Addition type silicone adhesive composition and preparation method thereof

A silicone rubber and adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the harmfulness of silane coupling agents, the inability of silane coupling agents to achieve bonding effect, and affect physical and mechanical properties. and electrical properties to achieve good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

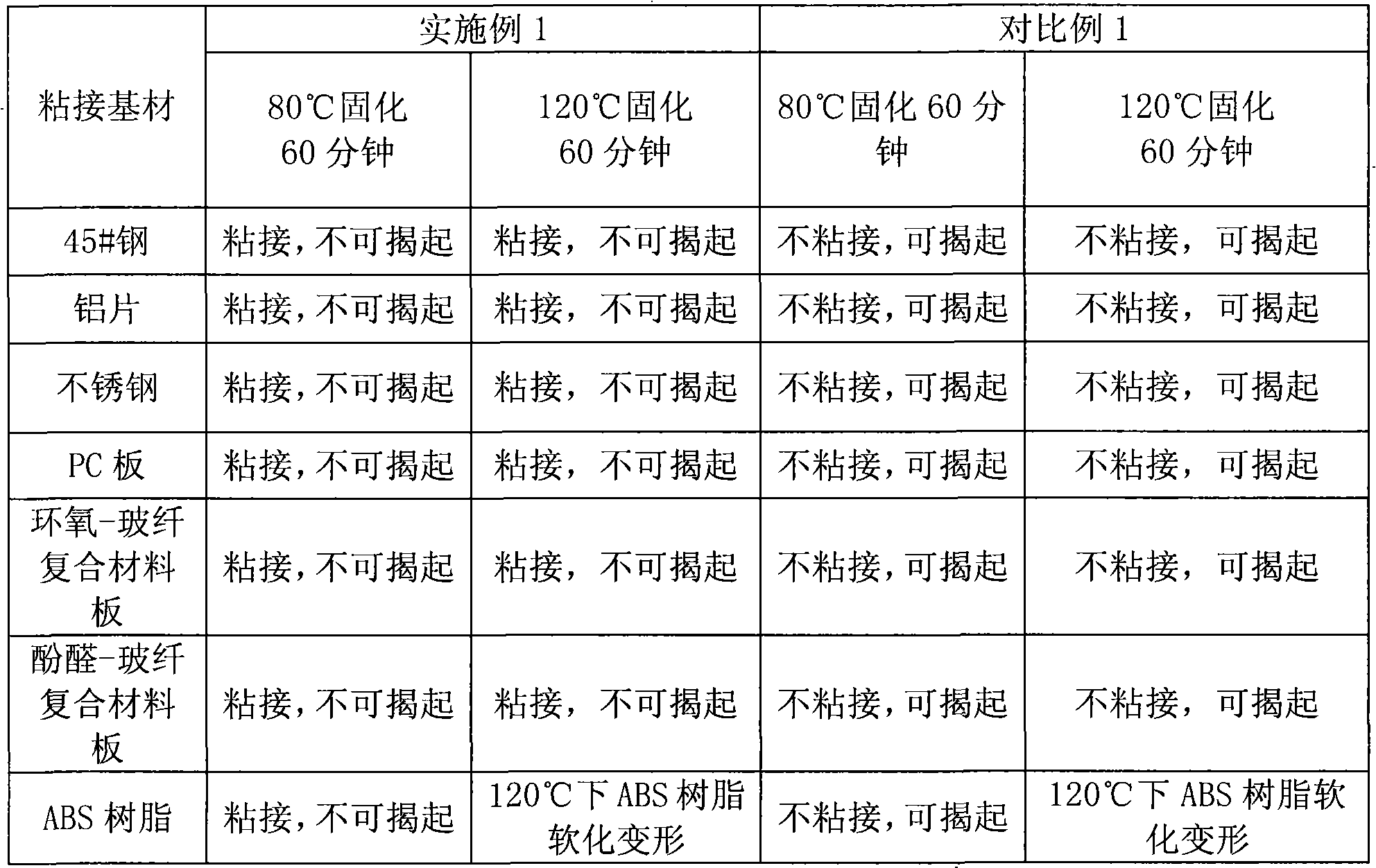

Examples

Embodiment 1

[0022] Add 100 parts of dimethyl hydrogen-containing silicone oil with a hydrogen content of 1.2% and 40 parts of hydroxyethyl methacrylate to 140 parts of anhydrous ethyl acetate solvent, stir evenly at room temperature and under the protection of nitrogen, and then heat up to 70°C , add a small amount of self-made catalyst, remove the catalyst after reacting for 10 hours under nitrogen protection, and remove the solvent ethyl acetate by distillation under reduced pressure to obtain (B) component.

[0023] Select 100 parts by mass of an organopolysiloxane with a viscosity of 5000 cps whose end group is vinyl, add 10 parts of surface-modified fumed silica and 0.5%wt dimethylhexynol, and then add (B) synthesized by the present invention. 5 parts of components, based on 100 parts by mass of the above basic composition, 20 ppm of platinum catalyst was added. Mix the vinyl-terminated organopolysiloxane, surface-modified fumed silica and dimethylhexynol under vacuum for 20-30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com