Ultrathin solid electrolyte of lithium battery and preparation method thereof

A solid electrolyte, lithium battery technology, applied in solid electrolyte, electrolyte battery manufacturing, electrolyte and other directions, can solve the problems of complex synthesis method, affecting the performance of electrolyte lithium ion battery, difficult to control thickness and uniformity, etc., to reduce the macro thickness, The overall structure is uniform and dense, and the performance is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

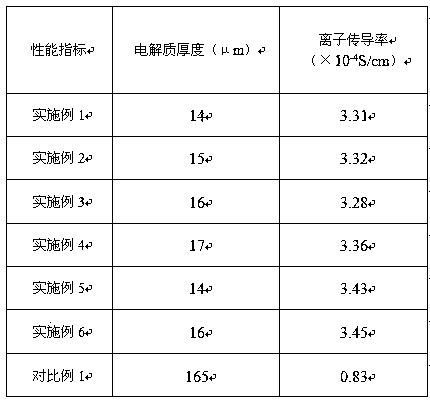

Examples

Embodiment 1

[0029] Will Li 2 S and P 2 S 5 The powder was added into tetrahydrofuran (THF) solvent, Li 2 S, P 2 S 5 The molar ratio of THF to THF is 3:1:6. Under the condition of heating in a water bath at 66°C, vigorously stir the reaction at a speed of 680r / min for 24.5h. Dry at 16Pa for 19h to obtain white powder Li 3 P.S. 4 3THF; add 28kg of white powder into 72kg of anhydrous acetonitrile solvent, stir and react at a speed of 360r / min for 44min under heating in a water bath at a temperature of 86°C, until the solution turns blue completely; then immerse the polished silicon substrate in the solution , after standing still for 8.5h, the substrate was taken out, then hot-pressed for 7s at a temperature of 206°C and a pressure of 206MPa, and finally the substrate was peeled off to obtain an ultra-thin solid electrolyte for a lithium battery.

[0030] testing method:

[0031](1) Average thickness: the electrolyte membrane prepared by the present invention is cut into a sample of ...

Embodiment 2

[0035] Will Li 2 S and P 2 S 5 The powder was added into tetrahydrofuran (THF) solvent, Li 2 S, P 2 S 5 The molar ratio of THF to THF is 3:1:6, and the temperature is 62°C under the condition of water bath heating, and the reaction is vigorously stirred at a speed of 650r / min for 25h. After the reaction is completed, filter, and then the obtained white precipitate is at room temperature. Dry at 12Pa for 21h to obtain white powder Li 3 P.S. 4 3THF; add 25kg of white powder into 75kg of anhydrous acetonitrile solvent, stir and react at a speed of 320r / min for 48min under heating in a water bath at a temperature of 82°C, until the solution turns blue completely; then immerse the polished copper substrate in the solution After standing for 8 hours, the substrate was taken out, and then hot-pressed for 8 seconds at a temperature of 202°C and a pressure of 202 MPa, and finally the substrate was peeled off to obtain an ultra-thin solid electrolyte for a lithium battery.

[003...

Embodiment 3

[0038] Will Li 2 S and P 2 S 5 The powder was added into tetrahydrofuran (THF) solvent, Li 2 S, P 2 S 5 The molar ratio of THF to THF is 3:1:6, and the temperature is 68 °C under the condition of water bath heating, and the reaction is vigorously stirred at a speed of 760r / min for 24 hours. Dry at 18Pa for 19h to obtain white powder Li 3 P.S. 4 3THF; add 35kg of white powder into 65kg of anhydrous acetonitrile solvent, stir and react at a speed of 380r / min for 42min under heating in a water bath at a temperature of 88°C, until the solution turns blue completely; then immerse the polished nickel substrate in the solution , after standing for 9 hours, the substrate was taken out, then hot-pressed for 6 seconds at a temperature of 208°C and a pressure of 208 MPa, and finally the substrate was peeled off to obtain an ultra-thin solid electrolyte for a lithium battery.

[0039] The test method is consistent with Example 1, and the obtained data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com