Treating and recycling zero-emission technology and equipment for coking phenol-cyanogen wastewater

A technology of cyanide wastewater and coking phenol, which is applied in the field of zero discharge technology and equipment for the treatment and reuse of coking phenol cyanide wastewater, to achieve the effects of prolonging service life, long hydraulic retention time, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

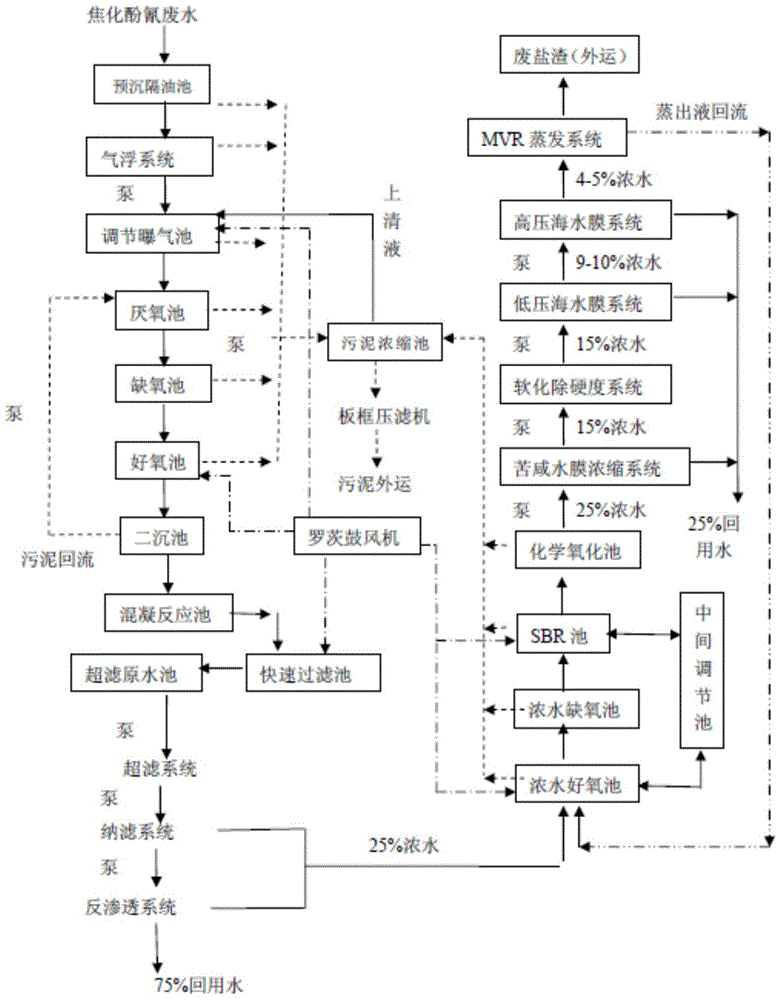

[0028] Embodiment one: see figure 1 , a zero-discharge process for the treatment and reuse of coking phenol cyanide wastewater. The coking phenol cyanide wastewater enters the pre-sedimentation grease trap, and after removing part of the oil in the pre-settling grease trap, it is pumped into the air flotation system. After being treated by the air flotation system, the large Part of the oil and insoluble and part of soluble inorganic matter and organic matter are removed and enter the regulating aeration tank. After the water volume is adjusted and the water quality is homogenized, it enters the anaerobic tank. Most of the sludge is returned to the inlet end of the anaerobic tank to increase the concentration of anaerobic suspended sludge.

[0029] The effluent from the anaerobic tank enters the anoxic tank, and after being hydrolyzed by anaerobic and facultative bacteria to remove part of the phenol cyanide and a large part of ammonia nitrogen, the macromolecular insoluble or...

Embodiment 2

[0051] Embodiment 2: A zero-discharge equipment for the treatment and reuse of coking phenol cyanide wastewater, which has a pre-sedimentation grease trap, an air flotation system, an adjustable aeration tank, an anaerobic tank, an anoxic tank, an aerobic tank, a secondary sedimentation tank, and a mixing tank. Coagulation reaction pool, rapid filtration pool, ultrafiltration raw water pool, ultrafiltration system, nanofiltration system, reverse osmosis system, concentrated water aerobic pool, concentrated water anoxic pool, SBR pool, chemical oxidation pool, brackish water membrane concentration system , Softening and hardness removal system, low-pressure seawater membrane system, high-pressure seawater membrane system, MVR evaporation system, sludge concentration tank, filter press, Roots blower.

[0052] Pre-sedimentation grease trap, air flotation system, regulating aeration tank, anaerobic tank, anoxic tank, aerobic tank, secondary settling tank, coagulation reaction tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com