Patents

Literature

224results about How to "Smooth glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

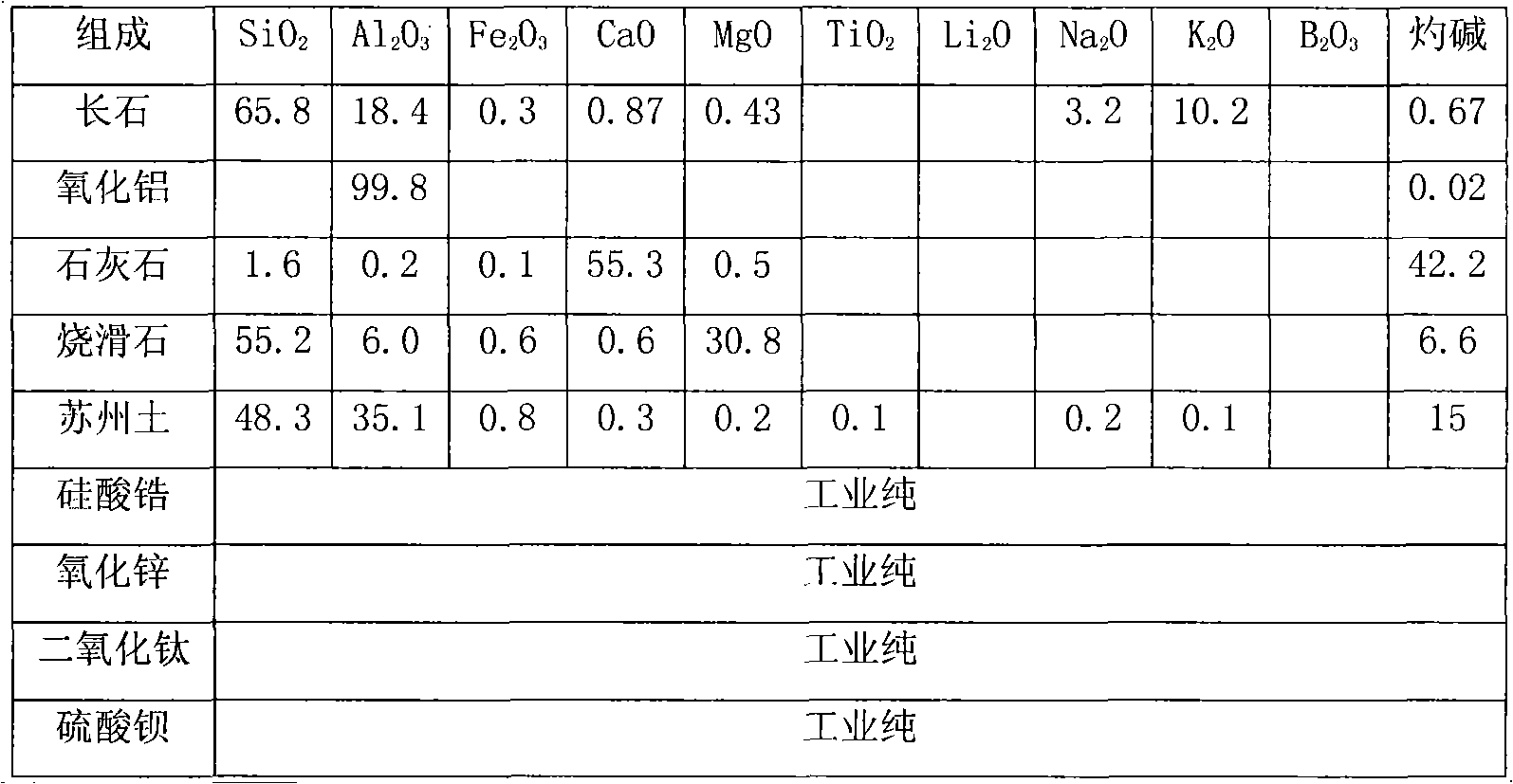

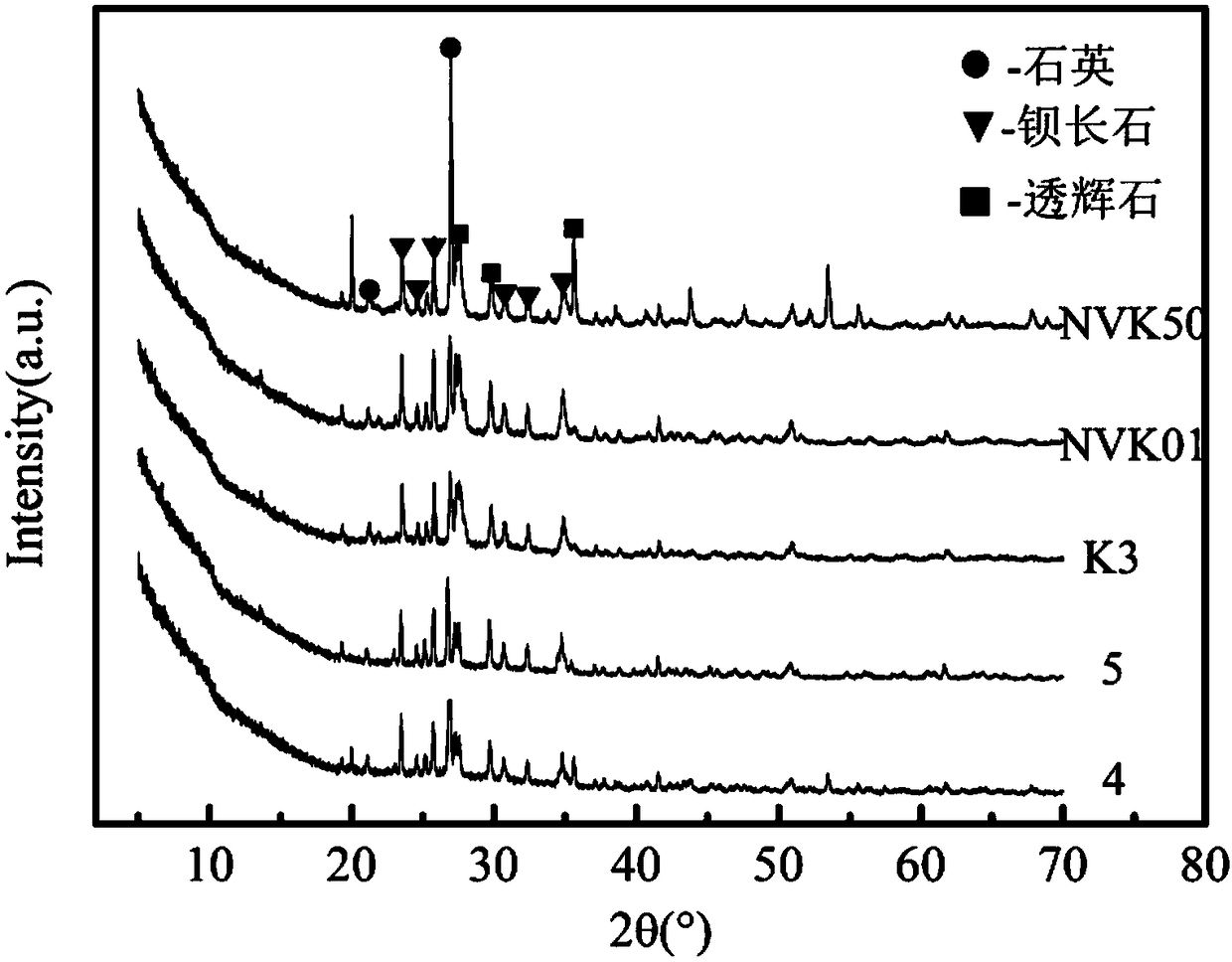

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

Warm eye-protection matte glaze for building ceramic tiles, and preparation technology thereof

The invention discloses a warm eye-protection matte glaze for building ceramic tiles, and a preparation technology thereof. The preparation technology comprises the following steps: (1) weighing clay,feldspar, quartz, talcum, dolomite, limestone, borax, zirconium silicate, zinc oxide, alumina, barium carbonate and strontium carbonate according to the chemical composition range, crushing the weighed materials to form 180-350 mesh particles, mixing the particles, sintering the obtained mixture at 1480-1580 DEG C to form a glassy melt, and quenching the glassy melt with water to obtain a matte frit for the ceramic tile glaze; and (2) adding clay raw materials and a glaze slip performance regulator to the frit, and performing full wet ball-milling to obtain a matte glaze slip. The compositionof the formula is slightly changed, so the glaze obtained after sintering has the advantages of high strength, high wear resistance, high aging resistance and long service life; the glaze is flat, fine and smooth, is free of pinholes, and has silky or velvet gloss, and the glossiness of the glaze is 3-5 DEG less than that of existing products, so the glaze makes people have soft, quiet and comfortable eye-protection feeling; and the tile matte glaze has tender and soft hand feeling, and is warm.

Owner:FOSHAN UNIVERSITY +1

Reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and preparation method of reddish-black jun porcelain glaze

InactiveCN103288493AImprove coloring abilityReduce energy consumption and pollutionCalciteCeramic glaze

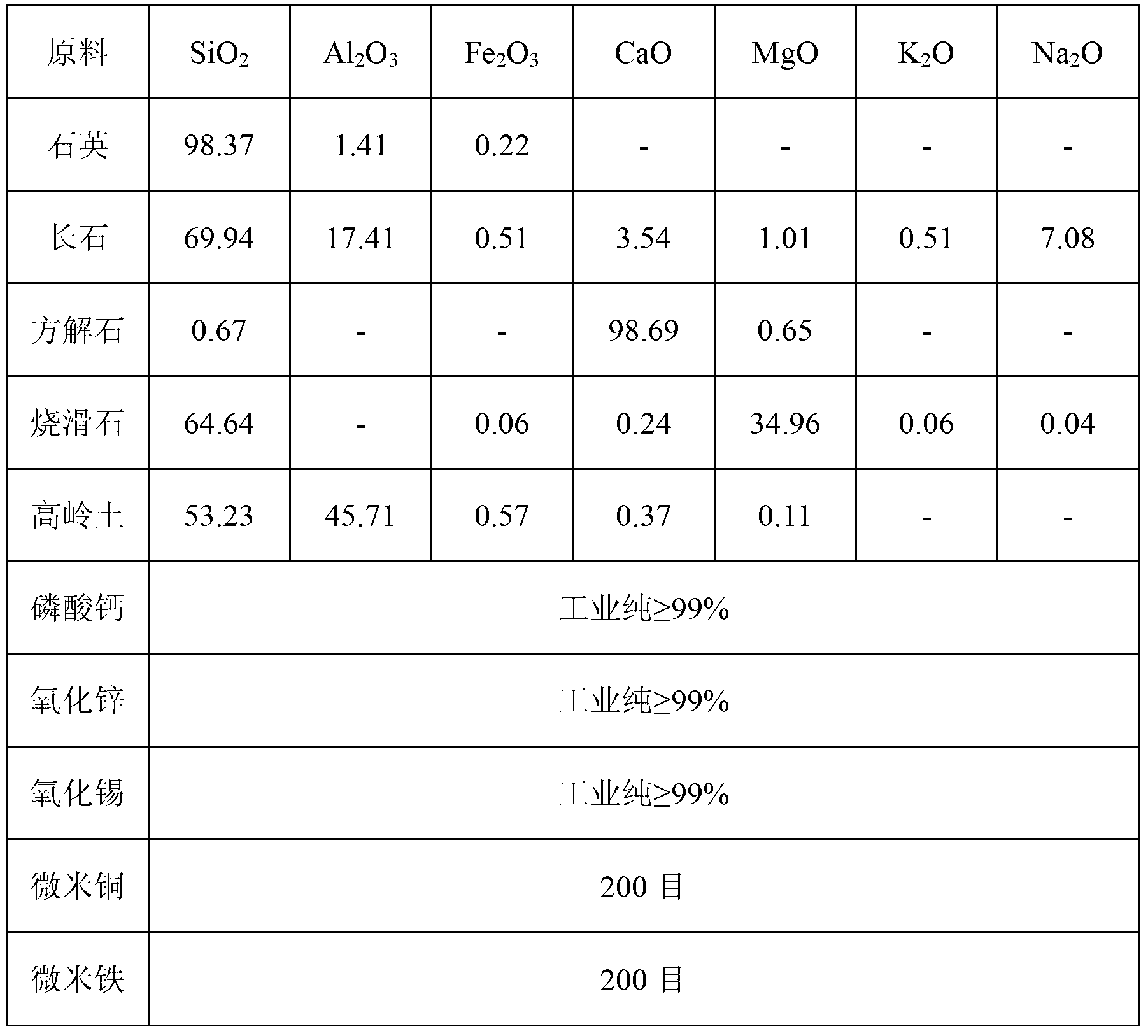

The invention discloses a reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and a preparation method of the reddish-black jun porcelain glaze, belonging to the preparation filed of ceramic glazes. The preparation method of the reddish-black jun porcelain glaze comprises the following steps of: (1), mixing the following components in percentage by weight: 45%-50% of feldspar, 20%-30% of quartz, 14%-17% of calcite, 5%-7% of talcum, 2.5%-3.5% of kaolin and 2.9%-3.5% of calcium phosphate, so as to obtain a material mixture, and adding and sufficiently mixing the following materials (based on the total weight of the material mixture): 0.3%-2% of ZnO, 1.5%-4% of SnO2, 0.2%-2% of Fe, 0.1%-1.5% of Cu, 0.1%-0.5% of cellulose and 0.5%-1.5% of sodium tripolyphosphate, so as to obtain a glaze mixture; (2), carrying out wet-process ball-milling on the glaze mixture to obtain glaze pulp; (3), applying the glaze pulp on a biscuit firing billet for firing for 20 minutes-40minutes in a neutral or weak oxidative atmosphere, and cooling to obtain the reddish-black jun porcelain glaze. The preparation method of the reddish-black jun porcelain glaze is simple and easy to implement, board in firing temperature range and easily controllable in firing atmosphere. And the reddish-black jun porcelain glaze obtained by the preparation method disclosed by the invention is simple in composition, smooth and flat in glazed surface, high in stability and bright in reddish-black color.

Owner:SHAANXI UNIV OF SCI & TECH

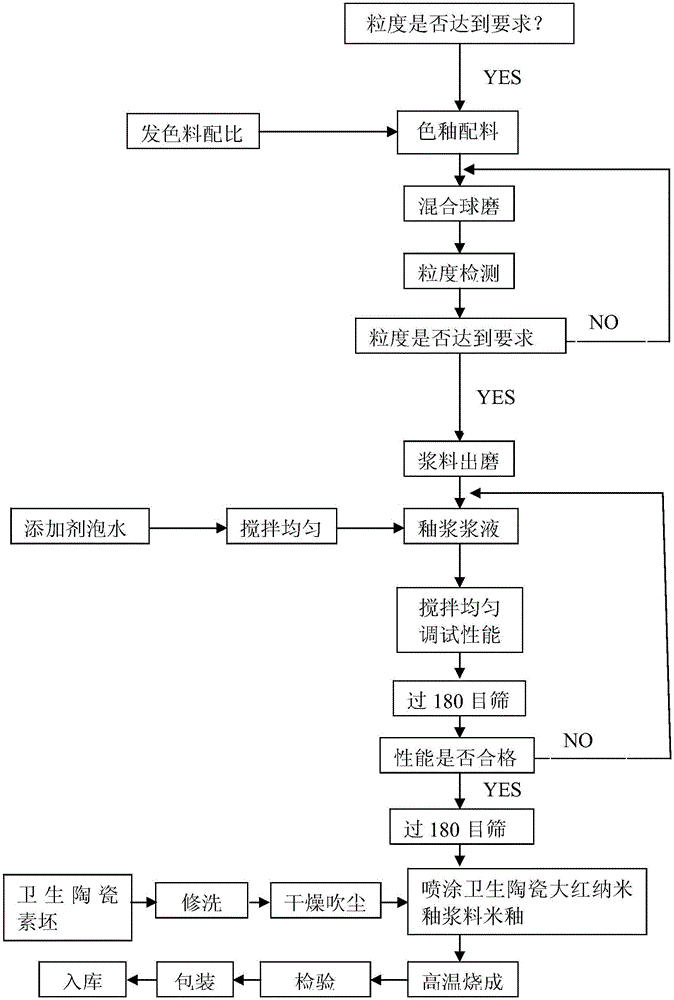

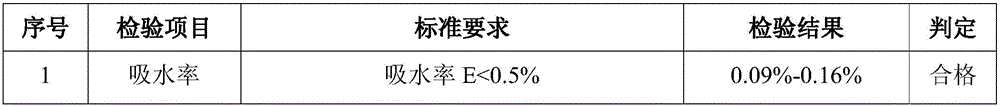

Bright red nanometer glaze slip for ceramic sanitary wares as well as preparation method and application of bright red nanometer glaze slip

The invention discloses a bright red nanometer glaze slip material for ceramic sanitary wares, as well as a preparation method and application of the bright red nanometer glaze slip material. The bright red nanometer glaze slip material specifically comprises water as a medium, and the following components in percentage: 20-25% of feldspar, 40-45% of quartz, 16-20% of calcium carbonate, 2-3% of dolomite, 3-5% of zinc oxide, 2-4% of kaolin, 2-5% of nanometer zirconium, 3.5-6% of nanometer aluminum oxide, 9-12% of 060 bright red chromophoric materials, 1-3% of Z309 claret chromophoric materials and an appropriate amount of CMC for ceramics. The bright red nanometer glaze slip material disclosed by the invention is resistant to high temperature and can bear long-time high-temperature calcination, so that the application of bright red nanometer glaze for the ceramic sanitary wares in the production of the ceramic sanitary wares comes true, and the defects that color becomes black and pigments are volatilized after high-temperature calcination are overcome.

Owner:JOMOO KITCHEN & BATHROOM

Manufacturing method of matte transparent glazed ceramic sheet

The invention provides a manufacturing method of a matte transparent glaze ceramic sheet. The method comprises the following steps: spraying a biscuit with a ground glaze, printing, spraying with a matte transparent glaze, firing, and edging to obtain the finished product, wherein the matte transparent glaze comprises the following raw materials in percentage by weight: 80-93% of frit, 3-11% of calcined zinc oxide, 4-8% of air knife soil, 0.1-0.4% of methyl cellulose and 0.2-0.6% of sodium tripolyphosphate, and the frit is prepared from calcite, barium carbonate, strontium carbonate, potassiumfeldspar, kaolin, sodium carbonate, quartz sand and dolomite. According to the invention, zirconium dioxide is not added into the obtained matte transparent glazed ceramic sheet, transparency is good, calcined zinc oxide is used for adjusting expansion of glaze to achieve the purpose of adjusting the shape of a brick, and air knife soil improves the suspension property and viscosity of the glaze;and after the matte transparent glaze is sintered, the glossiness is 5-20 degrees, the glaze surface is smooth, a printing layer can be placed below the matte transparent glaze, the printing layer isprevented from being scratched, and the matte transparent glaze layer can also be used for polishing.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

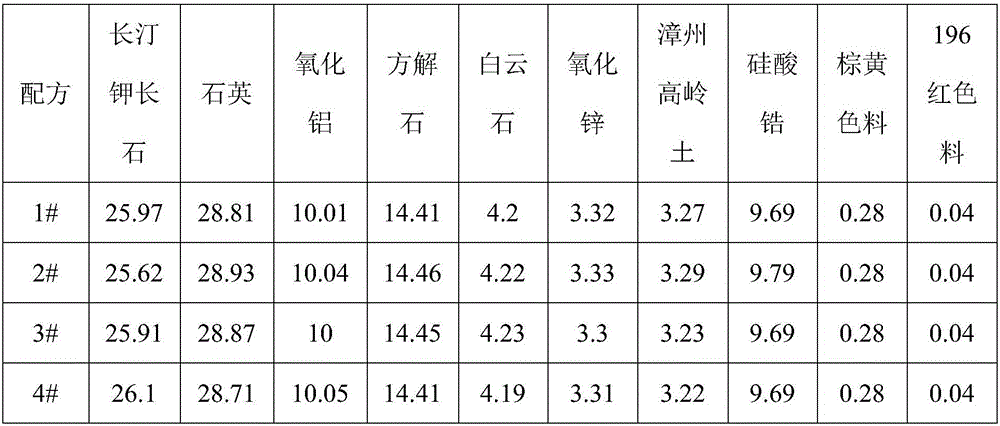

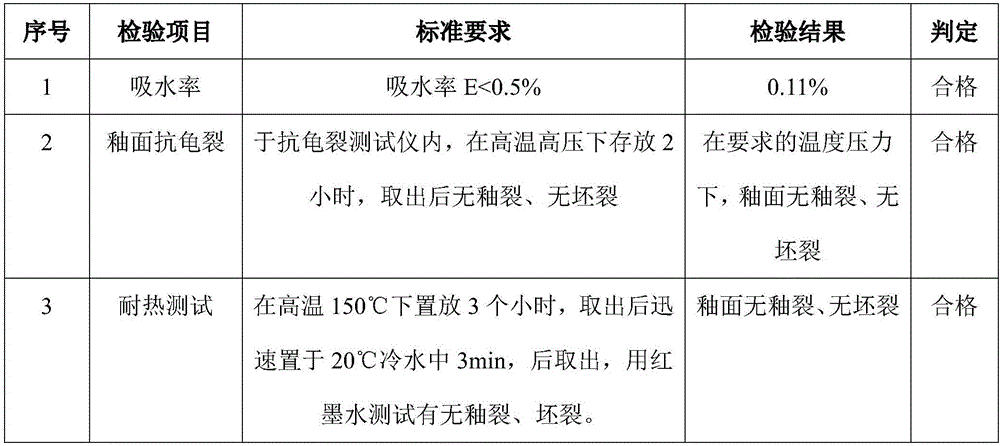

Preparation method of matte glaze sanitary ceramic

The invention discloses a preparation method of matte glaze sanitary ceramic. The preparation method comprises the steps of carrying out ball milling on 27.8%-29% of quartz, 25.5%-26.9% of Changding potassium feldspar, 13.55%-15.5% of calcite, 3.83%-4.3% of dolomite, 3%-3.3% of Zhangzhou kaolin, 9%-10.1% of zirconium silicate, 9.83%-10.1% of aluminum oxide, 3.2%-3.4% of zinc oxide, 0.03%-0.04% of sodium carboxymethylcellulose and 1.06%-1.95% of sodium carbonate until the particle size of slurry is smaller than 10 microns and the ratio is 60%-65%, adding ceramic pigments, continuing to carry out ball milling until the particle size of slurry is smaller than 10 microns and the ratio is 69%-71%, sieving by virtue of a 180-mesh sieve so as to obtain uniform sanitary ceramic matte glaze slurry, spraying the sanitary ceramic matte glaze slurry to the surface of a sanitary ceramic blank, adequately drying, firing in a tunnel kiln at 1200-1250 DEG C for 15-18 hours, and cooling, so as to obtain the matte glaze sanitary ceramic product. The prepared matte glaze sanitary ceramic has a special matte effect and pure colors and is rich in aesthetic perception, and the problem of poor sewage resistance of traditional matte glaze is further overcome.

Owner:JOMOO KITCHEN & BATHROOM

Daily used reinforced ceramic and its preparation process

InactiveCN1724459ARegular shapeReduce production complexityClaywaresHeat stabilityUltimate tensile strength

A strengthened ceramic for daily purpose is proportionally prepared from albite, talc and clay. Its preparing process features sintering twice respectively at 1250-1350 deg. C and at 1100-1200 deg. C. Its advantages are fine quality, high whiteness, and high strength and thermal stability.

Owner:QINGDAO UNIV OF SCI & TECH

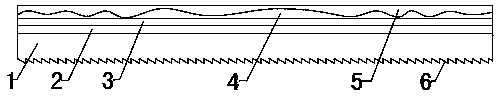

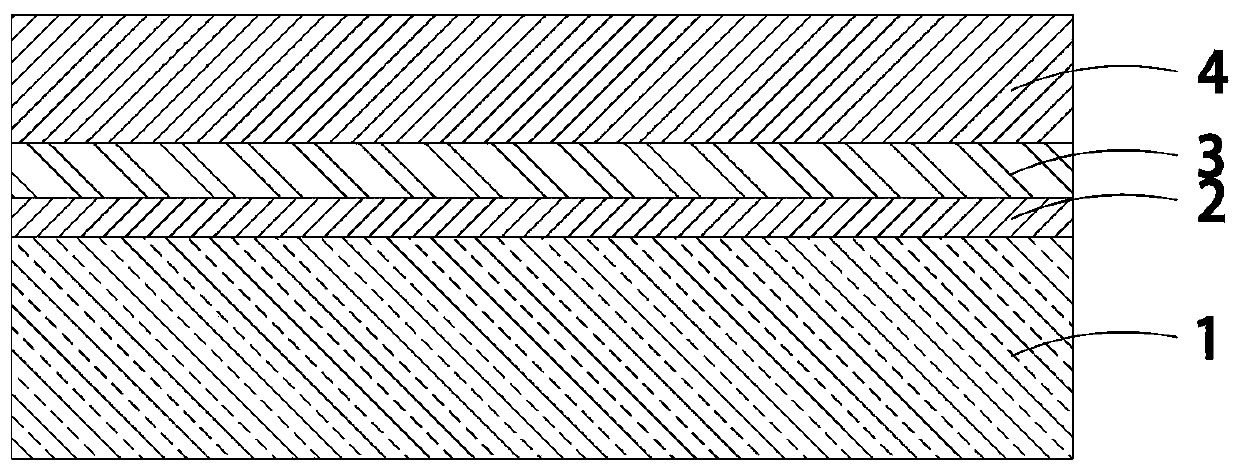

Microcrystal mirror polishing wall tile and manufacturing method thereof

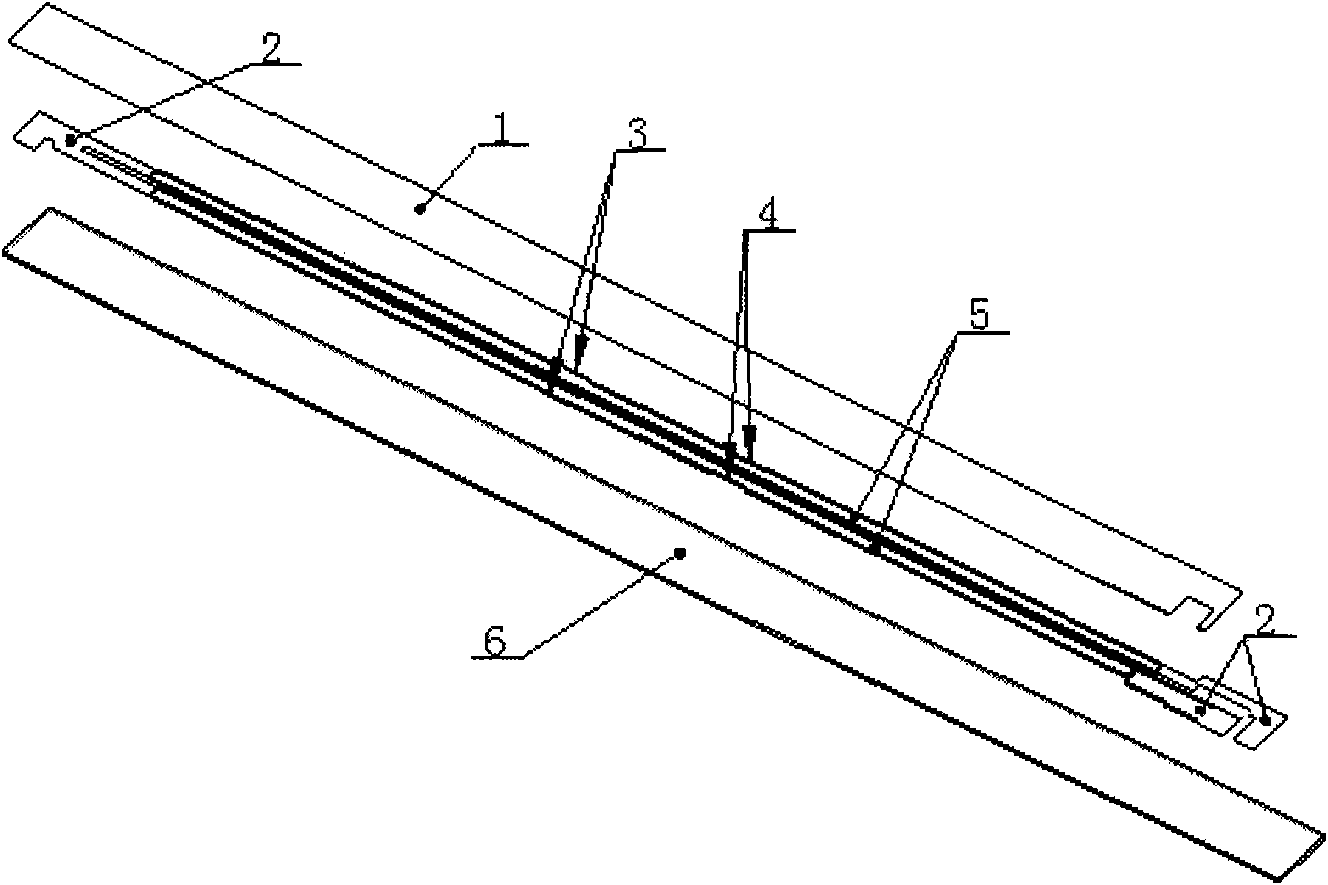

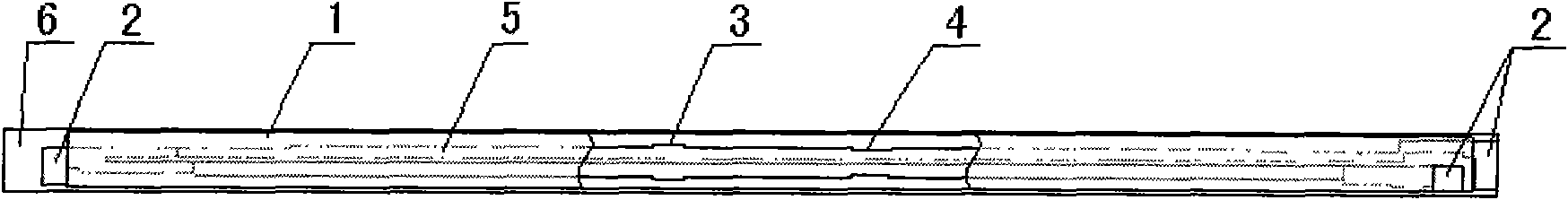

The invention relates to a microcrystal mirror polishing wall tile and a manufacturing method thereof and belongs to the technical field of ceramic glazing tiles. The microcrystal mirror polishing wall tile is characterized in that a greenware bottom tile (1) is provided with a glaze surface layer which is formed by applying a ground glaze layer (2), a surface glaze layer (3), an enameling layer (4) and a full-polishing glaze layer (5) layer by layer from bottom to top. The manufacturing method is characterized by comprising the following steps: once firing the greenware bottom tile firstly, and sequentially applying the ground glaze, the surface glaze and the full-polishing glaze on the greenware bottom tile after water spraying; enameling on the surface glaze; and then carrying out secondary firing. According to the microcrystal mirror polishing wall tile disclosed by the invention, as the special constituted surface glaze layer is added, under glaze colors are realized on the greenware bottom tile; as the problem that expansion coefficients among glaze layers of a microcrystal glaze surface of a ceramic green body which is sintered at low temperature are not matched is solved, the glaze surface cannot crack.

Owner:ZIBO GELUNKAI CERAMIC CO LTD

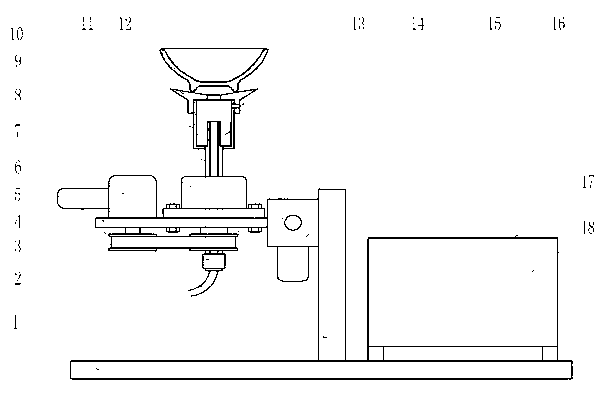

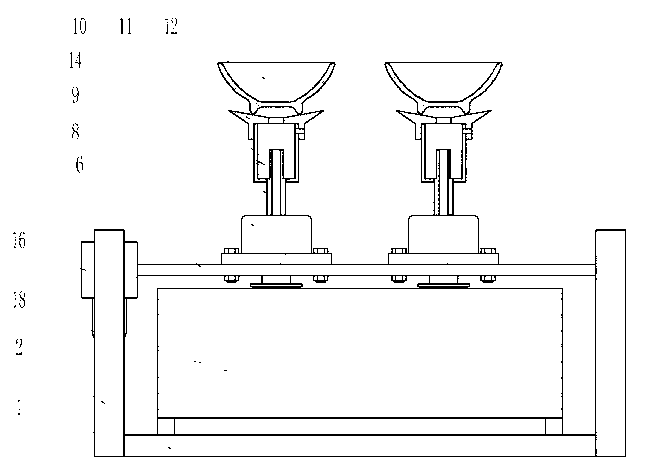

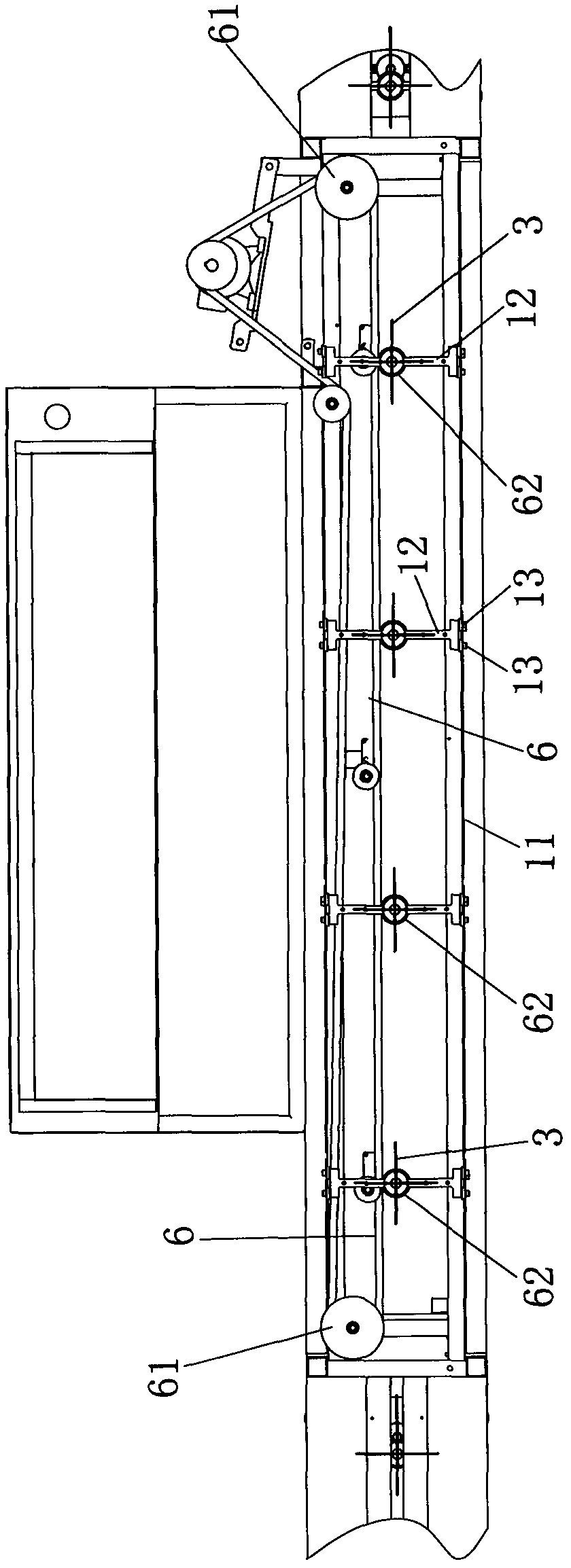

Automatic glazing device for domestic ceramics

The invention discloses an automatic glazing device for domestic ceramics. The automatic glazing device comprises a sucking disc device, a supporting plate and a rack upright post, wherein the sucking disc device is used for absorbing a bowl blank; the supporting plate is used for supporting the sucking disc device and sucking disc rotation speed reducers; the sucking disc device is connected with the supporting plate by a bearing; the bearing base of the bearing is fixed on the supporting plate by a bolt; a glaze sucking hole is formed on the side surface of the sucking disc device; and glaze water in a glaze sucking and storing barrel can be supplemented through the glaze sucking hole in a glaze soaking process. Two speed reducers are combined in different spaces and at different times, i.e., the sucking plate is driven by the sucking plate rotation speed reducers to rotate; and the whole sucking plate device and the supporting plate are driven by the supporting plate speed reducer to rotate, so that the automatic glazing process of the whole device is realized, thereby solving the problems that the existing glazing device is low in efficiency, poor in glazing quality and large in labor intensity; moreover, the automatic glazing device has the advantages of complete and uniform glazing effect, good glazing effect, high efficiency and high automation degree.

Owner:GUANGXI BEILIU CITY ZHICHENG CERAMIC AUTOMATION TECH

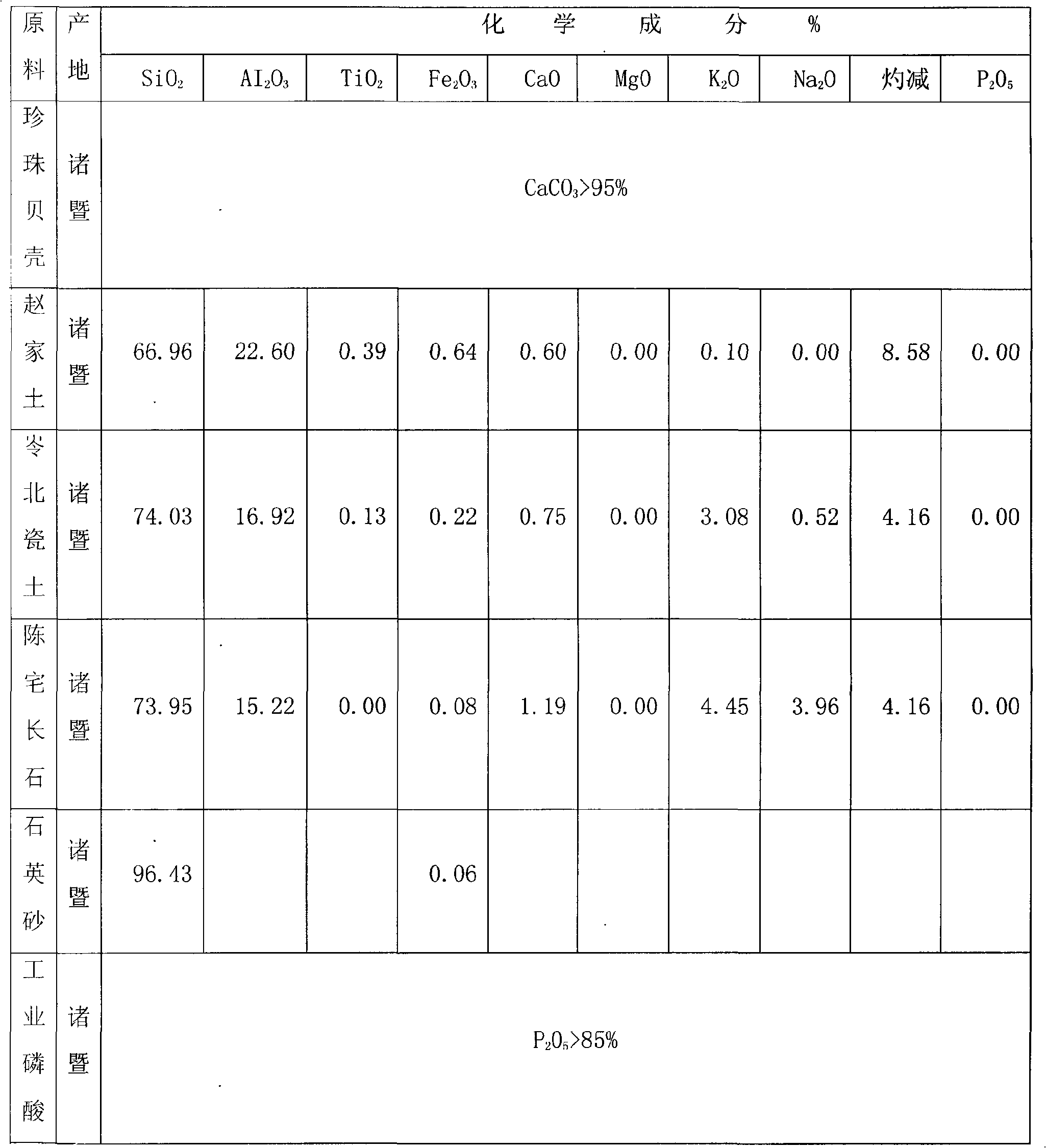

Pearl shell treating process as well as ceramic and glaze prepared by materials prepared by same

The invention discloses a treating process for preparing ceramic materials by pearl shells and wasted pearl bodies, and simultaneously further discloses a formula and a sintering technology for preparing daily-used ceramic and glaze by powder materials prepared by the treating process. The formula of shell porcelain body is as follows: 17-30 percent of mineral powder prepared by treatment, 10-20 percent of porcelain clay, 45-58 percent of kaoline, 0-5 percent of quartz, and 5-15 percent of feldspar; the formula of glaze of shell porcelain body is as follows: 1.36-4 percent of mineral powder prepared by treatment, 0,8-4 percent of porcelain clay, 3.6-11.6 percent of kaoline, 0-1 percent of quartz, 0.4-3 percent of feldspar, and 80-92 percent of high-boron high-zinc lead-free transparent frit; and the sintering technology of the shell porcelain is as follows: 1170-1220 DEG C of high-temperature plain temperature, and 1050-1100 DEG C of low-temperature glaze firing temperature. The invention has the advantages of energy conservation and consumption reduction, safety and environmental protection, and economy and practicalness.

Owner:ZHEJIANG DONGWEI CERAMICS

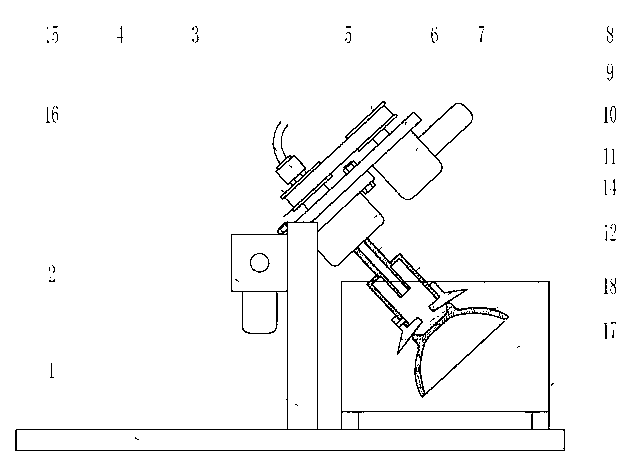

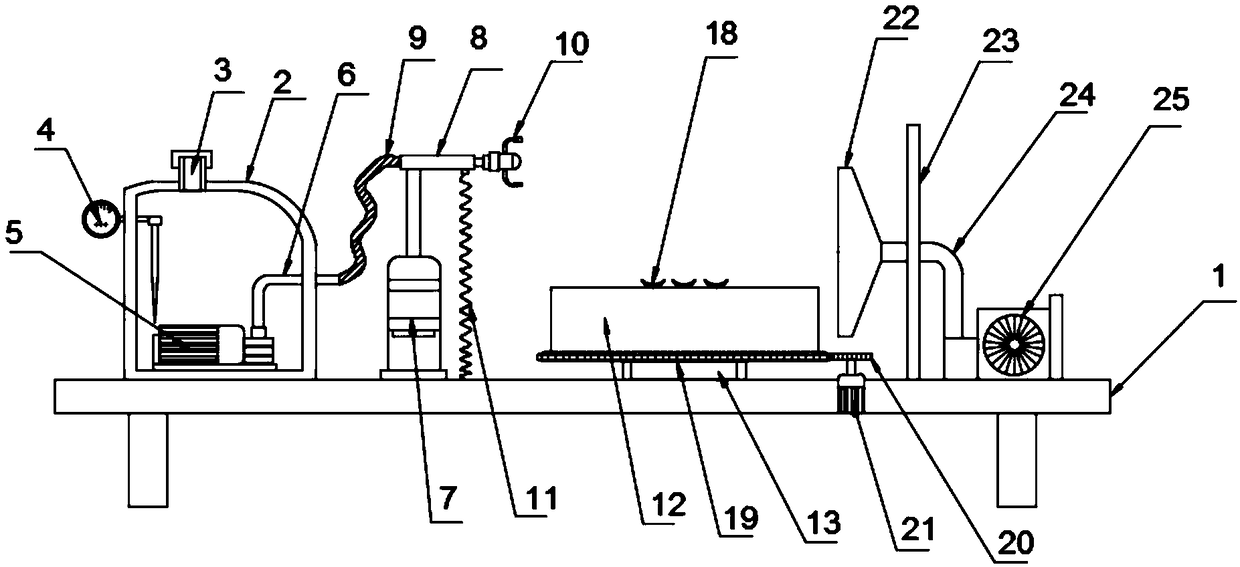

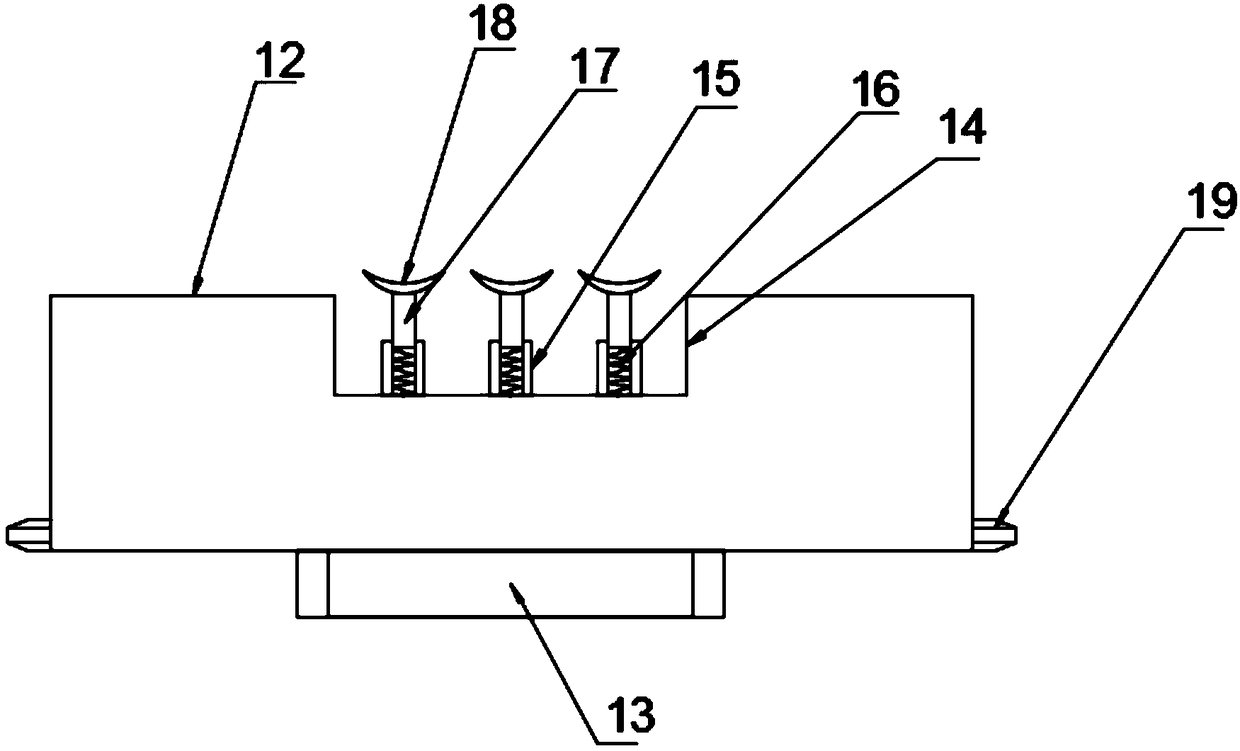

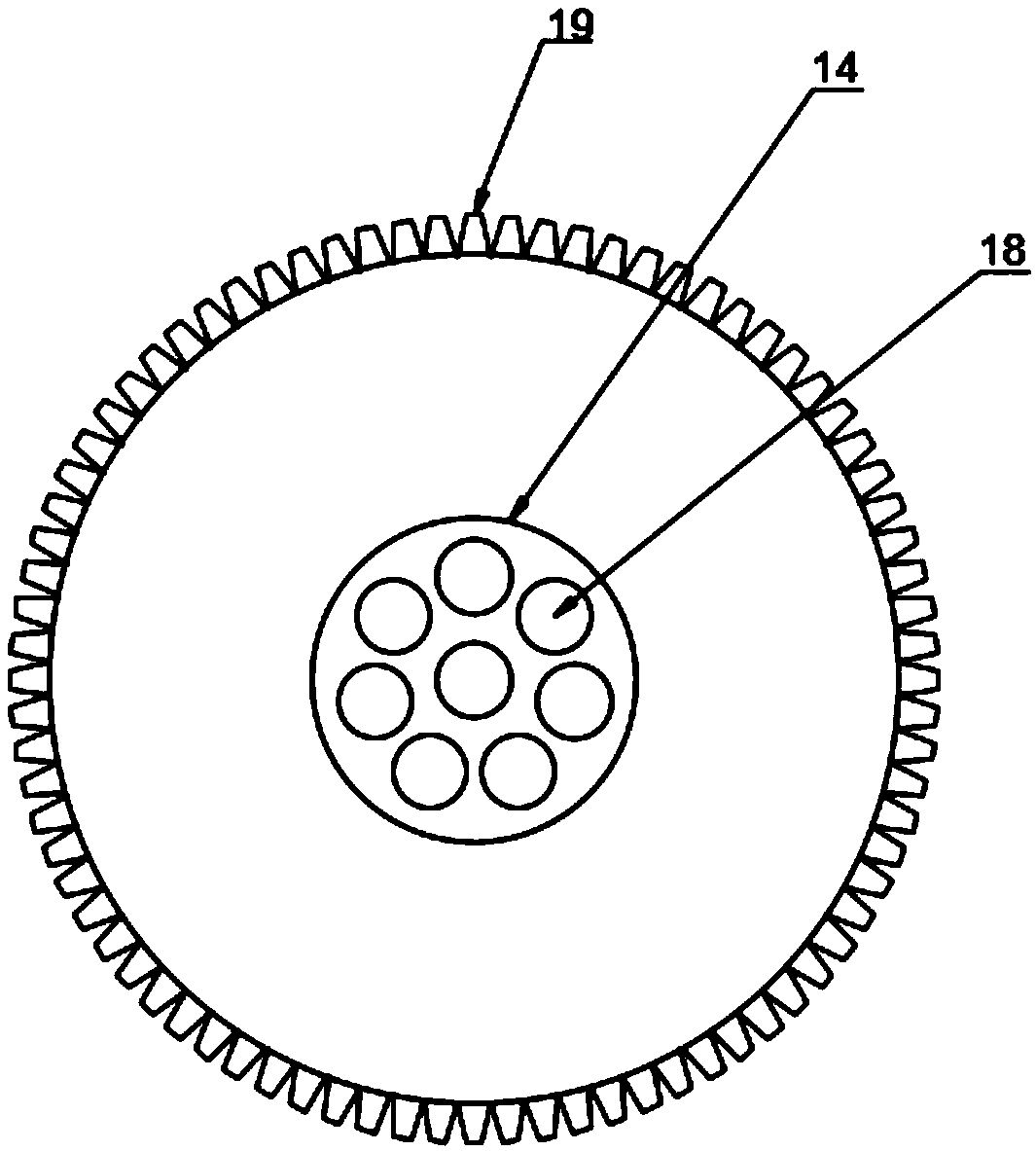

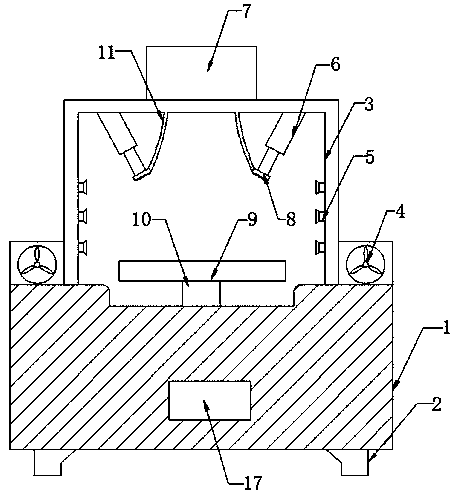

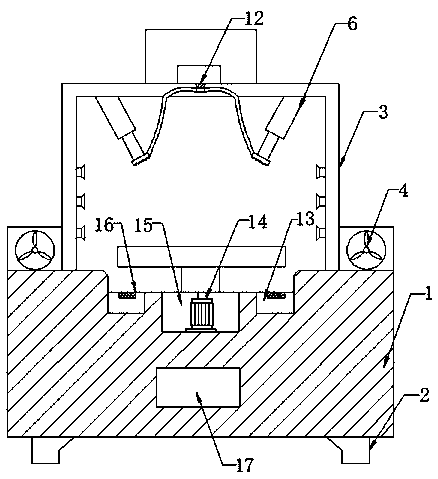

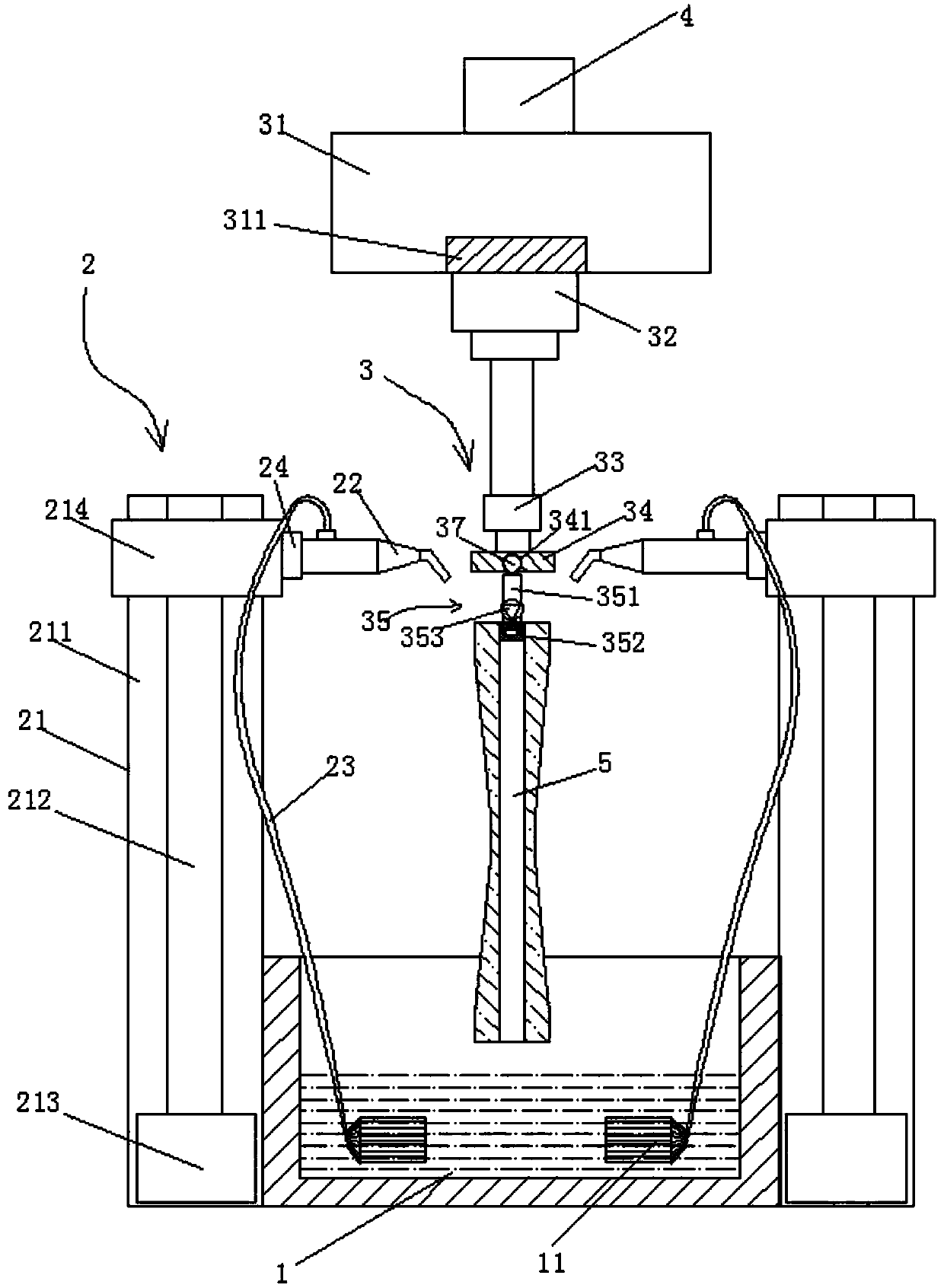

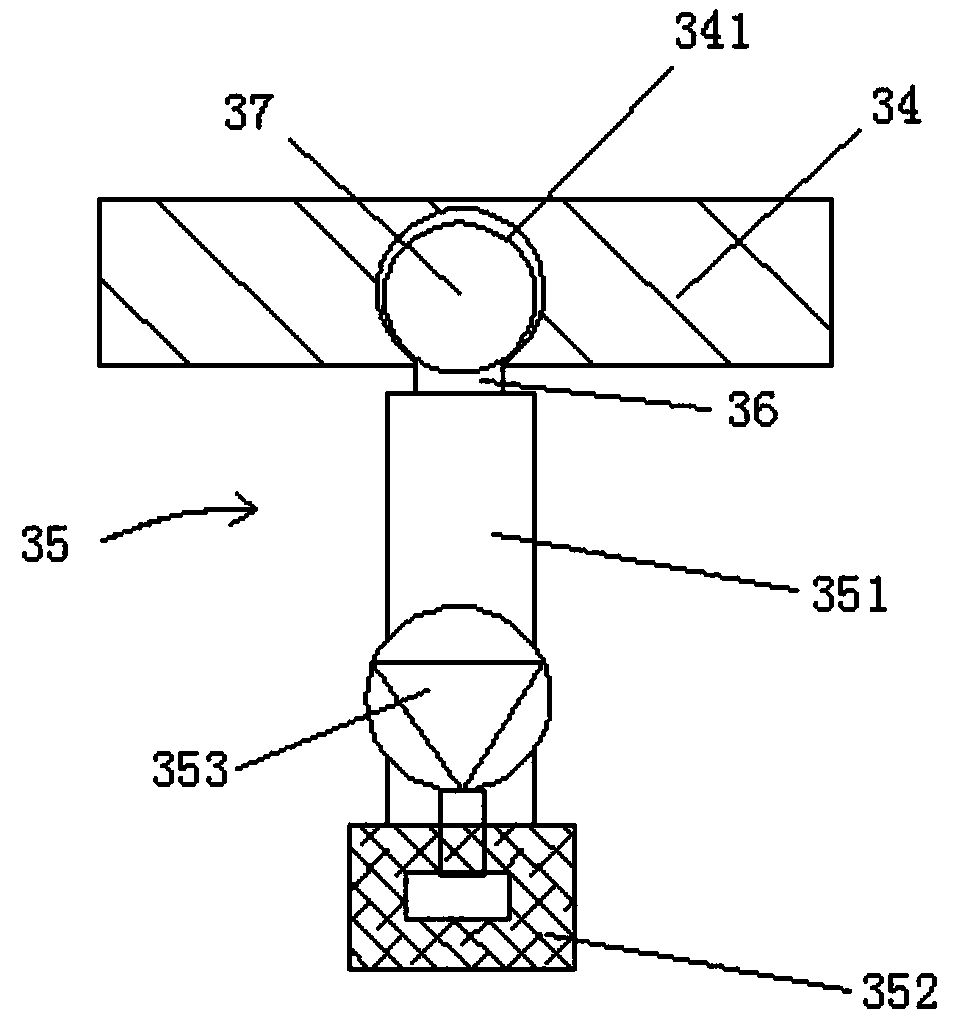

Multi-station automatic glaze spraying machine for ceramic

InactiveCN108858704AImplement suction lockSpray glaze smoothCeramic shaping apparatusEngineeringCeramic

The invention relates to a multi-station automatic glaze spraying machine for ceramic. The multi-station automatic glaze spraying machine comprises a supporting base plate, a fixing device and a glazespraying device; the fixing device is installed at the top of the left end of the supporting base plate; the glaze spraying device is installed at the top of the right end of the supporting base plate; the glaze spraying device comprises a glaze spraying side plate, a glaze spraying push rod, a parallel mechanism, a glaze spraying support plate, a positioning mechanism, a glaze spraying mechanismand a scraping and conveying mechanism. The multi-station automatic glaze spraying machine provided by the invention can solve the problems that in an existing ceramic glaze spraying process, different fixing tools are required if the ceramic is different in size, the position of the ceramic cannot be locked, the ceramic is easily changed in position in rotation; when the outer side surface of the ceramic is subjected to glaze spraying action manually, the manual glaze spraying effect is poor, the ceramic glaze spraying is out of flatness, the redundant glaze material cannot be recycled, thethickness of the glaze material on the surface of the ceramic cannot be regulated and the like; and the multi-station automatic glaze spraying machine can realize the functions of sucking and lockingthe ceramic, limiting the ceramic when the ceramic rotates and implementing overall uniform glaze spraying on the outer side surface of the ceramic.

Owner:ZHEJIANG NANSONG CERAMIC

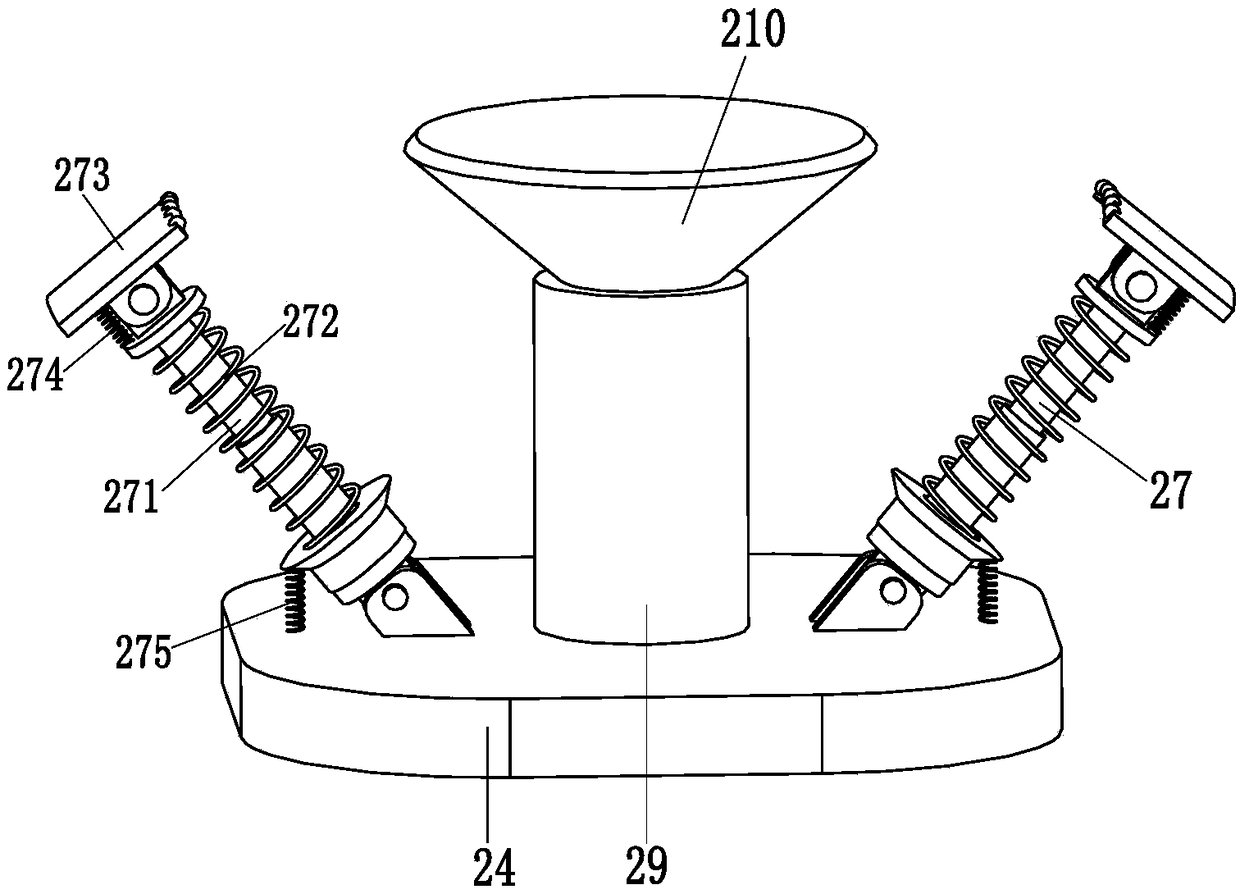

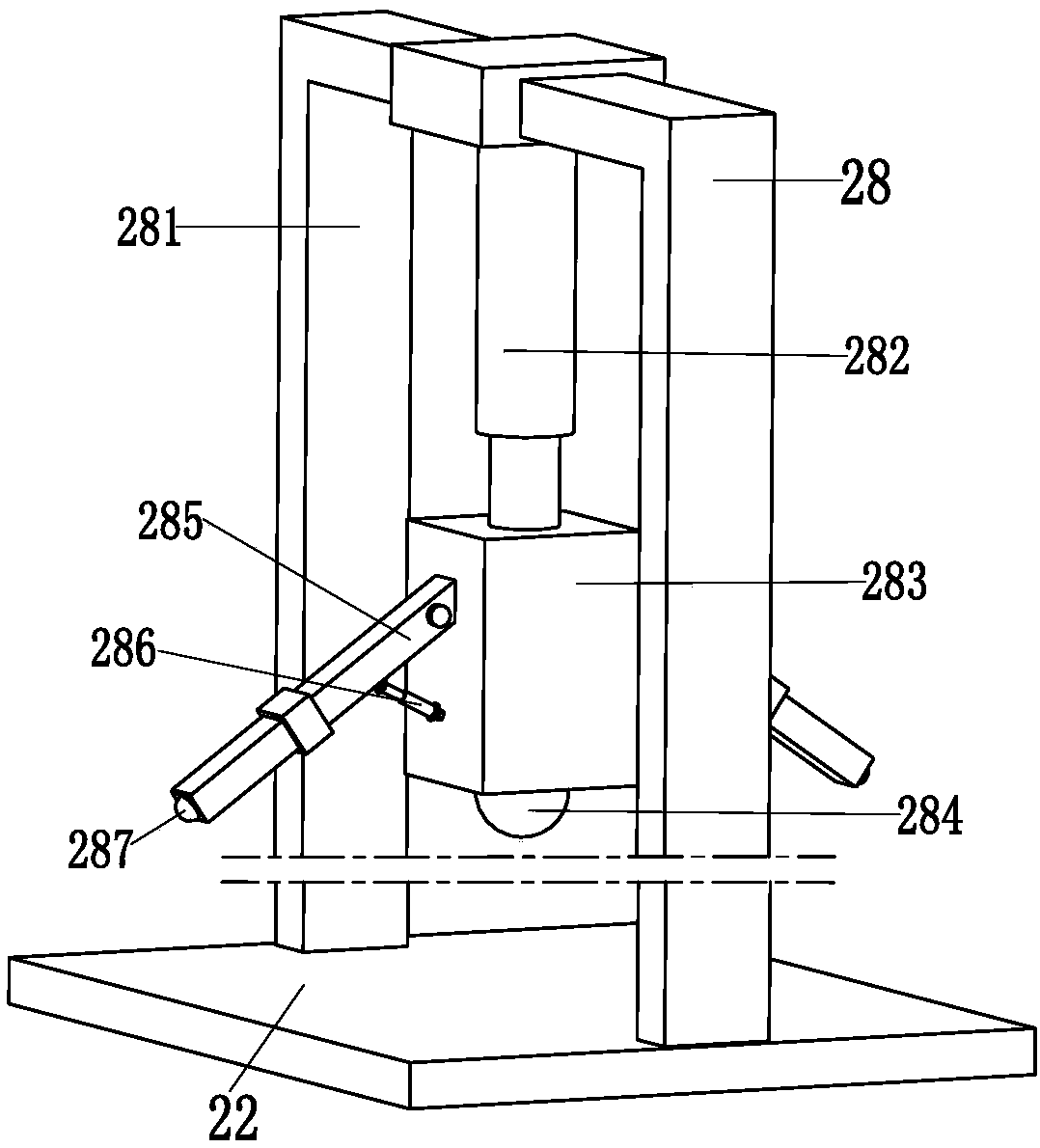

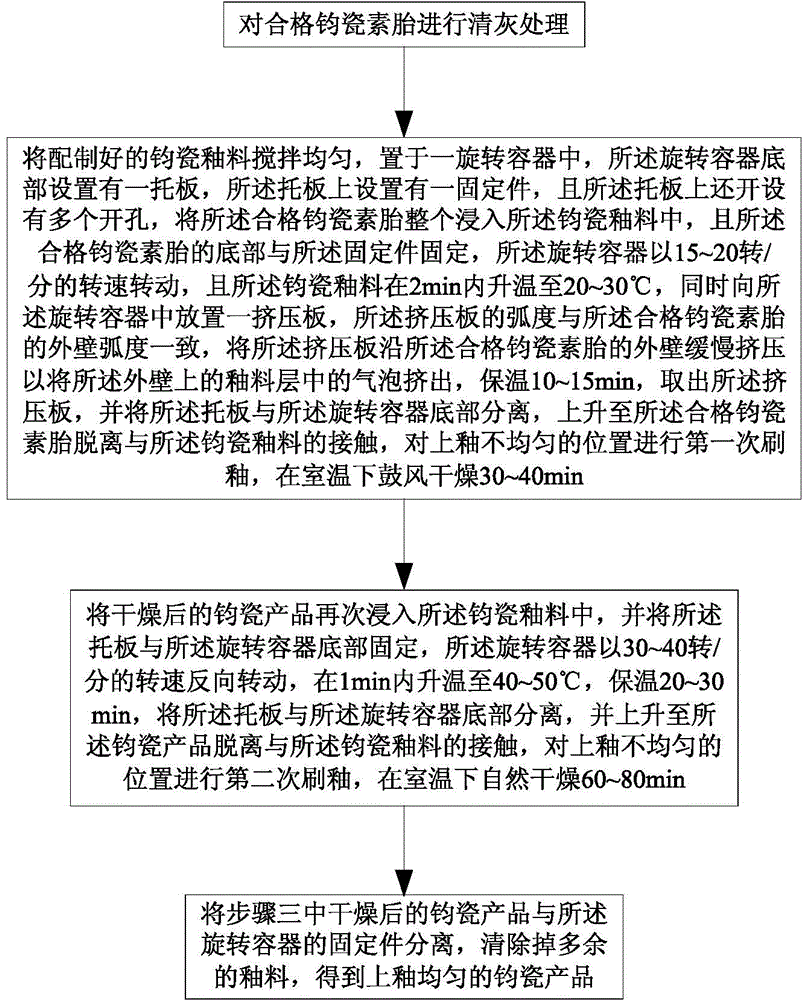

Glazing method of jun porcelain glaze

The invention relates to the field of porcelain glazing and particularly relates to a glazing method of jun porcelain glaze. The glazing method comprises the following steps: performing ash removal treatment on a qualified jun porcelain base; uniformly stirring the prepared jun porcelain glaze and putting into a rotary container; placing a support plate at the bottom of the rotary container and placing a fixing member on the support plate; immersing the whole qualified jun porcelain base into the jun porcelain glaze and fixing with the fixing member; rotating the rotary container and heating the glaze; lifting the support plate until the qualified jun porcelain base gets rid of contact with the jun porcelain glaze and performing first glaze brushing, and performing forced air drying at room temperature; immersing the dried jun porcelain product into the jun porcelain glaze again, reversely rotating the rotary container, heating the glaze and performing second glaze brushing, and drying naturally at room temperature; and clearing redundant glaze to obtain a uniformly glazed jun porcelain product. According to the method provided by the invention, the labor capacity of workers is reduced and mechanization of the jun porcelain glazing operation is realized on the premise of guaranteeing uniform jun porcelain glazing and meeting the quality requirements.

Owner:XUCHANG UNIV

Full-automatic atomization glaze spraying device for ceramic ornaments

The invention discloses a full-automatic atomization glaze spraying device for ceramic ornaments. The full-automatic atomization glaze spraying device for ceramic ornaments comprises a workbench. A glaze can is arranged on the workbench. A feeding pipe is arranged on the top of the glaze can. A liquid indicator is arranged on the glaze can. A pressure pump is arranged at the bottom of an inner chamber of the glaze can. A first connecting pipe is arranged on the pressure pump. A linear actuator is arranged on one side of the glaze can. A second connecting pipe is arranged at the top end of thelinear actuator. A connecting hose is arranged at one end of the second connecting pipe. A rotary sprayer is arranged at the other end of the second connecting pipe. Isolation cloth is arranged on oneside of the linear actuator. A placement platform is arranged on one side of the isolation cloth. With the full-automatic atomization glaze spraying device for ceramic ornaments, a blank can be placed more steadily, and is not prone to shaking during glaze spraying operation, and therefore, the glazing quality of the blank is improved; and a driving motor is used for working, a first gear is driven by a second gear at the end of an output shaft of the driving motor to rotate so that the blank placed on the workbench can be enabled to rotate to receive more uniform glaze spraying during operation, the blank is glazed more uniform, and the glazing efficiency is improved at the same time.

Owner:FOSHAN KEFENG CULTURE COMM CO LTD

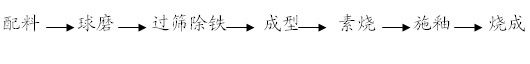

Ceramic product, and preparing and sintering process thereof

The invention relates to a ceramic product which is characterized in that raw material components comprise washing kaolin, Changxing white mud, Fujian pottery stone, feldspar and burned talcum, wherein after blending, sodium humate and sodium silicate are added and ball-milled in a cylinder to obtain a grouting blank of the ceramic product, and the ceramic product is obtained by screening iron, molding, biscuiting, glazing and sintering. According to the invention, a reasonable blank formula, and a preparing and sintering process are adopted, the sintered ceramic product has the advantages of high intensity, high compactness, low water absorption, high dimensional accuracy, corrosion resistance, leakage resistance, good heat stability, no deformation, no crack, and smooth and clear glaze, and has no vices such as pinholes, thin glaze and contracted glaze, so that the defective percentage is reduced, the production efficiency is improved, the production cost is decreased, the artistic degree of the appearance of the ceramic product is promoted; and the method is suitable for high-level ceramic products such as high-grade ceramic wine bottles.

Owner:江苏省宜兴彩陶工艺厂

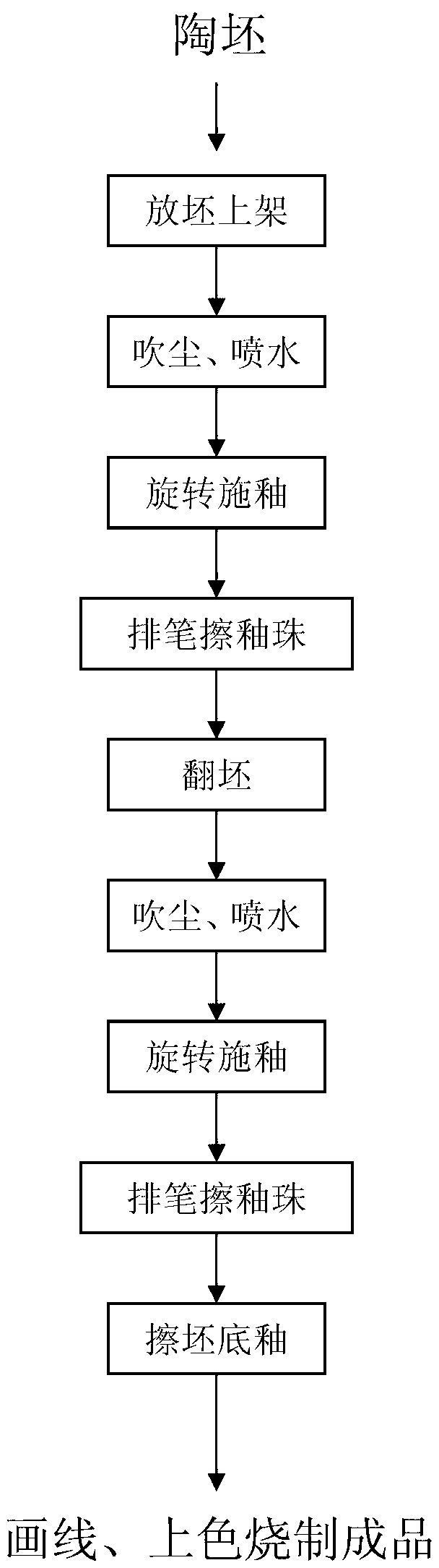

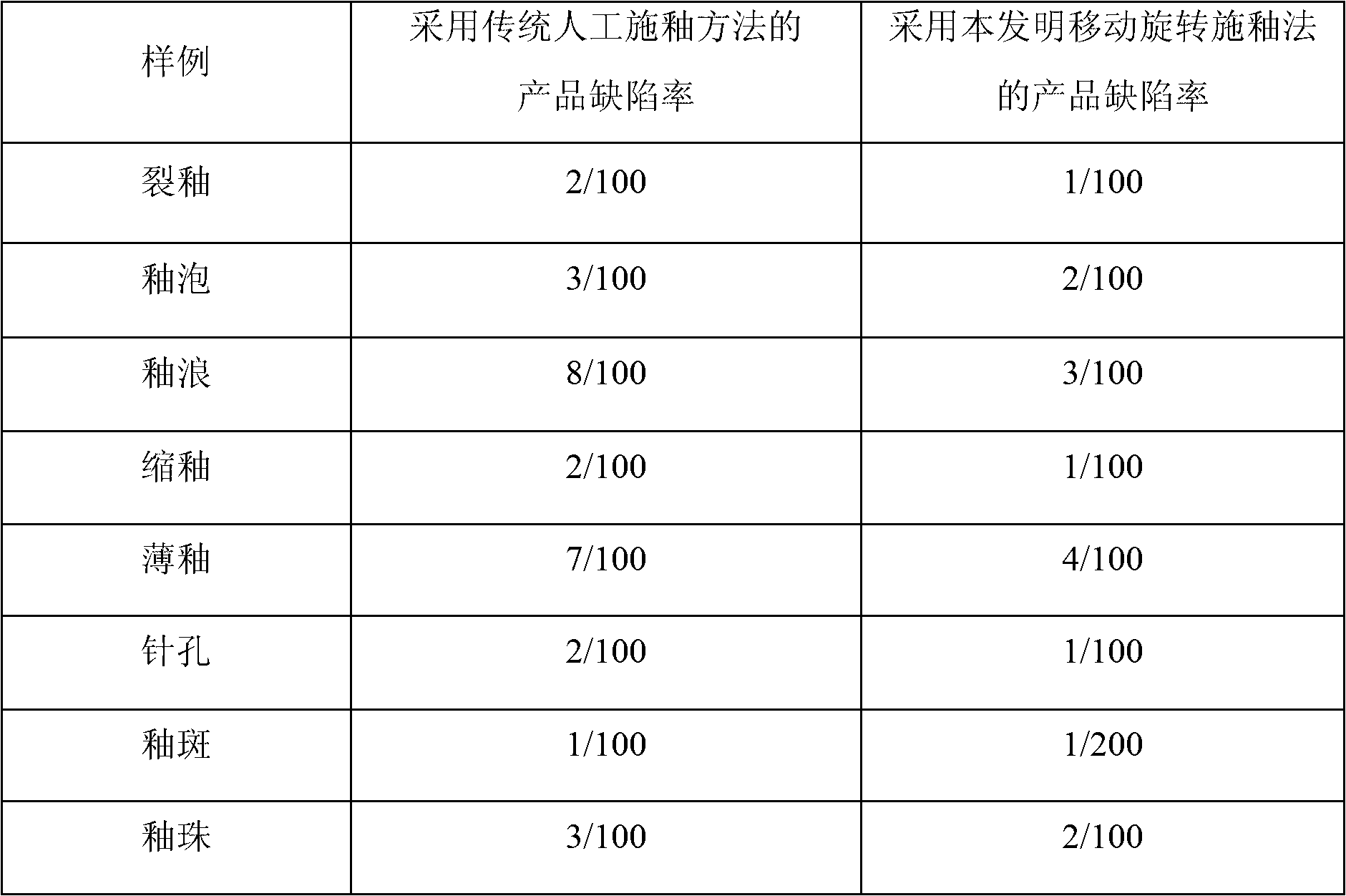

Automatic glazing method for ceramic bowl blank

The invention discloses an automatic glazing method on a domestic ceramic bowl blank surface. Glaze slip is sprayed in the forward motion and rotation process of the blank, the glaze is uniformly coated on the blank surface under the centrifugal force generated by the rotation of the blank, and meanwhile, excessive glaze slip is thrown out from the edge of the blank and collected for cyclic use. The invention can be matched with a large-scale production line, and can be used for small-scale workroom production. The invention overcomes the defects of cracking, bubbling, waving and the like caused by improper operation and other reasons in the artificial glazing process. The blank produced in the mode of glaze slip spraying in the rotation process has the advantages of no waving, uniform glazing and smooth glaze surface; and the invention greatly enhances the production efficiency, and can not generate pollution capable of obviously hurting the human body in the production process.

Owner:GUANGXI BEILIU ZHIYU CERAMIC AUTOMATION EQUIPCO

Guangdong Jun Blue glaze prepared from commonly used raw materials in ceramics factory and preparation method of Guangdong Jun Blue glaze

The invention belongs to the preparation field of traditional Guangdong Jun glaze in Foshan Shiwan art ceramics, and discloses a Guangdong Jun Blue glaze prepared from commonly used raw materials in a ceramics factory and a preparation method of the Guangdong Jun Blue glaze. The method comprises the following steps: using common glaze raw materials widely applied in the existing ceramics factory such as feldspar, quartz, limestone, calcined talc, black clay, cattle and sheep ashes and chemical toners CuO, CoO, Fe2O3 and the like to replace the lead-containing traditional raw materials such as ramulus mori ashes, miscellaneous wood ashes, straw ashes, canal mud, jade powder, carnelian cobble, copper ore, yellow stone, star cinnabar, graphite and Lion mountain ashes which are complex or expensive in treatment, or nearly exhausted, or large in toxicity to the environment. The Guangdong Jun glaze disclosed by the invention is wide in raw material resource, low in cost, simple in preparation process, and unnecessary to renovate the equipment, the obtained Guangdong Jun glaze formula is simple in composition, smooth in glaze, high in stability, and has the color characteristics of the Guangdong Jun glaze.

Owner:FOSHAN UNIVERSITY

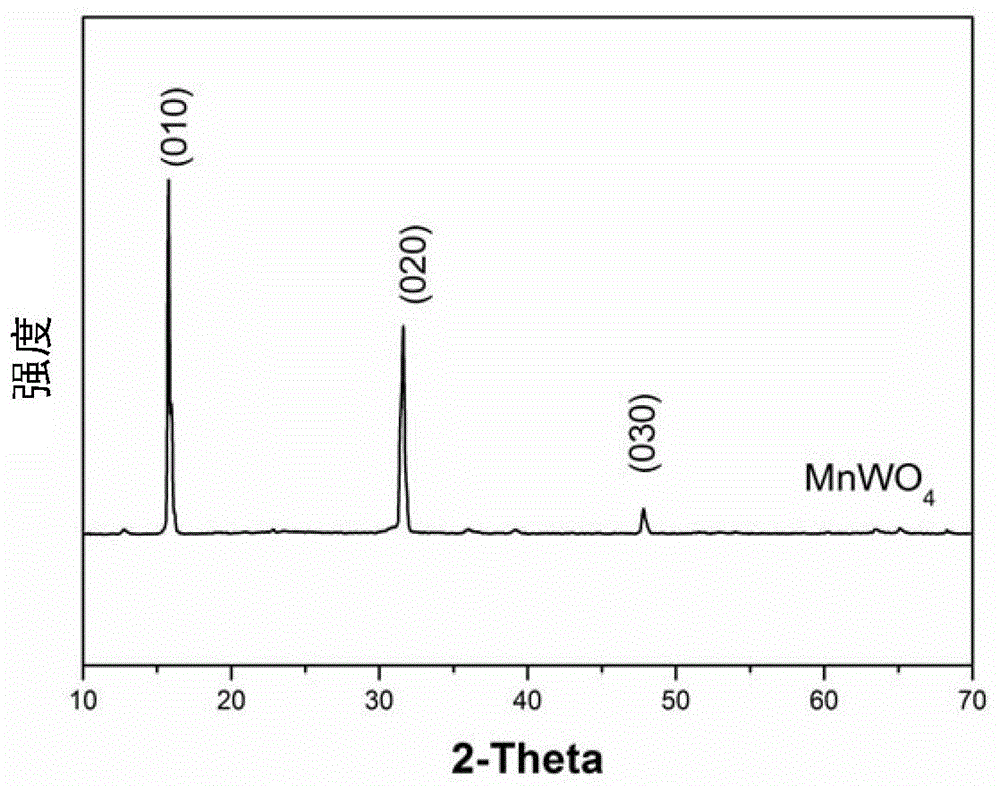

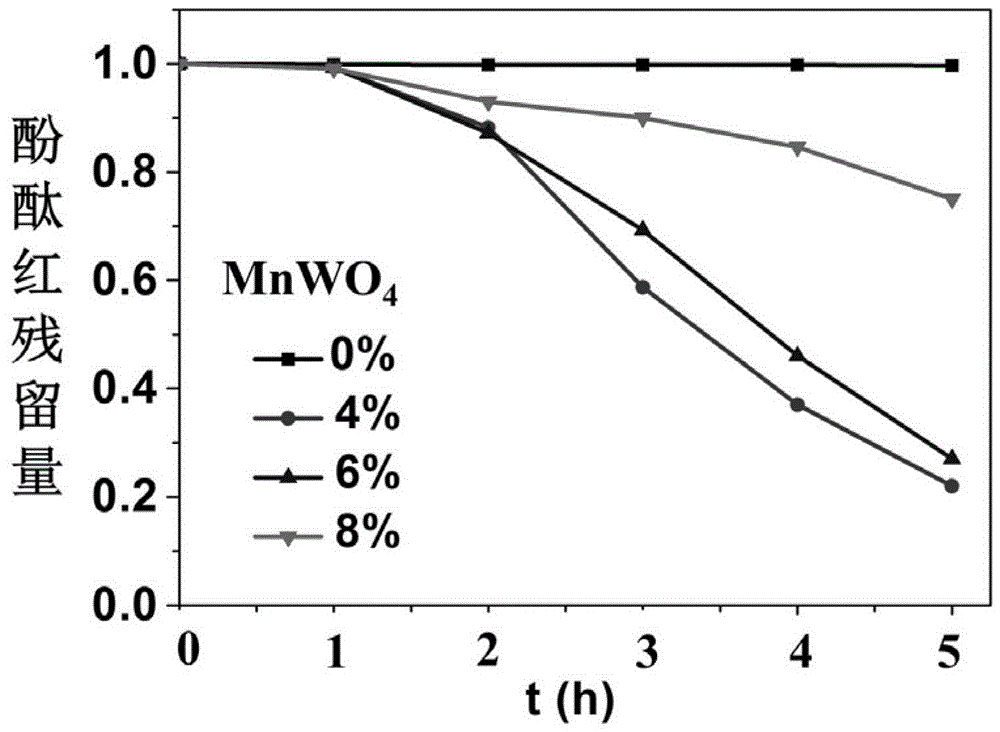

Glaze composition prepared from manganese tungstate as active material and having photocatalytic function and preparation method of glaze composition

ActiveCN106673439AHigh melting temperatureGood suspensionMetal/metal-oxides/metal-hydroxide catalystsTungstateMaterials science

The invention relates to glaze composition prepared from manganese tungstate as an active material and having a photocatalytic function and a preparation method of the glaze composition. The glaze composition is prepared from powder A, MnWO4 and kaolin, wherein the mass percentage of the powder A, MnWO4 and kaolin is (84%-88%): (4%-8%): (6%-10%); the powder A comprises raw materials by weight as follows: 20%-30% of SiO2, 5%-10% of Al2O3, 40%-50% of P2O5, 1.5%-2.5% of MnO, 12%-14% of Li2O, 6%-8% of Na2O and 12%-13% of K2O. The glaze composition contains the powder A as a main component, contains an appropriate amount of MnWO4, and has an excellent photocatalytic function on the basis of a good glaze effect.

Owner:MONALISA GRP CO LTD

Light-emitting painted pottery glaze composition

The invention relates to a light-emitting painted pottery glaze composition which is characterized in that the glaze material is prepared from the components of, by weight, 45-55 parts of nano-silica, 25-35 parts of electronic-grade red lead, 0.4-0.6 part of graphene, 0.4-0.6 part of glyceryl behenate, 0.4-0.6 part of hydroxypropyl-beta-cyclodextrin, 0.4-0.6 part of modified corn starch, 4-6 parts of copper oxide, 1-2 parts of polyethylene wax, 0.1-0.3 part of iron oxide, 1-3 parts of potassium feldspar micro-powder, 0.4-0.6 part of silver nitrate, and 1-3 parts of sea mud. The painted pottery fired with the glaze composition has a crystal clear, bright and smooth glaze, and an excellent decorative effect. With the modified sea mud, the glaze never peels from a finished product, and the product can be preserved permanently.

Owner:柳培健

Method for preparing medium-temperature high-alumina high-strength domestic ceramics

The invention discloses a method for preparing medium-temperature high-alumina high-strength domestic ceramics. The method comprises the following production steps: 1, preparing a blank, namely by taking corundum, potassium feldspar, kaolin, ball clay, talc, zinc oxide and zirconia as raw materials, performing wet milling, removing iron, performing filter pressing, pugging, and preparing an ejection material for later use; 2, preparing a glaze, namely taking potassium feldspar, quartz, talc, kaolin, stalactite, zinc oxide and corundum as raw materials of the glaze, mixing the materials, and performing ball milling; removing iron from ball-milled material through an iron removal machine, passing the material through a 325-mesh screen, and preparing a finished glaze for later use; and 3, performing a product manufacturing process comprising molding, fettling, glazing and firing, thereby preparing the medium-temperature high-alumina high-strength domestic ceramic product. The domestic ceramic product prepared by the method is high in yield, regular in appearance and flat in glaze surface; the thermal shock resistant test proves that the domestic ceramic product of 200 DEG C is not cracked when added into water at the temperature of 20 DEG C for performing heat exchange once; the Vickers microhardness of the glaze surface is higher than 6.0GPa; and the shock strength is higher than 1.5J / cm<2>.

Owner:CHAOZHOU LIANJUN CERAMICS CO LTD

Frit used for producing Longquan celadon, Longquan celadon frit glaze and production method of frit glaze

The invention discloses a frit used for producing Longquan celadon, a Longquan celadon frit glaze and a production method of the frit glaze. Raw materials of the frit comprise, by weight, 45-95% of rare earth tailings, 1-30% of Longquan porcelain clay, 1-25% of alumina powder, 1-15% of kaolin, 1-30% of yellow glaze soil, 0-25% of potash feldspar, 0-20% of quartz and 0-10% of talcum. The rare earth tailings are adopted as a main raw material of the frit, so the recycling of the rare earth tailings is realized, and the use amounts of other routine Longquan celadon raw materials are greatly reduced; and trace rare earth elements in the rare earth tailings have an obvious color development promoting effect on the celadon glaze, so extra addition of a coloring agent or a ceramic coloring chemical engineering raw material to the glaze is prevented, thereby the manufacturing cost of the Longquan celadon frit glaze is reduced, the color appearance of the glaze is stable, and industrial large-scale production is facilitated.

Owner:LISHUI UNIV

Preparation method of wet-process dry-grain polished crystal brick and polished crystal brick

ActiveCN110981197AEasy to recycleEasy to adjust the glaze amountCeramic shaping apparatusTextile printerProduction line

The invention discloses a preparation method of a wet-process dry-grain polished crystal brick and the polished crystal brick. The preparation method comprises the following steps: preparing a green brick; performing drying for the first time; applying surface glaze; performing ink-jet printing; applying dry particle protective glaze; performing drying for the second time; and performing firing and molding. The wet-process dry-grain polished crystal brick sequentially comprises a green brick layer, a cover glaze layer, a printing layer and a dry-grain protective glaze layer from bottom to top.The polished crystal brick with excellent performance is prepared by controlling production process parameters and the setting of proper components and proportion of dry particles and dry particle protective glaze. The method is suitable for existing production equipment, and a production line does not need to be modified; a glaze spraying process is adopted, a glaze layer is more uniform, and abell jar is adopted for glaze spraying, so that the glaze amount is more convenient to adjust, and the recycle is easy; the required glaze layer is thinner and is only 1 / 5 of the dosage of dry-processdry particles, so that the dosage is lower, the firing period is shorter, the production cost is reduced, and the production efficiency is improved; meanwhile, compared with a dry method, the defectsof bubbles, pinholes and the like of the glaze layer are fewer, and color development is finer and richer.

Owner:FOSHAN OCEANO CERAMICS

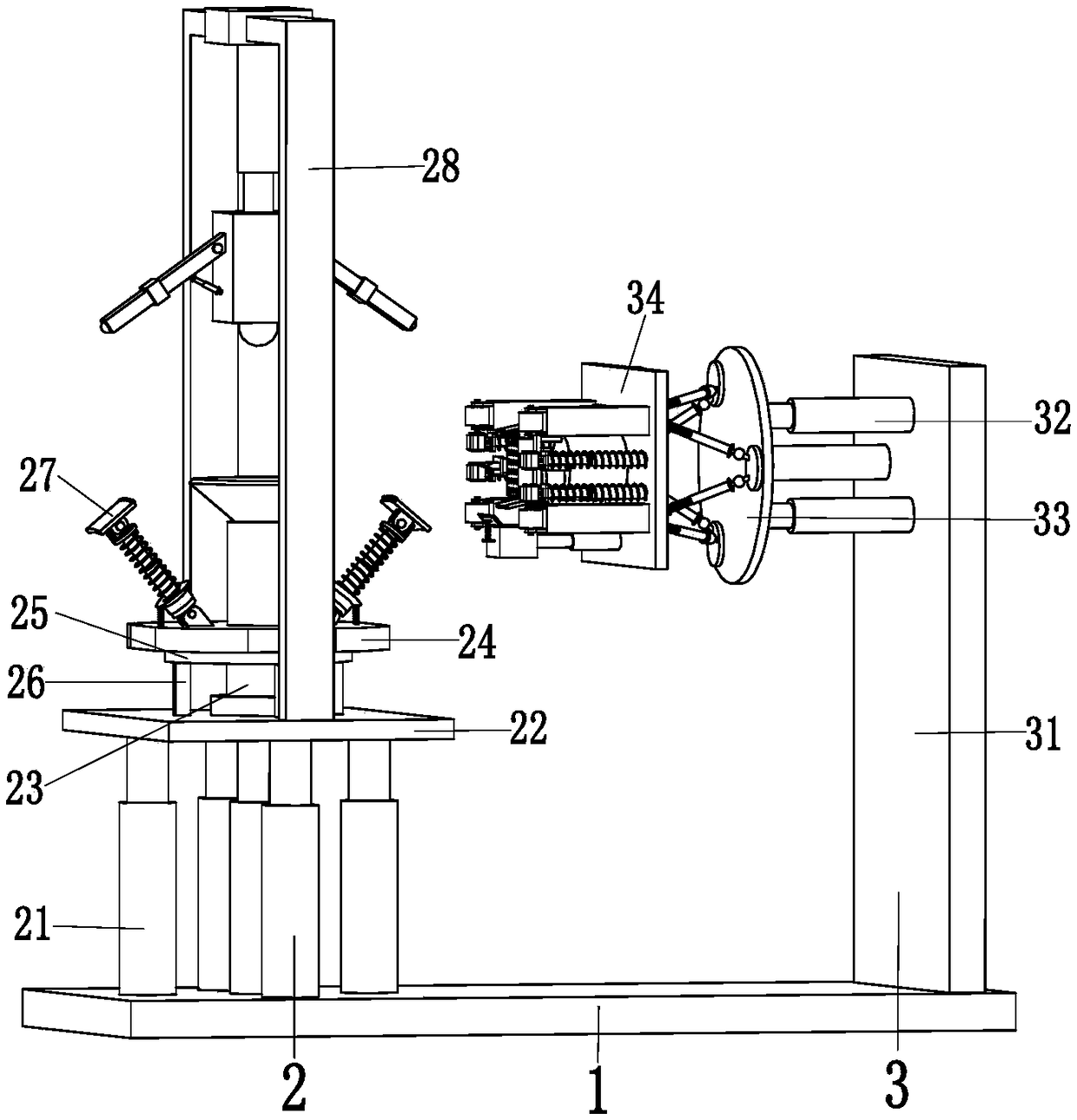

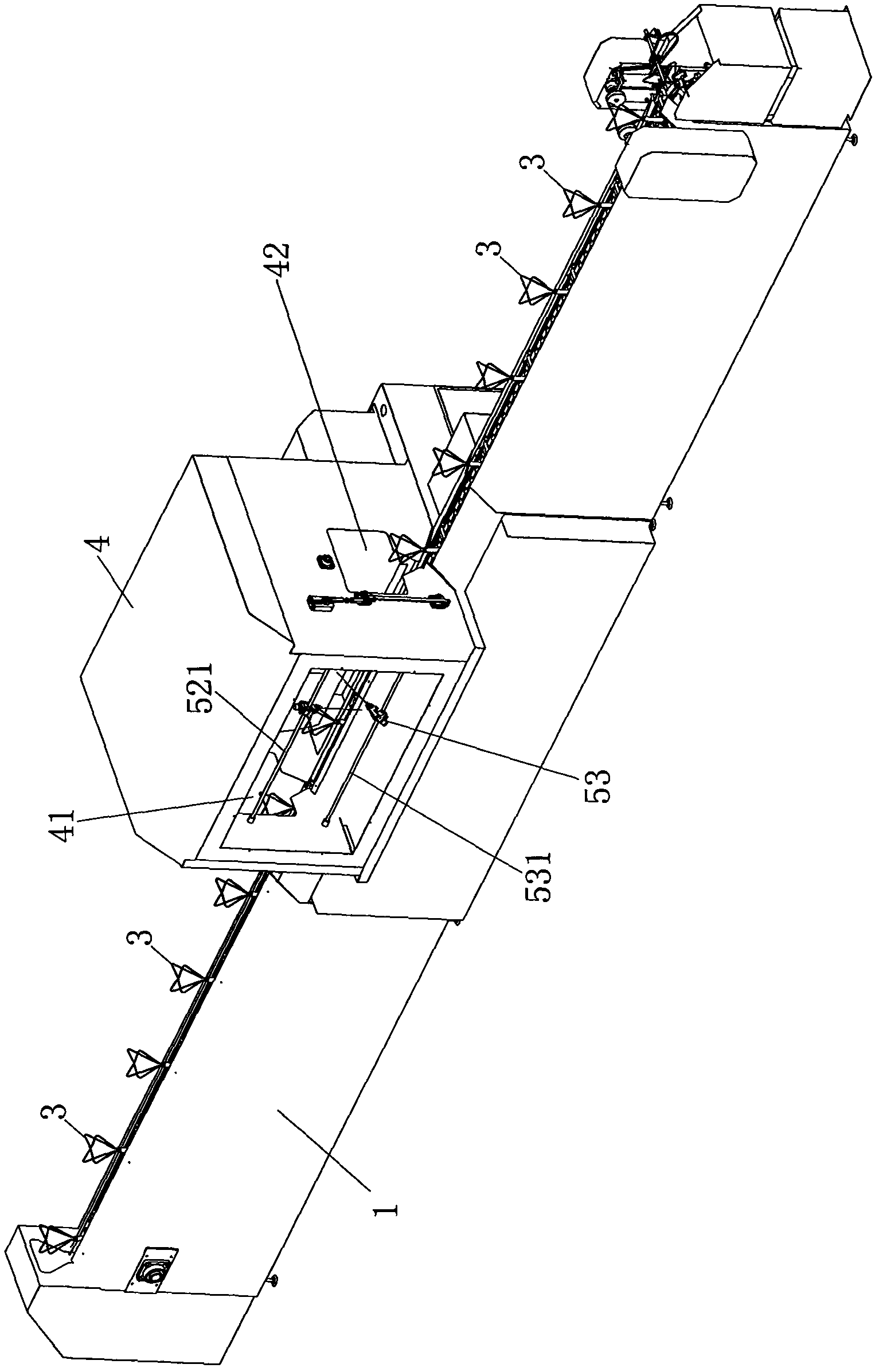

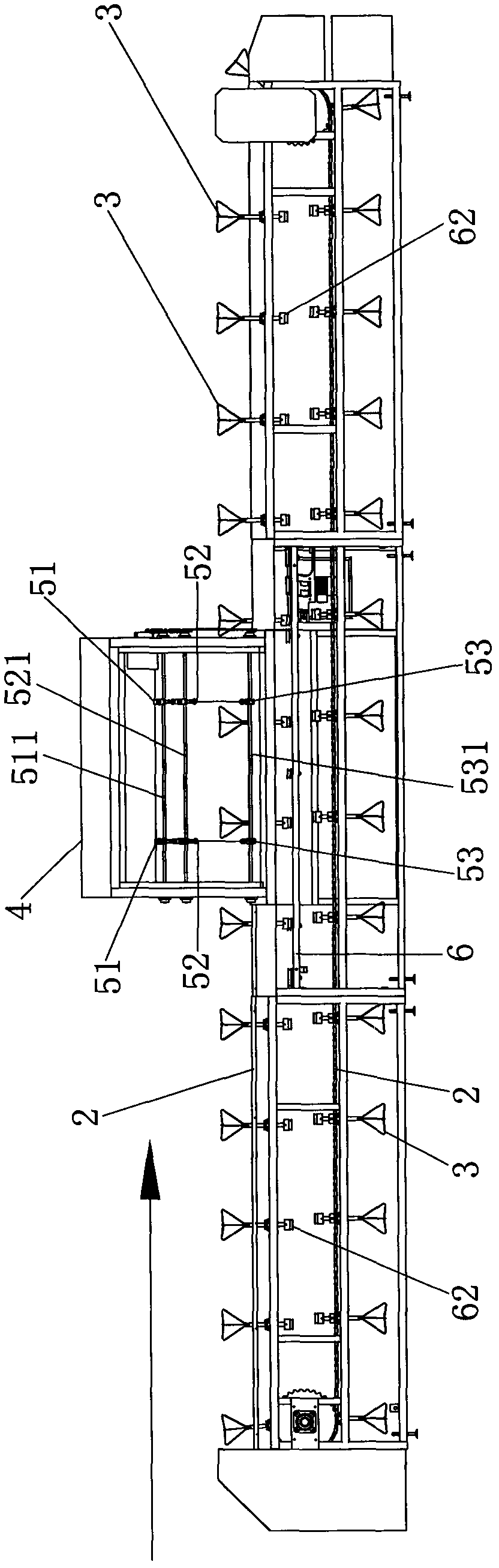

Device for automatically spraying glaze to open ceramic product

The invention discloses a device for automatically spraying glaze to an open ceramic product. The device comprises a rack which is provided with a first motor and two circulation chains; a longitudinal guide rail is arranged near each circulation chain; a plurality of horizontal cross rods are connected between the left and right circulation chains; a workpiece support for placing the ceramic product is arranged in the center of each horizontal cross rod in a rotatable way; each workpiece support is provided with a revolving shaft, and each workpiece support is coaxially and fixedly connectedwith a driven wheel; a glaze spraying box is arranged above the two longitudinal guide rails, and a plurality of glaze spraying units are arranged in the glaze spraying box; each glaze spraying unit comprises three glaze spraying guns, each glaze spraying gun of each glaze spraying unit is fixedly arranged on one revolving shaft, and the device is also provided with a glaze spaying gun point swinging mechanism for driving the revolving shaft of each glaze spraying gun to rotate; and a transmission belt is arranged below the glaze spraying box. The device can automatically apply glaze to the open ceramic product, and high glazing quality and automaton level are achieved.

Owner:CHAOZHOU ZHONGCHUANG ELECTROMECHANICAL EQUIP

Corrosion reaction glaze and preparation method thereof

The invention discloses a corrosion reaction glaze and a preparation method thereof and belongs to the field of preparation of reaction glazes. The reaction glaze comprises a priming glaze and a finishing glaze; the priming glaze is prepared from the following components in percentage by mass: 18-23% of potash feldspar, 6-13% of soda feldspar, 7-12% of calcite, 3-8% of Guizhou soil, 15-25% of frit, 6-12% of quartz, 6-15% of zinc oxide and 12-19% of zirconium silicate; the finishing glaze is prepared from the following components in percentage by mass: 15-25% of potash feldspar, 8-12% of soda feldspar, 11-16% of quartz, 5-10% of calcite, 5-10% of Guizhou soil, 24-35% of frit, 0.5-3% of zirconium silicate, 2-5% of zinc oxide, 2-6% of silver grey and 0.2-0.5% of cobalt black. A designed pattern surface can be generated by adjusting raw material components of the priming glaze and the finishing glaze, corroding an oil silk screen on a glaze blank to print patterns and reacting under the high-temperature condition. Lines on the pattern surface of ceramic products produced by corrosion reaction are relatively clear, vivid, natural and dense, and have strong stereoscopic effects; and the effect is colorful and bright.

Owner:醴陵市恒辉瓷厂

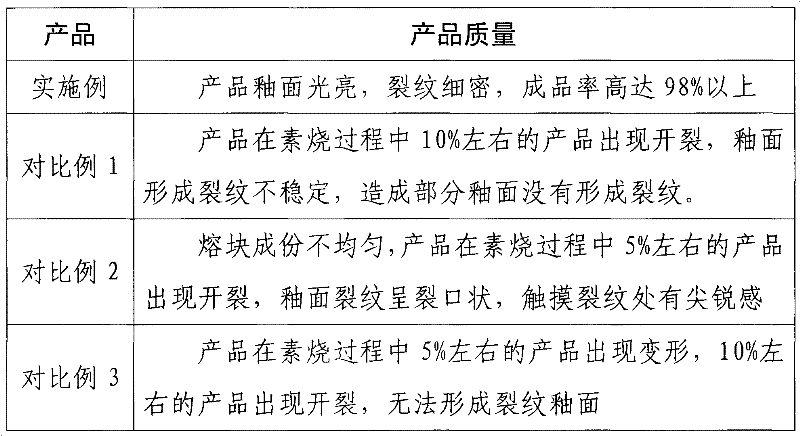

Method for producing ceramic product with crack glaze by use of waste ceramic material and waste glass

ActiveCN102503570ASmooth cracked glazeSmooth glazeTransportation and packagingCeramic materials productionStalactiteFrit

The invention discloses a method for producing ceramic products with crack glaze by use of waste ceramic material and waste glass, comprising the steps of taking waste ceramic material, waste glass, zircon sand and talc; after mixing, crushing and sieving the mixture, melting the mixture till the mixture is molten; performing water quenching and drying, and obtaining frit for later use; putting frit, feldspar, diatomite, stalactite and kaolin to a ball grinder; adding fresh water to ball-grind, and sieving; sieving, removing iron, filter pressing and pugging, and obtaining ceramic mud for later use; using the ceramic mud to produce ceramic blank, performing biscuiting; using the crack glaze to glaze the biscuited blank, and finally obtaining the product. The product manufactured by the invention has smooth glaze, fine crack and high yield; and large amounts of waste ceramic materials and waste glass can be recycled.

Owner:黄秋生

Glazing equipment for ceramic production

The invention discloses glazing equipment for ceramic production. The equipment comprises a base, a groove is formed in the top of the base, a supporting column is fixedly arranged at the top end of the groove, the top end of the supporting column is fixedly connected with the middle of the bottom end of a workbench, the bottom end of the supporting column is rotationally connected with an outputshaft of a motor, the motor is arranged in a motor cavity formed in the base, the two sides of the top end of the base are fixedly connected with the two ends of a U-shaped supporting plate, and dryers are fixedly arranged on the two sides of the outer wall of the U-shaped supporting plate. According to the glazing equipment for ceramic production, the motor arranged in the base drives the workbench to rotate so as to drive ceramic to rotate, so that uniform glazing of the ceramic is guaranteed; through spray heads arranged on the inner wall of the U-shaped supporting plate, drying of sprayedglaze liquid is accelerated, and the working efficiency is improved; through collecting boxes arranged at the top of the base, the dropped glaze liquid is effectively recycled, and the production costis reduced; and the spray heads are arranged at one ends of electric telescopic rods so that the spraying height of the second spray heads can be conveniently controlled.

Owner:江苏康姆罗拉特种陶瓷有限公司

Method for decreasing glaze pinholes and bubbles

The invention mainly relates to the technical field of ceramic glaze processing and discloses a method for decreasing glaze pinholes and bubbles; the method comprises: mixing materials, melting for the first time, quenching for the first time, melting for the second time, quenching for the second time, ball-milling and pulverizing, and glazing and firing; the method is simple and convenient to perform, and can decrease glaze pinholes and bubbles by 90.9% and save product cost by 21.2%; the raw materials are crushed, water is added for melting, mixing well the materials is facilitated, sodium nitrate solution is added for quenching, double melting and quenching are performed, emission of the gas from the materials is quickened, the stability, mobility and compactness of the glaze are improved, glaze can be applied evenly, the cost can be saved as low-temperature slow firing is performed, the glaze has bright color and zero pinholes and bubbles, has matching expansion coefficient, and has smooth surface, good corrosion resistance and service life extended by 16.4%.

Owner:界首市伟盛古窑彩陶制作发展有限公司

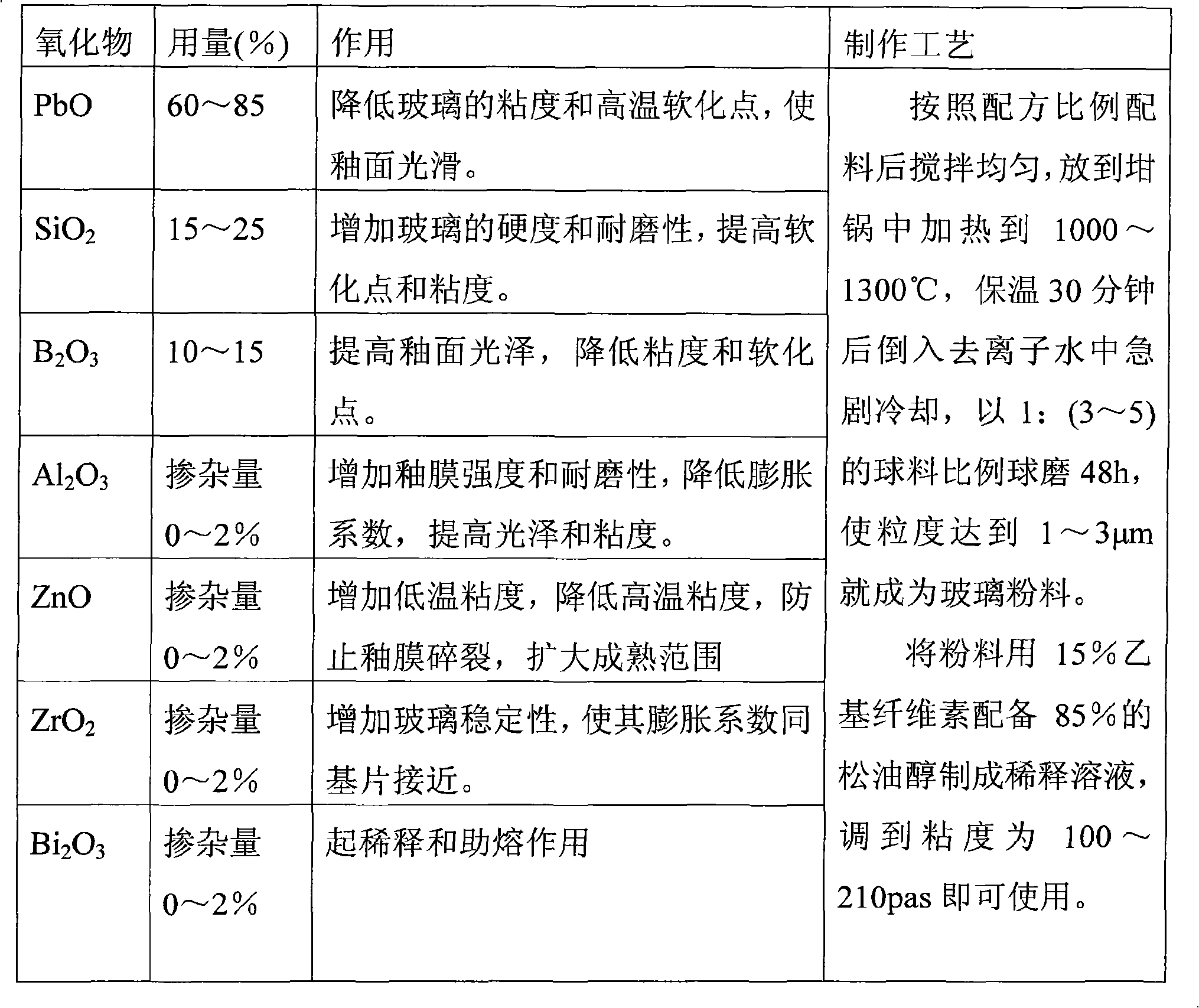

Ceramic heating piece for laser printer and manufacturing process thereof

ActiveCN101598924ALow priceImprove thermal conductivityElectrographic process apparatusHeating element materialsComputer printingThin membrane

The invention relates to a ceramic heating piece for a laser printer and a manufacturing process thereof, wherein a ceramic substrate is sintered with a film heating wire, two ends of the film heating wire are provided with extraction electrodes, a medium covering layer is arranged outside the film heating wire, the ceramic substrate is made from aluminum oxide, and the covering layer is made from glass glaze. The manufacturing process comprises the following steps: printing a conductive sizing agent on the substrate, performing high temperature sintering for the first time, printing a noble metal sizing agent, performing the high temperature sintering for the second time, printing a glass glaze sizing agent, and performing the high temperature sintering for the third time. The ceramic heating piece has the advantages of having low price, providing a convenient and practical objective condition for the regeneration of a damaged laser printer, and being advantageous for the development and the popularization of environmental protection and regeneration.

Owner:BEIJING LASER HI TECH CO LTD

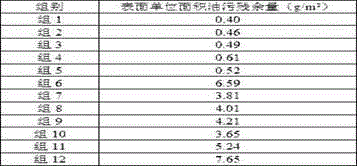

Easy-cleaning ceramic glaze as well as preparation method and application thereof

The invention discloses an easy-cleaning ceramic glaze as well as a preparation method and application thereof. The easy-cleaning ceramic glaze consists of the following raw materials in percentage by weight: 33-35% of potash feldspar, 10-12% of kaolin, 13-15% of calcium oxide, 8-10% of magnesium oxide, 6-8% of zinc oxide and 24-26% of quartz. All the raw materials are mixed and crushed to perform wet ball milling so as to obtain a glaze slip, and the glaze slip is subjected to iron removal, screening and aging for later use. According to the easy-cleaning ceramic glaze disclosed by the invention, various metal oxides are added in the formula of an easy-cleaning daily ceramic glaze to improve the easy-cleaning degree of the ceramic glaze and generate a synergistic action, the easy-cleaning degree and the glossiness of the obtained easy-cleaning ceramic glaze are much higher than those of the ceramic glaze in the past, and a glaze surface is smooth and nonstick to greasy dirt, so that the easy-cleaning ceramic glaze not only has significant self-cleaning capability and easy-cleaning property, but also has effective sterilizing, antibacterial, odor-removing and enzyme-preventing effects; and meanwhile, the obtained easy-cleaning ceramic glaze is leadless, green and safe.

Owner:GUANGDONG SHUNXIANG ENERGY SAVING LIGHTING TECH

Automatic glazing device for porcelain insulator

The invention discloses an automatic glazing device for a porcelain insulator and belongs to the field of porcelain insulators. The automatic glazing device for the porcelain insulator comprises a glaze liquid pond and glaze spraying mechanisms arranged on the two opposite sides of the glaze liquid pond; a grabbing mechanism comprises a rack, a lifting cylinder, an electric machine, a fixed rod and a grabbing unit; the grabbing unit comprises a grabbing rod, a rubber gas bag and an electric gas pump; the rubber gas bag is arranged at the bottom end of the grabbing rod; the electric gas pump isfixed to the grabbing rod, and a pump opening is connected with the rubber gas bag though a ventilation pipeline; the top end of the grabbing rod is fixedly connected with a round bead ball through aconnection rod; a spherical groove is formed in the fixed rod from the bottom; and the round bead ball is rotationally fixed in the spherical groove. According to the automatic glazing device for theporcelain insulator, it is effectively avoided that because the porcelain insulator is too thin or too long, the porcelain insulator generates interior cracks to be broken under the inclined condition, and meanwhile, the vertically arranged porcelain insulator is more uniform in glaze spraying.

Owner:萍乡市中南电瓷厂

Diatomite ceramic mud

The invention belongs to the field of ceramic materials, in particular to a diatomite ceramic mud. A diatomite ceramic mud, comprising the following raw materials in parts by weight: 30-50 parts of refined diatomite, 20-30 parts of kaolin, 4-6 parts of talcum powder, 4-6 parts of quartz, and 2-4 parts of nano-titanium dioxide , 3-5 parts of activated carbon powder, 3-5 parts of aluminum oxide, 1-3 parts of chromium oxide, 6-10 parts of white carbon black, 1-2 parts of citrate, and 1-3 parts of negative oxygen ions. The diatomite ceramic mud material provided by the present invention contains the diatomite component of diatomite in the mud material, which can not only make the glazed surface of the product smooth, hard and durable, but also be placed in the indoor environment to effectively absorb the moisture in the air. Harmful substances, release negative ions, purify the air.

Owner:青岛宏致复合织造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com