Refuse/oil removing device and refuse/oil recovery bag

a technology of refuse/oil and recovery bag, which is applied in the direction of sedimentation settling tank, liquid displacement, separation process, etc., can solve the problems of affecting the environment, including rivers, and the pipe diameter may be reduced or blocked, so as to improve the rate of settling down full-time, the amount of oil accumulated in the second tank of the grease trap can be greatly reduced, and the recovery bag attaching and detaching work is easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described hereinunder with reference to the drawings.

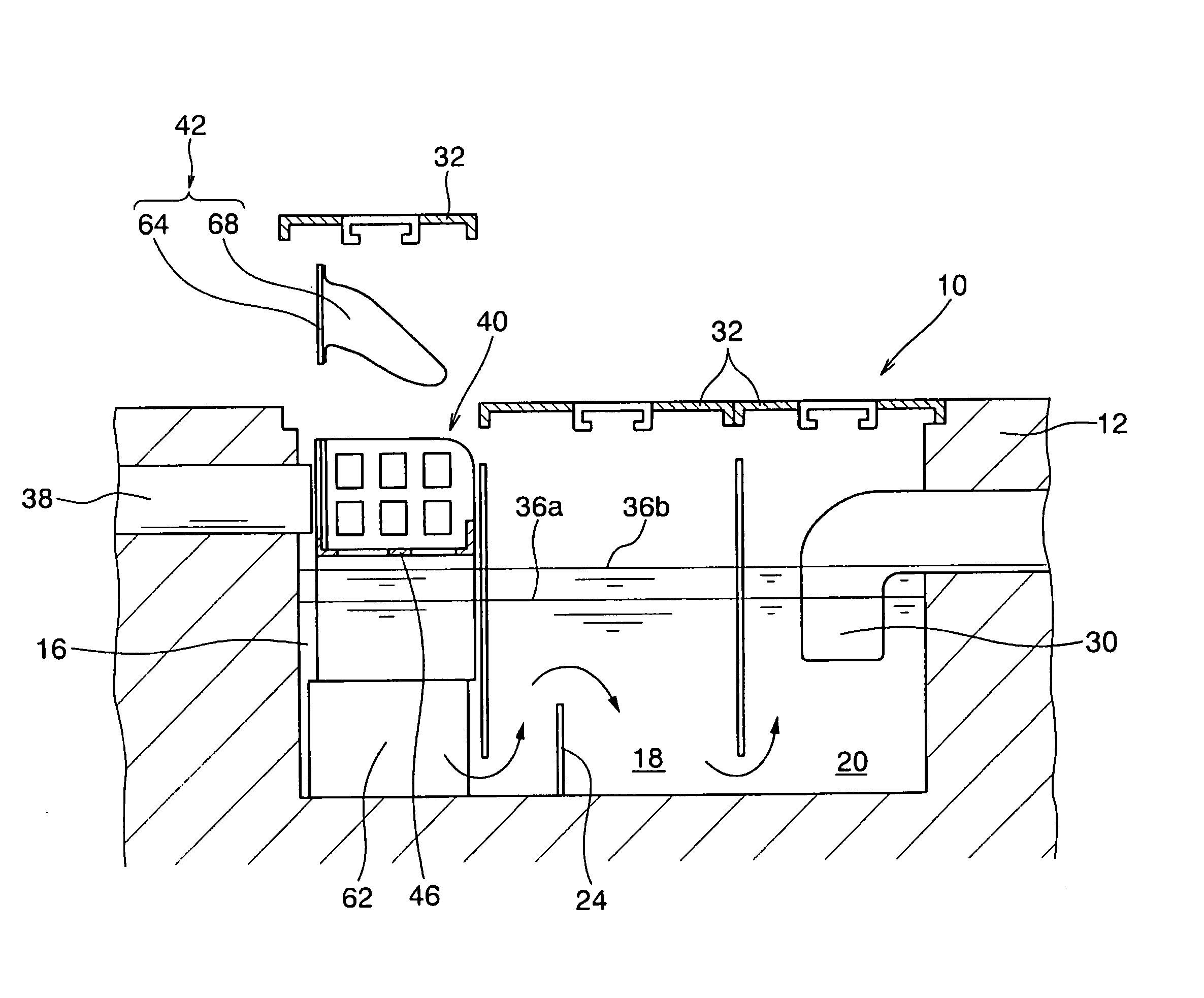

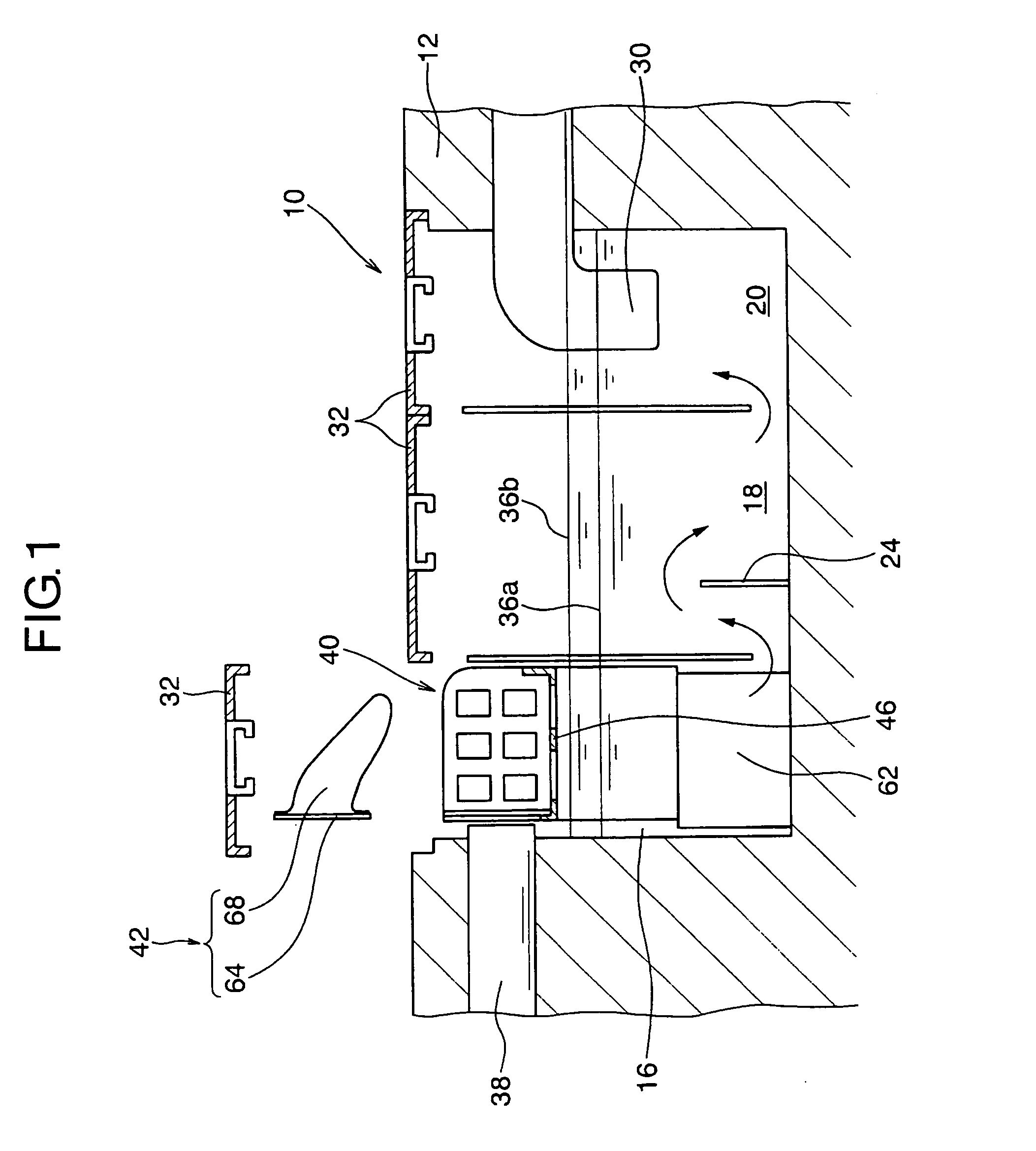

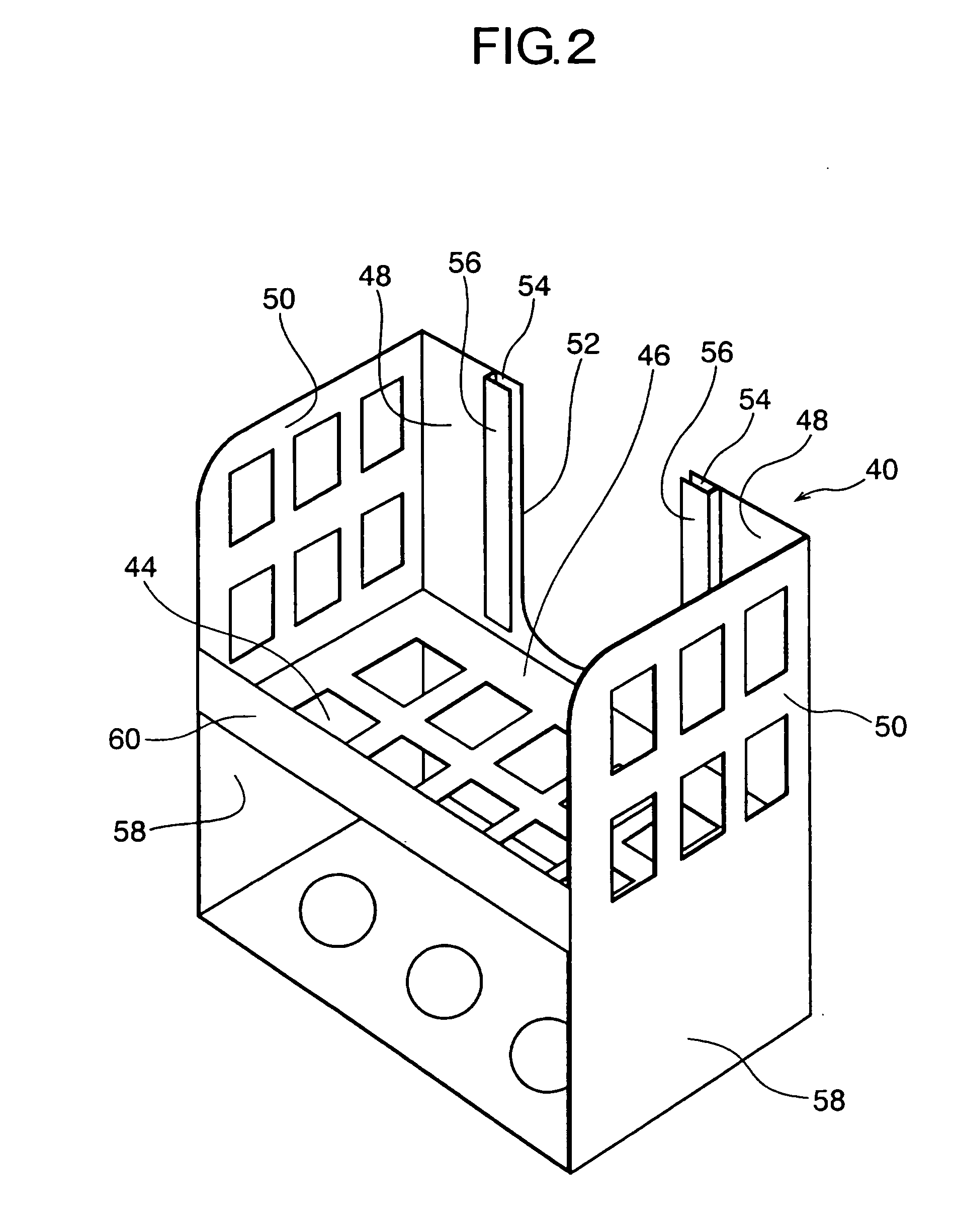

[0050]FIG. 1 is a sectional view showing a state in which a refuse / oil removing device according to the present invention is provided within a grease trap, FIG. 2 is a perspective view showing an example of support means used in the present invention, and FIG. 3 is a perspective view showing an example of a recovery bag used in the present invention. In FIG. 1, the same reference numerals as in FIG. 10 represent the same members as in FIG. 10. In the present invention there is used a conventional, known grease trap 10, provided it is preferable that an outlet side of an upstream drain passage for introducing drainage into a first tank 16 be not a gutter but a drain pipe 38. In the refuse / oil removing device according to the present invention, support means 40 shown in FIG. 2 and a recovery bag 42 shown in FIG. 3 are used instead of the residue basket 26 shown in FIG. 10.

[0051] The support mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com