Liquid amonia pressurized precipitation and hydrothermal modification process for preparing magnesium hydroxide fire retardant

A magnesium hydroxide and hydrothermal modification technology, applied in the direction of magnesium hydroxide, etc., can solve the problems of low ammonia utilization rate, large amount of waste water, and harsh working environment, so as to increase ammonia concentration, reduce water consumption, and have no environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

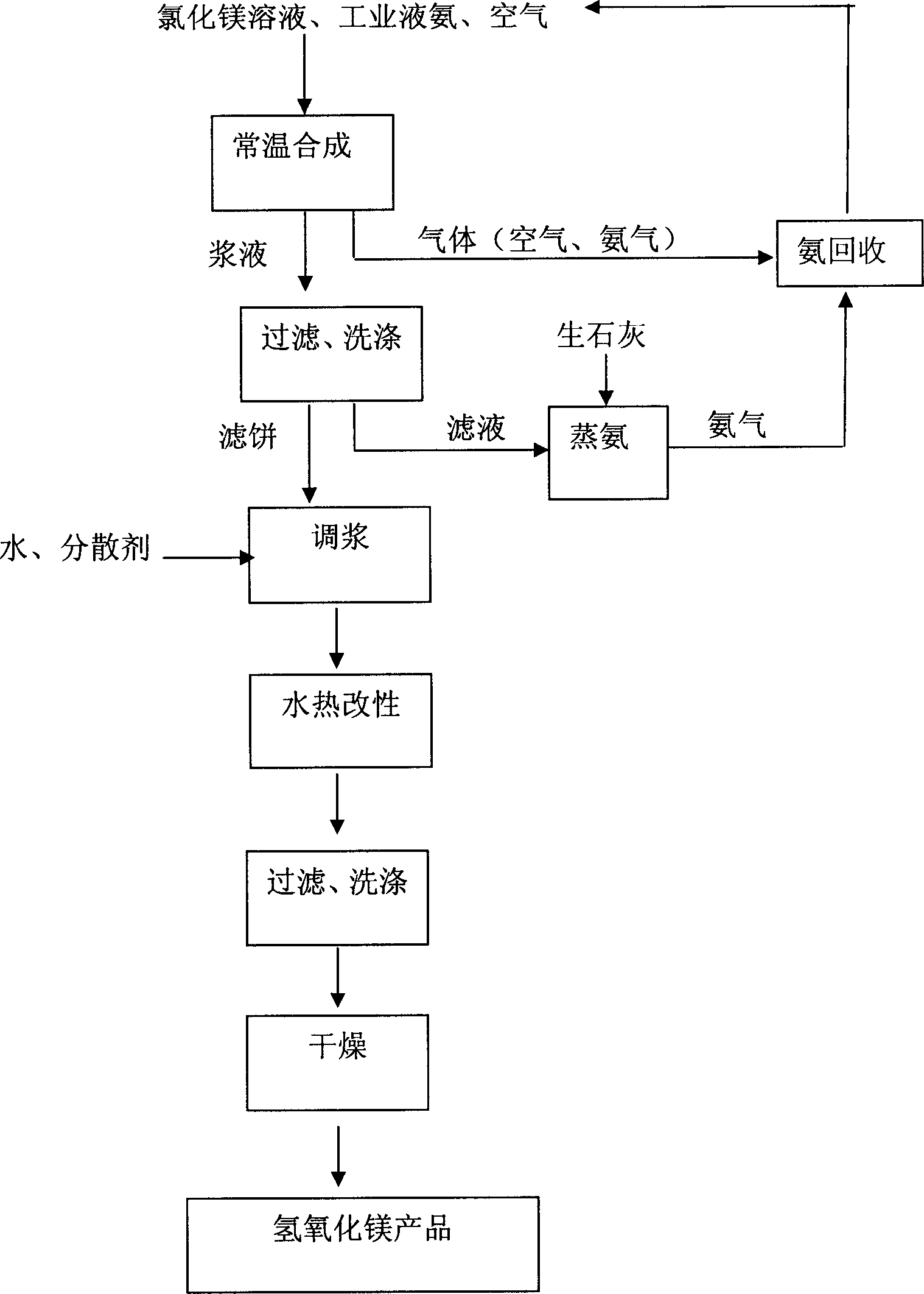

Method used

Image

Examples

Embodiment 1

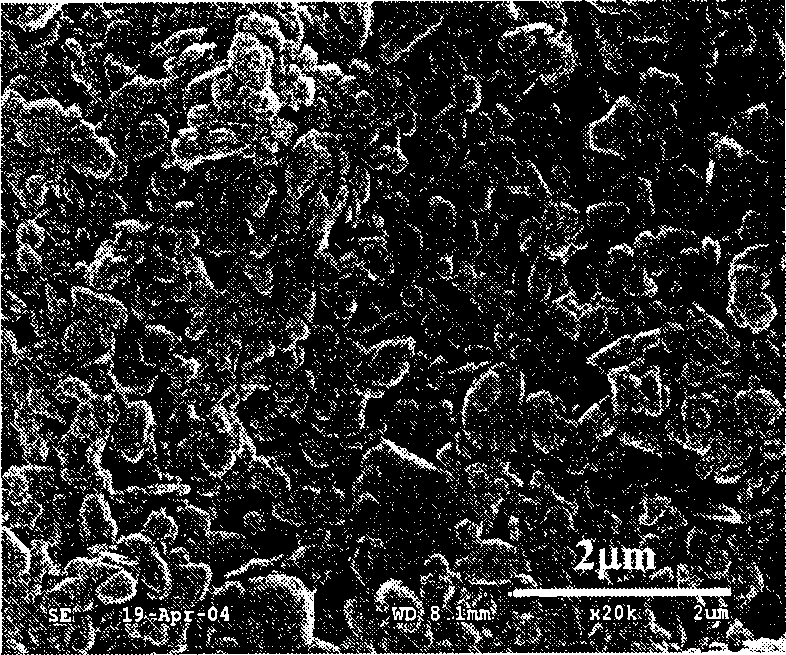

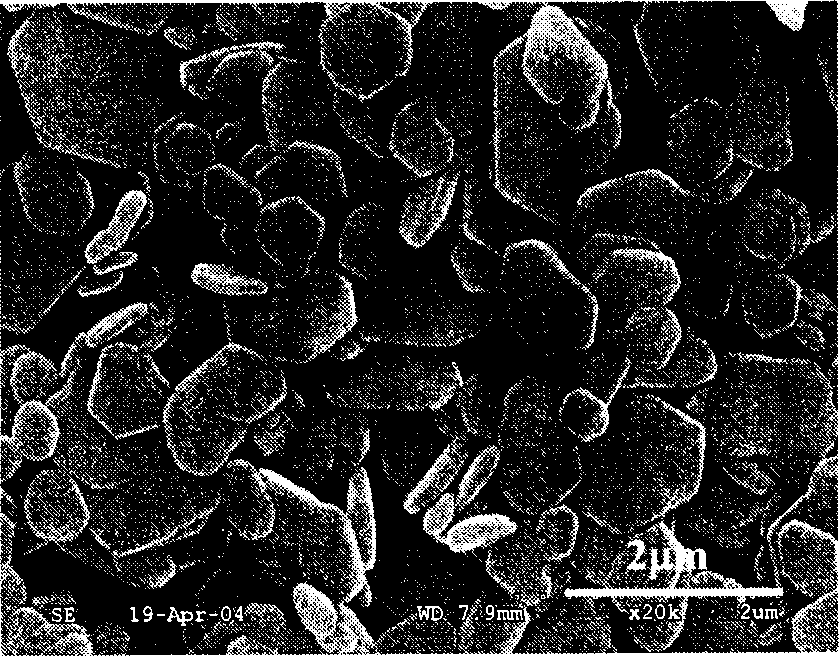

[0030]Prepare 40 liters of 10% (w / v) magnesium chloride solution and add it to a closed reactor, and feed (0.7 mol / min) liquid ammonia at a constant speed under the condition of stirring (150 rpm) at 15°C for 1 hour. Enter air to maintain the reactor pressure at 0.05 MPa, and continue the reaction for 3 hours. After the reaction, the gas phase is discharged into the ammonia recovery device. After the slurry is filtered and washed, a slurry with a solid content of 5% is made under stirring (150 rpm) and added to the hydrothermal reactor, and then 0.1% polyacrylic acid is added. , stirred at 250°C (150 rpm) for 6 hours, then cooled, filtered, washed, dried (105°C, 4 hours), and pulverized to obtain particles with an average primary particle size of 2.0 μm and an average aggregated particle size of 3.0 μm. Specific surface area 5m 2 / g, hexagonal flaky magnesium hydroxide particles with a purity of 99.5%. Put the normal-temperature synthetic filtrate and 5.2 kg of quicklime int...

Embodiment 2

[0032] Prepare 40 liters of 40% (w / v) magnesium chloride solution and add it to a closed reactor, and feed (2.8 mol / min) liquid ammonia at a constant speed under the condition of stirring (150 rpm) at 90 ° C for 1 hour. Air was added to maintain the reactor pressure at 0.5 MPa, and the reaction was continued for 1 hour. After the reaction, the gas phase is discharged into the ammonia recovery device. After the slurry is filtered and washed, a slurry with a solid content of 30% is made under stirring (150 rpm) and added to the hydrothermal reactor, and then 0.01% hexadecimal Sodium phosphate, stirred at 100°C (150 rpm) for 1 hour, then cooled, filtered, washed, dried (105°C, 4 hours), and crushed to obtain particles with an average primary particle size of 0.5 μm and an average aggregated particle size of 4.0 μm, specific surface area 30m 2 / g, hexagonal flaky magnesium hydroxide particles with a purity of 98.0%. Put the normal-temperature synthetic filtrate and 21.5 kg of qu...

Embodiment 3

[0034] Prepare 40 liters of 20% (w / v) magnesium chloride solution and add it to a closed reactor, and feed (1.5 mol / min) liquid ammonia at a constant speed under the condition of stirring (150 rpm) at 40°C for 1 hour. Air was added to maintain the reactor pressure at 0.2 MPa, and the reaction was continued for 3 hours. After the reaction, the gaseous phase is discharged into the ammonia recovery unit. After the slurry is filtered and washed, a slurry with a solid content of 15% is made under stirring (150 rpm) and added to the hydrothermal reactor, and then 0.05% ethanol is added. Stir at 180°C (150 rpm) for 4 hours, then cool, filter, wash, dry (105°C, 4 hours), and pulverize to obtain particles with an average primary particle size of 1.0 μm and an average aggregated particle size of 2.0 μm. Surface area 15m 2 / g, hexagonal flaky magnesium hydroxide particles with a purity of 98.5%. Put the normal-temperature synthetic filtrate and 10.8 kg of quicklime into a closed ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com