Chemical looping combustion device and method for staged oxidation of solid fuel

A chemical looping combustion and solid fuel technology, applied in the direction of solid fuel combustion, combustion methods, fluidized bed combustion equipment, etc. Reduce and other problems, achieve extensive social benefits and industrial application prospects, reduce reactivity and improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

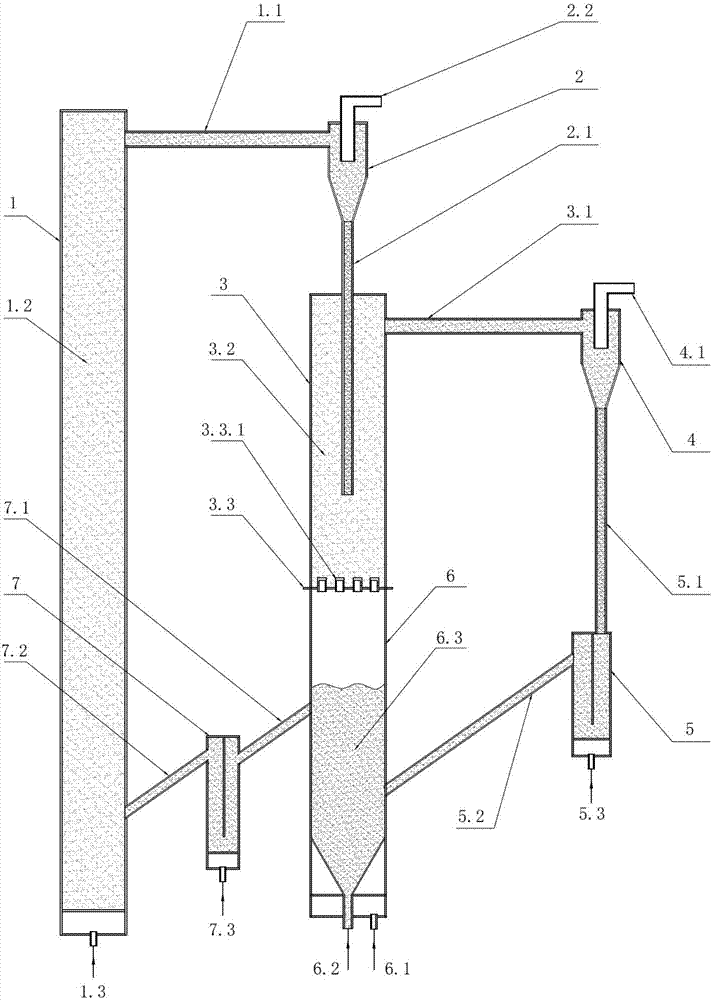

[0035] The method of a chemical chain combustion device for staged oxidation of solid fuels is that the solid fuels are burned without direct contact with air, and the solid fuels are solid fuels containing hydrocarbons, including coal, biomass, and domestic sludge. The solid fuel enters the gasification reactor 6, and the oxidation-reduction reaction is alternately cycled between the air reactor 1, the fuel reactor 3 and the gasification reactor 6 through the oxygen carrier to realize the combustion process of the solid fuel. Including oxidized oxygen carrier particles 1.2, depleted oxidized oxygen carrier particles 3.2 and reduced oxygen carrier particles 6.3; the specific method includes the following steps:

[0036] 1) Gasification-oxidation reaction: when combustion occurs, the fluidization gas enters the gasification reactor 6 through the second fluidization gas inlet 6.1 arranged at the bottom of the gasification reactor 6, and the solid fuel is disposed in the gasificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com