Glaze spraying device for closestool water storage tank

A water storage tank and glaze spraying technology, which is applied in the field of glaze spraying devices for toilet water storage tanks, can solve the problems of heavy workload of workers, large glaze thickness, and color difference, and achieve the effect of convenient use and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

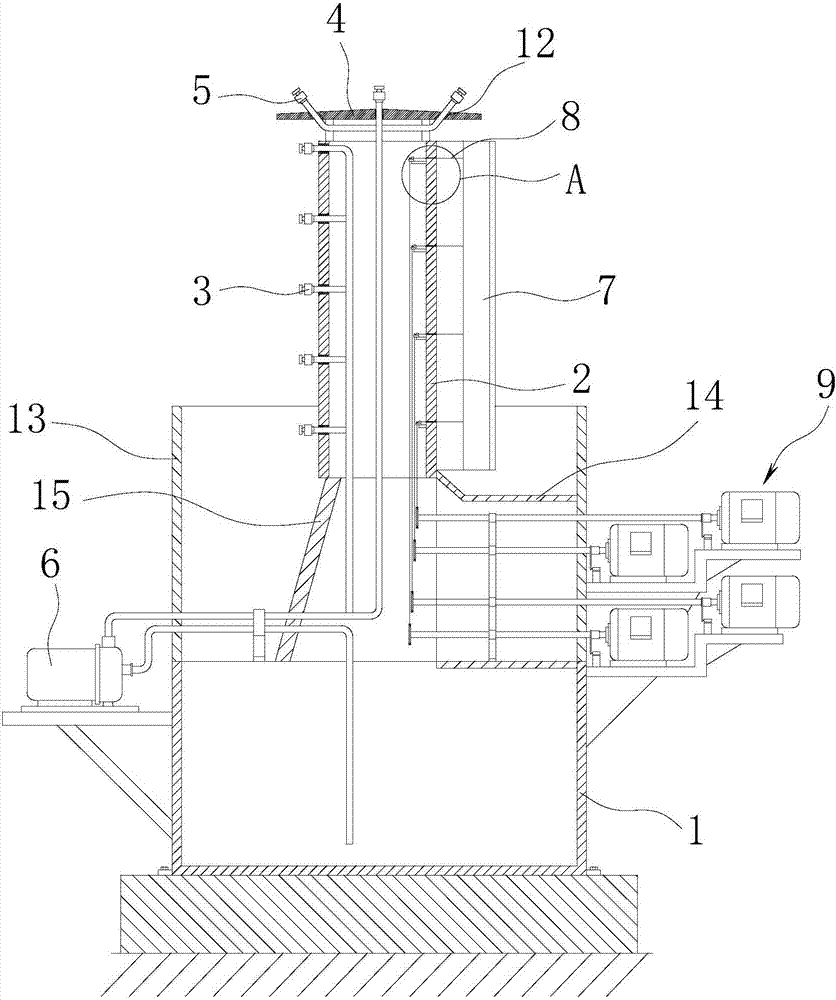

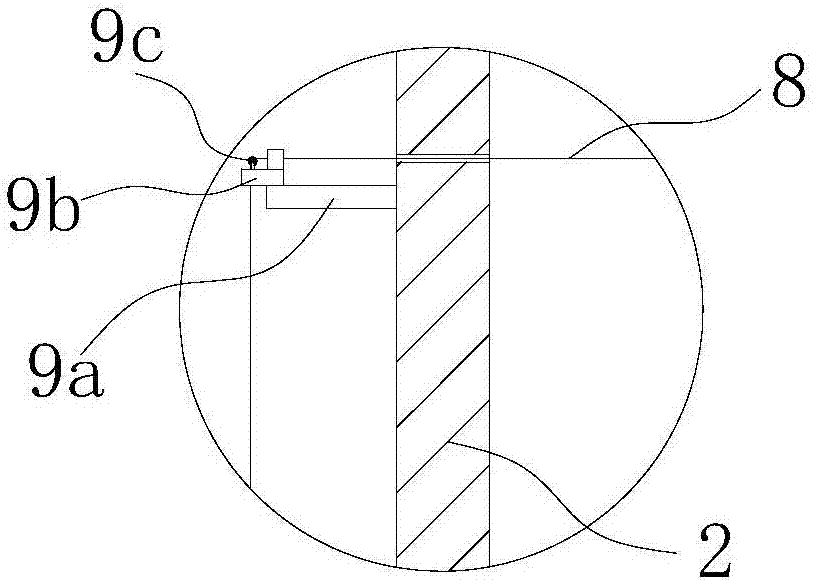

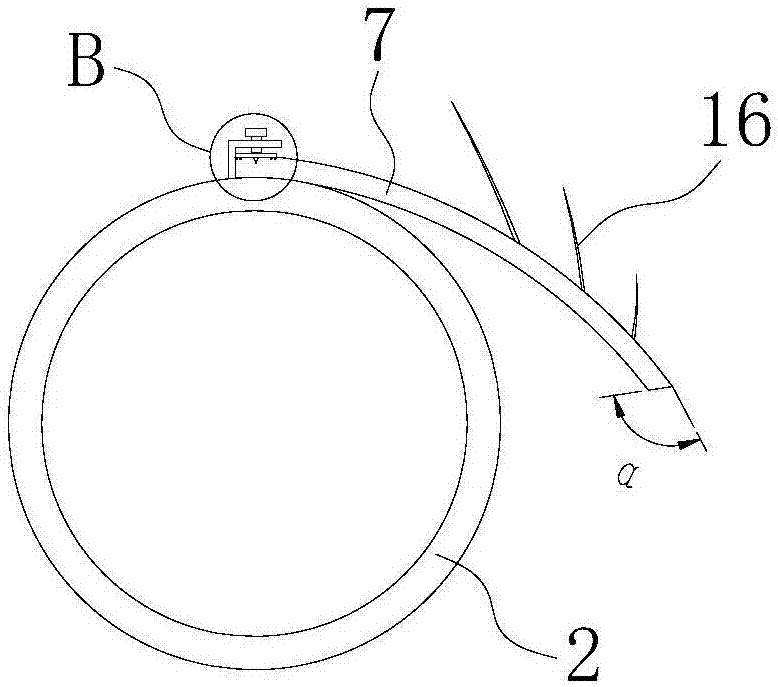

[0022] refer to Figure 1 to Figure 5 As shown, a glaze spraying device for a toilet water storage tank according to the present invention includes a liquid storage tank 1 arranged on a support, and an installation cylinder 2 is arranged above the liquid storage tank 1 . The upper end of the liquid storage tank 1 is provided with a splash-proof sleeve 13, and the upper end of the splash-proof sleeve 13 is higher than the lower end of the installation cylinder 2. The splash-proof sleeve 13 can prevent the glaze from splashing to the outside of the device and avoid environmental pollution. A number of first nozzles 3 are distributed along the vertical direction on the side wall of the installation cylinder 2, a fixed seat 4 is arranged on the upper side of the installation cylinder 2, and a plurality of second nozzles 5 are distributed on the fixed seat 4, each of the first and second nozzles 3,5 cooperate to spray glaze on the inner wall of the green body; the edge of the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com