Patents

Literature

130results about "Preparation by ammonia-carboxylic acid reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidized-bed catalyst for ammoxidation of propylene or isobutylene

InactiveCN1736592AEasy loadingIncrease reaction pressurePreparation by ammonia-carboxylic acid reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureHigh load

The invention provides a fluid-bed catalyst, which can withstand high voltage and high load, contains non corrosive halide, and has a high single-pass yield. The catalyst comprises metal oxide containing multi active component of Mo, Bi, Fe, Ni and Sm, and a carrier of SiO2, Al2O3 or the mixture. It can be used to prepare the high selective acrylic with propone. Comparing with the prior technique, in the condition of keeping the single- pass yield of acrylic, with the invented catalyst, production capacity of fluid-bed reactor can be improved by 20- 30%, and the usage of the catalyst can decreases by 35%.

Owner:YINGKOU XIANGYANG CATALYST

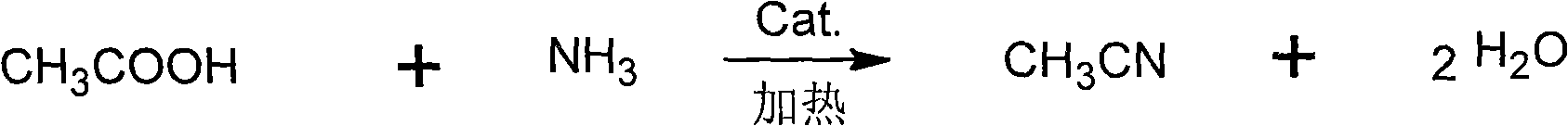

Method for synthesizing acetonitrile through one-step ammoniating method with acetic acid

ActiveCN101830829AReduce typesReduce contentPreparation by ammonia-carboxylic acid reactionCarboxylic acid nitrile purification/separationChemical treatmentSynthesis methods

The invention discloses a method for synthesizing acetonitrile through a one-step ammoniating method with acetic acid. The method comprises the following steps of: (1) reacting acetic acid with liquid ammonia in a fixed-bed reactor provided with a catalyst of aluminum oxide to generate a mixed gas containing the acetonitrile; and (2) continuously refining the gas mixture to obtain an acetonitrileproduct. By adopting the method, the acetonitrile product is relatively pure, the purity can reach more than 99.9%, the separation process is relatively simple, the process is short, the energy consumption in the production process is low, the energy consumption of a unit product is about 40% of the energy consumption with a by-product method, and the cost is lower. The separation process adopts a physical separation method, and avoids the problem of generating a great deal of wastewater and waste gas in the chemical process in the by-product method. Meanwhile, because the synthesis method isadopted, the limitation that the yield is restricted by the main product can be thoroughly avoided.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY

Method for preparing high-purity acetonitrile from acetic acid and ammonia by two steps

ActiveCN101891648AReduce typesReduce contentPreparation by ammonia-carboxylic acid reactionCarboxylic acid nitrile purification/separationChemical treatmentSynthesis methods

The invention discloses a method for preparing high-purity acetonitrile from acetic acid and ammonia by two steps, which comprises the following steps of: (1) neutralizing acetic acid and ammonia to generate ammonium acetate; (2) mixing aqueous solution of ammonium acetate and gaseous ammonia, preheating, and making the mixture enter a fixed bed reactor filled with a catalyst aluminium oxide for reaction to generate acetonitrile-containing mixed gas; and (3) continuously refining the mixed gas to obtain the acetonitrile. The 70 to 80 weight percent acetic acid is taken as a raw material, and the produced acetonitrile product has the advantages of less varieties and low content of impurities, high purity of over 99.9 percent, simple separation process, shorter flow, low energy consumption only about 40 percent of that of a byproduct method in unit product, and lower cost. The separation process is a physical separation method, and avoids generating a great amount of wastewater and waste gas in the chemical treatment process of the byproduct method. Meanwhile, a synthesis method is adopted, so the limitation that the yield is limited by a main product can be radically eliminated.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY

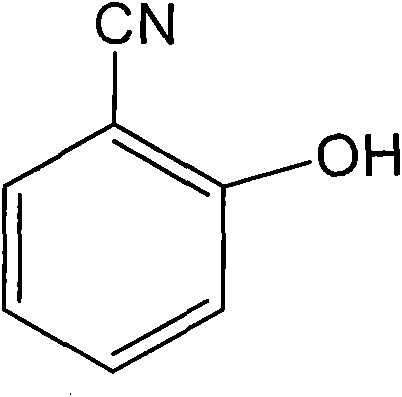

Method for preparing 2-hydroxybenzonitrile from ammonium salicylate as raw material

InactiveCN102174002AIncrease contentPreparation by ammonia-carboxylic acid reactionSalicylic acidMethyl salicylate

The invention discloses a method for preparing 2-hydroxybenzonitrile from ammonium salicylate as a raw material, comprising the following steps of: introducing ammonia gas or ammonia water to a salicylic acid slurry until the pH of the solution is 7.5-13.0, then evaporating to obtain ammonium salicylate solid; forming a mixture from the ammonium salicylate solid, urea, sulfamic acid, a catalyst and a solvent, wherein the catalyst is prepared from 0.0001-10 of magnesium oxide, 0.0001-5 of aluminum oxide, 0.0001-8 of calcium oxide, 0.0001-8 of silicon oxide and 0.0001-10 of artificial zeolite, and the solvent is prepared from 0.0001-10 of o-methyl phenol, 0.0001-6 of p-methyl phenol, 0.0001-8 of diethylene glycol, 0.0001-9 of methyl salicylate, 0.0001-10 of diphenyl oxide and 0.0001-12 of dichlorophenol; and after insulating at 150-180 DEG C for 0.5-10.0 hours and insulating at 190-260 DEG C for 0.5-10.0 hours, filtering or centrifuging the material, evaporating to remove the solvent, crystallizing, recrystallizing, and drying to obtain the 2-hydroxybenzonitrile product of which the mass percentage composition is greater than 90%.

Owner:YANCHENG INST OF TECH

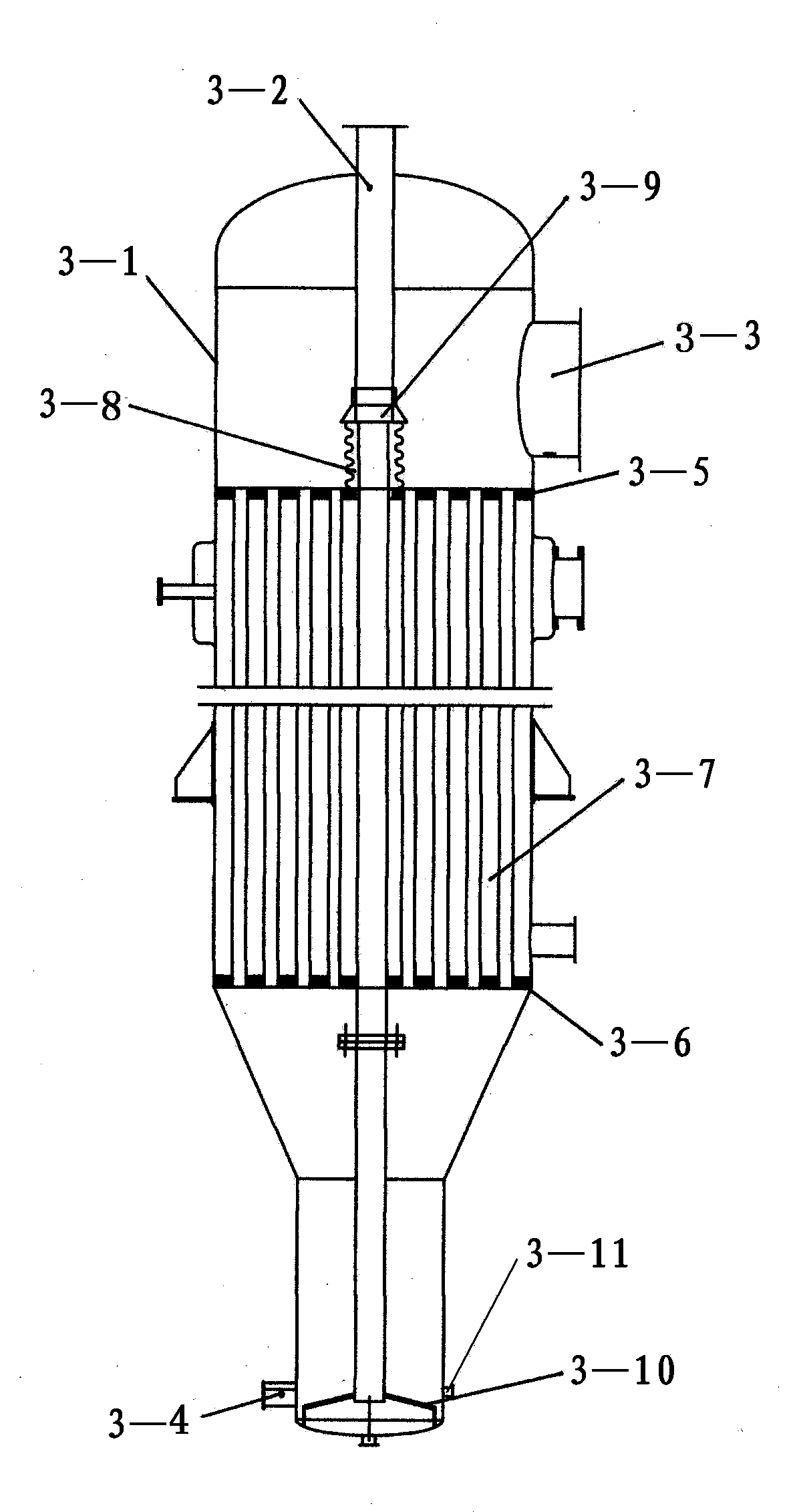

Method and equipment for production of adiponitrile from adipic acid

ActiveCN103896805ACatalyst content is stableNormal responsePreparation by ammonia-carboxylic acid reactionPhosphateGas phase

The invention relates to a method and equipment for production of adiponitrile from adipic acid, and mainly solves the problem of unstable product quality in the prior art for production of adiponitrile from adipic acid. The method employs materials of fusing adipic acid, ammonia, phosphate and a diluent. The production method is as below: mixing phosphoric acid with the diluent in a pipeline mixer; conducting neutralization of adipic acid and ammonia in a cyanation reactor; sending reaction products into the bottom of a separation tower for separation; recovering gas phase of light components from an outlet; sending the diluent recovered by a gas lifting plate into the pipeline mixer, mixing the diluent with phosphoric acid in the pipeline mixer, and sending the mixture into the cyanation reactor to dilute adipic acid; and sending a liquid phase to a scraper type evaporator. The employed equipment includes an adipic acid storage tank, an ammonia compressor, a cyanation reactor, a pipeline mixer, a separation tower, a tail gas removal tower, a phosphoric acid storage tank and a scraper type evaporator. The invention has the advantage of a good quality of the produced adiponitrile product.

Owner:ANSHAN GUORUI CHEM

Method for synthesizing hexanediamine by taking caprolactam as raw material

ActiveCN110423201AMild reaction conditionsEasy post-processingOrganic compound preparationCarboxylic acid amides preparationEnd-groupHexamethylenediamine

Owner:ZHENGZHOU UNIV

Preparation method for long carbon chain nylon PA1313 and product

ActiveCN109180931AReduce use costImprove solubilityOrganic compound preparationAmino compound preparationAlcoholWastewater

The invention discloses a preparation method for long carbon chain nylon PA1313. The preparation method comprises the following steps: taking 1,13-tridecanedioic acid as a raw material; preparing 1,13-tridecylamine through cyanation and amination; preparing PA1313 salt by taking 1,13-tridecylamine and 1,13-tridecanedioic acid as raw materials and water as a solvent; putting PA1313 salt and water at a certain ratio into a polymerizing kettle; performing melt polymerization, thereby acquiring PA1313 with a certain molecular weight. In the cyanation step of the method, an ammonia gas recycling technique is adopted, so that the use ratio of ammonia gas is greatly increased and the emission of wastewater and exhaust gas is reduced; in the salt forming and polymerizing process, water is used forreplacing ethyl alcohol as a reaction medium, so that the safety of industrial production is promoted, the safety level of equipment is reduced, the investment in equipment is reduced and the recycling cost of solvent is lowered.

Owner:ZHENGZHOU UNIV

Preparation method of adiponitrile and product thereof

ActiveCN108821997AHigh selectivityExtended operating cycleOrganic compound preparationCarboxylic compound preparationPhosphoric acidAdipic acid

The invention relates to a preparation method of adiponitrile. The preparation method comprises the following steps: firstly performing a reaction on adipic acid and ammonia at 155-200 DEG C to produce diammonium adipate, and then dehydrating under a catalytic reaction of phosphoric acid or ammonium phosphate to produce adiponitrile; a product can be further separated in a separation tower. The reaction is performed on the adipic acid and the ammonia gas at the low temperature of 155-200 DEG C to produce H4NOOC(CH2)4COONH4 first, and then high-temperature cyanation is performed, so that the opportunity of producing a by-product and a coke from the adipic acid at high temperature is effectively avoided, not only the yield is increased by 3-5%, but also the operation cycle of a production device is prolonged by 30-60 days, and the production per unit time is increased. Liquid phosphoric acid is used as a catalyst, firstly ammonium salt of the phosphoric acid is produced, and the ammoniumphosphate can be mixed with ammonium salt of the adipic acid very well, so that the catalytic performance is improved better and the selectivity of the adiponitrile is increased by more than 2%.

Owner:重庆华峰聚酰胺有限公司 +1

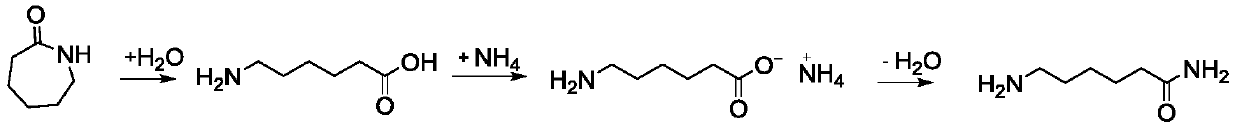

Method for producing hexamethylenediamine key intermediate 6-aminocapronitrile by continuous gas-phase two-step method

ActiveCN111574401AReduced Catalytic PolymerizationReduce polymerizationOrganic compound preparationCarboxylic acid amides preparationAminocapronsäurePtru catalyst

The invention provides a method for producing a hexamethylenediamine key intermediate 6-aminocapronitrile by a continuous gas-phase two-step method. The method comprises the following steps: S1, mixing caprolactam and water in a gas phase state to carry out continuous hydrolysis or mixing caprolactam and ammonia water in a gas phase state to carry out continuous hydrolysis ammoniation reaction toobtain a first product system containing 6-aminocaproic acid, 6-aminocaproic acid ammonium salt and / or 6-aminocaproamide; and S2, carrying out continuous gas-phase catalytic ammoniation and dehydration reaction on the first product system and ammonia gas to obtain a second product system containing 6-aminocapronitrile. According to the patent of the invention, the problem that water generated by reaction in a one-step process promotes polymerization reaction of the raw material caprolactam is reduced from the source, and the selectivity of aminocapronitrile is improved; and the problems of catalyst deactivation and pressure drop rise caused by polymerization and coking of caprolactam in the reactor are effectively reduced, the stability of the device is improved, and the service life of the catalyst is prolonged.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Method for synthesizing high purity acetonitrile by ammoniating acetic acid

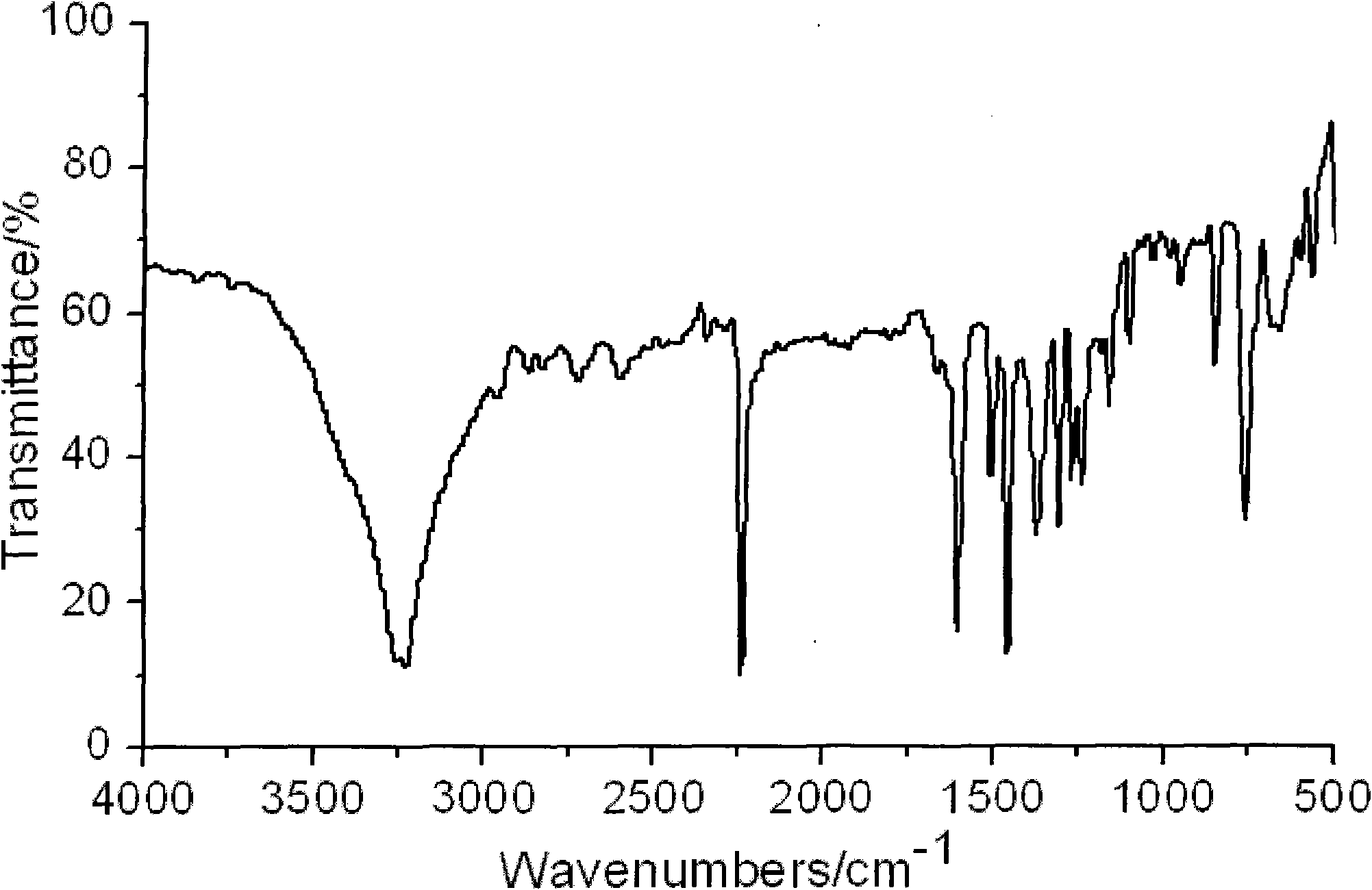

InactiveCN101597242AEasy to operateRaw materials are easy to getPreparation by ammonia-carboxylic acid reactionMetal/metal-oxides/metal-hydroxide catalystsAcetic acidAcetonitrile

The invention discloses a method for synthesizing high purity acetonitrile by ammoniating acetic acid; acetic acid and liquid ammonia are respectively vaporized, acetic acid is preheated to 100-250 DEG C, liquid ammonia is preheated to 100-300 DEG C, the preheated two gases enter a reactor for mixing, ammoniation reaction is carried out under the action of an acetic acid ammoniation catalyst to obtain acetonitrile. The invention has available materials, simple technology, easy operation and high purity of the product.

Owner:NANTONG ACETIC ACID CHEM

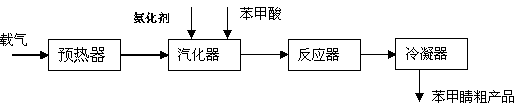

Method for preparing cyanobenzene by ammonifying benzoic acid gaseous phase

The invention discloses a method for preparing cyanobenzene by ammonifying benzoic acid gaseous phase. The method comprises the following steps: mixing gaseous benzoic acid and an ammonifying agent and carrier gas, and performing catalysis through a catalyst fixed bed, wherein the mol ratio of the benzoic acid to the ammonifying agent to the carrier gas is 1: (1-5): (5-40); the adopted carrier gas can be reaction raw material gas or inert gas, a condenser is arranged behind the reactor, the crude product is condensed to separate out the water phase, and then the rectifying and purifying are performed. The reaction flow is simple, the cyanobenzene is prepared by ammonifying the benzoic acid gaseous phase, the three wastes are prevented, and the economic benefit and the environment benefit are obvious.

Owner:WUHAN UNIV

Catalyst as well as preparation and application thereof

ActiveCN104549378AHigh activityGood choicePhysical/chemical process catalystsPreparation by ammonia-carboxylic acid reactionDissolutionHigh activity

The invention belongs to the field of preparation of catalysts, and relates to a catalyst as well as preparation and application thereof. The catalyst consists of a precursor and an auxiliary and is obtained by hydro-thermal treatment; according to the percentage by weight, the precursor is 70-90 percent, and the auxiliary is 10-30 percent; the precursor is formed by adding a phosphorus source into deionized water to agitate and dissolve and adding a screened aluminum source after dissolution and drying till the weight is constant. The catalyst has the advantages of high activity, good selectivity, long service life and the like, thereby having good industrial application prospect.

Owner:SHENYANG RES INST OF CHEM IND

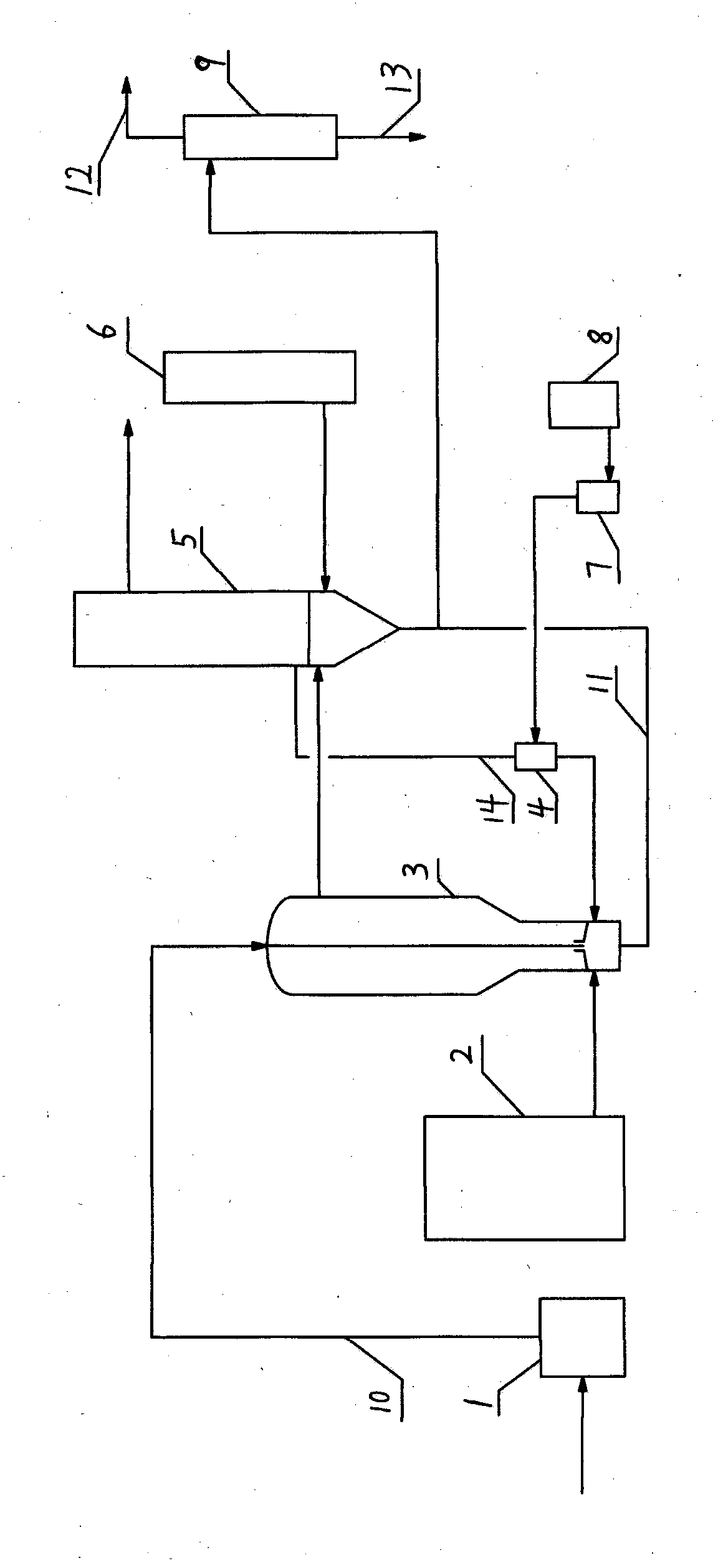

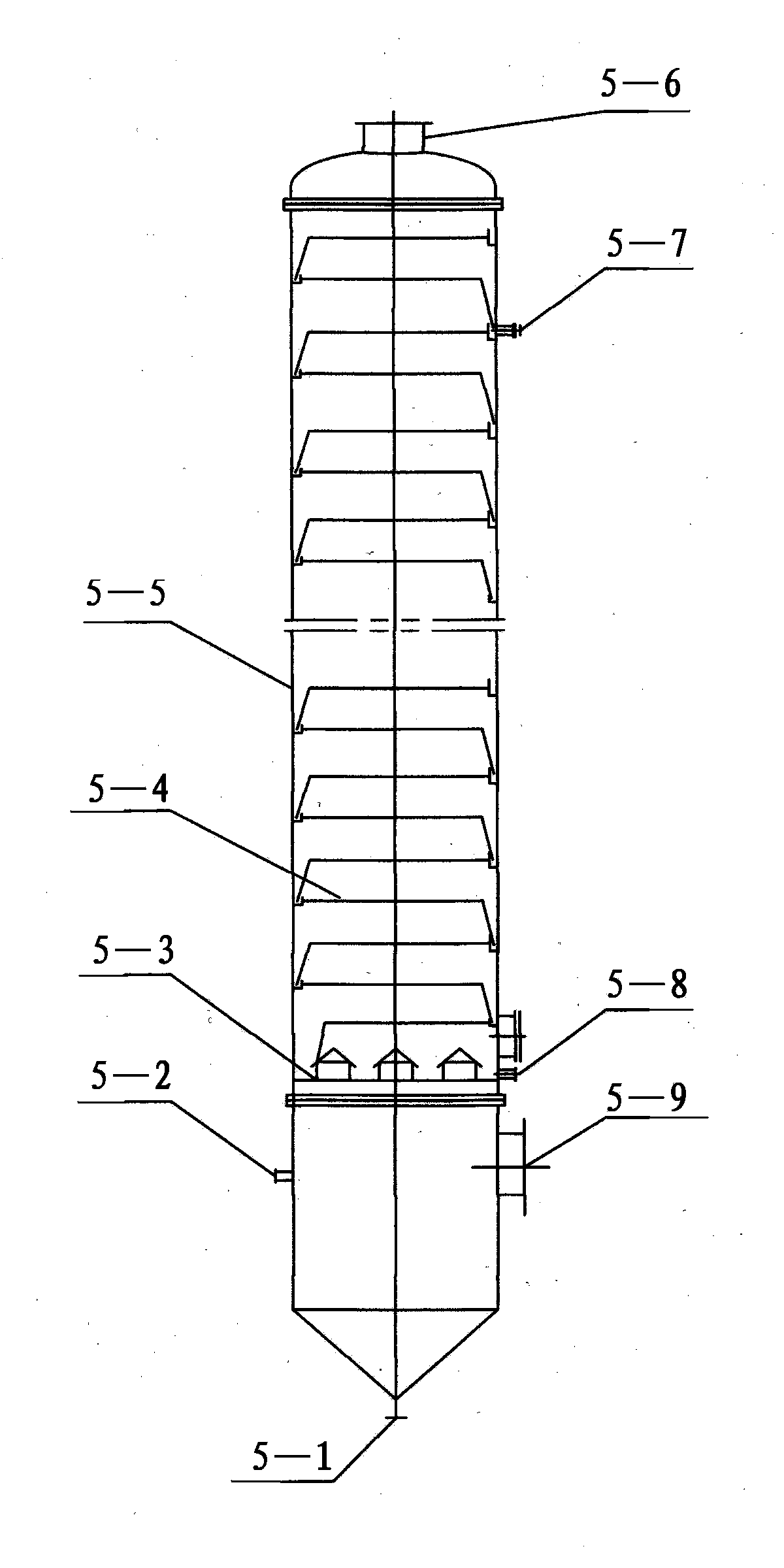

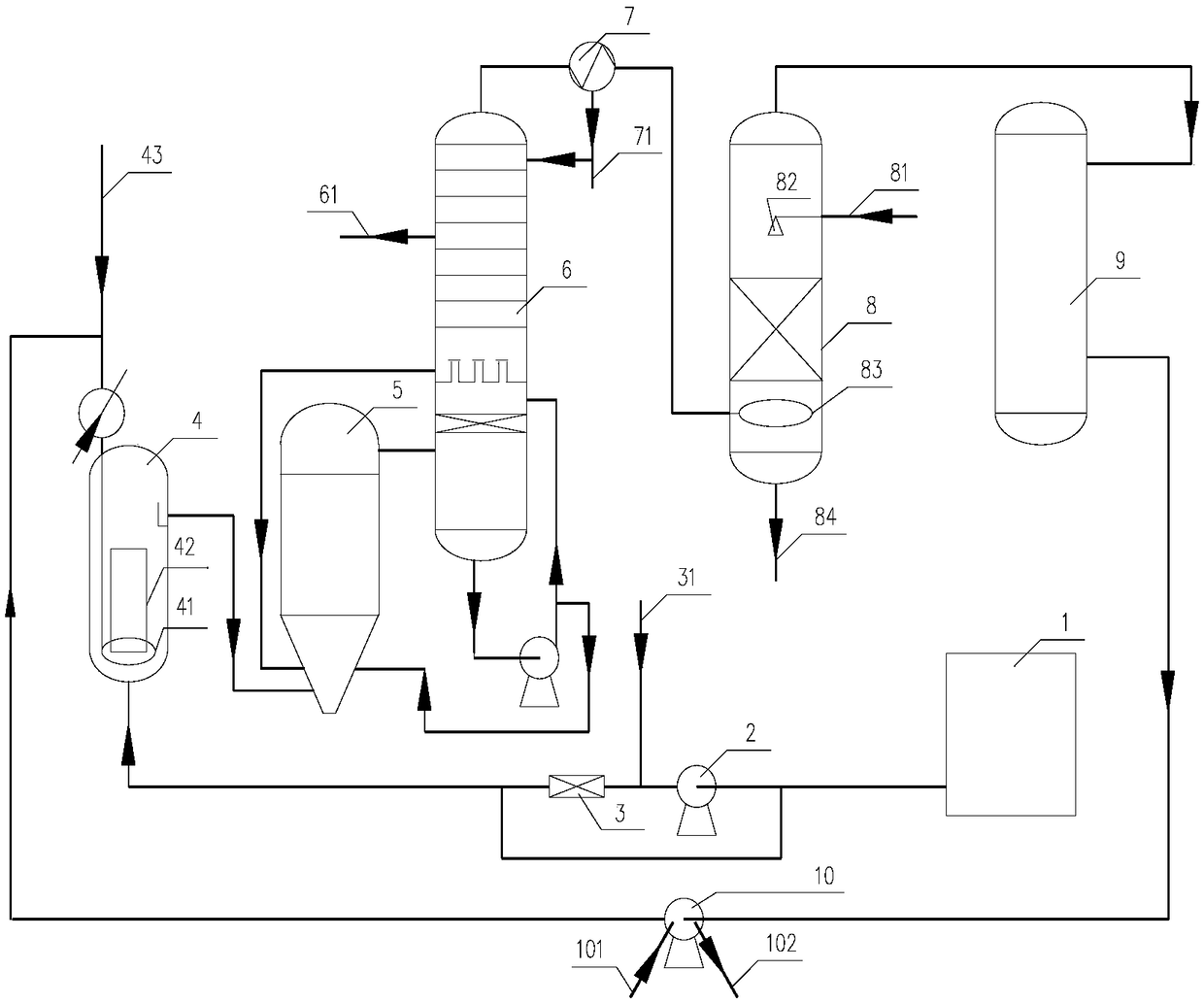

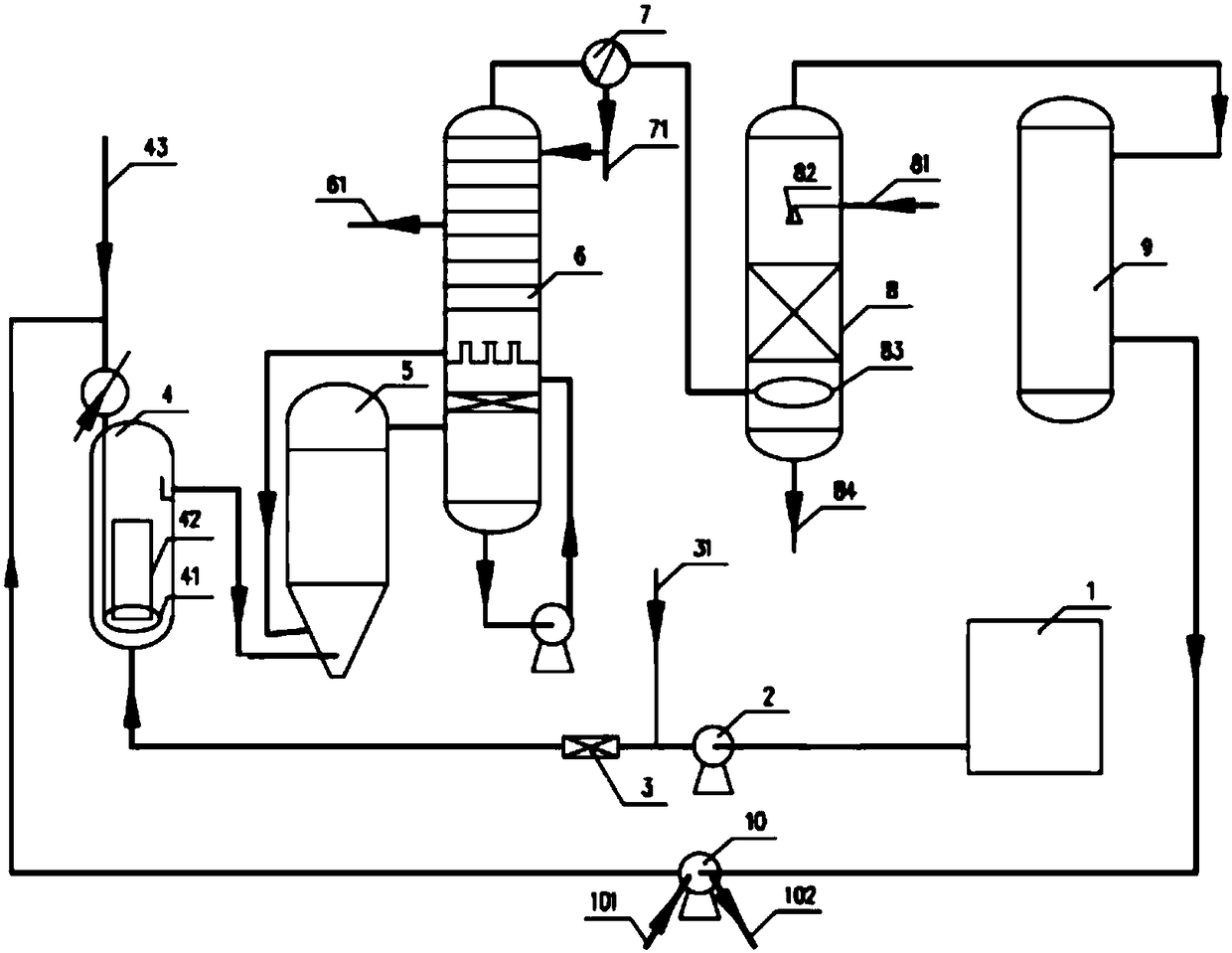

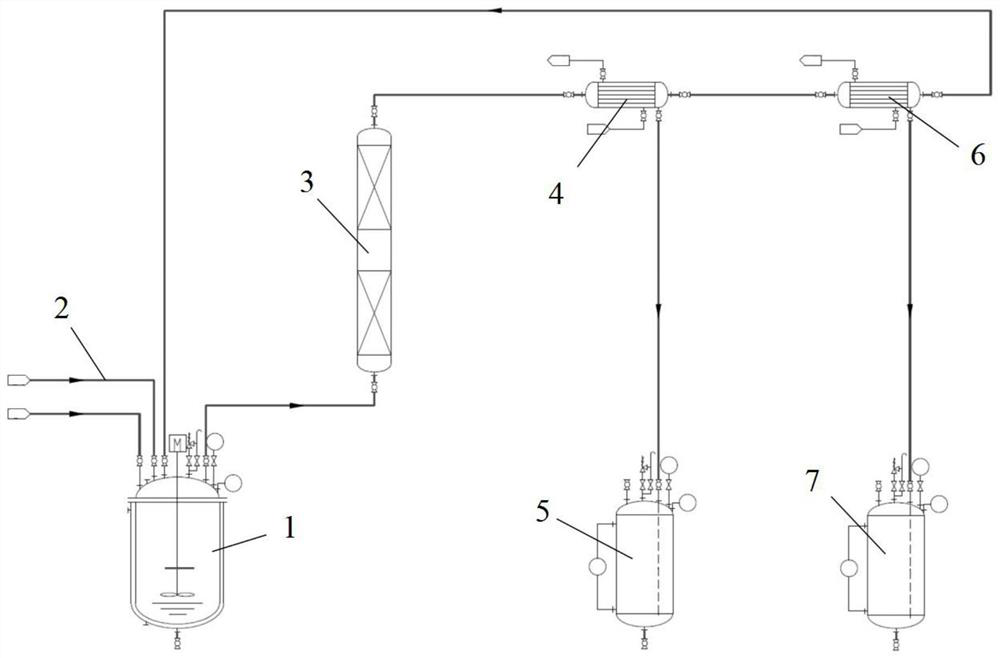

Adiponitrile production system

ActiveCN108409606AAvoid decompositionAvoid cokingPreparation by ammonia-carboxylic acid reactionDecompositionPhosphoric acid

The invention relates to an adiponitrile production system which comprises an adipic acid storage tank, a mixer, an adipic acid ammoniation reactor, a cyanation reactor, a separation tower, an ammoniagas cooler, an ammonia gas decarburization tower, a circulating ammonia gas dehydrator and a liquid ring compressor. The adipic acid storage tank is connected to the mixer by a pipeline, a branch fordelivering liquid phosphoric acid is arranged on the pipeline, the mixer is connected to an inlet of the adipic acid ammoniation reactor, an ammonia gas inlet and adipic acid ammoniation product andammonia gas outlets are further formed in the adipic acid ammoniation reactor, the adipic acid ammoniation product and ammonia gas outlets are connected with the cyanation reactor by pipelines, and the cyanation reactor is connected to the separation tower. The adiponitrile production system has the advantage that the shortcomings of decomposition and condensation coking of adipic acid in existingproduction routes at the high temperatures and the like can be overcome by the aid of the adiponitrile production system.

Owner:重庆华峰聚酰胺有限公司 +1

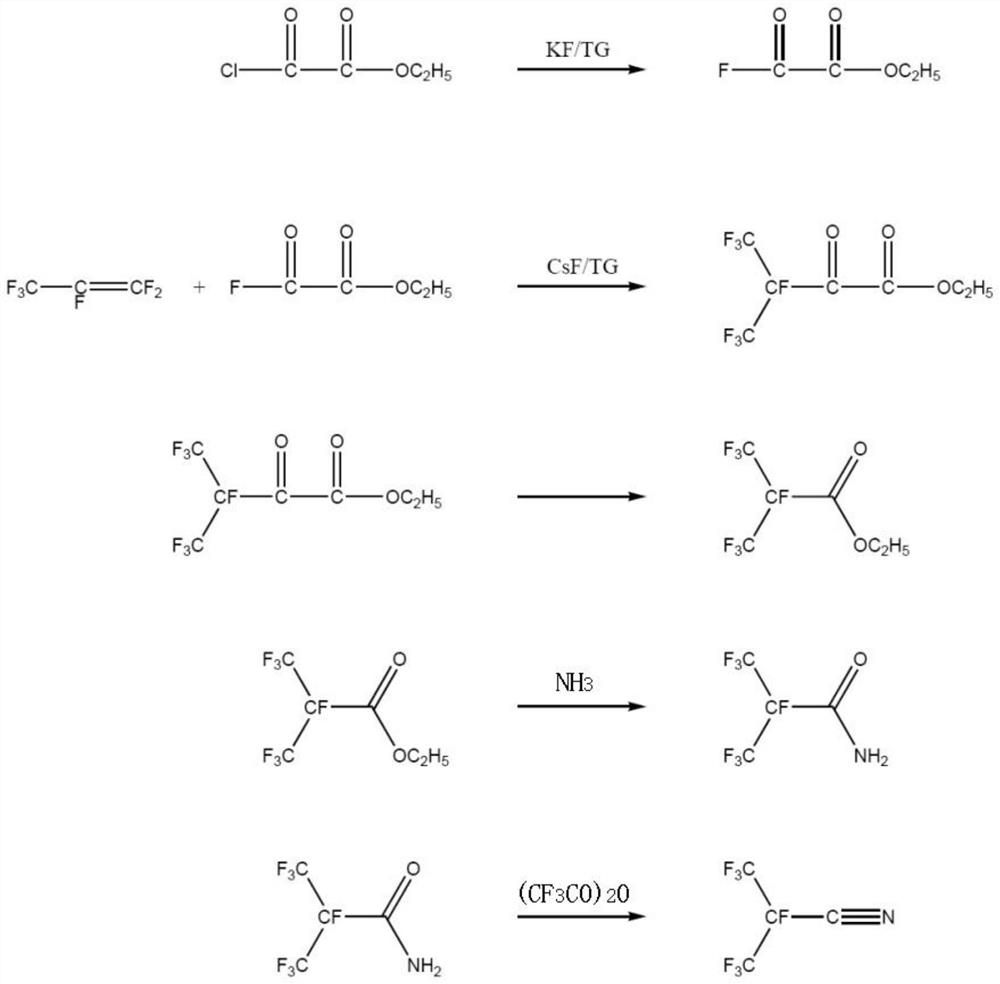

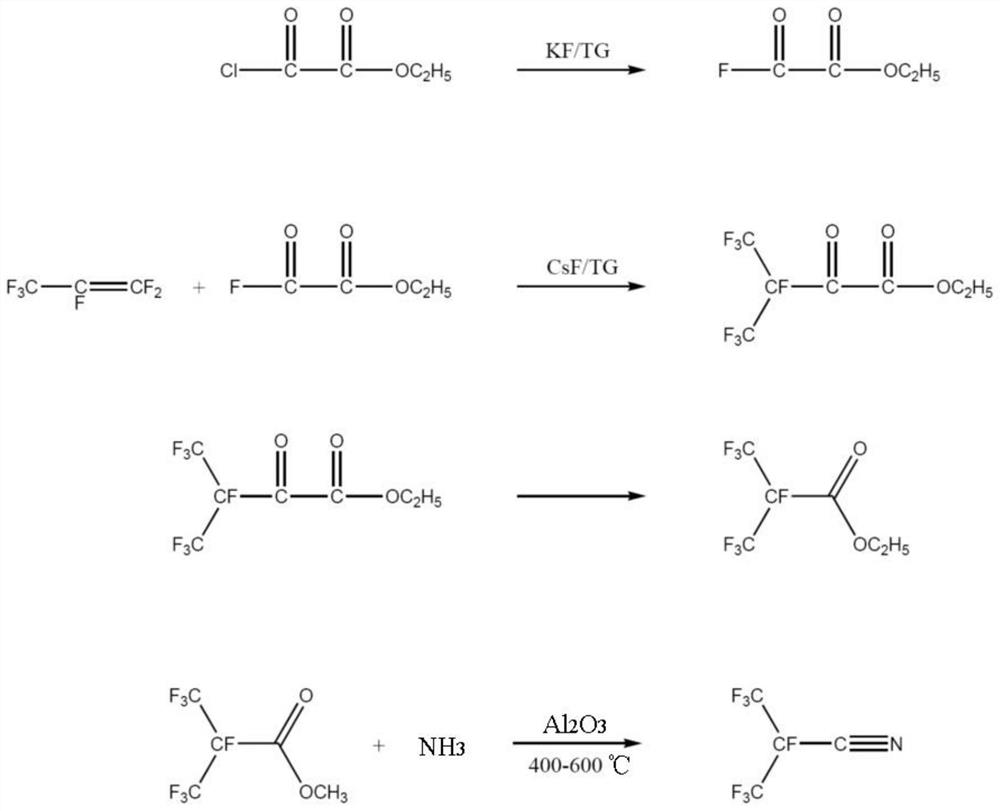

Synthetic method of perfluoroisobutyronitrile

PendingCN111825568ASynthetic process safetyEfficient synthesis processOrganic compound preparationCarboxylic acid esters preparationOxalyl fluoridePtru catalyst

Owner:福建省漳平市九鼎氟化工有限公司

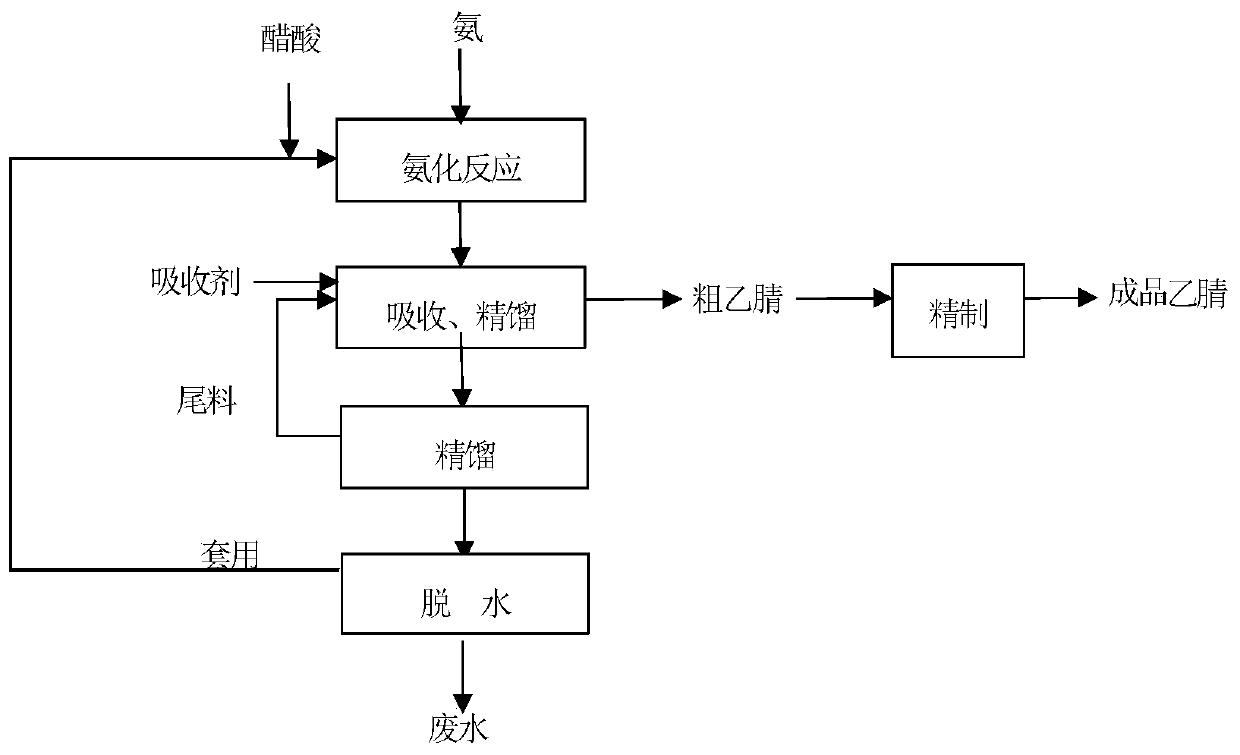

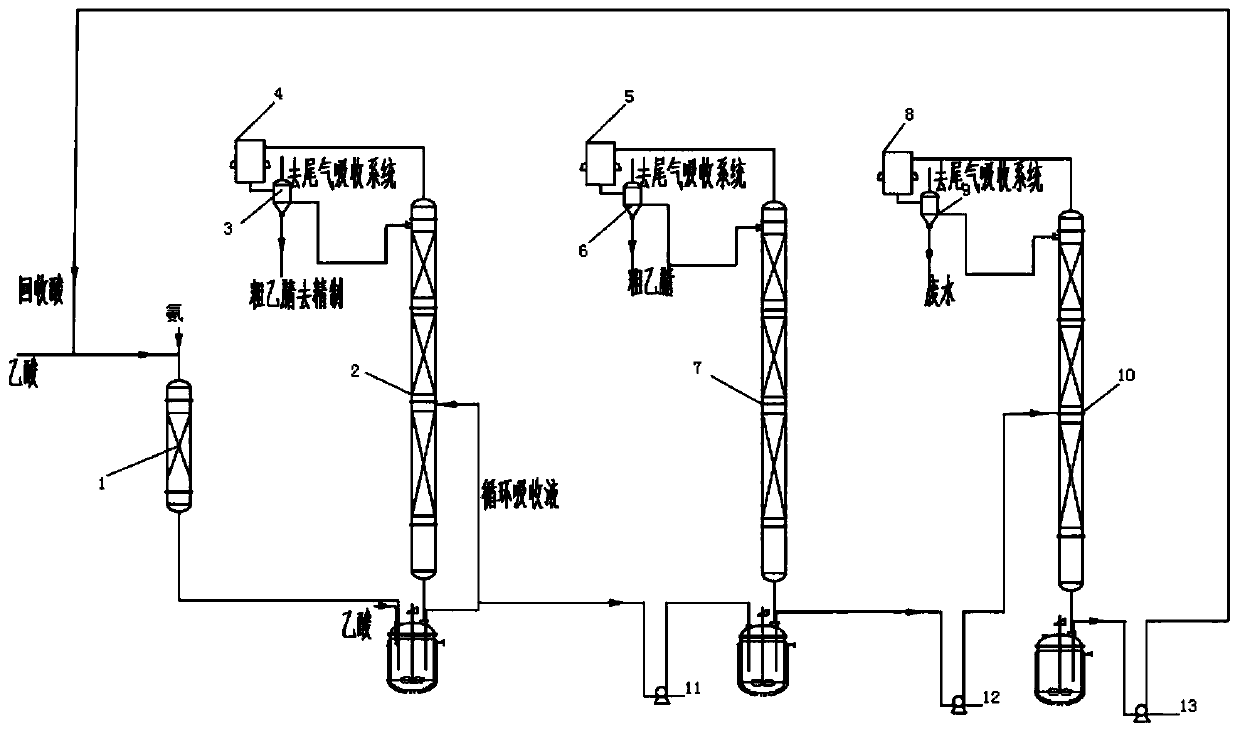

Novel continuous process for preparing acetonitrile

PendingCN111018741AImprove continuityReduce labor intensityPreparation by ammonia-carboxylic acid reactionCarboxylic acid nitrile purification/separationAcetic acidPtru catalyst

The invention belongs to the technical field of chemical engineering, and relates to a novel process for preparing acetonitrile by ammoniation of acetic acid. The method comprises the following steps:performing an ammoniation reaction on acetic acid, recycled acid and ammonia under the catalysis of a solid acid catalyst, performing acetic acid absorption and ammonia removal processes on high-temperature reaction gas after the reaction, performing a rectification process by taking gas-phase high temperature as a heat source, obtaining crude acetonitrile with the water content of 30% at the tower top, and refining the crude acetonitrile to obtain the finished product acetonitrile; and recovering acetonitrile tailings from a tower bottom liquid through atmospheric distillation, dehydrating with a dehydrating agent, and recycling the bottom liquid to the ammoniation reaction. The process is simple to operate, acetic acid is used for absorbing excessive ammonia, the bottom liquid is recycled, and the cost is reduced and the efficiency is improved; and the high-temperature gas-phase heat source is used for rectification, so that the energy consumption is reduced.

Owner:NANTONG ACETIC ACID CHEM +1

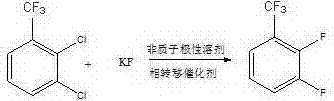

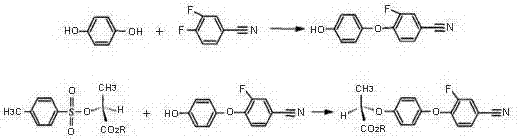

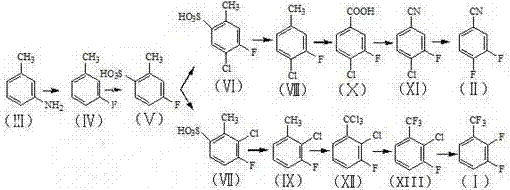

Continuous production method for industrially preparing 2,3-difluorobenzotrifluoride and 3,4-difluorobenzonitrile

ActiveCN107488098ALow application costAvoid it happening againOrganic compound preparationPreparation by halogen replacementTolueneRaw material

The invention discloses a continuous production method for industrially preparing 2,3-difluorobenzotrifluoride and 3,4-difluorobenzonitrile. The preparation process of the 2,3-difluorobenzotrifluoride comprises the preparation step of an intermediate raw material for benzene sulfonamide and benzenesulfonylurea herbicides, and the preparation process of the 3,4-difluorobenzonitrile comprises the preparation step of a cthalofop-butyl intermediate raw material. The method is suitable for industrial production; and compared with the prior art, the method has the advantages of low cost, high production method and less pollution.

Owner:ZIBO FEIYUAN CHEM CO LTD

Halogenated terephthalonitrile preparation method

InactiveCN1422843AOrganic compound preparationPreparation by ammonia-carboxylic acid reactionHalogenChloride

The invention is a method to prepare multi-halogen substituted terephthalonitrile. The halogen substituted terephthalyl chloride, molecular formula C1OC-C6HnX4-n-COCl, and liquid amine react to produce halogen substituted terephthalyl amine, then which forms the halogen substituted terephthalonitrile by dehydration. The above reaction can be one-step synthesized. In the formula, n=0.3, X=F, Cl or Br.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Solid phosphorus acid catalyst for producing adiponitrile and preparation method of solid phosphorus acid catalyst

ActiveCN106140234AImprove dehydration ratePhysical/chemical process catalystsPreparation by ammonia-carboxylic acid reactionCentrifugationSulfate

The invention discloses a solid phosphorus acid catalyst for producing adiponitrile and a preparation method of the solid phosphorus acid catalyst. The preparation method of the solid phosphorus acid catalyst comprises the steps as follows: diatomite is impregnated in a phosphoric acid and sulfate mixed solution, and a carrier is separated through centrifugation after impregnation balance, and then drying and roasting are performed, wherein the concentration of phosphoric acid is 55wt%-95wt%, the concentration of sulfate is 15wt%-25wt%, the roasting temperature is 300-700 DEG C, sediment is cooled and then subjected to preforming, particles between 10 meshes and 50 meshes are screened, and the solid phosphorus acid catalyst is formed. One novel green catalyst is developed for production of adiponitrile with an adipic acid liquid phase method, and the catalysis effect is improved while various defects caused by traditional catalysts are overcome.

Owner:PETROCHINA CO LTD

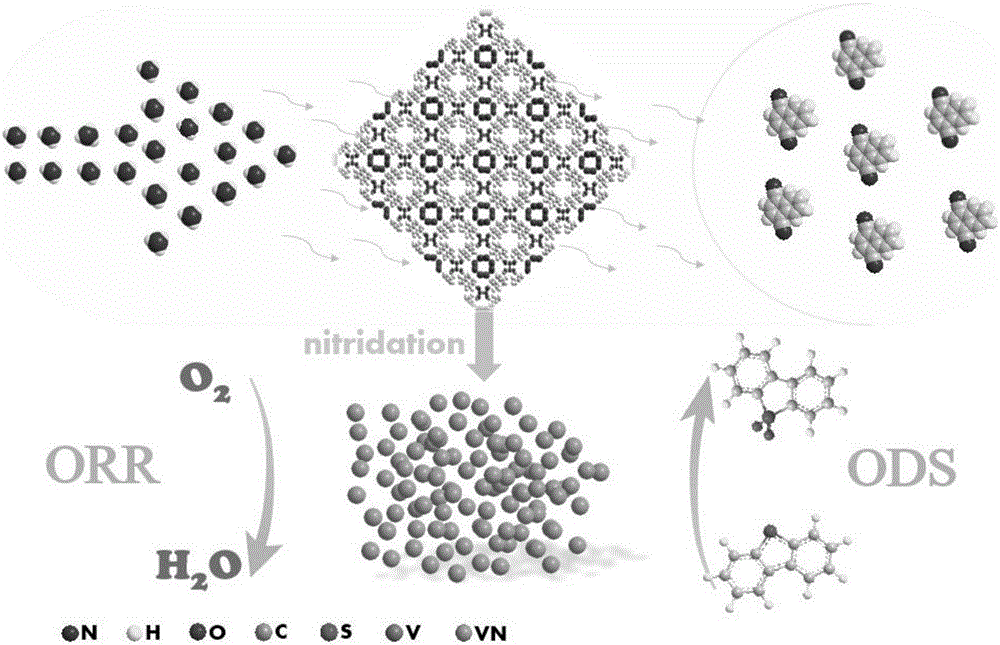

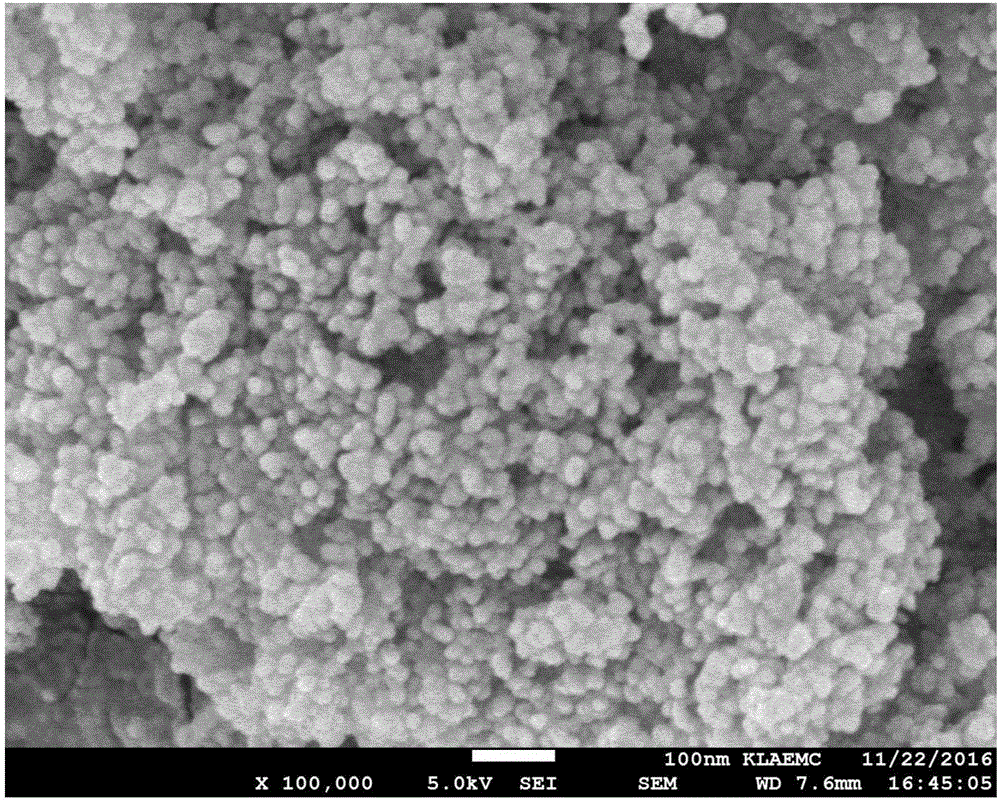

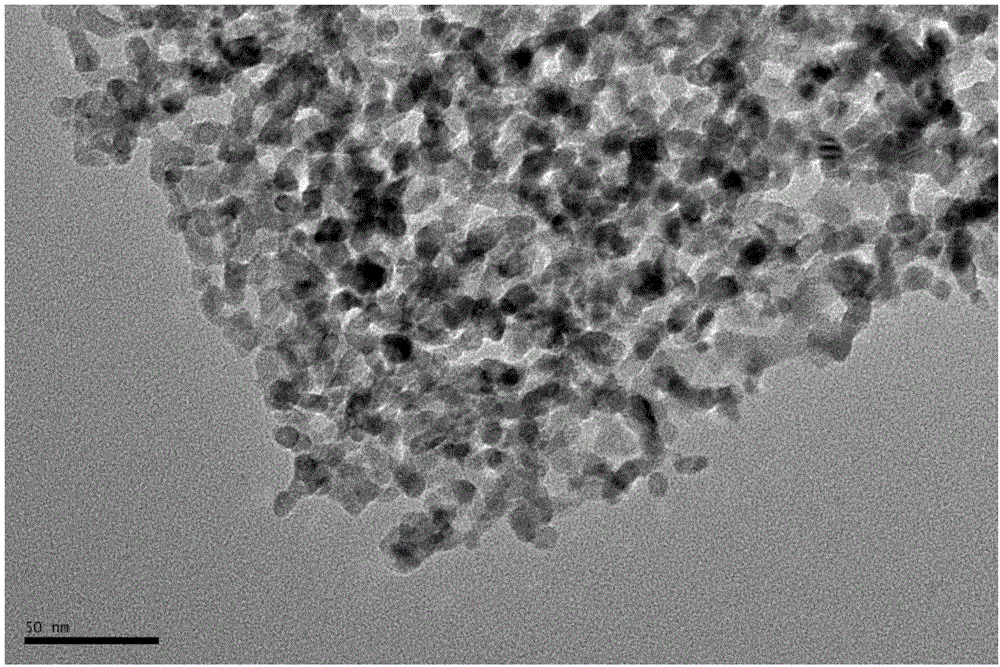

Method of synchronously synthesizing organic matter and metal compound nanoparticles based on MOFs material

ActiveCN106829887AInhibit synthesisReduce pollutionNitrogen-metal/silicon/boron binary compoundsNanotechnologyCarbonizationMetal-organic framework

The invention relates to a method of synchronously synthesizing an organic matter and metal compound nanoparticles based on an MOFs material. The invention aims to solve the problem of recycling an organic ligand when the metal compound nanoparticles are synthesized from MOFs through high-temperature carbonization and pyrolysis. On the one hand, the metal nanoparticles which are small in size and uniform are synthesized by means of a range limiting effect of the MOFs and on the other hand, the organic ligand is reconstructed along with a solid phase organic reaction, so that the problems that the program is complex, the cost is high and dimension is not uniform in an existing process of preparing the metal compound nanoparticles are solved, and meanwhile, the organic ligand which is cheap and complex in structure is recycled, so that generation of greenhouse gas and harmful gas is avoided, and the cost is greatly lowered. The method provided by the invention mainly employs the solid organic reaction of synthesizing the metal compound nanoparticles and the organic ligand by means of a metal organic framework.

Owner:NANKAI UNIV

Process for ammoximation of carbonyl compounds

ActiveUS7408080B2Shorten the timeDelayed recoveryOrganic compound preparationOrganic chemistry methodsDissolutionAmmonia

The present invention discloses a process for the ammoximation of carbonyl compounds, wherein a reaction in a liquid reaction system comprising a carbonyl compound, ammonia and hydrogen peroxide is carried out in the presence of a sillicon-containing catalyst, characterized in that a liquid silicon-containing assistant is added to the reaction system so that the silicon concentration in the system reaches a range of between 0.1 and 10000 ppm. In the process according to the present invention, the deactivation of catalyst due to dissolution of silicon in the catalyst can be reduced, thus lifetime of the catalyst extended and the stable operation time elongated.

Owner:CHINA PETROCHEMICAL CORP +1

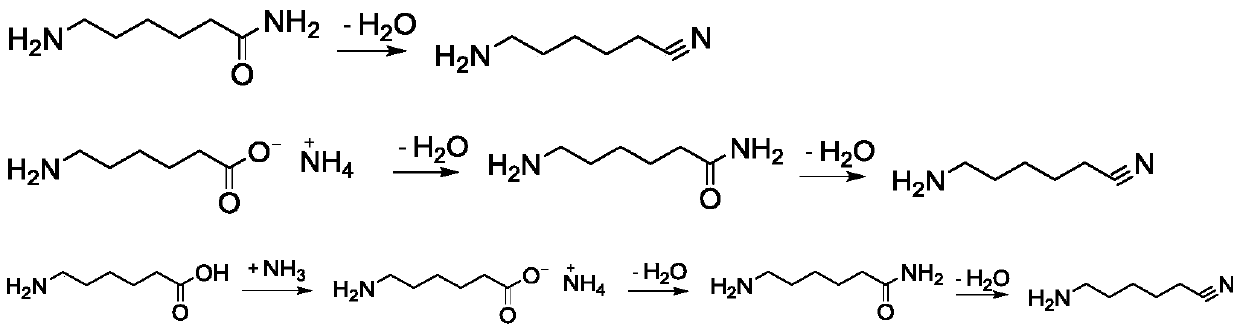

Method for preparing azelaic diamine

ActiveCN106220513AImprove efficiencyHigh yieldOrganic compound preparationAmino compound preparationHydrogenation reactionRenewable biomass

The invention discloses a method for preparing azelaic diamine. Azelaic acid is taken as a raw material, azelaic dinitrile is prepared through a neutralization reaction, a dehydration reaction and a decompression reaction sequentially, and azelaic diamine is prepared through a hydrogenation reaction of the azelaic dinitrile. Compared with the prior art, the method has the advantages as follows: a process route with a simple process and extremely high efficiency and yield is provided; meanwhile, renewable biomass resources are taken as raw materials and are wide in source, and all the processes are relatively simple and can be implemented, so that the method has great social significance and great economic value.

Owner:南京荔枝生物科技有限公司

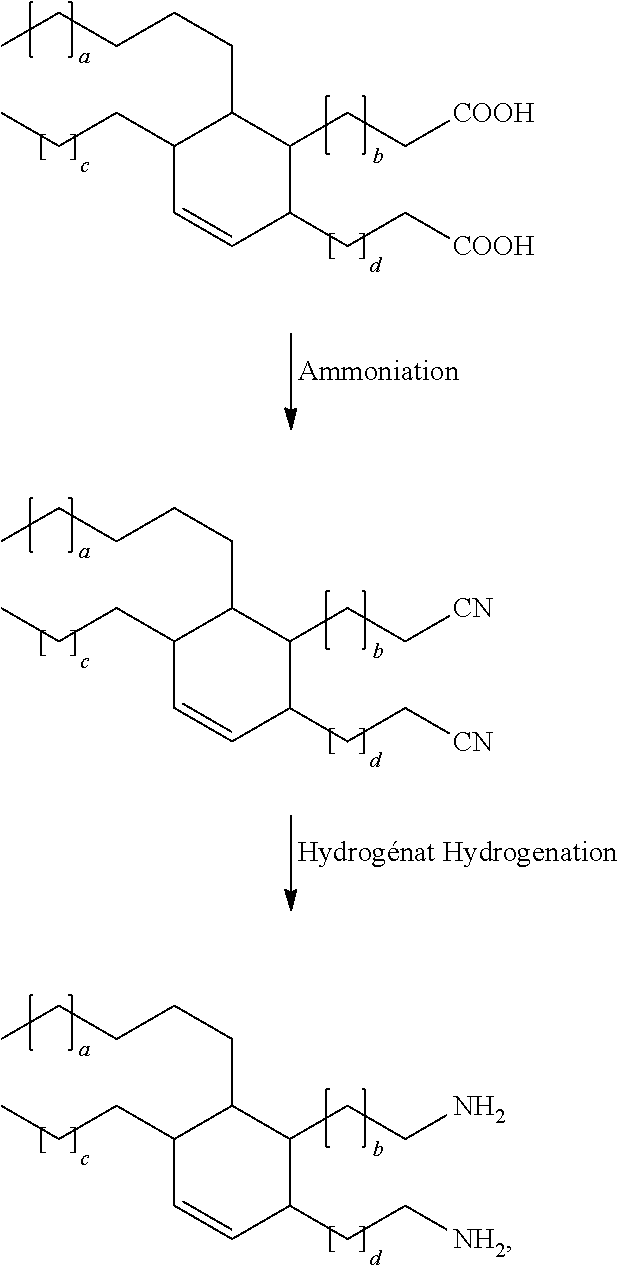

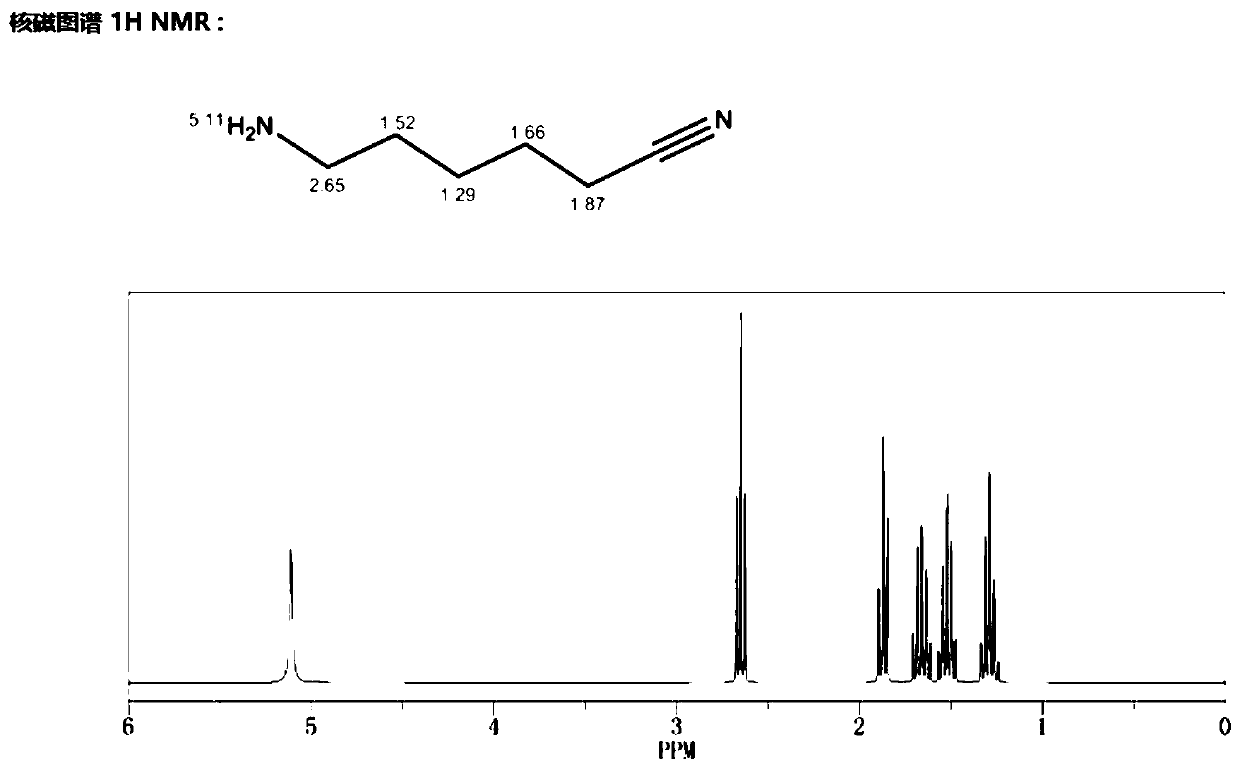

Method for the synthesis of high purity primary diamines and/or triamines

InactiveUS20110190541A1Reduce the amount requiredHigh purityOrganic compound preparationAmino compound preparationDiamineNitrile

The present invention relates to a process for the preparation of primary di- and / or triamines of high purity from nitriles which can themselves originate from dimer and / or trimer acids.This process comprises a stage of ammoniation of the acid functional groups and a stage of hydrogenation of the nitrile functional groups to give primary amine functional groups and does not require additional purification stage(s).

Owner:CECA SA

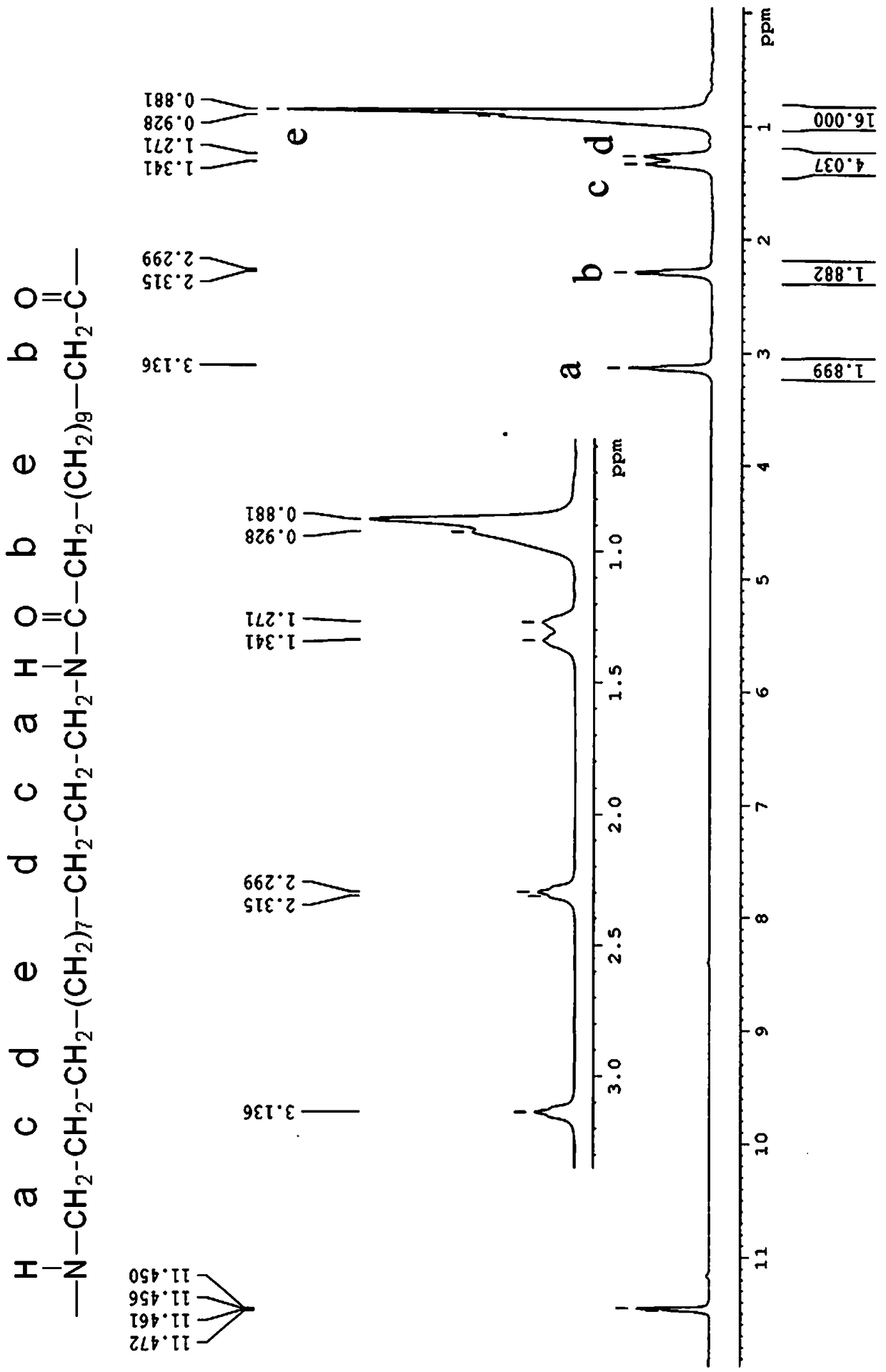

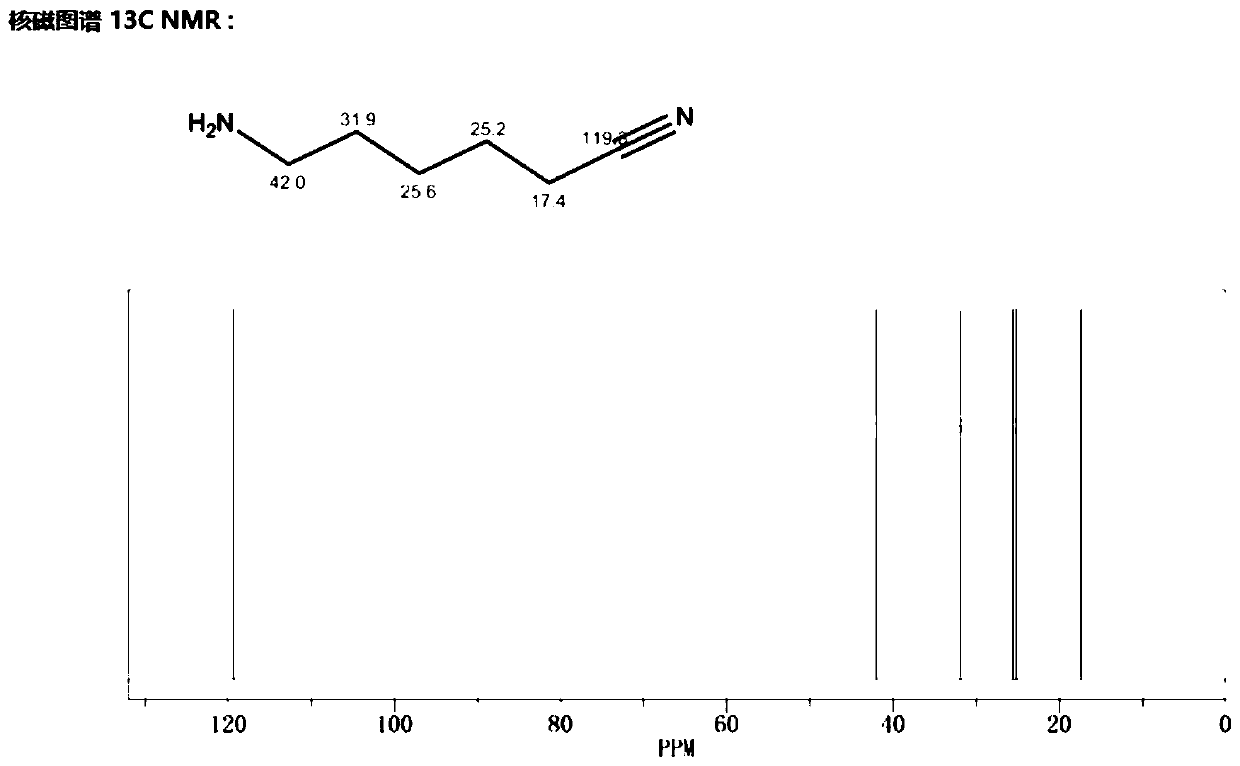

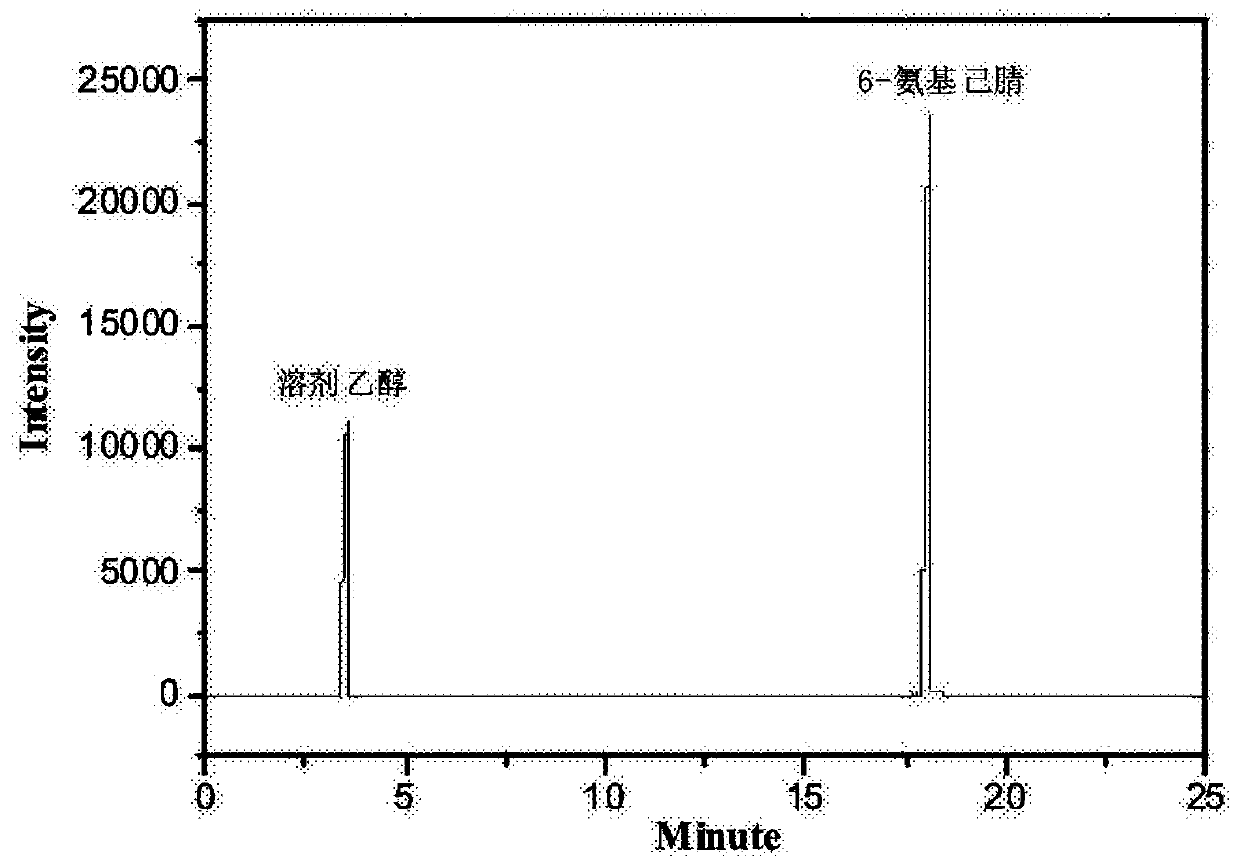

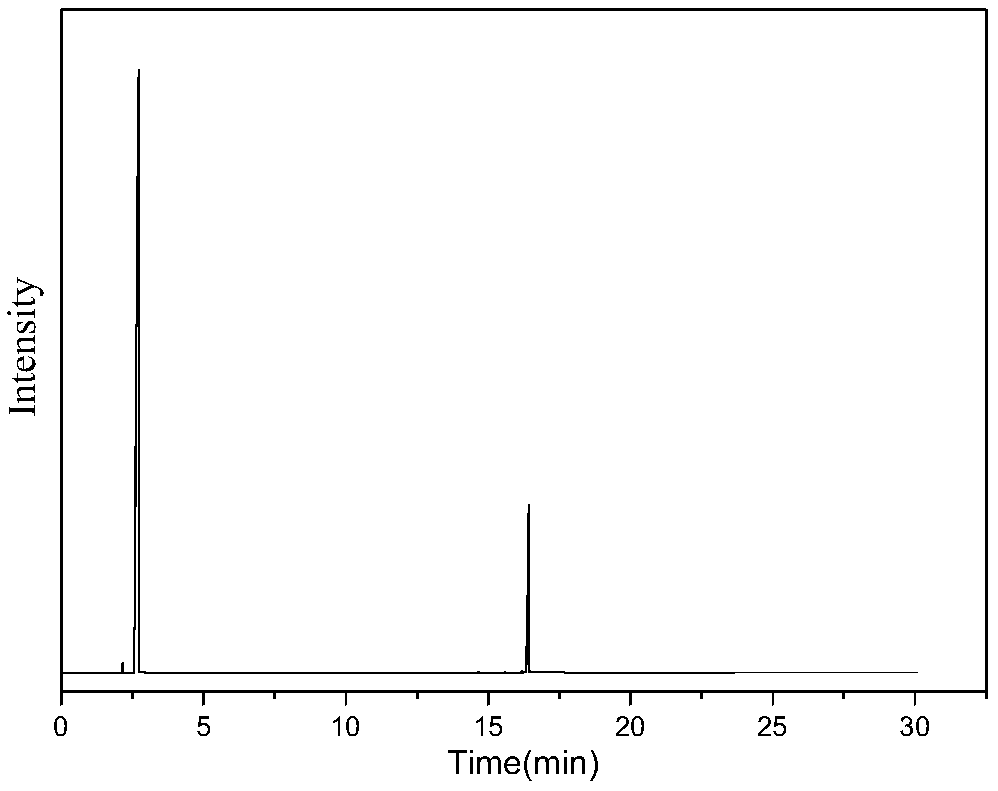

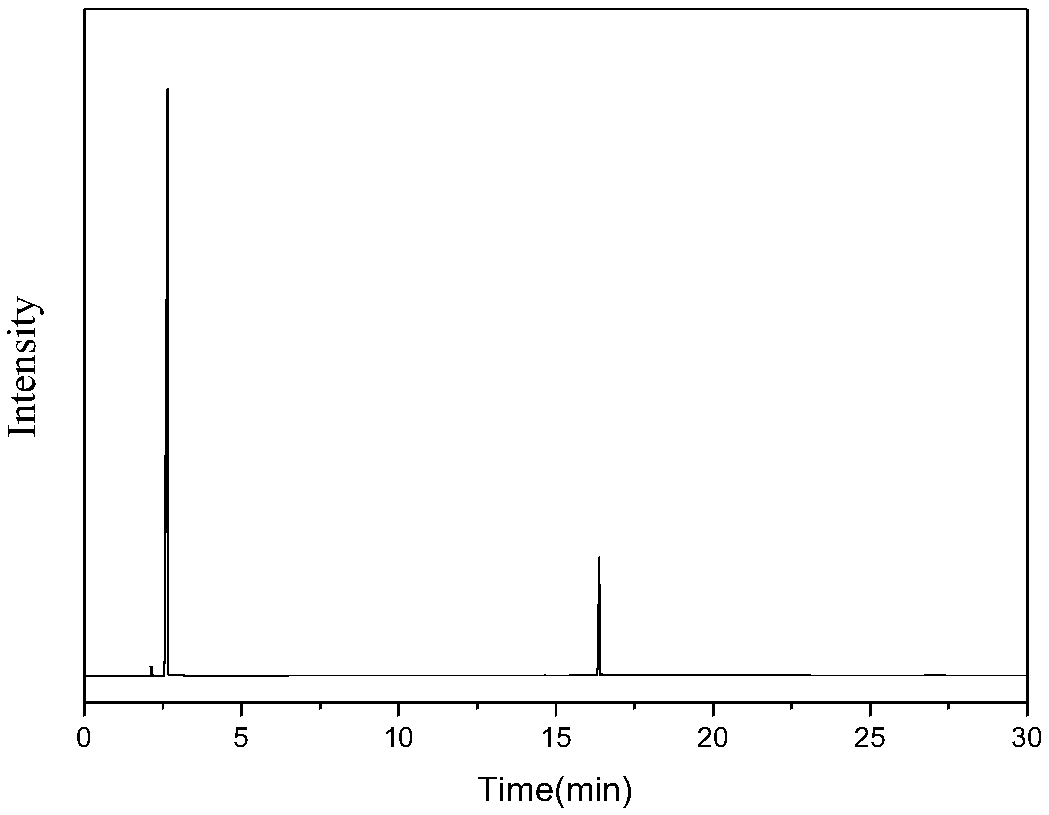

Method for preparing 6-aminocapronitrile product

ActiveCN111233704AReduce pollutionLow reaction temperatureOrganic compound preparationAmino-carboxyl compound preparationAminocapronsäureAlcohol

The invention relates to a method for preparing a 6-aminocapronitrile product. The method comprises the following steps: A, uniformly mixing caprolactam, an acidic solution and the like according to acertain ratio, then adding the mixture into a reaction kettle, heating and stirring the mixture and carrying out a reaction; B, after the caprolactam reaction in the step A is completed, removing low-boiling-point substances under reduced pressure, and recrystallizing the reaction product to obtain 6-aminocaproate; C, uniformly mixing the 6-aminocaproate obtained in the step B, alcohol, an ammoniating agent, a dehydrating agent and the like according to a certain ratio, adding the mixture into a reaction kettle, and heating and stirring the mixture and carrying out a reaction; and D, rectifying the reaction liquid obtained in the step C, and separating and purifying the reaction liquid to obtain 6-aminocapronitrile. According to the method for preparing the 6-aminocapronitrile product, the reaction conversion rate is high, the purity of the 6-aminocapronitrile product can reach 98% or above, the reaction conditions are mild, and the preparation process is relatively simple.

Owner:湖北三宁碳磷基新材料产业技术研究院有限公司 +1

Preparation method of isophthalonitrile

InactiveCN109761851AEasy to makeLow reaction temperatureOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by ammonia-carboxylic acid reactionPhosphateDistillation

The invention relates to a preparation method of isophthalonitrile. The preparation method of isophthalonitrile comprises the following steps: adding isophthalic acid to a cyanation reactor, and adding an ethyl methylimidazolium dihydrogen phosphate ionic liquid accounting for 15%-50% by volume of isophthalic acid; introducing ammonia, and performing a reaction; after the reaction, performing distillation purification on a crude isophthalonitrile product to obtain isophthalonitrile. The ethyl methylimidazolium dihydrogen phosphate ionic liquid serves as a solvent and a catalyst to be used forpreparing isophthalonitrile from isophthalic acid by cyanation, compared with the prior art, the raw materials are easily available, the operation is simple, the catalyst is simple to prepare, and thereaction temperature is reduced.

Owner:SINOPEC YANGZI PETROCHEM +1

Preparation method of adiponitrile

InactiveCN109206343AShorten the timeReduce the temperaturePreparation by ammonia-carboxylic acid reactionBulk chemical productionOrganic synthesisPhosphate

Belonging to the field of organic synthesis, the invention discloses a preparation method of adiponitrile. The specific steps include: (1) preparation of ethyl methylimidazole dihydrogen phosphate ionic liquid; and (2) application of the ethyl methylimidazole dihydrogen phosphate ionic liquid as a solvent and catalyst to the preparation process of adiponitrile by cyanation of adipic acid. The reaction time and temperature are reduced to certain extent, so that side reactions are decreased and the yield is increased.

Owner:SINOPEC YANGZI PETROCHEM +1

Method for preparing p-hydroxybenzonitrile

InactiveCN105418455AContinuous automated productionThe reaction steps are simplePreparation by ammonia-carboxylic acid reactionOrganic solventReaction temperature

The invention discloses a method for preparing p-hydroxybenzonitrile. The method comprises the following steps: adding filler and a catalyst into a fixed-bed reactor, dissolving feed, i.e., methyl p-hydroxybenzoate in an organic solvent, then, adding the solution into the fixed-bed reactor together with water, controlling the reaction temperature of the reactor to 300-480 DEG C and the reaction pressure of the reactor to 0-0.1KPa, carrying out continuous discharging, and carrying out rectification, thereby preparing p-hydroxybenzonitrile. The method is energy-saving and environment-friendly, continuous automated production can be achieved, reaction steps are simplified, process flows are reduced, and the problem in former p-hydroxybenzonitrile production that waste gases, waste water and waste residues are severe and the continuous automated production cannot be achieved is solved.

Owner:JIANGSU RUIDA TECH CO LTD

Hydroxy benzonitril preparation process

InactiveCN106431981ATake advantage ofReduce wastePreparation by ammonia-carboxylic acid reactionOrganic synthesisReaction temperature

The invention discloses a hydroxy benzonitril preparation process and belongs to the technical field of organic synthesis. The hydroxy benzonitril preparation process is characterized by comprising the steps of enabling salicylic acid, urea, sulfamic acid and a catalyst to react in a solvent, and separating to obtain hydroxy benzonitril, wherein the catalyst is a mixture of magnesium oxide and cyanuric chloride at the weight ratio of 1:(1-2), the reaction temperature is 140-160 DEG C, and the materials of the salicylic acid, the urea, the sulfamic acid and the catalyst are added at the weight ratio of 1:(0.8-1.2):(1.4-1.8):(0.05-0.2). The efficient and practical compound catalyst is creatively used, the salicylic acid is directly used as the material, the hydroxy benzonitril is synthesized in a one-step method, the product is easy to separate and purify, the operation is convenient, the product purity is high, and the yield is high.

Owner:禹城禹圳生物科技有限公司

Catalyst for synthesizing p-hydroxybenzonitrile (2-hydroxybenzonitrile) and preparation method of catalyst

ActiveCN106694023ASimple processEasy to operateMolecular sieve catalystsPreparation by ammonia-carboxylic acid reactionFixed bedCopper nitrate

The invention discloses a catalyst for synthesizing p-hydroxybenzonitrile (2-hydroxybenzonitrile) and a preparation method of the catalyst. Phosphoric acid, copper nitrate, stannous oxalate and ammonium molybdate are dissolved in deionized water, an impregnation liquid is prepared, and a bar-shaped Silicalite-1 molecular sieve is impregnated in the impregnation liquid for 12-24 h at the room temperature; the impregnated molecular sieve is dried in a drying oven at 80-120 DEG C for 6-24 h and roasted in a muffle furnace at 450-600 DEG C for 4-12 h, and the catalyst is obtained. The catalyst is prepared from active components in terms of the mass percentage of the carrier as follows: 0.5-15% of P2O5, 0.1%-3.0% of CuO, 0.5%-4.5% of SnO and 0.2%-2% of MoO3. The catalyst is prepared with a conventional impregnation method, and the technological process is simple and easy to operate; the all-silicon molecular sieve is used as an active carrier and has a synergistic effect with all active oxide components, and the prepared catalyst is applicable to the continuous production process of p-hydroxybenzonitrile (2-hydroxybenzonitrile) by use of a fixed bed reactor and has the advantages of high raw material conversion rate, high product selectivity and long service life in the p-hydroxybenzonitrile (2-hydroxybenzonitrile) synthesis process.

Owner:CHINA CATALYST HLDG CO LTD

Method for preparing 1-amino-2-cyano cyclopentene

ActiveCN109608360AOrganic compound preparationPreparation by ammonia-carboxylic acid reactionCyclopenteneDistillation

The invention provides a method for preparing 1-amino-2-cyano cyclopentene. According to the method, a gas-phase ammonolysis reaction is carried out by taking dimethyl adipate and ammonia gas as raw materials, and a solid acid catalyst is selected as a catalyst. Through the method, a mixture containing 1-amino-2-cyano cyclopentene and adiponitrile is prepared through high-temperature gas-phase ammoniation, and then the pure 1-amino-2-cyano cyclopentene is obtained by utilizing reduced pressure distillation and recrystallization technologies. According to the method, the raw materials are easily available, the method is simple and feasible, product purity is high, and large-scale preparation of the target product can be prepared.

Owner:CHINA TIANCHEN ENG

One-step synthetic method of p-(o-)hydroxybenzonitrile

ActiveCN106699601AAvoid complexityAvoid operabilityPreparation by ammonia-carboxylic acid reactionOrganic solventActive component

The invention discloses a one-step synthetic method of p-(o-)hydroxybenzonitrile. The one-step synthetic method comprises the following steps: dissolving methyl p-(o-)hydroxybenzoate in an organic solvent, and then putting dissolved methyl p-(o-)hydroxybenzoate together with free ammonia into a catalyst-loaded fixed bed reactor a through a pipeline to synthesize p-(o-)hydroxybenzonitrile through one step under the conditions that the reaction temperature is 250-550 DEG C and the reaction pressure is 0-1.0Mpa, wherein the mass ratio of the free ammonia to the methyl p-(o-)hydroxybenzoate is (2-10):1, the space velocity for the free ammonia and the methyl p-(o-)hydroxybenzoate to enter the fixed bed reactor together is 0.5-5.0h<-1>, and the catalyst is obtained by kneading active components including P2O5, CuO, SnO and MoO3 with a carrier. The method disclosed by the invention adopts a production form with the fixed bed reactor, is more suitable for continuous production, and avoids complexity of an original intermittent reaction process and cumbersome reaction operation, and the production capacity is greatly improved; and meanwhile, the use level of the free ammonia is relatively low, so that excessive free ammonia can also be recycled after gas-liquid separation, the method is further improved in cost saving and environmental protection.

Owner:CHINA CATALYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com