High-precision dropping funnel

A dropping funnel, a high-precision technology, applied in chemical instruments and methods, chemical/physical processes, feeding devices, etc., can solve the problems of inconvenient adjustment of the dropping rate of the dropping funnel, slowing of the dropping rate, and inconvenience in use. , to achieve the effect of reducing the cost of experimental equipment, dripping at a uniform speed, and avoiding unexpected interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

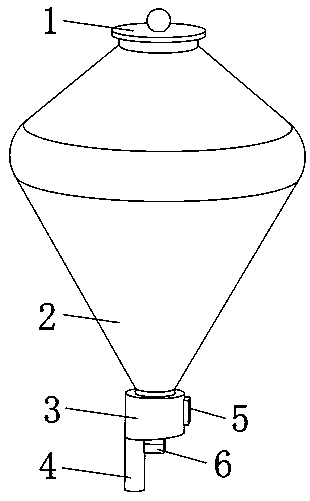

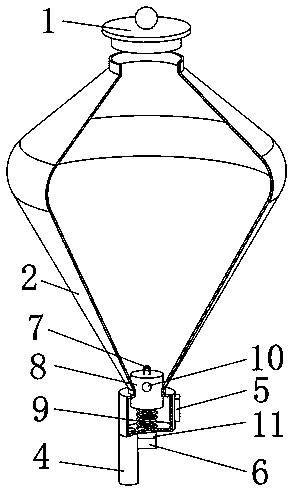

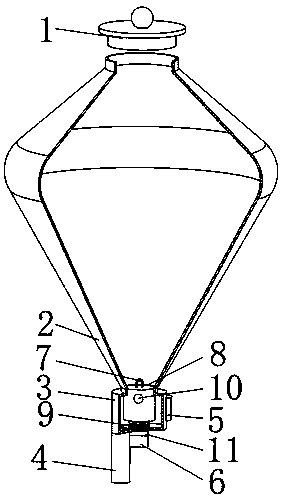

[0035] Example 1: Please refer to Figure 1-3 , this embodiment discloses a high-precision dropping funnel, including a dropping funnel body 2, a liquid discharge port is provided at the lower end of the dropping funnel body 2, and a housing 3 is provided at the lower end of the dropping funnel body 2, and the housing 3 The inner cavity of the dropping funnel body 2 communicates with the inner cavity of the dropping funnel body 2 through a liquid discharge port.

[0036] Specifically as figure 2 As shown, a sealed and sliding magnetic block 8 is provided at the discharge port, and several grooves 10 are provided on the outer peripheral side of the magnetic block 8 close to the dropping funnel body 2. The bottom side of the magnetic block 8 and the housing 3 An elastic piece 9 is arranged between the bottom sides of the inner cavity, and the elastic piece 9 is fixed on the bottom side of the magnetic block 8 or the bottom side of the inner cavity of the housing 3 .

[0037] ...

Embodiment 2

[0057] Embodiment two: if figure 2 As shown, this embodiment discloses a high-precision dropping funnel, its structure is roughly the same as that of Embodiment 1, the difference is that a pull ring 7 is installed on the magnetic block 8 of this embodiment; the external hook Stretch into the dropping funnel body 2, and the hook hooks the pull ring 7, so that the magnetic block 8 is removed from the dropping funnel body 2, which facilitates the cleaning of the high-precision dropping funnel.

Embodiment 3

[0058] Embodiment three: as figure 1 , Figure 4 and Figure 5 As shown, this embodiment discloses a high-precision dropping funnel, the structure of which is roughly the same as that of Embodiment 1. The difference is that a cover 1 is installed on the liquid inlet on the upper part of the dropping funnel body 2 in this embodiment.

[0059] The magnetic block 8 is provided with a perforation 15 which communicates up and down, the upper part of the perforation 15 communicates with the lower end of the air duct 14, and the upper end of the air duct 14 extends to the upper part of the inner cavity of the dropping funnel body 2 .

[0060] When the dropping funnel body 2 is close to the maximum amount of volatile liquid to be titrated, cover 1 is required to completely block the feeding port at the upper end of the dropping funnel body 2 to prevent the volatile liquid to be titrated in the dropping funnel body 2 Volatile.

[0061] Initially, the electromagnet 6 is energized to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com