Method for centralized treatment and comprehensive utilization of foam drainage during gas production in oil-gas fields

A centralized treatment, oil and gas field technology, applied in mining wastewater treatment, degassed water/sewage treatment, water/sewage treatment, etc., can solve problems such as the inability to achieve effective operation of evaporation devices, and achieve stable discharge standards and comprehensive effects of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

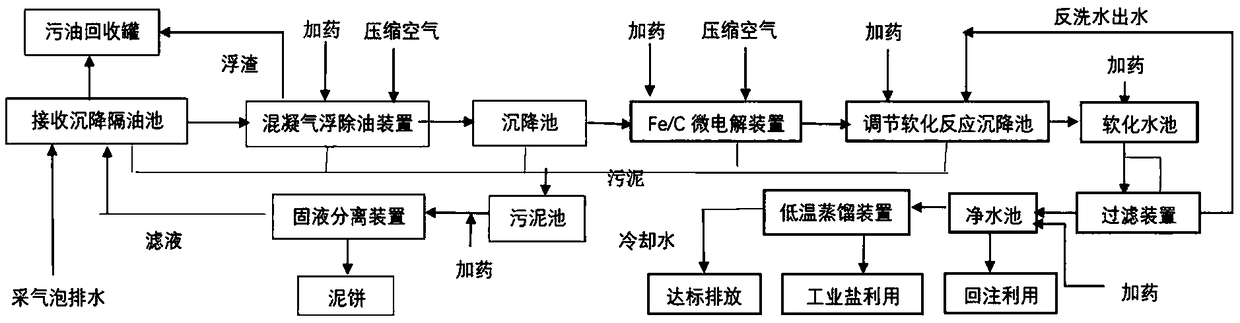

Image

Examples

Embodiment 1

[0036] This embodiment takes the application of air bubble drainage treatment in the exploration and development production of West Sichuan Gas Field of Sinopec Southwest Oil and Gas Branch Company as a specific example to specifically illustrate the method of the present invention for centralized treatment and comprehensive utilization of air bubble drainage in oil and gas field production.

[0037] In 2016, Sinopec Southwest Oil and Gas Company used this method to implement daily production of 400m in Sichuan Chuanxi Gas Field Exploration and Development Production Bubble Drainage 3 The specific operation steps of operation project, centralized processing and comprehensive utilization are as follows:

[0038] a. Centrally transport and collect the air bubble drainage produced in the single well gas production process to the receiving settlement oil trap, and recover the free oil obtained from the upper part by gravity separation into the 100m 3 Storage in the waste oil recov...

Embodiment 2

[0047] This embodiment takes the application of fracturing flowback fluid treatment by the downhole operation company of Sinopec Southwest Petroleum Engineering Company as a specific example to specifically illustrate the method of the present invention for centralized treatment and comprehensive utilization of air bubble drainage in oil and gas fields. The specific operation process is as follows:

[0048] a. Collect the fracturing flowback fluid generated during the acidizing and fracturing operation of drilling and collect it in the receiving and settling grease trap, and recover the free oil obtained from the upper part by gravity separation into the waste oil recovery tank for storage; after separation, the suspended solids settle The solid phase sludge is obtained at the bottom of the grease trap, and the solid sludge is sent to the sludge dewatering system through the sludge collection system and sludge pump for treatment; the initial degreasing and fracturing flowback f...

Embodiment 3

[0056] This example takes Sinopec Inner Mongolia Wushen Banner drilling waste press filter water treatment application as a specific example to specifically illustrate the method of the present invention for centralized treatment and comprehensive utilization of air bubble drainage in oil and gas fields. The specific operation process is as follows:

[0057]a. Collect the filter press water produced by the solid-liquid separation of drilling waste into the receiving settling tank for gravity separation. After separation, part of the suspended solids settles to the bottom of the settling tank to obtain solid phase sludge. The solid sludge passes through the sludge collection system and The sludge is pumped into the sludge dewatering system for treatment; after settling, the press-filtered water enters the coagulation air flotation device;

[0058] b. Lift the filtered water obtained in step a into the coagulation and air flotation device through the sewage pump, and add aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com