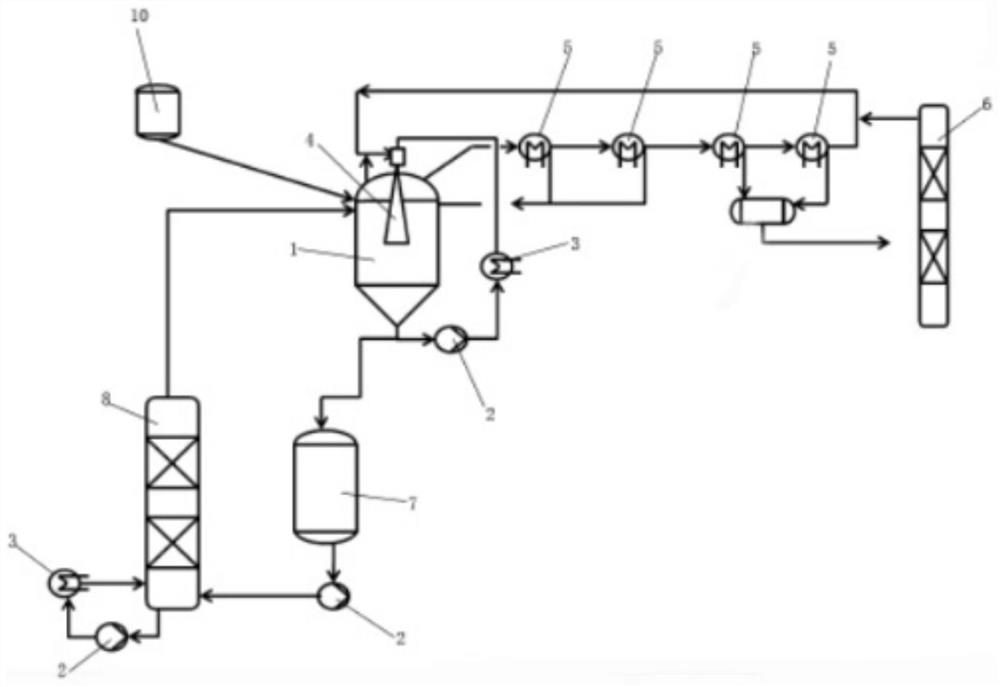

Process for synthesis of n-octylamine using loop reactor

A loop reactor, n-octylamine technology, applied in chemical instruments and methods, ammonia-carboxylic acid reaction preparation, preparation of organic compounds, etc., can solve problems such as restricting industrialization, high reaction temperature, and increasing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Dodecylbenzenesulfonate is obtained by the following preparation method: 1) the metered n-octanoic acid and dodecylbenzenesulfonic acid are dropped into at one time from the feeding port of the raw material preparation tank; Raise the temperature to 60°C, stir and keep warm for 30min, so that n-octanoic acid and dodecylbenzenesulfonic acid are evenly mixed; 3) put the measured metal oxide into the feed port of the raw material preparation tank, and stir for 2h; 4) After the reaction, 60 Keep warm at -80°C for standby; the molar ratio between dodecylbenzenesulfonic acid and metal oxide is 1:1.2; n-octanoic acid is used as a diluent, and the input amount is equal to the input amount of alkylbenzenesulfonic acid; metal oxide The material is selected according to the specific dodecyl sulfonate used in the embodiment, for example, when a single metal ion alkylbenzene sulfonate such as zinc dodecylbenzene sulfonate is used in the embodiment, the selected The metal oxide is Zn...

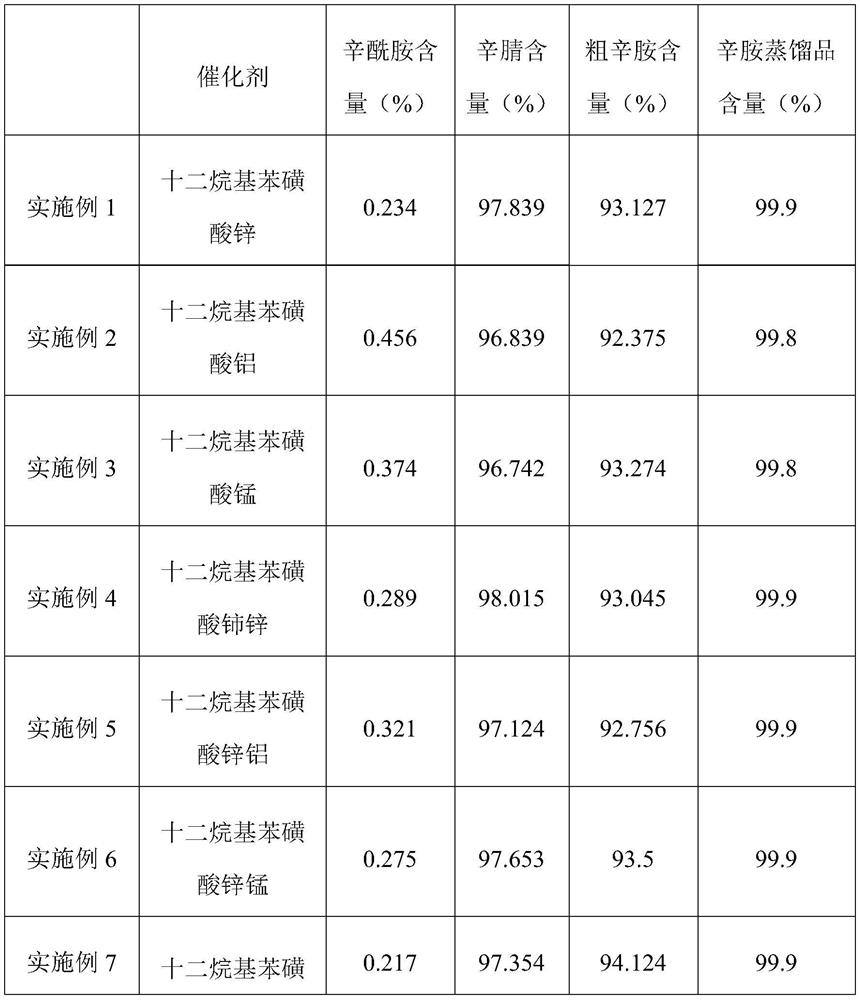

Embodiment 1

[0054]Feed 18t of n-octanoic acid into the loop reactor, then add 360kg of zinc dodecylbenzenesulfonate as a catalyst, replace it with nitrogen, feed liquid ammonia, start the reaction circulation pump, raise the temperature to 150°C, and keep it for 2 hours , continue to heat up to about 200°C, and react at 0.8MPa for 12 hours. After the reaction is completed and cooled, the discharge material enters the distillation tower for vacuum distillation; octanonitrile distillate can reach 99%, and its octanoic acid conversion rate is 97-99%. , the selectivity reaches 90-98%, and the distillation yield of octylnitrile reaches 97%. Feed the octonitrile distillate into the loop reactor, in the presence of 324kg Raney nickel catalyst, feed the hydrogen with a purity of 99%, 300kg liquid ammonia as a reaction inhibitor, the total pressure is at 4.0MPa, and the temperature is at 150°C Under the conditions, the reaction was carried out for 6 hours. After the reaction was completed, the cru...

Embodiment 2

[0056] Feed 18t of n-octanoic acid into the loop reactor, then add 360kg of aluminum dodecylbenzenesulfonate as a catalyst, replace it with nitrogen, feed liquid ammonia, start the reaction circulation pump, raise the temperature to 150°C, and keep it for 2 hours , continue to heat up to about 200°C, and react at 0.8MPa for 12 hours. After the reaction is completed and cooled, the discharge material enters the distillation tower for vacuum distillation; octanonitrile distillate can reach 99%, and its octanoic acid conversion rate is 97-99%. , the selectivity reaches 90-98%, and the distillation yield of octylnitrile reaches 97%. Feed the octonitrile distillate into the loop reactor, in the presence of 324kg Raney nickel catalyst, feed the hydrogen with a purity of 99%, 300kg liquid ammonia as a reaction inhibitor, the total pressure is at 4.0MPa, and the temperature is at 150°C Under the conditions, the reaction was carried out for 6 hours. After the end, a crude product was o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com