Patents

Literature

133 results about "Grease trap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grease trap (also known as grease interceptor, grease recovery device, grease capsule and grease converter) is a plumbing device (a type of trap) designed to intercept most greases and solids before they enter a wastewater disposal system. Common wastewater contains small amounts of oils which enter into septic tanks and treatment facilities to form a floating scum layer. This scum layer is very slowly digested and broken down by microorganisms in the anaerobic digestion process. Large amounts of oil from food preparation in restaurants can overwhelm a septic tank or treatment facility, causing release of untreated sewage into the environment. High-viscosity fats and cooking grease such as lard solidify when cooled, and can combine with other disposed solids to block drain pipes.

Enzyme and bacterial combination in a slowly dissolvable matrix for septic tanks, grease traps and waste treatment

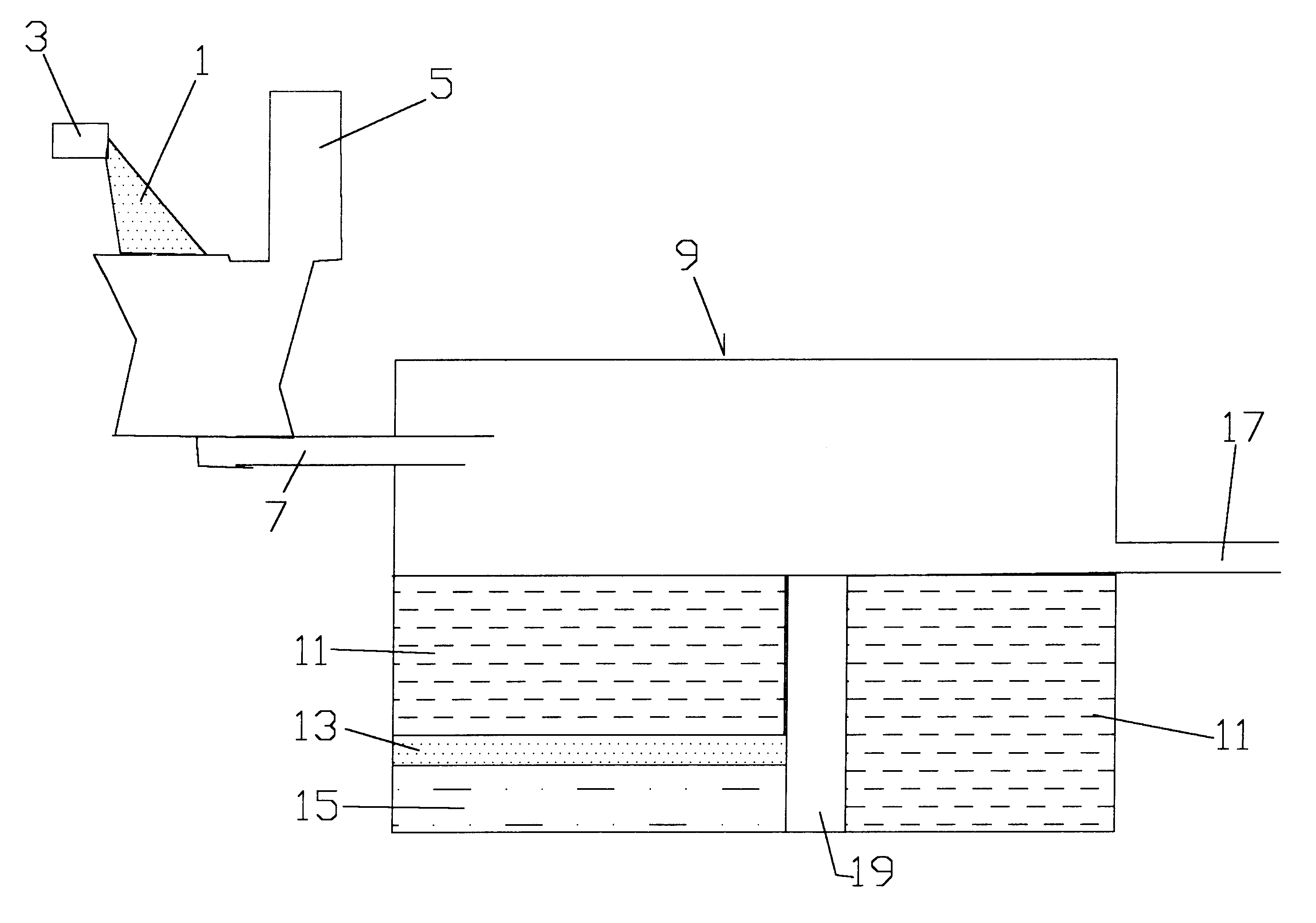

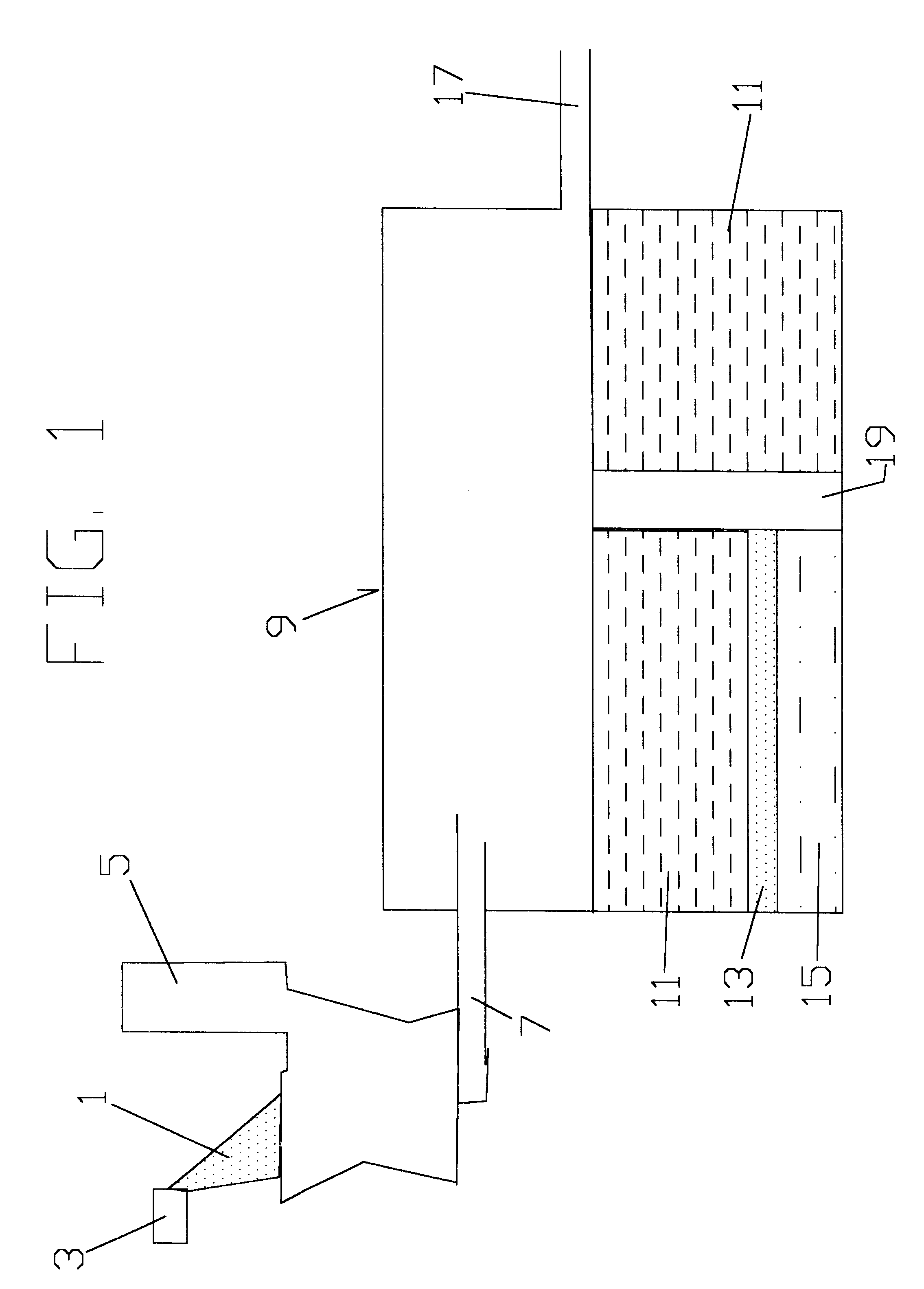

Sewage waste digestive bacteria and enzymes are incorporated into a slow release material and delivered to the site of the waste to digest the solid waste. The slow release material is made heavy so the enzymes and bacteria will be delivered to the sludge in the bottom of a sewage digester chamber and made fat soluble so that the enzymes and bacteria will be delivered to the grease in the waste system to be digested. This selective delivery system prevents the enzymes and bacteria from being diluted in grey water rendering them less effective and discharged from the sewage system without digesting waste.

Owner:NOVOZYMES AS

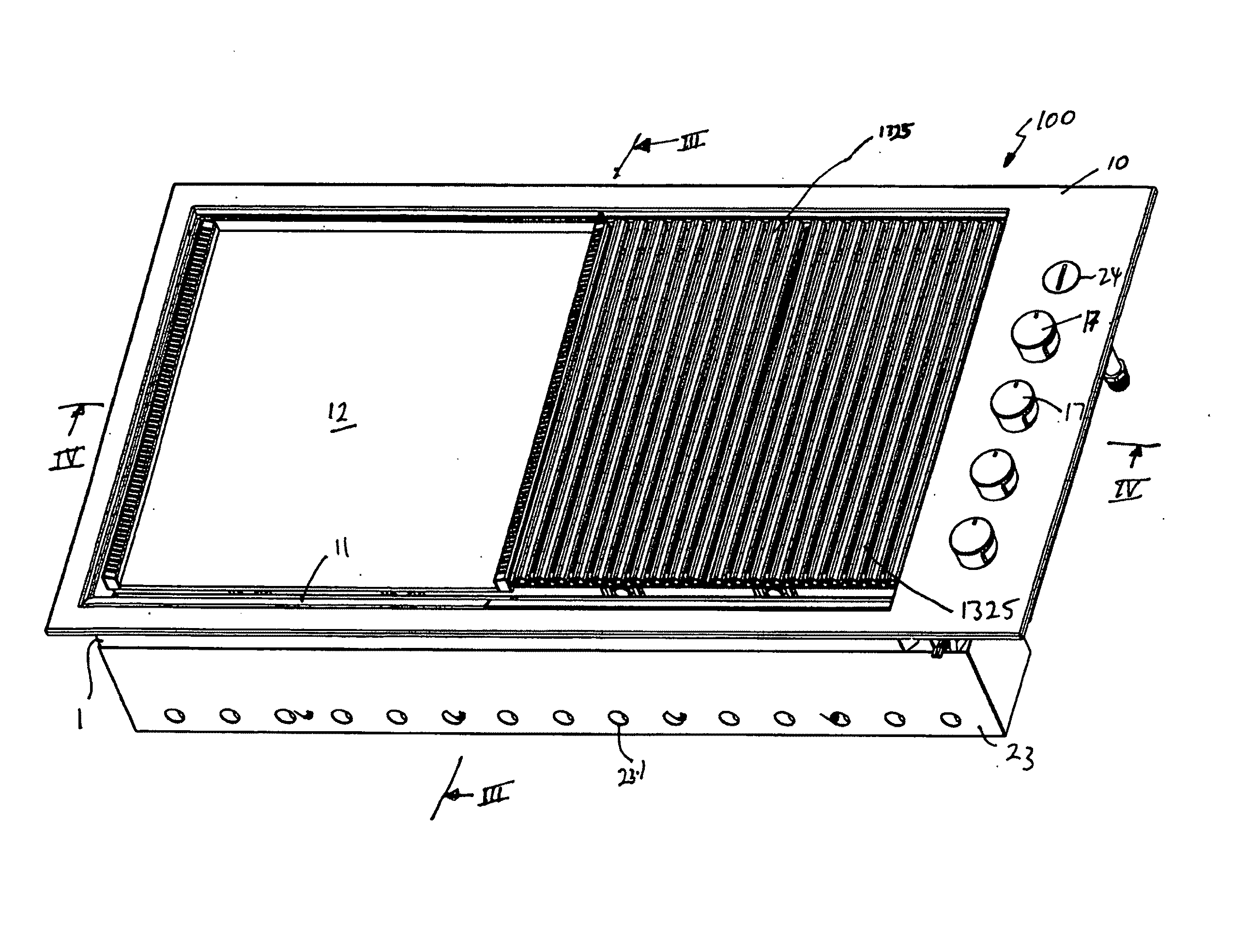

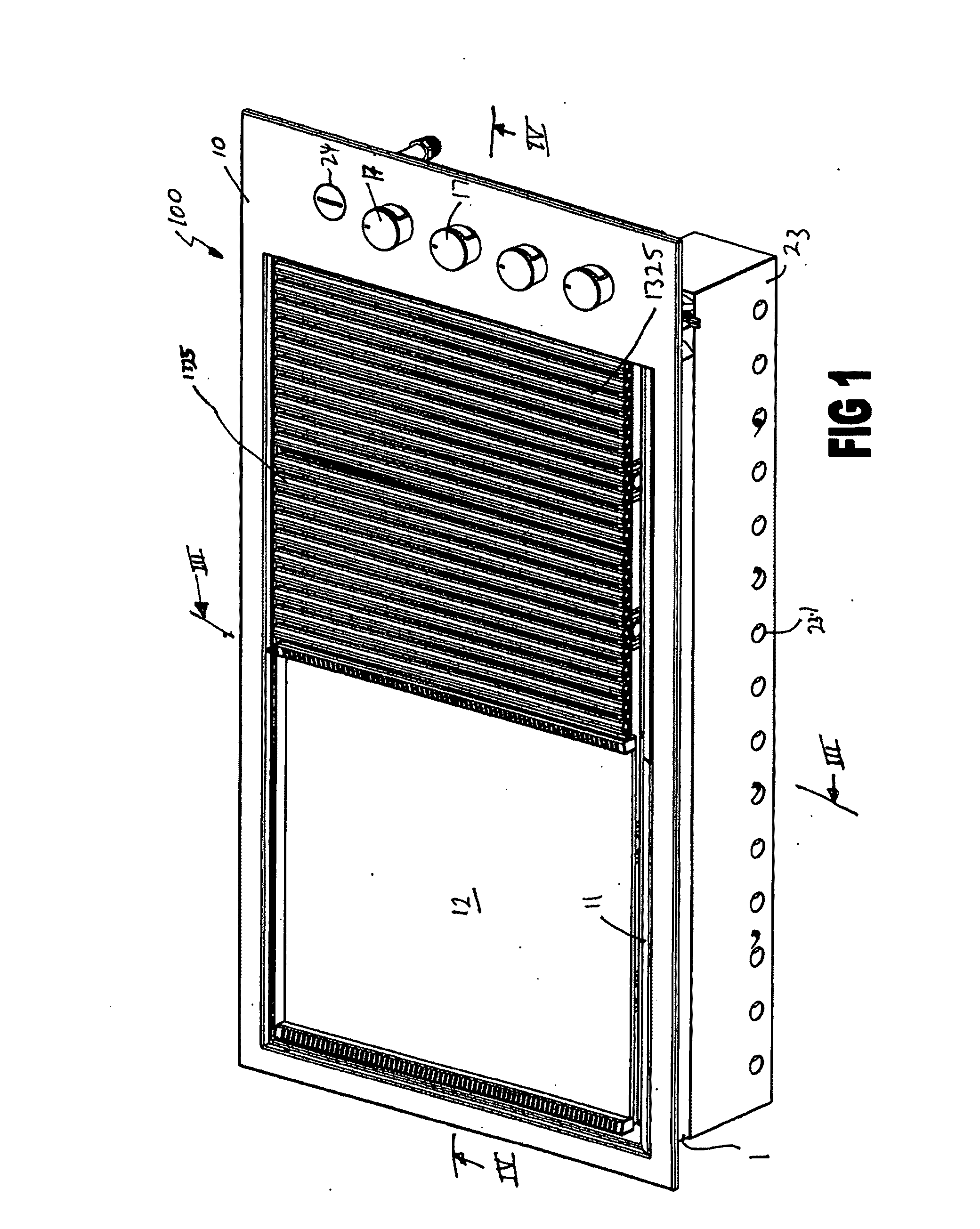

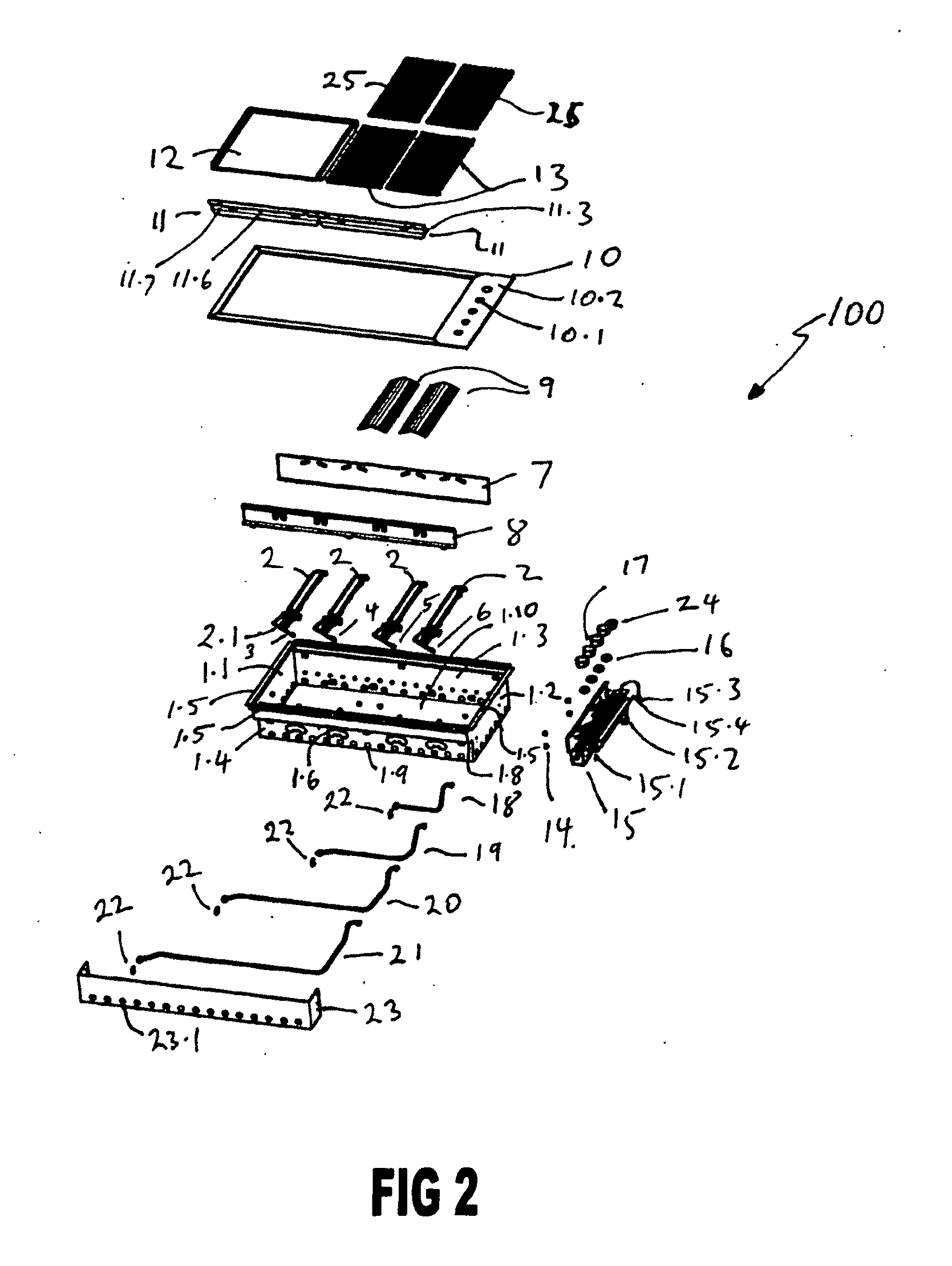

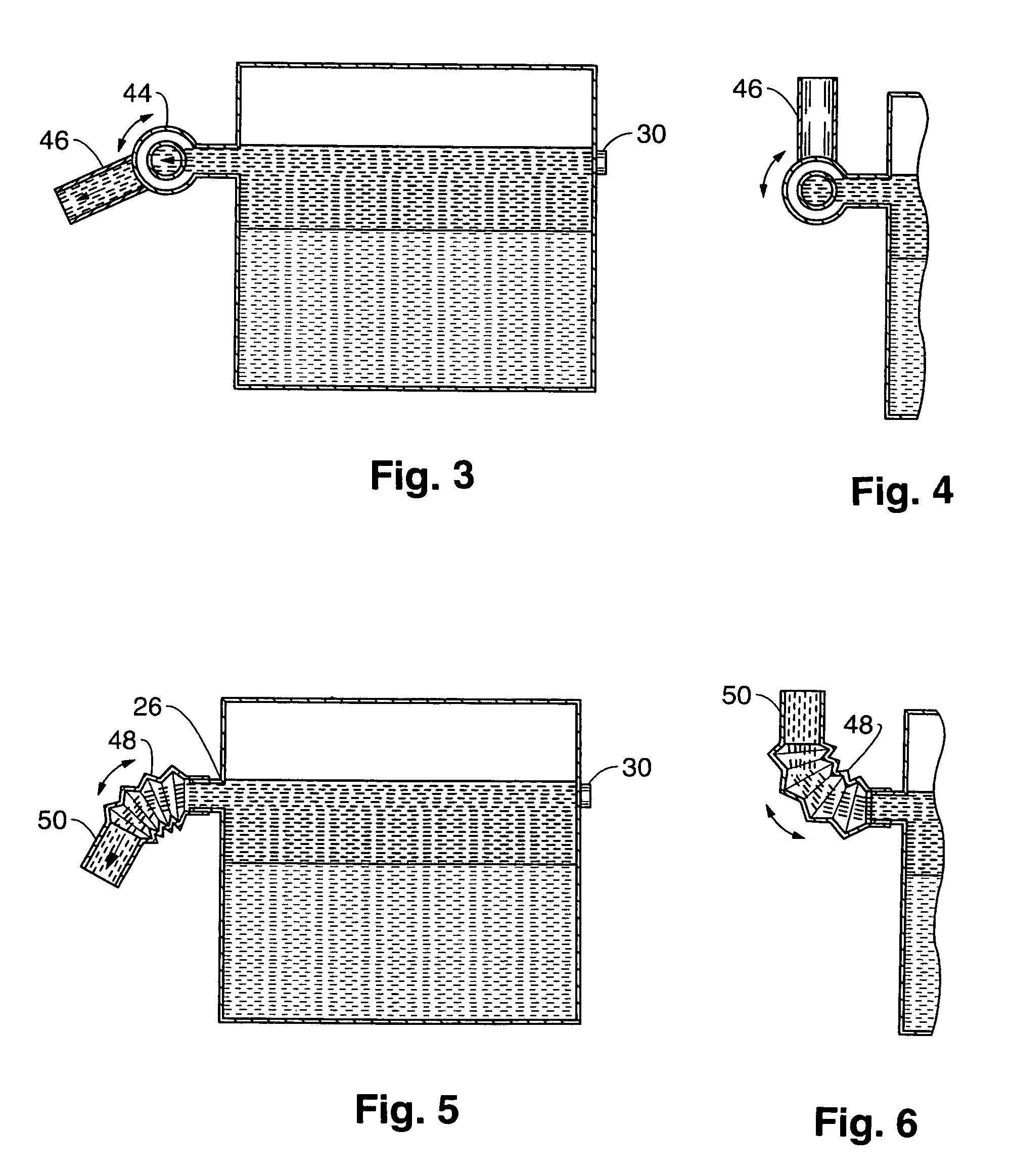

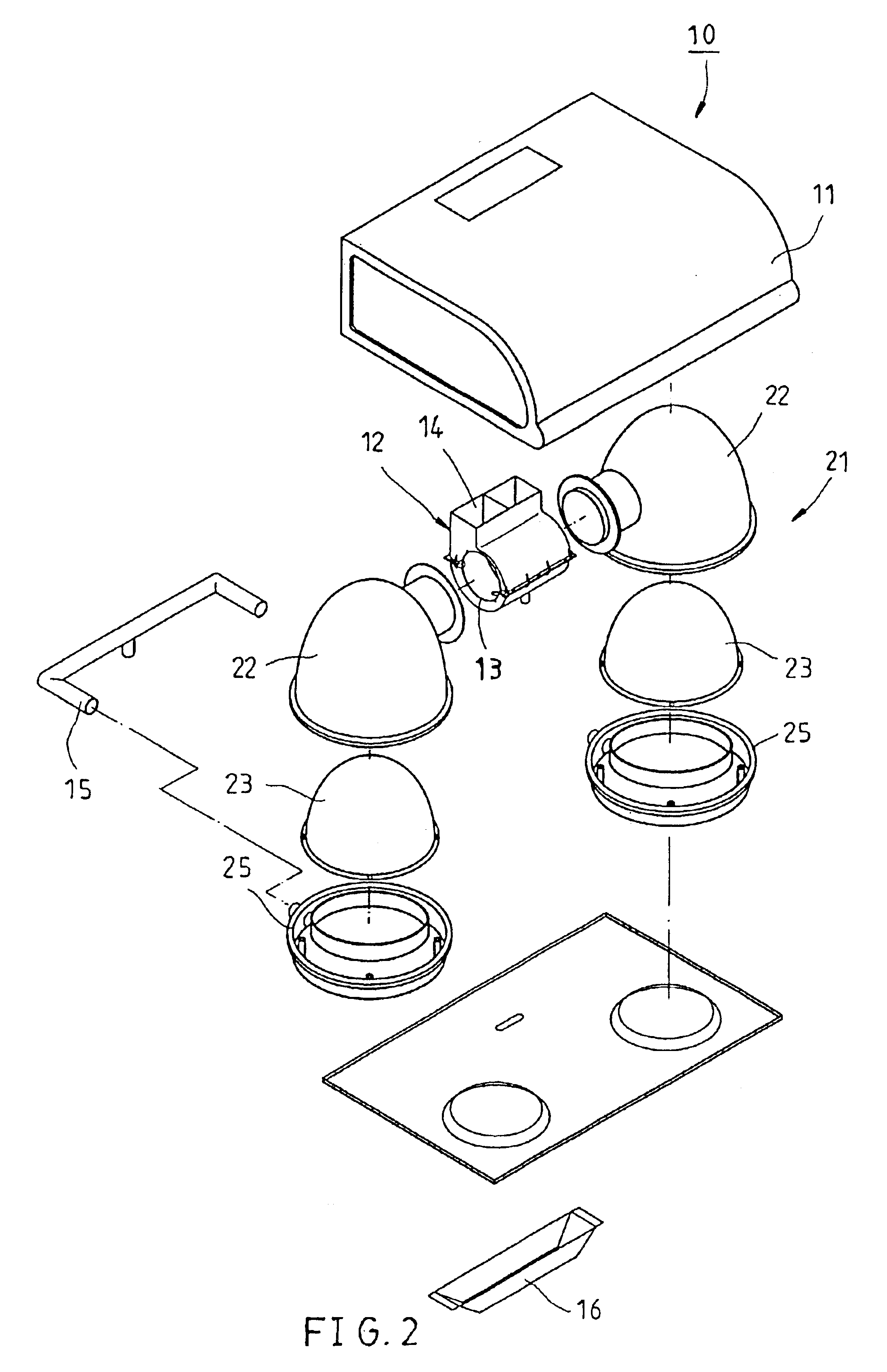

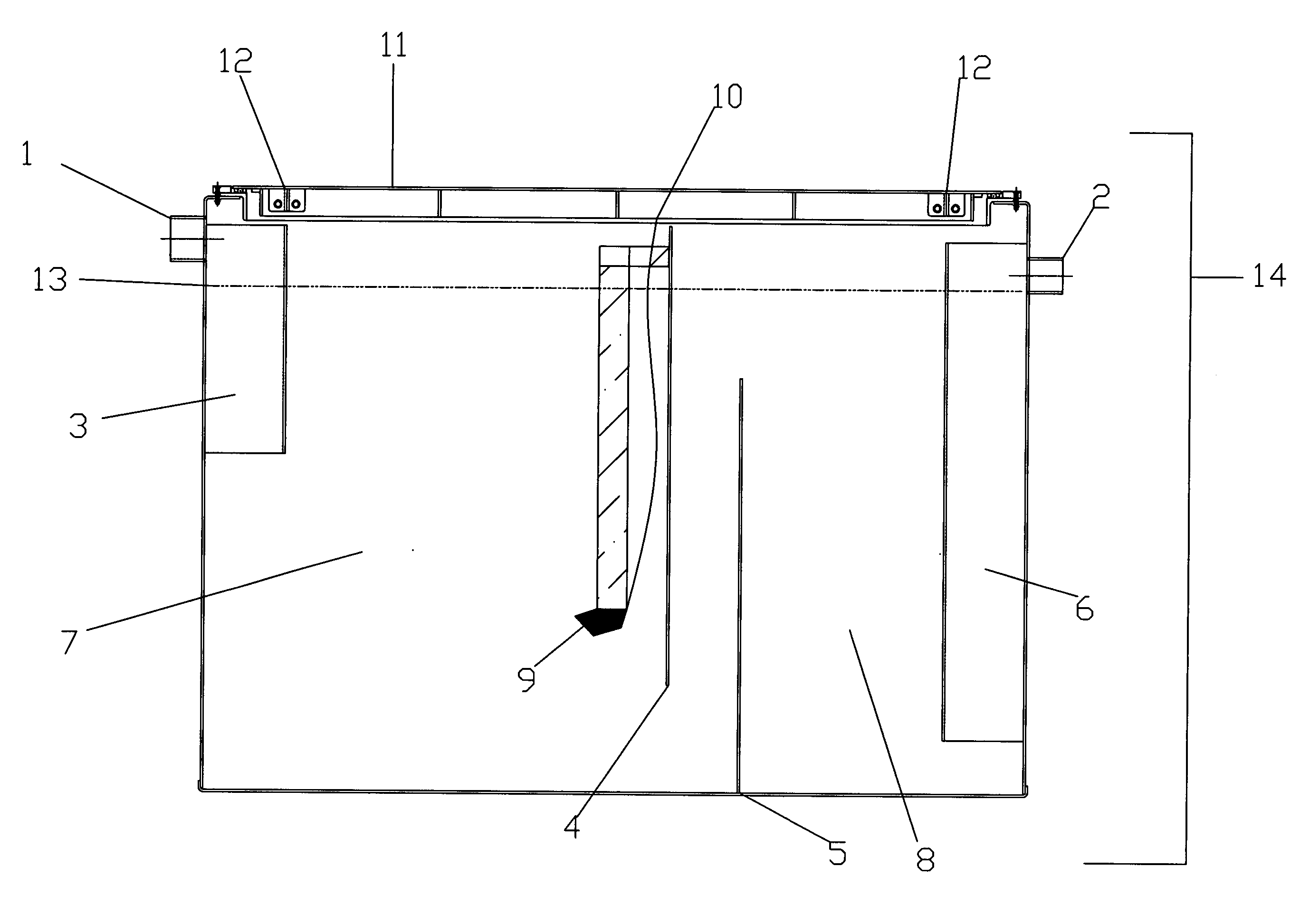

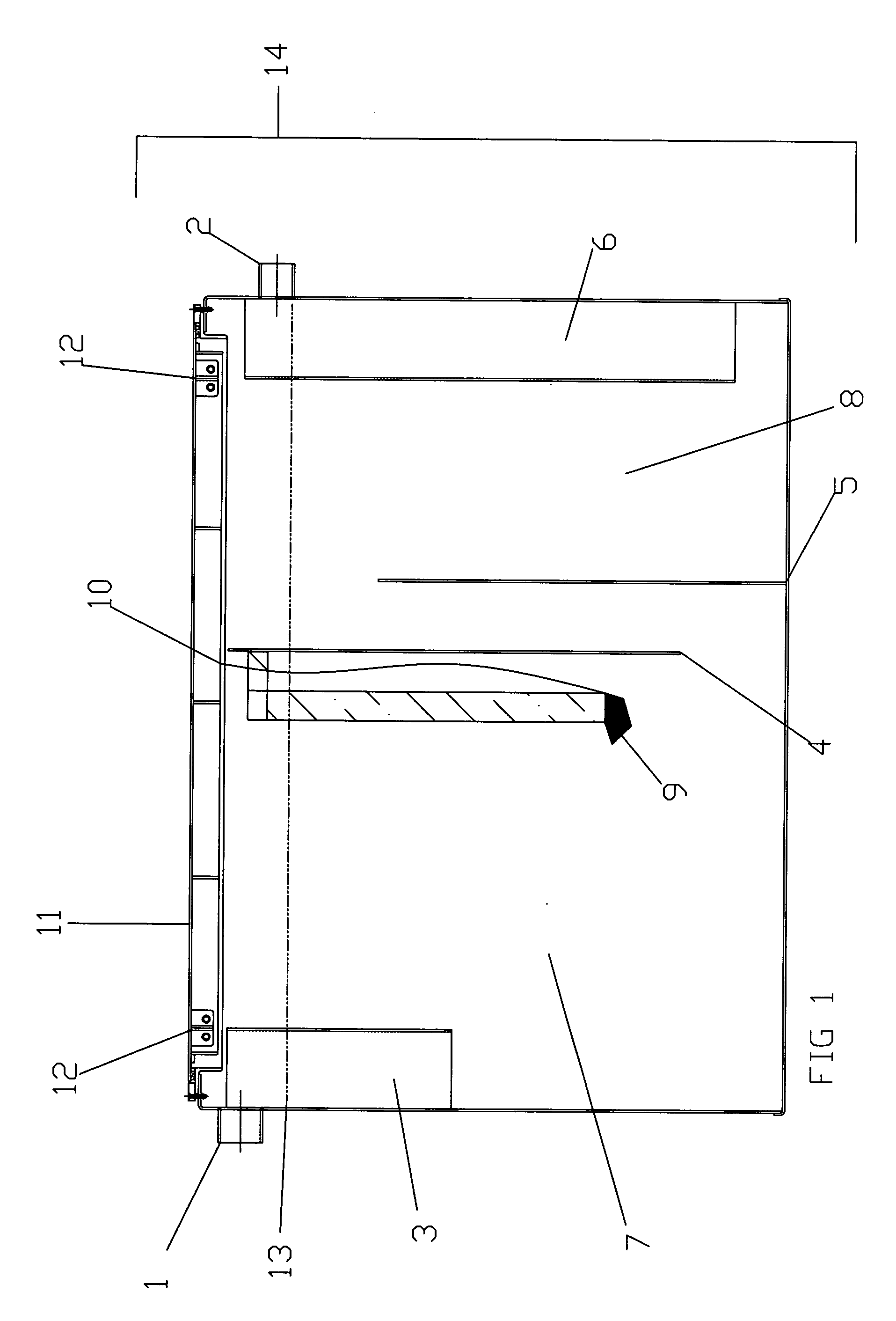

Barbecue and barbecue components

InactiveUS20100175682A1Domestic stoves or rangesLighting and heating apparatusCollection systemEngineering

The present invention provides a barbecue (100) having an outer cabinet (1) which is adapted to fit into a bench top via hole in said bench, said cabinet (1) having an upper periphery adapted to engage an upper surface of said bench, said barbecue including along at least a portion of one side a trough (26) which extends downwardly from said upper periphery, said barbecue (100) having a wall (8) separating said trough (26) from a combustion chamber (2.2) wherein there is located at least one burner (2), whereby said wall (8) includes a viewing panel (8.3, 8.4) so that an operator standing close to said one side can view flame on said burner (2) through said trough (26) and said panel (8.3, 8.4). The present invention also provides a lid (200), a hotplate or griddle (12) and a grease collection system with a removable grease collector (11) which extends along at least a part of a forward edge of the hotplate (12) or grille (1325) so as to receive grease or liquid or other substances therefrom. The present invention also provides a grille assembly (1325) comprising an upper (25) and a lower grid (13) and a drop-in bench barbecue (100).

Owner:AB ELECTROLUX

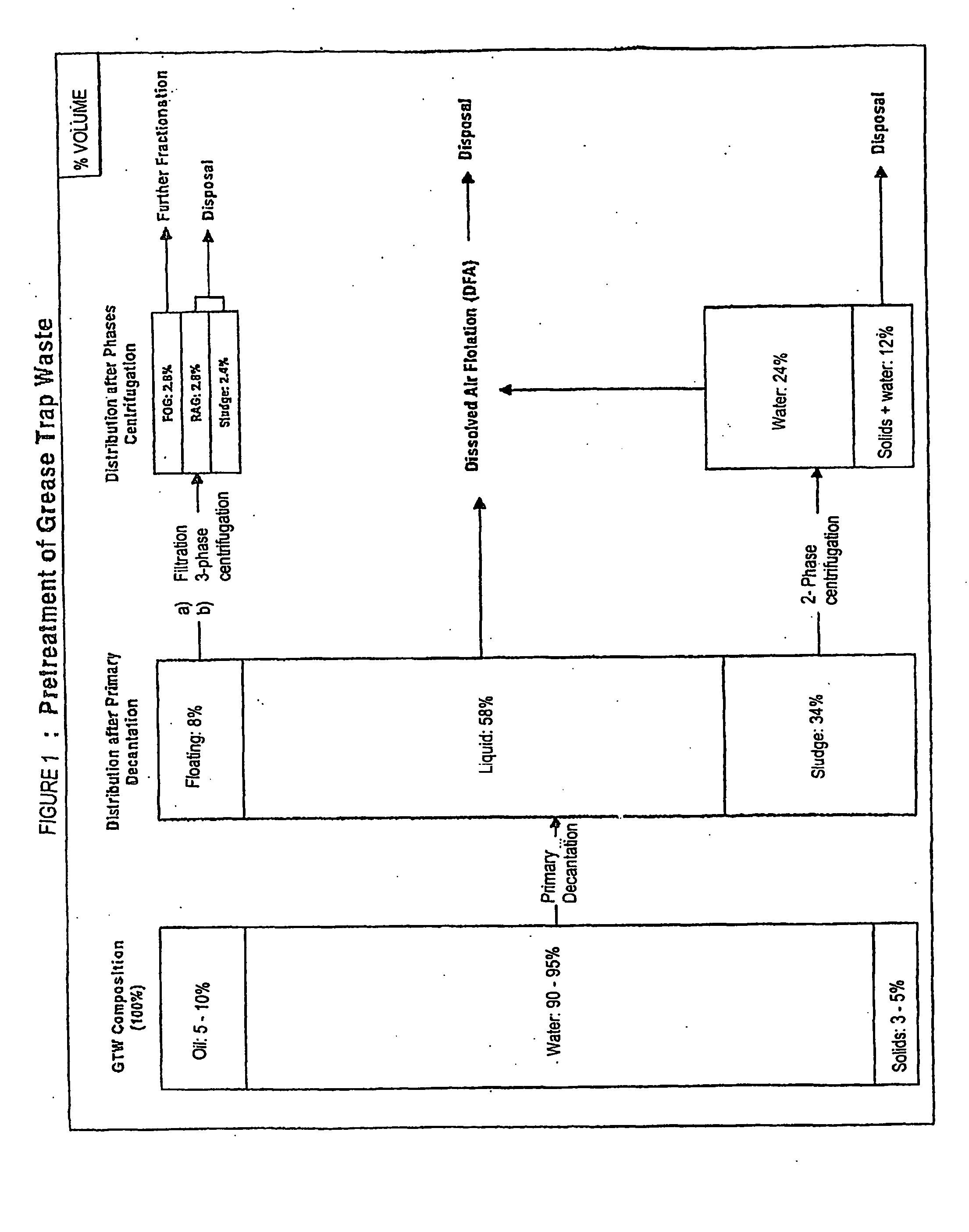

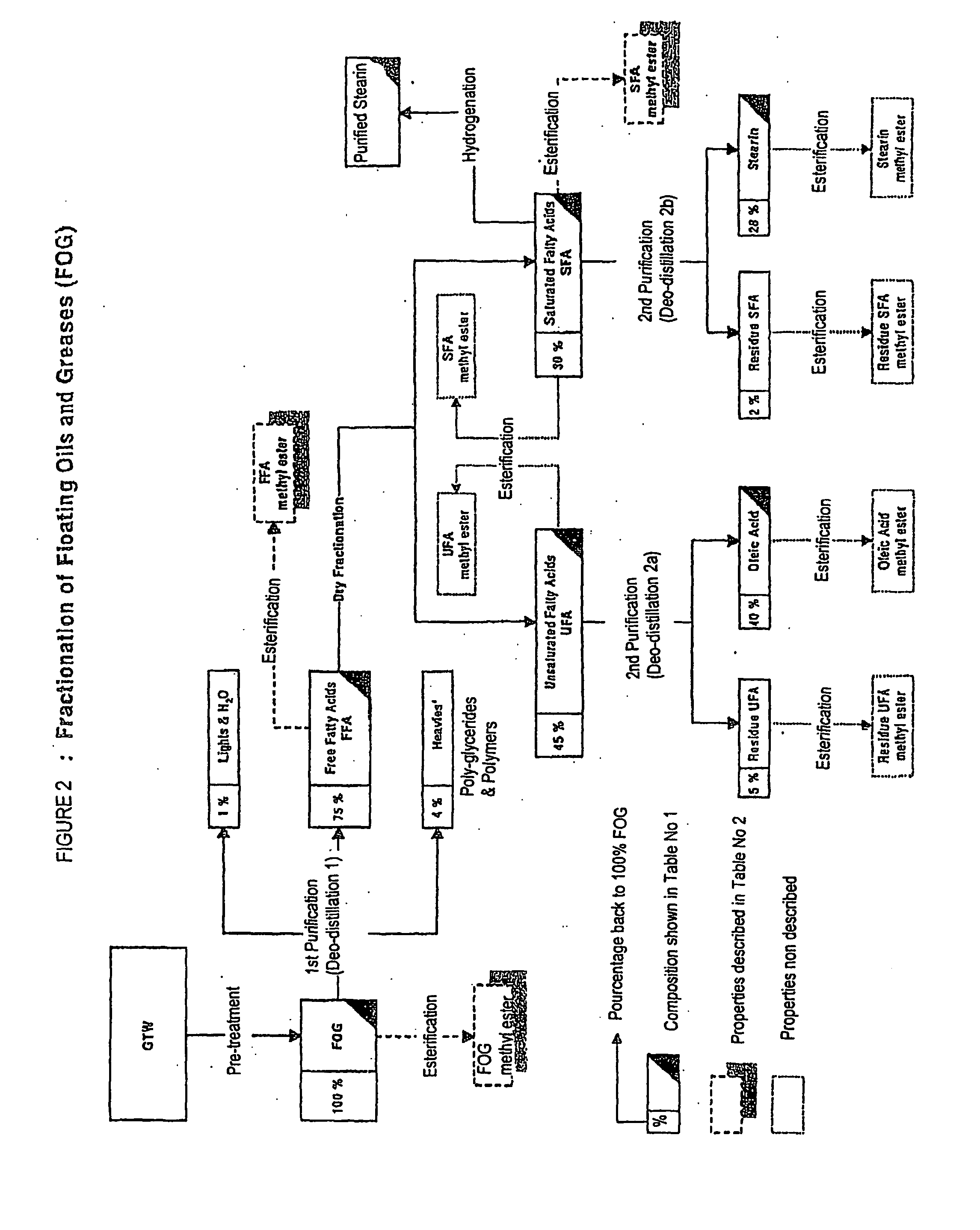

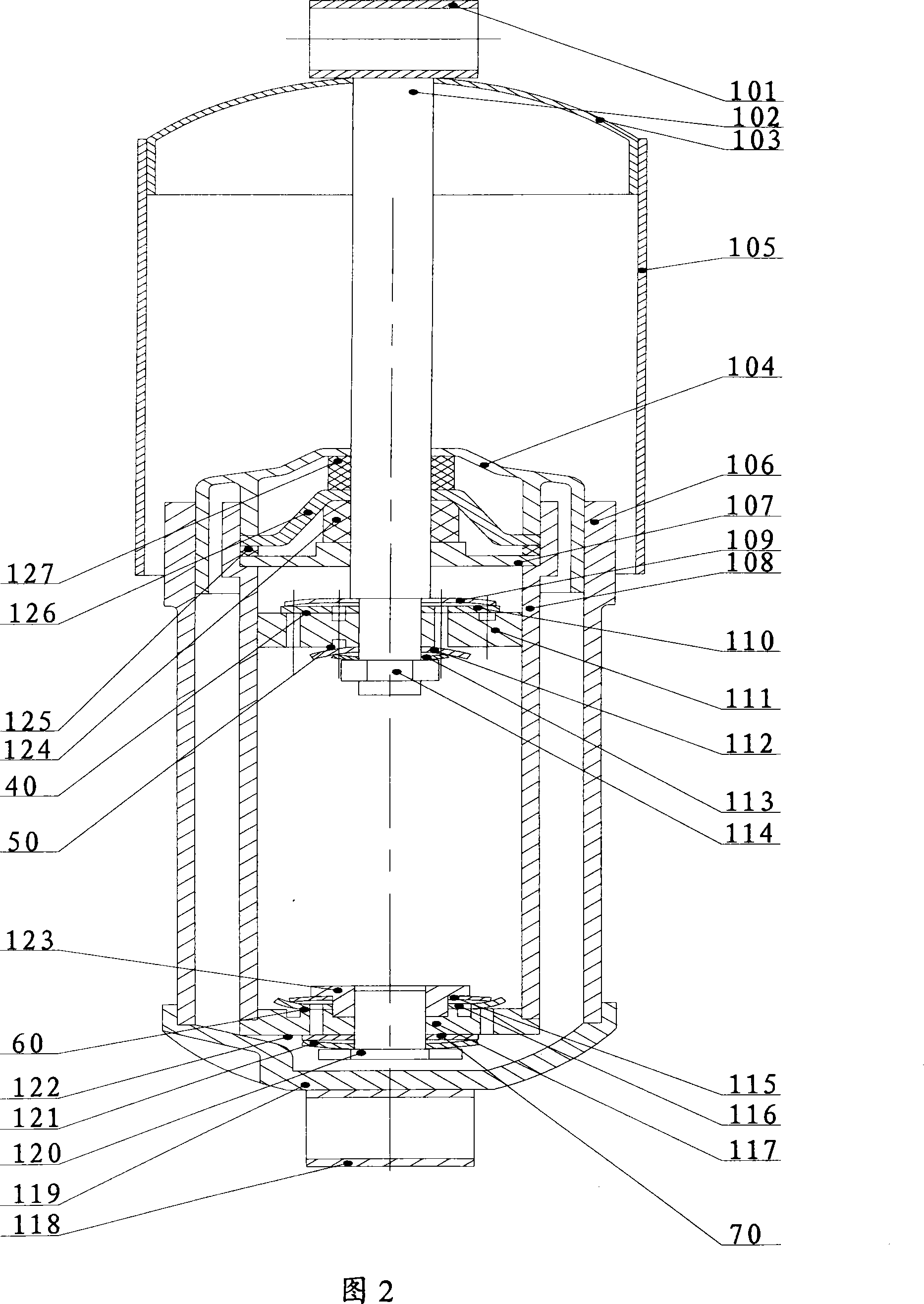

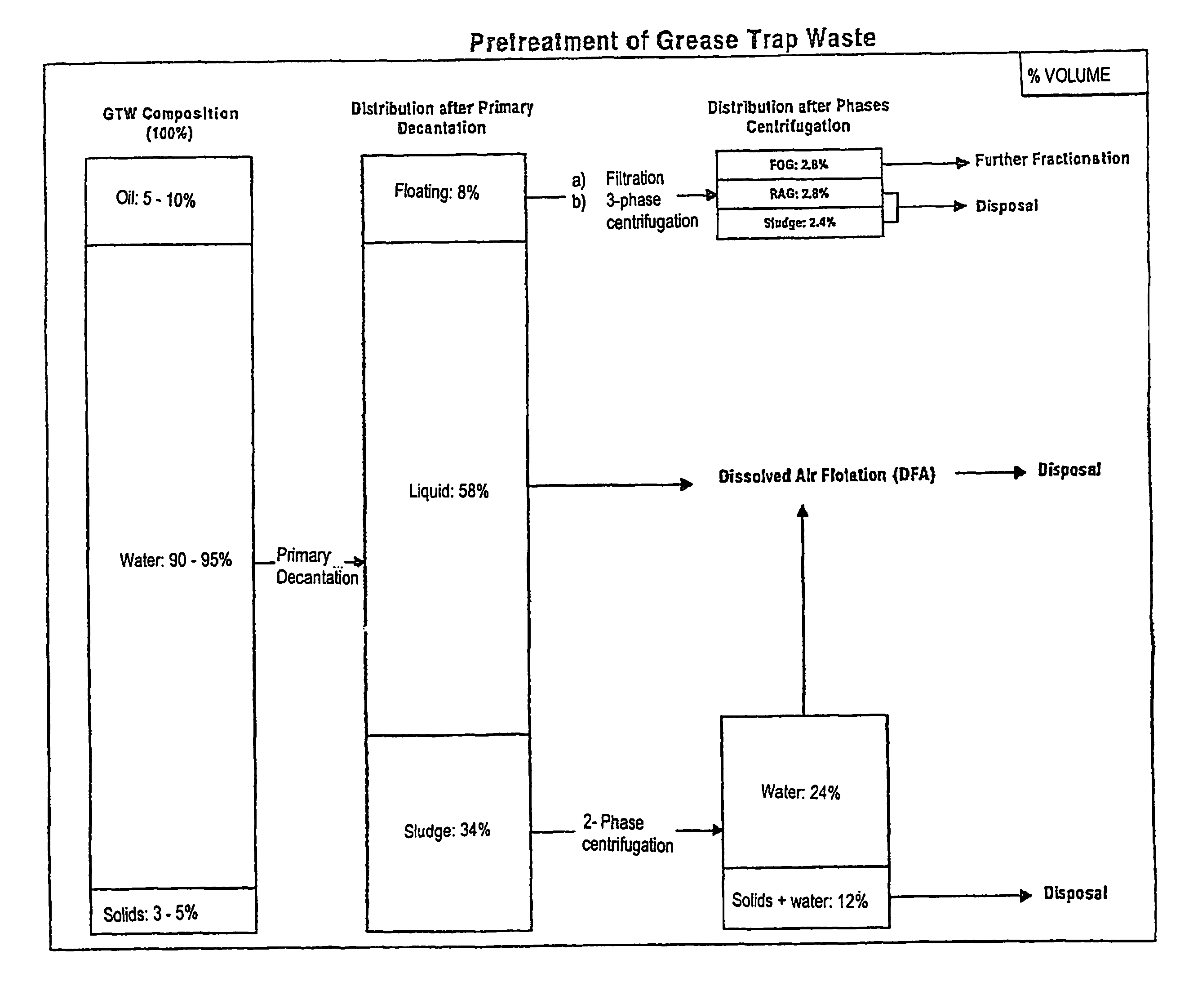

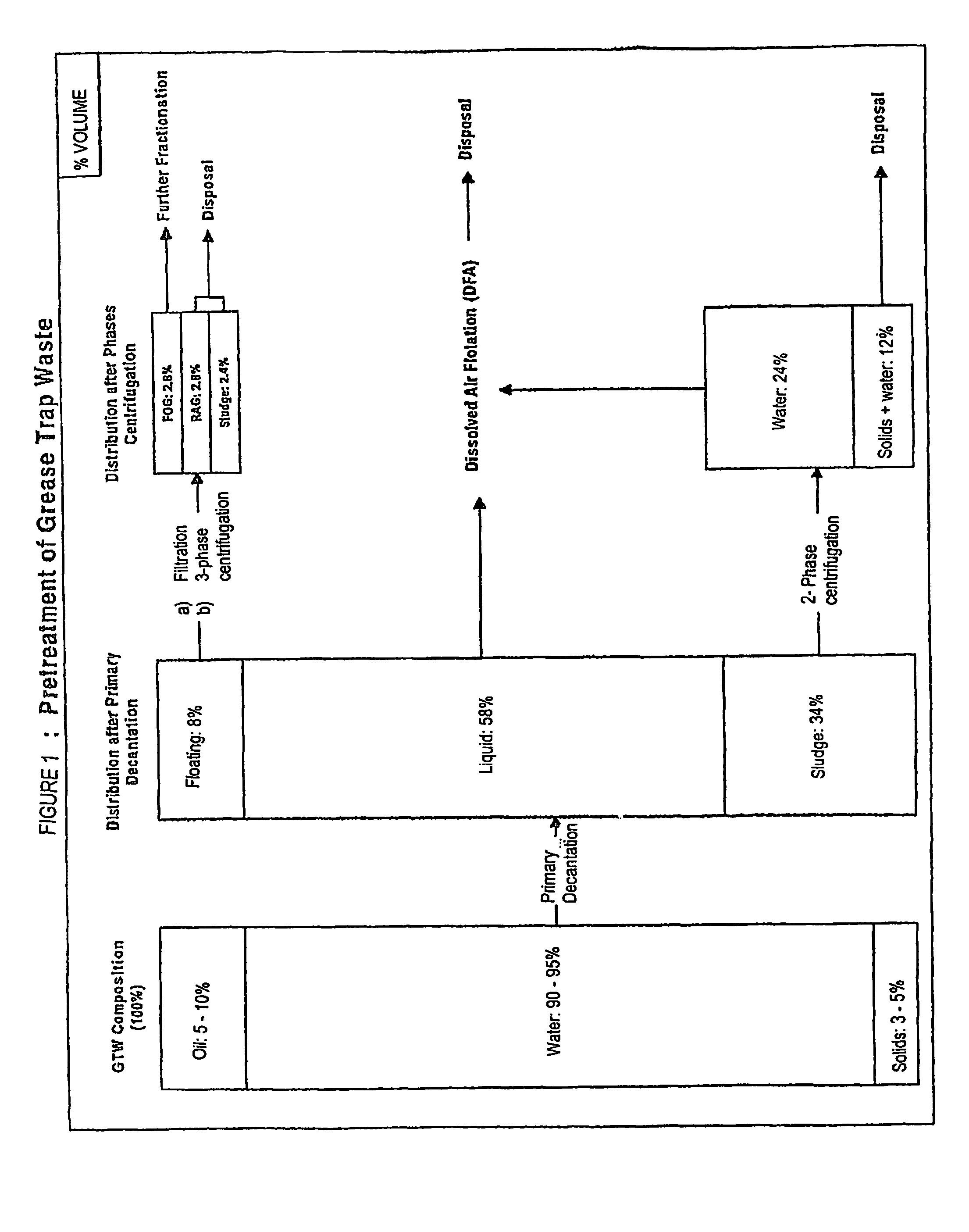

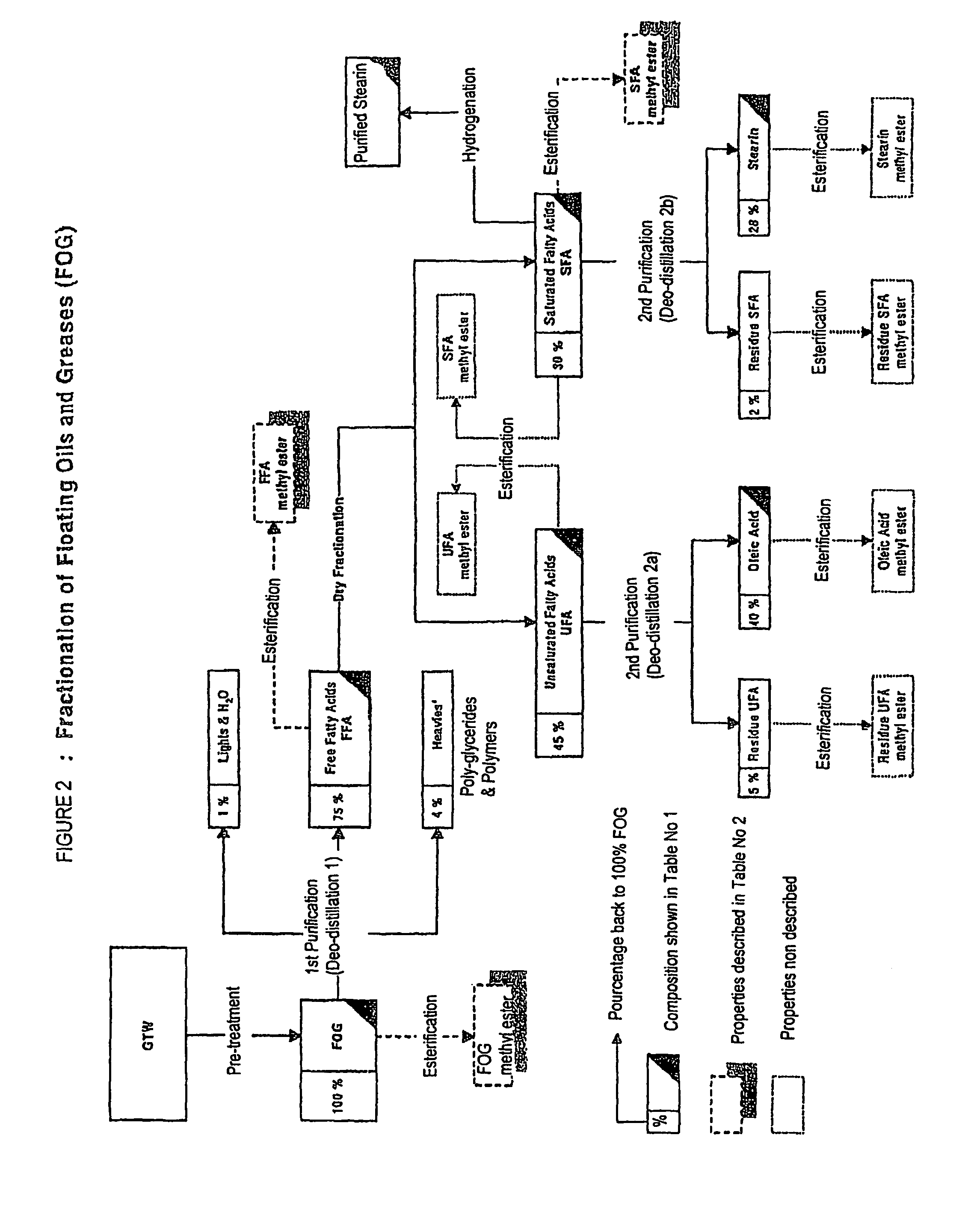

Method for fractionating grease trap waste and uses of fractions therefrom

InactiveUS20050085653A1Fatty oils/acids recovery from wasteFatty acid hydrogenationOleic Acid TriglycerideGrease trap

A process for producing unsaturated and saturated free fatty acid from trap oils, trap greases, brown greases and grease trap waste as starting material. The process consist in subjecting the starting material to a pretreatment, a first purification step, a fractional step, a second purification step and eventually a hydrogenation step. Methyl esters of unsaturated and saturated free fatty acids, oleic acid and stearin is obtained from this process.

Owner:PROLAB TECH

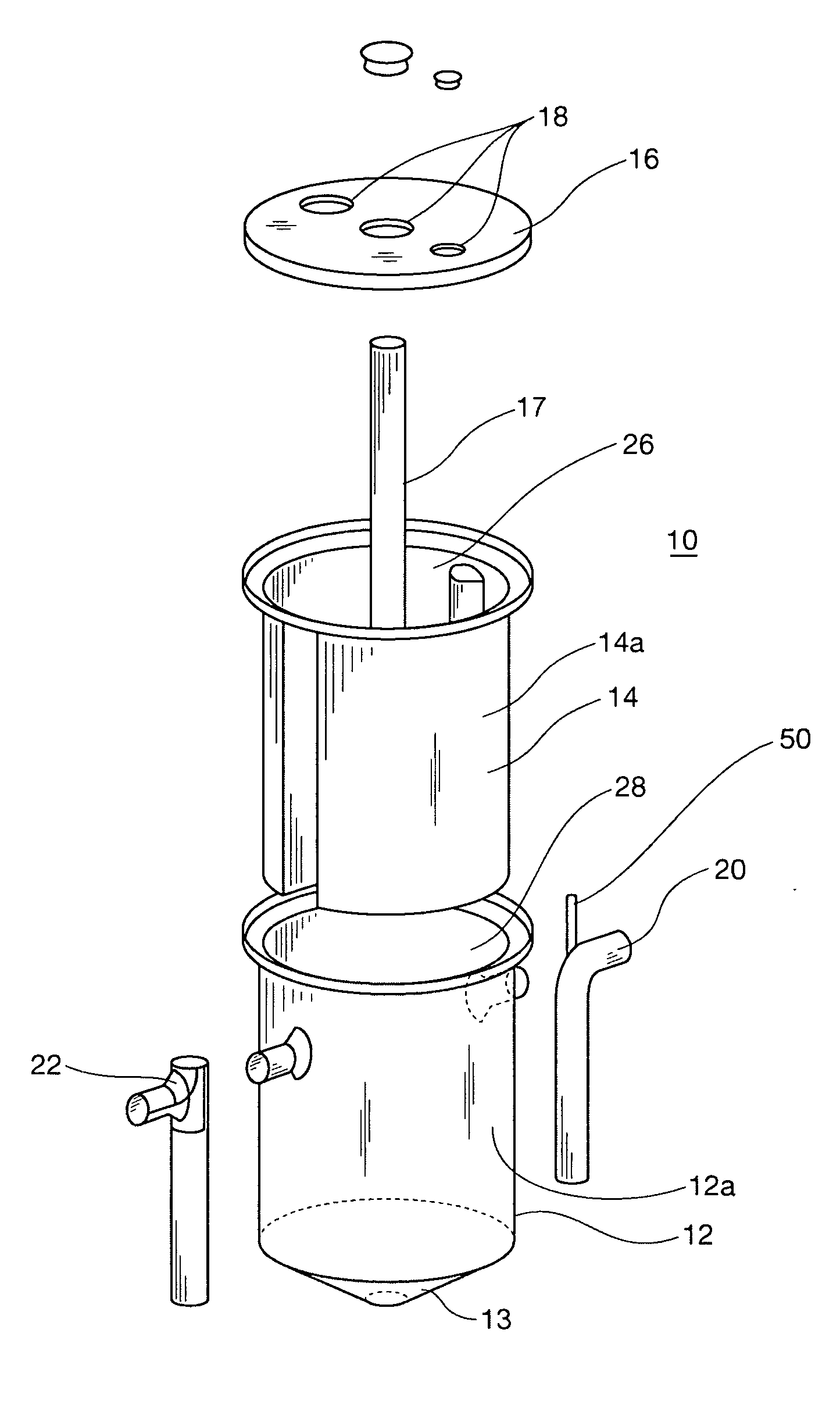

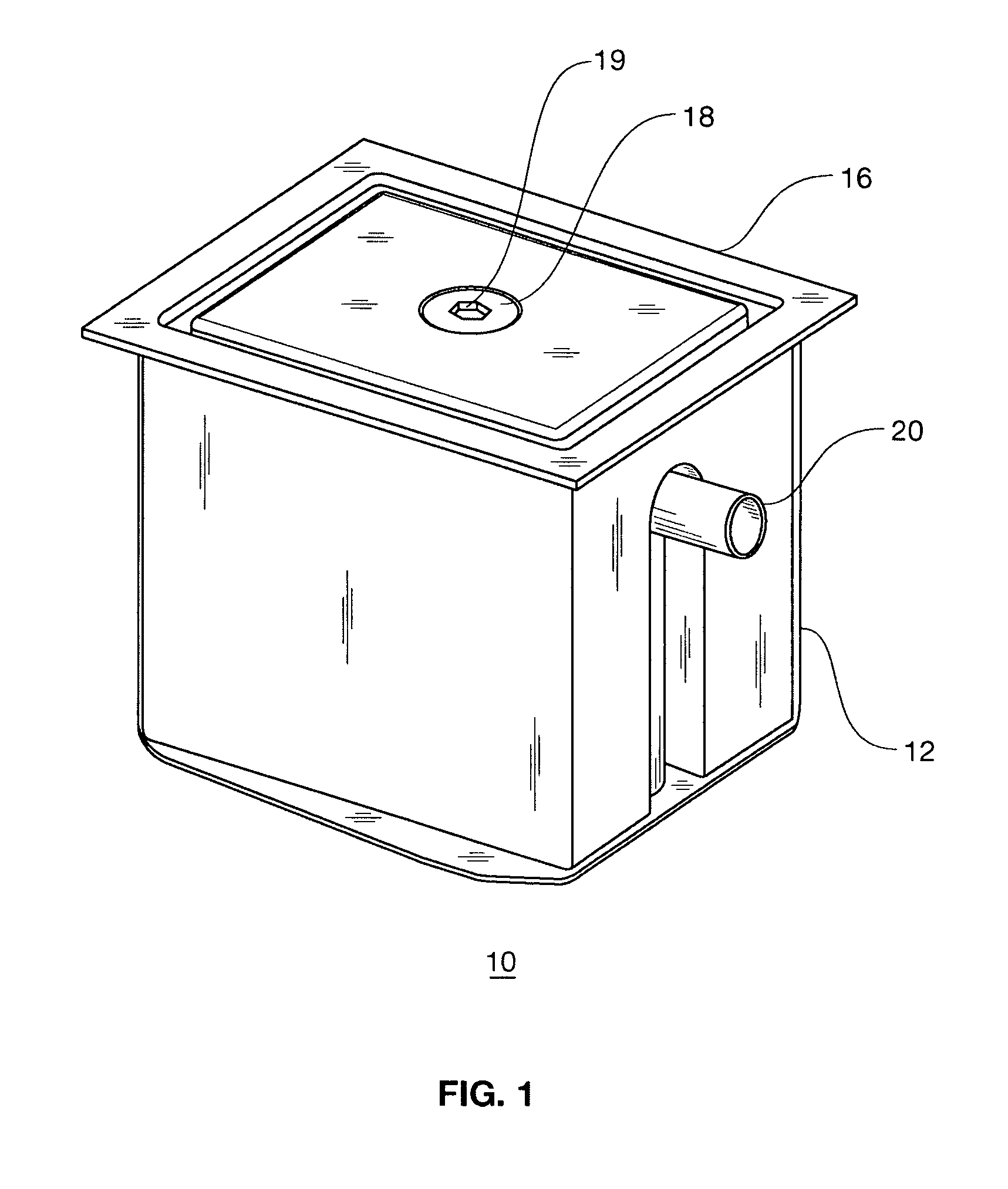

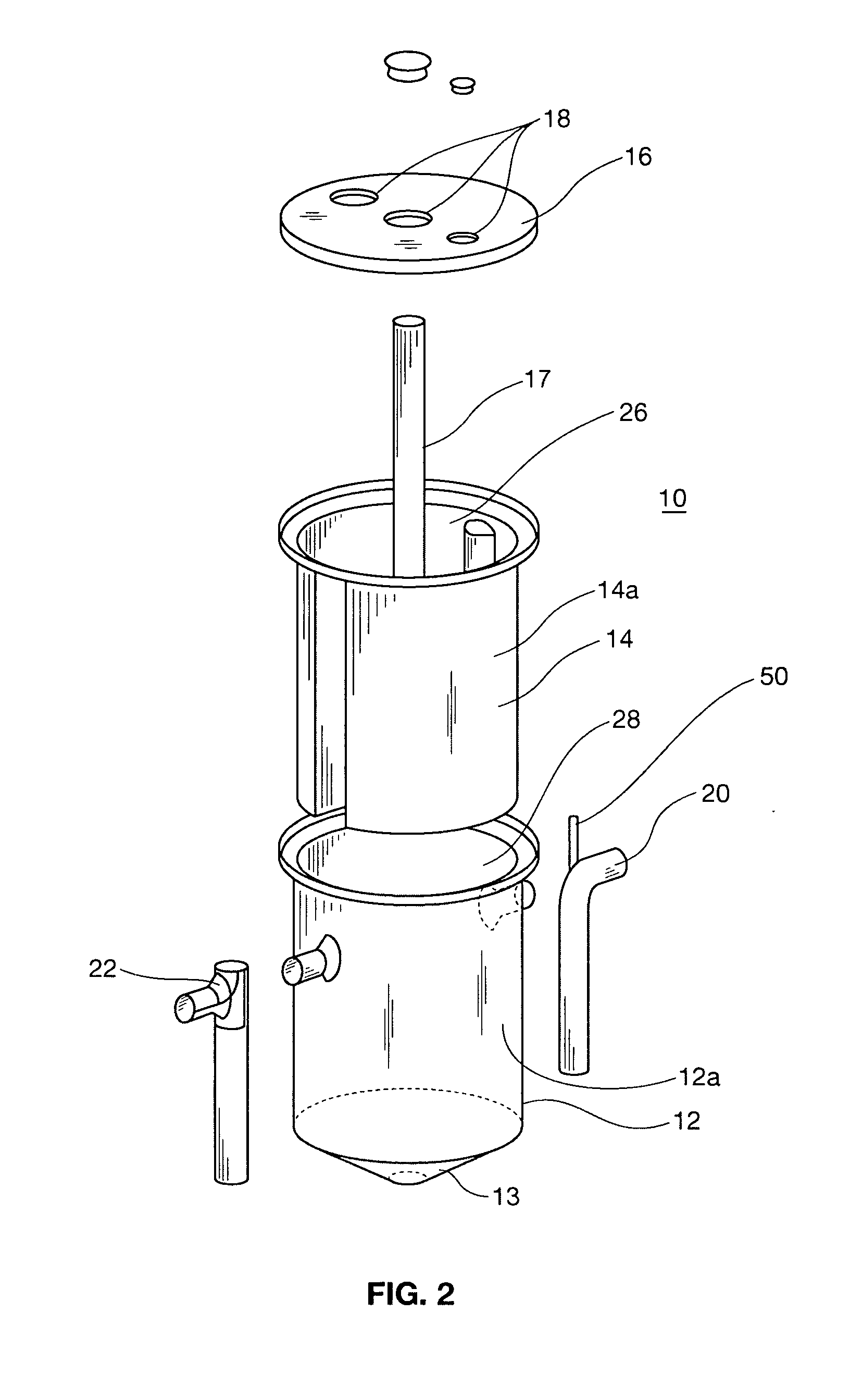

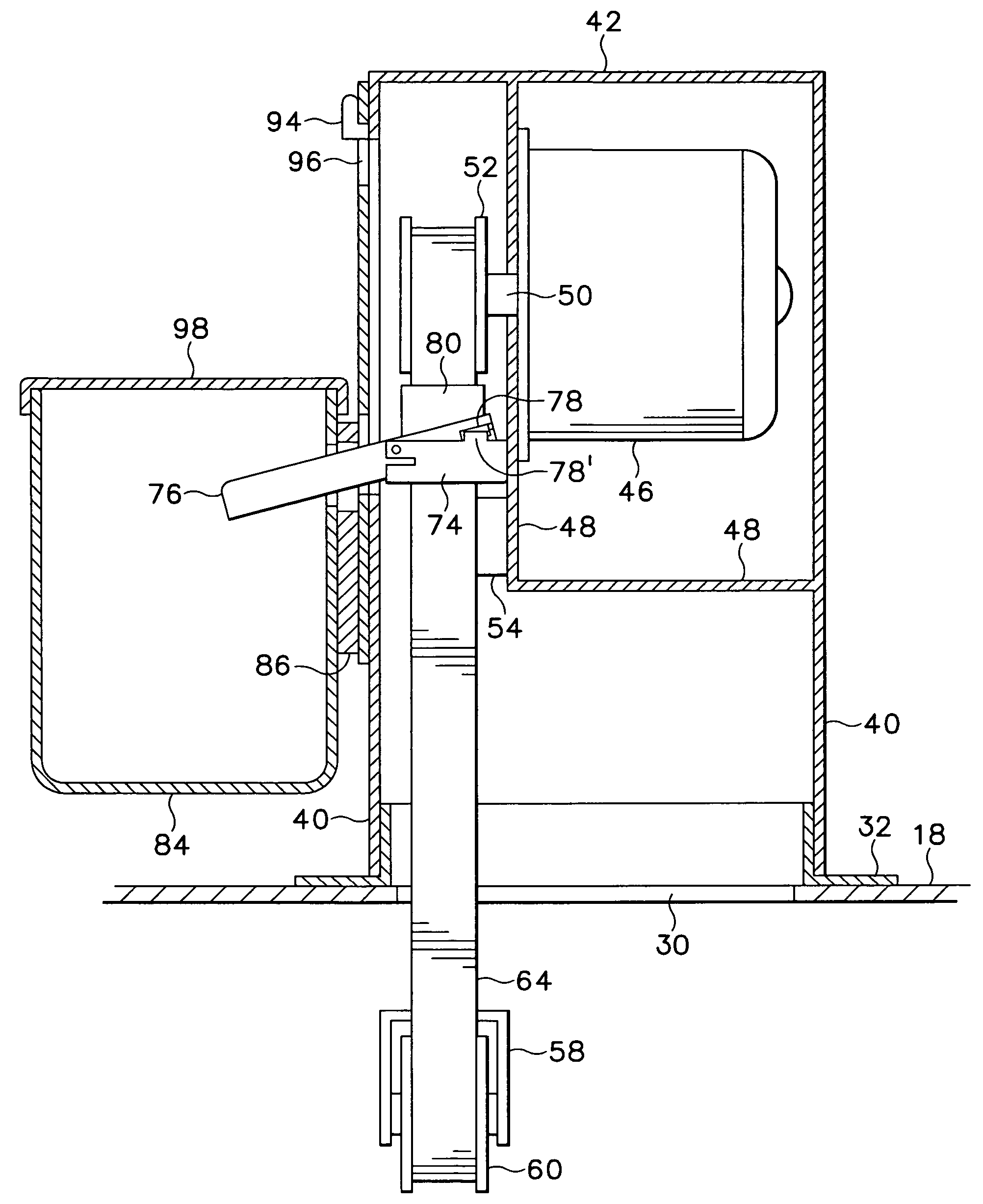

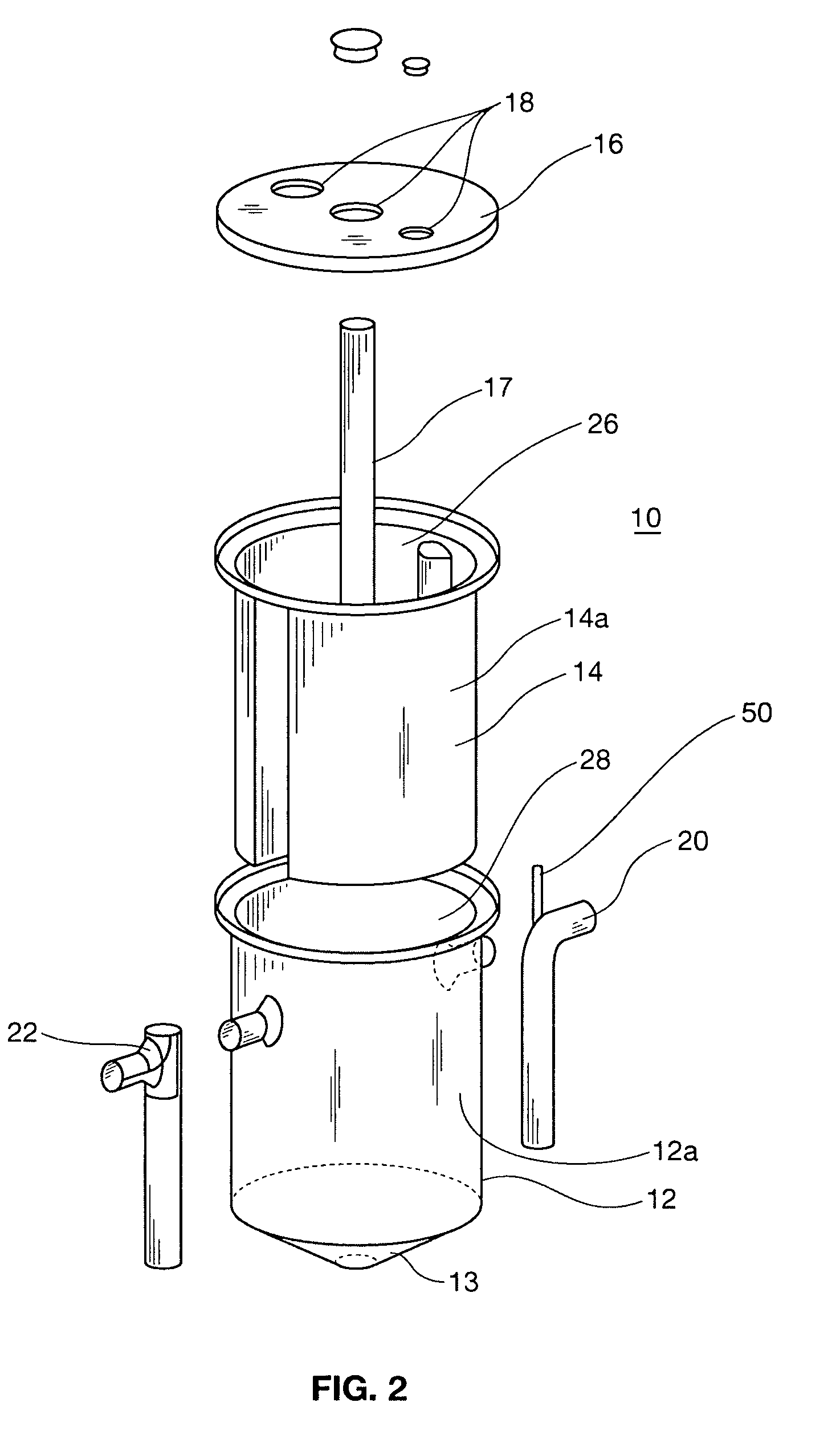

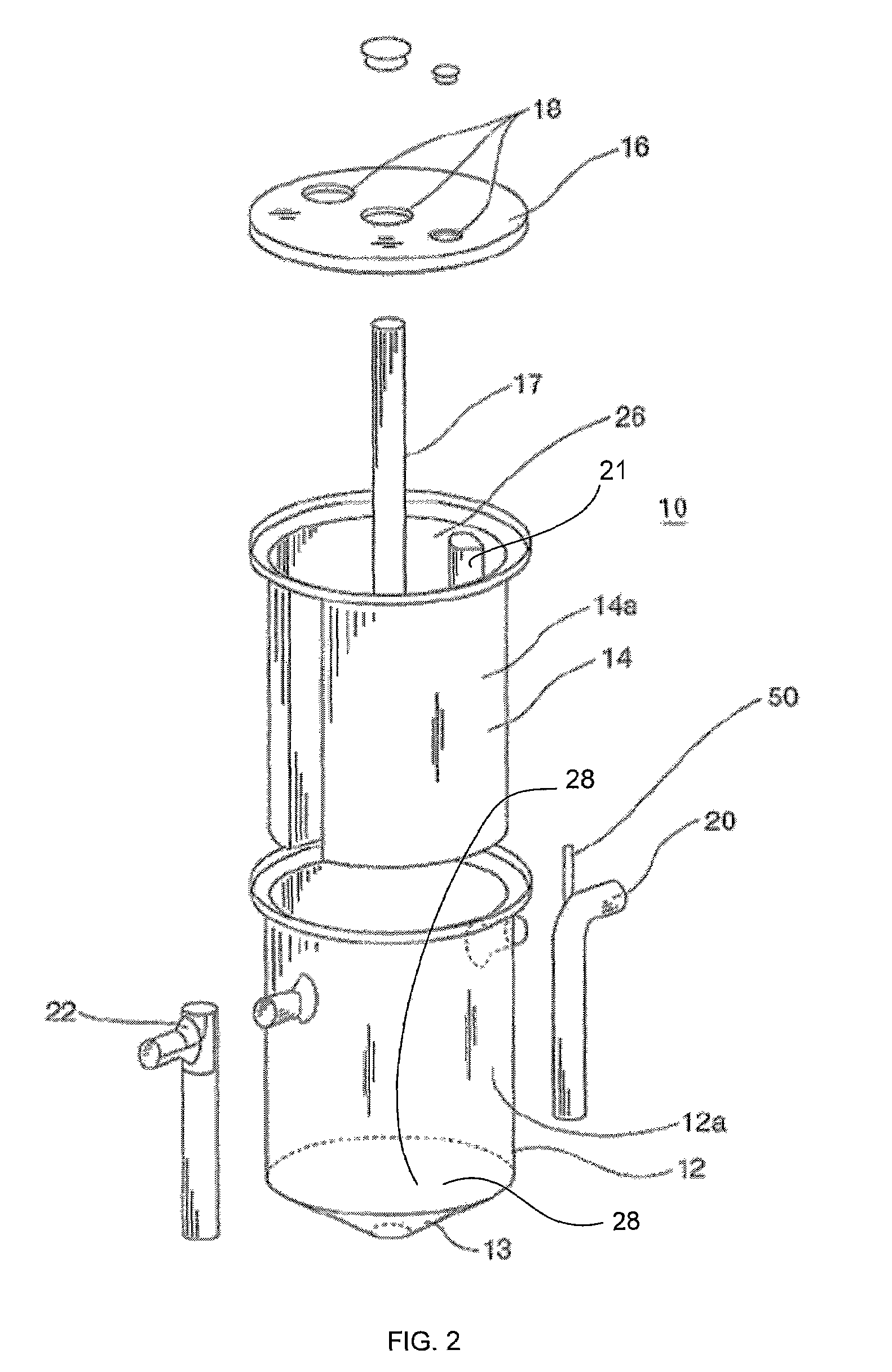

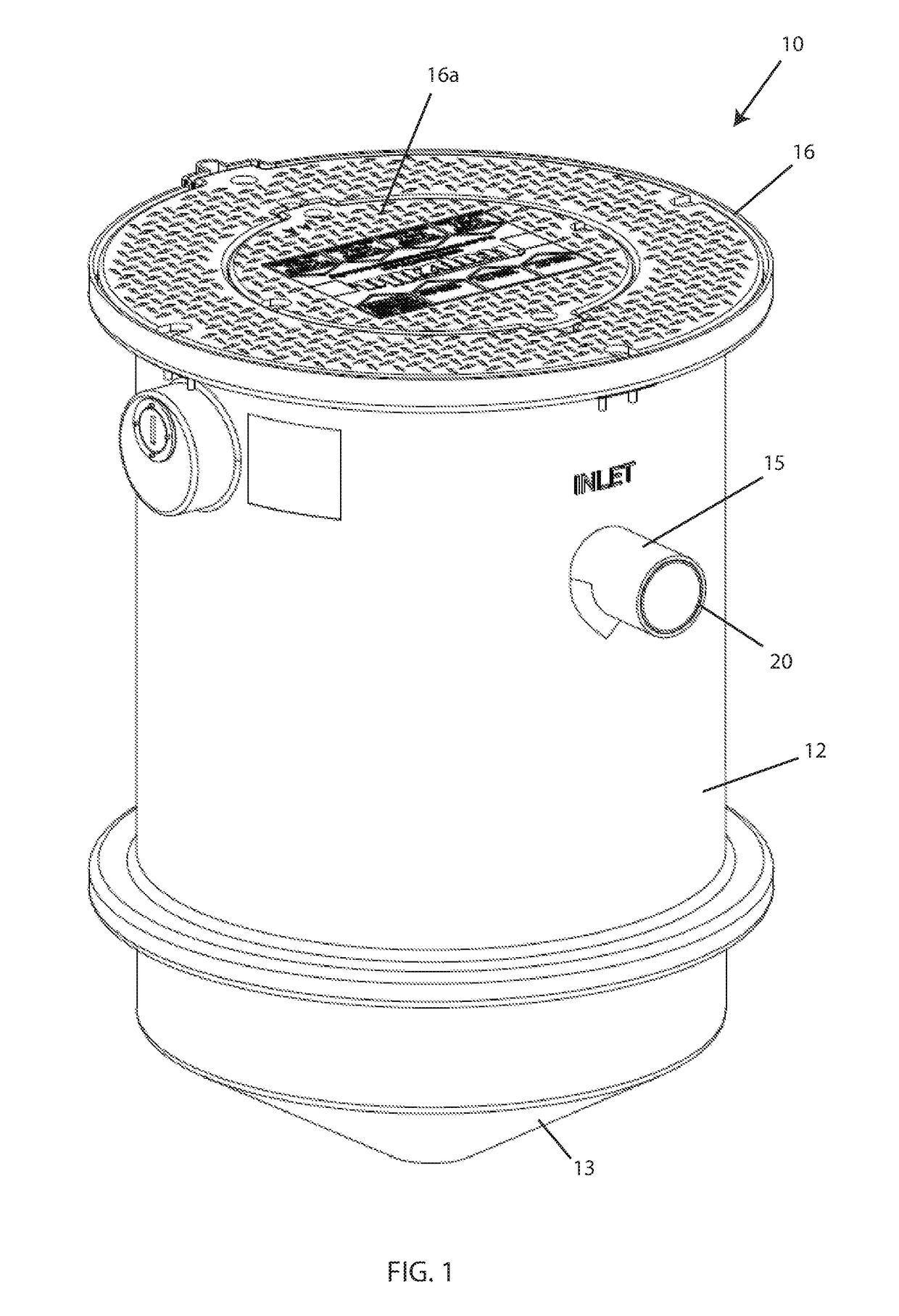

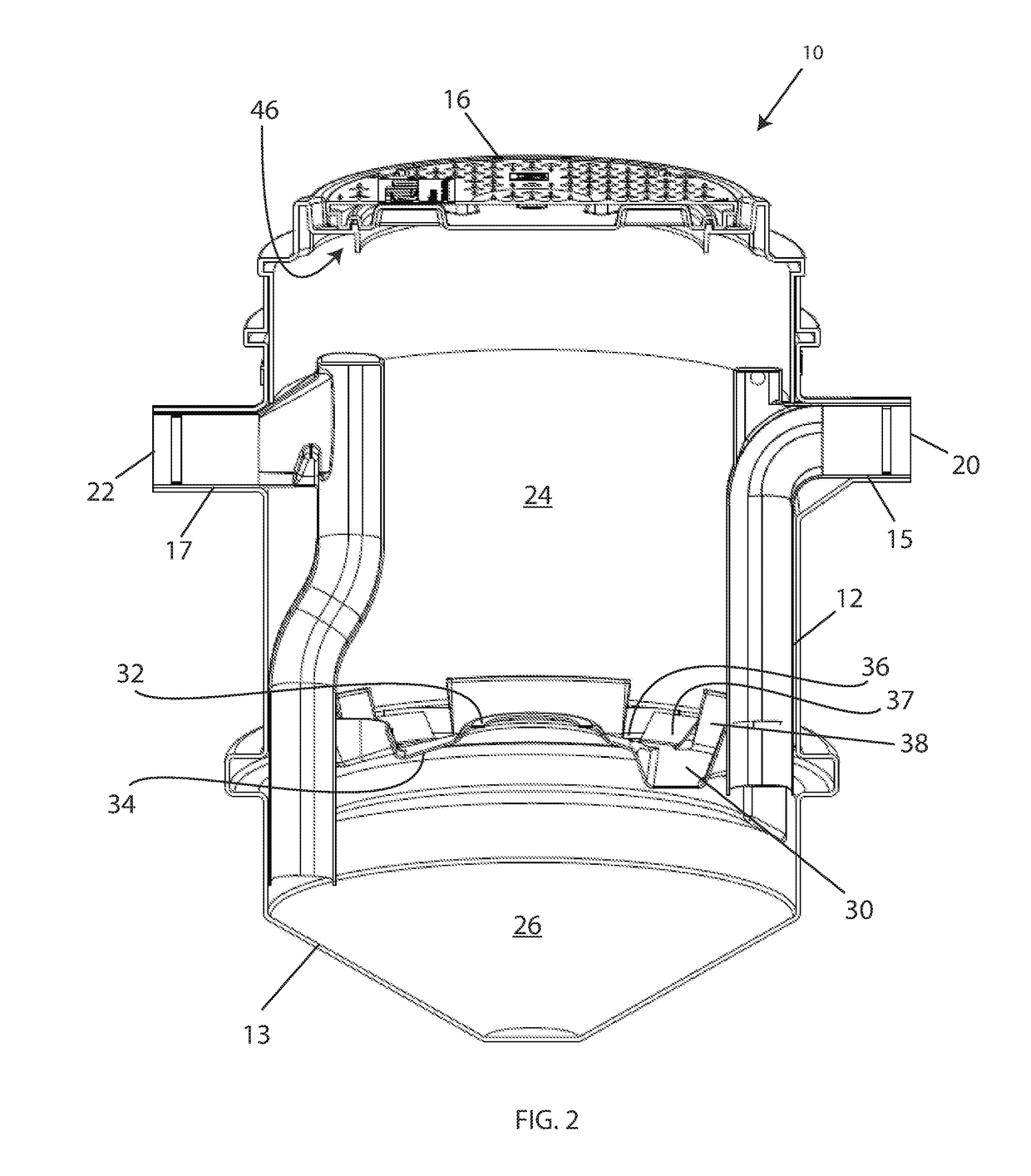

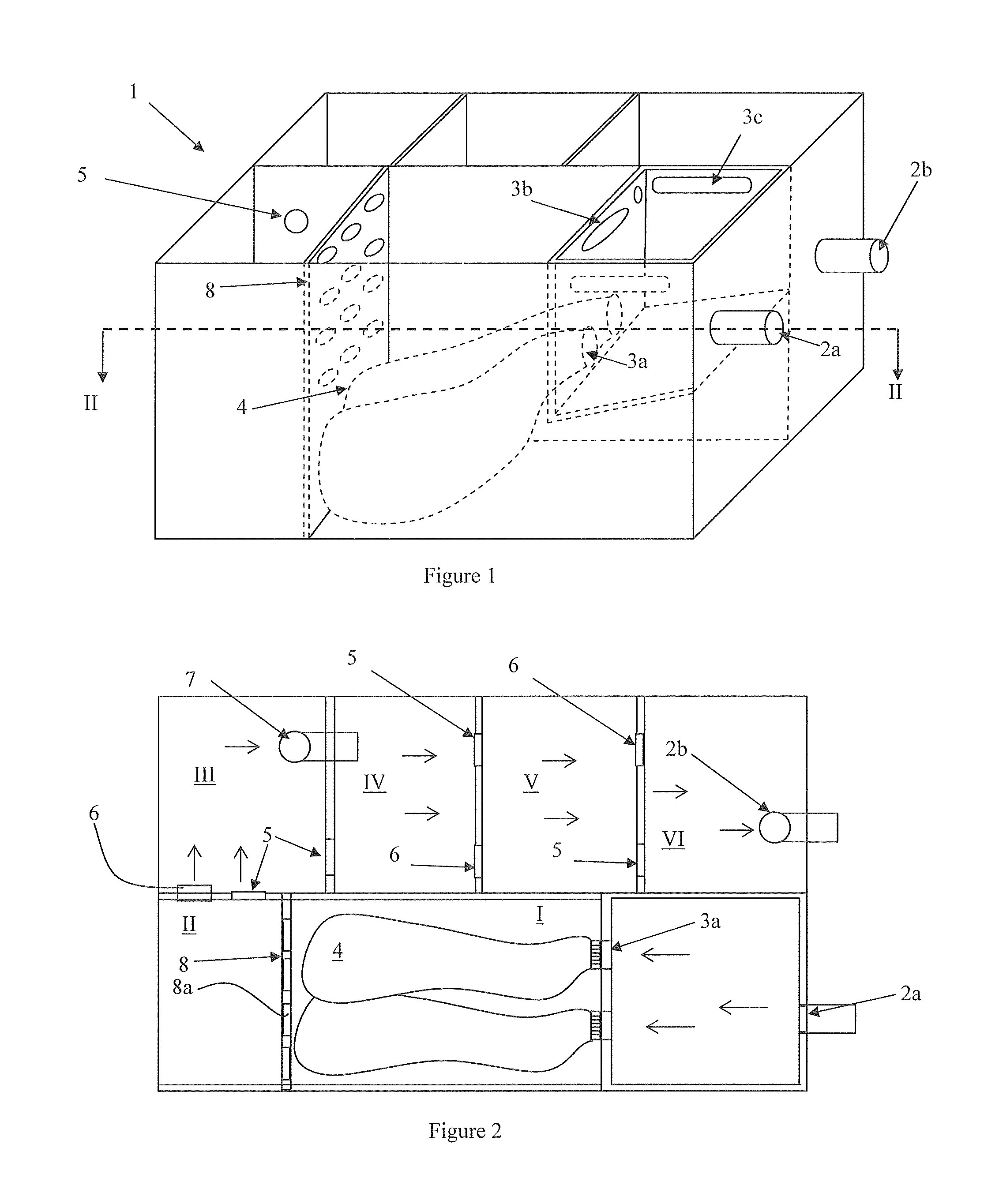

Passive grease trap using separator technology

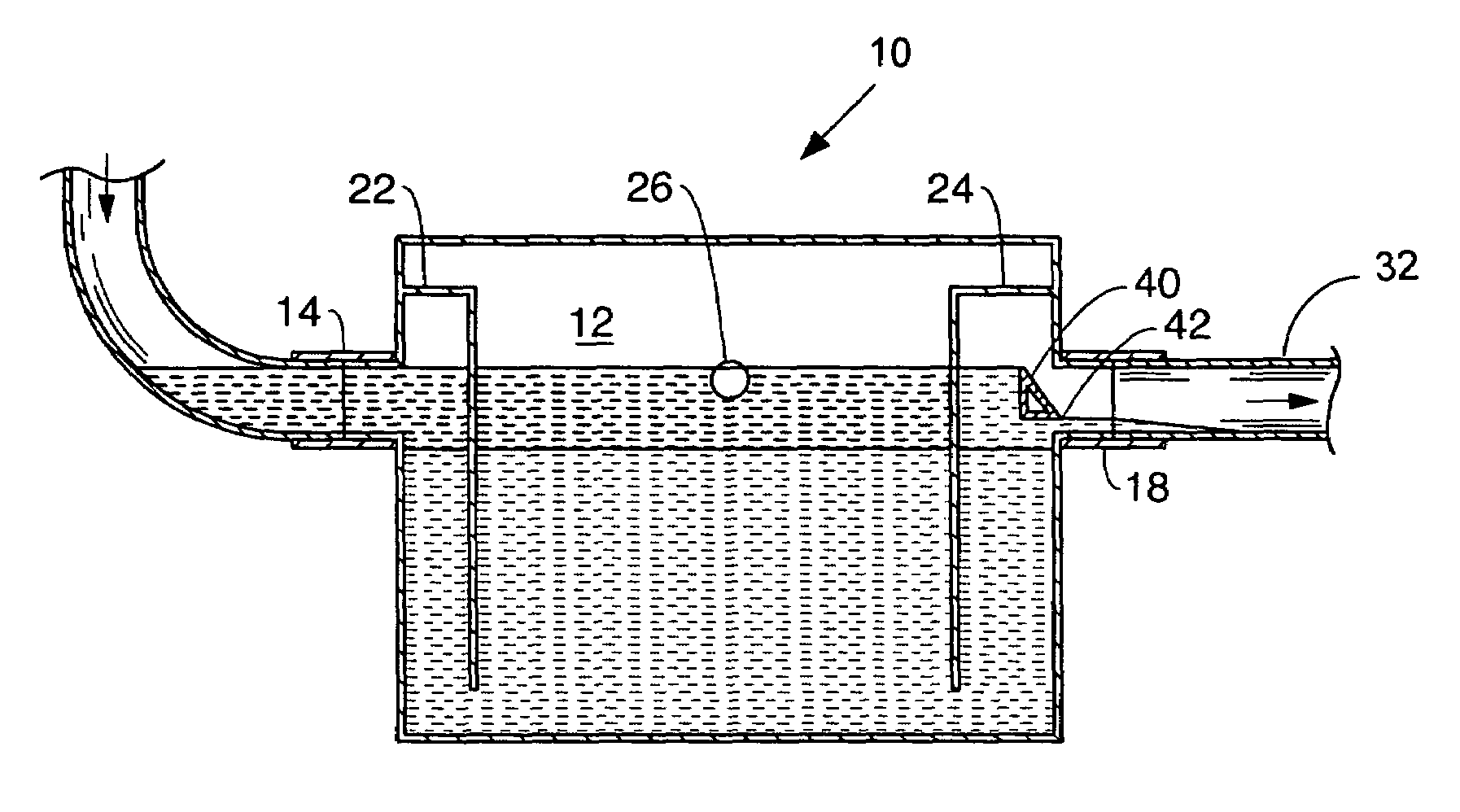

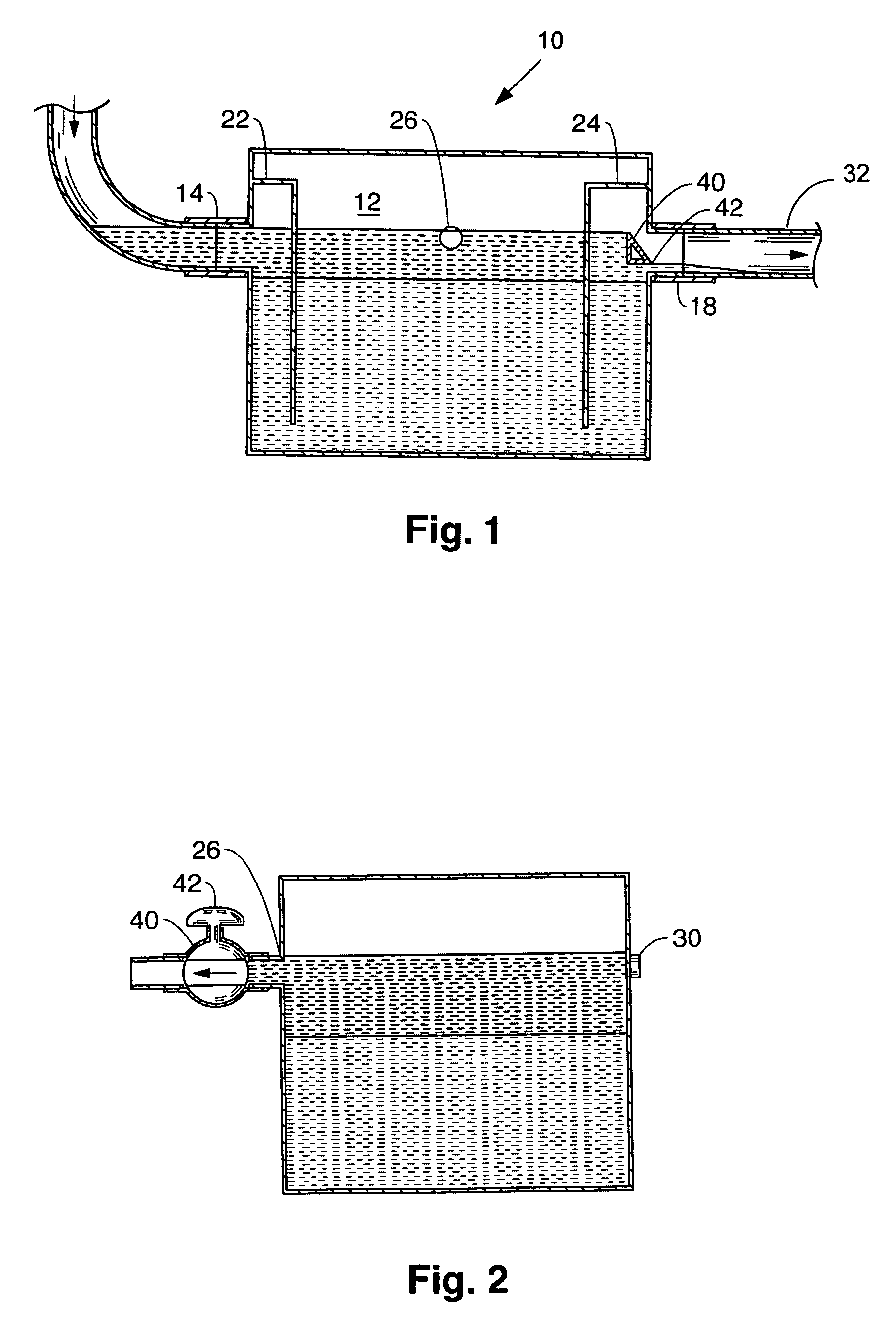

A grease trap for separating grease and solid waste from waste water. The grease trap includes a tank having a downwardly shaped bottom. An upwardly shaped divider divides the tank into an upper chamber and a lower chamber. A hole near an upper part of the divider allows waste into the upper chamber. An inlet invert in the tank receives incoming waste water, while an outlet invert removes water from the tank. A lid covers the tank. A pipe extends through the lid, upper chamber, and lower chamber for sucking solid waste out of the lower chamber.

Owner:THERMACO INC

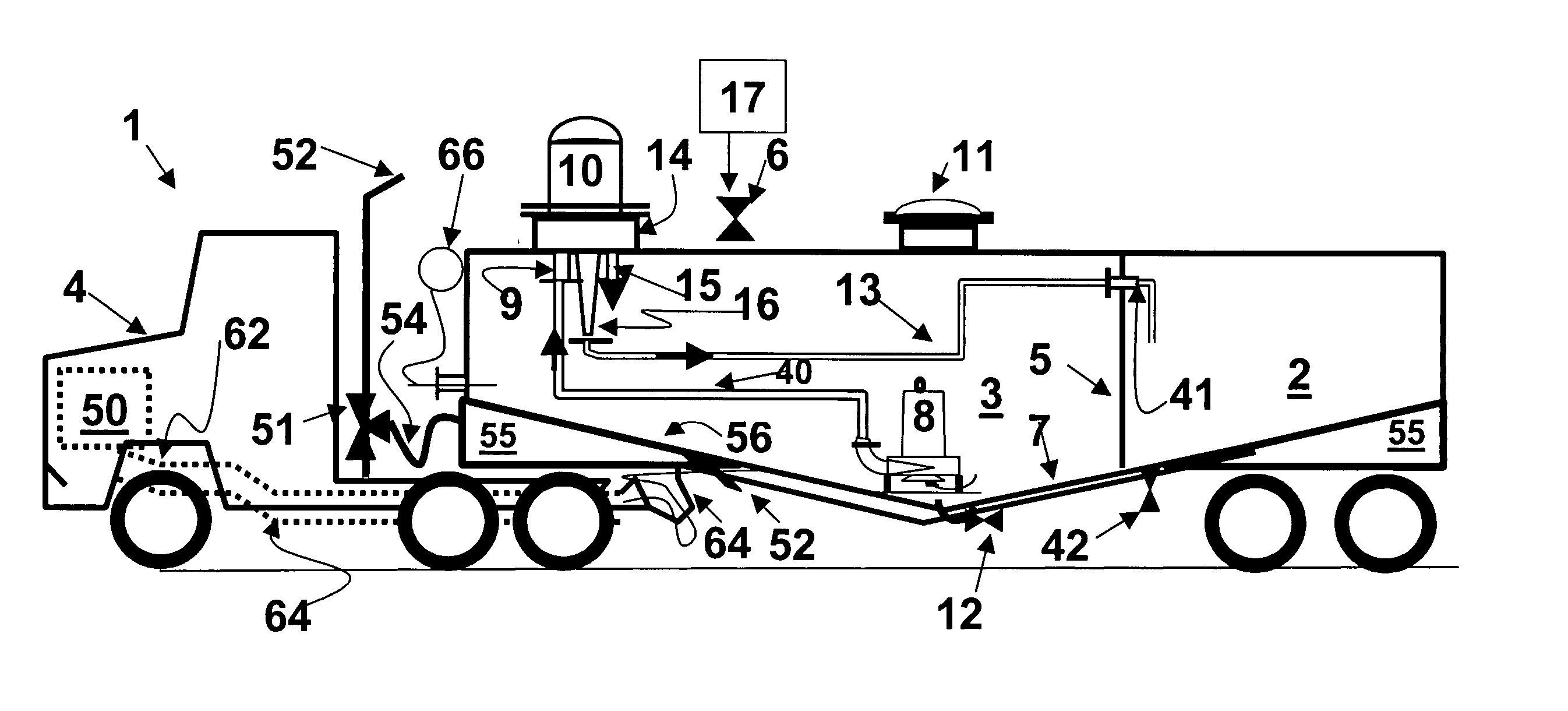

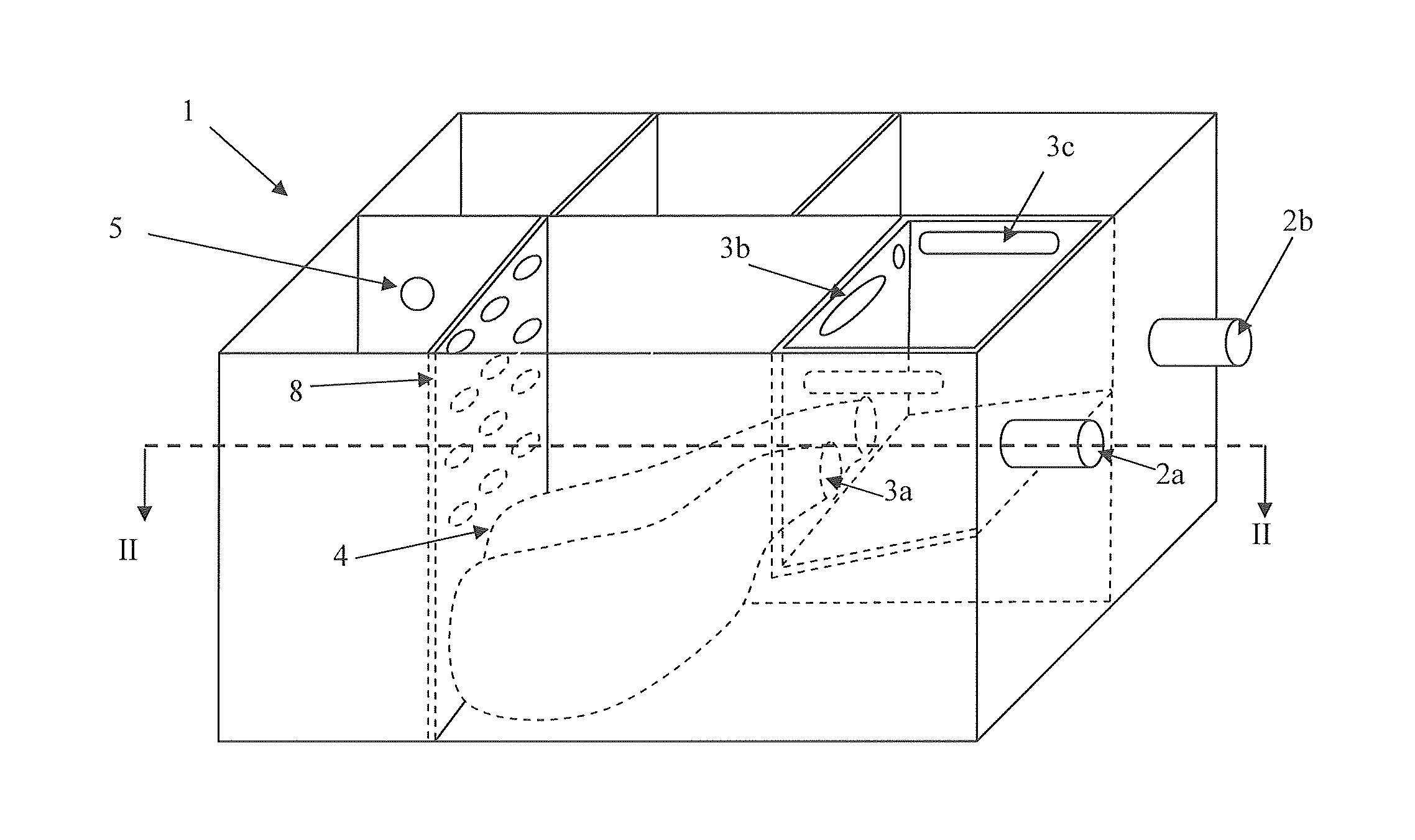

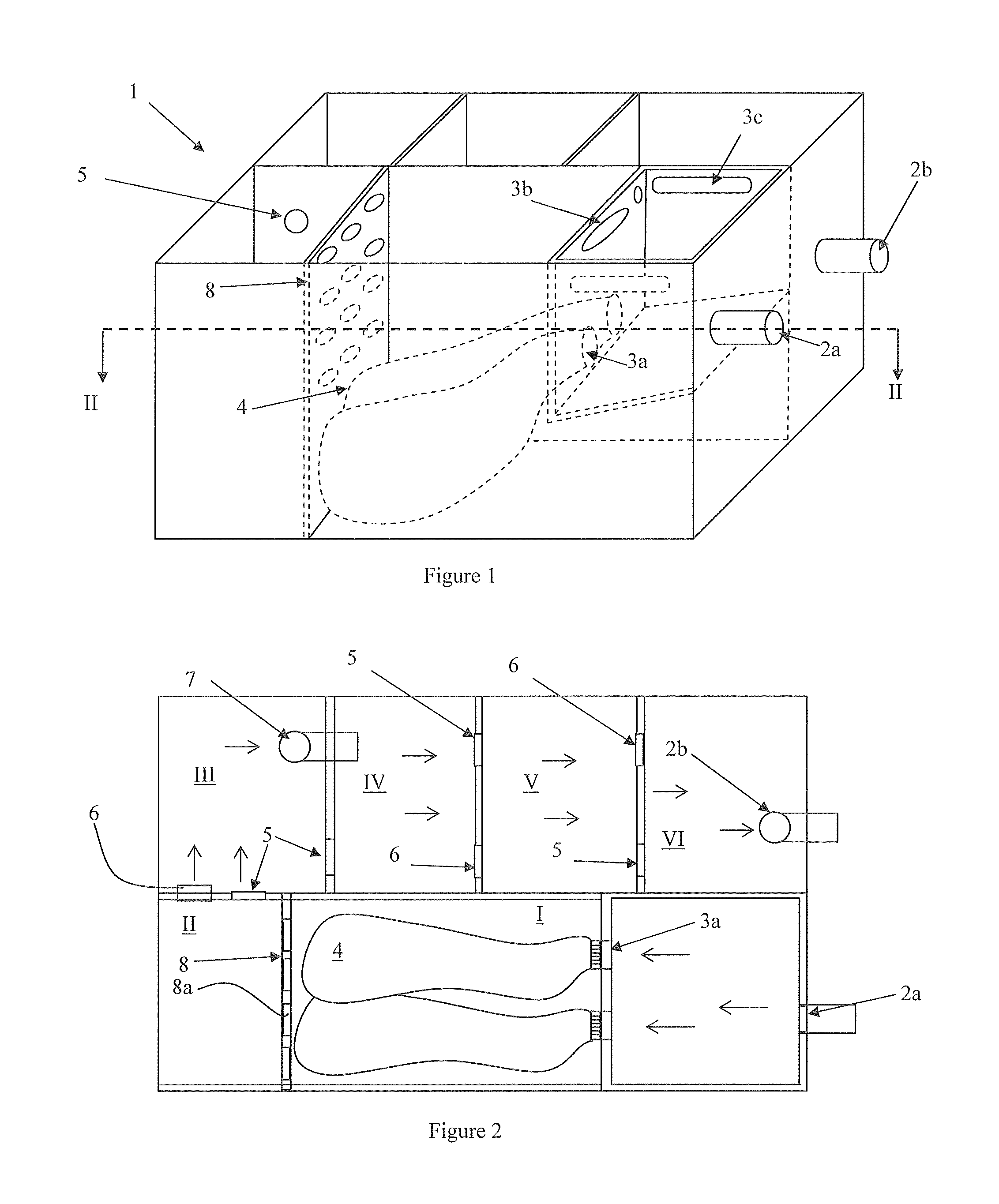

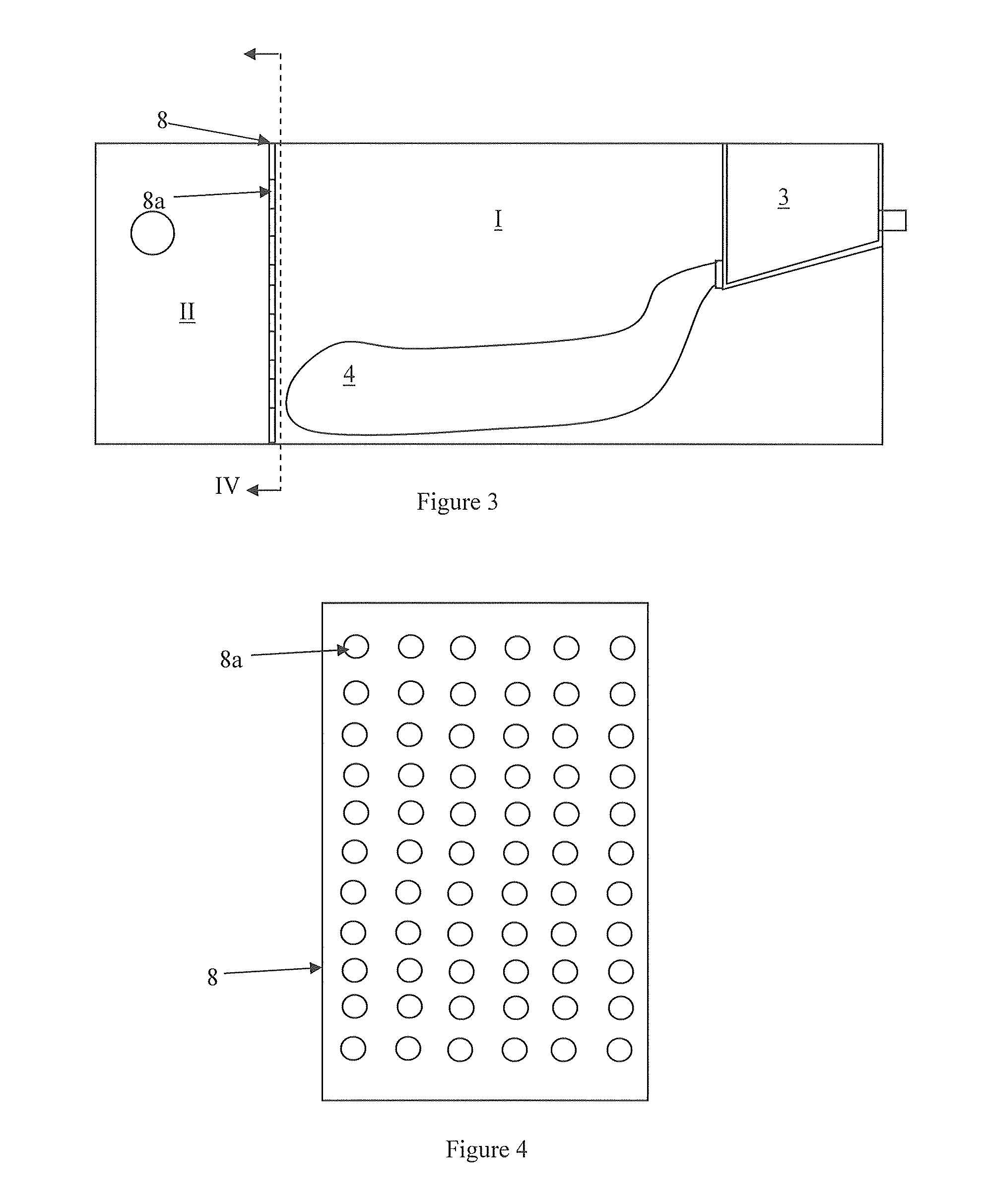

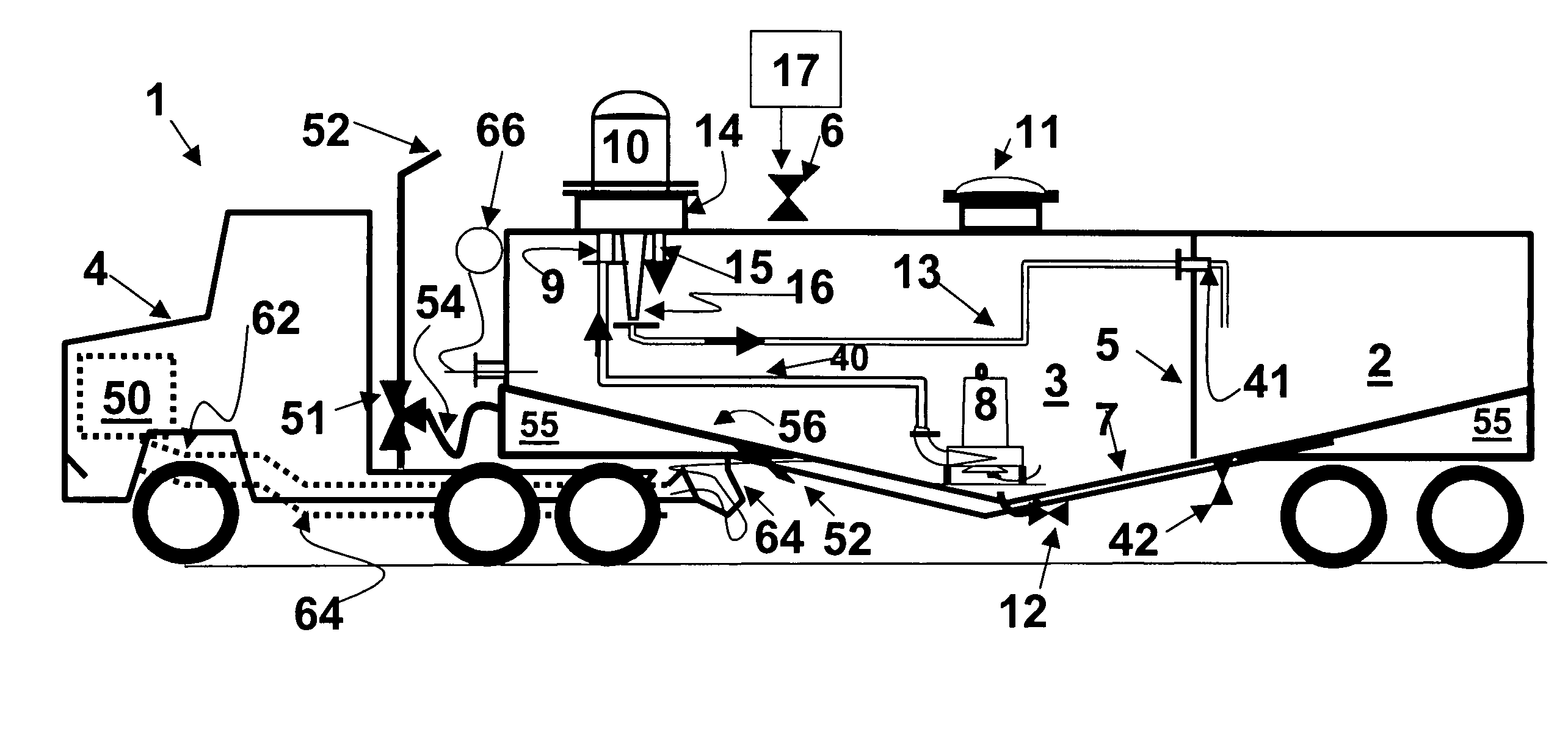

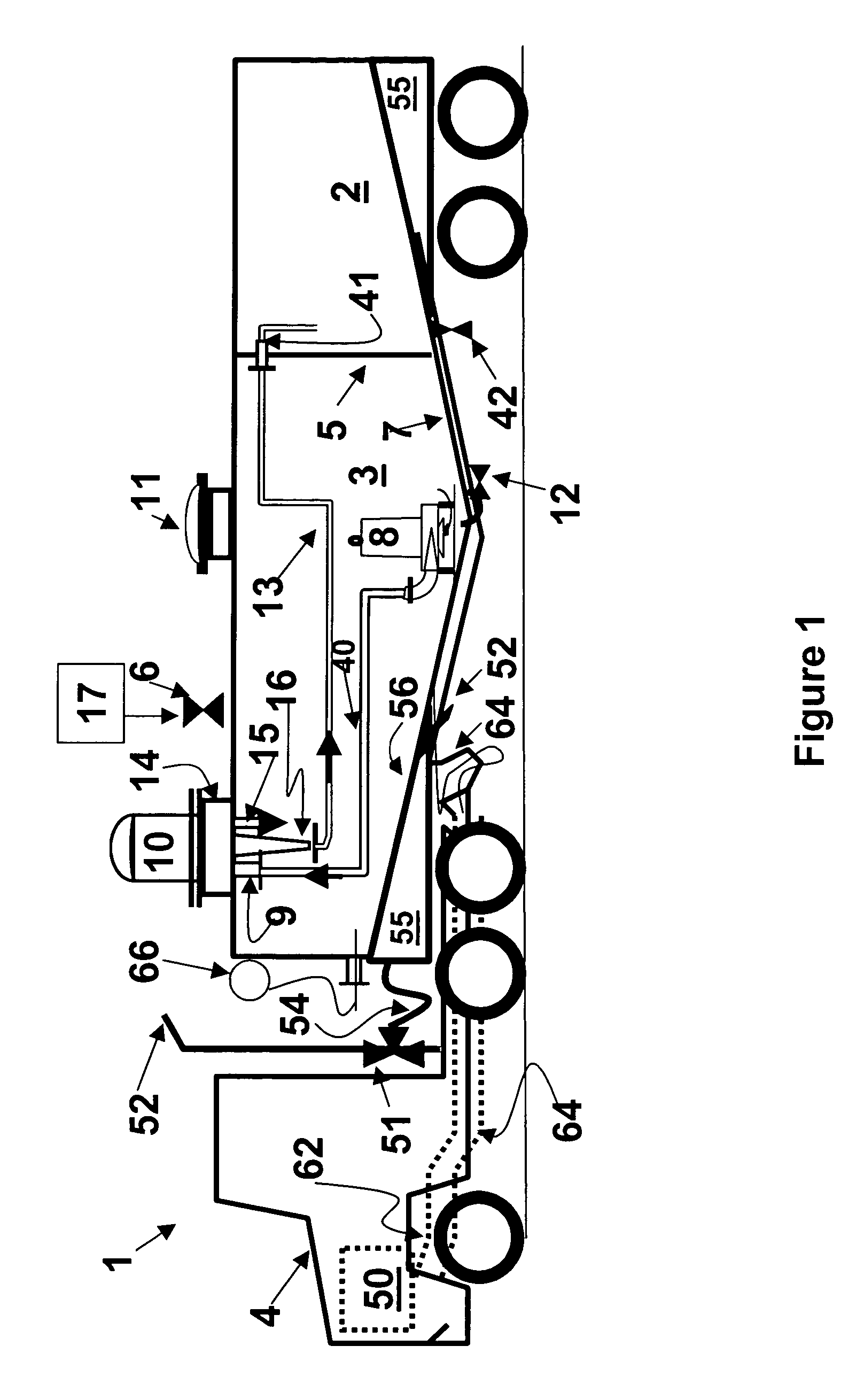

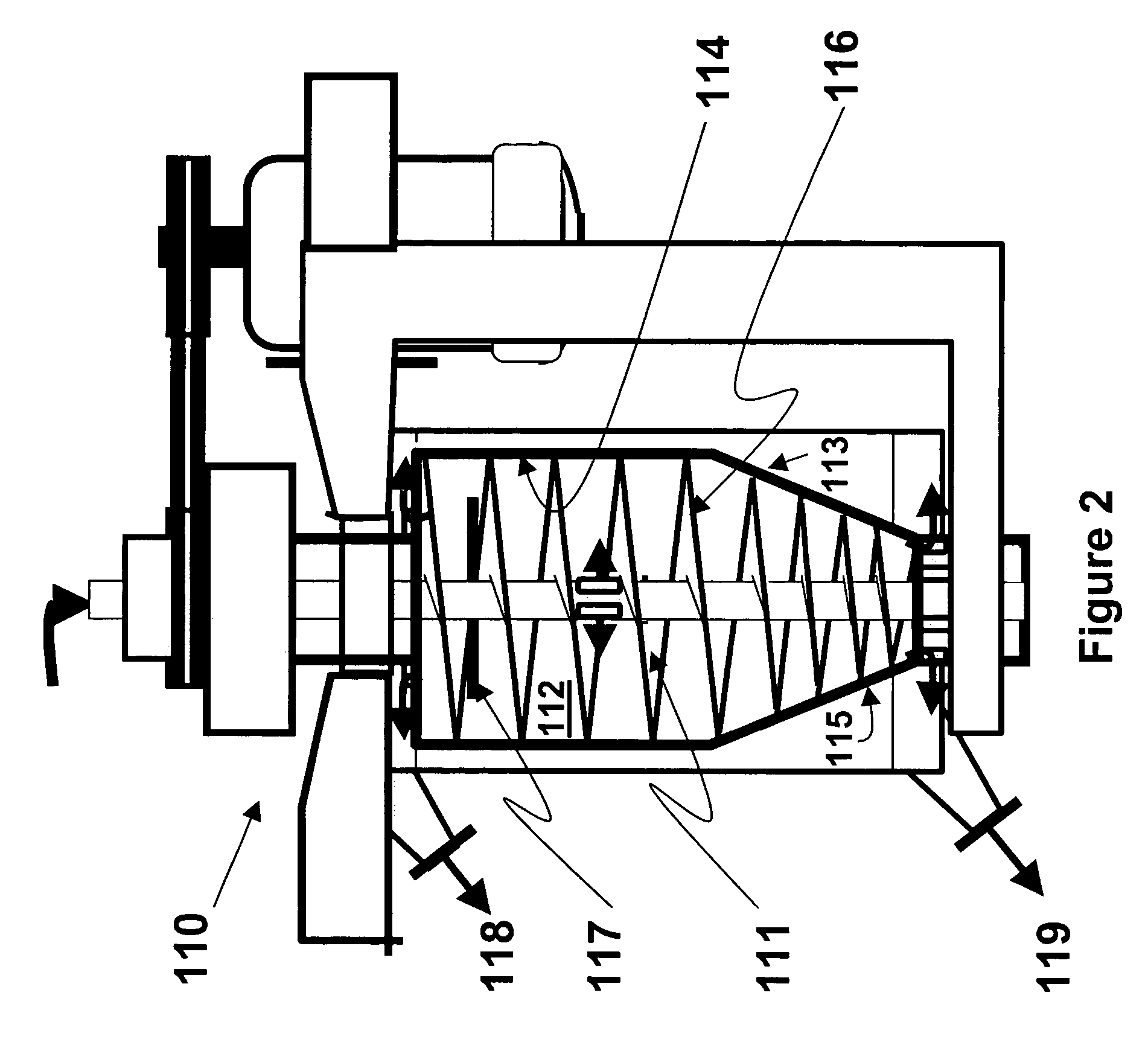

Separation system for the removal of fat, oil or grease from wastewater

InactiveUS20050247647A1Accelerate separation of aqueous phaseEasy to separateReversed direction vortexLoose filtering material filtersOil and greaseHigh density

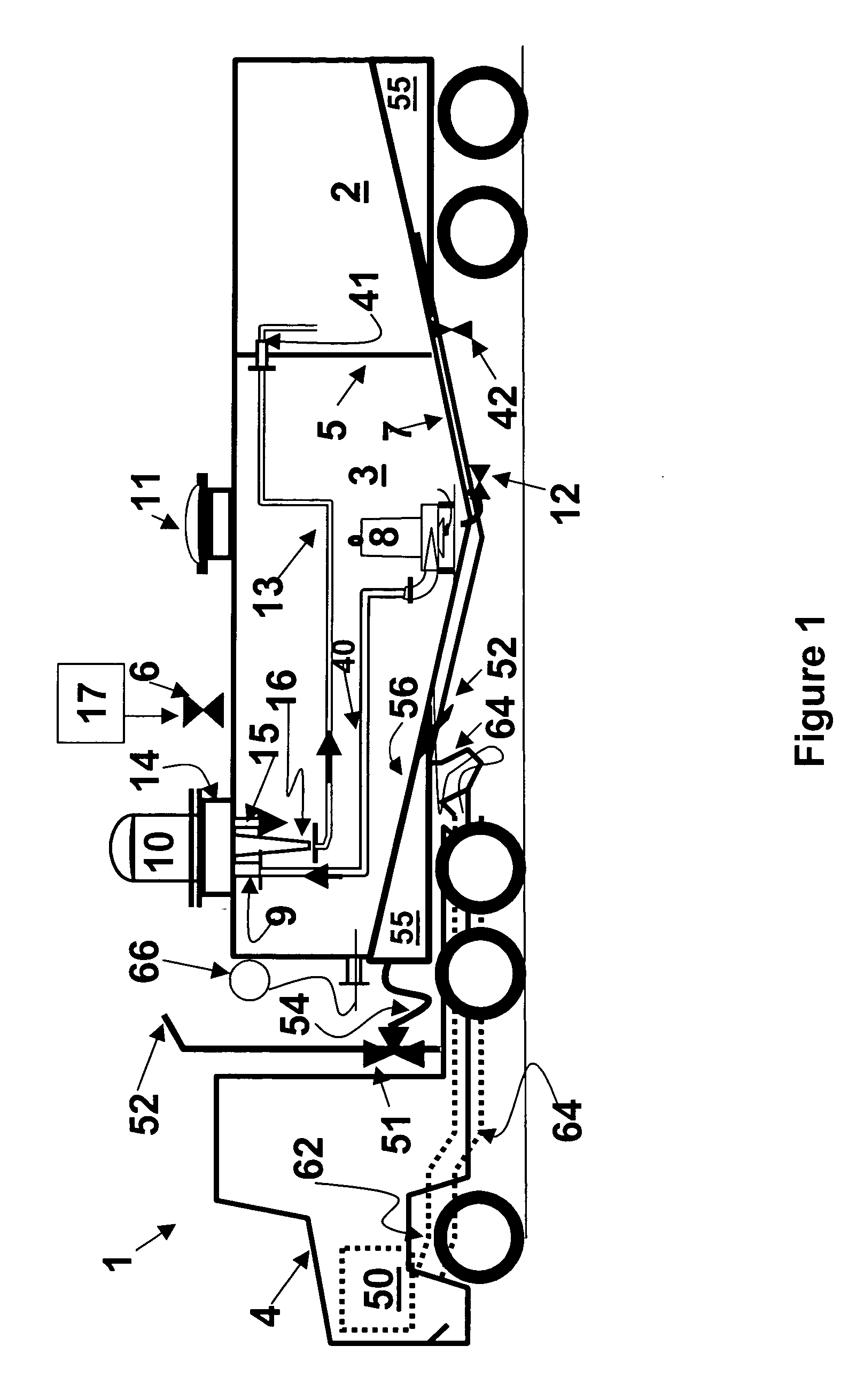

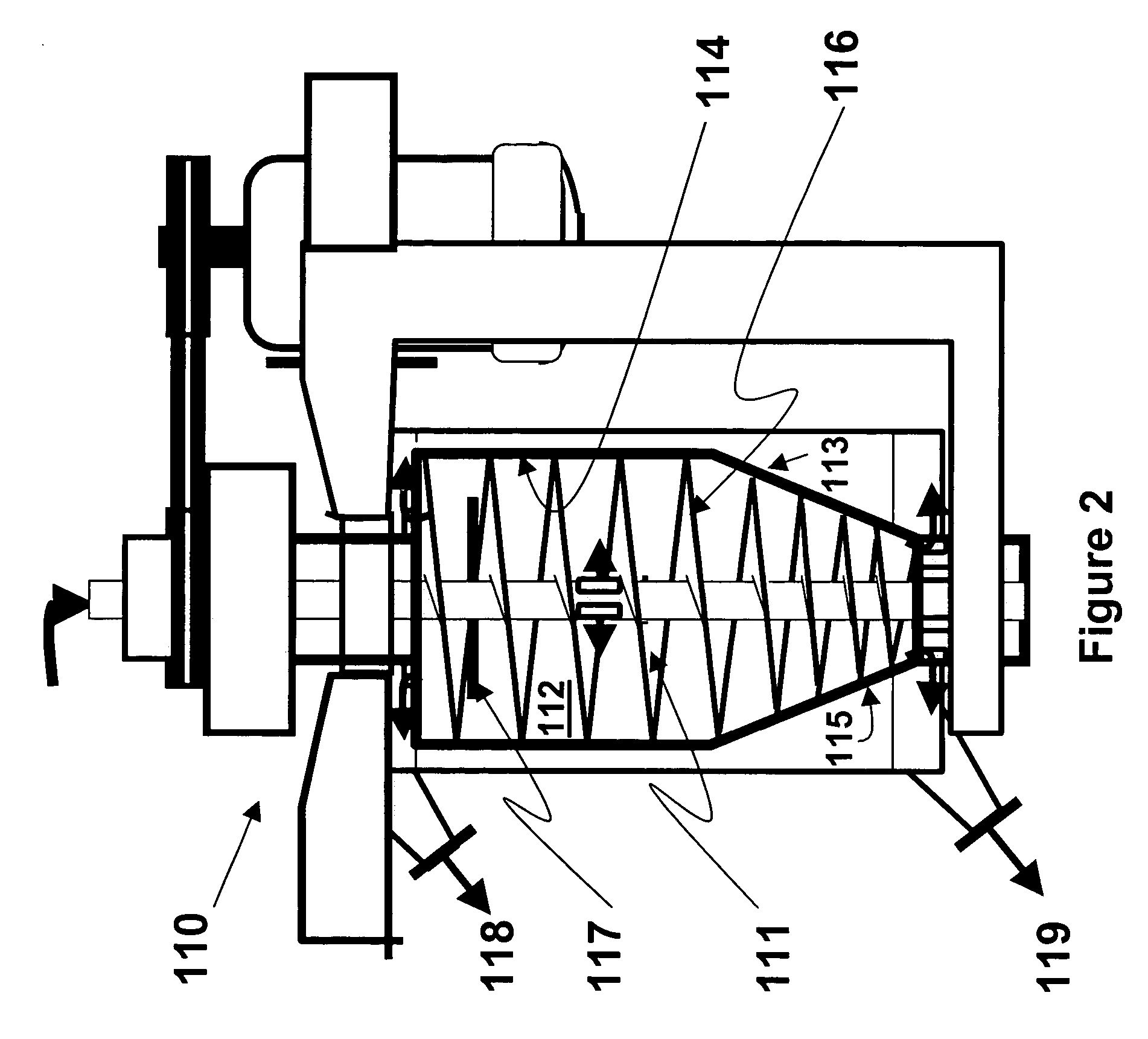

A wastewater separation system for separating an aqueous phase from an organic phase comprising oil, fat and / or grease in wastewater is disclosed. The wastewater may be collected from restaurant grease traps, as well as other food preparation facilities, schools, hospitals, processing plants and the like. A separator, such as a centrifugal separation device, comprises a wastewater inlet, an organic phase outlet for discharging low density liquid and solids and an aqueous phase outlet for discharging water and possibly other high density liquids and solids. The system can be portable and can be mounted on a vehicle for collection and treatment at various sites. Heat can be introduced to the system to accelerate the separation of the aqueous phase from the organic phase of the wastewater.

Owner:HILLS BLAIR H

Low cost indoor grease trap

An oil / grease removal assembly includes a container having an inlet to receive effluent from a kitchen sink. A drain connection spaced above the container bottom defines a static water level for contained liquid and connects to a sewer. A baffle extends downwardly below the static water level so water can flow below the baffle to the drain, while retaining floating oil / grease. Means intermittently raise the liquid level in the container above the static water level. Floating oil / grease can flow out through a port when the liquid level in the container is raised above the static water level.

Owner:THERMACO INC

Impact filter with grease trap

ActiveUS7947123B2Efficient removalCombination devicesAuxillary pretreatmentBiochemical engineeringGrease trap

Owner:ILLINOIS TOOL WORKS INC

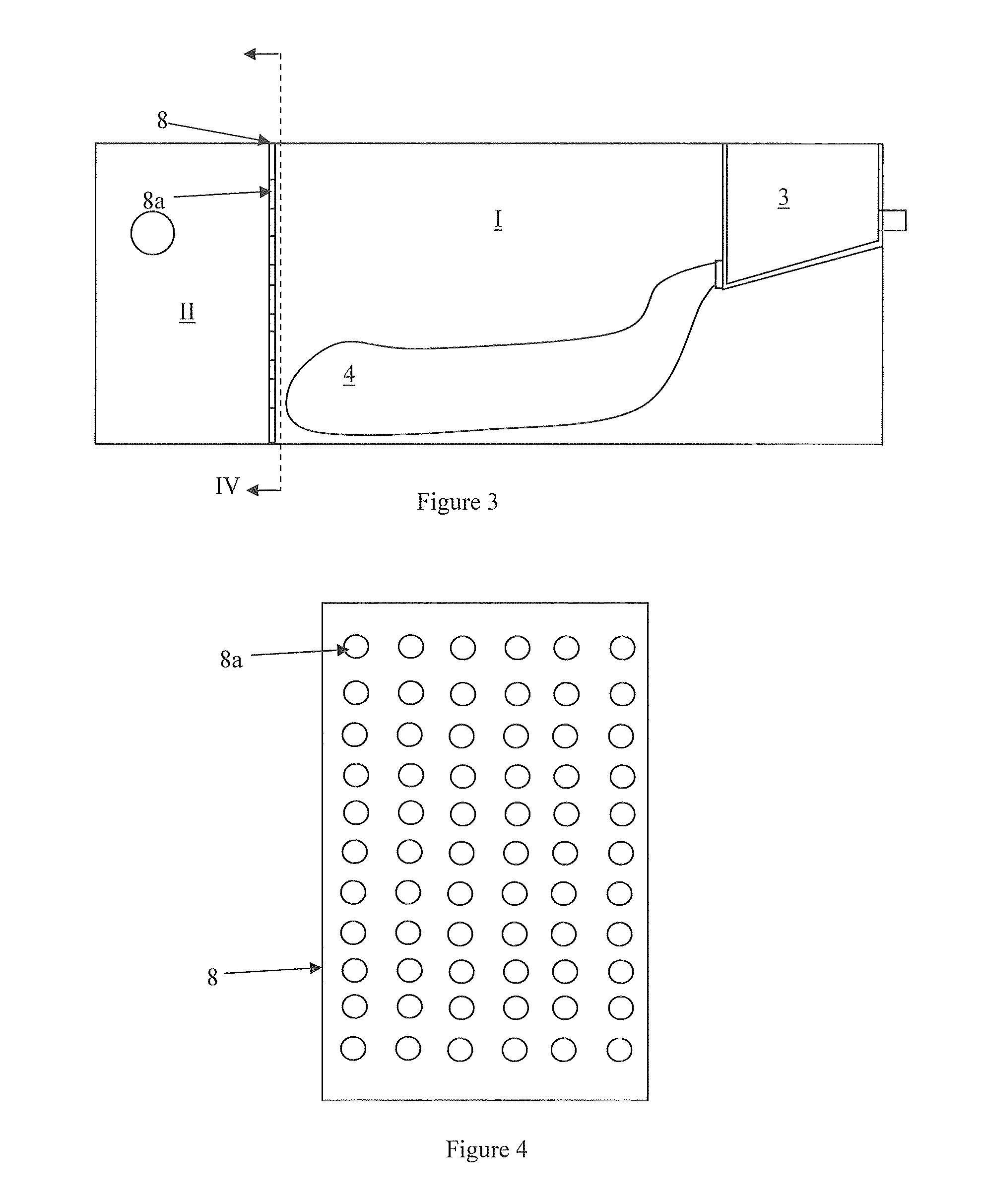

Refuse/oil removing device and refuse/oil recovery bag

InactiveUS7815800B2Improve rate of settling downPromote recoveryLiquid suspension thickening by filtrationLiquid displacementOil and greaseEngineering

A refuse / oil removing device and a refuse / oil recovery bag are provided which can remove refuse and oil contained in drainage discharged from a restaurant in a simple manner without contact with the refuse and oil. A support base of a support unit is disposed in the interior of a grease trap at a position higher than the water level. A recovery bag is attached to the support unit and plural layers of bag portions of the recovery bag are put on the support base. The bag portions are each formed of a material which permits the adhesion of oil thereto and a large number of water passing holes are formed in each of the bag portions. Drainage is introduced inside the innermost one of the plural layers of bag portions and is passed through the bag portions, allowing refuse and oil to adhere to the bag portions. In this way, the job of replacing the recovery bag can be simplified and the amount of oil accumulated within the grease trap can be decreased.

Owner:KOMATSU KIYOSHI

Process for treating septage

InactiveUS7070693B2Easy to dehydrateQuality improvementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSolid fractionPasteurization

A process and apparatus for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process will convert the septage into Biosolids (sludge) and water dischargeable to the environment. The treated septage achieves pathogen reduction, and reduced vector attraction. Treatment of septage by pasteurization causes the destruction of harmful pathogens. Pasteurization of septage having high water content provides for even temperature elevation and distribution of heat within the thermal mass of the septage allowing for consistent pathogen destruction. An alkaline compound is utilized to form a filter cake from the solids fraction of the pasteurized septage preventing vector attraction, while producing a beneficial bio-solid. The liquid fraction of the septage is treated by biological process allowing for its discharge into the environment.

Owner:KELLY ROBERT J

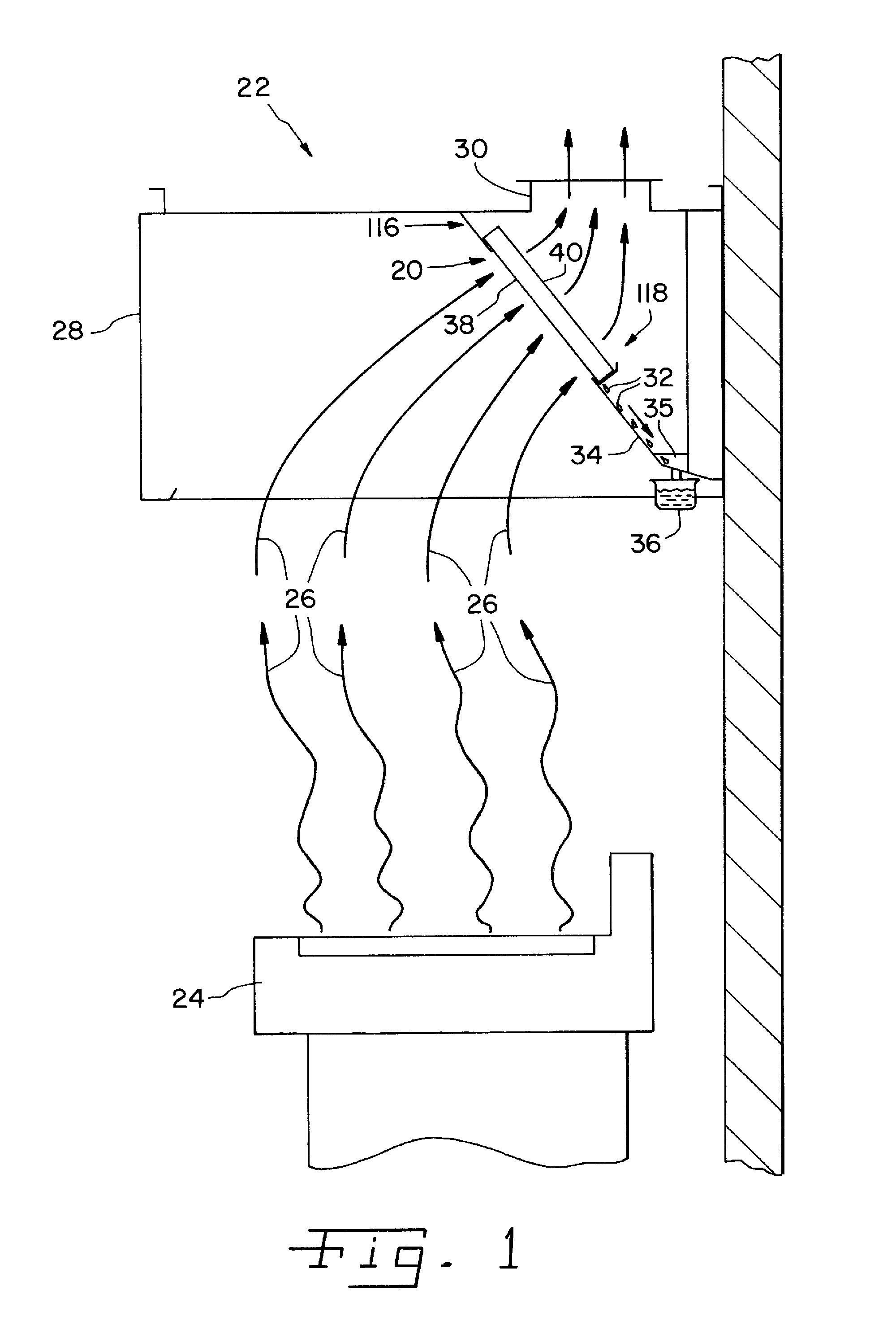

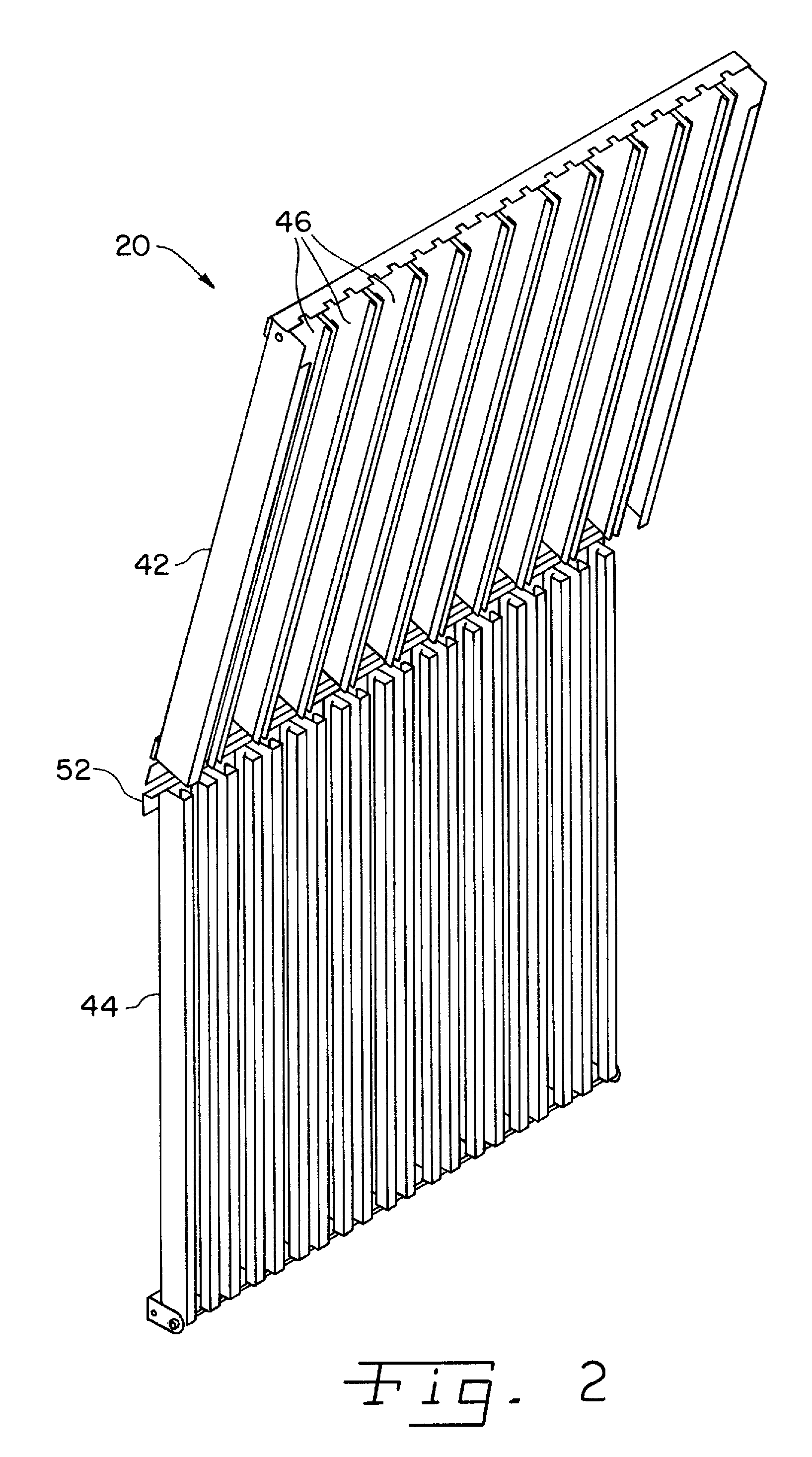

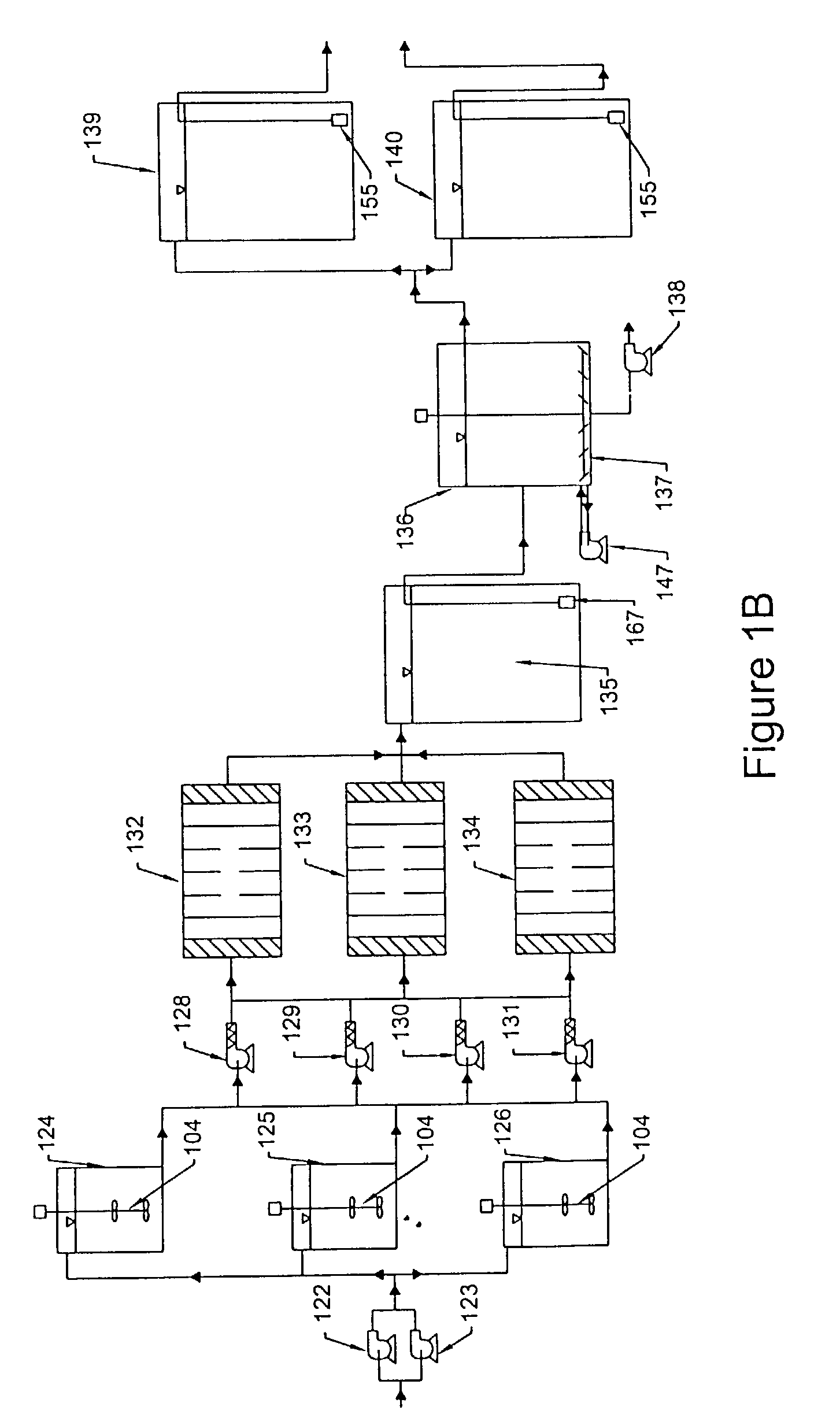

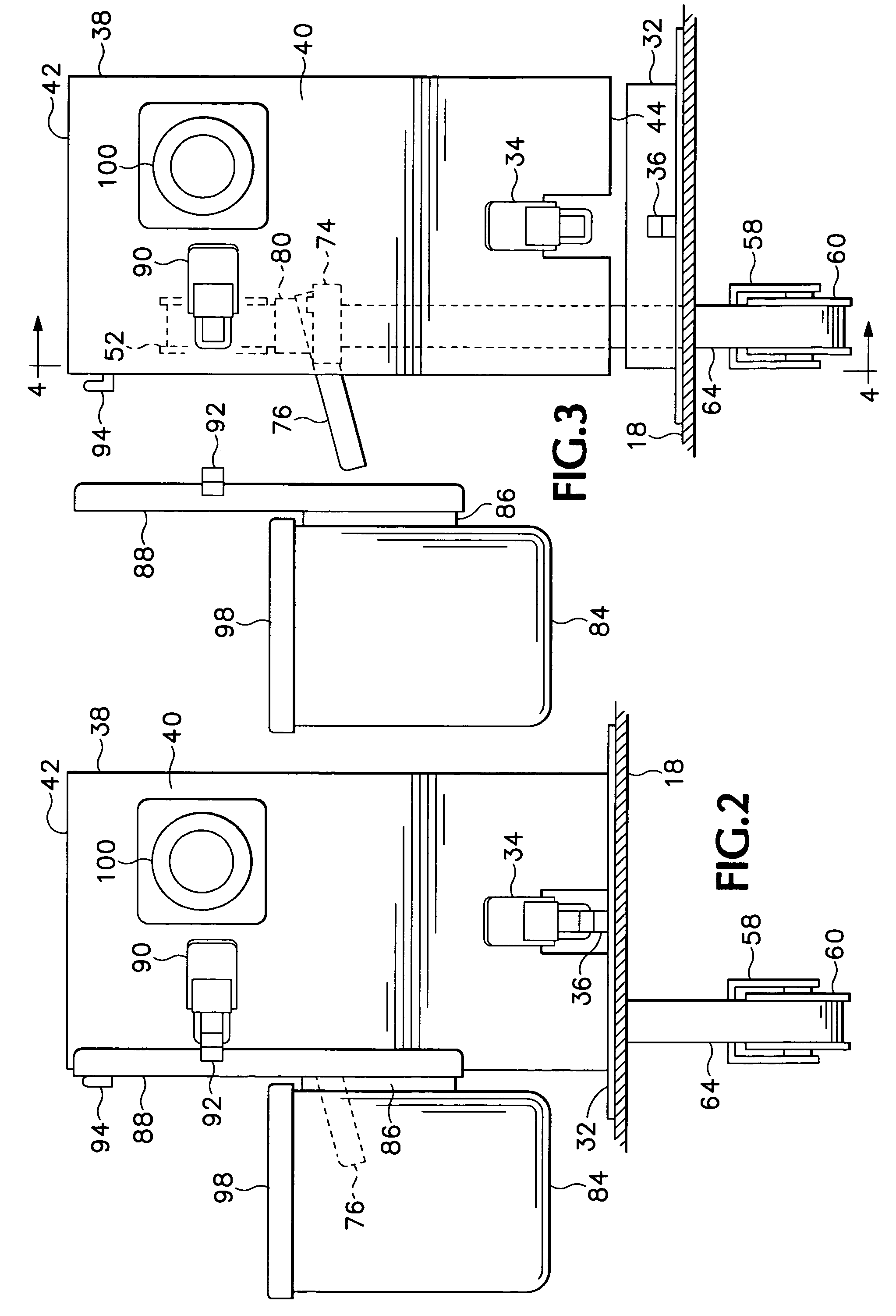

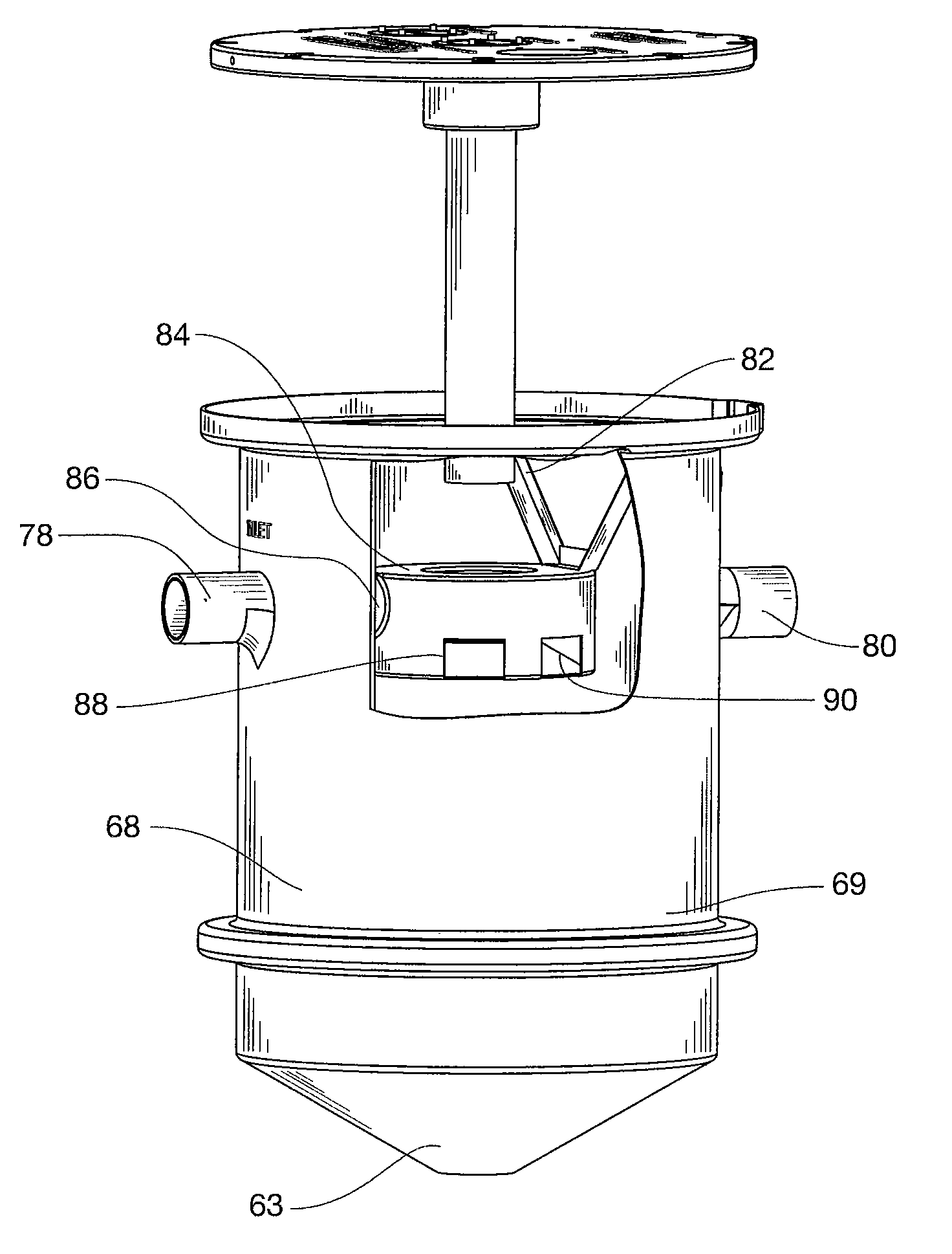

Tower-type grease removal apparatus for commercial grease trap assemblies

InactiveUS7296694B2Rule out the possibilityAvoid the needFatty/oily/floating substances removal devicesWater cleaningTowerGrease trap

A grease skimming and removal apparatus for use with grease trap settling tank apparatus provides a vertically elongated, vertically extending tower housing on the top wall of a grease trap tank and provides a power driven, vertically elongated, vertically extending rotating skimmer belt loop arranged to skim and transport grease and oils from wastewater contained in the grease trap tank to a vertically-elevated position above the top wall of the settling tank for gravity discharged therefrom and into a collection vessel releasably secured to the tower housing above the top wall of the grease trap tank.

Owner:WEYMOUTH BRET M

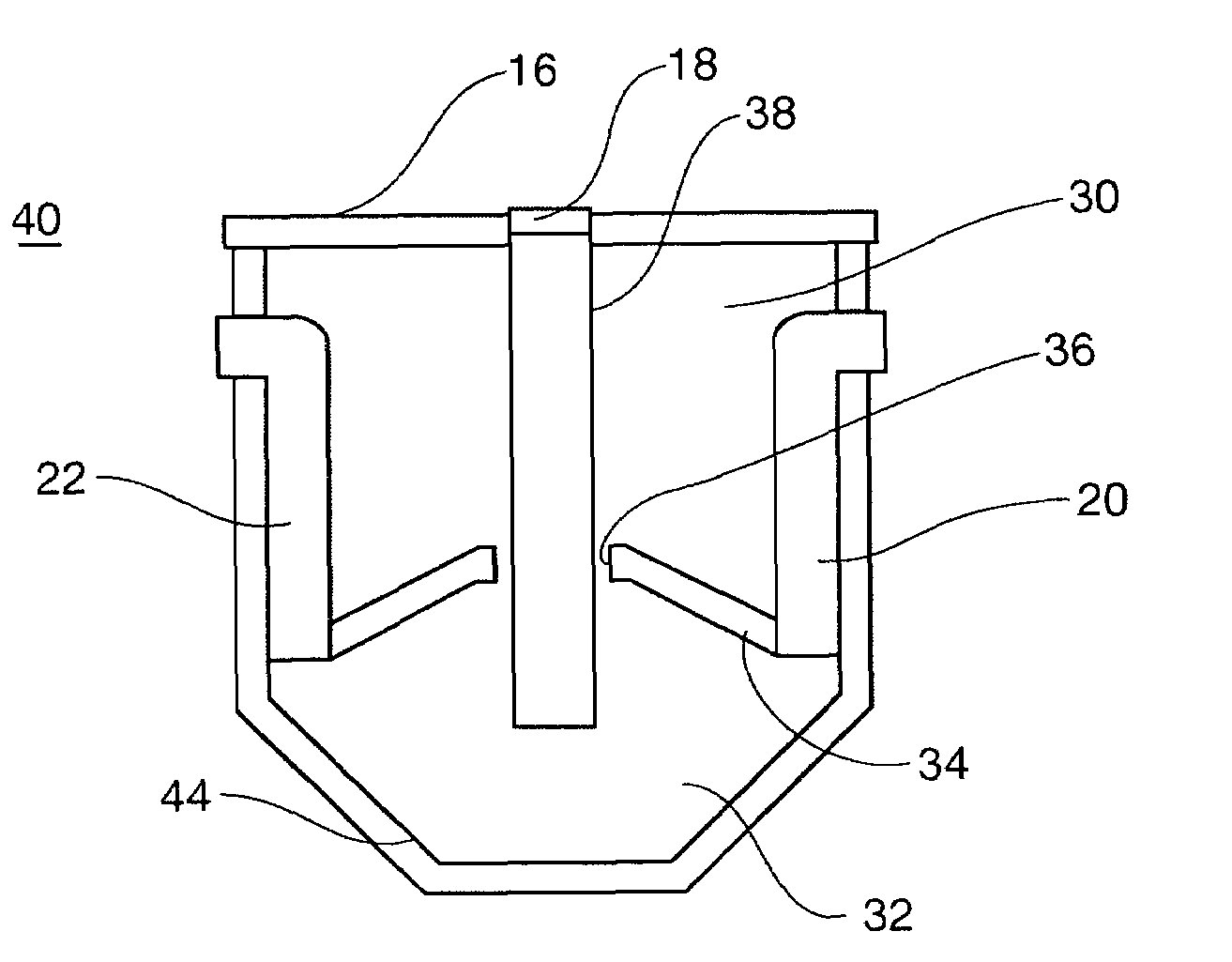

Passive grease trap using separator technology

A grease trap for separating grease and solid waste from waste water. The grease trap includes a tank having a downwardly shaped bottom. An upwardly shaped divider divides the tank into an upper chamber and a lower chamber. A hole near an upper part of the divider allows waste into the upper chamber. An inlet invert in the tank receives incoming waste water, while an outlet invert removes water from the tank. A lid covers the tank. A pipe extends through the lid, upper chamber, and lower chamber for sucking solid waste out of the lower chamber.

Owner:THERMACO INC

Passive grease trap with pre-stage for solids separation

ActiveUS7641805B2Reduce entrainmentEase wasteSeparation devicesWater/sewage treatmentWater dischargeResidence time

A solids collector for collecting solids in waste water that are heavier than water includes a roto-molded plastic container having a cylindrical sidewall and a downwardly sloping bottom. An inlet and outlet are connected to the sidewall substantially above the sloping bottom so that solids that are heavier than water in the waste water coming into the container through the inlet have residence time in the container long enough to gravitationally separate towards the bottom. Waste water depleted of solids that are heavier than water discharge from the container through the outlet.

Owner:THERMACO INC

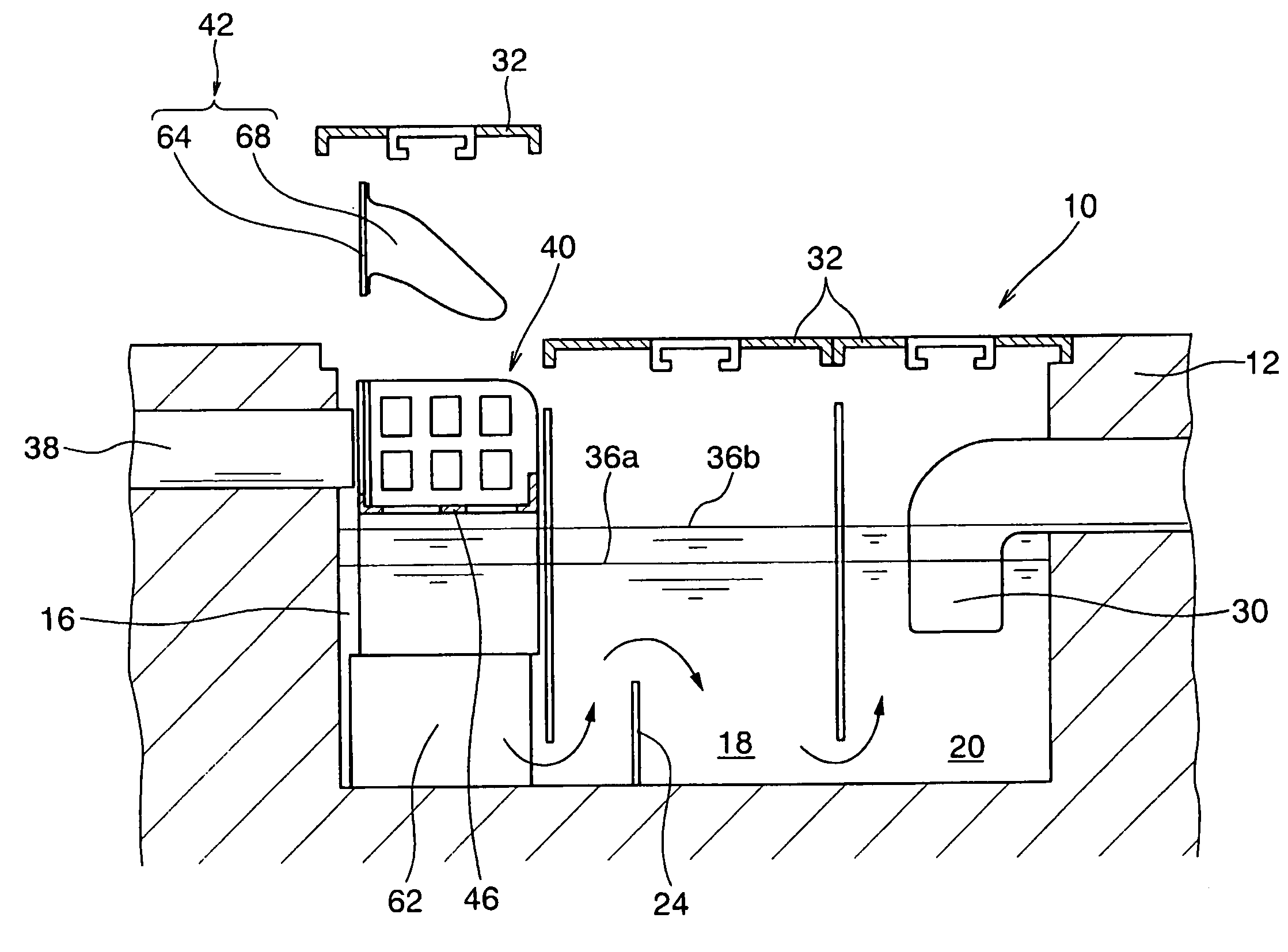

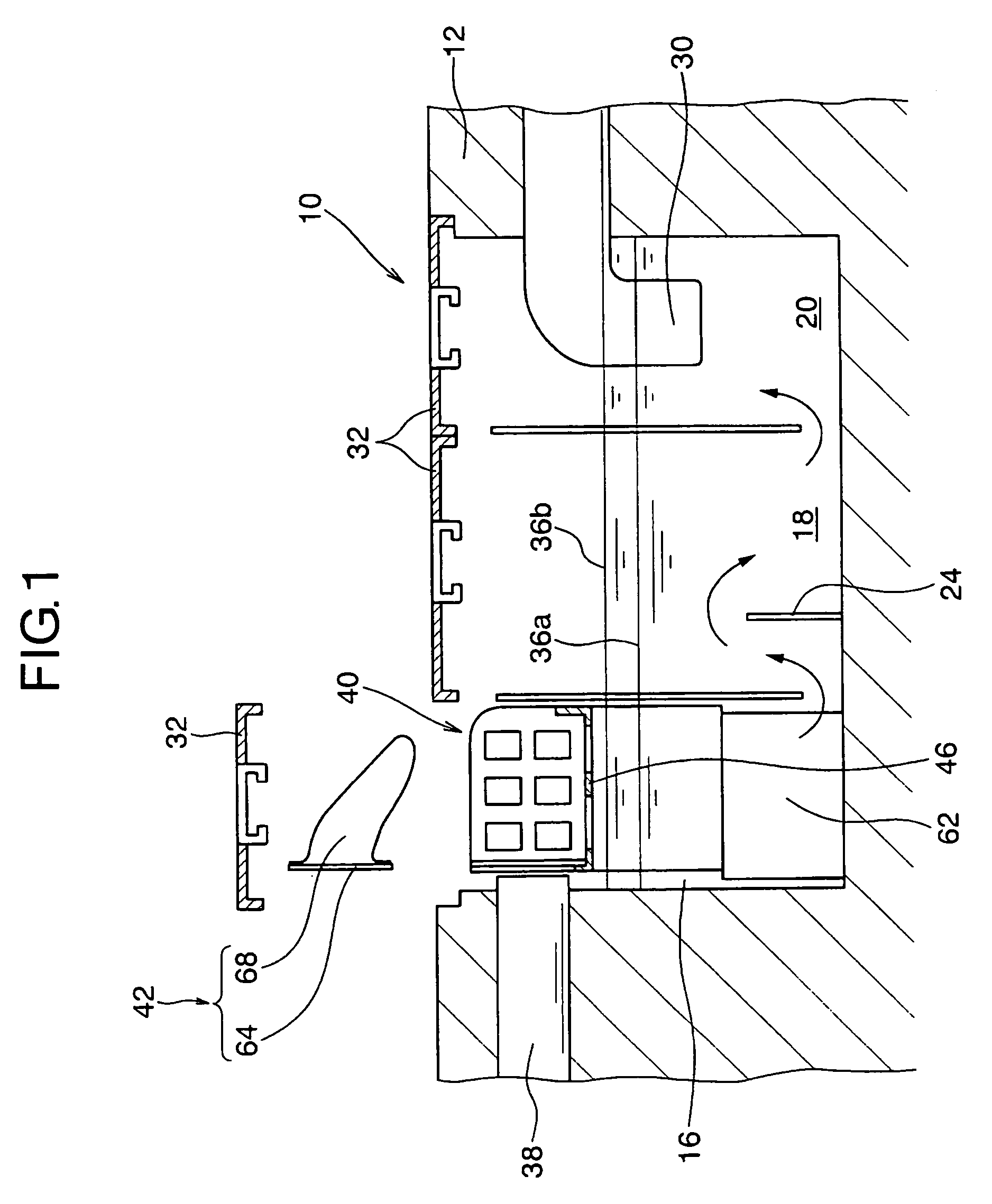

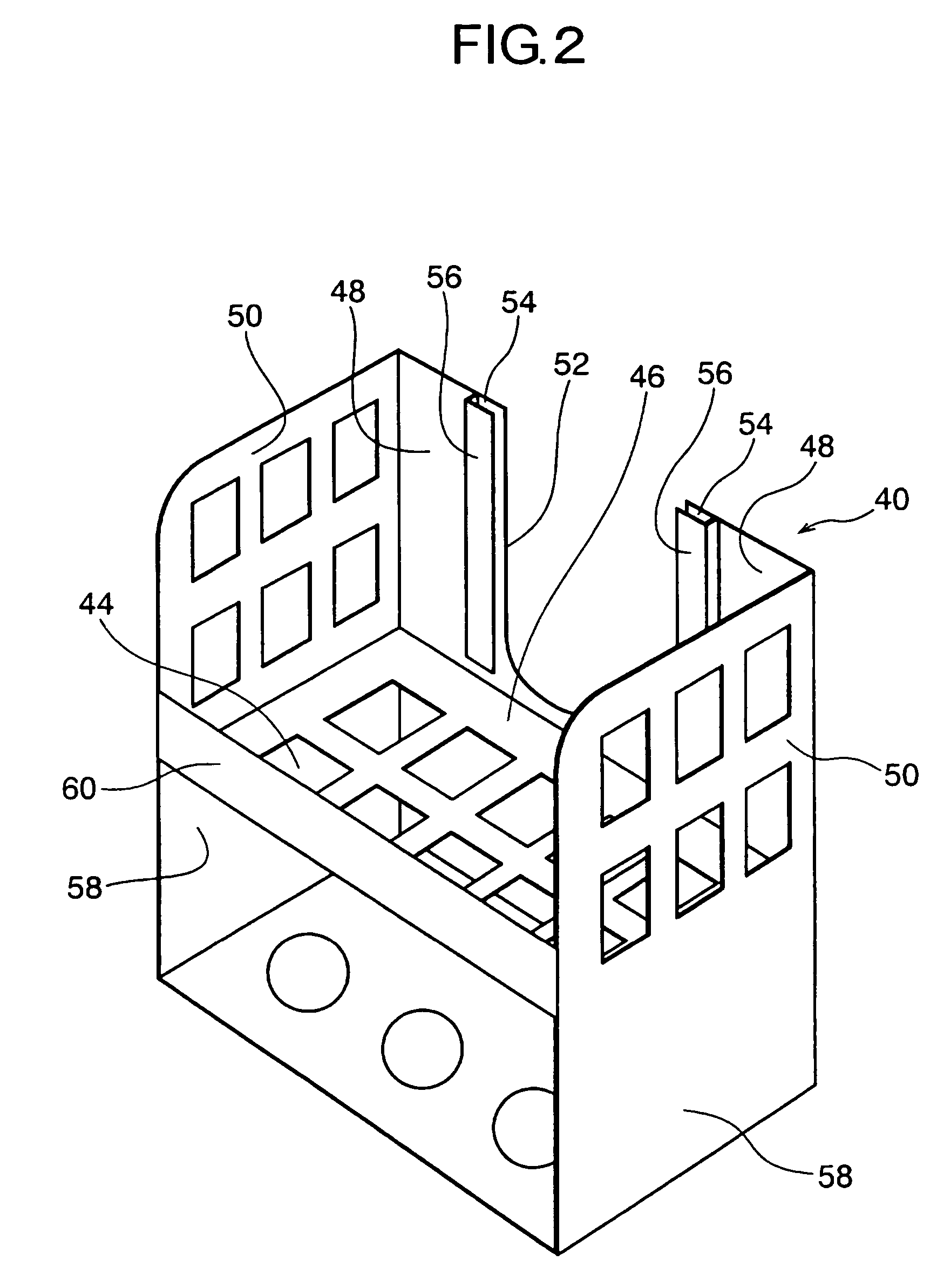

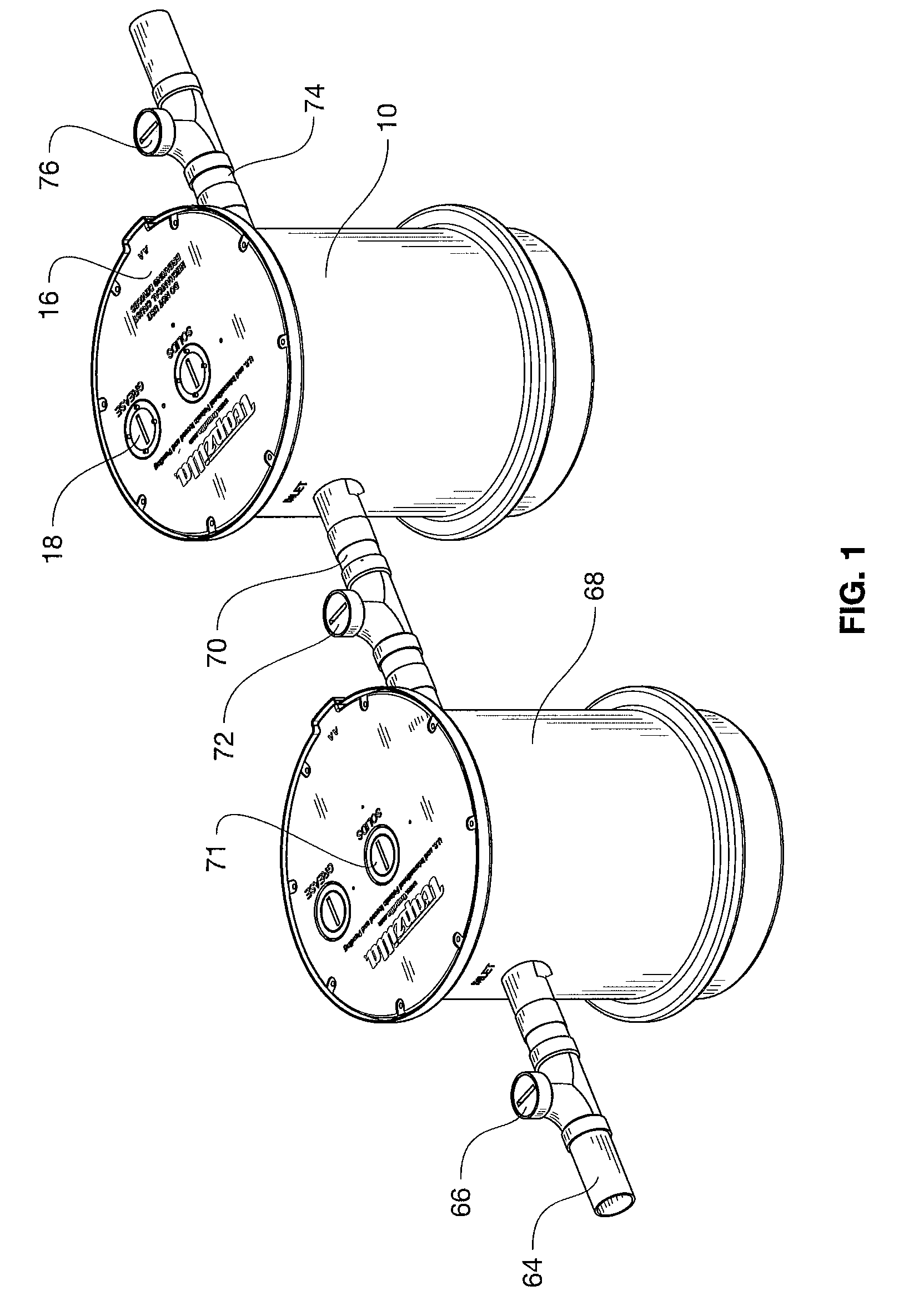

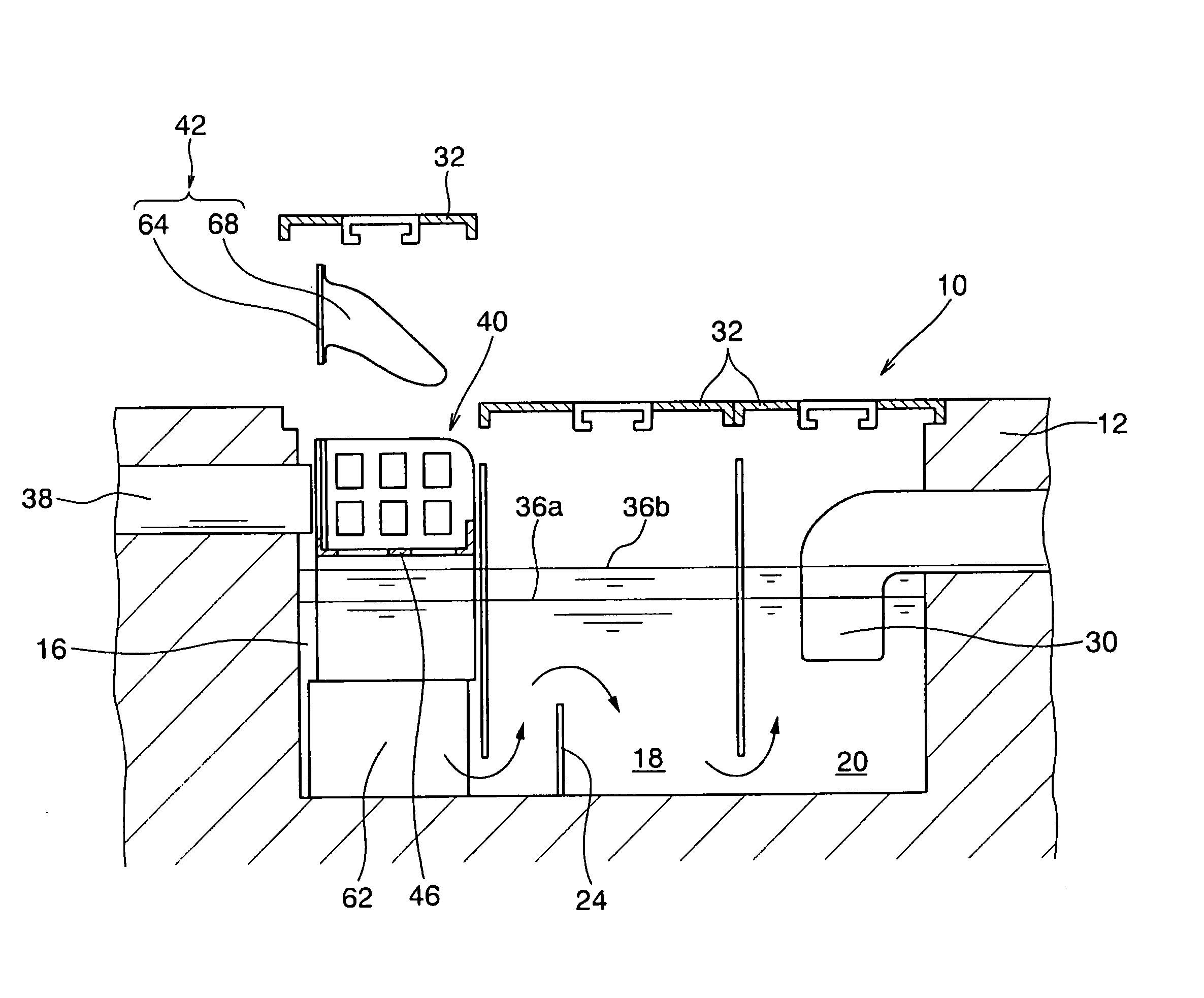

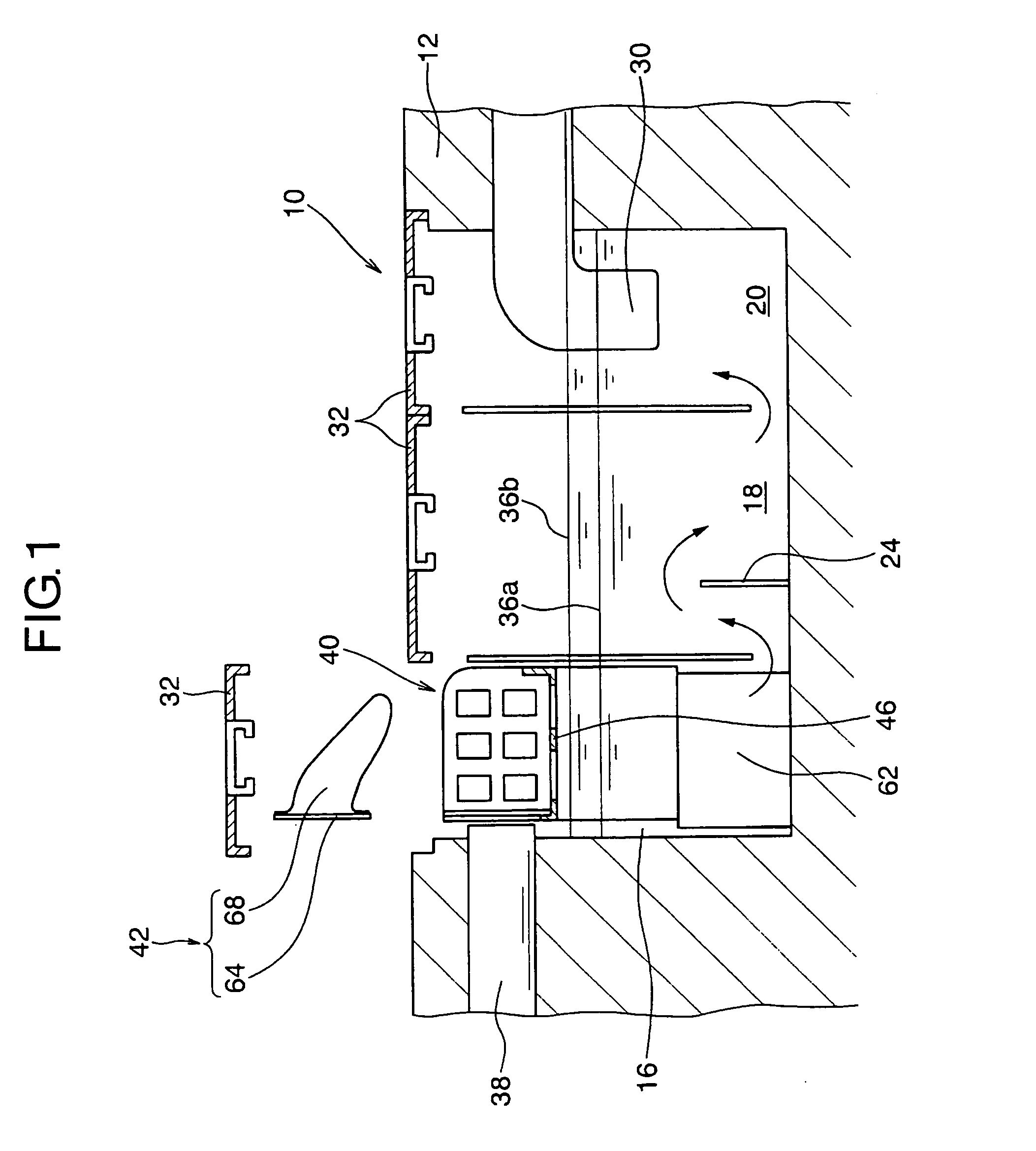

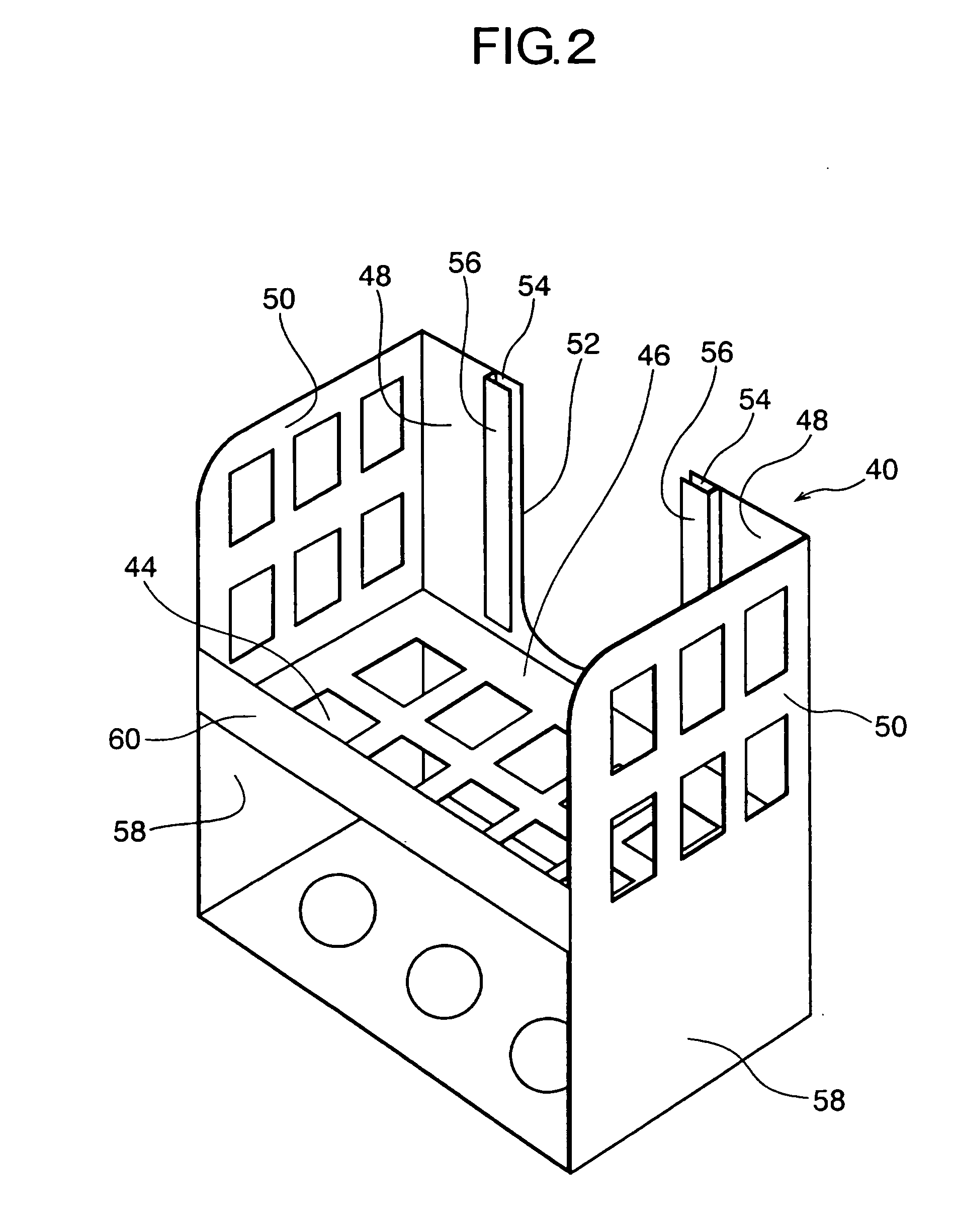

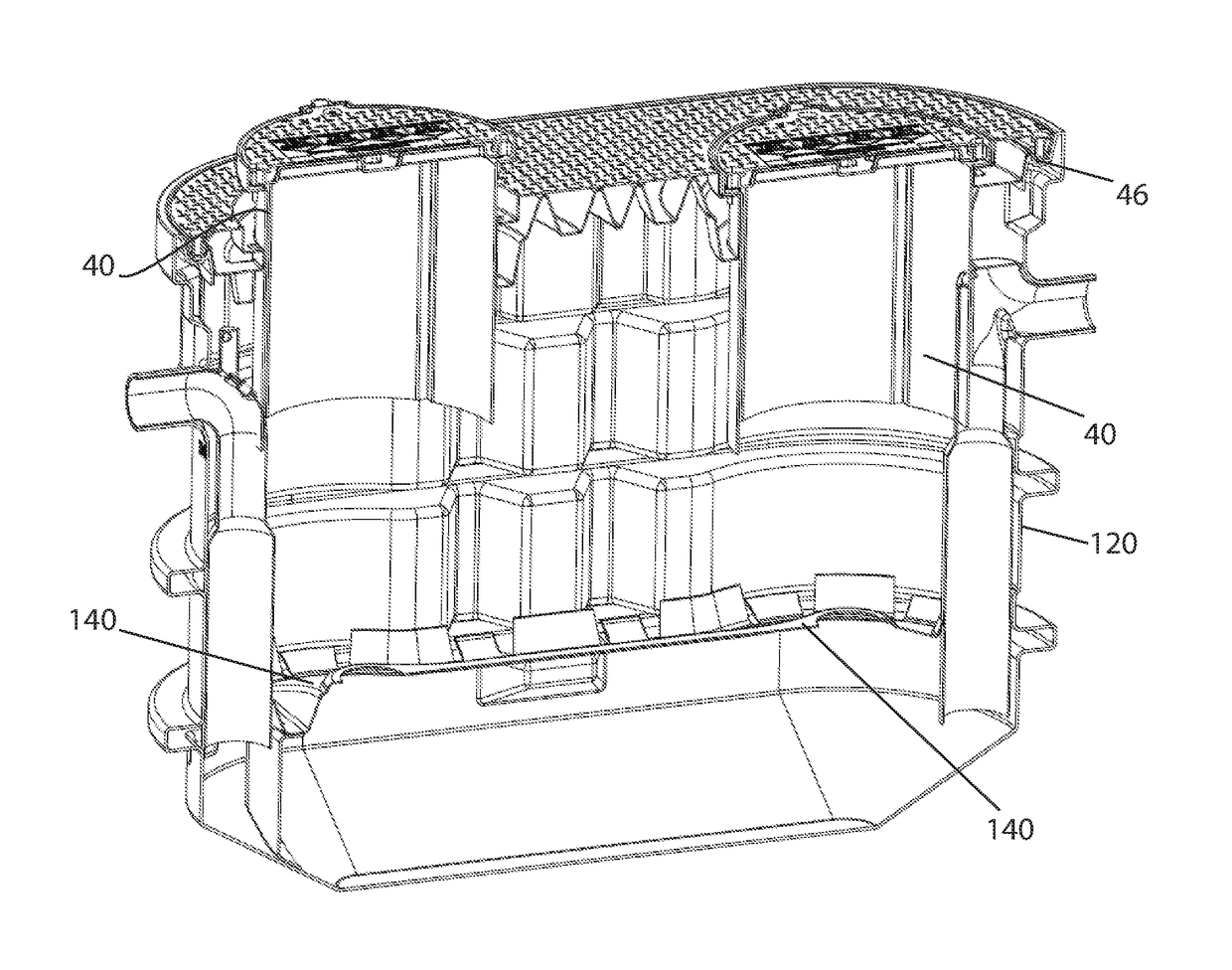

Refuse/oil removing device and refuse/oil recovery bag

InactiveUS20070095749A1Improve rate of settling downSimple working processLiquid suspension thickening by filtrationLiquid displacementEngineeringGrease trap

A refuse / oil removing device and a refuse / oil recovery bag are provided which can remove refuse and oil contained in drainage discharged from a restaurant in a simple manner without contact with the refuse and oil. A support base 46 of support means 40 is disposed in the interior of a grease trap 10 at a position higher than a water level 36b. A recovery bag 42 is attached to the support means 40 and plural layers of bag portions 68a, 68b, and 68c of the recovery bag 42 are put on the support base 46. The bag portions 68a, 68b, and 68c are each formed of a material which permits the adhesion of oil thereto and a large number of water passing holes 72 are formed in each of the bag portions 68a, 68b, and 68c. Drainage is introduced inside the innermost one of the plural layers of bag portions 68a, 68b, and 68c and is passed through the bag portions 68a, 68b, and 68c in this order, allowing refuse and oil to adhere to the bag portions. In this way the work of replacing the recovery bag 42 can be simplified and the amount of oil accumulated within the grease trap 10 can be decreased.

Owner:KOMATSU KIYOSHI

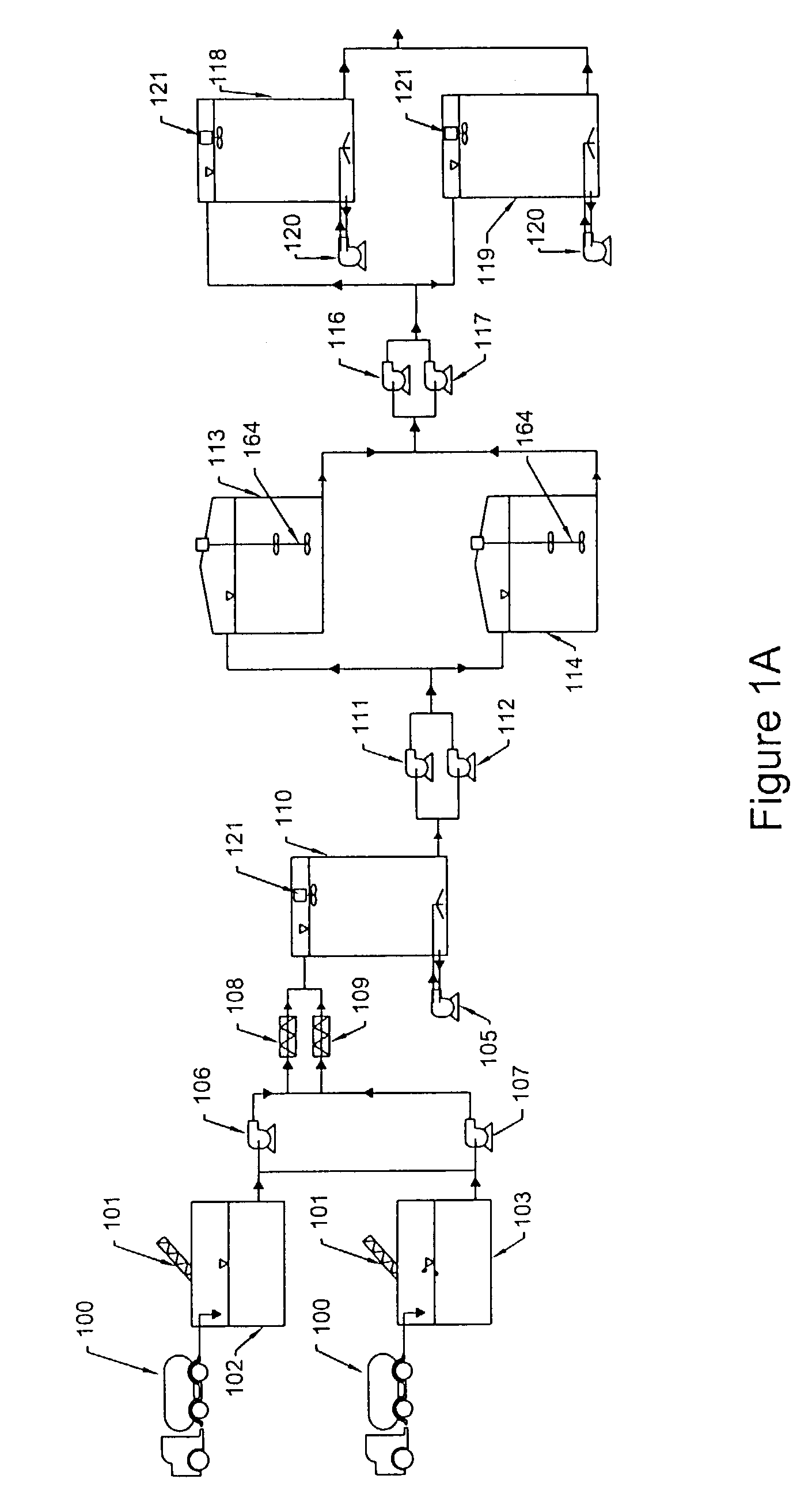

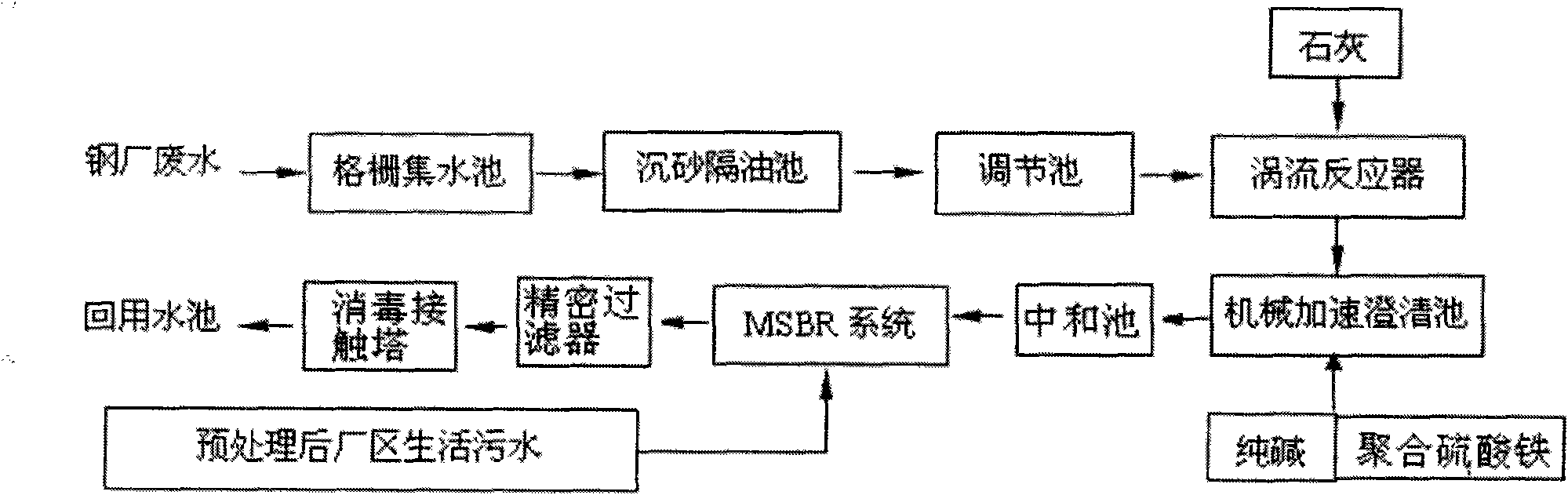

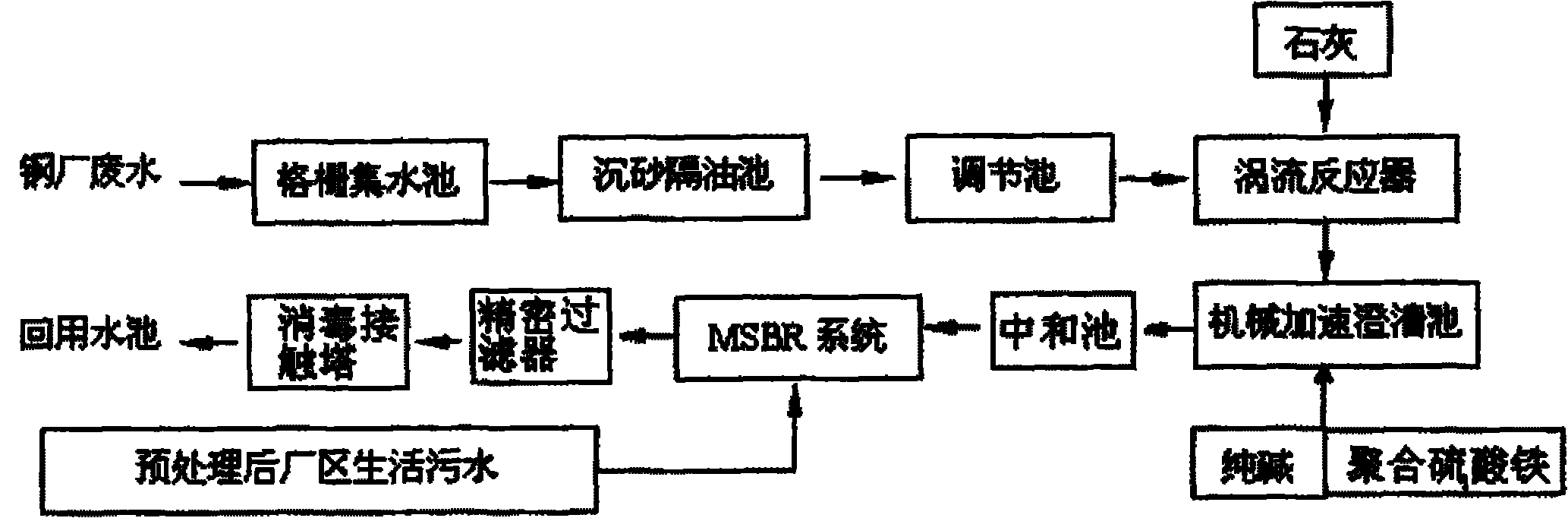

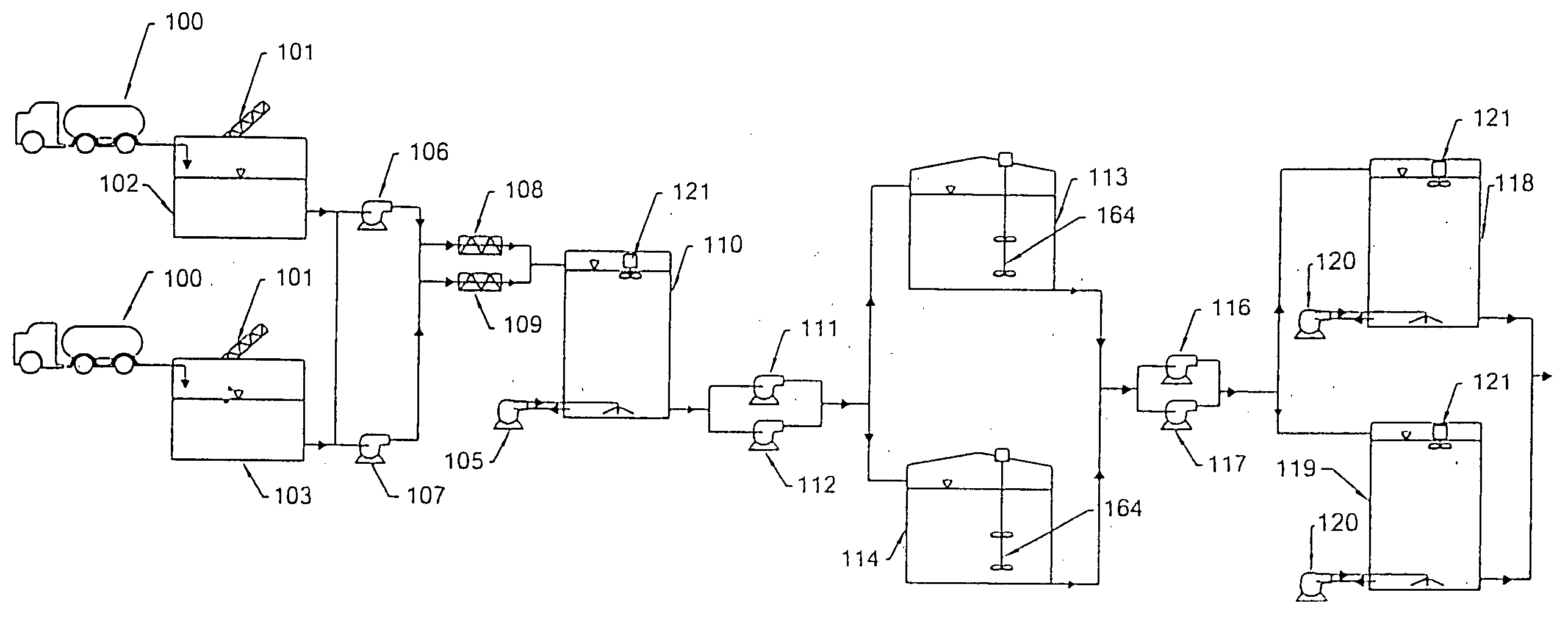

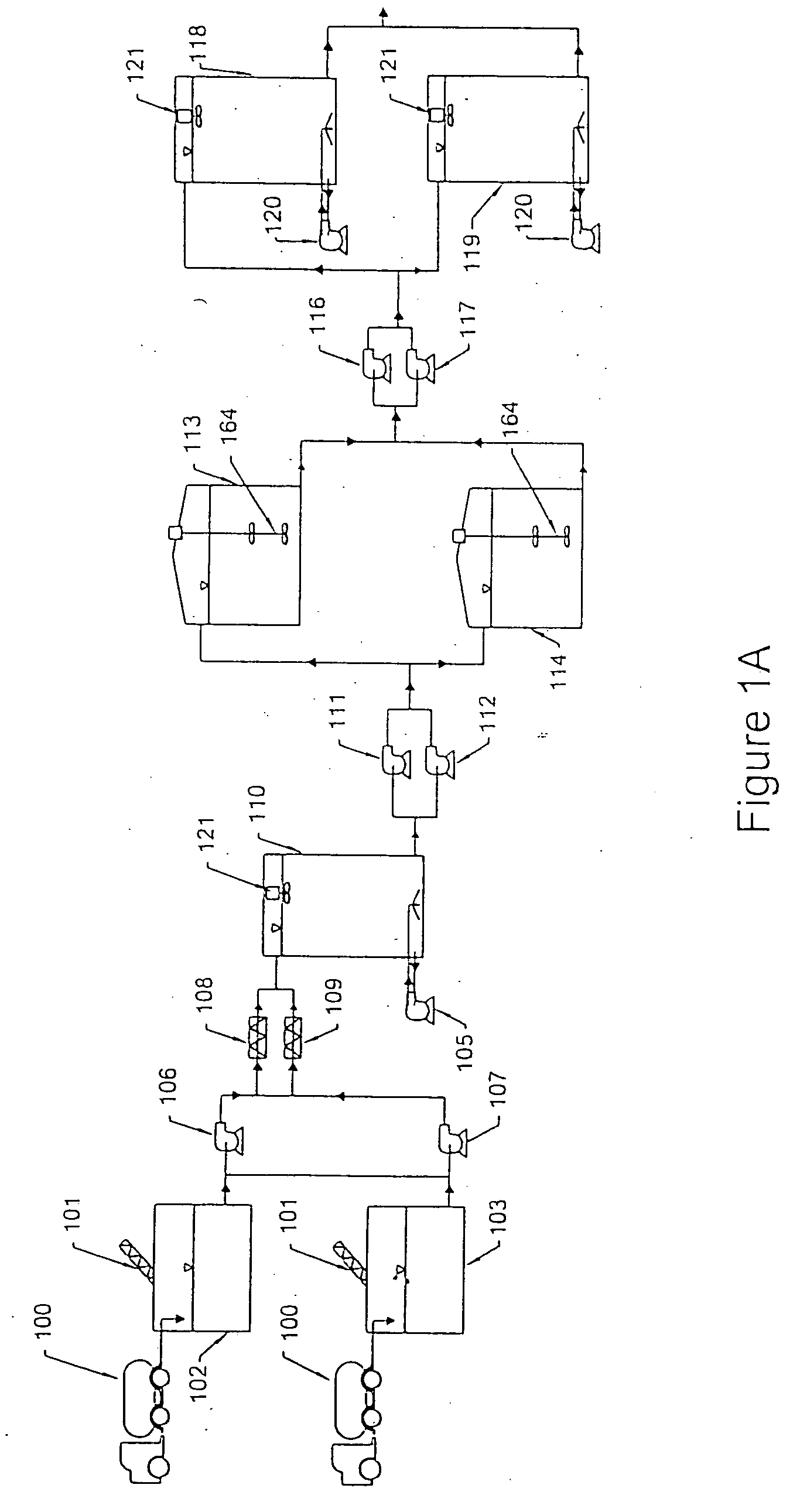

Method for treating and recycling waste water of steel plants

ActiveCN102086078AAchieving "zero" emissionsAlleviate water shortageMultistage water/sewage treatmentWater qualityWater flow

The invention relates to a method for treating and recycling waste water of steel plants, which belongs to sewage treating and recycling technology field. The method comprises the steps that: the waste water of the steel plants flows through a grating collecting pit; the waste water treated from the grating collecting pit is lifted to a sand settling grease trap by a submersible sewage pump; the waste water treated from the sand settling grease trap flows into an equalizing tank to adjust water quality and water amount, and then is quantificationally lifted into an eddy current reactor containing lime by the pump; the waste water treated from the eddy current reactor flows into a machinery acceleration clarification pool, then flows into an MSBR system and an intermediate pool in sequence, afterwards is driven into a precision filter by a filtering pump to remove suspension; the filtered water is sufficiently contacted with ozone for ozone disinfection; the disinfected waste water flows into a reuse pool and is driven to each reuse water point; and thus the whole process of treating and recycling the waste water of the steel plants is achieved. The invention has the advantages of high temperature backwater system for water supplement, all for production, realization of waste water free-discharging, environmental protection and water resource conservation.

Owner:CHINA NORTH ENERGY CONSERVATION & ENVIRONMENT PROTECTION

Process for treating septage to extract a bio-fuel

InactiveUS20070056902A1Uniform and thorough heat treatmentGreat pathogen reductionSludge treatmentOther chemical processesAlternative fuelsBiofuel

A process for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process converts septage into sludge usable as a bio-fuel. The conversion of the septage makes it desirable as an alternative fuel source, as the sludge has a high BTU value due to the large percentage of grease in the septage.

Owner:KELLY ROBERT J

Passive grease trap using separator technology

ActiveUS9932247B1Increase capacityIncrease the extension lengthFatty/oily/floating substances removal devicesSewerage structuresFuel tankGrease trap

An apparatus and method for a grease trap for separating grease and solid waste from waste water. The grease trap includes a tank having a downwardly shaped bottom. An upwardly shaped baffle insert divides the tank into an upper chamber and a lower chamber. An outlet port near an upper part of the baffle allows waste into the upper chamber. An inlet invert in the tank receives incoming waste water, while an outlet invert removes water from the tank. A removable cover covers the tank and allows access for removal of accumulated grease and solid wastes.

Owner:THERMACO INC

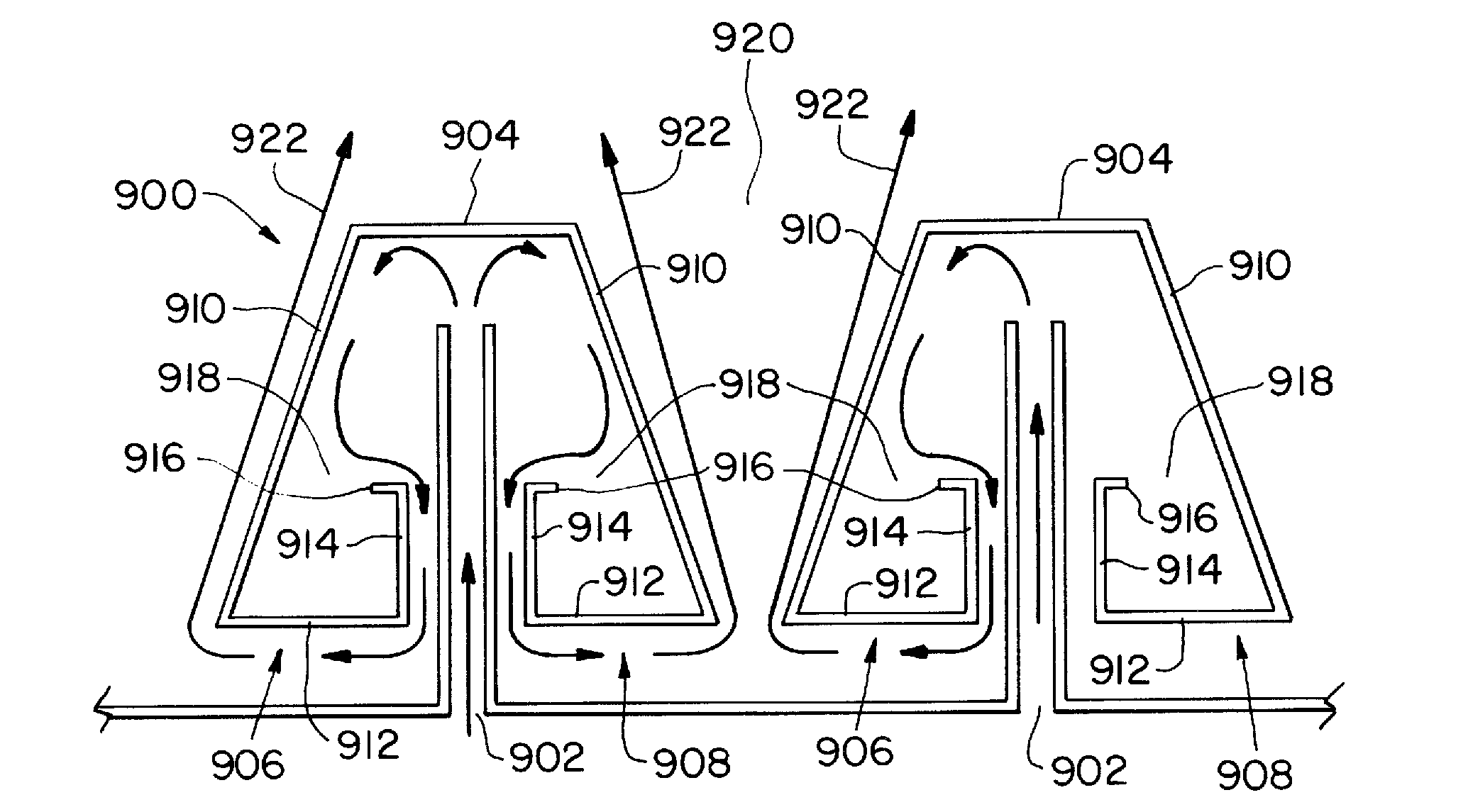

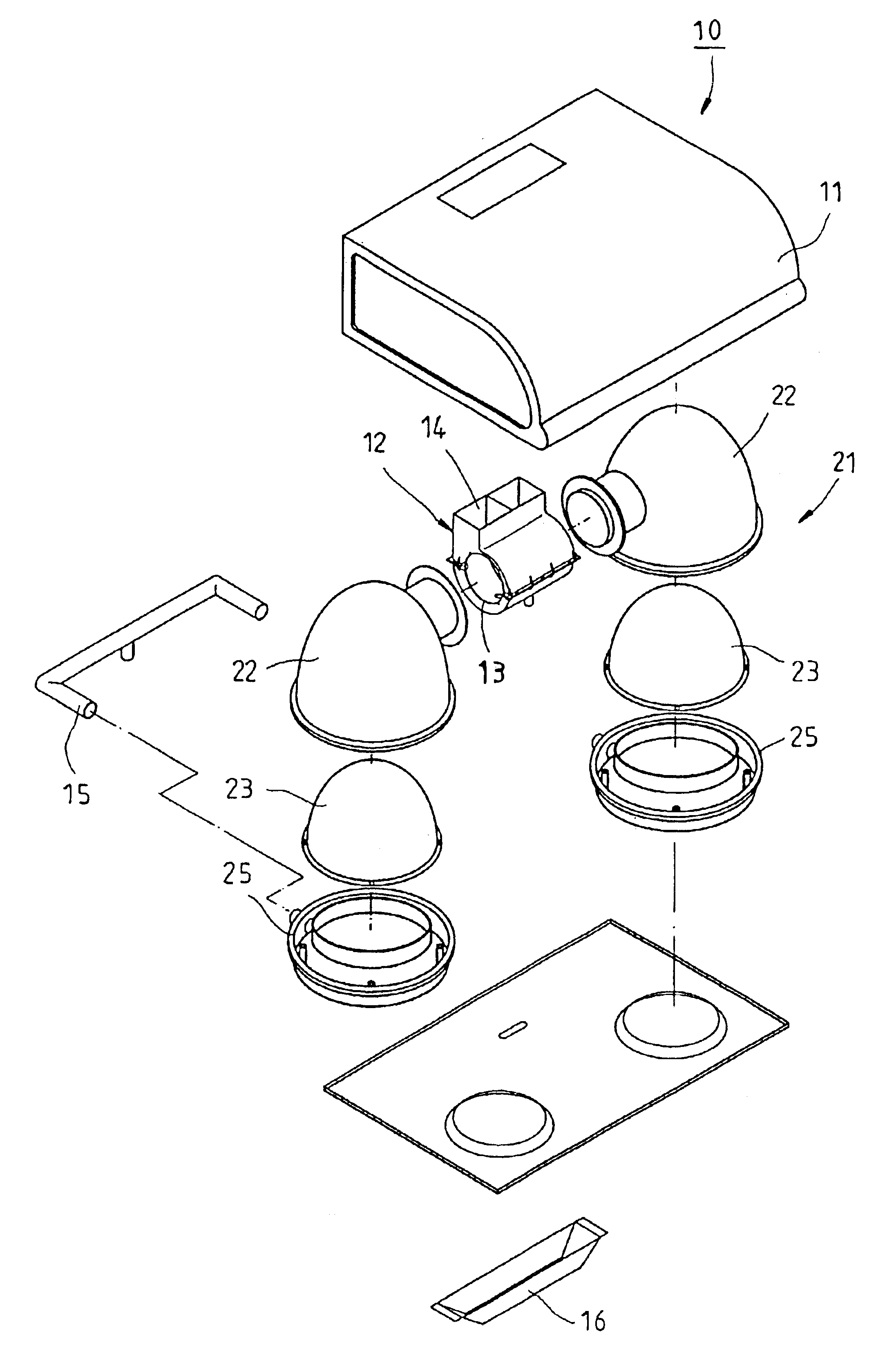

Smoke guide structure for kitchen hood

InactiveUS6913014B2Prevent leakageEfficiently expelledDomestic stoves or rangesLighting and heating apparatusGrease trapSmoke

A smoke guide structure used in a kitchen hood having a housing, an air buffer with an air inlet and an air outlet provided inside the housing, and a fan and fan motor assembly provided inside the air buffer and adapted to draw off smoke produced during cooking is disclosed to include an outer shell mounted inside the housing, an inner shell mounted inside the outer shell, an air path defined between the outer shell and the inner shell and connected to the air inlet of the air buffer, and a grease trap fastened to an orifice of the air path and adapted to accumulate waste grease produced in the air path.

Owner:CHIANG PI TANG

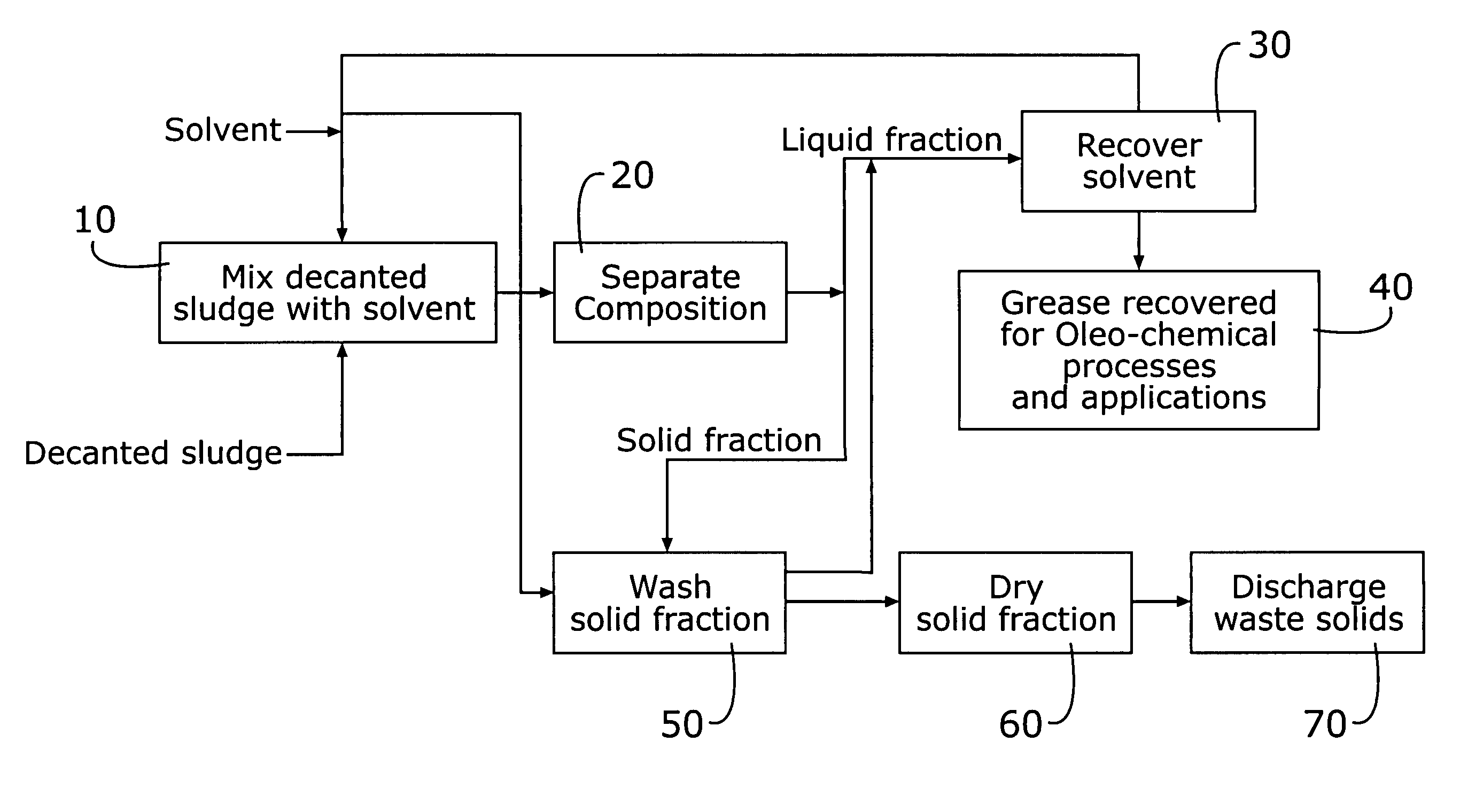

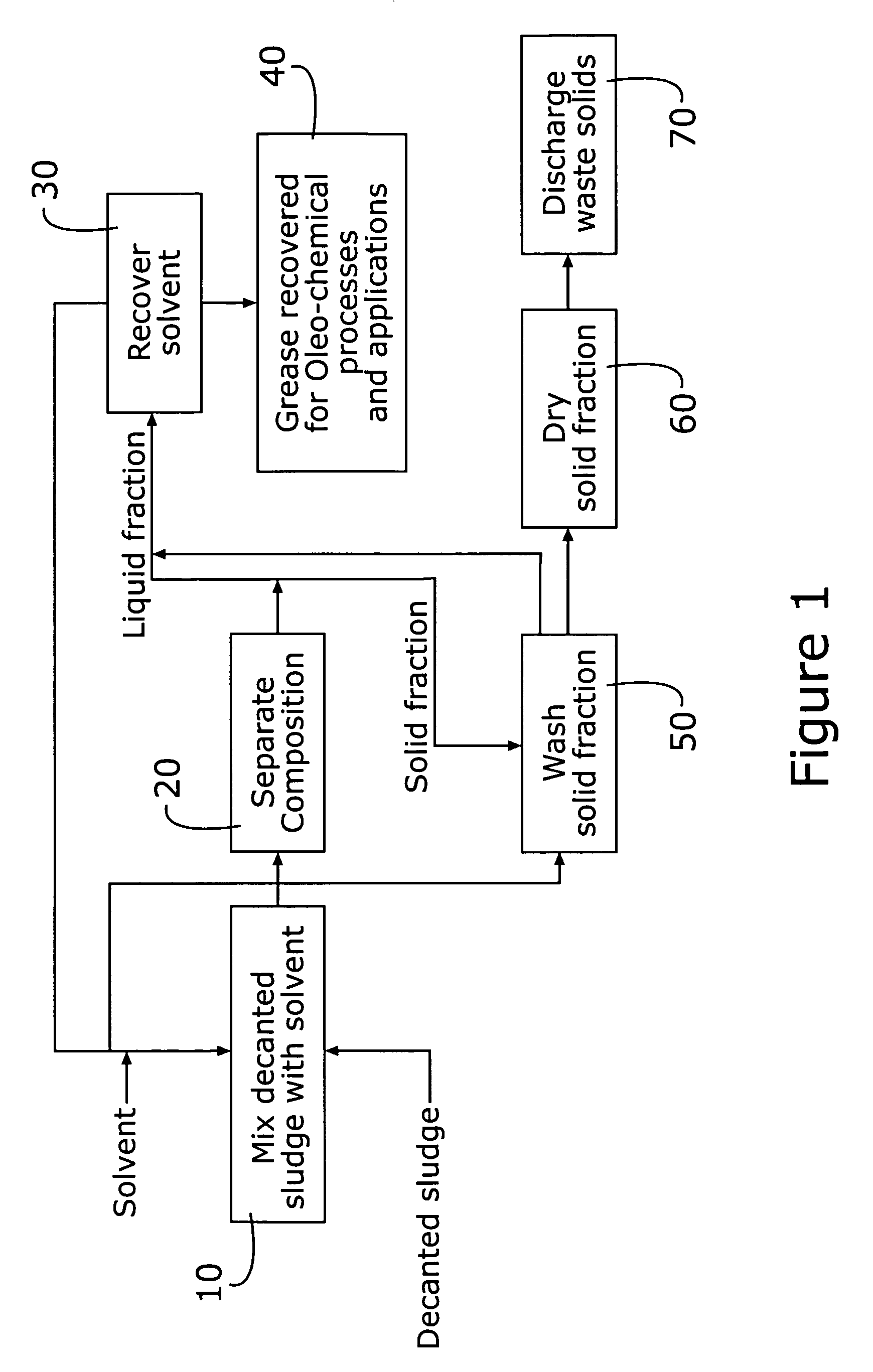

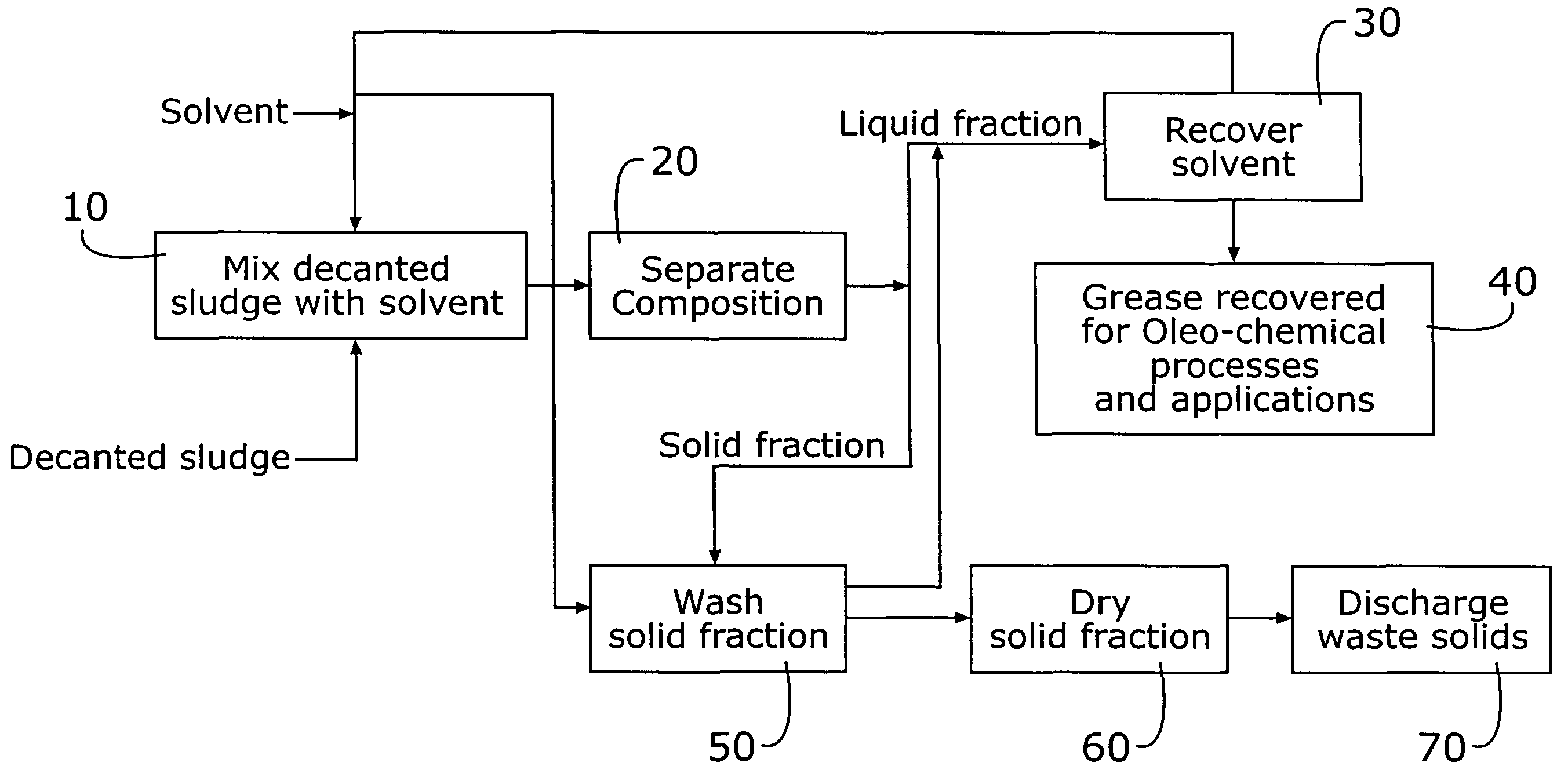

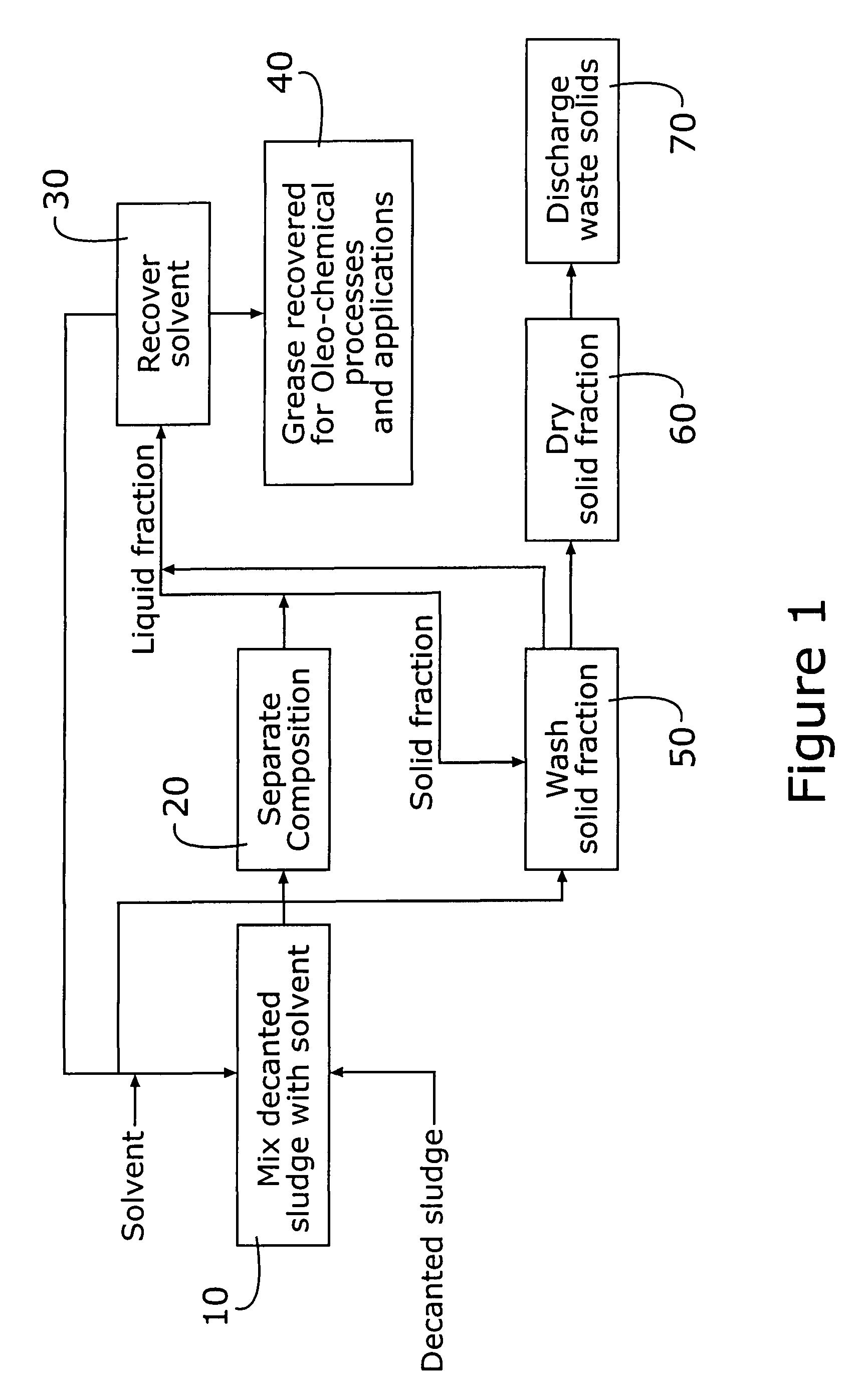

Grease trap waste treatment and fat, oil, and grease (FOG) recovery system

InactiveUS7338602B1Simplifying disposal conditionEliminate environmental problemsLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesOil and greaseSludge

A method to process grease trap waste or refuse and remove organic matter, and reclaim fats, oils, and grease (FOG) found in it. The process is initiated after dewatering the grease trap material to increase its concentration; the resulting sludge is then mixed with a solvent. The dissolved fractions of fats, oils, and grease are separated using mechanical methods. The solids are washed to further remove any traces of fats, oils, and grease. The solids, substantially free from organic content, are dried to remove any water and / or organic matter remaining, rendering inert solids that can be safely disposed of according to Environmental Protection Agency (EPA) regulations. All fats, oils, and, grease fractions are separated, containing no inert materials, and no water. The solvent is recuperated (recycled), allowing it to be used over again. The recuperated grease fractions, highly pure and homogeneous, constitute an excellent raw material for further oleo-chemical processes and applications.

Owner:PARJUS JOSE ALEJANDRO +2

Grease trap waste treatment and fat, oil, and grease (FOG) recovery system

InactiveUS7967985B1Simple conditionsLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesOil and greaseSludge

A method to process grease trap waste or refuse and remove organic matter, and reclaim fats, oils, and grease (FOG) found in it. The process is initiated after dewatering the grease trap material to increase its concentration; the resulting sludge is then mixed with a solvent. The dissolved fractions of fats, oils, and grease are separated using mechanical methods. The solids are washed to further remove any traces of fats, oils, and grease. The solids, substantially free from organic content, are dried to remove any water and / or organic matter remaining, rendering inert solids that can be safely disposed of according to Environmental Protection Agency (EPA) regulations. All fats, oils, and, grease fractions are separated, containing no inert materials, and no water. The solvent is recuperated (recycled), allowing it to be used over again. The recuperated grease fractions, highly pure and homogeneous, constitute an excellent raw material for further oleo-chemical processes and applications.

Owner:PARJUS JOSE ALEJANDRO +2

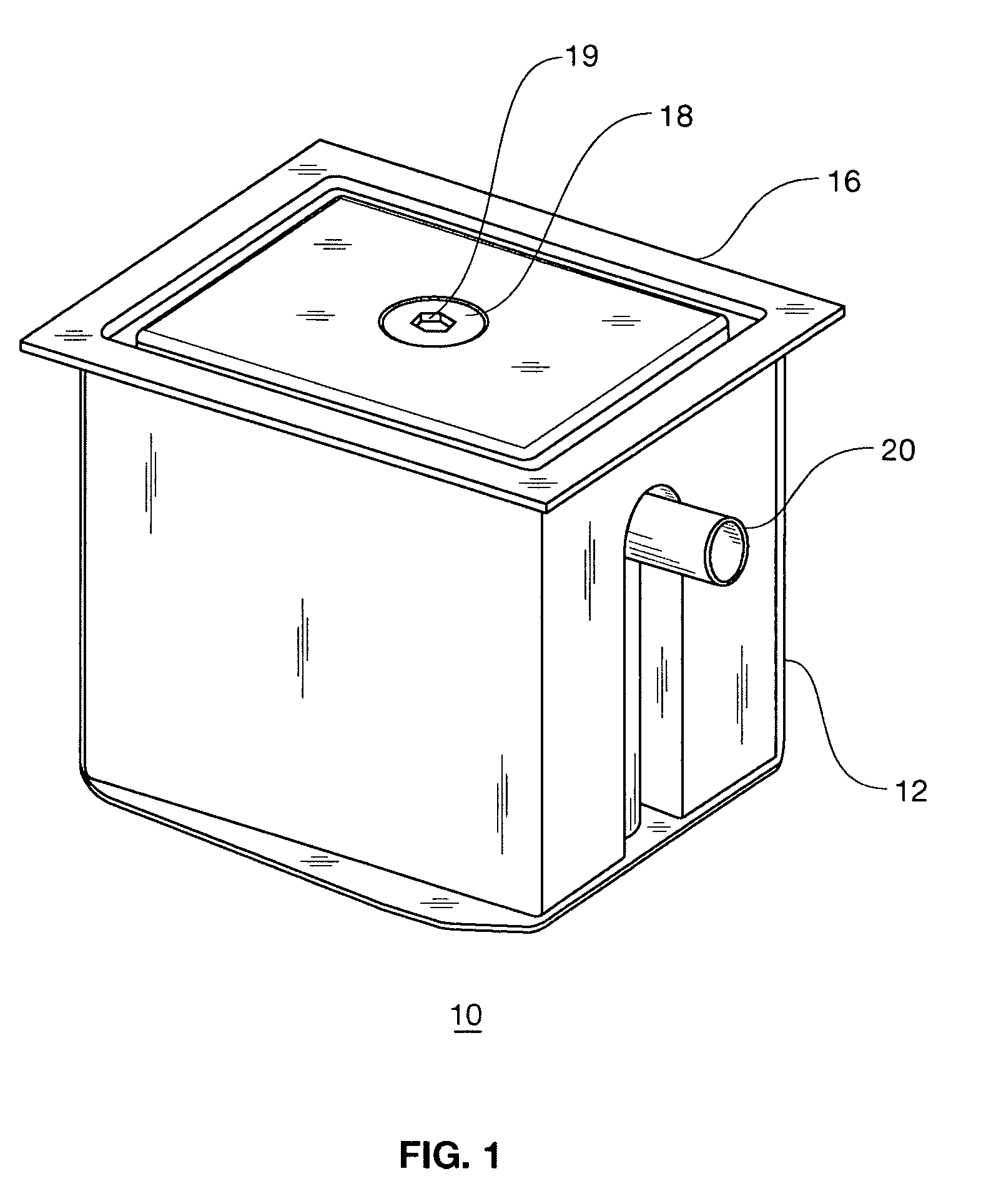

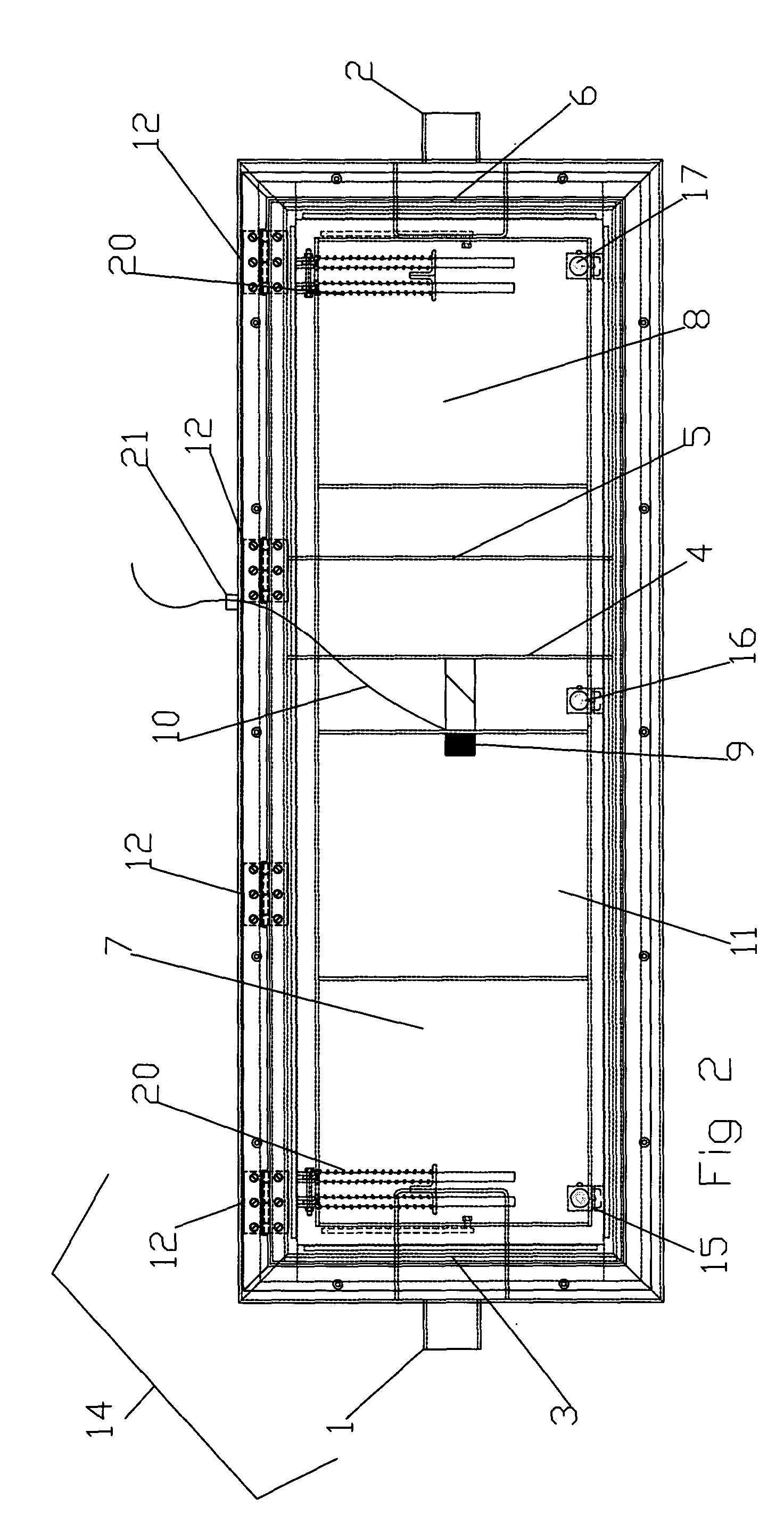

Grease Trap with Detachable Residue Interceptor

ActiveUS20100122954A1Reduce turbulenceEasy to followLiquid displacementLoose filtering material filtersSolid particleGrease trap

An apparatus and method to separate grease and solids from wastewater before reaching the sewers using a grease trap, wherein said grease trap comprises a detachable residue trap reducing turbulence and including a mesh which efficiently trap solid particles from the water waste in other to make easier the compliance with regulating agencies.

Owner:RODRIGUEZ JOVET FELIX JUAN

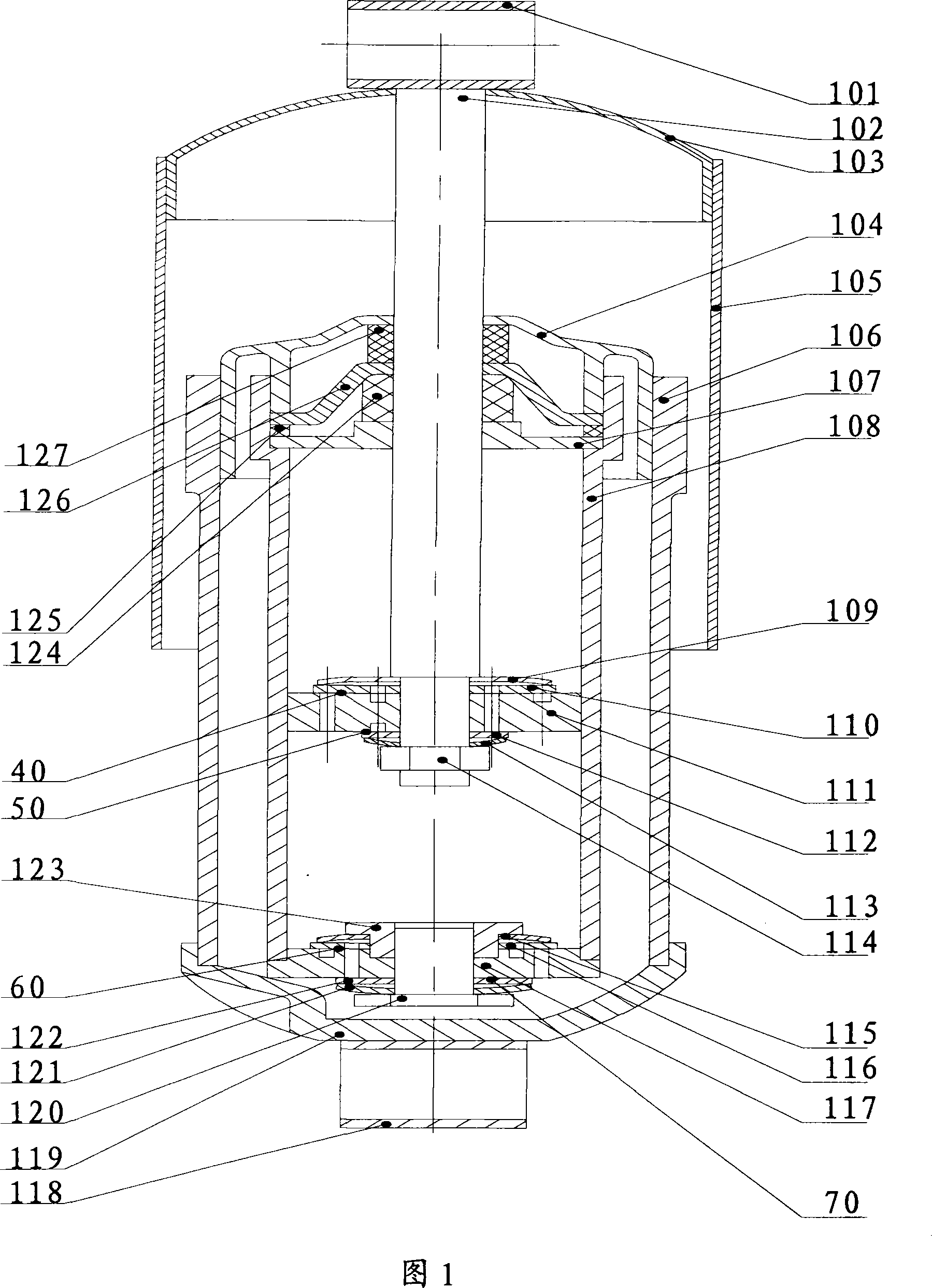

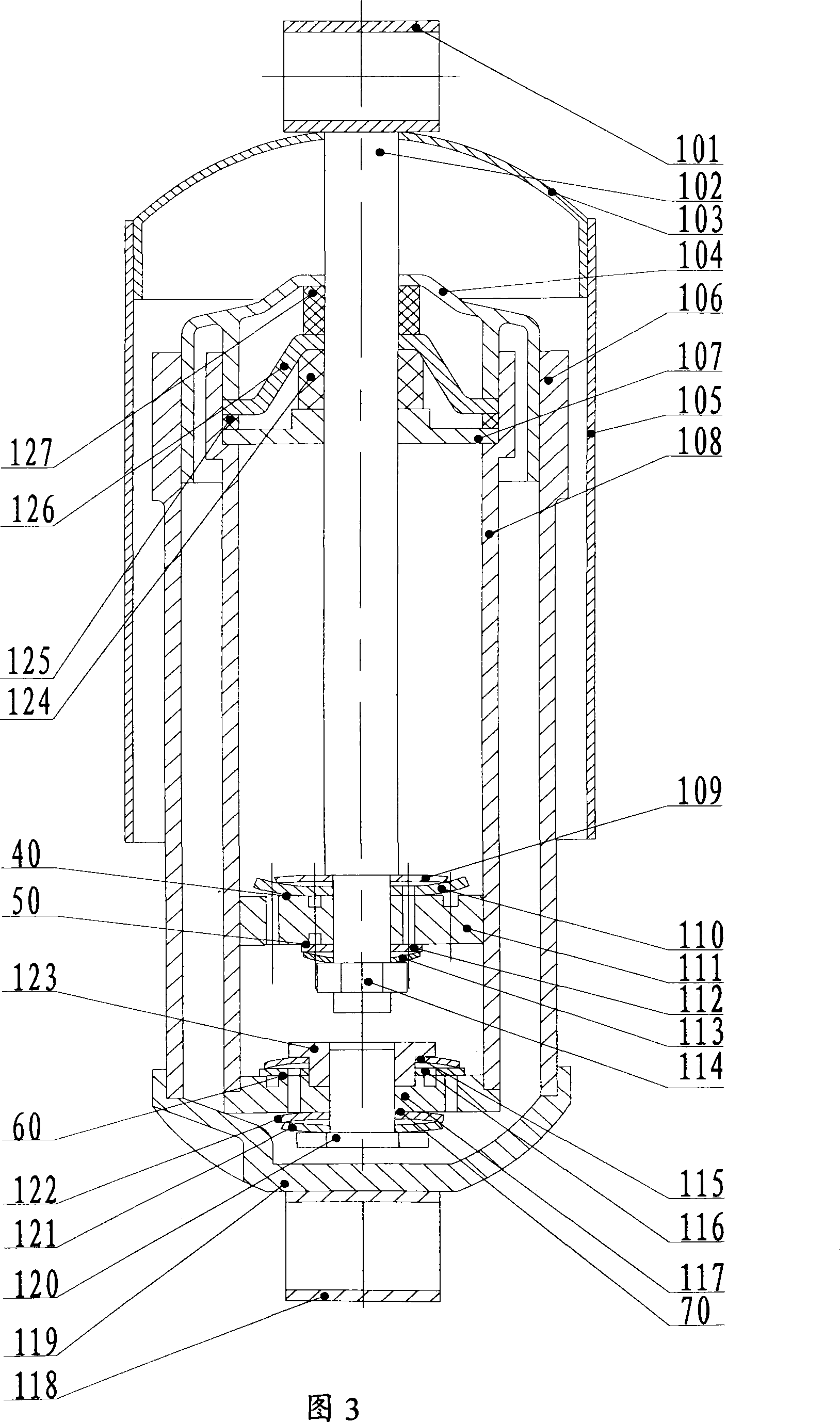

Automobile shock absorber

InactiveCN101162034AOvercome the shortcomings of oil leakage (seepage)To achieve the effect of no leakageLiquid based dampersEngineeringPiston rod

The invention provides an automobile oscillating damper, comprising an outer barrel, an inner barrel, a cylinder rod, a piston and hydraulic liquid, wherein, the part of the cylinder rod arranged inside a working cylinder is covered with an elastic grease trap sleeve, the upper end of the grease trap sleeve is fixed on a piston rod guide holder, while the lower end of the grease trap sleeve is fixed on a lower ledger plate of the piston; the piston rod guide holder is provided with a grease nipple which leads to the working cylinder and is covered by a grease nipple cover; the grease trap sleeve is of a wavy and cylindrical shape and is embedded with a ring-shaped framework along the circumferential direction in a spaced manner. The invention changes the state that oil liquid directly touches the cylinder rod and the piston rod guide holder which have relative movement in the prior oscillating damper, and the structure that an oil seal is used to seal the cylinder rod and the piston rod guide holder, instead, oil liquid is sealed in the grease trap sleeve by the invention, thereby not only relative movement between the cylinder rod and the piston rod guide holder but also oscillation damping effect is not influenced; the invention can also achieve the non-leakage effect of oil liquid, has simple structure, easy achievement and can be widely applied to various vehicles.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method for fractionating grease trap waste and uses of fractions therefrom

InactiveUS7161017B2Fatty oils/acids recovery from wasteFatty acid hydrogenationStearic acidOleic Acid Triglyceride

Owner:PROLAB TECH

Grease interceptor (trap) and servicing method

InactiveUS20050029201A1Easy to installAvoid problemsLiquid separation auxillary apparatusWater treatment parameter controlSludgeGrease trap

A grease trap and management tank is disclosed herein. The trap has two compartments, a forward and rear compartment separated by two baffles so that grease and oils may rise and solids and sludge settle out and not be introduced into a sewer line. An ultra sonic monitoring device is also shown with local record keeping and alarm capabilities as well as remote management options through phone line, wireless or internet communications. Servicing may be scheduled according to this data to prevent any problems with the trap. The grease trap also features an access door that opens to reveal the entirety of the grease trap for easy cleaning. Since the dimensions of the tank do not exceed the width and height of standard doorways, installation indoors is greatly simplified. Along with adaptable risers, the trap may be made of metal, plastic or any other suitable material, installed indoors and mounted in concrete or any other suitable construction material.

Owner:RODIS NANCY JEANNINE

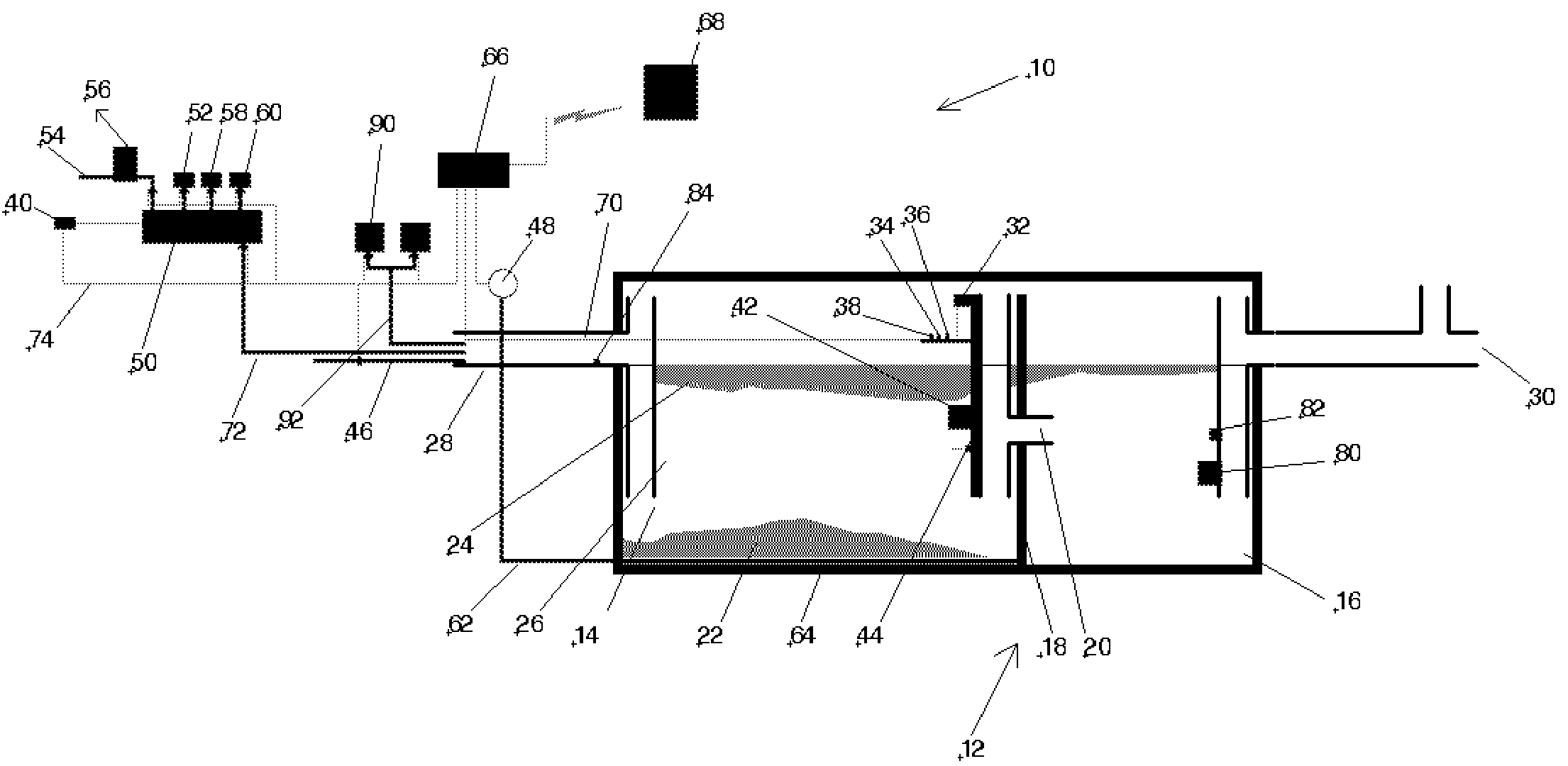

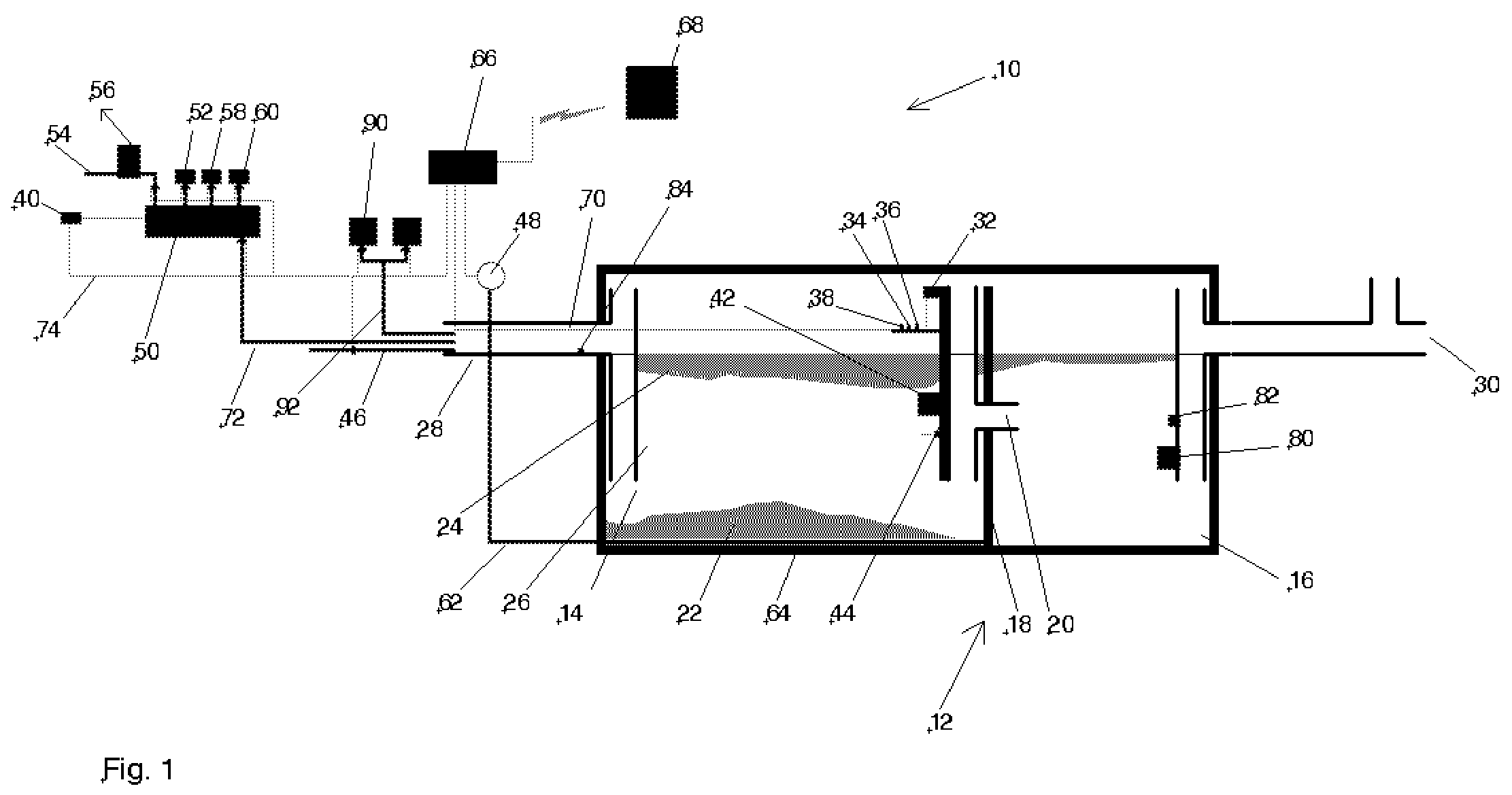

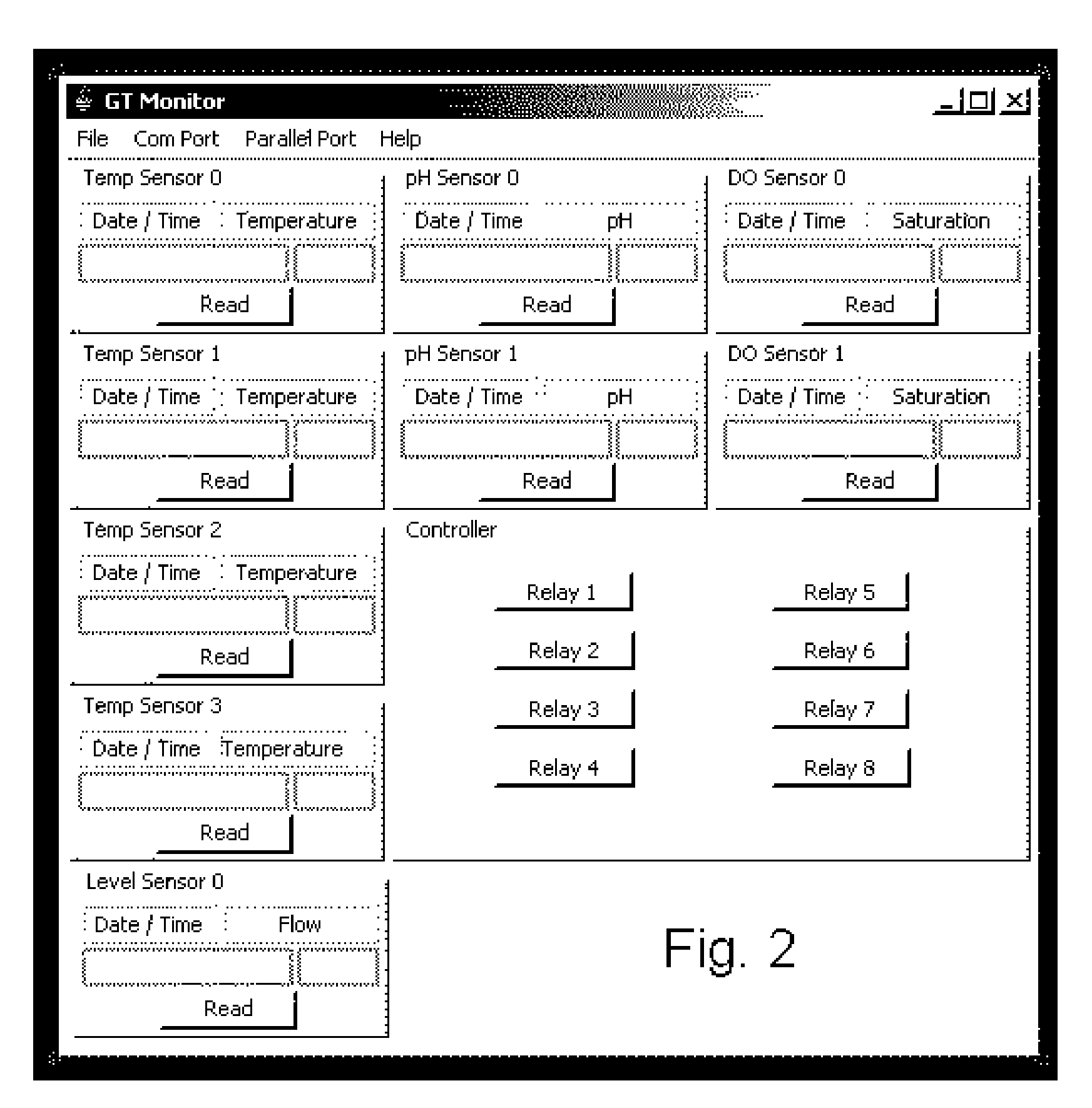

Organic waste management system

InactiveUS7288187B1Reduce the temperatureIncreased oxygen levelsWater treatment parameter controlFatty/oily/floating substances removal devicesOxygenEnzyme

A method of managing organic waste and an organic waste management system. The method includes the steps of receiving organic waste liquids and solids in a collection vessel, such as a grease trap. The dissolved oxygen is monitored, the pH level is monitored, the flow is monitored, and the temperate of the organic waste liquids and solids in the collection vessel are all monitored and data is generated therefrom. Enzymes and bacteria are generated / supplied and delivered along with other reagents to the collection vessel in response to the data. In addition, dissolved oxygen, air, or equivalent is applied to the collection vessel in response to the data so that the organic waste liquids and solids are degraded.

Owner:BOVAIRD

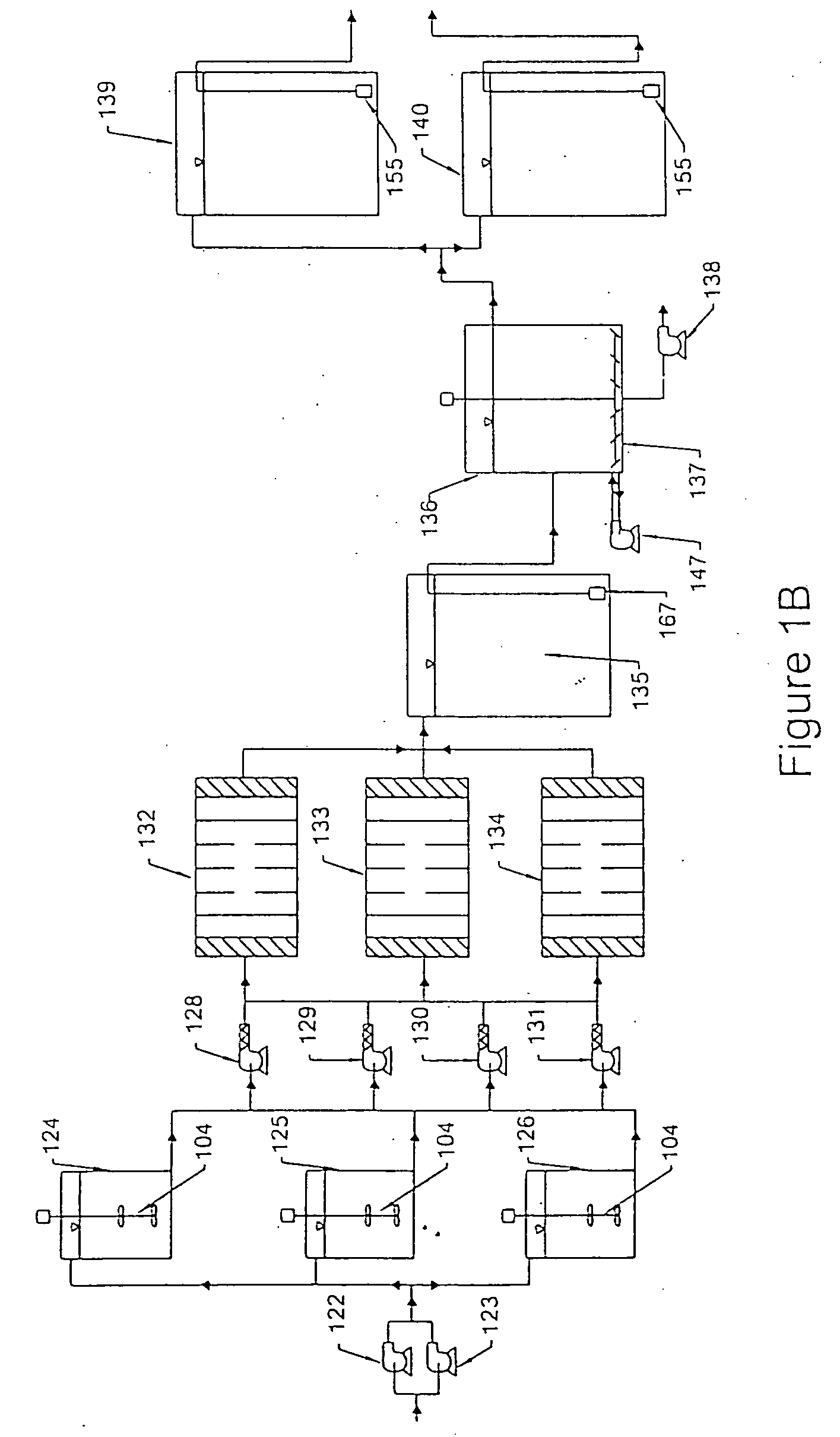

Industrial wastewater comprehensive treatment system and technique

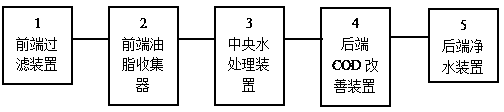

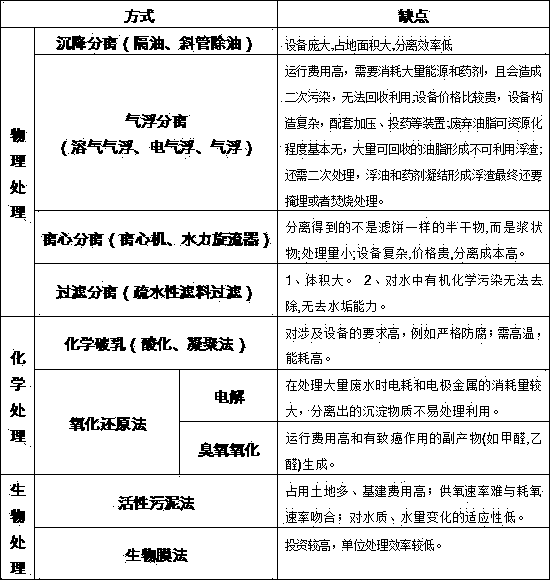

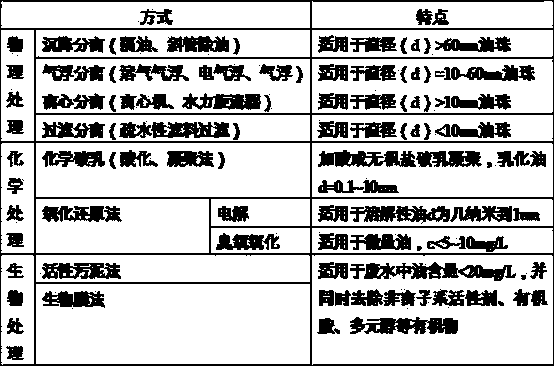

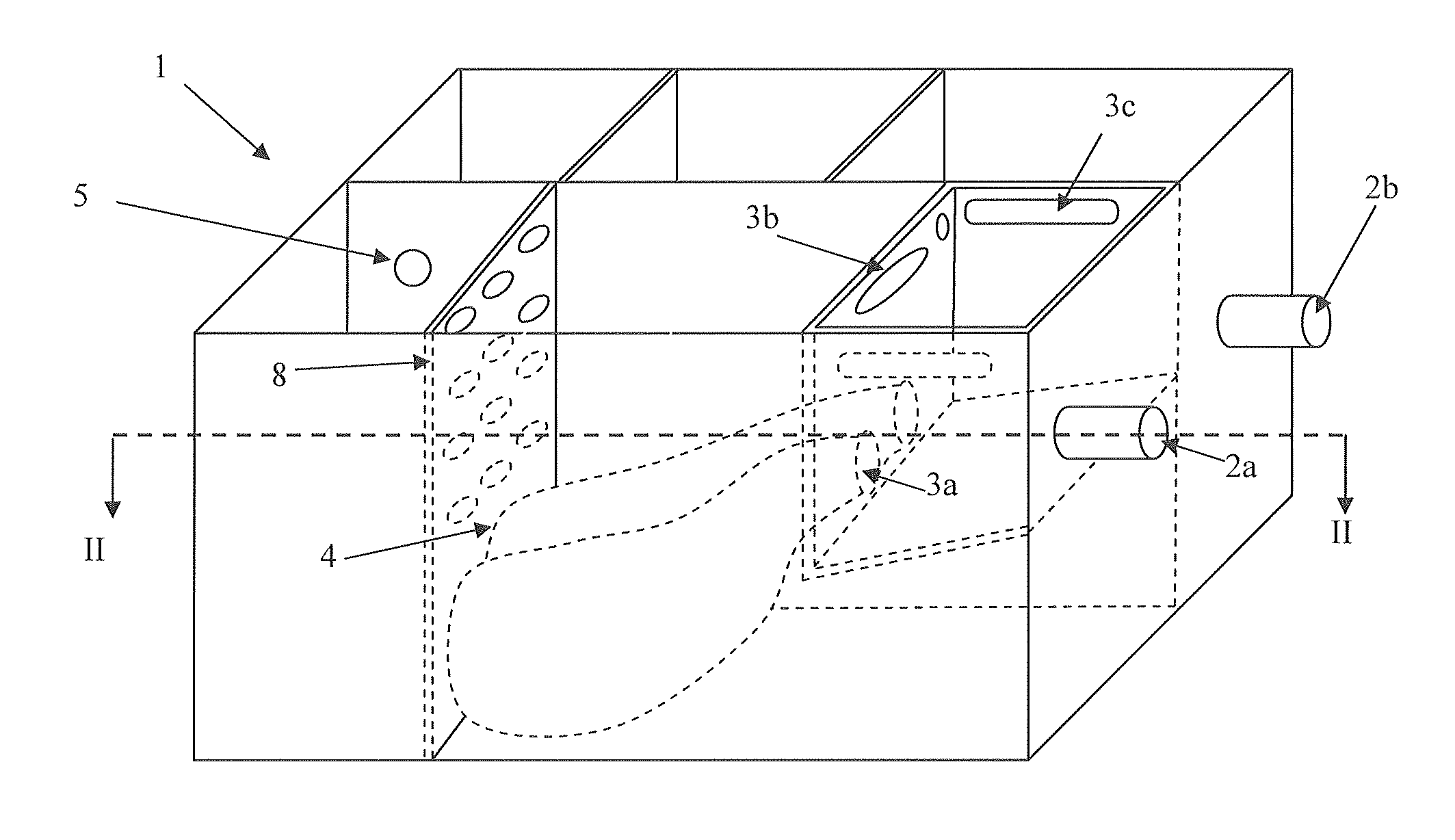

ActiveCN104045200AReduce sensitivityWill not cause secondary pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentIndustrial waste waterChemical oxygen demand

The invention provides an industrial wastewater comprehensive treatment system which comprises a front-end filter unit, a front-end grease collector, a central water treatment device, a back-end COD (chemical oxygen demand) improvement device and a back-end water purifier which are sequentially connected. The invention also provides an industrial wastewater comprehensive treatment technique of the treatment system. The system and technique can extract water in the industrial wastewater and leave over pollutants, so that the treated industrial wastewater can reach the water quality standard for drinking water; and the system adopts the pure physical separation technique, does not need any chemical reagent, can not cause secondary pollution, has low sensitivity for the components of the fluid to be treated, and does not need to greatly adjust the technique and equipment system due to the component difference of the treated fluid.

Owner:SUZHOU DIHILL GREEN TECH

Grease trap with detachable residue interceptor

ActiveUS8153004B2Easy to followEasy to removeLiquid displacementLoose filtering material filtersOil and greaseSolid particle

An apparatus and method to separate grease and solids from wastewater before reaching the sewers using a grease trap, wherein said grease trap comprises a detachable residue trap reducing turbulence and including a mesh which efficiently trap solid particles from the water waste in other to make easier the compliance with regulating agencies.

Owner:RODRIGUEZ JOVET FELIX JUAN

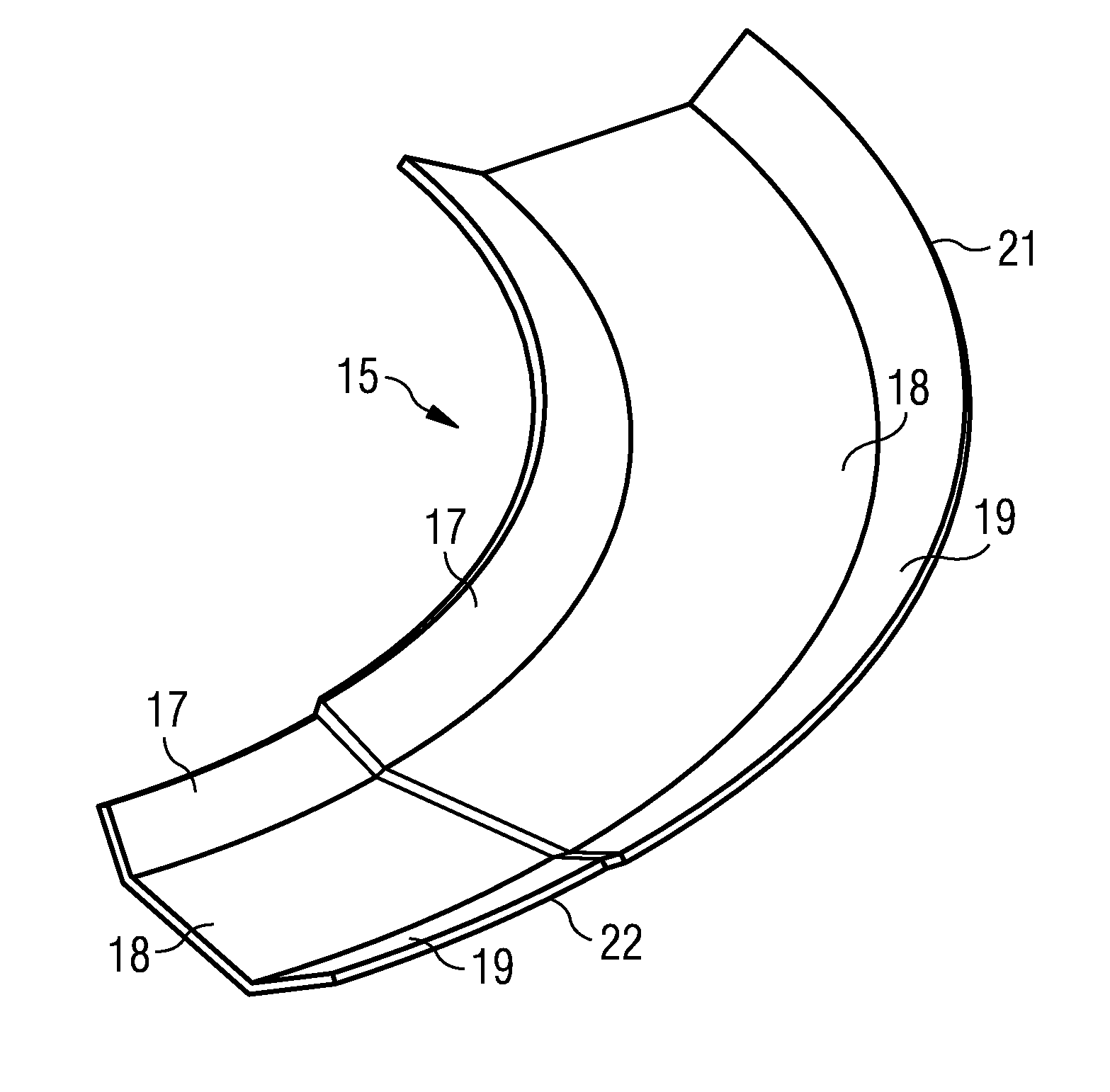

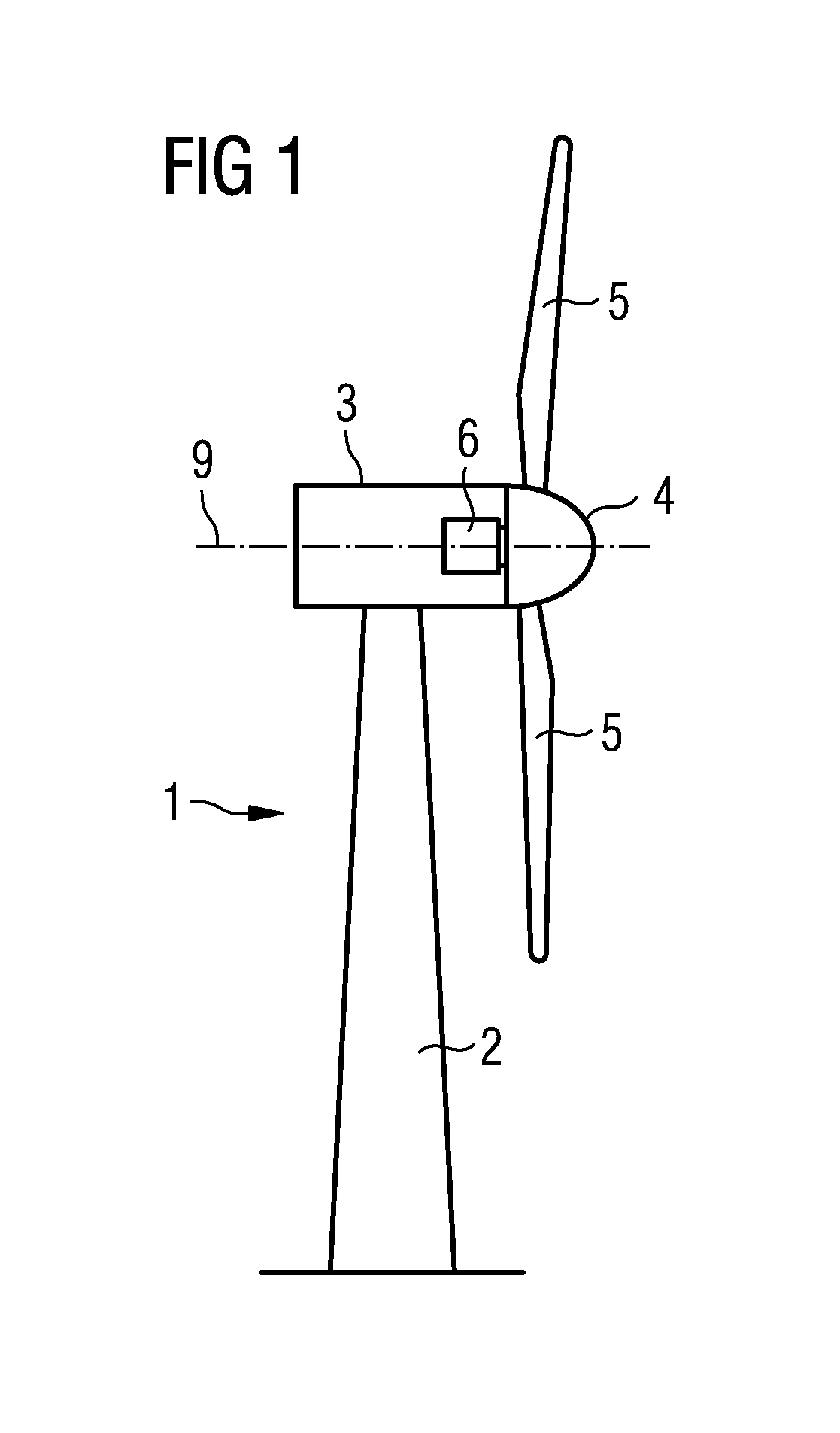

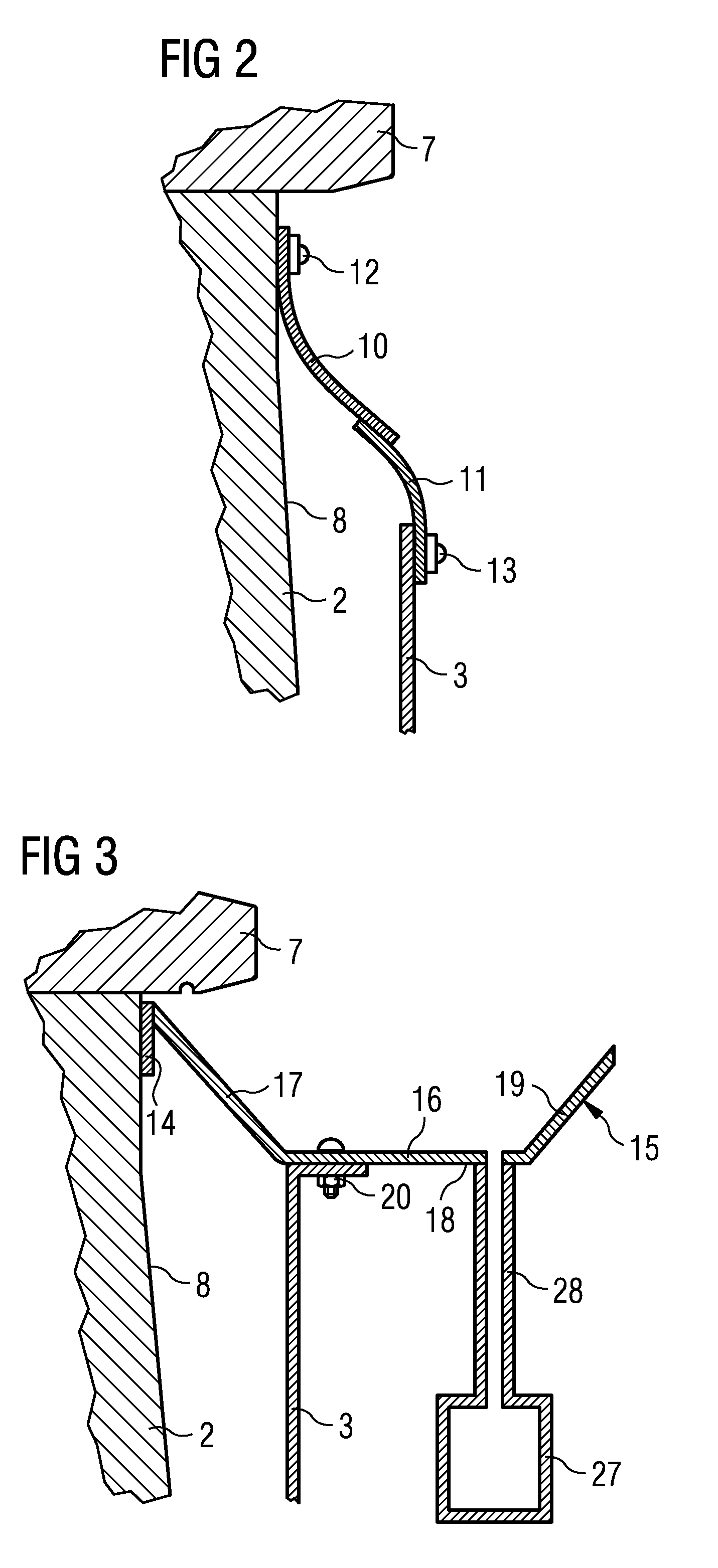

Grease collector, wind turbine nacelle and method for collecting excess grease

ActiveUS20120224963A1Overcome disadvantagesImprove sealingEngine sealsWind motor controlNacelleYaw system

A grease collector is described, which is connectable to a wind turbine nacelle. The grease collector includes a channel with a flexible side portion for providing a sealing between the nacelle and a wind turbine tower. Moreover, a wind turbine nacelle and a wind turbine with a grease collector and a method for collecting excess grease which is emitted from a yaw system of a wind turbine are provided.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

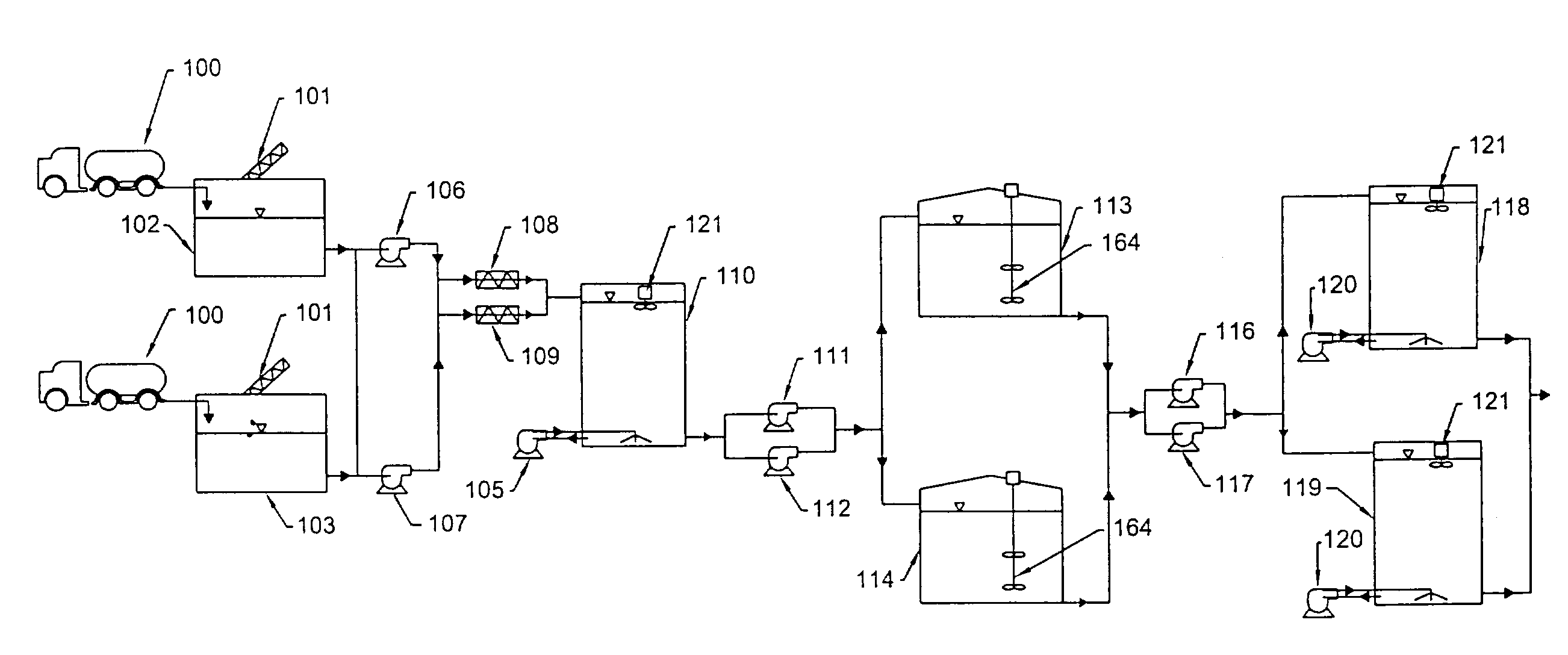

Separation system for the removal of fat, oil or grease from wastewater

InactiveUS7510661B2Easy to separateReversed direction vortexLoose filtering material filtersOil and greaseHigh density

A wastewater separation system for separating an aqueous phase from an organic phase comprising oil, fat and / or grease in wastewater is disclosed. The wastewater may be collected from restaurant grease traps, as well as other food preparation facilities, schools, hospitals, processing plants and the like. A separator, such as a centrifugal separation device, comprises a wastewater inlet, an organic phase outlet for discharging low density liquid and solids and an aqueous phase outlet for discharging water and possibly other high density liquids and solids. The system can be portable and can be mounted on a vehicle for collection and treatment at various sites. Heat can be introduced to the system to accelerate the separation of the aqueous phase from the organic phase of the wastewater.

Owner:HILLS BLAIR H

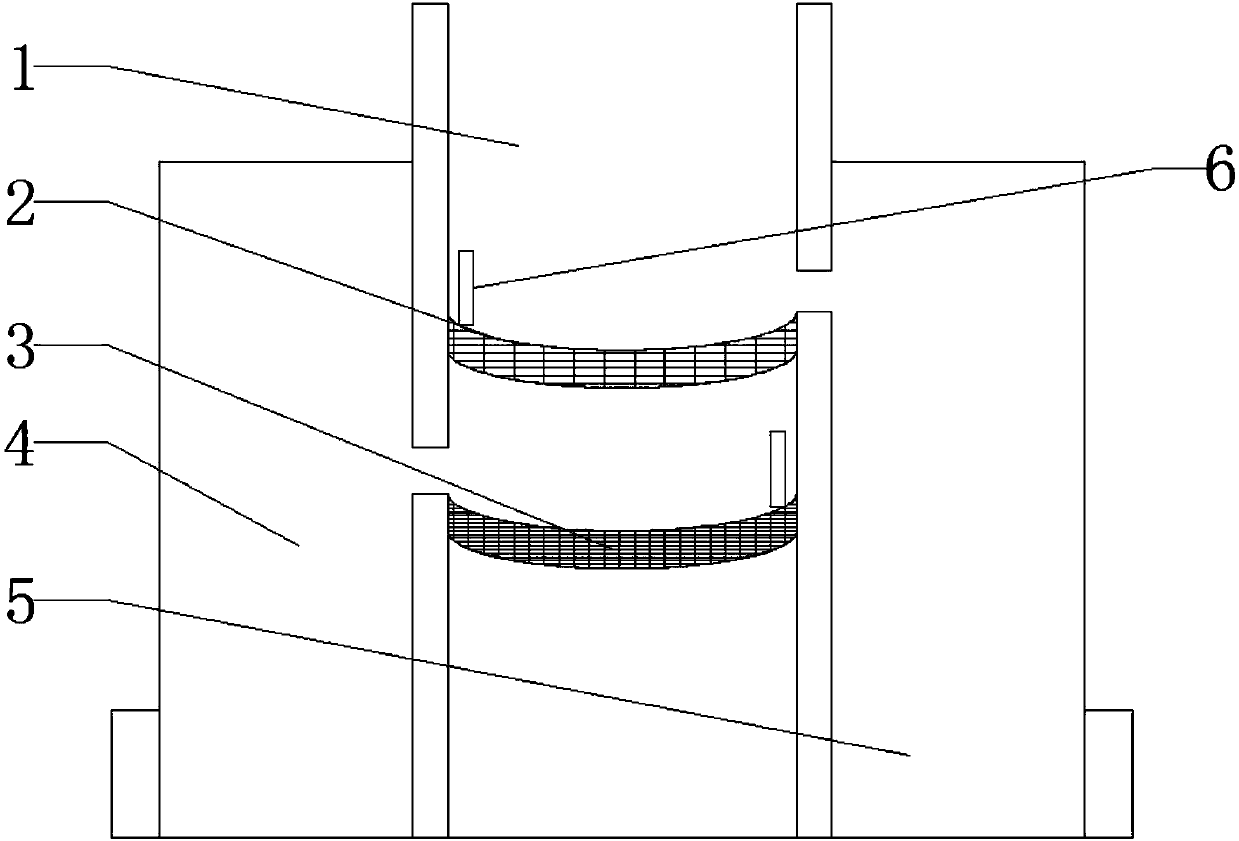

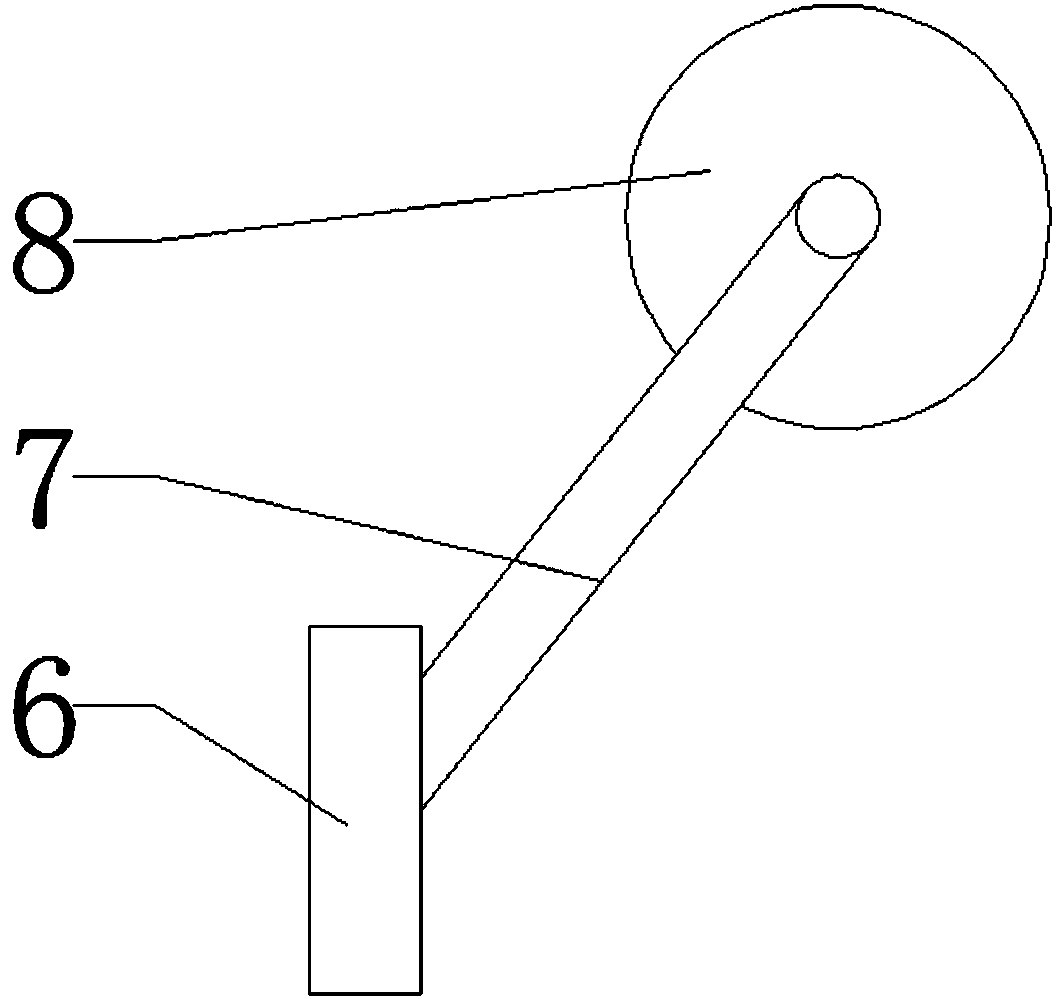

Sewage separation device provided with grease separation device

InactiveCN107935112AImprove processing efficiencyFatty/oily/floating substances removal devicesTreatment involving filtrationSlagSewage

The invention discloses a sewage separation device equipped with an oil separation device, which comprises a sewage pipeline, a primary filter screen, a fine filter screen, an oil dirt bucket, a solid residue bucket, a scraper, a connecting rod and a motor. The primary filter screen and the fine filter screen, wherein the fine filter screen is located under the primary filter screen, and openings are provided at the installation places of the primary filter screen and the fine filter screen on the sewage pipeline, and the oil dirt bucket and the solid residue bucket are connected at the opening, wherein The solid residue bucket communicates with the installation opening of the primary filter, and the oil dirt bucket communicates with the installation opening of the fine filter. Scrapers are installed on both the primary filter and the fine filter, and each scraper is connected to a Motor connection. The present invention is equipped with a metal filter screen in the sewage pipeline, which can isolate insoluble solid matter and viscous oil stains, and classify and store them respectively by the scraper, and isolate the oil stains before sewage treatment, which is beneficial to improve Efficiency of sewage treatment.

Owner:HEFEI HONGRUN ENVIRONMENTAL PROTECTION TECHCO

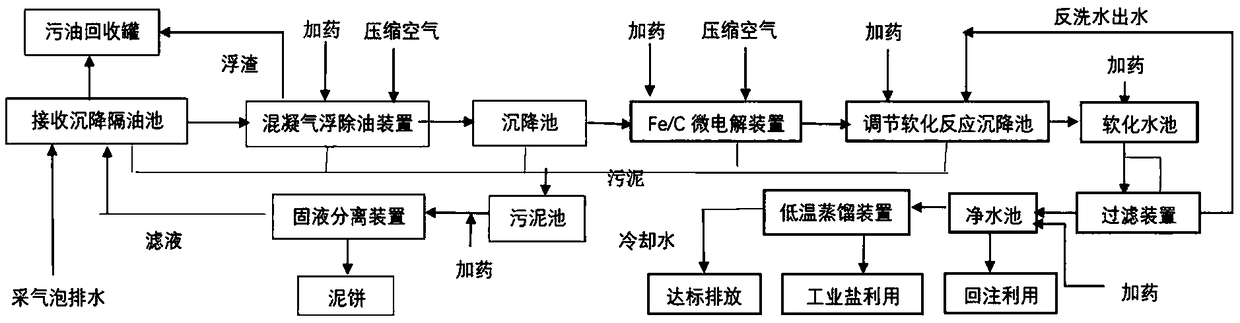

Method for centralized treatment and comprehensive utilization of foam drainage during gas production in oil-gas fields

PendingCN108911332AImprove the effect of low temperature multiple effect evaporation treatmentModerate operating costsWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningElectrolysisSoftened water

The invention discloses a method for centralized treatment and comprehensive utilization of foam drainage during gas production in oil-gas fields. The method comprises the steps: firstly, collecting the drainage into a grease trap for treatment so as to obtain solid sludge and preliminarily-treated drainage; and conveying the treated drainage to a coagulation air-floatation degreasing device, andperforming aeration and degreasing treatment so as to obtain solid sludge and secondarily-treated drainage; conveying the obtained drainage to an iron-carbon micro-electrolysis device, performing a micro-electrolysis reaction so as to obtain sludge after the reaction treatment is conducted, conveying the obtained drainage to a softening reaction sedimentation tank, performing softening hardness removal treatment, performing settlement to obtain sludge, conveying the obtained drainage to a water softening pool for softening treatment so as to obtain qualified softened water, and conveying the obtained qualified softened water into a water purification pool, wherein the obtained qualified water can be directly applied to re-injection or multi-effect evaporation treatment and is subjected toup-to-standard discharge; and performing centralized treatment and recovery on the sludge obtained in the steps. Grease and salts in the foam drainage wastewater during gas production can be recoveredfully, the foam drainage obtained after the centralized treatment is conducted can be introduced into an evaporation system for evaporation treatment, and the obtained drainage is subjected to up-to-standard discharge and can be utilized comprehensively as oilfield re-injection water, so that resource utilization is achieved.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com