Patents

Literature

61results about How to "Normal response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

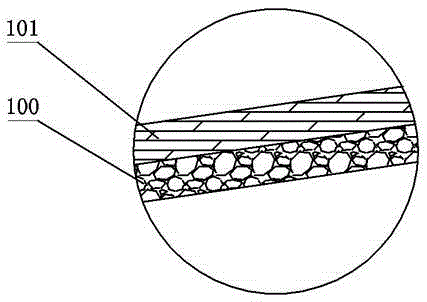

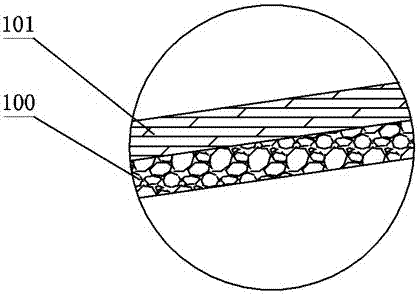

Reinforcing yarn size for glass fibers and preparation method thereof

The invention relates to a reinforcing yarn size for glass fibers and a preparation method thereof, and belongs to the technical field of sizes for glass fibers. The size comprises 4.0-5.5% of a filmogen emulsion, 1.7-4% of a lubricating agent, 0.5-1.5% of a water soluble epoxy resin binder, 0.2-1.0% of an inorganic antistatic agent, 0.5-1.5% of an aminosilane coupling agent and the balance softened water. The filmogen emulsion comprises polyethylene glycol-4000 (PEG-4000), boron trifluoride diethyl etherate, epoxy resin E-44, epoxy resin E-20 and water with a ratio of (1-2): (0.005-0.01): (1-1.5): (0.8-1.2): (8-10). Glass fibers drawn through the size can bear repeatedly bending deformation and have a good textile performance, and woven glass fiber cloth can be applied to production of composite materials without heat treatment and is quick in soakage and high in binding force when compounded with matrix resin.

Owner:SICHUAN FIBERGLASS GRP

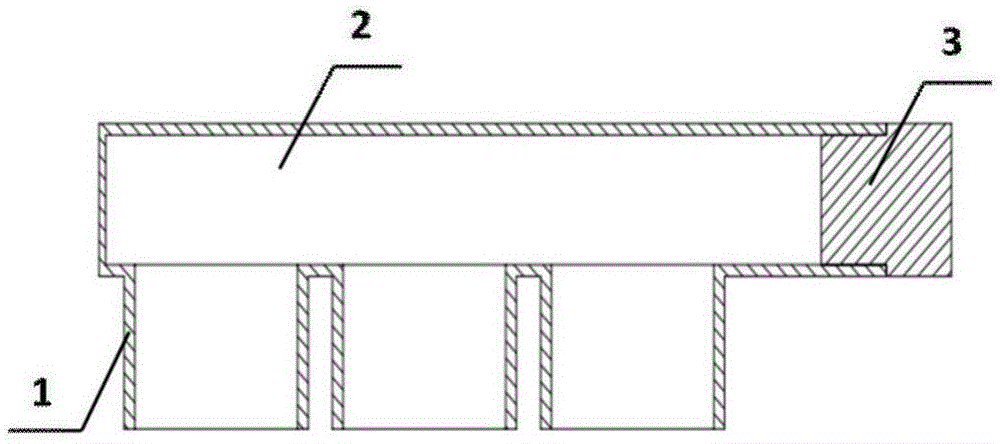

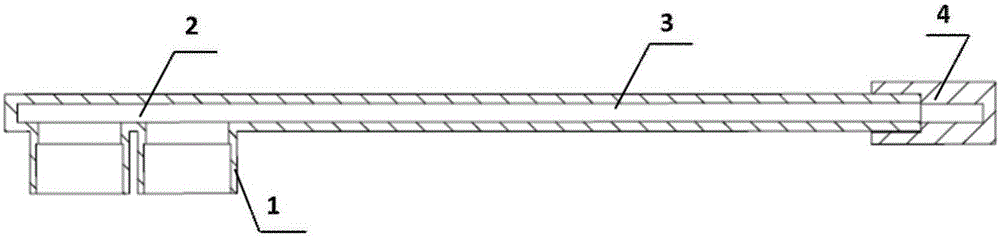

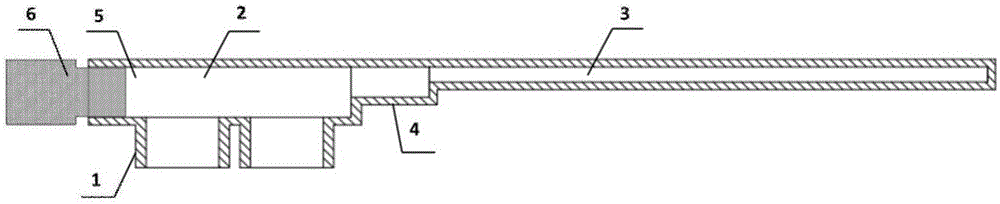

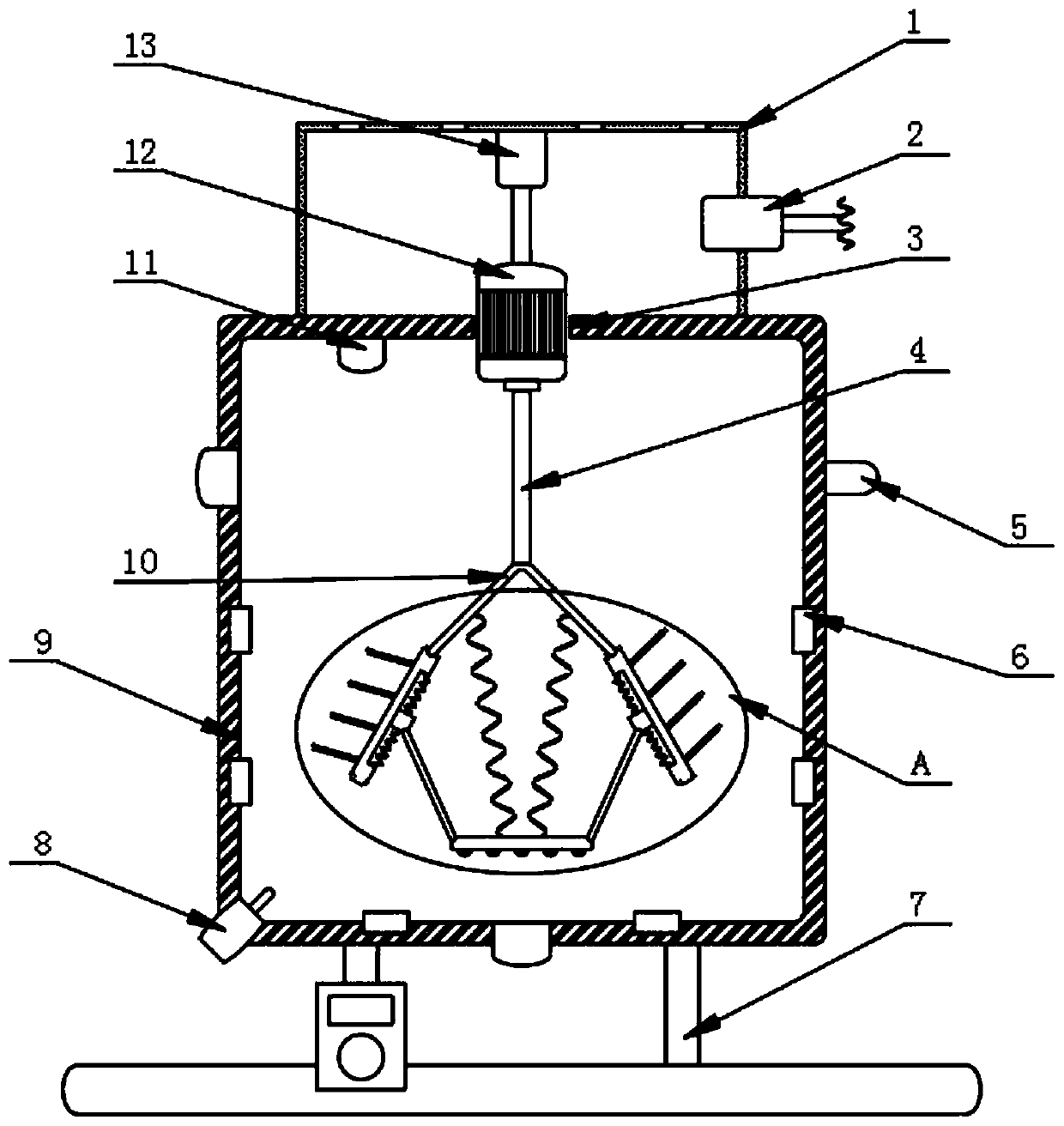

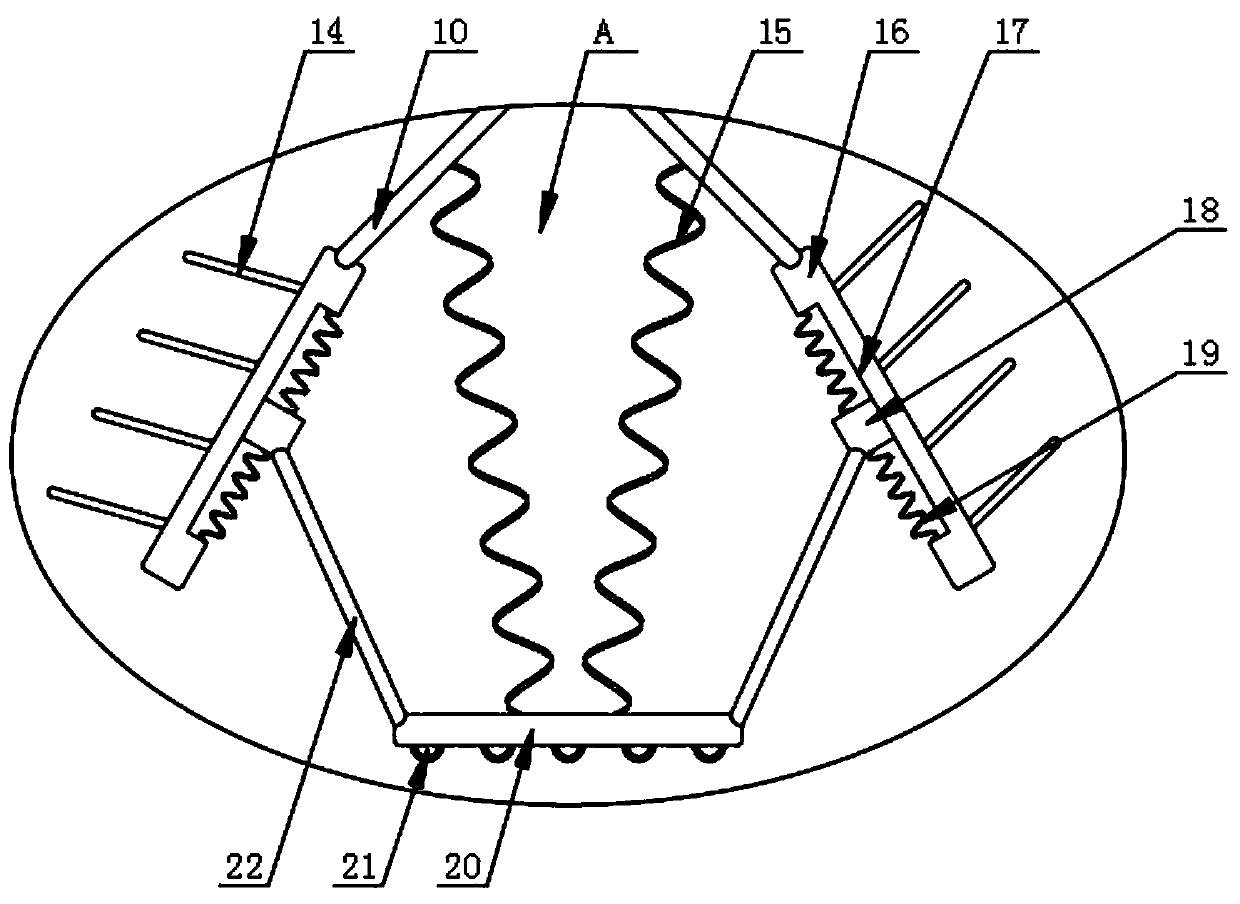

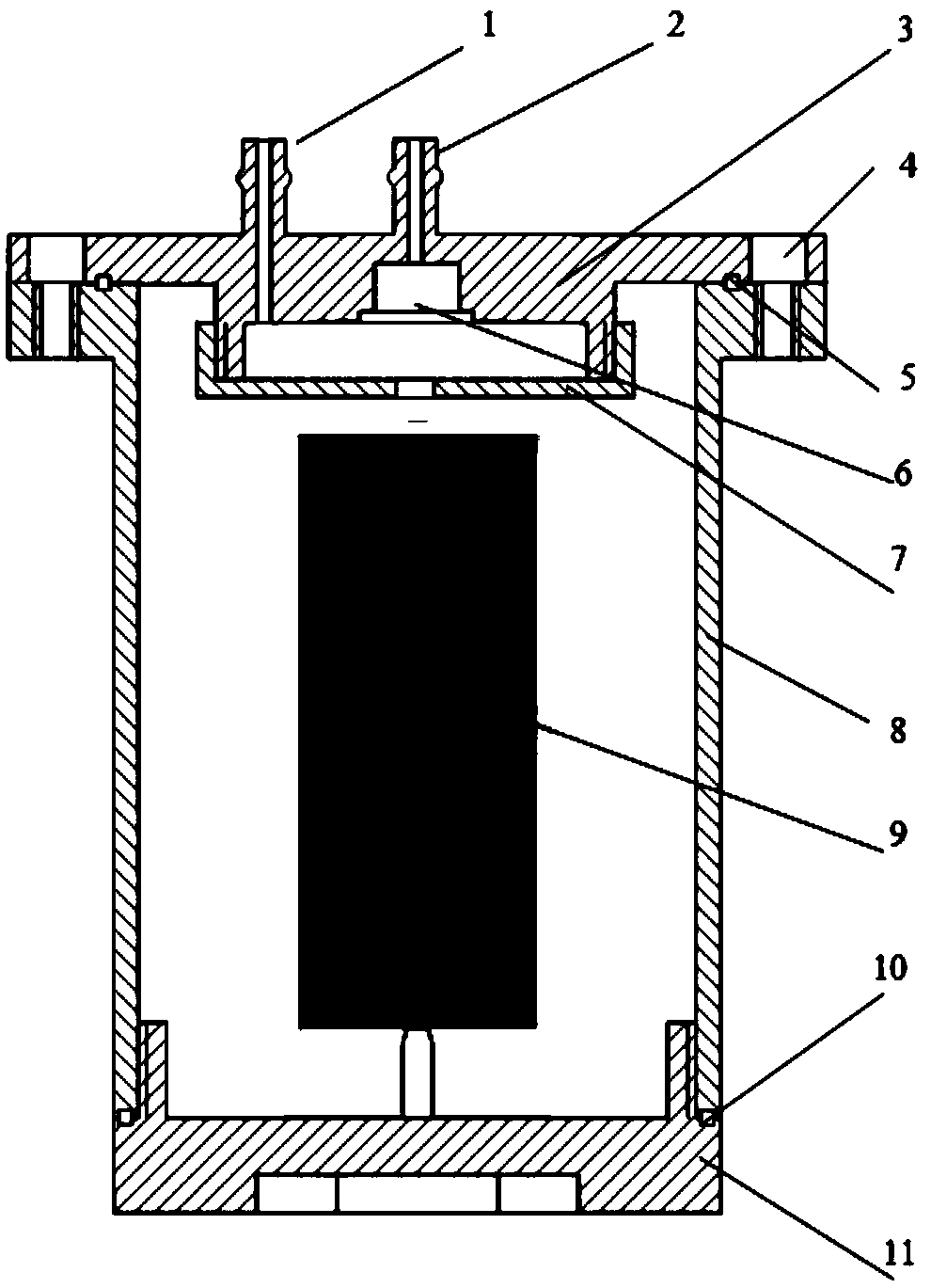

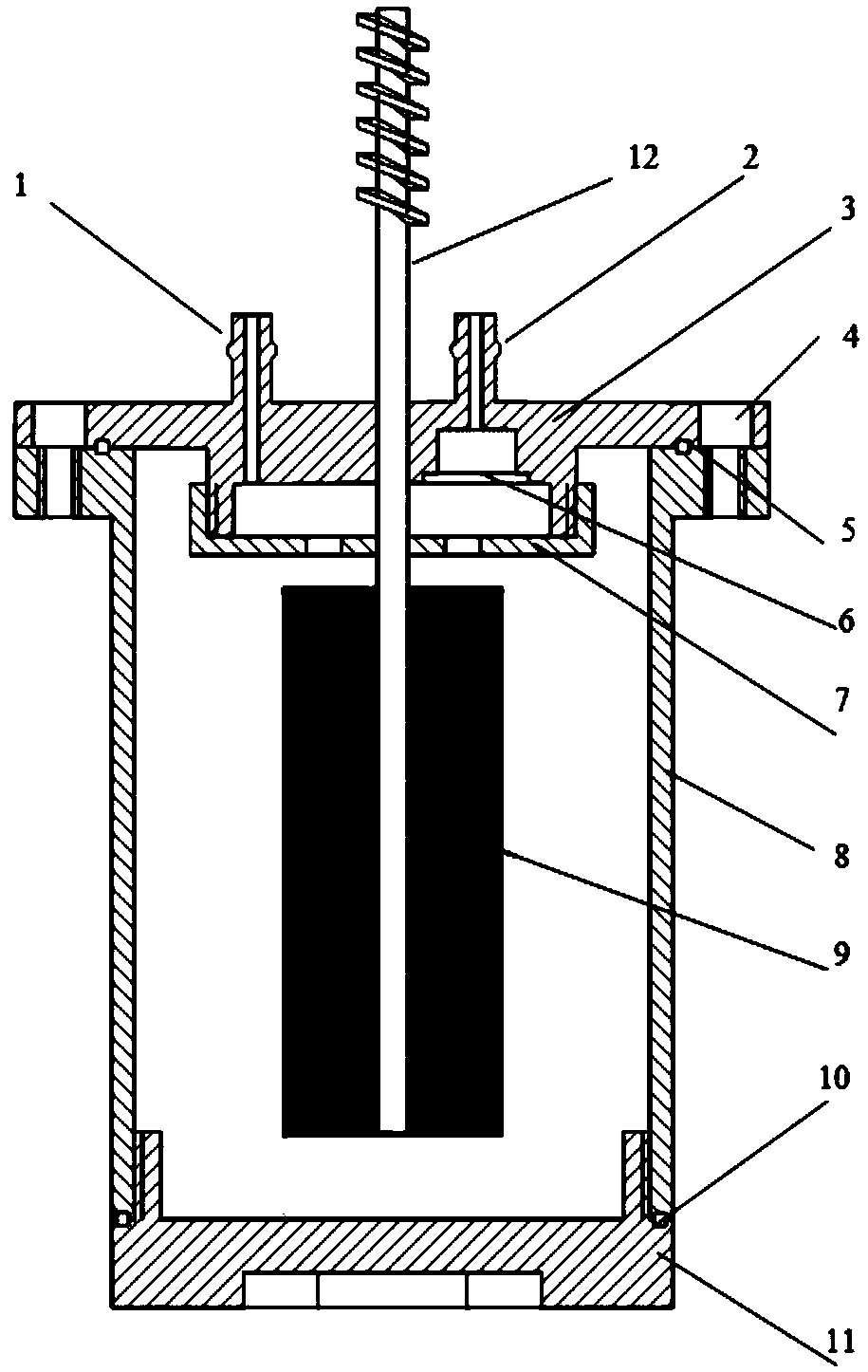

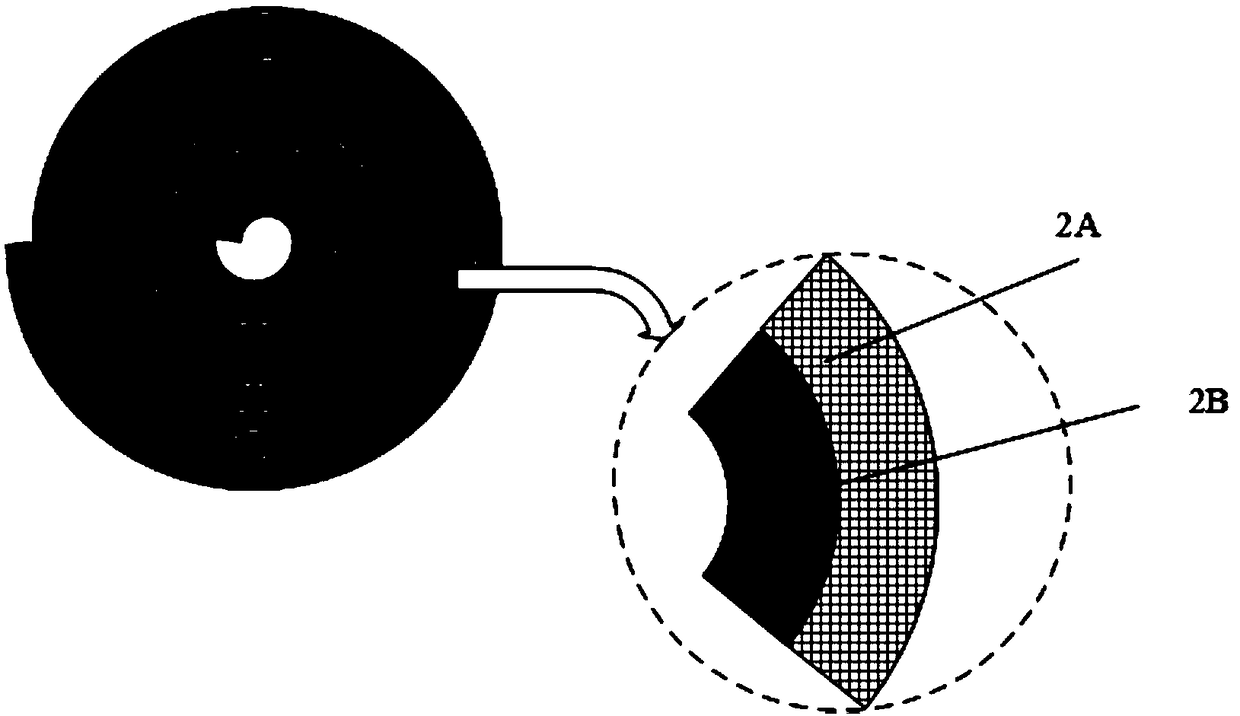

Sealed portable nucleic acid detection apparatus and method thereof

InactiveCN105063180AGood versatilityReduce testing costsBioreactor/fermenter combinationsBiological substance pretreatmentsMolecular biologyBiophysics

The present invention provides a portable visualized nucleic acid detection method and a sealed portable nucleic acid detection apparatus. The nucleic acid detection apparatus comprises a visualized mixing container, wherein the visualized mixing container is provided with a plurality of connection ports, such that the visualized mixing container can be used as the total sealing body for connecting the nucleic acid amplification reaction tube on the visualized mixing container and the detection reaction liquid storage container on the visualized mixing container, or can be adopted as the total sealing body for connecting the nucleic acid amplification reaction tube on the visualized mixing container and the dilution storage container on the visualized mixing container. According to the present invention, the nucleic acid isothermal amplification reaction can be performed without interference in the case of achievement of no reaction tube opening, the subsequent detection can be normally performed according to the sequence, and the apparatus and the method can be suitable for chromogenic assay and test paper strip assay.

Owner:ZHEJIANG UNIV +1

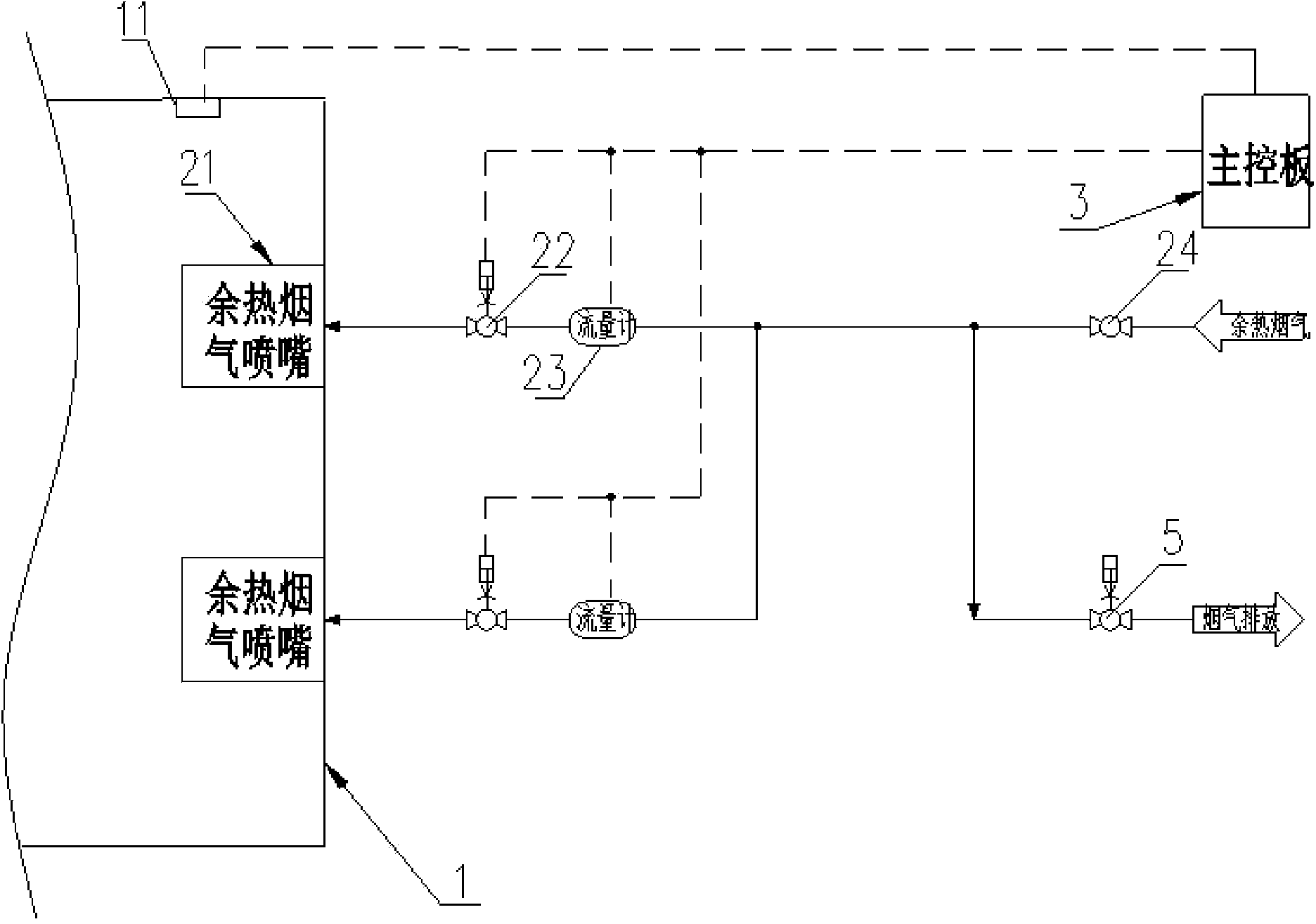

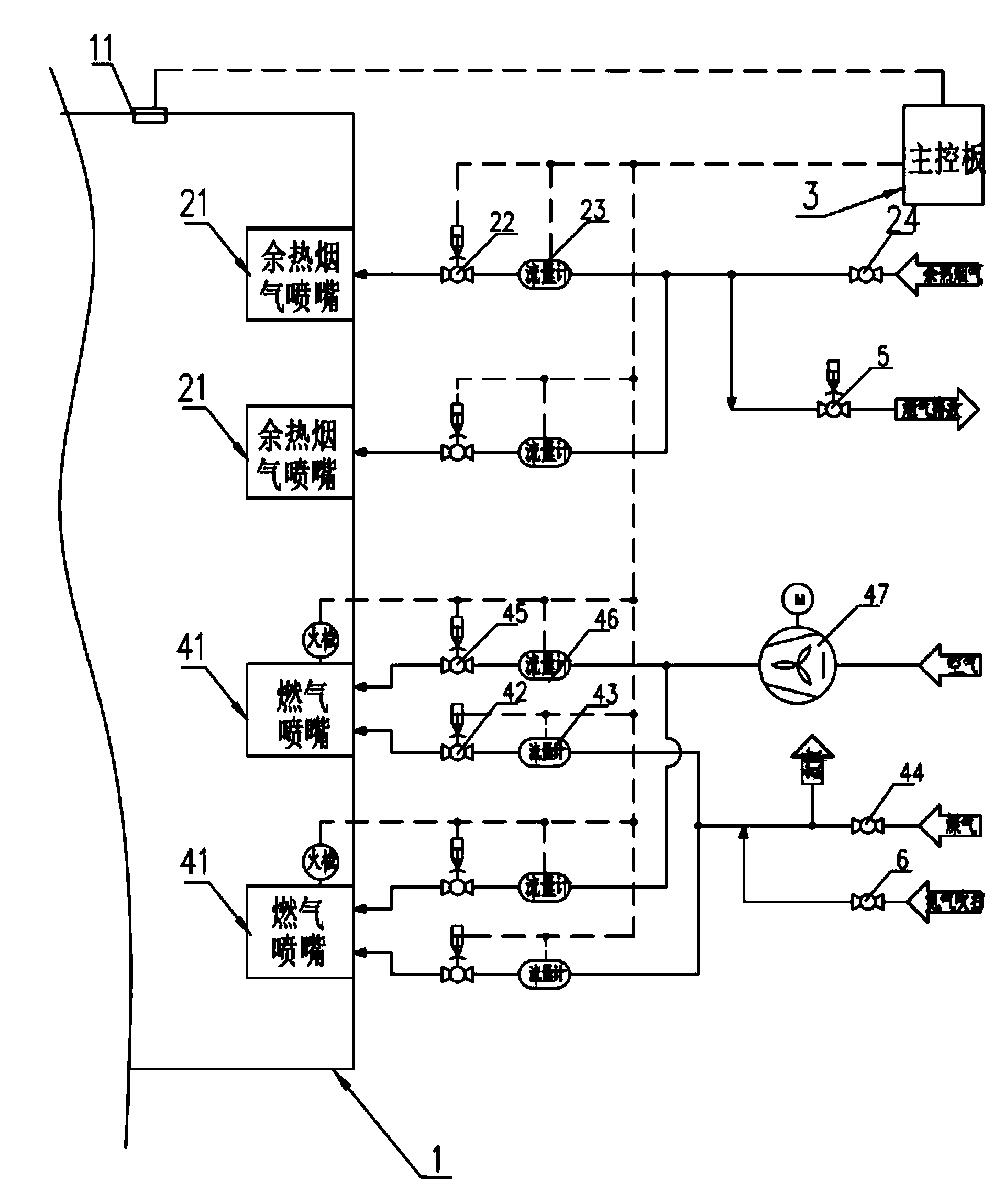

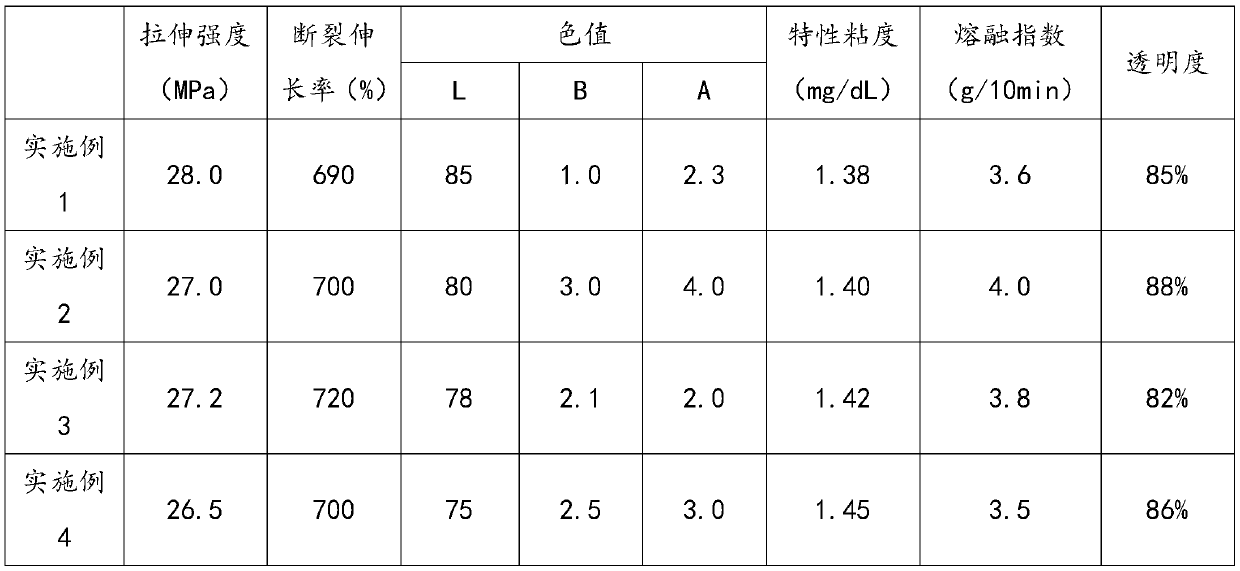

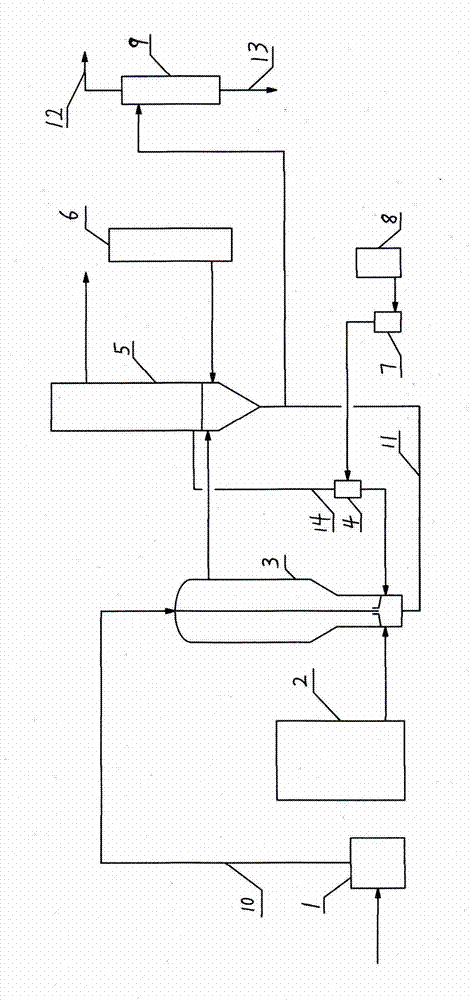

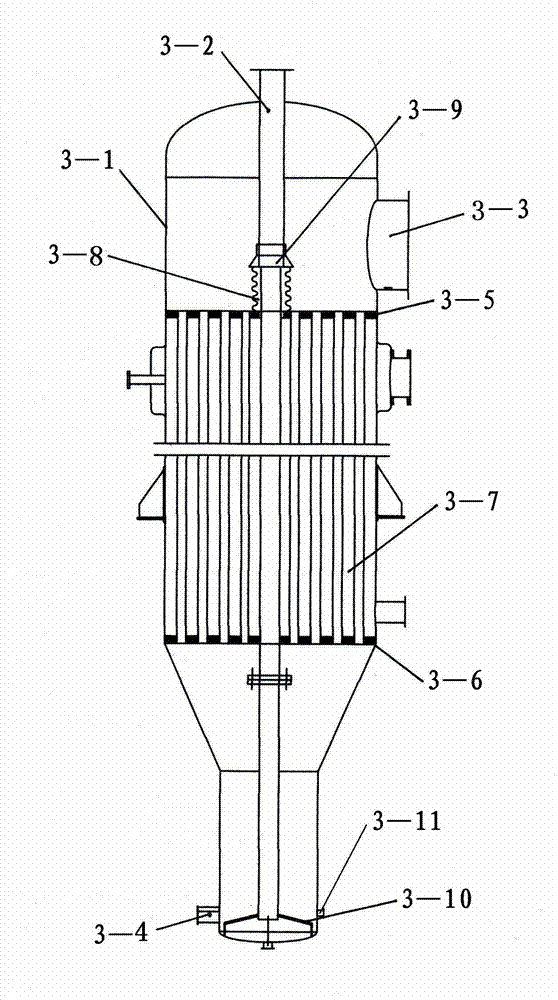

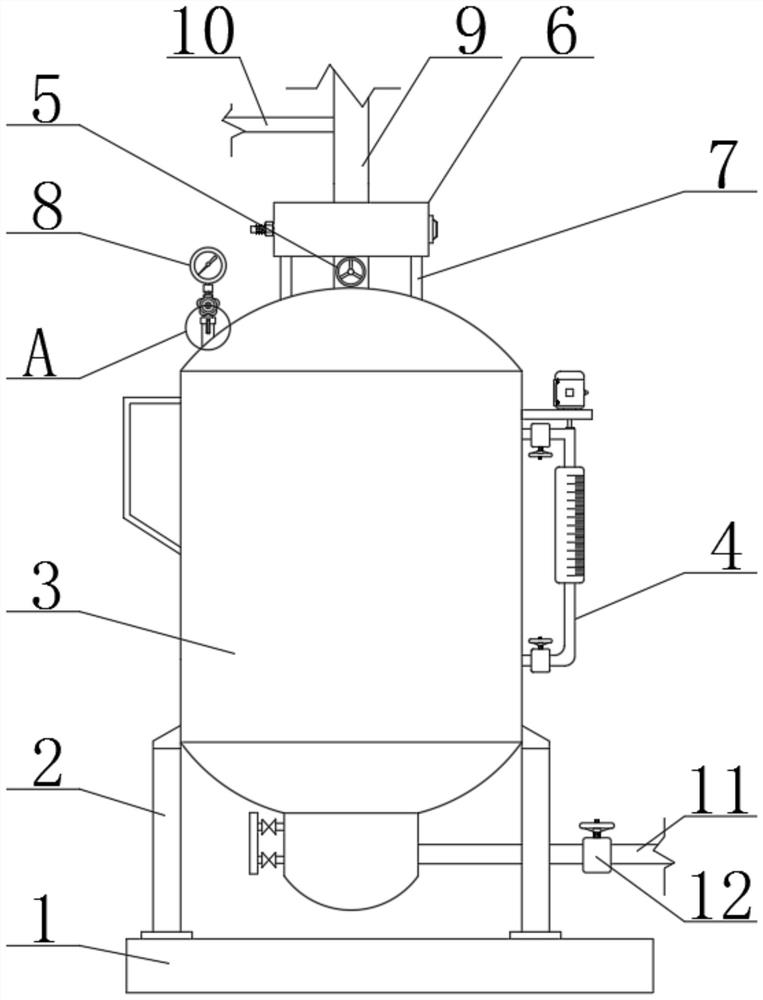

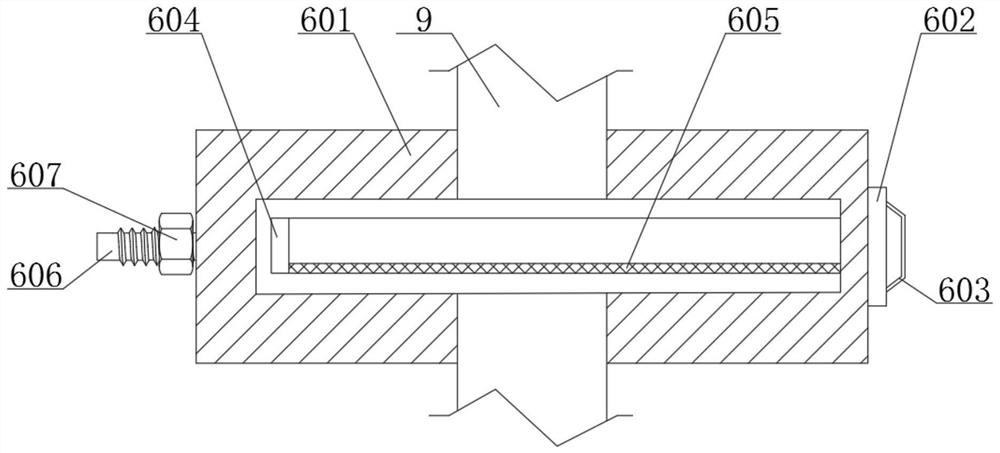

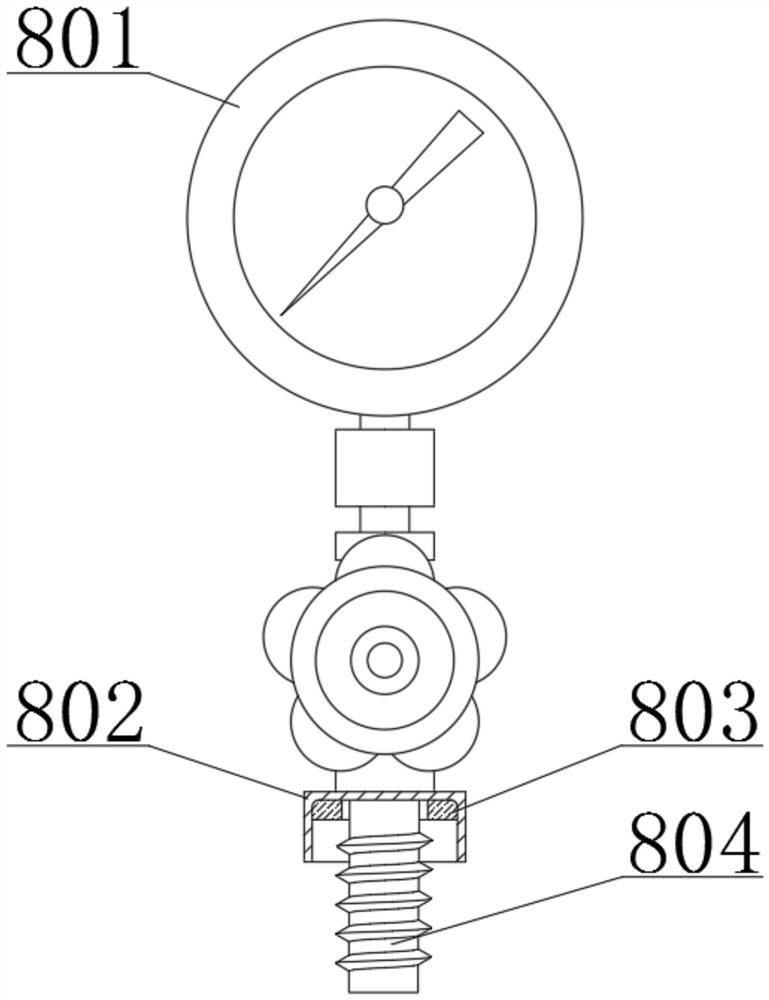

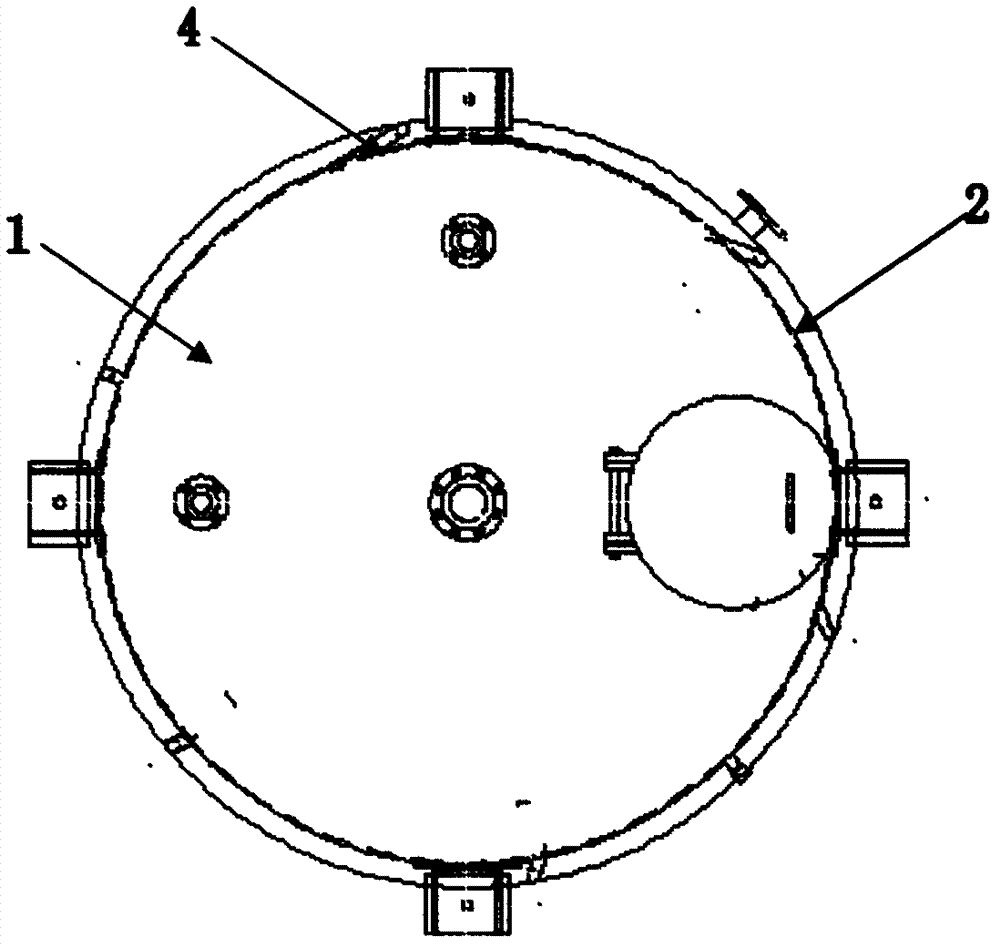

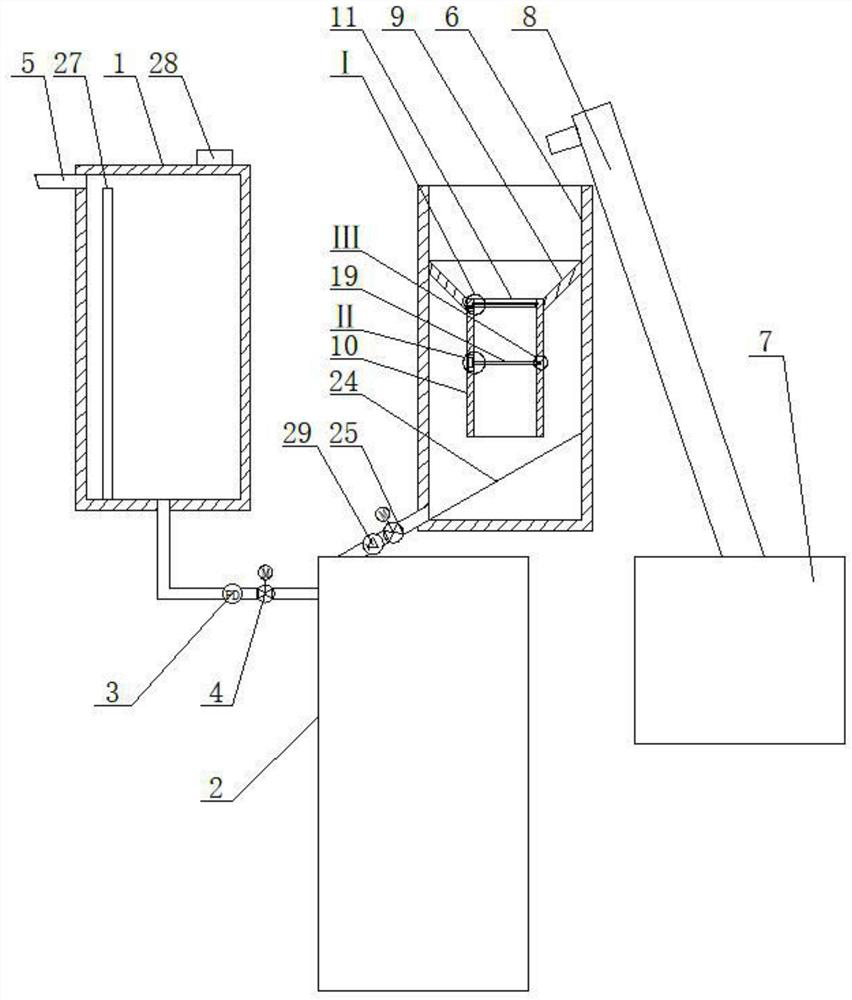

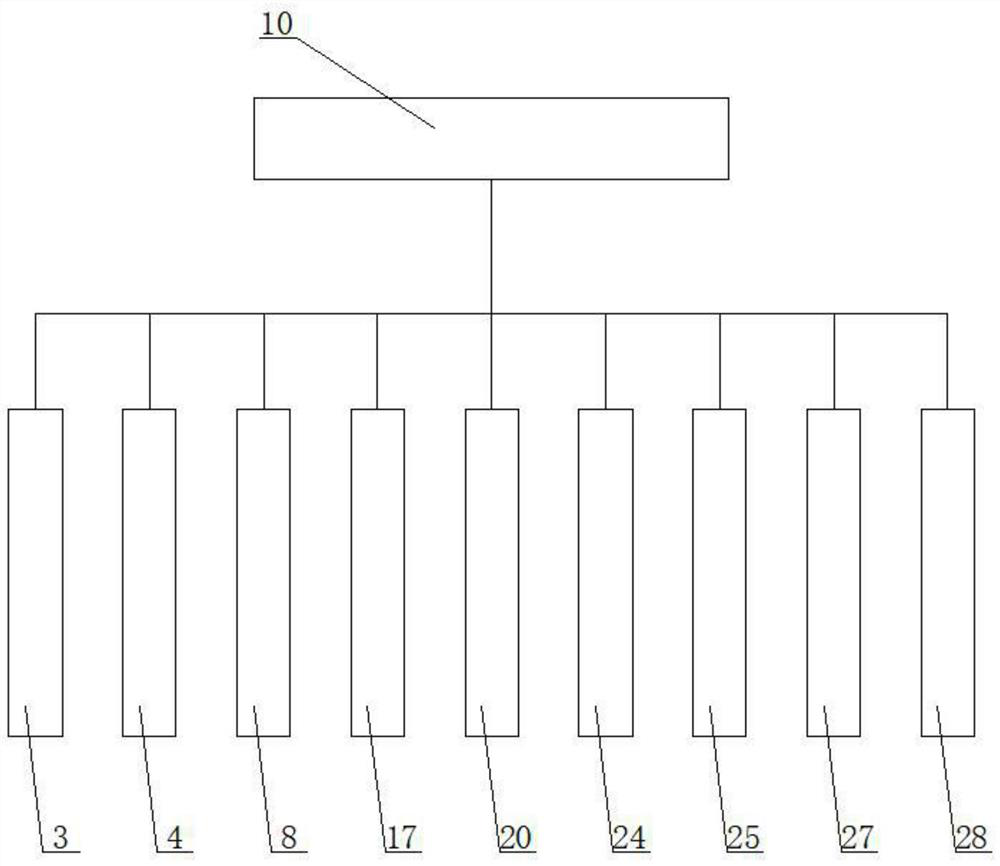

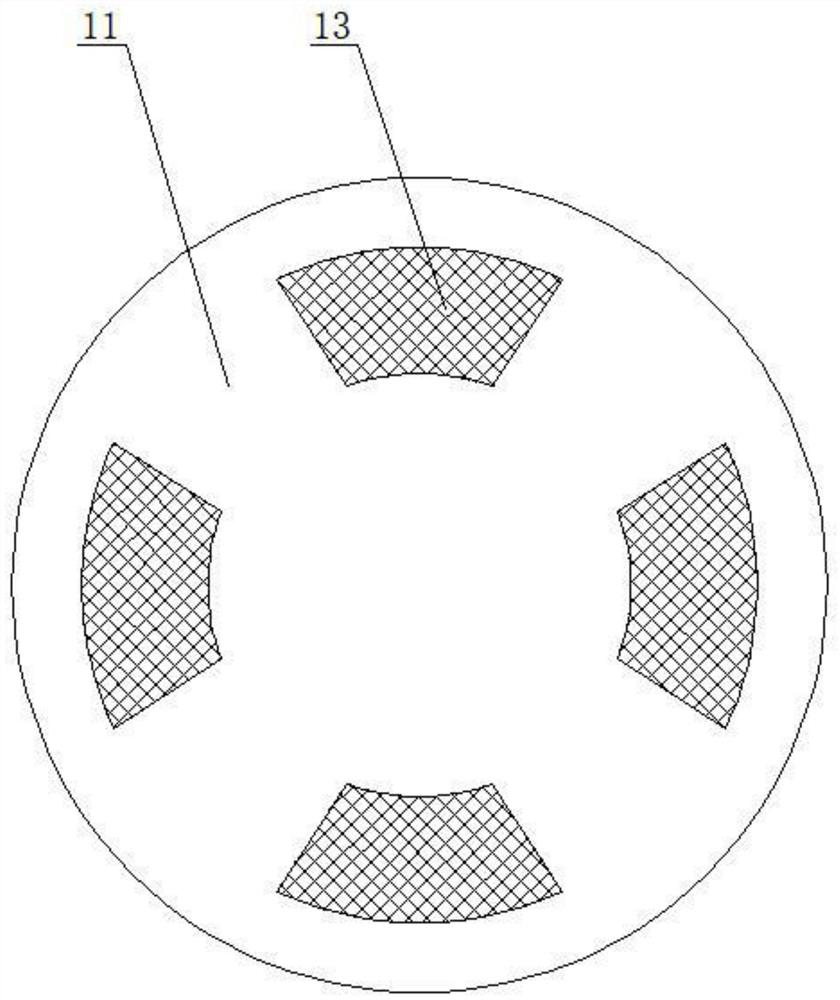

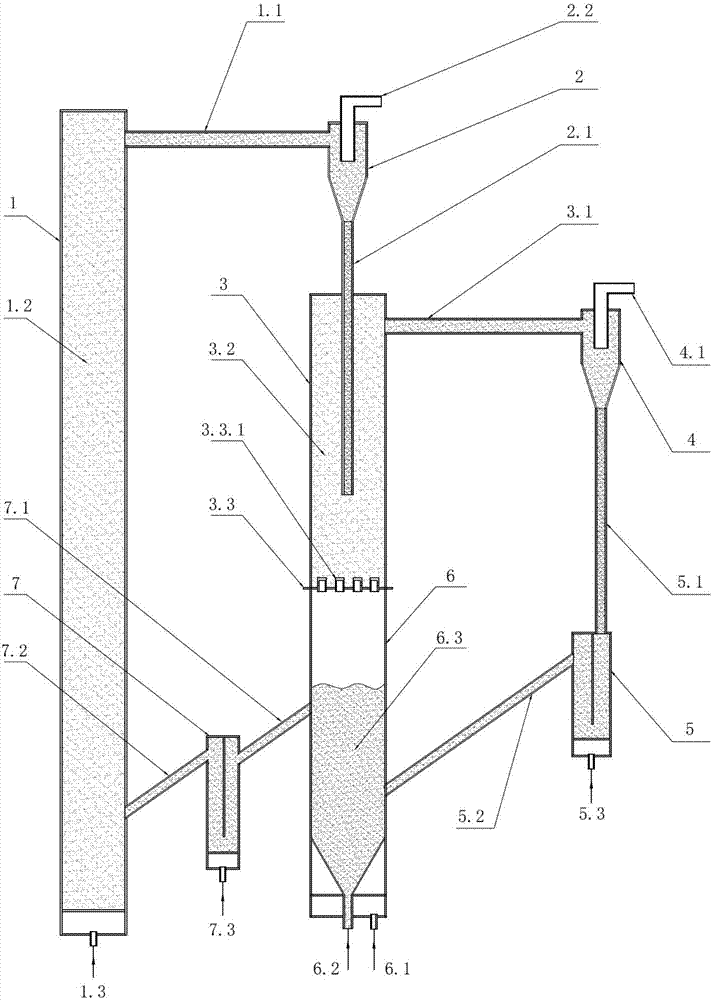

System for performing hydrochloric acid waste fluid spray roasting through industrial waste heat and control method

ActiveCN104344741ANormal responseImprove energy savingChemical industryControl devices for furnacesChemical industryLiquid waste

The invention is applicable to the fields of metallurgical, machining and chemical industries, and provides a system for performing hydrochloric acid waste fluid spray roasting through industrial waste heat and a control method. The system comprises a roasting furnace, wherein one or more waste heat flue gas nozzles are arranged in the furnace bosh tangential direction of the roasting furnace; each waste heat flue gas nozzle is connected with a waste heat supply system through a waste heat supply pipe; a waste heat flow regulating valve, a waste heat flow meter and a waste heat switching valve are arranged on each waste heat supply pipe; the system comprises a main control board; a temperature sensor is arranged at the furnace top or on the furnace bosh of the roasting furnace; the main control board is connected with the temperature sensor, the waste heat flow regulating valves and the waste heat flow meters. The system uses industrial waste heat as a heat source, provides reaction temperature and heat for the roasting furnace for high-temperature decomposition, uses fuel gas as an auxiliary heat source under the condition that the waste heat source cannot be provided or the heat cannot meet requirements, and guarantees that the reaction is performed normally. The system has an obvious energy-saving effect, and is low in running cost.

Owner:WISDRI ENG & RES INC LTD

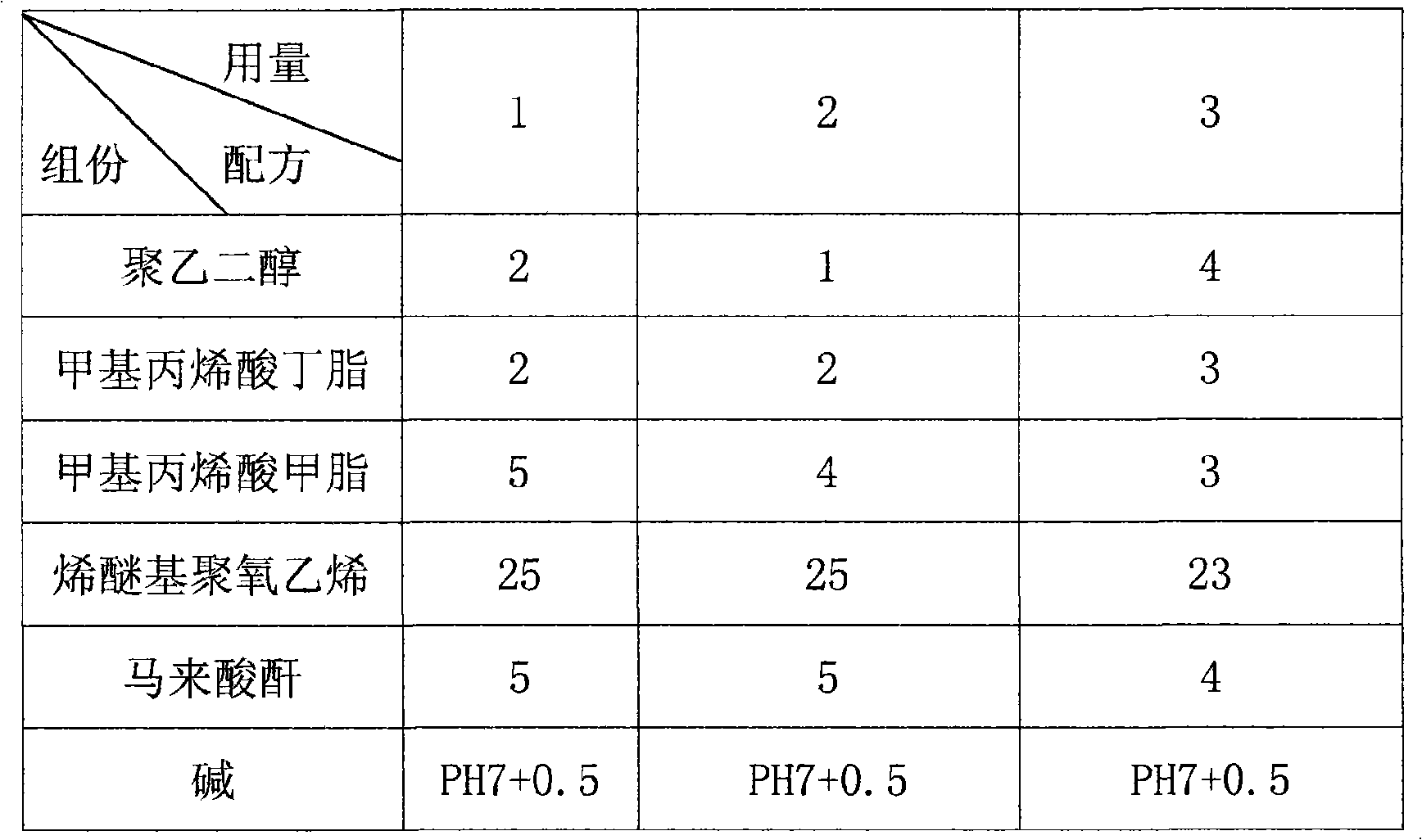

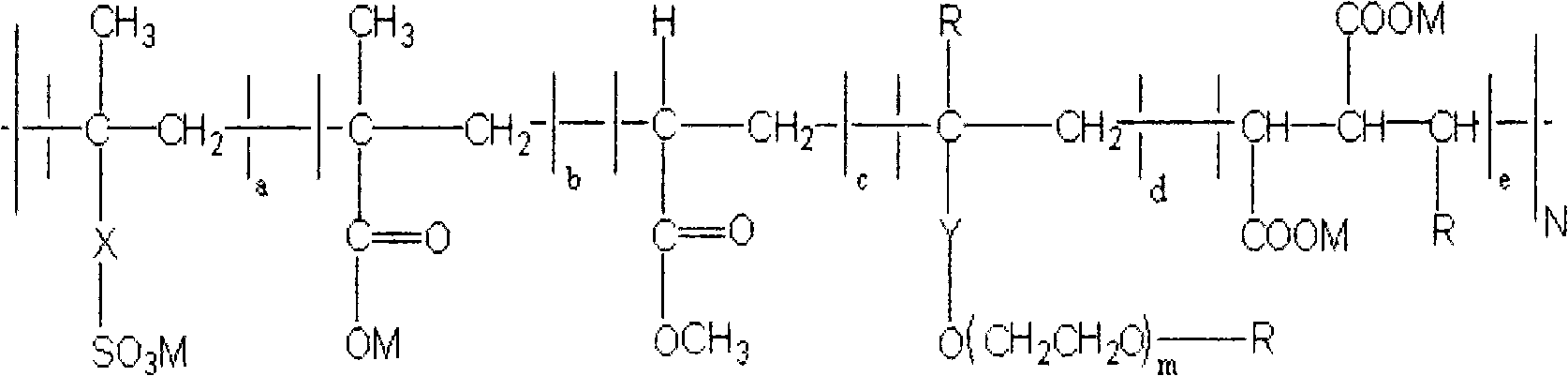

Process for synthesizing high performance water reducing agent of polyocarboxy acid

A synthesis process for a polycarboxylate high performance water reducing agent is characterized in that the polycarboxylate high performance water reducing agent is made from the raw materials with the following weight portions of 1 to 4 portions of polyethylene glycol, 2 to 3 portions of butyl methacrylate, 3 to 5 portions of methyl methacrylate, 23 to 25 portions of vinyl ether polyoxyethylene and 4 to 5 portions of maleic anhydride. Water is heated to 70 DEG C to 100 DEG C in a reaction kettle, part of the reactants is taken to pour into the reaction kettle to stir, melt, mix evenly and heat, alkali with 0.5 weight portions is added to neutralize after the reaction is completed, and the process is completed. The synthesis process has no nitrogen protection and does not use de-ionized water equipment, does not need separate titration, and can simultaneously carry out the addition and the mixture. The process has the characteristics of simple flow, simple and convenient operation, excellent performance-price ratio, safety, environment protection, etc.

Owner:宫世全

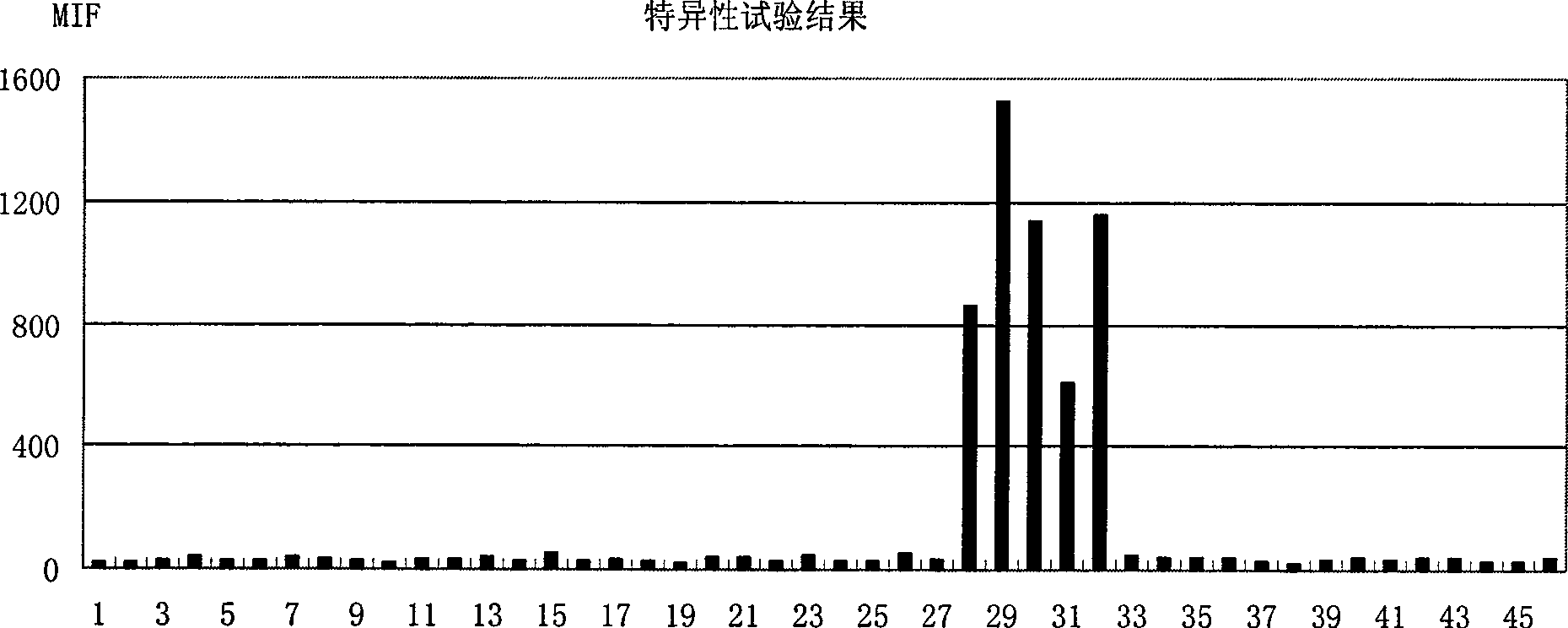

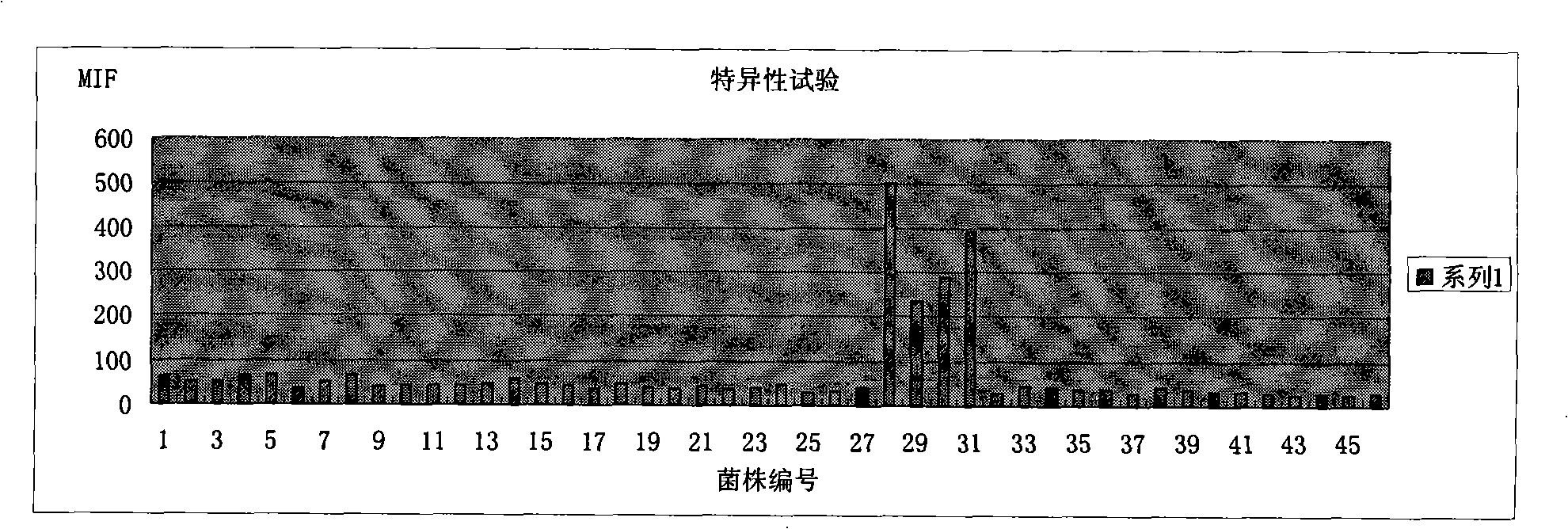

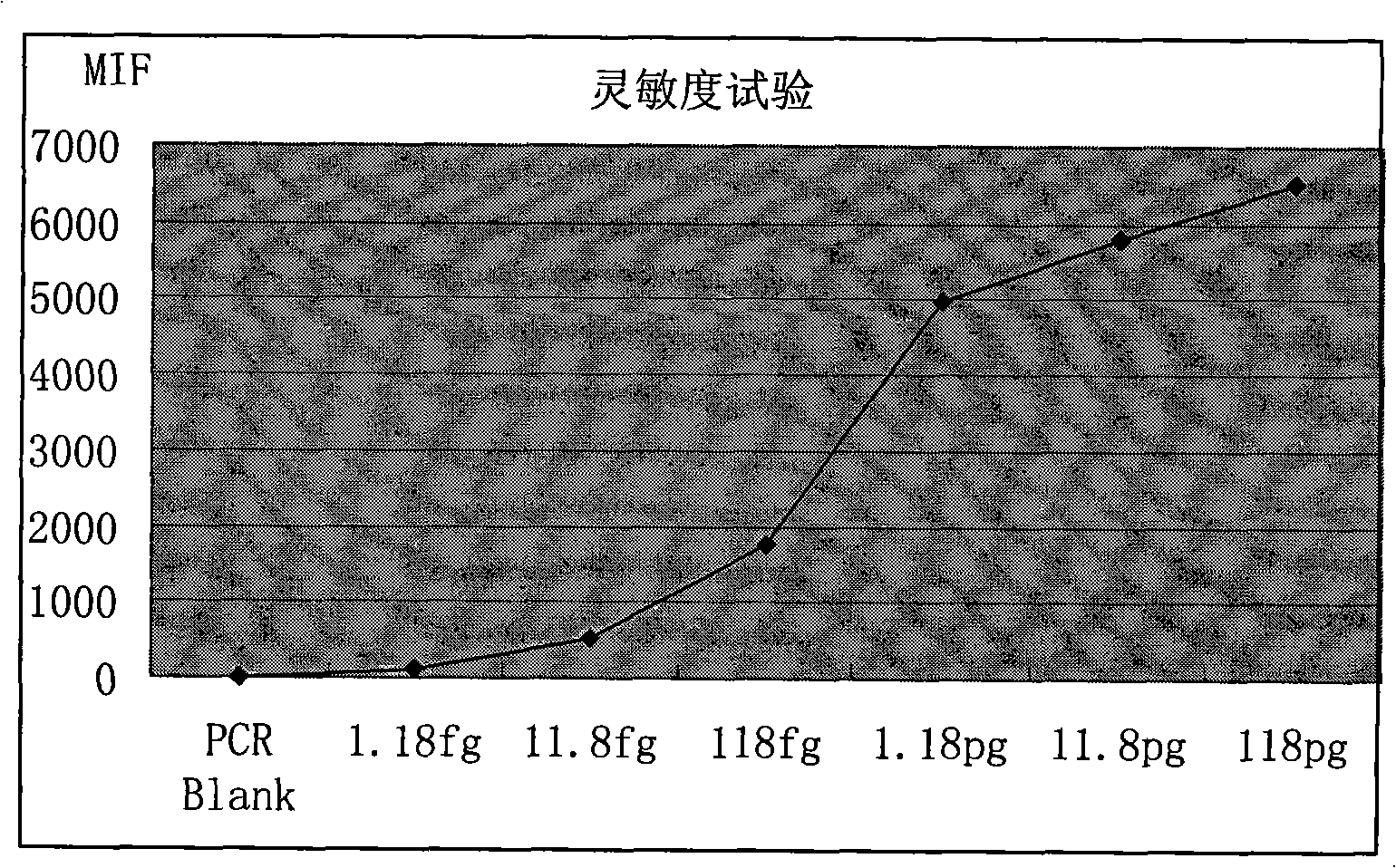

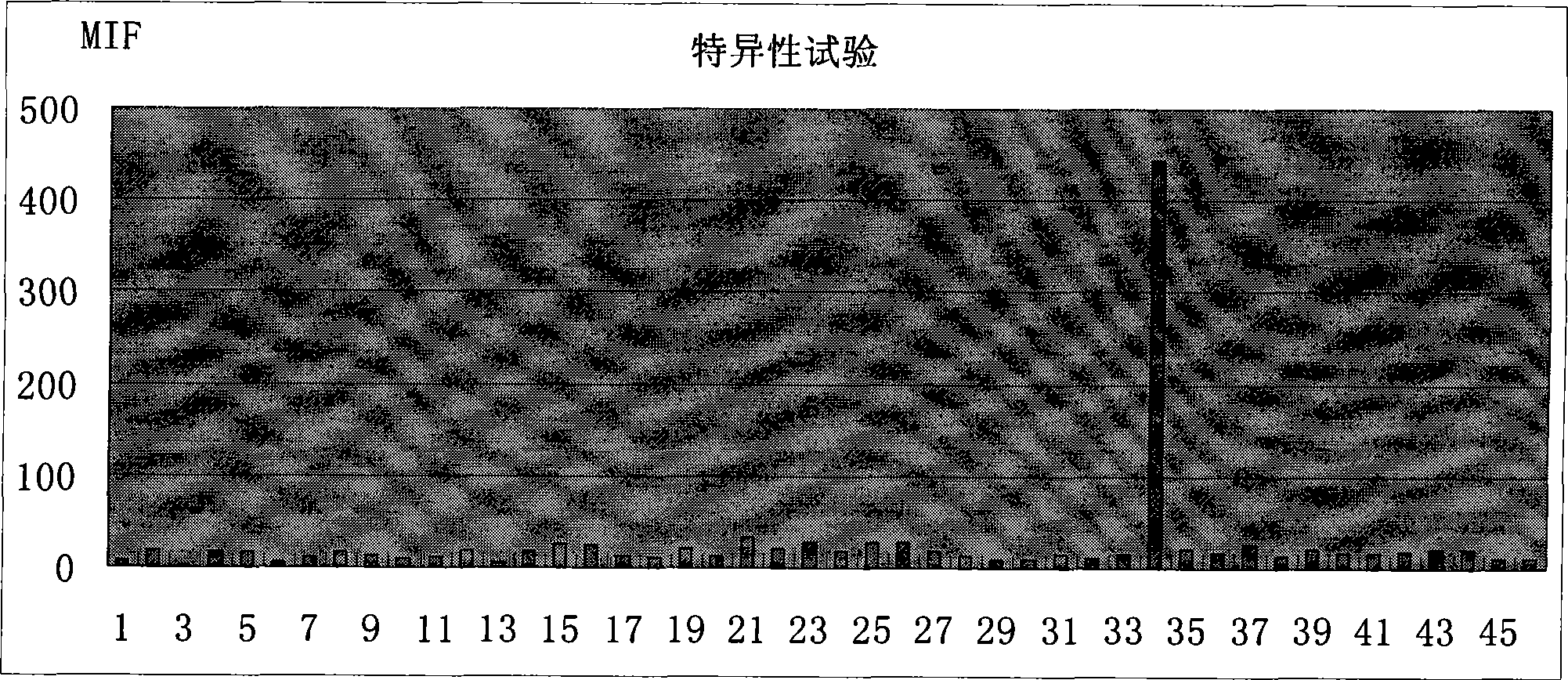

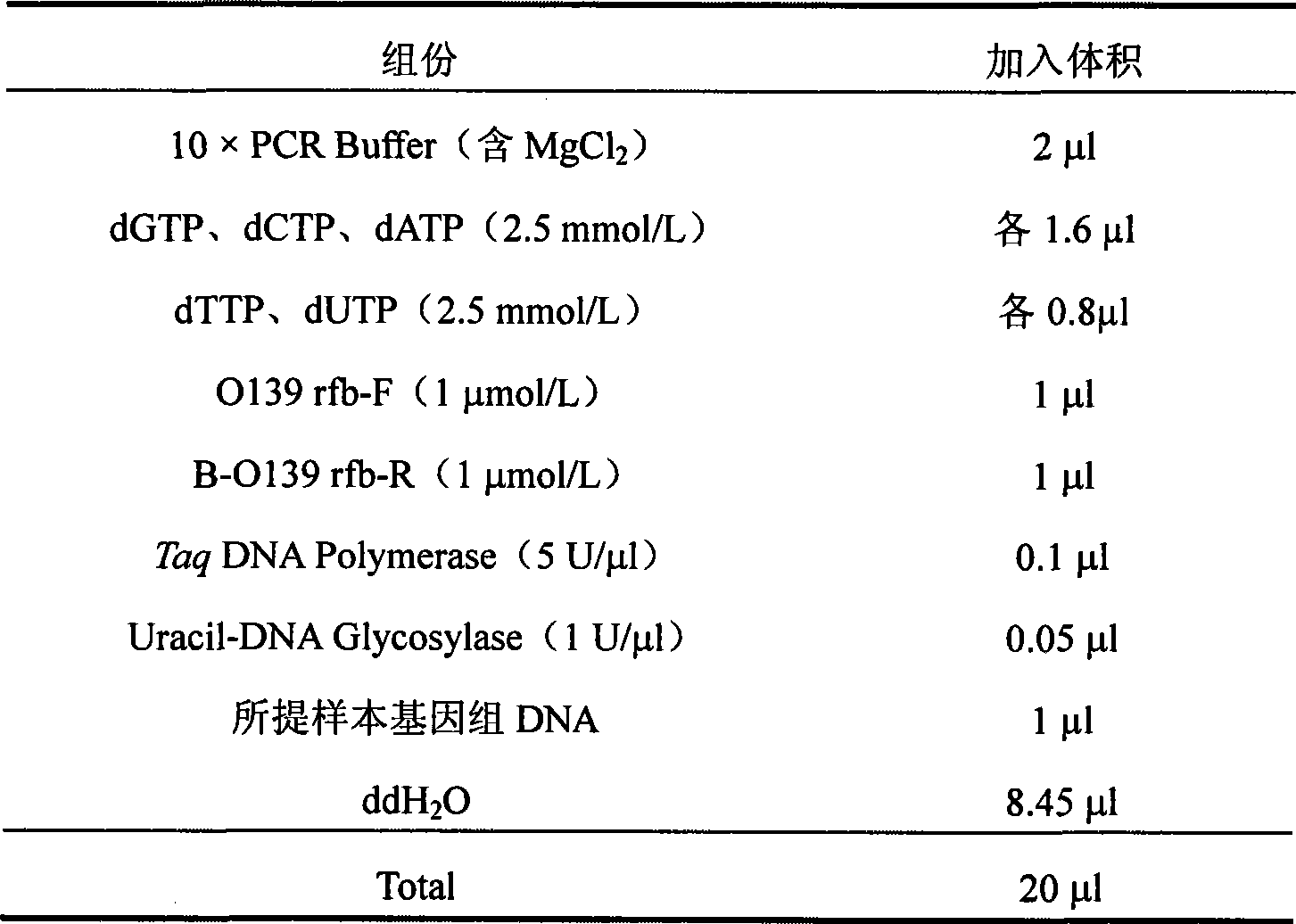

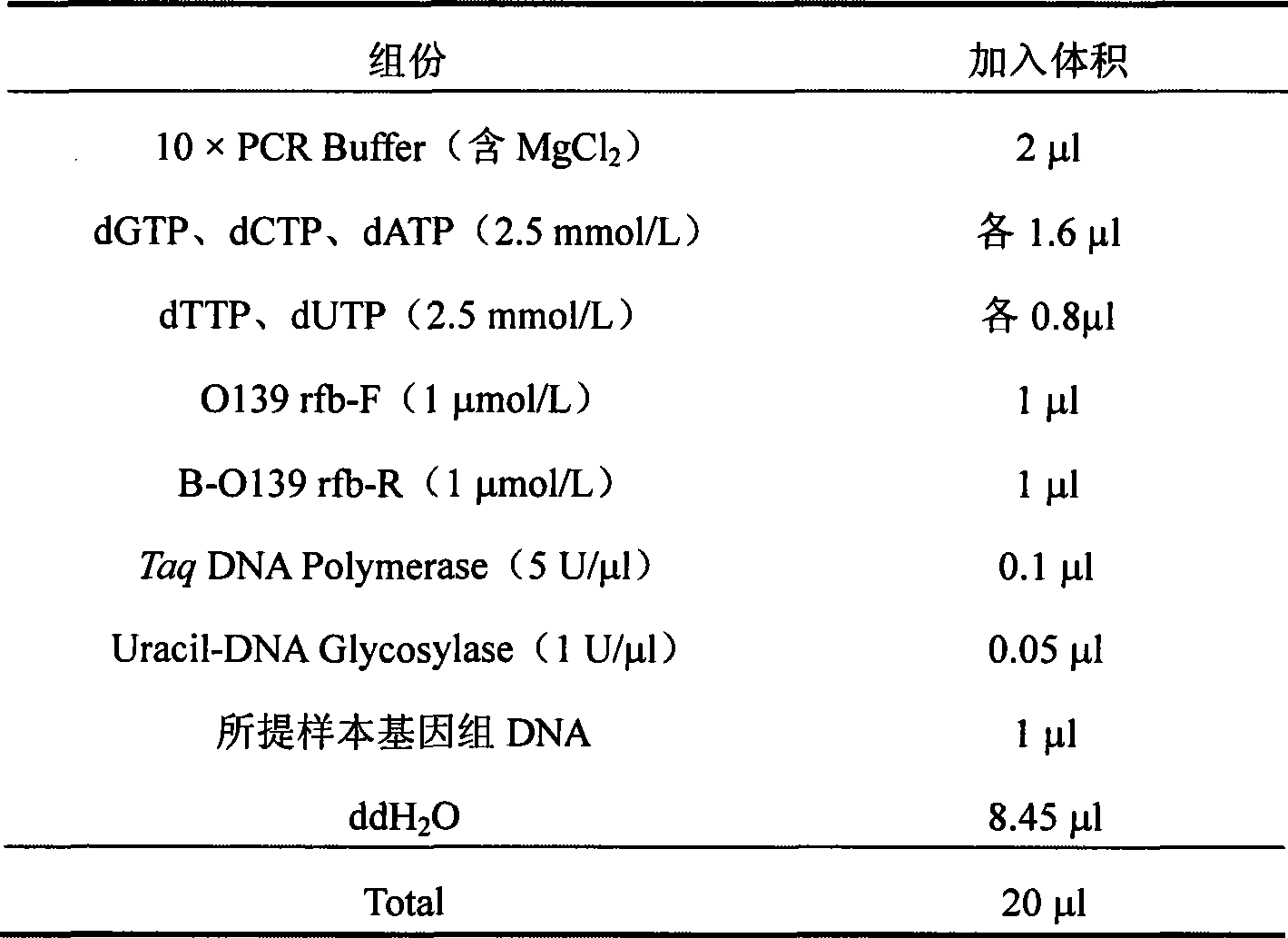

Method for detecting Shigella by using suspension chip technology

InactiveCN101429545AStrong specificityHigh sensitivityMicrobiological testing/measurementFluorescence/phosphorescenceAntigenMicrosphere

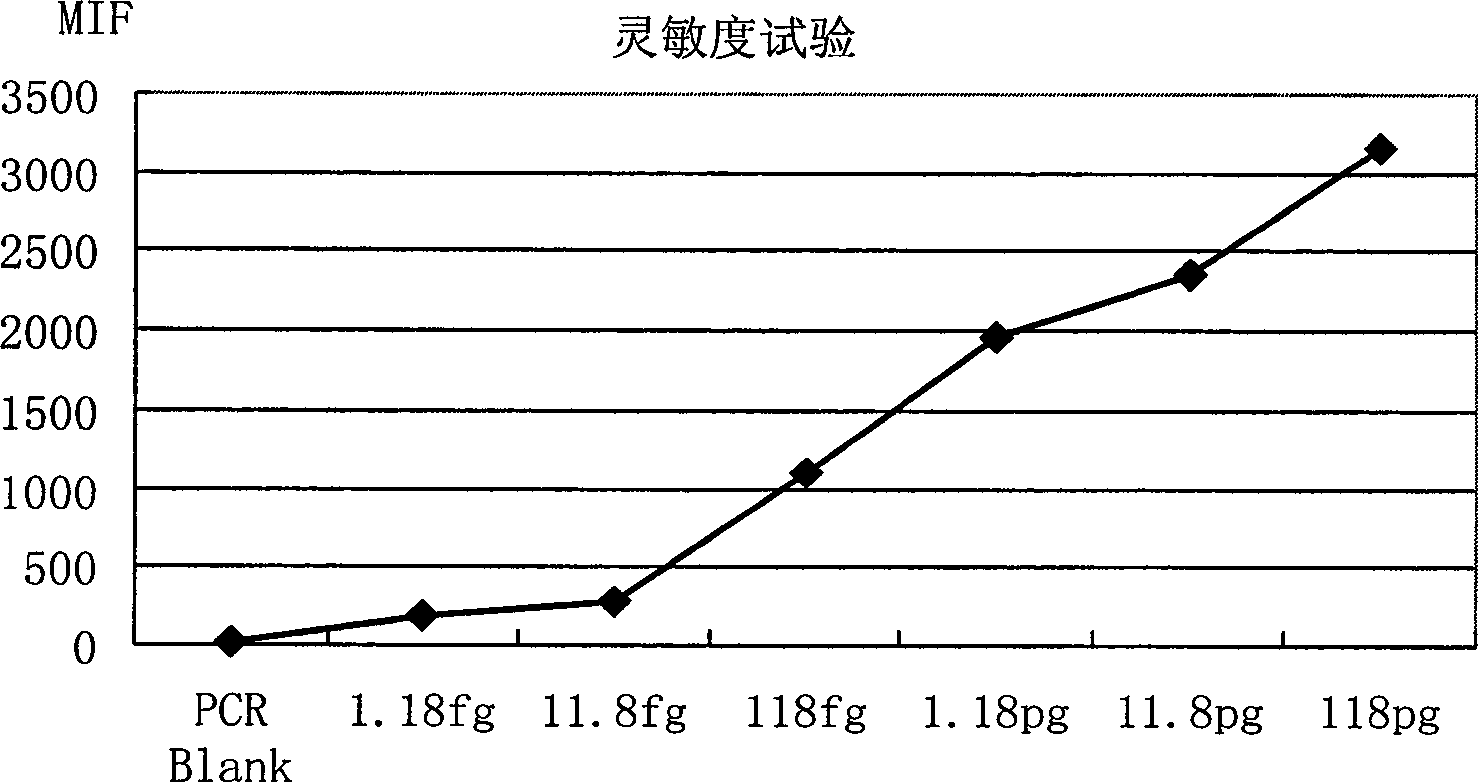

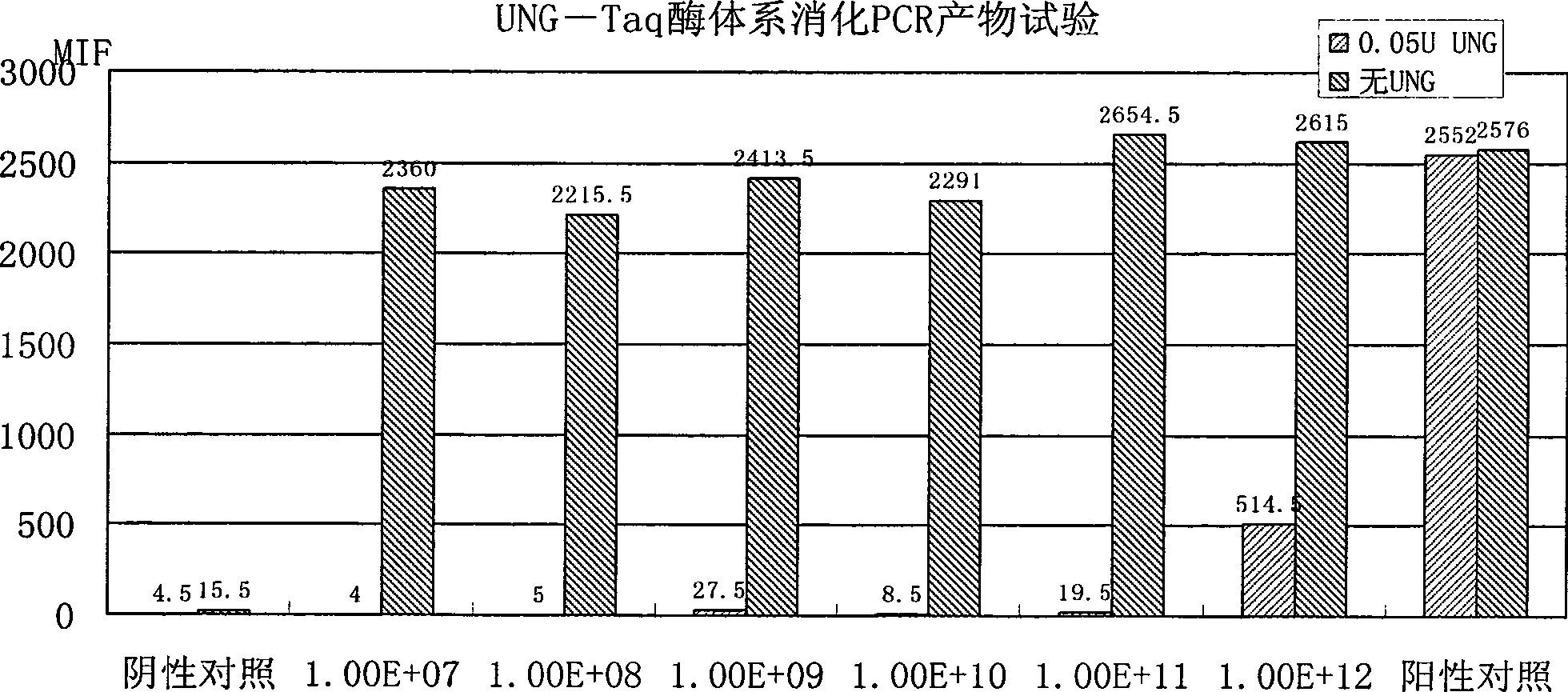

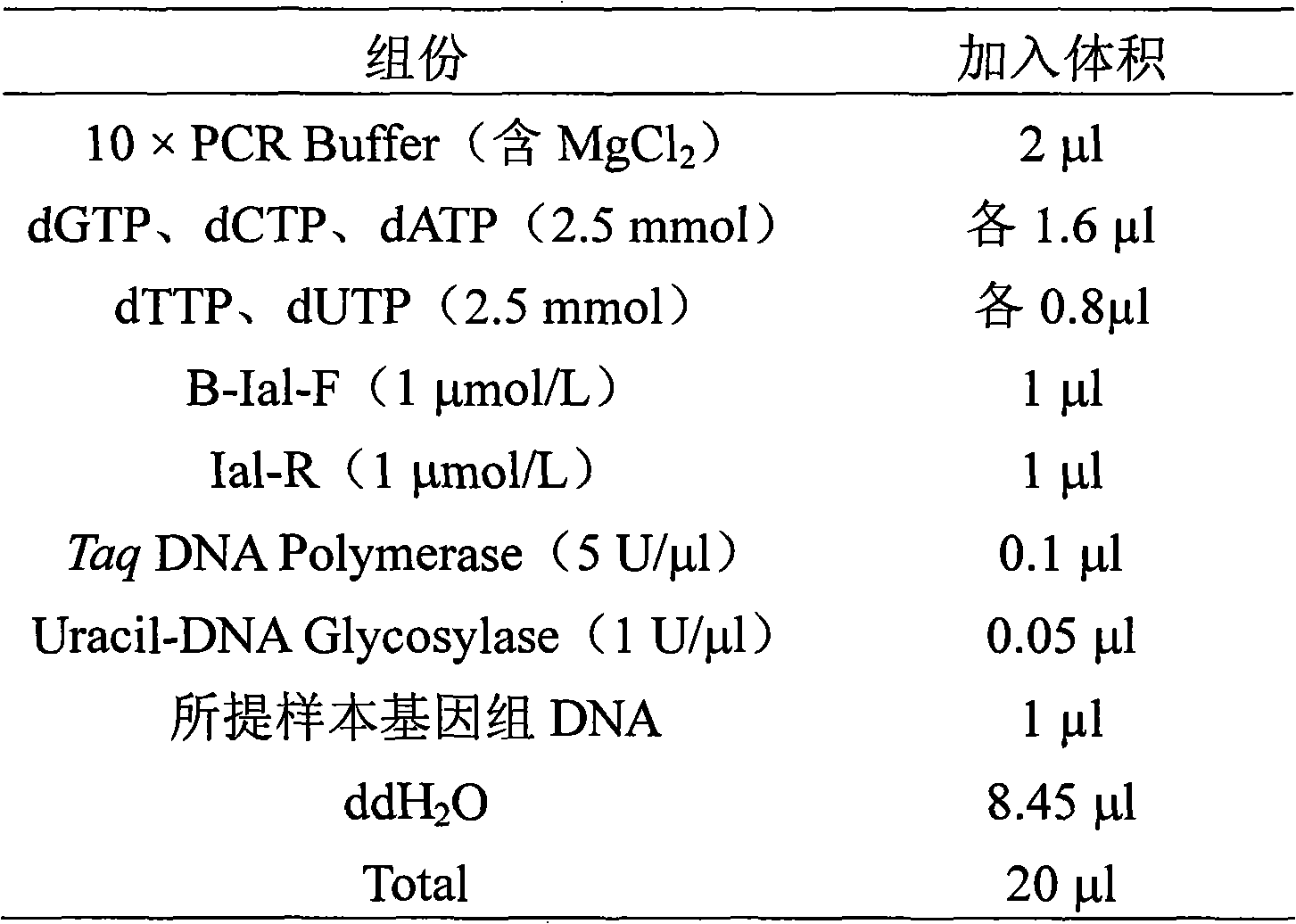

The invention relates to a suspension chip for detecting shigella and a detecting method thereof. The suspension chip comprises a microsphere carrier and an oligonucleotide probe fixed on the carrier, wherein the oligonucleotide probe is a fragment of DNA sequence in specific gene invasive plasmid antigen H screened from the shigella. The detecting method comprises the following steps: after a genome DNA in a sample to be detected is amplified and labeled by a designed primer, using the suspension chip to hybridize the genome DNA, and judging whether the sample to be detected contains the shigella according to hybridized fluorescence intensity. The suspension chip has high detection sensitivity which can reach a level of 1.18fg genome DNA (1fg corresponds to 2 numbers of bacteria), so the method can fully meet detection requirements of clinical samples and environmental samples, has the characteristics of high specificity, simple operation, low cost and the like, and is easy to popularize. And the method adopts a PCR reaction system of UNG-Taq enzyme to reduce PCR false positive results greatly.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI

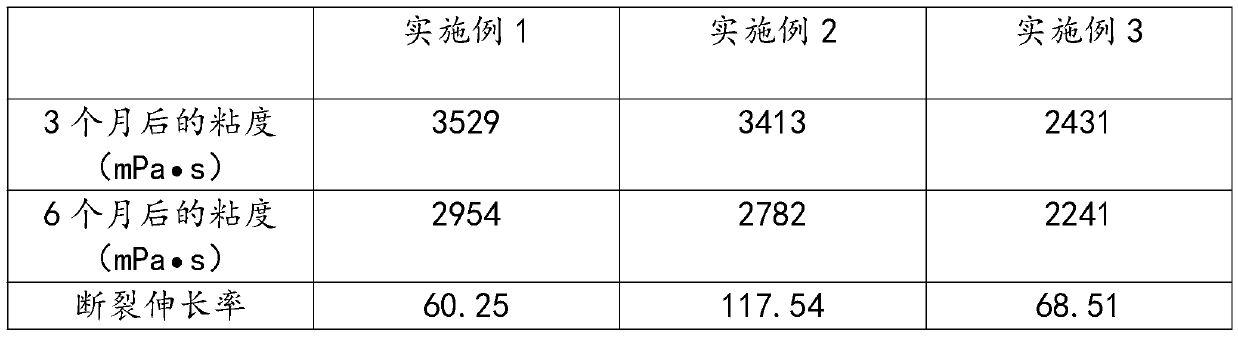

Solvent-free genuine leather laminating adhesive and preparation method thereof

ActiveCN110499133AAdd flexible segmentsPlay a space protection rolePolyureas/polyurethane adhesivesMaterial analysisXylyleneAdhesive

The invention discloses a solvent-free genuine leather laminating adhesive and a preparation method thereof. The solvent-free genuine leather laminating adhesive is formed by uniformly mixing a component A, a component B and a component C, and the component A is composed of diethylene glycol, 1,2-propylene glycol and sebacic acid according to a weight percentage ratio of 3:3:4; the component B iscomposed of xylylene diisocyanate, methylene diphenyl diisocyanate and polyether polyol according to a weight percentage ratio of 3:3:4, and the hydroxyl value of the polyether polyol is 112 mgKOH / g;the component C is composed of 2,6-di-tert-butyl-p-cresol and 3,5-dimethylpyrazole according to a weight percentage ratio of 1:1; and a weight percentage ratio of the component A to the component B tothe component C is 5:8:2. The service life of the solvent-free genuine leather laminating adhesive is greatly prolonged, so that the use effect is prevented from being greatly reduced as time goes on; an excellent adhesive effect can be achieved while ensuring the coating flexibility; and the evaporation efficiency of water is greatly improved while a mixed liquid is fully and uniformly mixed.

Owner:宿州鹏御源新材料科技有限公司

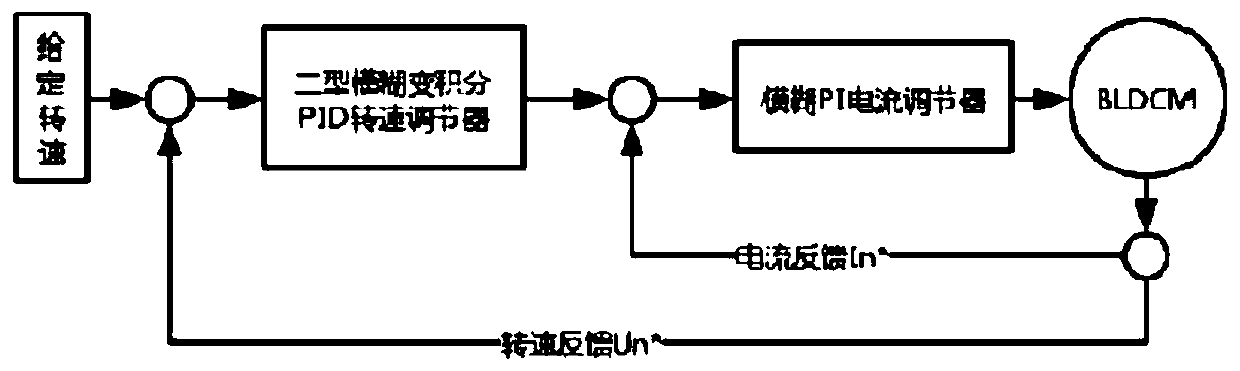

Preparation method of fully biodegradable copolyester

The invention discloses a preparation method of fully-biodegradable copolyester, relates to the technical field of fully-biodegradable copolyester preparation, and solves the problems of poor tensileyield strength, tearing resistance and light transmittance of the existing fully-biodegradable copolyester. According to the preparation method, main raw materials contain aromatic dibasic acid, aliphatic diol and aliphatic dibasic acid, wherein the aromatic dibasic acid is one of terephthalic acid or isophthalic acid; the aliphatic diol is one of C4-C10 saturated diols, and the aliphatic dibasicacid is adipic acid. The disclosed copolyester has strong fracture resistance, excellent elasticity, good processability and strong light transmission, and can hardly be snapped.

Owner:四川中科兴业高新材料有限公司

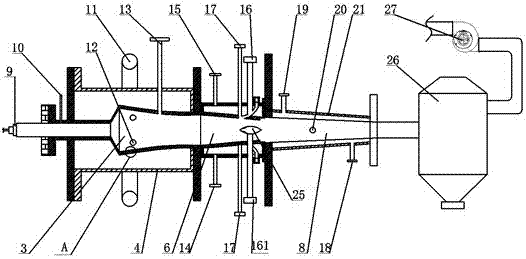

Efficient metallurgical rotary kiln for treating lead-zinc oxide ore

PendingCN106766870AGuaranteed reduction temperatureNormal responseRotary drum furnacesMetallurgical industryFuel gas

The invention relates to an efficient metallurgical rotary kiln for treating lead-zinc oxide ore and belongs to the field of structural designs and application of non-ferrous metallurgical industry equipment. The efficient metallurgical rotary kiln for treating lead-zinc oxide ore comprises a rotary kiln body, a feed opening, air blasting equipment, an air inlet pipe, a heat exchanger, a hot air adding opening, a discharge opening, an exhaust gas outlet, a rotary kiln support roller, a rotary kiln mechanical transmission component and a hot air pipe. As the heat exchanger is added to the outside of a reduction area to heat air produced by the air blasting equipment up to about 500 DEG C, air required for in-kiln reaction is provided while an in-kiln material is heated up, accordingly, the temperature of the reduction area reaches 1,200-1,300 DEG C, and normal reaction is guaranteed. Besides, a gas nozzle is arranged at the head part of the rotary kiln, and if the temperature of the reduction area does not reach 1,200-1,300 DEG C, the gas nozzle can be ignited for heating, so that the temperature of the reduction area is guaranteed, effective volatile reaction of the material in the reduction area is ensured, meanwhile, in-kiln material coking is reduced, and the production cycle of the rotary kiln is prolonged.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

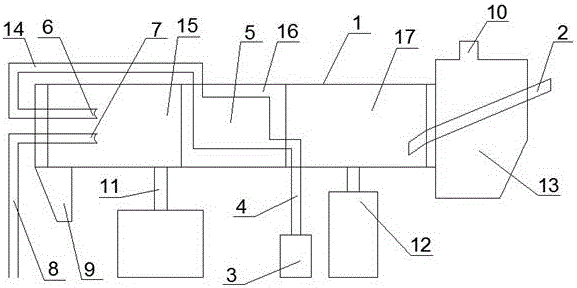

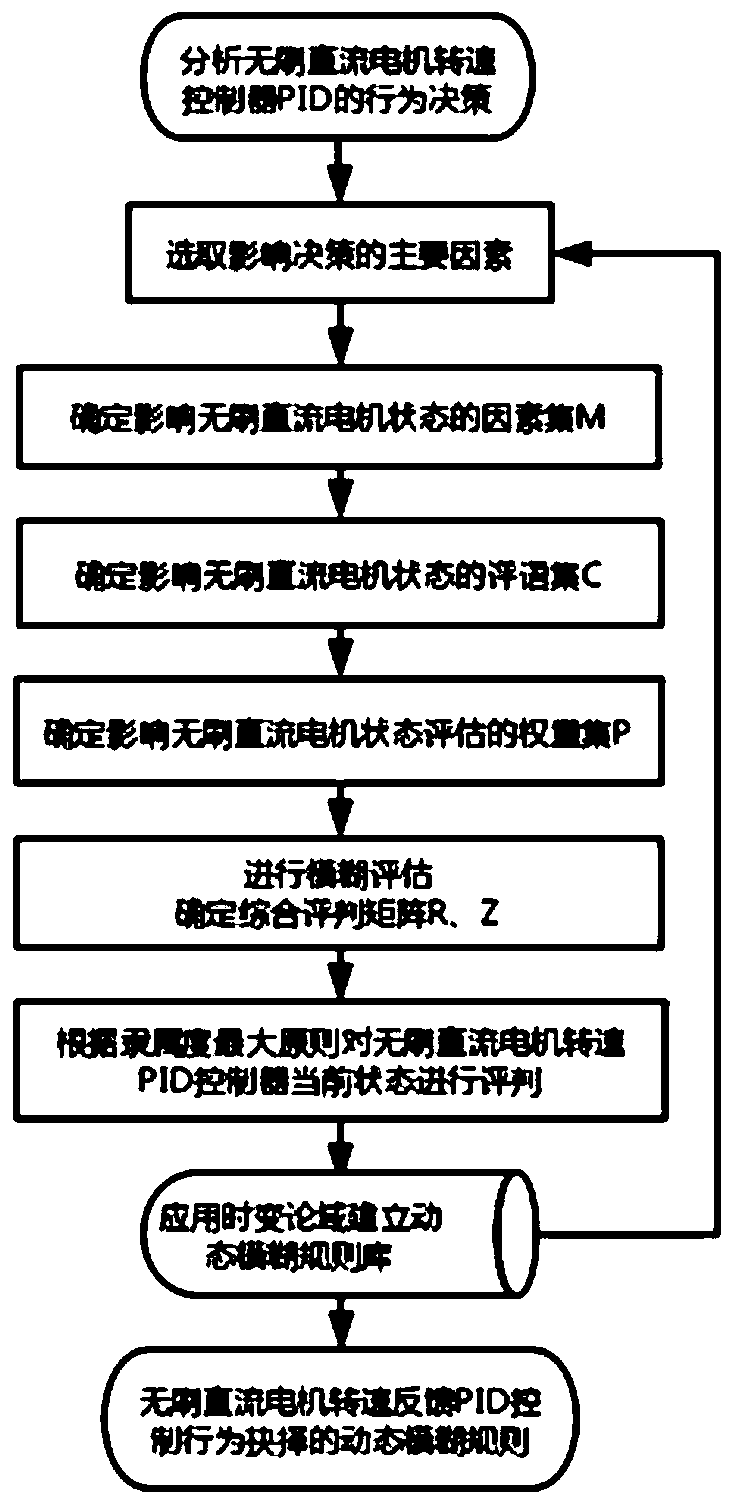

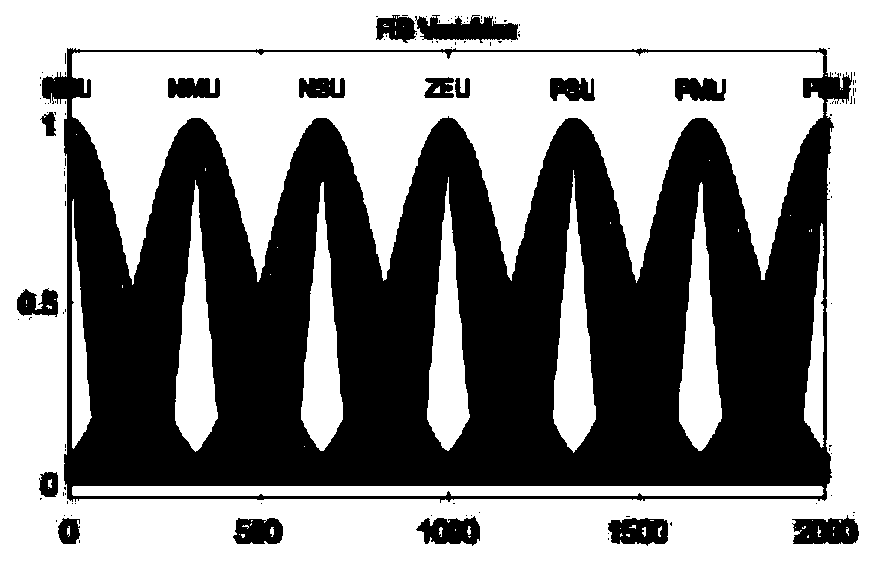

Brushless DC motor control method based on interval type-2 fuzzy variable integral PID

PendingCN111381492AFast speed responseGuaranteed uptimeControllers with particular characteristicsMotor speedDC - Direct current

The invention discloses a brushless DC motor control method based on interval type-2 fuzzy variable integral PID, and the method comprises the steps: analyzing the behavior decision of a brushless direct current motor rotating speed controller PID, and selecting main factors affecting the decision; determining a factor set influencing the state of the brushless direct current motor; determining acomment set influencing the state of the brushless direct current motor; determining a weight set influencing the state of the brushless direct current motor; carrying out the fuzzy evaluation to determine a comprehensive evaluation matrix; evaluating the current state of the rotating speed PID controller of the brushless direct current motor according to the maximum membership principle; establishing a dynamic rule base by applying a time-varying domain of discourse; determining the PID control parameters according to a dynamic rule base; and correcting the PID control parameters by using a variable integral algorithm to obtain a control voltage. According to the brushless DC motor control method based on interval type-2 fuzzy variable integral PID, the motor rotating speed response can be improved, and the adjusting time can be shortened. And the defects of poor robustness, low influence speed and the like are overcome, so that the motor is more stable and reliable in the operation process.

Owner:HUNAN SHENGDING TECH DEV CO LTD

Method for detecting pathogenic shigella by using suspending chip technique

InactiveCN101403000AControl false negativesGeneration of controlMicrobiological testing/measurementFluorescence/phosphorescenceMicrosphereGenomic DNA

The invention relates to a suspension chip used in the detection of pathogenic shigella, and a detection method of the suspension chip which comprises a microsphere carrier and an oligonucleotide probe which is fixed on the chitosan microsphere; wherein, the probe is a segment of DNA sequence of the gene of a specific genic invasion associated locus (invasion associated locus, Ial) screened from the pathogenic shigella. After the genomic DNA of samples to be tested is amplified and marked by utilizing a designed primer, the suspension chip is used for hybridization and whether the pathogenic shigellae is contained in the samples to be tested can be judged according to the crossbred fluorescent intensity. The suspension chip which is high in detection sensitivity can reach the level of the DNA of an fg grade genome, can meet the needs of the detection of clinical samples and environmental samples, is characterized by high specificity, simple operation, low cost, and the like, and can be easily popularized. Furthermore, a PCR reaction system of UNG-Taq enzyme is adopted, which greatly reduces the results of false positive of the PRC.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI

Application of nursing agent in automobile engine line

The present invention relates to the application of a kind of care agent on automobile engine circuit, and this care agent is made of ethane, heptane, octane, nonane, decane or is made of ethane, heptane, octane, propane, butane, bromine Heptane is prepared according to a certain weight percentage ratio; the preparation method is to firstly dissolve heptane and octane, put them in a reactor for preheating, then add polymer resin, stir thoroughly and cool to room temperature, and then add ethyl alkane, butane or nonane, stir to make it fully miscible; finally add penetrating agent and anti-drying agent, and fully stir to obtain the product of the present invention. After testing, the care agent of the present invention has 100% insulation, can withstand 51,700 volts of high voltage, can eliminate the problem of aging, cracking and leakage of lines, and forms a protective film on all lines and wire joints of the engine to prevent the intrusion of water vapor and moisture, and avoid oxidation. After spraying the care agent on the car engine line, it can reduce noise, reduce engine vibration, and reduce engine spontaneous combustion rate.

Owner:诸自力 +1

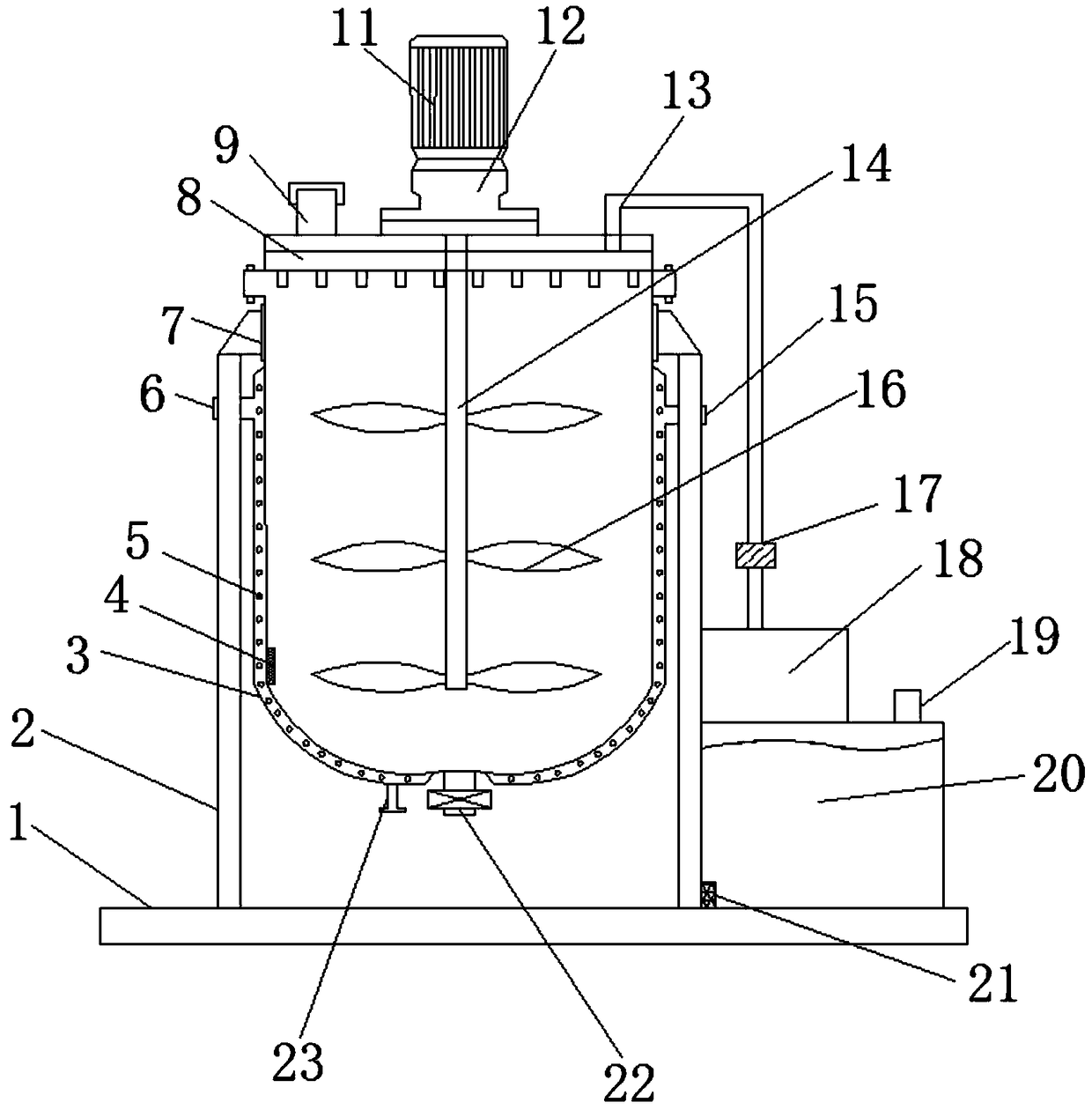

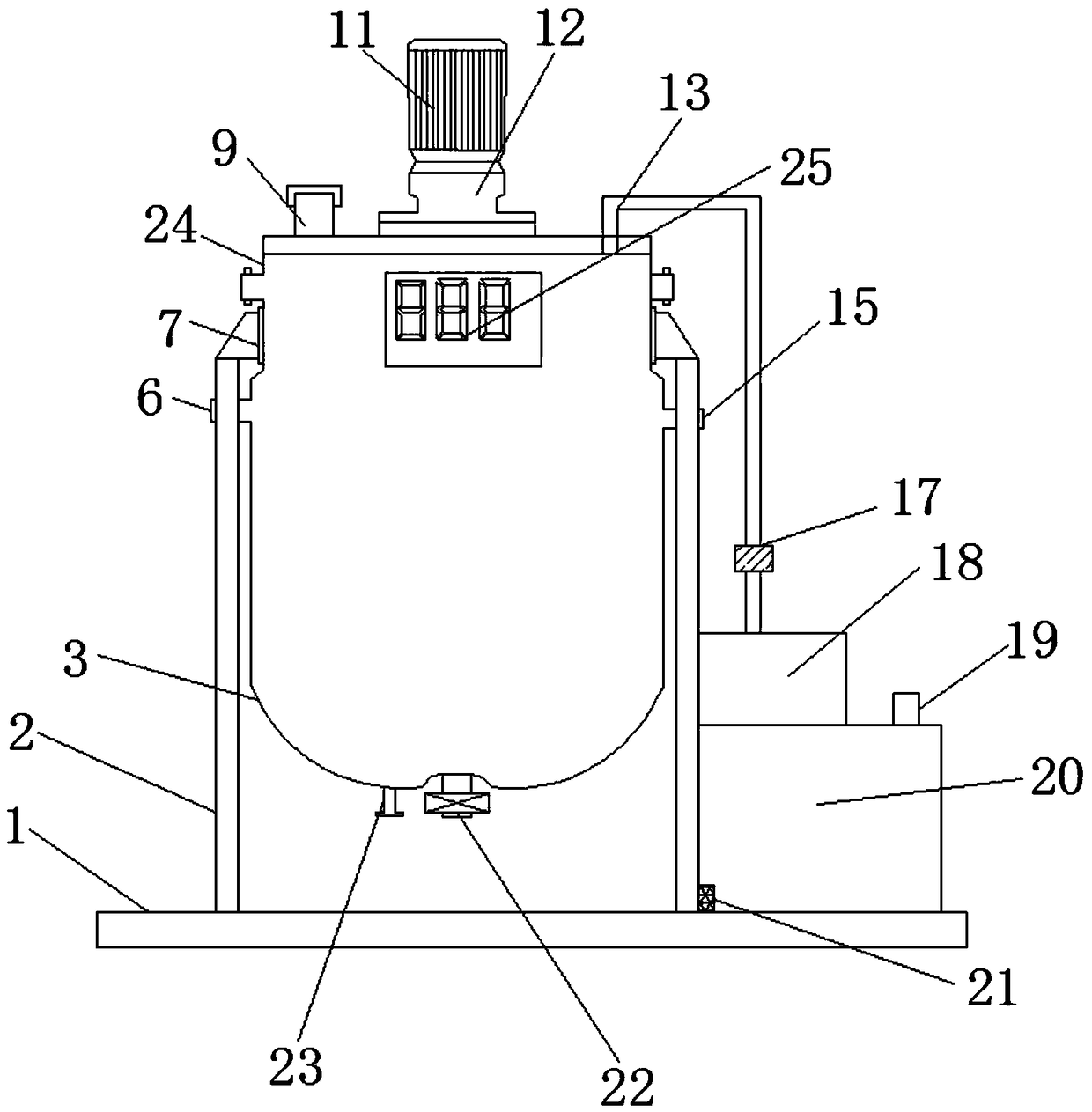

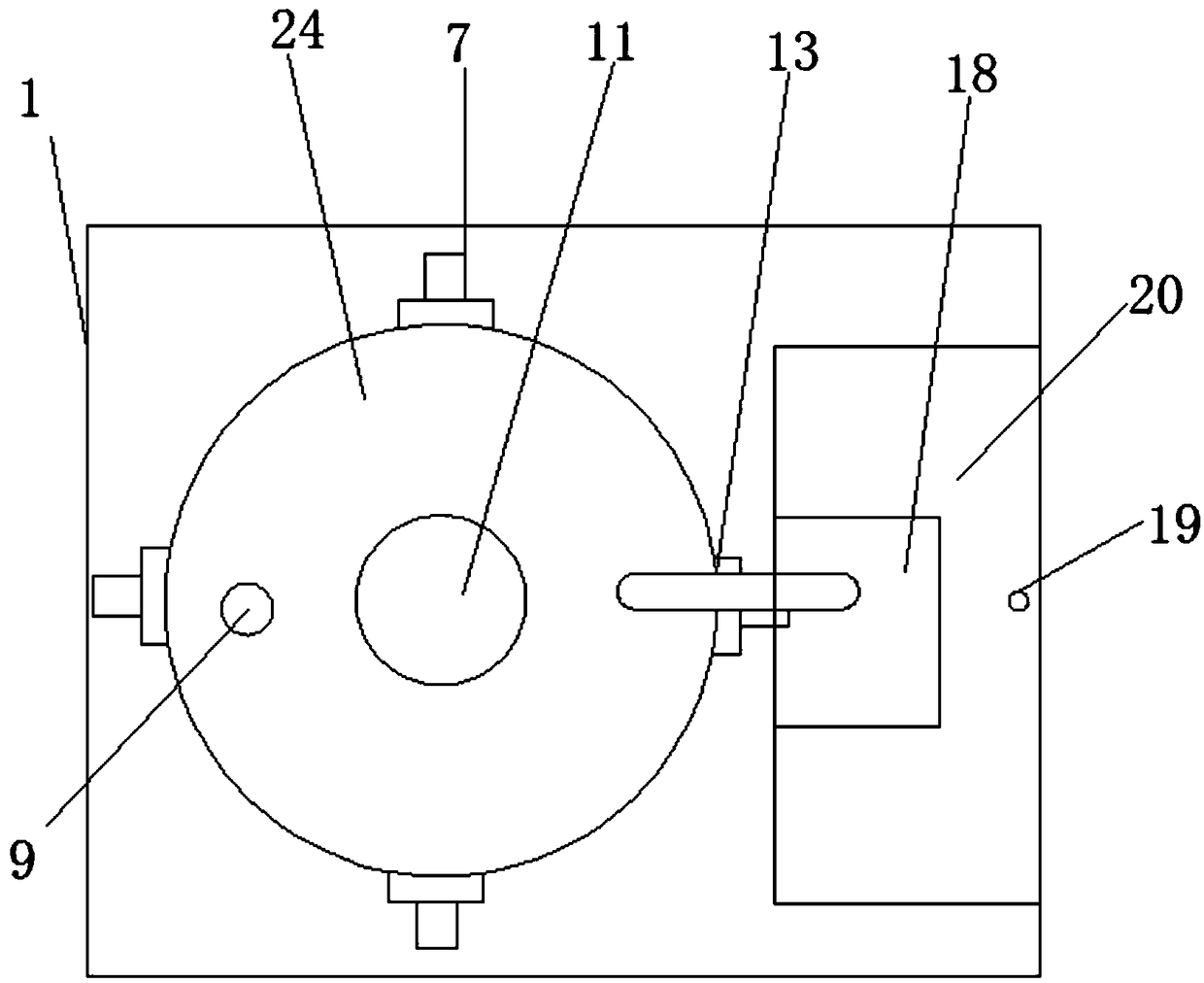

Conveniently temperature-adjustable reaction device for chemical industry production

PendingCN108607493ARapid coolingMonitor temperature in real timeChemical/physical/physico-chemical stationary reactorsFeed devicesChemical industryEngineering

The invention discloses a conveniently temperature-adjustable reaction device for chemical industry production. The device comprises a base, four equidistantly distributed supporting legs are connected at the top of the base through bolts, lug seats are connected at the tops of the supporting legs through bolts, a reaction tank is connected on one side of lug seat through bolts, a speed reducer isconnected at the top of the reaction tank through a bolt, and a motor is connected at the top of the speed reducer through a bolt. According to the device, high-temperature steam enters a heating cavity through a steam heating inlet, the reaction tank can be heated, a heating wire can also heat the reaction tank, and the temperature in the reaction tank is monitored by a temperature sensor in real time and transmitted to a process or through a signal wire. When the temperature needs to be rapidly cooled, cooling water can be led in through a cooling water inlet and is discharged through a water outlet, so that the reaction tank can be rapidly cooled, two heating mechanisms ensure normal reaction, and the temperature is quite conveniently adjusted.

Owner:ZHENGZHOU UNIV

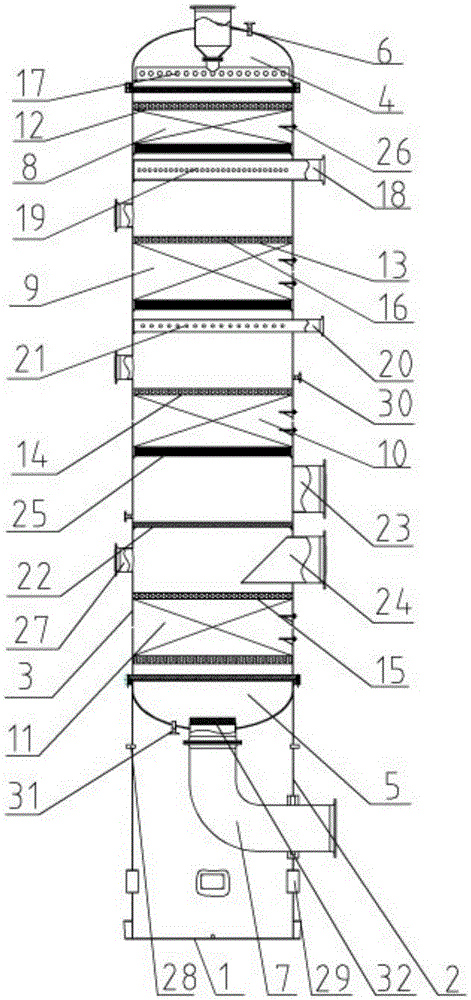

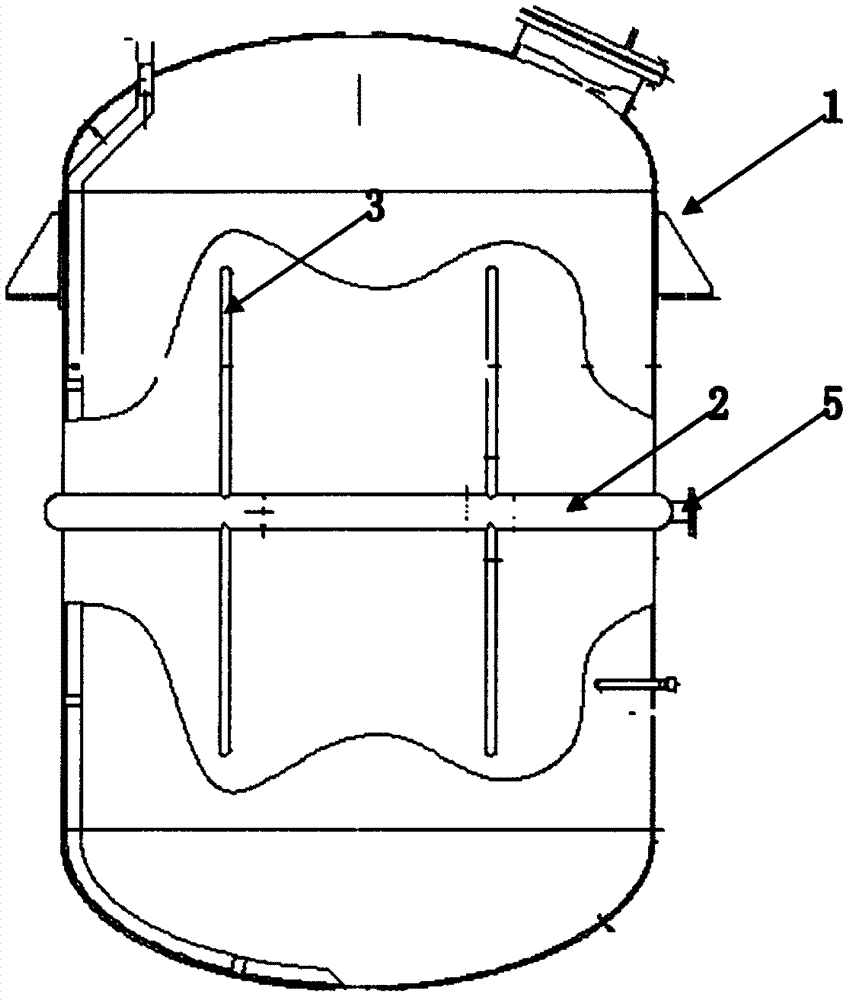

Multi-section type heat insulation fixed bed reactor for PX production

InactiveCN105413591AReduce lossFully contactedChemical/physical processesFixed bedProcess engineering

The invention discloses a multi-section type heat insulation fixed bed reactor for PX production. The multi-section type heat insulation fixed bed reactor comprises a basic component, a skirt support and a reactor body, wherein a first reaction region, a second reaction region, a third reaction region and a fourth reaction region are arranged in the reactor body in sequence from top to bottom; a fixed bed layer filled with a catalyst is arranged above each reaction region; a sieve pipe distributor is arranged below each reaction region; a first cold material inlet is formed in the side wall between the first reaction region and the second reaction region; a second cold material inlet is formed in the side wall between the second reaction region and the third reaction region; a heat exchange pipe outlet and a heat exchange pipe inlet are formed between the third reaction region and the fourth reaction region. The multi-section type heat insulation fixed bed reactor for PX production solves the problems that the existing fixed bed reactor is poor in heat dissipation effect, easily causes inactivation of catalysts and high loss of the catalysts and affects the reaction efficiency; meanwhile, by the adoption of material feeding from the side wall, heat in the reactor can be effectively used, and the heat supply cost is reduced.

Owner:CHONGQING TIANYI HENGHUA TECH CO LTD

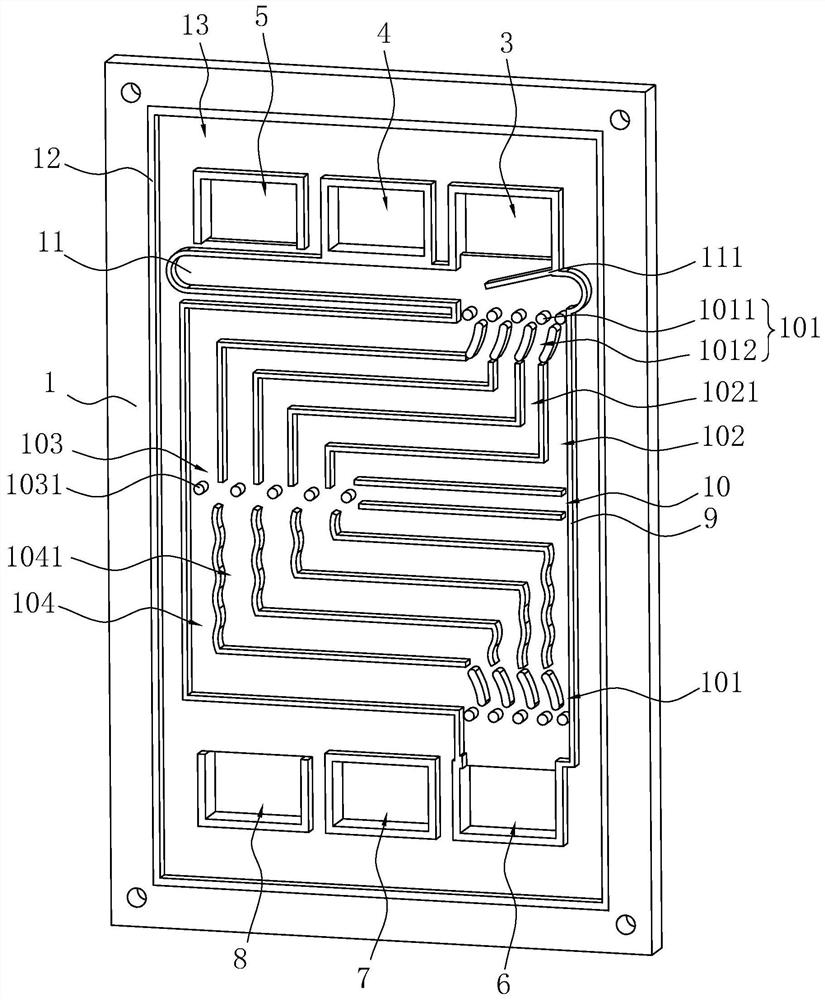

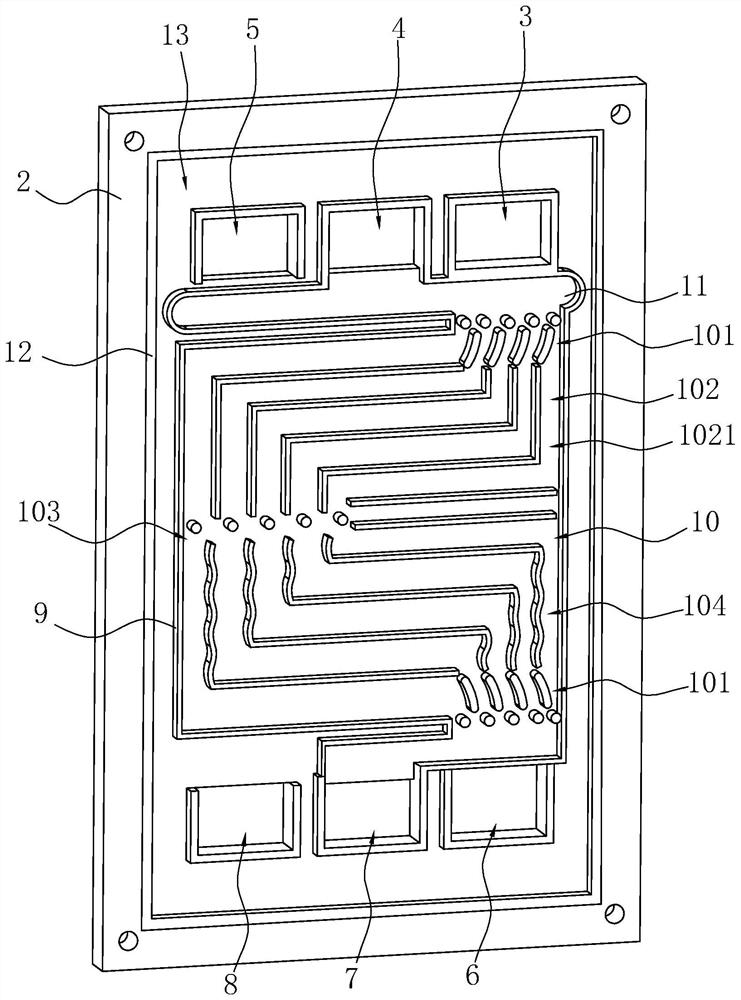

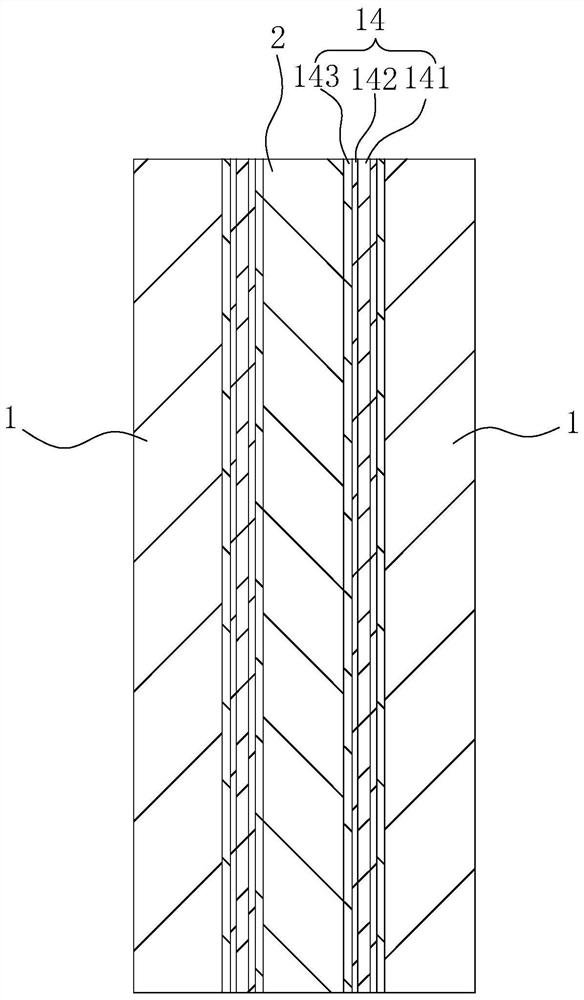

Air-cooled proton exchange membrane fuel cell metal bipolar plate and fuel cell thereof

The invention relates to an air-cooled proton exchange membrane fuel cell metal bipolar plate and a fuel cell thereof. The bipolar plate comprises a first metal plate and a second metal plate. The first metal plate and the second metal plate are each provided with a first metal frame, a fuel gas inlet and an oxidizing agent inlet which are formed in one side of the first metal frame, and a fuel gas outlet and an oxidizing agent outlet which are formed in the other side of the first metal frame, and the fuel gas inlet and the fuel gas outlet in the first metal plate are communicated with the first metal frame. The oxidizing agent inlet and the oxidizing agent outlet in the second metal plate communicate with the first metal frame, a gas flow channel is formed in the first metal frame and comprises first buffer flow channels arranged at the head end and the tail end of the gas flow channel correspondingly, and each first buffer flow channel comprises a plurality of flow dividing columns distributed at equal intervals; and a flow dividing groove is formed between every two adjacent flow dividing columns, and the end, away from the flow dividing columns, of each flow dividing groove inclines in the direction away from the first metal frame. The effect of improving the reaction rate of the fuel cell is possessed.

Owner:嘉寓氢能源科技(辽宁)有限公司

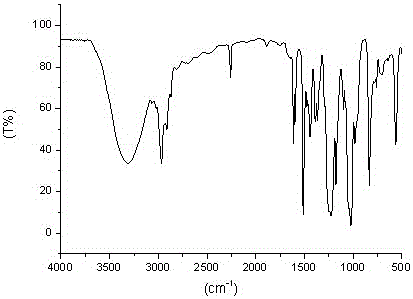

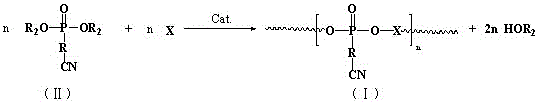

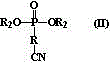

Polyphosphate oligomer flame retardant and preparation method thereof

ActiveCN106188549AGood technical effectHigh phosphorus contentGroup 5/15 element organic compoundsPhosphateBisphenol AF

The invention provides a polyphosphate oligomer flame retardant represented as the formula (I) and preparation method thereof, wherein R refers to a C1-C5 alkylene group, e.g., a methylene group; X refers to a bisphenol structure unit, which can be bisphenol A, diphenol, bisphenol AF, bisphenol S, bisphenol fluorene, resorcinol and the like; n is a positive integer from 2 to 20. The preparation method includes the steps of: under a catalytic condition of a catalyst, performing a bulk polymerization reaction to a phosphate monomer (II) and a bisphenol monomer, wherein alcohol or phenol removal occurs in the process and the reaction is free of HCl escape. The production is high in contents of both phosphorus and nitrogen and is low in low-volatile ingredient. The method is simple, is short in reaction time, is low in environment pollution and is easy to achieve in industrial production.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Hydrogen-generating fuel rod, preparation method thereof and hydrogen generator based on hydrogen-generating fuel rod

ActiveCN109231166AIncrease energy densityImprove securityHydrogen productionFuel cellsVapor–liquid separatorHydrogen

The invention discloses a hydrogen-generating fuel rod, a preparation method thereof and a hydrogen generator based on the hydrogen-generating fuel rod. The hydrogen-generating fuel rod is prepared from solid basic metal hydroboron, catalyst and hydrophilic porous medium material. The hydrogen generator comprises an outer shell, a top cover, a bottom cover, a gas-liquid separator, a liquid guide plate and the hydrogen-generating fuel rod. The hydrogen-generating fuel rod and the hydrogen generator can avoid the problems caused by the usage of basic metal hydroboron solution, can be conveniently carried and replaced and are high in energy density.

Owner:XI AN JIAOTONG UNIV

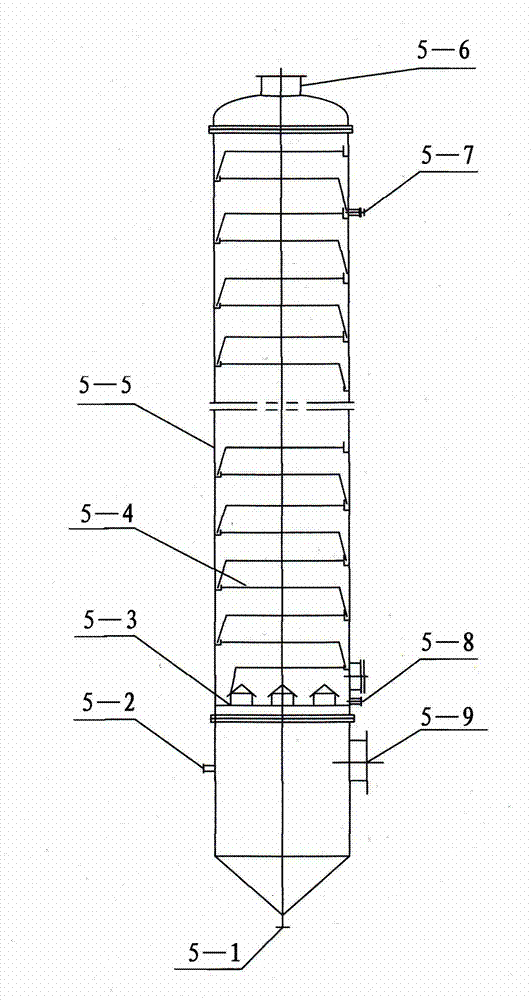

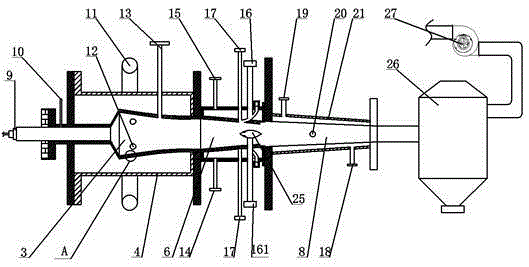

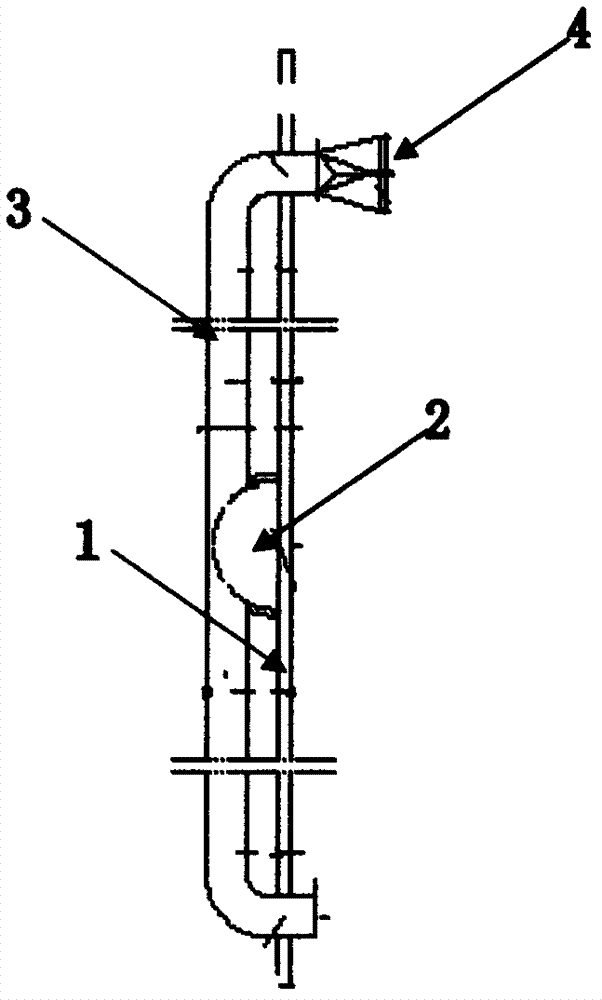

Method and equipment for production of adiponitrile from adipic acid

ActiveCN103896805BCatalyst content is stableNormal responsePreparation by ammonia-carboxylic acid reactionO-Phosphoric AcidFluid phase

The invention relates to a method and equipment for production of adiponitrile from adipic acid, and mainly solves the problem of unstable product quality in the prior art for production of adiponitrile from adipic acid. The method employs materials of fusing adipic acid, ammonia, phosphate and a diluent. The production method is as below: mixing phosphoric acid with the diluent in a pipeline mixer; conducting neutralization of adipic acid and ammonia in a cyanation reactor; sending reaction products into the bottom of a separation tower for separation; recovering gas phase of light components from an outlet; sending the diluent recovered by a gas lifting plate into the pipeline mixer, mixing the diluent with phosphoric acid in the pipeline mixer, and sending the mixture into the cyanation reactor to dilute adipic acid; and sending a liquid phase to a scraper type evaporator. The employed equipment includes an adipic acid storage tank, an ammonia compressor, a cyanation reactor, a pipeline mixer, a separation tower, a tail gas removal tower, a phosphoric acid storage tank and a scraper type evaporator. The invention has the advantage of a good quality of the produced adiponitrile product.

Owner:ANSHAN GUORUI CHEM

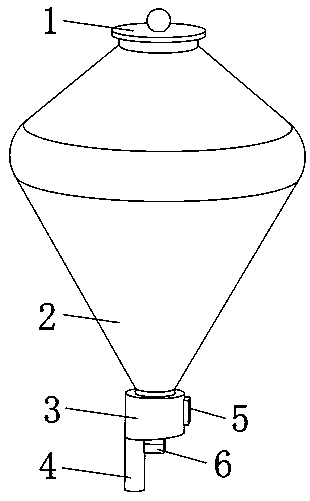

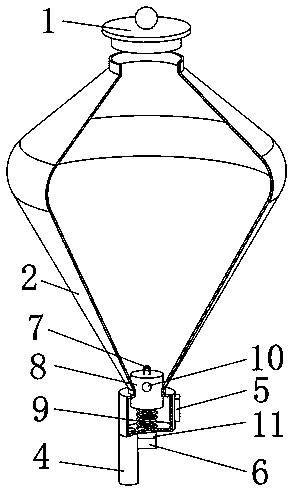

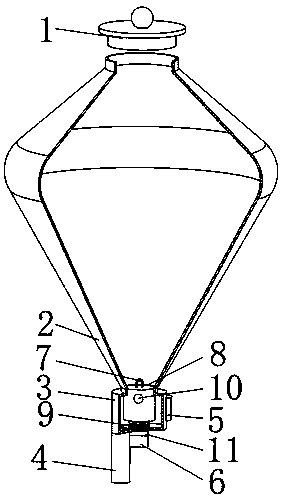

High-precision dropping funnel

ActiveCN111249997APrevent Unplanned OutagesConstant drip rateFeed devicesElectrical connectionControl theory

The invention discloses a high-precision dropping funnel. The high-precision dropping funnel comprises a dropping funnel body, wherein a liquid outlet is formed in the lower end of the dropping funnelbody; a shell is arranged at the lower end of the dropping funnel body; the inner cavity of the shell communicates with the inner cavity of the dropping funnel body through the liquid outlet; a hermetically sliding magnetic attraction block is arranged at the liquid outlet; a plurality of grooves are formed in positions, close to the dropping funnel body, of the peripheral side of the magnetic attraction block; an elastic piece is arranged between the bottom side of the magnetic attraction block and the bottom side of the inner cavity of the shell; an electromagnet is fixed to the bottom sideof the shell; the input end of the electromagnet is electrically connected with the output end of the controller; the controller controls the electromagnet to work periodically; the electromagnet works to attract the magnetic attraction block to move downwards; the grooves move into the shell from the interior of the dropping funnel body; a communicating hole allowing the interior and the exterior of the shell to be communicating is formed in the lower side of the shell; and the communicating hole communicates with the upper end of a liquid outlet pipe. According to the high-precision dropping funnel, constant-speed dropping is achieved, a dropping speed is constant, accidental interruption of dropping is avoided, and the dropping speed is convenient to adjust.

Owner:李翠芝

Liquid separator

PendingCN111773788AEasy to observeGood use valueGaseous fuelsHollow article cleaningPhysicsVALVE PORT

The invention relates to the technical field of liquid separation equipment and relates to a liquid separator. The liquid separator comprises a base and supporting legs, supporting legs distributed left and right are fixedly connected to the upper end face of the base. Liquid separation tanks are fixedly connected to the upper end surfaces of the supporting legs, the center of the upper end surface of the liquid separation tank is communicated with a feeding pipe, the outer side of the feeding pipe is fixedly connected with a filtering device, a second valve is arranged below the filtering device, the rear end face of the second valve is fixedly connected with a feeding pipe, an air injection pipe is arranged above the filtering device, the right end face of the air injection pipe communicates with the feeding pipe, supporting columns are fixedly connected to the left side and the right side of the lower end face of the filtering device, and the lower end faces of the supporting columns are fixedly connected with the liquid separation tanks. According to the liquid separator, through the arrangement of a filtering frame, a limiting threaded rod, a nut and a screen, liquid can be filtered in advance, it is guaranteed that the liquid discharged into the liquid separation tank does not contain impurities, it is guaranteed that the reaction in the liquid separation tank is conducted normally, the product quality is guaranteed, and meanwhile the service life of the liquid separation tank is guaranteed.

Owner:付学才

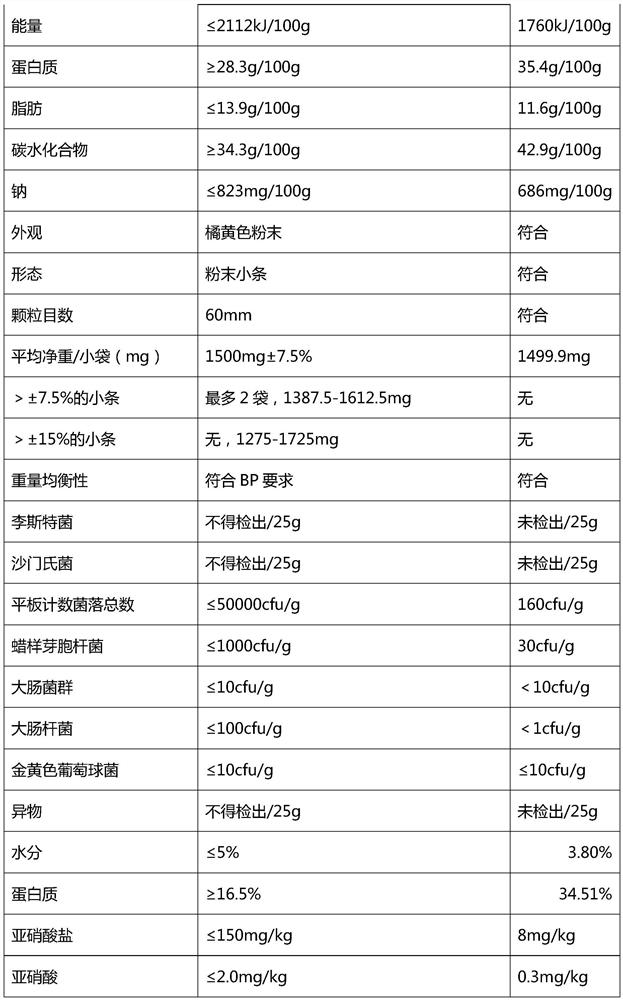

Modified milk powder and preparation method thereof

PendingCN111802459AAvoid destructionImprove microcirculationMilk preparationOther dairy technologyBiotechnologyWhey protein powder

The invention discloses modified milk powder. The modified milk powder is characterized by comprising the following components: 60-80 parts of milk powder, 3-7 parts of lutein ester, 15-25 parts of colostrum powder, 2-4 parts of whey protein powder, 0.3-0.8 of part glucan, 0.1-0.3 part of beta-carotene, and 2-6 parts of composite fruit and vegetable powder, wherein the milk powder is cow milk powder, goat milk powder or mixed powder of cow milk powder and goat milk powder, the milk powder contains 25% of whole milk powder and 75% of skimmed milk powder, the colostrum powder is bovine colostrumpowder, sheep colostrum powder or mixed powder of bovine colostrum powder and sheep colostrum powder, the composite fruit and vegetable powder is prepared from 1-3 parts of blueberry juice powder and1-3 parts of lycium ruthenicum. By adopting the technical scheme of the invention, the additive and the milk powder are physically mixed, so that the nutritional ingredients and activity of compositions are ensured as much as possible, existing equipment is used for production, and the increase of the production cost is avoided.

Owner:上海紫丁进出口有限公司

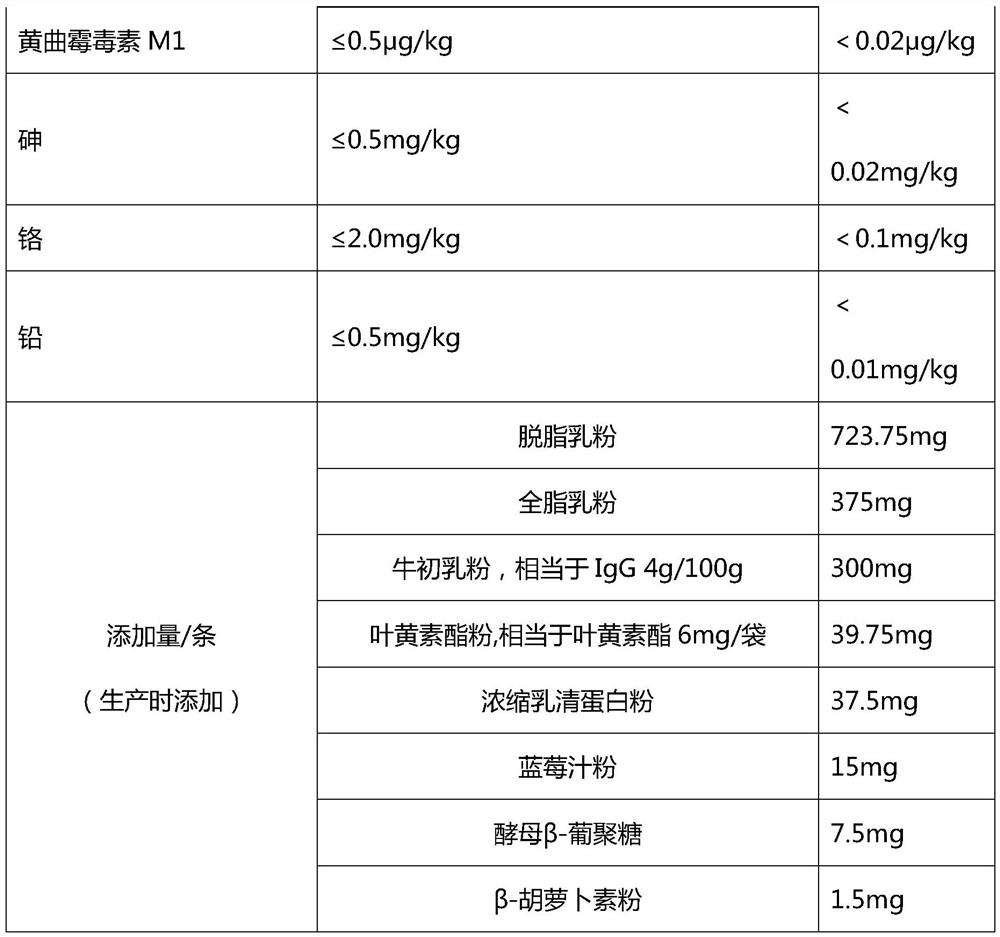

Method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride by taking sodium fluorosilicate as raw material

InactiveCN102557043BAdequate responseWell mixedFluorine/hydrogen-fluorideHalogenated silanesDust controlSilicon tetrafluoride

Owner:SEDIN NINGBO ENG

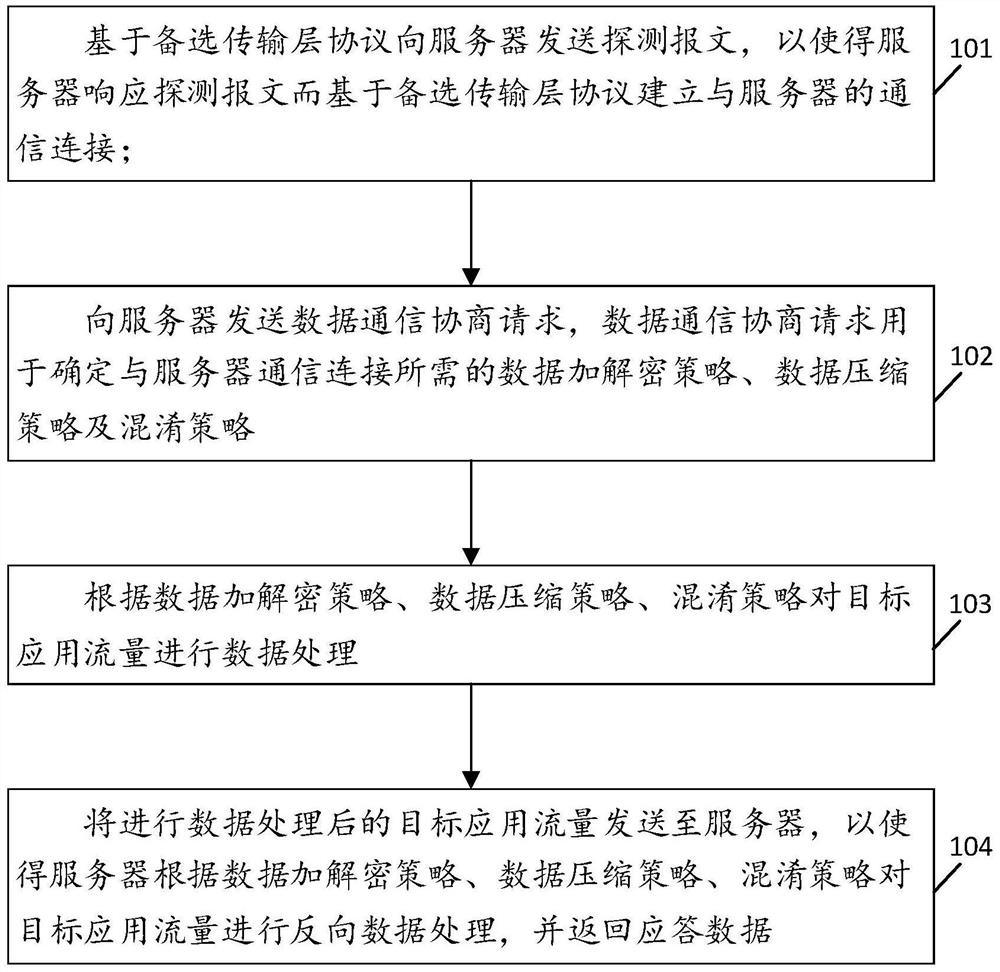

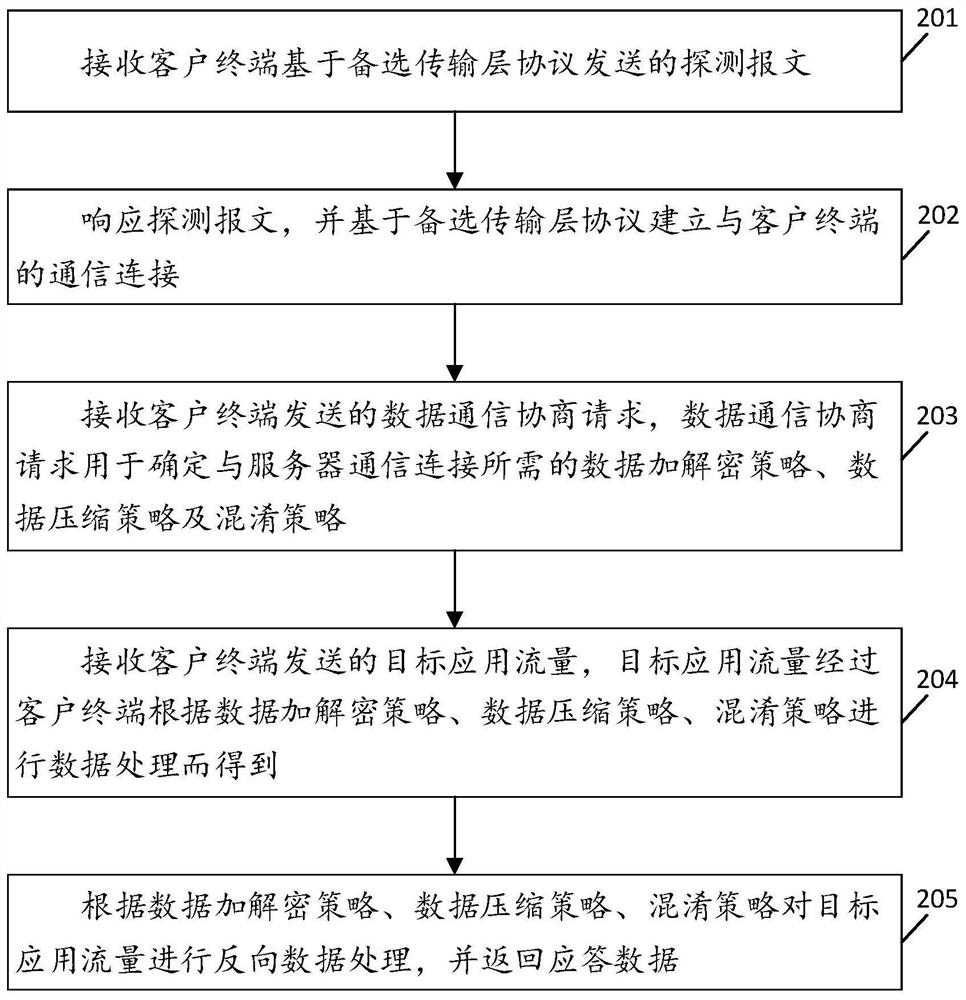

Confusion communication method based on protocol, client terminal, server and storage medium

ActiveCN112565217ANormal responseOvercome the shortcomings of low flexibility and applicabilityData switching networksOn-ProtocolEngineering

The invention provides a confusion communication method based on a protocol, a client terminal, a server and a storage medium, and the method comprises the steps: transmitting a detection message to the server based on an alternative transmission layer protocol, so that the server builds the communication connection with the server based on the alternative transmission layer protocol; sending a data communication negotiation request to a server, wherein the data communication negotiation request is used for determining a data encryption and decryption strategy, a data compression strategy andan confusion strategy required by communication connection with the server; performing data processing on the target application traffic according to the data encryption and decryption strategy, the data compression strategy and the confusion strategy; and sending the target application traffic subjected to the data processing to the server, so that the server returns response data. According to the method and the device, the problem that the DPI system mistakenly intercepts the application or the service can be solved, and meanwhile, the defect of low flexible applicability caused by agency and confusion only for one protocol in an existing mistaken interception solution is overcome.

Owner:BEIJING TOPSEC NETWORK SECURITY TECH +2

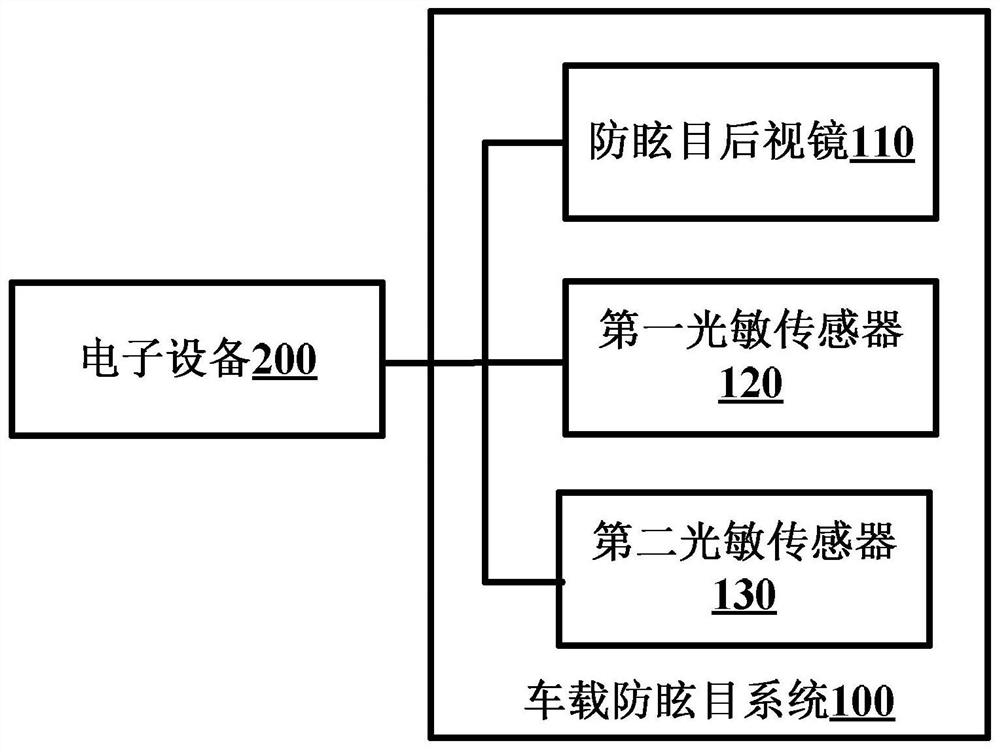

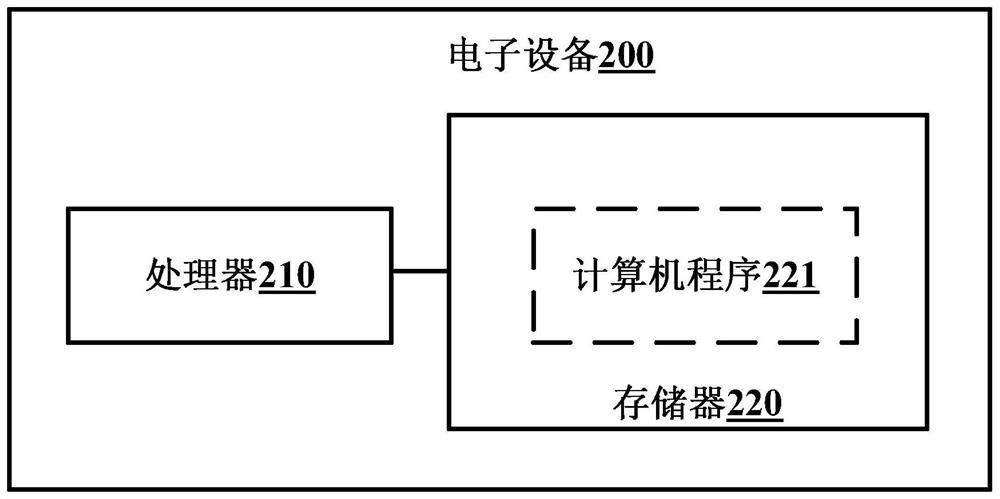

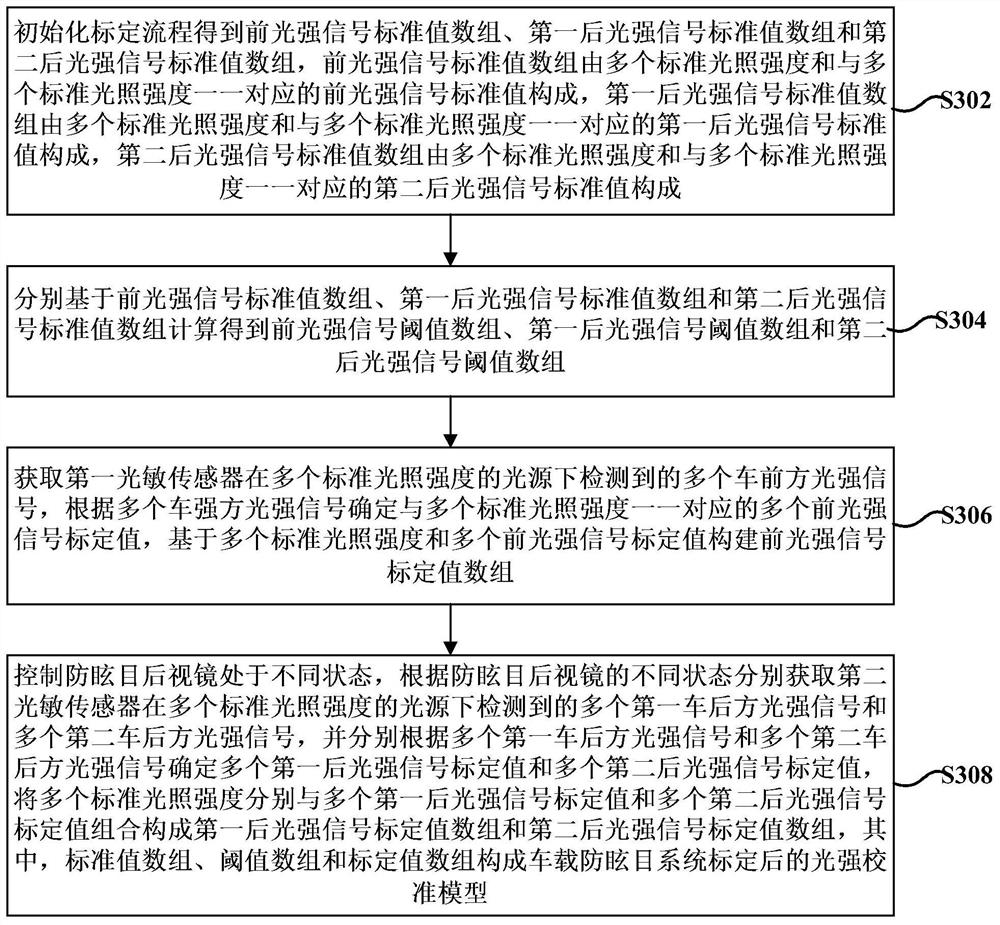

Control method and control system of anti-dazzling rearview mirror

The invention provides a control method and a control system of an anti-dazzling rearview mirror. The method comprises the steps: acquiring a light intensity signal in front of a vehicle and a light intensity signal behind the vehicle; calibrating the light intensity signal in front of the vehicle to obtain an actual light intensity signal in front of the vehicle; determining the current state of the anti-dazzling rearview mirror; calibrating the light intensity signal behind the automobile according to the current state of the anti-dazzling rearview mirror, and acquiring an actual light intensity signal behind the automobile; and determining a voltage output control strategy for the anti-dazzling rearview mirror according to the actual light intensity signal in front of the vehicle, the actual light intensity signal behind the vehicle and the current state of the anti-dazzling rearview mirror. Based on the technical scheme provided by the invention, the light intensity signal in front of the vehicle and the light intensity signal behind the vehicle are respectively calibrated to obtain an actual light intensity signal in front of the vehicle and an actual light intensity signal behind the vehicle, so that the detection error of the photosensitive sensor can be reduced as much as possible, the reliability of an anti-dazzling algorithm is ensured, and the anti-dazzling rearview mirror can respond normally; and therefore, user experience is improved.

Owner:ECARX (HUBEI) TECHCO LTD

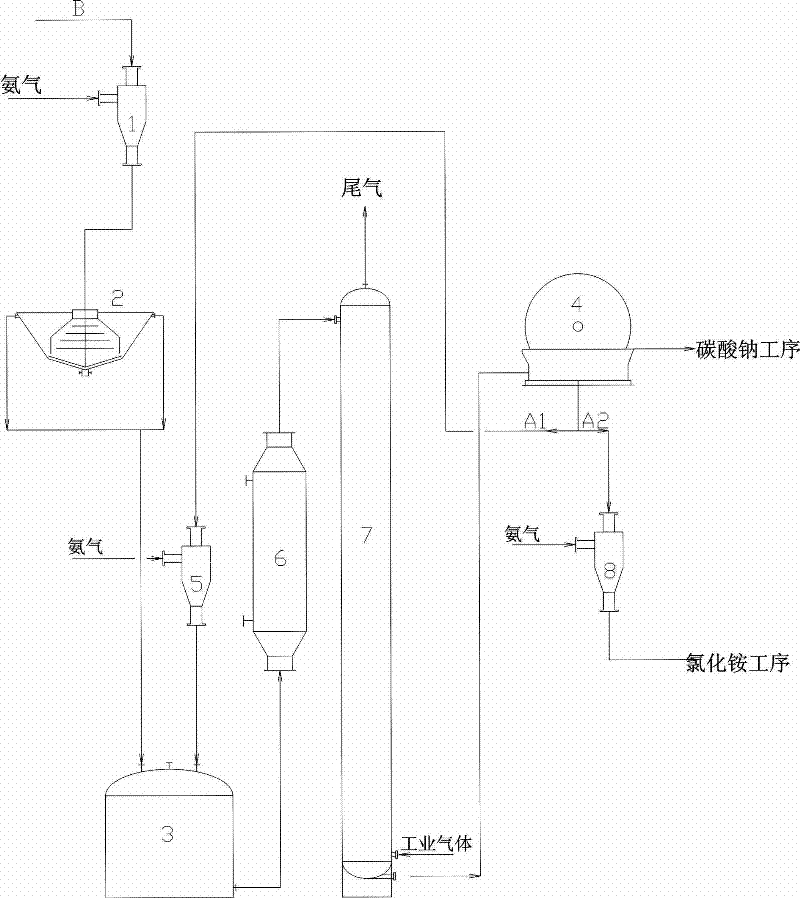

Process for removing carbon dioxide in combined alkali preparation method

The invention especially relates to a process for removing carbon dioxide produced in a combined alkali preparation method, which belongs to the technical field of combined alkali preparation methods. The process is as follows: mother liquor obtained after separation of solid sodium bicarbonate from liquid coming out from a decarburization tower is divided into two parts, i.e., A1 and A2, and A1 enters into a mixer after absorbing ammonia; after ammonium chloride is separated from mother liquor used in a procedure for producing ammonium chloride, the mother liquor adsorbs heat and ammonia, impurities of calcium-magnesium ions in the mother liquor are removed, and then the mother liquor is mixed with A1; obtained mixed liquor enters into the decarburization tower after cooling so as to remove carbon dioxide. The process provided in the invention enables a reaction for removing carbon dioxide to be carried out normally under the condition that a built-in or external cooler is not provided, i.e., that no cooling means is needed for heat exchange of decarburization liquid in the decarburization tower from the moment the decarburization liquid enters into the decarburization tower to the moment the decarburization liquid goes out from the decarburization tower; the decarburization tower can stably operate for a long period, with an operational period being more than 60 days; a goodabsorption effect of carbon dioxide is achieved, and a utilization rate reaches more than 99.6%.

Owner:张志广 +1

Continuous production oxidation furnace and production method of highly pure titanium dioxide

ActiveCN105271387AImprove oxidation resistancePromote oxidationChemical industryTitanium dioxideChemical reactionOxygen

A continuous production oxidation furnace of highly pure titanium dioxide comprises a furnace body, the furnace body is formed by an inner container and a pressure container wrapping the inner container, and the furnace body is sequentially divided into a toluene burning segment, a bathroom segment and a scar beating salt segment. The furnace has the characteristics of energy saving, purity improvement and efficiency increase. The material of the inner container is ceramic, and the ceramic has extremely high oxidation resistance, avoids various chemical reaction oxidations and guarantees smooth implementation of reactions; and hot oxygen rings improve full oxygen and promote combustion, cooling water is used to cool a product obtained after a reaction, and a nucleation gas added in the bathroom segment can control the quality of TiO2 particles generated after oxidation, so a generated gas-solid mixture is cooled, and scabbing of an oxidation reactor is prevented. A production method also disclosed in the invention has the advantages of tail gas recycling, gas recycling, use efficiency improvement and resource waste reduction.

Owner:仙桃市中星电子材料有限公司

Dispersed feeding device for kettle

The invention provides a dispersed feeding device for a kettle, which is applicable to a chemical reaction kettle system for machining a liquid-state material and is particularly applicable to a reaction kettle system for dispersing a mixed material at a high speed, such as an oxidization-reduction polymerization system. The main realization manner is as follows: firstly, a feeding general pipe is arranged around a kettle body of a reaction kettle; the feeding general pipe is a pipe-shaped body; the pipe-shaped body is tightly adhered to a kettle body; an inlet end is a feeding opening; the pipe-shaped body is provided with a plurality of feeding branch pipes; one ends of the feeding branch pipes are feeding ends which are connected with the feeding general pipe; and outlet ends extend toward upper and lower kettle bodies of the reaction kettle. The outlet ends of the feeding branch pipes are tail ends which are provided with feeding spraying nozzles; the feeding spraying nozzles are in a flat shape; the feeding branch pipes stretch into the inner wall of the reaction kettle and a certain included angle is formed between a two-dimensional plane of the flat spraying nozzles and a tangential plane of the inner wall of the reaction kettle; and the included angle is an acute angle.

Owner:许洪军

Sulfamic acid production device

InactiveCN111871348ARealize continuous automatic additionGuaranteed accuracyAmidosulfonic acidChemical/physical/physico-chemical stationary reactorsProcess engineeringEnvironmental engineering

A sulfamic acid production device comprises: a sulfuric acid storage tank, wherein a reaction kettle is arranged below the sulfuric acid storage tank, the sulfuric acid storage tank is connected withthe reaction kettle through a pipeline, and a volumetric flowmeter and a first electromagnetic valve are arranged on the pipeline between the sulfuric acid storage tank and the reaction kettle; the top of the sulfuric acid storage tank is communicated with a sulfuric acid liquid inlet pipe, the top of the reaction kettle is connected with the bottom of the urea feeding device through a pipeline, the top of the urea feeding device and the top of the urea feeding device are arranged in an opening mode, and a urea pool is arranged below the urea feeding device;the urea in urea pool is fed into urea feeding device through spiral feeder, and a urea quantitative feeding device is arranged in urea feeding device. According to the invention, urea can be continuously and automatically added, it isguaranteed that the reaction is normally conducted, meanwhile, sulfur trioxide can be prevented from leaking into air to pollute the environment, so taht the healthy production environment is guaranteed, and the reaction can be carried out successfully.

Owner:SHANDONG XINGDA CHEM

Method for detecting Vibrio cholerae O139 by using suspension chip technology

InactiveCN101440403AControl false negativesGeneration of controlMicrobiological testing/measurementFluorescence/phosphorescenceAntigenMicrosphere

The invention relates to a suspended chip and a method for detecting vibrio cholerae O139. The suspended chip comprises a microspheric carrier and an oligonucleotide probe fixed on the carrier, wherein the oligonucleotide probe is a DNA sequence in a vibrio cholerae O139-specific gene rfb screened from gene clusters of O-antigen of vibrio cholerae. A designed primer is used to proliferate and label the genomic DNA of the sample under test, hybridization is performed with the suspended chip, and then whether the sample under test contains vibrio cholerae O139 or not is judged. The suspended chip has high sensitivity, reaches the level of fg genomic DNA, satisfies the requirement of detection on clinical and environmental samples, and is characterized by high specificity, simple operation, low cost and easy generalization. The invention adopts a UNG-taq catalytic PCR system which dramatically decreases the frequency of false-positive outcome in PCR.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI

Chemical looping combustion device and method for staged oxidation of solid fuel

ActiveCN104848207BImprove combustion efficiencyGuaranteed combustion efficiencyFluidized bed combustionSolid fuel combustionCycloneWater vapor

The invention discloses a chemical looping combustion device for solid fuel grading oxidation and a method thereof. The device is a circulating loop formed by an air reactor, an air cyclone separator, a fuel reactor, a fuel cyclone separator, a return feeder, a gasification reactor and an isolator. The method includes the steps that solid fuel is subjected to gasification reaction in the gasification reactor, generated gas fuel and oxygen carrier at a poor oxidation state are subjected to oxidation reaction, generated weak reduction gas enters the fuel reactor, and the generated weak reduction gas and oxygen carrier at an oxidation state are subjected to deep oxidation reaction, are converted into carbon dioxide and steam and are discharged; oxygen carrier at a reduction state in the air reactor and air are subjected to oxidation reaction to generate oxygen carrier particles at an oxidation state, and after being separated by the air cyclone separator, the oxygen carrier particles at an oxidation state enter the fuel reactor and are reduced to oxygen carrier at a poor oxidation state through weak reduction gas; after being separated by the fuel cyclone separator, the oxygen carrier at the poor oxidation state enters the gasification reactor through the return feeder and is reduced to the oxygen carrier at a reduction state through the solid fuel gasification products, and finally the oxygen carrier particles at a reduction state are returned to the air reactor through the isolator and are regenerated to form the oxygen carrier at the oxidation state.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com