Method and equipment for production of adiponitrile from adipic acid

A technology of adipic acid and adiponitrile, which is used in ammonia-carboxylic acid reaction preparation, organic chemistry and other directions, can solve problems such as difficult control of operating parameters, serious reactor coking, unstable product quality, etc., and achieve normal reaction and raw materials. Low consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

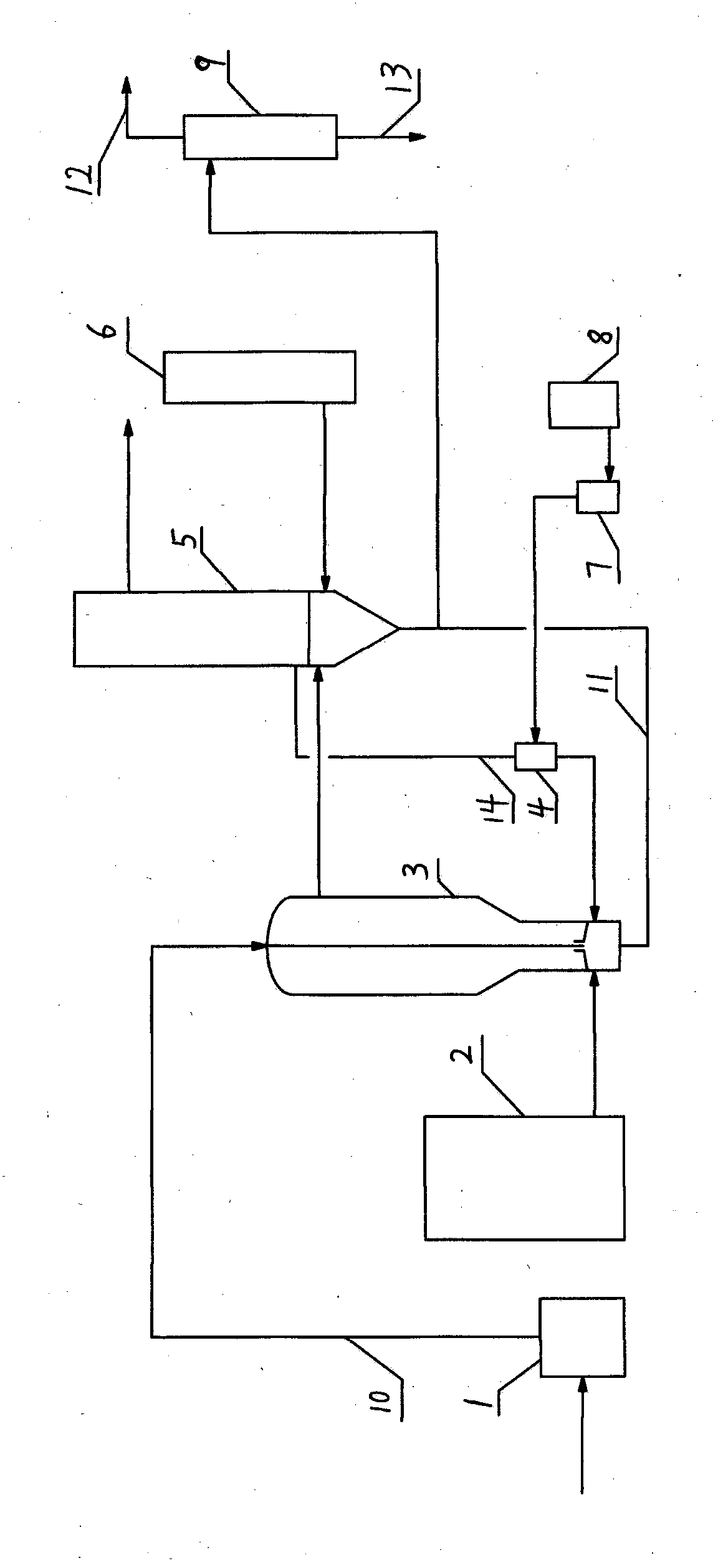

[0024] The weight ratio of the materials and materials used in the production of adiponitrile from adipic acid is: molten adipic acid: ammonia: phosphoric acid: thinner=1: 1.5: 0.003: 2.2;

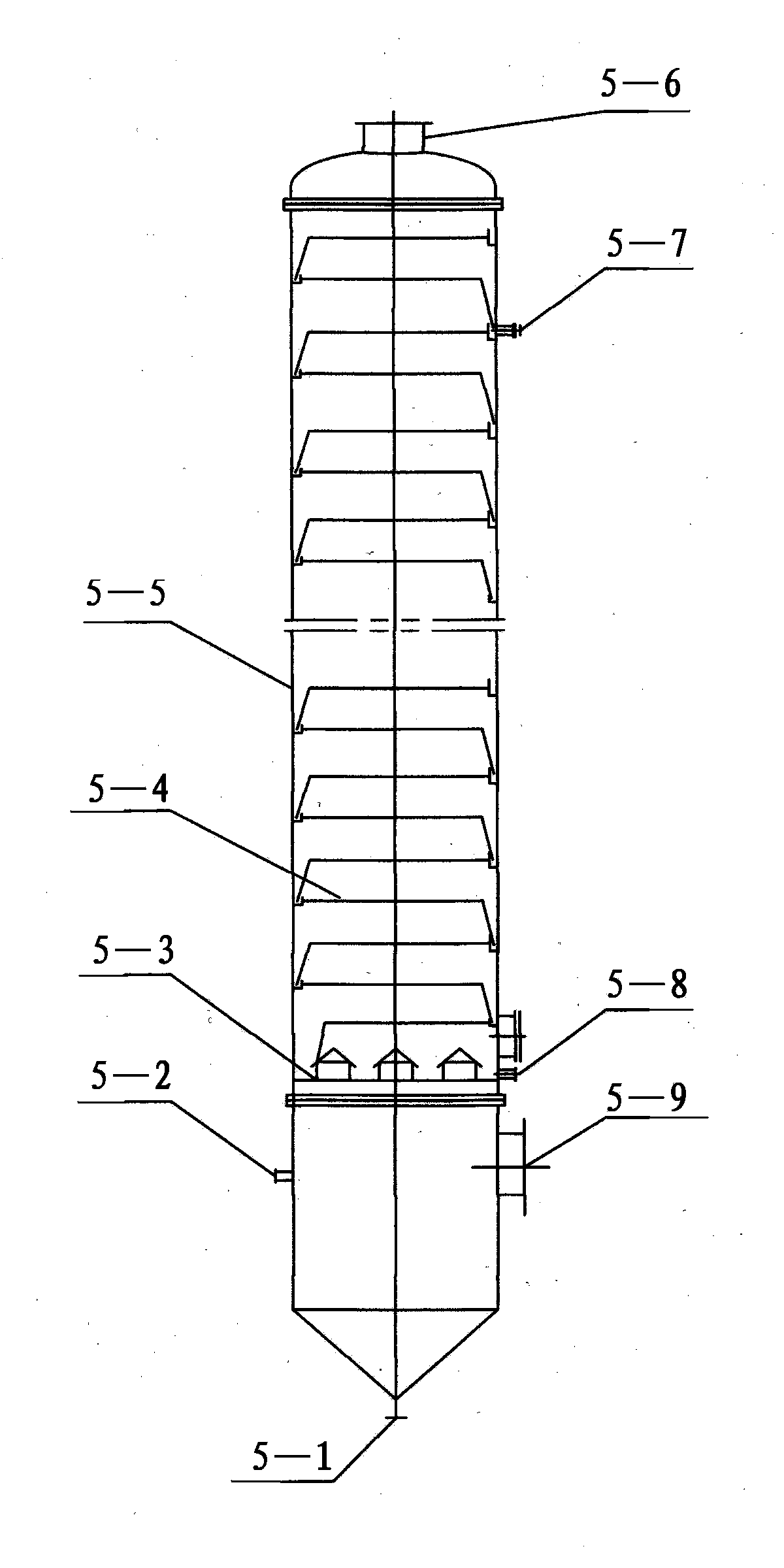

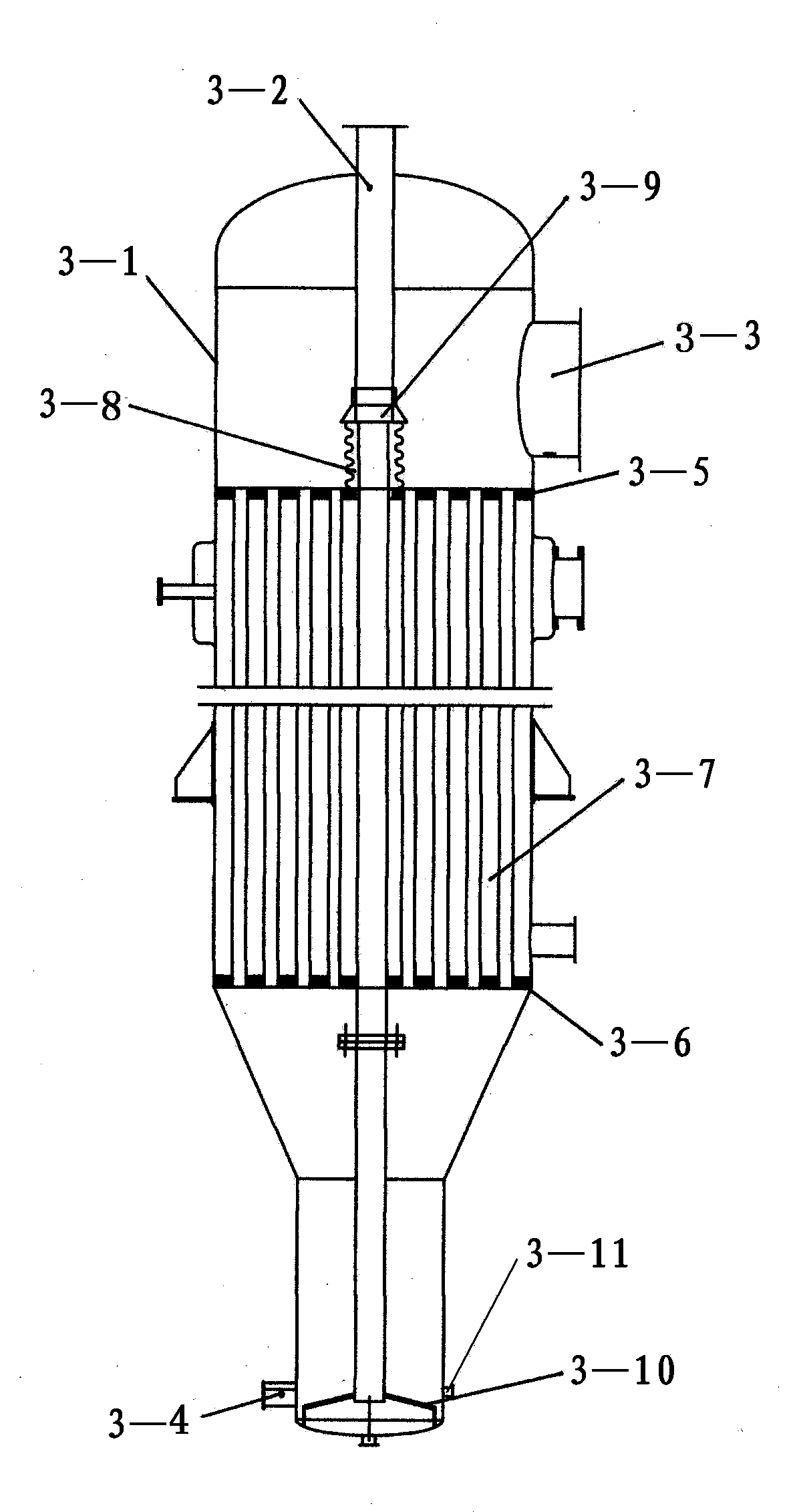

[0025] Concrete production method is: when original start-up, replace melting adipic acid with adiponitrile and join in the nitrilation reactor 3, and add phosphoric acid, the weight ratio of adiponitrile and phosphoric acid is 1: 0.004; Heating nitrilation reactor, Gradually raise the temperature, establish the circulation between the nitrilation reactor 3 → the bottom of the separation tower 5 → start the thermal cycle line 11 → nitrilation reactor 3; when the temperature in the nitrilation reactor reaches 100 ° C, after being compressed by the ammonia compressor 1 The gas ammonia enters in the central tube of the nitrilation reactor 3 through the ammonia pipeline 10, and the gas ammonia enters the bottom of the nitrilation reactor from the top of the central tube and flows upwards, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com