Preparation method of high-content alliin garlic slice

A technology for alliin and garlic slices, which is applied in the field of preparation of high-content alliin garlic slices, can solve the problems of low alliin content in garlic slices, low alliin conversion rate, difficult color control and the like, and achieves product color. Controllable, good appearance and stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

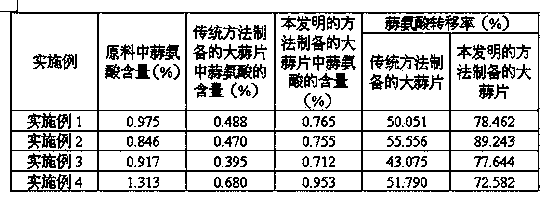

Examples

Embodiment 1

[0022] ⑴Raw material processing: remove the stalks of fresh garlic, split, peel, and remove the film coating;

[0023] (2) High-temperature enzyme elimination: put the garlic obtained in step (1) into an airtight container, the garlic accounts for 80% of the volume of the airtight container, heat it with steam at 100°C for 10 minutes, and take out the garlic after cooling;

[0024] (3) Slicing: the garlic obtained in step (2) is cut into thin slices with a thickness of 2 mm;

[0025] ⑷Drying: firstly, the garlic sliced in step ⑶ is subjected to microwave treatment for 8 minutes under a microwave condition of a vacuum degree of 30pa and a microwave frequency of 2450MHz±50MHz, and then the garlic sliced in step ⑶ is dried under the conditions of a vacuum degree of 15pa and a temperature of 40°C When the moisture content is less than or equal to 7%, the finished product is obtained.

Embodiment 2

[0027] ⑴Raw material processing: remove the stalks of fresh garlic, split, peel, and remove the film coating;

[0028] (2) Enzyme inactivation at high temperature: put the garlic obtained in step (1) into an airtight container, the volume percentage of which is 70% of the volume of the airtight container, heat it with steam at 110°C for 3 minutes, and take out the garlic after cooling;

[0029] (3) Slicing: the garlic obtained in step (2) is cut into thin slices with a thickness of 3 mm;

[0030] (4) Drying: first immerse the sliced garlic in step (3) in a Vc solution with a mass concentration of 0.03% for 10 seconds, and control the temperature of the Vc solution at 10°C, then place the sliced garlic in step (3) in a vacuum of 40pa and a microwave frequency of 2450MHz± Under the microwave condition of 50MHz, microwave treatment for 9 minutes, then dry the sliced garlic in step (3) under the condition of vacuum degree of 20pa and temperature of 40°C until the moisture co...

Embodiment 3

[0032] ⑴Raw material processing: remove the stalks of fresh garlic, split, peel, and remove the film coating;

[0033] (2) Enzyme inactivation at high temperature: place the garlic obtained in step (1) in a blast drying oven, heat at 105°C for 40 minutes, and take out the garlic after cooling;

[0034] (3) Slicing: the garlic obtained in step (2) is cut into thin slices with a thickness of 4mm;

[0035] (4) Drying: first immerse the sliced garlic in step (3) in a Vc solution with a mass concentration of 0.05% for 5 seconds, and control the temperature of the Vc solution at 4°C, then place the sliced garlic in step (3) in a vacuum of 60pa and a microwave frequency of 2450MHz± Under the microwave condition of 50MHz, microwave treatment for 15min, then dry the sliced garlic in step (3) at a vacuum degree of 30pa and a temperature of 45°C until the moisture content is ≤7% to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com