Patents

Literature

322results about How to "Easy to discharge slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

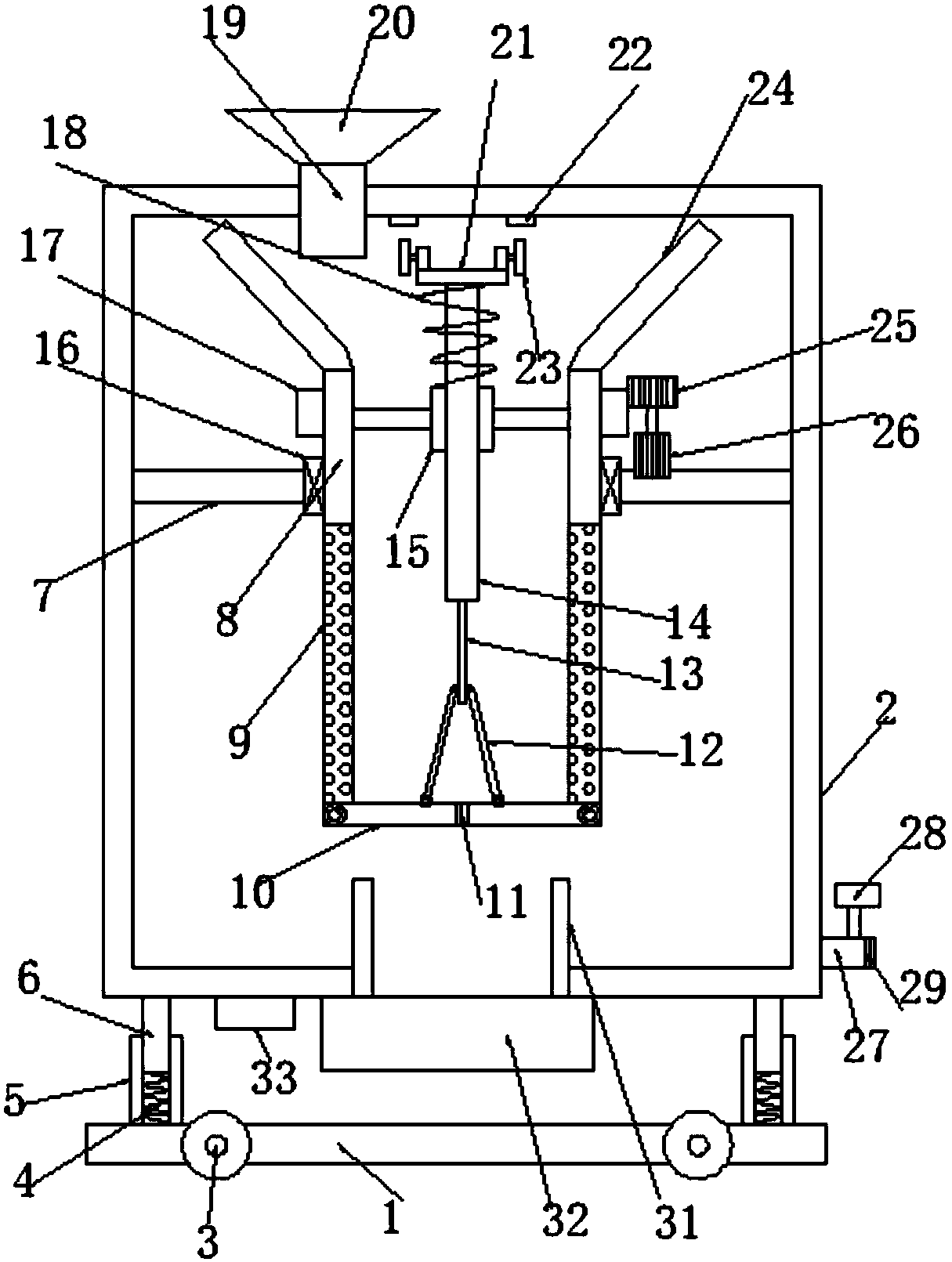

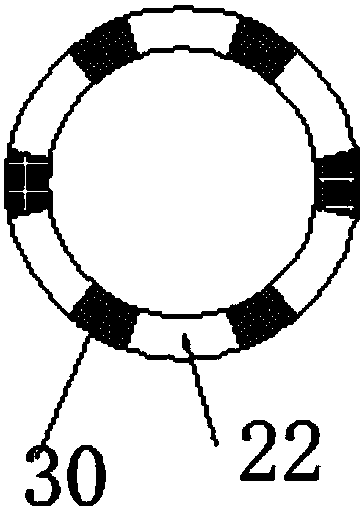

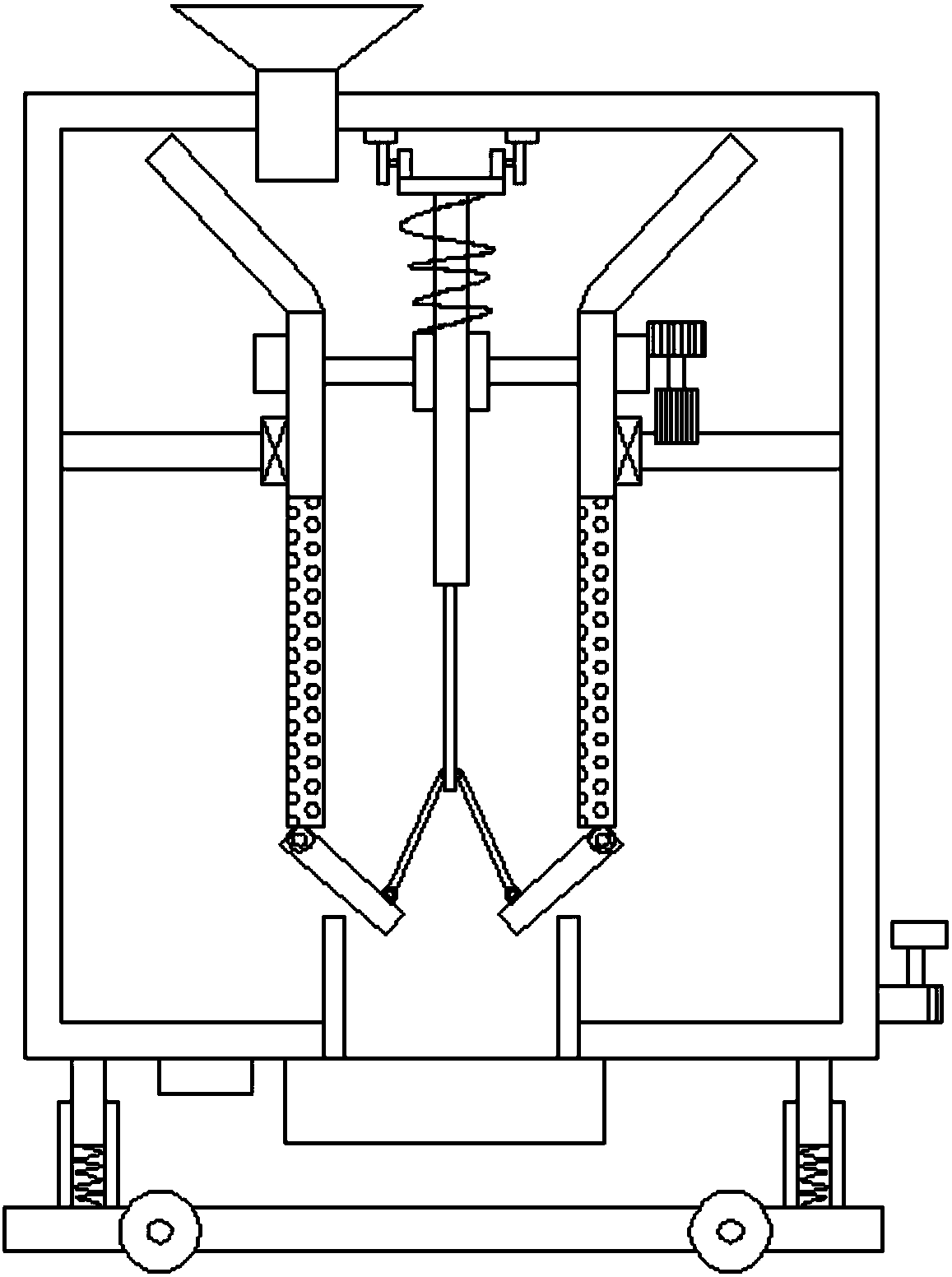

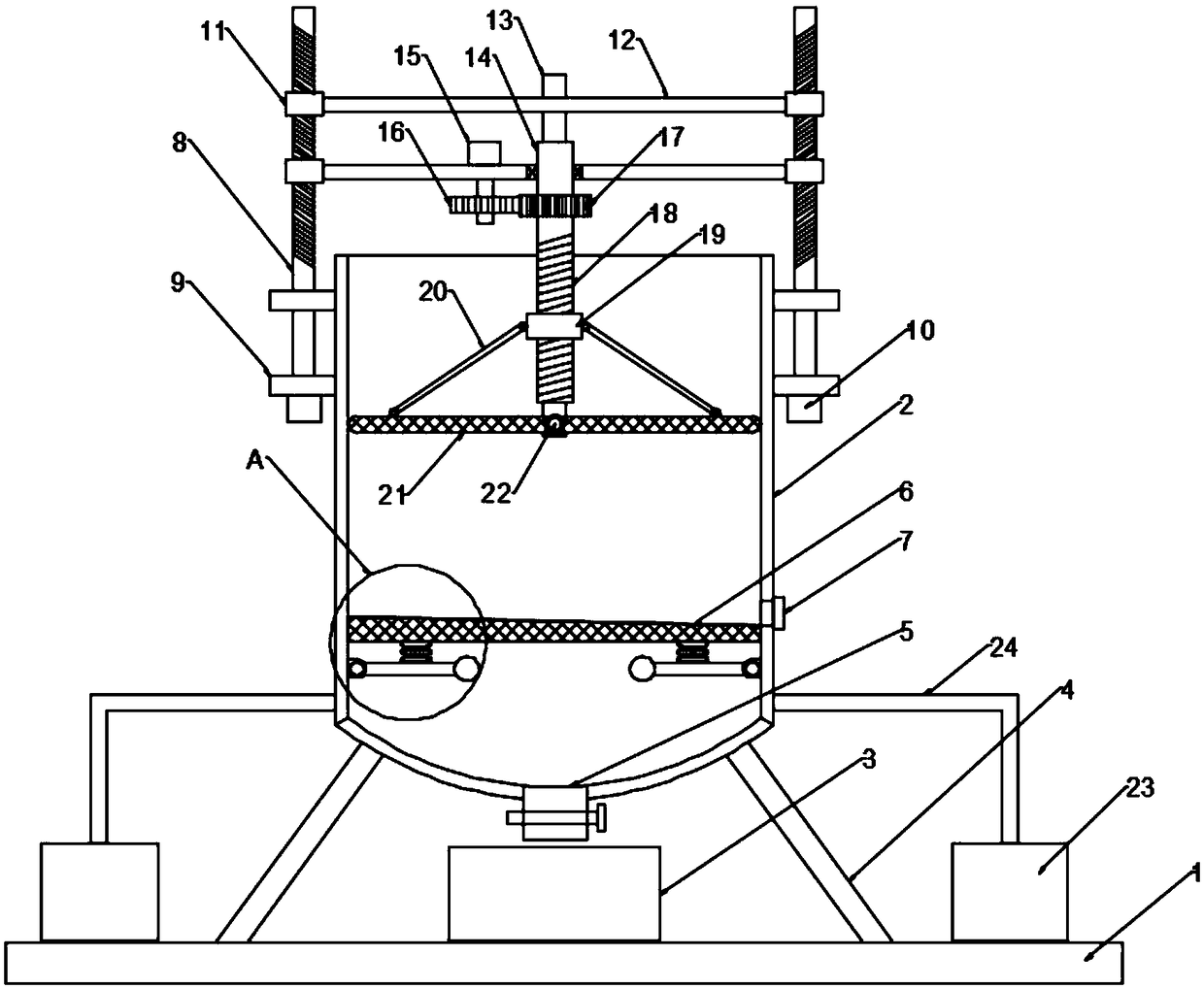

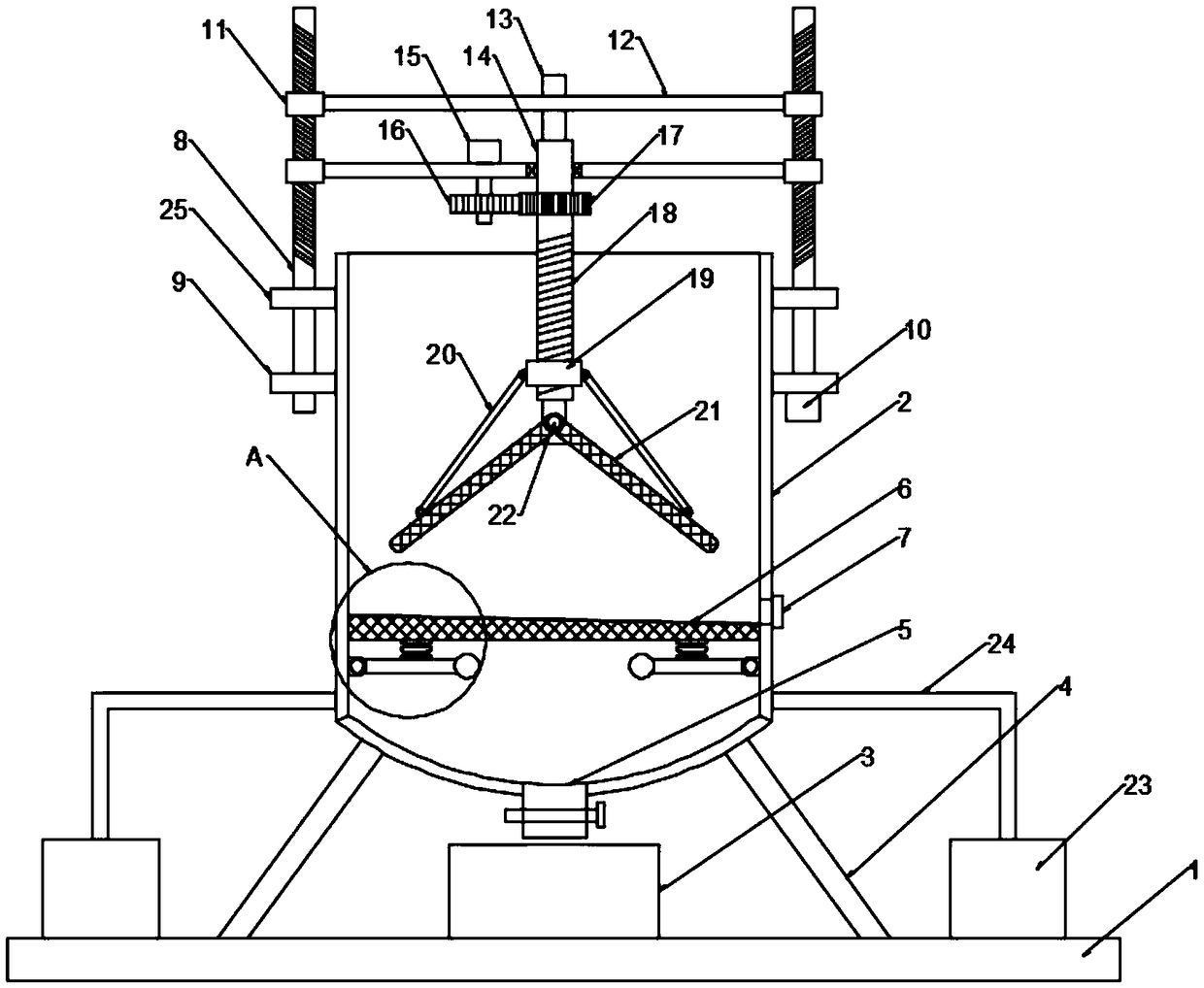

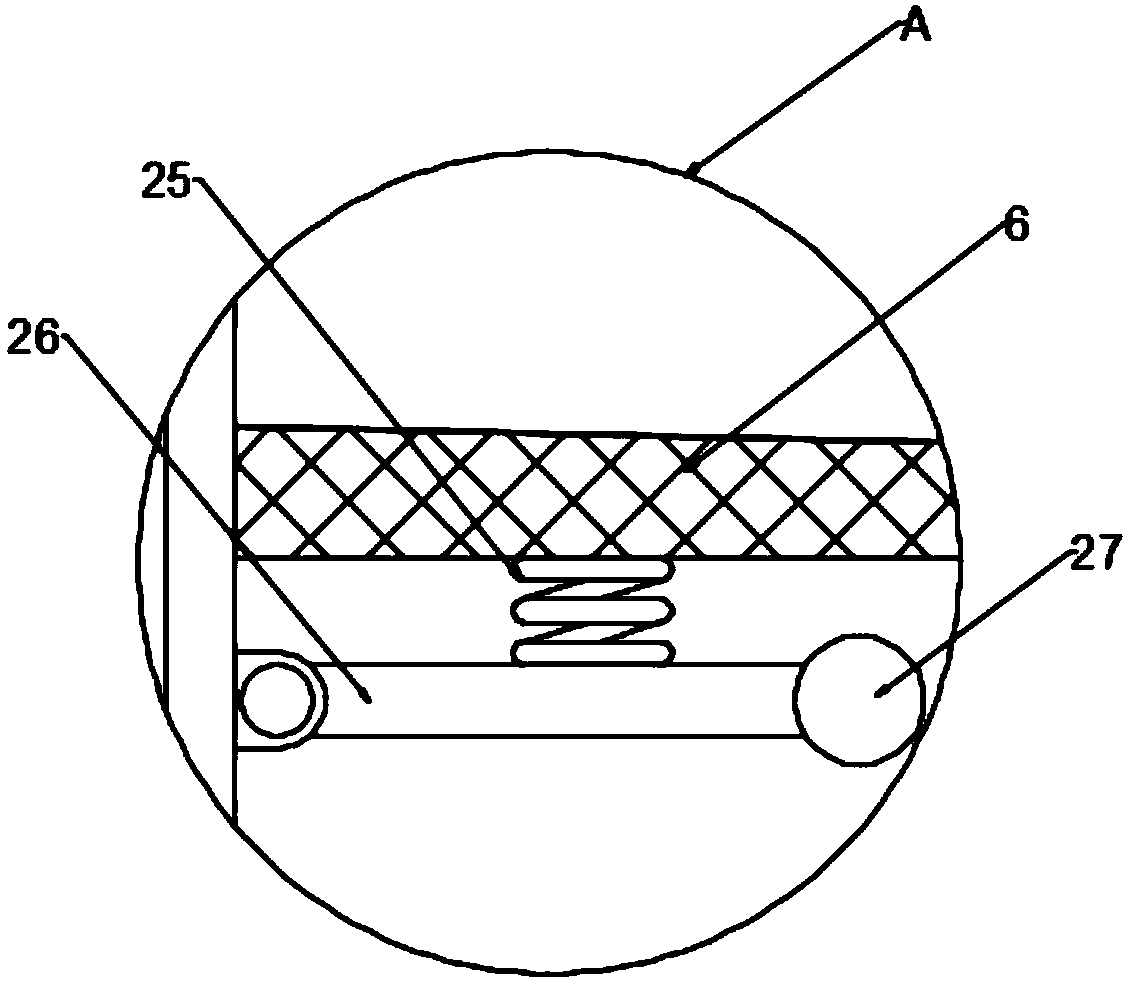

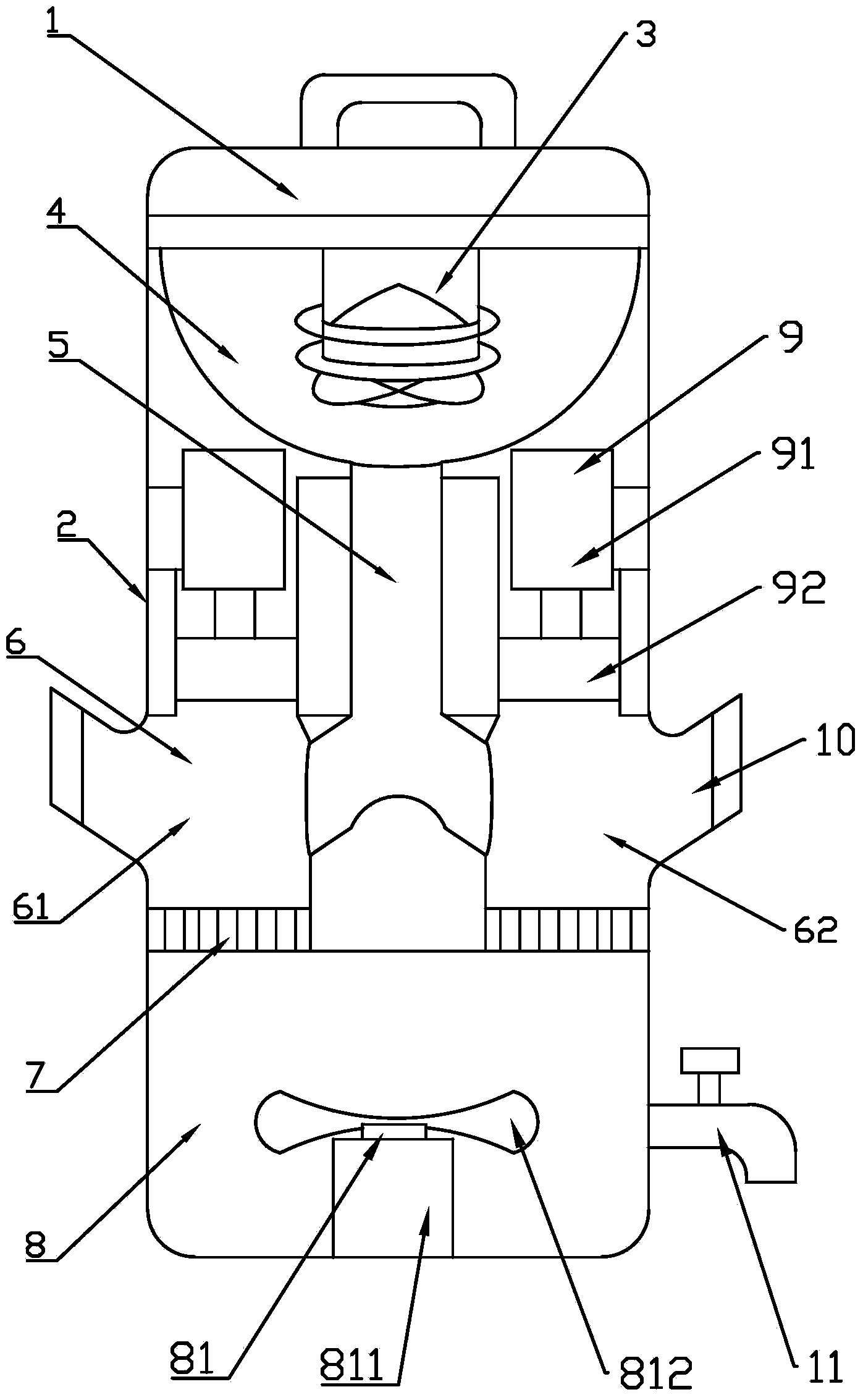

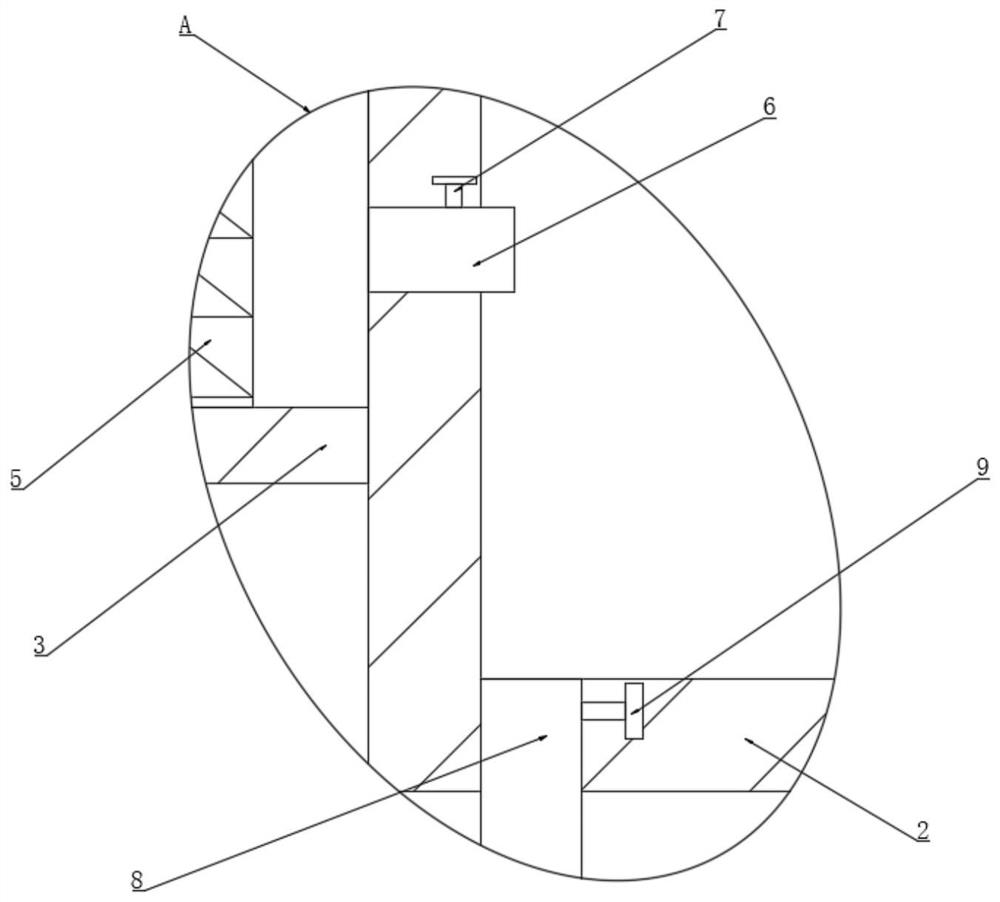

Rotary centrifugal type traditional Chinese medicine solid-liquid separation device

The invention discloses a rotary centrifugal type traditional Chinese medicine solid-liquid separation device, which comprises a base and a processing box. The left and right sides of the base are provided with rollers for convenient transportation of the device, a processing box is arranged above the base, and the lower end of the processing box is symmetrical on both sides. A support rod is provided, the lower end of the support rod is provided with a support sleeve, the lower end of the support sleeve is connected and fixed with the base, and a shock-absorbing spring is arranged inside the support sleeve, and the shock-absorbing spring connects and fixes the support sleeve and the support rod. It helps to improve the anti-seismic performance of the device, thereby making the transportation of the device more stable. A rotating drum is suspended in the middle of the processing box. The structure of the invention is simple and reasonable, and the rapid separation of solid and liquid can be realized through centrifugal screening, which greatly improves the At the same time, the bottom of the screening and separation cylinder is provided with an openable bottom plate to facilitate subsequent slag discharge treatment. In addition, the device also has a vibration mechanism, which helps to improve the slag discharge effect and has strong practicability.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

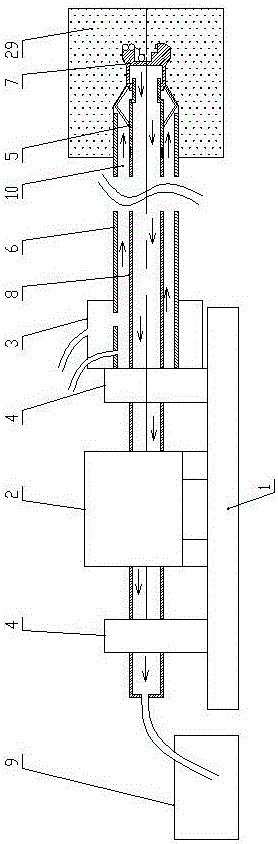

Chinese herbal medicine crushing juice extracting device convenient to discharge slag

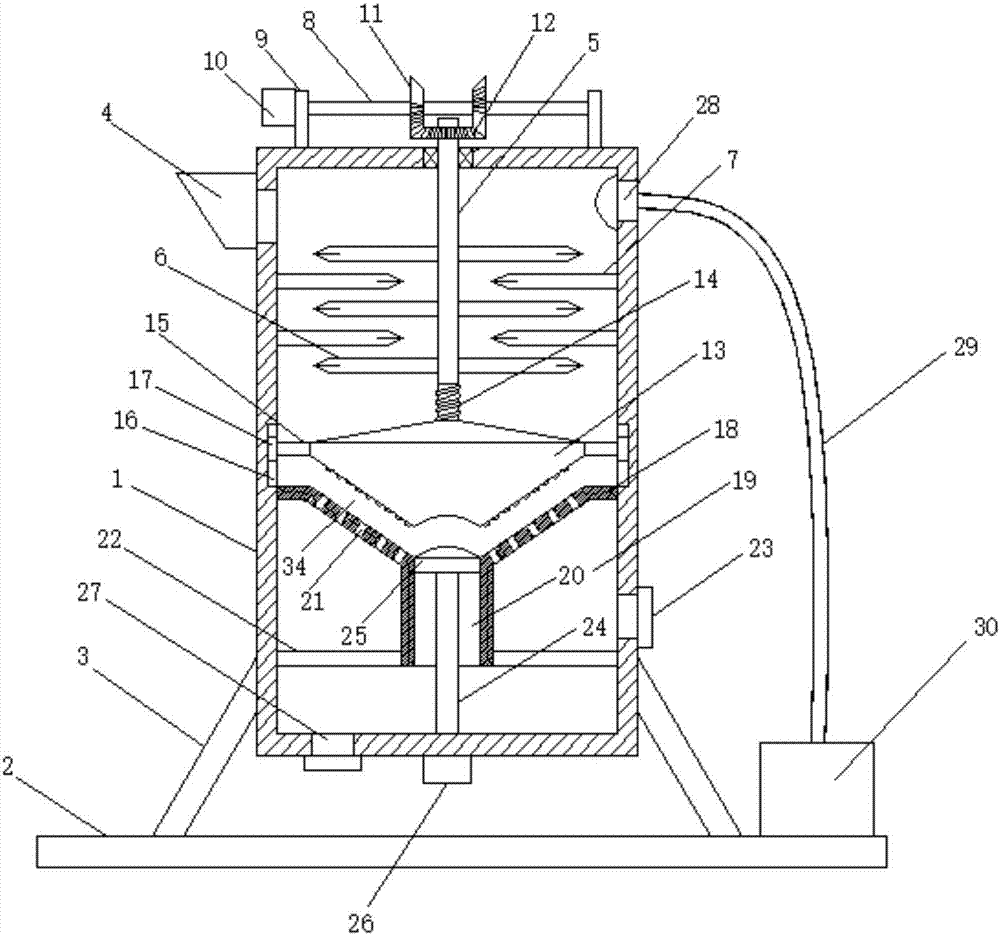

The invention discloses a Chinese herbal medicine crushing juice extracting device convenient to discharge slag. The device comprises a crushing extraction cylinder; a driving rotating shaft coaxial with the crushing extraction cylinder is arranged in the crushing extraction cylinder; multiple rotary cutting blades are arranged on the side wall of the driving rotating shaft; an extrusion disc block is arranged in the crushing extraction cylinder; a fixed extrusion plate is arranged on the lower side of the extrusion disc block; an extrusion extracting groove cooperating with the lower end of the extrusion disc block is formed in the middle part of the fixed extrusion plate; multiple liquid passing holes are formed in the edge side of the extrusion extracting groove; a blockage plate in tight sliding connection with the inner wall of a slag removing channel is arranged in the slag removing channel; the lower end of the blockage plate is connected with a hydraulic cylinder arranged on the bottom wall of the crushing extracting cylinder through a hydraulic push rod; and a slag discharge port is formed in the bottom wall of the crushing extracting cylinder. The device is simple in structure, convenient to discharge Chinese herbal medicine slag, better in crushing effect, better in extracting effect of Chinese herbal medicine extruding juice, convenient to collect and flow out, convenient to operate and higher in practicability.

Owner:四川康晨生物科技有限公司

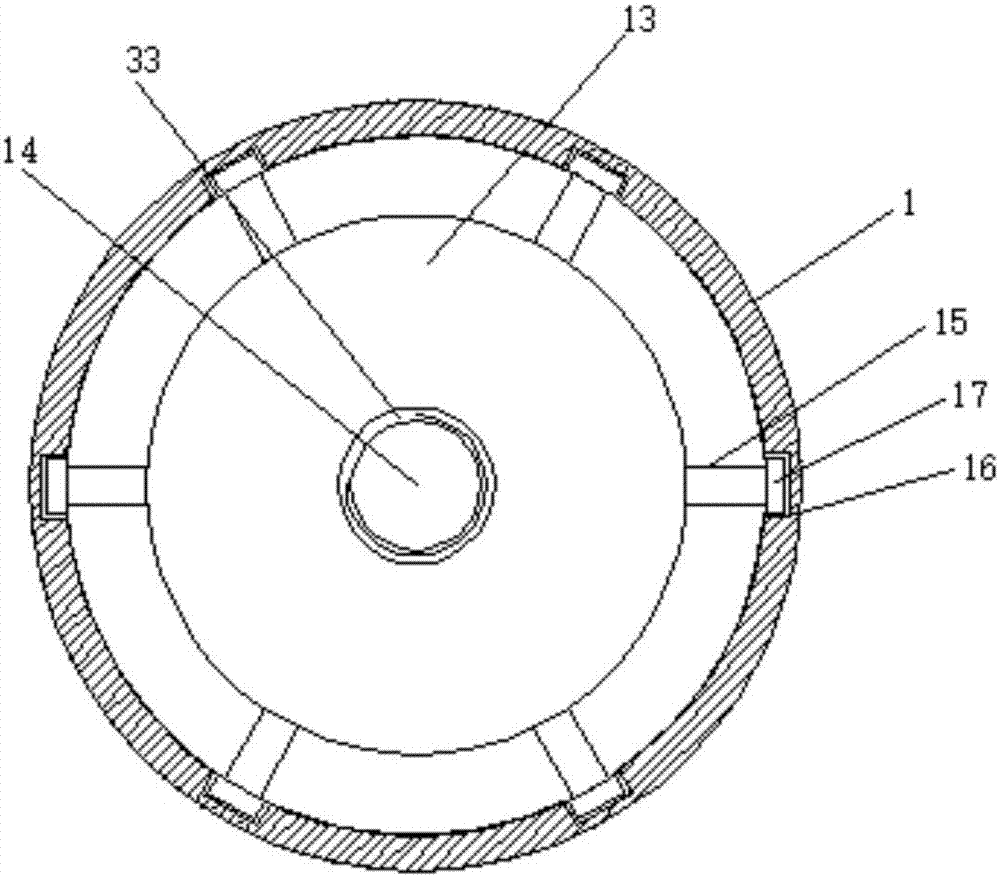

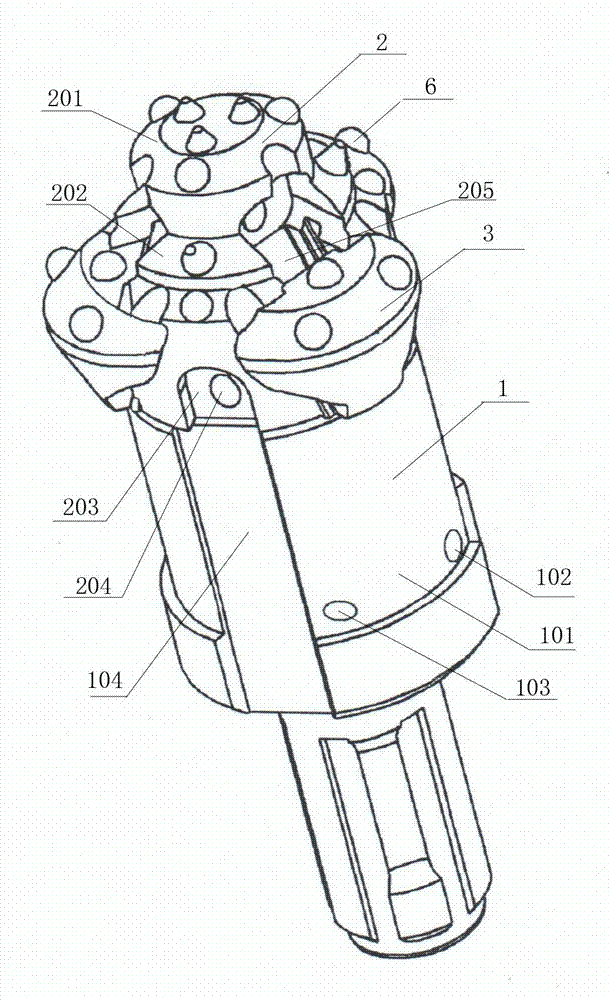

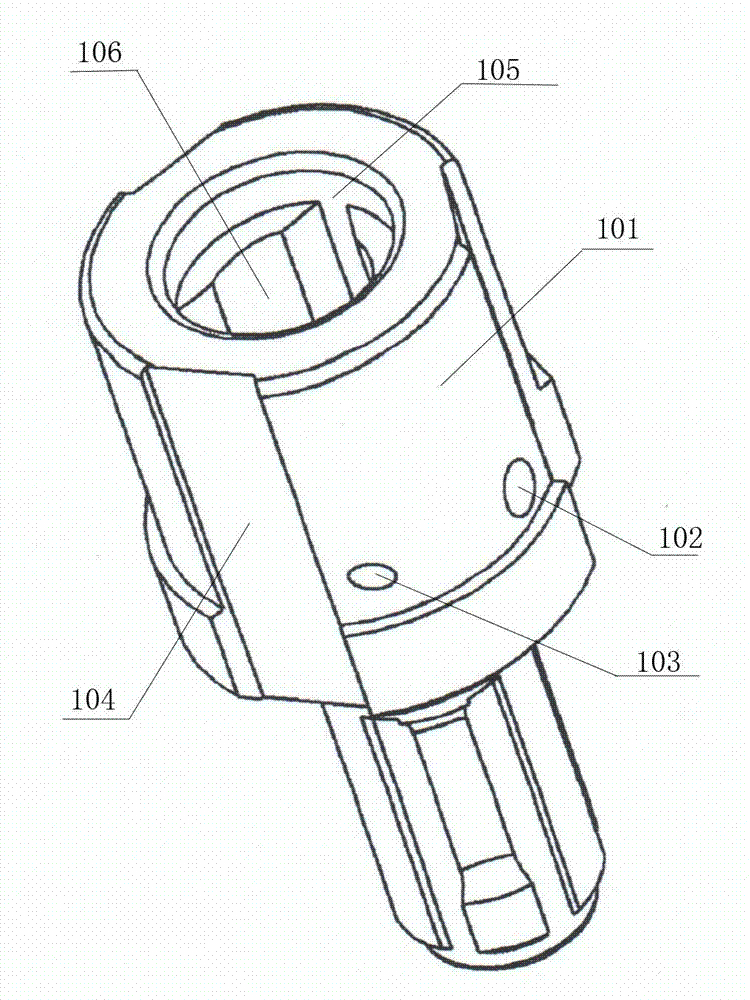

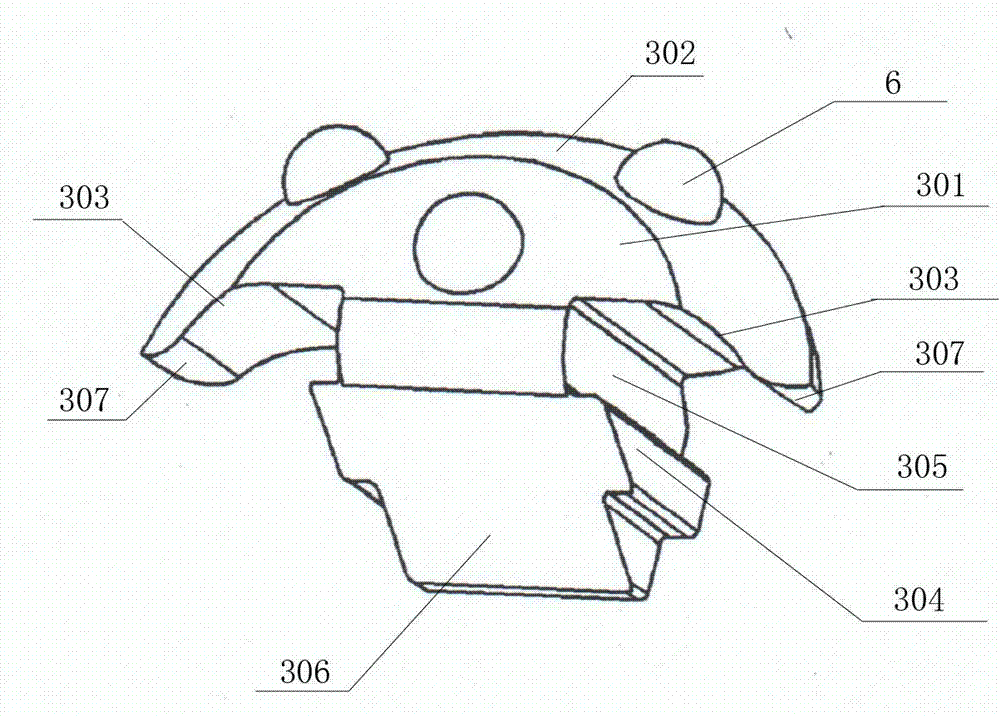

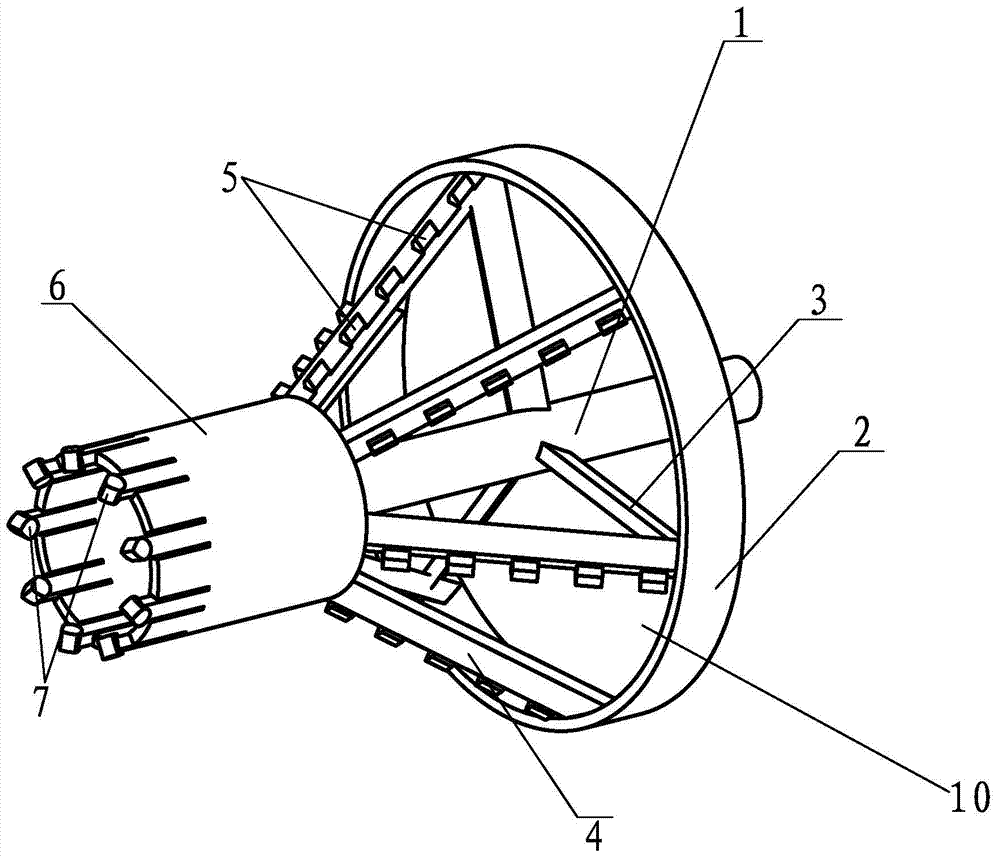

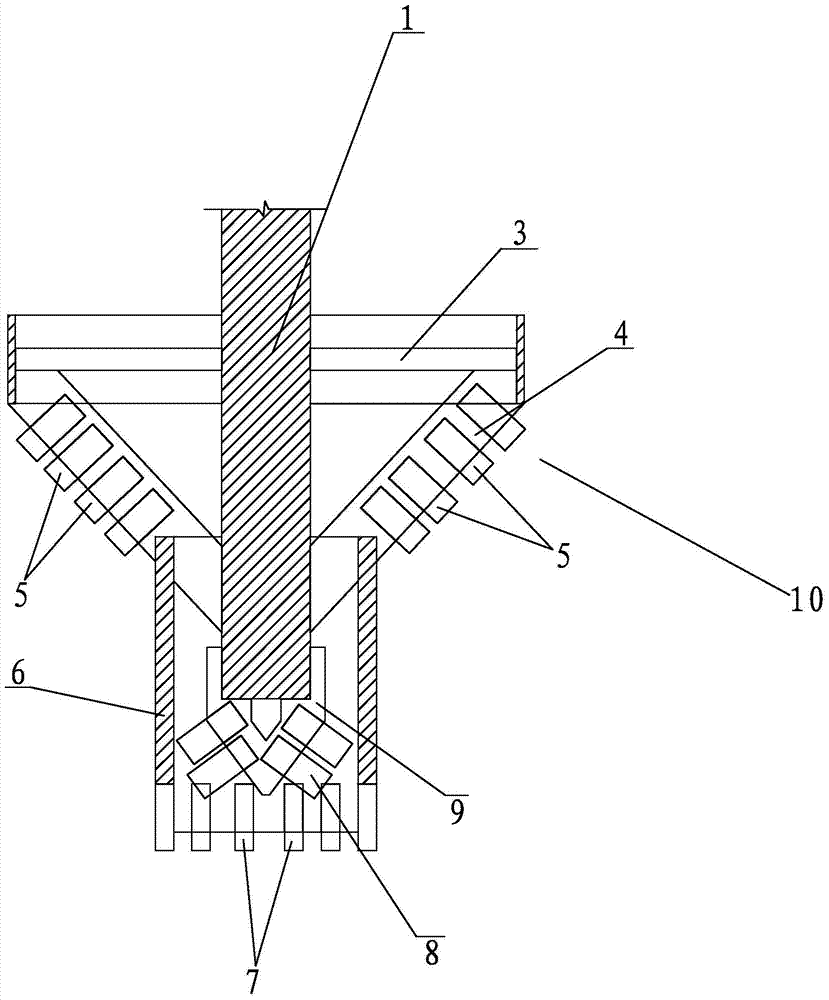

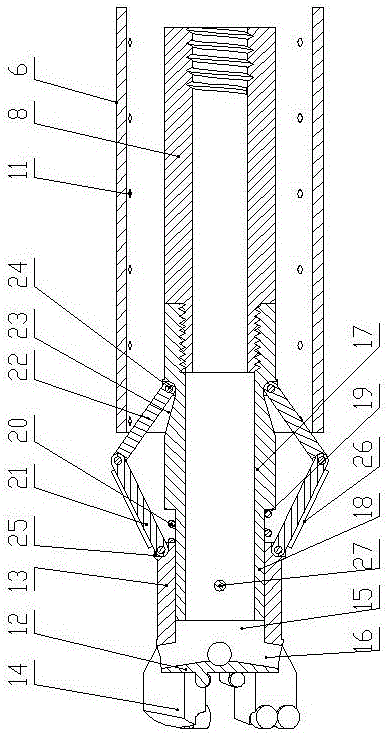

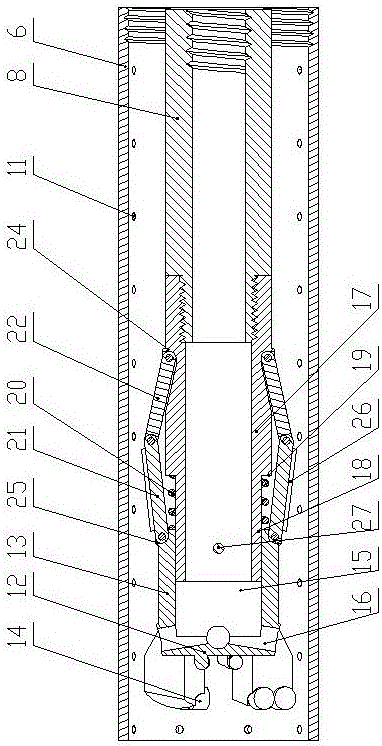

Concentric sliding block simultaneous casing drilling tool, center drilling bit and centralizer

ActiveCN102926663AReduce areaNo swingDrill bitsBorehole drivesClassical mechanicsTorque transmission

The invention discloses a concentric sliding block simultaneous casing drilling tool, a center drilling bit and centralizer. The concentric sliding block simultaneous casing drilling tool is formed by the centralizer, a ladder-shaped tapping center drilling bit and semicircle-shaped expanding drilling pieces, wherein the ladder-shaped tapping center drilling bit is connected and matched with a hole to which the centralizer is aligned for torque transmission, the ladder-shaped tapping center drilling bit is connected and located through a locating groove, a locating hole, a solid cylindrical pin and a hollow expansion pin, three semicircle-shaped expanding drilling pieces are in torque transmission through a T-shaped oblique groove and an R arc-shaped oblique groove, mutual included angles of the T-shaped oblique groove and the R arc-shaped oblique groove are 120 degrees by using an axis of the ladder-shaped tapping center drilling bit as the center, the semicircle-shaped expanding drilling pieces slide backwards to the end surface of the centralizer along the T-shaped oblique groove and the R arc-shaped oblique groove when being subjected to rock resistance and can be located, an expanding simultaneous casing can be formed, and the semicircle-shaped expanding drilling pieces slide downwards, can be narrowed and withdrawn due to the resistance of a pipe boot during upward drawing. According to the concentric sliding block simultaneous casing drilling tool disclosed by the invention, the front area of the tapping drilling bit is small, the force is concentrated, and the tapping drilling bit can crush harder or large rocks firstly at stages at crushing speed.

Owner:广汉珂普瑞科技有限公司

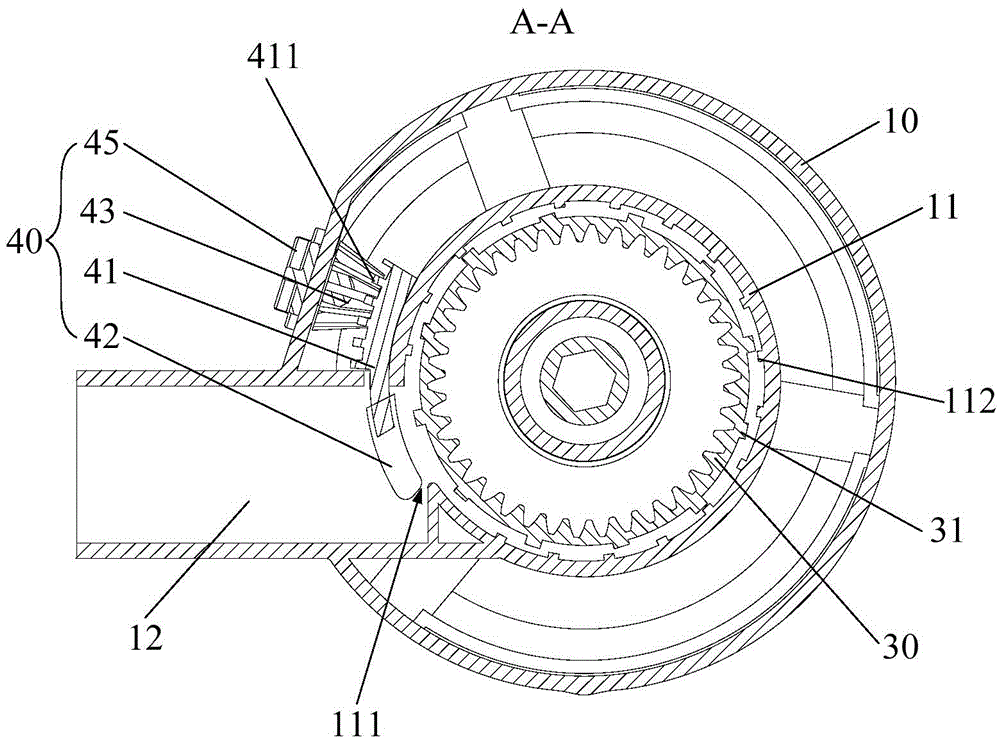

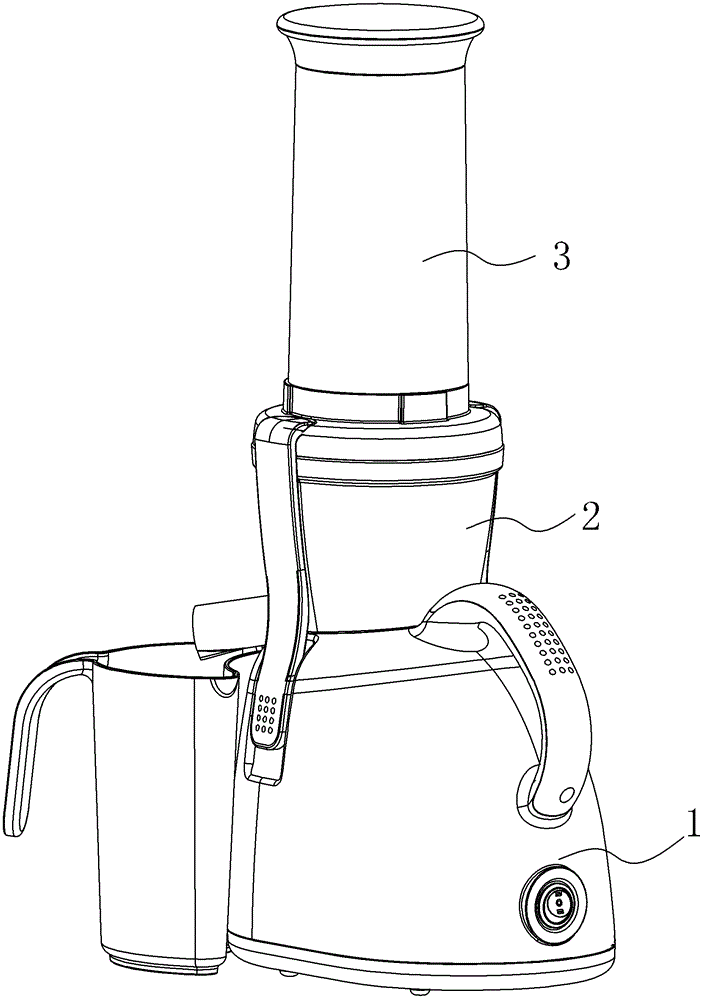

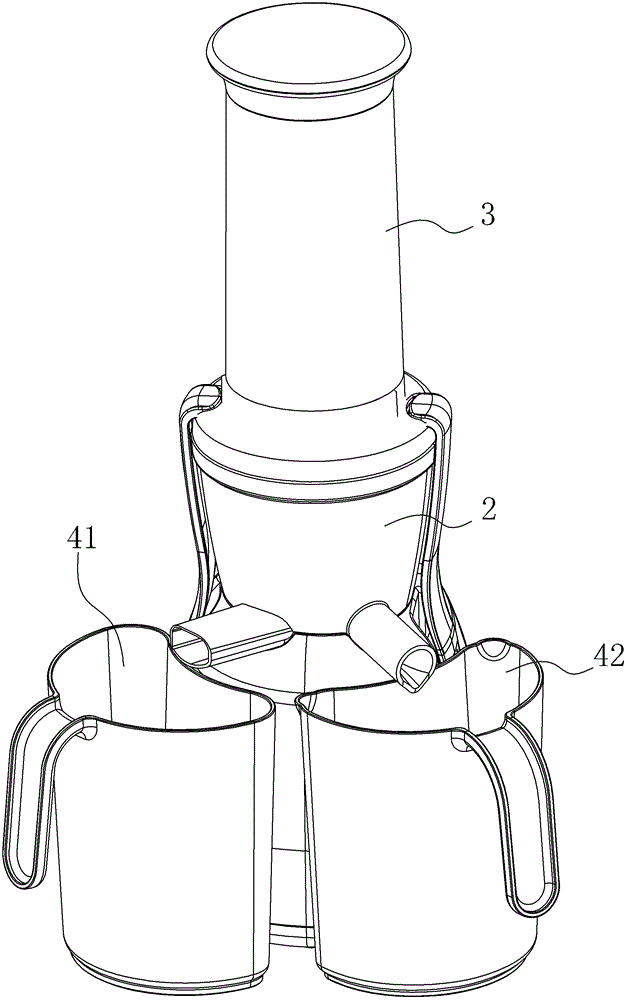

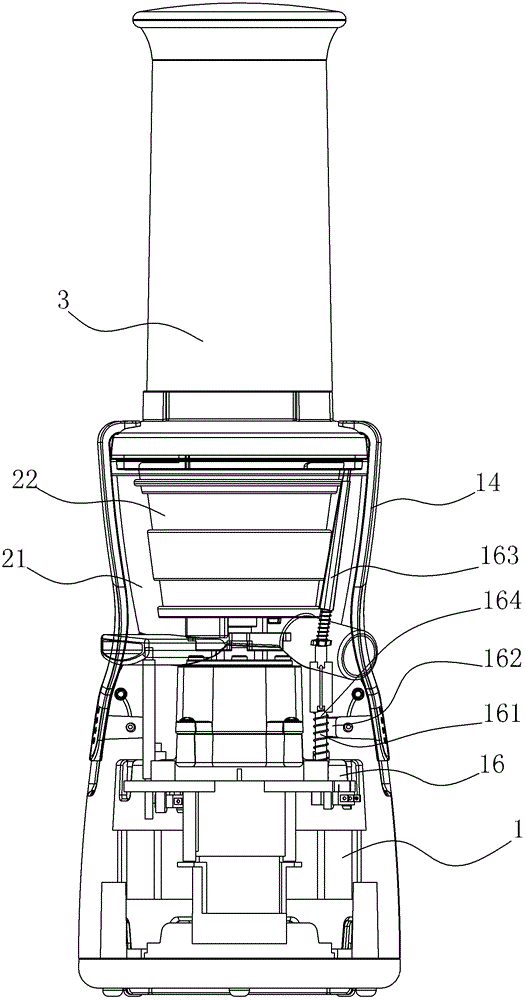

Squeezing type juicer

Owner:胡伟

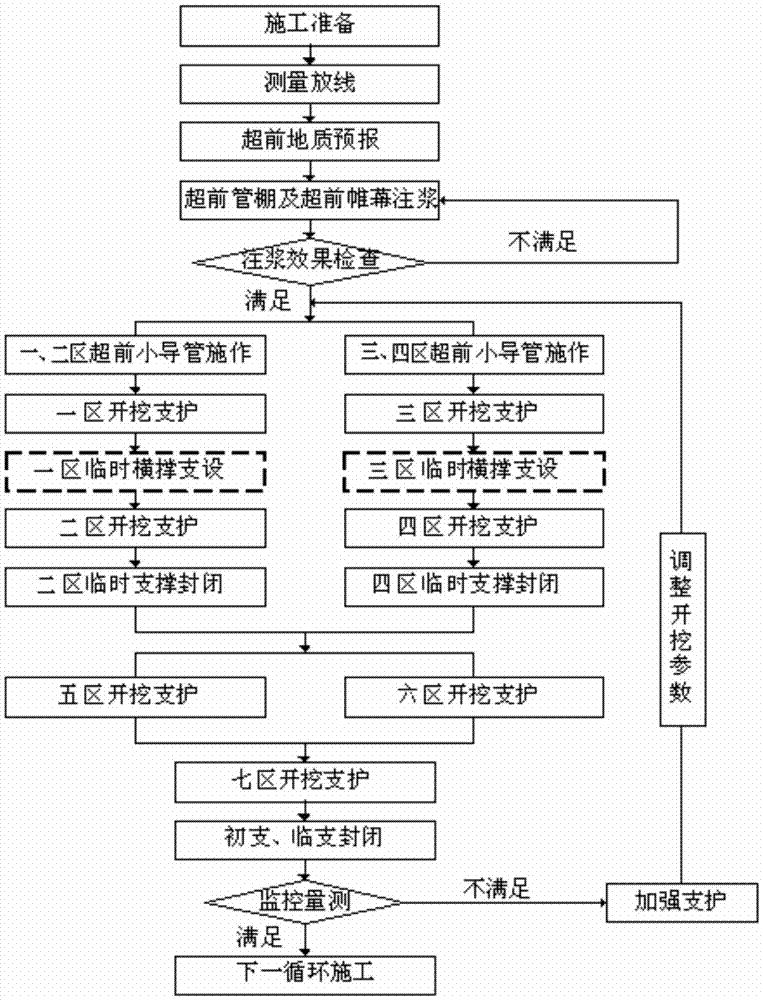

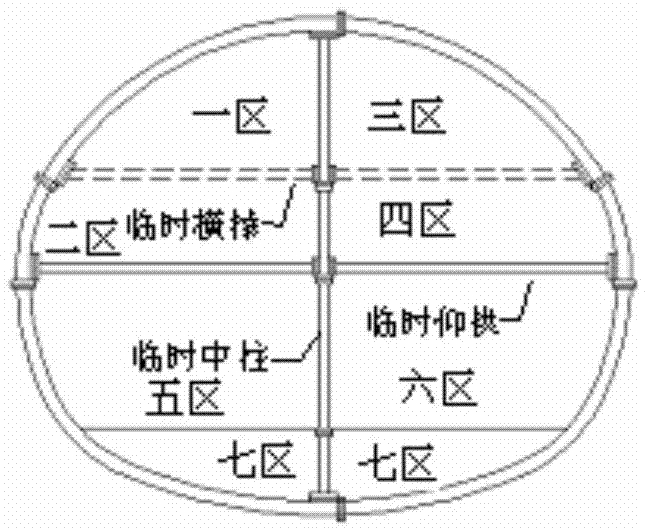

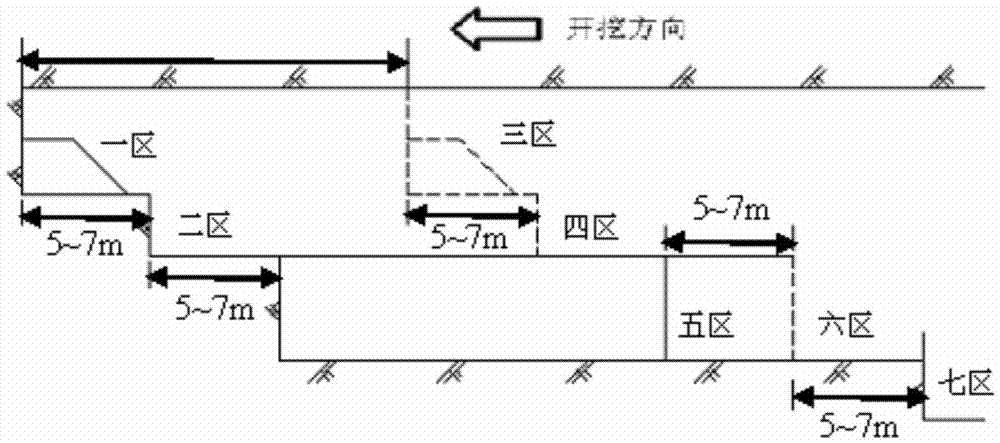

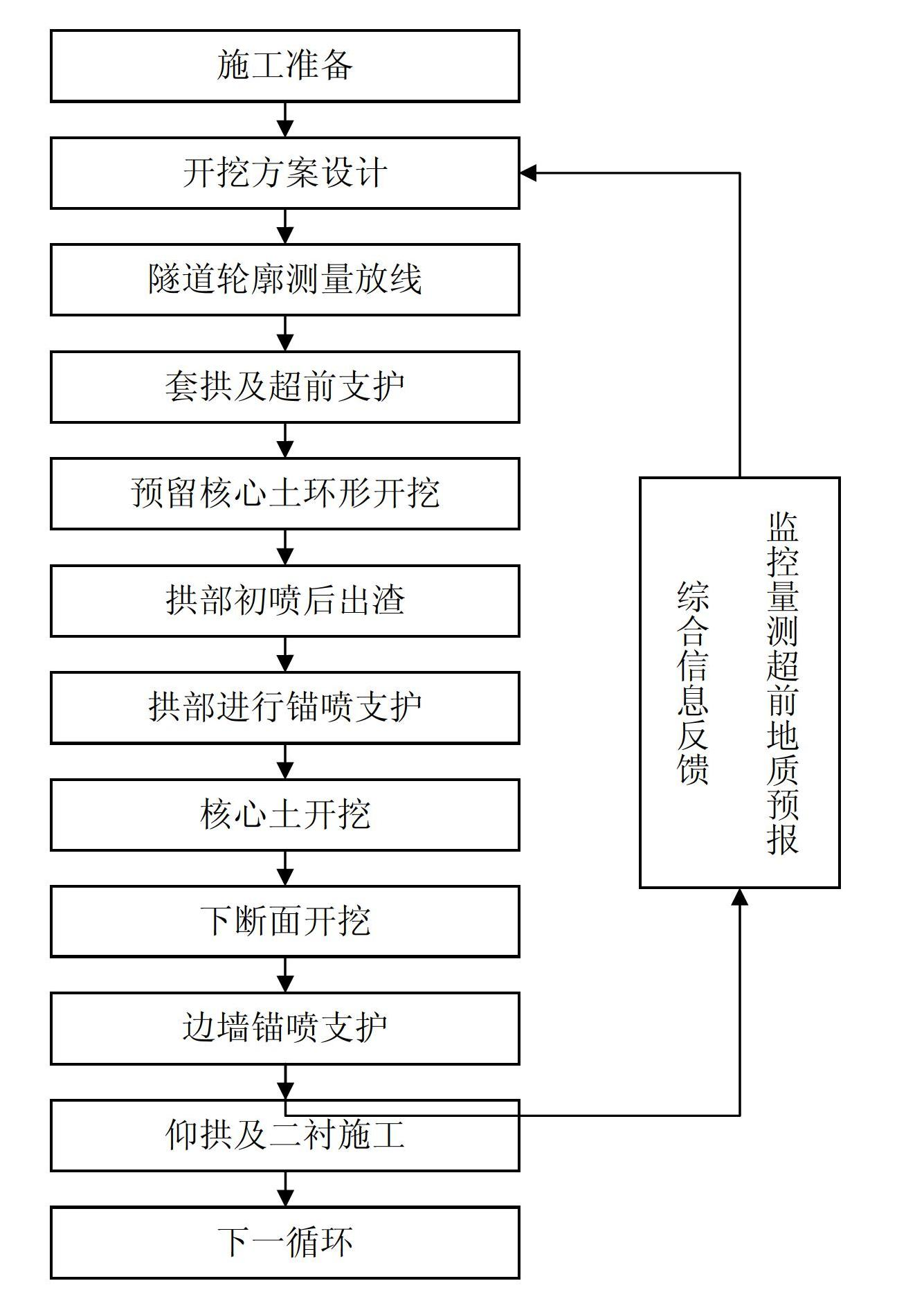

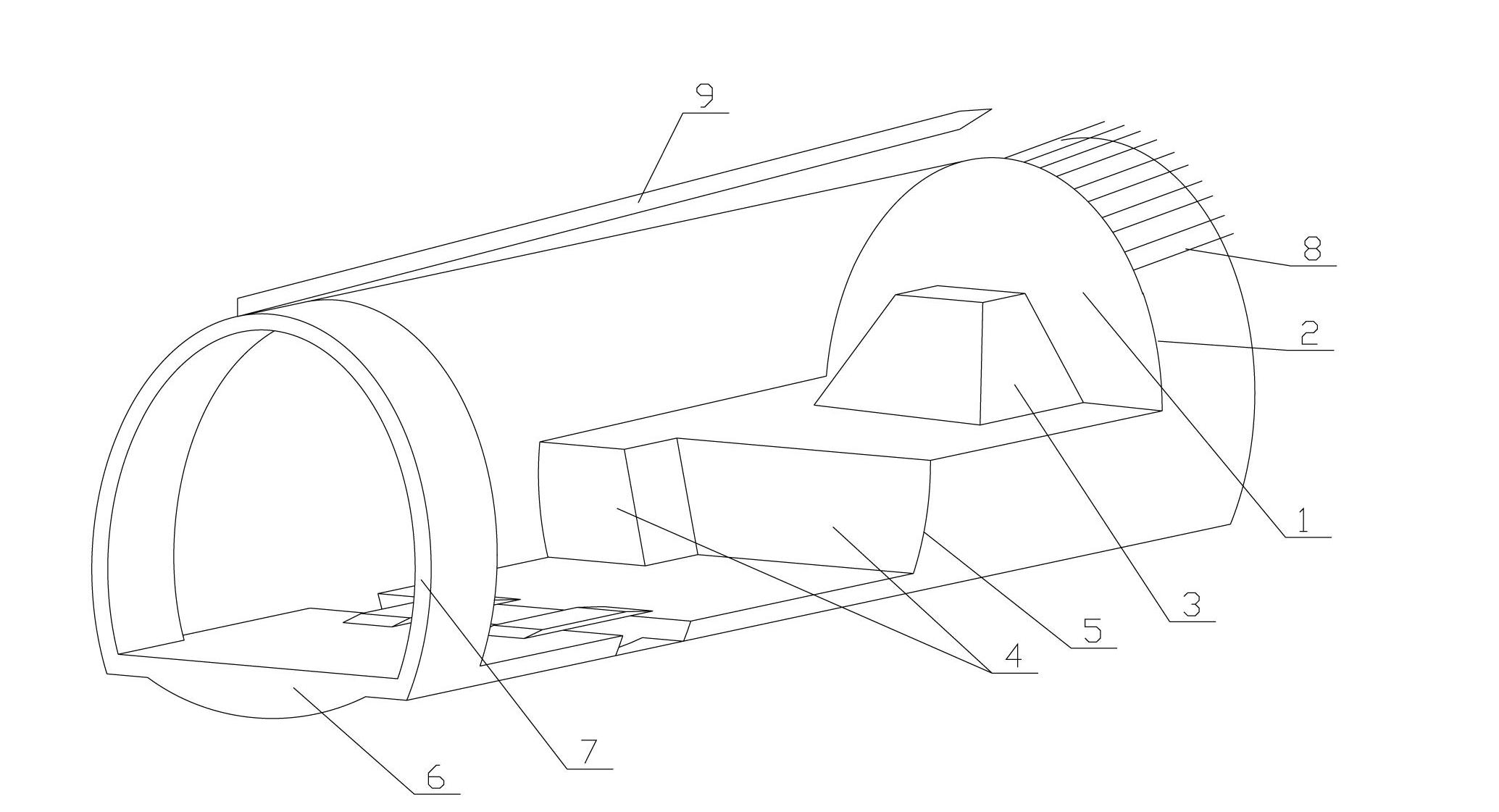

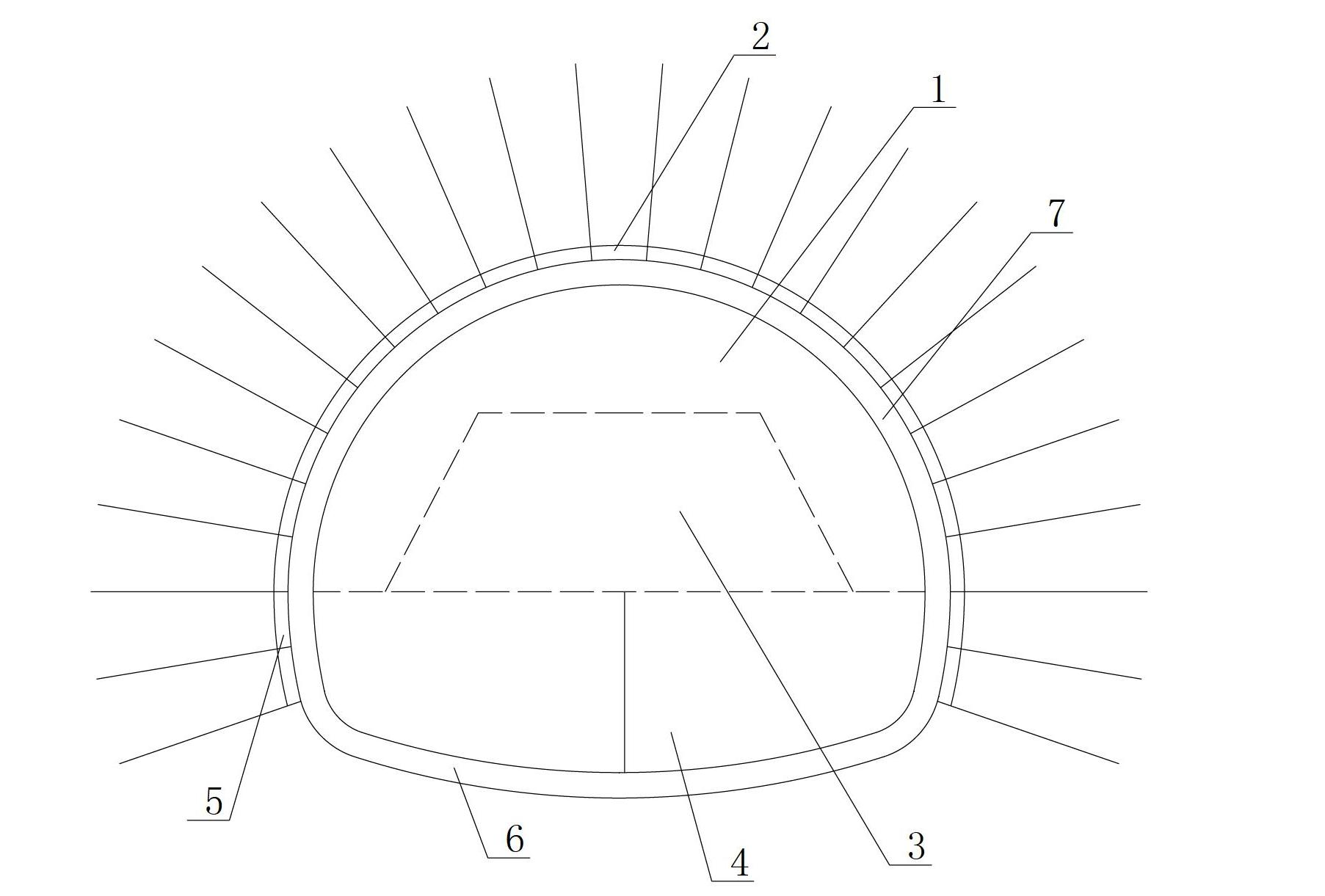

Construction method of shallow-buried subsurface-excavated cross-shaped cross-strut tunnel

ActiveCN105443132AEasy to operateQuality is easy to controlUnderground chambersTunnel liningConstruction designEnvironmental geology

The invention discloses a construction method of a shallow-buried subsurface-excavated cross-shaped cross-strut tunnel. The method includes the following steps of conducting construction preparation, conducting measurement and pay-off on a tunnel advanced support and the tunnel contour line according to construction design requirements, conducting advanced geological forecasting through the geophysical prospecting advanced geological forecasting and drilling advanced geological forecasting combined mode, conducting advanced pipe shed grouting and advanced curtain grouting, checking the grouting effect, entering the next procedure if the grouting effect meets the construction requirement, conducting advanced pipe shed and advanced curtain grouting again if the grouting effect does not meet the construction requirement, conducting excavation support construction on construction areas on by one from top to bottom and from left to right, conducting primary support and temporary support sealing and conducting monitoring and measuring after the primary tunnel transverse end face construction is completed, repeatedly executing the steps for the next circulation of construction if the design requirement is met, conducting support strengthening if the design requirement is not met, and regulating excavation parameters to conduct excavation support construction again till the design requirement is met.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

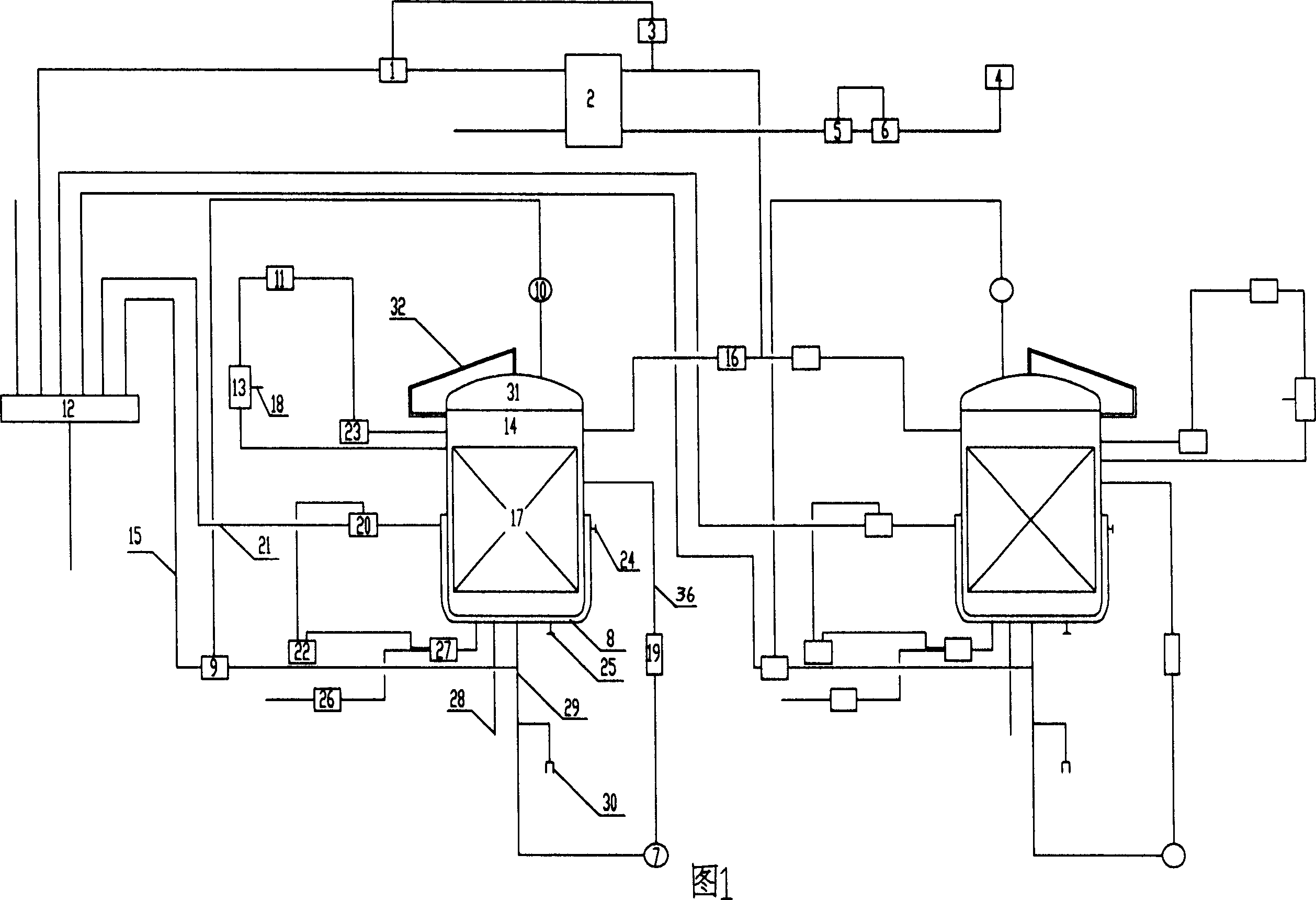

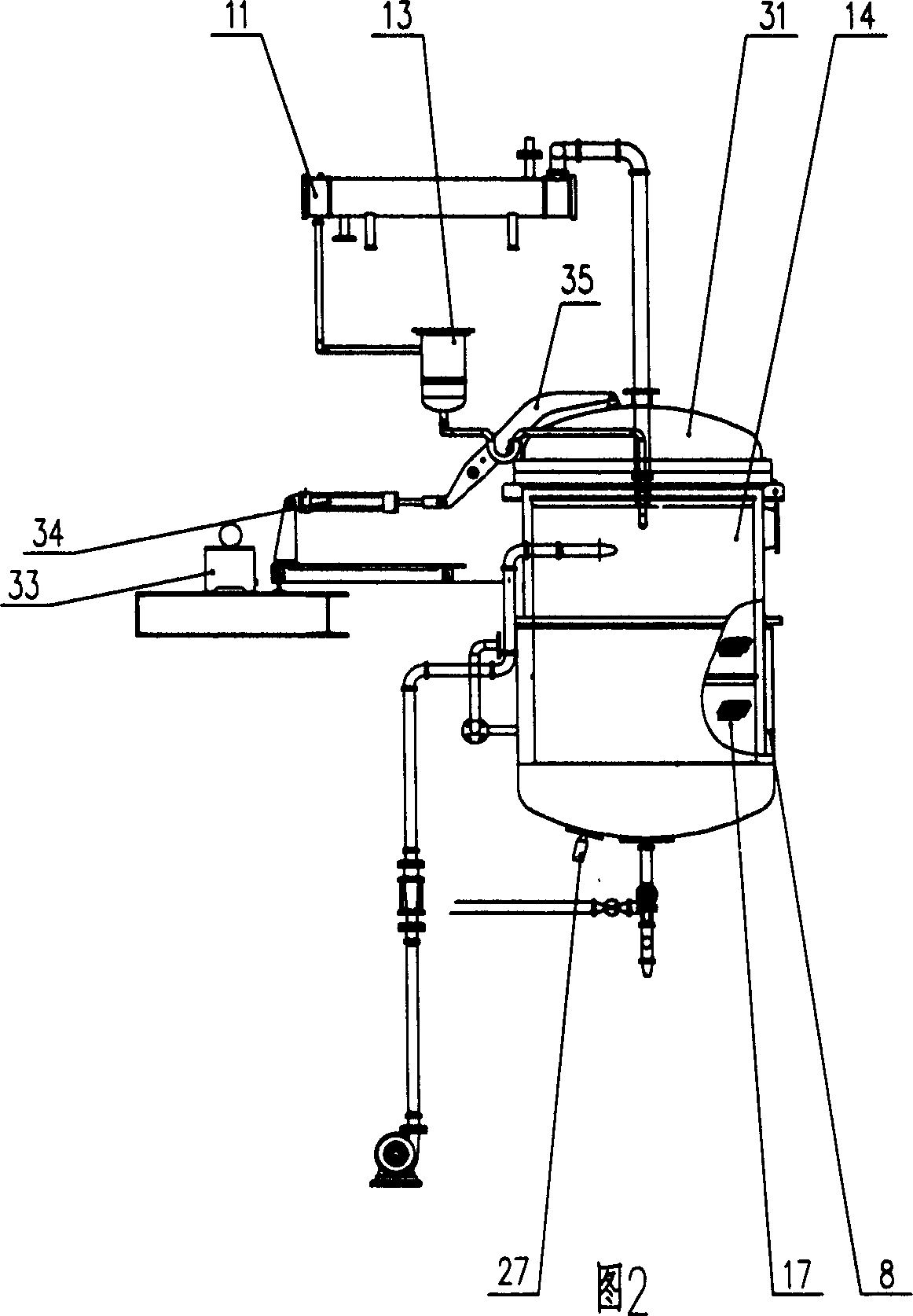

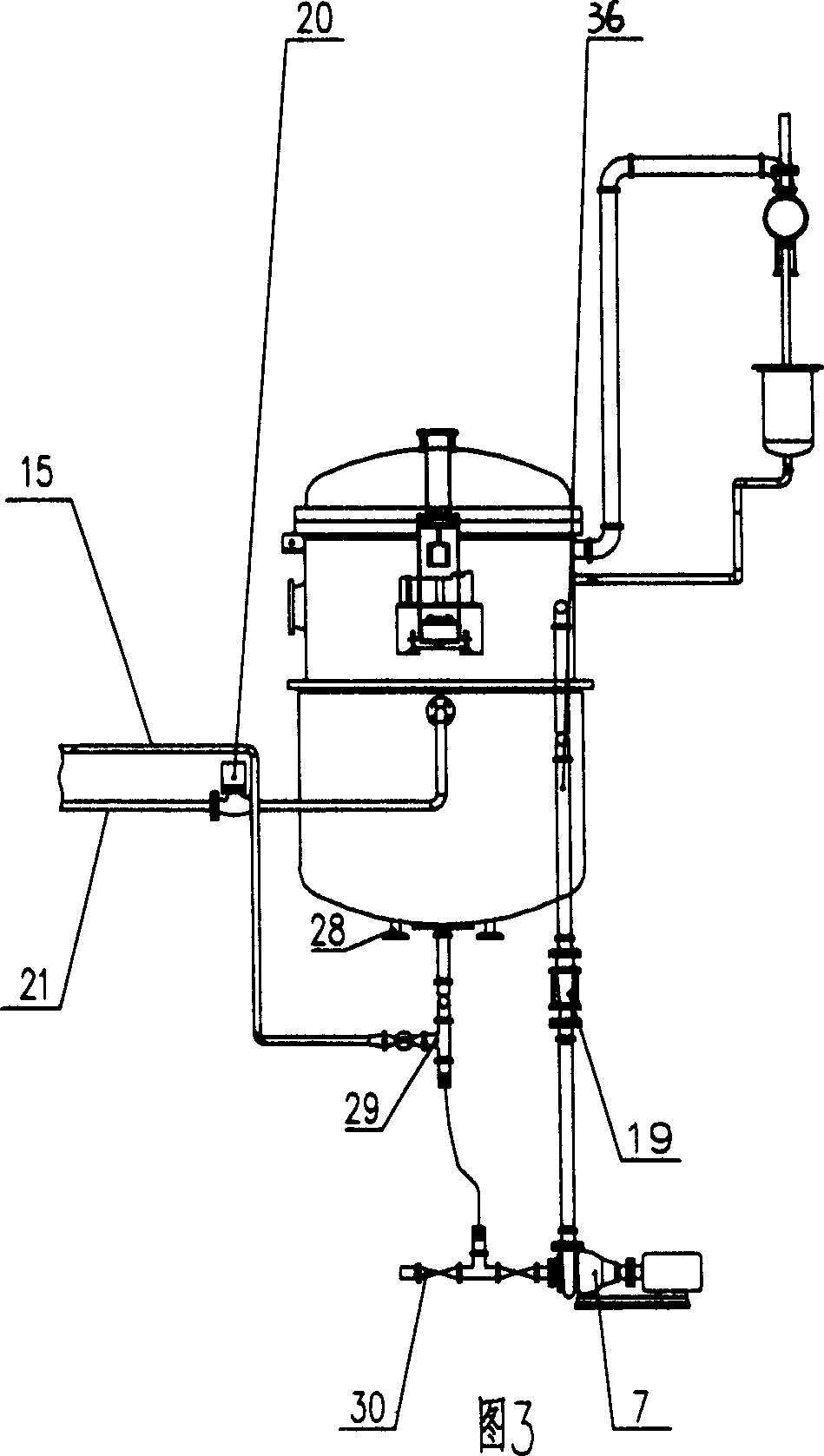

Material of Chinese medicine extracting process and apparatus thereof

An apparatus for extracting active components from raw Chinese-medicinal material features that the first circulating loop is composed of extractor, pipeline, condenser and oil-liquid separator and the second circulating loop is composed of said first one, pipeline and circulating pump. Its process includes such steps as loading the raw Chinese-medicinal material in basket, putting it in extractor, filling solvent, heating by steam, extracting cyclically, condensing the aromatic oil vapor, oil-water separating, and reusing the separated solvent.

Owner:云南昆船电子设备有限公司

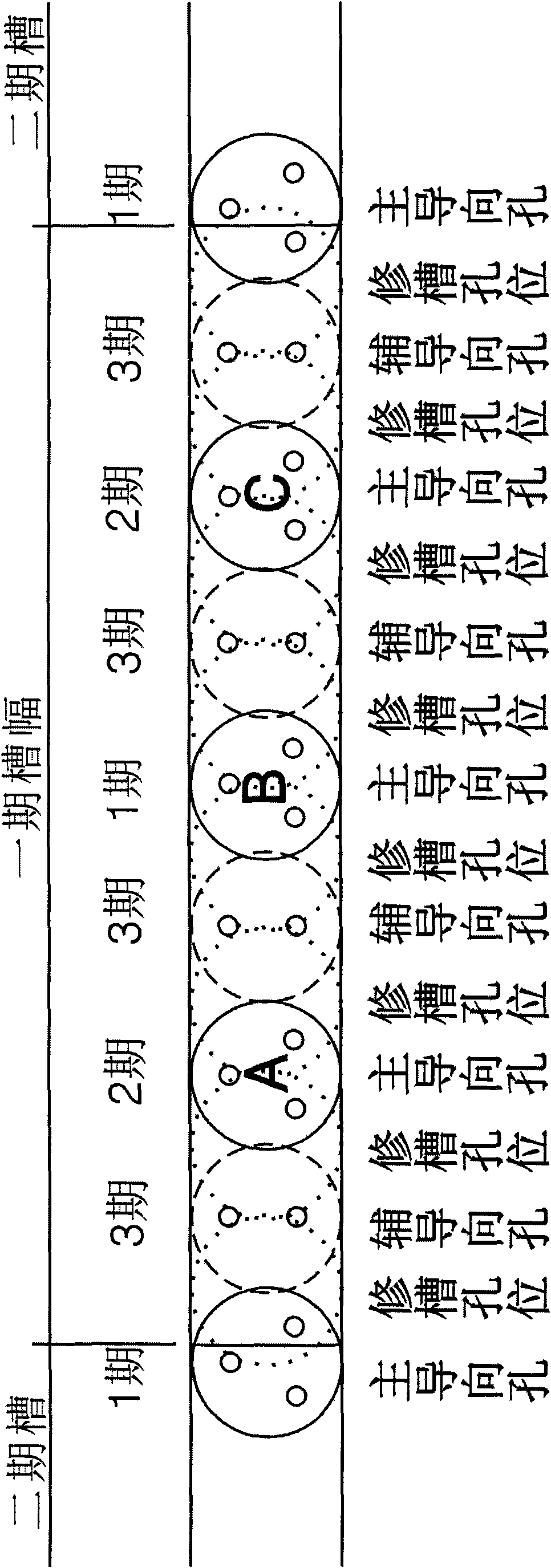

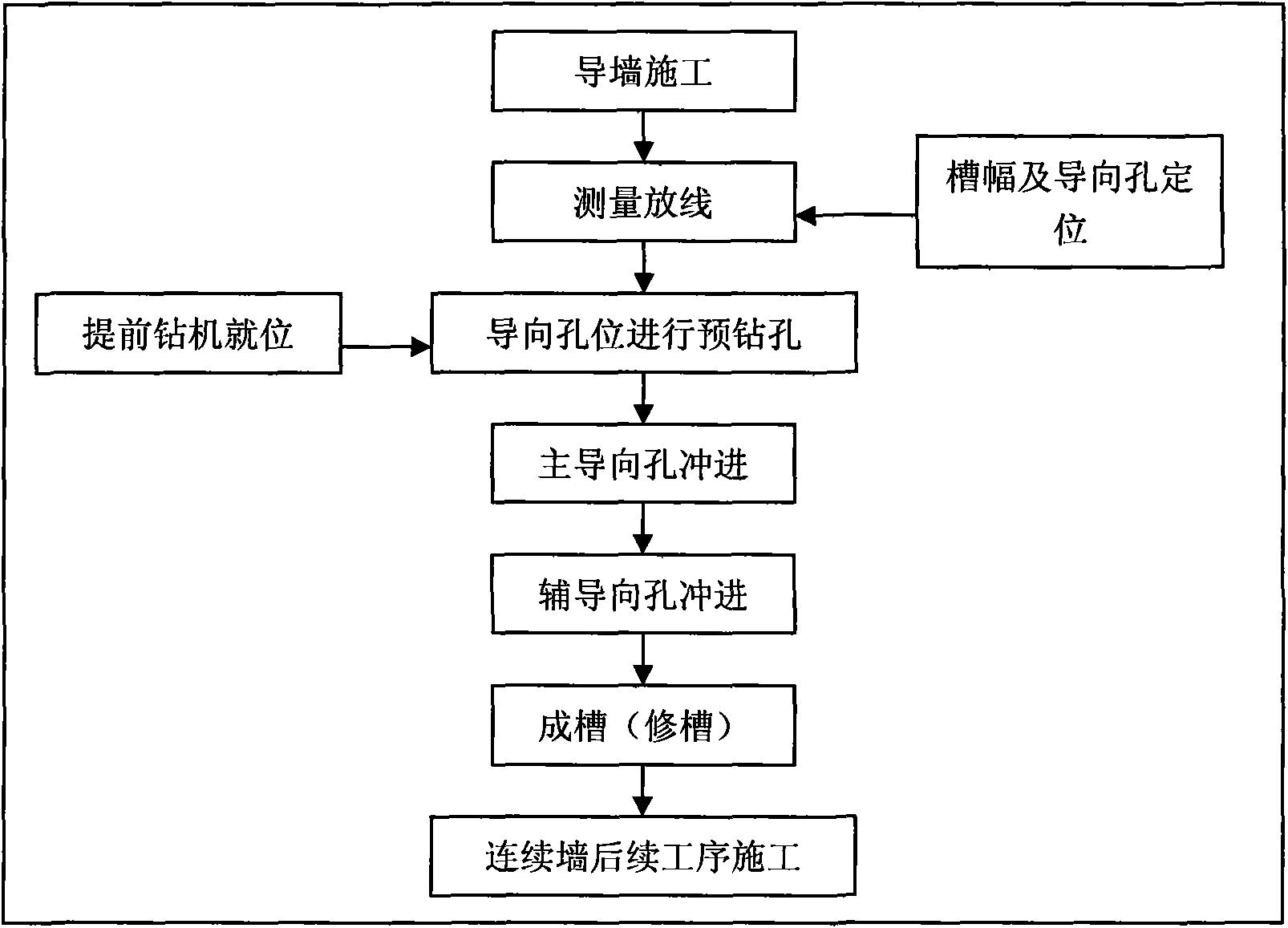

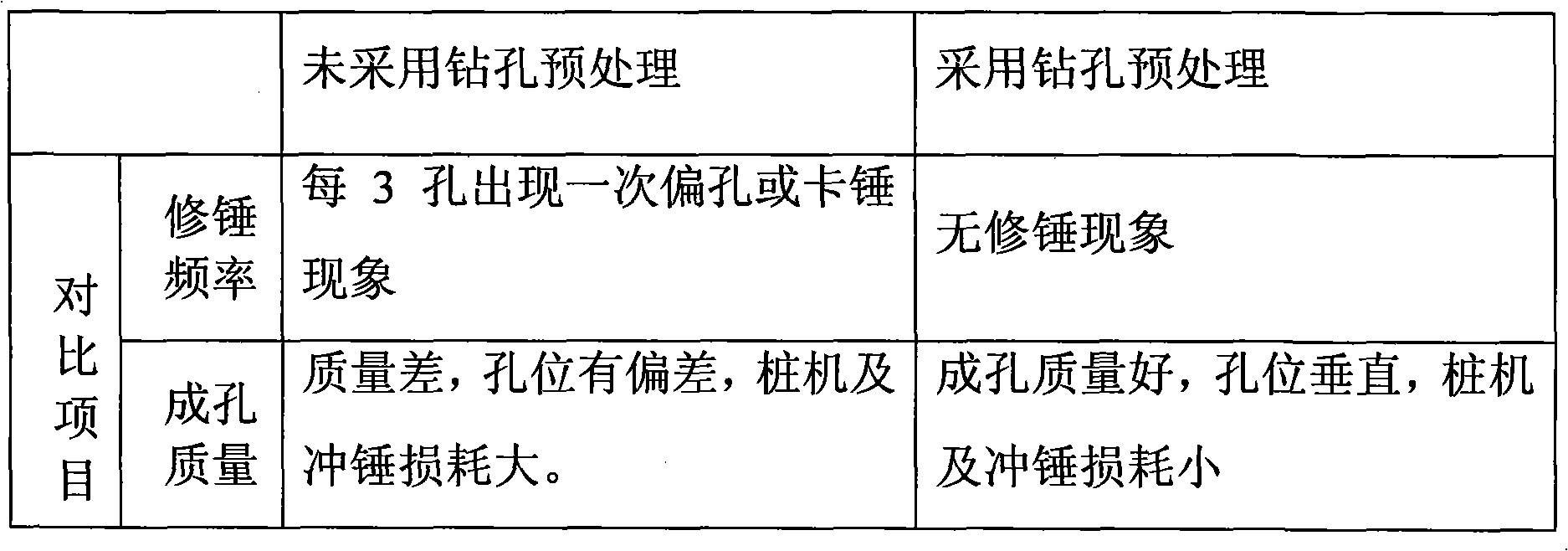

Preconditioning process of continuous wall for weak weathering terrane grooving construction

InactiveCN101586340AEasy constructionEasy to discharge slagExcavationsBulkheads/pilesBuilding construction

The present invention provides a preconditioning process of a continuous wall for the weak weathering terrane grooving construction, firstly determining a main guide hole and an assistant guide hole, then implementing a prepared hole to the main and the assistant guide holes during the construction process of each weak weathering rock geologic continuous wall, then diving into the guide holes, and grabbing a groove by using a hydraulic crab bucket grooving machine, and then enciphering the grooving hole, finally grooving by repairing the groove through the hydraulic crab bucket grooving machine. The process of the invention is capable of improving the construction quality greatly and avoiding a plurality of difficulties of punching the rock and forming the hole, thus it is capable of ensuring the continuous wall to be completed in a prospective time, and providing a golden and well-knit foundation for a pressing engineering construction period.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

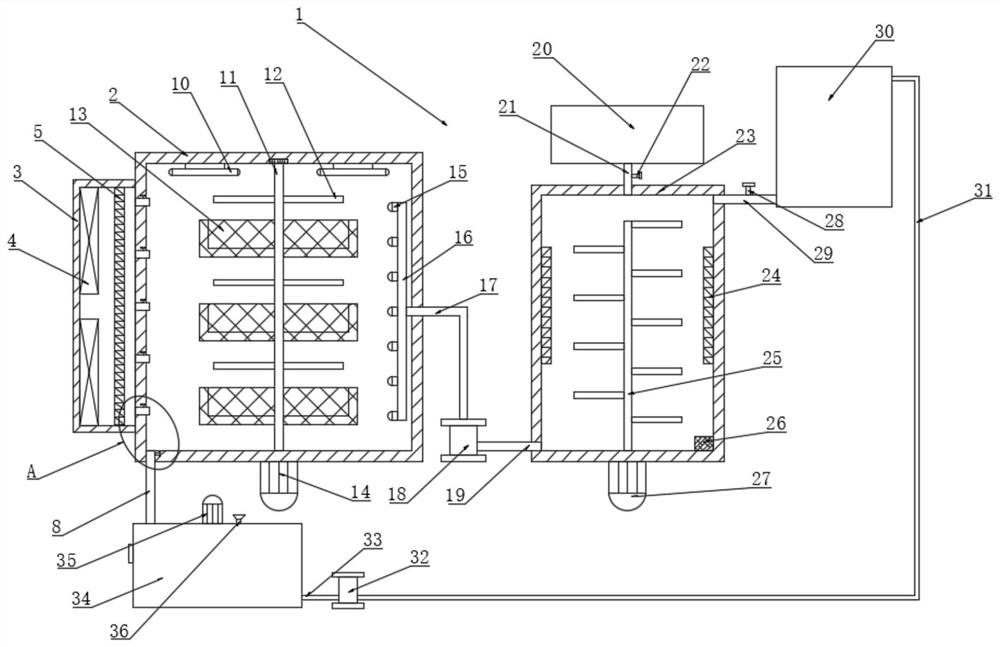

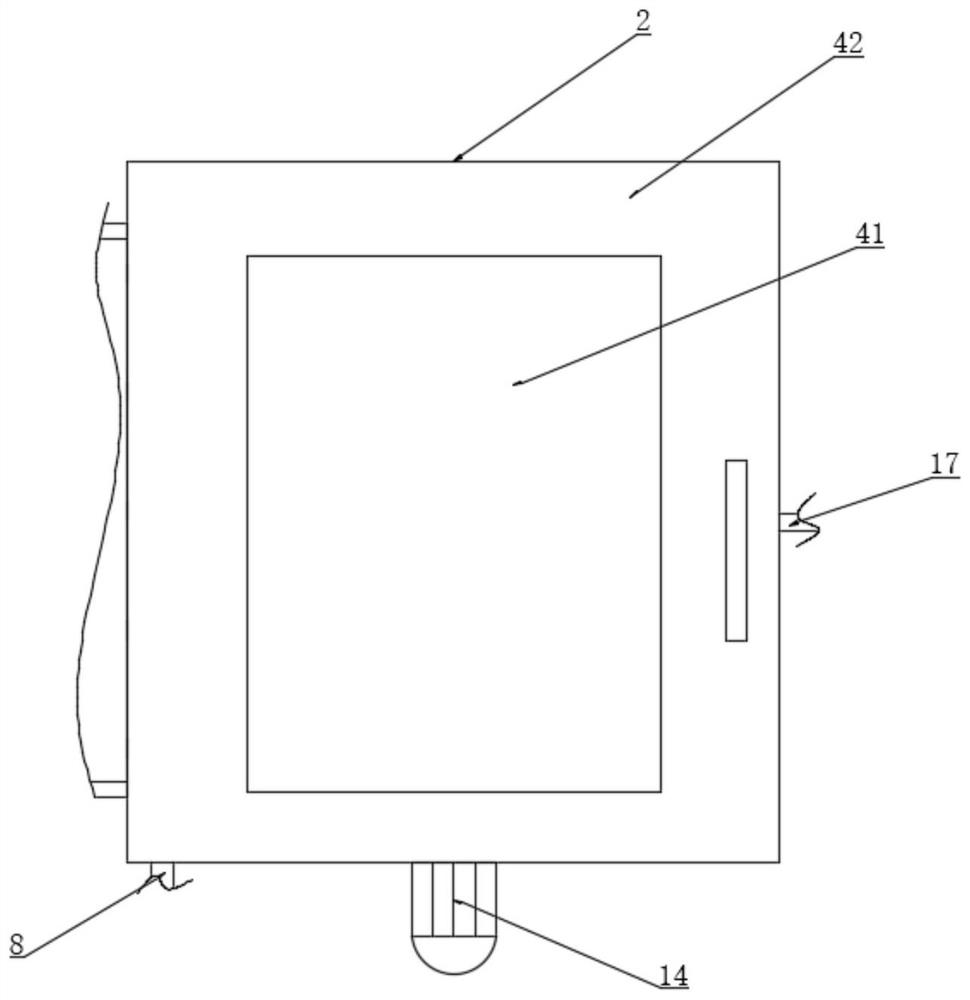

Unhulled rice seed water separation device capable of conveniently discharging residues

ActiveCN108722652AExtended shelf lifeImprove drying efficiencyDrying gas arrangementsDrying solid materialsSludgeEngineering

The invention discloses an unhulled rice seed water separation device capable of conveniently discharging residues. The unhulled rice seed water separation device comprises a base plate and a water separation box body, the side walls of the water separation box body are fixedly connected to the base plate through supporting rod frames, vertical lifting screw rods are installed on the two side walls of the water separation box body through fixing rod seats, an adjusting motor is further arranged on a connecting and fixing plate located on the lower side, and an output shaft of the adjusting motor is connected with the outer side wall of an adjusting sleeve through a transmission mechanism; and the lower ends of the lifting screw rods are connected with lifting motors arranged on the fixingrod seats, an elastic filtering baffle net is further arranged inside the water separation box body, a dirt discharging port is formed in the bottom wall of the water separation box body, the joint ofan air guide pipe and the side wall of the water separation box body is located on the lower side of the elastic filtering baffle net. According to the unhulled rice seed water separation device, thestructure is simple, water separation effect is obvious, unhulled rice seeds can be cleaned, dirt can be discharged, meanwhile, the unhulled rice seeds can be dried so that the storage time of the unhulled rice seeds can be long, the residues can be conveniently discharged, and the practicability is relatively high.

Owner:江西东坚米业有限公司

Method for excavating mountain tunnels in weak surrounding rock-fractured zones or shallow covered slope sections

InactiveCN102678126AEasy to discharge slagImprove construction progressUnderground chambersTunnel liningShotcreteFracture zone

The invention discloses a method for excavating mountain tunnels in weak surrounding rock-fractured zones or shallow covered slope sections, which includes the following steps: (1) cover arch and forepoling; (2) tunnel cutting, including the following steps: (a) the annular part of the upper cross section of the portal of the buried tunnel is first cut, a core soil part is formed on the upper cross section, and an arch is formed; (b) combined bolting and shotcrete is carried out on the arch; (c) the core soil part is cut; (d) the lower cross section of the portal of the buried tunnel is cut; (e) first shotcrete and combined bolting and shotcrete are carried out on the left and the right sidewalls; (f) an inverted arch is lined and backfilled; (g) secondary lining is carried out; (3) step 2 is repeated until the leading pipe shed construction of the next tunnel section is carried out; (4) step 3 is repeated until the tunnel runs through the weak surrounding rock-fractured zone of a mountain. The construction space is large, multi-working face parallel operation can be carried out, and the working efficiency is high; and since the core soil is reserved on the upper cross section and the left and the right cross sections on the lower cross section are staggerly cut forward, the cut working face can be kept stable.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

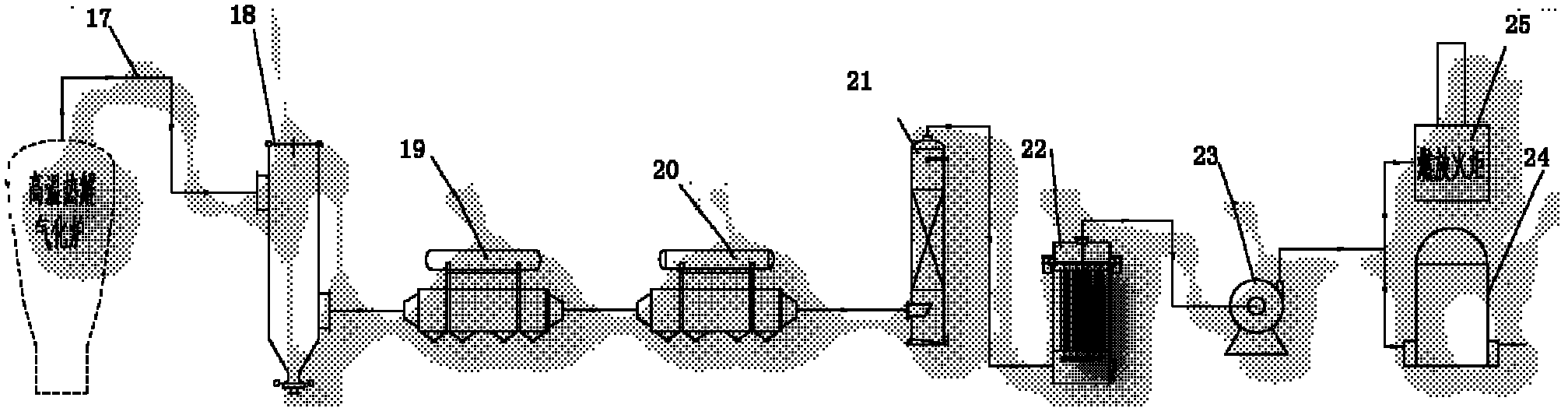

High temperature normal pressure biomass gasification island process

The invention provides a high temperature normal pressure biomass gasification island process. The process comprises the procedures of pretreatment and storage of biomass, gasification by using a biomass gasification furnace, cooling of gasified crude gasification gas, rinsing, dedusting and storage of fresh gasification gas, wherein in gasification by using the biomass gasification furnace, an external heat source is used to supply heat, reaction temperature in the gasification furnace is controlled to be 1300 to 1750 DEG C, liquid state slag removal is adopted by the gasification furnace, cooling of gasified crude gasification gas is realized through recovery of sensible heat by a quenching tower and a two-stage heat boiler, cooled crude gasification gas is subjected to rinsing and electric precipitation, fresh gasification gas is stored in a gas storage cabinet, and whole gasification island equipment operates under a negative pressure or a positive pressure of 0 to 50 KPa. According to the process, the external heat source is utilized for gasification, which enables the quality of crude gasification gas to be improved; a normal pressure fixed bed is employed for gasification, which enables the equipment of gasification furnace body to have the advantages of simpleness, small investment and easy operation; feeding, deslagging and purifying systems are simple; a wide variety of raw materials are applicable, gasification of various biomass, MSW, raw coal, sludge and the like can be realized, and blended gasification of a plurality of fuels can be realized; systems and equipment are mature, and a high localization degree is obtained.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

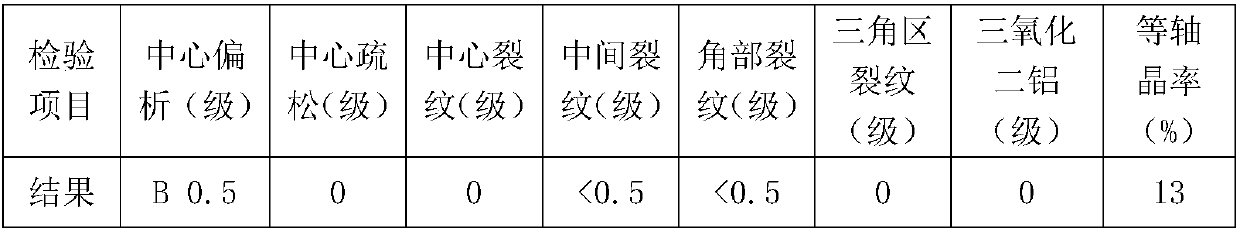

Casting method of spheroidal graphite cast iron valve

ActiveCN108531803AStable productionReduce manufacturing costFoundry mouldsFurnace typesElectricitySlag

The invention discloses a casting method of a spheroidal graphite cast iron valve, and relates to the spheroidal graphite cast iron valve. The method comprises the steps of model making, modeling, smelting, pouring, heat treatment and obtaining of a finished product valve casting. Alloy elements are not added, the spheroidal graphite cast iron valve with the supersize can be stably produced, a dedicated slag blocking device is arranged at the front end of a transverse sprue, when molten iron of the transverse sprue is introduced into the front end, the slag blocking effect is achieved, it is ensured that a mold cavity is rapidly and stably filled with the molten iron, oxide inclusions are reduced, a heat preservation top riser is adopted, and is placed on the top of the valve, and castingfeeding, slag discharging and exhausting are facilitated; a chilling block is arranged at the position, on the large and thick section and the portion with the large wall thickness difference, in thecasting, chromite sand is used around an even core and a shaft head in a shaft hole of the casting, the upper portion of an annular belt is paved with chromite sand, it is ensured that the casting canbe subject to directional sequential solidification, and meanwhile, the casting surface quality is ensured, and the method is particularly suitable for making a spheroidal graphite cast iron water and electricity butterfly valve with the supersize and the large section.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

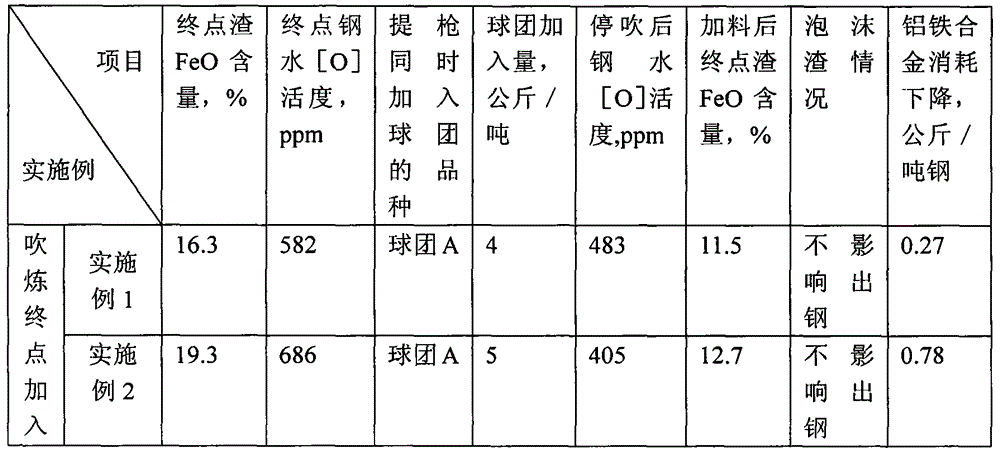

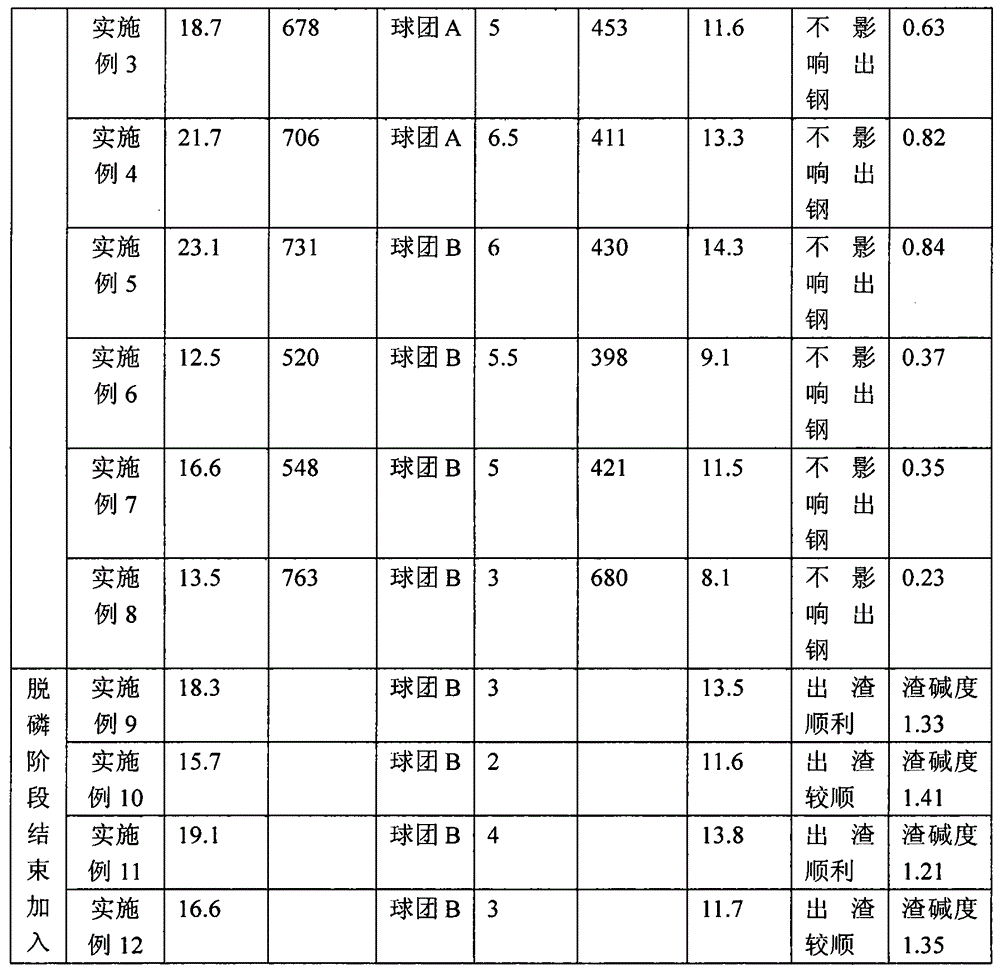

Carbon-containing slag suppression cold-bonded pellet and utilization method thereof

ActiveCN106148686AEfficient use ofSimple processManufacturing convertersProcess efficiency improvementSpecific gravityTar

The invention discloses a carbon-containing slag suppression cold-bonded pellet and a utilization method thereof. In the carbon-containing slag suppression cold-bonded pellet, the TFe content is smaller than or equal to 45%, the carbon content is larger than or equal to 5%, the content of volatile components (including decomposable gas) is larger than or equal to 10%, and the specific gravity is smaller than or equal to 3.5 g / cm<3>. The pellet is added into a converter from a high bin while lance lifting is about to be finished through blowing in the dephosphorization stage of the converter or when lance lifting is about to be finished through the blowing end point of the converter, and then deslagging or tapping is carried out. The carbon-containing slag suppression cold-bonded pellet and the utilization method have the beneficial effects that iron and carbon in gas dust sludge or other iron and carbon containing metallurgy dust sludge can be efficiently utilized, and waste paper pulp, tar slag and other waste are used as additives for pelletizing; the process is simple, and cost is low; the pellet is only used as slag, heat energy of the slag is fully utilized, and the influence of the temperature of molten steel is extremely low; foam slag can be suppressed effectively, and deslagging or tapping in the dephosphorization stage is facilitated; and by means of reduction of FeO in the pellet and FeO in the slag, the yield of the molten steel is increased, consumption of a deoxidizing agent and an alloy is reduced, and slag-splashing furnace protection work is facilitated.

Owner:王虎

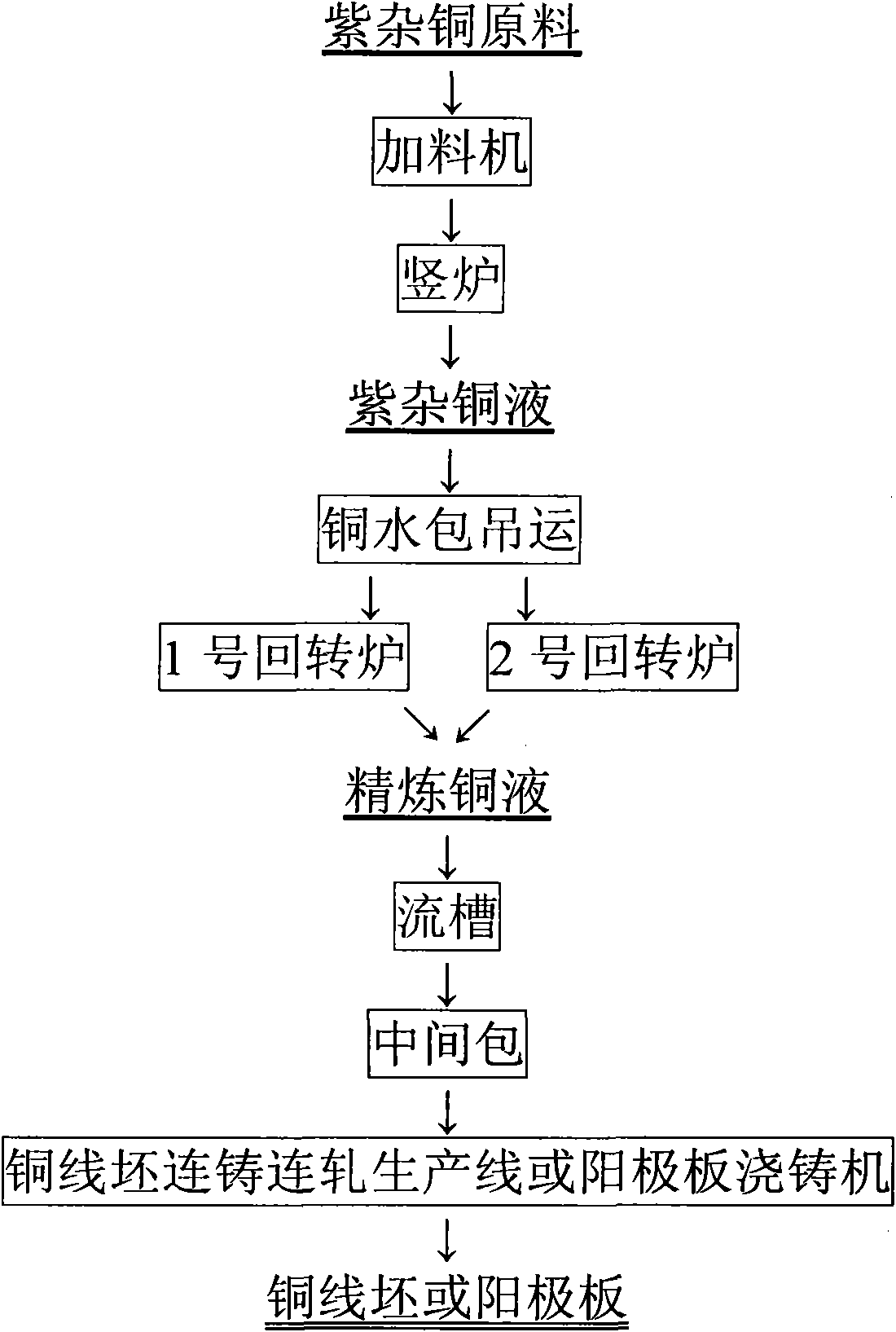

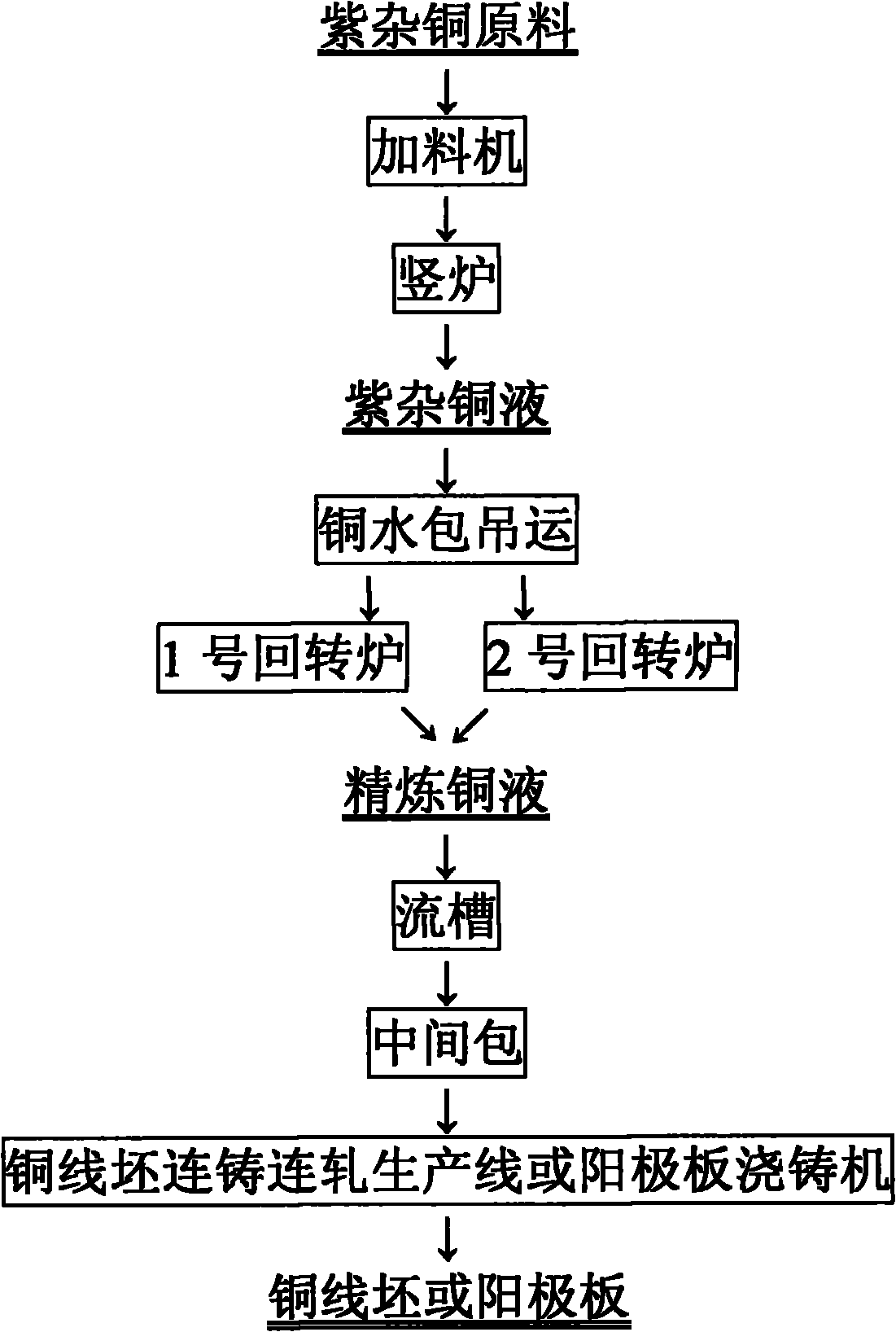

Shaft furnace, copper water bag and rotary furnace combined type fire refining process for raw red copper

InactiveCN101845557AImprove melting efficiencyIncrease profitFurnace typesOxidation-Reduction AgentHigh energy

The invention relates to a fire refining process for raw red copper. The process is characterized by adopting a shaft furnace, a copper water bag and at least one rotary furnace and comprising the following steps of: 1) charging the raw material of the raw red copper into the shaft furnace by using a charging machine and smelting the raw red copper in the shaft furnace into raw red copper liquid; 2) lifting and charging the raw red copper liquid smelted and produced from the shaft furnace into the rotary refining furnace by using the copper water bag to perform redox refining to obtain the refined copper liquid; and 3) allowing the refined copper liquid to directly enter a tundish through a launder to finish the subsequent procedures. According to the fire refining process, a holding furnace is saved, so the fire refining process has the advantages of high energy utilization ratio, high production continuity and good labor condition.

Owner:GANZHOU JIANGWU NEW TYPE ALLOY MATERIAL

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

Single-waist multi-leaf hose bit for bored pile and drilling construction method thereof

ActiveCN104747088AGuaranteed verticalityOvercome direction uncertaintyDrill bitsBulkheads/pilesEngineeringDirectivity

The invention belongs to the field of building construction and particularly relates to a single-waist multi-leaf hose bit for a bored pile and a drilling construction method thereof. The technological process comprises the steps of positioning and sampling, centering in position, forming a hole, clearing the hole for the first time, descending a reinforcement cage, descending a guide pipe, clearing the hole for the second time and pouring concrete. The single-waist multi-leaf hose bit for the bored pile comprises a single-waist multi-leaf taper bit body. A positioning and guiding cylinder is fixedly welded to the end of the single-waist multi-leaf taper bit body. A plurality of positioning and guiding cylinder tungsten steel heads are distributed on a circumferential edge opening of one end of the positioning and guiding cylinder. The single-waist multi-leaf hose bit of the bored pile and the drilling construction method thereof have the advantages that the directivity is good, the hole forming perpendicularity is high, the wall protecting effect is good, deslagging is convenient, the hole forming speed is high, and the rock breaking speed is high.

Owner:ZHEJIANG YUJIAN CONSTR GRP CO LTD

Rubbing squeezing all-in-one machine with mixing function

InactiveCN103637667ASolve the problem of not being able to put the pulpAddress effectivenessStrainersFruit juiceEngineering

The invention discloses a rubbing squeezing all-in-one machine with a mixing function. The rubbing squeezing all-in-one machine comprises an end cover and a barrel body, the lower portion of the end cover is fixedly provided with a fruit rubbing machine, and a fruit crushing groove, a crushing jam falling channel, a squeezing cavity, a pomace filtering plate and a fruit juice containing cavity are sequentially arranged in a tube body from top to bottom. The squeezing cavity comprises a first squeezing cavity and a second squeezing cavity, the upper end of the crushing jam falling channel is communicated with the bottom of the crushing groove, and the lower end of the crushing jam falling channel is provided with two branch channels. The two branch channels are communicated with the first squeezing cavity and the second squeezing cavity respectively, and the upper portion of the first squeezing cavity and the upper portion of the second squeezing cavity in the tube body are respectively and correspondingly provided with a small type squeezing machine. A stirring device is arranged in the fruit containing cavity, the stirring device comprises a power motor and stirring teeth, and the stirring teeth are mounted on an output shaft of the power motor. The rubbing squeezing all-in-one machine has the advantages of being reasonable in structural design, high in squeezing efficiency, convenient to use and the like, and is suitable for being widely popularized and used in families.

Owner:常元蓉

Soft and broken seam drilling and reaming device

InactiveCN106837179AAvoid the effects of extractionEffect extractionDrilling machines and methodsSlagWater flow

The invention discloses a soft and broken seam drilling and reaming device which comprises a bracket, a power drive device, a rotary seal water supply an air supply device, a guide support frame, a drill connector, a hole protecting tube, a center reflux drill, an inner chip removal drill pipe and a slag collecting container; the hole protecting tube sleeves the outside of the inner chip removal drill pipe; and a plurality of gas discharge holes are uniformly distributed on the tube wall of the hole protecting tube. A drill hole is supported during drilling and reaming operation, so that collapse and contraction are avoided and extraction of a drilling tool is affected. High-pressure airflow of the rotary seal water supply an air supply device pushes flow to reach the center reflux drill and water slag is discharged outwards through the inner chip removal drill pipe. A formed hole is prevented from being destroyed by an outer chip removal flow and the drill when the drill is pulled out, the problems that the formed hole is easy to slump and contract and the gas is not easily discharged in a soft and broken seam can be effectively solved and the gas extraction quality is improved. The construction speed of a gas extraction hole is improved, the construction security is ensured and the soft and broken seam drilling and reaming device is an innovation of the soft and broken seam drilling and reaming device.

Owner:HENAN POLYTECHNIC UNIV

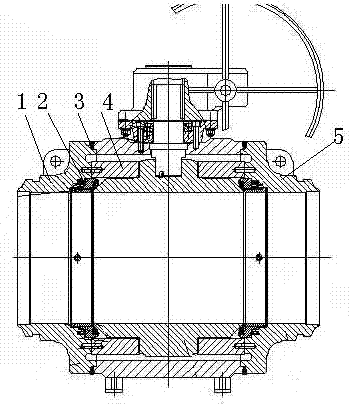

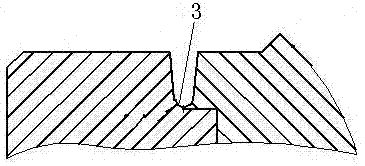

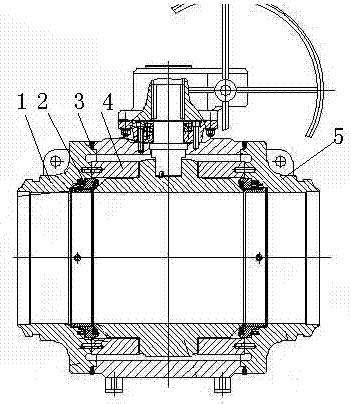

Automatic narrow-gap submerged arc welding process for all-welded fixed ball valve with medium and large calibers

ActiveCN102363239AHigh precisionHigh form factorArc welding apparatusWorkpiece edge portionsSlagEngineering

The invention discloses an automatic narrow-gap submerged arc welding process for all-welded fixed ball valves with medium and large calibers. The process comprises the following steps of: performing general assembly of products; 2) performing pre-welding preparation; 3) selecting materials; 4) selecting a weld joint, wherein the weld joint used during welding is a 'U'-shaped groove; 5) selecting process parameters; and 6) welding, namely welding the integral annular weld joint continuously at one time by a left welding method. By the process, a production process is reasonable, welding is performed after the general assembly and performance tests of the products, the process parameters which can meet the key requirements of weld penetration, low linear energy, low interlayer temperature, ultra-low welding deformation and high accuracy are selected, the materials and a welding skill are selected, and the welding groove is improved, namely a V-shaped groove and the like are changed into the 'U'-shaped groove; and by the process, slag and convenient to discharge, the key requirements of heat crack prevention, high toughness, small welding deformation and high welding accuracy are met, and the safety of a valve seat seal ring in a valve is protected effectively in the welding process.

Owner:CRETE GRP CO LTD

Purification method for coal tar soft pitch

InactiveCN102839008AImprove solubilityHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionPurification methodsCentrifugation

The present invention relates to a purification method for coal tar soft pitch. The method is characterized by comprising: stirring and uniformly mixing coal tar soft pitch with a softening point of 30-60 DEG C and a solvent according to a mass ratio of 1:0.5-1.5 at a temperature of 120-300 DEG C; carrying out thermal and adding the resulting material to a continuous centrifuge; carrying out continuous centrifugation separation at the same temperature to obtain a supernatant and residue; carrying out vacuum distillation on the supernatant; removing the solvent to obtain the purified pitch; and recovering the solvent to reuse. The method of the present invention has the following advantages and effects that a dissolution property of the soft pitch in the solvent and a process yield can be significantly improved, difficulties of mixing and separation are significantly decreased, and operation and maintenance are convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method of improving yield of continuous casting molten steel

ActiveCN107745099AReduce exposureEasy to discharge slagMelt-holding vesselsCasting cleaning apparatusSlagRepair material

The invention relates to a method for improving a yield of continuous casting molten steel. The method comprises steps of (1) forwardly moving an tundish retaining wall, (2) spraying a repairing material to a slag line position of the tundish retaining wall, (3) constructing a slag overflow groove in a tail part of the tundish, (4) adjusting molten steel flow via a sliding plate during casting, closing the sliding plate when slag is discharged and then re-opened after five to eight seconds, and repeating the work until the molten steel of a large pack is fully cast into the tundish, (5) increasing a flow of the large pack casting molten steel via adjustments of the sliding plate, arising a molten steel liquid level of the tundish, timely discharging steel slag via the slag overflow groove,decreasing the molten steel flow after the slag discharging work is finished, so the molten steel liquid level of the tundish can restore to a normal height, and (6) repeating the step (4) and step (5) until the whole casting process is completed. The tundish structure is improved, the sliding plate is controlled during a large pack casting process and the slag of the tundish is timely discharged, so the molten steel yield can be greatly improved.

Owner:UNIV OF SCI & TECH LIAONING

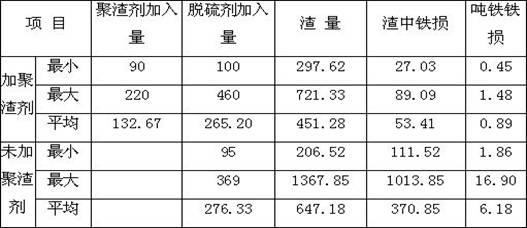

Method for preparing slag conglomeration agent for iron steel

InactiveCN102586516AImprove performanceHigh viscosityRecycling and recovery technologiesSlagFluorite

The invention relates to a method for preparing a slag conglomeration agent for molten iron steel, in particular to a method for preparing a slag conglomeration agent for iron steel. The method comprises the following steps: (1) crushing 15 to 20 percent by weight of albite, 20 to 25 percent by weight of fluorite, 10 to 15 percent by weight of raw vermiculite, 10 to 15 percent by weight of calcium carbonate and 20 to 30 percent by weight of waste glass; (2) pulverizing with the particle size of 0.1 to 3.0 mm; (3) batching, that is, mixing the materials; (4) milling, wherein 1 to 5 percent of common salt is added for milling, the milling temperature is 20 to 30 DEG C, and the milling time is 10 to 30 min; and (5) detecting and packaging. Through the adoption of the slag conglomeration agent for iron steel, which is prepared according to the method, easy slag collection and slag discharge are realized, deslagging iron loss is reduced fundamentally, and the basicity and the melting temperature of furnace slag are reduced so as to improve the fluidity of desulphurized iron slag.

Owner:德清县力拓炉料有限公司

Screw extrusion-type juice extractor

ActiveCN104083066AGuarantee the effect of juiceAvoid the problem of accumulation at the bottom of the screenStrainersEngineeringExtrusion

The invention provides a screw extrusion-type juice extractor which comprises a juice collecting cup, a screw and a filter screen support. A residue collecting groove is formed in the bottom face of the juice collecting cup, the cross sectional area of the residue collecting groove is smaller than the bottom face area of the juice collecting cup, a residue discharging opening is formed in the lateral wall of the residue collecting groove, an adjusting device is installed on one side of the residue discharging opening, and the area of the residue discharging opening can be adjusted through the adjusting device; the screw is arranged in the juice collecting cup in the axial direction of the juice collecting cup, and a residue scraping part is arranged at the lower end of the screw and located in the residue collecting groove; the filter screen support is in a hollow column shape and is connected into the juice collecting cup in a clamped mode, the screw is located in the filter screen support, a filter screen is installed on the filter screen support, and a juice collecting cavity is formed between the filter screen and the cup wall of the juice collecting cup. By means of the screw extrusion-type juice extractor, the filter screen support is easily and conveniently installed, residues are prevented from being accumulated at the bottom of the filter screen, the filter screen is easily and conveniently washed, and meanwhile the juice outlet rate of the juice extractor is increased.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Efficient medical instrument cleaning device

InactiveCN112191612AEasy to cleanAchieve recyclingDrying gas arrangementsCleaning using liquidsActivated carbonMedicine

The invention discloses an efficient medical instrument cleaning device, and belongs to the technical field of medical instruments. The problems that an existing medical instrument cleaning device isincomplete in cleaning and cannot effectively perform drying treatment, and water resources are wasted are solved. According to the technical key points, the efficient medical instrument cleaning device comprises a device body, medical instruments are placed on a placement disc, water and cleaning fluid enter a mixing box, heating is carried out by a second heating pipe, stirring is carried out through driving of a second motor, the cleaning fluid and the water are uniformly mixed to reach the required temperature, a first water pump operates, the mixed solution is sprayed out through a high-pressure spray head, a first motor drives the placing disc to rotate, an ultrasonic vibration rod vibrates for cleaning, ultraviolet sterilization, disinfection and drying treatment is performed aftercleaning is completed, sewage enters a sewage treatment tank, filtering is carried out by a filter screen, slags are discharged by a slag discharge door, a disinfectant is put in, a third motor starts, mixed disinfection is accelerated, sterilizing is carried out by an activated carbon layer, and the treated solution is pumped by a second water pump and flows back into the water tank. The efficient medical instrument cleaning device has the advantages of good cleaning effect, capability of effectively performing drying treatment and capability of recycling water resources.

Owner:李柯楠

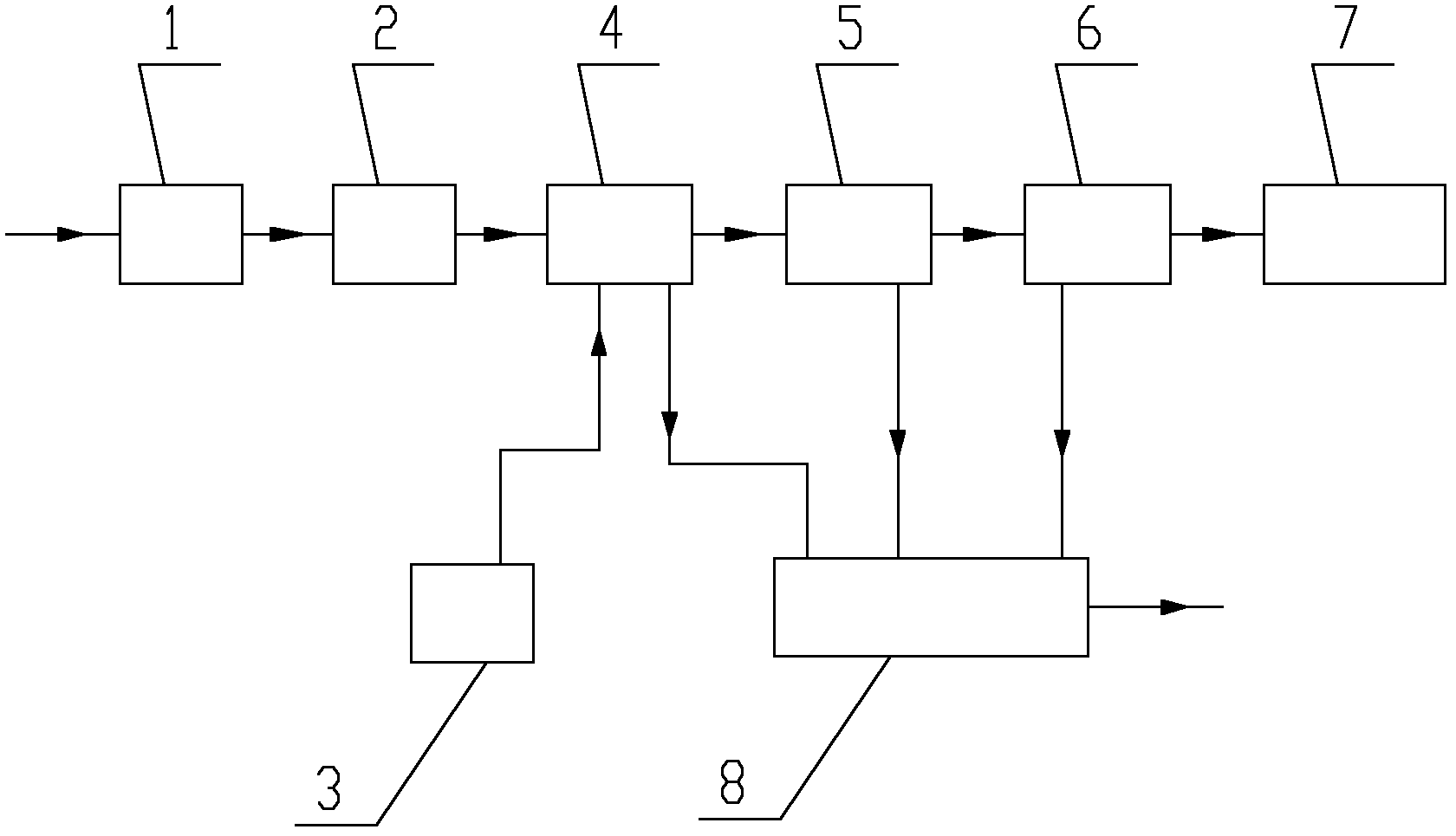

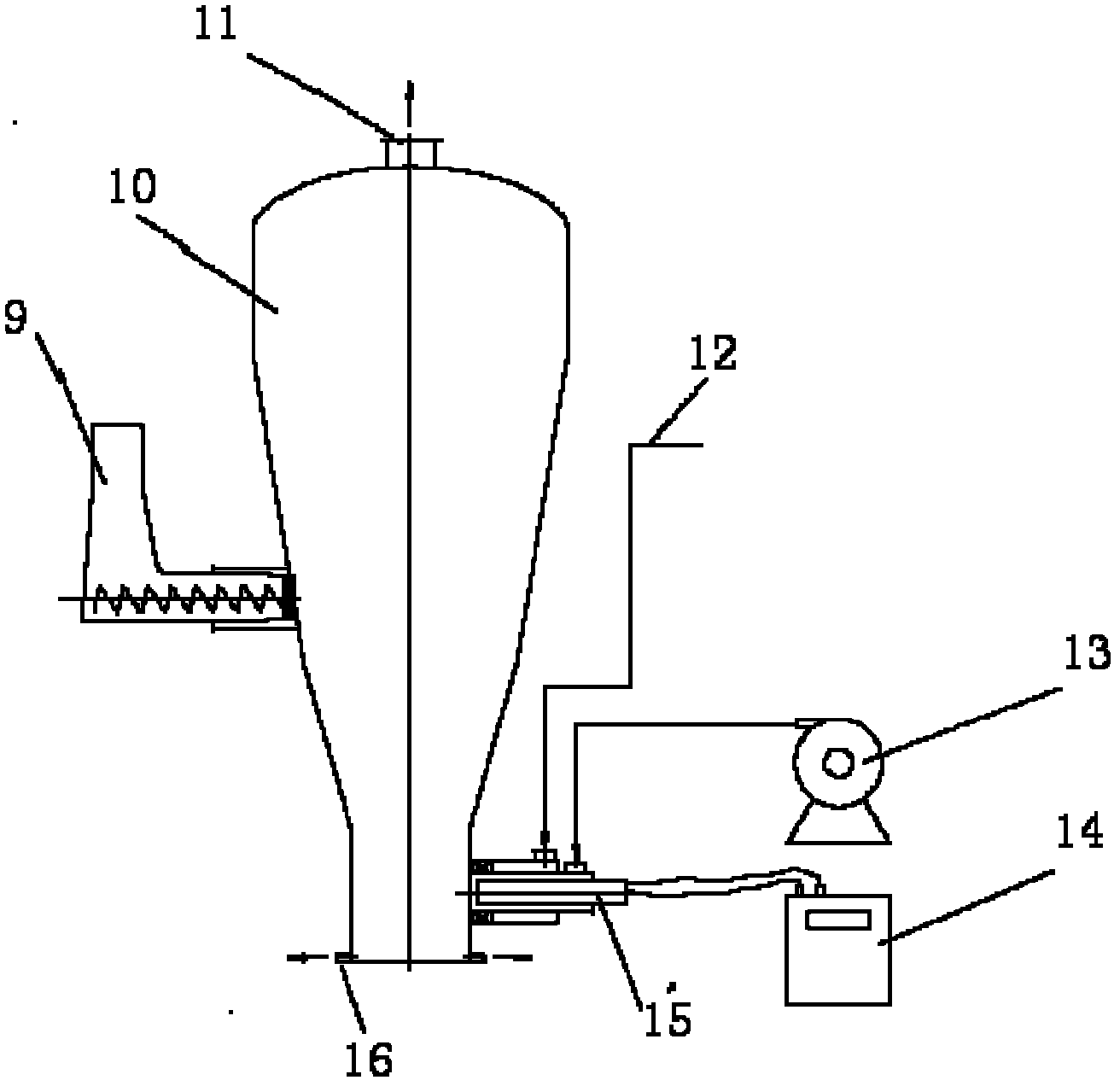

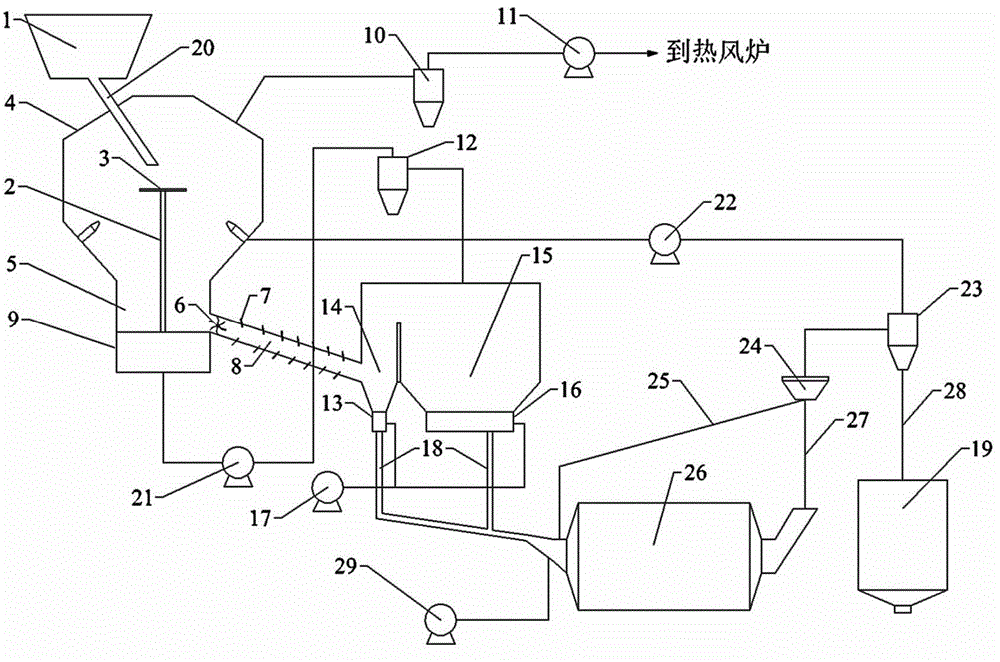

Dry-type granulation treatment waste heat recovery system

ActiveCN104388611AHigh recovery rateImprove qualityRecycling and recovery technologiesWaste heat treatmentWaste heat recovery unitSlag

The invention discloses a dry-type granulation treatment waste heat recovery system which comprises a slag storage bin, a granulation cooling unit, a primary waste heat recovery unit, a secondary waste heat recovery unit and a tertiary waste heat recovery. The system is characterized in that the top of the granulation cooling unit is provided with a first air outlet; the first air outlet is connected with a high-temperature booster fan through a pipeline; a granulator is arranged in the granulation cooling unit, positioned below a charging pipe and driven by a rotating shaft to rotate; the primary waste heat recovery unit is arranged below the granulation cooling unit; the bottom of the primary waste heat recovery unit is provided with a first fluidized bed and a slag discharge pipe; the slag discharge pipe is communicated with the secondary waste heat recovery unit; the bottom of the secondary waste heat recovery unit is provided with a spray bed; and the upper part of the secondary waste heat recovery unit is communicated with the upper part of the tertiary waste heat recovery unit. The system implements the dry-type granulation function and high-efficiency waste heat recovery, and can be widely used in the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

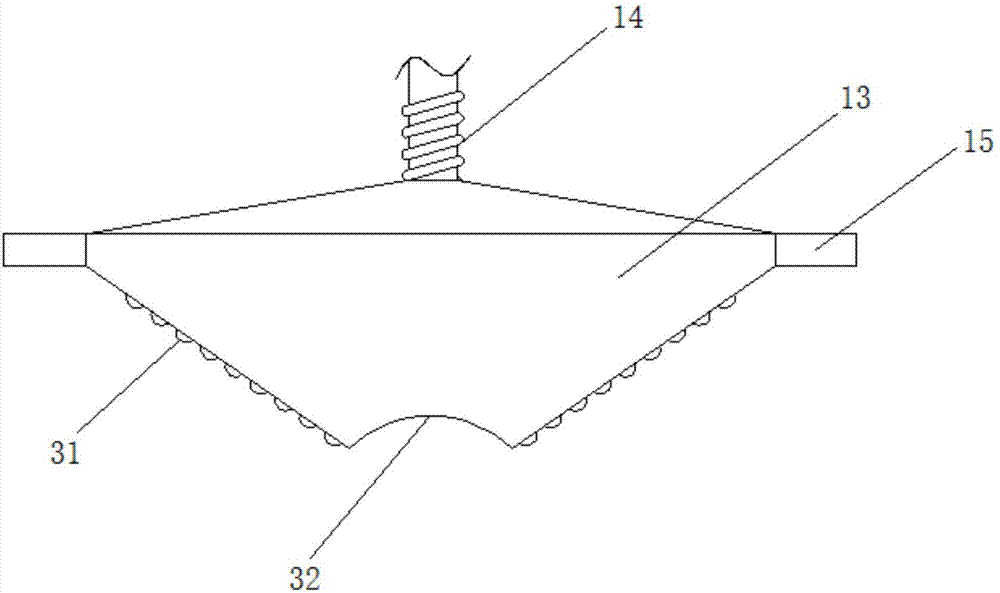

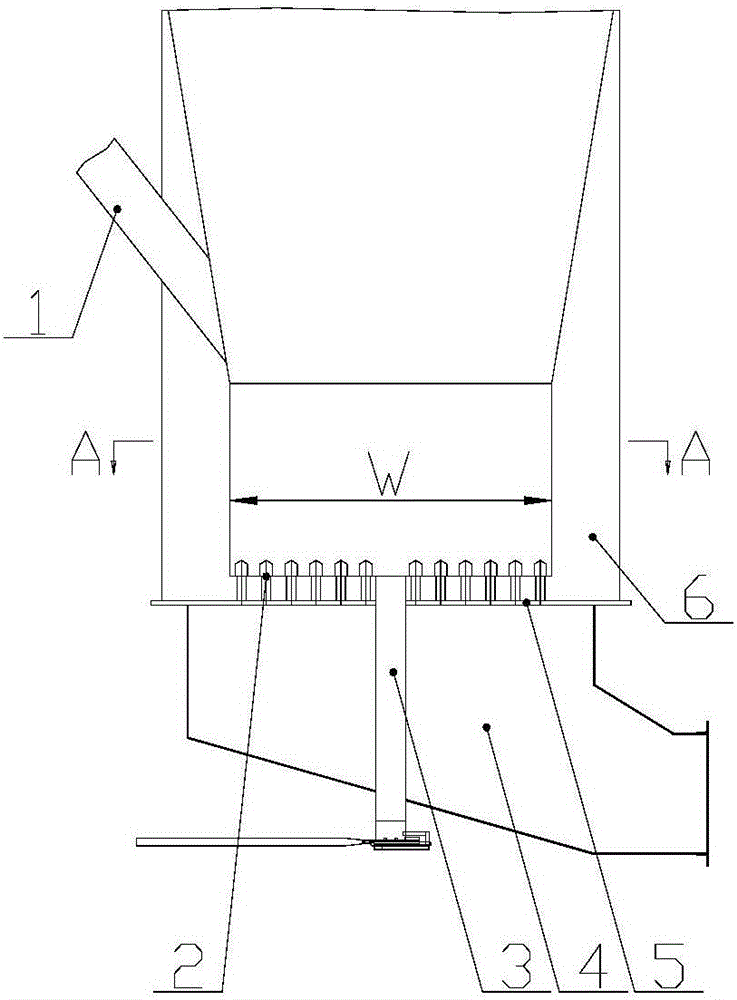

Wind distribution device facilitating discharging of big particle matter and multi-flow circulating fluidized bed boiler

ActiveCN105927972AEasy dischargeEasy to discharge slagFluidized bed combustionApparatus for fluidised bed combustionParticulatesSlag

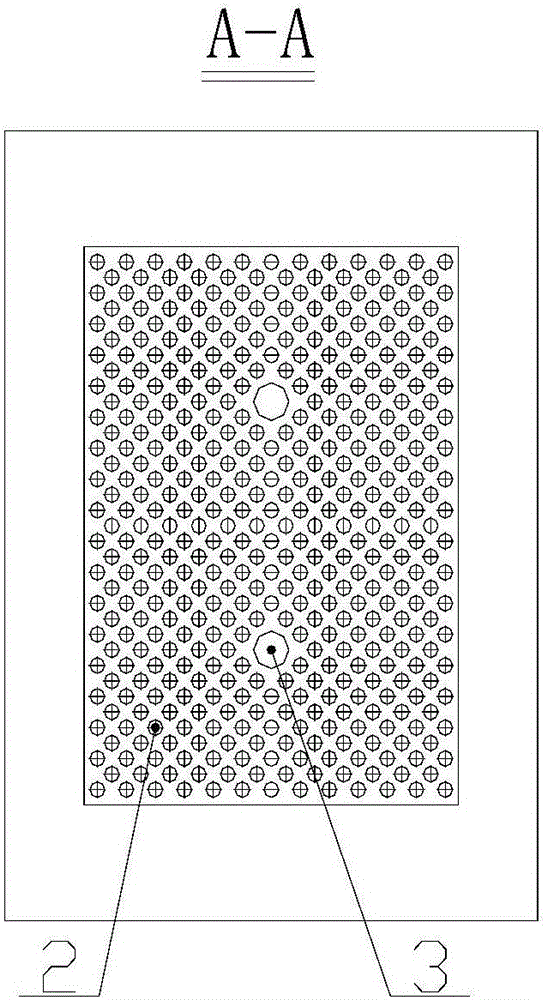

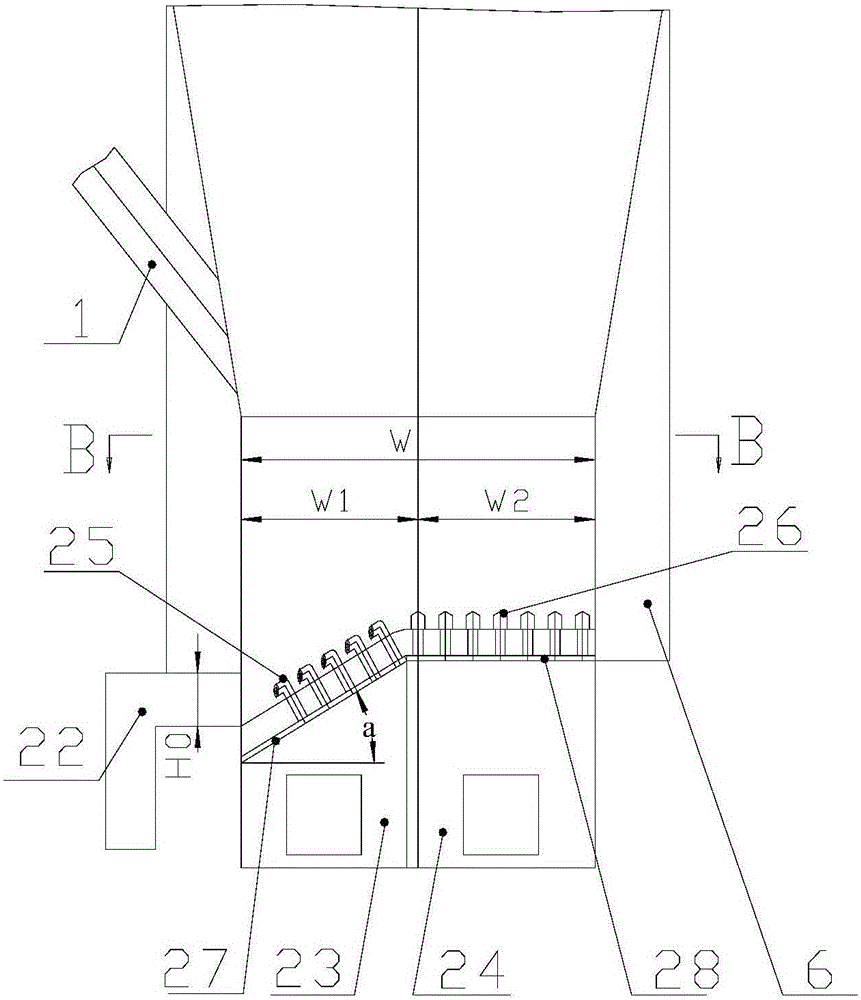

The invention relates to a wind distribution device facilitating discharging of big particle matter and a multi-flow circulating fluidized bed boiler. A horizontal wind distribution plate (28) of the wind distribution device is arranged horizontally. An inclined wind distribution plate (27) inclines downwards from one edge of the horizontal wind distribution plate (28), is in butt joint with the horizontal wind distribution plate (28) and then is arranged in the middle of a hearth. Other edges of the horizontal wind distribution plate (28) and other edges of the inclined wind distribution plate (27) are fixed to the inner ring of the hearth. A plurality of second wind caps (26) are arranged on the horizontal wind distribution plate (28). A plurality of first wind caps (25) capable of directionally outputting wind are arranged on the inclined wind distribution plate (27). A first wind chamber (23) supplies wind to the inclined wind distribution plate (27). A second wind chamber (24) supplies wind to the horizontal wind distribution plate (28). Slag dropping pipes (22) are arranged on the same side of the inclined wind distribution plate (27) and located in the lowest position of an inclined section. The wind distribution device can smoothly discharge the big particle matter disturbing uniform outlet air of the wind distribution plates, and accordingly it can be guaranteed that materials in the hearth are fluidized continuously and uniformly.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

Reducing agent for production of industrial silicon

The invention provides a reducing agent for production of industrial silicon, which relates to a reducing agent. The reducing agent comprises, by mass, 0 to 100% of a petroleum coke particle and 0 to 100% of a modified petroleum coke particle, wherein the granularity of both the petroleum coke particle and the modified petroleum coke particle is in a range of 5 to 60 mm. The reducing agent has no less than 76% of dry basis fixed carbon, no more than 1% residual ash, no more than 8% of coarse ash, 10 to 16% of volatile matters and no more than 8% of moisture. Compared with a conventional petroleum coke reducing agent, the reducing agent provided by the invention has the following advantages: permeability of the reducing agent is at least doubled, feeding loss and furnace surface burning loss of petroleum coke are reduced by more than 6%, the degree of graphitization at a temperature of 1300 DEG C is decreased by more than 50%, relative resistivity retention time is prolonged by more than 20 min, reductibility is improved by more than 30%, and a furnace age is almost doubled.

Owner:廖良

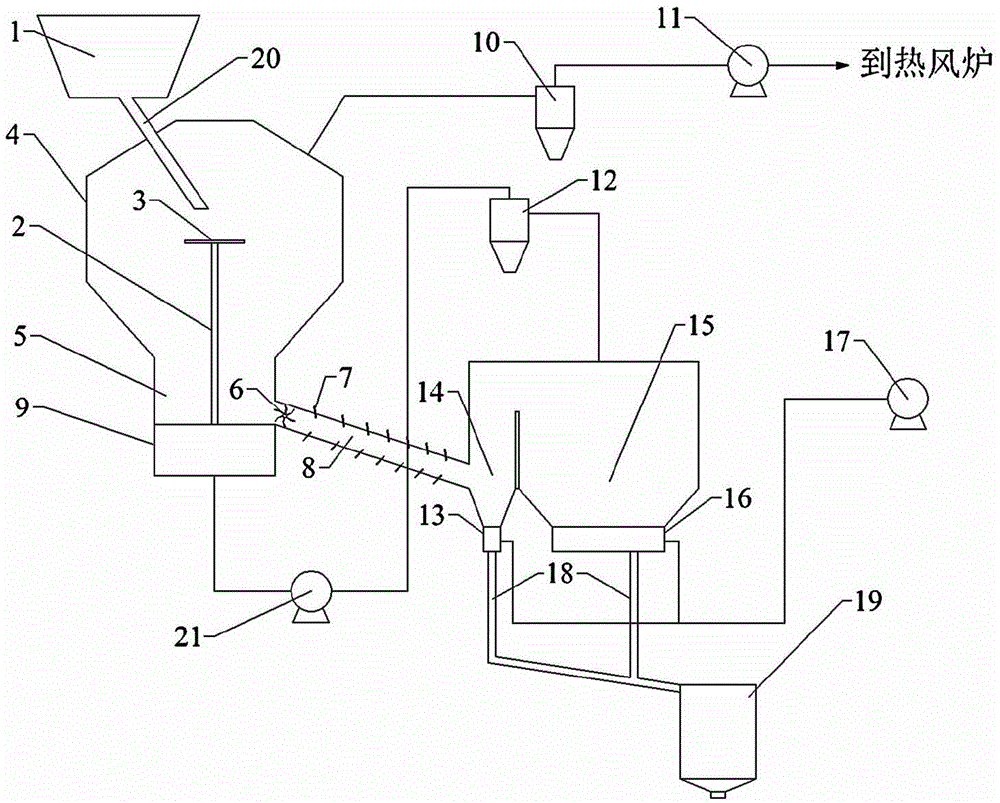

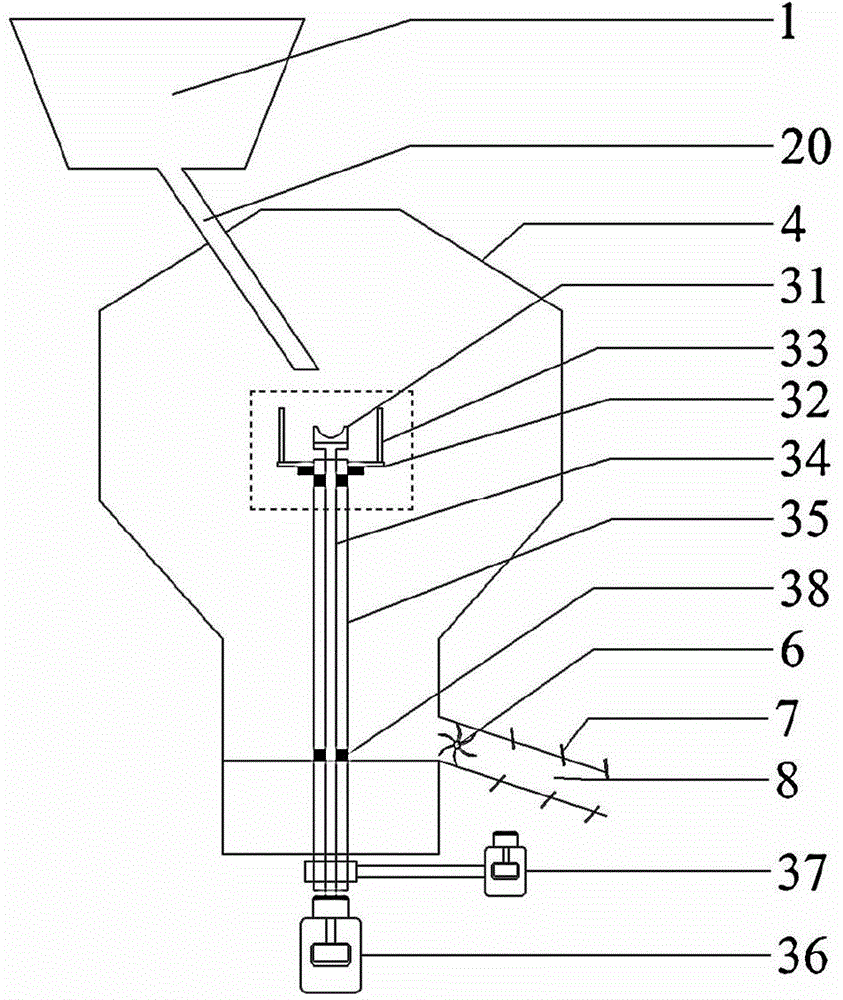

Two-section type entrained-flow bed gasification device for biomasses and gasification method

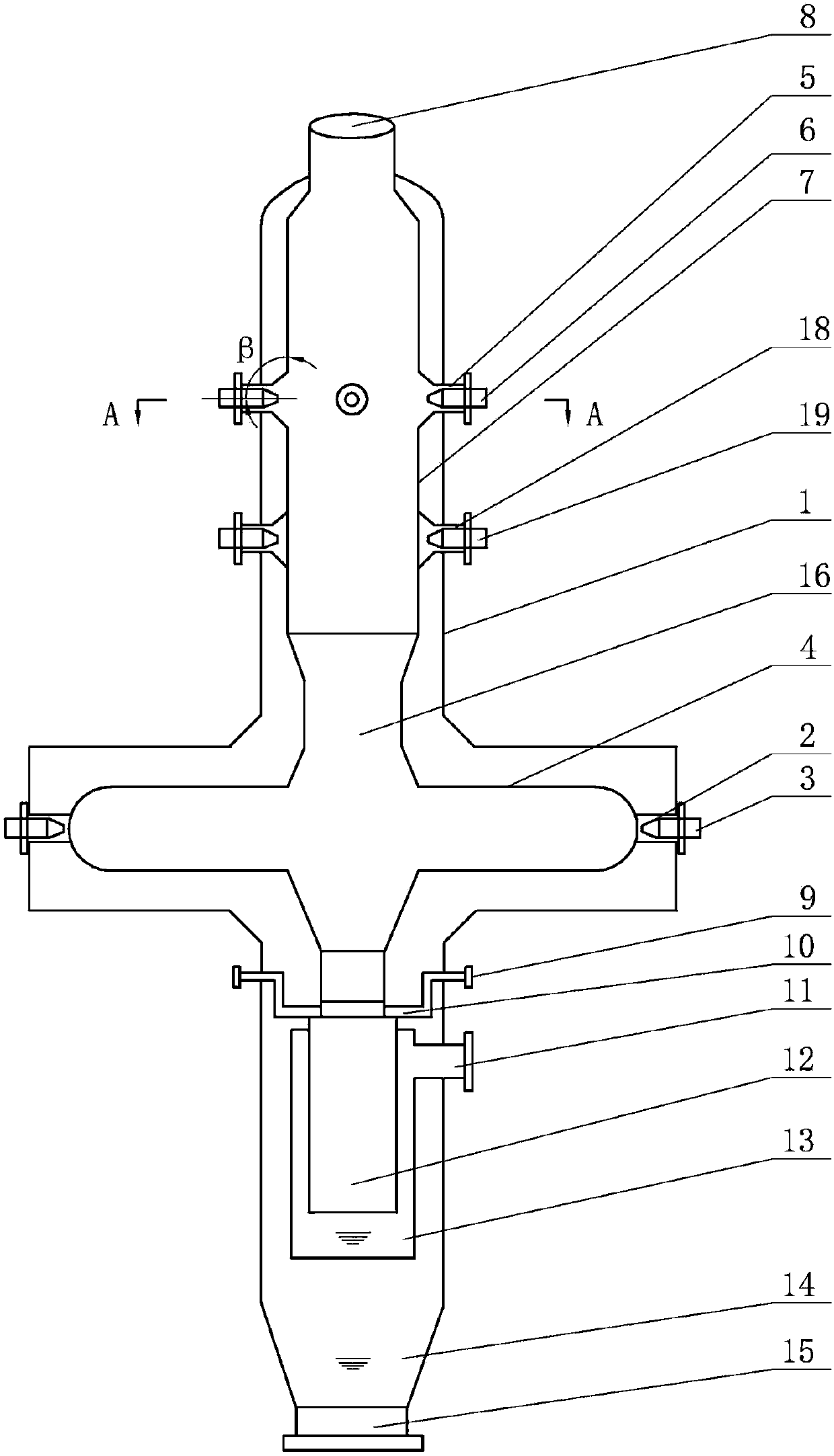

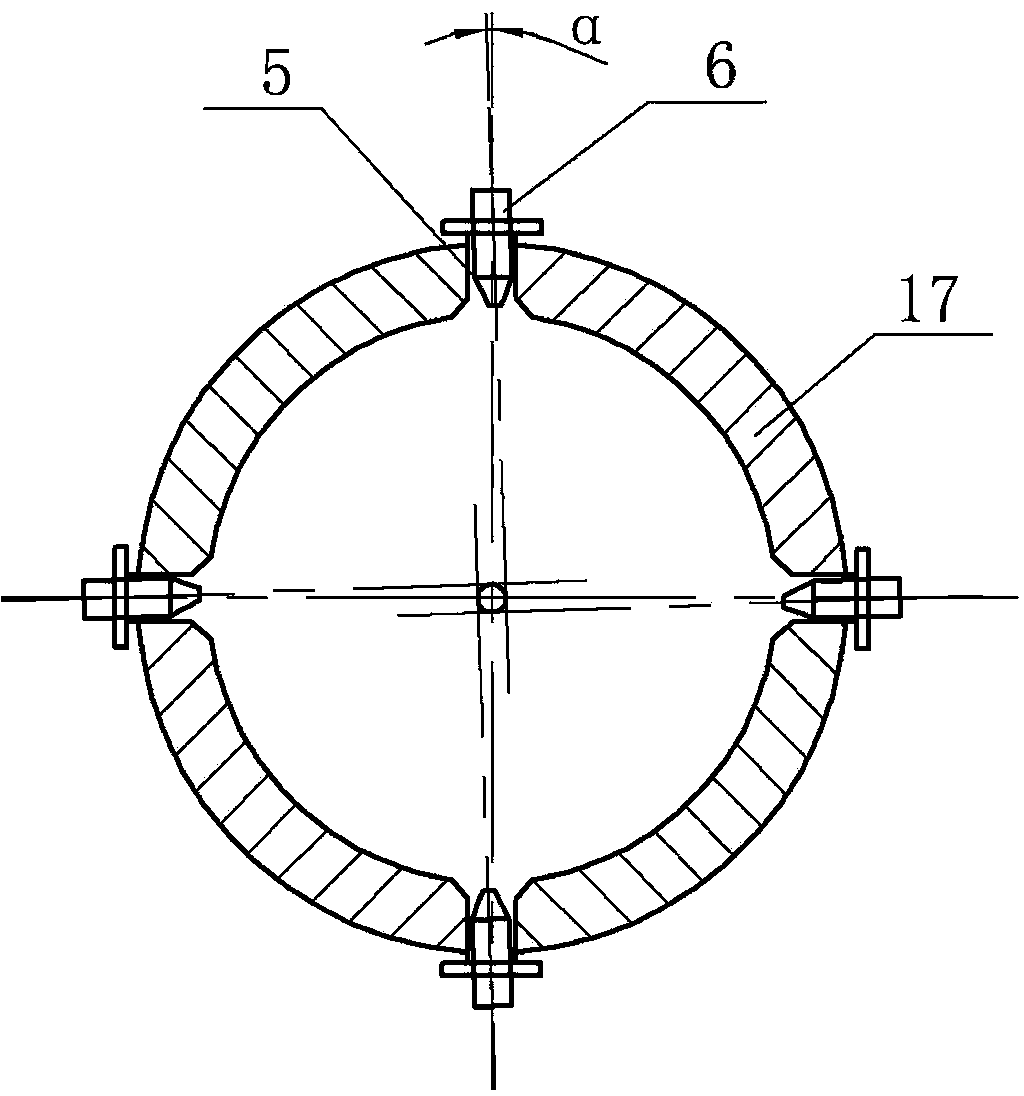

InactiveCN103740410AExtended service lifePromote combustionGranular/pulverulent flues gasificationProcess engineeringFuel gas

The invention relates to a two-section type entrained-flow bed gasification device for biomasses and a gasification method. The two-section type entrained-flow bed gasification device comprises a furnace shell, wherein the furnace shell is internally provided with a gasification chamber and a synthesis gas cooling chamber; the gasification chamber is divided into an upper-section gasification chamber and a lower-section gasification chamber; a synthesis gas outlet is arranged at the top of the upper-section gasification chamber; the axes of the upper-section gasification chamber and the lower-section gasification chamber are vertically crossed; the synthesis gas cooling chamber is arranged below the lower-section gasification chamber; a dreg tank is arranged at the bottom of the furnace shell; a dreg discharging opening of the dreg tank is arranged at the bottom of the dreg tank; at least one layer of a side face process nozzle chamber is arranged at the periphery of the upper-section gasification chamber; at least two side face process nozzles are symmetrically arranged in the side face process nozzle chamber; oppositely-arranged type process nozzle chambers are coaxially arranged on the two sides of the lower-section gasification chamber; two oppositely-arranged type process nozzles are coaxially arranged on the oppositely-arranged type process nozzle chambers; at least two secondary oxygen feeding spray gun chambers are arranged between the side face process nozzle chamber and the lower-section gasification chamber; the secondary oxygen feeding spray gun chambers are internally provided with secondary oxygen feeding spray guns. The two-section type entrained-flow bed gasification device for the biomasses can be used for gasifying pure oxygen fuel gas; the gas yield is increased by one time when being compared with that of an interval type gasification process.

Owner:河南金土地科技服务有限公司

Fume exhaust device for combustion boiler facilitating removal of dirt on inner wall

InactiveCN108980874AImprove the effect of impurity removalImprove convenienceSolid removalChimneysCombustionControl engineering

The invention discloses a fume exhaust device for a combustion boiler facilitating removal of dirt on inner wall. The fume exhaust device for the combustion boiler comprises a bottom plate, a fume exhaust cylinder is fixed to the outer wall of the top of the bottom plate by bolts, and a heat insulation sleeve with specifications adaptive to specifications of the fume exhaust cylinder is fixed to the outer wall of one side of the fume exhaust cylinder by bolts. A horizontally placed transverse plate is welded to the outer wall of one side of the fume exhaust cylinder, a motor is fixed to the outer wall of the top of the transverse plate by bolts, a first bevel gear is welded to the outer wall of one side of an output shaft of the motor, a groove is formed in the outer wall of one side of the fume exhaust cylinder, a bearing is welded in the groove, and a connecting shaft is welded to the inner wall of the bearing. The motor of the fume exhaust device works to drive the gears to mesh, sothat a spiral scraper rotates to remove the dirt attached to the inside of the fume exhaust cylinder, the impurity removal capability of the device is improved, part of impurity particles in flue gasis filtered and separated, and is discharged from an access opening, and the convenience of impurity removing of the device is improved.

Owner:HUBEI AIFUWEI ENVIRONMENTAL ENERGY TECH CO LTD

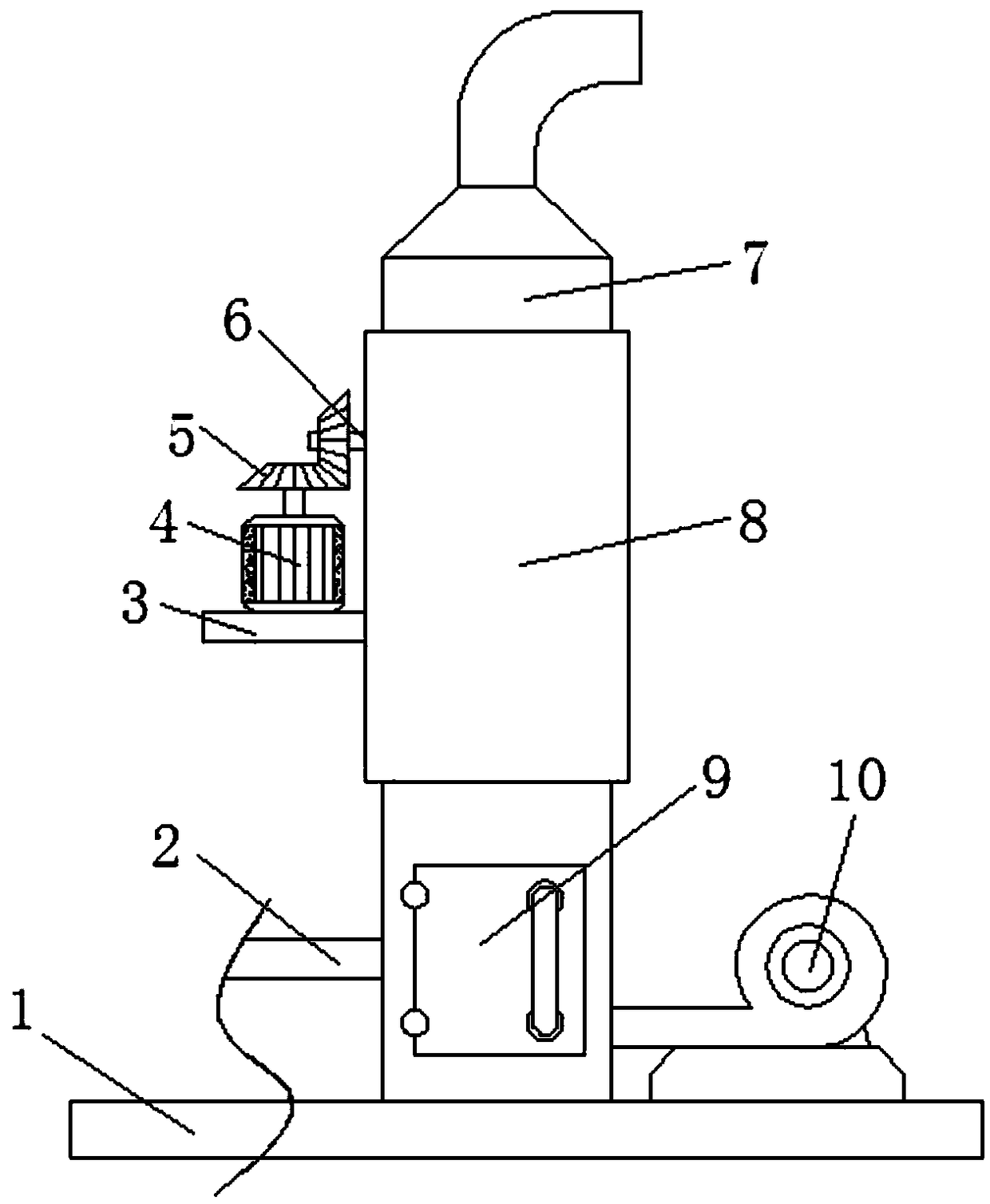

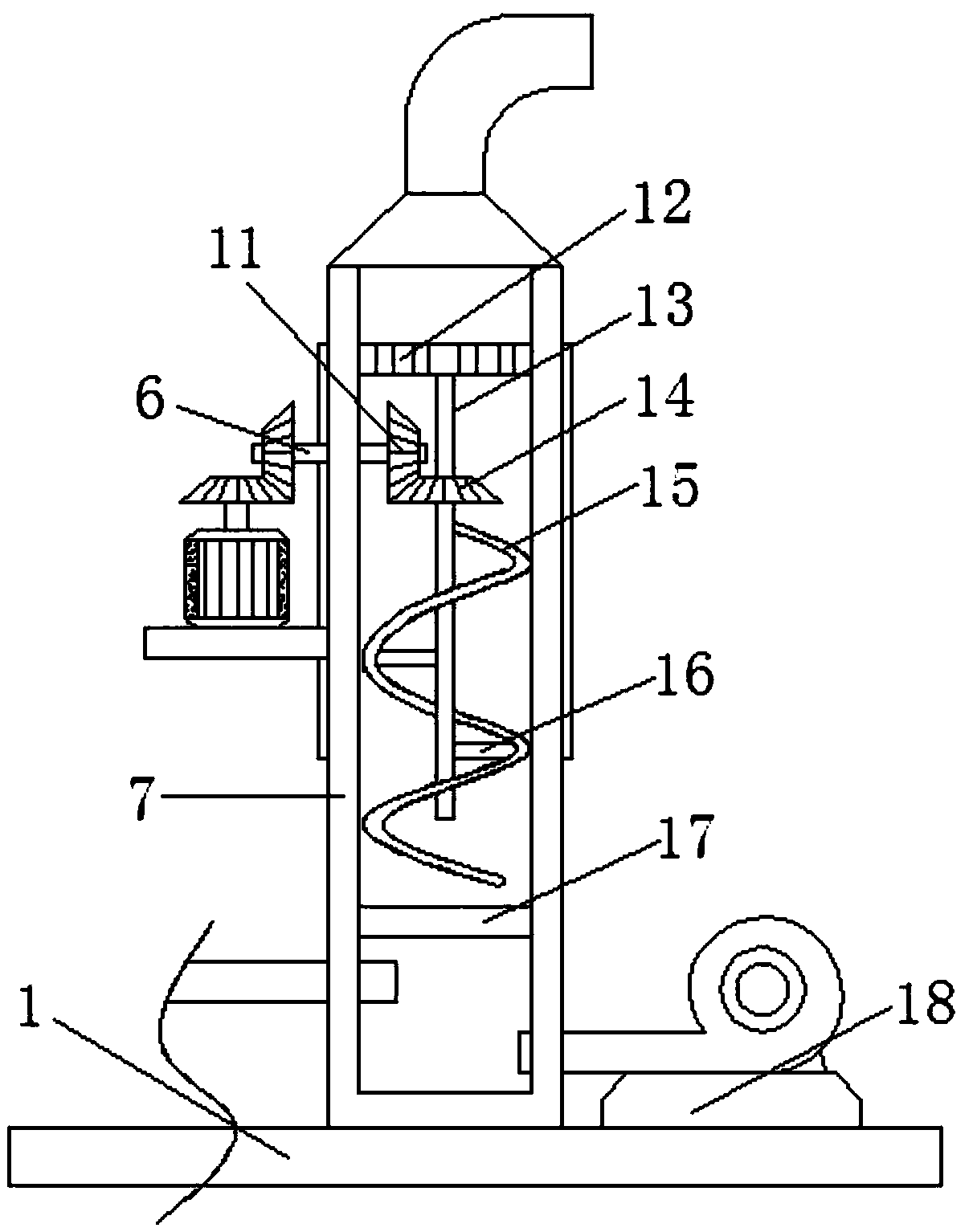

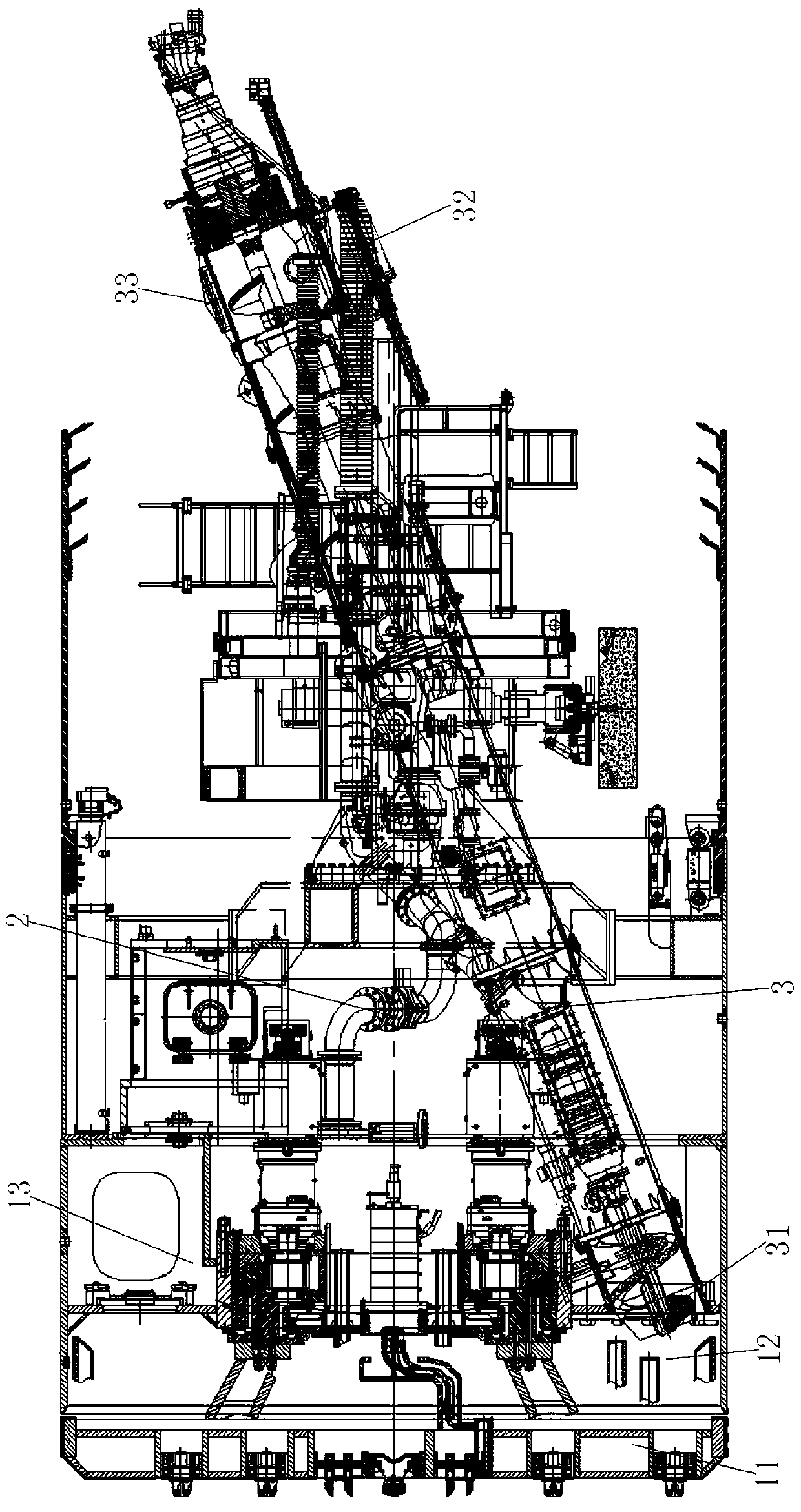

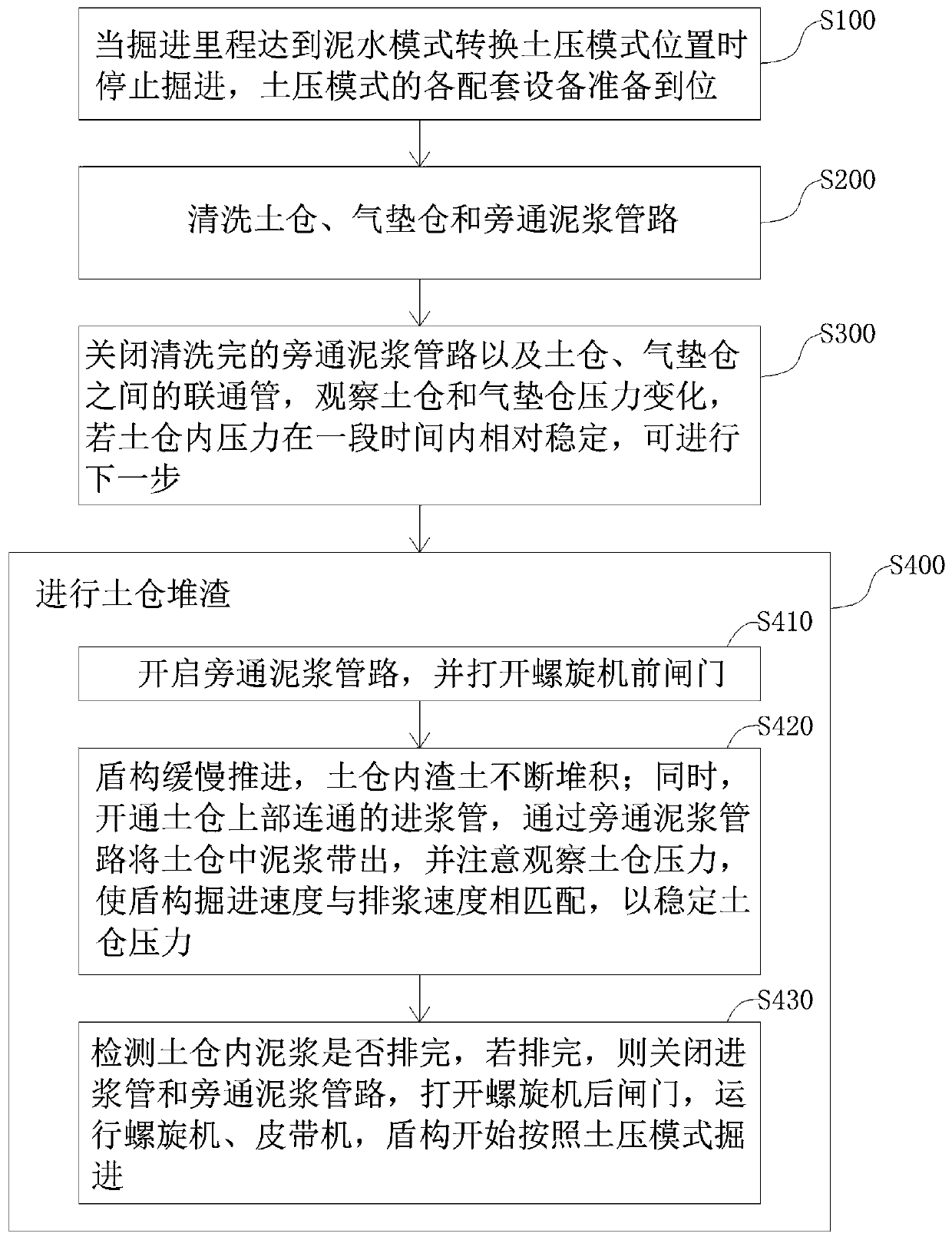

Muddy water/soil pressure dual-mode shield and driving mode conversion method thereof

The invention discloses a muddy water / soil pressure dual-mode shield and a driving mode conversion method thereof. The muddy water / soil pressure dual-mode shield is provided with devices and supporting equipment required for driving in a muddy water mode and a soil pressure mode, and can adopt muddy water and soil pressure dual modes for driving. During converting of the muddy water mode into thesoil pressure mode, after a bypass mud pipeline and a communicating pipe are closed, the pressure changes of a soil bin and an air cushion bin are observed, and then whether conversion can be carriedout or not is judged, so that the stable pressure of the soil bin in the conversion process is ensured advantageously; and in the reverse flow mud discharging process, the mud discharging speed can becontrolled through a mud discharging pump and is matched with the driving speed of the shield, and thus the stable pressure in the soil bin can be actively maintained. During converting of the soil pressure mode into the muddy water mode, a part of muck is discharged through a screw conveyor firstly, and the screw conveyor discharges the muck quickly, so that the conversion efficiency is improvedadvantageously; and reserved muck is subjected to muck-mud replacement through a back-washing mode so that the situation that gushing appears when the screw conveyor discharges the remaining small amount of muck, and consequently, the pressure of the soil bin loses stability can be prevented.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

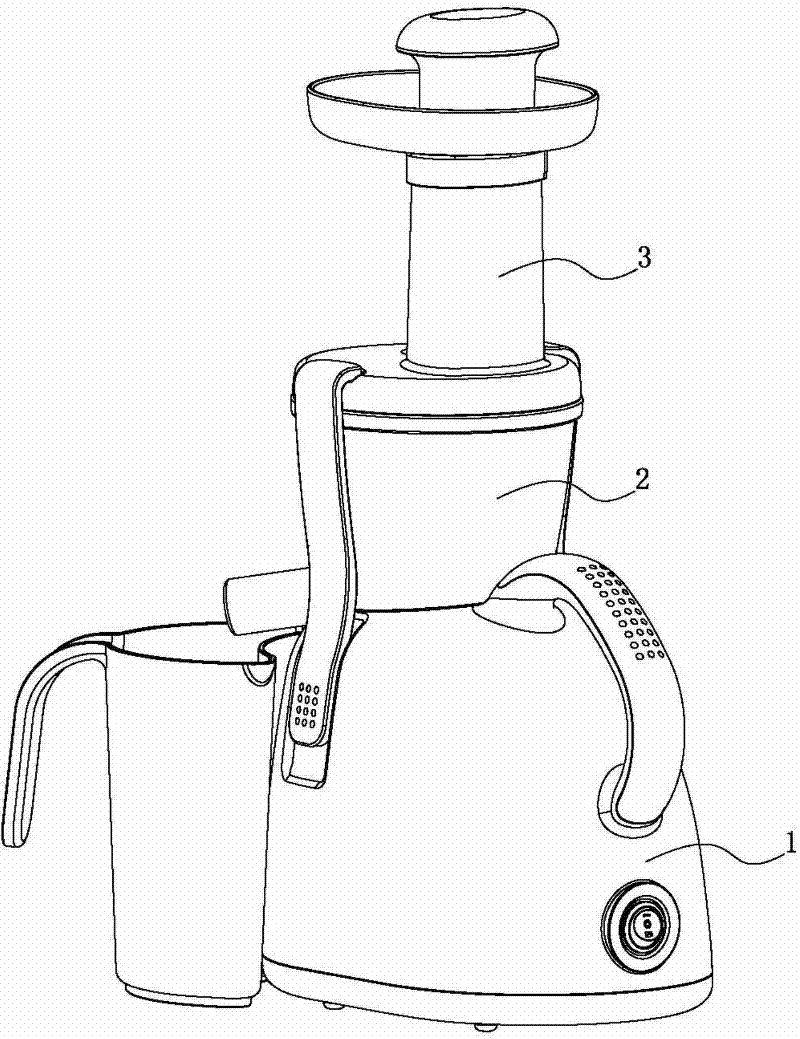

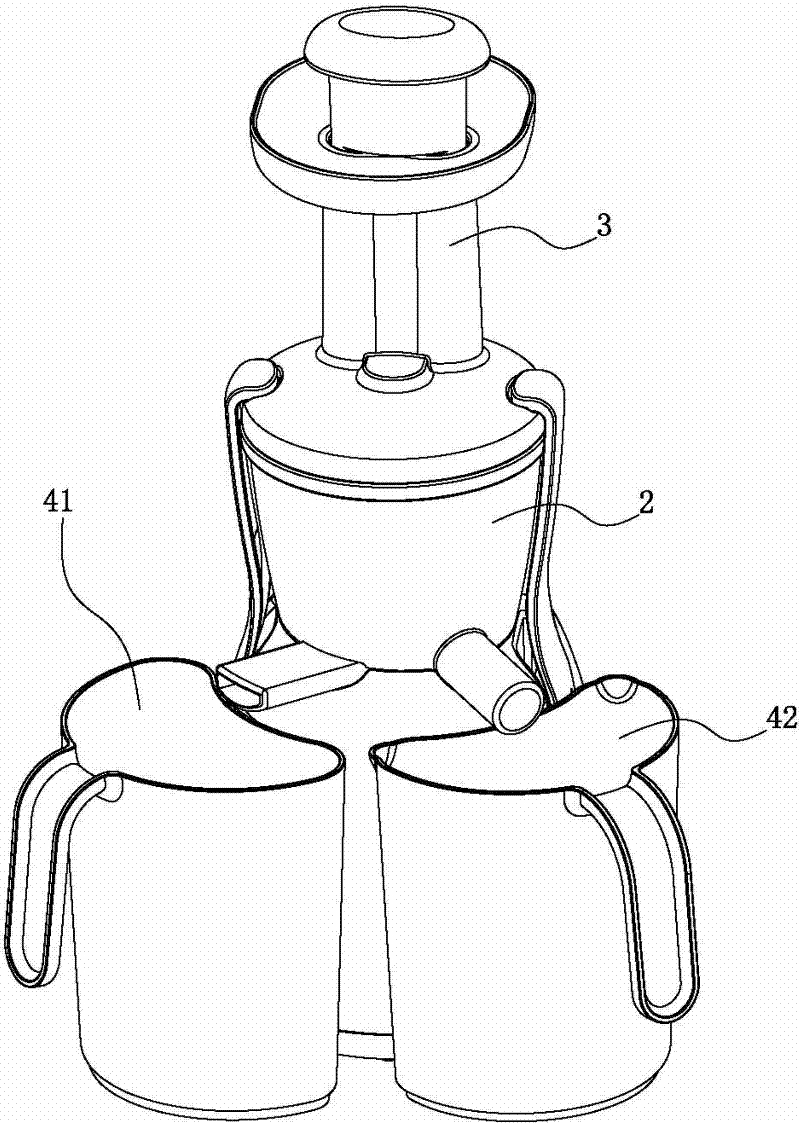

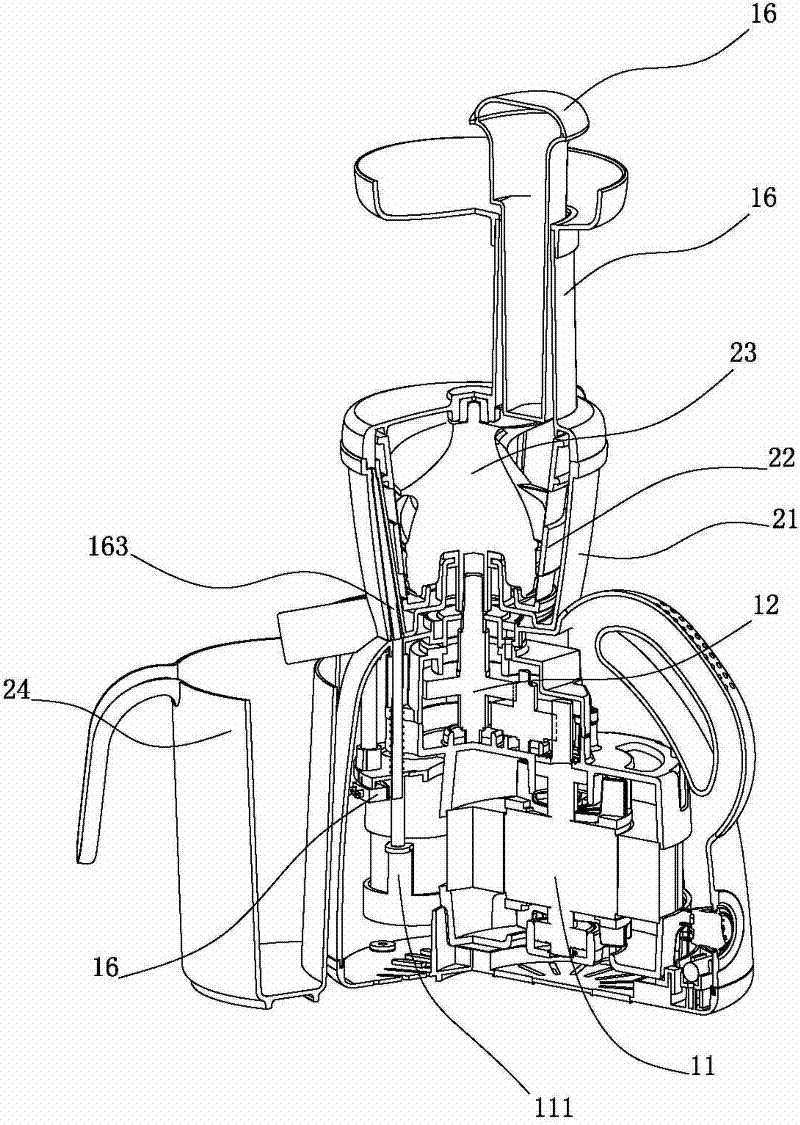

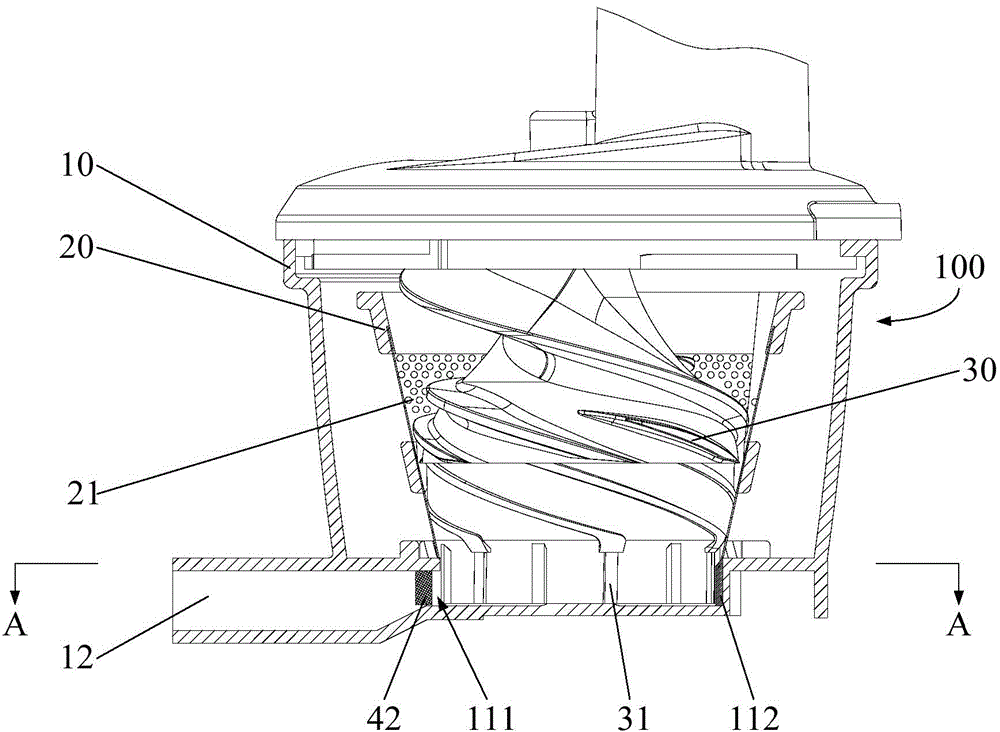

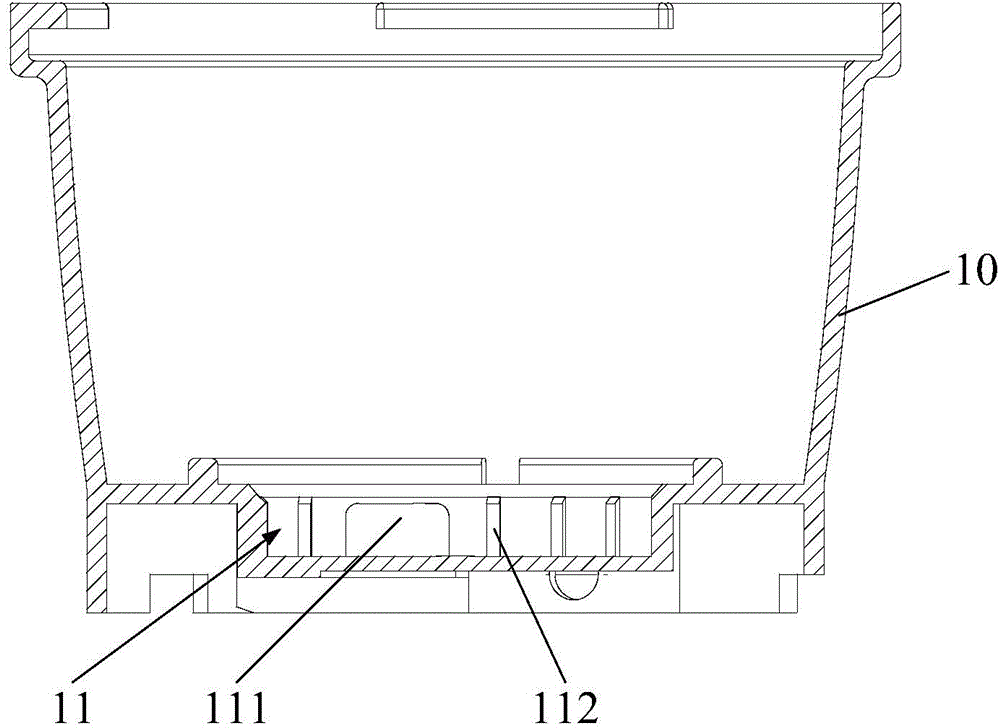

Squeezing type juicer

The invention discloses a squeezing type juicer. The squeezing type juicer comprises a base, a squeezing assembly mounted on the base, and a feeding assembly buckled on the squeezing assembly. A drive component is disposed inside the base, and a drive shaft is arranged at the top of the base. The squeezing assembly comprises a cup body, a meshed barrel fixedly mounted in the cup body and a screw rod located in the meshed barrel. The cup body is provided with a juice outlet and a pomace draining channel. A juice collection annular groove is formed at the bottom of the cup body and is communicated with the juice outlet. A pomace collecting annular groove is formed at the bottom of the meshed barrel and is communicated with the pomace draining channel. According to the invention, a rotating brush, a transmission mechanism of the rotating brush and a transmission gear located at the bottom of the screw rod in the prior art are omitted, so that the juicer is simpler in structure, is lower in failure rate, is prolonged in service lifetime, is more stable in operation, and is more convenient to wash.

Owner:NINGBO KEDLY APPLIANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com