Method and device for synthesizing superfine magnesium hydrate fire retardant

A technology of ultra-fine magnesium hydroxide and flame retardant, applied in the direction of magnesium hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effects of shortening mixing time, good dispersion, and improving microscopic mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

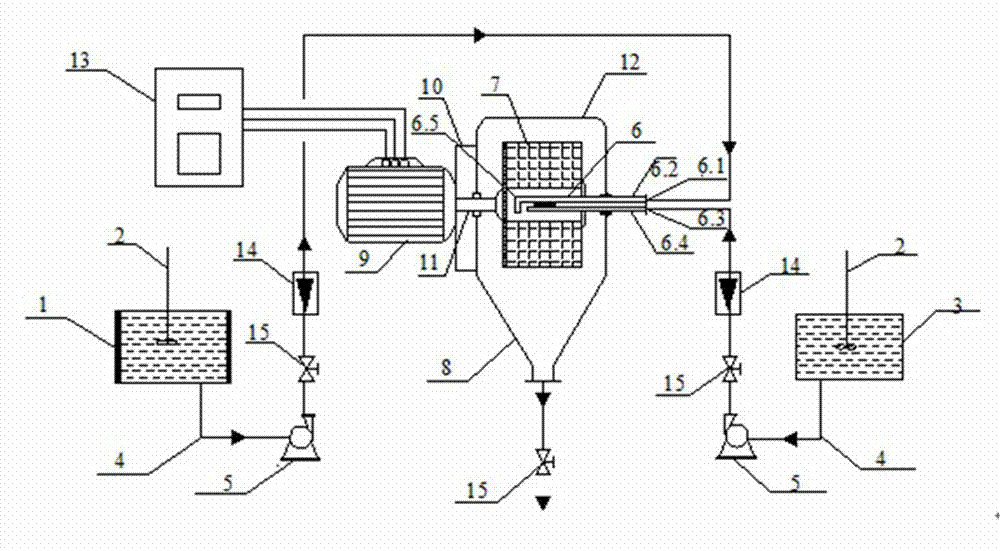

[0041] Adopt technological process of the present invention to attach figure 1 , put the prepared magnesium chloride solution with a concentration of 0.5 mol / L in storage tank I, and put the sodium hydroxide solution with a concentration of 1.0 mol / L in storage tank II. Turn on the hypergravity reactor, and control the speed of the hypergravity reactor at 900r / min by adjusting the frequency converter. Turn on the corrosion-resistant pump, and control the volume flows of the magnesium chloride solution and the sodium hydroxide solution at 20L / h and 20L / h, respectively, by adjusting the flowmeter. The liquid-liquid contact reaction was carried out in a high-gravity reactor, the reaction temperature was controlled at 50°C, and the reaction time was 0.5h. The magnesium hydroxide slurry synthesized through the above steps is filtered, washed, dried and ground to obtain a magnesium hydroxide product with an average particle diameter of 17.0 nm.

Embodiment 2

[0043] Adopt technological process of the present invention to attach figure 1 , put the prepared magnesium chloride solution with a concentration of 2.0 mol / L in storage tank I, and put the sodium hydroxide solution with a concentration of 4.0 mol / L in storage tank II. Turn on the supergravity reaction device, and control the speed of the supergravity reactor at 1500r / min by adjusting the frequency converter. Turn on the corrosion-resistant pump, control the volume flow rate of magnesium chloride solution and sodium hydroxide solution at 120L / h and 120L / h respectively, carry out liquid-liquid contact reaction in the supergravity reactor, control the reaction temperature at 80°C, and the reaction time is 2.5h. The magnesium hydroxide slurry synthesized by the above steps is filtered, washed, dried and ground to obtain a magnesium hydroxide product with an average particle diameter of 10.0 nm.

Embodiment 3

[0045] Adopt technological process of the present invention to attach figure 1 , put the prepared magnesium chloride solution with a concentration of 1.0mol / L in the liquid storage tank I, put the sodium hydroxide solution with a concentration of 2mol / L in the liquid storage tank II, turn on the supergravity reaction device, and adjust the frequency converter The rotating speed of the supergravity reactor is controlled at 1200r / min. Turn on the corrosion-resistant pump, control the volume flow rate of magnesium chloride solution and sodium hydroxide solution at 90L / h and 90L / h respectively, and carry out liquid-liquid contact reaction in the supergravity reactor. The reaction temperature is controlled at 70°C, and the reaction time is 1.0h. The magnesium hydroxide slurry synthesized through the above steps is filtered, washed, dried and ground to obtain a magnesium hydroxide product with an average particle size of 7.0 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com