Patents

Literature

58results about How to "Does not affect mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

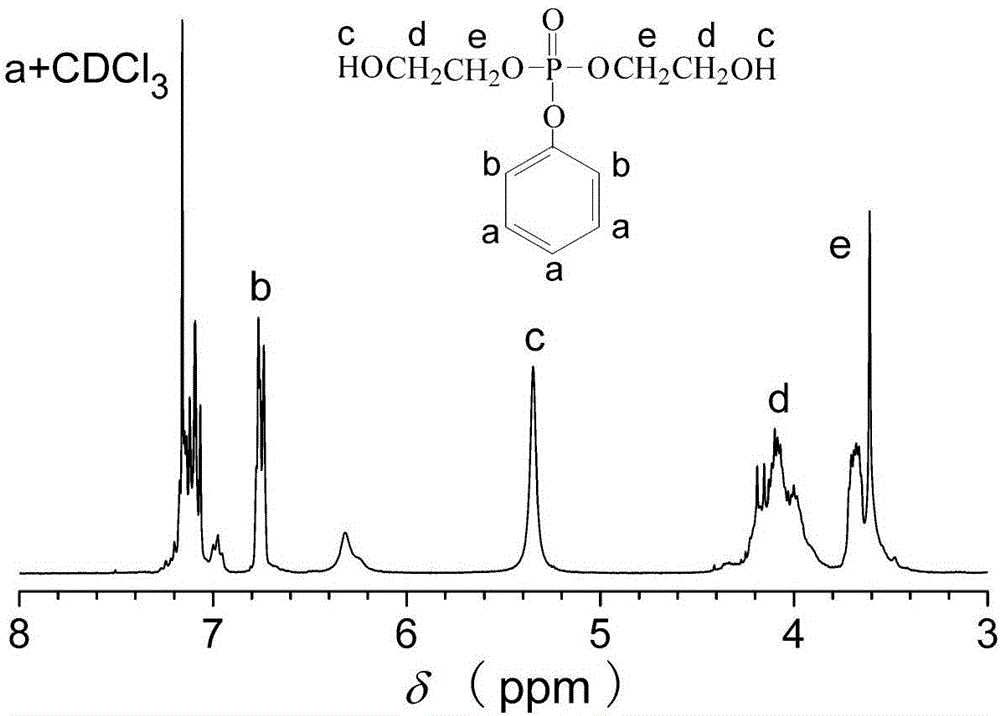

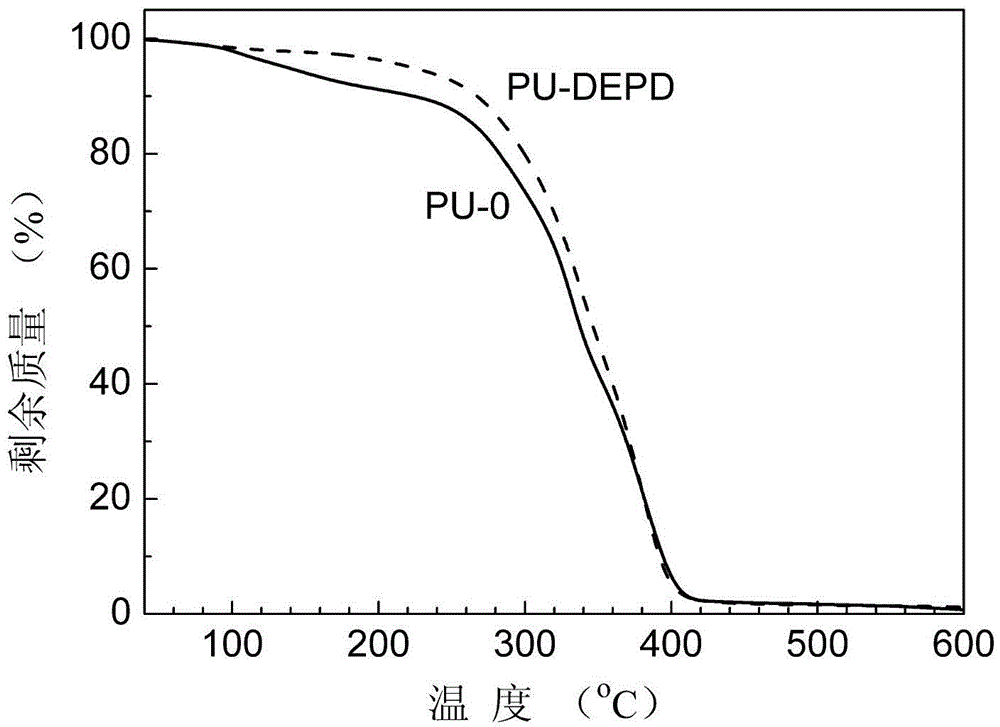

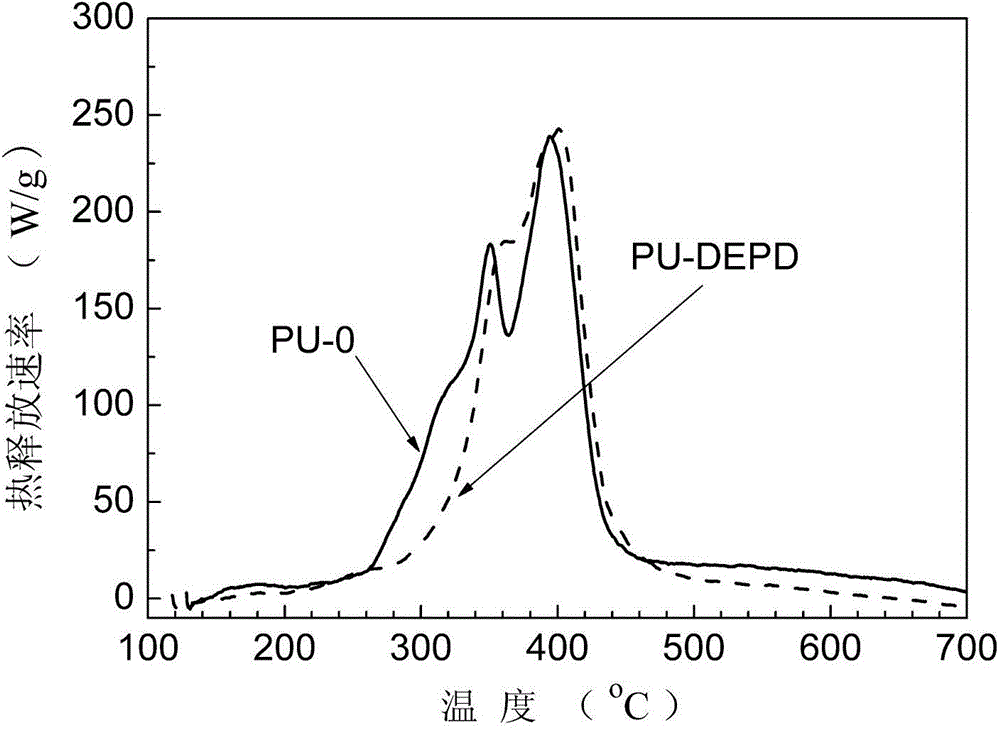

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

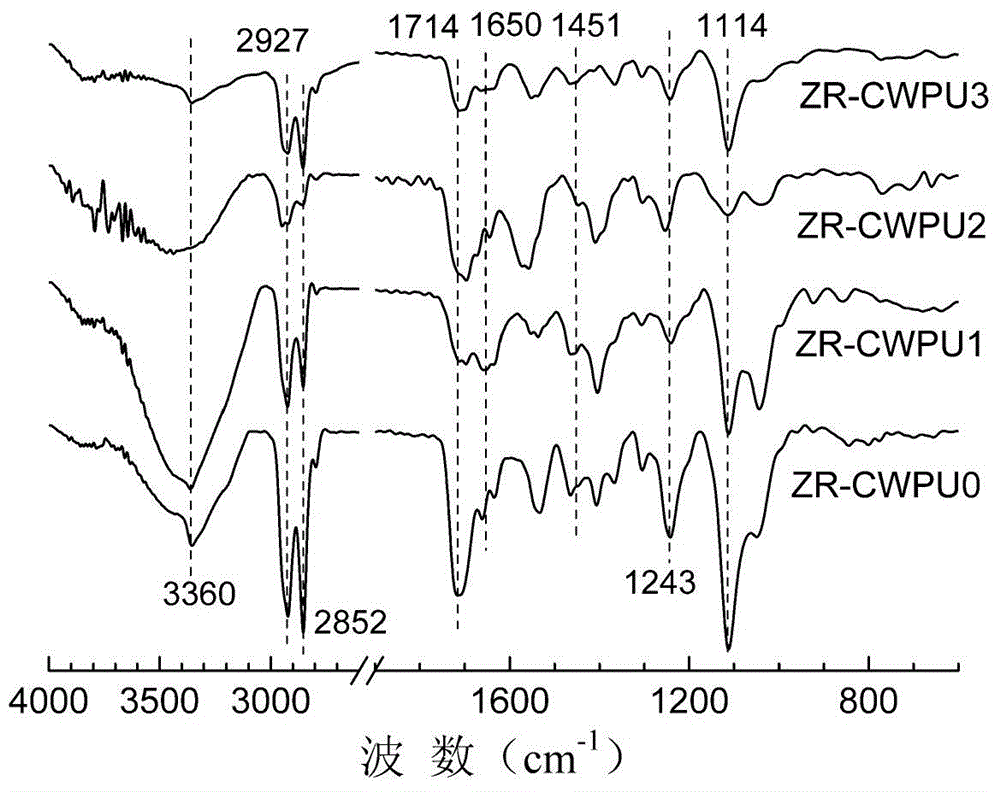

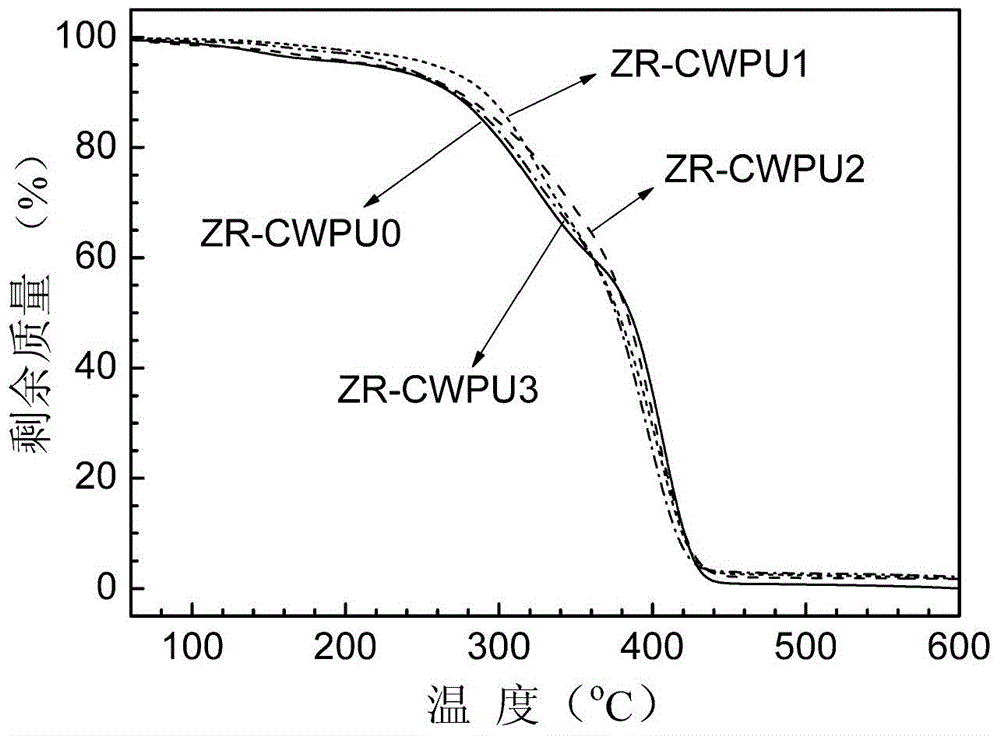

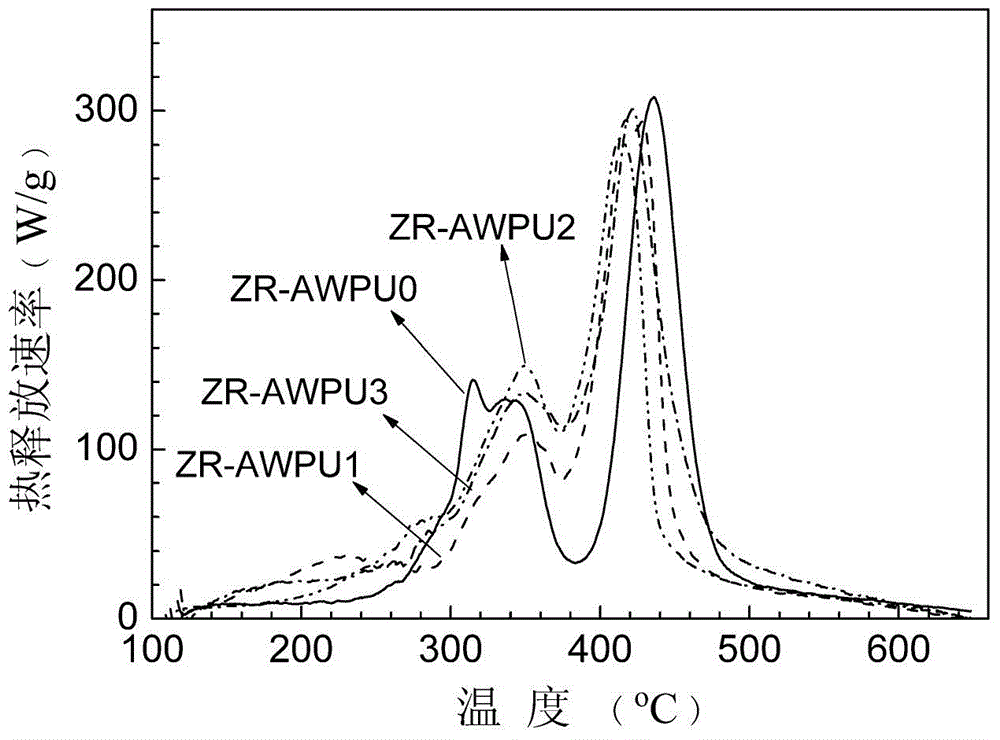

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

High-concentration white polyolefine agglomerate and its prepn process

InactiveCN1487012ADoes not affect mechanicsDoes not affect printing performanceParaffin waxHigh concentration

The high-concentration white polyolefin agglomerate consists of pigment, plastic assistants and carrier resin, nd the plstic assistants include polyvinyl wax, zinc stearate, bright lubricant, compatibilizer-bulking material, crosslinking agent and liquid paraffin. The preparation process includes mixing via high speed stirring, extruding the mixture in a double-screw extruder, cooling, stoving, and pelletizing. The present invention has the features of high whiteness, low consumption, high dispersivity, etc., and is suitable for plastic product with polyethylene, polypropylene or their copolymer as basic material and suitable for injection molding, blowing to film, hollow forming and extruding to produce sheet, flat belt, wire and pipe.

Owner:山东色母料厂

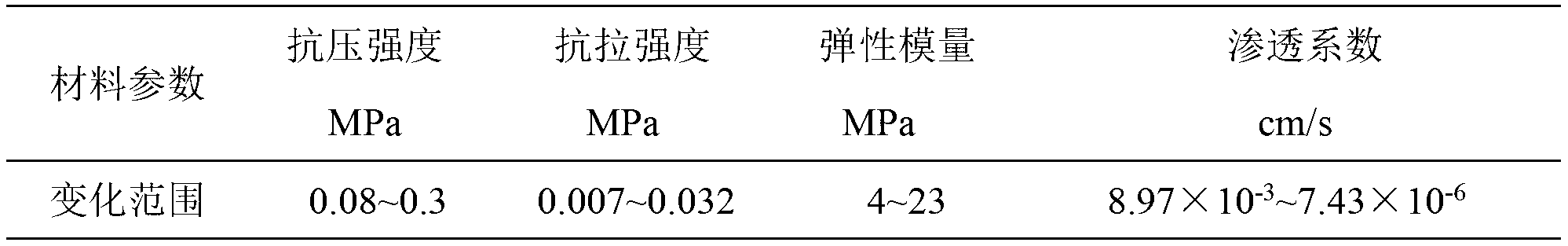

Fault analog simulation material used for fluid-solid coupling model test and preparation method thereof

InactiveCN103183495ADoes not affect the water rationality indexDoes not affect mechanicsWater resistantModel test

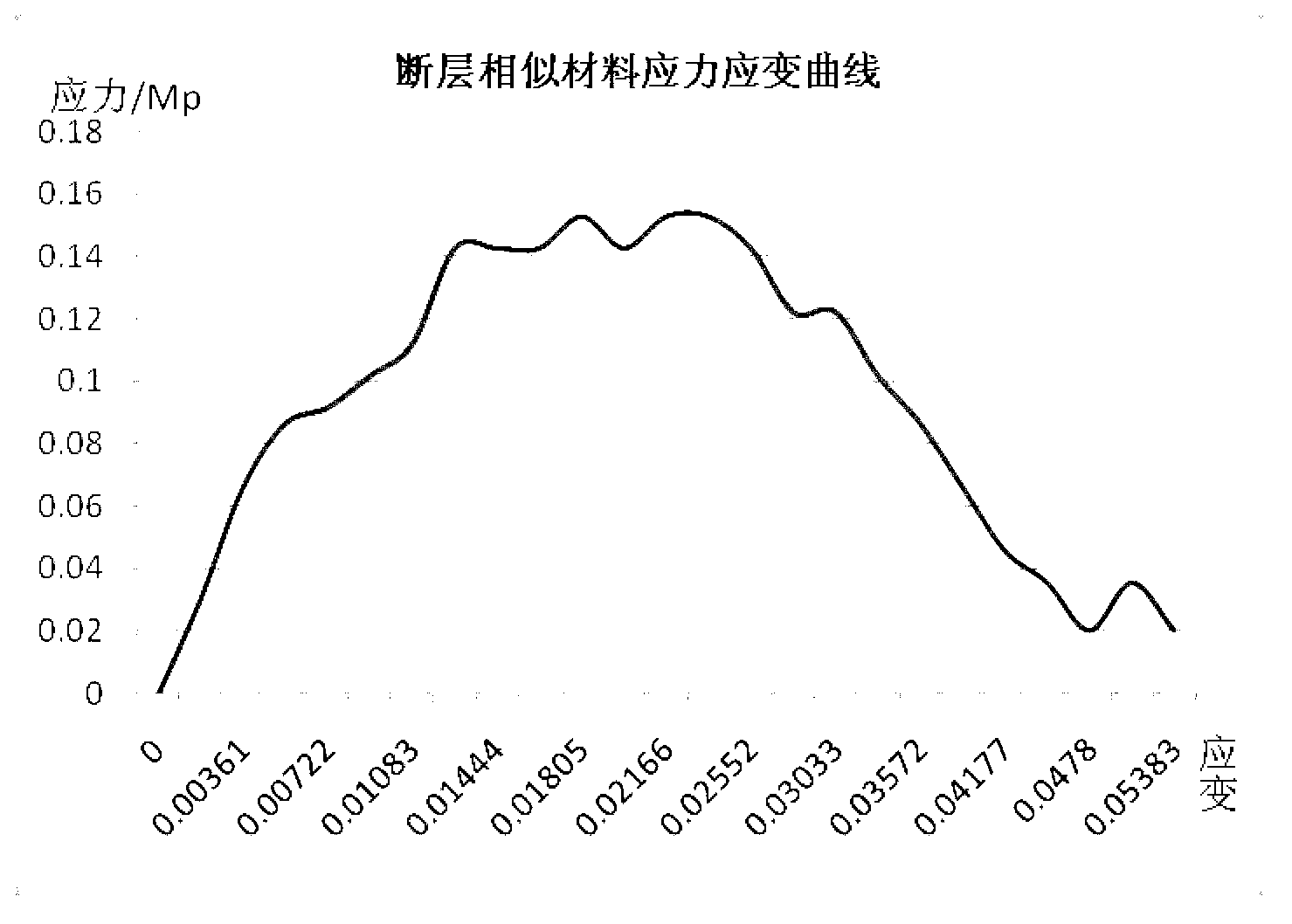

The invention discloses a fault analog simulation material used for a fluid-solid coupling model test, which comprises components in parts by weight as follows: 1 part of quartz sand, 0.05-0.25 part of talcum powder, 0.05-0.15 part of gypsum powder, 0.08-0.2 part of Vaseline and 0.1-0.2 part of water. The material adopts gypsum as a cementing agent, so as to achieve simulation for fault fluid-solid coupling characteristics; the talcum powder and the quartz sand are adopted as conditioning agents to regulate the weight of the material; and the Vaseline is adopted as a water resistant agent to regulate permeability of the material, simultaneously adopted as a plastic cementing agent of the material, and used for simulating the fault fluid-solid coupling characteristics under different permeability conditions, and real-time comparison with surrounding rock fluid-solid coupling characteristics in the same experiment is achieved. The fault analog simulation material in the fluid-solid coupling model test disclosed by the invention can regulate the strength and the permeability of the material within a larger range, and simulate various types of faults at various levels of intensity.

Owner:SHANDONG UNIV

Medicine balloon based on hydrogen bond effects and coating method thereof

InactiveCN102657900ADoes not affect physical and chemicalDoes not affect mechanicsSurgeryPharmaceutical delivery mechanismAdhesion forceBiomedical engineering

The invention relates to the medical instrument field, and concretely relates to a medicine balloon based on a hydrogen bond effect. The medicine balloon comprises a balloon surface and a medicine coating containing active medicines, wherein the balloon surface is processed or modified to have hydrophilic groups, and the hydrogen bond effects exist between the balloon surface and the medicine coating. The invention also relates to a coating method of the medicine balloon. The hydrogen bond effects which increase the adhesion force between the medicine coating and the balloon surface guarantee the ductility of the coating, and are benefit for loading the medicines on the balloon surface.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

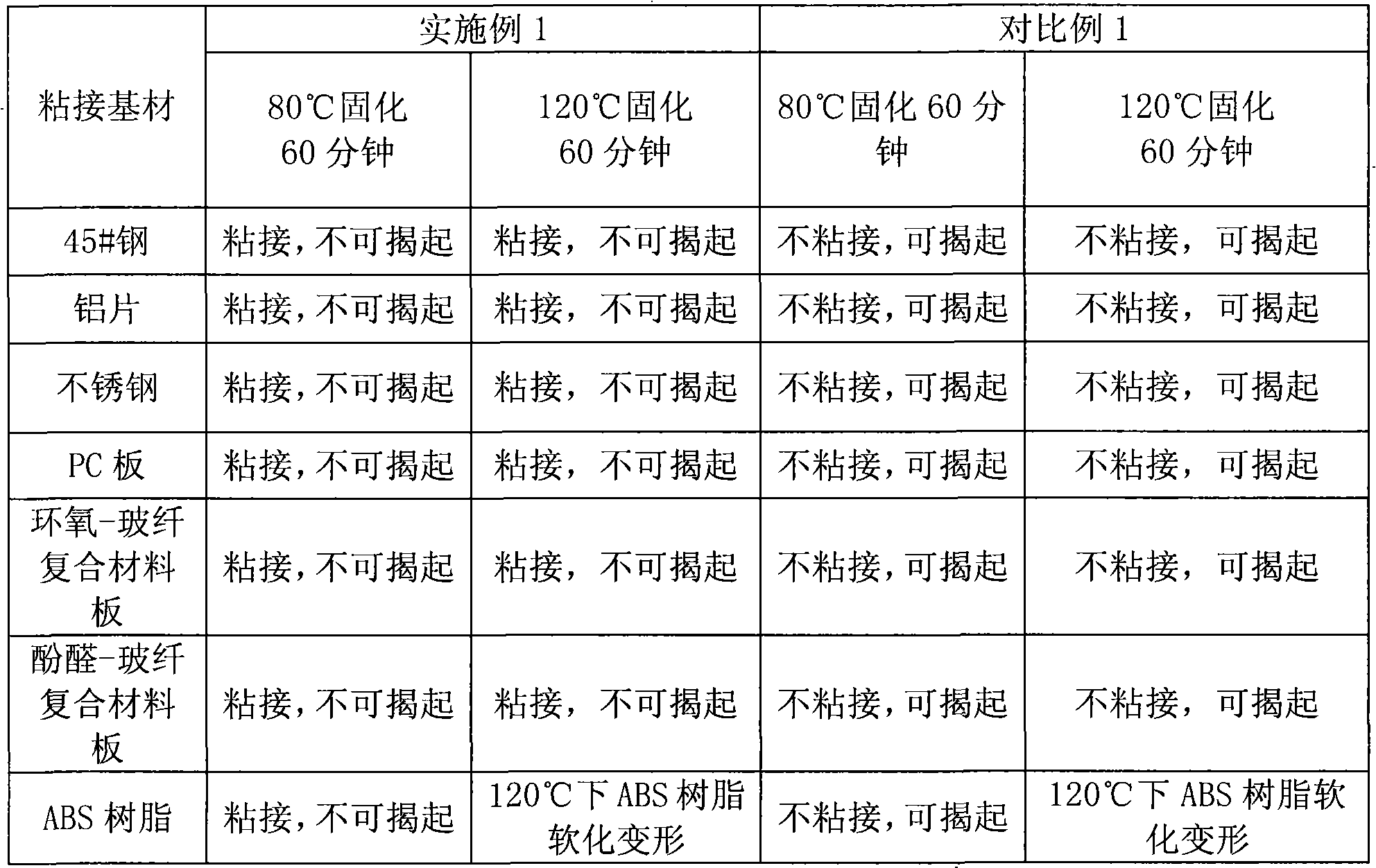

Addition type silicone adhesive composition and preparation method thereof

InactiveCN101787256ADoes not affect mechanicsDoes not affect electrical performanceNon-macromolecular adhesive additives(Hydroxyethyl)methacrylateAlkyne

The invention discloses an addition type silicone adhesive composition and a preparation method thereof. The addition type silicone adhesive composition comprises (A) 60 to 100 mass parts of organopolysiloxane, (B)1 to 10 mass parts of substance obtained by reacting Si-H groups in the organopolysiloxane with hydroxyls in hydroxy ethyl acrylate or hydroxy propyl methacrylate; (C) 1 to 50 mass parts of gaseous-phase silica, (D) 0.001 to 0.01 weight parts of alkyne inhibitor, and (E) 0.1 to 2 mass parts of platinum catalyst, wherein the content of platinum atoms is 5-2,000ppm; and the preparation method of the addition type silicone adhesive composition comprises the following steps: uniformly mixing the (A), (C) and (D) in vacuum, then sequentially adding (B) and (E) to carry out vacuum defoamation, and solidifying the obtained mixture for 5 to 60 minutes at the temperature of between 80 and 210 DEG C.

Owner:TONSAN ADHESIVES INC

High-flame retardant property solvent-free polyurethane synthetic leather and preparation method thereof

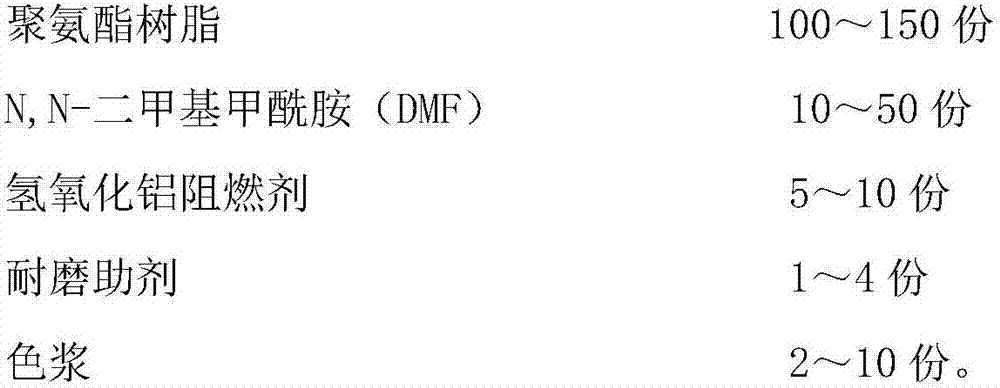

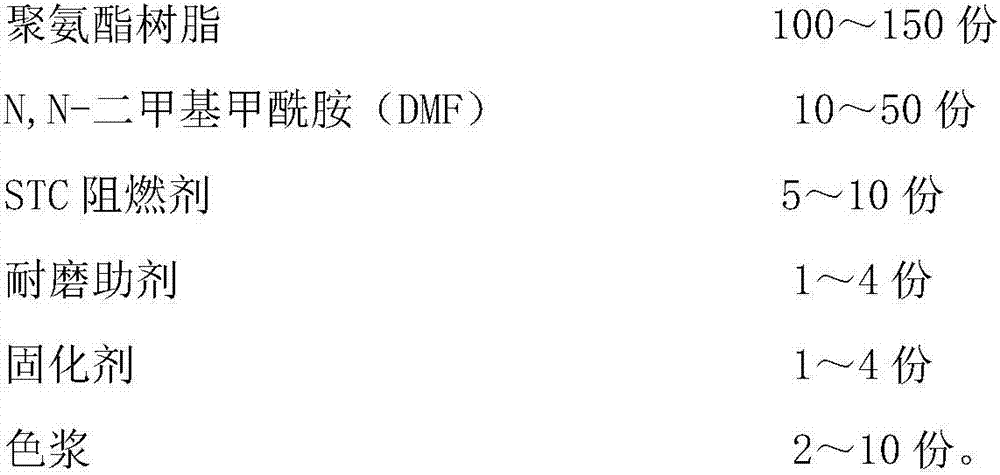

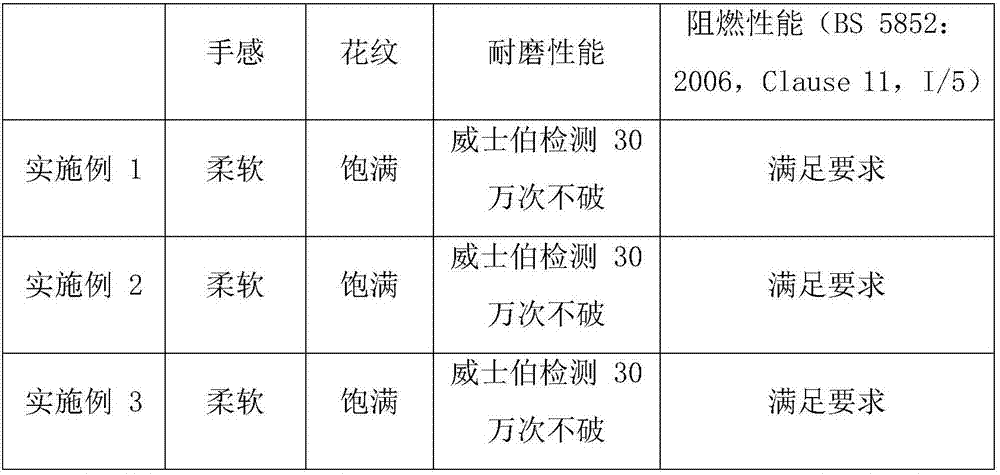

InactiveCN107503168AImprove flame retardant performanceImprove wear resistanceTextiles and paperSurface layerAlcohol

The invention relates to high-flame retardant property solvent-free polyurethane synthetic leather and a preparation method thereof. The polyurethane synthetic leather is composed of a surface layer, an intermediate layer and a base fabric, wherein a solvent-free layer is arranged between the intermediate layer and the base fabric; the solvent-free layer is formed by mixing a component A and a component B according to a mass ratio of 100:(40-50); the component A is composed of the following components in parts by mass: 100-120 parts of polyhydric alcohol component material CC 6945-100C-A, 20-40 parts of a compound flame retardant and 0.05-0.1 part of a catalyst; and the component B is an isocyanate prepolymer CC 6945-100C-B. According to the polyurethane synthetic leather disclosed by the invention, the flame retardant property of the synthetic leather can meet the requirements of 'BS 5852:2006, Clause 11, I / 5' on the premise of not influencing the mechanical property and hand feeling of the synthetic leather.

Owner:ANHUI ANLI MATERIAL TECH

Extinction type thermoplastic elastomer for preparation of wire and cable

ActiveCN102304266ADoes not affect mechanicsDoes not affect liquidityPlastic/resin/waxes insulatorsElastomerAntioxidant

The invention discloses an extinction type thermoplastic elastomer for preparation of a wire and a cable. The extinction type thermoplastic elastomer is characterized by being preparing from the following raw material components by weight percent: 20-60% of styrene elastomer, 20-50% of mineral oil, 0-40% of reinforcing agent, 5-40% of extinction modification material, 0.1-1% of antioxidant, 0.1-1% of processing aid and 5-20% of mineral filling material, wherein the reinforcing agent is at least one of allyl resin and styryl resin, and the extinction modification material is dynamically-vulcanized thermoplastic elastomer or crosslinkable resin / crosslinking agent composition. The extinction type thermoplastic elastomer has the advantages that the crosslinkable resin / crosslinking agent composition or thermoplastic vulcanized rubber is adopted in a basic material, thus the matt effect is good, and the mechanical property and flowability of the material are not influenced.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

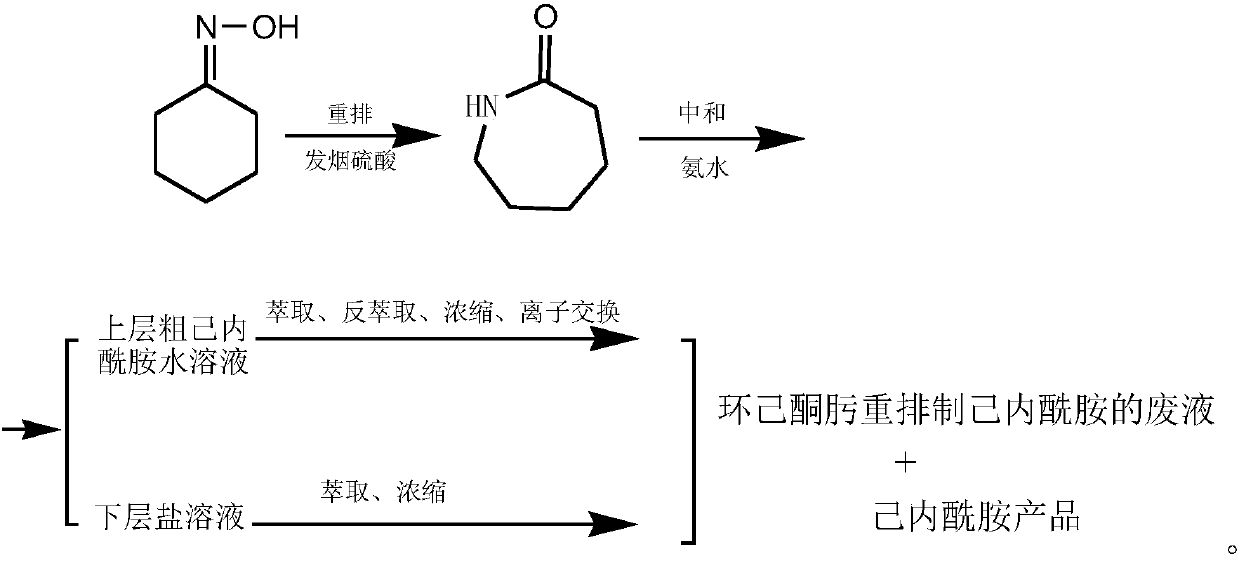

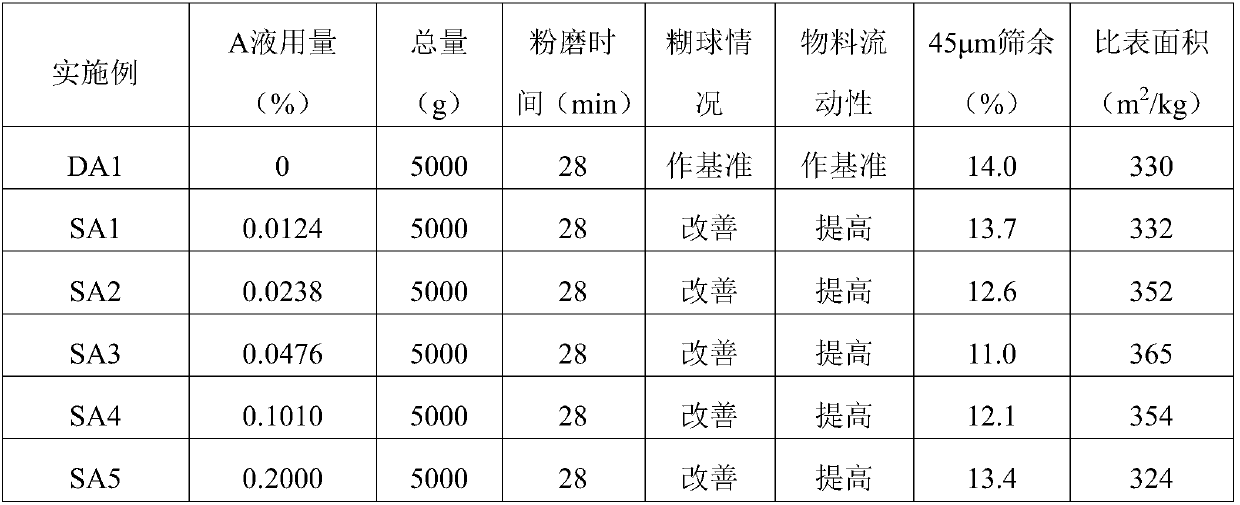

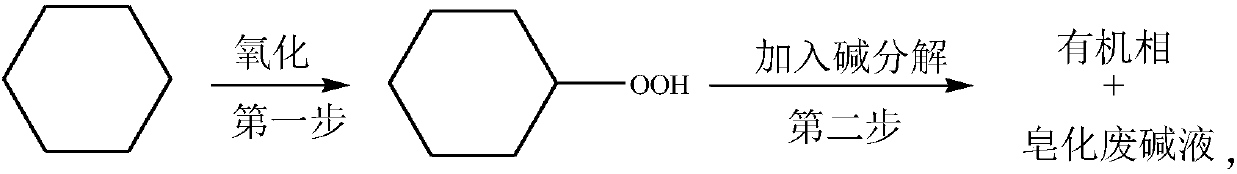

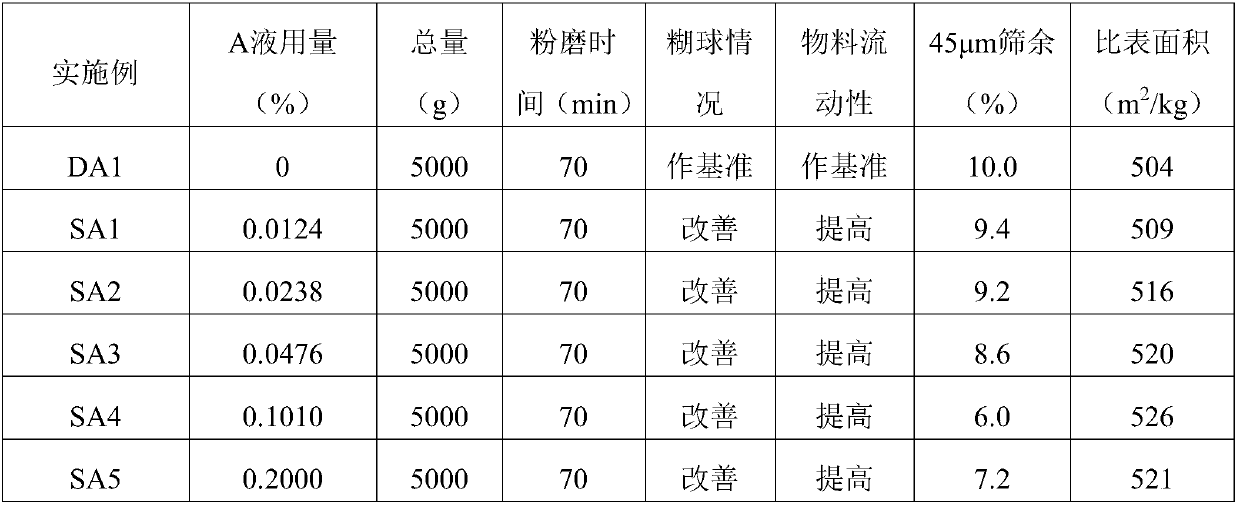

Grinding aid and application thereof

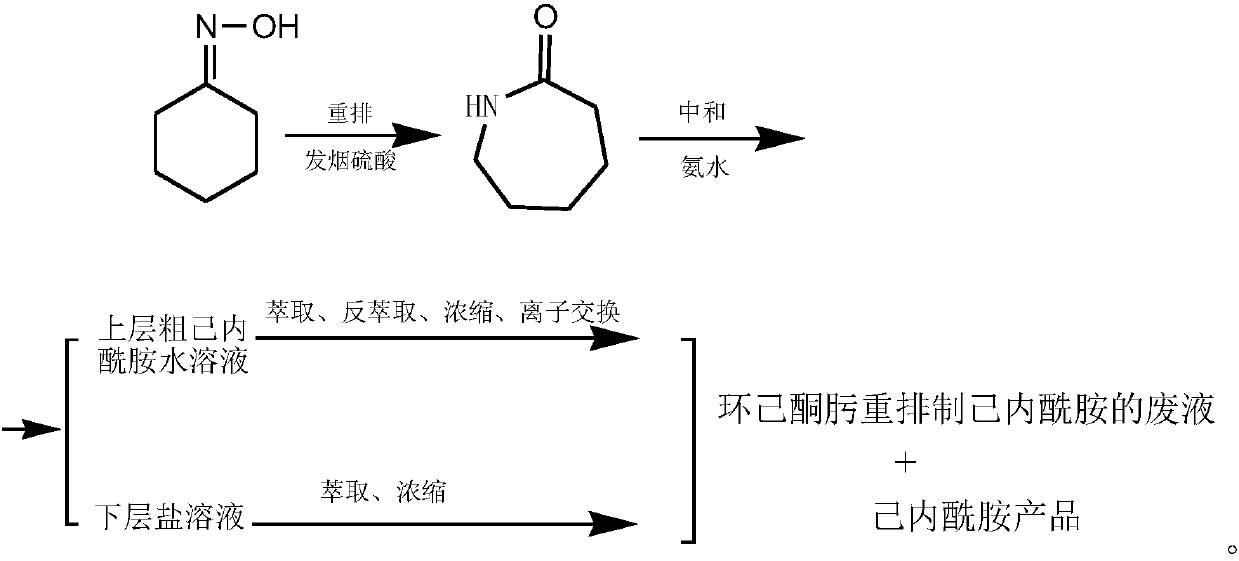

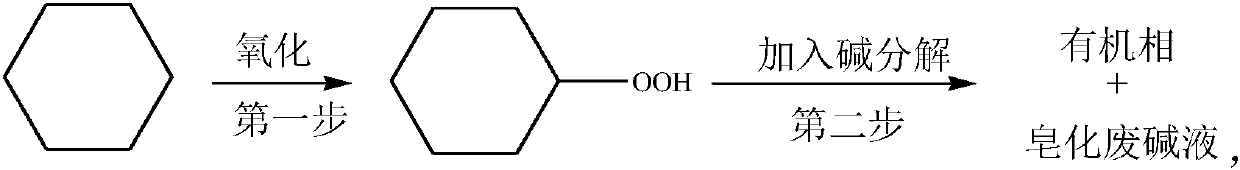

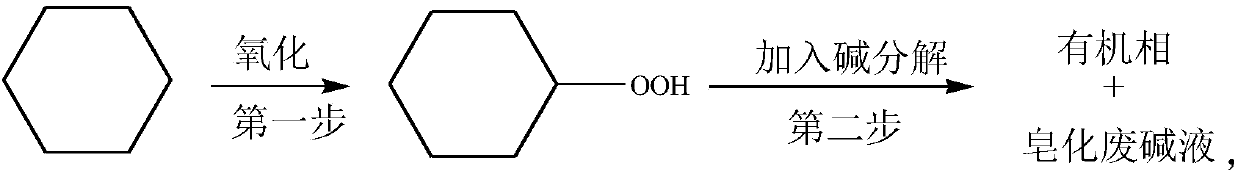

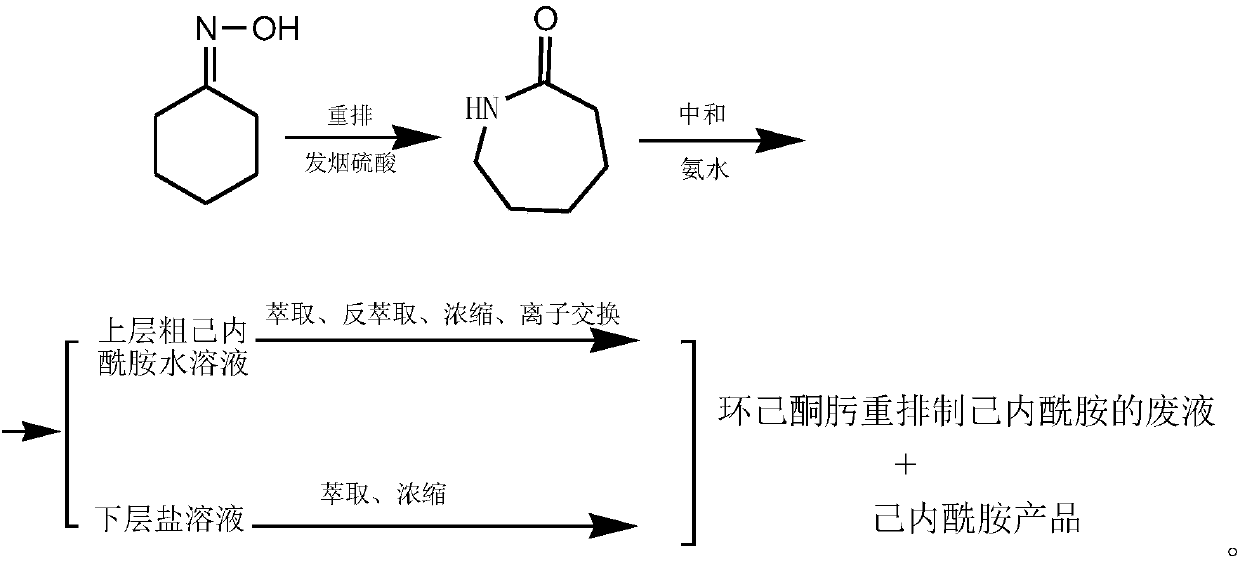

ActiveCN108017299ASolve the problem of reasonable handlingImprove liquidityLiquid wasteCyclohexanone

The invention provides a grinding aid and an application thereof. The grinding aid contains a waste liquid obtained after production of caprolactam from cyclohexanone. The grinding aid recycles the waste liquid obtained after production of caprolactam from cyclohexanone, and has a good grinding aiding effect.

Owner:湖南昌迪环境科技有限公司

Cement grinding method and cement grinding aid

ActiveCN108017297ASolve the problem of reasonable handlingDoes not affect construction performanceCyclohexanoneCement grinding

The invention provides a cement grinding method and a cement grinding aid. The method includes: subjecting a to-be-grinded cement material and a cement grinding aid to grinding treatment together; wherein the cement grinding aid contains waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation. The cement grinding method provided by the invention can take the waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation as the grinding aid for cement grinding.

Owner:湖南昌迪环境科技有限公司

Black agglomerate specially for polystyrene resin and its prepn process

InactiveCN1487018ADoes not affect mechanicsDoes not affect printing performanceHigh resistancePolymer science

The black agglomerate consists specially for polystyrene resin consists of black pigment 20-35 wt%, dispersing lubricant 15-30 wt%, dispersing lubricant 15-30 wt% and carrier resin 45-65 wt%. The preparation process includes mixing the components in the said proportion, kneading in high speed kneading machine of 800-1500 rpm, extruding in double-screw extruder, cooling, stoving and pelletizing. The present invention has the features of less added amount, good dispersivity, high heat resistance, high light resistance, high stability, etc. The black agglomerate is added into polystyrene resin to obtain black plastic product with homogeneous blackness, high brightness and no influence on the mechanical performance.

Owner:山东色母料厂

Flame-retardant glycol containing phenyl phosphate-based symmetrical structure and preparation method thereof

InactiveCN104592297AHas flame retardant propertiesRegular structureGroup 5/15 element organic compoundsEthyl acetateTetrahydrofuran

The invention discloses reaction-type flame-retardant glycol containing a phenyl phosphate-based symmetrical structure and a preparation method thereof. The preparation method is characterized by comprising the following steps: reacting phenyl dichlorophosphate with dihydric alcohol in a tetrahydrofuran or ethyl acetate solution in the presence of triethylamine, placing the tetrahydrofuran or ethyl acetate solution of dihydric alcohol and triethylamine into an ice-water bath, stirring and dropwise adding the tetrahydrofuran or ethyl acetate solution of phenyl dichlorophosphate; and filtering a precipitate and then removing the solvent in the filtrate to obtain the product with a structural general formula specified in the description, wherein n is an integer ranging from 2 to 6. According to the preparation method disclosed by the invention, micromolecular dihydric alcohol is introduced in the phenyl dichlorophosphate group in a manner of chemical bonding, so that the obtained dihydric alcohol molecular structure contains both the phenyl dichlorophosphate group and two hydroxyl groups with symmetrical structures and same reaction activity, and can partially or completely replace the micromolecular dihydric alcohol without a flame-retardant characteristic, so that the prepared polymer material has a flame-retardant characteristic; the raw materials in the preparation method disclosed by the invention are easily available, synthesis and post-treatment processes are simple, the cost is low, and the yield can achieve more than 90%.

Owner:UNIV OF SCI & TECH OF CHINA

Cement mixture grinding method and cement mixture grinding aid

ActiveCN108017298ASolve the problem of reasonable handlingDoes not affect construction performanceCyclohexanoneSaponification

The invention provides a cement mixture grinding method and a cement mixture grinding aid. The method includes: subjecting a to-be-grinded cement mixture and the cement mixture grinding aid to grinding treatment together; specifically, the cement mixture grinding aid contains waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation. The cement mixture grinding method provided by the invention can take the waste saponification lye generated in preparation of cyclohexanone by cyclohexane oxidation as the grinding aid for cement mixture grinding.

Owner:湖南昌迪环境科技有限公司

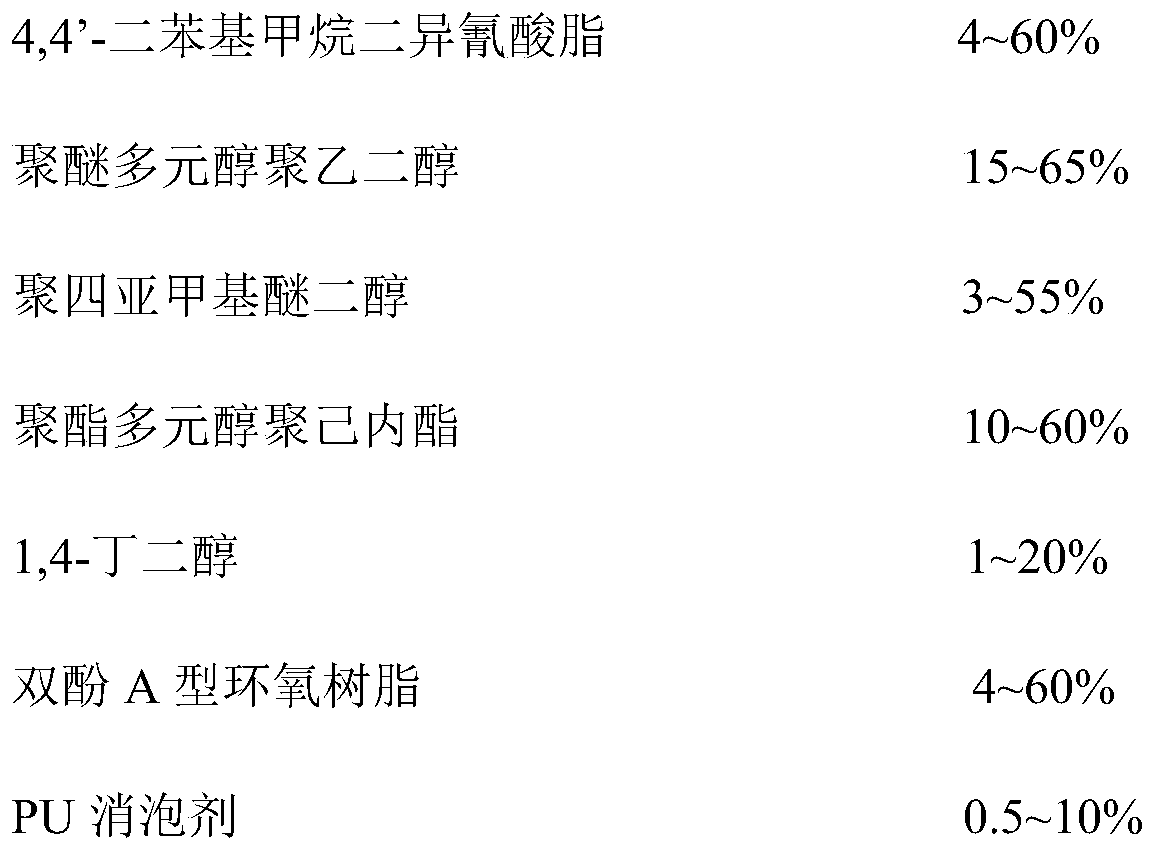

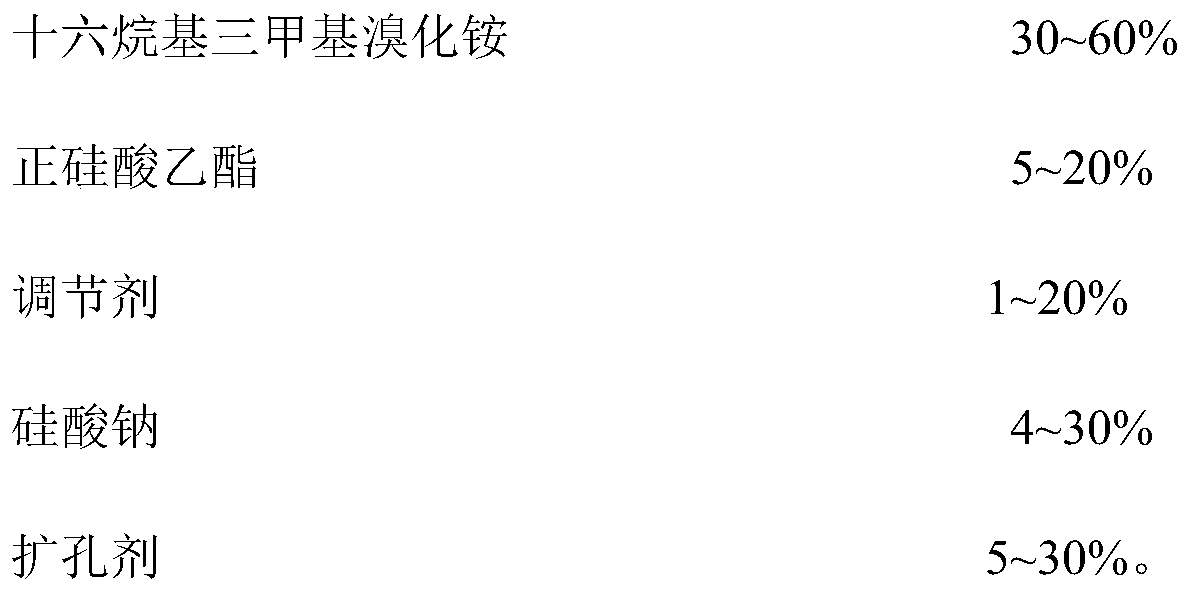

Anti-fouling coating capable of releasing anti-fouling agent and preparation method thereof

ActiveCN109749616AImprove wear resistancePlay a role in sheddingAntifouling/underwater paintsPaints with biocidesPolyesterToxicant

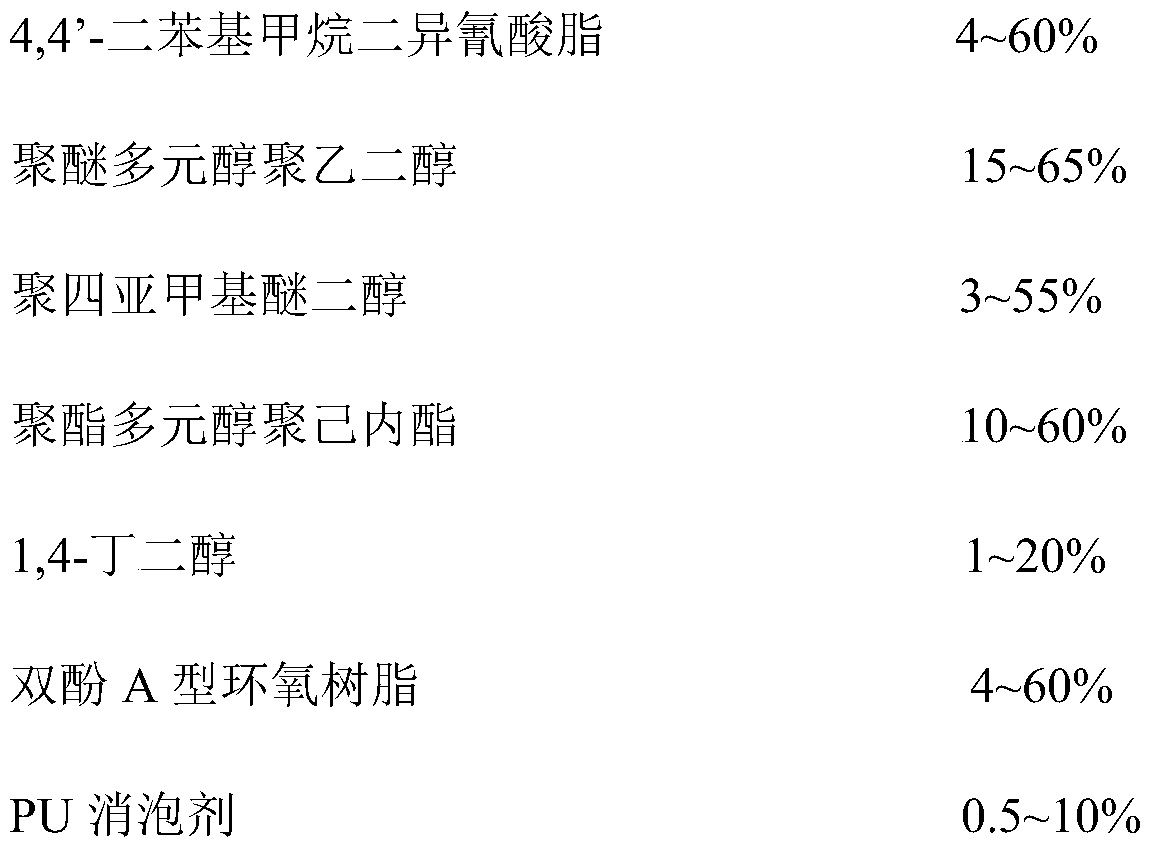

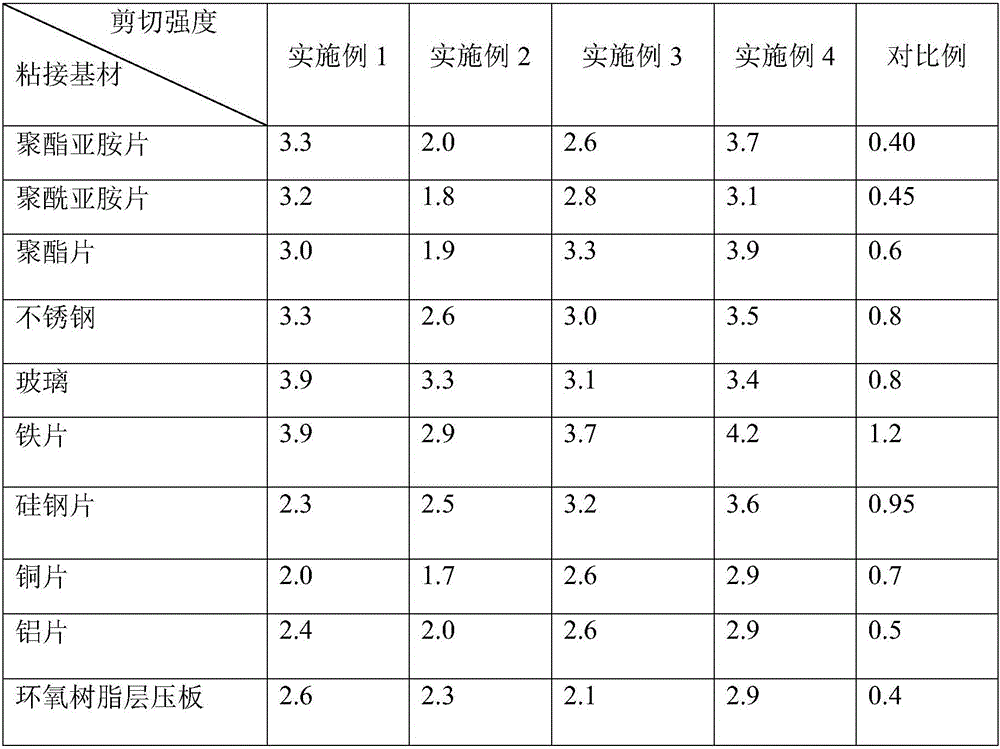

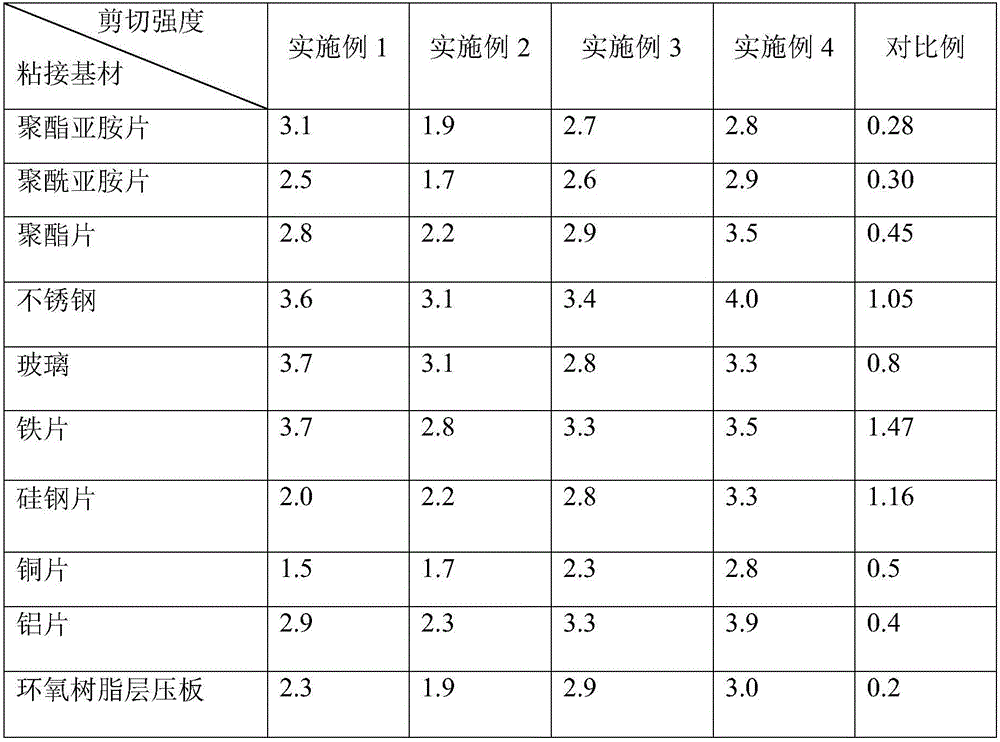

The invention discloses an anti-fouling coating capable of releasing an anti-fouling agent and a preparation method thereof. The coating comprises 4,4'-diphenylmethane diisocyanate, polyether polyol polyethylene glycol, polytetramethylene ether glycol, polyester polyol polycaprolactone, 1,4-butanediol, bisphenol-A epoxy resin and a PU defoamer. A second component comprises mesoporous silica particles and an anti-fouling component. A first component is mixed with the second component according to a mass ratio of (20-50):1, so the anti-fouling coating capable of releasing the anti-fouling agentcan be obtained. The anti-fouling coating is capable of introducing oligomer polyalcohol and polycyanate, in the precondition of guaranteeing controllable release performance of the anti-fouling agent, not affecting excellent mechanical property and adhesive power and the like of polyurethane. At the same time, mesoporous silica has high wear resistance, wear resistance of the coating can be improved, and service life is prolonged. The method is simple in process, lower in cost, and suitable for industrial production without a toxicant release problem, so the coating has good application prospect in the ocean anti-fouling field.

Owner:XI AN JIAOTONG UNIV

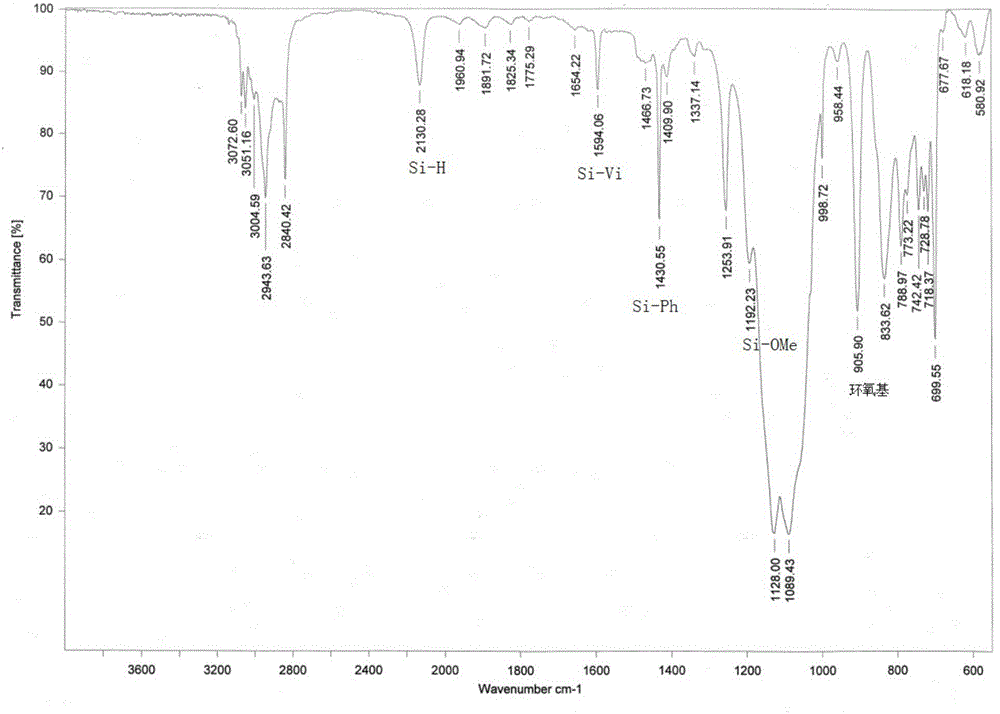

Tackifier for addition type organosilicon impregnating resin and preparation method thereof

The invention relates to a tackifier for addition type organosilicon impregnating resin and a preparation method thereof. The molecular formula of the tackifier is (Me2R1SiO0.5)a(MeR2SiO)b(PhSiO1.5)c(R3SiO1.5)d, wherein a, b, c and d represent the mole number of each chain link of the tackifier; and it is at least guaranteed that in R1 and R2, vinyl and hydrogen groups coexist. The tackifier is obtained by hydrolytic condensation of silane monomers containing hydrogen groups, vinyl, phenyl groups and other reactive groups under the effect of a catalyst. The prepared tackifier can remarkably improve high temperature adhesive properties of the addition type organosilicon impregnating resin, the tackifier and the impregnating resin are good in compatibility, the appearance, hardness and other mechanical properties of the resin are not affected after the mixing, and the tackifier has important application to motor and engine insulation impregnation.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Anti-aging epoxidized natural rubber and preparation method thereof

The invention discloses anti-aging epoxidized natural rubber and a preparation method thereof.The method comprises the steps that stearate is added to deionized water, surfactant is added in the state of ultrasonic dispersion, the mixture is put into a water bath, continuous ultrasonic stirring is conducted, modified stearate dispersions are obtained, then epoxidized natural latexes are added, ultrasonic stirring is conducted continuously, and epoxidized natural rubber in a latex state is obtained; rare earth carboxylate is added onto a double-roller open mixing machine to be subjected to mixing with a vulcanization processing agent, and the anti-aging epoxidized natural rubber is obtained.The prepared anti-aging epoxidized natural rubber is excellent in performance, the processing property and the physical mechanical property of sizing materials are not affected, and meanwhile the anti-aging property is significantly improved; the anti-aging epoxidized natural rubber can be used for epoxidized natural rubber products such as high-performance green tires, rubber tubes, medical latex products and shoe soles.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

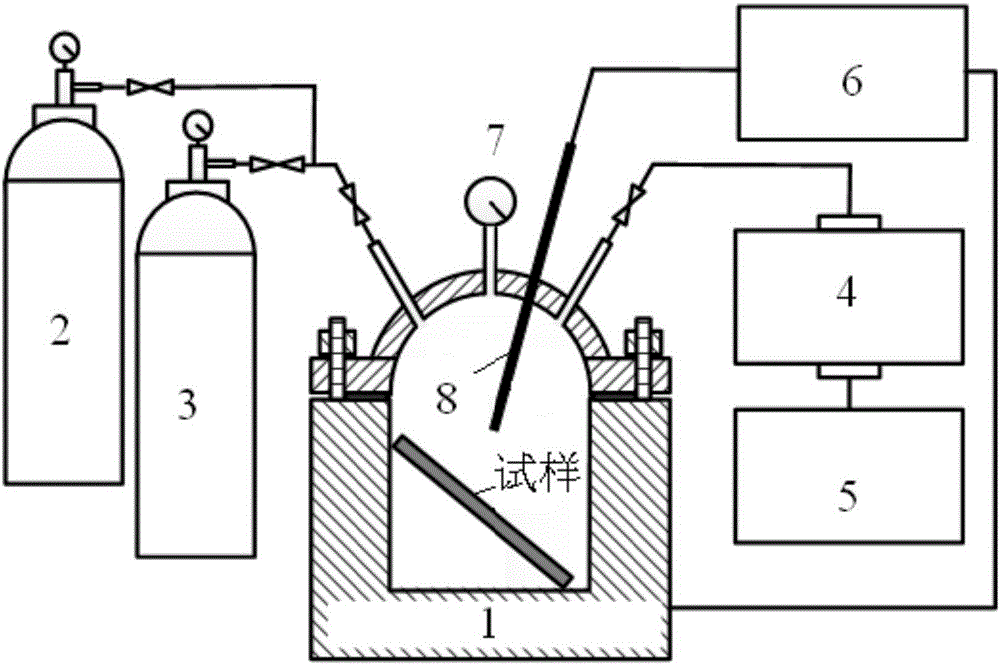

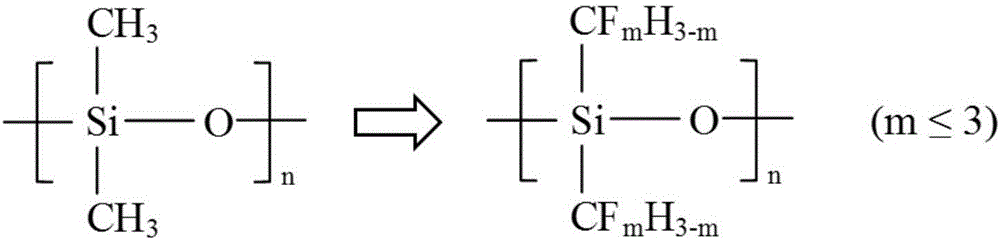

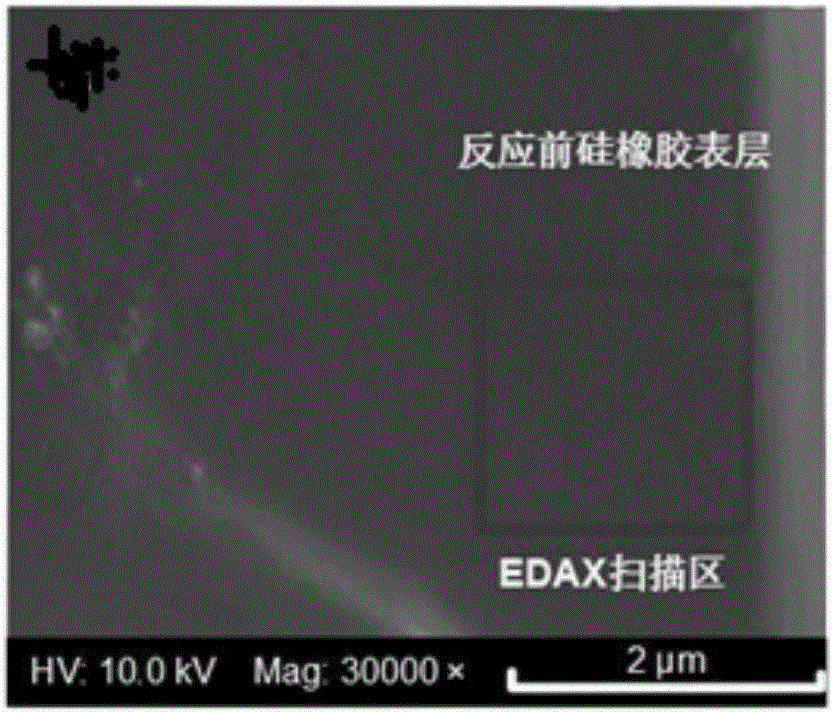

Direct current cable accessory silicon rubber insulation surface layer molecular structure regulation and control device and method

InactiveCN106847422AInhibit injectionAvoid accumulationInsulating conductors/cablesEngineeringElectronegativity

The present invention discloses a direct current cable accessory silicon rubber insulation surface layer molecular structure regulation and control device and method. The method comprises the following steps: (1) employing a vacuum pump to extract internal air of a reactor, closing the vacuum pump after vacuum pumping is completed, opening a nitrogen cylinder reducing valve, injecting nitrogen into the reactor and reaching an environment air pressure, and repeatedly performing the process for at least five times; (2) slowing filling fluorine and nitrogen gas mixture with 20% of volume fraction of fluorine into the reactor to allow the air pressure in the reactor to reach up to 300 mbar; (3) going on filling fluorine into the reactor until the air pressure of the reactor reaches up to 500 mbar to allow the fluorine and nitrogen gas mixture to react with silicone rubber samples, keeping the temperature in the reactor at 25 DEG C, replacing C-H bond in the silicone rubber sample surface layer molecule with C-F bond after a certain reaction time, and obtaining the silicone rubber samples with a surface layer molecular structure forming a space charge shielding layer having electronegativity. The direct current cable accessory silicon rubber insulation surface layer molecular structure regulation and control device and method can enhance the charge screening effect of the direct current cable accessory silicon rubber insulation space.

Owner:TIANJIN UNIV

Fiber-toughened wear-resistant cable material and preparation method thereof

The invention discloses a fiber-toughened wear-resistant cable material and a preparation method thereof. The material is characterized by being prepared from the following raw materials by weight: 90 to 100 parts of polyethylene, 10 to 15 parts of red phosphorus, 3 to 5 parts of paraffin, 0.5 to 1 part of a silane coupling agent kh570, 15 to 25 parts of nanometer calcium carbonate, 0.8 to 1.6 part of polyvinyl alcohol, 2 to 4 parts of copper powder, 5 to 8 parts of polystyrene resin, 1 to 3 parts of zinc borate, 5 to 10 parts of pentaerythritol stearamide, 2 to 3 parts of ethylenethiourea, 3 to 5 parts of glass fiber, 2 to 4 parts of oxidized polyethlene wax, 3 to 4 parts of reinforcing carbon black and a proper amount of absolute ethanol. According to the invention, the preparation method is simple; material sources are extensive; the prepared cable material has good comprehensive performances and long service life, and is worth popularization.

Owner:HEFEISHI SHENZHAO ELECTRONICS

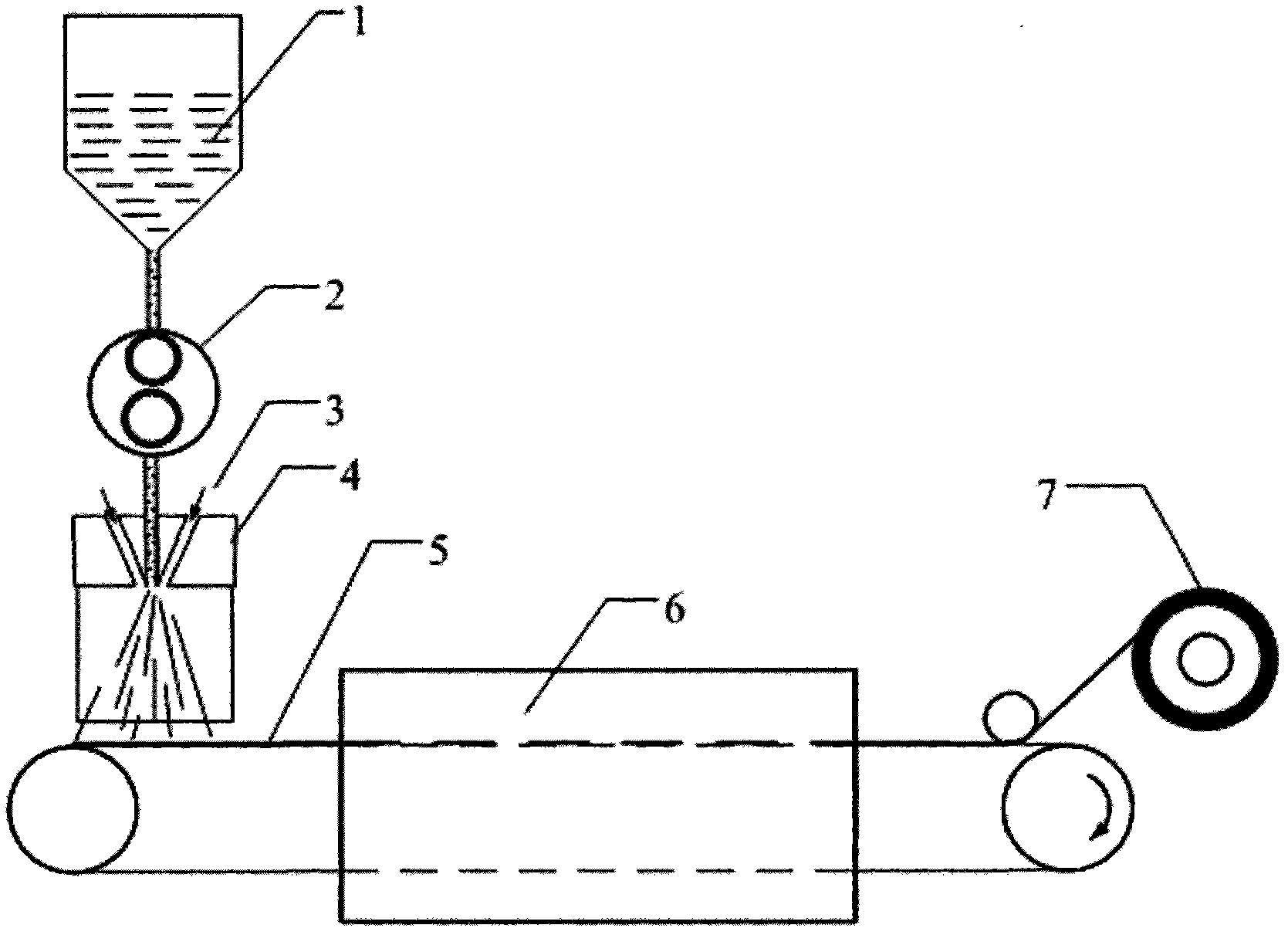

Toughening material of composite material and preparation method toughening material

ActiveCN102505355AThe overall thickness is thinSmall fiber diameterNon-woven fabricsYarnPolymer science

The invention belongs to a composite material high performance technology, relates to toughening material of composite material and a preparation method of the toughening material. The toughening material is made of non-woven cloth comprising thermoplastic polymer fiber, the thickness of the non-woven cloth is 5 to 50 micrometers, and the fiber diameter of the non-woven cloth is about 0.2 to 5 micrometers. The preparation method comprises the steps as follows: yarns are sprayed out through solution; the yarns are deposited to become the non-woven cloth; and then the fiber non-woven cloth toughening material is formed through drying and collection. The method adopting a solution spray process to prepare the non-woven cloth toughening material can effectively improve the preparation efficiency, and realize the mass manufacture of the toughening material. The toughening material prepared by the method can obviously improve the compression performance of impacted resin matrix composites, and compared with the prior art, the method has the advantages that the compression strength of the impacted resin matrix composites is improved by 50 to 150 percent, the heat resisting property and the mechanical property of composite material, as well as the flowing of resin during the forming of the composite material, are not affected, and the yield and the quality stability of the composite material are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

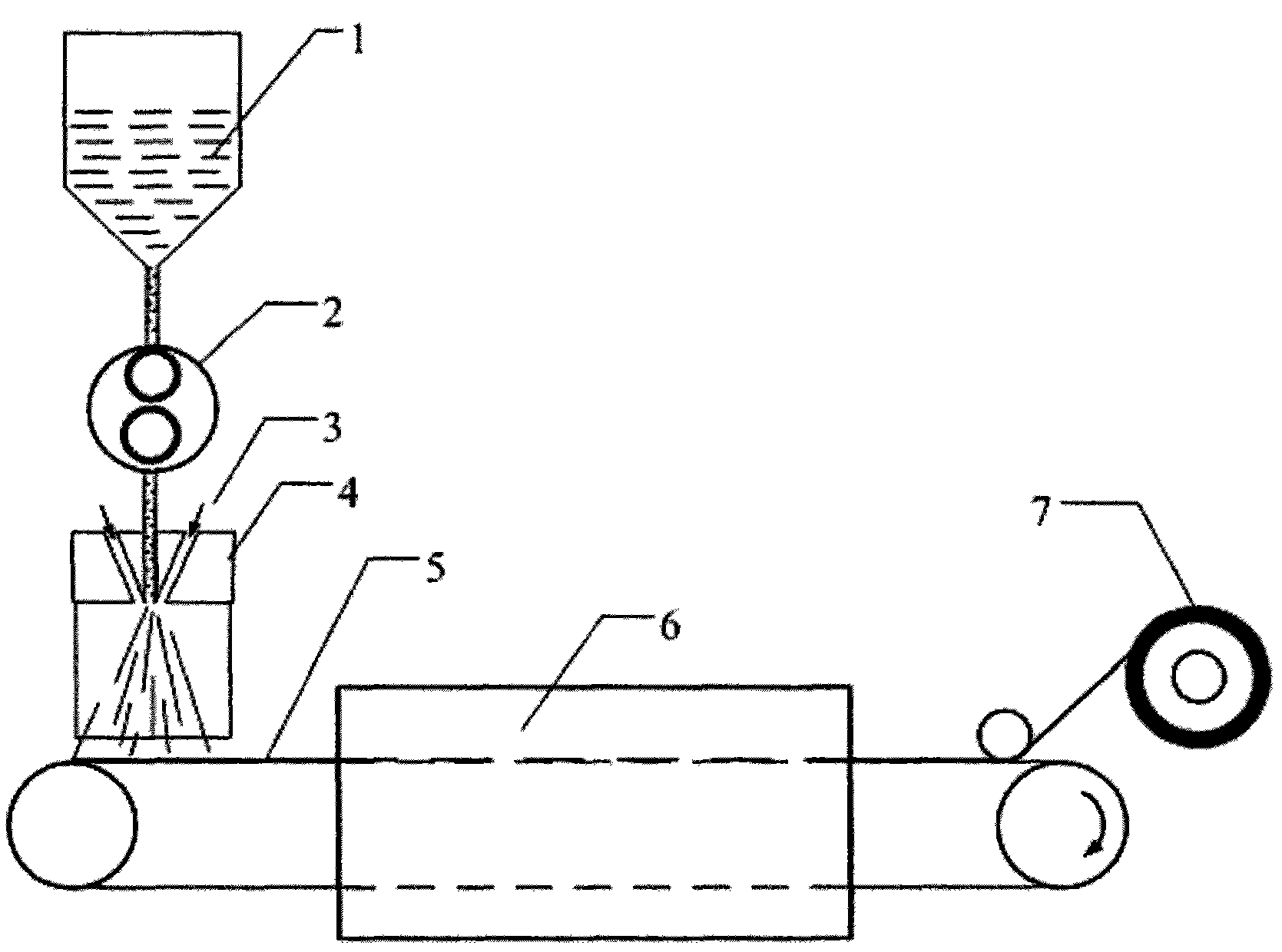

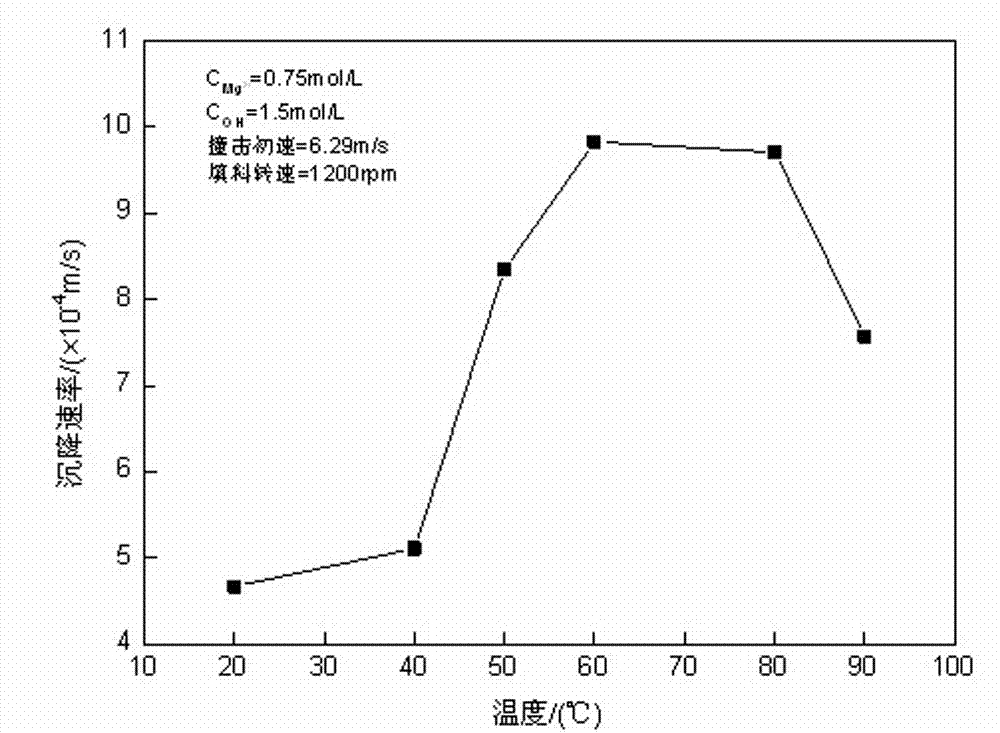

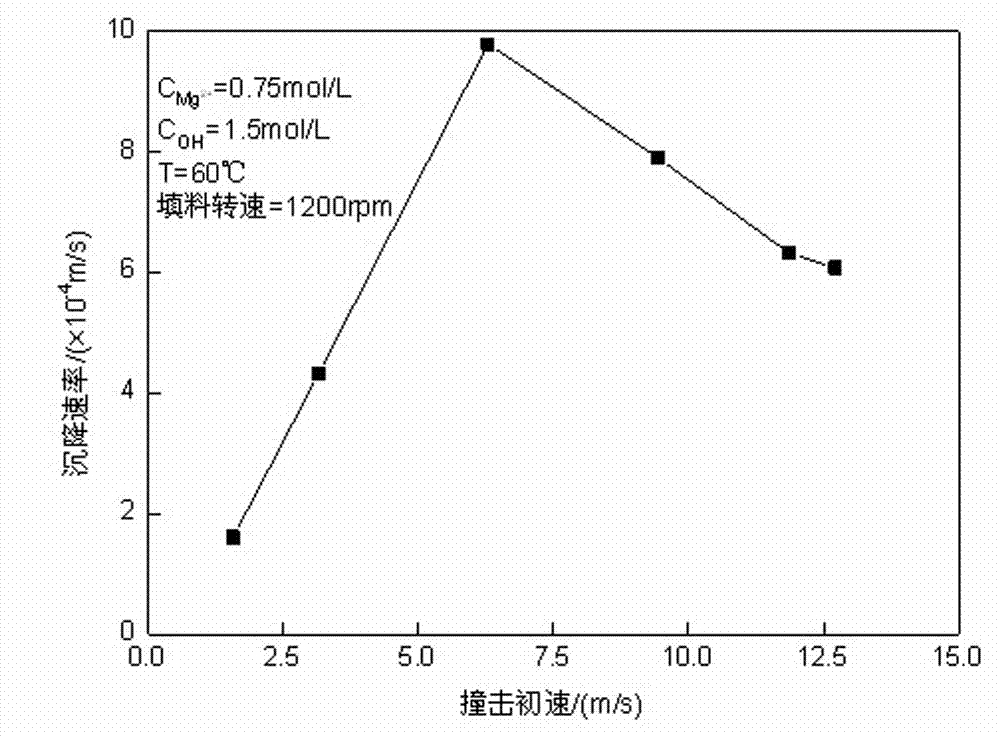

Method and device for synthesizing superfine magnesium hydrate fire retardant

ActiveCN103043689AIncrease contact areaShorten mixing timeMaterial nanotechnologyMagnesium hydroxideChlorideSodium hydroxide

The invention belongs to the technical field of the inorganic chemical industry, specifically relates to a method and a device for synthesizing a superfine magnesium hydrate fire retardant, and aims to solve the problem that existing magnesium hydrate synthesizing methods have respectively different disadvantages. The method comprises the steps that a magnesium chloride solution and a sodium hydroxide solution enter a liquid distributor from a liquid inlet of a supergravity reactor to realize first rapid uniform mixing and reacting, and then the solutions penetrate through a padding layer in a radial direction from inside to outside to realize second rapid uniform mixing and reacting. The device comprises the supergravity reactor, the liquid distributor of the supergravity reactor comprises a liquid inlet pipe I and a liquid inlet pipe II, the liquid inlet I is straight-pipe-shaped, the liquid inlet pipe II is straight-pipe-shaped and is provided with a 90-degree bend at the front end, and nozzles are formed at the front ends of the liquid inlet pipes. The device has the advantages that the structure is simple, the operation is simple and convenient, the device runs stably, the energy consumption is low, the technological design is reasonable, and the mixing efficiency of reactants can be enhanced, so that the product dispersibility is good, the grain size distribution is uniform, and the padding performance and the dispersing performance of the superfine magnesium hydrate fire retardant in a high polymer material are improved.

Owner:ZHONGBEI UNIV

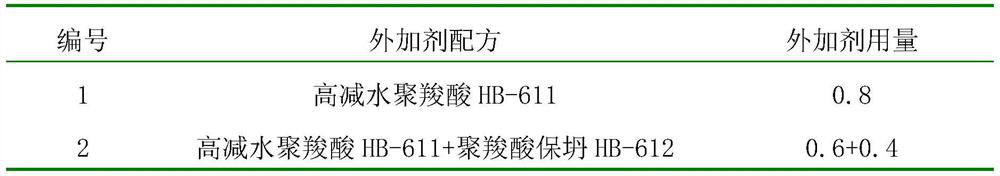

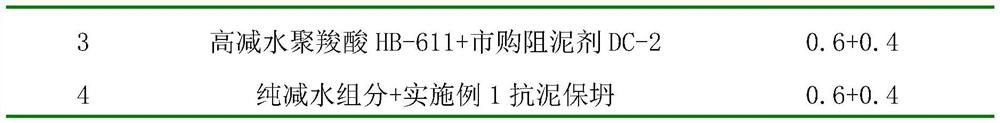

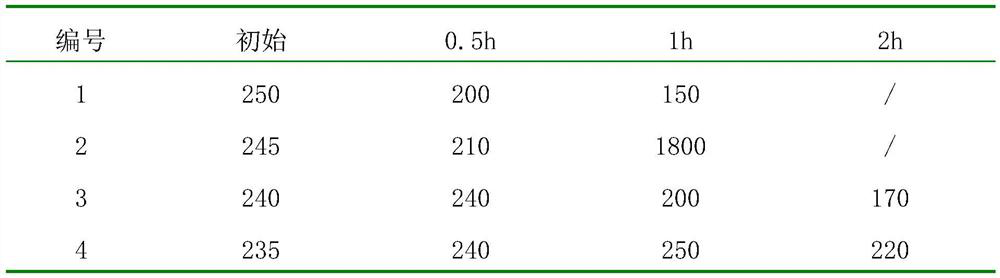

Mud-resistant polycarboxylic acid slump-retaining water reducing agent and preparation method thereof

PendingCN112961290AWith water reducing rateImprove adaptabilityPhosphoric Acid Esters(Hydroxyethyl)methacrylate

The invention discloses a mud-resistant polycarboxylic acid slump-retaining water reducing agent, which is prepared from the following components in parts by weight: 300 to 340 parts of isopentenol polyoxyethylene ether, 10 to 30 parts of dimethyl diallyl ammonium chloride, 2 to 4 parts of an initiator, 20 to 40 parts of hydroxyethyl acrylate, 15 to 30 parts of 2-hydroxyethyl methacrylate phosphate, 3 to 5 parts of sodium alpha-allylsulfonate, 0.6 to 1.2 parts of a reducing agent, 0.4 to 1.0 part of a chain transfer agent, and 250 to 300 parts of deionized water. The preparation method comprises the following steps: mixing deionized water, isopentenol polyoxyethylene ether and dimethyl diallyl ammonium chloride, and then adding an initiator to obtain a mixed solution; and respectively dropwise adding a solution A and a solution B, and adding liquid caustic soda to adjust the pH value. Compared with the traditional slump retaining agent, the product provided by the invention has a certain water-reducing rate, does not influence the setting time and mechanical properties of concrete, and has good adaptability under the condition of high clay content; and the synthesis process is simple, and has the advantages of energy conservation and consumption reduction.

Owner:山东惠邦建材科技股份有限公司 +1

Preparation method of high-performance heat-insulating composite plate

The invention discloses a preparation method of a high-performance heat-insulating composite plate. The preparation method of the high-performance heat-insulating composite plate particularly comprises the following steps: firstly, preparing cellulose toughened silicon dioxide aerogel particles from a cotton raw material as a raw material; secondly, mixing and stirring the prepared cellulose toughened silicon dioxide aerogel particles and cement uniformly; thirdly, sequentially adding a polycarboxylic acid water reducer, river sand, nanometer titanium dioxide, a foam stabilizer, a curing agentand deionized water, and mixing and stirring uniformly; fourthly, adding a foaming agent and stirring to prepare slurry; and finally, putting the prepared slurry into a mold to perform compression molding, and maintaining, demolding and cutting to prepare the high-performance heat-insulating composite plate. The prepared composite plate has excellent mechanical property and high heat-insulating property.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

Odorless addition type liquid silicone rubber tackifier and preparation method and application thereof

InactiveCN108164705ARaw materials are easy to getLow costMacromolecular adhesive additivesHydrogenOrganic solvent

The invention discloses an odorless addition type liquid silicone rubber tackifier and a preparation method and application thereof. The preparation method is as follows: mixing an organic compound containing phenyl and vinyl groups, a platinum catalyst and an organic solvent evenly for standby use; adding phenyl hydrogen-containing silicone oil and an organic solvent to a round bottom flask, heating up while stirring, and dropwise adding a mixture containing the organic compound containing the phenyl and vinyl groups, the platinum catalyst and the organic solvent into the round bottom flask whenthe temperature of the round bottom flask reaches 60-90DEG C for the adding time of 1-2h; after the adding is completed, controlling the reaction temperature at 60-100 DEG C for 1-8h; and after thereaction is completed, cooling a reaction solution to room temperature, filtering the reaction liquid by suction, and performing rotary evaporateion to get the tackifier. The preparation process is simple, the raw material is cheap and easy to obtain, the method is easy in industrial production, and the tackifier is colorless and tasteless, good in stability, has good compatibility with additiveliquid silicone rubber (LSR), and does not affect the odor and optical and mechanical properties of the LSR.

Owner:SHENZHEN KANGLIBANG TECH

Environment-friendly fluorine coating for solar battery back plate

ActiveCN107778509ASolve weather resistanceSolve cohesionSynthetic resin layered productsCoatingsPolyethylene terephthalate glycolEmulsion

The invention discloses an environment-friendly fluorine coating for a solar battery back plate. The environment-friendly fluorine coating comprises an aqueous functionalized vinylidene fluoride emulsion, wherein the aqueous functionalized vinylidene fluoride emulsion is prepared from a resin consisting of a vinylidene fluoride monomer, a fluorine-containing acrylic monomer and a vinyl monomer ina copolymerization manner. The environment-friendly fluorine coating disclosed by the invention is excellent in adhesive property with PET (Polyethylene Terephthalate), free of primer and simple in preparation process, and the problem that the weather resistance and the adhesive property of a fluorine coating cannot be both taken into account is solved.

Owner:乐凯胶片股份有限公司

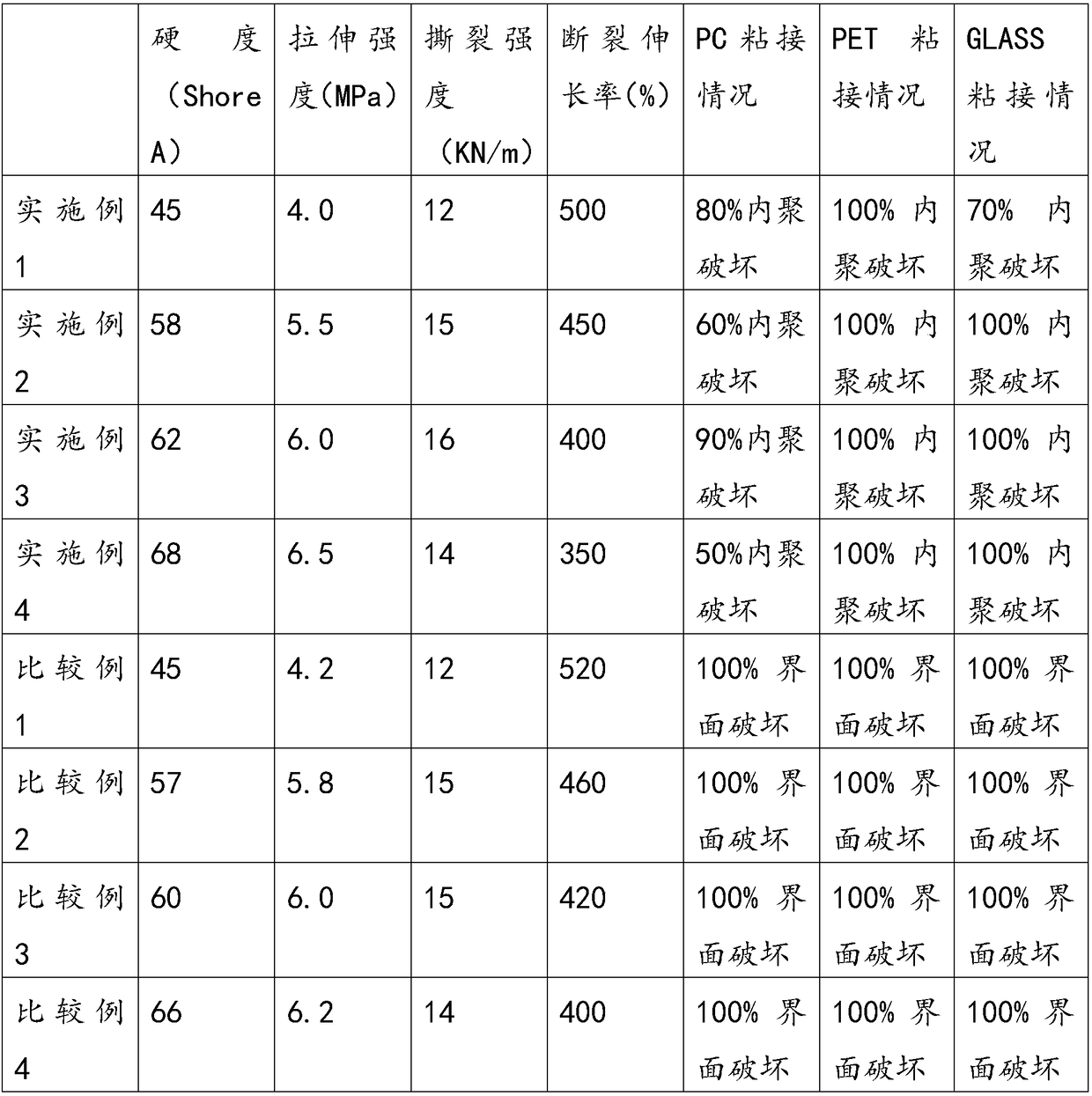

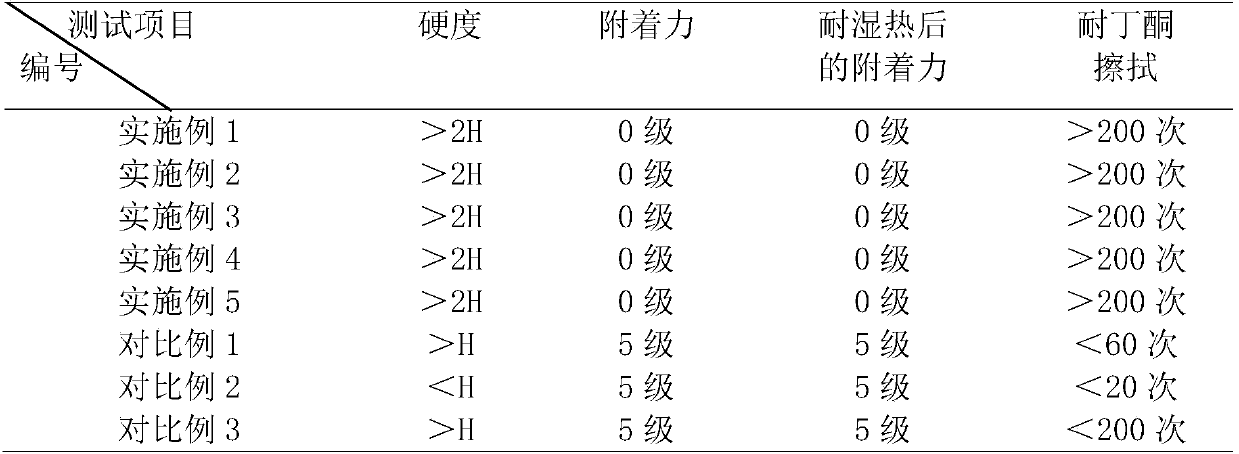

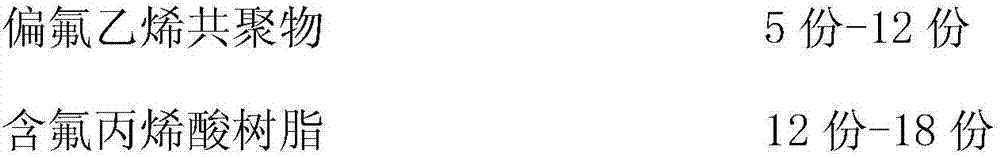

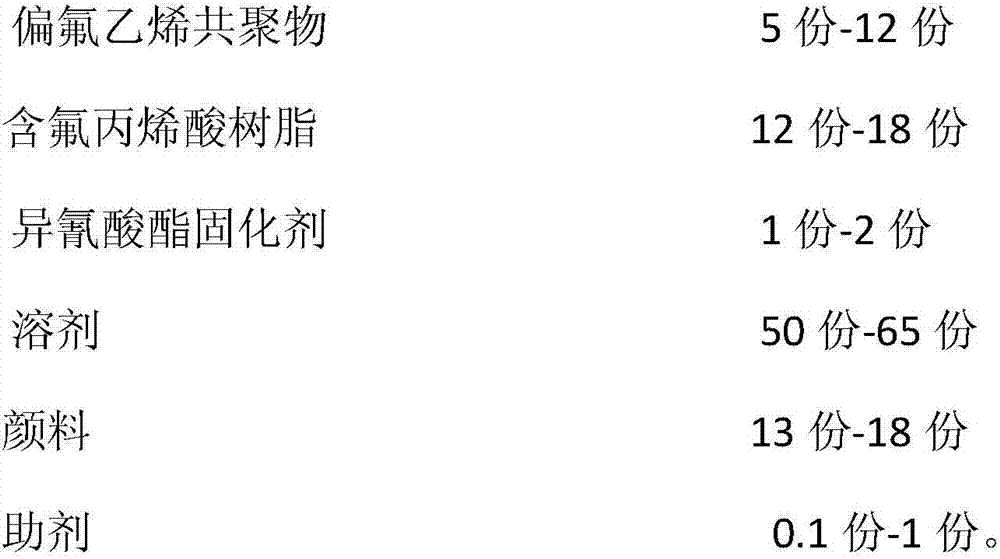

Paint for solar cell backsheet

ActiveCN107083139ADoes not affect mechanicsDoes not affect thermal stabilityCoatingsSemiconductor devicesAcrylic resinHardness

The invention relates to paint for solar cell backsheet. The paint comprises the following components in parts by mass: 5-12 parts of a vinylidene fluoride copolymer, 12-18 parts of fluorine containing acrylic resin, 1-2 parts of an isocyanate curing agent, 50-60 parts of a solvent, 13-18 parts of a pigment, and 0.1-1 part of an auxiliary agent. The paint can satisfy requirements of the solar cell backsheet on butanone resistance, high hardness and good laminated apparent, and after the paint is boiled under pressure for 100 hours, the paint has good adhesive force for a solar cell backsheet base material.

Owner:乐凯胶片股份有限公司

Composite copper layer polyvinyl chloride leakage waveguide feeder line and manufacturing method thereof

The invention discloses a composite copper layer polyvinyl chloride leakage waveguide feeder line and a manufacturing method thereof. The composite copper layer polyvinyl chloride leakage waveguide feeder line, in structure, radially comprises a copper foil layer, a polyvinyl chloride hard circular tube and a flame retardant protection layer in sequence from an inner diameter to an outer diameter,wherein the outer surface of the polyvinyl chloride hard circular tube is also provided with a plurality of slots along the length direction; and the opposite side of the slot is a joint place of a ridge structure. The composite copper layer polyvinyl chloride leakage waveguide feeder line is scientifically designed, and high-frequency communication requirements, signal stability, light weight, and easy installation under a complicated environment can be met.

Owner:JIANGSU TRIGIANT TECH

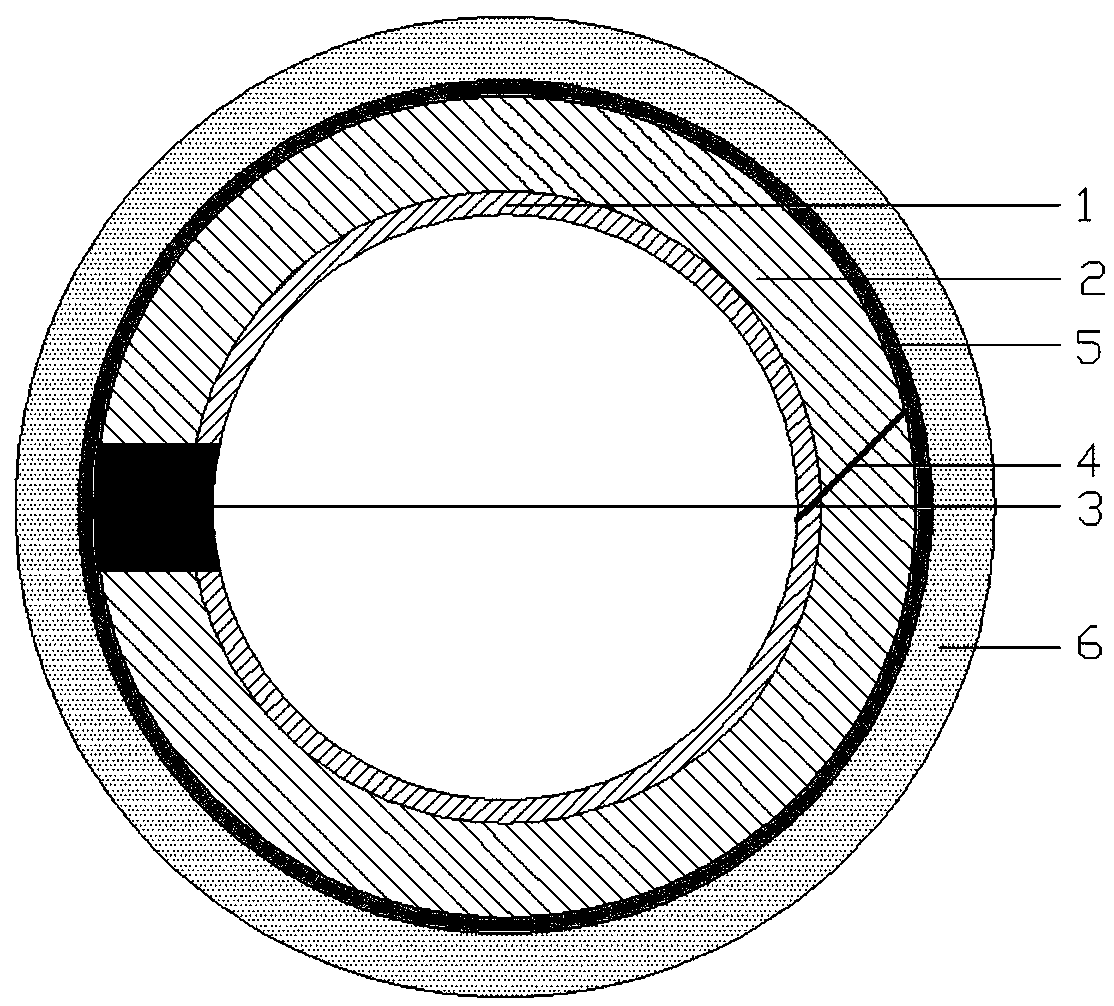

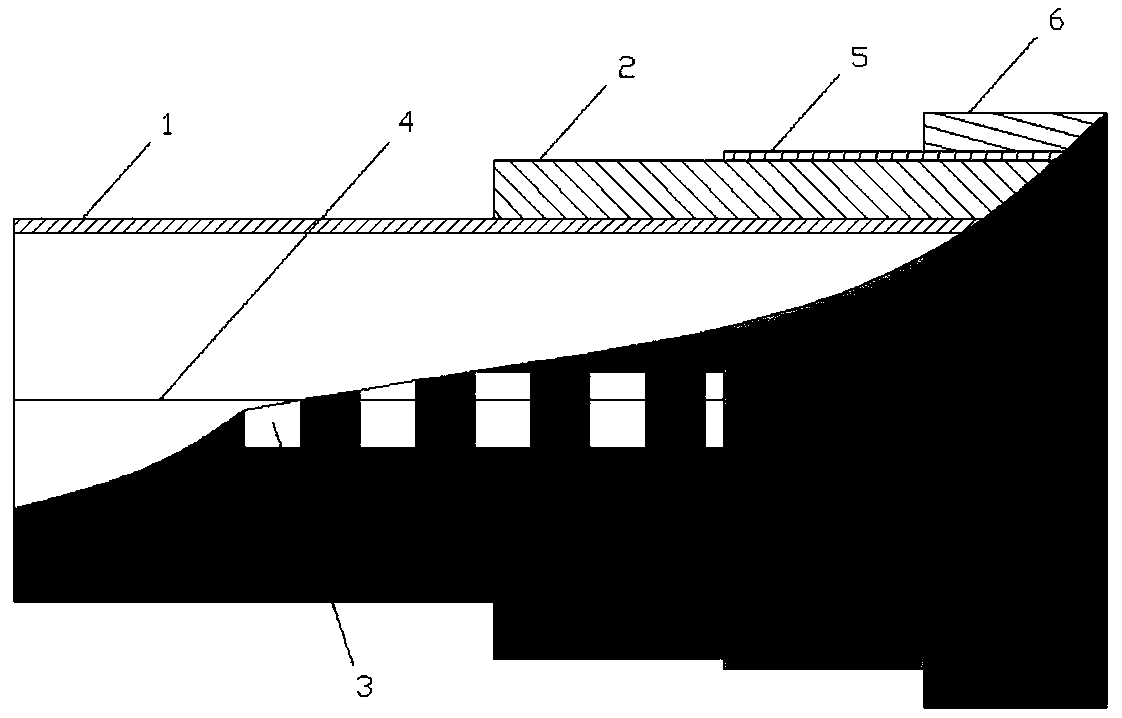

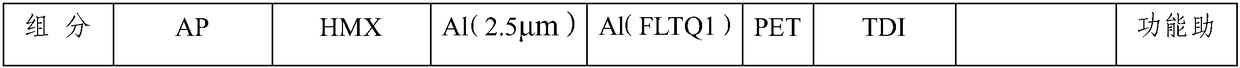

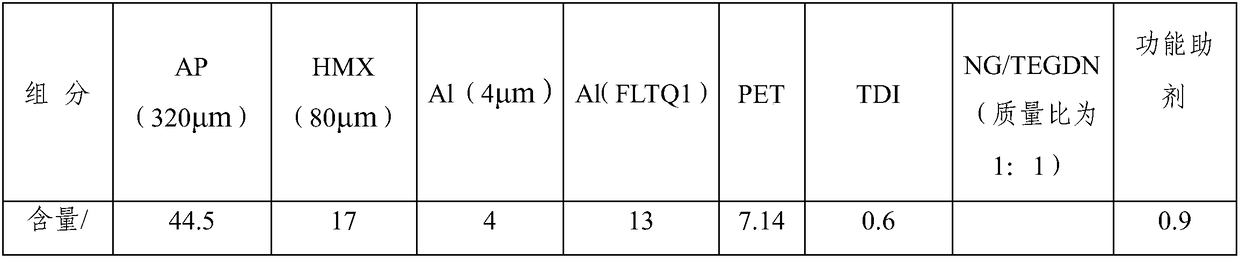

High-solid-content NEPE solid propellant slurry, propellant and preparation method

ActiveCN108530239ASolve the problem of poor technology and difficult pouringDoes not affect propellant energyExplosive working-up apparatusPressure gas generationMicrometerAmmonium perchlorate

The invention provides high-solid-content NEPE solid propellant slurry, propellant and a preparation method, and belongs to the technical field of solid propellant. The preparation method of the slurry comprises the following steps that raw materials are weighed, wherein the raw materials comprise ammonium perchlorate, ammonium nitrate explosives, aluminum powder, an adhesive system, a curing agent and a functional agent, the aluminum powder is superfine aluminum powder or a mixture of the superfine aluminum powder and FLTQ1 aluminum powder, and the particle size d50 of the superfine aluminumpowder ranges from 2.5 micrometers to 13 micrometers; part of the adhesive system and the weighed aluminum powder, ammonium nitrate explosives and functional agent are mixed, a mixture is obtained, and the mass of part of the adhesive system accounts for 9.5% to 12% of the total mass of the raw materials; the weighed ammonium perchlorate and ammonium nitrate explosives are added into the obtainedmixture, mixing is carried out, then the curing agent and the remaining adhesive system are added, mixing is carried out, and the propellant slurry is obtained. According to the high-solid-content NEPE solid propellant slurry, propellant and the preparation method, the process performance of the propellant slurry can be obviously improved on the premise of not influencing the energy, mechanical property and mixing time of the propellant.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

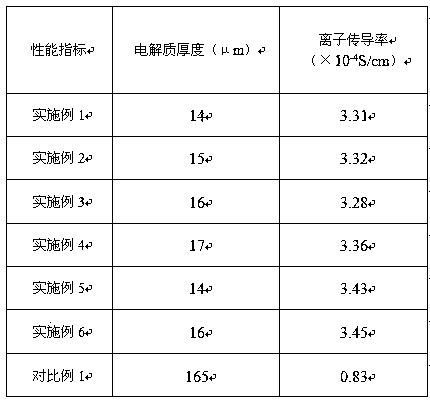

Ultrathin solid electrolyte of lithium battery and preparation method thereof

InactiveCN109698383AGood effectAchieve ultra-thin structureSolid electrolytesFinal product manufactureWater bathsAcetonitrile

The invention belongs to the technical field of lithium batteries, and provides an ultrathin solid electrolyte of a lithium battery and a preparation method thereof. In the method, Li2S and P2S5 are added into tetrahydrofuran, the mixture is heated in a water both and stirred for a reaction, obtained white power is added into anhydrous acetonitrile, a water bath heating is carried out for a reaction until the solution completely turns blue, a polished substrate is immersed in the solution, taken out after standing and hot-pressed, and the substrate is peeled off to prepare the ultrathin solidelectrolyte of the lithium battery. Compared with a conventional method, the solid electrolyte prepared by the preparation method of the invention is formed by stacking nanosheets, is uniform and compact in overall structure, significantly reduces the macroscopic thickness of the electrolyte without affecting the mechanical and chemical properties of the electrolyte, and realizes an ultrathin structure. The preparation method is simple and is suitable for large-scale industrial production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

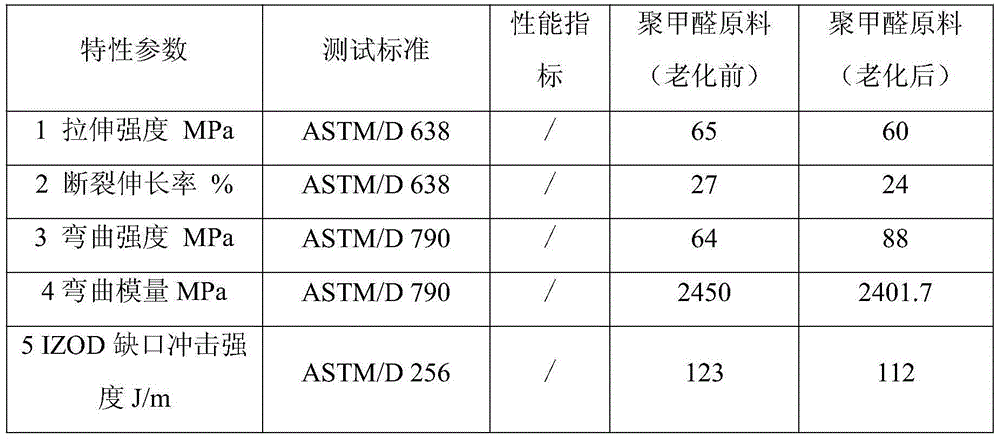

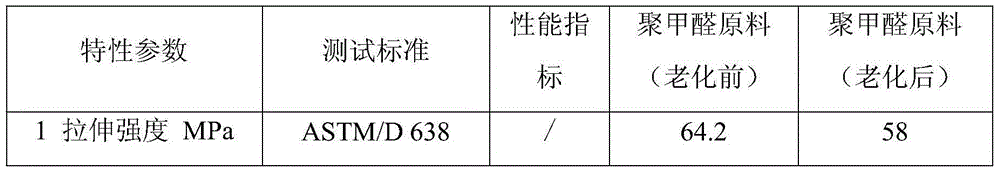

Weather-resistant polyoxymethylene

The invention aims to provide weather-resistant polyoxymethylene which is resistant to acid, strong alkali, sunlight ultraviolet radiation and the like. The weather-resistant polyoxymethylene comprises the following components in parts by weight: 75-90 parts of a polyoxymethylene raw material, 1.0-3.0 parts of an antioxidant, 7.0-11.0 parts of an ultraviolet absorber, 0.5-1.5 parts of a TAS-2A dispersed lubricant, 1.0-5.0 parts of nano zinc oxide, 1.0-3.0 parts of a stabilizing agent, and an appropriate amount of white oil. The weather-resistant polyoxymethylene preferably comprises the following components in parts by weight: 85 parts of the polyoxymethylene raw material, 2.0 parts of the antioxidant, 9.0 parts of the ultraviolet absorber, 1.0 part of the TAS-2A dispersed lubricant, 3.0 parts of nano zinc oxide, 2.0 parts of the stabilizing agent, and an appropriate amount of the white oil. The weather-resistant polyoxymethylene provided by the invention is resistant to acid, strong alkali and sunlight ultraviolet radiation, and cannot influence mechanical properties of a material at the same time.

Owner:QINGDAO YISHIBAO PLASTIC

Anti-blocking master batch for thermoplastic polyurethane film and preparation method of anti-blocking master batch

InactiveCN113480842AReduce coefficient of frictionGood anti-adhesionPolymer scienceThermoplastic polyurethane

The invention relates to an anti-blocking master batch for a thermoplastic polyurethane film and a preparation method of the anti-blocking master batch. The master batch comprises the following components: 90-95% of TPU, 0.5-5% of an anti-blocking agent and 0.5-2% of an antistatic agent, wherein the contents of the components sums to 100%. The anti-blocking master batch disclosed by the invention is a special anti-blocking master batch for aliphatic TPU; and after being used, the anti-blocking agent is quickly dispersed on the surface of the film to form a lubricating molecular layer, so the friction coefficient of the film is reduced, and an excellent anti-blocking effect is achieved.

Owner:浙江凯阳新材料股份有限公司

Formula of environment friendly edge banding strips

The invention relates to the technical field of composite material, in particular to a formulation of an environment-friendly edge banding. The formulation is to prepare PVC materials with different hardness through adding a stabilizing agent, a reinforcing agent, a lubricant, a styrene modifier, a processing aid and other substances into polyvinyl chloride. The formulation not only reduces processing temperature and improves planeness of a product by adding the processing aid without affecting mechanical property, fire resistance, high-strength weather fastness and other physical performances of PVC, but also ensures excellent product performance of the edge banding with small usage of the polyvinyl chloride and low cost; and the product does not contain a heavy metallic salt stabilizingagent, and can protect human health from being hurt, thereby being an environment-friendly product.

Owner:XIONG YI PLASTIC PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com