White microlite

A microcrystalline, white technology, applied in the field of building materials, achieves the effects of wide source of raw materials, convenient and simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

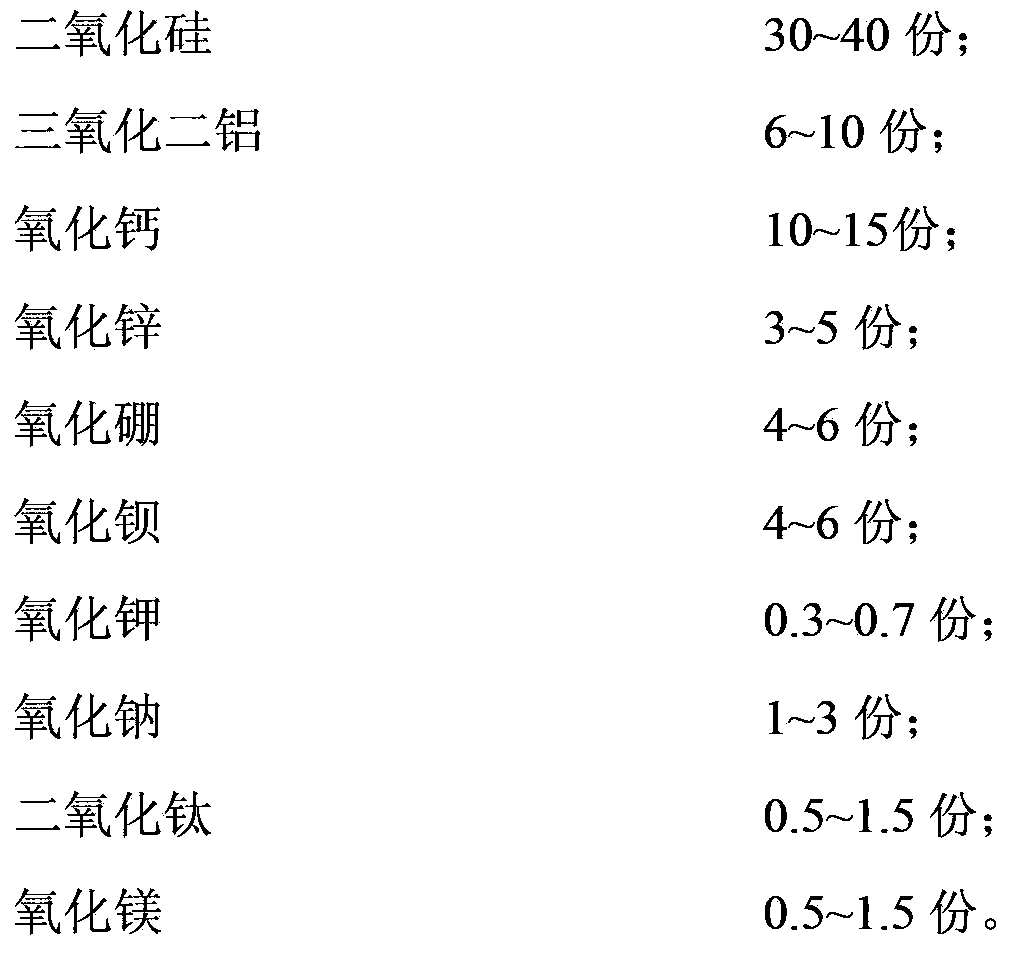

[0024] A kind of white microcrystalline stone, its composition and parts by weight are as follows:

[0025]

[0026] The preparation method of above-mentioned white microcrystalline stone, the steps are as follows:

[0027] After accurately weighing each raw material, the natural inorganic material is melted into glass liquid (magma) in a furnace up to 1600 ° C, quenched in water, and then crystallized at 1200 ° C to form microcrystalline stone (stone), and then polished and cut , deep processing, and inspection, the finished product of white microcrystalline stone will be obtained.

Embodiment 2

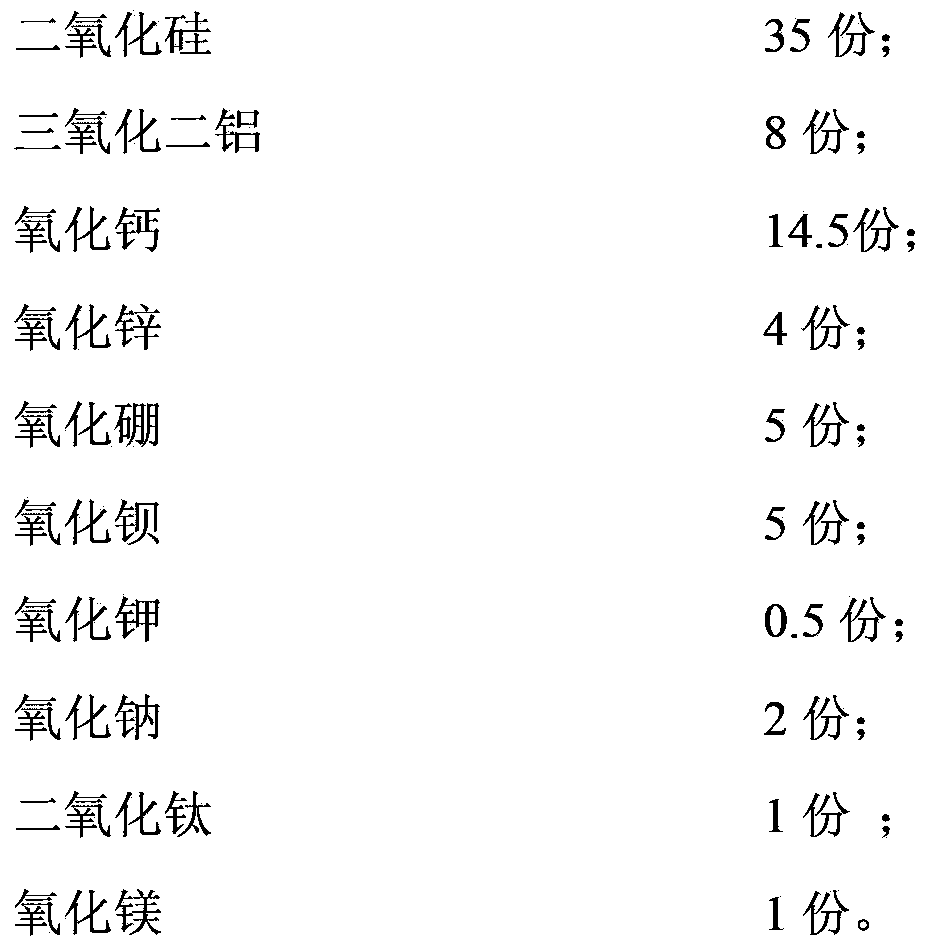

[0029] A kind of white microcrystalline stone, its composition and parts by weight are as follows:

[0030]

[0031] The preparation method of above-mentioned white microcrystalline stone is with embodiment 1.

Embodiment 3

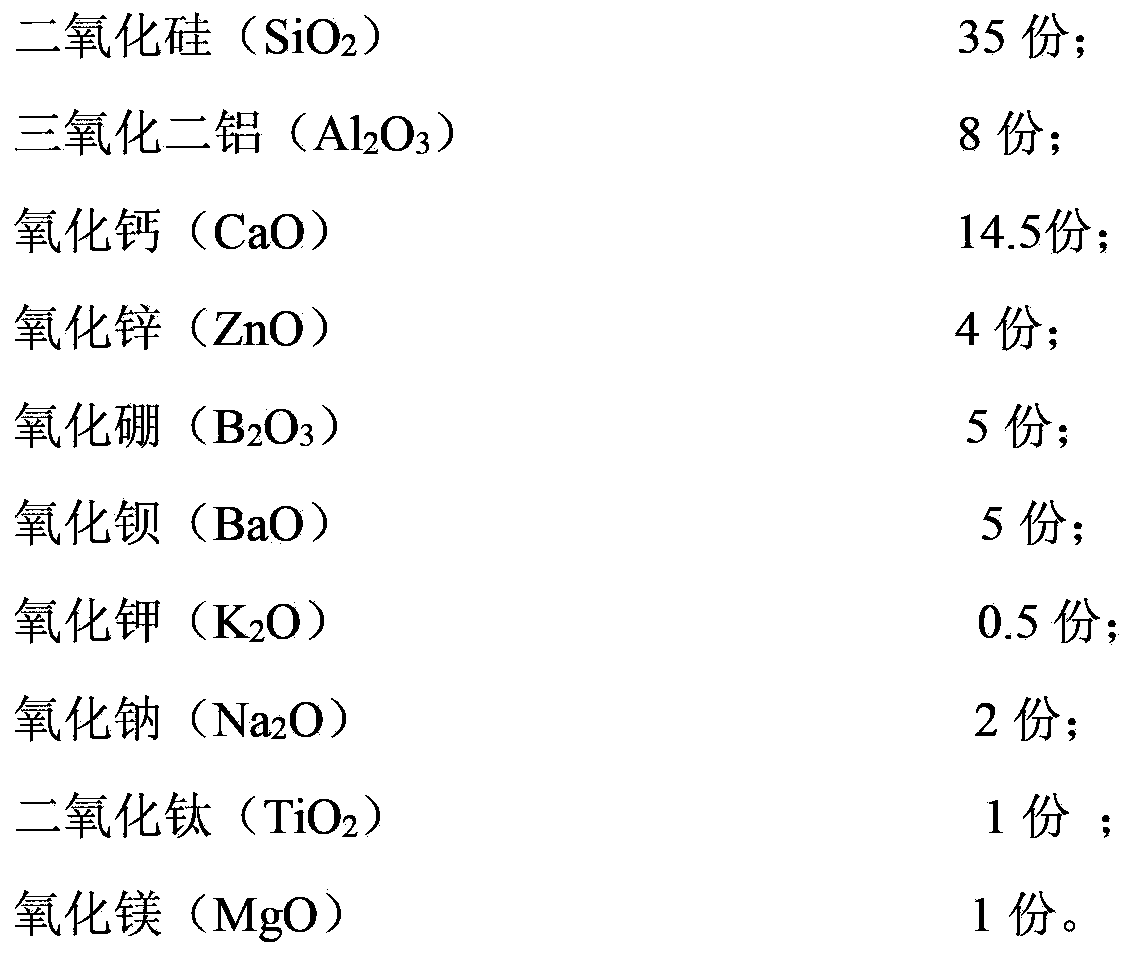

[0033] A kind of white microcrystalline stone, its composition and parts by weight are as follows:

[0034]

[0035] The preparation method of above-mentioned white microcrystalline stone is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com