Automatic bead flipping machine

A technology of steel traveler and wrapping machine, which is applied to tires, other household appliances, household appliances, etc., to achieve the effects of reducing labor intensity, improving work efficiency, and safe operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

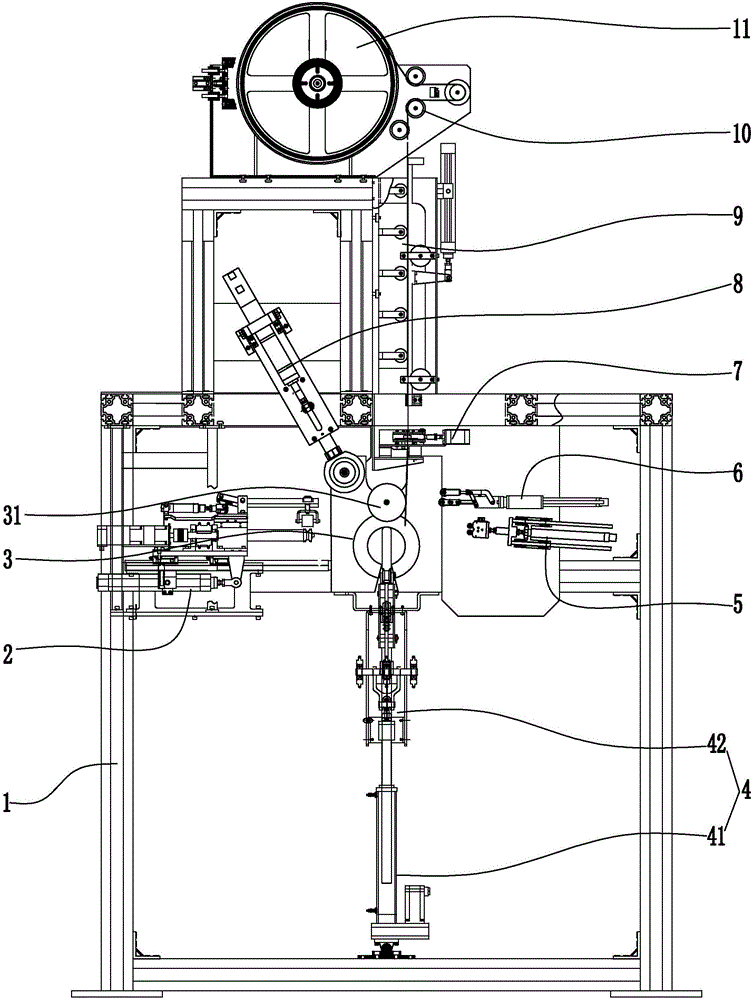

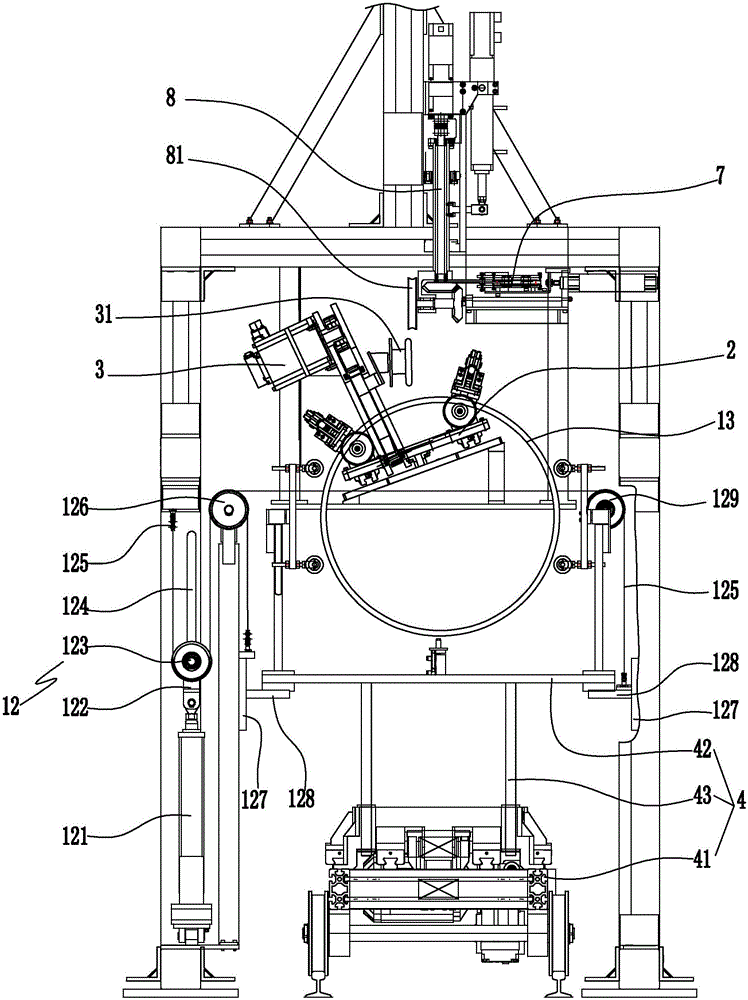

[0046] Such as figure 1 , figure 2 , image 3 As shown, a traveler automatic wrapping machine includes a frame 1, a traveler conveying device 4, a cloth wrapping wheel fixed-length cloth loading mechanism, a traveler rotation drive device 2 arranged on the frame, and a second cloth push rod mechanism 5 and the traveler wrapping mechanism 3.

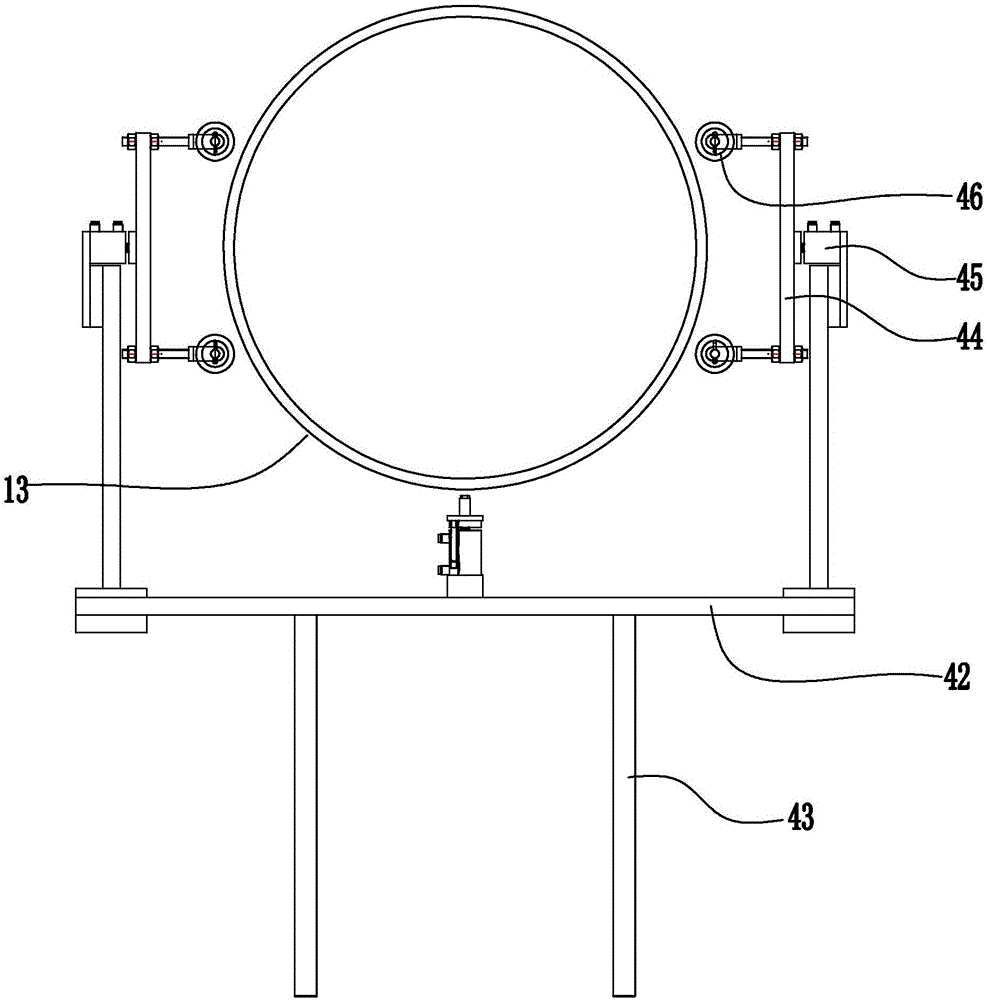

[0047] The traveler conveying device 4 comprises a conveying rail, a conveying cart 41 movable along the conveying rail, a traveler placing device arranged on the conveying cart, and a traveler elevating mechanism 12 arranged on a frame for lifting the traveling traveler placing device. There are vertical mounting holes on the transport cart. The traveler placement device includes a placement frame 42, a vertical guide post 43 arranged on the placement frame and matched with the vertical mounting hole,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com