Weather-resistant polyoxymethylene

A polyoxymethylene and weather-resistant technology, applied in the chemical field, can solve problems such as difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (1) Take the raw materials of the following weight ratio:

[0012] Polyoxymethylene raw material: 85 Antioxidant: 2.0 Ultraviolet light absorber: 9.0 TAS-2A dispersion lubricant: 1.0 Nano zinc oxide: 3.0 Stabilizer: 2.0 White oil: Appropriate amount.

[0013] (2) First dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder to melt and extrude, cool, pelletize, and pack the finished product; wherein, the twin-screw extruder The temperature of the first zone is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, the fourth zone is 200-205°C; the fifth zone is 190-200°C, and the residence time is 1-2 minutes , the pressure is 10-15Mpa.

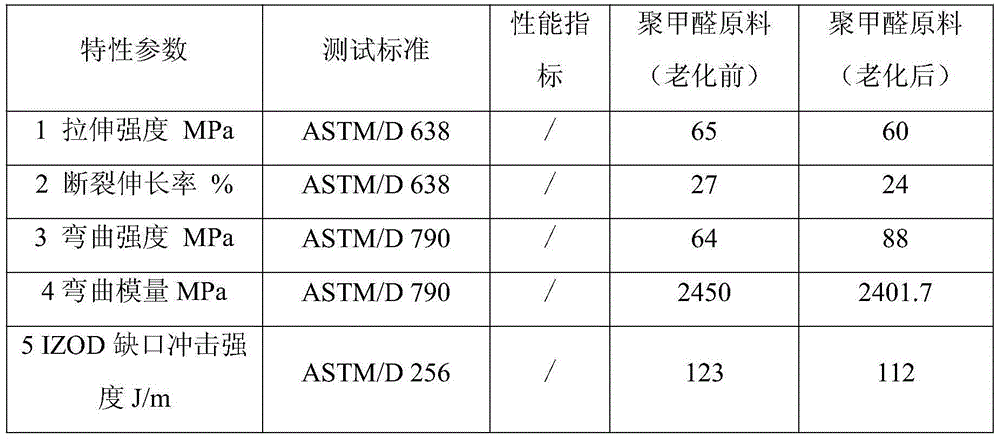

[0014] The physical performance parameters of the above-mentioned weather-resistant polyoxymethylene are as follows:

[0015]

[0016] According to the above data, the above-mentioned weather-resistant polyoxymethylene is a weather-resistant ...

Embodiment 2

[0018] (1) Take the raw materials of the following weight ratio:

[0019] Polyoxymethylene raw material: 75 Antioxidant: 1.0 UV absorber: 7.0 TAS-2A dispersion lubricant: 0.5 nanometer zinc oxide: 1.0-5.0 Stabilizer: 1.0 White oil: appropriate amount.

[0020] (2) First dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder to melt and extrude, cool, pelletize, and pack the finished product; wherein, the twin-screw extruder The temperature of the first zone is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, the fourth zone is 200-205°C; the fifth zone is 190-200°C, and the residence time is 1-2 minutes , the pressure is 10-15Mpa.

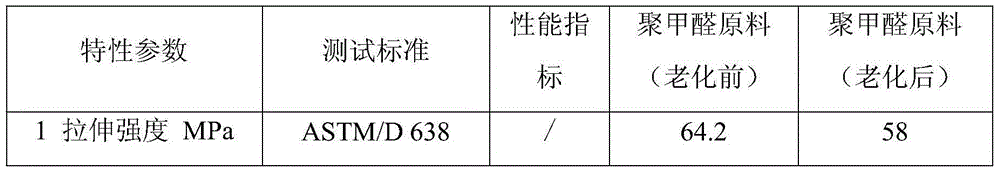

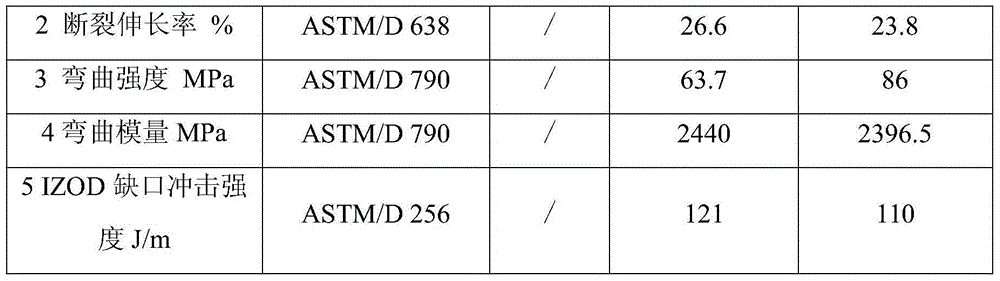

[0021] The physical performance parameters of the above-mentioned weather-resistant polyoxymethylene are as follows:

[0022]

[0023]

[0024] According to the above data, the above-mentioned weather-resistant polyoxymethylene is a weather-resi...

Embodiment 3

[0026] (1) Take the raw materials of the following weight ratio:

[0027] Polyoxymethylene raw material: 90 Antioxidant: 3.0 Ultraviolet light absorber: 11.0 TAS-2A Dispersed lubricant: 1.5 Nano zinc oxide: 5.0 Stabilizer: 3.0 White oil: Appropriate amount.

[0028] (2) First dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder to melt and extrude, cool, pelletize, and pack the finished product; wherein, the twin-screw extruder The temperature of the first zone is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, the fourth zone is 200-205°C; the fifth zone is 190-200°C, and the residence time is 1-2 minutes , the pressure is 10-15Mpa.

[0029] The physical performance parameters of the above-mentioned weather-resistant polyoxymethylene are as follows:

[0030]

[0031] According to the above data, the above-mentioned weather-resistant polyoxymethylene is a weather-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com