Patents

Literature

31results about How to "Stable color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

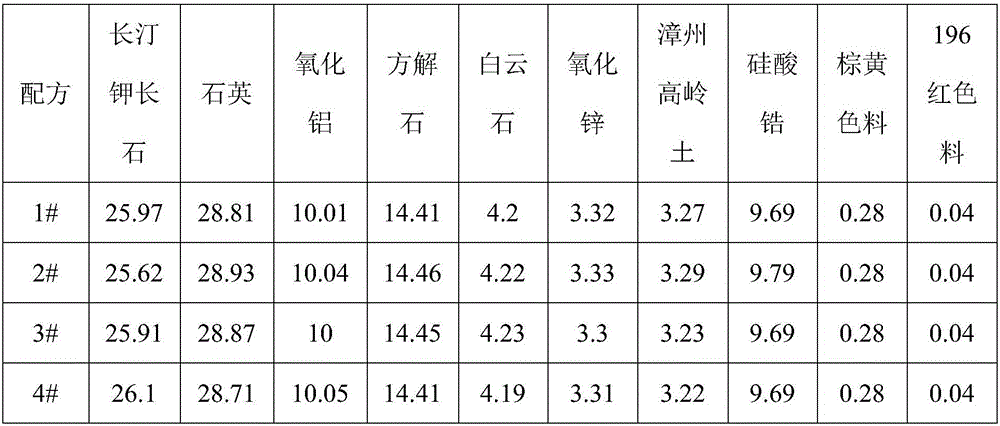

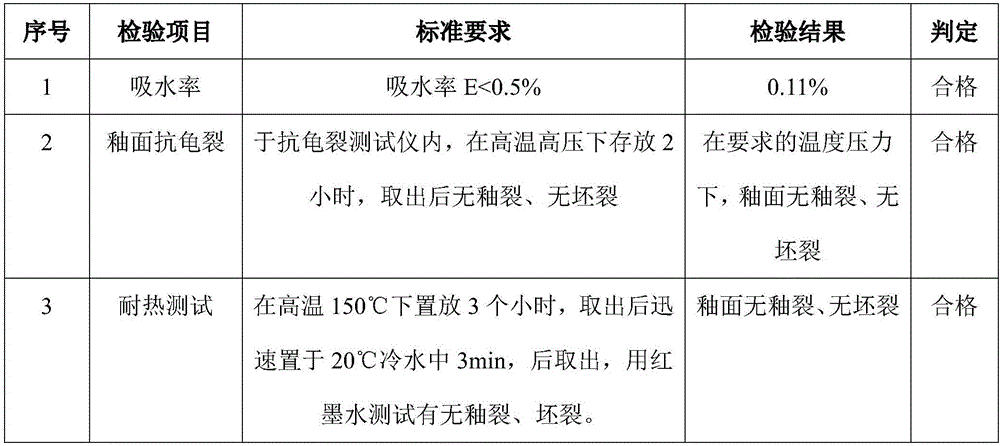

Preparation method of matte glaze sanitary ceramic

The invention discloses a preparation method of matte glaze sanitary ceramic. The preparation method comprises the steps of carrying out ball milling on 27.8%-29% of quartz, 25.5%-26.9% of Changding potassium feldspar, 13.55%-15.5% of calcite, 3.83%-4.3% of dolomite, 3%-3.3% of Zhangzhou kaolin, 9%-10.1% of zirconium silicate, 9.83%-10.1% of aluminum oxide, 3.2%-3.4% of zinc oxide, 0.03%-0.04% of sodium carboxymethylcellulose and 1.06%-1.95% of sodium carbonate until the particle size of slurry is smaller than 10 microns and the ratio is 60%-65%, adding ceramic pigments, continuing to carry out ball milling until the particle size of slurry is smaller than 10 microns and the ratio is 69%-71%, sieving by virtue of a 180-mesh sieve so as to obtain uniform sanitary ceramic matte glaze slurry, spraying the sanitary ceramic matte glaze slurry to the surface of a sanitary ceramic blank, adequately drying, firing in a tunnel kiln at 1200-1250 DEG C for 15-18 hours, and cooling, so as to obtain the matte glaze sanitary ceramic product. The prepared matte glaze sanitary ceramic has a special matte effect and pure colors and is rich in aesthetic perception, and the problem of poor sewage resistance of traditional matte glaze is further overcome.

Owner:JOMOO KITCHEN & BATHROOM

Color master batch for polyester and preparation method thereof

The invention discloses black master batch for polyester and a preparation method thereof. The color master batch for polyester is prepared from the following components by mass percentage: 60-90% of pigment, 15-30% of carrier, 0.1-2% of dispersant, and 0.1-1% of anti-oxidant. The beneficial effects reside in that: when used for coloring a polyester product, the polyester black master batch provided by the invention has advantages of good dispersibility and stable color, overcomes easy generation of problems of uneven color, big aberration and influence on intensity of the polyester product when the general master batch is used for coloring polyester in the prior art, avoids environment pollution, guarantees color and purification of the product, and is convenient for using. The preparation method provided by the invention has advantages of simpleness, practicality and wide application prospect.

Owner:QINGDAO XINZHAN PLASTIC

High temperature scarlet ceramic pigment and production method thereof

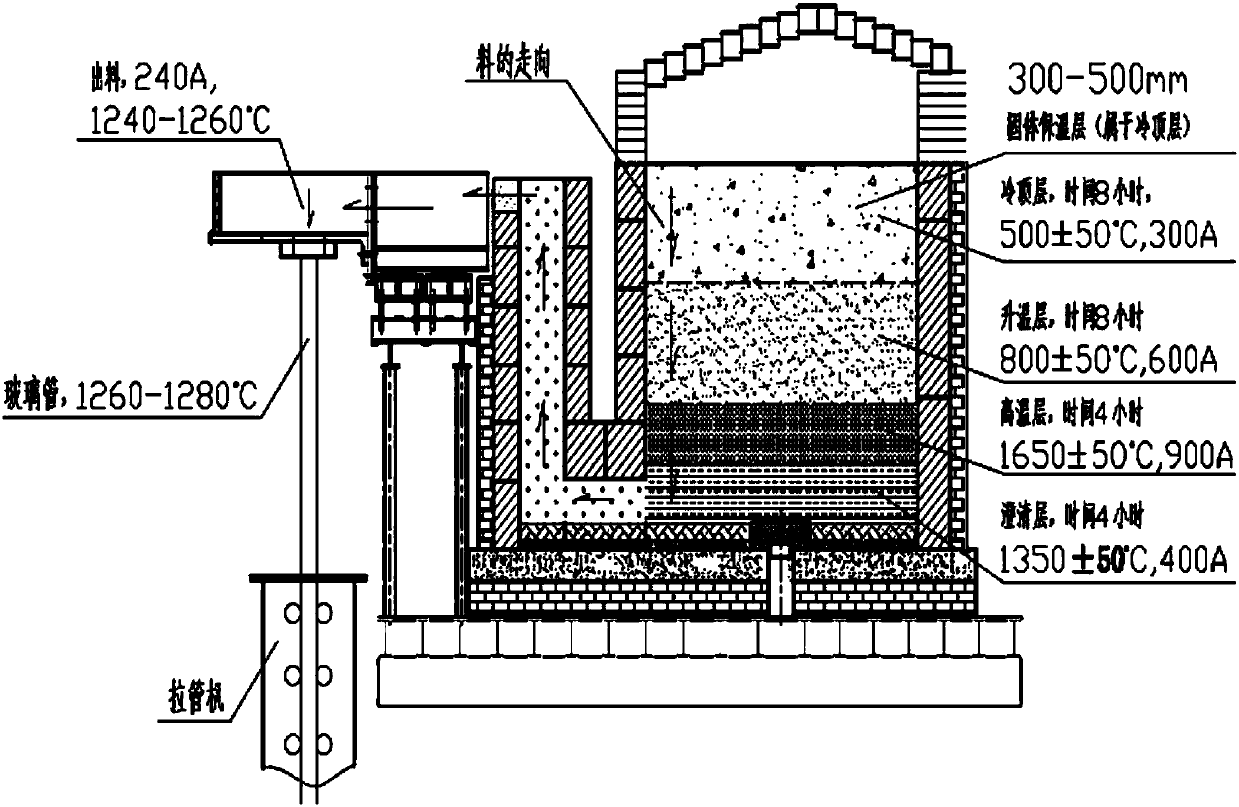

The invention provides a high temperature scarlet ceramic pigment and its preparing process, wherein the raw materials comprise (by weight percent) yttrium oxide 63.50-66.50, aluminum oxide 30.50-34.50, chromium hemitrioxide 0.90-1.90, and mineralization agent 1-5. The preparing process consists of weighing raw materials and batching, grinding the batches and sieving, drying and dewatering, synthesizing in a high-temperature electric resistance furnace, thermal insulating and naturally cooling, grinding, rinsing and sieving.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Blue background and mottled spot composite Tang jun glaze and technology for preparing jun porcelain through same

The invention provides a blue background and mottled spot composite Tang jun glaze and a technology for preparing jun porcelain through the same. Firstly, casing body raw materials are smashed and molded, and a prime casing is fired; then, the prime casing is soaked into blue background glaze slurry to be subjected to glazed, and after the blue background glaze slurry attached to the surface of the prime casing is dried, mottled spot glaze slurry is applied to local points on the surface of the prime casing; after the mottled spot glaze slurry attached to the surface of the prime casing is dried, the prime casing is placed in a kiln to be fired, and then the blue background and mottled spot composite Tang jun glaze jun porcelain is obtained. According to the blue background and mottled spot composite Tang jun glaze and the technology for preparing the jun porcelain through the same, due to the fact that iron elements, copper elements and cobalt elements are added in the blue background glaze according to specific proportions and a secondary glazing mode is used, glaze layer hacking is uniform and is not prone to bursting. The technology breaks through the overglaze color or underglaze color coloring technology adopted by a common mottled spot porcelain, the economic value of the jun porcelain is creatively increased on the aspects of glaze colors and a coating, the technology represents the advanced level of the manufacturing technology in China, and the social value of the jun porcelain is improved.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Dyeing technology of cotton linen blend yarn

The invention discloses a dyeing technology of a cotton linen blend yarn. The dyeing technology comprises the following steps of: preparing; releasing a cylinder; scouring and bleaching; dyeing; fixing color; washing; dewatering; drying; spooling; and packing. The scouring prescription is changed in the dyeing technology of the cotton / linen blend yarn disclosed by the invention, so that the dye-uptake of the cotton / linen blend yarn can be improved; the step of fixing color is increased in the process of dyeing, so that the cotton / linen blend yarn is more stable in color; after the dyeing technology disclosed by the invention is adopted, the dye-uptake can be improved, the color is more stable, the market competitiveness of products can be preferably improved, and the economic benefit can be improved.

Owner:太仓市隆丝达针织时装有限责任公司

Method for coloring up sintered glass-ceramic

A process for colouring the sintered microcrystal glass includes adding one or more high-temp inorganic pigments to the smelted color-less glass blocks, pulverizing, mixing, smelting at 1200-1350 deg.C, quenching in water to obtain blocks, shaping, and sintering for crystallizing. Its advantages are rich colors and uniform and stable color.

Owner:广东和美陶瓷有限公司

Manufacturing process of casual belt

ActiveCN104256981AImprove friction resistanceStable colorLeather websDyeing processFastenerEngineering

The invention discloses a manufacturing process of a casual belt. The method comprises the following steps of (1) dyeing including selecting leather, mixing paints according to a required color to dye the leather and then drying the leather naturally; (2) high-temperature pressing including pressing the dyed leather through a press at 30-50 DEG C, and then performing manual color retrouching; (3) arc scorching including arcing the leather through an arc press to form scorched edges at 100-200 DEG C, wherein the width of the scorched edges is determined according to the design width of molds; (4) striping including cooling the edge-scorched leather and striping the cooled leather through a striping machine; (5) weaving including performing manual weaving and mounting fasteners. The manufacturing process of the casual belt is simple in process; manufactured belts are high in strength, less prone to deformation, high in rub resistance and color fastness, free from color change, attractive in appearance and durable.

Owner:ANHUI DINGHENG LEATHER PROD

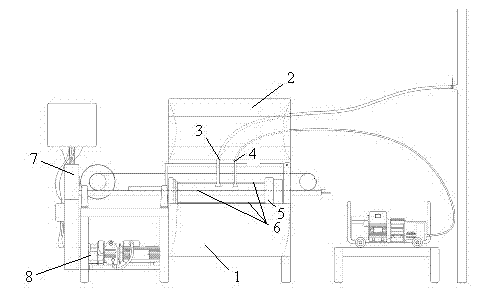

Full-automatic omnibearing rubber roller cleaning device

The invention provides a full-automatic omnibearing rubber roller cleaning device which belongs to the technical field of printing-dyeing machines. The full-automatic omnibearing rubber roller cleaning device comprises a working platform, a rotating motor, a swinging motor capable of moving leftward and rightward, a water spraying device and a drying hole. In the cleaning process, the swinging motor capable of moving leftward and rightward drives the water spraying device and the drying hole to swing leftward and rightward; the rotating motor drives a rubber roller to do circumferential rotation; and the cleaning device and a part to be cleaned move simultaneously to lead the cleaning to be more thoroughly. In the printing process of ceramic tiles, the printing glaze material on the surfaces of the ceramic tiles is easy to enter the rubber roller so as to block mesh holes and further influence the effect of printing products. The traditional rubber roller cleaning equipment only can clean 20% of the residual glaze material in the rubber roller, while the full-automatic omnibearing rubber roller cleaning device can clean the residual glaze material in the rubber roller thoroughly and guarantee the color stability of the printing products. According to the full-automatic omnibearing rubber roller cleaning device, the operation is simple and convenient, the cleaning is thorough, the whole cleaning process is full-automatic, and workers only need to install the rubber roller on a bracket, so that the labor is saved.

Owner:海鸥冠军有限公司

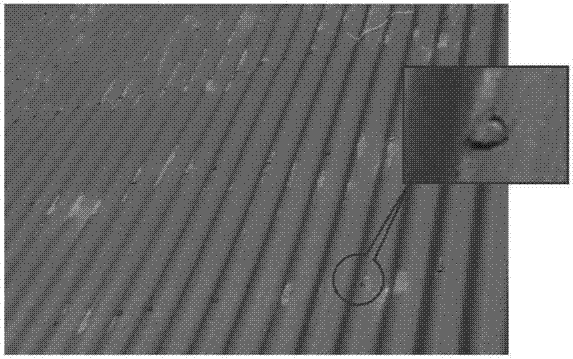

Method for loading hydroxyl iron oxide nanoparticle composite structural colors on carbon fiber woven fabrics and carbon fiber woven fabrics obtained according to method

ActiveCN110656488AStable colorNot easy to fadeCarbon fibresUltrasonic/sonic fibre treatmentIron oxyhydroxideWoven fabric

The invention discloses a method for loading hydroxyl iron oxide nanoparticle composite structural colors on carbon fiber woven fabrics and the carbon fiber woven fabrics obtained according to the method. The method includes steps: step one, ultrasonically dispersing ferric trichloride powder into deionized water, stirring at the room temperature until solution turns from colorless to orange, adding ammonium fluoride powder into the solution, stirring to obtain transparent clear solution, and transferring the mixed solution into a reactor; step two, cutting the carbon fiber woven fabrics washed with acetone and ethanol mixed solution into a certain size, and soaking in the reactor; step three, performing hydrothermal reaction in a high-temperature drying oven to enable loading of hydroxyliron oxide nanoparticles on the surfaces of the carbon fiber woven fabrics by different densities and thicknesses to finally obtain the carbon fiber woven fabrics in different structural colors. Therefore, the technical problem of deposition of the structural colors on the surfaces of the carbon fiber woven fabrics is solved. The preparation method is simple, feasible and high in repeatability, adopted raw materials are environmentally friendly, safe and nontoxic, and easiness in implementation of industrialization is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

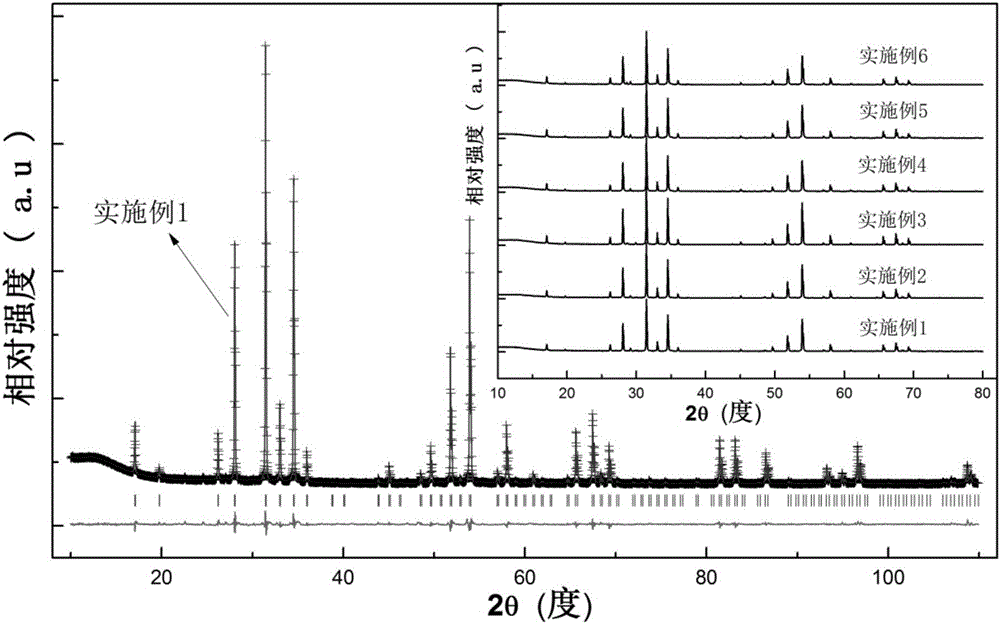

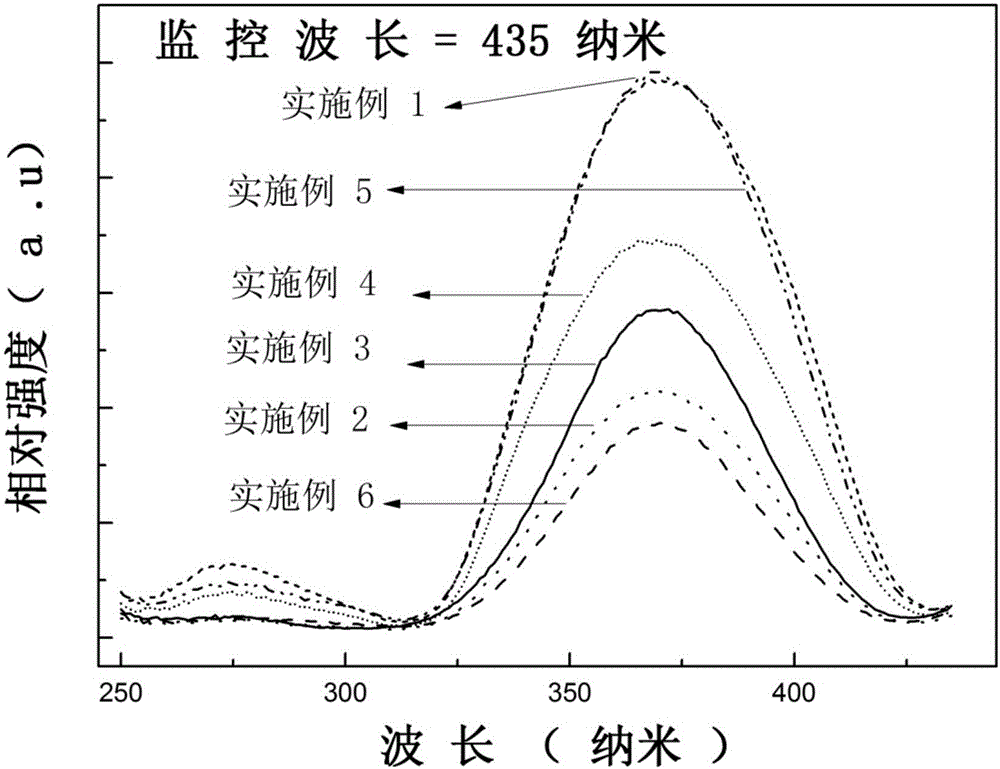

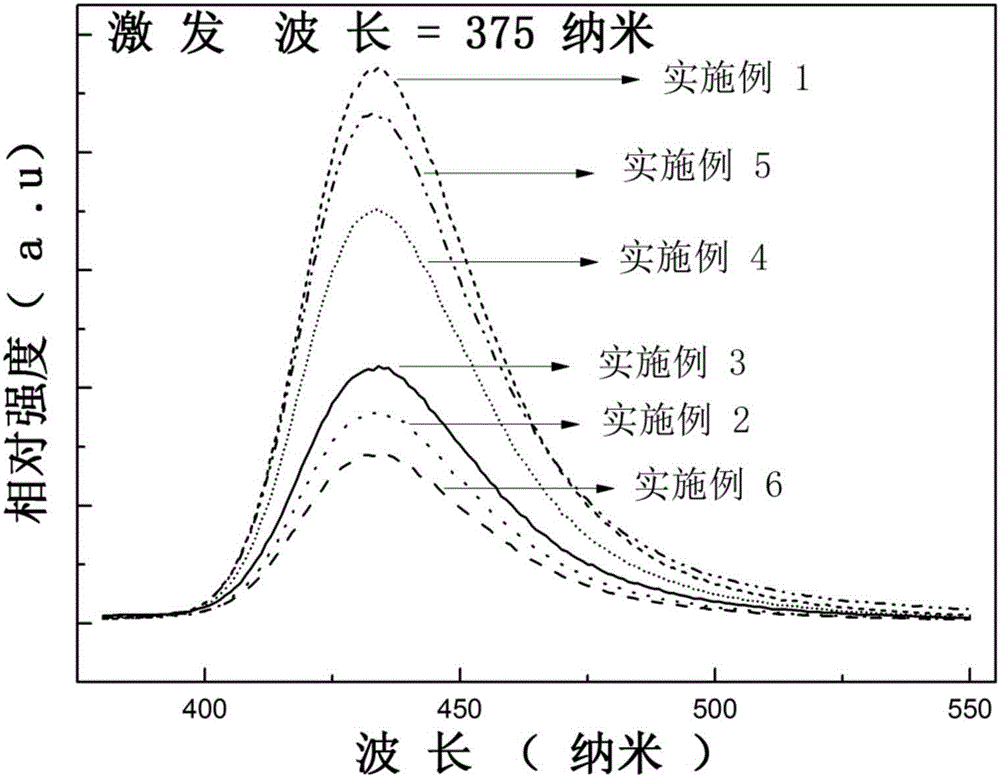

Near-UV excitation blue light fluorescent powder used for white light LED and preparation method thereof

InactiveCN106590646AStable colorHigh lumen efficiencyZirconium compoundsLuminescent compositionsSolventRare-earth element

The invention provides near-UV excitation blue light fluorescent powder used fro a white light LED and a preparation method thereof. The chemical formula of the blue light fluorescent powder is Ca4-xZrGe3O12:xBi3+, wherein 0.01<=x<=0.4. The method includes the concrete steps that a calcium-containing compound, a zirconium-containing compound, a bismuth-containing compound and a germanium-containing compound are mixed with a cosolvent boron-containing compound to be calcined for 3-8 hours at the temperature of 1300-1400 DEG C and cooled to obtain the fluorescent powder. Non-rare earth ions are adopted as an activator, germinate without rare earth elements is adopted as a substrate material, and the activator and the substrate material are synergistically cooperated to obtain the blue light fluorescent powder Ca4-xZrGe3O12:xBi3+ (0.01<=x<=0.04). Emitted blue light is stable in color development, luminous efficiency is high, no rare earth elements are contained, and the high cost of the blue light fluorescent powder is lowered.

Owner:CHANGAN UNIV

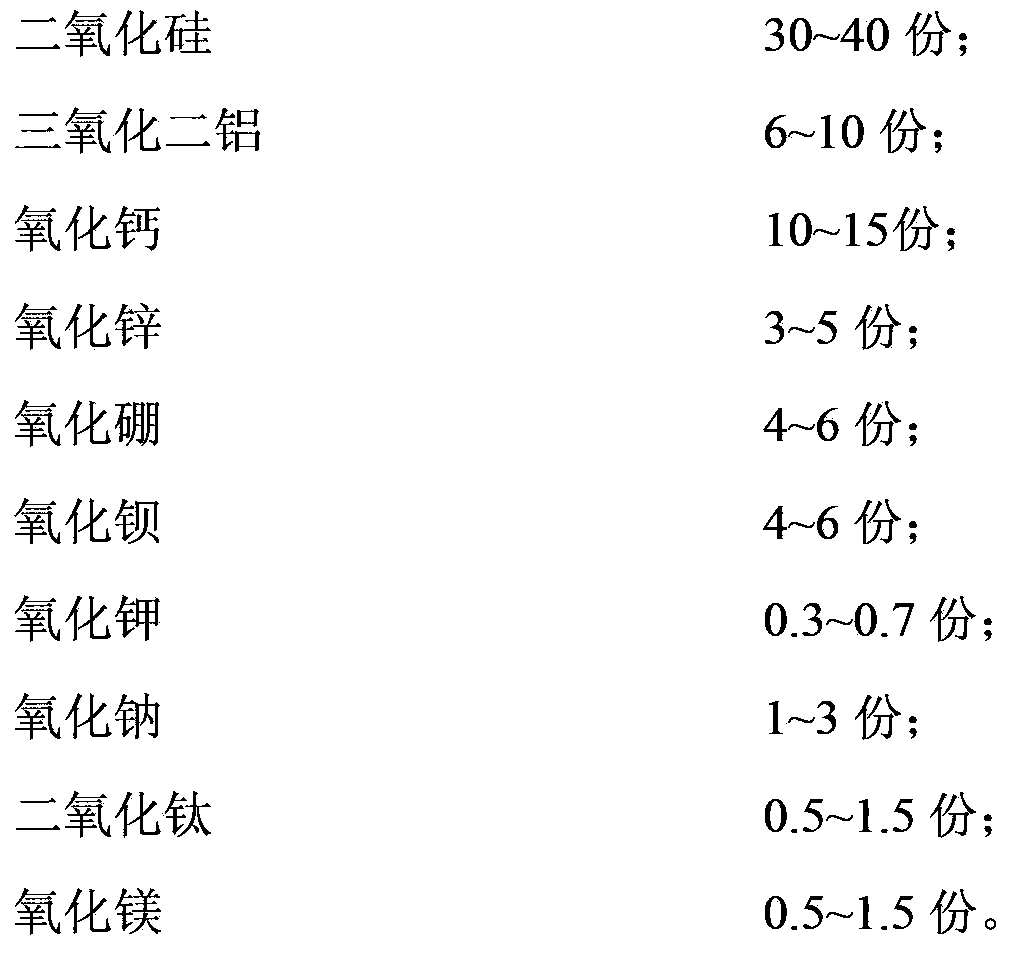

White microlite

The invention relates to white microlite comprising the following components by weight: 30-40 parts of silicon dioxide; 6-10 parts of aluminum oxide; 10-15 parts of calcium oxide; 3-5 parts of zinc oxide; 4-6 parts of boron oxide; 4-6 parts of barium oxide; 0.3-0.7 part of potassium oxide; 1-3 parts of sodium oxide; 0.5-1.5 parts of titanium oxide; and 0.5-1.5 parts of magnesium oxide. The white microlite is stable in color, bright in color, long in service life, low in cost, and convenient to manufacture, fills the species of pattern and color of existing microlite, is novel in pattern and unique in color, and greatly satisfy the demand of people for the microlite in living and production.

Owner:TIANJIN JUHUAJING TECH DEV

Preparation method of zirconium silicate wrapped carbon black pigment by microwave synthesis

The invention discloses a preparation method of zirconium silicate wrapped carbon black pigment by a microwave synthesis. The preparation method comprises the following steps of: synthesizing the black pigment with high parcel rate by using high pigment carbon black or high wear-resistant carbon black or acetylene carbon black as raw materials through a microwave heating method at a temperature of 900-1000 DEG C. The synthesis method is simple in technology, fast in synthesis speed and low in synthesis temperature, the prepared black pigment is pure in color and stable in performance, and the usage temperature can be 1300 DEG C, so that the black pigment can be widely used in high-temperature glaze of various ceramic products, and has a high economic value.

Owner:JINGDEZHEN CERAMIC INSTITUTE

White jade color high borosilicate glass and preparation method thereof

ActiveCN107601873AModerate transparencyStable colorGlass furnace apparatusGlass productionTransmittanceChemistry

The invention discloses white jade color high borosilicate glass and a preparation method thereof. On the basis of maintaining original properties of high borosilicate 3.3 glass, the glass is internally colored, and by selecting a coloring agent in a formula of the high borosilicate 3.3 glass, selecting the ratio of the coloring agent to other materials, and strictly controlling the melting temperature and the melting time, so that the effect that a coloring agent is not volatilized is achieved, the prepared glass is of a white jade color, is uniformly distributed and is free of bubble or water wave, and is excellent in refractive index or light transmittance.

Owner:HUAILAI TIANYUAN SPECIAL TYPE GLASS

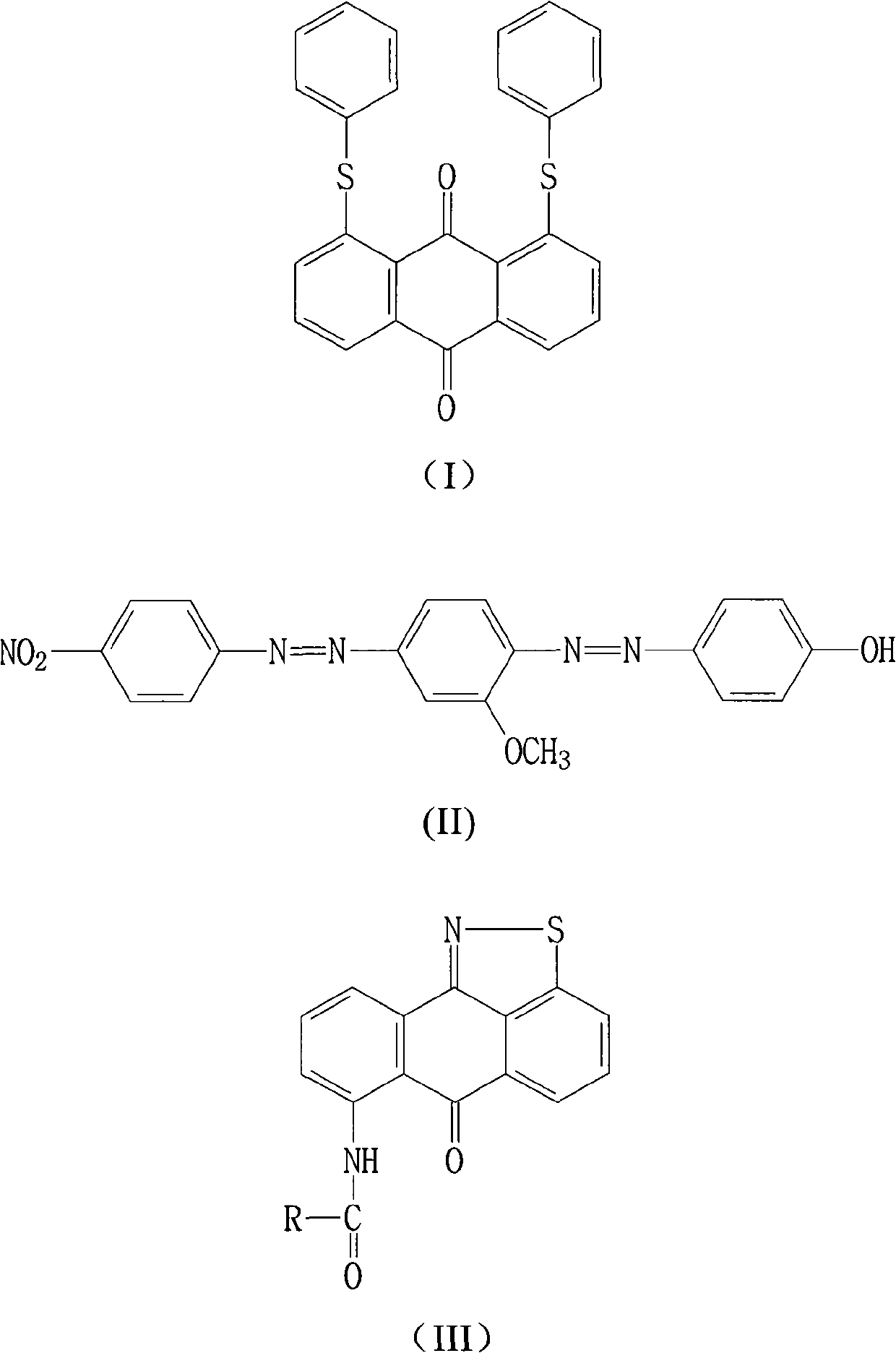

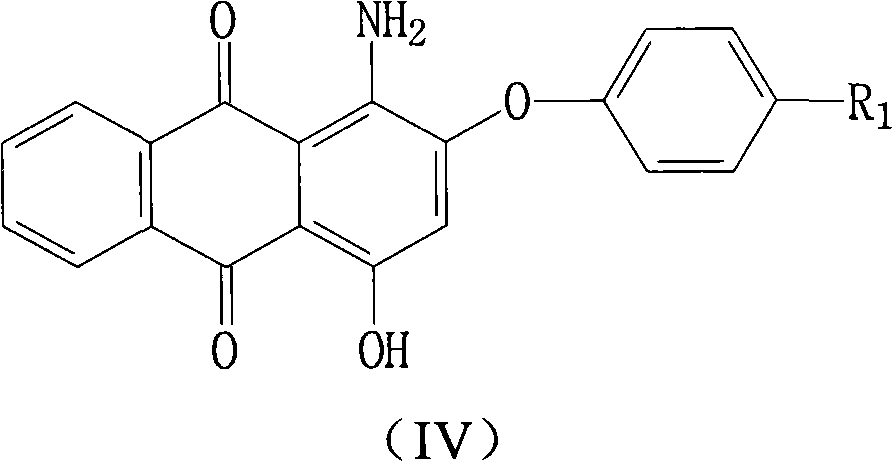

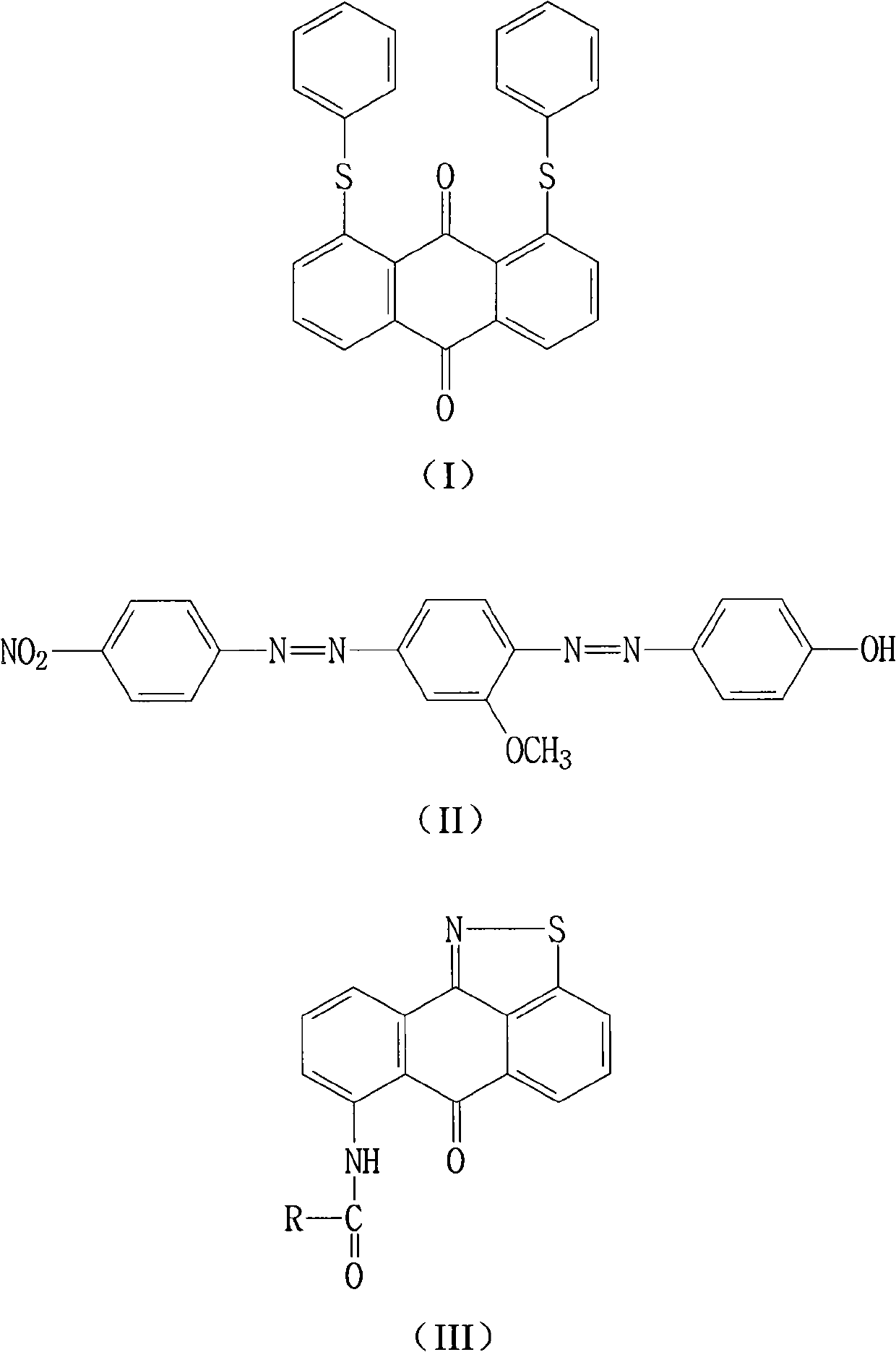

Yellow disperse dye composition with high light fastness and application thereof

ActiveCN102127314AGood light stabilityStable colorOrganic dyesDyeing processIntermediate GradeTextile

The invention discloses a yellow disperse dye composition with high light fastness. The yellow disperse dye composition comprises at least two yellow dyes shown in structural formulas (I), (II) and (III), wherein R is methyl, ethyl or propyl. The yellow disperse dye composition has stable light fastness under the condition of long-term irradiation, particularly when the dye ensures relatively light color in the final dyeing, the light fastness is superior to that when the color is relatively dark, and can meet the requirement of light fastness of the color of intermediate-grade auto inner ornamental cloth.

Owner:SHANGHAI YILIAN CHEM TECH

Anti-static rubber

The invention relates to the field of chemical engineering material and safety protection, in particular to an anti-static rubber. The anti-static rubber is prepared form 24%-40% of nitrile rubber, 10%-16% of natural rubber, 15%-18% chlorinated polyethylene, 15%-30% of carbon black, 5%-6% of an anti-static agent, 1.8%-2.5% of an accelerant, 3%-4% of dibutyl ester and 10%-15% of titanium dioxide. According to the anti-static rubber, by adopting titanium dioxide to replace calcium carbonate as a padding due to the reinforcing, anti-aging and replenishing effects of titanium dioxide when adding titanium dioxide into rubber, from the perspective of physical performance, adding titanium dioxide instead of calcium carbonate makes rubber more aging resistant, insolation resistant, not prone to cracking, stable in color, large in stretch rate and strong in acid-base resistance property, besides improves ozone and ultraviolet resistant capability, and accordingly improves the performance of rubber pad when in use outside; the thermostability of titanium dioxide is high, and the heat resistance of the anti-static rubber pad is improved; besides titanium dioxide has semi-conductive property, is good in conductivity, improves the stability of resistance of the surface of the anti-static rubber pad, and accordingly the releasing ability to static of the anti-static rubber is improved.

Owner:CHUANGXUANBAO PANTUO ANTI STATIC TECH SHANGHAI CO LTD

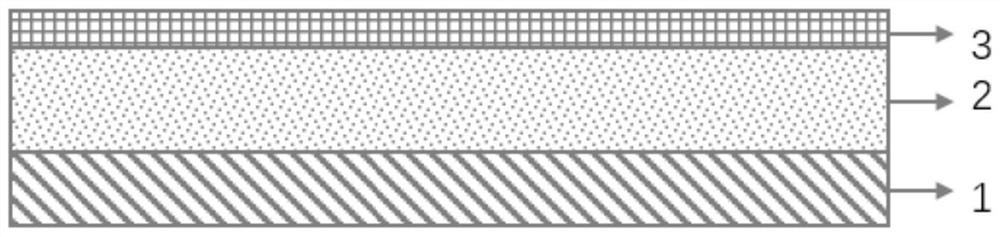

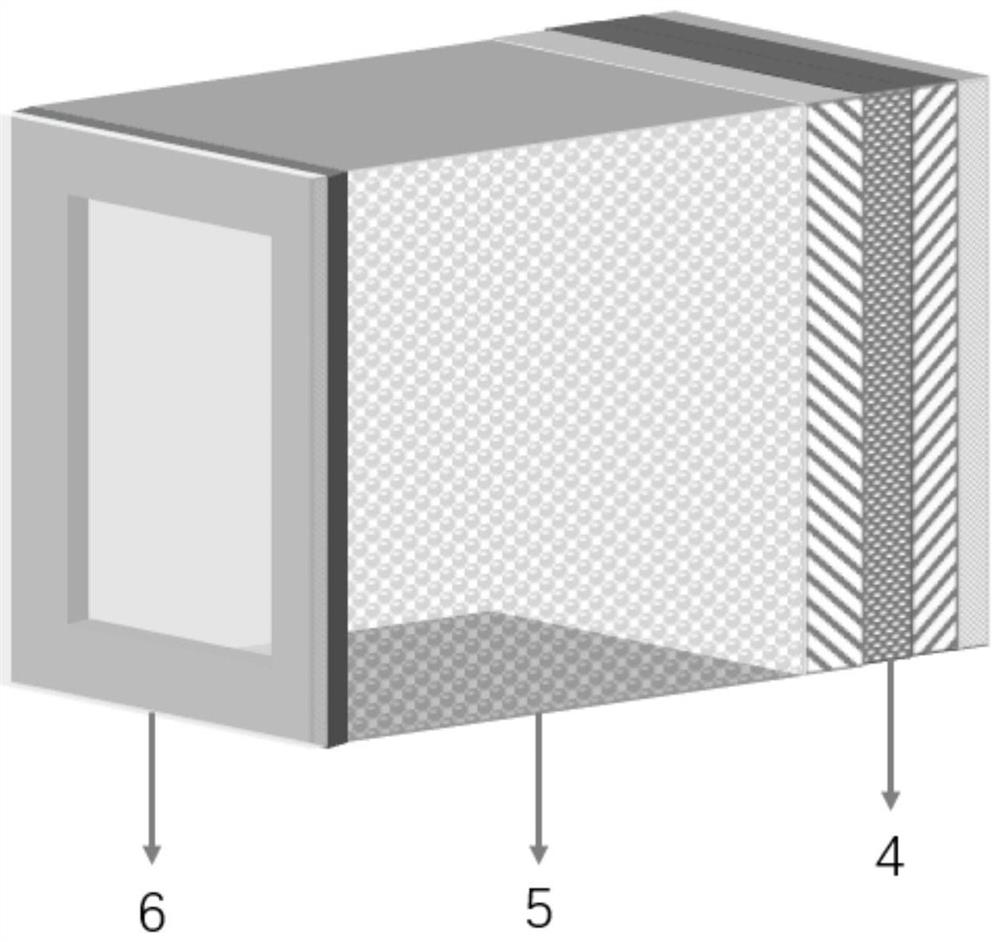

Multi-color metal oxide electrochromic battery and preparation method and application thereof

ActiveCN112117442AStable colorReduce radiation effectsFinal product manufactureAlkaline accumulator electrodesPhysicsElectrical battery

The invention discloses a multi-color metal oxide electrochromic battery and a preparation method and application thereof. The multi-color metal oxide electrochromic battery comprises a working electrode, an electrolyte and a counter electrode, wherein the working electrode is a multi-color metal oxide electrochromic electrode and comprises a first optical structure layer and a second optical structure layer which are opposite to each other and arranged in parallel, a dielectric layer is arranged between the first optical structure layer and the second optical structure layer, the dielectric layer is composed of metal oxide, the bonding interface of the dielectric layer and the first optical structure layer and the bonding interface of the dielectric layer and the second optical structurelayer are the first surface and the second surface of the dielectric layer respectively, and the first surface and the second surface are matched with the dielectric layer to form an optical cavity. The multi-color metal oxide electrochromic battery provided by the invention shows different colors under different battery electric quantities; the multi-color metal oxide electrochromic electrode provided by the invention belongs to a structural color, is stable in color, is particularly slightly influenced by temperature, illumination and radiation, and does not age or lose color.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

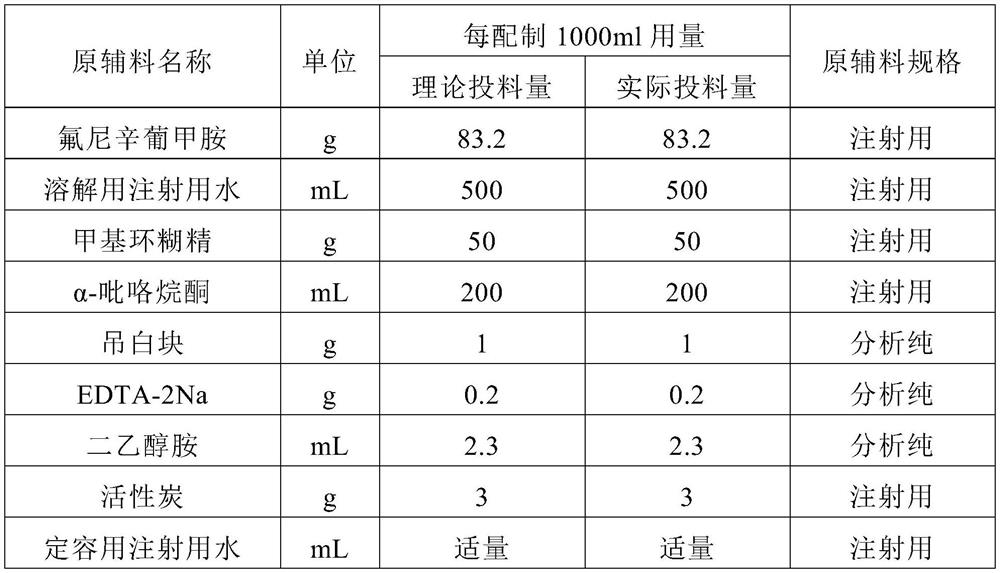

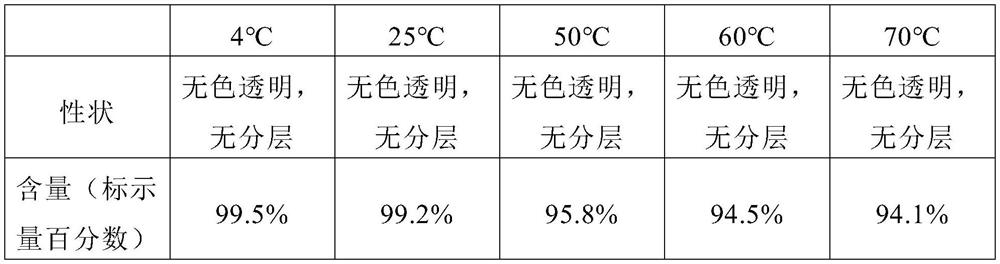

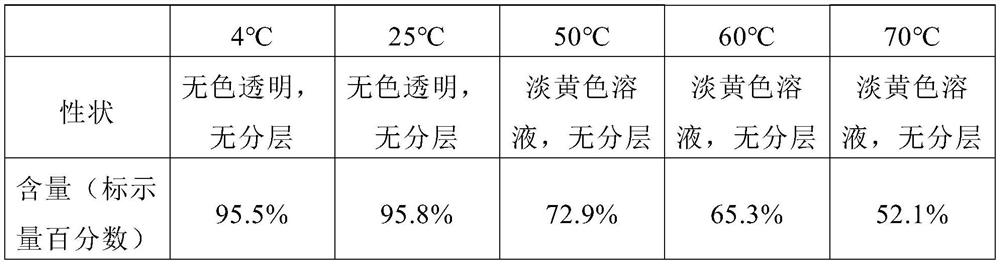

Preparation method of flunixin meglumine injection

The invention relates to a veterinary drug injection, in particular to a preparation method of a flunixin meglumine injection, which comprises the following steps: dissolving flunixin meglumine in water for injection, adding an organic solvent and uniformly stirring, then adding sodium formaldehyde sulfoxylate and EDTA-2Na, stirring and dissolving, then adding a stabilizer and heating and stirring for dissolving, and finally adding a stabilizer and uniformly stirring to obtain the flunixin meglumine injection. Cooling, adding an acid-base regulator, and complementing the water for injection; and adding activated carbon into the obtained mixed solution, standing, filtering through a filter, filling nitrogen, subpackaging and sterilizing to obtain the flunixin meglumine injection. Compared with the prior art, the flunixin meglumine injection has the advantages that the nicotinamide or cyclodextrin stabilizer, the mixed solvent and the acid-base regulator are adopted, the dissolving property is more excellent, the effects of a cosolvent and the stabilizer are played at the same time, and the problems that flunixin meglumine medicine is poor in solubility and prone to discoloration are effectively solved.

Owner:江西益昕葆生物科技有限公司 +1

Method for producing denim fabric dyed with environmental-protection dye with sizing and dyeing combined machine

The invention discloses a method for producing a denim fabric dyed with an environmental-protection dye with a sizing and dyeing combined machine. The method includes processes of dyeing, weaving andfinishing and specifically includes using the ASLGA386B type sizing and dyeing combined machine for dyeing and sizing to obtain a sizing dye A; then weaving the sizing dye A with a ZAX-e-190 air jet loom in a three-up one-down right twill weave mode to obtain a fabric B; finally, conducting singeing on the fabric B by adopting an LMH003 singeing machine and then pre-shrinking the fabric twice by aMorrison pre-shrinking machine. The denim fabric produced by the method is provided with rich color selection space on the basis of ensuring the performance, and meets the requirements for large scale and market diversification. By means of optimized design of the processes of dyeing, weaving and finishing, all physical indicators of the denim fabric are well balanced, and the denim fabric has vast market prospects.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

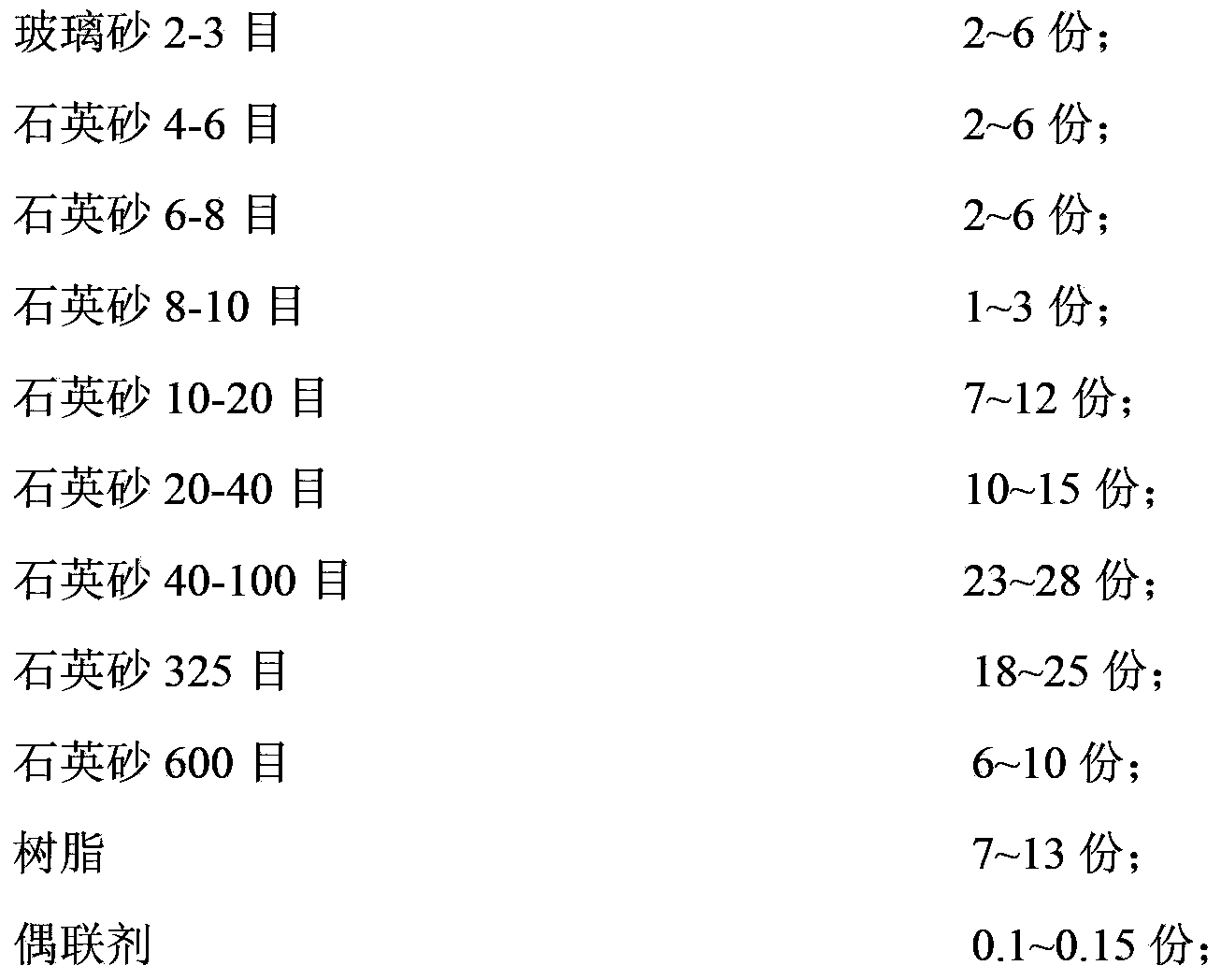

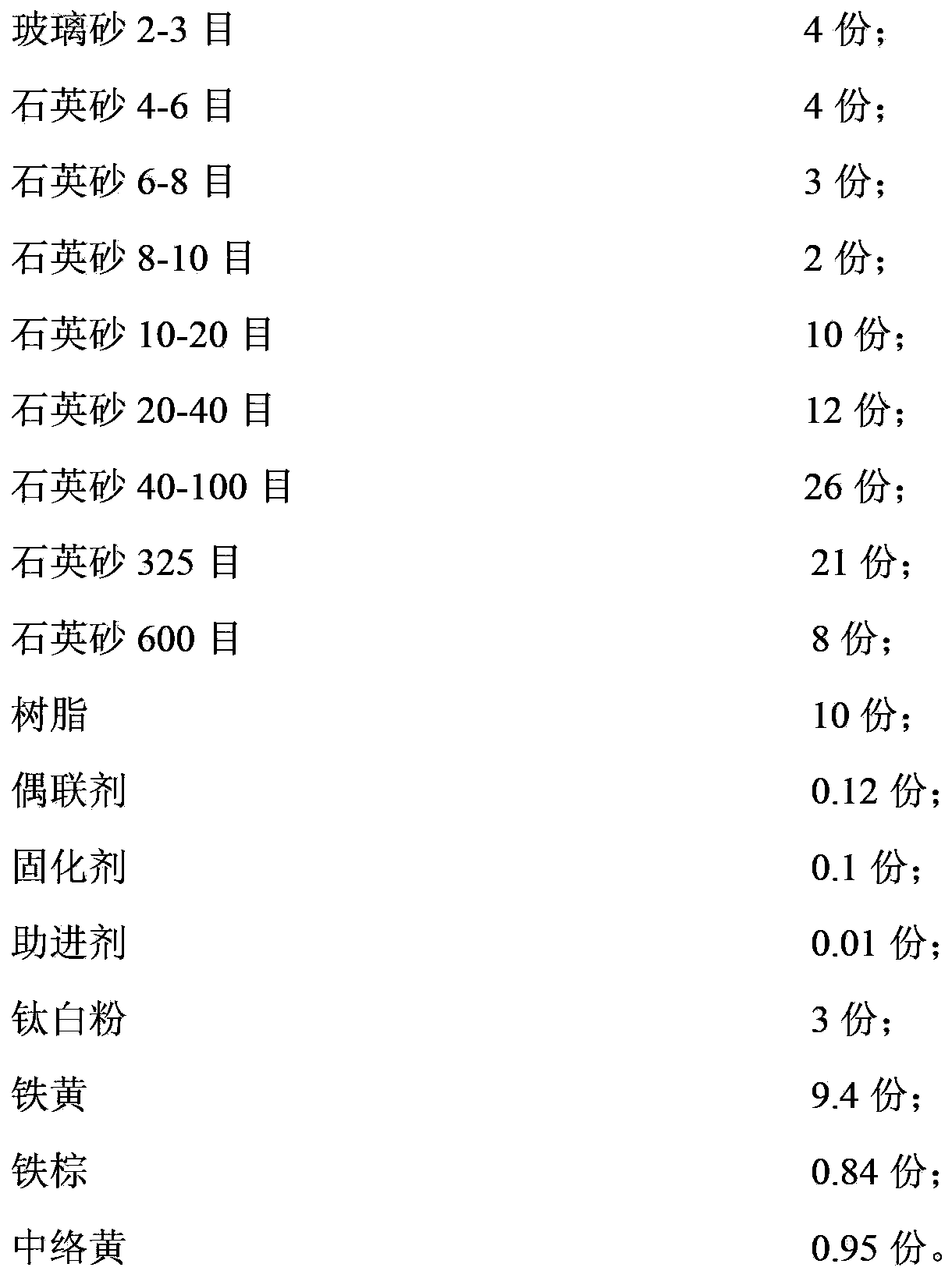

Artificial light yellow quartz stone and preparation method thereof

InactiveCN104326670AStable colorBright colorGlass shaping apparatusGlass productionTitanium dioxideArtificial light

The invention relates to an artificial light yellow quartz stone comprising the following components by weight: 2-6 parts of glass sand of 2-3 mesh; 2-6 parts of quartz sand of 4-6 mesh; 2-6 parts of quartz sand of 6-8 mesh; 1-3 parts of quartz sand of 8-10 mesh; 7-12 parts of quartz sand of 10-20 mesh; 10-15 parts of quartz sand of 20-40 mesh; 23-28 parts of quartz sand of 40-100 mesh; 18-25 parts of quartz sand of 325 mesh; 6-10 parts of quartz sand of 600 mesh; 7-13 parts of resin; 0.1-0.15 part of a coupling agent; 0.05-0.15 part of a curing agent; 0.005-0.015 part of a promoting agent, 2-5 parts of titanium dioxide; 8-12 parts of iron oxide yellow; 0.5-1 part of iron oxide brown and 0.6-1.2 parts of pigment yellow. The artificial light yellow quartz stone has the advantages of color stability, bright color, long service life, low cost, and convenient manufacture, fills the existing species of quartz stone patterns and colors, is novel in pattern and unique in color, and greatly satisfies the demand of people for artificial quartz stone in living and production.

Owner:TIANJIN JUHUAJING TECH DEV

Preparation method of white light OLED new material

InactiveCN108794755AGood thermal stabilityStable colorSolid-state devicesSemiconductor/solid-state device manufacturingChemistryElectricity

The invention relates to the field of preparation of a new material, in particular to a preparation method of a white light OLED new material. The invention discloses the preparation method of the white light OLED new material. The polymer white light OLED new material is prepared through coupling reaction; the polymer material has good heat stability; and due to the fact that the polymer materialis a monomolecular system, so even if under long-time action of light, electricity and heat, phase separation does not occur, the color of a chromophore is quite stable, and the device property is greatly improved.

Owner:张玲

Paint with jade luster and preparation method thereof

The invention provides a paint with jade luster and a preparation method thereof. The paint is composed of, by mass, 35-40 parts of polymethyl methacrylate, 5-15 parts of isooctyl polymethacrylate, 6-12 parts of titanium dioxide, 4-10 parts of resin, 2-6 parts of a film-forming agent, 5-10 parts of a thickener, 1-3 parts of a wetting agent and 30-40 parts of a pigment component, wherein the pigment component is composed of azure and yellow pigments and at least comprises 20-30 parts of an aqueous pigment and 10-20 parts of an oil pigment. The various components of the paint provided by the invention produce good synergistic effect; in particular, the paint with jade gloss is prepared by blending fat-soluble and water-soluble pigments; and the prepared paint has the characteristics of low cost, a stable color, long-lasting gloss, high hardness, good flexibility, good scratch resistance and good miscibility, is non-toxic and environmentally-friendly, and accords with the concept of healthy living.

Owner:NANJING YIHE CULTURE CREATIVE CO LTD

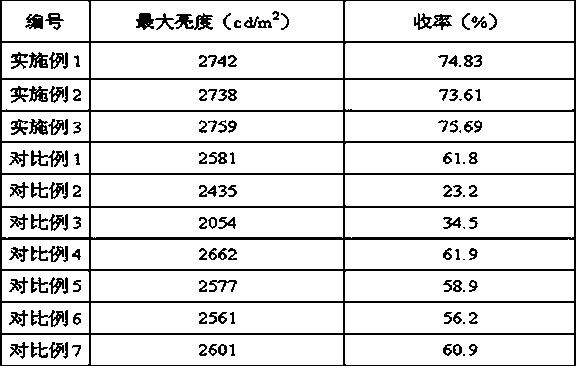

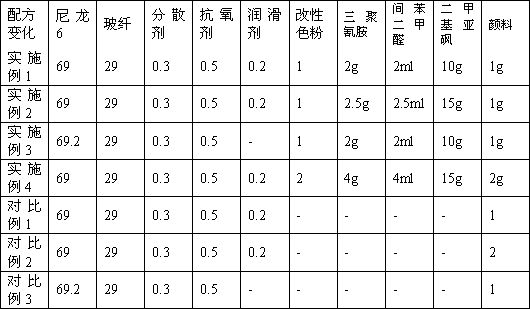

Low-frosting blue light red nylon material and preparation method thereof

The invention provides a low-frosting blue light red nylon material. The raw materials comprise 60%-80% of nylon, 20%-30% of glass fibers, 0.1%-0.5% of dispersing agents, 0.1%-0.5% of antioxidants, 0.1%-0.3% of lubricating agents and 0.3%-1% of modified toner. Under the condition that the original hue of the pigment is not changed, the natural color of the pigment is treated, the particle size of the pigment dye is enlarged, the possibility of precipitation of the pigment dye in a high-temperature environment is reduced, the frosting condition can be effectively improved, and meanwhile the frosting condition is further improved by adjusting an auxiliary system. After the nylon material provided by the invention is subjected to injection molding to form a product, the product is placed in a steam box to be steamed for 4 hours, and the product does not frost or fade.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Cynura bicolor colored health-care noodles and preparation method thereof

InactiveCN106387662AStable colorGood elasticity and toughnessFood ingredient functionsArtificial colorsBiology

The present invention discloses a preparation method of colored health-care noodles containing cynura bicolor anthocyanin and chlorophyll. Fresh cynura bicolor leaf blades are used as a main raw material, an anthocyanin extract and a green leaf blade slurry are prepared, and the anthocyanin extract and green leaf blade slurry are respectively mixed with accessory materials of wheat flour, etc. to prepare the purple and green cynura bicolor health-care noodles. The method is simple in manufacturing processes and the products are nutritious, healthy, bright in color, excellent in exterior quality, and have commercial values. The noodles are resistant to storing and boiling, and the color is not easy to fade and change. The noodles do not contain artificial colors and preservatives, are free of safe hazards, have health-care effects of preventing oxidation, lowering blood sugar, etc., and are in line with safe and healthy effect needs of a majority of consumers.

Owner:FUJIAN ACADEMY OF AGRI SCI SUBTROPICAL AGRI RES INST

Violet ceramic pigment and preparation method thereof

The invention relates to violet ceramic pigment and a preparation method thereof, and belongs to the technical field of ceramic pigment preparation. The violet ceramic pigment comprises the following raw materials by weight: 1 to 5 parts of stannic oxide, 0.2 to 0.5 part of chromium oxide green, 0.5 to 0.8 part of silicon dioxide, 10 to 20 parts of zinc oxide, 10 to 20 parts of citric acid, 1 to 5 parts of chrome-tin amethyst, and 0.1 to 0.5 part of sodium fluorosilicate. The preparation method comprises the following steps: mixing the raw materials uniformly, stirring to obtain a uniform mixture, and carrying out sufficient grinding for 4 to 6 hours; calcining the mixture powder at 500 to 550 DEG C for 8 to 10 hours; adding the calcined powder into purified water which is 20 to 25 times of the calcined powder in weight, stirring 30 to 60 minutes, filtering to remove water, and drying; grinding the dried solid with a ball mill, and sieving with a 350 to 400-mesh screen, so as to obtain the violet ceramic pigment. The violet ceramic pigment is narrow in particle size distribution, stable in color generation, low in color difference variation, and high in stability under a high-temperature condition; moreover, the preparation process is simple, the equipment requirement is low, and industrial production is easy to realize.

Owner:赖清甜

Skin-whitening and spot-fading emulsion containing rhodiola rosea extracting solution and preparation method of skin-whitening and spot-fading emulsion

InactiveCN108324643AGood blemish effectStable colorCosmetic preparationsToilet preparationsChemistryEmulsion

The invention provides skin-whitening and spot-fading emulsion containing a rhodiola rosea extracting solution and a preparation method of the skin-whitening and spot-fading emulsion. The skin-whitening and spot-fading emulsion comprises an amino acid moisturizer, mushroom glucan, BSASM, aloe vera concentrate, the rhodiola rosea extracting solution and an amino acid skin-whitening agent. The prepared skin-whitening and spot-fading emulsion has good spot-fading effect, the effective rate reaches 100%, a spot-fading effect is not easy to rebound, the skin-whitening effect is also quite remarkable, the color of the product is stable and cannot be changed easily, stimulation to human bodies cannot be caused, and the skin-whitening and spot-fading emulsion is a skin-whitening and spot-fading product with excellent performance.

Owner:GUANGZHOU KEYING COSMETICS CO LTD

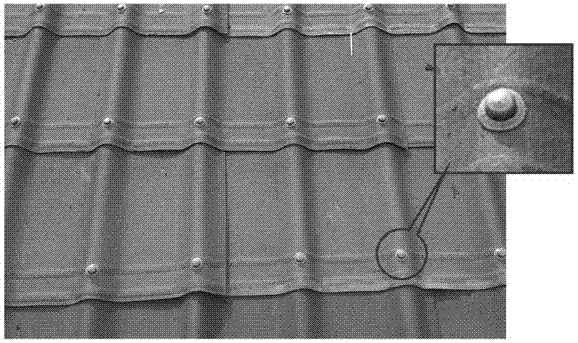

Weather-resistant polypropylene material for preparing asphalt pantile fastening nail cap

The invention discloses a weather-resistant polypropylene material for preparing an asphalt pantile fastening nail cap. The material is characterized by being prepared from the following raw materials in percentages by weight: 2-2.5% of a weather-resistant material, 2% of an inorganic pigment, 0.8% of a coupling agent, 20% of an elastomer, 0.1-0.15% of a DCUP peroxide vulcanizing agent, 0.2% of an Ni-1 active quencher, 0.5% of a lubricant, 10% of talc powder and the balance of polypropylene. After the weather-resistant polypropylene material for preparing the asphalt pantile fastening nail cap disclosed by the invention is prepared into the fastening nail cap and fixes an weather-resistant polypropylene material for preparing an asphalt pantile fastening nail cap, the edge of the plastic nail cap does not deform and the nail cap and the pantile surface are closed so as to block seepage of rainwater; the fastening nail cap is durable and does not fade and age, and a phenomenon that the nail cap is disjointed is avoided, and the nail still keeps the tensioning force as the nail is fixed.

Owner:沈阳新歌特塑胶有限公司

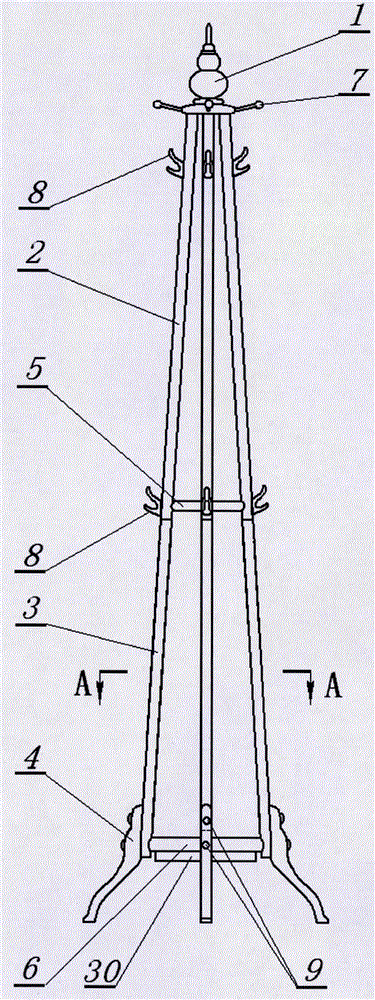

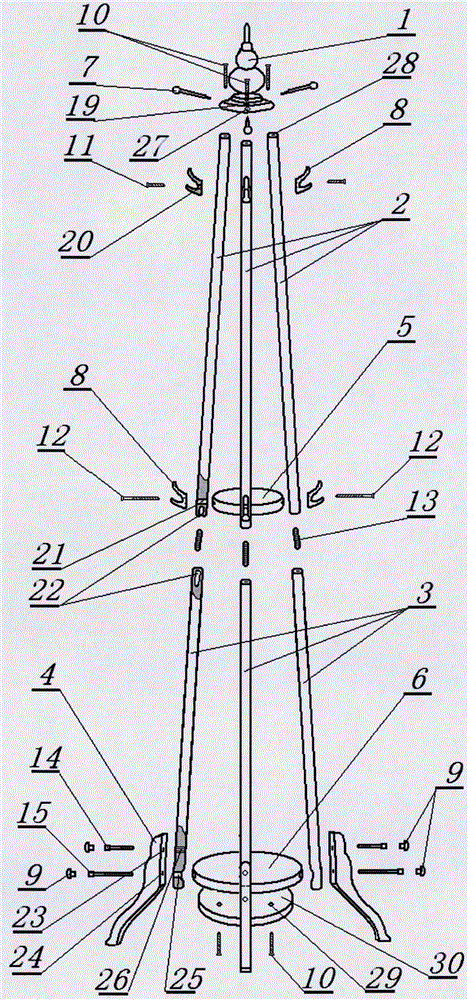

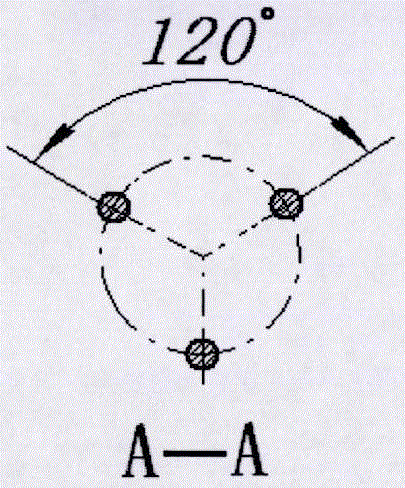

Self-help assembling vertical type solid wood hanger

The invention provides a self-help assembling vertical type solid wood hanger. The self-help assembling vertical type solid wood hanger is a set of goods composed of a wooden component, a fastener, a weighting block and a dual-purpose wrench and can be formed as a package; the main body of the hanger is divided into an upper-section component and a lower-section component which are connected through three ring pattern round wooden pins; self-help assembling and disassembling can be achieved by an ordinary consumer only with the distributed dual-purpose wrench; a traditional process that the solid wood vertical type hanger must be assembled in a factory is changed; the effect of breaking up the whole into parts is achieved when the hanger leaves the factory; the mass of the solid wood vertical type hanger is reduced; not only are the packaging cost, the storage cost and the transportation cost reduced, but also a remarkable convenience is brought to e-commerce on online sales; modeling of the hanger is simple; the mechanical property of the triangle structure of the installed vertical type hanger is stable and firm; and the advantages of a traditional solid wood vertical type hanger which is stable in color quality and comfortable in hand feel are maintained.

Owner:王岳剑

Detection reagent and kit for rapidly detecting potassium bromate

PendingCN112834492AColor development time is shortStable colorTesting starch susbtancesMaterial analysis by observing effect on chemical indicatorPotassium iodineRapid detection

The invention provides a detection reagent and a kit for rapid detection of potassium bromate, the detection reagent is used for rapid detection of potassium bromate in food, the detection reagent comprises a detection reagent A and a detection reagent B, the detection reagent A is 0.5-1.0 mol / L inorganic acid, and the detection reagent B is 1.8-2.3 mol / L potassium iodide solution. When the pH value of the reagent is 1-3, the reagent is short in developing time, stable in color and high in detection rate, and does not need to be kept away from light in the developing process. And the rapid detection requirement can be met. The kit for rapidly detecting potassium bromate comprises the detection reagent A, the detection reagent B, a centrifugal tube, a colorimetric card plate, a transfer pipette and the like. When detection is needed, a to-be-detected sample is firstly treated, the detection reagent A and the detection reagent B are added into the treated sample, the mixture is mixed and left to stand, then color comparison is carried out on the color gradation on the colorimetric card plate, and whether the to-be-detected sample contains potassium bromate or not is obtained according to the comparison result. Through a comparison test, the detection limit of the detection kit disclosed by the invention is 5mg / kg.

Owner:GUANGZHOU ANNUO FOOD SCI & TECH CO LTD

Preparation method for changing color of granite after electrolysis

The invention discloses a preparation method for changing color of granite after electrolysis, belonging to a processing method of building material products. The invention can effectively improve the defects of dark and grey color, many rusty spots (pocks) and the like of the G601 granite through the electrolysis technology to allow the granite to turn to grey white or light green, so that the problems of granite with high price caused by insufficient output of white ground (white granite) on the market and the like are solved. G601 granite turns to grey white or light green from original grey through the electrolysis technology, so that the effects of beautiful white, green, noble quality and elegance are achieved, which is an invention of human. The test results of national building material industry stone material quality supervision and inspection test center show that the produced slabstone product after electrolysis has change in material quality, and the test results of aging quality test in laboratory show that the slabstone product has stable color, uniform material quality, and no color-return situation after being used.

Owner:FUJIAN XISHI

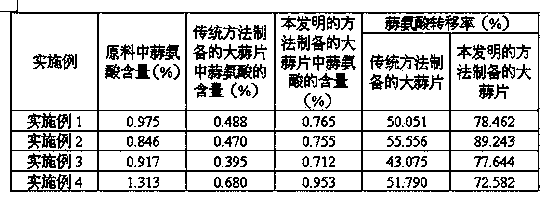

Preparation method of high-content alliin garlic slice

The invention discloses a preparation method of high-content alliin garlic slice, aiming at overcoming the defects that the conventional preparation technology of the garlic slice is low in alliin conversion rate, the obtained garlic slice is low in alliin content, the color is hard to control, and the quality of finished products is influenced. The preparation method comprises the following steps of: (1) treating raw materials; (2) inactivating enzymes at high temperature: putting the garlic treated by the step (1) into a sealed container, feeding water vapor with the temperature of 100-110 DEG C, and heating for 3-10 minutes; or putting the garlic treated by the step (1) into an air dry oven, and heating at the temperature of 105-115 DEG C for 20-40 minutes; (3) slicing; and (4) drying: carrying out microwave vacuum drying on the sliced garlic, and then carrying out vacuum drying on the sliced garlic till the water content is less than or equal to 7%. According to the preparation method disclosed by the invention, the conversion rate of the alliin reaches up to about 90%, and the obtained garlic slice is high in alliin content, controllable in product color, good in appearance, and good in quality.

Owner:NINGBO LIWAH PLANT EXTRACTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com