Multi-section type heat insulation fixed bed reactor for PX production

A technology of adiabatic fixed bed and reactor, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large catalyst loss, waste of heat, and ineffective use of heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

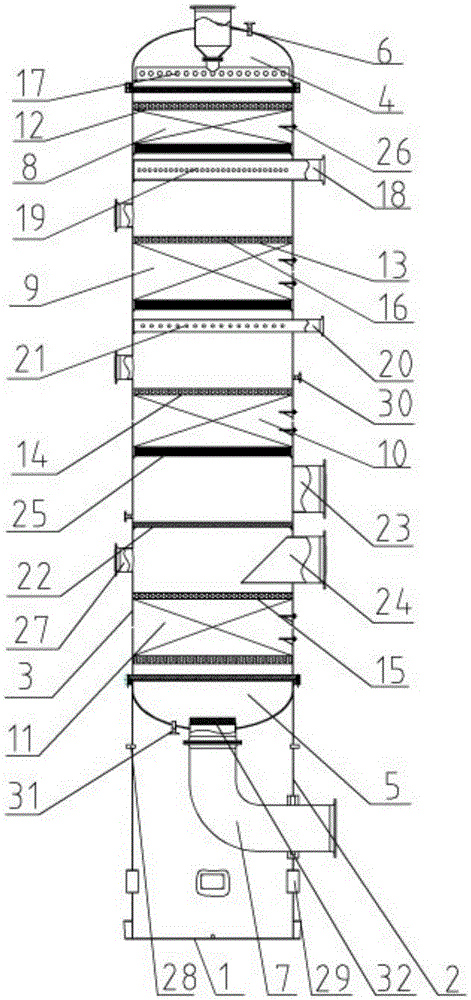

[0019] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Reference attached figure 1 , the present invention includes: comprising a base component 1, a skirt 2 and a reactor body 3, the reactor body 3 is installed on the skirt 2, the skirt 2 is installed on the base component 1, and the top of the reactor body 3 is connected with an upper seal Head 4, the bottom of the reactor body 3 is connected with a lower head 5, the upper head 4 is provided with a main feed port 6, and the lower head 5 is provided with a discharge port 7; the upper part of the reactor body 3 to the lower part is sequentially A first reaction zone 8, a second reaction zone 9, a third reaction zone 10 and a fourth reaction zone 11 are provided; a first stage fixed bed 12 is arranged between the first reaction zone 8 and the main feed port 6, and the second A second section of fixed bed 13 is provided betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com