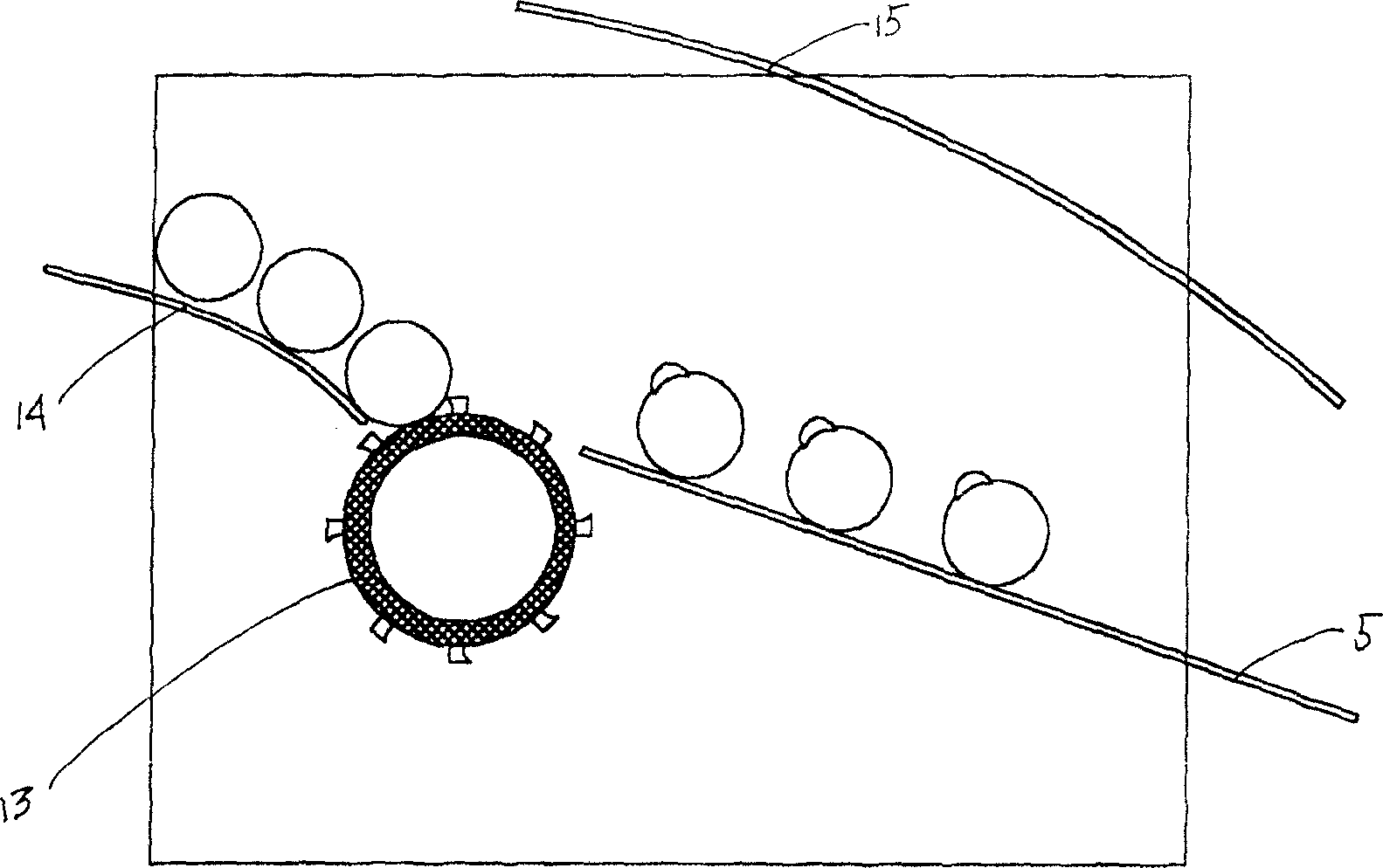

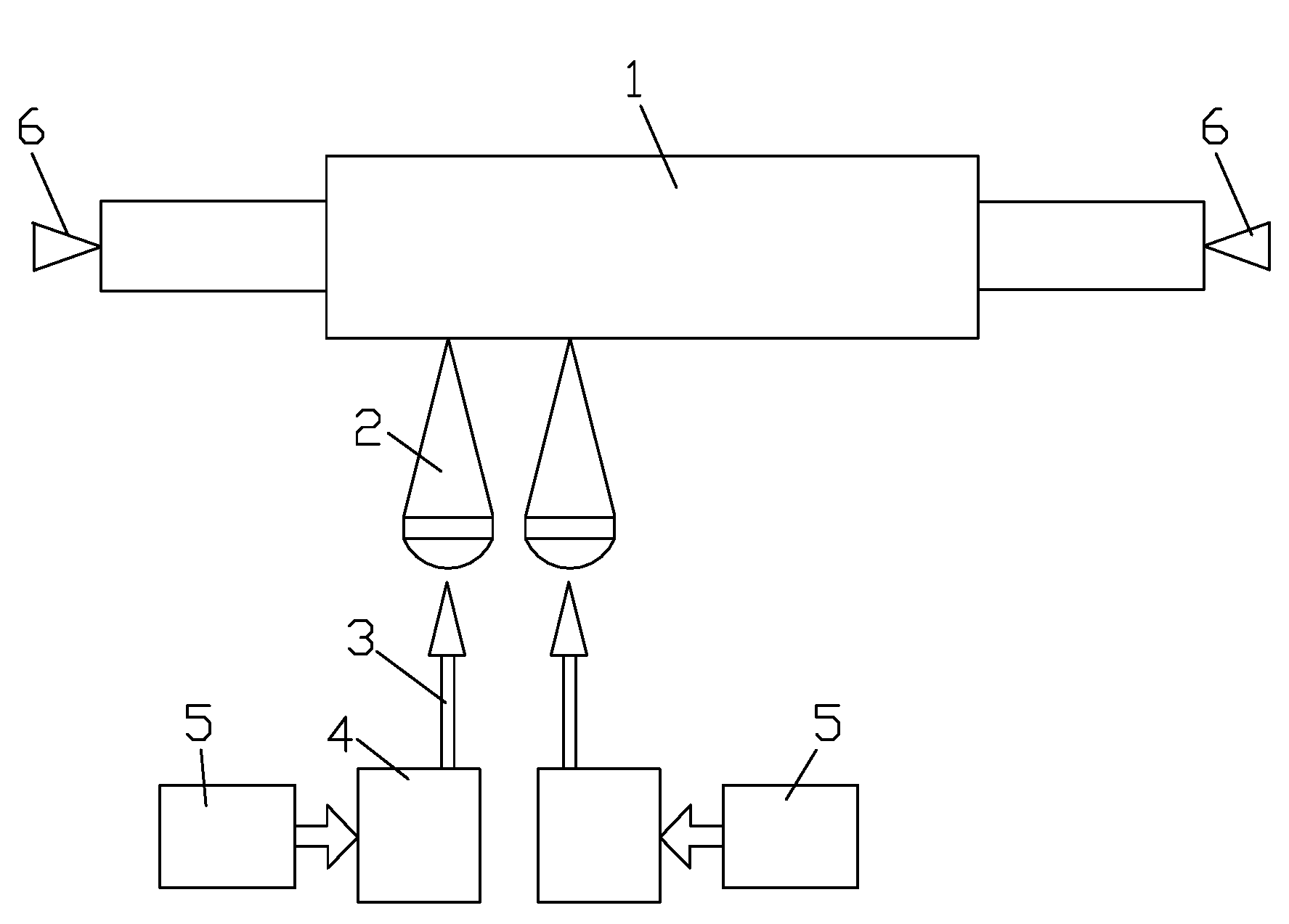

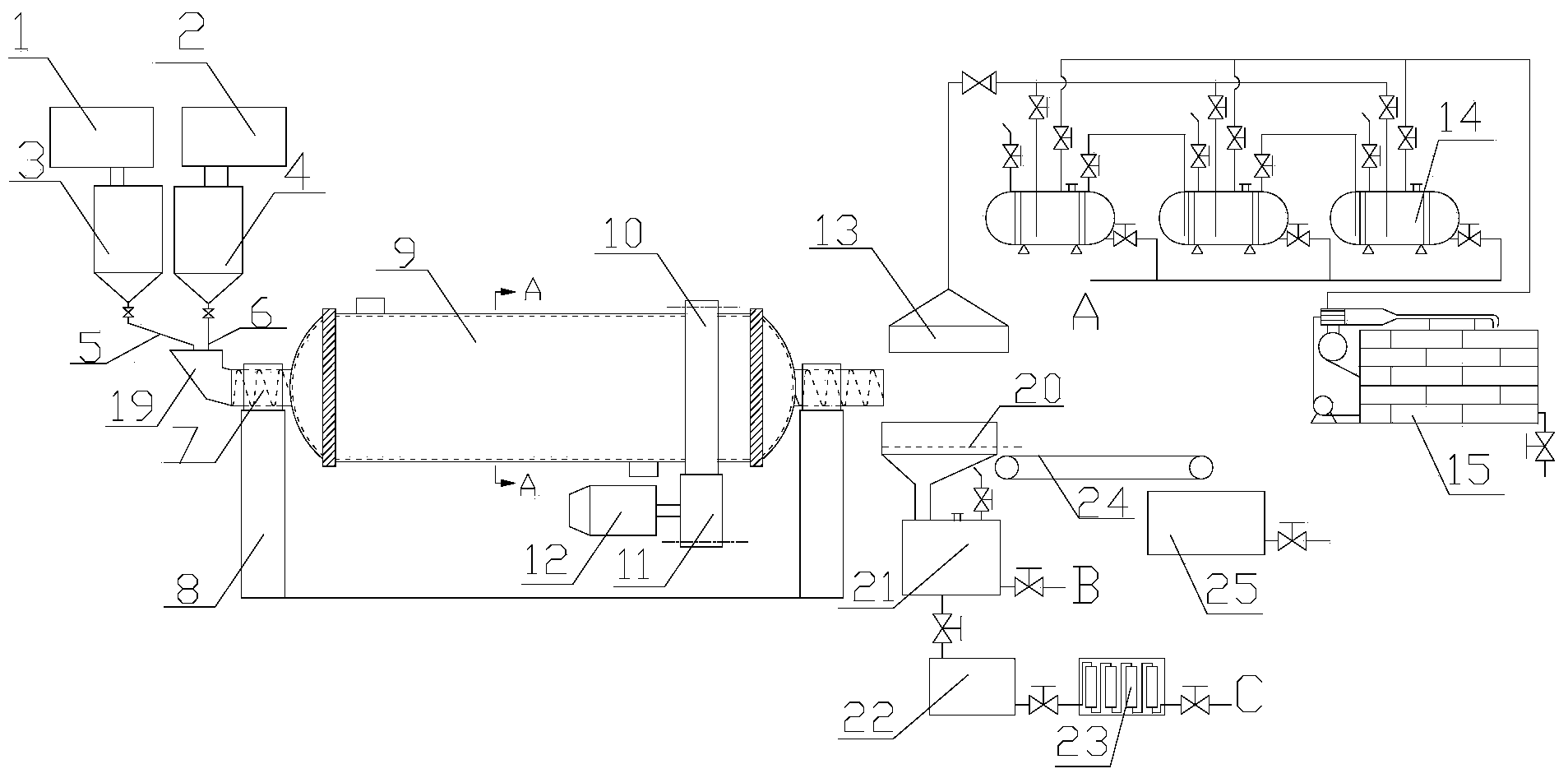

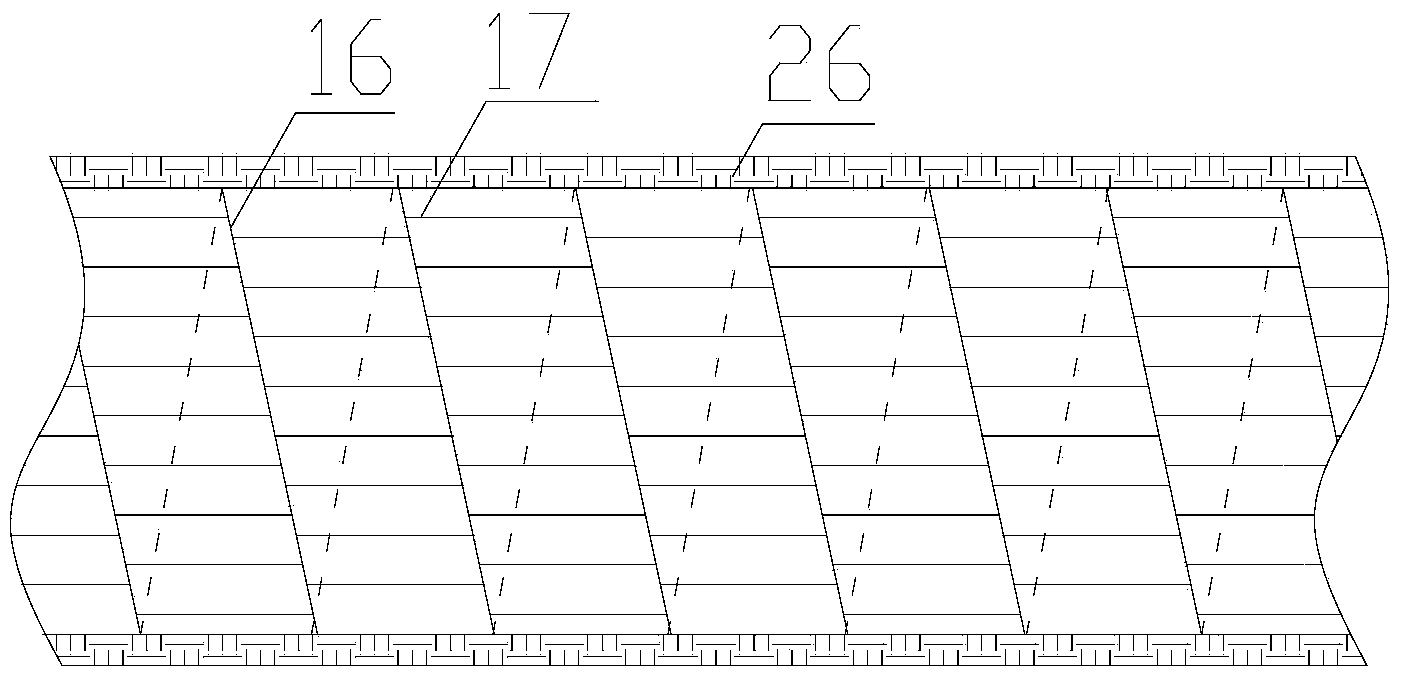

Method and device for continuous acid pickling purification of quartz sand

ActiveCN104058413ARealized by continuous pickling and purificationImproving the effect of pickling and impurity removalSilicaQuartzSpiral line

The invention provides a method for continuous acid pickling purification of quartz sand. The method comprises the steps of heating, material loading, acid pickling, deacidifying, water washing, acid recovering and tail gas treatment. The invention also provides a device for implementing the method to perform continuous acid pickling purification on quartz sand; the device comprises a heating unit, a storage unit, a drum mixer, a water washing unit, an acid recovery unit and a water-jet vacuum unit; spiral line plates are arranged on the inner wall of a drum of the drum mixer, 20-60 lifting plates are mounted between two adjacent spiral line plates, two adjacent lifting plates and the spiral line plates on the two sides thereof are combined to form a lifting bucket, a driven gear is arranged on the outer wall of the drum of the drum mixer in a sleeved manner, a charging opening and a discharging opening are formed in the two ends of the drum, and spiral line plates are mounted on the inner walls of both of the charging opening and the discharging opening. The method and the device are capable of realizing sufficient acid pickling purification of the quartz sand by virtue of continuous automatic feeding, turning over and discharging of the quartz sand and acid liquor; as a result, the production efficiency and the quality of product are improved, and the acid is recycled and absorbed by use of alkaline so that the production cost is reduced, and meanwhile, the environmental pollution is reduced.

Owner:田辉明

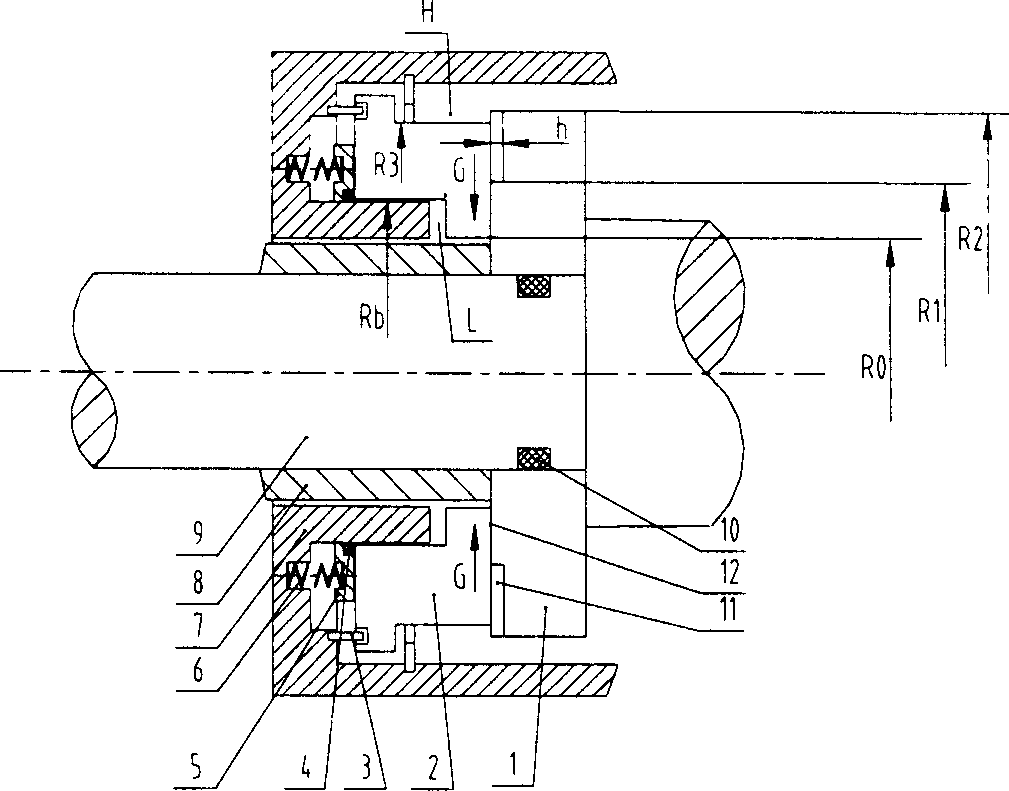

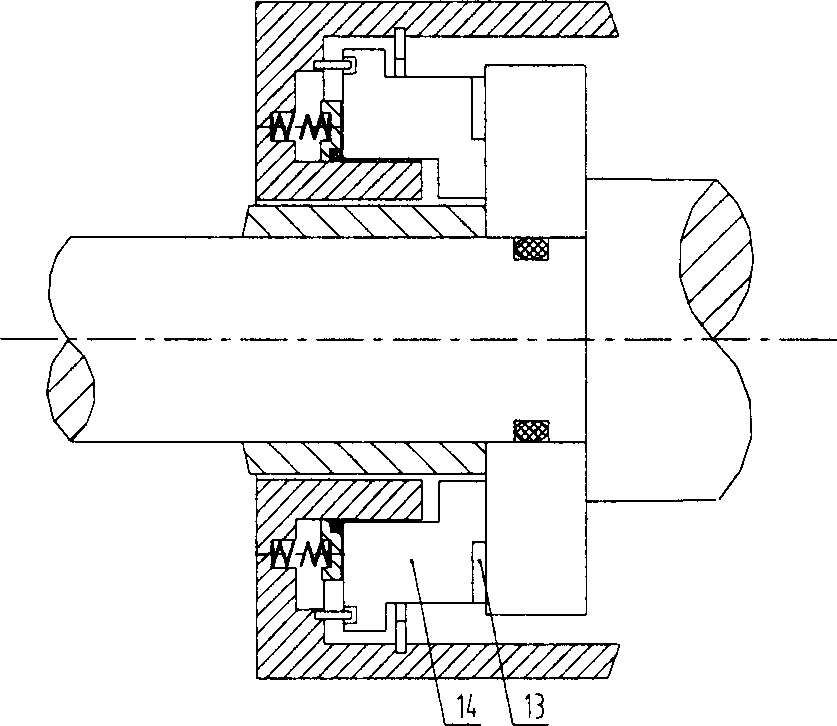

Novel mechanical sealing performance testing apparatus

InactiveCN102589821ASame specific pressureReduce the effects of measurement inaccuraciesMeasurement of fluid loss/gain rateEngineeringAxial force

The invention discloses a novel mechanical sealing performance testing apparatus which is characterized in that a main shaft penetrates through a left end cover and a right end cover on a sealing cavity shell; two pairs of measured sealing rings with the same size are arranged on main shafts at the left end and the right end in the sealing cavity shell; no additional axial force generates at any test medium pressure; two sections of threads of which screw pitches are same and the spiral line directions are opposite are machined on a long shaft sleeve which is in clearance fit with the main shaft; the long shaft sleeve is clockwise rotated to drive a left nut and a right nut which are screwed with the long shaft sleeve to equidistantly move leftwards and rightwards; and a left pressure spring and a right pressure ring are pushed to respectively press two moving rings, so that specific pressures borne by a left pair of sealing surfaces and a right pair of sealing surfaces are identical. The two pairs of sealing rings with the same size are adopted for testing; an average value of test results of the sealing rings is used as a test torque and leakage rate of mechanical sealing of the model number, and thus the influence on the accuracy of the torque and the leakage rate caused by accidental factors such as mounting when only one pair of sealing rings are used for testing is reduced.

Owner:滁州扬安高科技术有限公司

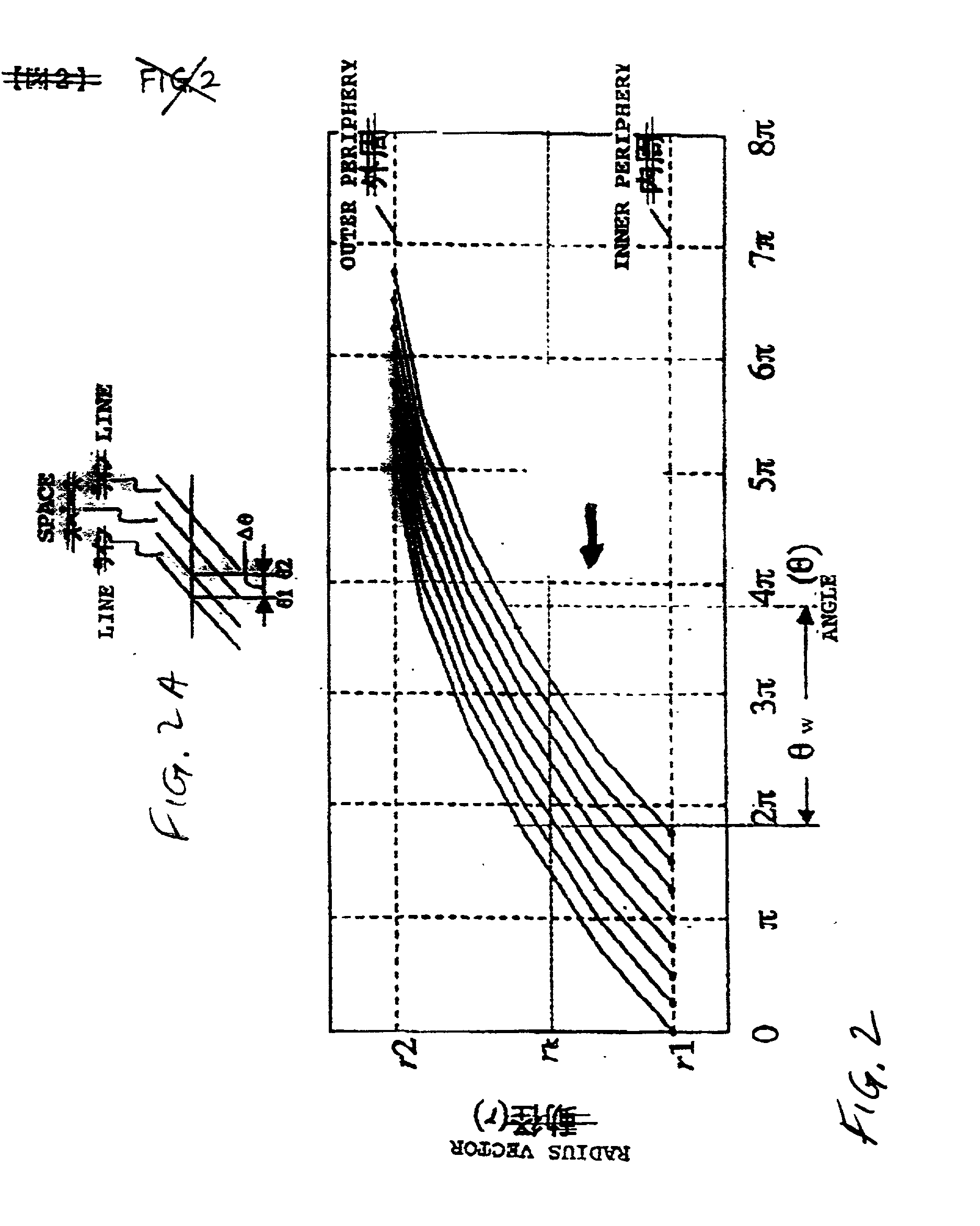

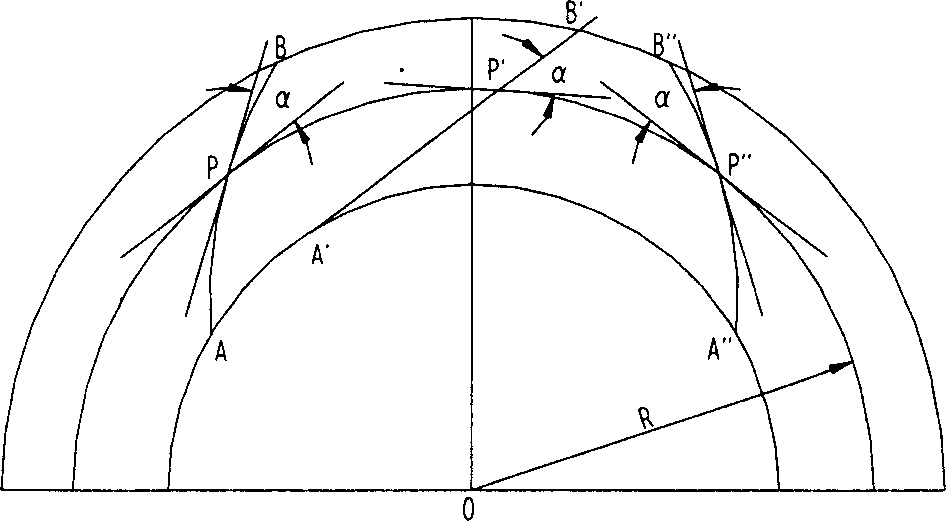

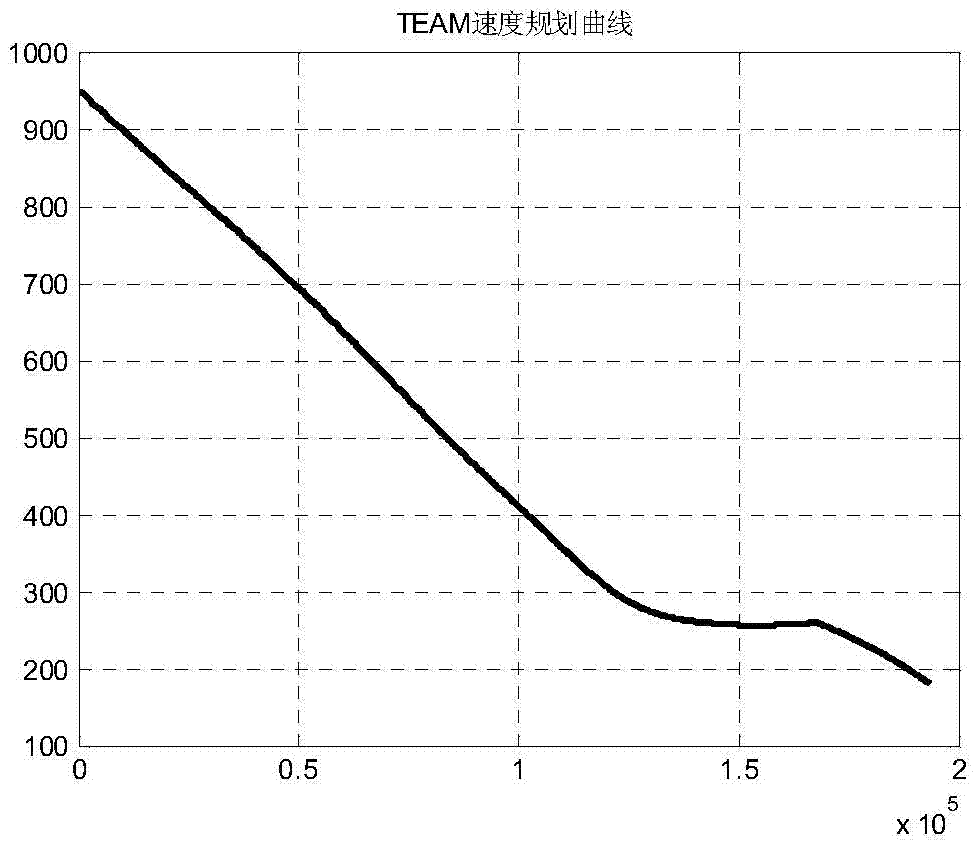

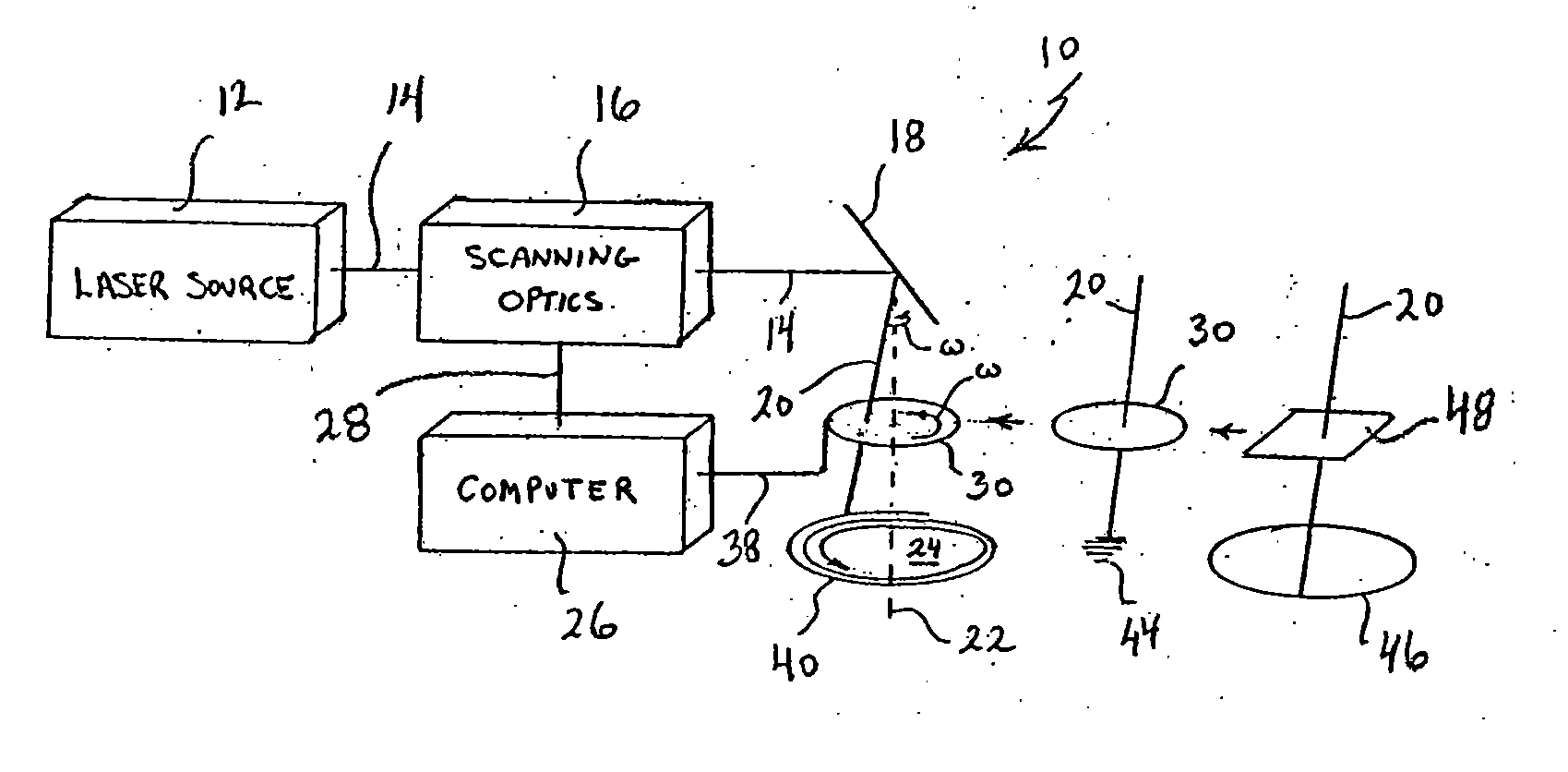

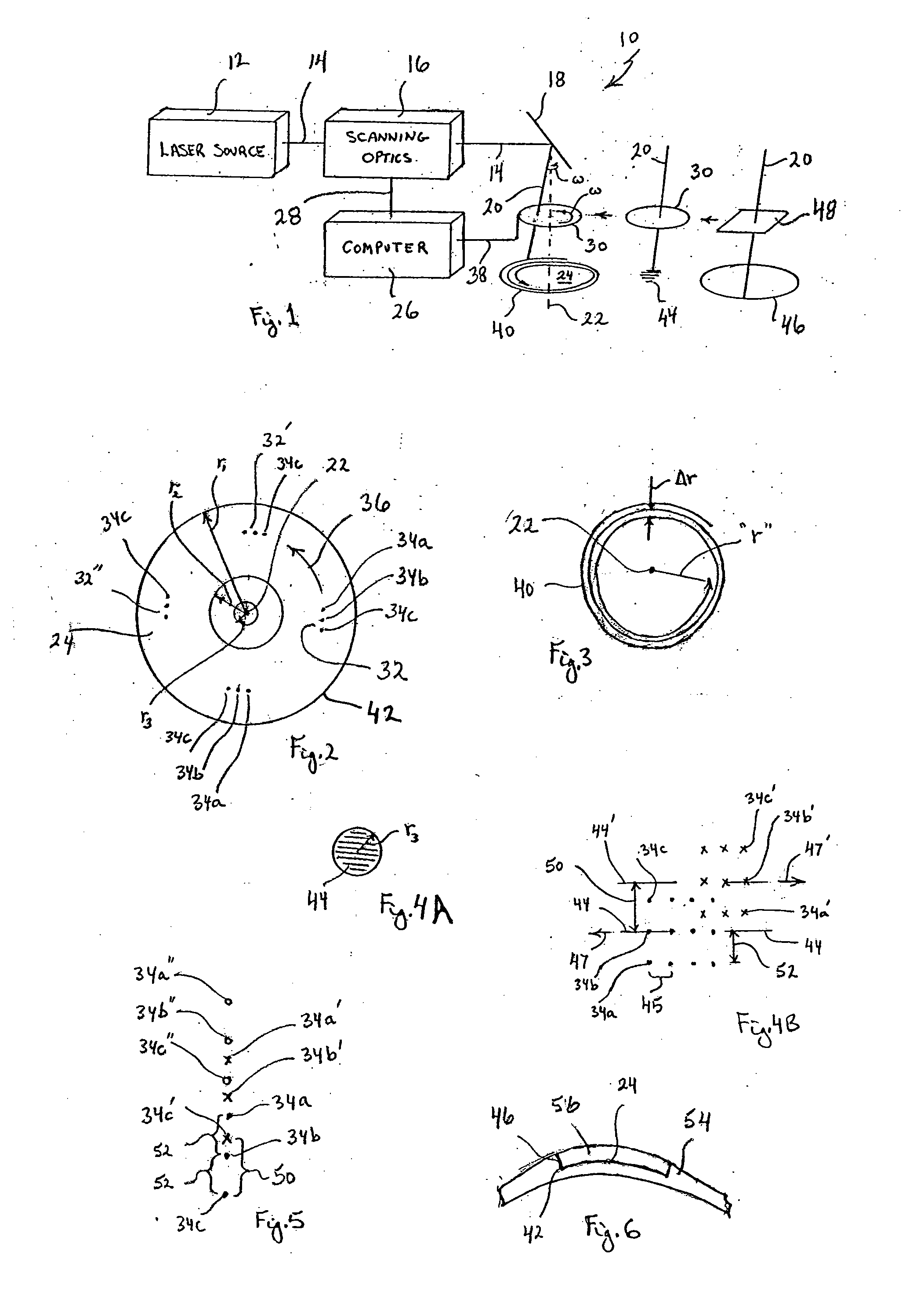

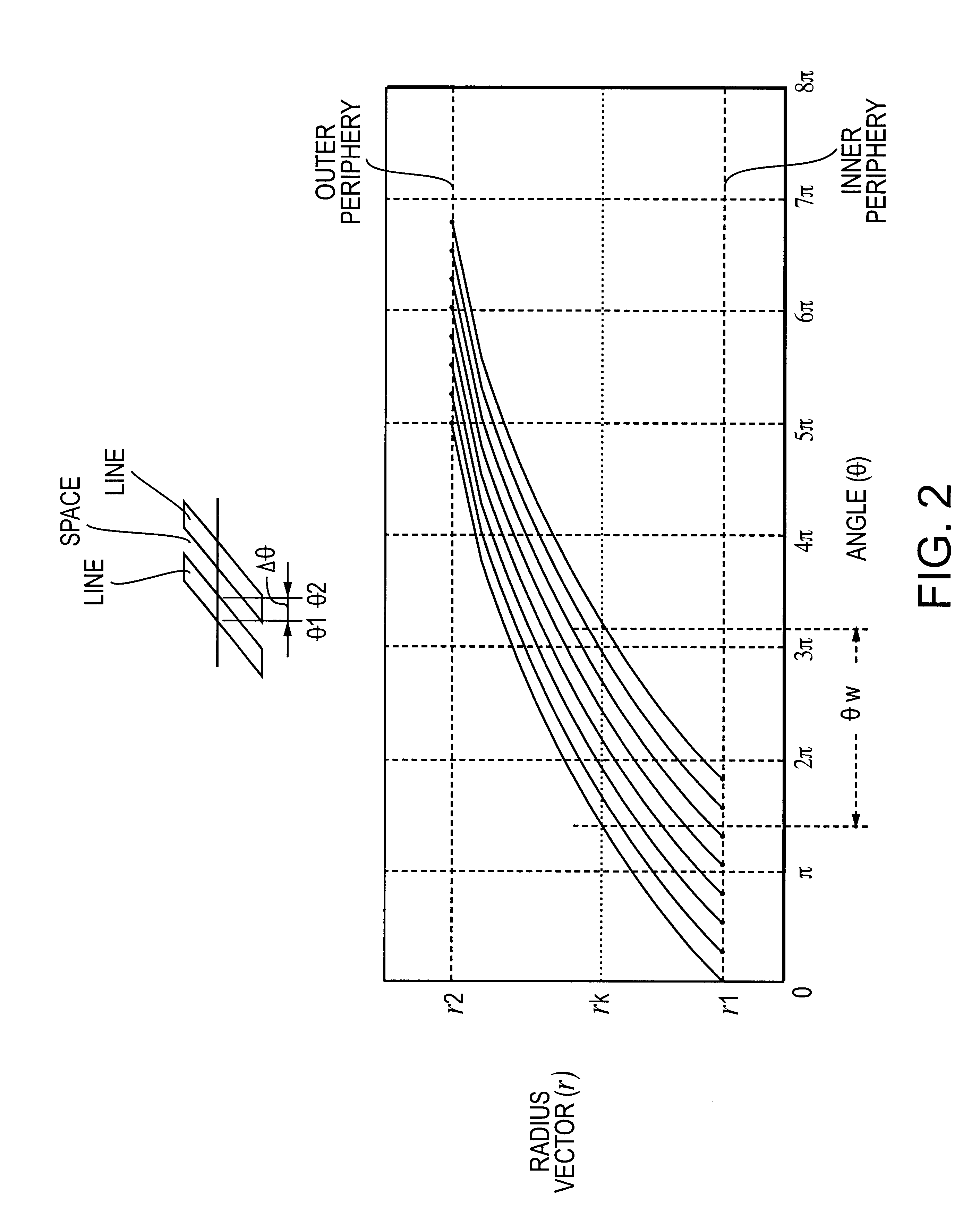

System and Method for Photoablation Using Multiple Focal Points with Rotating Beam Splitter

A system and method for performing ophthalmic surgery requires splitting a laser beam into a pattern having a plurality of focal points. The pattern is then moved along a spiral path according to a predetermined, two-phase protocol. In the first phase, a radial spacing “Δr” between spiral lines, and the velocity of the pattern “rω” are held constant as the radius “r” is decreased from r1 to r2. In the second phase the angular velocity “ω” is held constant and the radial spacing “Δr” is proportionally increased as “r” is further decreased from r2 to r3. Additional LIOB is required both inside r3, as r is reduced to zero and, then, along the periphery of the treatment area for a rim cut at r1.

Owner:TECHNOLAS PERFECT VISION

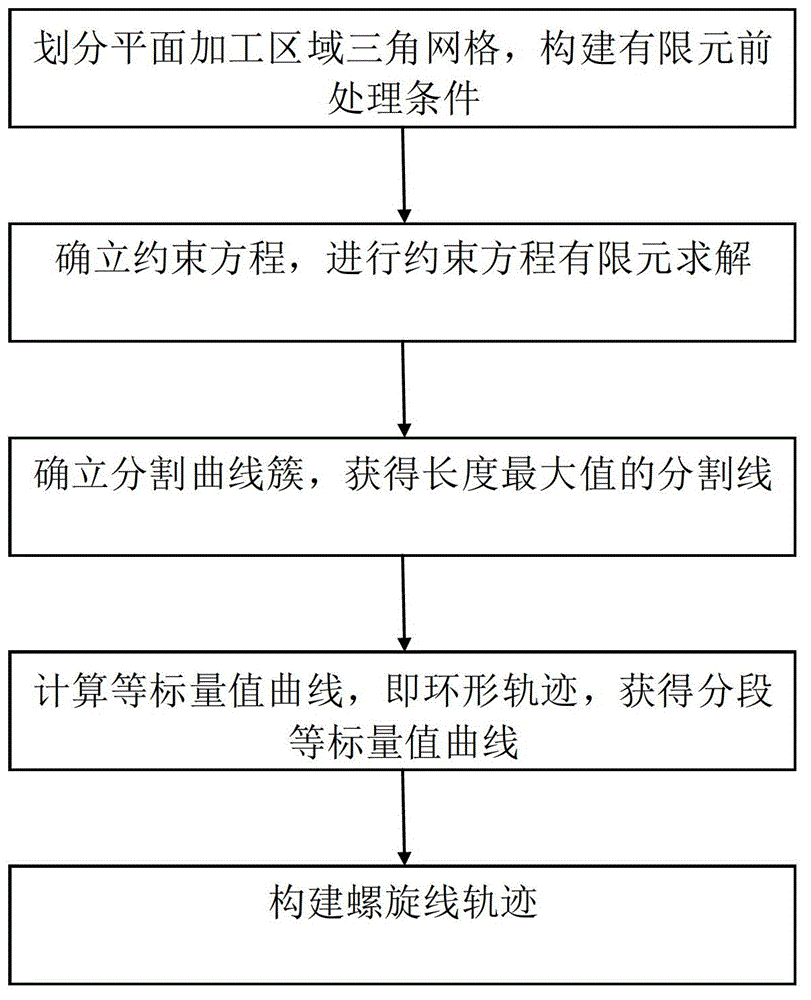

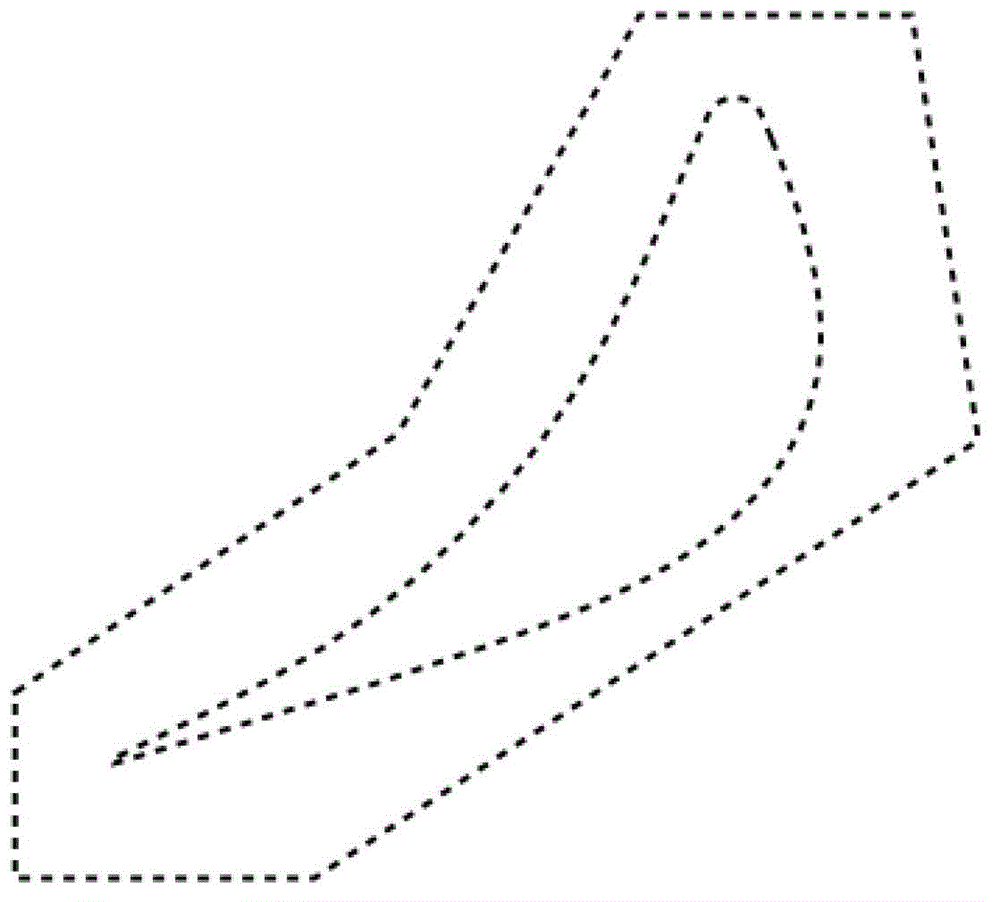

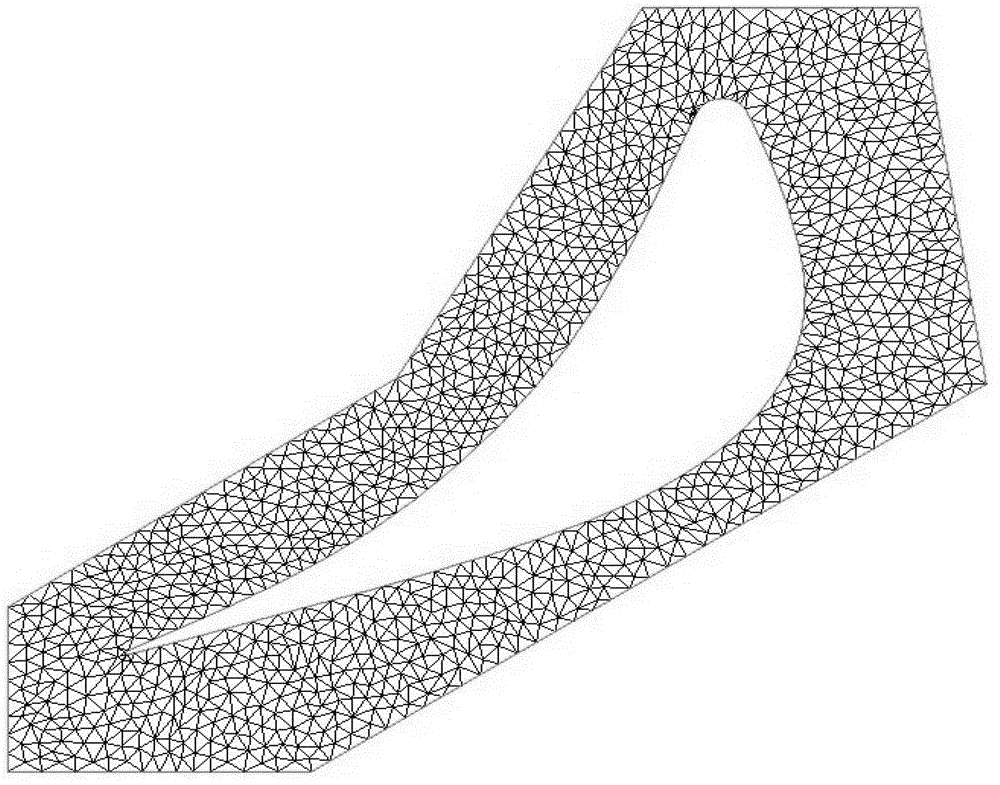

Generation method of planar spiral and annular milling tracks

ActiveCN102945019AReduce lossReduce vibrationProgramme controlComputer controlNumerical controlField function

The invention discloses a generation method of planar spiral and annular milling tracks. The generation method comprises the following steps: acquiring a plane machining region of a multi-shaft cutter, performing triangle grid division on the plane machining region to construct an energy field; establishing a constraint equation of the energy field, performing finite element solution on the constraint equation to obtain a field function; establishing a divide curve family according to the finite element solution to acquire a cutting line of a length maximum value; calculating equal scalar value curves according to the cutting line of the length maximum value, and cutting the plane machining region into m sub-regions, wherein m is an positive integer; and respectively performing interpolation on each pair of equal scalar value curves in the m sub-regions to obtain spiral lines. According to the generation method of the planar spiral and annular milling tracks, the vibration generated in the machining process of a numerical control machine tool can be reduced, at the same time, the processing efficiency is improved, and the loss of the cutter is reduced.

Owner:FOSHAN HUASHU ROBOTICS CO LTD

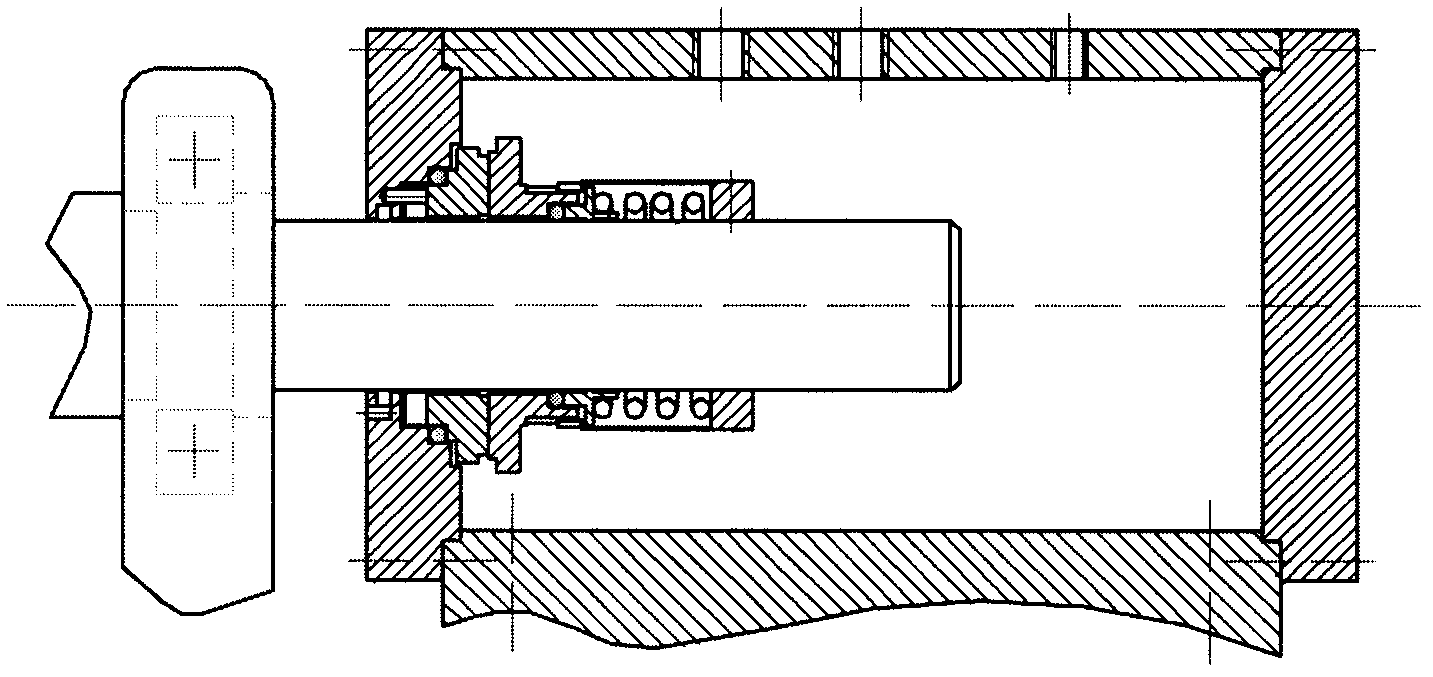

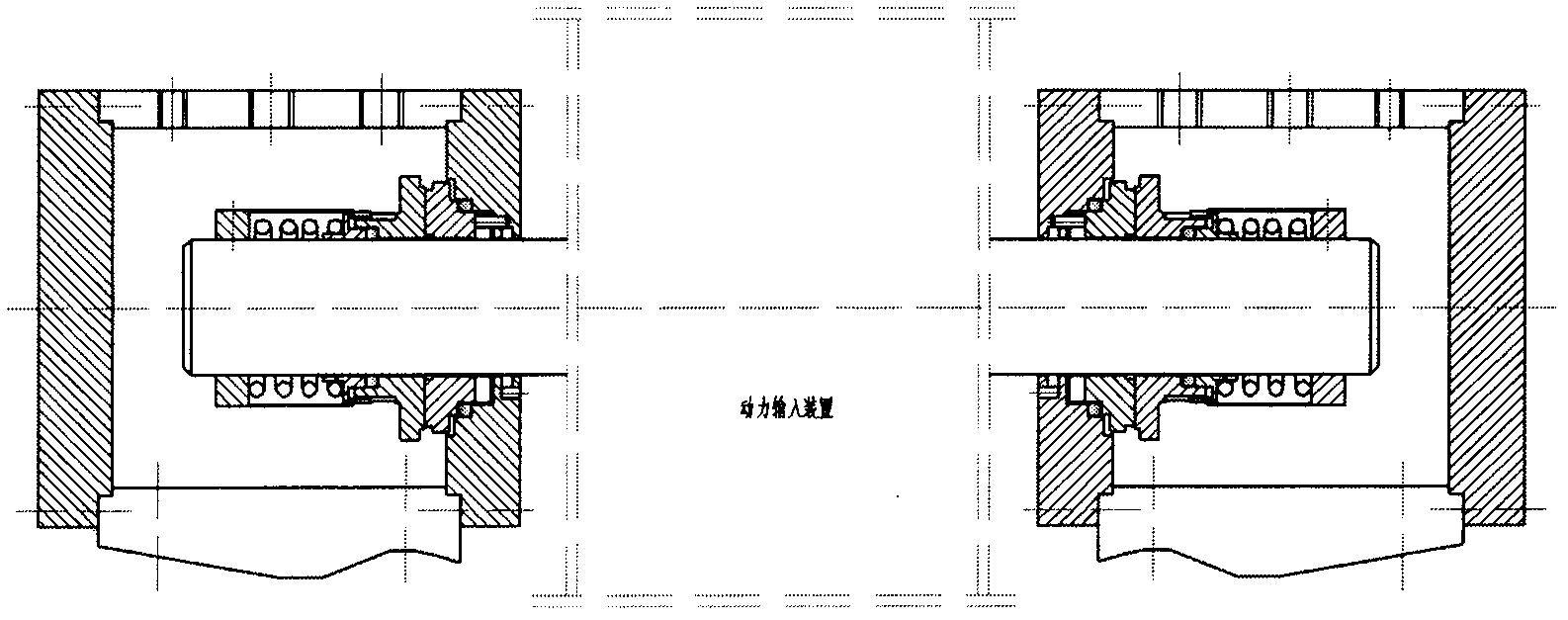

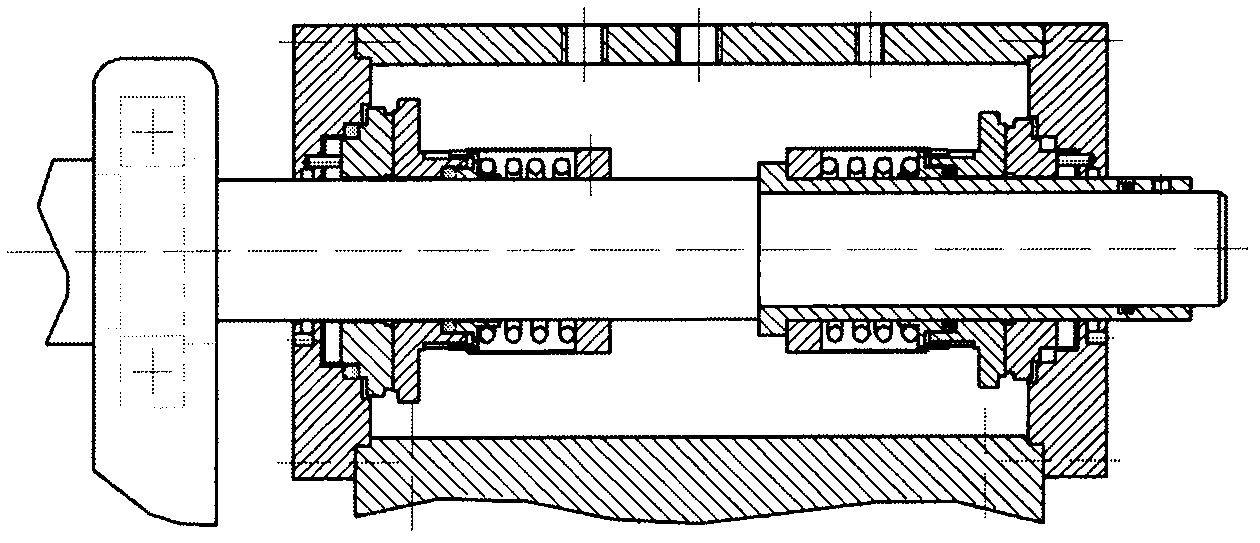

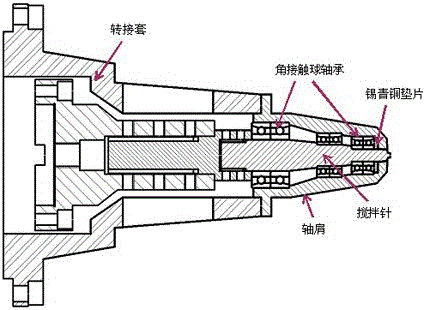

Novel stir friction welding tool for non-thinned post-welded material surface

The invention discloses a novel stir friction welding tool for a post-welded material surface nearly free of differences. A shaft shoulder of the stir friction welding tool is connected with a main machine through a special reducing sleeve, kinetic friction matching of a stirring needle and the shaft shoulder can be achieved, and the stirring needle and the shaft shoulder are designed and manufactured in a split mode; the stirring needle rotates along with a spindle at a high speed, and the shaft shoulder is fixed to a non-rotating part of a main machine head; and the stirring needle and the shaft shoulder move reliably and oppositely through a bearing set. According to the novel stir friction welding tool for the non-thinned post-welded material surface, the effect that reliable kinetic friction matching of the stirring needle and the shaft shoulder is achieved is ensured through bearing selection and structural design; the split type stirring needle is specially designed and based on the static shaft shoulder, a small shaft shoulder of an inclined surface structure is machined at the end of the split type stirring needle, and a spiral line is machined on the end surface of the small shaft shoulder, so that upsetting force is applied to weld metal, and material closing up is conducted at the same time; and through the shaft shoulder based on special material selecting and structural design, the forward resistance of the novel stir friction welding tool is reduced, flashes are eliminated, and good forming of a weld surface is ensured.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

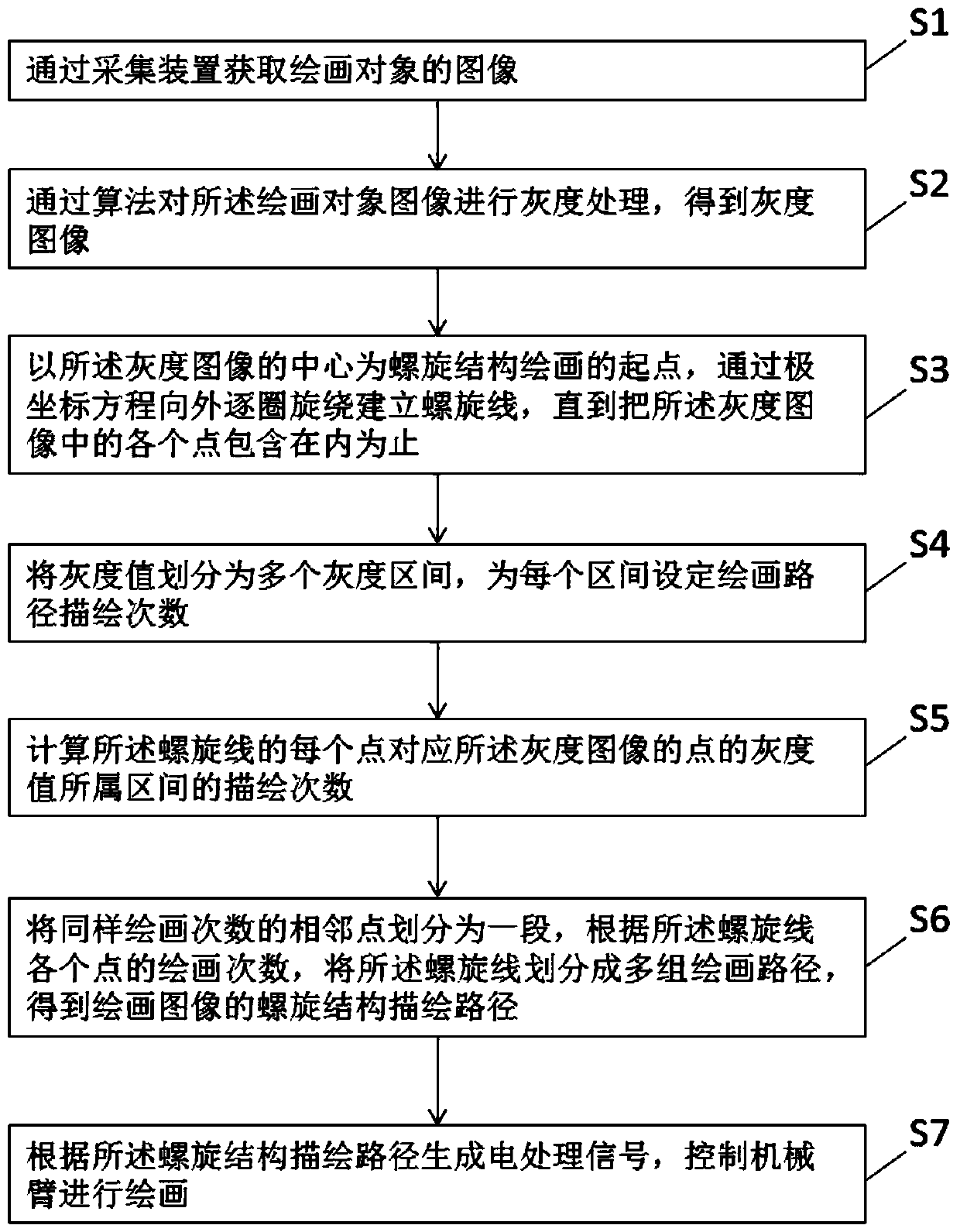

Intelligent sketch drawing method and device, storage medium and terminal equipment

ActiveCN109993810ASolve the technical problem of directly recognizing image lines for paintingImprove realismTexturing/coloringManufacturing computing systemsTerminal equipmentPath generation

The invention discloses an intelligent sketch drawing method. The method comprises the steps that S1, acquiring an image of a drawing object through an acquisition device; S2, performing gray processing on the drawing object image through an algorithm to obtain a gray image; S3, taking the center of the gray level image as a starting point of a spiral structure drawing, and establishing a spiral line outwards circle by circle through a polar coordinate equation until each point in the gray level image is contained in the spiral line; S4, dividing the gray value into a plurality of gray intervals, and setting drawing path description times for each interval; S5, calculating the description frequency of the interval to which the gray value of the point of the gray image corresponding to eachpoint of the spiral line belongs; S6, dividing adjacent points with the same number of times of drawing into a section, and dividing the spiral line into a plurality of groups of drawing paths according to the number of times of drawing of each point of the spiral line to obtain a spiral structure description path of the drawn image; and S7, generating an electric processing signal according to the spiral structure description path, and controlling the mechanical arm to draw.

Owner:GUANGDONG INTELL VISION TECH CO LTD

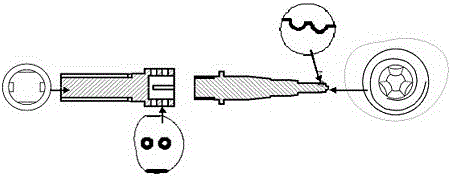

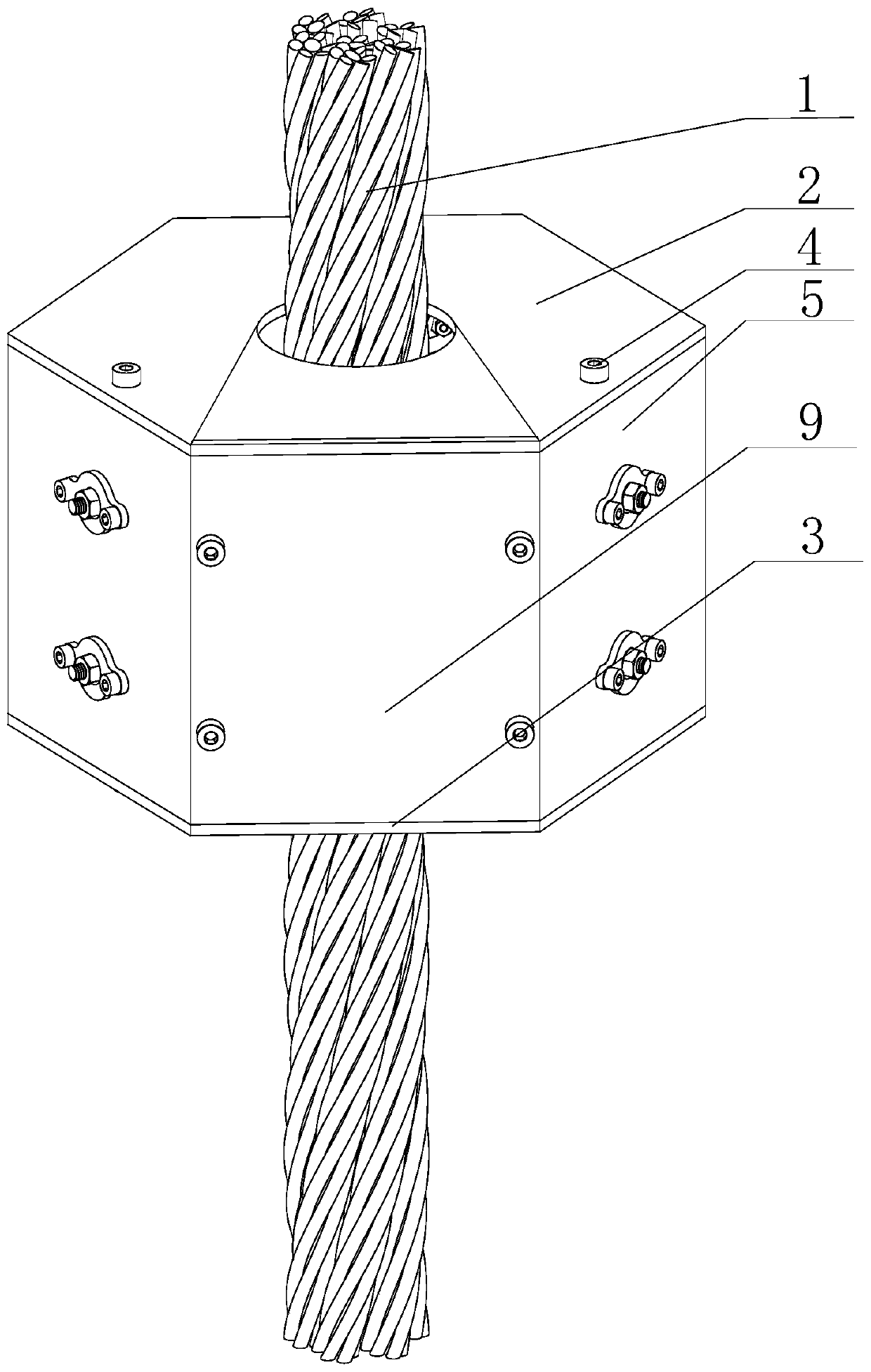

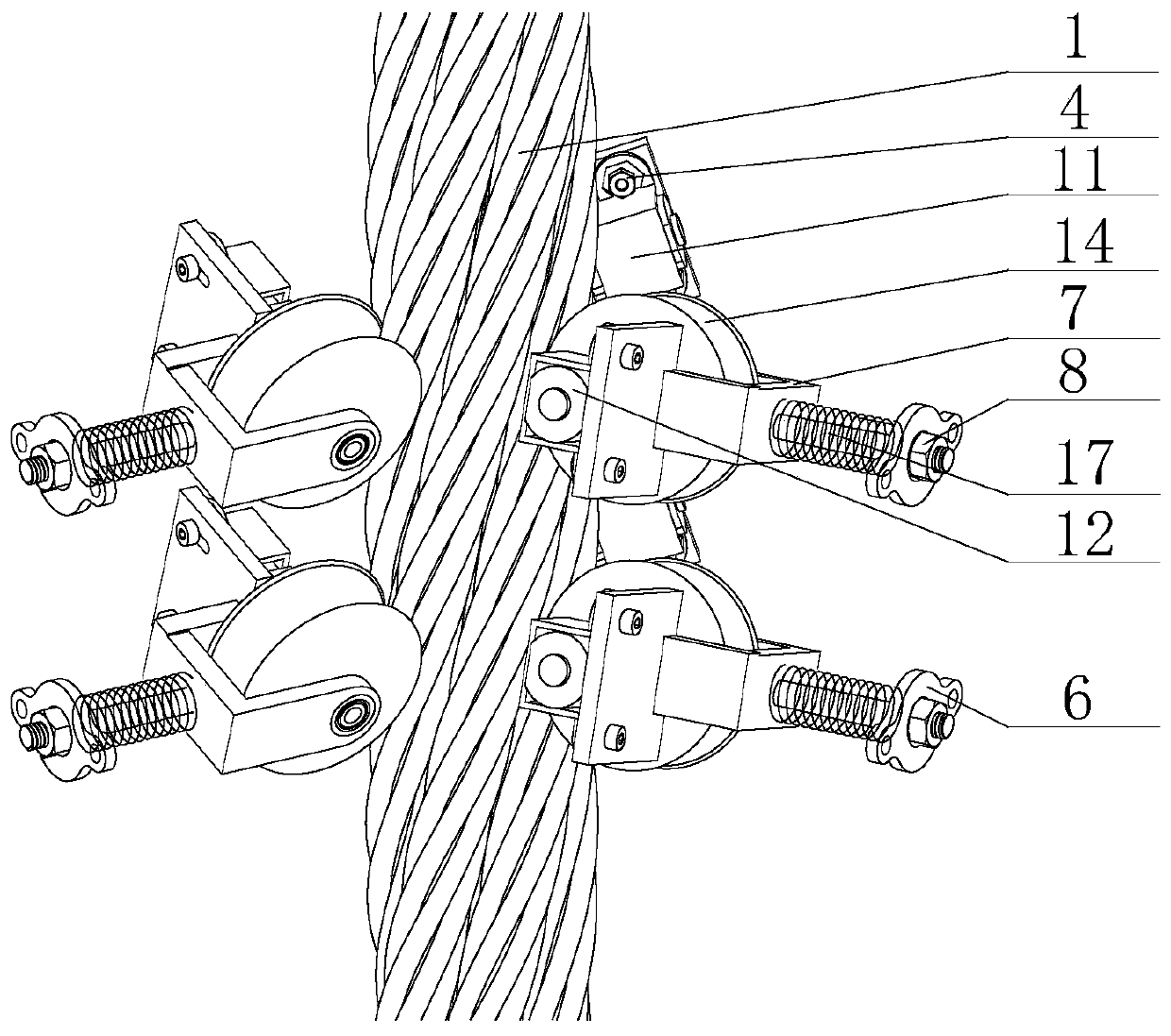

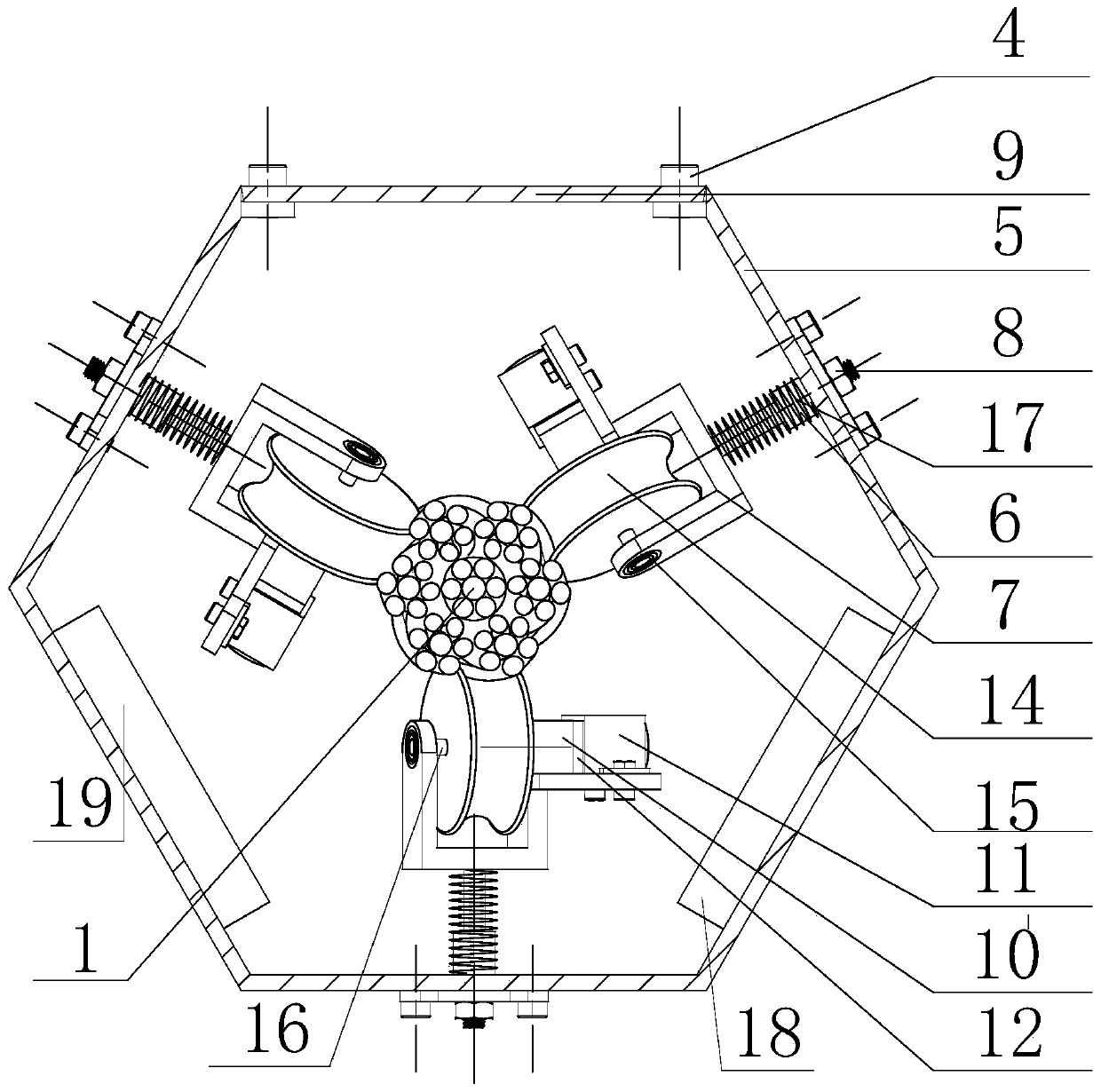

Steel wire rope twist direction climbing robot

The invention discloses a steel wire rope twist direction climbing robot. The steel wire rope twist direction climbing robot includes a plurality of modules, wherein climbing devices are arranged in outer shells of the modules, the climbing devices include tensioning supports, rolling wheels are mounted in tensioning supports, rubber sheets are arranged on the circumferences of the outer edges ofthe rolling wheels, shafts are arranged on the back sides of the tensioning supports, holes are formed in the outer shells close to the shafts, linear bearings are mounted at the positions of the holes, the shafts of the tensioning supports penetrate through the linear bearings and the holes, limiting anti-loose nuts are mounted on shafts outside the outer shells, and springs are further arrangedbetween the back sides of the tensioning supports and the inner walls of the outer shells. Compared with the prior art, the steel wire rope twist direction climbing robot can roll in the direction ofa spiral line twisted in a steel wire rope, the needed driving force is smaller and stable, and the bearing capacity is high; and the climbing robot can work under a special environment and can meet the requirement of anti-explosion; and the shafts of the tensioning supports move telescopically relative to the linear bearings, and the certain buffering obstacle crossing ability and the disturbanceresistant capacity are achieved.

Owner:CHINA UNIV OF MINING & TECH

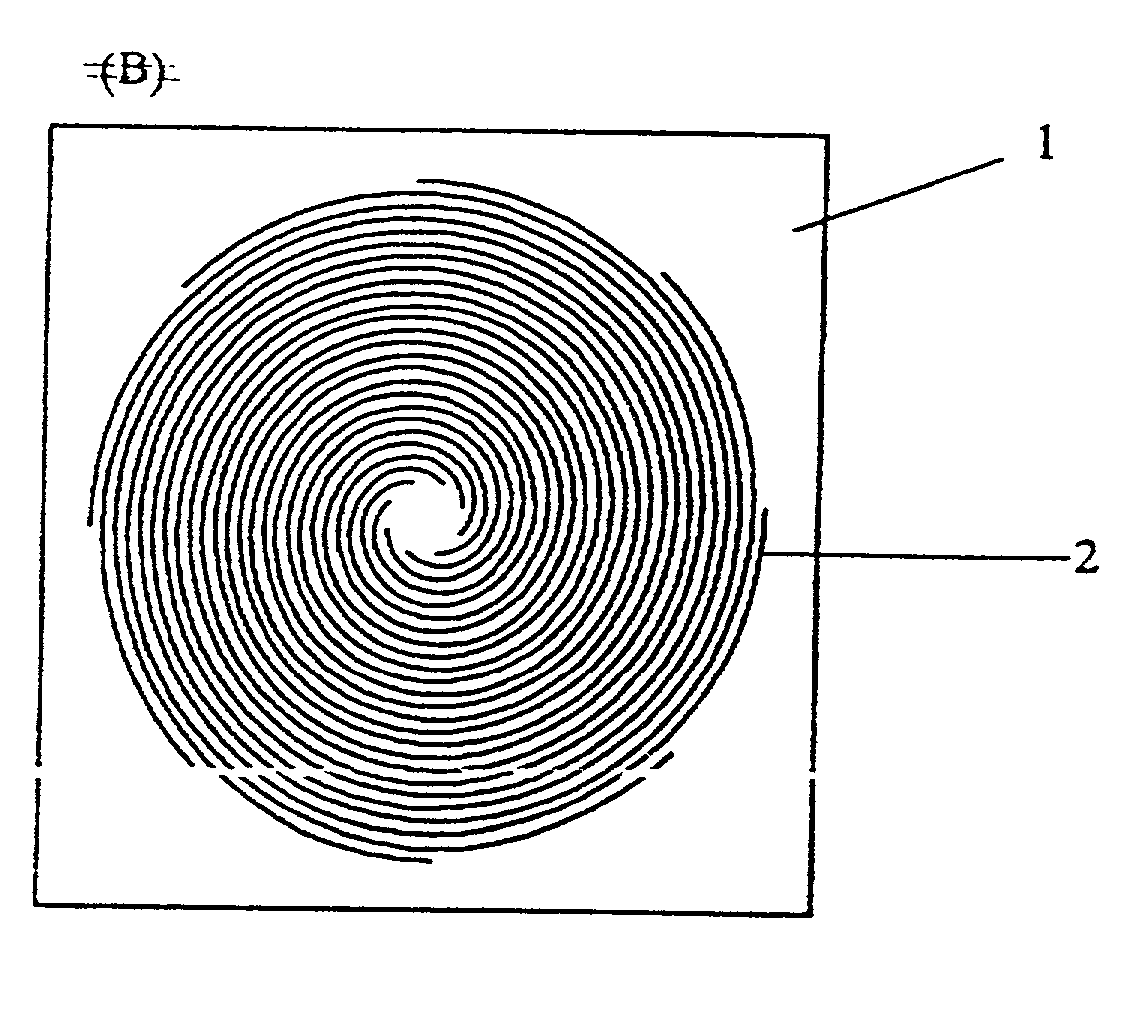

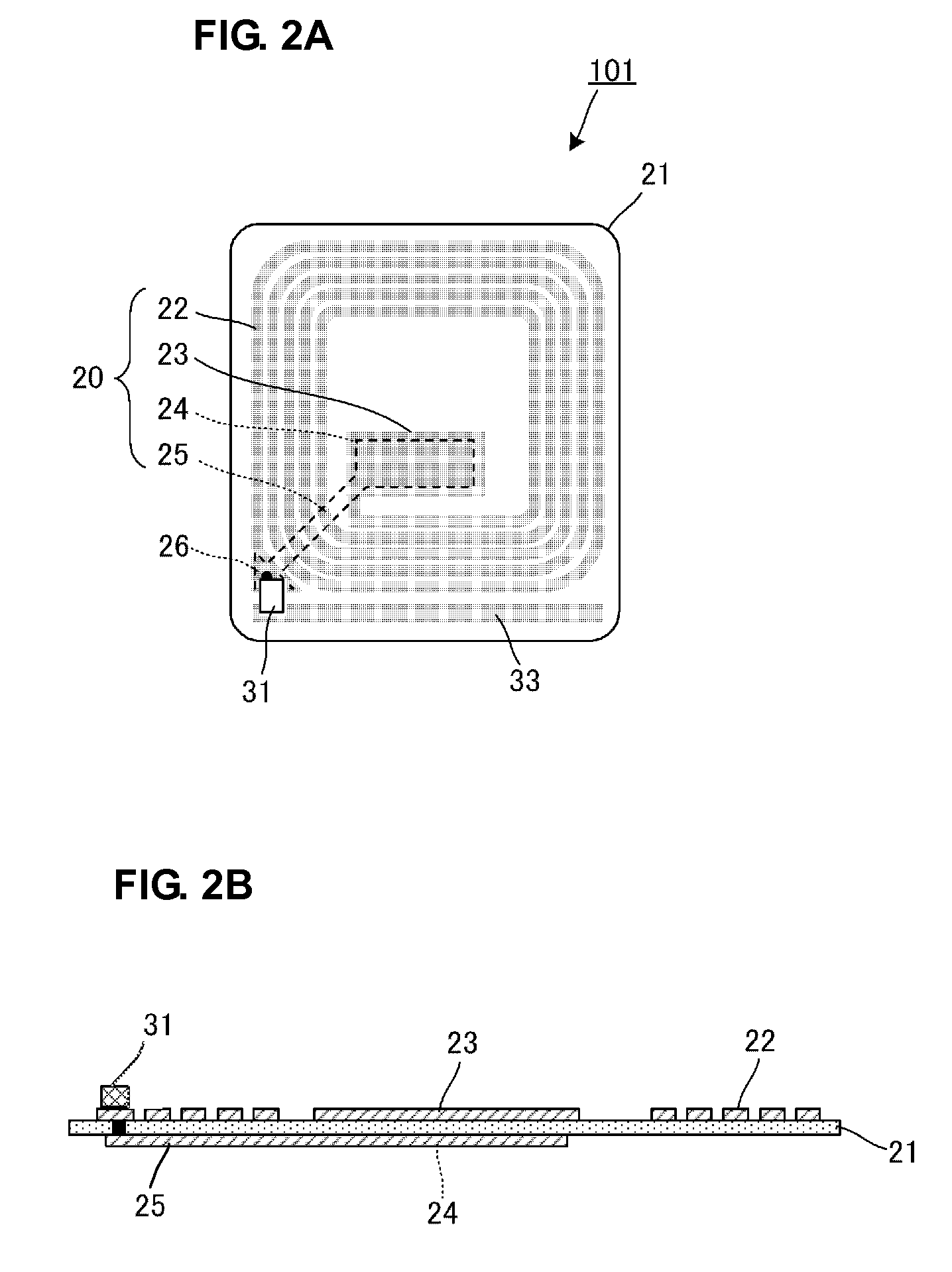

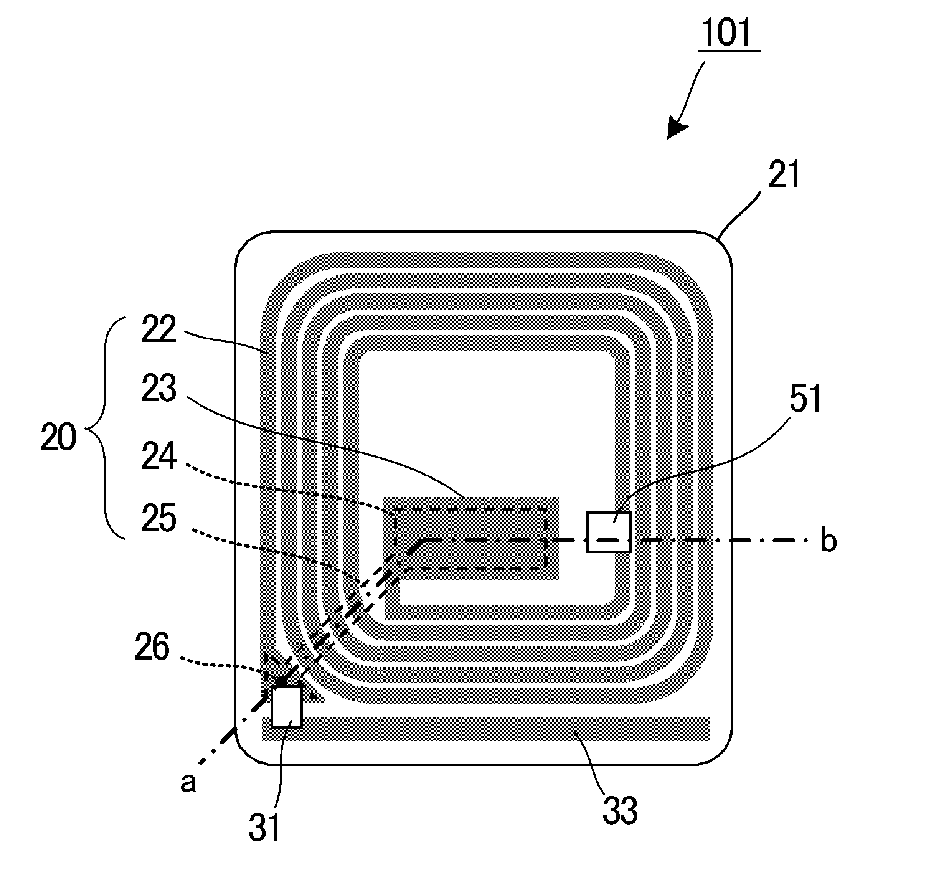

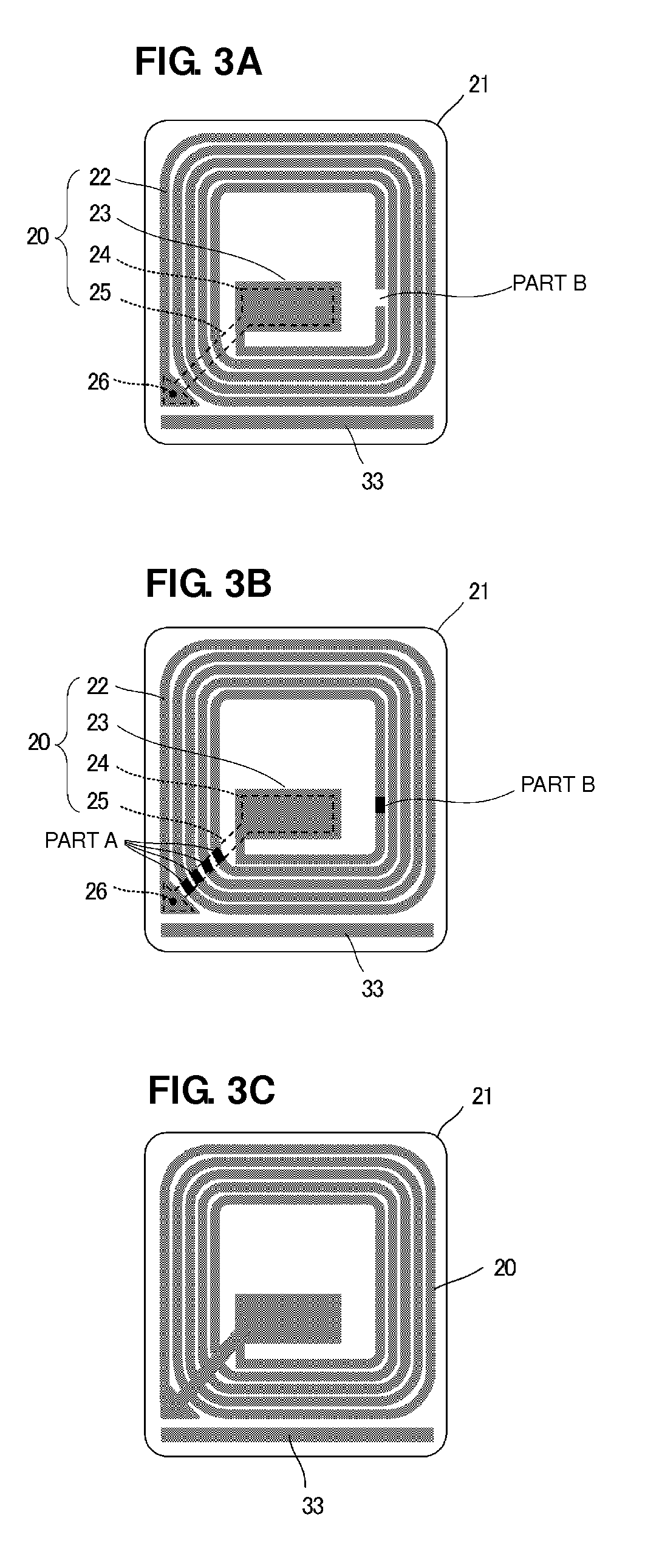

Resonator, filter, duplexer, and communication device

A resonator can provide good loss characteristics by effectively suppressing power losses due to an edge effect. In addition, a filter, a duplexer, and a communication device incorporating the resonator are formed. In the resonator, a plurality of spiral lines are disposed on a surface of a dielectric substrate in such a manner that the inner and outer ends of the lines are aligned respectively along an inner periphery and an outer periphery which are centered around a central point on the substrate so that the lines do not cross each other. With this arrangement, the edge effect in the spiral lines is substantially canceled, by which power losses due to the edge effect can be effectively suppressed.

Owner:MURATA MFG CO LTD

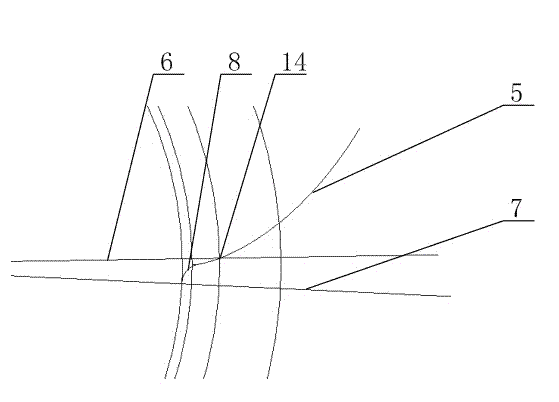

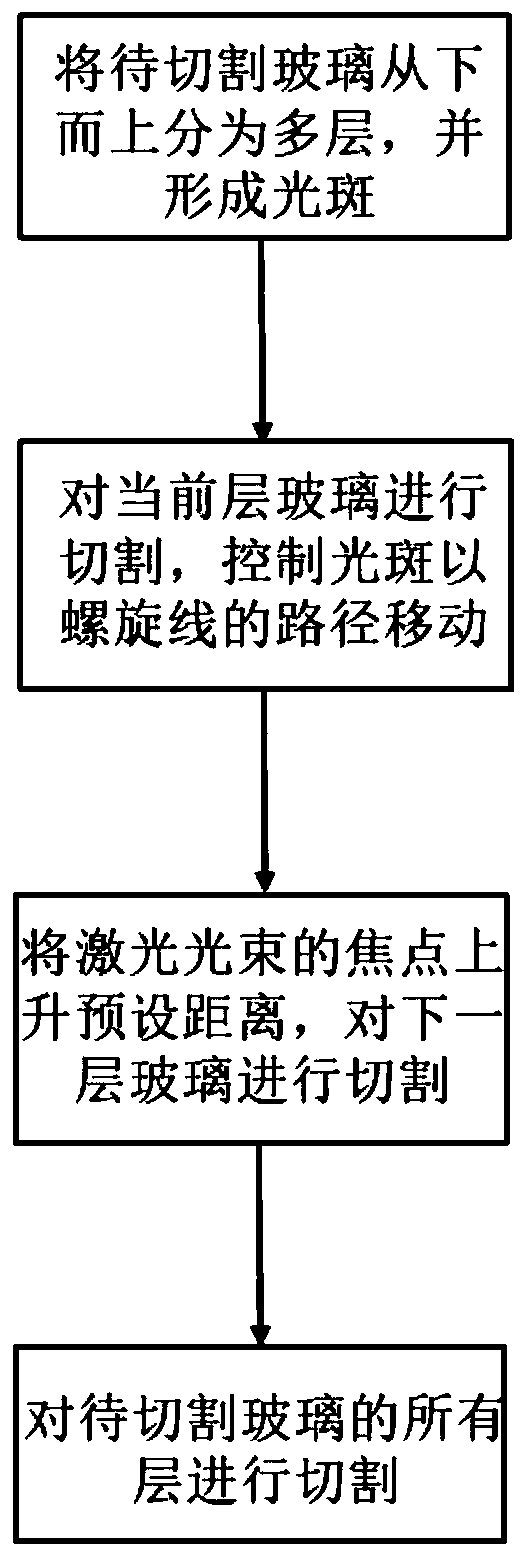

Glass three-dimensional columnar hole laser cutting method

InactiveCN110091078AFully cutEasy to discharge slagWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingSlag

The invention belongs to the technical field of laser processing and particularly discloses a glass three-dimensional columnar hole laser cutting method which comprises the following steps: dividing to-be-cut glass into a plurality of layers from bottom up, and focusing a laser beam on the surface of the to-be-cut glass to form a light spot; controlling the light spot to move on the current-layerglass in a spiral line path, and finally cutting to form a circular ring groove on the current-layer glass; after cutting the current-layer glass, ascending the focal point of the laser beam by a preset distance, and then cutting the next-layer glass; and repeating the operations until cutting all layers of the to-be-cut glass to finish the glass three-dimensional columnar hole laser cutting. According to the glass three-dimensional columnar hole laser cutting method, the to-be-cut glass is cut from bottom up to ensure that the laser beam works within the effective cutting range so as to facilitate slag discharging while improving the cutting efficiency of the laser beam; and in addition, the light spot is controlled to move in the spiral line path on each layer of glass so as to fully cutthe glass, and slag discharging is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

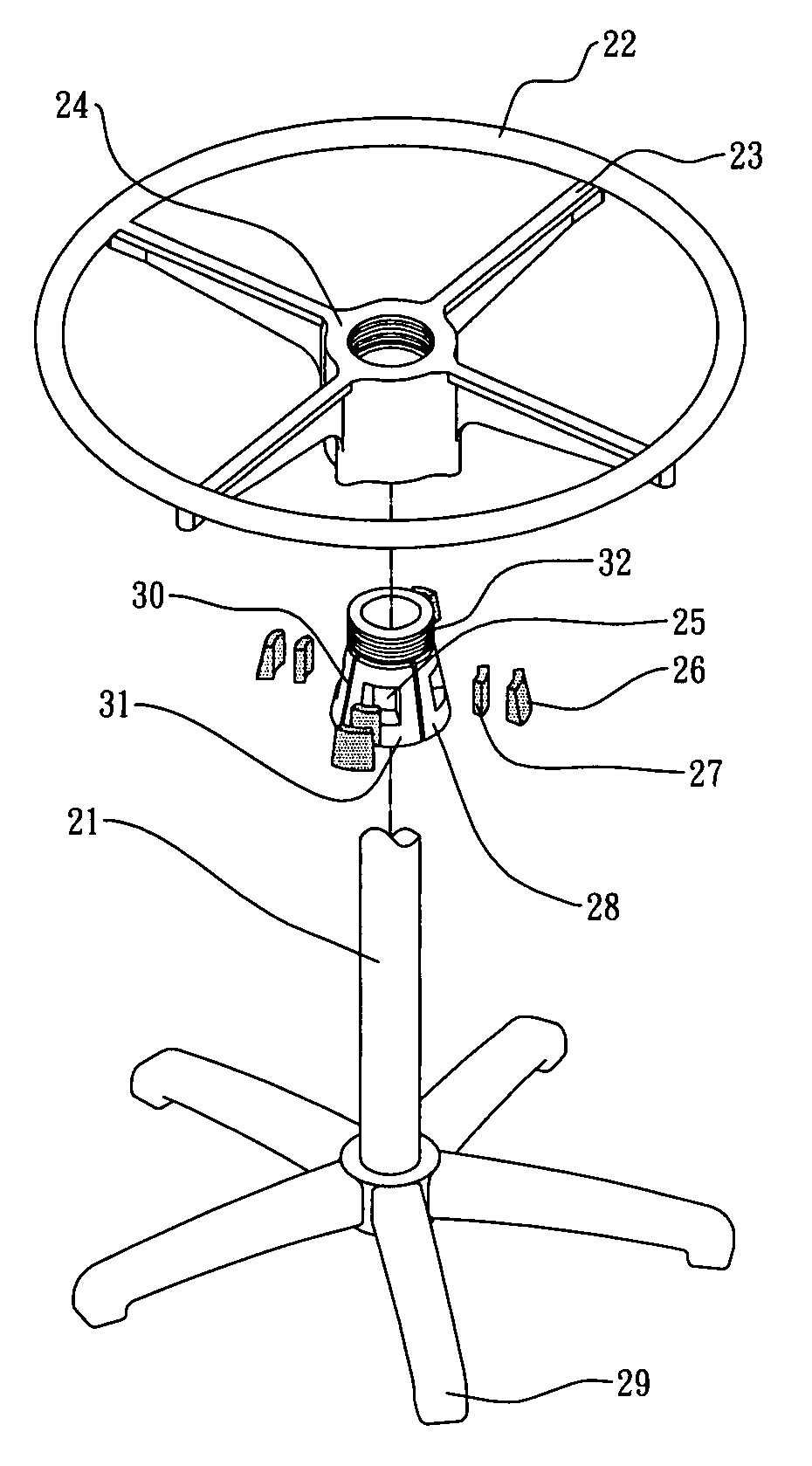

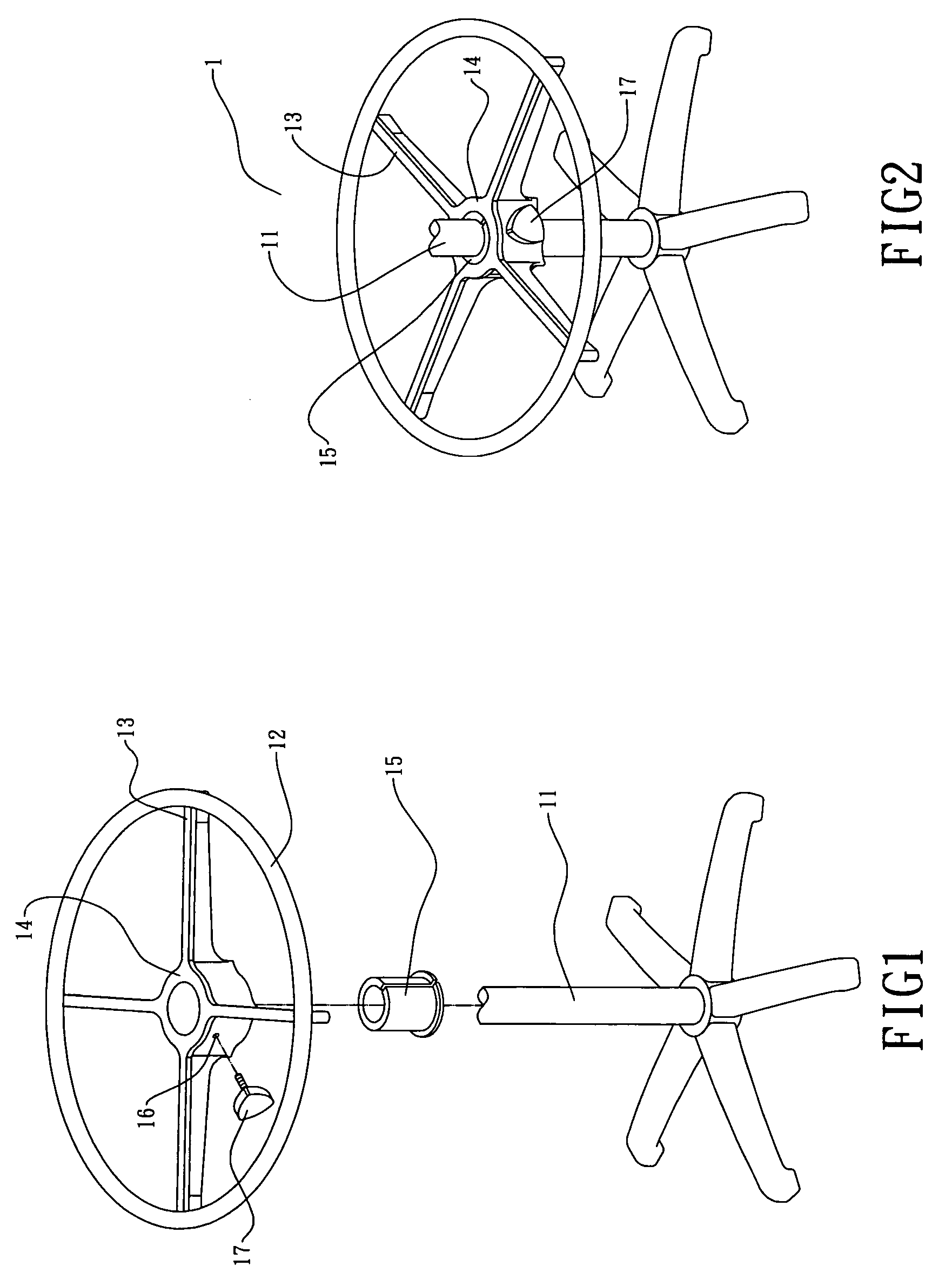

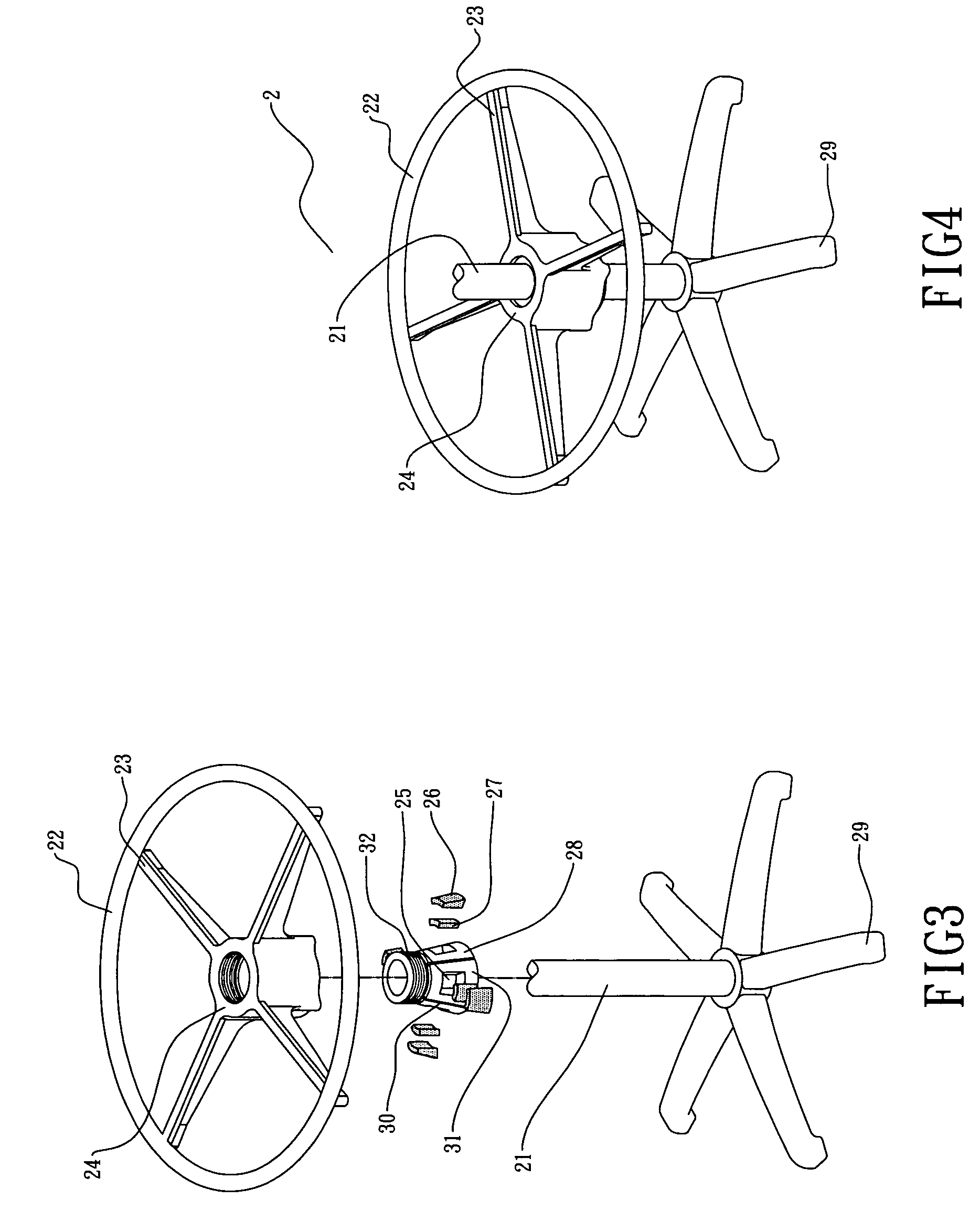

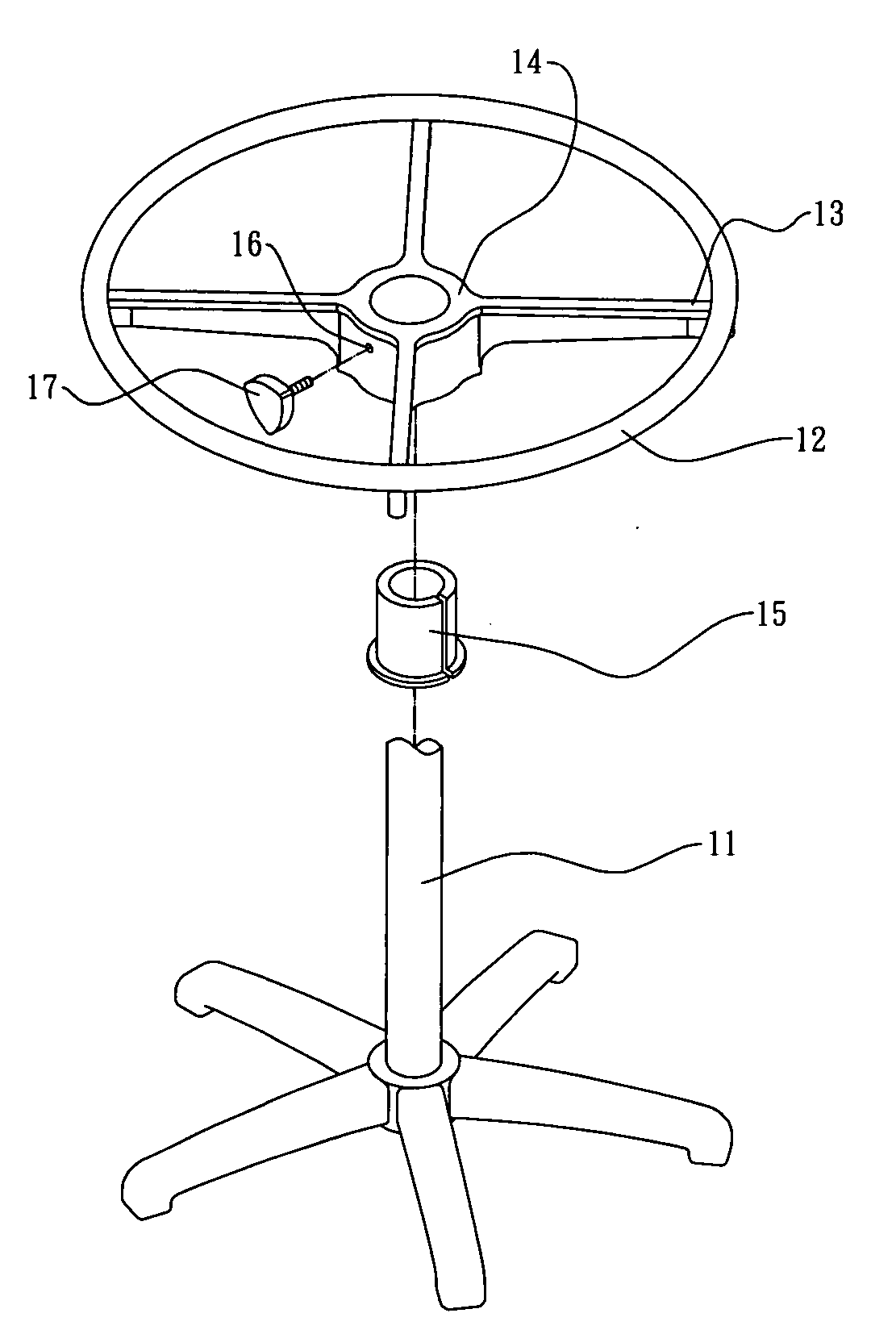

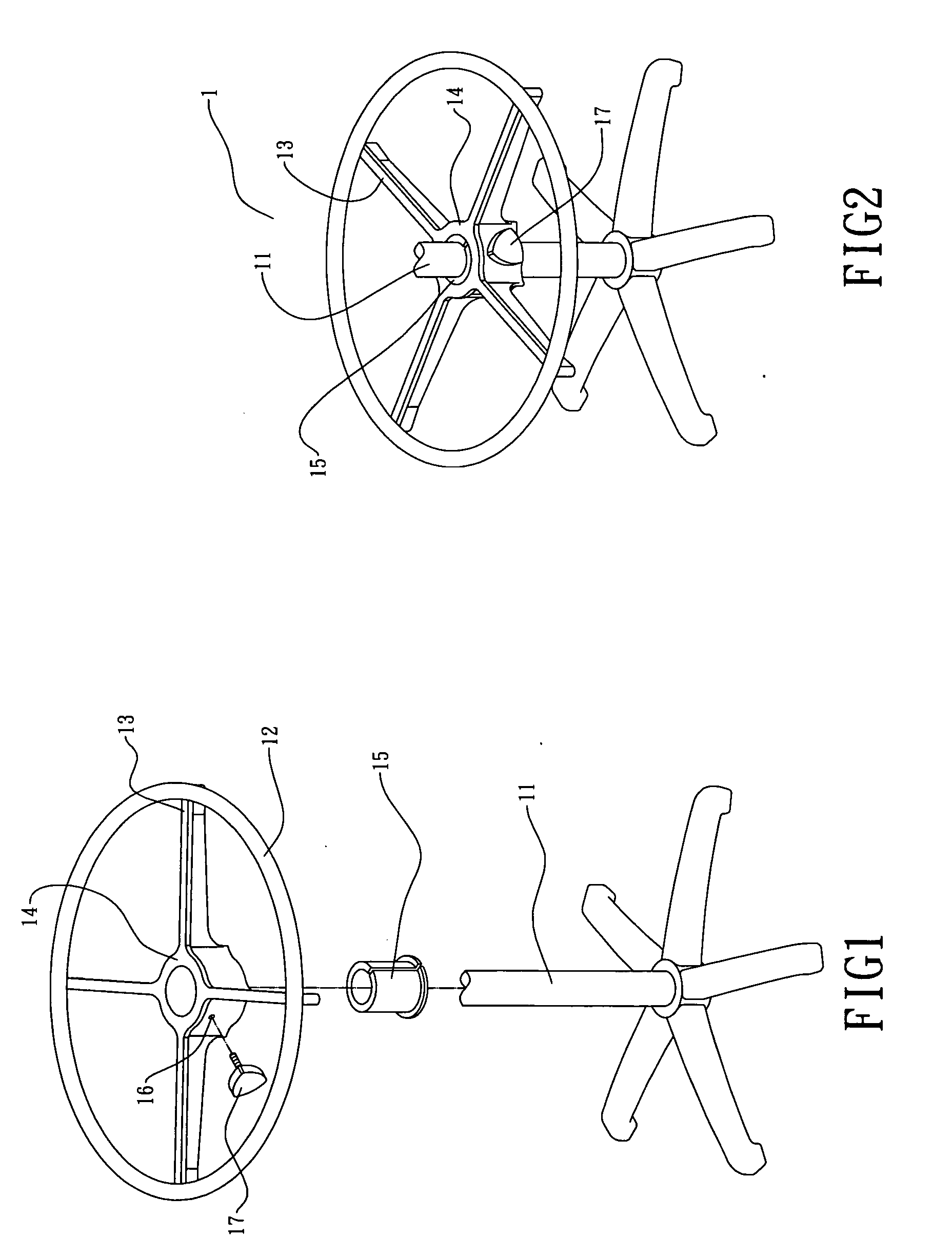

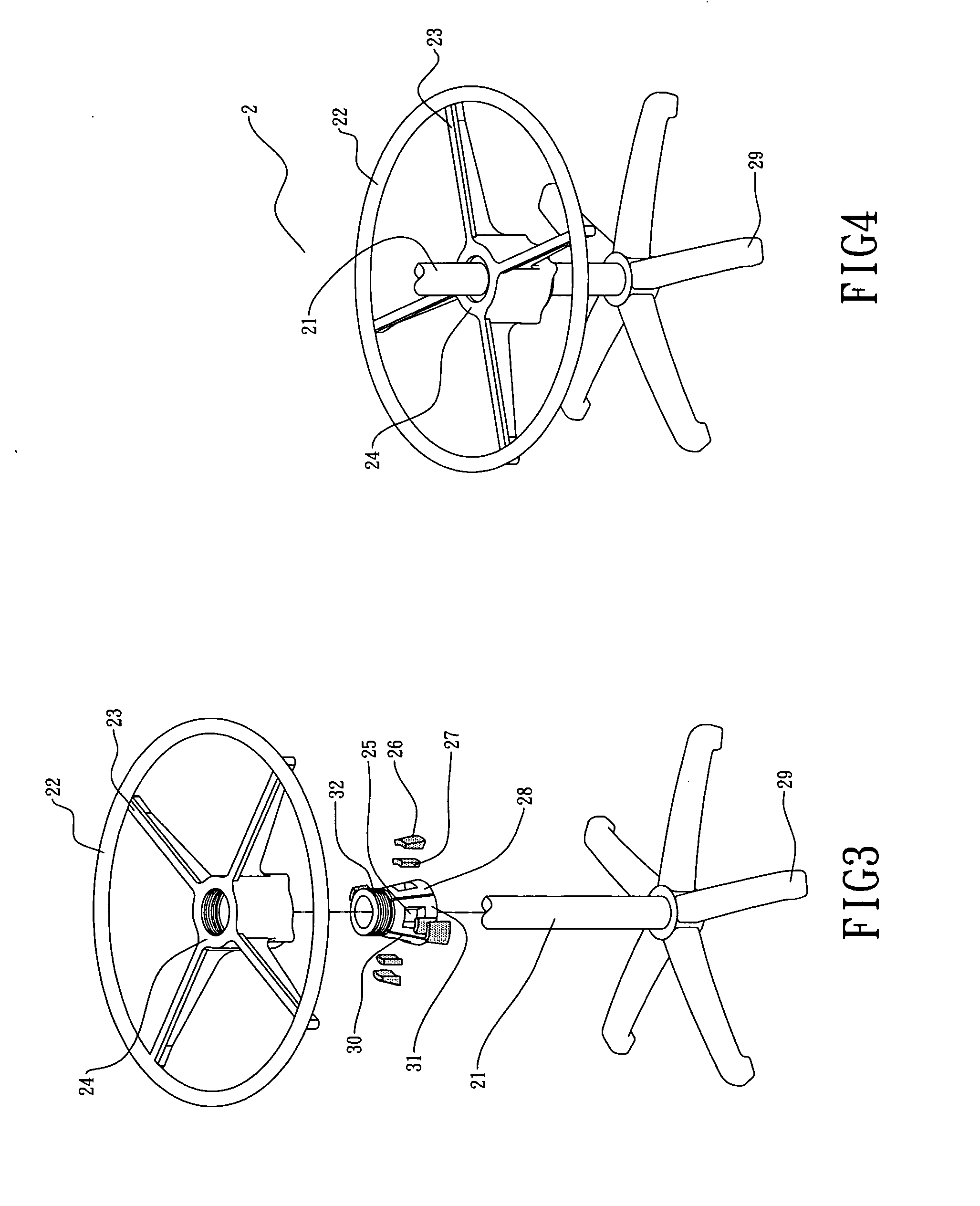

Height adjustable pedal ring mechanism for bar stool

ActiveUS7229054B2Quick changeStable and safe for userHigh stoolsStands/trestlesEngineeringSpiral line

This invention relates to a height adjustable pedal-ring mechanism for bar stool. This mechanism comprises a main shaft, a taper sleeve, a cross-shaped support frame with a central tube, a pedal ring, and a base frame. The pedal ring is connected to the cross-shaped support frame. The taper sleeve has an outer spiral line on the upper part of the taper sleeve and an outer gradient slope on the lower part of the taper sleeve. The cross-shaped support frame is equipped with a central tube at the central part of the cross-shaped support frame. The central tube has an inner spiral line matching with the outer spiral line of the taper sleeve and an inner gradient slope matching with the outer gradient slope of the taper sleeve. This mechanism employs the outer gradient slope of the taper sleeve and the inner gradient slope of the central tube to fix the vertical position of the pedal ring.

Owner:HU JUNG HUA

Embattling method of logarithmic spiral array antennas

InactiveCN101931124AIncrease cell spacingLarge apertureLogperiodic antennasHelical antennasPhase differenceArray element

The invention discloses an embattling method of logarithmic spiral array antennas. An antenna array uses N logarithmic spirals to embattle; a single logarithmic spiral line function is as follows: r=e, and an antenna unit is displaced on the logarithmic spiral line function r=e, wherein (r, phi) is a position coordinate of any point on the logarithmic spiral line under polar coordinates, r is a distance from the point to an original point (unit: wavelength), namely a relative wavelength number, phi is an angle relative to a polar axis (0 degree), and a is a parameter of the logarithmic spiral line function and is an optimizable constant for designing the array; the antenna unit n on each logarithmic spiral is arranged at the position of phi n along the spiral line function; the phase difference between adjacent units is delta phi; N spiral lines rotate 360 degrees / N rounding a rotating shaft in turn; r of the initial starting point of each logarithmic spiral line is the same; the phase position of the initial starting point of the first starting point on each spiral line is phi0; m array elements are respectively arranged on each spiral line from the initial starting point at an interval of delta phi; one array element can be placed at the center of the array, namely original point, or not; when the parameter a, delta phi and phi0 are determined, an array manifold is determined; and the total antenna unit number of N logarithmic spiral arrays is Nm+1.

Owner:SOUTHEAST UNIV

Height adjuctable pedal ring mechanism for bar stool

ActiveUS20060175518A1Stable and safe for userQuick changeHigh stoolsStands/trestlesEngineeringSpiral line

This invention relates to a height adjustable pedal-ring mechanism for bar stool. This mechanism comprises a main shaft, a taper sleeve, a cross-shaped support frame with a central tube, a pedal ring, and a base frame. The pedal ring is connected to the cross-shaped support frame. The taper sleeve has an outer spiral line on the upper part of the taper sleeve and an outer gradient slope on the lower part of the taper sleeve. The cross-shaped support frame is equipped with a central tube at the central part of the cross-shaped support frame. The central tube has an inner spiral line matching with the outer spiral line of the taper sleeve and an inner gradient slope matching with the outer gradient slope of the taper sleeve. This mechanism employs the outer gradient slope of the taper sleeve and the inner gradient slope of the central tube to fix the vertical position of the pedal ring.

Owner:HU JUNG HUA

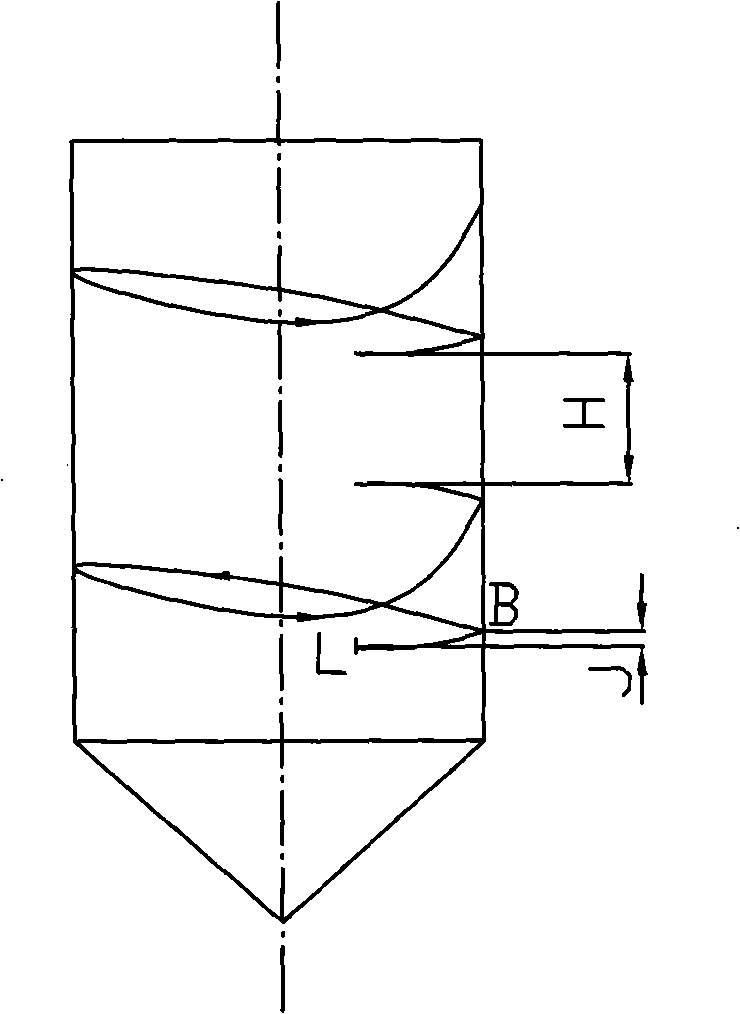

Inner screw thread milling technique

InactiveCN101274380AArbitrary processingAccurate connectionThread cutting machinesNumerical controlMilling cutter

The invention relates to an internal thread milling technique which comprises the steps as follows: a drill bit is installed on a numerical control miller for processing an underport and then the drill bit is withdrawn to be replaced by an internal thread milling cutter provided with a plurality of teeth, the milling cutter is rotated and pushed into the L position of a cutting point at the bottom of the underport and then rotated by 360 degrees by surrounding the core of the port in a spiral line track in the underport to mill thread that is provided with a plurality of thread pitches on a side wall, then the milling cutter is drawn back to the core of the port along a radial direction and withdrawn for a height H to a direction leaving the underport along the radial direction of the underport so as to lead the point of the milling cutter to be completely tallied with the track points of the prior guide distance thread, thereby correctly connecting the prior and the post guide distances; the steps are repeated to mill the internal thread that meets the requirements for the depth of the thread according to the requirements, then the milling cutter is withdrawn and the processing is finished. The milling technique of the invention can complete a plurality of moving guide distances, process the internal threads with different depth at will according to the design requirement, guarantee correct connection between every two adjacent moving guide distances according to a precise calculation formula and improve processing precision and production efficiency.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com