Weather-resistant polypropylene material for preparing asphalt pantile fastening nail cap

A technology of weather-resistant polypropylene and corrugated tiles, which is applied in the field of weather-resistant polypropylene materials, can solve the problems of asphalt corrugated tiles from scratching, falling off, mildew in the house, and deterioration of material properties, so as to improve aging resistance, long-lasting color, The effect of color stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Preparation of fixed nail caps for asphalt corrugated tiles

[0017] The material used is weather-resistant polypropylene material, and the raw materials are as follows: AO-18 antioxidant 0.5%, PS-2 phosphate auxiliary antioxidant 0.1%, HALS-1 / HALS-3 hindered amine composite stabilizer 1%, UVA -19UV absorber 0.4%, pigment 1.5%, TiO 2 Rutile type 0.5%, coupling agent 0.8%, elastomer 20%, DCUP peroxide curing agent 0.15%, TAIC isocyanurate active co-vulcanizing agent 0.02%, bismaleic anhydride grafting agent 1.5%, Ni- 1 Active quencher 0.2%, lubricant (PE wax) 0.5%, talcum powder 10%, the balance is polypropylene.

[0018] The preparation method is a conventional method.

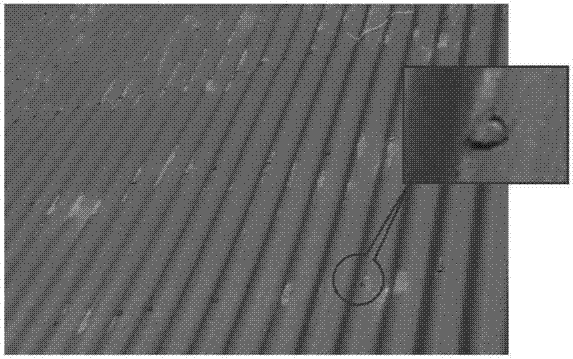

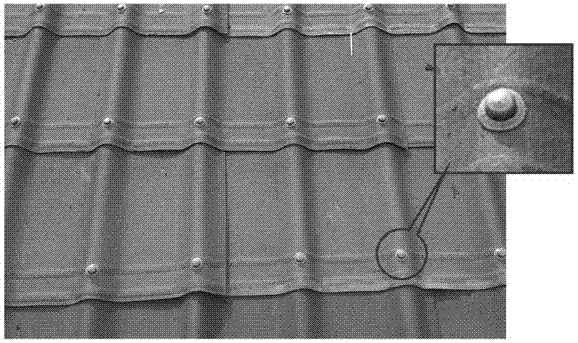

[0019] The asphalt corrugated tile fixed nail cap (such as image 3 shown), after two years of use, its photos are as follows figure 2 As shown (Jundaline asphalt corrugated tile), after two years of use, the color of the nail cap has little fading and the brim edge has not been damaged. ...

Embodiment 2

[0020] Example 2 Preparation of fixed nail caps for asphalt corrugated tiles

[0021] The material used is weather-resistant polypropylene material, and the raw materials are as follows: AO-18 antioxidant 0.5%, PS-2 phosphate auxiliary antioxidant 0.1%, HALS-1 / HALS-3 hindered amine composite stabilizer 1%, UVA -19UV absorber 0.4%, pigment 1.5%, TiO 2 Rutile type 0.5%, coupling agent 0.8%, elastomer 20%, DCUP peroxide curing agent 0.1%, TAIC isocyanurate active co-curing agent 0.02%, bismaleic anhydride grafting agent 2%, Ni-1 Active quencher 0.2%, lubricant (oleic acid amide) 0.5%, talcum powder 10%, the balance is polypropylene.

Embodiment 3

[0022] Example 3 Preparation of fixed nail caps for asphalt corrugated tiles

[0023] The material used is weather-resistant polypropylene material, and the raw materials are as follows: AO-18 antioxidant 0.5%, PS-2 phosphate auxiliary antioxidant 0.1%, HALS-1 / HALS-3 hindered amine composite stabilizer 1%, UVA -19UV absorber 0.4%, pigment 1.5%, TiO 2 Rutile type 0.5%, coupling agent 0.8%, elastomer 20%, DCUP peroxide curing agent 0.15%, TAIC isocyanurate active co-curing agent 0.02%, bismaleic anhydride grafting agent 2%, Ni-1 0.2% active quencher, 0.5% lubricant (erucamide), 10% talc, and polypropylene as the balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com