Patents

Literature

356results about How to "Guaranteed stable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

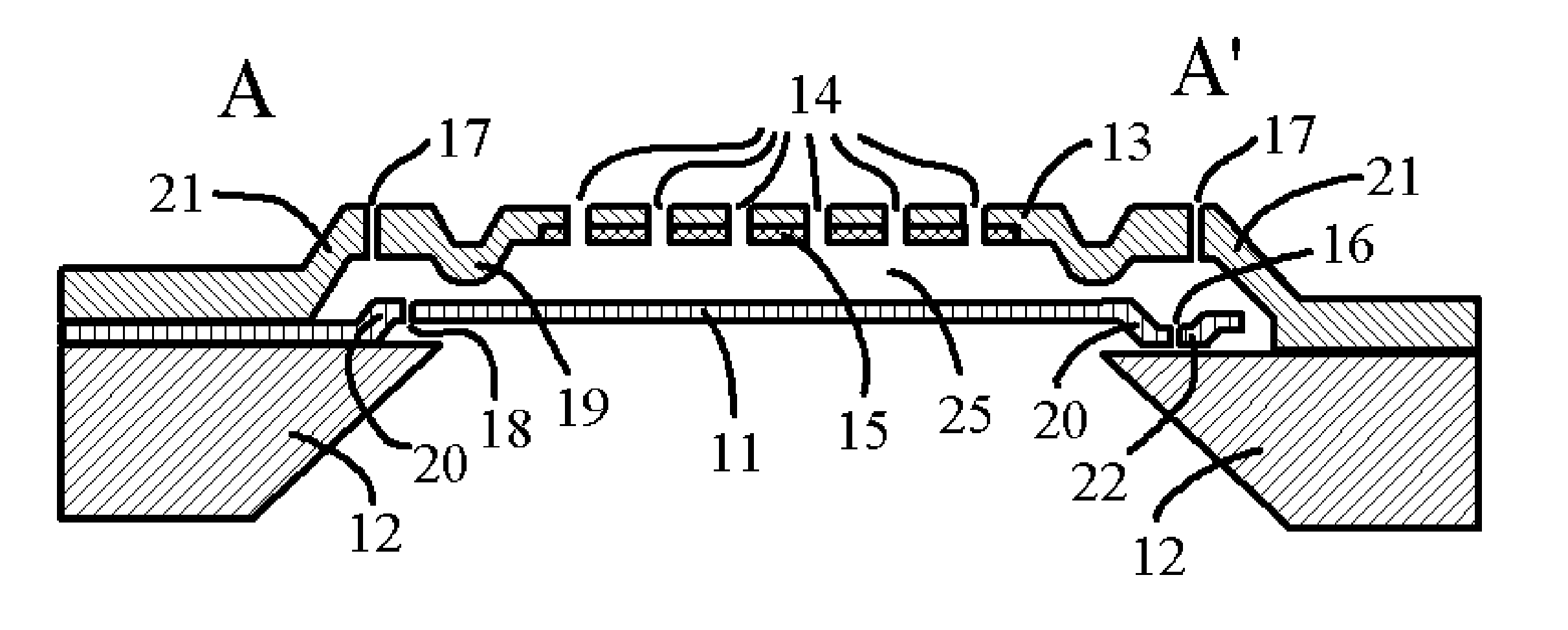

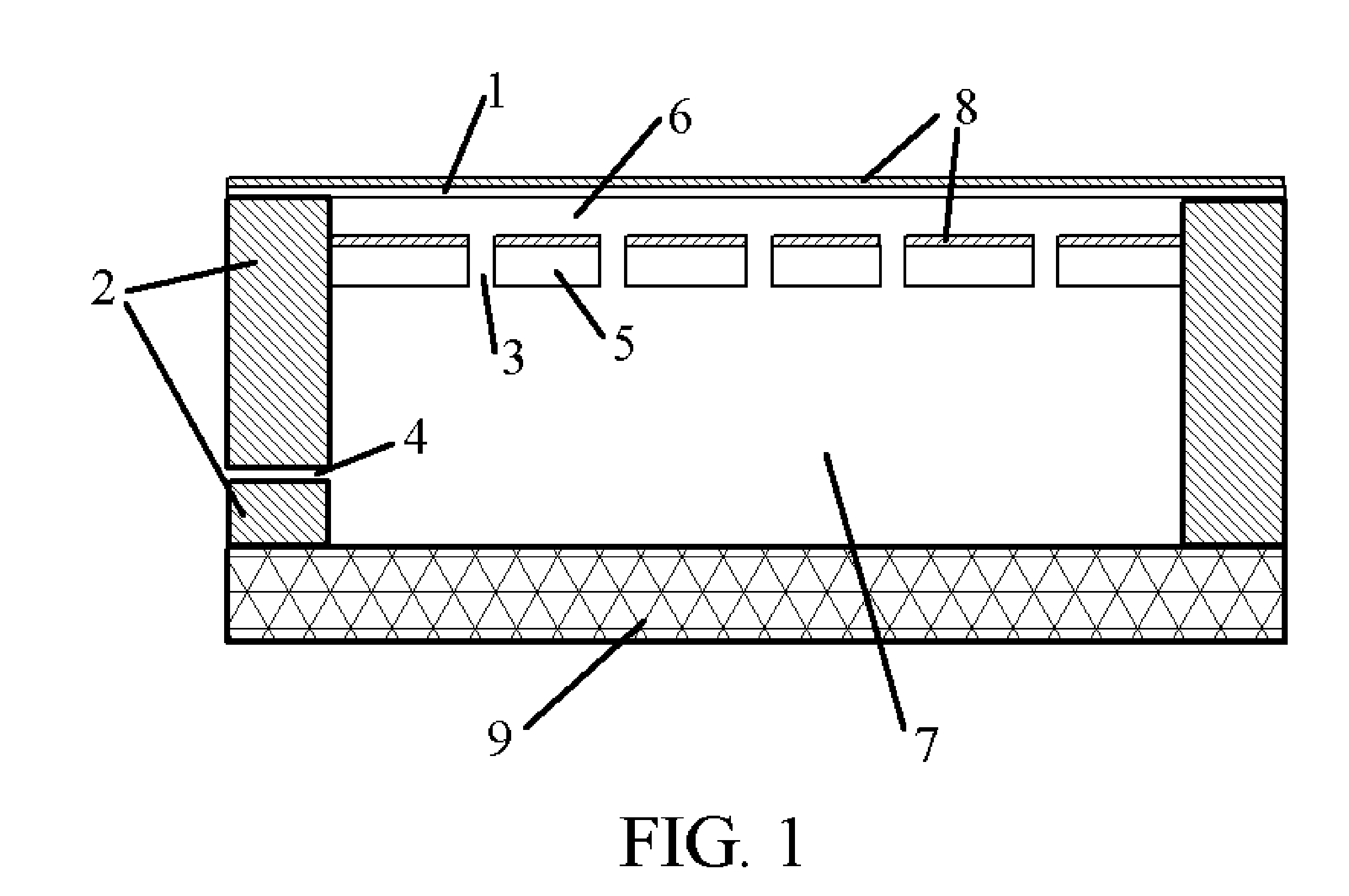

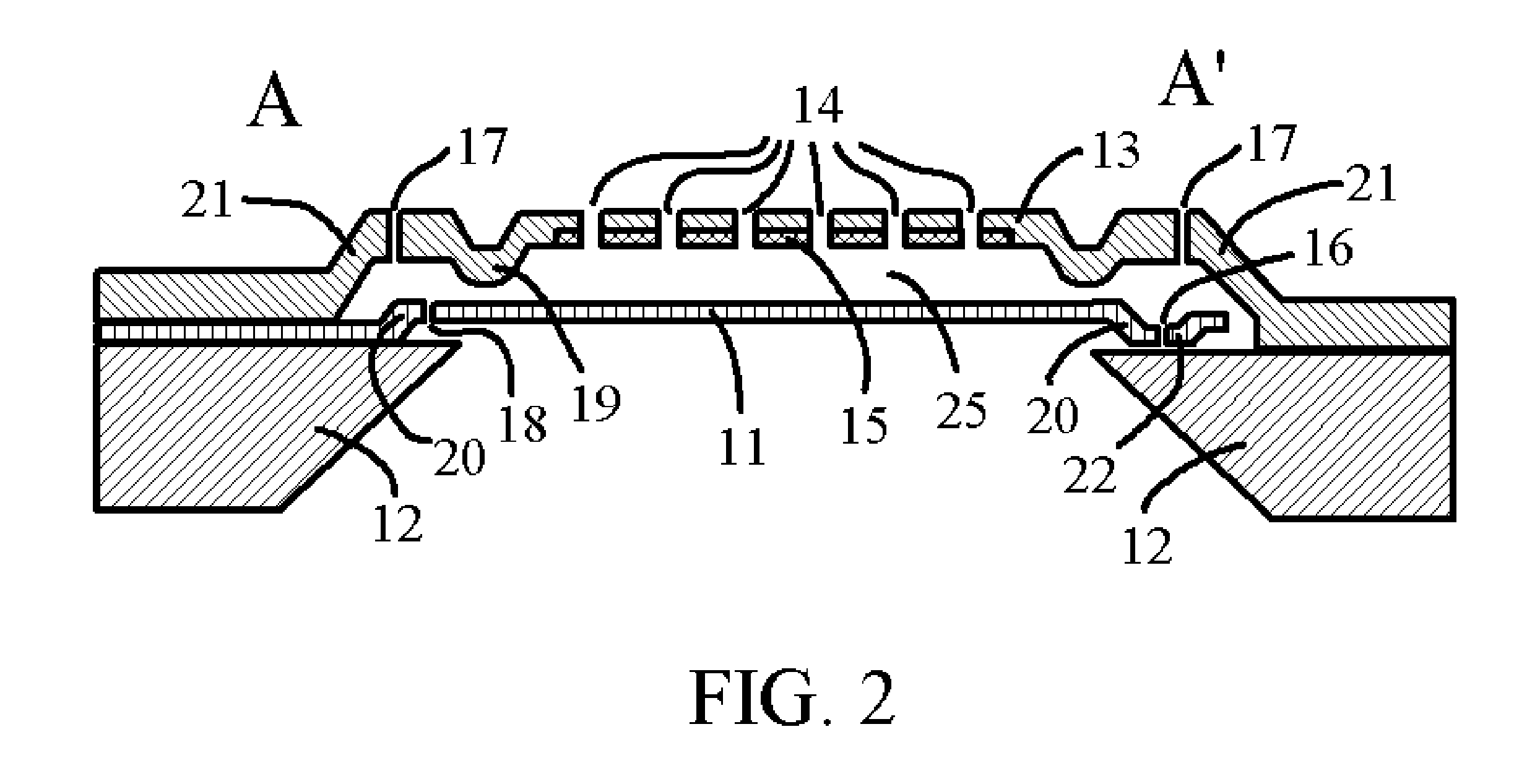

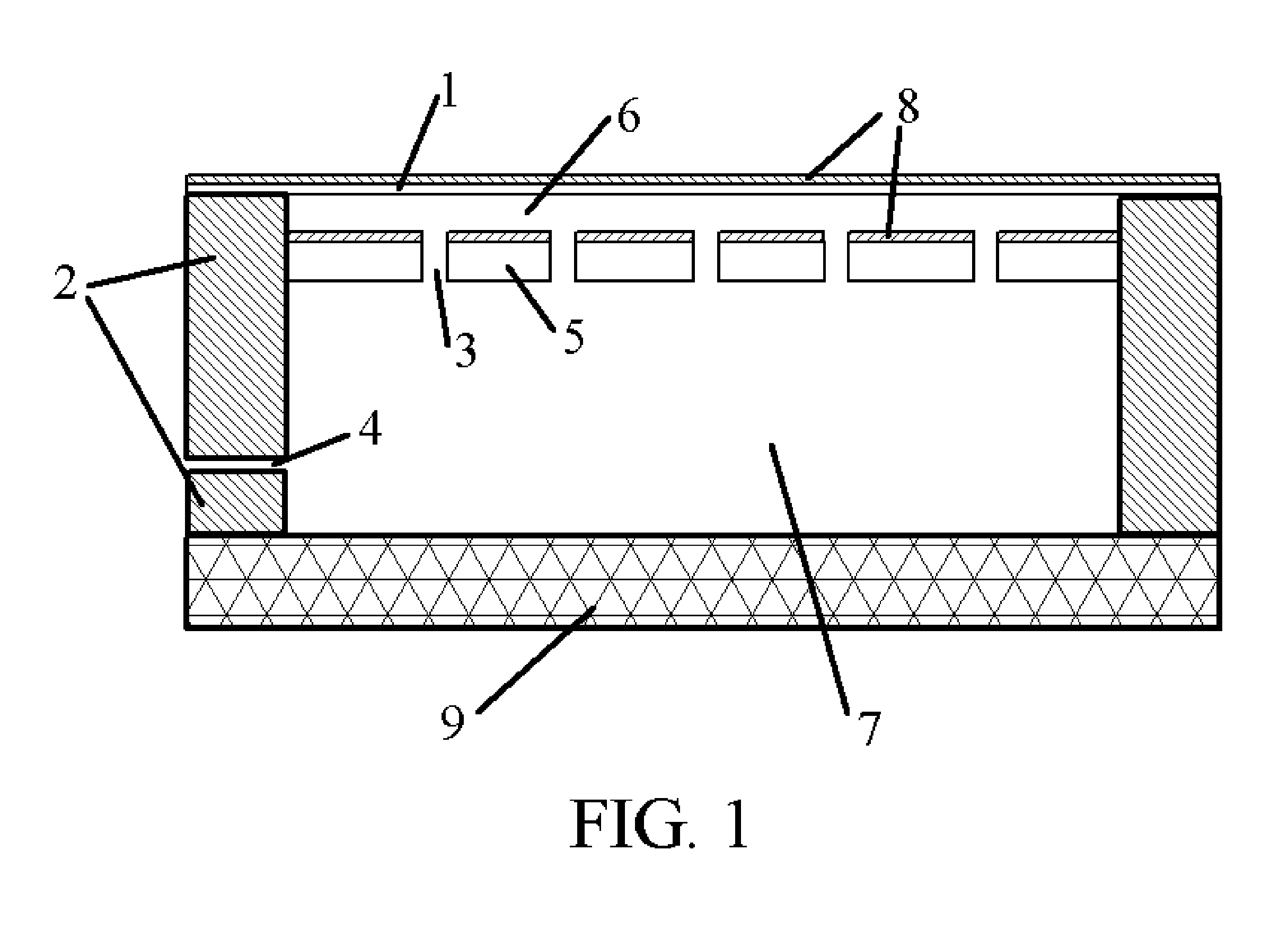

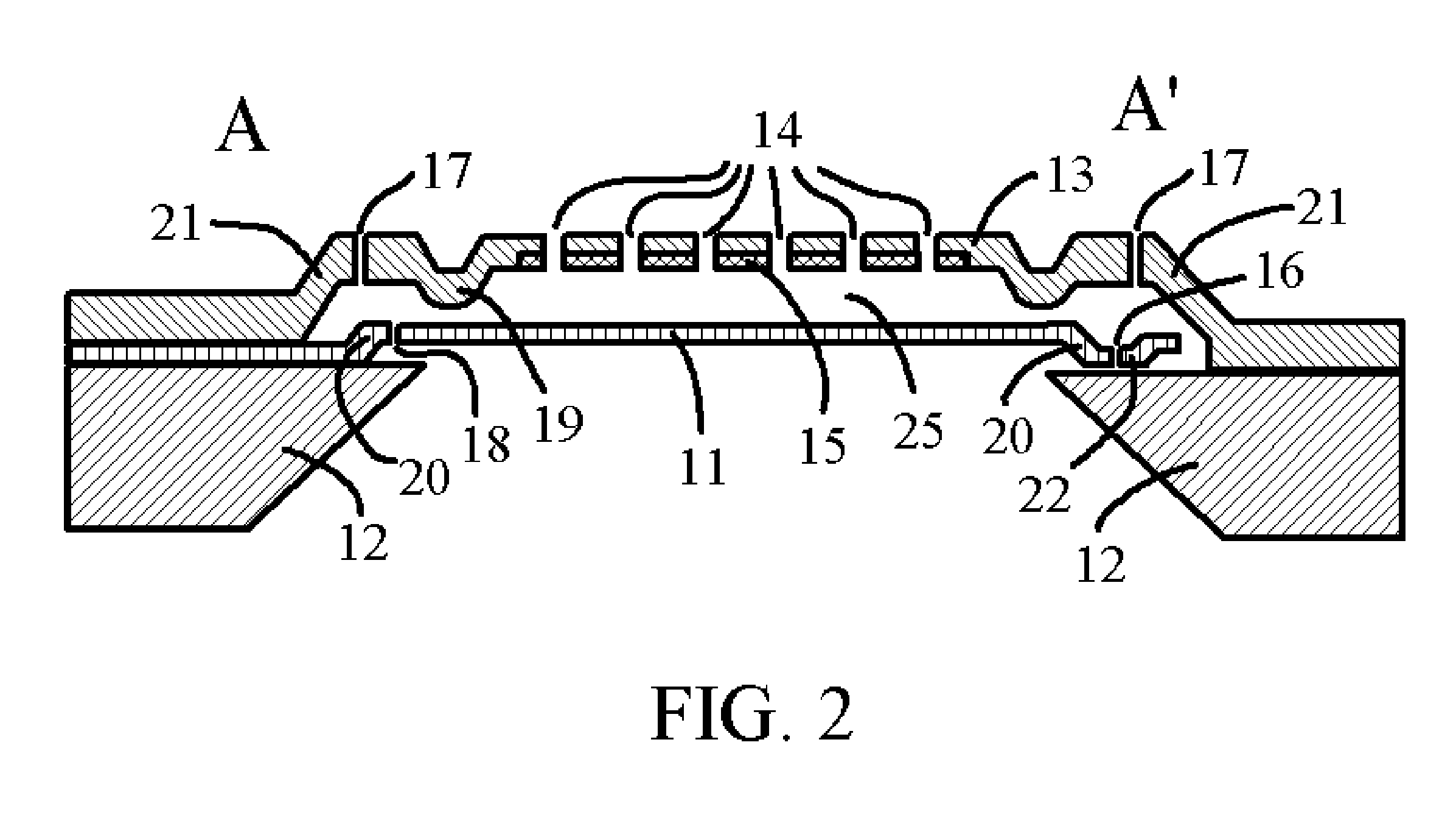

Capacitive micromachined acoustic transducer

ActiveUS20060233401A1Wide bandwidthHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsAcoustic filtersEngineering

A micromachined capacitive acoustic transducer including an electrode formed by a perforated plate and another electrode formed by a shallowly corrugated membrane anchored at one or more positions on the substrate which also supports the said perforated plate is described. Also disclosed includes: a fixed perforated plate; a movable shallowly corrugated membrane having holes to form acoustic filter to a certain frequency or a range of frequencies spaced from the perforated plate that is anchored in one or more location but loose at other locations; a support structure in the perforated plate maintaining the minimum separation between the membrane and the perforated plate near the perimeter.

Owner:NEOMEMS TECH INC WUXI CHINA

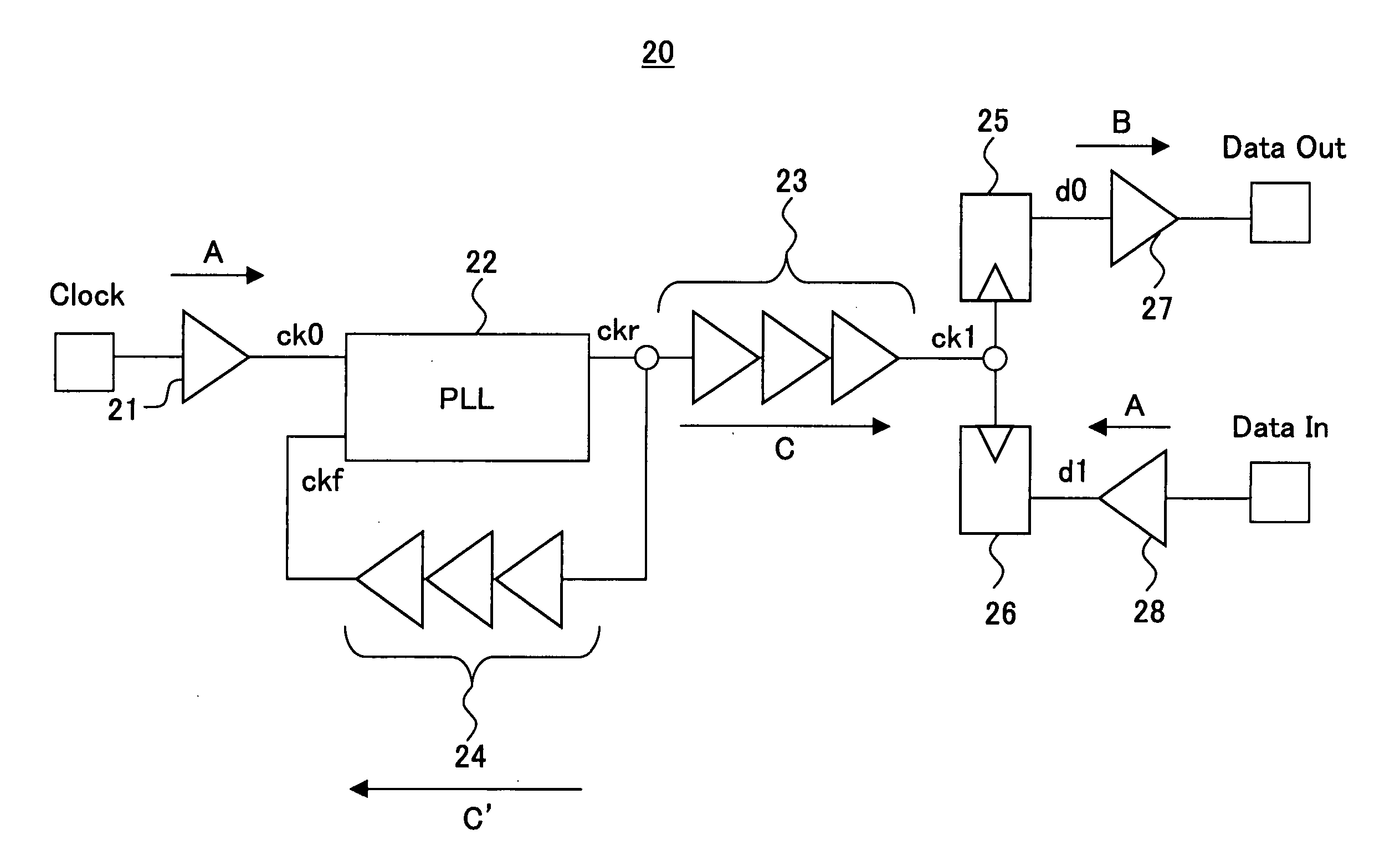

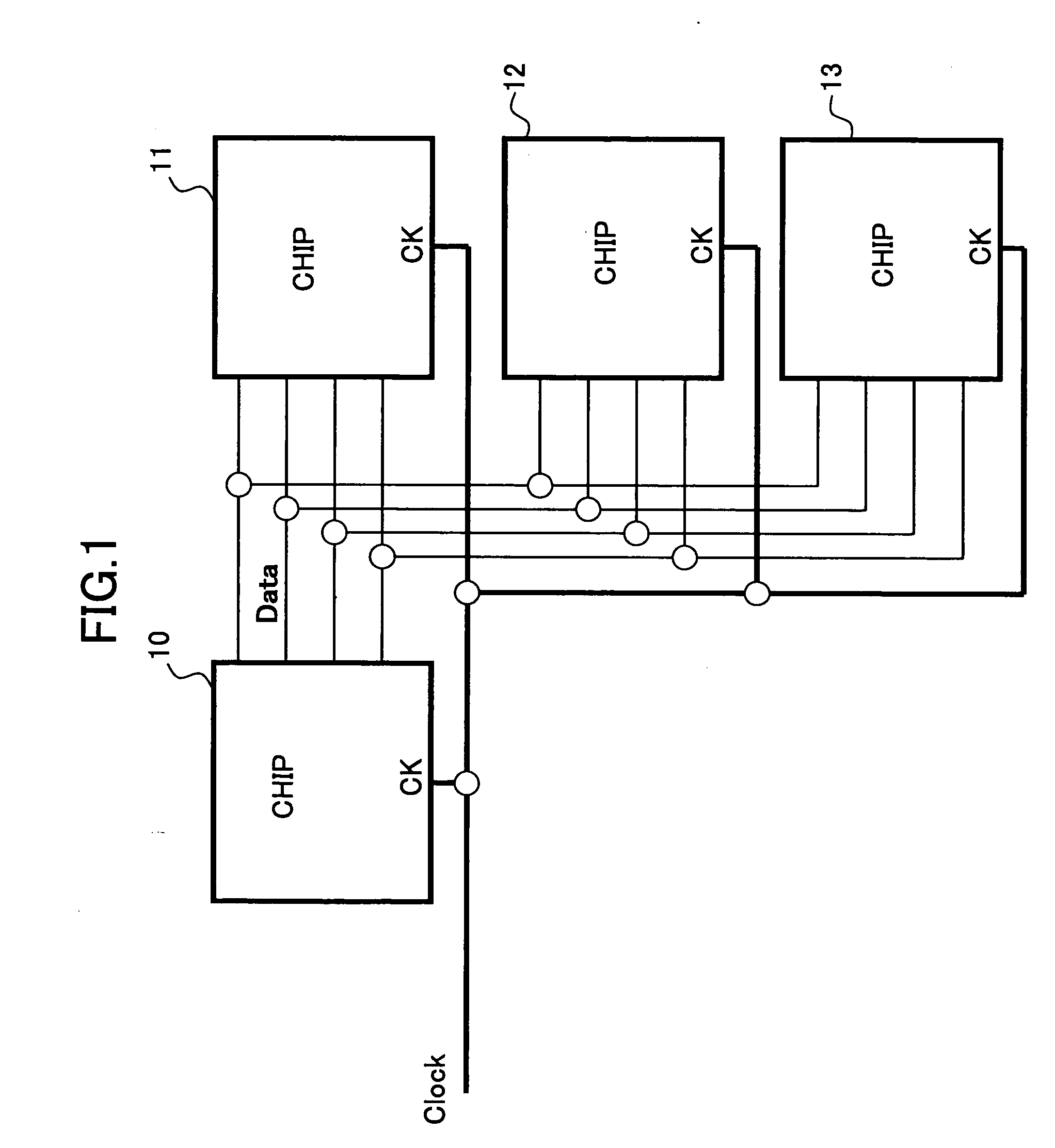

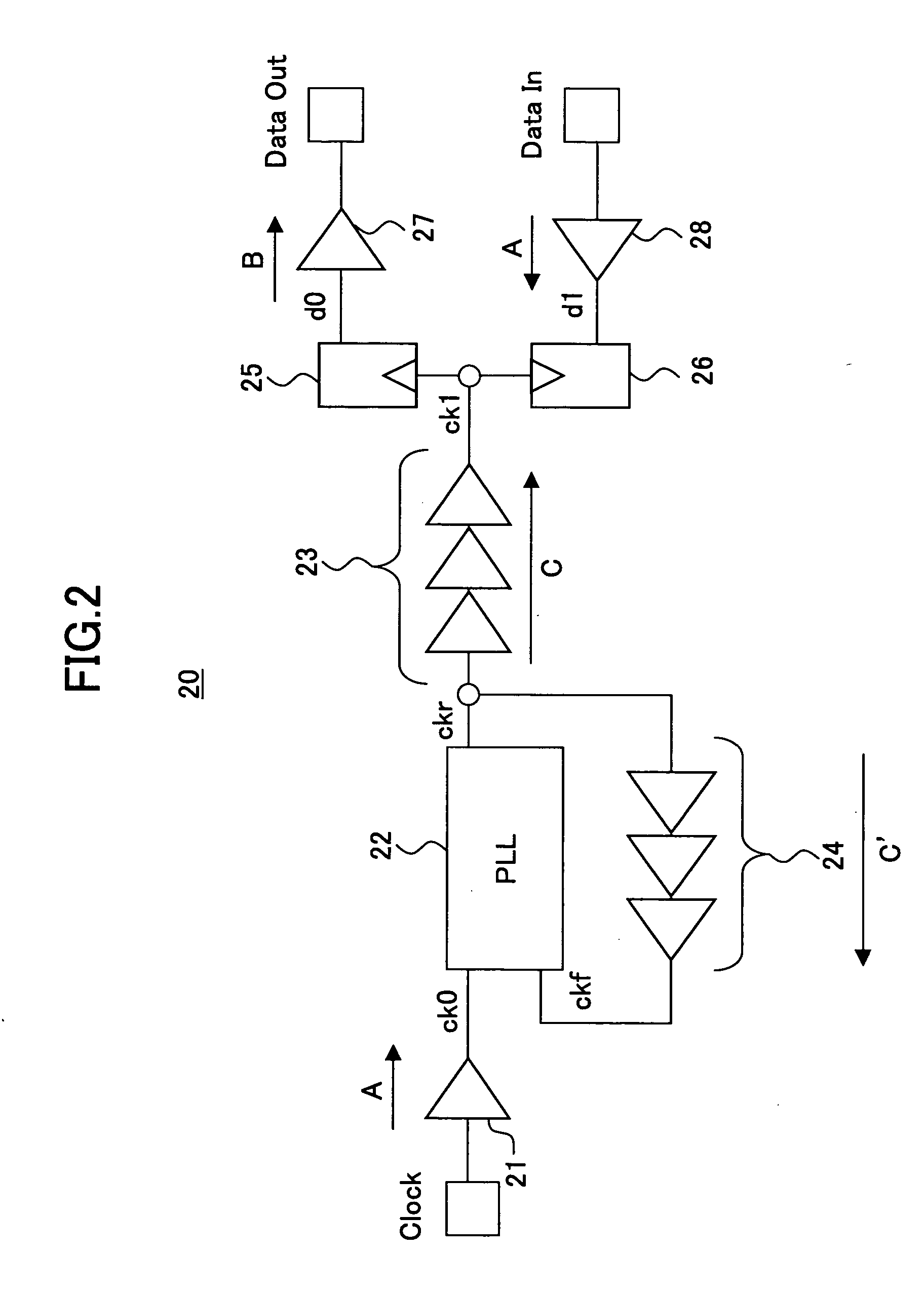

Timing adjustment circuit and memory controller

ActiveUS20050242850A1Stable and reliable data input/output operationGuaranteed stable operationPulse automatic controlElectric digital data processingControl storeEngineering

A circuit for timing adjustment includes a PLL circuit configured to generate a phase-adjusted clock signal in response to phase comparison between an input clock signal and a delayed clock signal, a feedback path configured to delay the phase-adjusted clock signal for provision as the delayed clock signal to the PLL circuit, a first timing correction circuit configured to add a predetermined delay time to the feedback path, an output data circuit configured to supply output data at first timing responsive to the phase-adjusted clock signal, a second timing correction circuit configured to delay the first timing by the predetermined delay time to generate second timing different from the first timing, and an input data circuit configured to latch input data at the second timing.

Owner:FUJITSU LTD

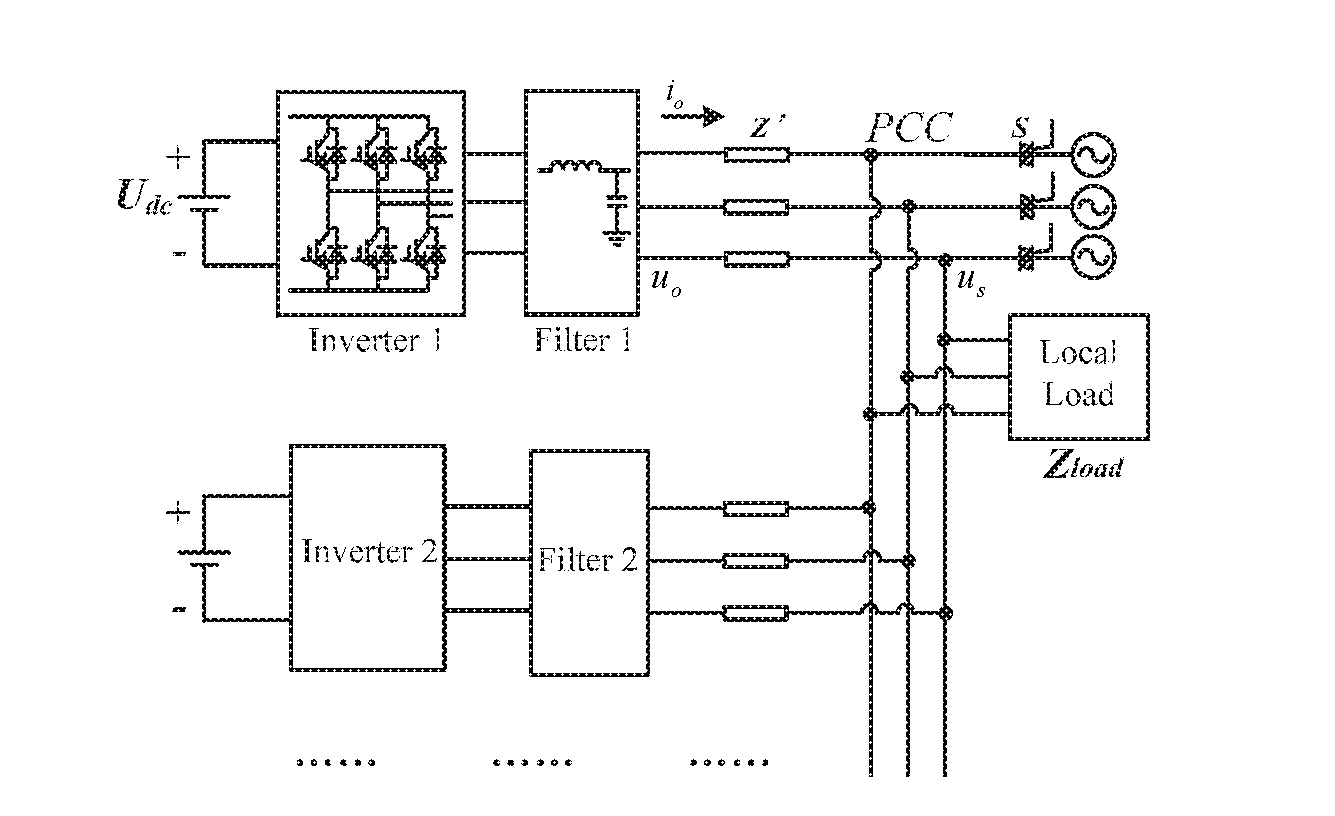

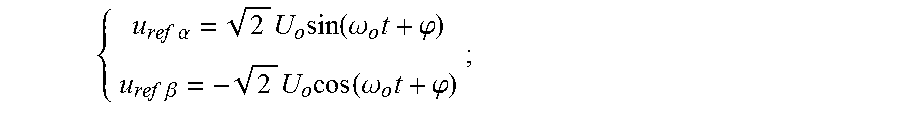

Steady state control method for three-phase double-mode inverter

InactiveUS20170047862A1Guaranteed stable operationGood effectEfficient power electronics conversionAc-dc conversionPower controlPhase lead

A steady state control method for a three-phase double-mode inverter. Off-grid steady state control is composed of outer loop power droop control, voltage feed-forward quasi-resonant control, and inner current loop dead-beat control. Therefore, the response speed of the inverter is raised, and the influence caused by the load fluctuation of a micro-grid is inhibited. Based on the off-grid steady state control, grid-connected steady state control introduces phase lead control to the power droop control. Therefore, the output voltage of the inverter is always slightly ahead of the power grid voltage, which avoids the energy pour backward phenomenon of the inverter due to a phase error, and realizes stable and reliable running in the grid-connected mode.

Owner:HUNAN UNIV +1

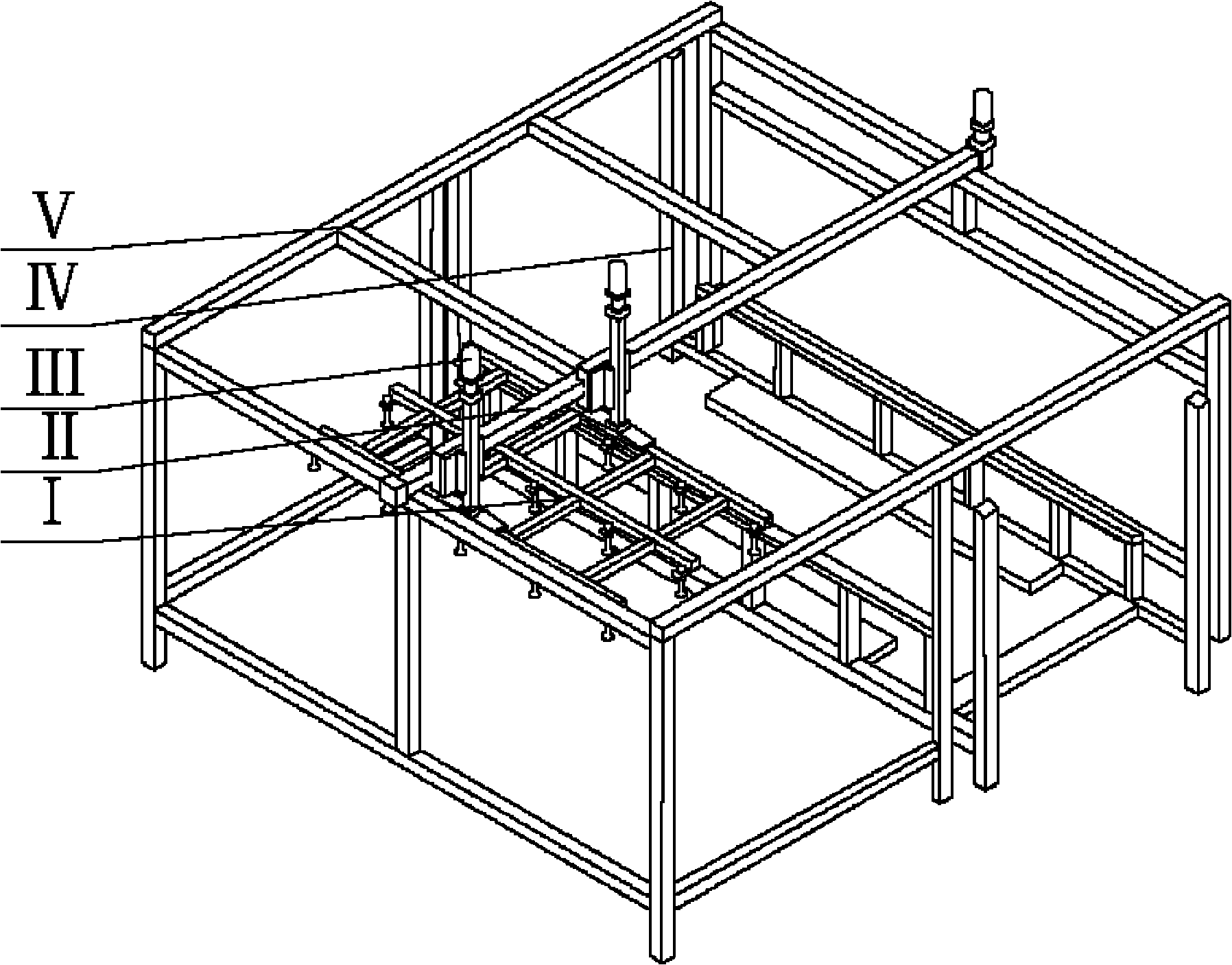

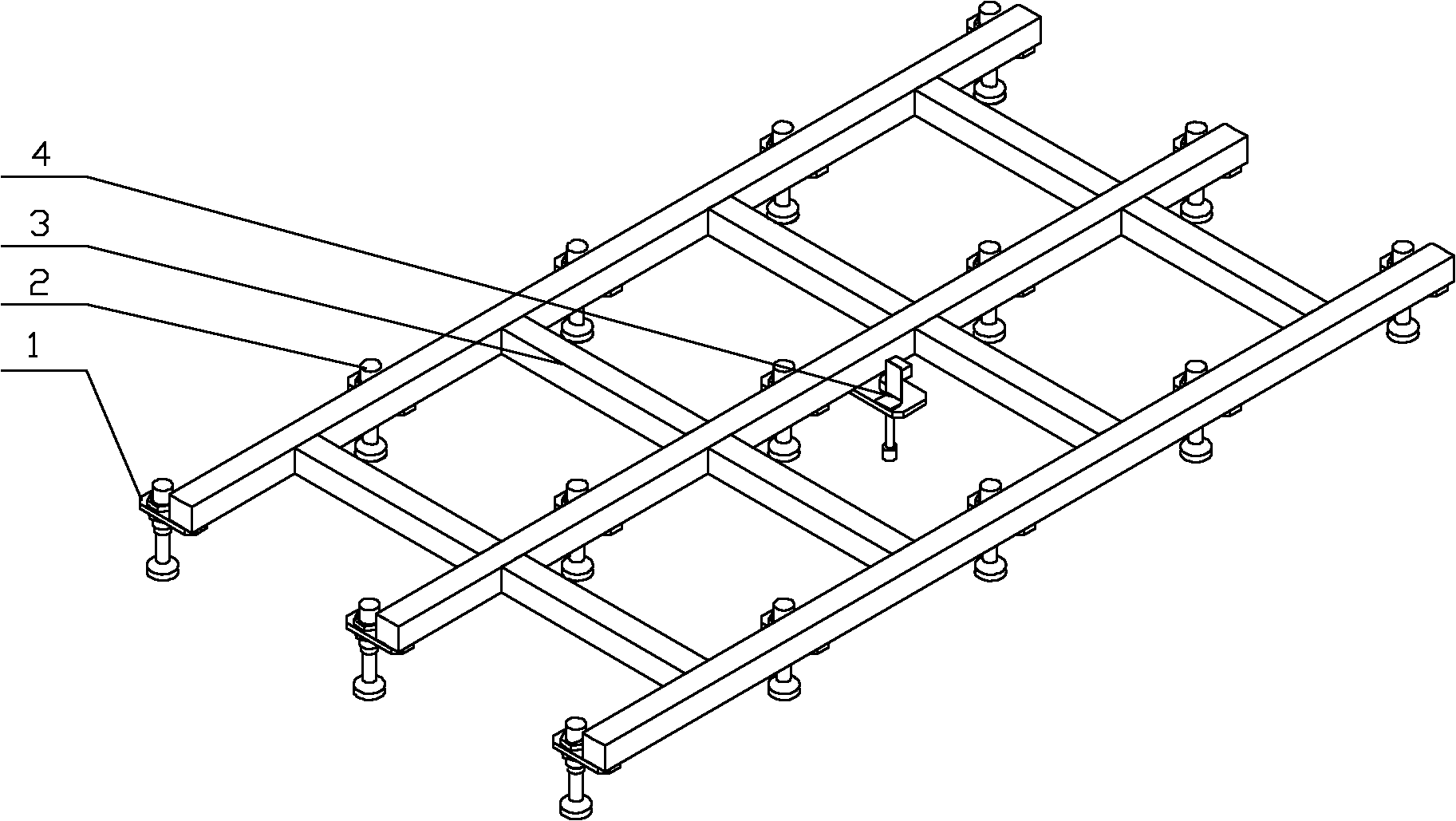

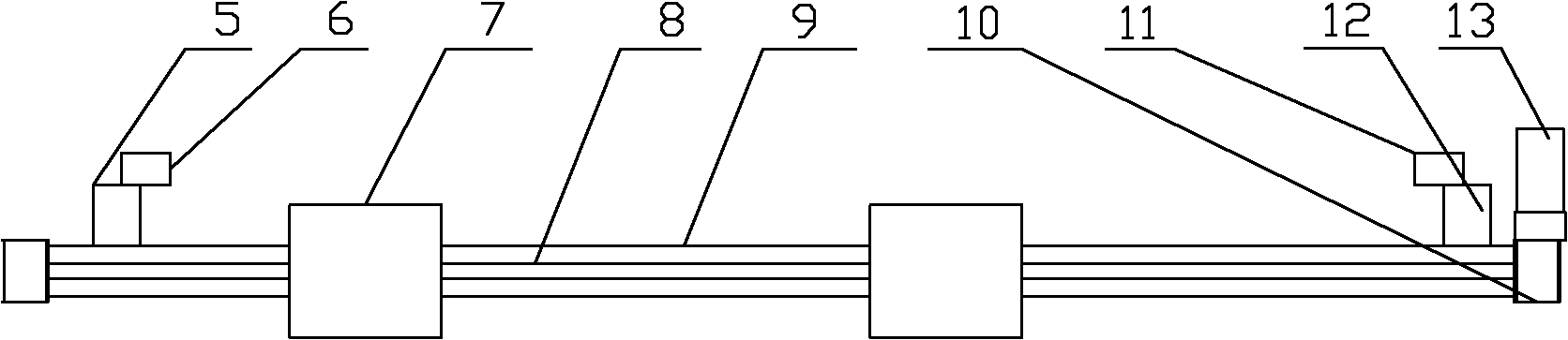

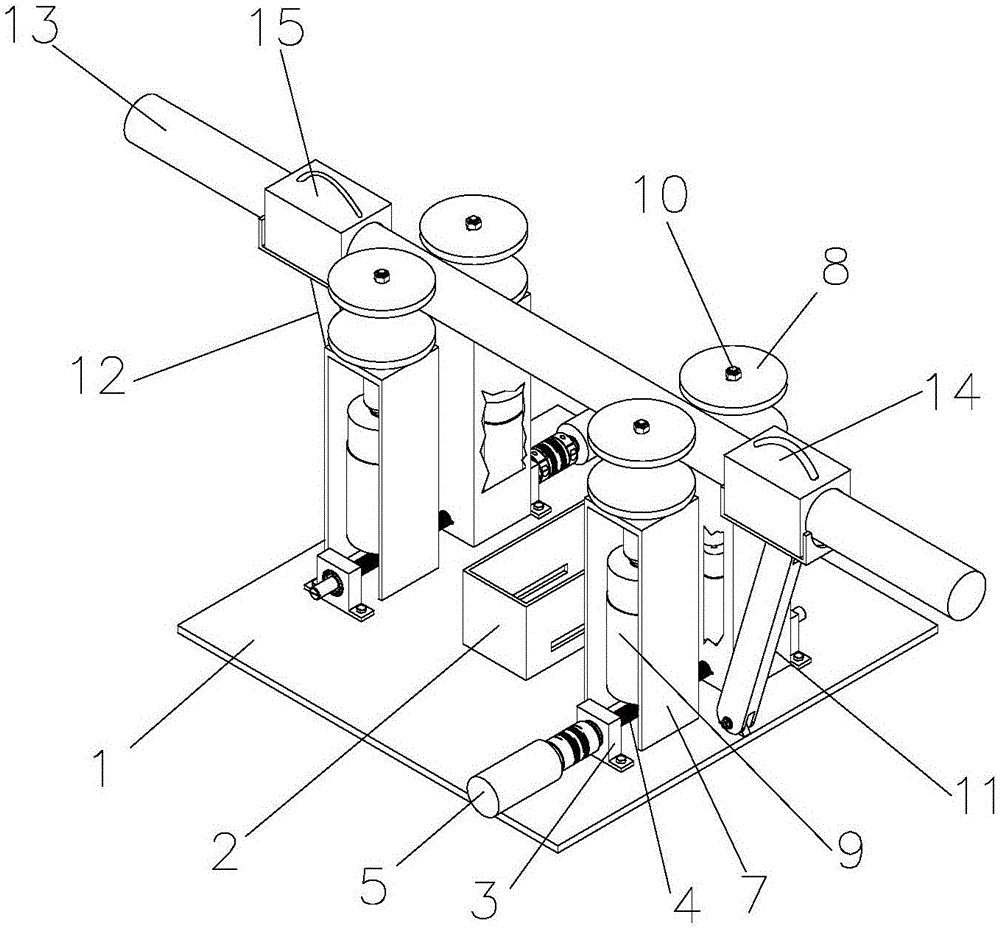

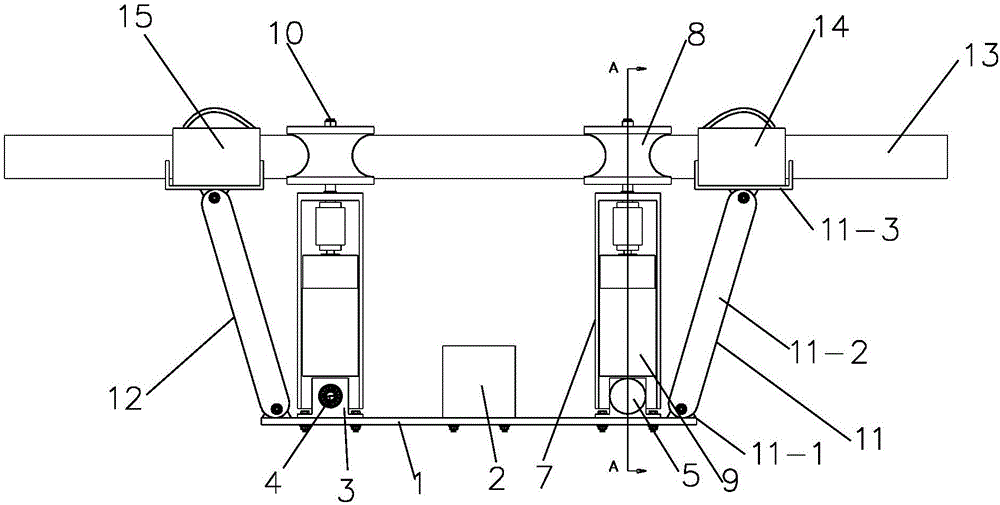

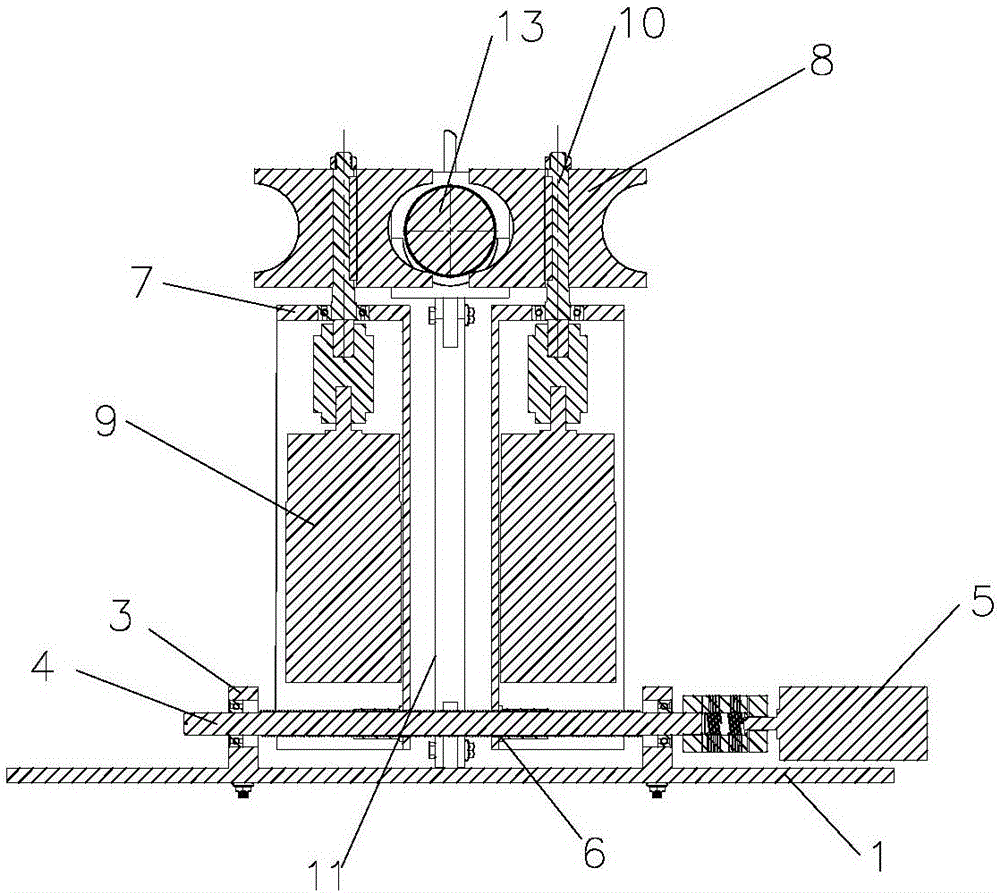

Loading and unloading handling mechanical arm for solar cell module

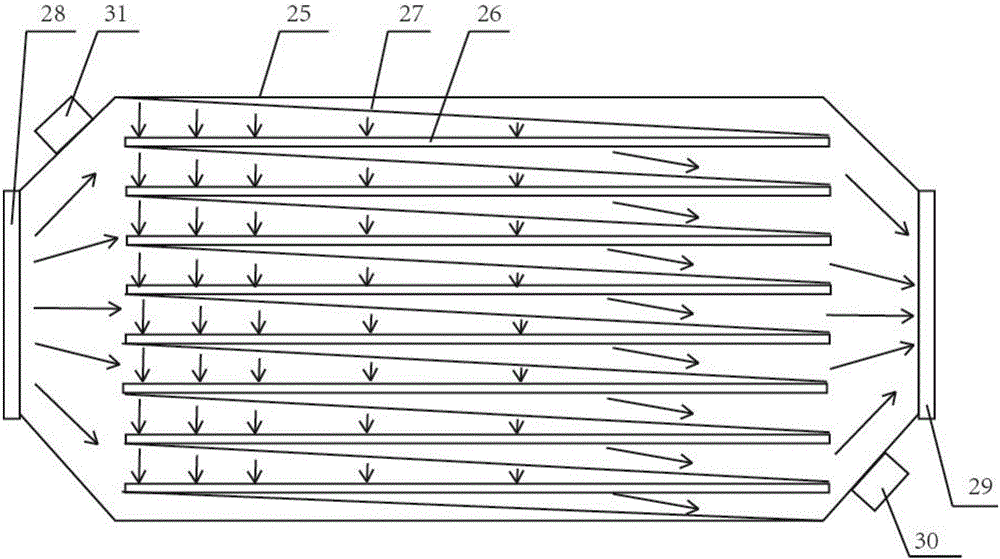

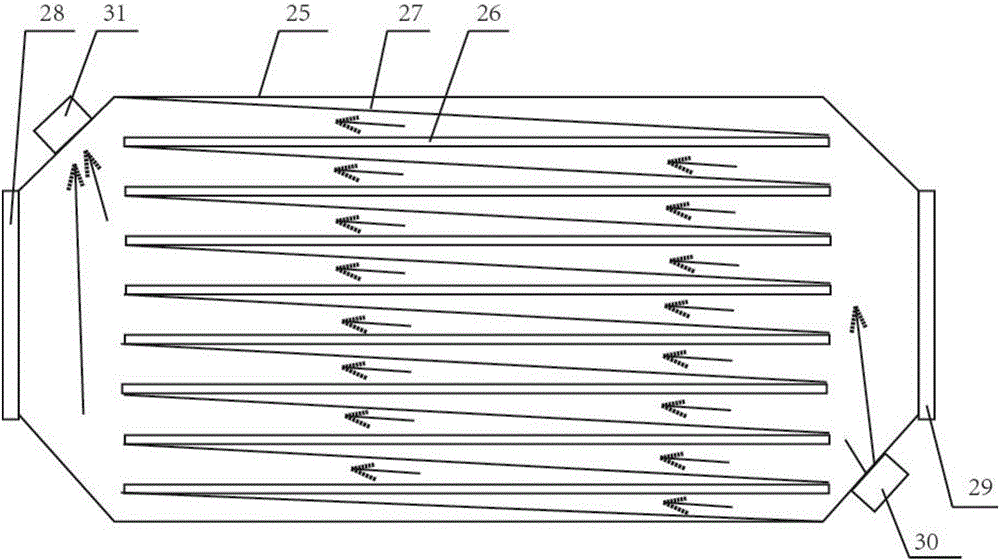

ActiveCN102107783AEven by forceAvoid bending momentCharge manipulationConveyor partsInteraction layerSolar cell

The invention provides a loading and unloading handling mechanical arm for a solar cell module, and the mechanical arm provided by the invention is used for realizing the functions of loading and unloading in a solar cell module producing process. The loading and unloading handling mechanical arm is characterized by consisting of a mechanical arm mechanism I, a horizontal motion unit II, two vertical motion units III, a pallet lift mechanism IV and a frame V, wherein the mechanical arm mechanism is of an aluminum alloy frame combined structure, and is provided with a plurality of groups of sucker modules so as to realize safe handling of solar cell modules in different specifications; and the horizontal motion unit and the vertical motion units adopt servo motors as drive, and drive the mechanical arm mechanism through a synchronous cog belt and a ball screw assembly respectively to realize accurate motion positioning in horizontal and vertical directions, and the motion units of two directions can independently or simultaneously move. A position servo control system is of a hierarchical control structure formed by a human-computer interaction layer, a motion control layer and a servo control layer. The handling mechanical arm has the advantages of large working space, high positioning accuracy, small motion inertia, reliable and smooth motion and suitability for handling large-sized fragile solar cell modules in different specifications.

Owner:YINGKOU JINCHEN AUTOMATION CO LTD

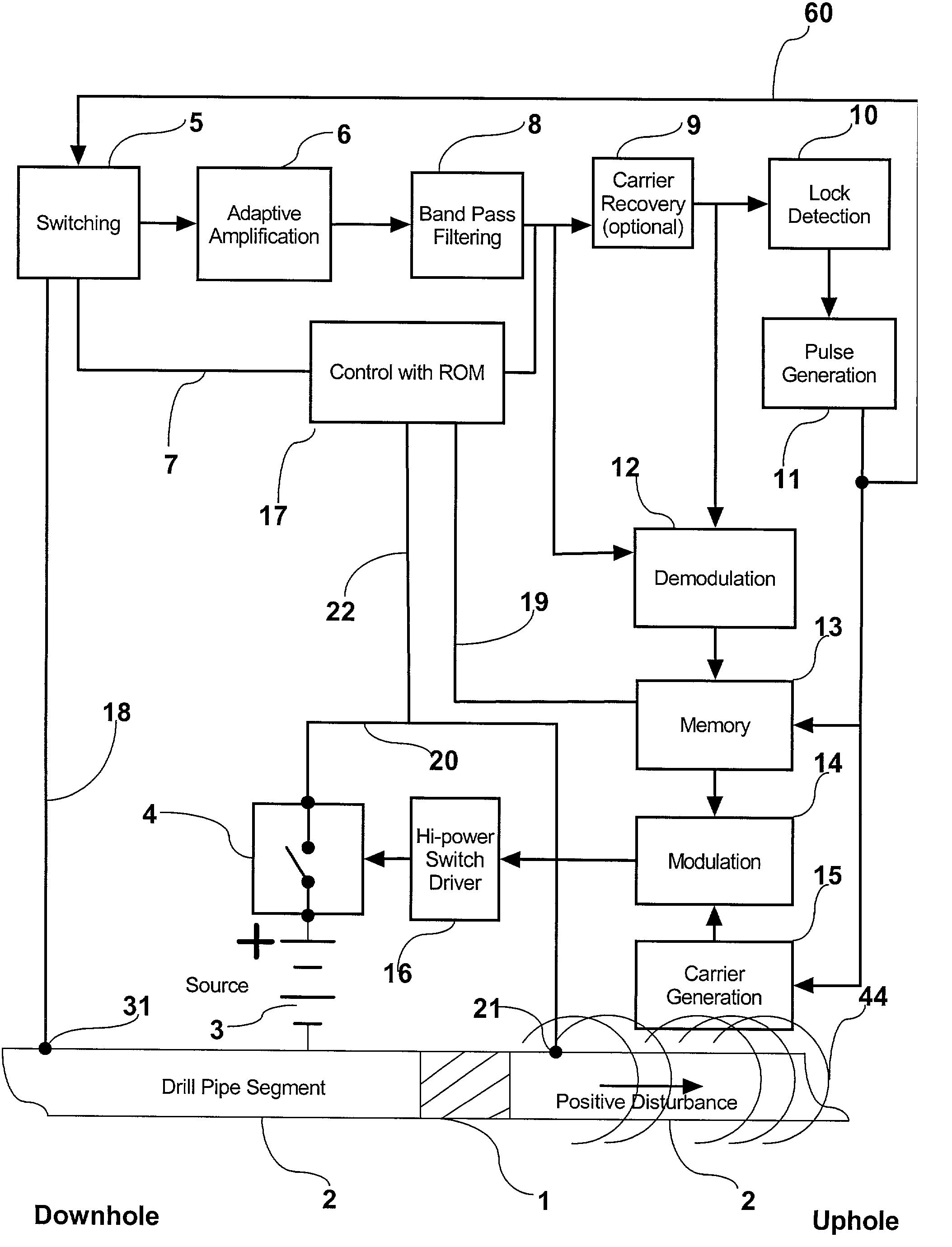

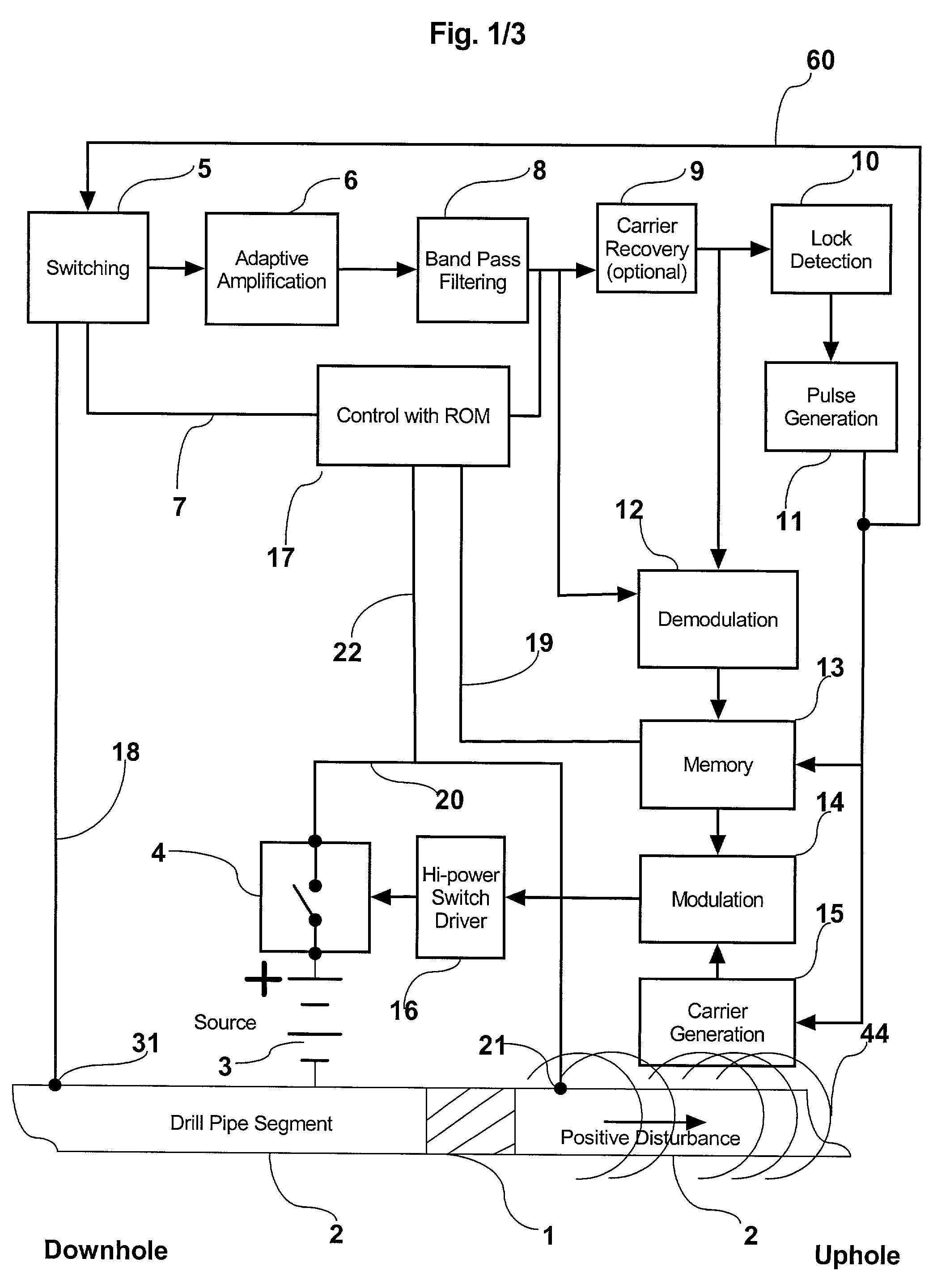

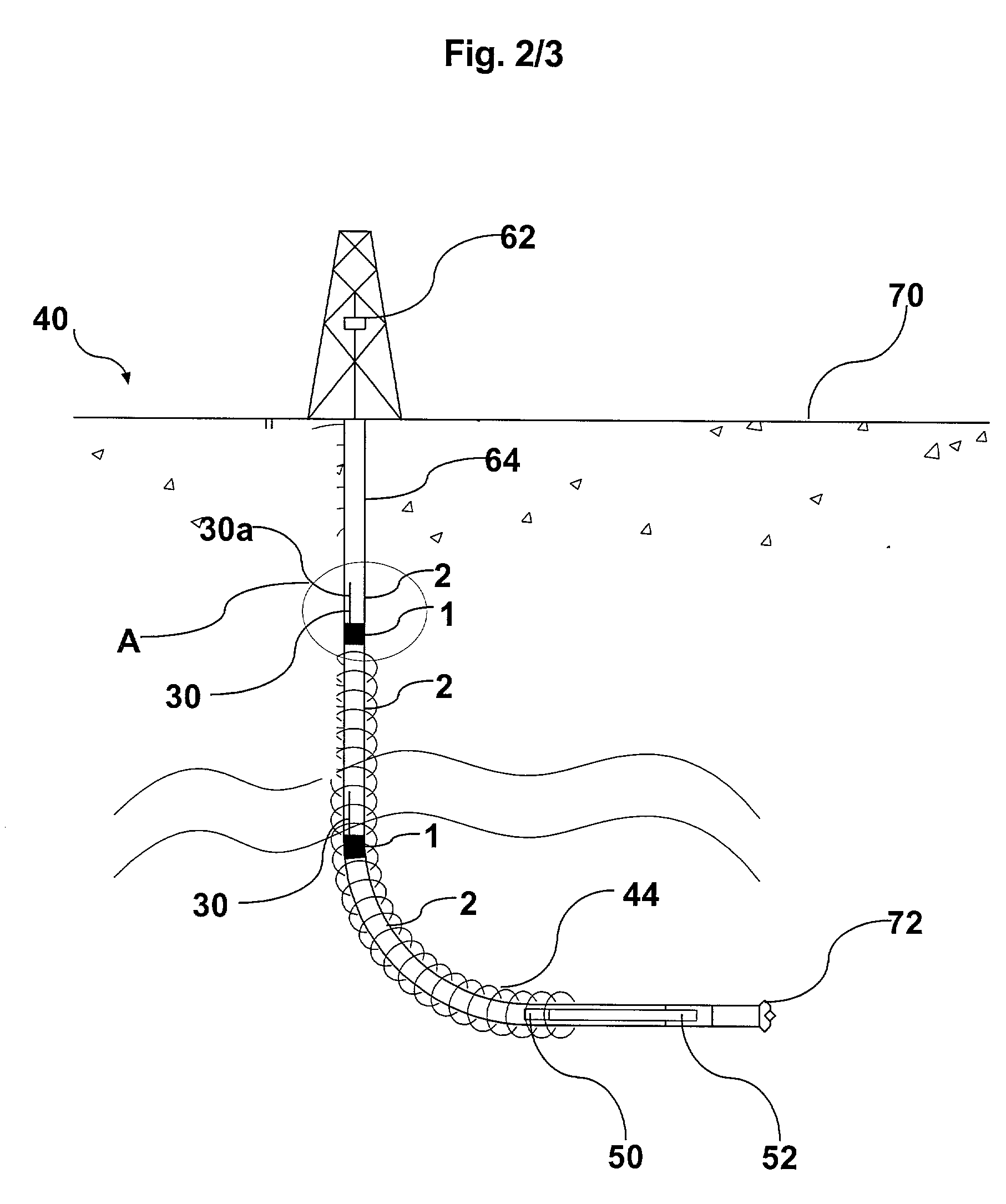

Apparatus, system, and method for detecting and reimpressing electrical charge disturbances on a drill-pipe

InactiveUS20030102980A1Reduce battery power consumptionDesensitizing data receptionElectric signal transmission systemsConstructionsElectricityEngineering

A signal repeater, a system utilizing one or more signal repeaters, and a method fordetecting a transient disturbance in the surface charge on drill pipe, which system, apparatus and method are collectively used to transfer data from deep-well and high-conductivity formation subterranean environments to a point nearer to the surface. The signal repeater comprises a housing that is securably mountable to the interior of a pipe-string disposed in a wellbore, which repeater receives and stores electrical signals for resending at an appropriate time.

Owner:RYAN ENERGY TECH

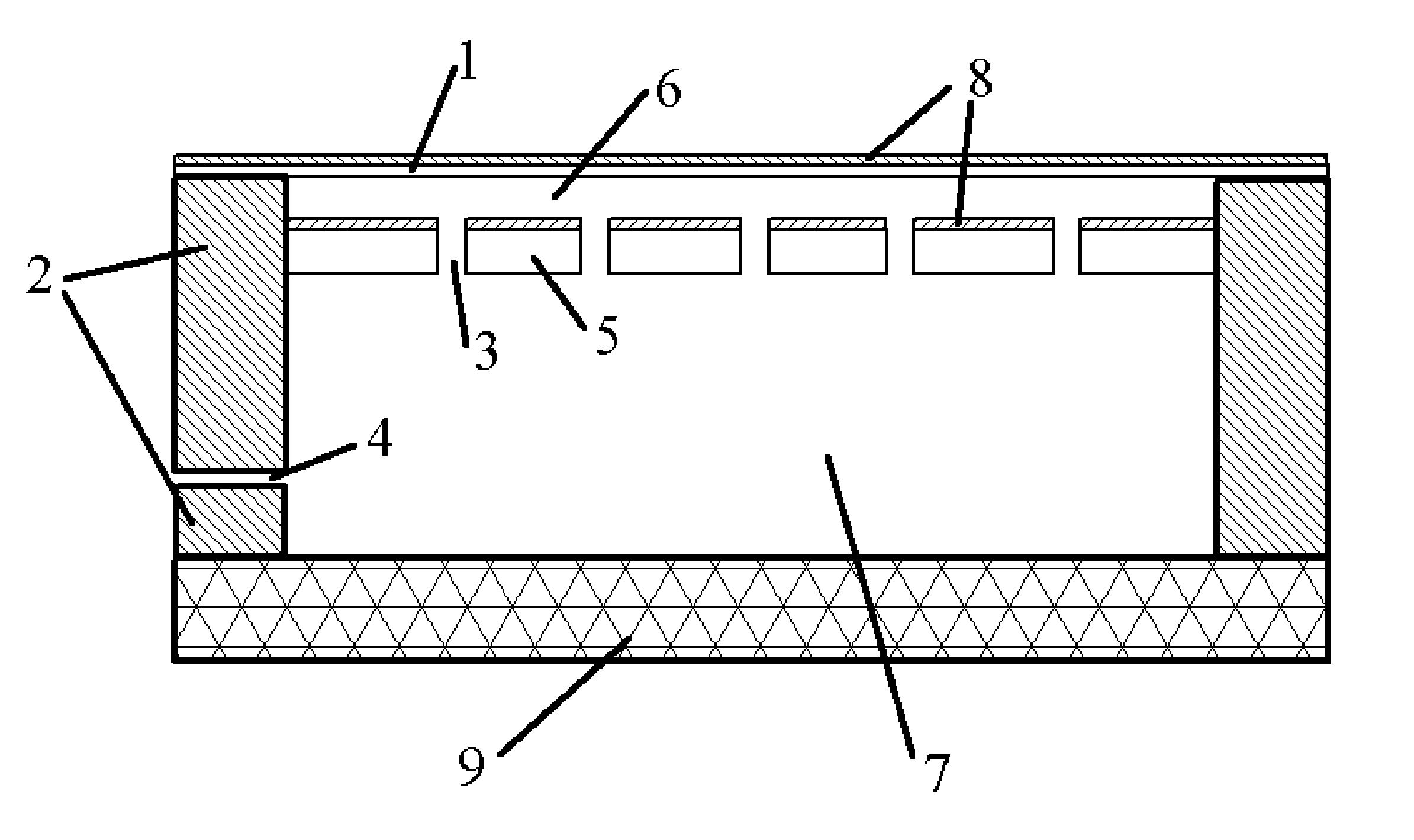

Capacitive micromachined acoustic transducer

ActiveUS7152481B2Wide bandwidthHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsMembrane anchorTransducer

A micromachined capacitive acoustic transducer including an electrode formed by a perforated plate and another electrode formed by a shallowly corrugated membrane anchored at one or more positions on the substrate which also supports the said perforated plate is described. Also disclosed includes: a fixed perforated plate; a movable shallowly corrugated membrane having holes to form acoustic filter to a certain frequency or a range of frequencies spaced from the perforated plate that is anchored in one or more location but loose at other locations; a support structure in the perforated plate maintaining the minimum separation between the membrane and the perforated plate near the perimeter.

Owner:NEOMEMS TECH INC WUXI CHINA

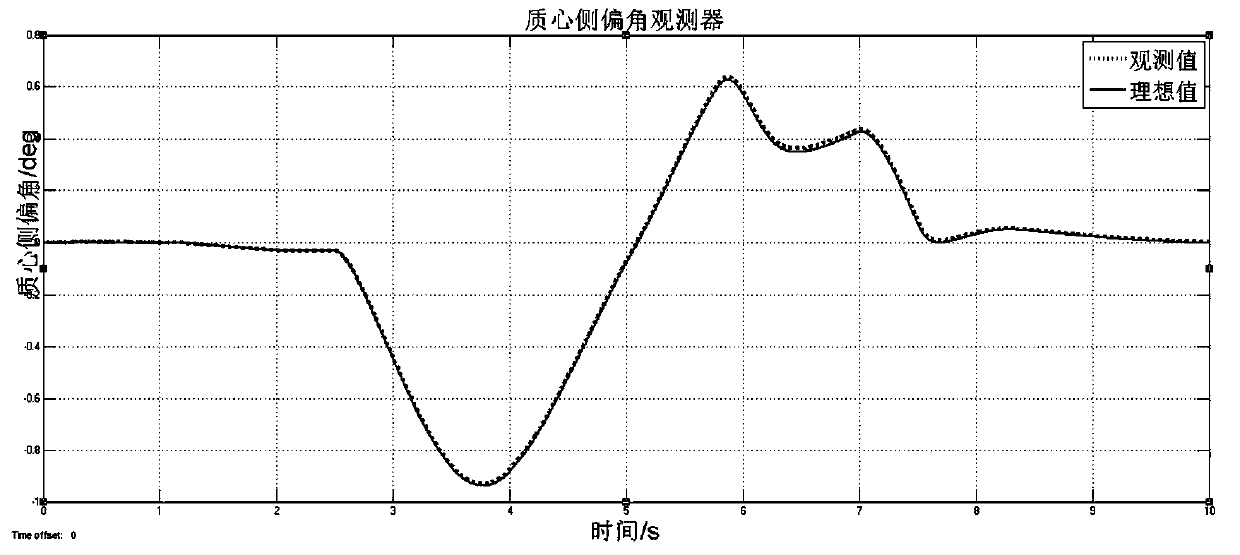

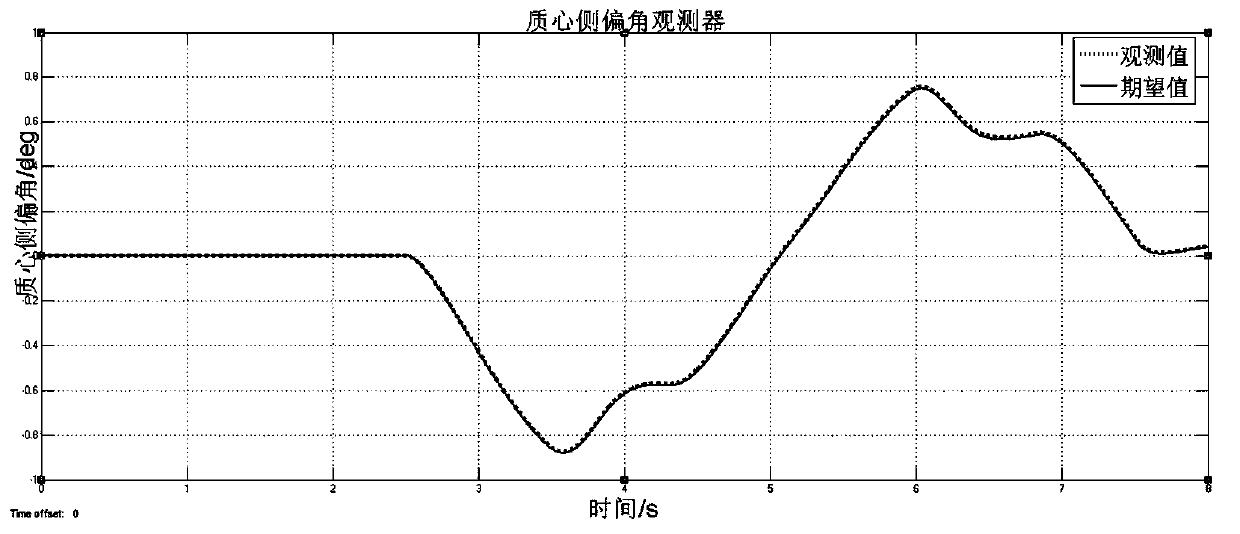

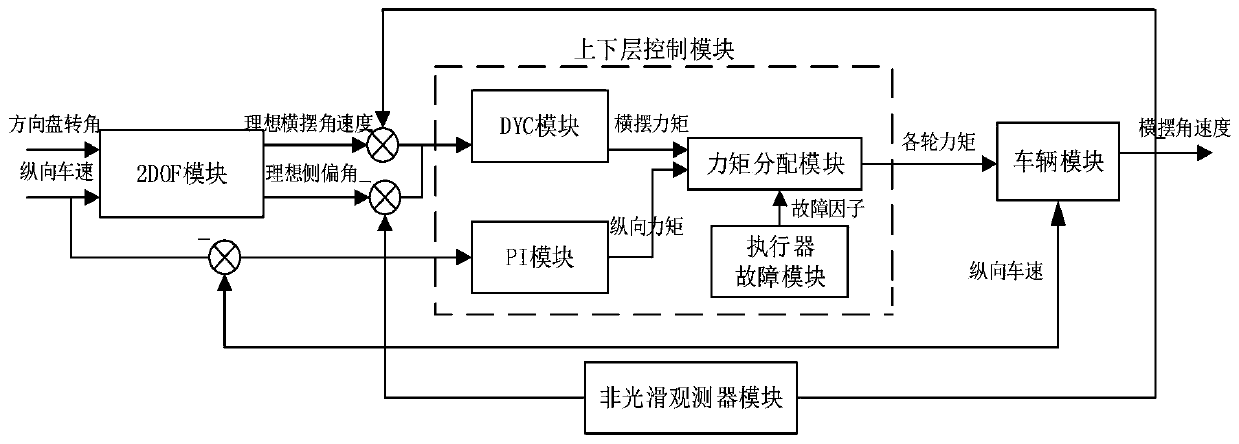

Hub electric automobile direct yawing moment control method with fault tolerance function

ActiveCN109733205AGuaranteed stable operationLow costSpeed controllerElectric energy managementTerminal sliding modeElectric machinery

The invention discloses a hub electric automobile direct yawing moment control method with a fault tolerance function. The method mainly includes the steps that a linear two-degree-of-freedom model isestablished, the ideal yaw velocity and the ideal mass center side slip angle of a vehicle are obtained, a state observer is established, and the actual mass center side slip angle of the vehicle isestimated; a seven-degree-of-freedom vehicle dynamic model is established as a control object, a fault factor is introduced, and a vehicle dynamic model with a drive motor fault is established; basedon an adaptive terminal sliding mode theory and a PI control theory, an upper layer controller is designed, and a virtual control command is obtained; and based on fault information and a moment optimal distribution method, a fault tolerance lower layer controller is designed, and the traveling performance and safety performance of the vehicle are guaranteed after the fault occurs. The proposed method guarantees the traveling safety after the fault occurs, under the condition that the executor fault exists or not, the traveling stability of the vehicle can be guaranteed, and the traveling stability range is enlarged. Meanwhile, the control coordination of four wheels is improved, and the response performance of the fault vehicle is improved.

Owner:JIANGSU UNIV

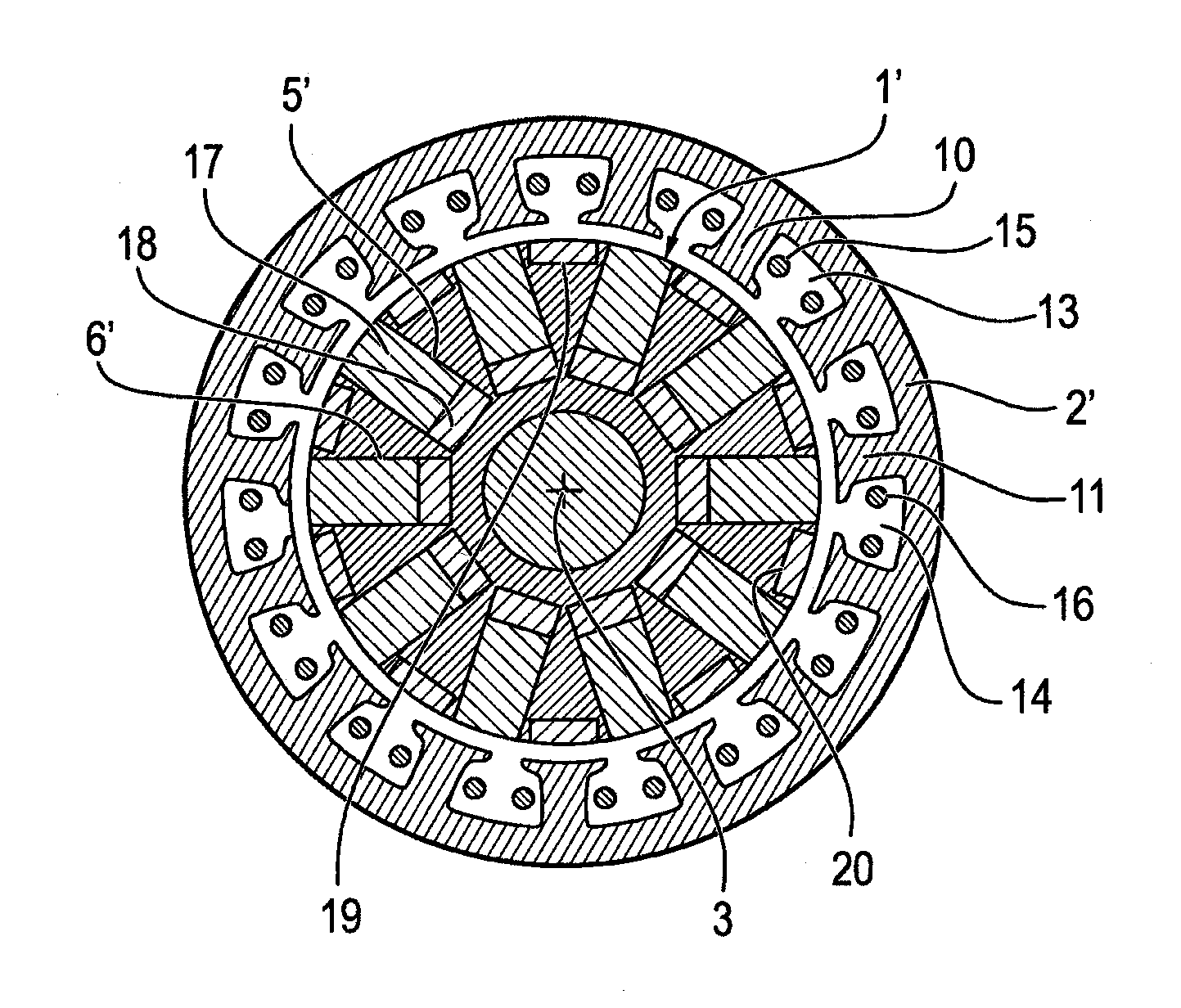

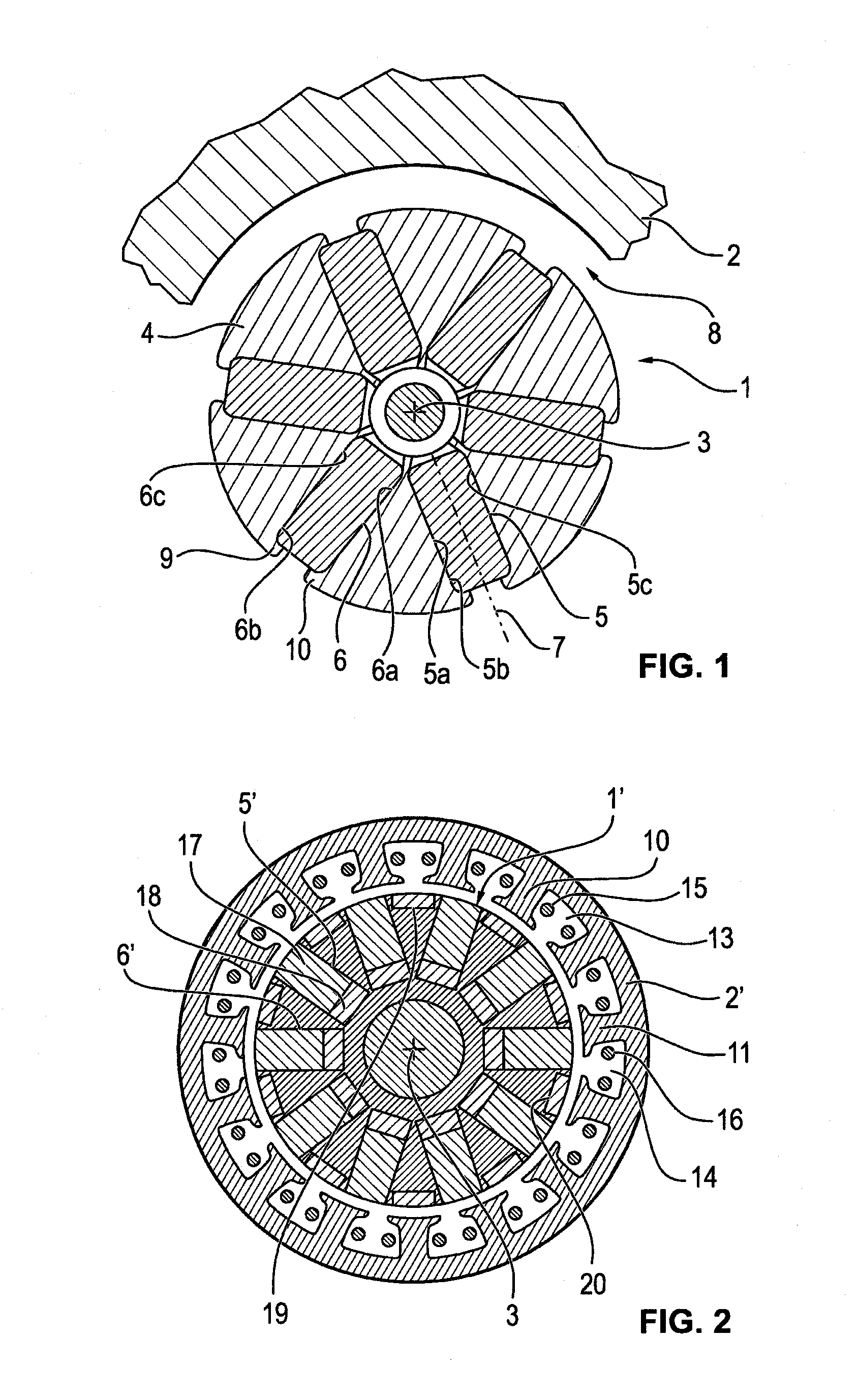

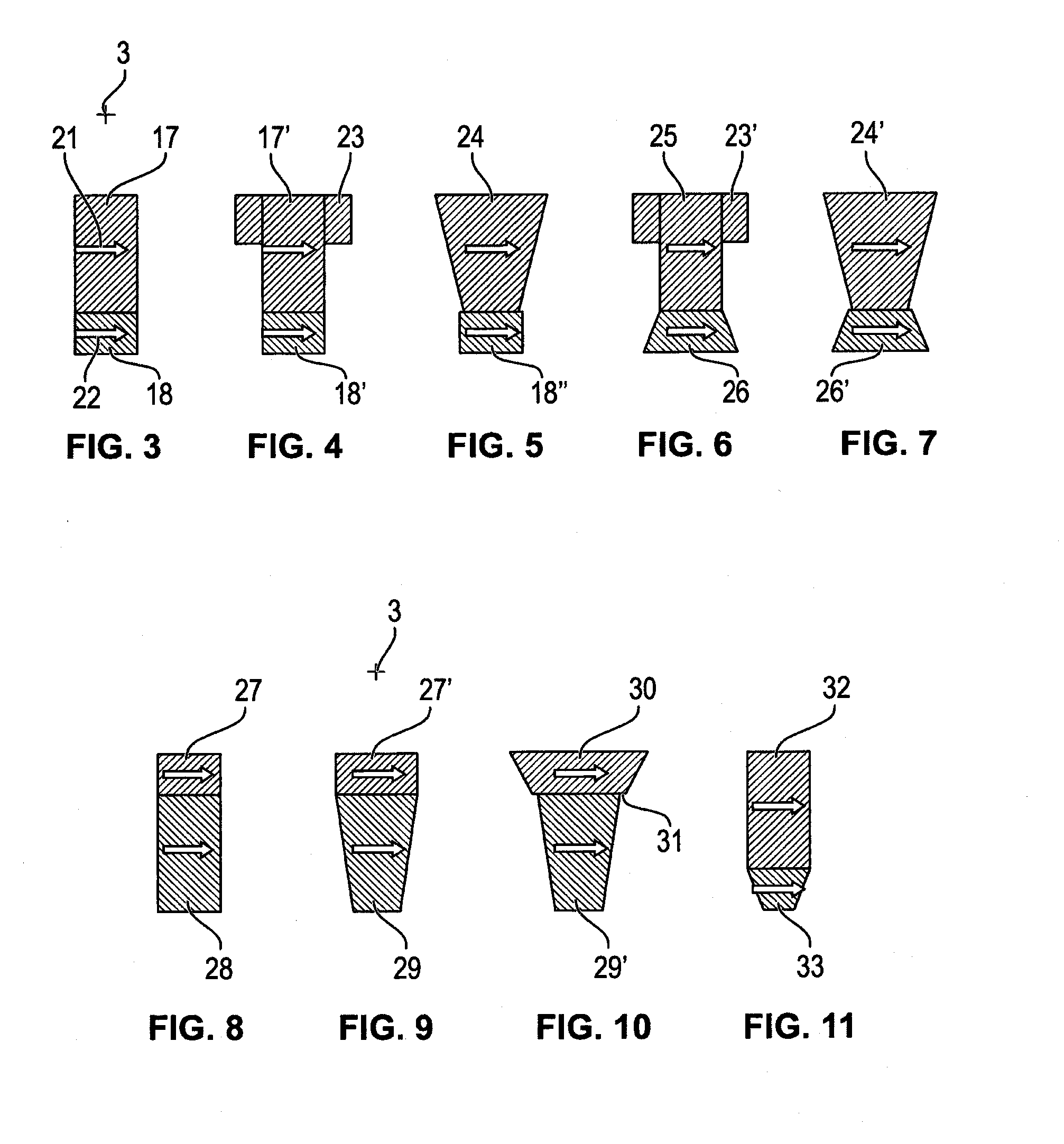

Efficient electric machine

ActiveUS20150001980A1Reduce manufacturing costGuaranteed stable operationWindingsMagnetic circuit rotating partsElectric machineMagnet

An electric machine having a stator and a rotor which is mounted so as to be rotatable about a rotor axis and has a rotor body, in which at least two permanent magnets are arranged in receptacles, a first of which component magnets is associated with a first set of permanent magnets, and a second of which component magnets is associated with a second set of permanent magnets. The permanent magnets of the first set differ from the permanent magnets of the second set with respect to the material composition, In particular to the magnetic properties, and wherein at least one permanent magnet of the first or second set or at least one composite body has a contour, the cross-sectional face of which, being located perpendicularly with respect to the longitudinal axis, decreases within the respective receptacle towards that end thereof which is radially further to the outside.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

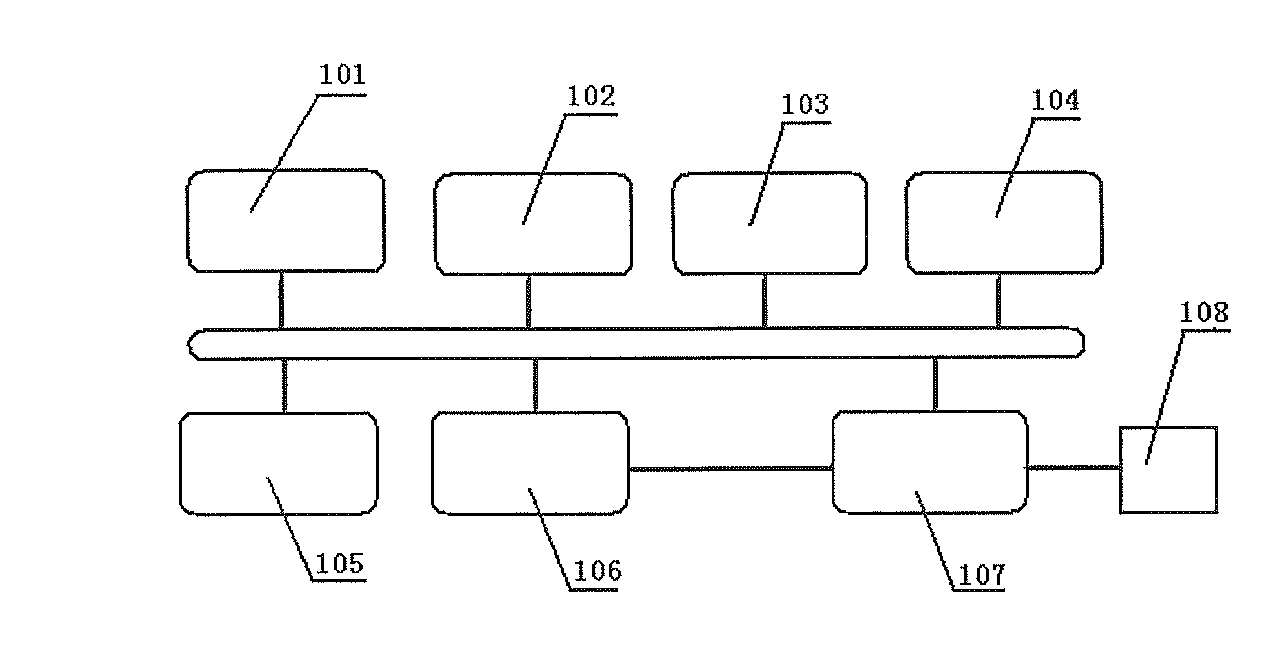

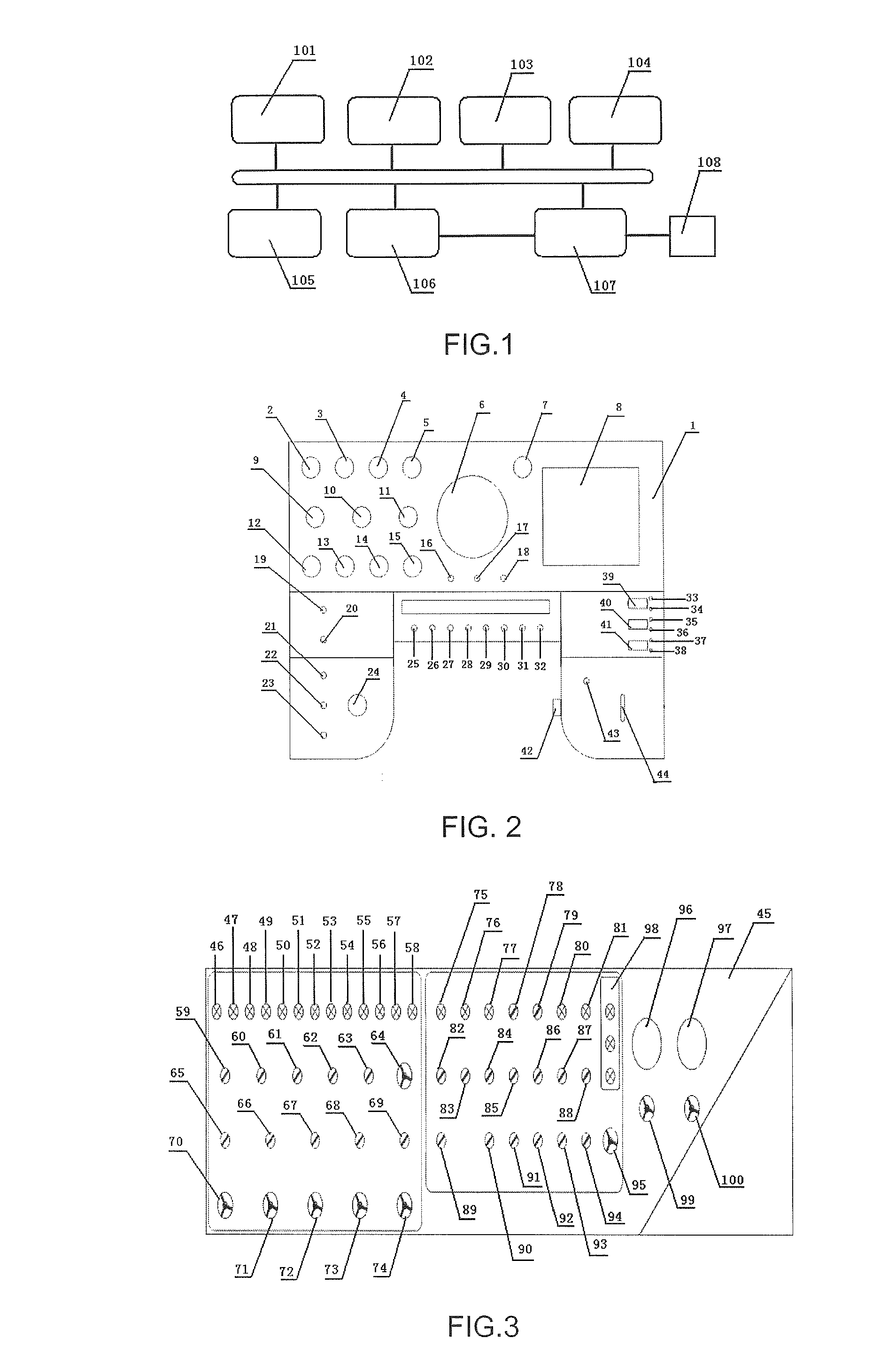

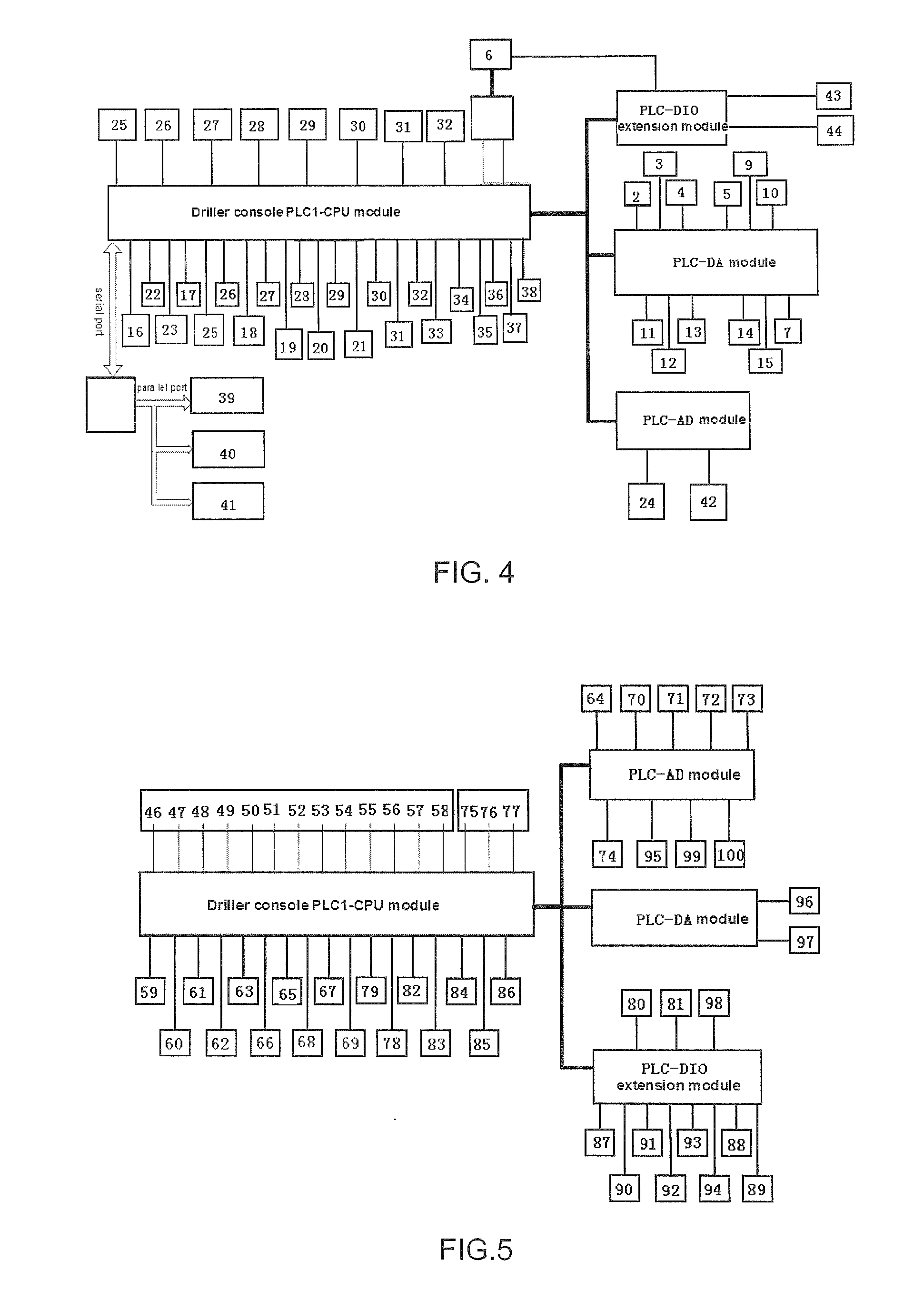

Distributed Drilling Simulation System

ActiveUS20120219933A1Accelerated trainingShorten the training periodCosmonautic condition simulationsSurveyTraining periodGraphics

A distributed drilling simulation system includes a choke manifold, a high pressure manifold, a blowout preventer console, a choke console, a remote console, a driller console, a teacher console and a graphic projecting unit, wherein the driller console, the remote console, the blowout preventer console, the choke console, the choke manifold, and the high pressure manifold are interconnected through a PPI (processor / peripheral interface) protocol. The teacher console is connected with the PPI protocol through a PPI interface. A communication program and a main control program run on a main control computer and a graphic processing program runs on a graphic computer. The invention has the advantages of realizing high-degree top driving drilling simulation, enhancing the field sense for teaching and training, shortening the training period and reducing the training cost.

Owner:CHENGDU ESIMTECH GASOLINEEUM EQUIP SIMULATION TECH EXPL

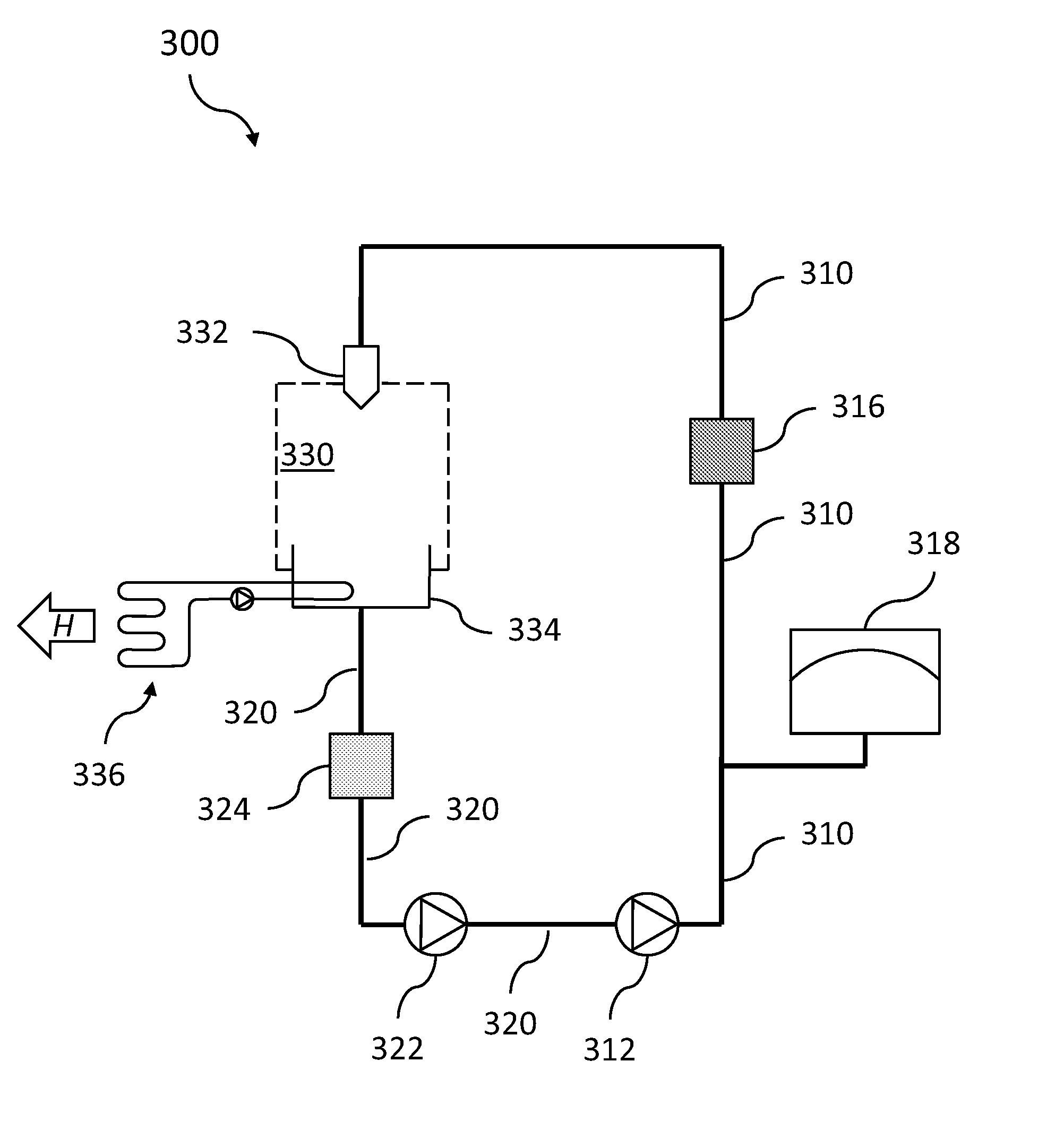

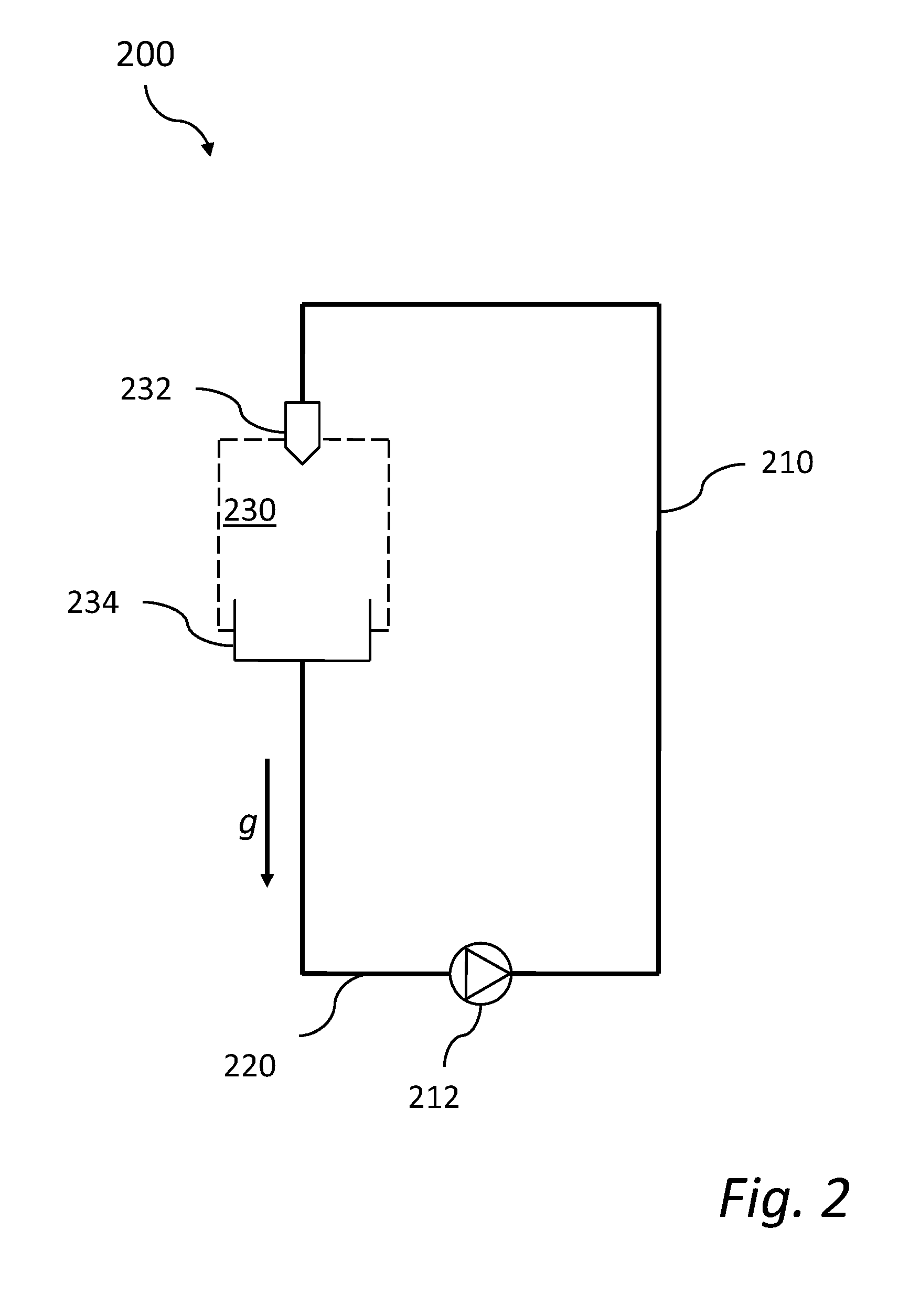

Supply of a liquid-metal target in x-ray generation

ActiveUS20120057680A1Extended operating timeShortened maintenance intervalsX-ray tube anode coolingX-ray tube electrodesSpray nozzleWire source

Closed-loop circulation for providing liquid metal to an interaction region at which an electron beam is to impact upon the liquid metal to produce X-rays is presented. In a method according to the invention, the pressure of the liquid metal is raised to at least 10 bar using a high-pressure pump. The pressurized liquid metal is then conducted to a nozzle and ejected into a vacuum chamber in the form of a spatially continuous jet. After passage through the vacuum chamber, the liquid metal is collected in a collection reservoir, and the pressure of the liquid metal is raised to an inlet pressure, e.g. using a primer pump, suitable for the inlet of the high-pressure pump. The invention also relates to a corresponding circulation system and an X-ray source provided with such circulation system.

Owner:EXCILLUM

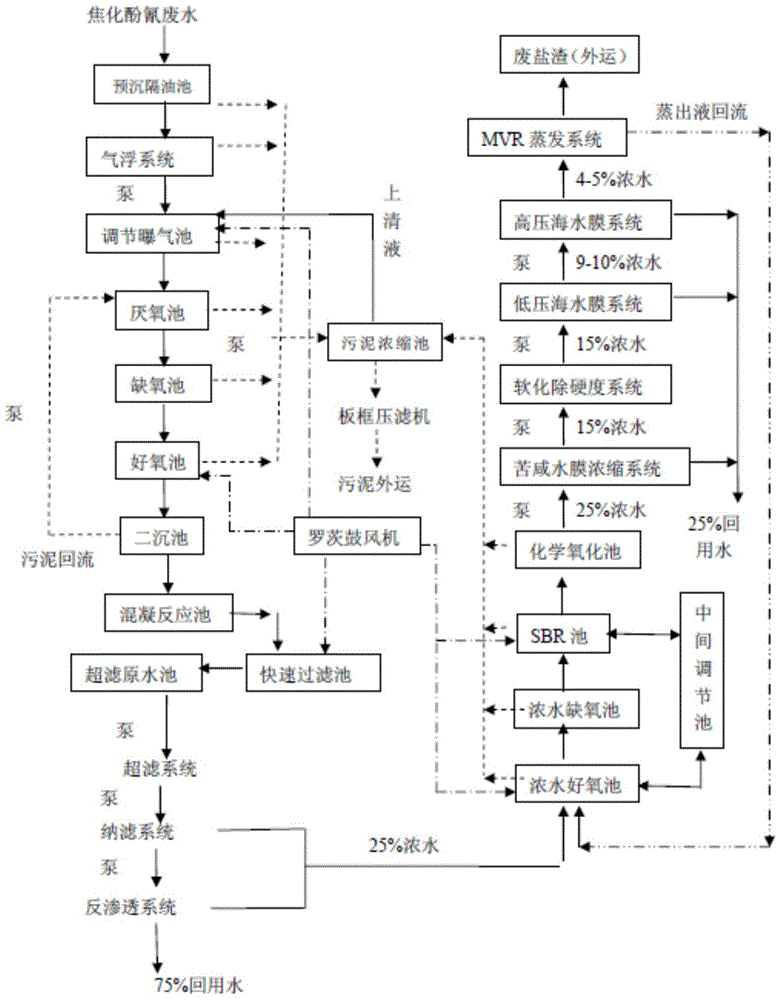

Treating and recycling zero-emission technology and equipment for coking phenol-cyanogen wastewater

ActiveCN104803548AGuaranteed stable operationStrong load impact resistanceMultistage water/sewage treatmentSeawaterZero emission

The invention discloses a treating and recycling zero-emission technology for coking phenol-cyanogen wastewater. According to the treating and recycling zero-emission technology, a pre-sedimentation oil separating tank, an air floating system, an adjusting aeration tank, an anaerobic tank, an anoxic tank, an aerobic tank, a secondary sedimentation tank, a coagulating reaction tank, a quick filtering tank, an ultrafiltration raw water tank, an ultrafiltration system, a nanofiltration system, a reverse osmosis system, a concentrated water aerobic tank, a concentrated water anoxic tank, an SBR tank, a chemical oxidation tank, a bitter water film concentrating system, a softening rigidity removing system, a low-pressure sea-water film system, a high-pressure sea-water film system, an MVR evaporating system, a sludge thickening tank, a press filter and a Roots blower are adopted for technological treatment. The invention further discloses treating and recycling zero-emission equipment for coking phenol-cyanogen wastewater. The treating and recycling zero-emission technology and equipment are high in treatment efficiency and low in cost, and have the advantages that zero emission of sewage can be realized.

Owner:ZHEJIANG BEROOT ENVIRONMENTAL PROTECTION TECH CO LTD

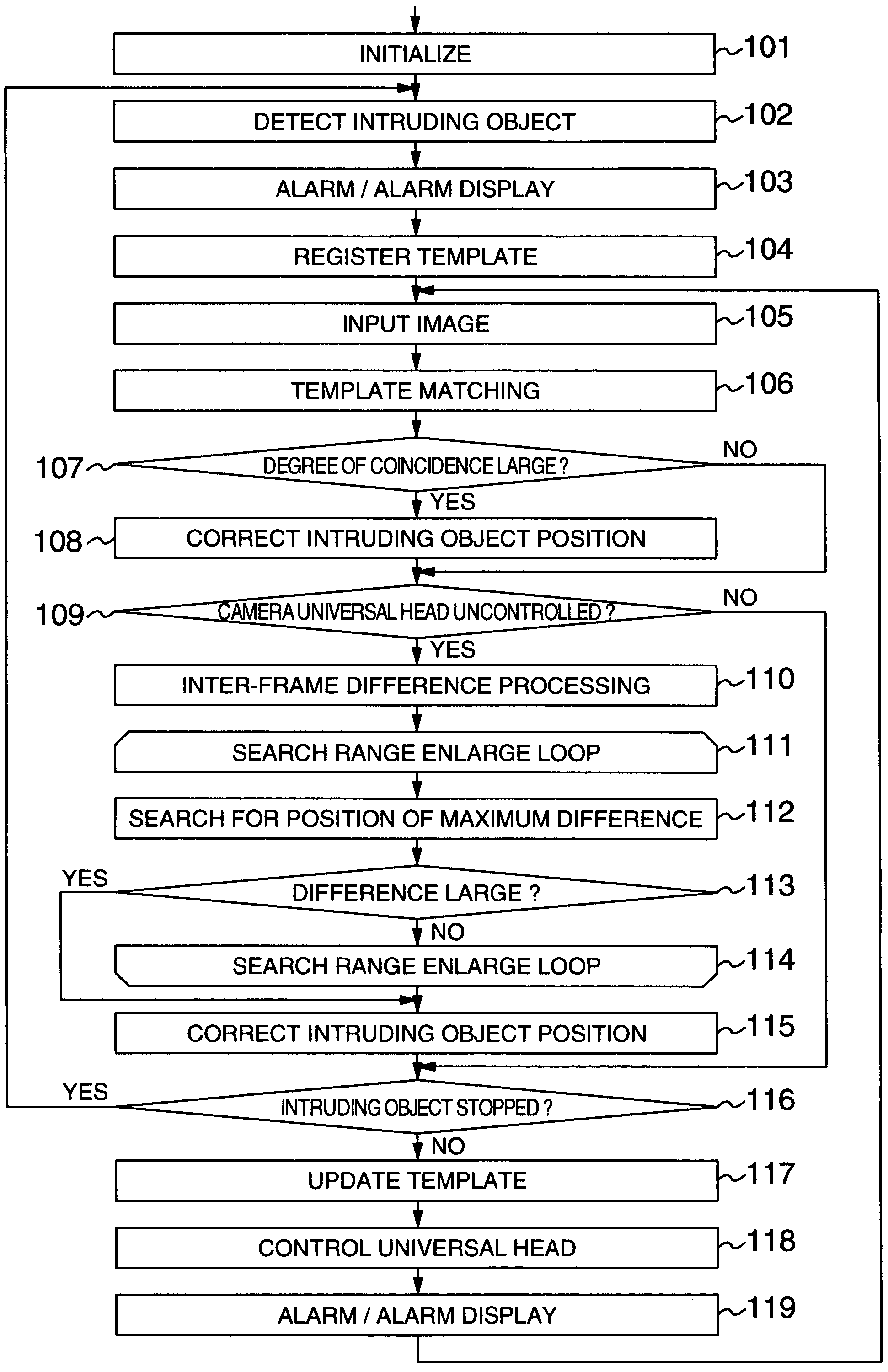

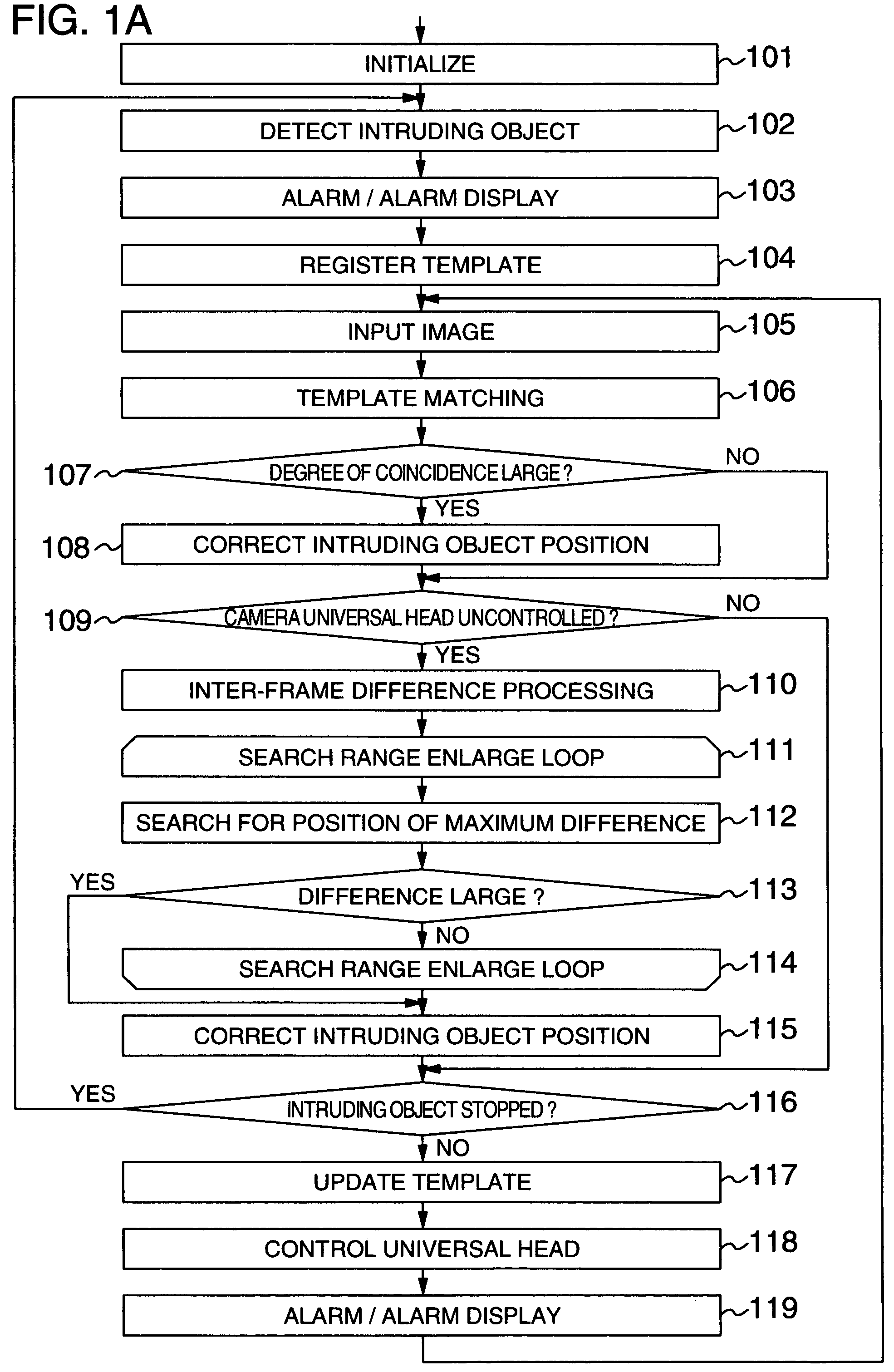

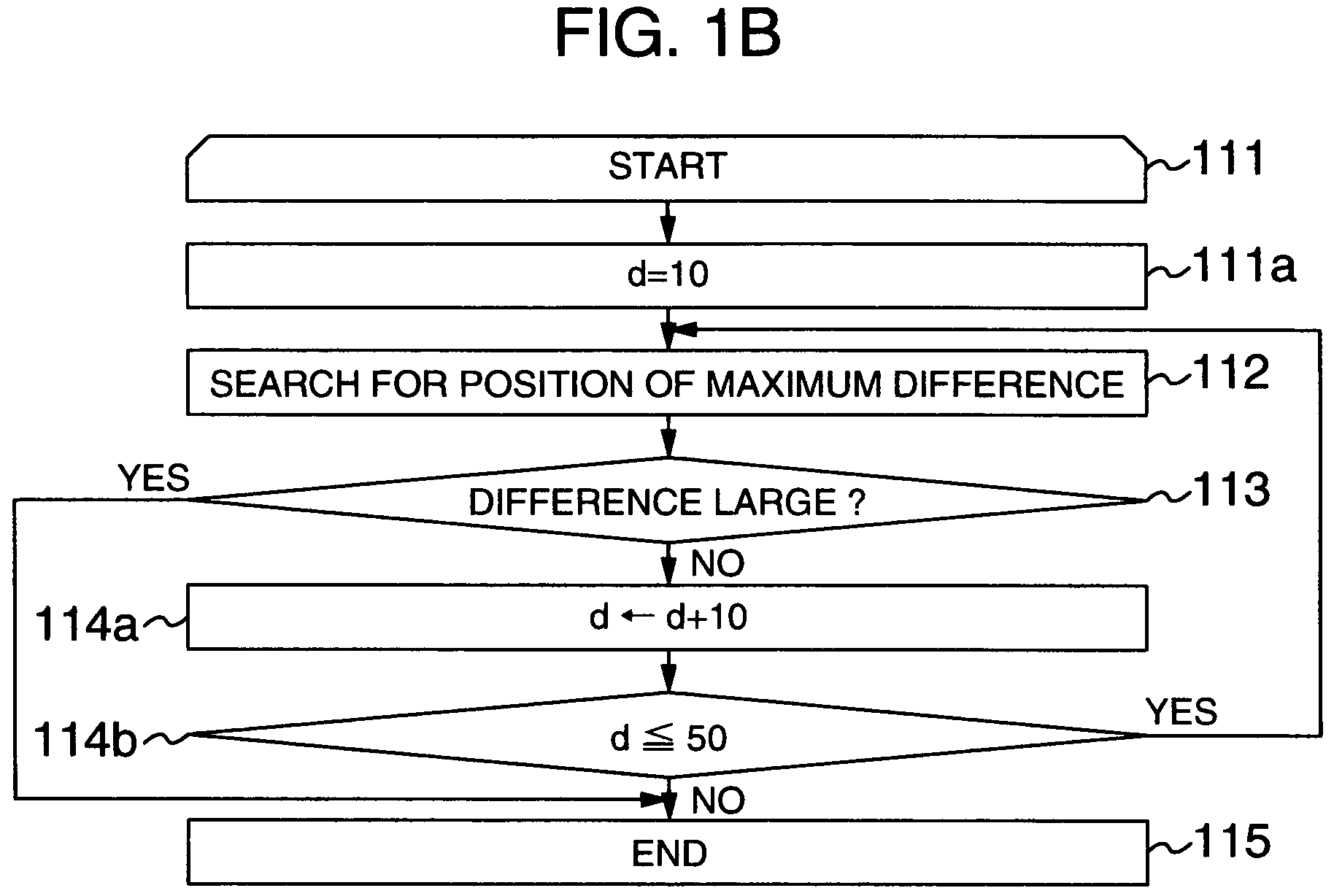

Object tracking method and object tracking apparatus

InactiveUS7400344B2Reduce displacementGuaranteed stable operationImage enhancementTelevision system detailsComputer vision

Owner:KOKUSA ELECTRIC CO LTD

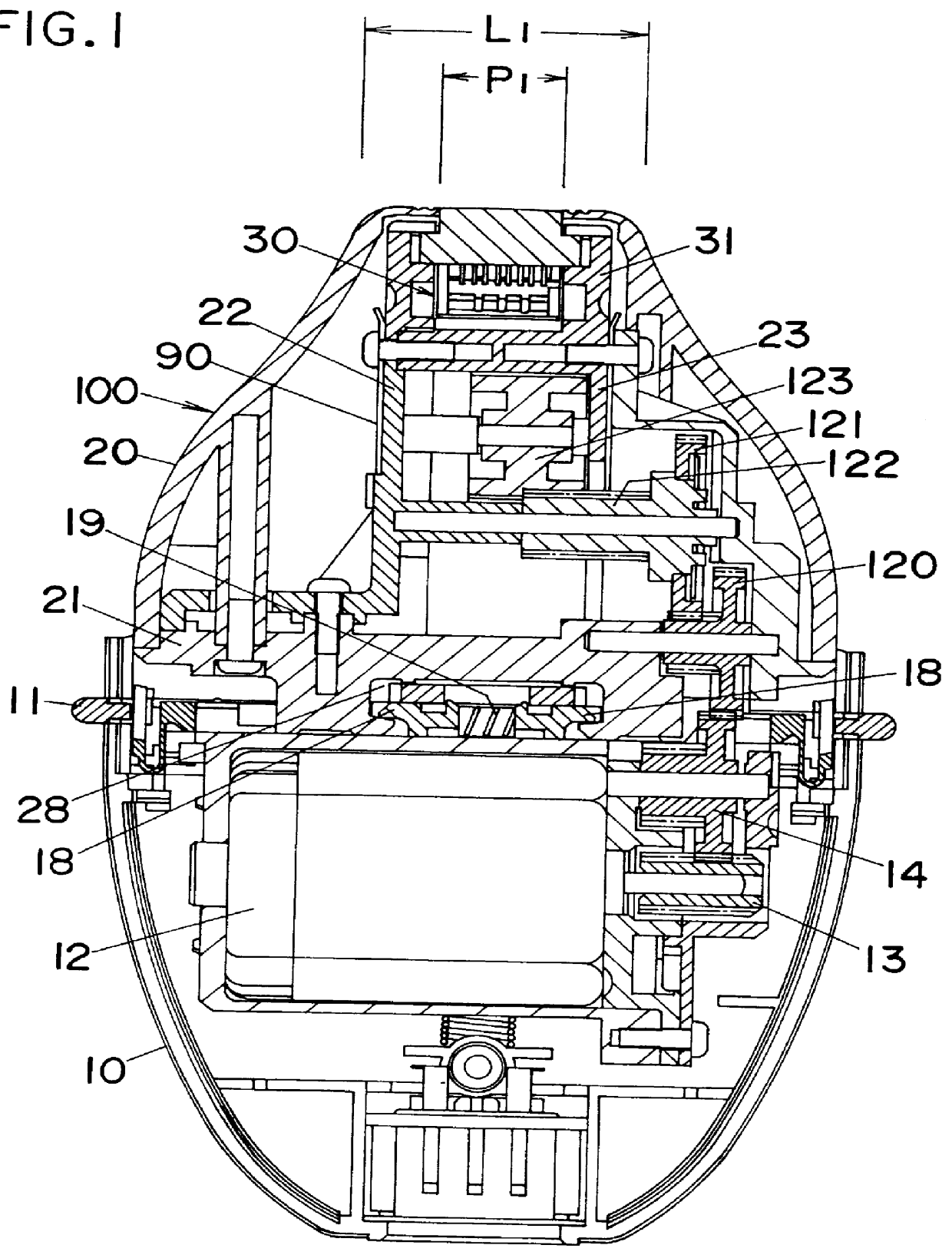

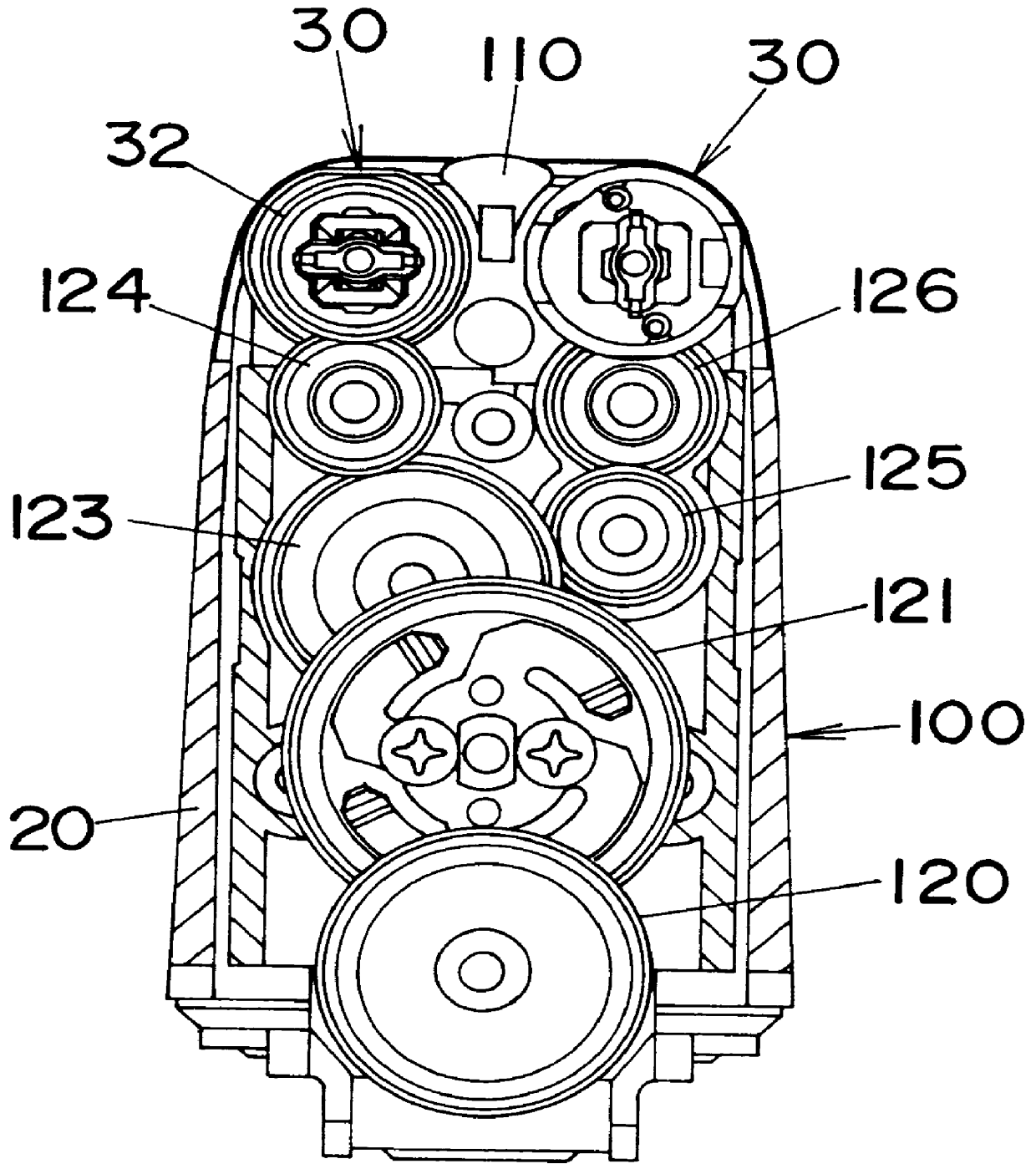

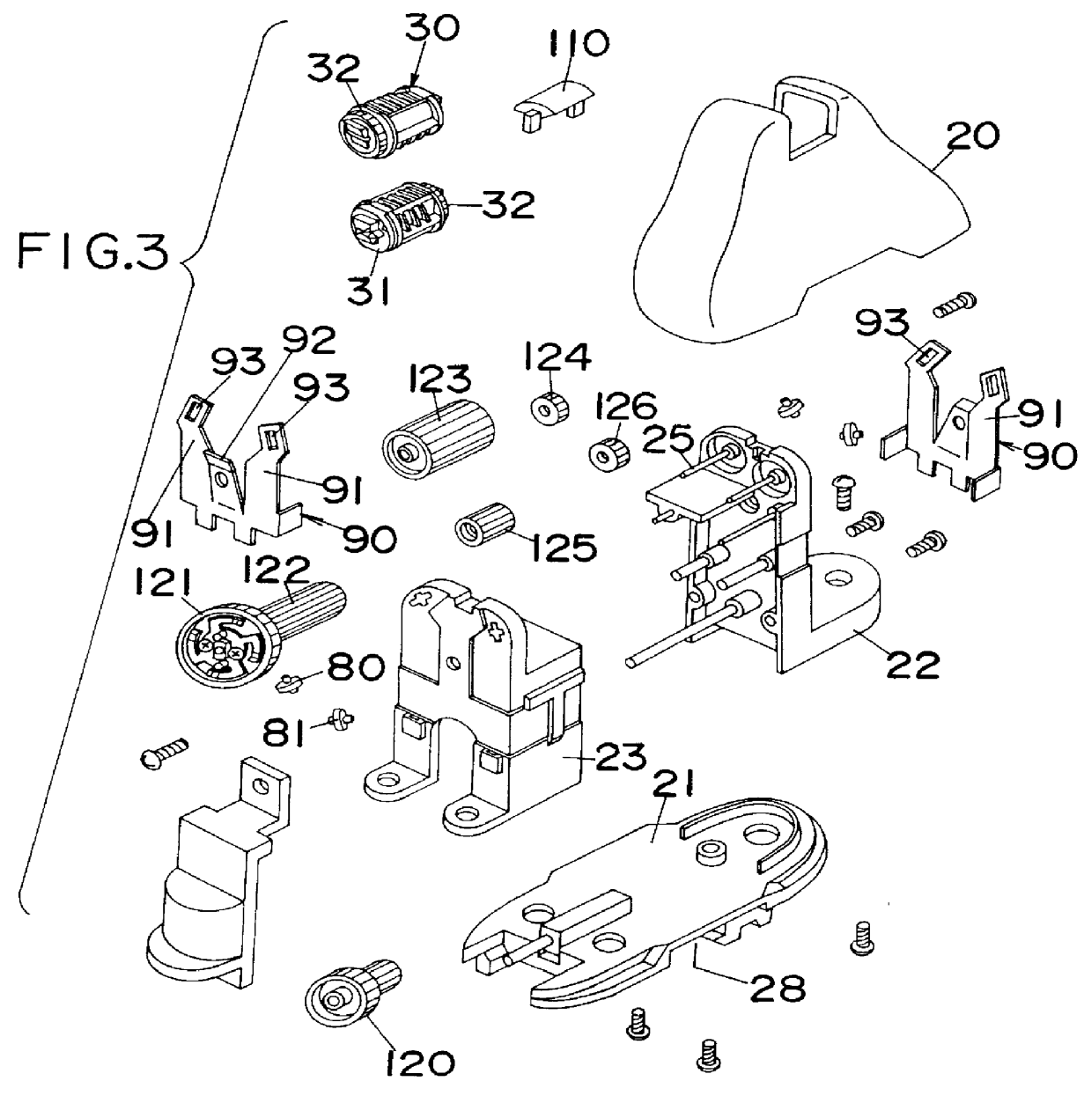

Epilating device for removal of body hairs

InactiveUS6045559AImprove efficiencyGuaranteed stable operationHair-singeingSurgeryEpilationsComputer module

An improved epilating device is capable of effectively removing the hairs at different skin portions of the human body. The epilating device includes a single housing which is shaped to be grasped by the hand of a user and which includes a drive source. The housing carries a first epilation module provided at its top with a first plucking head which is driven by the drive source to effect the plucking of the body hairs. The first plucking head has a length defining therealong a first epilation zone. Also carried on the housing is a second epilation module provided at its top with a second plucking head which is driven commonly by the drive source to effect plucking of the body hairs. The second plucking head has a length defining therealong a second epilation zone. The first and second epilation modules are shaped respectively to have individual top ends of different external dimensions along the lengths of the first and second plucking heads and to have the first and second epilation zones of different lengths. Thus, the first and second epilation module can be selected depending upon the intended skin portion for optimum hair plucking at that portion.

Owner:MATSUSHITA ELECTRIC WORKS LTD

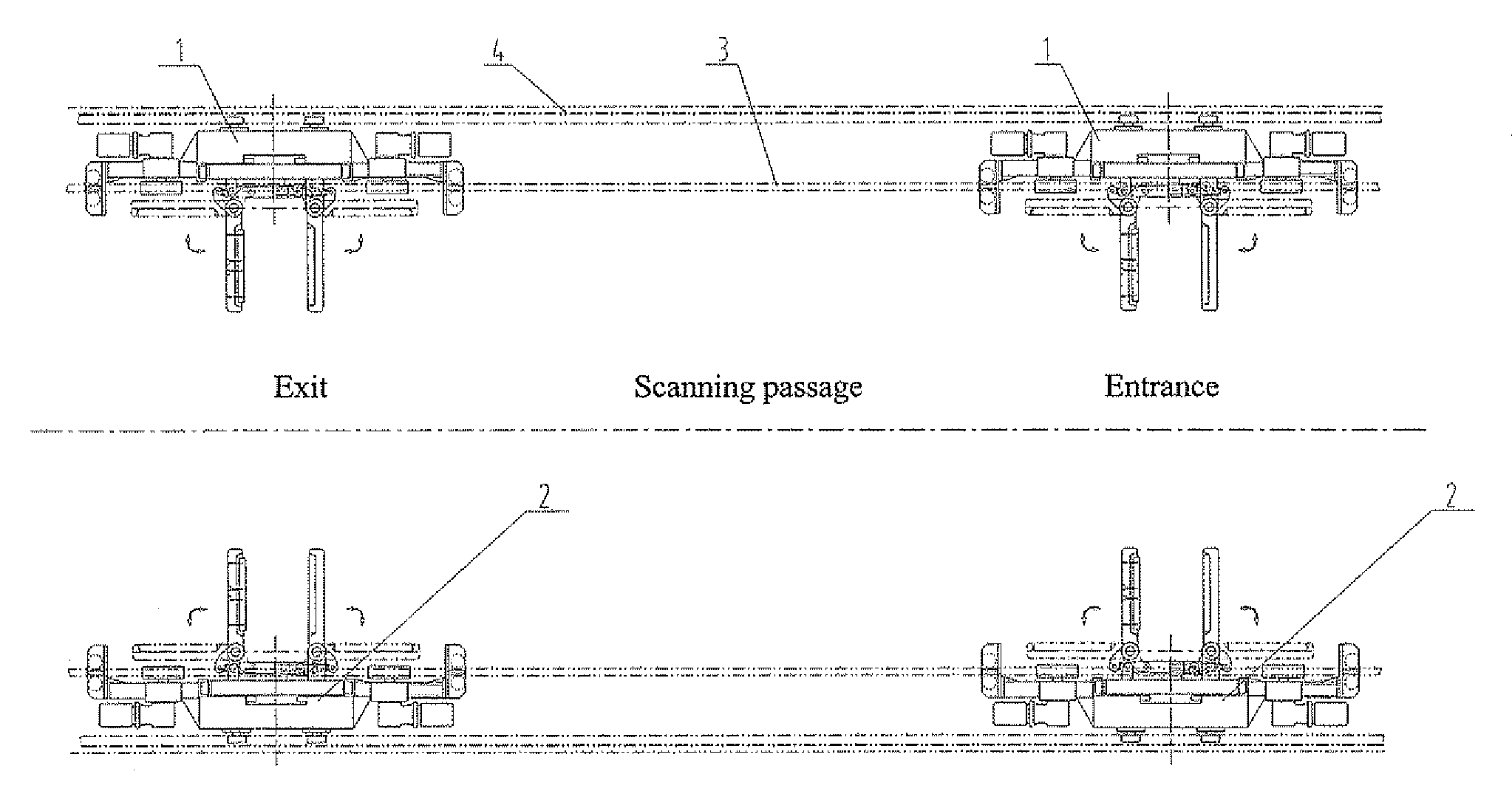

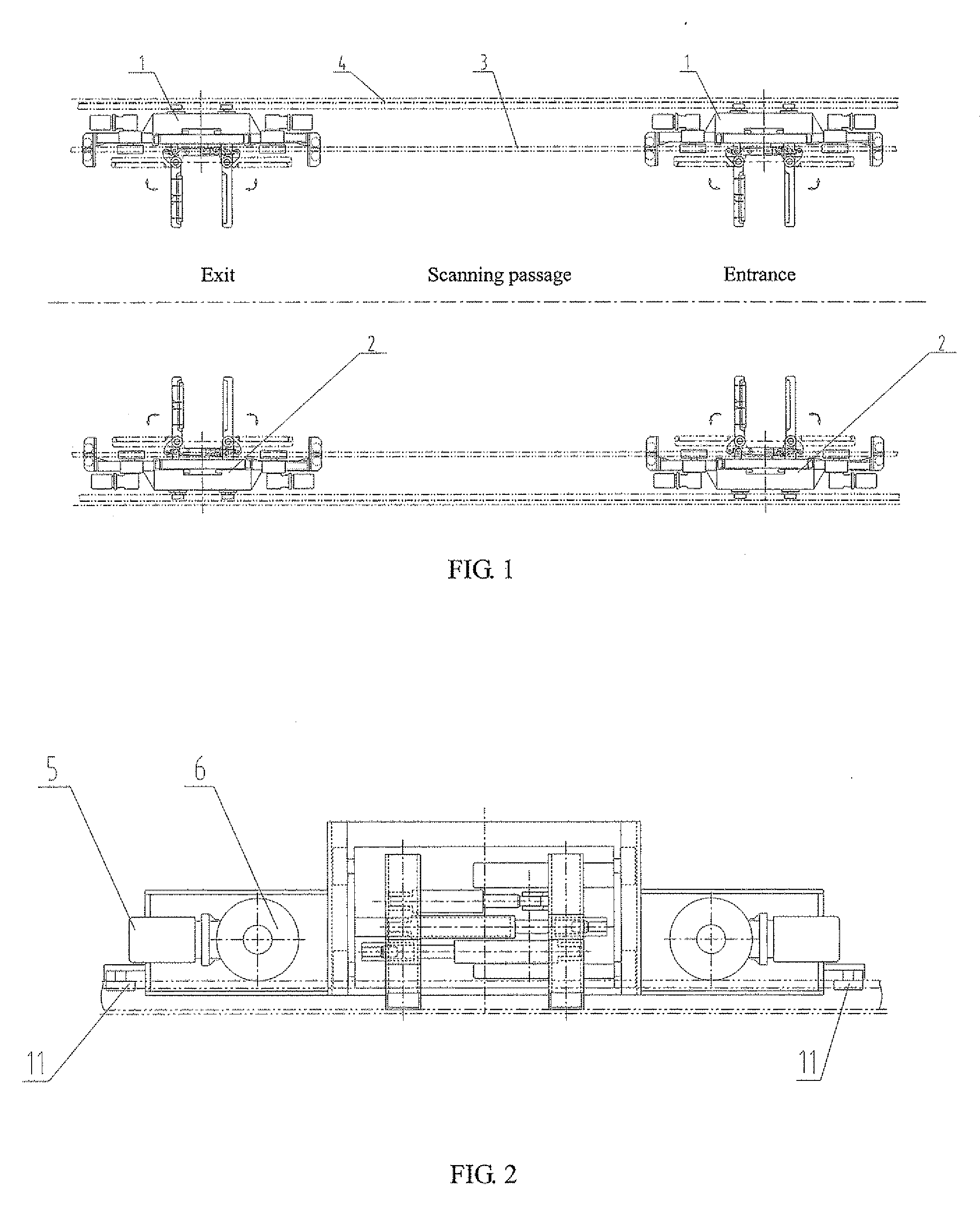

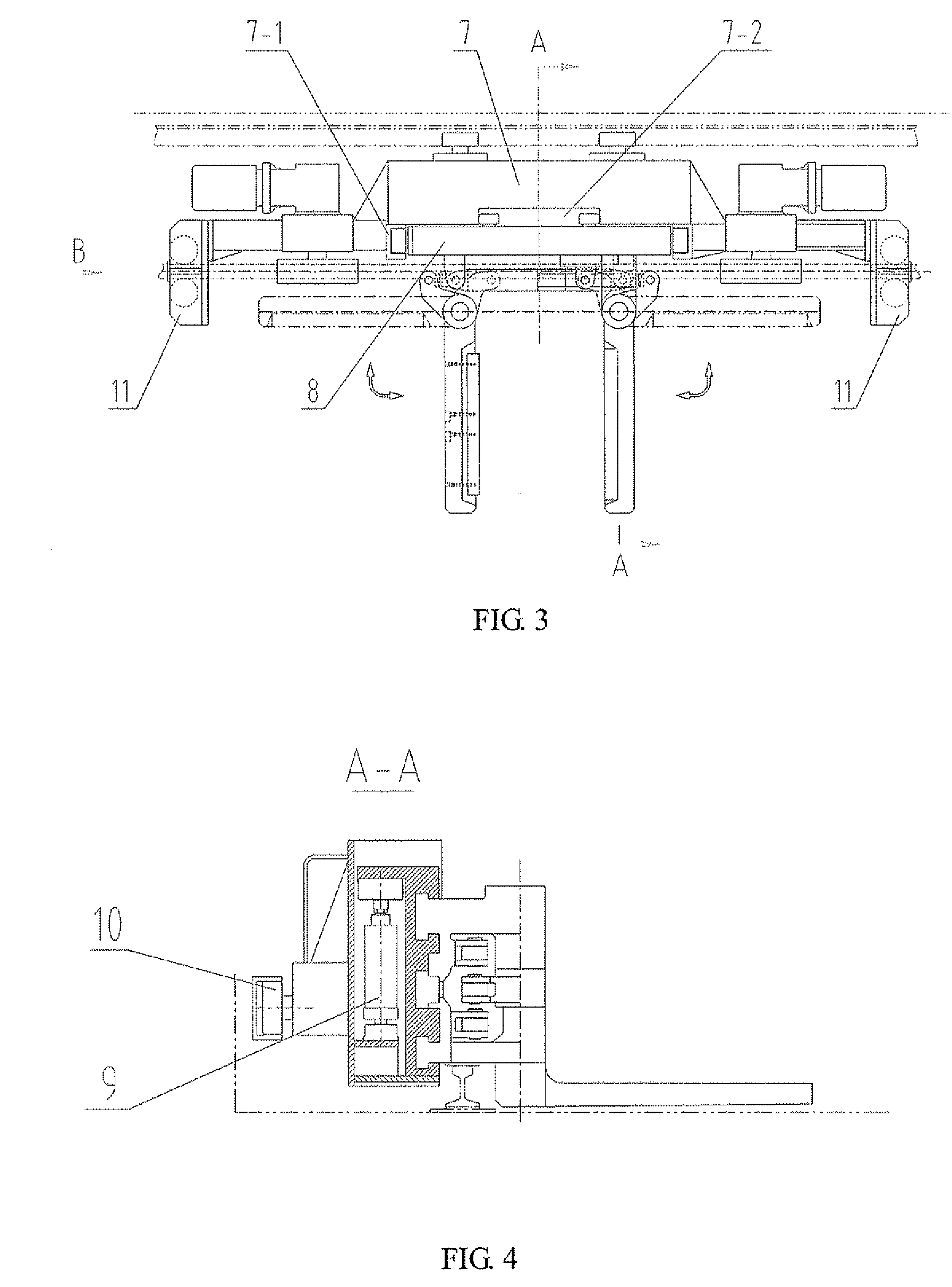

Trailer system and method for inspecting vehicle by radiation imaging of vehicle through trailer system

ActiveUS20080159840A1Guaranteed stable operationSimple structureSlipwaysTramway railsRadiation imagingSelf driving

The present invention relates to a trailer system, and particularly to a self-driving trailer system for a radiation imaging inspection system and a method for inspecting a vehicle by radiation imaging of a vehicle through the trailer system. The self-driving trailer system comprises two trailers symmetrical in structure. Each of the trailers comprises a driving device, running wheels, a trailer body, a carrying device, a lift cylinder, a balance wheel, and two pairs of guide wheels. The driving device, the running wheels, and the balance wheel are coupled with the trailer body. The carrying device is coupled with the trailer body through the lift cylinder. A front carrying arm and a rear carrying arm can clamp front wheels of a vehicle under inspection, and move upwards and downwards by the lift cylinder. The trailer system according to the present invention is smooth and reliable in operation and simple in structure, and is applicable to different diameters of wheels of container lorries under inspection and is convenient in operation.

Owner:NUCTECH CO LTD +1

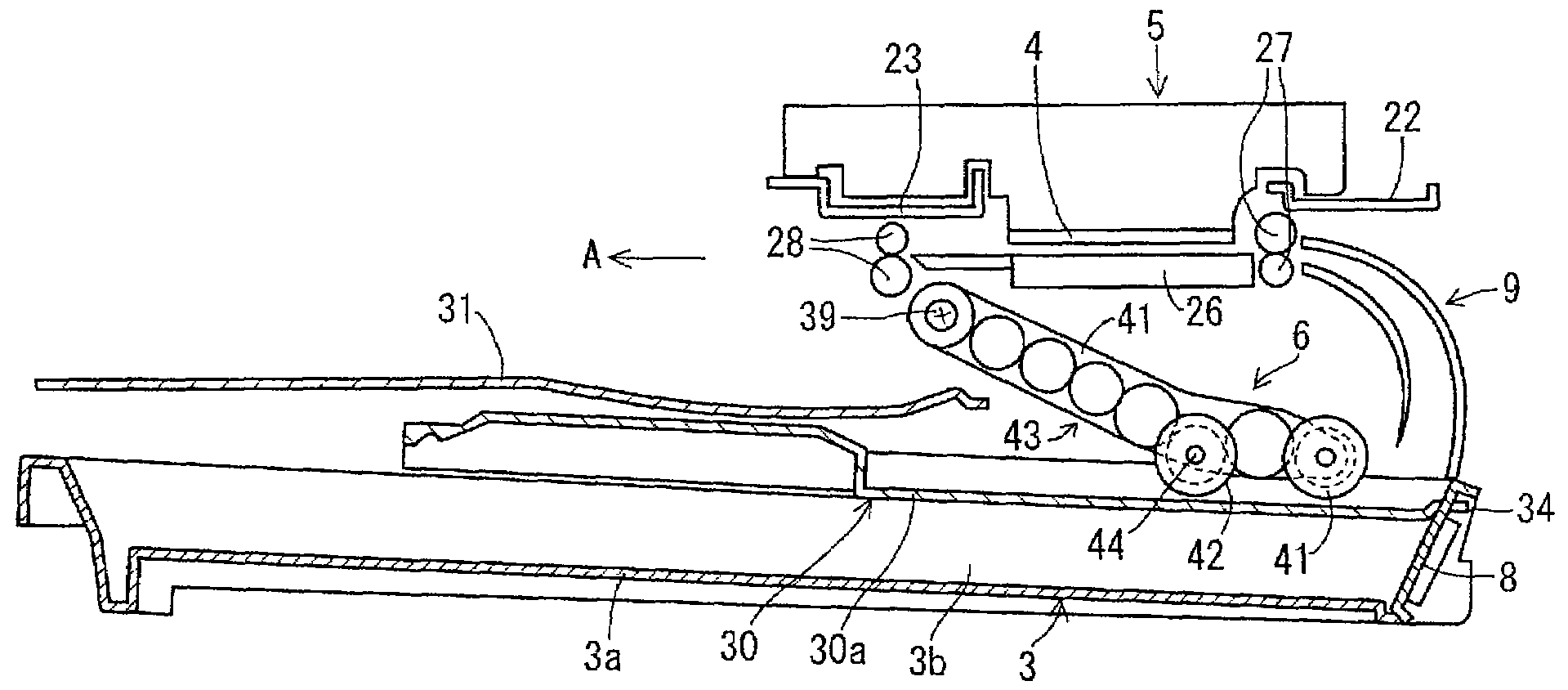

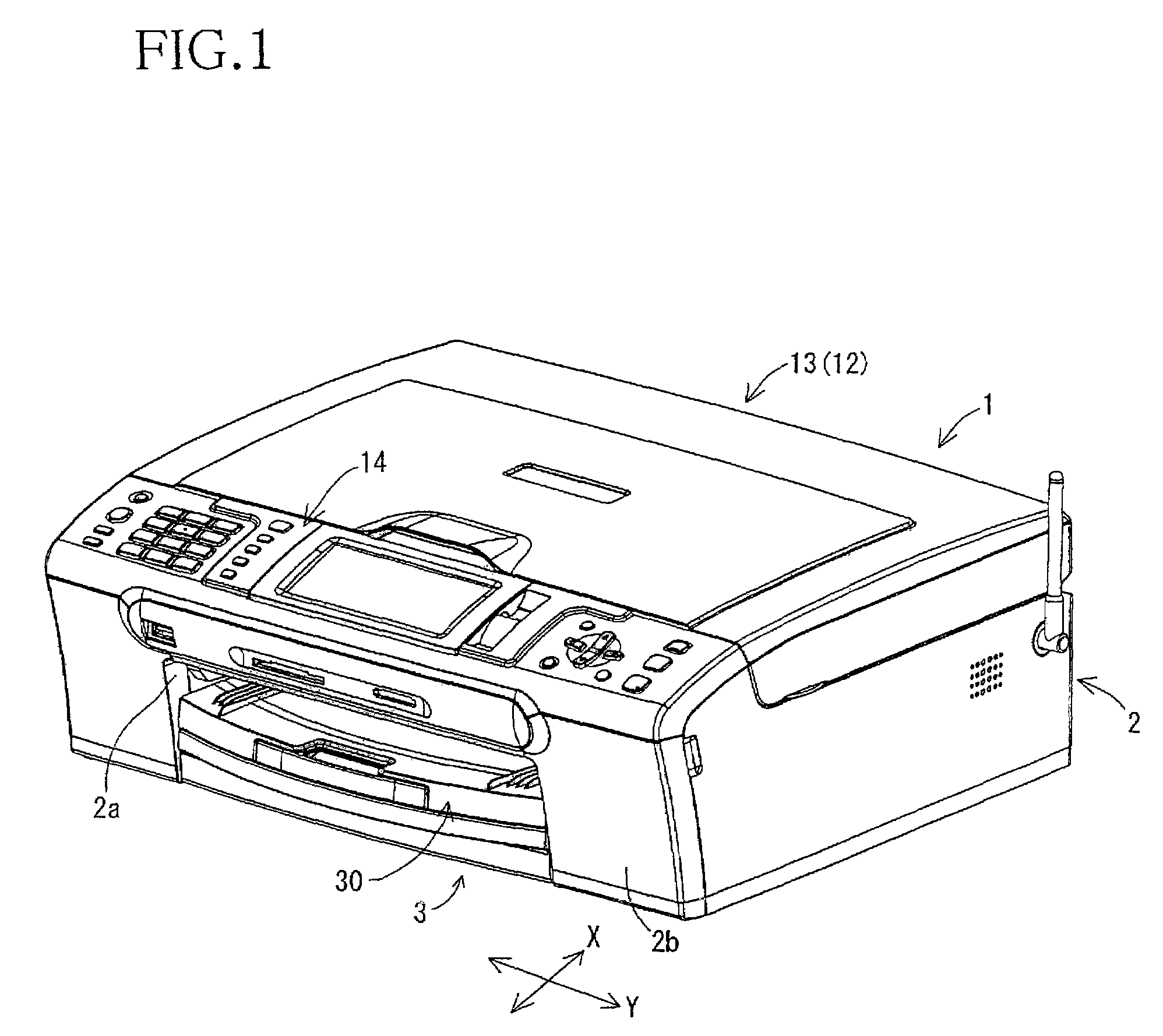

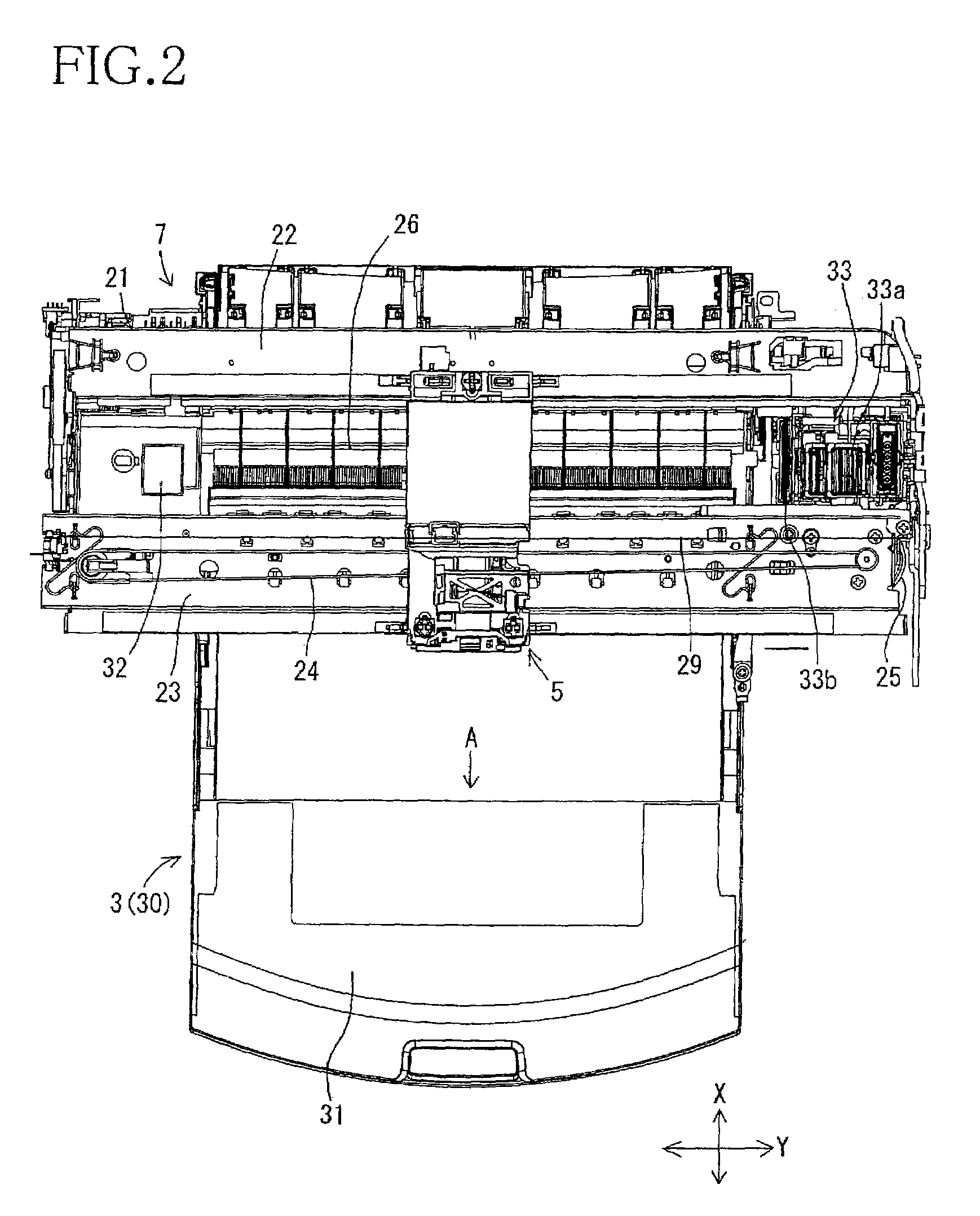

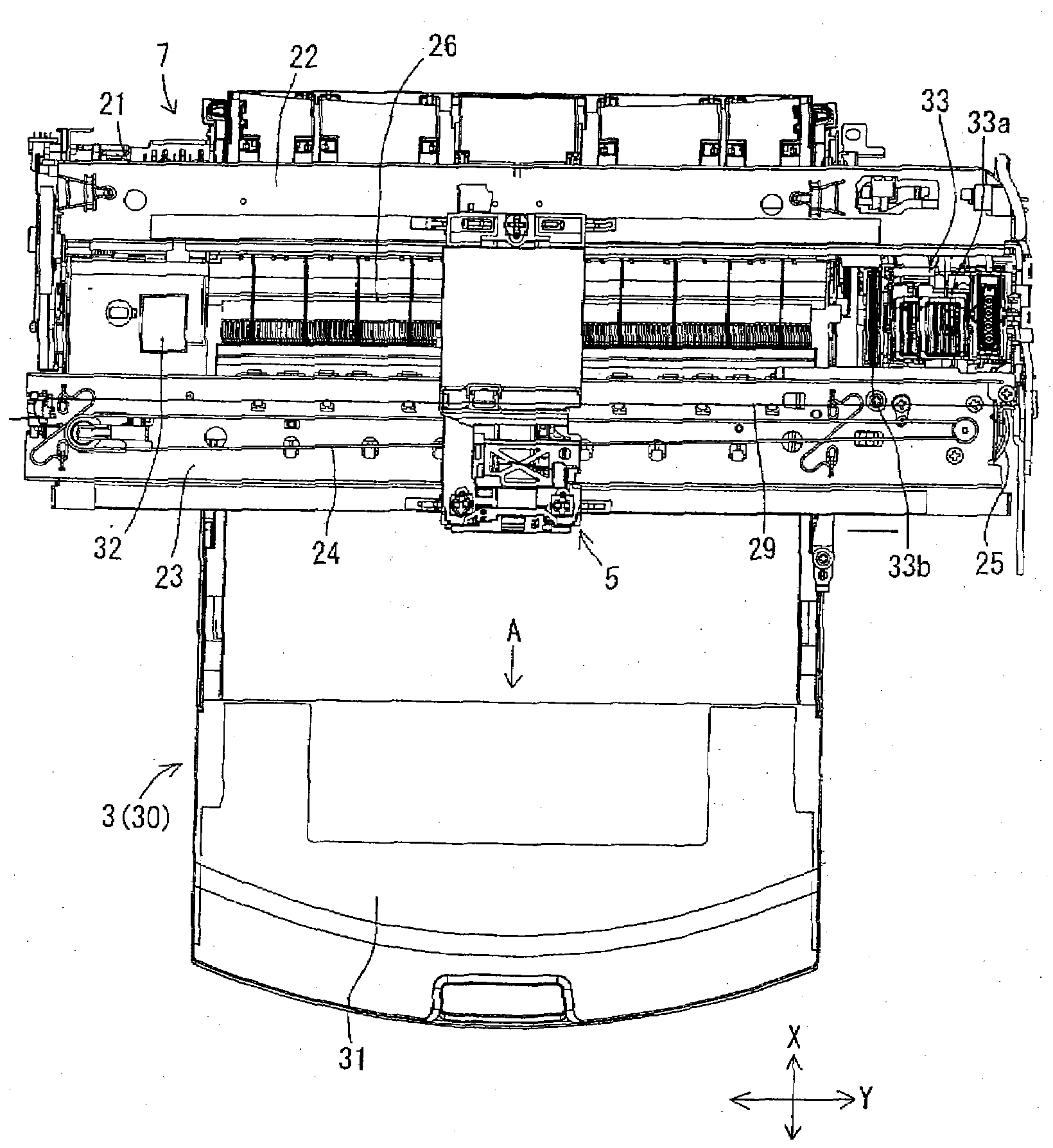

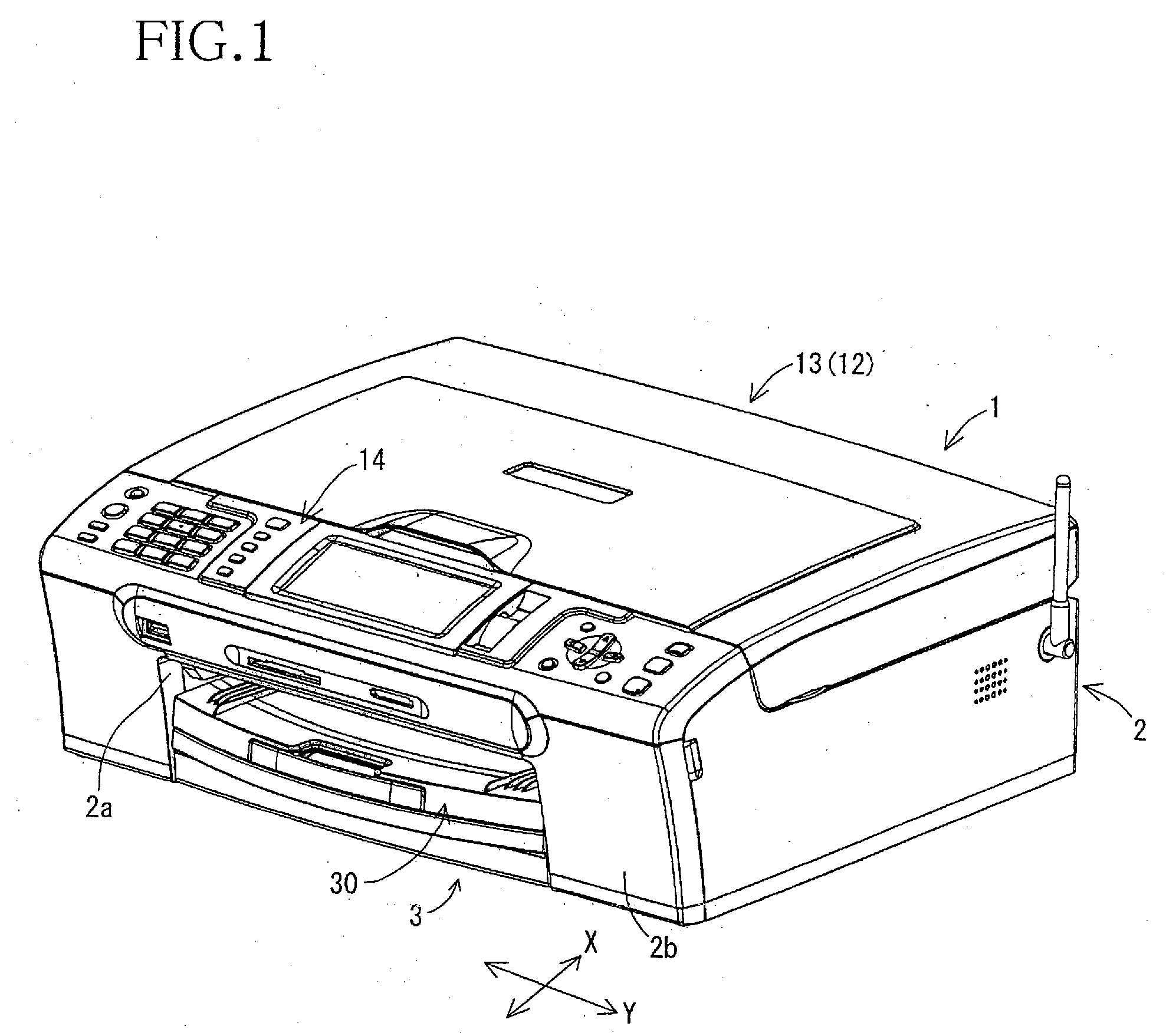

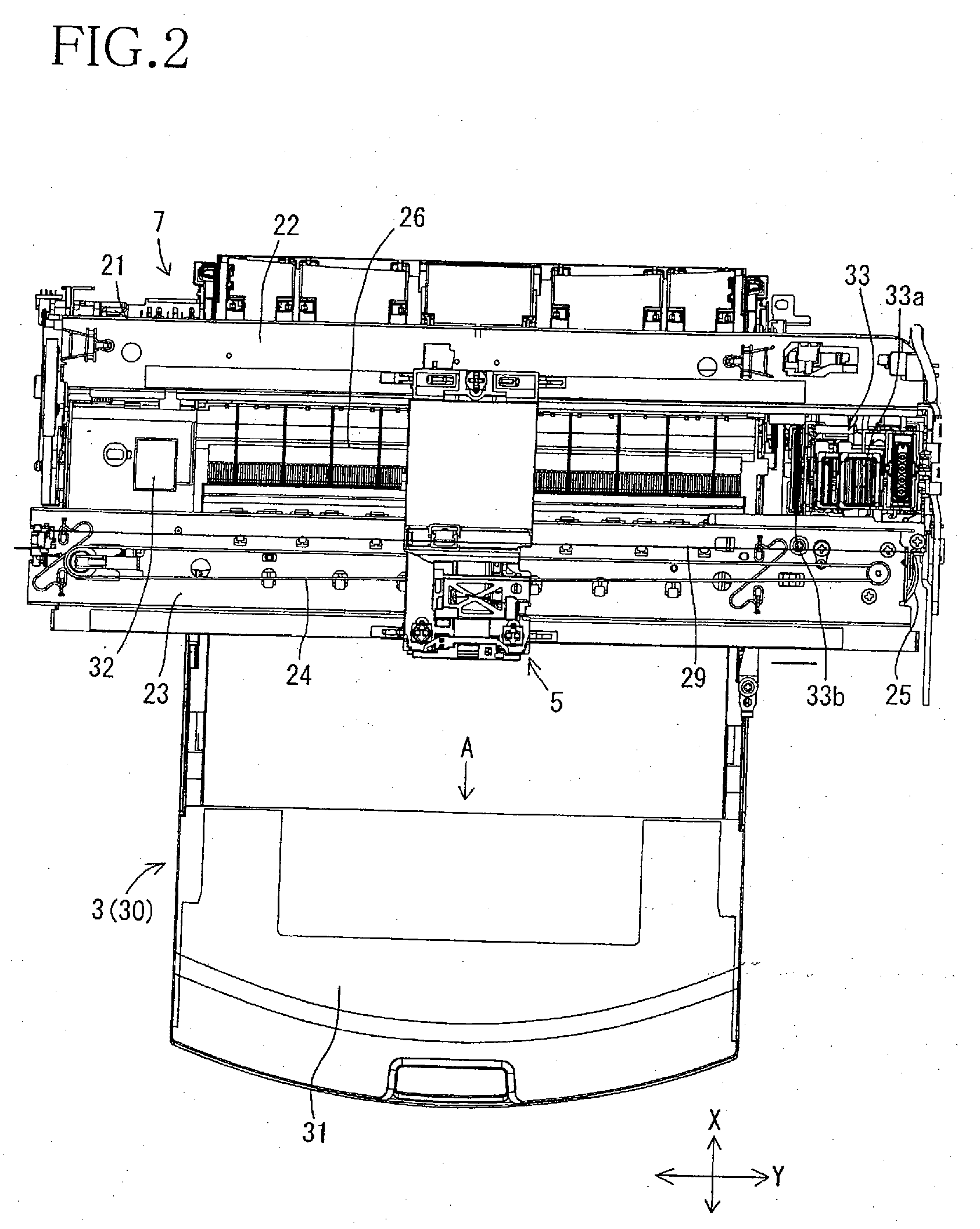

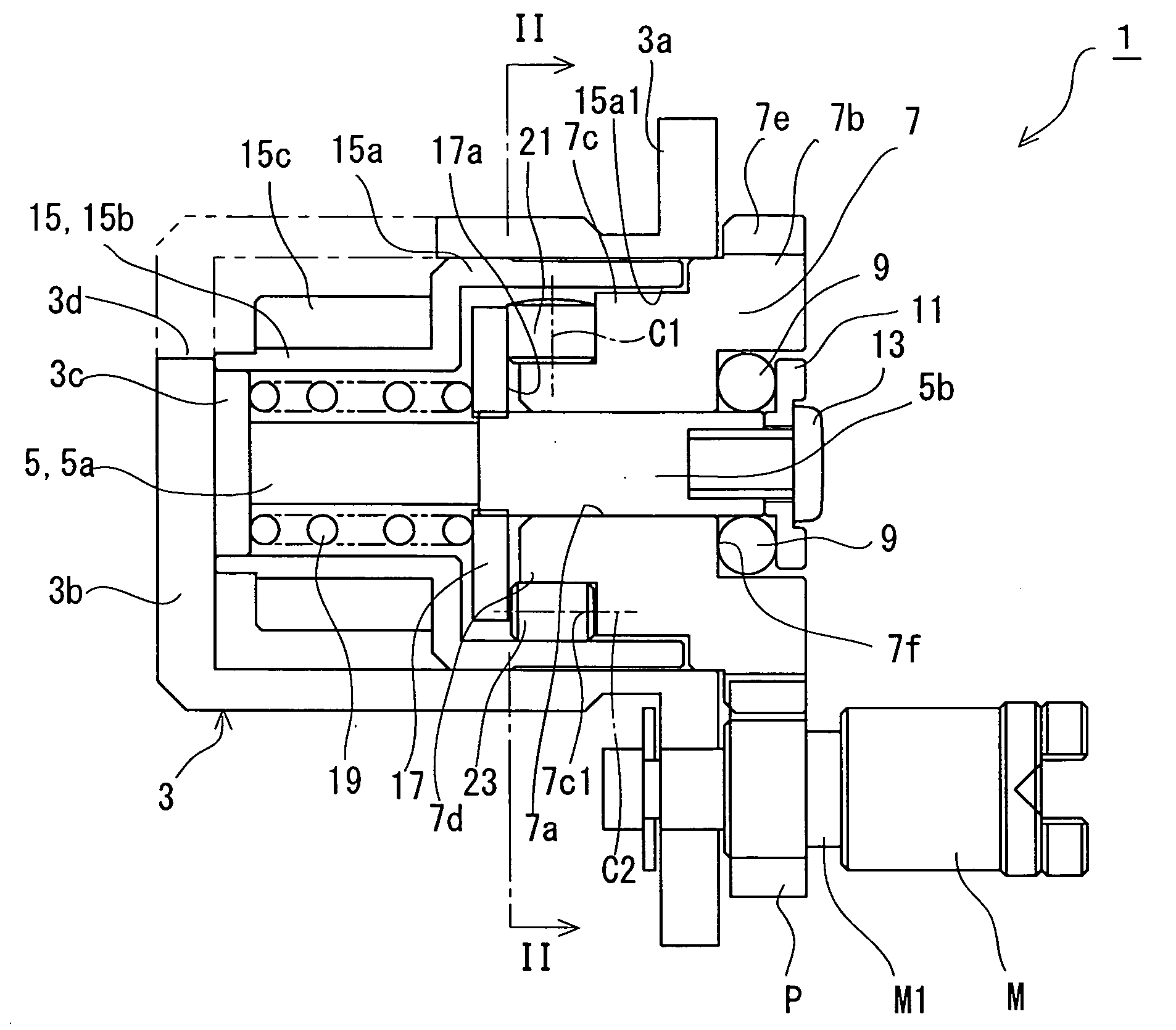

Recording-sheet supplying apparatus and image recording apparatus

InactiveUS7600745B2Avoid simple structuresHeavy weightArticle feedersArticle separationImage recordingEngineering

Owner:BROTHER KOGYO KK

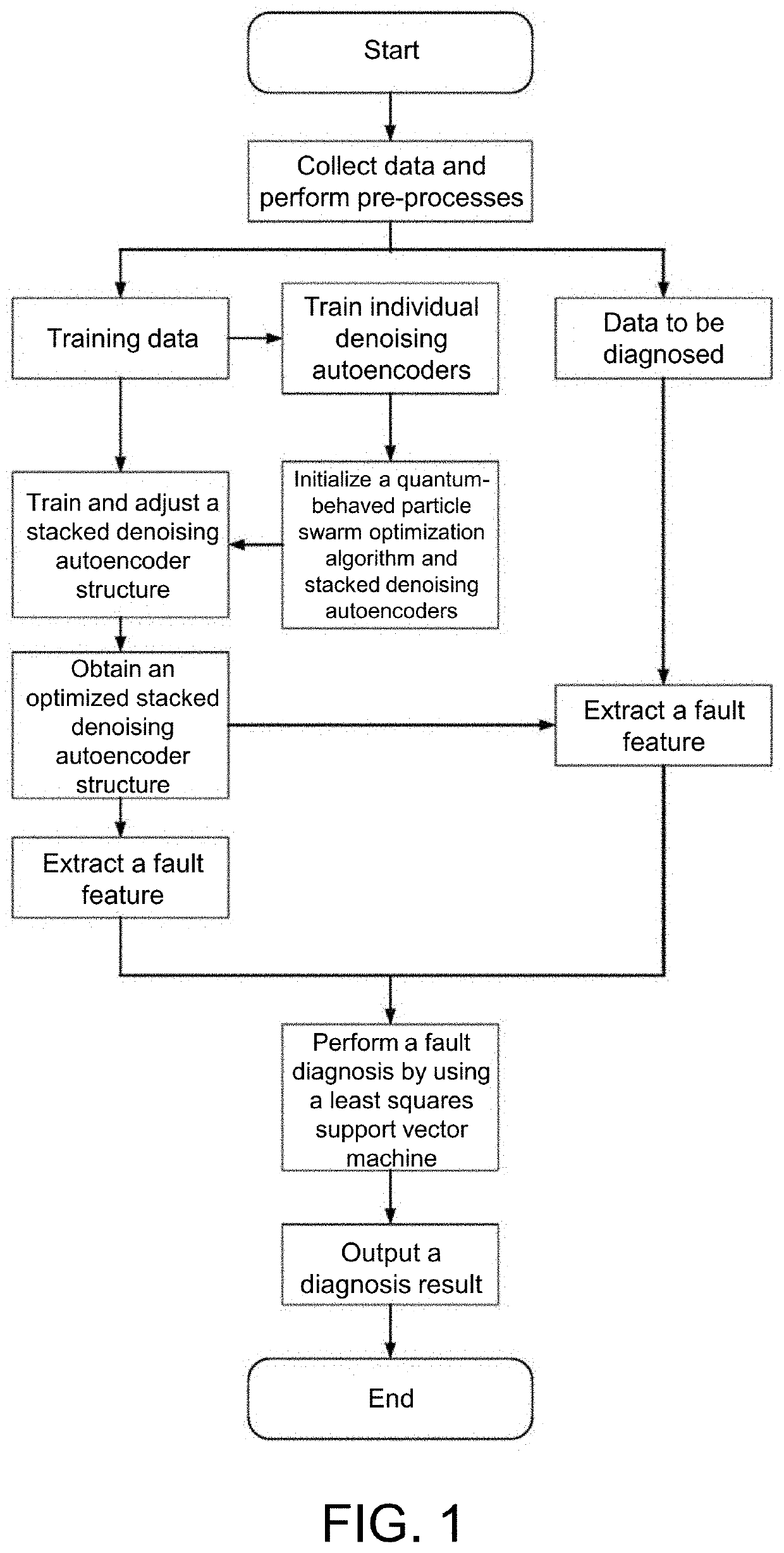

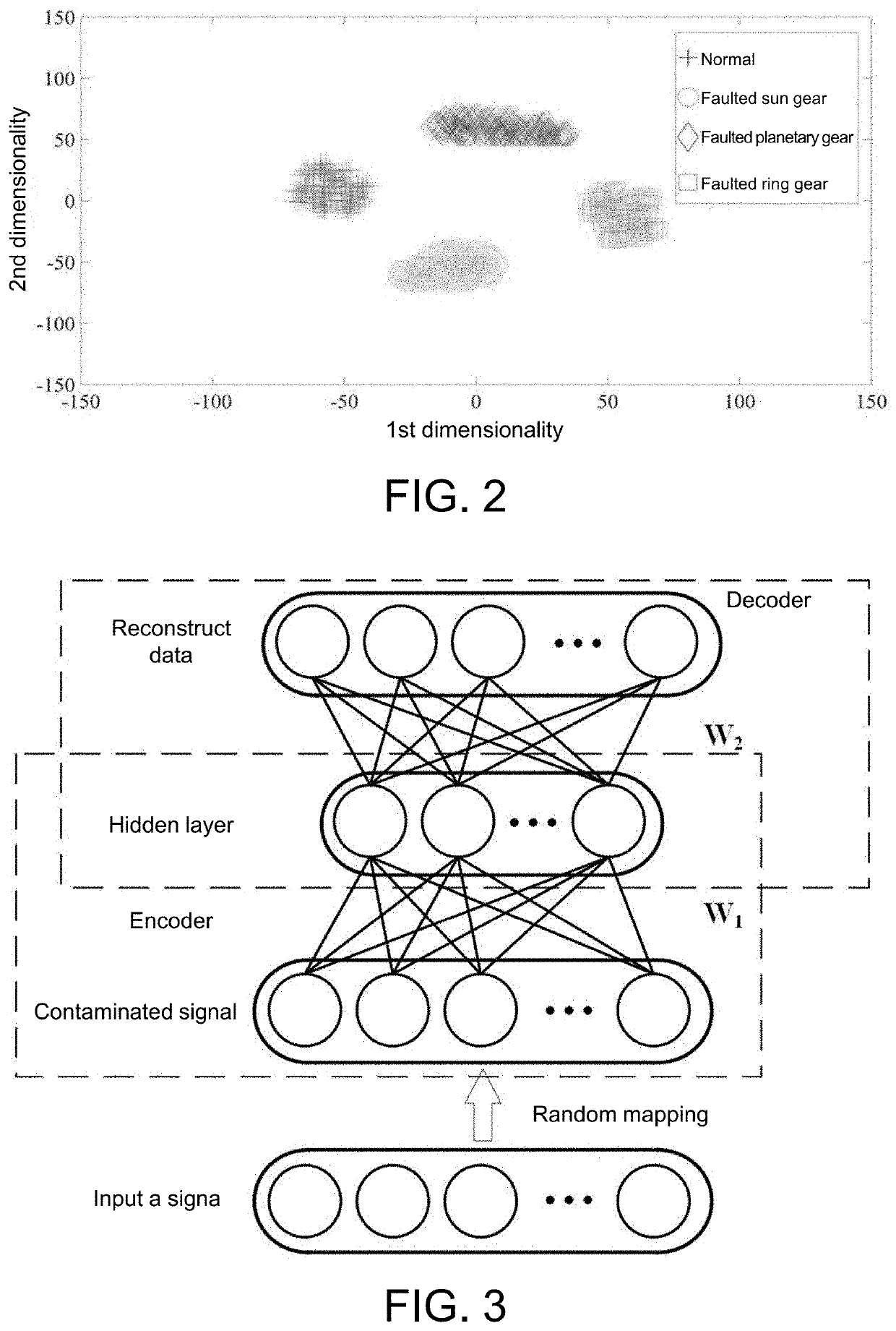

Method and system for fault diagnosis of gearbox of wind turbine generator

InactiveUS20210270244A1Efficient extractionEfficient identificationMachine part testingEngine fuctionsLeast squares support vector machineControl engineering

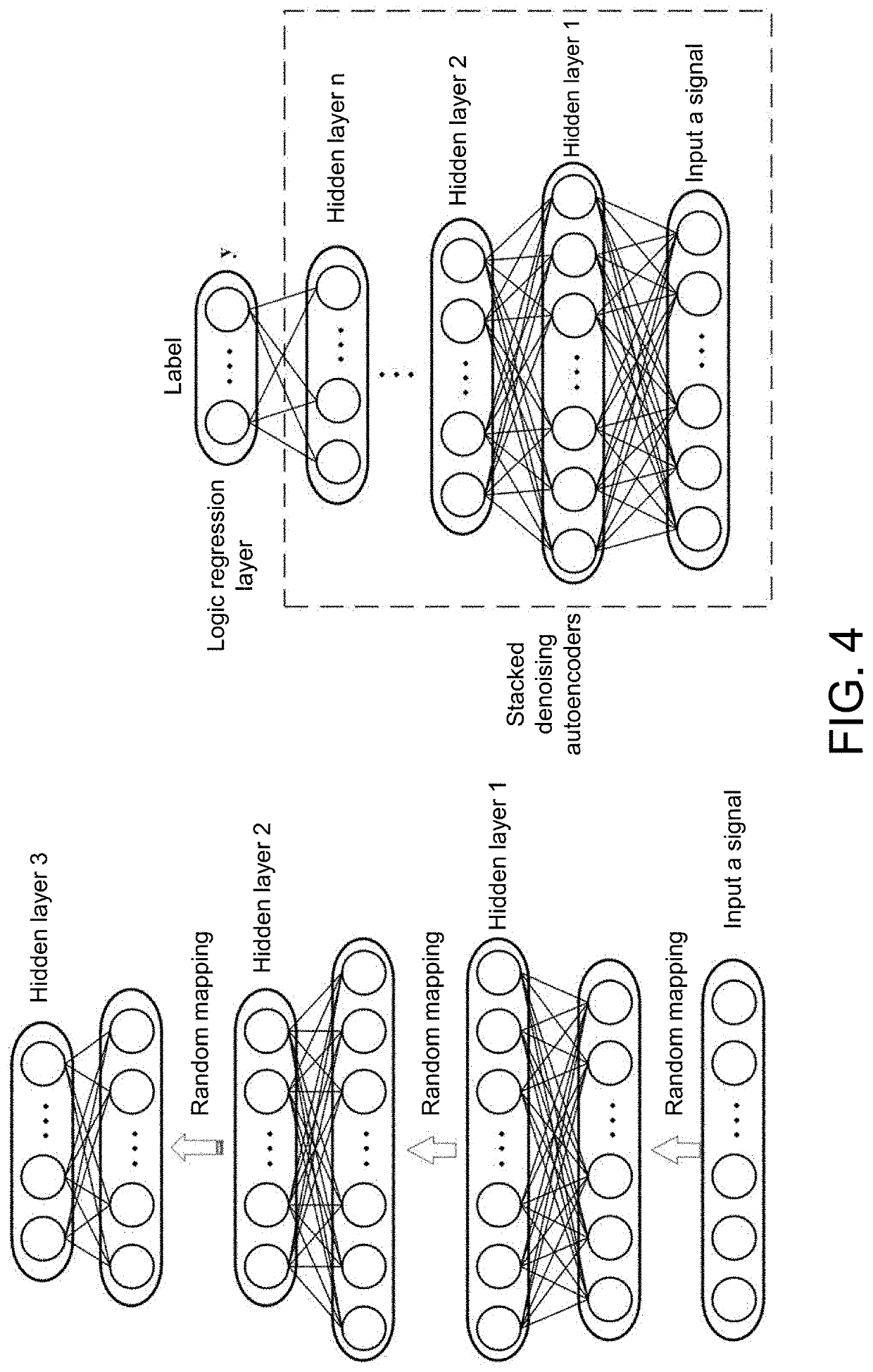

The invention provides to a method and a system for fault diagnosis of a gearbox of a wind turbine generator based on stacked denoising autoencoders and relates to fault diagnosis. Signals obtained by pre-processing original vibration signals collected when the gearbox of the wind turbine generator is in different working states are used as training data. The training data are input into stacked denoising autoencoders. Meanwhile, a quantum-behaved particle swarm optimization algorithm is introduced to optimize the structure and parameters. Then, pre-processed test signals are input into the stacked denoising autoencoders that are trained to extract high-dimensionality fault features contained in the original vibration signals. Then, the extracted fault features are input into a least squares support vector machine to complete the fault diagnosis of the gearbox.

Owner:WUHAN UNIV

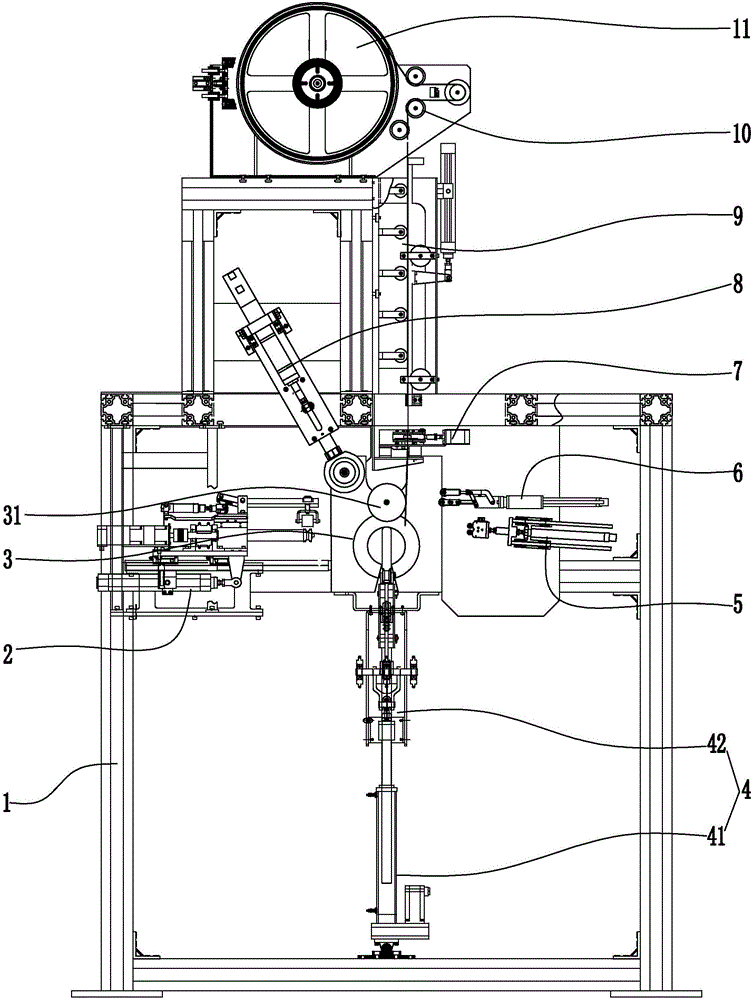

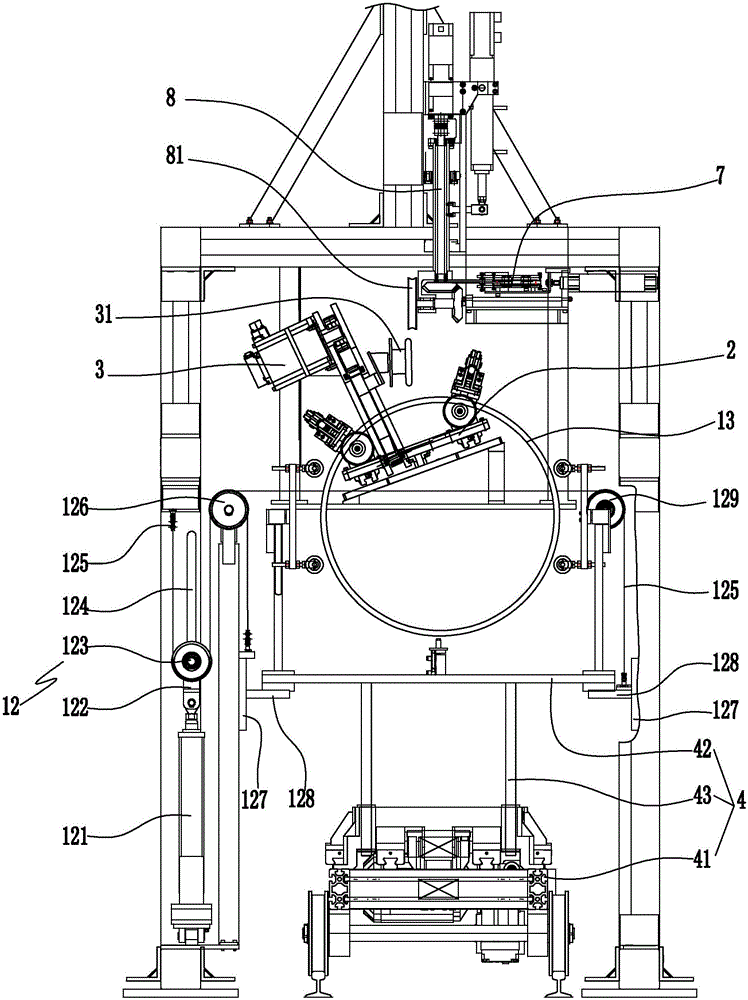

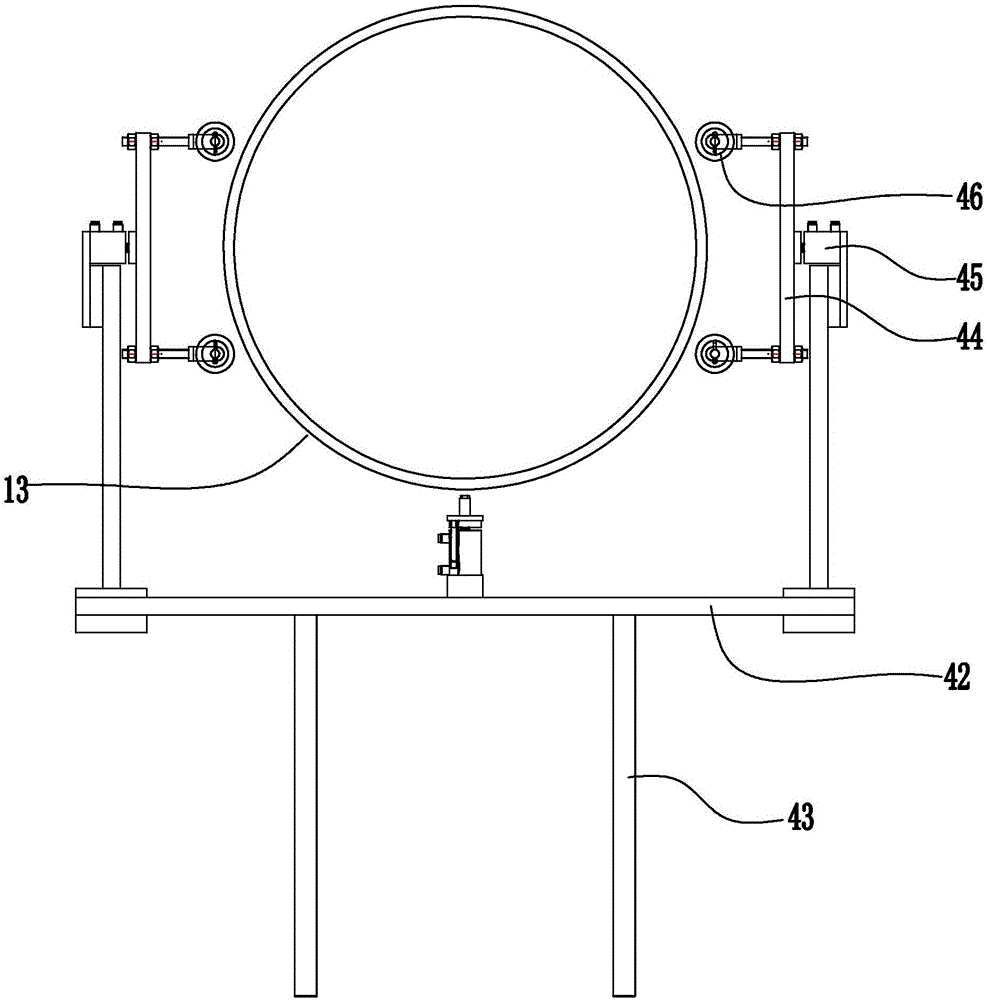

Automatic bead flipping machine

ActiveCN106079504ARealize automatic deliveryReduce labor intensityTyresEngineeringMechanical engineering

The invention discloses an automatic bead flipping machine. According to the automatic bead flipping machine, automatic bead conveying, feeding and discharging and bead flipping can be achieved, so that labor intensity is greatly relieved, and the working efficiency is improved. The automatic bead flipping machine comprises a machine frame, a bead rotation driving device, a bead flipping mechanism and a bead conveying device, wherein the bead rotation driving device, the bead flipping mechanism and the bead conveying device are arranged on the machine frame. The bead conveying device comprises a conveying rail, a conveying trolley, a bead storage device and a bead lifting mechanism, wherein the conveying trolley can move along the conveying rail, the bead storage device is arranged on the conveying trolley, and the bead lifting mechanism is arranged on the machine frame and used for lifting the bead storage device. Vertical installation holes are formed in the conveying trolley. The bead storage device comprises a storage rack, vertical guide columns, a left bead clamping mechanism and a right bead clamping mechanism, wherein the vertical guide columns are arranged on the storage rack and matched with the vertical installation holes, and the left bead clamping mechanism and the right bead clamping mechanism are arranged on the storage rack.

Owner:机械科学研究院浙江分院有限公司

Suspension bridge steel wire rope damage patrolling robot

ActiveCN107175665AJudging the degree of damageEasy for daily maintenanceProgramme-controlled manipulatorMaterial magnetic variablesRemote controlEngineering

The invention discloses a suspension bridge steel wire rope damage patrolling robot. The suspension bridge steel wire rope damage patrolling robot comprises a base, a patrolling device arranged on the base and conducting patrolling on suspension bridge steel wire rope damage, and a control device controlling the patrolling device. The process for patrolling a steel wire rope includes the steps that firstly, the patrolling device is installed; secondly, the patrolling robot conducts patrolling on the suspension bridge steel wire rope; thirdly, after the robot finish patrolling, the robot returns to the initial end of the suspension bridge steel wire rope; fourthly, the first step, the second step and the third step are repeatedly conducted many times; and fifthly, damage state data are obtained. The suspension bridge steel wire rope damage patrolling robot is novel and reasonable in design, low in using cost, easy to operate, good in safety and capable of conveniently and rapidly finishing the suspension bridge steel wire rope damage patrolling operation; through the arrangement of the control device, a user remotely controls the patrolling robot to conduct high-altitude detection through a wireless remote control transmitter, and safety hidden danger of workers during high-altitude operation is avoided; and design is ingenious and reasonable, reliability and stability are achieved, the size is small, and practicability is high.

Owner:XIAN UNIV OF SCI & TECH

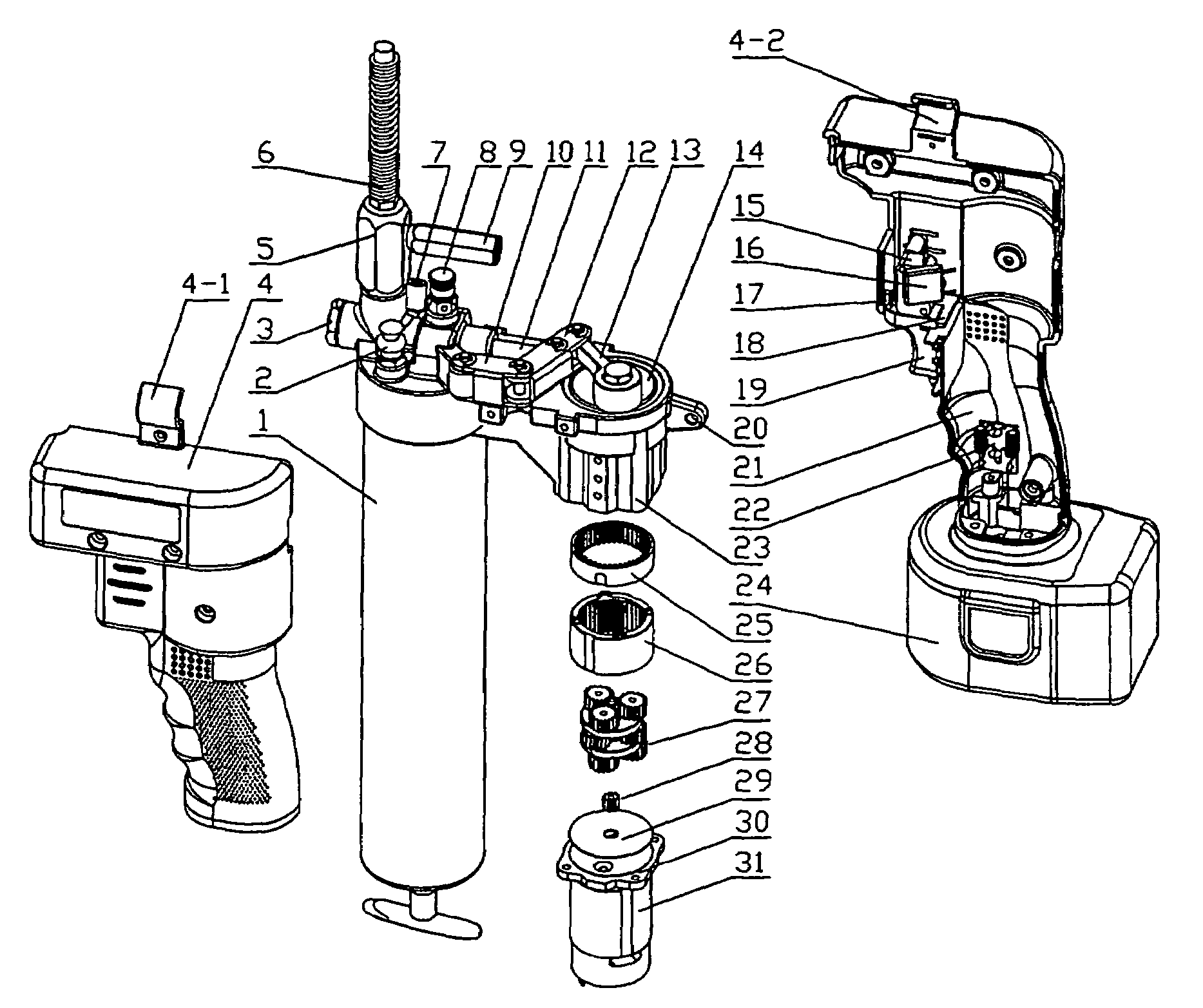

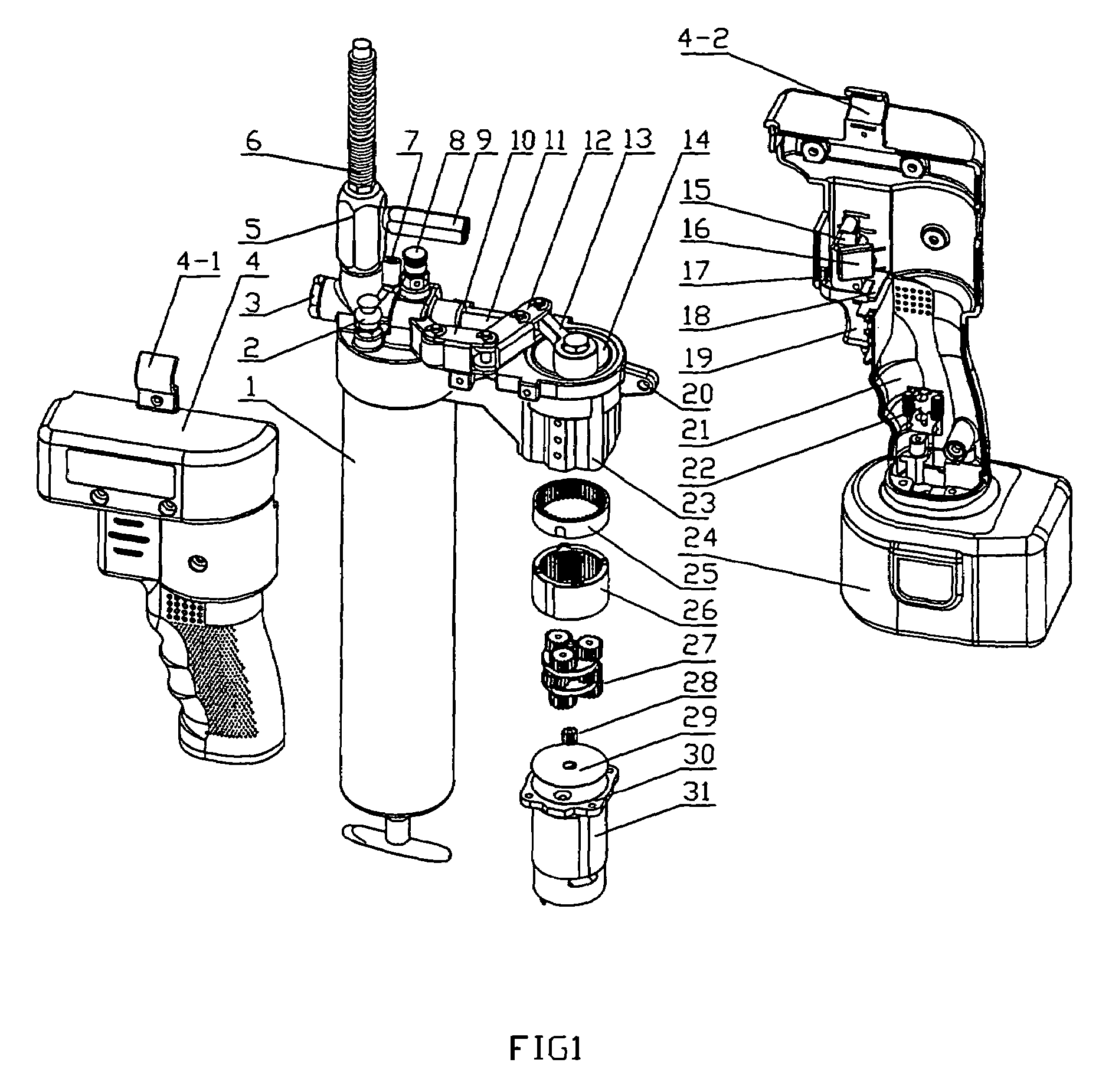

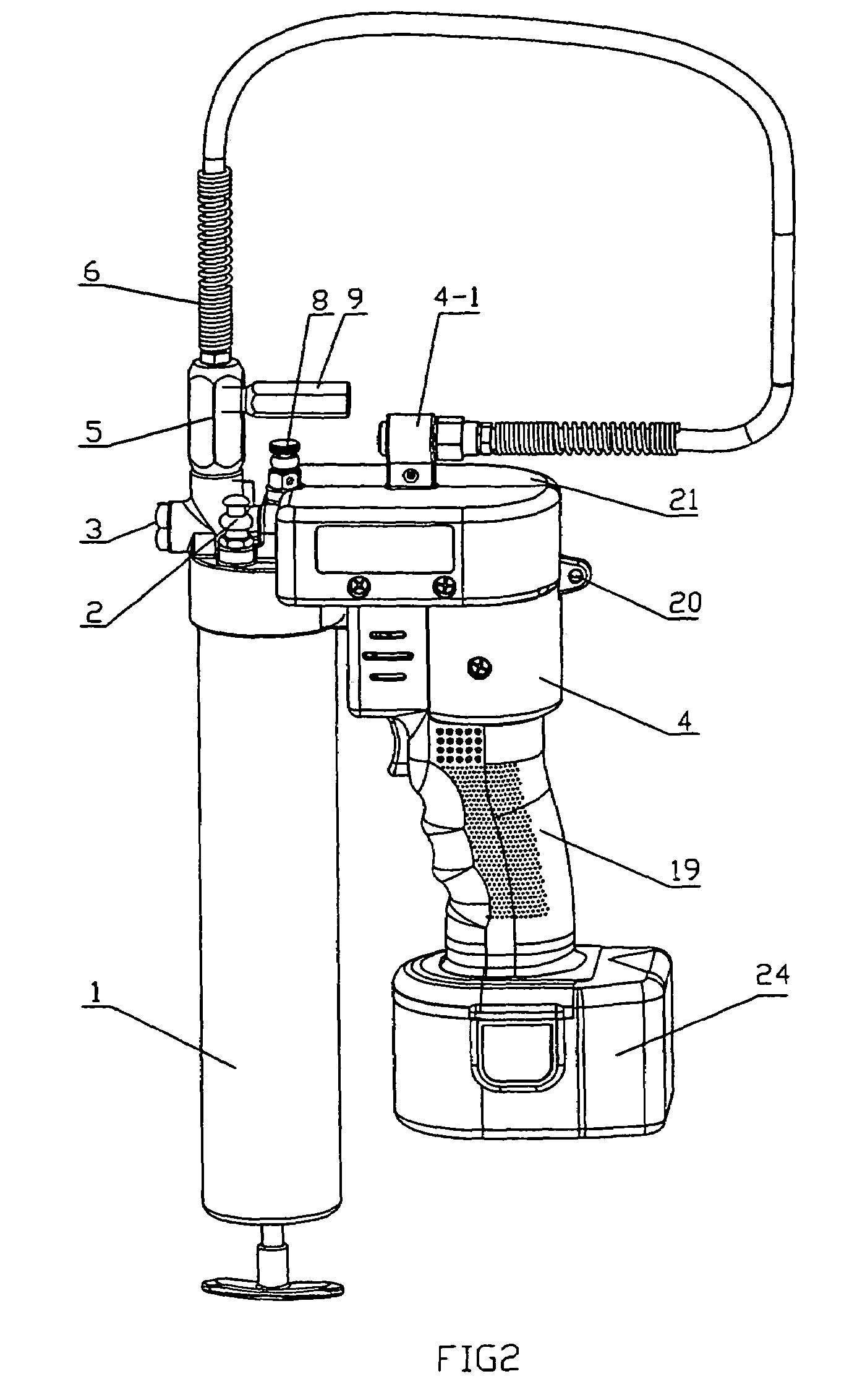

Portable electric grease gun

InactiveUS7267198B2Easy to transportSimple and compact structureManual lubricationLarge containersEngineeringMechanical engineering

This invention discloses a portable electrical grease gun which relates to electric tool field. The portable electrical grease gun according to the present invention, in which conventional slide block assembly driving structure is replaced by a crank link mechanism. As a result, the structure of the product is compact and simple. The crank link mechanism is constructed at low cost. The friction is low during operation. The operation is stable and reliable. It is easy for bulk production. In addition, the volume of the portable electrical grease gun according to the present invention is small so that it is easy to take and operate conveniently.

Owner:CEN JIANLI

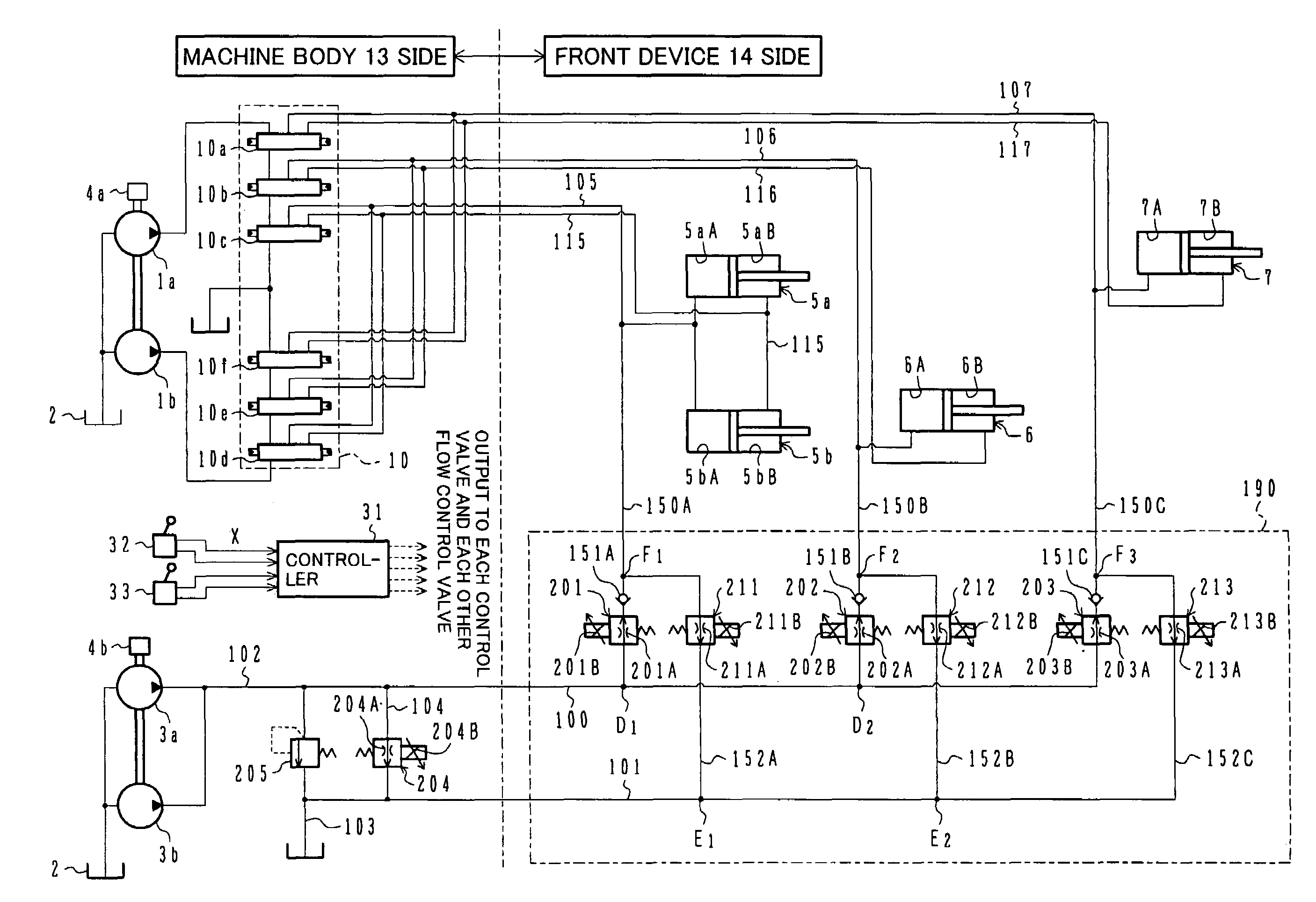

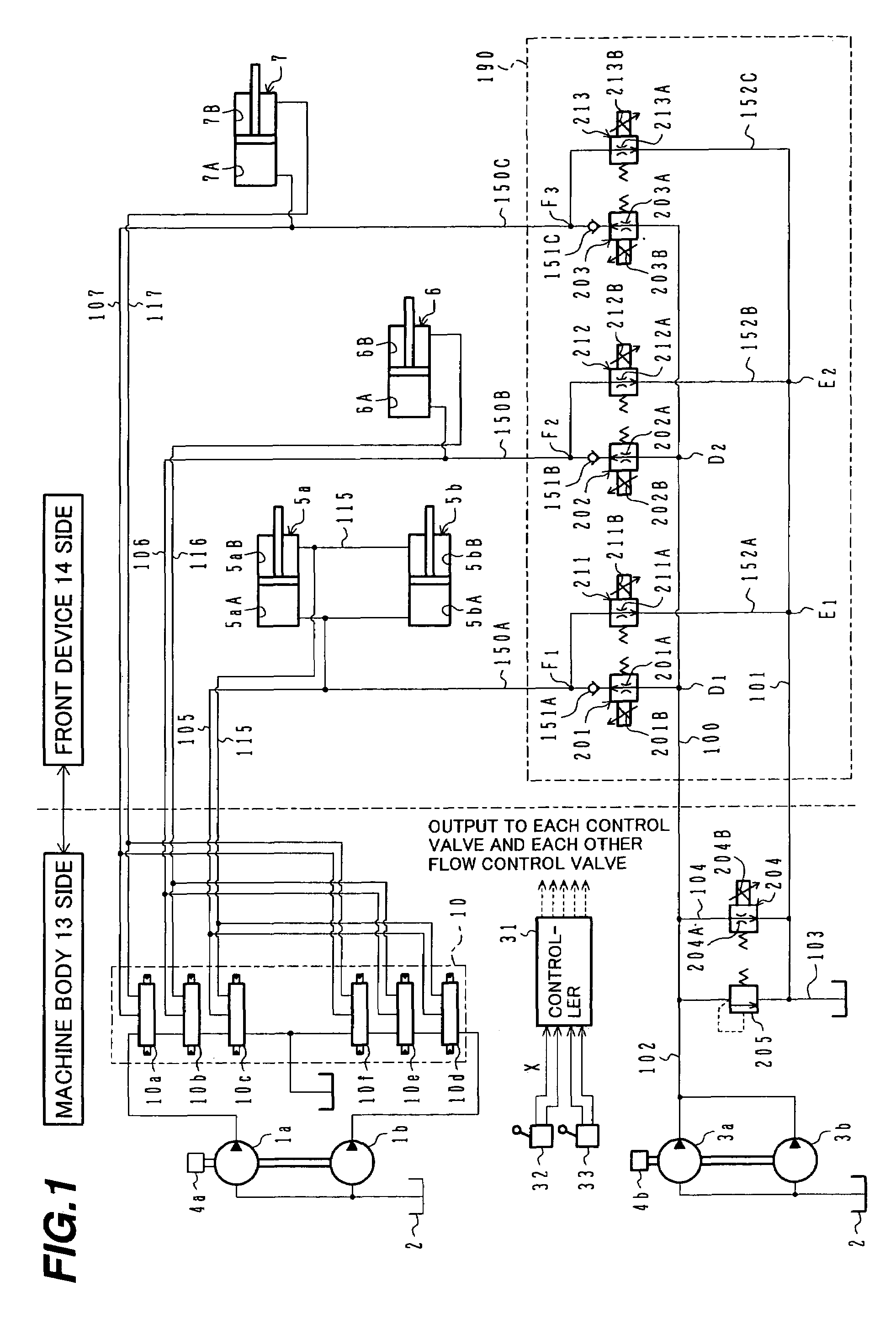

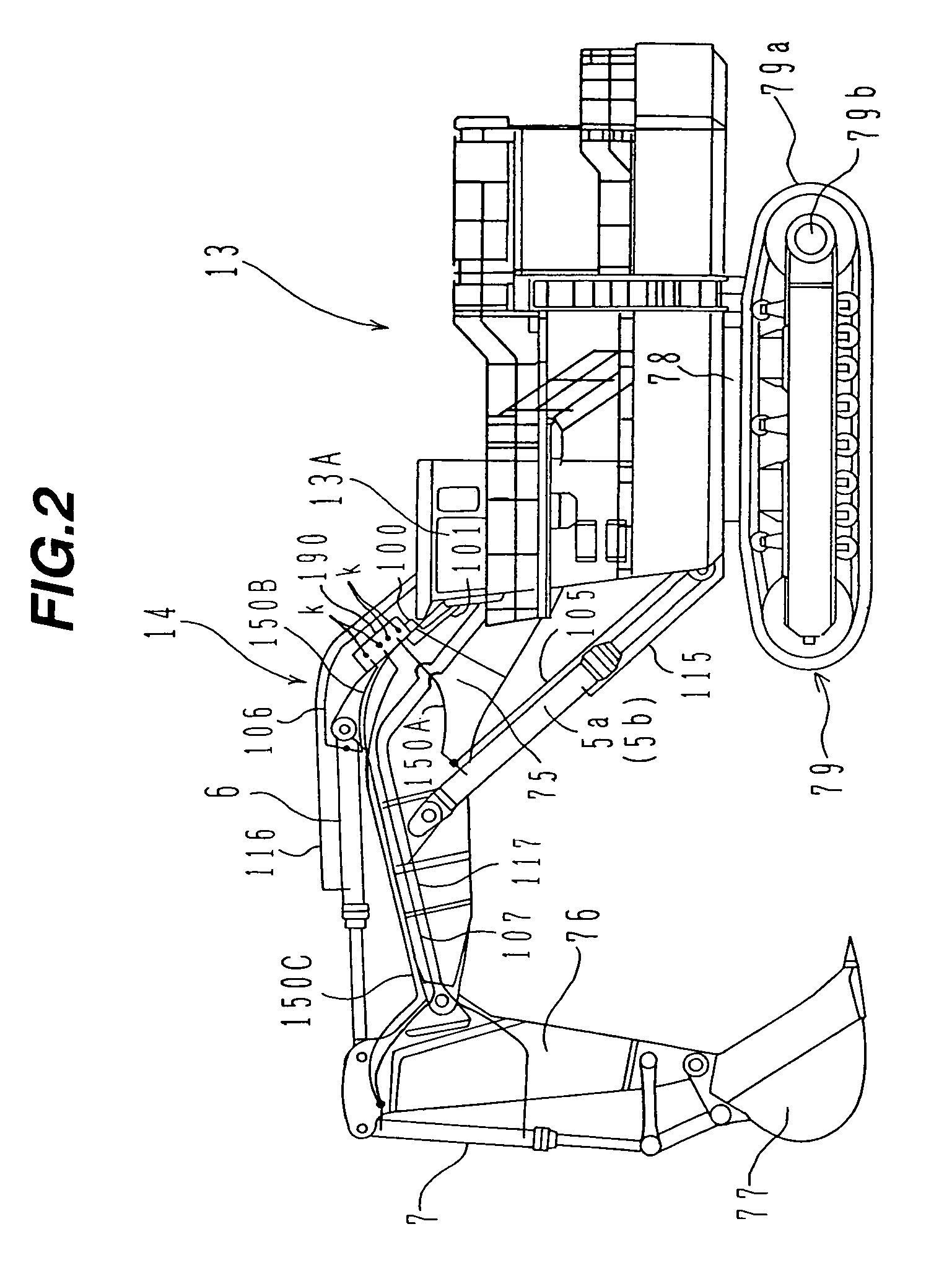

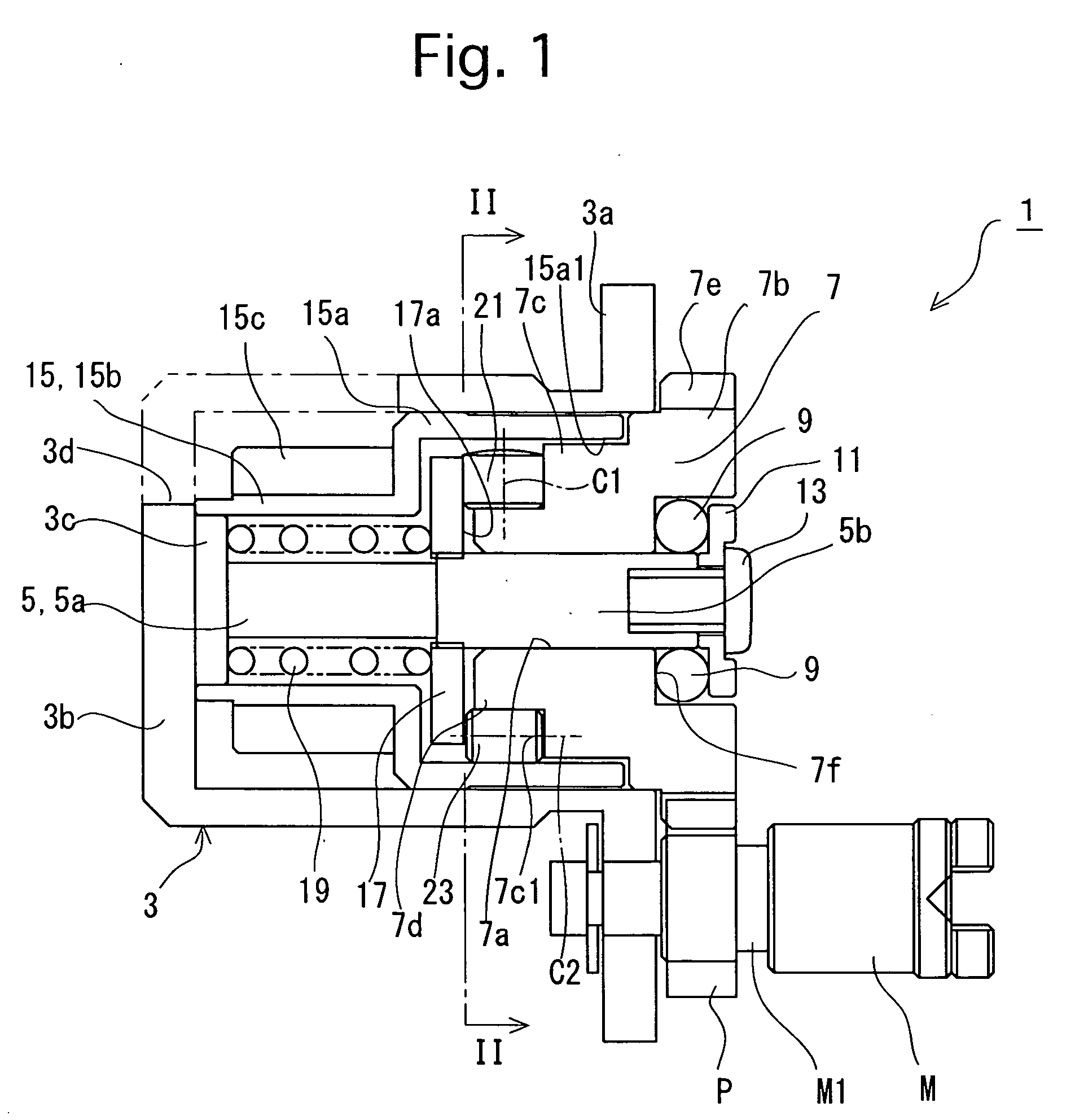

Hydraulic driving system of construction machinery

ActiveUS7500360B2Optimize layoutReduce total pressure lossFluid couplingsServomotorsHydraulic cylinderHydraulic pump

A hydraulic drive system comprises directional flow control valves (10a-f) for selectively supplying a hydraulic fluid from a first hydraulic pump (1a, 1b), inflow control valves (201-203) disposed respectively in branch lines (150A-C) branched from a supply line (100) for supplying a hydraulic fluid delivered from a second hydraulic pump (3a, 3b) to rod pushing-side chambers (5aA, 5bA, 6A, 7A) of hydraulic cylinders, a bypass flow control valve (204) disposed in a line (104) connecting the supply line (100) and a reservoir (2), and a controller (31) for computing control variables corresponding to operation command signals from control levers (32, 33) and controlling the inflow control valves (201-203) and the bypass flow control valve (204) in accordance with the computed control variables. Thus, the number of flow control valves and the length of piping required for their connection can be reduced, and a total pressure loss can be further reduced.

Owner:NIHON KENKI CO LTD

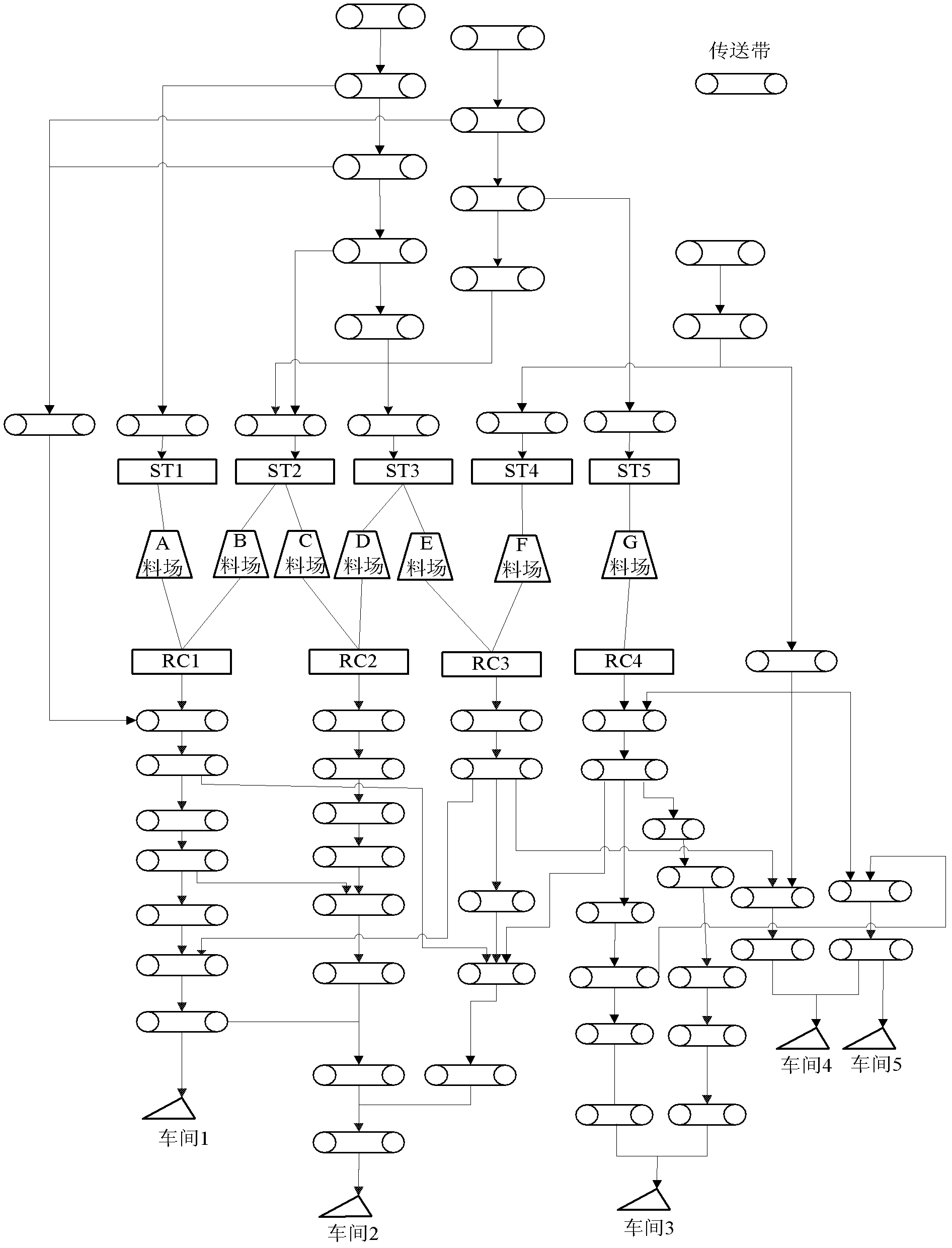

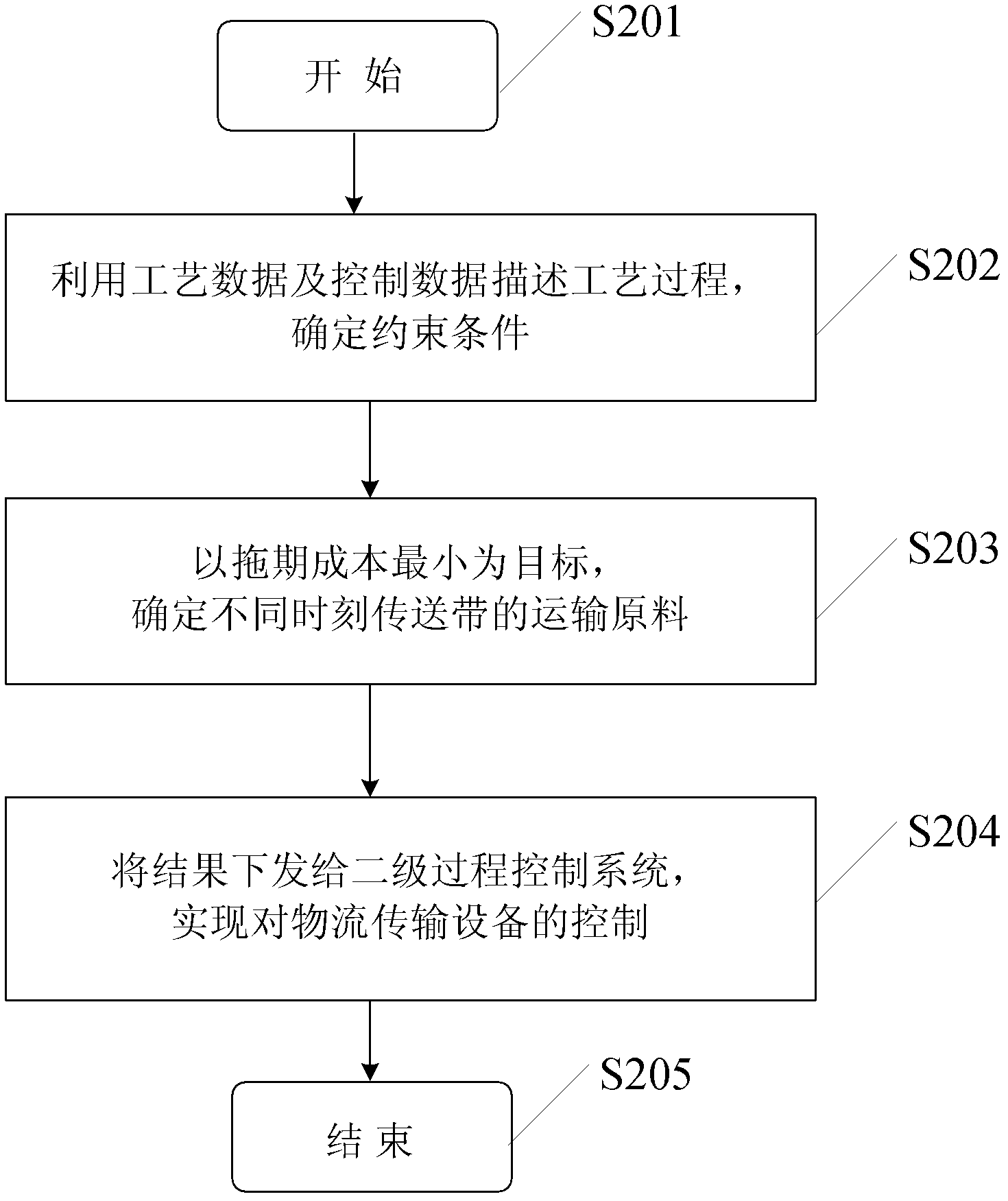

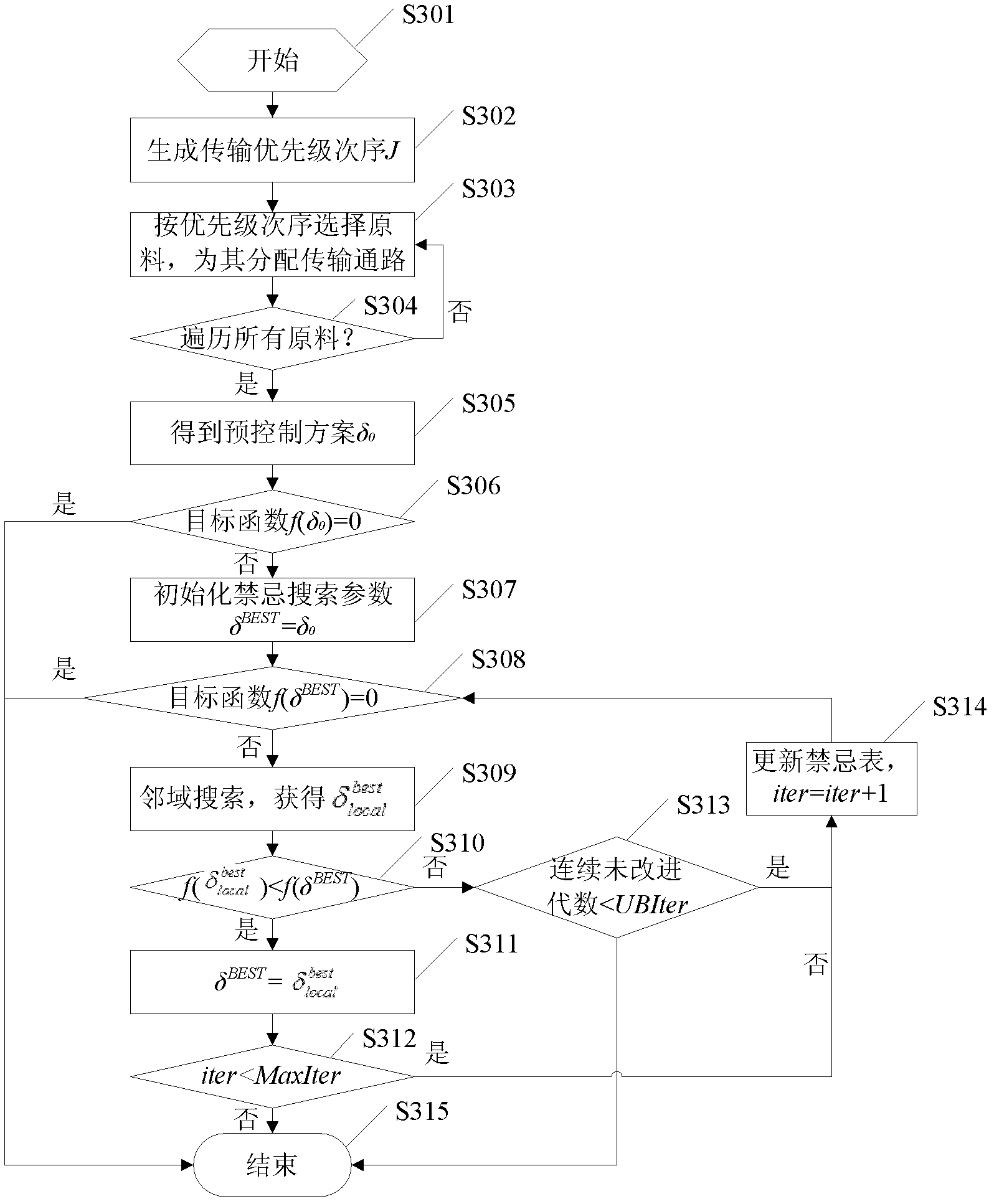

Control method and control device for steel raw material yard logistics transmission equipment

ActiveCN102583032AAvoid interruptions in raw material supplyGuaranteed stable operationControl devices for conveyorsWork statusProduction logistics

A control method and a control device for steel raw material yard logistics transmission equipment belong to the technical field of steel raw material production logistics. The control method includes the steps: describing a technical process and determining constraint conditions of the technical process by the aid of process data and control data during transmission of a conveyor belt; calculating raw materials conveyed by the conveyor belt at different time in order to minimize tardiness cost; and issuing results to a secondary process control system to control the logistics transmission equipment. The method is used for scientifically and quantitatively describing process features of the steel raw material transmission equipment during control, and controlling the transmission equipment by means of intelligent optimization algorithm based on description, so that a raw material transmission production system is in optimal operating state, the problems of interruption of raw material supply and the like caused by unreasonable distribution are avoided to a large extent, stable operation of the equipment is ensured, production is balanced, the utilization rate of the equipment is increased, production cycle is shortened, and production efficiency is improved.

Owner:NORTHEASTERN UNIV

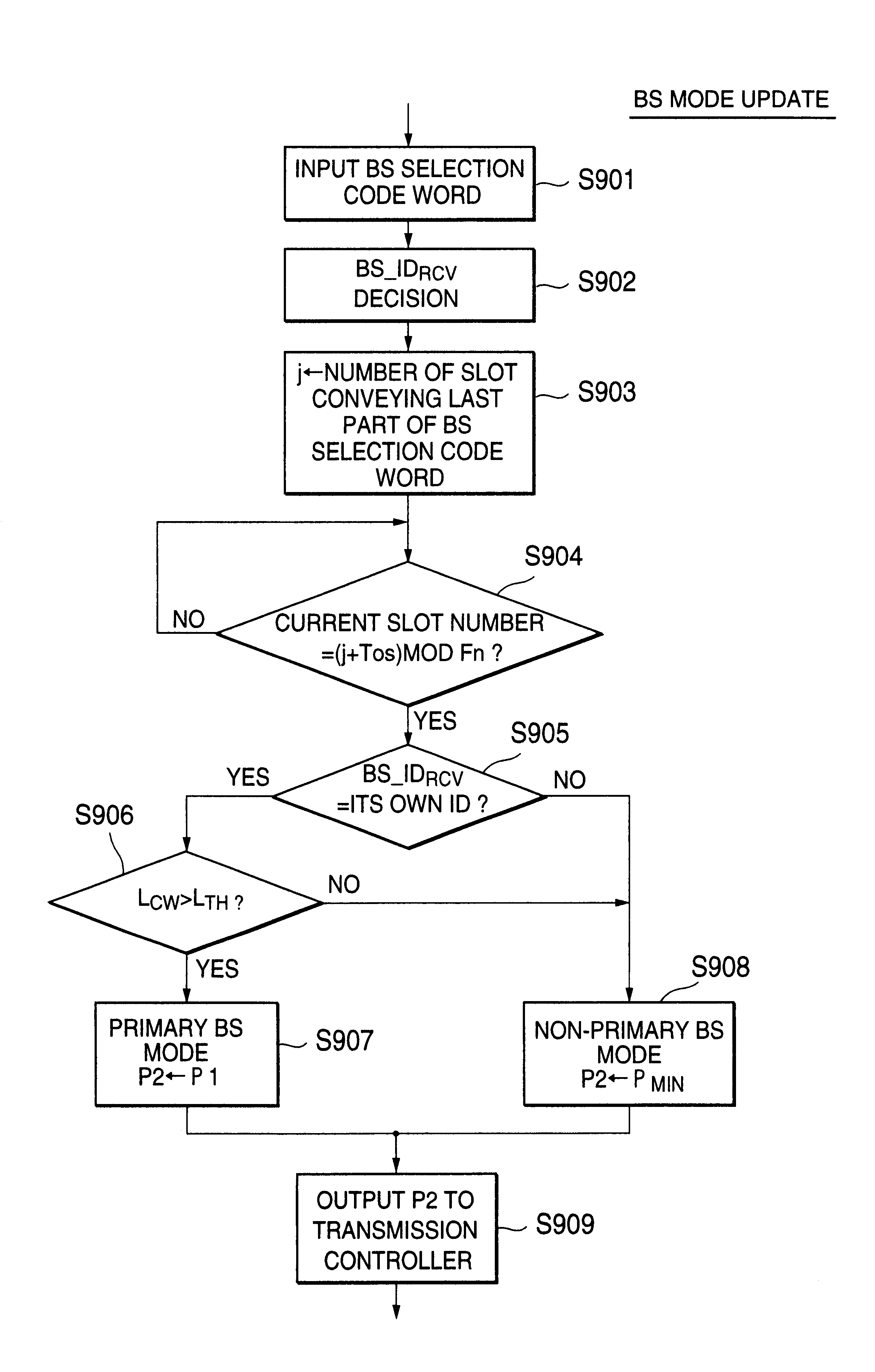

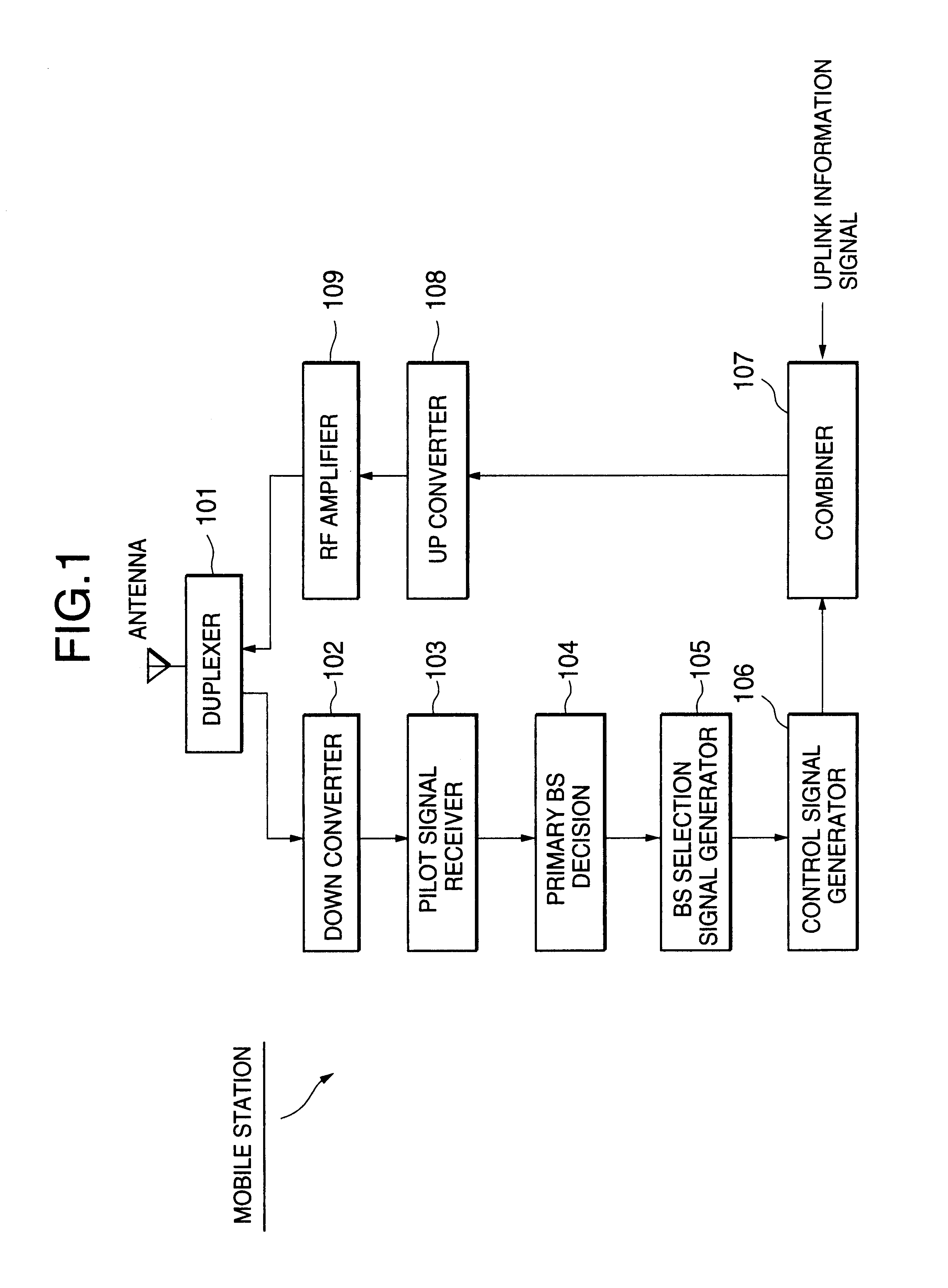

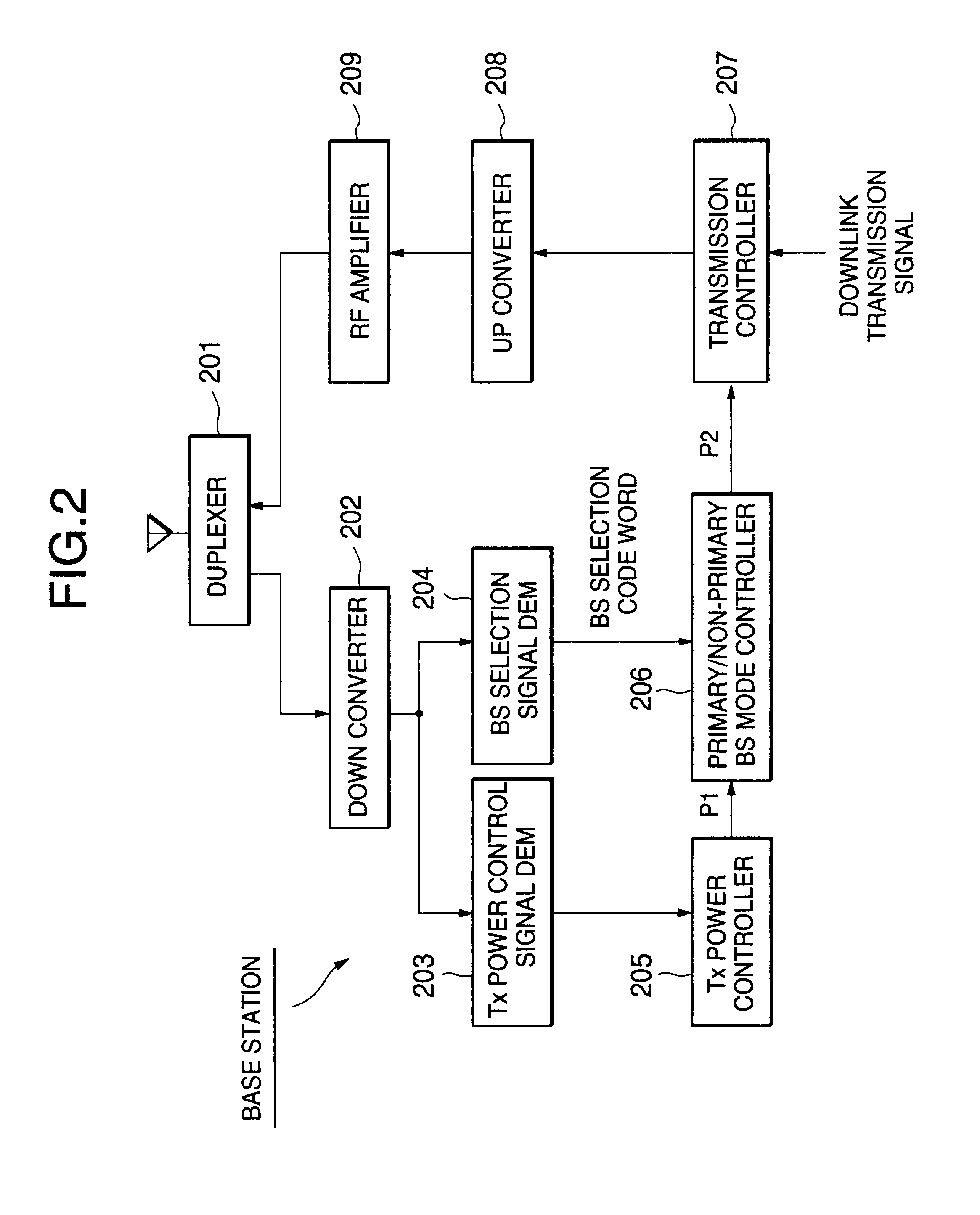

Transmission power control method and system

InactiveUS6847818B1Wrong selectionAvoid lostPower managementSite diversityMobile stationSoft handover

A transmission power control technique allowing stable and reliable signal transmission in soft handover is disclosed. Each of the base stations involved in soft handover measures an amount of loss of the base station selection signal. When the amount of loss of the base station selection signal exceeds a threshold, the transmission power of the downlink signal is not set to the minimum level but to the normally controlled level. Further, a transmission power update timing of each base station is determined so that the downlink signal received at the mobile station changes in transmission power at a predetermined timing synchronized with that of other base stations.

Owner:NEC CORP

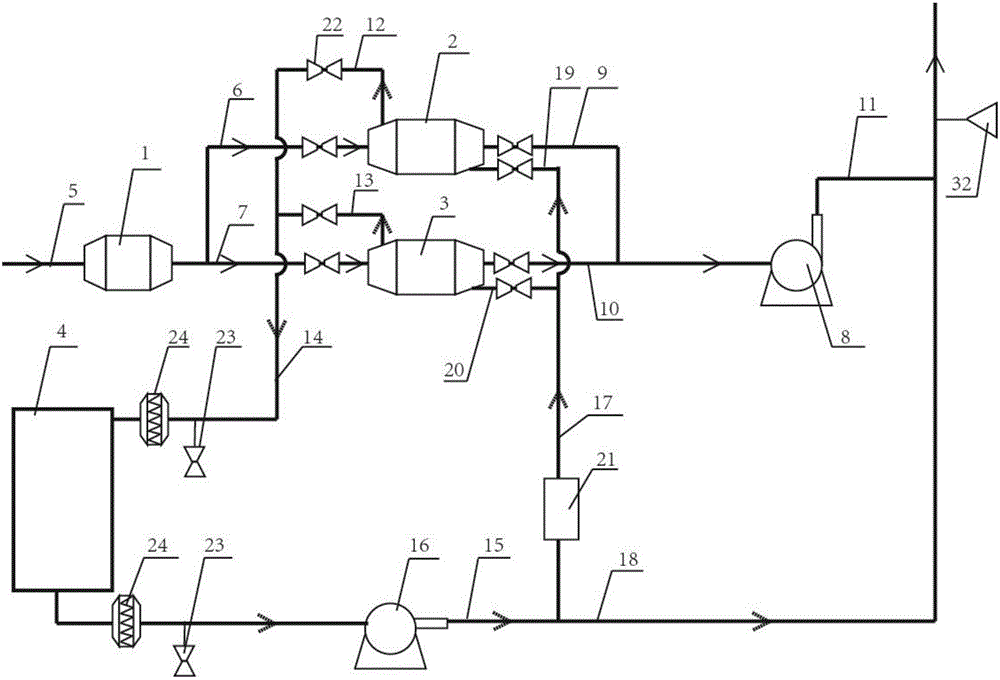

Adsorption and catalysis integrated device for organic waste gas

InactiveCN106178825ANo secondary pollutionLow investment costGas treatmentDispersed particle filtrationActivated carbonDesorption

The invention discloses an adsorption and catalysis integrated device for organic waste gas. The device comprises a filtering unit, a first activated carbon adsorption tank, a second activated carbon adsorption tank and a catalytic combustion bed, wherein to-be-treated waste gas enters the filtering unit through a waste gas pipe, the filtering unit communicates with the first activated carbon adsorption tank and the second activated carbon adsorption tank through a first waste gas inlet pipe and a second waste gas inlet pipe respectively, and a first desorption gas inlet pipe and a second desorption gas inlet pipe are arranged on the first activated carbon adsorption tank and the second activated carbon adsorption tank and communicate with a gas inlet of the catalytic combustion bed through a main desorption gas inlet pipe; a gas outlet of the catalytic combustion bed is connected with a gas outlet channel, and the gas outlet channel communicates with a desorption fan.

Owner:霍普科技(天津)股份有限公司

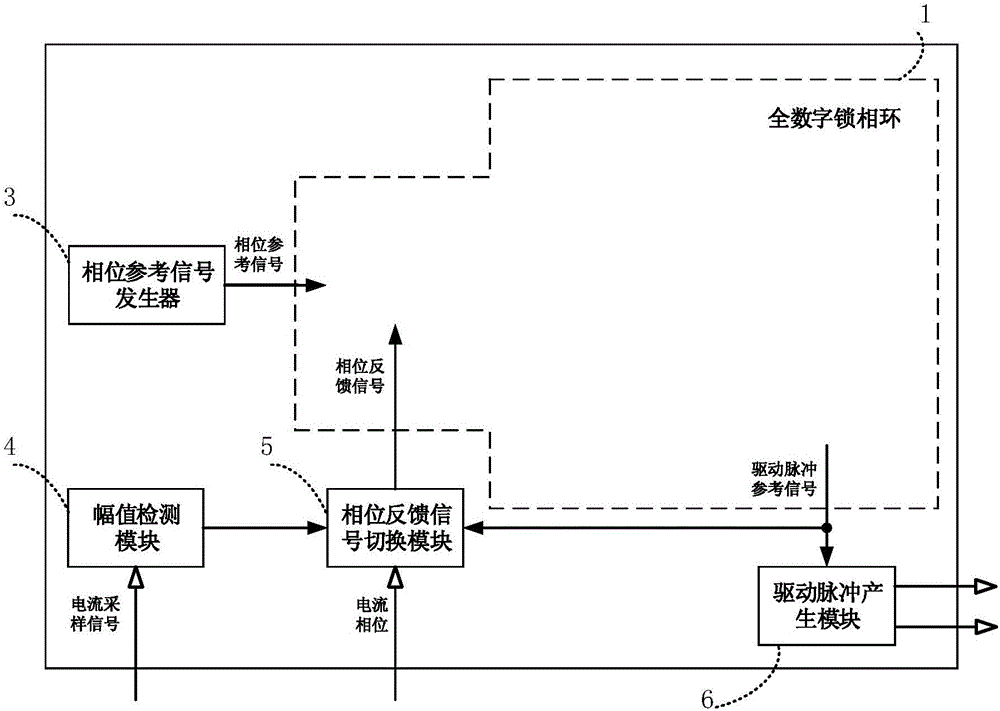

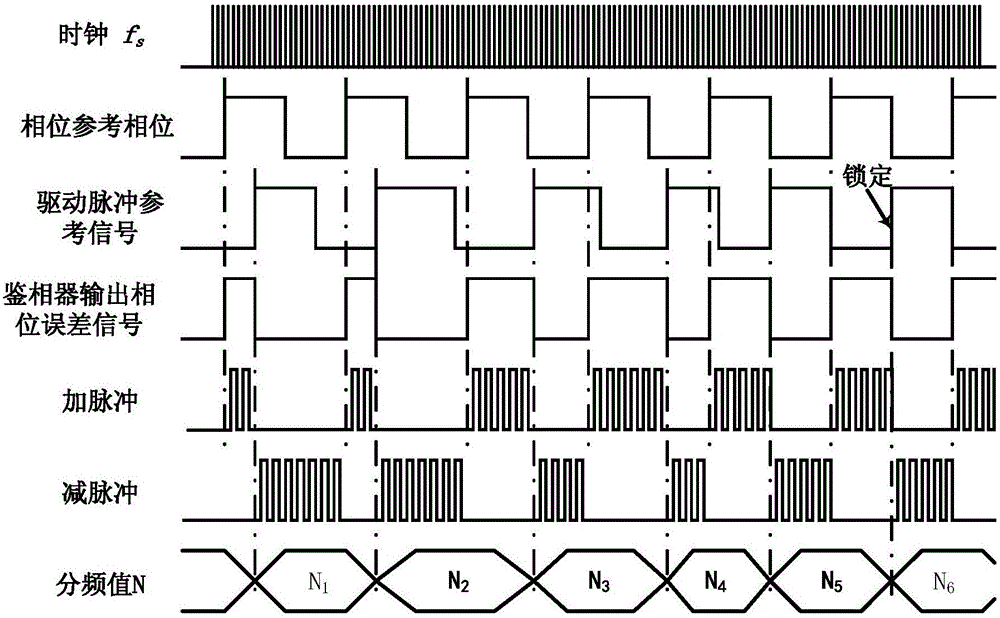

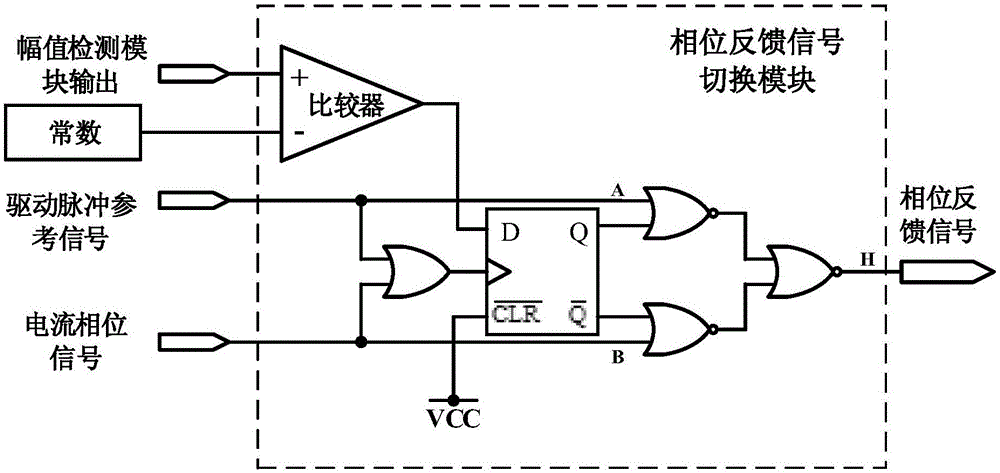

Full-digital phase-locked loop-based resonant current phase controller and method

InactiveCN106655844AGuaranteed stable operationGood phase control accuracyEfficient power electronics conversionVoltage-current phase anglePhase differenceClosed loop

The embodiment of the invention discloses a full-digital phase-locked loop-based resonant current phase controller and a method thereof, wherein the phase of a resonant current in an application scenario wherein medium-high-frequency and load parameters are changing within a large range can be controlled. According to the embodiments of the invention, the full-digital phase-locked loop-based resonant current phase controller comprises a full-digital phase-locked loop, a communication module, a phase reference signal generator, a phase feedback signal switching module, an amplitude detection module and a driving signal generation module. According to the invention, according to the phase difference between a phase reference signal and a phase feedback signal, the frequency and the phase of a drive pulse reference signal can be adjusted quickly. Therefore, the phase reference signal of the resonance current phase can be automatically tracked and controlled. The problems in the prior art that the traditional method is poor in control accuracy and complicated in parameter design of a control loop system can be avoided. Moreover, according to the technical scheme of the invention, the implementation scheme is simple and the parameter design is flexible. The requirements of medium-high-frequency multi-phase resonant currents, such as digitized phase or phase difference, accurate closed loop control and the like, can be met.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

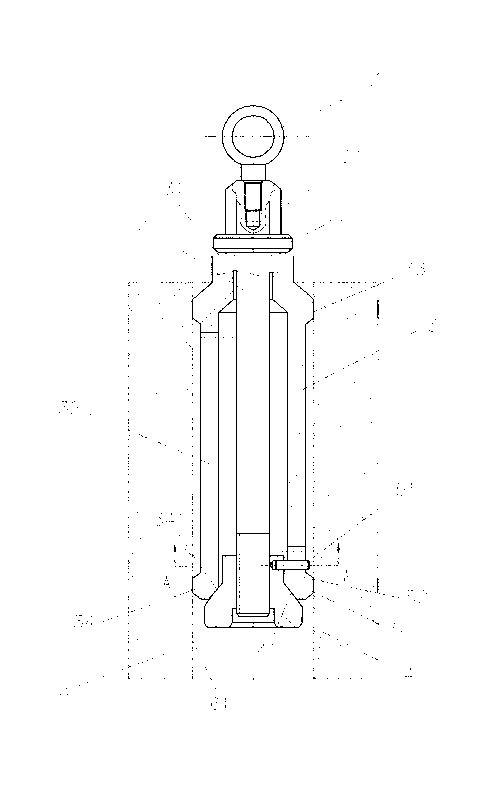

Vertical hoisting tool of piston pin

ActiveCN103241648ACompact and lightweightLow manufacturing costLoad-engaging elementsPistonEngineering

The invention discloses a vertical hoisting tool of a piston pin. The vertical hoisting tool comprises a collar bolt, an adjusting bolt, an elastic expansion sleeve, a conical ejection block and a conical ejection block anti-rotating mechanism, wherein a hoisting bolt is fixed on the upper end of the adjusting bolt, the adjusting bolt penetrates through the elastic expansion sleeve, the lower end of the adjusting bolt is in threaded connection with the upper end of the conical ejection block; and a plurality of axial elastic grooves are uniformly distributed at the lower part of the elastic expansion sleeve, the upper end and the lower end of the elastic expansion sleeve respectively extend in the radial direction to form an upper guide section and a lower expansion section, an inner conical hole in the lower end of the lower expansion section is matched with an outer conical surface of the middle part of the conical ejection block, and the conical ejection block anti-rotating mechanism is arranged on the lower end of the elastic expansion sleeve. The vertical hoisting tool is light and compact in structure, low in manufacturing cost and safe and convenient to use, and the piston pin can be rapidly clamped, hoisted or unloaded only by one person. The machining auxiliary cost of the piston pin is reduced, the working efficiency is improved by three times, and the entire operation process is labor-saving, safe and reliable.

Owner:CSSC MARINE POWER

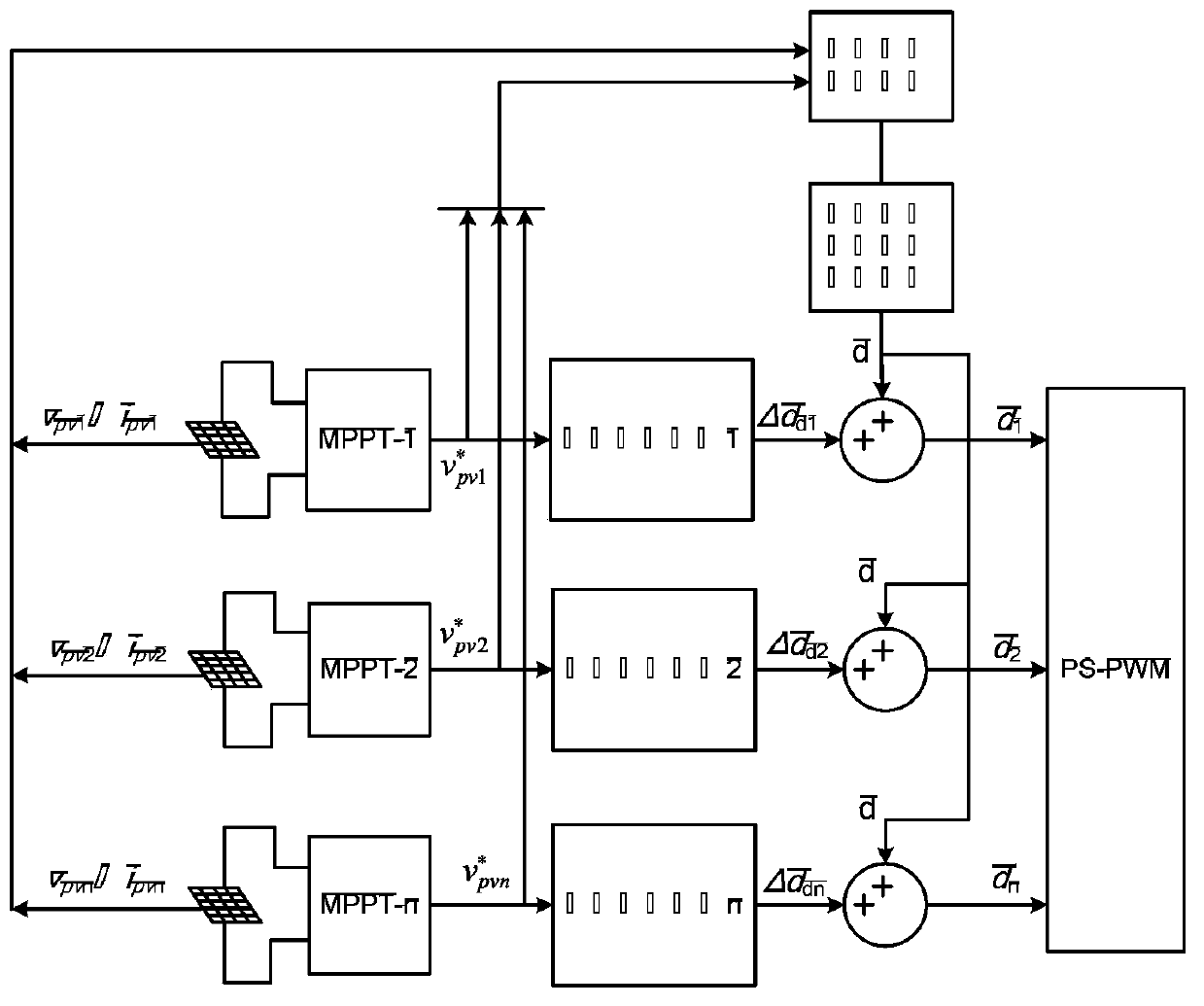

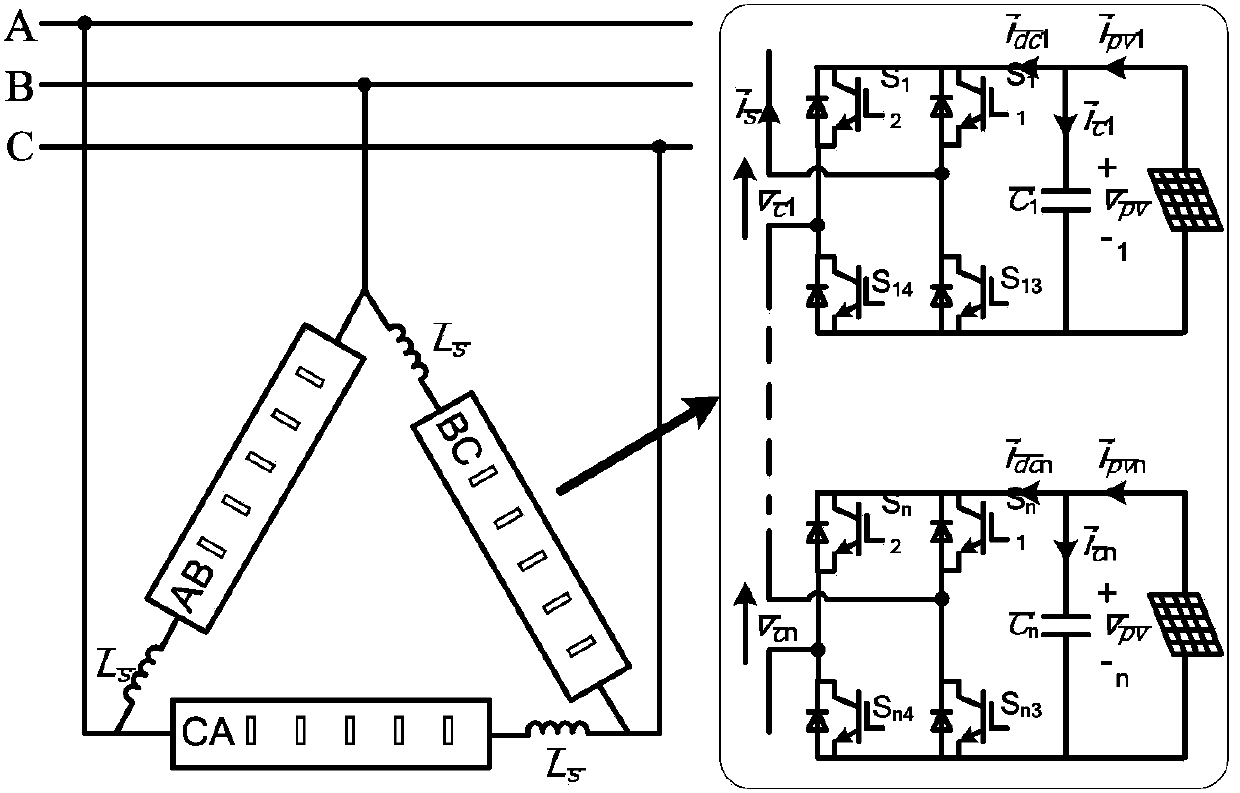

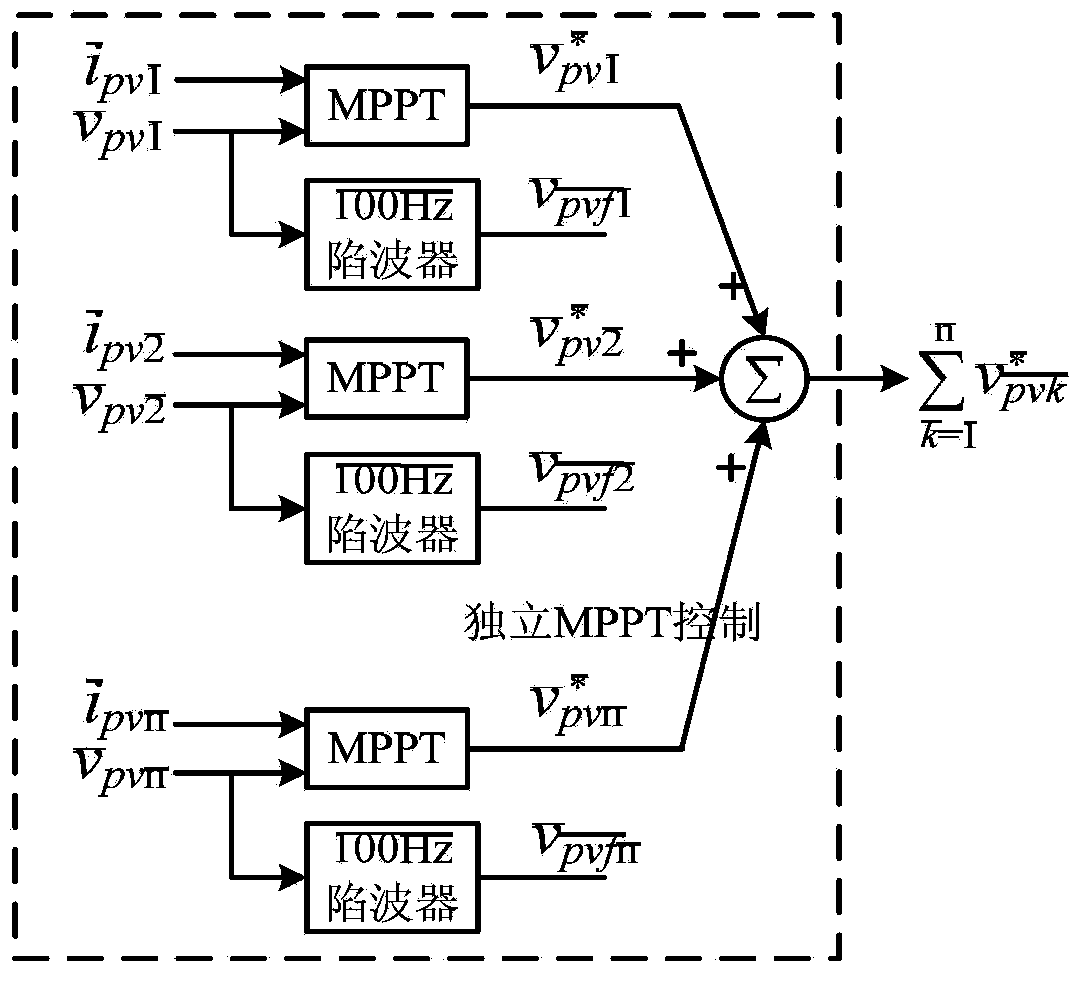

Power balancing control method of cascaded photovoltaic grid-connected inverter

InactiveCN103795077AAchieving power balanceGuaranteed stable operationSingle network parallel feeding arrangementsRatio valuePower grid

The invention brings forward a power balancing control method of cascaded photovoltaic grid-connected inverter on the partial shadow condition. The method comprises the following steps: (1), carrying out independent maximum power point tracking (MPPT) controlling on H bridges of all cascade units to obtain all-stage direct-current voltage instruction values and then carrying out PI controlling on a general direct-current voltage to obtain a grid-connected current instruction value; (2), carrying out quasi-proportional resonant (PR) control of the grid-connected current and grid voltage feedforward control so as to obtain initial duty ratio values of the H bridges; (3) carrying out per-unit processing on actual values of the direct-current side voltages of the cascade units according to the respective direct-current side voltage instruction values of all the cascade units, carrying out comparison with 1 and carrying out PI controlling so as to obtain active correction values of the duty ratios of the H bridges, and realizing power balancing control based on the duty ratio correction. According to the control method, floating control of the grid-connected current can be realized; and power balancing of all power units of the cascade inverter can be maintained. The provided control method has advantages of clear conception, simple control structure, and easy engineering realization and the like.

Owner:SOUTHEAST UNIV

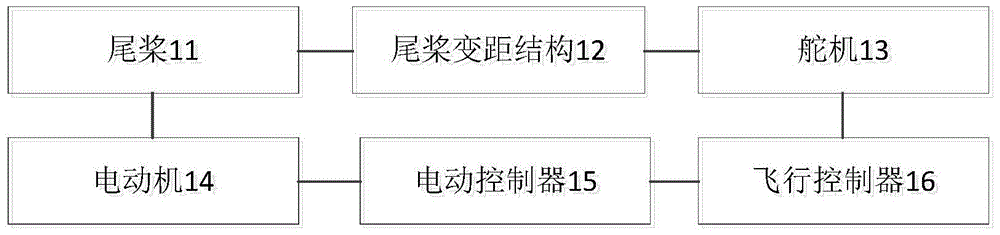

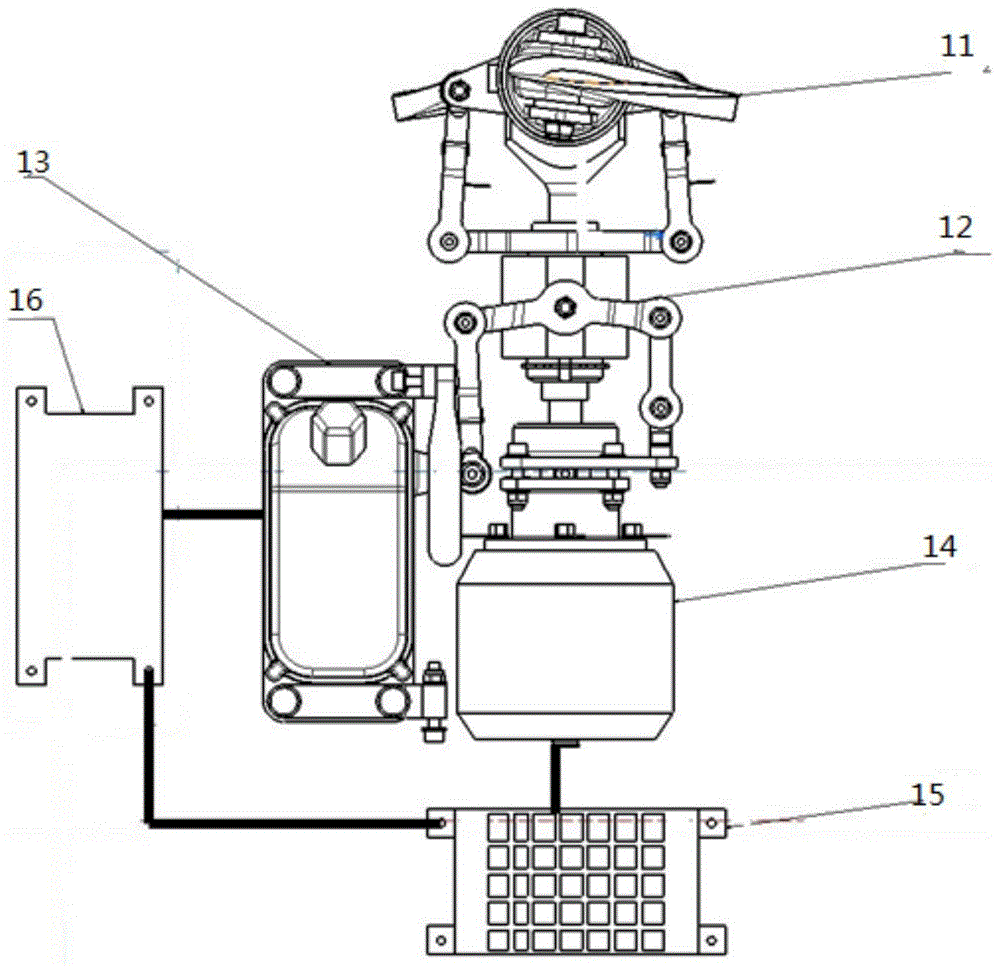

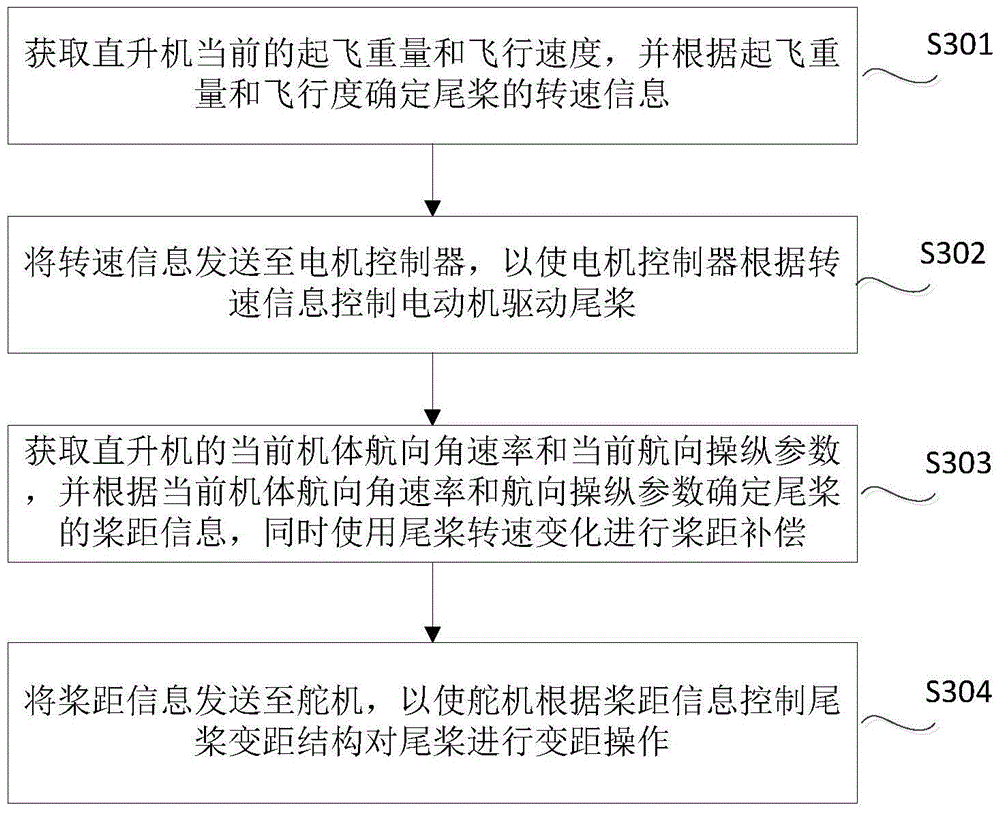

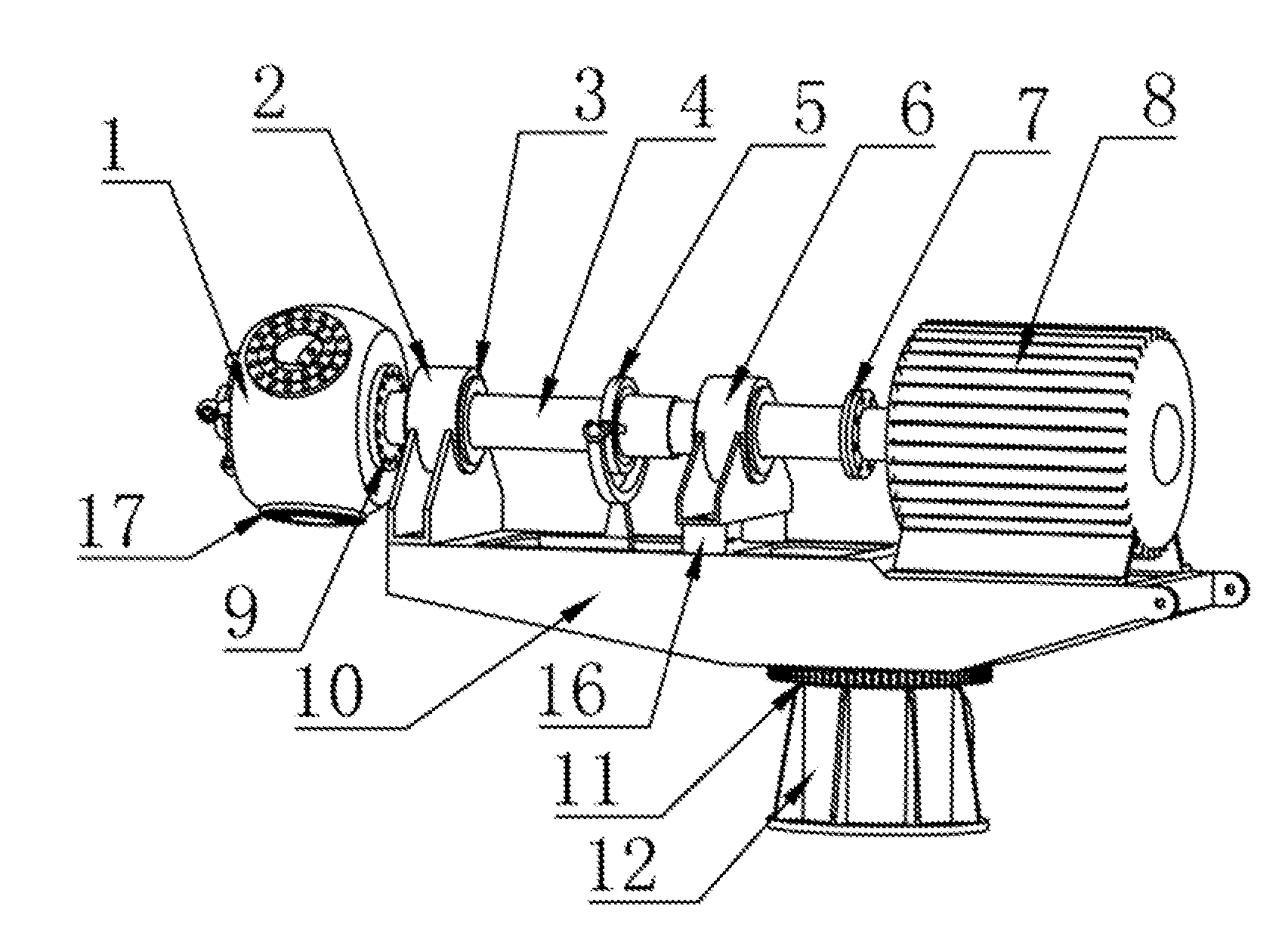

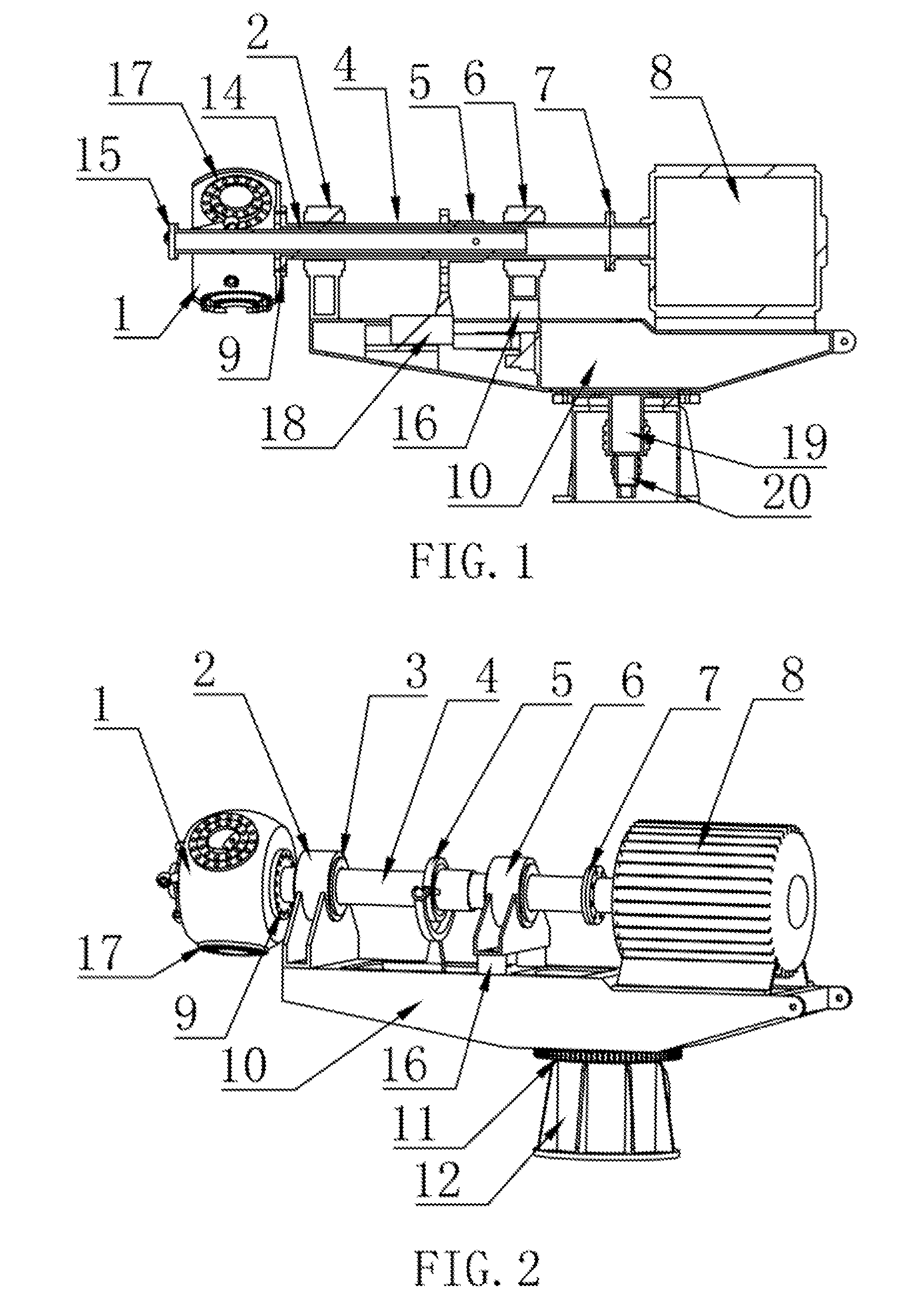

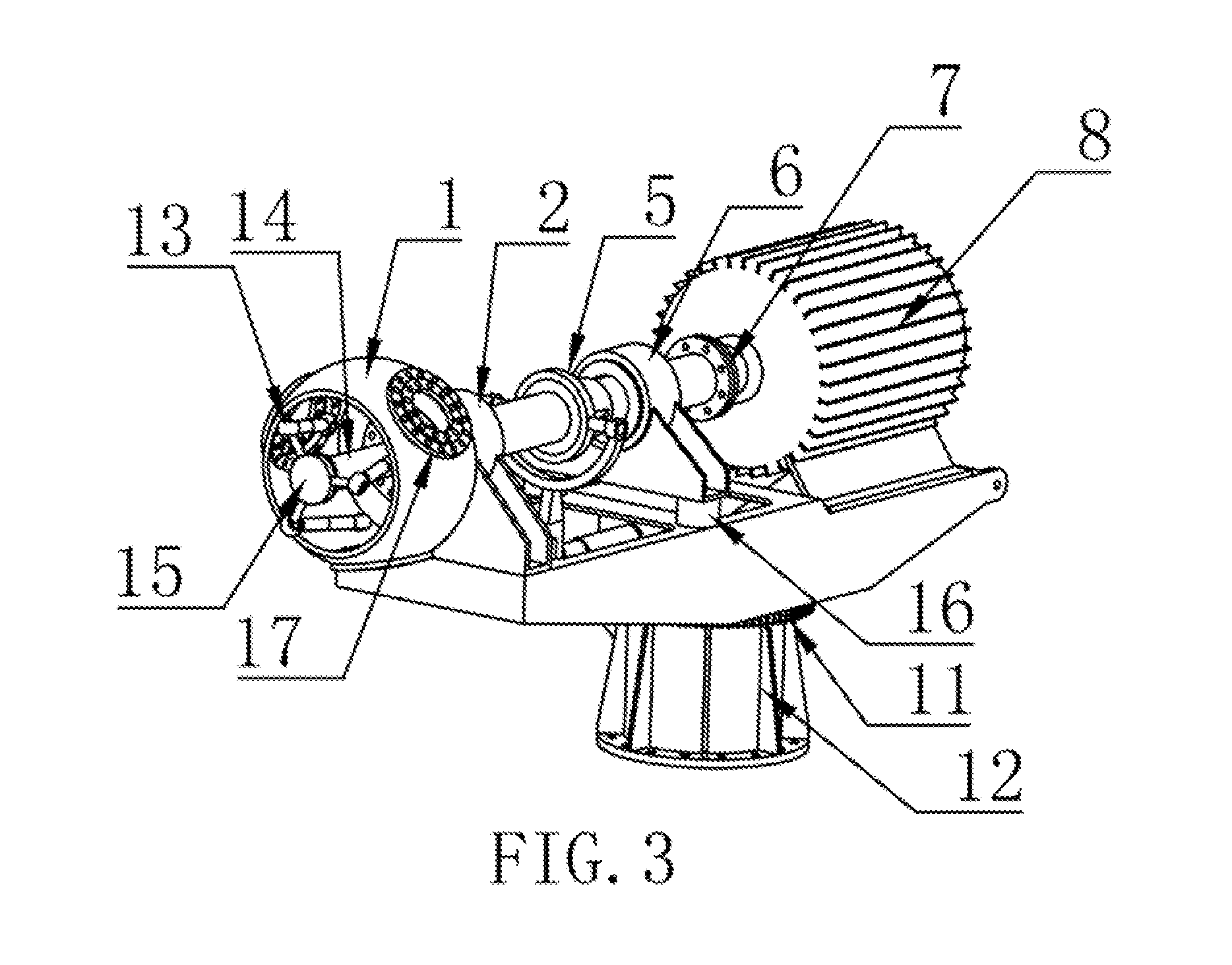

Tail rotor driving system of helicopter, control method thereof and helicopter

The invention discloses a tail rotor driving system of a helicopter and a control method thereof. The tail rotor driving system comprises a tail rotor. A tail rotor variable-pitch structure is connected with the tail rotor and carries out variable-pitch operation on the tail rotor, so that the tension of the tail rotor is changed through pitch adjustment; a steering engine is connected with the tail rotor variable-pitch structure to control the tail rotor variable-pitch structure, so that pitch adjustment on the tail rotor is achieved; a motor is connected with the tail rotor to drive the tail rotor; a motor controller is connected with the motor to control the rotation speed of the motor; a fly controller is connected with the steering engine and the motor controller, determines tail rotor rotation speed information according to the obtained current take-off weight and fly speed of the helicopter and sends the information to the motor controller to control the motor to drive the tail rotor, and determines tail rotor pitch information according to the obtained current airframe course angle speed and current course operation parameter of the helicopter and sends the information to the steering engine to control the tail rotor variable-pitch structure to carry out variable-pitch operation on the tail rotor. The tail rotor driving system determines the best rotation speed of the tail rotor, lowers the power consumption of the tail rotor and guarantees stable operation of the tail rotor.

Owner:珠海隆华直升机科技有限公司

Downwind Variable Pitch Wind Turbine Generator

InactiveUS20130011262A1Simple structureHigh efficiency and reliabilityPropellersPump componentsButt jointFan blade

The invention designs a downwind variable pitch wind turbine generator which mainly comprises a wheel hub, a main shaft, a generator, a frame and a base, wherein a synchronizing disc is arranged in the wheel hub, the synchronizing disc is connected with a fan blade connection slewing bearing through two joint bearings which are in mutual butt joint, one end of a reciprocating rod arranged in the main shaft is connected with the synchronizing disc, the other end of the reciprocating rod is connected with a displacement sleeve, an electric push rod is arranged in the frame, and the displacement sleeve is connected with the electric push rod. The downward variable pitch wind turbine generator is mainly suitable for medium and small-sized fans, and a pitch control mechanism of the downward variable pitch wind turbine generator can control three blades to change pitch simultaneously and keep the pitch-changing amplitude consistent; and the pitch control mechanism can enable each blade to change the pitch to a certain negative angle, realize the shutdown of the downward variable pitch wind turbine generator and keep the shutdown state under harsh conditions, such as hurricane and the like. The frame can rotate 360 degrees relative to the base so as to adapt to all wind directions. In addition, the downwind variable pitch wind turbine generator is further provided with an anemometer and a controller, so that the reaction is more sensitive and the downwind variable pitch wind turbine generator can be suitable for wind direction and wind speed, which change suddenly.

Owner:ZHEJIANG HUAYING WIND POWER GENERATOR

Recording-sheet supplying apparatus and image recording apparatus

InactiveUS20090001652A1Avoid simple structuresHeavy weightRotary pressesArticle feedersImage recordingEngineering

Owner:BROTHER KOGYO KK

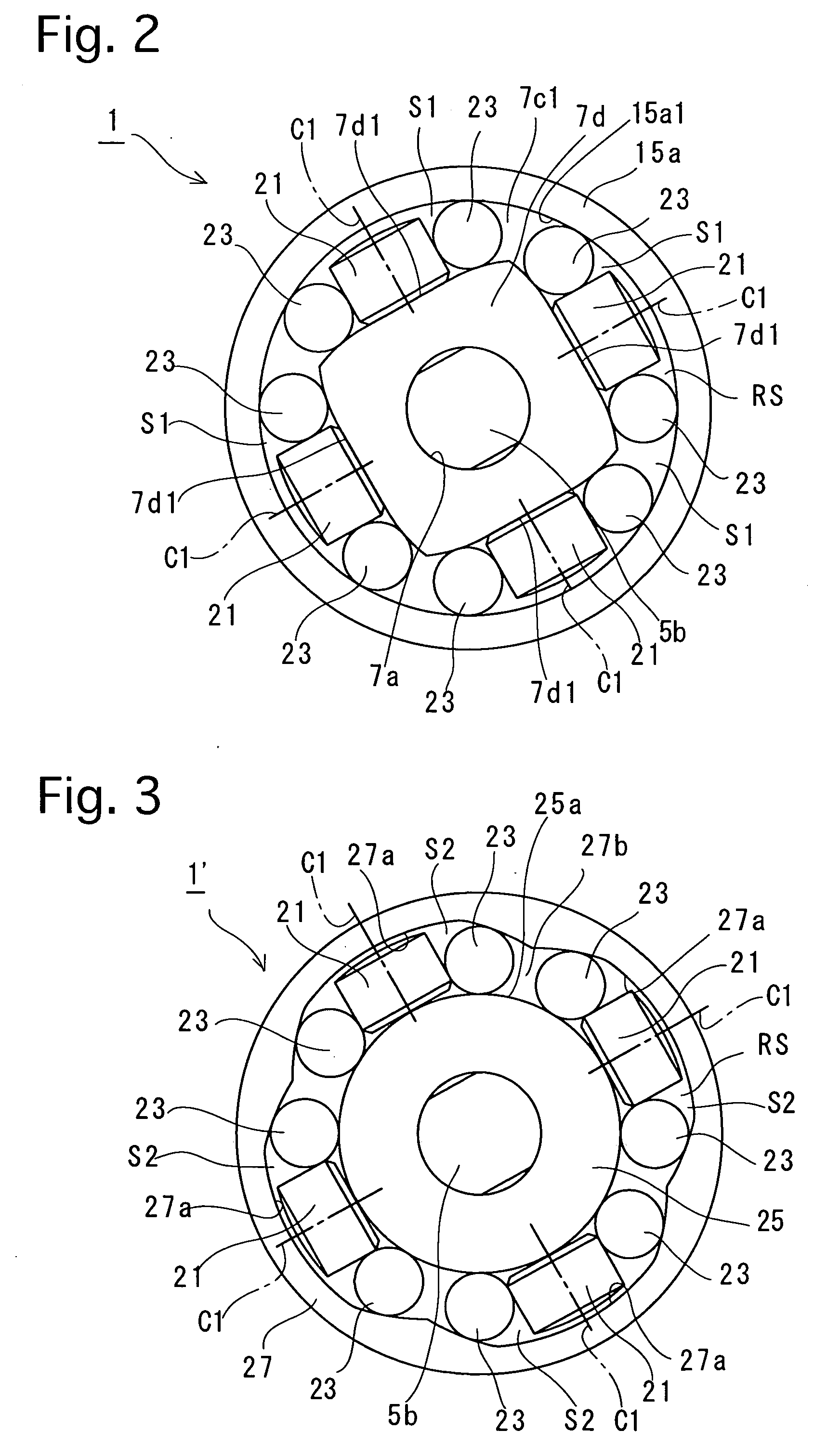

One-way rotational transfer mechanism

ActiveUS20050072646A1Simple structureSusceptible to use conditionYielding couplingFriction clutchesTransfer mechanismControl theory

A one-way rotational transfer mechanism includes a rotary input shaft; a rotary output shaft provided around the rotary input shaft; a circumferentially-uneven-width-space forming portion formed on the rotary input shaft to form at least one accommodation space having different radial widths at different circumferential positions; a differential rotating member installed in the accommodation space, the differential rotating member revolving around the axis of the rotary input shaft in a same direction as a rotational direction of the rotary input shaft while revolving at a slower speed; and a freely movable torque transfer member installed in the accommodation space. The circumferentially-uneven-width-space forming portion is shaped so that the torque transfer member wedges between the circumferentially-uneven-width-space forming portion and an inner peripheral surface of the rotary output shaft to transfer torque from the rotary input shaft to the rotary output shaft.

Owner:RICOH IMAGING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com