Patents

Literature

82results about How to "Avoid too thick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

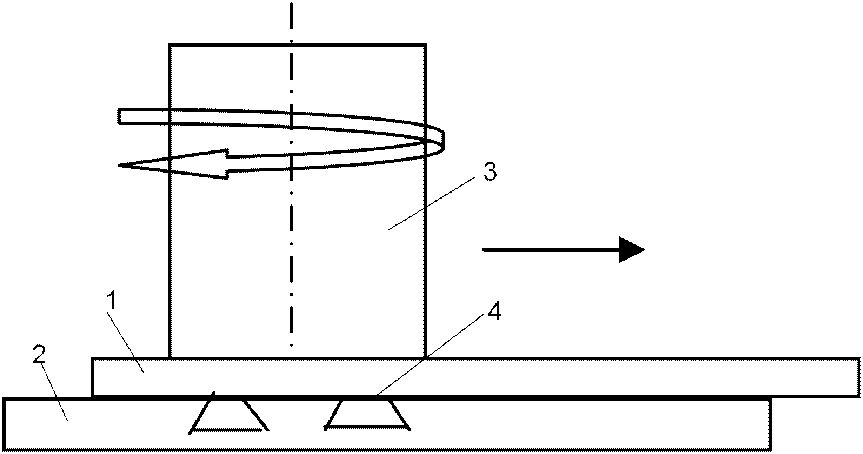

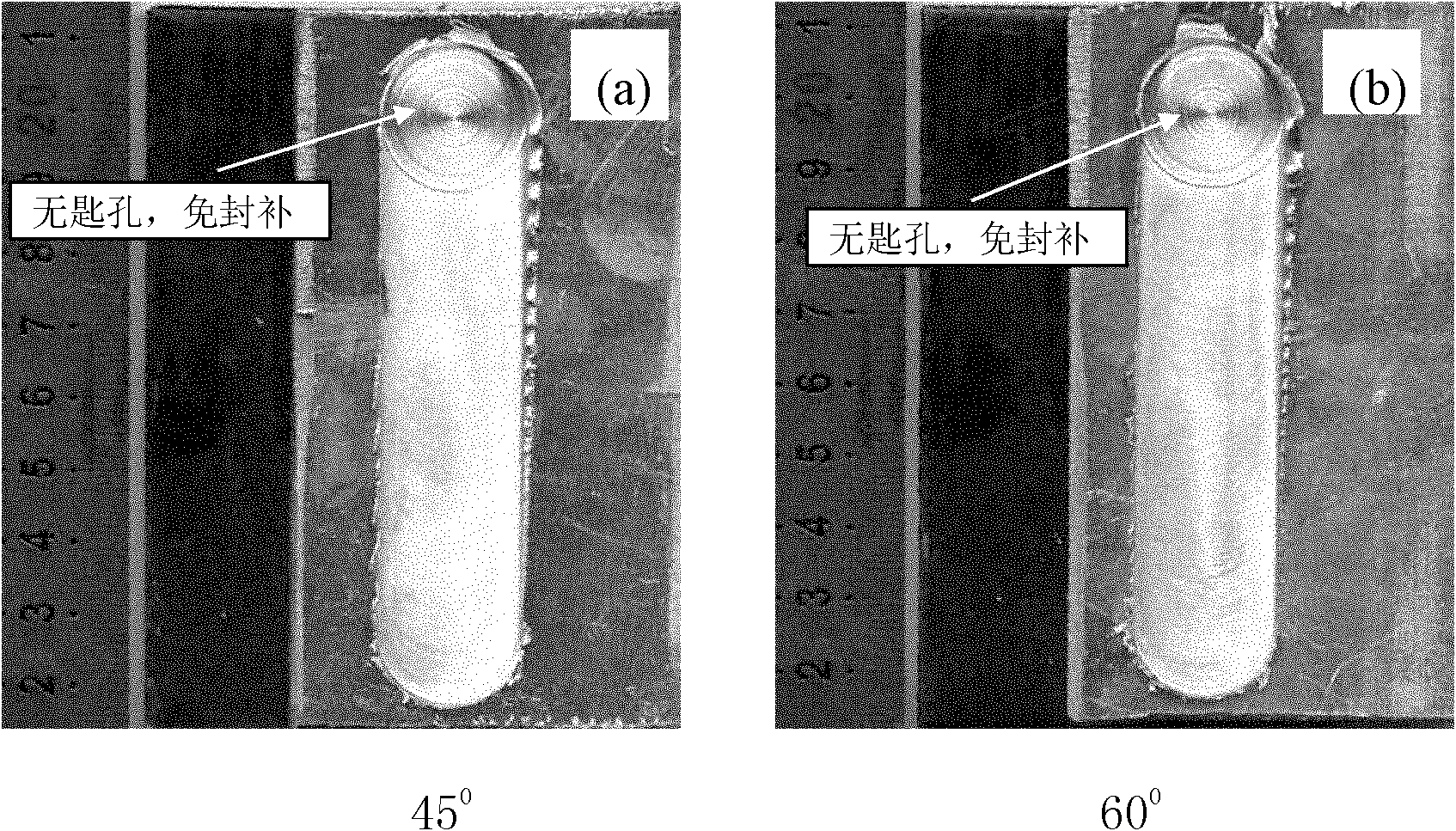

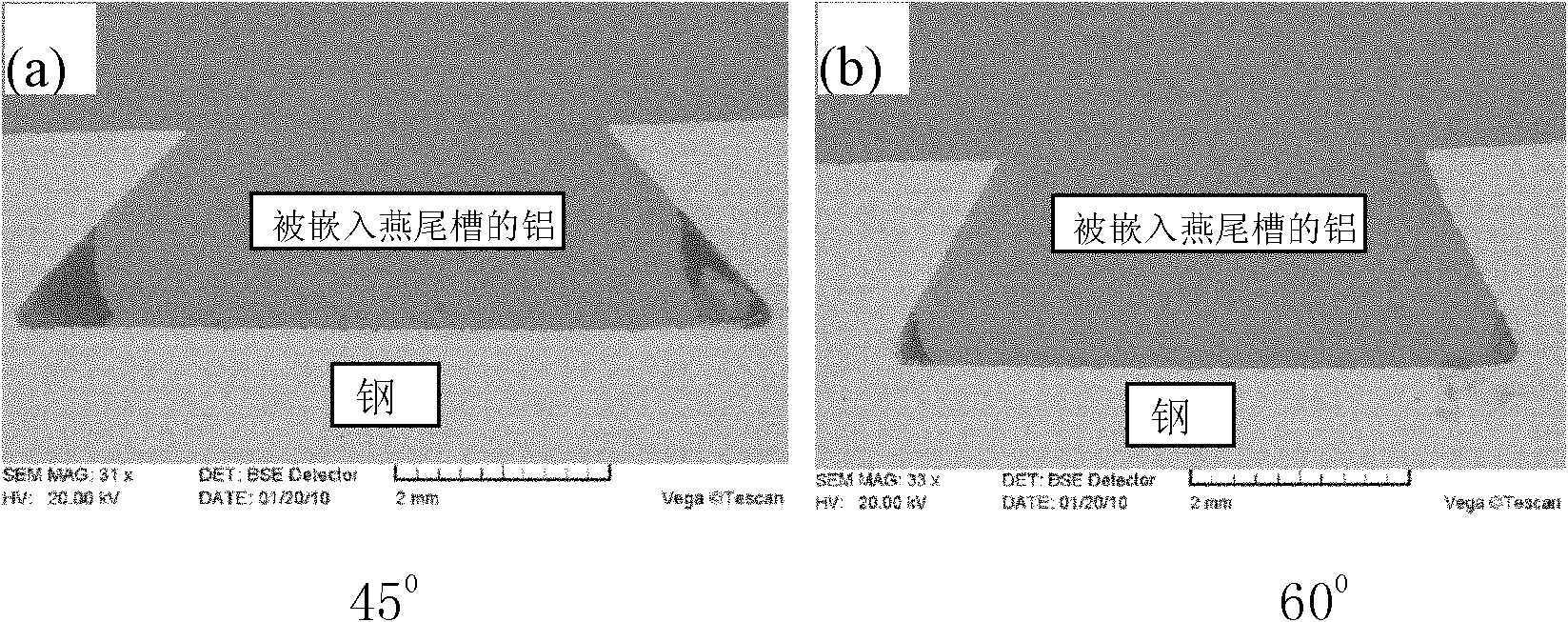

Embedded stirring and rubbing slit welding method

InactiveCN102120287AImprove bindingSignificant energy savingNon-electric welding apparatusNeedle freeHard metal

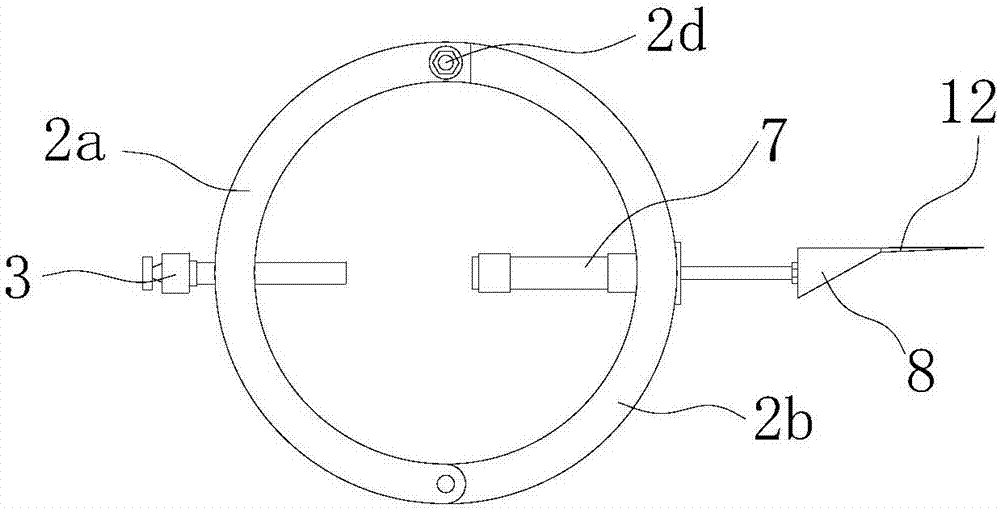

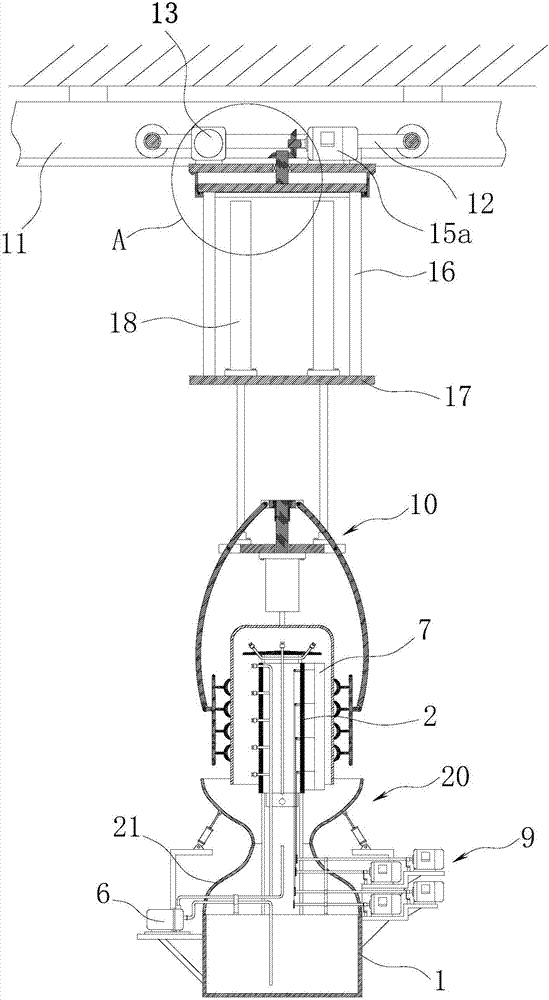

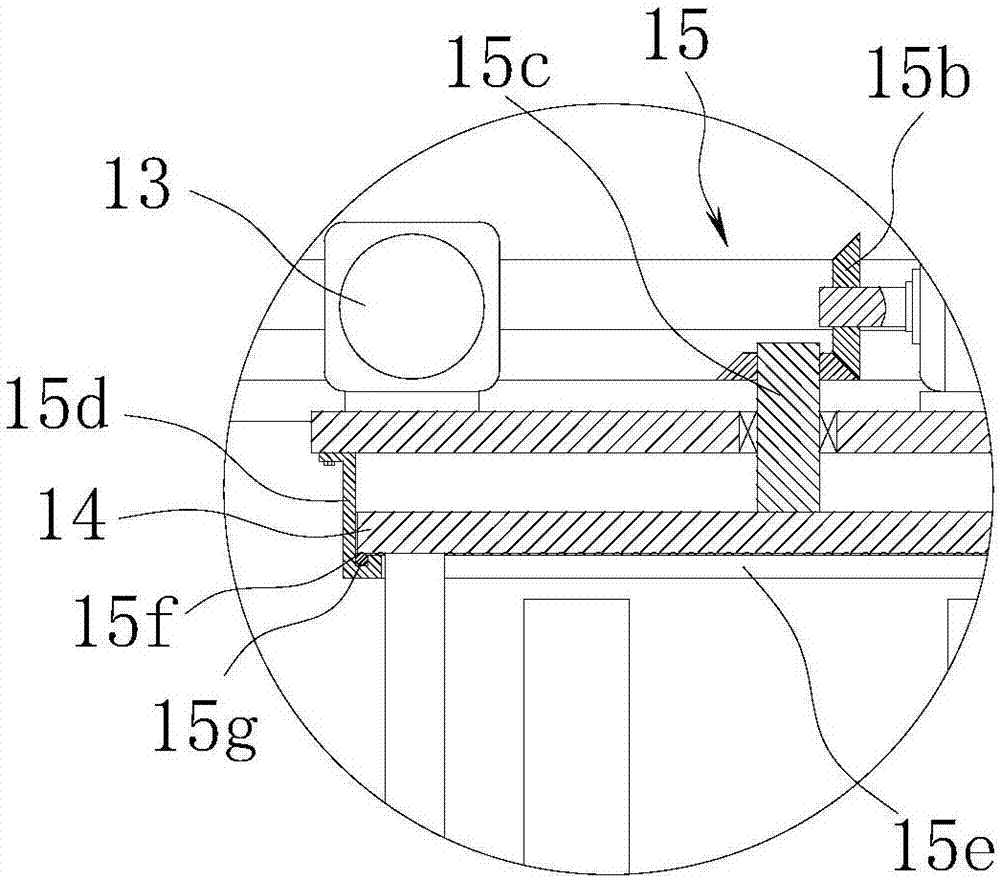

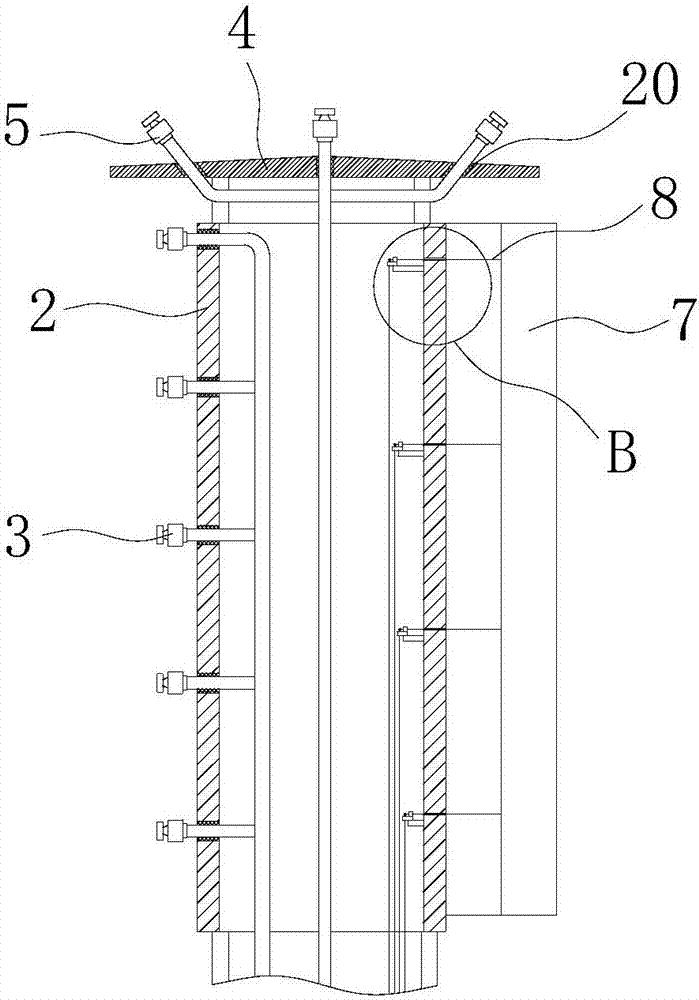

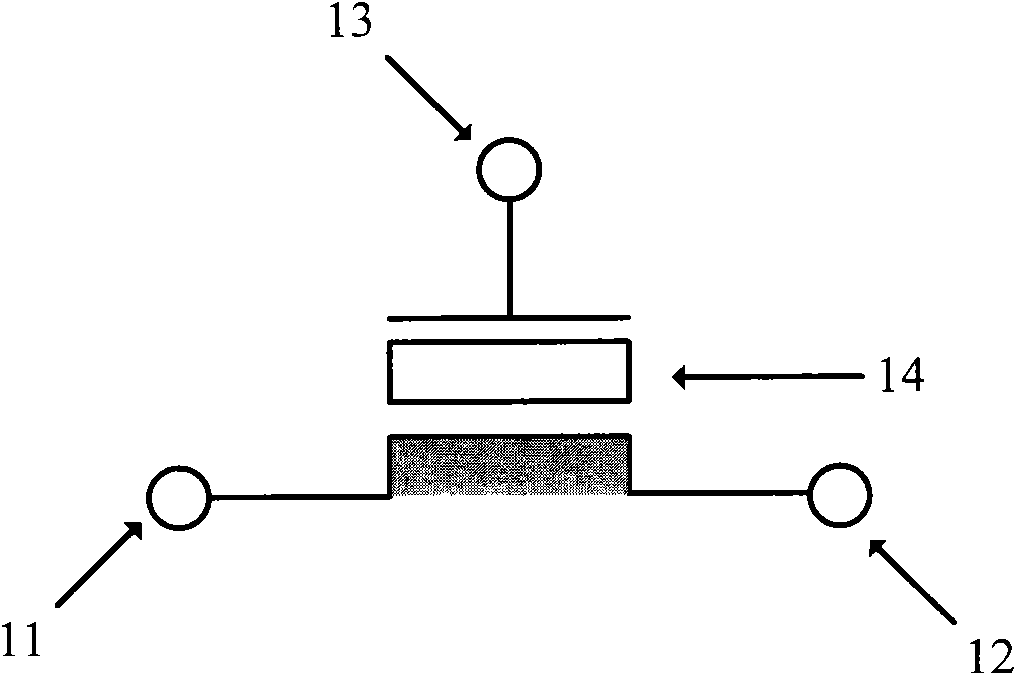

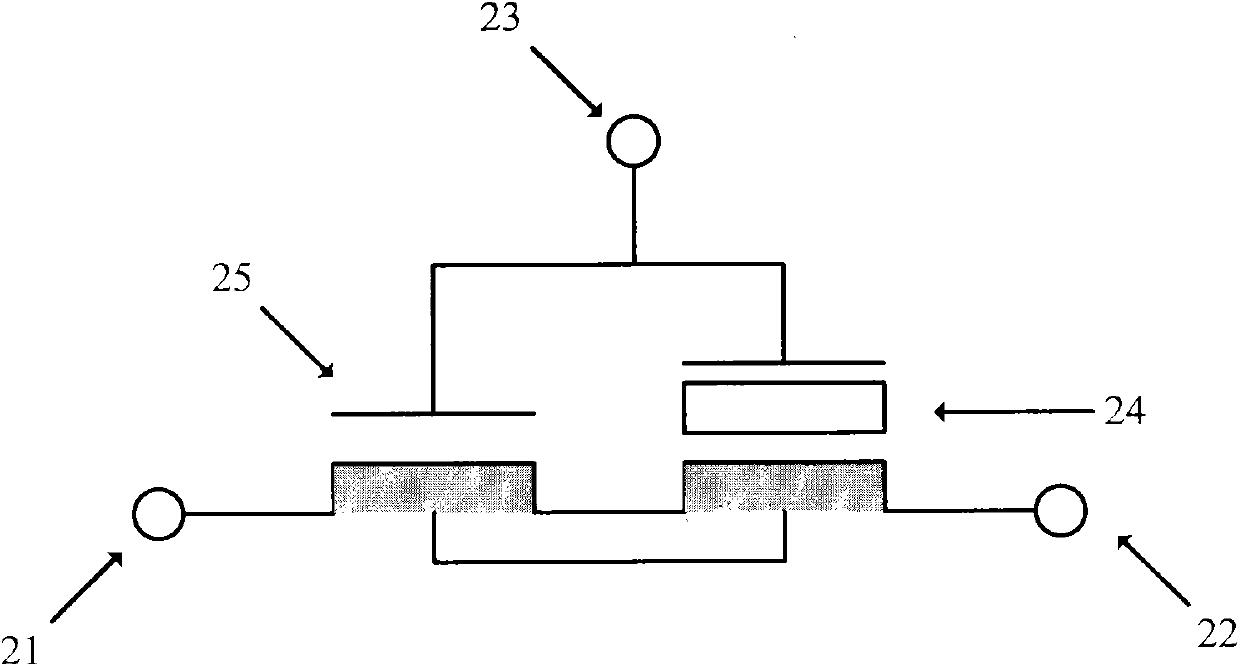

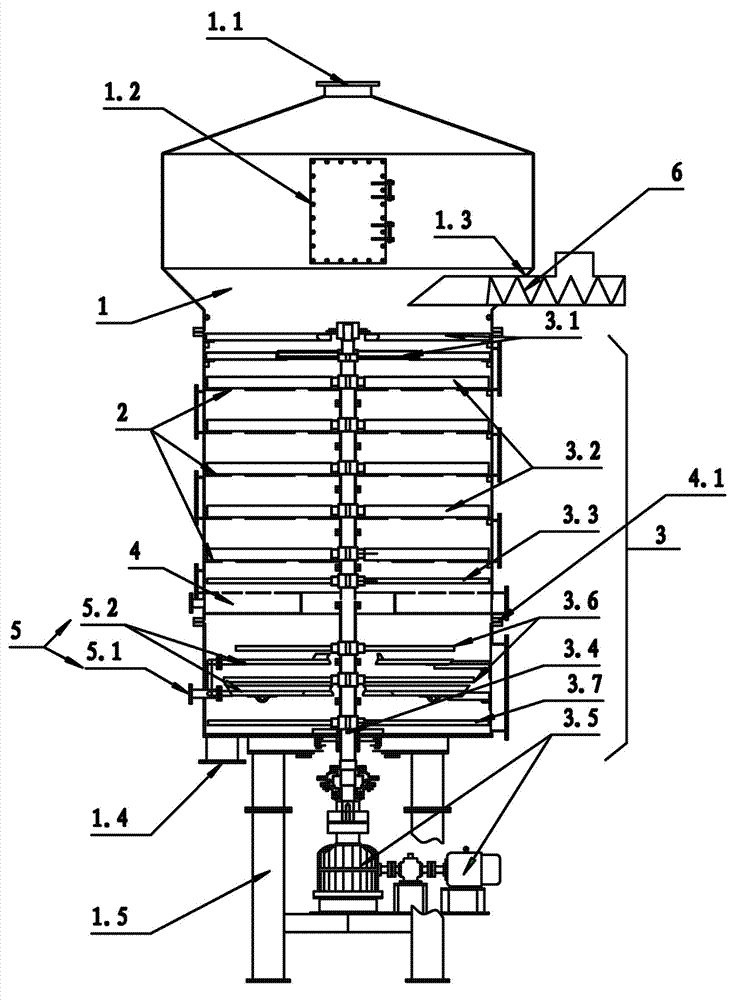

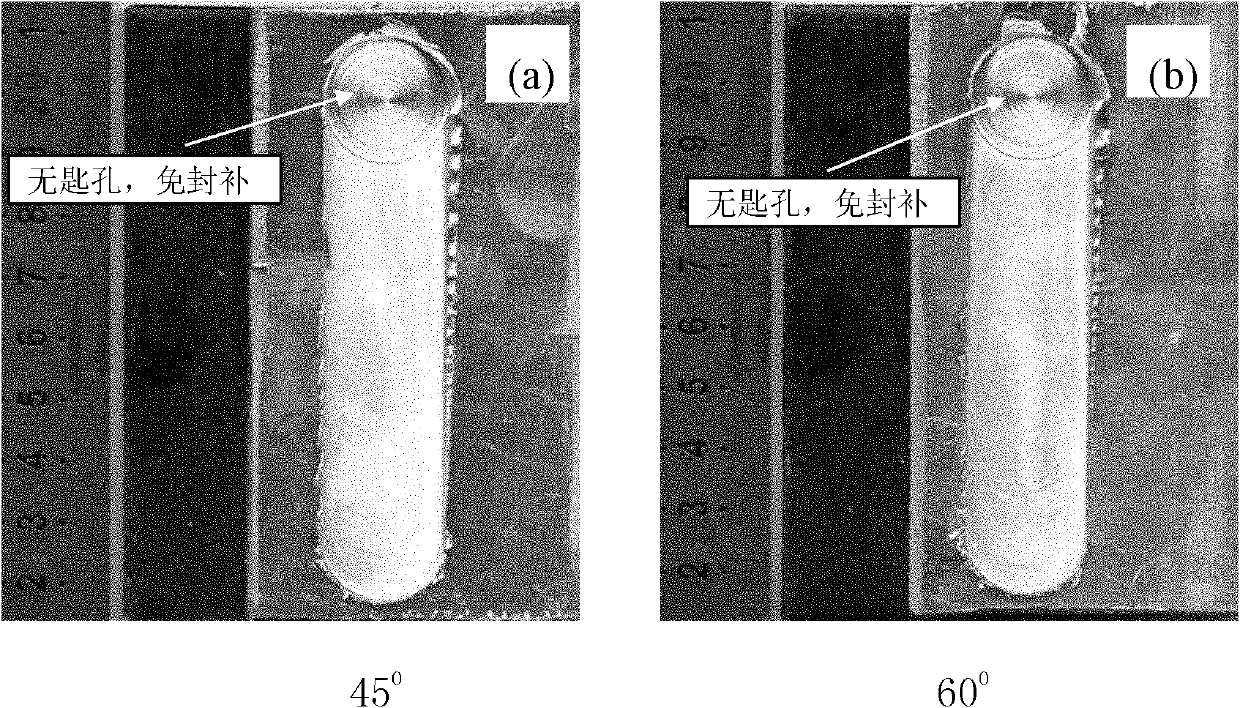

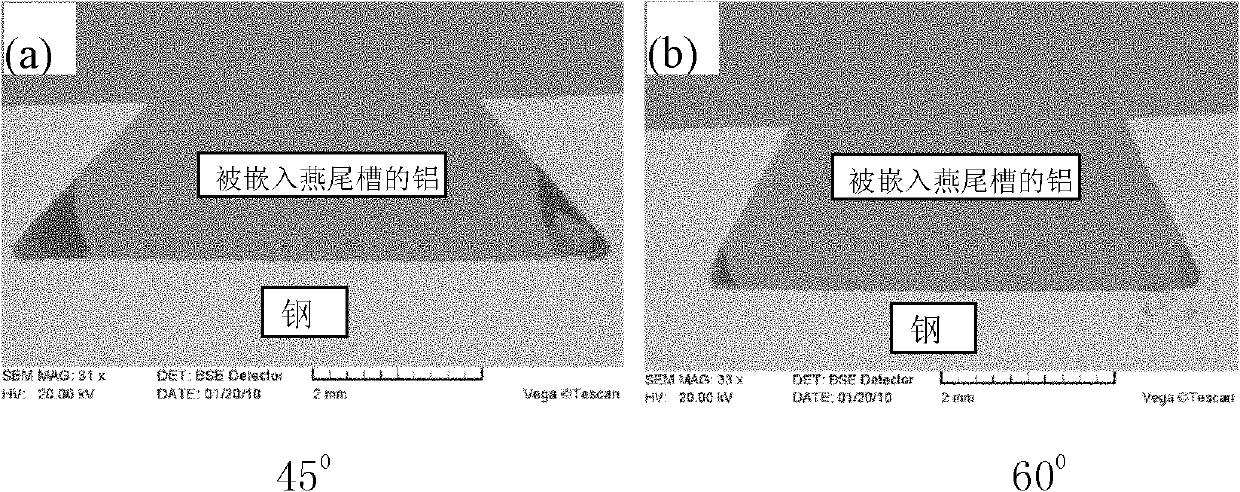

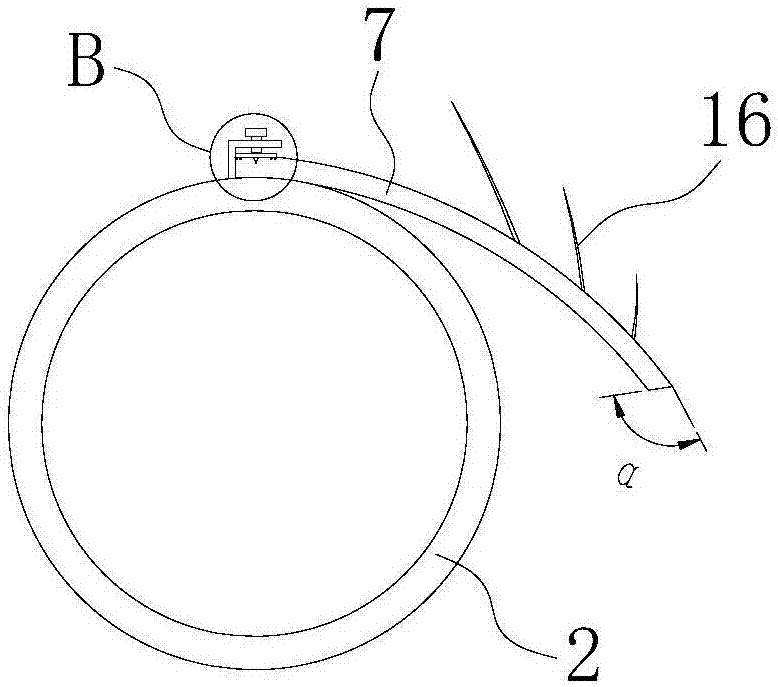

The invention discloses an embedded stirring and rubbing slit welding method for dissimilar metals, which is especially suitable for large-area lap connection of aluminum or magnesium or harder metal materials. The embedded stirring and rubbing slit welding method comprises the steps of: firstly, processing one or more dovetail grooves on a second harder base material; secondly, assembling according to a lap connection form, and placing an aluminum plate on the upper sides of the dovetail grooves of the second harder base material; using a needle-free stirring head and installing in an inclining manner; starting the stirring head to rotate and enabling the stirring head to be in contact with the upper surface of the aluminum plate, wherein the pressing depth of the stirring head is limited to about between 0.1mm and 2mm and a welding interface needs not to be penetrated; after rubbing and preheating for several seconds at the starting end, moving the rotating stirring head or operating platform so that the aluminum plate is helically extruded in a groove of a lower plate and the welding or cladding is completed. Compared with the resistance slit welding, the method disclosed by the invention has remarkable energy saving advantage. Compared with the traditional stirring rubbing welding, the method disclosed by the invention has the advantages of no keyhole and no abrasion to needles by the harder base material. The method can be used for welding, and can also be used for preparing a bimetal composite plate.

Owner:西安英特金属复合材料有限公司

Titaniferous stainless steel electroslag remelting casting powder

The invention discloses titaniferous stainless steel electroslag remelting casting powder which is prepared from the raw materials in parts by weight as follows: 46.0-50.0 parts of fluorite, 20.0-24.0 parts of alumina powder, 18.5-22.5 parts of lime, 3.5-5.5 parts of fused magnesite, 2.0-4.0 parts of titanium dioxide as well as other components: 0.0-0.6 part of SiO2, 18.0-22.0 parts of CaO, 20.0-24.0 parts of Al2O3, 4.2-5.8 parts of MgO, 2.0-4.0 parts of TiO2, 45.0-51.0 parts of CaF2, less than 0.03 part of S and less than 0.03 part of C. Slag is formed by the casting powder according to strict quality control standard so as to ensure that the impurity content is low, the purity is high and the slag is dry and free from moisture. In the electroslag remelting process, desulfuration and deoxygenation effects are enhanced, the resistivity is improved, and the casting powder is free from cutoff in arcing, good in lubrication and relatively easy to popularize and apply.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

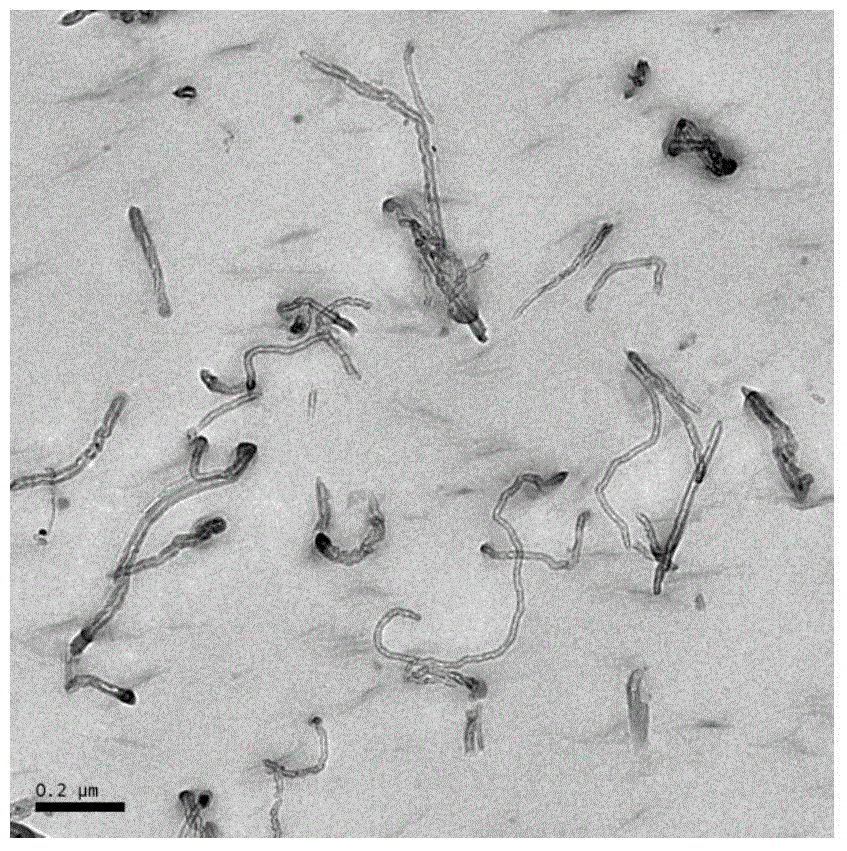

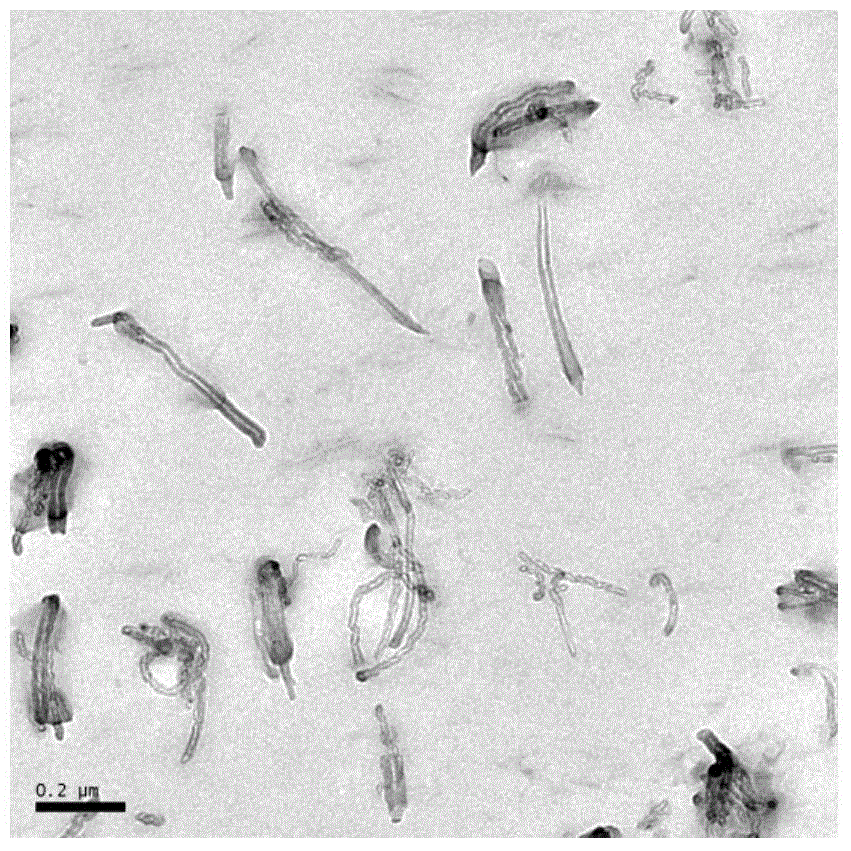

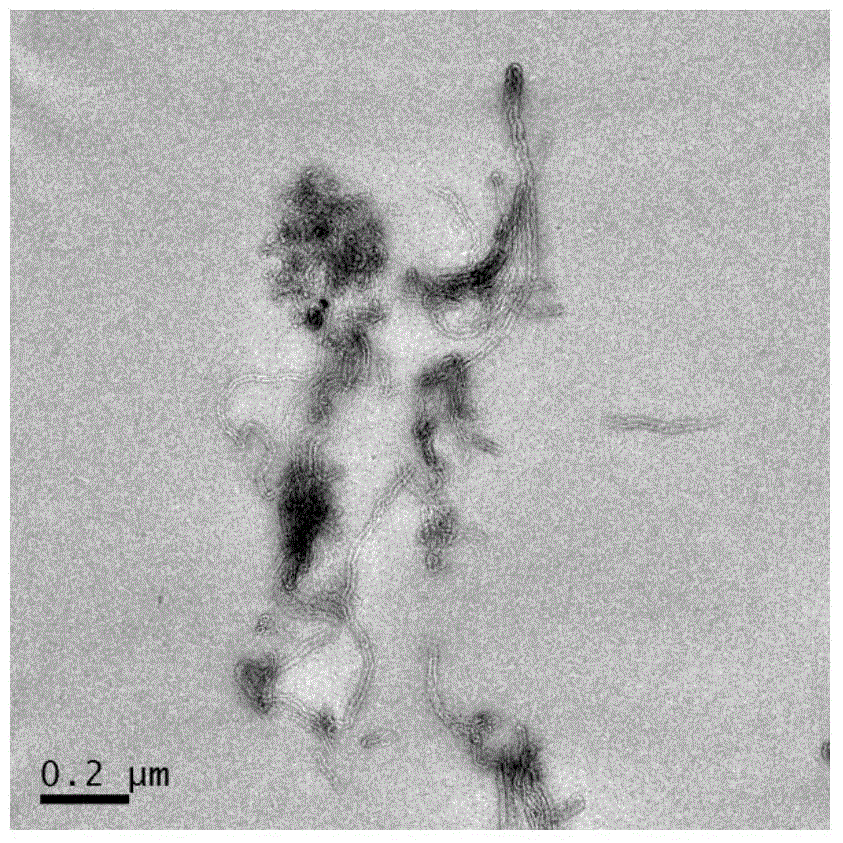

Carbon nanotube / polylactic acid conductive composite material and preparation method thereof

The present invention relates to the field of polymer materials, and further relates to a carbon nanotube / polylactic acid conductive composite material and a preparation method thereof. The carbon nanotube / polylactic acid conductive composite material contains the following groups in blending: 100 parts by weight of polylactic acid and 0.5-10 parts by weight of a modified carbon nanotube conductive powder; the material can also include 0.2-4.0 parts by weight of a non-ion surface active agent, can also further comprise 0.03-0.05 part by weight of an antioxidant. The method of the invention is simple in operation process and suitable for continuous mass production. The obtained carbon nanotube / polylactic acid conductive composite material has good carbon nanotube dispersion, improved aggregation phenomena, good anti-antistatic and conductive properties, and biodegradability and biological compatibility, and can be applied to the fields of electronics, communication and bio-engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hot galvanizing process

InactiveCN105734476AAvoid over corrosionAvoid destructionHot-dipping/immersion processesThioureaPhosphate

The invention discloses a hot galvanizing process. The hot galvanizing process is characterized in that thiourea with concentration being 0.12% is added during pickling, wherein a picking temperature is 50 DEG C, so that a workpiece can be prevented from being over-etched, and hydrogen absorption capacity of ferro matrix can be reduced; an ultrasonic cleaning agent with concentration being 7.5% is added during ultrasonic cleaning, so that greasy dirt and corrosion on the surface of a workpiece can be quickly removed; the ultrasonic cleaning agent is trichloro ethylene which does not contain phosphate, is harmless to aquatic life, is harmless to a human body and is free of stimulation on skin; the cooling comprises the following two steps: a first step, slow cooling, wherein a cooling speed is 10 DEG C / S, and the workpiece is cooled to a temperature of 650 DEG C; and a second step, quick cooling, wherein the workpiece is cooled by a cooling fan, and is cooled to a temperature of 445 DEG C, so that the structure of the workpiece can be prevented from being damaged; pure aluminum with concentration being 0.02% is added into a zinc pot before galvanizing, so that mobility, at a relatively low temperature, of a hot galvanizing solution is improved, a coating is prevented from being thickened, and the appearance of the coating is improved; a bearing produced by adopting the method has the advantages of corrosion resistance, great bonding strength of a galvanized coating and long usage time, is great in market potential and is wide in prospect.

Owner:徐开文

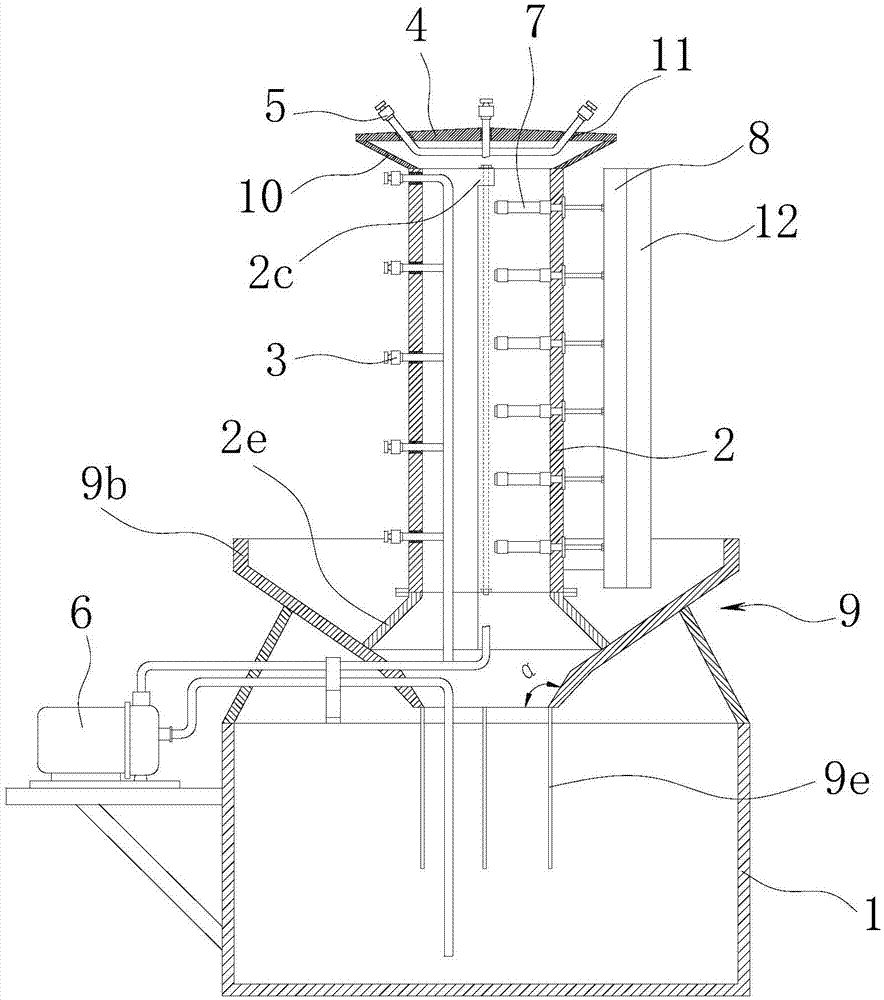

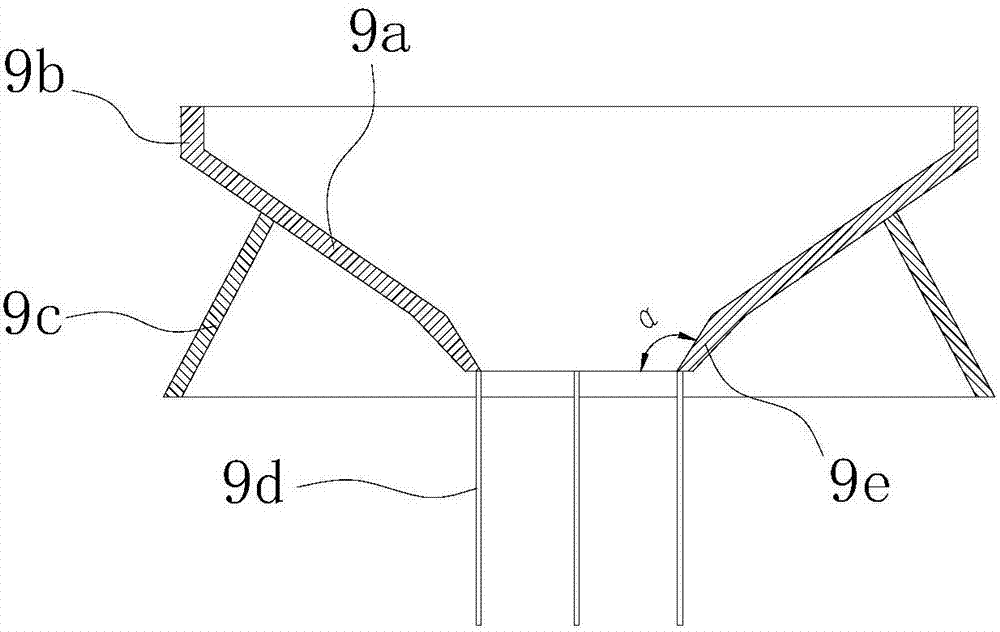

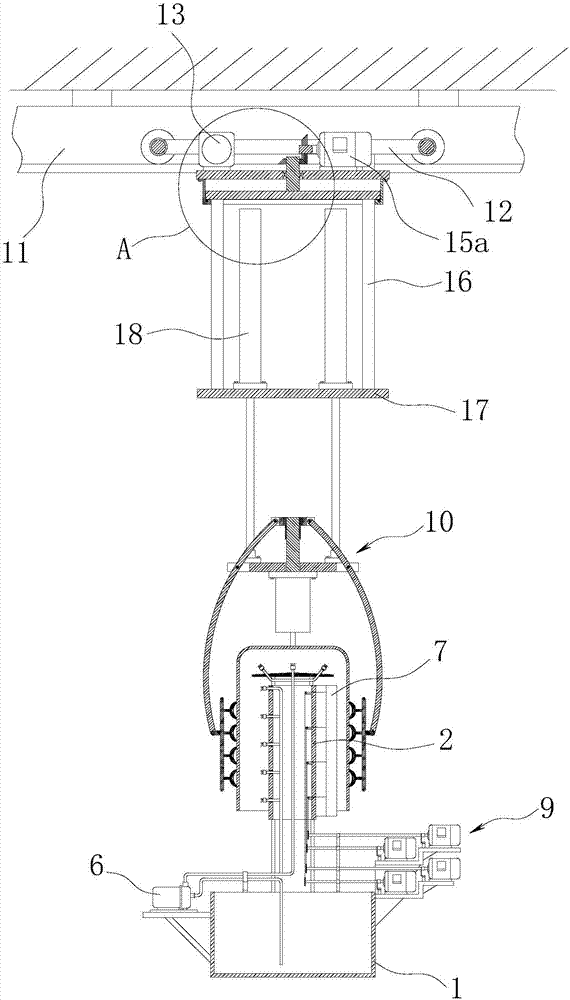

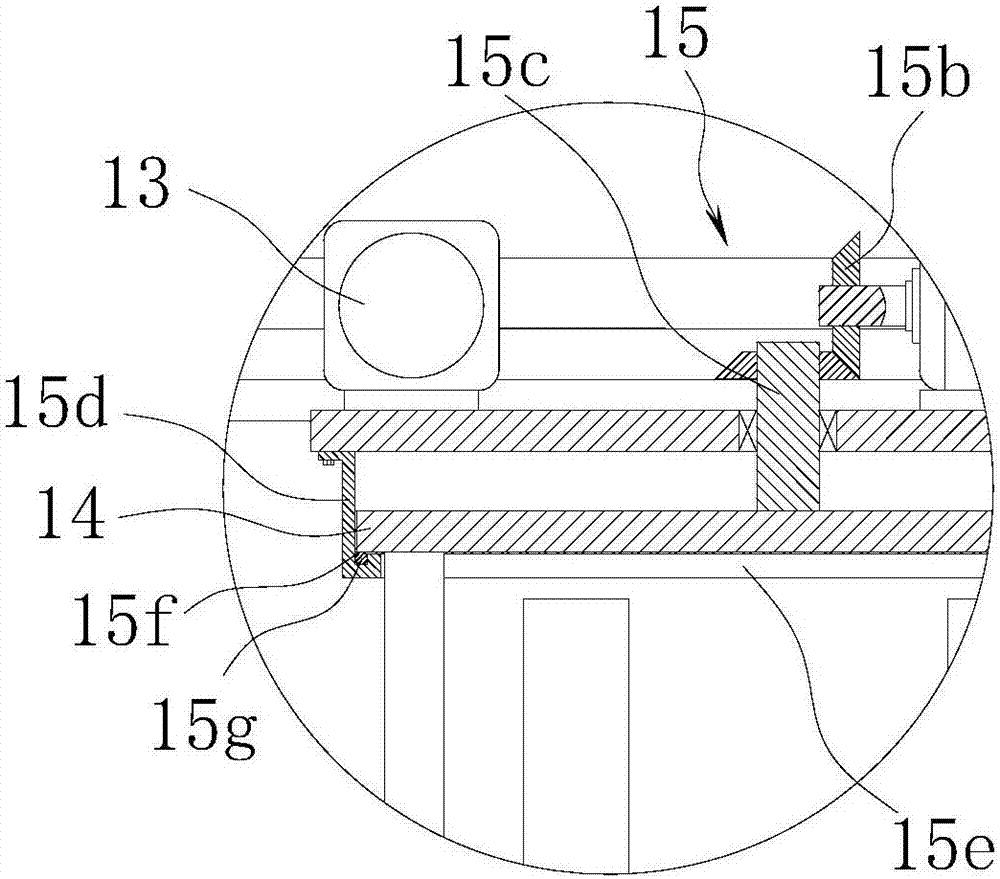

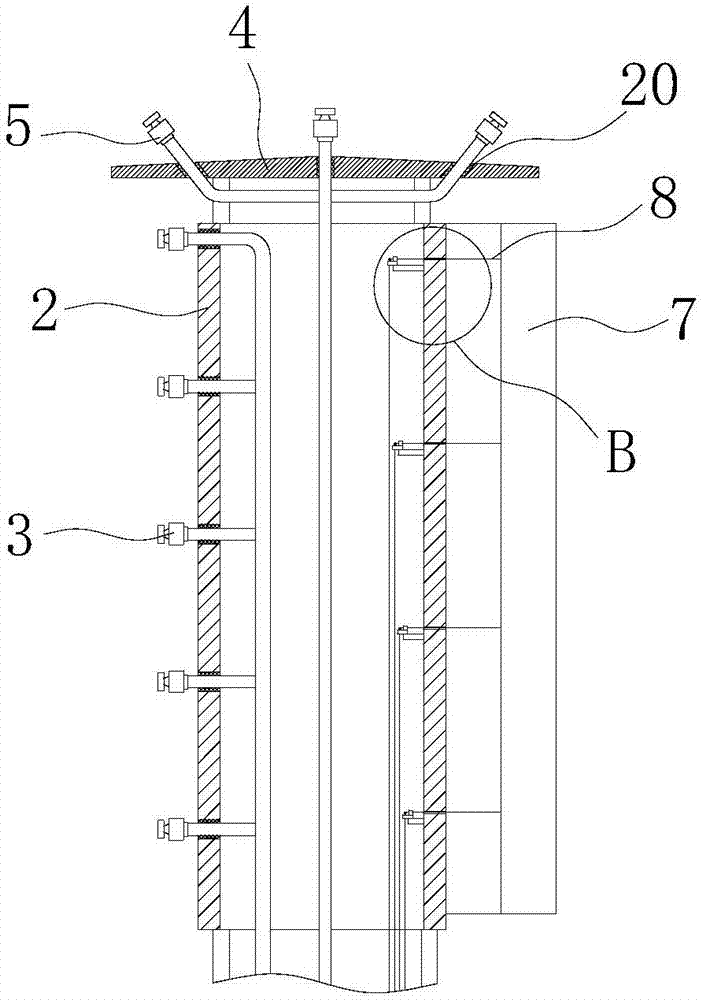

Glaze spraying device for production of ceramic products

ActiveCN107160544AGood flexibilityAvoid scratchesCeramic shaping apparatusLiquid storage tankCeramic glaze

The invention discloses a glaze spraying device for production of ceramic products and belongs to the technical field of ceramic production equipment. The glaze spraying device is technically characterized by comprising a liquid storage tank; a flow guide cover is arranged on the liquid storage tank; a mounting barrel is arranged in the flow guide cover; a plurality of first nozzles are vertically distributed on the side wall of the mounting barrel; a fixing seat is arranged on the upper side of the mounting barrel; a plurality of second nozzles are distributed on the fixing seat; the first nozzles and the second nozzles cooperate to spray glaze on inner walls of blanks; the first nozzles and the second nozzles are connected with a glaze spraying pump arranged on the outer side of the liquid storage tank through pipelines; the liquid inlet end of the glaze spraying pump extends into the liquid storage tank; a plurality of scraper plate adjusting cylinders are vertically arranged on the mounting barrel on sides of the first nozzles at intervals and are connected with an external compressor; and the free ends of telescopic rods of the scraper plate adjusting cylinders are connected through a rubber plate. The glaze spraying device is convenient to use and good in effect and is used for glazing of the blanks.

Owner:TANGSHAN MONOPY CERAMIC

Adjustable glaze spraying device for ceramic product production

ActiveCN107297813AEasy to handleIncrease clamping forceAuxillary shaping apparatusSpray nozzleEngineering

The invention discloses an adjustable glaze spraying device for ceramic product production, and belongs to the technical field of ceramic production equipment. The device is technically characterized by comprising a liquid storage groove; an installation cylinder is arranged above the liquid storage groove, a plurality of first nozzles are distributed on the side wall of the installation cylinder in the vertical direction, a fixing base is arranged on the upper side of the installation cylinder, a plurality of second nozzles are distributed on the fixing base, and the first and second nozzles are matched to spray glaze on the inner wall of a blank; the first and second nozzles are communicated and connected with a glaze spraying pump arranged on the outer side of the liquid storage groove through a pipeline, and the liquid inlet end of the glaze spraying pump stretches into the liquid storage groove; an adjustable collecting mechanism is arranged between the installation cylinder and the liquid storage groove, a rubber scraper plate is arranged on the outer wall of the installation cylinder in the vertical direction, and a plurality of connecting lines are distributed at the close end, away from the installation cylinder, of the rubber scraper plate in the vertical direction at intervals. The adjustable glaze spraying device for ceramic product production is convenient to use and good in effect and can be used for glazing the blank.

Owner:大埔县益成实业有限公司

Manufacturing method of oxide layer between splitting grids

InactiveCN102024692APrecise thickness controlAvoid too thickSemiconductor/solid-state device manufacturingOptoelectronicsRapid thermal processing

The invention relates to a manufacturing method of an oxide layer between splitting grids, which comprises the following step of: carrying out in-situ vapor generation by using a rapid thermal processing device so as to form the oxide layer on the surface of a common source region between the splitting grids. The manufacturing method can accurately control the thickness of the oxide layer formed on the highly doped common source region so as to avoid over thickness of the oxide layer. Moreover, the thickness of the formed oxide layer is uniform, and the smiling effect is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

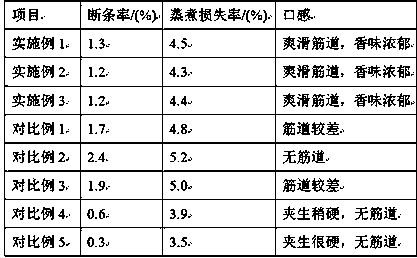

Preparation method of instant tough and chewy coarse cereal nutritious noodles

InactiveCN110292094AFull of nutritionSmooth ripeningVegetable proteins working-upFermentationMouthfeel

The invention mainly relates to the technical field of noodle processing, and discloses a preparation method of instant tough and chewy coarse cereal nutritious noodles. The method comprises the stepsof coarse cereal dough making, first dough kneading, first fermentation, second dough kneading, second fermentation, shaping, curing and drying. The instant tough and chewy coarse cereal nutritious noodles prepared through the preparation method of the instant tough and chewy coarse cereal nutritious noodles are rich in nutrition, tough, chewy, smooth, free of additive, natural and healthy, in the eating aspect, a lot of cooking time is saved; boiling water is added in the coarse cereal powder, stirring is conducted, the coarse cereal powder can be rapidly cured at a high temperature, the aroma and cohesiveness of the coarse cereal powder are increased, the coarse cereal powder can be rapidly bonded with flour, noodle processing and shaping are facilitated, and the tough and chewy taste of the noodles is improved.

Owner:太和县叶顺食品厂

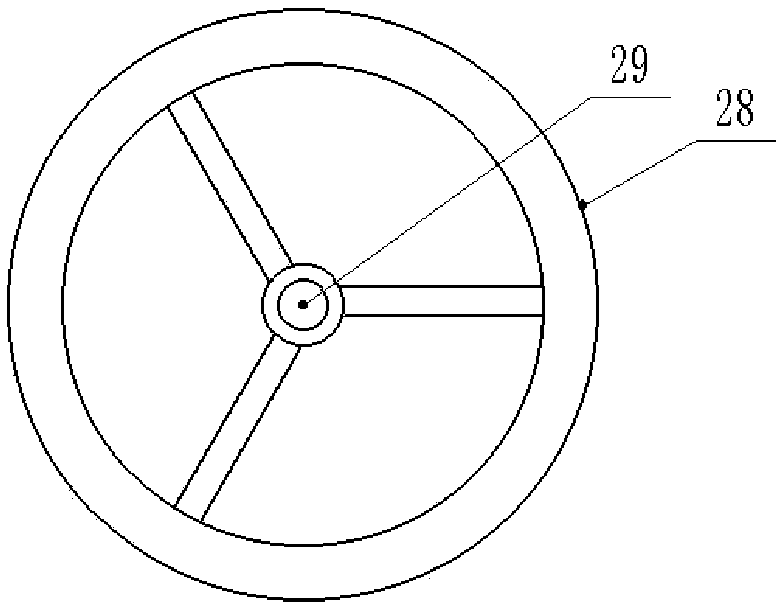

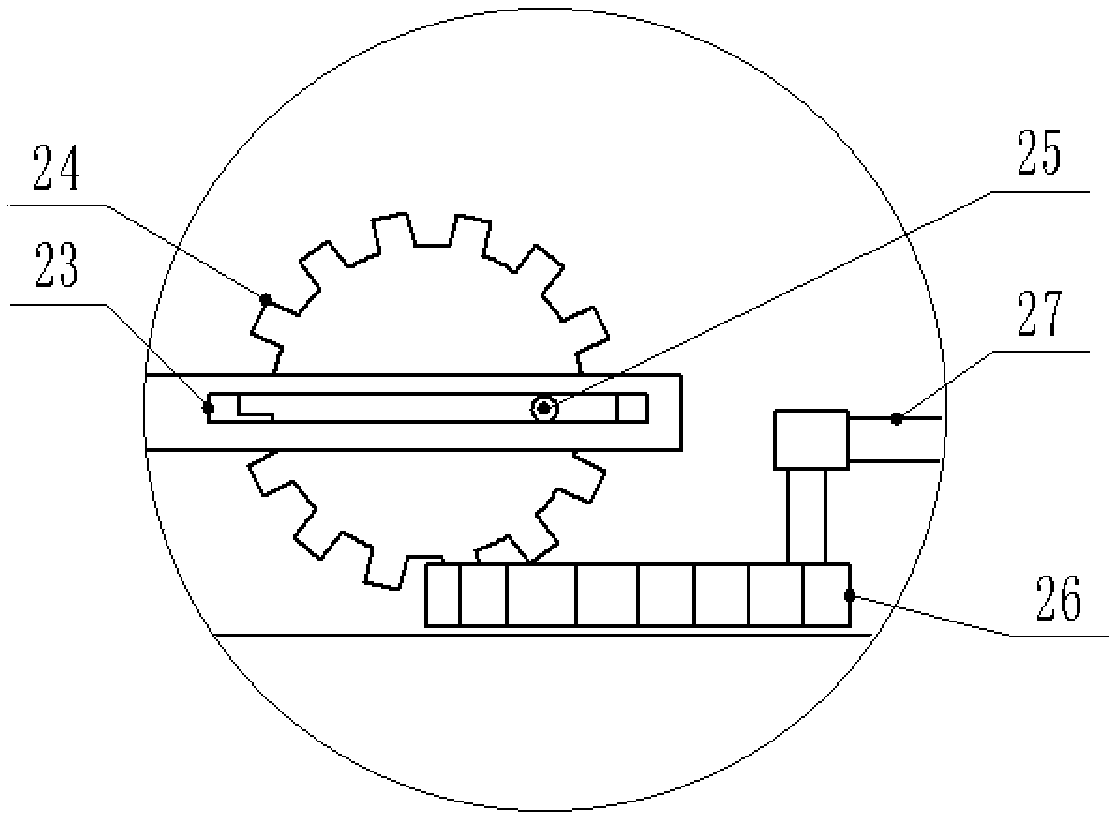

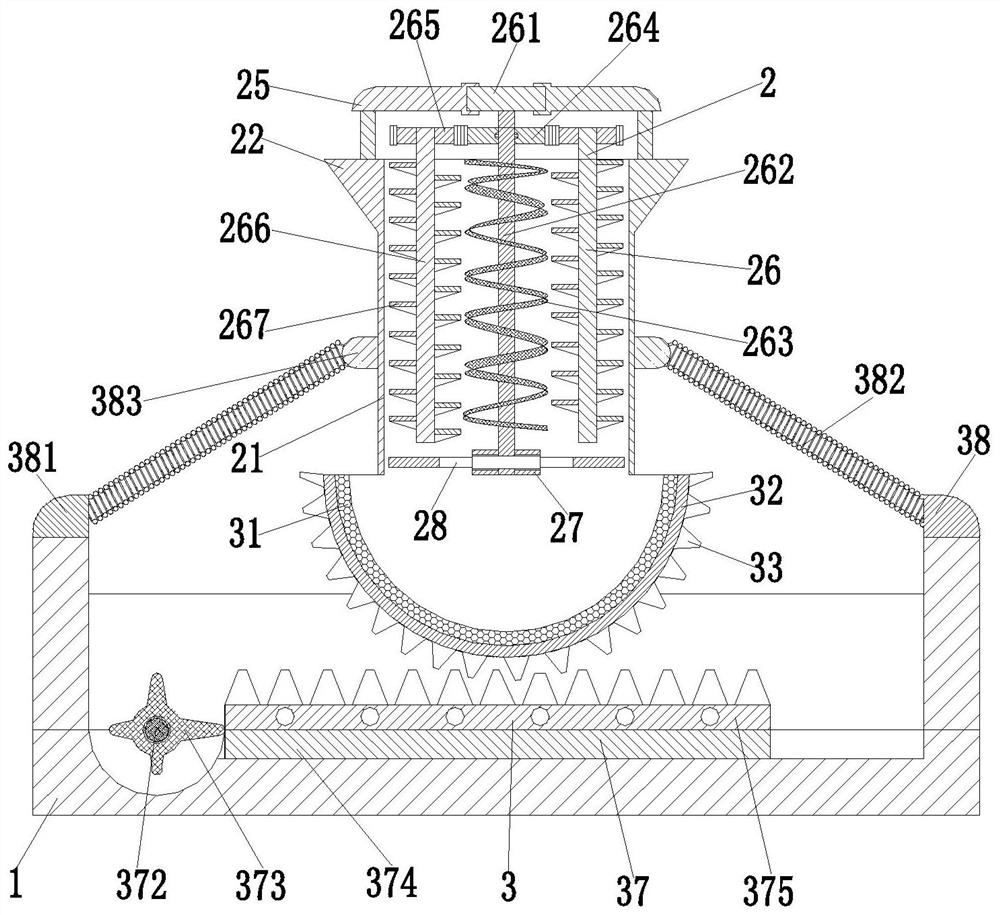

Painting device for valve handwheel

InactiveCN108212670AImprove cleanlinessFirmly connectedLiquid surface applicatorsCoatingsGear wheelEngineering

The invention relates to the field of valve production, and discloses a painting device for a valve handwheel. The painting device comprises a paint groove; a rack is arranged on the paint groove; a rack is slidably connected onto the rack; a small gear is meshed with the rack; a cross rod is rotatably connected to the rack; a fixed position is arranged on the cross rod; the fixed position is sleeved with an elastic inflation barrel; a vertical pipe is arranged on the rack; a piston which is in clearance fit with the vertical pipe is arranged in the vertical pipe; the inside of the vertical pipe is divided into an upper pipeline and a lower pipeline by the piston; a connection rod is arranged in the upper pipeline; two ends of the connection rods are separately hinged to the rack and the piston; an inflation pipe is connected between a lower end of the lower pipeline and the elastic inflation barrel; a paint inlet pipe is connected with the paint groove; a rotary shaft is rotatably connected into the paint groove; a turbine is fixedly connected to one end of the rotary shaft and is located at a connection opening of the paint inlet pipe and the paint groove; and an elastic belt isconnected between the other end of the rotary shaft and the cross rod. By adopting the painting device, while the handwheel is painted, a through hole of the handwheel is prevented from being paintedwith paint; and machining efficiency of the handwheel is improved.

Owner:CHONGQING QIANYAN MACHINERY CO LTD

Method for synchronous coat-sealing by using waste tire rubber asphalt according to particle size of crushed rock

InactiveCN102191737AAvoid too thickAvoid exposureIn situ pavingsSolid waste managementCrushed stoneAsphalt

The invention provides a method for synchronous coat-sealing by using waste tire rubber asphalt according to the particle size of crushed rock, which adopts the following technical scheme: the method mainly comprises the following steps of: confirming the particle size of the crushed rock, crushing waste tires, grinding the crushed waste tires into powder, screening ingredients, and carrying out synchronous coat-sealing on the crushed stones, wherein in the process of implementing the formula, when the particle size is 9.5-13.2mm, the use quantity of the crushed stone is 14kg / m<2>, and the use quantity of the waste tire rubber asphalt is 2.2kg / m<2>; and when the particle size is 4.75-9.5mm, the use quantity of the crushed stone is 11.2kg / m<2>, and the use quantity of the waste tire rubber asphalt is 1.8kg / m<2>. The method disclosed by the invention has the following advantages that: the technical process is detailed, phenomena of a reduced cohesive force and a too thick waste tire asphalt film are avoided, and the use quantities of different waste tire rubber asphalts can be confirmed according to the particle size of the crushed stone; thus, the asphalt film can be prevented from exposure, the wrapping force of the crushed stone is increased, and the adhesive force of the waste tire rubber asphalt and the crushed stone can be effectively ensured.

Owner:SHANXI CHANGSHENG ROAD ENG

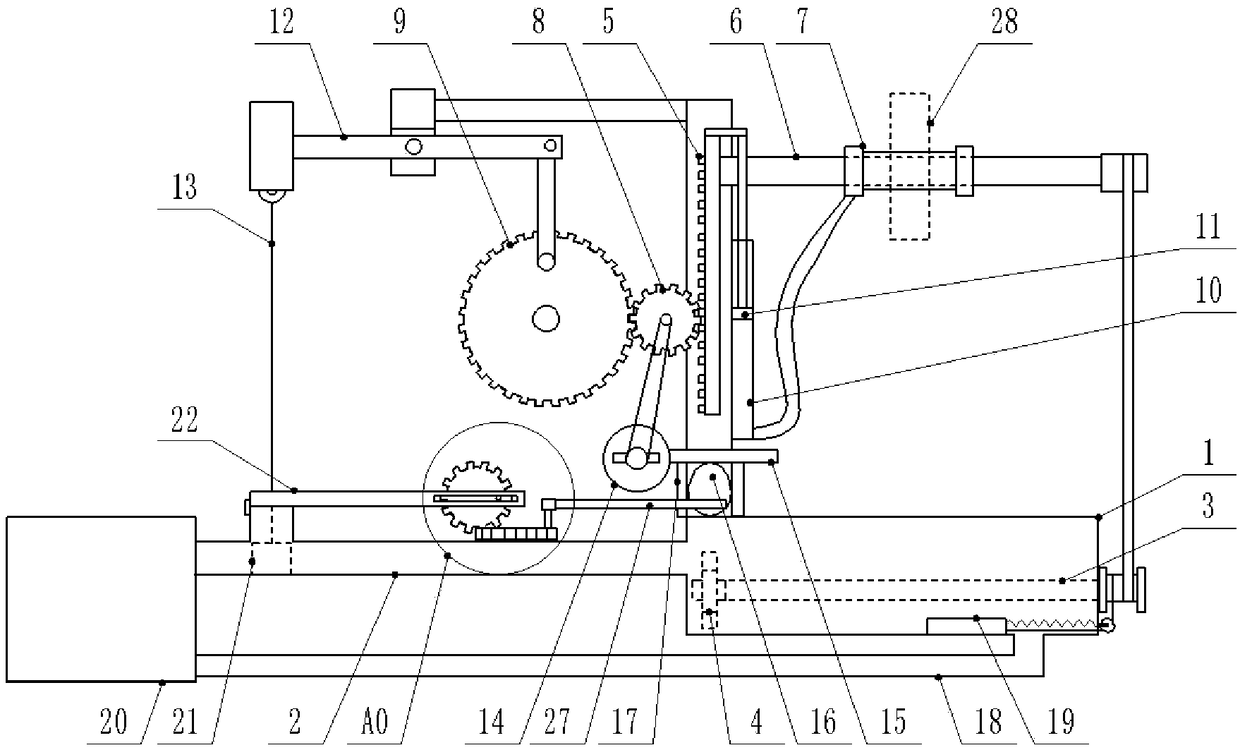

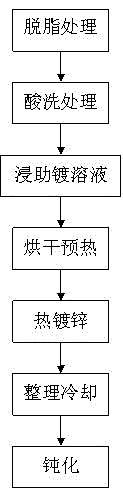

Surface galvanizing technology for guide hook of drop-out fuse

InactiveCN102912274AAvoid excessive corrosionImprove surface activityHot-dipping/immersion processesEvaporationEngineering

The invention discloses a surface galvanizing technology for a guide hook of a drop-out fuse, comprising the following steps: 1) ungrease treatment; 2) cleanup acid treatment; 3) plating solubilizing assistant immersion; 4) drying prewarming; 5) hot galvanizing; 6) finishing cooling; and 7) passivating. According to the technology, a corrosion inhibitor is added to acid cleaning liquor so that the over corrosion when the guide hook is acid-cleaned can be prevented and the hydrogen absorption amount of an iron substrate is reduced; a small amount of glycerin is added to plating solubilizing assistant so that the activity of the surface of the guide hook can be promoted and the evaporation of the plating solubilizing assistant is reduced; and tiny metallic aluminium is added to galvanizing flux so that the flowing of the galvanizing flux can be strengthened, the over thickness of a cladding layer is prevented and the appearance of the cladding layer is improved. Through the technology, the guide hook of the drop-out fuse can achieve the cladding layer with good uniformity; the cladding layer is not easy to drop out and has good tenacity, elasticity, abrasion resistance and corrosion resistance; and the cladding layer is incapable of becoming rusty under outdoor conditions.

Owner:CHANGSHU QIANGSHENG PUNCHING

Method of preparing PCB with improvement on back hole drilling burrs and small crimping hole

ActiveCN110430677AAvoid too thickPrevent small hidden dangersMultilayer circuit manufacturePrinted element electric connection formationCopper platingTin plating

The invention relates to the technical field of printed circuit boards, in particular to a method of preparing a PCB with improvement on back hole drilling burrs and a small crimping hole. The production design requirements are met by one-time electroplating to the thickness of the hole copper during the whole plate electroplating, a pattern electroplating process in a positive film process is correspondingly changed, only tin plating rather than copper plating is performed at a window opening, over thick hole copper in a crimping hole (part of a second through hole) by electroplating in the case of pattern electroplating can thus be avoided, the crimping hole copper thickness is not affected by the pattern electroplating process, and the hidden danger that over thick hole copper in the crimping hole to result in a small crimping hole can be effectively prevented. Besides, etching processing is carried out after back drilling, the aperture burrs formed at the aperture in the case of back drilling can be removed, and thus, through the method disclosed in the invention, the problems of the aperture burrs of the back drilling hole and the problem of a small crimping hole can be improved at the same time.

Owner:珠海崇达电路技术有限公司

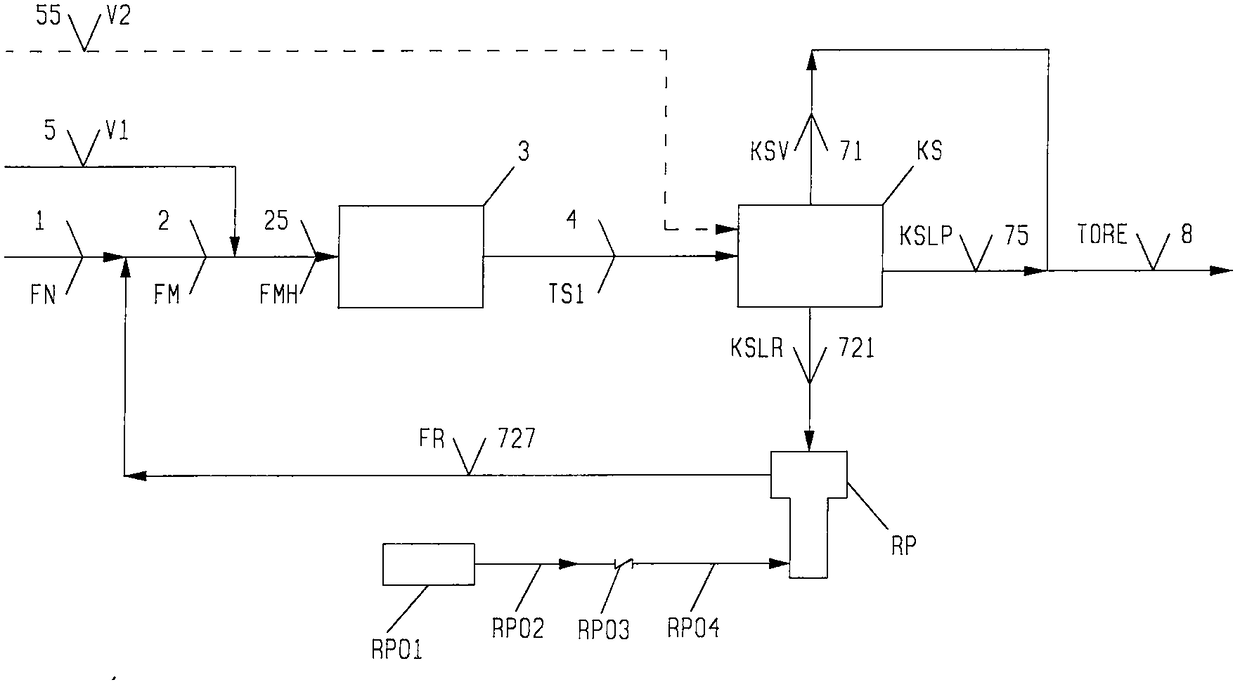

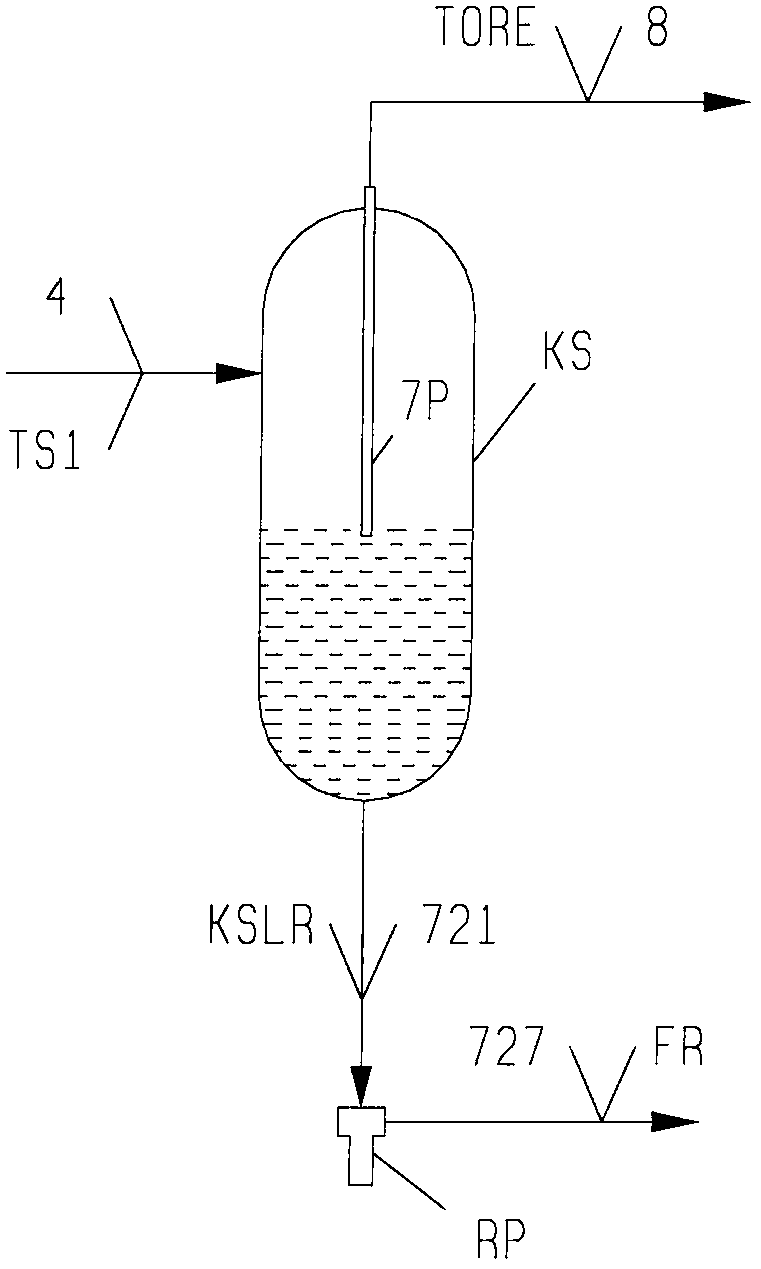

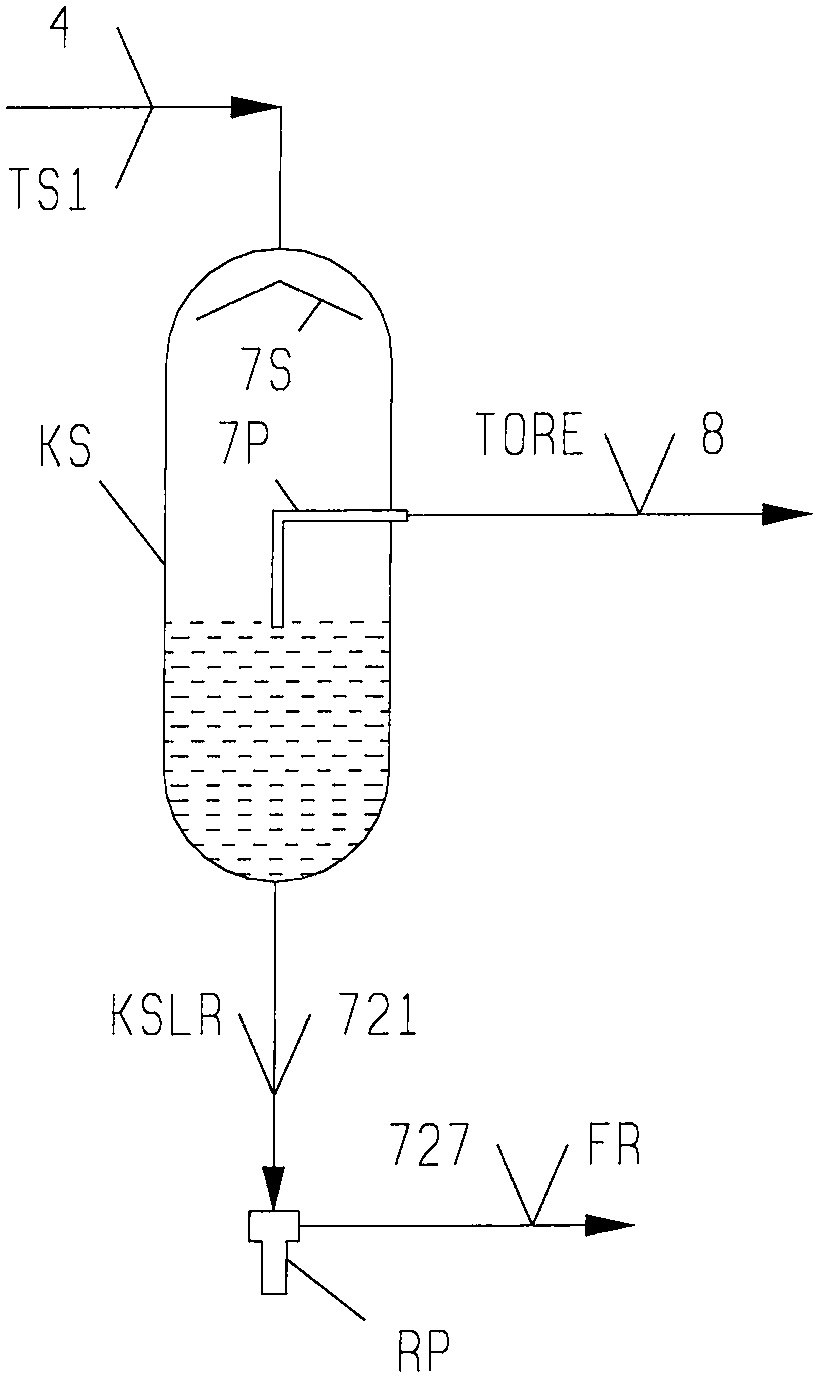

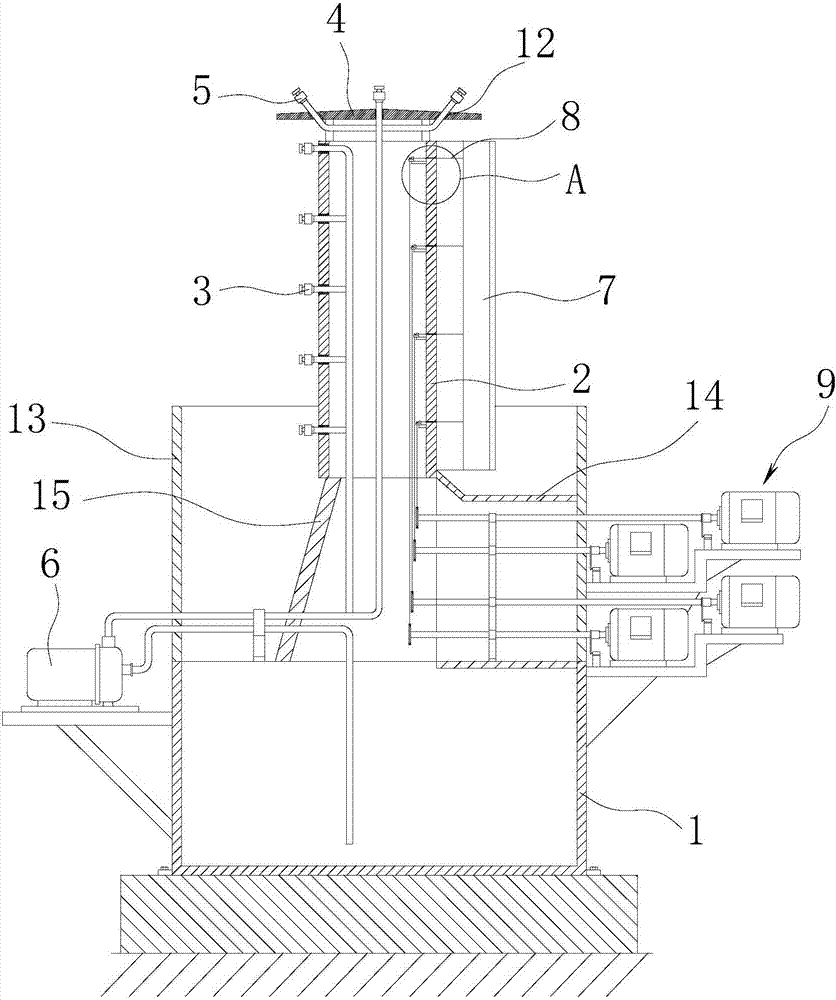

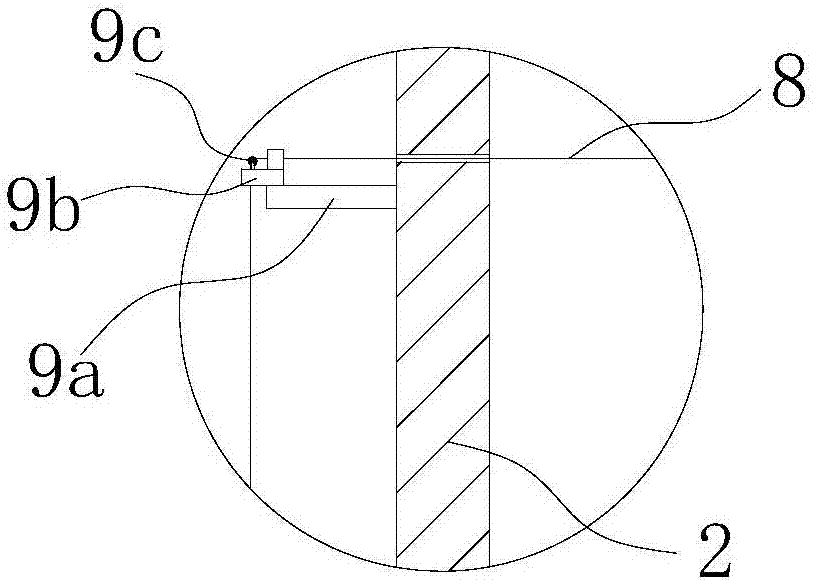

Desolventizing humidifier

ActiveCN102899160AImprove recycling ratesIncrease humidityFatty-oils/fats refiningFatty-oils/fats productionEngineeringSolvent

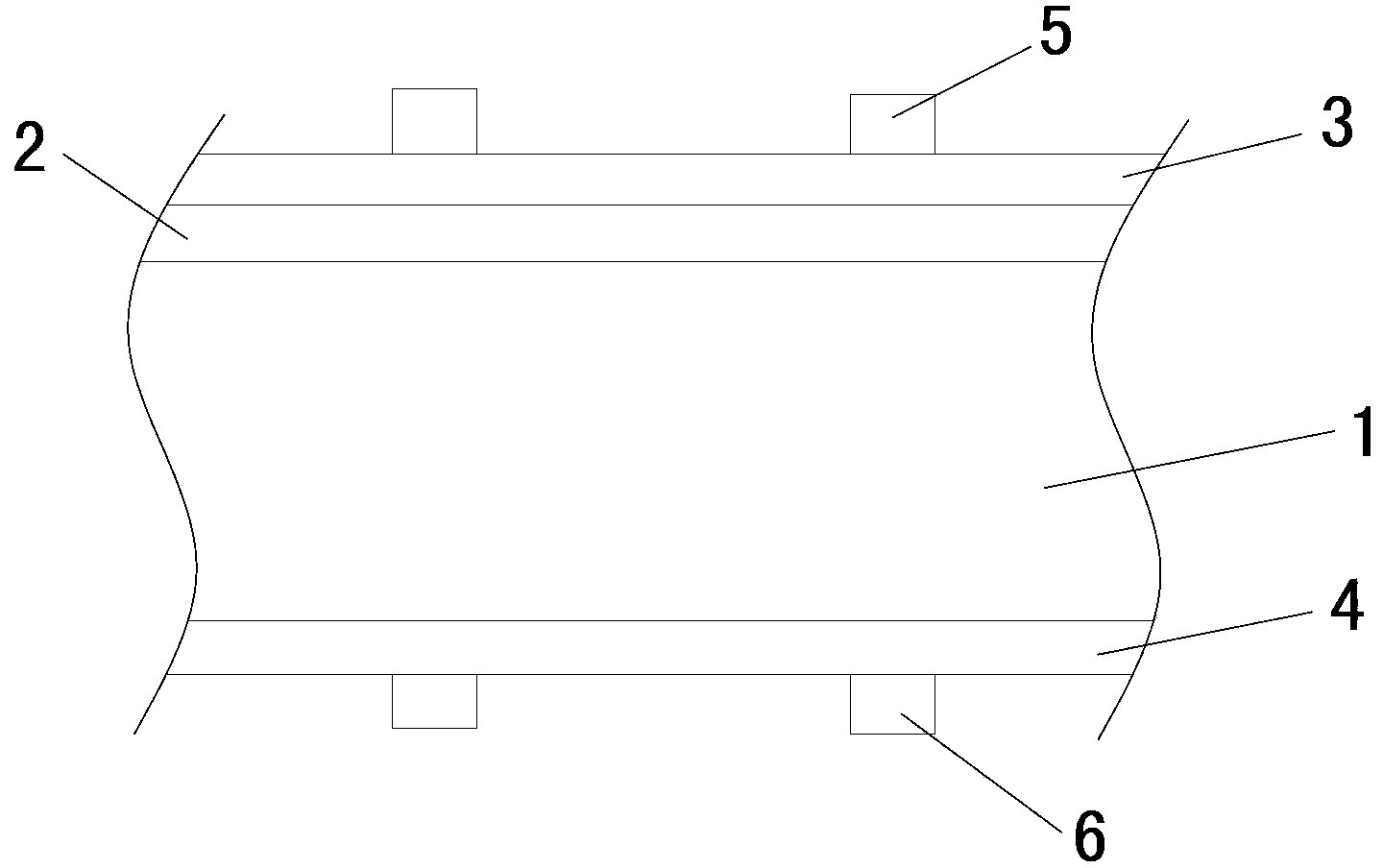

The invention provides a desolventizing humidifier which comprises a tank body, multi-layer sieve plates, a steam plywood case I and a discharge device. The multi-layer sieve plates are fixed in the tank body, the steam plywood case I is fixed on the tank body and arranged at the bottoms of the multi-layer sieve plates, and the discharge device is arranged in the tank body. The tank body comprises a steam outlet, a feed port and a discharge port, wherein the steam outlet is arranged at the top, the feed port is connected with a feed device, and the discharge port is arranged at the bottom of the tank body. The discharge device comprises a vertical shaft arranged in the center of the tank body and a drive mechanism driving the vertical shaft to rotate. A distribution device, scraper boards, a harrow rod I and a harrow rod III are fixed successively on the vertical shaft from top to bottom. The scraper boards are arranged above and matched with the multi-layer sieve plates, the harrow rod I is introversive and arranged above and matched with the steam plywood case I, and the harrow rod III is extroversive and arranged above and matched with the tank body bottom. Steam is fed into the steam plywood case I, and steam outlets are arranged on the upper portion of the steam plywood case I. Compared with the prior art, the desolventizing humidifier has the advantages of being high in solvent recovery rate and dephenolized cottonseed protein quality.

Owner:济南中棉生物科技有限公司 +1

Crystalline silicon solar cell and manufacturing method thereof

InactiveCN103390675AImprove efficiencyImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationScreen printingCopper

The invention provides a crystalline silicon solar cell and a manufacturing method of the crystalline silicon solar cell. The manufacturing method includes the steps that a crystalline silicon slice with PN junctions is used as a substrate, two layers of transparent conducting thin films are deposited on the front and the back of the substrate respectively, and electroplating copper grid line electrodes are arranged on the transparent conducting thin films on the front and the back of the substrate respectively. According to the crystalline silicon solar cell and the manufacturing method of the crystalline silicon solar cell, SiNx is replaced by TCO, and silk-screen printing silver grid lines are replaced by electroplating copper. Due to the fact that the silk-screen printing silver grid lines are replaced by the electroplating copper, electrode grid lines can be more exquisite, smaller in light shielding area, and lower in cost because silver is replaced by copper. Due to the fact that the TCO has high light transparency and electrical conductivity, antireflective films and the inactivation effect of the SiNx can be replaced, a certain effect for collecting current is achieved, the number of the grid lines can be reduced, more importantly, the electroplating copper can be resisted from infiltrating into silicon, and the defects in the process of directly electroplating copper on a silicon cell are overcome. In addition, cost of TCO production equipment is far lower than cost of SiNx production equipment. The TCO and the electroplating copper are combined, therefore, manufacturing cost is low, the preparing process is simple, and efficiency of the cell can be effectively improved.

Owner:上海太阳能工程技术研究中心有限公司

Manufacturing method of HDI plate back drilling hole

InactiveCN111107715AOptimize the production processReduce the problem of draped copper wireConductive material chemical/electrolytical removalCircuit precursor manufactureElectroless platingCopper wire

The invention discloses a manufacturing method of an HDI plate back drilling hole. The method comprises the steps that a production board is drilled, drilled holes comprise a through hole needing backdrilling, and the through hole is metalized through electroless plating copper; a layer of thin copper is flash-plated on the production board through full-board electroplating, wherein the thicknessof a thin copper layer formed during flash-plating is 5 to 8 microns; tin is electroplated on the production board to enable the board surface copper layer and the hole copper to be covered by the tin layer; depth-controlled back drilling is carried out on the through hole needing back drilling according to the design requirement, so that the copper layer at the back drilling part in the throughhole is removed, and a stepped back drilling hole is formed; acid etching treatment is carried out on the production board, and tin is removed; and full-board electroplating treatment is carried out on the production board, and the board surface copper layer and the hole copper are plated to the thickness required by the design. According to the method, by optimizing the production technological process, the problem that a conventional etching process cannot solve the problem of hole blocking of a back drilling burr copper wire is effectively solved; back drilling manufacturing of the HDI plate is achieved; and the percent of pass is high.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Embedded stirring and rubbing slit welding method

InactiveCN102120287BImprove bindingAvoid too thickNon-electric welding apparatusNeedle freeEngineering

The invention discloses an embedded stirring and rubbing slit welding method for dissimilar metals, which is especially suitable for large-area lap connection of aluminum or magnesium or harder metal materials. The embedded stirring and rubbing slit welding method comprises the steps of: firstly, processing one or more dovetail grooves on a second harder base material; secondly, assembling according to a lap connection form, and placing an aluminum plate on the upper sides of the dovetail grooves of the second harder base material; using a needle-free stirring head and installing in an inclining manner; starting the stirring head to rotate and enabling the stirring head to be in contact with the upper surface of the aluminum plate, wherein the pressing depth of the stirring head is limited to about between 0.1mm and 2mm and a welding interface needs not to be penetrated; after rubbing and preheating for several seconds at the starting end, moving the rotating stirring head or operating platform so that the aluminum plate is helically extruded in a groove of a lower plate and the welding or cladding is completed. Compared with the resistance slit welding, the method disclosed by the invention has remarkable energy saving advantage. Compared with the traditional stirring rubbing welding, the method disclosed by the invention has the advantages of no keyhole and no abrasion to needles by the harder base material. The method can be used for welding, and can also be used for preparing a bimetal composite plate.

Owner:西安英特金属复合材料有限公司

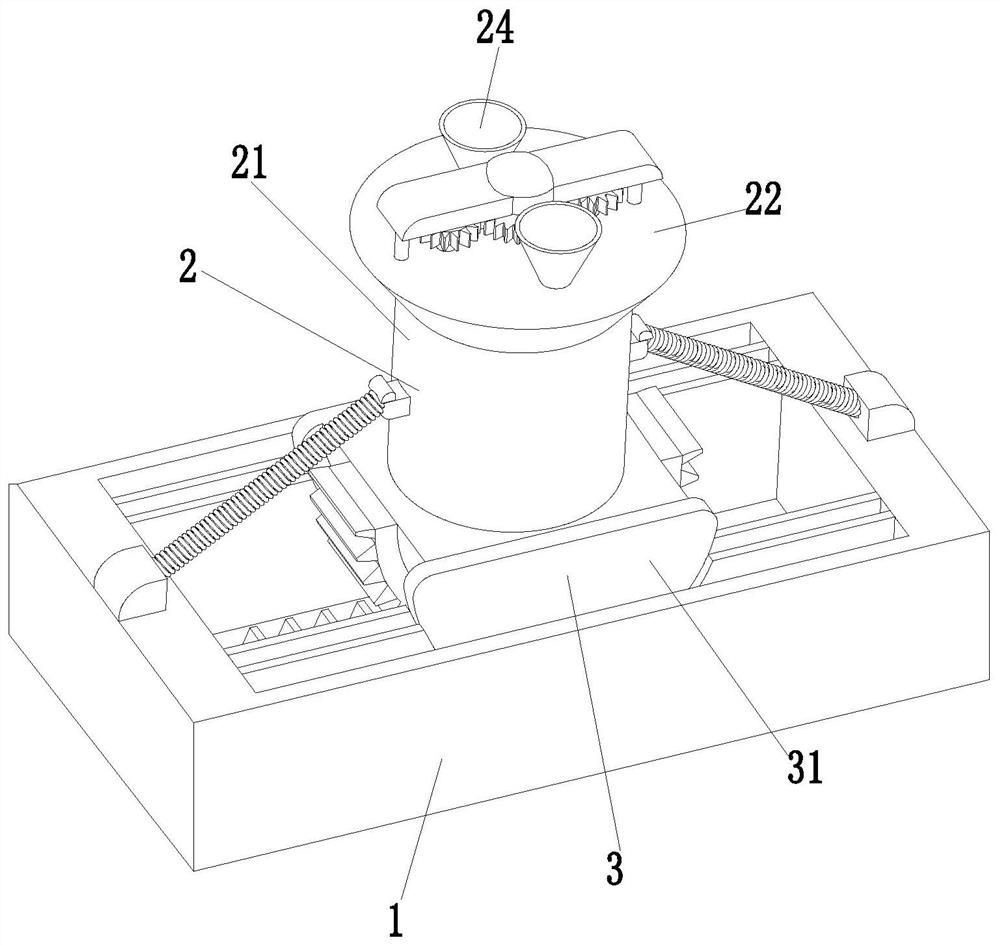

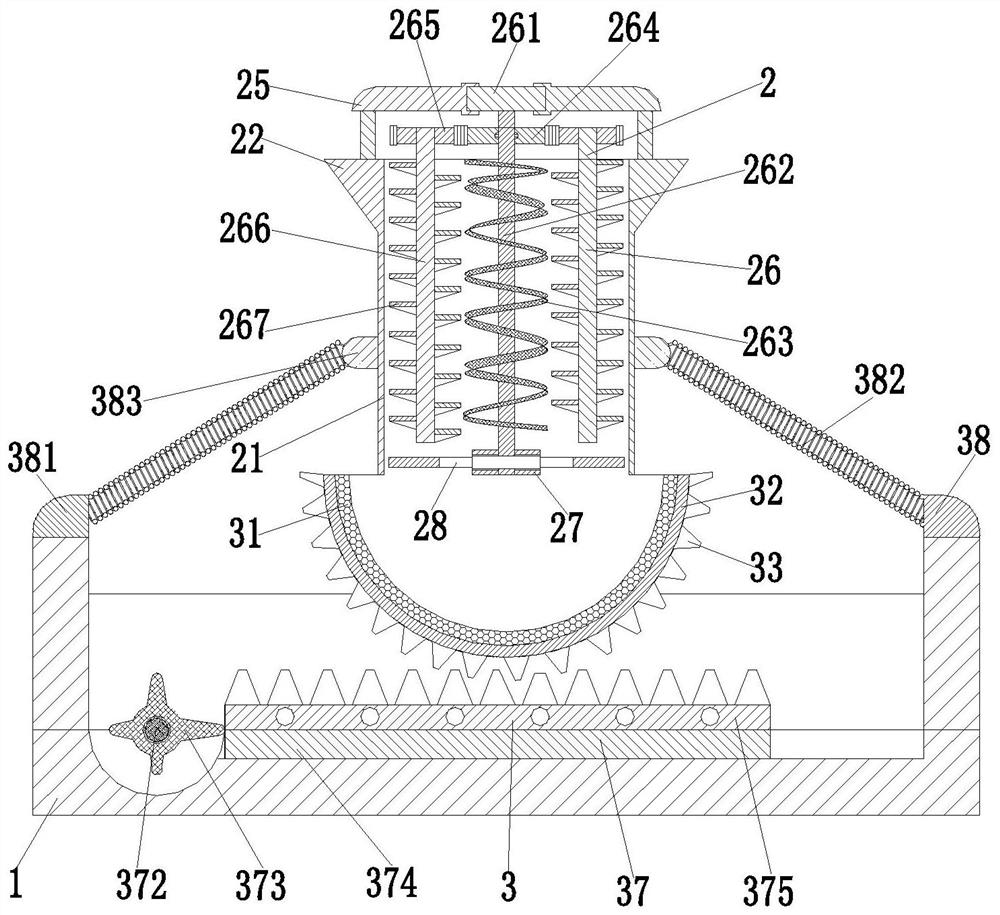

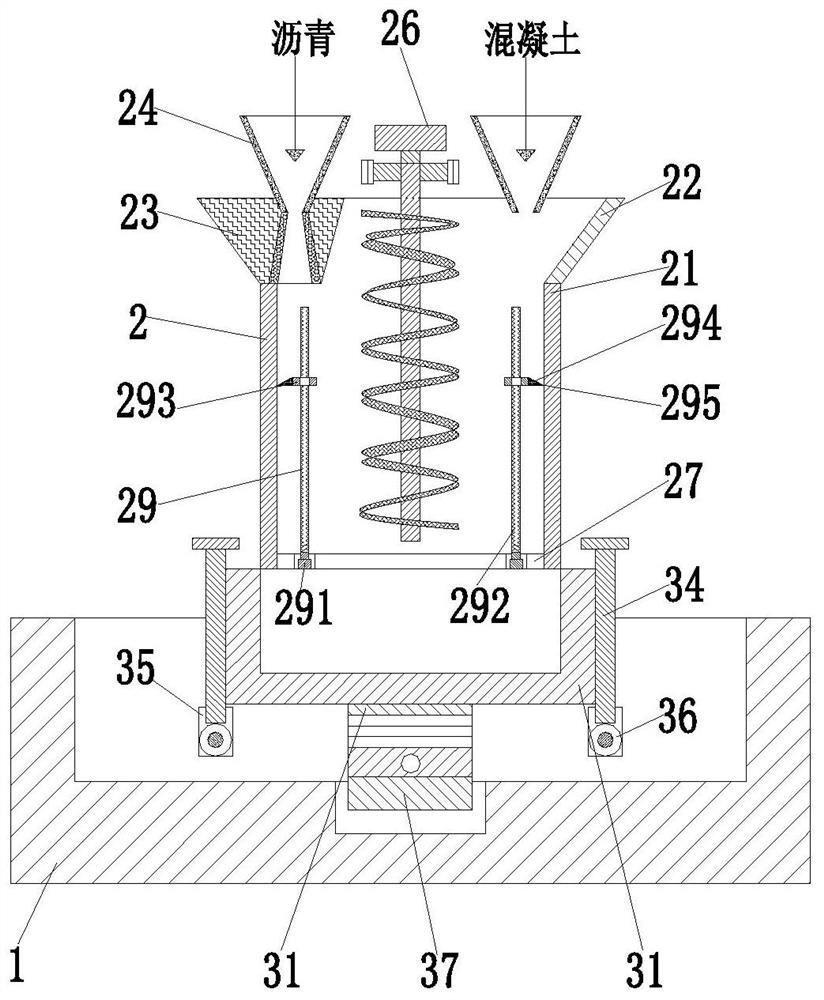

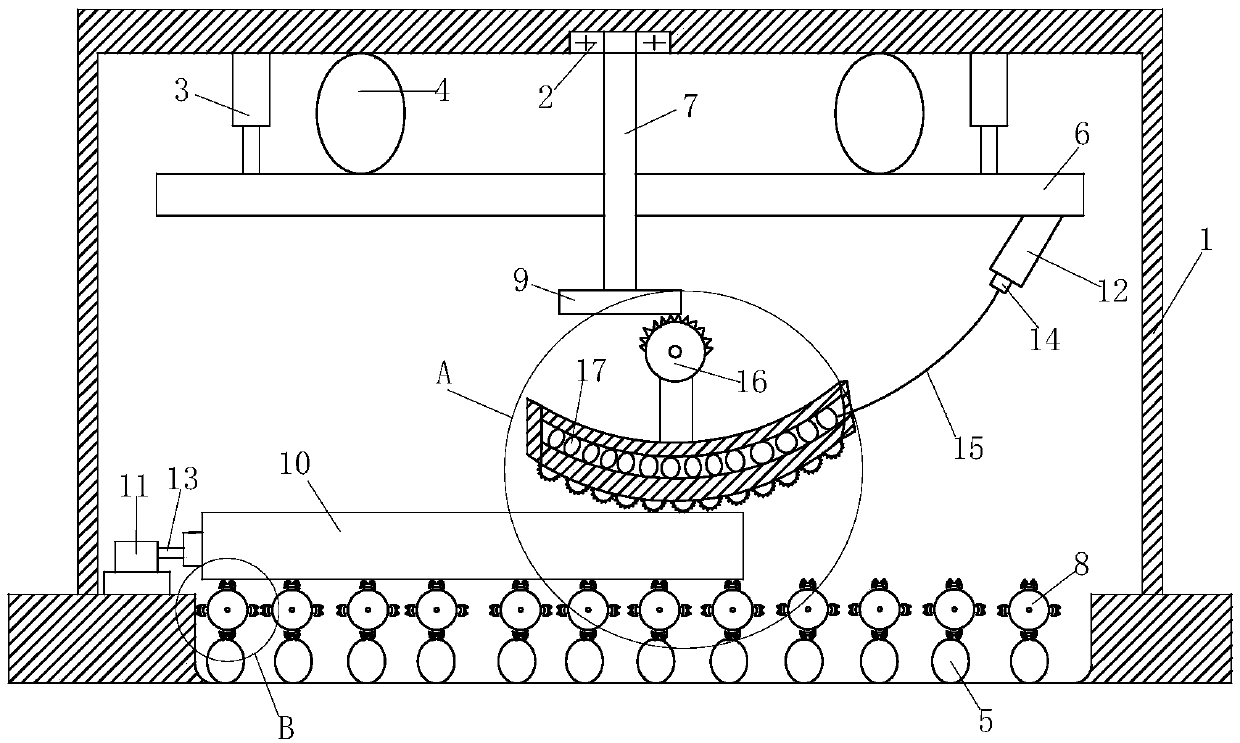

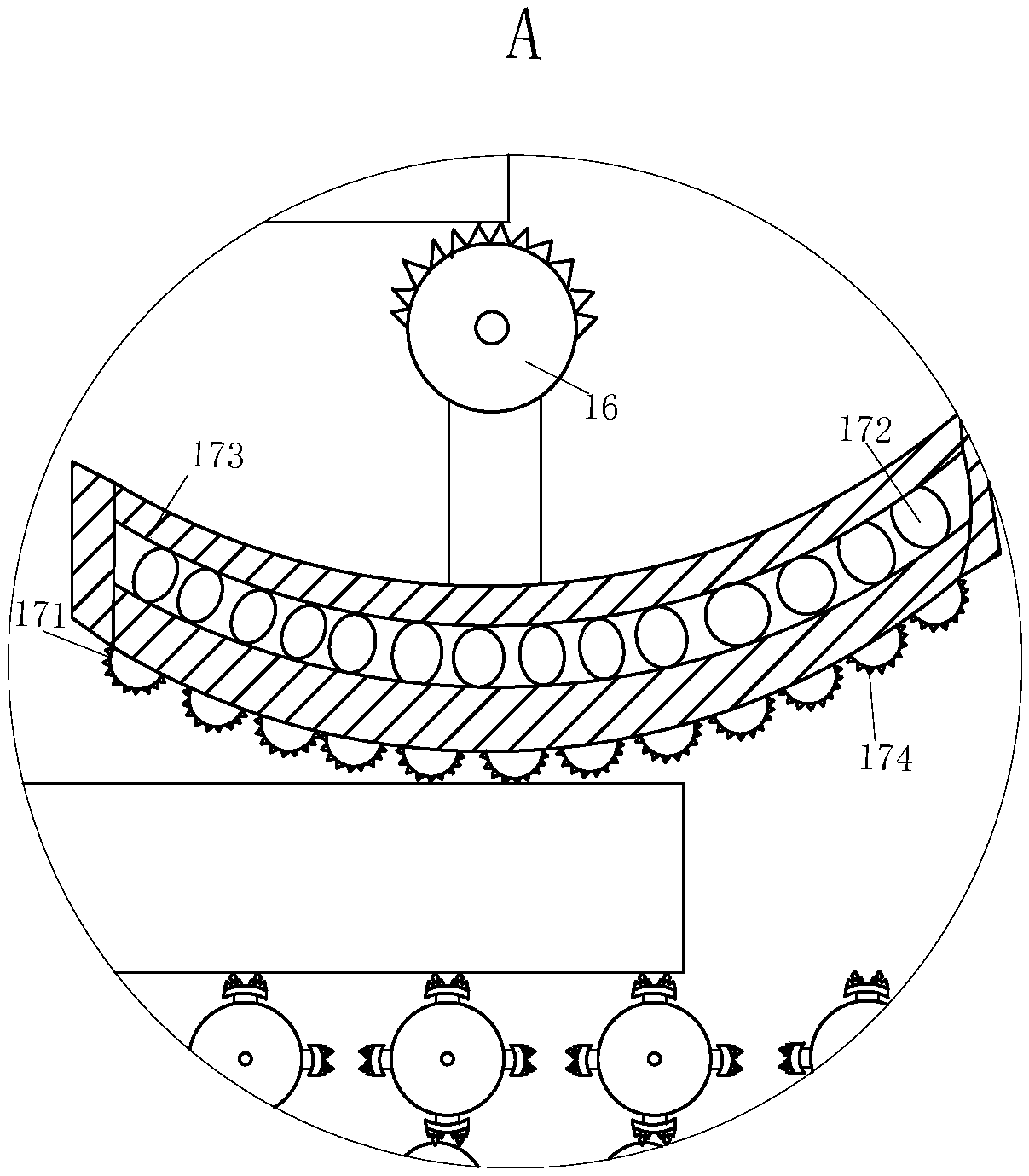

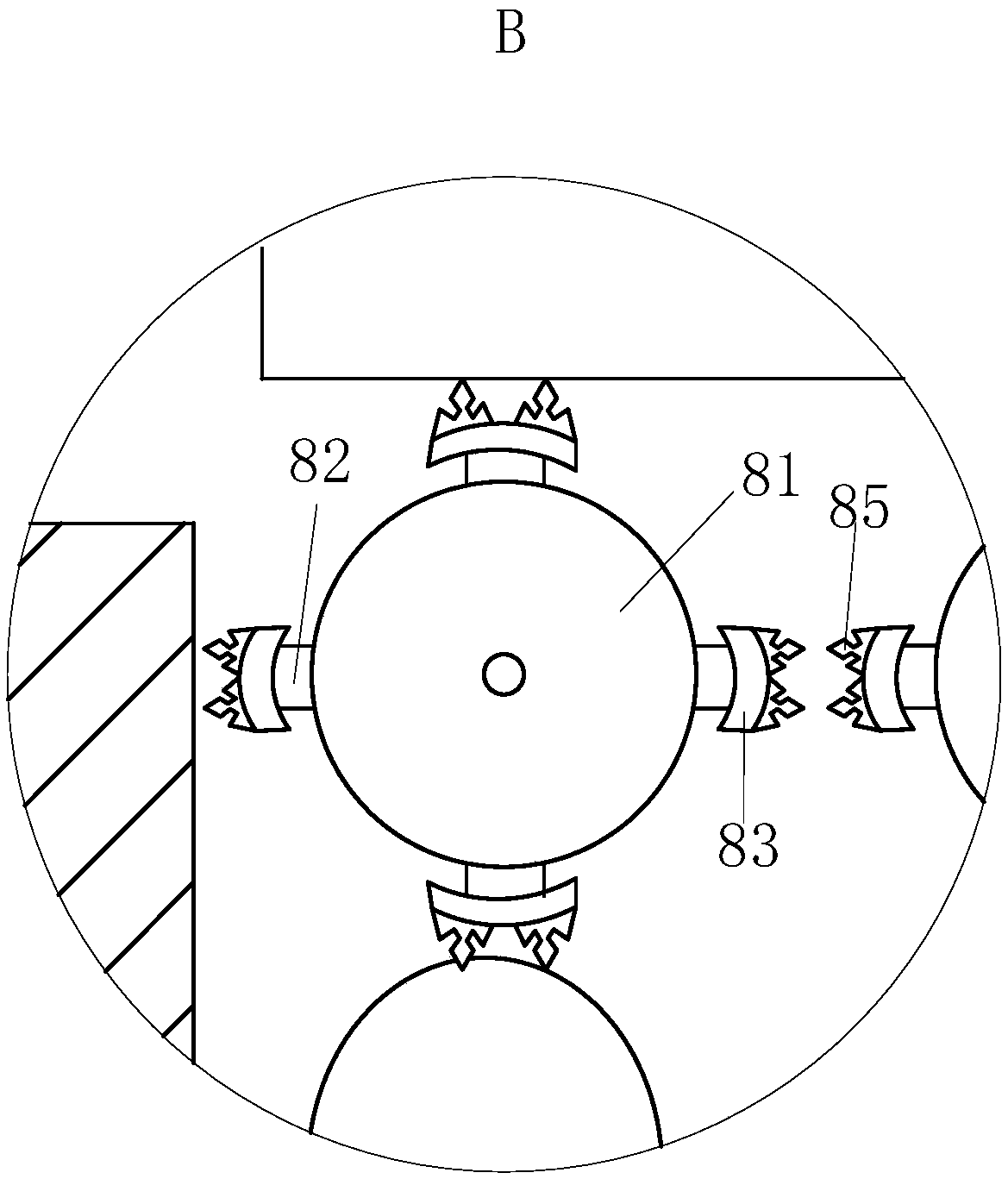

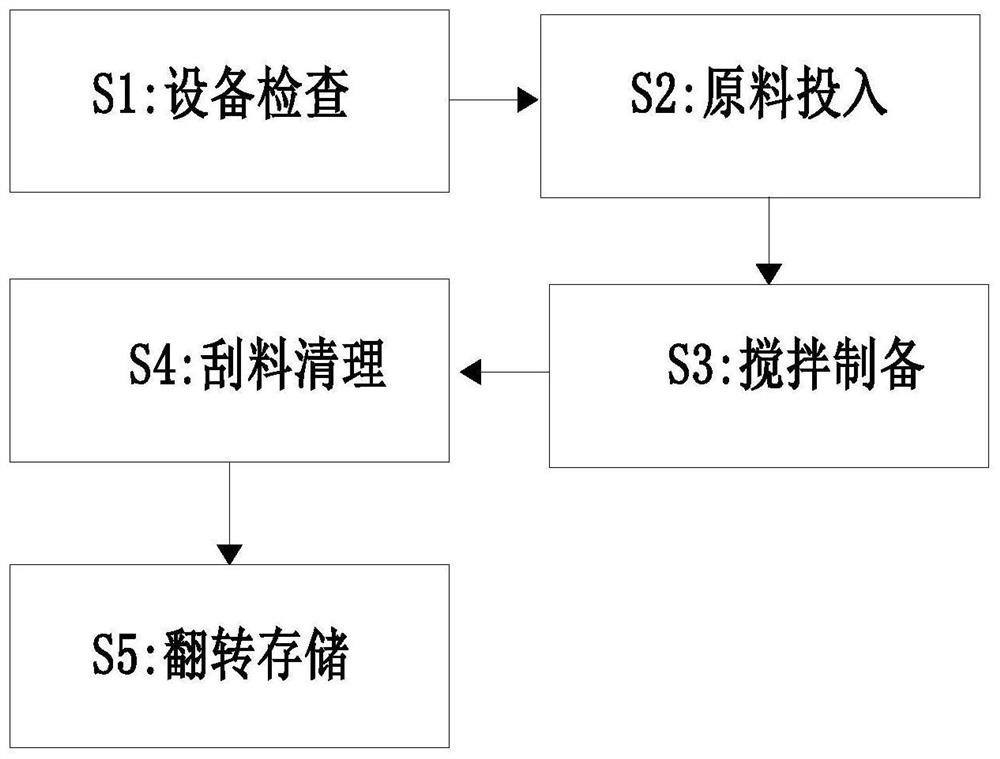

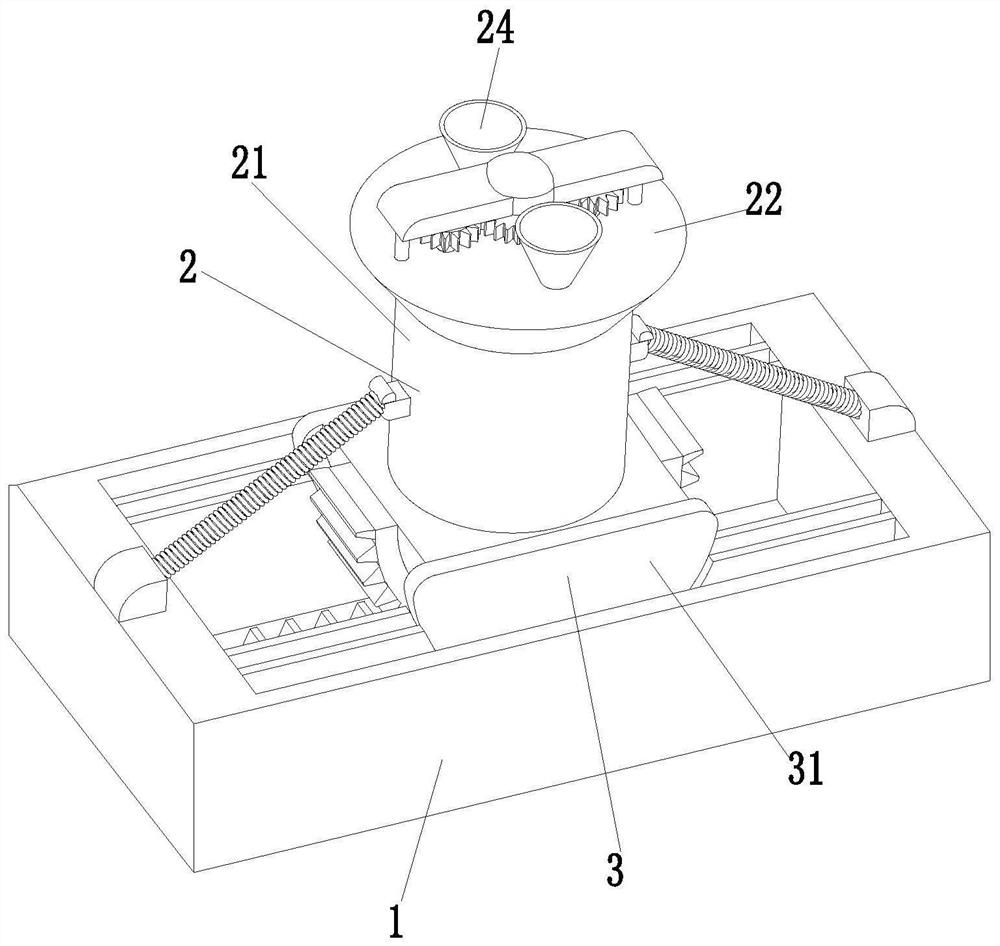

Asphalt concrete preparation system

ActiveCN111976001AIncrease viscosityQuality improvementMixing operation control apparatusHollow article cleaningStructural engineeringBituminous concrete

The invention relates to an asphalt concrete preparation system. The asphalt concrete preparation system comprises a supporting seat, a stirring mechanism and a turnover mechanism, wherein the supporting seat is of a box body structure with an upward opening, the stirring mechanism is arranged in the middle of the supporting seat, and the turnover mechanism is installed at the lower end of the stirring mechanism. The asphalt concrete preparation system can solve the problems that when an existing asphalt concrete preparation device is used for feeding asphalt raw materials, asphalt cannot be heated and emulsified, the asphalt raw materials and concrete raw materials cannot be thoroughly and uniformly stirred, the grading ratio of the asphalt to concrete is influenced, then the viscosity ofthe formed asphalt concrete is influenced, the inner wall of a stirring kettle cannot be scraped and cleaned in time, stirring blades are prone to adhering to solidified asphalt, so that a thick asphalt layer can be accumulated after long-time use, the stirring quality of the asphalt concrete is influenced, the stirring and mixing efficiency is low, and the use quality of the asphalt concrete isinfluenced.

Owner:浙江龙游九坤沥青混凝土有限公司

Multi-head glue spraying device for sand mold casting

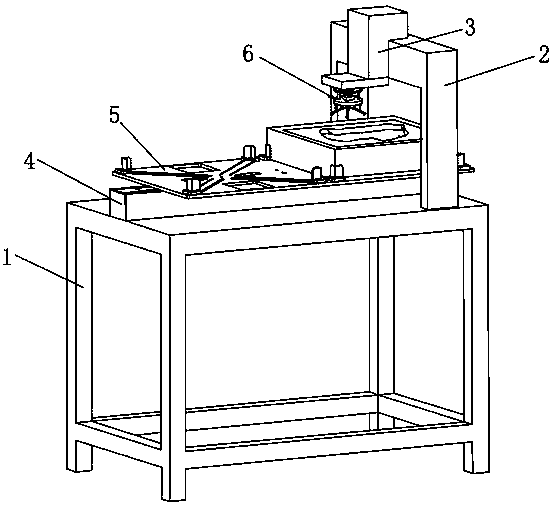

The invention discloses a multi-head glue spraying device for sand mold casting. The multi-head glue spraying device for sand mold casting comprises a rack, a portal frame is arranged on the rack, a sliding block is arranged on the portal frame, a linear conveying sliding table is arranged on the rack, a multi-head glue spraying mechanism is arranged at the bottom of the sliding block, the multi-head glue spraying mechanism comprises a rotating seat which is arranged at the bottom of the sliding block, an upper base plate is arranged at the bottom of the rotating seat, a lower base plate is arranged below the upper base plate, a plurality of positioning rods are arranged between the upper base plate and the lower base plate; and a vertically-downward stroke sleeve is arranged in the middleof the lower base plate, a movable rod is arranged in the stroke sleeve, a lifting disc is arranged at the bottom of the movable rod, a plurality of first linkage frames and second linkage frames arearranged between upper base plates of the lifting disc, first atomization glue spraying heads are arranged on the first linkage frames, and second atomization glue spraying heads are arranged on thesecond linkage frames. According to the multi-head glue spraying device for sand mold casting, spraying an inner cavity of a sand mold is carried out through the multi-head glue spraying mechanism, and the multi-head glue spraying device has the characteristics of being wide in spraying face and uniform in spraying.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

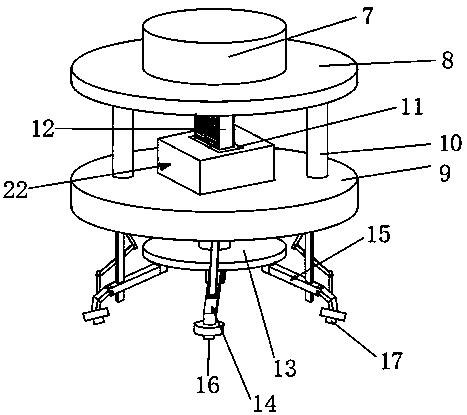

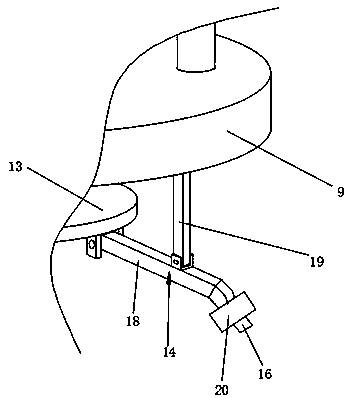

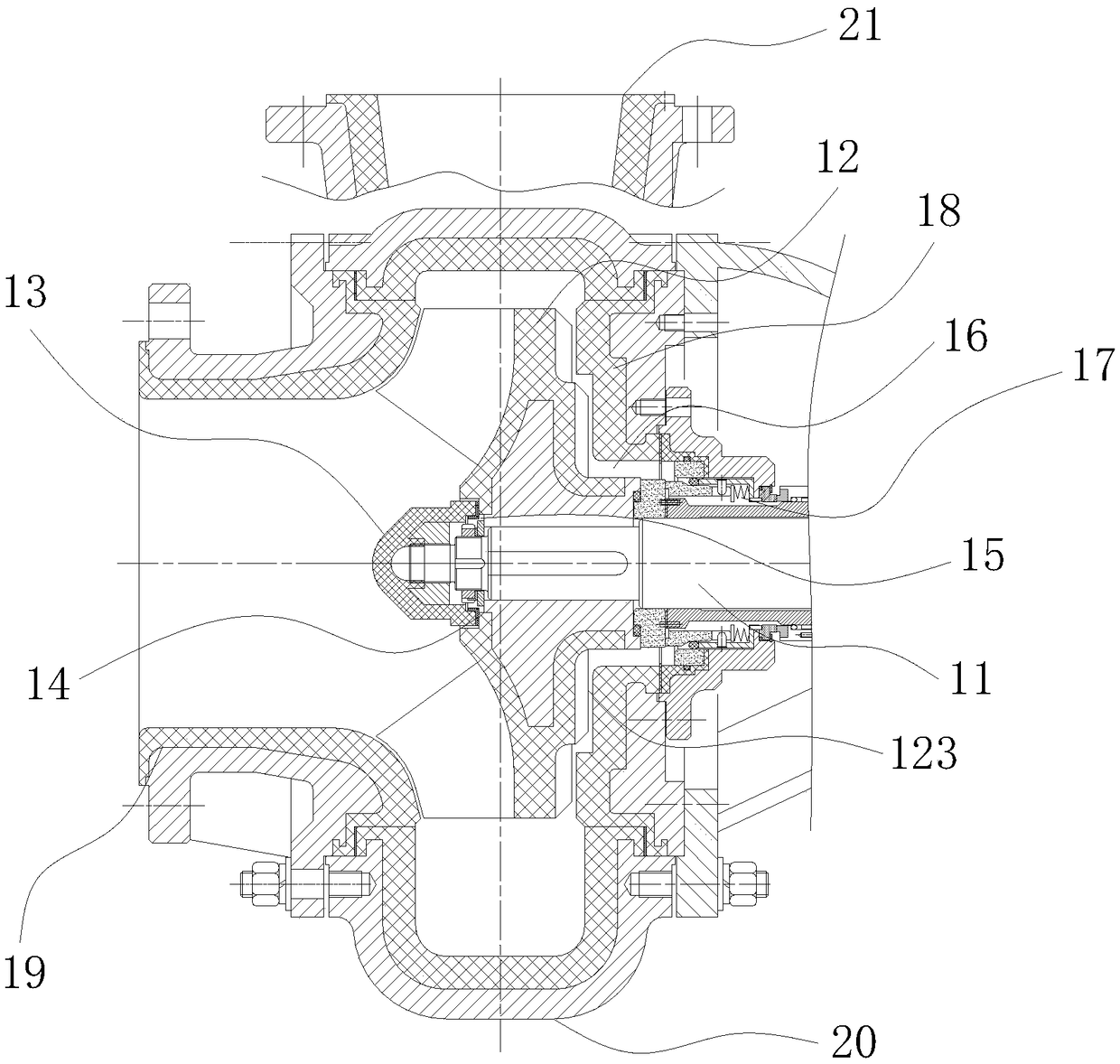

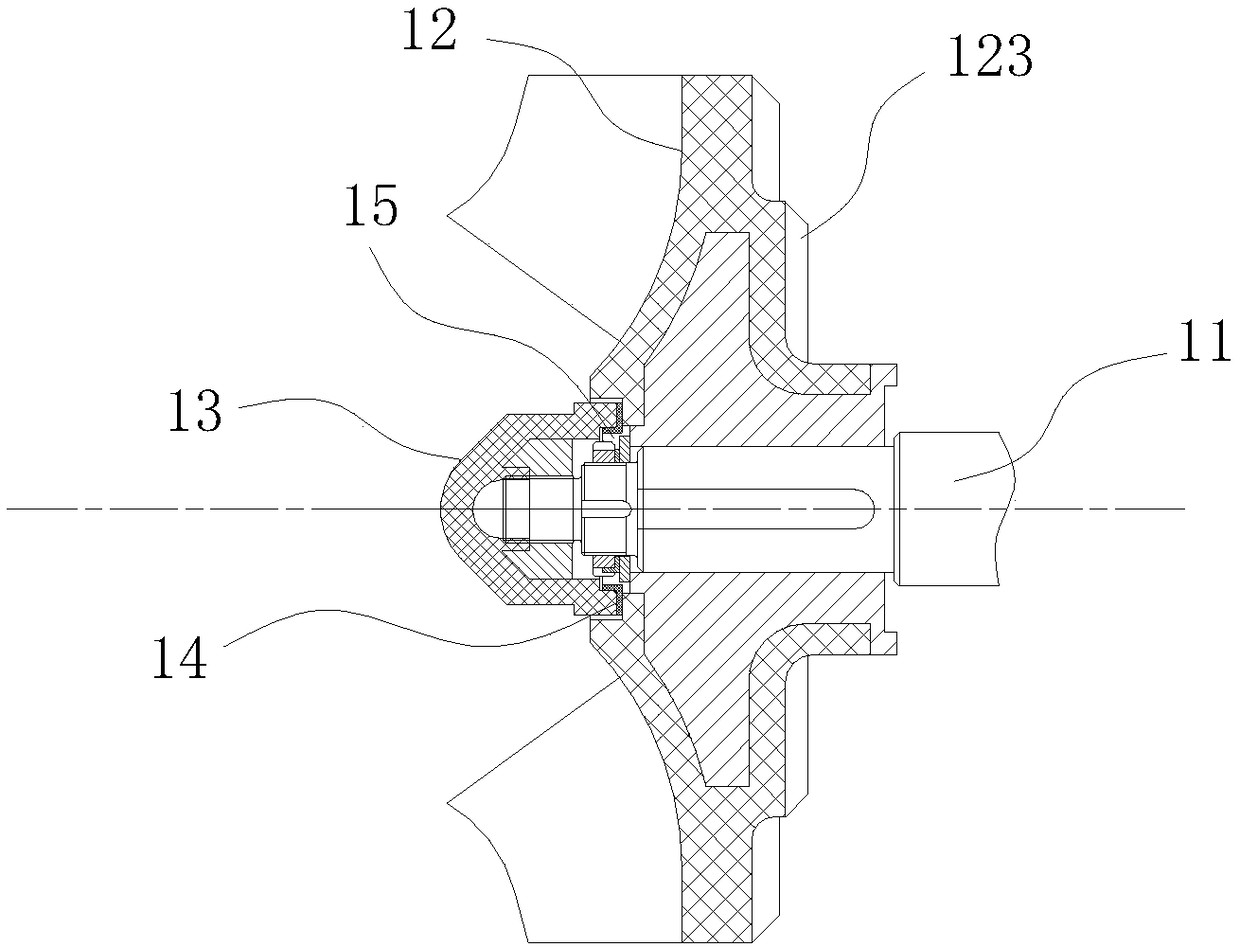

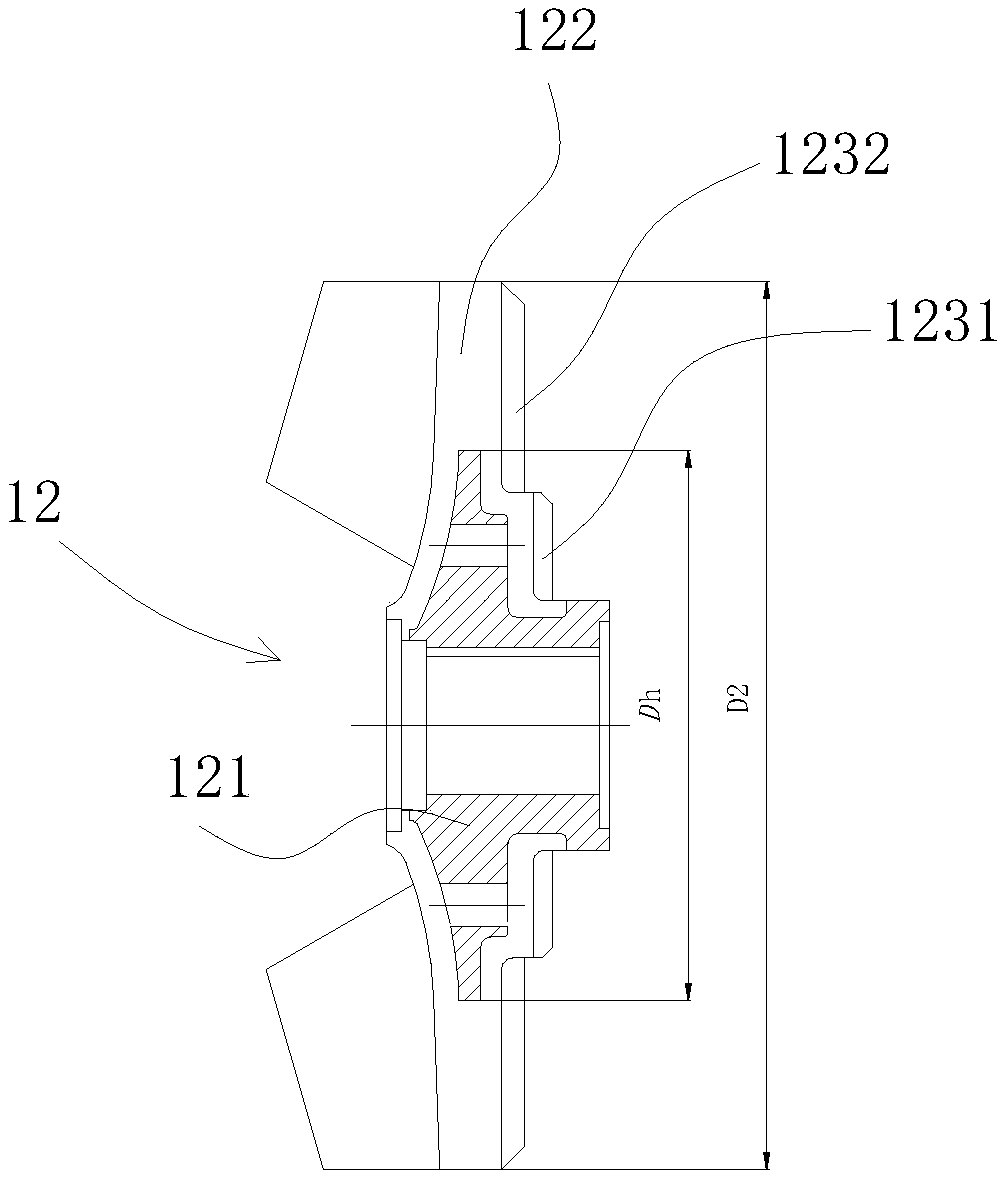

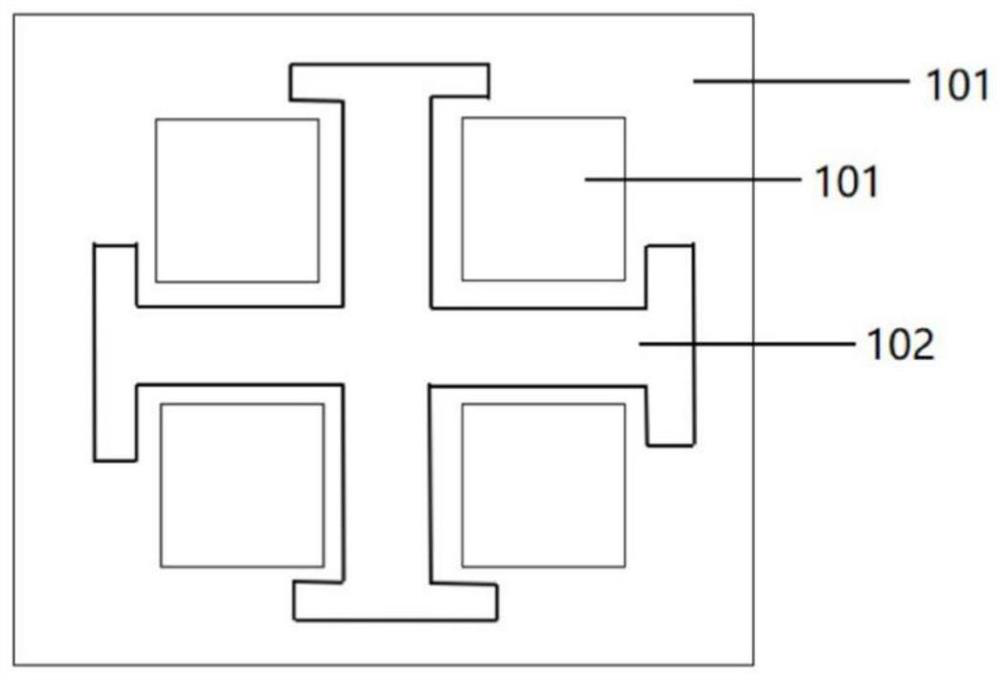

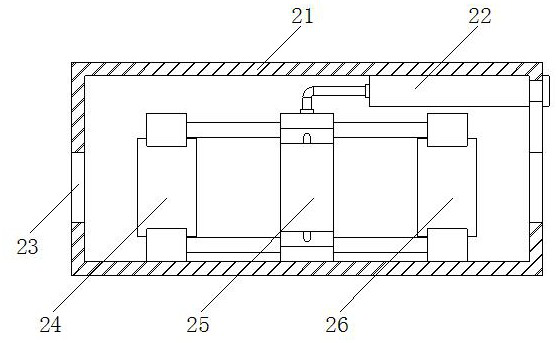

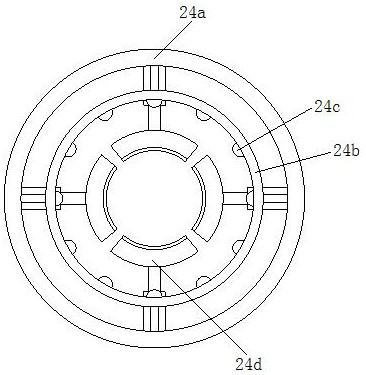

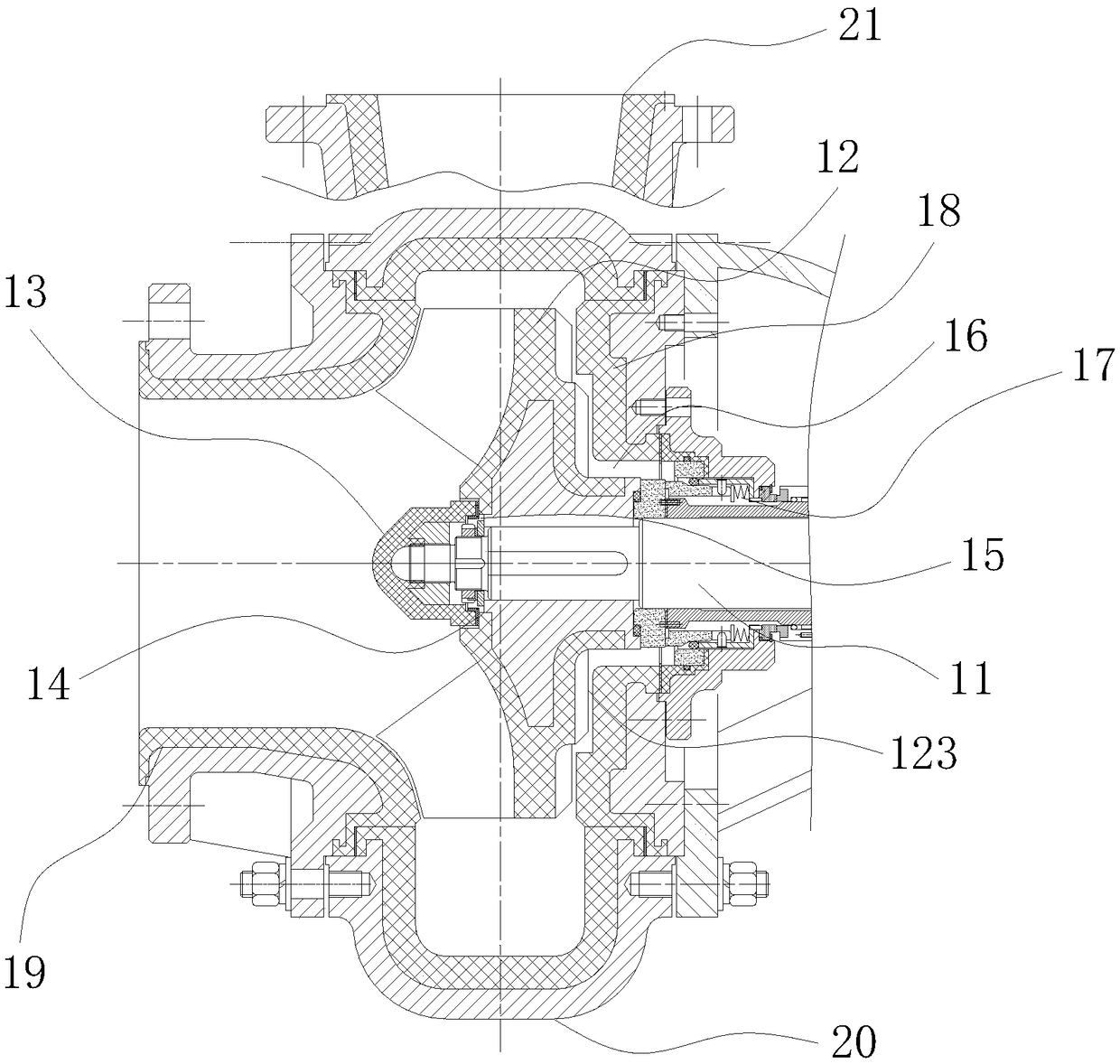

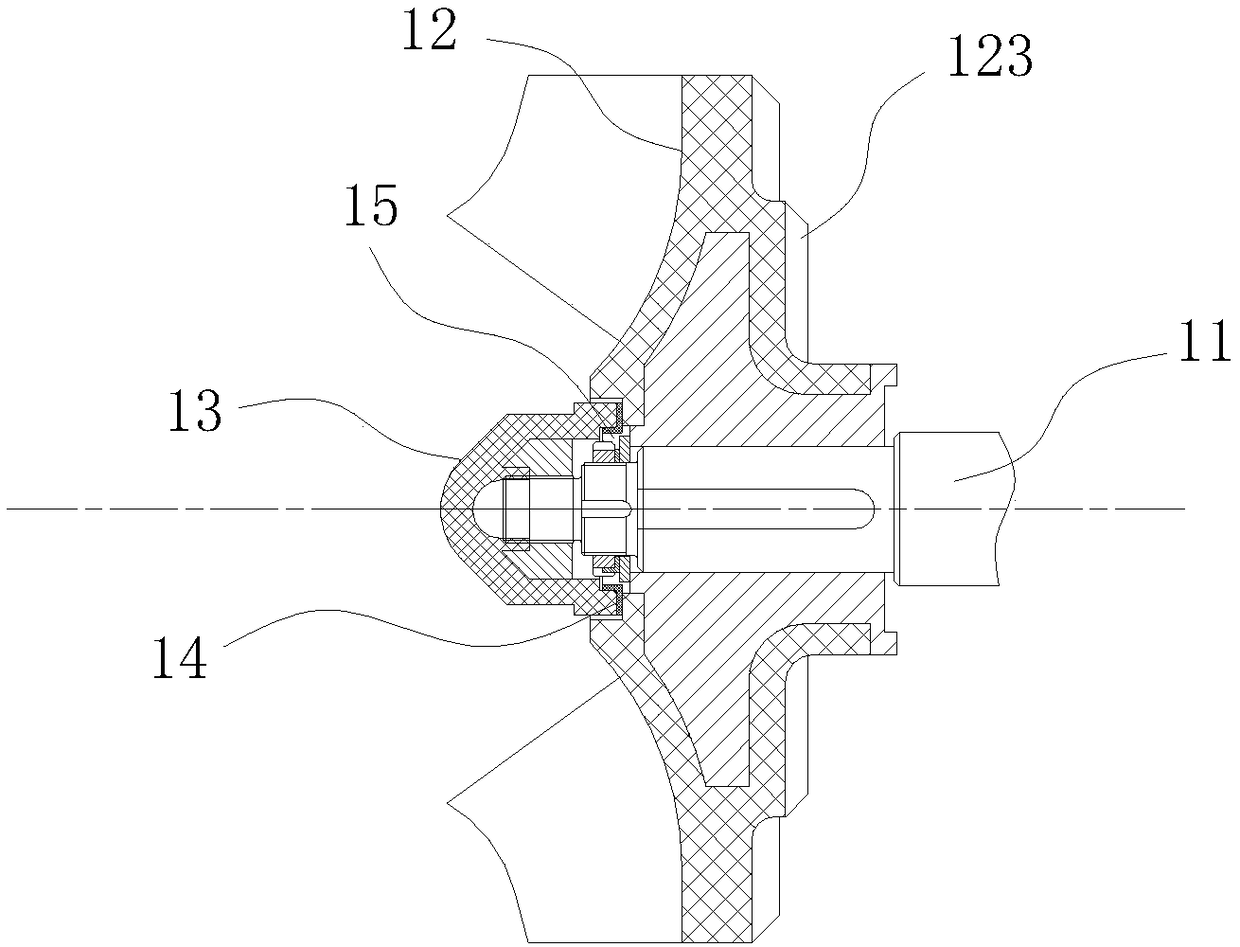

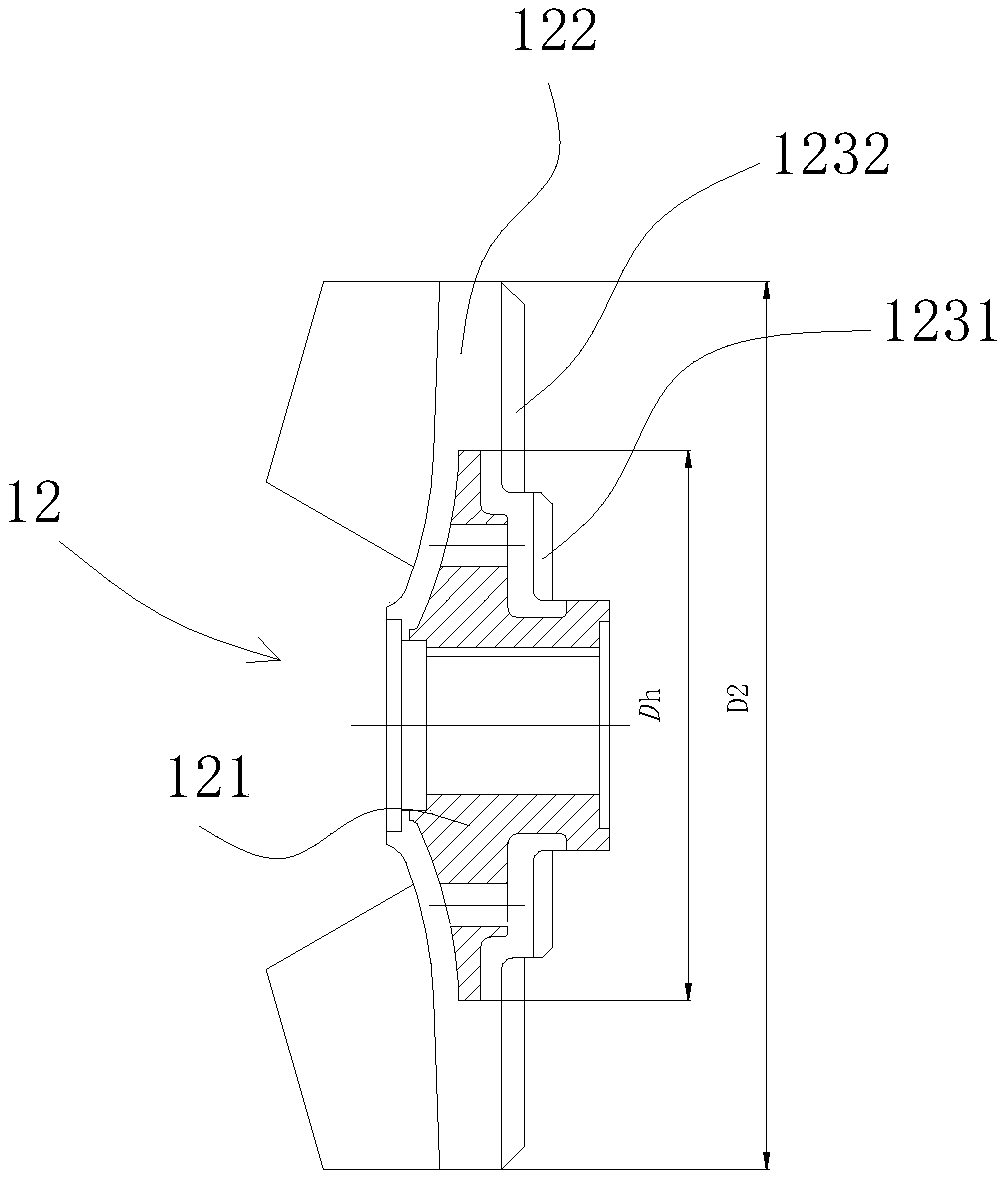

Desulphurization pump with combined impeller rotor

PendingCN109386497AEasy to install and removeLight weightSpecific fluid pumpsPump componentsImpellerCorrosion

The invention relates to a desulphurization pump with a combined impeller rotor. The desulphurization pump comprises the combined impeller rotor, a pump case, a pump inlet part, a pump outlet part anda pump back cover plate, wherein the pump inlet part, the pump outlet part and the pump back cover plate are installed on the pump case to form a pump cavity for containing the combined impeller rotor in an enclosure manner; the combined impeller rotor comprises an impeller body installed on a pump shaft, the impeller body comprises a metal hub lining and a nonmetal blade lining body with which the peripheral surface of the metal hub lining is wrapped in a compression-molding manner, and the nonmetal blade lining body is made from an ultrahigh molecular weight polyethylene material. Accordingto the desulphurization pump with the combined impeller rotor, the deadweight of the impeller body is reduced, and the material cost is saved; in addition, the strength of the impeller body is also guaranteed while it is avoided that the impeller rotor is too thick; the impeller body is resistant to wear and corrosion, and a vibration value of the pump can be reduced; meanwhile, processing is easy, the cost is low, and the running efficiency of the pump is greatly improved.

Owner:HEFEI UNIV OF TECH +1

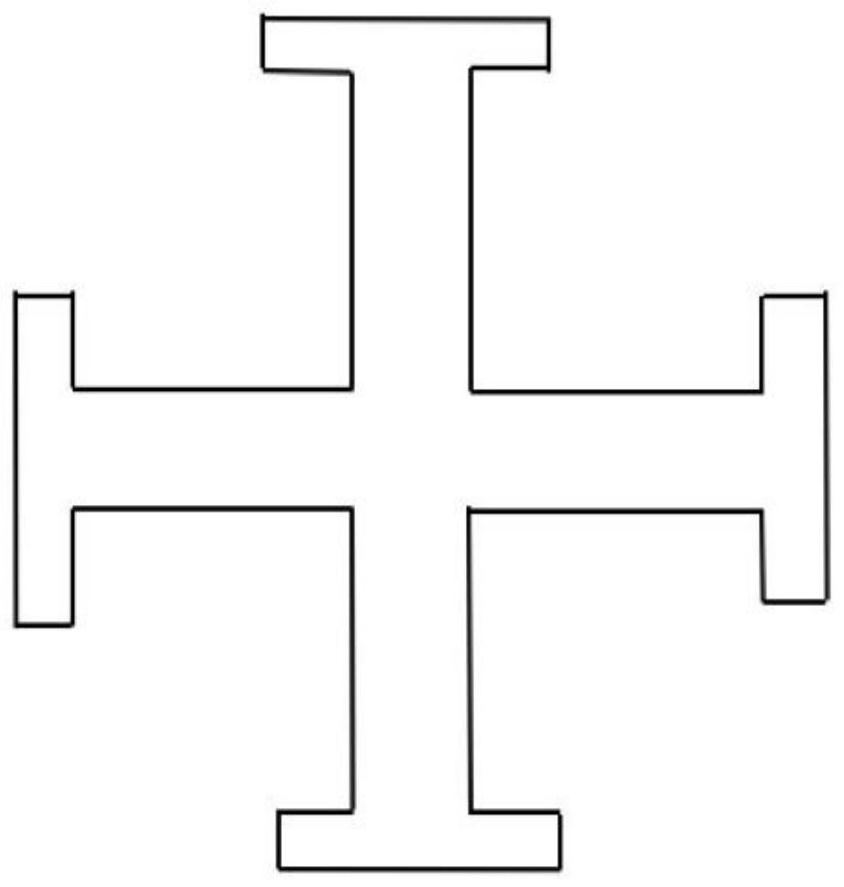

Diamond/block copper substrate diffusion bonding process and structure based on diamond indirect stretching structure

ActiveCN114367730AUniform thicknessAvoid too thickNon-electric welding apparatusBonding processAlloy

The invention discloses a diamond / block copper substrate diffusion bonding process and structure based on a diamond indirect stretching structure. The structure mainly comprises a cuboid block copper substrate, and a three-dimensional diamond film which is arranged in an array mode and is in a geometric figure shape and a cross shape and is used for fixing the diamond film. The diffusion bonding process comprises the following steps: carrying out mechanical polishing treatment on a block copper substrate, carrying out plasma cleaning, sputtering an alloy solder on the surface, applying temperature and pressure to a diamond film and the block copper substrate in a vacuum environment to realize diffusion bonding of the diamond film and the block copper substrate, opening the block copper substrate in a displacement / force / heat / electricity manner to drive the diamond film to stretch, and carrying out diffusion bonding on the diamond film and the block copper substrate. And the strain is indirectly generated. The thickness of the alloy solder layer can be uniform and controllable, the shear strength and bonding area of diffusion bonding are improved, the reliability of diffusion bonding is improved, the geometric figure structure is adjusted to adapt to the to-be-stretched film, and the universality of the diamond film is improved while efficient and indirect stretching of the diamond film is achieved.

Owner:WUHAN UNIV

Plate surface treatment device

ActiveCN109531310AAvoid too thickPrevent too thick, the arc grinding plate will be stuck when grinding the metal plateGrinding drivesPlane surface grinding machinesEngineeringGrinding wheel

The invention belongs to the technical field of hardware plate machining, and particularly relates to a plate surface treatment device. The plate surface treatment device comprises a grinding box, a bearing, electric push rods, a first air bag, a second air bag, a movable plate, a screw rod, grinding wheels, a circular plate, a hardware plate, a first air cylinder, an elastic rope, a gear and an arc grinding plate; the electric push rods drive the movable plate to move up and down, and the movable plate moves up and down to drive the screw rod to rotate; the screw rod rotates to drive the circular plate to rotate; the circular plate rotates to drive the gear to rotate, and the gear rotates to drive the arc grinding plate to polish the hardware plate; the first air bag and a third air bag are used for grinding hardware plate on the arc grinding plate, the arc grinding plate and the hardware plate can be prevented from being clamped; when the arc grinding plate is used for grinding the hardware plate, the first air cylinder is contracted and restored to drive the hardware plate to move, so that the double-sided grinding is realized, the grinding efficiency is higher, and the grindingquality is better.

Owner:临沂福友畜牧科技有限公司

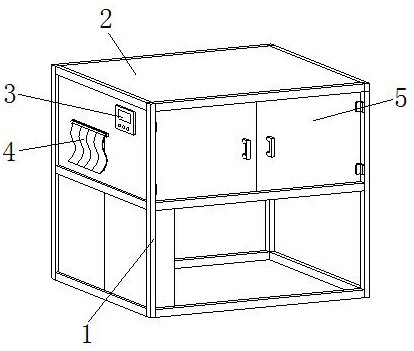

Saving-type environment-friendly electroplating spraying box

The invention discloses a saving-type environment-friendly electroplating spraying box. The saving-type environment-friendly electroplating spraying box structurally comprises a supporting frame, a spraying box, a control panel, a shielding cloth and a box door, wherein the upper end of the supporting frame is welded to the outer side of the spraying box. The water on the outer surface of a circular pipe is absorbed by a sponge pad, the gas is ejected from an air jet nozzle, the water on the outer surface of the circular pipe is completely removed, meanwhile a micromotor drives a rotating wheel to rotate, so that a rotating annular pipe rotate around a fixed sliding rail circumferentially, a coating in a conveying pipe is discharged into the rotating annular pipe, finally is ejected from arotating nozzle, circular bubbles with different sizes on a paint film of the outer surface of the circular pipe are prevented, the circular pipe is conveyed forward and enters into a supporting ring, a support bracket is extruded through the self diameter of the circular pipe, the bottom of the circular pipe is scraped with a scraping strip, so that surplus paint at the bottom of the circular pipe is scraped, a coating at the bottom of the circular pipe is prevented from being too thick, the smoothness of the paint film is ensured, and falling blocks are prevented.

Owner:邵东市和天电镀中心有限公司

Compound impeller rotor

The invention relates to a compound impeller rotor. The compound impeller rotor comprises an impeller body installed on a pump shaft, the impeller body comprises a metal hub lining and a non-metal blade lining body wrapped and machined on the peripheral surface of the lining of the metal hub in a compression molding mode, and the non-metal blade lining body is composed of an ultrahigh molecular weight polyethylene material. The impeller body is compounded by two materials of metal and plastic. Excellent abrasive resistance of ultrahigh molecular weight polyethylene and high strength of metal are combined, the weight of the impeller body is reduced, and the material cost is reduced; in addition, the phenomenon of high thickness of the impeller body is avoided, and the strength of the impeller body is ensured. The impeller body is wear-proof and corrosion-proof, in addition, the unbalanced eccentric torque and starting inertia of the impeller body are reduced, and the balance degree of the impeller body is ensured; the dynamic balance degree of the impeller body is ensured, the vibration valve of a pump can be conveniently reduced, the rotor is easy to machine and low in cost, and the running efficiency of the pump is greatly improved.

Owner:HEFEI UNIV OF TECH +1

Household smell security system

The invention discloses a household smell security system. The system comprises a smell detection unit, a smell comparison unit, a processing unit, and a control unit, the smell detection unit, the smell comparison unit, and the processing unit are connected to the control unit, the smell detection unit is used for detecting indoor smell and sending the detected smell concentration value to the smell comparison unit, the smell comparison unit is used for receiving the smell concentration value sent by the smell detection unit, comparing the smell concentration value with a preset smell concentration value, and sending a comparison result to the control unit, and the control unit is used for controlling the processing unit to conduct processing operation according to the comparison result of the smell comparison unit. According to the household smell security system, household smell can be well protected in an effective manner, and over-strong or sharp smell can be eliminated.

Owner:湘潭凌天六维节能环保科技有限公司

Preparation method of bituminous concrete

InactiveCN112127234AIncrease viscosityQuality improvementRoads maintainenceStructural engineeringBituminous concrete

The invention relates to a preparation method of bituminous concrete, and the preparation method uses a device assisting in the preparation of the bituminous concrete. The device assisting in the preparation of the bituminous concrete comprises a supporting base, a stirring mechanism and an overturning mechanism, wherein the supporting base is of a box body structure with an upward opening; the stirring mechanism is arranged at the middle part of the supporting base; and the overturning mechanism is mounted at the lower end of the stirring mechanism. The preparation method of the bituminous concrete can solve the problem that when bitumen materials are fed into an existing device for preparing the bituminous concrete, bitumen can not be heated and emulsified, and the bitumen materials andconcrete materials can not be thoroughly and uniformly stirred, resulting in the influence on the grading ratio of the bitumen to concrete and the influence on the viscosity of formed bituminous concrete. The preparation method of the bituminous concrete can also solve the problem that the inner wall of a stirring tank can not be scraped clean in time, and solidified bitumen is prone to be adheredto stirring blades, resulting in the accumulation of a thick bitumen layer after long-time use, the influence on the stirring quality of the bituminous concrete, low efficiency of stirring and mixing, and the influence on the using quality of the bituminous concrete.

Owner:深圳立豪建筑材料工程有限公司

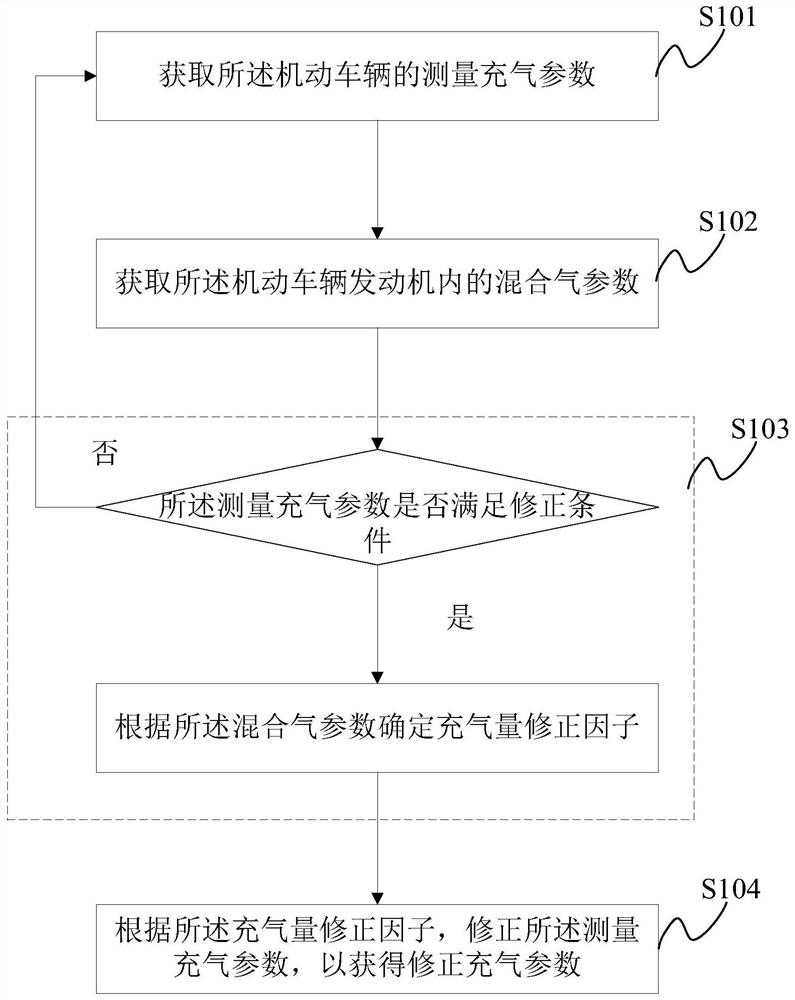

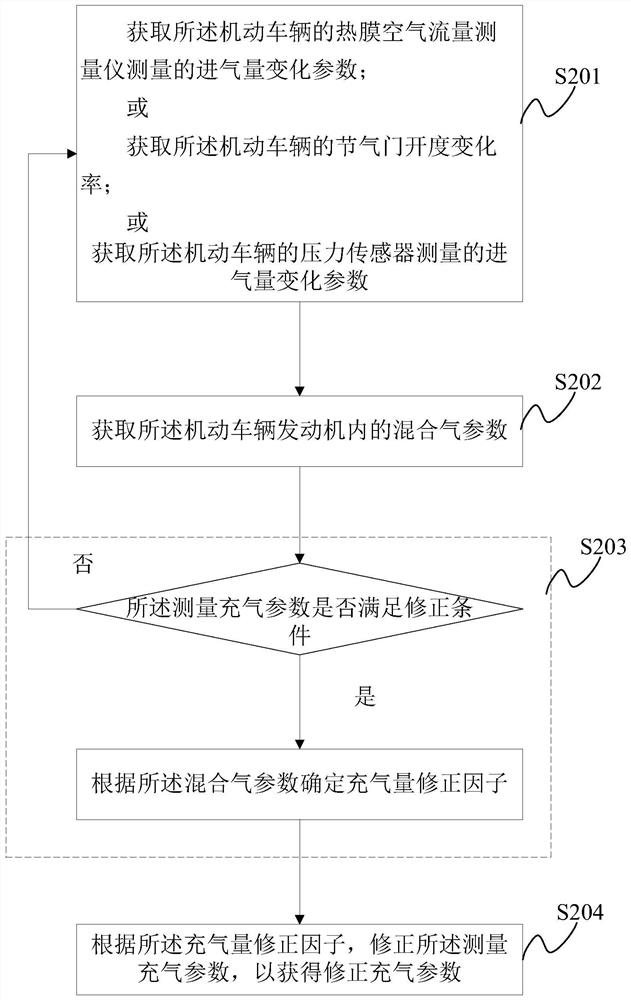

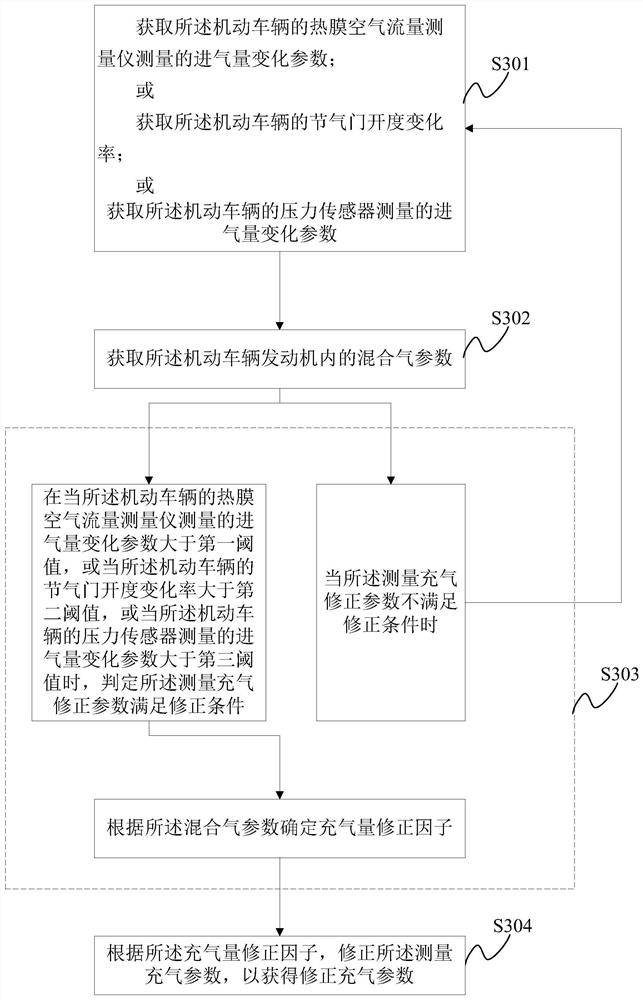

Inflation amount control method and system

PendingCN112555038AImprove running smoothnessAvoid too thickElectrical controlMachines/enginesControl theoryMotorized vehicle

The invention discloses an inflation amount control method and system. According to the inflation amount control method, an inflation amount correction factor is determined according to obtained mixedgas parameters after obtaining measurement inflation parameters of a motor vehicle and judging that the measurement inflation parameters meet a correction condition, the measurement inflation parameters are corrected by using the inflation amount correction factor, and corrected inflation parameters are obtained, so that the inflation amount of the motor vehicle calculated according to the corrected inflation parameters is close to the actual air inflow in an engine, and the purpose that the corrected inflation parameters are closer to the actual air inflow of the engine is achieved. The situation that mixed gas in an air cylinder is too thick or too thin due to the fact that the oil injection amount calculated by the engine according to the inflation amount with the large deviation fromthe actual inflation amount has the large deviation from the actually-needed oil injection amount is avoided, and the running smoothness of the motor vehicle is improved.

Owner:SAIC MOTOR

Automatic glaze spraying equipment for water storage tank of toilet

ActiveCN107116671AEasy to handleLarge clamping forceCeramic shaping apparatusWater storage tankSpray nozzle

The invention discloses automatic glaze spraying equipment for a water storage tank of a toilet and belongs to the technical field of ceramic production equipment. The automatic glaze spraying equipment is technically characterized by comprising a liquid storage tank, wherein a mounting cylinder is arranged above the liquid storage tank, a plurality of first spray nozzles are distributed on the side wall of the mounting cylinder in the vertical direction, a fixed seat is arranged on the upper side of the mounting cylinder, a plurality of second spray nozzles are distributed on the fixed seat, and the first spray nozzles and the second spray nozzles cooperate to spray a glaze to the inner wall of a blank; the first spray nozzles and the second spray nozzles are in communication connection with a glaze spraying pump arranged outside the liquid storage tank through pipes, and a liquid inlet end of the glaze spraying pump extends into the liquid storage tank; a rubber scraper is arranged on the outer wall of the mounting cylinder in the vertical direction, a plurality of connecting lines are distributed in the vertical direction at intervals near an end part of the end, far from the mounting cylinder, of the rubber scraper, and free ends of the connecting lines penetrate the mounting cylinder and are connected with a line length adjusting device. The automatic glaze spraying equipment for the water storage tank of the toilet is convenient to use and good in effect and is used for spraying the glaze to the blank.

Owner:江苏世丰企业管理咨询有限公司

Coal-oil slurry heating furnace system using thermal circulation liquid stream in process of hydrogenating direct liquefaction of coal

InactiveCN108659877AFlexible quantity controlAvoid too thickLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHeating timeProcess engineering

Provided is a coal-oil slurry heating furnace system using a thermal circulation liquid stream in the process of hydrogenating direct liquefaction of coal. The thermal circulation liquid material obtained from an outlet material of the coal-oil slurry heating furnace or a downstream front reactor of coal liquefaction is returned to the inlet of the heating furnace through a circulation pump, and optimization of a flow pattern, increase of the temperature of the liquid material in the furnace and shortening of the heating time can be achieved by flexibly regulating the flow rate of the liquid material in a heating furnace tube, so that improvement of the heat transfer efficiency, slow-down of coking in the furnace tube, slow-down of corrosion of the furnace tube and increase of the flexiblerange of flow operation of the coal-oil slurry feed are facilitated, decrease of the temperature shock amplitude of an inlet pipeline of the heating furnace is facilitated when the coal slurry is interrupted, and expanding of the range of coal types for a coal hydrogenating direct liquefaction device is facilitated.

Owner:洛阳瑞华新能源技术发展有限公司

Glaze spraying device for closestool water storage tank

ActiveCN107139316AHigh hardnessEasy to scrapeAuxillary shaping apparatusWater storage tankSpray nozzle

The invention discloses a glaze spraying device for a closestool water storage tank and belongs to the technical field of ceramic production equipment. According to the technical scheme, the glaze spraying device is characterized by comprising a liquid storage tank, wherein an installation barrel is arranged on the upper portion of the liquid storage tank, the liquid storage tank is provided with an anti-splashing sleeve, and the upper end of the anti-splashing sleeve is higher than the lower end of the installation barrel; the side wall of the installation barrel is provided with a plurality of first spray nozzles in the vertical direction, the upper side of the installation barrel is provided with a fixing seat, the fixing seat is provided with a plurality of second spray nozzles, and all the first spray nozzles and the second spray nozzles are matched to perform glaze spraying on the inner wall of a blank body; all the first spray nozzles and the second spray nozzles are in communicating connection with a glaze spraying pump on the outer side of the liquid storage tank through pipelines, and the liquid feeding end of the glaze spraying pump extends into the liquid storage tank; and the outer wall of the installation barrel is connected with an installation plate in the vertical direction through a pressing mechanism, and the position, close to the end outer wall, of the free end of the installation plate is provided with a plurality of flattening scrapers in the vertical direction. The glaze spraying device for the closestool water storage tank provided by the invention is convenient to use and good in effect and is used for glazing the blank body.

Owner:TANGSHAN MONOPY CERAMIC

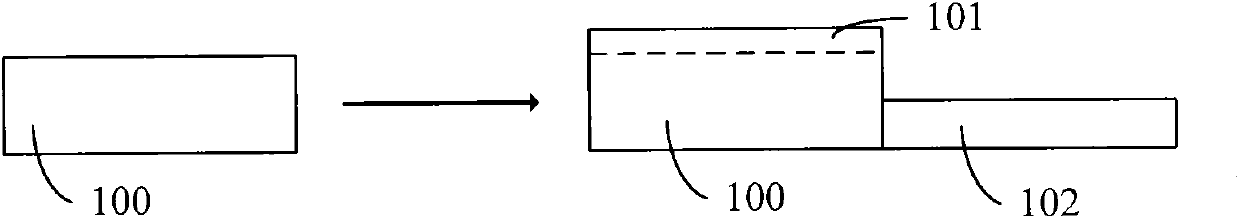

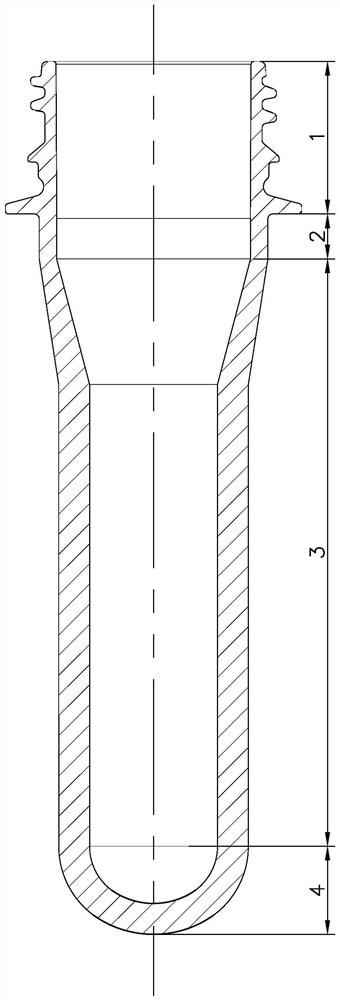

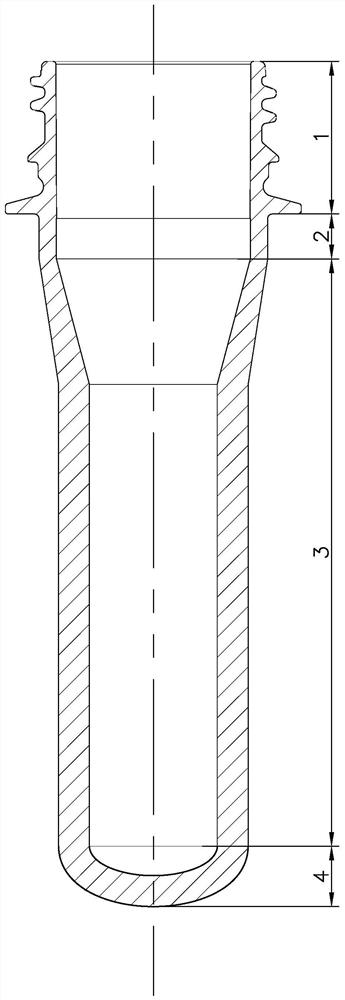

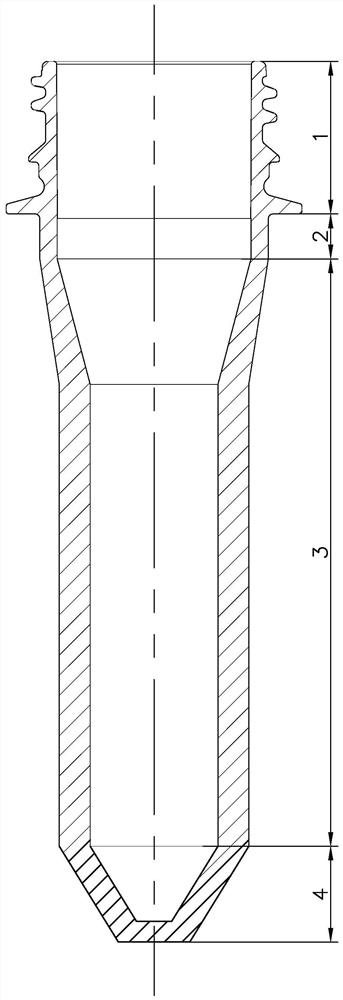

Bottle blank structure beneficial to stretch blow molding

A bottle blank structure beneficial to stretch blow molding comprises a bottle blank which is integrally formed through injection molding, and the bottle blank comprises a bottle opening, a bottle neck, a blank body and a blank bottom, all of which are sequentially connected. The blank bottom is arranged to be an upper bottom and a lower bottom which are connected, the bottommost end of the lower bottom is lower than a convergent point formed by extension lines of a generatrix curve section I of the upper bottom, so that the lower bottom protruding downwards is formed by the blank bottom on the basis that the upper bottom is formed, the lower bottom serves as a pre-stretching structure of the blank bottom, so that the blank bottom is fully unfolded in the stretch blow molding process, serious material accumulation of the bottle bottom is avoided, more materials are distributed to the remaining parts of the bottom of the bottle blank, and therefore when the bottle blank is designed, the wall thickness of the blank bottom can be designed to be smaller, and the purpose of light weight is achieved.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com