Patents

Literature

1717 results about "Magnesium chlorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick Answer. The formula for magnesium chlorate is Mg(ClO3)2. It appears as white soluble crystals or powder and is used to make other chemicals, such as microbiocide, herbicide and defoliant.

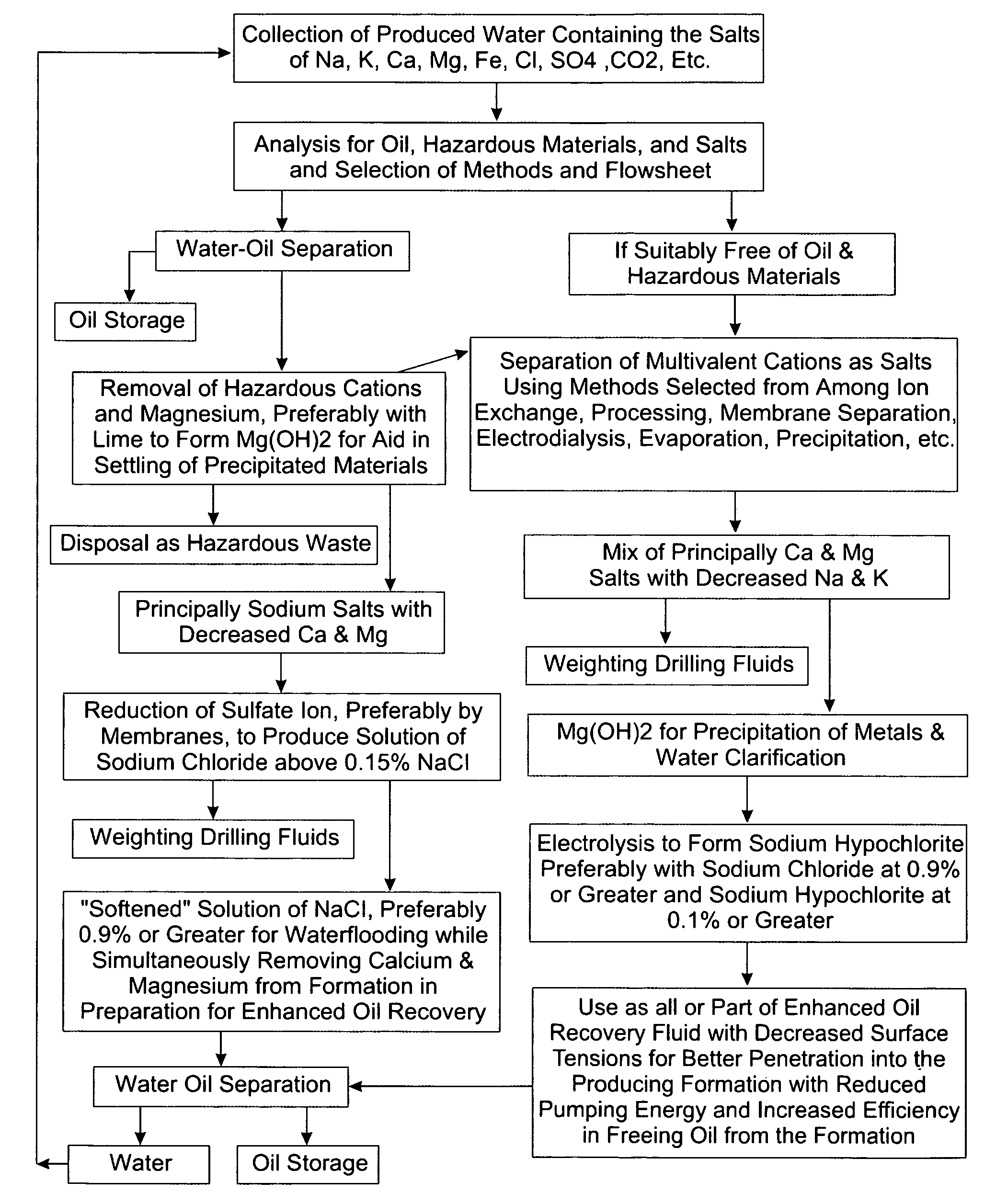

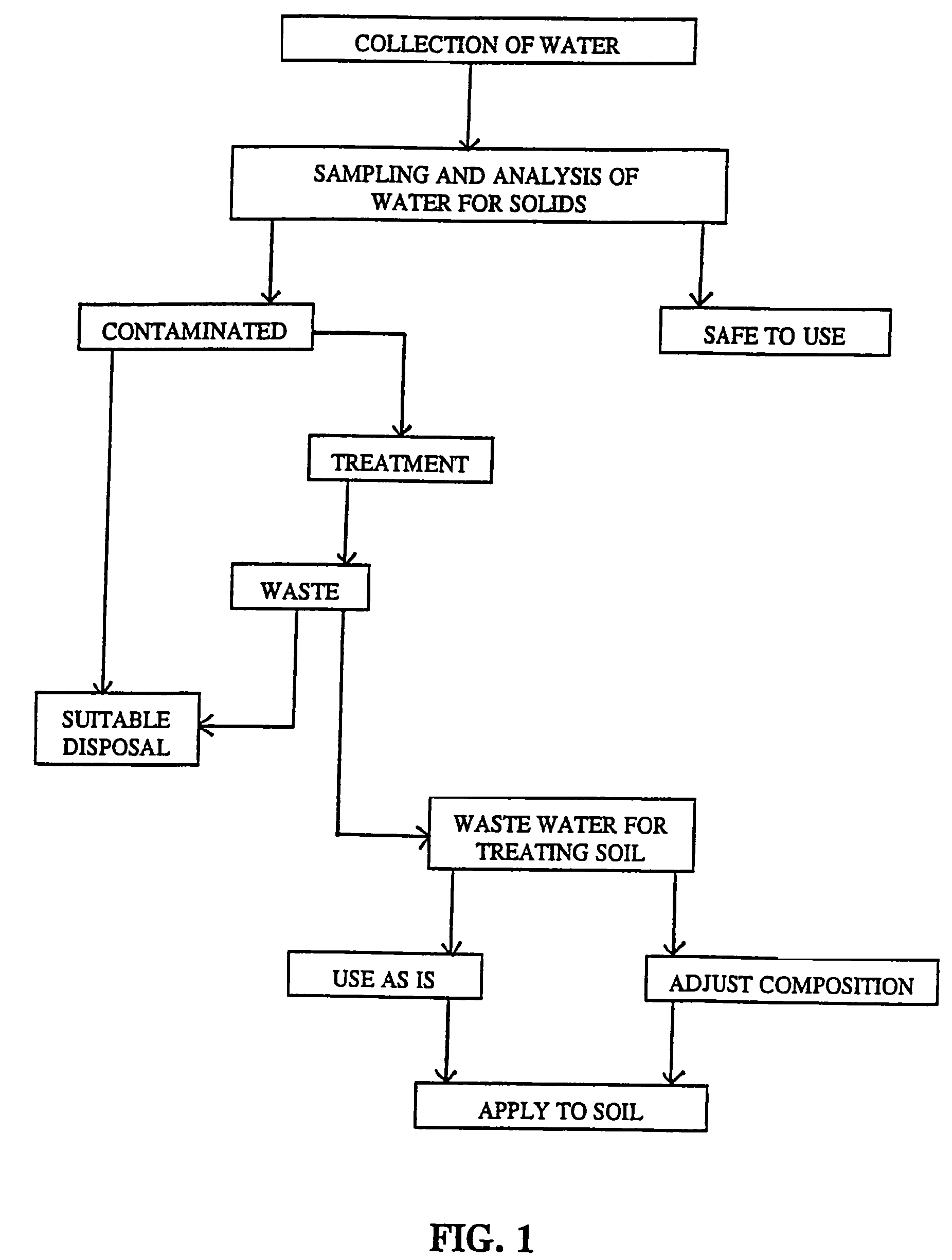

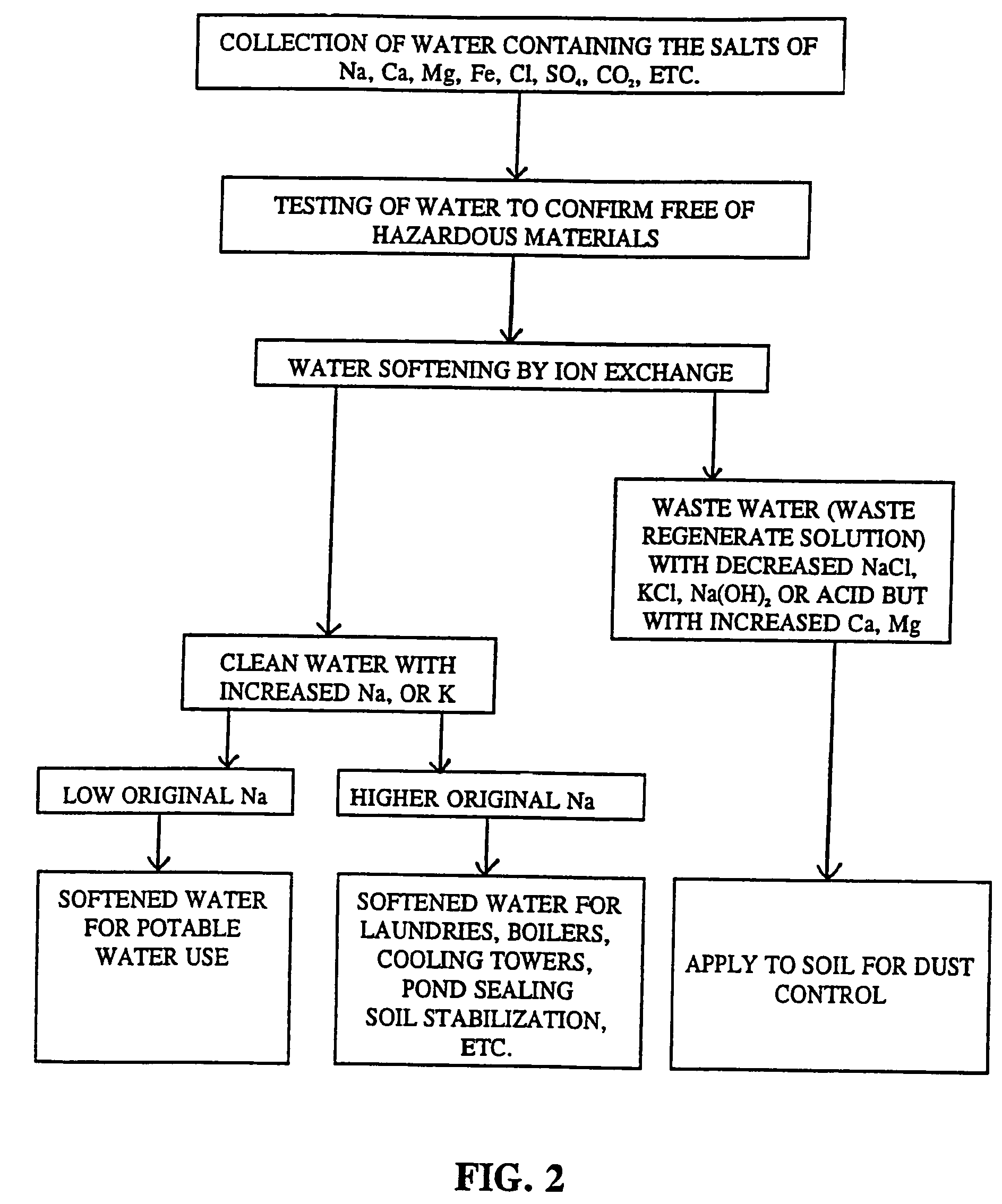

Methods of improving oil or gas production with recycled, increased sodium water

InactiveUS7717173B2Reduction tendencySpecific water treatment objectivesScale removal and water softeningLiquid productEnvironmental engineering

A method of improving oil or gas well production has the steps of (a) collecting contaminated water having 0.15% or more by weight of the salts of Na, Ca, Mg, K, Cl, SO4 or CO3 or combinations thereof (b) separation processing the contaminated water to produce i.) a first separated liquid product having increased sodium chloride and decreased magnesium chloride and calcium chloride or combinations thereof than the collected water, and ii) a second solid or liquid product having decreased sodium chloride and increased magnesium chloride and calcium chloride or combinations thereof than the collected water, and (c) injecting the first liquid product into an oil or gas well formation to improve production.

Owner:ECYCLING

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

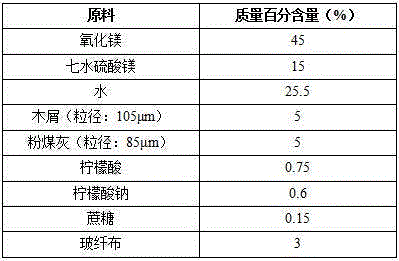

Novel inorganic decoration base material plate and preparation method thereof

InactiveCN105130350AImprove water and moisture resistanceAdjust clotting timeSucroseMoisture absorption

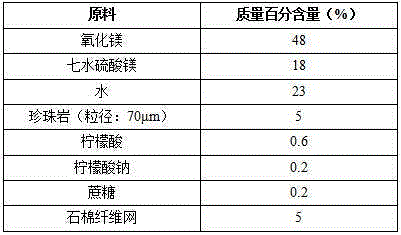

The present invention discloses a novel inorganic decoration base material plate and a preparation method thereof. The novel inorganic decoration base material plate is prepared from the following raw materials by weight: 45-50% of magnesium oxide, 15-20% of magnesium sulfate, 1-1.5% of a modifier, 5-10% of a filler, 1-5% of a reinforcing material, and the balance of water. According to the present invention, the magnesium sulfate is used to replace the magnesium chloride as the gelling material, such that the prepared base material plate almost does not contain chlorine ions; the mixture of citric acid, sodium citrate and sucrose is adopted as the modifier so as to adjust the condensation time and significantly increase the water resistance and the dampness resistance of the base material plate; and the prepared base material plate has characteristics of good waterproof performance, no moisture absorption efflorescence, high strength, cracking deformation resistance, good flexibility, good durability, significantly improved fireproof performance, no formaldehyde release during production and use processes, safety and environmental protection, and can be widely used as the base plates of fireproof plates, suspended ceiling plates, decorative plates, partition boards and other plates.

Owner:惠州美森板业有限公司

Method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution

The invention discloses a method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution. The method comprises the following steps: adding a purifying agent into the roasting-method vanadium solution, wherein the purifying agent is polyaluminium chloride, magnesium chloride or calcium chloride, or the purifying agent is polyaluminium chloride and magnesium chloride, or polyaluminium chloride and calcium chloride; uniformly stirring the roasting-method vanadium solution containing the purifying agent, standing for settling, then filtering, and adding ammonium salt into the filtrate to precipitate vanadium; and finally, calcining meta-ammonium and deaminizing to prepare vanadium pentoxide with the purity being higher than 99.5%. Polyaluminium chloride serving as the purifying agent can be used for polymerizing jellies with several molecules into large particles with several tens of thousands of molecules, even hundreds of thousands of molecules. The large-particle molecular polymer is easy to settle in the vanadium solution and can be separated from the solution. The method provided by the invention has the advantages that the consumption of polyaluminium chloride is low, the flocculation process is simple, the flocculation capacity is strong, the flocculation speed is high, pollution is hardly caused and the cost is low.

Owner:贵州义信矿业有限公司

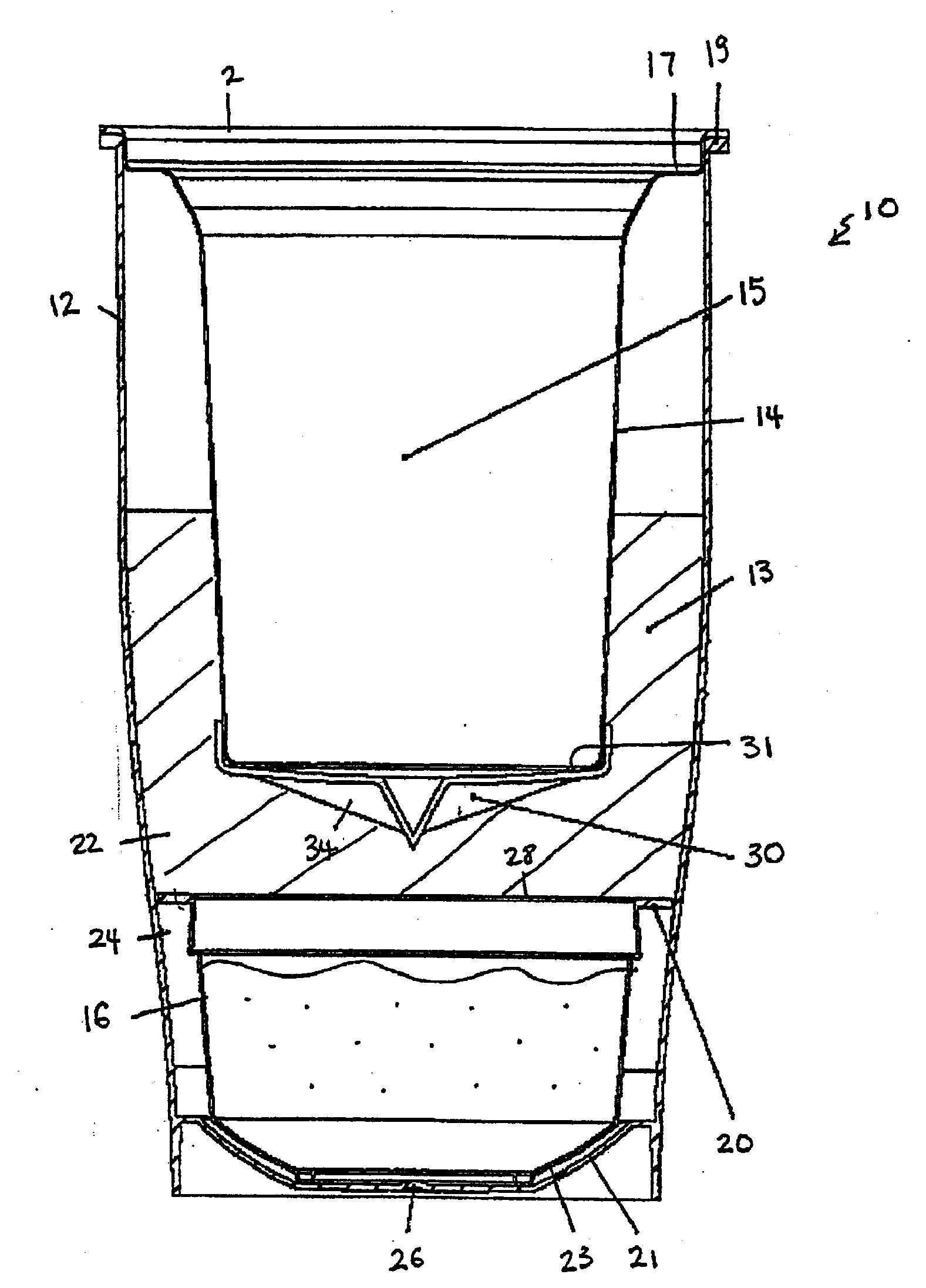

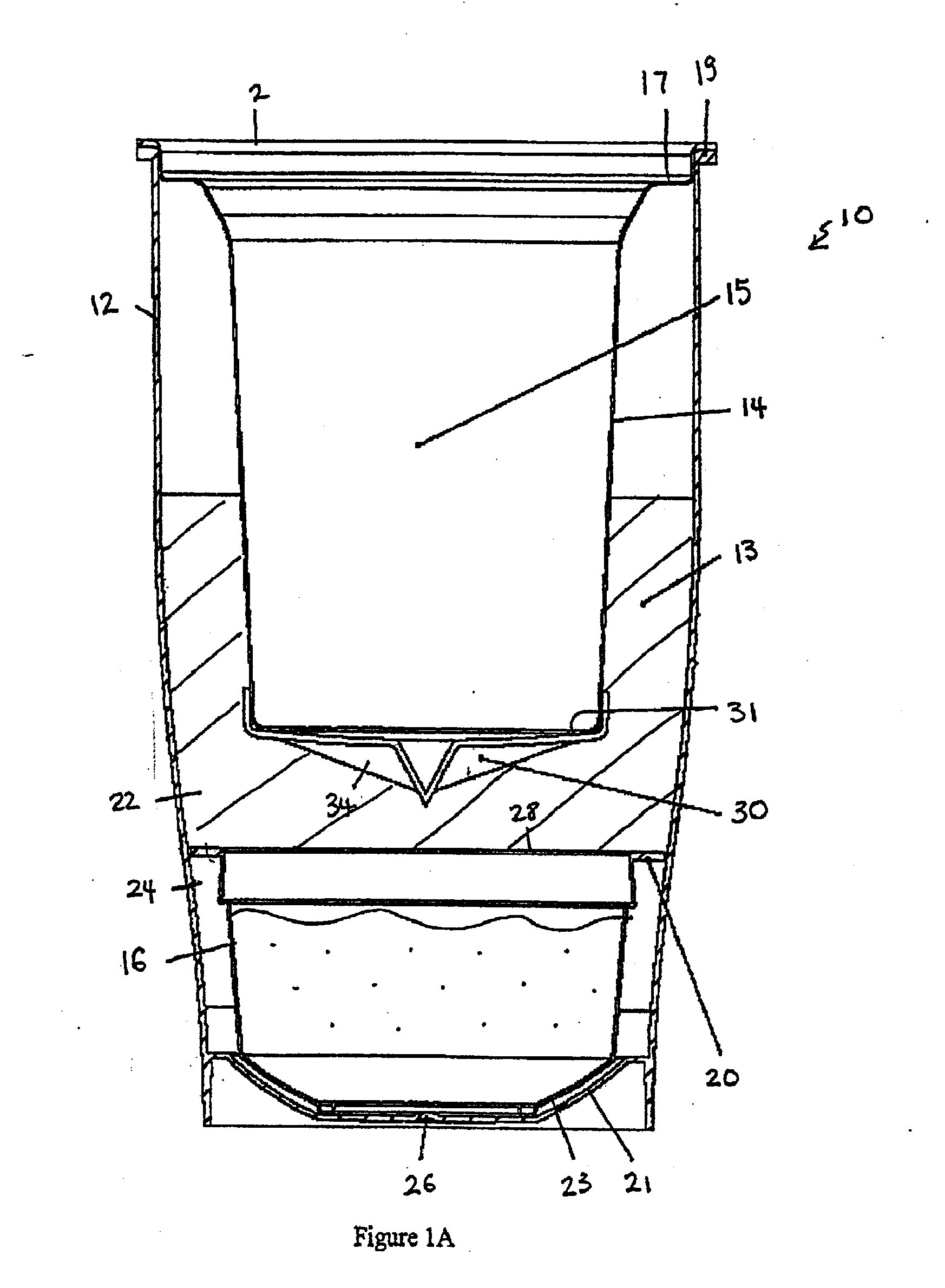

Self-heating apparatuses using solid chemical reactants

InactiveUS20090078711A1Exothermal chemical reaction heat productionDomestic cooling apparatusCompound (substance)Chloride

Owner:HEAT WAVE TECH

Chlorine magnesium cement compound foaming insulation board and preparation method thereof

The invention discloses a chlorine magnesium cement compound foaming insulation board and a preparation method thereof. The chlorine magnesium cement compound foaming insulation board is made from the following raw materials: magnesium oxide, magnesium chloride, water, coal ash, water-retaining agent, water repellent, modifying agent, fiber, polyphenyl granules and foaming agent. The preparation method comprises the following steps of pouring the magnesium oxide, the coal ash, the water-retaining agent, the water repellent and the fiber into a mixer to form a dry powder material; adding the magnesium chloride and the modifying agent into water to form a liquid material, and adding the dry powder material into the liquid material to form a mixture; pouring the polyphenyl granules into the mixture, mixing until mixture liquid wraps up the polyphenyl granules evenly so as to obtain a paste; adding the foaming agent to manufacture a foam paste; pouring the foam paste into a mould, wherein glass fiber grid cloth is paved at the bottom of the mould; after the mould is filled, paving a layer of glass fiber grid cloth on the upper layer of the foam paste, pressing and moulding the foam paste; and finally hardening, form stripping and maintaining. The chlorine magnesium cement compound foaming insulation board disclosed by the invention has the characteristics of lighter weight, heat insulation, durability, fire resistance and environment protection, and also has excellent mechanical properties.

Owner:JIANGSU NIGAO SCI & TECH +1

Foam cement insulation board containing industrial solid waste and preparation method thereof

he invention relates to a foam cement insulation board and a preparation method thereof, and provides a foam cement insulation board containing industrial solid wastes and a preparation method thereof. The foam cement insulation board is composed of a mixture A and a mixture B. The mixture A comprises 55-65% of cement, 10-20% of gypsum powder, 8 -15% of hydrogen peroxide,3-4% of a flocculant, 1-2% of a water reducing agent, 1-2% of a coagulant, 2-3% of a cement waterproof agent, 1-2% of lithium carbonate, 1-2% of fiber, and 1-2% of solid master batch. The mixture B comprises 35-47% of a base material, 35-39% of a magnesium chloride solution, 10-15% of magnesium oxide, 2-5% of a binding agent, 2-3% of industrial hydrogen peroxide, 1-2% of lanthanide rare earth and 5-7% of an additive. The Foam cement insulation board provided by the invention has advantages of fireproof, waterproof, light weight, compressive and flexural resistance and high strength, and effectively utilizes industrial solid waste, facilitates environmental protection, and truly realizes turning wastes into treasures.

Owner:ZHENJIANG ZHONGRUI ENERGY SAVING TECH

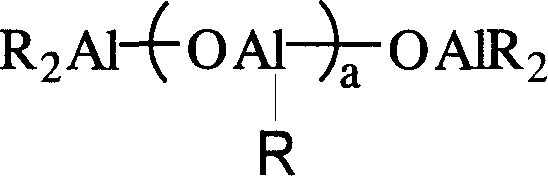

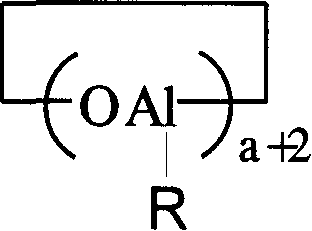

Catalyst for olefin polymerization or copolymerization at high temperature

The catalyst for olefin polymerization or copolymerization at high temperature consists of three components, including component A, component B and component C. The component A is solid prepared through dissolving magnesium chloride in organic epoxy compound or organic phosphorus compound to form solution, mixing the solution with titanium tetrahalide and separating assistant to separate soli, and treating with electron donor and titanium tetrahalide. The component B is mixture of aluminoxane and alkyl aluminum compound. The component C is organic silane. At polymerization temperature higher than 90 deg.c, the catalyst has high stereo selectivity and high activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

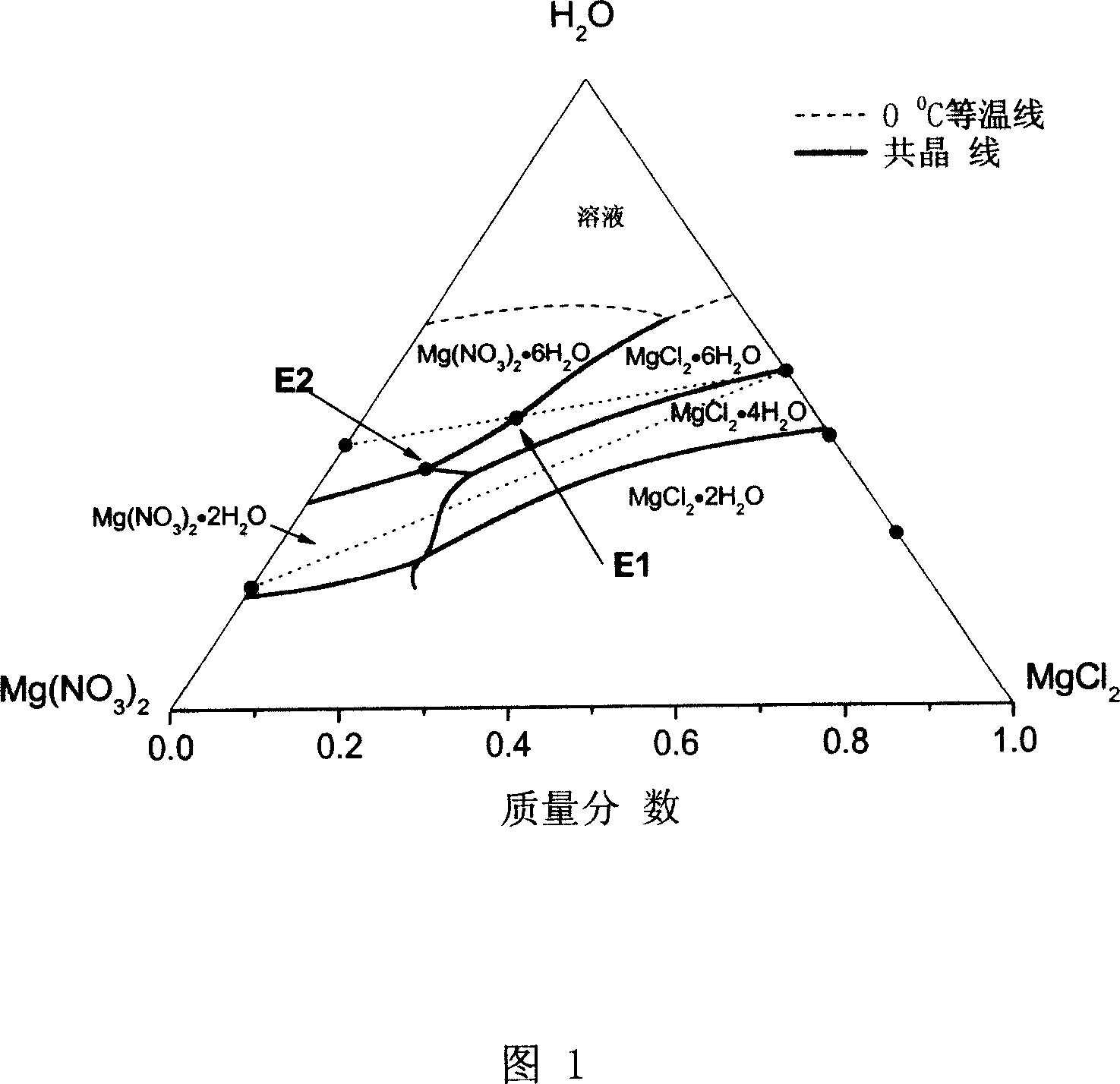

Heat-storage medium and its use

InactiveCN1940006ALow toxicityNo supercooling performanceHeat proofingHeat-exchange elementsChemistryMagnesium nitrate

Owner:HUNAN UNIV +1

Water-preserving materials and process for preparing same

The invention discloses a new thermal insulation material and its preparing method, that includes the materials in weight portion as follows: 20-70 portions of perlite, 2-15 portions of fiber, 15- 70 portions of magnesium oxide, 5-20 portions of magnesium sulfate, 2-8 portions of magnesium chloride, 0.5-2 portions of foaming agent, 2-15 portions of bonding agent, 10-80 portions of urea-formaldehyde resin. As confirmed by the experiment, the thermal insulation in the invention has the advantages of heat preservation, heat insulation, fireproof, moisture proof, sound insulation, non-dispersed in water, and can be used broad in the area of architecture, chemical engineering, storage, and high or low temperature tube.

Owner:无锡裕宸建筑节能科技有限公司

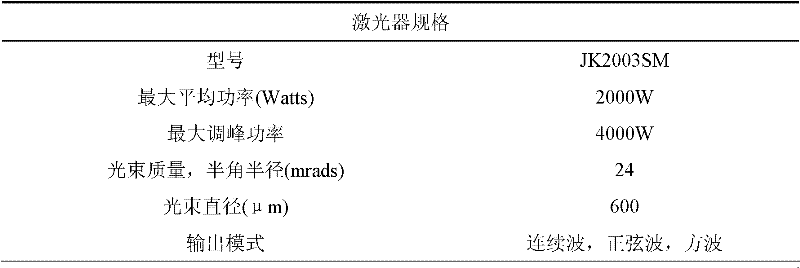

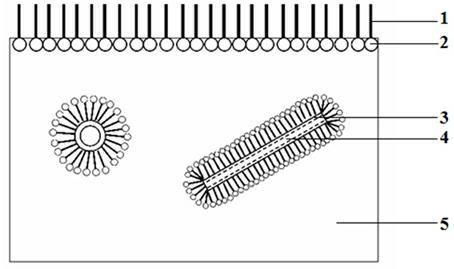

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

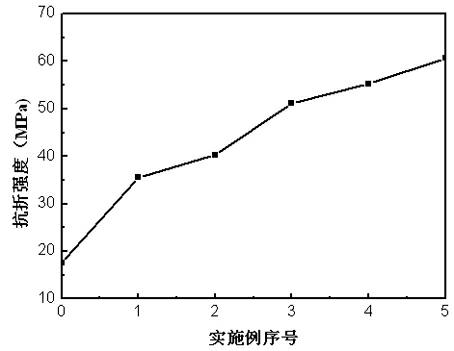

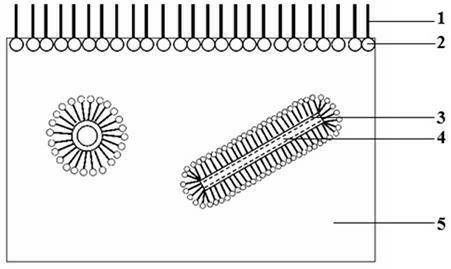

Modified magnesium oxychloride cement product and preparation method thereof

The invention discloses a modified magnesium oxychloride cement product and a preparation method thereof. The modified magnesium oxychloride cement product comprises the following components in part: 100 parts of light burned magnesium oxide powder (75-to-95-weight-percent MgO), 10 to 75 parts of magnesium chloride (absolute MgCl2), 100 to 150 parts of water, 2 to 50 parts of crystal whiskers, 0.02 to 0.5 part of crystal whisker surface modifier and 2 to 20 parts of anionic surfactant. The modified magnesium oxychloride cement product provided by the invention has high water resistance, excellent surface finishment and high breaking strength and is insusceptible to re-bittering. In addition, the problems of low mechanical strength and low surface finishment of products, serious wear of grinding tool and the like of reinforcement by glass fiber are solved effectively.

Owner:SOUTHEAST UNIV

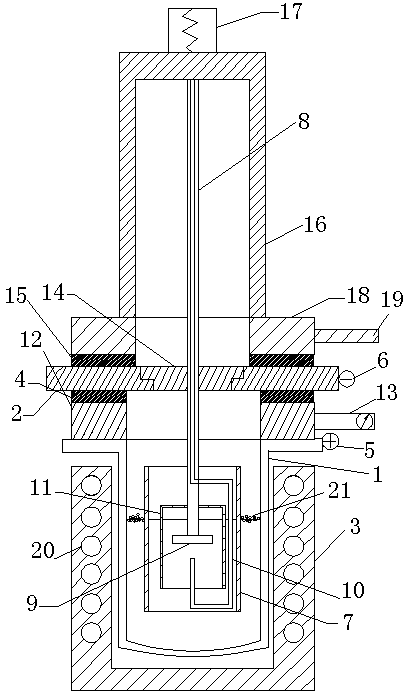

Method of Manufacturing Pure Titanium Hydride Powder and Alloyed Titanium Hydride Powders By Combined Hydrogen-Magnesium Reduction of Metal Halides

ActiveUS20130315773A1Reduce oxideFacilitated DiffusionMultiple metal hydridesTransition element hydridesTitanium chloridePowder mixture

The invention relates to energy-saving manufacturing of purified hydrogenated titanium powders or alloying titanium hydride powders, by metallo-thermic reduction of titanium chlorides, including their hydrogenation, vacuum separation of titanium hydride sponge block from magnesium and magnesium chlorides, followed by crushing, grinding, and sintering of said block without need for hydrometallurgical treatment of the produced powders.Methods disclosed contain embodiments of processes for manufacturing high-purity powders and their use in manufacturing near-net shape titanium and titanium-alloy articles by sintering titanium hydride and alloyed titanium hydride powders produced from combined hydrogen-magnesium reduction of titanium chlorides, halides and hydrides of other metals. Additional titanium hydride powder introduced with titanium tetrachloride beneficially affects the kinetics of magnesium-thermic reduction due to formation of the additionally-emitted atomic hydrogen, which helps to reduce presence of oxides and so cleans inter-particle interfaces of the product and enhances diffusion between all of components of the powder mixture.

Owner:ADVANCED MATERIALS PRODS

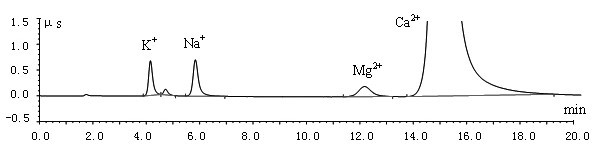

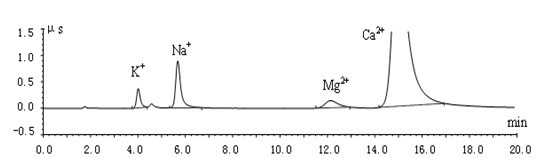

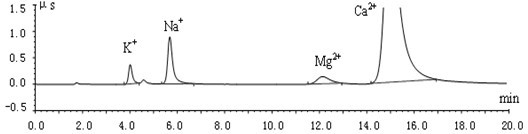

Method for determining content of potassium, sodium, calcium and magnesium in cigarette paper simultaneously

The invention discloses a method for determining content of potassium, sodium, calcium and magnesium in cigarette paper simultaneously, which includes the following steps: cutting 100+ / -0.1 mg of a cigarette paper sample, using 100mL of 0.02mol / L hydrochloric acid as an extracting agent, ultrasonic-extracting for 18-22min to obtain extract liquor, selecting 5.0mL of the extract liquor to a 25mL volumetric flask, bringing to the volume with 0.02mol / L hydrochloric acid to obtain diluent, and filtering the diluent through a 0.45 mu m filtering film to obtain sample liquid to be detected; selecting sodium chloride, potassium chloride, hexahydrate magnesium chloride and anhydrous calcium chloride, using pure water as solvent, preparing mixed standard solution through gradual diluting, and adding 0.02mol / L hydrochloric acid to prepare series standard working solution; detecting and analyzing the series working solution and the sample liquid to be detected respectively through an ion chromatographic instrument; and drawing a standard curve and calculating results. The method is fast and simple to operate, high in sensitivity, low in detection limit, good in recovery rate, and suitable for batch analyzing of important inorganic elements in the cigarette paper.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

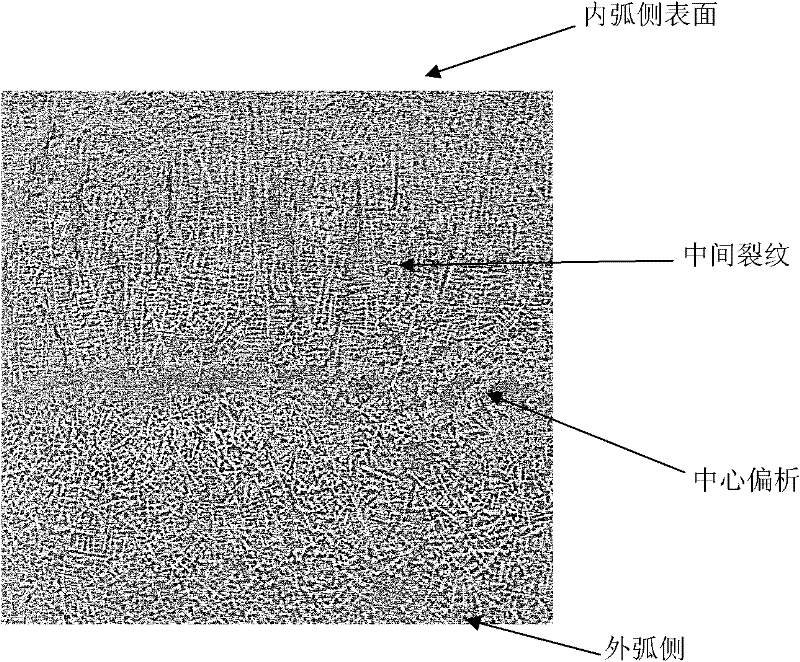

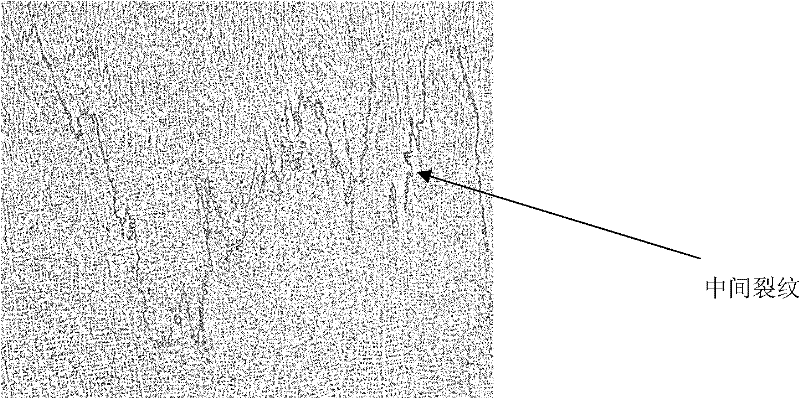

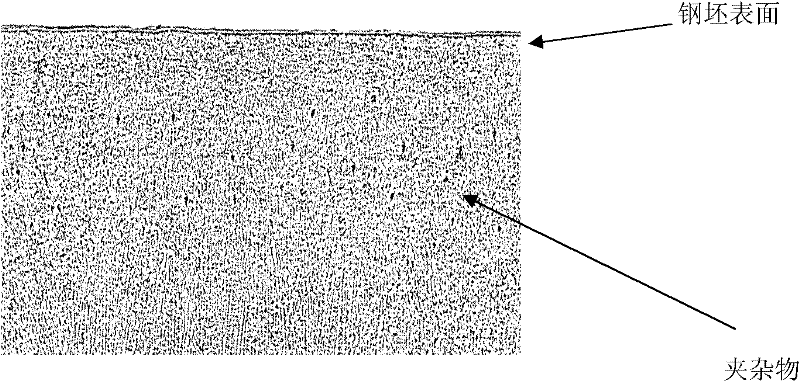

Dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of continuous cast blank and preparation method thereof

ActiveCN102174699ASolve the problem that the dendritic solidification structure of the continuous casting slab cannot be clearly displayedDisplay without reductionPreparing sample for investigationOptically investigating flaws/contaminationAlcoholCopper chloride

The invention discloses a dendritic crystal corrosion macroscopic examination reagent for solidification structures and defects of a continuous cast blank and a preparation method thereof. The reagent comprises the following components by mass percent: 0.28-1.09% of copper chloride, 0.17-0.27% of magnesium chloride, 0.56-1.60% of ferric chloride, 1.28-1.30% of hydrochloric acid with the mass concentration of 36-38%, 54.70-55.80% of absolute ethyl alcohol and the balance of water. The preparation method comprises the following steps: adding the water into a container, and then adding the copper chloride, magnesium chloride, ferric chloride and hydrochloric acid; and adding the absolute ethyl alcohol after all the added raw materials are fully dissolved, and evenly stirring. Compared with the prior art, the invention solves the problem that other corrosive reagents can not clearly display the dendritic crystal solidification structures of a continuous cast blank; and the reagent has the characteristic of original-size display without expansion or reduction for interior defects of a continuous cast blank when used for dendritic crystal corrosion macroscopic examination on the solidification structures and defects of the continuous cast blank.

Owner:苏州东大汉森冶金实业有限公司

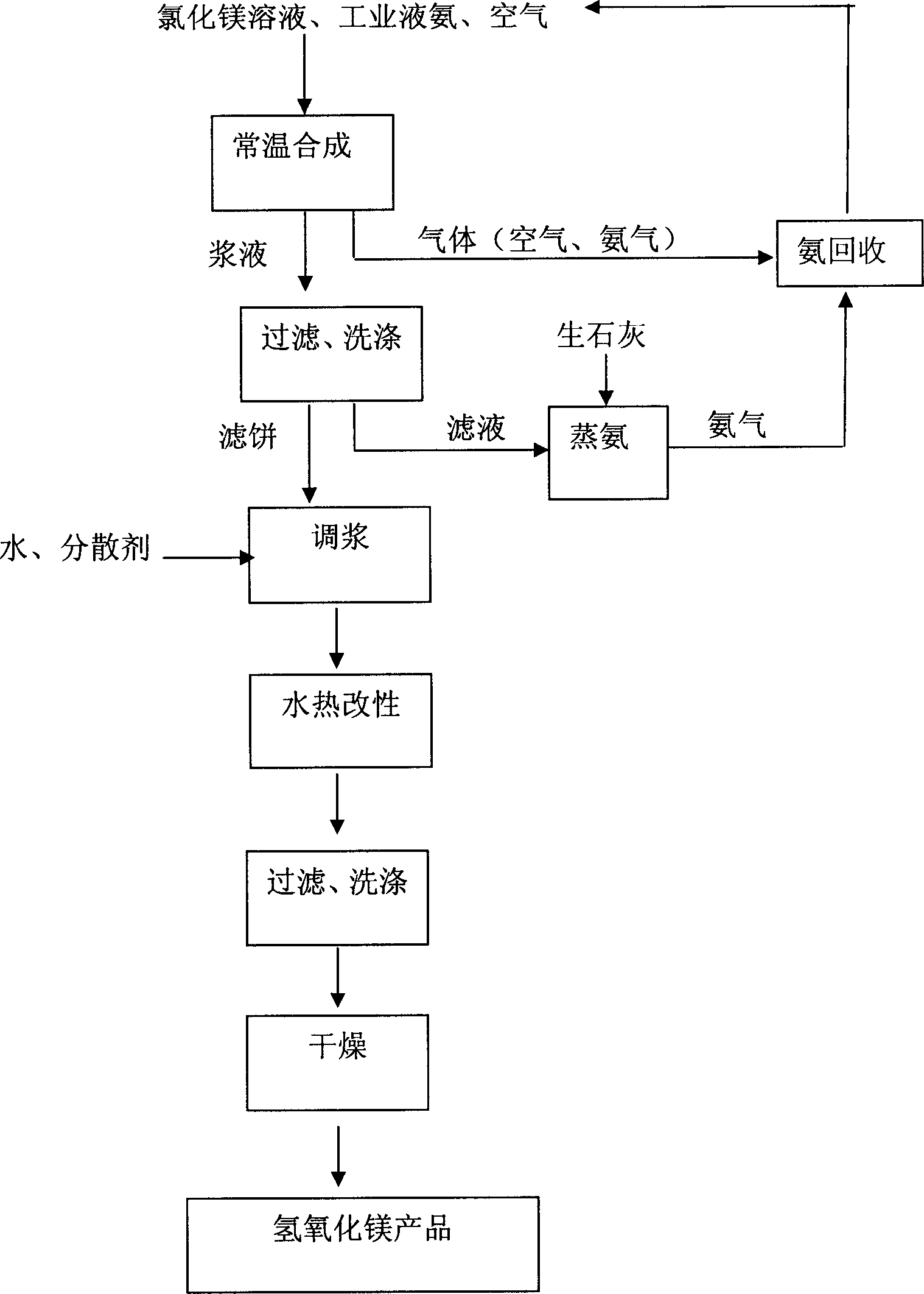

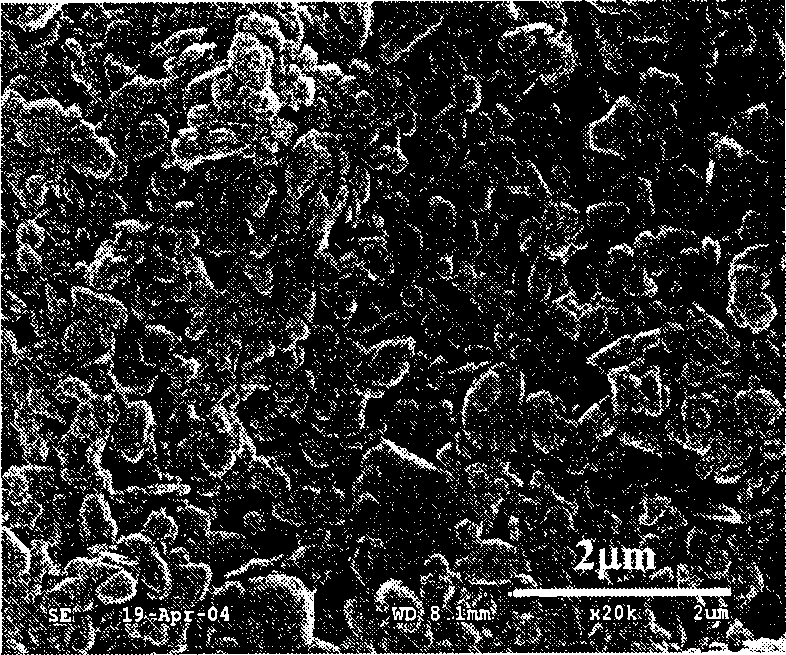

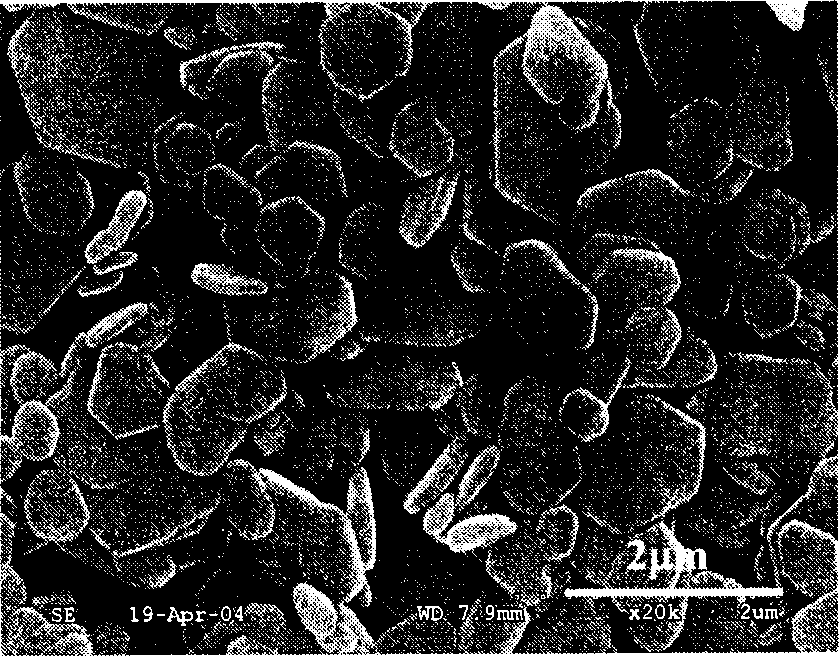

Liquid amonia pressurized precipitation and hydrothermal modification process for preparing magnesium hydroxide fire retardant

InactiveCN1740269AHigh purity ammoniaEasy to manufactureMagnesium hydroxideInorganic ChemicalGranularity

The present invention belongs to the field of inorganic chemical technology, and proposes one kind of liquid ammonia pressurized precipitation and hydrothermal modification process for preparing magnesium hydroxide fire retardant. Through the first precipitation reaction of magnesium chloride material with liquid ammonia as precipitant at 15-90 deg.c and sealed and pressurized conditions to synthesize magnesium hydroxide, and the subsequent modification of the normal temperature synthesized magnesium hydroxide at 100-250 deg.c in the presence of dispersant of 0.01-0.1 % for 1-6 hr, magnesium hydroxide fire retardant is prepared, which has primary granularity of 0.3-2.0 micron, average coagulation particle size of 1.0-4.0 micron, specific surface area of 5-30 sq m / g, and magnesium hydroxide content over 98 %. The magnesium hydroxide fire retardant may be used in rubber, plastic, building material, etc.

Owner:TSINGHUA UNIV

Method of manufacturing pure titanium hydride powder and alloyed titanium hydride powders by combined hydrogen-magnesium reduction of metal halides

ActiveUS9067264B2Cost-effectiveAvoid pollutionMultiple metal hydridesTransition element hydridesTitanium chloridePowder mixture

The invention relates to energy-saving manufacturing of purified hydrogenated titanium powders or alloying titanium hydride powders, by metallo-thermic reduction of titanium chlorides, including their hydrogenation, vacuum separation of titanium hydride sponge block from magnesium and magnesium chlorides, followed by crushing, grinding, and sintering of said block without need for any hydro-metallurgical treatment of the produced powders. Methods disclosed contain embodiments of processes for manufacturing high purity high-purity powders and their use in manufacturing near-net shape titanium and titanium-alloy articles by sintering titanium hydride and alloyed titanium hydride powders produced from combined hydrogen-magnesium reduction of titanium chlorides, halides and hydrides of other metals. Additional titanium hydride powder introduced with titanium tetrachloride beneficially affects the kinetics of magnesium-thermic reduction due to formation of additionally-emitted atomic hydrogen, which helps to reduce presence of oxides, and so cleans inter-particle interfaces of the product and enhances diffusion between all components of the powder mixture.

Owner:ADVANCED MATERIALS PRODS

Method for catalyzing dynamic kinetic resolution of arylamine via racemization catalyst

InactiveCN102533922AGood stability for repeated useMild reaction conditionsOrganic chemistry methodsChemical recyclingChlorobenzenePtru catalyst

The invention discloses a method for catalyzing dynamic kinetic resolution of arylamine via a racemization catalyst, comprising the following steps of: 1) adding p-chlorophenol, n-pentanoic acid, dicyclohexylcarbodiimide and 4-dimethylamino-pyridine, and carrying out mixing, filtration, drying, concentration and column chromatography to obtain a pentanoic acid p-chlorophenyl ester acyl donor; 2) carrying out coprecipitation on magnesium chloride solution and aluminum chloride solution and carrying out water-heat treatment to obtain chloridion intercalated hydrotalcite, adding the chloridion intercalated hydrotalcite in lauryl sodium sulfate aqueous solution, and carrying out backflow, cooling, centrifugation, water washing, acetone washing and drying to obtain a carrier; 3) adding palladium salt and the carrier, and carrying out heating, ascorbic acid addition, centrifugation, water washing, acetone washing and freeze-drying to obtain the racemization catalyst; and 4) adding arylamine, the acyl donor, lipase and the racemization catalyst in toluene and placing in a stainless steel reactor to add hydrogen so as to obtain amide. The method provided by the invention is used for catalyzing the dynamic kinetic resolution of arylamine, has rapid reaction rate, low temperature, high conversion rate and high product optical purity, and has great application value.

Owner:ZHEJIANG UNIV

Micro-pore magnesite foam concrete

The invention belongs to the technical field of building energy conservation and provides a solid magnesite foam concrete wallboard and a production technology of a building block, wherein the solid magnesite foam concrete wallboard is light in weight, high in strength and excellent in heat-insulating and sound-insulating effects. The solid magnesite foam concrete wallboard consists of 15-60% of magnesium oxide, 5-15% of magnesium chloride, 15-25% of water, 15-45% of inorganic padding, 0.5-1.5% of gas-generating agent, 0.01-0.1% of foaming agent, 0-1% of short fiber and a reinforcing material. The production technology provided by the invention has the advantages that: 1) the weight of the magnesite foam concrete can be controlled according to applications; 2) the shape of the magnesite foam concrete can be changed according to the applications; 3) more than 95% of micro-pore magnesite foam concrete has a bubble diameter between 0.1mm and 1mm, the bubble sealing property is excellent, bubbles are not communicated with one another, halogen reduction is avoided, the water resistance is excellent, the weight is light, the strength is high, the shock resistance is strong, and the heat-insulating and sound-insulating effects are excellent; 4) the padding can be selected according to a local condition by taking wastes and residues of a local factory, deposited materials in a river and a lake and the like as raw materials; and 5) production is convenient, energy is saved, environment is protected, and a wall building-block, a door core plate, a fireproof plate, a partition plate, a heat-insulating plate and a sound-insulating and sound-absorbing material can be manufactured.

Owner:山发寿 +2

Cast-in-situ straw/ash magnesium oxychloride cement wall and construction method

InactiveCN101818531AAvoid ignitionImprove flame retardant performanceSolid waste managementWallsSocial benefitsAdhesion process

The invention discloses a cast-in-situ straw / ash magnesium oxychloride cement wall and a construction method. The straw / ash magnesium oxychloride cement wall is obtained by processing straw, ash, light burned magnesia, magnesium chloride and the like and performing in-situ casting under the action of a modifier. The straw / ash magnesium oxychloride cement wall comprises the following raw materials in percentage by mass: 45 and 60 percent of magnesium oxide, 25 to 40 percent of solution of magnesium chloride, 2 to 20 percent of straw, 5 to 15 percent of ash and 0.5 to 2 percent of modifier. When the wall is cast in situ, the magnesium oxide, the solution of magnesium chloride, the straw, the ash and the modifier are mixed and stirred, and water is added into the mixture according to the water absorption of the straw to perform one-time forming through in-situ casting after the mixture is stirred uniformly. The wall is characterized in that the doping volume of the straw can be changed according to design requirements, and the straw can be used as inner and outer partition plates; the binding power is strong, so the adhesion process of the cast-in-situ wall materials and the conventional wall materials is avoided; due to the addition of the straw, the volume weight of products is reduced and the heat-insulating and heat-shielding performance of the products is improved; and a large amount of waste material ash, straw and the like is utilized to relieve the environmental burden effectively and reduce the cost, so the wall has great economic and social benefits.

Owner:SOUTHEAST UNIV

Phase transformation heat accumulating material

The invention discloses a phase change thermal storage material which is composed of substance according to mass ratio of 85-98 parts of trihydrate sodium acetate, 1-10 parts of carboxymethyl cellulose, 0.5-3.5 parts of hexahydrate magnesium chloride, 0.1-2.5 parts of sodium carboxymethyl cellulose, and 0-10ppm parts of nanophase powdered carbon. Raw materials of the phase change thermal storage material have rich supply and low cost. The phase change thermal storage is large (larger than 280MJ / m3), the thermal coefficient is large (larger than 0.8W / m,k),and the phase change temperature is 54-60 DEG C, thereby favoring recycle of condenser heat of air conditioners and other waste heat recovery field. The condenser depression is relatively small (3 DEG C-5 DEG C), which greatly favors releasing of required heat.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

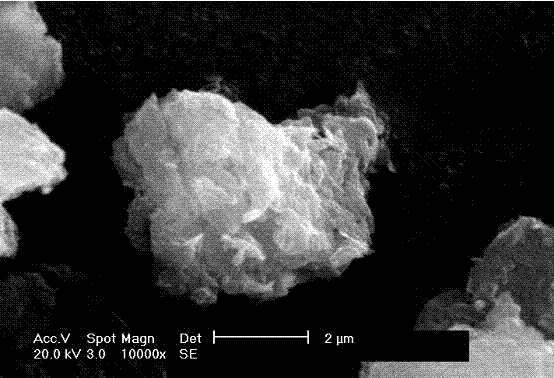

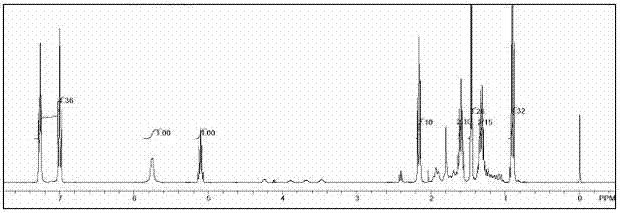

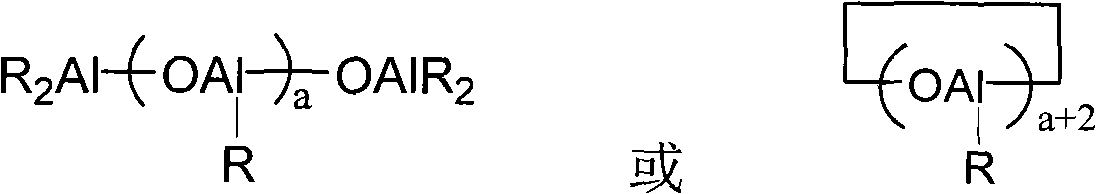

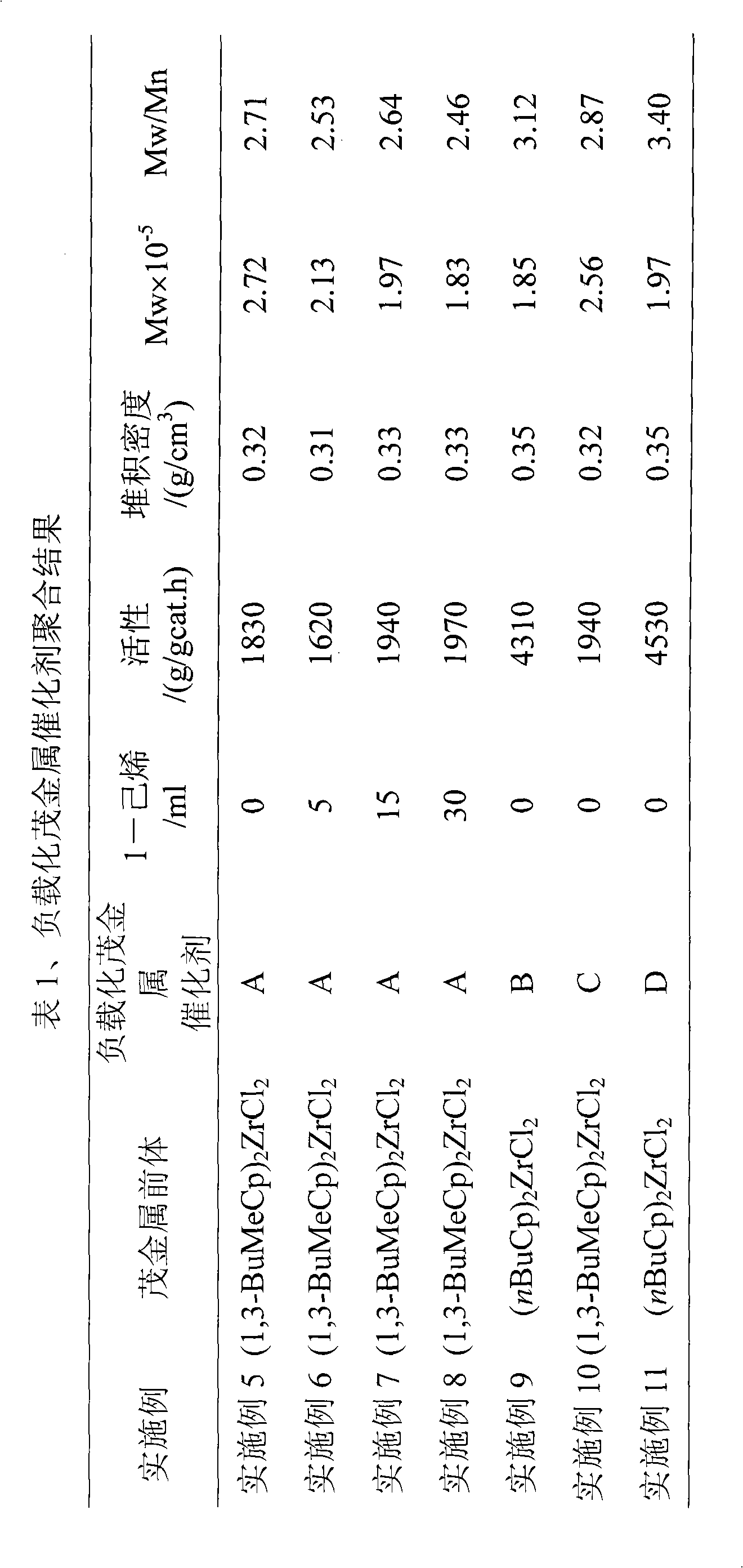

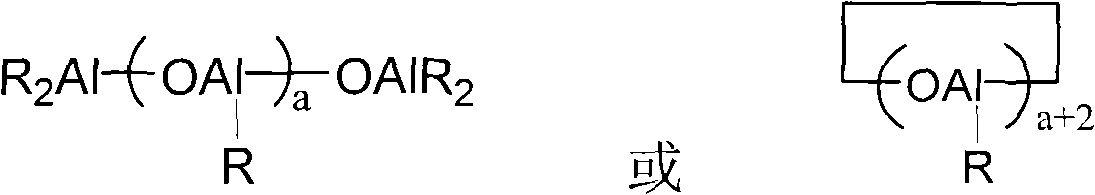

Method for preparing magnesium chloride loaded metallocene catalyst

The invention discloses a method for preparing a loaded metallocene catalyst by taking magnesium chloride as a carrier, which comprises the following steps of: (1), preparation of a magnesium chloride carrier; (2), preparation of a magnesium chloride carrier of alkyl aluminoxane; and (3), preparation of a magnesium chloride loaded metallocene catalyst, wherein the magnesium chloride carrier is prepared by adopting a spraying method in which etrahydrofuran is taken as a solvent. In the method, preparation of the magnesium chloride carrier is simple; and the obtained loaded catalyst granule has good shape and adjustable size. The obtained loaded metallocene catalyst catalyzes copolymerization of ethylene and high-grade alpha-olefin with high copolymerization activity, and has the excellent granule shape of obtained rein powder materials, and high stacking density; and the loaded metallocene catalyst can be suitable for a slurry packing method and a gas phase polymerization process.

Owner:CHINA PETROLEUM & CHEM CORP +1

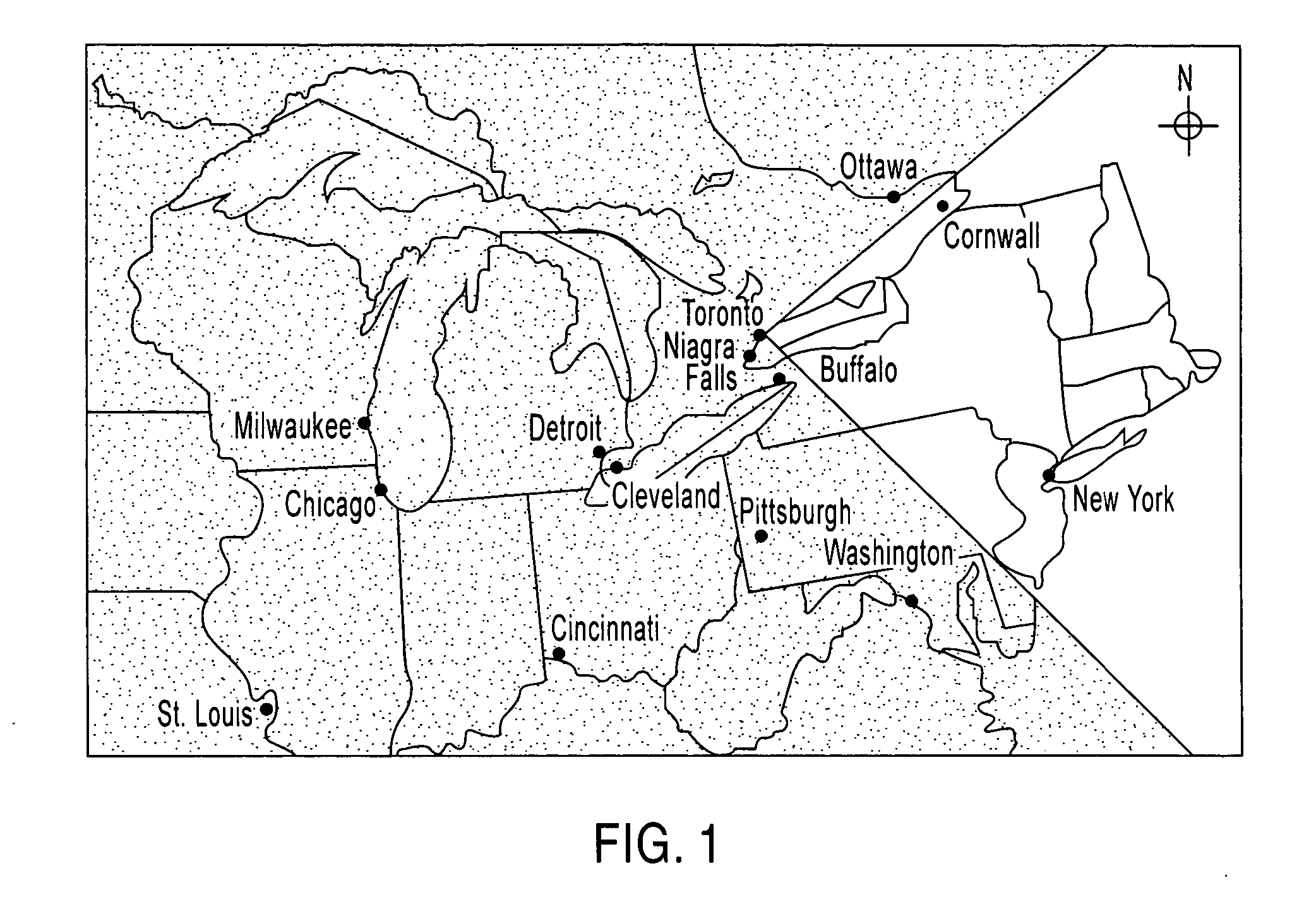

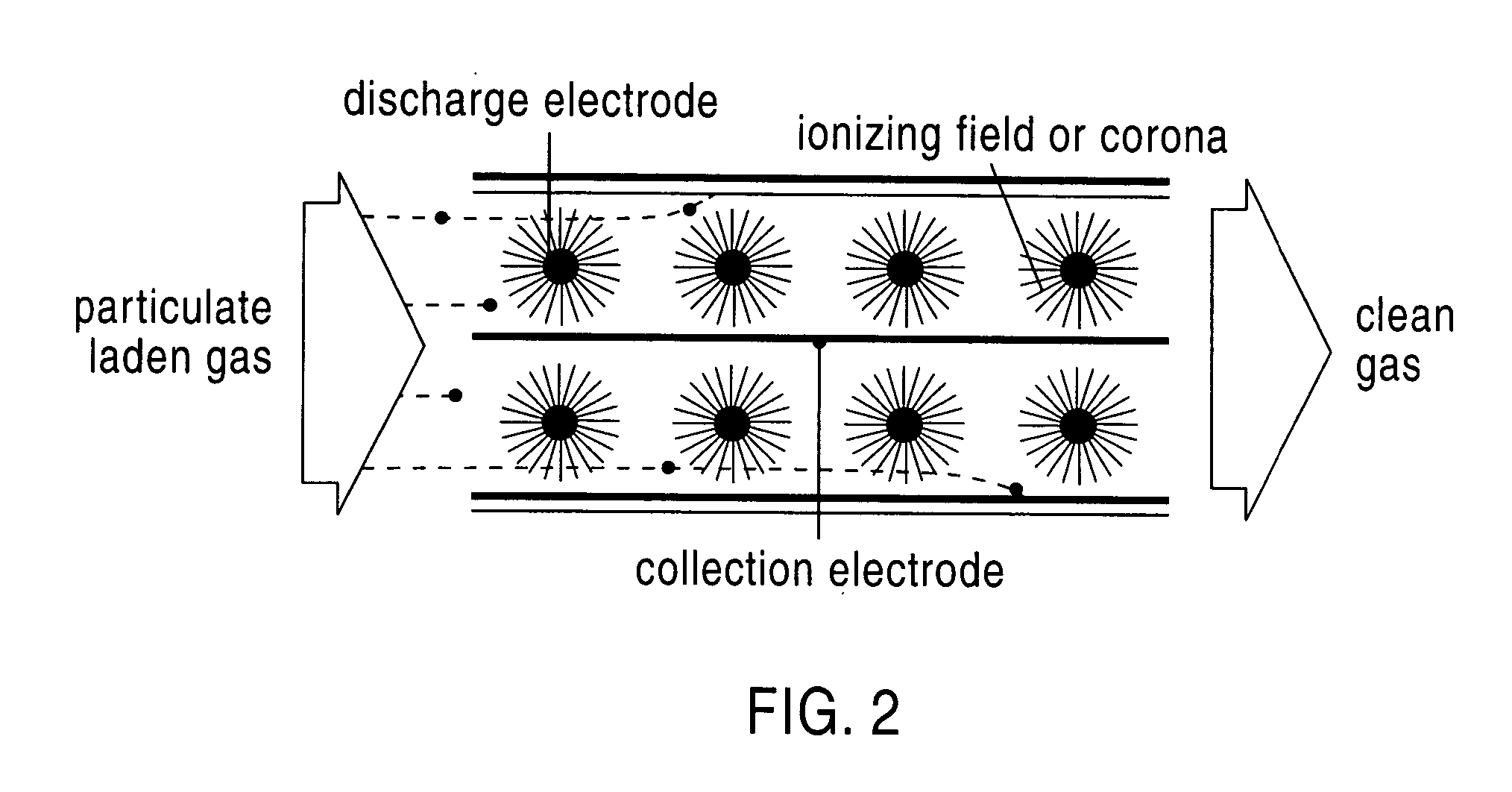

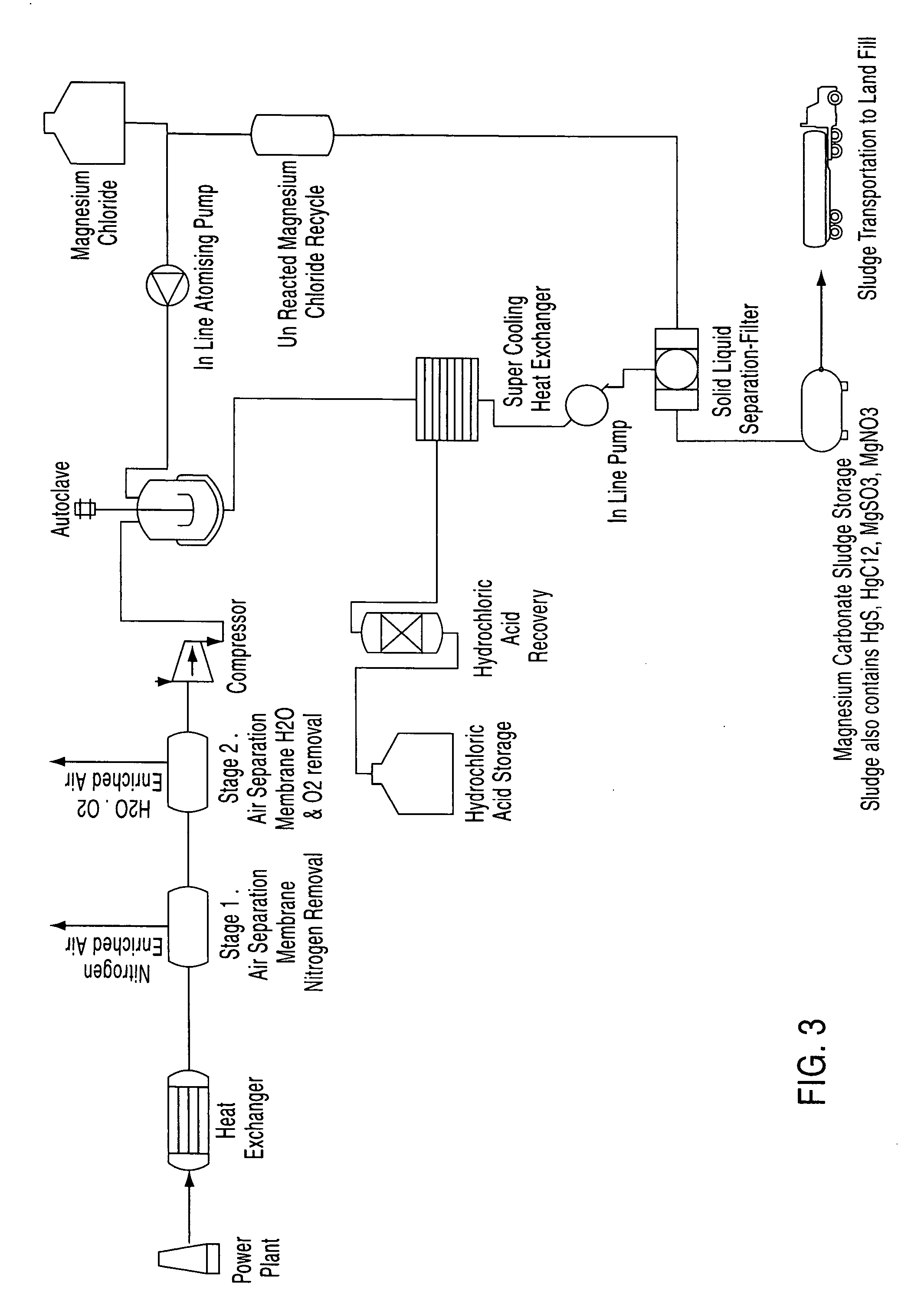

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

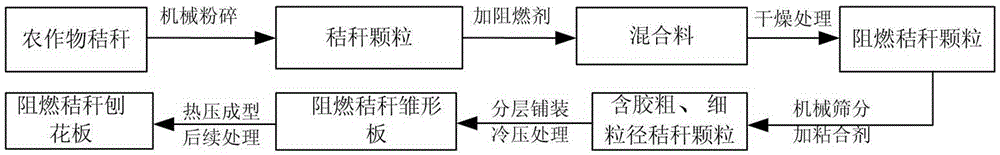

Flame-retardant straw shaving board and manufacturing method thereof

ActiveCN105345911AStable structureWaterproofDomestic articlesFlat articlesPolyvinyl alcoholPhosphoric acid

The invention provides a flame-retardant straw shaving board. The flame-retardant straw shaving board comprises, by weight, 7-9 parts of straw particles, 0.5-1.5 parts of flame retardants and 0.3-1.0 part of binders, wherein the flame retardants comprise magnesium oxide, magnesium chloride, trisodium phosphate, polyvinyl alcohol and ammonium polyphosphate. The flame-retardant straw shaving board is good in flame retardance, water resistance and insect resistance and low in formaldehyde content and has good physical and mechanical performances; a wooden shaving board can be replaced by the flame-retardant straw shaving board which can be applied to the field of decoration of various buildings and manufacturing of furniture. The invention further provides a manufacturing method of the flame-retardant straw shaving board. The hot press molding technology is mainly adopted for modifying and shaping the raw materials, so that not only is the wood resource saved, but also the whole production process is environmentally friendly and free of pollution.

Owner:信阳美丽真好秸秆新材科技有限公司

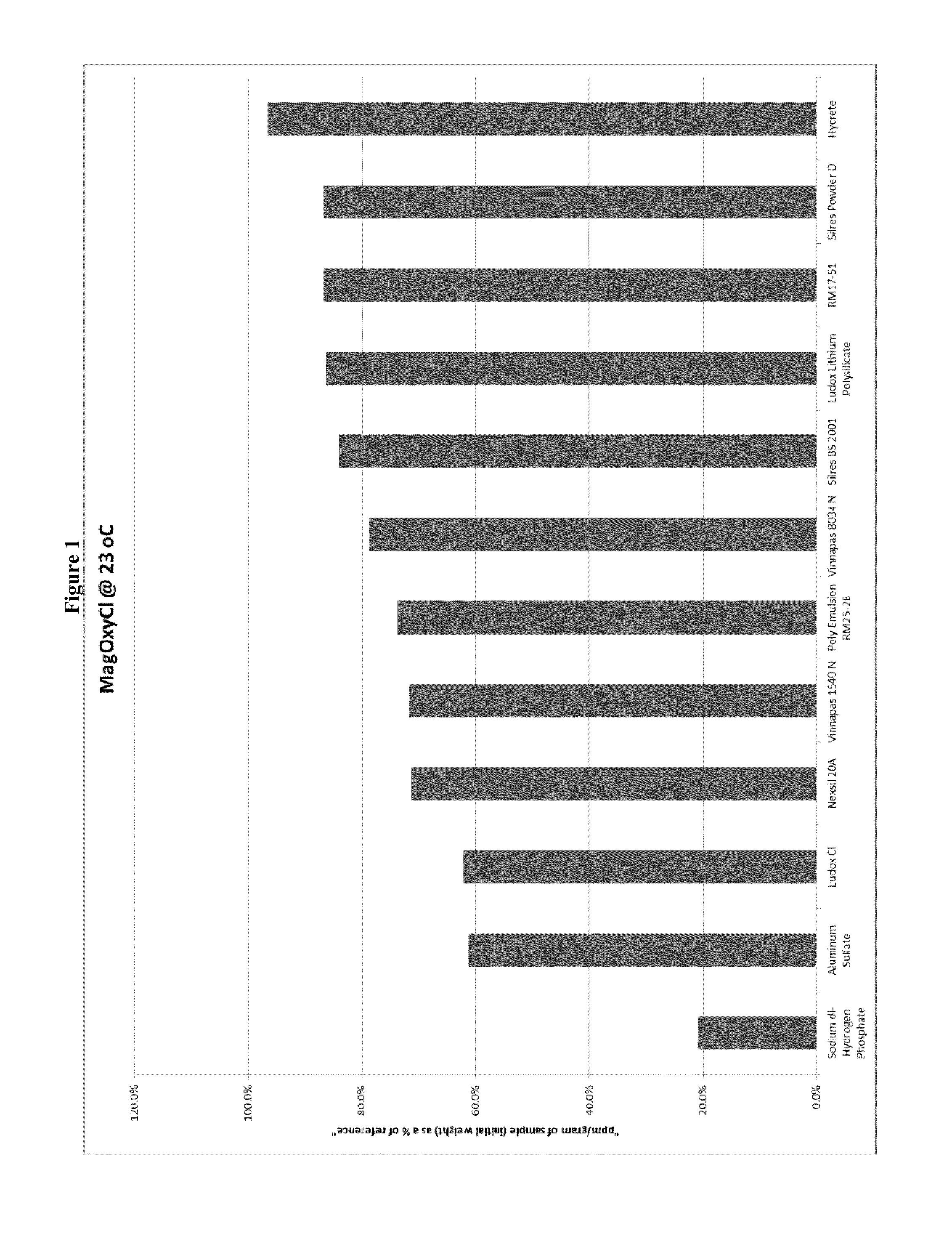

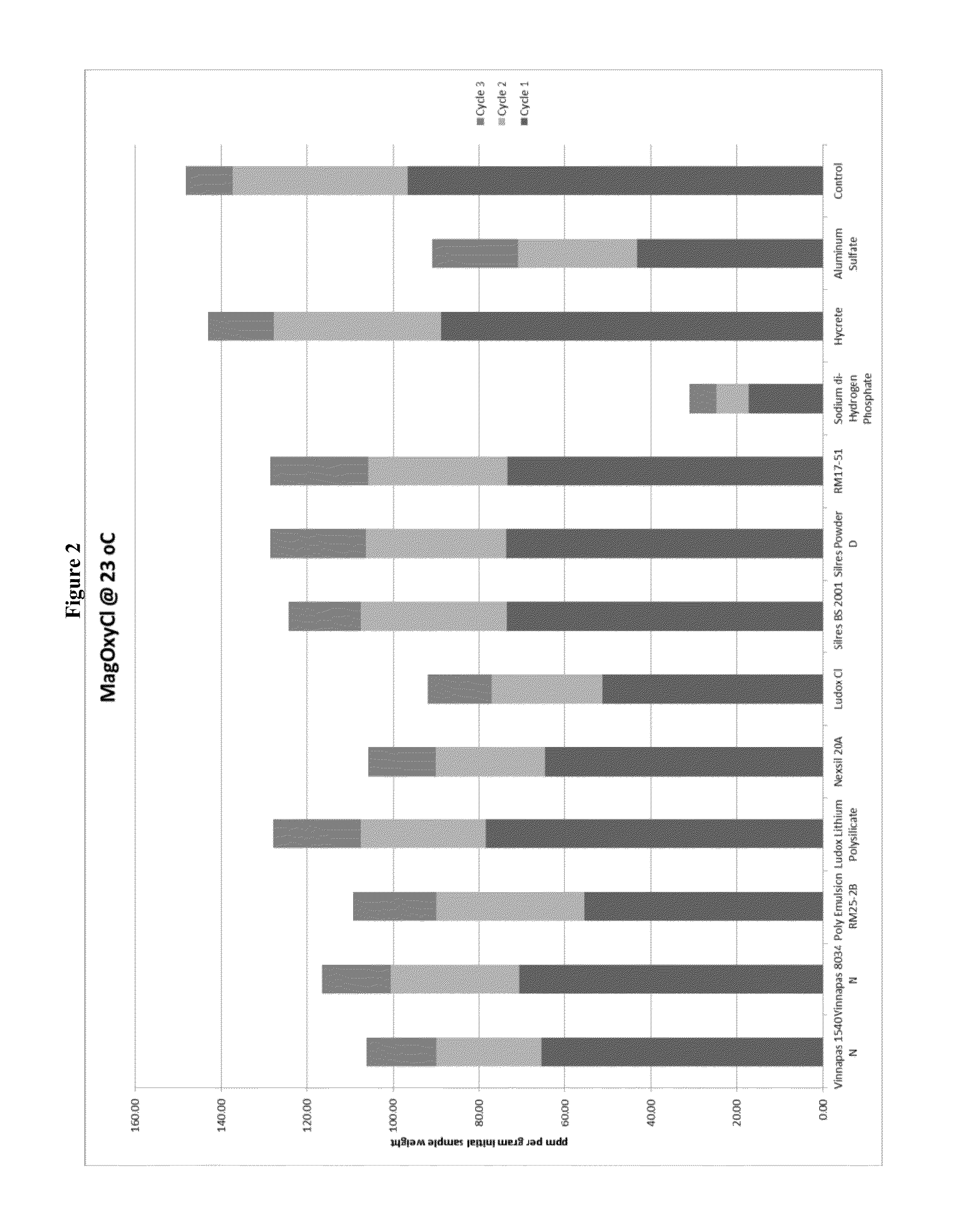

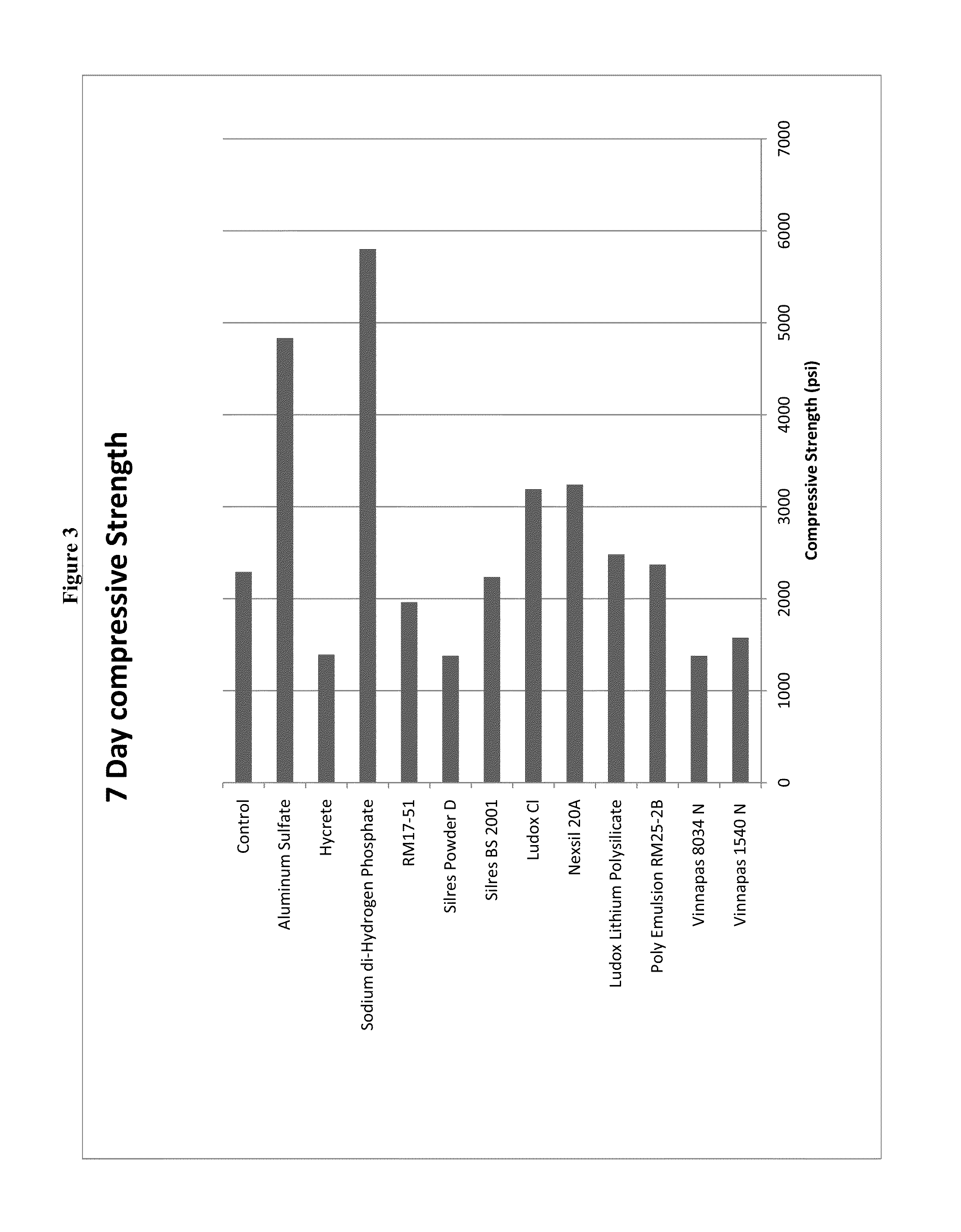

Method and compositions for improving performance properties of magnesium oxychloride cements

ActiveUS20130263759A1Improve water resistanceEarly water resistanceSolid waste managementMonomagnesium phosphatePhosphate

Despite the excellent properties associated with Magnesium OxyChloride (Sorel) based cements and Magnesium OxySulfate based cements, water and corrosion resistance has been limiting factors for achieving greater commercial applications. Such issues can be addressed by incorporating various alkali metal phosphates, such as Magnesium mono- or dihydrogen phosphate (MgHPO4 or MgH2PO4) with alkali metal fatty acids; such as Magnesium Stearate; and metal or alkali metal sulfates such as Aluminum Sulfate or Magnesium Sulfate. Water resistance is further enhanced by either pre-carbonating the mix water or the liquid magnesium chloride phase of the cements, or by adding a carbonate into the powder phase. Accelerated cure of this system has also been obtained by using various inorganic metal oxides. Additionally, improved corrosion resistance is achieved through the use of certain phosphates, zeolites, nitrites and other novel additives.

Owner:PREMIER MAGNESIA

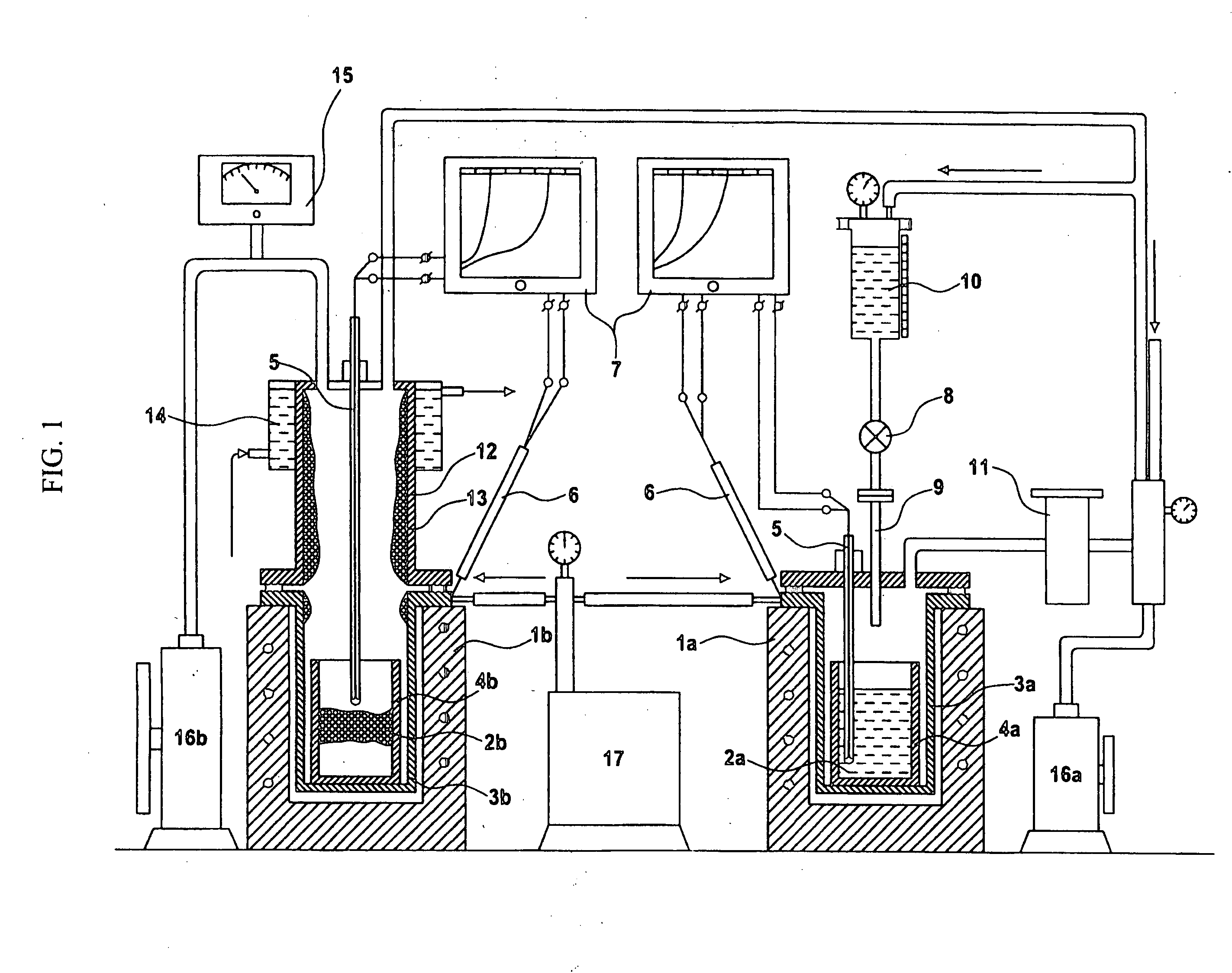

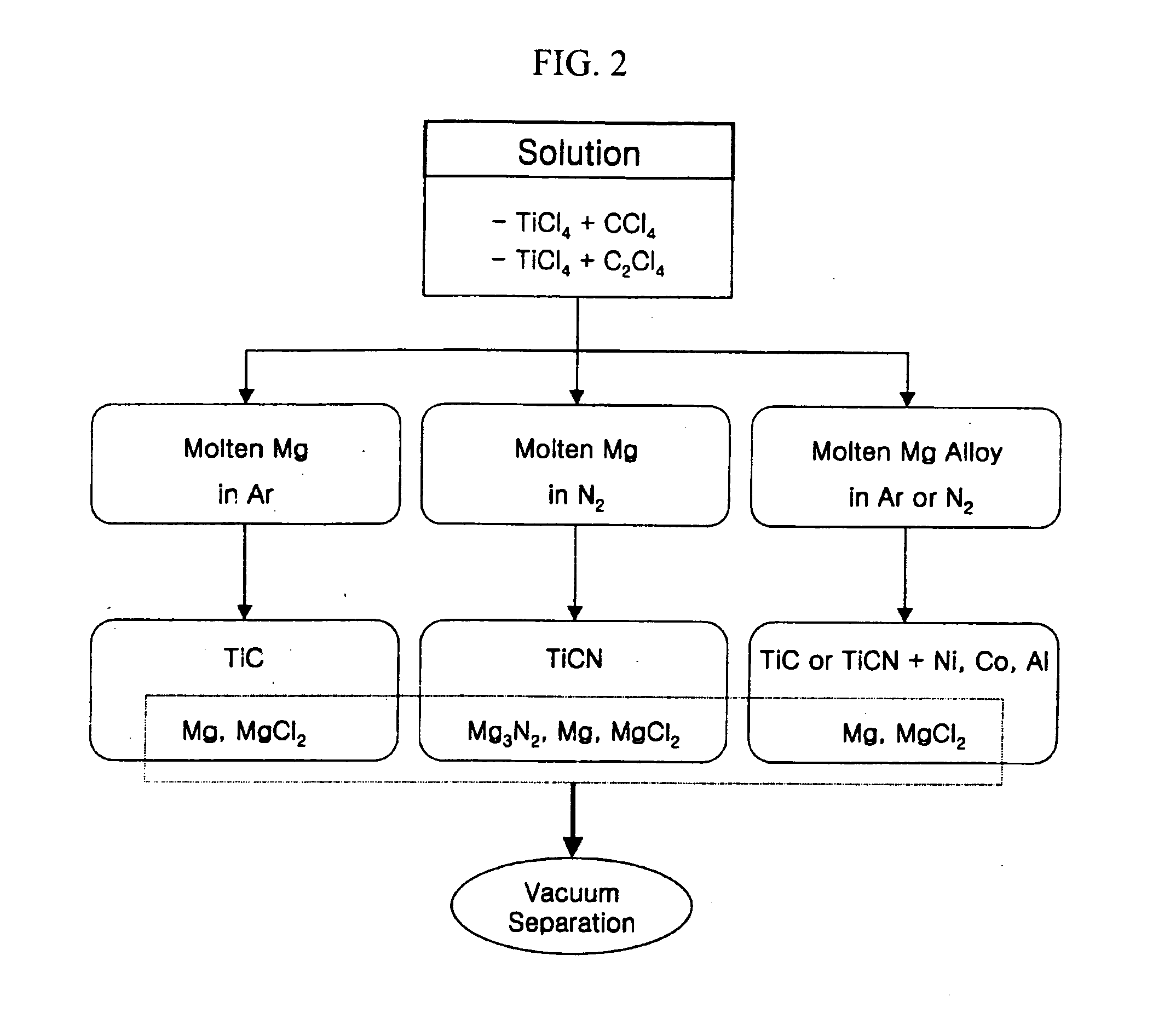

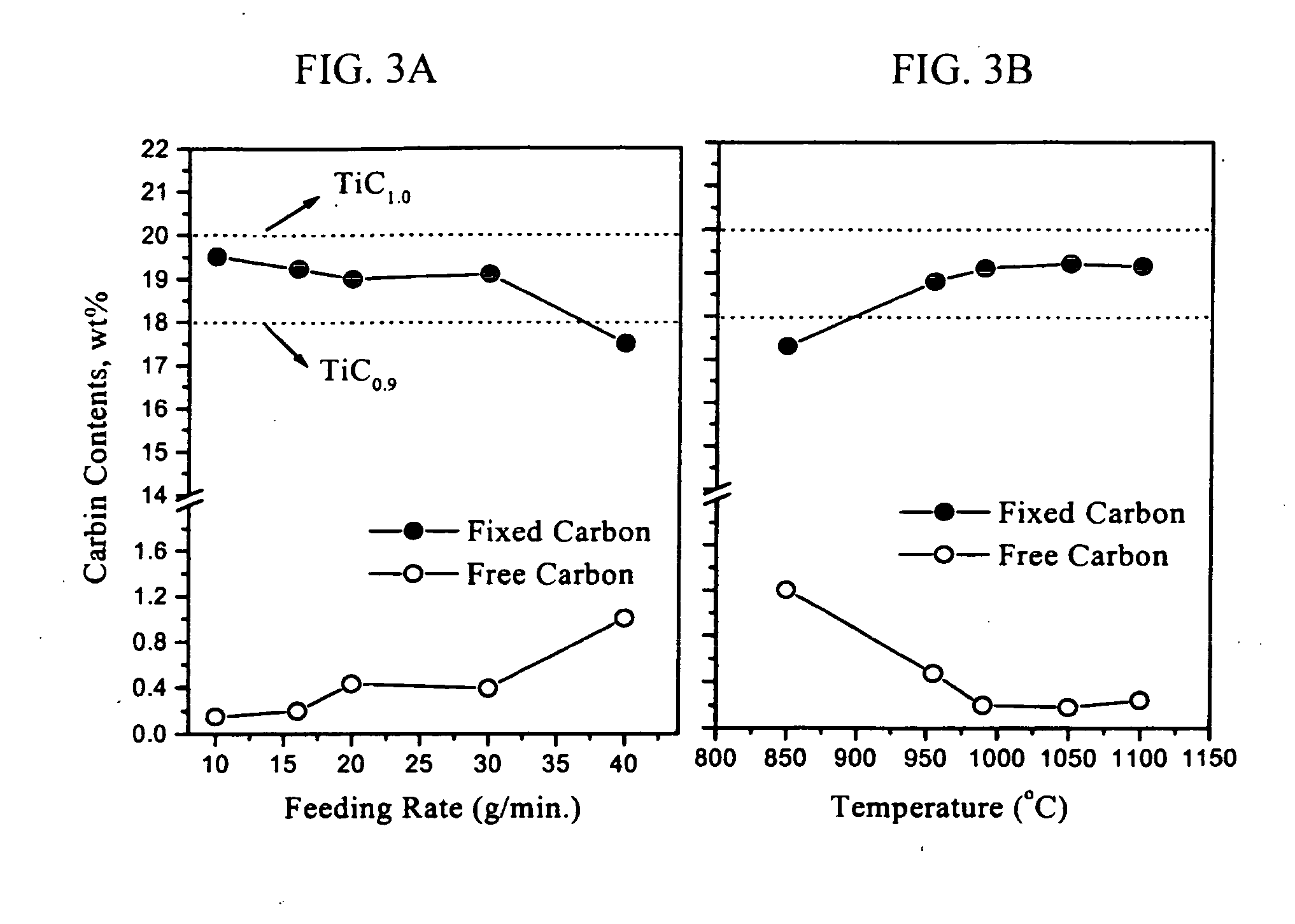

Method for manufacturing nanophase TiC-based composite powders by metallothermic reduction

Disclosed herein is a method for economically manufacturing high quality TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders by means of metallothermic reduction. The method comprises the steps of preparing a starting solution of titanium tetrachloride (TiCl4) in a carbon chloride, feeding the starting solution into a closed container containing molten magnesium (Mg) under inert atmosphere, vacuum-separating unreacted liquid-phase Mg and magnesium chloride (MgCl2) remaining after reduction of magnesium from the closed container, and collecting a TiC compound from the closed container. TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders having a particle size of a few tens nm can be manufactured in a simpler manner using economically advantageous starting materials such as titanium tetrachloride and carbon chlorides.

Owner:KOREA INST OF MASCH & MATERIALS

Heat-insulation, fire-resistance and heat-preservation material for wall body

The invention discloses a heat-insulation, fire-resistance and heat-preservation material for a wall body. The heat-insulation, fire-resistance and heat-preservation material is characterized by comprising the following raw materials in parts by weight: 25-40 parts of expanded perlite, 15-20 parts of light ceramsite, 5-10 parts of phosphate, 5-10 parts of magnesium chloride, 5-10 parts of magnesium hydroxide, 5-20 parts of fiber, 2-8 parts of silicate, 1-3 parts of a high-temperature ceramic adhesive, 1-5 parts of alum and 10-25 parts of coal ash. The heat-insulation, fire-resistance and heat-preservation material for the wall body, provided by the invention, has the advantages of water resistance, fire resistance, corrosion resistance, high strength, long service life and the like.

Owner:江西省朝晖城市建设工程有限公司

Method and device for producing titanium by fused salt electrolysis process

The invention provides a method and device for producing titanium by a fused salt electrolysis process, relating to a device adopting titanium tetrachloride as a raw material to directly produce high purity titanium by the fused salt electrolysis process. The method is characterized by adopting titanium tetrachloride as the raw material, introducing titanium tetrachloride into mixed fused salt of sodium chloride and potassium chloride, adopting magnesium as an anode and titanium as a cathode to electrolyze titanium tetrachloride to generate magnesium chloride and titanium, directly depositing the generated titanium on the titanium cathode and separating the generated titanium to obtain a titanium product. The method and device for producing titanium by a fused salt electrolysis process have the beneficial effects that the method and the device can be used for directly producing the high purity titanium from titanium tetrachloride without using titanium sponge as a raw material, can save the cost and can be used for producing titanium with higher purity; the produced high purity titanium is shaped like a cylinder or a square column; and a titanium ingot in the shape can be directly used as a raw material of an electron beam smelting furnace or a consumable electrode vacuum furnace in the next process, thus saving the processes of briquetting and welding and further saving the cost.

Owner:SIX NINE TECH

Fireproof insulation board and preparation process thereof

The invention relates to the field of building materials, and particularly discloses a fireproof insulation board and a preparation process thereof. The fireproof insulation board of the invention comprises the following components by weight: 10-15% of organic fireproof insulation particles, 10-15% of melamine resin, 30-40% of magnesium oxide, 20-30% of magnesium chloride, 0.01-0.1% of air-entraining agents, 9-25% of inorganic filling materials; the organic fireproof insulation particles are organic foaming insulation particles with particle surfaces coated by fire retardants. The preparation process of the fireproof insulation board comprises the following five steps of fire retardant slurry preparation, fire retardant coating, drying, mixture preparation, and fireproof insulation board molding. The fireproof insulation board of the invention has A-grade fireproof performance, has a thermal conductivity coefficient of 0.05-0.06 w / m.k, is a lightweight fireproof insulation board material, and is widely applicable to internal and external walls of buildings, colour steel sandwich panels, and fireproof door core plates.

Owner:四川威尔达节能科技有限公司

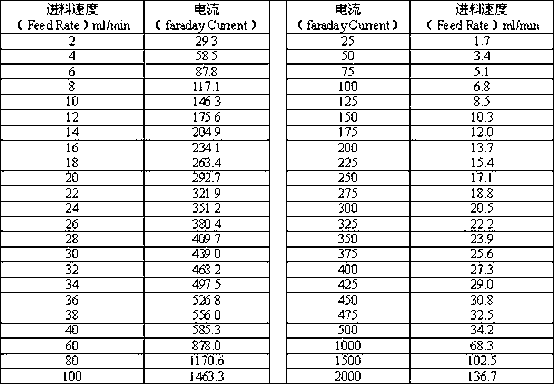

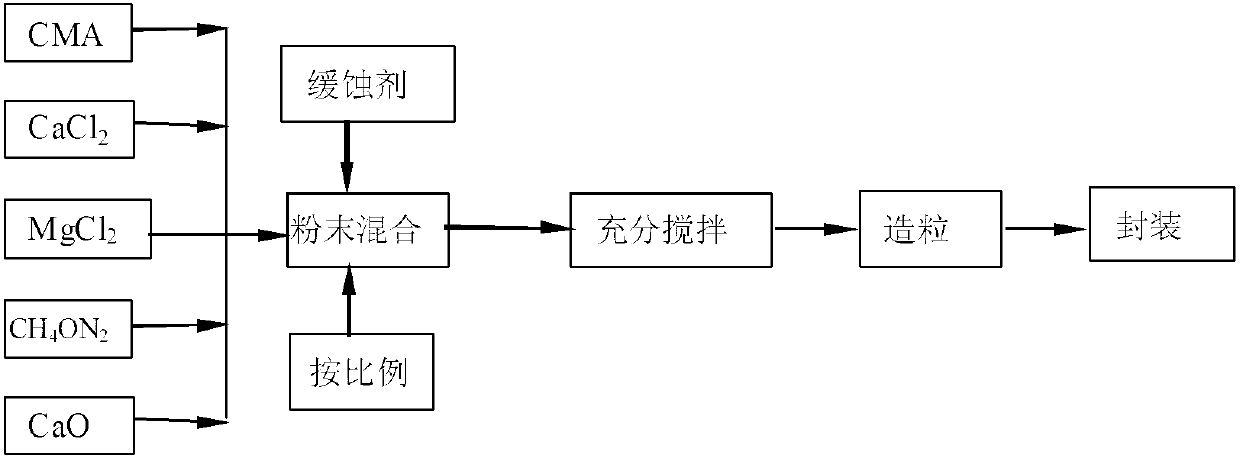

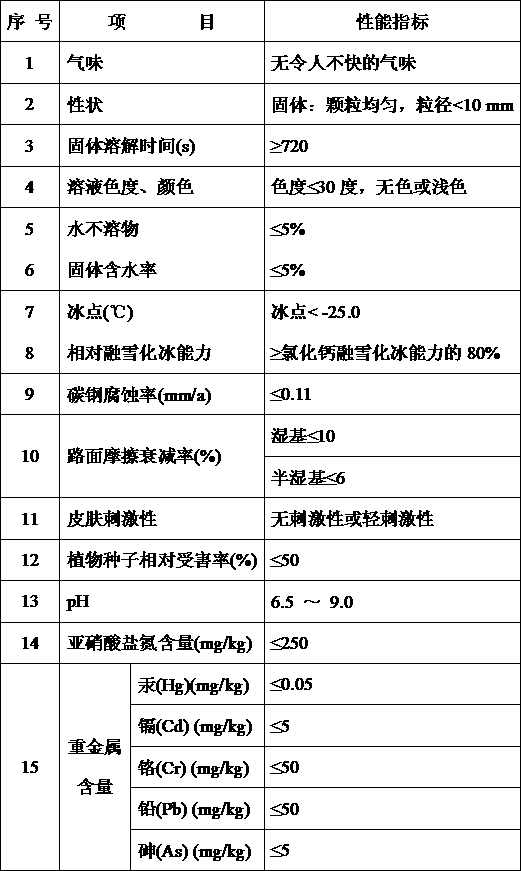

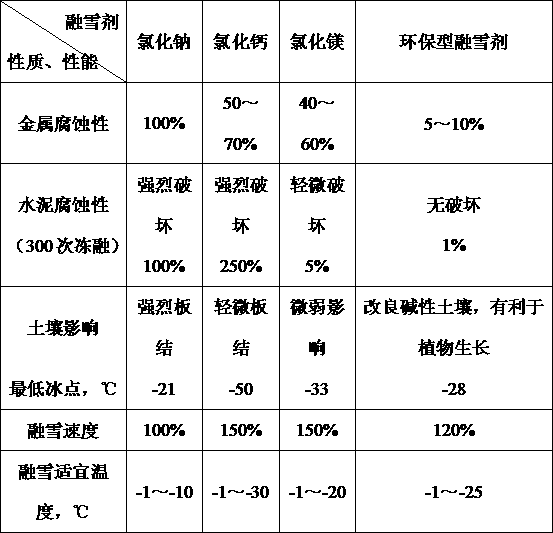

Environment-friendly snow melting agent and preparation method thereof

ActiveCN103342988AReduce manufacturing costSimple production processOther chemical processesSnow meltingEthylic acid

The invention relates to an environment-friendly snow melting agent and a preparation method of the snow melting agent, and belongs to the field of the snow melting agents. The snow melting agent is prepared from acetates and chlorine salts with low corrosivity as the main raw materials by mixing acetates including potassium acetate, magnesium acetate and calcium acetate with calcium chloride and magnesium chloride in a certain proportion, as well as a small quantity of corrosion inhibitor. The common fault that a common inorganic snow melting agent is high in corrosivity is effectively overcome, the cost is reduced, and therefore the snow melting agent is suitable for promotion and application.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com