Patents

Literature

71results about How to "Does not affect processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

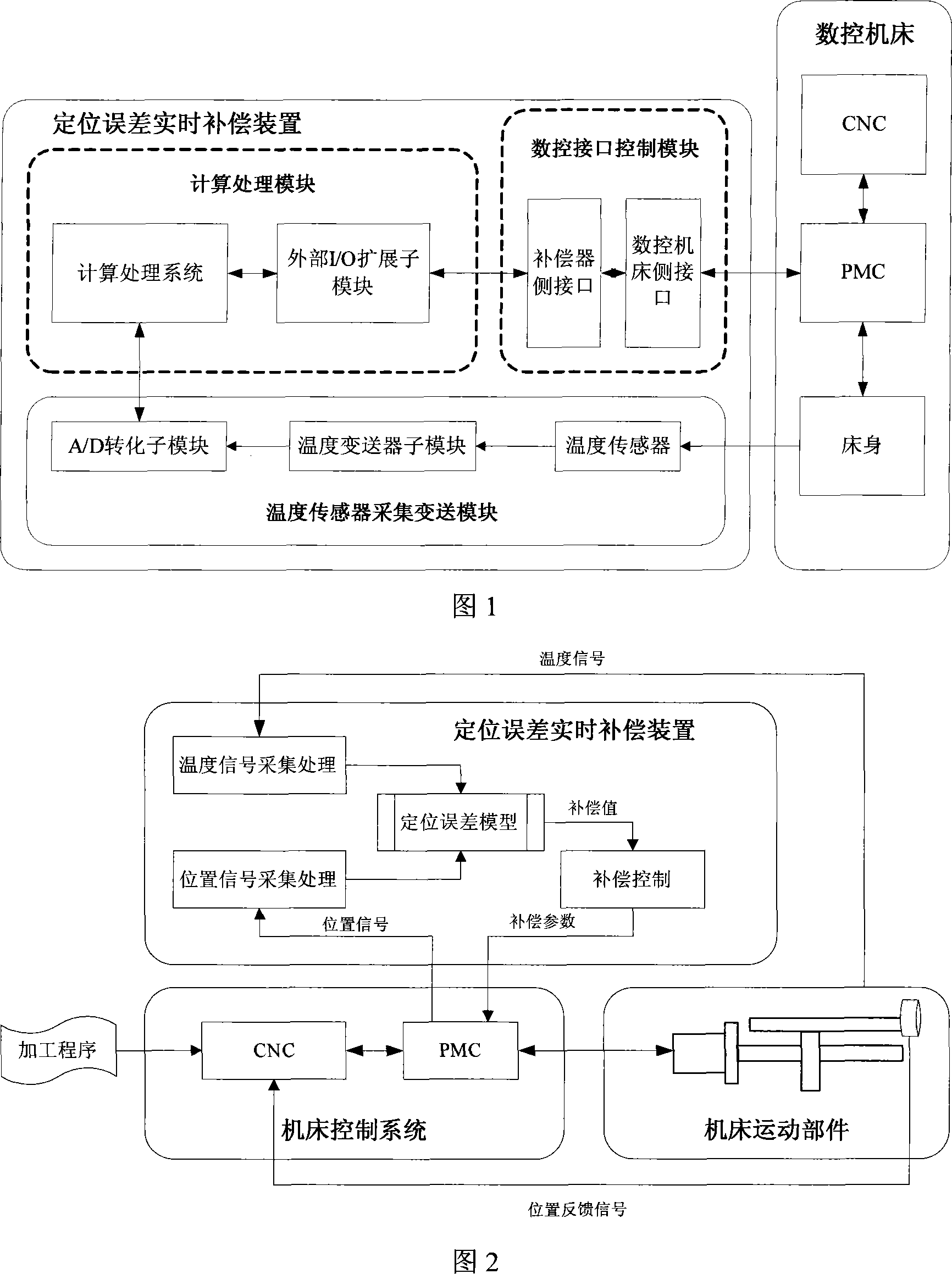

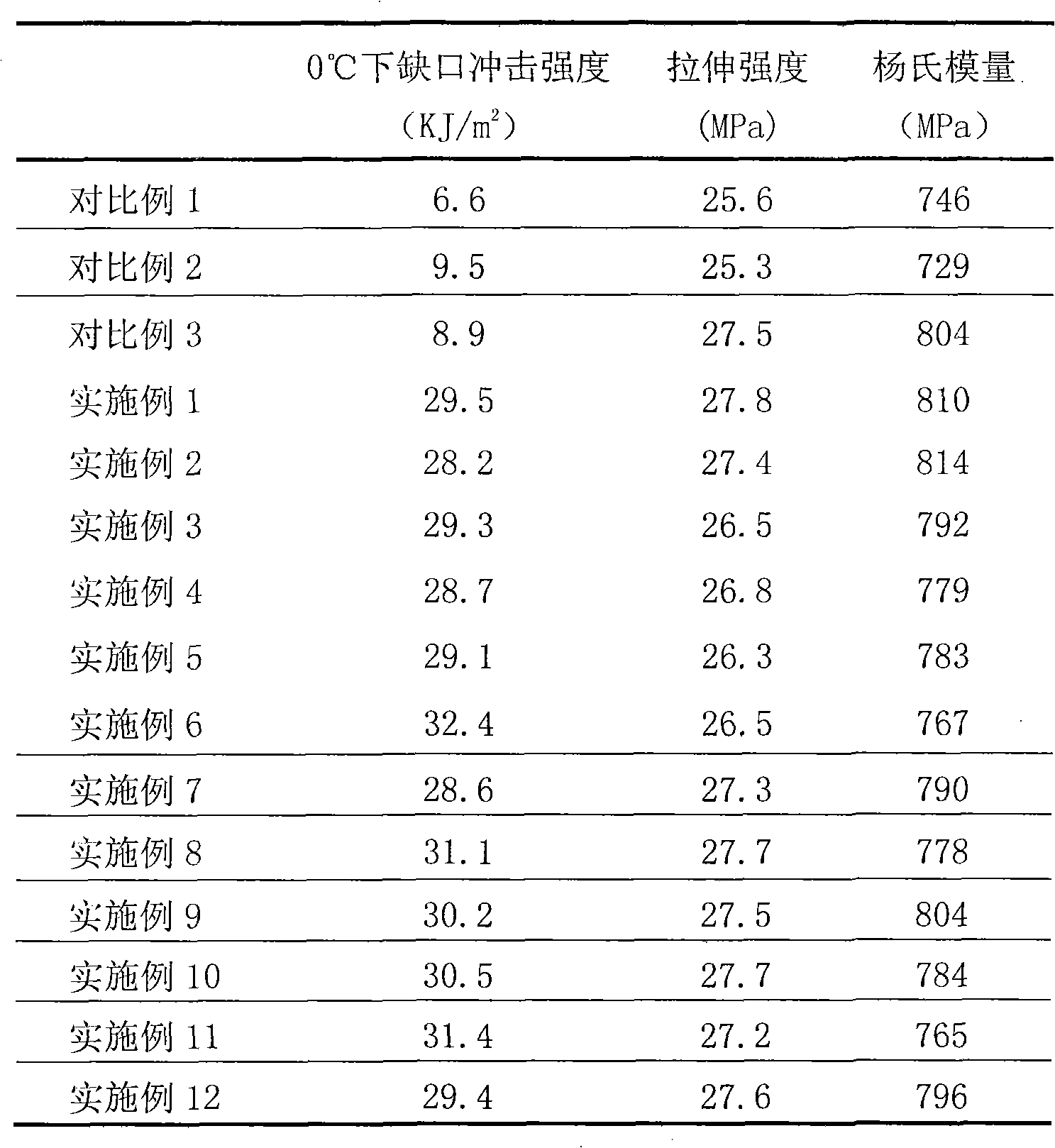

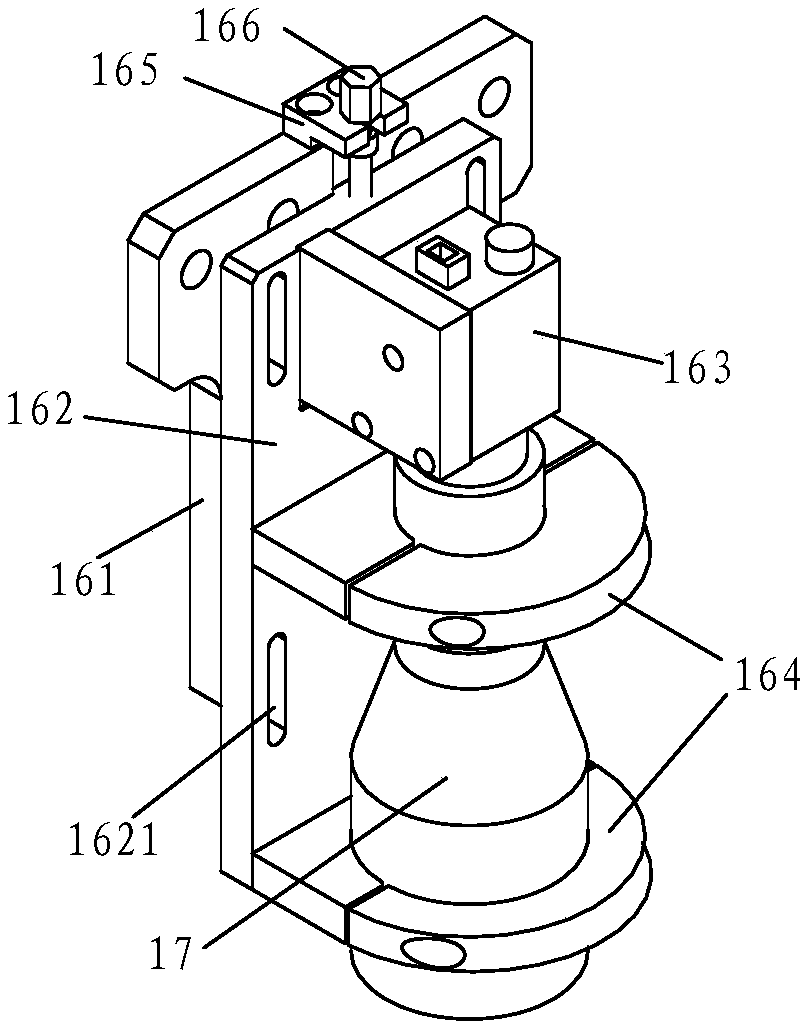

Digital control machine tool positioning error real-time compensation device

InactiveCN101122791ARealize the compensation functionLow costProgramme controlComputer controlProcess moduleDigital control

The invention relates to a position-error real time compensation device of numerical control machine. The position-error real time compensation device that is machine- outside-coordinate-bias-based comprises a compute and process module, an acquisition and transmitter module of a temperature sensor and a numerical control interface control module. A processing system of the compute and process module collects temperature signals of numerical control machine while receiving signals of machine coordinate location from the numerical control system, entering the signals into a mathematical model of positional error that is previously set up to obtain compensation value and delivering the compensation value to the numerical control machine by an inter face of the numerical control system to complete the whole compensation process. The invention completes the compensation operation by design of the interface and software, which does not affect previous numerical control system and processor. The hardware is relatively simple and the software is flexible to modify with good commonality.

Owner:SHANGHAI JIAO TONG UNIV

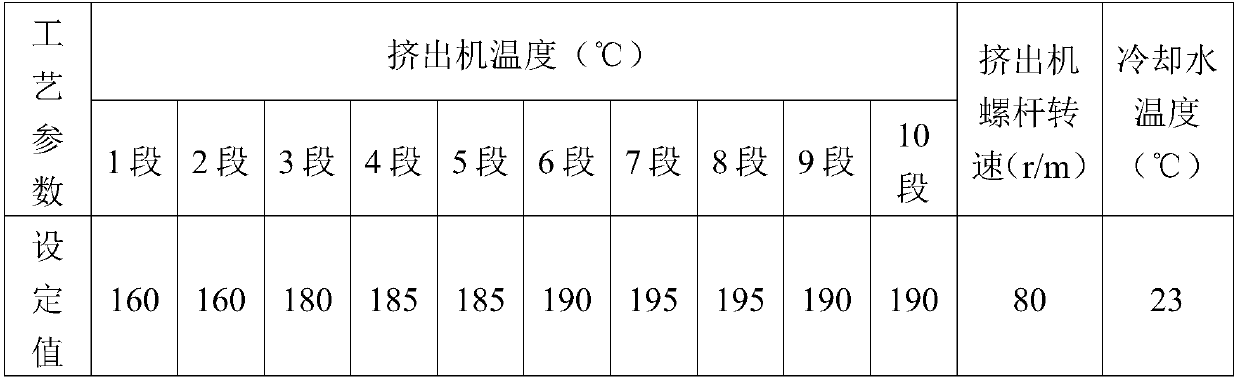

Method for preparing low-temperature flexible random copolymerization polypropylene product

The invention discloses a method for preparing a low-temperature flexible random copolymerization polypropylene product, which comprises the following steps of: melting and blending 100 parts of random copolymerization polypropylene resin containing less than 4 percent of ethylene monomers and 5 parts of beta nucleating agent to prepare a beta nucleating agent master batch; melting and blending 2 to 10 parts of beta nucleating agent master batch, 100 parts of random copolymerization polypropylene resin containing less than 4 percent of ethylene monomers and 0.1 to 0.5 part of antioxidant to prepare random copolymerization polypropylene modified aggregates, and performing injection molding on the aggregates to form a product; and finally, annealing the product at the temperature of 90 and 120 DEG C for 1 to 12 hours, and placing at the room temperature for over 48 hours. The product prepared by the method has the balanced mechanical property and can maintain excellent rigidity while improving low-temperature toughness substantially, so the method provides the new technology for the preparation of copolymerization polypropylene products of products such as tubular products, electrical and electronic equipment, home appliances, automobiles and the like which have the excellent low-temperature toughness.

Owner:SICHUAN UNIV

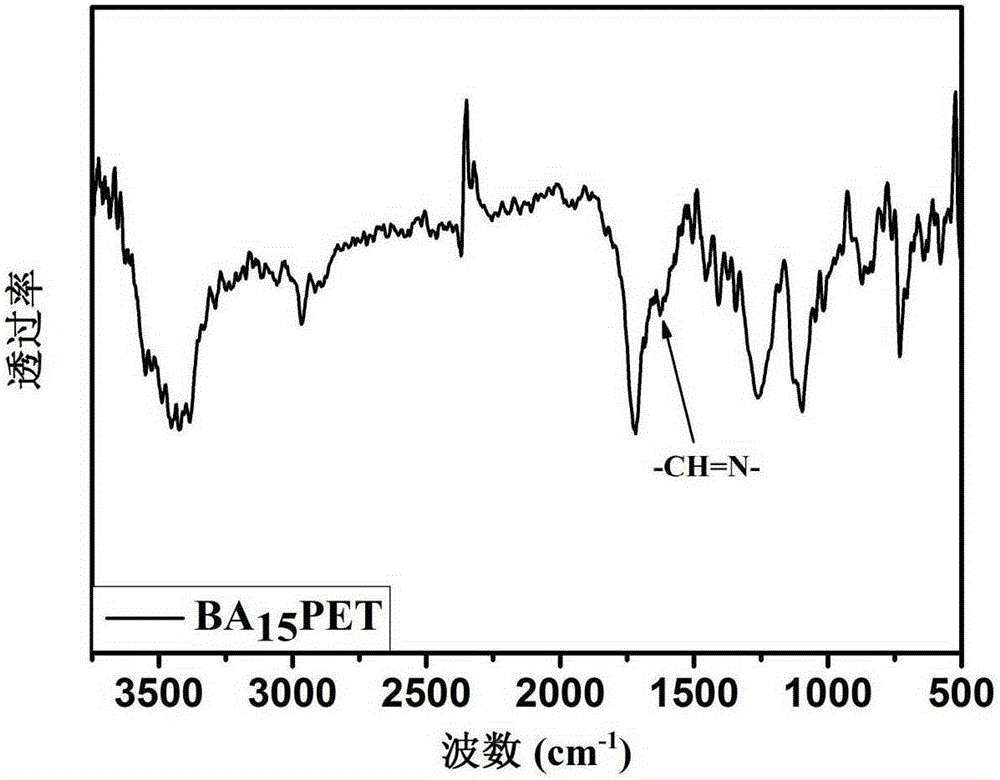

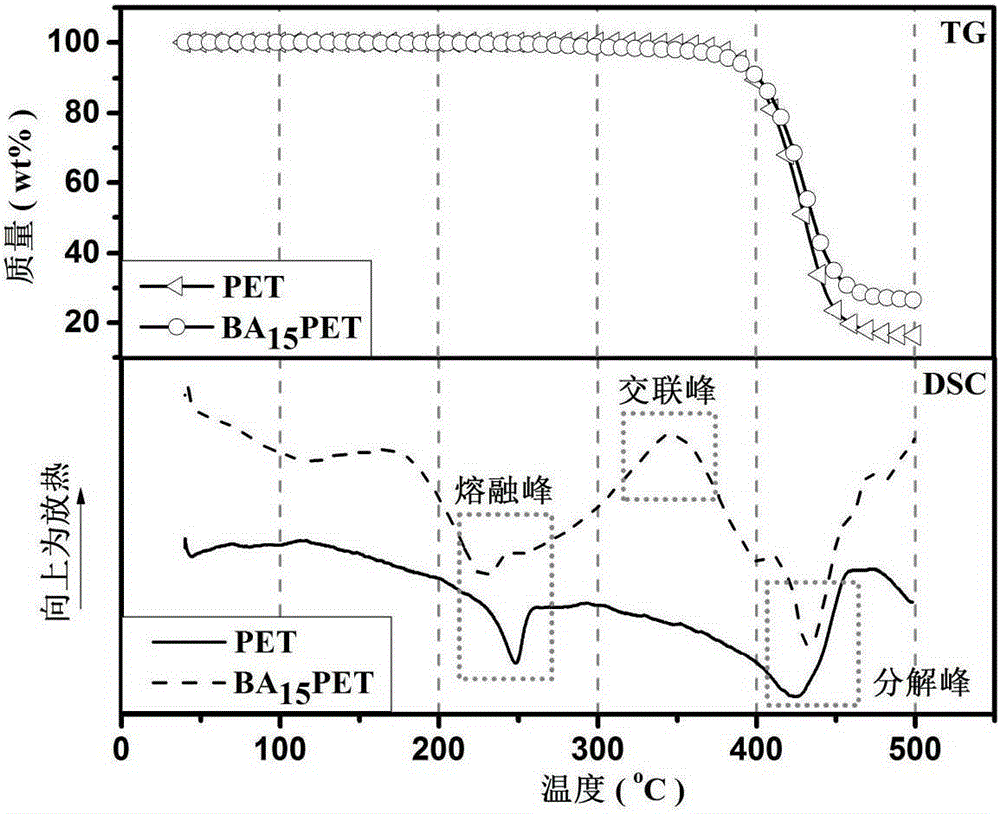

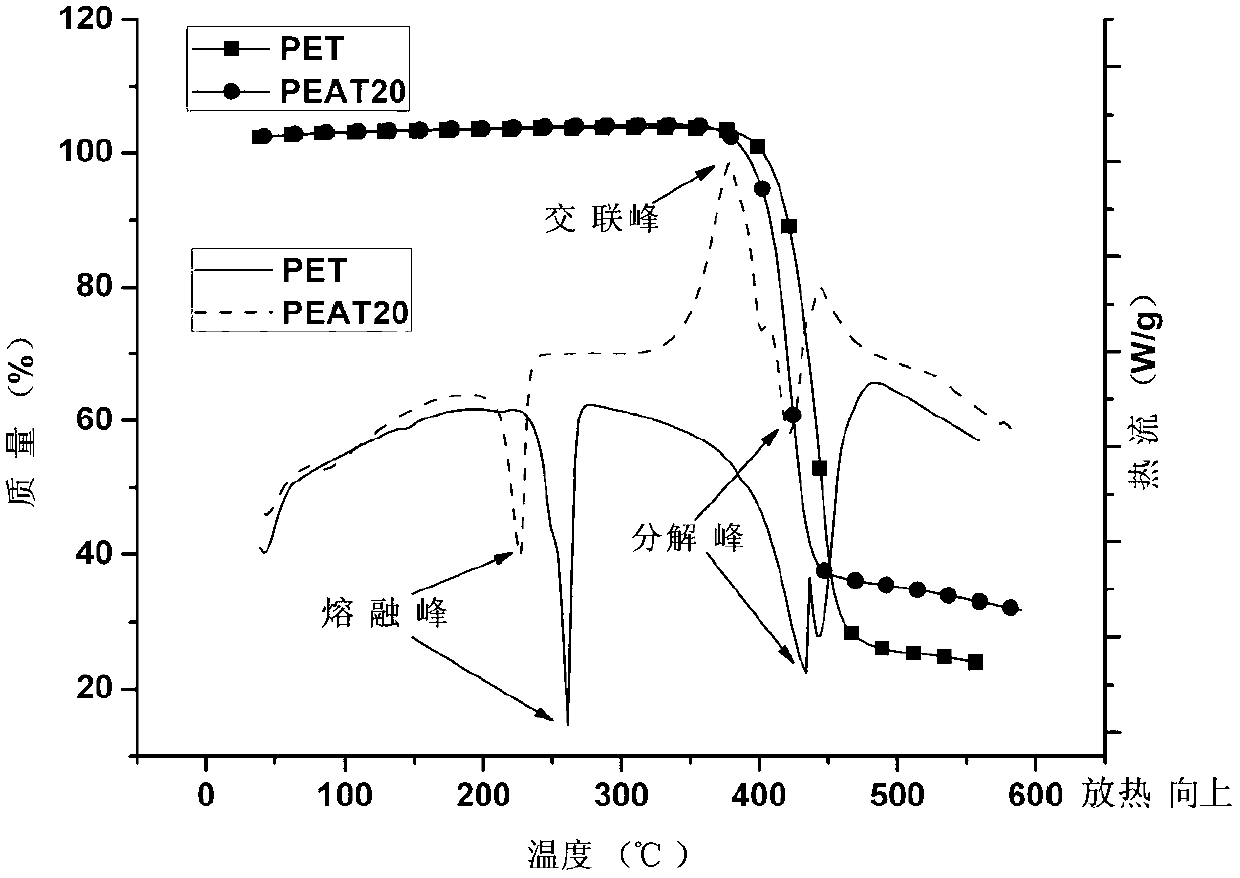

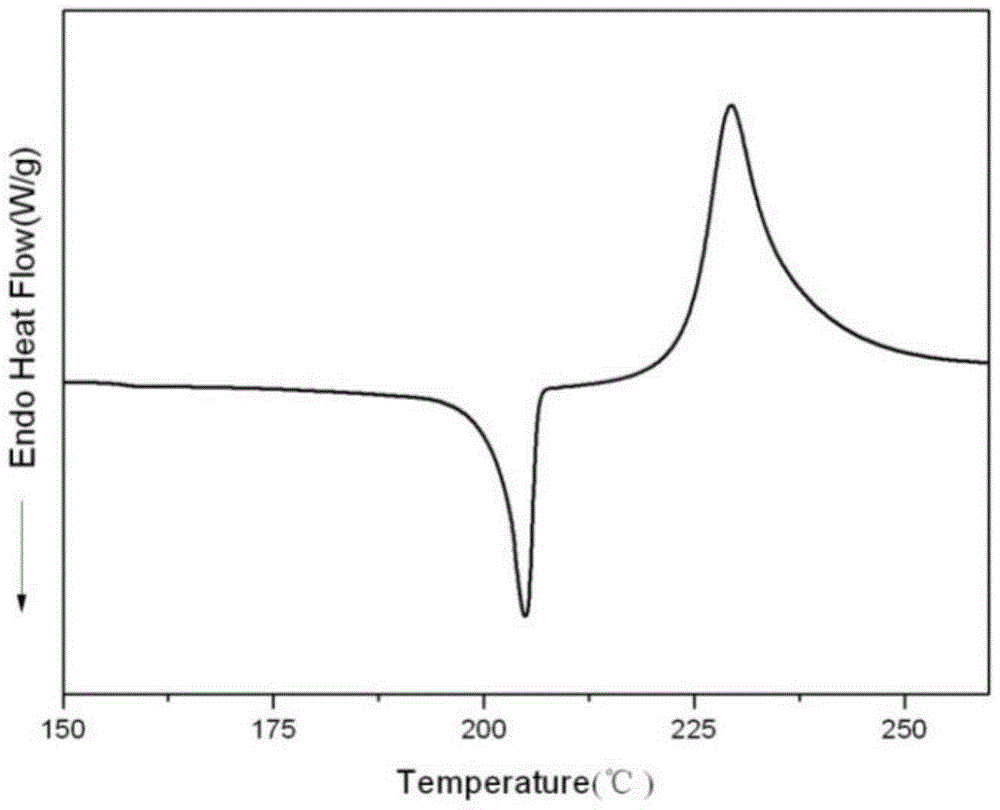

High-temperature self-crosslinking anti-flaming anti-dripping copolyester based on Schiff base structure and preparation method thereof

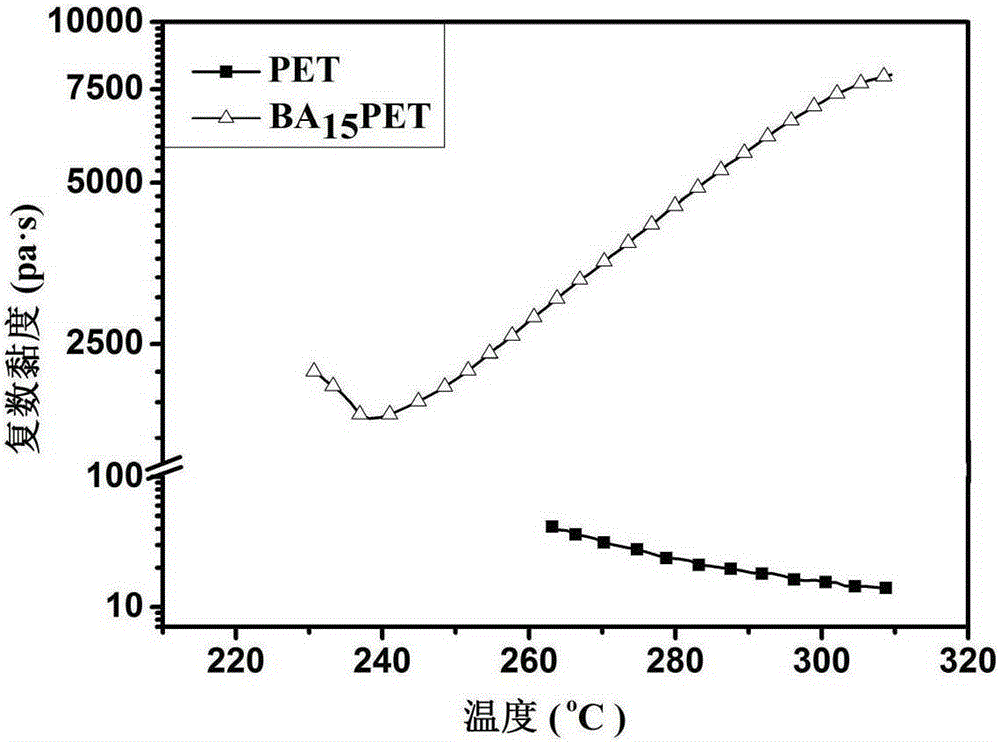

The invention discloses high-temperature self-crosslinking anti-flaming anti-dripping copolyester based on a Schiff base structure. The high-temperature self-crosslinking anti-flaming anti-dripping copolyester is obtained by introducing structural units represented in III or IV on the basis of polyester structural units represented in I and II and carrying out random copolymerization. The intrinsic viscosity number [eta] of copolyester is 0.30-1.10 dL / g, and the limit oxygen index is 24.0-40.0%; the vertical flame class is V-2-V-0; the peak heat release rate p-HRR in a cone calorimeter test is lowered by 33-83% compared with pure PET. The invention further discloses a preparation method of the high-temperature self-crosslinking anti-flaming anti-dripping copolyester. The introduced crosslinking group is a Schiff base group, and the anti-flaming anti-dripping efficiency is high, so that the melt viscosity of polyester can be rapidly improved through the self-crosslinking group char formation effect and stable chemical crosslinking without adding other fire retardant, and the copolyester has the excellent anti-flaming and anti-dripping performance.

Owner:SICHUAN UNIV

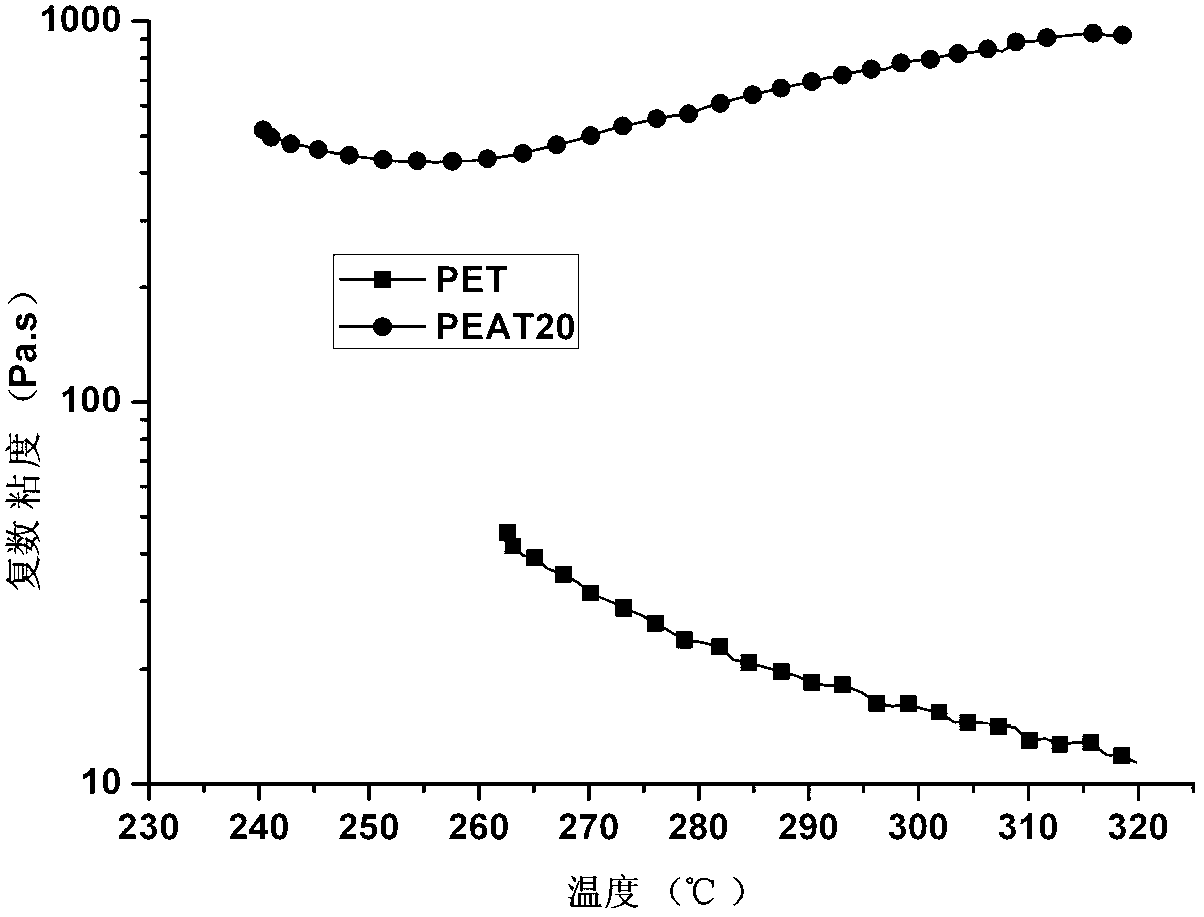

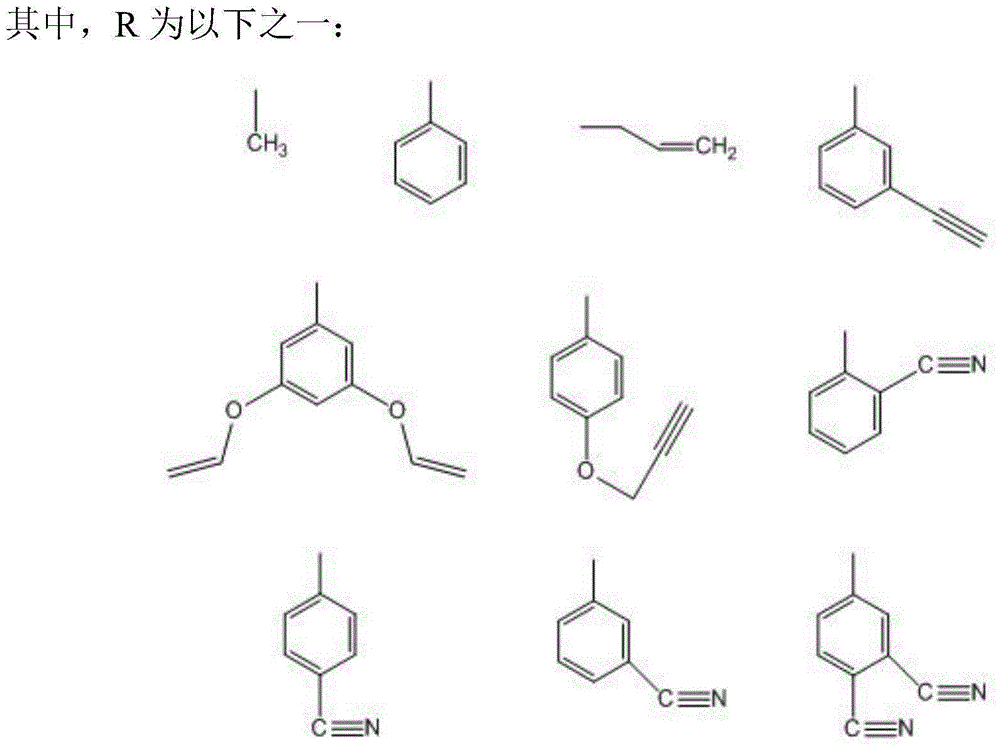

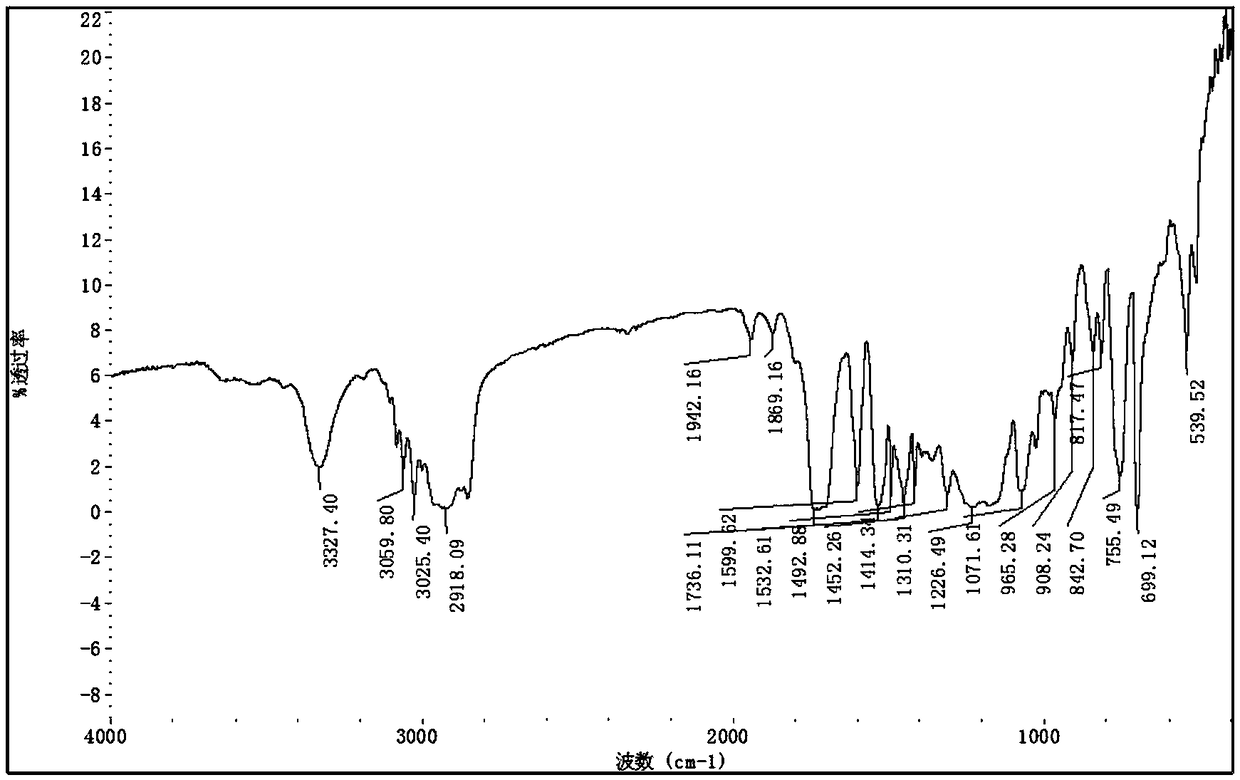

Azobenzene structure based high-temperature self-cross-linked expanded flame-retardant anti-dripping copolyester and preparation method thereof

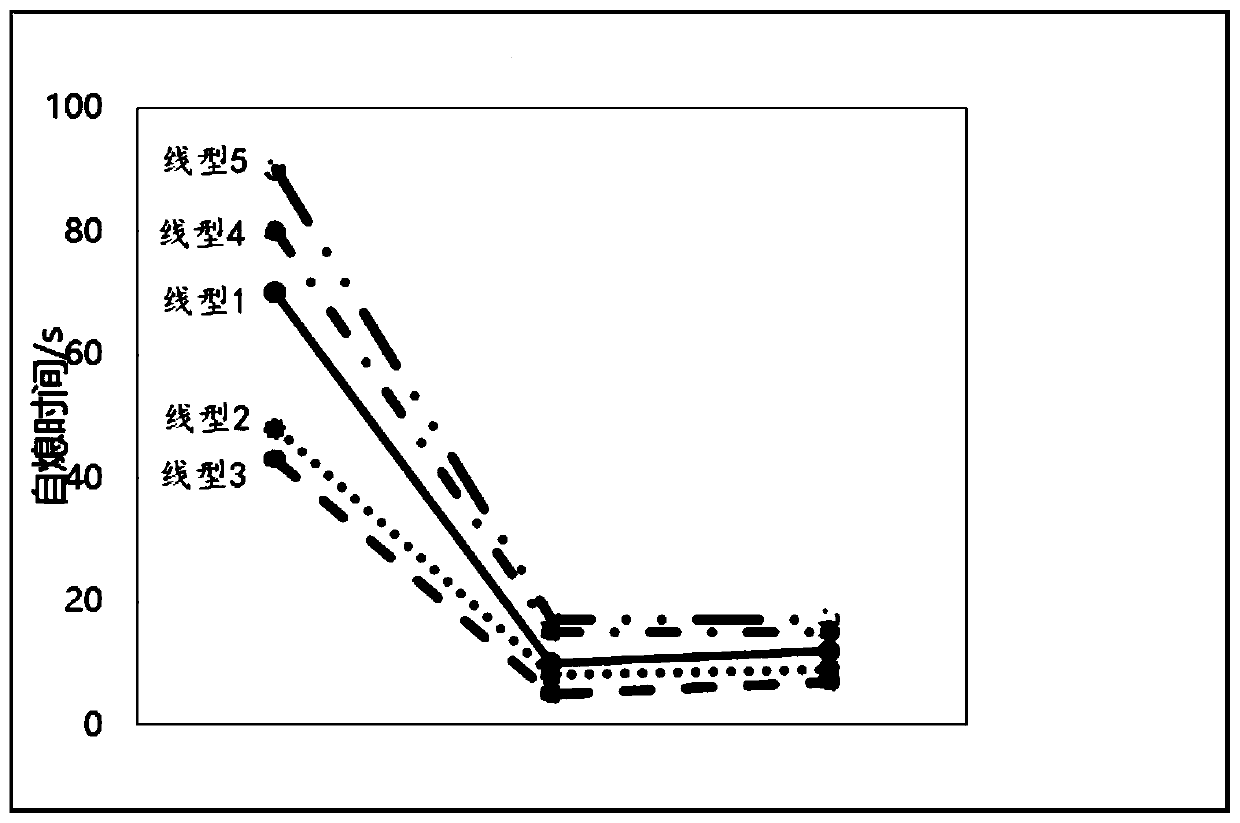

ActiveCN102863611ADoes not affect synthesisDoes not affect processabilityCopolyesterChemical compound

The invention discloses azobenzene structure based high-temperature self-cross-linked expanded flame-retardant anti-dripping copolyester and a preparation method thereof. The copolyester is composed of structural units represented as I, II and III or structural units represented as I, II, III and IV by means of random copolymerization, and the intrinsic viscosity [eta] of the copolyester is 0.25-1.30dL / g. A high-temperature self-cross-linked group introduced into the copolyester is an azobenzene-structured compound with a unique pi-pi large conjugated system, has no influence on copolyester synthesis and processing and can be heated to burn for quick thermochemical crosslinking to form carbon at high temperature to form a separation layer, so that excellent flame retardation and anti-dripping effects can be obtained. The selected compound with the azobenzene structure is cheap, and the method is mature in process, simple and convenient to operate, easy to control and suitable for industrial production.

Owner:SICHUAN UNIV

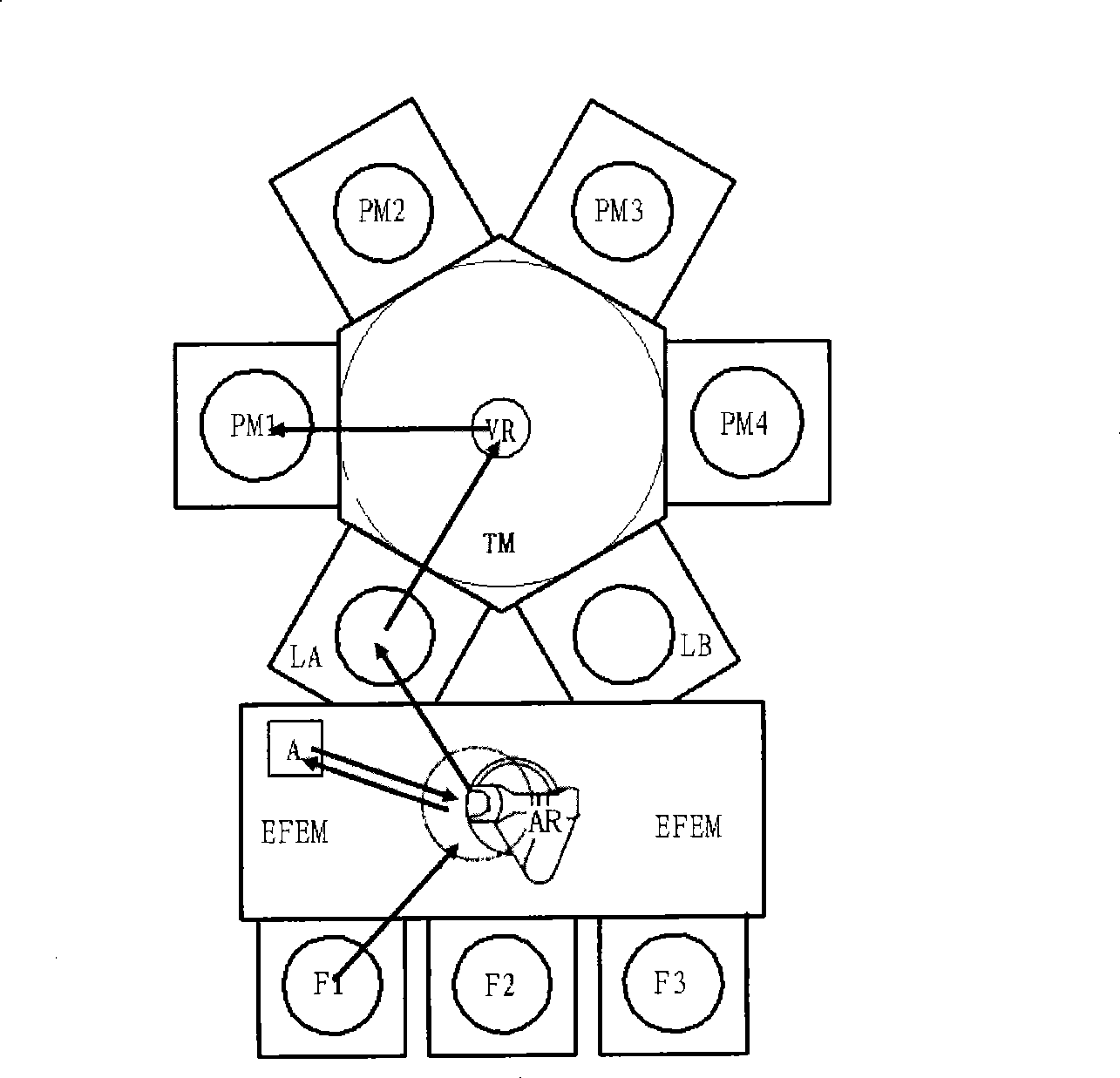

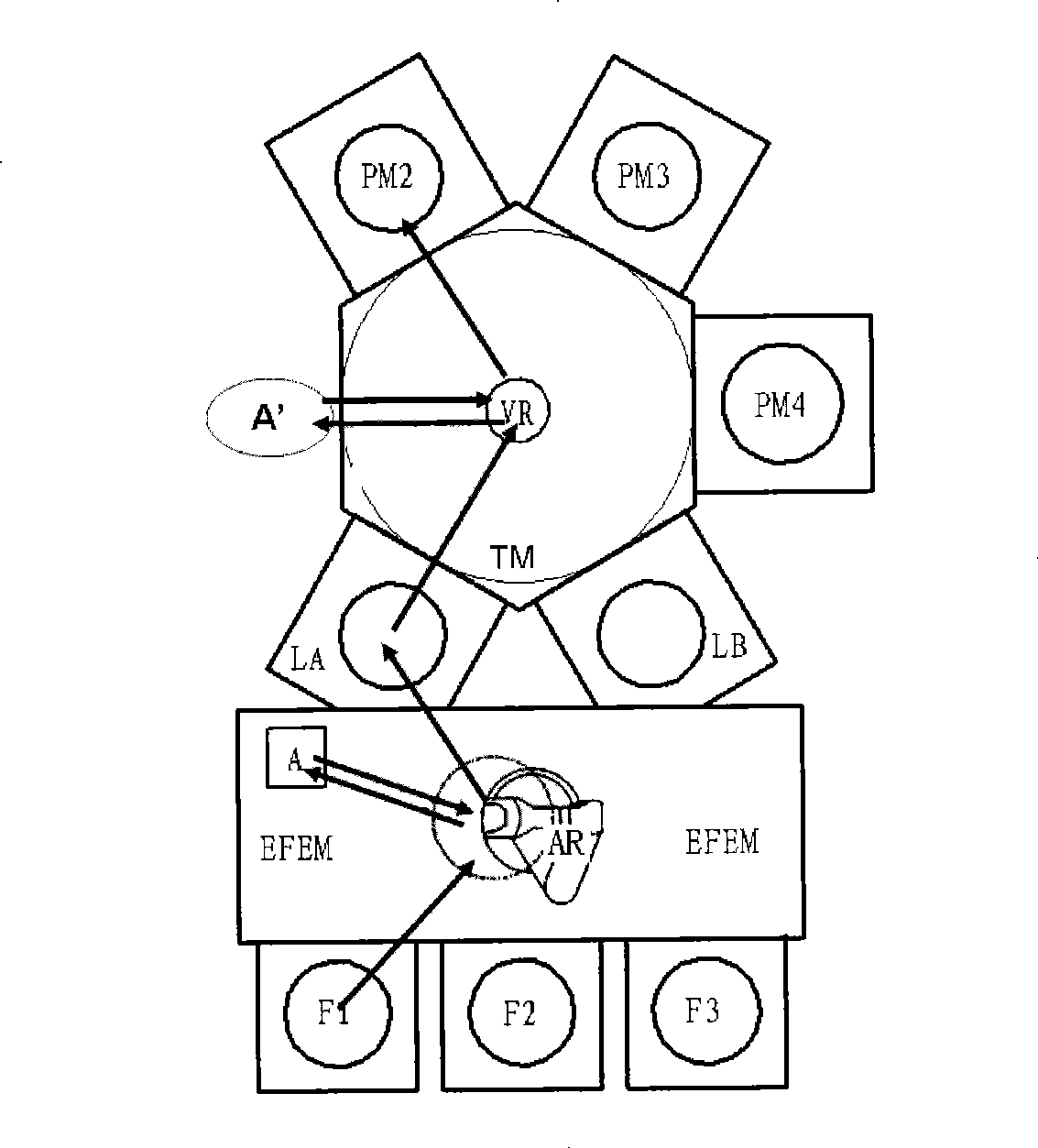

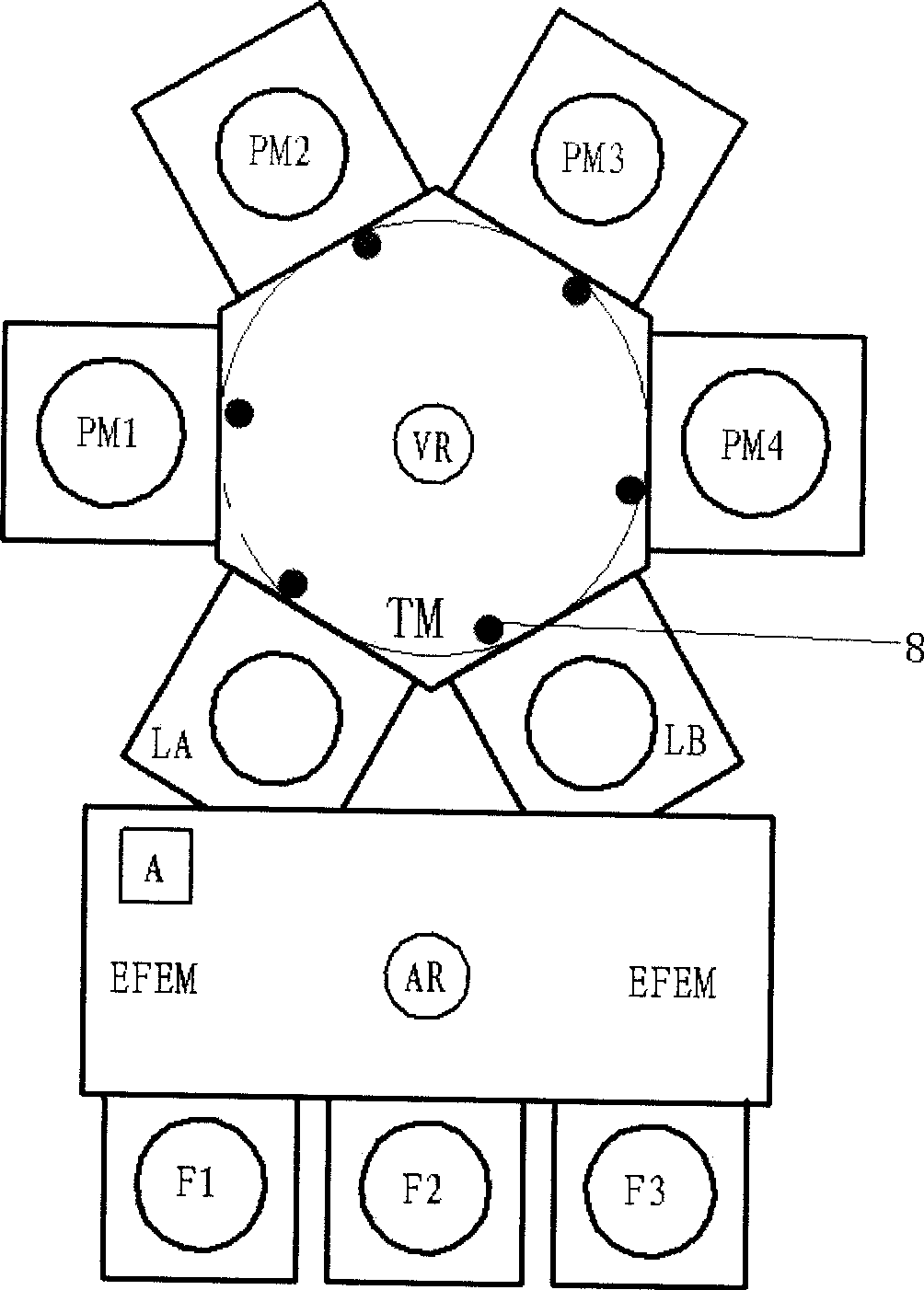

Wafer transmission system

ActiveCN101383311ADoes not affect processabilityDoes not affect productivityConveyor partsEngineeringManipulator

The invention discloses a wafer transmission system which comprises a vacuum transmission cavity connected with a plurality of cavities, and each wafer channel which is arranged between the vacuum transmission cavity and each cavity is provided with an optical fibre sensor which is used for sensing the position information of a wafer; the optical fibre sensor comprises a transmitting terminal and a receiving terminal, a light which is transmitted by the transmitting terminal is perpendicular to the surface of the wafer, and the position of the optical fibre sensor slightly deflects to a center line of the wafer channel. When a vacuum mechanical arm is used for transmitting the wafer among the cavities, the position information of the wafer can be sensed by the sensor, the transmission system can calibrate the position bias of the wafer according to the position information, and the processing capability and the output rate of a mechanical table can not be influenced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Negative ion material and synthetic leather material modified therefrom and application thereof

InactiveCN1664229ADoes not affect processabilityPerformance is not affectedTextiles and paperIonChemistry

Owner:李上辉

Antibacterial glaze material

An antibacterial glaze material comprises a nano zirconium phosphate silver-loaded antibacterial agent, nano titanium dioxide, zinc oxide, copper oxide, Jiushan local glaze stone, quartz, talcum, copper ores and calcite. The antibacterial glaze material has the advantages that the nano zirconium phosphate silver-loaded antibacterial agent and the nano titanium dioxide are added into the glaze material, so that the glaze material has good antibacterial property, is non-toxic and pollution-free, and is suitable for the glaze formula of Jun porcelain kitchenware such as plates and bowls; the glaze material is good in fluidity, less prone to blistering and good in glossiness, and Jun porcelain glaze prepared by the glaze material is stable and uniform in color.

Owner:崔松伟

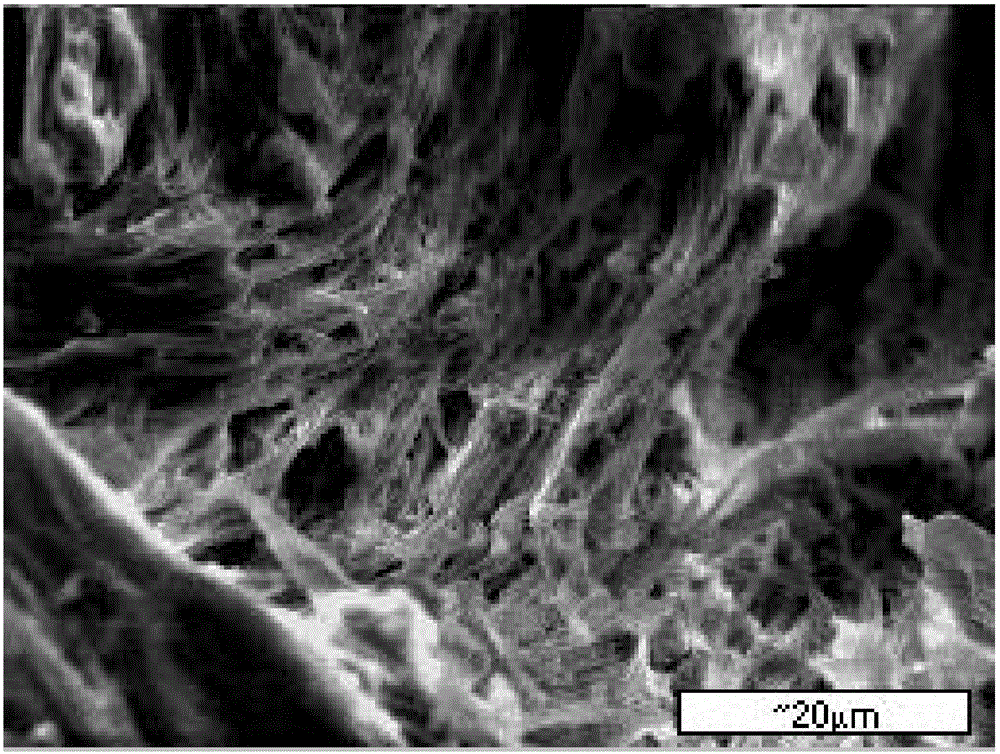

Method for preparing composite material capable of forming in situ conductive microfiber network

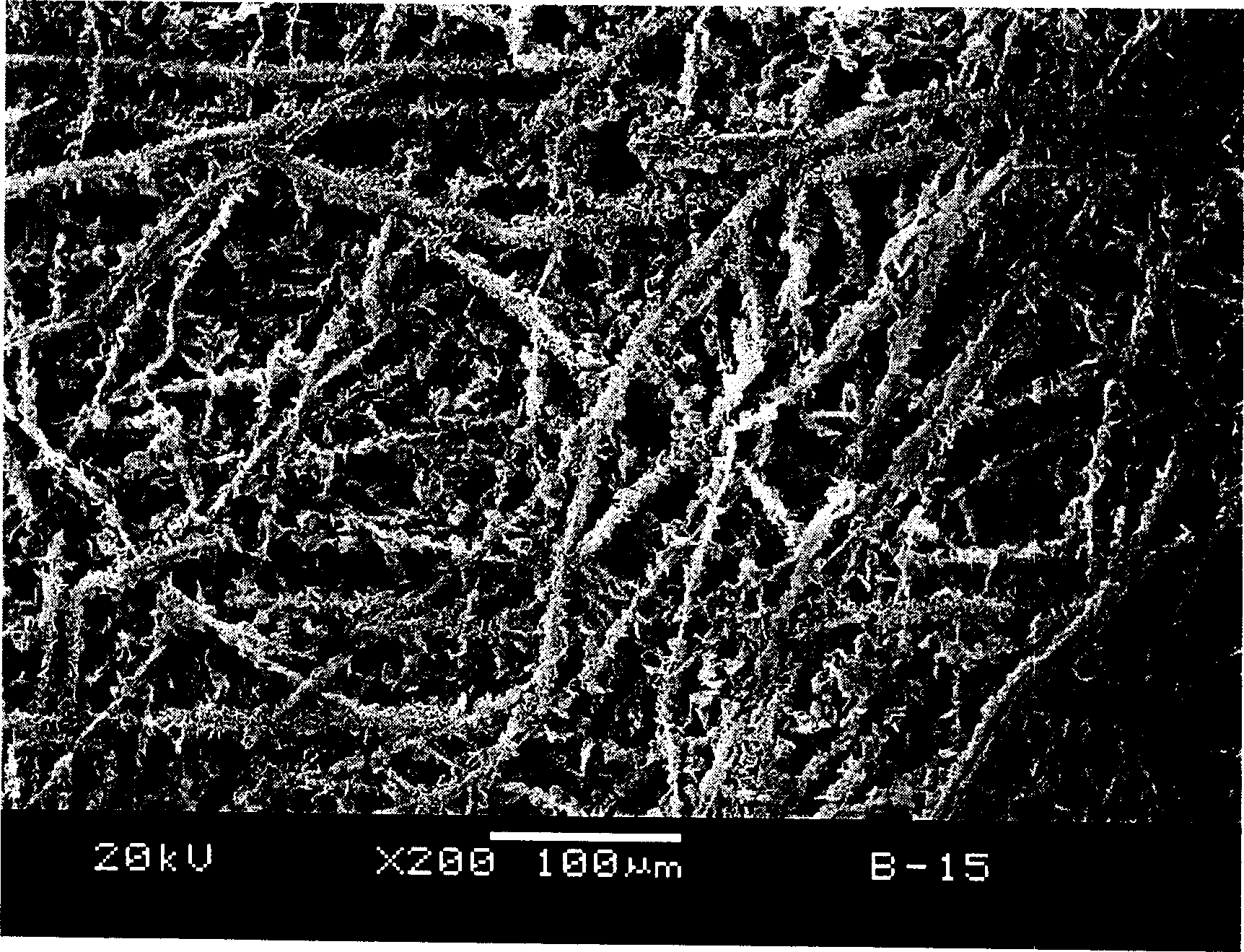

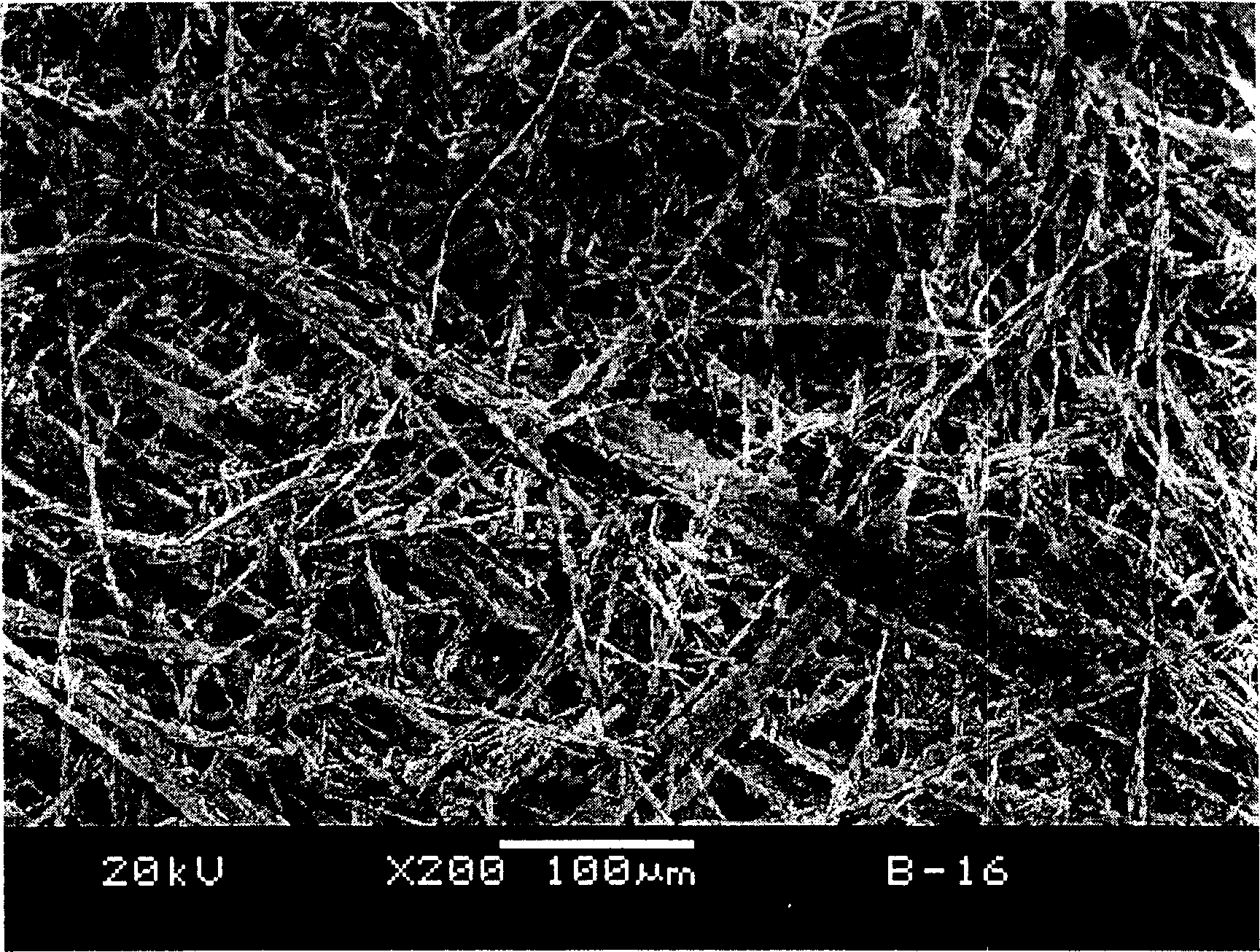

InactiveCN1528816ANot to be meltedReduce the conductive percolation valueNon-conductive material with dispersed conductive materialThermoplasticMasterbatch

The invention discloses a manufacturing method of a kind of compound material which can forms in situ conductive fibre network. The weight shares are 70-95 shares of low melting point thermal plasticity plastics, 5-30 shares of high melting point thermal plasticity plastic, and 7.5-30 shares of conductive fillers in each 100 shares of above two plastic, the process is drying, masterbatch producing, fusing and mixing, thermal extension, cooling, prilling. The conductive fillers in the invention are in the fibre phase of high melting point, these fibre phases can form the conductive network in product. Thus, the fillers are reduced and the conductive prolonged penetrating value, but doesn't affect the workability and mechanical performance of the compound, reversely, the in situ fibre has a certain enhancing effect to the compound. The method is simple.

Owner:SICHUAN UNIV +1

Modified plant fiber material type glass moldproof parting powder

ActiveCN102924942AImprove adsorption capacityPrevent mildewBiocideFungicidesOrganic acidMaterial type

The invention discloses a modified plant fiber material type glass moldproof parting powder which is prepared by carrying out surface modification on plant fiber pulverized substances. The preparation method comprises the following steps: screening plant fiber pulverized substances, mixing with a modifier solution, standing, treating under the absolute pressure of 100-500kPa at the temperature of 0-300 DEG C for 0.1-48 hours, and finally, directly drying to obtain the modified plant fiber material type glass moldproof parting powder. The modifier is selected from one or mixture of organic acids, inorganic acids or acid salts. The moldproof parting powder has the advantages of favorable flowability, adsorptivity and natural degradability, can postpone the glass from becoming moldy, basically does not generate flying ash, and is clean and convenient. The glass using the product can be easily cleaned after long-term storage, and can not influence the subsequent processing and use of the glass.

Owner:南京汉旗新材料股份有限公司

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

Application of a flame retardant dicyandiamide in pyrotechnic composition

InactiveCN109180395AGood compatibilityAvoid the disadvantage of high mechanical sensitivityNon-explosive/non-thermic compositionsPyrotechnic compositionFireworks

The invention discloses an application of a flame retardant dicyandiamide in a pyrotechnic composition. 5-30% of 100 mesh or above powdery dicyandiamide obtained by crushing is added to the pyrotechnic composition, water is used as a dilution solvent, a colored luminescent aster capable of reducing the combustion rate and prolonging the flashing time is prepared through a routine bright bead processing method, and the pattern of the bursting flower of the colored luminescent aster in air can be changed; and the pyrotechnic composition obtained by using the dicyandiamide as a flame retardant without changing the composition compatibility and the processing technology of existing pyrotechnic composition mixtures has the advantages of low sensitivity, high safety coefficient, no moisture absorption and good stability, and can be widely used in photochromic pyrotechnic compositions of various firework products.

Owner:浏阳市梦幻烟花制造有限公司

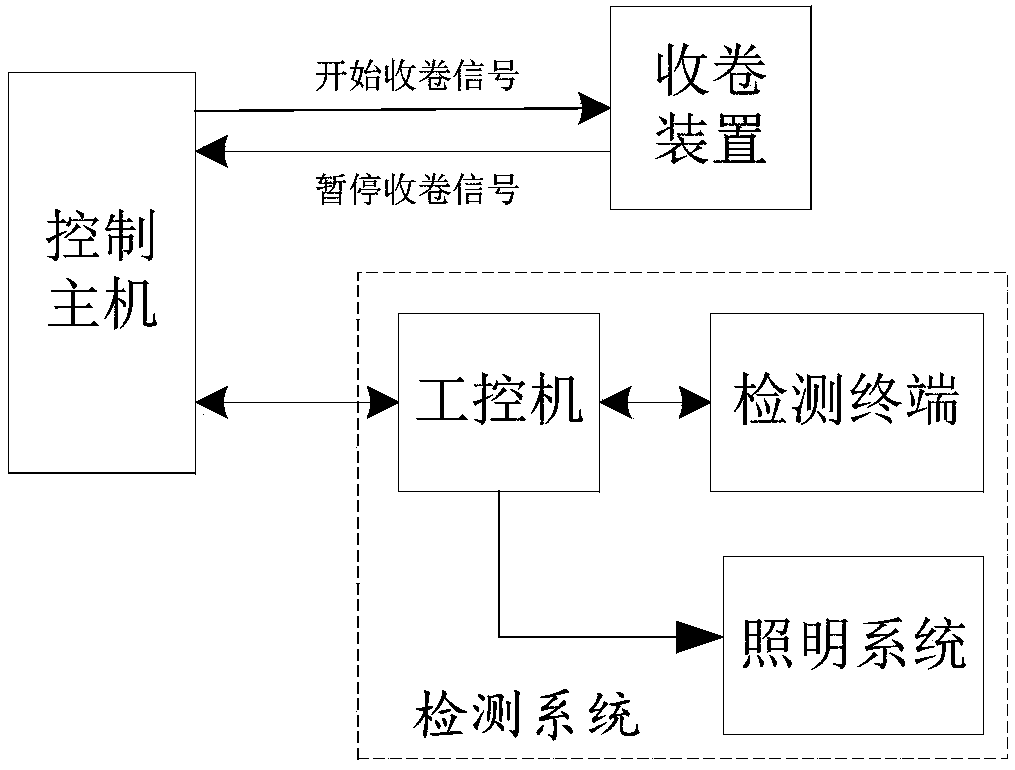

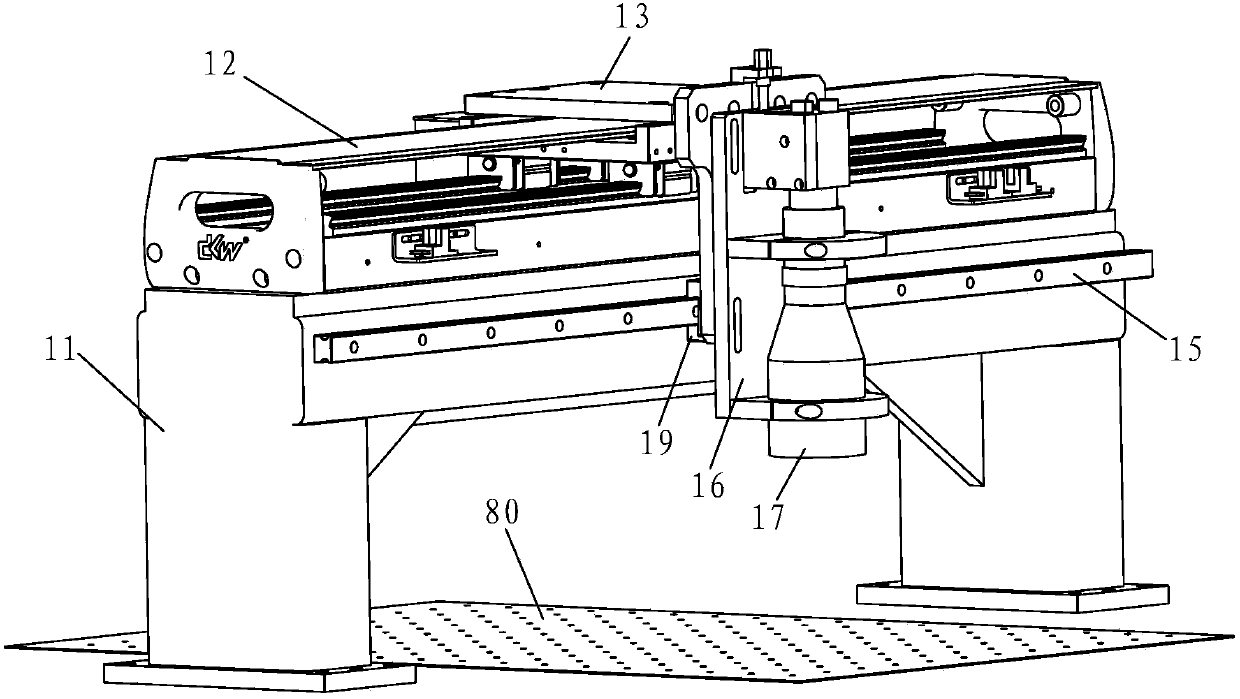

Steel strip punching processing detection system and method based on vision measurement

ActiveCN107907063ARealize high-precision punching detection requirementsHigh precisionUsing optical meansPunchingEngineering

The invention discloses a steel strip punching processing detection system and method based on vision measurement. The method comprises steps: a linear motor is controlled to drive a camera to move tothe right from a working origin point O arranged at the left side of the steel strip, a first image of the upper surface of the steel strip is acquired, a left-side edge of a punching steel strip isdetermined, and the actual movement distance Xa' when the linear motor moves to the left-side edge of the steel strip from the working origin point O is calculated; the linear motor is controlled to drive the camera to move to the right continuously, the camera acquires multiple second images of the upper surface of the steel strip, punching feature information on the second images is recognized,and in combination with a pixel equivalence gamma, the detection result of the punching feature information is determined; and the camera moves to the right continuously and acquires a third image ofthe upper surface of the steel strip, the right-side edge of the punching steel strip is recognized and determined, and the actual movement distance Xb' from the working origin point O to the right-side edge is calculated. The camera is used to realize wide-size punching steel strip processing detection, the detection result is precise, and high-precision detection requirements are met.

Owner:HUNAN UNIV OF ARTS & SCI

Active quick dissolving full valued bone powder, and preparation method

InactiveCN1915092AMeet nutritional needsDoes not affect processabilityFood preparationFood additiveGranularity

An instant active whole-value bone powder with nano-class granularity contains collagen (more than 13%), Ca (more than 15%) and minerals (more than 45%). Its preparing process is also disclosed.

Owner:大连础明生物科技有限公司

Anion materials, modified leather materials thereby, and use thereof

InactiveCN1664113ADoes not affect processabilityPerformance is not affectedLeather surface finishingIonChemistry

The invention discloses a negative ion material, comprising the following components and content: negative ion powder, 20-89 share by weight; coupling agent, 0.1-20share by weight; antibacterial agent, 10-35 share by weight; the said negative ion possesses the function of generating and emitting negative ion, antibiotic and eliminating peculiar smell and caring human body. Also disclosed is derma material modified by said negative ion and the application; applying the negative ion material in the shoemaking material it will emit negative ion continuously in the walking process, which improves the blood micro circulation in foot and increases the comfort and decreases the fatigue, and the negative ion also provides the shoes with the function of antibiosis and deodorization.

Owner:李上辉

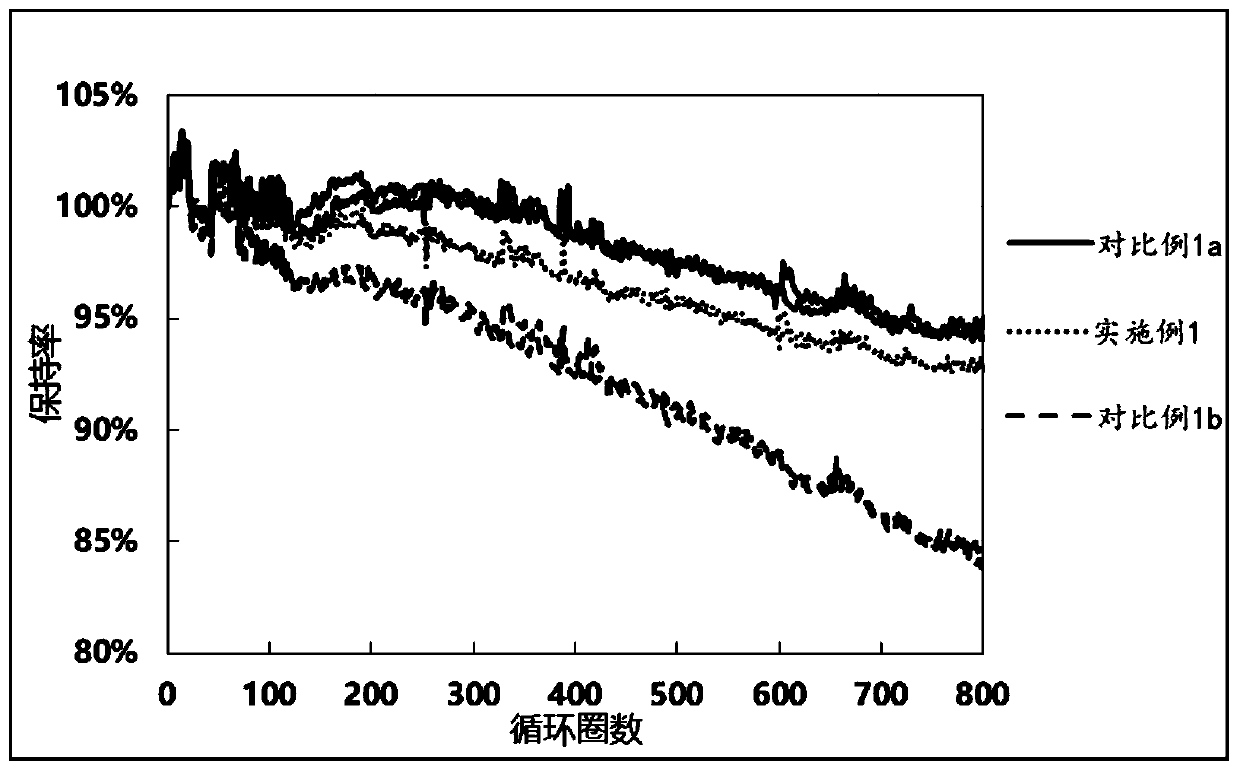

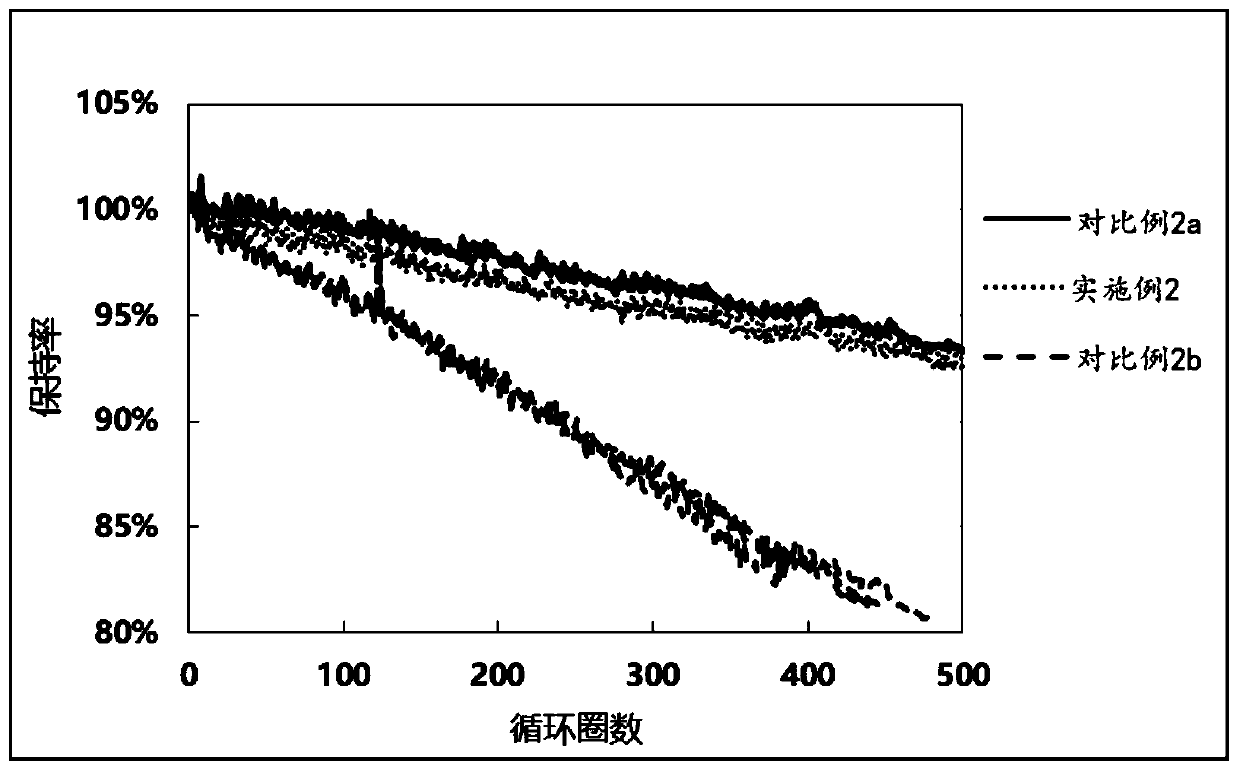

Preparation method of high-flame-retardancy lithium ion battery

InactiveCN109841908AAdd lessAvoid uncontrolled combustionFinal product manufactureCell electrodesSlurryPole piece

The invention discloses a preparation method of a high-flame-retardancy lithium ion battery. The preparation method comprises the steps of: evenly mixing a positive electrode active substance and a flame retardant, adding a conductive agent, PVDF and NMP into the mixture, kneading and stirring the mixture to obtain a positive electrode slurry, and coating the positive electrode slurry on aluminumfoil to obtain a positive electrode pole piece; evenly mixing a negative electrode active substance, a conductive agent, SBR, CMC and water to obtain a negative electrode slurry, coating the negativeelectrode slurry on copper foil to obtain a negative electrode pole piece; winding the positive electrode pole piece, the negative electrode pole piece and a membrane into a pole group, and manufacturing the pole group into a lithium ion battery after performing operations such as baking, shell entering, electrolyte injection, aging and formation on the pole group. According to the preparation method, the flame retardant is directly added into to the positive electrode slurry, and the combustion reaction can be inhibited or prevented by physical or chemical means after thermal runaway of the battery occurs; the flame retardant only forms a film at the positive electrode without loss at the negative electrode, thus the additive amount of the flame retardant is reduced, and the lithium precipitation situation of the negative electrode of the battery is reduced to a certain extent; and since the ignition point of the flame retardant is high, the addition of the flame retardant into the positive electrode slurry does not affect the original performance such as the cycle performance and processing performance of the battery.

Owner:上海力信能源科技有限责任公司

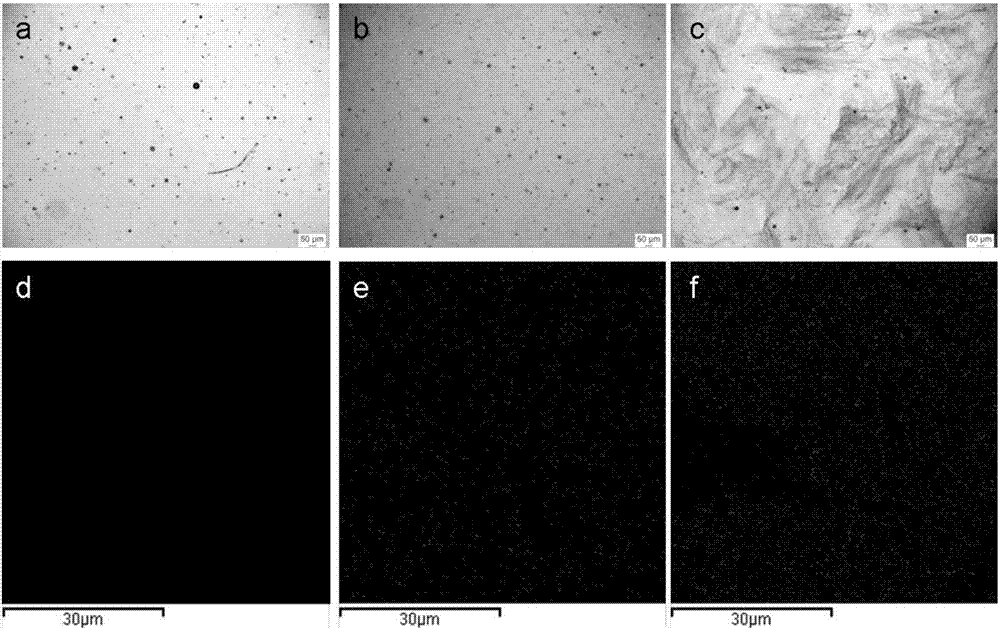

Method for preparing inorganic nanoparticle/polyethylene copolymer composite material

InactiveCN106674705AHigh mechanical strengthImprove toughnessCarvacryl acetateCross-linked polyethylene

The invention discloses a method for preparing an inorganic nanoparticle / polyethylene copolymer composite material. The method comprises the following steps: performing oleophylic modification treatment on calcium carbonate, zinc oxide, aluminum oxide, titanium dioxide and silicon dioxide inorganic nanoparticles, performing blending dispersion on a copolymer of modified inorganic nanoparticles and an ethylene-vinyl acetate copolymer in an internal mixer at 100-130 DEG C, adding aids at 120-160 DEG C, performing melting and blending so as to cross-link polyethylene and inorganic nanoparticles / ethylene-vinyl acetate copolymer, granulating, and processing, thereby obtaining living or production articles. The oxygen index of the inorganic nanoparticle / polyethylene copolymer composite material disclosed by the invention is approximate to 30%. The inorganic / organic nano composite material disclosed by the invention is excellent in machinability, good in flame retardancy, good in antibacterial property, good in tensile and impact resistance and applicable to processing of tubes, films, daily articles and the like which are closely associated with living.

Owner:赵洪全

3,3',5,5'-tetramethyl-4,4'-biphenyldiglycid ether preparation method

InactiveCN1733745AReduce processing viscosityImprove solubilityOrganic chemistryPolymer scienceEther

The invention relates to a process for preparing 3,3',5,5'-tetramethyl-4,4'-biphenyl didycidyl ether, wherein the 3,3',5,5'-tetramethyl-4,4'-biphenol is reacted with excess epichlorohydrin under the action of phase transition catalyst. The prepared has low epoxy equivalent weight, high yield, and simple reaction steps.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method for low temperature toughness isotatic polypropylene product

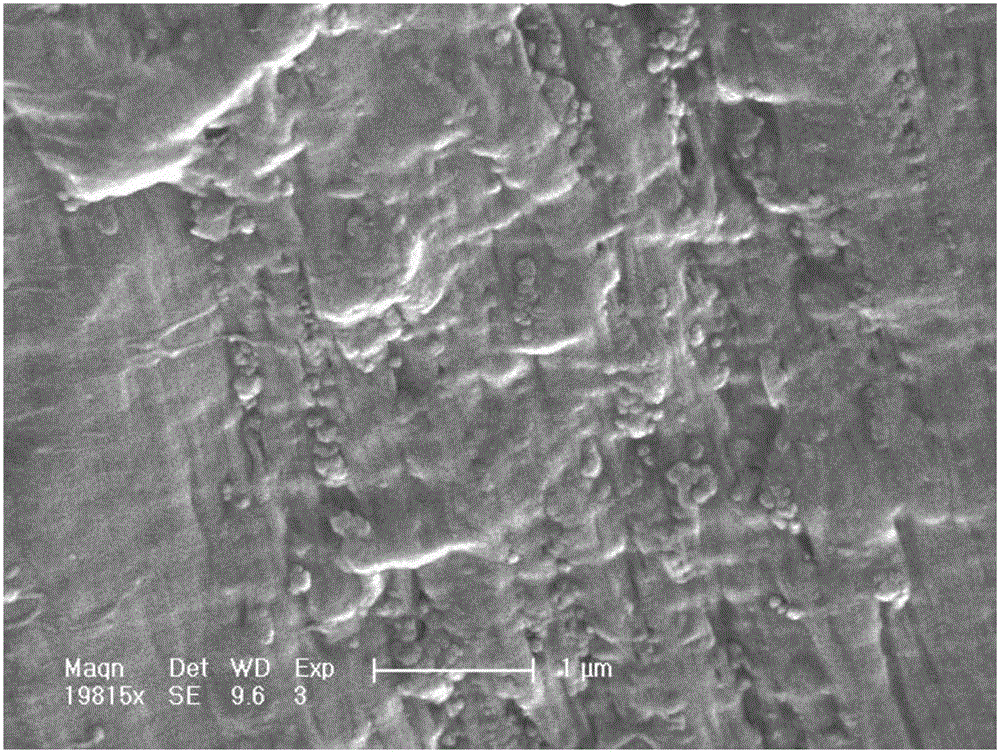

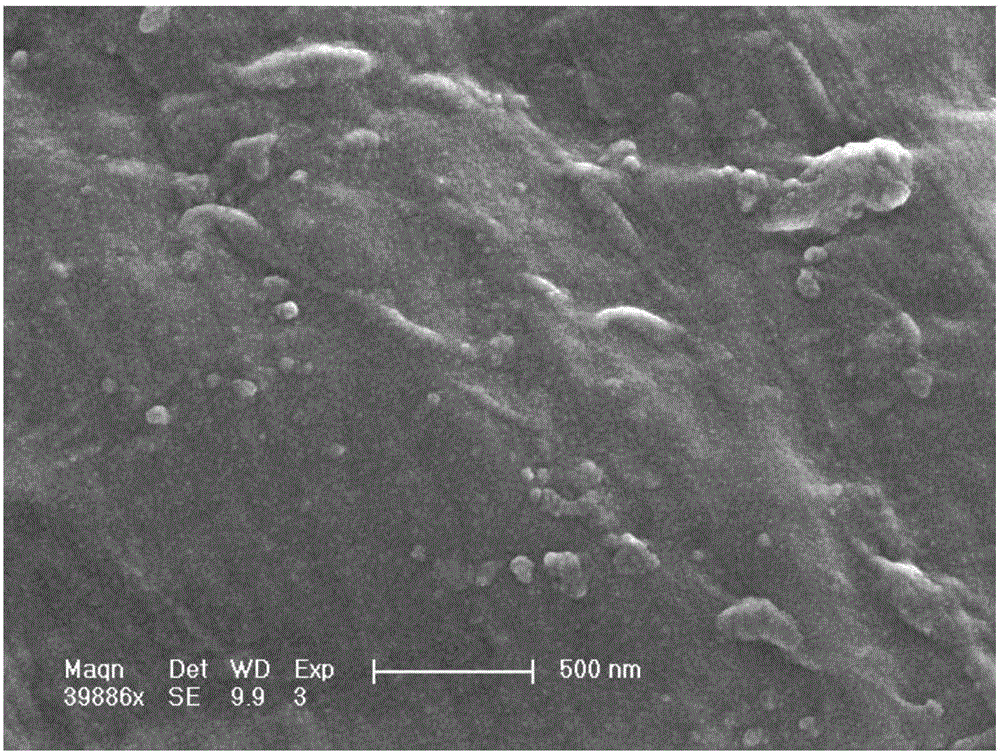

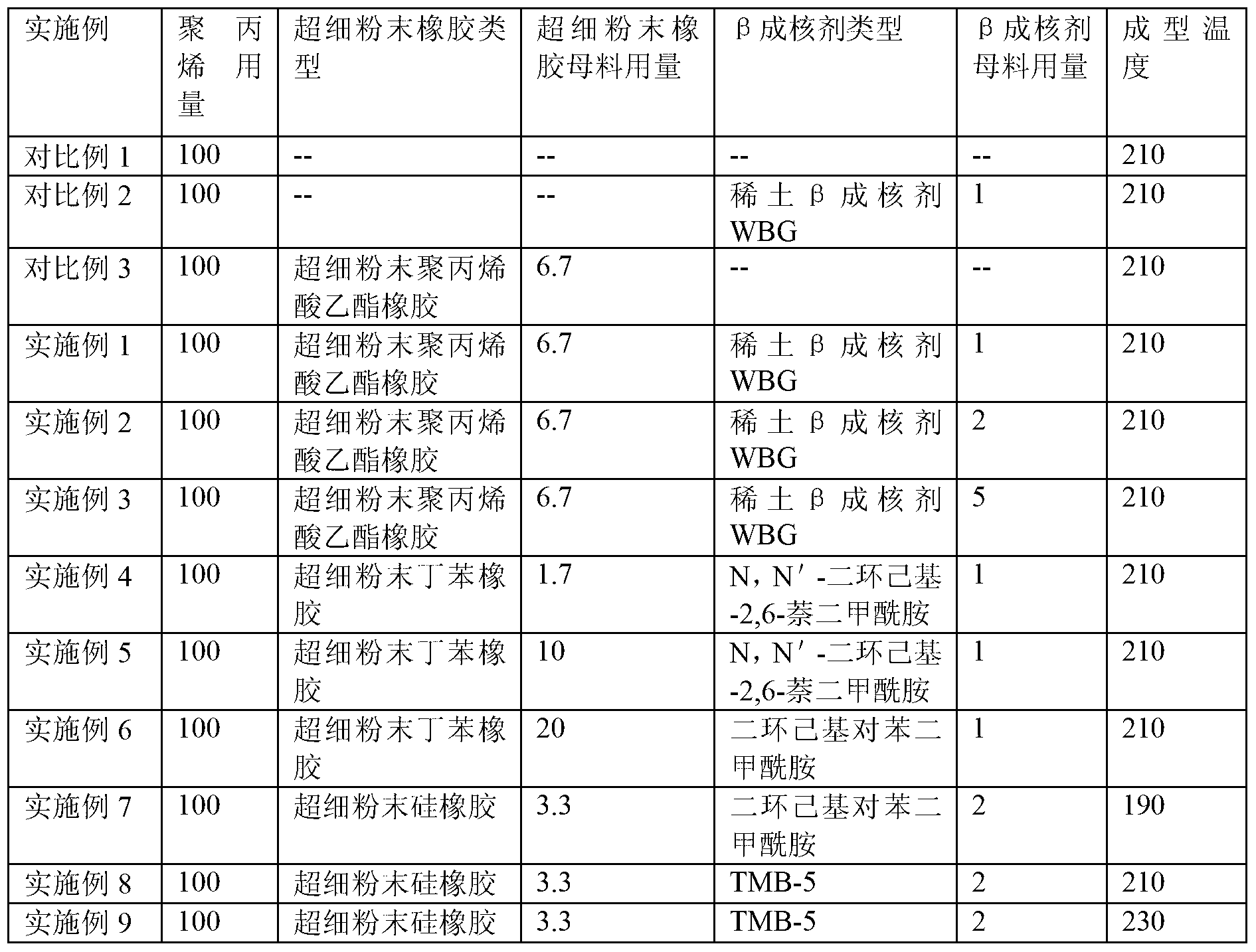

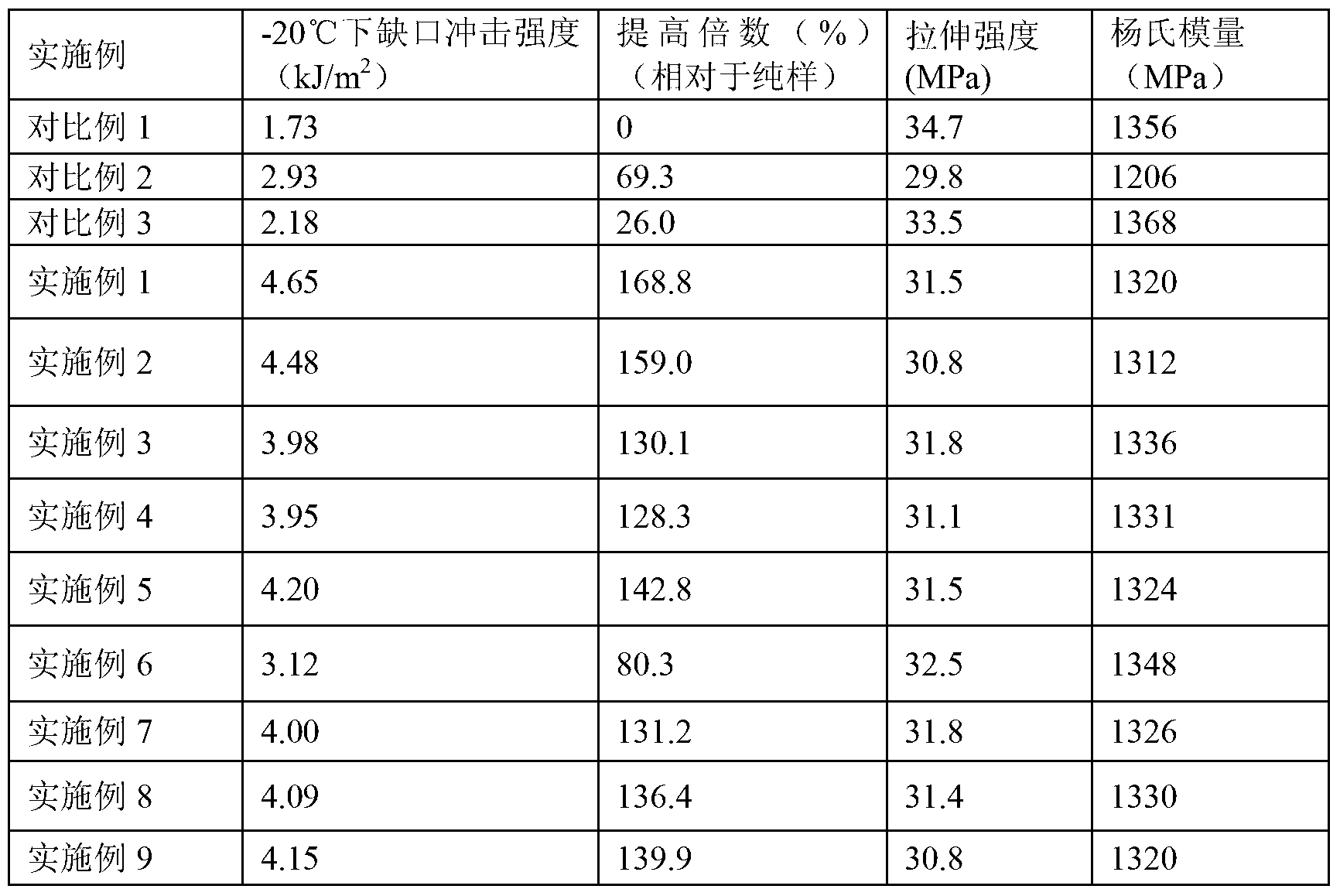

ActiveCN103265758ALower glass transition temperatureGood low temperature performancePolypropyleneRubber technology

The invention discloses a preparation method for a low temperature toughness isotatic polypropylene product. The preparation method comprises the following steps of (1) pre-mixing 100 parts of isotatic polypropylene resin and 5 parts of beta nucleating agent to obtain a mixture and then putting the mixture into a twin-screw extruder, and carrying out melt blending and extruding to obtain beta nucleating agent master batch; (2) pre-mixing 100 parts of isotatic polypropylene resin and 30 parts of superfine powder rubber to obtain a mixture and then putting the mixture into the twin-screw extruder, and carrying out melt blending and extruding to obtain superfine powder rubber master batch; (3) pre-mixing 100 parts of isotatic polypropylene resin, 1-5 parts of beta nucleating agent master batch, 1.7-20 parts of superfine powder rubber master batch and 0.1-0.2 part of antioxygen to obtain a mixture and then putting the mixture into the twin-screw extruder, and carrying out melt blending and extruding to obtain isotatic polypropylene modified granules; and (4) carrying out injection moulding on the isotatic polypropylene modified granules, so as to obtain the low temperature toughness isotatic polypropylene product. According to the method, the technical measures of adding both the beta nucleating agent and the superfine powder rubber are adopted, so that the properties, especially the low temperature impact toughness of the product are greatly improved.

Owner:SICHUAN UNIV

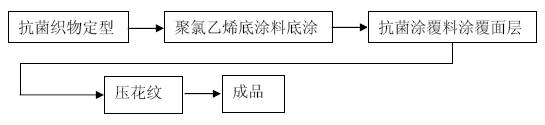

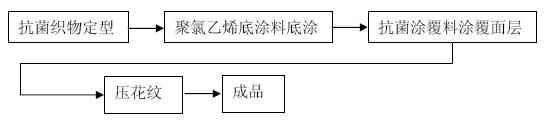

Manufacturing method for environment-friendly antiseptic polyvinyl chloride light-type conveyer belt and antiseptic coating material

InactiveCN102173335ALong-lasting bactericidal effectDurable bacteriostasisConveyorsAntifouling/underwater paintsSurface layerPolyvinyl chloride

The invention relates to a manufacturing method for an environment-friendly antiseptic polyvinyl chloride light-type conveyer belt, and an antiseptic coating material. The manufacturing method comprises the steps of: drying the antiseptic fabric by a far infrared heating drying oven and tentering and sizing; on the antiseptic fabric, carrying out first coat by using the polyvinyl chloride resin as the primer and then heating and plastifying by the far infrared heating drying oven; coating the antiseptic PVC coating material on the priming coat and then heating and plastifyinh by the far infrared heating drying oven to form an antiseptic PVC coating surface layer; and sending the conveyer belt with the antiseptic PVC coating surface layer to the far infrared heating drying oven again for embossing to obtain the environment-friendly antiseptic polyvinyl chloride light-type conveyer belt. The antiseptic coating material related by the invention has the advantages that: the antibacterial agent belongs to broad-spectrum antibacterial agents, has durable sterilization and bacteriostatic effects, and is harmless for the human body and has high chemical stability and heat stability; the additive amount of the antibacterial agent is small, and the antibacterial agent is well compatible with the polyvinyl chloride paste and does not influence the processing performance and mechanical property of the conveyer belt; and the antiseptic coating material fully meets the America FDA (Food And Drug Administration) food hygienic standard and European REACH (Registration, Evaluation and Authorization of Chemicals) laws, has good antiseptic effect and is durable.

Owner:SHANGHAI YONGLI BELTING +1

Environment-friendly low-smoke fire-retardant acrylonitrile-butadiene-styrene (ABS) resin and preparation method thereof

InactiveCN103509309AImprove flame retardant performanceHigh smoke suppression effectHalogenCombustion

The invention relates to the technical field of fire-retardant resins, and discloses an acrylonitrile-butadiene-styrene (ABS) resin and a preparation method thereof. The resin is prepared from the following components in parts by weight: 1000 parts of ABS resin, 150-350 parts of halogen flame retardants, 30-70 parts of synergistic fire retardant, 30-70 parts of smoke suppressant, 1-10 parts of antioxidant, and 1-10 parts of lubricant. The preparation method comprises the following steps: fully and evenly mixing the 1000 parts of ABS resin, 150-350 parts of halogen flame retardants, 30-70 parts of synergistic fire retardant, 30-70 parts of smoke suppressant, 1-10 parts of antioxidant and 1-10 parts of lubricant; feeding the materials to a double-screw extruder through a precise metering feeder after completely mixing; fully fusing the materials under the conditions of shearing, mixing and conveying of screws; and finally preparing granules after extruding, bracing and cooling. The ABS resin disclosed by the invention is low in smoke generation in combustion, does not generate harmful gases such as dioxin, does not generate molten droplets, accords with the instruction of restriction of hazardous substances (ROHS) of the European Union, and is low in cost and convenient to process.

Owner:HEFEI GENIUS NEW MATERIALS

Cake riched in full-valence animal bone powder

InactiveCN1849894AUnique preparation methodDoes not affect processabilityDough treatmentBakery productsFood additiveAdditive ingredient

The present invention relates to a cake richly containing complete animal bone powder. It includes flour for making cake and additive, in which the animal bone powder is added. It is characterized by that its calcium content is high, and its animal bone powder grain size is up to nano-grade, so that it contains rich nutrients.

Owner:大连础明生物科技有限公司

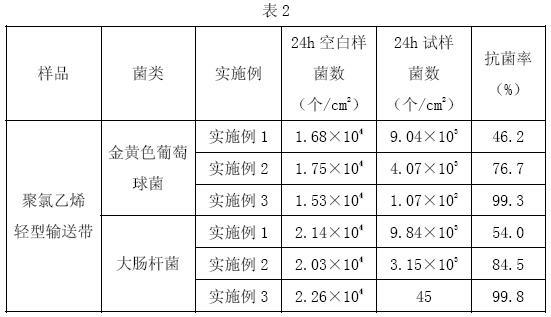

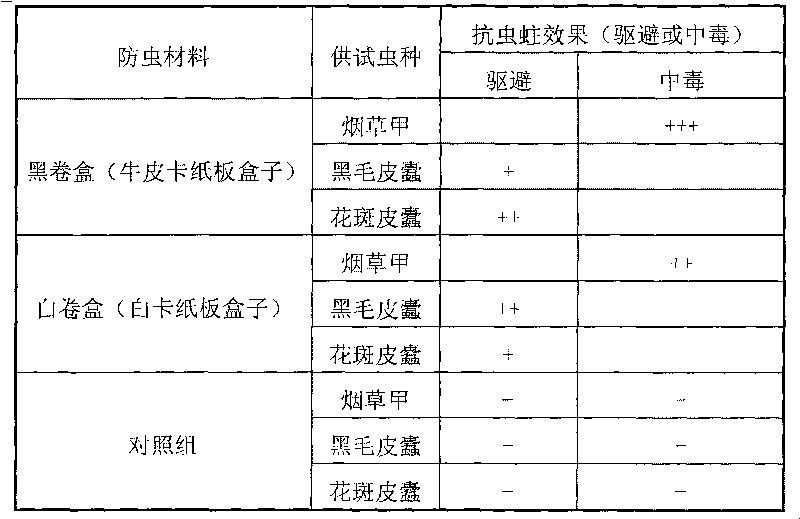

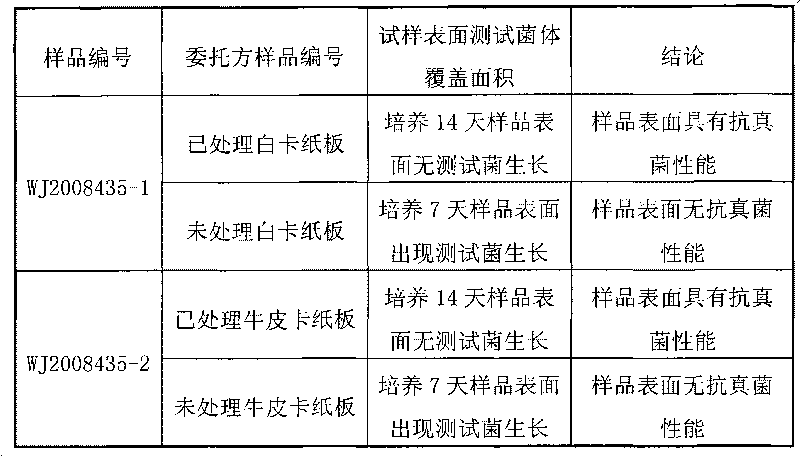

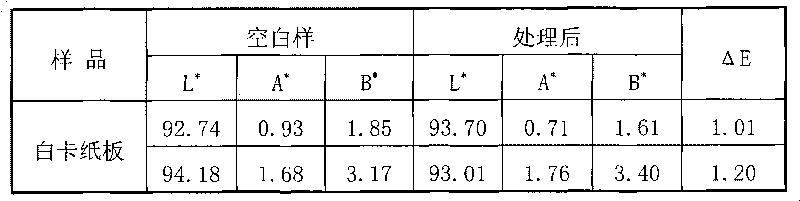

Treating fluid for cultural relic collection packaging material and treating method thereof

ActiveCN101725076AHas a buffering effectDoes not affect processabilityWax additionPaper/cardboardHuman bodyFire resistance

The invention discloses a treating fluid for a cultural relic collection packaging material and a treating method thereof. The treating fluid comprises a component A and a component B. The component A consists of the following materials: 10 weight parts of W-18 wax emulsion and 120 to 150 weight parts of water; and the component B consists of the following materials: 10 to 15 weight parts of boric acid, 13 to 15 weight parts of borax, 8 to 12 weight parts of sodium octaborate, 6 to 12 weight parts of sodium fluoride and 1,000 weight parts of water. The treating method comprises the following steps: firstly, placing a material to be treated in the component A, and drying the material in shade after immersing; and secondly, placing the material in the component B and drying the material in the shade after immersing, namely finishing the treatment on the cultural relic collection packaging material. Through detection, the material treated by the treating fluid and the treating method has good fire resistance, has insect expelling and mildew proof effects with non-volatility, odorlessness, high efficiency and low toxicity, has a buffering effect on an acidic gas in air, overcomes influences on cultural relics, a preservation environment and a human body caused by a volatile insect repellant and a mildew preventive, has the characteristics of low cost, convenient purchase, and convenient transport and storage, and has wide market development prospect.

Owner:SHAANXI NORMAL UNIV

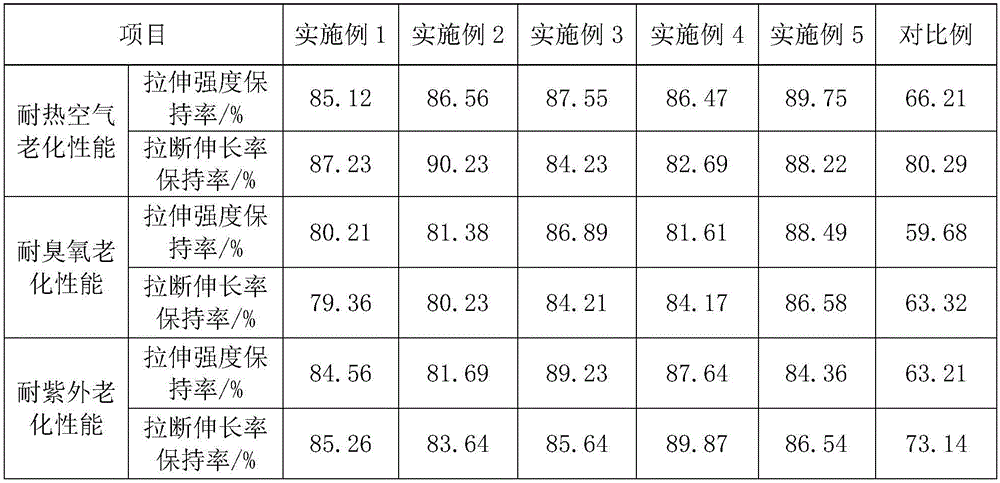

Anti-aging epoxidized natural rubber and preparation method thereof

The invention discloses anti-aging epoxidized natural rubber and a preparation method thereof.The method comprises the steps that stearate is added to deionized water, surfactant is added in the state of ultrasonic dispersion, the mixture is put into a water bath, continuous ultrasonic stirring is conducted, modified stearate dispersions are obtained, then epoxidized natural latexes are added, ultrasonic stirring is conducted continuously, and epoxidized natural rubber in a latex state is obtained; rare earth carboxylate is added onto a double-roller open mixing machine to be subjected to mixing with a vulcanization processing agent, and the anti-aging epoxidized natural rubber is obtained.The prepared anti-aging epoxidized natural rubber is excellent in performance, the processing property and the physical mechanical property of sizing materials are not affected, and meanwhile the anti-aging property is significantly improved; the anti-aging epoxidized natural rubber can be used for epoxidized natural rubber products such as high-performance green tires, rubber tubes, medical latex products and shoe soles.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Application of dicyandiamide in fireworks medicament

InactiveCN1763470AGood compatibilityAvoid the disadvantage of high mechanical sensitivityFireworksCombustionFireworks

The invention discloses a dicyandiamide combustion inhibitor in the flame powder domain, which comprises the following steps: adding the disintegrated 5-30 percent dicyandiamide powder with more than 100 order in the flame powder; diluting the solution with water in the manufacturing course, which drops the combustion speed in the air. The invention can delay the color flare time in the air, which changes the shape pattern.

Owner:邹立生

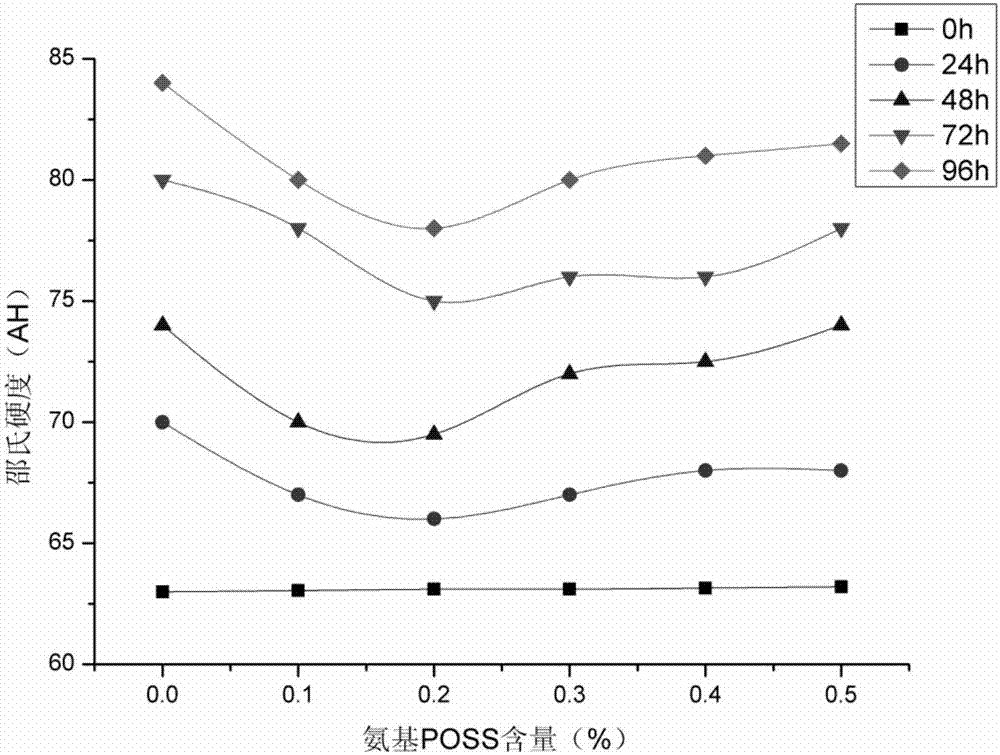

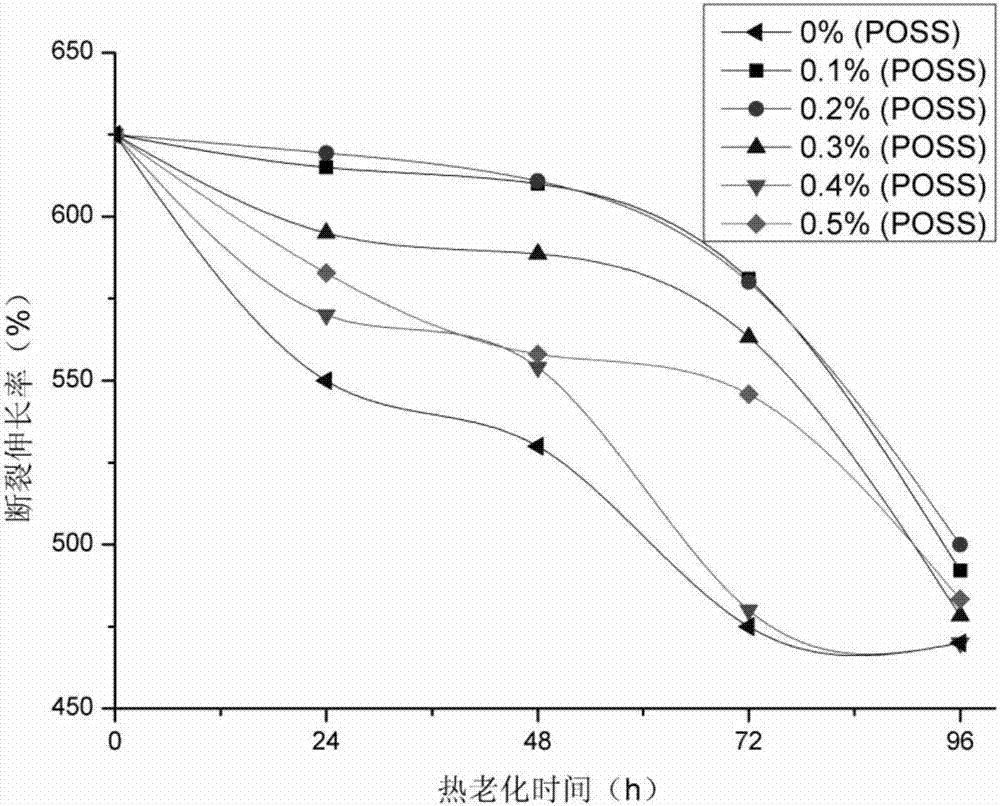

Rubber anti-aging paint, and preparation method and application thereof

InactiveCN107118656AHigh strengthDoes not affect processabilityPretreated surfacesEpoxy resin coatingsPolymer scienceAdditive ingredient

The invention provides rubber anti-aging paint, and a preparation method and application thereof. The rubber anti-aging paint comprises the following ingredients in parts by weight with the total weight being 1000 parts: 200 to 350 parts of resin, 0.2 to 3.5 parts of auxiliary agents, 0 to 5 parts of POSS (polyhedral oligomeric silsesquioxane) and 641.5 to 799.8 parts of water. The paint can be used as a rubber coating. The rubber anti-aging paint provided by the invention comprises the POSS; the POSS can improve the intensity of the coating after film forming; through a cage-shaped three-dimensional structure, the self molecular dimension is larger; potential physical cross linking points are formed in the coating; the curing crosslinking of the paint is facilitated, so that the coating inside structure stability is improved; the sealing performance and the thermal stability of the coating are effectively increased. When the addition of the POSS is 0.2 percent, the improvement effect of the coating on the rubber is most obvious; the stretch intensity is 9.2 MPa; the break elongation rate is 620 percent.

Owner:HUBEI UNIV OF TECH

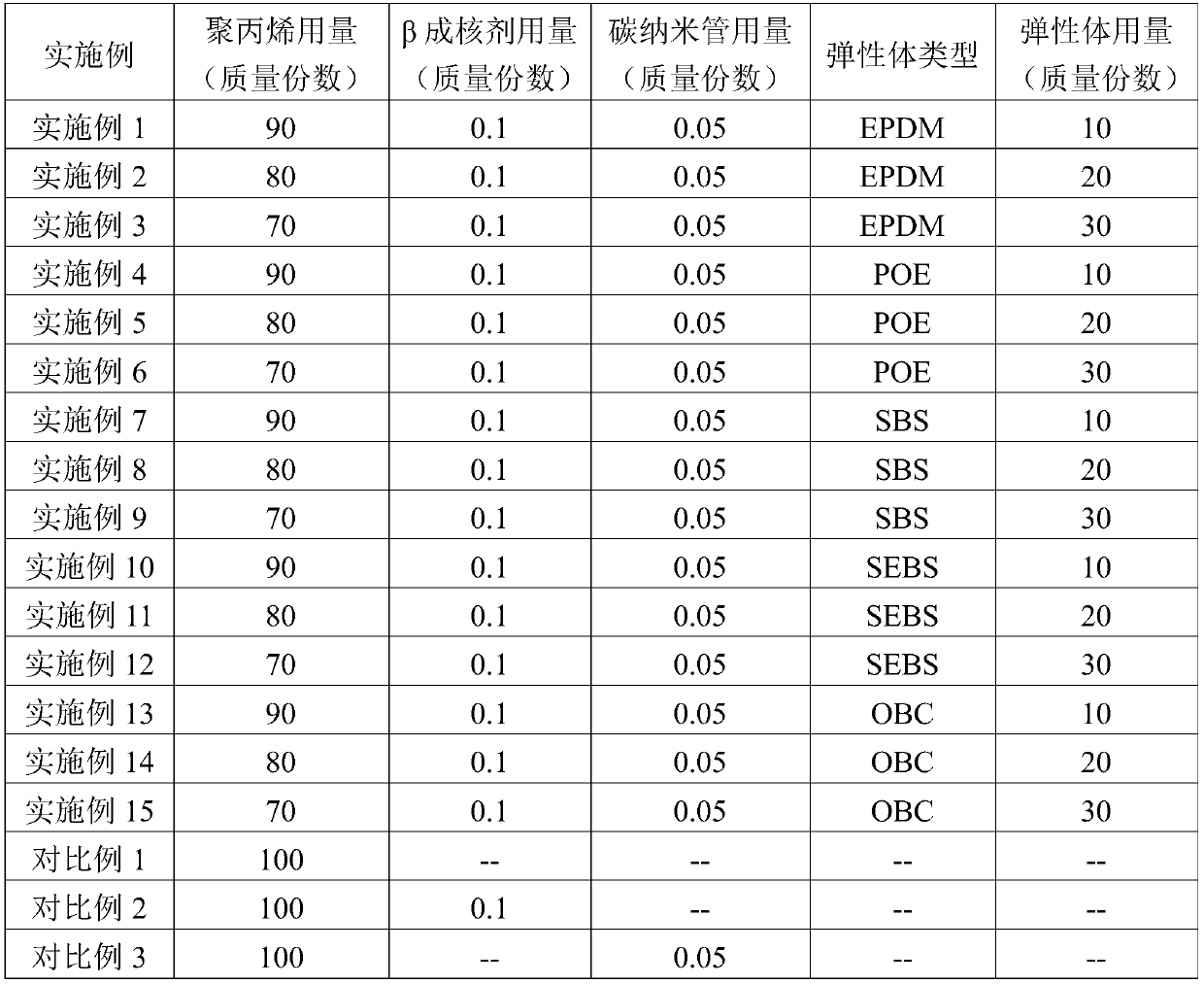

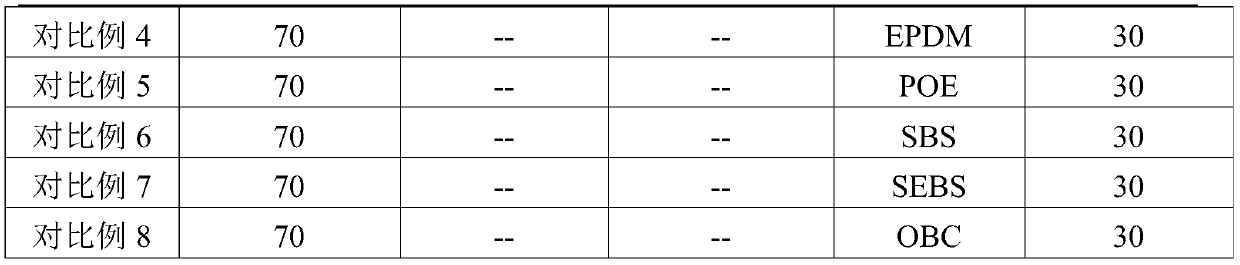

High-toughness polypropylene/elastomer composite material and preparation method thereof

The invention relates to a high-toughness polypropylene / elastomer composite material and a preparation method thereof. The composite material is composed of polypropylene, an elastomer, a beta nucleating agent and carbon nanotubes. The preparation method comprises the following steps: premixing the carbon nano tubes, the beta nucleating agent, the elastomer and the polypropylene, then performing melt blending granulation on the pre-mixture through an extruder, and preparing the high-toughness polypropylene / elastomer composite material product by an injection molding machine. According to the polypropylene composite material, the carbon nano tubes, the beta nucleating agent and the elastomer toughened polypropylene are added at the same time, and the polypropylene composite material shows excellent toughness due to the synergistic toughening effect of the carbon nano tubes, the beta nucleating agent and the elastomer toughened polypropylene. The method is simple in operation process, and the polypropylene composite material is prepared by using the industrial conventional double-screw extruder and the injection molding machine, so that production cost is low, and the method is suitable for large-scale industrial production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

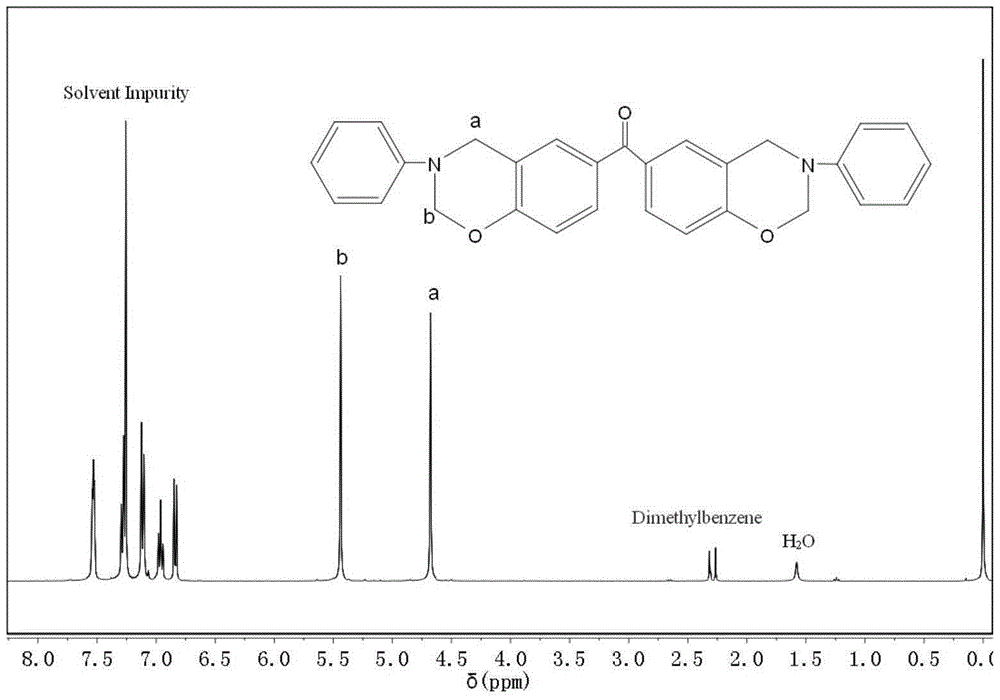

Novel thermosetting ultraviolet stabilizer and preparation method thereof

InactiveCN105199102AGood adhesionImprove anti-shedding effectOrganic chemistryFibre typesUltraviolet protectionDimethylbenzenes

The invention relates to a novel thermosetting ultraviolet stabilizer and a preparation method thereof. The preparation method particularly comprises the following steps: (1) mixing 4,4'-dihydroxybenzophenone, an amine compound and paraformaldehyde, adding dimethylbenzene, and enabling reaction for 4 h at 100 DEG C; then washing with a sodium hydroxide solution and deionized water, filtering, spin-flashing and drying to obtain a thermosetting ultraviolet stabilizer resin monomer; (2) before use, dissolving the resin in a solvent, uniformly coating the surface of a target material requiring protection with the solvent, and heating and curing after volatilization of the solvent to form a protective layer with an ultraviolet protection function on the surface of the target material. The novel thermosetting ultraviolet stabilizer and the preparation method thereof have the advantages that the novel ultraviolet stabilizer is thermosetting resin, the surface of the target material can be uniformly coated with the thermosetting resin, and curing can be performed to form the ultraviolet protective layer, the adhesiveness is good, and as coating is performed on the well processed and formed material surface, influence on the processing process and the intrinsic properties of the material can be avoided.

Owner:EAST CHINA UNIV OF SCI & TECH

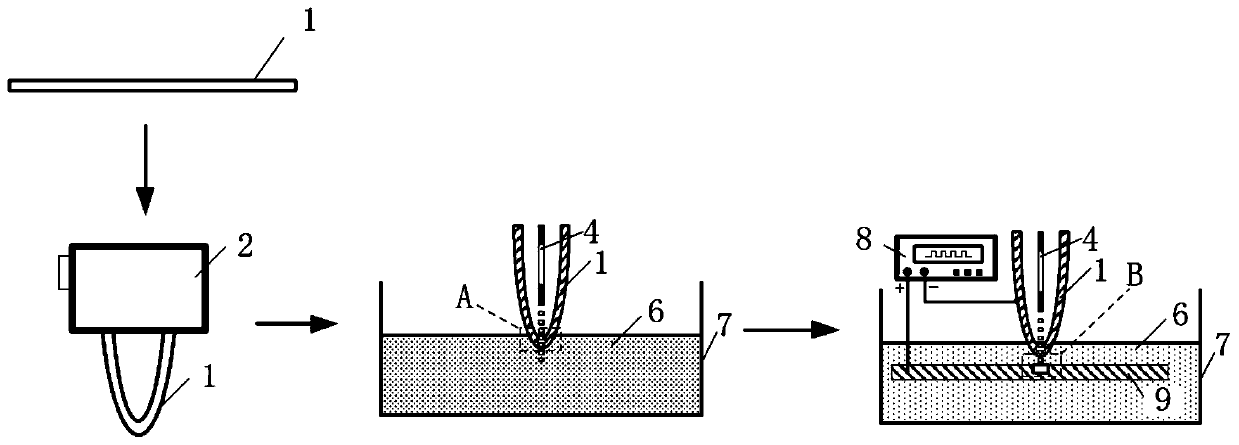

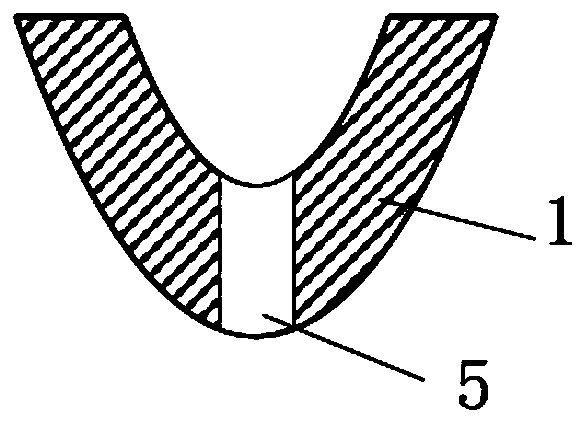

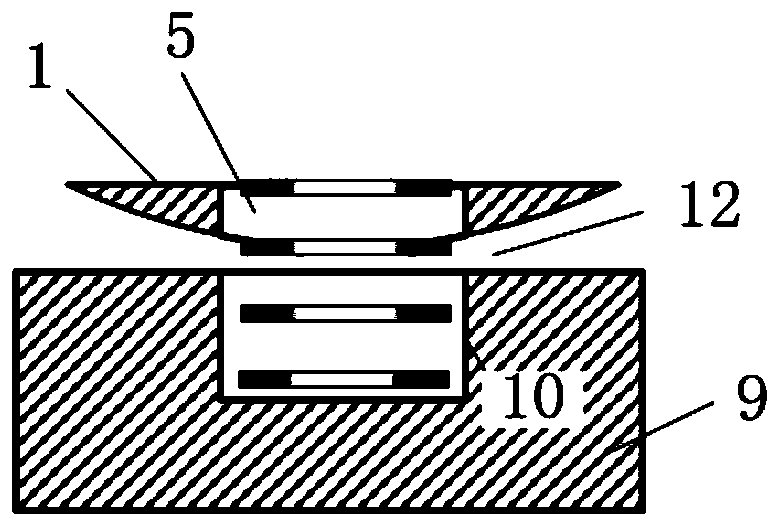

Machining method for forming microstructure on surface of workpiece and control system

ActiveCN111360345AImprove processing efficiencyImprove processing stabilityLaser beam welding apparatusElectrical-based auxillary apparatusElectrolytic agentMachined surface

The invention relates to a machining method for forming a microstructure on the surface of a workpiece. The machining method comprises the steps of S1, providing a metal material immersed into electrolyte as a cathode and forming a penetration microstructure penetrating through the cathode on the cathode; and S2, providing a workpiece as an anode, and conducting laser-electrolysis composite machining on the workpiece according to the penetration microstructure on the cathode to form the required microstructure on the surface of the workpiece. By forming the penetration microstructure penetrating through the cathode on the cathode, the coupling ratio of a laser energy field and an electrochemical energy field in the process of forming the required microstructure on the surface of the workpiece through laser-electrolysis composite machining is effectively increased. Accordingly, the electrochemical solution rate of the material can be effectively promoted through a laser beam with the low energy density, the machining efficiency and machining stability of micro electrolytic machining are improved under the condition of hardly affecting the machining locality and machined surface quality, and flexible preparation of the large-area microstructure can be realized easily.

Owner:SUZHOU UNIV

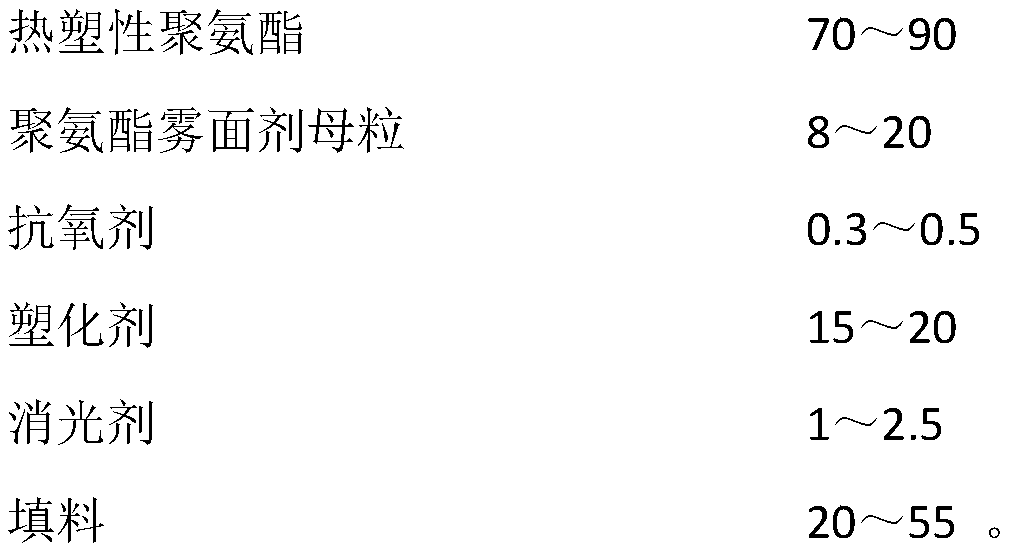

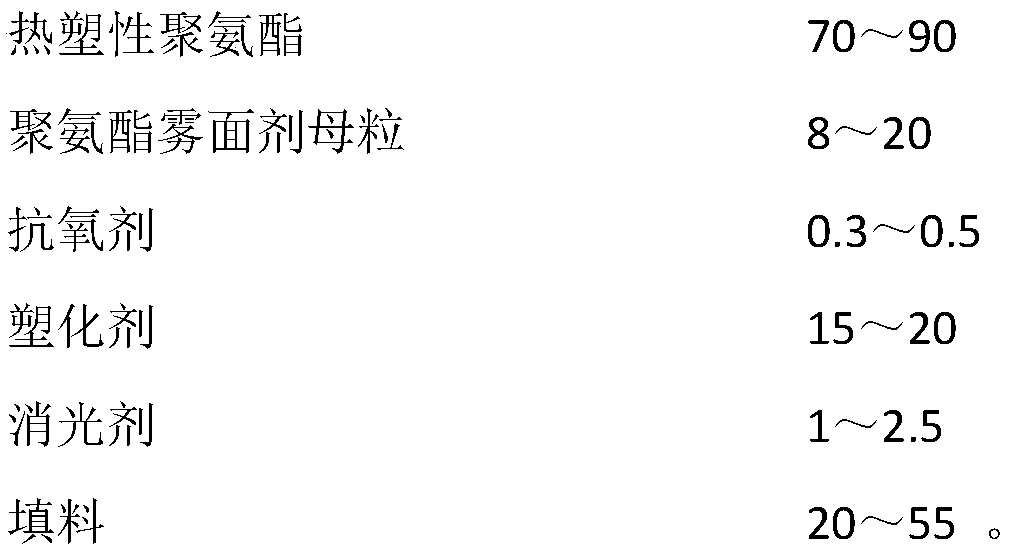

Matte TPU (Thermoplastic Polyurethane) material and preparation method thereof

ActiveCN109265967ADoes not affect mechanical propertiesLong-term retention of mechanical propertiesThermoplastic polyurethaneMechanical property

The invention relates to the field of high polymer materials and in particular relates to a matte TPU (Thermoplastic Polyurethane) material and a preparation method thereof. The invention provides a polyurethane matte agent master batch and a matte polyurethane composition, wherein preparation raw materials of the polyurethane matte agent master batch comprise polyurethane a styrene-ethylene-butadiene-styrene copolymer and an acrylate copolymer, wherein the weight ratio of the polyurethane to the styrene-ethylene-butadiene-styrene copolymer to the acrylate copolymer is (2 to 5) to (2 to 4) to1. The matte polyurethane composition has very good mechanical properties and matte effect.

Owner:广州增城市大发塑胶颜料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com